Patents

Literature

265results about How to "Add accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

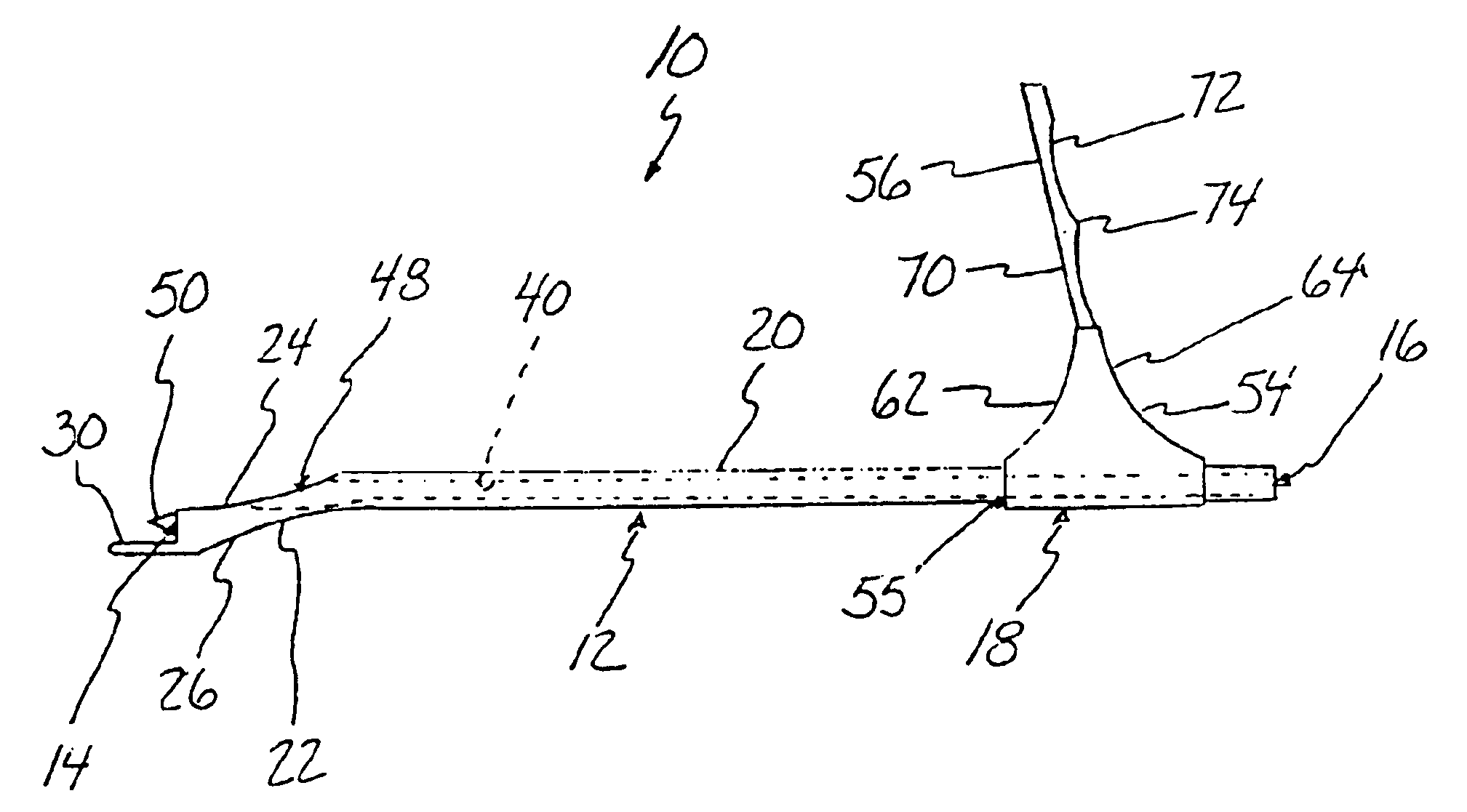

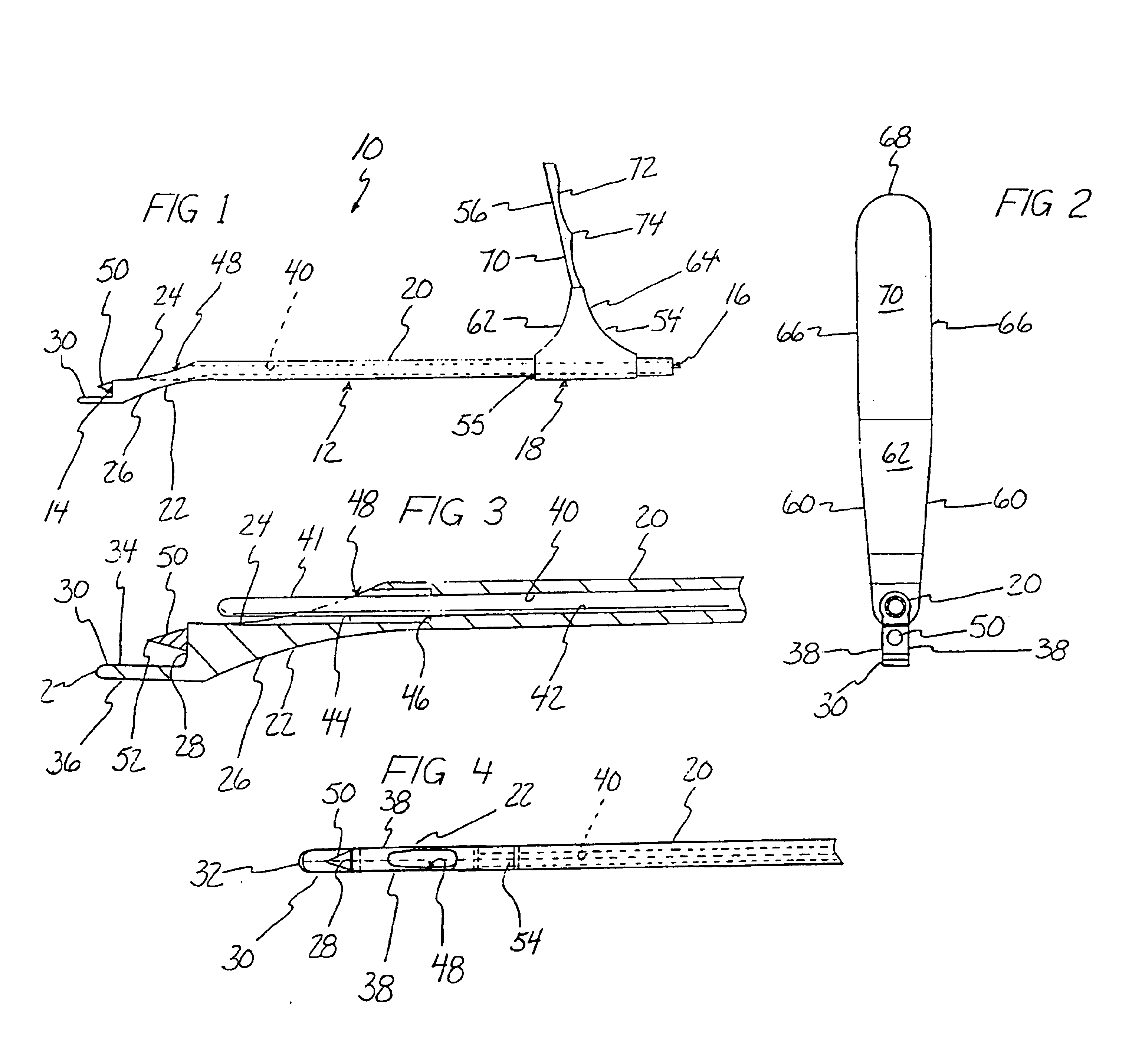

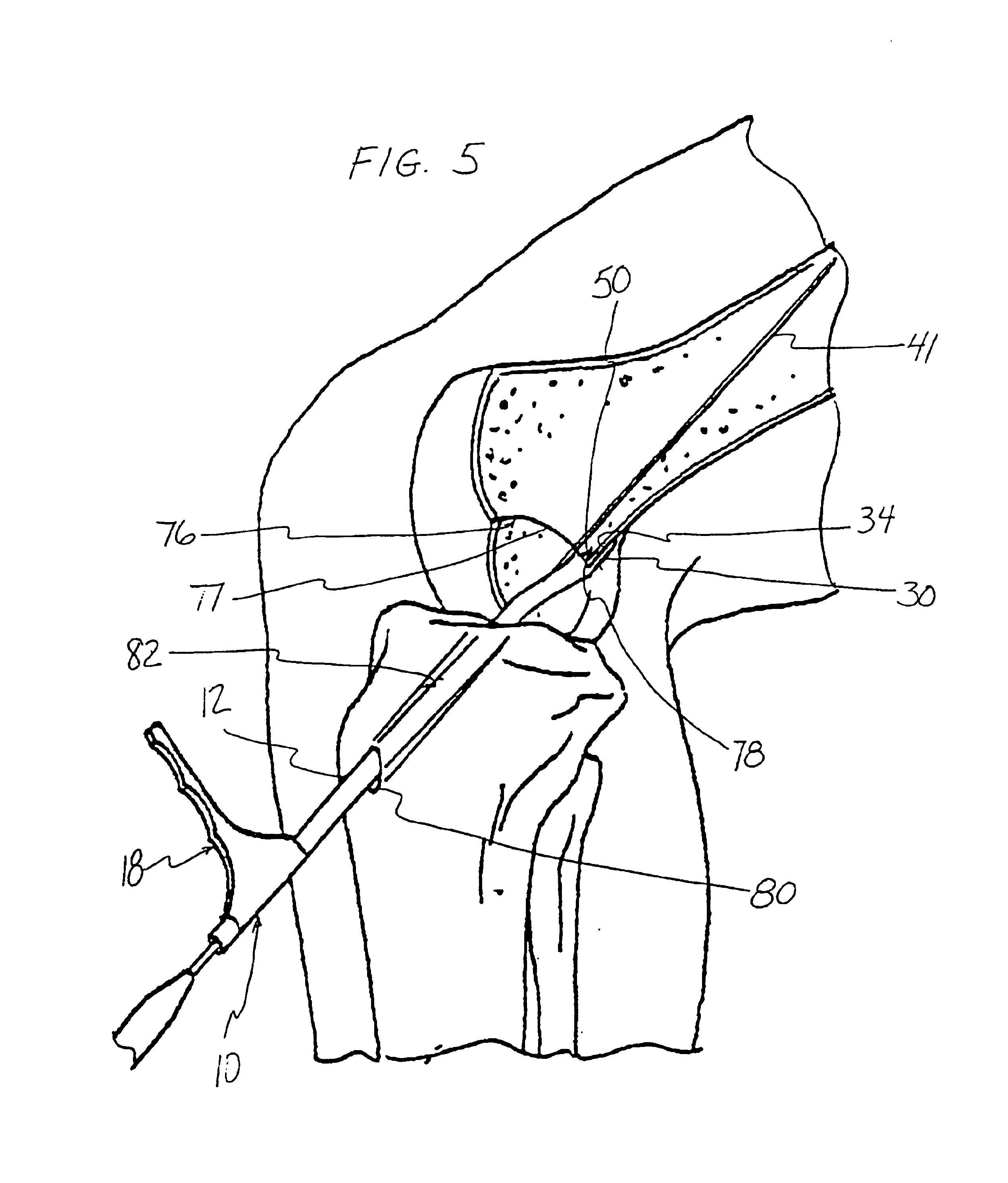

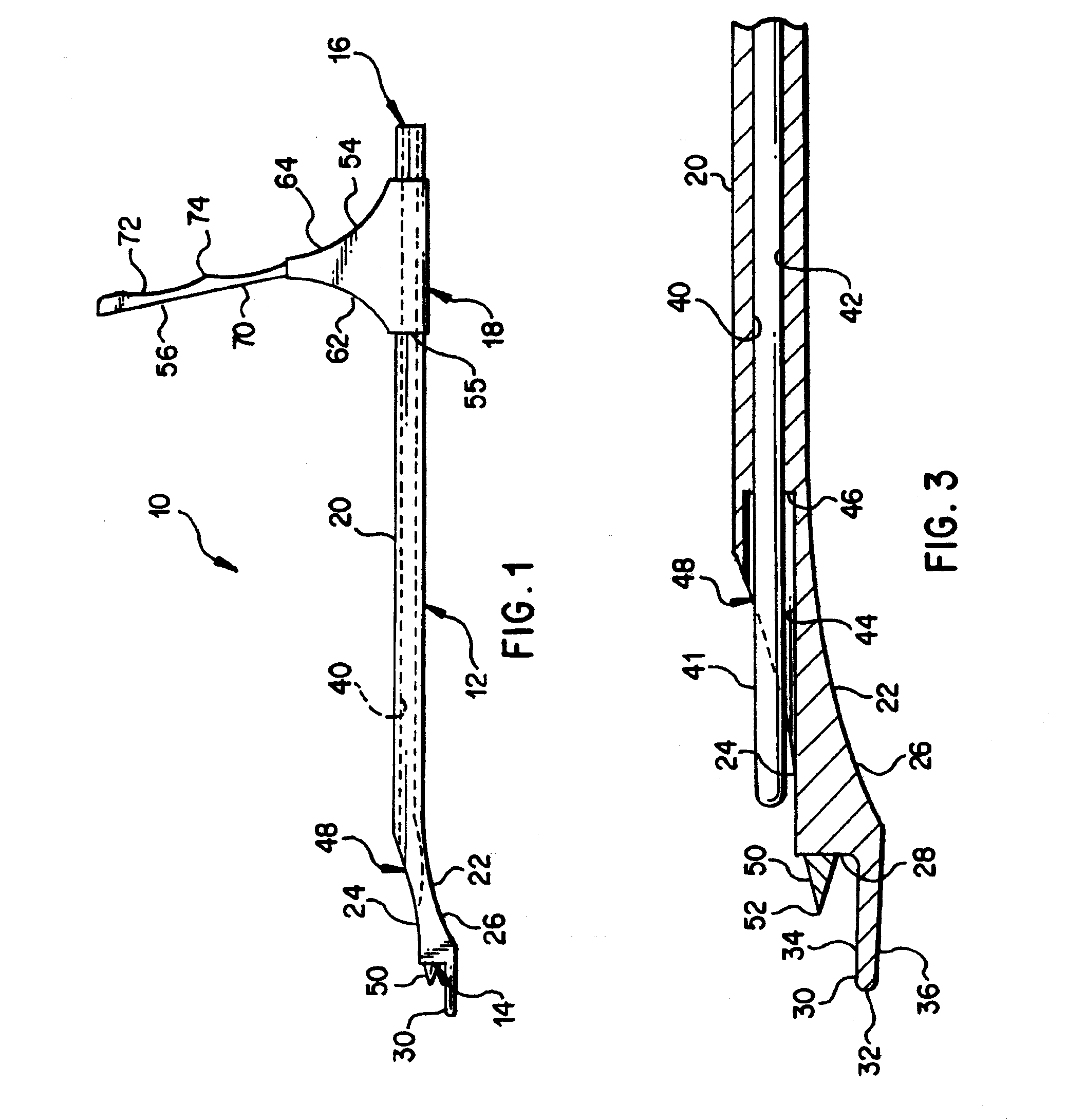

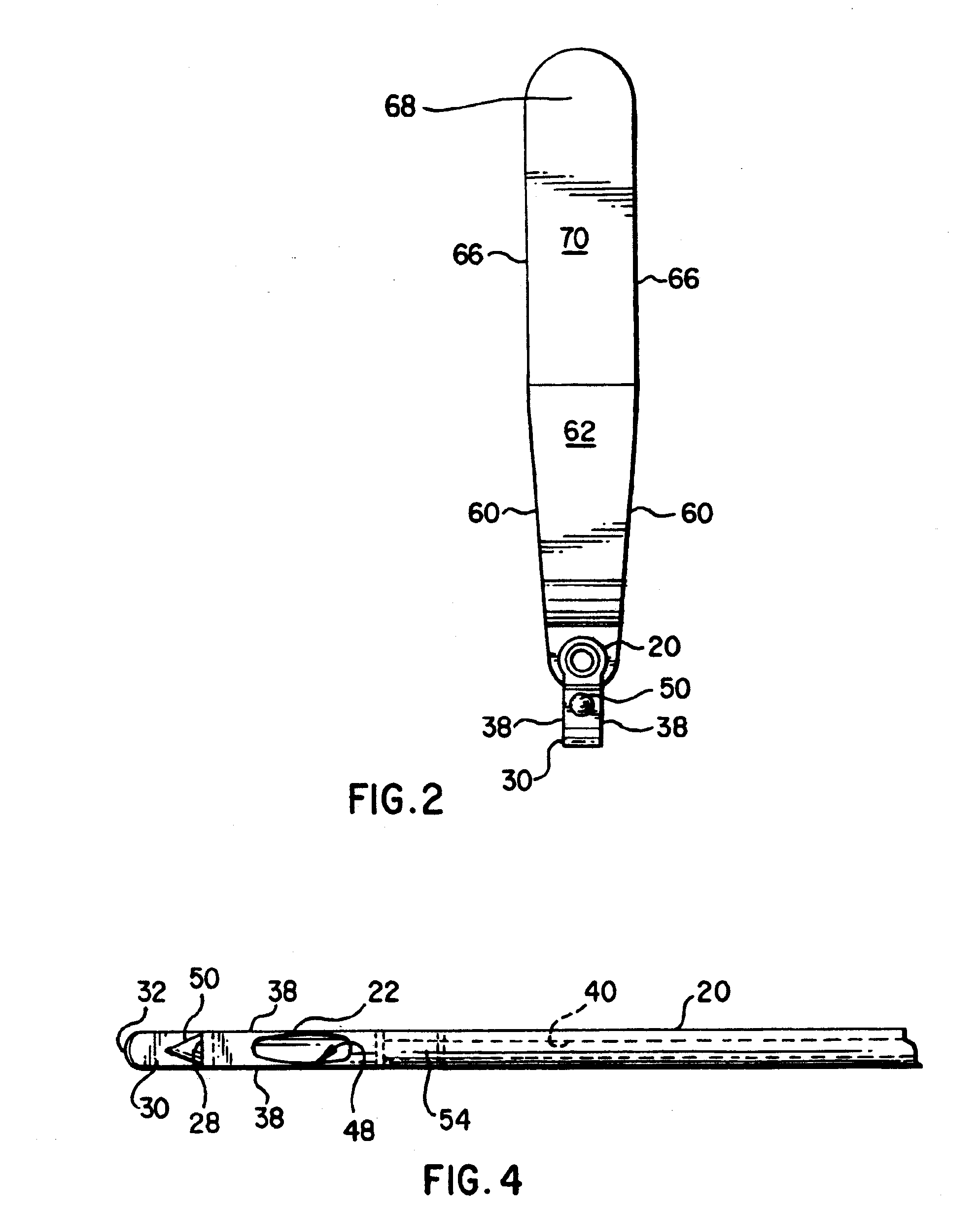

Methods of precisely forming bone tunnels in cruciate ligament reconstruction of the knee

InactiveUS6878150B1Precise positioningMinimal sizeJoint implantsLigamentsBone tunnelCruciate ligament

A femoral guide for precisely positioning a guide wire on a bone surface of the femur includes a body having a lumen for receiving a guide wire and a tongue protruding from the body for engaging an edge or reference point on the bone surface with the tongue being spaced a predetermined distance from a longitudinal axis of the lumen. The lumen includes an opening allowing a guide wire extending through the lumen to contact the bone surface at a location spaced from the edge substantially the predetermined distance with the tongue engaging the edge. A stylus on the body can be driven into the bone to secure and stabilize the femoral guide prior to driving the guide wire into the bone through the lumen. With the guide wire driven into the bone, a bone tunnel can be formed substantially concentrically or coaxially along the guide wire such that a longitudinal axis of the bone tunnel will be disposed from the edge substantially the predetermined distance. Methods of precisely forming bone tunnels include the steps of engaging an edge of a bone surface with a tongue of the femoral guide, inserting a guide wire through a lumen of the femoral guide, driving the guide wire into the bone through the lumen and forming a bone tunnel in the bone along the guide wire such that a longitudinal axis of the bone tunnel will be disposed from the edge engaged by the tongue a distance substantially equal to the distance that the tongue is disposed from a longitudinal axis of the lumen.

Owner:MCGUIRE DAVID A +1

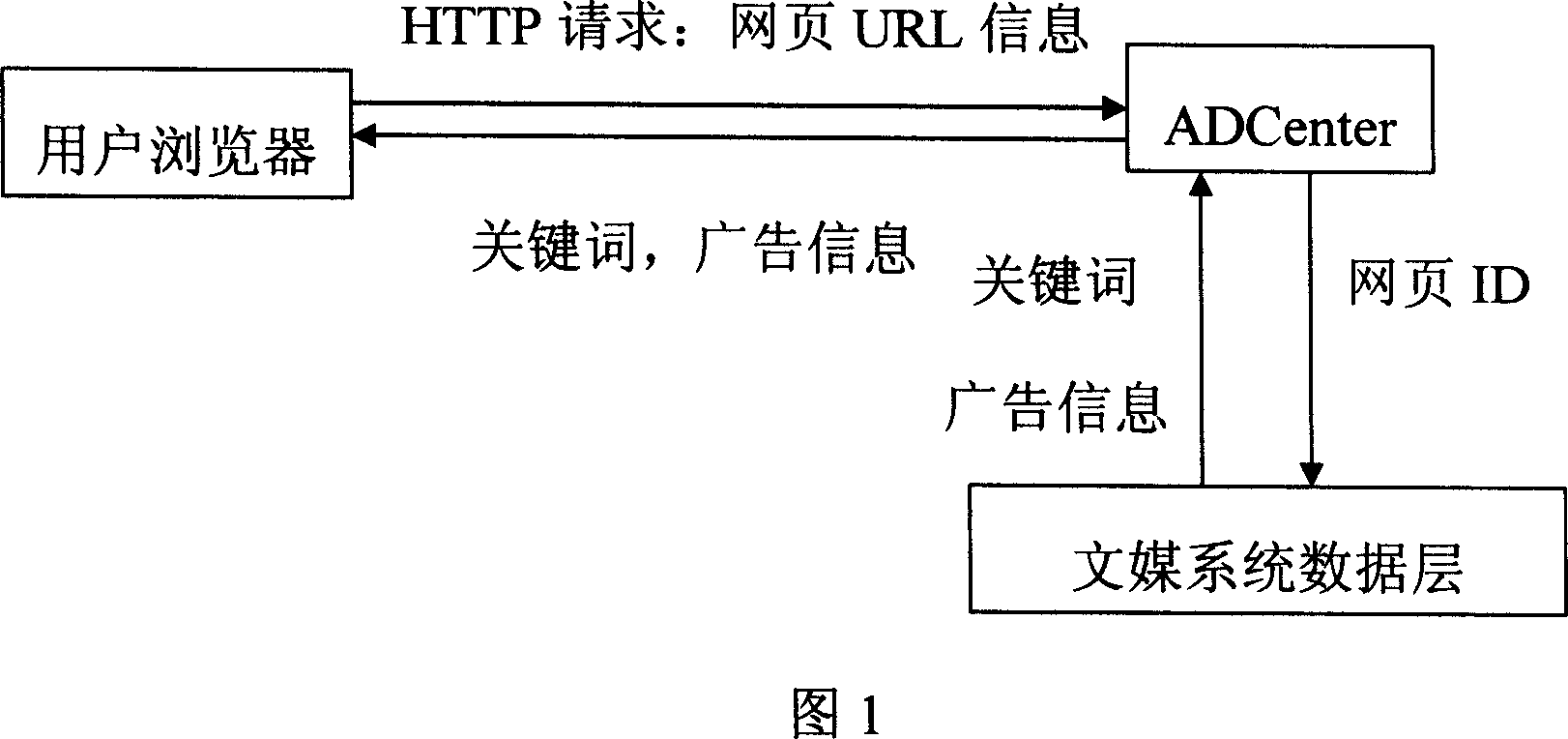

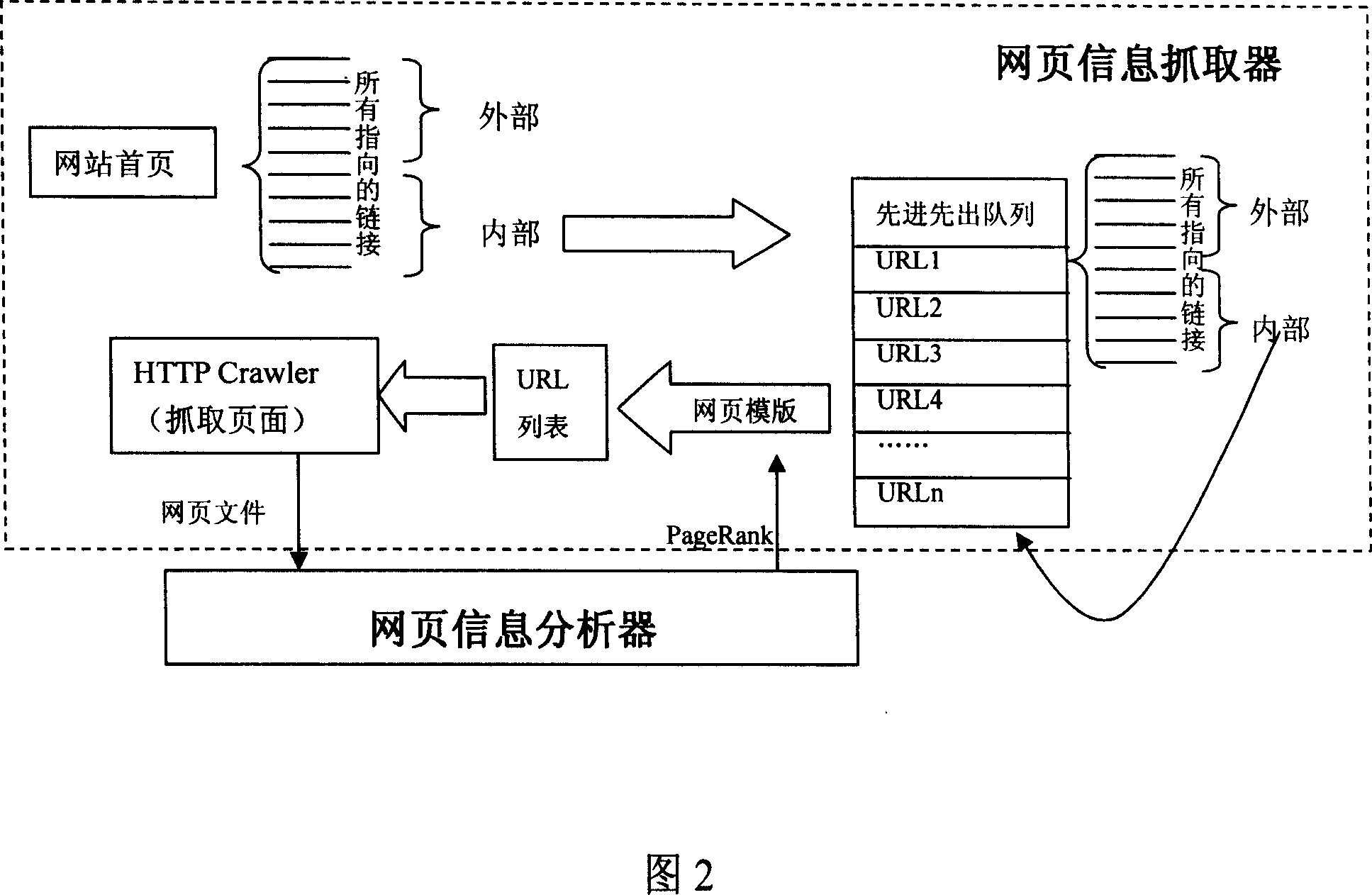

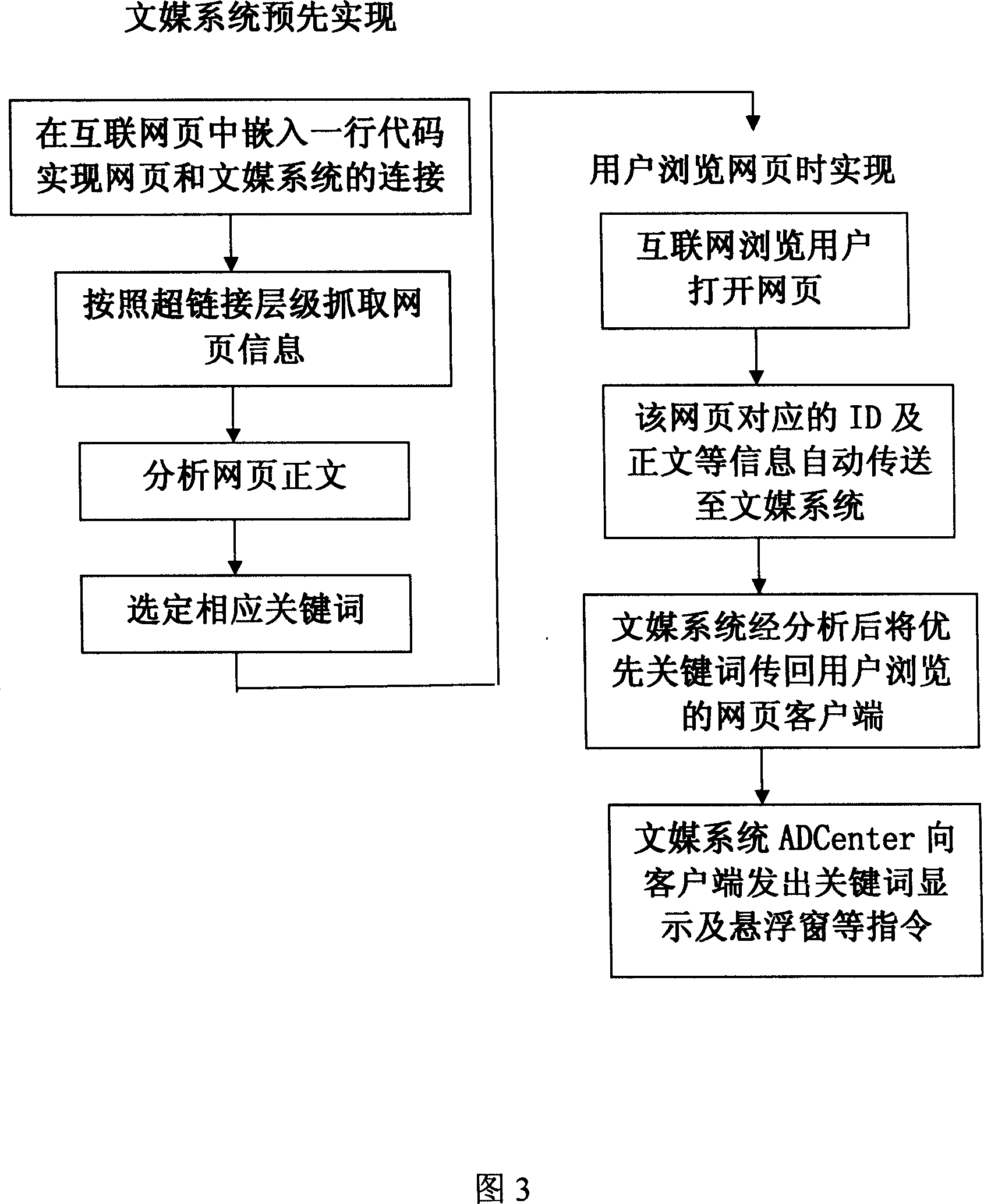

Common interconnection network content keyword interactive system

InactiveCN1932817APromote innovationIncrease initiativeSpecial data processing applicationsClient-sideArray data structure

Mutual universal network content keyword mutual system with true matching keyword and simply and rapidly adding keyword at real time. It relates to web page information grasp-organ, web page information analyzer to analyze the grasped page text, keyword index module to count matrix of web page and keyword. It also owns keyword demand module to find out keyword array which corresponds to the ID of web pages of keyword filtrating needed in the said web page, keyword matrix and JavaScript code interface. Then calculate the intersection about advertisement keyword bank to get a series of keywords and to classify and screen out the front keywords according to web page and advertisement keyword and advertisement keyword bank. Its AD Center module incepts HTTP demand sent by JavaScript code, calculates web pages ID corresponding URL, sends ID demand to keyword demand module, incepts the feedback keyword and the corresponding mutual advertisement information and adds them to the web page user ending by alternating with JavaScript code interface.

