Patents

Literature

76results about How to "Guaranteed to work together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

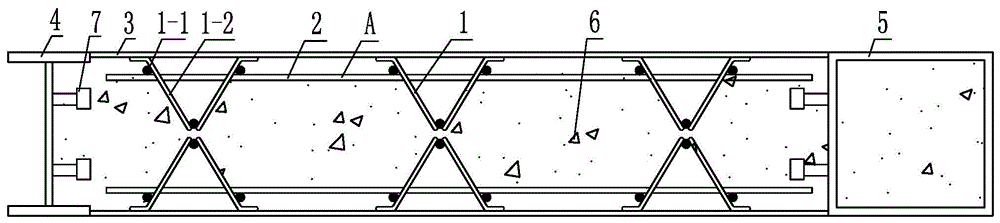

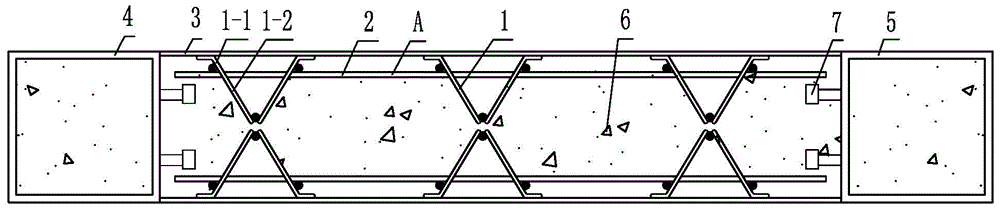

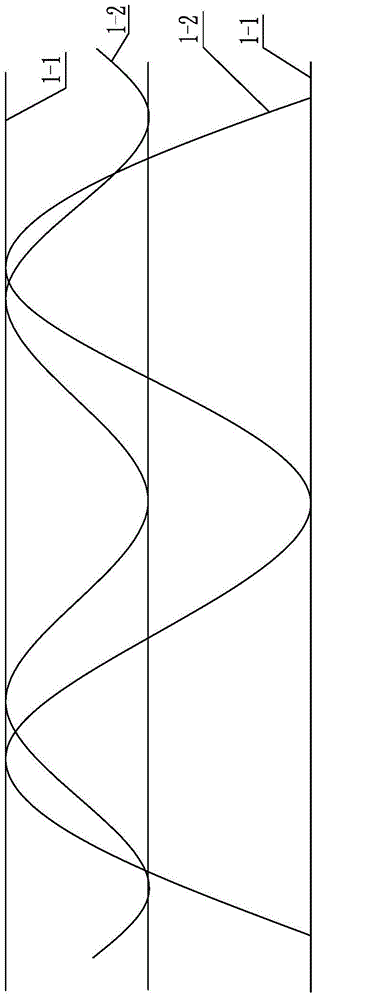

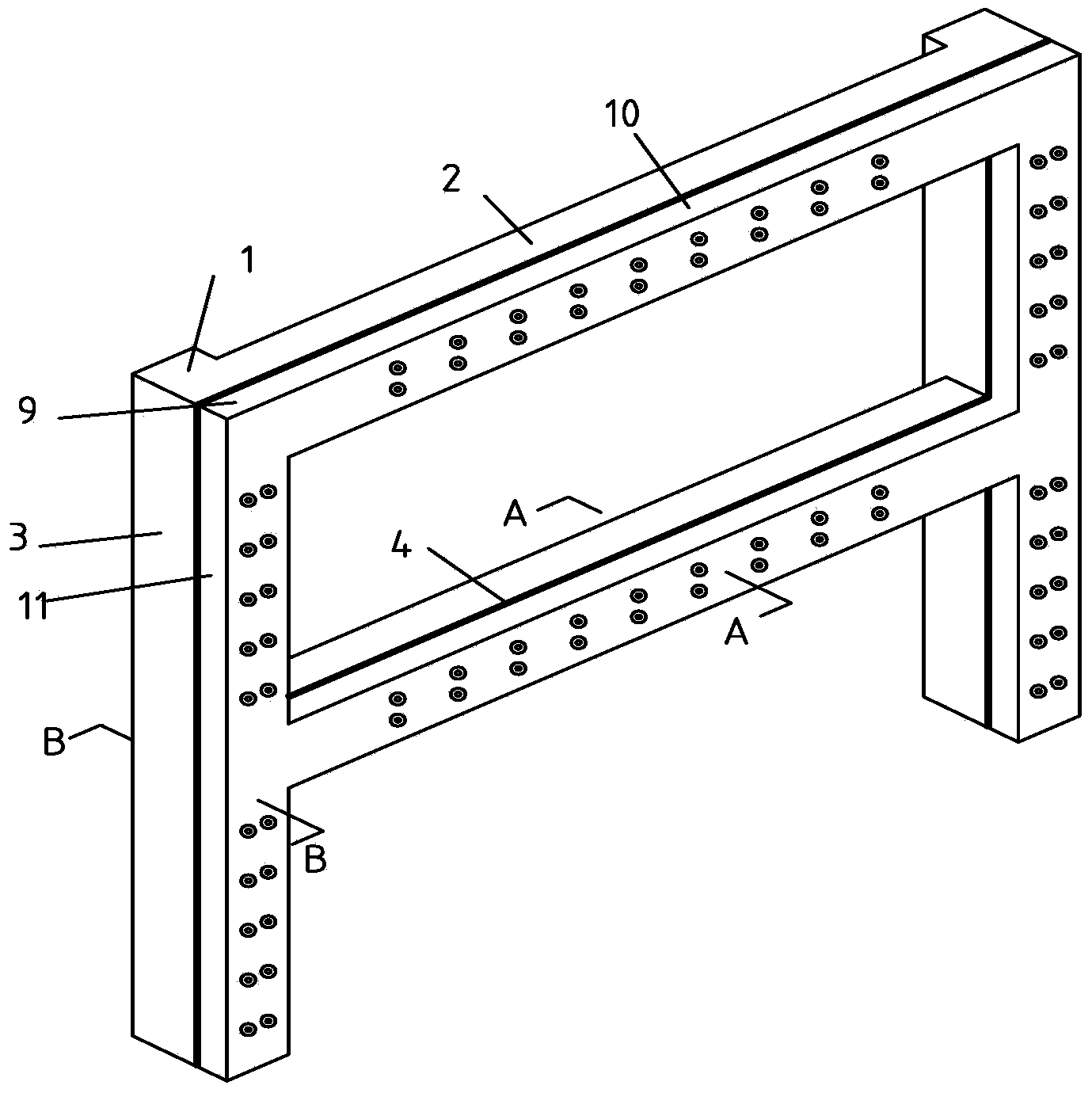

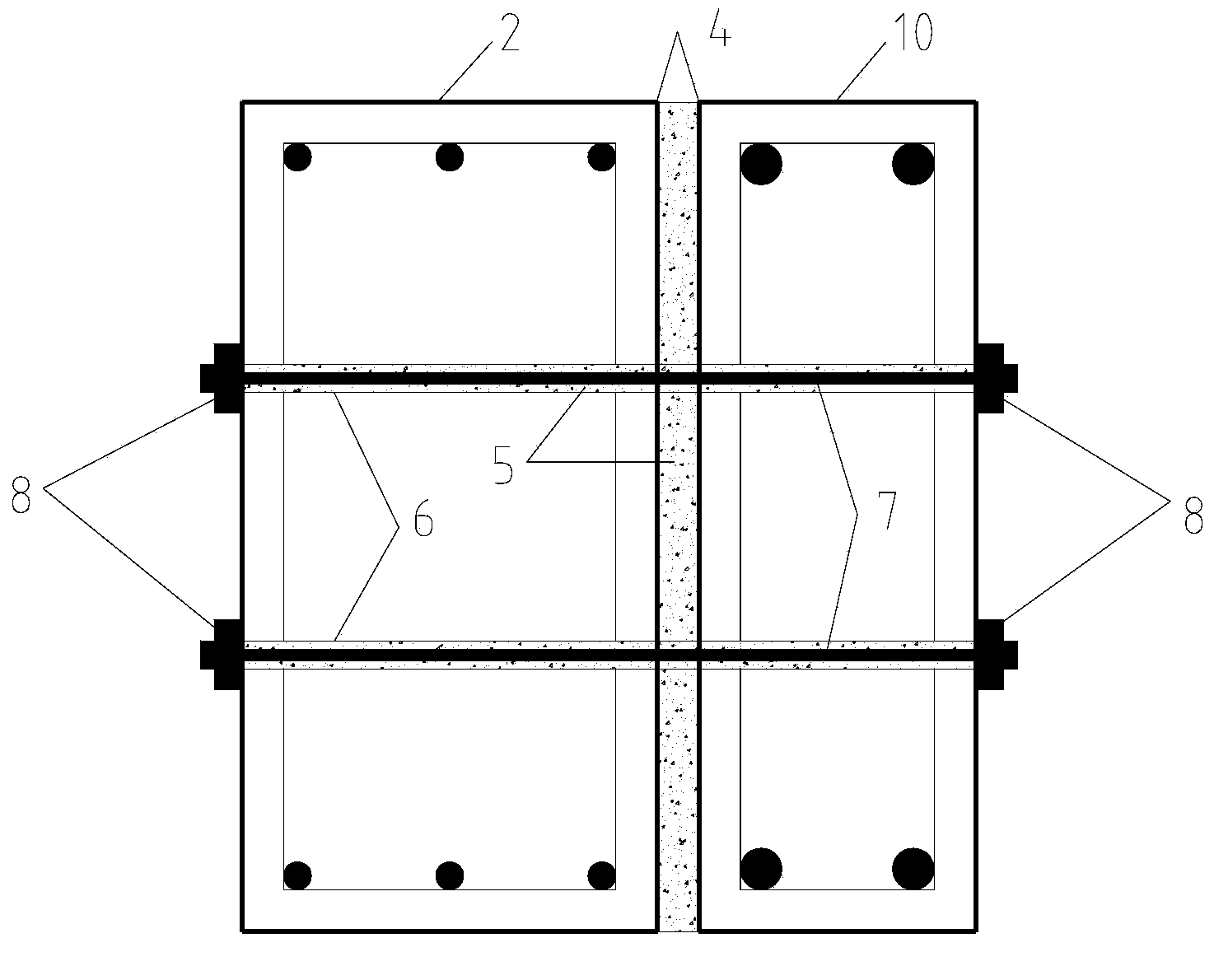

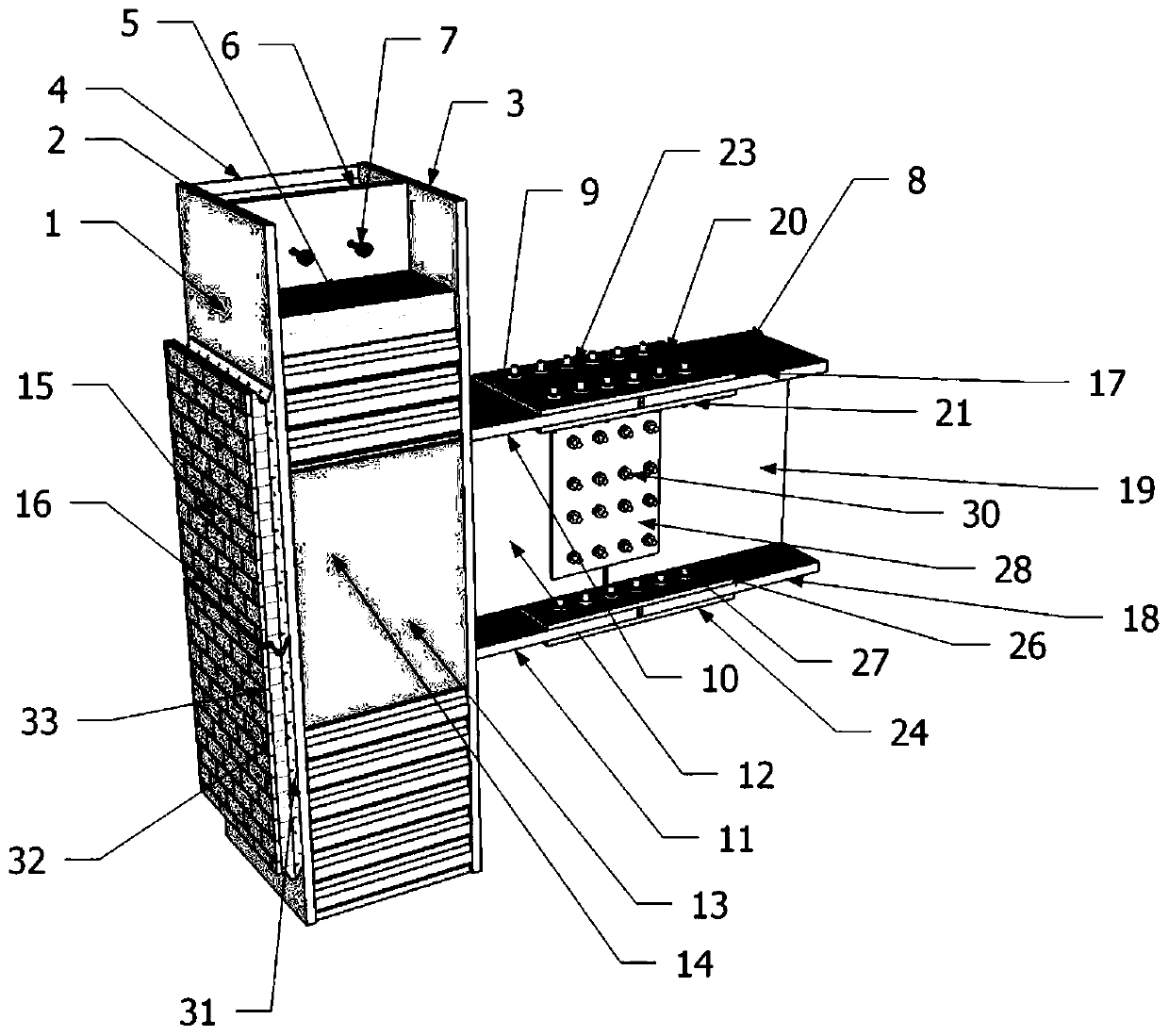

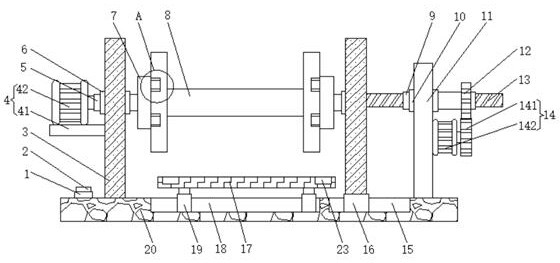

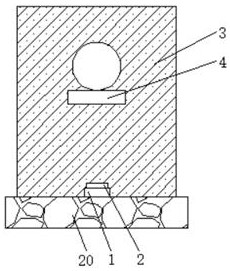

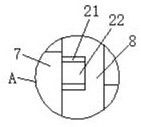

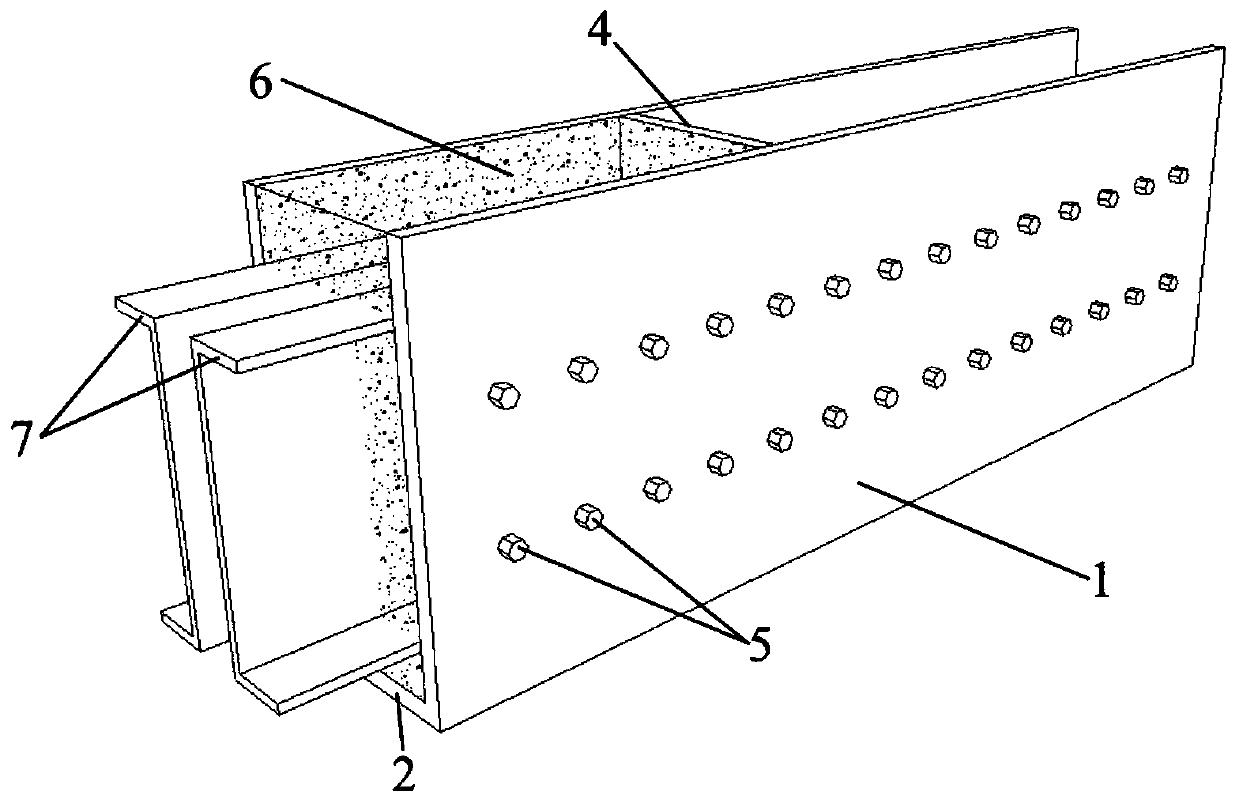

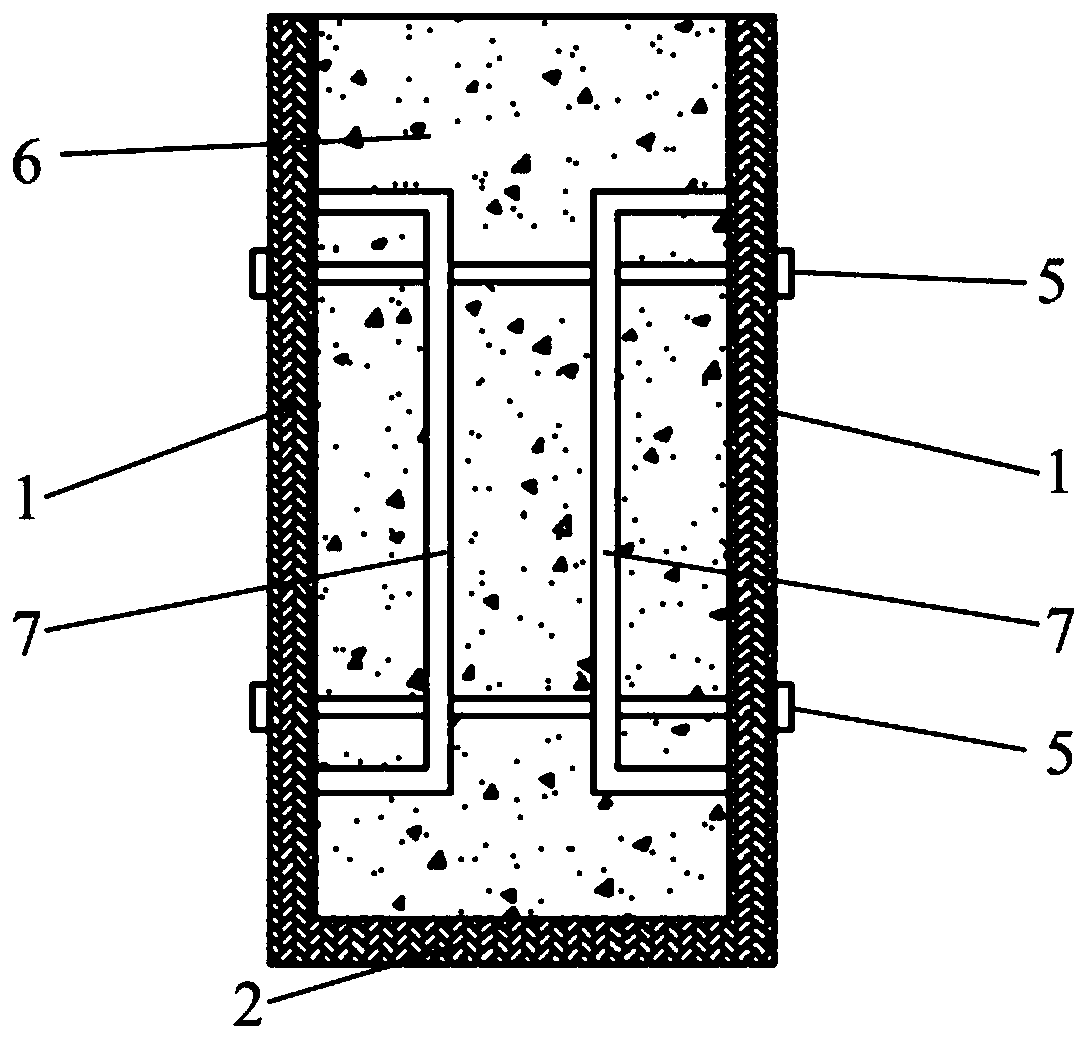

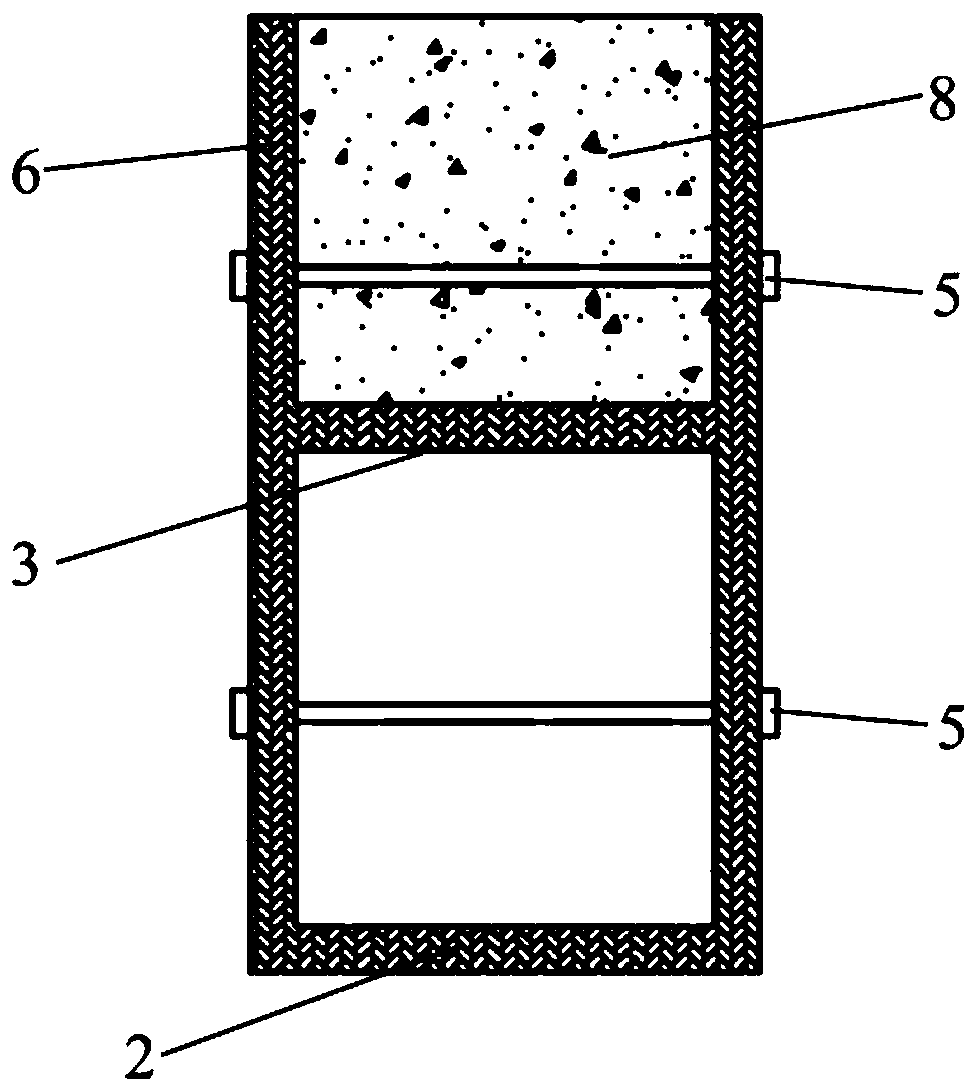

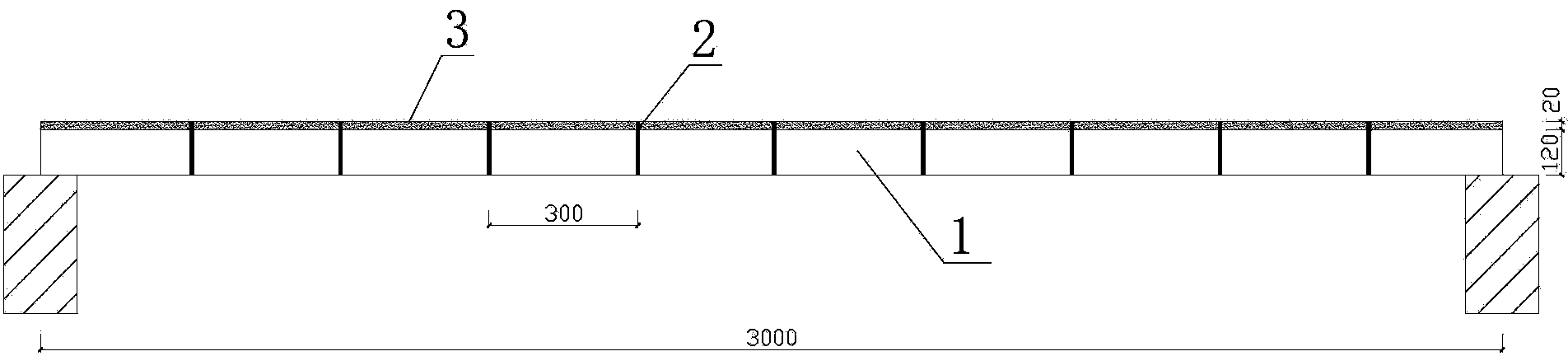

Steel bar truss stiffened steel concrete composite shear wall

InactiveCN104929281AImprove bearing capacityIncreased shear capacityWallsSheet steelReinforced concrete

