Patents

Literature

39results about How to "Prevent overcooking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

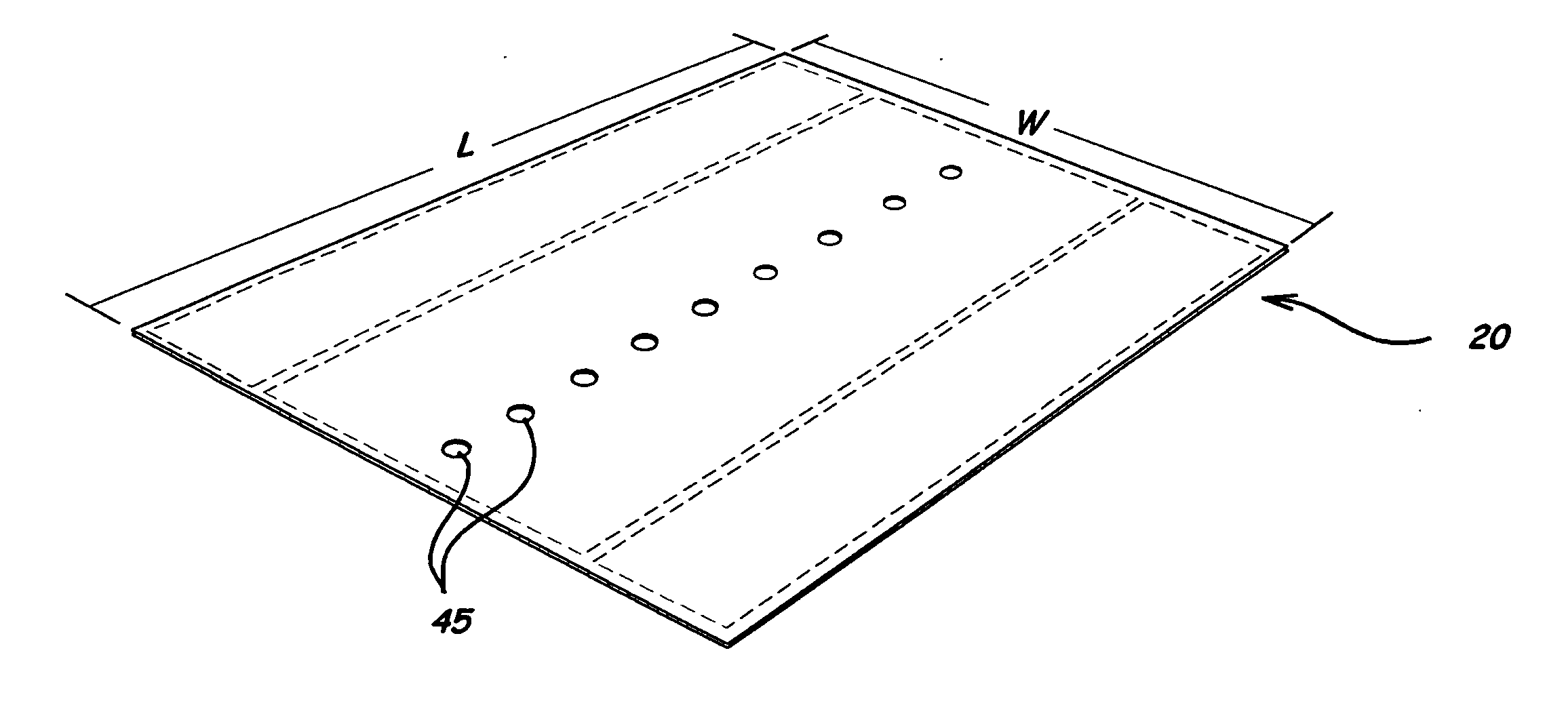

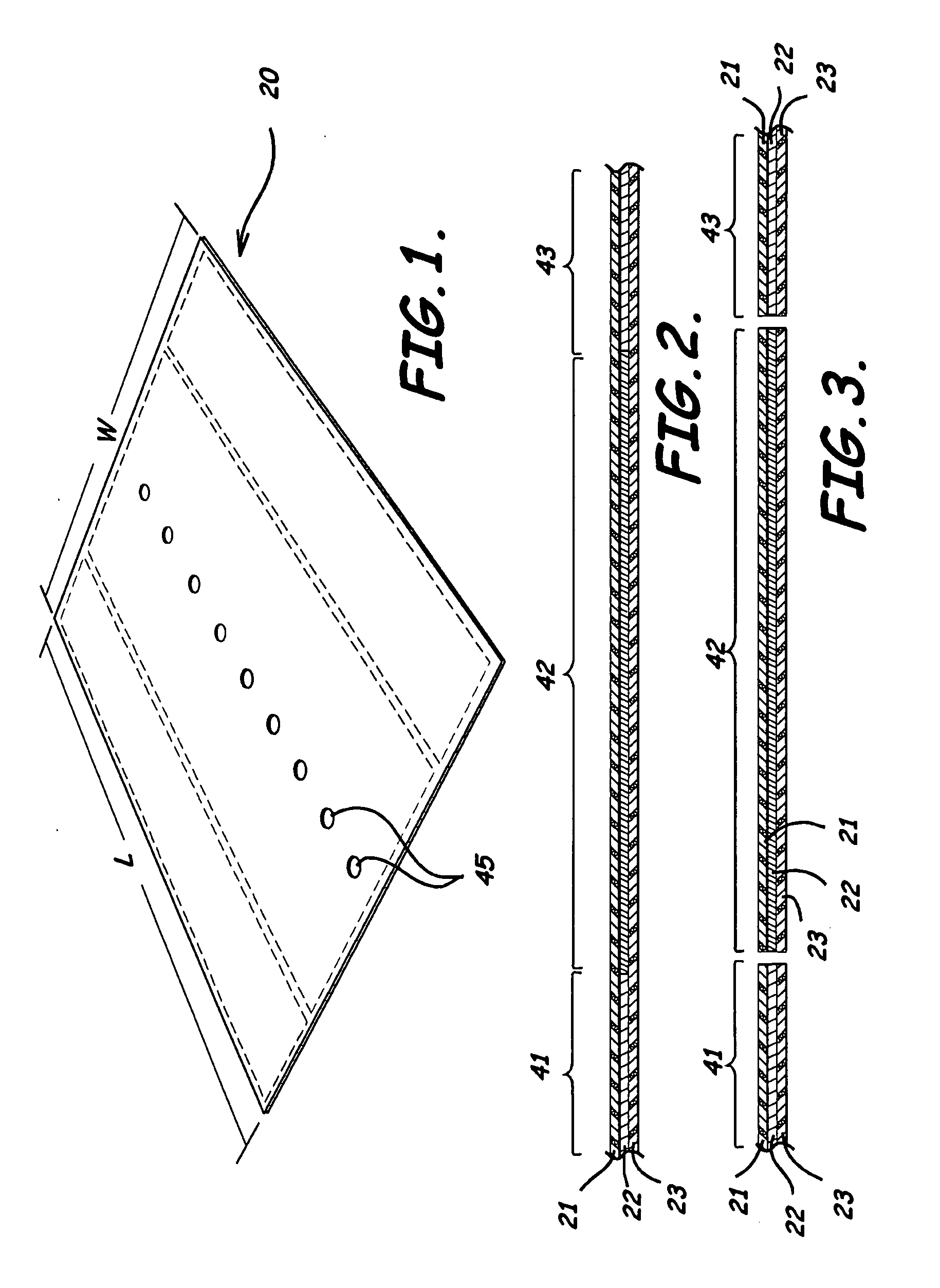

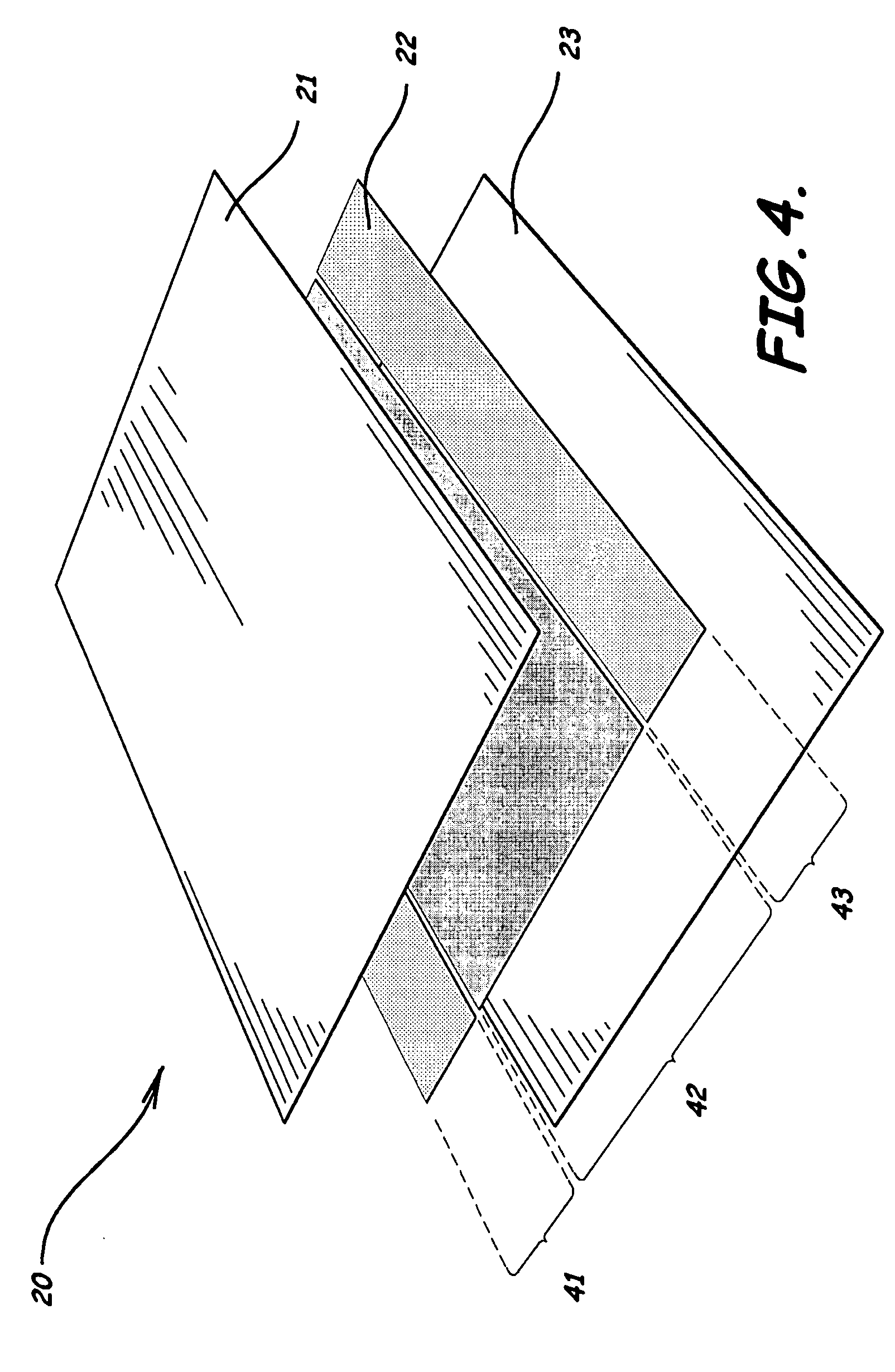

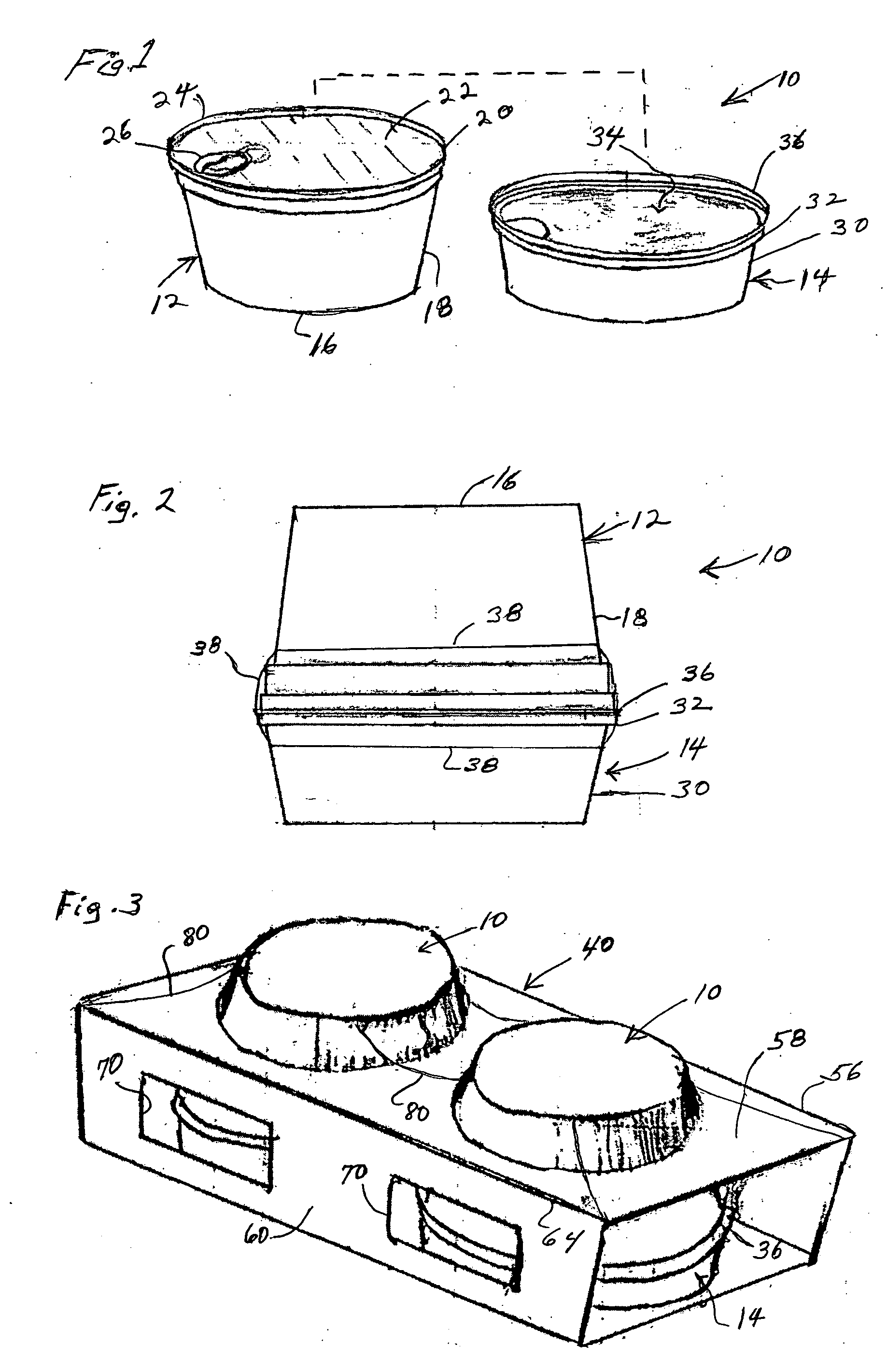

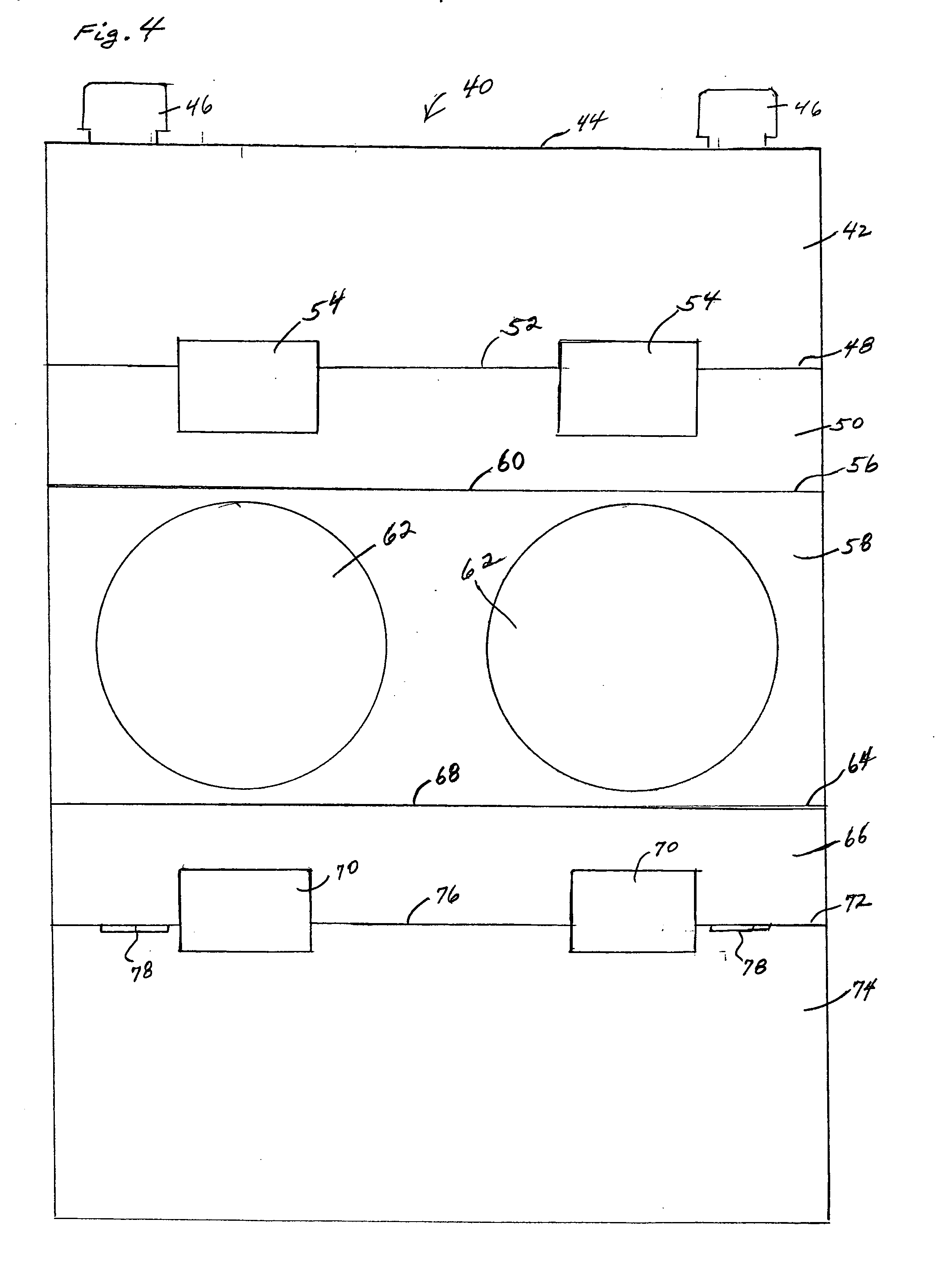

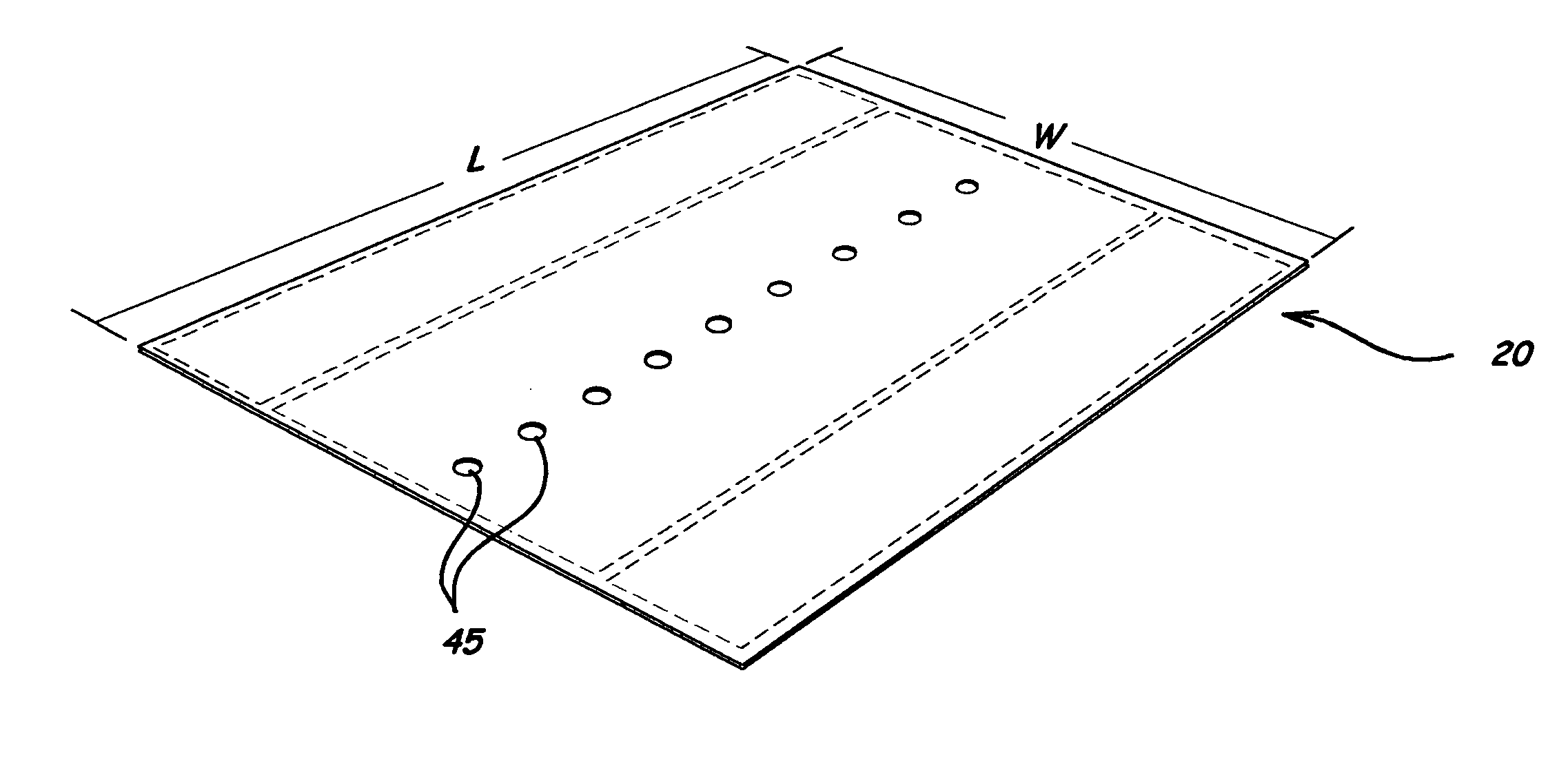

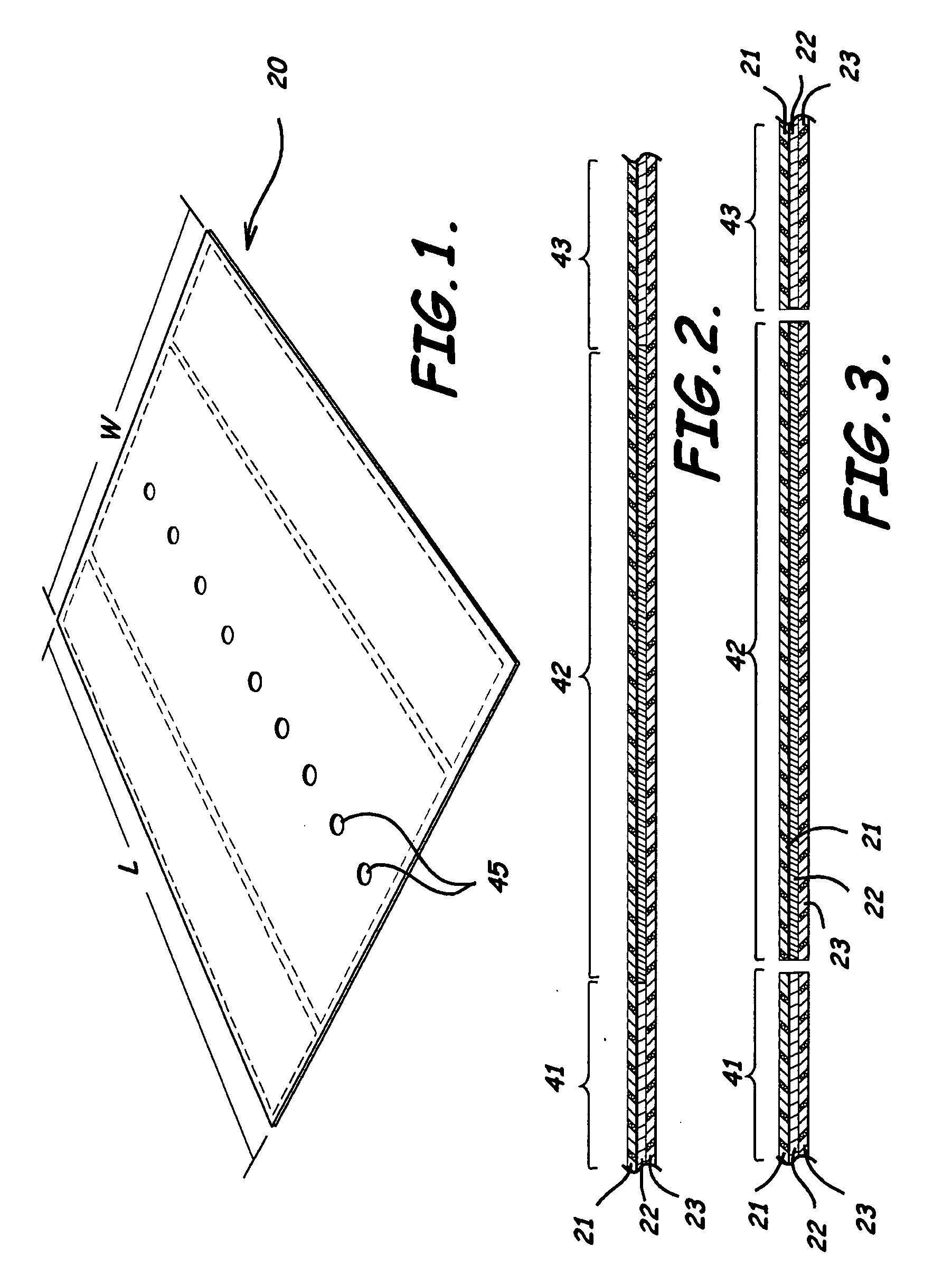

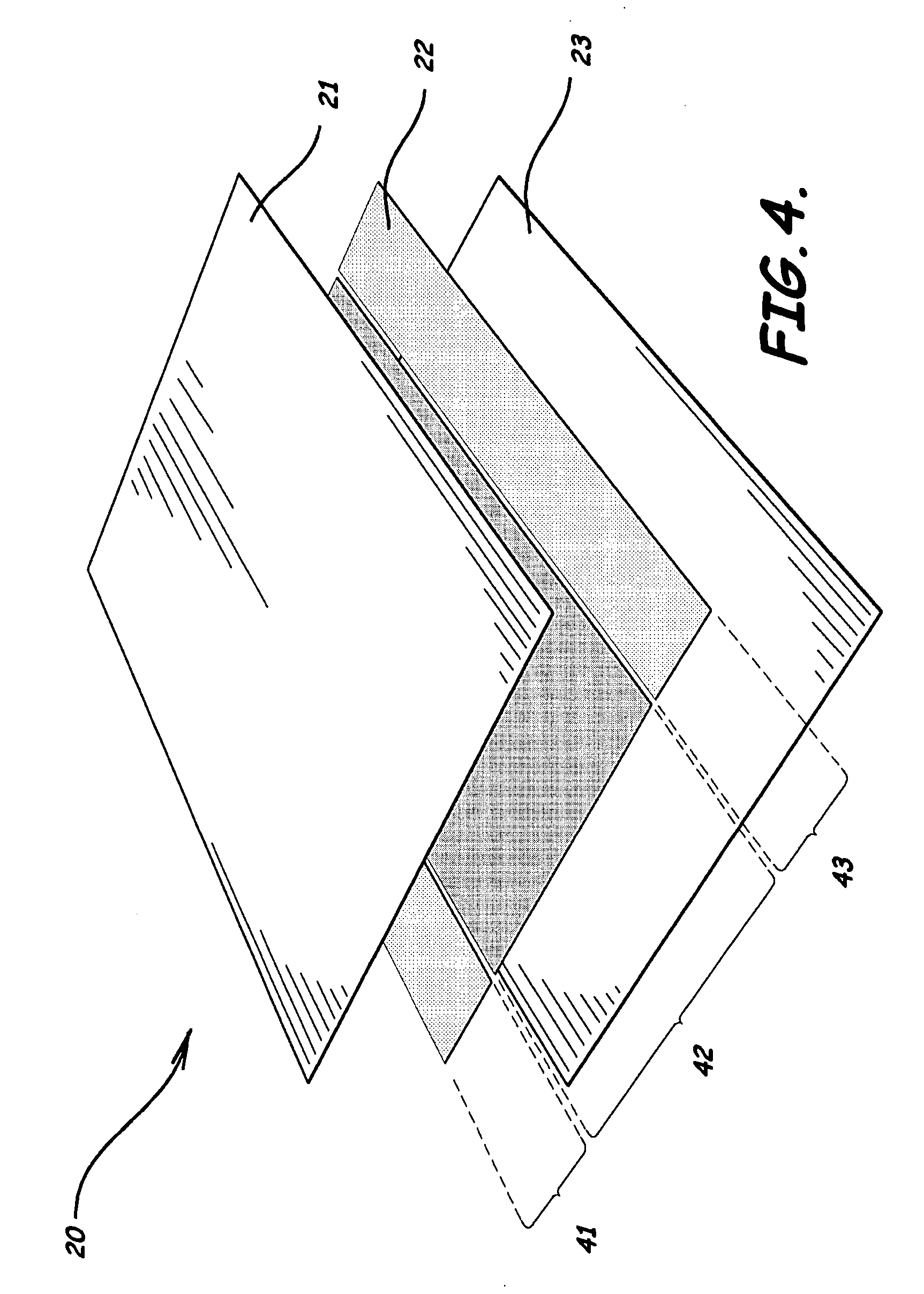

Microwave cooking package for food products and associated methods

InactiveUS20060289519A1Avoid problemsPrevent overcookingVenting meansMicrowave heatingMicrowave ovenEngineering

A microwave cooking package and combination of a food product and microwave cooking package. The cooking package intimately contacts and substantially surrounds the food product as the food product is cooked in a microwave oven. The package provides for venting of moisture in specific regions of the food product and distribution of heat across the extent of the food product to facilitate cooking of the entire food product and more uniform browning and crisping of the outer surface of the food product. The cooking package is preferably used for cooking a dough enclosed food product in a microwave oven. The package of the present invention allows the food product to be uniformly cooked to a golden brown color with a crispy, crunchy consistency.

