Patents

Literature

116results about How to "Prevent local buckling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft steel shearing lag return damper

The invention relates to a shear hysteretic damper, which comprises an upper rigid connecting plate and a lower rigid connecting plate which are connected with a building structure, a hysteretic energy-consuming web plate, and a flange plate, wherein the rigid connecting plates and the flange plate are fixedly connected to the hysteretic energy-consuming web plate. At least one side of the hysteretic energy-consuming web plate is provided with transverse stiffening ribs or / and longitudinal stiffening ribs. The flexibility-fineness ratio parameter of the hysteretic energy-consuming web plate is between 0.2 and 0.5, the plate thickness ratio of the flange plate to the web plate is not less than 4, the rigidness ratio of the stiffening ribs is not less than 3.0, and the shape factor is between 0.5 and 1.5. The hysteretic energy-consuming web plate is made of rolled steel the yield strength of which is not more than 235MPa, the flange plate and the rigid connecting plates are made of the rolled steel the yield strength of which is not less than 235MPa, and the stiffening ribs are made of the rolled steel the yield strength of which is not less than 235MPa. The shear hysteretic damper has the advantages of simple structure, stable performance, low manufacture and maintenance cost, small space occupation ratio, easy space distribution, replacement after an earthquake and the like.

Owner:TONGJI UNIV

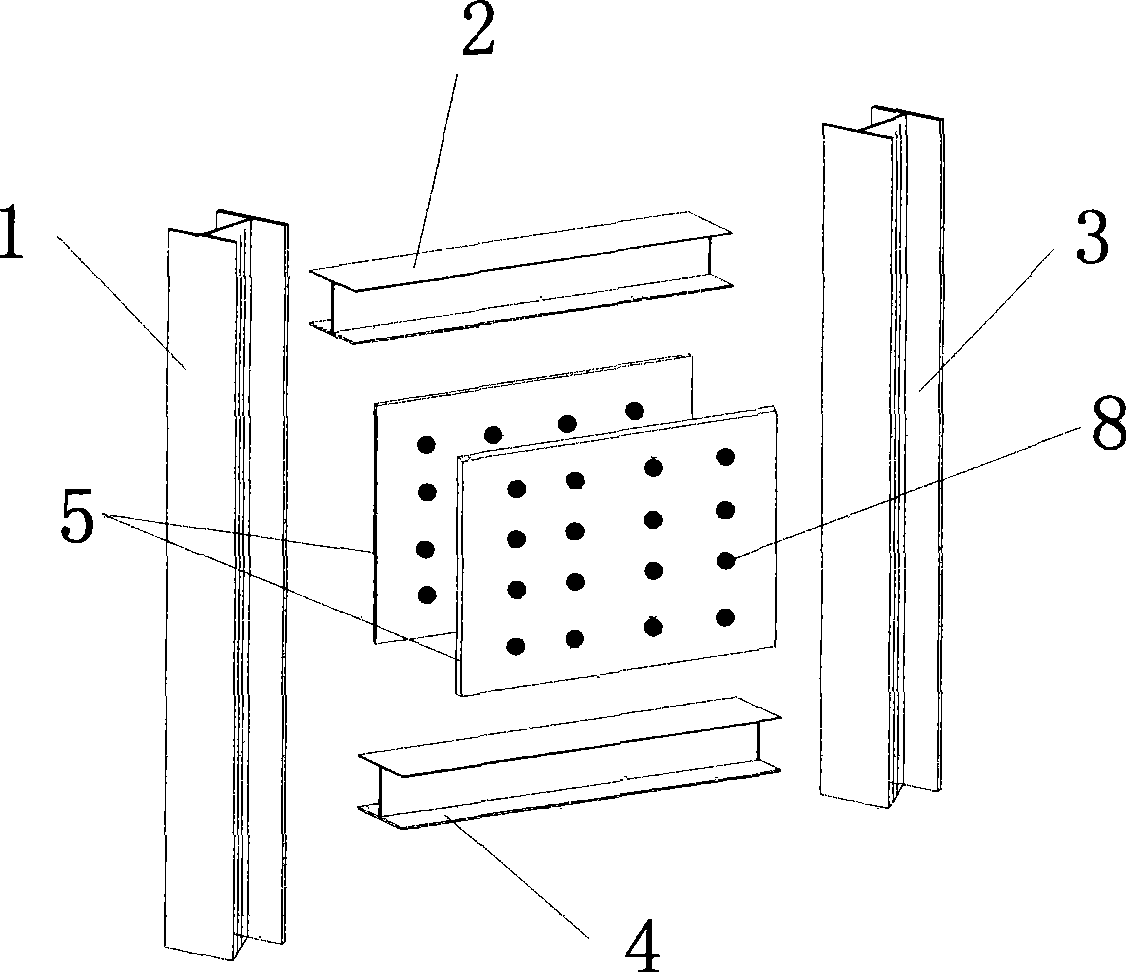

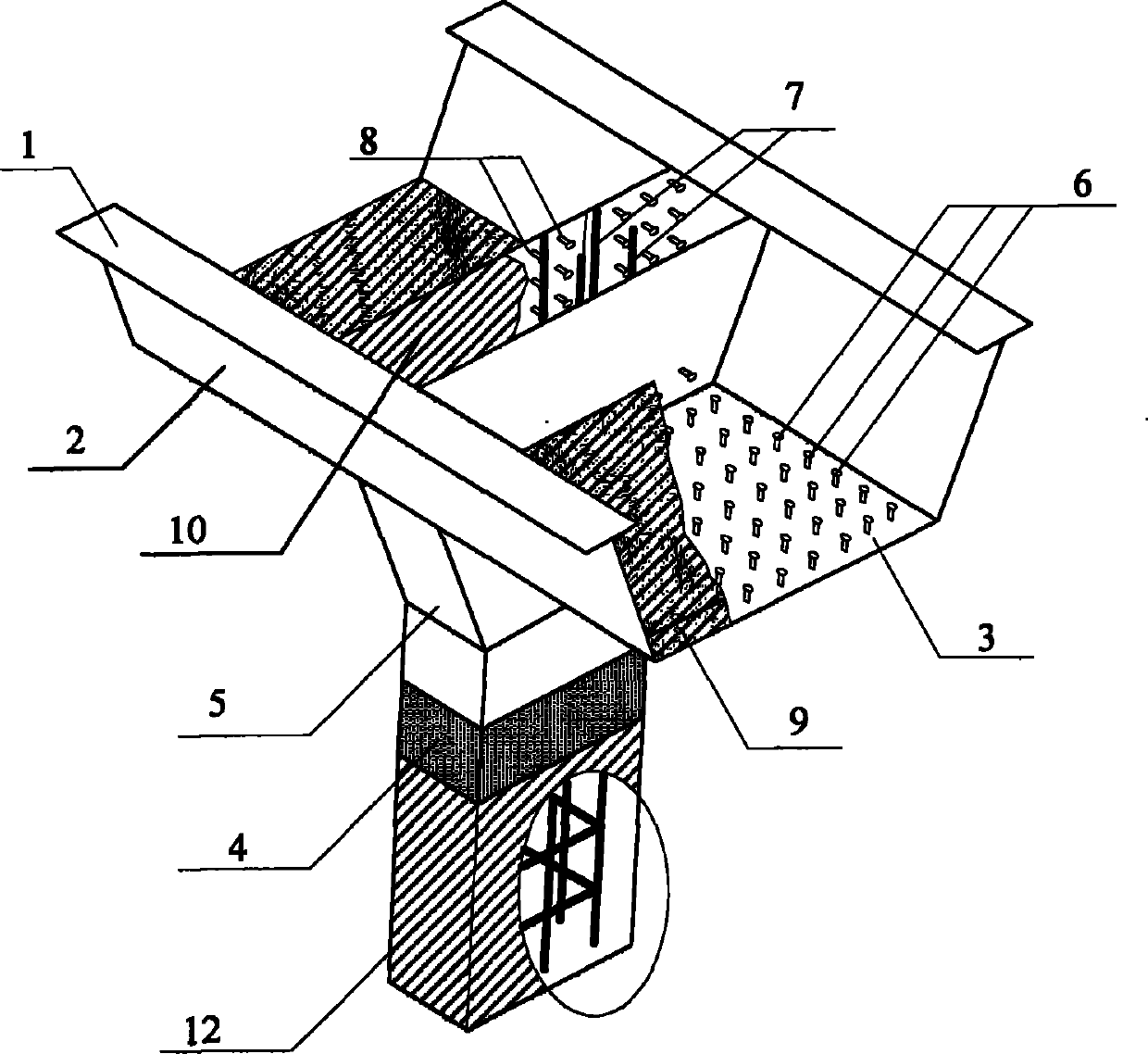

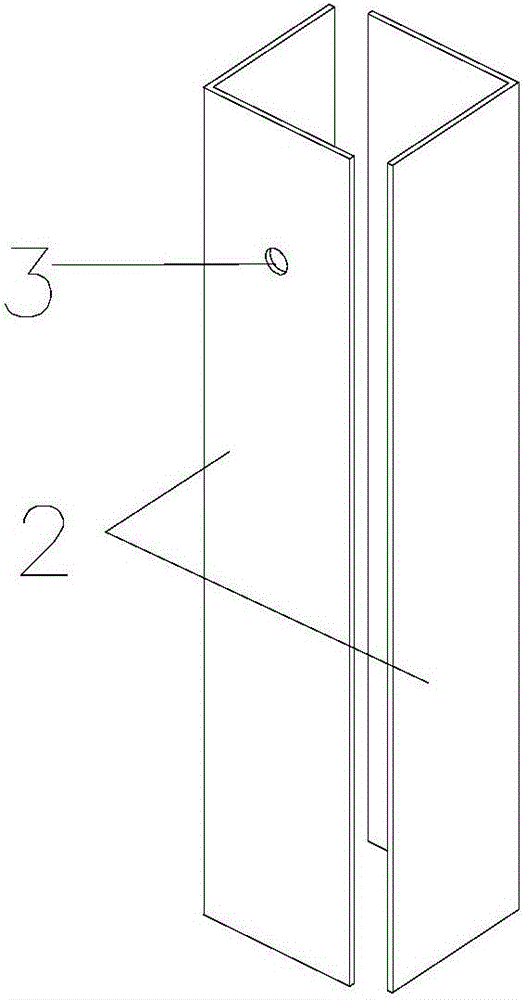

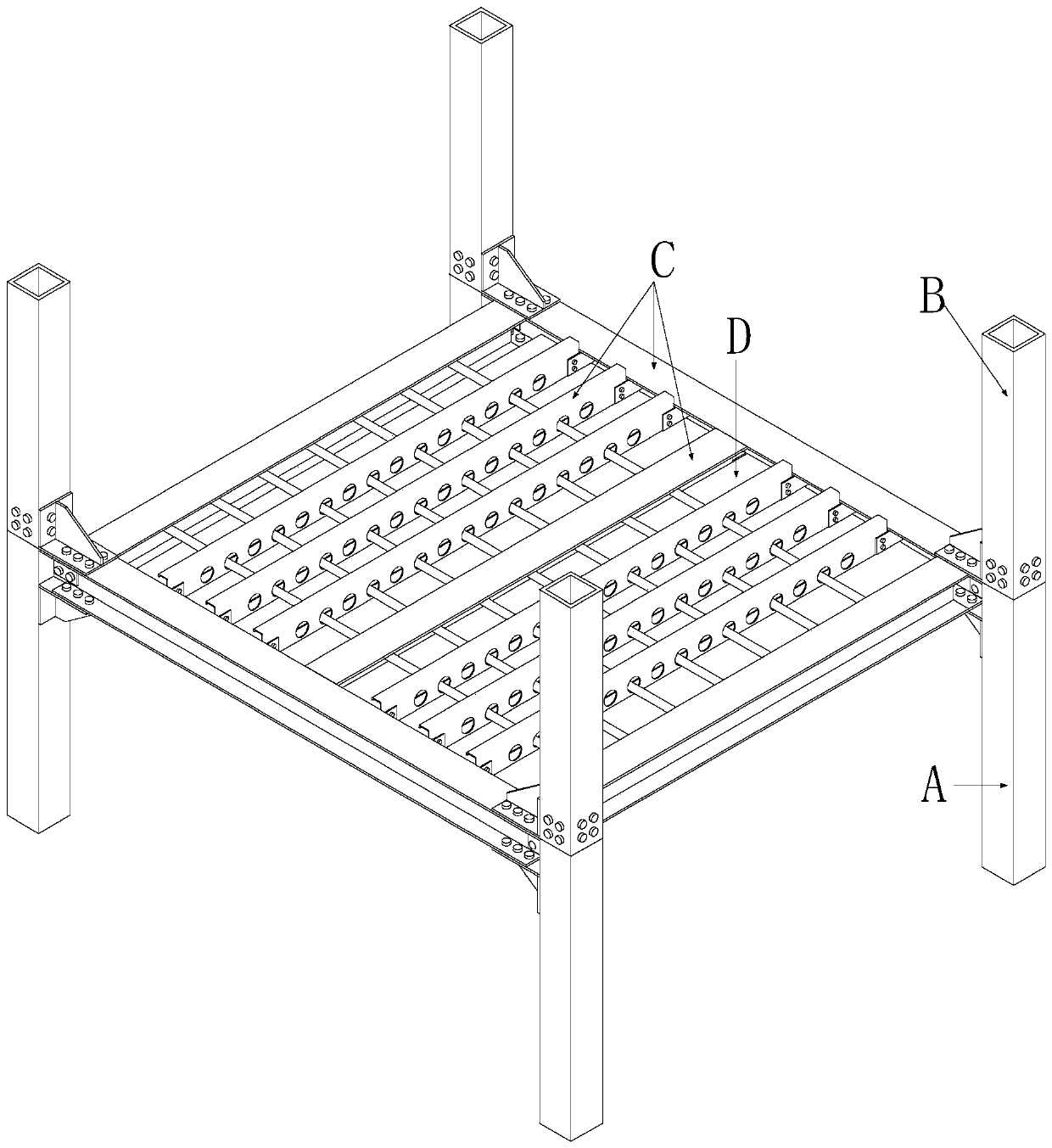

Steel bar truss stiffened steel concrete composite shear wall

InactiveCN104929281AImprove bearing capacityIncreased shear capacityWallsSheet steelReinforced concrete

The invention discloses a steel bar truss stiffened steel concrete composite shear wall, relates to a shear wall and belongs to the field of building structures. The steel bar truss stiffened steel concrete composite shear wall aims to solve the problems that an existing steel concrete shear wall is poor in anti-seismic property, prone to crack and complex in construction when connected with steel members. The steel bar truss stiffened steel concrete composite shear wall comprises a second stiffening member, concrete, a first stiffened steel body and a plurality of shearing-resistant connecting keys. The first stiffened steel body comprises a first stiffening member, two steel plates, a plurality of transverse steel bars and a plurality of steel bar trusses. Each steel bar truss comprises two erection steel bars and three longitudinal steel bars, wherein the three longitudinal steel bars are arranged in a triangular shape, and the steel bar trusses are arranged in parallel between the two steel plates in the horizontal direction. The erection steel bars are connected to the steel plates. The transverse steel bars are horizontally arranged between the two steel plates, and the transverse steel bars are connected with the steel bar trusses. The first stiffening member and the second stiffening member are provided with the shearing-resistant connecting keys, and the concrete is poured on the first stiffening steel body and the second stiffening member.

Owner:HARBIN INST OF TECH

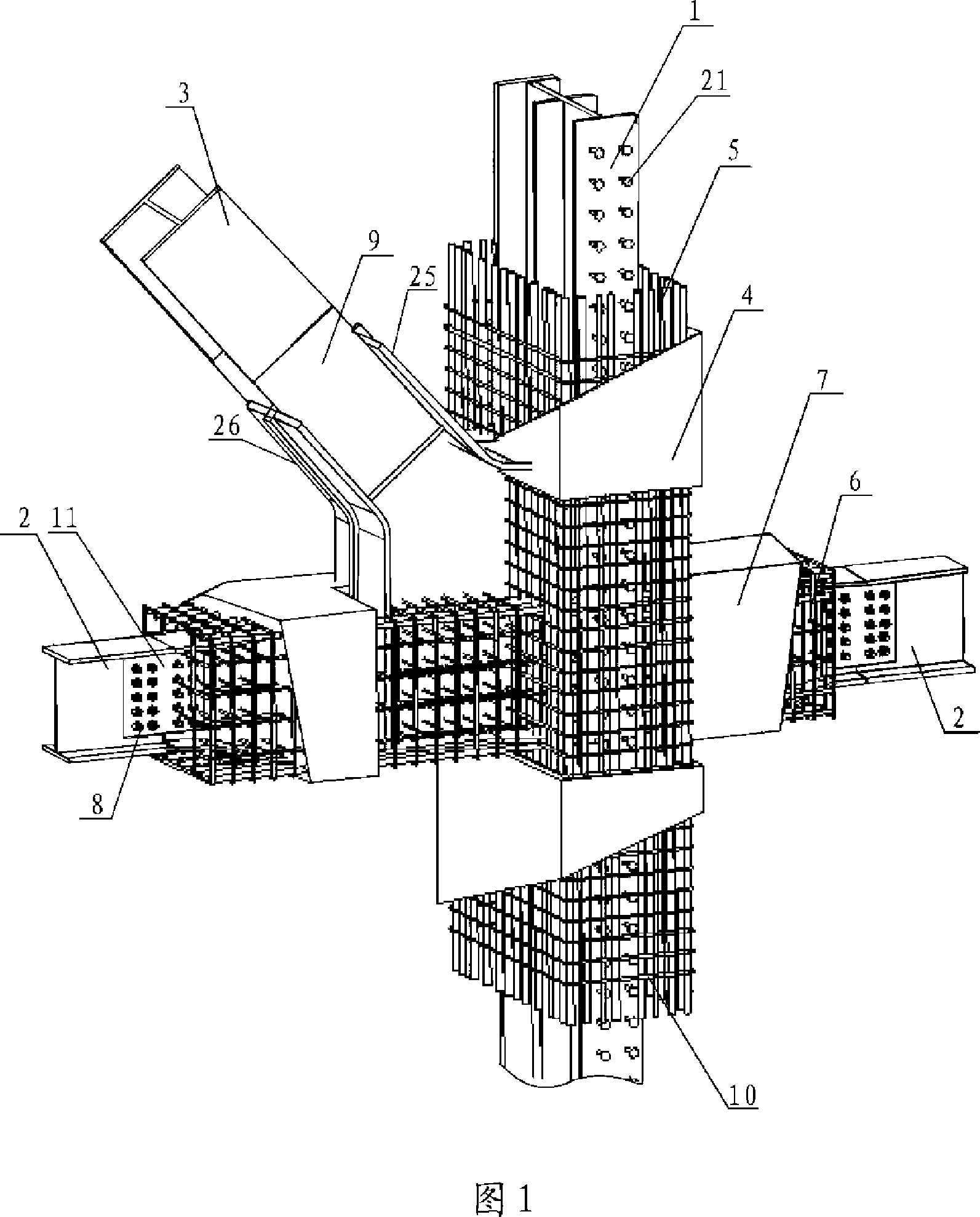

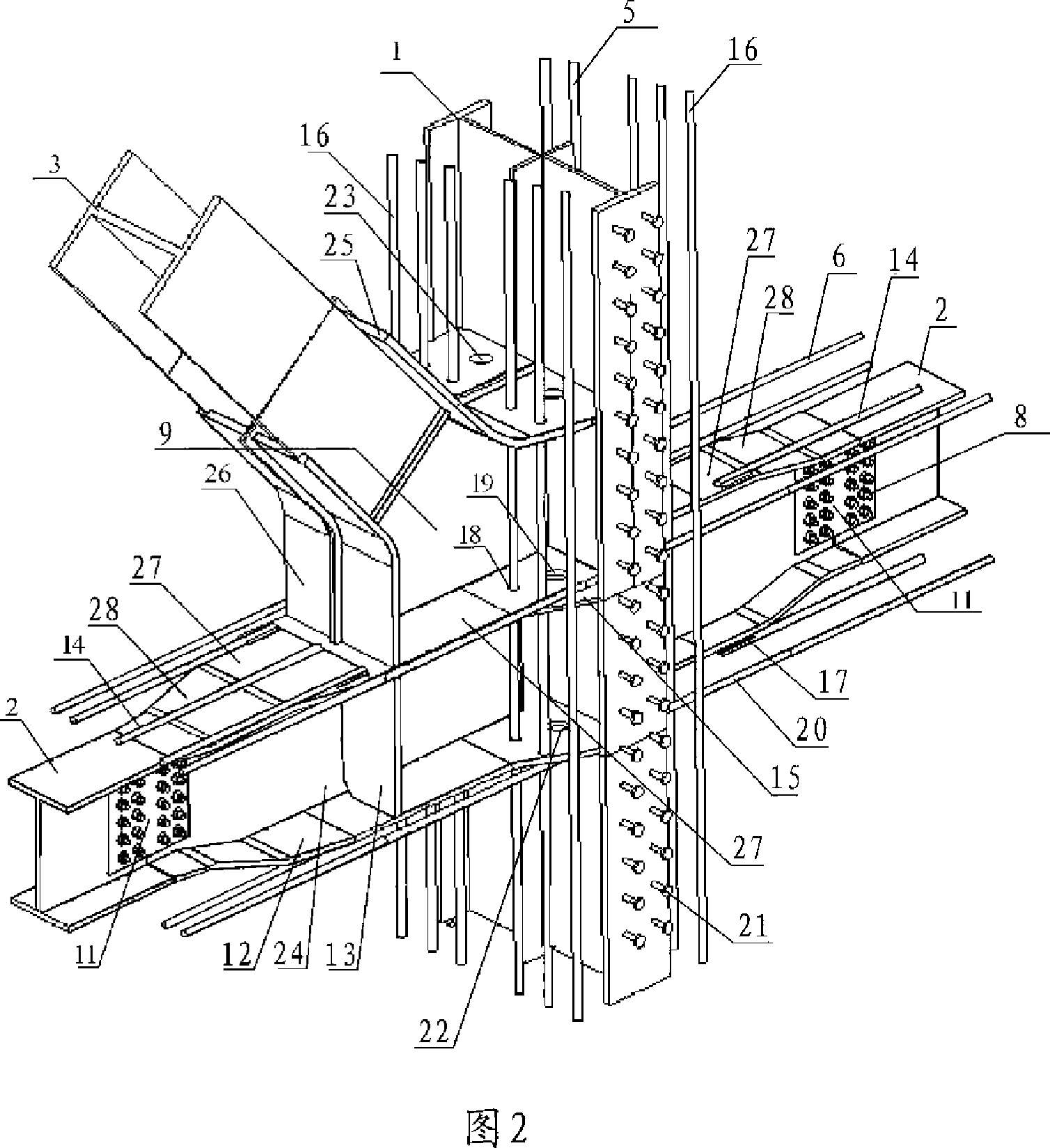

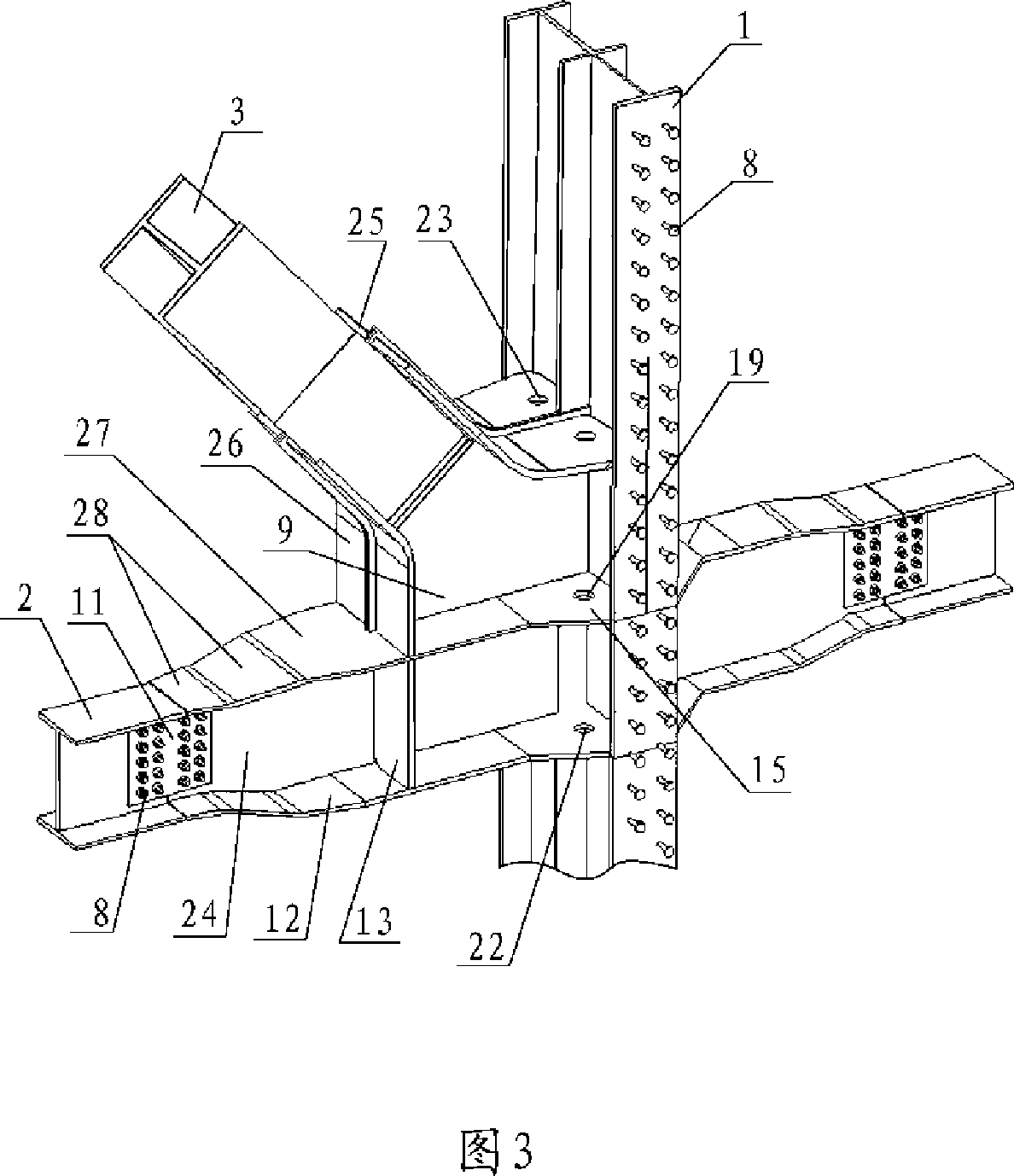

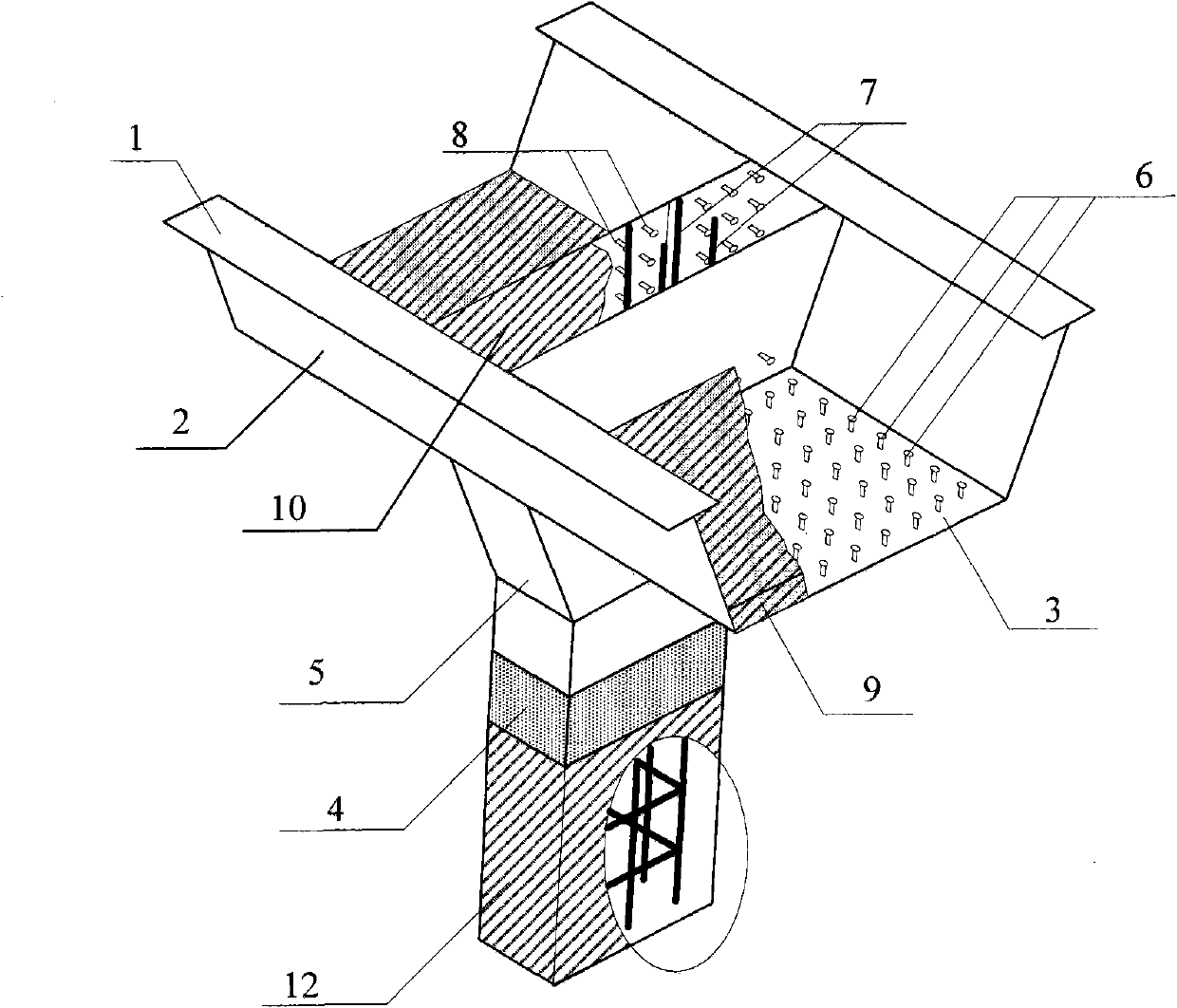

Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

ActiveCN101024975AImprove seismic performanceImprove synergyBuilding constructionsReinforced concreteInto-structure