Owner:陈远

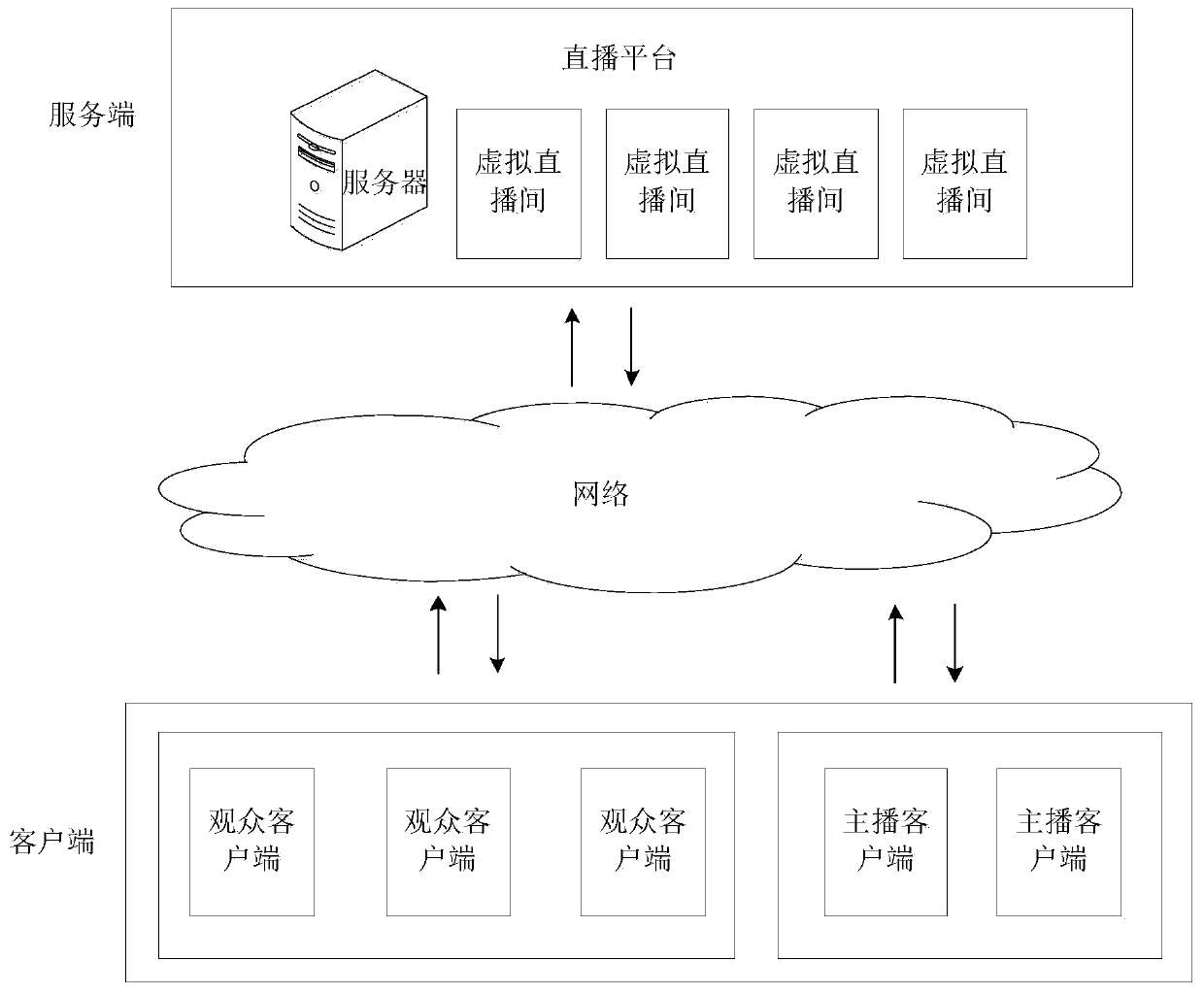

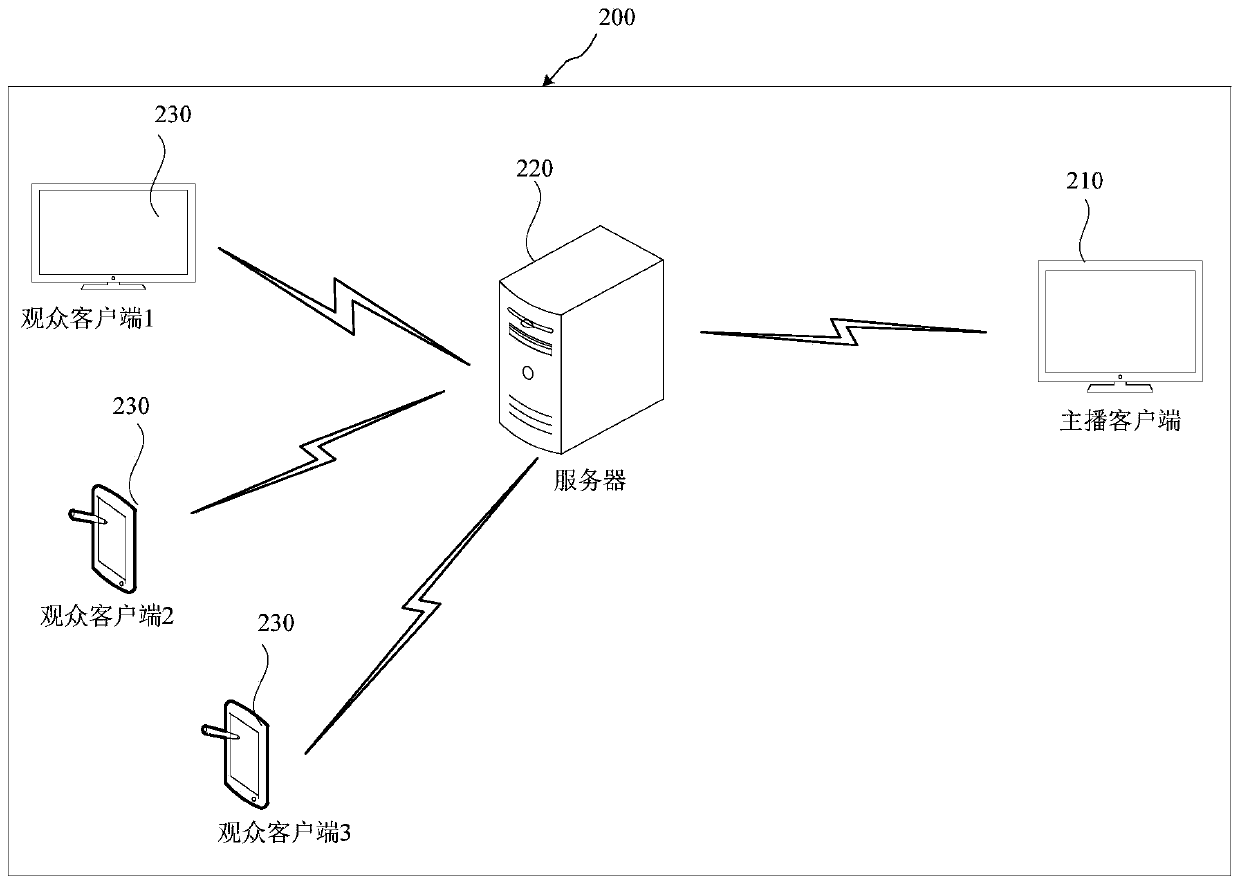

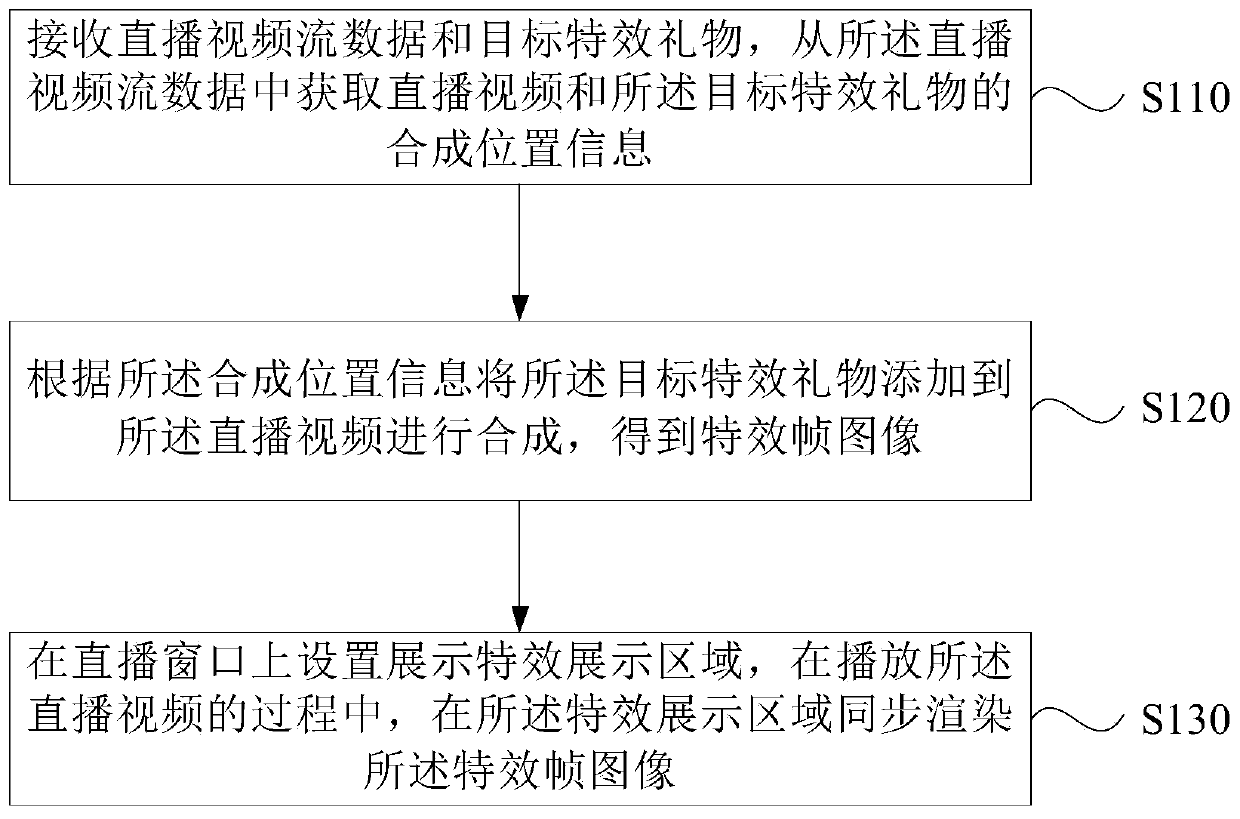

Virtual gift special effect rendering method and device and live broadcast system

ActiveCN110475150ADisplay does not affectImprove display effectSelective content distributionComputer graphics (images)Stream data

The embodiment of the invention provides a virtual gift special effect rendering method and device, a live broadcast system, equipment and a storage medium, and relates to the technical field of livebroadcast. The virtual gift special effect rendering method comprises the steps: receiving live broadcast video stream data and a target special effect gift, and obtaining the synthesis position information of a live broadcast video and the target special effect gift from the live broadcast video stream data, wherein the synthesis position information comprises a target position where a target special effect gift obtained by identifying the live video based on the anchor client is synthesized on the live video; adding the target special effect gift to the live video for synthesis according tothe synthesis position information to obtain a special effect frame image; and setting a display special effect display area on the live broadcast window, and synchronously rendering the special effect frame image in the special effect display area in the process of playing the live broadcast video. According to the technical scheme, the special effect of the virtual gift is not only limited to the live video playing area of the client, and rendering and displaying can be carried out across the video playing area.