Owner:EXOPACK TECH

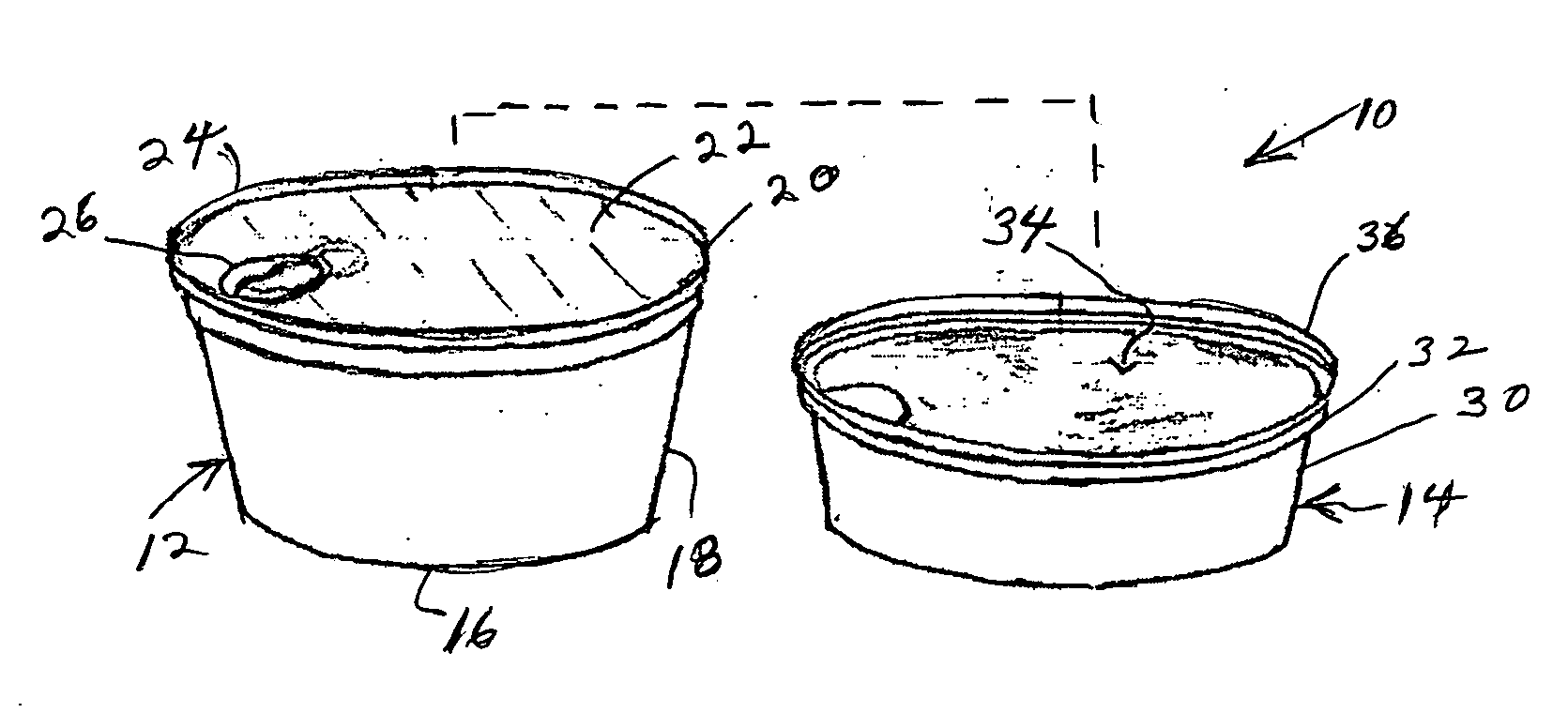

Process for packaging foods and packaged product

InactiveUS20060222747A1Without loss of taste and texturePrevent overcookingMeat/fish preservation by heatingMeat/fish preservation by freezing/coolingSufficient timeEngineering

A packaged shellfish product and a process for producing the shellfish are provided by the invention. The shellfish is heat-treated to partially cook the shellfish followed by rapid cooling to stop the cooking process. The partially cooked shellfish is then packaged in a sealed container and heated for sufficient time and temperature to fully cook the shellfish. The resulting packaged shellfish has an extended refrigerated shelf life. In one embodiment, the packaged shellfish is stable for about 45-60 days without loss of flavor or texture.

Owner:OCEAN TECH

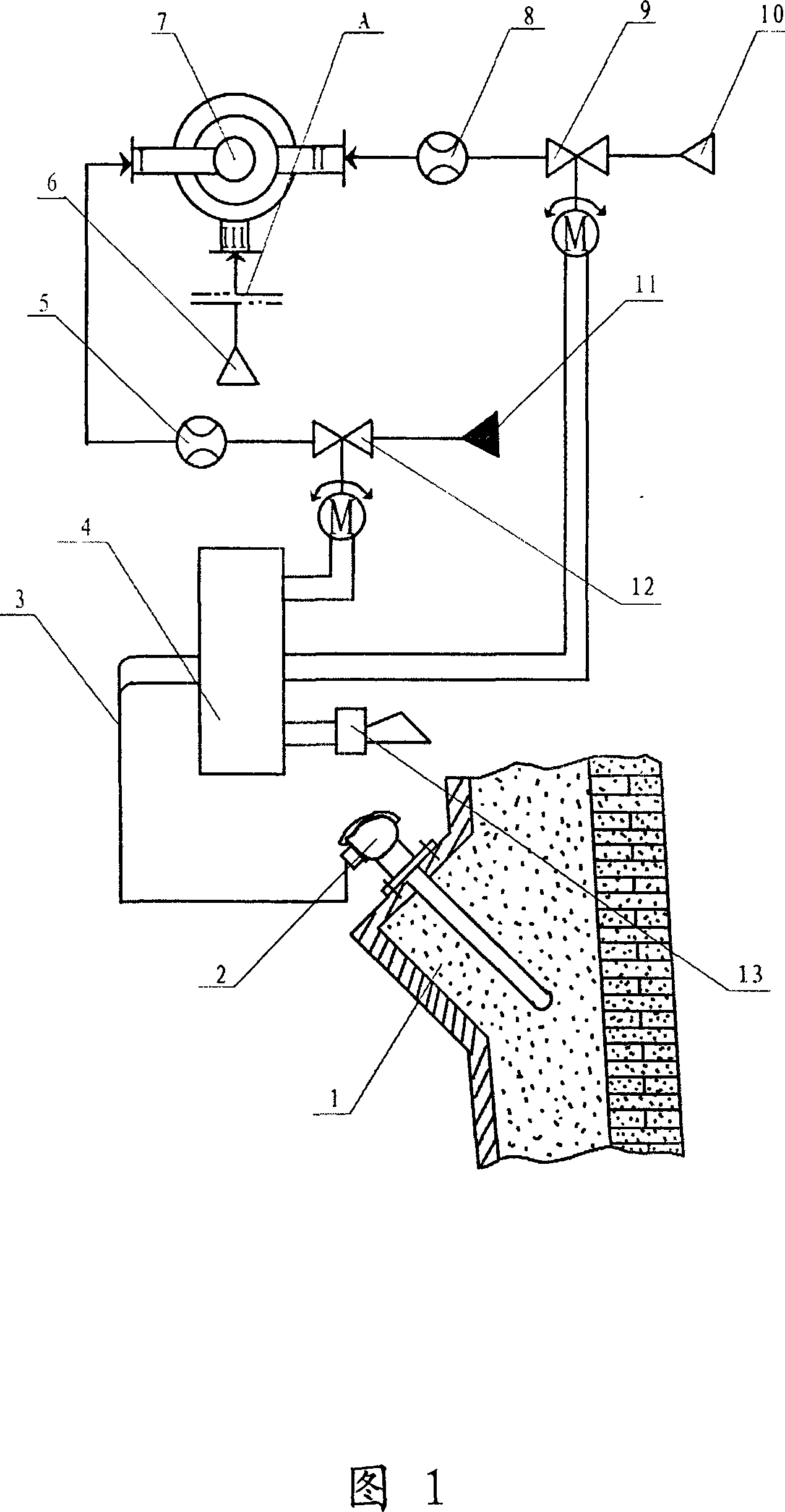

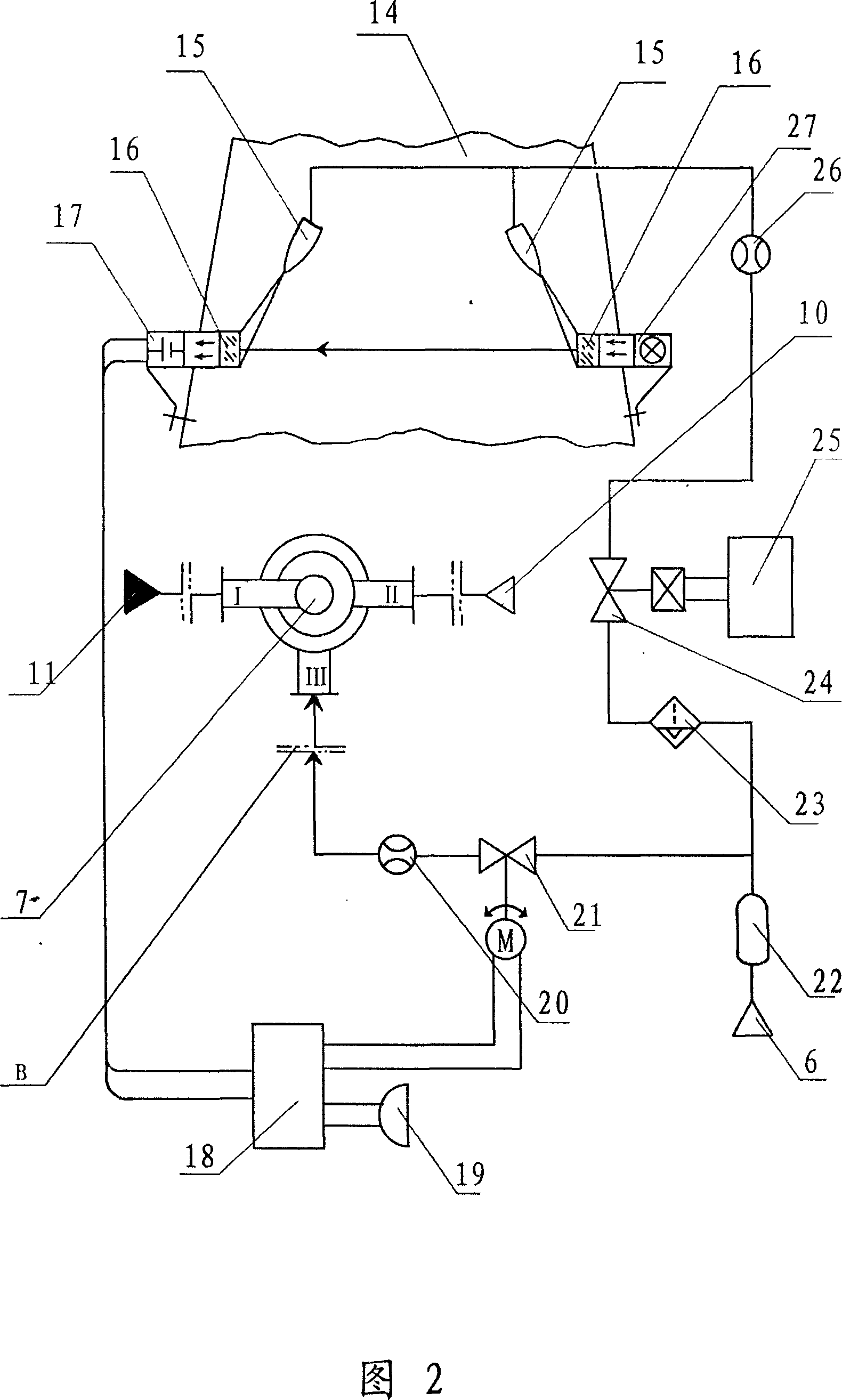

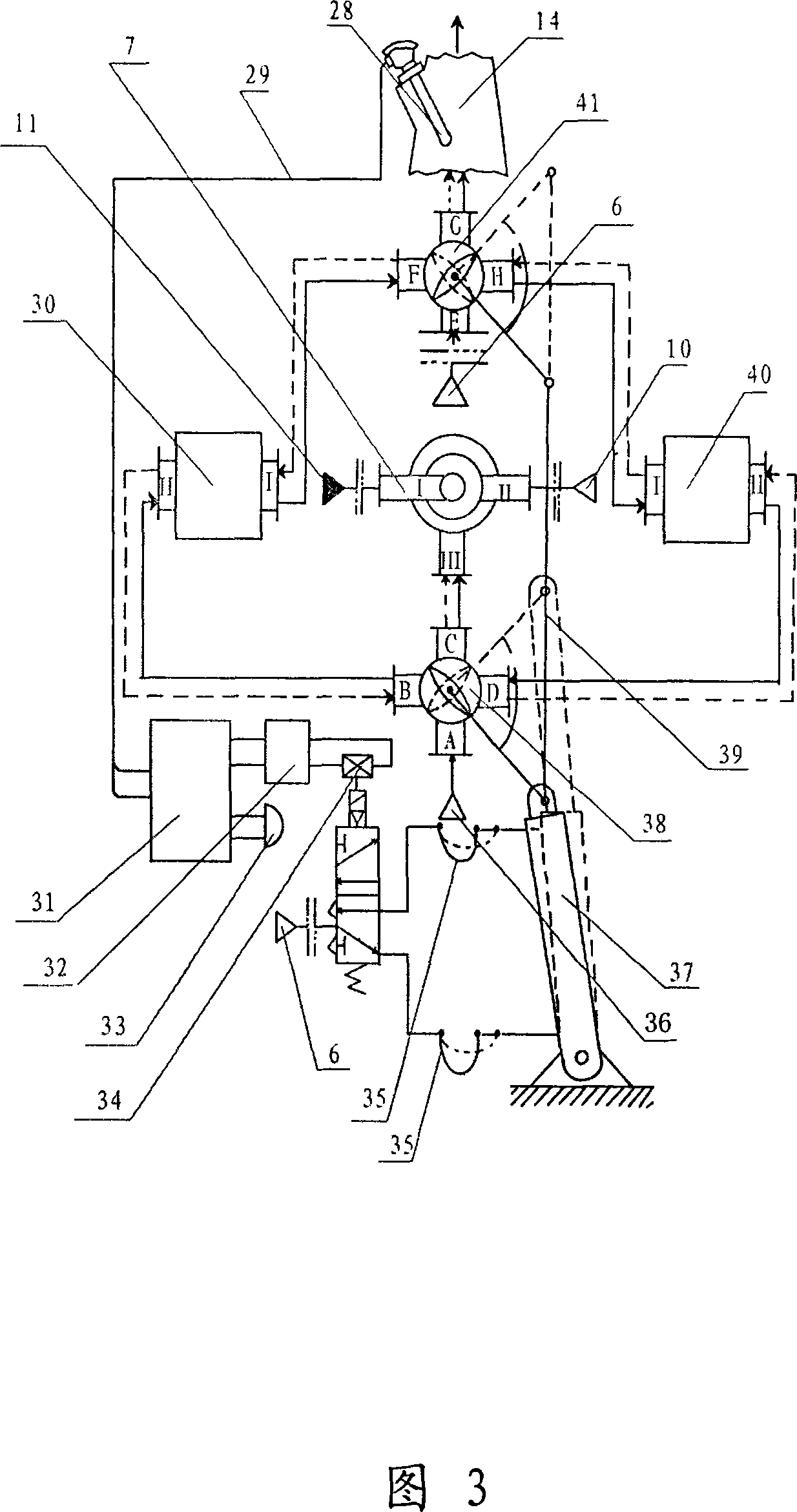

Automatic observing and controlling method for roasting heat accumulating type steel ladle and the device using the method

InactiveCN101121200AImprove roast qualityPrevent from being baked throughCasting safety devicesVolumetric Mass DensitySmoke

The present invention discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature. The present invention also discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature; the present invention can ensure the sufficient burning of fuel and the heating quality of the ladle; the present invention can thoroughly remove the defect that the smoke and dust will pollute the environment and the energy-saving effect is obvious.

Owner:江苏兴利来特钢有限公司

Method for mullet artificial breeding in batches

InactiveCN108293923AExtended use timeImprove efficiencyClimate change adaptationPisciculture and aquariaBroodstockINCREASED EFFECT

A method for mullet artificial breeding in batches belongs to the field of fishery. The invention relates to a technical field of aquaculture, in particular to the method for mullet artificial breeding in multiple batches, and is characterized by comprising a whole process of the six stages of parent postpartum recovery, parent breeding, parent antenatal breeding in batches, parent fish selectionand hasten parturition, oosperm incubation and larval breeding; female fish occupying proportion is increased, the grouping is carried out at a low temperature period, and temperature and light control breeding in a back room is combined; according to the method, the use time of artificial breeding equipment is prolonged, the technical problem is solved that mullet artificial breeding for a long time in multiple batches is difficult, the egg grain cardinal number of breeding groups with same quantity is doubled or more, three batch breeding in a breeding season is achieved, the breeding time is prolonged by three times or more, and the fish fry breeding quantity is increased by three times or more. The fish yield-increasing effect in a breeding period is significant, and the method is applicable to industrialization large-scale development.

Owner:上海能淦水产专业合作社

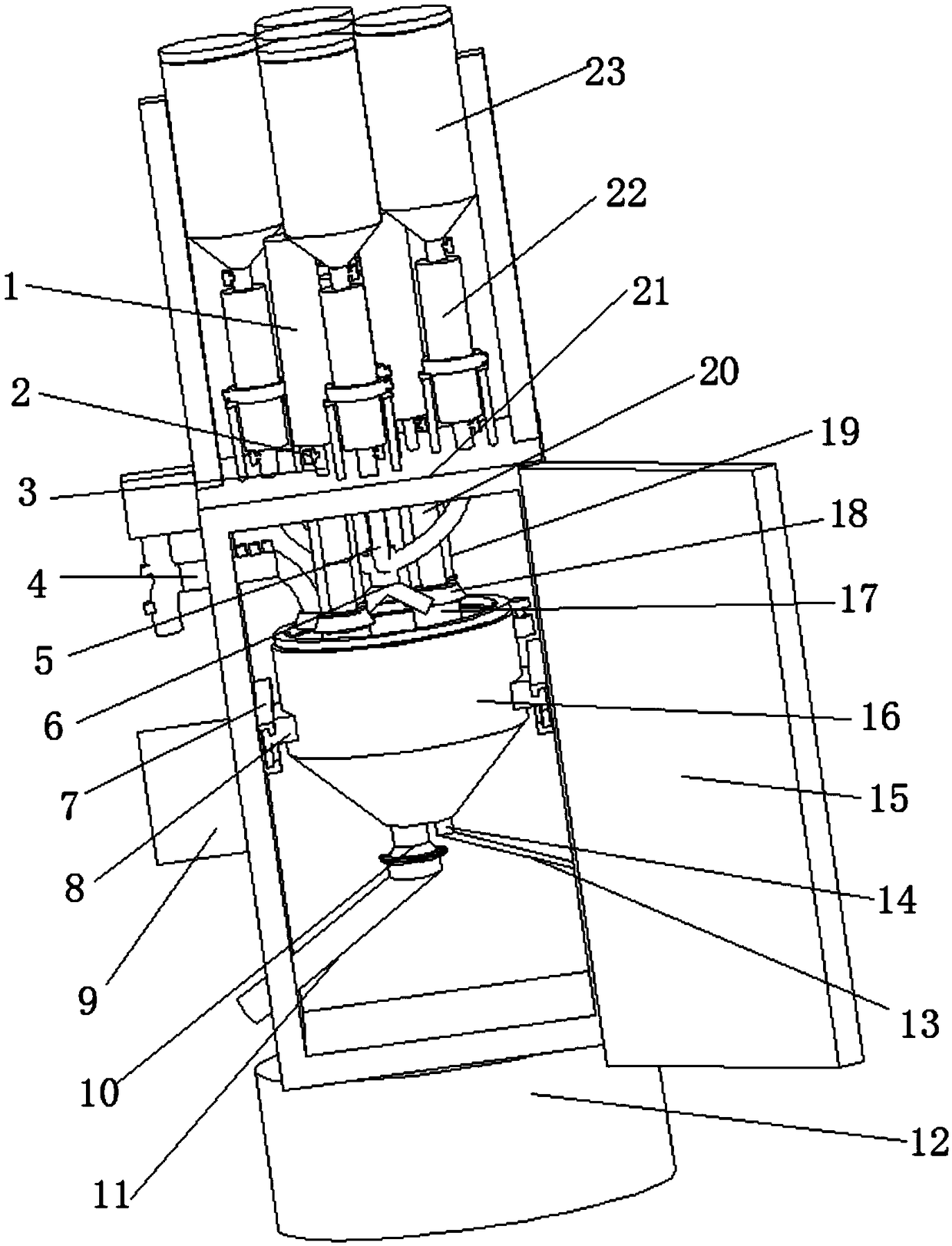

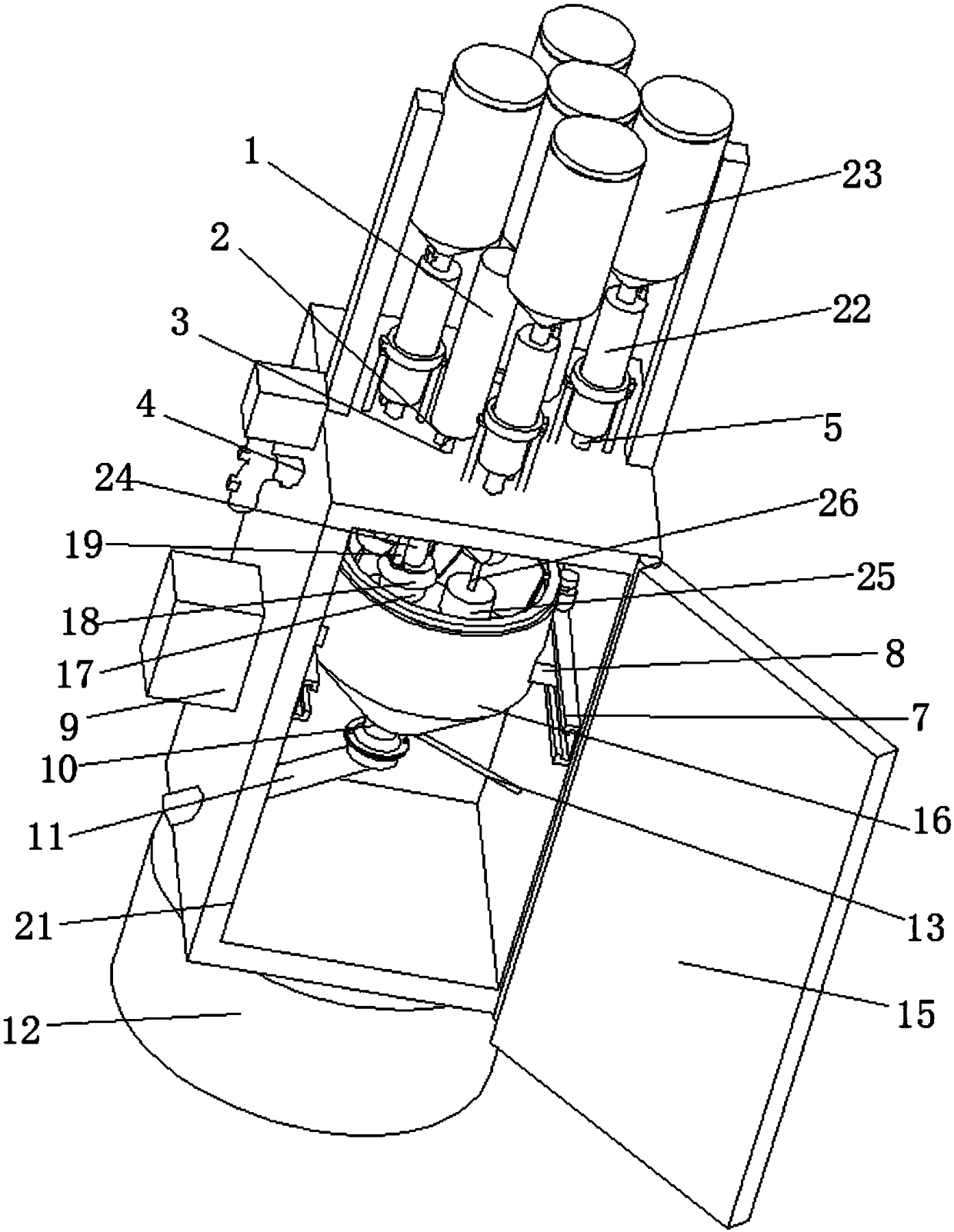

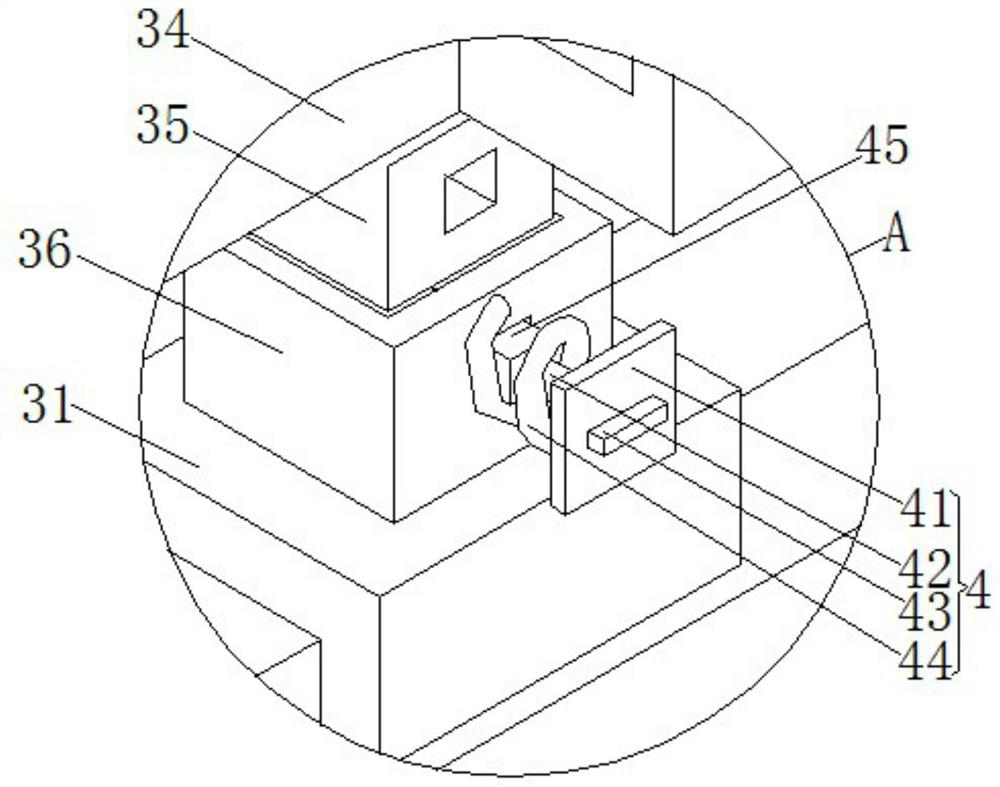

Food material preprocessing machine having sugar adding function

ActiveCN108771483APrevent overcookingEasy to take outCooking vesselsFood materialPulp and paper industry

The invention discloses a food material preprocessing machine having a sugar adding function. The food material preprocessing machine belongs to the field of a cereal processing machine. The food material preprocessing machine having the sugar adding function includes a tank body and a controller. A mixing processing cylinder is slidably connected to the tank body; a first telescopic cylinder is fixedly connected to the tank body; the first telescopic cylinder is slidably connected to a second telescopic cylinder; a quantitative sugar cylinder is fixedly connected to the lower end of the second telescopic cylinder; the upper end of the quantitative sugar cylinder is provided with a plurality of sugar flowing out through holes; the quantitative sugar cylinder is slidably connected to a pushing sugar flowing out plate; the lower end of the pushing sugar flowing out plate is fixedly connected to a lifting rod; the lower end of the lifting rod passes through the quantitative sugar cylinderand is fixedly connected to a floating block; and the floating block is located in the mixing processing cylinder. Through adoption of the food material preprocessing machine, height adjustment of the floating block is achieved according to the amount of cereals, so that the floating block drives the sugar flowing out plate to lift and drop by the lifting rod, thereby achieving a change of the sugar amount in the quantitative sugar cylinder, and accurate addition of the sugar amount is achieved, and mouthfeel is ensured.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Breeding method for brachymystax lenok triploid fingerling

InactiveCN107810888APrevent overcookingReduce stimulationClimate change adaptationPisciculture and aquariaDiseaseWater baths

The invention relates to a breeding method for brachymystax lenok triploid fingerling. The breeding method comprises the following steps: in 15 to 20 min after fertilization, placing fertilized ova into a water bath at 17 to 20 DEG C, and carrying out transition for 1 min; then carrying out heat treatment in a water bath at 26 DEG C for 10 to 20 min; and carrying out incubation in an incubator with an incubation water temperature of 6 to 10 DEG C. The brachymystax lenok triploid fingerling can be obtained in about 30 days through the method provided by the invention. According to the invention, the fertilized ova reach an eyed rate of 80% or above and an incubation rate of 90% or above in an incubation period; and flow cytometer detection results show that a triploid rate of the fingerlingobtained by using the method provided by the invention reaches 100%. The breeding method for the brachymystax lenok triploid fingerling provided by the invention alleviates problems like high mortality of parent brachymystax lenok after propagation, slow growth speed and low disease resistance of young brachymystax lenok and low survival rate of juvenile brachymystax lenok in mouth-opening acclimation, has advantages like low cost and easy operation, and has good market value.