The invention is a variable section conversion node for profiled steel concrete framework-steel support structure, interconnecting in-pillar profiled steel, in-beam profiled steel, steel support, in-pillar reinforced concrete and in-beam reinforced concrete and pouring then into an organic whole, where the steel support is orthogonally connected with in-pillar an in-beam profiled steel flange plates by section conversion, the web of the in-beam profiled steel in the node connection position is converted into heightening variable section web and the top surface of the heightening variable section web is welded with widening variable section upper wing plate, the bottom surface of the heightening variable section web is welded with widening variable section lower wing plate; the shape of the steel support in the node connecting position is converted into structure of variable section node conversion region and two flange plates of the steel support in variable section conversion region are orthogonally connected with the in-pillar and in-beam profiled steel respectively. And the invention intensifies fore bearing performance of node regions of the profiled steel concrete framework-steel support structure and ability of cooperating of profiled steel and reinforced concrete.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

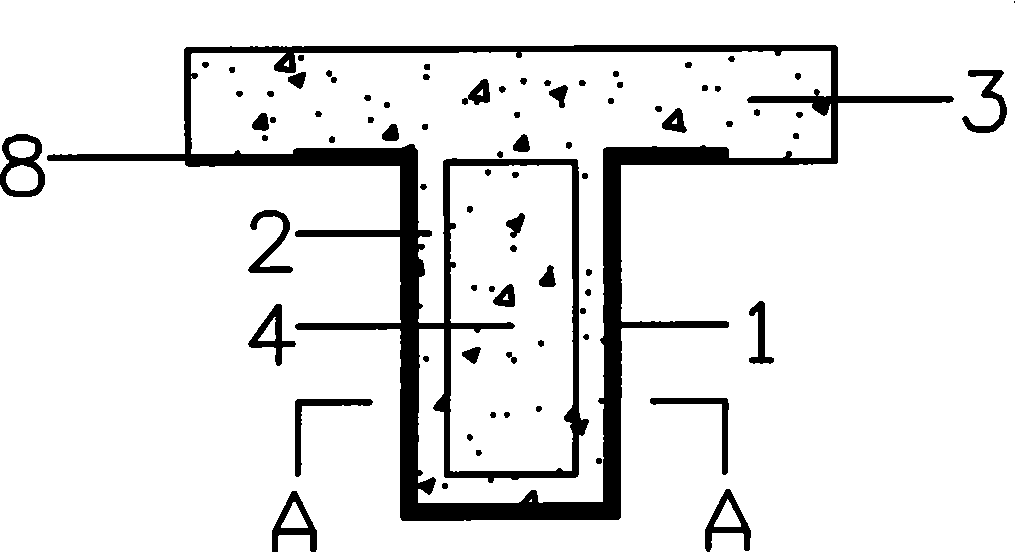

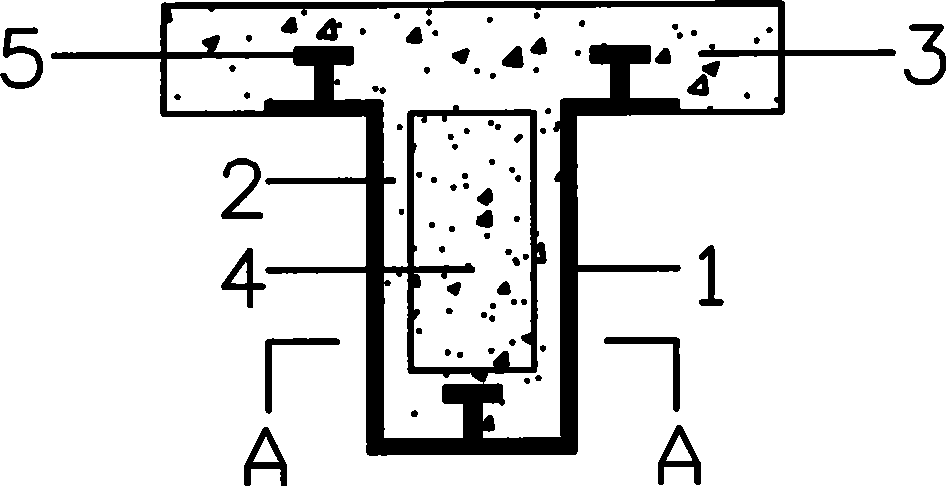

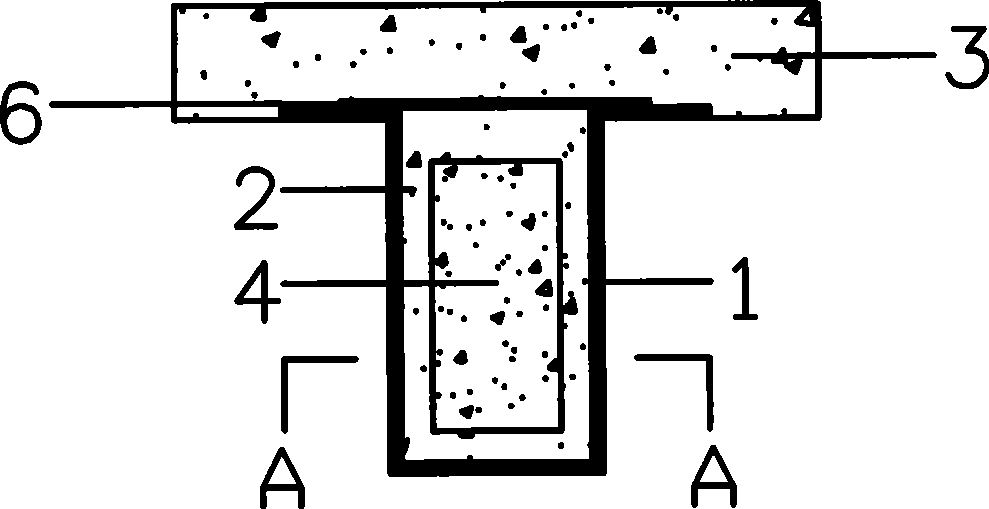

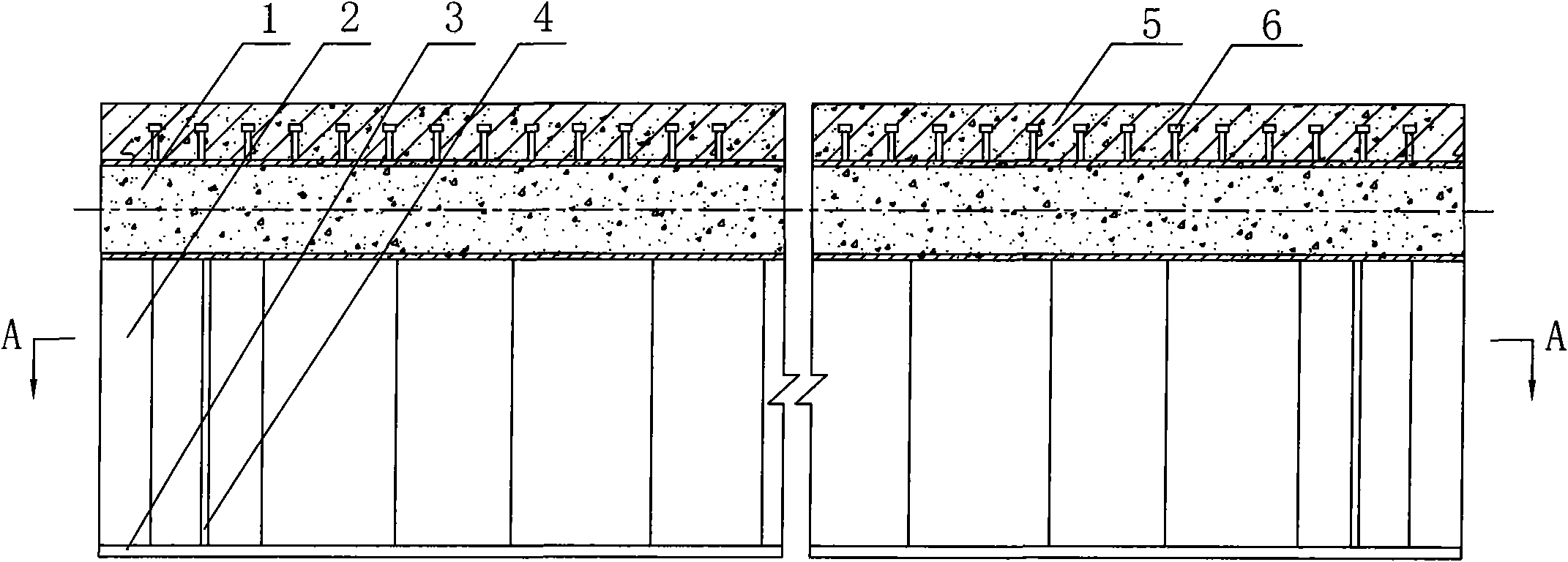

U-shaped steel-coated Regenerated composite beam of and construction method thereof

InactiveCN101418631AIncrease stiffnessImprove ductilityFloorsLoad-supporting elementsFloor slabRebar

The invention discloses a U-shaped steel-encased regenerated composite beam and a construction method thereof. The U-shaped steel-encased regenerated composite beam comprises one or more disused concrete blocks, new concrete, and U-shaped encased steel, the disused concrete blocks are arranged inside the U-shaped encased steel, and the gap between the disused concrete block and the U-shaped encased steel is filled with the new concrete. The method includes the following steps: the U-shaped encased steel is made as the formwork of a beam and is integrated with the formwork of the floor slab or roof slab; a layer of new concrete is first poured into the U-shaped encased steel, then the disused concrete blocks and new concrete are alternately put into the U-shaped encased steel, tamping is utilized then to distributed the disused concrete blocks into the new concrete; steel bars of the floor slab or the roof slab are put into the formwork of the floor slab or the roof slab, and the new concrete is poured into the formwork of the floor slab or the roof slab. The invention can save a great amount of energy consumed in the processes of breaking, screening, purifying and the like for the concrete waste.

Owner:SOUTH CHINA UNIV OF TECH

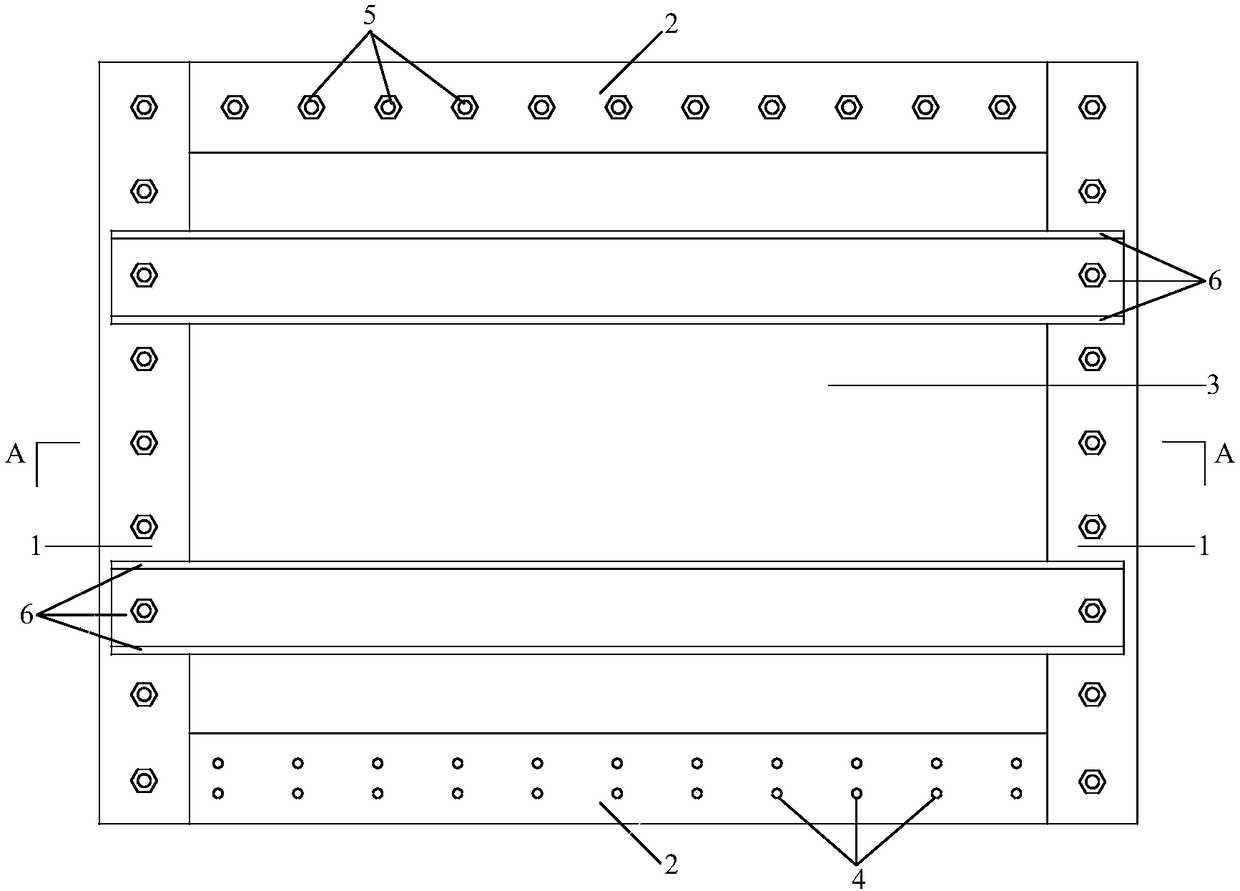

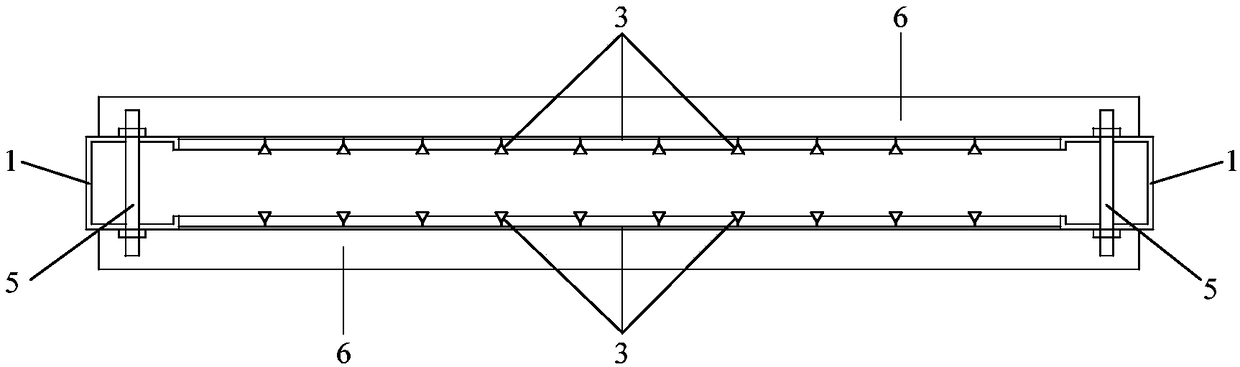

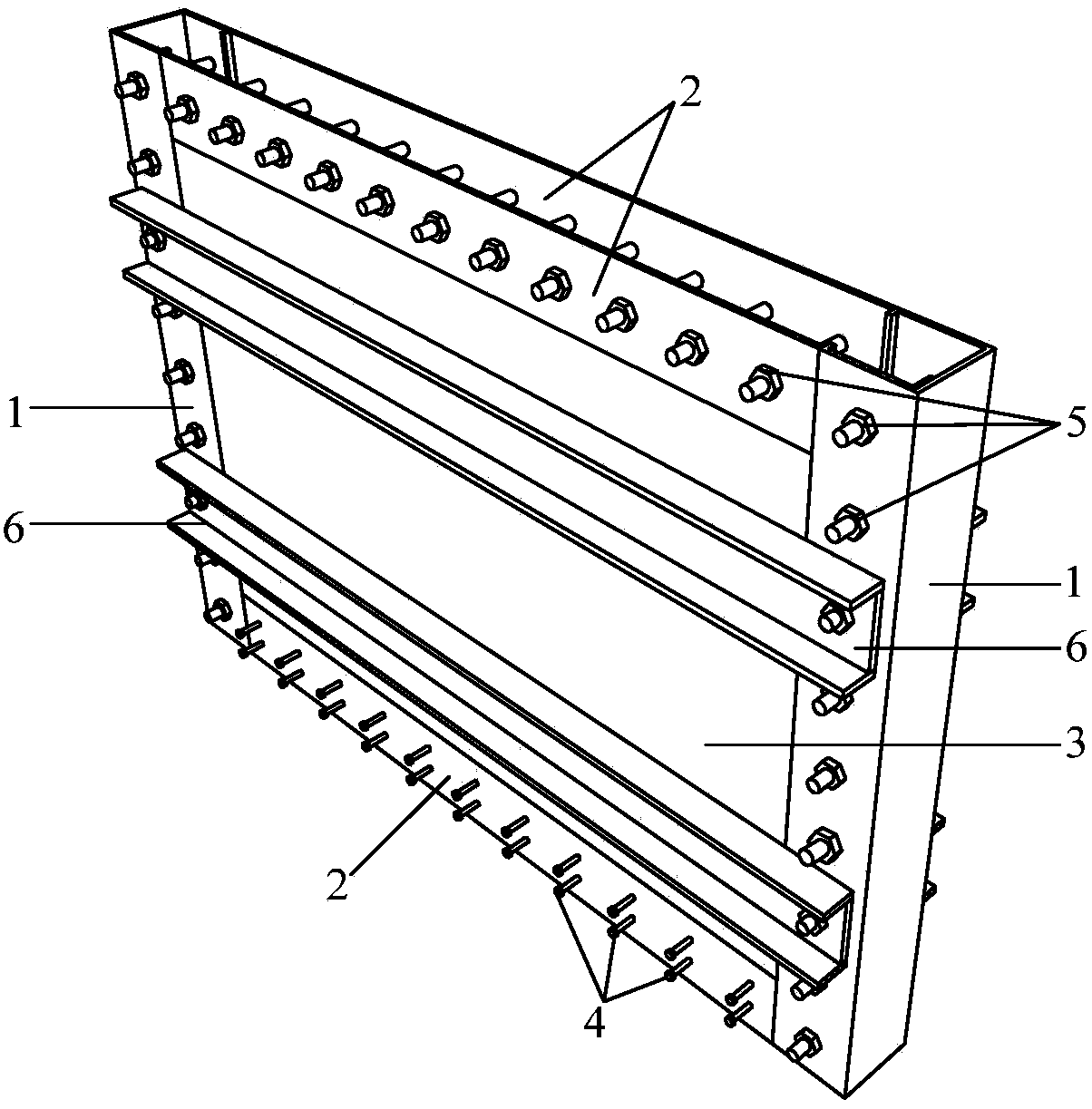

Shear Type Stiffened Metal Damper

The invention discloses a shear-type stiffened metal damper, which comprises an energy-dissipating steel plate, stiffening ribs are respectively arranged on the left and right sides of the energy-dissipating steel plate, horizontal connecting steel plates are respectively arranged on the upper end and the lower end of the energy-dissipating steel plate, Flange plates are arranged at the front end and rear end respectively, the stiffeners on the left side and the right side of the energy dissipation steel plate are arranged symmetrically or asymmetrically, and the stiffeners on the same side of the energy dissipation steel plate are arranged without crossing. The invention utilizes the advantages of relatively large initial rigidity when the steel plate is stressed in the plane, and prevents the buckling of the energy-dissipating steel plate by means of stiffening, thereby ensuring the energy-dissipating capacity and stability of the damper; There are no cross welds, and the stiffeners can be set in full length without truncating, which is convenient for welding, and the welding quality is easy to guarantee.

Owner:SHANGHAI SAFE SEISMIC RETROFIT & VIBRATION CONTROL TECH

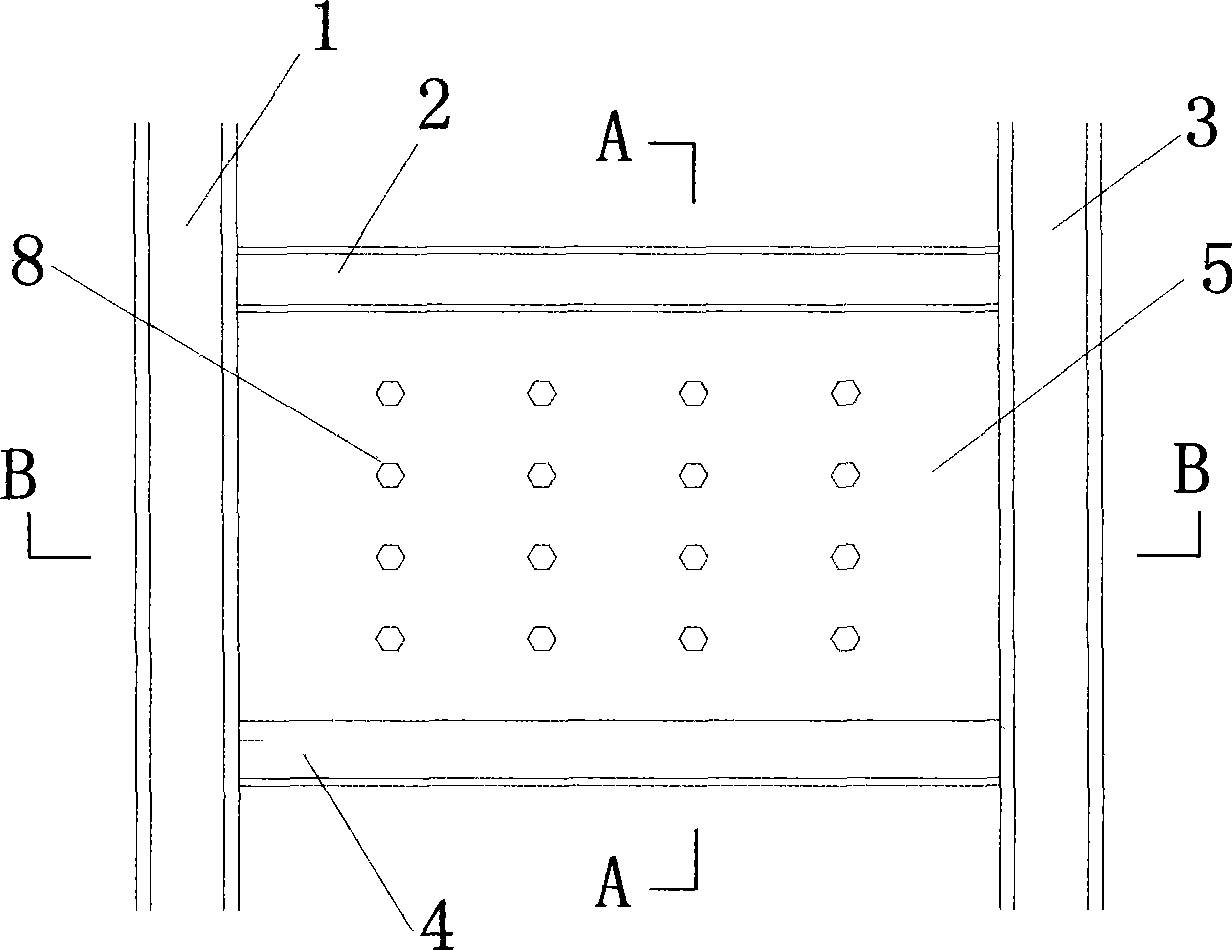

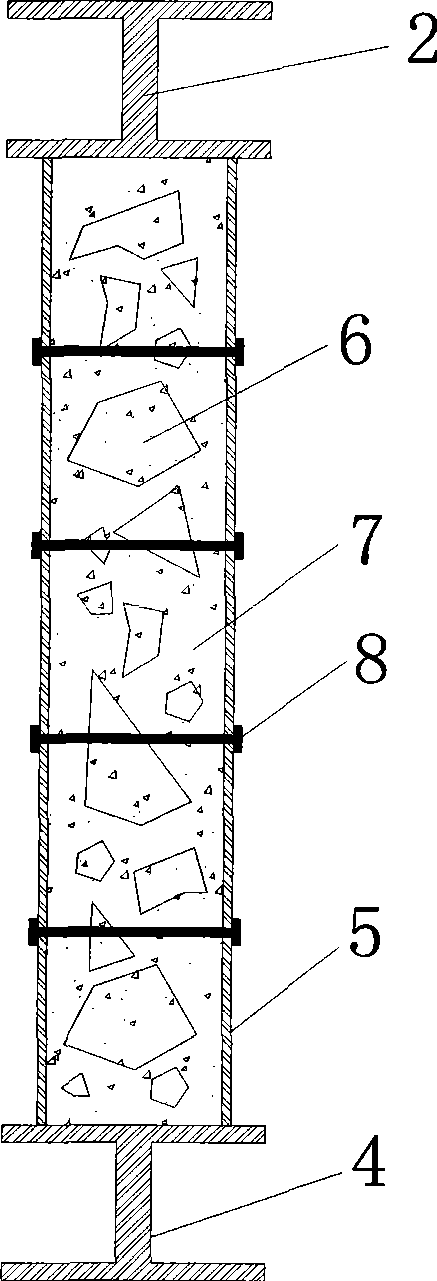

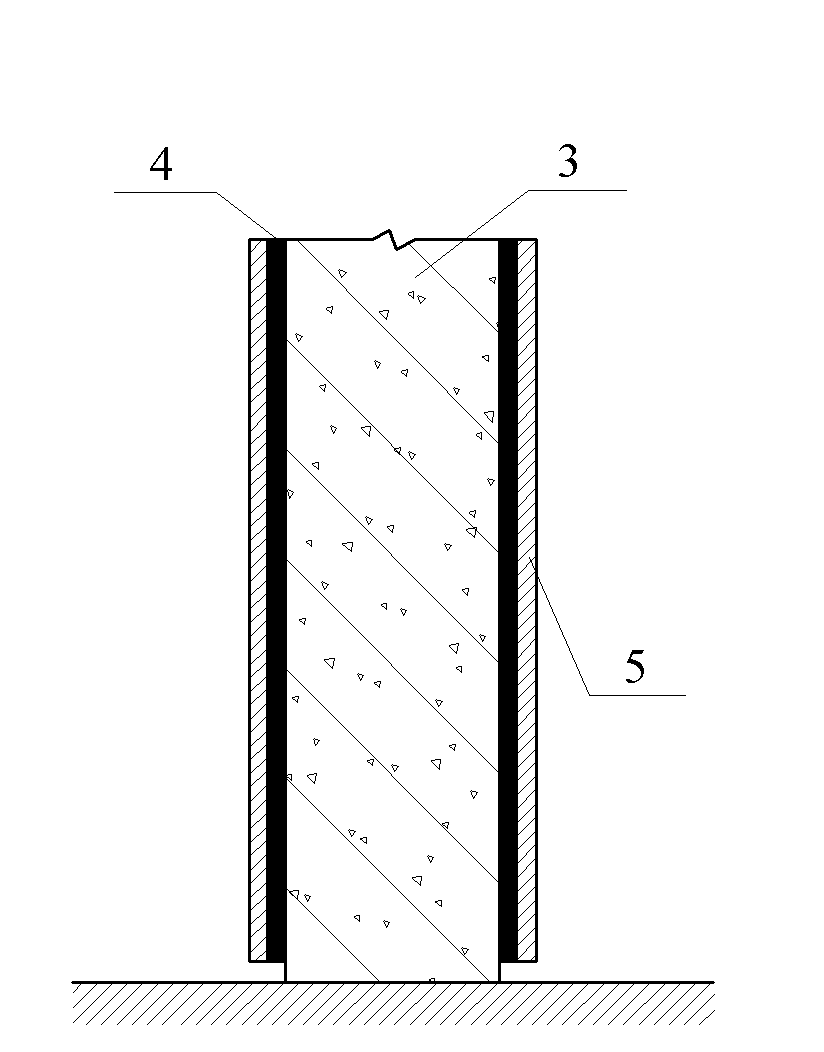

Steel sheet regeneration mixed wall and construction method thereof

The invention discloses a steel plate regenerative composite wall and a construction method thereof. Holes are reserved on front and back corresponding positions of a front steel plate and a back steel plate of the steel plate regenerative composite wall, bolts pass through the reserved holes to connect the two steel plates, concrete is filled between the two steel plates, the concrete comprises new concrete and one or more waste concrete blocks, and the new concrete is filled among the waste concrete blocks and between the waste concrete blocks and the steel plates; the mass ratio of the waste concrete blocks to the new concrete is 1.4 to 1.1; and the diameter of the waste concrete block is more than 50 millimeters. The steel plate regenerative composite wall is suitable for a building structure, has the characteristics of large side rigidity resistance, good ductility, high bearing capacity and the like, has stable hysteresis performance and large absorbed energy in destructive process, can reduce large usage amount of templates, and can use the waste concrete to reach the aim of environmental protection, energy saving and discharge reduction.

