Patents

Literature

193results about How to "Guaranteed not to be oxidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

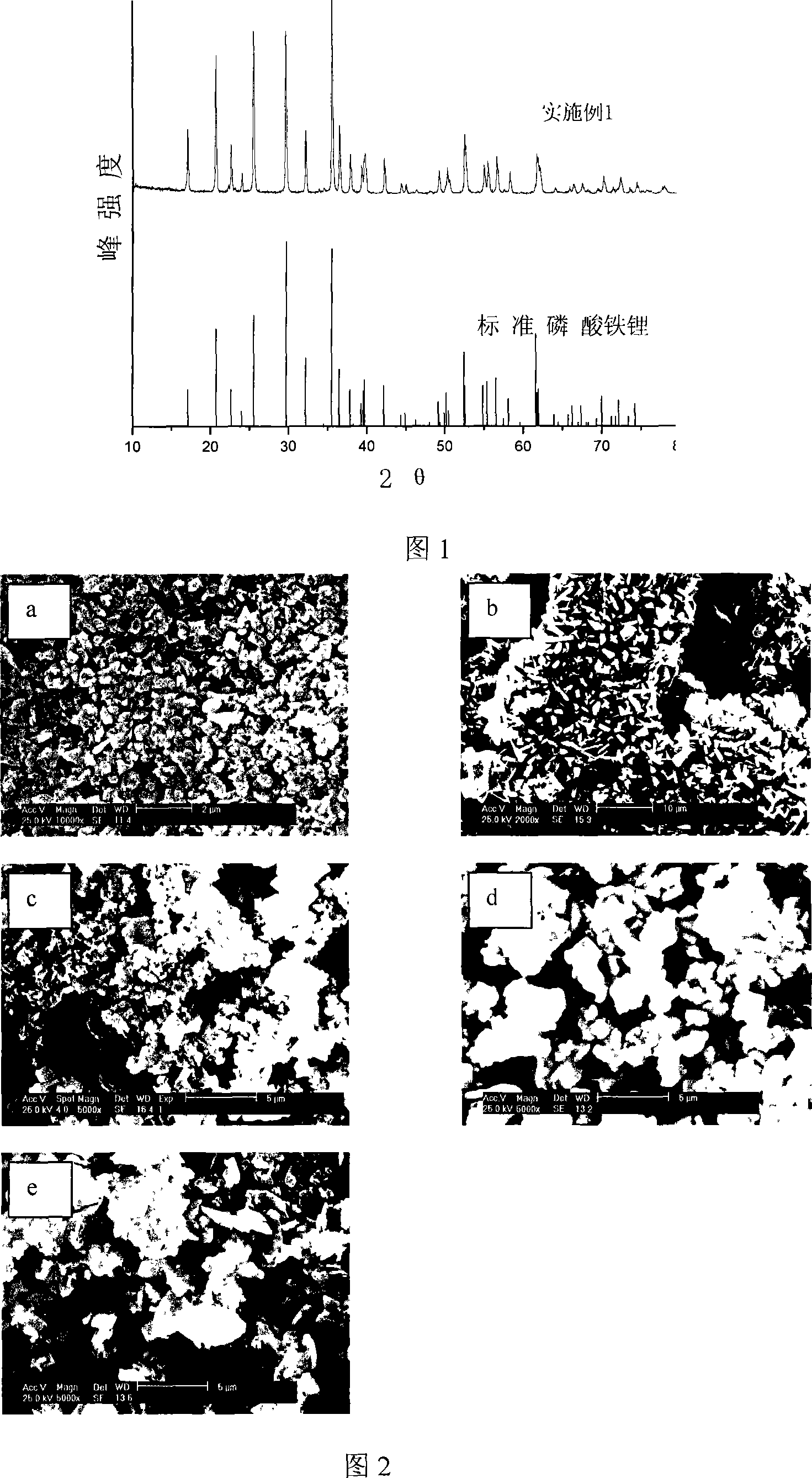

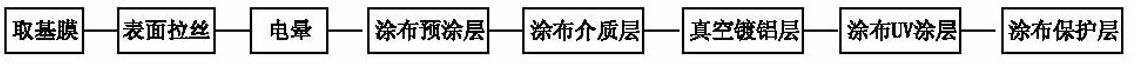

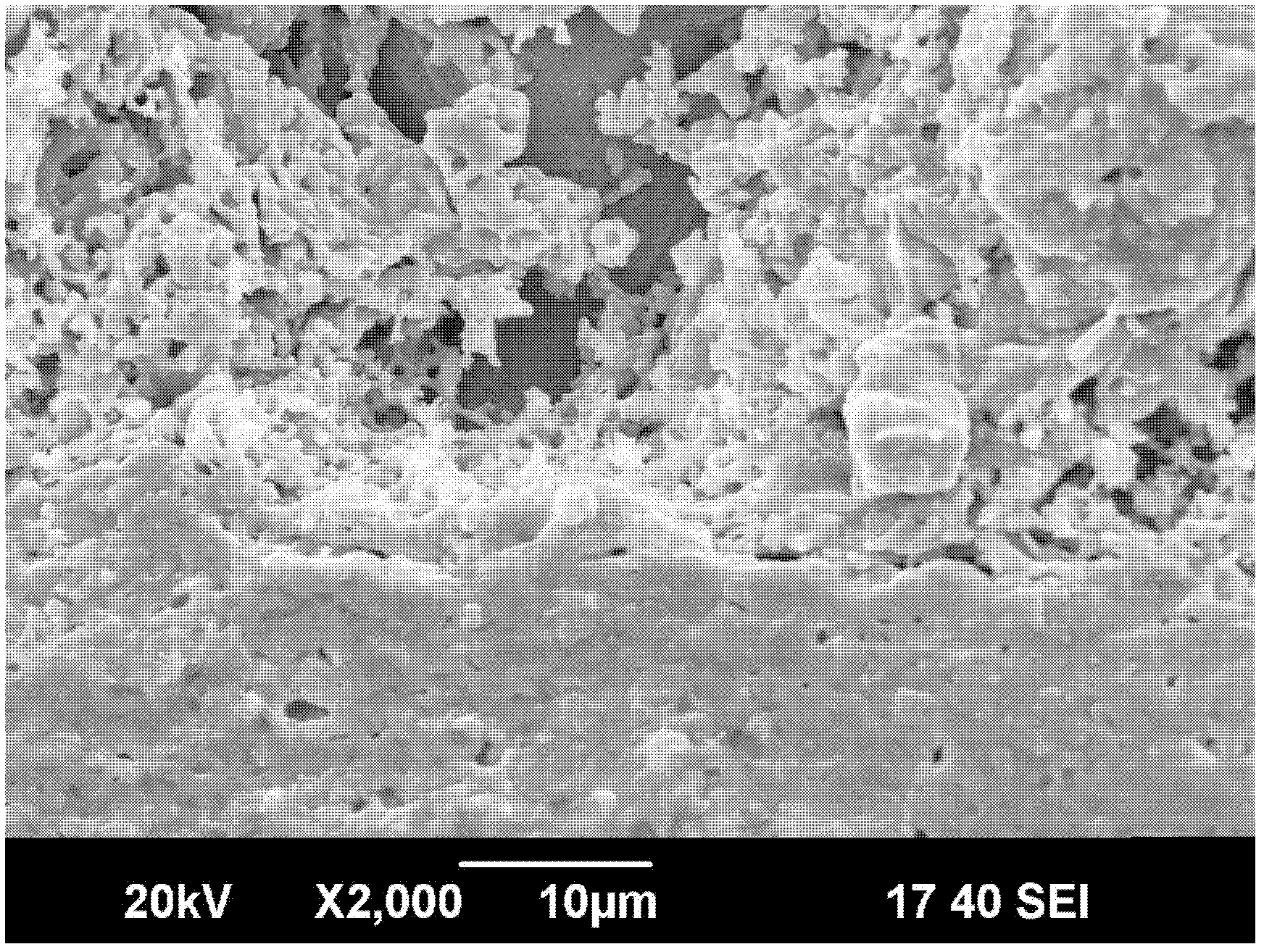

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

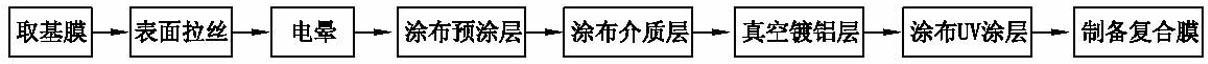

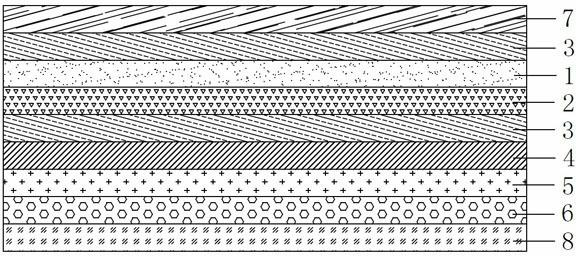

Manufacture process of imitation stainless steel metal drawbench film

InactiveCN102642439AIncrease the dyne coefficientHigh fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterAcrylic coating

The invention discloses a manufacture process of an imitation stainless steel metal drawbench film, which comprises the following steps: 1 taking a base film which is a polyester (PET) film; 2 conducting surface drawbench and surface polishing one surface of the base film; 3 conducting surface corona and conducting corona processing on two surfaces of the base film, 4 conducting precoat coating and conducting network roller coating on the surface of the base film receiving surface drawbench and corona processing through methyl methacrylate coating, 5 conducting media layer coating and conducting network roller coating on a precoat through acrylic coating, 6 conducting vacuum aluminizing on the media layer, 7 conducting ultraviolet (UV) coating coating and conducting network roller coating on one face of the base film without surface drawbench through colored translucent UV coating, and 8 conducting protection layer coating and preventing an aluminizing layer from being oxidized. The manufacture process improves product structure firmness, and ensures optimum using effects of products. The products can show different gloss effects from dumb light to high light, thereby meeting requirements for environment protection.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

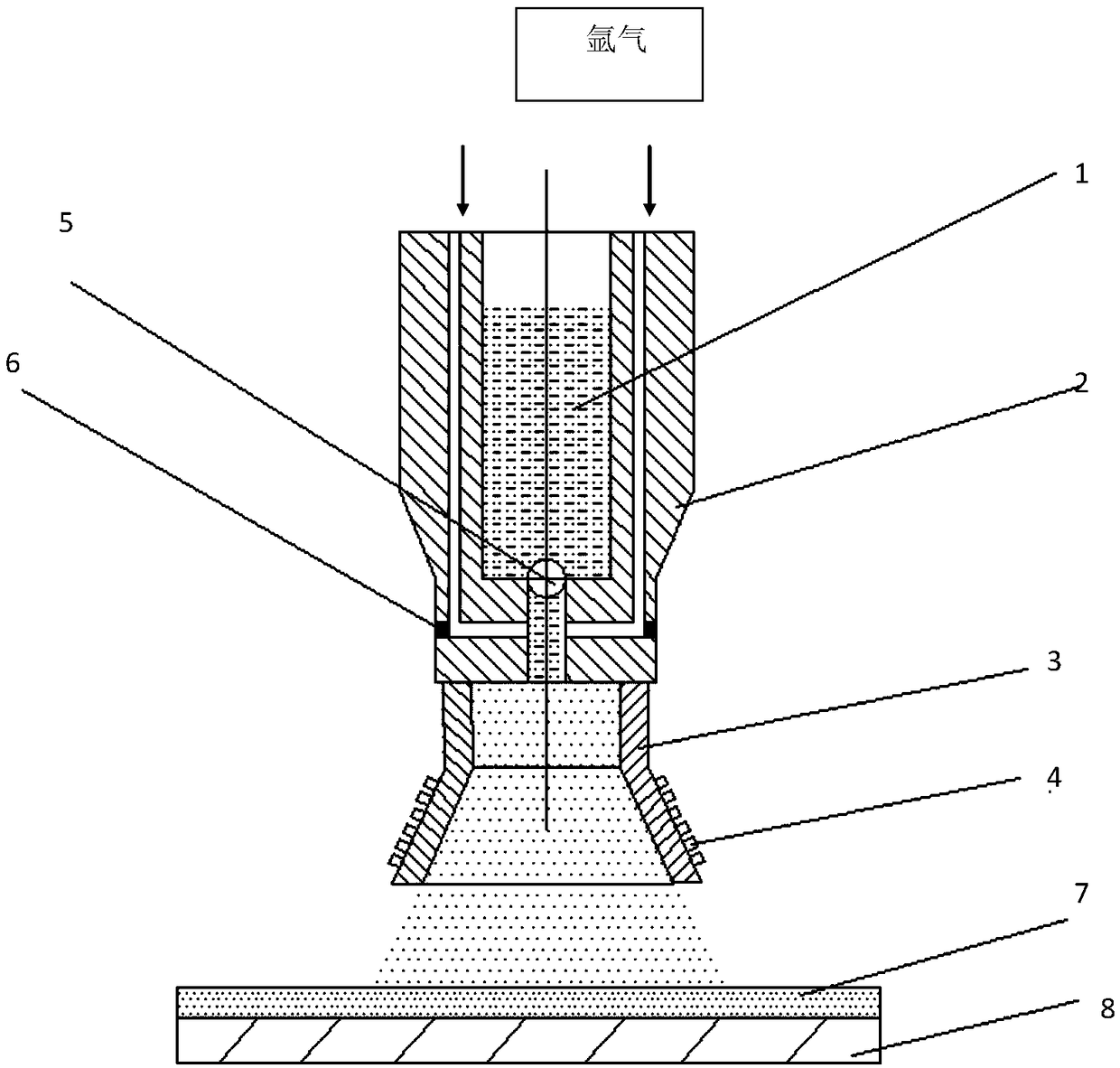

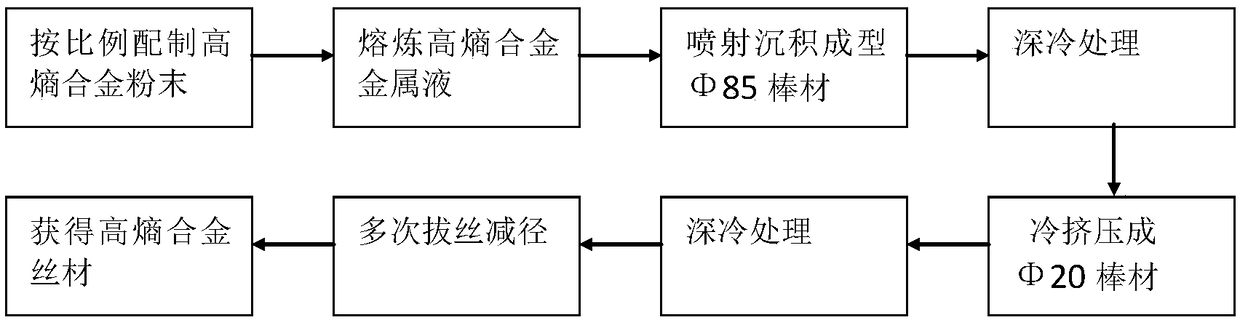

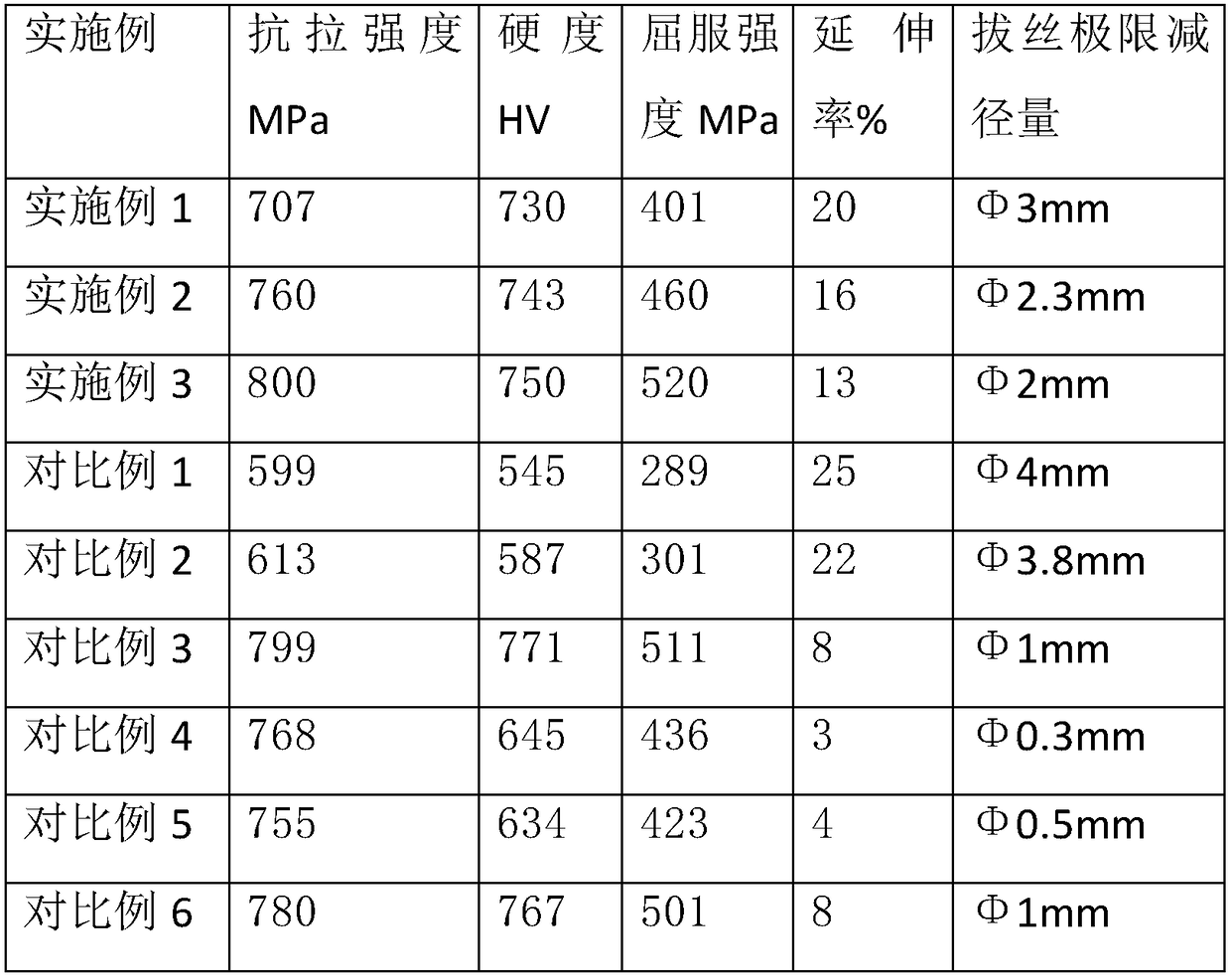

High-entropy alloy solid wire for arc cladding and preparation method thereof

ActiveCN109234601AImprove plasticityHigh strengthMetallic material coating processesHigh entropy alloysRoom temperature

