Bidirectional ribbed multi-cavity concrete-filled steel tube pier and framework and construction method thereof

A technology for concrete-filled steel tubes and bridge piers, which is applied in bridges, bridge parts, bridge materials, etc., can solve the problems of poor confinement effect of core concrete and large amount of concrete, so as to reduce the phenomenon of steel pipe detachment and core concrete cracking, and enhance the restraint and The effect of high ferrule ability and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

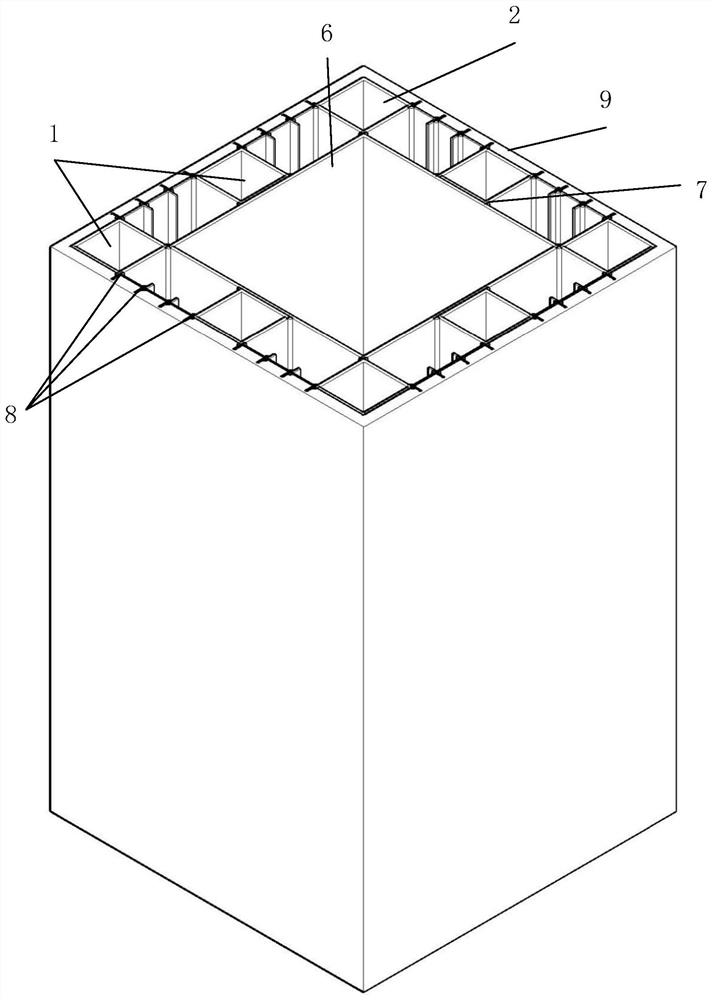

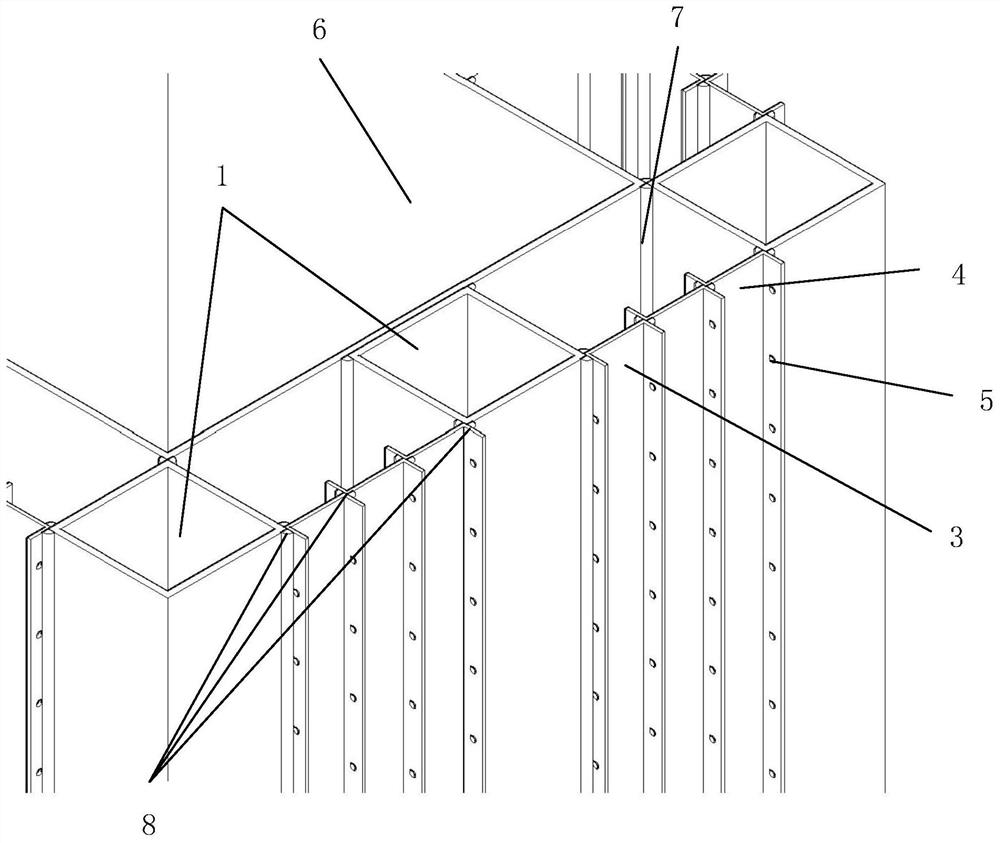

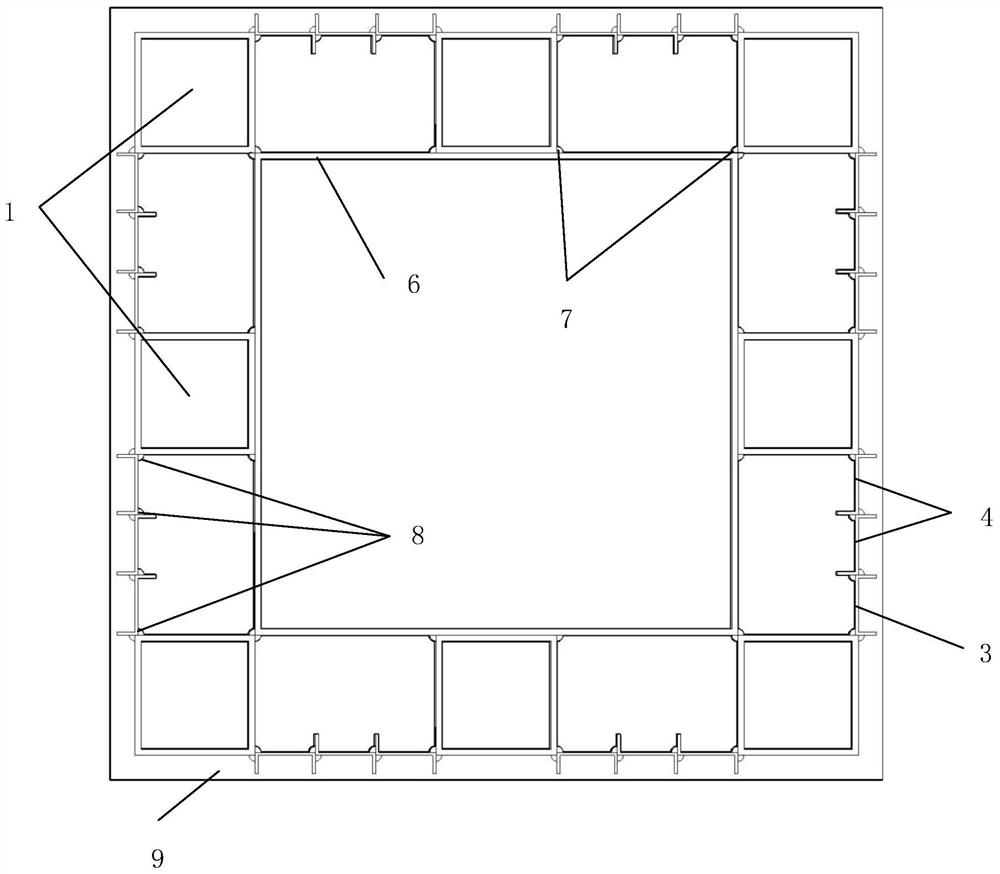

[0035] A bridge pier skeleton, comprising: central steel pipe column 6, outer pipe 1, two-way ribs 3, two-way ribs 4, rib holes 5, first weld 7, second weld 8, concrete protection layer 9 and inner concrete 2.

[0036] The central steel pipe column 6 is located at the center of the pier, and its cross section is one of symmetrical polygons such as rectangle and hexagon.

[0037] The outer pipes 1 are evenly distributed around the central steel pipe column 6 at intervals, and the cross section of the outer pipes 1 is one of symmetrical polygons such as rectangles and hexagons. A first weld 7 is provided at the joint between the central steel pipe column 6 and the outer pipe 1 .

[0038] Two-way ribs 4 and two-way ribs 3 are connected between two adjacent outer tubes 1 through the second weld 8 in sequence: outer tube 1, two-way ribs 3, two-way ribs 4, and outer tube 1, wherein the two-way There is one rib 3 and several bidirectional ribs 4 . Each of the ribs includes a base ...