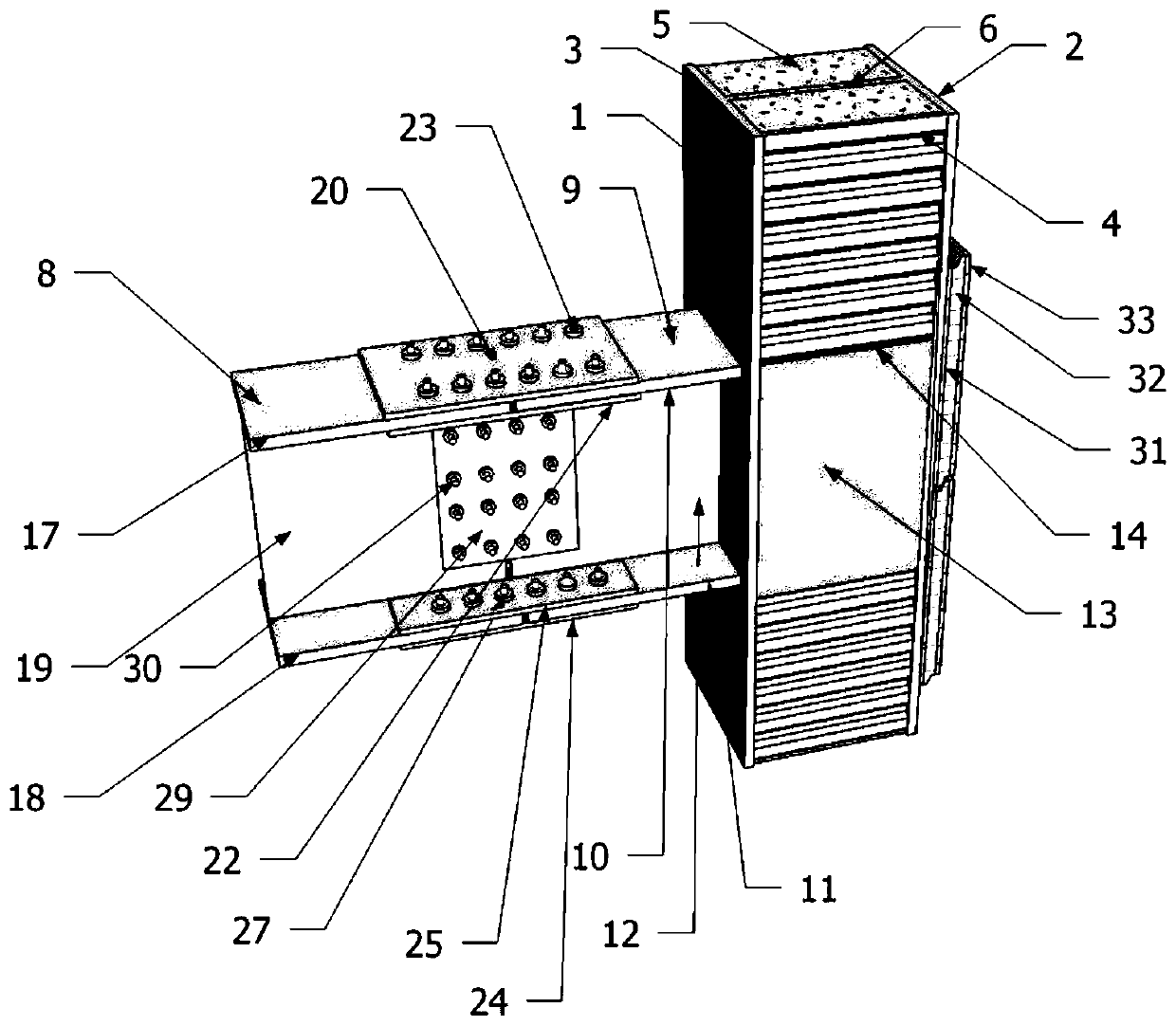

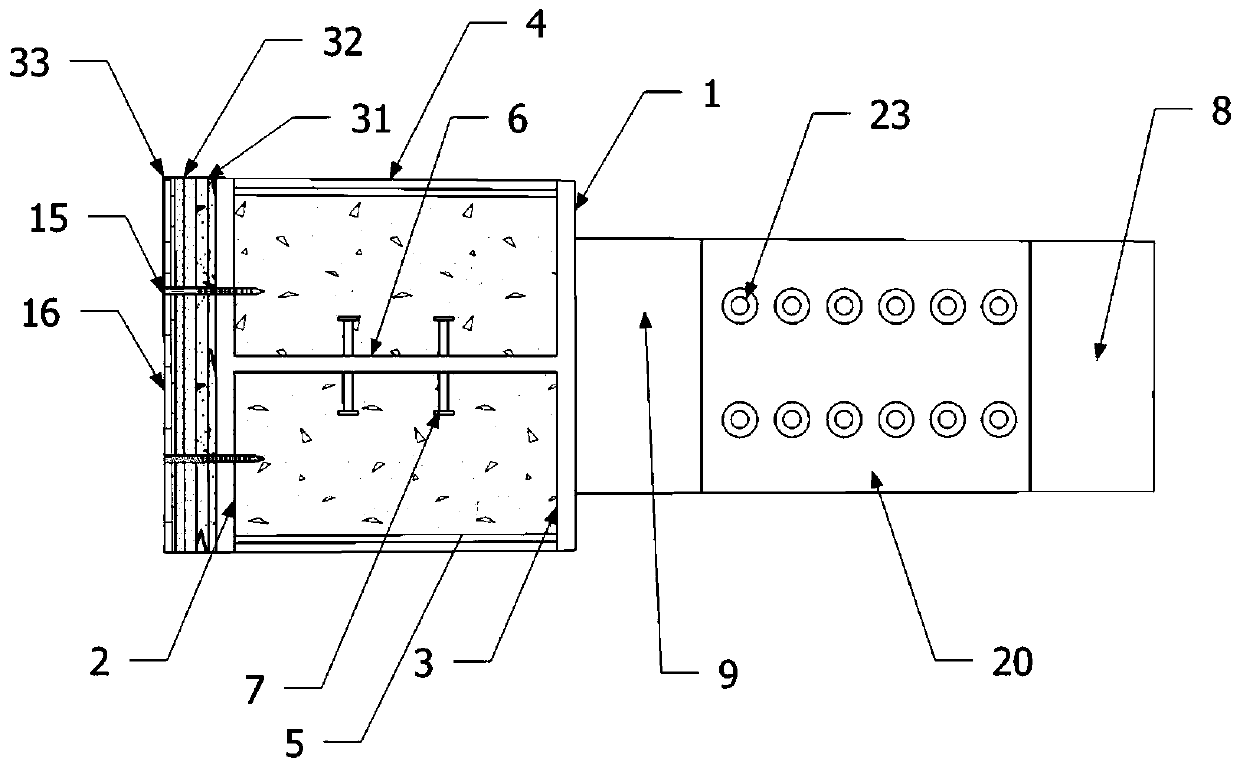

The invention discloses a steel bar truss stiffened steel concrete composite shear wall, relates to a shear wall and belongs to the field of building structures. The steel bar truss stiffened steel concrete composite shear wall aims to solve the problems that an existing steel concrete shear wall is poor in anti-seismic property, prone to crack and complex in construction when connected with steel members. The steel bar truss stiffened steel concrete composite shear wall comprises a second stiffening member, concrete, a first stiffened steel body and a plurality of shearing-resistant connecting keys. The first stiffened steel body comprises a first stiffening member, two steel plates, a plurality of transverse steel bars and a plurality of steel bar trusses. Each steel bar truss comprises two erection steel bars and three longitudinal steel bars, wherein the three longitudinal steel bars are arranged in a triangular shape, and the steel bar trusses are arranged in parallel between the two steel plates in the horizontal direction. The erection steel bars are connected to the steel plates. The transverse steel bars are horizontally arranged between the two steel plates, and the transverse steel bars are connected with the steel bar trusses. The first stiffening member and the second stiffening member are provided with the shearing-resistant connecting keys, and the concrete is poured on the first stiffening steel body and the second stiffening member.

Owner:HARBIN INST OF TECH

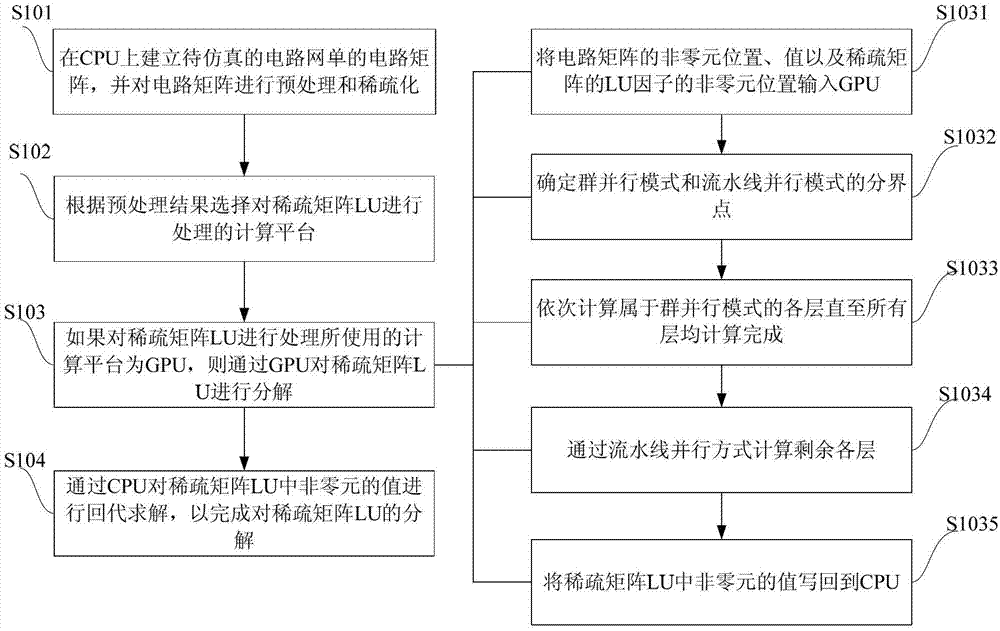

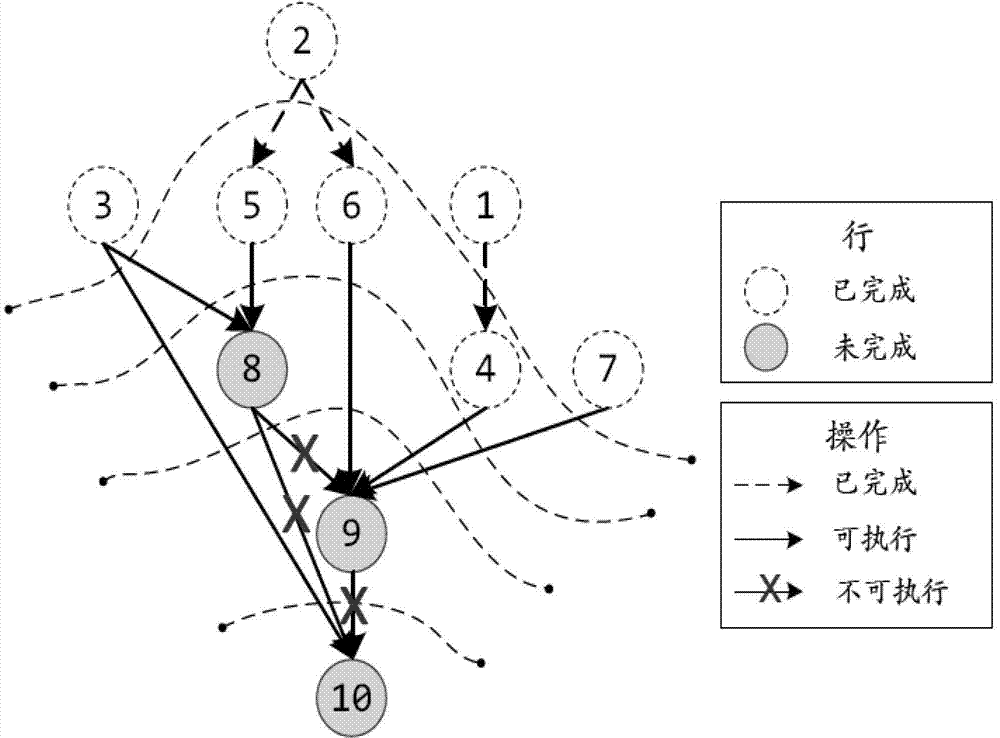

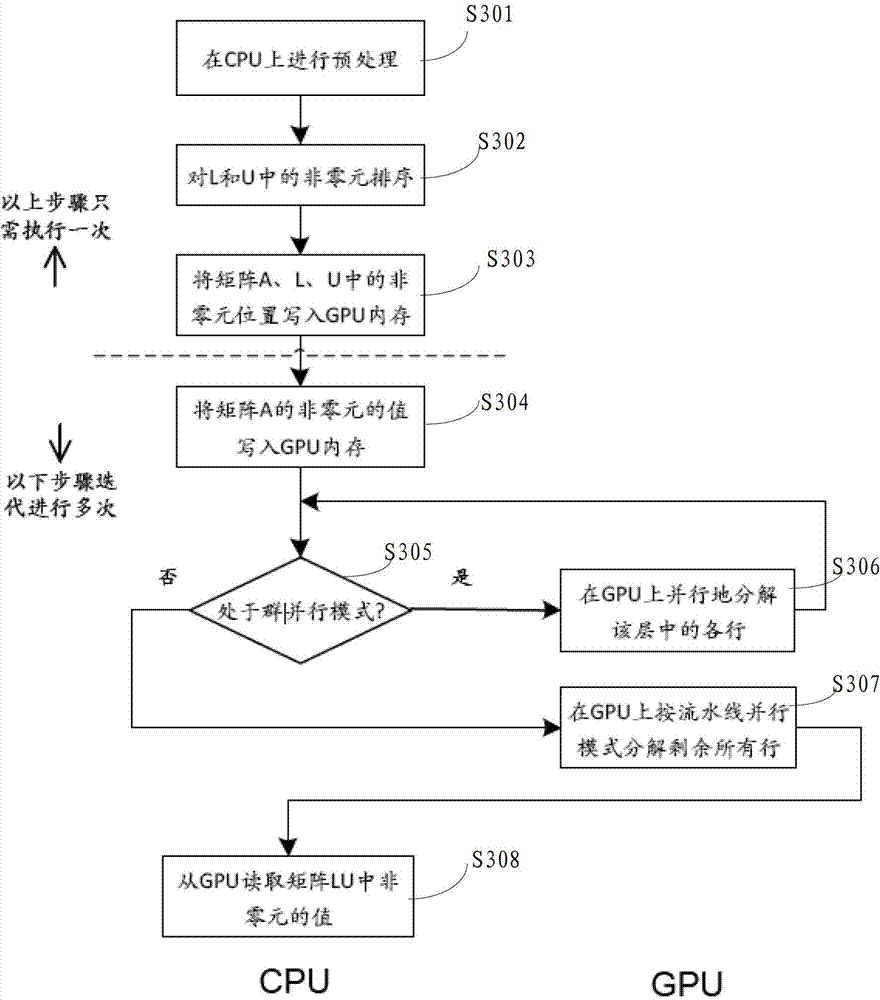

Sparse matrix LU decomposition method based on GPU

InactiveCN103399841AGuaranteed to work togetherReduced simulation timeComplex mathematical operationsAlgorithmDecomposition

The invention provides a sparse matrix LU decomposition method based on a GPU. The sparse matrix LU decomposition method includes the following steps: A, building a to-be-simulated circuit matrix of a circuit network on a CPU, and performing preprocessing and rarefaction on the circuit matrix; B, selecting a computing platform for processing a sparse matrix LU according to preprocessing results; C, performing decomposition on the sparse matrix LU through the GPU if the computing platform which is used is the GPU; D, performing back substitution solution on values of non-zero elements in the sparse matrix LU through the CPU so as to complete decomposition of the sparse matrix LU. According to the sparse matrix LU decomposition method, the computing platform can be selected automatically according to the number of floating-point operation times in decomposition, the task on the CPU and the task on the GPU can be distributed reasonably, coordinated operation of a plurality of threads on the GPU is guaranteed, and therefore the computing speed is improved and circuit simulation time is shortened.

Owner:TSINGHUA UNIV

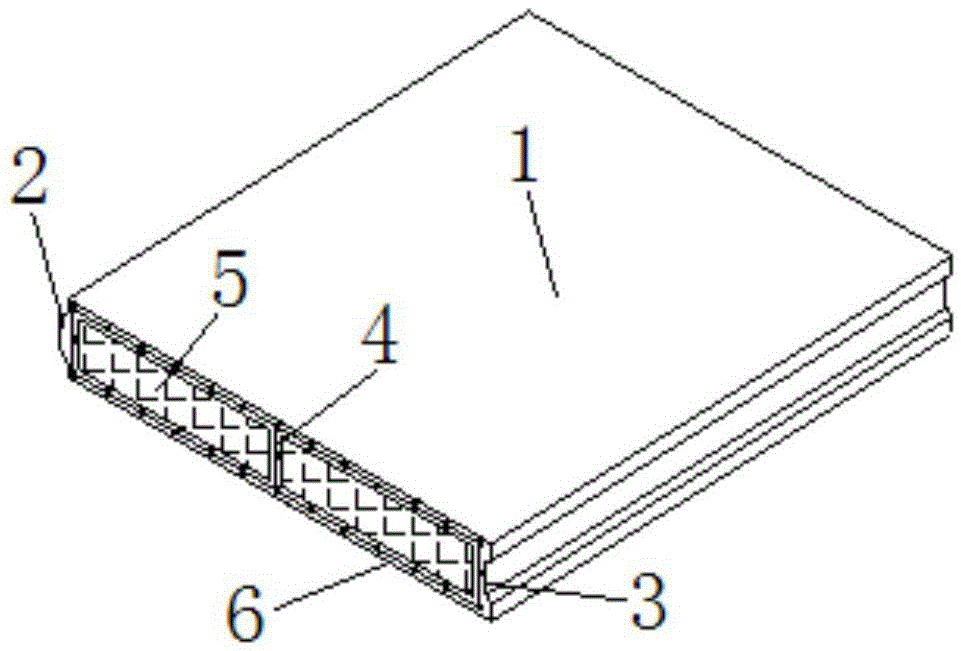

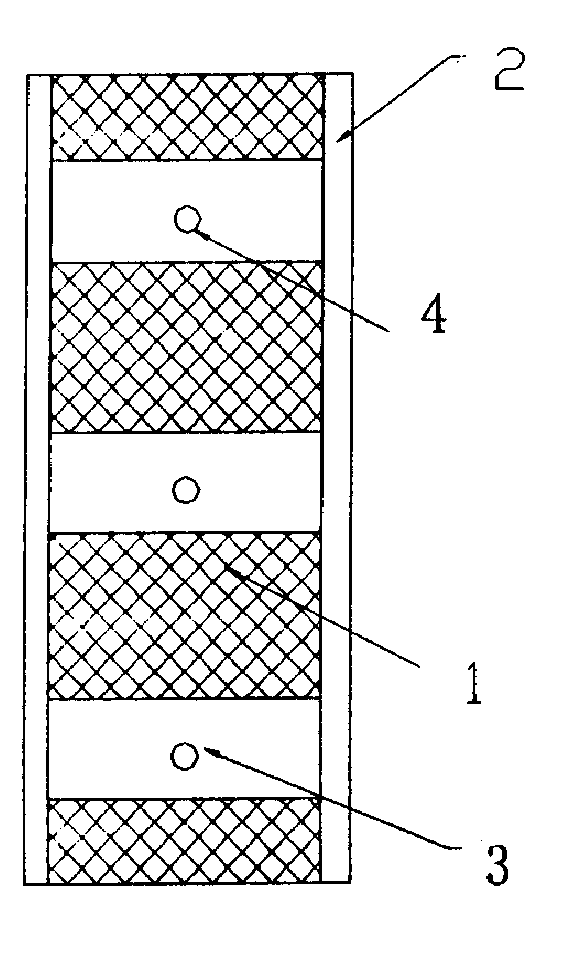

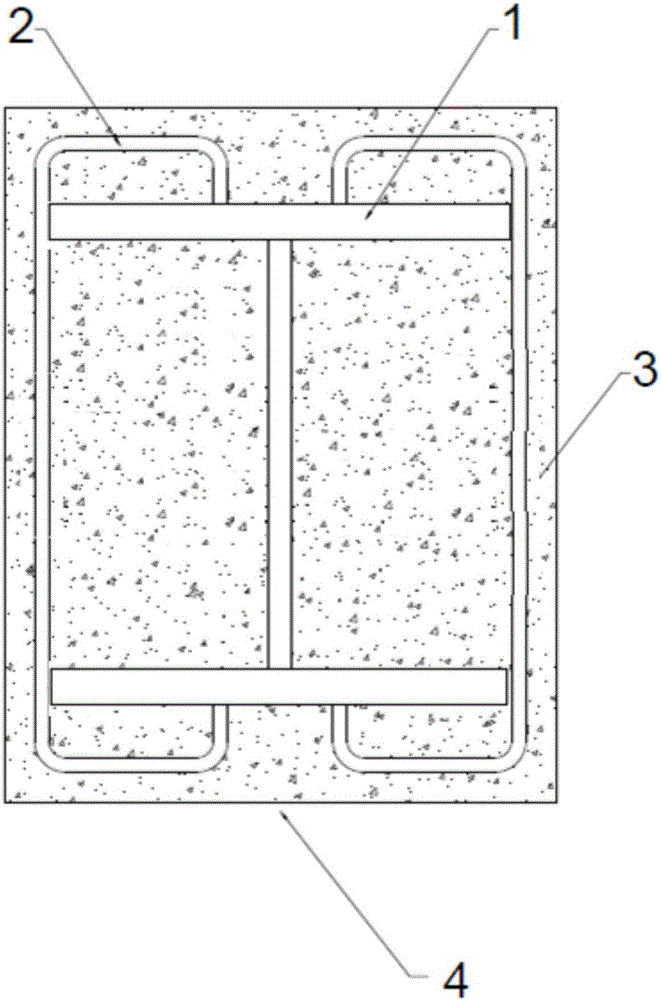

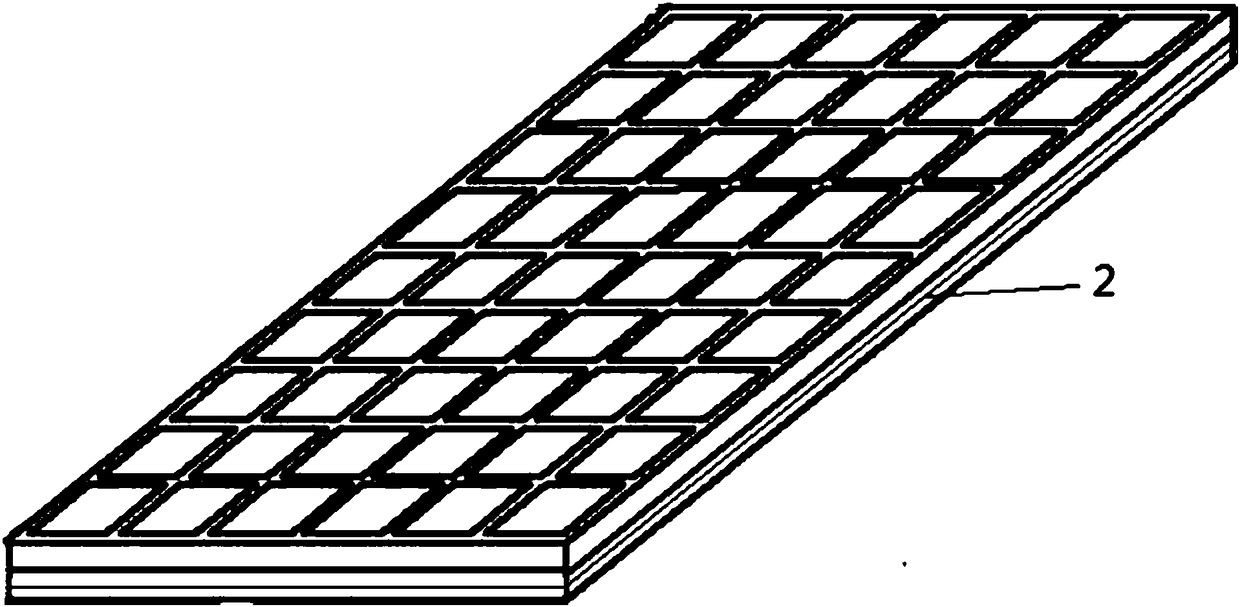

Composite heat-preserving wallboard

ActiveCN105421652AImprove carrying capacityImprove stabilityCeramic shaping apparatusBuilding componentsCrack resistanceEngineering

The invention discloses a composite heat-preserving wallboard which is composed of panels, rib plates, a core material and reinforcing materials. The panels comprise an upper panel and a lower panel. The rib plates comprise an outside rib plate A and an outside rib plate B. The panels and the rib plates form a cross section in a closed geometry form. The core material is placed into the cross section. The reinforcing materials are placed in the panels and the rib plates. The panels and the rib plates are made of concrete. A heat preserving core material is adopted as the core material. Meshed prestress long-fiber reinforcing grids are adopted as the reinforcing materials and compounded with the panels and the rib plates made of the concrete. According to the composite heat-preserving wallboard, as the meshed prestress long-fiber reinforcing grids are compounded, on the premise of hardly increasing the mass additionally, the panels and the rib plates are reinforced, it is ensured that the rib plates are effectively connected with the panels at the two sides, the fracture surface in the closed geometry form is formed, and crack resistance and ultimate bearing capacity of the composite heat-preserving wallboard are greatly improved.

