Patents

Literature

35results about How to "Enhanced hoop effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

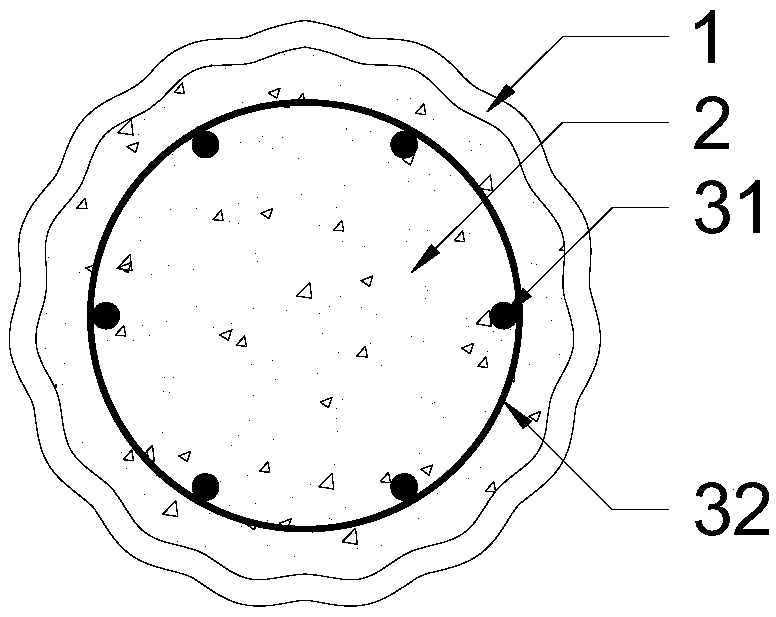

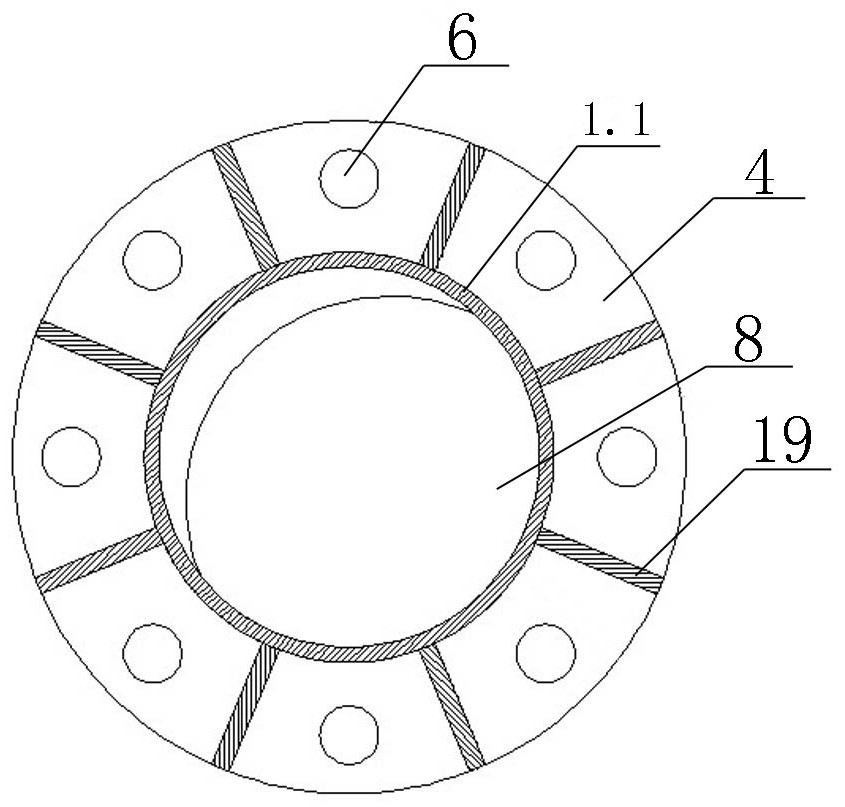

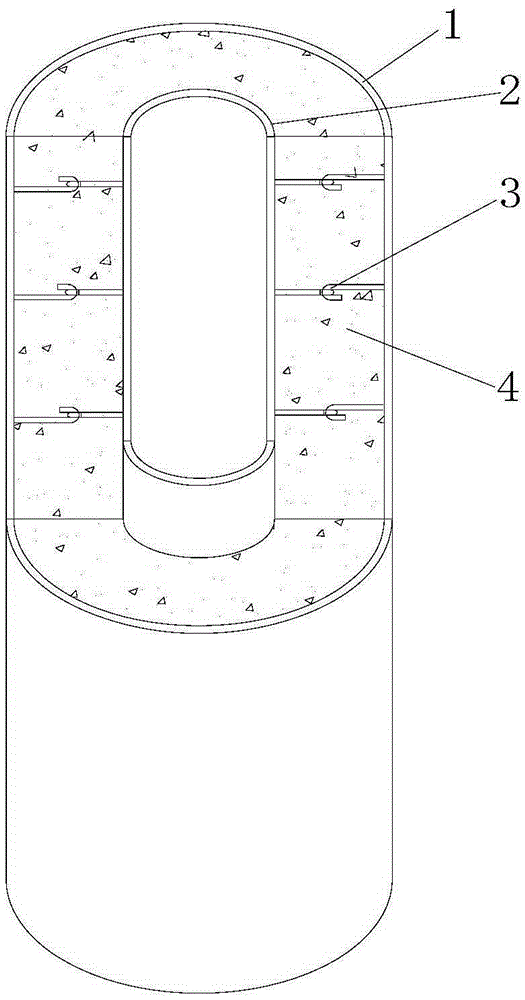

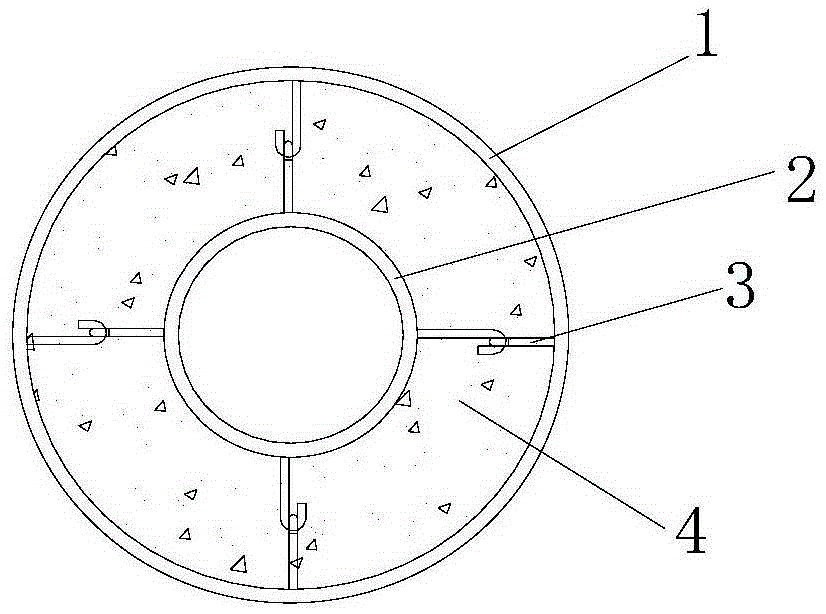

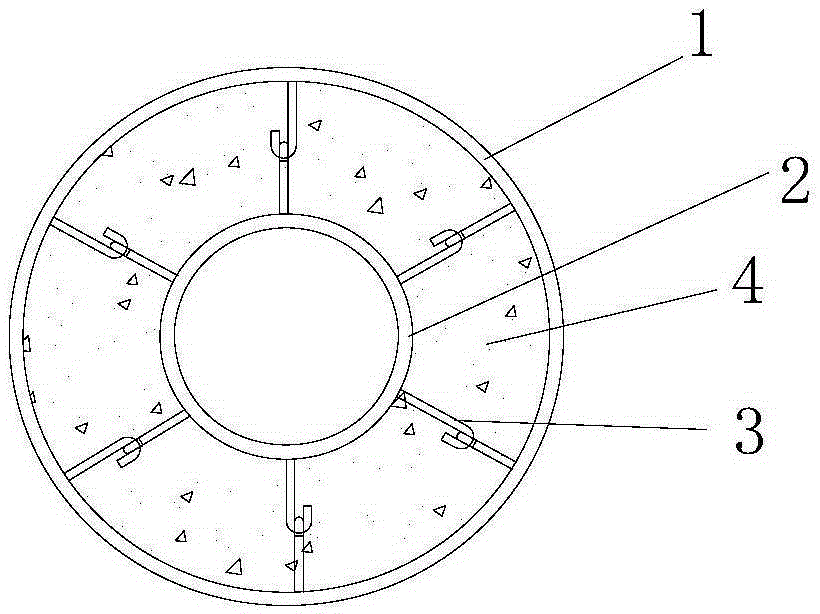

SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs

InactiveCN102979251ALight structureImprove seismic performanceArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of PBL stiffening ribs arranged between the outer steel tube and the inner steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube, the inner steel tube and the plurality of PBL stiffening ribs are equal in longitudinal length; the plurality of PBL stiffening ribs are arranged along the peripheral direction of the inner steel tube; the inner lateral wall of each PBL stiffening rib and the inner lateral wall of the inner steel tube are fastened and connected into a whole, and the outer lateral wall and the outer lateral wall of the outer steel tube are fastened and connected into a whole. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

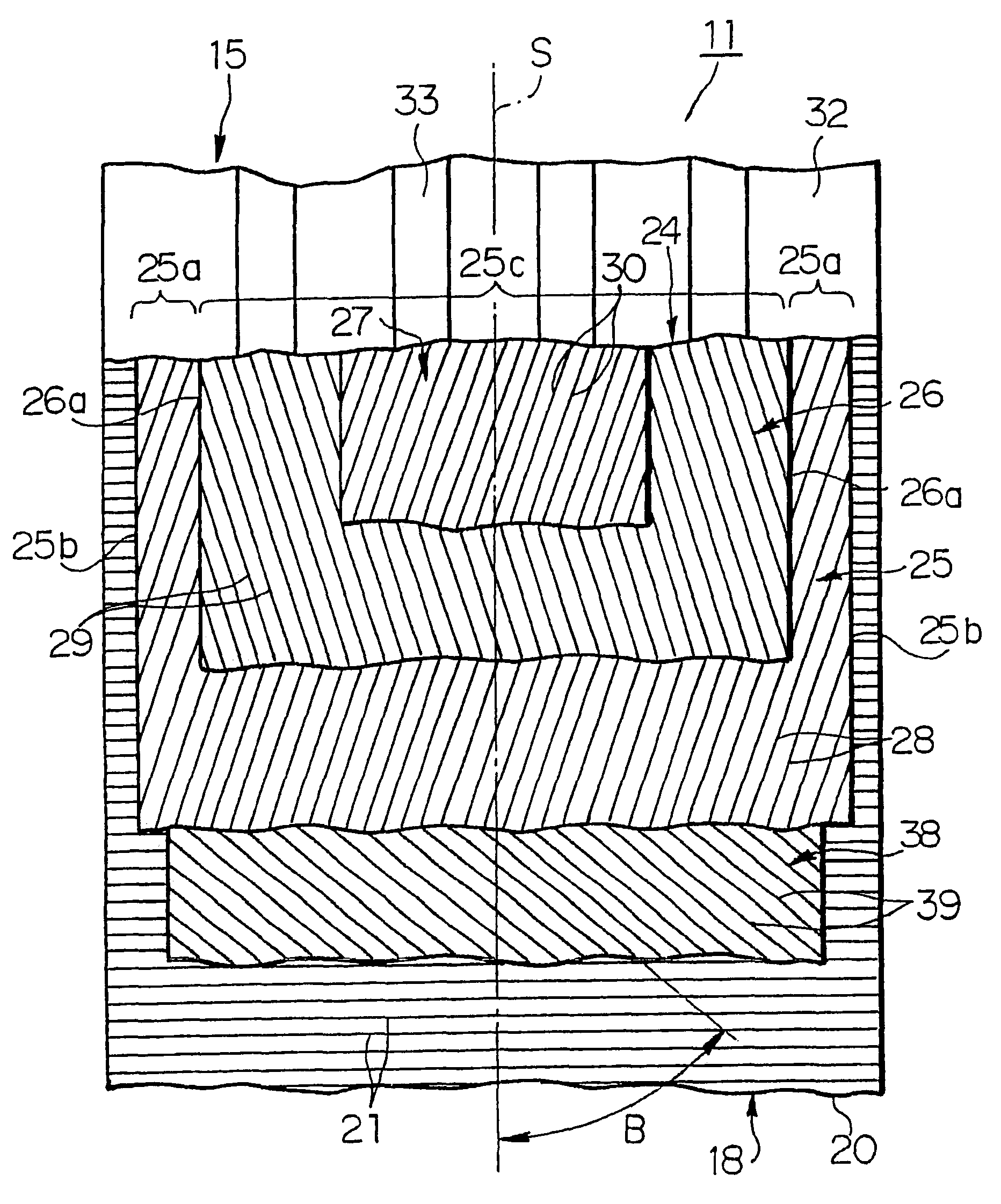

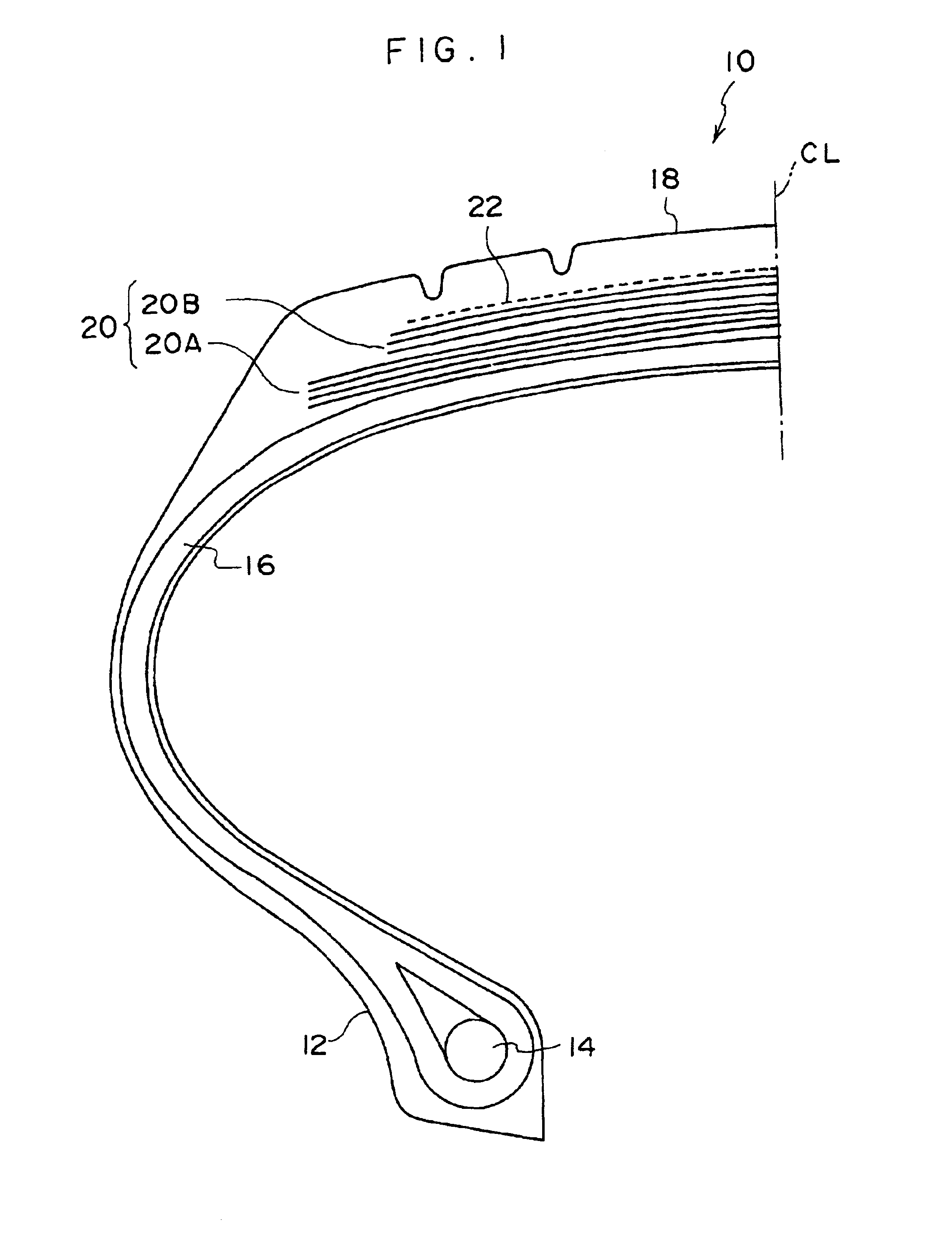

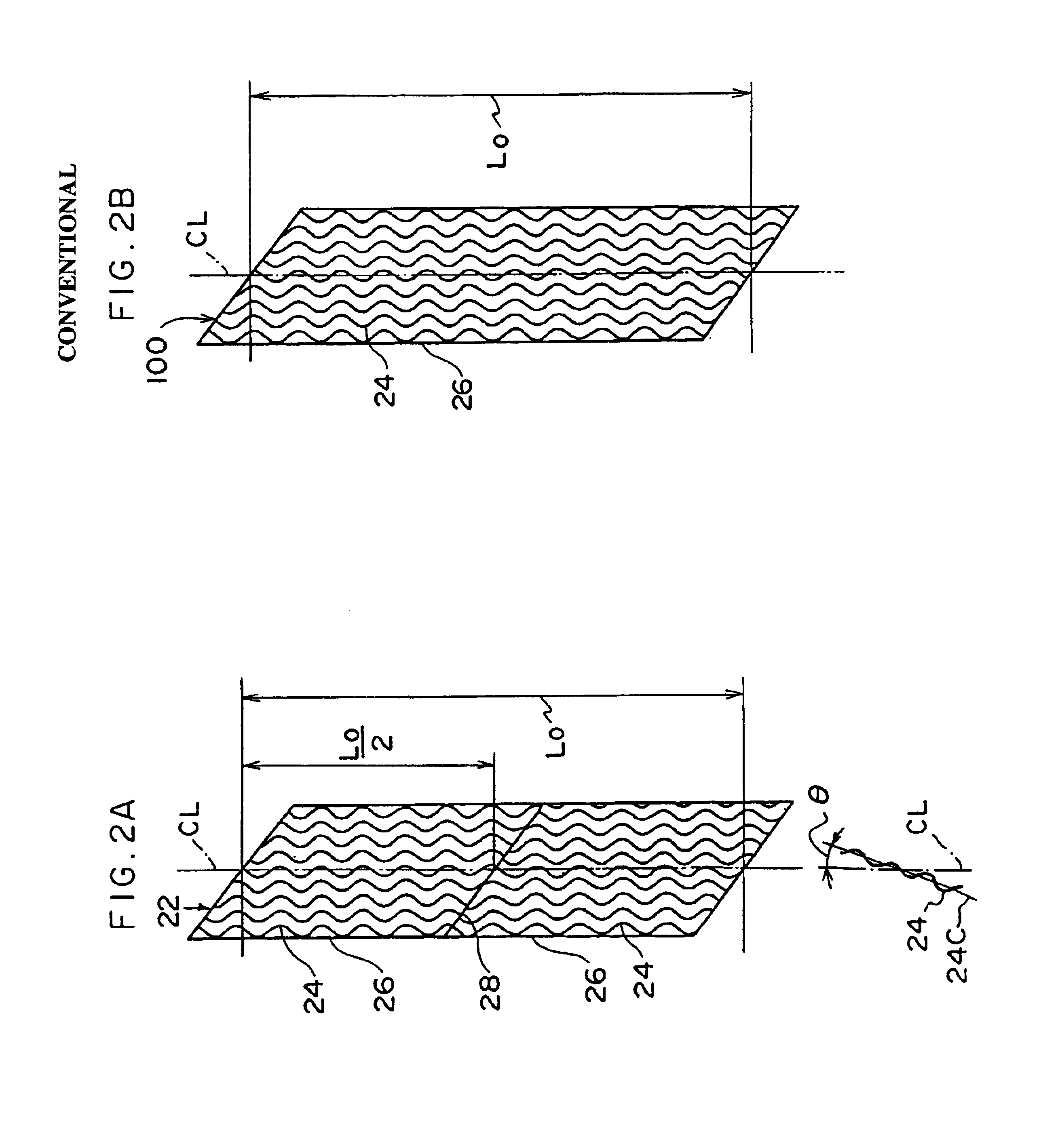

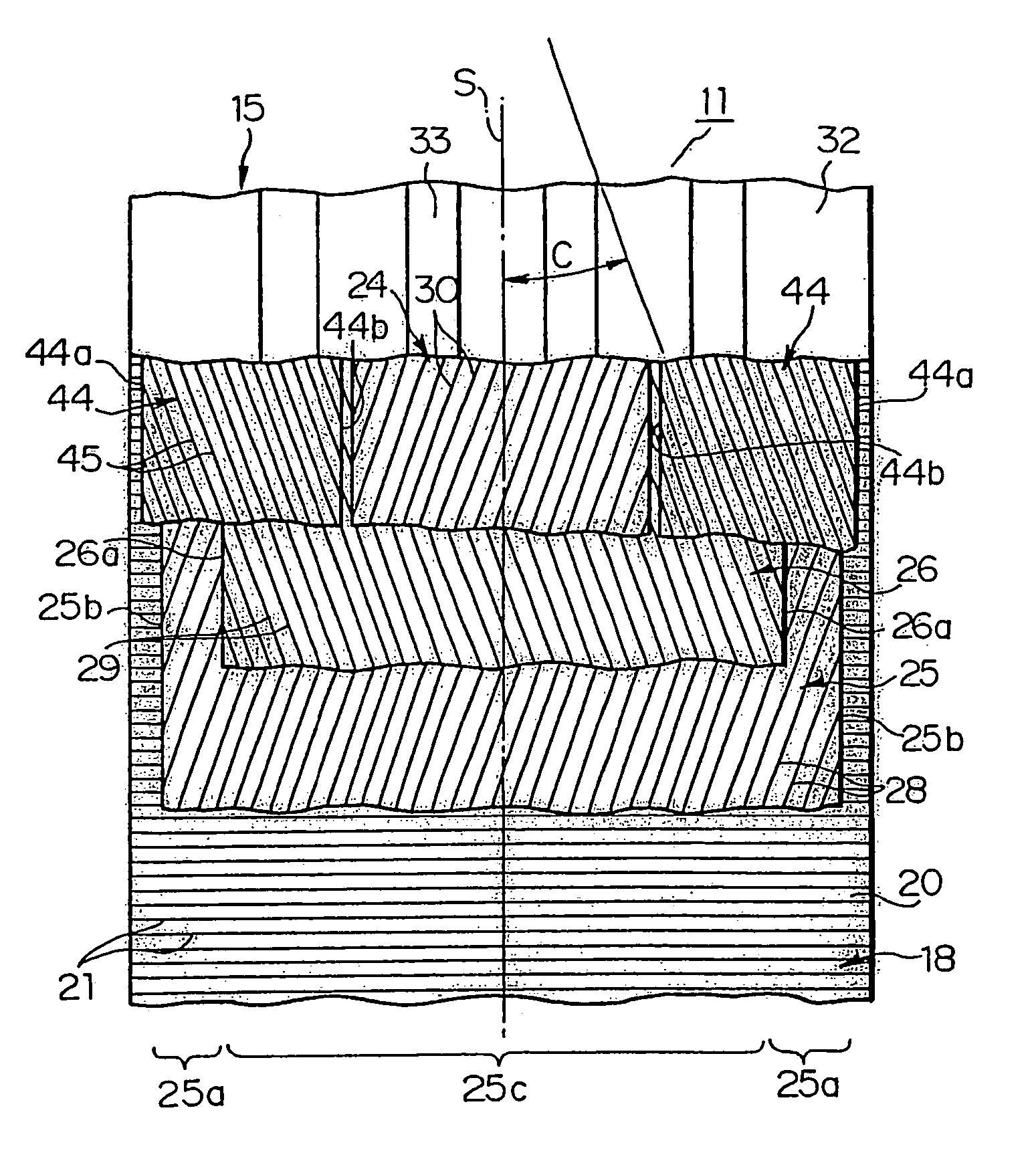

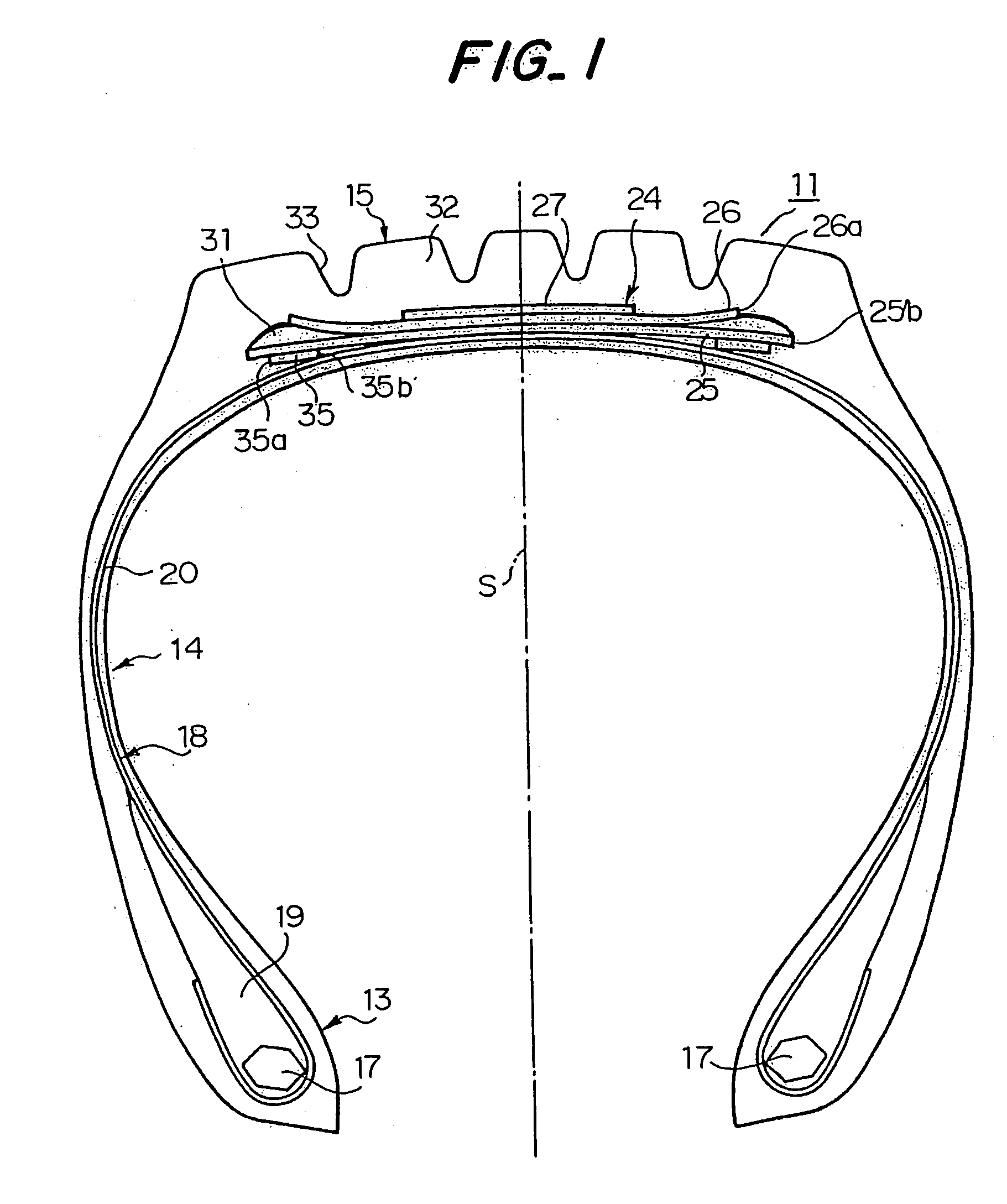

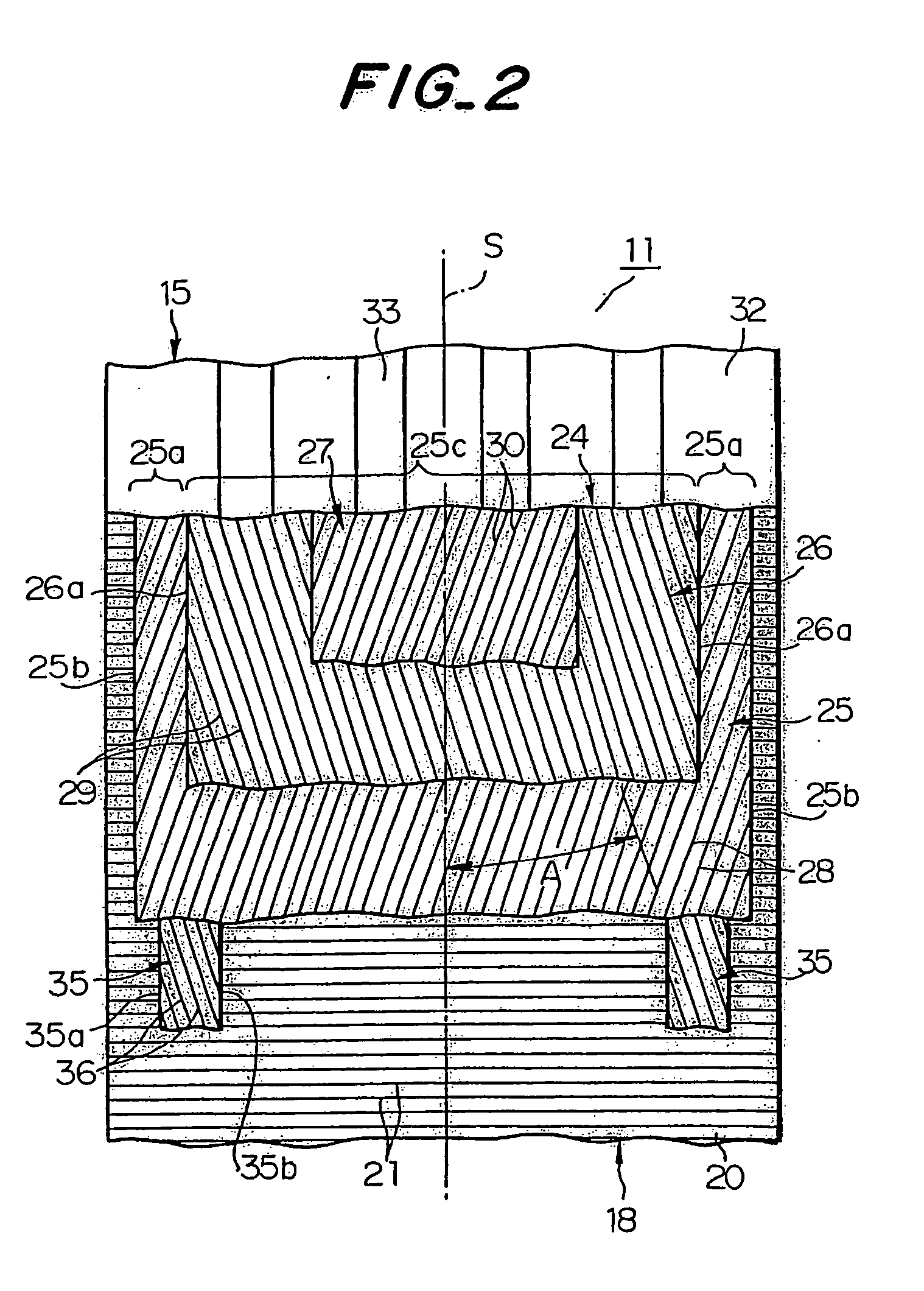

Pneumatic radial tires

InactiveUS6668890B1Avoid separationEnhanced hoop effectPneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