The invention discloses a high-entropy alloy solid wire for arc cladding. The solid wire is a high-entropy alloy composed of 5 base elements: Co, Cr, Fe, Mn and Ni and a non-base element: Er. The preparation method comprises the following steps: (1) ball milling: weighing Co powder, Cr powder, Fe powder, Ni powder, Mn powder and Er powder according to molar fractions, and adding the powder into ahigh-energy ball mill for ball milling; (2) spray deposition molding: melting the high-entropy alloy powder, atomizing and depositing the solution into a cylindrical mold with high-pressure argon to obtain a high-entropy alloy bar; (3) cryogenic treatment: soaking the high-entropy alloy bar in liquid nitrogen at -196 DEG C for 48 h; (4) extrusion process: extruding the high-entropy alloy bar tilla diameter is phi 20 mm, and naturally heating the alloy bar to room temperature; (5) wire drawing process: soaking the extruded high-entropy alloy bar in the liquid nitrogen at -196 DEG C for 24 hours, performing wire drawing and reduction for multiple times, and finally obtaining the solid wire with the diameter of phi 2 mm.

Owner:JIANGSU UNIV OF TECH

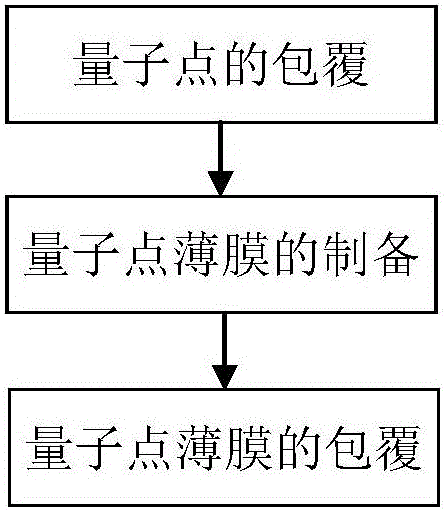

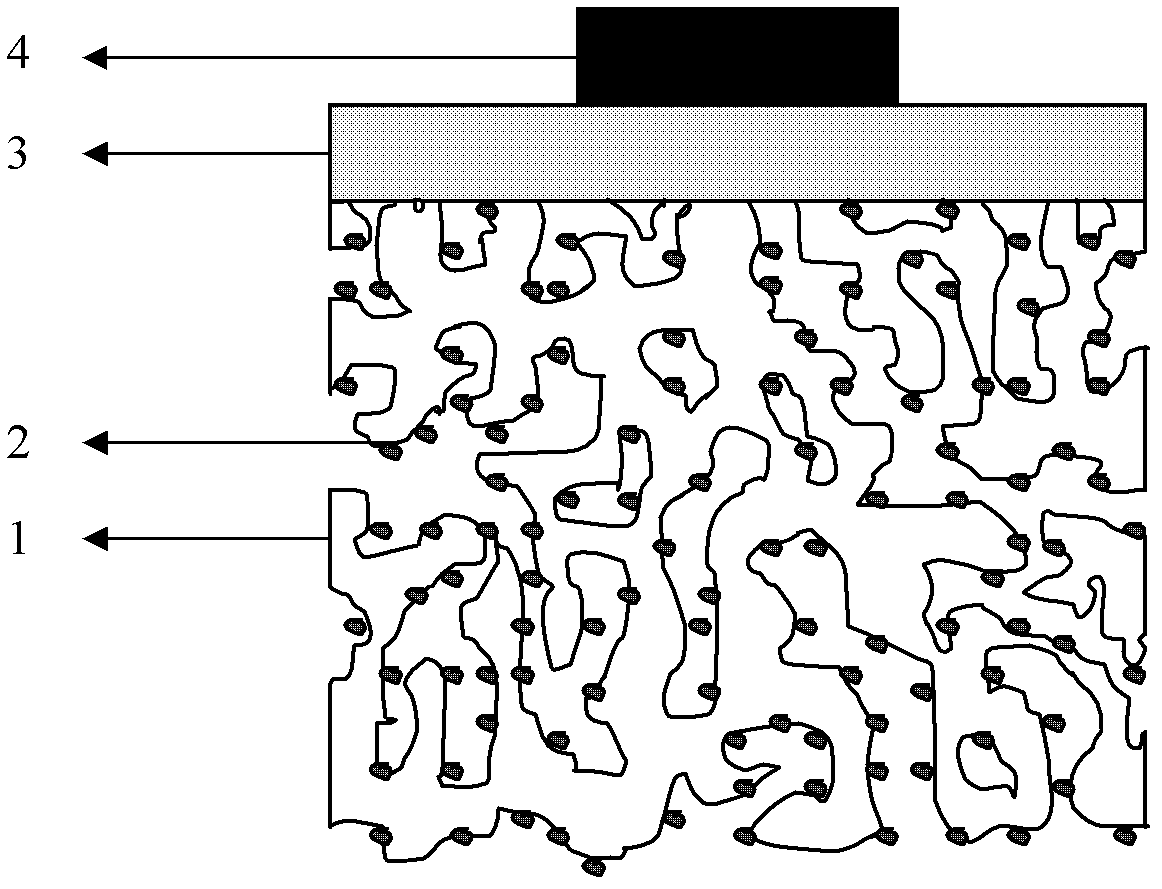

Preparation method of quantum dot film

ActiveCN105779968APlay a protective effectAchieve protectionChemical vapor deposition coatingOrganic filmPolyethylene terephthalate

Disclosed is a preparation method of a quantum dot film. The preparation method of the quantum dot film comprises the following steps that (1) a metal oxide film with the nanometer or sub-micron thickness is formed on the surfaces of quantum dots in a deposition mode through an atomic layer deposition technology so as to cover the quantum dots; (2) the quantum dots with covering metal oxide coat an organic film polyethylene terephthalate substrate, so that the quantum dot film is obtained through preparation; and (3) oxide films with the nanometer or sub-micron thickness are formed on the surface of the quantum dot film and the surfaces of the quantum dots in a deposition mode through a spatial separation atomic layer deposition technology so as to ensure that the quantum dots are not oxidized. According to the preparation method of the quantum dot film, due to the fact that the method with the step that passive films cover the surfaces of the quantum dots step by step is adopted to prepare the quantum dot film, the problem that due to the fact that the quantum dots are prone to being oxidized, the luminescence performance of the quantum dots is lost is solved, and the preparation method has the advantages of being simple in preparation technology, low in preparation cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

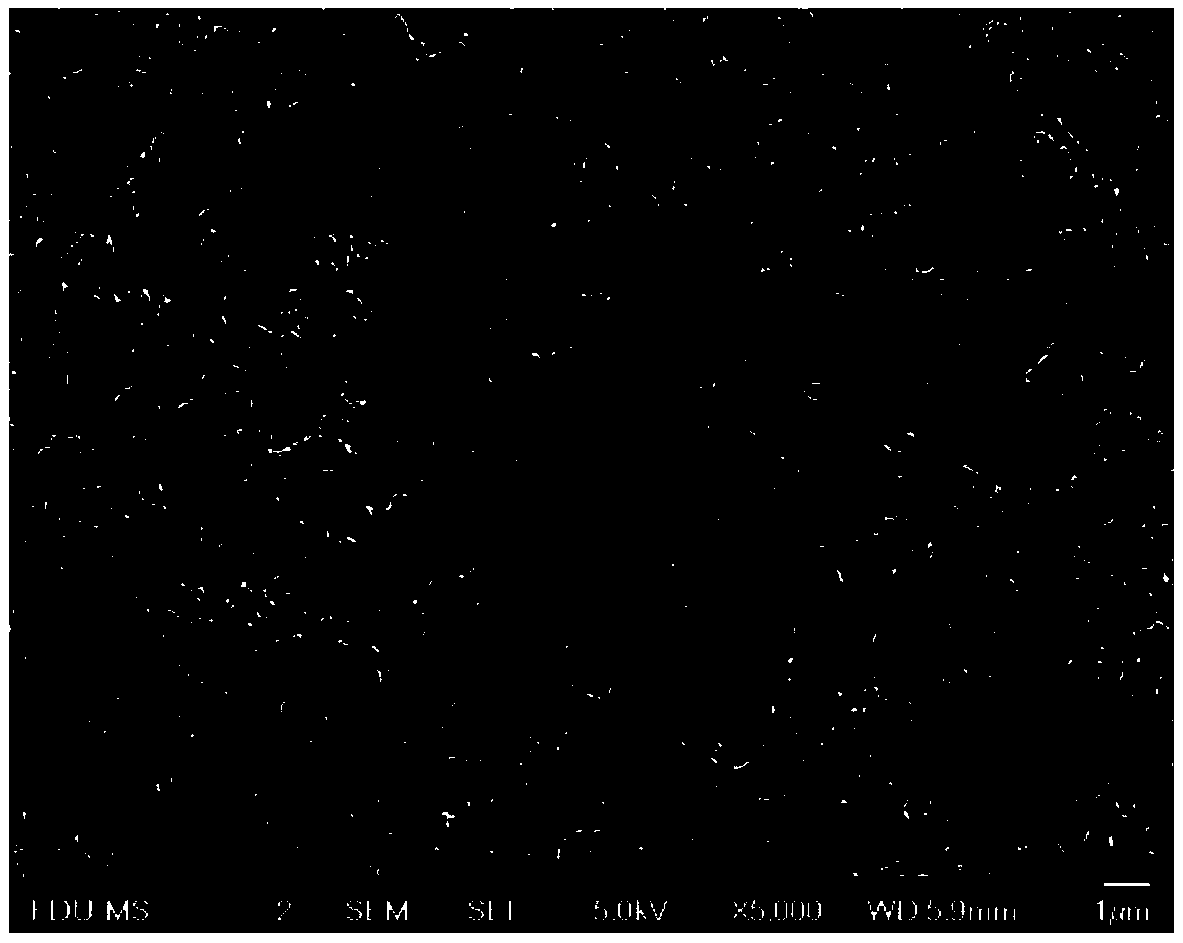

Nano-copper soldering paste, preparing method thereof and copper-copper bonding method

ActiveCN109317859AGuaranteed not to be oxidizedPromote sinteringWelding/cutting media/materialsSoldering mediaNano copperSoldering

The invention belongs to the technical field of electronic materials, and discloses nano-copper soldering paste, a preparing method thereof and a copper-copper bonding method achieved through the nano-copper soldering paste. The nano-copper soldering paste comprises, by mass percent, 50 to 90% of nano-copper particles, 5 to 25% of hydramine and 0 to 45% of a viscosity modifier. The nano-copper soldering paste is used for copper-copper bonding, the sintering temperature can be reduced, oxidation and agglomeration of the nano-copper particles can be avoided, in the 200 DEG C air, sintering can be finished, and the copper-copper inter-connection structure with the higher shear strength can be obtained.

Owner:FUDAN UNIV

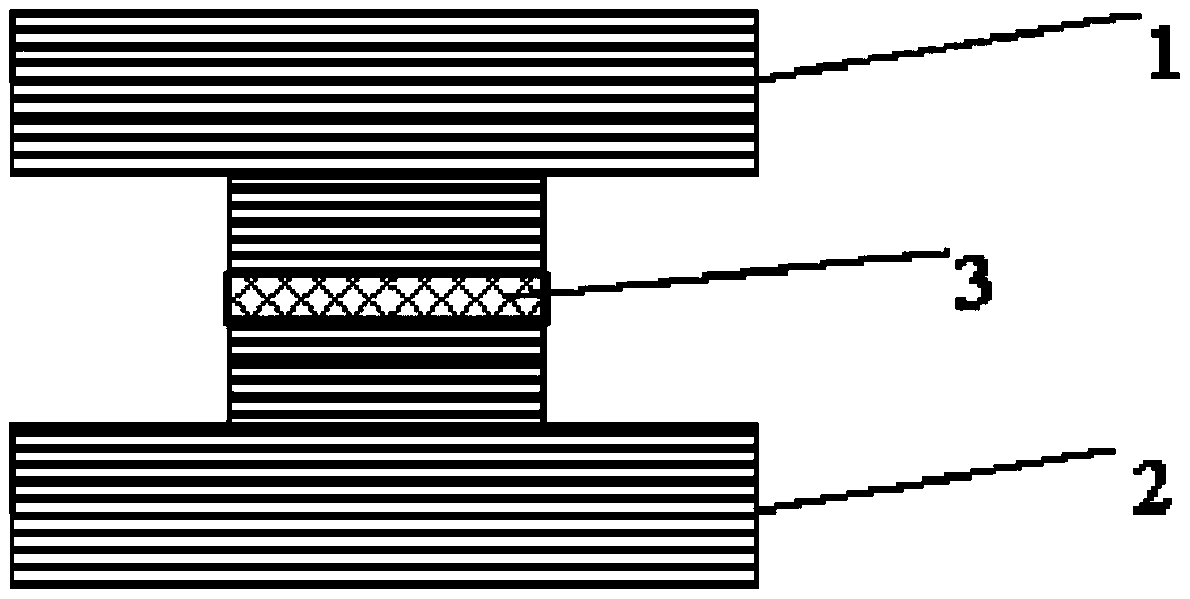

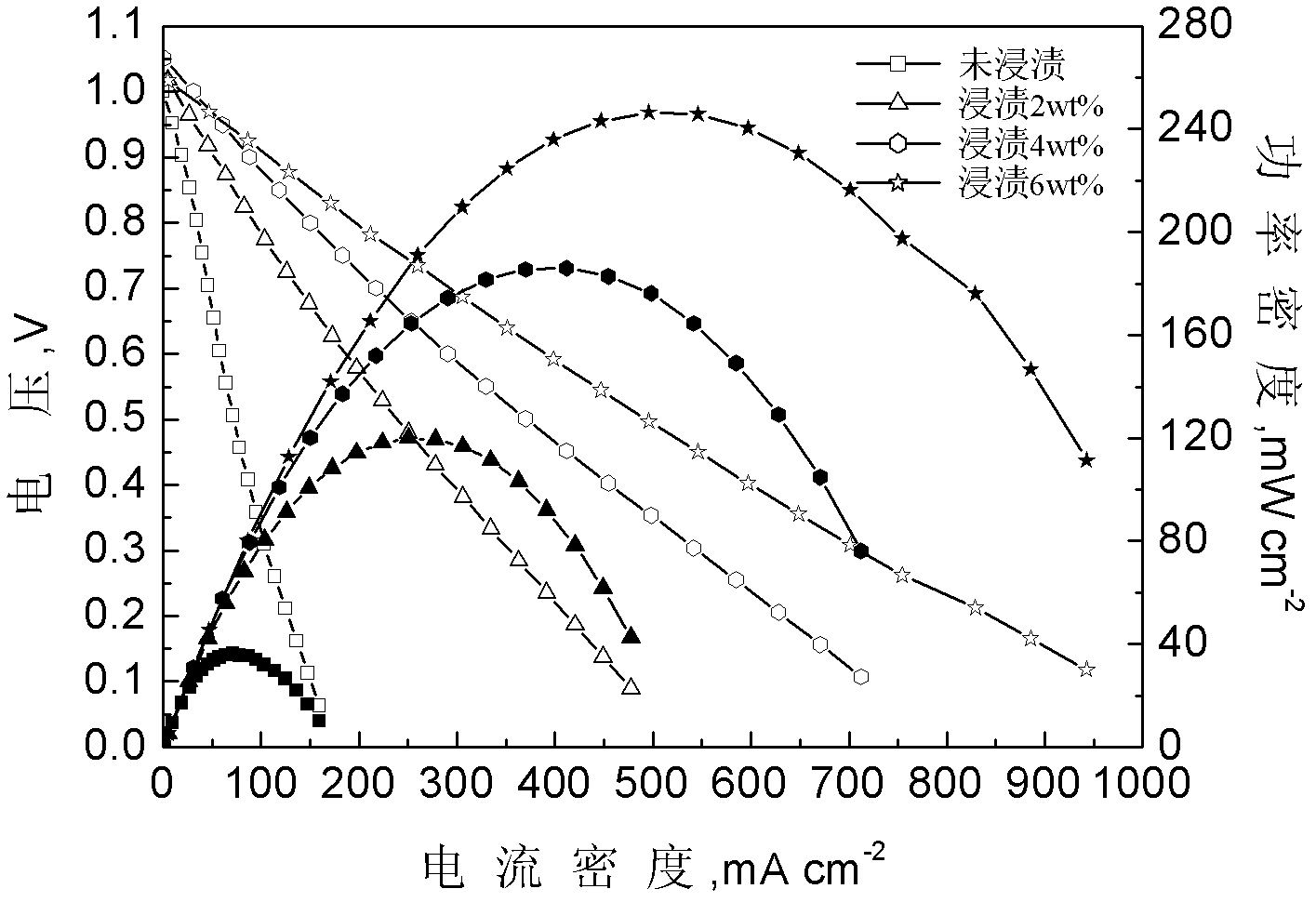

Three-layered structured oxide fuel cell supported by stainless steel and preparation method thereof