Owner:NANTONG SUDONG NEW EXTERNAL WALL INSULATION BOARDCO

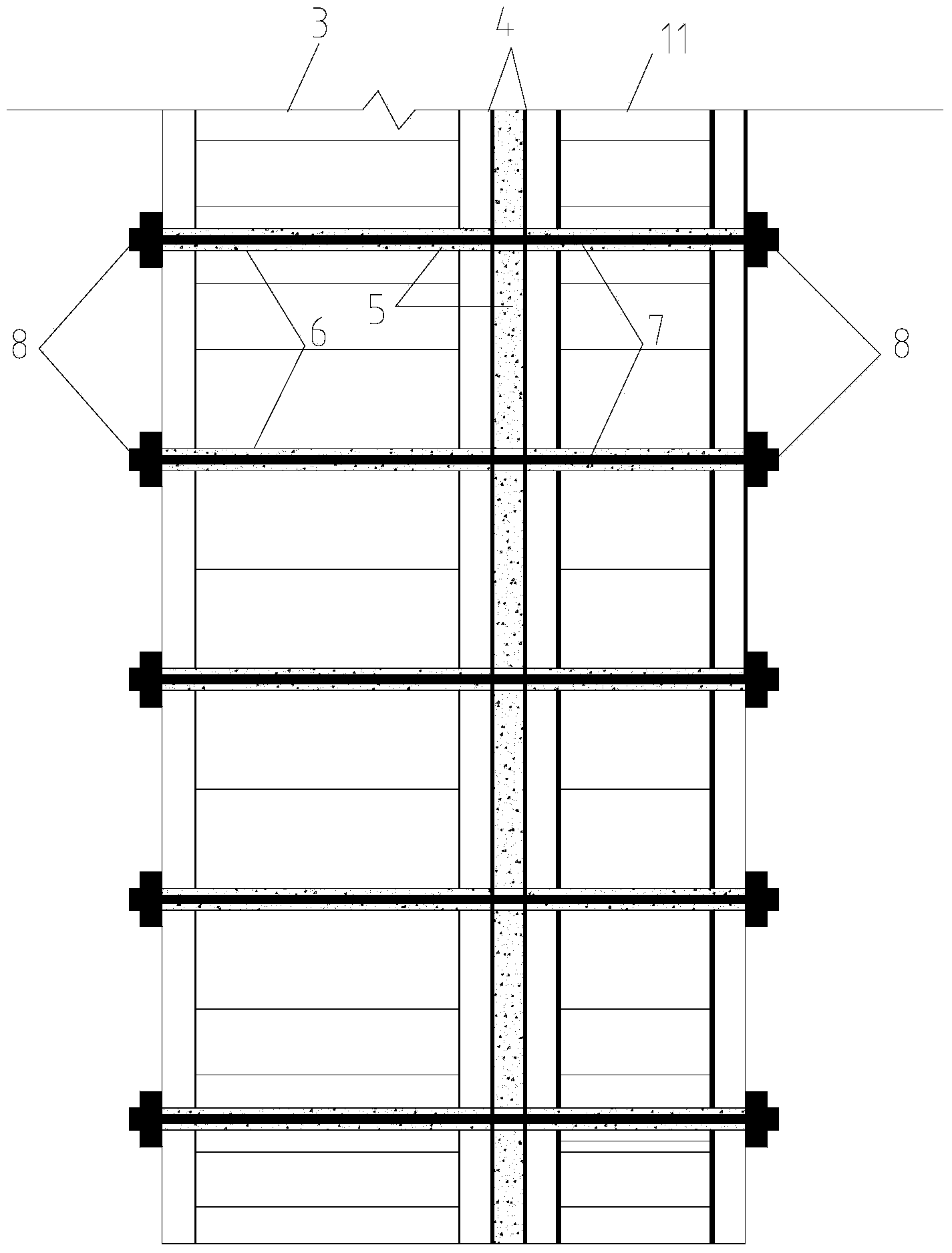

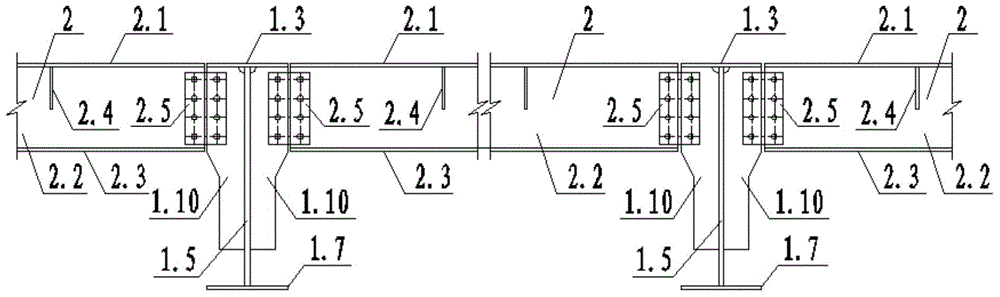

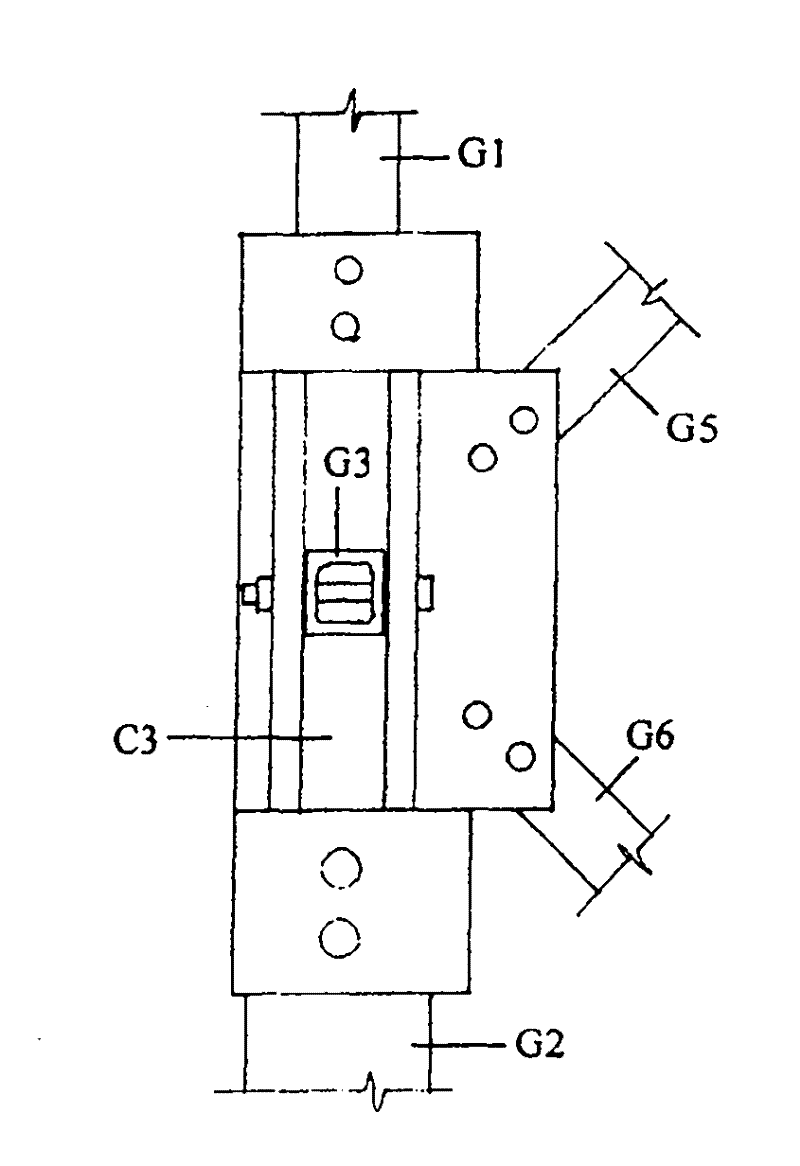

Method for using prefabricated reinforced concrete frame to reinforce existing structure through prestressing assembly

InactiveCN103711330AReduce assembly connection problemsTroubleshoot assembly connectionsBuilding repairsShock proofingReinforced concretePre stress

The invention discloses a method for using a prefabricated reinforced concrete frame to reinforce an existing structure through prestressing assembly, and belongs to the field of reinforced concrete structure aseismatic reinforcement in civil engineering. The method for using the prefabricated reinforced concrete frame to reinforce the existing structure through prestressing assembly comprises the steps that an existing reinforced concrete frame to be reinforced and the newly-added prefabricated reinforced concrete frame used for reinforcement are included, and the existing reinforced concrete frame to be reinforced and the newly-added prefabricated reinforced concrete frame used for reinforcement are connected into a whole in an assembly mode through unbonded prestressed reinforcing steel bars; after rebars on newly-added prefabricated frame beams, rebars on joints of newly-added prefabricated frame columns, rebars on connectors between upper-layer newly-added prefabricated frame columns and lower-layer newly-added prefabricated frame columns are bound, concreting is carried out on the rebars to form a whole; gaps are reserved between the newly-added prefabricated reinforced concrete frame and the existing reinforced concrete frame, and are sealed by mortar; channels are reserved in the newly-added prefabricated frame beams and the newly-added prefabricated frame columns, and channels are formed in existing frame beams and existing frame columns, and correspond to the channels of the newly-added prefabricated reinforced concrete frame in position; the unbonded prestressed reinforcing steel bars penetrate through the channels, are tensioned, and are anchored through anchoring tools. The seismic capacity of the structure reinforced through the method is improved by 1-2 times.

Owner:BEIJING UNIV OF TECH

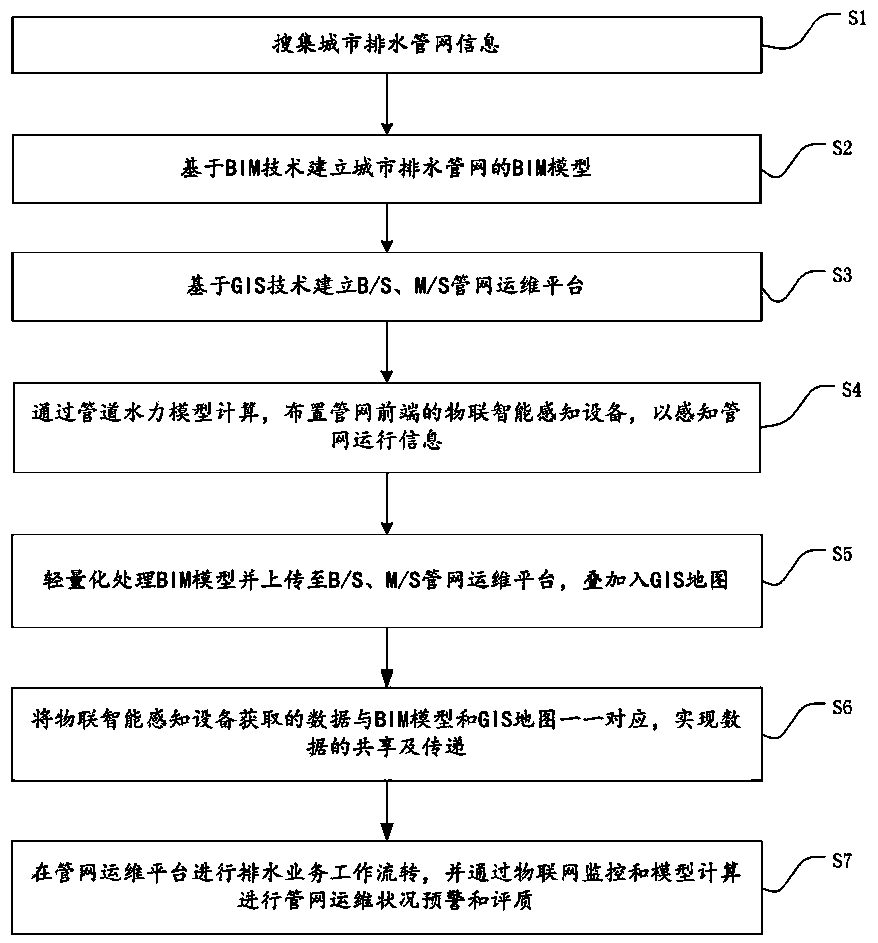

Urban drainage pipe network operation and maintenance method based on pipe network construction model and Internet of Things

PendingCN111046514AImprove management efficiencyImprove maintenance efficiencyGeometric CADData processing applicationsComputer networkThe Internet

The invention discloses an urban drainage pipe network operation and maintenance method based on a pipe network construction model and the Internet of Things. The method comprises the following stepsof: collecting urban drainage pipe network information; establishing the BIM model of the urban drainage network based on a BIM technology; establishing a B / S, M / S pipe network operation and maintenance platform based on a GIS technology; arranging the internet-of-Things intelligent sensing equipment at the front end of the pipe network through calculation of a pipeline hydraulic model so as to sense pipe network operation information; carrying out lightweight processing on the BIM model, uploading the BIM model to the B / S, M / S pipe network operation and maintenance platform, and superposing the BIM model into a GIS map; enabling the data obtained by the Internet-of-Things intelligent sensing equipment to be in one-to-one correspondence with the BIM model and the GIS map, and achieving thesharing and transmission of the data; performing drainage service workflow on a pipe network operation and maintenance platform, and performing pipe network operation and maintenance condition earlywarning and quality evaluation through Internet of Things monitoring and model calculation. The urban drainage pipe network operation and maintenance method based on the pipe network construction model and the Internet of Things is reasonable in arrangement, and refinement and scientization of drainage pipe network operation management and maintenance are achieved.

Owner:HUAJIANG CONSTR OF CHINA CONSTR FIRST BUILDING GROUP CORP +2

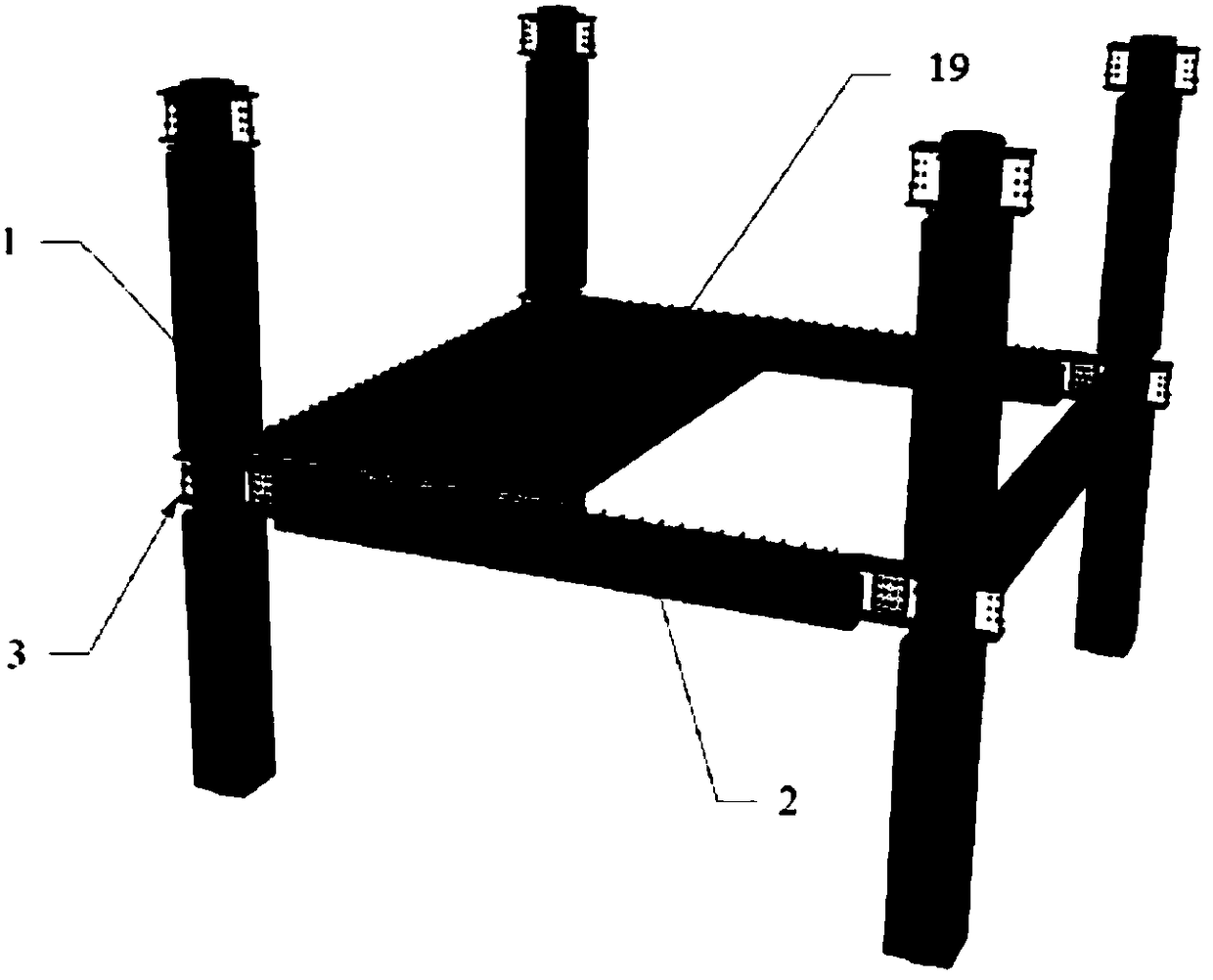

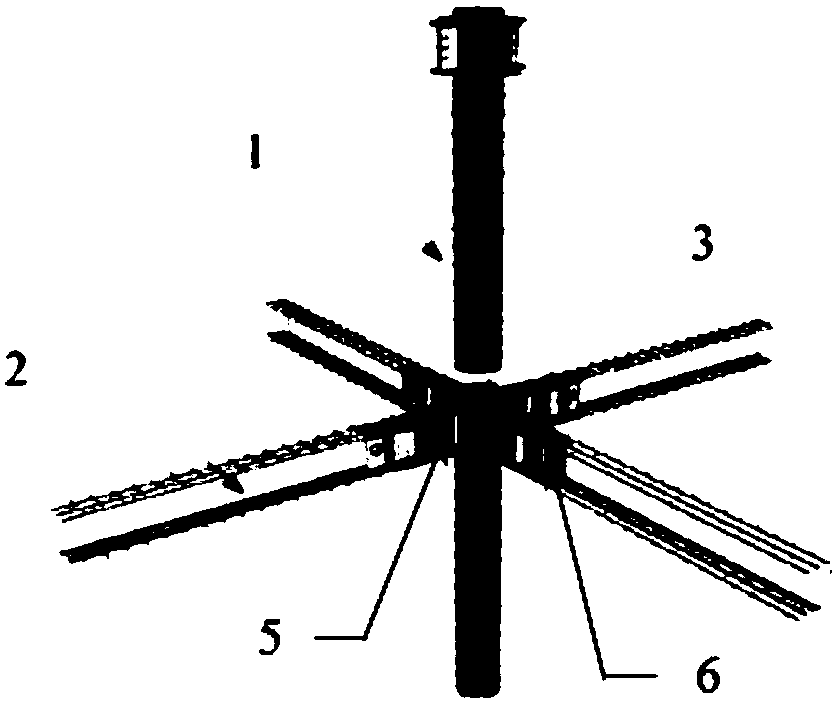

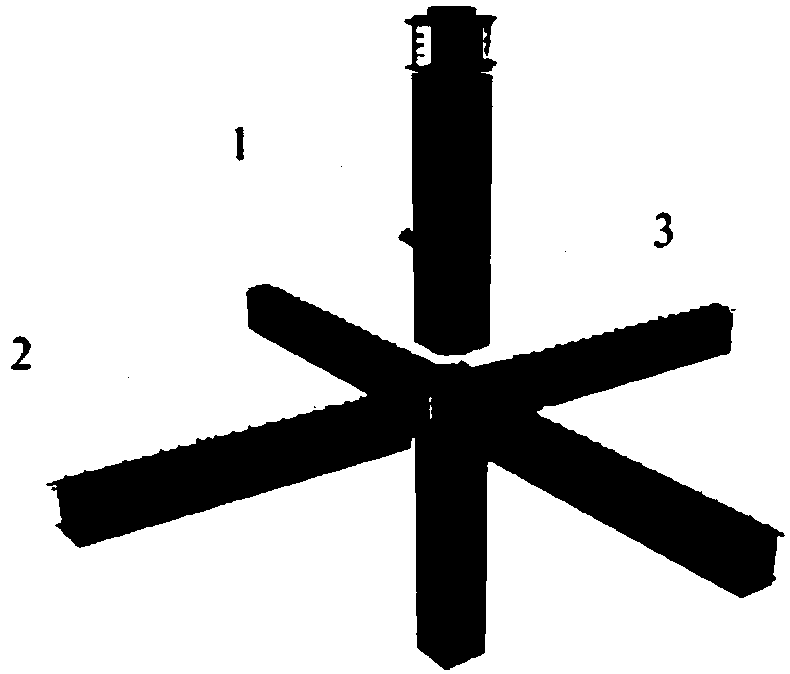

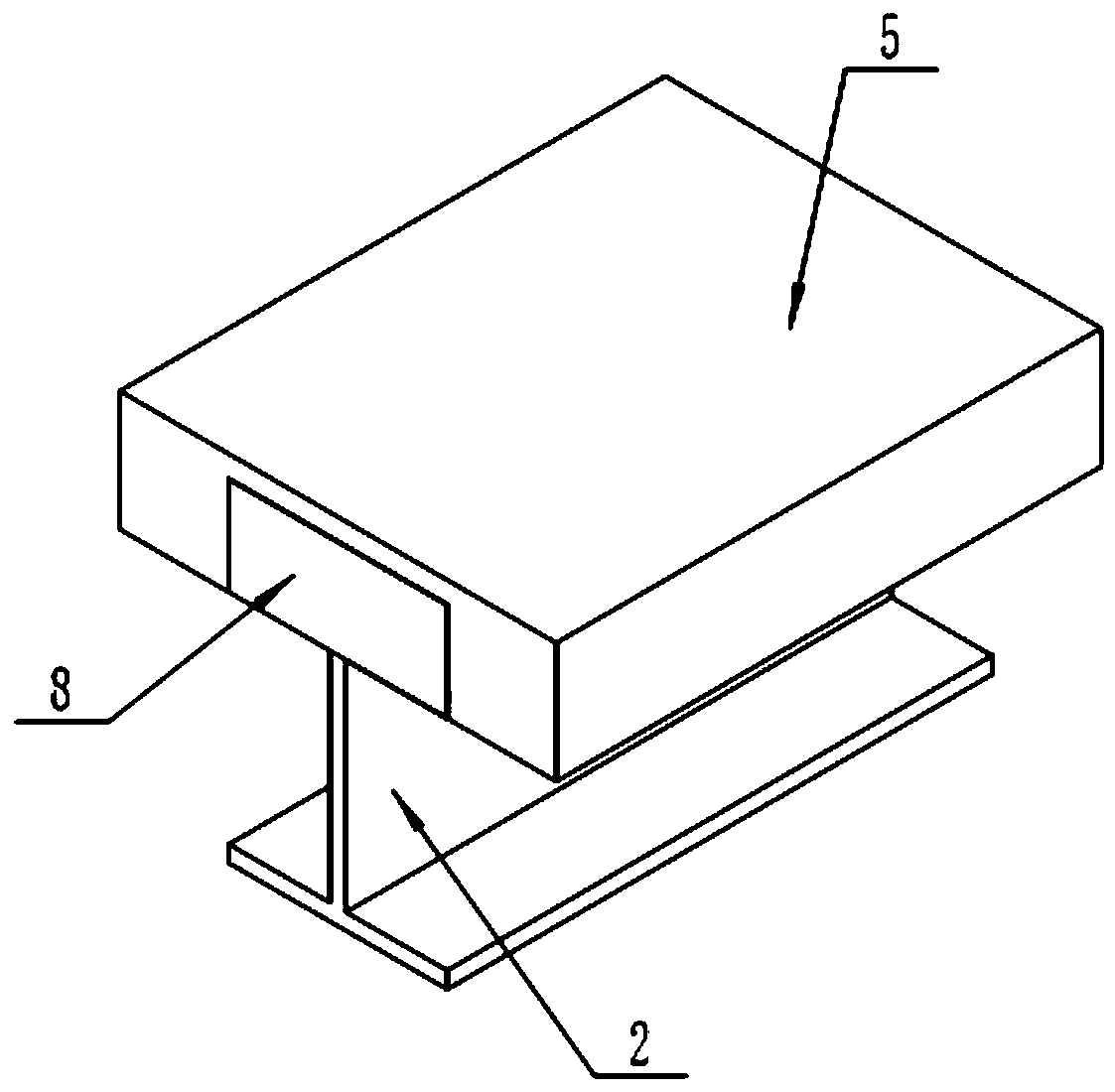

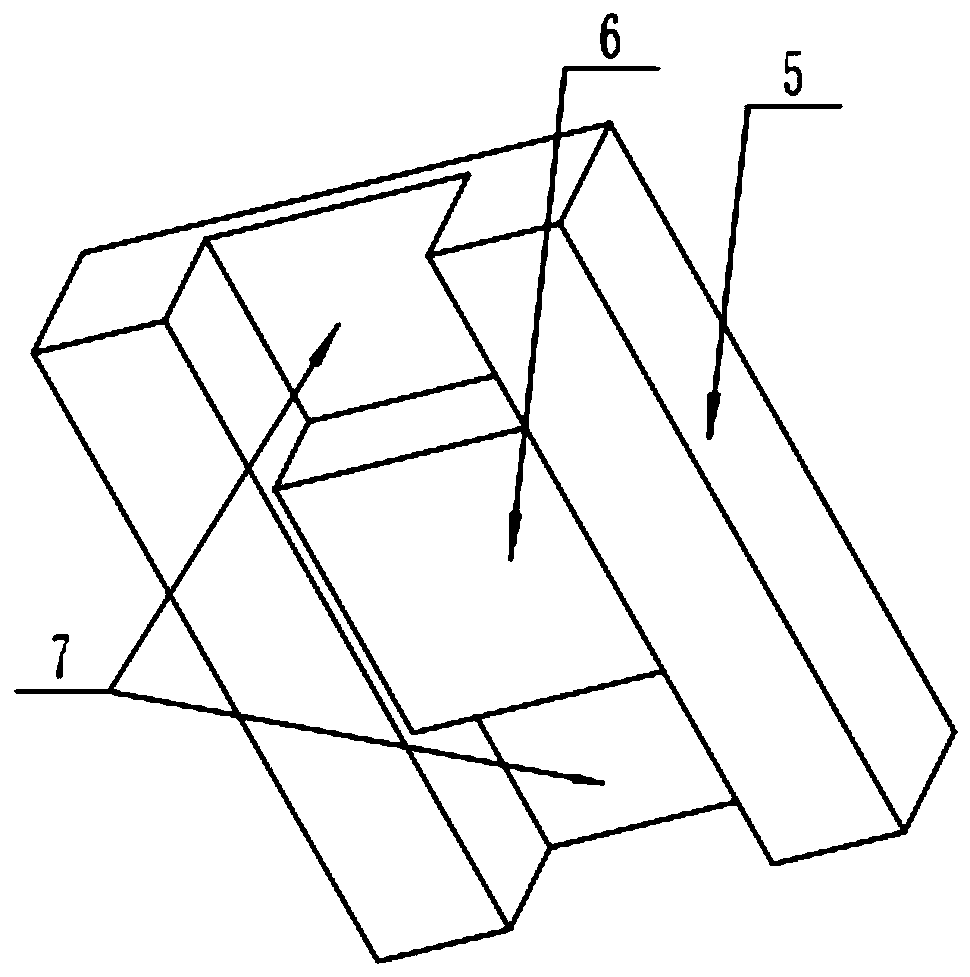

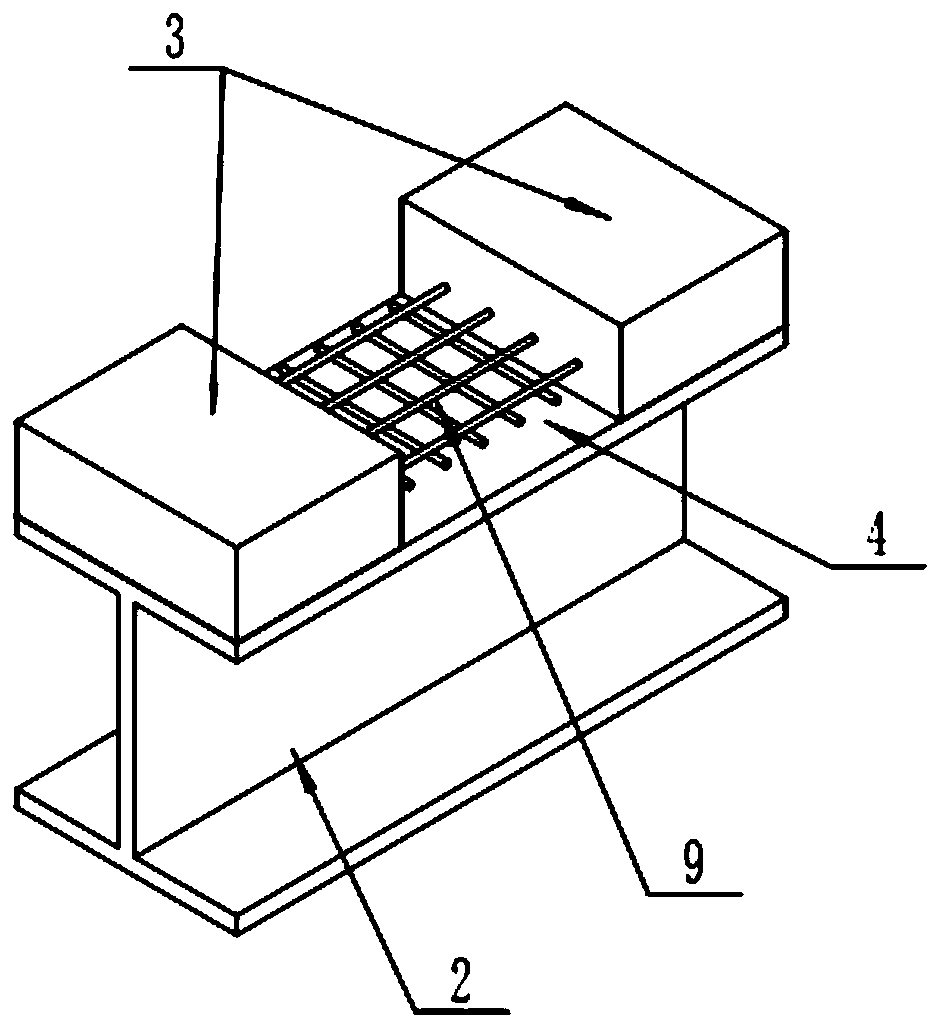

Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

PendingCN108457422AReduce shipping weightSave on rental costsLoad-supporting elementsFloor slabSurface layer

The invention discloses a prefabricated pre-stressed beam member, a fabricated combined frame structure and an installation method of the fabricated combined frame structure. The fabricated combined frame structure comprises prefabricated column members with hollow steel pipes inside, prefabricated pre-stressed beam members, cast-in-place concrete inside the prefabricated column hollow steel pipes, a laminated floor slab prefabricated base plate and laminated surface layer concrete. The middle sections of the hollow steel pipes of the prefabricated column members are covered with concrete, anda beam-column joint zone provided with short H-shaped steel beams is arranged at both ends of each middle section. The prefabricated pre-stressed beam member comprises a concrete laminated pre-stressed beam and interposed H-shaped steel beams at both ends of the pre-stressed beam. The short H-shaped steel beams in the beam-column joint zone and the interposed H-shaped steel beams of the prefabricated pre-stressed beam member are combined by bolt welding or connected by bolting. Joints of the hollow steel pipes of the upper and lower sections of the prefabricated column members are connected by welding. The fabricated combined frame structure integrates the advantages of a steel structure and a prefabricated concrete structure, and has high installation efficiency and good safety, and manpower and material resources are greatly saved.