Embodiment 2

[0044] A bridge pier, which uses the pier skeleton in Example 1, and the pier can be made into two structures: hollow pier and solid pier, wherein the hollow pier is filled with concrete 2 except for the central steel pipe column 6; the solid pier does not have a center Concrete 2 is poured into the inner space of the steel pipe column and the first weld 7 .

[0045] The concrete protective layer 9 is poured in the outer rib area of the bridge pier, and the thickness of the protective layer is greater than the flange length of the two-way rib 3 and the two-way rib 4.

Embodiment 3

[0047] A bridge pier construction method, comprising the steps of:

[0048] a. Prefabricate the two-way ribs 3 and the two-way ribs 4 in the factory;

[0049] b. Weld the outer pipe 1 evenly at intervals around the central steel pipe column 6, and connect the diagonal gaps at the joints with the first weld 7;

[0050] c. Splice two-way ribs 3 and two-way ribs 4 in sequence between two adjacent outer tubes 1, so that the inner and outer ribs are evenly distributed, and the diagonal gaps at the joints are connected by the second weld 8;

[0051] d. Concrete 2 is poured in the inner space other than the steel pipe column 6 in the center of the pier;

[0052] e. Concrete protection layer 9 is poured in the outer rib area of the pier, and the thickness of the protection layer 9 is greater than the length of the flanges of the two-way rib 3 and the two-way rib 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com