Owner:北京市水生野生动植物救护中心

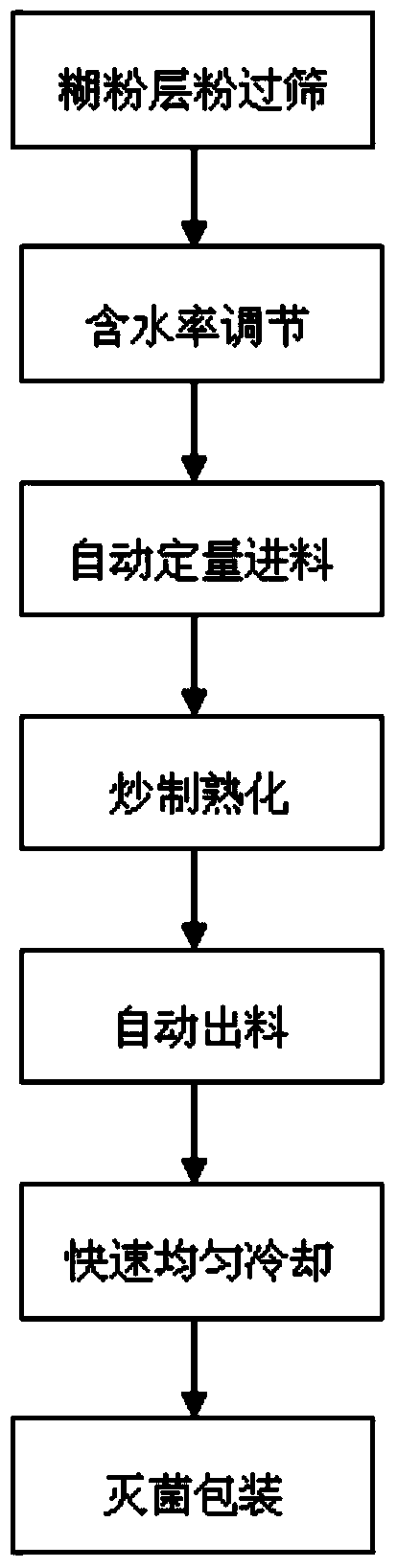

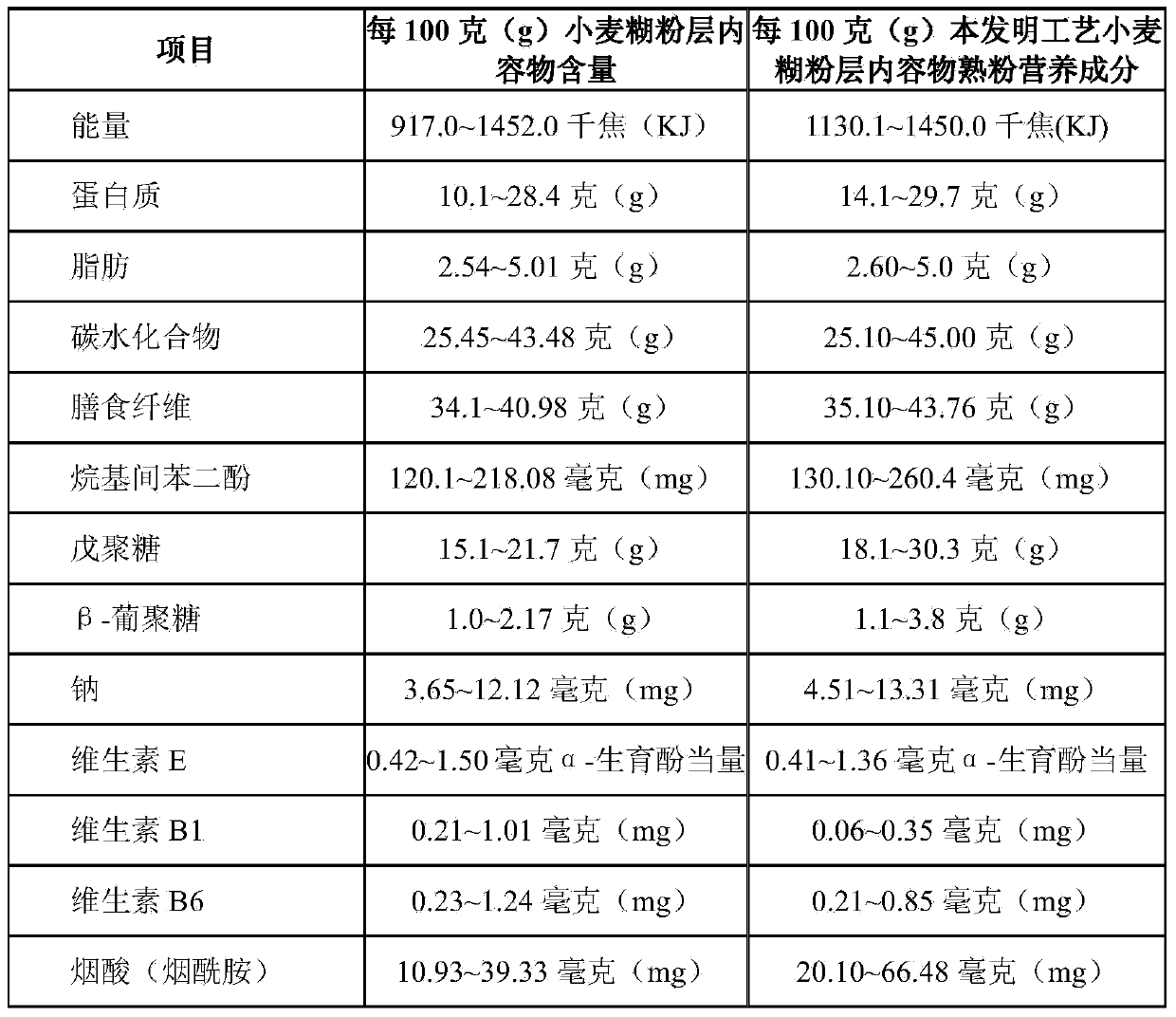

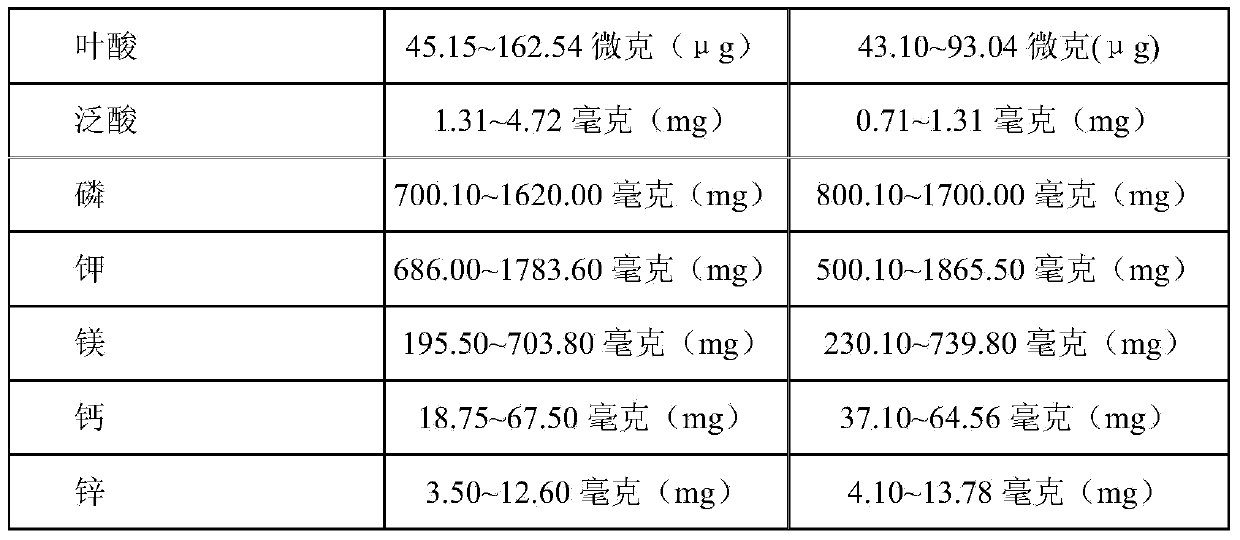

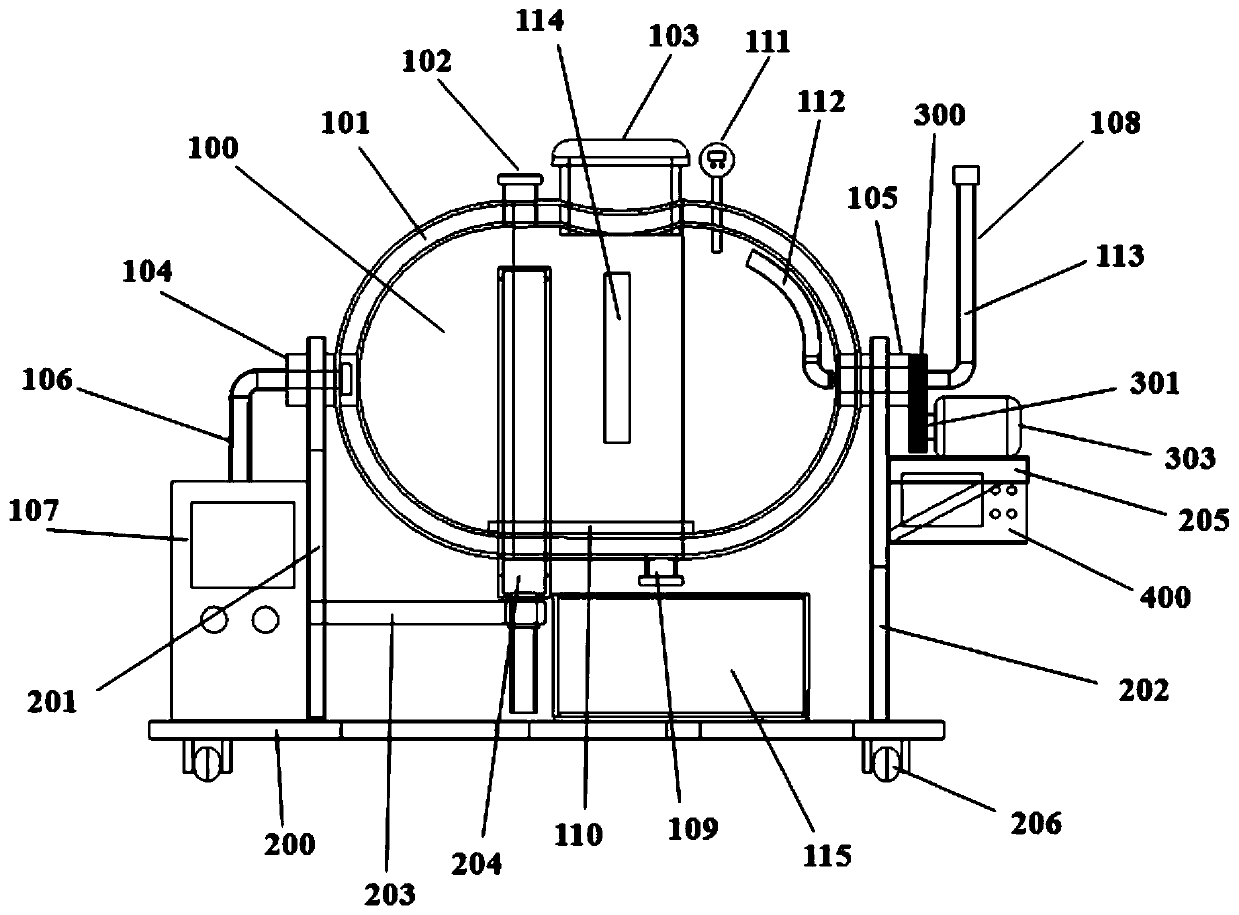

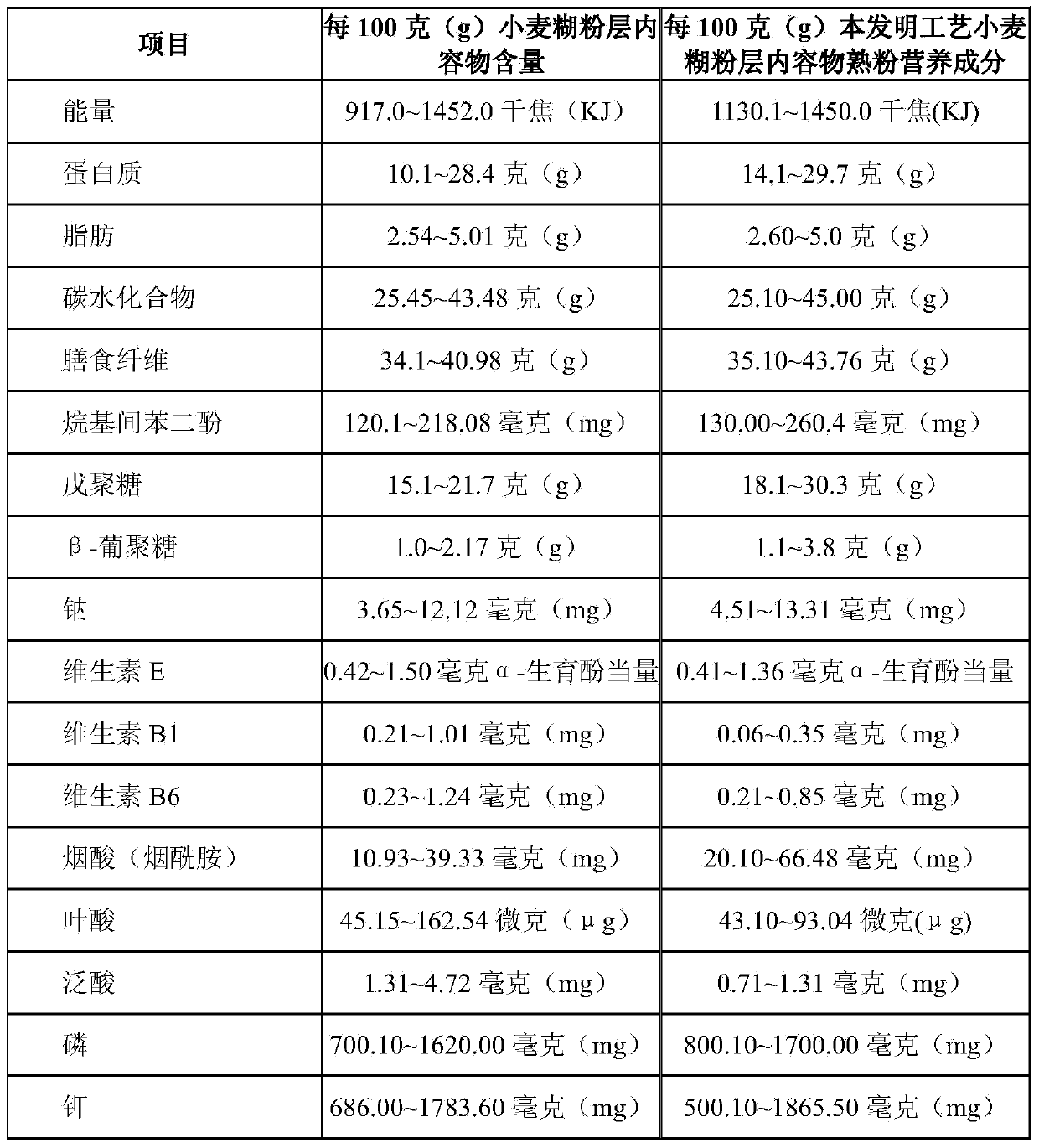

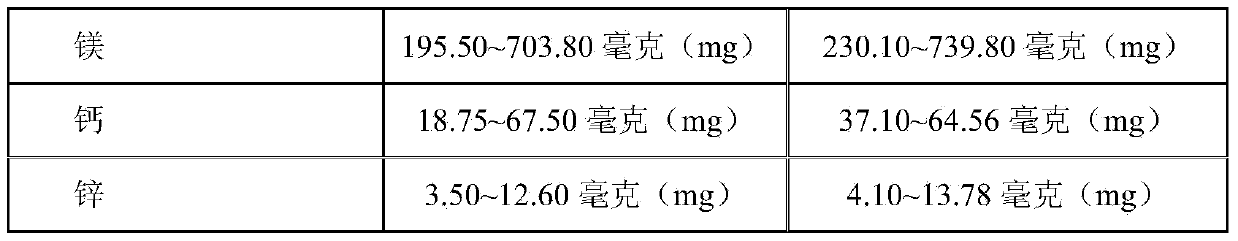

Ripening process for wheat aleurome layer content, and product thereof

The invention discloses a ripening process for wheat aleurome layer content (wheat aleurome layer powder) and a production thereof, and belongs to the food processing field. The process comprises the following steps of screening the wheat aleurome layer content with average particle size smaller than 75 [mu]m and moisture content lower than 16%; feeding materials automatically and quantitatively; roasting while controlling a temperature below 143 DEG C while roasting and a moisture content in a roasting device within 42-76%; discharging the material automatically when a temperature reaches the temperature set by the roasting step; cooling rapidly and uniformly; and sterilizing and packaging. The wheat aleurome layer content roasted powder produced by the process has an excellent taste, is convenient for subsequent processing and treatment, has thick wheat fragrance, and can retain nutritional ingredients of the wheat aleurome layer content to the maximum degree. Meanwhile, physical properties and nutritional characteristics of the product of the wheat aleurome layer content roasted powder prepared by the process are stable; and the wheat aleurome layer content roasted powder prepared by the process has relatively long quality guarantee period and wide applications.