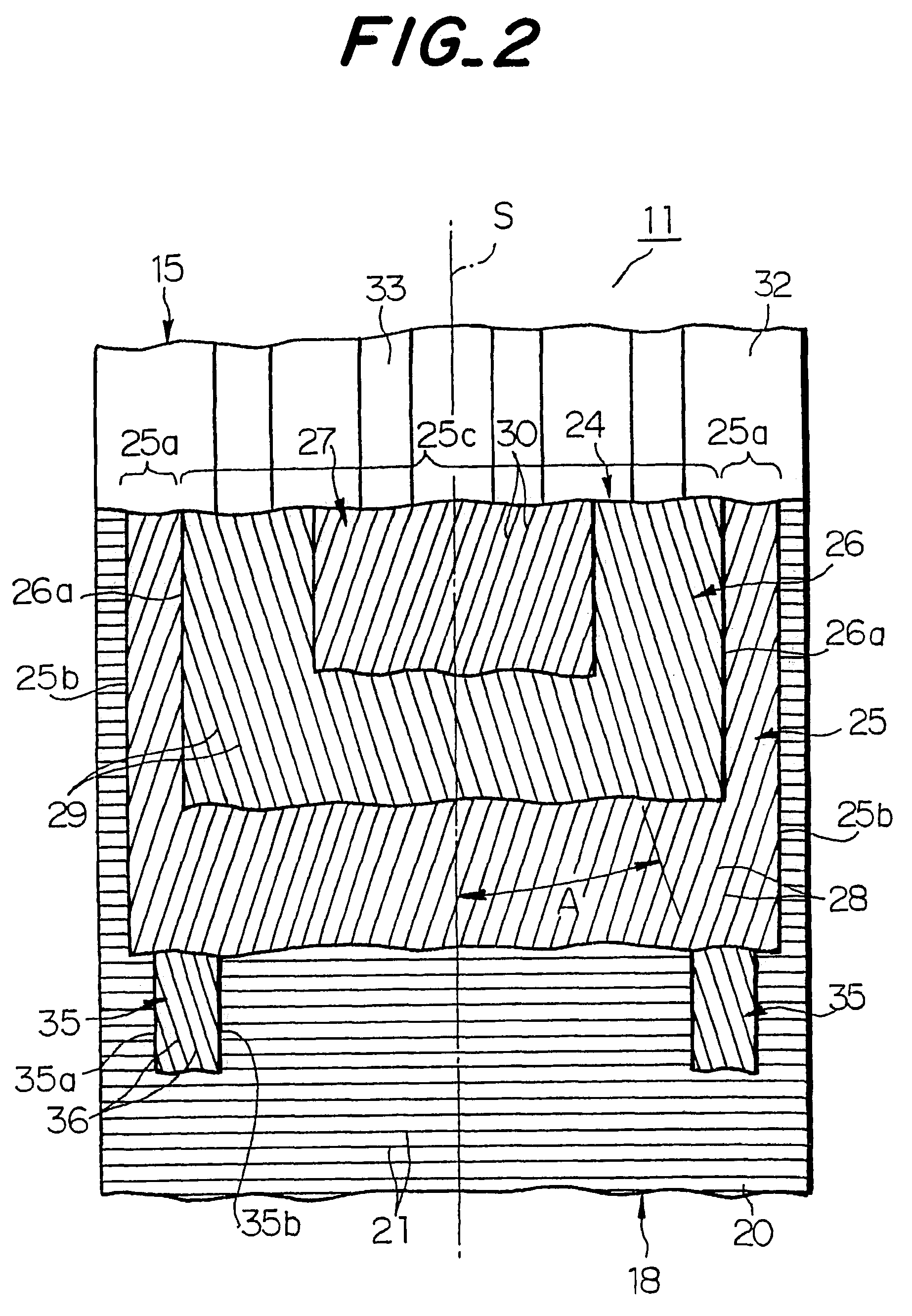

In a pneumatic radial tire comprising a belt of at least two belt layers, in which the belt comprises a maximum-width belt layer containing many cords slantly arranged with respect to an equatorial plane of the tire and a narrow-width belt layer arranged at the outside of the maximum-width belt layer in the radial direction and containing many cords arranged in an oppositely inclined direction to the cords of the maximum-width belt layer, the belt end separation is controlled by arranging a reinforcing layer containing many cords arranged in an oppositely inclined direction to the cords of the maximum-width belt layer so as to overlap with an outer end portion of the maximum-width belt layer located outward from an outer end of the narrow-width belt layer in the widthwise direction thereof.

Owner:BRIDGESTONE CORP

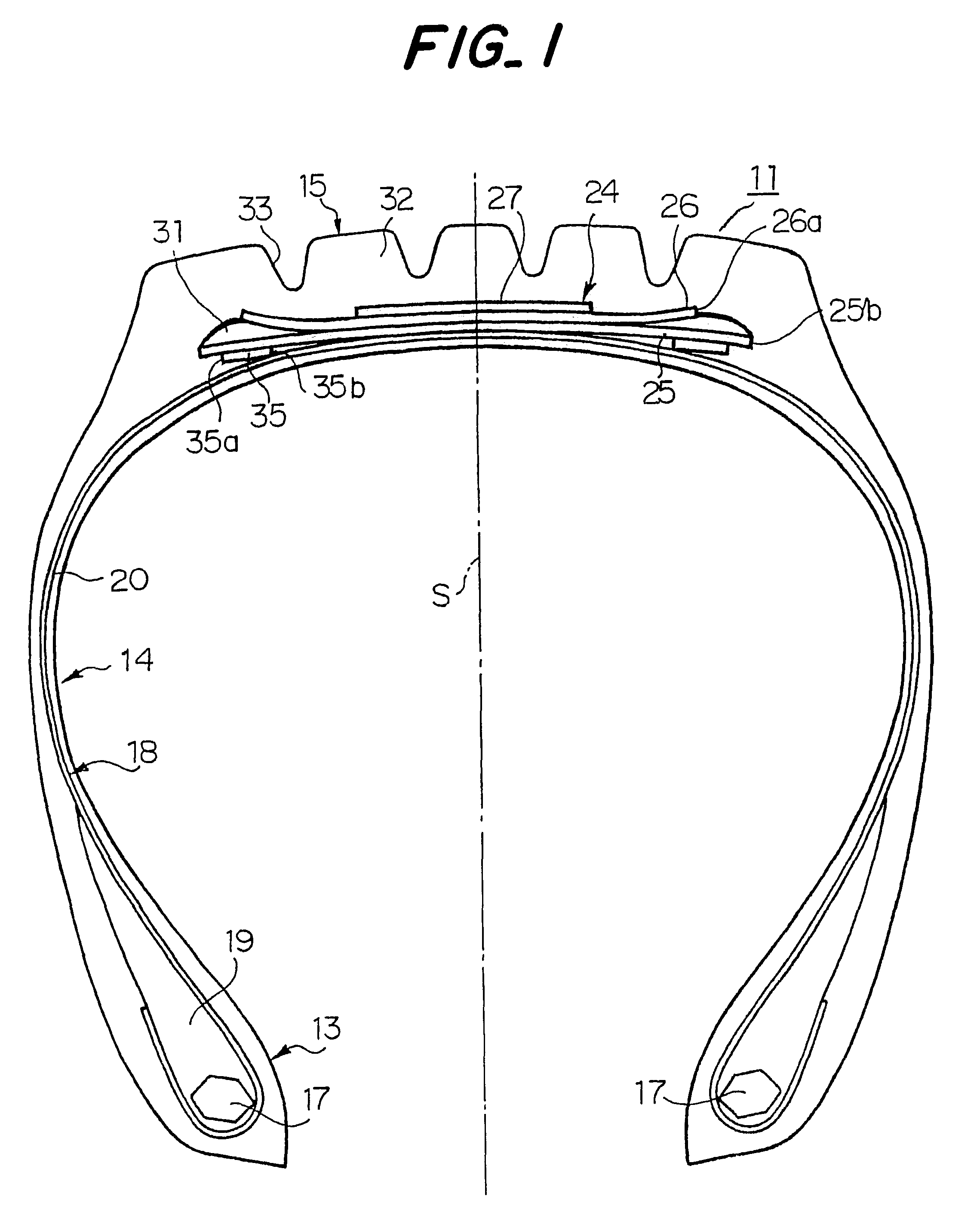

Pneumatic tire

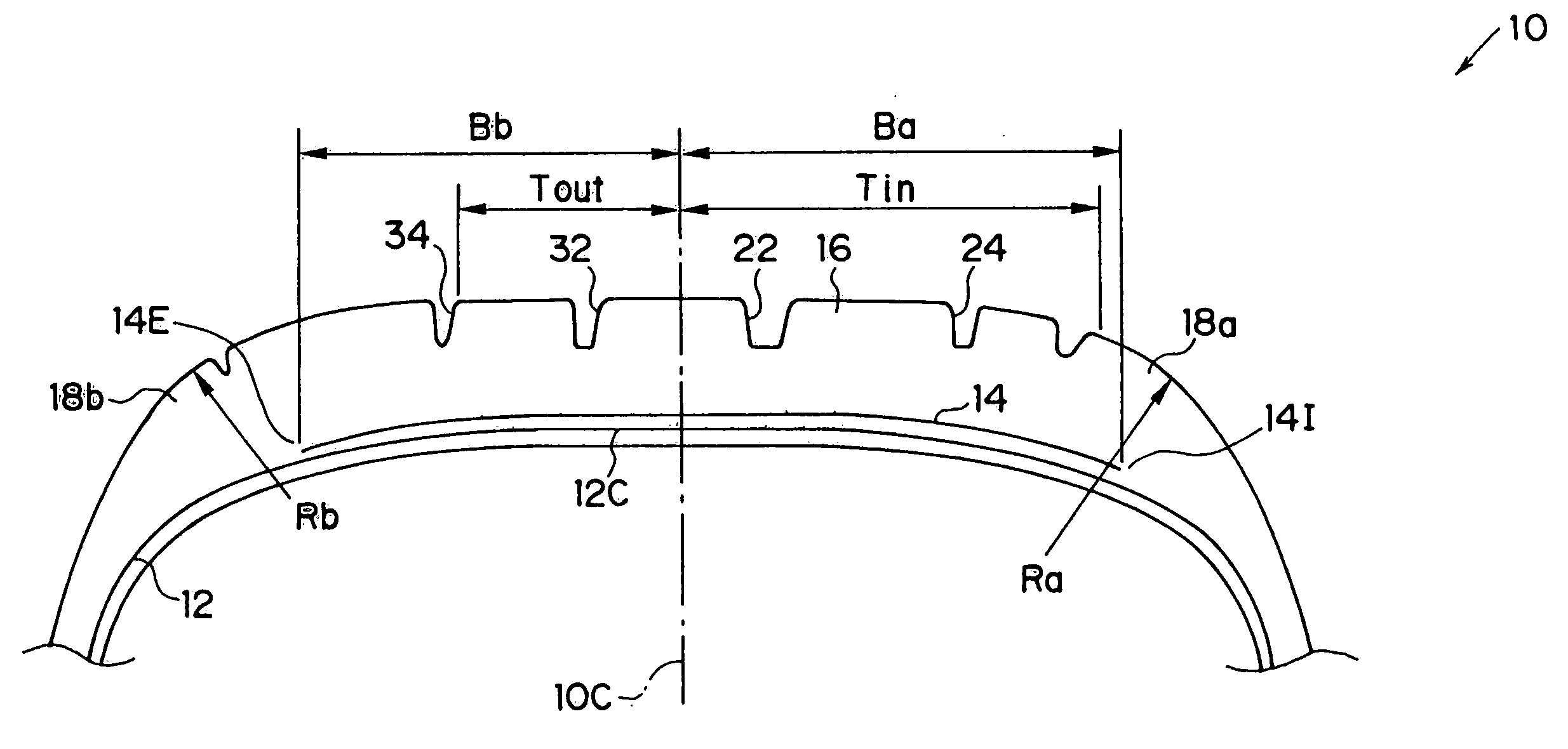

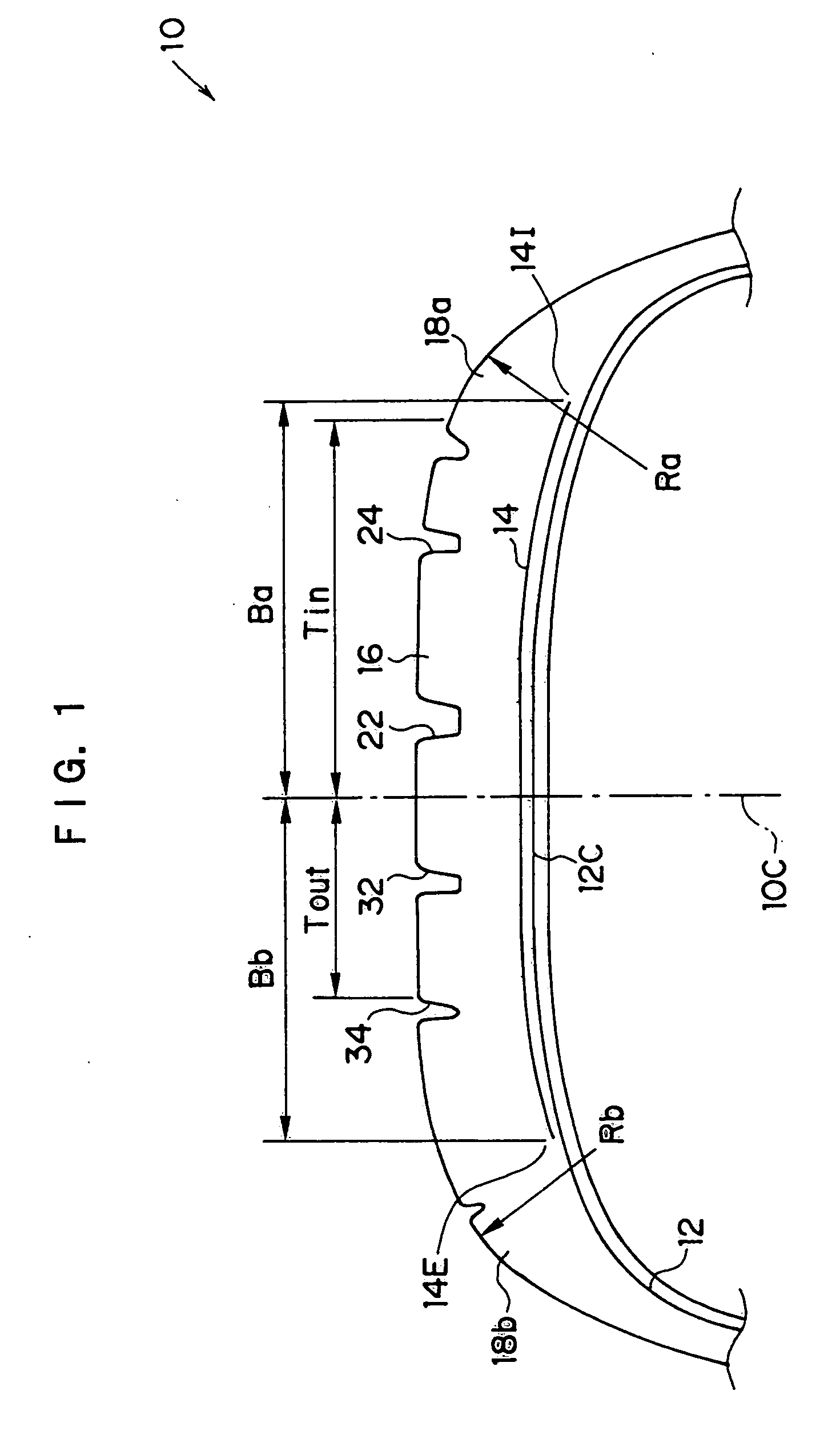

InactiveUS20060266455A1Suppress sectionReduce tensionPneumatic tyre reinforcementsTyre tread bands/patternsEngineeringCentrifugal force

An object is to provide a pneumatic tire having an enhanced high-speed durability without deterioration in steering stability. A pneumatic tire 10 includes a belt 14 and a tread section 16 on an outside of a crown part 12C in this order, and has different negative ratios of the tread section 16 between both sides of a tire equatorial plane 10C. A belt width Ba from a belt end 14I on the higher negative ratio side to the tire equatorial plane 10C and a belt width Bb from a belt end 14E on the lower negative ratio side to the tire equatorial plane 10C satisfy a relationship of Ba>Bb. It is thereby possible to efficiently suppress a shoulder section 18 from projecting due to a centrifugal force during high-speed rolling. It is thereby possible to efficiently reduce a strain and a heat generated in a rubber member of the shoulder section 18, and efficiently enhance high-speed durability. Further, by ensuring that a grounding width on an OUT side is equivalent to that of a conventional one, it is possible to prevent deterioration in steering stability.