Owner:广州方硅信息技术有限公司

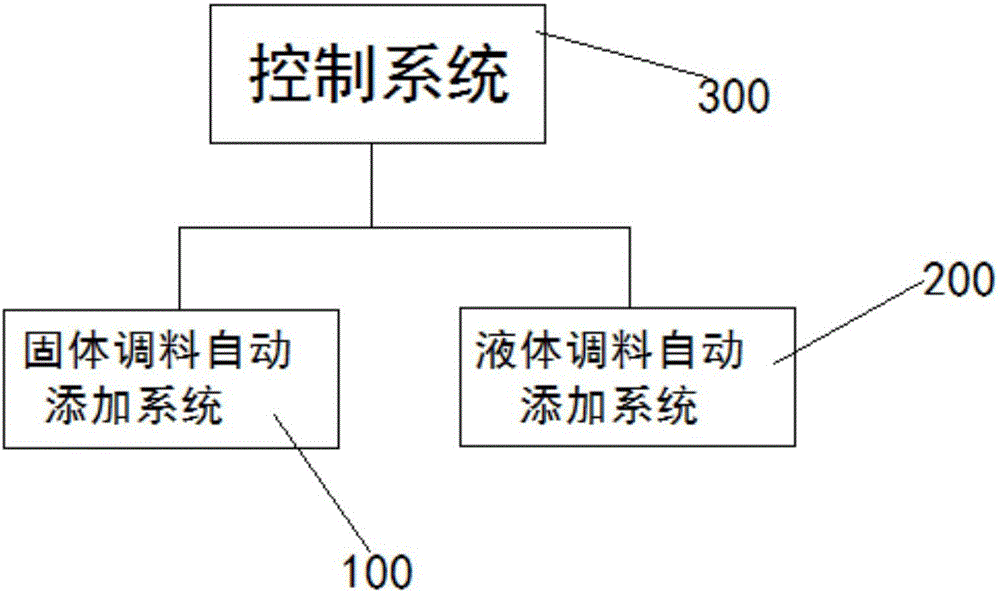

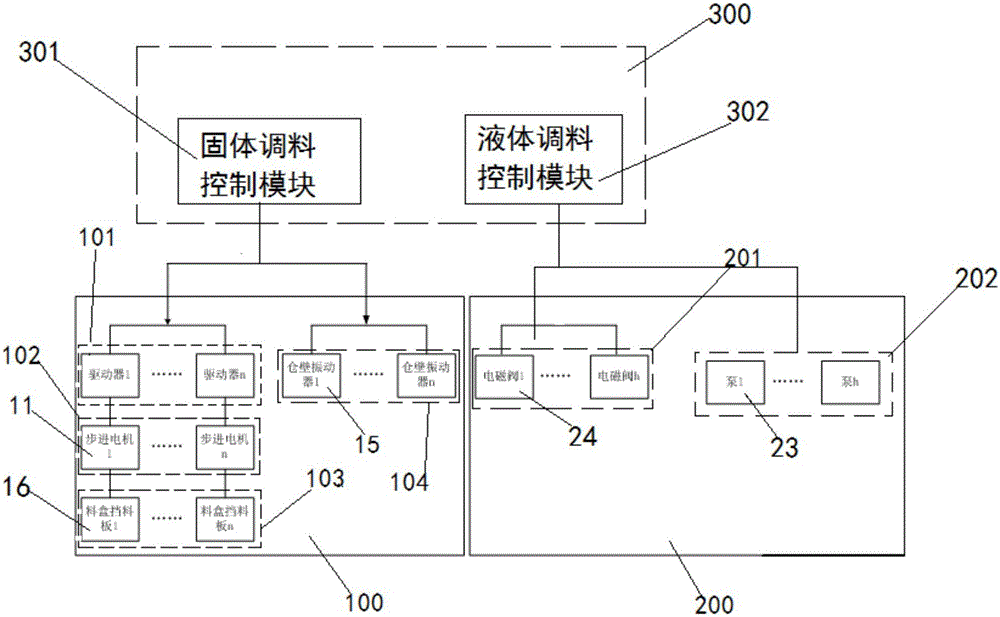

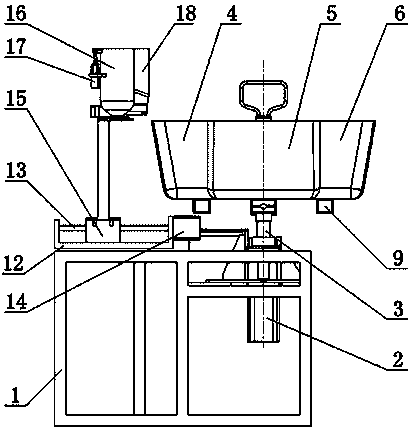

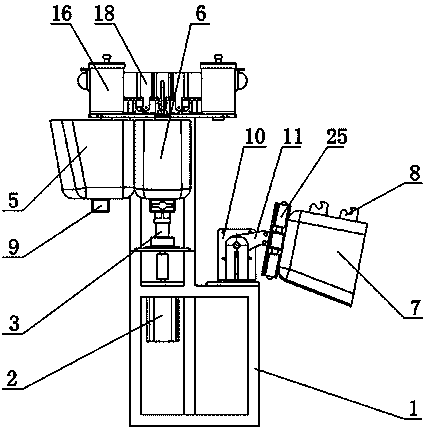

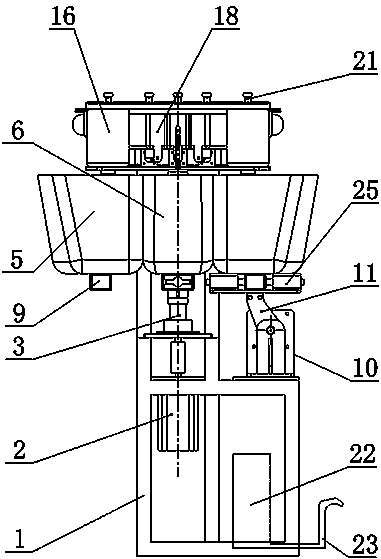

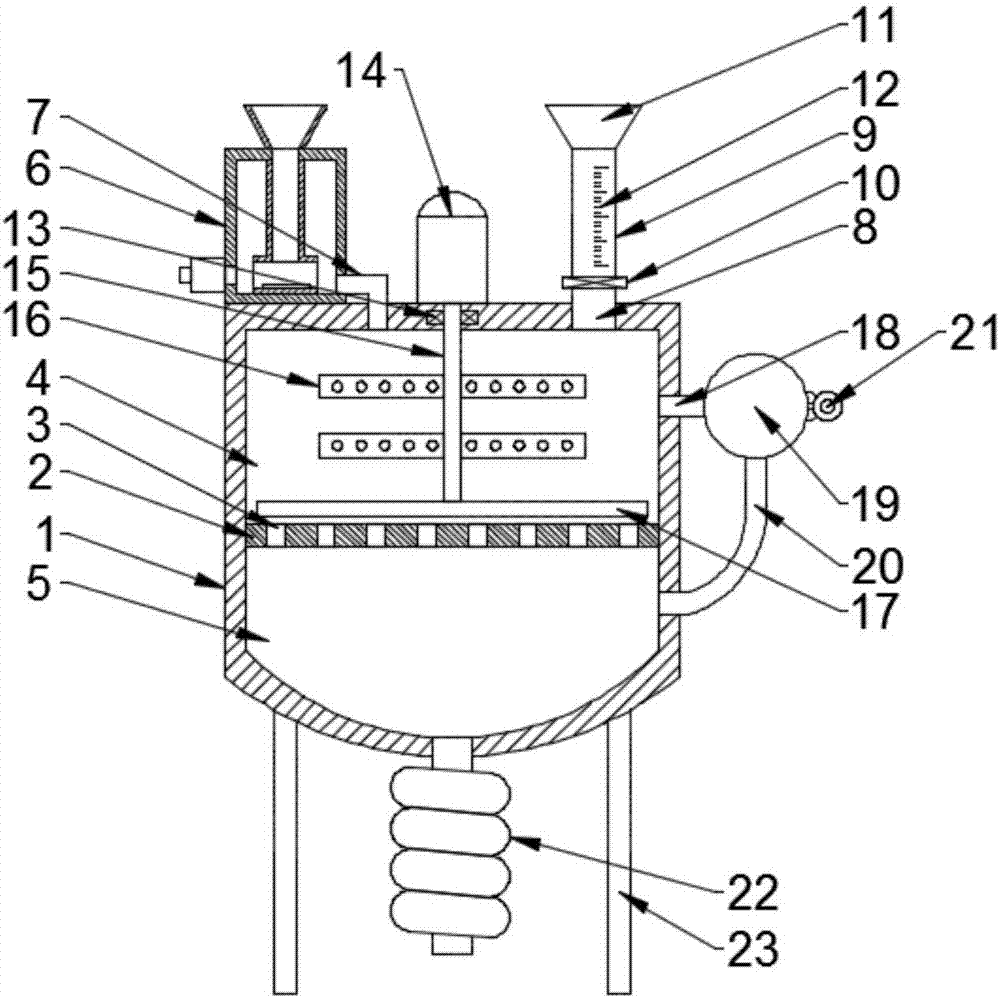

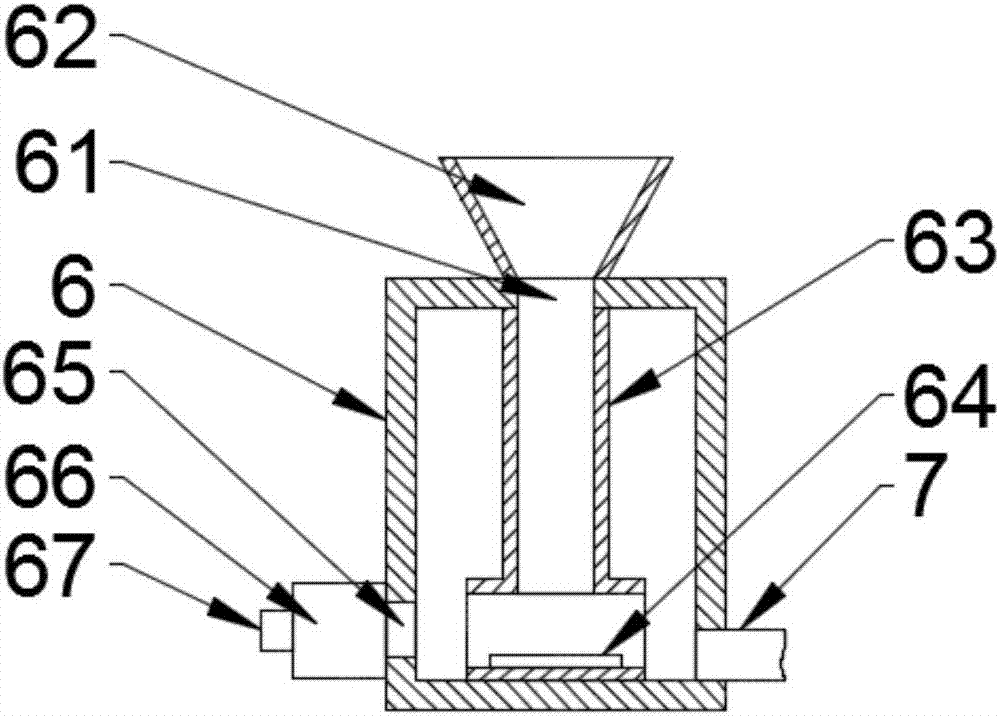

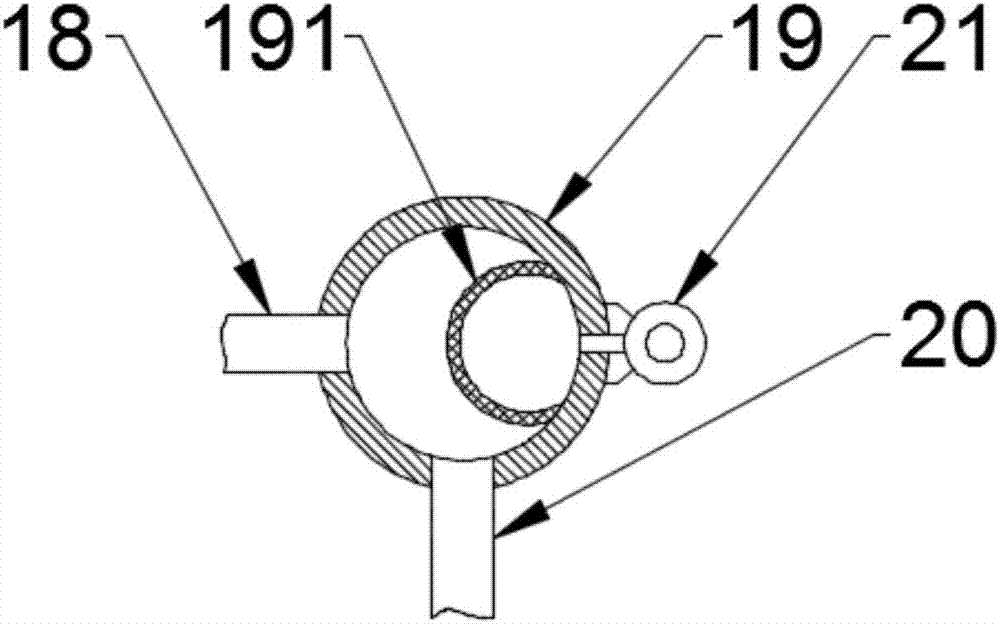

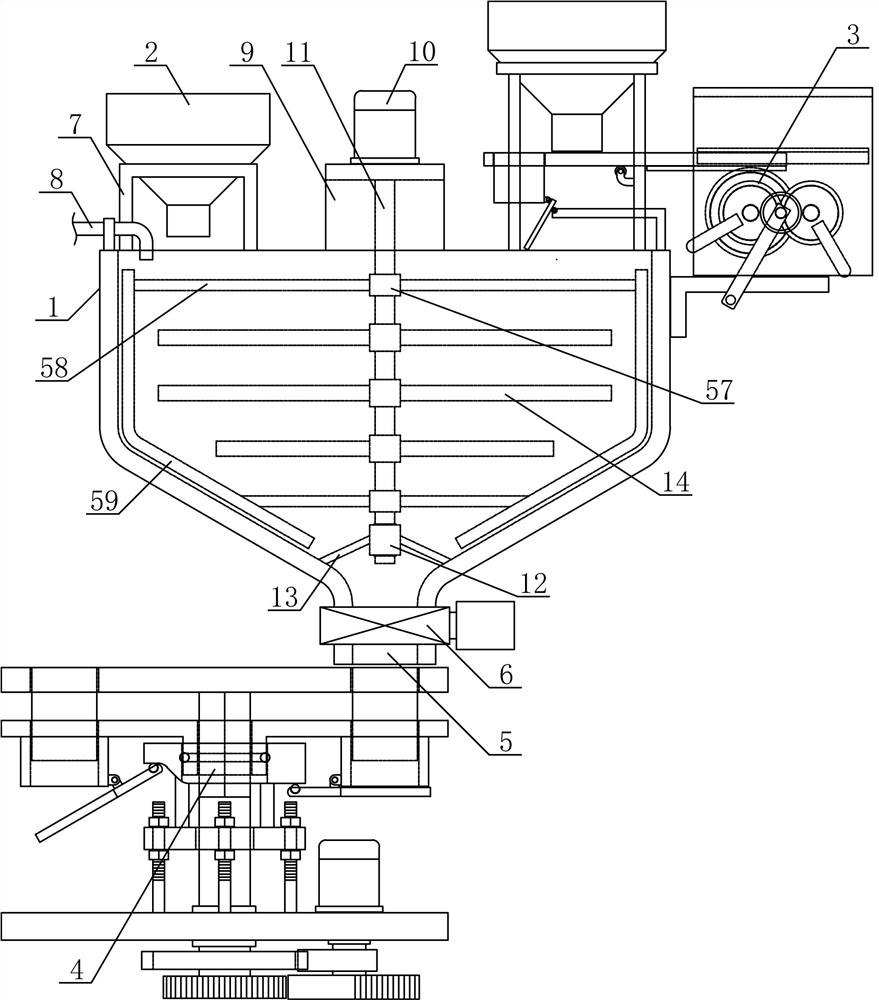

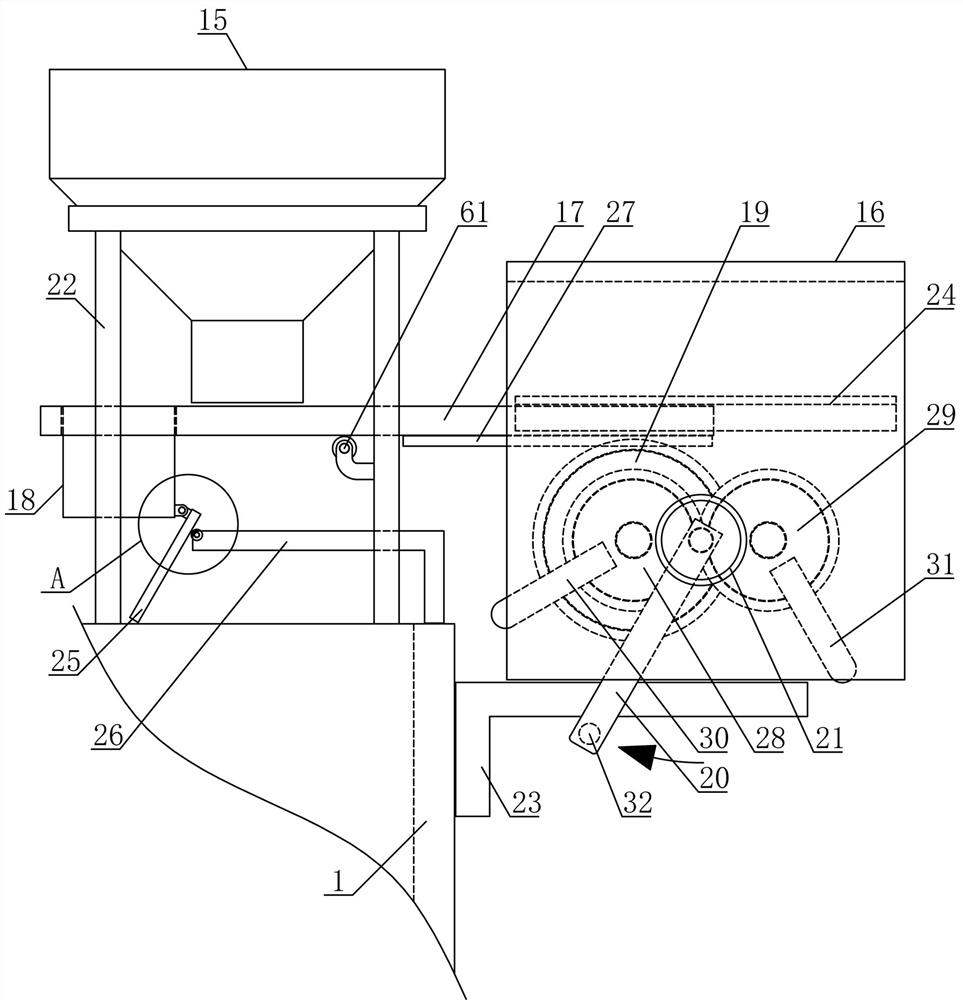

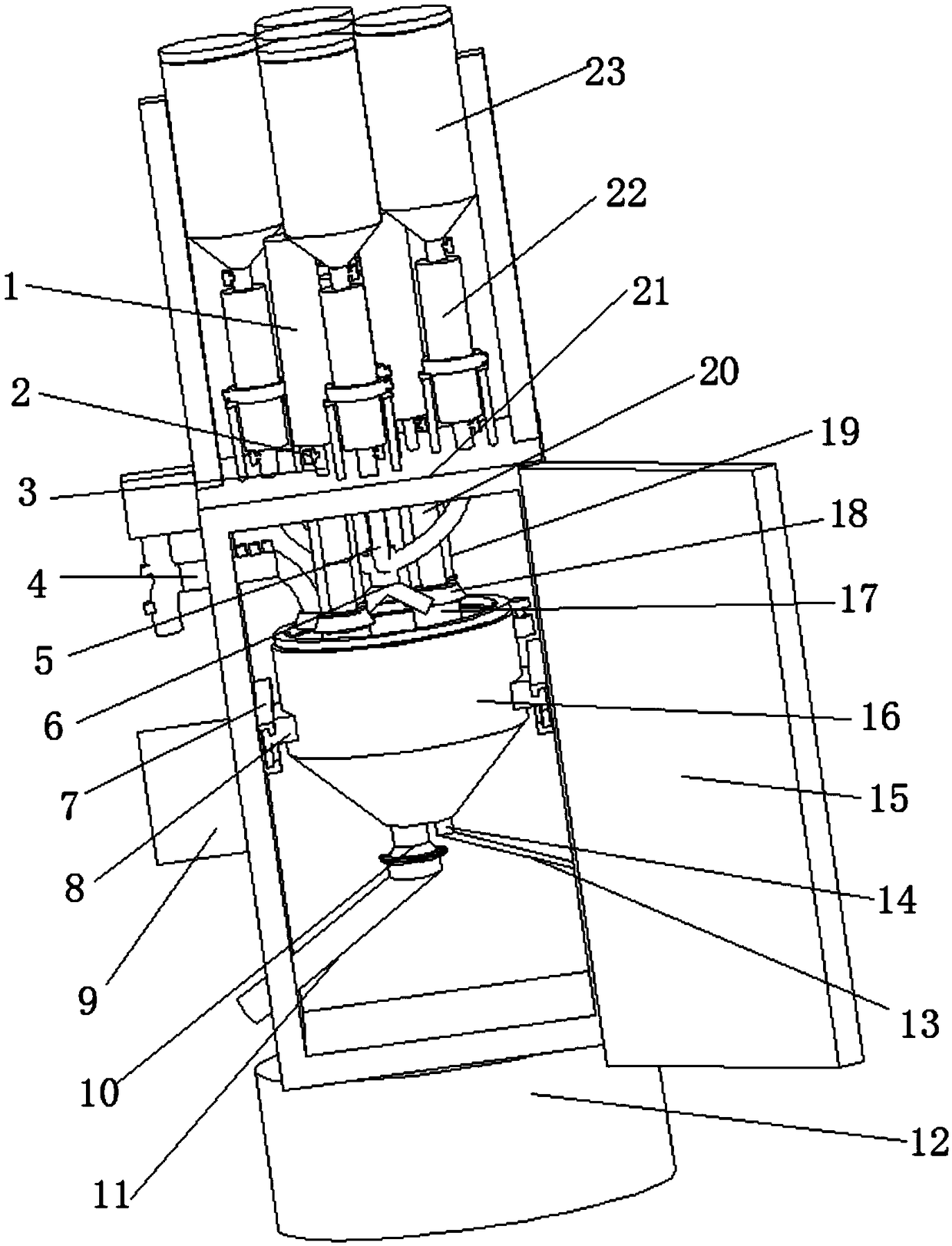

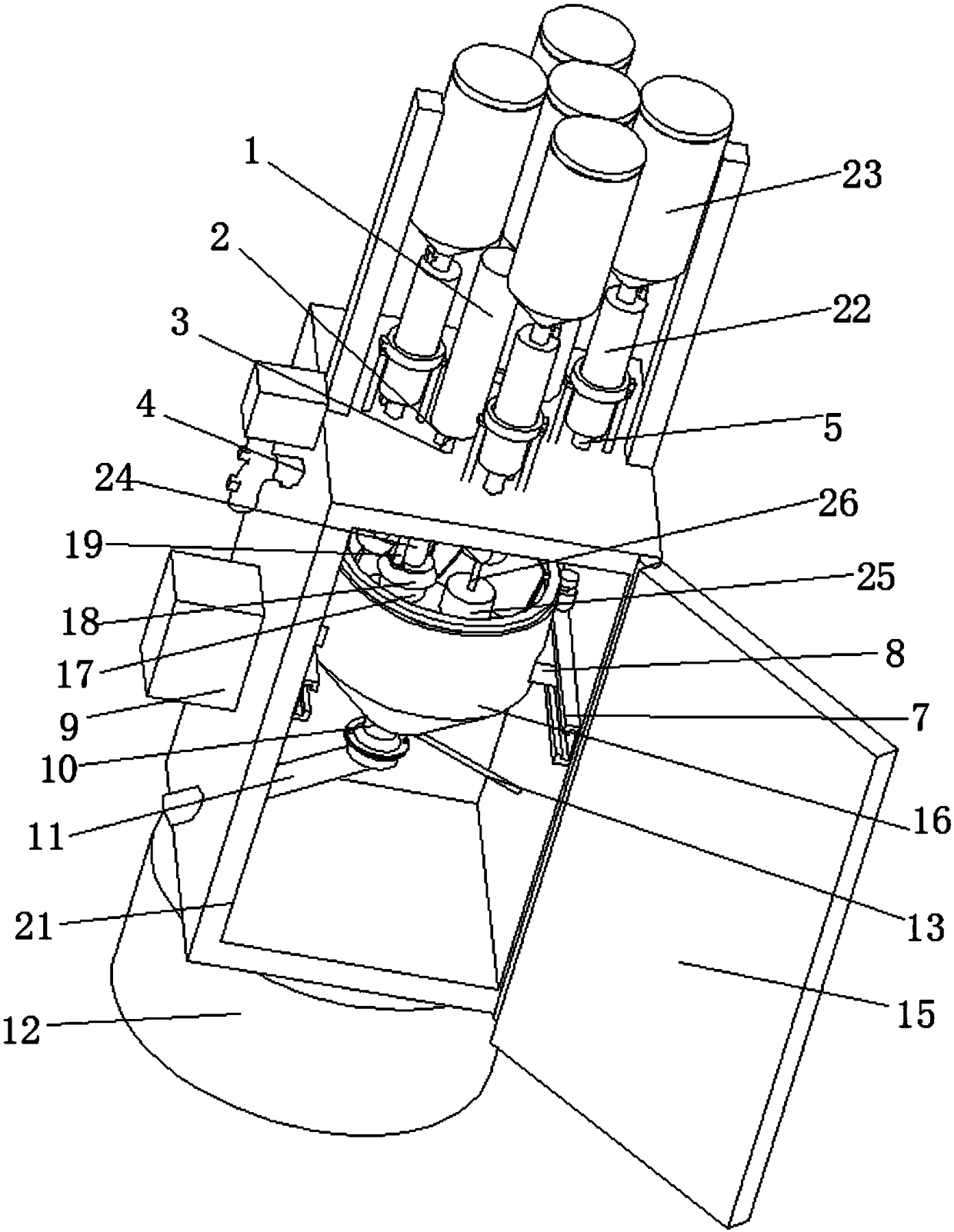

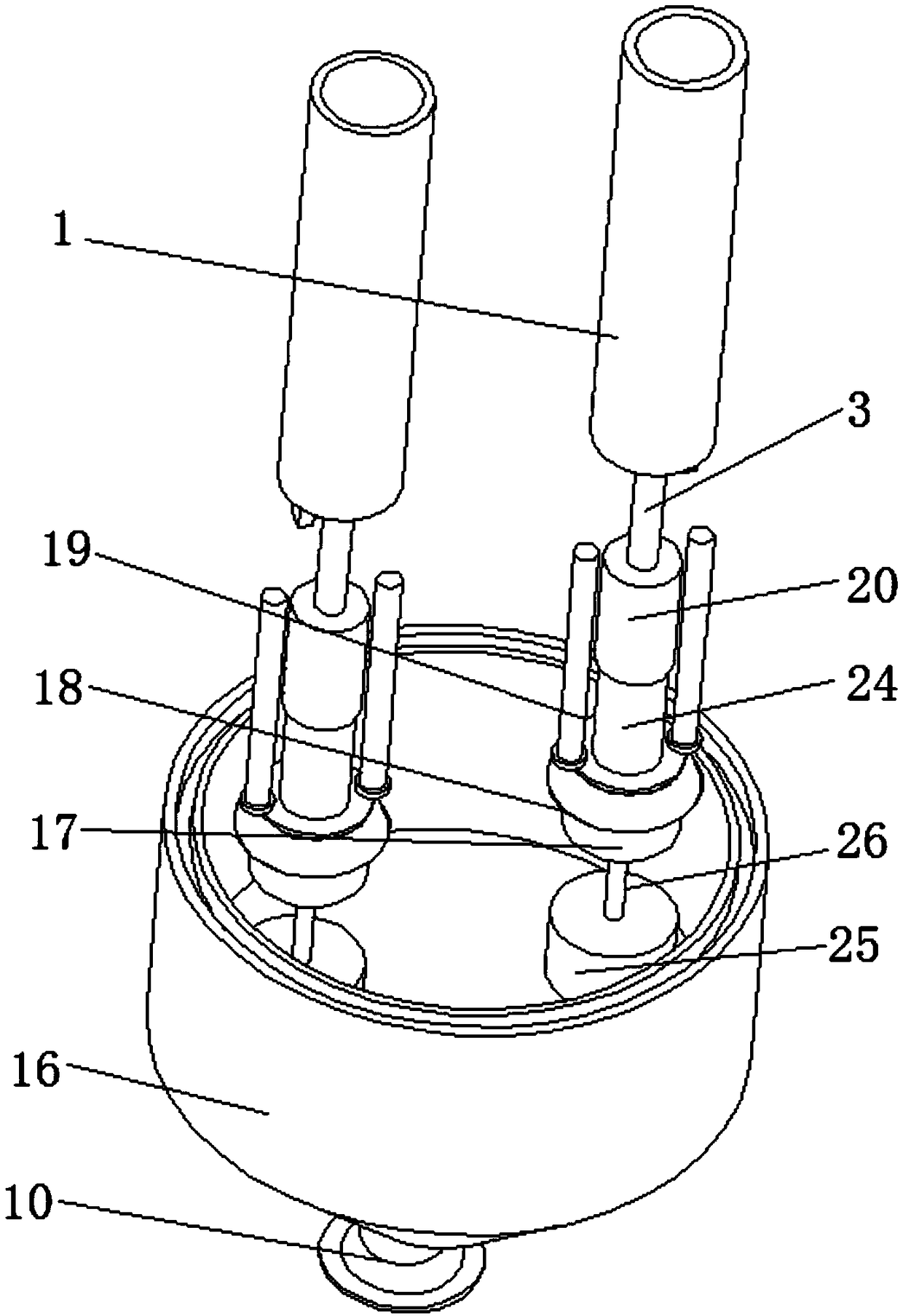

Seasoning automatic adding system for intelligent vegetable cooking machine and control method of system

The invention discloses a seasoning automatic adding system for an intelligent vegetable cooking machine. The system comprises a solid seasoning automatic adding system, a liquid seasoning automatic adding system and a control system. The solid seasoning automatic adding system and the liquid seasoning automatic adding system are mutually independent and are connected with the control system respectively. In the prior art, when an intelligent vegetable cooking device works, seasonings are still added by a vegetable cooking person according to the addition of the vegetable cooking person, so that the addition time of the seasonings are not stable and the addition amount is not precise, however, such problems are solved by the system. The invention further discloses a control method of the seasoning automatic adding system for the intelligent vegetable cooking machine.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Femoral Guide and Methods of Precisely Forming Bone Tunnels in Cruciate Ligament Reconstruction of the Knee

InactiveUS20010016746A1Precise positioningShorten the timeJoint implantsLigamentsBone tunnelCruciate ligament

<heading lvl="0">Abstract of Disclosure< / heading> A femoral guide for precisely positioning a guide wire on a bone surface of the femur includes a body having a lumen for receiving a guide wire and a tongue protruding from the body for engaging an edge or reference point on the bone surface with the tongue being spaced a predetermined distance from a longitudinal axis of the lumen. The lumen includes an opening allowing a guide wire extending through the lumen to contact the bone surface at a location spaced from the edge substantially the predetermined distance with the tongue engaging the edge. A stylus on the body can be driven into the bone to secure and stabilize the femoral guide prior to driving the guide wire into the bone through the lumen. With the guide wire driven into the bone, a bone tunnel can be formed substantially concentrically or coaxially along the guide wire such that a longitudinal axis of the bone tunnel will be disposed from the edge substantially the predetermined distance. Methods of precisely forming bone tunnels include the steps of engaging an edge of a bone surface with a tongue of the femoral guide, inserting a guide wire through a lumen of the femoral guide, driving the guide wire into the bone through the lumen and forming a bone tunnel in the bone along the guide wire such that a longitudinal axis of the bone tunnel will be disposed from the edge engaged by the tongue a distance substantially equal to the distance that the tongue is disposed from a longitudinal axis of the lumen.

Owner:MCGUIRE DAVID A +1

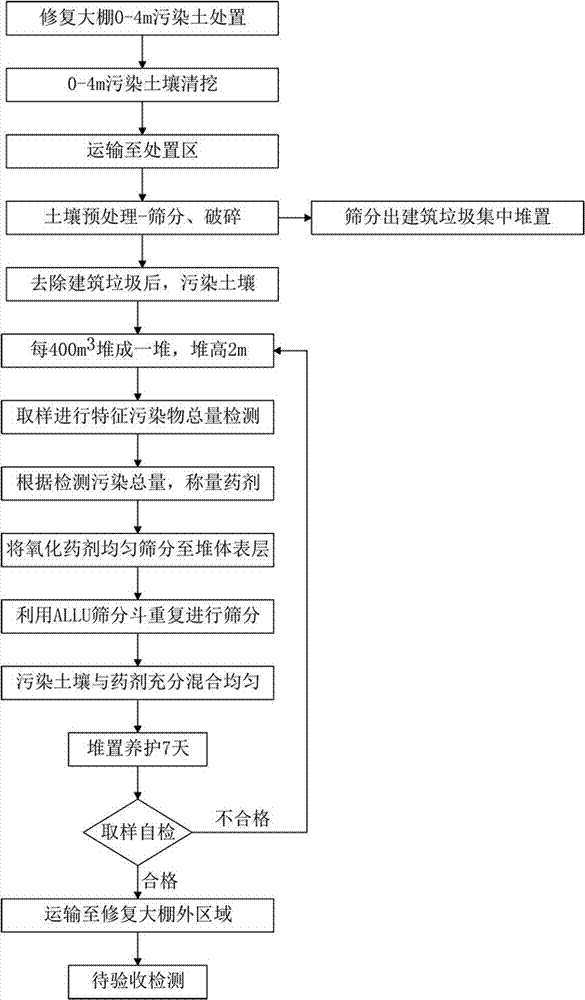

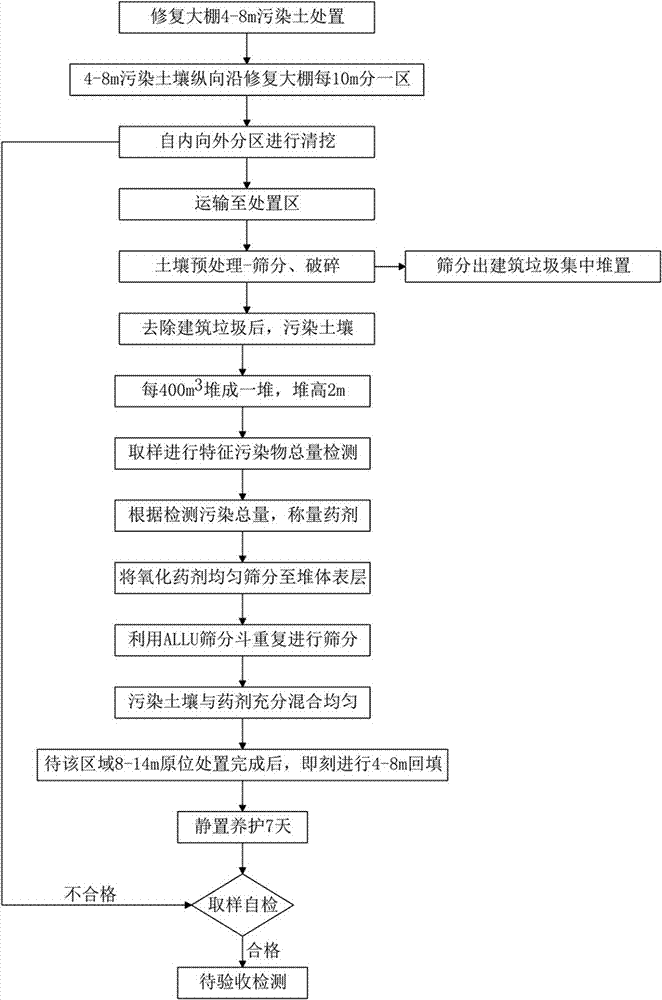

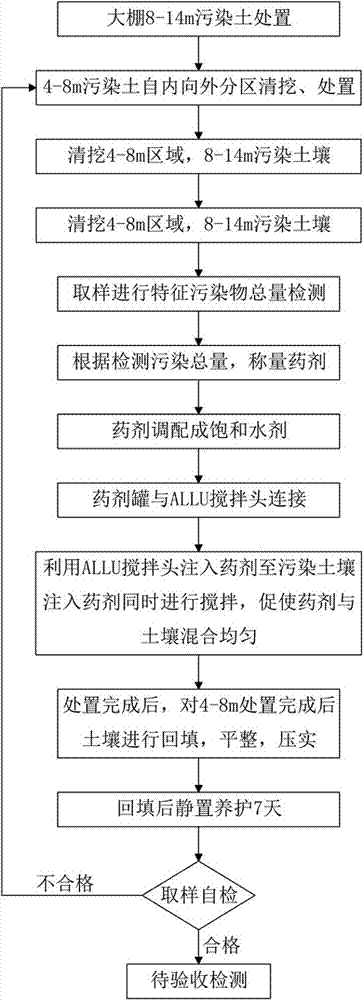

Remediation technology for organic contaminated soil

InactiveCN107214189AAvoid safety hazardsAdd accurateContaminated soil reclamationSoil sciencePollution soil

The invention relates to a remediation technology for organic contaminated soil. According to the remediation technology for the organic contaminated soil, layered stepped type back excavation construction treatment is adopted, a remediation greenhouse has the height limit of 14m, the soil is divided into 3 layers, the soil with the depth of 0-4m is a first layer, the soil with the depth of 4-8m is a second layer, and the soil with the depth of 8-14m is a third layer, wherein the soil with the depth of 0-4m adopts an ex-situ chemical oxidation remediation technology and is transported to a region outside the greenhouse after being remedied, the soil of a region with the depth of 4-8m is excavated one by one every 10m along the remediation greenhouse from inside to outside in the vertical direction and is transported to other regions in the greenhouse for rapid ex-situ chemical oxidation remediation, and meanwhile, the excavation region with the depth of 8-14m is subjected to in-situ chemical oxidation remediation. The remediation technology for the organic contaminated soil has the advantages that the layered stepped type back excavation construction treatment is adopted, and therefore the technology cannot be limited by equipment and can be safer, and the treatment effect can be better.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

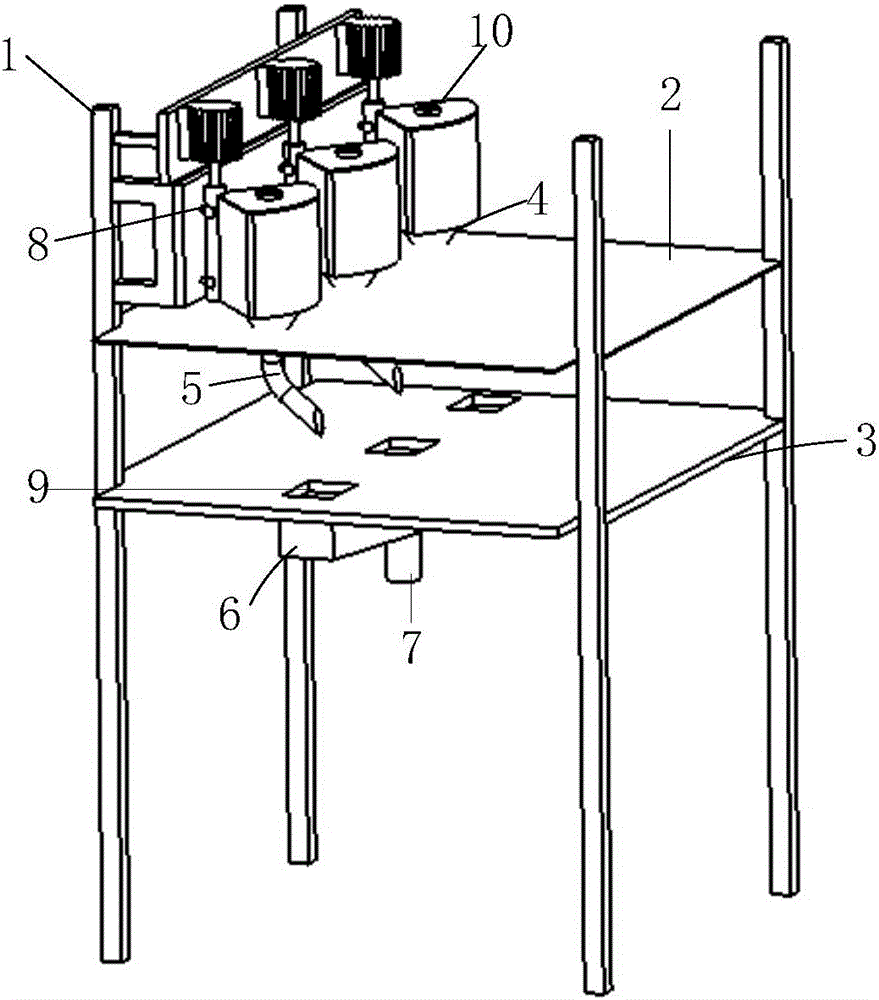

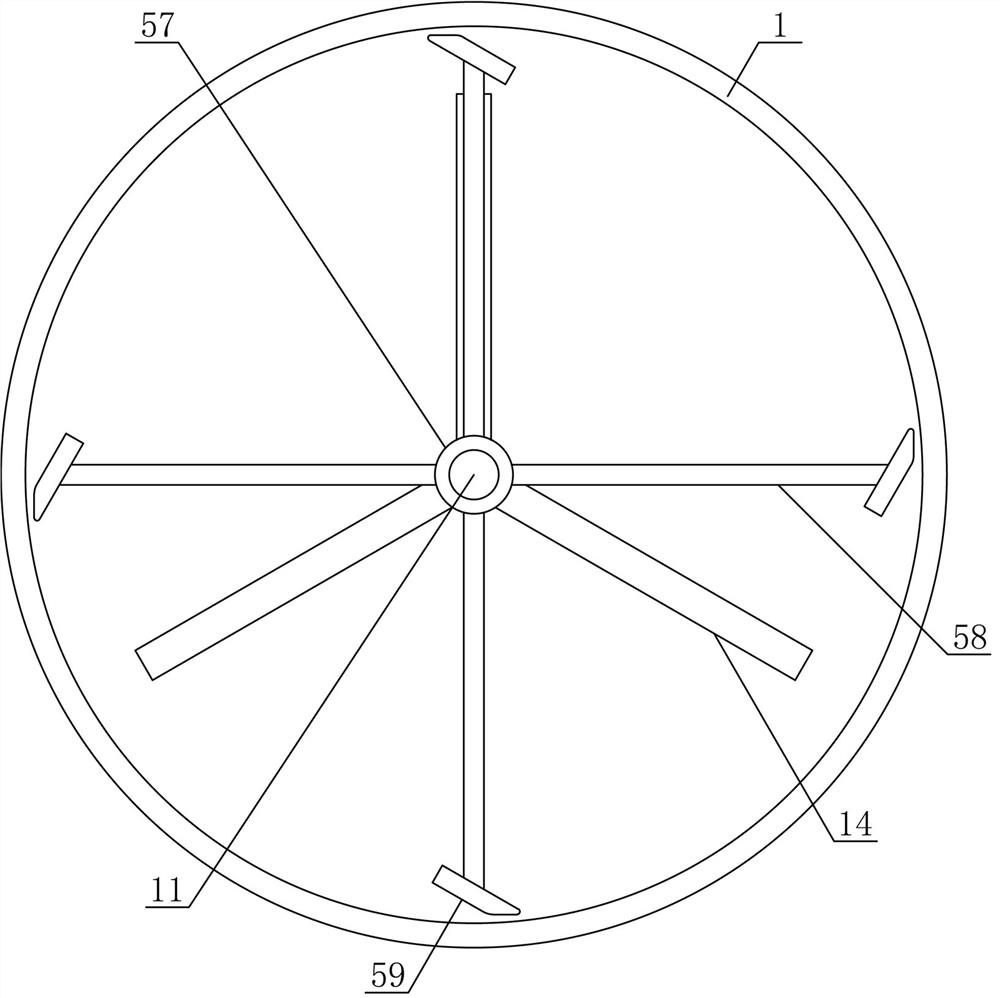

Automatic charging mechanism of intelligent cooker

The invention relates to an automatic charging mechanism of an intelligent cooker. The automatic charging mechanism comprises a base, a rotary material feeding device, a seasoning adding device and a material pouring-into-boiler device, wherein the rotary material feeding device comprises a motor A, a rotary shaft and a plurality of material boxes; a hanging frame sleeves the upper end of the rotary shaft; the hanging frame is in a regular polygon shape; the plurality of material boxes are uniformly hung at the edge of the hanging frame at intervals; a clamping groove is further formed in the bottom of each material box; the seasoning adding device comprises a seasoning box slide seat, a screw rod, a motor C, a linear movable frame, a liquid seasoning box and a solid powder seasoning box; the material pouring-into-boiler device comprises a motor B and a vegetable feeding rocking bar; the motor B is fixedly mounted on the base and an output end of the motor B is in transmission connection with the lower end of the vegetable feeding rocking bar; and an electromagnet is arranged at the upper end of the vegetable feeding rocking bar. The automatic charging mechanism of the intelligent cooker has the advantages that main materials and seasonings can be fully automatically charged in a high-precision manner, the structure is exquisite and simple and the intelligent degree is high; and dishes cooked by the automatic cooker have a relatively good taste.

Owner:MEISHAN HUACHEN TECH CO LTD

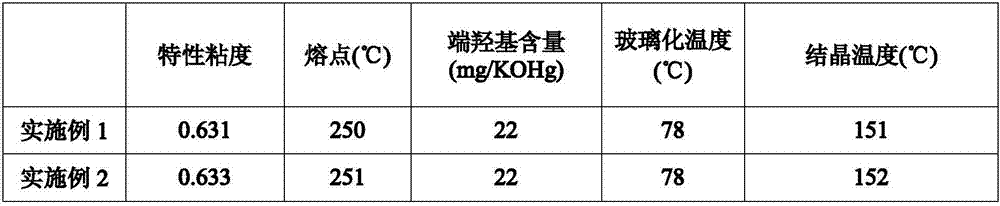

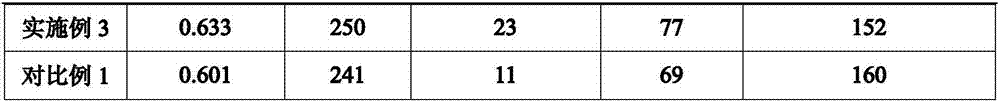

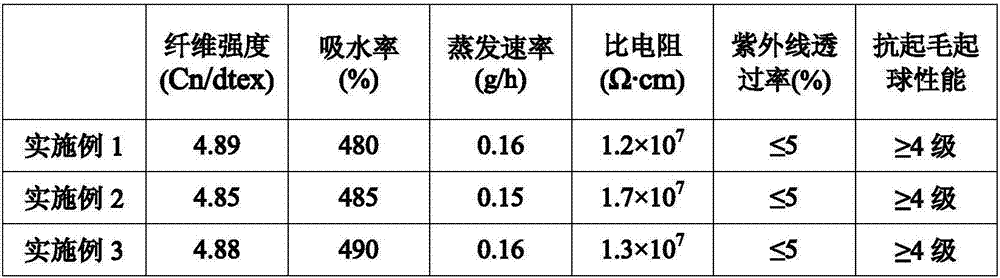

Preparation method of super cotton-like polyester fiber by continuous polymerizing melt direct spinning

ActiveCN107201567AReduce generationAdd accurateArtificial filament heat treatmentMelt spinning methodsFiberPolyester

The invention relates to a preparation method of super cotton-like polyester fiber by continuous polymerizing melt direct spinning. The preparation method sequentially comprises the following steps of first esterification reaction procedure, second esterification reaction procedure, polymerizing reaction procedure and spinning procedure. The preparation method has the advantages that ethylene glycol, a reaction monomer containing a hydrophilic group, polyethylene glycol and an additive are prepared into a moisture absorbing mother liquid, the moisture absorbing mother liquid is added into the second esterification reaction procedure, the additive can be thinned by the preparation of the moisture absorbing mother liquid, the accurate adding is realized, the production of side reaction is reduced, and the spinnability and product stability are improved; the polyester melt can be continuously produced, and sent into the spinning equipment to directly spin, the super cotton-like polyester fiber is produced by the continuous melt direct spinning technique, the blending and drying procedure with conventional slices is reduced, and the cost is greatly reduced; the quality of the prepared super cotton-like polyester fiber is stable, and the product property is uniform.

