Method for reinforcing concrete columns by adopting UHPC

A technology for concrete columns and concrete structures, which is used in construction, building maintenance, building construction, etc., can solve the problems of large space occupied by concrete columns, affecting the building area, and increasing labor costs, so as to improve compactness and homogeneity. performance, reducing labor costs and time costs, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

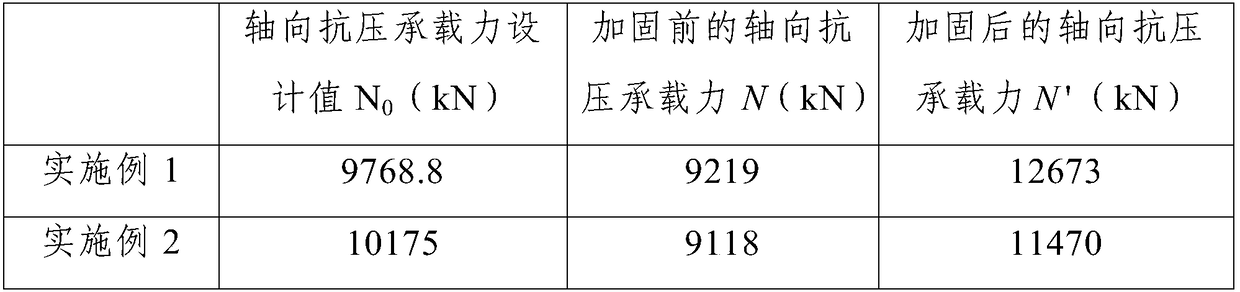

[0030] Taking C35 concrete column (length 700mm×width 700mm×height 4800mm) as an example, the design value of axial compressive strength of C35 concrete is f c0 =16.7N / mm 2 , the reinforcement of C35 concrete column is: longitudinal reinforcement 16D20, stirrup C8@100 / 200, design value of longitudinal reinforcement tensile strength f y0 =435N / mm 2 , design value of compressive strength of longitudinal reinforcement f y0' =410N / mm 2 , design value of stirrup tensile strength f yg =360N / mm 2 ; Design value of axial compressive bearing capacity of C35 concrete column N 0 =9768.8kN.

