Coating paint for magnesia carbon bricks

A magnesia-carbon brick and coating technology, applied in the field of materials, can solve problems such as crushing of magnesia-carbon bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

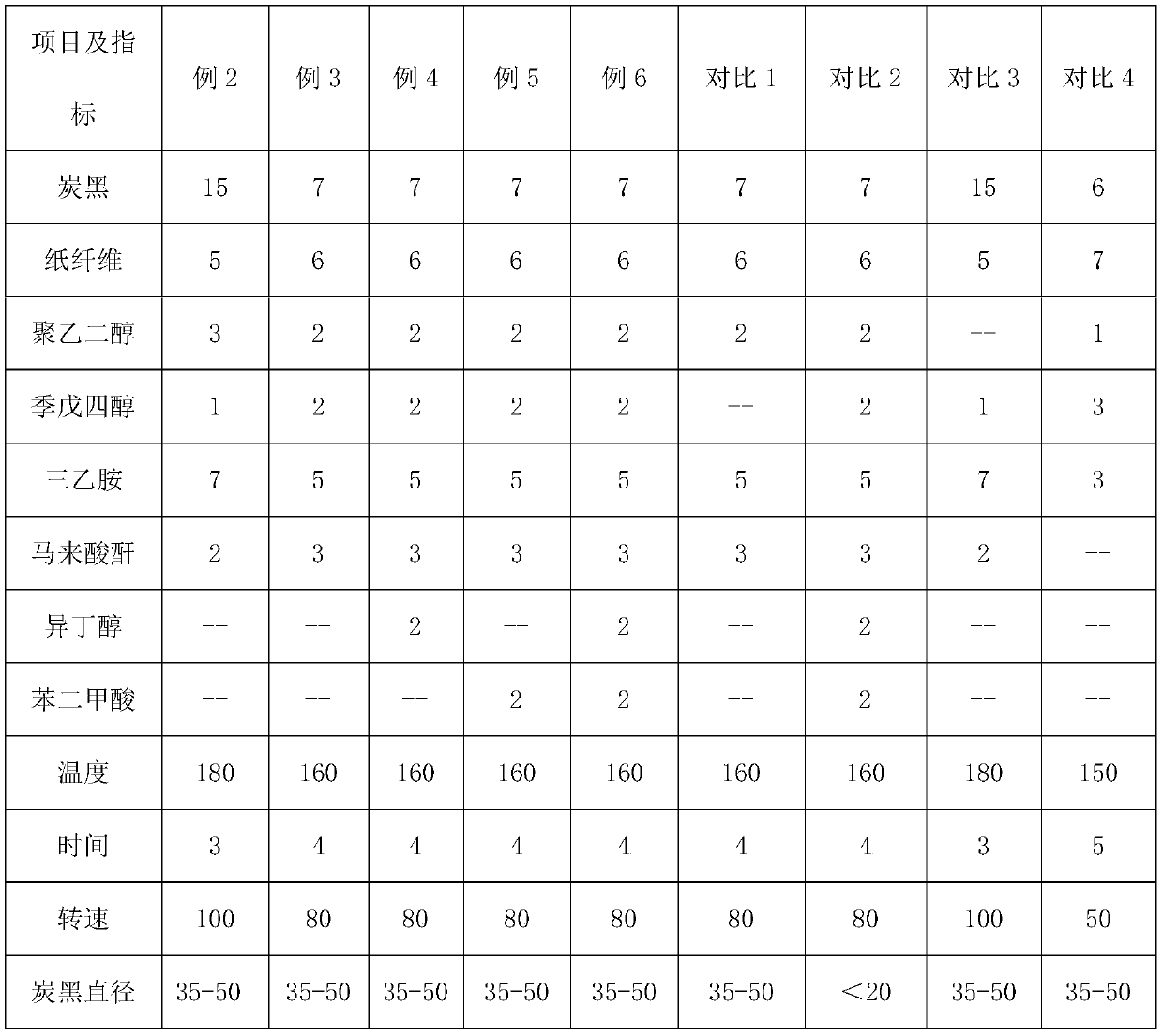

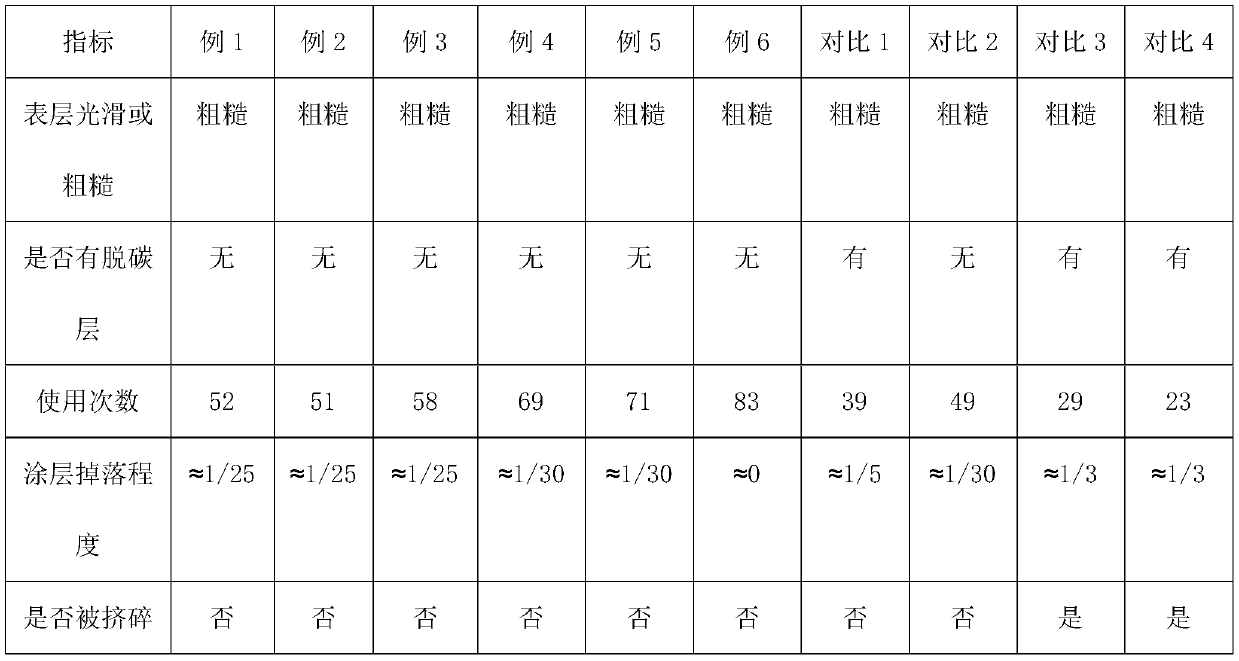

[0027] The preparation method of the above-mentioned coating paint is to add each component into a heating container according to a predetermined ratio, then heat at 150-180°C for 3-5 hours, stir evenly at a stirring speed of 50-100 rpm during heating, and finally cool to room temperature That's it.

[0028] The method of using the above-mentioned coating paint is to evenly spray or brush the prepared coating paint on the surface of the magnesia-carbon brick and then dry it naturally, then heat it at 150°C for 2 hours, and finally cool it to room temperature. Preferably, the thickness of the coating on the surface of the magnesia carbon brick is 0.2-0.25mm.

Embodiment 1

[0030] A coating coating for magnesia carbon bricks, the components of the coating coating include carbon black, paper fiber, polyethylene glycol, pentaerythritol, triethylamine, maleic anhydride and water, wherein each of the coating coating The components are 6% by weight of carbon black, 7% of paper fiber, 1% of polyethylene glycol, 3% of pentaerythritol, 3% of triethylamine, 4% of maleic anhydride, and the balance is water.

[0031] The particle size of the carbon black is 35-50 μm, and the fiber length of the paper fiber is 0.5-2 mm;

[0032] The preparation method of the above-mentioned coating paint is to add each component into a heating container according to a predetermined ratio, then heat at 150°C for 5 hours, stir evenly at a stirring speed of 50 rpm during heating, and finally cool to room temperature.

[0033] The method of using the above-mentioned coating paint is to spray or brush the prepared coating paint evenly on the surface of the magnesia-carbon brick a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com