Owner:SANFANGXIANG GROUP CO LTD

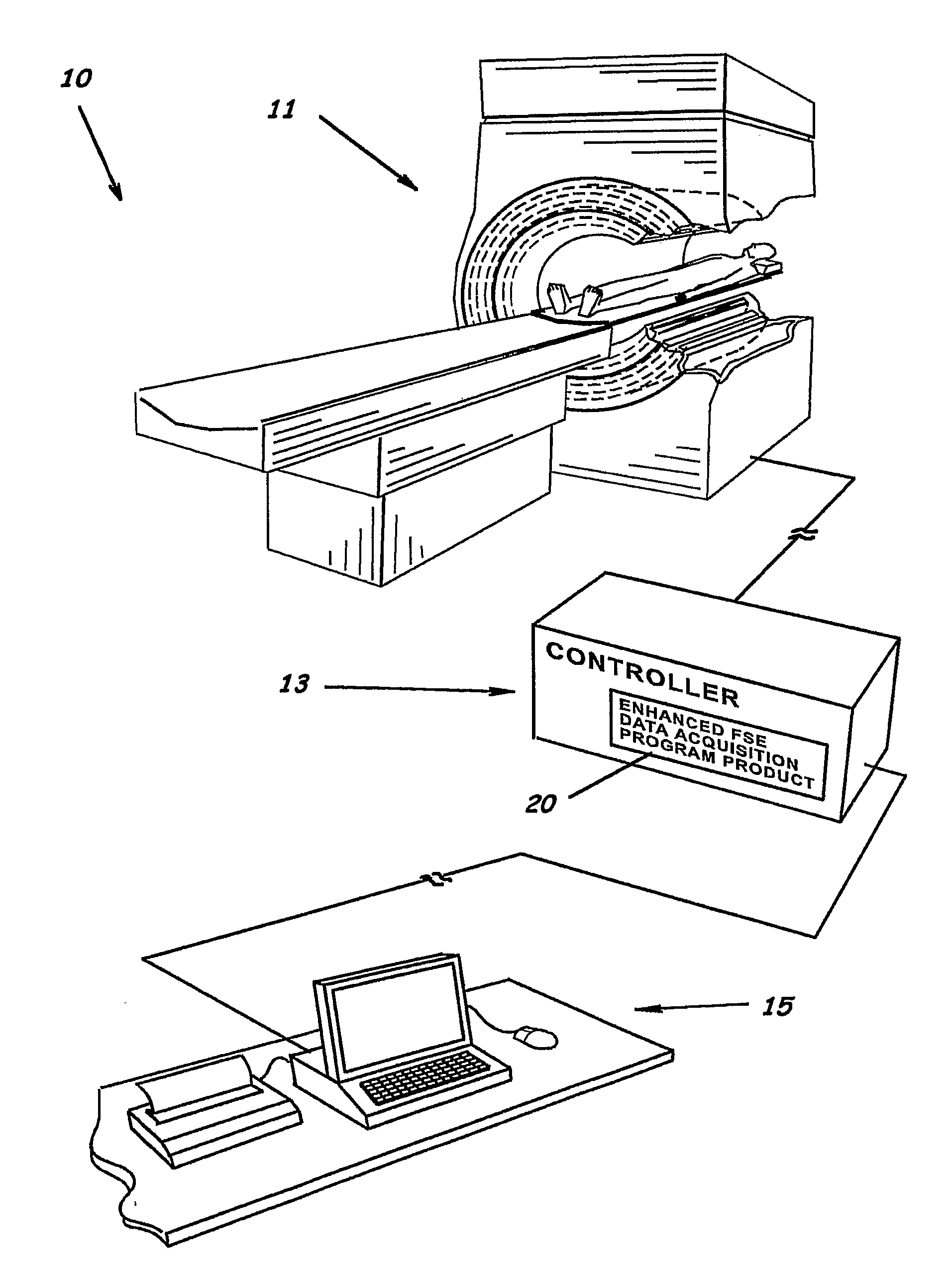

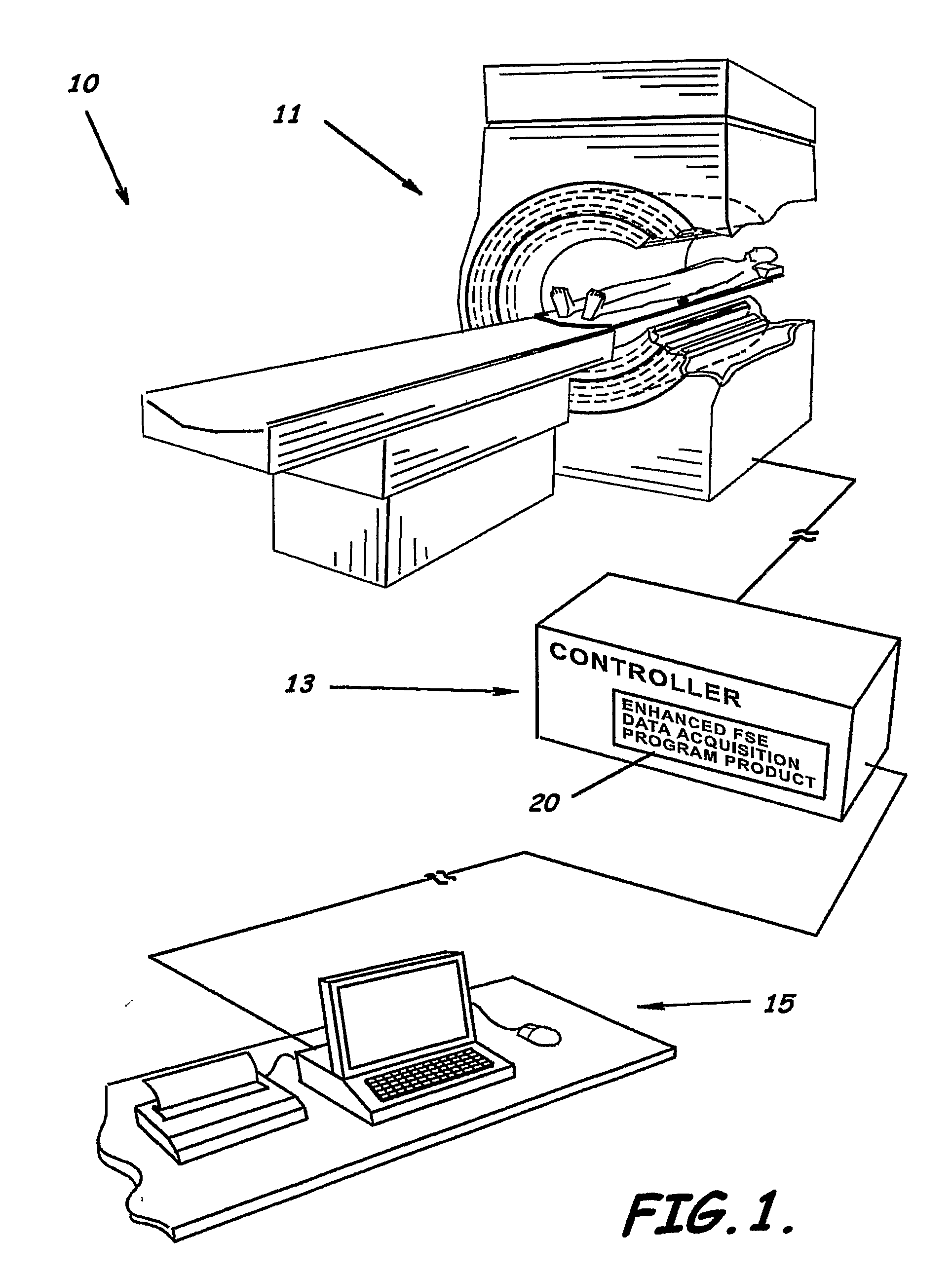

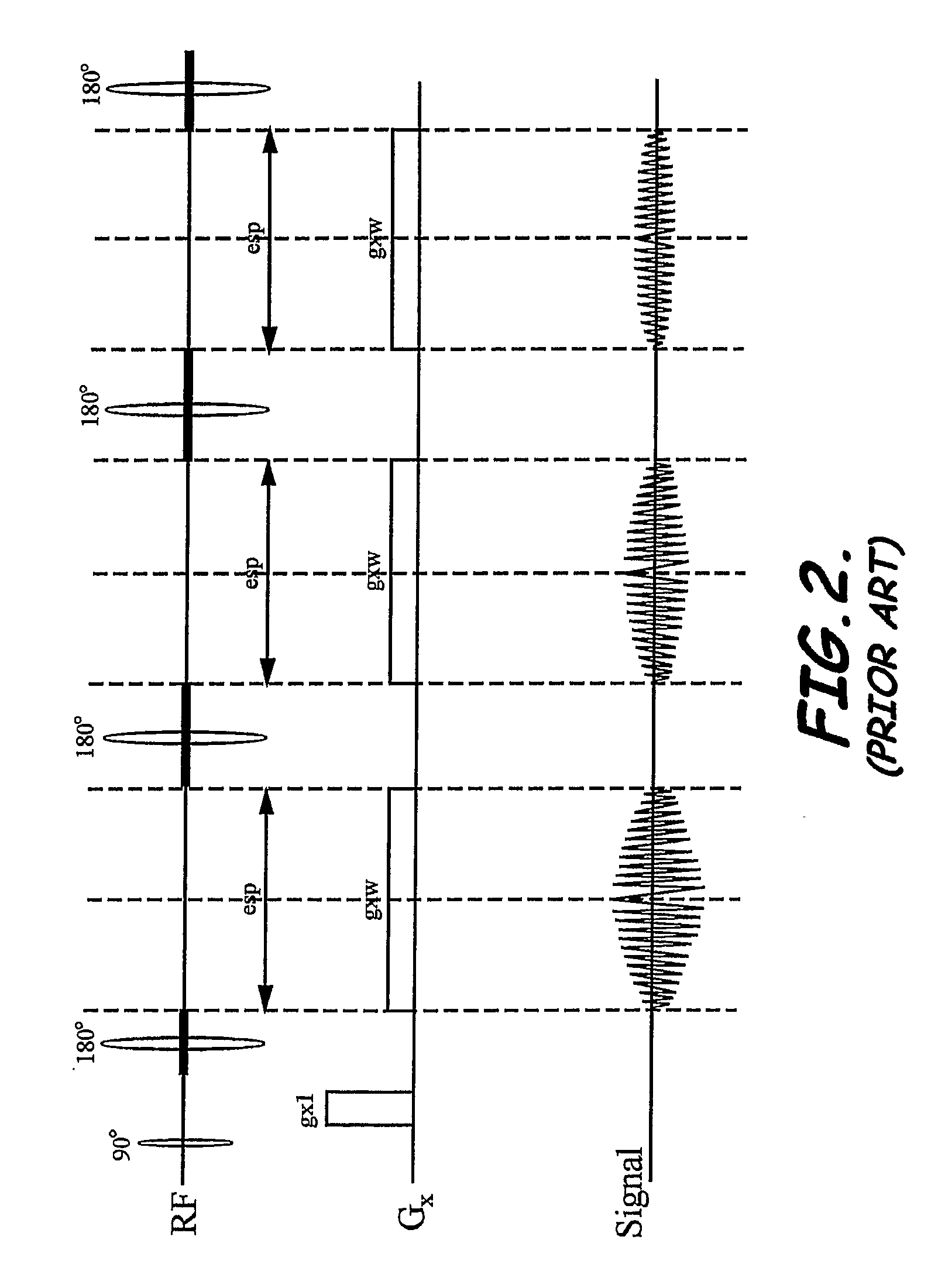

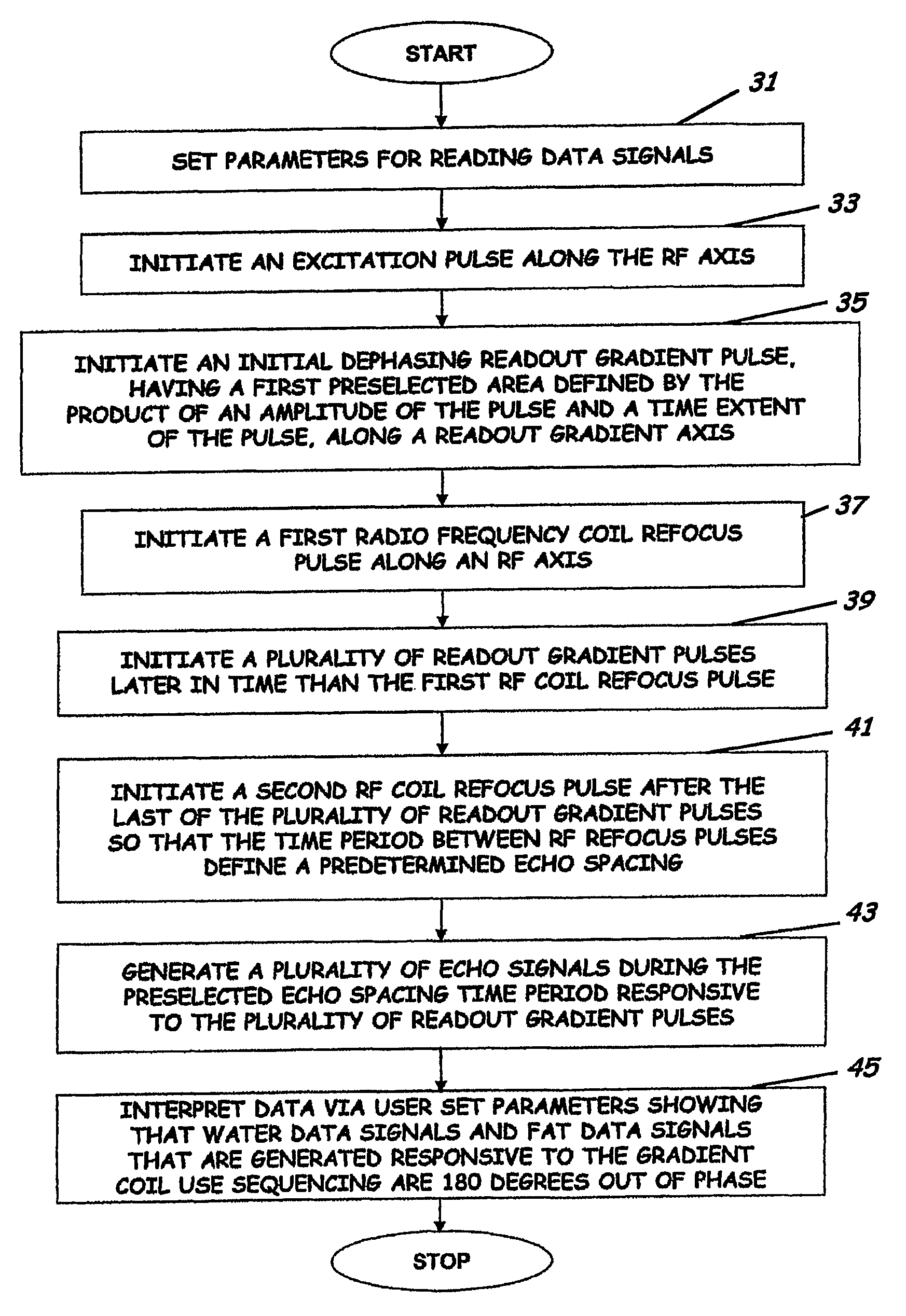

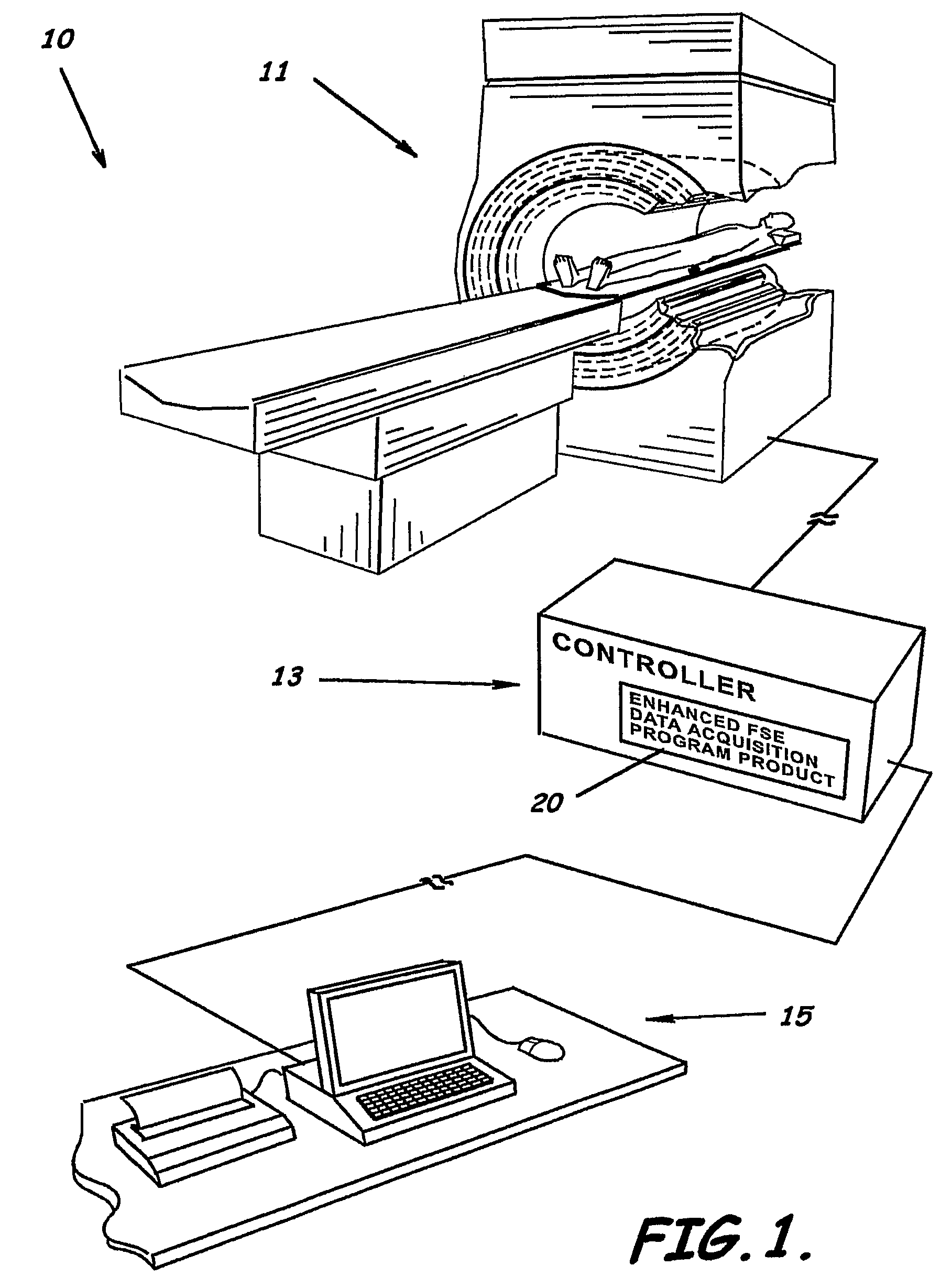

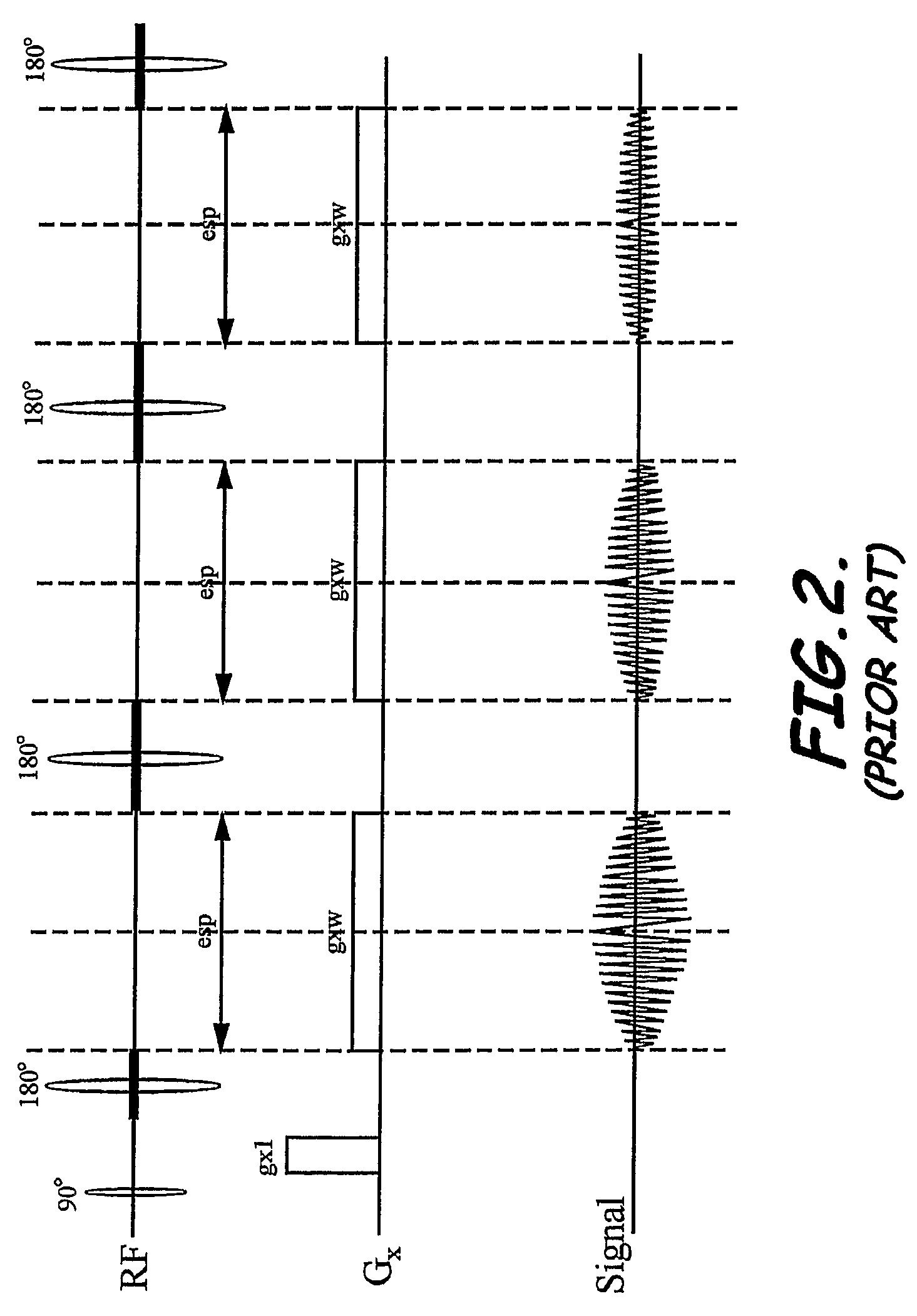

System, program product, and method of acquiring and processing MRI data for simultaneous determination of water, fat, and transverse relaxation time constants

ActiveUS20090093704A1Extension of timeEfficiently determine separateDiagnostic recording/measuringSensorsSingle imageRelaxation time constant

A system, program product, and method to determine water, fat, and transverse relaxation time constants in MRI scanning are provided. A method includes initiating readout gradient pulses to collect echo signals with identical phase encoded gradients to thereby produce a plurality of images, instead of a single image with a single readout gradient. A receiver bandwidth used for collecting the echo signals can be determined responsive to an acquisition matrix size along the readout axis and a time duration for water and fat signals to evolve by a preselected phase angle. In a modified FSE implementation, for example, a method includes using readout gradient pulses that use substantially all of the echo spacing time periods between successive refocus RF pulses. By exploiting the phase and the amplitude relationship between the images, the method can include processing the images to generate separate water and fat images, as well as quantitative maps of transverse relaxation time constants.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

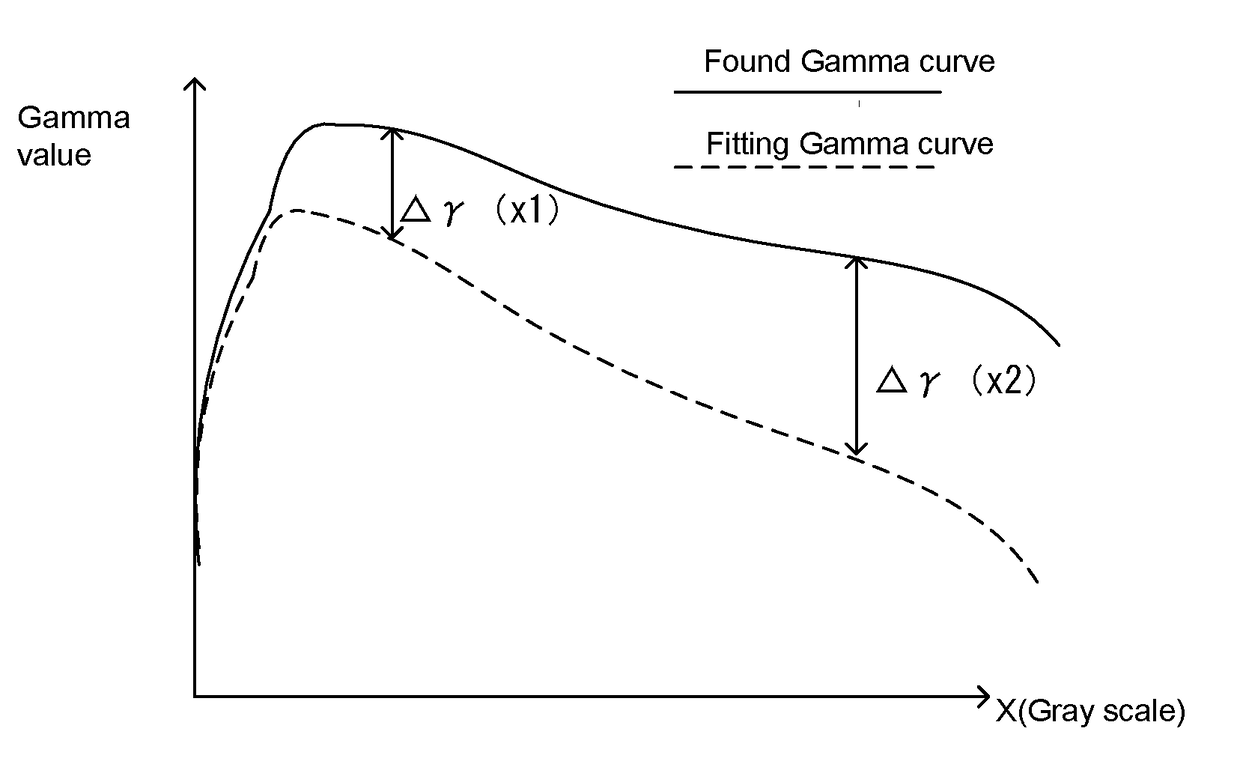

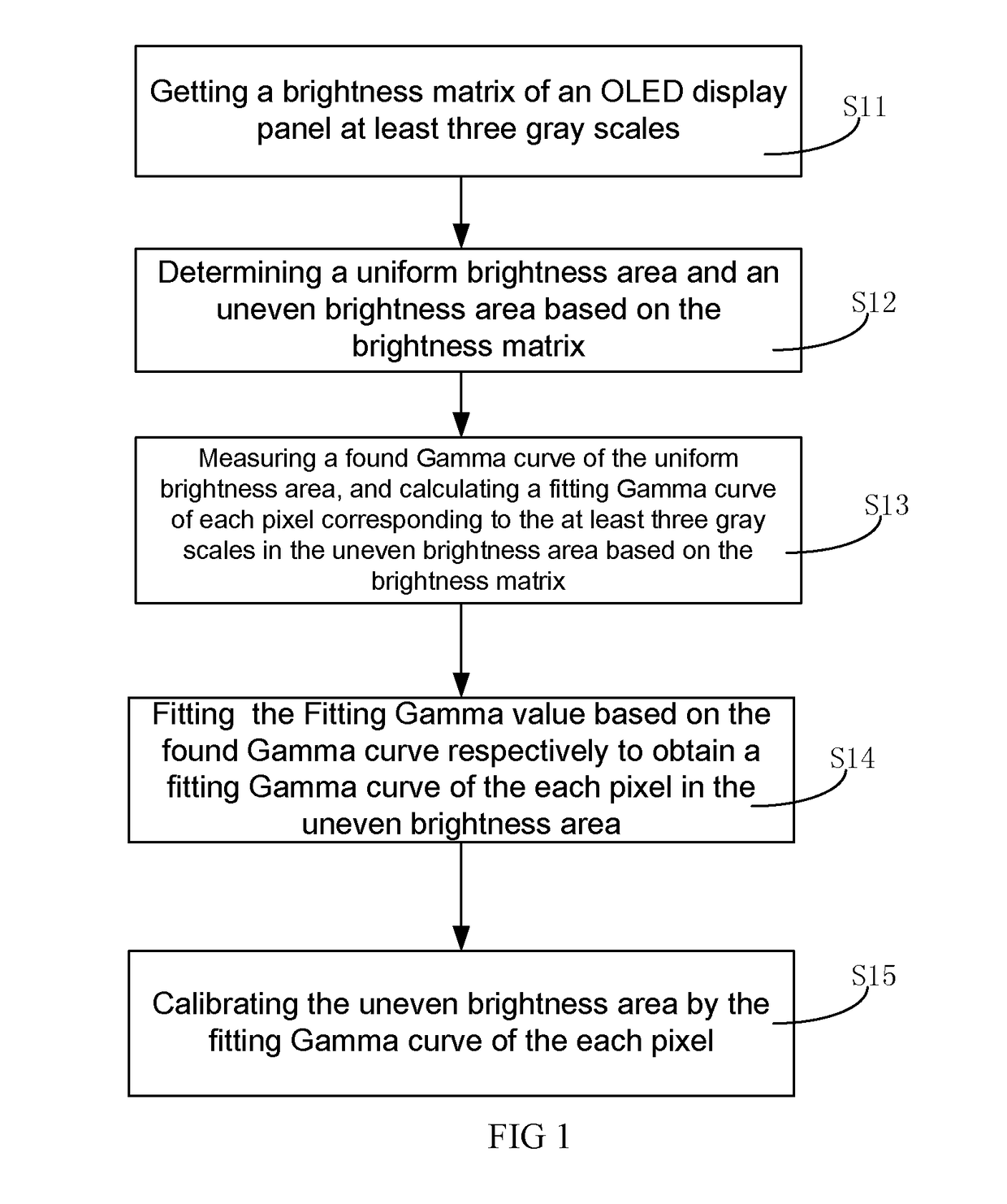

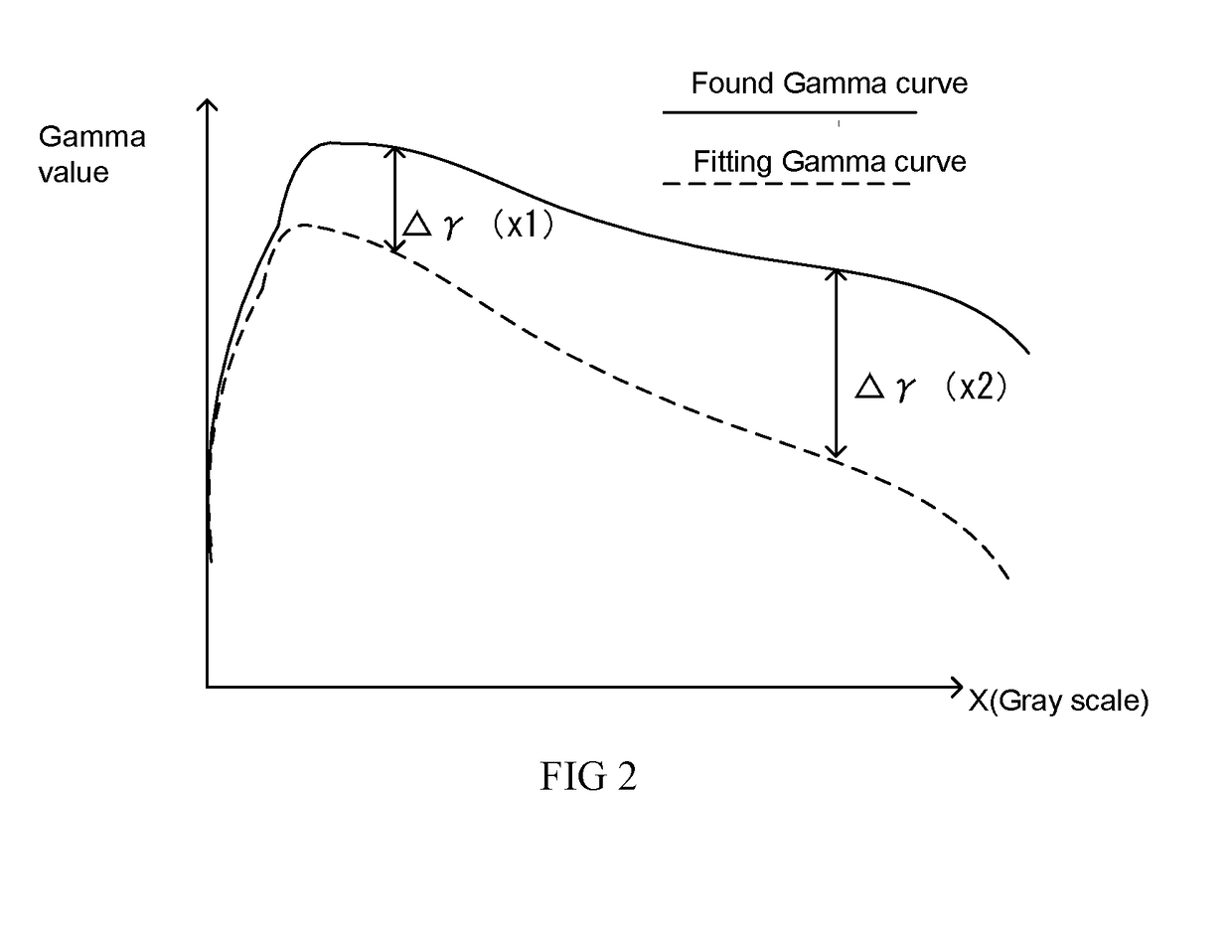

Method For Calibrating Brightness Unevenness Of OLED Display Panel

ActiveUS20180040295A1Add accurateAccurate CalibrationCathode-ray tube indicatorsComputer scienceBrightness perception

The present disclosure provides a method for calibrating brightness unevenness of an OLED display panel, the method includes: getting a brightness matrix of an OLED display panel in at least three gray scales, and determining a uniform brightness area and an uneven brightness area, and calculating a fitting Gamma value of each pixel corresponding to the at least three gray scales in the uneven brightness area, and fitting the fitting Gamma curve of the each pixel in the uneven brightness area, and calibrating the brightness of the uneven brightness area based on the fitting Gamma curve of the each pixel. The present disclosure can improve the accurate of the calibrating brightness and the efficiency of the calibration.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

