Patents

Literature

1555results about How to "Low boiling point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

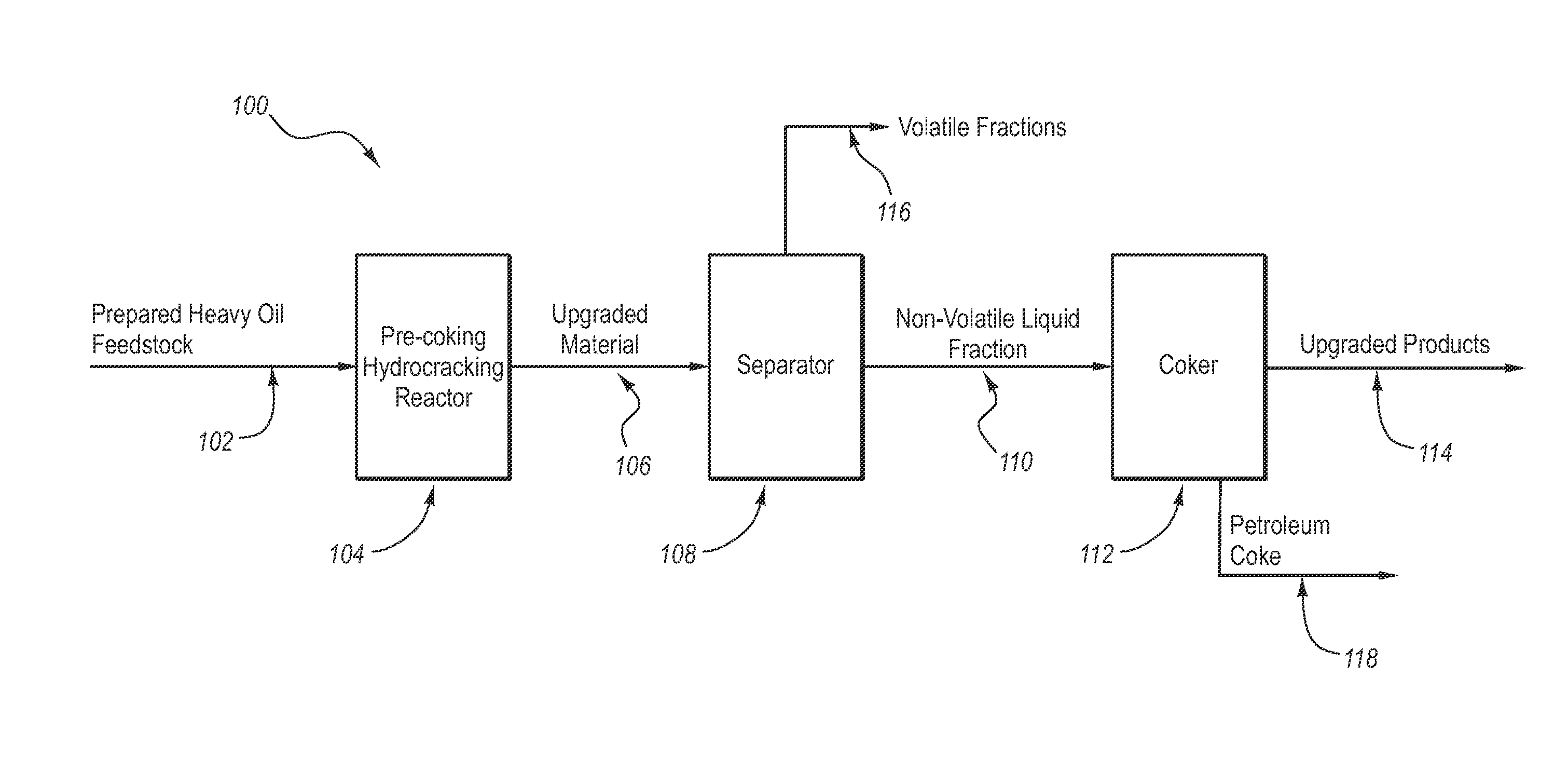

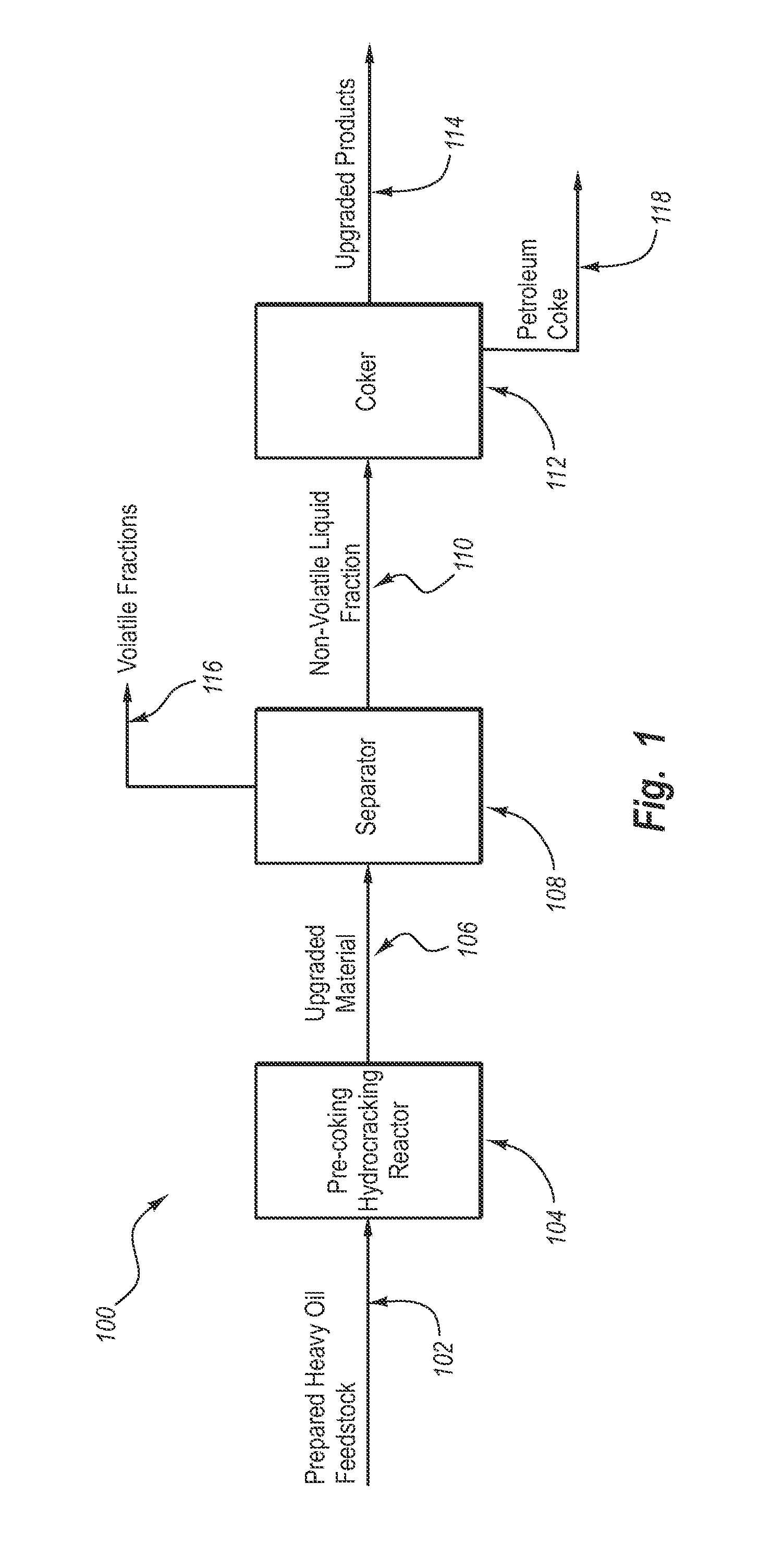

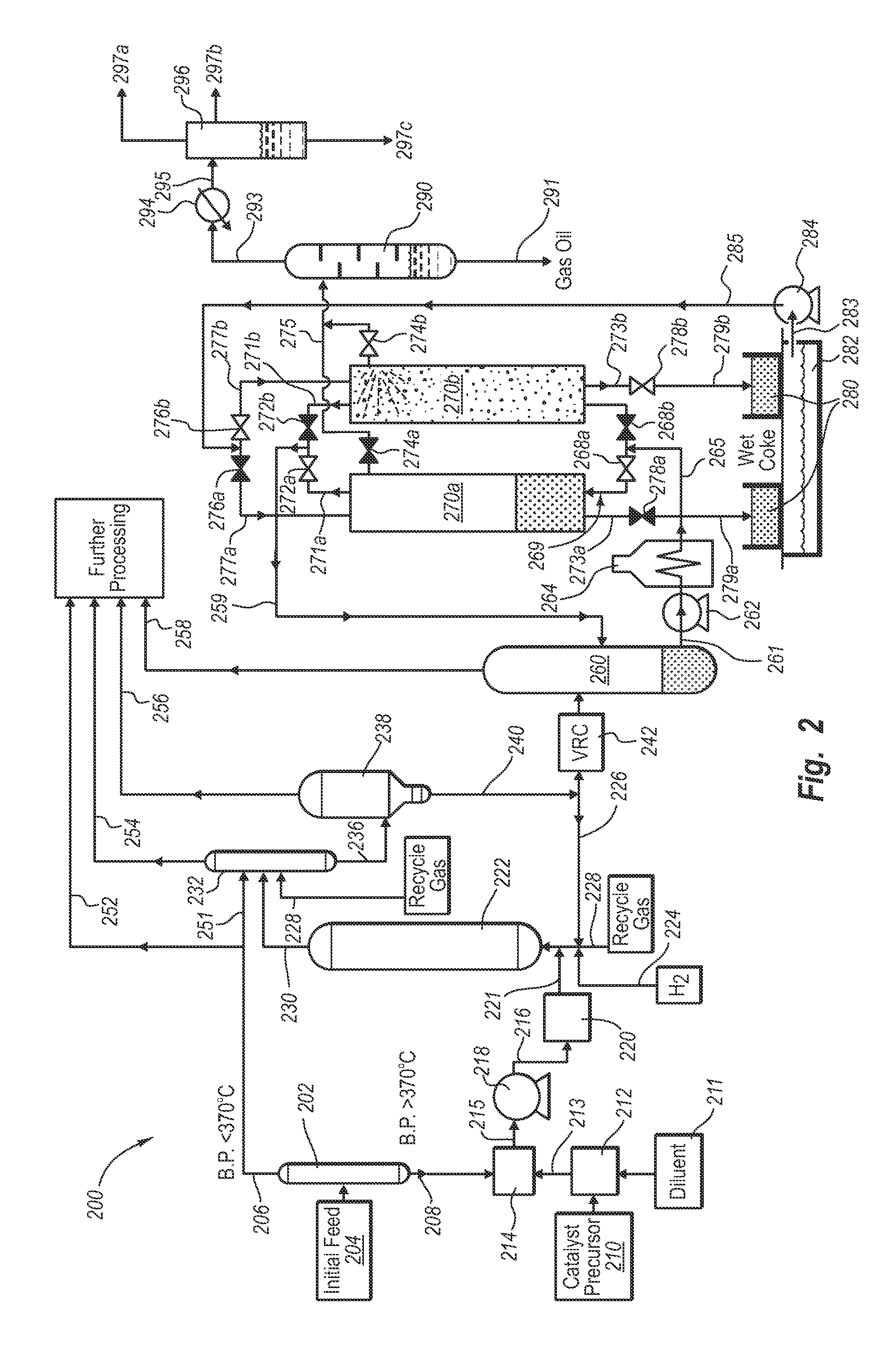

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