Owner:SOUTHEAST UNIV +2

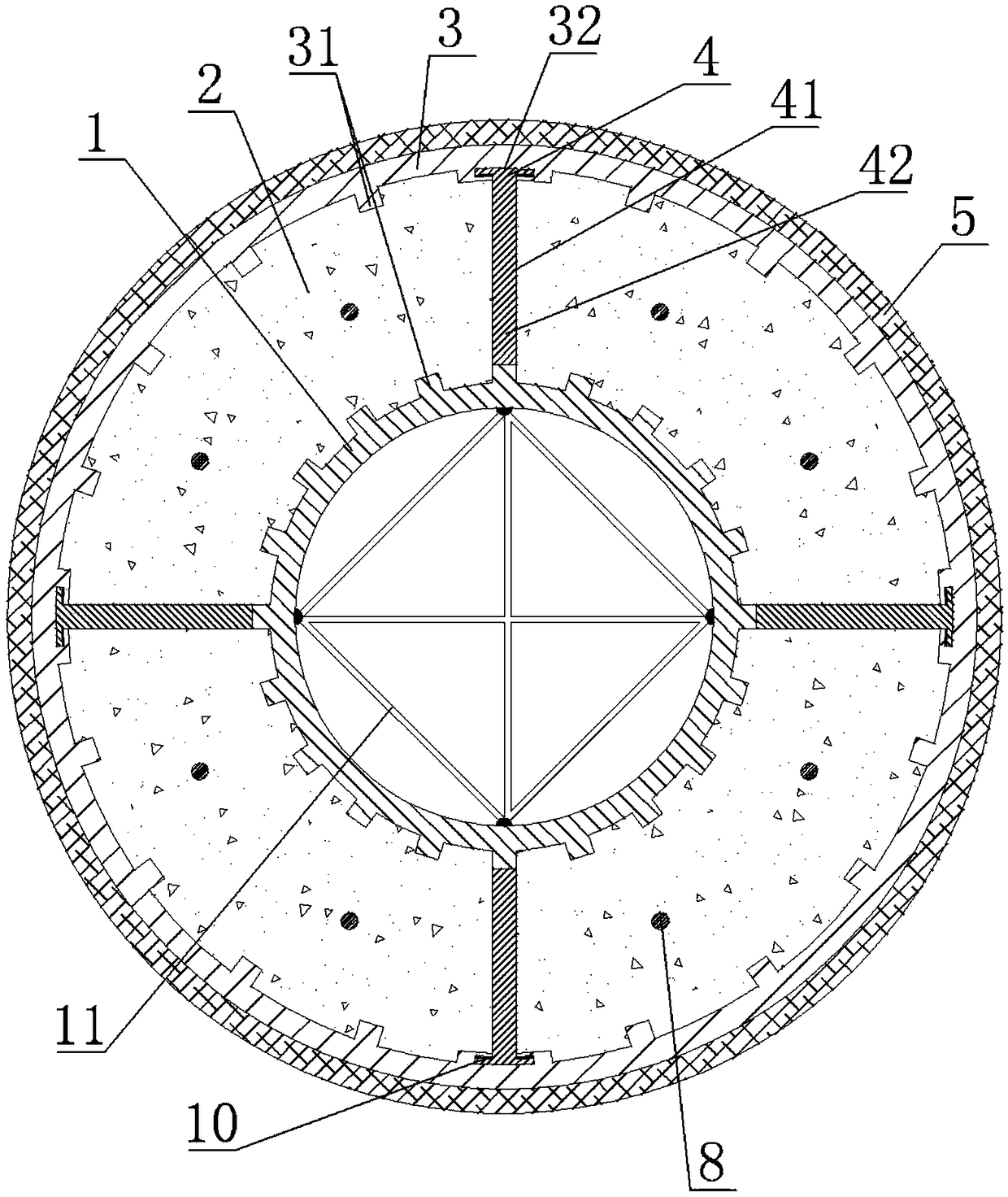

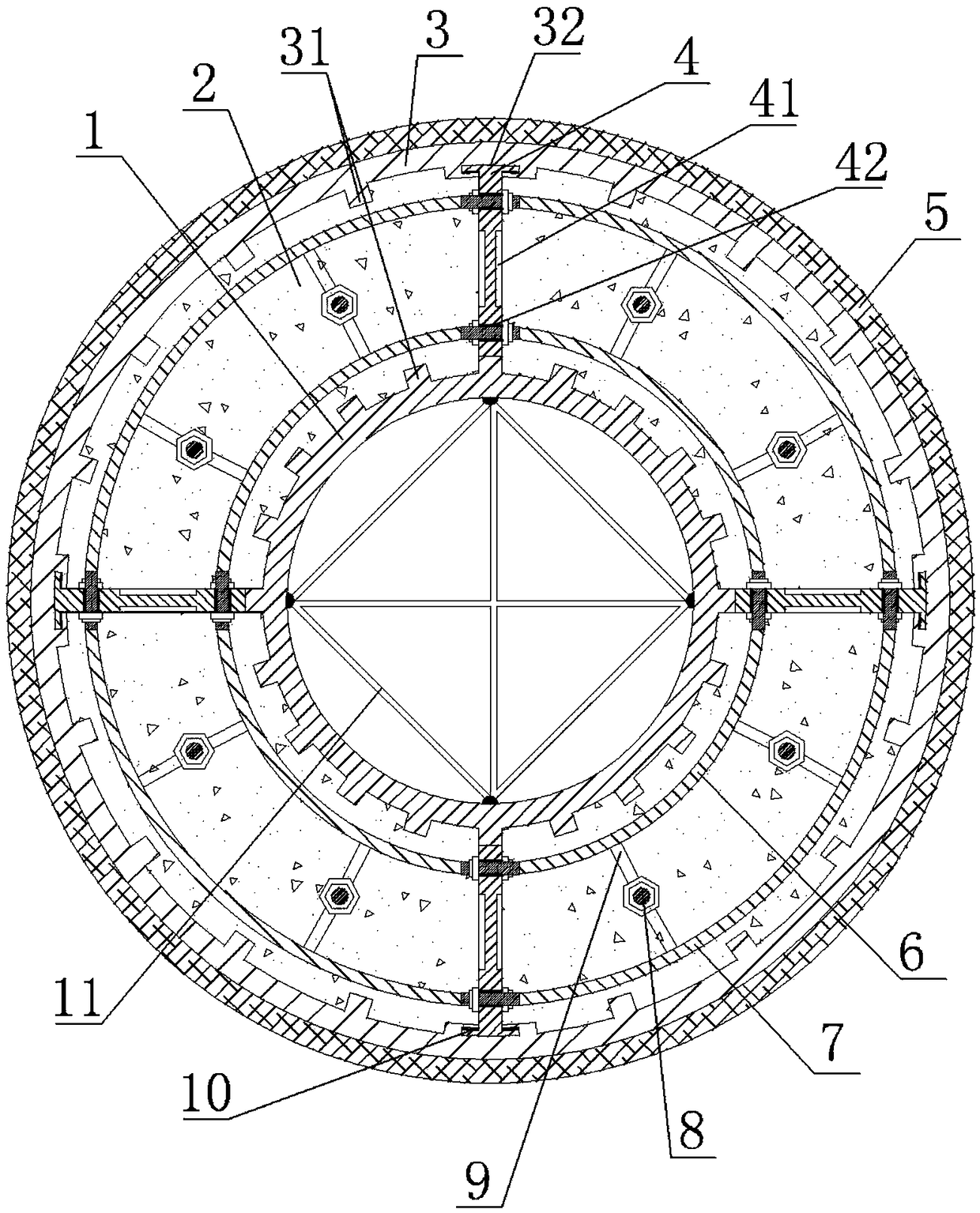

Hollow-sandwich multi-cavity steel pipe concrete member and preparation method thereof

PendingCN109403205ASolve the rustLow maintenanceStrutsBridge structural detailsClamp connectionStressed state

The invention discloses a hollow-sandwich multi-cavity steel pipe concrete member and a preparation method thereof. The hollow-sandwich multi-cavity steel pipe concrete member comprises an internal steel pipe and an external steel pipe which are concentrically placed; a space between the internal steel pipe and the external steel pipe is filled with concrete; a plurality of transverse diaphragms are uniformly distributed on the external wall of the internal steel pipe around the axis of the internal steel pipe; each transverse diaphragm is placed along the full length of the internal steel pipe in the axial direction; the external end part of each transverse diaphragm is in clamping connection with a groove formed in the internal wall of the external steel pipe; convex teeth are arranged on the internal wall of the external steel pipe and the external wall of the internal steel pipe; a plurality of shear grooves are uniformly formed in the side surfaces of the transverse diaphragms inthe axial direction; a plurality of external cylinders made of carbon fiber composite materials are bonded outside the external steel pipe in the annular direction; and the external cylinders are notconnected with the end part of the external steel pipe. According to the hollow-sandwich multi-cavity steel pipe concrete member, the corrosion resistance is high, less separation phenomena between the steel pipe walls and the concrete are less, the steel pipes are unlikely to generate local buckling, and the stressed states of the concrete in three directions are uniform.

Owner:CENT SOUTH UNIV

Technology for making pressure bearing member of reinforced concrete

InactiveCN1343825AImprove mechanical propertiesImprove bearing capacityBuilding repairsReinforced concreteHigh load

A method for reinforcing the pressure-bearing concrete member features that the fibre-reinforced plastics (FRP) is used to wrap the said concrete member and the shaped steel pressing on the FRP is fixed to it via fasteners. Its advantages include greatly improved mechanical performance, high load-bearing power and deformation resistance.