Owner:JIAXING SION RUSSIAN TECH TRANSFORMATION CENT +1

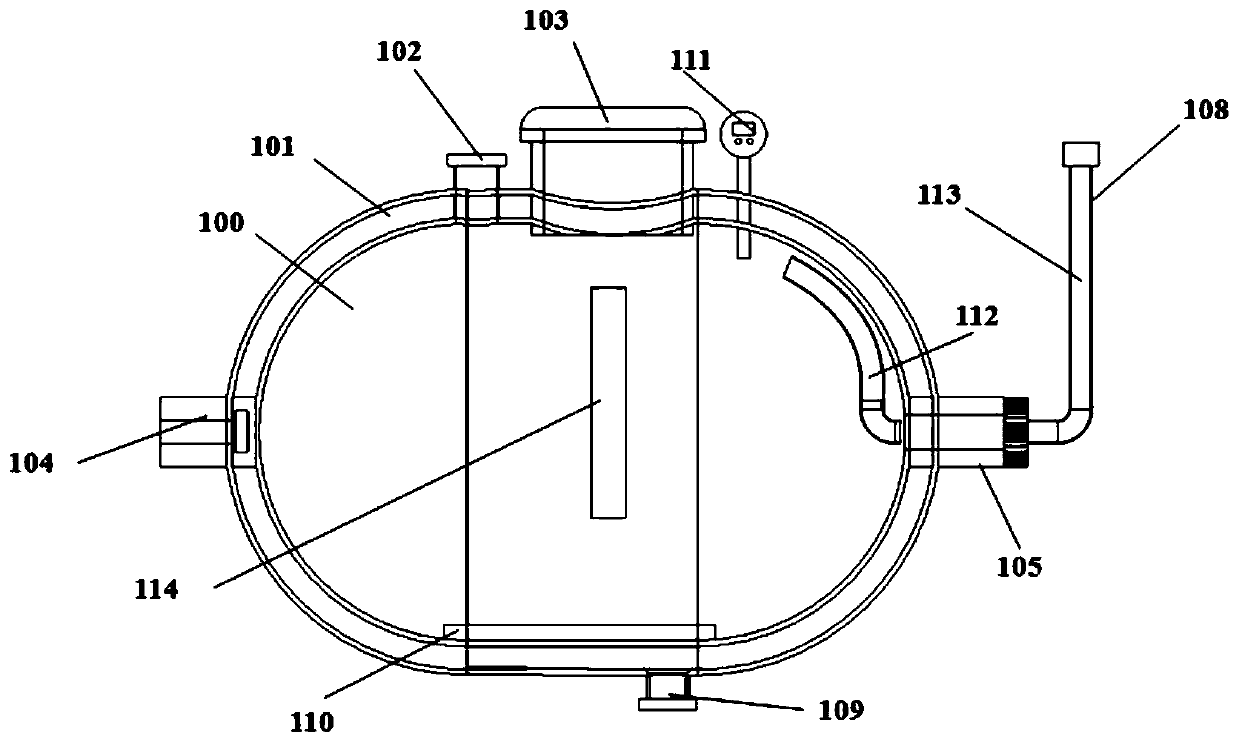

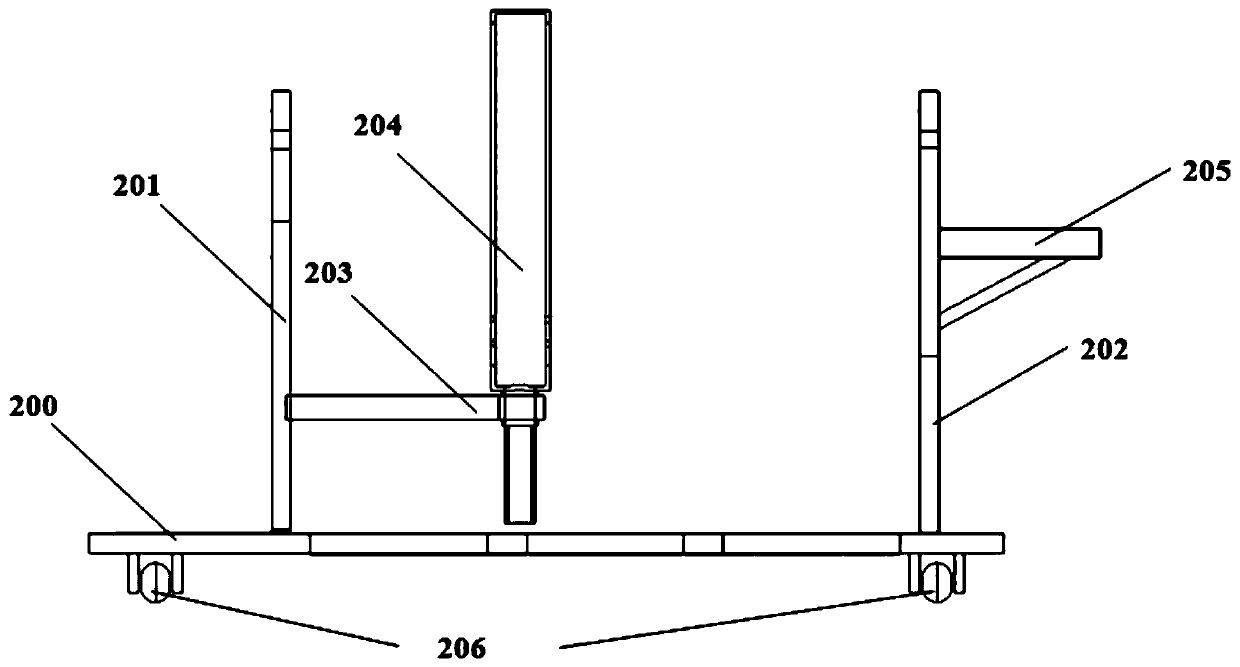

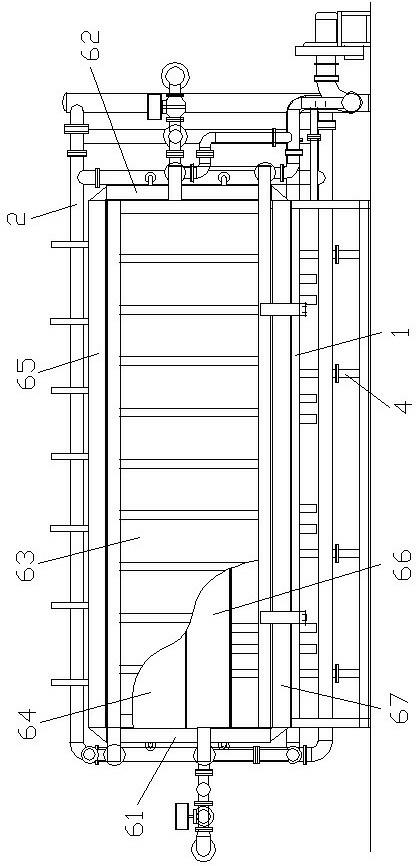

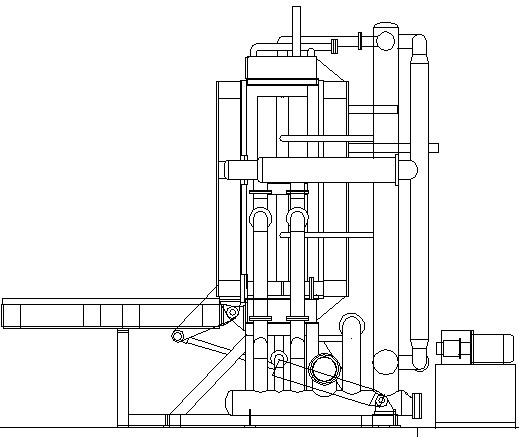

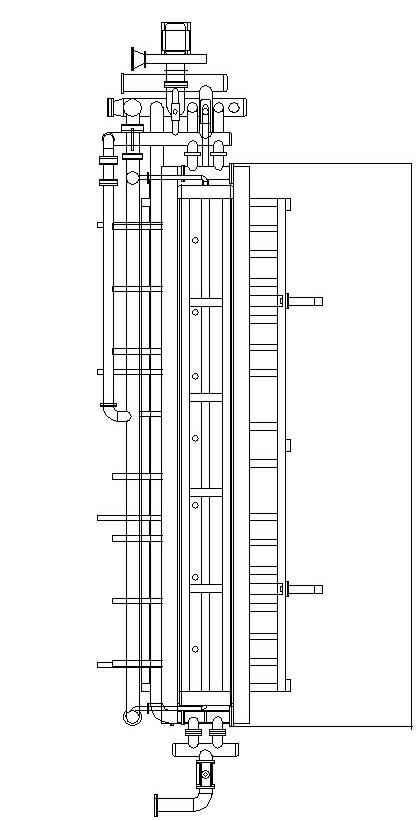

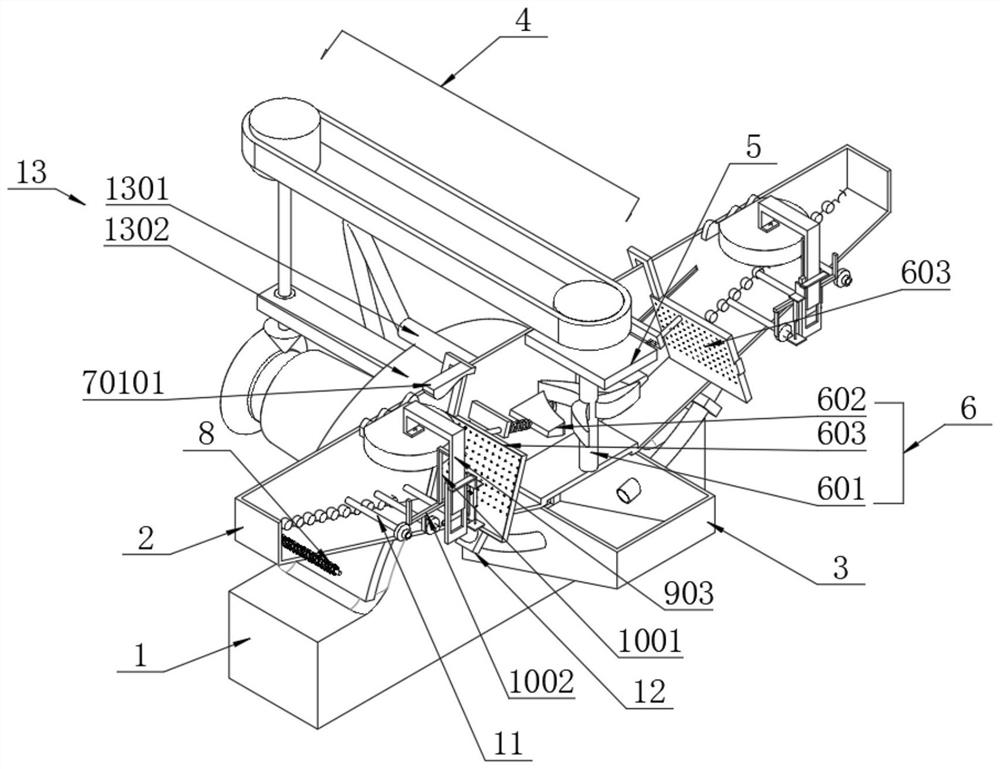

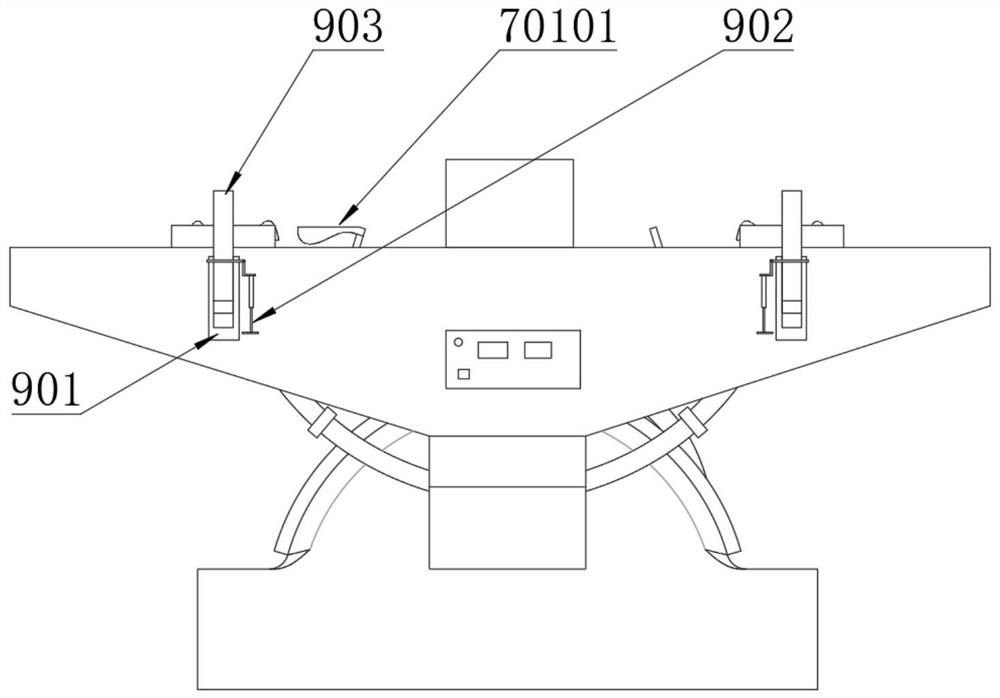

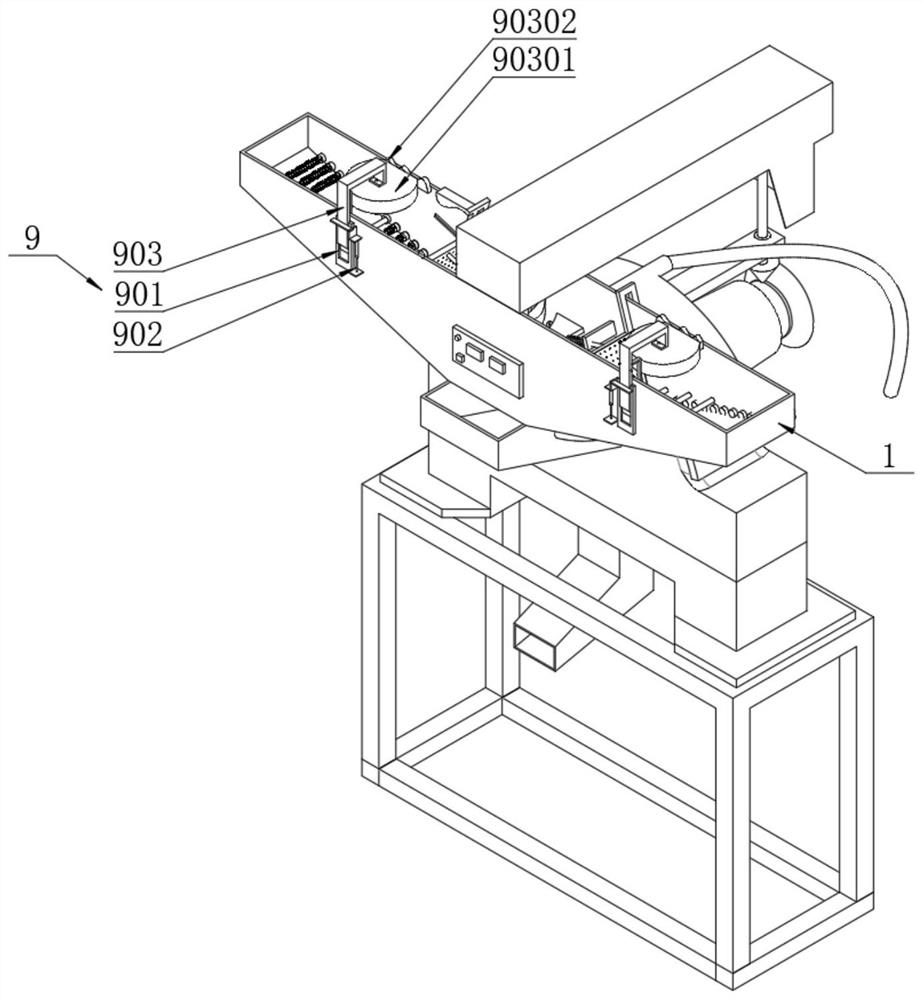

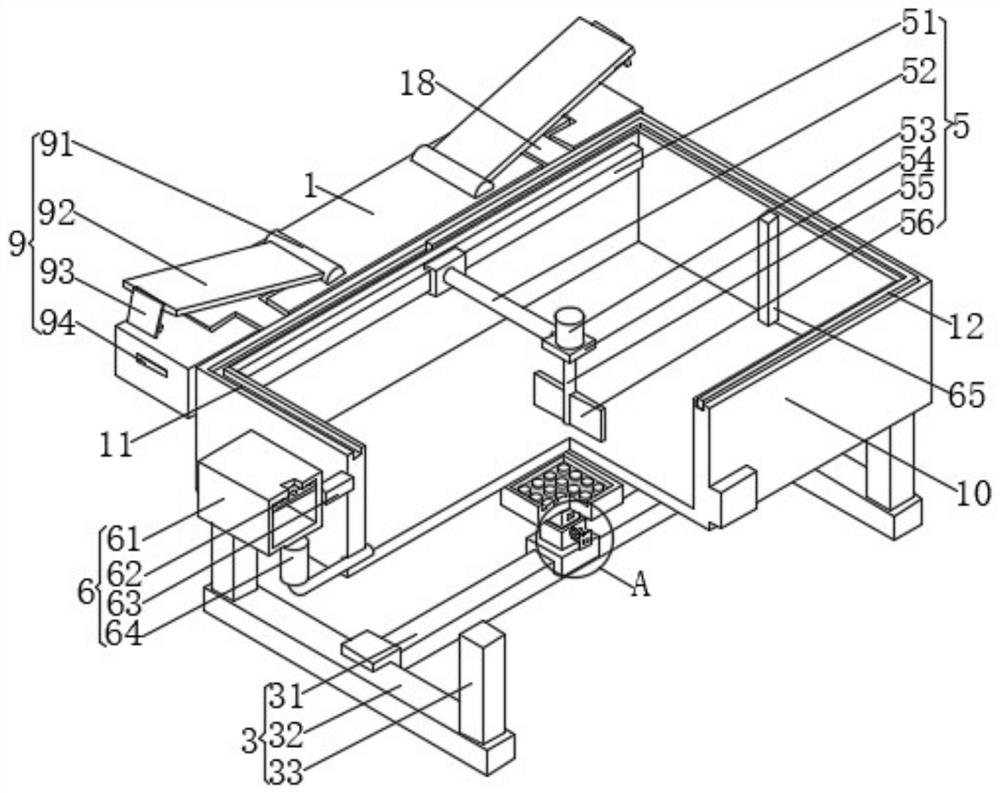

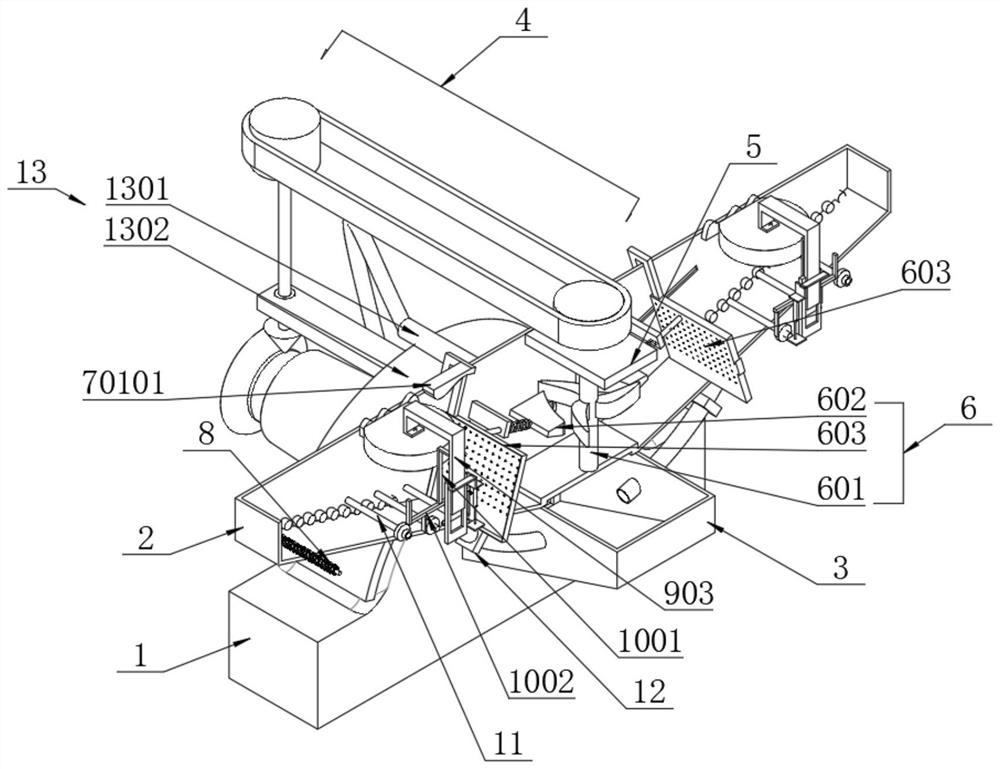

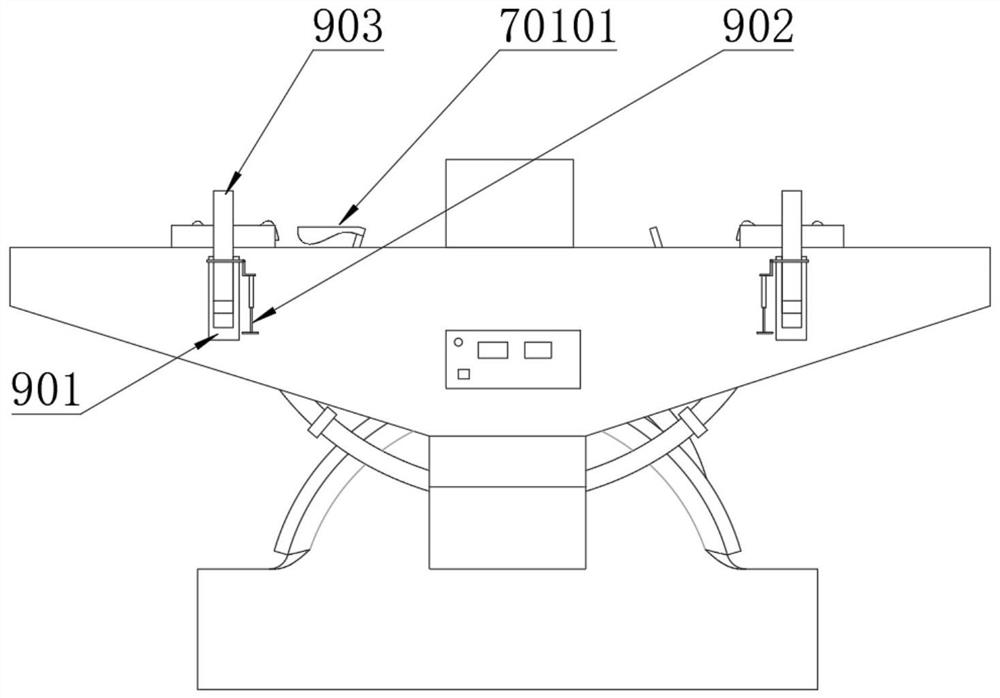

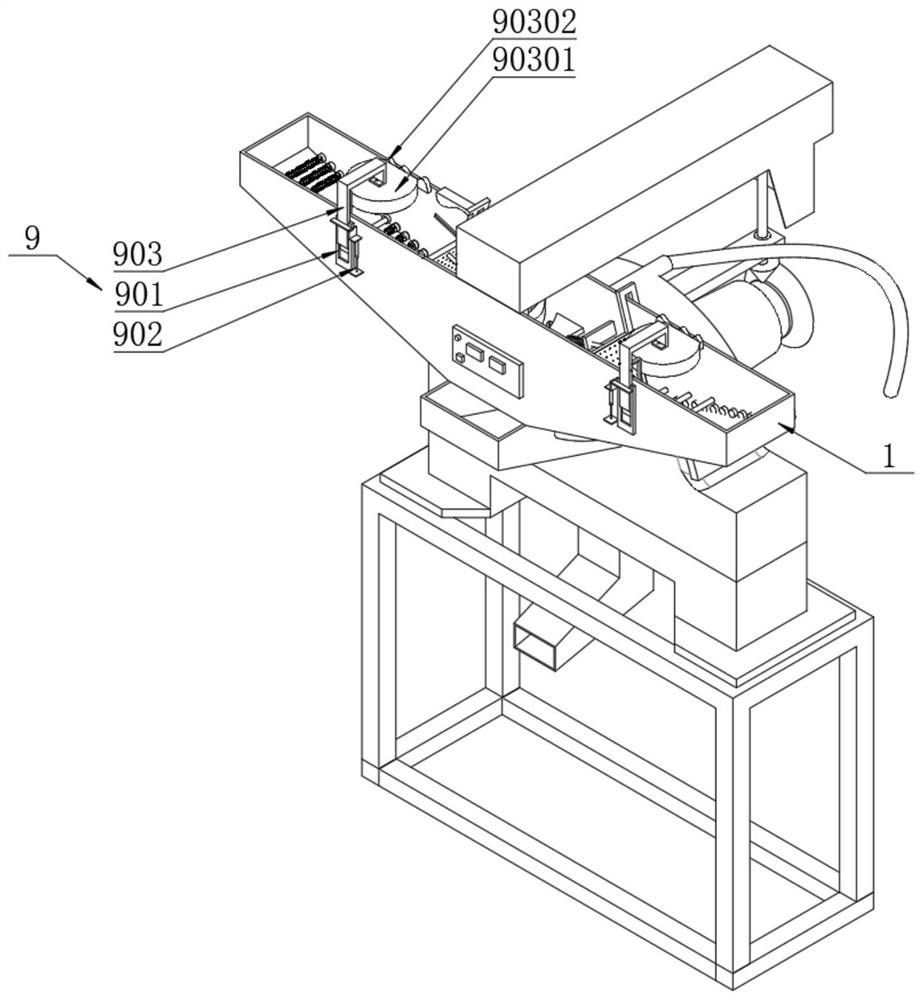

Sauced product halogenated processing equipment and method thereof

The invention discloses sauced product halogenated processing equipment and a method thereof. The sauced product halogenated processing equipment comprises: a halogen can, which is an elliptical tankbody having a double-wall structure, a steam interlayer is formed between the double walls, and a water supply and drainage port and a feeding port are arranged through the double wall from the outside of the halogen can, the water supply and drainage port and the feeding port are connected to the inside of the halogen can, and the left and right sides of the halogen can are respectively providedwith a sealed rotating shaft I and a rotating shaft II; a support mechanism, which is horizontally provided with a support platform, and a halogen canister support I and a halogen canister support IIare arranged vertically upwards from the support platform, and the halogen canister support I is connected with a drainage guide groove through a drainage guide bracket; and a rotating system and a control system. The equipment combines the characteristics and requirements of the processing technology of the original sauce and braised meat products, adopts the horizontal rotation of the halogen can and the steam heating to realize a design idea of pre-cooking, discharging, pickling, sauce halogenating, the equipment increases the production efficiency, and is suitable for industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

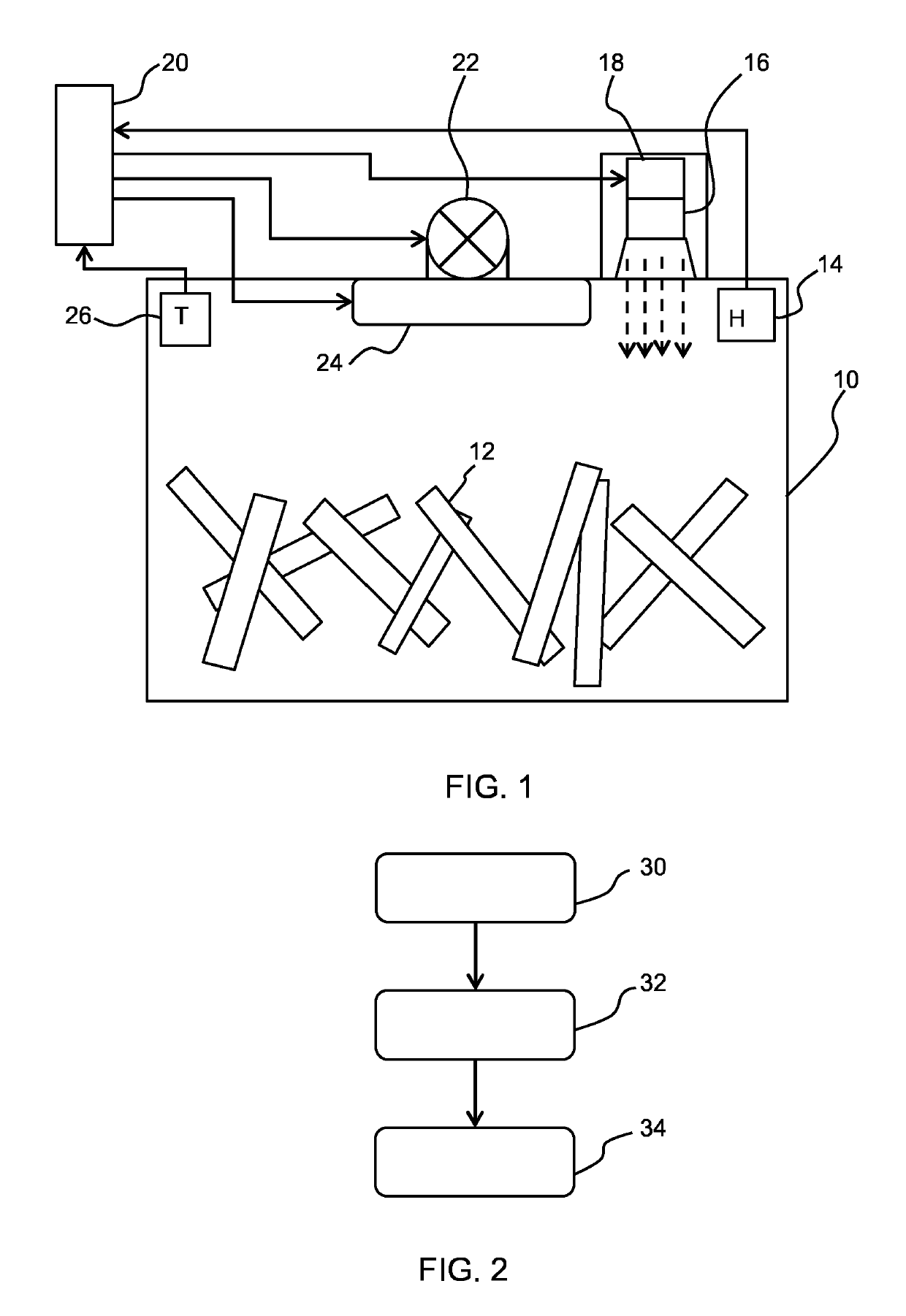

Appliance and method for cooking potato chips

InactiveUS20190110504A1Improve textureCrispy textureFruits/vegetable preservation by dehydrationChipped potatoesHigh humidity

A cooking appliance and method for cooking potato chips are provided. The appliance has a humidity control system, an air flow generation system and a heating system. The cooking process has a relatively low temperature and high humidity cooking cycle, a low humidity dehydration process and a relatively high temperature low humidity browning process. These three cycles enable good crisp crust formation for fresh non-frozen chips which are cooked using an air / steam based cooking process rather than a deep fat frying process.

Owner:KONINKLJIJKE PHILIPS NV

Manufacturing method of noodles

InactiveCN107223867AShorten face-to-face timeLower temperature riseFood preservationFood electrical treatmentEngineeringRaw material

The invention relates to a manufacturing method of noodles. The method comprises the following manufacturing steps: atomization flour mixing, fermentation, calendaring, slitting, sterilization, drying, packaging and the like. Compared with the prior art, the raw material flour is firstly atomized, after mist is obtained, and the mist is mixed with water after atomization, so that the problem that the quality of dough is reduced caused by the fact that the flour and the water are mixed unevenly and the mixing time long in the flour mixing process is mainly solved. Moreover, the link of sterilization is added in the processing and manufacturing process, the technology of low-temperature plasma sterilization is utilized, the original bacteria carrying amount of the product is effectively reduced, in combination with fresh-keeping packaging, the food safety of the noodles is improved, and the quality of the noodles is guaranteed.