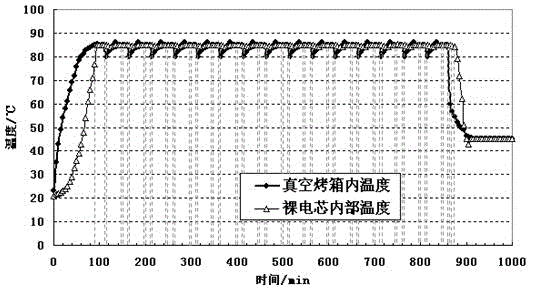

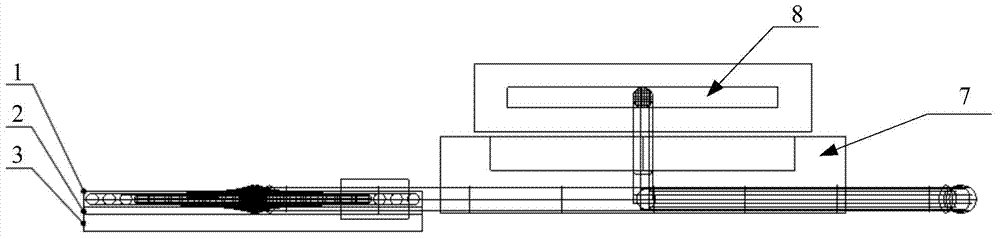

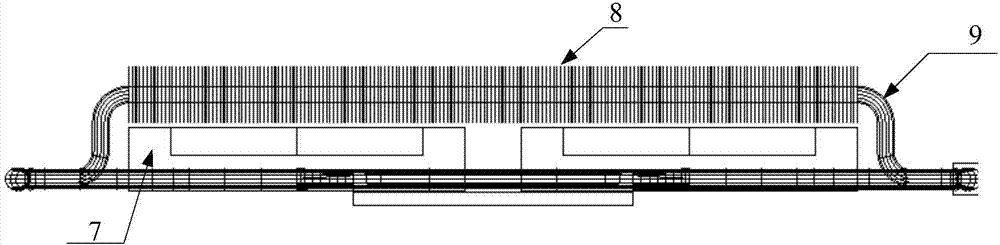

Rapid drying method for lithium ion battery cell

ActiveCN105115250ALow boiling pointImprove water removal effectDrying using combination processesBoiling pointNitrogen gas