Owner:BRIDGESTONE CORP

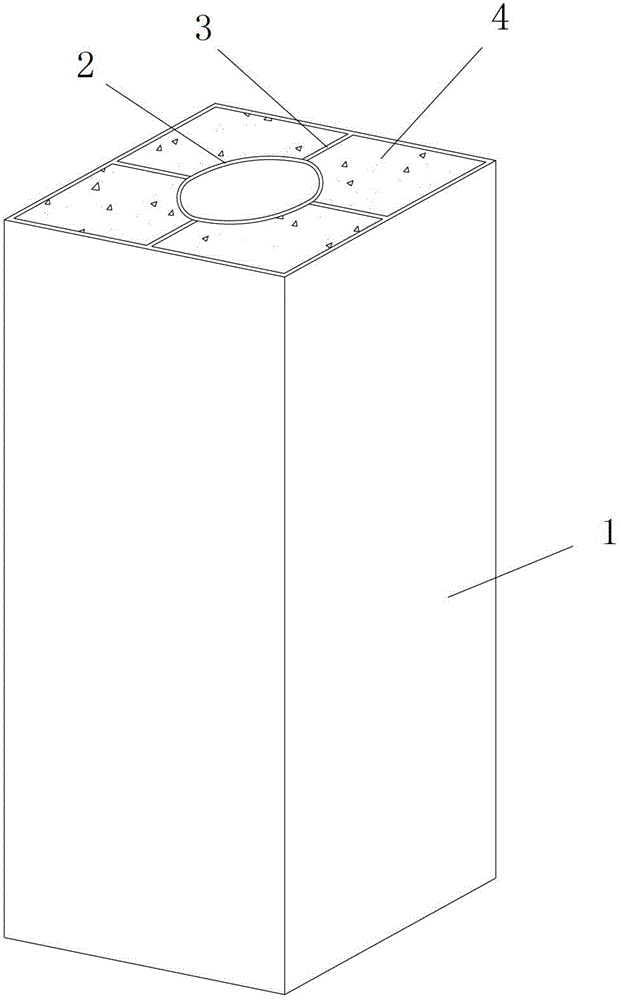

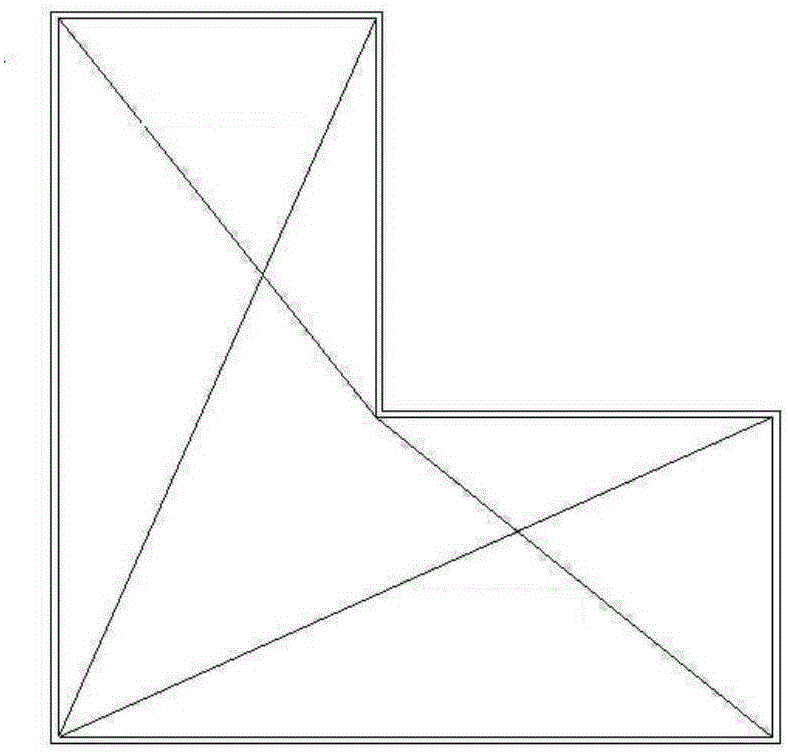

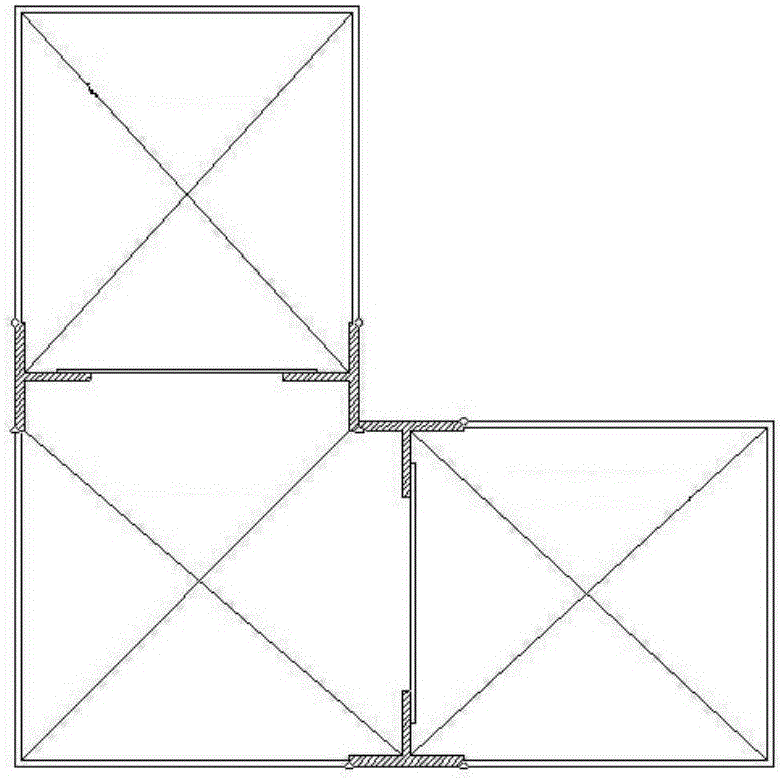

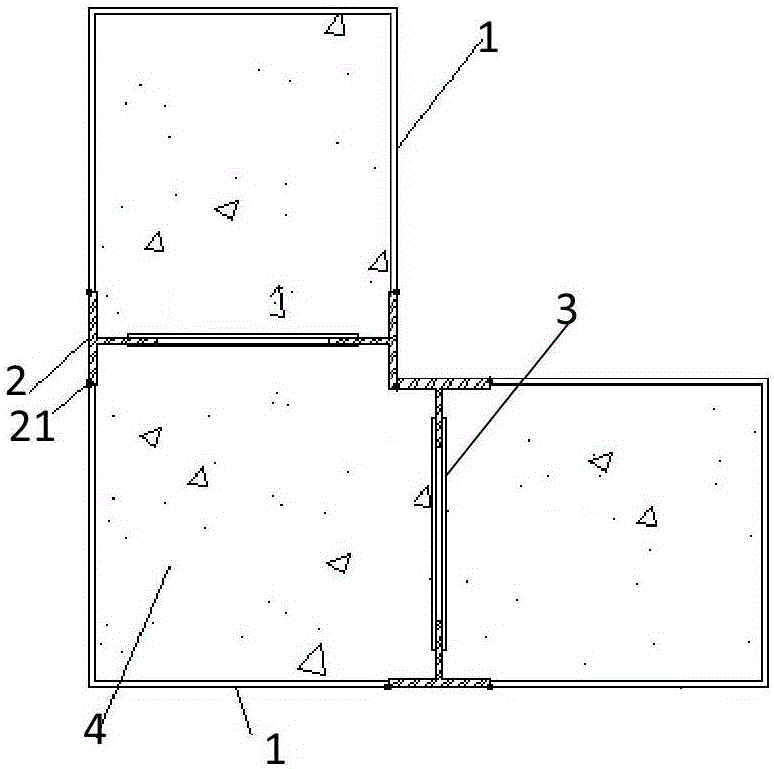

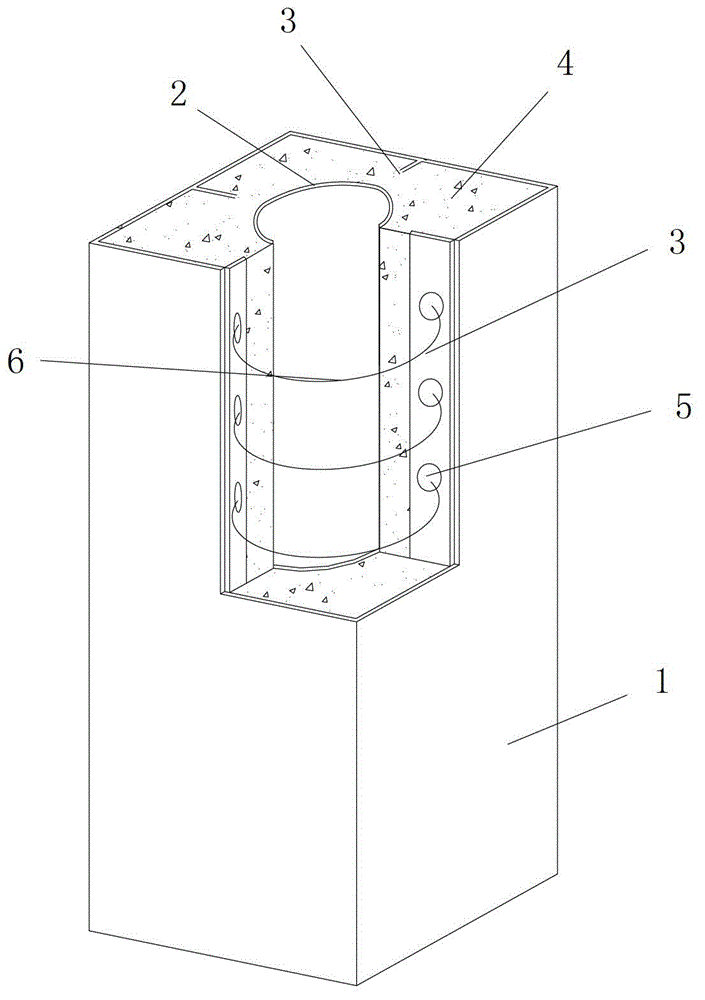

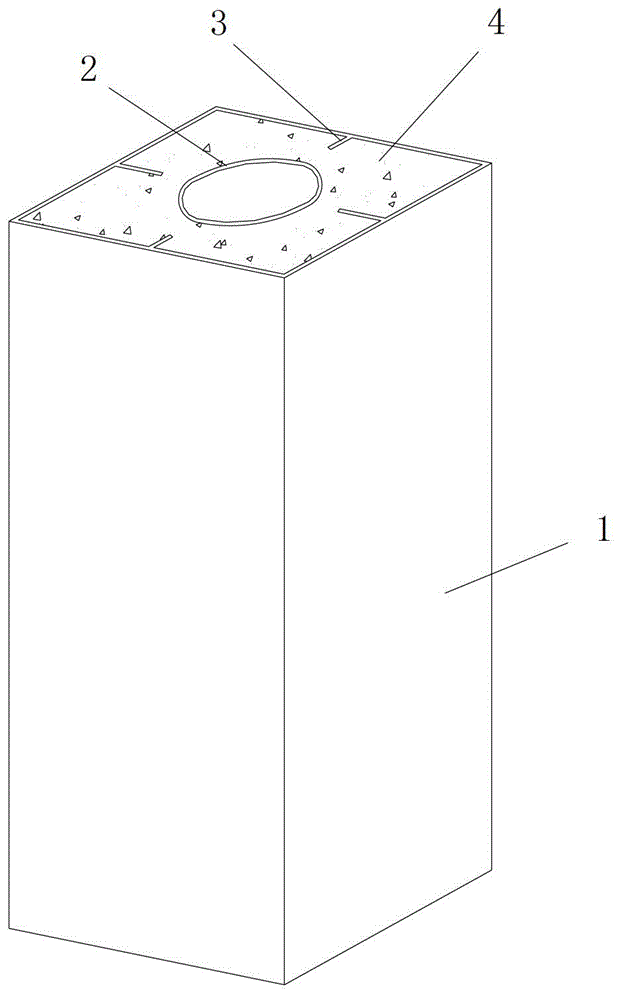

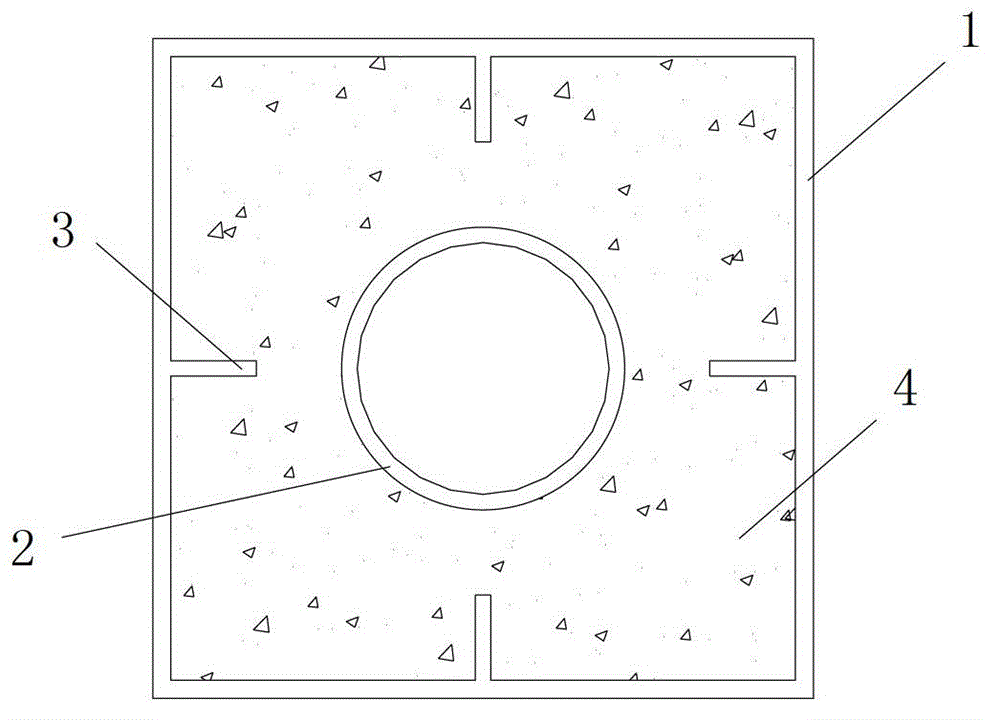

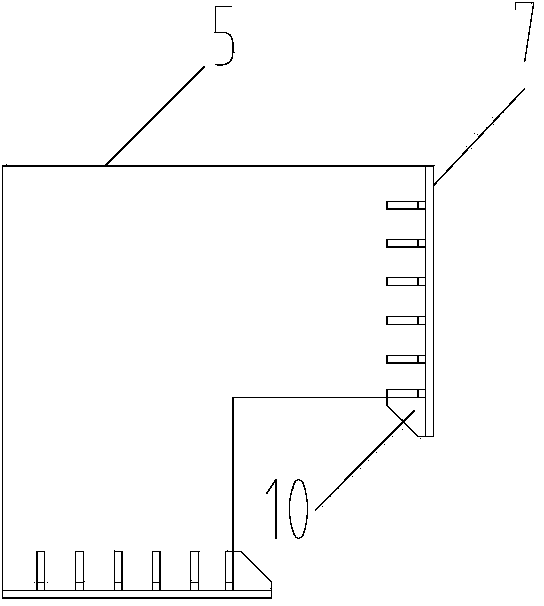

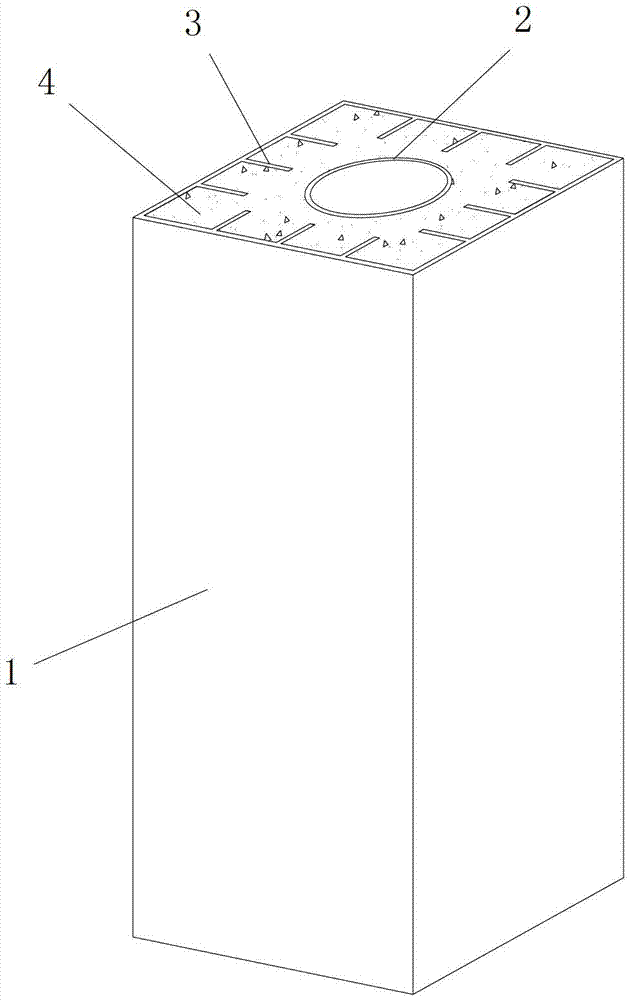

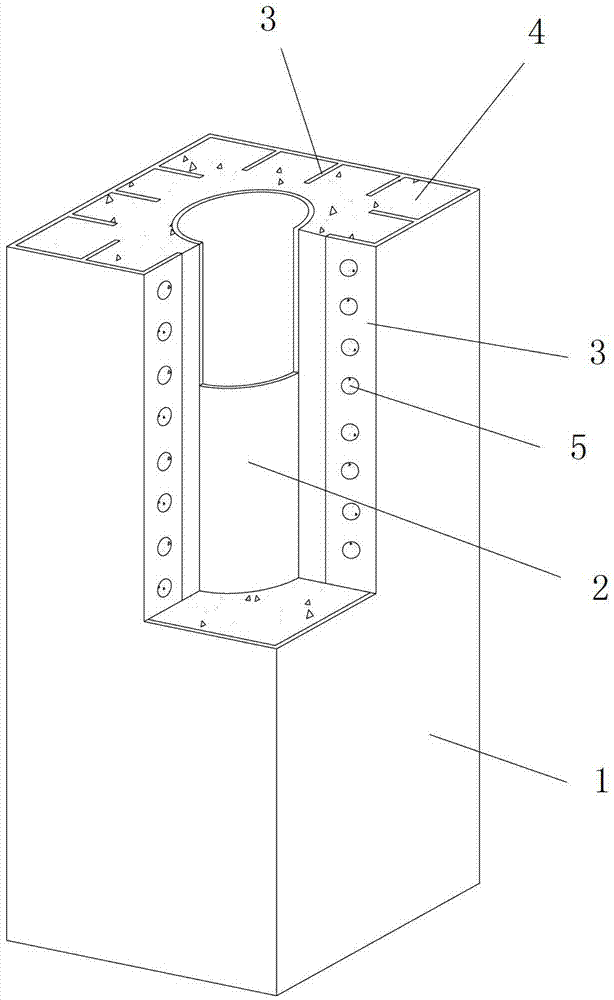

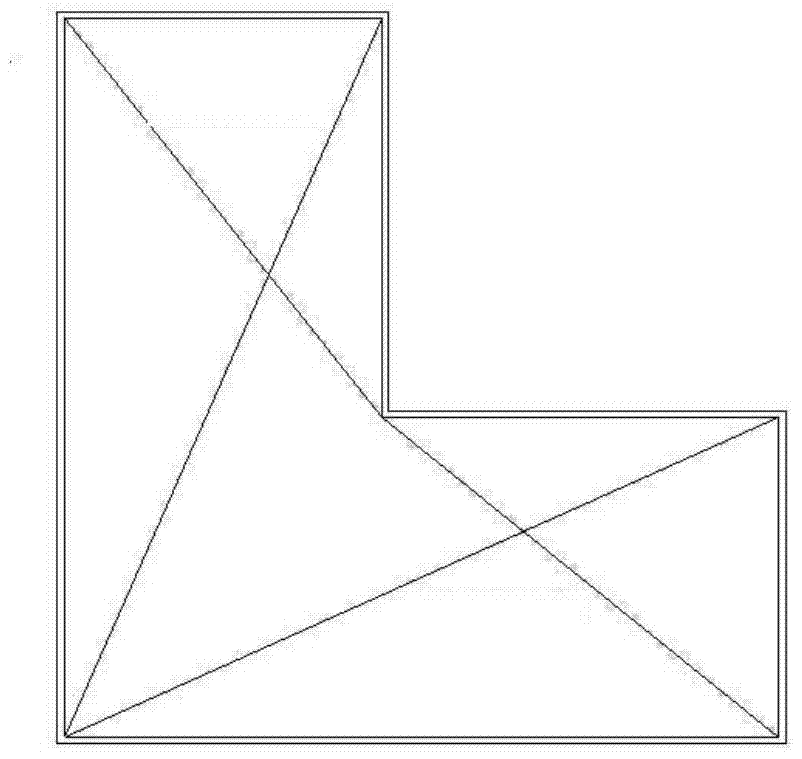

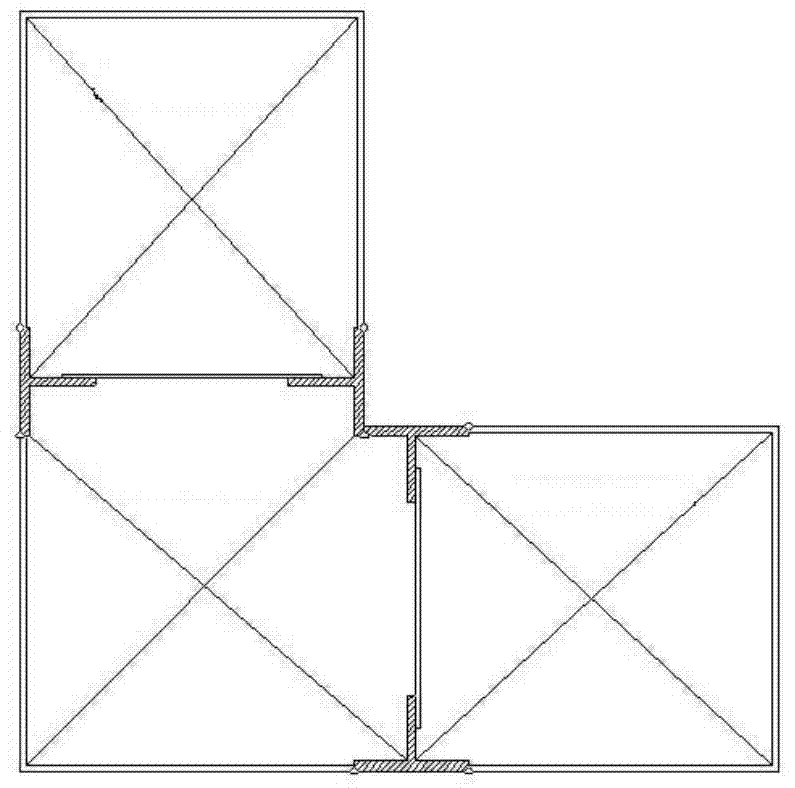

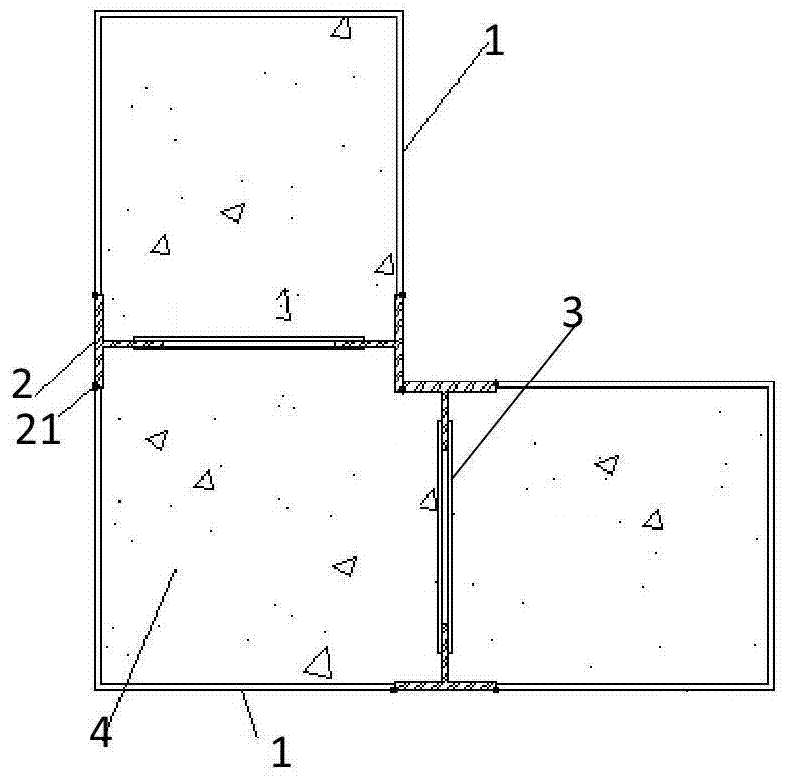

Inner truss type steel tube concrete L-shaped column and construction method thereof

InactiveCN105113717AReduce effective widthImprove bearing capacityStrutsBuilding material handlingSteel platesSteel tube

The invention discloses an inner truss type steel tube concrete L-shaped column and a construction method thereof. The inner truss type steel tube concrete L-shaped column comprises a wrapping steel tube, filling concrete and an inner truss; the inner truss comprises T-shaped steel, inner truss subunits and T-shaped steel web lacing bars; the inner truss subunits are formed by welding the T-shaped steel; the T-shaped steel web lacing bars are longitudinally welded in a T-shaped steel web and the inner truss subunits along the T-shaped steel in a stacked manner; the T-shaped steel and the inner truss subunits are positioned at edges and corners of a quadrangle; the cross section of the wrapping steel tube is inversely L-shaped or n-shaped; and the wrapping steel tube is fixedly welded with flange plates of the T-shaped steel. The inner truss is tensioned at a corner of a special-shaped steel tube, so that effective width of a steel plate is reduced, a fulcrum is provided for deformation of the steel plate out of a plane, anti-unsteady capability of the steel plate can be improved, a hooping effect of the column is improved, and the bearing capacity of a steel tube concrete special-shaped column is improved obviously.

Owner:HOHAI UNIV

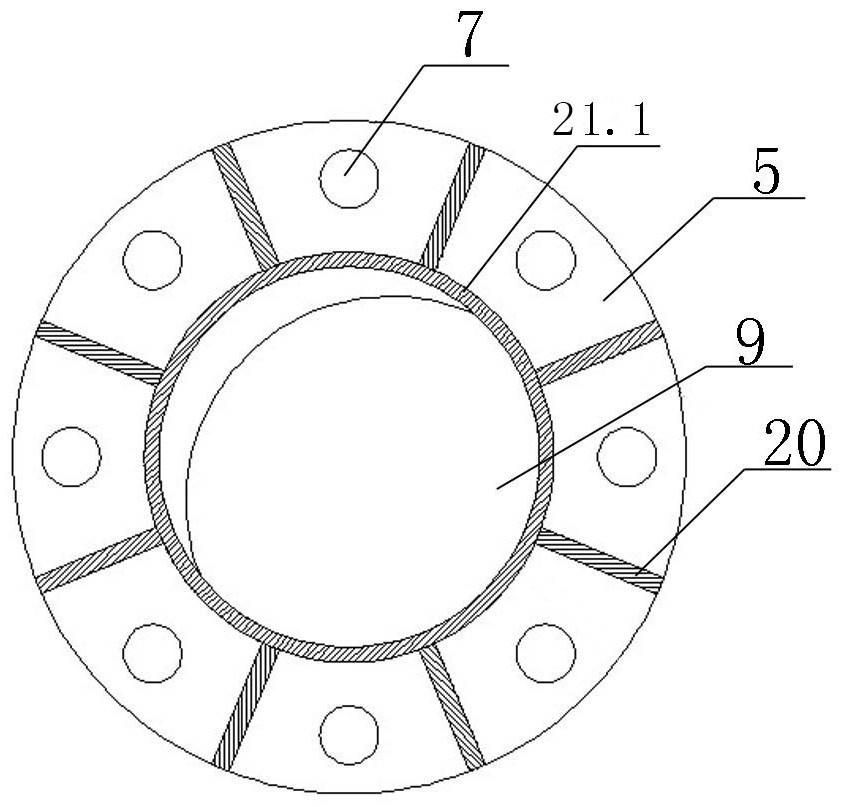

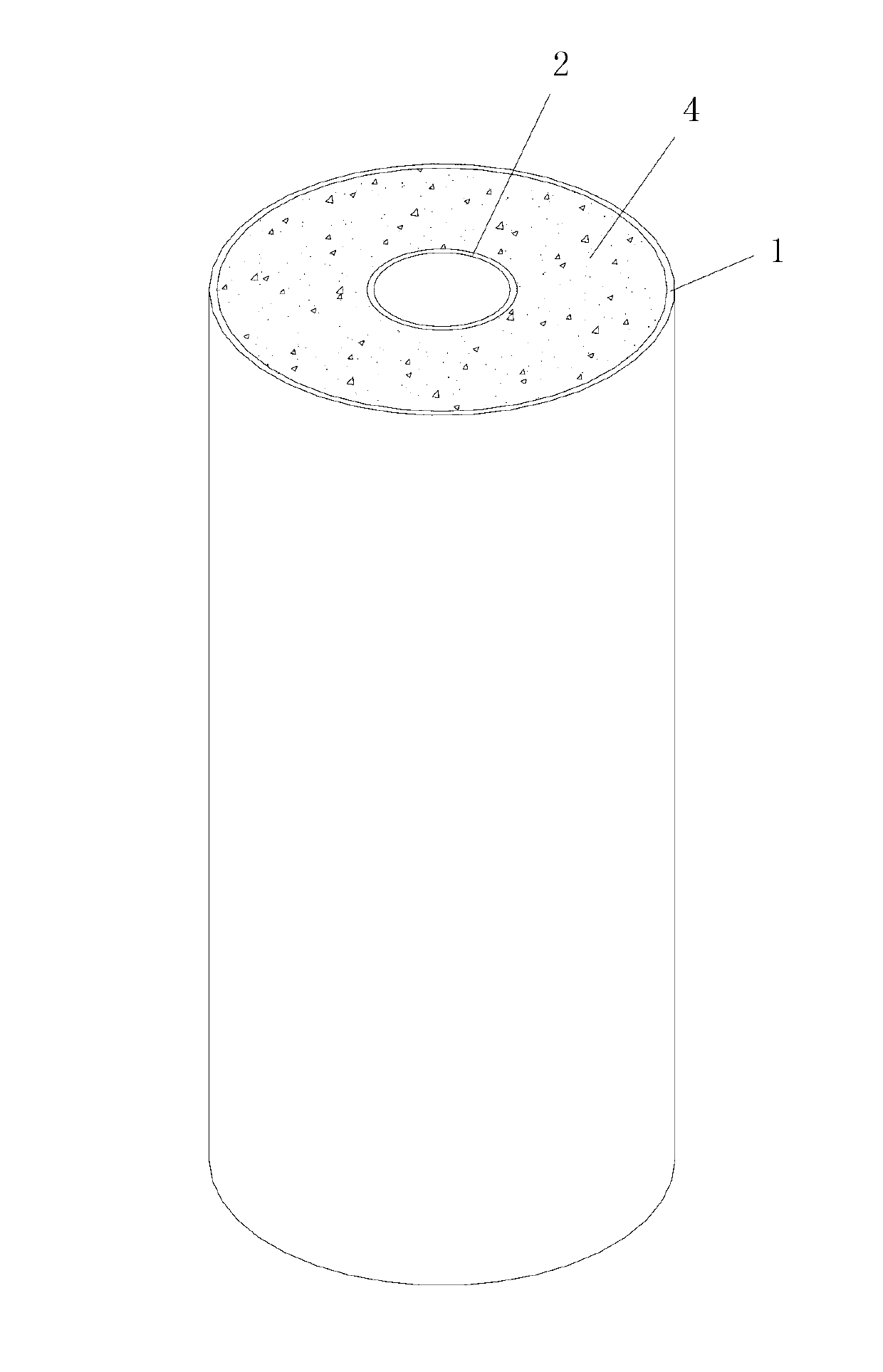

SCS (structure cabling system) encased structure based on longitudinal stiffening ribs

InactiveCN102979250ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on longitudinal stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of longitudinal stiffening ribs arranged at the inner lateral wall of the outer steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube and the inner steel tube are coaxially arranged; the plurality of longitudinal stiffening ribs are arranged along the peripheral direction of the inner steel tube; the outer steel tube, the inner steel tube and the plurality of longitudinal stiffening ribs are equal in the longitudinal length, and the transverse width of each longitudinal stiffening rib is the distance between the outer steel tube and the inner steel tube at the arranged positions. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