Owner:TIANJIN XINGDA PEACE FOOD

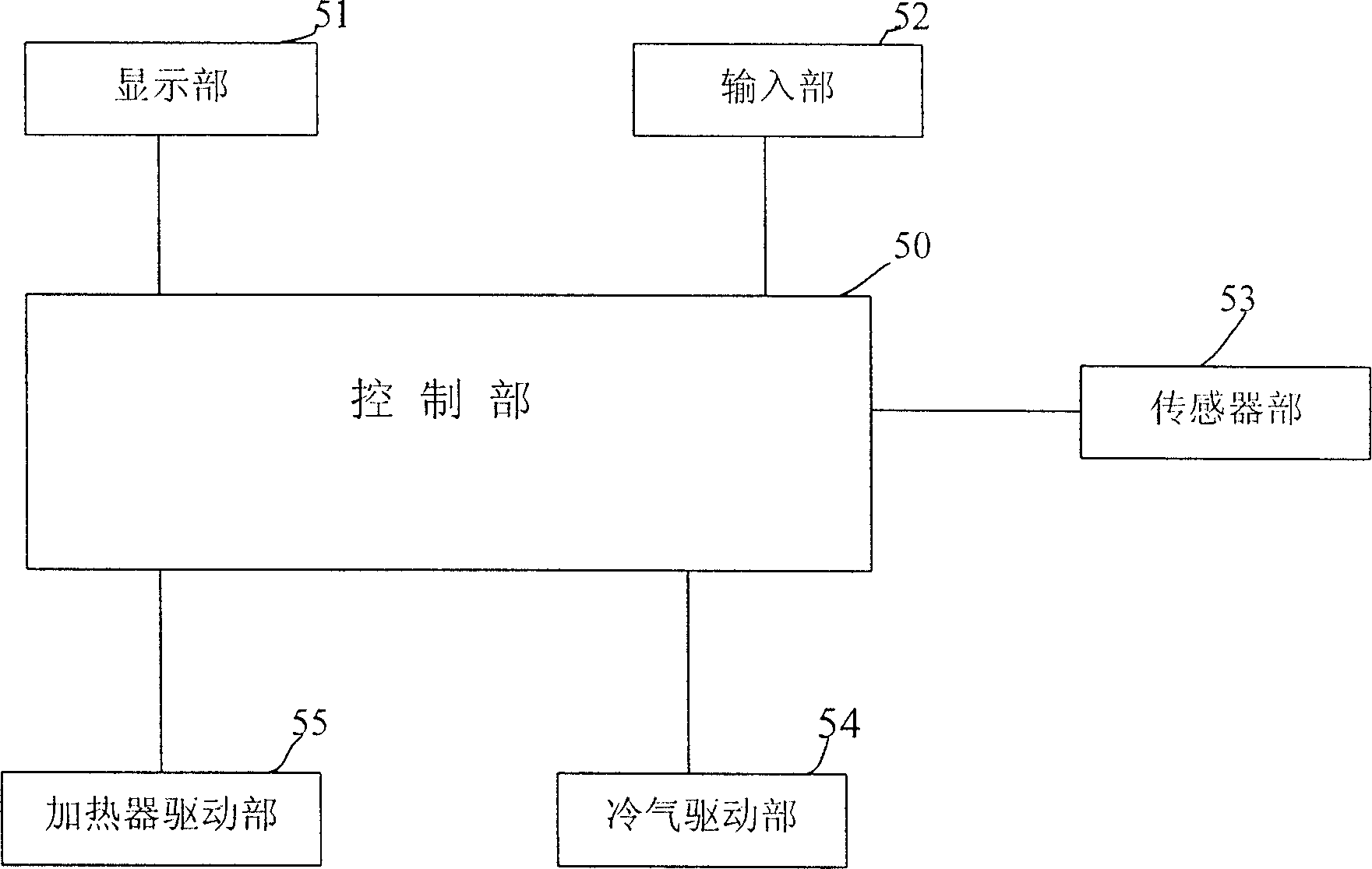

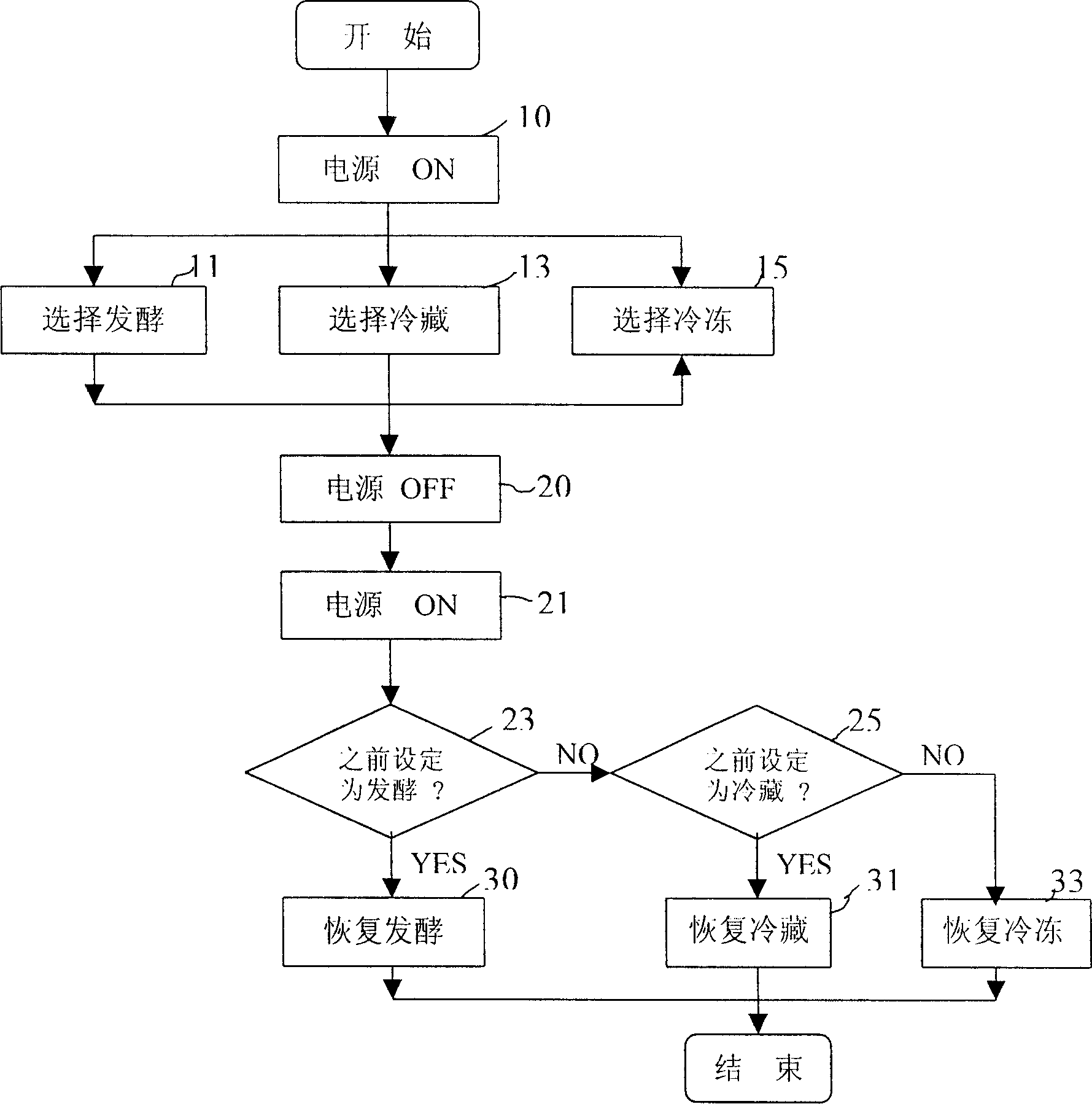

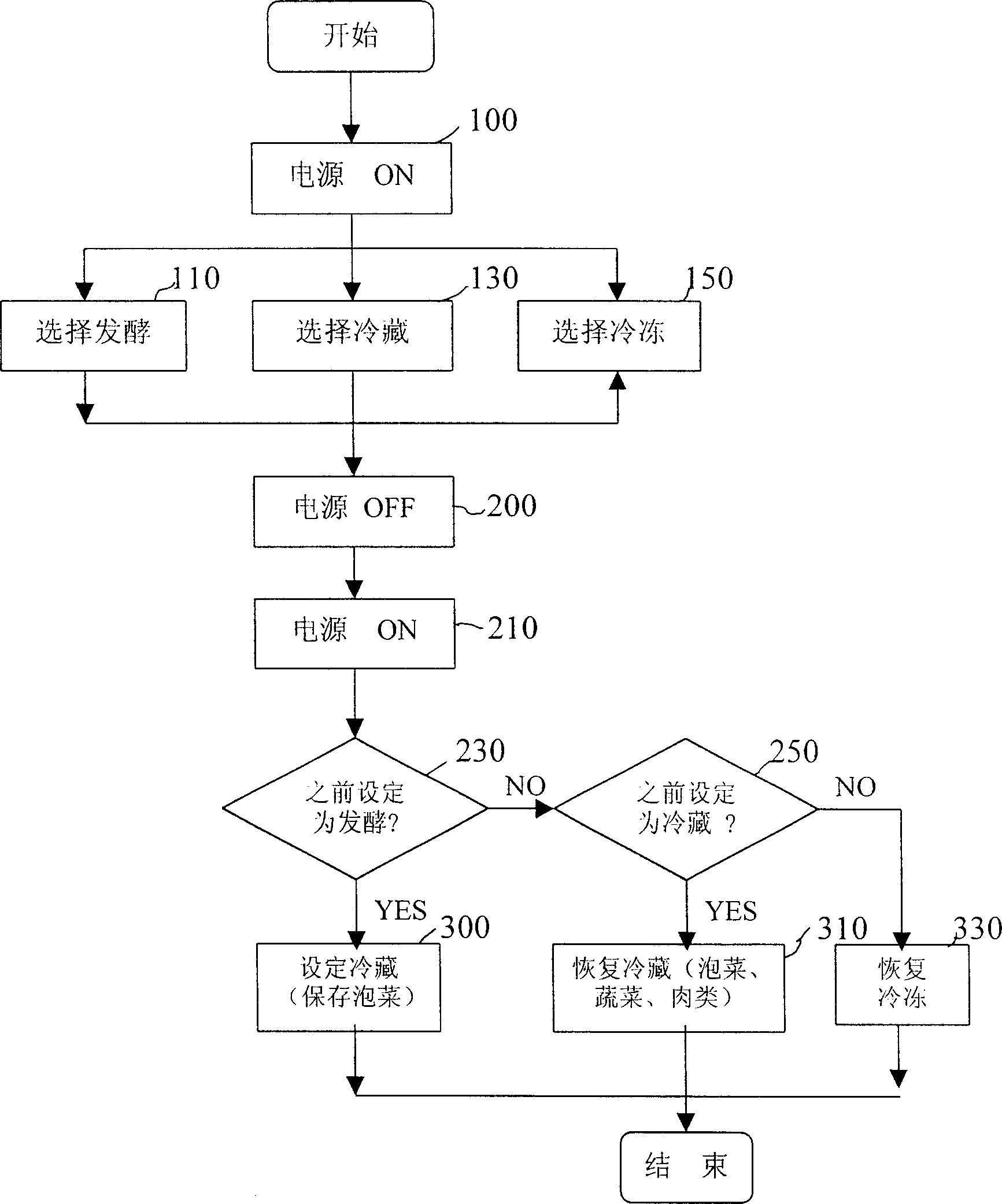

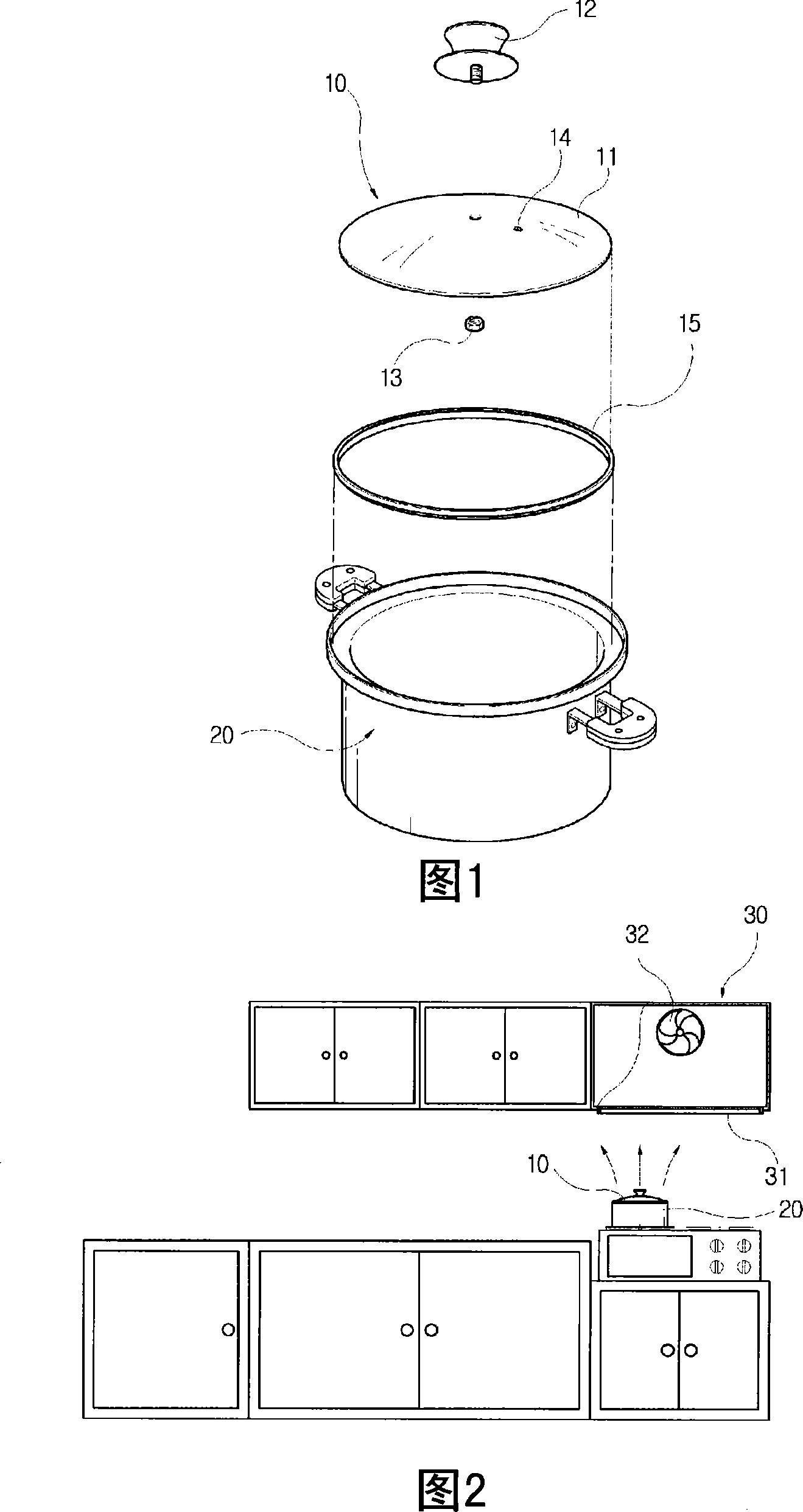

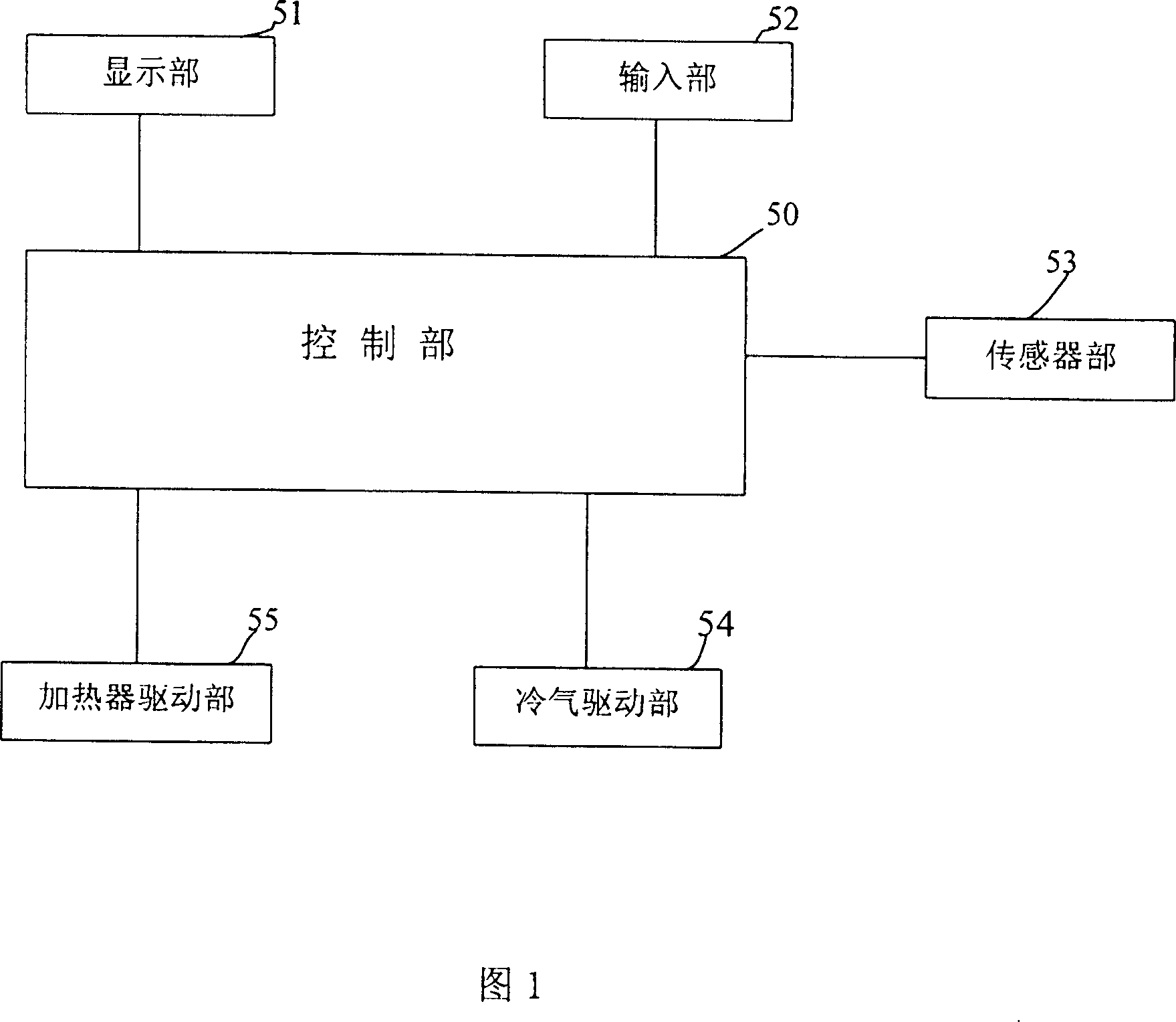

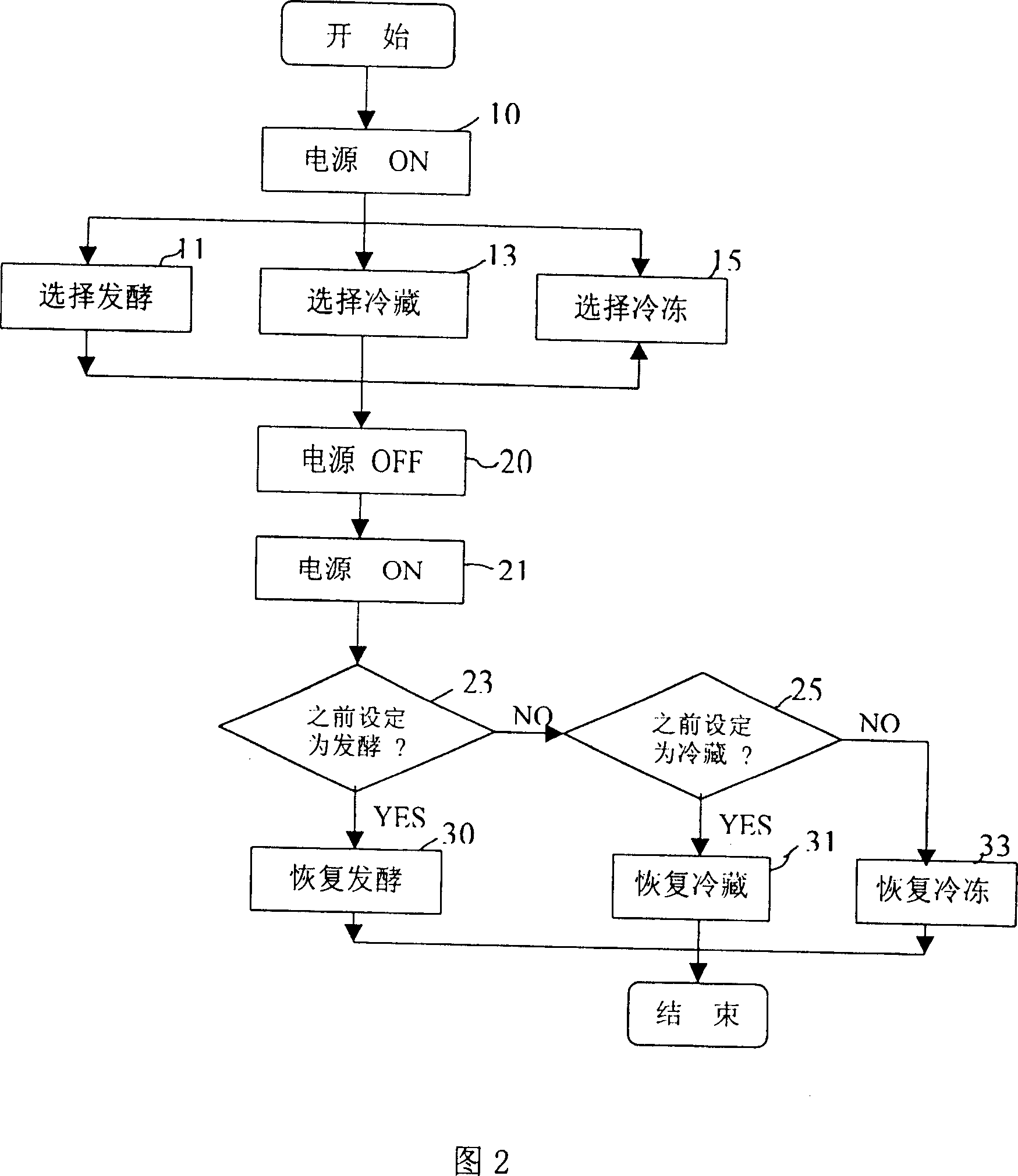

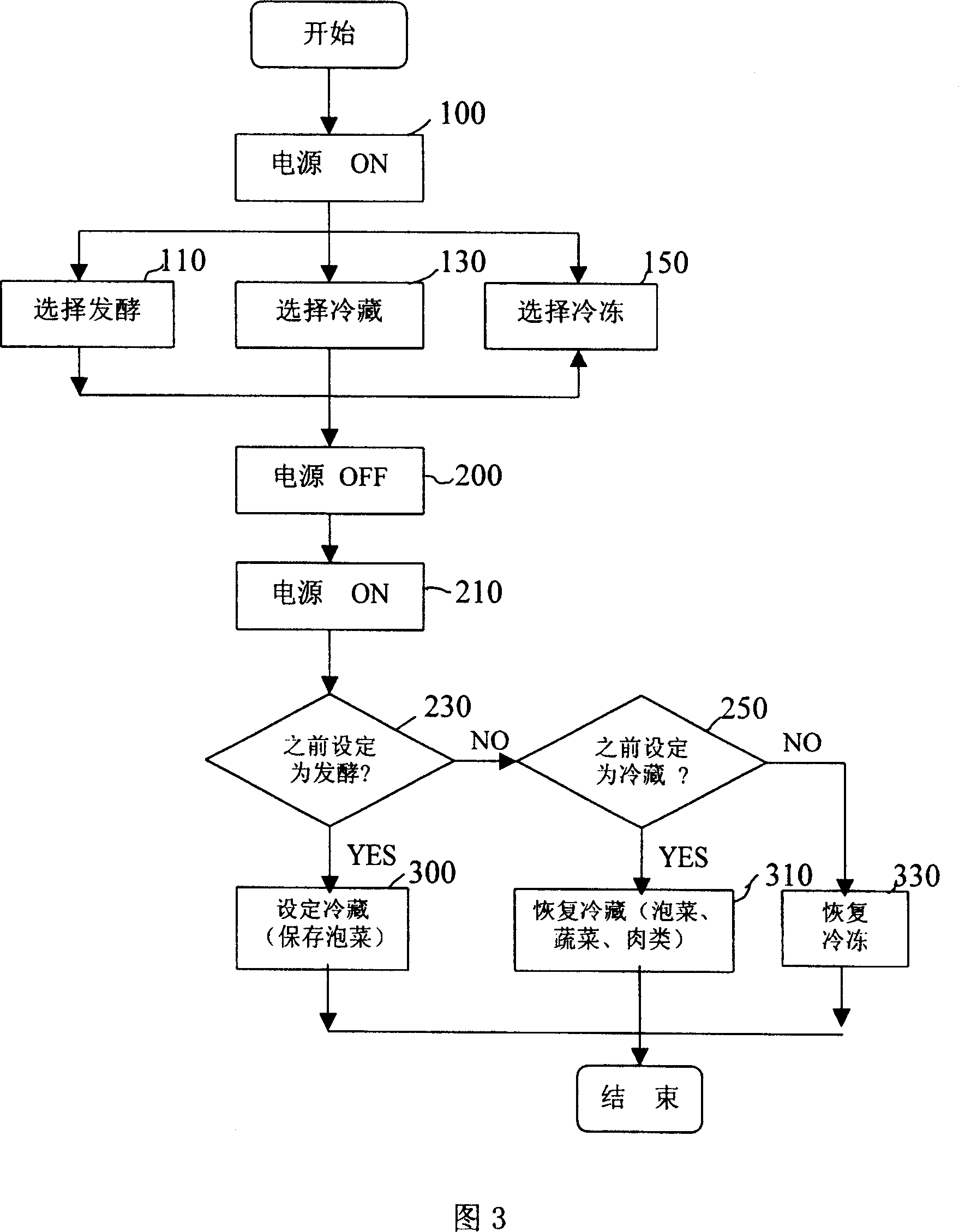

Power interruption recovering controlling method for kimchi refrigerator

InactiveCN1435660APrevent overcookingPrevent spoilageDomestic cooling apparatusLighting and heating apparatusElectric power systemEngineering

A restoration control method after electric power lost for the refrigerator used to prepare kimchi is characterized by that when the electric power is lost, all the operations for preparing kimchi are stopped, and after the electric power is restored, what operation that is executing before power lost is judge and the operation continues.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

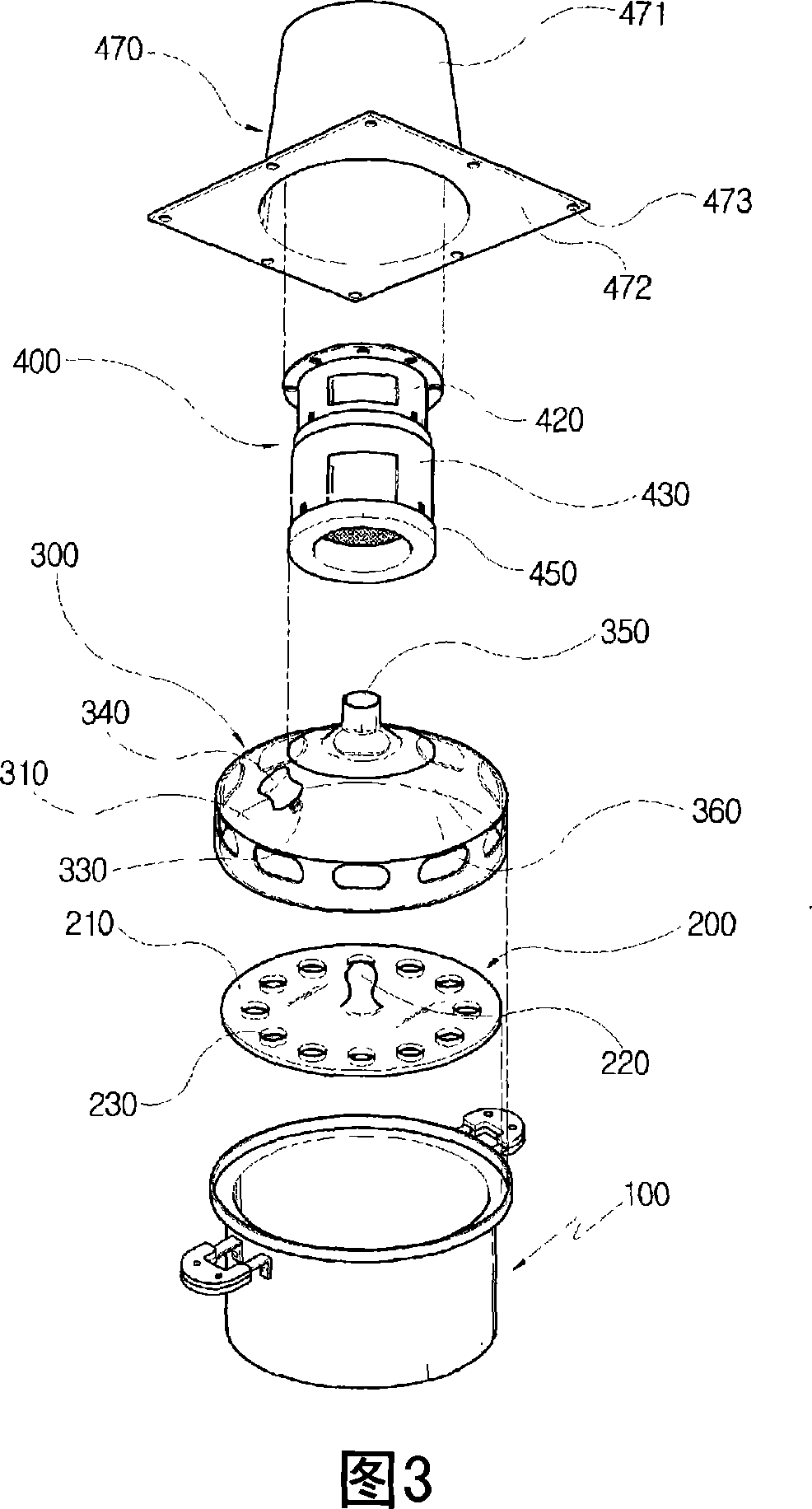

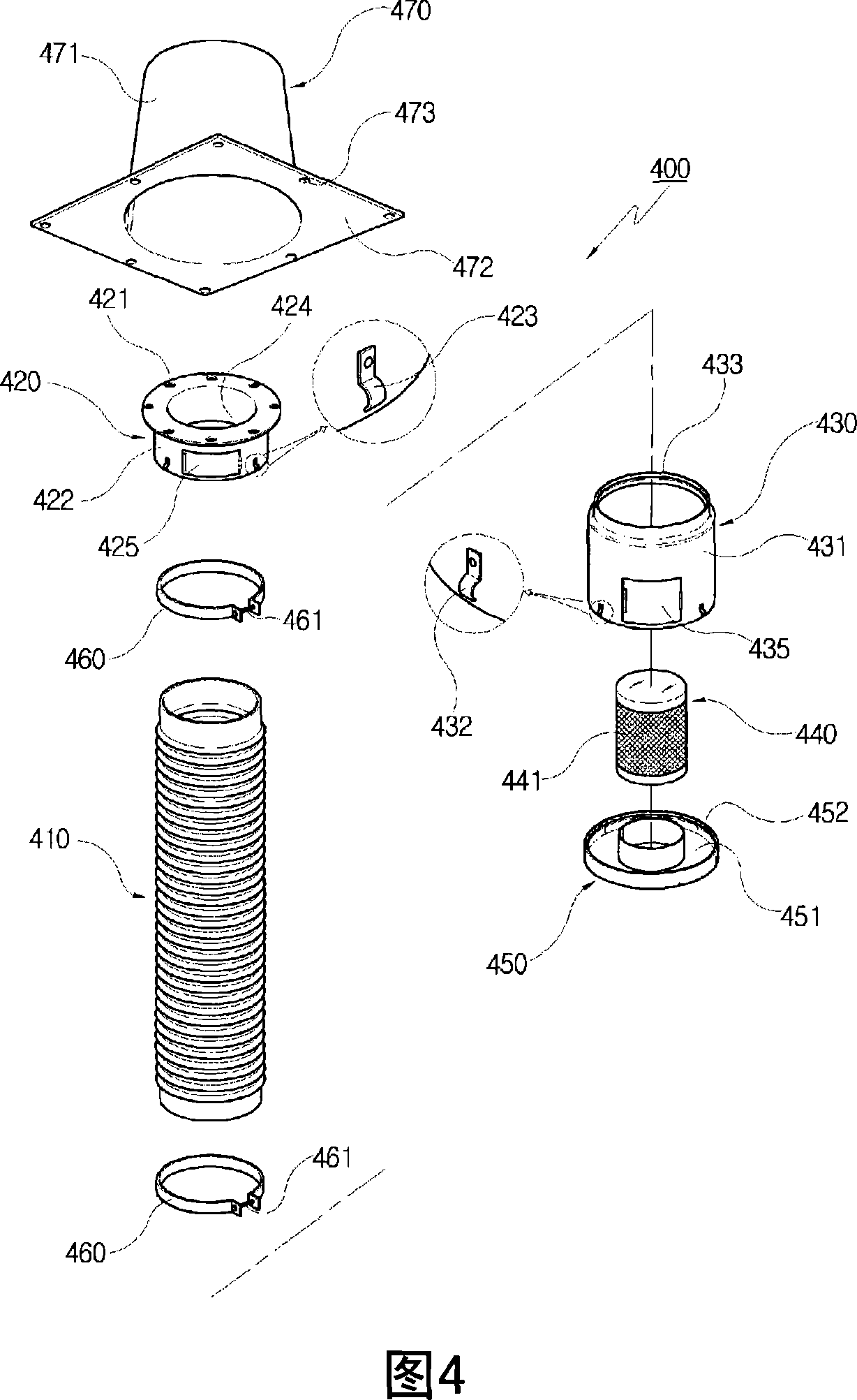

Apparatus for discharging the smell in the lid of cooking receptacle

InactiveCN101160082ASmooth dischargeInhibited DiffusionDomestic stoves or rangesLighting and heating apparatusIndoor airEngineering

Disclosed is a device for effectively discharging high-temperature vapor and food smell generated in a cooking receptacle during cooking directly to a range hood through a venting member, thereby preventing the vapor and smell from permeating the indoor air. The high-temperature vapor and smell generated during cooking move upward through venting holes of an inner lid, enter into a space provided under an outer lid, meet cold air introduced from air inlet holes of the outer lid, and rise by convection thereby to be smoothly discharged out through a venting hole of the outer lid. The device includes a venting member fixed to a lower surface of a range hood and having a flexible corrugated tube which is height-adjustable between the outer lid and the range hood.