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

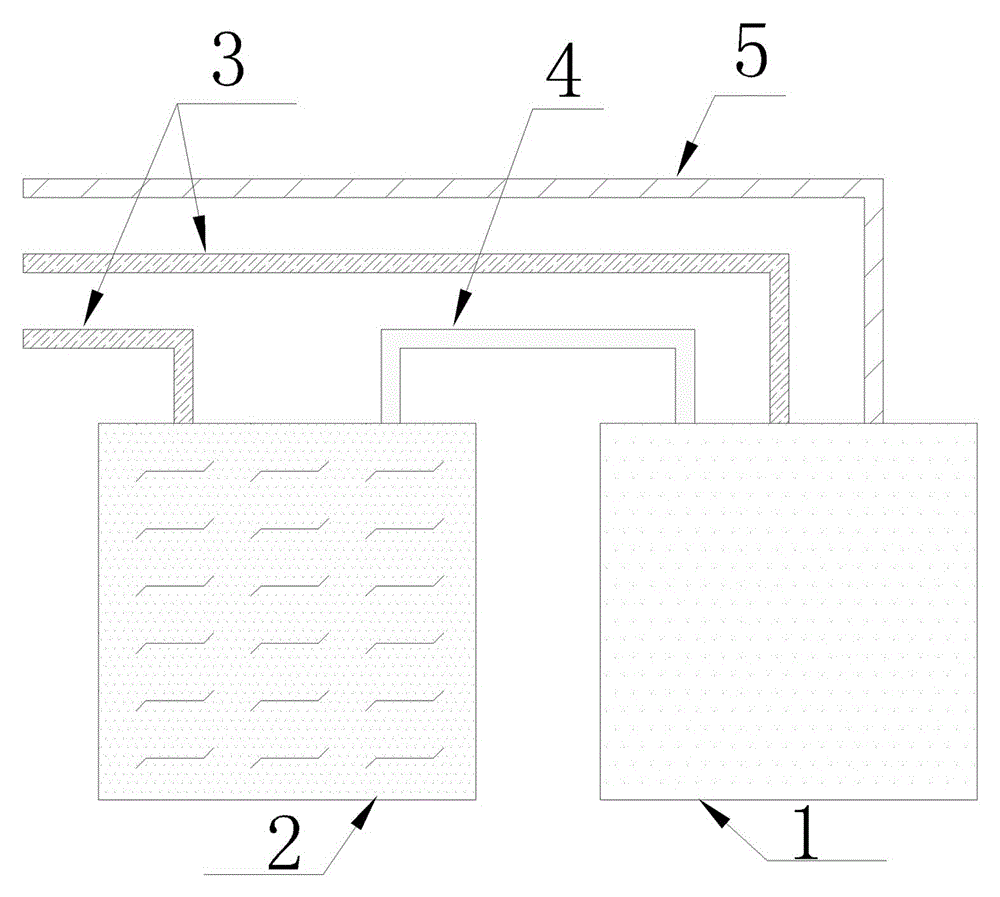

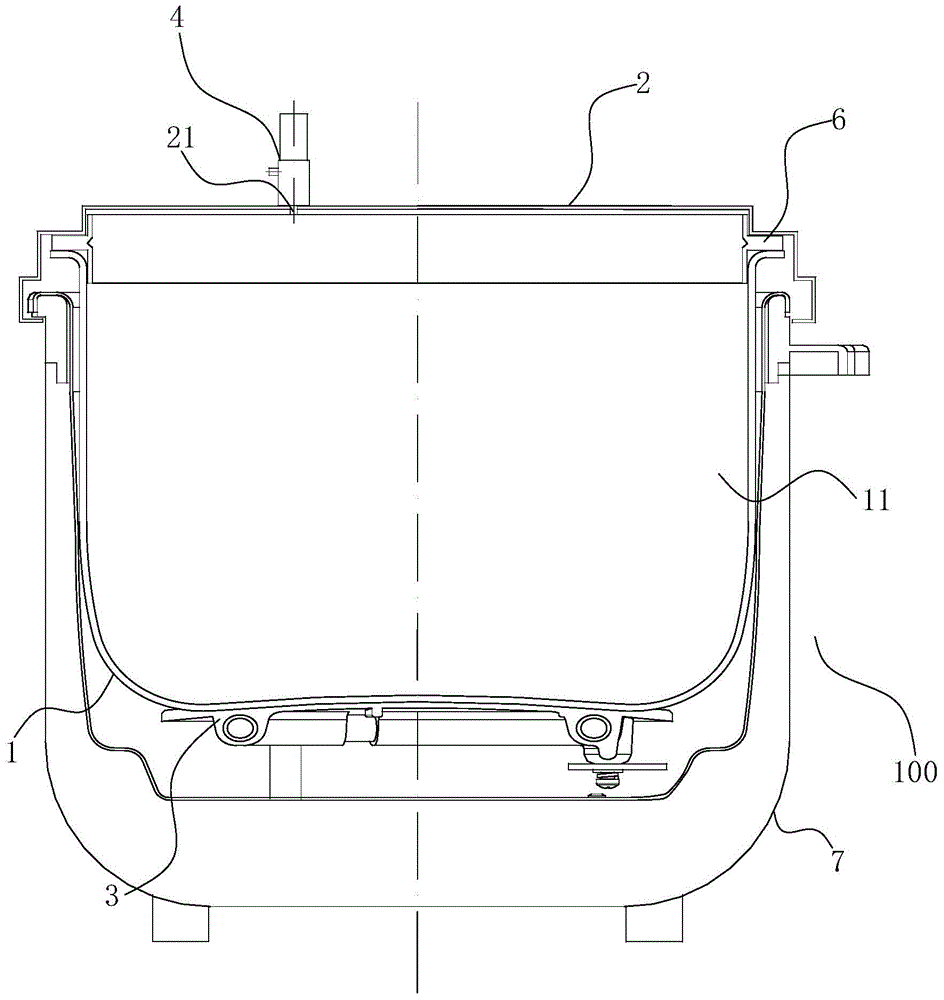

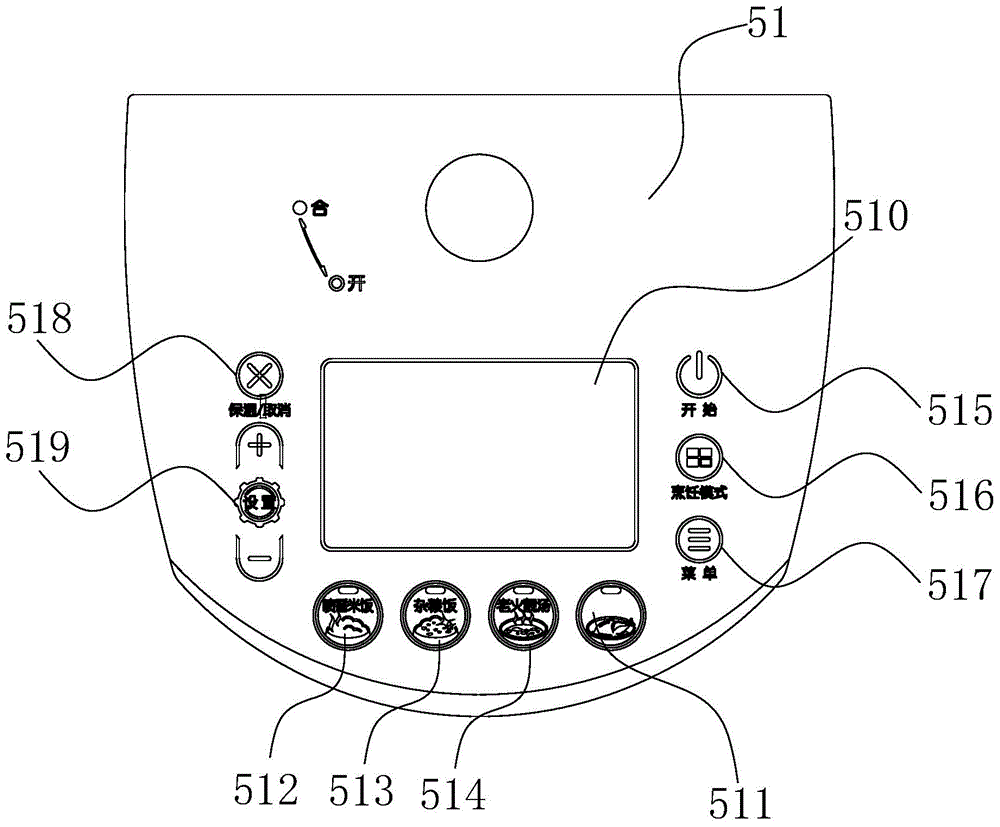

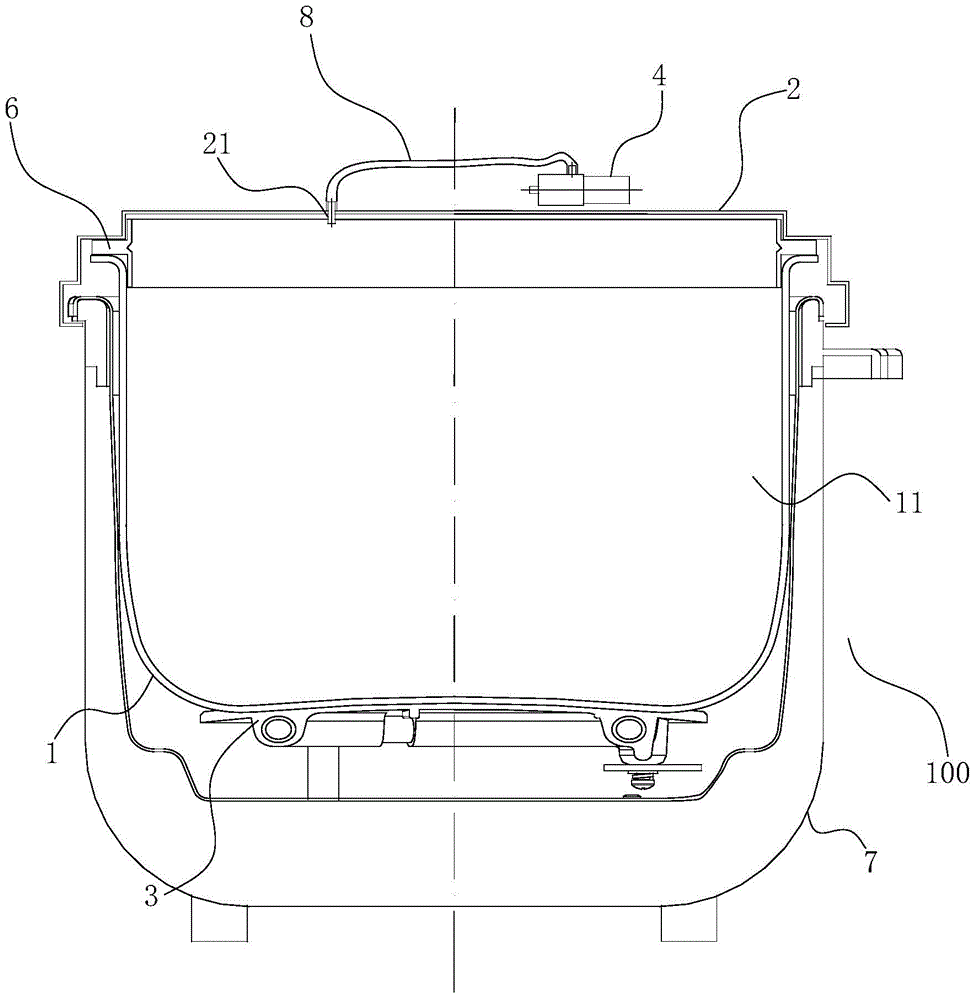

Cooking utensil and control method thereof

The invention discloses a cooking utensil and a control method thereof. The cooking utensil comprises a pot body, a pot cover, a heating device, an exhaust device and a panel component, wherein the pot cover is arranged at the top of the pot body and a cooking cavity is defined by the pot cover together with the pot body; the heating device is arranged outside the pot body; the exhaust device is communicated with the cooking cavity so as to exhaust at least partial gas inside the cooking cavity; the panel component is arranged on the pot body or the pot cover; a vacuum cooking switch is arranged on the panel component; and as the vacuum cooking switch is pressed, the exhaust device and the heating device are controlled to work so as to cook food inside the cooking cavity. According to the cooking utensil disclosed by the invention, the entire process of cooking can be completed since a user presses the vacuum cooking switch which is arranged on the panel component, without other operations in an intermediate process, so as to greatly facilitate the user; and by virtue of the exhaust device, pressure inside the cooking cavity is reduced and boiling point of water inside the cooking cavity is lowered, so as to effectively protect nutritional components of food inside the cooking cavity.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