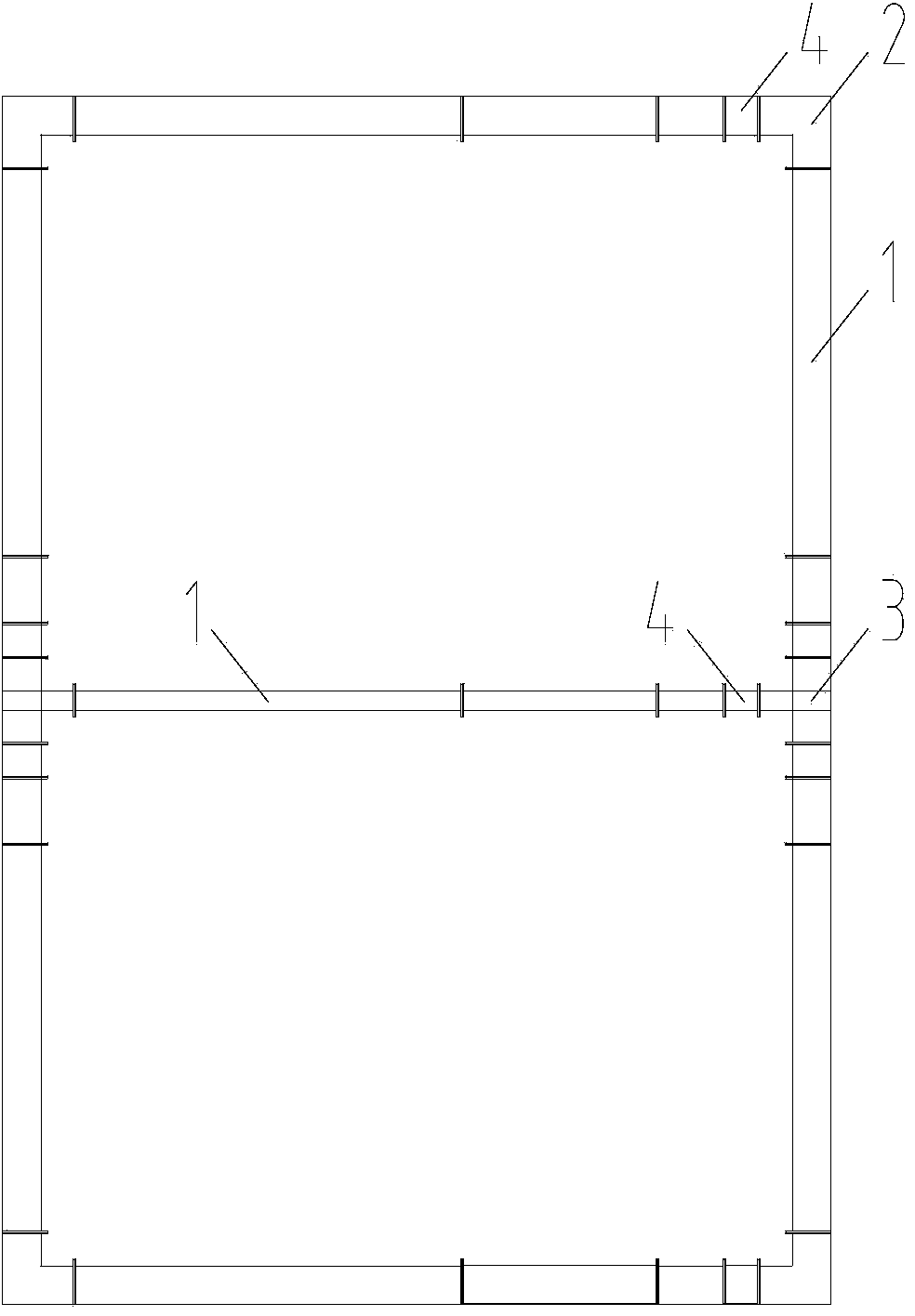

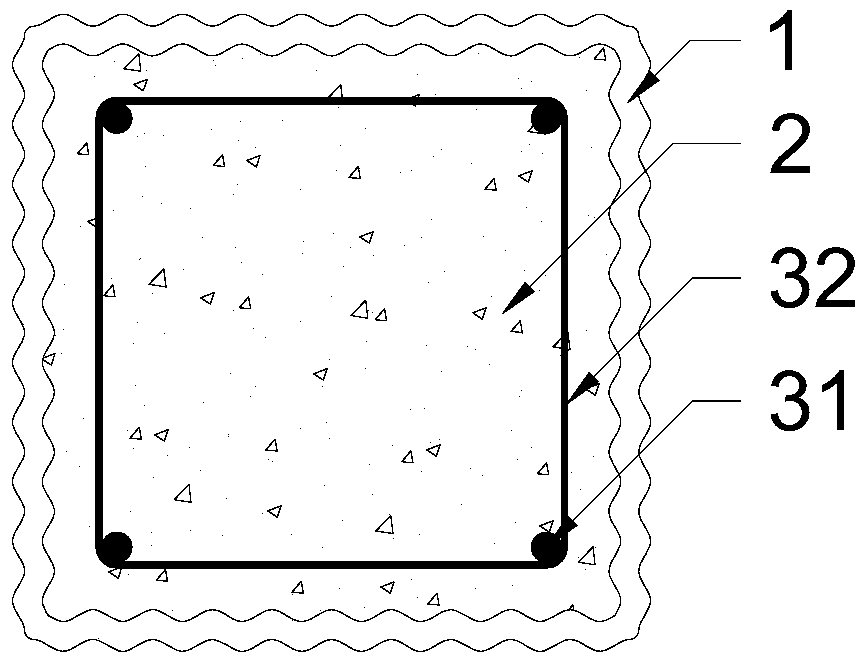

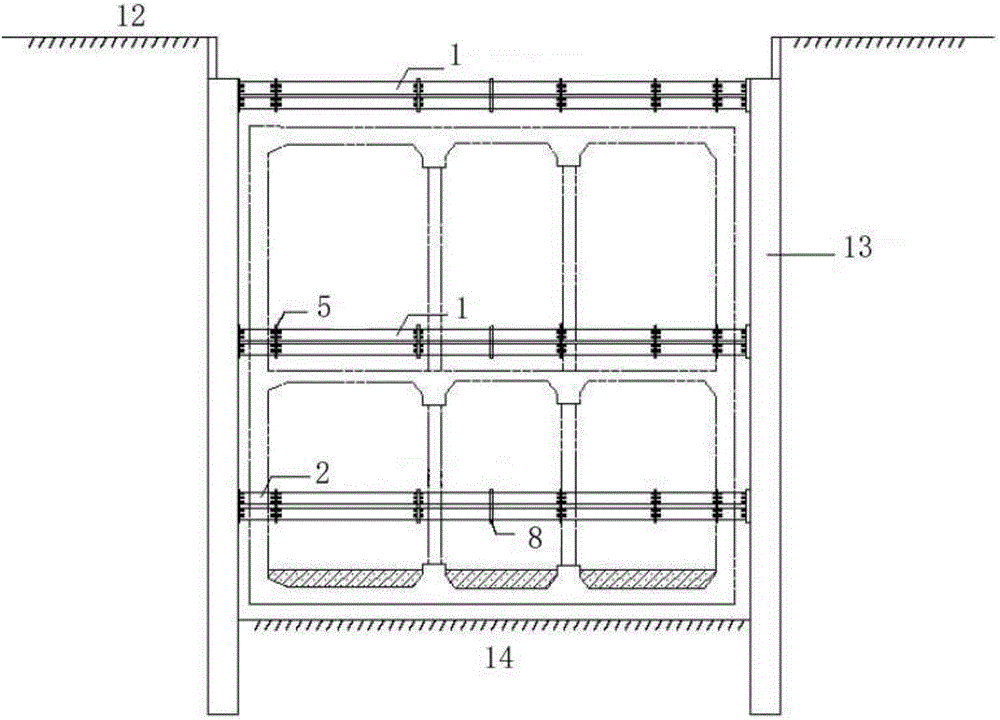

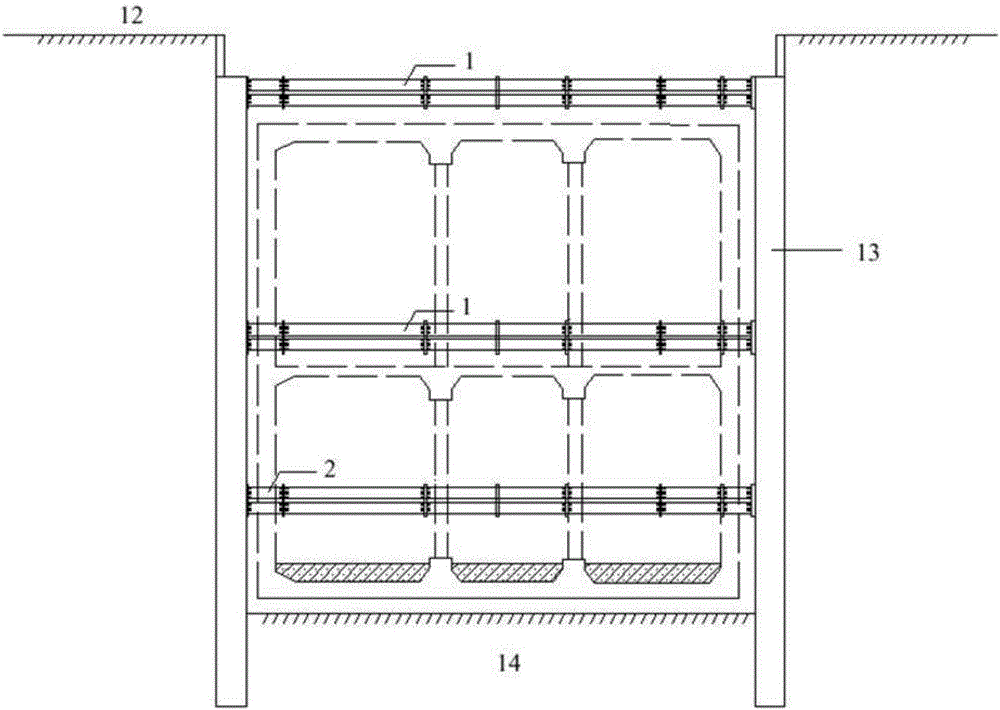

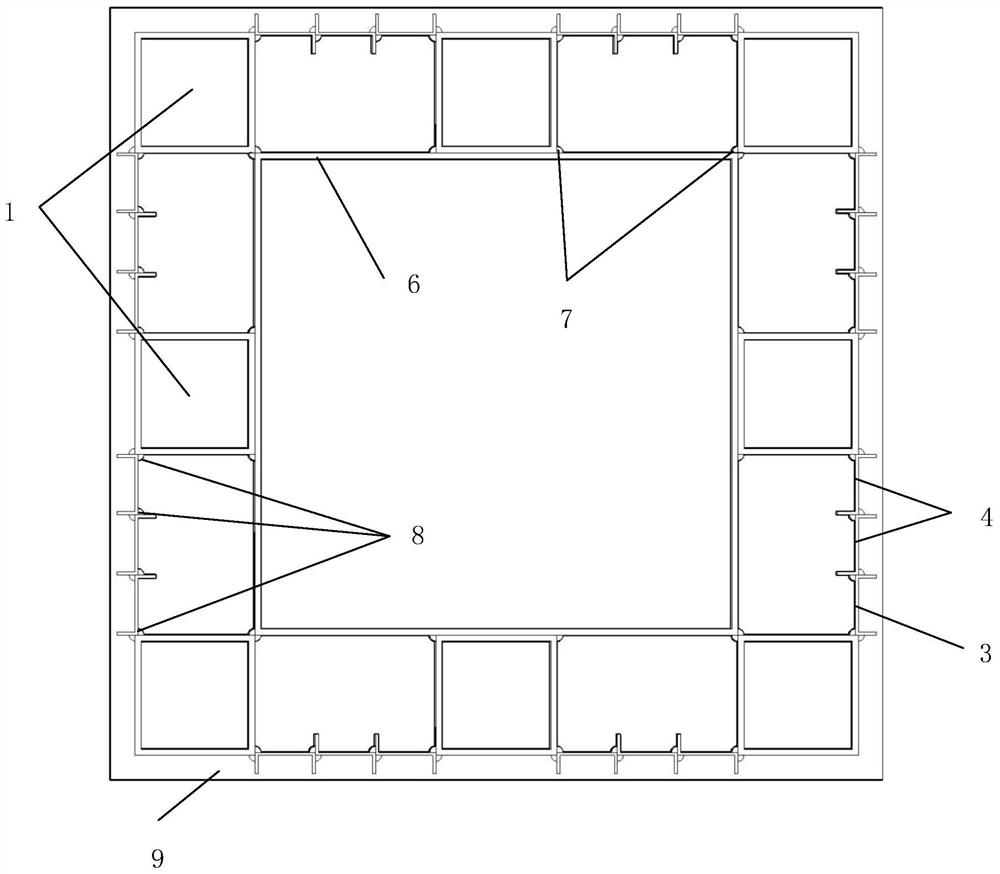

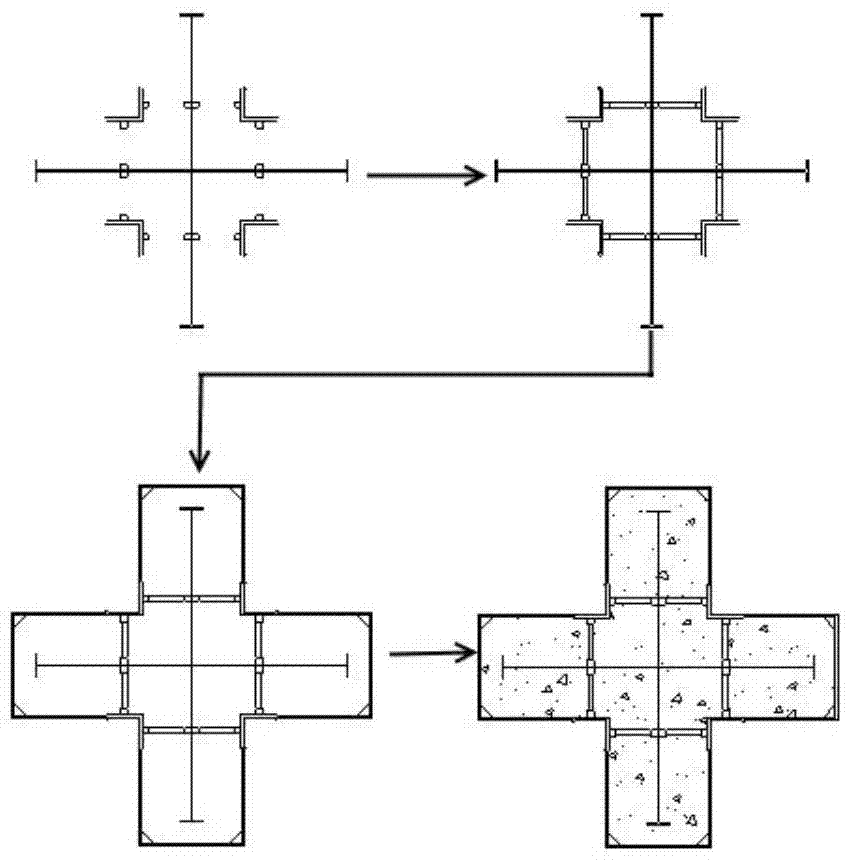

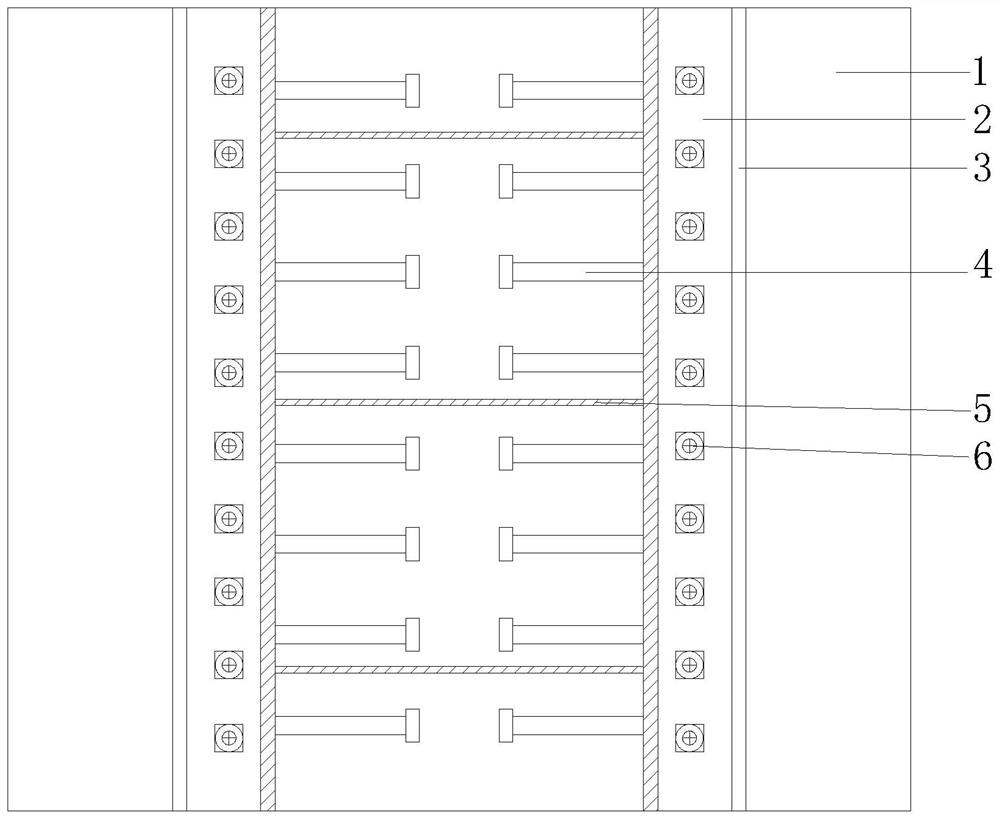

Shield vertical shaft assembling type concrete-filled steel tube inner support system and construction method thereof

InactiveCN103541733ARealize factory manufacturingQuick assemblyShaft liningStructural deformationSupporting system

The invention relates to a shield vertical shaft assembling type concrete-filled steel tube inner support system and a construction method thereof and belongs to the technical field of shield vertical shaft inner support. The system comprises multiple layers of concrete-filled steel tube inner support frames. Each concrete-filled steel tube inner support frame is spliced by four kinds of rectangular concrete-filled steel tube components including standard rectangular concrete-filled steel tube straight supports, rectangular concrete-filled steel tube straight corners, rectangular concrete-filled steel tube tee joints and rectangular concrete-filled steel tube short connection straight supports. Fast component connection is completed by high-strength bolts. Each component is formed by filling micro-expansion concrete into steel tubes with rectangular sections. Assembling construction of the inner support system is achieved, the problems that steel support is poor in overall stability and small in rigidity and has internal rust are solved, the problems that concrete support is complex in construction and high in manufacturing cost are solved, and the concrete-filled steel tube inner support system is good in integrity and reusable, and capable of strictly controlling structural deformation.

Owner:BEIJING UNIV OF TECH

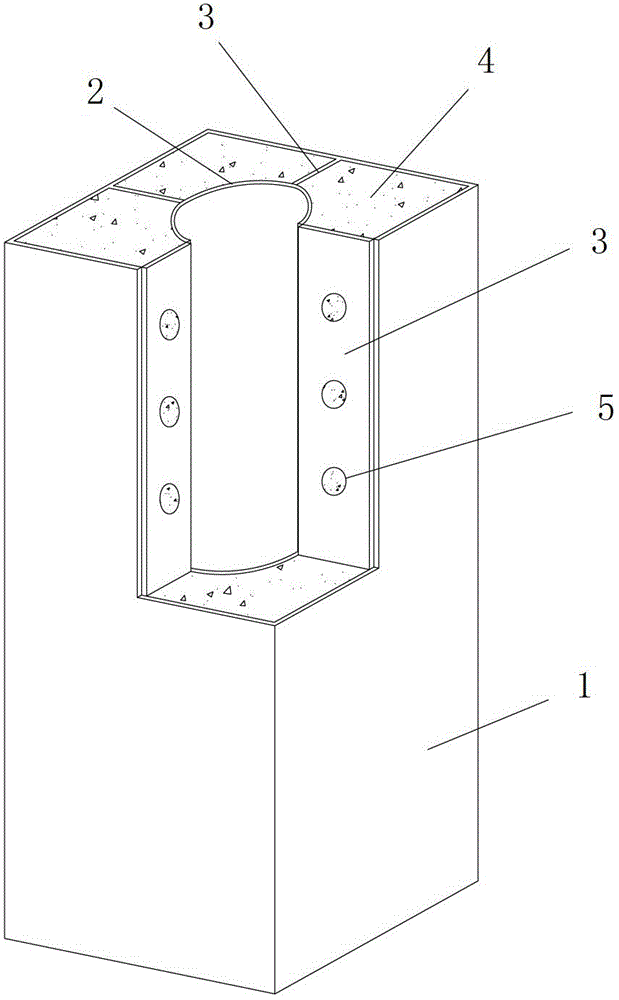

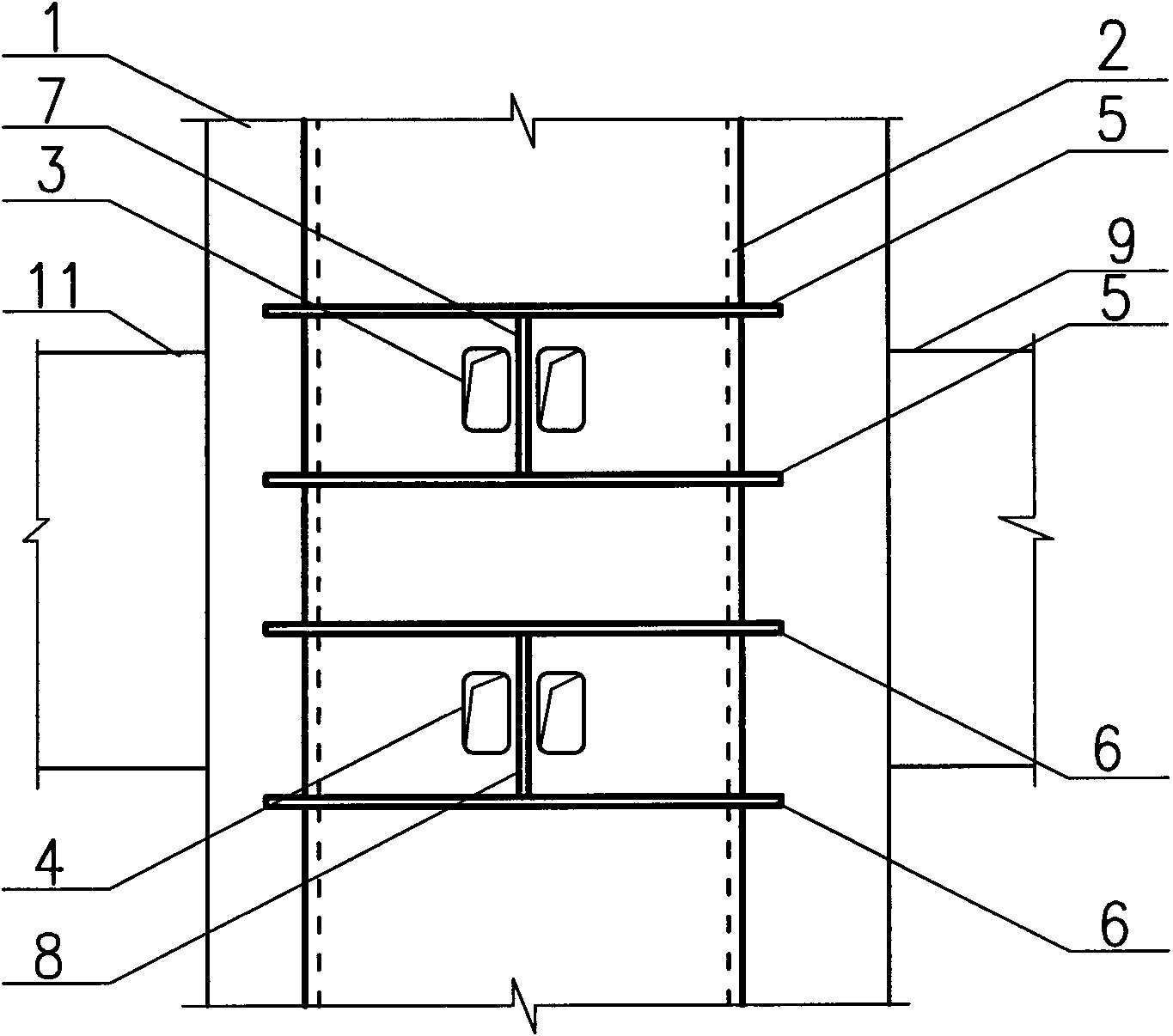

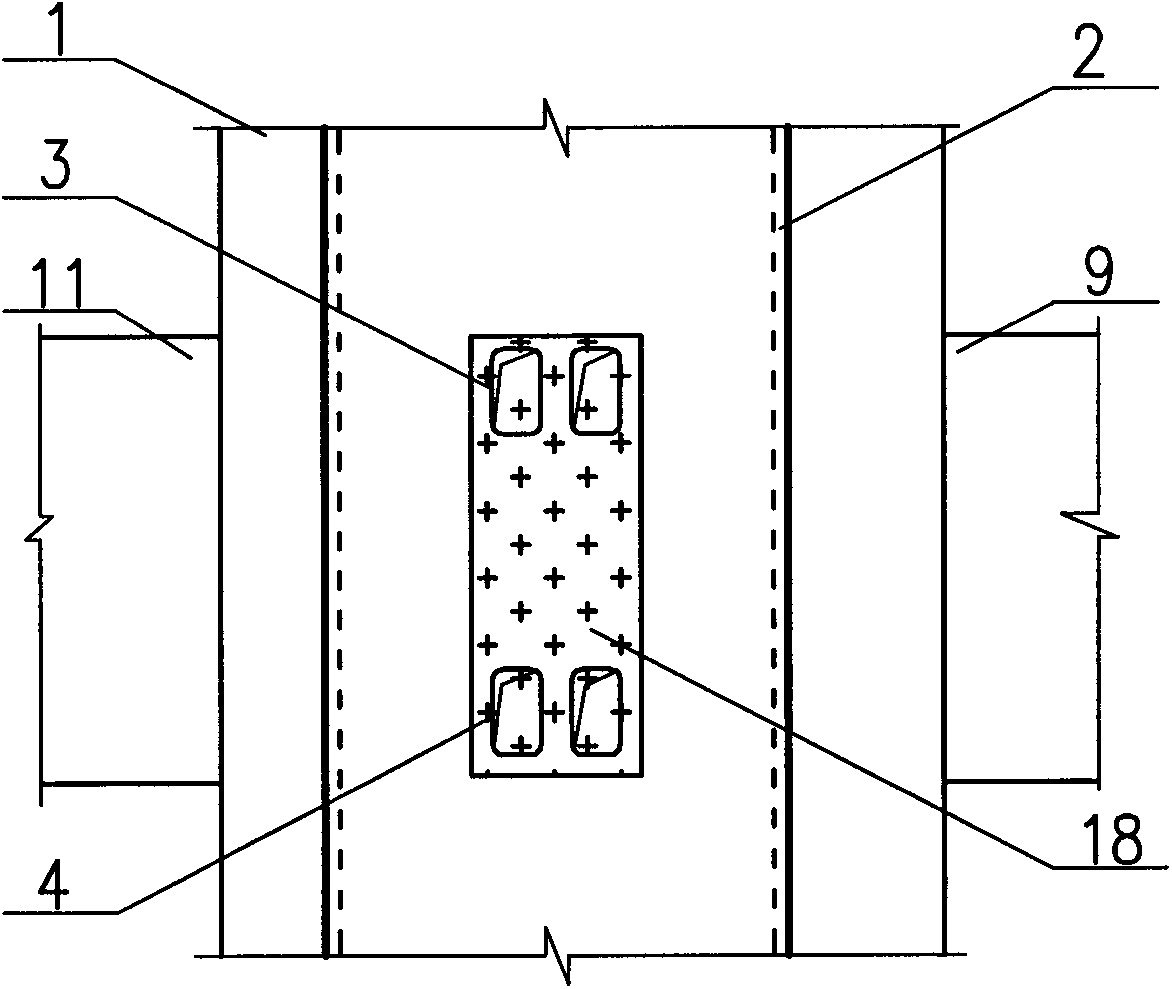

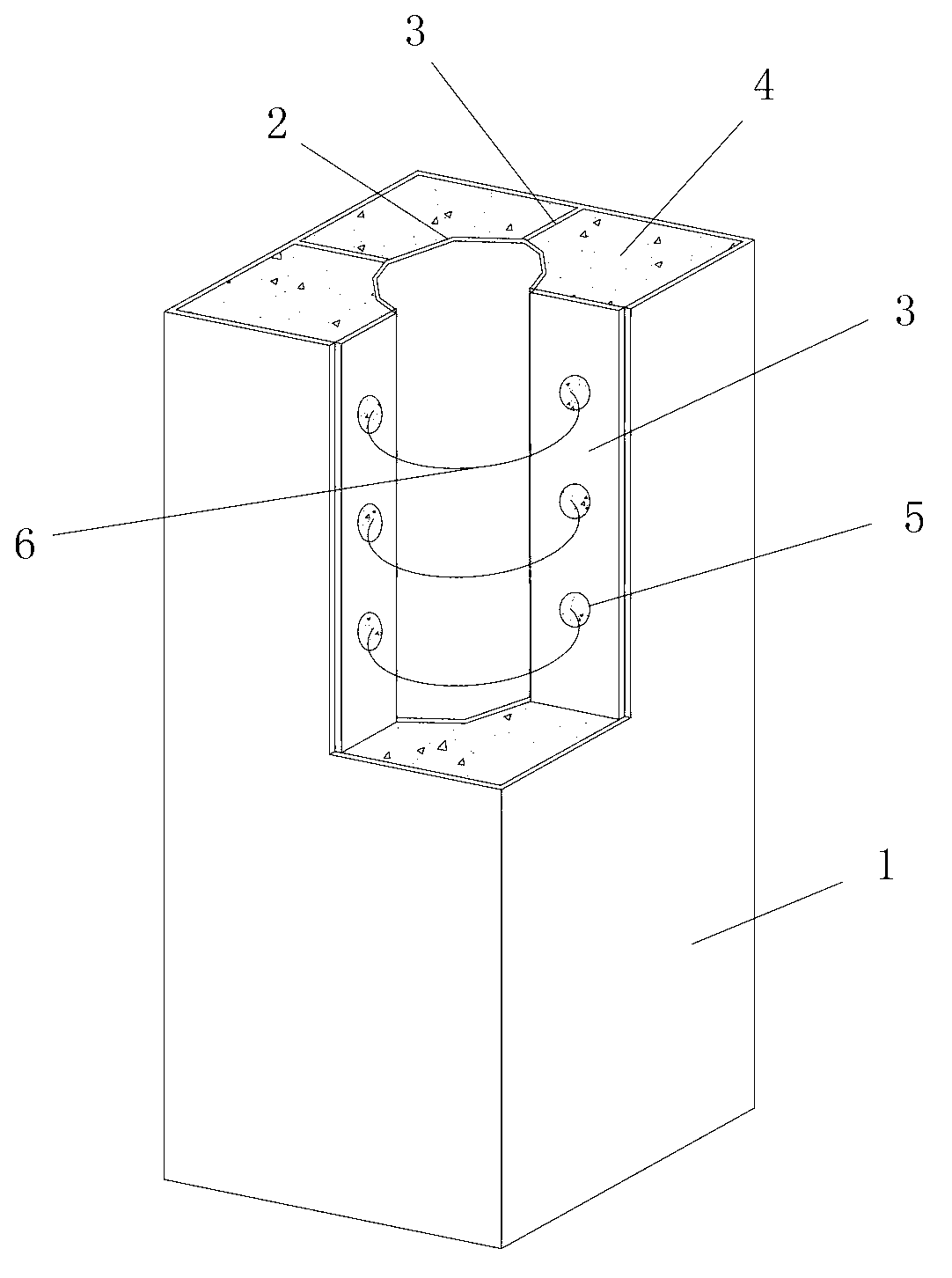

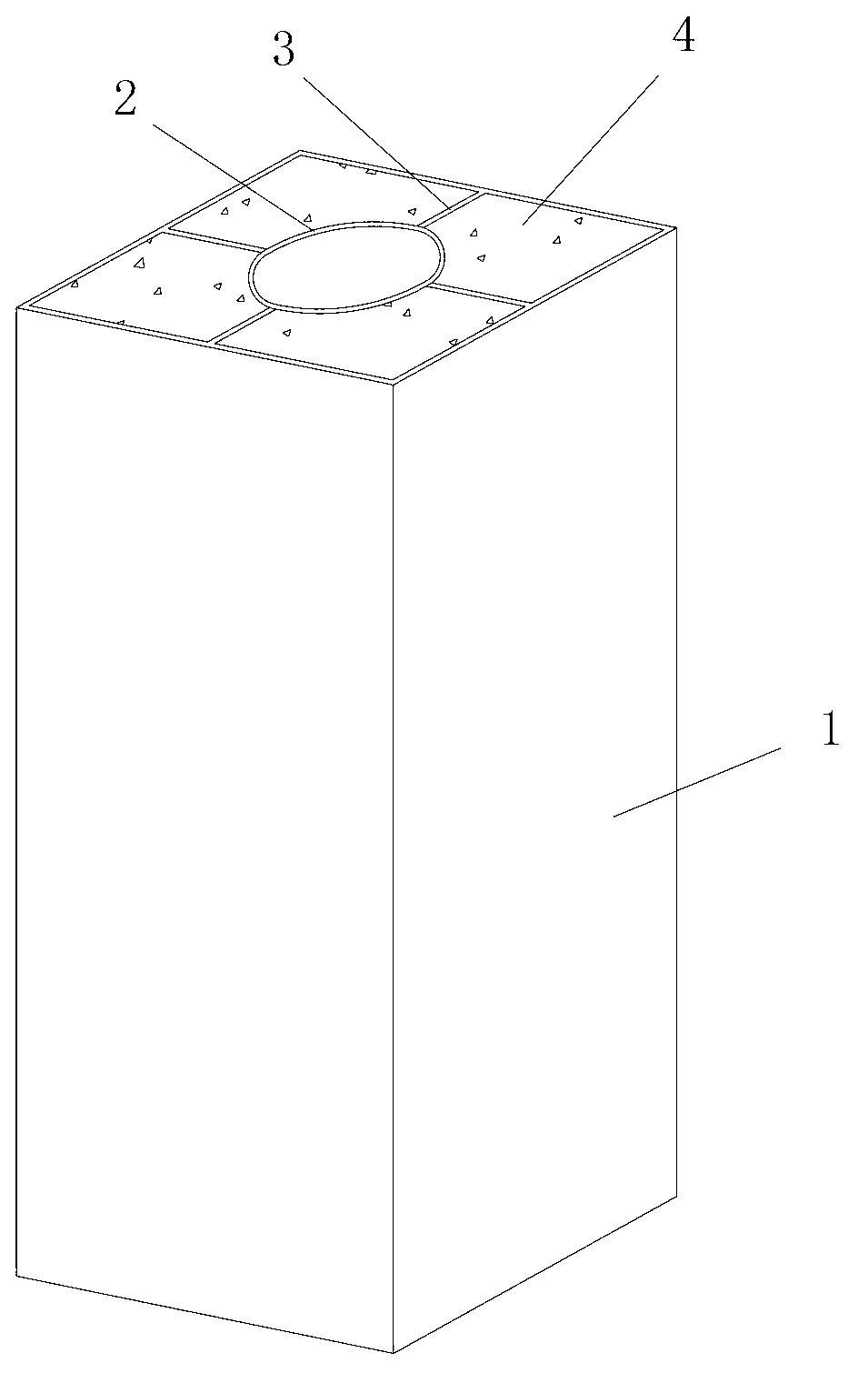

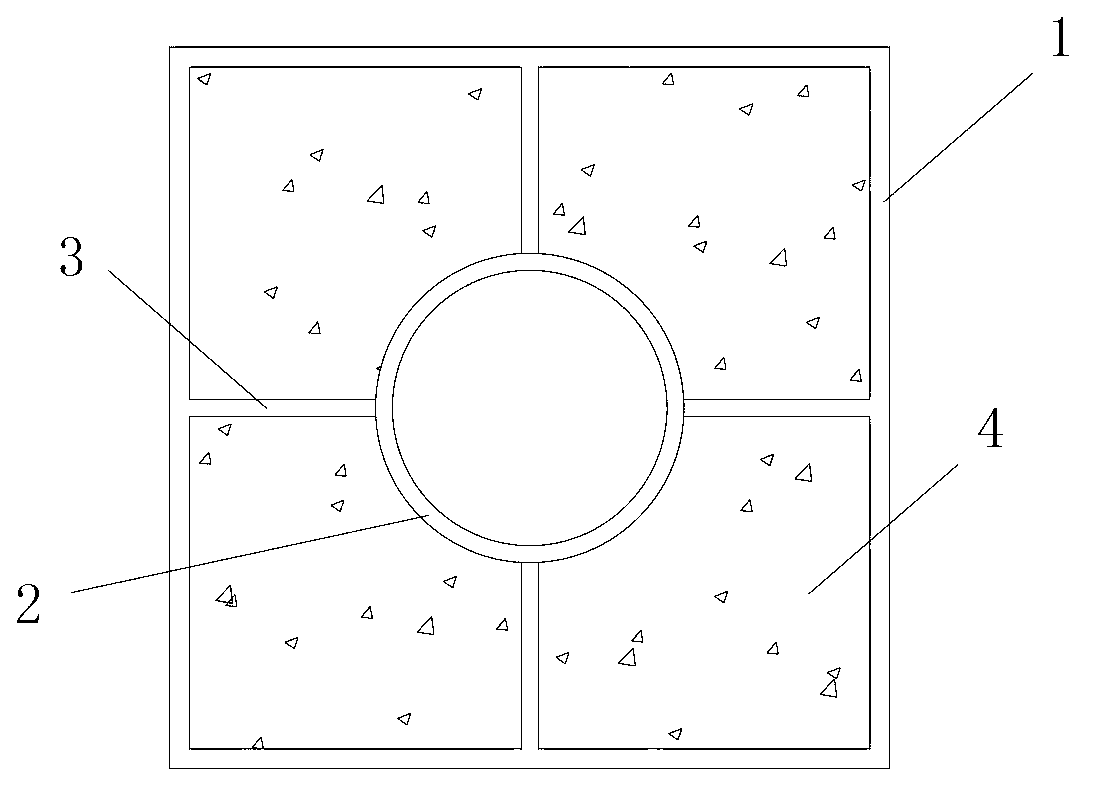

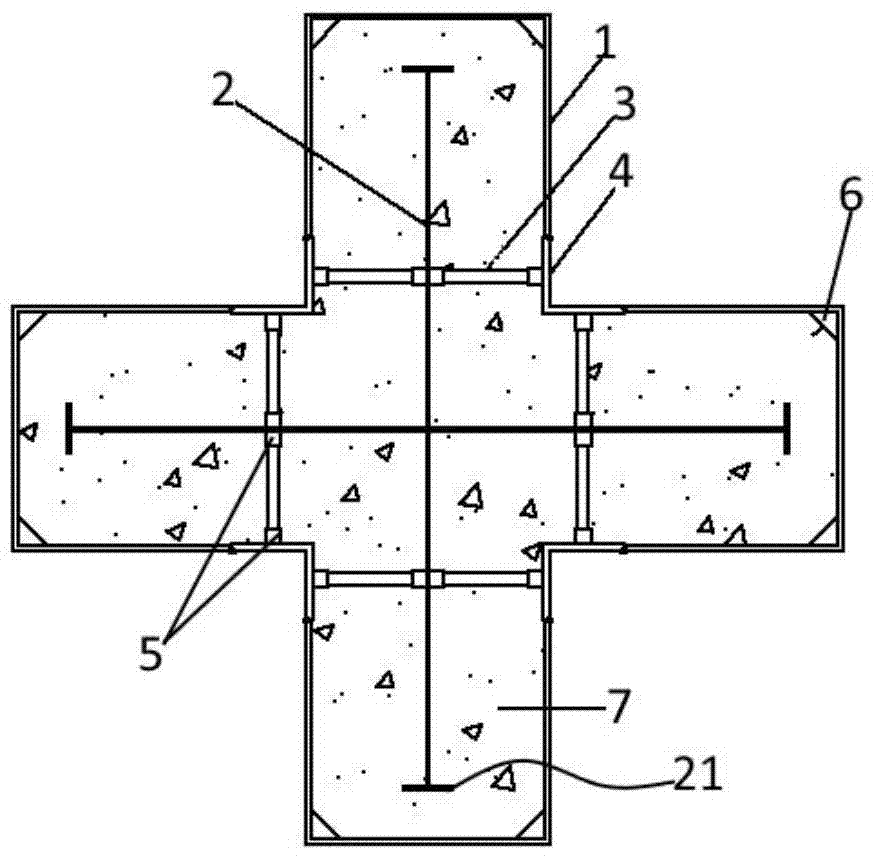

Connected node of concrete filled steel tube combination column and reinforced concrete beams

ActiveCN103397704ADirect force transmissionGuarantee a tight bondBuilding constructionsRebarSteel tube

The invention discloses a connected node of a concrete filled steel tube combination column and reinforced concrete beams. The concrete filled steel tube combination column and the reinforced concrete beams are intersected to the connected node. Open holes are formed in steel tubes, corresponding to the intersected positions of the reinforced concrete beams, of the concrete filled steel tube combination column. The upper end and the lower end of each reinforced concrete beam and the upper end and the lower end of the concrete filled steel tube combination column are respectively provided with two open holes, namely two upper end open holes and two lower end open holes. Longitudinal ribs inside reinforced concrete beams penetrate through the open holes in the tube wall and are anchored on core concrete inside the steel tubes. The positions above the upper end open holes, the positions below the upper end open holes, the positions above the lower end open holes and the positions below the lower end open holes are respectively provided with an annular reinforcing plate. Vertical reinforcing plates are arranged on the portions, between the open holes which have the same height and small gaps, of the tube wall. The concreted node of the concrete filled steel tube combination column and the reinforced concrete beams is used under the condition that multiple beams are slantly intersected to the node in a small-angle mode, and holes are closely formed in the tube wall. When the heights of the cross sections of the multiple beams are different, the beam longitudinal ribs can also penetrate through the large open holes conveniently. According to the connected node of the concrete filled steel tube combination column and the reinforced concrete beams, stress concentration between the open holes of the tube wall can be conveniently controlled, meanwhile, the hoop effect of the tube wall with the open holes is reinforced, and the anti-seismic performance of the node can be ensured.