Owner:WUHAN UNIV

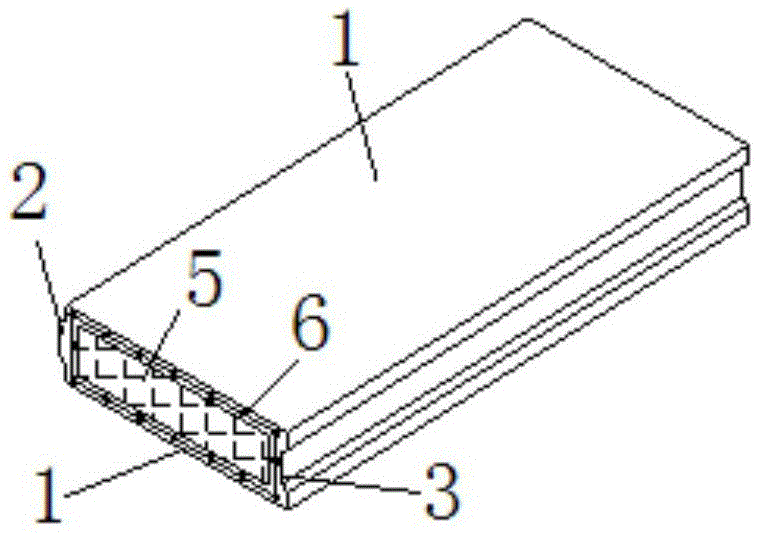

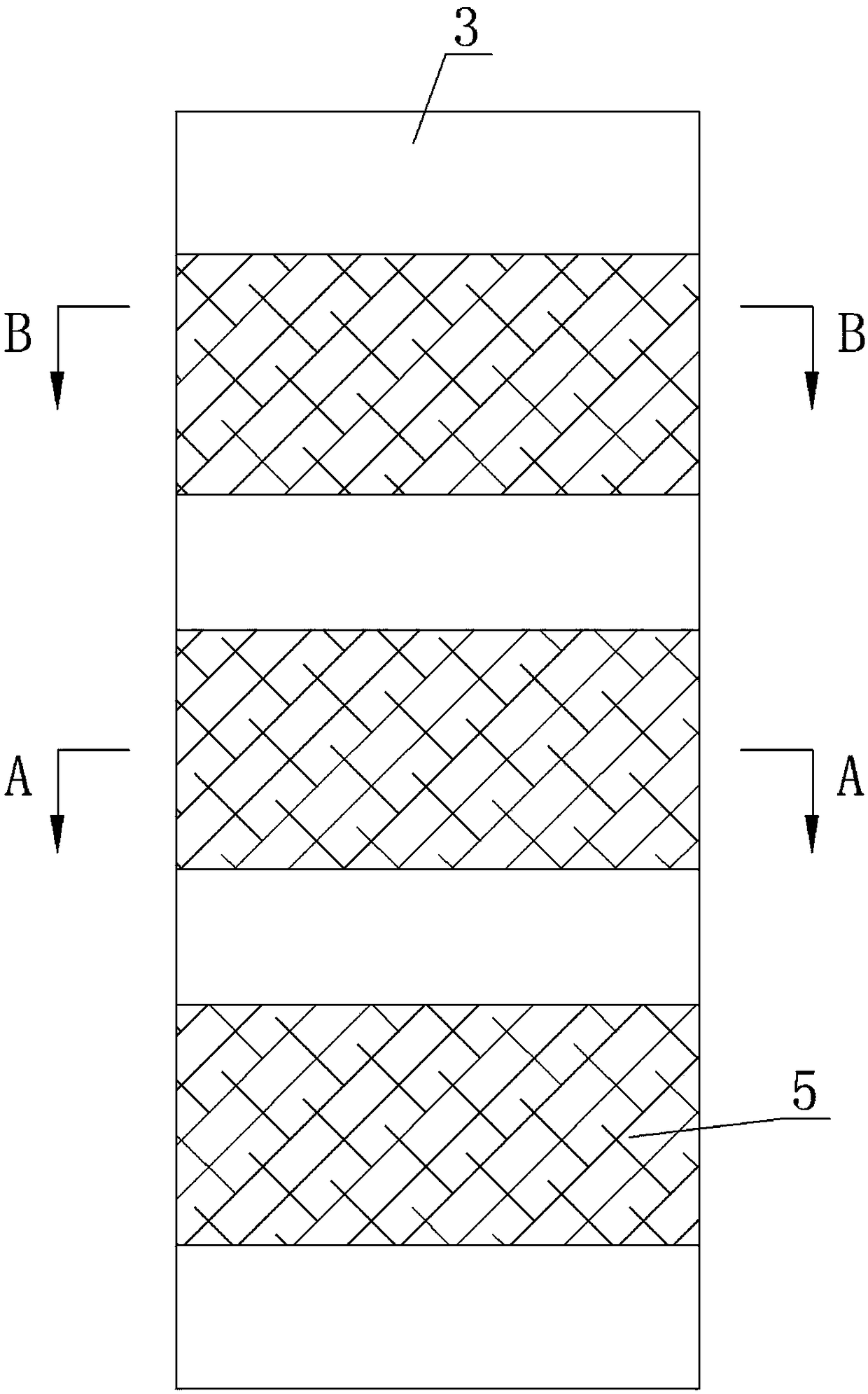

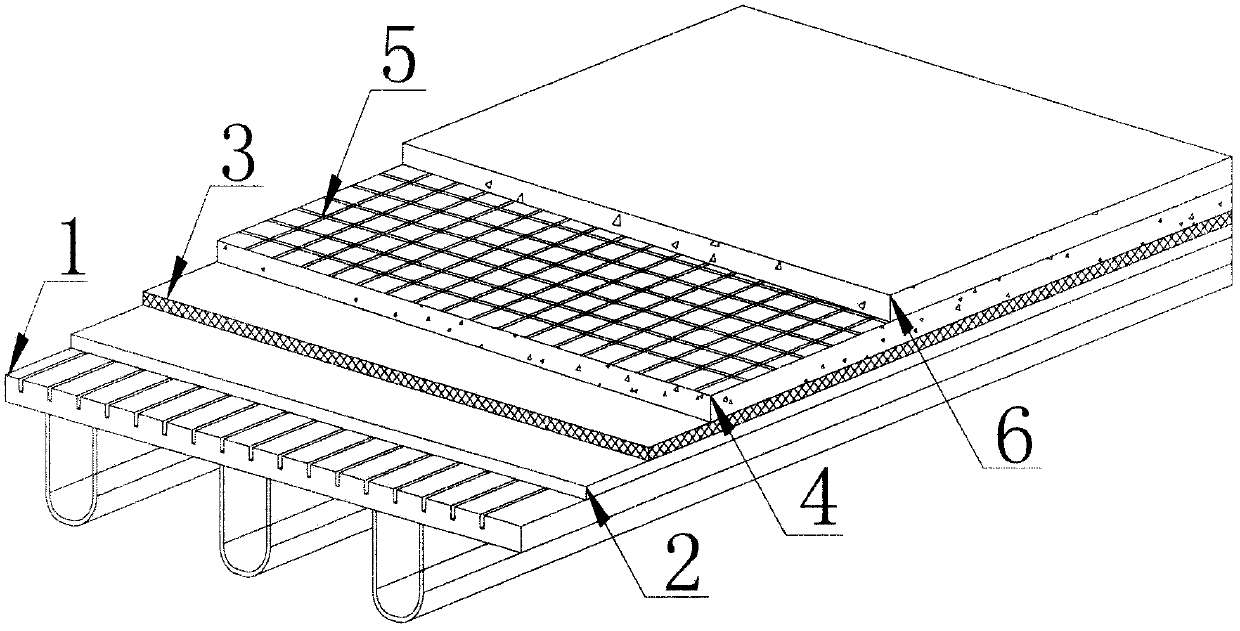

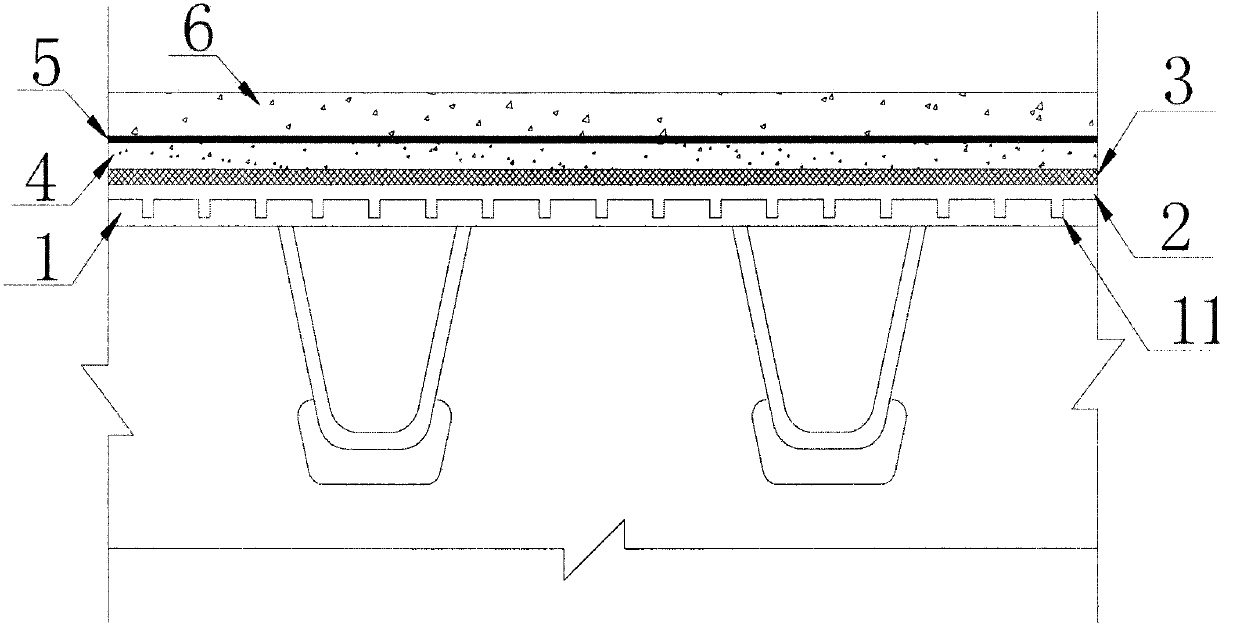

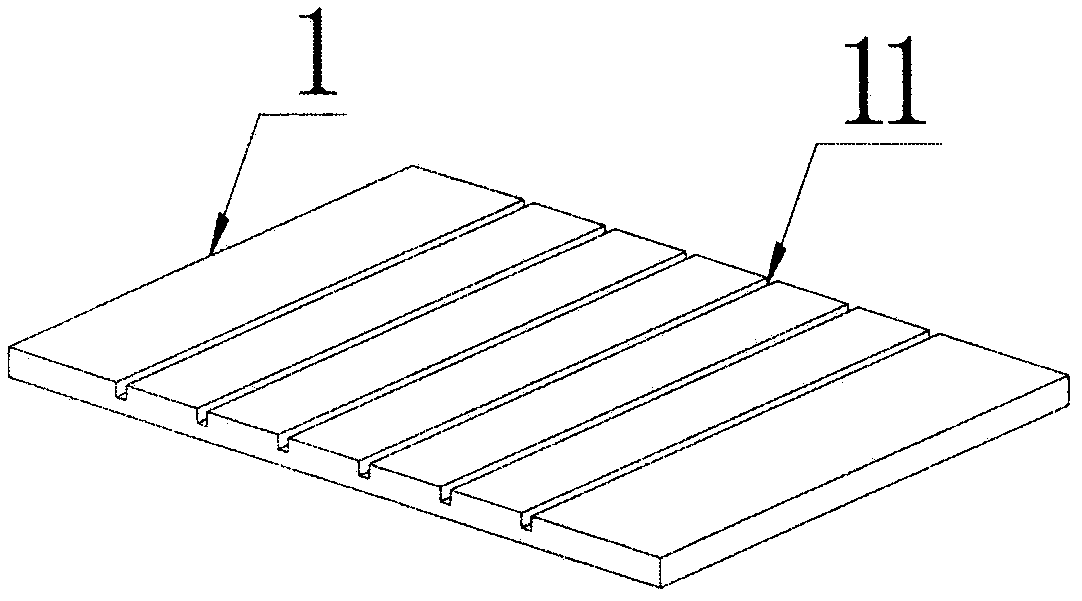

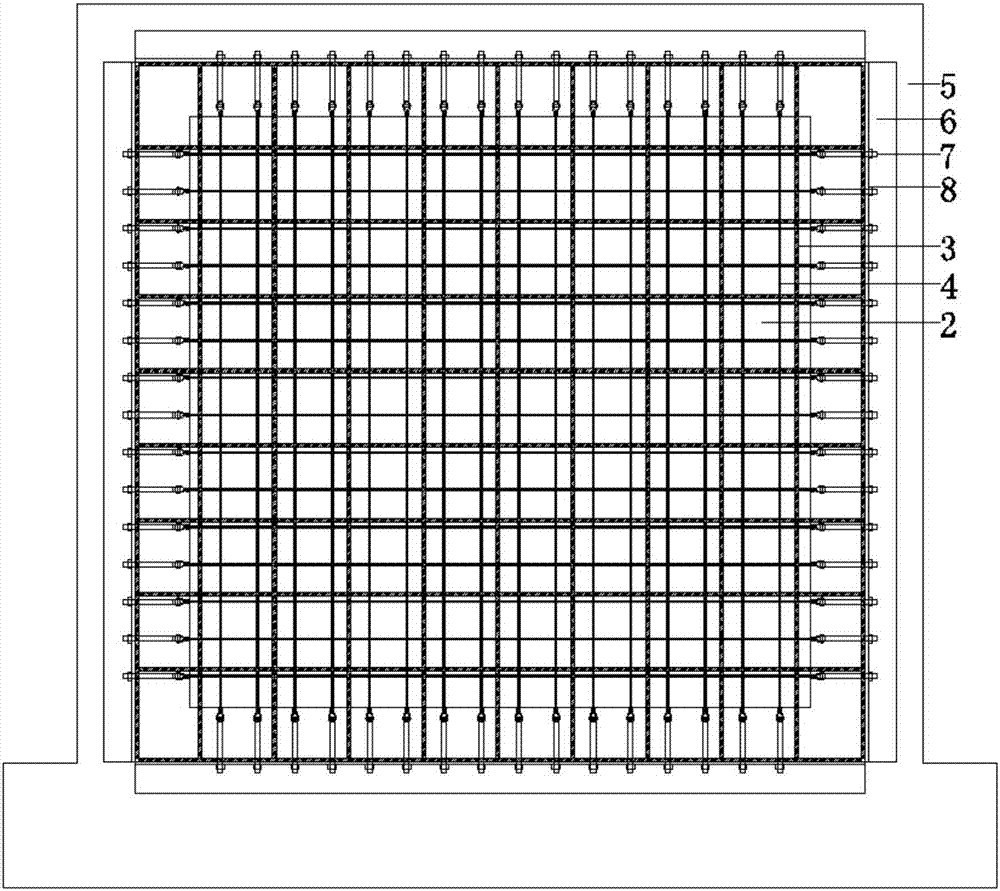

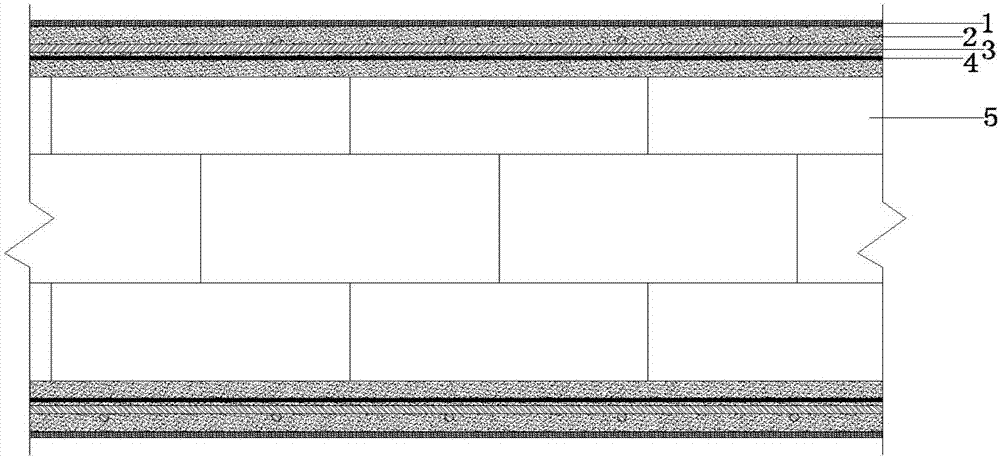

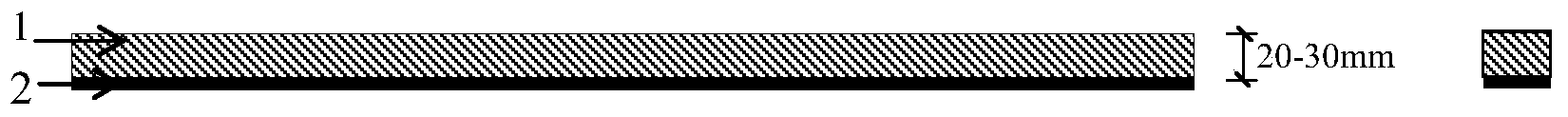

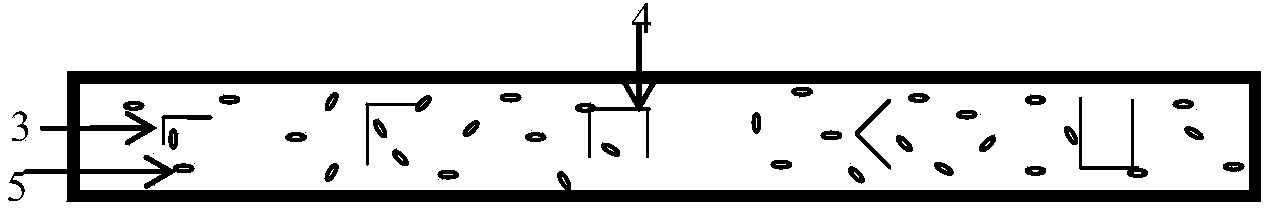

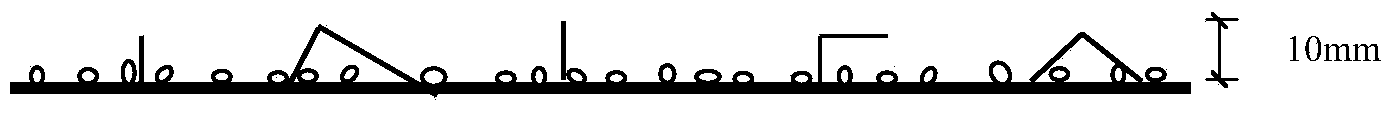

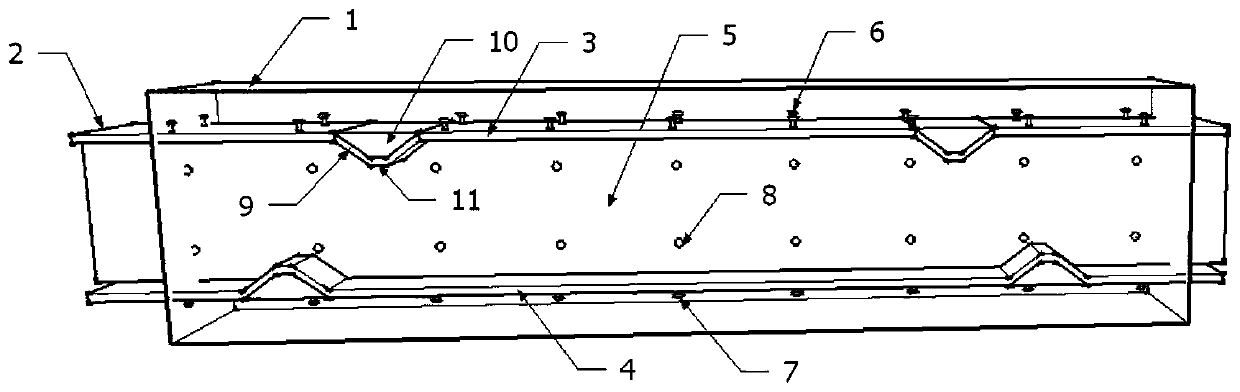

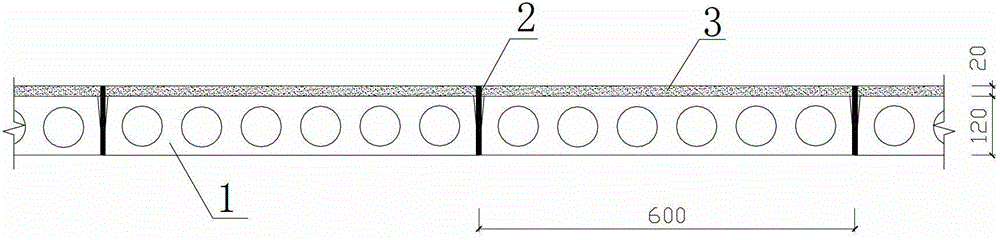

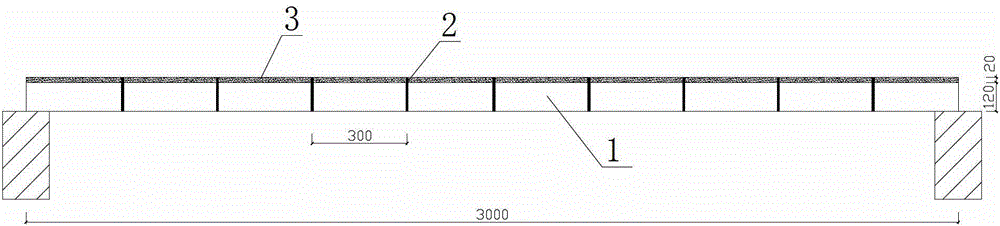

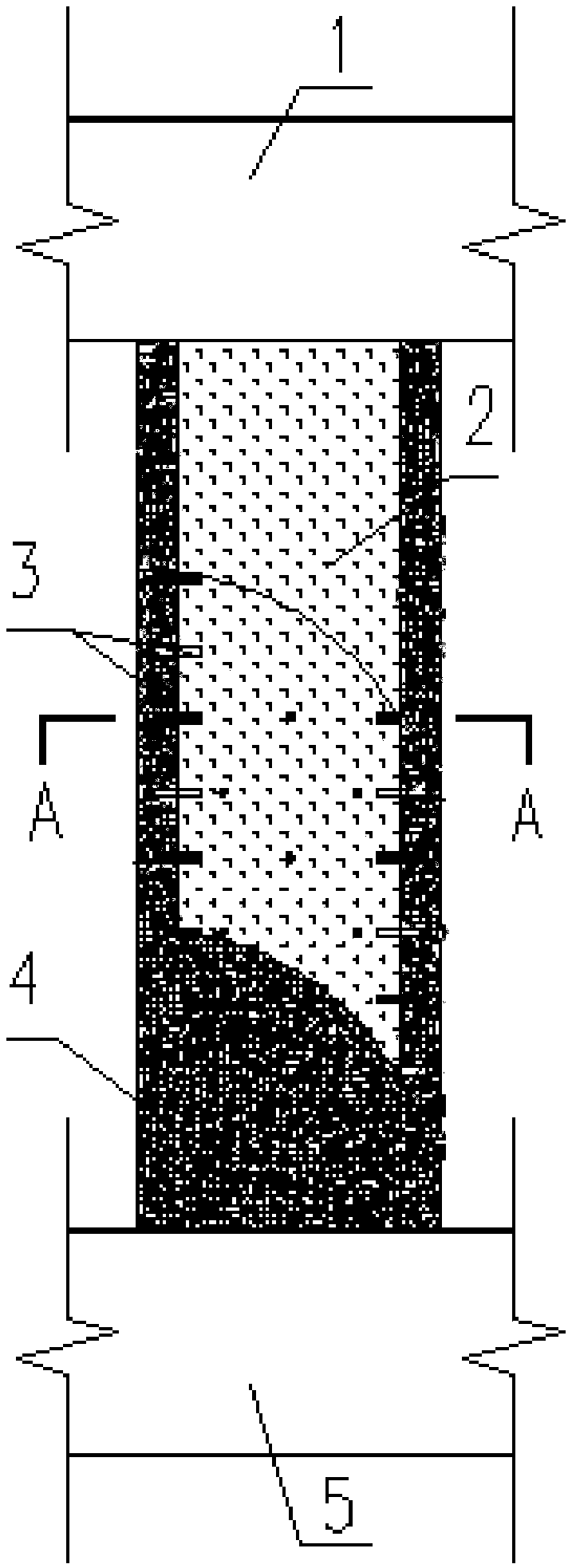

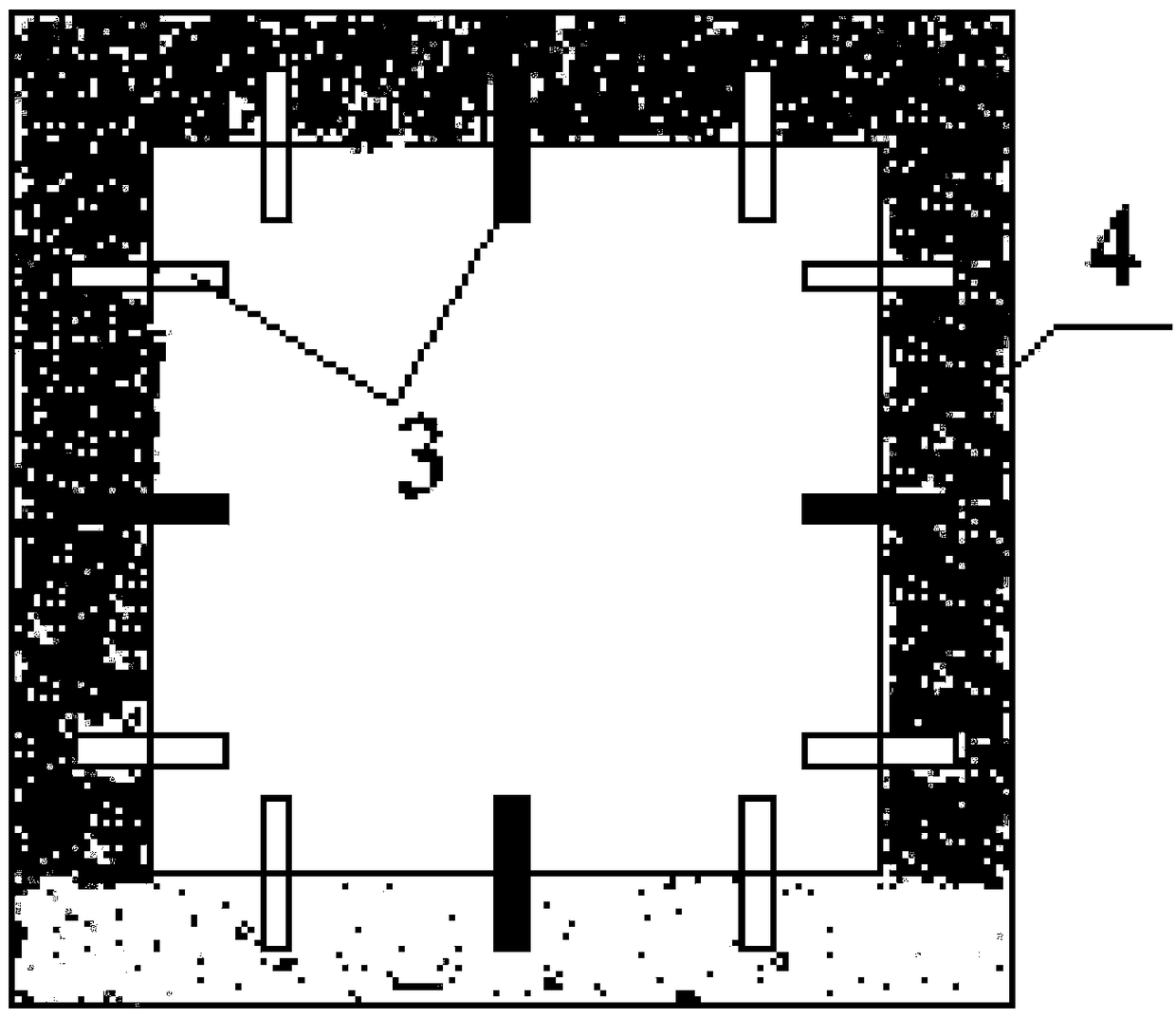

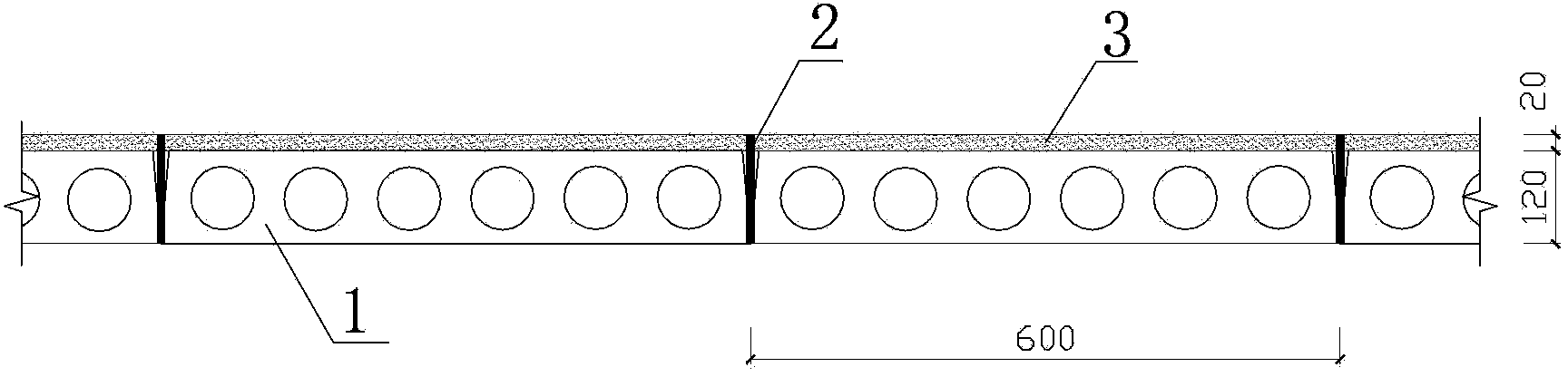

Steel bridge deck pavement structure with reinforced construction

PendingCN107815965AEasy to standardizeSimple construction processBridge structural detailsSteel platesJoint working

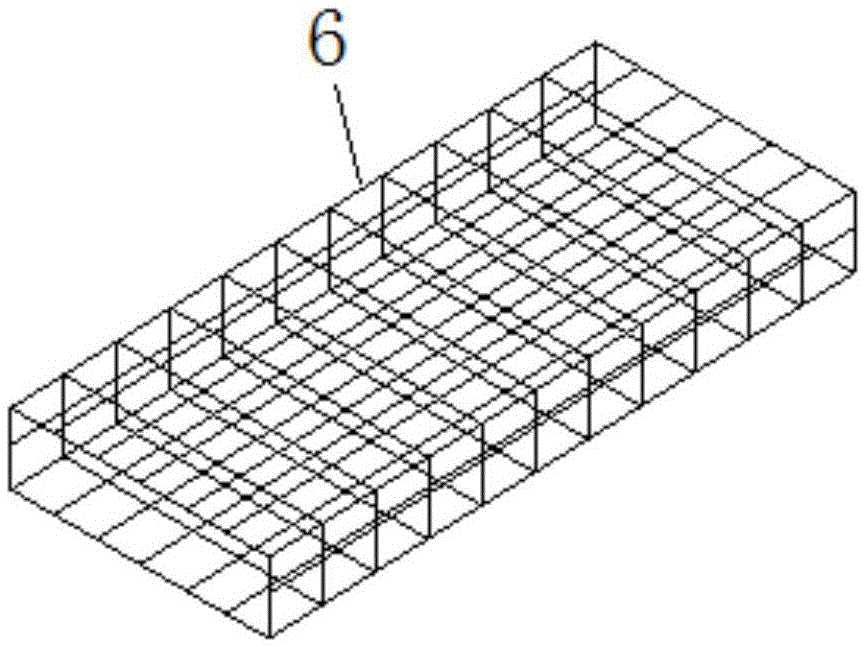

Provided is a steel bridge deck pavement structure with reinforced construction. The steel bridge deck pavement structure is jointly composed of a prefabricated reinforced steel plate (1), an anticorrosion layer (2), a waterproof layer (3), a lower surface layer (4), a fiber grid (5) and an upper surface layer (6) from bottom to top, and is characterized in that the top surface of the prefabricated reinforced steel plate (1) is provided with the reinforced construction, the fiber grid (5) is composed of longitudinal grid ribs (51) and transverse grid ribs (52) in a mutual interlaced mode, theinteriors of the lower surface layer (4) and the upper surface layer (6) are mixed with reinforced short fibers, and the fiber grid (5) is poured between the lower surface layer (4) and the upper surface layer (6) or into the upper surface layer (6), and achieves common working with the lower surface layer (4) and the upper surface layer (6) through surface construction. The steel bridge deck pavement structure with the reinforced construction has a good interlayer bonding performance, and can effectively prevent the risk of interlayer cracking and pavement layer fatigue cracking, meanwhile, through a novel prefabricated reinforced steel plate mode, the construction technology is simplified, the construction efficiency is greatly improved, the production installment cost is saved, the building cost of projects is reduced, and the normal use and durability needs of a bridge structure can be met.

Owner:NANJING FORESTRY UNIV

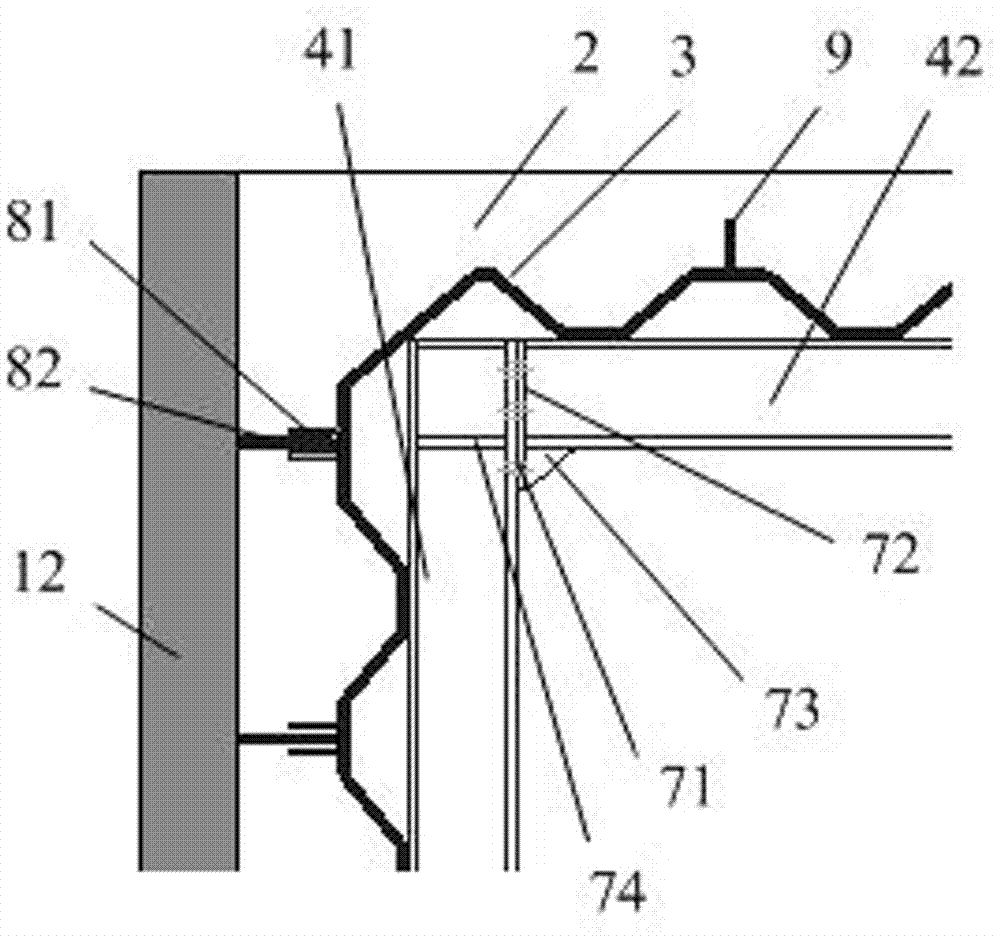

Novel enclosed steel-concrete composite beam

The invention provides a novel enclosed steel-concrete composite beam which comprises a C-shaped steel beam on the lower portion. The composite beam is formed by fixedly arranged profiled steel plates on an upper flange and in a beam rib of the C-shaped steel beam and pouring concrete on the whole face layer of the profiled steel plates. The novel enclosed steel-concrete composite beam is simple in structure, high in composite action, quick and convenient to construct, capable of realizing industrialized production, evident in economic benefit and capable of being applied to civil building floor structures and plays an active role in promoting housing industrialization.

Owner:HEFEI UNIV OF TECH +1

Welded stirrup steel framework beam/pillar

InactiveCN106522467AImprove bearing capacityIncreased shear capacityStrutsPillarsCrack resistanceAssembly line

The invention relates to the field of civil engineering structures, in particular to a welded stirrup-steel framework concrete component. The welded stirrup-steel framework concrete component is a combined structure component formed by welding stirrup on a steel framework and pouring concrete, and shear connectors and longitudinal steel reinforcements of a traditional steel framework concrete component are reduced. Due to the fact that the steel framework is wrapped with the concrete, structural stiffness and shear capacity are improved, and earthquake resistance can be improved remarkably. The steel framework has bearing capacity to a certain extent and is used for bearing loads in the construction stage, a formwork is suspended on the steel framework, formwork erection is omitted, and assembly line production is facilitated. The stirrup in the welded stirrup-steel framework concrete component can improve the crack resistance of the concrete on the one hand, and can be used as a shear part on the other hand, cooperative work of the steel framework and the concrete is ensured, the construction process is simplified, the steel reinforcement net rack binding process is omitted, the manufacturing time is shortened, and industrialized production of components is facilitated.

Owner:SHANDONG UNIV

Masonry wall body blast-resistant reinforcement structure

ActiveCN107060364AImprove adhesionGuaranteed to work togetherBuilding repairsFixed frameUltimate tensile strength

The invention provides a masonry wall body blast-resistant reinforcement structure comprising a wall body, mortar, a steel wire mesh piece and a fixed frame. The steel wire mesh piece is laid on the fixed frame connected with the wall body through fasteners; pins are arranged between the steel wire mesh piece and the wall body; one ends of the pins are fixedly connected with the wall body, and the other ends of the pins are fixedly connected with the steel wire mesh piece; reinforcing bars are arranged on the outer side of the steel wire mesh piece; the two ends of the reinforcing bars penetrate through the steel wire mesh piece and are connected with the fixed frame; and the mortar is smeared on the steel wire mesh piece and the reinforcing bars. According to the masonry wall body blast-resistant reinforcement structure, the steel wire mesh piece is arranged, and the pins are connected with the wall body and the steel wire mesh piece, so that the wall body does not collapse under the action of a blasting load; and the reinforcing bars are arranged on the outer side of the steel wire mesh piece, and the two ends of the reinforcing bars penetrate through the steel wire mesh piece and are connected with the fixed frame, so that the strength of the steel wire mesh piece and the ability of a masonry wall to resist the lateral load are improved, cracking of the wall body is limited or delayed, the projection velocity of fragments breaking away from the wall body is decreased, the number of the fragments is reduced, and the blast-resistant ability of the wall body is improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

High-ductility fiber concrete combined brick masonry wall and method for constructing same

ActiveCN102912892AImprove integrityImprove seismic performanceWallsBuilding material handlingFiberSurface layer

The invention discloses a high-ductility fiber concrete combined brick masonry wall and a method for constructing the same to solve problems of fragility, and poor seismic resistance and wholeness of prior common brick masonry walls. The high-ductility fiber concrete combined brick masonry wall is composed of a brick wall, short rebars and a high-ductility fiber concrete surface layer. During the construction, a masonry wall is constructed, the short rebars are embedded in vertical mortar joints of the brick wall, and the high-ductility fiber concrete is coated on the surface of the brick wall. According to the high-ductility fiber concrete combined brick masonry wall and the method for constructing the same, the compressive capacity, the shearing resistance and the seismic resistance of the brick masonry wall are better than those of a traditional brick wall, and brittle failure is not easy to occur; and simultaneously, the brick masonry wall is simple to construct and low in construction cost.