Owner:SOUTH CHINA UNIV OF TECH

Steel pipe concrete flange combining beam with concrete fender

ActiveCN101892626AIncreased torsional stiffnessReduce in quantityLoad-supporting elementsBridge structural detailsSteel tubeSinusoidal waveform

The invention relates to a steel pipe concrete flange combining beam with a concrete fender. A web is arranged in the length direction of a lower fender; the front surface and the back surface of the web are provided with stiffening ribs; the upper end of the web is provided with a steel pipe concrete upper flange formed by pouring self-compacting concrete in a steel pipe; and the upper end of a rectangular steel pipe concrete upper flange is provided with a concrete upper fender. The steel pipe of the rectangular steel pipe concrete upper flange is a rectangular steel pipe, and the cross section is in a rectangular annular shape. The web is in a trapezoidal waveform or sinusoidal waveform or planform shape. The invention can replace the traditional hot rolling I-steel and H-steel combining beam and a welding I-steel combining beam, has the advantages of convenient construction, light deadweight, large bearing capacity, high torsion rigidity, high ductility, and the like, is a combining structure which can fully exert the advantages of two materials of structural steel and high-performance concrete and has favorable application prospect in bridge and structure engineering.

Owner:CHANGAN UNIV

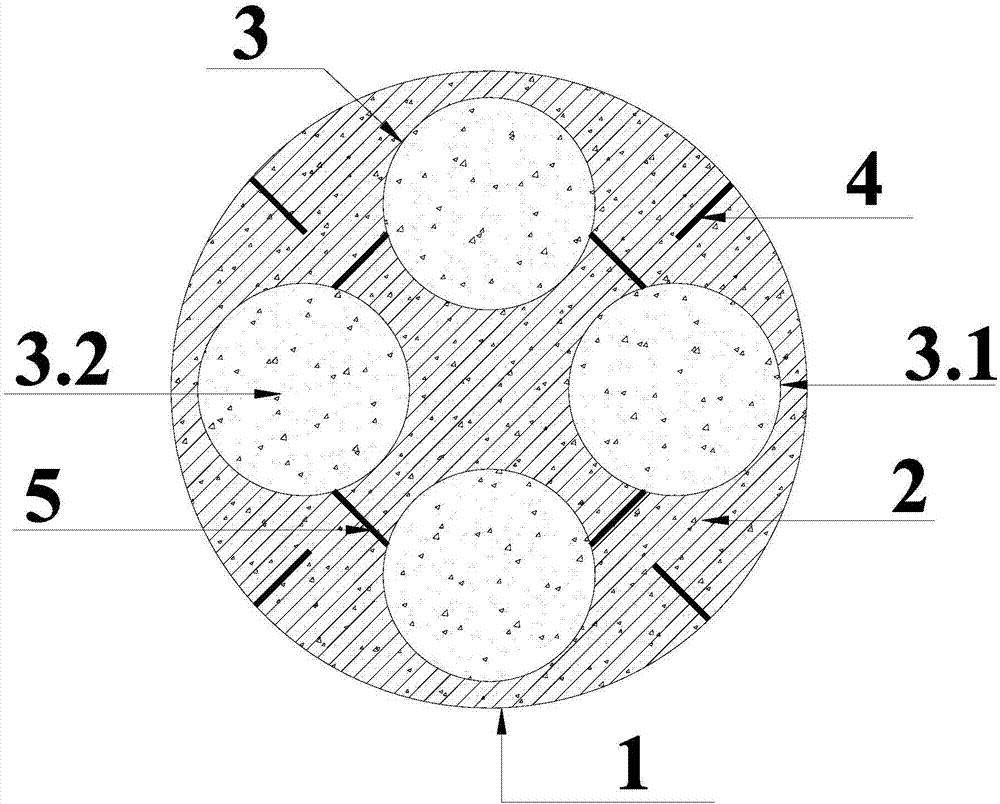

Fiber reinforced plastics-steel composite pipe restricted structural steel high-strength concrete column

InactiveCN102108761AIncreased durabilityReduce steel consumptionStrutsBridge structural detailsHigh strength concreteHooping

The invention discloses a fiber reinforced plastics-steel composite pipe restricted structural steel high-strength concrete column, which comprises longitudinal bars, hoopings, high-strength concrete, a structural steel and a fiber reinforced plastics-steel composite pipe; the longitudinal bars are distributed in the height direction of the column, the circular hoopings are sleeved in the height direction of the longitudinal bars, the structural steel is distributed in the hoopings along the height direction of the column, and the fiber reinforced plastics-steel composite pipe is sleeved outside of the hoopings in the height direction of the column; the fiber reinforced plastics-steel composite pipe is composed of a steel pipe used as an inner wall and a fiber reinforced plastics pipe used as an external wall, high-strength solid concrete is poured in the fiber reinforced plastics-steel composite pipe, and the fiber reinforced plastics-steel composite pipe is broken at two ends of the column. With the column provided by the invention, the axial compression ratio and the seismic performance of the structural steel high-strength concrete column are improved, and the endurance quality of the steel pipe restricted structural steel high-strength concrete column is also improved; and problems, such as high dosage of steel, troubles in connection with reinforced concrete beams, and the like, of the steel pipe structural steel high-strength concrete column are solved.

Owner:DALIAN UNIV OF TECH

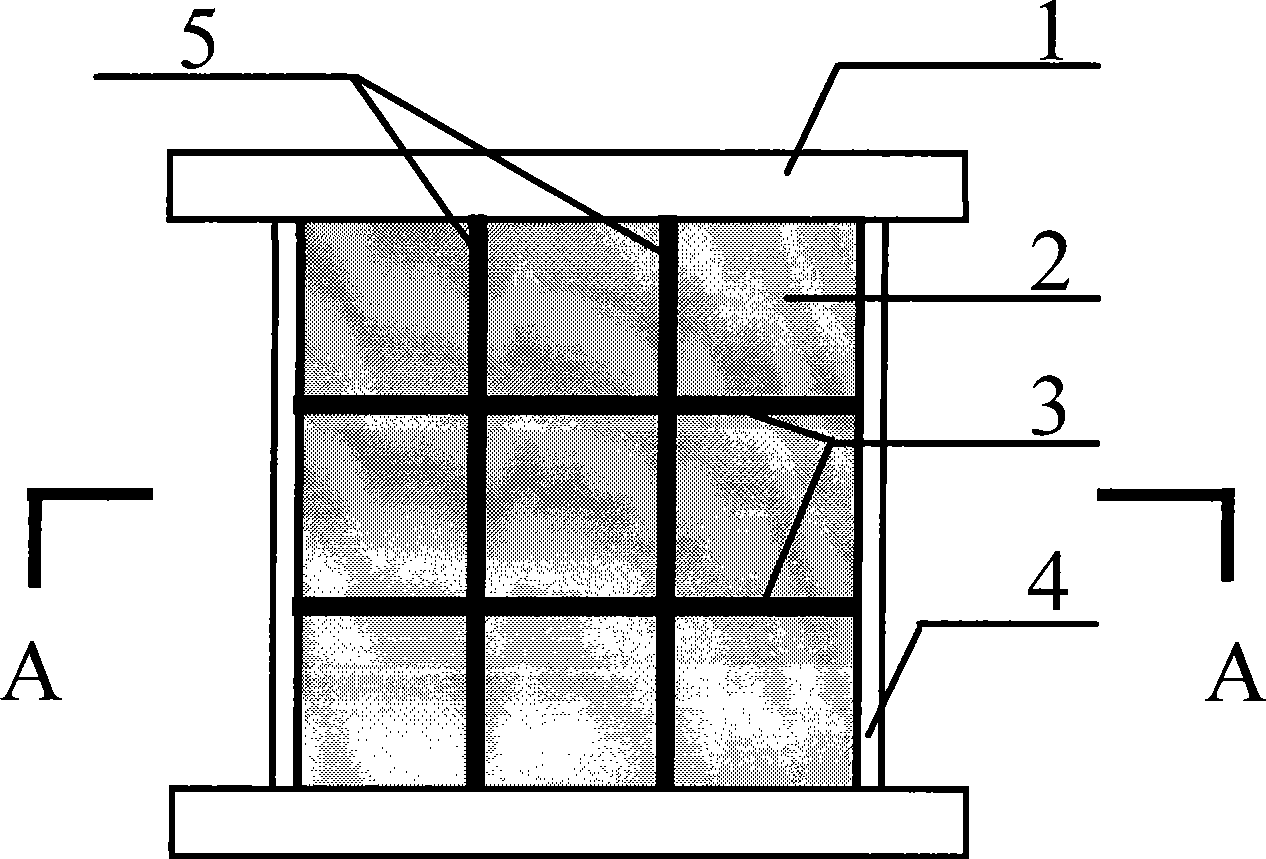

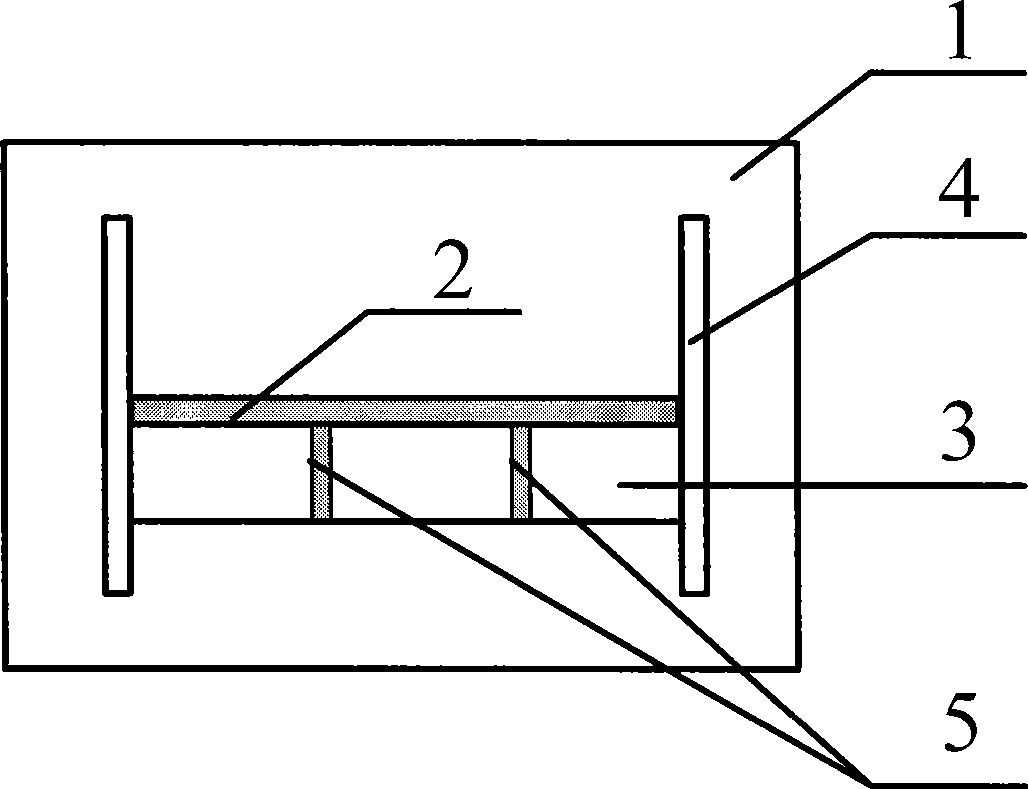

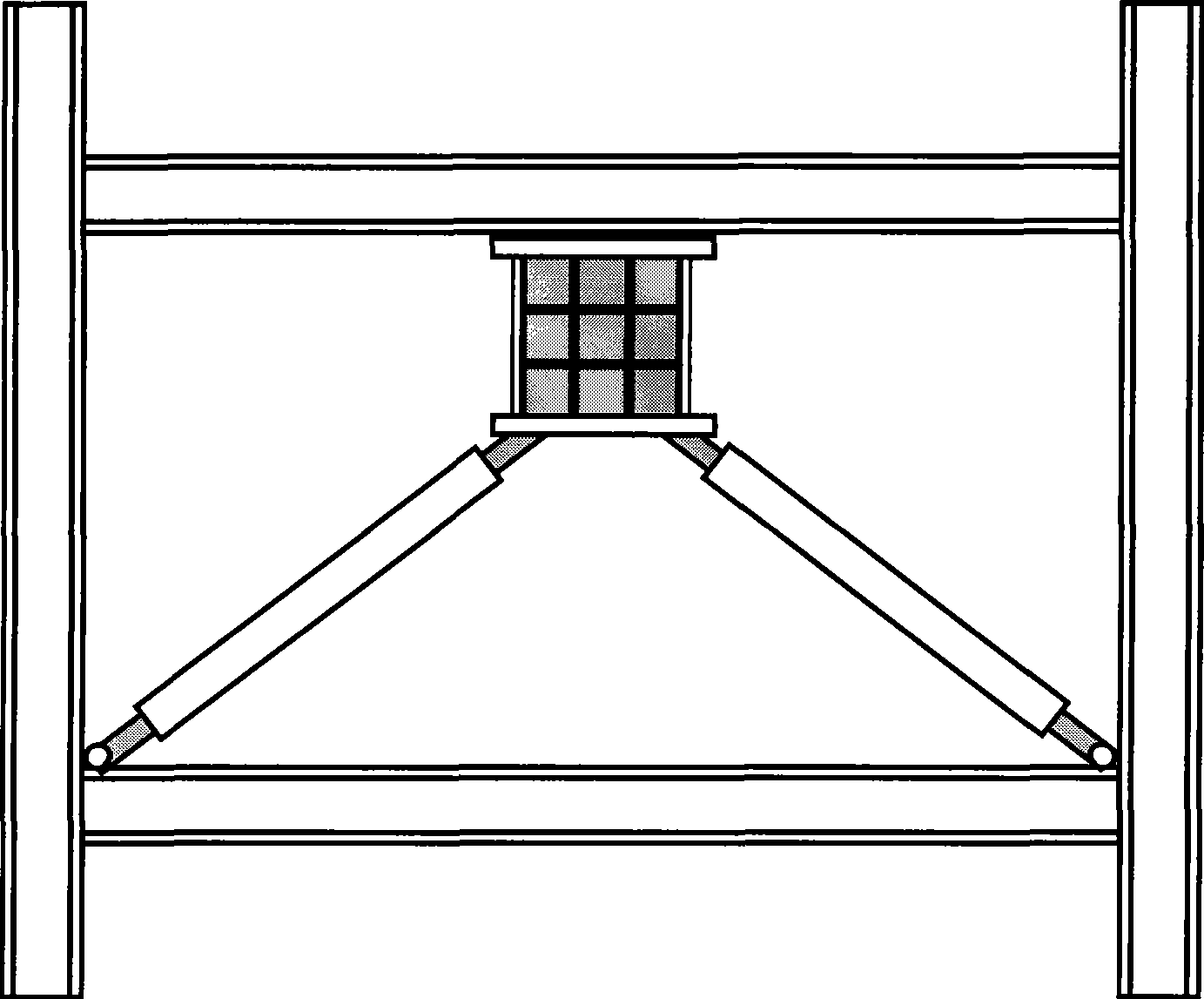

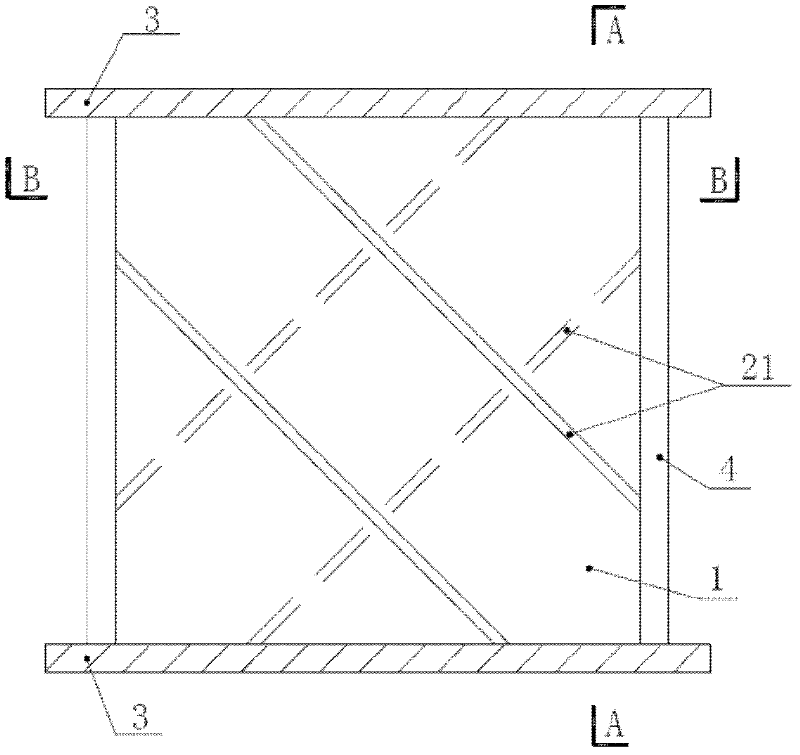

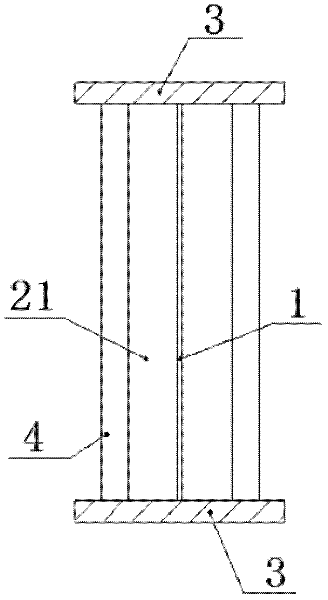

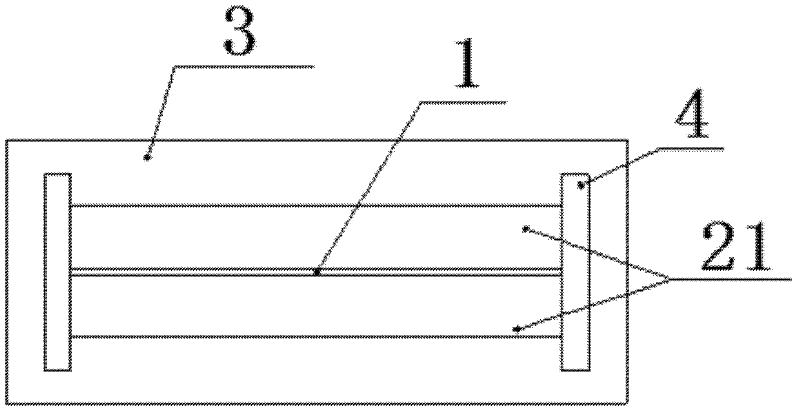

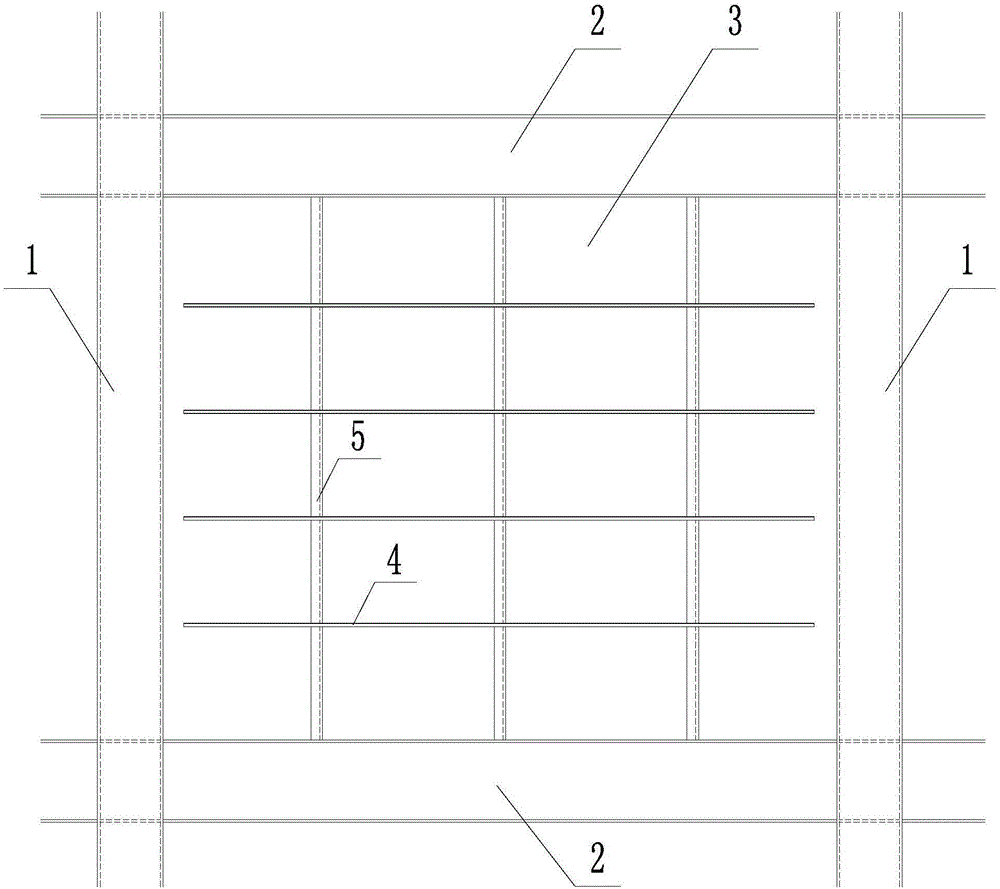

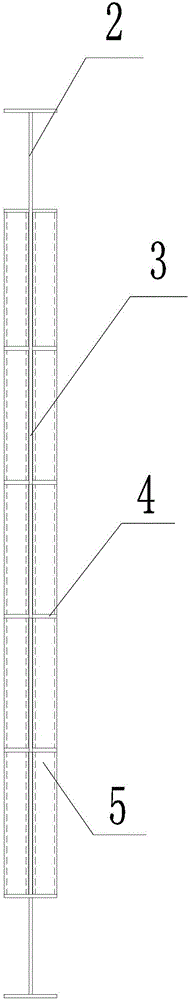

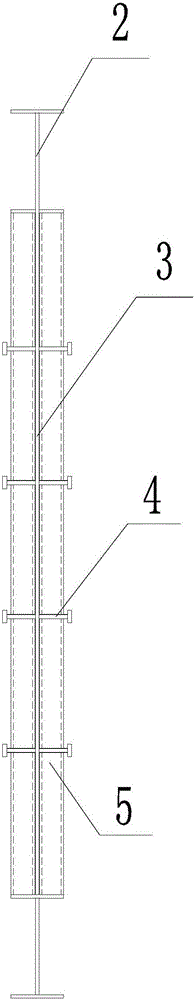

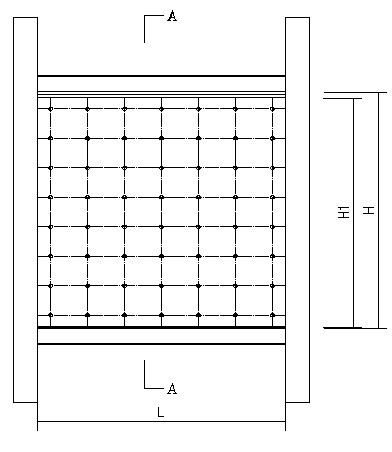

Anti-buckling steel plate seismic shear wall provided with stiffening ribs

ActiveCN106013506AGuaranteed stabilityPrevent local bucklingWallsProtective buildings/sheltersHorizontal forceShear capacity

The invention discloses an anti-buckling steel plate seismic shear wall provided with stiffening ribs. The anti-buckling steel plate seismic shear wall comprises a steel plate wall, horizontal stiffening ribs, vertical stiffening ribs, steel columns and steel girders, wherein the steel plate wall is arranged in a frame formed by the steel columns and the steel girders, and the multiple horizontal stiffening ribs are uniformly fixed on two side wall surfaces of the steel plate wall at vertical intervals and horizontally welded on the steel plate wall; the multiple vertical stiffening ribs are fixed between the horizontal stiffening ribs at horizontal intervals and are vertically arranged, and upper ends and lower ends of the vertical stiffening ribs are welded with the horizontal stiffening ribs; a gap is reserved between each vertical stiffening rib and the steel plate wall. According to the anti-buckling steel plate seismic shear wall provided with the stiffening ribs, overall buckling and local buckling of the steel plate wall can be prevented, so that the steel plate wall can only yield, and the shear capacity and the severe earthquake energy dissipation performance of the steel plate wall are improved; the anti-buckling steel plate seismic shear wall is simple in structure and reasonable in stress, can bear horizontal force under the action of the earthquakes, and is convenient to construct and high in degree of industrialization.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