InactiveCN102437358AExtended cycleStable outputSolid electrolyte fuel cellsFuel cell detailsElectrochemical responsePorosity

The invention relates to solid fuel battery, in particular to a solid oxide fuel cell supported by stainless steel and a preparation method thereof. A cell structure comprises an anode 1, an electrolyte film 3 and a cathode 4; the anode 1 is a porous stainless steel supported body, wherein the pore of the porous stainless steel supported body contains catalyst 2 capable of catalyzing an electrochemical reaction of the solid oxide fuel cell anode; the thickness of the stainless steel supported body is 0.1 mm to 3 mm; the porosity is 10% to 60%, while the thickness of a compact electrolyte film is 2 microns to 80 microns. The solid oxide fuel cell supported by the stainless steel is proved that the cell has good output performance and resistance to oxidization and reduction.

Owner:UNIV OF SCI & TECH OF CHINA

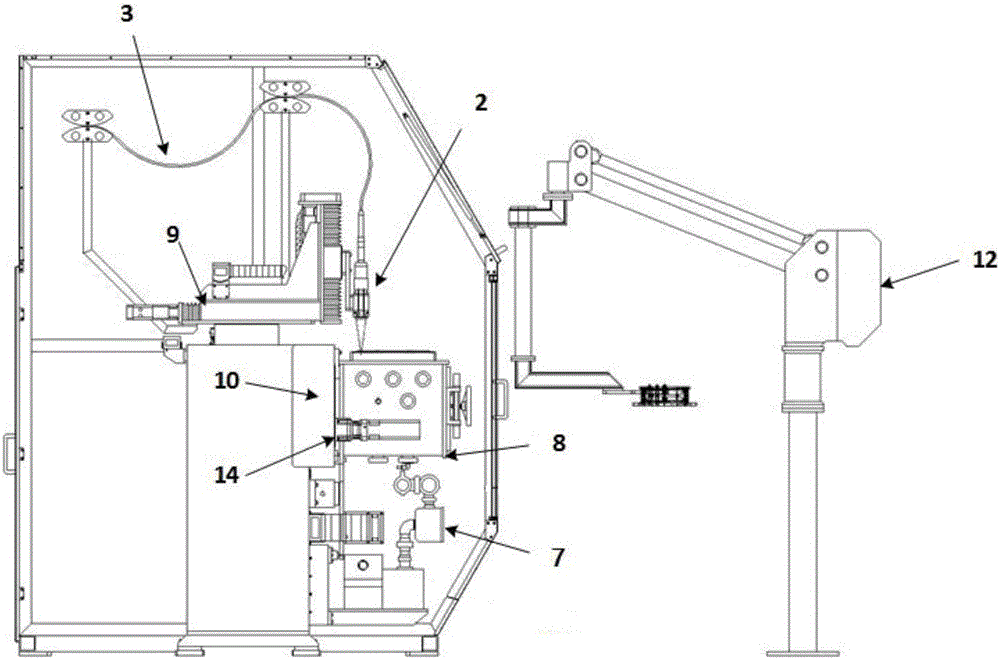

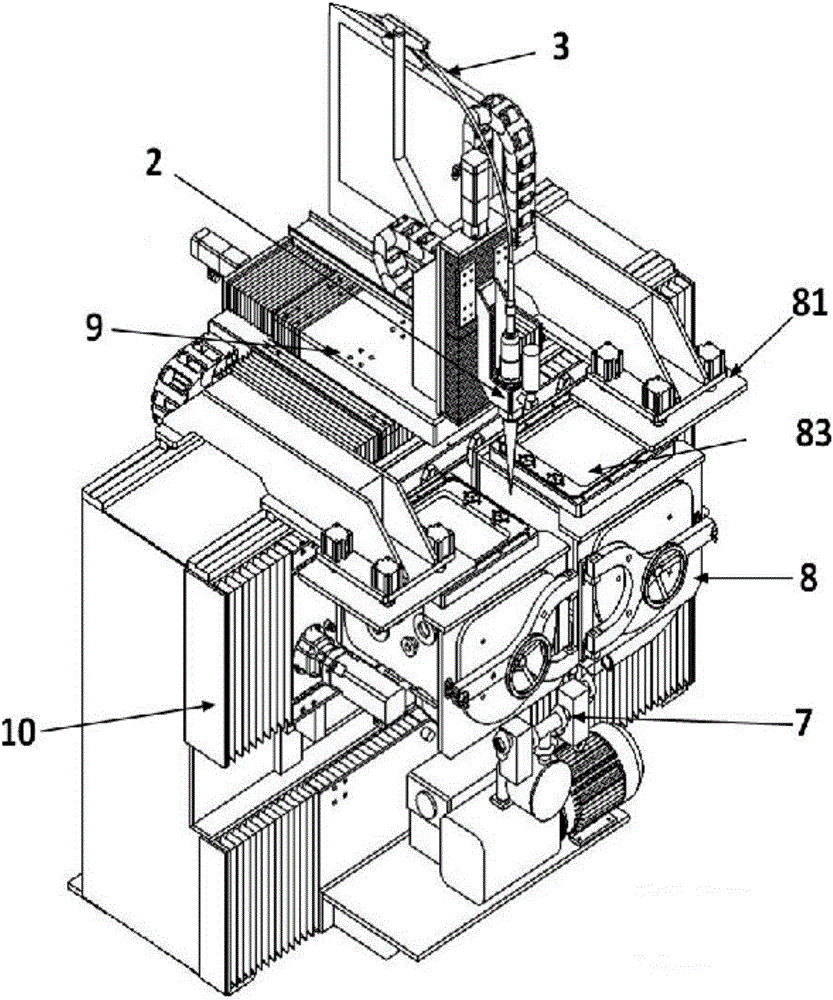

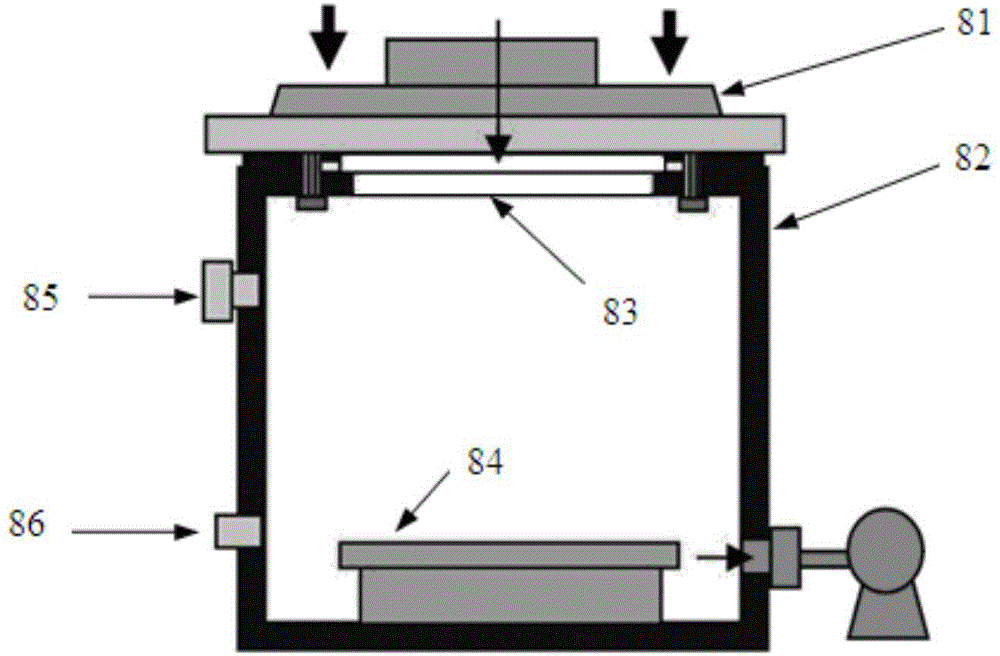

Vacuum laser welding system for grillwork

ActiveCN105710533AImprove flexibilityGood pointing stabilityLaser beam welding apparatusTransmittanceEngineering

The invention discloses a vacuum laser welding system for a grillwork and belongs to the technical field of laser welding. The vacuum laser welding system meets the requirements for the welding environment of the zirconium alloy grillwork and high precision. A laser welding head of the vacuum laser welding system is fixed to a three-dimensional movement mechanism. The three-dimensional movement mechanism drives the laser welding head to move. A laser signal input port of the laser welding head is connected with a laser signal output port of a laser device through an optical cable. A vacuum room is arranged under the laser welding head. The vacuum room is an airtight rectangular box body. Light-transmittance glass is arranged on the upper side wall of the box body. A worktable is arranged under the light-transmittance glass. The worktable is arranged on the bottom face of the vacuum room. A servo system drives the worktable to rotate and overturn through a workpiece position-changing mechanism. An argon charging opening and an exhaust opening are formed in the left side wall of the vacuum room. The vacuum laser welding system is suitable for welding the grillwork.

Owner:哈尔滨工大焊接科技有限公司

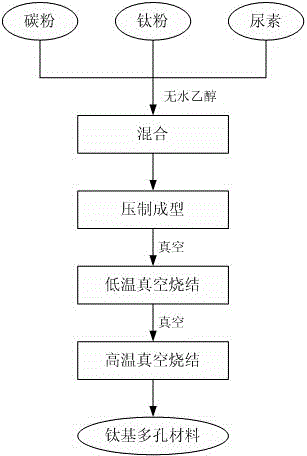

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

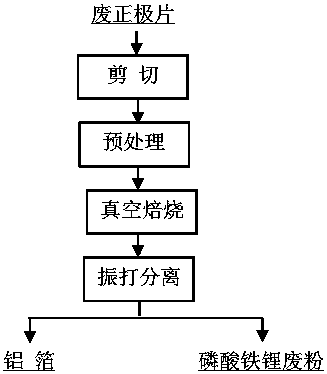

Vacuum separation method of waste lithium iron phosphate battery positive plate

ActiveCN110148801AAvoid pollutionEasy to recycleWaste accumulators reclaimingBattery recyclingLithium iron phosphateSteel ball

A vacuum separation method of a waste lithium iron phosphate battery positive plate comprises the following steps: cutting the waste lithium iron phosphate battery positive plate into loose sheets, and putting the loose pole plates into a vacuum furnace for vacuum roasting at the temperature of 350-450 DEG C for 1-6 hours; putting the calcined waste pole sheets into a vibrating screen in batches;adding steel balls with different particle sizes at the same time; and vibrating and screening to obtain aluminum foils on the vibrating screen and lithium iron phosphate waste powder under the vibrating screen. According to the method, the situation that aluminum foils are damaged and enters the lithium iron phosphate waste powder in the vibrating and screening process is reduced; and meanwhile,lithium is activated, and a foundation is laid for direct repair and recovery of a lithium iron phosphate pyrogenic process.

Owner:ZHUZHOU SMELTER GRP

Antioxidant coating for surface of aluminum oxide-silicon carbidee-carbon brick

The invention relates to an antioxidant coating for the surface of an aluminum oxide-silicon carbidee-carbon (ASC) brick. The antioxidant coating is aqueous paste substance formed by mixing a component A and a component B by a weight part proportion of 100:101.5-102.5, wherein the component A is powder formed by mixing 50-70 parts by weight of glaze powder, 2-5 parts by weight of alpha-AL2O3 micro-powder, 1-7 parts by weight of bentonite powder, 1-3 parts by weight of SiO2 micro-powder and 26-35 parts by weight of silicon carbide powder; the component B viscous fluid formed by dissolving 1.5-2.5 parts by weight of carboxymethyl cellulose into 100 parts by weight of water, and the glaze powder in the component A is fine powder prepared by drying and grinding an material formed by mixing, melting and quenching 40-60 parts by weight of borax, 12-18 parts by weight of quartz, 8-15 parts by weight of sodium carbonate, 12-15 parts by weight of calcite and 8-12 parts by weight of albite. After coated with the antioxidant coating, ASC bricks of the lining of a torpedo type mixed iron car has the service life prolonged at least for 50 heating numbers, which saves the refractory material.