Owner:香港华艺设计顾问(深圳)有限公司

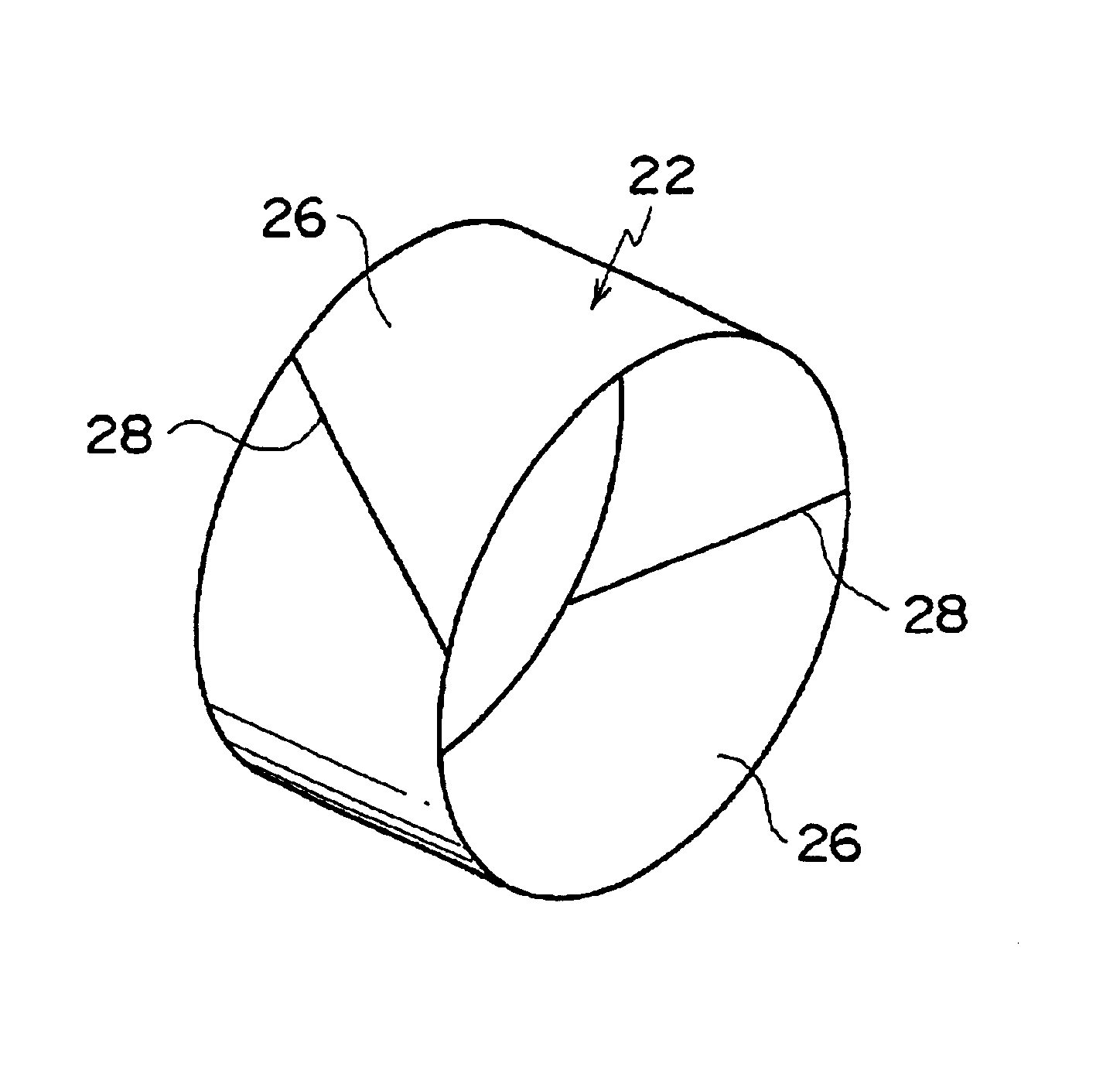

Pneumatic tire for airplane with reinforcing layer having two or more joint portions in the circumferential direction

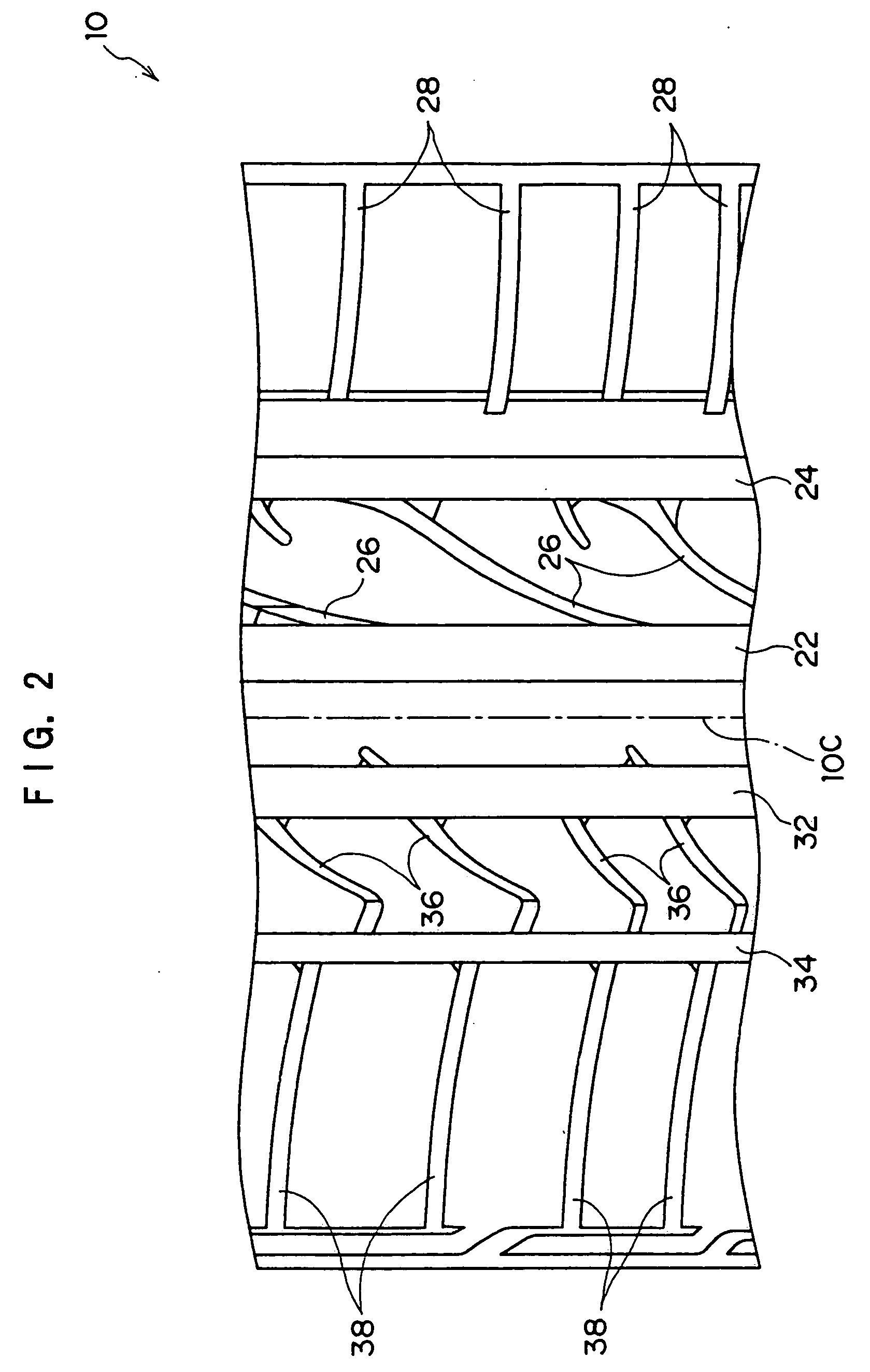

InactiveUS6843294B2Promote absorptionEnhanced hoop effectPneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

In a pneumatic tire for an airplane of the present invention, a reinforcing layer, which is disposed at an outer side, in the radial direction of the tire, of a belt, includes plural cords, the cords being provided such that the longitudinal direction thereof forms an angle of substantially 15° or less with respect to a tire circumferential direction. The reinforcing layer has two or more joint portions in the circumferential direction of the tire. In accordance with the present invention, a length of the cords forming the reinforcing layer in the tire circumferential direction can be made short, whereby a size (length) of tread pieces formed at a time when the tire is damaged can be made small and damage caused to an airplane can be reduced.

Owner:BRIDGESTONE CORP

Corrugated aluminum alloy pipe and concrete combination column

InactiveCN108842966AImprove bearing capacityImprove the immunityStrutsPillarsReinforced concreteShock resistance

The invention discloses a corrugated aluminum alloy pipe and concrete combination column. The corrugated aluminum alloy pipe and concrete combination column comprises an aluminum alloy pipe and concrete stuffed in the aluminum alloy pipe, wherein the concrete can be plain concrete or high performance concrete; the aluminum alloy pipe is a corrugated aluminum alloy pipe; and a reinforcing cage canalso be arranged in the aluminum alloy pipe, the reinforcing cage is made through binding up of longitudinal reinforcing bars and hoop bars, and the shape of the section of the reinforcing cage coincides with the shape center of the section of the corrugated aluminum alloy pipe. According to the corrugated aluminum alloy pipe and concrete combination column disclosed by the invention, the aluminumalloy pipe lighter in materials is used for restraining the concrete. Compared with a traditional steel pipe and concrete structure, the corrugated aluminum alloy pipe and concrete combination columnhas the advantages that the restraining effects are similar, but the self weight of structural members is lighter; when the corrugated aluminum alloy pipe is used, the situation that the pipe wall ofthe aluminum alloy pipe is untimely bent when the corrugated aluminum alloy pipe is pressed can be avoided; and besides, the cohesive force of the aluminum alloy pipe and the concrete can be improved. The corrugated aluminum alloy pipe and concrete combination column disclosed by the invention adopts a structure measure of synergy work of the corrugated aluminum alloy pipe and common concrete orreinforcing bar concrete or high performance concrete, is simple in structure and convenient to construct, and has the advantages of being light in weight, good in synergy work of different materials,high in bearing capacity and good in shock resistance.

Owner:TIANJIN FIRE RES INST

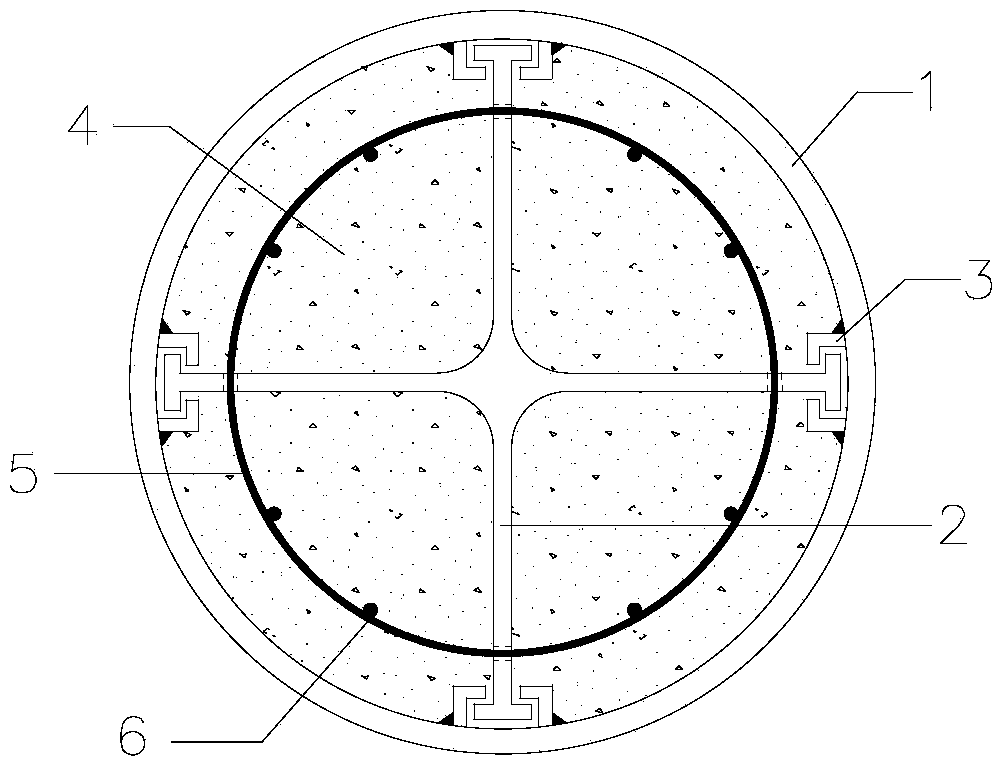

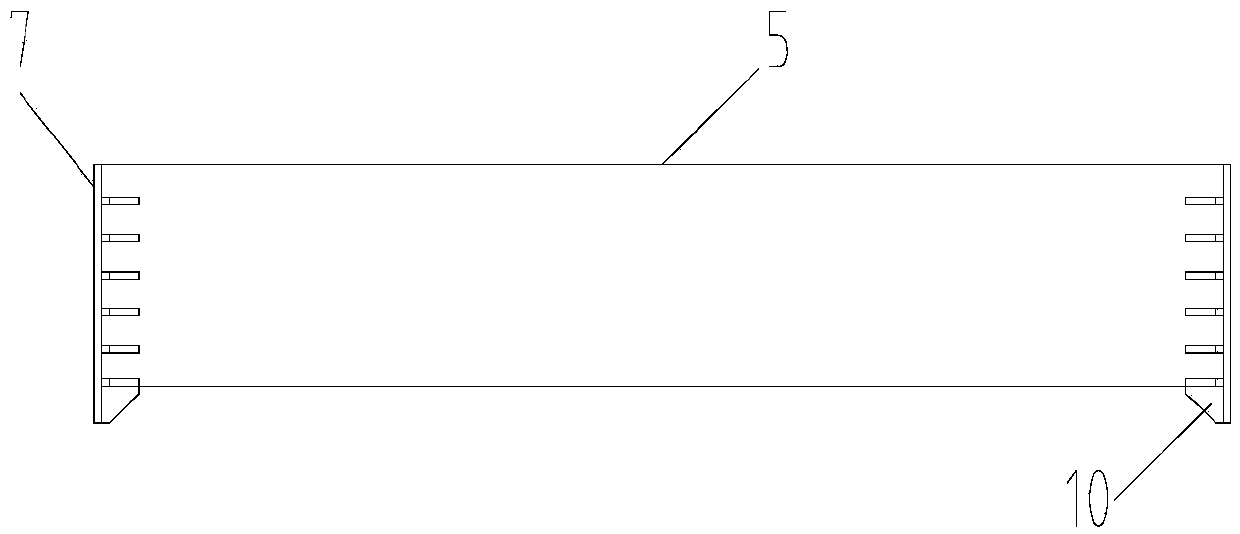

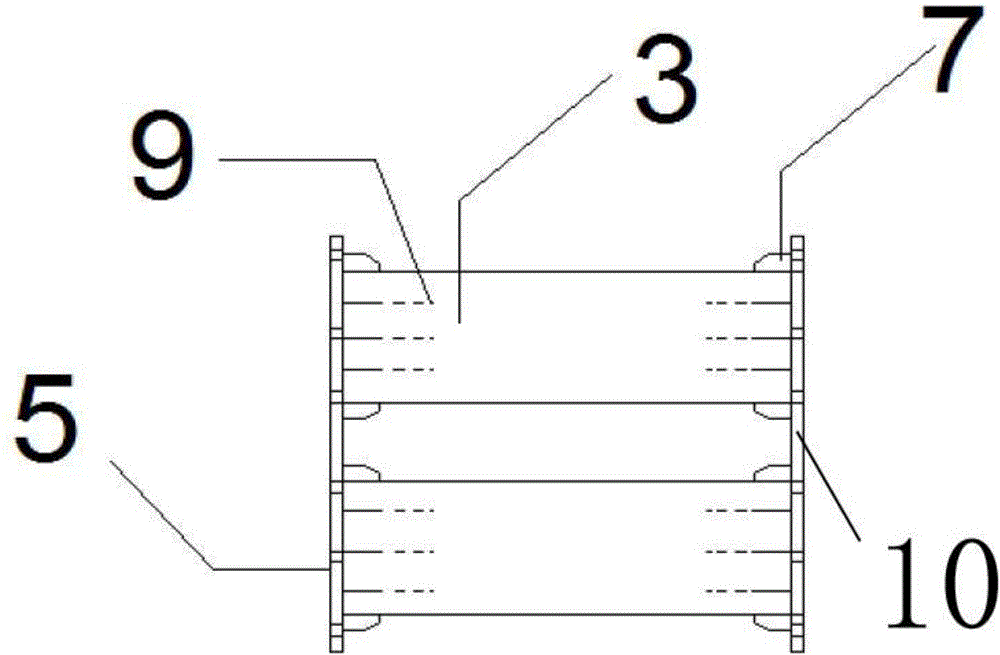

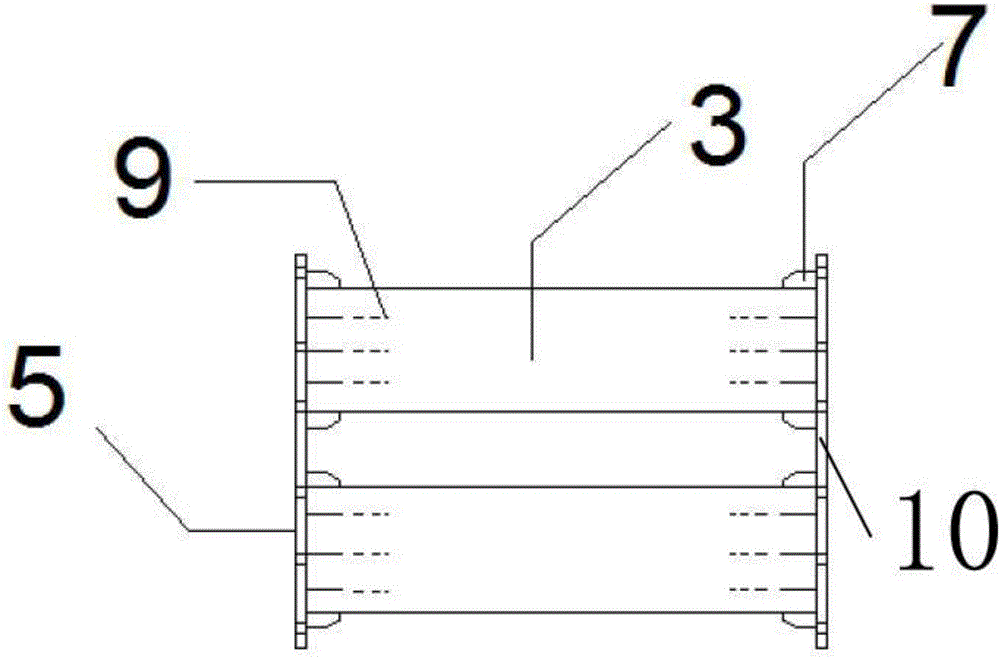

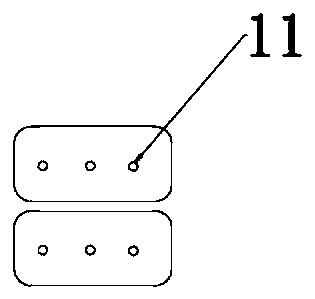

Assembled type four-combined-round-steel-pipe concrete inner support structure and manufacturing method

InactiveCN106351235AGuarantee processing qualityReliable mechanical propertiesExcavationsMetro stationHigh intensity

The invention relates to an assembled four-piece combined circular steel pipe concrete inner support structure and a manufacturing method, and belongs to the technical field of support and support in foundation pits of subway stations. The prefabricated four combined circular steel pipe concrete inner support structure includes different types of circular steel pipe concrete straight supports. Including short straight stay and standard straight stay. The straight supports are connected to each other by high-strength bolts. All components are composed of ultra-high-strength concrete filled round steel pipes, and the cross-sections of four round steel pipes are arranged in a square. The present invention satisfies the splicing needs of supports in foundation pits of different lengths by combining different forms of component lengths, and provides an assembled combined circle with high rigidity, reusability and low cost, which can be used as internal supports in the foundation pit or shaft enclosure structure system The inner support structure of concrete filled steel tube can effectively solve the problems of complex construction and high cost of concrete support. The comprehensive benefit is remarkable, and it has important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

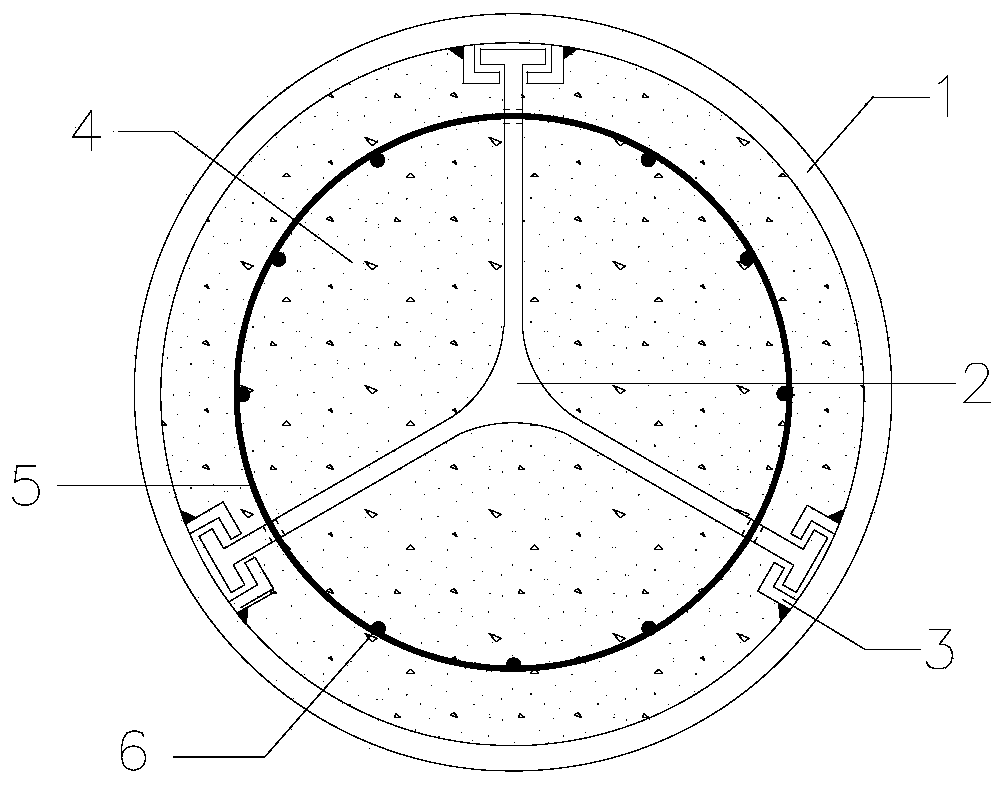

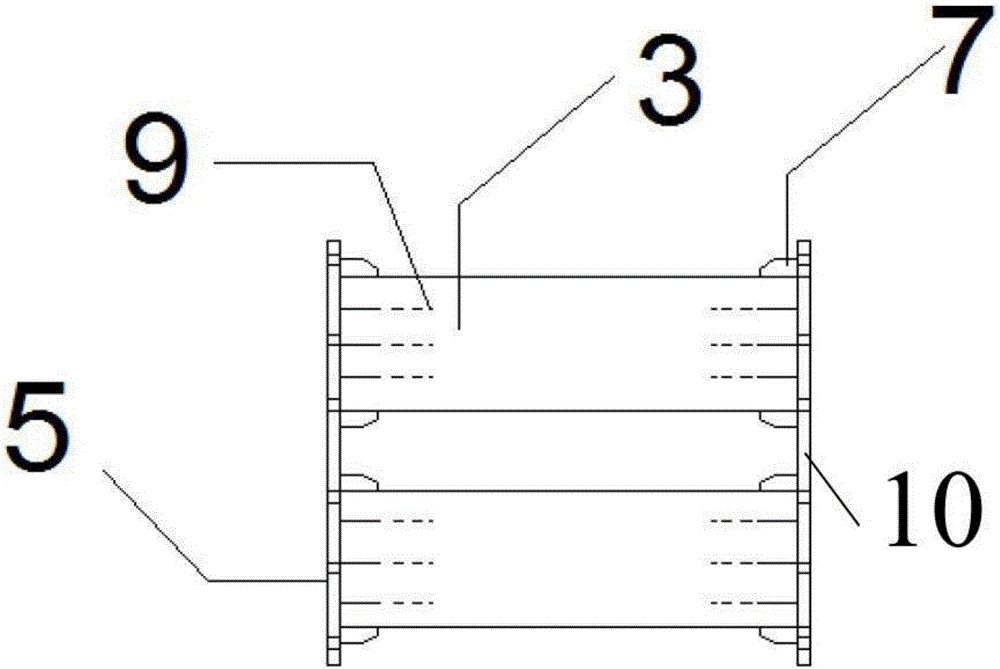

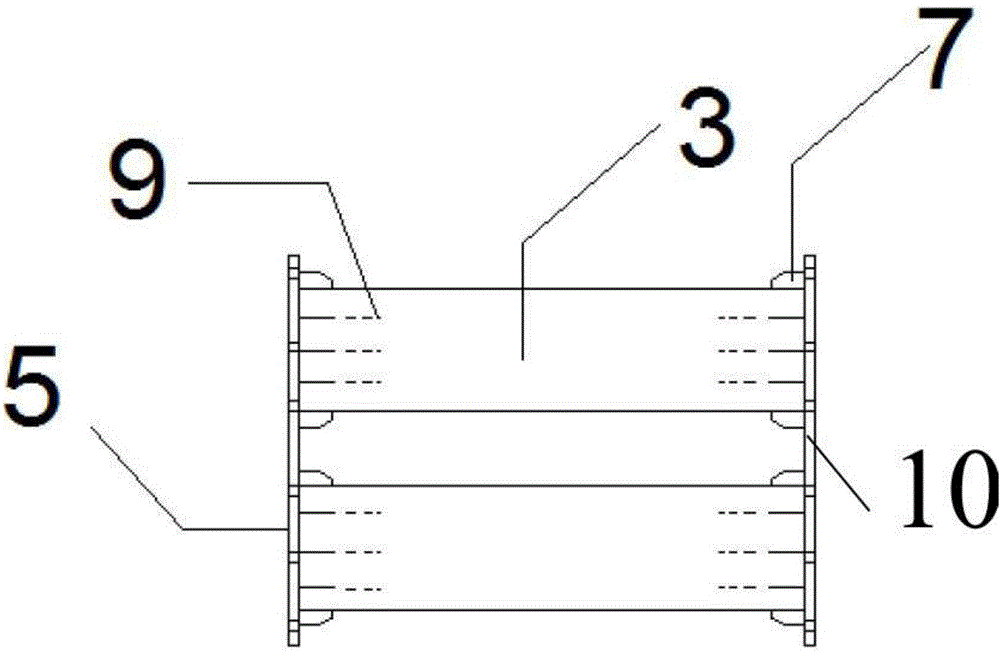

Assembled type three-combined-round-steel-pipe concrete inner support structure and manufacturing method