Owner:西安五和新材料科技集团股份有限公司

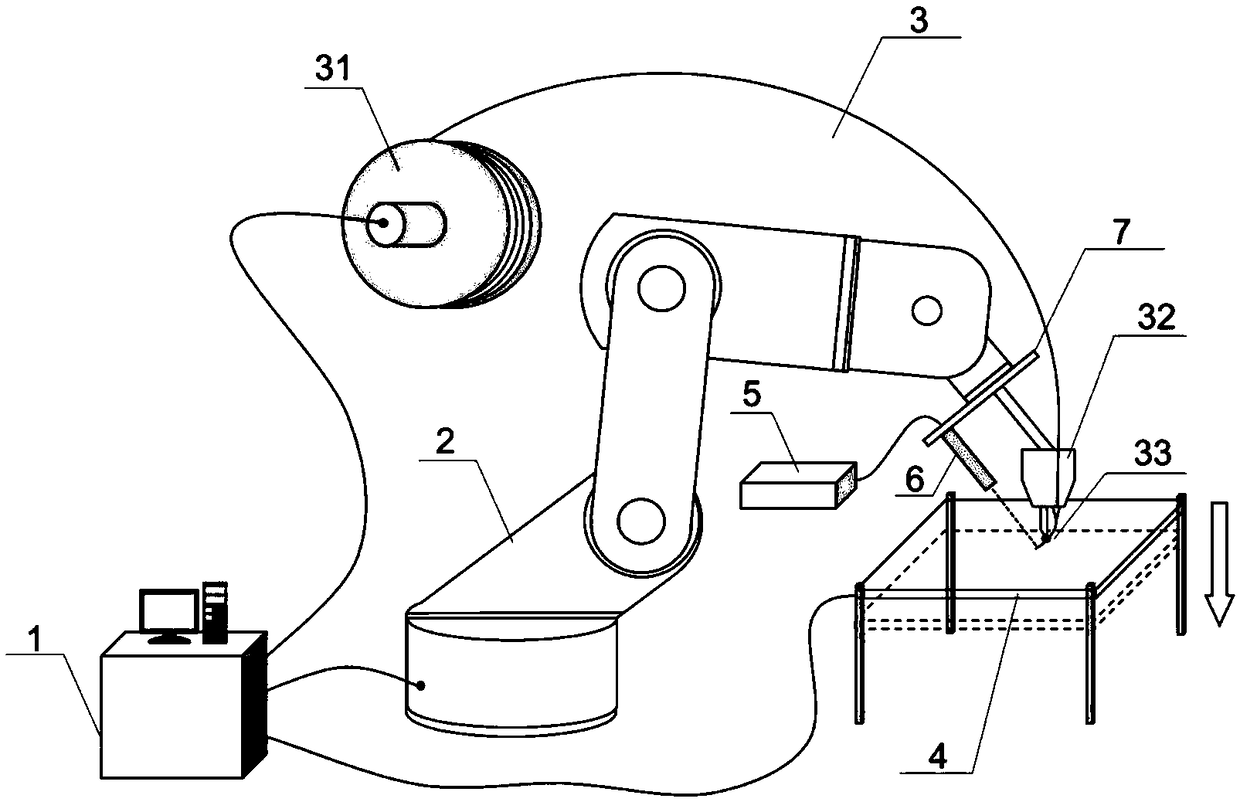

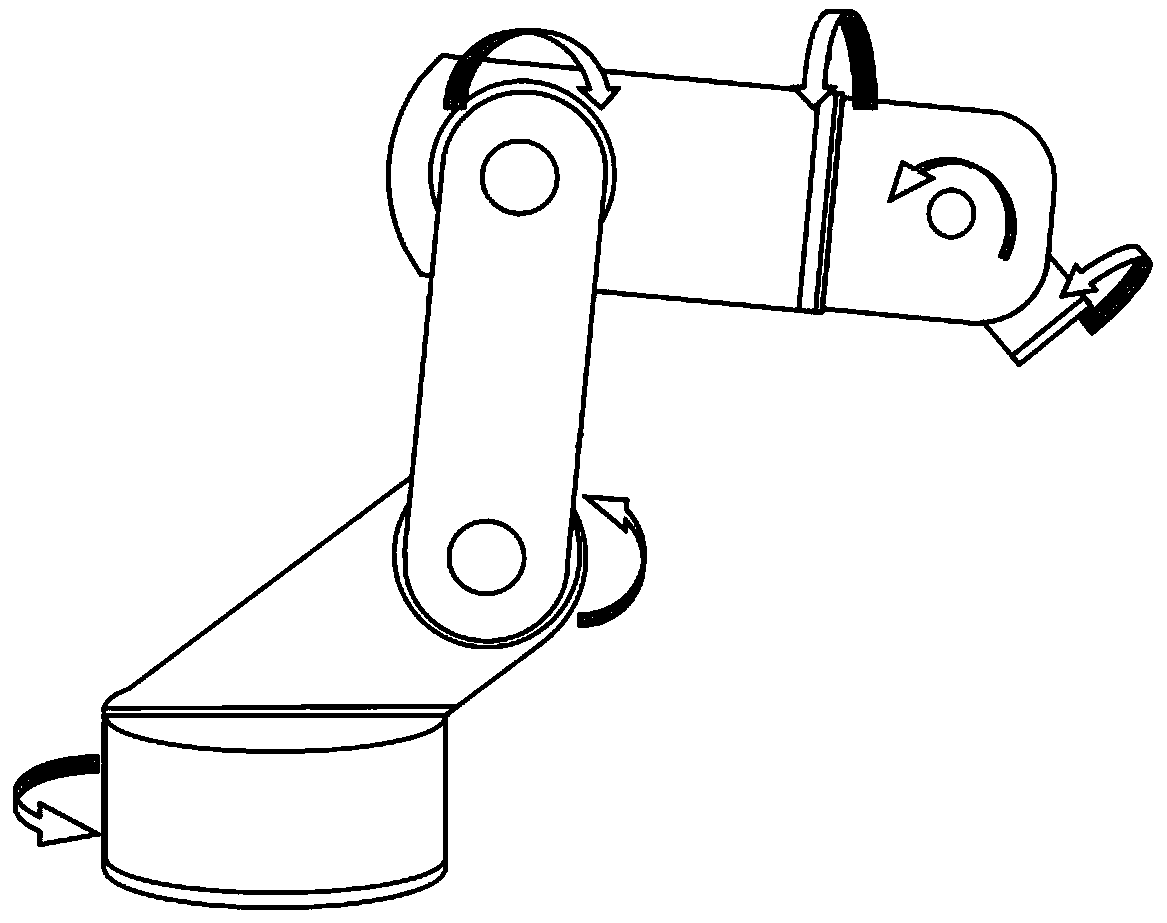

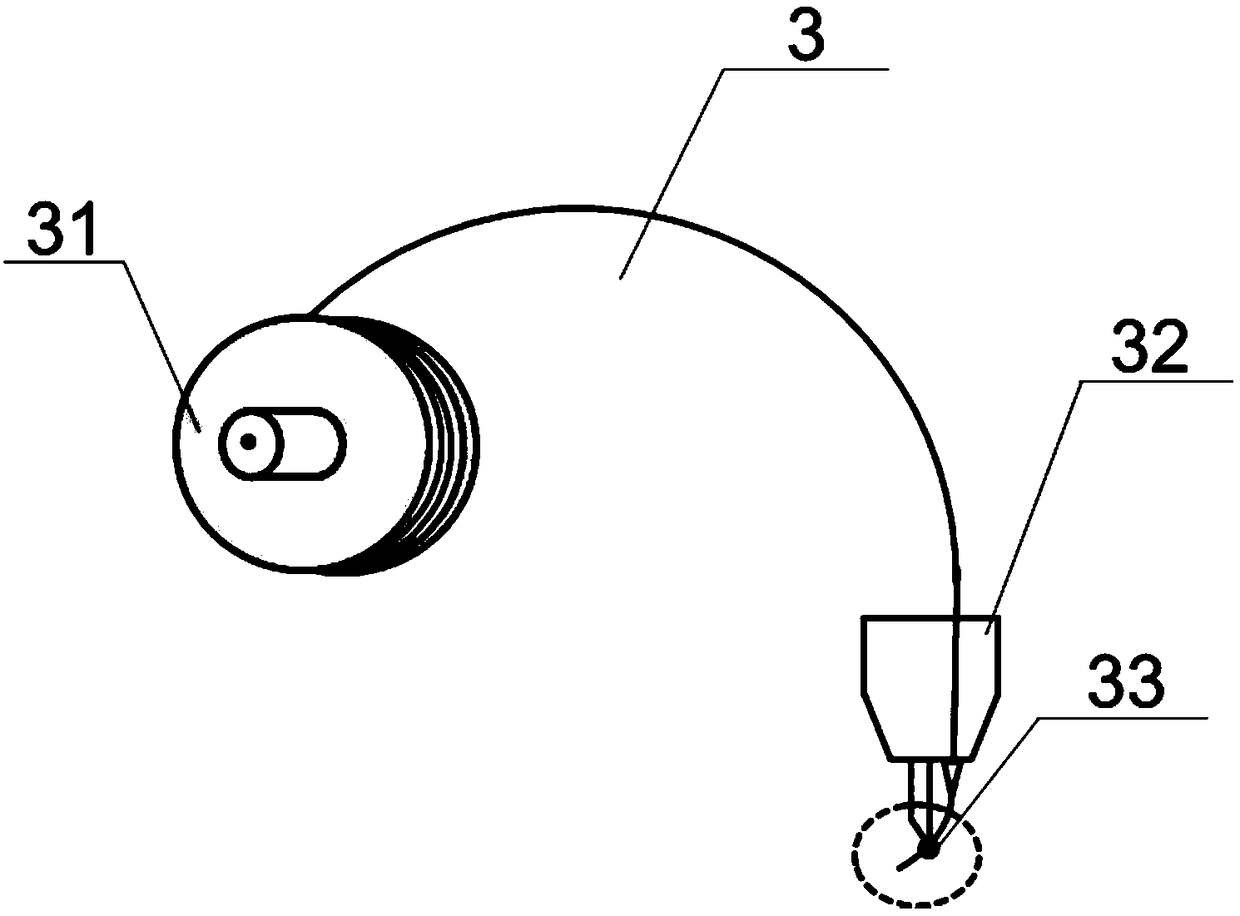

Laser additive manufacturing system and method for polymer wire

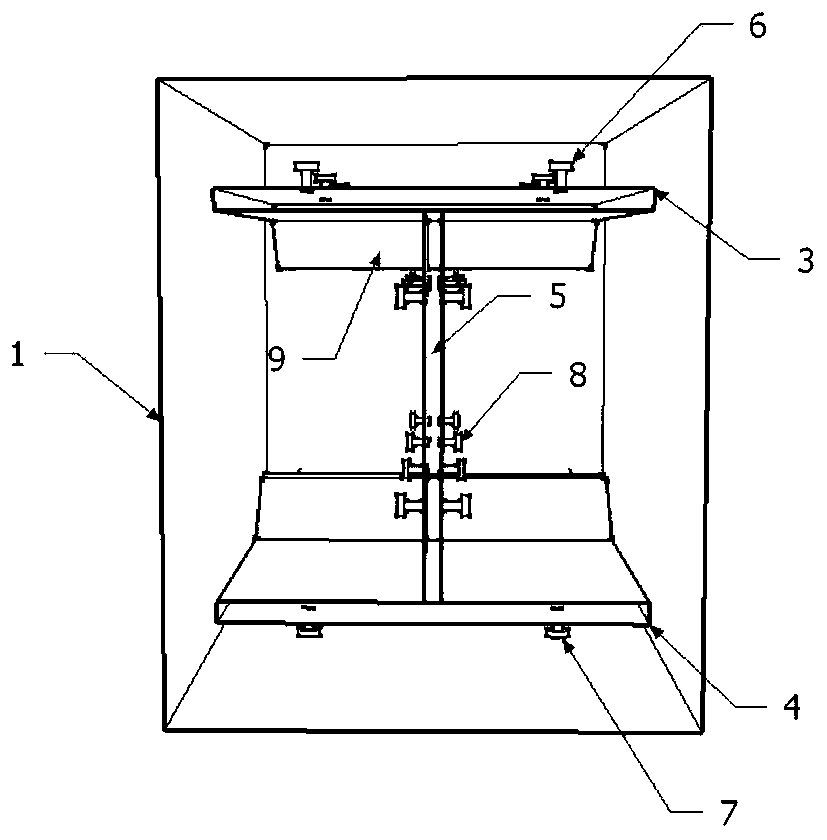

ActiveCN109159421AEasy to cleanExtended service lifeManufacturing heating elements3D object support structuresLaser additive manufacturingAdditive layer manufacturing

The invention belongs to the field of wire additive manufacturing, and discloses a laser additive manufacturing system and method for a polymer wire. The system comprises a lifting table, a wire conveying unit, an extruding unit, a robot and a laser device, wherein the lifting table is a working tabletop for forming a wire; the laser device is used for melting the wire extruded from the extrudingunit; the laser device is arranged outside the extruding unit to separate the melting of the wire from the extruding unit, namely separate wire conveying and melting, so that blockage of a sprayer ofthe extruding unit is avoided; a laser head and the extruding unit are fixed on a working table at the tail end of the robot, so that laser can directly shoot a wire extruding position at any time toensure that the wire is melted under the action of the laser as soon as the wire is extruded; the robot carries the extruding unit and a laser unit to move according to a preset track to realize melting and forming of the wire on a single slice layer; the lifting table goes down to realize forming of all the slice layers, so as to obtain a part to be formed. According to the laser additive manufacturing system disclosed by the invention, the problems of easiness in blockage, difficulty in cleaning, short service life and the like of the sprayer are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

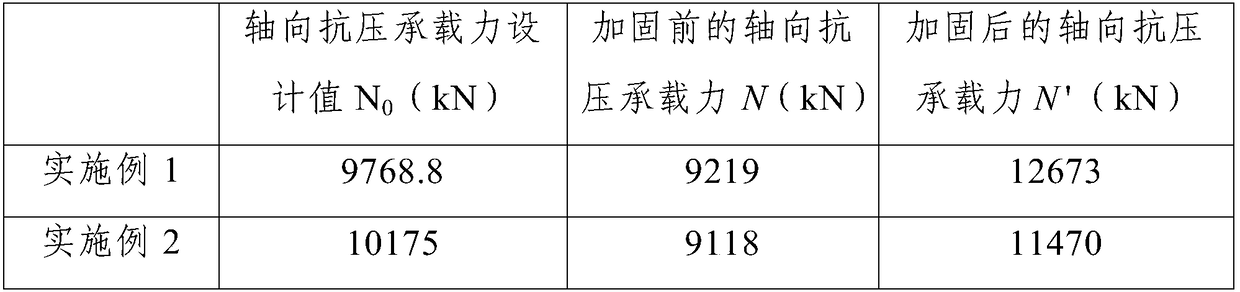

Partially prefabricated section steel-concrete combined column based on side plates and application of partially prefabricated section steel-concrete combined column

InactiveCN109797908AGood mechanical performanceComponent connections are firmStrutsPillarsDuctilityEngineering

The invention discloses partially prefabricated section steel-concrete combined column based on side plate and application of the partially prefabricated section steel-concrete combined column, and belongs to the technical field of buildings. The combined column is good in stress performance, stable in component connection, few and simple in construction process and high in construction efficiency; when the height of the combined column is 3000 mm and the section size is 350 mm*350 mm, the section size of I-shaped steel is 350 mm* 350mm* 6mm; when the thickness of an upper flange and a lower flange is 6 mm, the axial compression ultimate bearing capacity can reach 5733.2 kN, the ultimate flexural bearing capacity can reach 272.5 kN.m, and the ductility coefficient can reach 4.02.