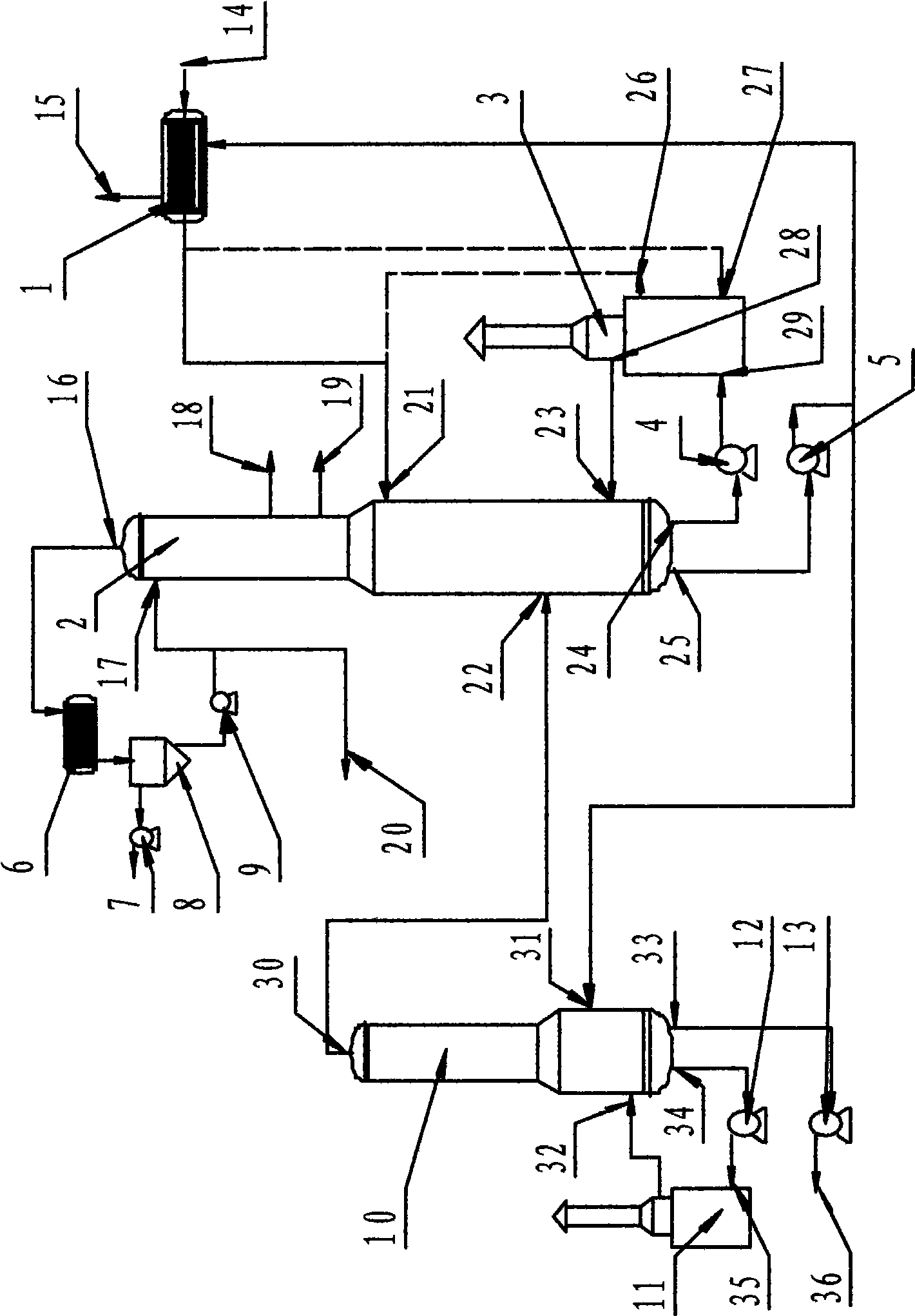

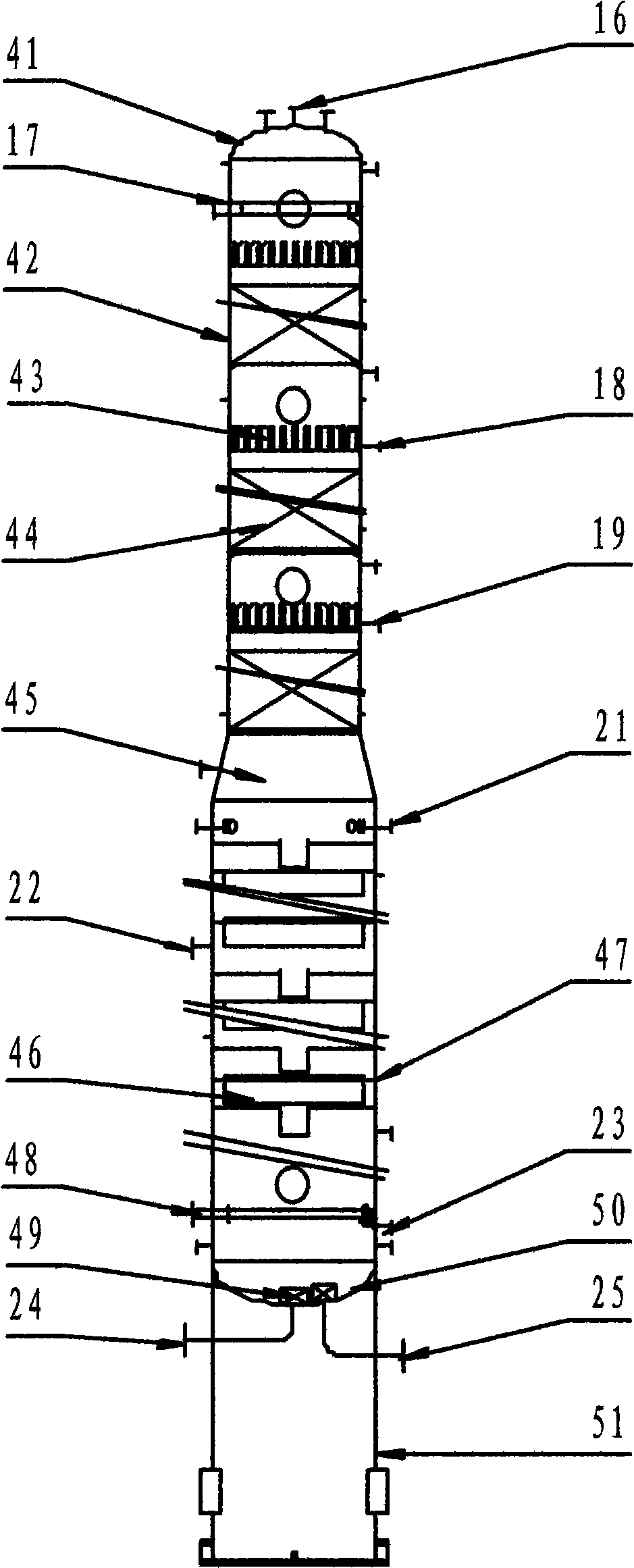

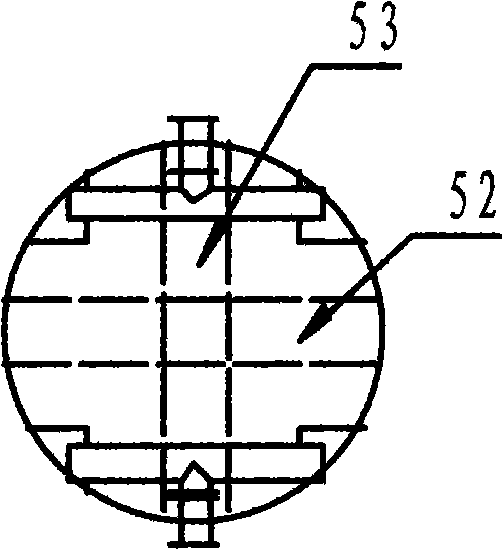

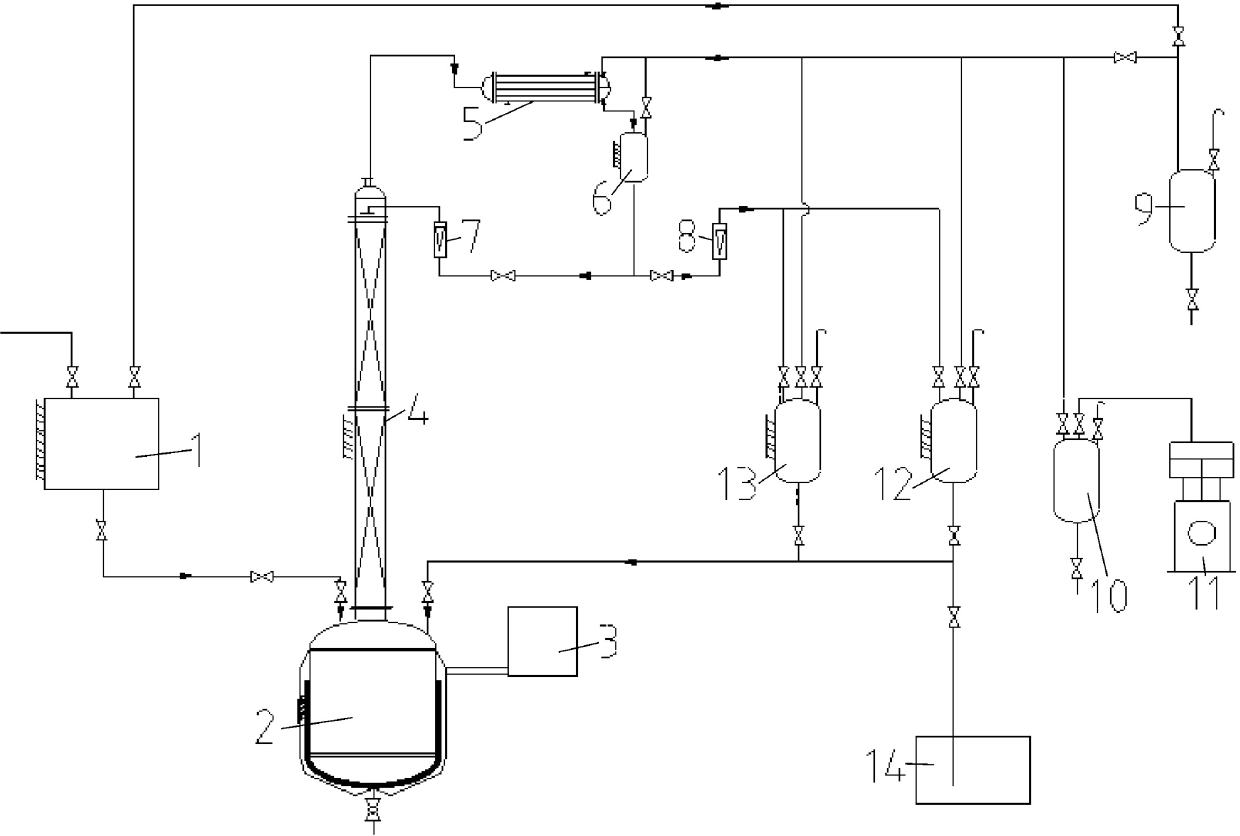