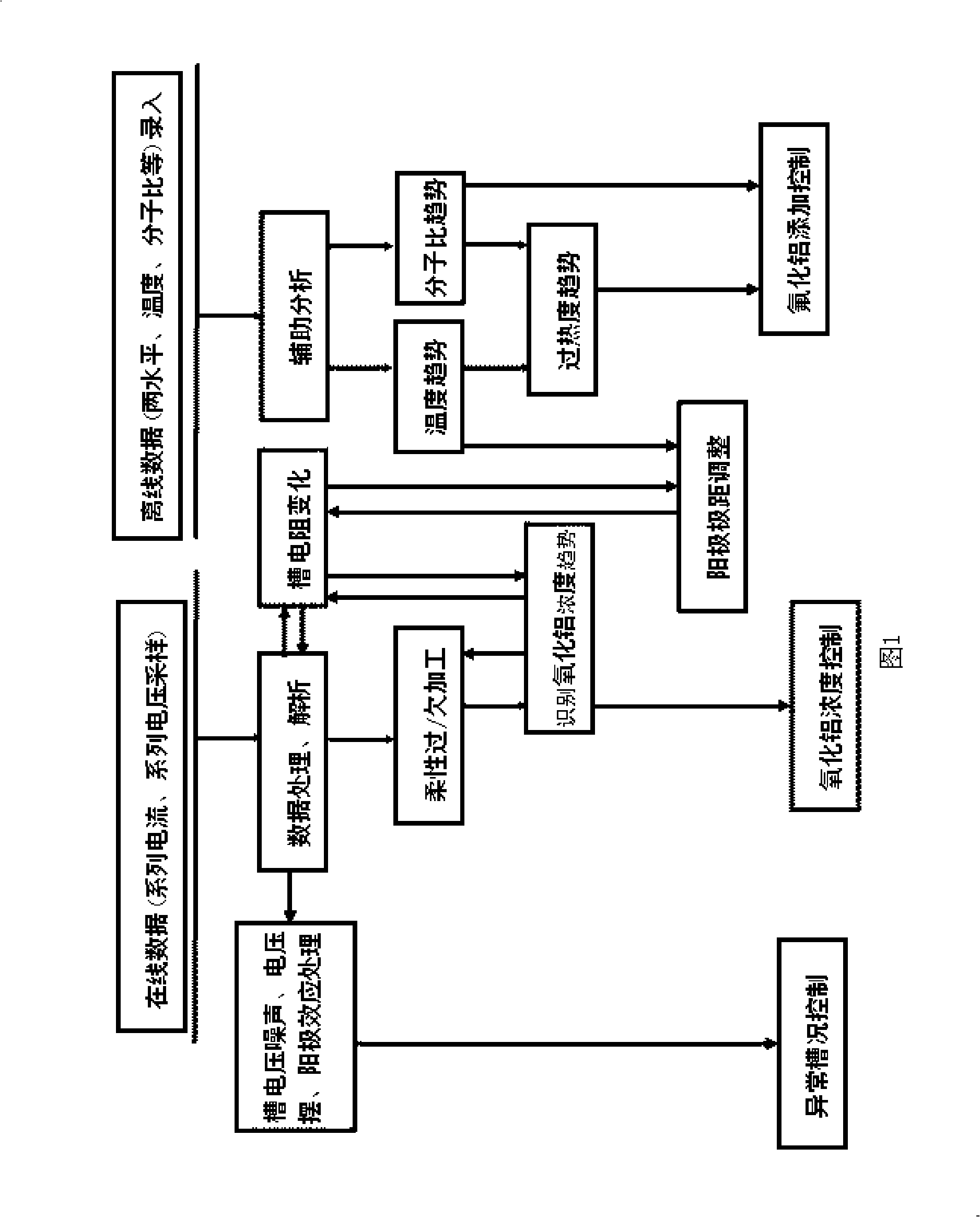

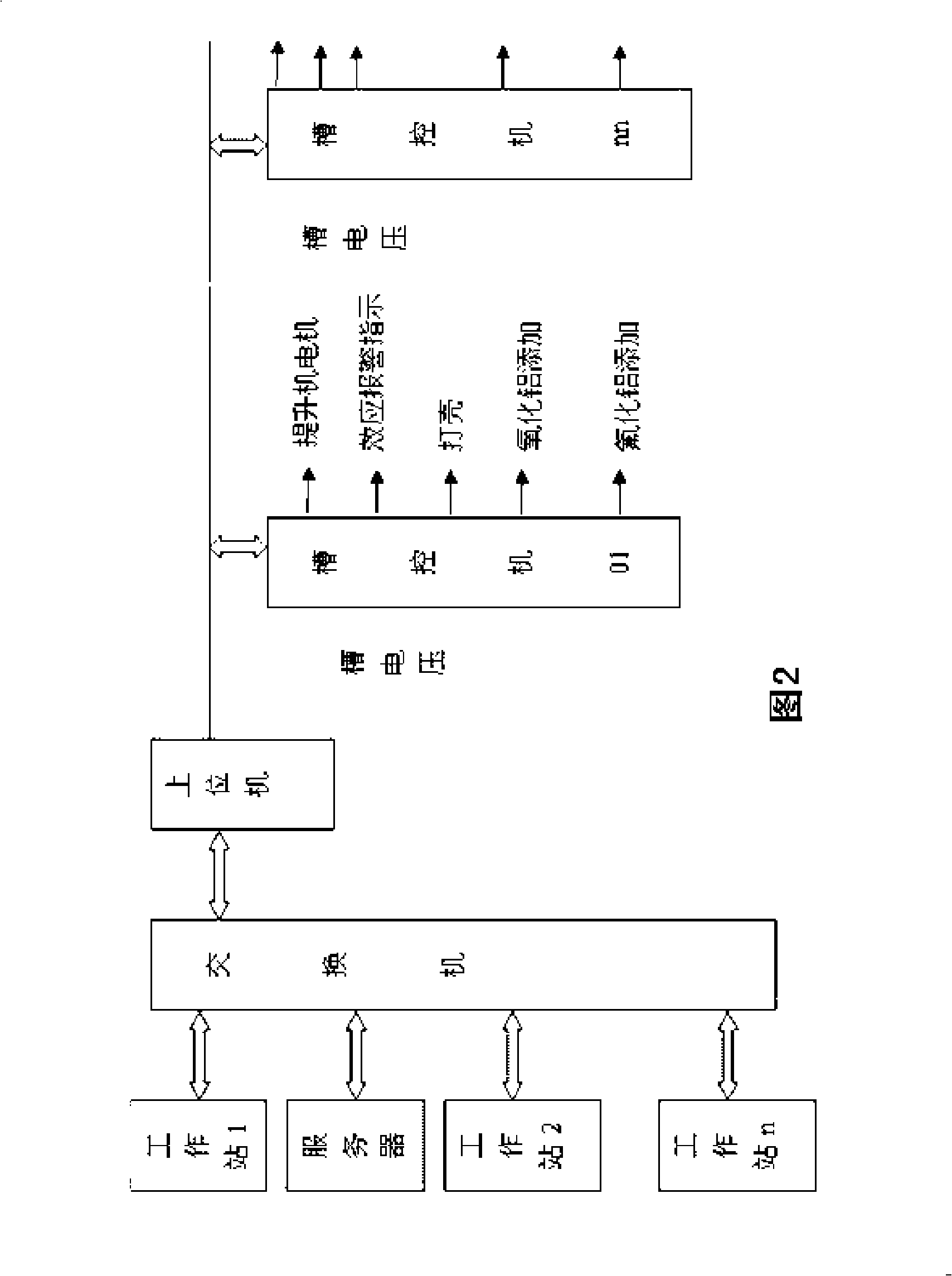

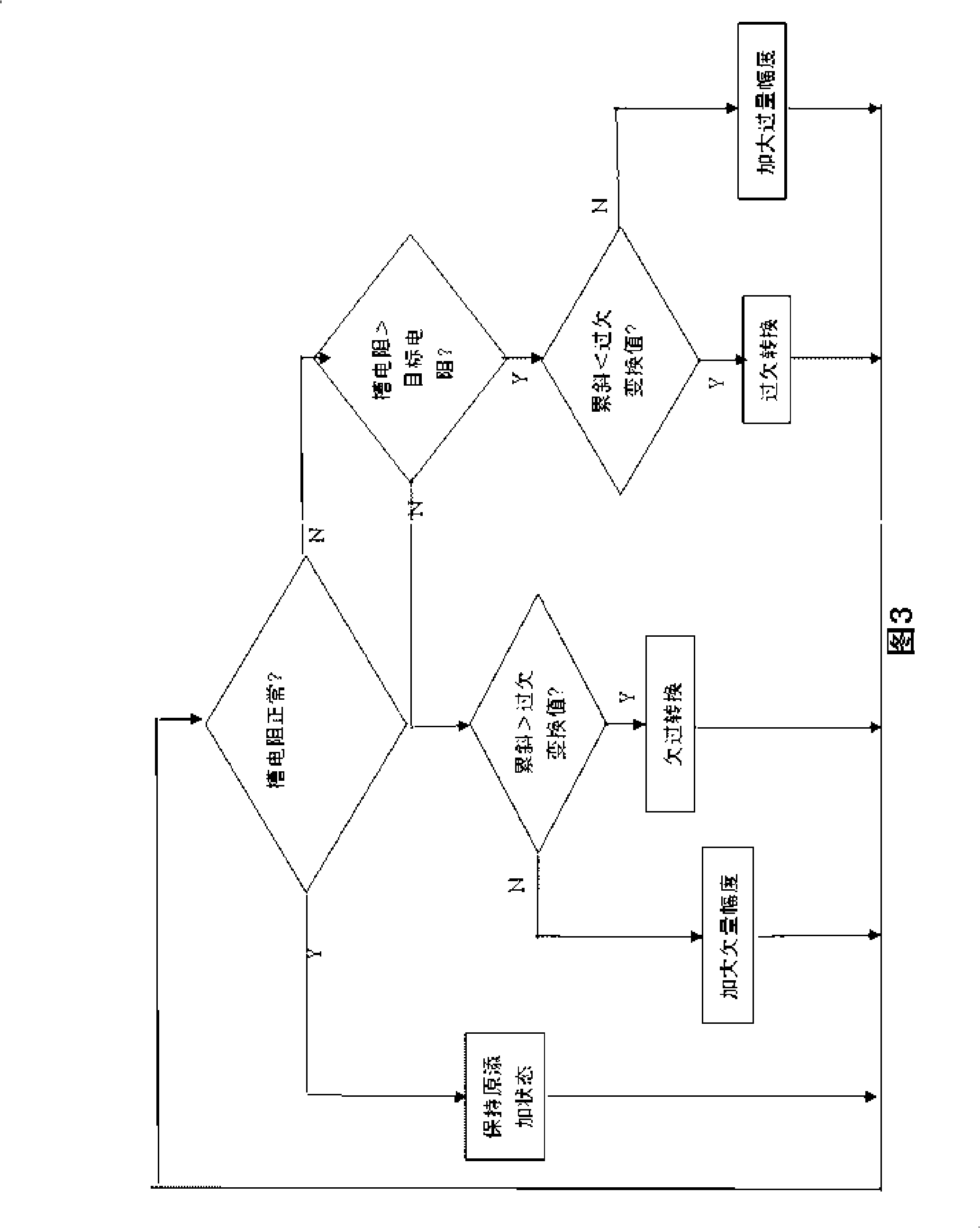

Computer real-time control method for monitoring temperature trend of aluminum cell

The invention discloses an aluminum electrolysis heat tendency computer real-time control method which can adapt the superheat or overcooling change of the tank circumstance in a wider range and monitor the superheat degree of the electrolytic tank in real time, which belongs to the automatic control field of the aluminum electrolysis. During the tank voltage analysis and control step, the tank voltage is analyzed in real time, the amplitude variable is calculated according to the voltage change curve, which comprises an instantaneous amplitude and an analysis cycle amplitude; and a target voltage control step is set, and the target voltage is adjusted between the setting voltage and the upper limit of the safety voltage according to the fluctuation situation of the tank voltage. In the invention, the amplitude variable is induced into the aluminium fluoride adding rate control step and the aluminium oxide adding rate control step, and the aluminium quantity planning step is set, to ensure the electrolytic tank to operate under the states of material balance and energy balance. The superheat degree can be controlled in real time through the aluminum electrolysis heat tendency computer real-time control method, to ensure the electrolytic tank to operate under the stable and highly effective state, and the management intensity and difficulty of the operator of the electrolytic tank to be reduced.

Owner:四川启明星铝业有限责任公司

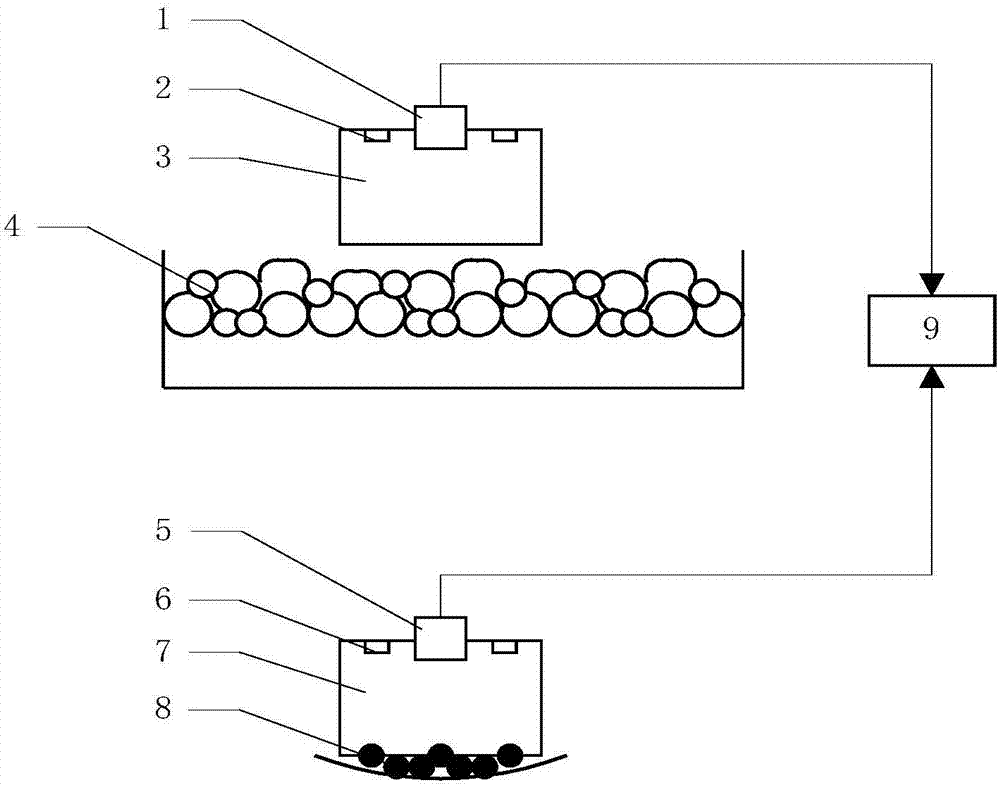

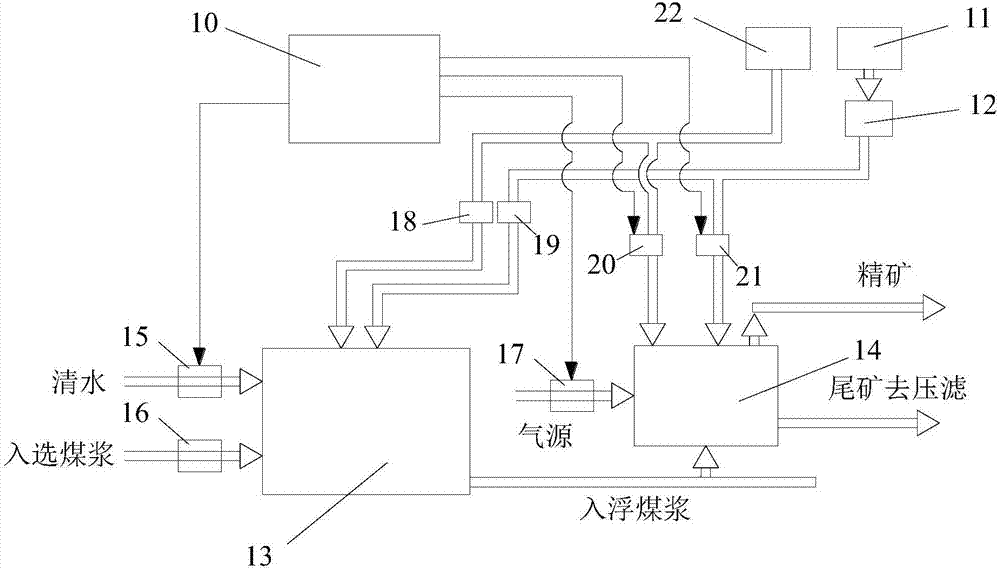

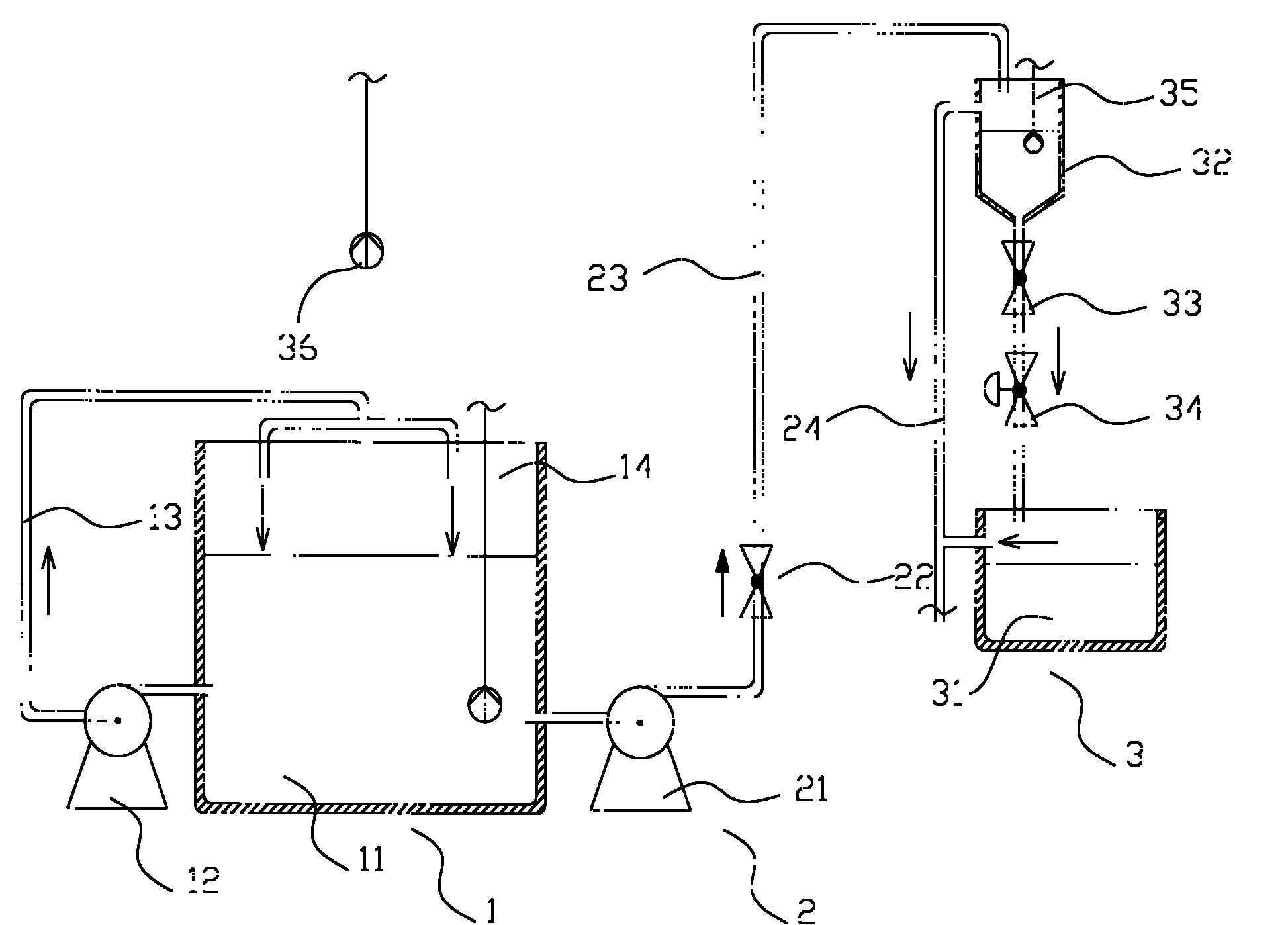

Coal flotation process automatic control system and method

The invention relates to a coal flotation process automatic control system and method. The coal flotation process automatic control system comprises a flotation machine, an ore slurry pre-treatment machine, a colloidal mill, a collecting agent storage tank, a frothing agent storage tank, detection equipment and executing equipment, wherein the colloidal mill is connected with each of the flotation machine and the ore slurry pre-treatment machine; the frothing agent storage tank is connected with each of the flotation machine and the ore slurry pre-treatment machine; the detection equipment connected with the executing equipment is arranged in the flotation machine. According to the coal flotation process automatic control system and method, a video camera is utilized to perform real-time detection on flotation froth and floatation tailings subjected to pressure filtration, so that the image information of froth and tailings subjected to pressure filtration can be collected and uploaded to an industrial personal computer, and meanwhile real-time state feature parameter values of the froth and tailings images are extracted and compared with a given threshold value determined by an off-line standard experiment, so as to obtain the froth information of enrichment clean coal and the coal leakage quantity information of tailings; besides, the dosage, the clear water quantity and the air input are adjusted in real time through the industrial personal computer according to the froth information and the coal leakage quantity by adopting the control method, the flotation machine can maintain a better working state, and a stable product quality can be ensured.

Owner:CHINA UNIV OF MINING & TECH

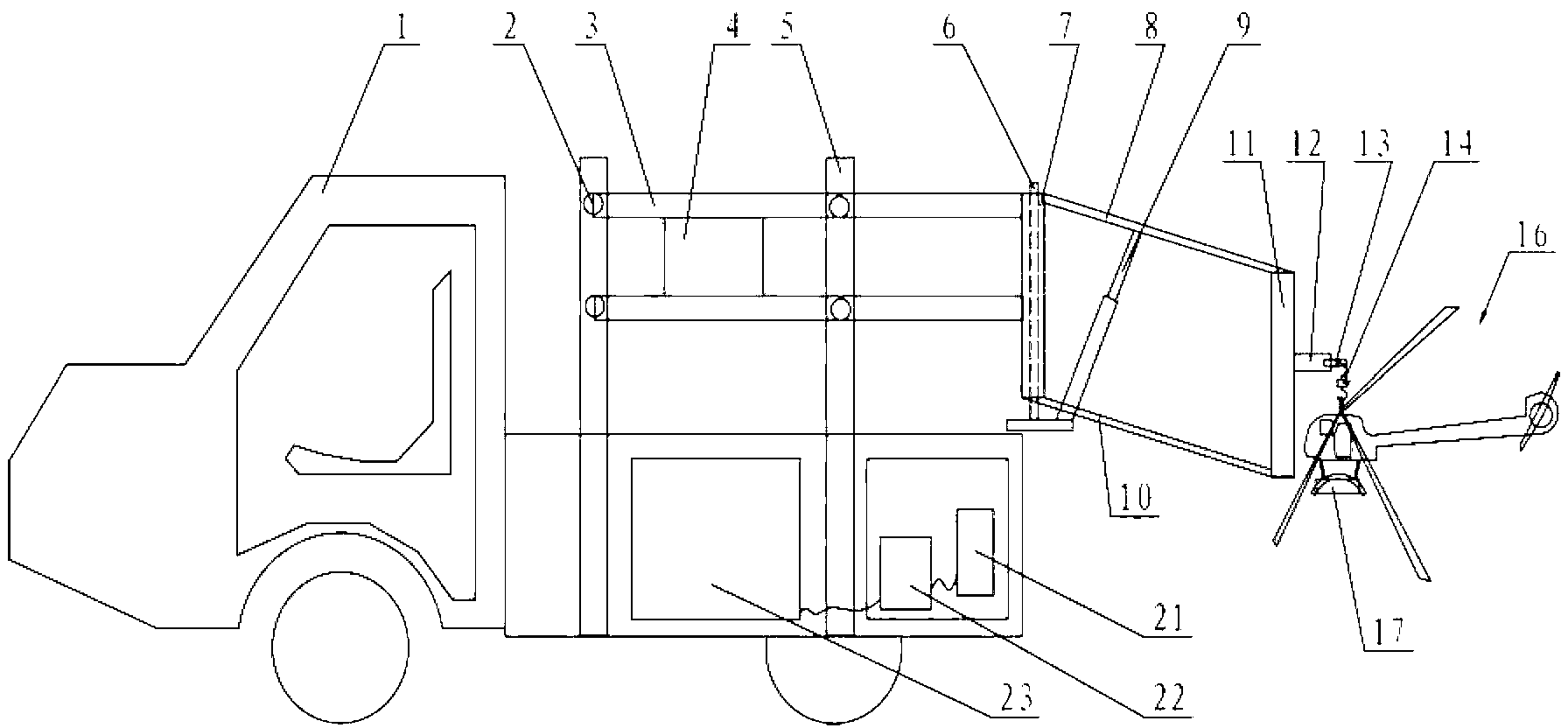

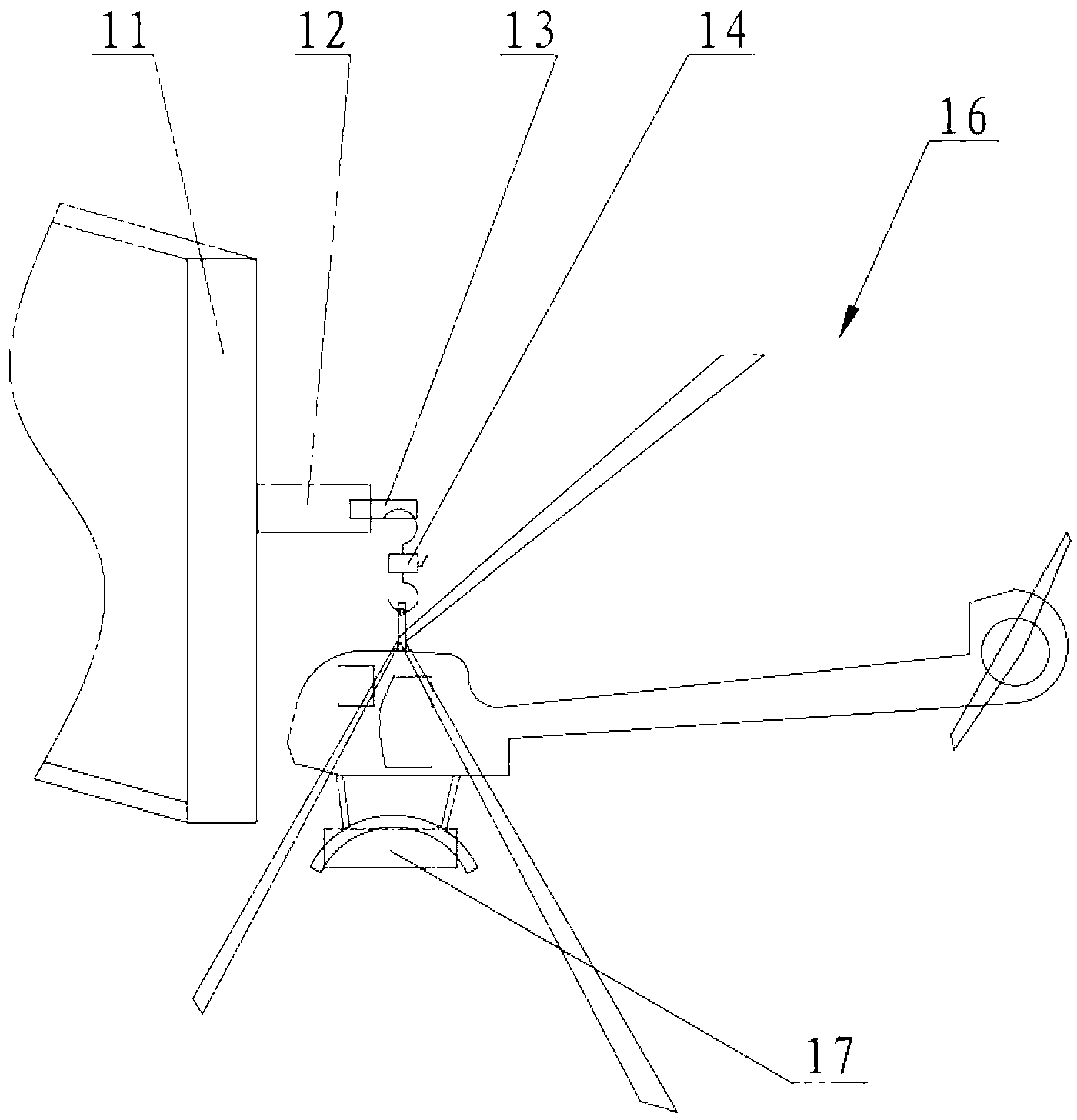

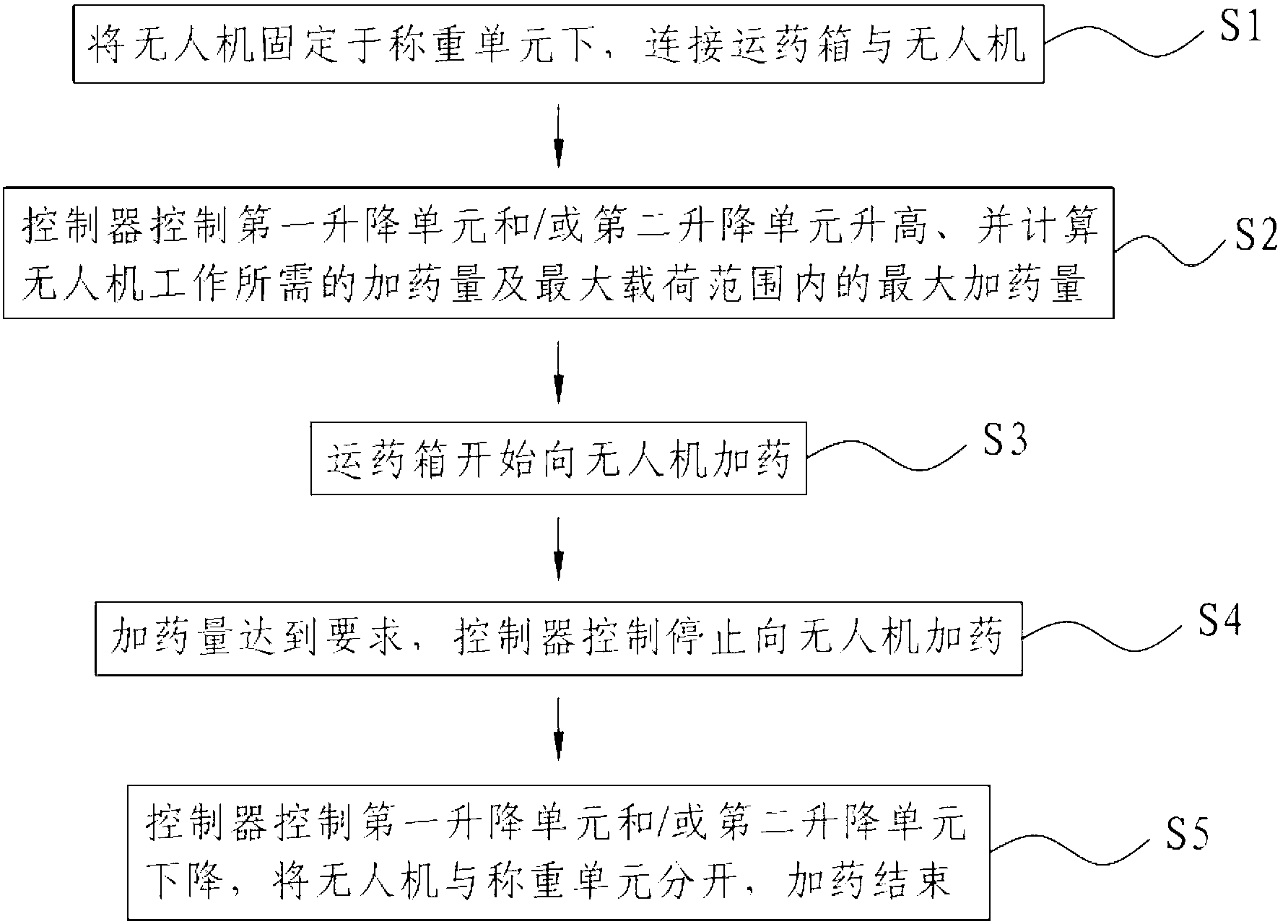

Automatic and accurate pesticide feeding device and method for agricultural UAV (unmanned aerial vehicle)

ActiveCN103299975AEfficient dosingImprove work efficiencyInsect catchers and killersPesticide applicationAgriculture

The invention relates to the technical field of agriculture, in particular to a pesticide spraying device and method, and particularly discloses an automatic and accurate pesticide feeding device and method for an agricultural UAV. The automatic and accurate pesticide feeding device for the agricultural UAV is characterized in that a first lifting unit is mounted on a trolley; a pesticide conveying box is arranged on the trolley, connected with the UAV and used for feeding pesticide to the UAV; a second lifting unit is connected with the first lifting unit, and a weighing unit is arranged on the second lifting unit; and a controller is used for controlling ascending and descending of the first lifting unit and the second lifting unit, receiving a signal of the weighing unit and controlling the pesticide conveying box to feed the pesticide to the UAV. According to the automatic and accurate pesticide feeding device, the accurate controlling of UAV dosage is achieved, the maximum take-off load is not exceeded when the pesticide is fed to the UAV, or fast and accurate feeding is realized according to a dosage requirement of accurate pesticide application, and the work efficiency of the UAV is improved; and further, the device can perform mobile operation, so that the problem that the carrying is inconvenient when the pesticide is fed to the UAV is solved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

