Hollow-sandwich multi-cavity steel pipe concrete member and preparation method thereof

A CFST and concrete technology, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of decreased bearing capacity of CFST structures, many welding spots on the board surface, and buckling of steel pipes, and achieves reduction and improvement of structural steel consumption. Work performance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

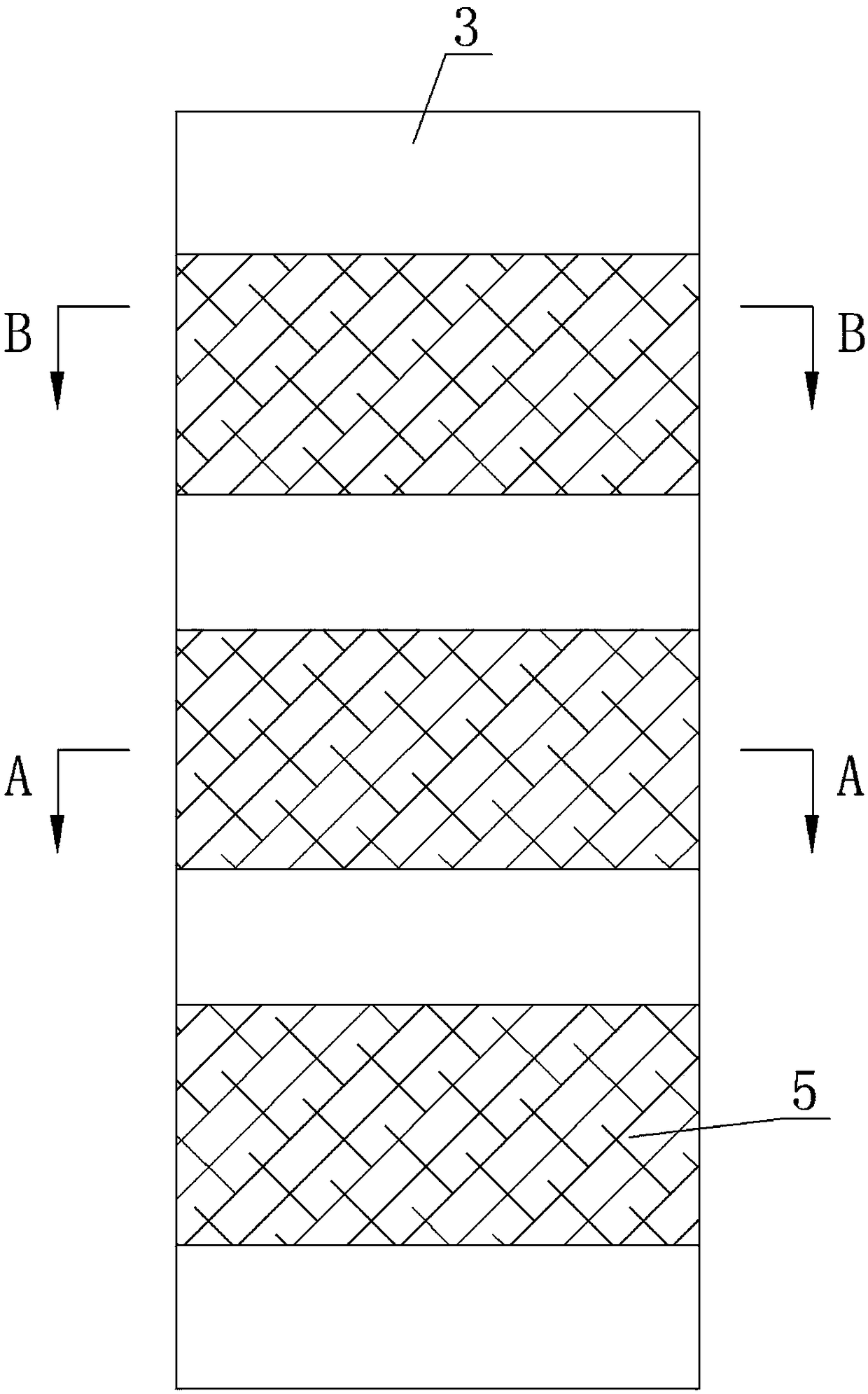

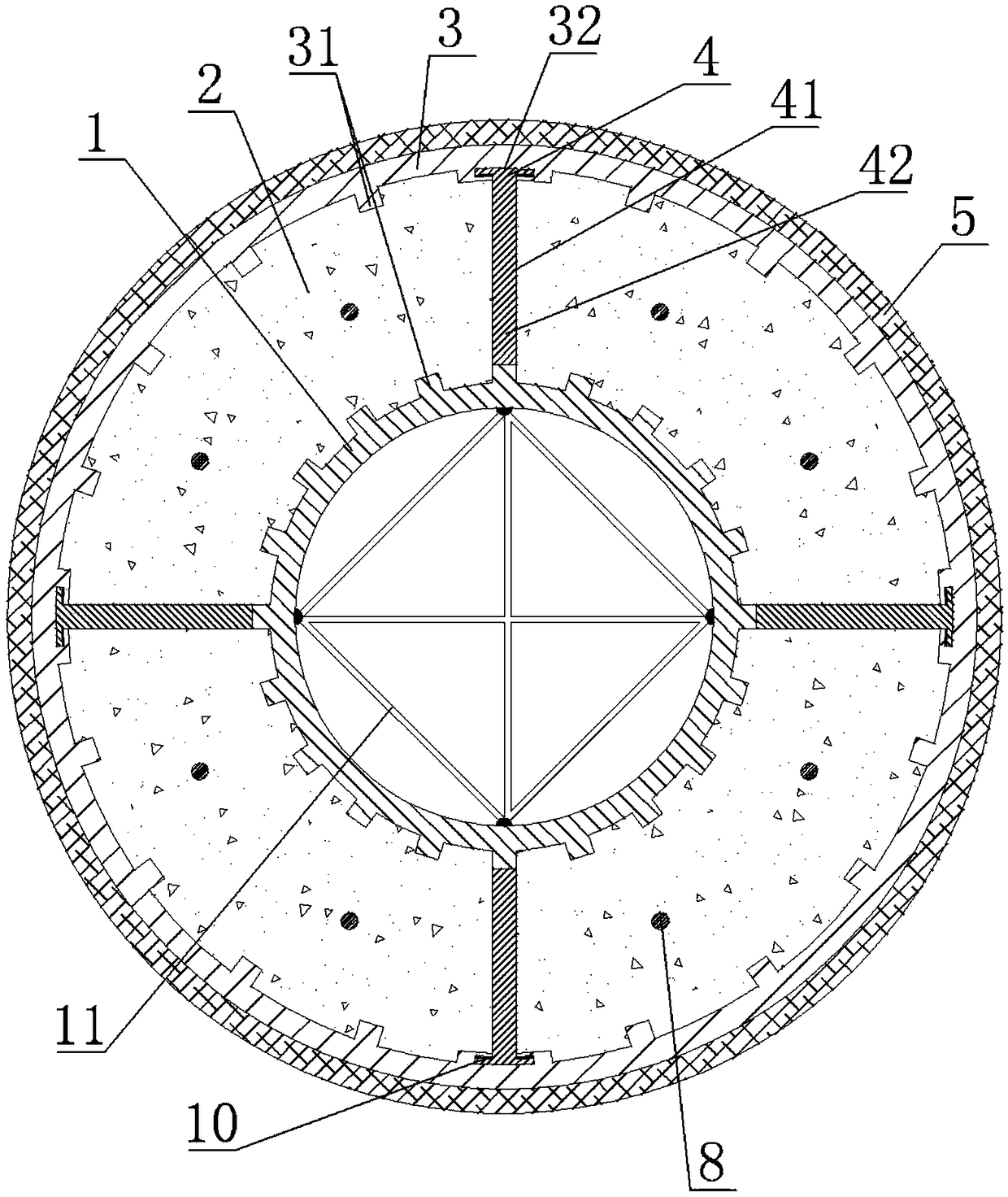