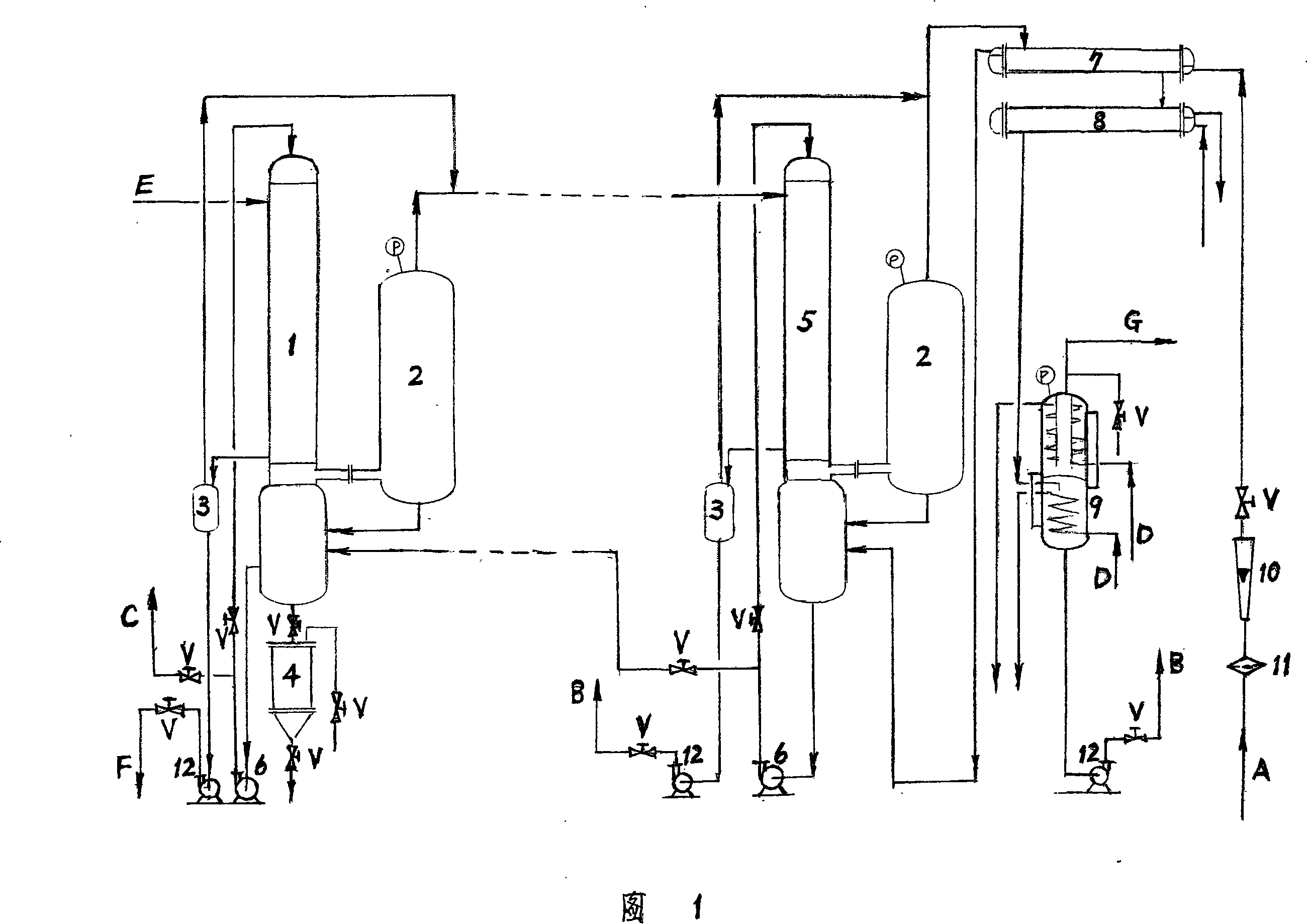

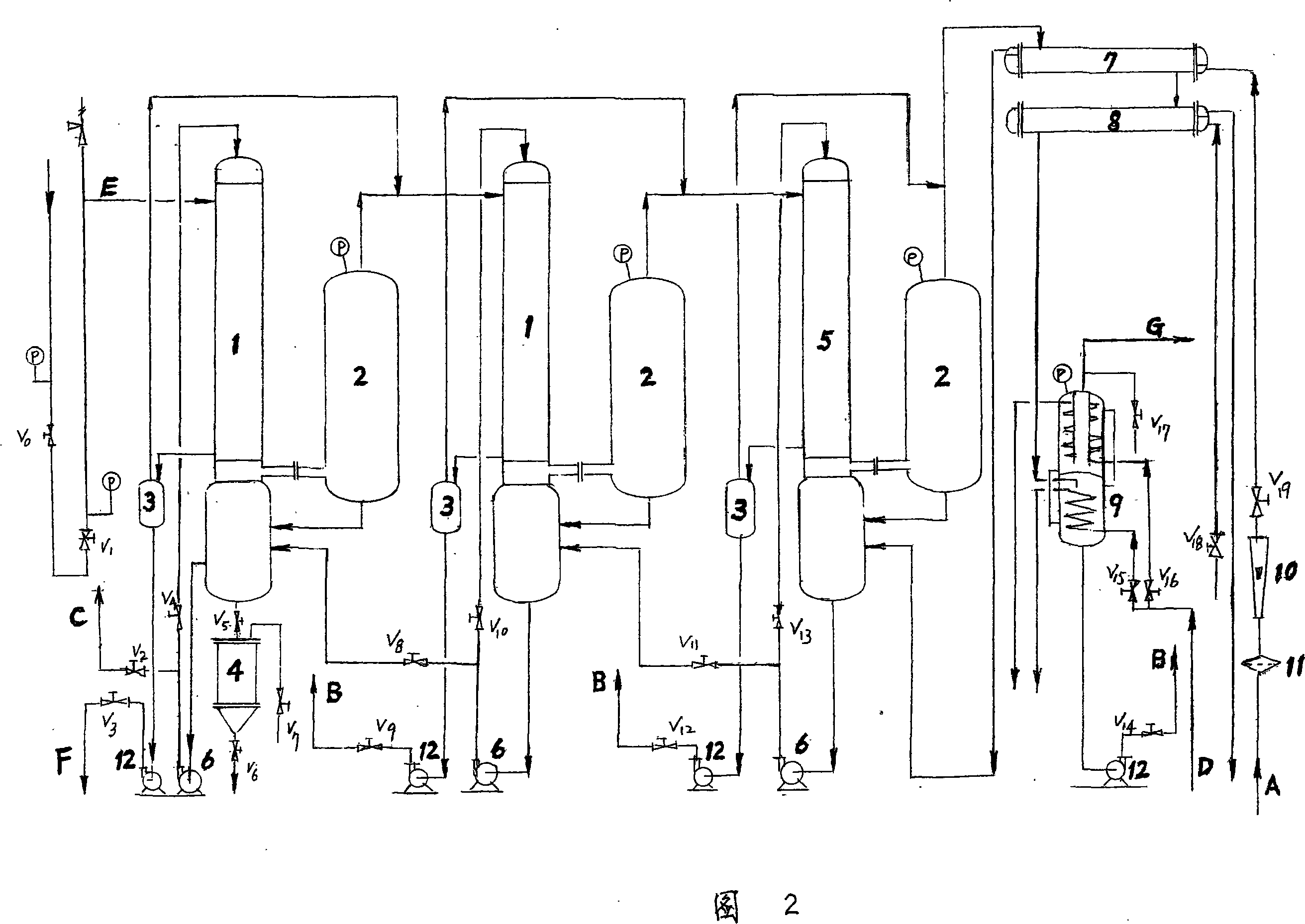

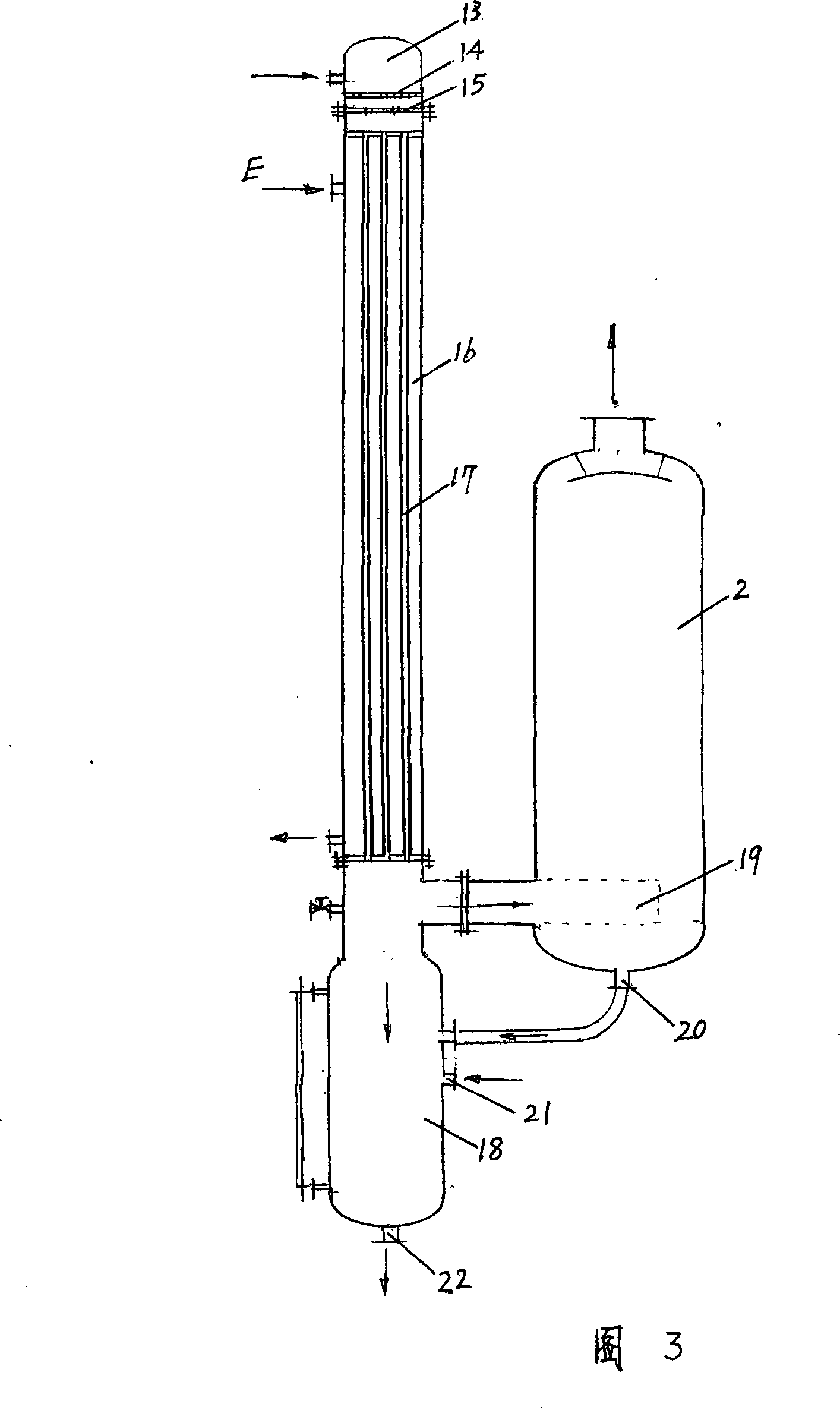

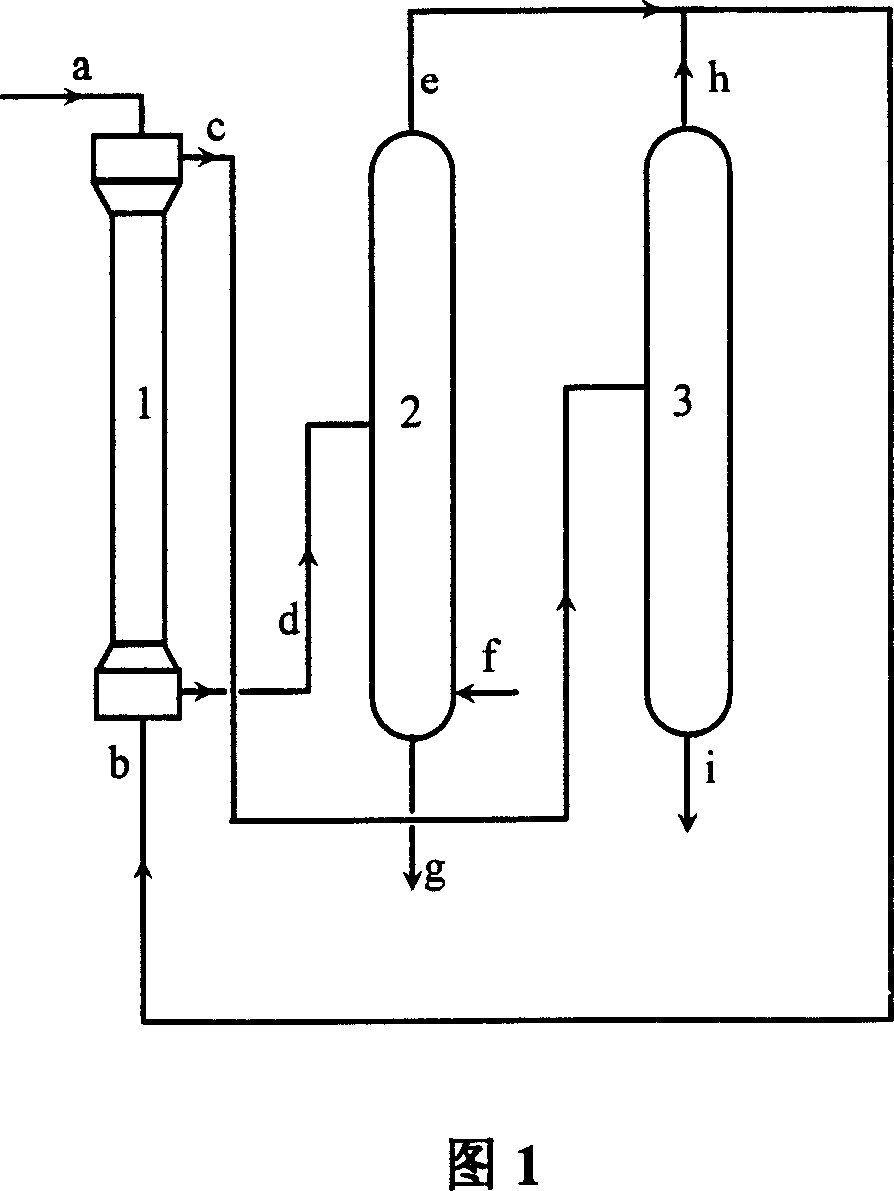

Process and equipment for negative pressure benzene removal

ActiveCN101544913ALow boiling pointReduce partial pressureCombustible gas purificationBenzeneThermodynamics