Owner:徐善子

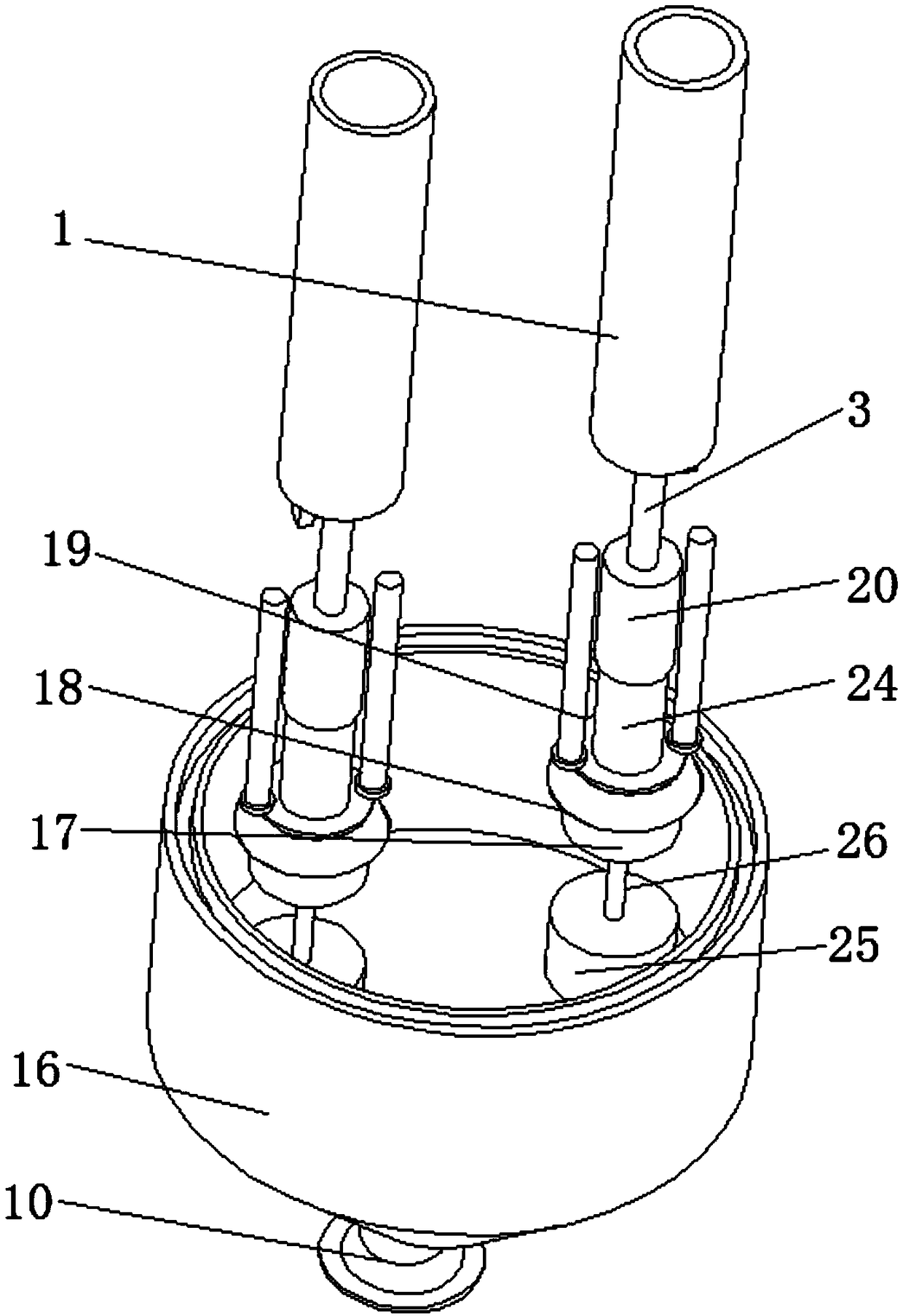

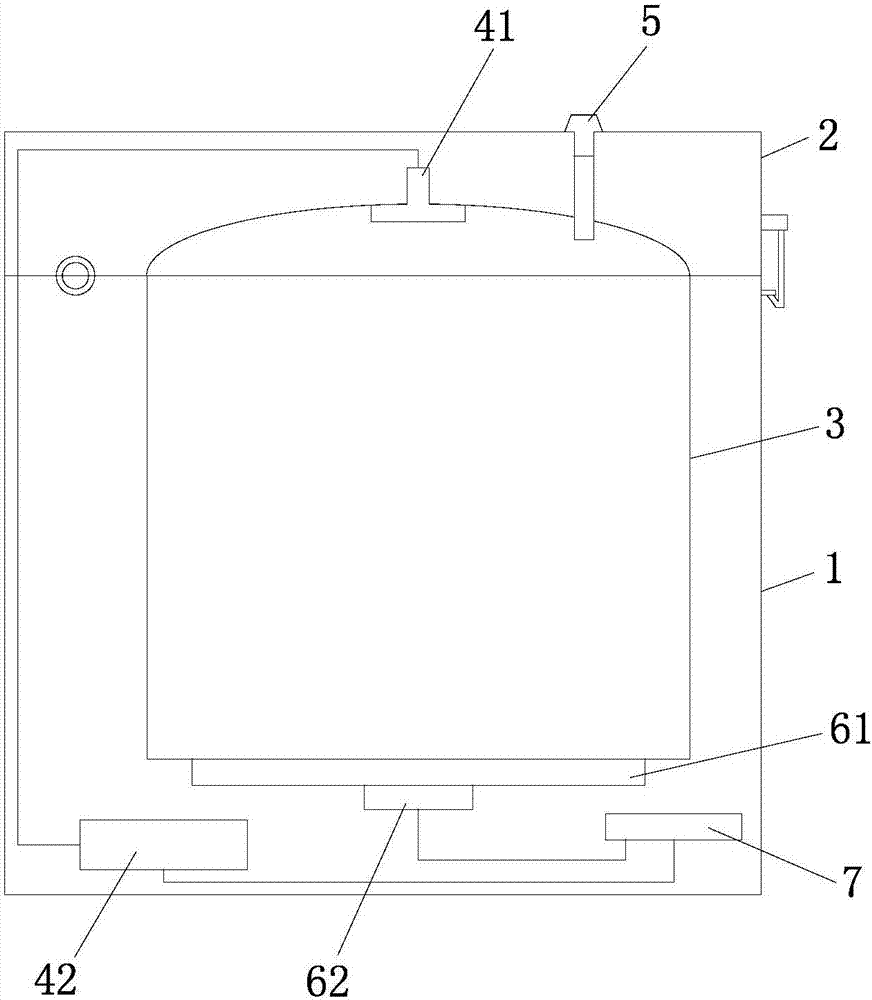

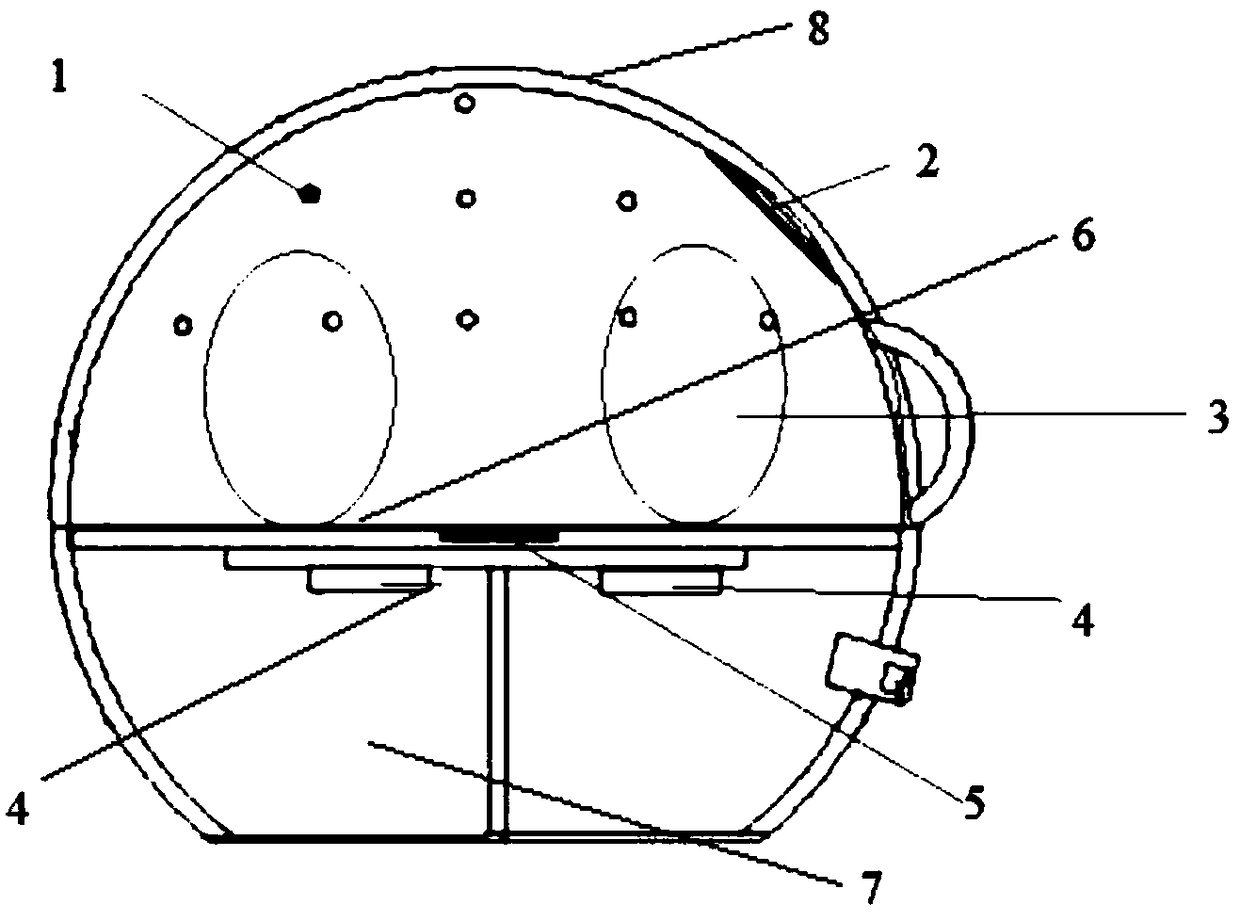

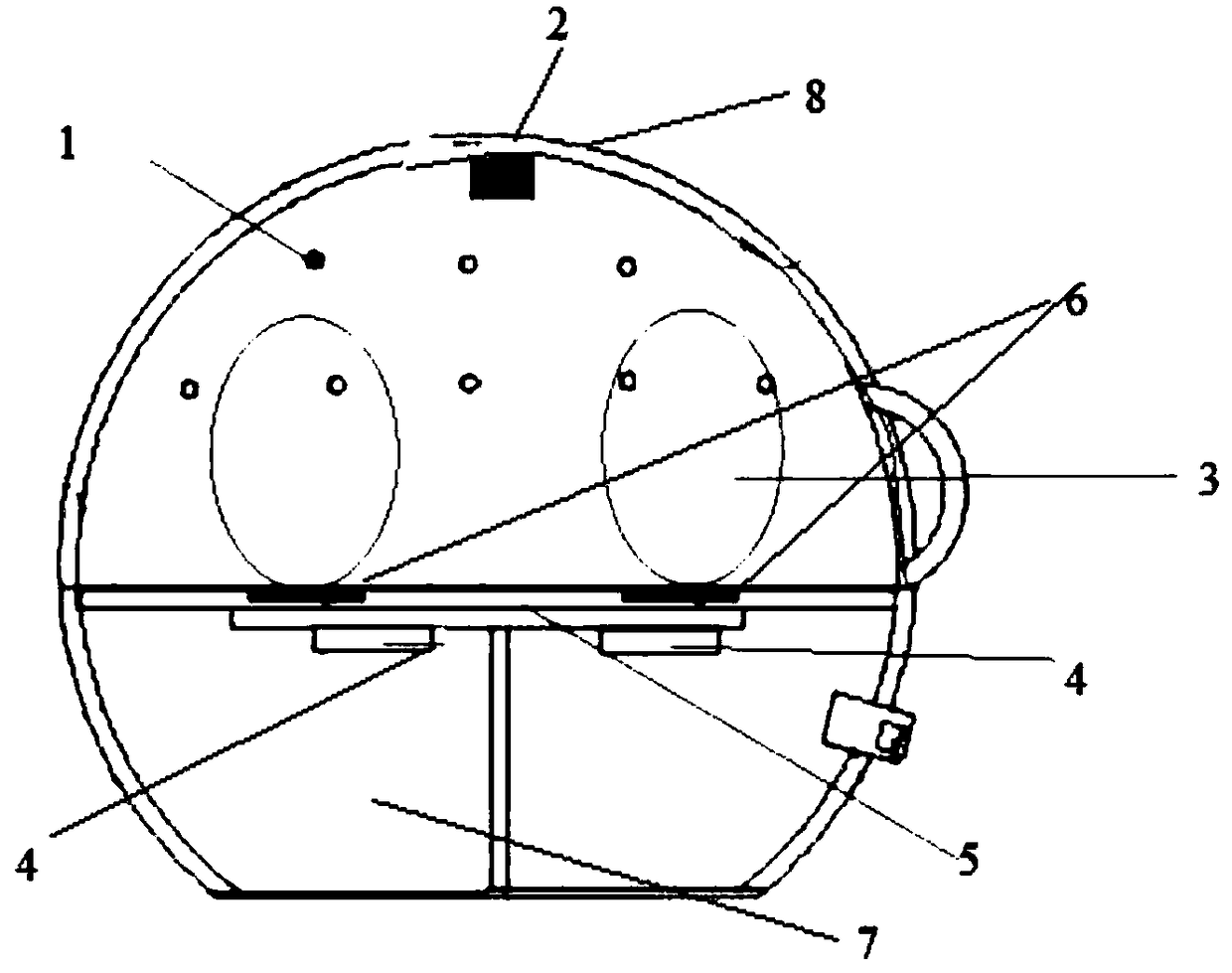

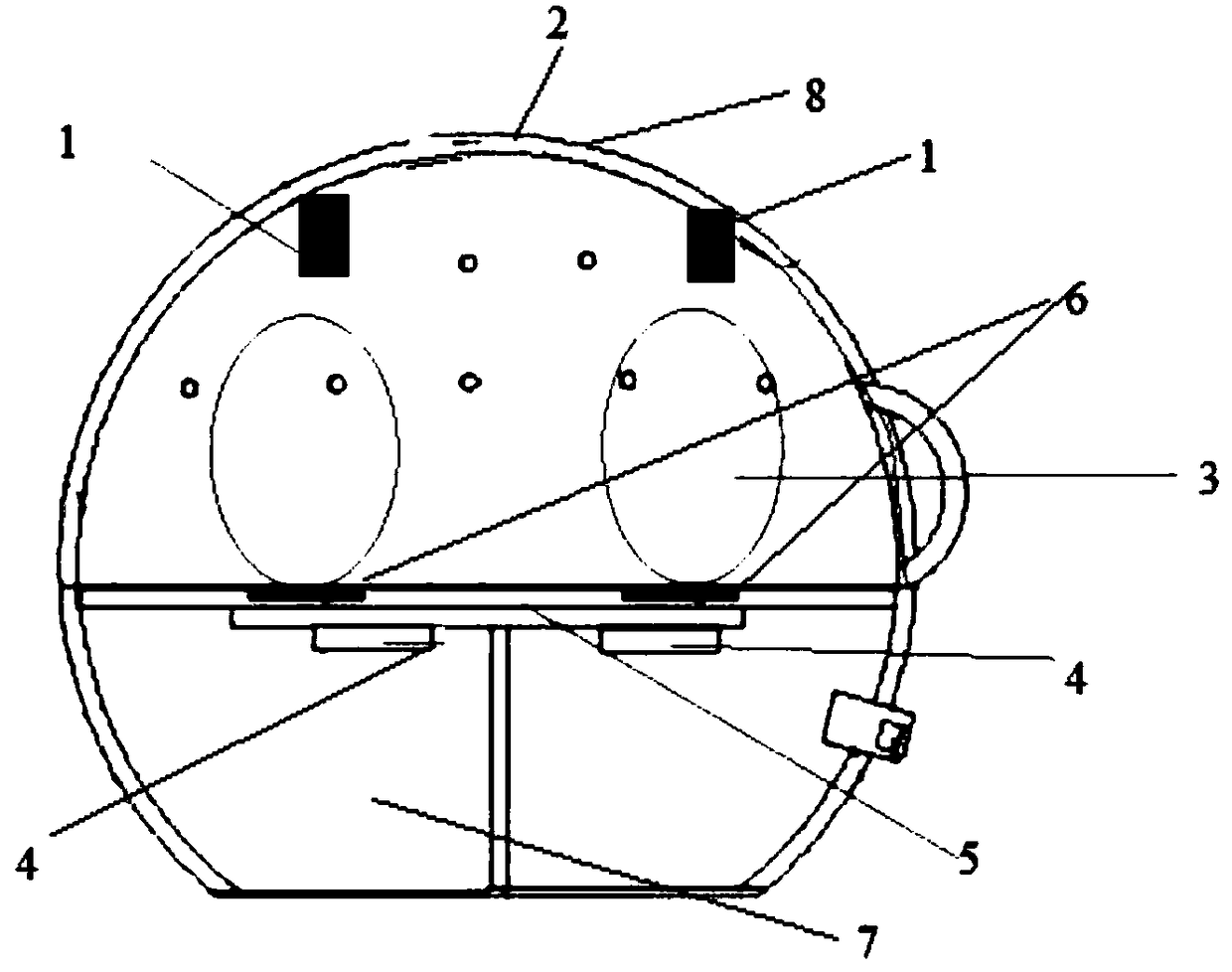

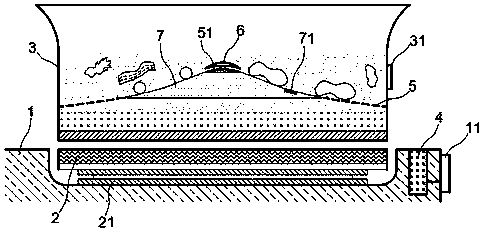

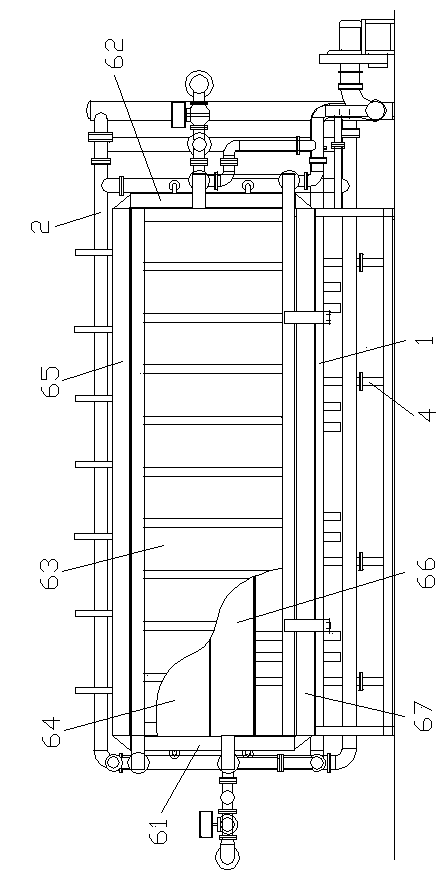

Vacuum smoldering pot

InactiveCN106983356ALow boiling pointAchieve low-temperature braised cookingVessels with intergral heatingCooking vessel constructionsBoiling pointEngineering

The invention relates to a vacuum smoldering pot. The vacuum smoldering pot includes a pot body and a cover, wherein the pot body is provided with a detachable liner, and the cover is connected to the liner and the pot body in a covering mode; the pot body or the cover is provided with a vacuumizing assembly, and the vacuumizing assembly is connected with the liner. According to the vacuum smoldering pot, through the vacuumizing assembly arranged in the smoldering pot, the liner can be vacuumized, the boiling point of food can be reduced under the vacuum or lower-pressure condition, the smoldering duration can be greatly prolonged, and the food is prevented from being overcooked. By adjusting the vacuum degree of the liner, the boiling point of the food is reduced, low-temperature smoldering cooking is achieved, and the vacuum smoldering pot is applicable to lower-temperature cooking.

Owner:广东鎏荹健康产业科技有限公司

Microwave cooking package for food products and associated methods

InactiveUS20060289518A1Avoid problemsPrevent overcookingVenting meansMicrowave heatingMicrowave ovenEngineering

A microwave cooking package and combination of a food product and microwave cooking package. The cooking package intimately contacts and substantially surrounds the food product as the food product is cooked in a microwave oven. The package provides for venting of moisture in specific regions of the food product and distribution of heat across the extent of the food product to facilitate cooking of the entire food product and more uniform browning and crisping of the outer surface of the food product. The cooking package is preferably used for cooking a dough enclosed food product in a microwave oven. The package of the present invention allows the food product to be uniformly cooked to a golden brown color with a crispy, crunchy consistency.

Owner:EXOPACK TECH

Wheat aleurone layer content cooked powder product and application thereof

InactiveCN104171837AHigh purityGreat tasteFood ingredient functionsFood preparationGranularityBULK ACTIVE INGREDIENT

The invention discloses a wheat aleurone layer content (namely wheat aleurone layer powder) cooked product and application thereof. The wheat aleurone layer content cooked product is a powder product which has a moisture content of less than 8% and is obtained by cooking a wheat aleurone layer content, the average granularity of the wheat aleurone layer content cooked product is less than 75 microns, and every 100g of the wheat aleurone layer content cooked product contains not lower than 35g of dietary fiber, not lower than 130mg of alkylresorcinol, not lower than 800mg of phosphorus and not lower than 18g of pentosan. The wheat aleurone layer content cooked product is formed through the steps of screening of the wheat aleurone layer content, full-automatic quantitative feeding, stir-frying, automatic discharging, quick cooling, metal detection, sterilization packing and the like. The wheat aleurone layer content cooked product can be used as a fluid beverage additive, puffed food, a health-care dietary fiber product, a functional health-care product or a nutritional health-care product rich in wheat physiological active ingredient with high nutritional value.

Owner:SHANDONG ZHISHIFANG FOOD TECH

Ready to eat food formulation containing yogurt and pureed cooked vegetables and process for manufacture thereof

InactiveUS20050226987A1Preserve freshness and tastePrevent fermentationMilk preparationWhey manufactureChemistryRefrigeration temperature

A ready to eat vegetable yogurt with homogenous uniform texture is provided at refrigeration temperatures with the taste of freshly cooked pureed vegetables in a yogurt with active cultures and taste and flavor enhancers. The cooked pureed vegetables are optimally cooked and their flavor and freshness are preserved in the product. The cooked pureed vegetable content may be 30-70% by weight providing high nutritional value for the ready to eat vegetable yogurt. The ready to eat vegetable yogurt may be provided with soy based yogurt or milk based yogurt. The manufacturing process for the ready to eat vegetable yogurt cooks the vegetables individually according to their cooking characteristics, cooled and pureed and mixed to the yogurt and blended to form a homogenous uniform mixture of ready to eat vegetable yogurt with smooth texture. It is maintained at all time, until consumed, at refrigeration temperatures to prevent fermentation and preserve freshness and taste of cooked pureed vegetables in the ready to eat vegetable yogurt.

Owner:SHERESHEVSKY MARINA

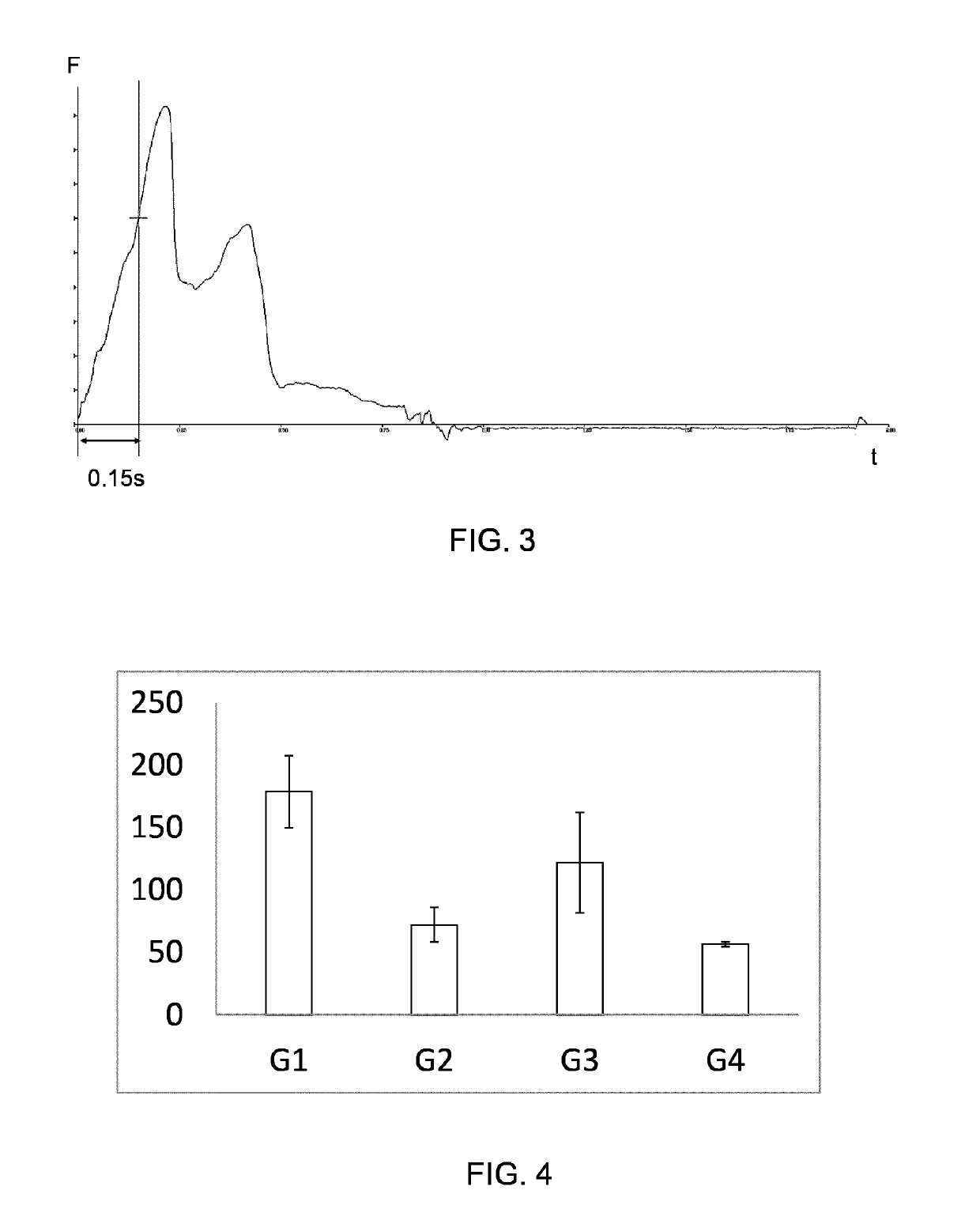

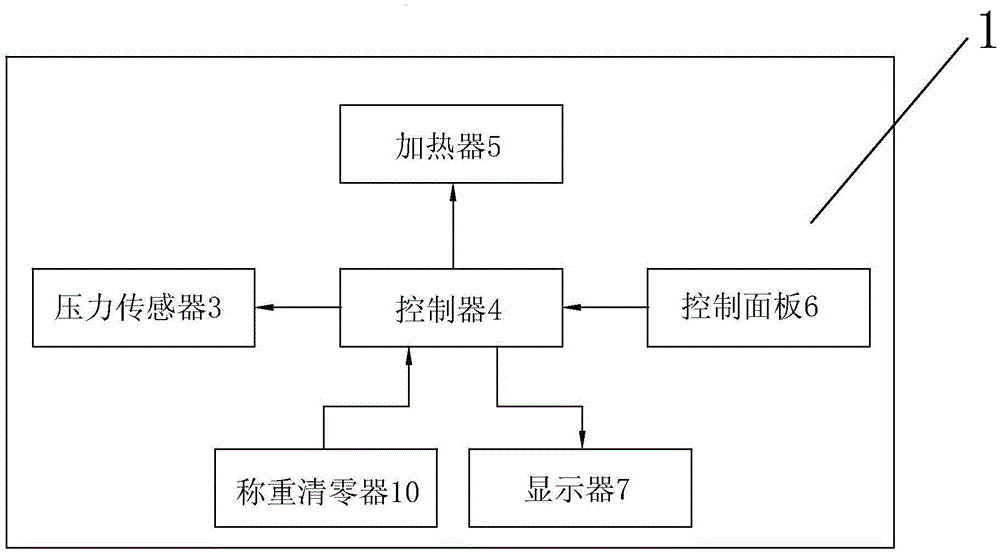

Egg cooker and control method for egg cooker

The invention provides an egg cooker and a control method for the egg cooker. The egg cooker comprises an egg cooking rack provided with through holes, heaters, a heating chamber, a cover and a controller; the egg cooker further comprises an ultrasonic transmitter arranged on the cover and an ultrasonic receiver arranged on the egg cooking rack, and the controller is respectively connected with the heaters, the ultrasonic transmitter and the ultrasonic receiver. The control method comprises the steps of S100, transmitting an ultrasonic signal and acquiring measurement information; S200, detecting raw and cooked state information of egg food in the egg cooker according to the measurement information; S300, comparing the raw and cooked state information with a preset raw and cooked state, and controlling the working state of the egg cooker according to the comparison result. According to the egg cooker and the control method, the automatic recognition of the degree of cooking of the eggfood is achieved, and the automatic stopping of heating is achieved according to the degree of cooking.