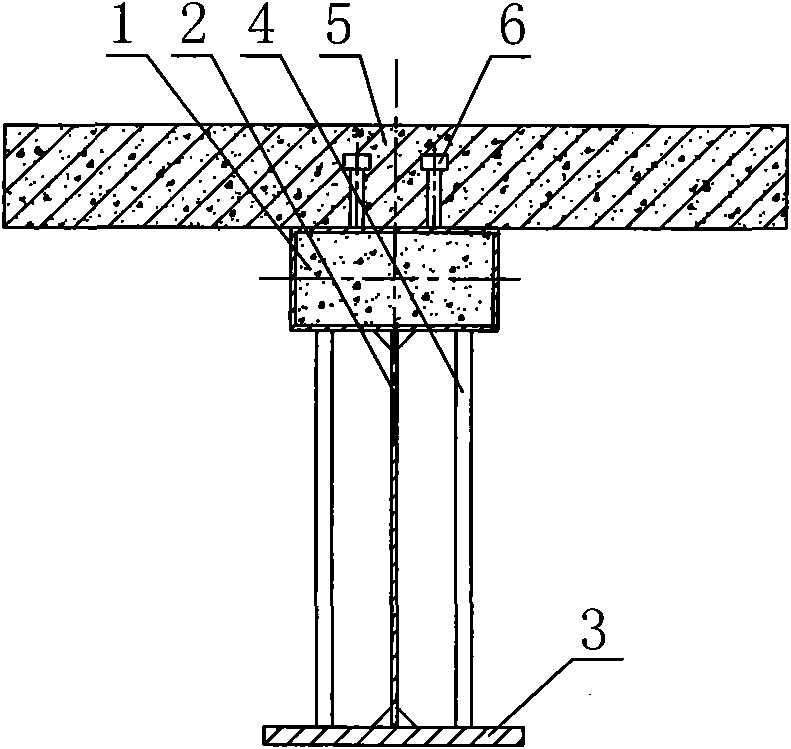

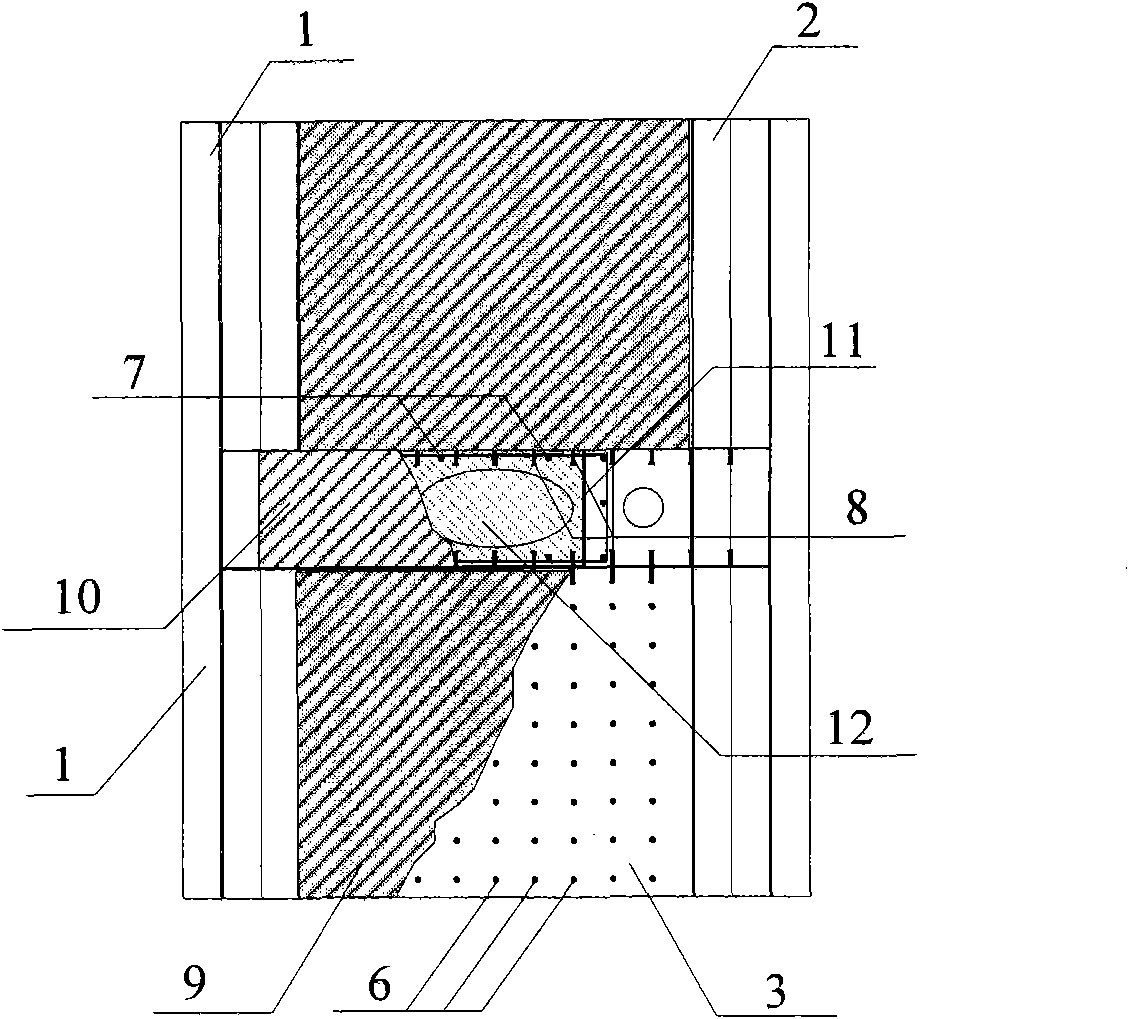

Rigid connection method for steel beam and concrete pier

The invention discloses a rigid connection method for a steel beam and a concrete pier, and belongs to the technical field of bridgework and combined structures. The rigid connection method is characterized in that: a steel sleeve extending outwards is arranged under a steel main beam; a steel sleeve is arranged on the top of a pier; the pier and the beam are fixedly connected through the connection between the steel sleeves; and the inner walls of the steel sleeves are provided with stud connecting pieces to prevent the steel sleeves from locally flexing and facilitate coaction of the steel sleeves and the concrete. The rigid connection method comprises the following steps of: hoisting the main beam provided with the steel sleeve extending outwards to the top of the pier with the steel sleeve, and taking connection measures; positioning a reinforcement cage in a pillar, and casting the concrete to the lower side of the upper wing edge of the main beam to form rigid connection nodes. The axial force on the top of the pier is mainly borne and transmitted through the concrete in a node core area; the bending moment of the top of the pier is mainly borne and transmitted through a diaphragm plate, tensioned steel bars and the concrete in the node core area; and the shear force is mainly transmitted by a web plate of the main beam and the concrete. The steel sleeves can make most unfavorable sections move outwards so as to improve the bearing capacity and tensility of the node area.

Owner:TSINGHUA UNIV

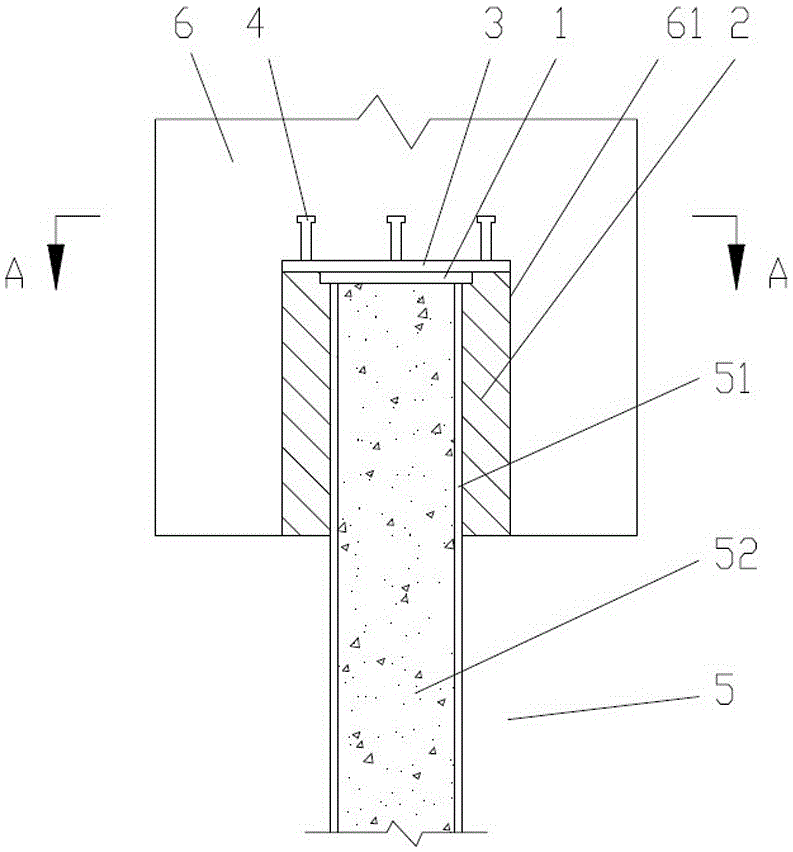

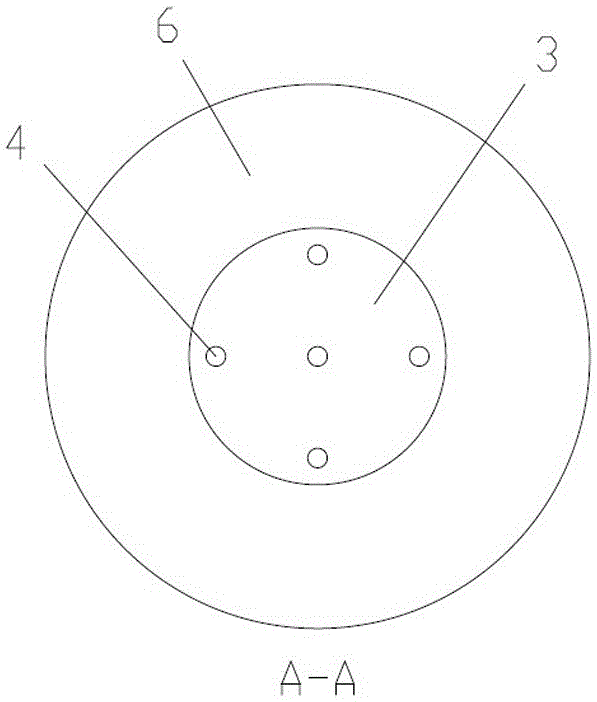

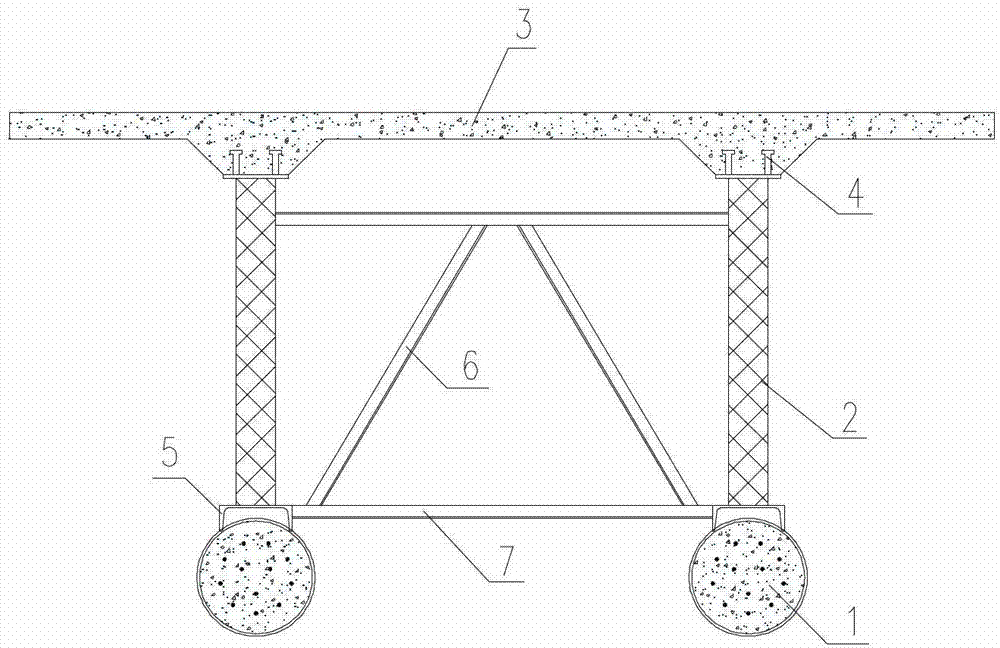

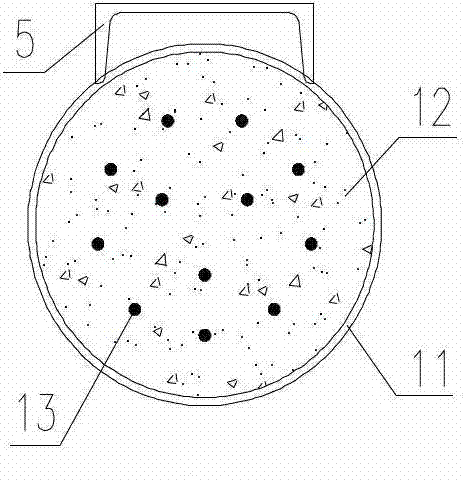

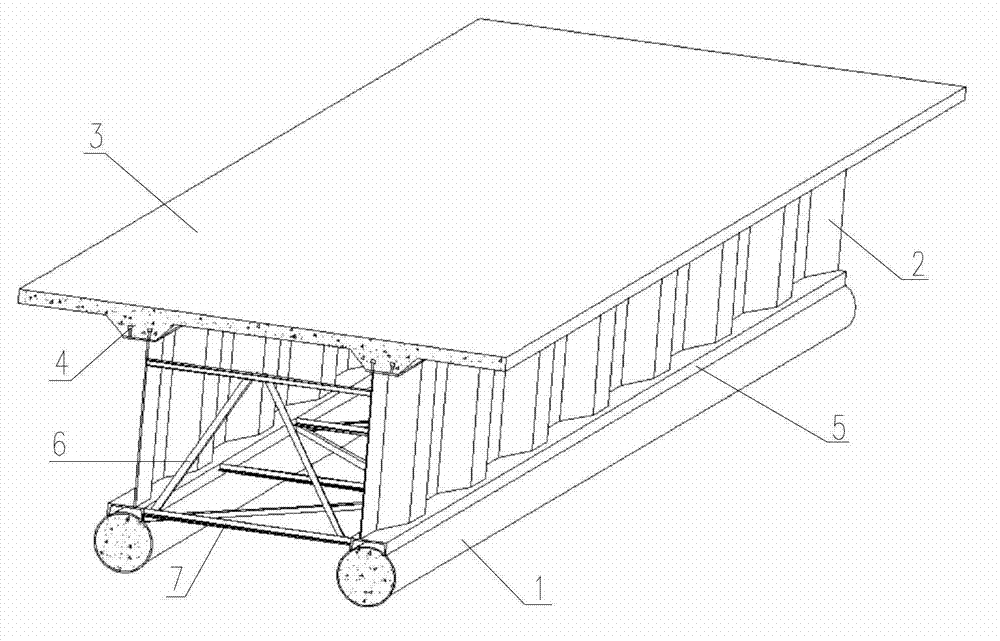

Flexible connection structure for pile and pile cap and construction method

InactiveCN105887875AIncrease stiffnessPrevent local bucklingBridge structural detailsBulkheads/pilesPile capStructural engineering

The invention relates to a flexible connection structure for a pile and a pile cap. The flexible connection structure comprises a top end steel plate, an elastic sleeve, an embedded steel plate and a plurality of shear nails, wherein the pile is a steel pipe concrete pile which comprises a steel pipe; concrete is poured into the steel pipe; the top end steel plate is welded and fixed at the top end of the steel pipe; the elastic sleeve sleeves the top end steel plate and the steel pipe; the multiple shear nails are welded and fixed at the tops of the embedded steel plate; the multiple shear nails and the embedded steel plate are arranged in the pile cap; the pile cap sleeves the top end of the pile, and a blind hole matched with the elastic sleeve is formed in a position, located on the embedded steel plate, on the pile cap; the bottom of the embedded steel plate is in contact with the tops of the elastic sleeve and the top end steel plate. The invention further relates to a construction method of the flexible connection structure for the pile and the pile cap. According to the flexible connection structure, a pile head and the pile cap rotate relatively, so that a transverse displacement allowance of the top structure is increased; meanwhile, the bending moment of the pile can be obviously reduced due to the transverse displacement.