Owner:常州市武进第一耐火材料有限公司

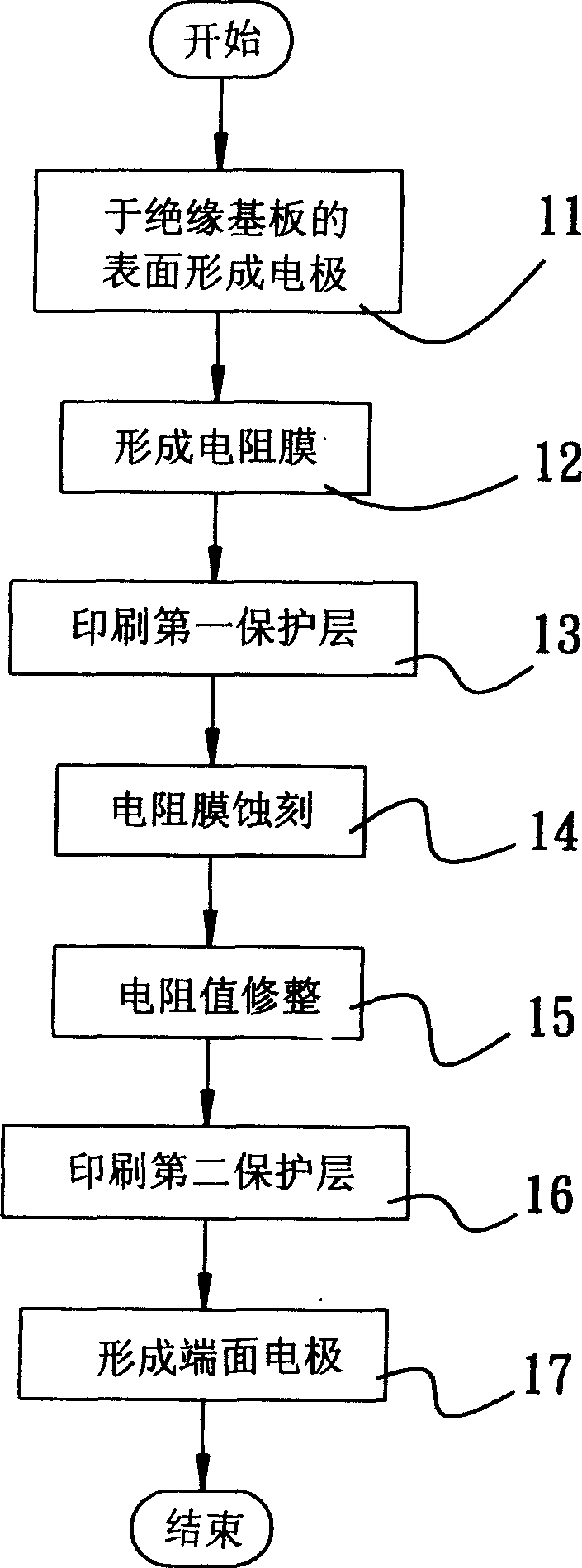

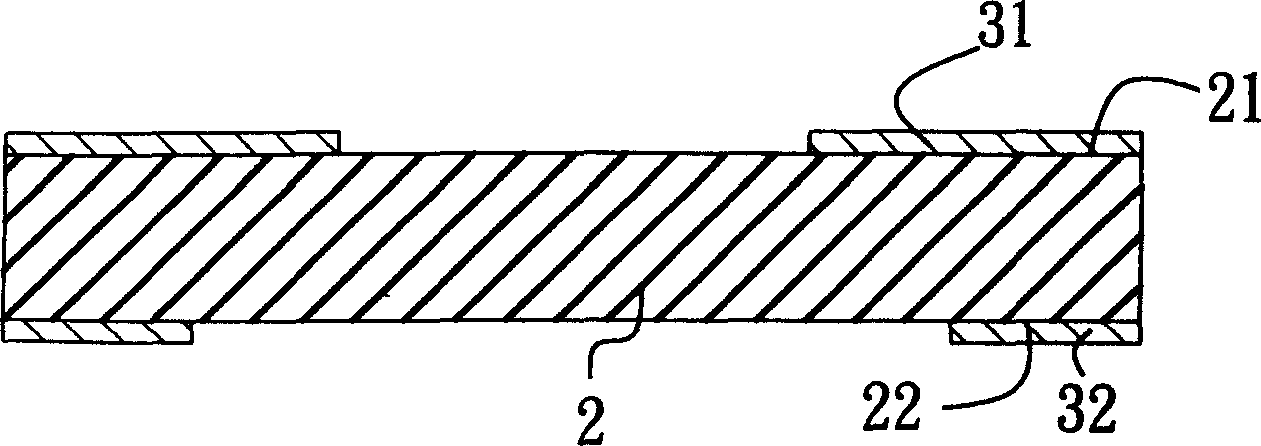

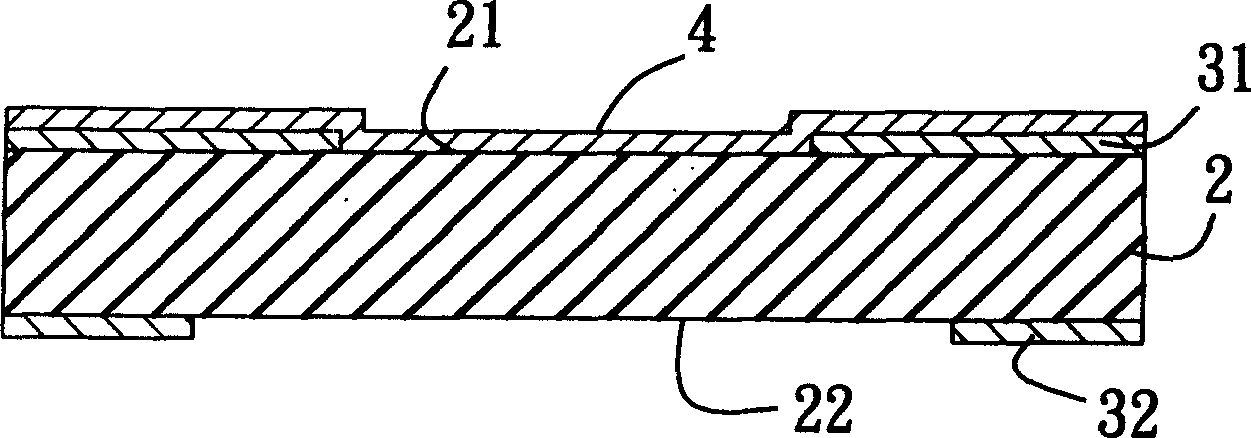

Method for manufacturing film resistance

InactiveCN1581370ASimplify the manufacturing processStable resistance film characteristicsPrinted circuit assemblingNon-adjustable resistorsSheet resistanceFilm resistance

First protection layer as a mask for etching resistance film further in order to form a patterned resistance film is formed on a resistance film through printing technique. The first protection layer can be utilized to protect resistance film, and does not need to be removed in following procedures. Thus, the invention simplifies fabricating flow and raises fineness rate of film resistor.

Owner:TA I TECH

Back surface field aluminum conductive slurry used for preparing silicon solar battery, and manufacturing method thereof

InactiveCN102737751AEasy to makeImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldAlloy

The invention provides back surface field aluminum conductive slurry used for preparing a silicon solar battery, and a manufacturing method thereof. The back surface field aluminum conductive slurry has a formula by mass percentage: 65-80% of aluminum powder, 10-19% of organic modifying solvent, 1-5% of lead-free glass powder, 0.1-8% of infiltration dispersant, and 0.1-3% of modifying nanometer level silicon powder, with the total amount being 100%. According to the back surface field aluminum conductive slurry obtained from the above formula, a sintered silicon chip and the aluminum powder and the nanometer level silicon powder in the slurry can form a silicon-aluminum alloy with a firm contact, thereby improving the electrical property and the photoelectric conversion efficiency of the battery, and the sintered silicon chip is required to be non-curved, have no aluminum bead, have a smooth surface, have no spot, have no lead, and meet environmental protection requirements.

Owner:SHANGHAI NEW TIANHE ELECTRONICS MATERIAL

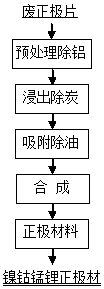

Comprehensive recovery method of waste lithium battery positive electrode piece

InactiveCN110144461AEasy to recycleAvoid pollutionCell electrodesWaste accumulators reclaimingRecovery methodSlag

The invention discloses a comprehensive recovery method of a waste lithium battery positive electrode piece. The method comprises the steps that a positive electrode leftover material and a wasted positive electrode piece are placed into a vacuum furnace to be calcinated, rapping and screening are conducted to obtain a positive active substance, the positive electrode active material is added to asulphuric acid leaching solution, second-stage leaching is conducted, and leached slag carbon and the leaching solution containing nickel, cobalt, manganese and lithium; activated carbon is added tothe leaching solution to perform adsorption deoiling and silica removing, nickel carbonate, cobalt carbonate, manganese carbonate or lithium carbonate is replenished to the filtered residue to obtainprecursors, ball milling, sintering, pulverizing, grinding and mesh screening are conducted on the precursors, and a nickel-cobalt-manganese-acid-lithium positive electrode material is obtained. The method has the advantages that the technology is reasonable, the separation cost is low, and there exists no pollution, toxin or harm.

Owner:ZHUZHOU SMELTER GRP

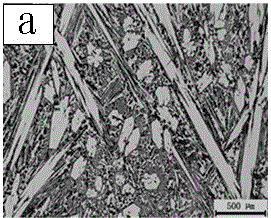

Preparing method for abrasion-resisting steel with oriented growth carbide

The invention belongs to the technical field of metal material preparing and machining, and discloses a preparing method for abrasion-resisting steel with oriented growth carbide. The method comprises the following steps that firstly, graphite powder, high-purity iron powder and alloy powder are weighed and matched; secondly, the mixed powder is taken out and pressed into cylindrical samples through a tablet press, and the cylindrical samples are stacked in a quartz tube; thirdly, the quartz tube is placed in a regional smelting furnace, and the quartz tube is heated in the vacuum state; and fourthly, the solidified and cooled samples are taken out, the quartz tube is broken, and the prepared abrasion-resisting steel material is obtained. The oriented solidification technology is adopted for preparing the abrasion-resisting steel with the oriented growth carbide, and the abrasion-resisting steel has high strength, tensile strength and hardness and high orientation performance. Meanwhile, the resolidification rate and the length of a melting region can be controlled by controlling the downward pulling speed and power of a heating coil, and abrasion-resisting steel materials different in carbide orientation degree and manner are prepared.

Owner:陕西华领新材料科技股份有限公司

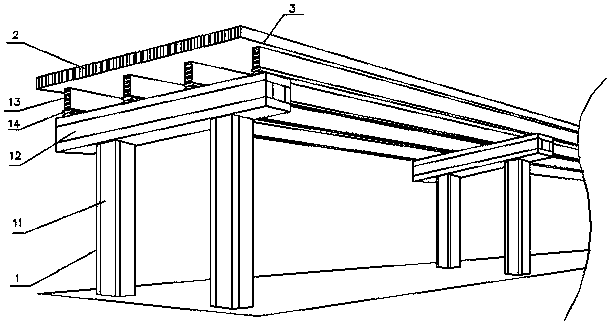

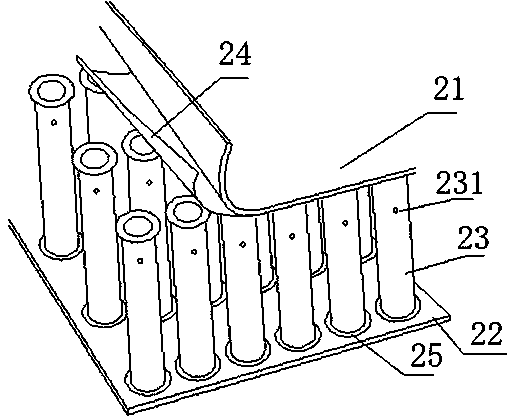

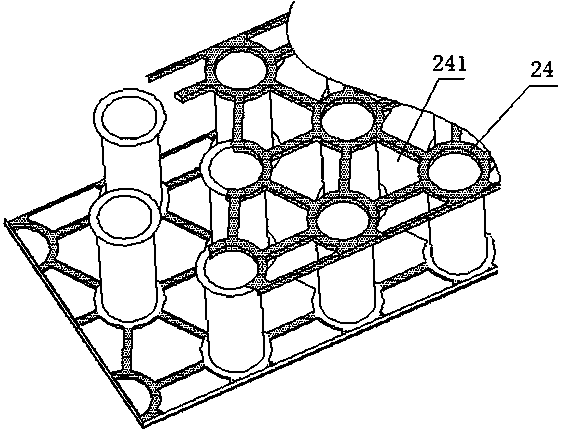

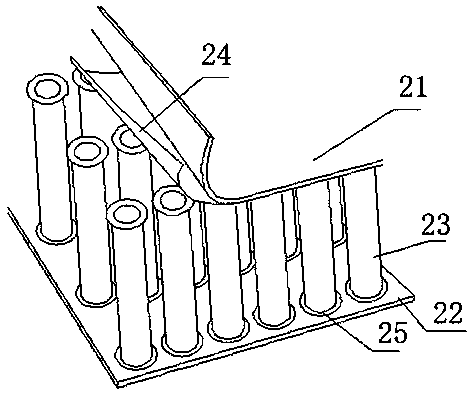

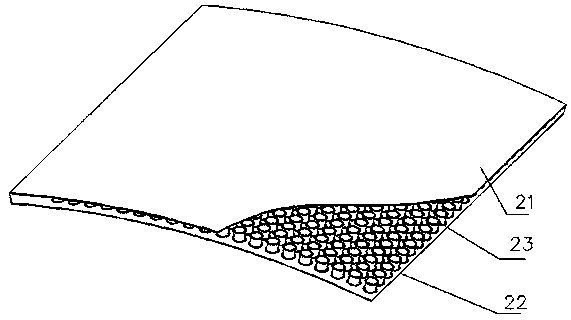

Viaduct structure

InactiveCN109403210AReduce stressIncrease the welding areaBallastwayDoors/windowsEngineeringTemperature resistance

A viaduct structure comprises a deck and a supporting body used for supporting the deck. The viaduct structure is characterized in that the deck and / or the supporting body is made of a metal plate; the metal plate comprises a first panel, a second panel and multiple hollow pipes, wherein the multiple hollow pipes are arranged between the first panel and the second panel; brazing layers are arranged between the hollow pipe and the first panel and between the hollow pipe and the second panels; and a turned-up edge is arranged at at least one end of each hollow pipe. The viaduct structure has theadvantages of light deadweight, high strength, stable structure, high pressure bearing capacity, sound insulation and noise reduction, high temperature resistance, vibration resistance, long servicelife and the like, and the viaduct structure can also be conveyed and spliced.

Owner:张跃

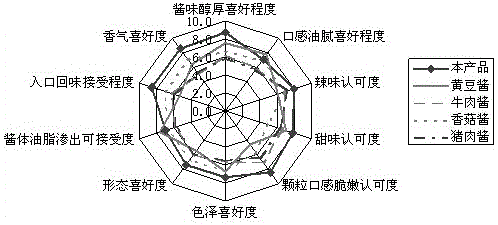

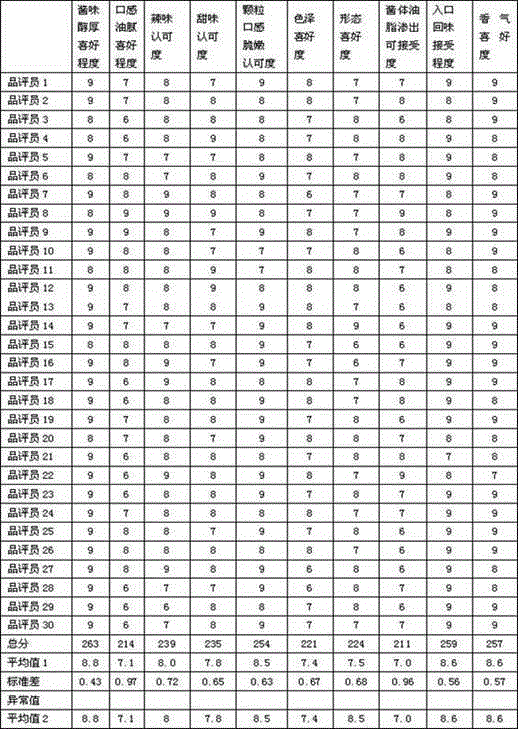

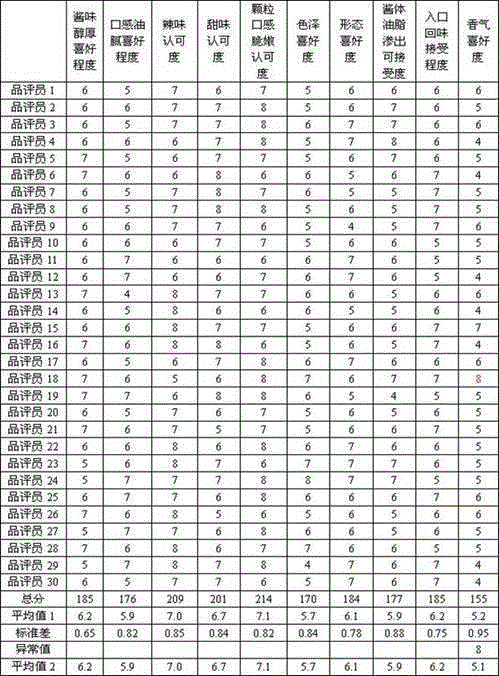

Bamboo shoot source and processing method thereof

The invention discloses a bamboo shoot source which is characterized by comprising the following raw materials in parts by weight: 120-180 parts of sliced bamboo shoots, 12-18 parts of sugar, 50-70 parts of a thick broad-bean sauce, 20-40 parts of fermented blank bean, 180-220 parts of water, 10-20 parts of shiitake, 20-40 parts of edible oil, 5-13 parts of bruised ginger, 1-5 parts of shredded pepper and 20-30 parts of wheat batter. A processing method for the bamboo shoot source is simple and feasible; residual bamboo shoots and shiitake are utilized as the main raw materials for preparation of the bamboo shoot source, so that the bamboo shoot source has a health function when the flavor is delicious; meanwhile, the waste materials can be turned into treasure, and thus the added values of the bamboo shoot and shiitake industries are greatly improved, and the production cost of the bamboo shoot source is reduced; as the processing method is simple and feasible, industrial production is facilitated.