Owner:JIANGNAN UNIV

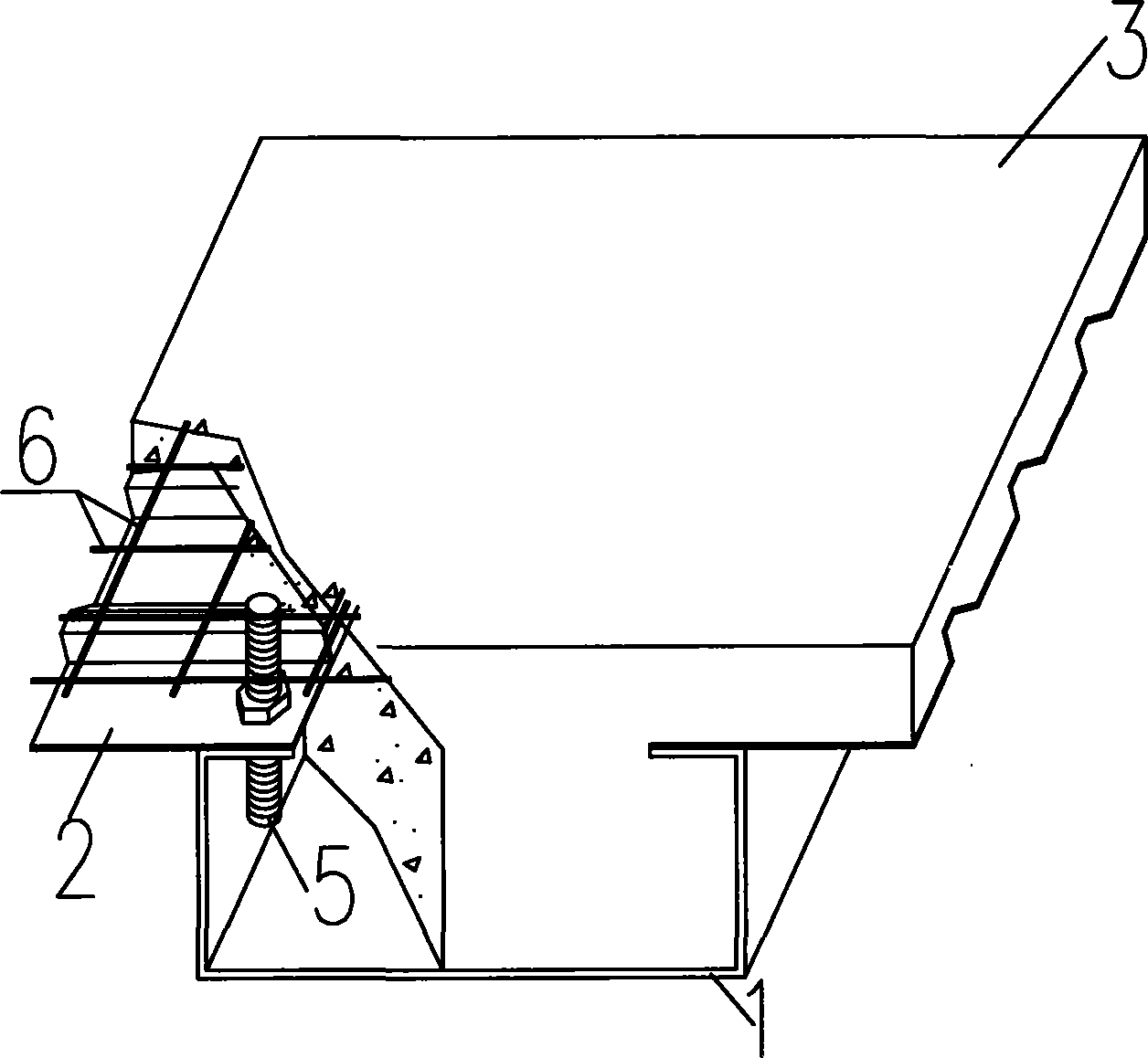

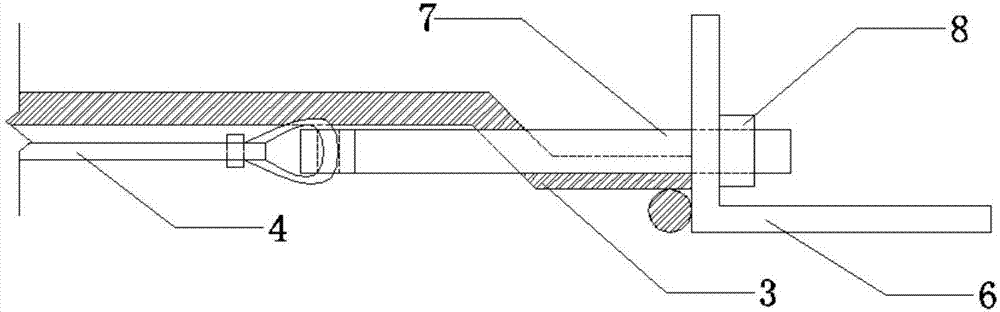

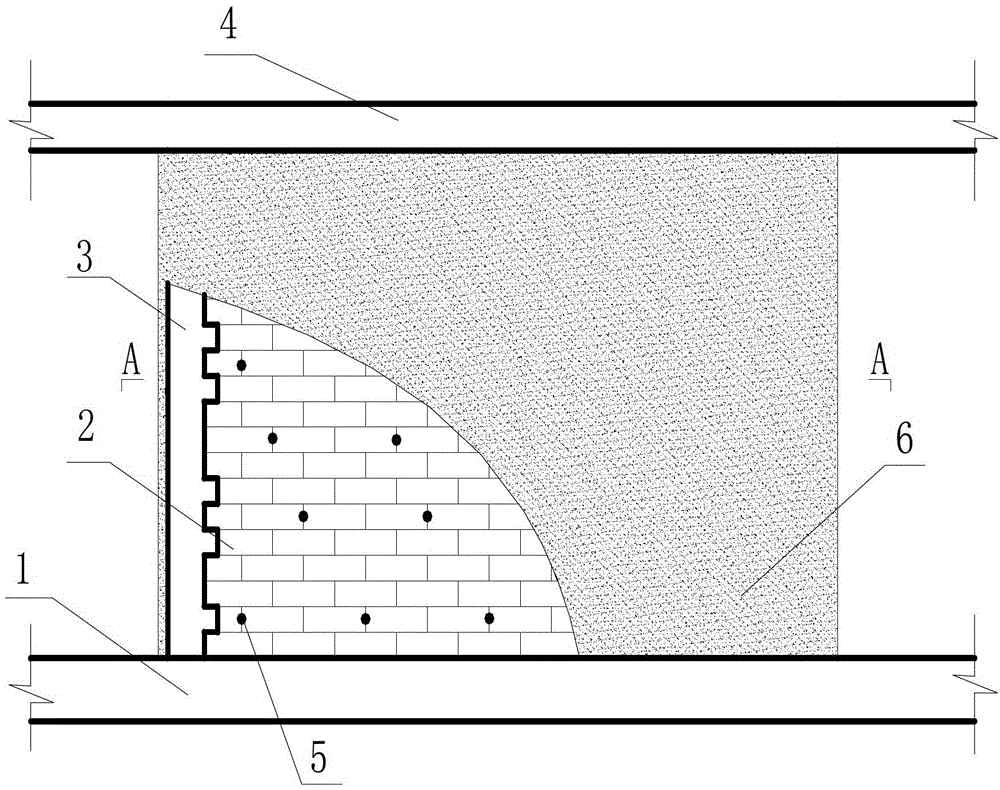

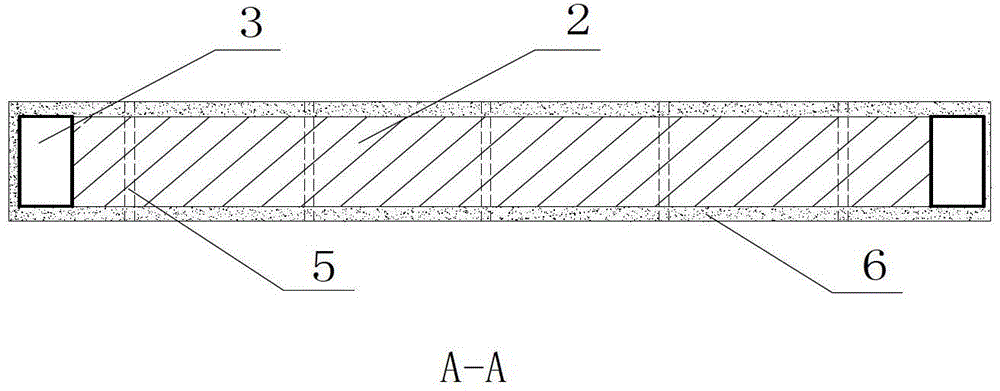

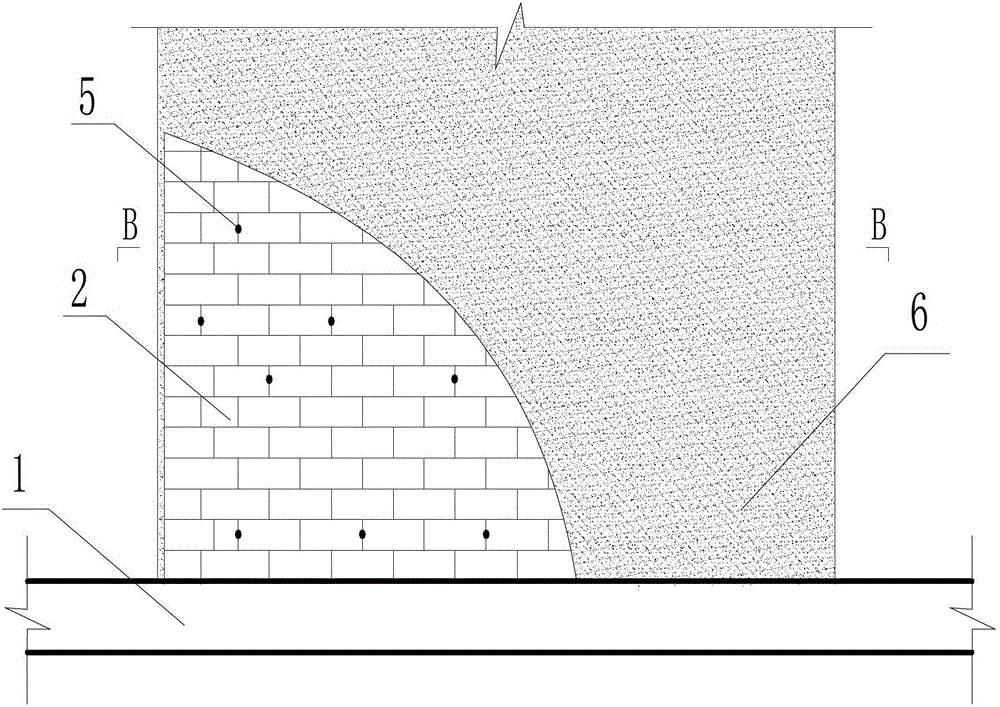

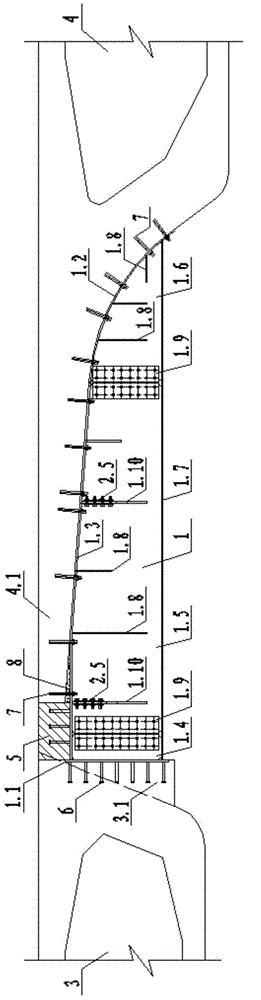

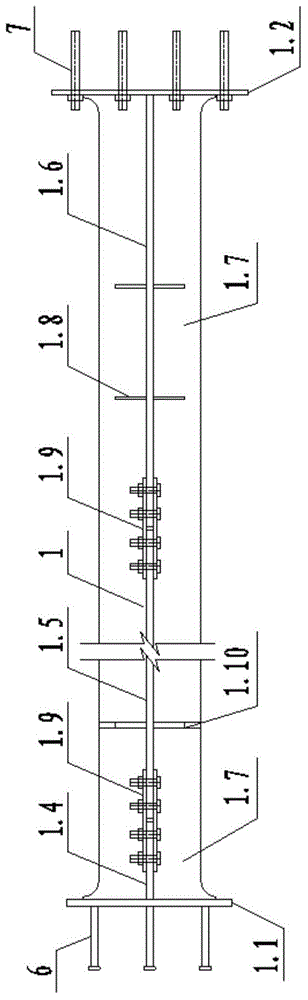

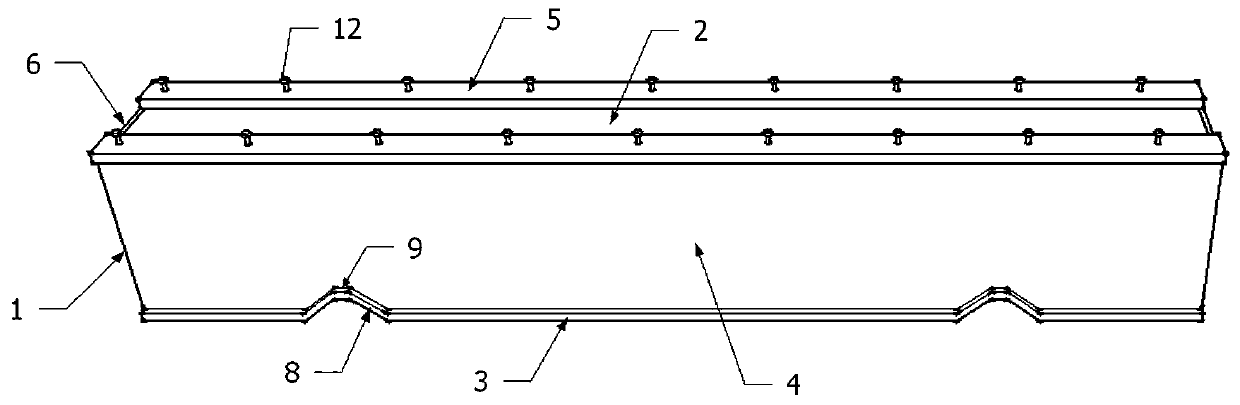

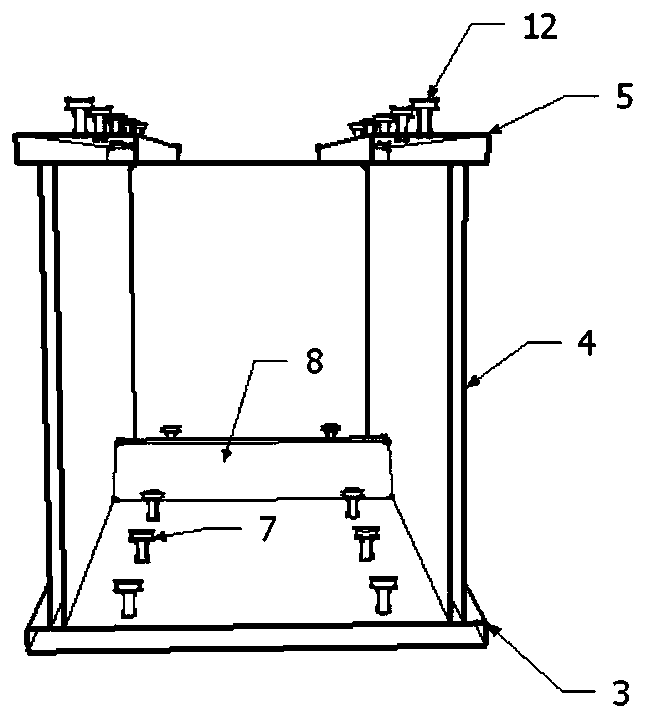

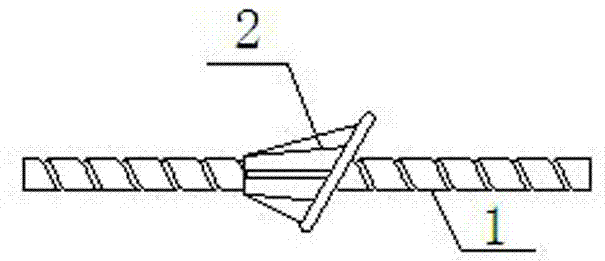

Rigid connection construction and contraction technology of shear beam for splicing prestressed concrete box girders

ActiveCN104963299AAvoid height differenceGuaranteed to work togetherBridge erection/assemblyBridge strengtheningPre stressEngineering

The invention discloses a rigid connection construction of a shear beam for splicing prestressed concrete box girders. The rigid connection construction comprises shear beams (1), small longitudinal beams (2), a new bridge box girder (3), an old bridge box girder (4), wet joints (5), shear bolt pins (6) and anchor bolts (7). The rigid connection construction has the advantages of reasonable structure, definite stress, convenient construction, and small traffic impact; besides, the rigid connection construction is economic and safe, is high in fatigue resistance and durability, also has the effect of structure reinforcement, and can enable the prestressed concrete box girders of a new bridge and an old bridge to form a good whole. The invention further provides a construction technology of the rigid connection construction of a shear beam for splicing prestressed concrete box girders.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

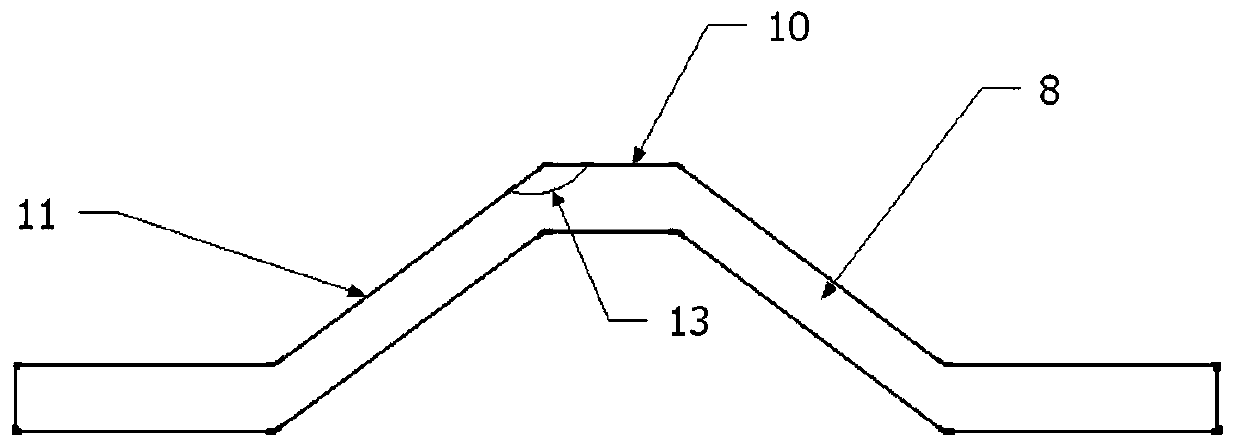

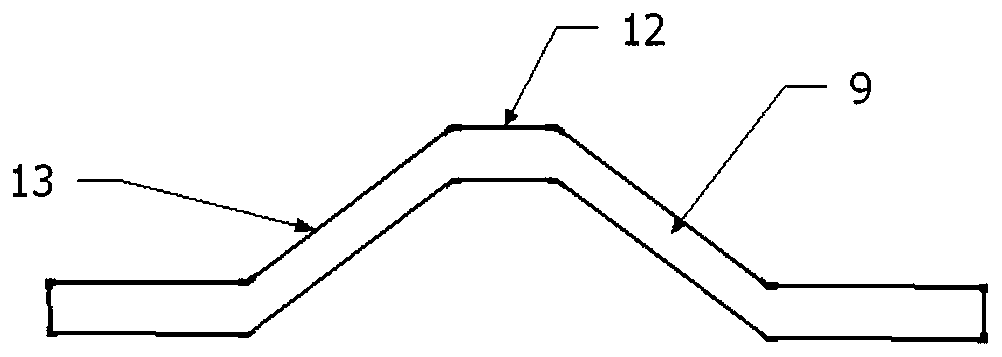

Corrugated box beam

ActiveCN109763415AImprove deformation abilityImprove collapse resistanceLoad-supporting elementsBridgesInverted uLarge earthquakes

The invention discloses a corrugated box beam, and belongs to the technical fields of construction and structural engineering. A corrugated bottom plate of the corrugated box beam provided by the invention bends and corrugates at inflection points near beam-column joints to form inverted U-shaped wavy protrusions, and the inverted U-shaped wavy protrusions deform greatly in the process of straightening under load, so that the deformation capacity of the corrugated box beam under earthquake action is greatly increased, and the collapse resistance capacity of the corrugated box beam under largeearthquakes is greatly enhanced; in addition, corrugated parts of the corrugated box beam are covered with non-stick films, so that the corrugated box beam is not bonded to concrete locally, and no affect is caused on the deformation of the inverted U-shaped wavy protrusions, the deformation capacity of the corrugated box beam under the earthquake action is further increased, and the collapse resistance capacity of the corrugated box beam under the large earthquakes is greatly enhanced.

Owner:JIANGNAN UNIV

Reinforced composite board based on concrete bending member

The invention relates to the technical field of building structure reinforcing, in particular to a reinforced composite board based on a concrete bending member. The composite board is formed by two parts including high-strength mortar and a prestress fiber material. The fiber material comprises a carbon fiber sheet, a glass fiber sheet and the like. The high-strength mortar is connected with the fiber material through a certain amount of steel fiber in the special shape, and the fiber material and the high-strength mortar are effectively bonded to form the novel composite board. The composite board can effectively overcome the shortcoming that the fiber material is peeled and damaged after the structure is stressed due to the fact that the concrete surface is unsmooth, greatly improves fiber strength utilization rate and improves a reinforcing effect.

Owner:HUNAN UNIV

Corrugated steel-concrete composite beam

ActiveCN109763603AImprove deformation abilityImprove collapse resistanceLoad-supporting elementsBridge materialsEngineeringPlastic hinge

The invention discloses a corrugated steel-concrete composite beam and belongs to the technical field of building and structural engineering. According to the corrugated steel-concrete composite beam,a corrugated beam section generates an obvious plastic hinge under the action of a major earthquake; a midspan section generates a crack first, and then the corrugated part is straightened. Therefore, the bending bearing capacity of the section of the corrugated part is enhanced, and then the yielding section of the beam is transferred to the midspan; the bearing force of the beam can also continue to be increased; when the midspan section is yielded, the deformation of the beam continues to be increased, and the bearing force is not increased any more till the beam is destroyed; through theadoption of the design, the corrugated steel-concrete composite beam is destroyed in prior to a column under the action of the earthquake so that the strong column and the weak beam are really realized; when the span of the corrugated steel-concrete composite beam is 5 m and the section dimension of the corrugated steel-concrete composite beam is 250mm*450mm, the ultimate bending bearing capacityof the corrugated steel-concrete composite beam can reach 212 kN.m, and the deflection limit of the corrugated steel-concrete composite beam can reach 59 mm.

Owner:JIANGNAN UNIV

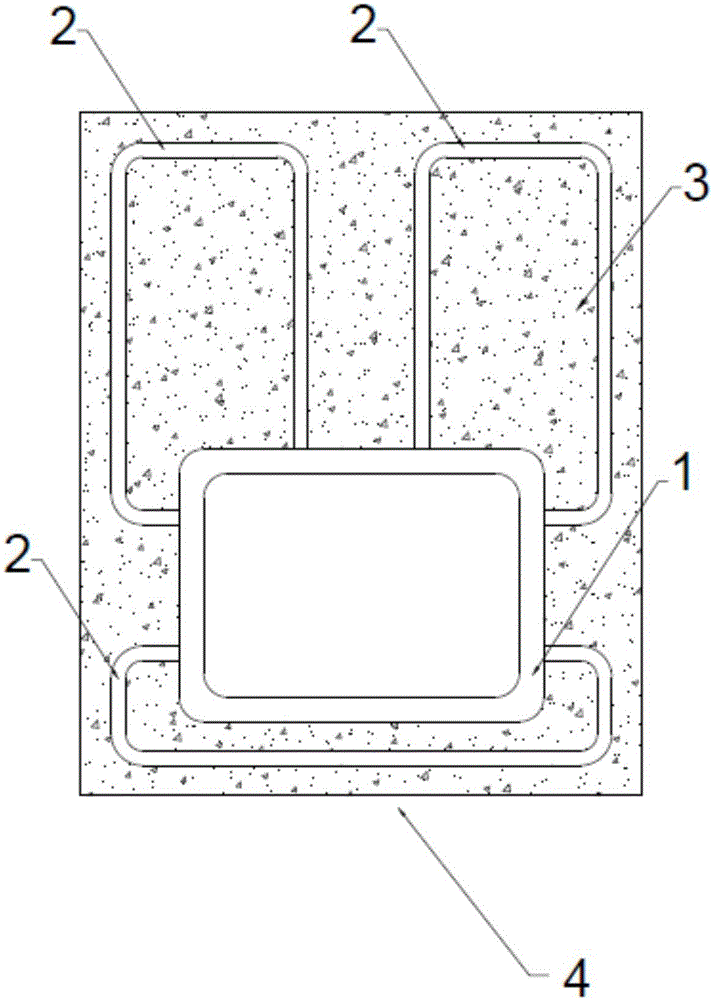

Template-free partial precast steel concrete combined underground comprehensive pipe rack

PendingCN107514012AIncrease stiffnessImprove bearing capacityArtificial islandsUnderwater structuresSheet steelEngineering

The invention provides a template-free partial precast steel concrete combined underground comprehensive pipe rack. The pipe rack is placed on a cushion layer, and comprises an inner layer, a middle layer and an outer layer; the outer layer is a precast concrete layer; the middle layer is a cast-in-place concrete layer and a precast steel plate layer; the inner layer is a steel skeleton consisting of an annular steel beam and a longitudinal steel beam; the precast concrete layer is connected with the cast-in-place concrete layer; the cast-in-place concrete layer is connected with the precast steel plate layer; the precast steel plate layer is connected with the steel skeleton; the three layers commonly bear external loads transferred by soil; during constructing, the precast concrete layer, the precast steel plate layer, the annular steel beam and the longitudinal steel beam are all machined in a factory and assembled on the spot; the cast-in-place concrete layer is cast; and the partial precast construction is realized without needing templates. The pipe rack has such advantages as low dead weight, no templates, short construction period and high industrialization degree.

Owner:SUZHOU UNIV OF SCI & TECH

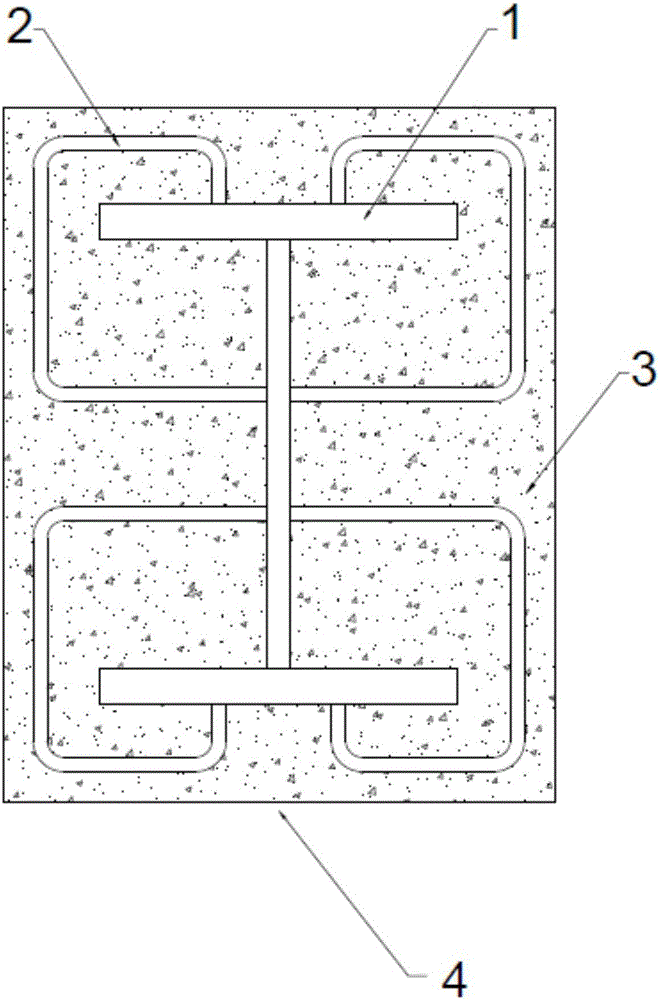

Manufacturing method for TRC inner wall grating type permanent formwork

InactiveCN108312297ALight weightSoftSolid waste managementSurface layering apparatusGratingReinforced concrete

The invention relates to a manufacturing method for a TRC inner wall grating type permanent formwork, and belongs to manufacturing methods for reinforced concrete construction formworks. The manufacturing method for the TRC inner wall grating type permanent formwork comprises the following steps that (1) the fibrage net surface is subject to gum dipping and sand blasting; (2) an inner formwork needed by the TRC permanent formwork grating type inner wall is installed; (3) an outer formwork is installed; (4) a fibrage net is installed; (5) pouring of high-performance fine concrete and maintenance are carried out; and (6) demolding is carried out. After the above steps are completed, the surface of the inner wall of the formwork has a grating type characteristic, and the TRC inner wall grating type permanent formwork is formed. By means of the formwork, the superficial area of the joint of cast-in-place concrete and the formwork is increased, the adhesive property of the two parts after pouring can be guaranteed, the interface position is not prone to generating shearing peeling damage, the weight of a traditional permanent formwork can be reduced, and the light and high strength effects are achieved in the construction process.

Owner:CHINA UNIV OF MINING & TECH

Construction method of high-ductility fiber concrete floor cast-in-place layer

The invention discloses a construction method of a high-ductility fiber concrete floor cast-in-place layer, and solves the problems of complicated construction process of the conventional prefabricated floor cast-in-place construction technology, and poor ductility and large dead load of the poured cast-in-place layer. The construction method comprises the following steps of: at first, embedding short reinforcing steel bars on a slab joint of the prefabricated floor slabs, and then pouring high-ductility fiber concrete on the surfaces of the prefabricated floor slabs. According to the invention, by utilizing the advantage of the mechanical property of the high-ductility fiber concrete, and good adhesive property between the high-ductility fiber concrete and a masonry structure, integrity, crack resistance and leakage resistance of a floor system and the masonry structure can be greatly improved, drop of the prefabricated floor system under the earthquake action can be avoided, and the anti-seismic property of the masonry structure is remarkably improved.

Owner:西安五和新材料科技集团股份有限公司

Method for reinforcing concrete columns by adopting UHPC

The invention discloses a method for reinforcing concrete columns by adopting UHPC. The method comprises the steps that 1, rough chiseling treatment is conducted on the surfaces of concrete columns; 2, multiple shear-resistant steel bars are implanted into the surfaces, undergoing rough chiseling treatment, of concrete columns, and parts of shear-resistant steel bars extend out of the surfaces ofthe concrete columns; 3, the surfaces of the concrete columns with implanted shear-resistant steel bars are coated with the UHPC until the UHPC completely wraps the parts, extending out of the surfaces of the concrete columns, of the concrete columns and the shear-resistant steel bars, and UHPC layers are formed. According to the method, the UHPC containing silica fume, sand and steel fiber is directly applied to the surfaces of the concrete columns with implanted shear-resistant steel bars to form the UHPC layers, the UHPC layers are bonded with original concrete to form a whole after reinforcement, the overall structure performance of the concrete columns is improved, the plastic deformation capability of the concrete columns is ensured, timber formworks are not needed in the reinforcement process, the reinforcement cost is reduced, the reinforcement speed is improved, and the use area of a building is not affected.

Owner:陕西建研结构工程股份有限公司

Automatic winding device convenient to disassemble for optical fiber cable production

The invention discloses an automatic winding device convenient to disassemble for optical fiber cable production. The device comprises a bottom plate, two baffle plates are arranged on the upper surface of the bottom plate, the lower surface of the left baffle plate is fixedly connected with the upper surface of the bottom plate, first bearings are clamped on opposite surfaces of the two baffle plates, and rotating shafts are sleeved with the two first bearings. According to the automatic winding device convenient to disassemble for optical fiber cable production, by arranging a second motor,a driving gear, a driven gear, a threaded column, a threaded barrel, a connecting plate, a sliding block, clamping blocks and clamping grooves, a worker pulls a roller to the right, the two clamping blocks are separated from the two clamping grooves, the roller falls on the upper surface of a push plate, an electric push rod is controlled to work, the electric push rod is shortened to drive the push plate to move downwards, the push plate drives the roller to move downwards, so that the worker can disassemble the roller more conveniently, the working strength of the worker is reduced, and theworking time of the worker is saved.

Owner:肖叶

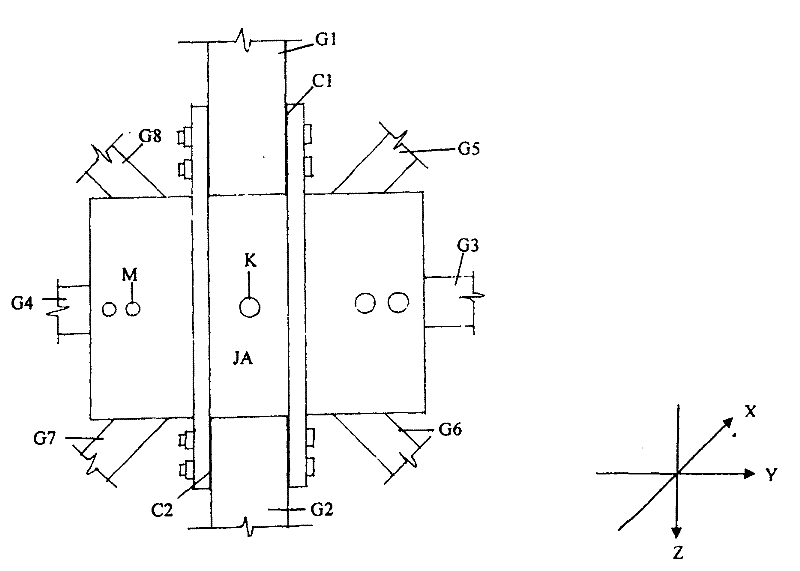

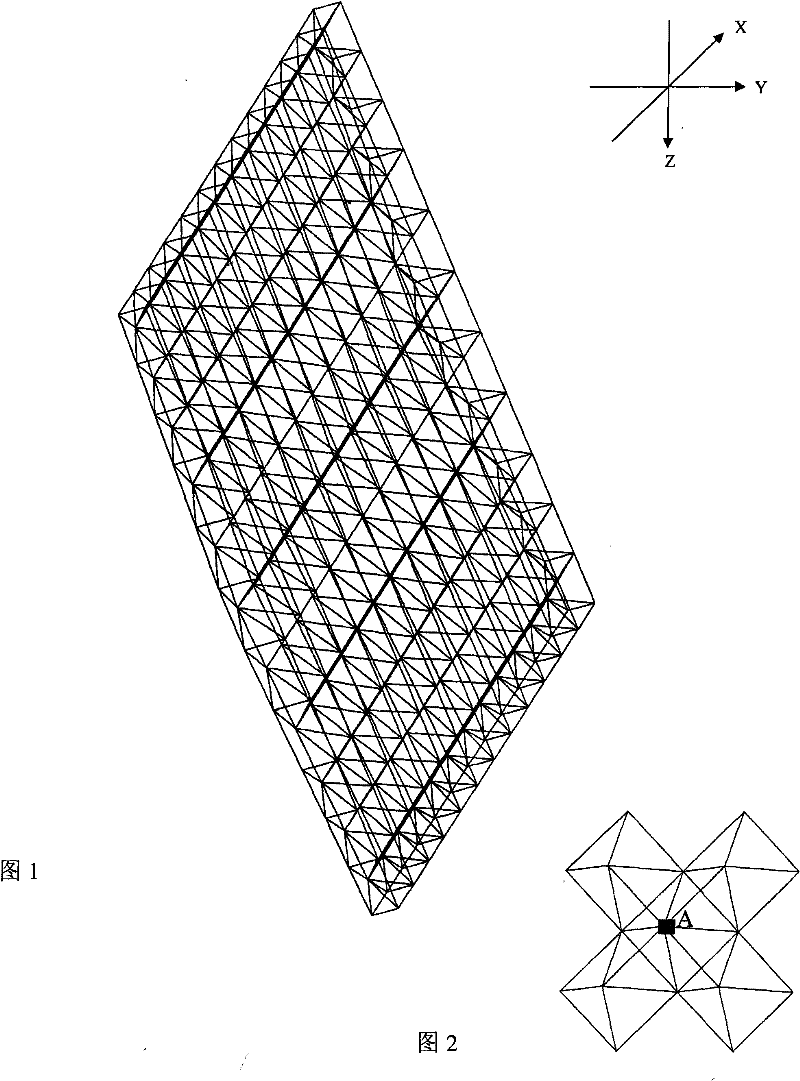

Body-like node aluminum alloy space truss structure

InactiveCN102304941AOutstanding FeaturesHighlight significant progressBridge structural detailsBuilding constructionsMaterials scienceAluminium alloy

A body-like node aluminum alloy space truss structure comprises all body-like space truss node bodies and all space truss chord members and web members, wherein the space truss node bodies are made of aluminum alloy materials, and the space truss chord members and the web members are made of the aluminum alloy materials and connected with the node bodies. The body-like node aluminum alloy space truss structure is characterized in that node body limb plates B1 and B2 connected to the space truss chord members in an X-axis direction are respectively arranged, or node body grooves C1 and C2 connected to the space truss chord members of the x-direction are arranged in positive and negative directions of the X axis located in the plane of the XY axes of the space truss according to requirements of connecting rods on each body-like node body; node body limb plates B3 and B4 connected to the space truss chord members in a Y-axis direction are respectively arranged or node body grooves C3 and C4 connected to the space truss chord members of the Y-direction are arranged in positive and negative directions of the Y axis located in the plane of the XY axes of the space truss; a node body limb plate B5 connected to the space truss web members G5 and G6 is arranged or a node body groove C5 connected to the space truss web members G5 and G6 is arranged in the plane of the space truss web members G5 and G6 at YZ side; and a node body limb plate B6 connected to the space truss web members G7 and G8 is arranged or a node body groove C6 connected to the space truss web members G7 and G8 is arranged in the plane of the web members G7 and G8 at (-Y)Z side. The space truss members converged at a node A(JA) and the space truss member ends corresponding to the node body limb plates are respectively provided with an opening so as to implant the node body limb plate, and the space truss member ends corresponding to the node grooves are directly implanted into the corresponding node grooves.