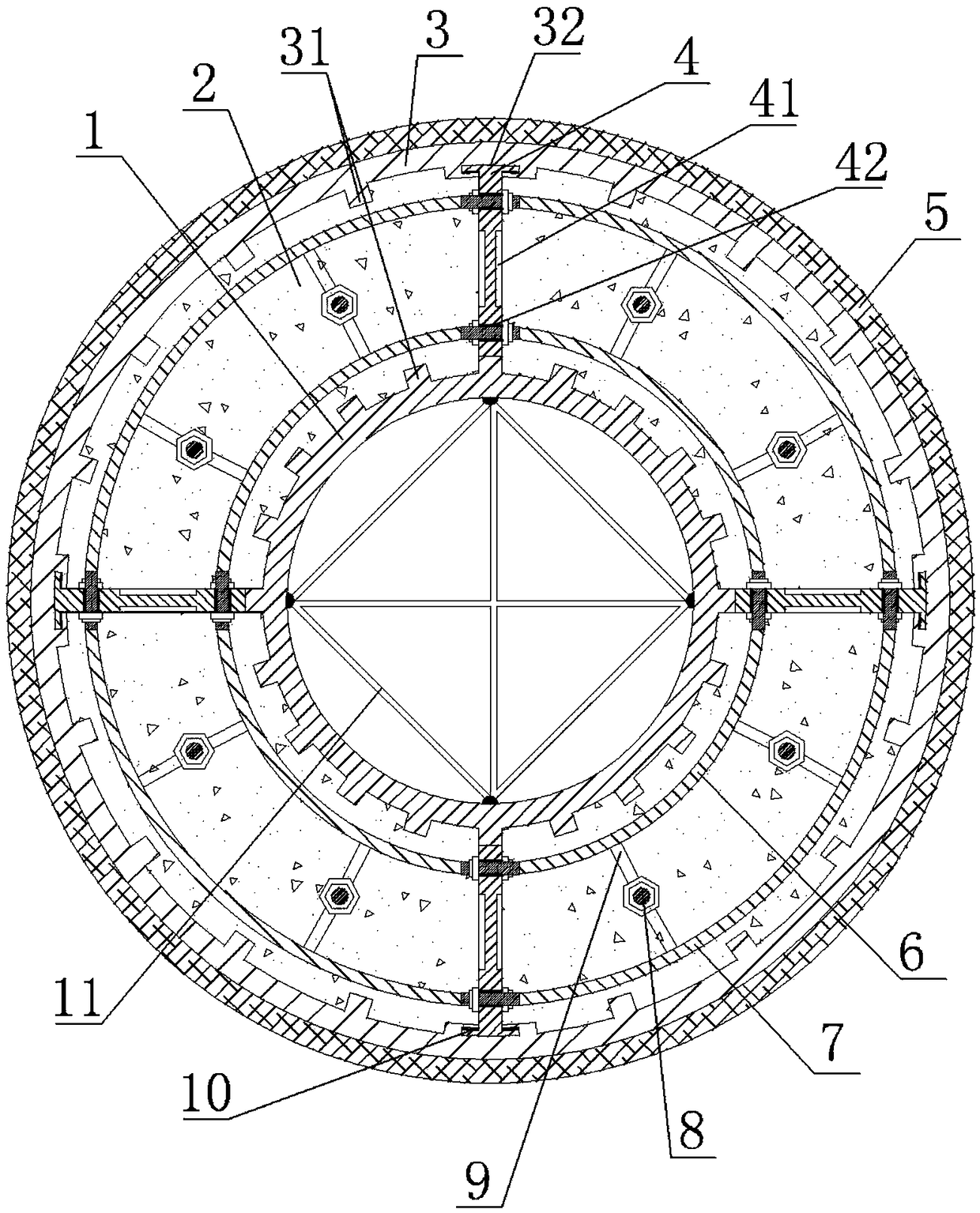

[0043] from Figure 1 to Figure 5It can be seen that the hollow interlayer multi-cavity steel pipe concrete member of the present invention includes a circular inner steel pipe 1, concrete 2, a circular outer steel pipe 3, a diaphragm 4, an outer cylinder 5, an arc inner tie rod 6, an arc External tie rod 7, prestressed rod 8, positioning steel bar 9, epoxy resin grout 10 and support iron 11,

[0044] There are four diaphragms 4, and each diaphragm 4 is vertically welded on the outer wall of the inner steel pipe 1 along the axis of the inner steel pipe 1. The four diaphragms 4 are evenly distributed around the axis of the inner steel pipe 1, and each diaphragm The length of the plate 4 is the same as that of the inner steel pipe 1, and each diaphragm 4 is arranged along the length of the inner steel pipe 1. The cross-section of the outer end of the diaphragm 4 is T-shaped, and on the front side of the diaphragm and the back side are axially evenly distributed with a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com