Owner:ZHEJIANG FORESTRY UNIVERSITY

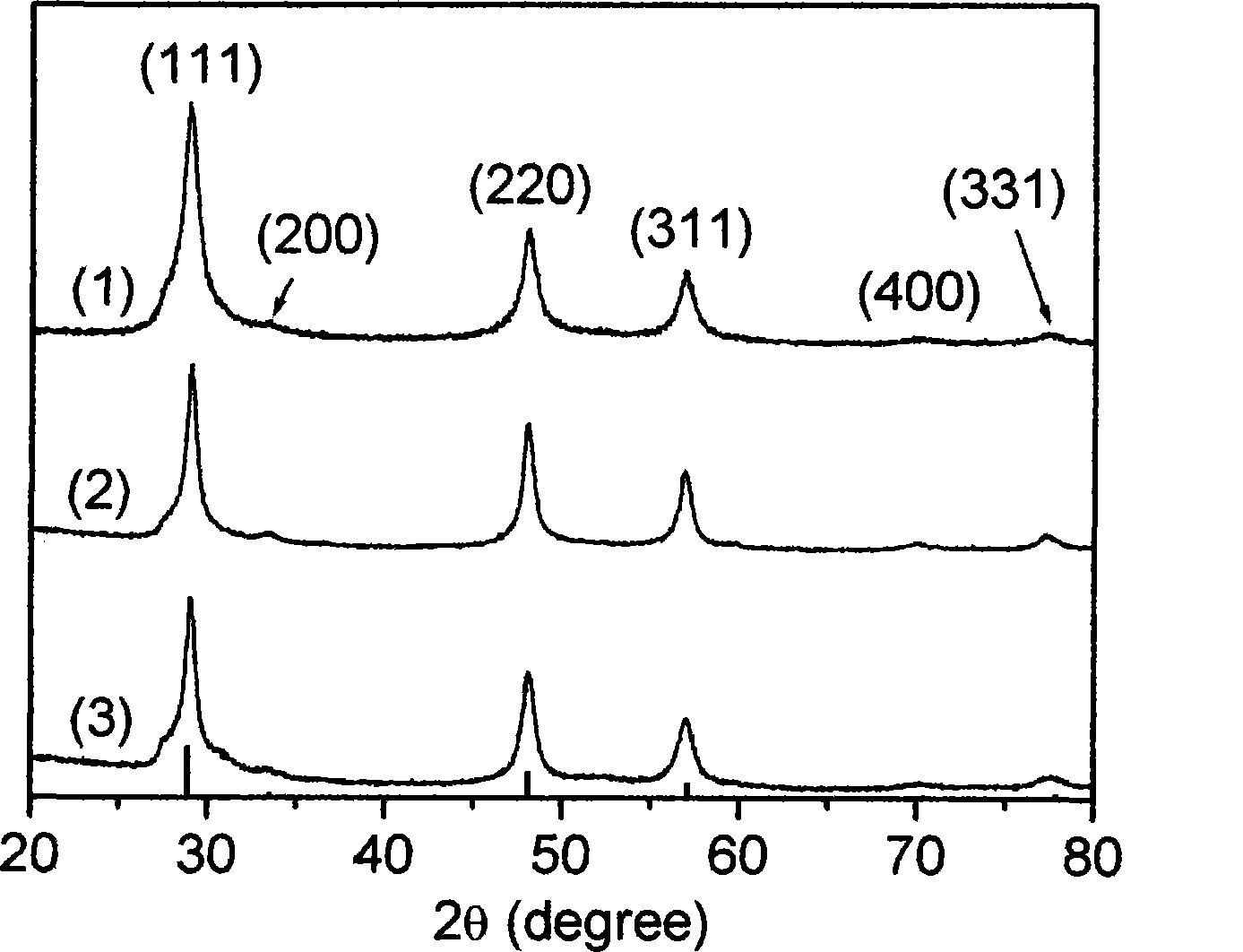

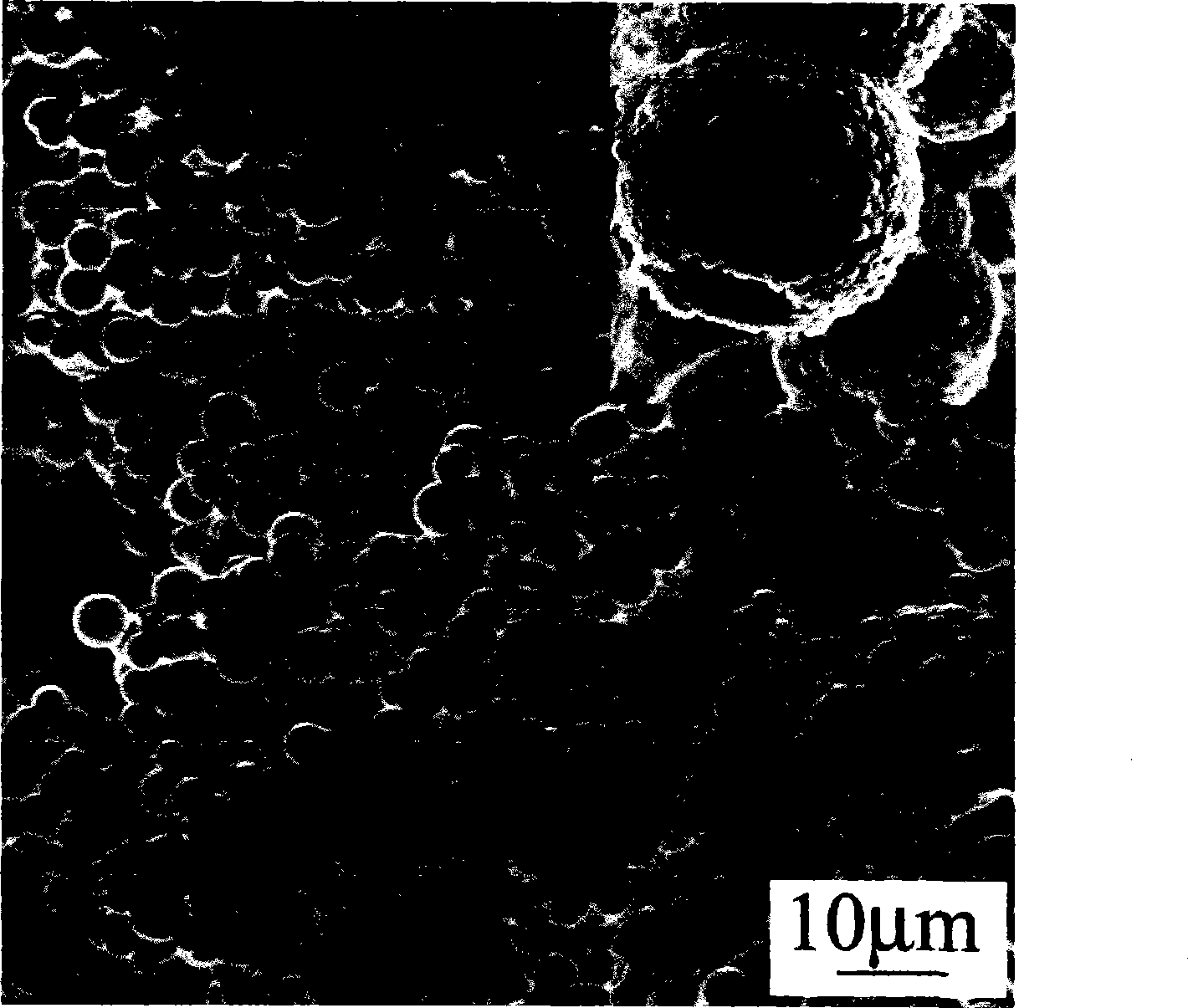

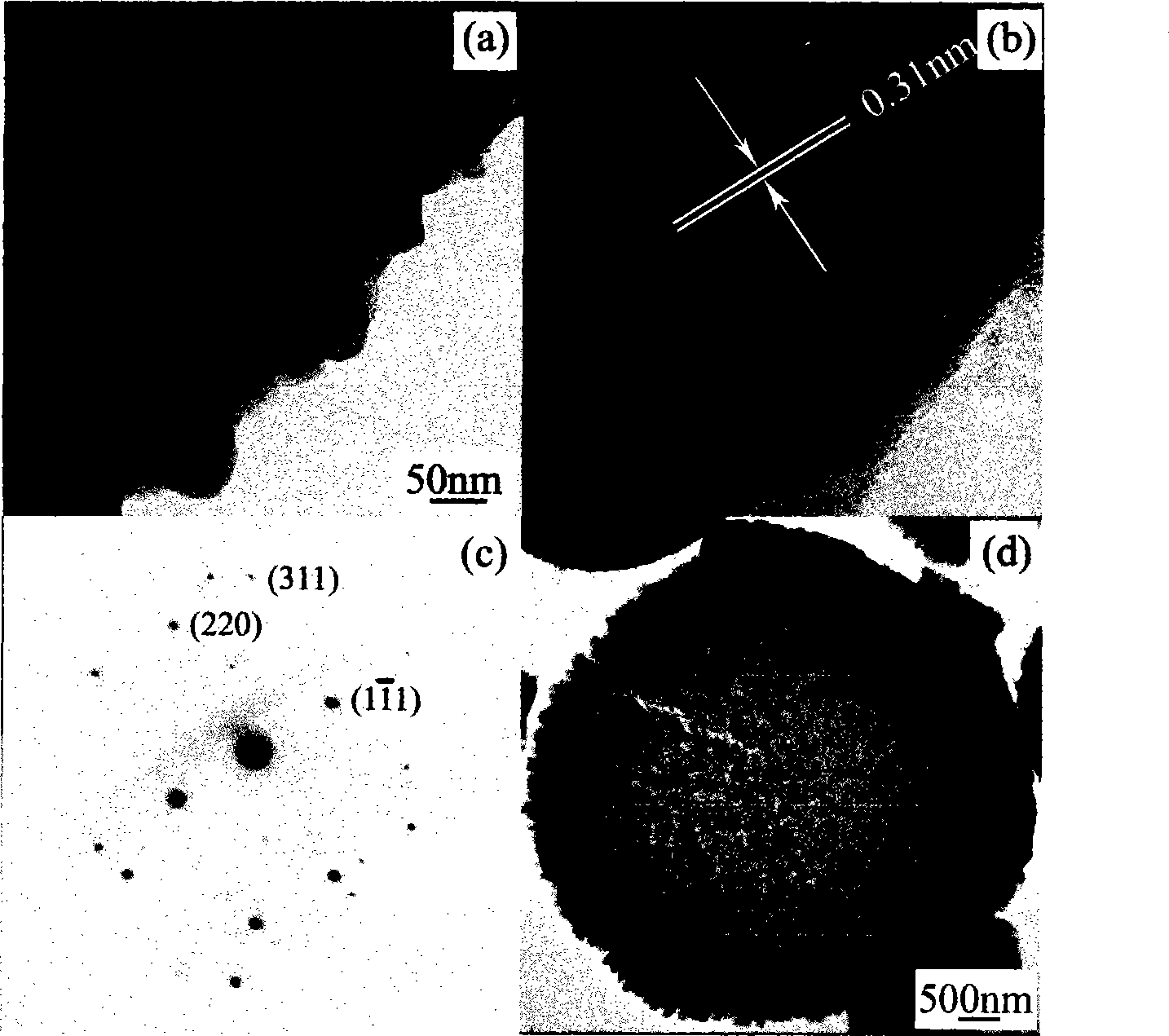

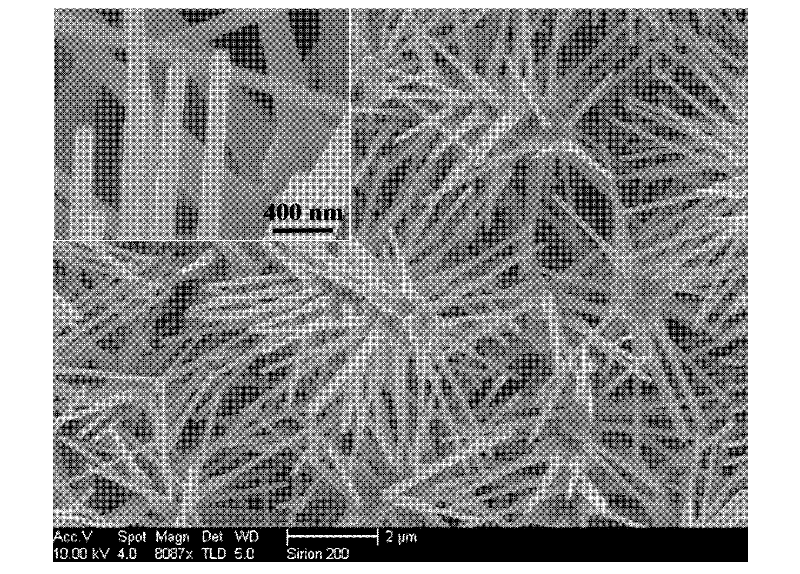

Zinc sulphide micron hollow sphere and preparation thereof

InactiveCN101486487AThe method is simple and fastLess materialZinc sulfidesMaterial consumptionPhotonics

The invention discloses a zinc sulfide micron hollow sphere and a preparation method thereof. The hollow sphere comprises zinc sulfide, particularly, the zinc sulfide takes the shape of a micron hollow sphere with the diameter of 0.7 to 6.5 Mum, and a spherical shell is formed by nanometer rod arrays. The rod axis of the nanometer rod arrays points to the center of the micron hollow sphere. The length of the nanometer rod is 100nm to 400nm and the diameter of the rod is 50nm to 200nm; the method includes a hydro-thermal method that comprises steps as follows: step one. zinc nitrate, thiacetamide and water are mixed to obtain a precursor solution, wherein, weight proportion of zinc nitrate, thiacetamide and water is 0.4 to 0.6:0.1 to 0.3:20 to 30; step two. the precursor solution reacts under the pressure of 5 to 8 multiplied by 10Pa and the temperature of 180 DEG C to 220 DEG C for 8h to 15h to obtain precipitate products, and then the precipitate products are washed by a solvent and processed by vacuum drying to obtain the zinc sulfide micron hollow sphere. The zinc sulfide micron hollow sphere can be widely applied to the fields of medicine engineering, cosmetics, biotechnology, photochemical catalysis, photonic devices and the like, and is characterized by simple and convenient preparation method, little material consumption and no pollution.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

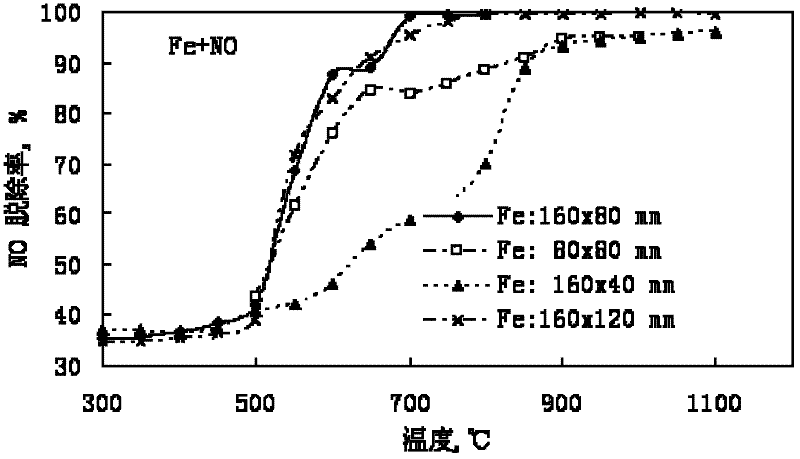

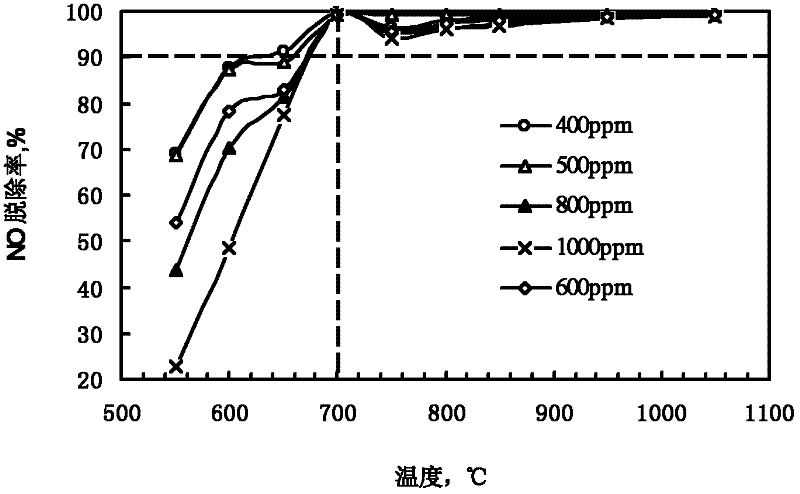

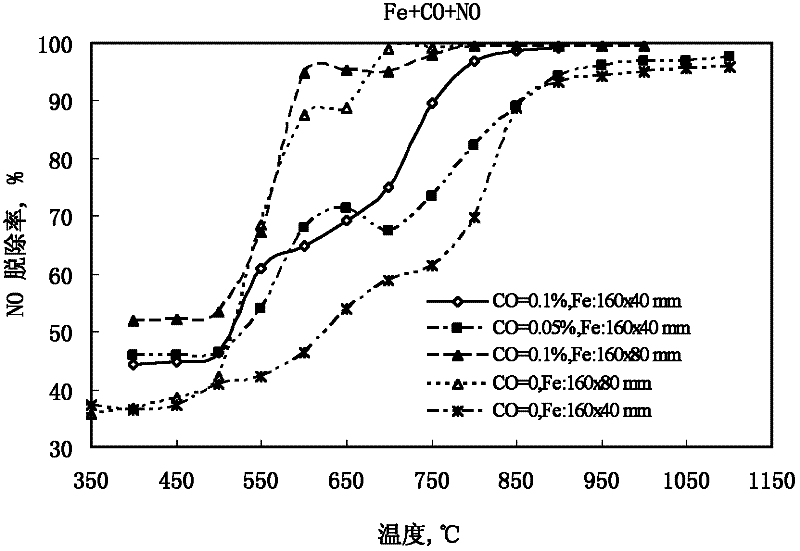

Method for reducing NO by using iron catalyst

InactiveCN102240505AImprove removal efficiencyGuaranteed not to be oxidizedDispersed particle separationNo removalPollution

The invention relates to a method for reducing NO by using an iron catalyst, comprising the following step of: enabling the gas NO generated in a coal burning process to be in contact with metallic iron at a temperature of 500-1100 DEG C. The invention has the advantages of simpleness, low cost and high efficiency without secondary pollution and can achieve the NO removal efficiency more than 95 percent at more than 750 DEG C.