Owner:林娟

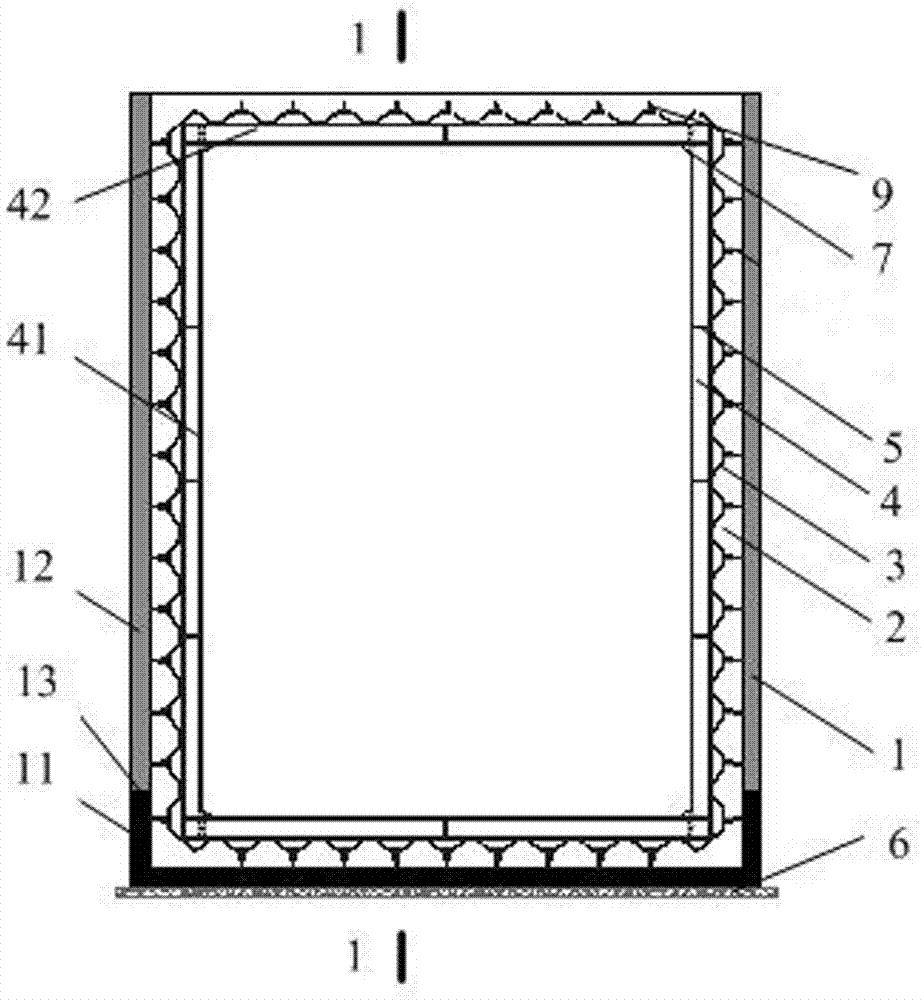

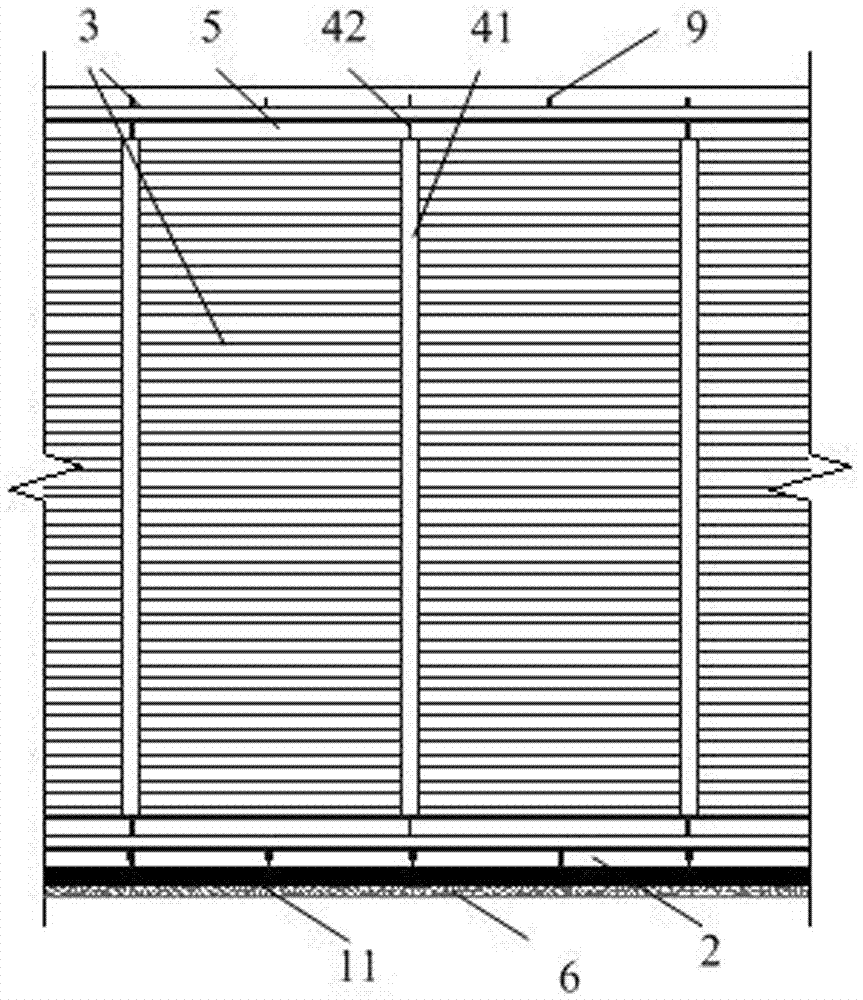

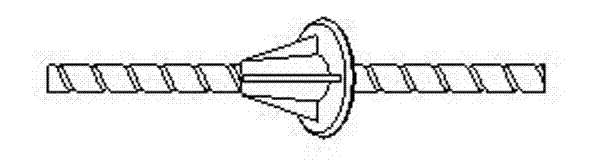

Non-metal connecting piece

ActiveCN102787682AImprove thermal performanceEffective against slippingWallsHeat proofingThermal insulationTension stress

The invention discloses a non-metal connecting piece, wherein a non-metal composite bar is embedded into a PVC rod sleeve at a certain angle to be connected and fixed, and the PVC rod sleeve is a triangular structure. The non-metal connecting piece not only can control the inserting depth of the non-metal composite bar, but also can ensure that the inserting angle of the non-metal connecting piece remains unchanged during the concrete formation process. The non-metal connecting piece revolutionarily breaks the shearing force into tension stress and compression stress, so as to bring the tension and compression resistance of the non-metal fiber bar into the fully play. By utilizing the non-metal connecting piece, the components can be stably connected, the defects of the existing technology are satisfactorily overcome, the product is popularized and applied, the construction quality of the structural thermal insulation integral wall body is further improved, and the structural safety becomes better.

Owner:NINGXIANG YUANDA RESIDENTIAL IND CO LTD

Lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam

The invention discloses a lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam. The fabricated beam is jointly composed of a middle FRPhollow box-groove section beam section and a pre-poured concrete filled beam section at both ends. The middle FRP hollow box-groove section beam section comprises a lower FRP box chamber and an upperFRP groove, a box-groove partition plate between the lower hollow box chamber and the upper groove adopts an FRP corrugated plate, and corrugations on the plate are used as shear-resisting connectingkeys between an FRP and the concrete. According to the lightweight fabricated reinforced box-groove-shaped FRP profile and sea sand concrete beam, the beam weight is decreased through the two aspectsof materials and structure, transportation is convenient, fast and reliable connection can be achieved with the plate and the column, construction is convenient and fast, good adaptability to severeengineering environments with severe corrosion such as coastal ports is achieved, and the good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

Steel-ECC-concrete composite beam and preparation method thereof

PendingCN109930466AAvoid overall stiffness reductionImprove bearing capacityClimate change adaptationBridge structural detailsRebarConcrete composites

The invention discloses a steel-ECC-composite composite beam and a preparation method thereof, and belongs to the field of building structures. The steel-ECC-concrete composite beam includes steel beams, at least two sets of shear key sets, ECC protection blocks, and concrete slabs with internal reinforcement. All shear key sets and ECC protection blocks are arranged on the top surfaces of the steel beams, each of the ECC protection blocks is wrapped with a set of shear key set, each of the shear key sets includes a plurality of spaced shear keys; the cross section of each ECC protection blockis rectangular, and the width of the outer contour of the bottom is equal to the width of the top surface of the steel beam. The width direction is parallel to the width direction of the steel beams,all ECC protection blocks are distributed in the axial direction of the steel beams, and a first groove is formed between adjacent ECC protection blocks and the top surfaces of the steel beams; between adjacent ECC protection blocks, a reinforcing mesh is arranged, and the reinforcing mesh penetrates through the first groove; the surfaces of the ECC protective blocks, not in contact with the topsurfaces of the steel beams, are provided with an adhesive layer, and the concrete plate is provided with a convexity matched with the first groove and a second groove matched with the ECC protectionblocks.

Owner:SOUTHWEST JIAOTONG UNIV

Construction method of high-ductility fiber concrete floor cast-in-place layer

The invention discloses a construction method of a high-ductility fiber concrete floor cast-in-place layer, and solves the problems of complicated construction process of the conventional prefabricated floor cast-in-place construction technology, and poor ductility and large dead load of the poured cast-in-place layer. The construction method comprises the following steps of: at first, embedding short reinforcing steel bars on a slab joint of the prefabricated floor slabs, and then pouring high-ductility fiber concrete on the surfaces of the prefabricated floor slabs. According to the invention, by utilizing the advantage of the mechanical property of the high-ductility fiber concrete, and good adhesive property between the high-ductility fiber concrete and a masonry structure, integrity, crack resistance and leakage resistance of a floor system and the masonry structure can be greatly improved, drop of the prefabricated floor system under the earthquake action can be avoided, and the anti-seismic property of the masonry structure is remarkably improved.

Owner:西安五和新材料科技集团股份有限公司

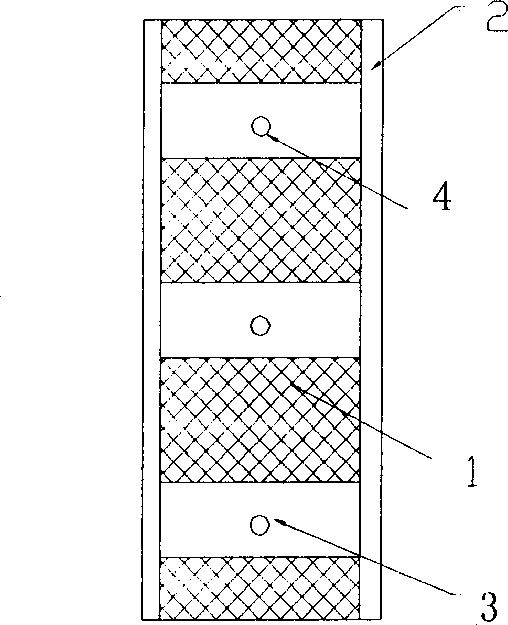

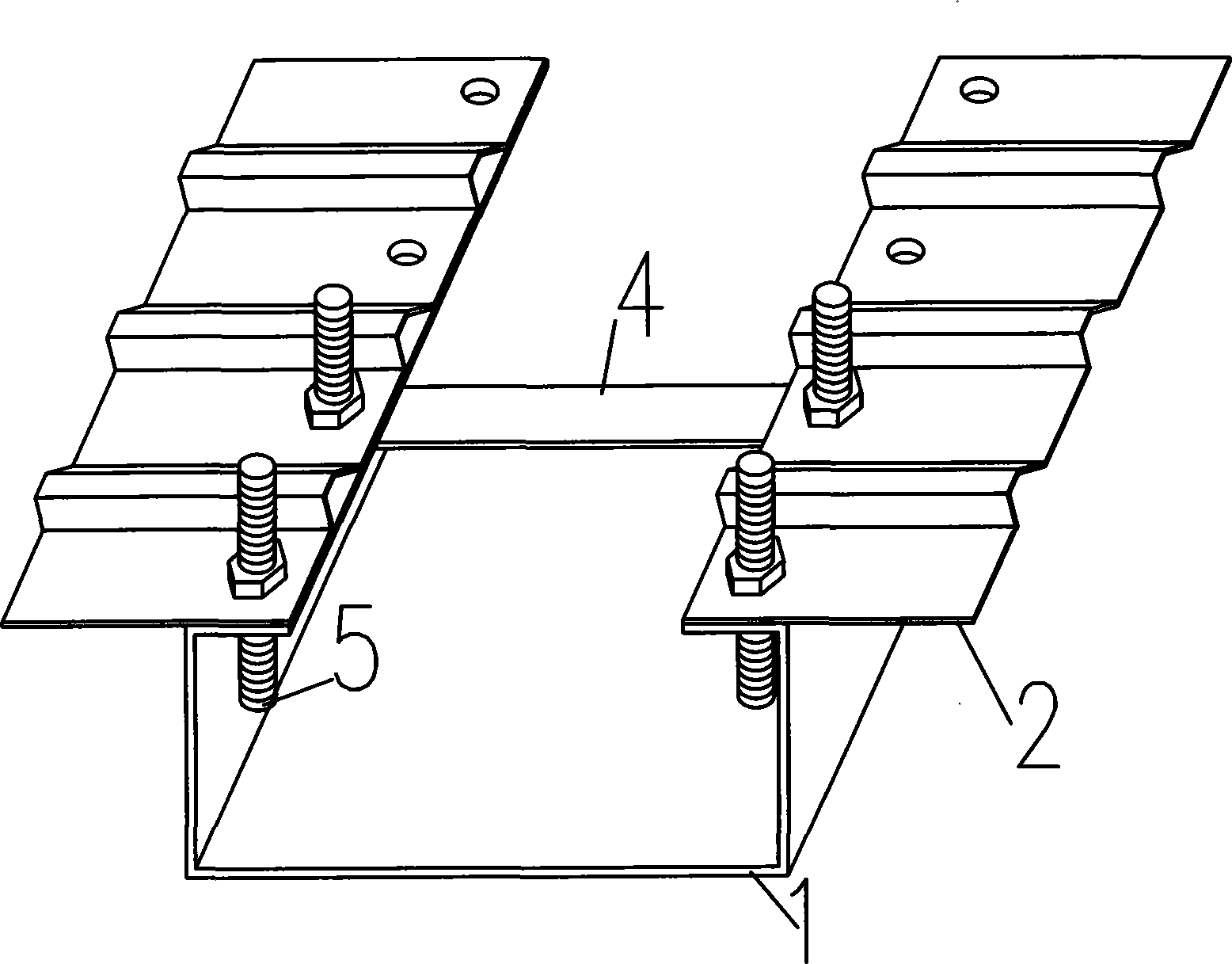

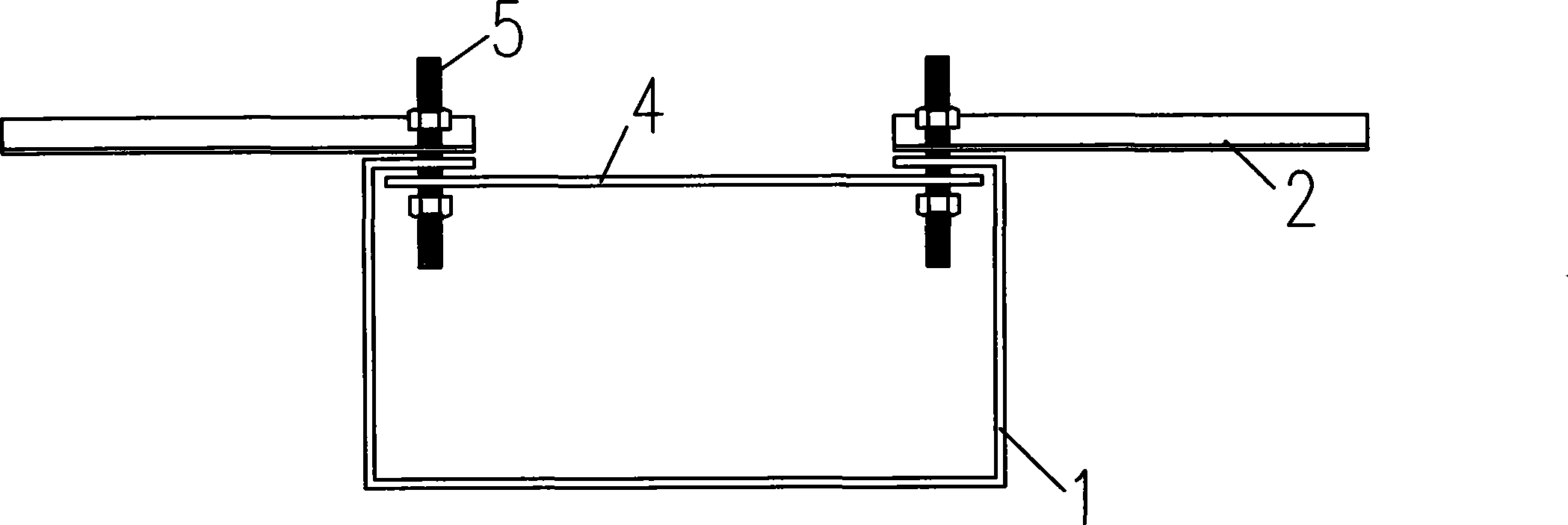

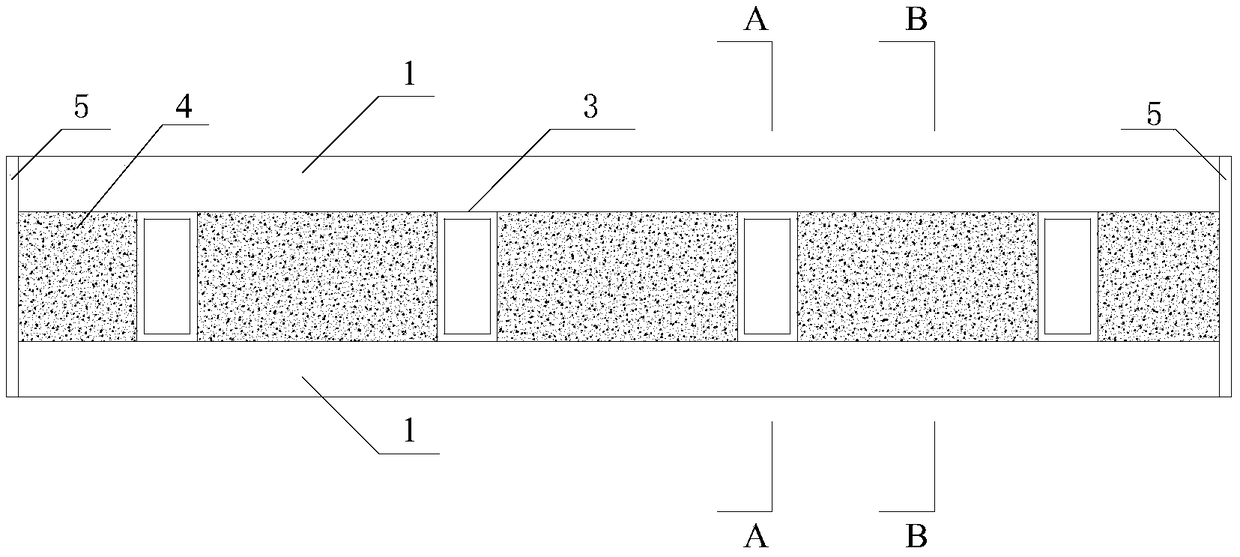

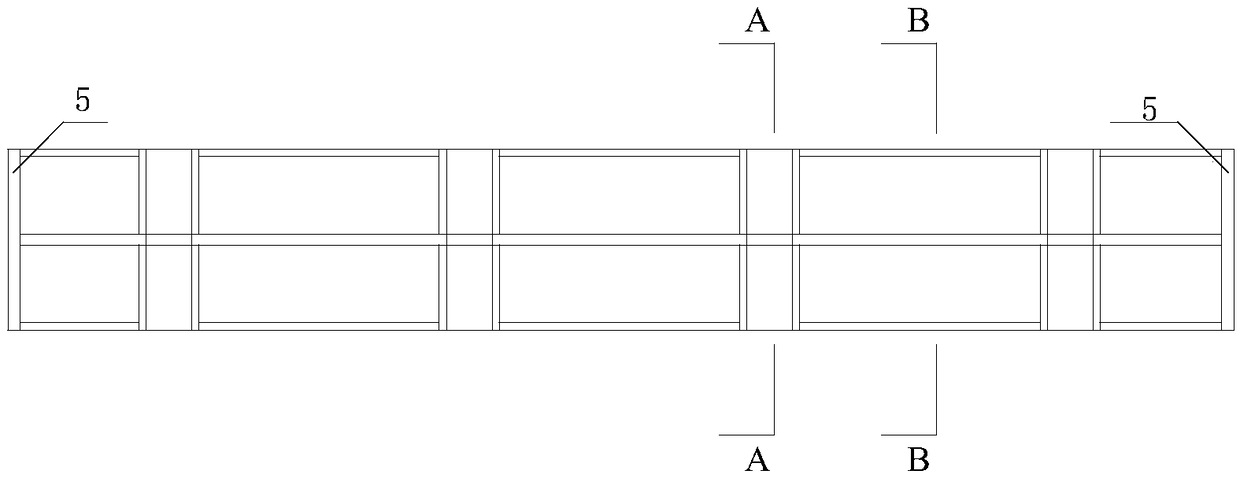

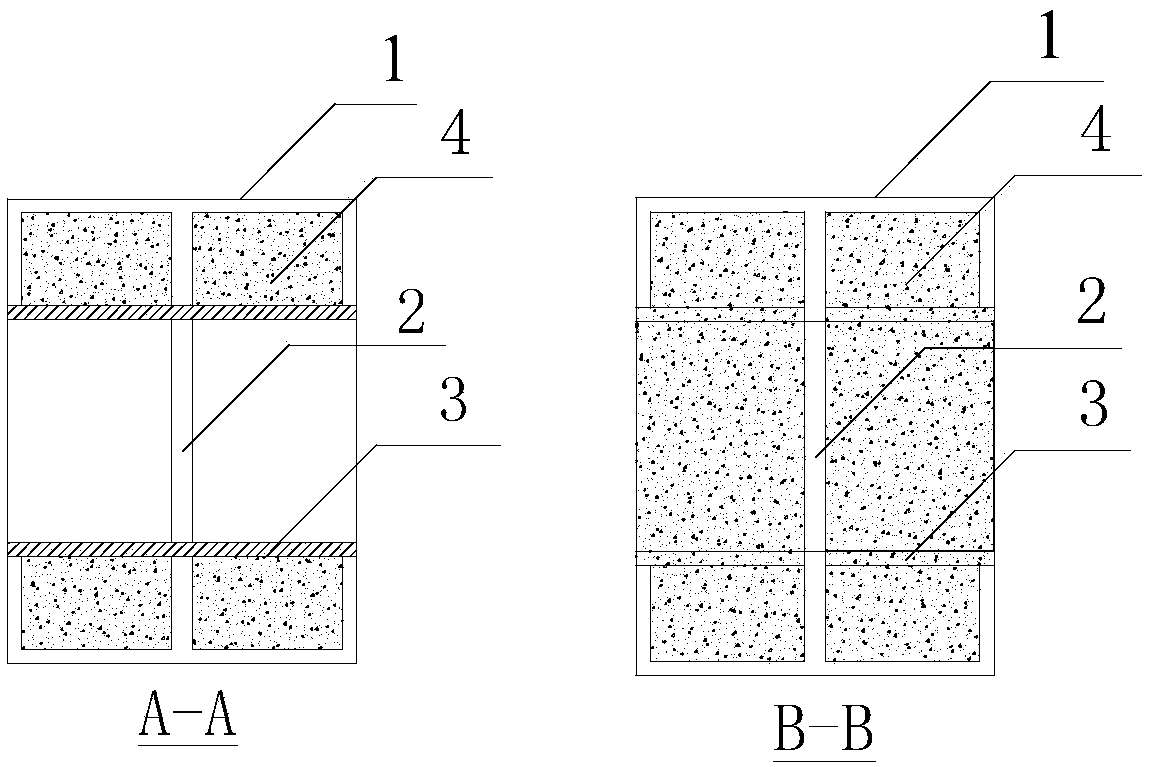

Anti-slip partially-encased type combined beam and prefabrication method thereof

ActiveCN109457866AGuaranteed to work togetherActs as an anti-stick-slipLoad-supporting elementsCeramic shaping apparatusMaterials sciencePrefabrication

The invention discloses an anti-slip partially-encased type combined beam and a prefabrication method thereof. The anti-slip partially-encased type combined beam comprises channel steel (1), a steel plate (2) with a hole, a square steel pipe (3), an inner filling concrete (4) and end steel plates (5), wherein the upper side and lower side of the steel plate (2) with the hole are respectively welded with the channel steel (1); the square steel pipe (3) penetrates through the hole of the steel plate (2) with the hole, and is welded on the hole; the end steel plates (5) are welded at both ends ofthe channel steel (1), and the concrete (4) is filled into a steel skeleton of the beam member formed by the channel steel (1) and the steel plate (2) with the hole, so as to finally form the anti-slip partially-encased type combined beam. The anti-slip partially-encased type combined beam has the advantages that the self weight of the member can be reduced, the anti-sticking slip function is realized, and the section steel and the concrete are ensured to work together.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com