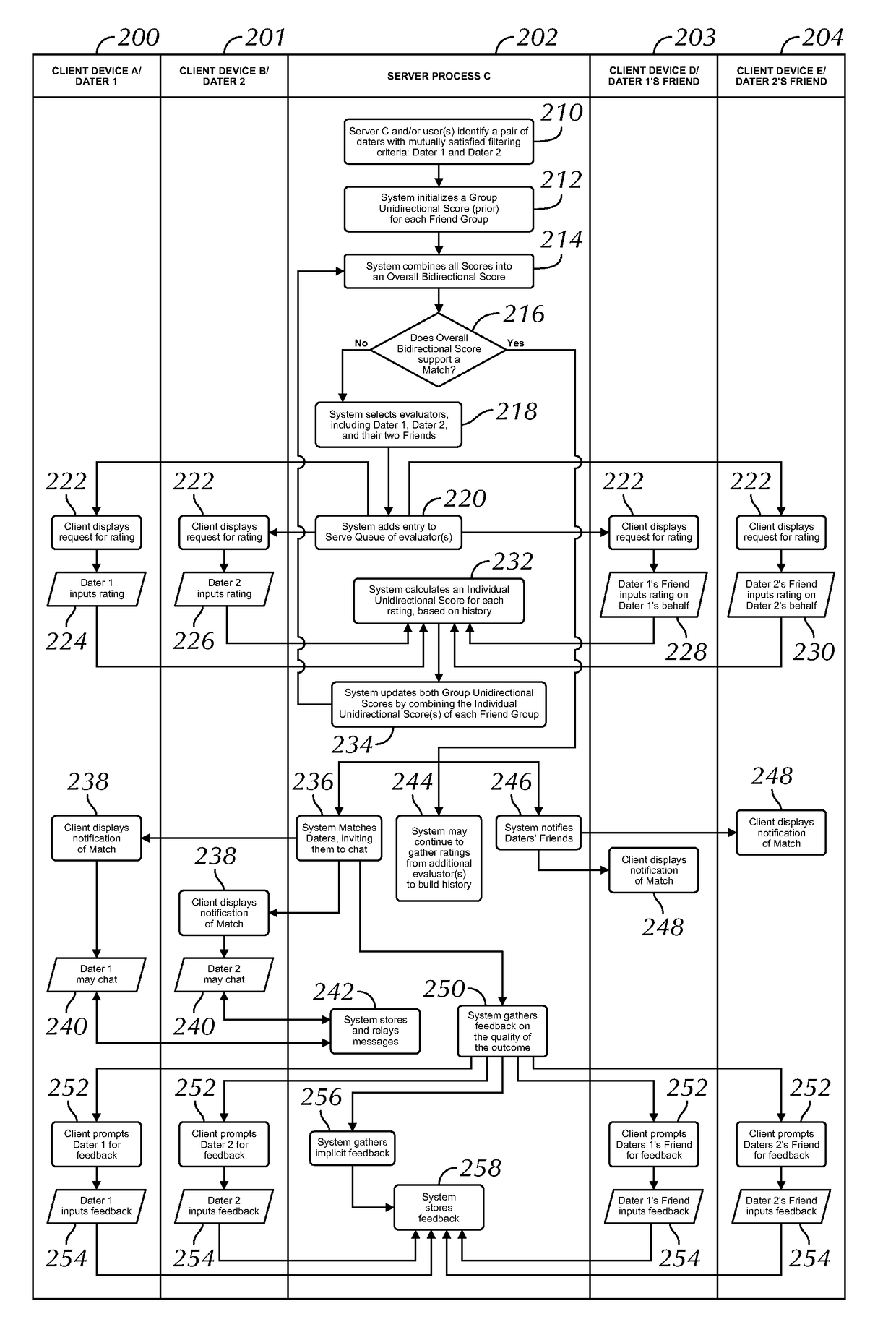

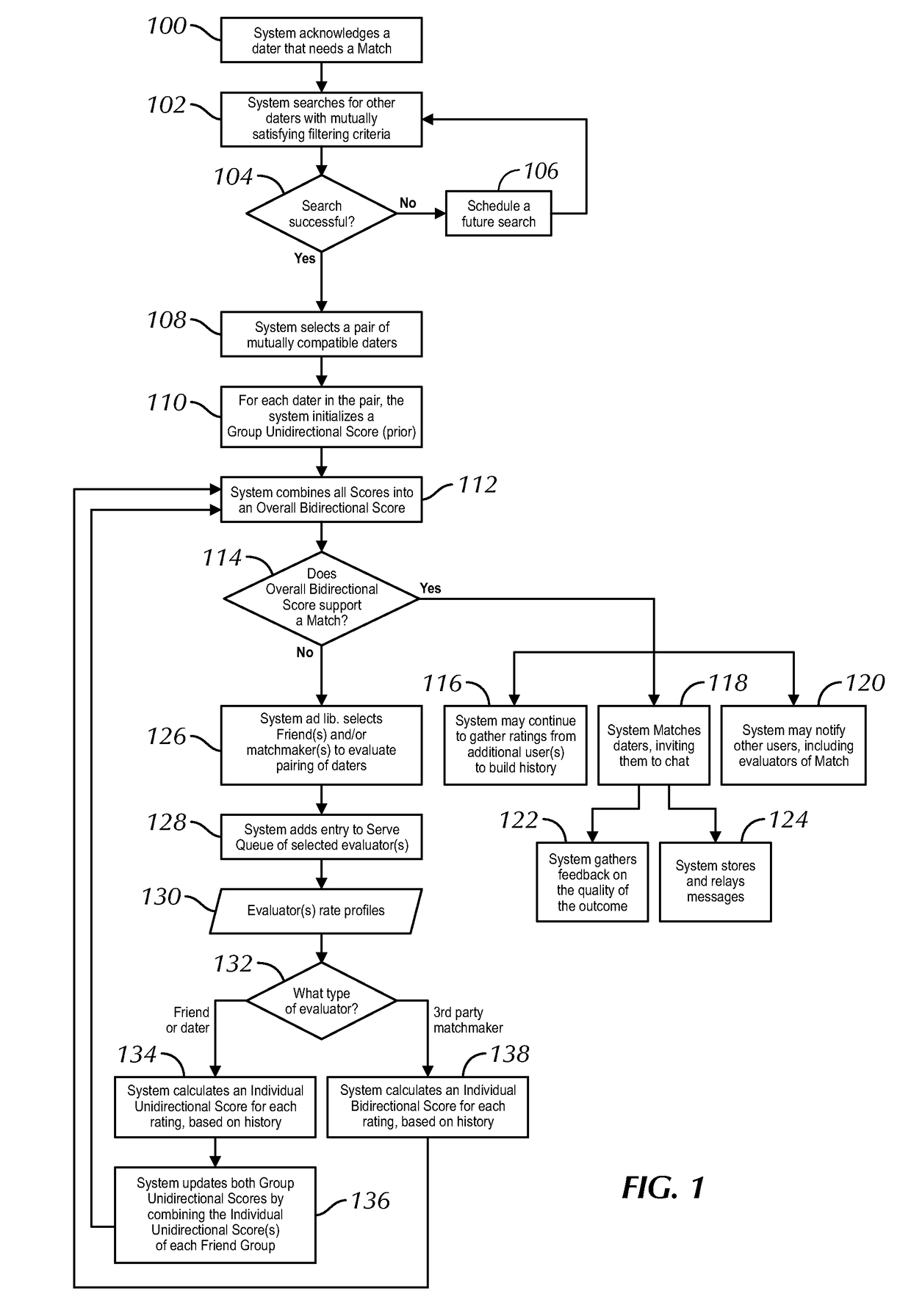

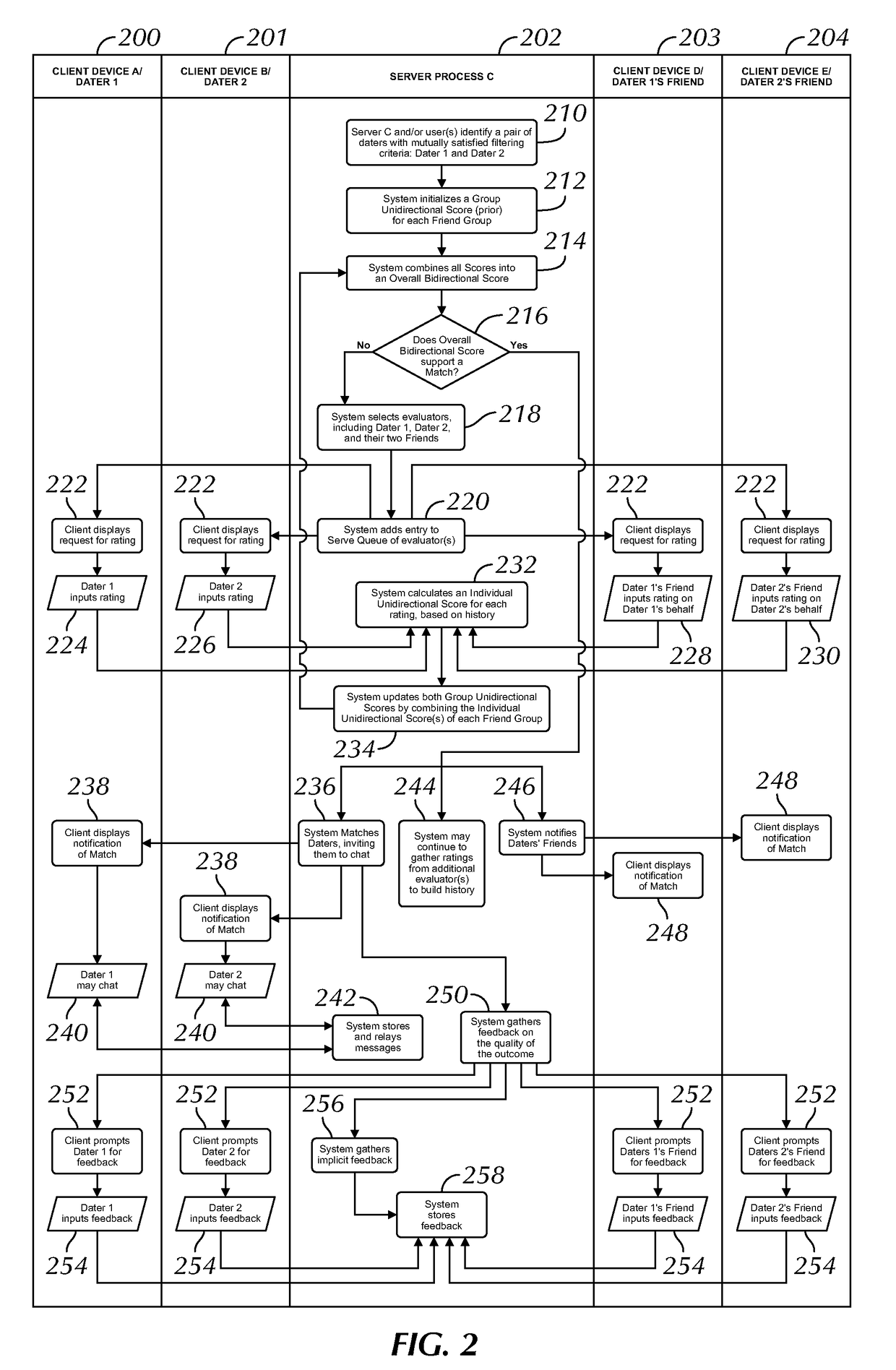

Electronic System to Romantically Match People by Collecting Input From Third Parties

ActiveUS20170300935A1Accurate informationResource optimizationDigital data information retrievalSensorsInternet privacyThird party

Methods and apparatus for a social-oriented computer system for matching daters. Daters establish friend connections with other users, including non-daters. After identifying candidate pairings of daters, the system solicits the opinions of users including the daters, their friends, and matchmakers. The system may analyze the opinions to determine whether a match would result in the satisfaction of both daters. If so, the system matches the daters, inviting them to communicate. The system may gather feedback on the match to help calibrate future matching.

Owner:SOCIAL DATA SCI INC

System, program product, and method of acquiring and processing MRI data for simultaneous determination of water, fat, and transverse relaxation time constants

ActiveUS7863895B2Extension of timeEfficiently determine separateDiagnostic recording/measuringSensorsSingle imageRelaxation time constant

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

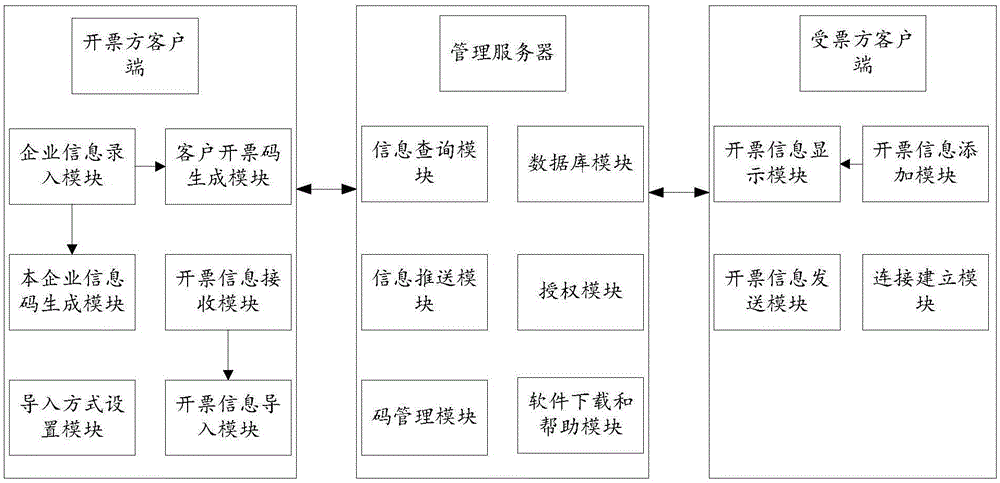

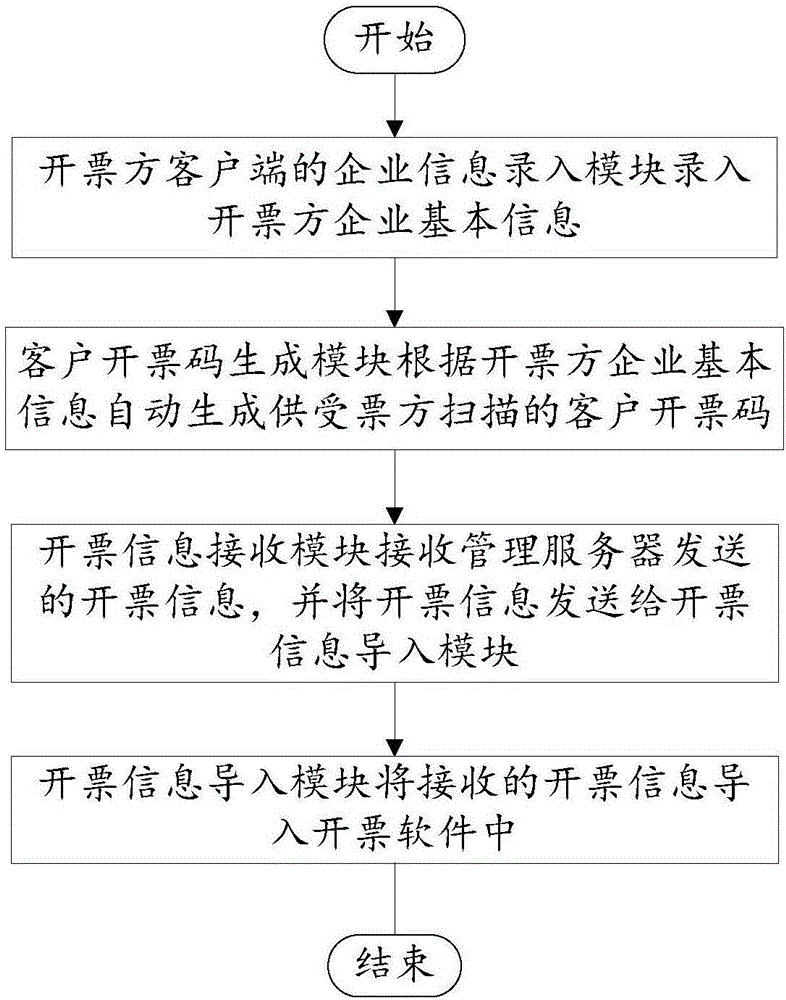

Intelligent invoicing system and method

ActiveCN106296317AEasy to manageFacilitate communicationBilling/invoicingSensing by electromagnetic radiationInvoiceComputer science

The invention relates to an intelligent invoicing system and method. The system comprises an invoicing side client and a management server, and the invoicing side client comprises an enterprise information inputting module which is used for inputting the basic information of an invoicing side enterprise; a client invoicing code generation module which is used for automatically generating a client invoicing code to be scanned by an invoice receiving side according to the basic information of the invoicing side enterprise; an invoicing information receiving module which is used for receiving the invoicing information transmitted by the management server, and transmitting the invoicing information to an invoicing information import module; and the invoicing information import module which is used for importing the invoicing information to invoicing software. The system achieves a purpose that the invoice receiving side accurately obtains the invoicing information, is short in time for waiting for the invoicing, is low in probability that the invoicing side makes out a wrong invoice, is high in invoicing efficiency, and enables the communication between two sides to be more smooth.

Owner:周小勇

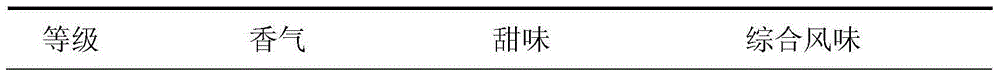

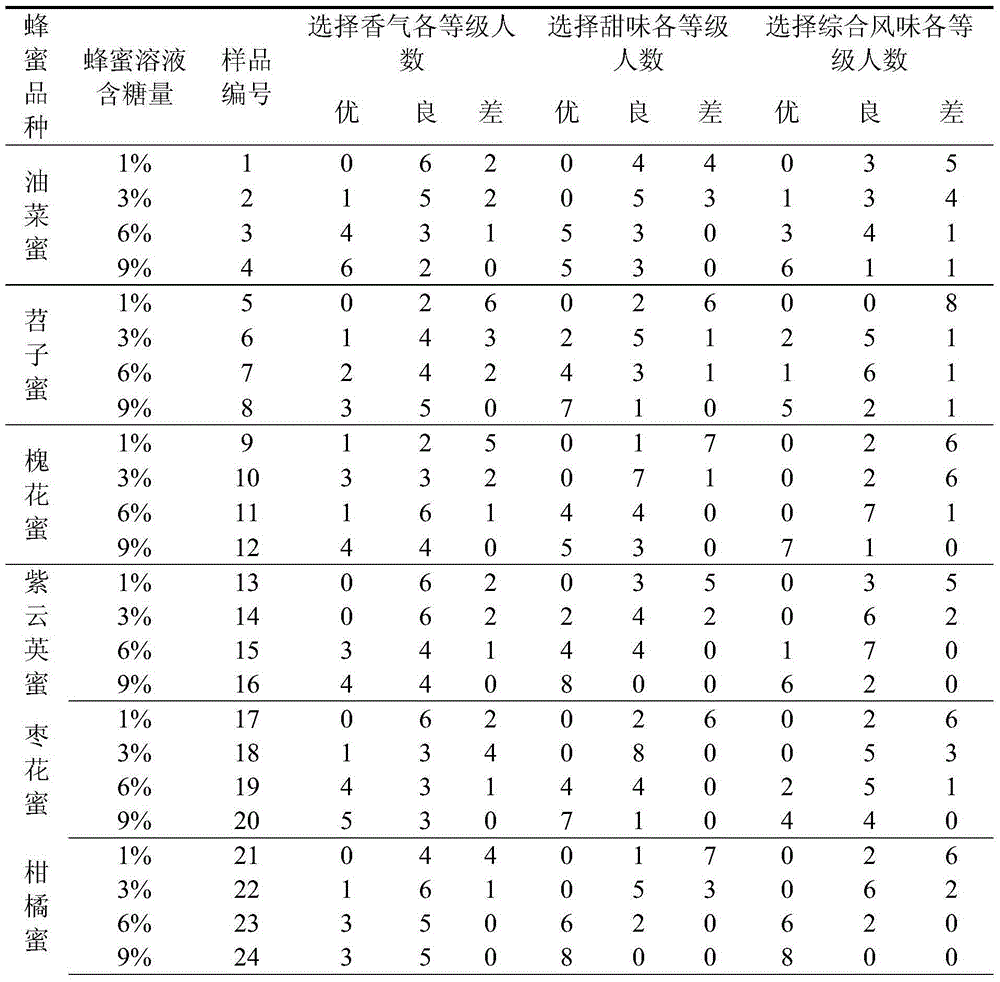

Method for comprehensively evaluating flavor and classifying sweetness of honey

InactiveCN104407114AAdd accurateConducive to flavor selectionTesting foodStatistical analysisClassification methods

The invention discloses a method for comprehensively evaluating flavor and classifying sweetness of honey. The method comprises the following steps: after the sugar content of the honey is determined according to weight percentage, according to the sugar content, sequentially setting honey solutions with n grades of concentration from low to high; then carrying out sensory evaluation by using fragrance, sweetness and flavor as evaluation indexes, and thus obtaining the final evaluation result through statistical analysis; classifying the sweetness of honey according to the result. The method comprehensively evaluates the honey so as to be beneficial to flavor selection of honey during adding. As the honey is classified according to the sweetness, when the honey is added, according to the needed sweetness grade, the honey is directly diluted to the corresponding concentration according to sugar concentration, and the accurate and quick adding of honey is realized. In addition, when the classification method is used for determining the sweetness of honey, the influence of human factors is reduced, so that the sweetness data is more scientific and objective.

Owner:CHONGQING ACAD OF ANIMAL SCI

Feed additive dosing device

PendingCN107224933AMeet the needs of useAdd accurateFeeding-stuffRotary stirring mixersEngineeringFeed additive

The invention discloses a feed additive dosing device. The feed additive dosing device comprises a mixing box, a feeding box and a dust collection box, wherein a separating baffle plate is arranged at the middle part of an inner cavity of the mixing box; the separating baffle plate is used for separating the inner cavity of the mixing box into a mixing cavity and a discharging cavity; the mixing cavity is internally provided with a stirring shaft; the top end of the stirring shaft penetrates through the top wall of the mixing box and is fixedly connected to a motor shaft of a motor; the bottom end of the stirring shaft is fixedly connected with a second stirring blade which is matched with the separating baffle plate; a plurality of first stirring blades are uniformly arranged at the middle part of the stirring shaft; a first feeding hole is formed in one side of the top wall of the mixing cavity; the top part of one side wall of the mixing cavity is in through connection with the dust collection box through an air inlet pipe. According to the feed additive dosing device disclosed by the invention, two weighing and dosing modes of the feeding box and a weighing drum are arranged, the using demands of different additives are met, and accurate adding of various additives is ensured; due to the arrangement of the dust collection box, flying dust generated by stirring the additives can be collected, and meanwhile, the collected flying additive smoke dust can return to the discharging cavity again, so that accurate proportioning of all the additives is ensured.

Owner:邹铁梅

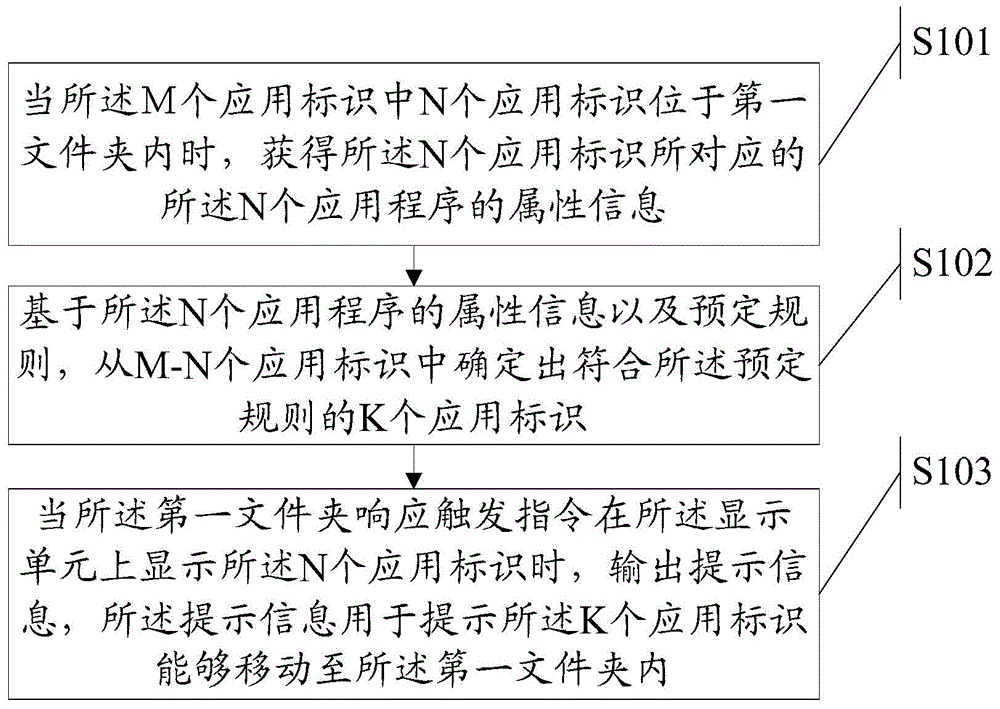

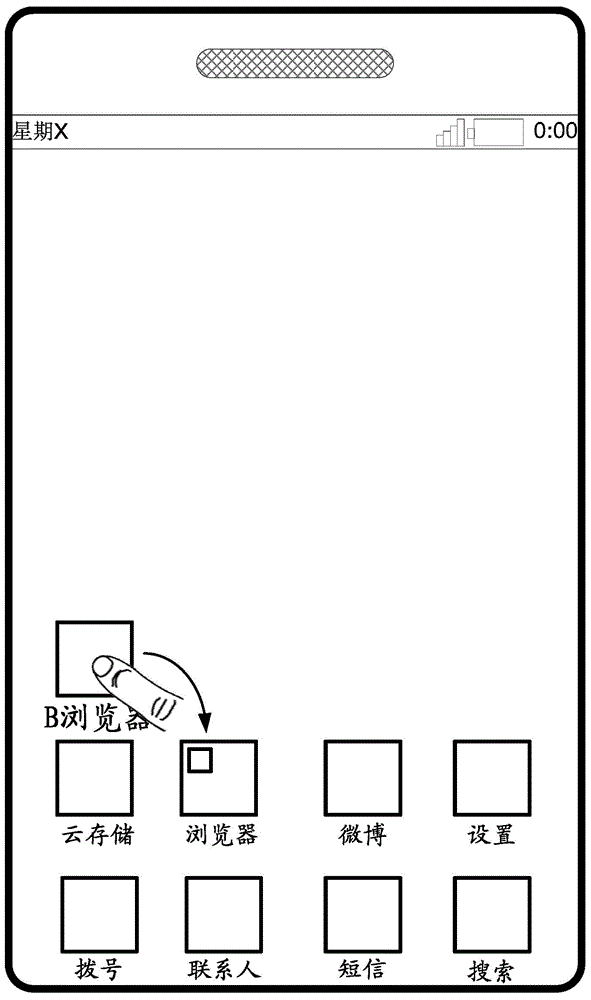

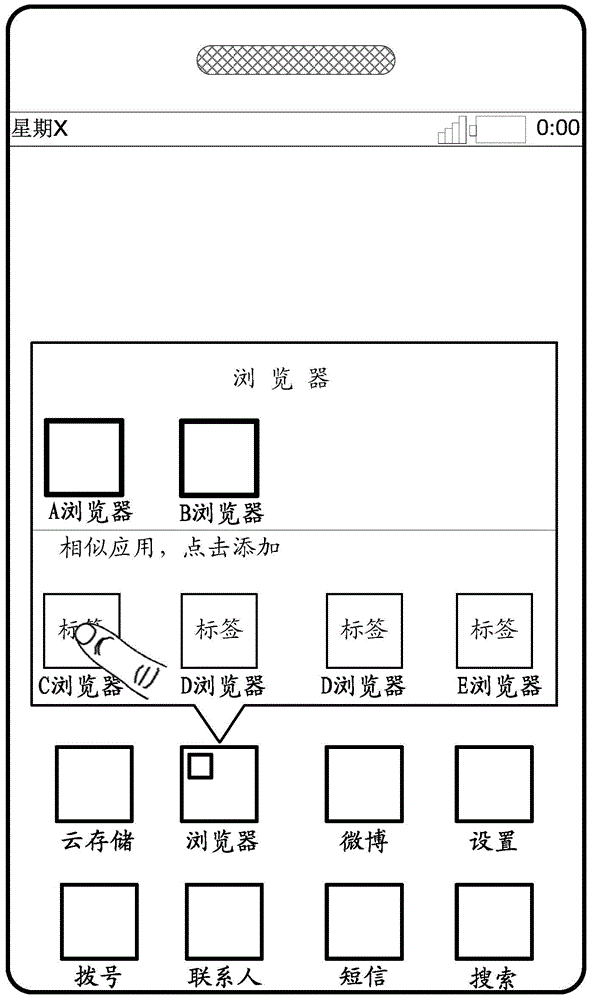

Information processing method and electronic equipment

ActiveCN104424221AAccurate classificationClassified completelySpecial data processing applicationsInput/output processes for data processingInformation processingComputer hardware

The present disclosure discloses information processing methods and electronic devices. The method is applied in an electronic device, the electronic device comprising a display unit, M applications being installed in the electronic device, each of the M applications having an application logo, M application logos corresponding to the M applications respectively, M being an integer no less than 2, the method comprising: obtaining attribute information of N applications corresponding to N application logos of the M application logos, when the N application logos are located in a first folder; determining K application logos of M−N application logos complying with a predetermined rule, based on the attribute information of the N programs and the predetermined rule; outputting prompt information when the N application logos are displayed on the display unit by the first folder responding to a trigger instruction, the prompt information prompting that the K application logos can be moved into the first folder.

Owner:LENOVO (BEIJING) LTD

Additive metering device for mixing mortar for construction

InactiveCN101108511AEasy to addAdd accurateLiquid ingredients supply apparatusMotor driveEngineering

The invention discloses an admixture measuring device used for mixing construction mortar, a weighting sensor support and hanging support or hanging; the admixture is opened at the bottom of the measuring vessel. Optimizedly, the bottom of the measuring vessel is also opened with admixture entrance. Optimizedly, the admixture entrance is arranged with a pipeline of transferring pump, the admixture adsorbs the measuring vessel along the pipeline in the admixture agent by a transmission pump. Optimizedly, the transmission pump adopts speed change motor driving. The device discloses in the invention arranges a weighing device on the measuring vessel, to achieve the measuring volume by the test vessel, which can prevent temperature error, and won't produce the watch error caused of shaking.