Owner:DONGHUA UNIV

Method for recycling positive electrode material of waste lithium iron phosphate battery

PendingCN113735087AHigh purityAvoid it happening againPositive electrodesWaste accumulators reclaimingIron phosphateHydrogen peroxide

The invention relates to a method for recycling a positive electrode material of a waste lithium iron phosphate battery. The method comprises the following steps of: (1) adding water into positive electrode powder of the waste lithium iron phosphate battery to prepare slurry, preheating the slurry, adding 98% sulfuric acid for leaching, and performing solid-liquid separation after the leaching is completed to respectively obtain leachate and leaching residues; (2) adjusting the pH value of the leachate, adding iron powder to replace and remove copper, continuously adjusting the pH value, removing aluminum by precipitation, and carrying out solid-liquid separation to obtain an impurity-removed solution; (3) supplementing sodium phosphate to adjust the mass ratio of iron to phosphorus; (4) introducing hydrogen peroxide below the liquid level of the base solution, spraying alkali liquor and the impurity-removed solution by using spraying equipment, adjusting the pH value, aging for 5-7 hours after iron in the solution is completely oxidized and precipitated, and performing solid-liquid separation to respectively obtain an iron phosphate precipitate and a lithium-containing solution; and (5) adjusting the pH value of the lithium-containing solution, and carrying out evaporation concentration and solid-liquid separation to obtain filtrate; and introducing carbon dioxide into the filtrate to obtain precipitated lithium. The method is simple, efficient and easy for batch industrial production.

Owner:JINCHUAN GROUP LIMITED +1

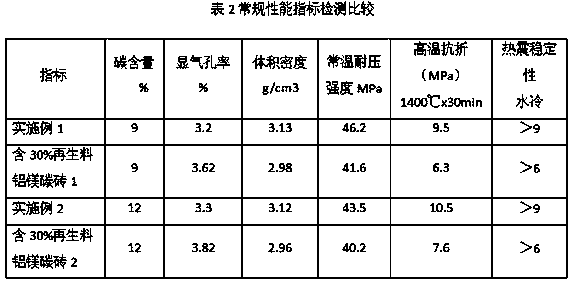

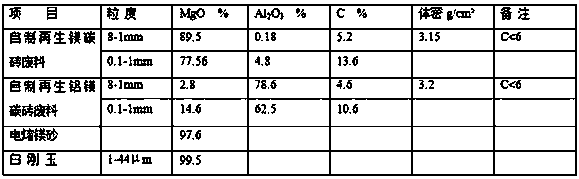

Method for making aluminum-magnesium carbon refectory brick from regenerated magnesium carbon bricks and aluminum-magnesium carbon bricks

The invention belongs to the technical field of refectory materials and in particular relates to a method for making an aluminum-magnesium carbon refectory brick from regenerated magnesium carbon bricks and aluminum-magnesium carbon bricks. The method comprises the following steps: 1, preparing aggregate; 2, preparing pre-mixed powder; 3, carrying out mixing refining; 4, carrying out a molding process; 5, drying. By adopting the method, the regenerated magnesium carbon bricks and the aluminum-magnesium carbon bricks are adopted as main raw materials, a part of an efficient additive is furtheradded, under the condition that a conventional production process is not changed, an aluminum-magnesium carbon brick which is high in medium-high temperature strength, high in volume density and excellent in corrosion resistance and thermal shock resistance is developed, and common industrial production can be carried out by using conventional experiment facilities.

Owner:LIAONING ZHONGMEI HLDG

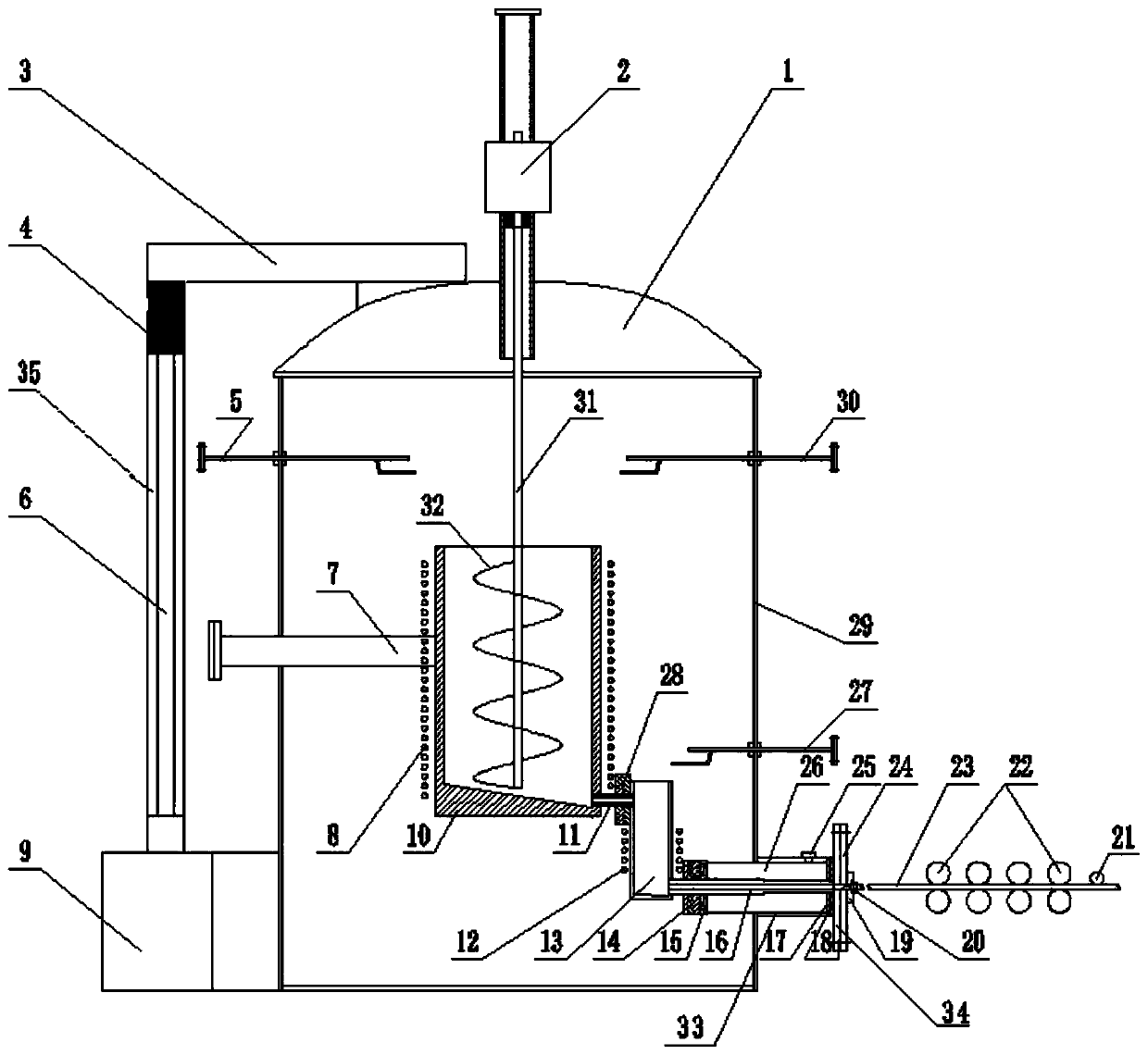

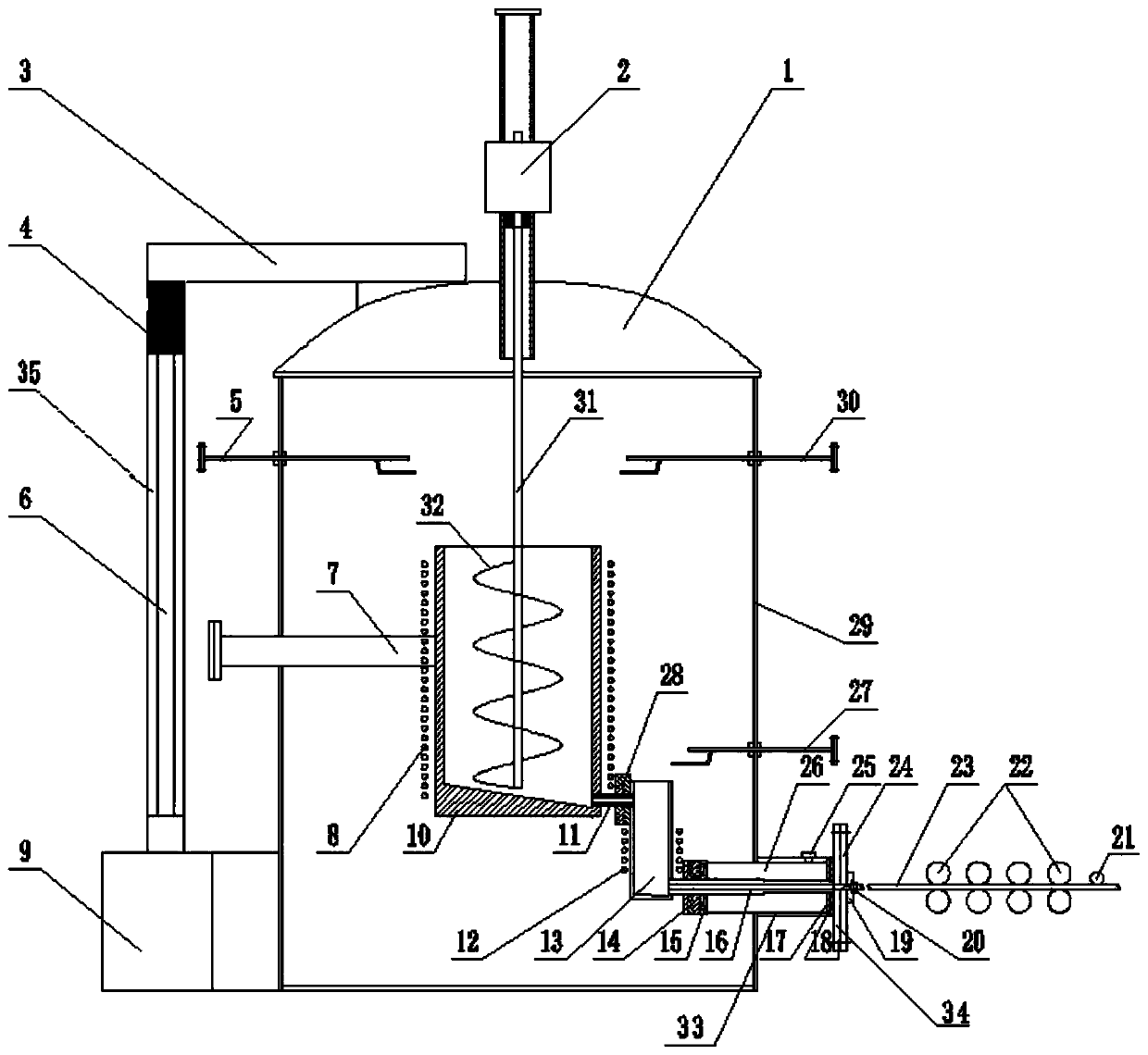

Horizontal guide type copper alloy wire rod vacuum continuous casting machine

The invention belongs to an alloy wire rod casting device, and particularly discloses a horizontal guide type copper alloy wire rod vacuum continuous casting machine. The machine comprises an vacuum device, a smelting device, a crystallizer device, a cooling device and a traction device. The smelting device is located in the vacuum device, the smelting device comprises a main crucible and an auxiliary crucible, the auxiliary crucible is located at the tail end of the main crucible; the crystallizer device is connected with the smelting device, the cooling device is used for cooling the crystallizer device; and the traction device is positioned at the tail end of the crystallizer device and is used for carrying out traction continuous casting on the alloy in the crystallizer. According to the vacuum continuous casting machine, vacuum melting is adopted, so that the alloy elements are prevented from being oxidized, and the continuous casting alloy range of the vacuum continuous casting machine is greatly increased. The double-crucible system of the main crucible and the auxiliary crucible ensures that the alloy is accurately added, the influence of the liquid disturbance of the maincrucible on the continuous casting stability is eliminated through double-crucible smelting, and the multicomponent alloy material which is uniform in component and stable in structure is obtained.

Owner:ZHEJIANG TONY ELECTRONICS CO LTD

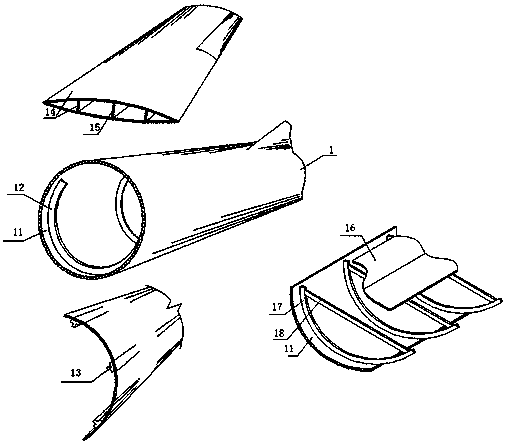

Aerial vehicle structure

An air vehicle structure comprises a framework structure and a skin connected with the framework structure, wherein at least one of the framework structure and the skin is made of plate metal; the plate metal comprises a first panel, a second panel as well as a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubesand the first panel as well as between the hollow tubes and the second panel; a turning edge is arranged at at least one end of the hollow tubes. The aerial vehicle structure has the advantages of being small in self-weight, high in strength, stable in structure, high in impact resistance, capable of insulating sound and reducing noise, resistant to high temperature, corrosion and vibration, longin service life, capable of being carried and spliced and the like.

Owner:张跃

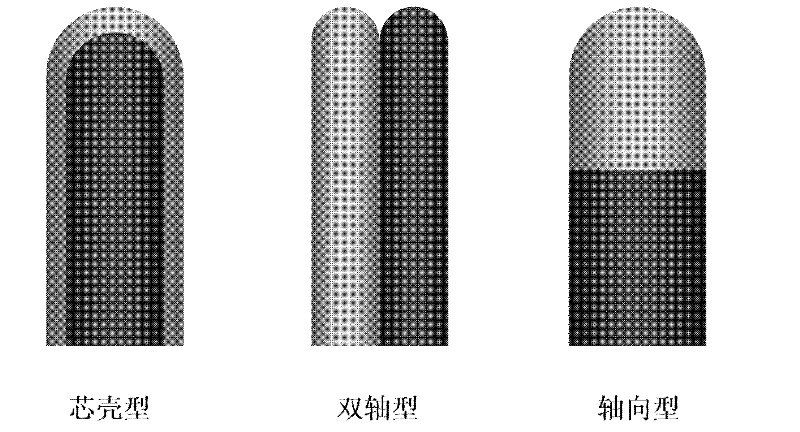

One-dimensional axial type nano zinc oxide / zinc sulfide heterojunction and preparation method thereof

InactiveCN102345162AClear interfaceEasy transitionFrom chemically reactive gasesFrom condensed vaporsHeterojunctionMaterials preparation

The invention relates to the field of nano material preparation, and specifically relates to a one-dimensional axial type nano zinc oxide / zinc sulfide heterojunction and a preparation method thereof. The prepared one-dimensional axial type comprises a zinc oxide nanorod and a zinc sulfide nanorod, and ends of the zinc oxide nanorod is connected with the zinc sulfide nanorod to form a heterojunction. A silicon chip, zinc oxide powder and graphite powder are mixed and placed in 950-1050 DEG C air for a insulation reaction; nano zinc oxide flower structures consisting a large amount of zinc oxide nanorods are obtained on the silicon chip; a layer of gold membrane with a certain thickness is sputtered on the silicon chip containing zinc oxide nanorods; finally, the silicon chip and the zinc sulfide powder are placed in high purity argon atmosphere for insulating reaction to obtain a final product the heterojunction with upper end of zinc oxide nanorod connected with zinc sulfide nanorod. The one-dimensional axial type heterojunction is easily prepared and at low costs. The heterojunction has great significance in development and application of nano device.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

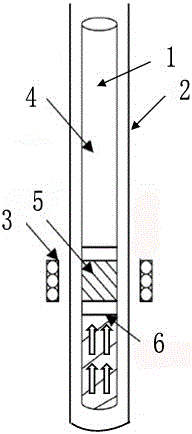

Motor rotor and end ring casting equipment and method thereof

PendingCN111799961AAvoid it happening againImprove product qualityStatorsAsynchronous induction motorsMolten stateElectric machine

The invention belongs to the technical field of motors, and particularly relates to motor rotor end ring casting equipment which comprises a positioning device used for fixing a rotor core, a formingdie used for casting an end ring, a heating device and a lifting device. The heating device is used for heating the metal raw material into a molten state in the forming mold. The lifting device is used for adjusting the distance between the positioning device and the forming mold, so that the lower end of the rotor core is immersed into the molten raw material in the forming mold. By the adoptionof the technical scheme, the metal raw materials are heated to be in the molten state in the forming die under vacuum or in the environment filled with inert gas, the lower end of the rotor is immersed in the molten metal raw materials, and the end ring is directly formed at the lower end of the rotor. The equipment is simple in structure, low in production cost and good in anti-oxidation effect.