Owner:FUZHOU UNIV

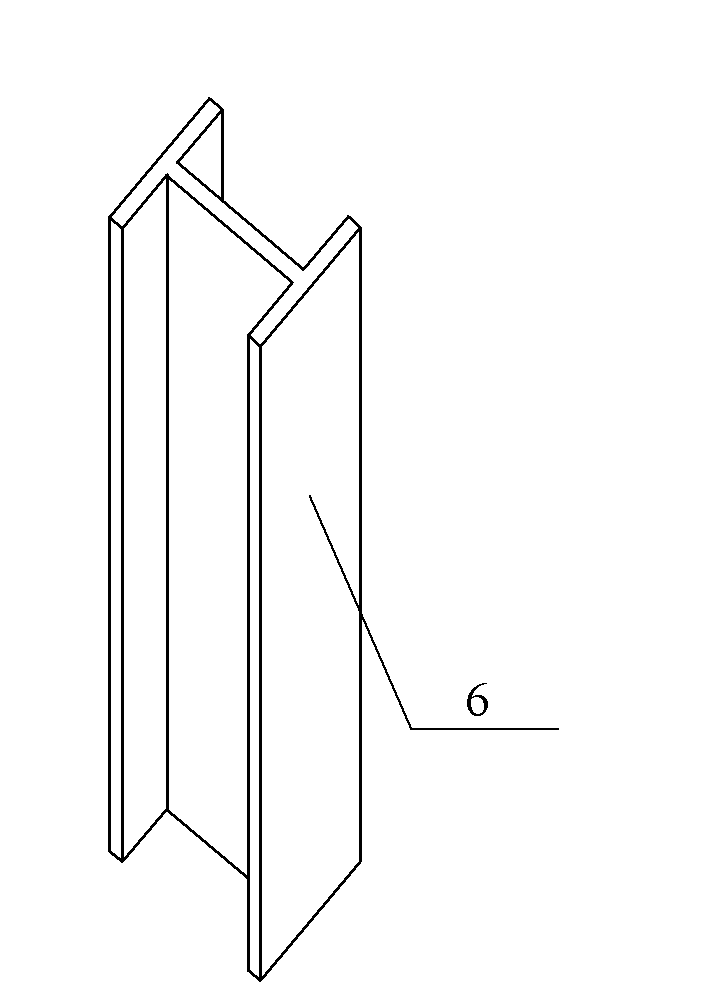

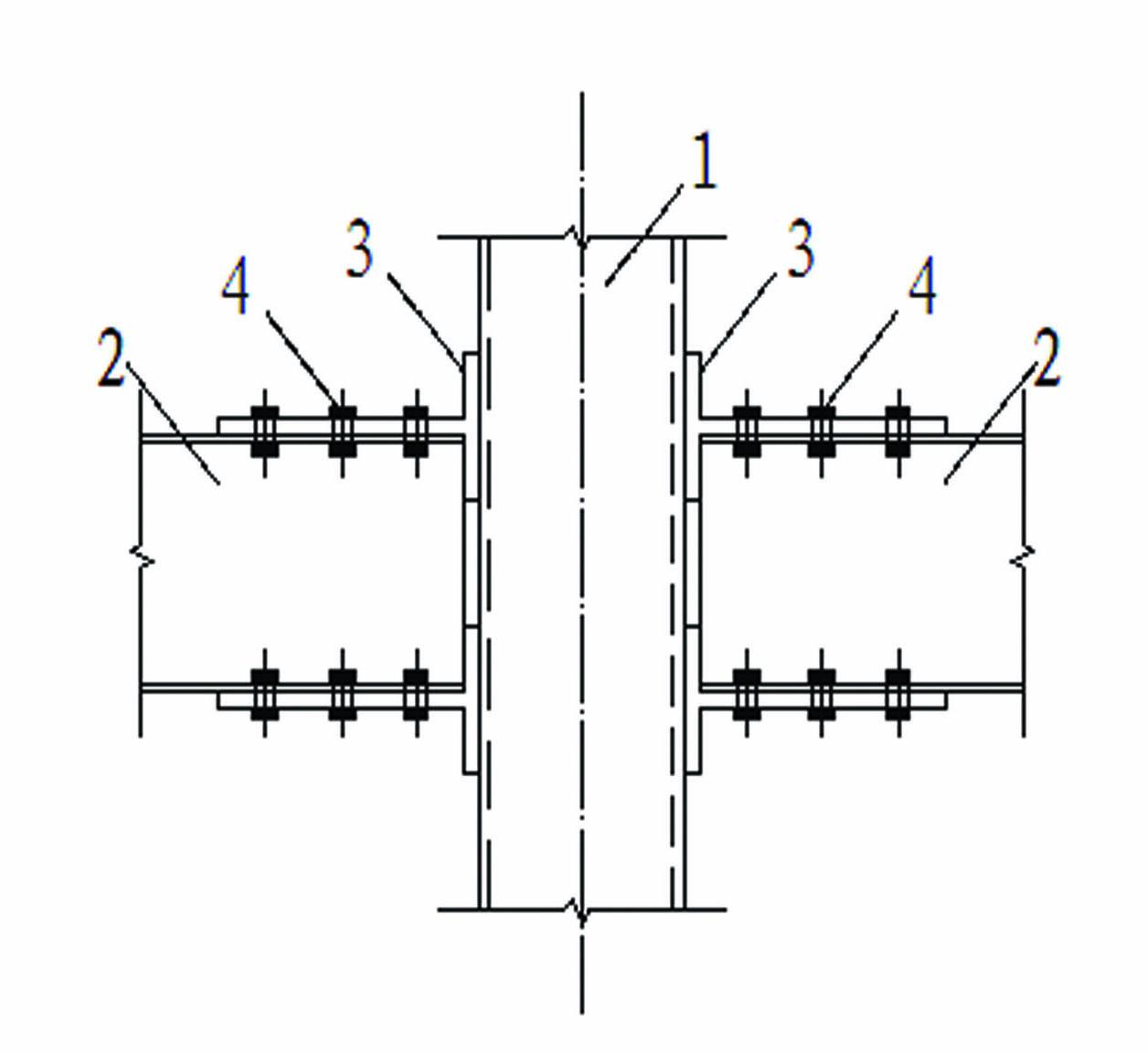

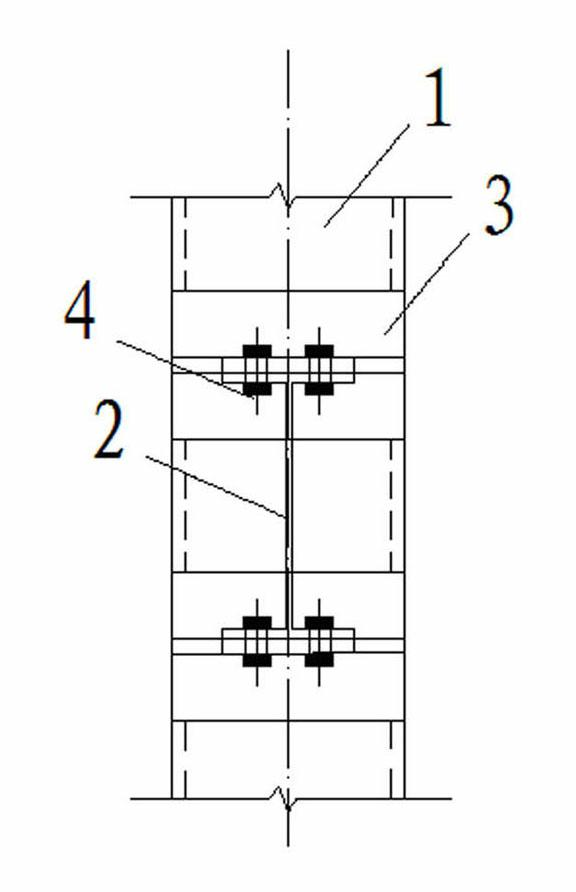

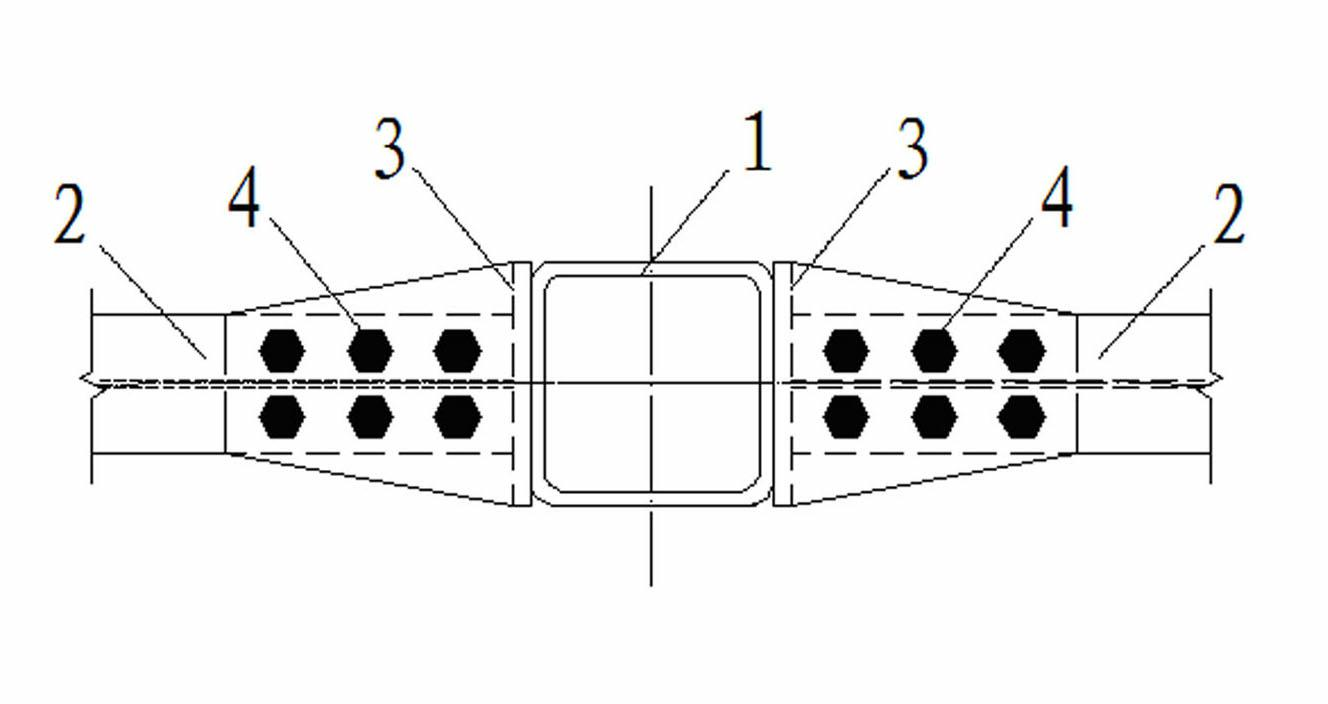

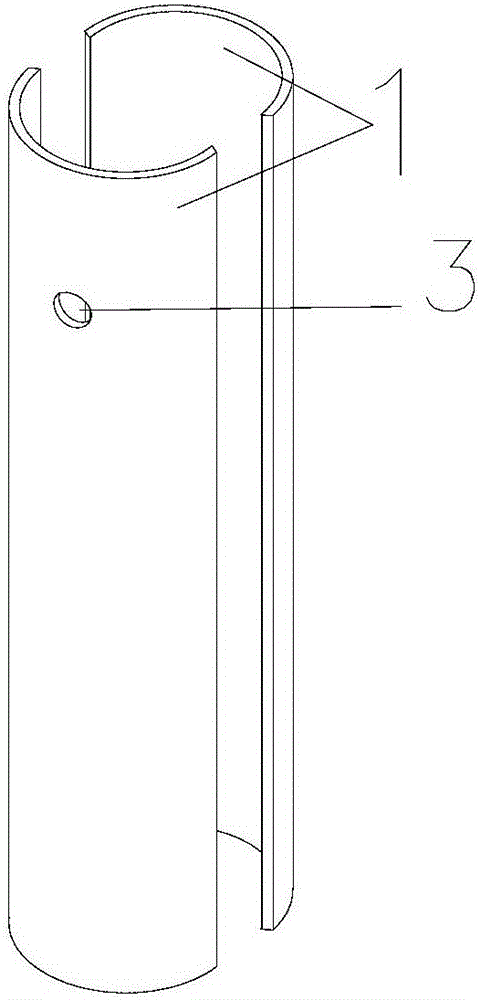

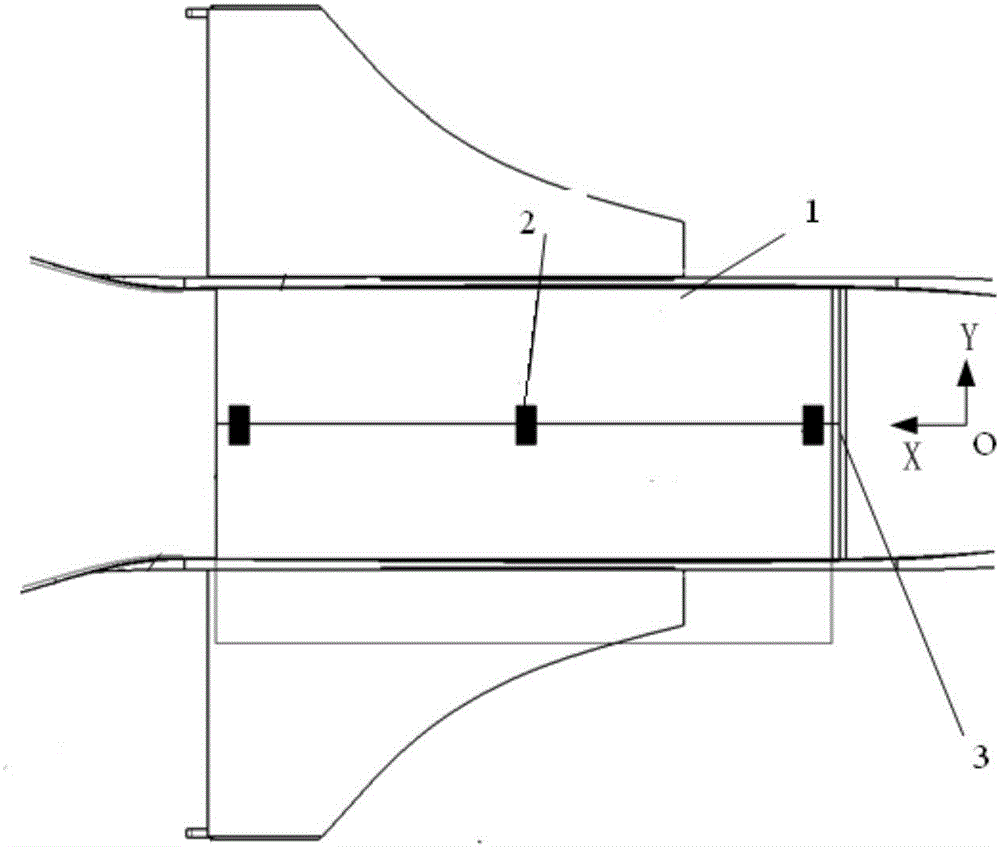

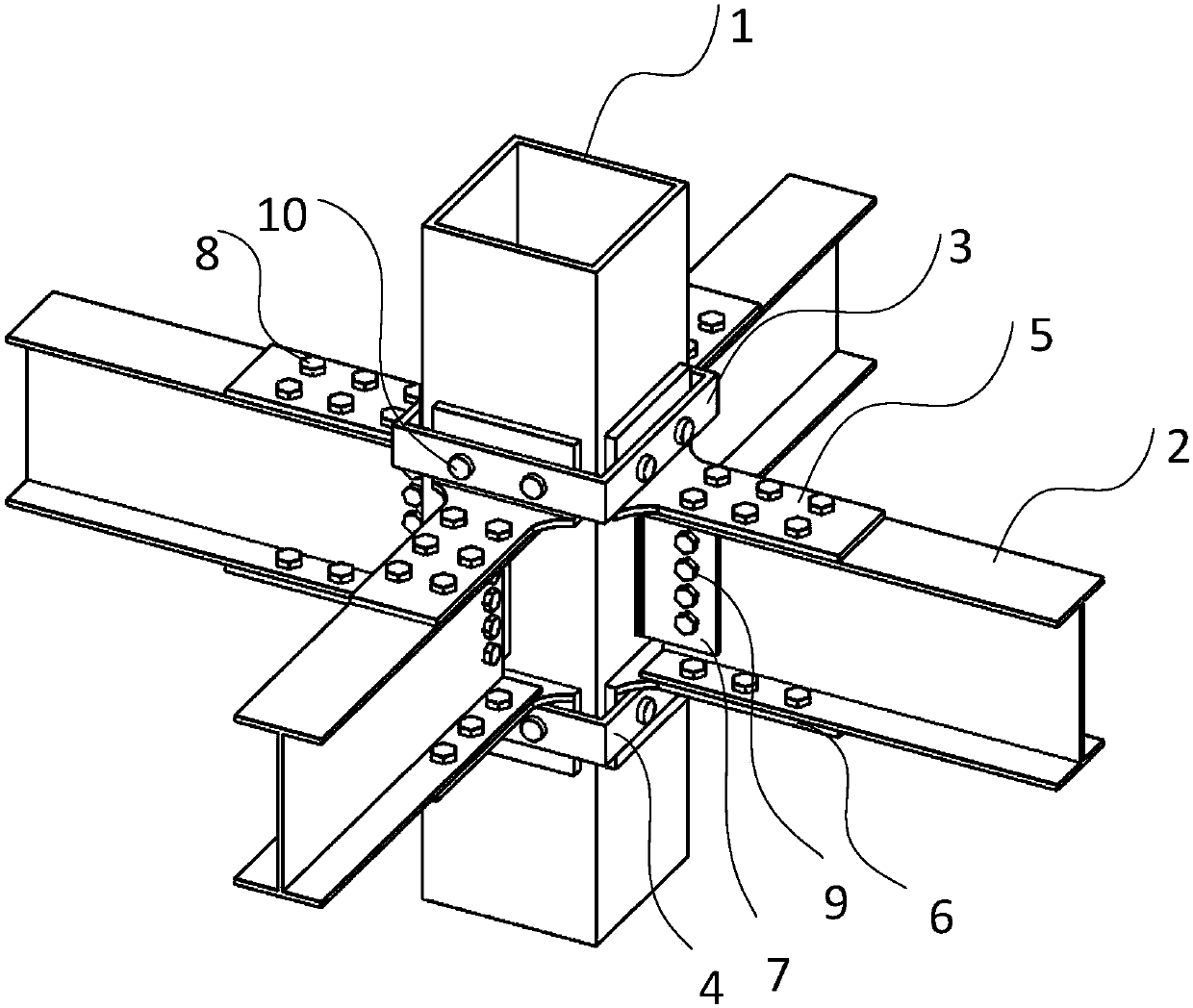

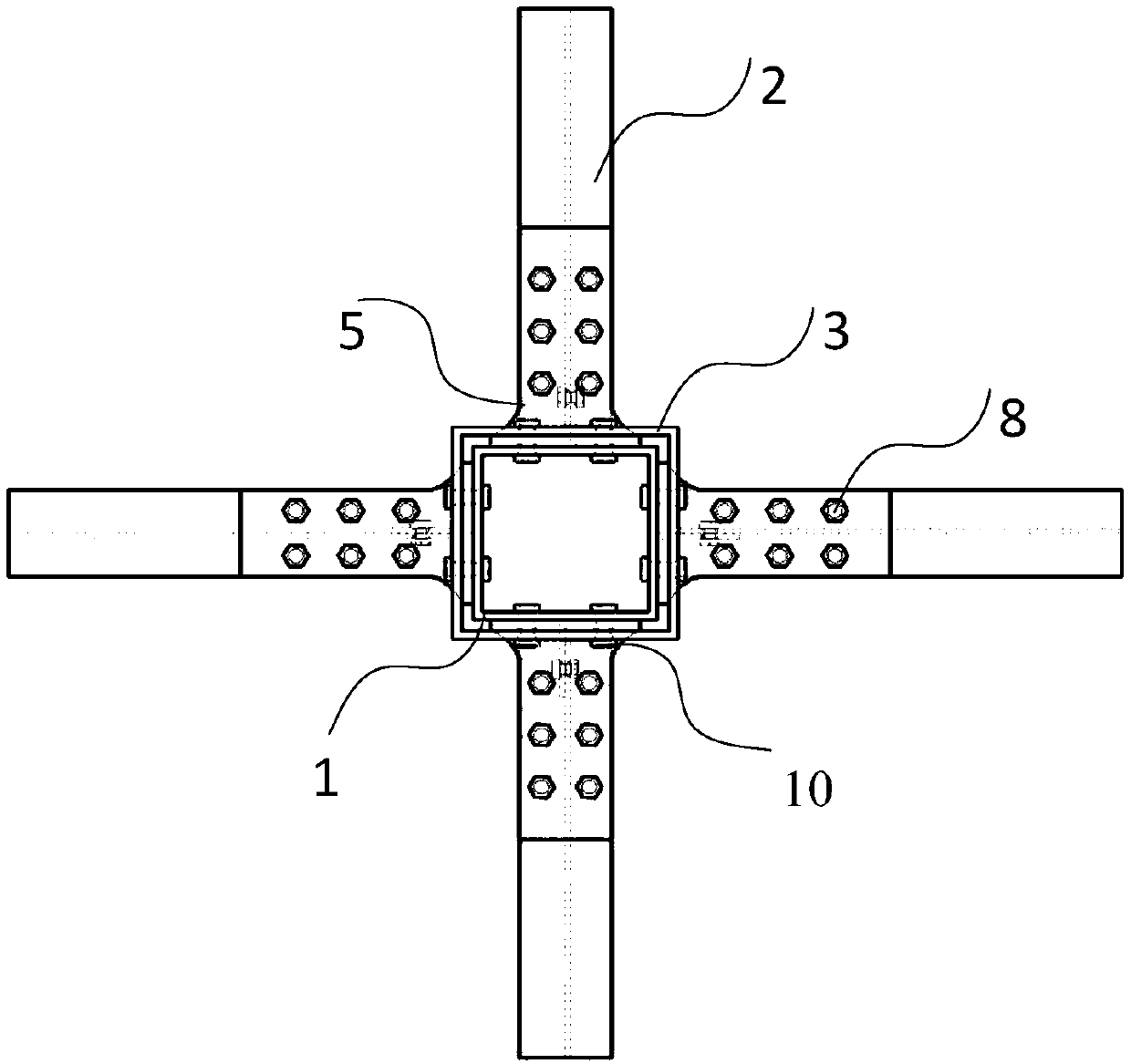

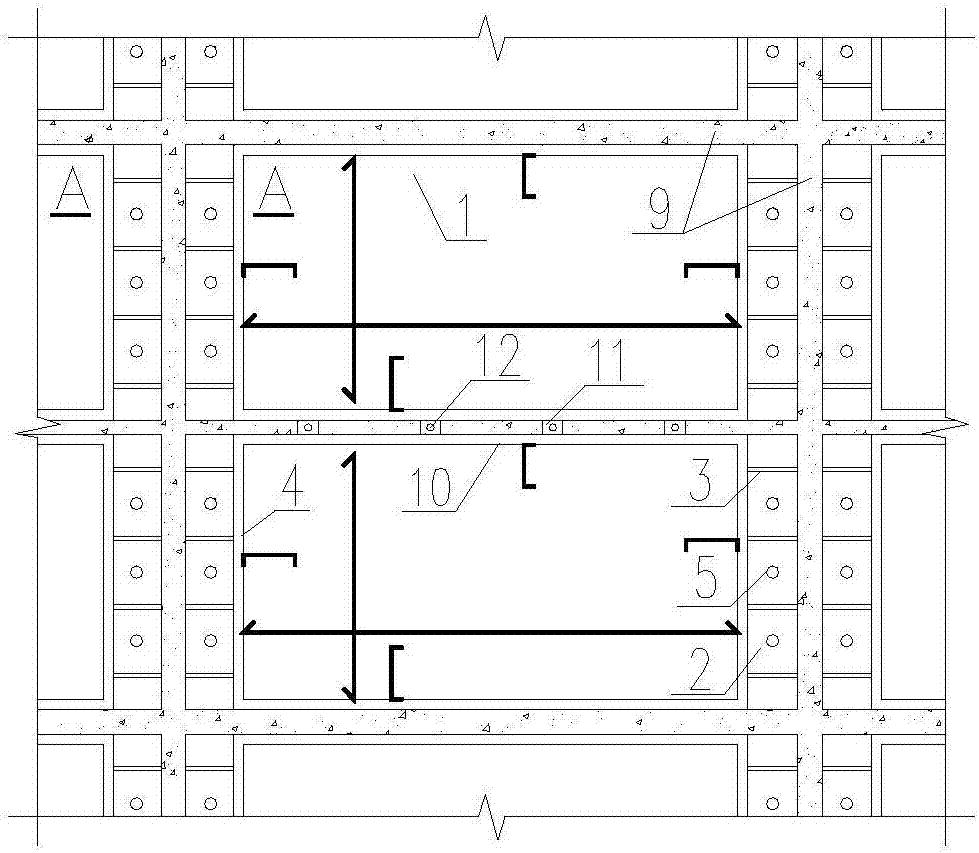

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

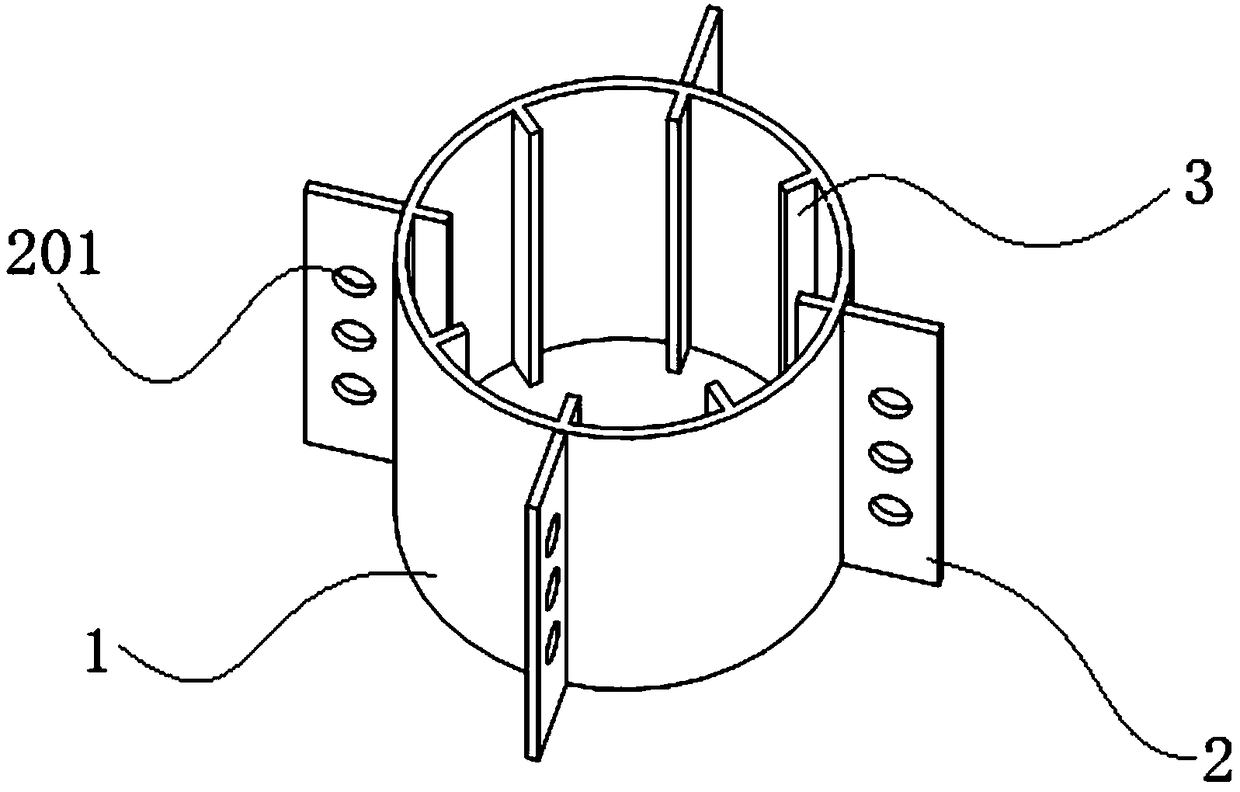

The steel-tube grouting quick-stabilizing column structure and construction method

ActiveCN106337570APrevent local bucklingAvoid high demandsBuilding repairsReinforced concrete columnRebar

The present invention relates to the field of stabilization with the aid of reinforced-concrete column structures, in particular to a steel-tube grouting quick-stabilization column structure and construction method. The cross-section of steel-tube grouting quick-stabilization column structure may be either round or square. A round-section steel-tube grouting quick-stabilizing column structure comprises two outer-casing semi-round steel tubes and ring-type restriction stirrups, and a square-section steel-tube grouting quick-stabilizing column structure comprises two outer-casing semi-round steel tubes and square restriction stirrups. The two outer casing steel tubes adopted by the present invention can double as formwork so as to avoid field formwork construction. The construction techniques only require installing and securing the semi-steel tubes on the field and injecting the high-strength grouting material, so the operating process is quite simple. Welding the two semi-steel tubes after the grouting material is injected can avoid the partial buckling of steel-tube wall caused by welding operation and the high requirements for skilled welders; therefore, it is quite simple and easy to implement the stabilization technique.

Owner:浙江书韬建设有限公司

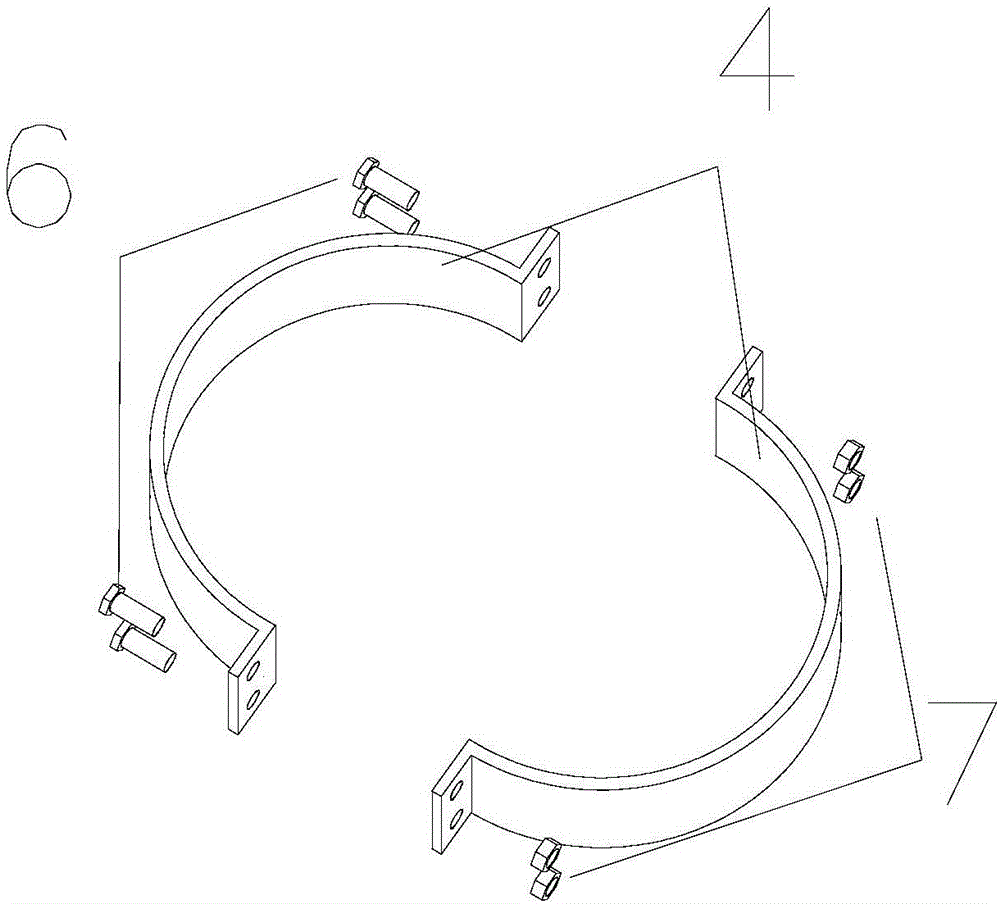

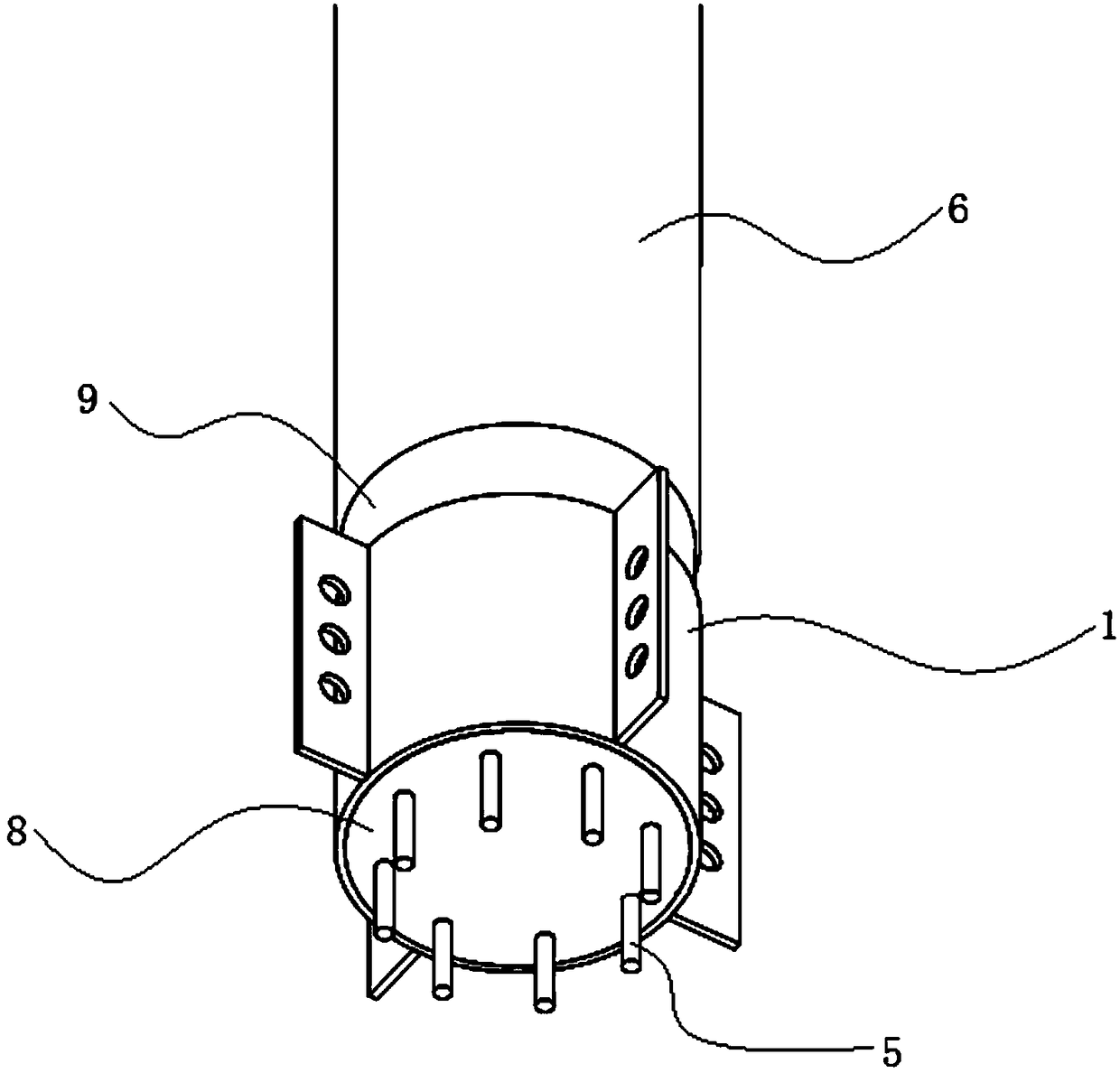

Connecting joint of prefabricated steel pipe restraining reinforced concrete pier and bearing platform

ActiveCN108360370ASimple molding processFast constructionBridge structural detailsBridge erection/assemblyReinforced concreteEngineering

The invention provides a connecting joint of a prefabricated steel pipe restraining reinforced concrete pier and a bearing platform and a construction method thereof. The connecting joint connects a prefabricated bridge pier and a bearing platform. The prefabricated bridge pier includes a steel pipe joint, an upper steel pipe and concrete. The steel pipe joint includes a lower steel pipe, a perforated steel plate and a connecting steel plate. The upper steel pipe is arranged above the lower steel pipe. The construction method of the connecting joint includes manufacturing a steel pipe joint, arranging longitudinal steel bars, pouring bridge pier concrete, hoisting a prefabricated pier and pouring filling concrete and the like. The connecting joint simplifies the formwork process. The construction speed is fast. The construction quality is improved. The construction environment is improved. The labor cost and the construction cost are saved. The bearing capacity of the connecting jointof the prefabricated pier and the bearing platform is improved on the basis of ensuring that the outer-wrapped steel pipe does not bear vertical load and greater lateral binding force on the core concrete is provided.

Owner:CHONGQING UNIV

Assembly type joint based on austenite SMA-steel plate set and martensite SMA bars

ActiveCN109057026AImprove the problem of brittle failureGood self-resetting performanceProtective buildings/sheltersShock proofingSteel frameMartensite

The invention discloses an assembly type joint based on an austenite SMA-steel plate set and martensite SMA bars. The joint comprises I-shaped steel beams, friction type high-strength bolts, high-strength steel rectangular end plates, dog bone type connecting steel plates, austenite SMA dog bone type connecting plates, austenite SMA dish-shaped springs, the martensite SMA bars and anchoring blocks. The upper and lower flanges of the steel beams are connected with the friction type high-strength bolts through the steel-SMA dog bone type connecting plate set, and webs of the steel beams are connected with the high-strength rectangular end plates through the martensite SMA bars. Furthermore, one end of each martensite SMA bar is fixed to the corresponding anchoring block on the web of each steel beam through a thread, and the other end of each martensite SMA bar is fixed through the corresponding high-strength bolt and a nut, wherein pretightening force is exerted on the other end of eachmartensite SMA bar. With the SMA-steel plate set, the restorability of the joint is improved; with the martensite SMA bars, the energy dissipation capacity of the joint is improved; through simple heating, deformation recovery after an earthquake can be realized; the joint is applied to a steel frame for resisting to the earthquake to obviously improve the earthquake-proof performance of a structure, and lowers repairing difficulty and repairing costs.