Owner:SANY HEAVY IND CO LTD (CN)

Method for smelting molten steel and adding rear earth by vacuum induction furnace

InactiveCN101649410AAdd accurateEasy to controlProcess efficiency improvementSteelmakingFerrosilicon

The invention relates to a method for smelting molten steel and adding rear earths by a vacuum induction furnace, comprising the following steps: I, raw material preparation, weighed rear earth wiresare bent into an M shape and distributed on ingot moulds, and then the ingot moulds are arranged in a high-vacuum induction furnace; II, charging, pure iron, ferroalloy or returned scrap steels are charged into a crucible of the vacuum induction furnace, and ferrosilicon and metal manganese are put into a hopper; III, vacuum pumping by closing a furnace cover, vacuum pumping is carried out for 12min to 16 min, and furnace burden is heated by supplying power; IV, furnace burden melting; V, refining, solid raw materials which are charged into the furnace are all melted to form molten steel; VI,inflation, after the refining is finished, vacuum pumping is stopped, and argon gas is charged into a cavity of the vacuum furnace; VII, alloying, under the protective atmosphere of the argon gas, rear earth element composition is regulated; VIII, final deoxidation, Al pills are added to carry out deoxidation; and IX, steel tapping casting, steel liquid is poured into the ingot moulds which are wound by the rear earth wires. The method for smelting the molten steel and adding the rear earths by the vacuum induction furnace has high recovery rate of rear earth elements.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

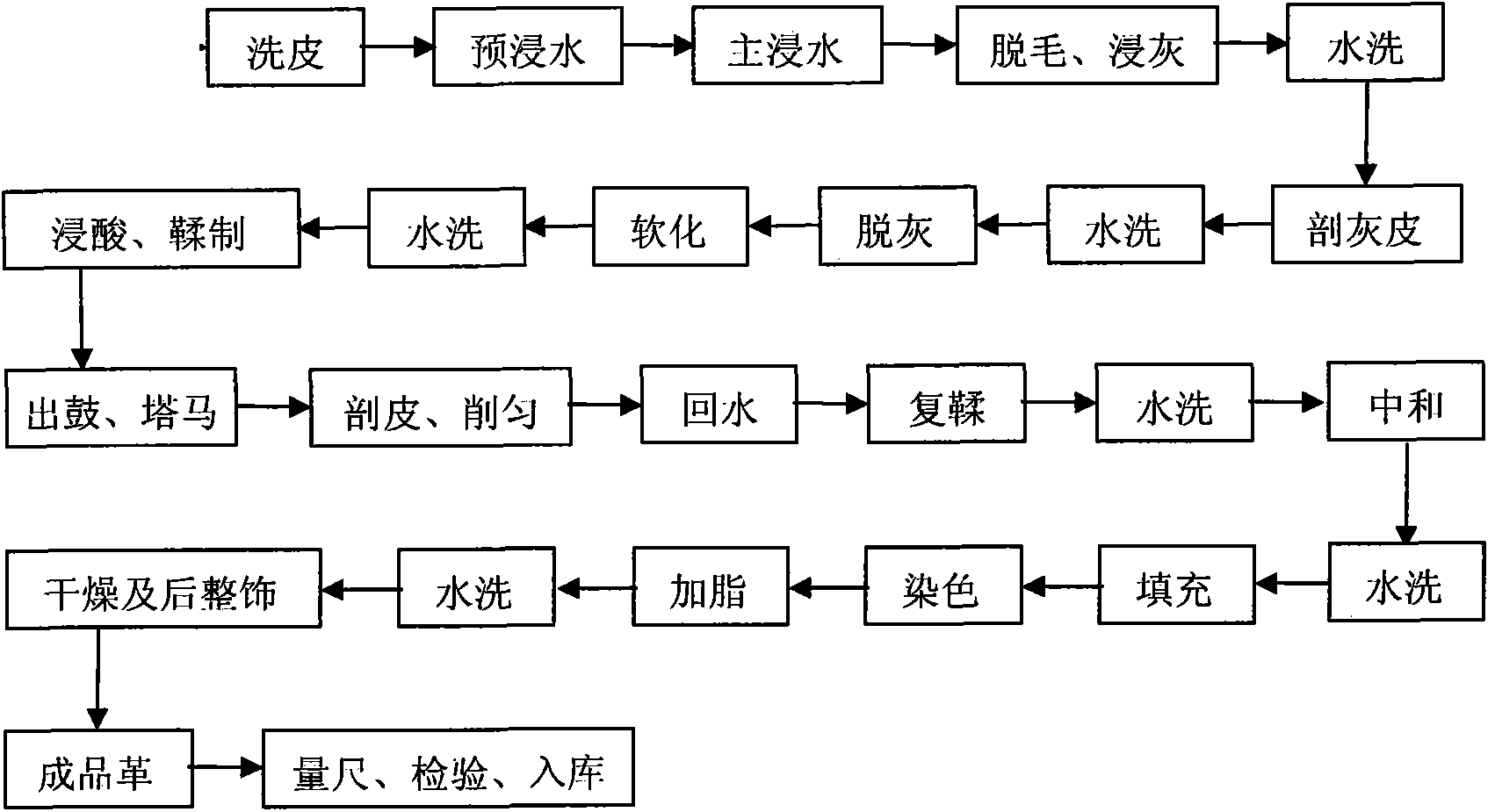

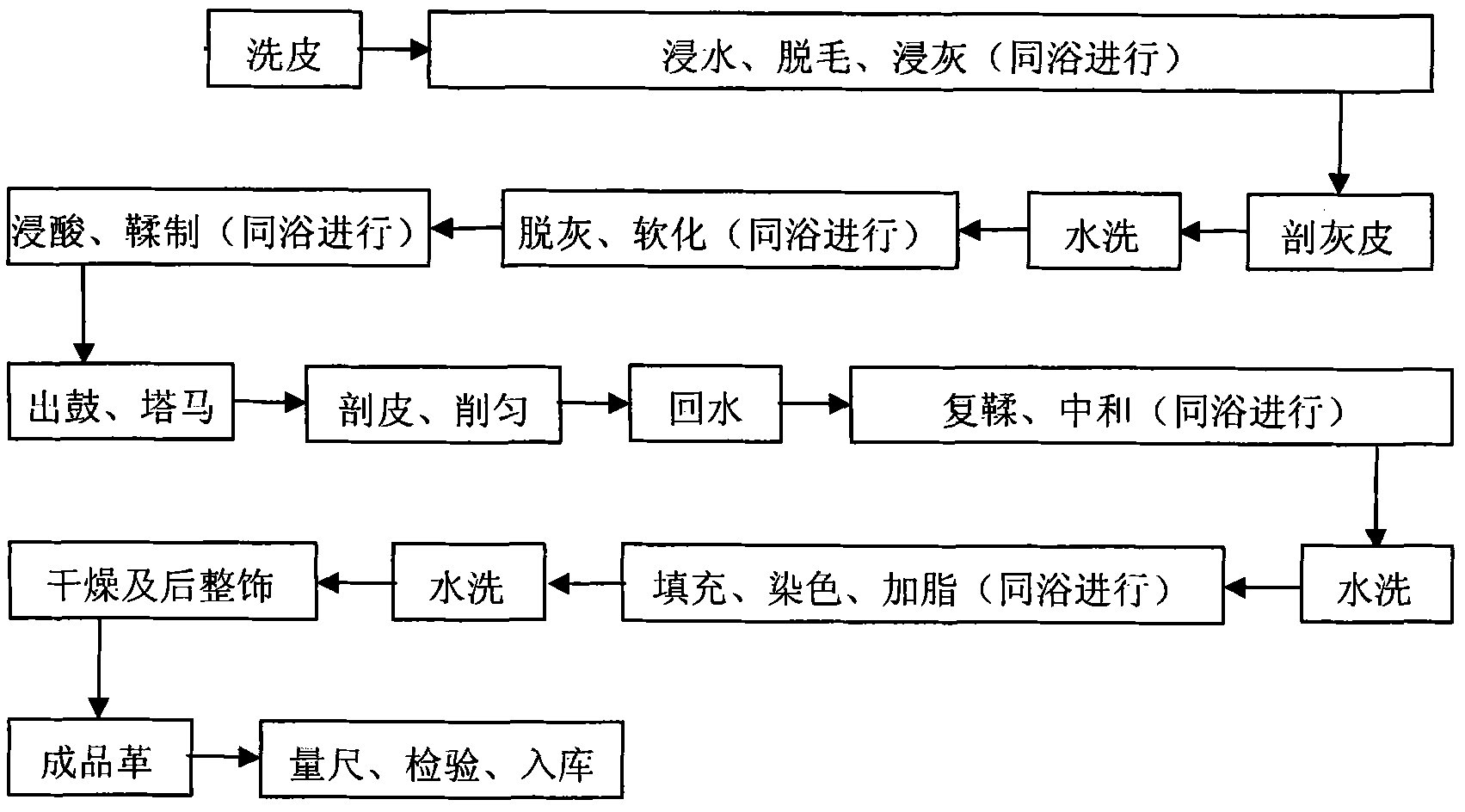

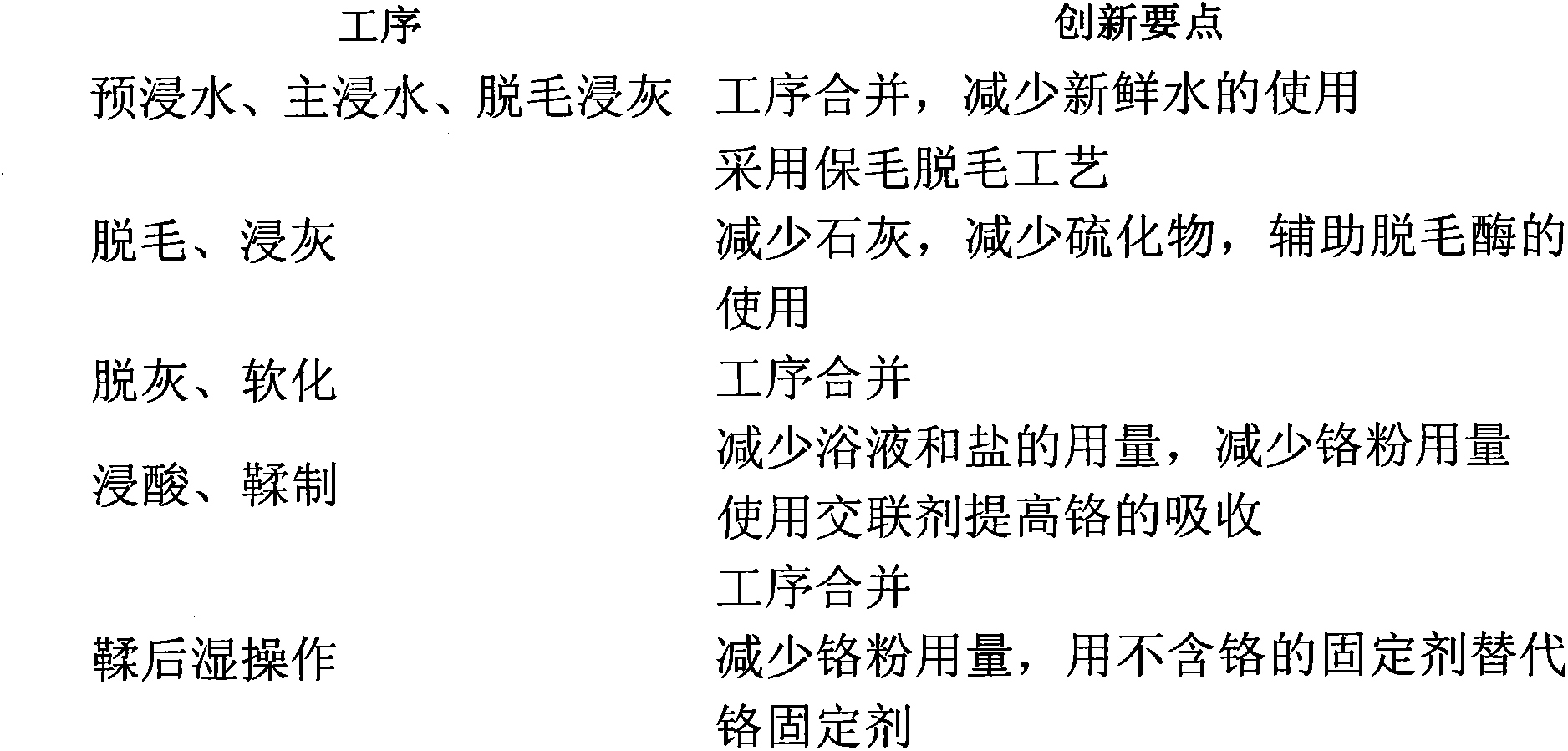

Integrated waterproof leather preparation method

ActiveCN103773906AHigh degree of automationWater consumption control and precise addition of various chemicalsTanning treatmentPre-tanning chemical treatmentChromiumEnvironmental resistance

The invention discloses an integrated waterproof leather preparation method which is characterized by comprising the following steps: (1) rapid bovine hide washing; placing a wet-salted bovine hide in a bath lotion in an overload drum, and discontinuously operating; (2) merging three processes, i.e., main immersion, hair removal and liming in one bath; (3) splitting a limed hide, and then, washing, wherein covered washing is adopted in the washing process; (4) merging two processes, i.e., deliming and softening in one bath; (5) merging two processes, i.e., pickling and tanning in one bath; (6) merging two processes, i.e., retanning and neutralizing in one bath; (7) merging three processes, i.e., filling, dyeing and stuffing in one bath; and (8) washing, wherein covered washing is adopted. After the integrated waterproof leather preparation method is carried out, the total water saving and emission reduction effects are as follows: the water consumption for production is reduced by 40-50%, the emission reduction of COD (Chemical Oxygen Demand) is 30%, the emission reduction of chromium is 90%, and the emission reduction of alkalinity is 60%. The clean characteristic and environment friendliness of the method are further improved.

Owner:徐州南海皮厂有限公司

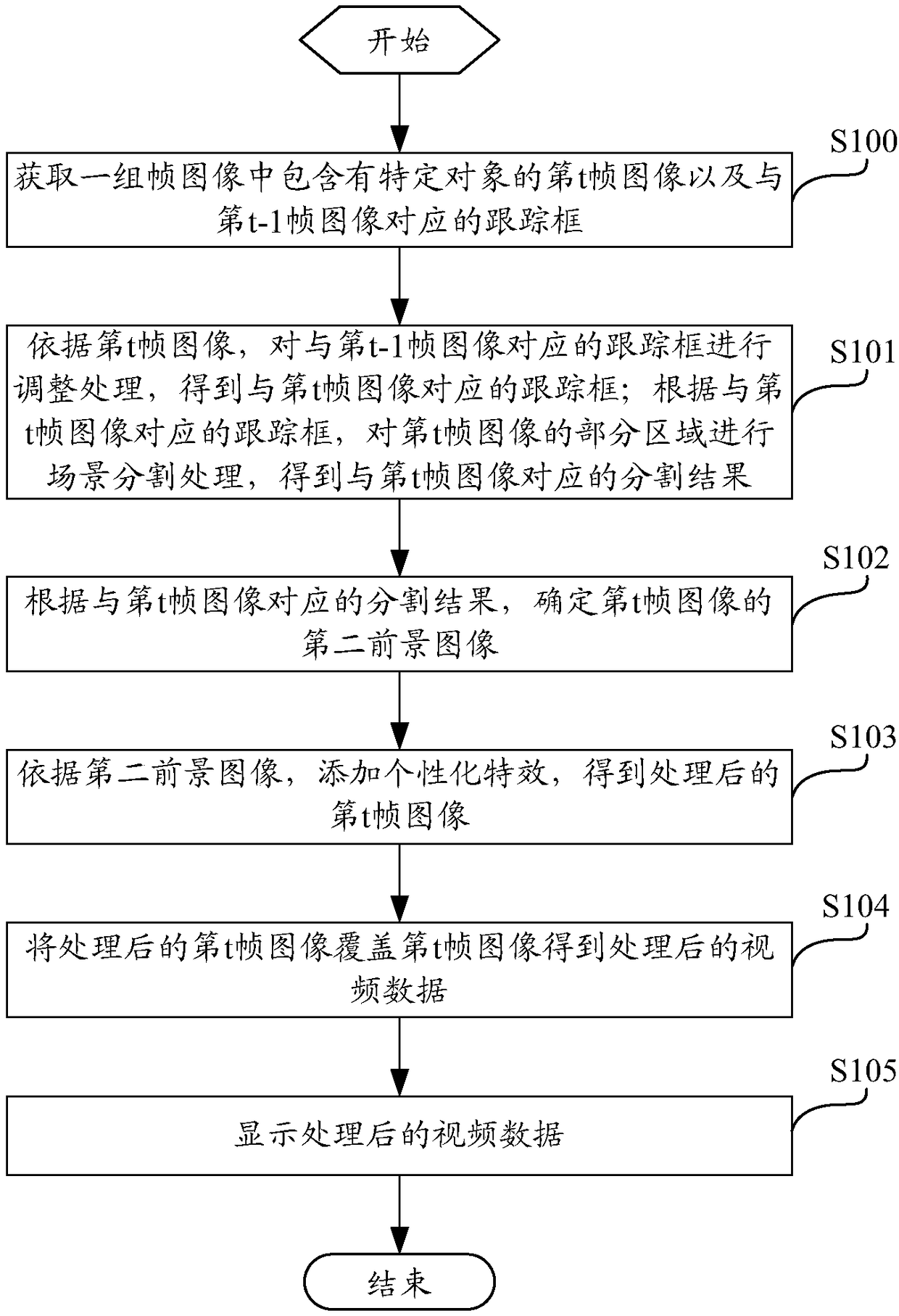

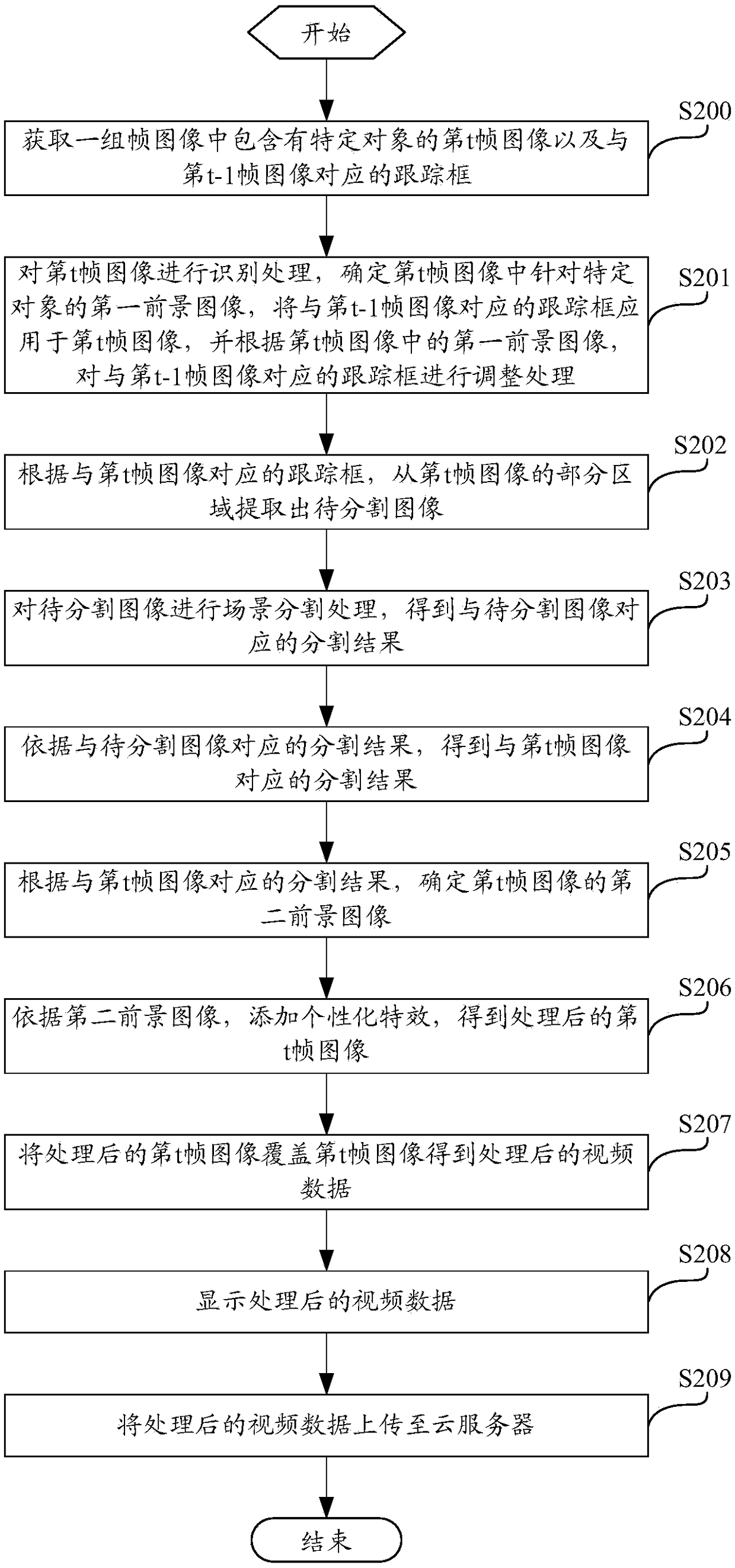

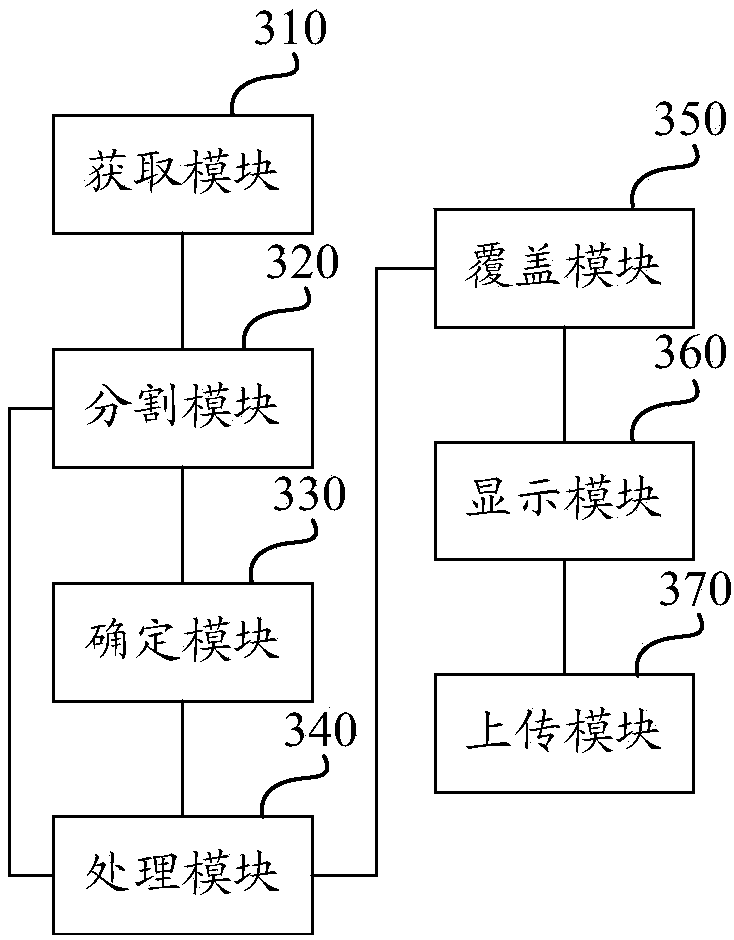

Video data real-time processing method and device based on adaptive tracking box segmentation

ActiveCN108111911AImprove Segmentation AccuracyReduce data processingImage enhancementImage analysisPersonalizationScene segmentation

The invention discloses a video data real-time processing method and device based on adaptive tracking box segmentation, a computer device and a computer storage medium. The method comprises the stepsof obtaining a (t)th frame image comprising a specific object in a group of frame images, and a tracking box corresponding to a (t-1)th frame image; adjusting the tracking box corresponding to the(t-1)th frame image according to the (t)th frame image, thereby obtaining the tracking box corresponding to the (t)th frame image; carrying out scene segmentation on a partial area of the (t)th frame image according to the tracking box corresponding to the (t)th frame image, thereby obtaining a segmentation result corresponding to the (t)th frame image; determining a second foreground image of the (t)th frame image according to the segmentation result; adding a personalized special effect according to the second foreground image, thereby obtaining a processed (t)th frame image; covering the (t)thframe image through utilization of the processed (t)th frame image, thereby obtaining processed video data; and displaying the processed video data. According to the technical scheme, the personalized special effect can be added to the frame image relatively precisely and rapidly.