InactiveCN106351234AGuarantee processing qualityReliable mechanical propertiesExcavationsSteel tubeMetro station

The invention relates to an assembled three-piece combined circular steel pipe concrete inner support structure and a manufacturing method, which belong to the technical field of support and support in foundation pits of subway stations. The prefabricated three combined circular steel pipe concrete inner support structure includes different types of circular steel pipe concrete straight supports. Including short straight stay and standard straight stay. The straight supports are connected to each other by high-strength bolts. All components are composed of ultra-high-strength concrete filled round steel pipes, and the cross-sections of the three round steel pipes are arranged in an inverted triangle. The present invention satisfies the splicing needs of supports in foundation pits of different lengths through the combination of different forms of component lengths, and provides a high rigidity, reusable, cost-reduced assembly-type combined circle used as internal supports in the foundation pit or shaft enclosure structure system The inner support structure of concrete filled steel tube can effectively solve the problems of complex construction and high cost of concrete support. The comprehensive benefit is remarkable, and it has important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

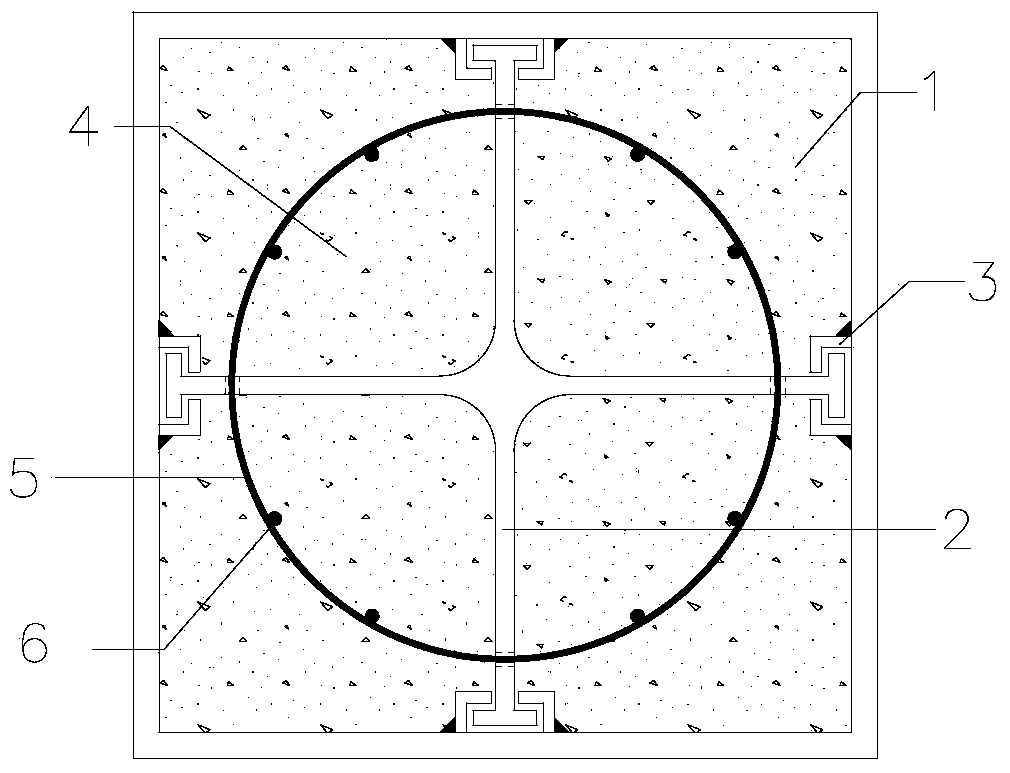

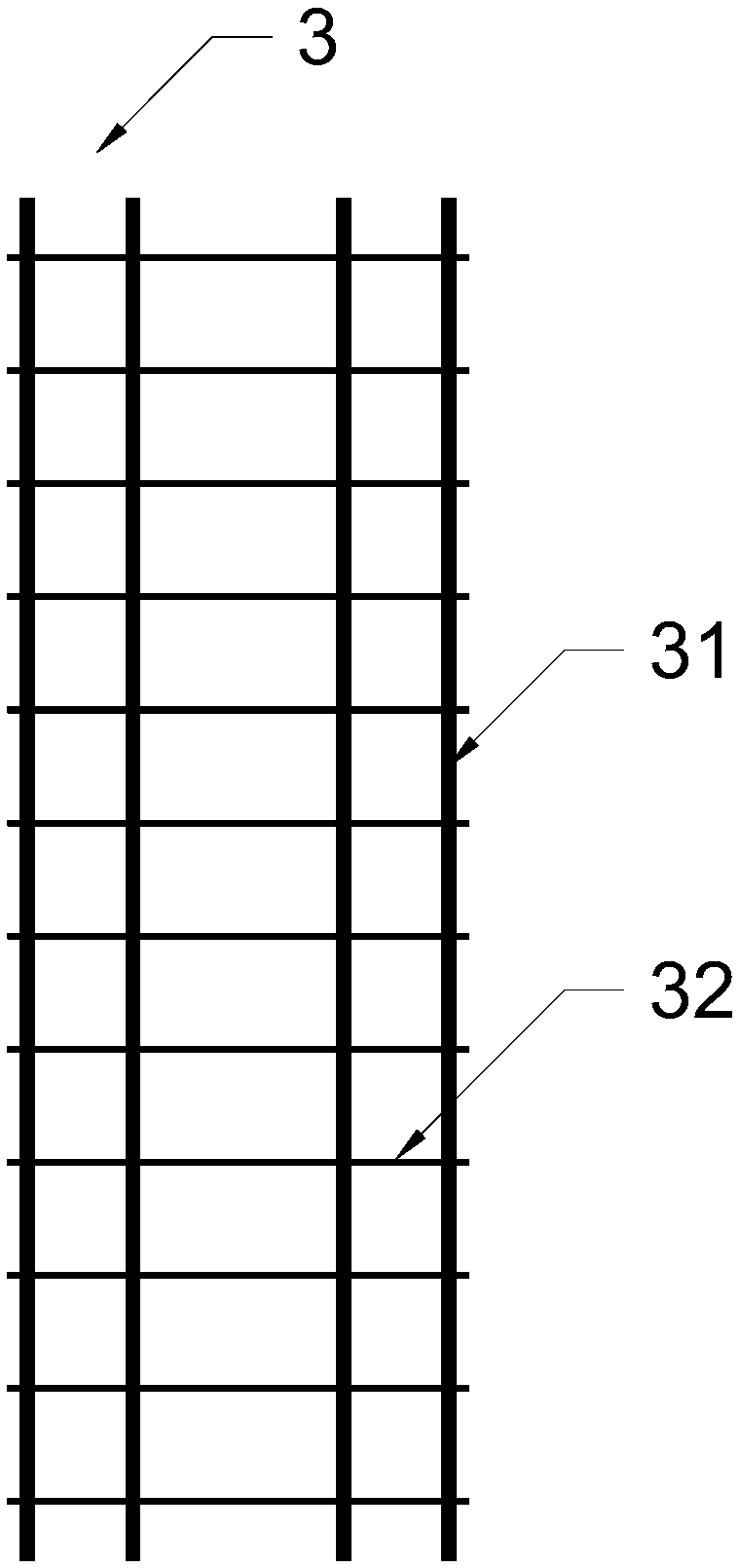

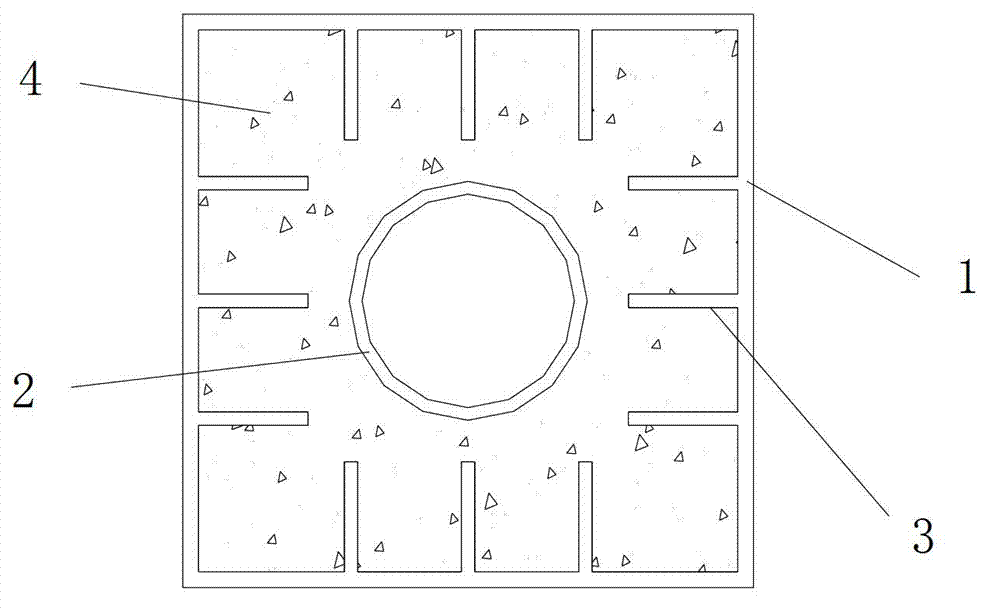

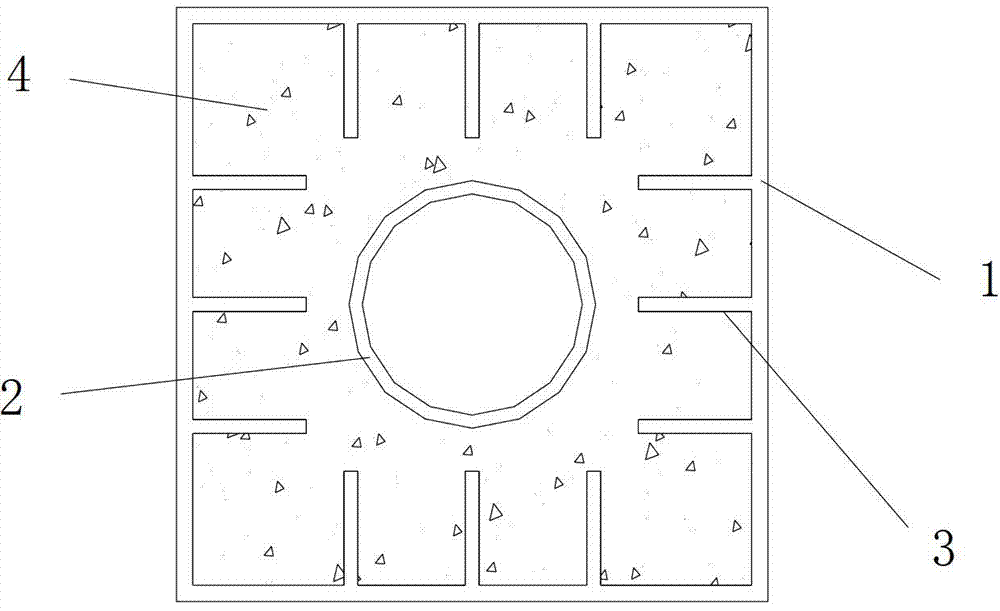

A double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs

InactiveCN103061449ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The present invention discloses a double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs, including a square steel pipe, a round steel pipe sleeved inside the square steel pipe, a plurality of PBL stiffening ribs laid between the square and round steel tube, a plurality of stirrups laid in the plurality of PBL stiffening ribs from top to bottom, and a concrete structure pouring formed by concrete filled in the cavity between the square steel tube and the round steel pipe, and the square steel pipe and the round steel pipe laid around the same axis. The layout directions of the plurality of PBL stiffening ribs are all the same with the central axis direction of the round steel pipe; the longitudinal lengths of the square steel pipe, the round steel pipe and the plurality of PBL stiffening ribs are the same; the plurality of PBL stiffening ribs are laid along the circumferential direction; and the plurality of stirrups are laid in parallel. The concrete structure of the invention has simple structure, reasonable design, easy construction and low construction cost, excellent mechanical properties and good use effect, and can solve many problems existing in current square steel concrete structures.

Owner:XIAN HIGHWAY INST +1

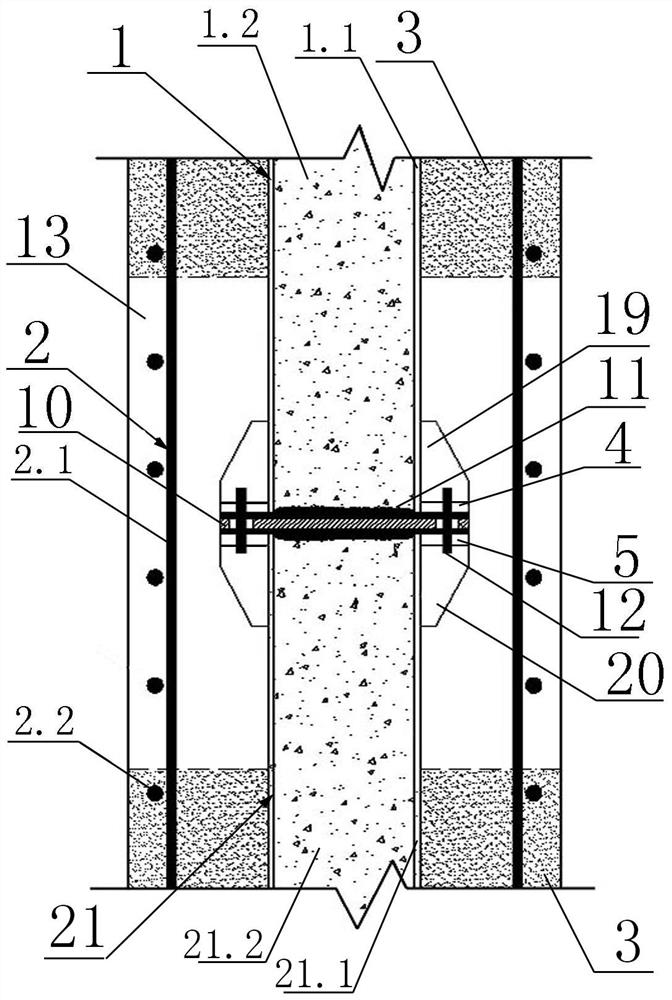

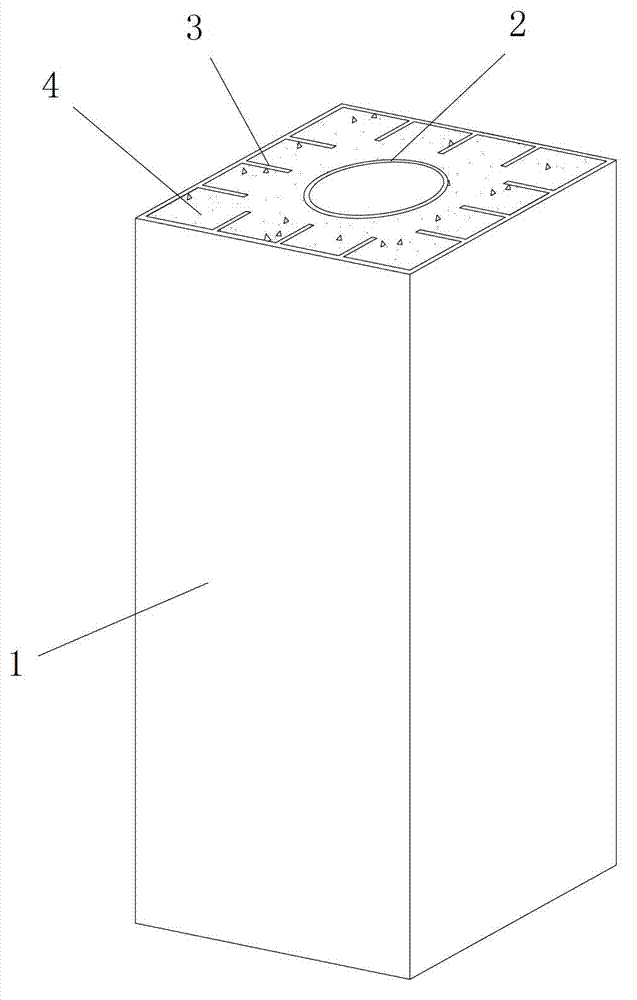

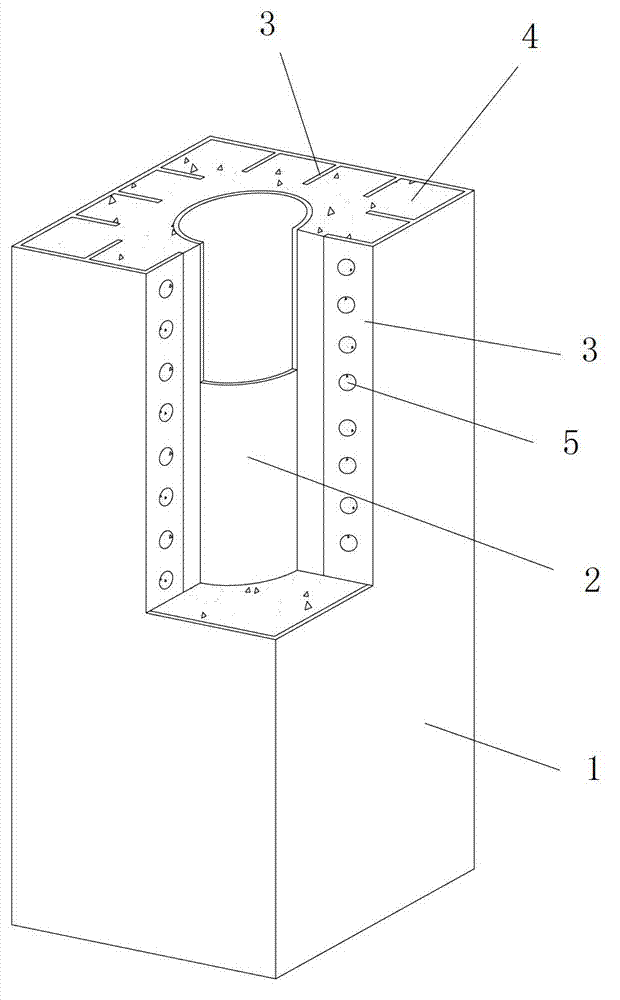

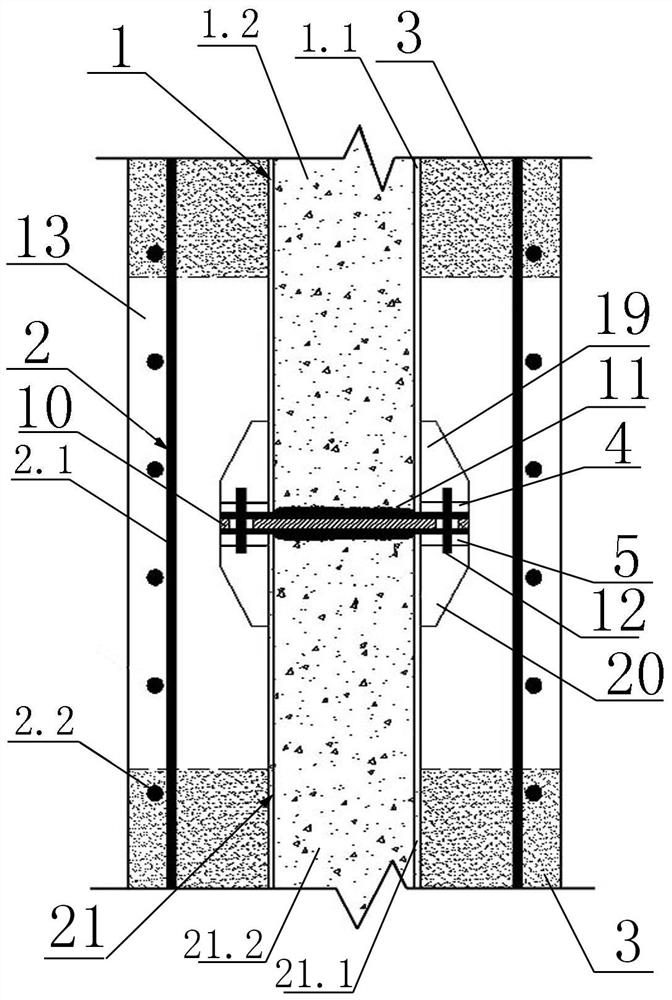

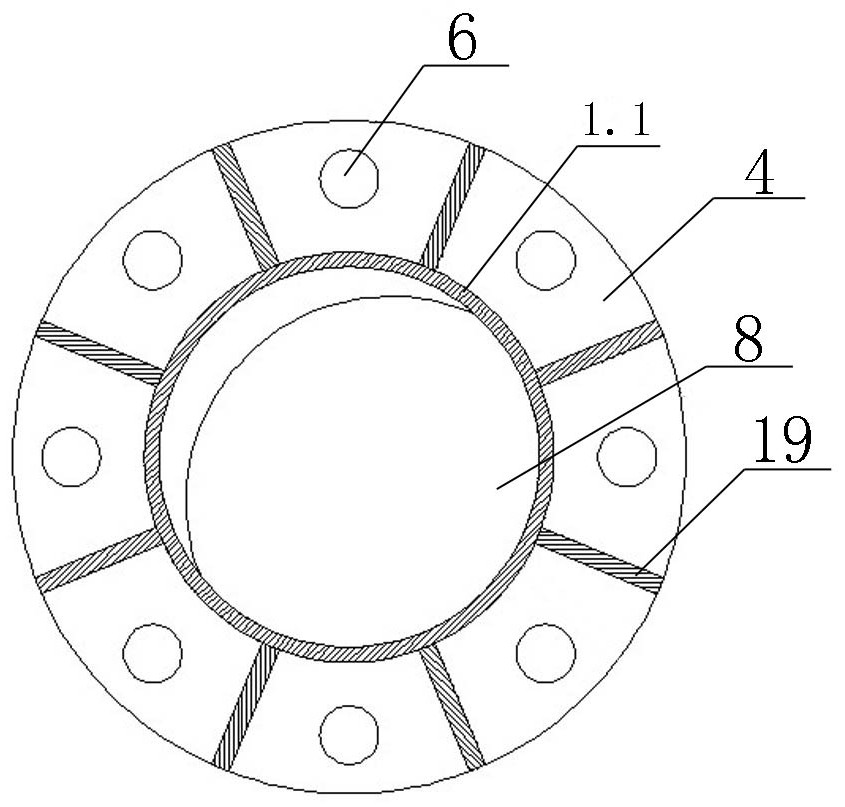

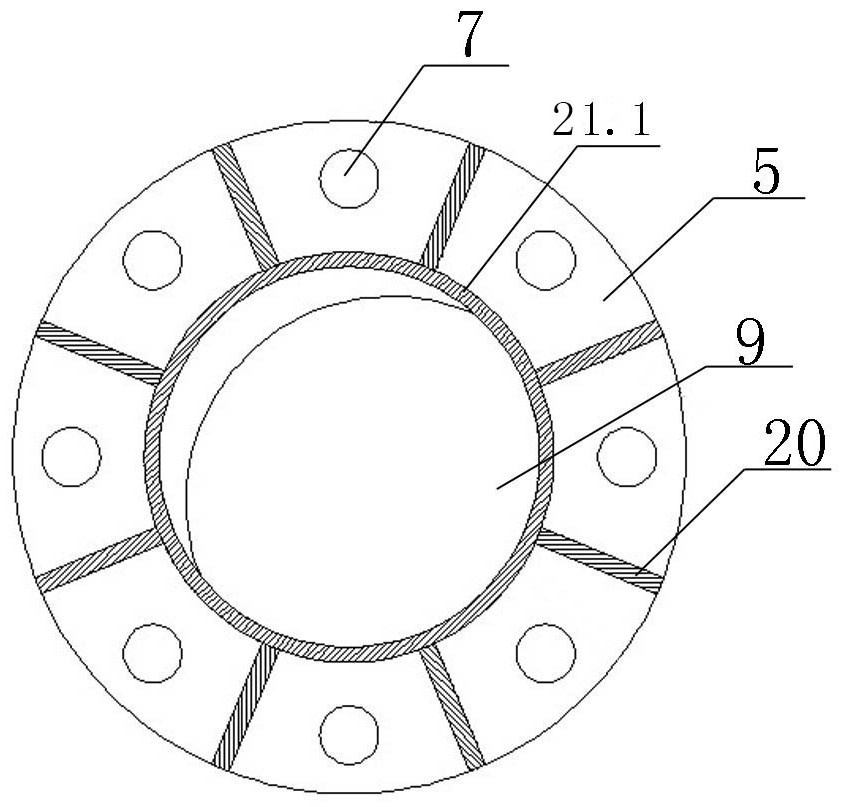

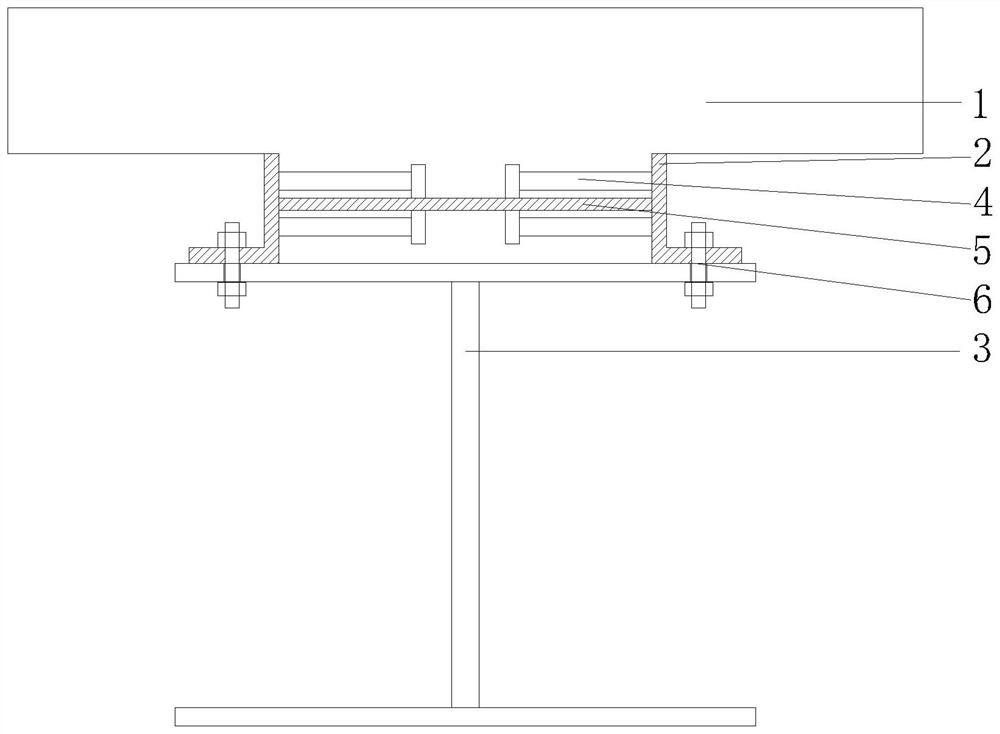

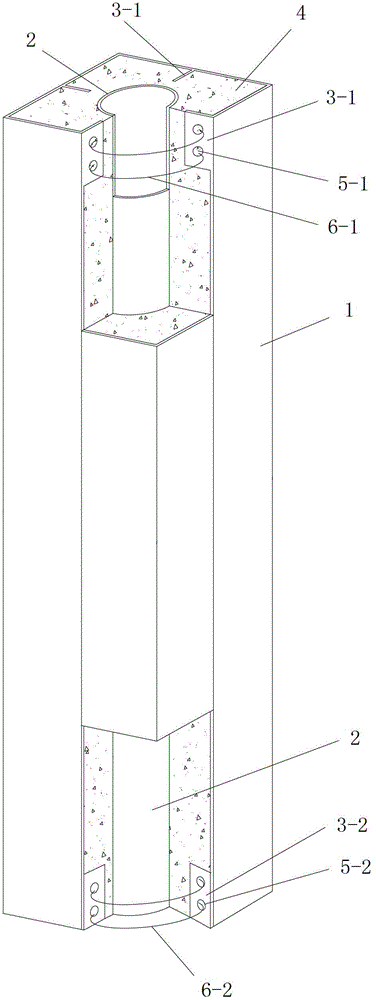

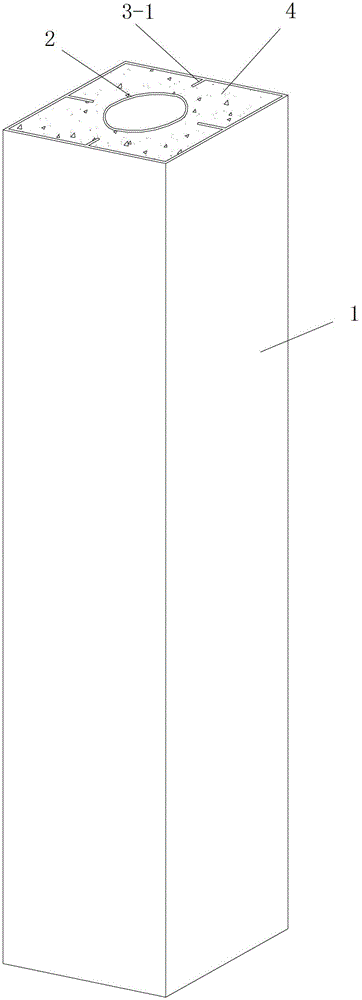

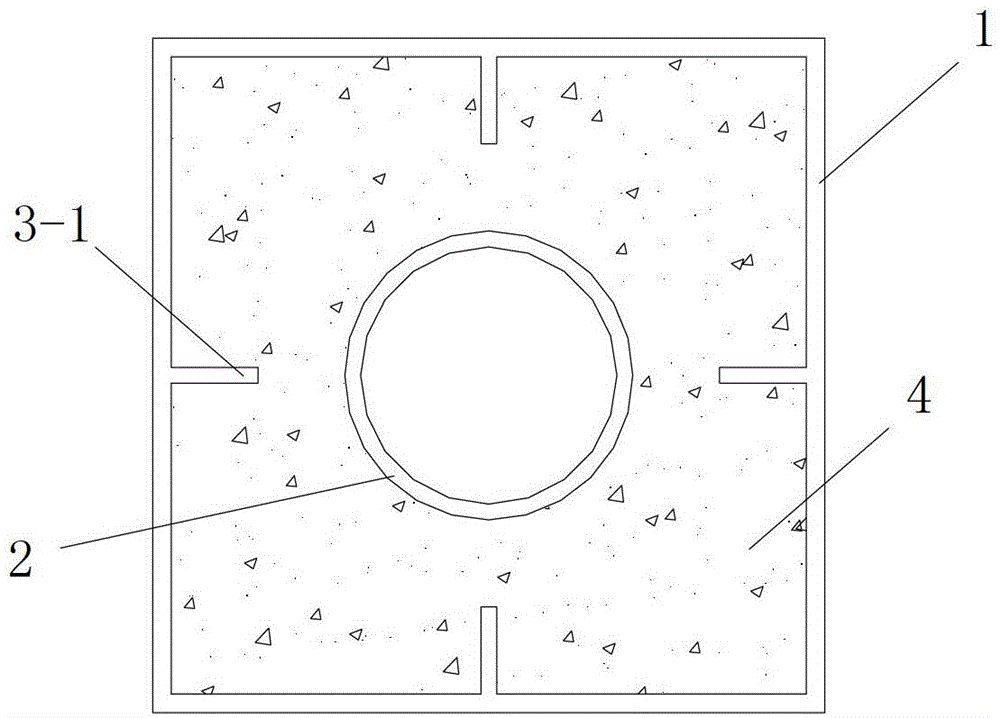

Lengthening joint containing prefabricated concrete-filled steel tube core column component and construction method of lengthening joint