Owner:HUNAN UNIV

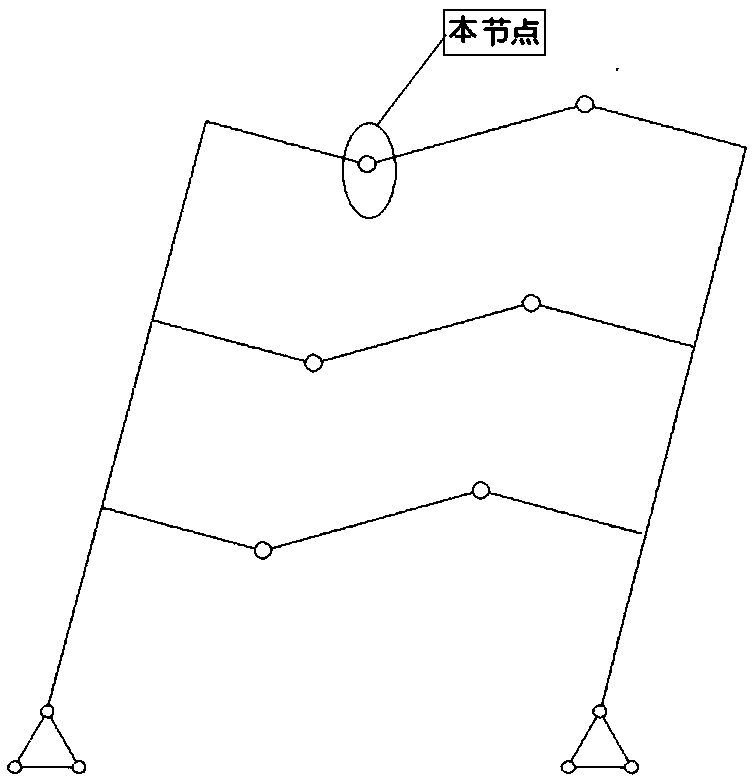

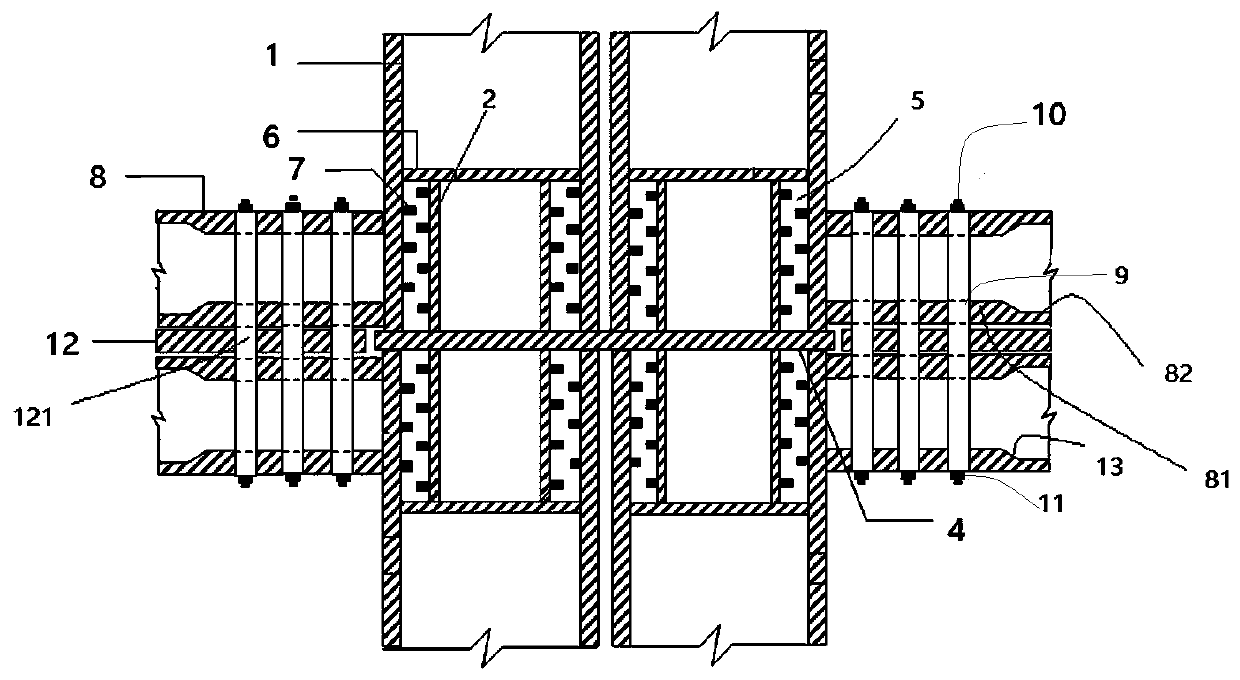

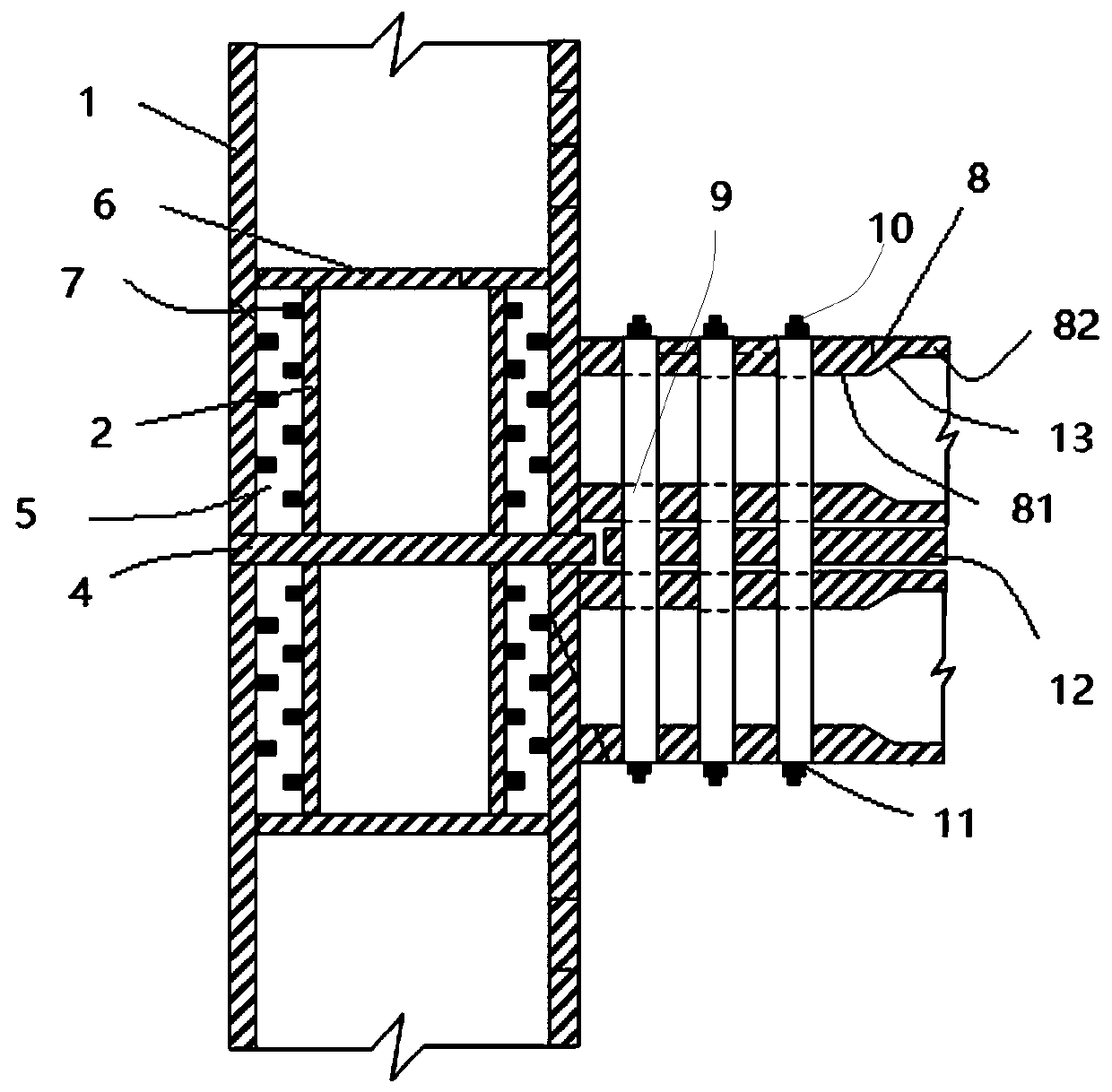

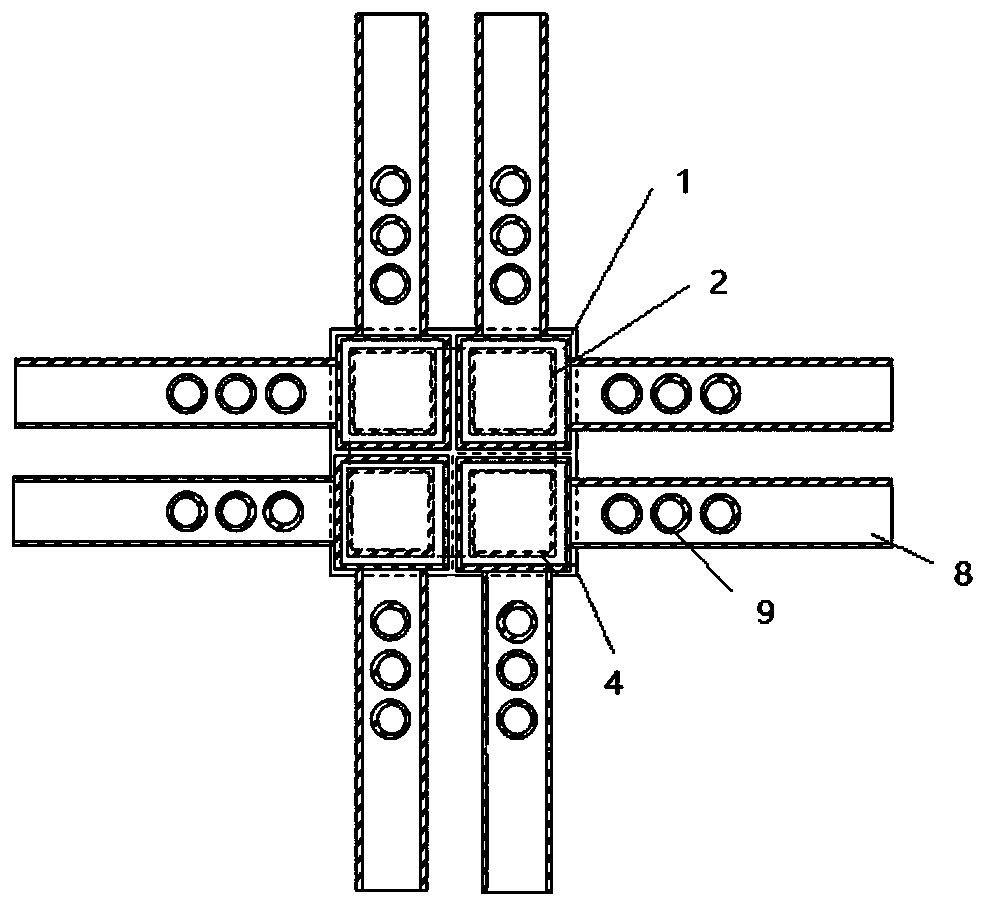

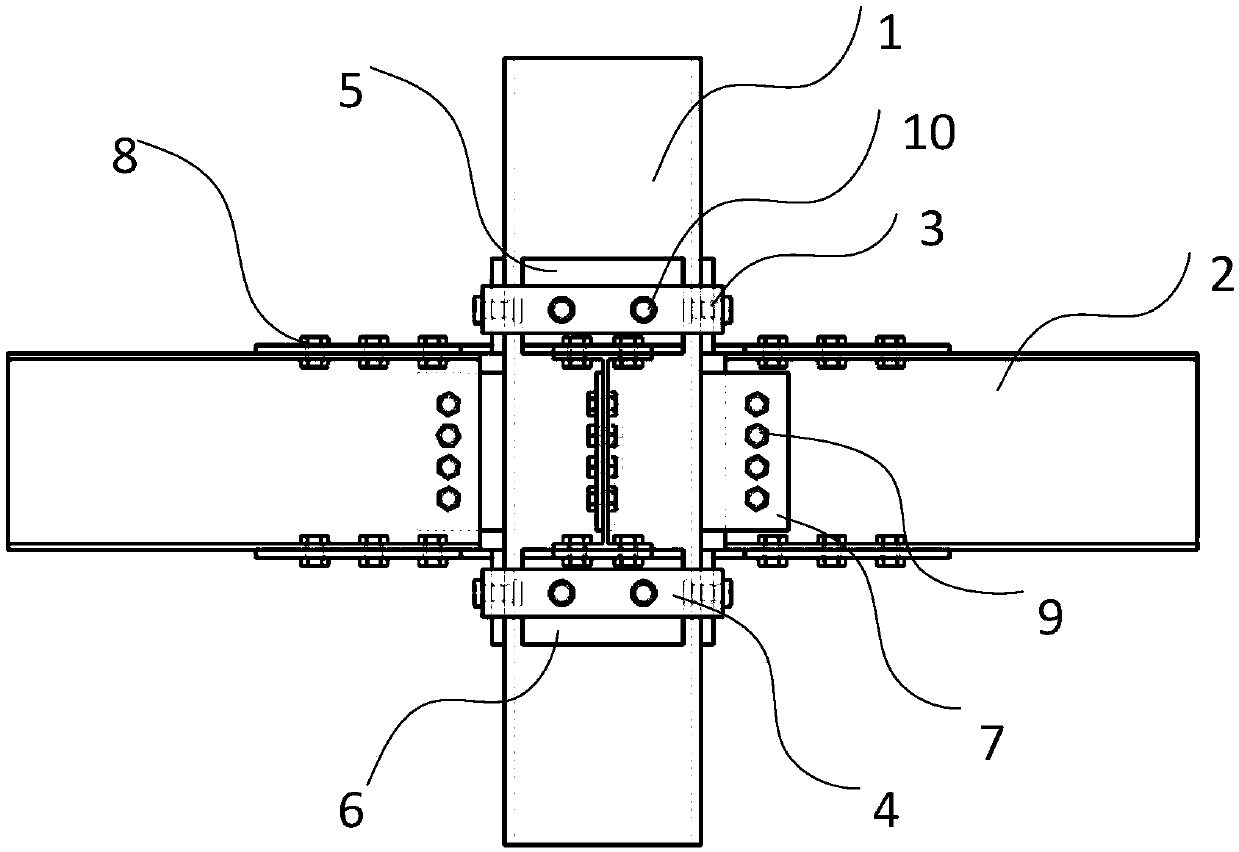

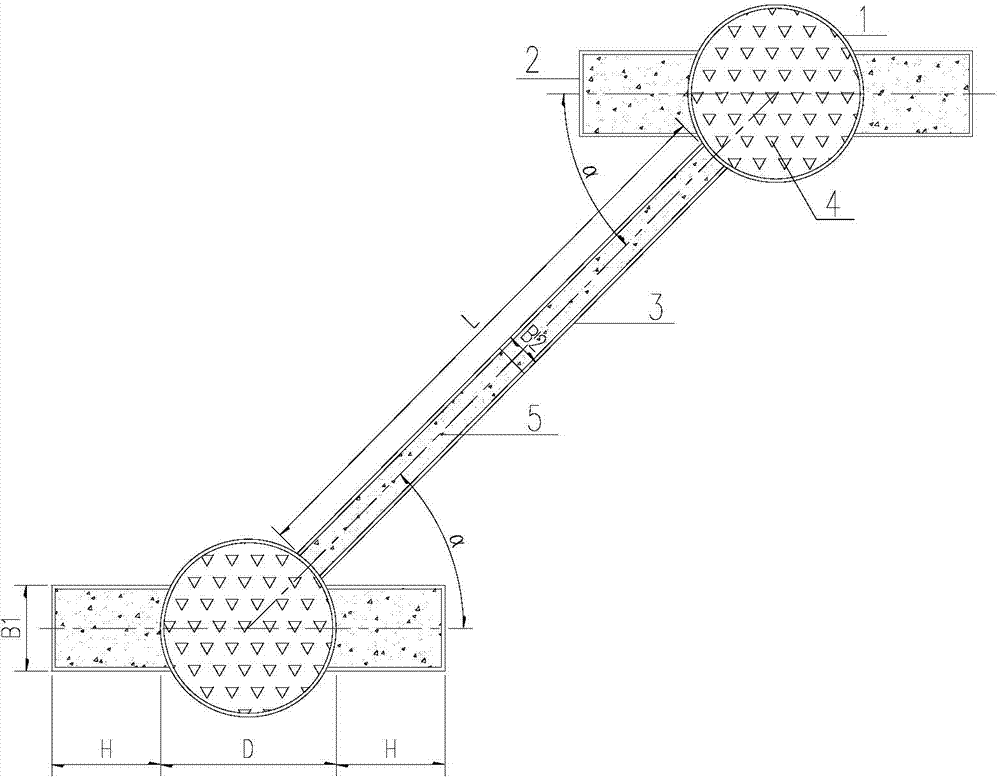

Connection structure for beam column nodes of module-assembly-type building

ActiveCN110878587AIncrease lateral stiffnessImprove integrityBuilding constructionsMechanical engineeringBeam column

The invention discloses a connection structure for beam column nodes of a module-assembly-type building. The structure can be applied to corner nodes, mid-side nodes and mid nodes of module-assembly-type beam column nodes. The structure greatly improves the rotation rigidity of the beam column nodes and helps to enhance constraint for column ends, thereby lowering the coefficient for effective length of columns. The columns with the same cross section have higher stable bearing force, and accordingly the lateral load resistance capacity and integrality of the module-assembly-type steel structure building are improved.

Owner:武汉理工大设计研究院有限公司

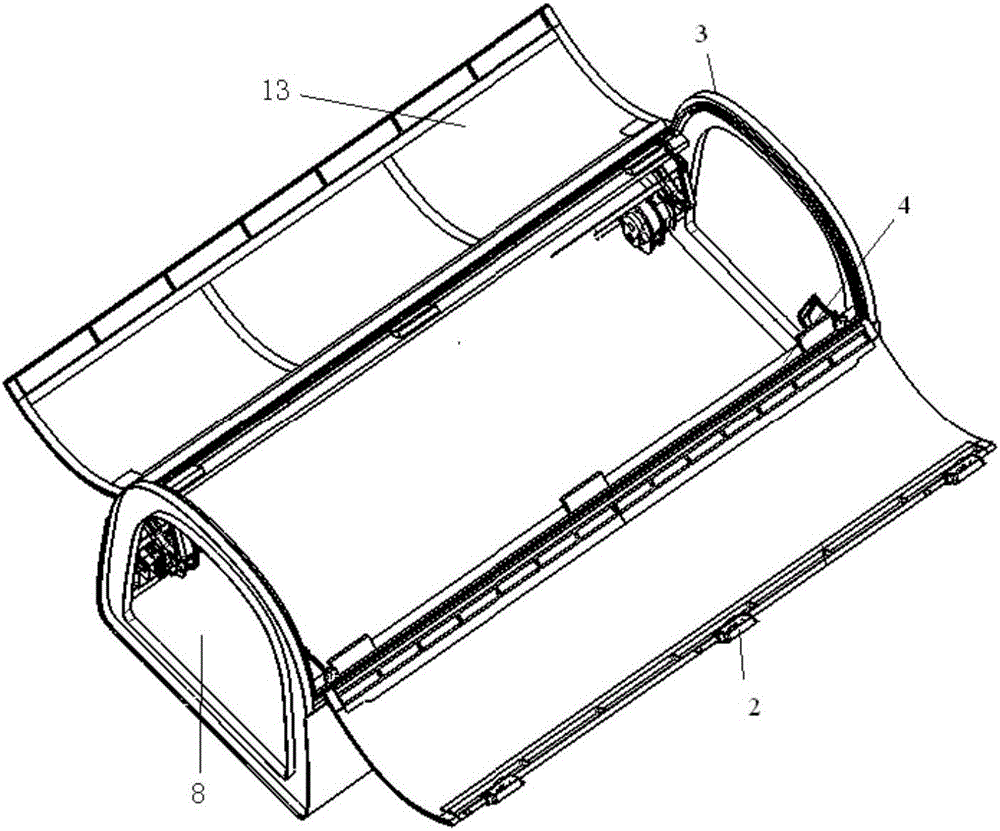

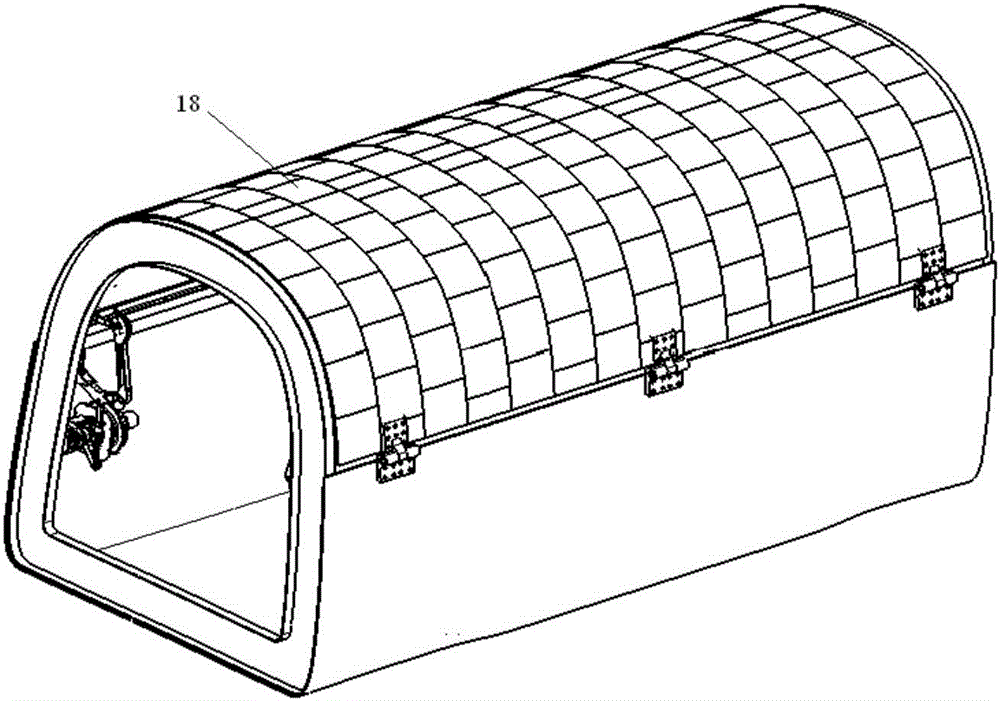

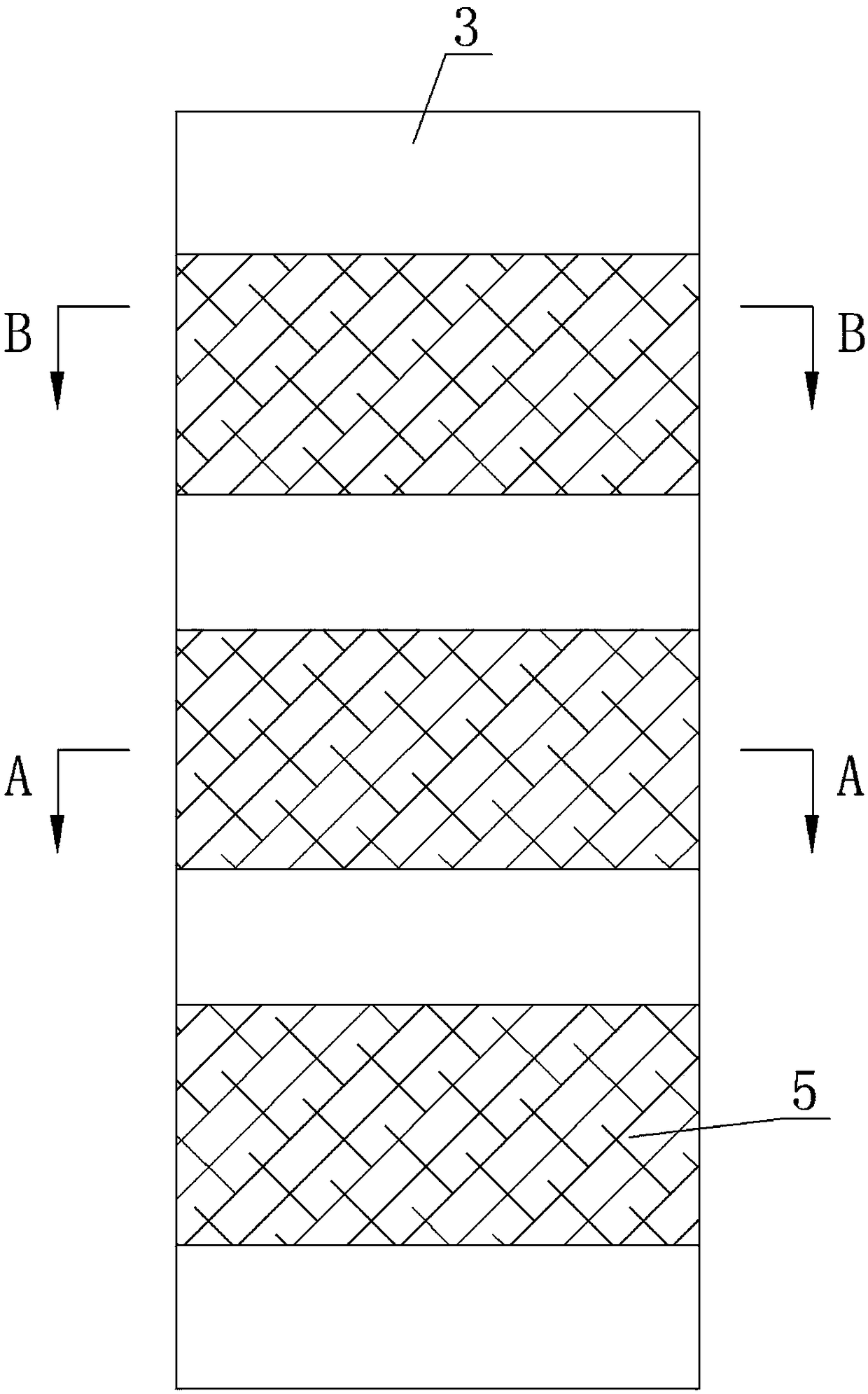

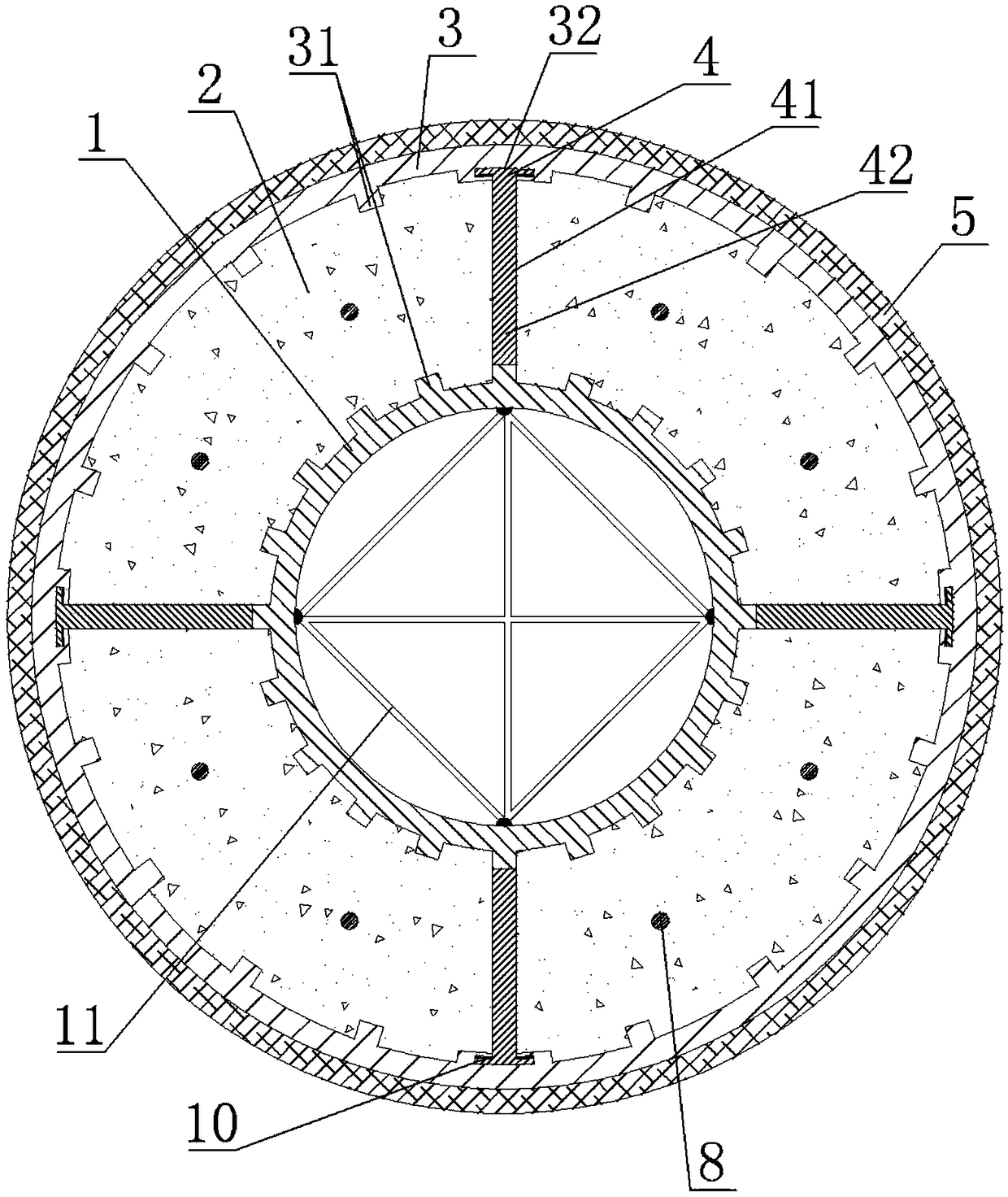

Effective load space cabin structure applicable to orbiter

ActiveCN106742065AImprove mechanical propertiesIncrease stiffnessCosmonautic vehiclesCosmonautic partsHoneycombOrbiter

The invention discloses an effective load space cabin structure applicable to an orbiter, comprising a cabin body and cabin doors; the cabin doors are connected to the cabin body; the cabin doors can open and close the cabin body; the cabin doors are two symmetrical opposite-opening structures, and every cabin door comprises an inner skin, an outer skin, main force bearing beams, honeycomb cores, a reinforcing rib and a heat protecting structure; the honeycomb cores are located between the inner skin and the outer skin; a guide flow slot is arranged on a contact position of the honeycomb cores and the outer skin, the reinforcing rib is arranged between the honeycomb cores, and connected to the main force bearing beams; three cabin door locks are evenly distributed on the main force bearing beams, the two cabin doors are locked to each other in the process of closing; the thermal protecting structure is arranged on the outer skin, and arranged in a staggering manner; the vapor return absorption of the surface of the thermal protecting structure under the natural environment is not more than 0.15%, thus the effective load cabin door structure is high in structural rigidity, good in structure compatibility and sealing property; meanwhile, the effective load space cabin structure can meet integration and lightweight requirements at the same time.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