Owner:BEIJING QIHOO TECH CO LTD

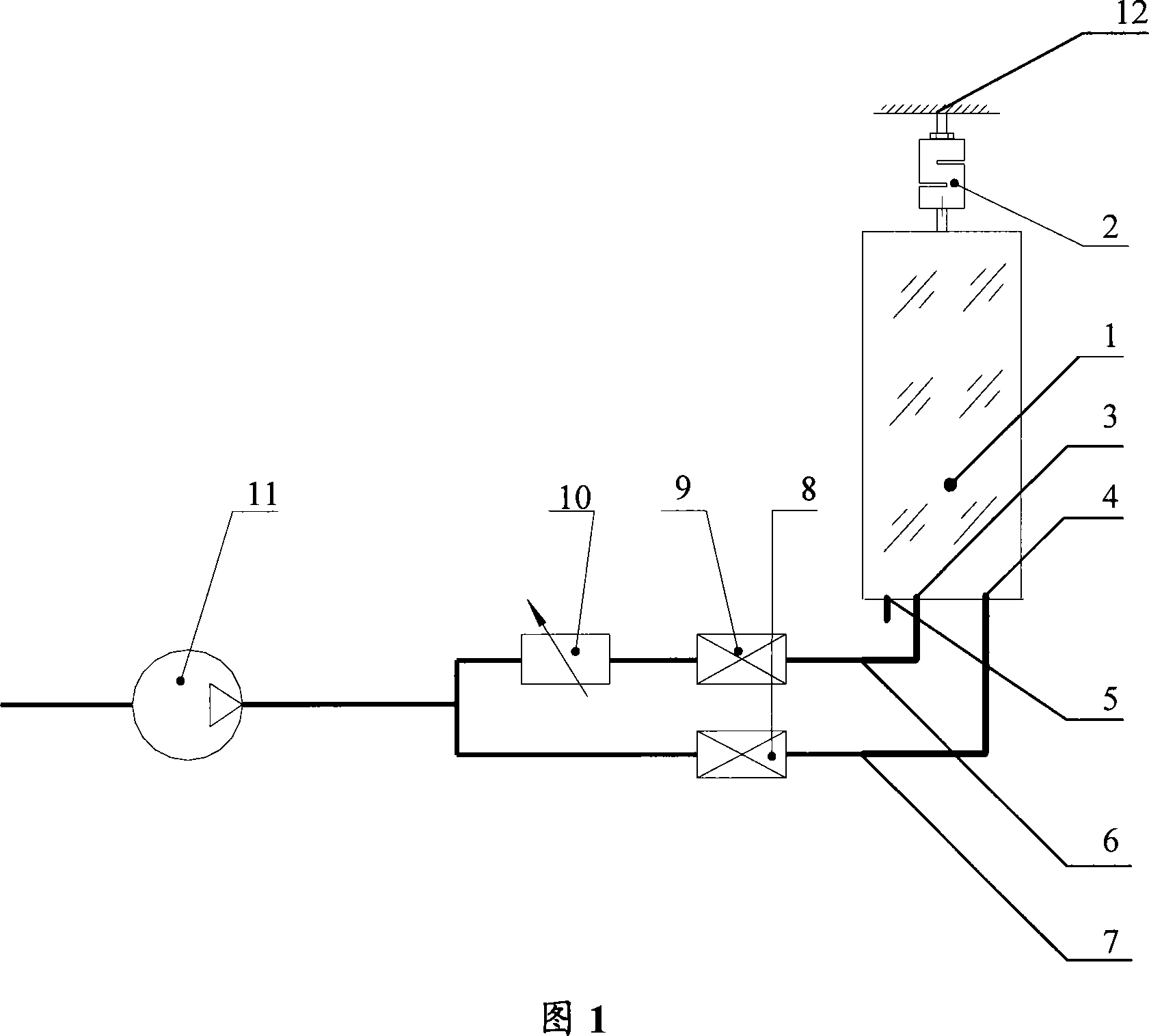

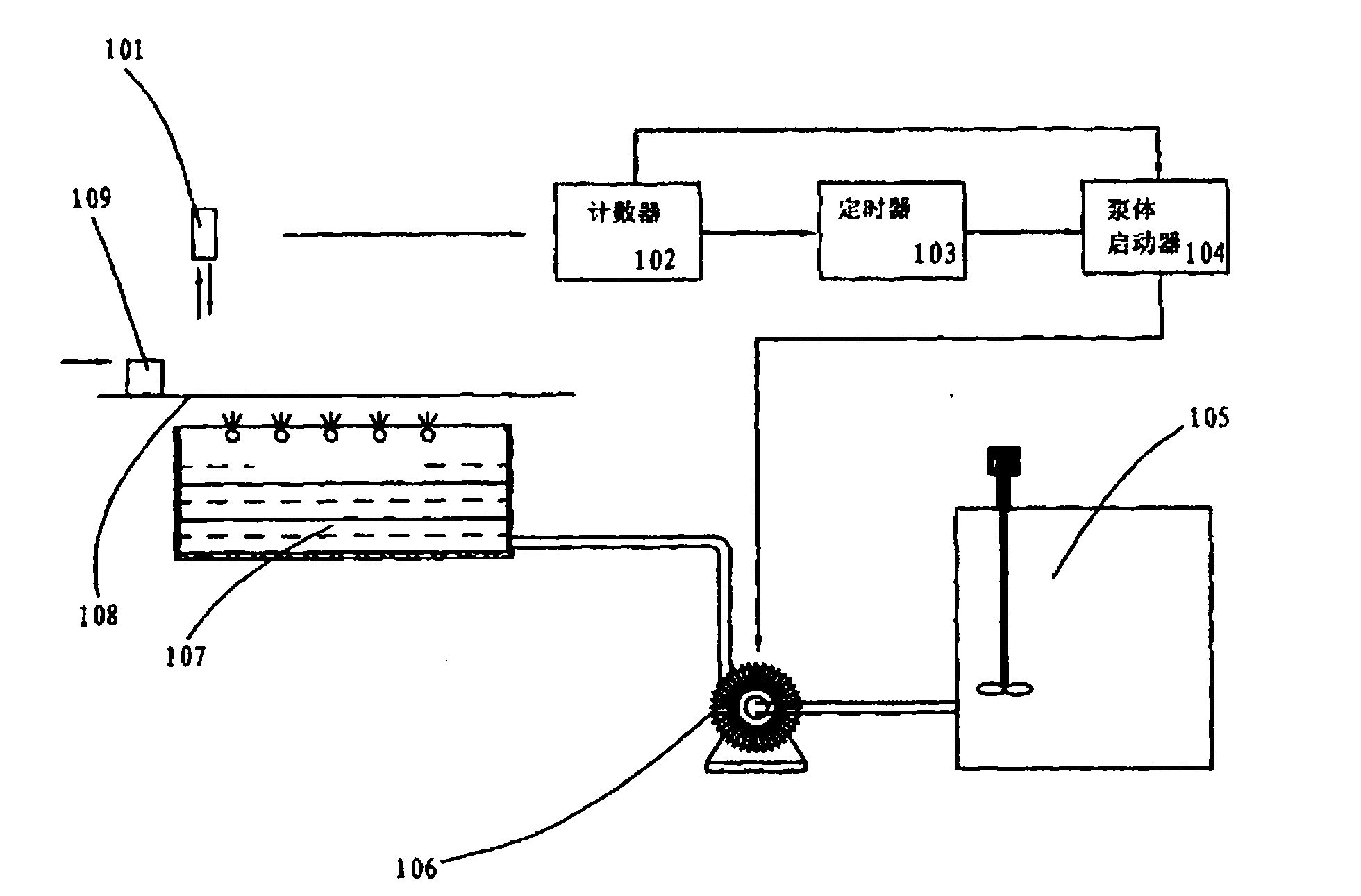

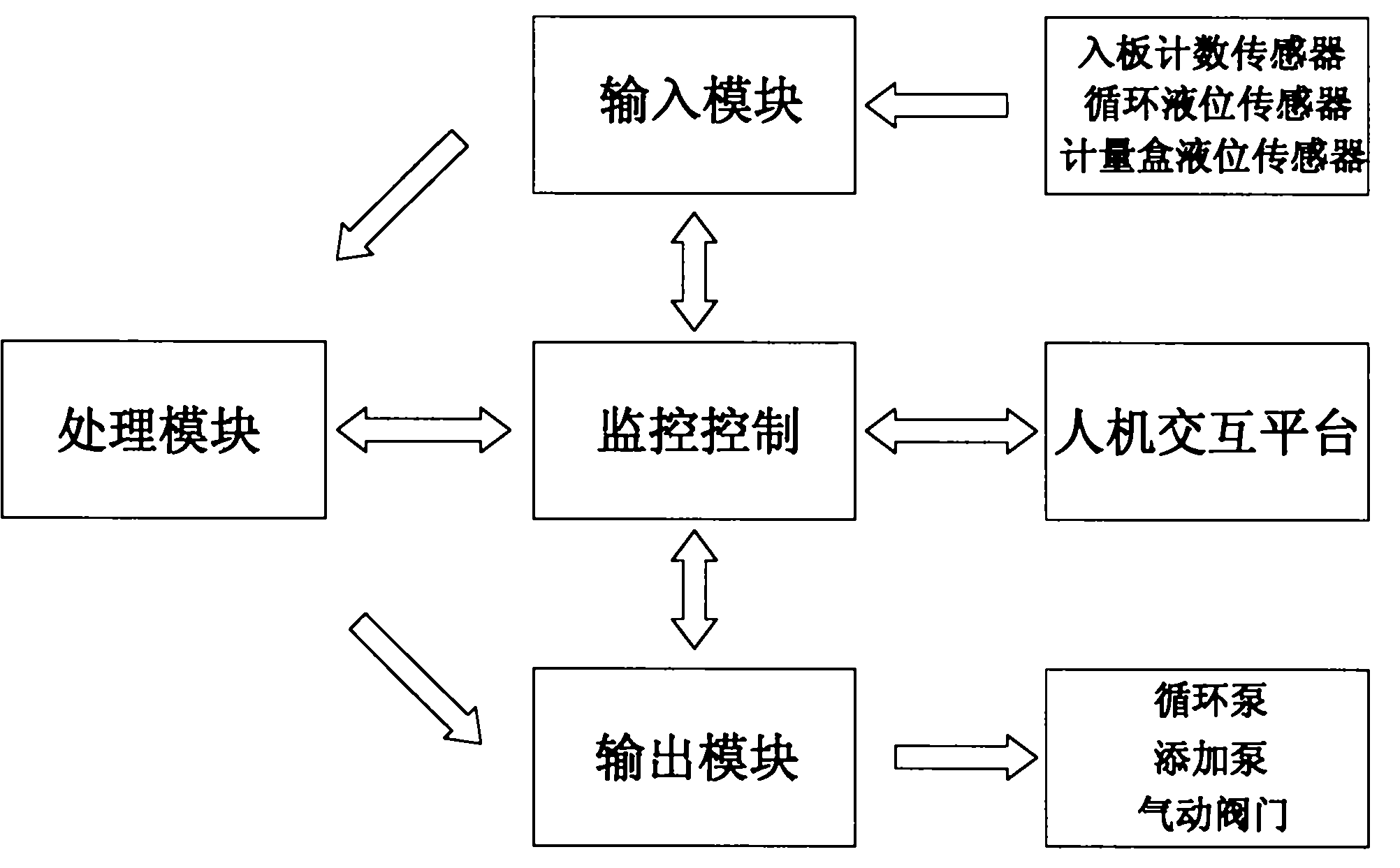

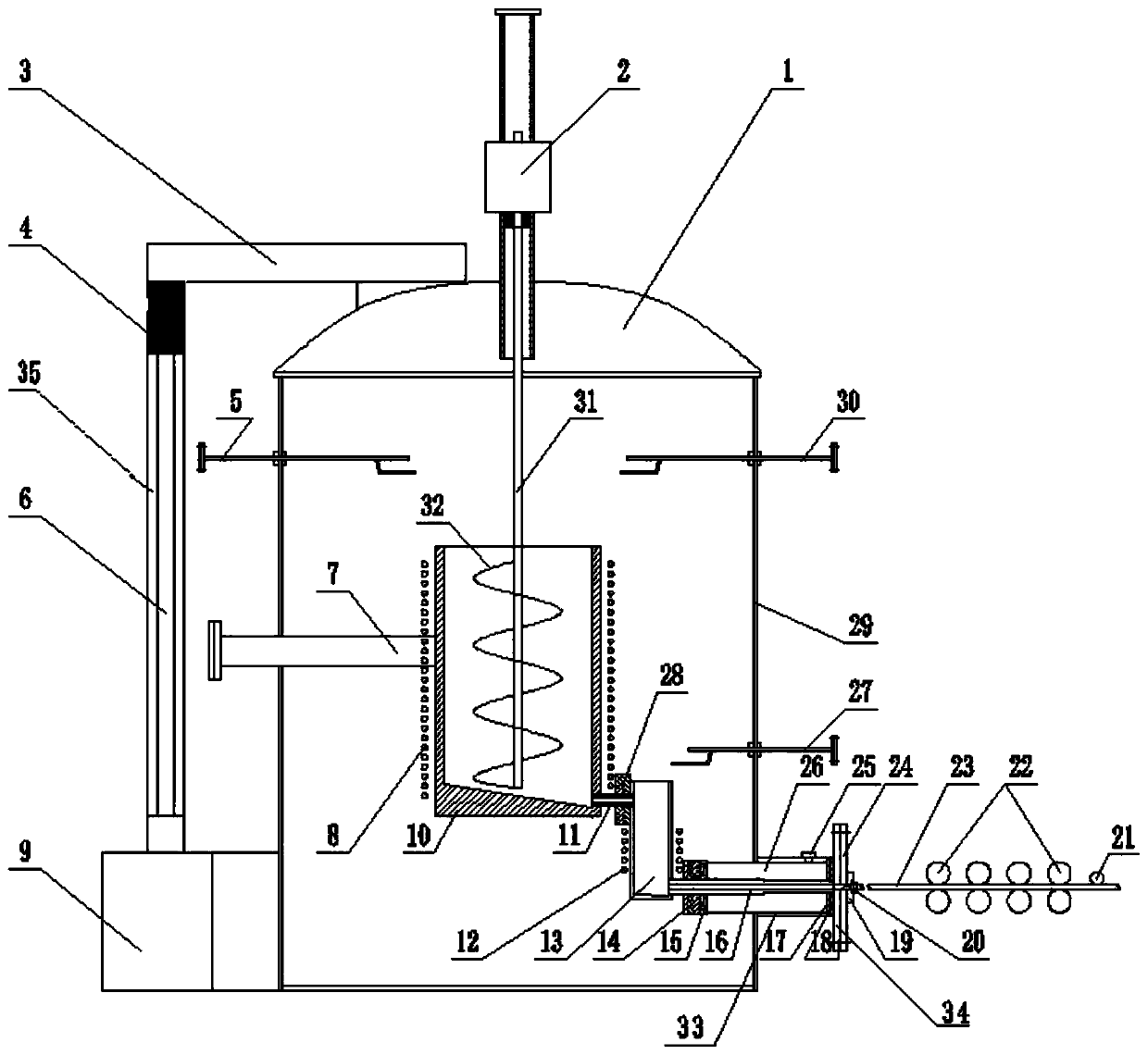

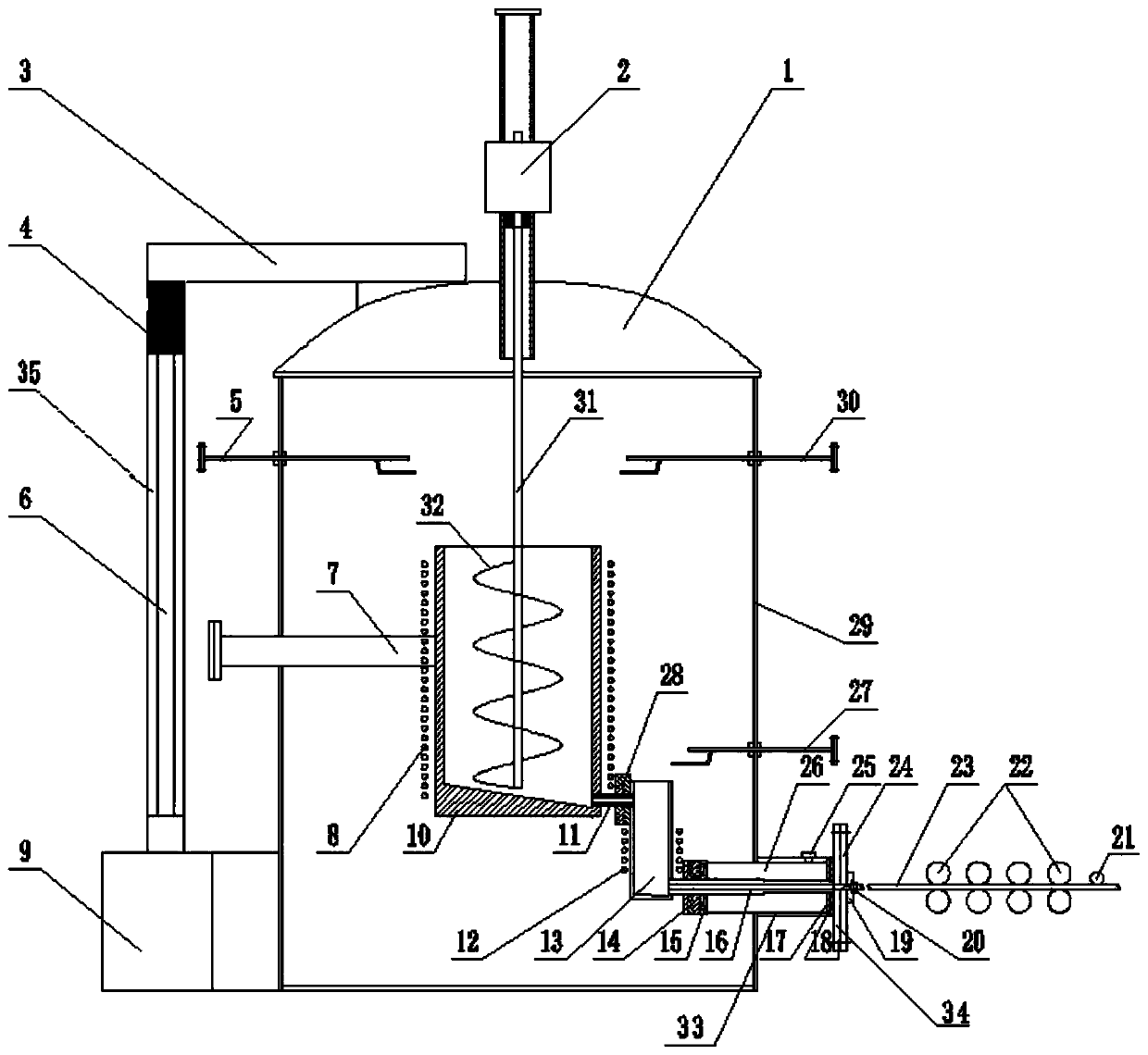

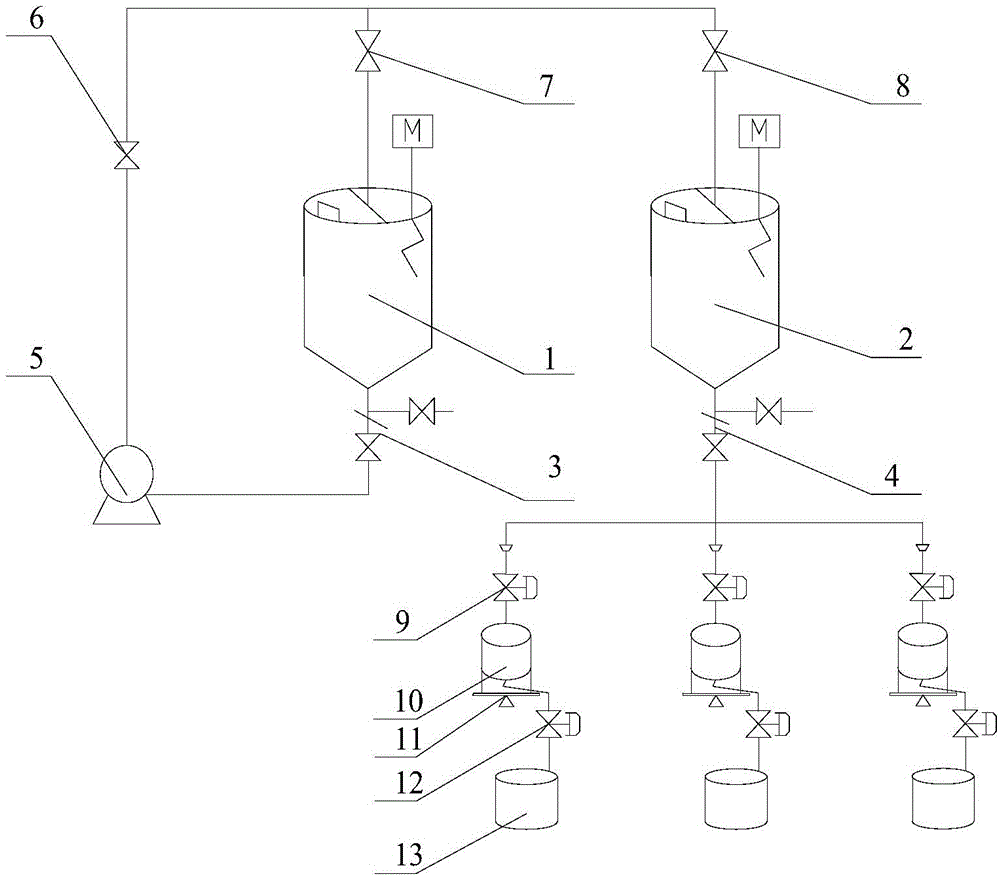

Automatic solution adding system

ActiveCN101873765AAdd accurateUniform inflow velocityLevel controlConductive material chemical/electrolytical removalControl systemEngineering

The invention discloses a solution adding system, which comprises an adding pump, a temporary solution storage cylinder, a control system, a solution transition box, a solution cylinder, a dead weight adjusting valve and a control valve, wherein the temporary solution storage cylinder is connected with a water suction port of the adding pump through a pipeline; the solution transition box is connected with a water outlet of the adding pump through a pipeline; the solution cylinder is connected with the solution transition box through a pipeline, and the vertical height of the solution transition box is greater than that of the solution cylinder; the dead weight adjusting valve and the control valve are arranged on the pipeline between the solution cylinder and the solution transition box; and the control system controls the opening and closing of the control valve. Because the solution transition box is higher than the solution cylinder, the solution in the solution transition box flows into the solution cylinder due to the action of gravity; and when the solution is added, the control valve is first opened, and the inflow speed of the solution flowing into the solution cylinder keeps uniform all the time due to the action of the dead weight adjusting valve, thus controlling the adding amount with time and fulfilling the purpose of accurately adding the solution.

Owner:SHENNAN CIRCUITS

Horizontal guide type copper alloy wire rod vacuum continuous casting machine

The invention belongs to an alloy wire rod casting device, and particularly discloses a horizontal guide type copper alloy wire rod vacuum continuous casting machine. The machine comprises an vacuum device, a smelting device, a crystallizer device, a cooling device and a traction device. The smelting device is located in the vacuum device, the smelting device comprises a main crucible and an auxiliary crucible, the auxiliary crucible is located at the tail end of the main crucible; the crystallizer device is connected with the smelting device, the cooling device is used for cooling the crystallizer device; and the traction device is positioned at the tail end of the crystallizer device and is used for carrying out traction continuous casting on the alloy in the crystallizer. According to the vacuum continuous casting machine, vacuum melting is adopted, so that the alloy elements are prevented from being oxidized, and the continuous casting alloy range of the vacuum continuous casting machine is greatly increased. The double-crucible system of the main crucible and the auxiliary crucible ensures that the alloy is accurately added, the influence of the liquid disturbance of the maincrucible on the continuous casting stability is eliminated through double-crucible smelting, and the multicomponent alloy material which is uniform in component and stable in structure is obtained.

Owner:ZHEJIANG TONY ELECTRONICS CO LTD

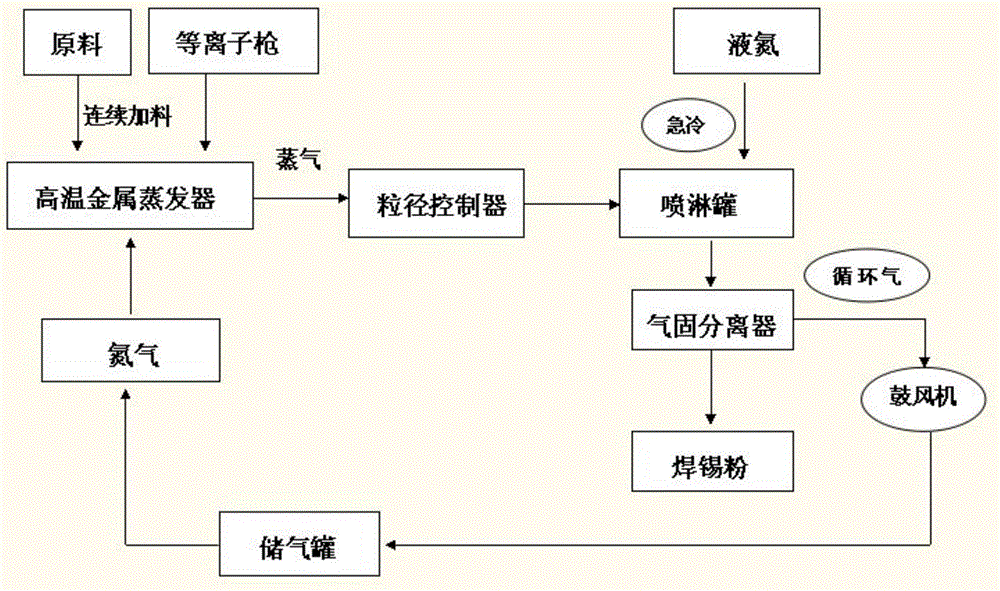

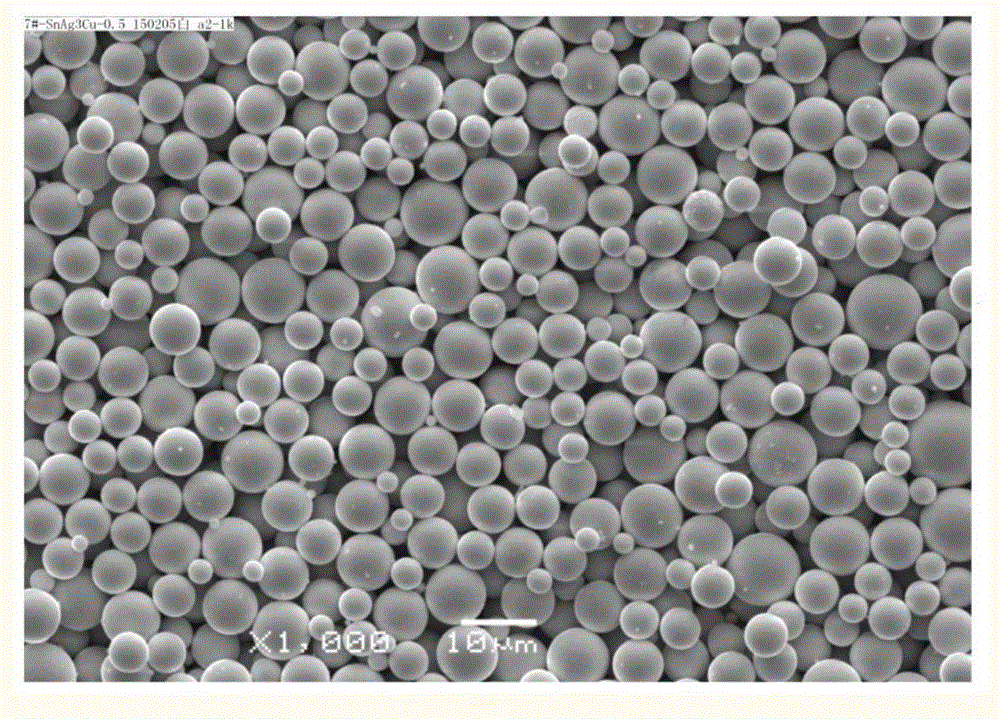

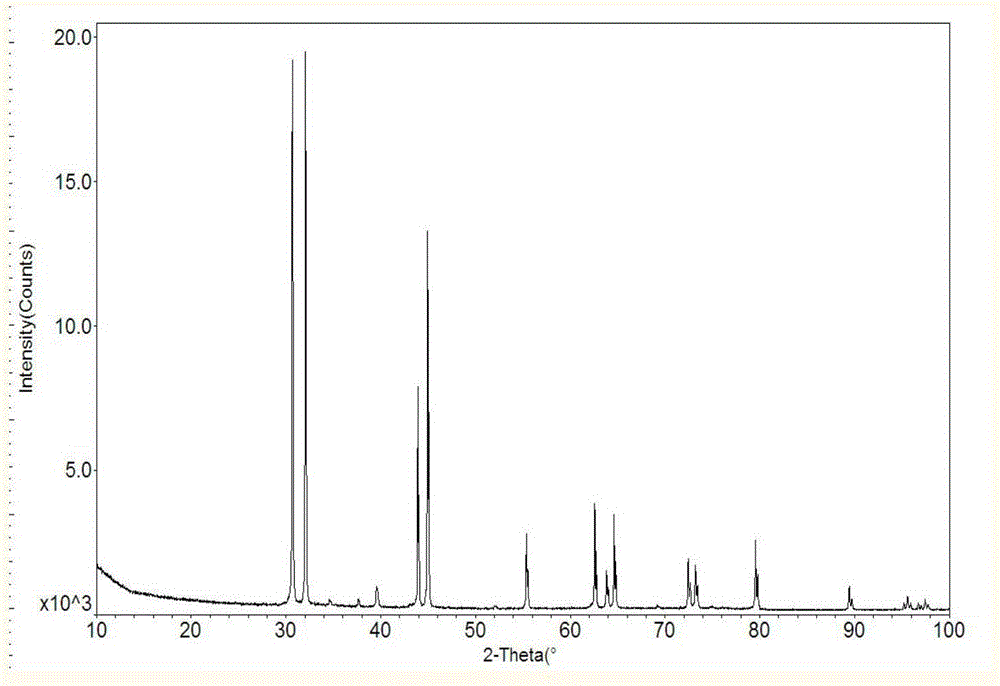

Method for producing superfine lead-free solder powder

The invention provides a method for producing superfine lead-free solder powder. The method is implemented in a reaction system composed of a high-temperature evaporator, a grain controller, a spraying tank, a collector and the like which are all communicated in sequence. Tin alloy is placed in the high-temperature evaporator to be heated and melted, the temperature is maintained for 1 to 3 hours to acquire even alloy liquid, the power of a plasma gun is then increased rapidly, the flow of nitrogen is adjusted, metal steam is conveyed to the grain controller so as to be gradually cooled, collide with one another and grow, and alloy drops are generated; the alloy drops enter the spraying tank through air flow and rapidly cooled through liquid nitrogen to form solder powder, the solder powder is conveyed to the collector along with the nitrogen, attached to the outer wall of a gas-solid separator in the collector and then collected to a collecting hopper at the bottom of the collector, and therefore the superfine solder powder is acquired, wherein the nitrogen is cyclically used. The superfine lead-free solder powder produced through the method is hemispherical, the average grain diameter ranges from 2 micrometers to 7 micrometers, the powder is distributed narrowly, the oxygen content is low, the purity is high, and alloy components are even.

Owner:JIANGSU BOQIAN NEW MATERIALS

Automatic charging system of additives

ActiveCN104667810ASimplified Addition SystemAccurate measurementMixer accessoriesControl systemNylon 66

The invention provides an automatic charging system of additives. The automatic charging system comprises a blending platform and a weighing device, wherein the blending platform comprises a blending tank, a storage tank, a conveying pump, a gate valve, a filter and a pipeline; the weighing device comprises a PLC control system and a material metering tank arranged under the PLC control system. According to the automatic charging system, an additive system is technically modified so that the automatic charging system can be used for accurately metering and adding and the production requirements are met; the problem that the additives need to be specially prepared on a special line in a production process is solved, the adding system of the additives is simplified and the cost is reduced; and the automatic charging system has a wide application market in a nylon 66 production industry.

Owner:中平神马江苏新材料科技有限公司

Concrete trial-manufacturing and processing device

ActiveCN113601710AAdd accurateConvenient and accurate additionDischarging apparatusMixing operation control apparatusArchitectural engineeringElectric machinery

The invention discloses a concrete trial-manufacturing and processing device, and belongs to the field of building material processing mechanical equipment. A main material feeding hopper and an ingredient feeding mechanism are arranged on the two sides of the upper portion of a concrete preparation kettle correspondingly, a concrete discharging control valve is fixedly arranged on a concrete discharging pipe in the middle of the lower side of the concrete preparation kettle, and a concrete discharging mechanism is arranged on the lower side of the concrete discharging pipe; and a preparation water inlet guide pipe is arranged on the concrete preparation kettle on the adjacent side of the main material feeding hopper, the output end of a concrete stirring motor is vertically and rotatably connected with a concrete stirring shaft, and a plurality of stirrers are horizontally and fixedly arranged on the concrete stirring shaft in sequence from top to bottom. According to the concrete trial-manufacturing and processing device, the structural design is reasonable, ingredients can be conveniently, accurately and quantitatively added according to the needs of concrete trial-manufacturing and processing, trial-manufacturing and processing of concrete of different specifications and batches are achieved, the processed concrete can be continuously and quantitatively transferred and discharged, the automation degree of concrete trial-manufacturing is improved, and the use needs are met.

Owner:桐乡市钟大建材有限公司

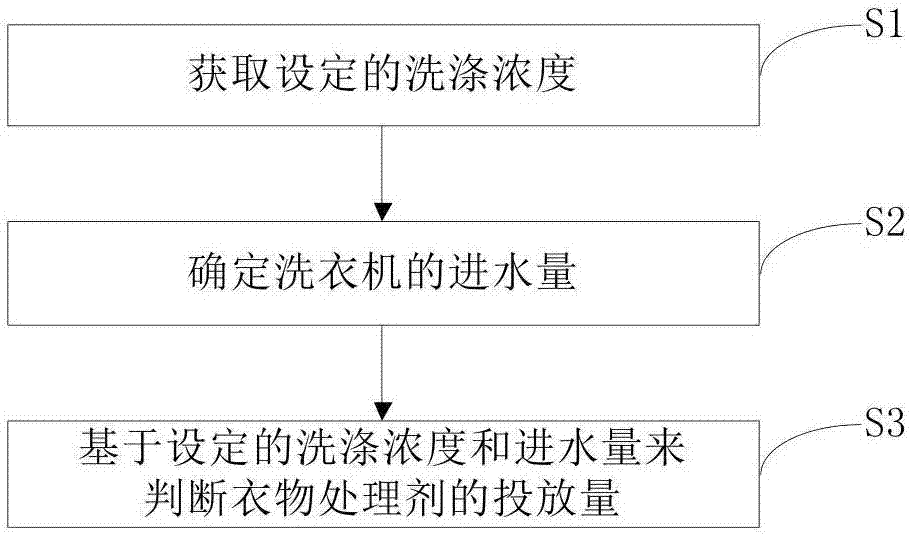

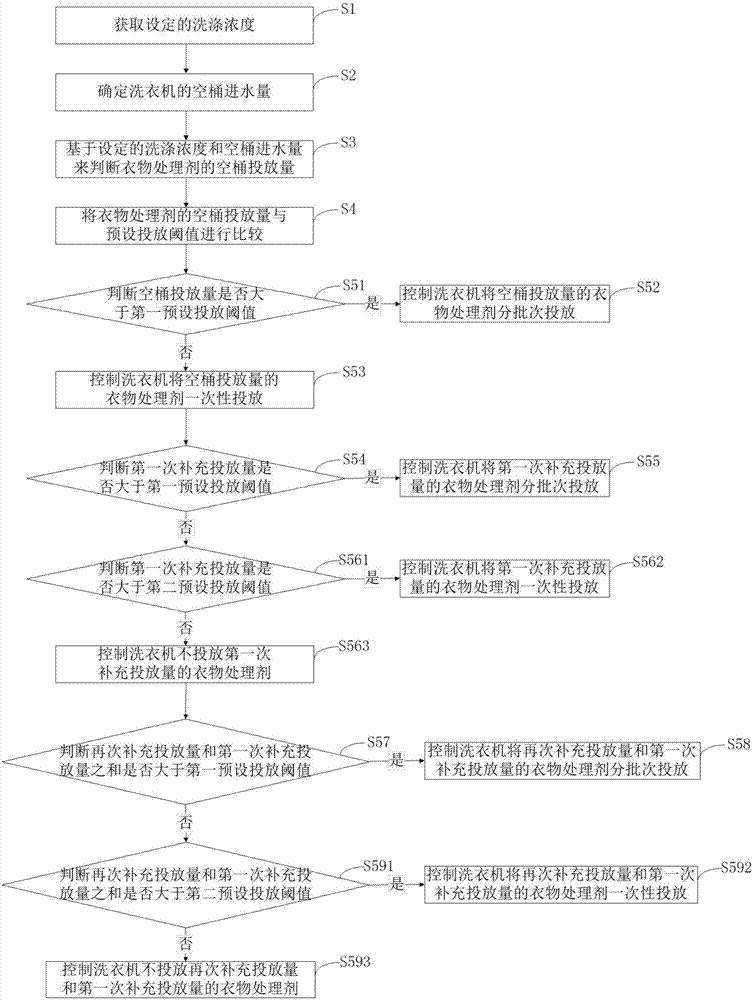

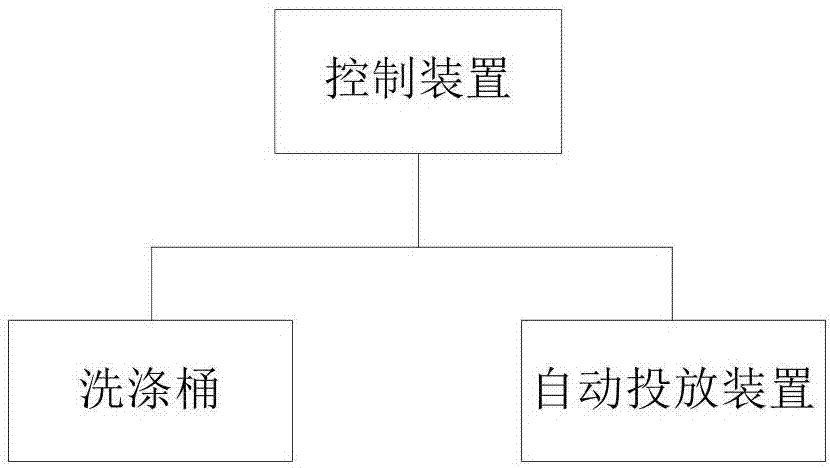

Cloth treating agent filling method for cloth treating device and cloth treating device

ActiveCN107964755AGuaranteed concentrationRealize split deliveryControl devices for washing apparatusTextiles and paperUrology

The invention relates to the technical field of a cloth treating device, and particularly provides a cloth treating agent filling method for a cloth treating device and the cloth treating device. Theinvention aims to solve the problem of low filling accuracy of the cloth treating agent of the existing cloth treating device. For this purpose, the cloth treating agent filling method includes stepsof acquiring setting washing concentration; confirming water inflow of the cloth treating device; judging the filling amount of the cloth treating agent on the basis of the set washing concentration and water inflow. The cloth treating device comprises a control device, and the control device is used for executing the cloth treating agent filling method. On the basis of the set washing concentration and water inflow, the filling amount of the cloth treating agent is judged, thus the filling precision of the cloth treating agent is improved, the concentration of the cloth treating agent in thewashing barrel is guaranteed, and the washing demand of a user is satisfied; a better cleaning effect is realized, thus the using experience is further improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Food material preprocessing machine having sugar adding function

ActiveCN108771483APrevent overcookingEasy to take outCooking vesselsFood materialPulp and paper industry

The invention discloses a food material preprocessing machine having a sugar adding function. The food material preprocessing machine belongs to the field of a cereal processing machine. The food material preprocessing machine having the sugar adding function includes a tank body and a controller. A mixing processing cylinder is slidably connected to the tank body; a first telescopic cylinder is fixedly connected to the tank body; the first telescopic cylinder is slidably connected to a second telescopic cylinder; a quantitative sugar cylinder is fixedly connected to the lower end of the second telescopic cylinder; the upper end of the quantitative sugar cylinder is provided with a plurality of sugar flowing out through holes; the quantitative sugar cylinder is slidably connected to a pushing sugar flowing out plate; the lower end of the pushing sugar flowing out plate is fixedly connected to a lifting rod; the lower end of the lifting rod passes through the quantitative sugar cylinderand is fixedly connected to a floating block; and the floating block is located in the mixing processing cylinder. Through adoption of the food material preprocessing machine, height adjustment of the floating block is achieved according to the amount of cereals, so that the floating block drives the sugar flowing out plate to lift and drop by the lifting rod, thereby achieving a change of the sugar amount in the quantitative sugar cylinder, and accurate addition of the sugar amount is achieved, and mouthfeel is ensured.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com