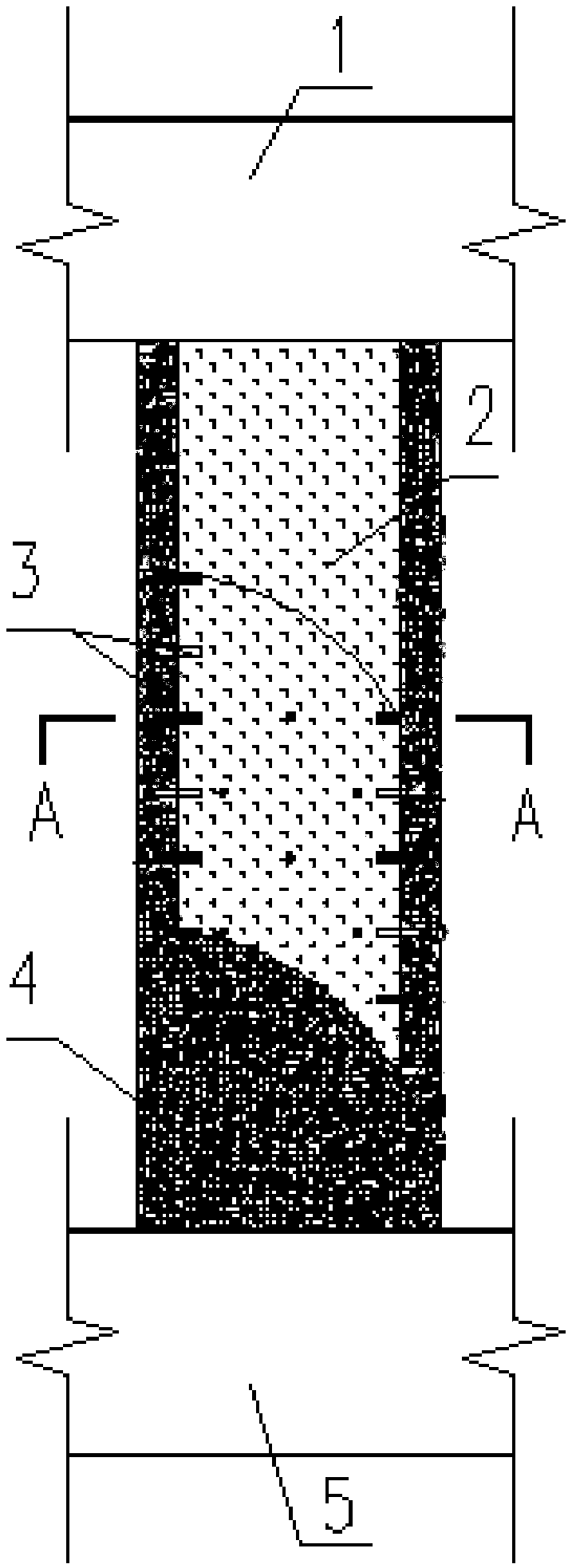

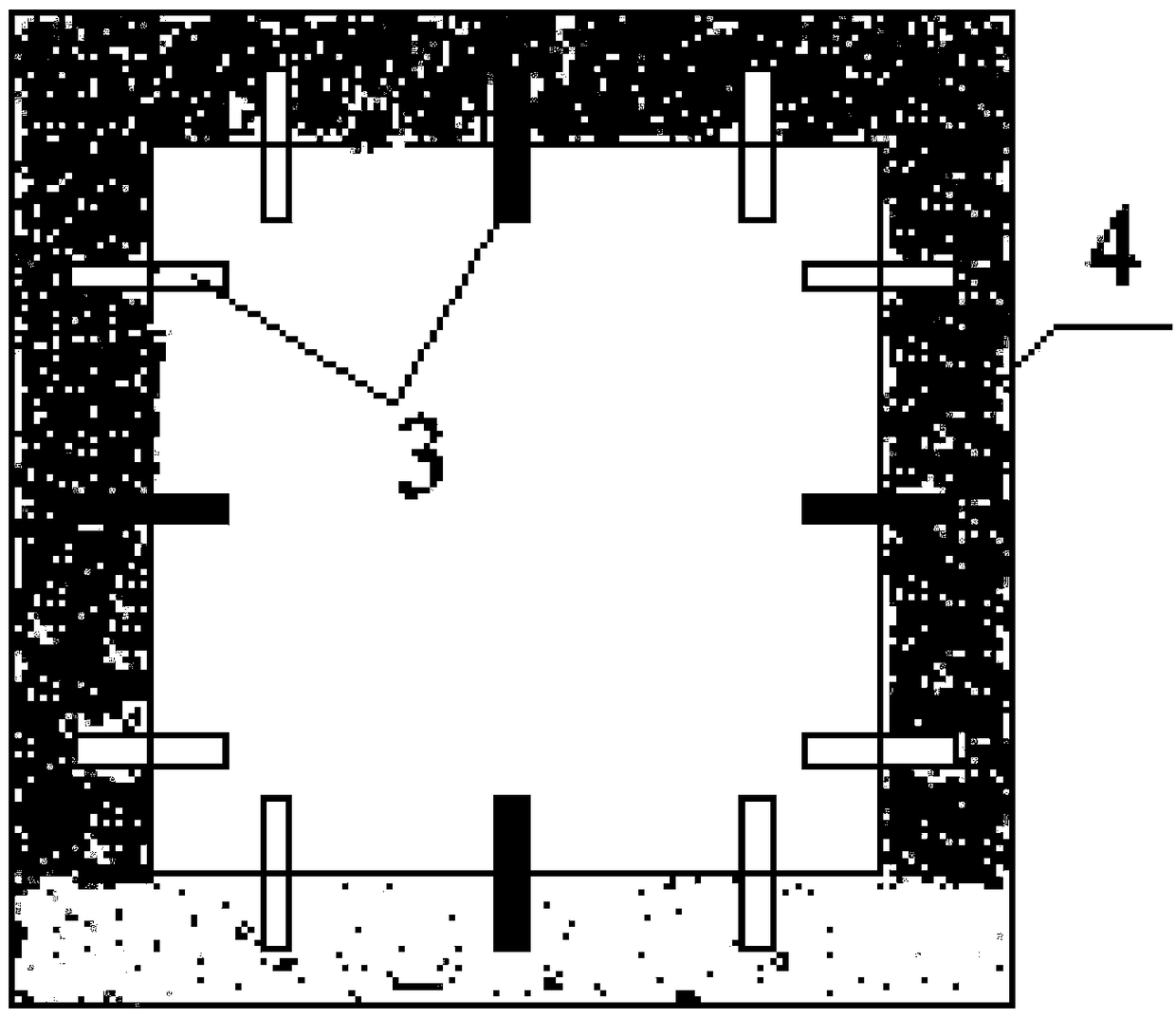

[0031] like figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0032] Step 1: Carry out roughening treatment on the surface of the concrete column 2; the roughening treatment adopts a 1.5kg-2.5kg pointed chisel hammer to chisel pits on the concrete bonding surface, forming spots with a depth of 3mm and a number of spots of 600 points / m 2 ~800 points / m 2 unifo...

Embodiment 2

[0037] Taking the C40 concrete column (length 650mm×width 650mm×height 4000mm) as an example, the design value of concrete axial compressive strength f c0 =19.1N / mm 2 ; The reinforcement of C40 concrete column is: longitudinal reinforcement 16D20, stirrup C8@100 / 200, design value of longitudinal reinforcement tensile strength f y0 =435N / mm 2 , design value of compressive strength of longitudinal reinforcement f y0' =410N / mm 2 , design value of stirrup tensile strength f yg =360N / mm 2 ; Design value of axial compressive bearing capacity of C40 concrete column N 0 =10175kN.

[0038] like figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0039] Step 1. The surface of the concrete column 2 is subjected to roughening treatment; the roughening treatment uses a 1.5kg-2.5kg pointed chisel hammer to chisel out pits on the concrete bonding surface, forming spots with a depth of 4mm-5mm, Plum blossom-shaped distribution with a spacing of 30mm;

...

Embodiment 3

[0044] Taking the C40 concrete column (length 700mm×width 700mm×height 4200mm) as an example, the design value of the axial compressive strength of concrete f c0 =19.1N / mm 2 ; The reinforcement of C40 concrete column is: longitudinal reinforcement 16D20, stirrup C8@100 / 200, design value of longitudinal reinforcement tensile strength f y0 =435N / mm 2 , design value of compressive strength of longitudinal reinforcement f y0' =410N / mm 2 , design value of stirrup tensile strength f yg =360N / mm 2 ; Design value of axial compressive bearing capacity of C40 concrete column N 0 =12000kN.

[0045] like figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0046] Step 1. The surface of the concrete column 2 is subjected to roughening treatment; the roughening treatment uses a 1.5kg-2.5kg pointed chisel hammer to chisel out pits on the concrete bonding surface, forming spots with a depth of 4mm-5mm, Plum blossom-shaped distribution with a spacing of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com