Owner:CHONGQING JINKANG POWER NEW ENERGY CO LTD

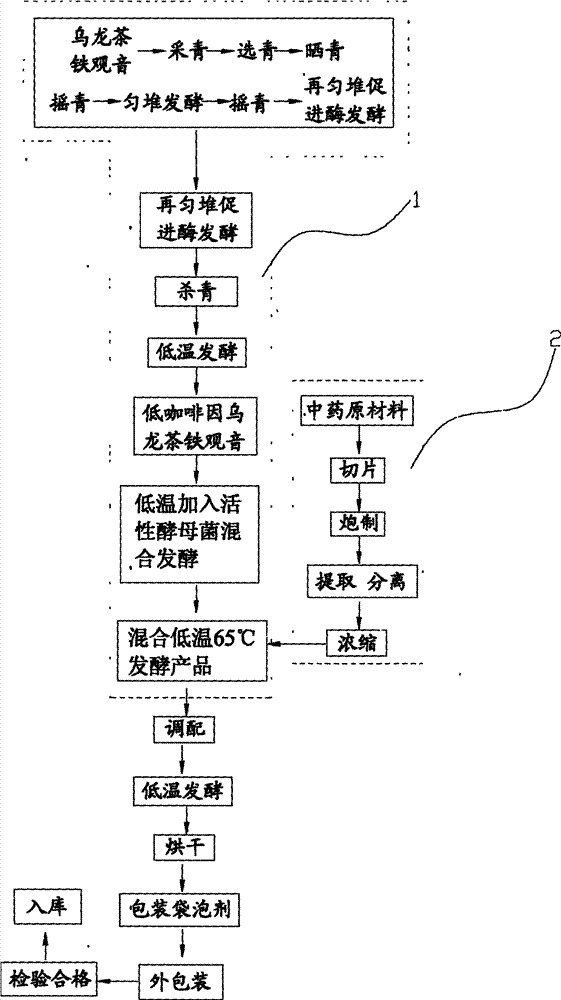

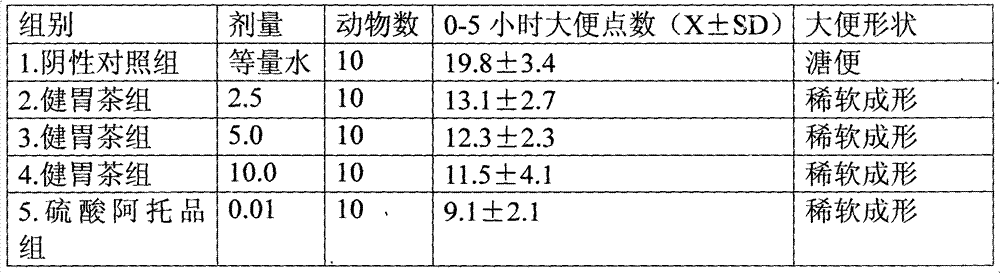

Astragali-date stomachic tea producing technology

ActiveCN102948518APreserve freshnessOvercome the bitter coldPre-extraction tea treatmentSide effectActive enzyme

The invention discloses an astragali-date stomachic tea producing technology which is mainly characterized in that various traditional Chinese medicinal materials are mixed with half-fermentative Tie Guanyin oolong tea, a pure traditional Chinese medicinal formula is adopted and a biological activity fermentation technology are adopted, and a mucus gel which is generated after thearubigins, tea polyphenol, catechin ingredients and traditional Chinese medicinal materials are combined and fermented is utilized for overcoming the defect of harming of tea to stomachs. Due to the application of a 65 DEG C low temperature fermentation technology, biological enzyme in tea leaves is effectively prevented from being oxidized; besides, an enzyme fermentation greening technology is utilized, so that a certain freshness of the tea leaves is kept, active enzyme is prevented from being oxidized and therefore effective ingredients are prevented from being damaged; and by the combination of pharmacological actions of the traditional Chinese medicinal materials with Tie Guanyin, smooth muscle spasm can be relieved, stomachache is secured, and no toxic and side effects are caused; and the astragali-date stomachic tea can be drunk by common people, is available for invigorating and nourishing stomachs and does not lose flavor of tea leaves.

Owner:厦门特伦制药有限公司

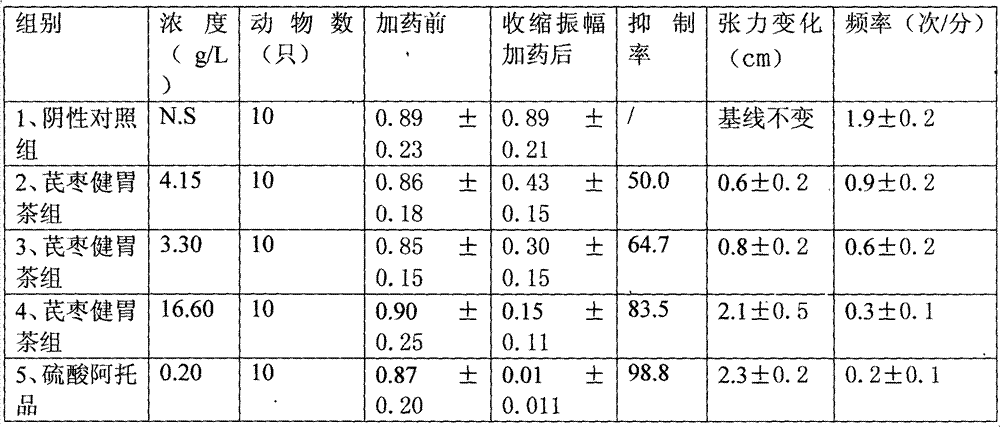

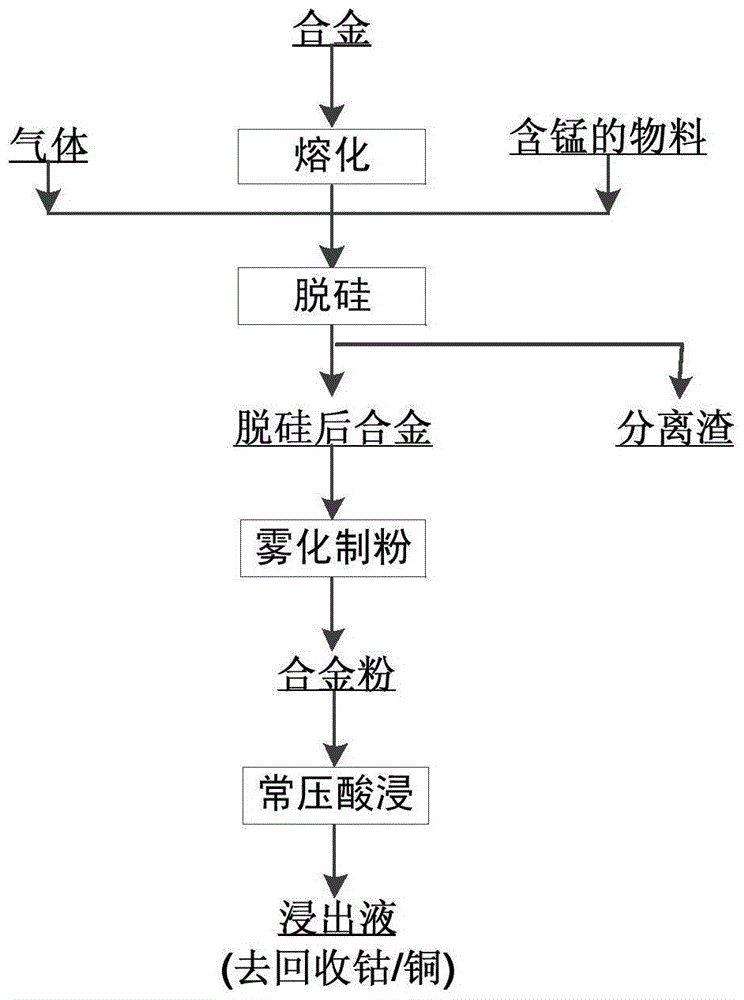

Method for leaching valuable metal from cobalt-copper white alloy

ActiveCN105063353AGuaranteed not to be oxidizedAchieve separationProcess efficiency improvementSlagManganese

The invention discloses a method for leaching valuable metal from cobalt-copper white alloy. The method includes the following steps that (1) the cobalt-copper white alloy is melted into an alloy melt, wherein the cobalt-copper white alloy contains silicon and almost contains no manganese; (2) a Mn-containing material is added into the alloy melt, and meanwhile gas is led in for blowing and slagging; (3) obtained slag is separated from the melt; (4) the melt with the slag separated out is atomized into alloy powder, wherein the mass friction of Mn in the alloy powder is 0.5%-20%; and (5) the alloy powder is subjected to acid leaching, and the valuable metal is recovered. Due to the fact that the Mn-containing material is added and reacts with the silicon in the cobalt-copper white alloy to generate the MnO-SiO2 slag, the silicon removal effect is achieved, and the method has the beneficial effects of being good in silicon removal effect and small in valuable metal loss. Besides, the melting temperature is much lower than the melting point of CaO-(MgO)-SiO2 binary system or ternary system slag in the prior art.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

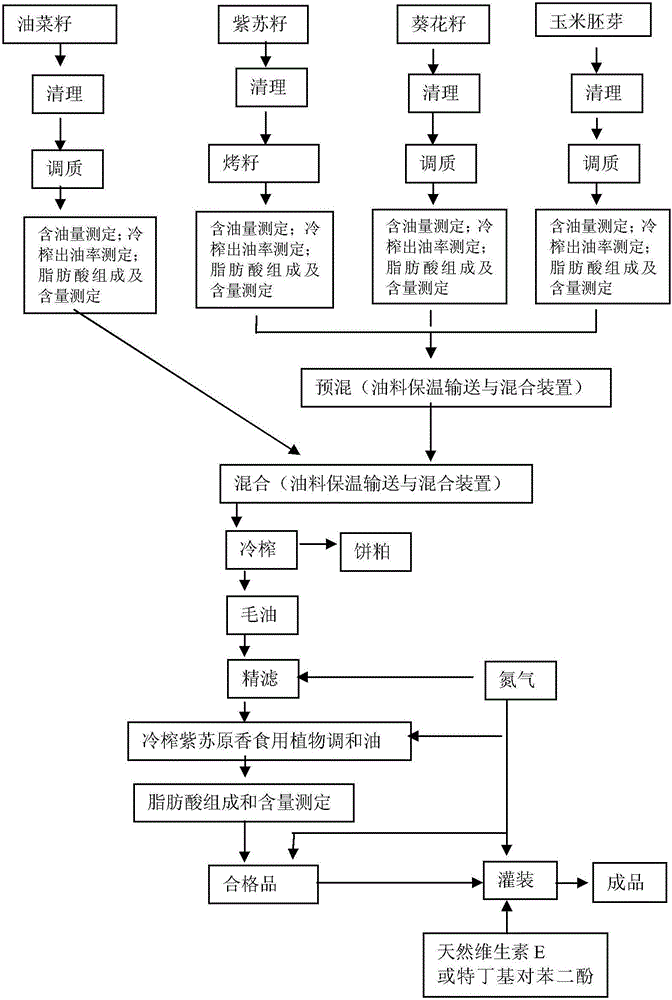

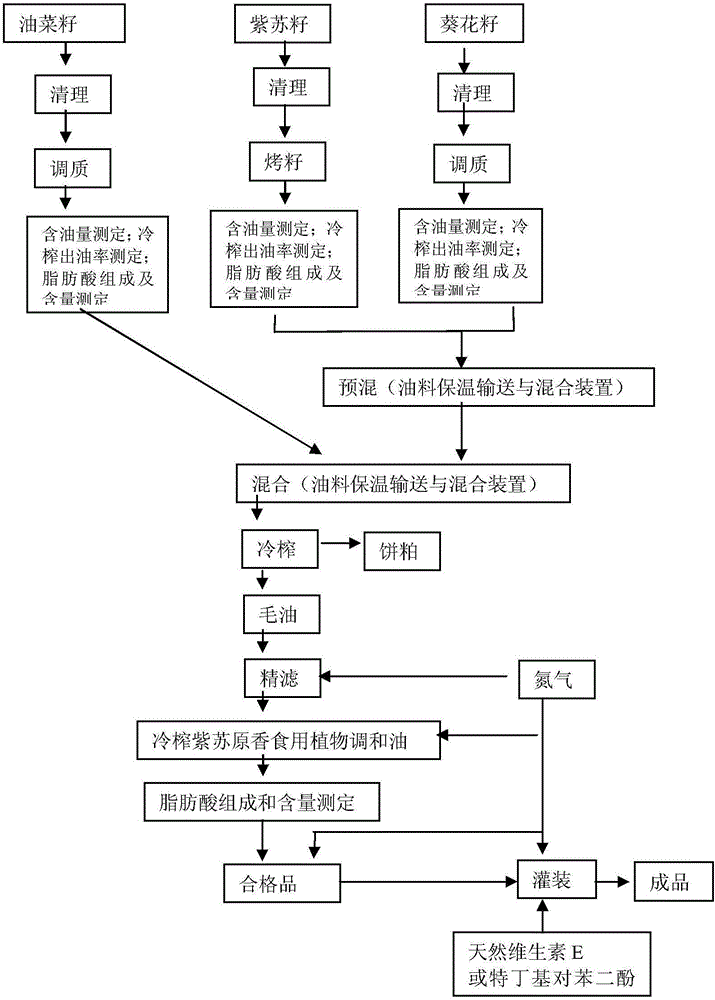

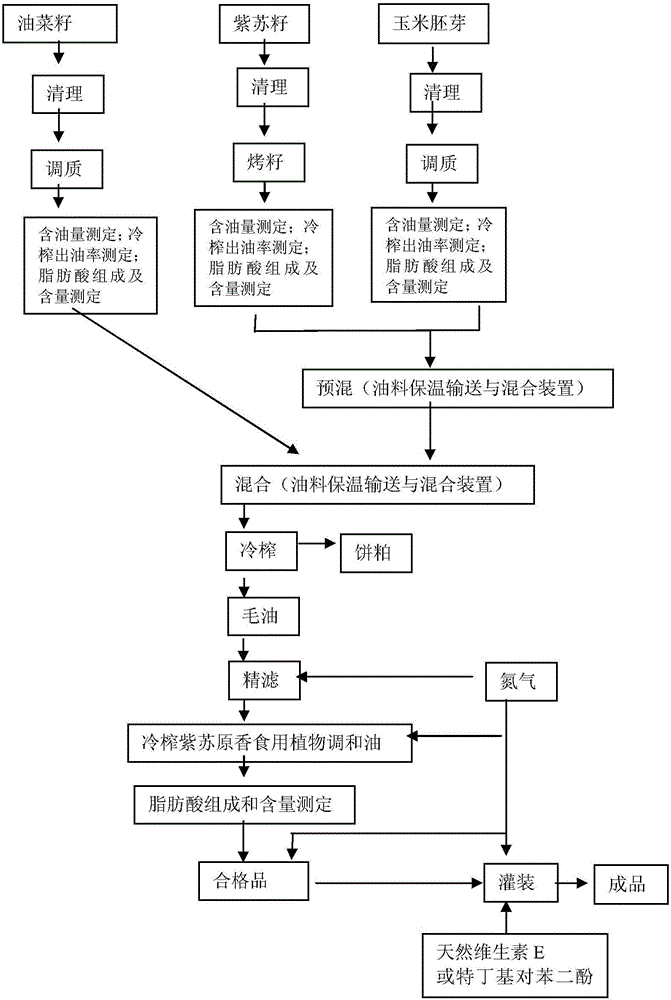

Original fragrant perilla edible blend oil and production process thereof

InactiveCN106167735AGuaranteed pass ratePrevent oxidative rancidityFatty-oils/fats refiningFatty-oils/fats productionFiltrationTert-Butylhydroquinone

The invention provides original fragrant perilla edible blend oil and a production process thereof. The production process includes the steps: cleaning and baking perilla seeds for preparing the original fragrant perilla edible blend oil to obtain baked perilla seeds; respectively cleaning and tempering other oil plants to obtain tempered oil plants; respectively measuring oil contents, fatty acid composition and fatty acid contents of the perilla seeds and the other oil plants; determining respective cold-pressed oil yield of the perilla seeds and the other oil plants by small-scale tests, calculating respective usage of the perilla seeds and the other oil plants according to preset composition of the perilla edible blend oil, and mixing the perilla seeds with the other oil plants according to the usage to obtain mixed oil plants; cold-pressing the mixed oil plant to obtain crude oil and cake meal; performing refined filtration for the crude oil to obtain cold-pressed blend oil; adding natural vitamin E or tertiary butylhydroquinone into the cold-pressed blend oil, and detecting the fatty acid composition and the contents to obtain the original fragrant perilla edible blend oil.

