Concrete-filled steel tube

A technology for steel pipe concrete and concrete regeneration, applied in the field of steel pipe concrete, can solve the problems of uneven distribution, damage, and detachment of steel pipe reinforcement effects, and achieve the effects of reducing local weak points, good fluidity, and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

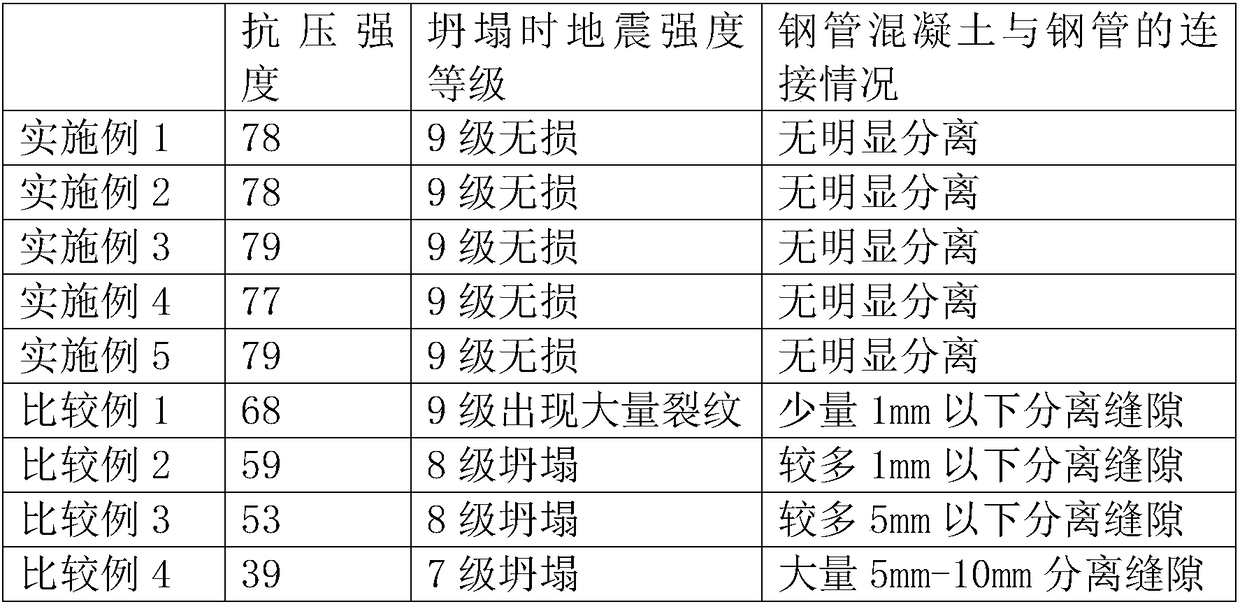

Examples

Embodiment 1

[0054] A kind of steel tube concrete, is made by following steps:

[0055] (1) Add 100kg of optically active polytrityl methacrylate and 45kg of silane coupling agent into the kneader, raise the temperature to 165°C, and stir at constant temperature for 180s to form a premix;

[0056] (2) Add 326kg of Portland cement, 16kg of water reducer and 175kg of water into the first stirring tank at a rotating speed of 80r / min, and stir for 10min to form cement slurry;

[0057] (3) Add 50kg of acetone in the second stirred tank, cool the premix to room temperature and then add it into the second stirred tank at a speed of 40r / min, and stir until the premix is completely dissolved to form a premix solution;

[0058] Then add the premix solution into the cement slurry in the first stirred tank, and stir with a rotating speed of 120r / min through the first stirred tank, and stir for 15 minutes to stir evenly;

[0059] (4) Add 20kg of cobalt salt, 22kg of fumed silica and 40kg of expansion ...

Embodiment 2

[0070] A kind of steel tube concrete, is made by following steps:

[0071] (1) Add 102kg of optically active polytrityl methacrylate and 46kg of silane coupling agent into the kneader, raise the temperature to 165°C, and stir at constant temperature for 180s to form a premix;

[0072] (2) Add 326kg of Portland cement, 17kg of water reducing agent and 175kg of water into the first stirring tank at a rotating speed of 80r / min, and stir for 10min to form cement slurry;

[0073] (3) Add 51kg of acetone in the second stirred tank, cool the premix to room temperature and then add it into the second stirred tank at a speed of 40r / min, and stir until the premix is completely dissolved to form a premix solution;

[0074] Then add the premix solution into the cement slurry in the first stirred tank, and stir with a rotating speed of 120r / min through the first stirred tank, and stir for 15 minutes to stir evenly;

[0075] (4) Add 22kg of cobalt salt, 23kg of fumed silica, and 44kg of ...

Embodiment 3

[0086] A kind of steel tube concrete, is made by following steps:

[0087] (1) Add 106kg of optically active polytrityl methacrylate and 48kg of silane coupling agent into the kneader, raise the temperature to 165°C, and stir at constant temperature for 180s to form a premix;

[0088] (2) Add 326kg of Portland cement, 18kg of water reducing agent and 175kg of water into the first stirring tank at a rotating speed of 80r / min, and stir for 10min to form cement slurry;

[0089] (3) Add 53kg of acetone in the second stirred tank, cool the premix to room temperature and then add it into the second stirred tank at a speed of 40r / min, and stir until the premix is completely dissolved to form a premix solution;

[0090] Then add the premix solution into the cement slurry in the first stirred tank, and stir with a rotating speed of 120r / min through the first stirred tank, and stir for 15 minutes to stir evenly;

[0091] (4) Add 24kg of cobalt salt, 24kg of fumed silica and 48kg of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com