Owner:台州市吉吉知识产权运营有限公司

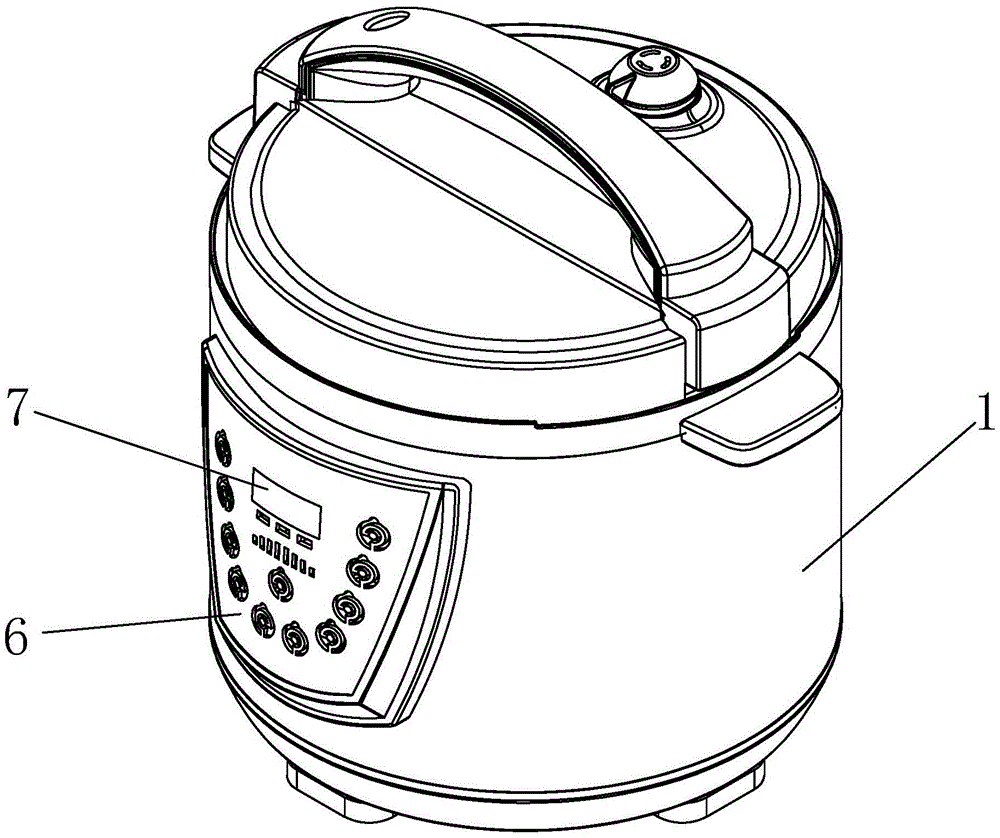

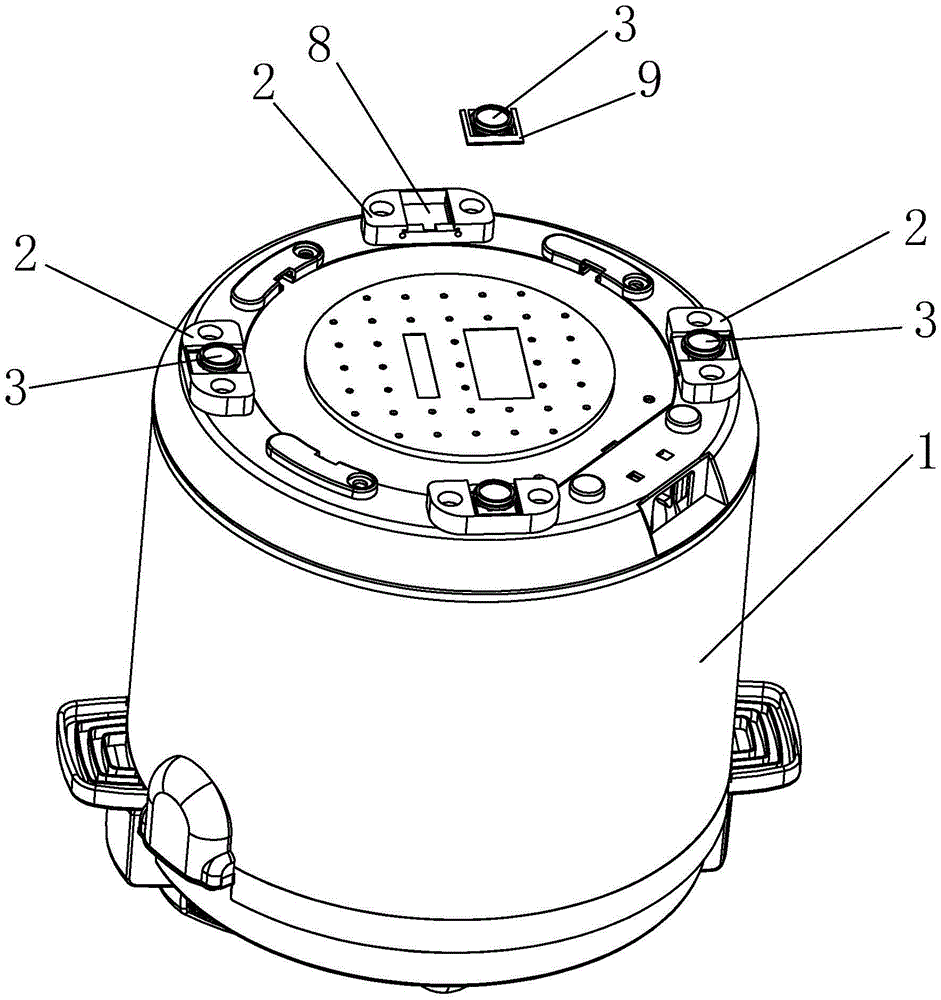

Novel electric pot

Owner:ZHONGSHAN JINGUANG HOUSEHOLD APPLIANCE MFG CO LTD

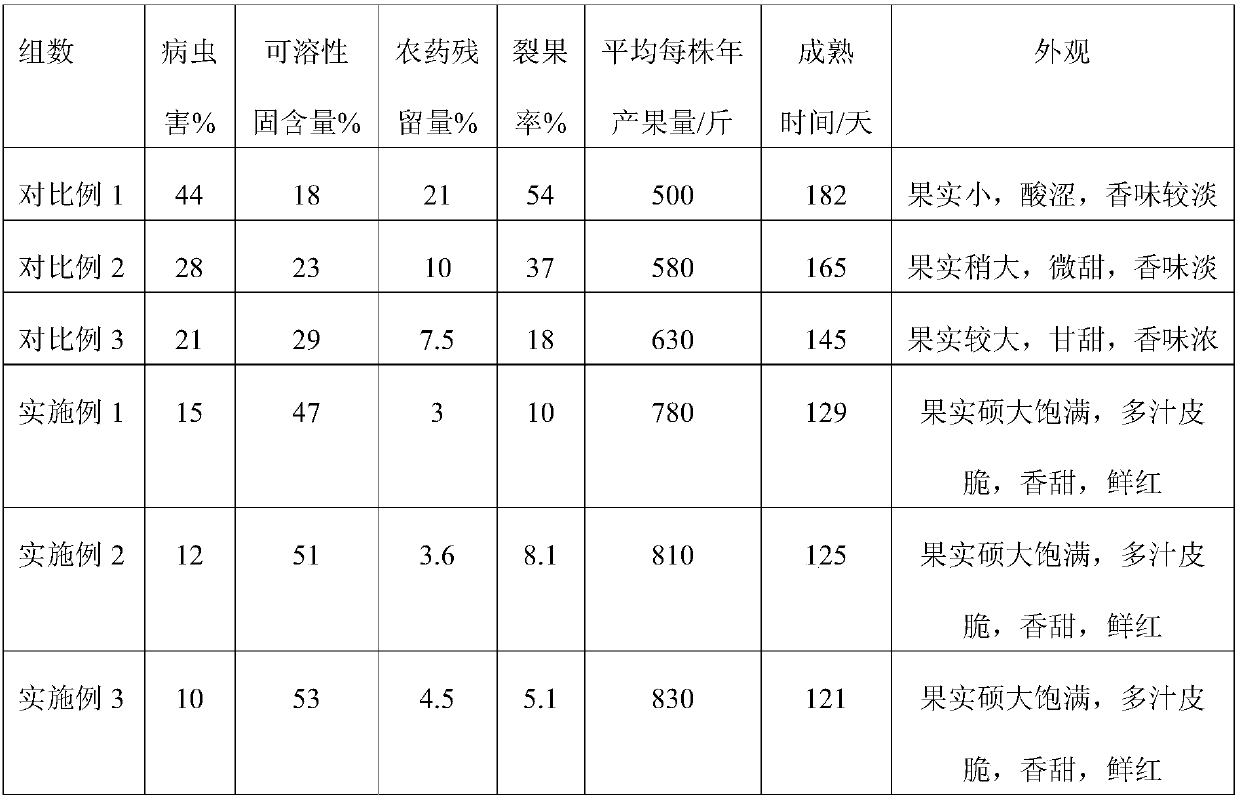

High-yield high-quality apple planting method

The invention relates to the technical field of fruit tree planting, in particular to a high-yield high-quality apple panting method. The method comprises the steps that 1, deep soil ploughing and soil exposure are conducted, and after a soil disinfectant is sprayed, film covering and fumigation disinfection are conducted; 2, tree seedlings are transplanted; 3, flowering is promoted, wherein a flower fertilizer is sprayed at the flowering stage of apples, flower thinning treatment is conducted, and the flower fertilizer is mainly prepared from potash fertilizer, chitosan oligosaccharide, propineb, gibberellic acid, paclobutrazol and the like; 4, fertilization management is conducted, wherein at the spring bud stage, an additional fertilizer prepared from lime powder, calcium magnesium phosphate and plant ash is spread, and at the young fruit stage, a young fruit stage liquid fertilizer is sprayed, wherein the young fruit stage liquid fertilizer is mainly prepared from calcium magnesiumphosphate, calcium superphosphate, calcium nitrate, spoiled glucose powder, bone meal, chitosan, proline, algal polysaccharides, glycine betaine, borax, a pimiento extract, mancozeb, a cell membranestabilizing enzyme and the like; 5, fruit tree management is conducted. The apples planted through the method have more flowers and are high in fruit setting rate, peel cracks are reduced, the apple yield is significantly improved, and the appearance and the fruit quality are improved.

Owner:桂林满梓玉农业开发有限公司

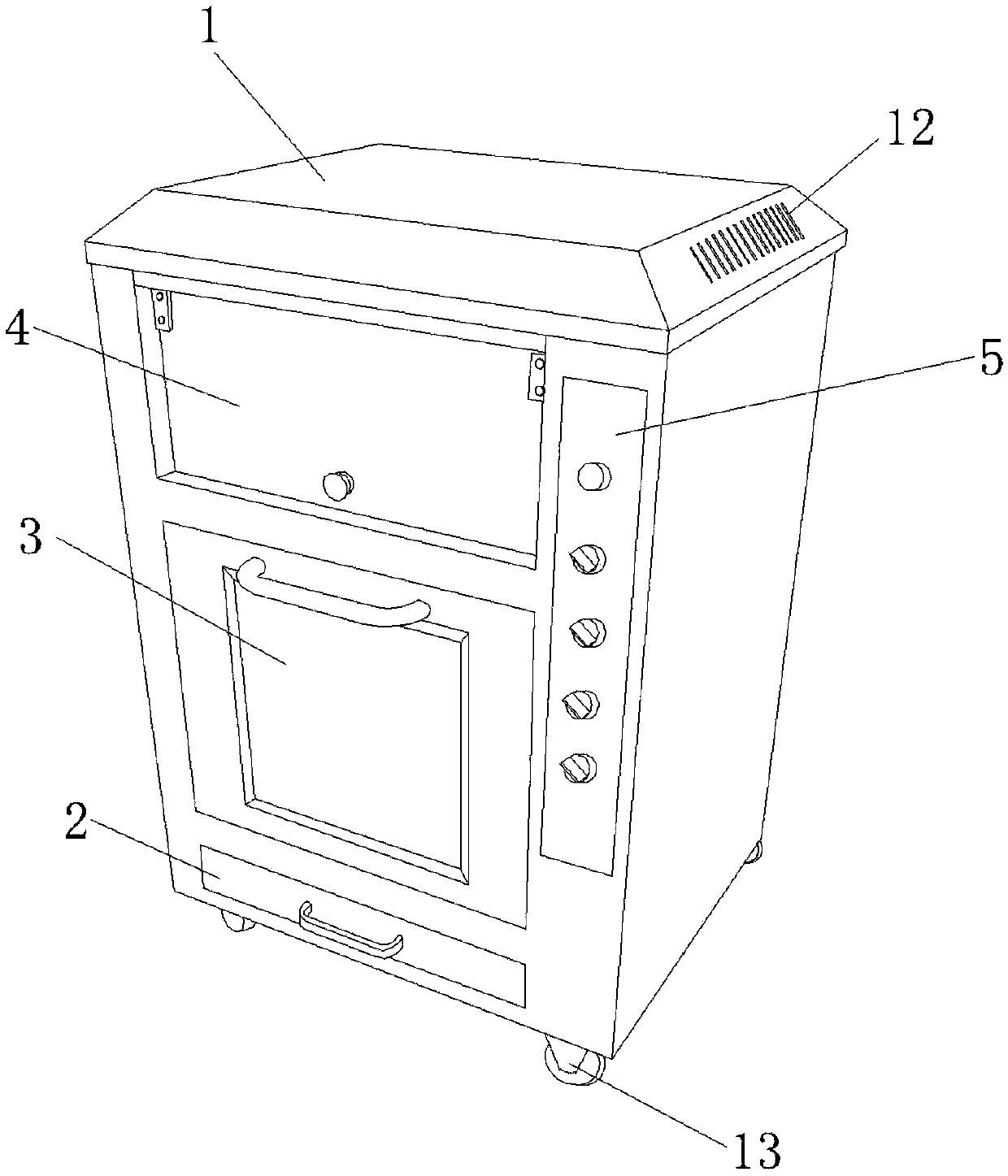

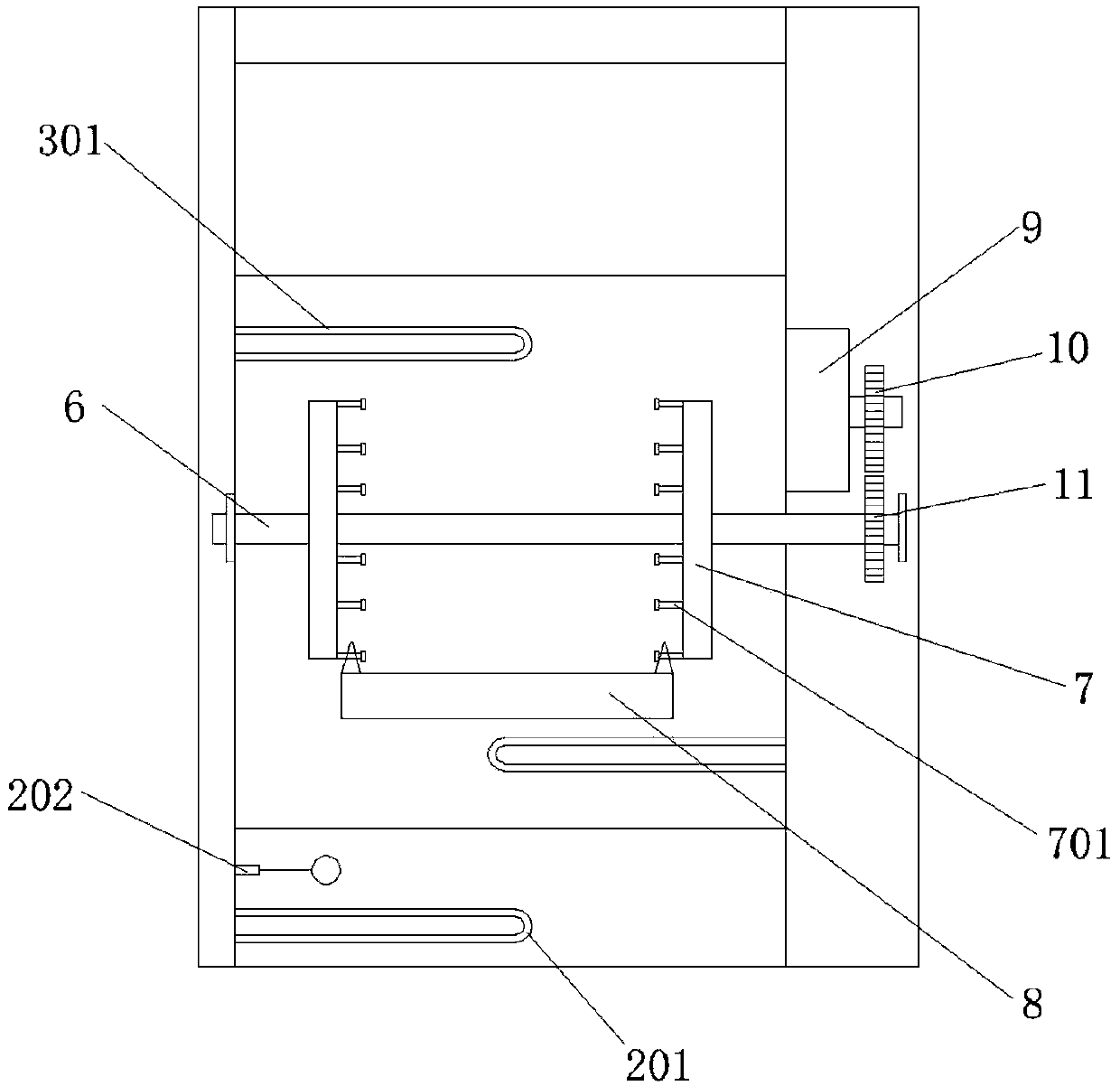

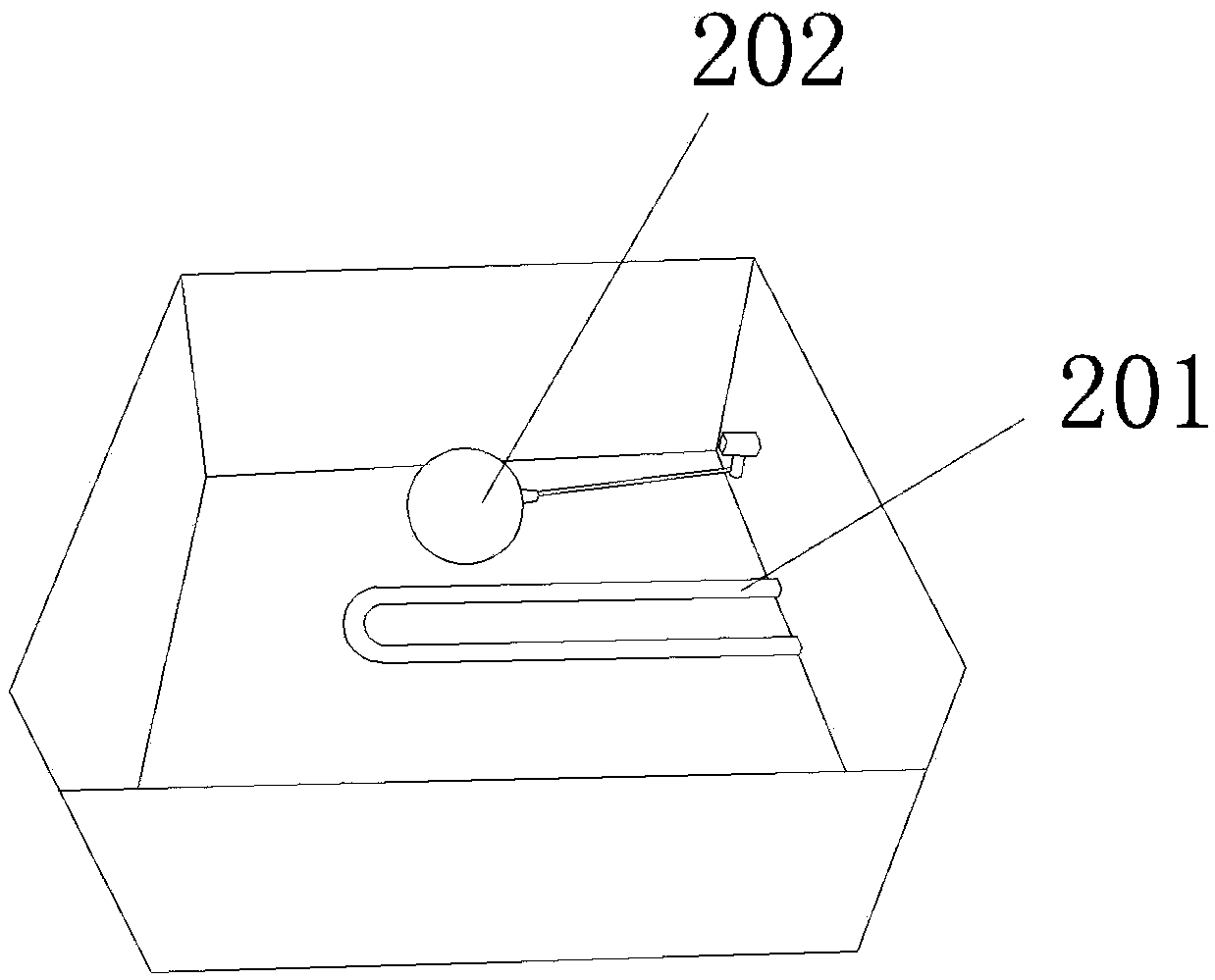

Heat preservation type sweet potato baking machine

PendingCN111214129ATo achieve insulationPrevent overcookingRoasting apparatusRoasters/grillsElectric machineryBall valve

The invention relates to the field of ovens, and discloses a heat preservation type sweet potato baking machine which comprises a machine body, a water tank, a baking area, a heat preservation area and a control area, a first heating pipe and a floating ball valve are arranged in the water tank, and a water inlet of the floating ball valve is communicated with an external water source; second heating pipes are connected to the upper faces and the lower faces of the left side and the right side in the baking area, a rotating shaft is further arranged in the baking area, two rotating discs are fixedly connected to the two ends of the rotating shaft, mutually-symmetrical hanging rods arranged along the outer rings of the rotating discs are arranged on the opposite sides of the two rotating discs, and hanging brackets in the direction of the rotating shaft are hung on the mutually-symmetrical hanging rods on the two sides. The rotating shaft is driven by a motor to rotate, the to-be-bakedsweet potatoes placed on the hanging brackets do circular motion and are fully baked in the baking area, water in the water tank is heated through the first heating pipe, water vapor is generated, thecooking effect is achieved, after part of the water is evaporated, the floating ball valve descends, external water flows into the cooking area, and therefore the water vapor is continuously generated through high temperature, and the lasting cooking effect is achieved.

Owner:江苏富佳伟业机械制造有限公司

Intelligent frequency conversion hot pot

ActiveCN108451344APrevent accidental ingestionJust cookedWarming devicesVessels with intergral heatingFrequency conversionEngineering

The invention relates to an intelligent frequency conversion hot pot. The intelligent frequency conversion hot pot comprises a supporting base, a heating plate and a pot body, and an adjusting panel which is electrically connected with the heating plate is installed on the supporting base; a pressure sensor is arranged between the supporting base and the heating plate and electrically connected with a control chip, and the control chip is electrically connected with the adjusting panel; a detachable isolation net is installed in the pot body, the middle of the isolation net protrudes upwards,a slope is formed around the middle of the isolation net, temperature difference sensing sheets are fixedly attached to the slope, and signal collecting units of the temperature difference sensing sheets are connected with a signal projector in pair; the signal projector is electrically connected with the control chip. The intelligent frequency conversion hot pot is exquisite in structure, the magnitude of heat power can be intelligently adjusted according to food taking speed of a hotpot customer, the heat power can be timely adjusted when new food is added into the pot, after the food is cooked, the heat power is automatically reduced, the mouthfeel of the food is guaranteed, the amount of generated vapor is reduced, and a comfortable eating environment is provided with the hotspot customer.