Owner:SANHE HOPEFULL BIOTECH

Method for manufacturing indium column

ActiveCN101132034AQuality assuranceSimple processFinal product manufactureSemiconductor/solid-state device manufacturingCooking & bakingIndium

The present invention discloses a method of processing indium cylinder, which is applied to semiconductor device and circuit processing. The method includes the positive-glue photolithography process which has steps of chip processing, pre-baking, glue coating, contraposition, exposure, development, hard baking, and the electron-beam-evaporation-and-micro-ultrasonic-stripping technology which has the steps of chip processing, loading wafer, vacuum pumping, evaporation, taking wafer, stripping. A metal layer or other media films are form between the positive-glue-coated layer to make the coating layer a structure of 'positive glue thick layer - media or metal film - positive glue thin layer', during the glue-coated process; the thin glue on the top are lithographed into patterns, and media or metal films in pattern windows are wet etched, finally, the bottom thick glue is removed by developing and indium film is stripped by electron beam evaporation and micro-ultrasonic stripping. The indium cylinder processed by the present invention has higher precision of its feature than it processed by current technology.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

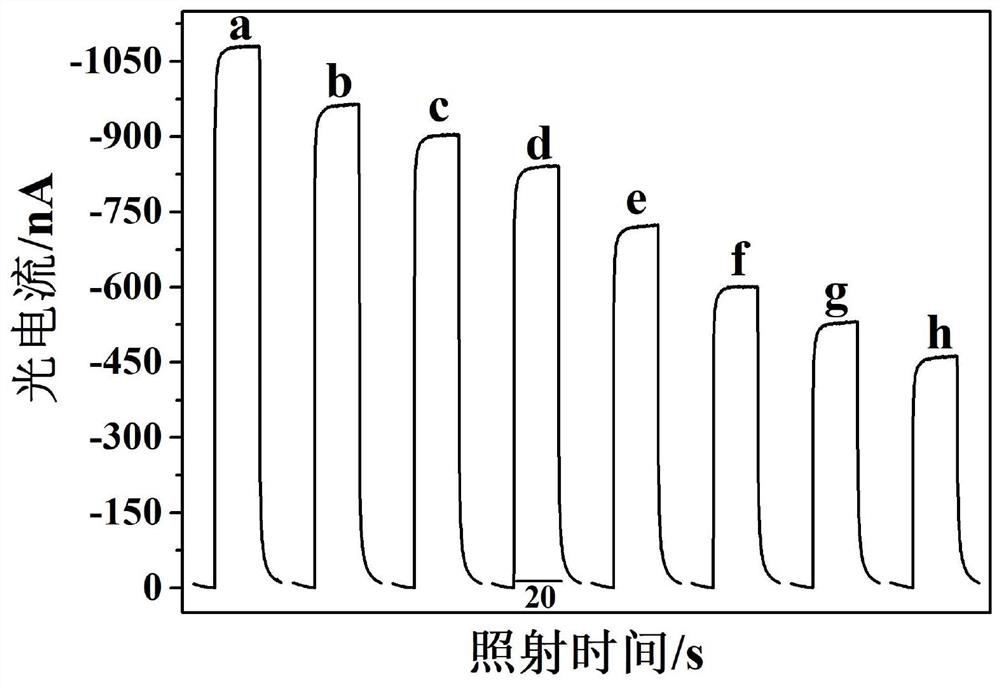

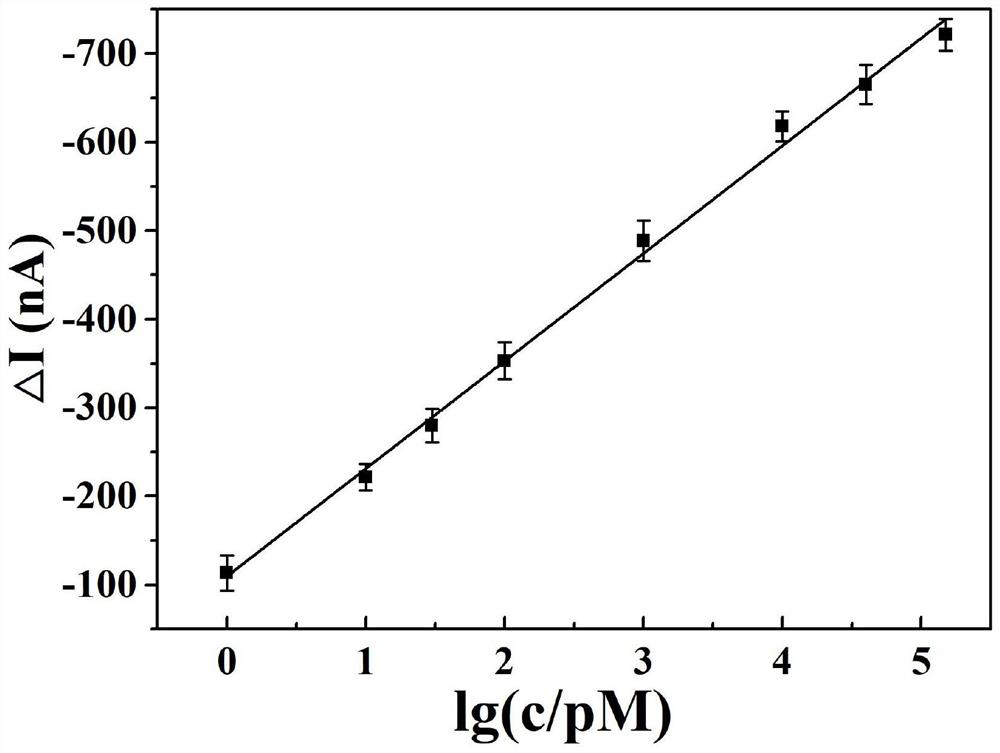

Double-electrode photoelectrochemical aptamer sensor as well as preparation method and application thereof

ActiveCN113049657AStrong photoelectric performanceEasy to fixTungsten oxides/hydroxidesNitrogen-metal/silicon/boron binary compoundsSpecific detectionNanoparticle

The invention discloses a double-electrode photoelectrochemical aptamer sensor as well as a preparation method and application thereof. The sensor comprises a first conductive glass electrode modified by a ternary composite material and used as a working electrode, a specific aptamer probe used as a counter electrode, and a second conductive glass electrode modified by reduced graphene oxide loaded with gold nanoparticles. The preparation method comprises the steps of preparing the working electrode and the counter electrode. The dual-electrode photoelectrochemical aptamer sensor has the advantages of high stability, long service life, strong anti-interference capability, high detection sensitivity, wide detection range, low detection limit and the like, can realize specific detection of pollutants (such as antibiotics) in media such as water bodies and organisms, and is high in utilization rate, high in use value and good in application prospect; and meanwhile, the preparation method has the advantages of simple process, convenience in operation, safety, low cost, no pollution, high preparation efficiency and the like, is suitable for large-scale preparation and is beneficial to industrial application.

Owner:HUNAN UNIV

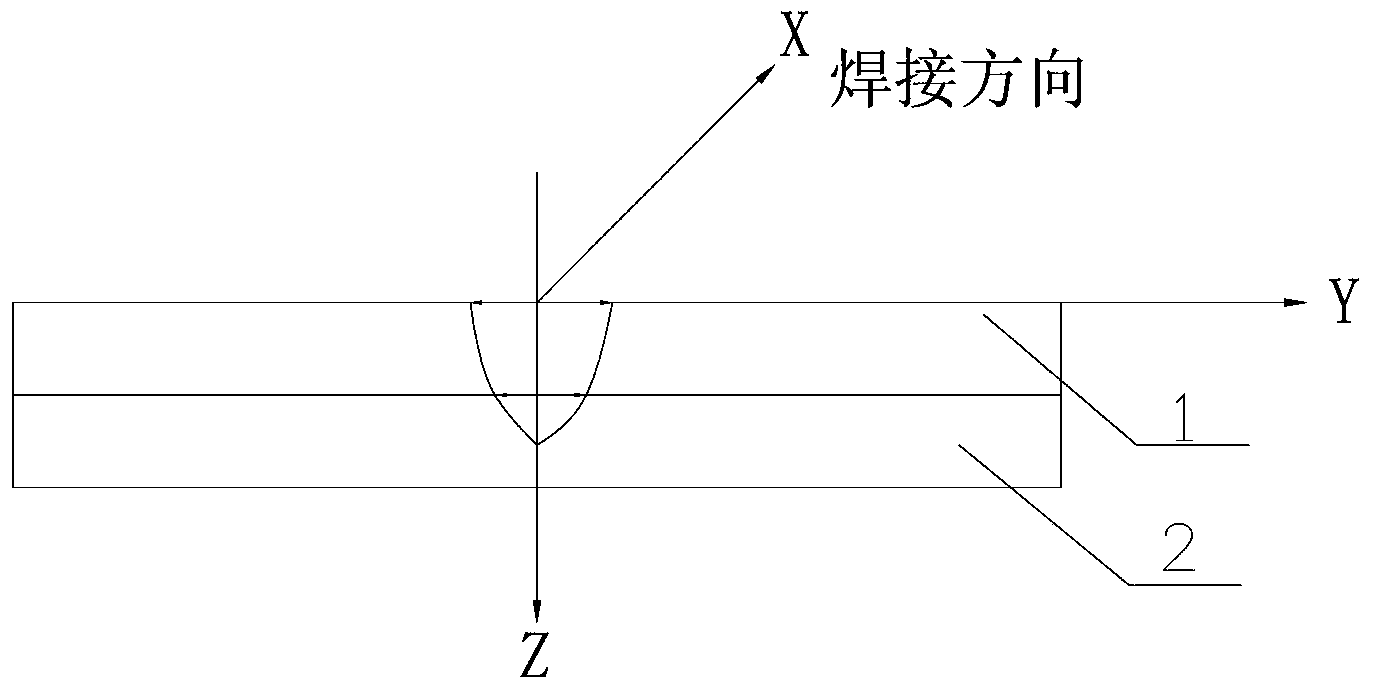

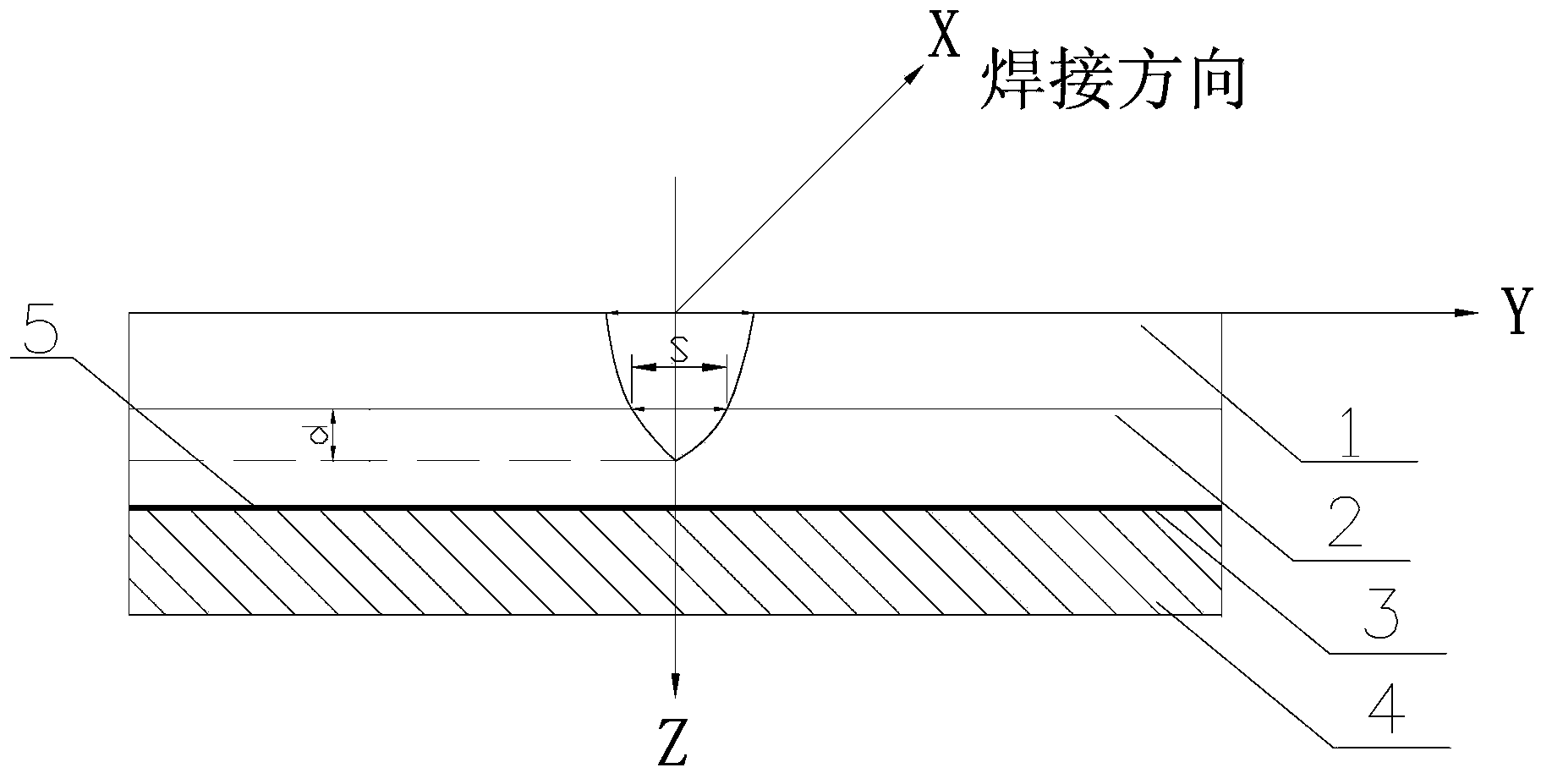

Method for welding non-coating stainless steel plate in laser mode

ActiveCN103658985AGuaranteed weld strengthGuaranteed bright appearanceVehicle componentsWelding/soldering/cutting articlesSteel platesWall plate

The invention relates to a method for welding a non-coating stainless steel plate in a laser mode. An upper layer panel and a lower layer panel are stacked up, a layer of protecting film is arranged on the exposed surface of the lower layer panel, and the upper layer panel and the lower layer panel are connected by enabling a laser welding light beam to penetrate through the protecting film to reach a certain depth of the lower layer panel. On the premise that the assembling precision meets the laser welding requirements, the welding technology methods are selected in the aspects of controlling the appearance quality and guaranteeing the connector connecting strength according to the product requirements for a railway vehicle non-coating stainless steel vehicle body and the technology characteristics, and a certain welding width and a certain welding depth are controlled by controlling the welding technology parameters such as welding power and welding speed. The welding joint cannot be oxidized and the welding heat can be more centralized by adopting the special technologies of welding the exposed wall plate provided with the protecting film and placing an aluminum alloy base plate on the lower surface of a workpiece, the strength of the welding joint is guaranteed, the back face of the exposed welding joint cannot deform obviously, and the color of the back face of the exposed welding joint cannot change obviously.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com