ActiveCN111749346ASmall sectionIncrease the usable areaStrutsProtective buildings/sheltersArchitectural engineeringRebar

The invention discloses a lengthening joint containing a prefabricated concrete-filled steel tube core column component and a construction method of the lengthening joint. The lengthening joint comprises an upper-section core column, a lower-section core column, a steel reinforcement framework, a joint concrete layer and out-of-tube concrete layers. The bottom end of the upper-section core columnis connected with an upper flange plate, the top end of the lower-section core column is connected with a lower flange plate, a connecting assembly comprises a connecting plate, bonding glue layers and high-strength bolts, the connecting plate is arranged between the upper flange plate and the lower flange plate, air holes are formed in the middle of the plate face of the connecting plate at intervals, the bonding glue layers are arranged between the connecting plate and the upper flange plate and between the connecting plate and the lower flange plate, and the upper-section core column and the lower-section core column are connected through the high-strength bolts; and the steel reinforcement framework is arranged around joints of the upper-section core column and the lower-section core column, and the joint concrete layer is poured between the out-of-pipe concrete layer on the outer side of the upper-section core column and the out-of-pipe concrete layer on the outer side of the lower-section core column. The technical problems that the thickness of an existing joint cannot be adjusted, inclination deviation exists, compression deformation is large, force transmission is not reliable, construction efficiency is low, and concrete in a steel pipe is difficult to pour are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

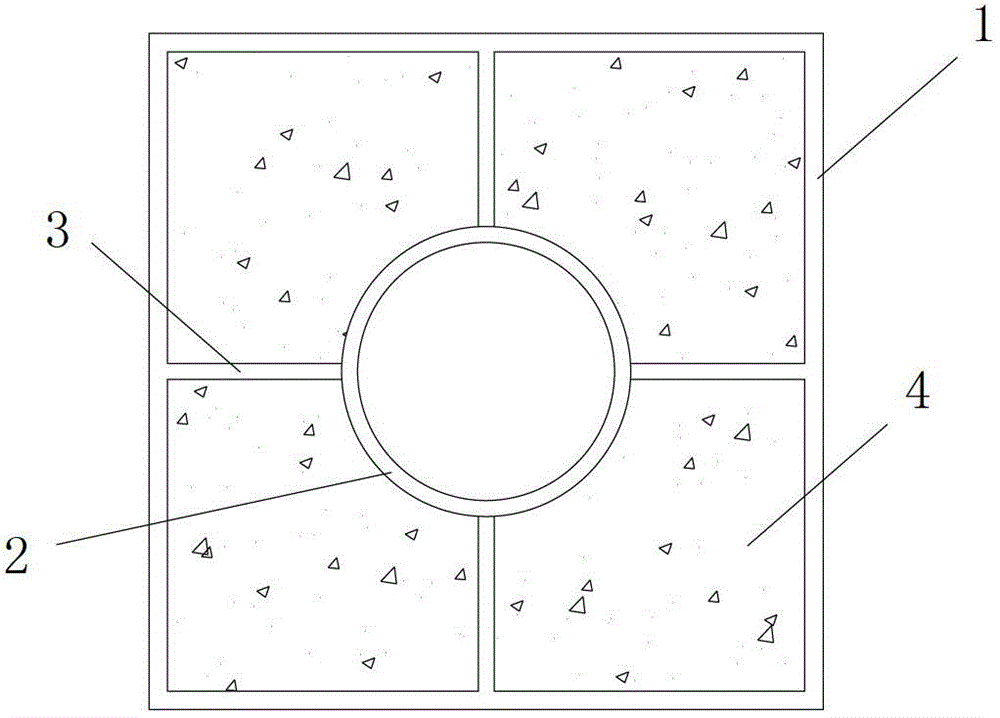

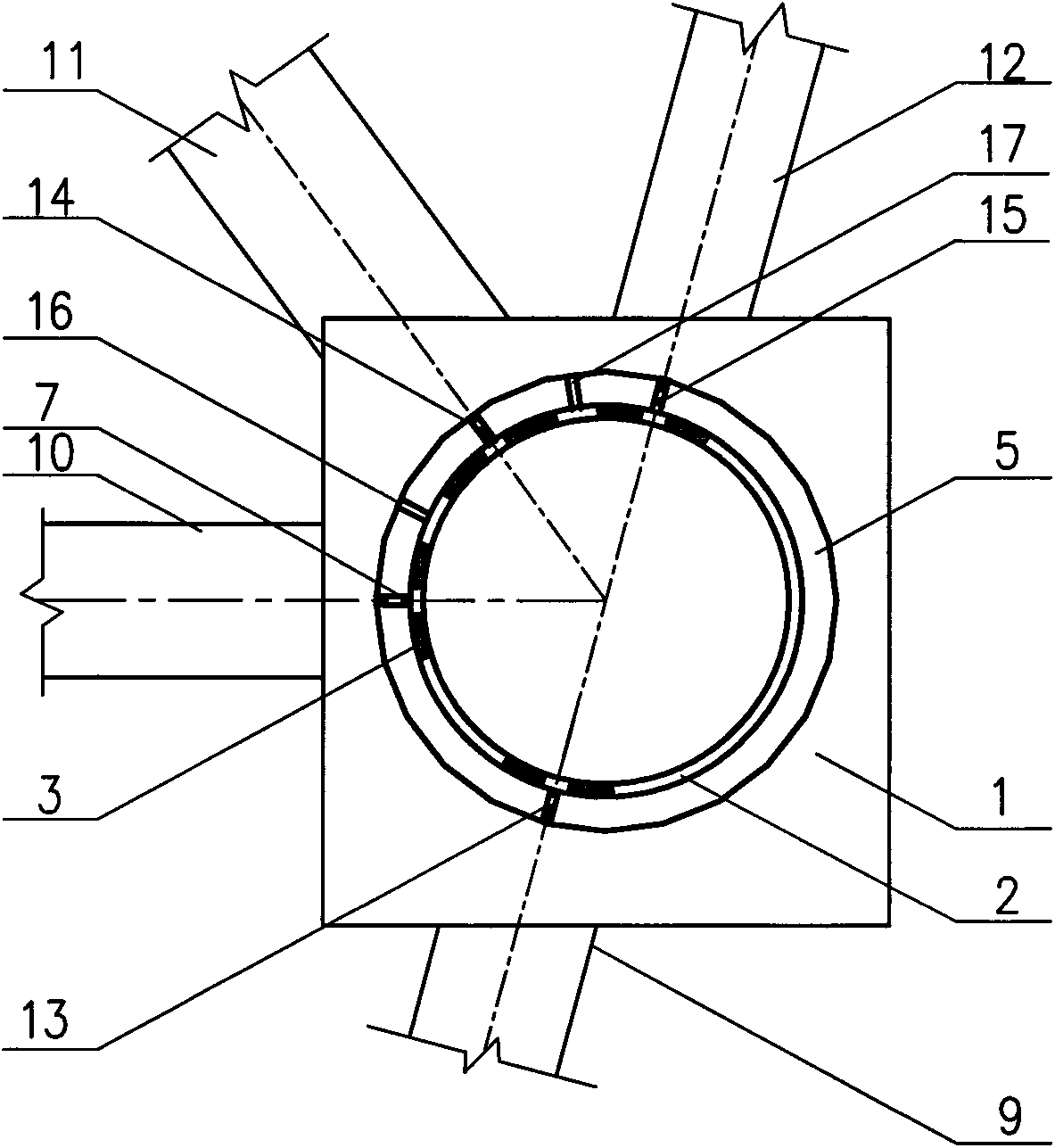

SCS square concrete-filled steel tube pier column

InactiveCN103031927ASimple structureReasonable designStrutsBridge structural detailsMechanical propertySteel tube

The invention discloses an SCS (square concrete-filled steel) tube pier column which comprises a square steel tube, a circular steel tube, four stiffening rib plate groups and a concrete structure, wherein the circular steel tube is mounted in the square steel tube in a sleeving manner; the four stiffening rib plate groups are arranged on four inner side walls of the square steel tube respectively; the concrete structure is formed by pouring concrete filled in a cavity between the square steel tube and the circular steel tube; each stiffening rib plate group comprises a plurality of longitudinal stiffening ribs that are arranged in parallel; the longitudinal stiffening ribs are perpendicular to the inner side walls of the square steel tube where the longitudinal stiffening ribs are located respectively; all the longitudinal stiffening ribs in the four stiffening rib plate groups have identical structures and sizes; the square steel tube and the circular steel tube are arranged coaxially; and the transverse width of each longitudinal stiffening rib is less than a distance between the square steel tube and the circular steel tube where the longitudinal stiffening rib is arranged. The pier column is simple in structure, reasonable in design, convenient to construct, lower in construction cost, good in mechanical property and good in use effect, and can effectively solve the problems existing in the existing square concrete-filled steel tube structure.

Owner:CHANGAN UNIV

Sequence control system (SCS) concrete filled steel tube bridge pier with shear nails added at bottom

InactiveCN102995554ASimple structureReasonable designBridge structural detailsSequence controlMechanical property

The invention discloses an SCS concrete filled steel tube bridge pier with shear nails added at bottom. The SCS concrete filled steel tube bridge pier comprises an outer steel tube, an inner steel tube, a top end shear resistant structure, a bottom end shear resistant structure and a concrete structure. The inner steel tube is sleeved inside the outer steel tube, the top end shear resistant structure is distributed between the top end of the outer steel tube and the top end of the inner steel tube, the bottom end shear resistant structure is distributed between the bottom end of the outer steel tube and the bottom end of the inner steel tube, the concrete structure is molded by pouring concrete filled in a cavity between the outer steel tube and the inner tube after the top end shear resistant structure and the bottom end shear resistant structure are distributed, the inner steel tube is a round steel tube, the outer steel tube and the inner steel tube are coaxially distributed, the outer steel tube is an outer steel tube one or two, the shape of the cross section of the outer steel tube one is a circle, and the shape of the cross section of the outer steel tube two is a rectangle or regular polygon. According to the SCS concrete filled steel tube bridge pier with stiffening ribs added at the bottom, the structure is simple, the design is reasonable, the construction is convenient, the construction cost is low, the mechanical property and the usage effect are good, and problems in concrete filled steel tube bridge piers are solved.

Owner:CHANGAN UNIV

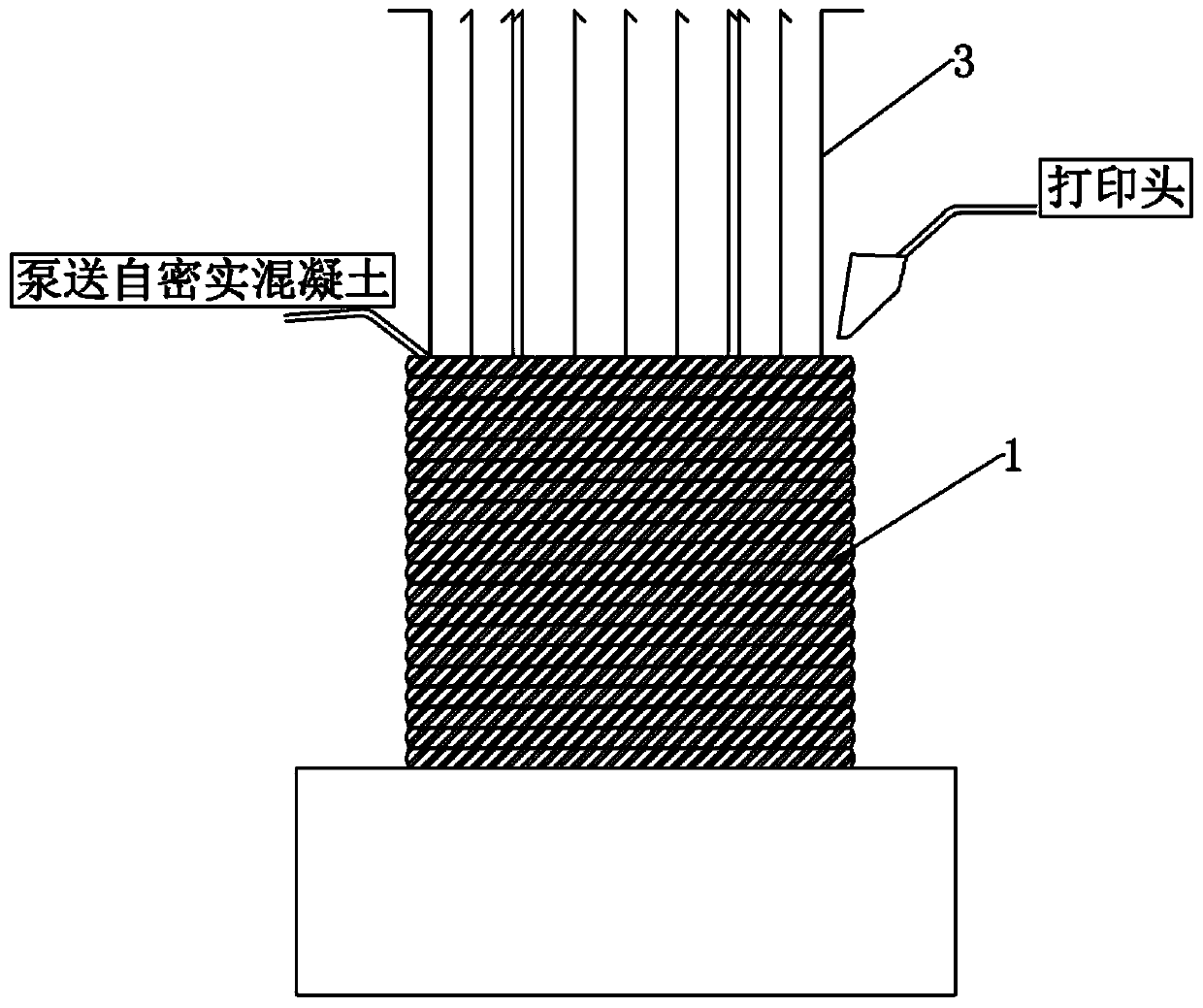

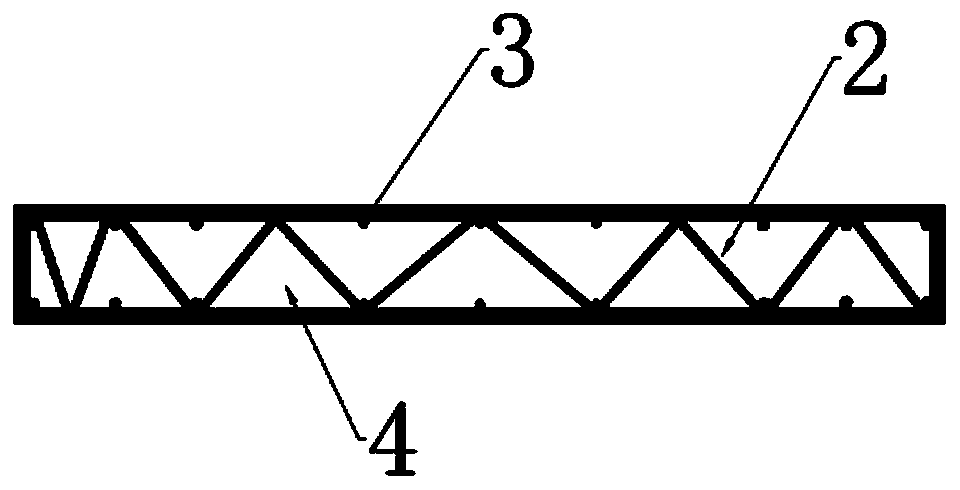

Method for reinforced 3D hybrid printing of shear wall

InactiveCN110370422AEasy to makeConstruction progress is fastWallsCeramic shaping apparatusShear wallAutomation

The invention provides a method for reinforced 3D hybrid printing of a shear wall. The method comprises the following steps that a 3D printer is firstly used for printing an outer layer reinforced hoop layer and an inner layer truss structure of the shear wall at the same time; then a mechanical lifting device is used for vertically inserting longitudinal bars in the hoop layer; and finally pumping and filling of self-compacting concrete into the hoop layer are achieved. The method has the advantages of being convenient to manufacture, reliable in connection, fast in construction progress, high in automation, high in bearing performance and capable of being widely applied to design and construction of a seismic structural wall of the general structure.

Owner:ZHEJIANG UNIV

Bidirectional ribbed multi-cavity concrete-filled steel tube pier and framework and construction method thereof

PendingCN111636297AReduce disengagementReduce crackingBridge structural detailsBridge erection/assemblyEarthquake resistancePipe

The invention aims to provide a bidirectional ribbed multi-cavity concrete-filled steel tube pier and a framework and a construction method thereof. High strength advantage is achieved, according to the technical scheme, a central pipe column and outer pipes surrounding the central pipe column are comprised, wherein two adjacent outer pipes are arranged at an interval, a rib plate is arranged at the interval between each two adjacent outer pipes; it is characterized in that each rib plate comprises a base plate and flanges led out from the base plate, the rib plates are divided into one-way rib plates and two-way rib plates, and second welding seams are arranged among the outer pipes, the one-way rib plates and the two-way rib plates. The constraint effect on core concrete can be enhancedthrough the inner and outer bidirectional ribs and the central steel pipe, the steel pipe disengagement phenomenon and the core concrete cracking phenomenon are reduced, the lateral resistance, bending resistance and seismic resistance of the pier are improved, and the corrosion resistance and durability are enhanced through an outer protection layer.