Owner:YONGKANG ANDONG ELECTRIC APPLIANCE CO LTD

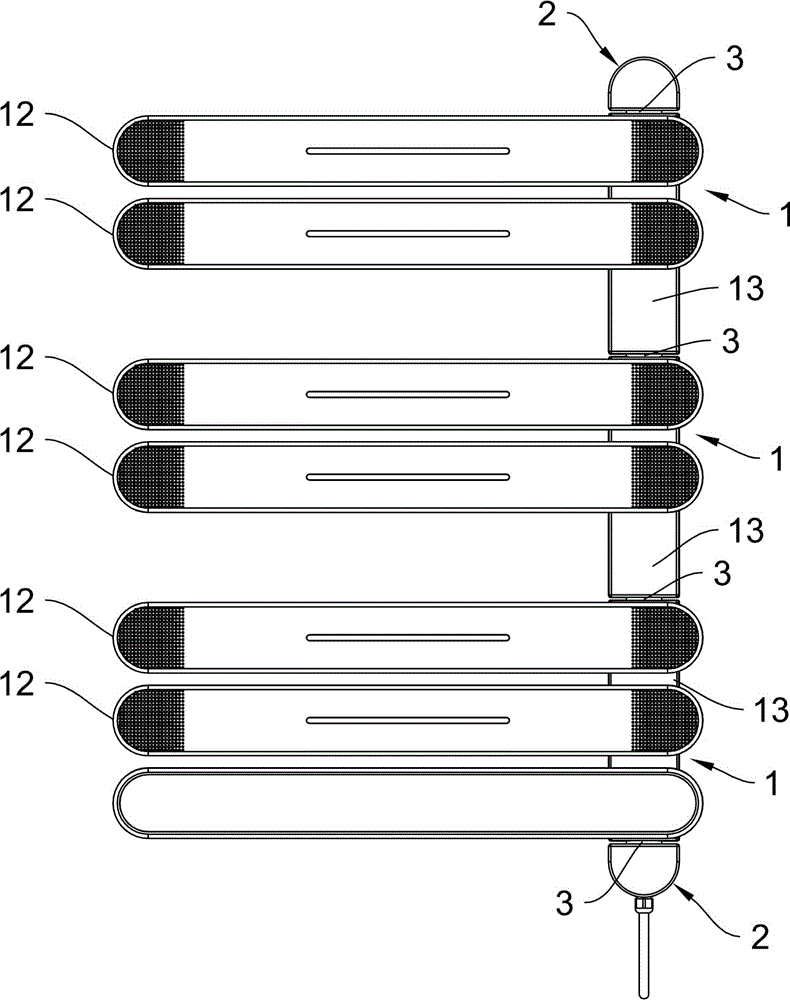

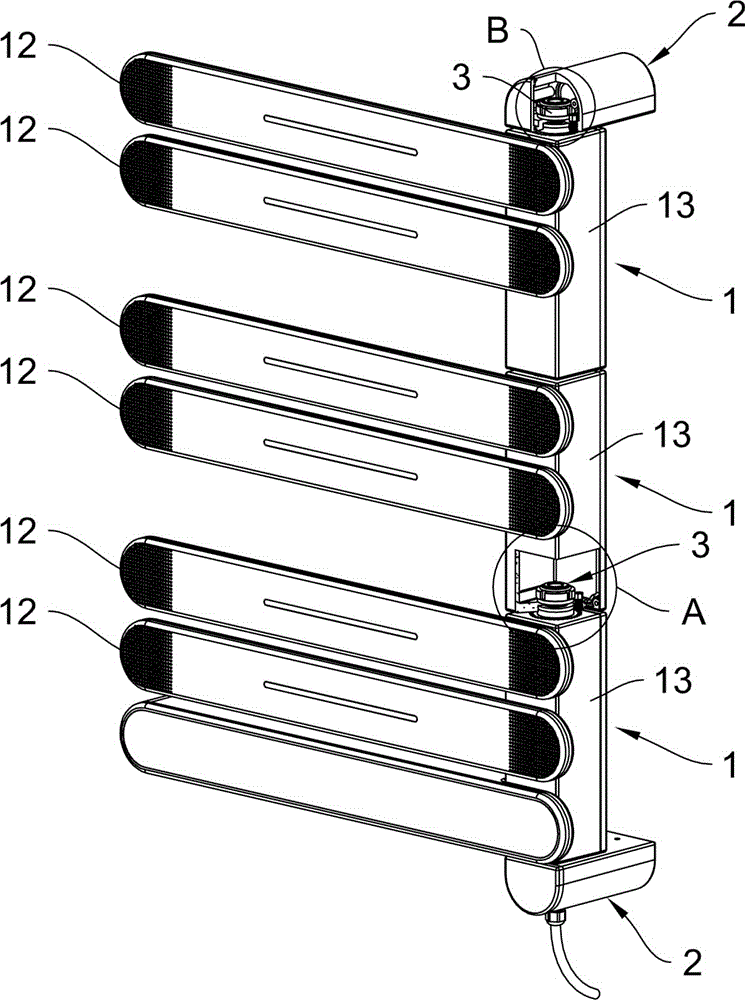

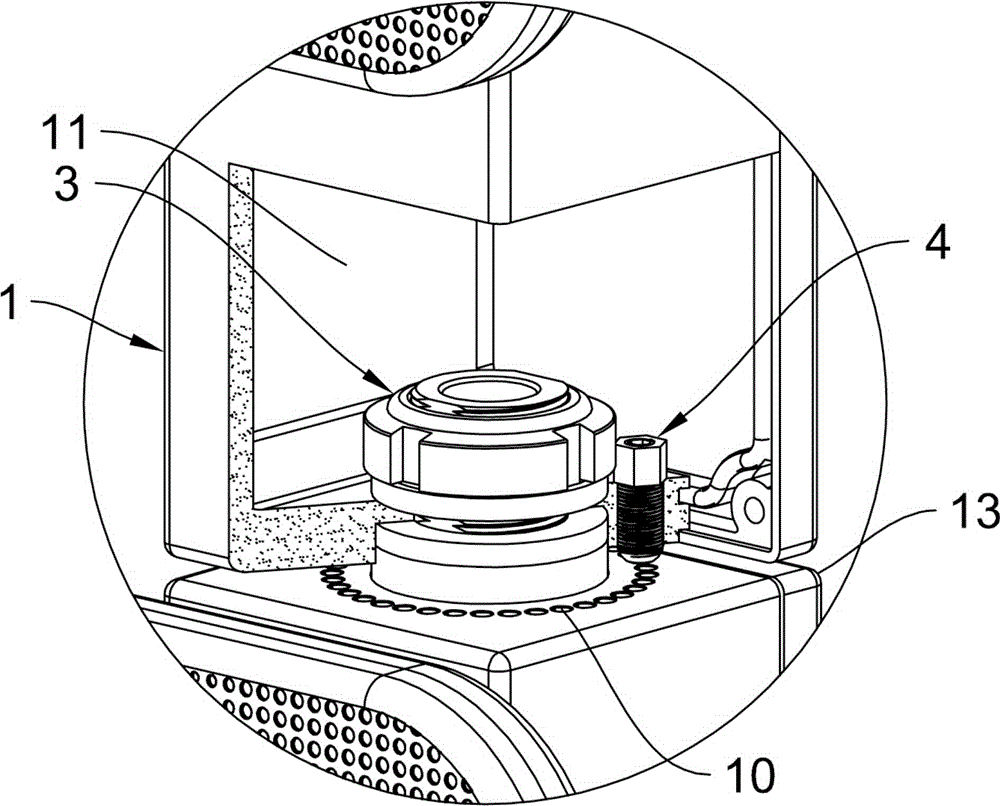

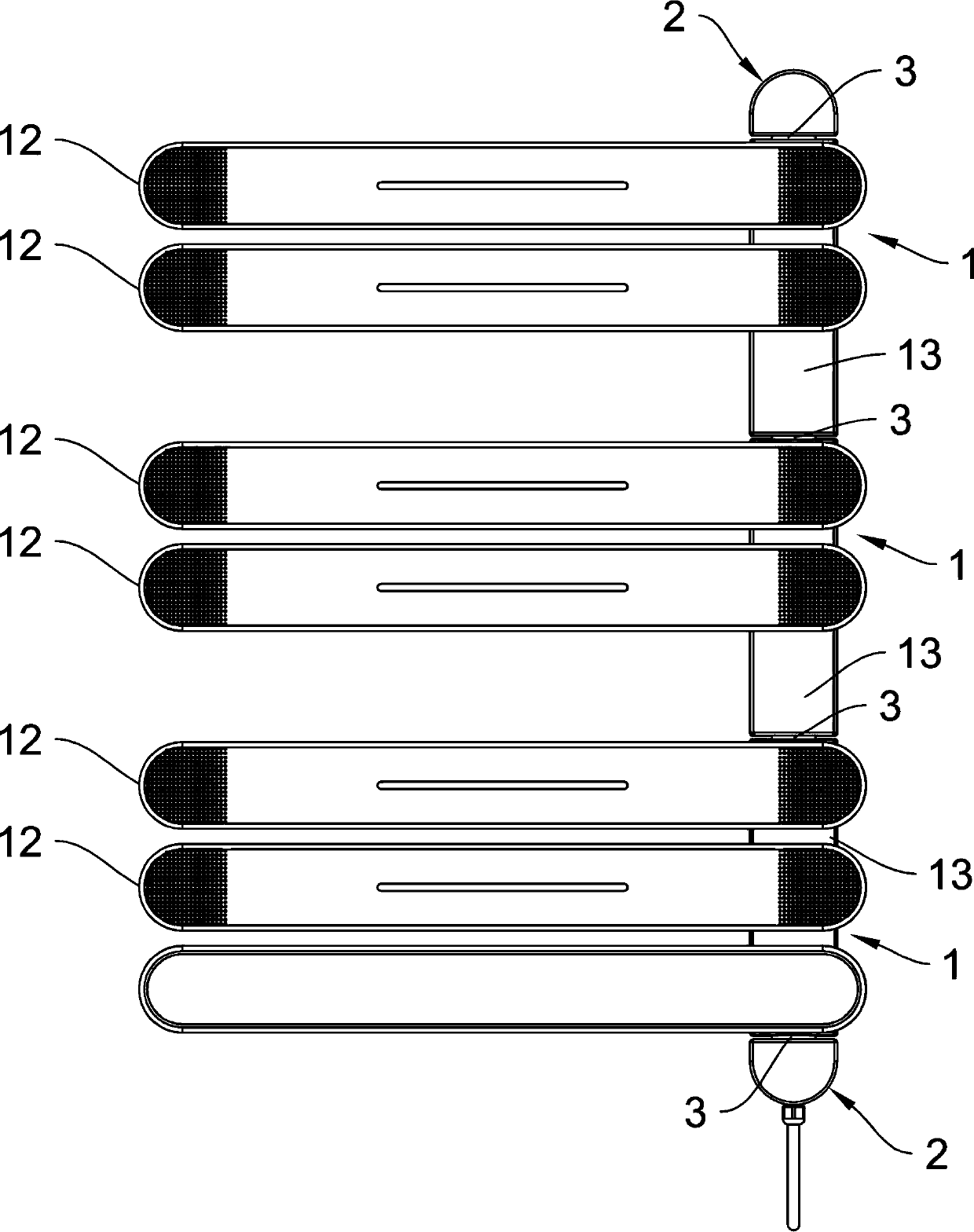

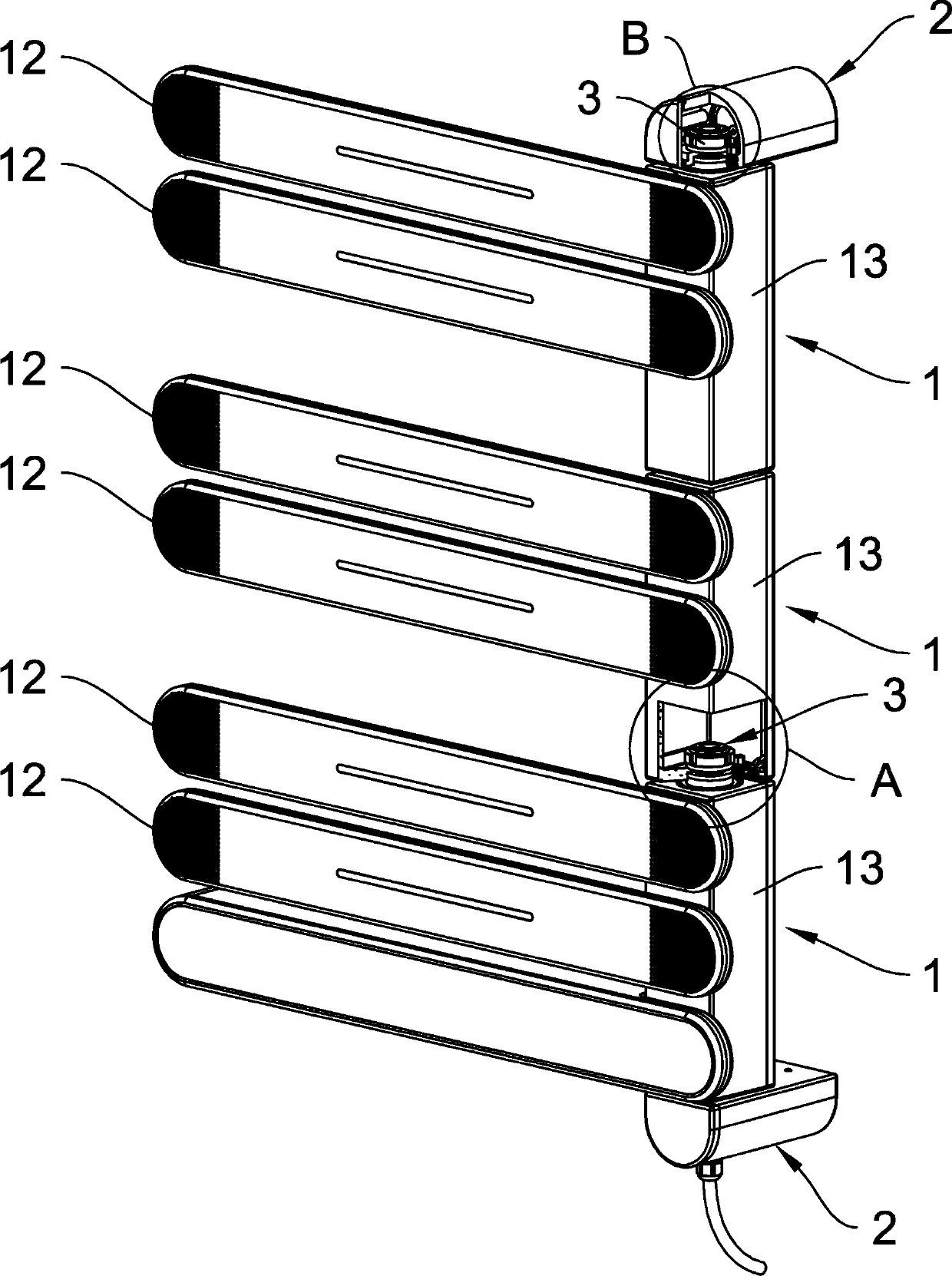

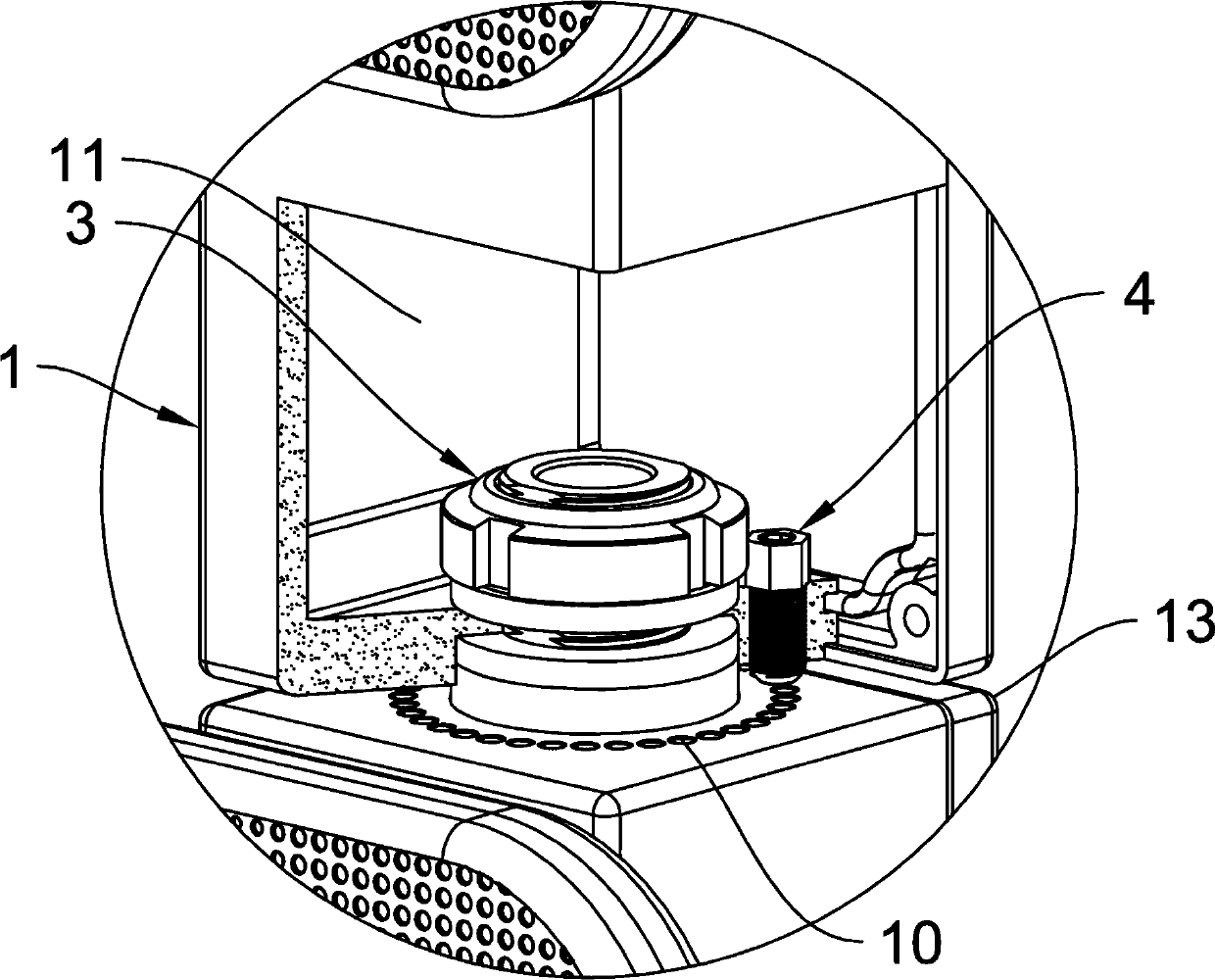

Drying hanger with intelligent remote control function

ActiveCN106592177AAvoid free turningAvoid shakingTextiles and paperLaundry driersRemote controlEngineering

The invention relates to a drying hanger with an intelligent remote control function. The drying hanger comprises the components of at least one cross bar hanger assembly, a fixing base, a rotatable connecting mechanism, a damping mechanism, a wireless communication module, and a circuit module which is internally provided with an intelligent control chip. The cross bar hanger assembly is provided with a heating assembly. The cross bar hanger assembly is connected with the fixing base through the rotatable connecting mechanism. The damping mechanism is arranged beside the rotatable connecting mechanism at the connecting part between the cross bar hanger assembly and the fixing base. The damping mechanism is provided with a bouncing position fixing member. The bouncing position fixing member acts on the cross bar hanger assembly or the fixing base. The circuit module is arranged on the cross bar hanger assembly or the fixing base. The wireless communication module is arranged on the circuit module. The drying hanger has advantages of high flexibility and high variety in use, wide application range, flexible swinging and accurate position fixing of the cross bar hanger assembly, no random swinging, better use effect, convenient packaging, convenient conveying, convenient transportation, and effective realization of a drying function and a remote control function.

Owner:KAIPING LEIJING WATER HEATING TECH DEV CO LTD

Power interruption recovering controlling method for kimchi refrigerator

InactiveCN100334411CPrevent overcookingPrevent spoilageDomestic cooling apparatusLighting and heating apparatusElectric power systemEngineering

A restoration control method after electric power lost for the refrigerator used to prepare kimchi is characterized by that when the electric power is lost, all the operations for preparing kimchi are stopped, and after the electric power is restored, what operation that is executing before power lost is judge and the operation continues.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

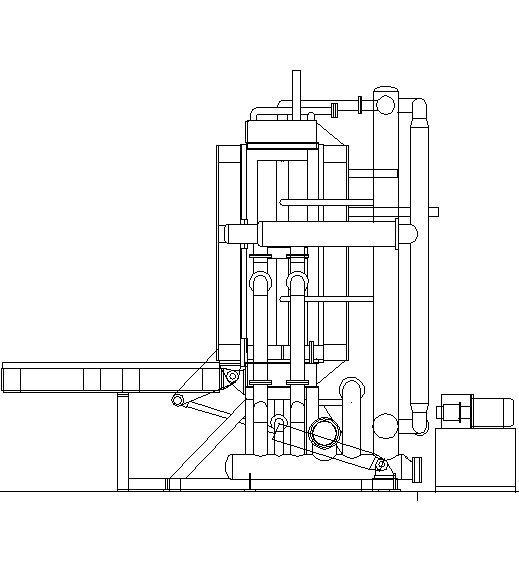

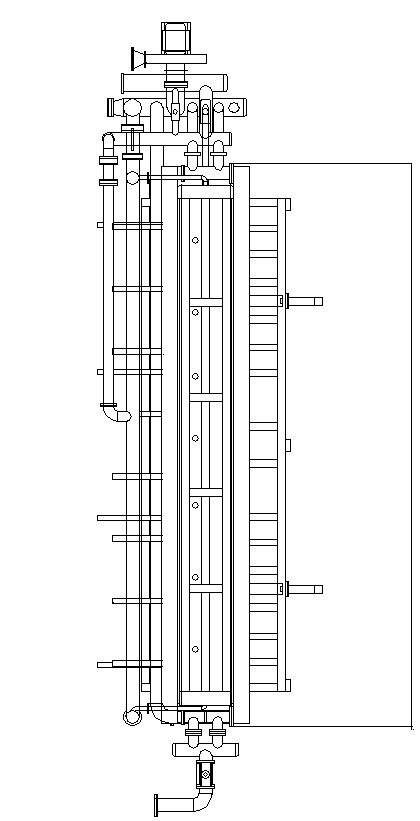

Foam plane-making machine capable of feeding air at two ends

The invention relates to a foam plane-making machine capable of feeding air at two ends. A structure of the existing foam panel-making machine is not rational. The foam plane-making machine capable of feeding air at two ends comprises a frame, a pipeline device, a left formwork, a right formwork, a front formwork, a rear formwork, a top formwork and a bottom plate, and further comprises an air frame bottom formwork and at least a set of lifting device; the lifting device comprises a worm rod, a worm wheel, a flange, a lead screw, a lead screw sleeve and a sealing socket; the worm rod and the worm wheel are mounted on the frame, the sealing socket is fixed in a sealing hole on the bottom plate, one end of the flange is fixed on the worm wheel through the flange, the lead screw sleeve penetrates into the sealing socket; the pipeline device comprises a left formwork connecting pipe, a right formwork connecting pipe, a circular loop pipe, a left total steam inlet pipe, a rear formwork left connecting pipe, a front formwork left connecting pipe, a right total steam inlet pipe, a rear formwork right connecting pipe, a front formwork right connecting pipe, a top formwork right connecting pipe and an air frame bottom formwork right connecting pipe. The structure provided by the invention is reasonable in structure design, scientific in layout, energy-saving and environmentally-friendly and high in working efficiency.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

Medicament grinding device for medical care

ActiveCN112845358ATo achieve the purpose of shaking cleaningIncrease inputDrying gas arrangementsDrying solid materialsNursing careEngineering

The invention relates to a medicament grinding device for medical care. The medicament grinding device comprises a grinding seat, rotary pushing mechanisms and an arm rod mechanism; a material opening is formed in the grinding seat, a cleaning cabin is installed at the top of the material opening, a built-in plate is welded to the middle of the cleaning cabin, and the rotary pushing mechanisms are arranged in the cleaning cabin through the built-in plate; the rotary pushing mechanisms are in driving connection with a power motor on the grinding seat through a belt transmission structure, so that when the grinding seat is electrified to work, the belt transmission structure drives the rotary pushing mechanisms to synchronously rotate, and the two rows of stirring shafts are linked with sieve plates; and the structural design is more ingenious, the purpose of coacting of three parts is achieved through one action, power sources of the sieve plates and the two rows of stirring shafts are all from the original power motor of the grinding seat, namely, an electric energy structure is saved, and when the sieve plates and the two rows of stirring shafts act together, the cleaning speed can be increased.

Owner:THE FIRST PEOPLES HOSPITAL OF CHONGQING LIANG JIANG NEW AREA

A drying hanger with intelligent remote control

ActiveCN106592177BAvoid free turningEasy to useTextiles and paperLaundry driersRemote controlPosition fixing

The invention relates to a drying hanger with an intelligent remote control function. The drying hanger comprises the components of at least one cross bar hanger assembly, a fixing base, a rotatable connecting mechanism, a damping mechanism, a wireless communication module, and a circuit module which is internally provided with an intelligent control chip. The cross bar hanger assembly is provided with a heating assembly. The cross bar hanger assembly is connected with the fixing base through the rotatable connecting mechanism. The damping mechanism is arranged beside the rotatable connecting mechanism at the connecting part between the cross bar hanger assembly and the fixing base. The damping mechanism is provided with a bouncing position fixing member. The bouncing position fixing member acts on the cross bar hanger assembly or the fixing base. The circuit module is arranged on the cross bar hanger assembly or the fixing base. The wireless communication module is arranged on the circuit module. The drying hanger has advantages of high flexibility and high variety in use, wide application range, flexible swinging and accurate position fixing of the cross bar hanger assembly, no random swinging, better use effect, convenient packaging, convenient conveying, convenient transportation, and effective realization of a drying function and a remote control function.

Owner:KAIPING LEIJING WATER HEATING TECH DEV CO LTD

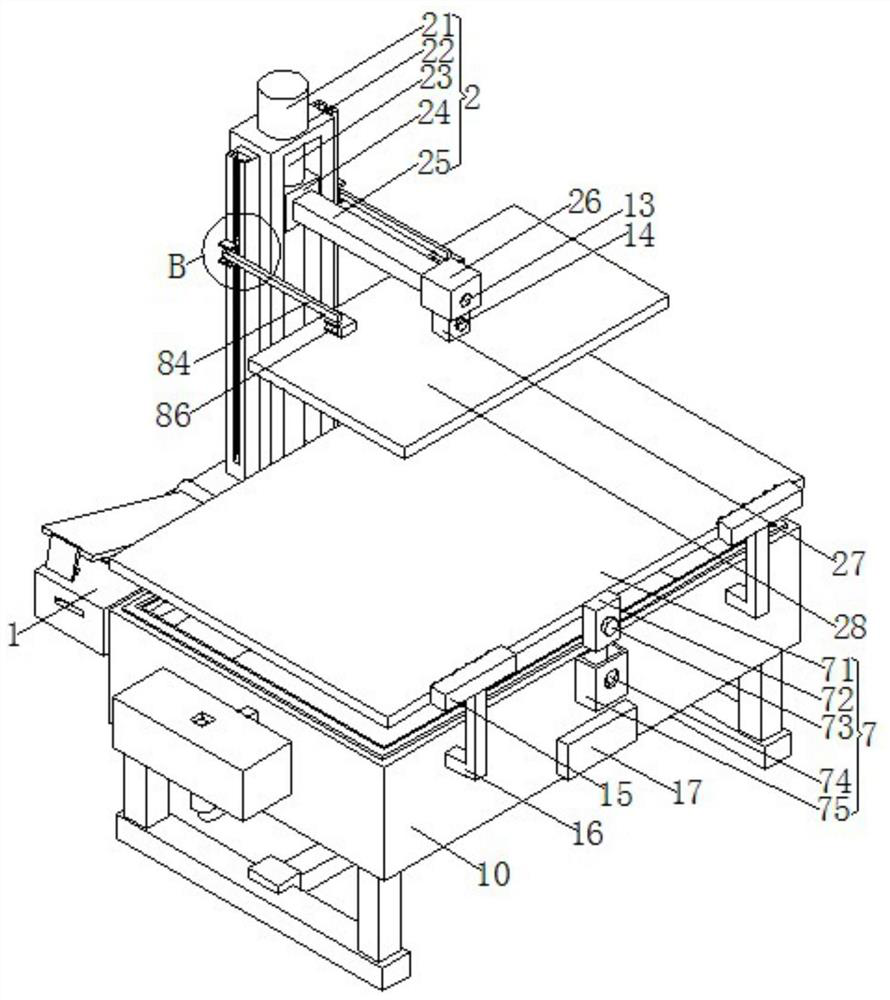

Photosensitive material curing layer forming structure in 3D printing

InactiveCN112373013AHigh precisionGood molding effectManufacturing enclosures3D object support structuresEngineeringStructural engineering

Owner:杭州致盾科技有限公司

Foam plane-making machine capable of feeding air at two ends

The invention relates to a foam plane-making machine capable of feeding air at two ends. A structure of the existing foam panel-making machine is not rational. The foam plane-making machine capable of feeding air at two ends comprises a frame, a pipeline device, a left formwork, a right formwork, a front formwork, a rear formwork, a top formwork and a bottom plate, and further comprises an air frame bottom formwork and at least a set of lifting device; the lifting device comprises a worm rod, a worm wheel, a flange, a lead screw, a lead screw sleeve and a sealing socket; the worm rod and the worm wheel are mounted on the frame, the sealing socket is fixed in a sealing hole on the bottom plate, one end of the flange is fixed on the worm wheel through the flange, the lead screw sleeve penetrates into the sealing socket; the pipeline device comprises a left formwork connecting pipe, a right formwork connecting pipe, a circular loop pipe, a left total steam inlet pipe, a rear formwork left connecting pipe, a front formwork left connecting pipe, a right total steam inlet pipe, a rear formwork right connecting pipe, a front formwork right connecting pipe, a top formwork right connecting pipe and an air frame bottom formwork right connecting pipe. The structure provided by the invention is reasonable in structure design, scientific in layout, energy-saving and environmentally-friendly and high in working efficiency.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

Method for manufacturing quick-frozen taros

ActiveCN102524366BDelay agingImprove qualityFood processingFruits/vegetable preservation by freezing/coolingCold airSteam cooking

The invention discloses a method for manufacturing quick-frozen taros, which can be used for carrying out quick-freezing and fresh-keeping on the taros by applying the methods of early-stage sterilization, continuous steam cooking, sterile cold-air cooling and individual quick-freezing on the basis of improving the safety and continuity of processing, so that the quality of the quick-frozen taroscan be improved, and the prepared quick-frozen taros are not easily aged, do not easily go bad and are complete in the organization structure and easy to cook.

Owner:漳州明德食品有限公司

Pharmaceutical grinding device for medical care

ActiveCN112845358BTo achieve the purpose of shaking cleaningIncrease inputDrying gas arrangementsDrying solid materialsNursing careEngineering

The invention relates to a pharmaceutical grinding device for medical care, which comprises a grinding seat, a push mechanism and an arm lever mechanism. The grinding seat is provided with a material port, and a cleaning cabin is installed on the top of the material port, and a cleaning cabin is welded in the middle of the cleaning cabin. The built-in plate is equipped with a revolving mechanism in the middle of the cleaning cabin through the built-in plate. The revolving mechanism is driven and connected with the power motor on the grinding seat through a belt transmission structure, so that when the grinding seat is powered on, the revolving mechanism is driven to rotate synchronously through the belt transmission structure. , the two rows of agitating shafts are linked to the sieve plate, and the structural design is more ingenious, that is, the purpose of the three parts acting together is achieved by one action, and the power source of the sieve plate and the two rows of agitating shafts comes from the original grinding seat. Power motors, i.e. power saving structures, and when they act together, speed up cleaning.

Owner:THE FIRST PEOPLES HOSPITAL OF CHONGQING LIANG JIANG NEW AREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com