Steel bar truss stiffened steel concrete composite shear wall

A technology of combining shear walls and steel trusses, applied to walls, building components, buildings, etc., can solve problems such as complex, poor seismic performance, easy cracking construction, etc., achieve good deformation ability, convenient construction, and speed up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

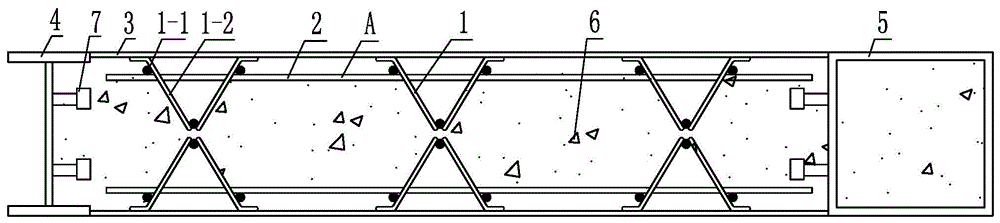

[0008] Specific implementation mode one: combine Figure 1-Figure 4 Illustrates that the steel-concrete composite shear wall reinforced by steel trusses in this embodiment includes a second reinforcement member 5, concrete 6, a first stiffening steel body A and a plurality of shear connection keys 7; the first stiffening steel body A includes a first Reinforcement member 4, two steel plates 3, multiple transverse steel bars 2 and multiple steel bar trusses 1;

[0009] Each steel bar truss 1 comprises two vertical reinforcement bars 1-2 and three longitudinal reinforcement bars 1-1; The vertical steel bars 1-2 are connected, and multiple steel bar trusses 1 are arranged side by side along the horizontal direction between the two steel plates 3. The vertical steel bars 1-2 are connected to the steel plates 3, and multiple horizontal steel bars 2 are horizontally arranged on the two steel plates. 3, and a plurality of transverse steel bars 2 are connected to a plurality of steel...

specific Embodiment approach 2

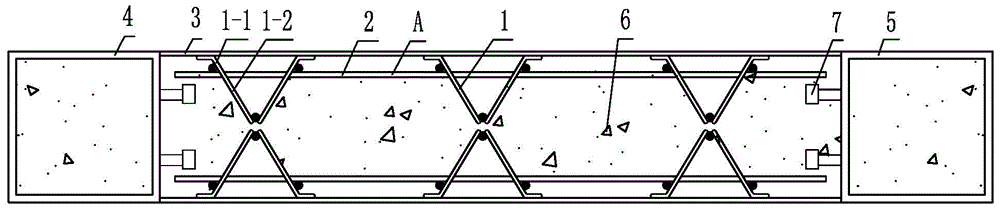

[0011] Specific implementation mode two: combination Figure 3-Figure 6 Explain that the steel-concrete composite shear wall stiffened by steel trusses in this embodiment also includes a second stiffened steel body B; the second stiffened steel body B has the same structure as the first stiffened steel body A, and the two A pair of thick sides of a steel plate 3 along the vertical direction are connected to the second reinforcement member 5, and a plurality of shear connection keys 7 in the second reinforcement member 5 are located between the two steel plates 3 in the second stiffened steel body B; The concrete 6 is poured in the second stiffened steel body B, and the first stiffened steel body A and the second stiffened steel body B are connected to form a -shaped or L-shaped or T-shaped or cross-shaped structure.

[0012] This embodiment adopts a second stiffened steel body B, the structure of the second stiffened steel body B is the same as that of the first stiffened stee...

specific Embodiment approach 3

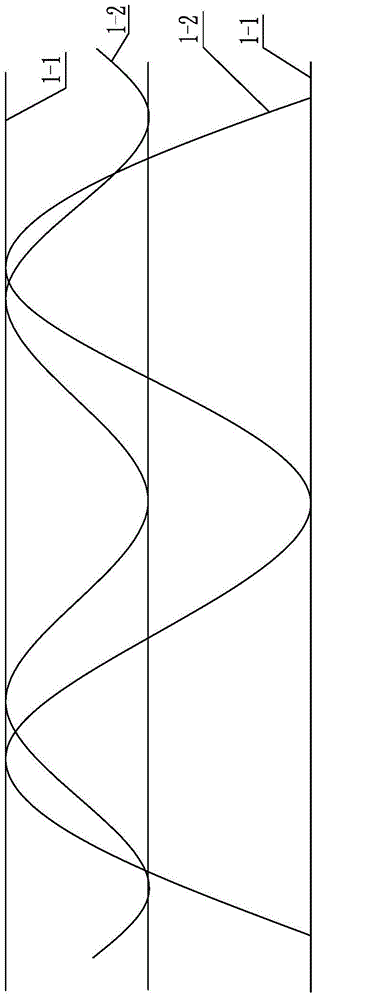

[0017] Specific implementation mode three: combination image 3 and Figure 4 To illustrate, the erection bars 1-2 of this embodiment are corrugated bars or trapezoidal bars. Such setting can improve the stable bearing capacity of the steel plate and prevent premature local buckling of the steel plate during construction and use. At the same time, the steel truss can ensure that the internal concrete and the steel plate work together as a whole. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com