Owner:JIANGNAN UNIV

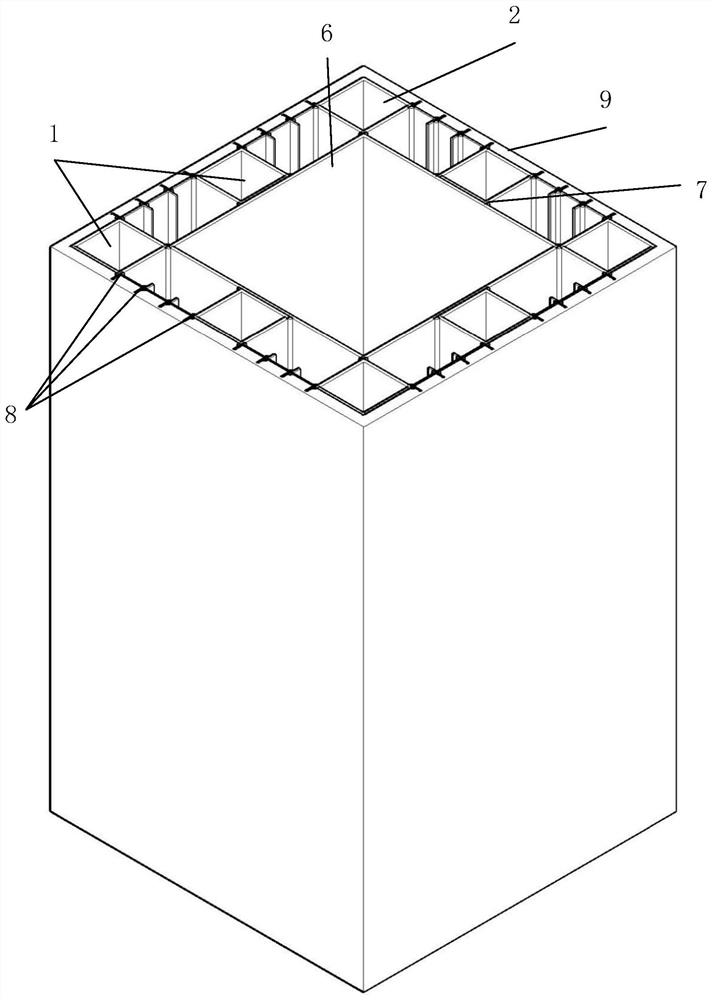

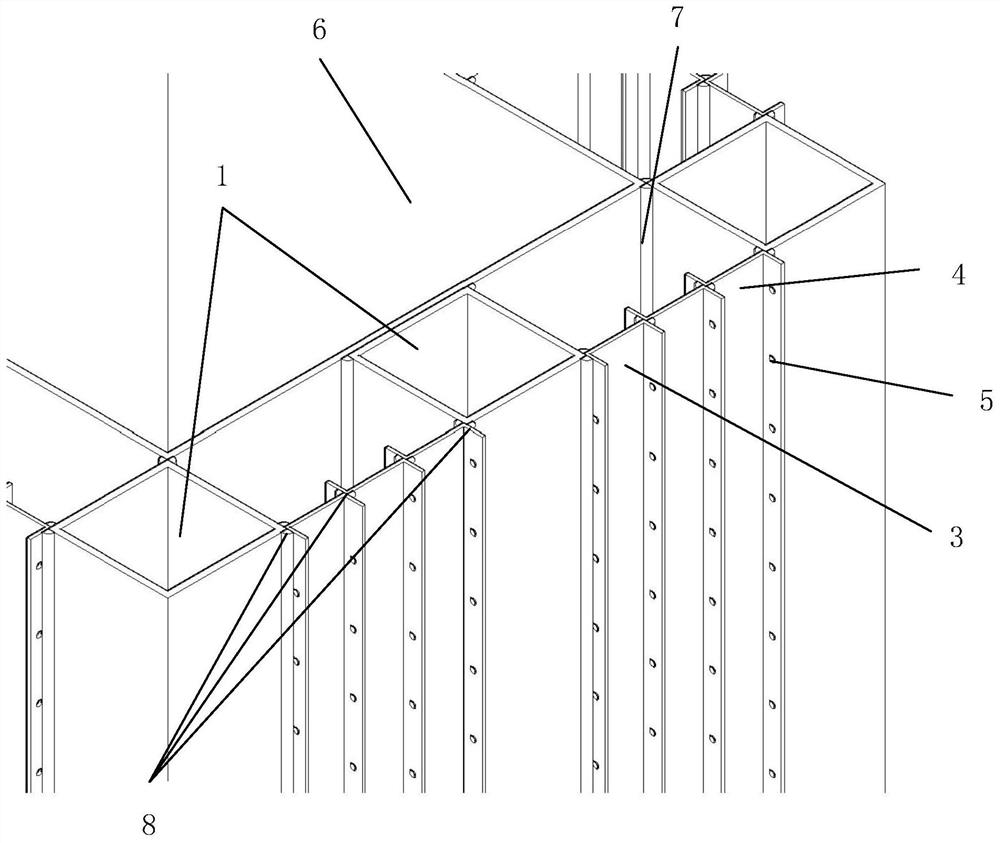

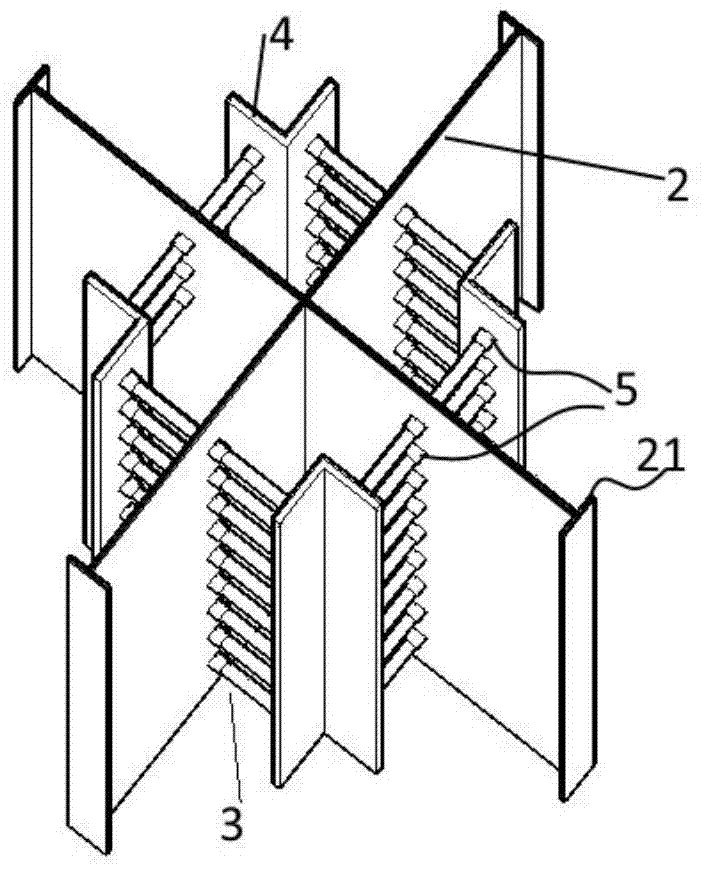

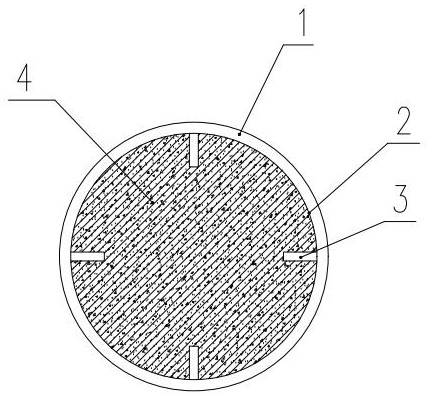

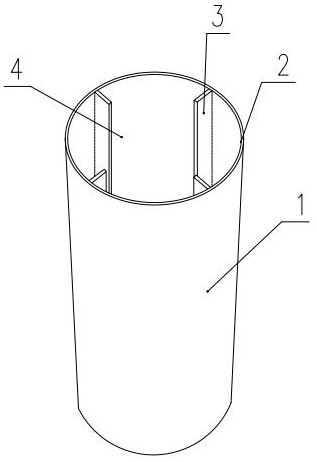

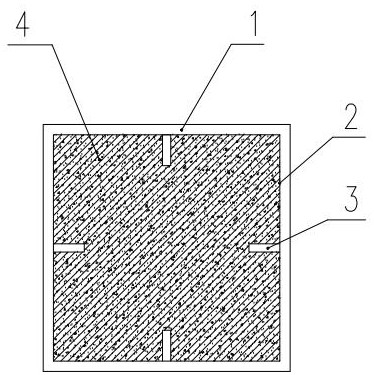

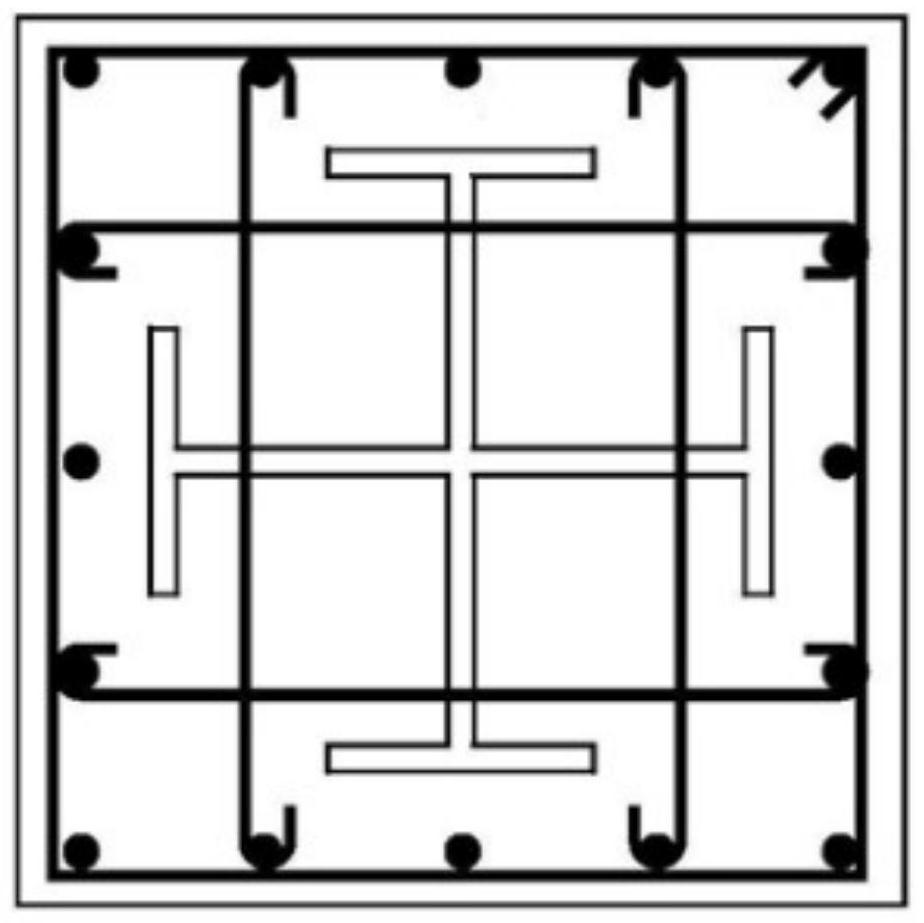

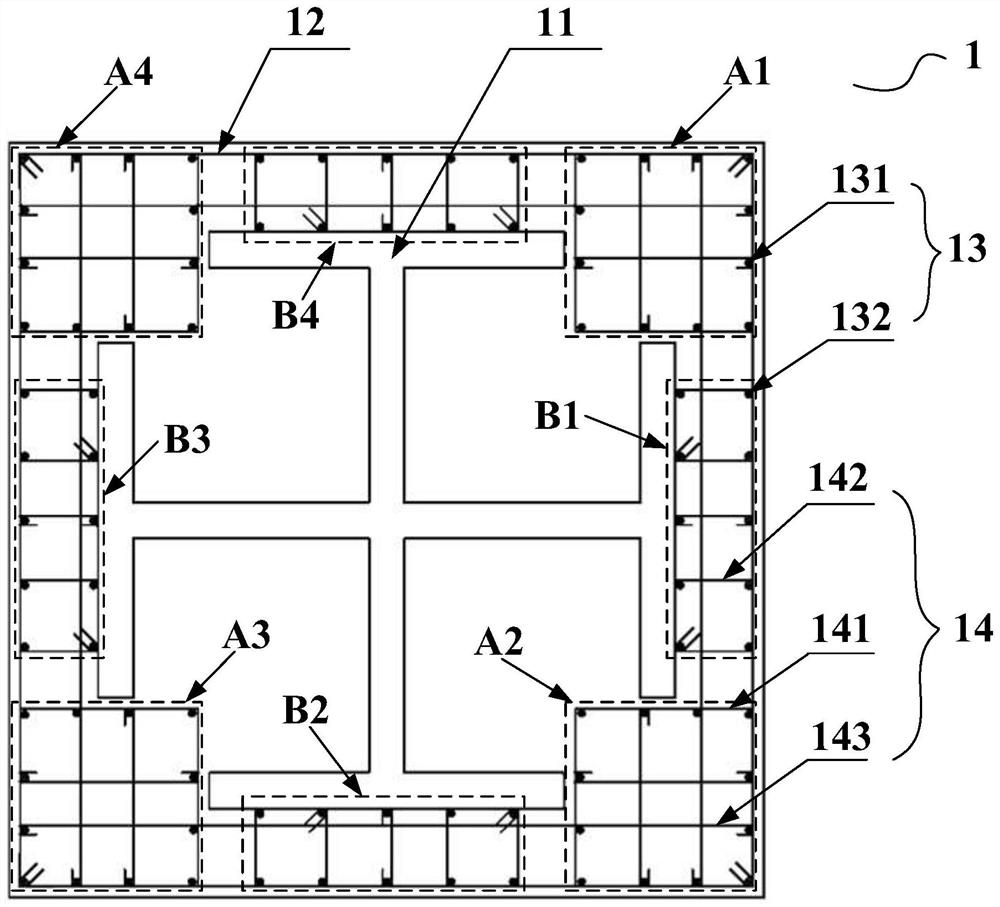

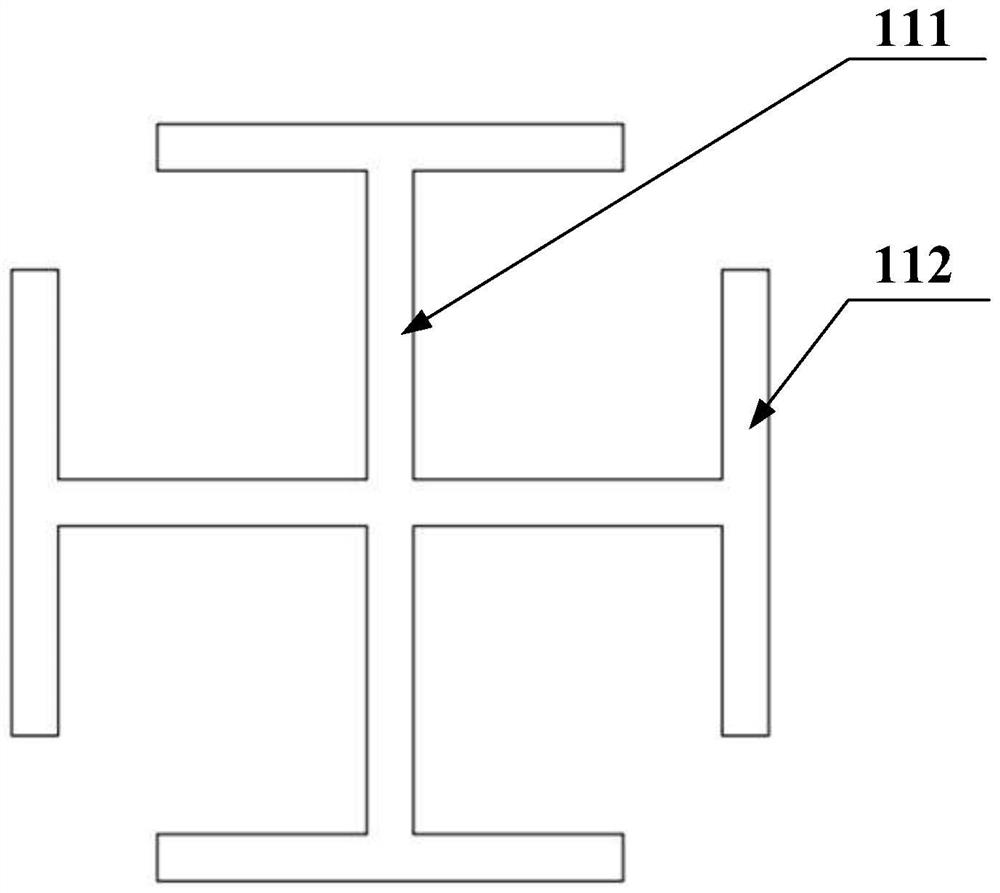

Internal truss system, steel-steel-concrete cross-shaped column and its construction method

InactiveCN105220833BEnhanced hoop effectIncreased load-bearing capacityStrutsPillarsShear capacitySteel tube

The invention discloses an inner truss system, a shape steel-steel pipe concrete cross column and a method for constructing the same. The shape steel-steel pipe concrete cross column comprises outer wrapping steel pipes, inner filled concrete and the inner truss system. The inner truss system comprises shape steel with a crossed transverse section, angle steel with an inverted-L-shaped transverse section, pressure sleeves and draw bars. The pressure sleeves are longitudinally arranged on web plates of the angle steel and the shape steel along a truss system, two ends of each draw bar are respectively fixedly connected with the corresponding pressure sleeve on the corresponding web plate of the shape steel and the corresponding pressure sleeve on the angle steel, and the angle steel is distributed to form quadrilaterals; the angle steel is fixedly connected with the outer wrapping steel pipes. The inner truss system, the shape steel-steel pipe concrete cross column and the method have the advantages that the bearing capacity and the shear capacity of column components can be improved by the steel pipes and the inner truss system, the ductility of the components can be obviously improved, and the anti-seismic capacity of structures can be enhanced; outer planar support effects can be realized by inner trusses for the web plates of the shape steel, accordingly, width-thickness ratios and height-thickness ratios of the web plates can be decreased, and the stability of the web plates can be improved.

Owner:HOHAI UNIV

Steel pipe and desert sand light aggregate concrete combination column

InactiveCN111827579AGuaranteed carrying capacityGuaranteed deformabilityStrutsCeramicwareSoil scienceMaterial supply

The invention discloses a steel pipe and desert sand light aggregate concrete combination column. The steel pipe and desert sand light aggregate concrete combination column comprises a steel pipe anddesert sand light aggregate concrete poured into the steel pipe. Preparation raw materials of the desert sand light aggregate concrete include desert sand. According to the steel pipe and desert sandlight aggregate concrete combination column, the bearing and deformation capacity of structural elements can be well guaranteed, and good heat insulating and heat resisting performance is achieved under the condition that the bearing requirements are met. The combination column is low in mass, materials are easy to draw, and the combination column has the accessory attributes of being simple in structure and convenient to transport and is especially suitable for remote towns with insufficient material supply, low human quality and deficient technical force in northwest regions. The desert sandlight aggregate concrete is restrained by the steel pipe, the hoop effect of the steel pipe is enhanced, the desert sand light aggregate concrete in the steel pipe is in a three-dimensional pressed state, the deformation of the desert sand light aggregate concrete is restrained, and the steel pipe and desert sand light aggregate concrete combination column has the beneficial effects of being convenient to construct, high in bearing force and good in anti-seismic performance and achieving energy saving and environmental friendliness.

Owner:FUZHOU UNIV

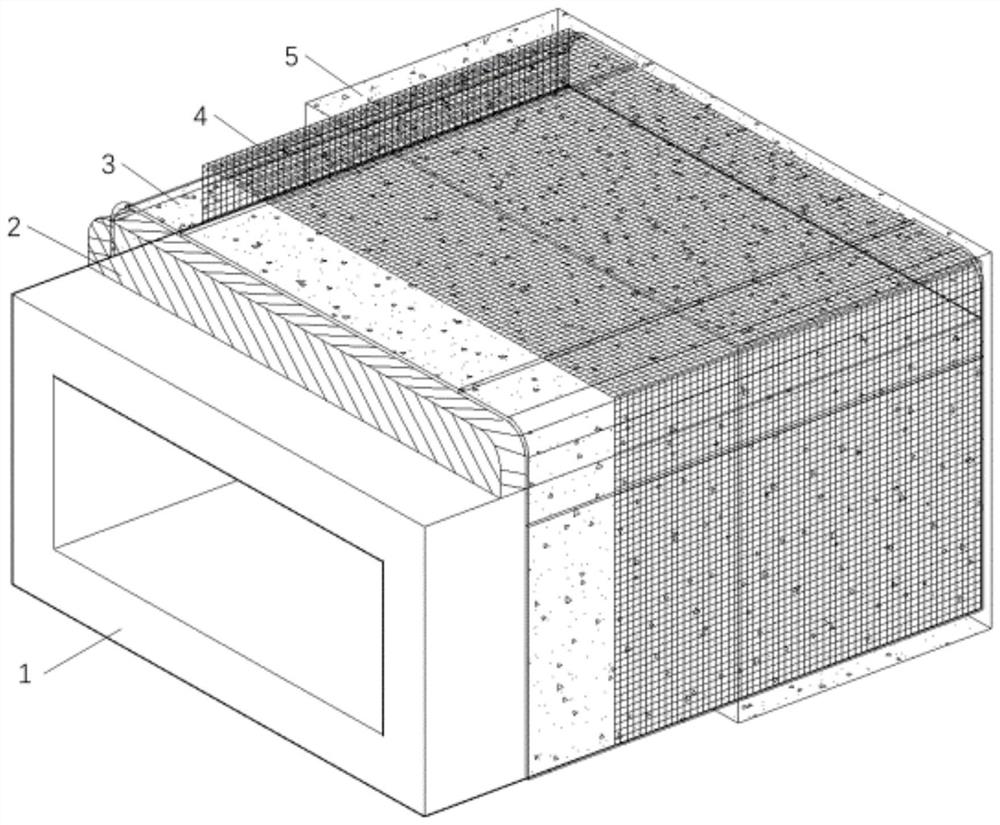

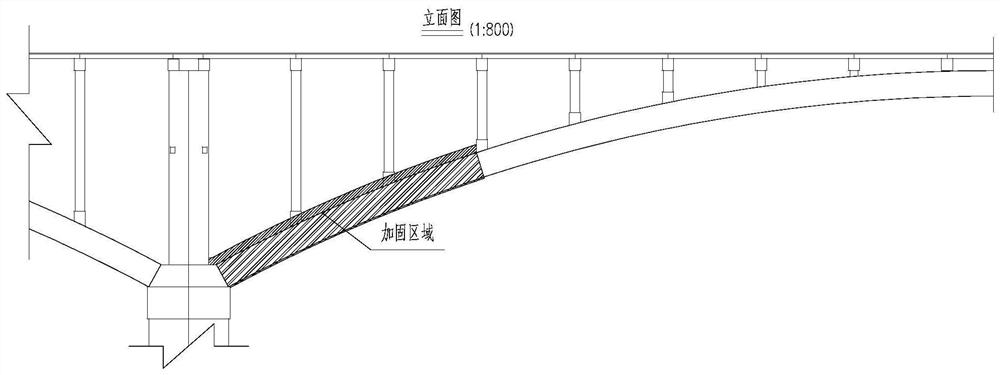

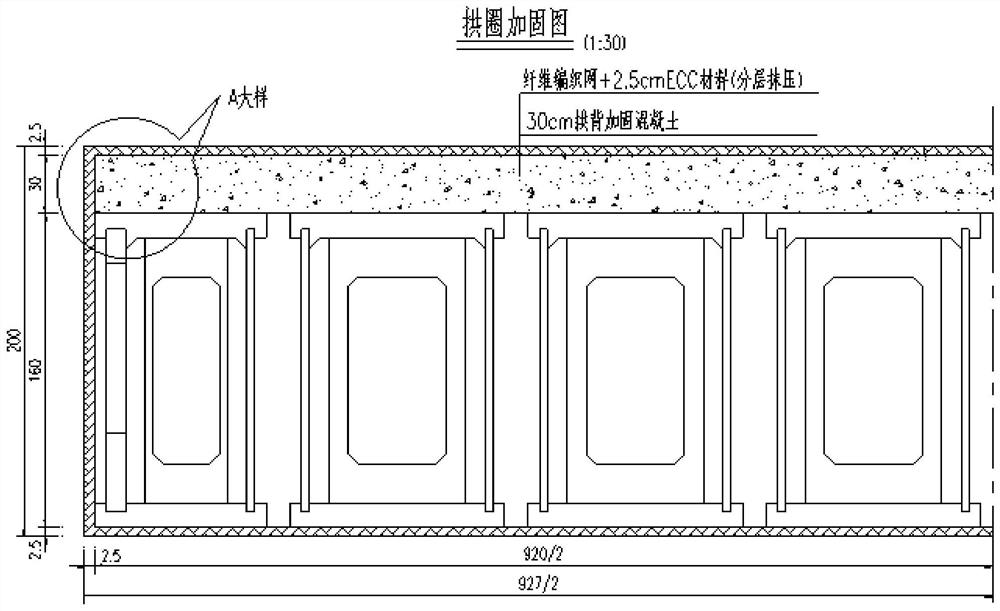

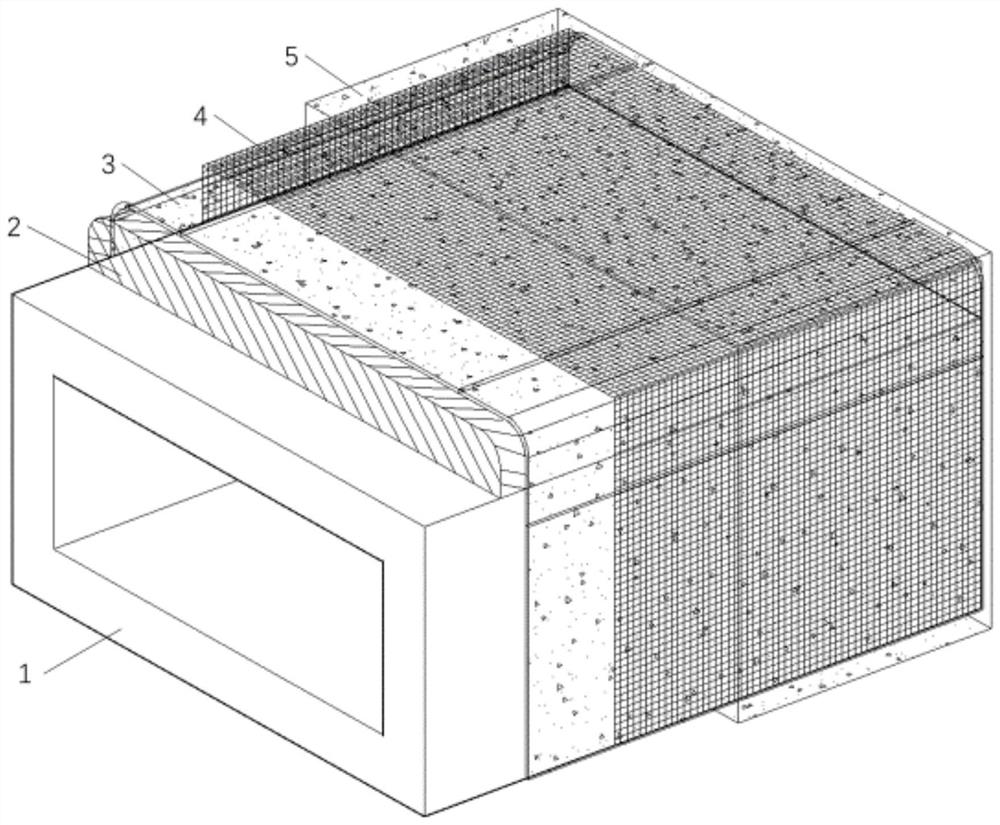

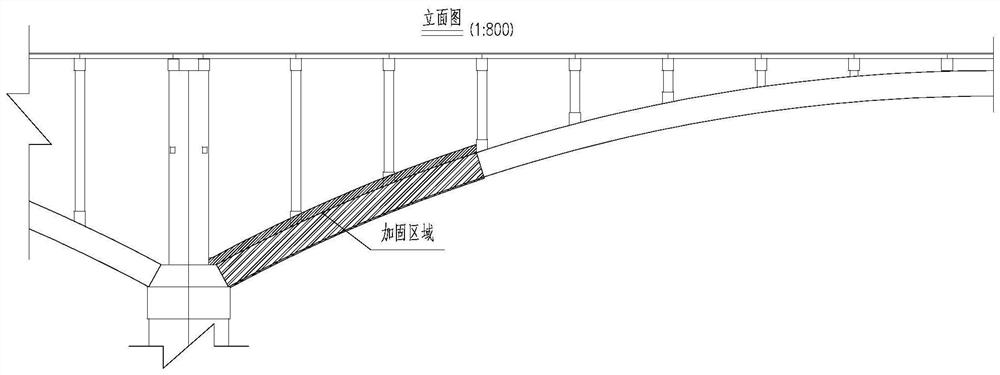

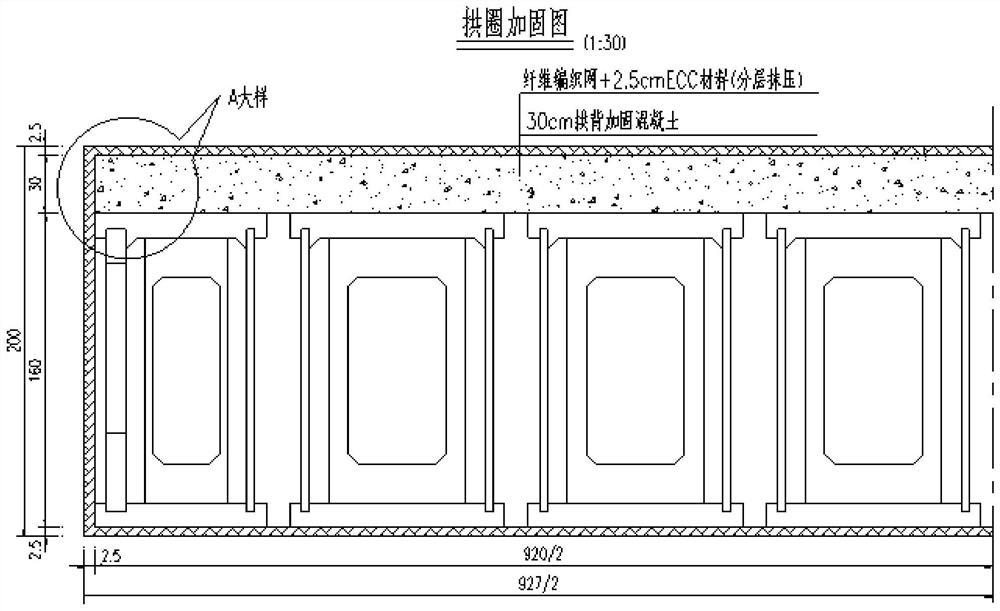

Method for reinforcing arch springing section of box by combining fiber woven mesh reinforced ECC with single-side increased section

ActiveCN111778881AIncrease the cross-sectional areaIncrease stiffnessClimate change adaptationBridge erection/assemblyTensile strainYarn

The invention discloses a method for reinforcing an arch springing section of a box by combining fiber woven mesh reinforced ECC (error correction code) with single-side increased section, which mainly uses arch back reinforced concrete, a fiber woven mesh and an ECC material. The arch back reinforced concrete not only remarkably improves the bearing capacity of the structure, but also has a ballasting effect; the fiber woven mesh meets the requirements of different tensile strength by increasing or decreasing the number of yarns and weaving fiber meshes with different section areas; the ECC material fiber doping amount should not exceed 2.5% of the total volume, the ultimate tensile strain should stably reach 1% or above, the obvious strain hardening characteristic is achieved, and structure surface crack development is effectively inhibited. The method is simple in field operation, the bearing capacity of the structure can be effectively improved, the cooperative stress problem of areinforcing layer and an original structure is solved to the maximum extent, the integrity of the reinforcing structure can be enhanced, and the durability of the structure can be remarkably improved.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Cross-shaped steel concrete column stirrup constraint structure and manufacturing method

PendingCN113175157AReduce porosityImprove carrying capacityStrutsBuilding reinforcementsReinforced concrete columnArchitectural engineering

The invention relates to the technical field of building structure design and civil engineering construction, in particular to a cross-shaped steel concrete column stirrup constraint structure and a manufacturing method. The problems that in the prior art, when stirrups are configured, holes need to be formed in profile steel to form an effective constraint effect on concrete, and construction is complex are solved. The cross-shaped steel concrete column comprises cross-shaped steel arranged in the center of the cross-shaped steel concrete column, peripheral stirrups arranged on the peripheries in all cross sections of the cross-shaped steel concrete column, and longitudinal bars arranged between the cross-shaped steel and the peripheral stirrups and extending in the column height direction. Each cross section of the cross-shaped steel concrete column is further internally provided with an internal stirrup for restraining the longitudinal bars. The stirrups do not penetrate through the profile steel, construction is convenient, the aperture ratio of the cross-shaped steel is reduced, and the bearing capacity of the steel reinforced concrete column can be improved.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

SCS square concrete-filled steel tube pier column

InactiveCN103031927BSimple structureReasonable designStrutsBridge structural detailsMechanical propertySteel tube

The invention discloses an SCS (square concrete-filled steel) tube pier column which comprises a square steel tube, a circular steel tube, four stiffening rib plate groups and a concrete structure, wherein the circular steel tube is mounted in the square steel tube in a sleeving manner; the four stiffening rib plate groups are arranged on four inner side walls of the square steel tube respectively; the concrete structure is formed by pouring concrete filled in a cavity between the square steel tube and the circular steel tube; each stiffening rib plate group comprises a plurality of longitudinal stiffening ribs that are arranged in parallel; the longitudinal stiffening ribs are perpendicular to the inner side walls of the square steel tube where the longitudinal stiffening ribs are located respectively; all the longitudinal stiffening ribs in the four stiffening rib plate groups have identical structures and sizes; the square steel tube and the circular steel tube are arranged coaxially; and the transverse width of each longitudinal stiffening rib is less than a distance between the square steel tube and the circular steel tube where the longitudinal stiffening rib is arranged. The pier column is simple in structure, reasonable in design, convenient to construct, lower in construction cost, good in mechanical property and good in use effect, and can effectively solve the problems existing in the existing square concrete-filled steel tube structure.

Owner:CHANGAN UNIV

Fiber woven mesh reinforced ECC combined with single-sided enlarged cross-section method to strengthen box arch foot section

ActiveCN111778881BIncrease the cross-sectional areaIncrease stiffnessClimate change adaptationBridge erection/assemblyYarnFiber

The invention discloses a fiber braided mesh reinforced ECC combined with a single-sided enlarged cross-section method for strengthening the box arch arch foot section. The bearing capacity of the structure is improved, and at the same time, it has the function of weight; the fiber woven mesh increases or decreases the number of yarns, and weaves fiber meshes with different cross-sectional areas to meet the needs of different tensile strengths; the fiber content of ECC materials should not exceed the total volume. 2.5%, its ultimate tensile strain should reach more than 1% stably, it has significant strain hardening characteristics, and can effectively inhibit the development of cracks on the surface of the structure. The invention is easy to operate on site, can effectively improve the bearing capacity of the structure, solves the problem of the coordinated force bearing between the reinforcement layer and the original structure to the greatest extent, can not only enhance the integrity of the reinforcement structure, but also significantly improve the durability of the structure.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

A kind of extension joint and construction method of prefabricated steel tube concrete core column member

ActiveCN111749346BSmall sectionIncrease the usable areaStrutsProtective buildings/sheltersArchitectural engineeringRebar

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Composite bolting shear key structure

PendingCN114411975ASimplify the assembly processAvoid local damageBridge structural detailsBuilding constructionsArchitectural engineeringPrecast concrete

The invention discloses a composite bolting shear key structure which comprises a prefabricated concrete bearing plate, a steel transition piece and a steel supporting piece, the steel transition piece is pre-buried in the prefabricated concrete bearing plate, the steel transition piece and the prefabricated concrete bearing plate form a whole, and the first end of the steel transition piece protrudes out of the prefabricated concrete bearing plate and is used for being in bolting connection with the steel supporting piece; the shear-resistant assembly is pre-buried in the prefabricated concrete bearing plate and comprises a plurality of studs and reinforcing steel ribs, and the studs are connected to the steel transition piece at intervals in the length direction; the steel transition pieces arranged on the two sides of the central axis of the prefabricated concrete bearing plate in the transverse direction form a connecting piece set, the two transverse ends of the reinforcing steel ribs are connected with the two steel transition pieces in the connecting piece set respectively, the multiple reinforcing steel ribs are arranged at intervals in the length direction, and the reinforcing steel ribs are connected with the two steel transition pieces in the connecting piece set. The post-cast concrete slotted hole (with concrete) can be avoided, the assembly degree of steel and concrete is improved, construction can be facilitated, the problem that the connection operation condition between the steel and the concrete is poor in construction is solved, and the shear resistance of the structure is improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Inner truss type CFST L-shaped column and its construction method

InactiveCN105113717BReduce effective widthImprove the ability to resist instabilityStrutsBuilding material handlingCarrying capacityFlange

The invention discloses an inner truss-type concrete-filled steel tube L-shaped column and a construction method thereof, wherein the inner-truss-type steel tube concrete L-shaped column comprises outsourcing steel pipes, inner filling concrete and an inner truss; the inner truss comprises T-shaped steel, The inner truss subunit welded by T-shaped steel, and the slivers of the T-shaped steel web in the T-shaped steel web and the inner truss subunit overlapped and welded along the T-shaped steel longitudinally; the T-shaped steel and the inner truss The truss sub-units are located at the corners of the quadrilateral, and the cross-section of the outsourcing steel pipe is Γ-shaped or Π-shaped, and is welded and fixed with the flange plate of the T-shaped steel. In the present invention, the inner truss is tied at the corner of the special-shaped steel pipe, thereby reducing the effective width of the steel plate, providing a fulcrum for the out-of-plane deformation of the steel plate, improving the anti-instability ability of the steel plate and improving the hoop effect of the column, so that the steel pipe The bearing capacity of concrete special-shaped columns is significantly improved.

Owner:HOHAI UNIV

SCS concrete filled steel tube pier reinforced by stirrup and stiffening rib at end

InactiveCN103015311BSimple structureReasonable designBridge structural detailsBridge materialsSteel tubeMaterials science

The invention discloses an SCS concrete filled steel tube pier reinforced by a stirrup and a stiffening rib at an end, which comprises an outer steel tube, an inner steel tube sleeved in the outer sleeve tube, a top reinforcing structure, a bottom reinforcing structure and a concrete structured poured and formed by concrete in a cavity between the outer and inner steel tubes. The inner steel tube is circular. The inner and outer steel tubes are coaxially arranged. The top reinforcing structure comprises a plurality of PBL stiffening ribs I and a stirrup I arranged from top to bottom. The bottom reinforcing structure comprises a plurality of PBL stiffening ribs II and a stirrup II arranged from top to bottom. The transverse width of each PBL stiffening rib I and each PBL stiffening rib II is smaller than the distance between the outer and inner steel tubes arranged at the position. The SCS concrete filled steel tube pier reinforced by the stirrup and the stiffening rib at the end is simple in structure, reasonable in design, convenient to construct, lower in construction cost, excellent in mechanical performance and good in using effect, and various problems of current concrete filled steel tube piers can be effectively solved.

Owner:CHANGAN UNIV

Pneumatic radial tires

InactiveUS20040079463A1Avoid separationEnhanced hoop effectPneumatic tyre reinforcementsWheelsMechanical engineeringRadial tire

In a pneumatic radial tire comprising a belt of at least two belt layers, in which the belt comprises a maximum-width belt layer containing many cords slantly arranged with respect to an equatorial plane of the tire and a narrow-width belt layer arranged at the outside of the maximum-width belt layer in the radial direction and containing many cords arranged in an oppositely inclined direction to the cords of the maximum-width belt layer, the belt end separation is controlled by arranging a reinforcing layer containing many cords arranged in an oppositely inclined direction to the cords of the maximum-width belt layer so as to overlap with an outer end portion of the maximum-width belt layer located outward from an outer end. of the narrow-width belt layer in the widthwise direction thereof.

Owner:BRIDGESTONE CORP

A scs concrete filled steel pipe pier with a built-in transverse connection structure at the end

InactiveCN104233949BSimple structureReasonable designBridge structural detailsMechanical propertySteel tube

The invention discloses an SCS concrete filled steel tube pier with transverse connecting structures arranged inside the two ends. The SCS concrete filled steel tube pier with the transverse connecting structure arranged inside the two ends comprises an outer steel tube, an inner steel tube, a top end connecting structure, a bottom end connecting structure and a concrete structure arranged between the outer steel tube and the inner steel tube, wherein both the outer steel tube and the inner steel tube are arranged vertically and coaxially, the top end connecting structure and the bottom end connecting structure are the transverse connecting structures which are both arranged between the outer steel tube and the inner steel tube, each transverse connecting structure comprises multiple groups of transverse connecting pieces which are arranged in the circumferential direction, each group of transverse connecting pieces comprises multiple transverse connecting pieces which are arranged from top to bottom, each transverse connecting piece is formed by connecting an outer connecting piece body and an inner connecting piece body, the outer connecting piece bodies are parallel to the inner connecting piece bodies, and the inner end of each outer connecting piece body and the outer end of the corresponding inner connecting piece body are connected into a whole. The SCS concrete filled steel tube pier with the transverse connecting structure arranged inside the two ends is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, good in use effect and capable of solving multiple problems of existing concrete filled steel tube piers.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com