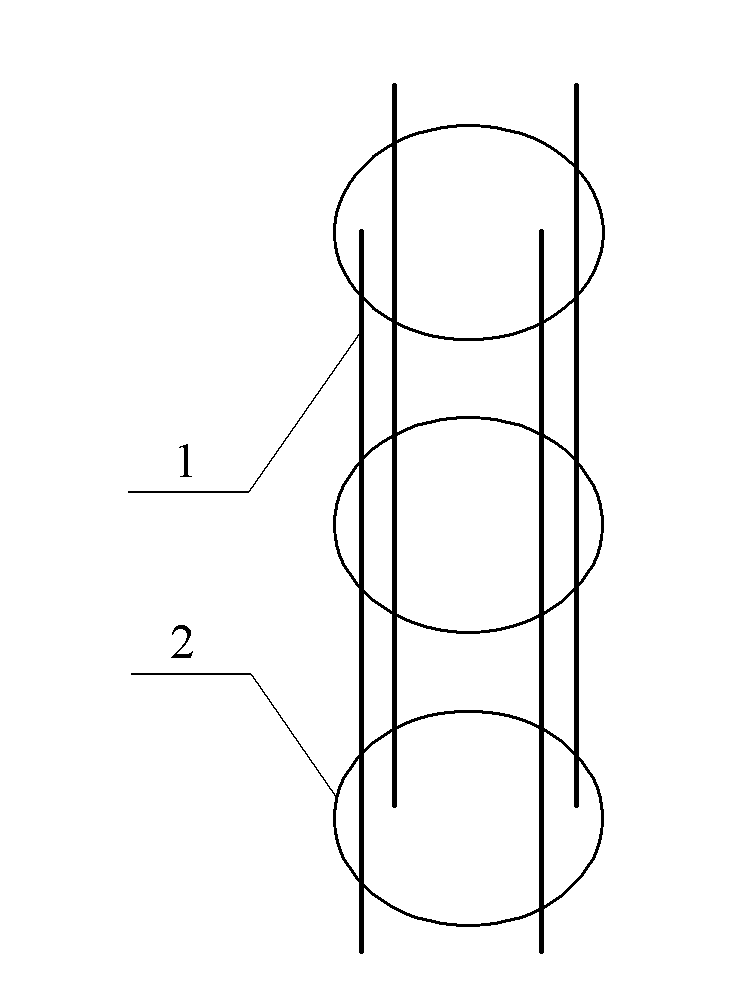

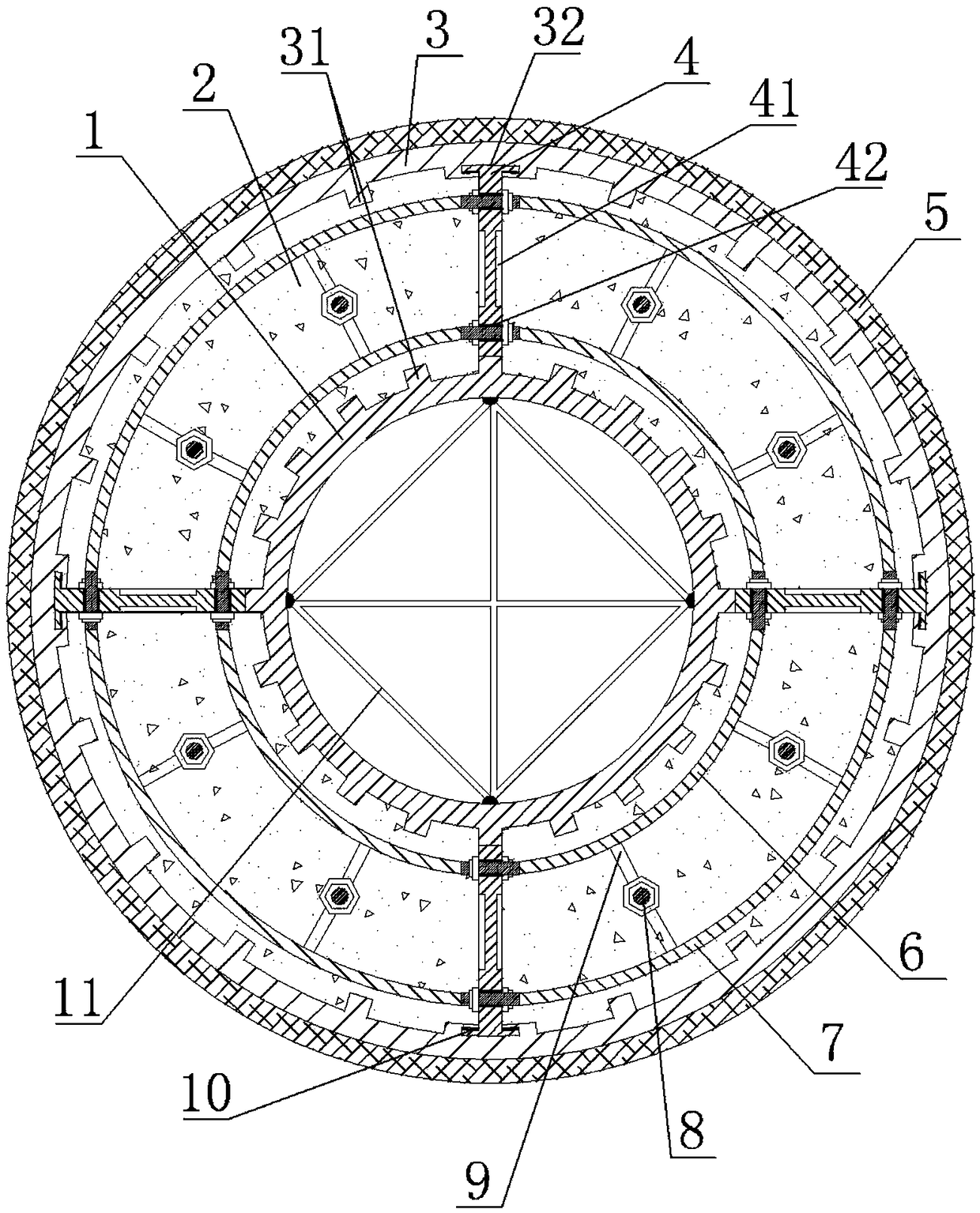

Hollow-sandwich multi-cavity steel pipe concrete member and preparation method thereof

PendingCN109403205ASolve the rustLow maintenanceStrutsBridge structural detailsClamp connectionStressed state

The invention discloses a hollow-sandwich multi-cavity steel pipe concrete member and a preparation method thereof. The hollow-sandwich multi-cavity steel pipe concrete member comprises an internal steel pipe and an external steel pipe which are concentrically placed; a space between the internal steel pipe and the external steel pipe is filled with concrete; a plurality of transverse diaphragms are uniformly distributed on the external wall of the internal steel pipe around the axis of the internal steel pipe; each transverse diaphragm is placed along the full length of the internal steel pipe in the axial direction; the external end part of each transverse diaphragm is in clamping connection with a groove formed in the internal wall of the external steel pipe; convex teeth are arranged on the internal wall of the external steel pipe and the external wall of the internal steel pipe; a plurality of shear grooves are uniformly formed in the side surfaces of the transverse diaphragms inthe axial direction; a plurality of external cylinders made of carbon fiber composite materials are bonded outside the external steel pipe in the annular direction; and the external cylinders are notconnected with the end part of the external steel pipe. According to the hollow-sandwich multi-cavity steel pipe concrete member, the corrosion resistance is high, less separation phenomena between the steel pipe walls and the concrete are less, the steel pipes are unlikely to generate local buckling, and the stressed states of the concrete in three directions are uniform.

Owner:CENT SOUTH UNIV

Composite steel pipe concrete column with built-in steel pipe beam tube

The invention discloses a composite steel pipe concrete column with a built-in steel pipe beam tube. The composite steel pipe concrete column comprises an outer tube steel pipe, wherein a plurality of inner tube steel pipe concrete columns are arranged in the outer tube steel pipe; each inner tube steel pipe concrete column comprises an inner tube steel pipe; inner tube concrete is filled in the inner tube steel pipe; the inner tube steel pipe concrete columns are connected through connecting lacing elements; a plurality of enhanced bonding ribs are arranged on the inner wall of the outer tube steel pipe; between-pipe concrete is filled between the outer tube concrete pipe and the inner tube concrete columns; The composite steel pipe concrete column with the built-in steel pipe beam tube has the advantages that the carrying force is high; the intensity storage is great; the durability is higher; the cross section dimension and the dead weight of the column component are reduced; the high-intensity materials are sufficiently utilized; the energy sources and the energy sources are saved; the sustainable development requirements are met.

Owner:HUBEI ENG UNIV

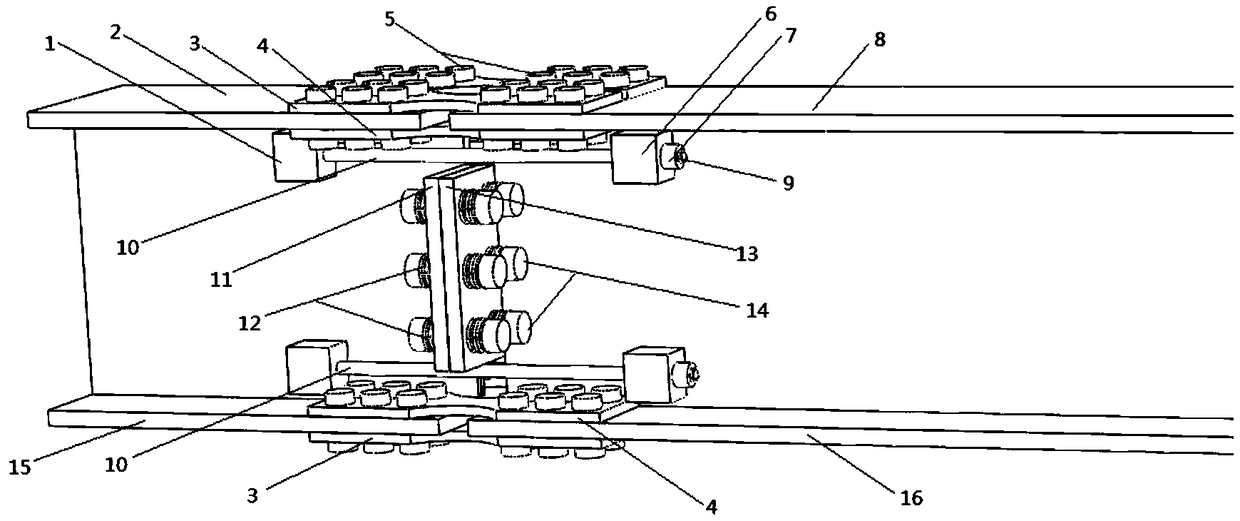

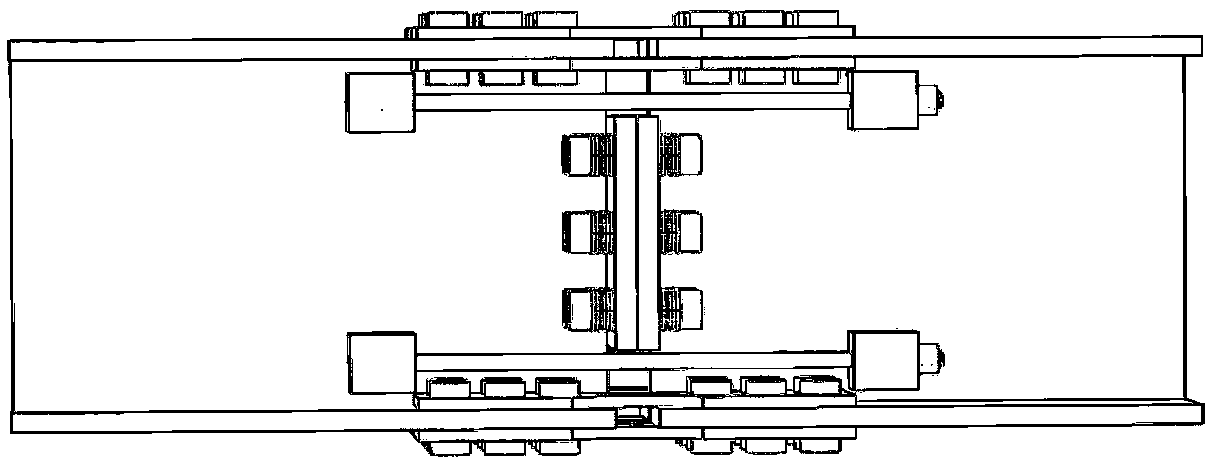

Rectangular steel pipe column-H steel beam full-bolt connection self-rigidity node and construction method

ActiveCN109537726AVarious formsIncrease productivityProtective buildings/sheltersBuilding material handlingEngineeringShort limbs

The invention discloses a rectangular steel pipe column-H steel beam full-bolt connection self-rigidity node and a construction method. The node comprises a rectangular steel pipe column, an H-shapedsteel beam and a connection force transmission part; the connection force transmission part comprises an upper rectangular hoop, a lower rectangular hoop, upper unequal limb angle steel, lower unequallimb angle steel and a vertical web connection plate; the upper unequal limb angle steel and the lower unequal limb angle steel comprise unequal limb angle steel short limbs connected with the rectangular steel pipe column and unequal limb angle steel long limbs connected with the flange of the H-shaped steel beam; the upper rectangular hoop and the lower rectangular hoop sleeve the outer sides of the unequal limb angle steel short limbs and are connected with the rectangular steel pipe column through one-way locking high-strength bolts; the vertical web connection plate is located on an H-shaped steel beam web, fixed to the rectangular steel pipe column and connected with the H-shaped steel beam web. The node is reasonable and reliable in force transmission, capable of achieving design standardization and manufacturing standardization, accurate and convenient to install, suitable for assembly-type connection of a square steel pipe column and an H-shaped steel beam structure and is asemi-rigid node with good ductility and high anti-seismic and energy-consumption capacity.

Owner:TIANJIN UNIV

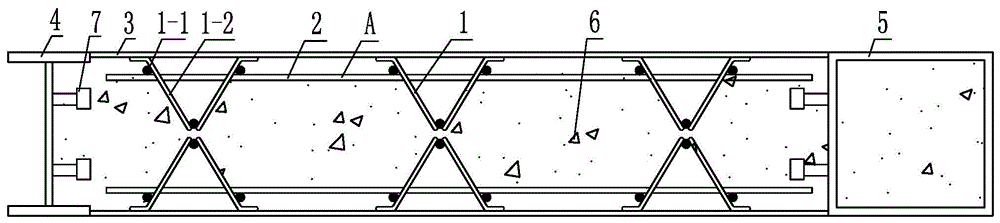

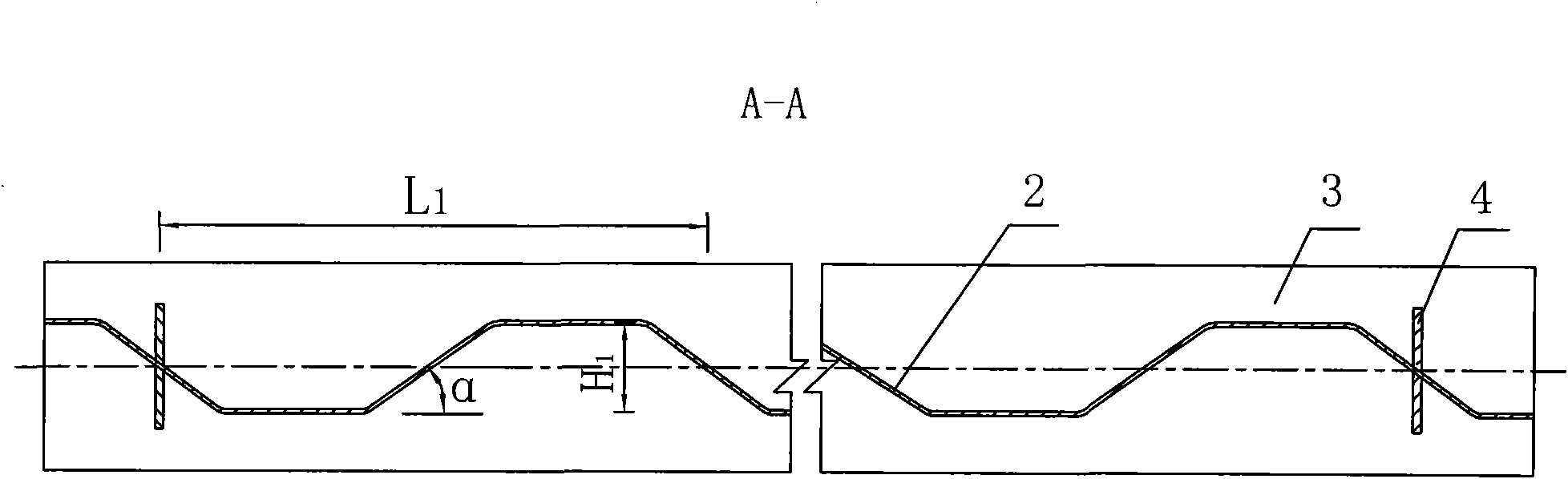

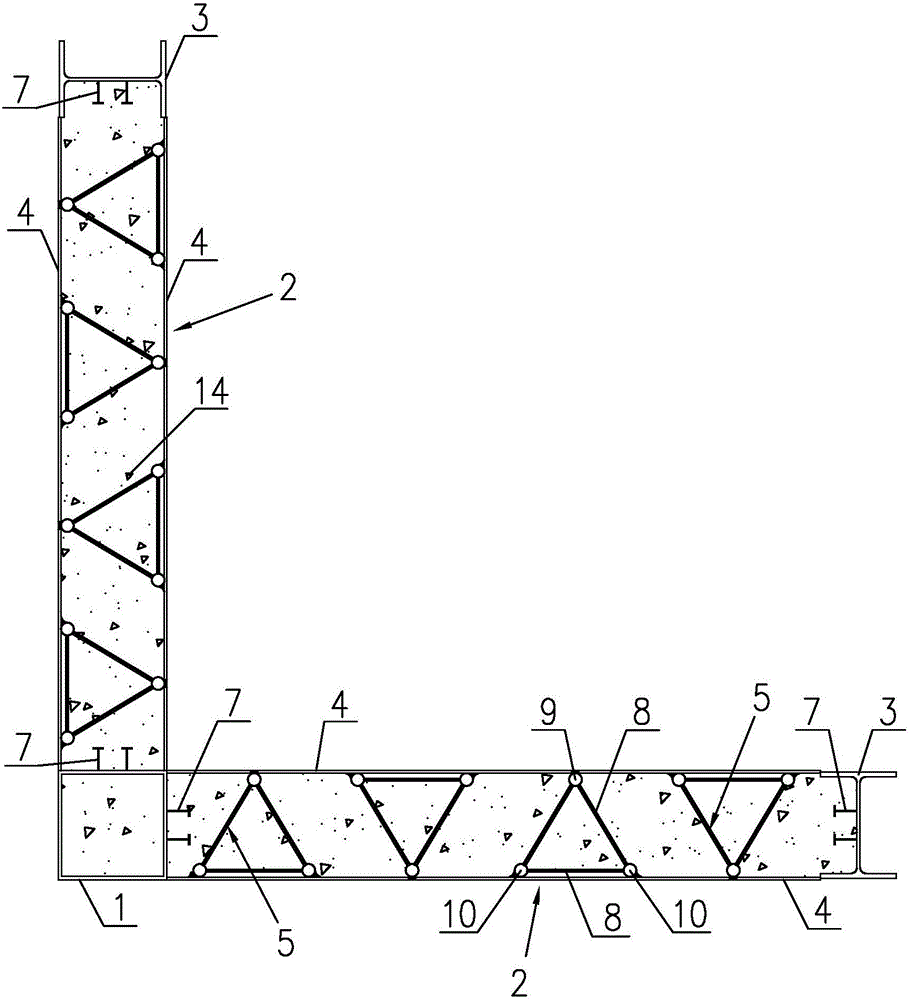

Double T-shaped composite beam provided with prestressed steel tube concrete core rods and fabrication method of double T-shaped composite beam

InactiveCN103031926AImprove bearing capacityImprove leaping abilityLoad-supporting elementsCeramic shaping apparatusHigh strength concreteRebar

The invention provides a double T-shaped composite beam provided with prestressed steel tube concrete core rods, which is formed by utilizing the prestressed steel tube concrete core rods as tensioned lower flanges, adopting corrugated steel plates as web plates and pouring an upper flange top plate with high-strength concrete. The prestressed steel tube concrete core rods consist of steel tubes, intra-tube concrete and prestressed steel bars, and have high tension capacities; as the prestressed steel tube concrete core rods are combined with the corrugated steel web plates for use, the advantages are complemented, the shear capacity and flexural capacity of a crossbeam are improved, and the crossing ability of the crossbeam is improved. The composite beam has the advantages of light weight, great crossing ability, high bearing ability, high stiffness, low cost and the like, can be suitable for volume production in prefabricated part factories, can serve as a roof beam for constructing a 30-48m oversized-span single-storey industrial factory building, and as a floor beam for constructing a 21-30m large-span multi-storey industrial factory building, meets the requirements of industrial production on a large space, and saves land.

Owner:SOUTHEAST UNIV

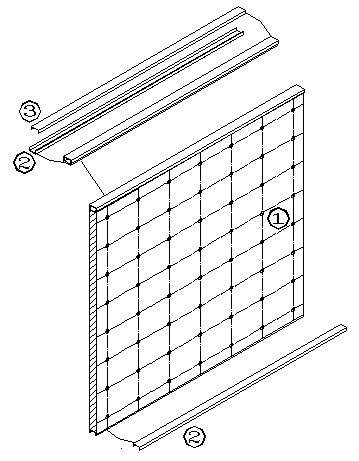

Prefabricated fabricated profiled steel sheet concrete shear wall and construction method thereof

The invention discloses a prefabricated fabricated profiled steel sheet concrete shear wall structure and a construction method. A thinner profiled steel sheet is adopted as an encased steel sheet ofa shear wall so as to reduce the whole steel ratio of the shear wall. In order to ensure the structural strength of the shear wall, a binder coating is additionally arranged between a steel material and concrete. The binder coating can effectively bind the steel material and the concrete, and outward local buckling of the profiled steel sheet can also be prevented. According to the prefabricated fabricated profiled steel sheet concrete shear wall structure and the construction method, the technical effects that on the basis that the structural strength is ensured, the steel ratio of a wall body of the prefabricated fabricated shear wall is reduced, the structure is simplified, and the construction difficulty is reduced are achieved.

Owner:HUAQIAO UNIVERSITY

Nine-shaft automobile chassis crane and steering control system thereof

InactiveCN102501898APrevent local bucklingImprove handling safety performanceSteering linkagesFluid steeringRocker armSteering system

The invention discloses a steering control system of a nine-shaft automobile chassis crane. The steering control system comprises a pull rod type steering transmission mechanism and a hydraulic power-assisted steering system, wherein the pull rod type steering transmission mechanism is used for controlling corresponding wheels on a first steering shaft, a second steering shaft, a third steering shaft, a fourth steering shaft and a fifth steering shaft to steer; the pull rod type steering transmission mechanism comprises a first rocker arm, a second rocker arm and a third rocker arm which are respectively used for controlling the wheels on the corresponding steering shafts to steer through a pull rod assembly; and the pull rod type steering transmission mechanism also comprises a first auxiliary rocker arm and an auxiliary pull rod assembly, the first auxiliary rock arm is arranged between any two adjacent rocker arms in the three rocker arms, and the auxiliary pull rod assembly is used for sequentially hinging the three rocker arms and the first auxiliary rocker arm. By using the steering control system, the condition that parts of the pull rod assembly are overlong is avoided, and the phenomenon that parts of the pull rod assembly is instable and bent can be effectively prevented; and furthermore, the safety performance in operating vehicles is improved on the basis of avoiding the abnormal wearing of a tire. On the basis, the invention also provides a nine-shaft automobile chassis crane with the steering control system.

Owner:XUZHOU HEAVY MASCH CO LTD

Composite steel plate shearing wall for improving stability

InactiveCN102691364ALarge shear buckling capacityGreatly increased shear buckling capacityWallsSheet steelSteel frame

The invention relates to a composite steel plate shearing wall for improving stability, which belongs to a lateral force resisting component in the technical field of structural engineering and is applied to newly construction of a frame-steel plate shearing wall and reinforcement and seismic rehabilitation of a constructed steel frame structure. Each of the top end and the bottom end of a composite plate is provided with a first channel steel connector, notches of the first channel steel connectors at the top end and the bottom end are arranged outwards, and a notch of a second channel steel connector is arranged inwards on the first channel steel connector at the top end of the composite plate. According to the composite steel plate shearing wall for improving stability, the form of clamping a hard polyurethane foam plate between two steel plates remarkably is adopted so as to increase the plane external stiffness of the cross section of the plate so that the steel plate shearing wall obtains great anti-shearing buckling bearing capacity to avoid entire buckling of the structure under the action of a larger horizontal load; and meanwhile, the steel plate is divided into small areas by dense bolts and is closely combined with the hard polyurethane foam plate to prevent partial buckling of the steel plate.

Owner:HOHAI UNIV

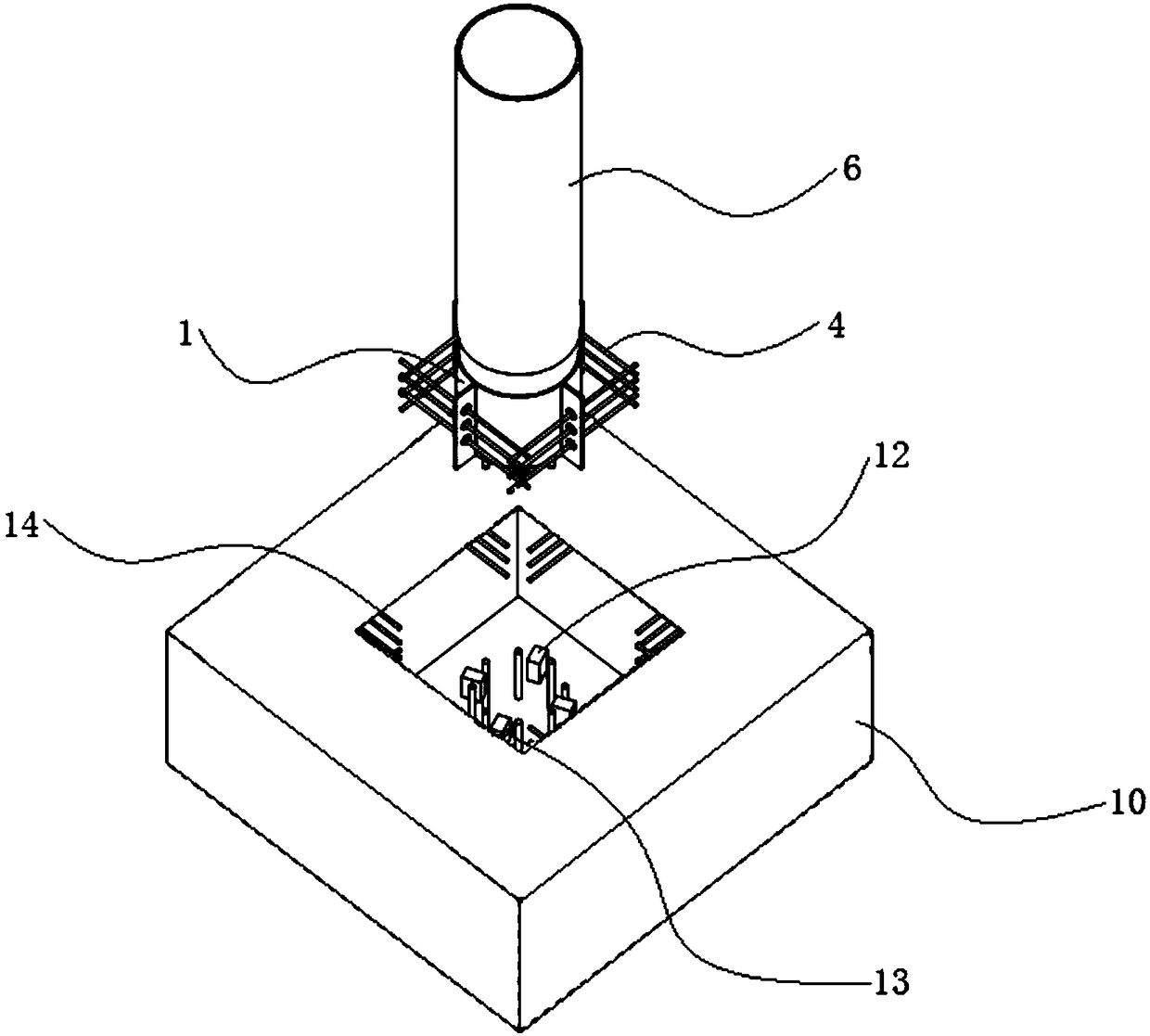

Grouting steel pipe connection device structure and connection method

ActiveCN106245765ALow skill level requiredSimple connection structureBuilding material handlingRebarMaterials science

The invention relates to the field of steel structure buildings, in particular to a grouting steel pipe connection device structure and a connection method. The produced grouting steel pipe connection device can be used for connecting steel pipe structures in the steel structure buildings. The steel pipe connection method adopting the grouting steel pipe connection device can serve as the method for connecting the steel pipe structures in the steel structure buildings. The structure comprises a high-strength steel bar with anchor hooks, an anchorage positioning steel plate, steel bar penetrating holes, an inner clamping ring, a lower connected steel pipe, a grouting hole and an upper connected steel pipe. By arranging the grouting steel pipe connection device between the ordinary connected steel pipes, the steel pipes are connected through a grouting method. The grouting steel pipe connection device can be prefabricated in a plant. Welding is not needed during on-site construction, the connection structure is simple, the requirement for the technical level of constructors is not high, the on-site construction difficulty is low, the construction quality can be guaranteed easily, environmental friendliness is achieved, energy is saved, and the requirement for current green buildings is better met.

Owner:SHENYANG SANXIN IND

Novel energyconsuming prefabricated shear wall and manufacturing and mounting method thereof

InactiveCN110130534AImprove bearing capacityImprove seismic performanceWallsProtective buildings/sheltersRebarShear wall

The invention discloses a novel energyconsuming prefabricated shear wall and a manufacturing and mounting method thereof, and relates to the technical field of prefabricated building construction. Thenovel energyconsuming prefabricated shear wall comprises a reinforced concrete slab, a profile steel energy consuming supportis arranged in the reinforced concrete slab, reinforcing meshes are arranged both in the reinforced concrete slab and at the top and bottom of profile steel energy consuming support, the reinforcing meshes are interwoven by horizontally distributed ribs and vertically distributed ribs, a positioning protrusion is arranged on each of the two sides of the top of the reinforced concrete slab, positioning grooves matching with the positioning protrusions are formed in boththe two sides of the bottom of the reinforced concrete slab, a stirrup and a beam steel are arranged at the top of the reinforced concrete slab, and an anchor steel is arranged at the bottom of the reinforced concrete slab. According to the novel energyconsuming prefabricated shear wall, bearing capacity is high, energy consuming capability is high, construction using the manufacturing and mounting method is convenient and quick, a next layer of prefabricated shear wall can be hoisted without concrete setting, and the construction period is greatly shortened.

Owner:CHINA MCC17 GRP

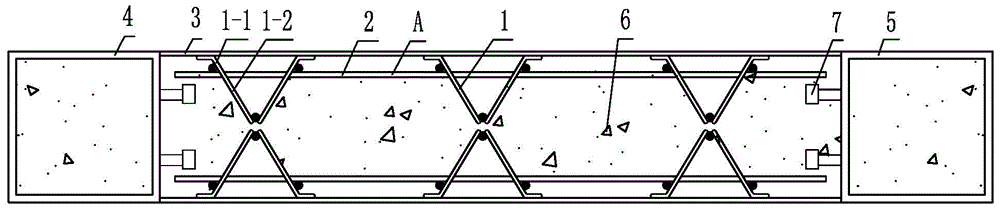

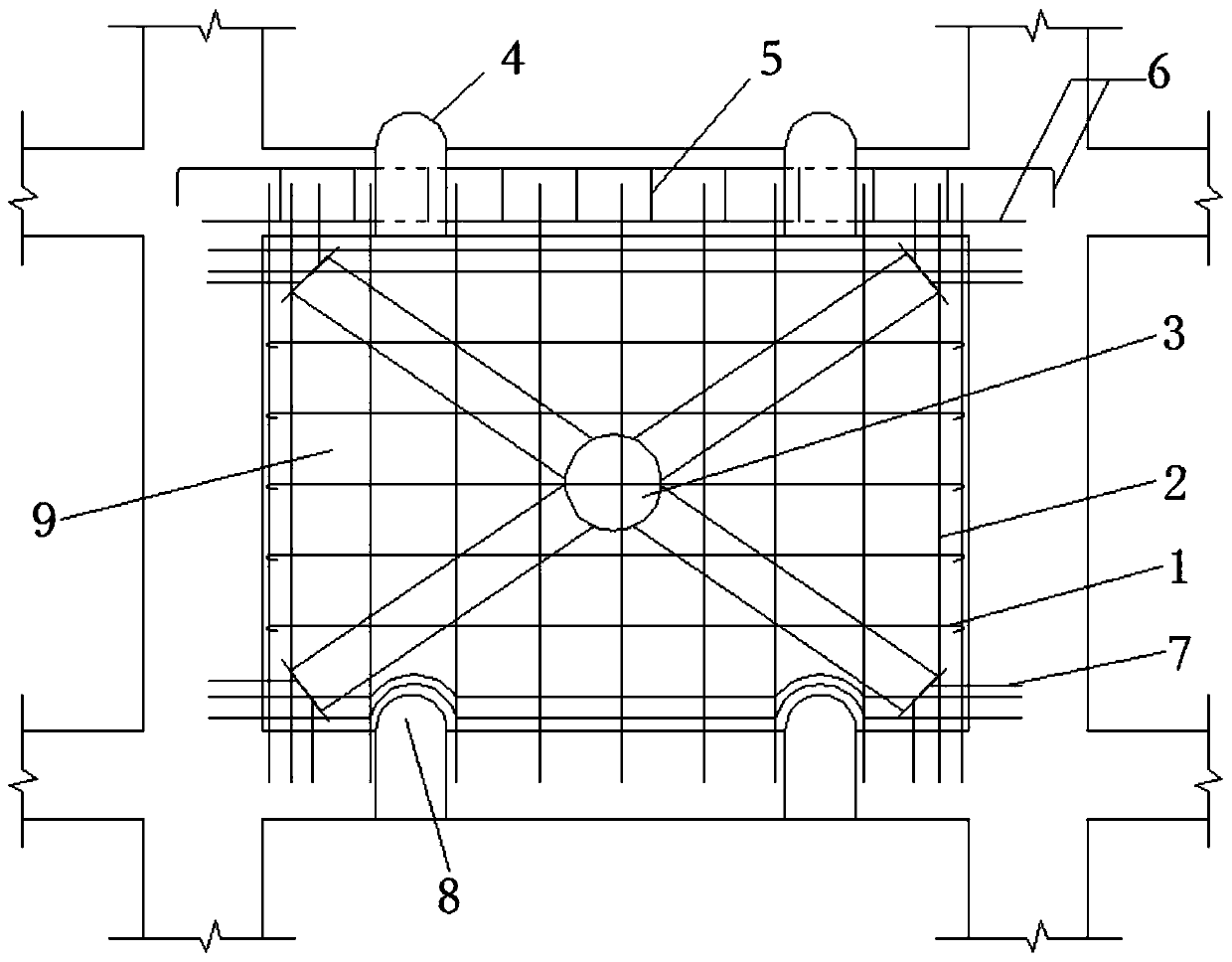

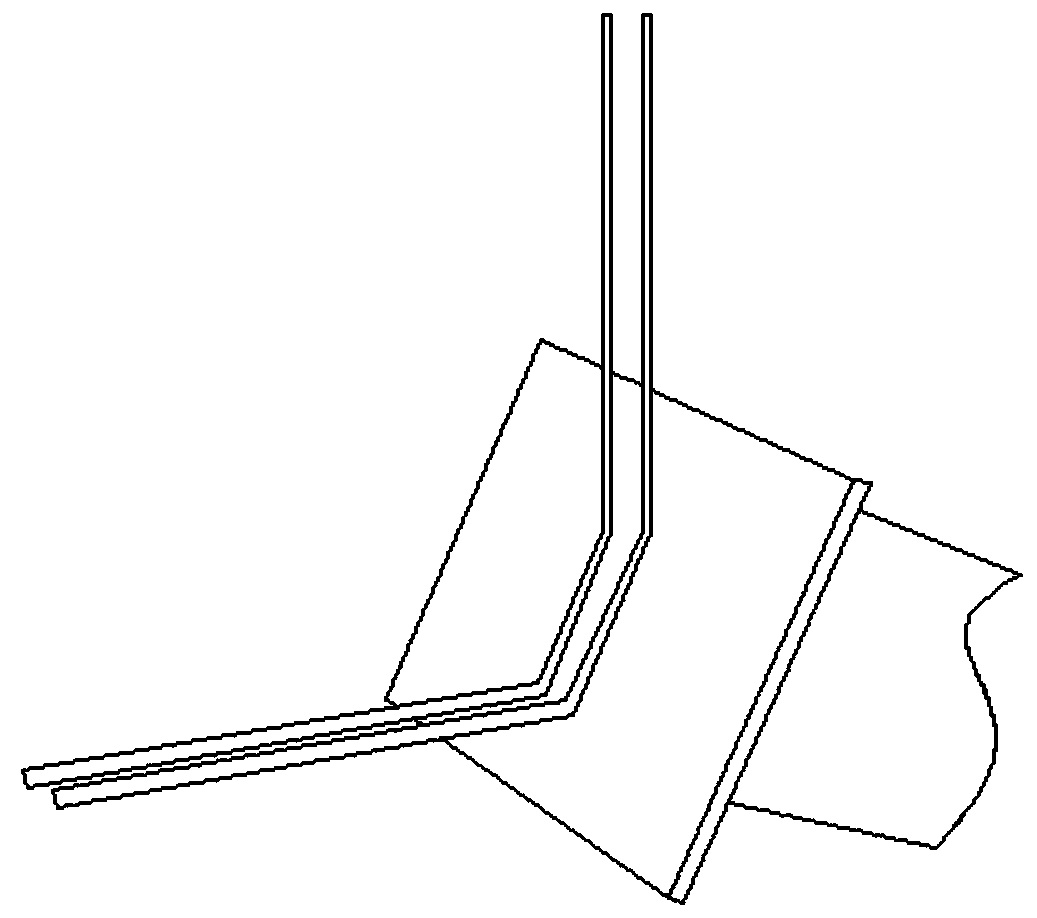

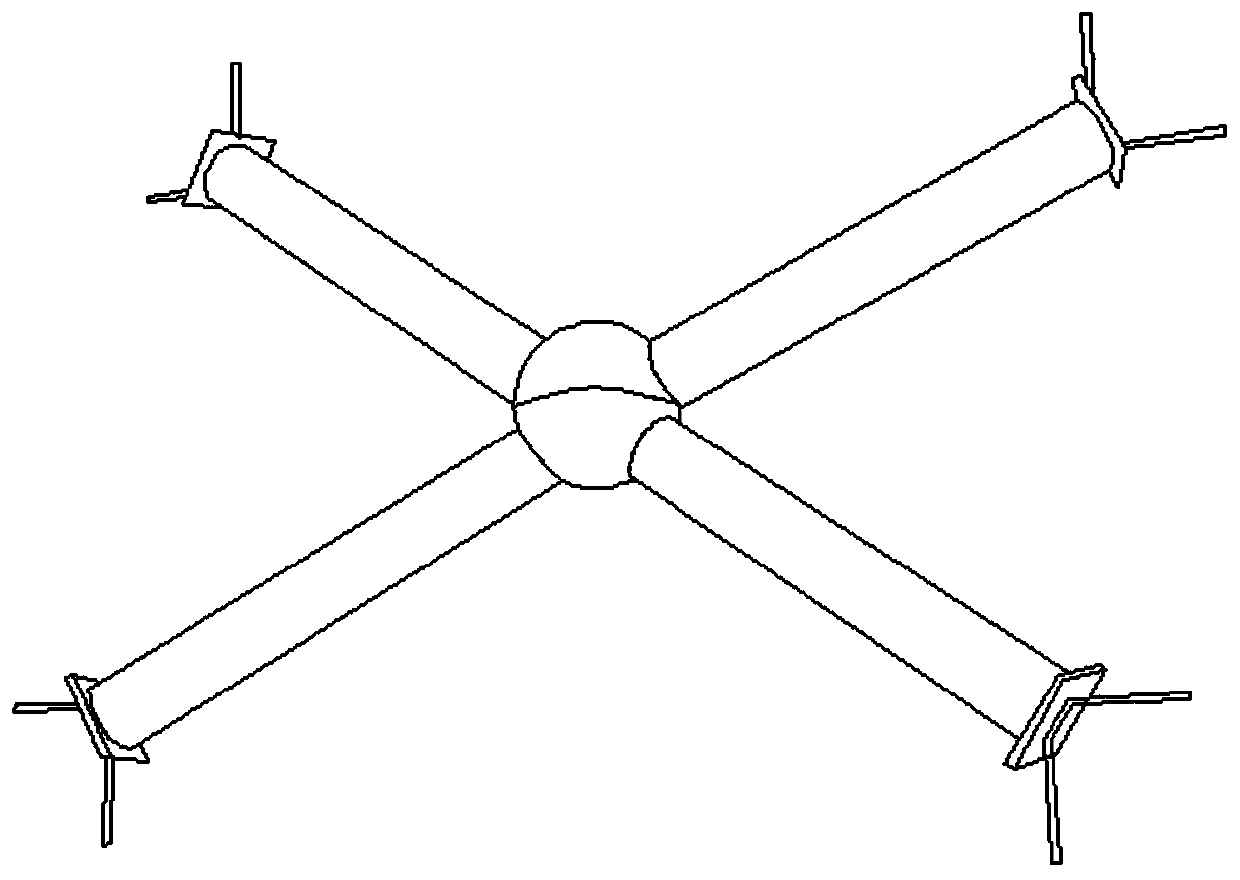

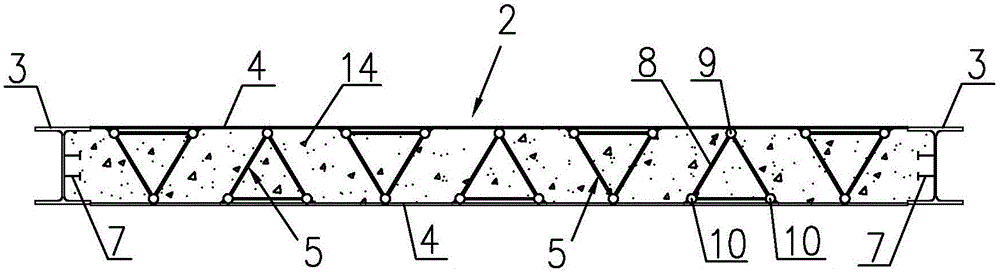

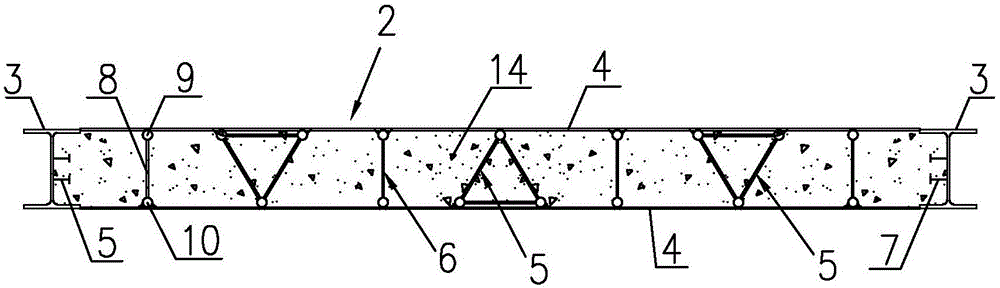

Built-in truss combined structure

InactiveCN106522420AImprove energy consumptionGood mechanical propertiesWallsEngineeringMechanical property

The invention discloses a built-in truss combined structure which comprises a combined body. The combined body is composed of steel plates and end columns. A cavity is formed among the end columns and the steel plates. Trusses are arranged in the cavity and fixed to the steel plates in a welded mode. Each truss comprises web members and chord members, wherein the chord members are fixed to the corresponding steel plates in a welded mode. Shear resisting components are arranged on the inner sides of the end columns. Concrete is poured in the cavity. The trusses and the shear resisting components are all arranged in the concrete. According to the built-in truss combined structure, advantages of steel and the concrete are fully achieved, and the structure has an excellent energy-dissipating capacity and a good mechanical property; the trusses are fixed to the steel plates in the welded mode, the steel plates on the two sides are restrained through the trusses, and premature occurrence of local buckling of the steel plates in the construction and use stage is prevented; and meanwhile, the cavity formed by the end columns and the steel plates can serve as a template for concrete pouring, and the construction cost is lowered.

Owner:浙江中南绿建科技集团有限公司

Recycled concrete Z-shaped pier stud

ActiveCN104328735AResource optimizationImprove bearing capacityBridge structural detailsBridge materialsBridge engineeringPost disaster

The invention discloses a recycled concrete Z-shaped pier stud, which is formed by welding two steel plates and two round steel pipes respectively with a U-shaped steel groove; ordinary aggregate concrete is cast in the U-shaped steel grooves and between the two parallel steel plates; recycled aggregate concrete is cast in the round steel pipes. The recycled concrete Z-shaped pier stud disclosed by the invention is capable of overcoming the problem that the use of recycled concrete is limited due to the fact that strength and endurance quality are poor and the like, is in favor of popularization and application and engineering garbage recycling of the recycled concrete in bridge engineering, and can be applied to skew bridges in regions with strong seismic intensity and regions that building materials are difficult to transport; for bridges damaged by earthquakes, the damaged bridges can be immediately crushed into the recycled concrete, and natural aggregate is replaced with part of the recycled concrete to repair or rebuild the bridges, so that the transport cost is reduced, and post-disaster reconstruction is advantageously recovered.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Assembled building system based on inner insertion plate and clamping plate connecting beam column nodes

The invention discloses an assembled building system based on inner insertion plate and clamping plate connecting beam column nodes. A lower column module comprises lower columns; all the lower columns are provided with first support plates, outer extension plates and inner insertion plates; an upper column module comprises upper columns; all the upper columns are provided with second support plates; the upper columns are correspondingly inserted in the inner insertion plates of the lower columns, and are connected through bolts; a beam module comprises a main beam and a secondary beam; wire passing holes are reserved on web plates of the main beam and the secondary beam; and the connection of all the modules is realized through bolts among the main beam web plate, the outer extension plates and clamping plates, between a main beam lower flange and the first support plates and between a main beam upper flange and the second support plates. Beam columns can be assembled in scene only byadopting bolts, so that the assembly speed is high, and the construction period is shortened. Ribbed support plates achieve a positioning effect on the beams to bear part of the bending moment. The upper and lower columns are conveniently installed by the inner insertion plates to reduce the lifting difficulty. The ribbed support plates and the clamping plates are provided to realize outer shifting of plastic hinges. Pipelines are separated from a main body structure, so that the maintenance is convenient, and the clearance is improved.

Owner:BEIJING UNIV OF TECH

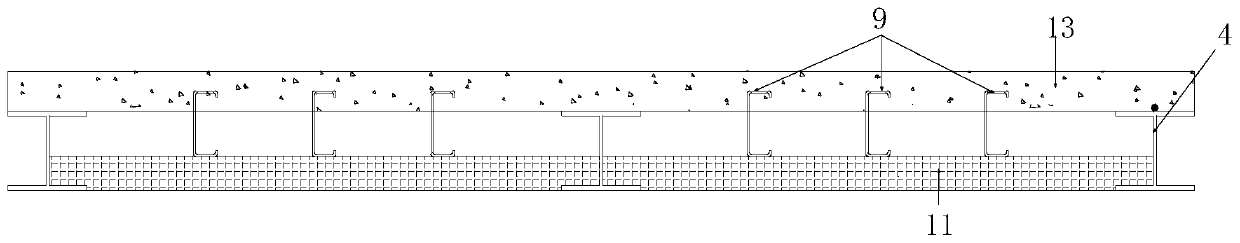

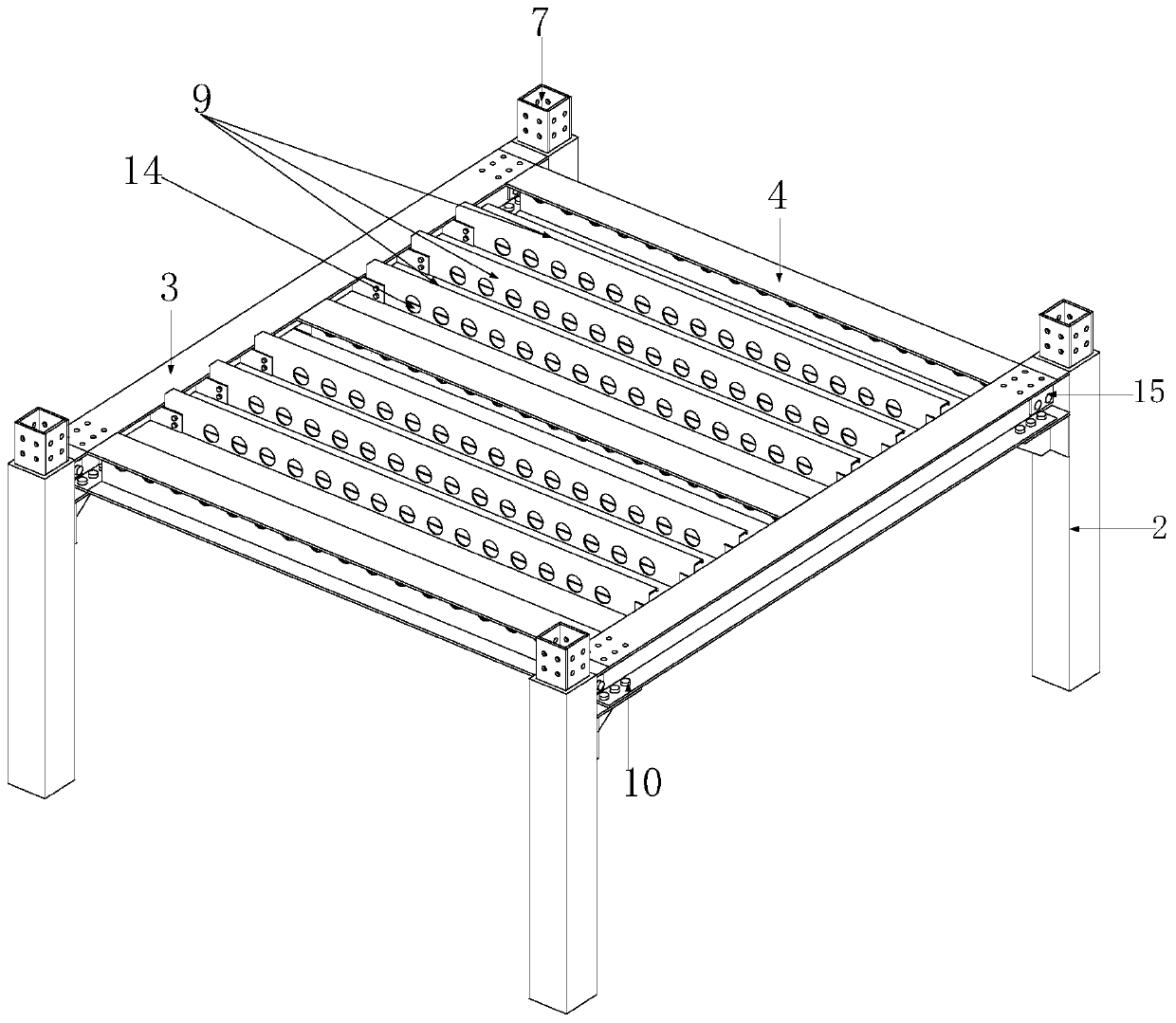

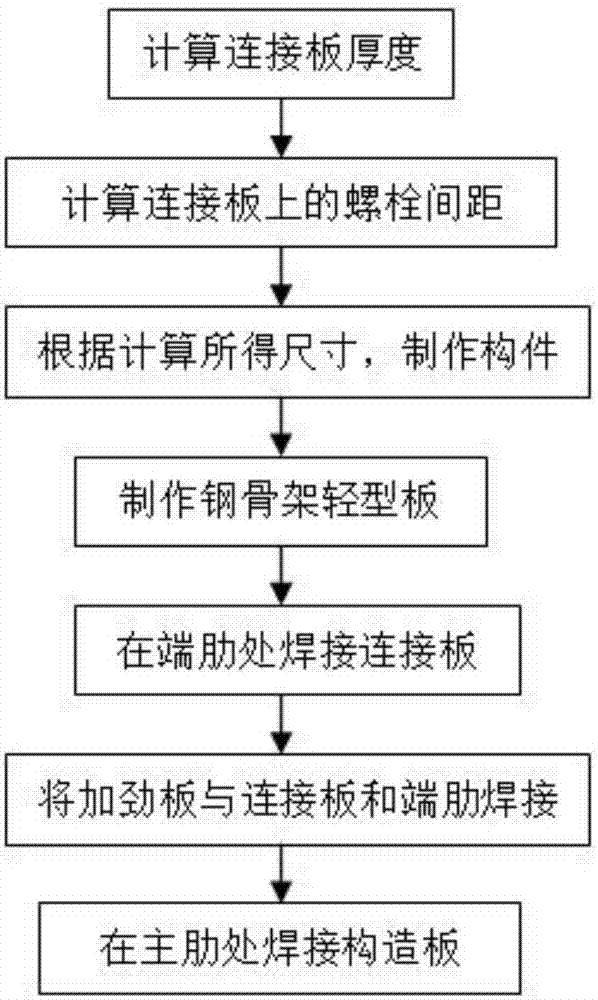

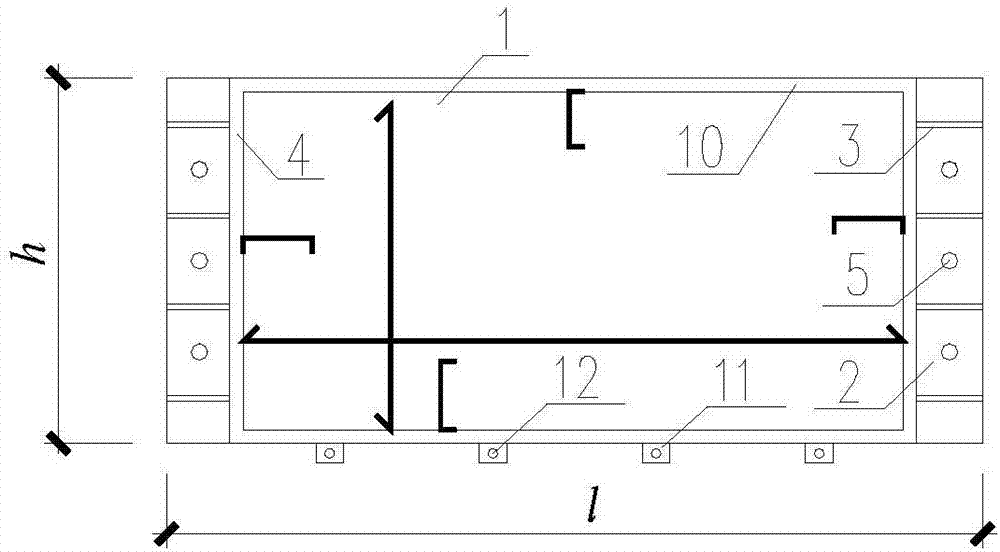

Full-bolt-assembly type steel framework light plate and manufacturing method thereof

The invention belongs to the field of civil engineering and relates to a full-bolt-assembly type steel framework light plate and a manufacturing method thereof. A connecting plate is welded to an end rib of a steel framework light plate body, and stiffening plate bodies are arranged between every two adjacent bolt holes in the connecting plate. In on-site mounting, connecting of the full-bolt-assembly type steel framework light plate and a frame beam upper flange is achieved through bolts. The manufacturing method of the full-bolt-assembly type steel framework light plate comprises the steps that the thickness of the connecting plate and the distance between the bolts are determined through calculation, and components are manufactured according to the calculation results; and the connecting plate is welded to the end rib of the steel framework light plate body, a structure plate body is welded to a main rib, and the stiffening plate bodies are arranged between every two adjacent bolt holes in the connecting plate. The full-bolt-assembly type steel framework light plate is connected with a frame beam through the bolts, so that the mounting efficiency is improved, and the connecting quality is ensured; and according to the manufacturing method of the full-bolt-assembly type steel framework light plate, the proper sizes of the components are determined, structural safety is ensured, and material waste is avoided.

Owner:QINGDAO TENGYUAN DESIGN ACCOUNTANTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com