The invention discloses a process and equipment for negative pressure benzene removal , belonging to technology and equipment for recovering resultant in the coking industry, in particular to technology and equipment for removing and recovering benzene contained in coke gas. To solve the problems existing in the prior art, the invention develops the process for non-steam and non-distillation debenzolization under the negative pressure operation condition is developed and designs a novel debenzolization tower thus the disadvantages of equipment and process for benzene removal by adopting tubefurnace for heating rich oil under normal pressure can be overcome. The invention mainly has the advantages that firstly, as benzene is removed by the negative pressure process, the boiling point of the benzene and the partial pressure of the benzene in gaseous phase are lowered, and the benzene can be removed without using direct steam for steaming and blowing, thus waste water generated by the steam is reduced and the environment can not be polluted; secondly, the productive rate of dry coal due to benzene removal is increased to be more than 1.35 percent from the original 1 percent, and the recovery ratio of the benzene is increased to be more than 35 percent; and thirdly, compared with the existing benzene removal process, the process reduces the energy consumption by more than 20 percent.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

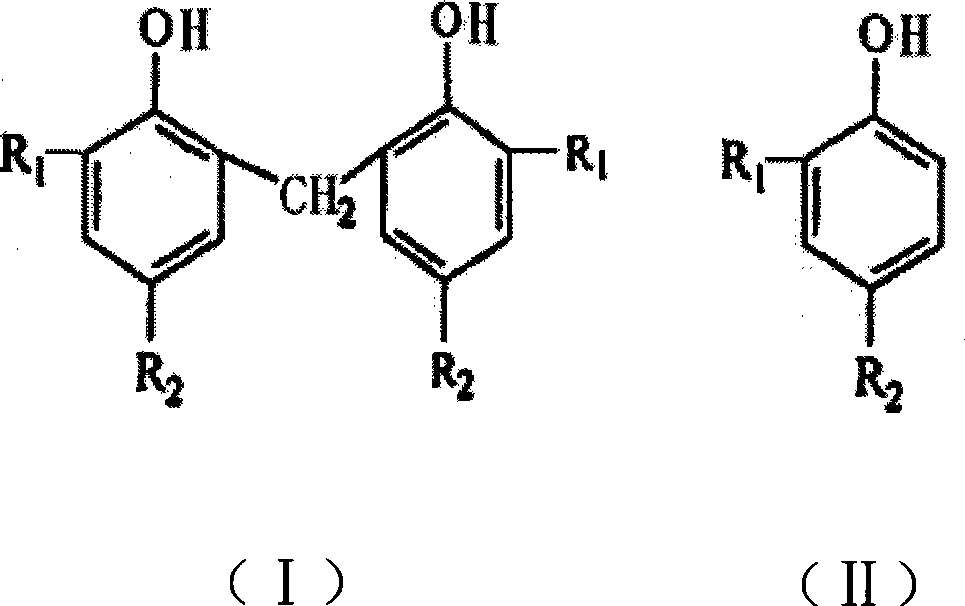

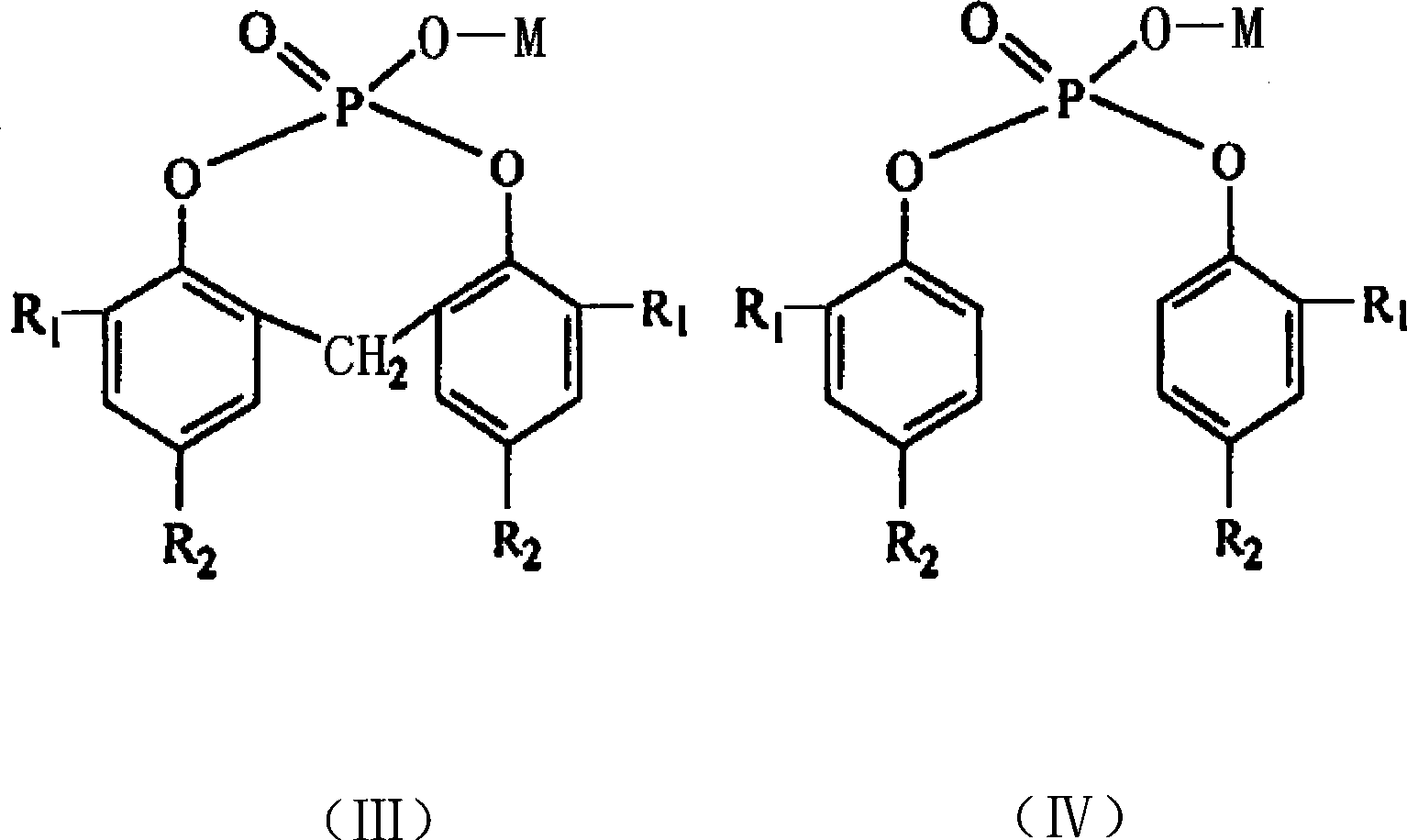

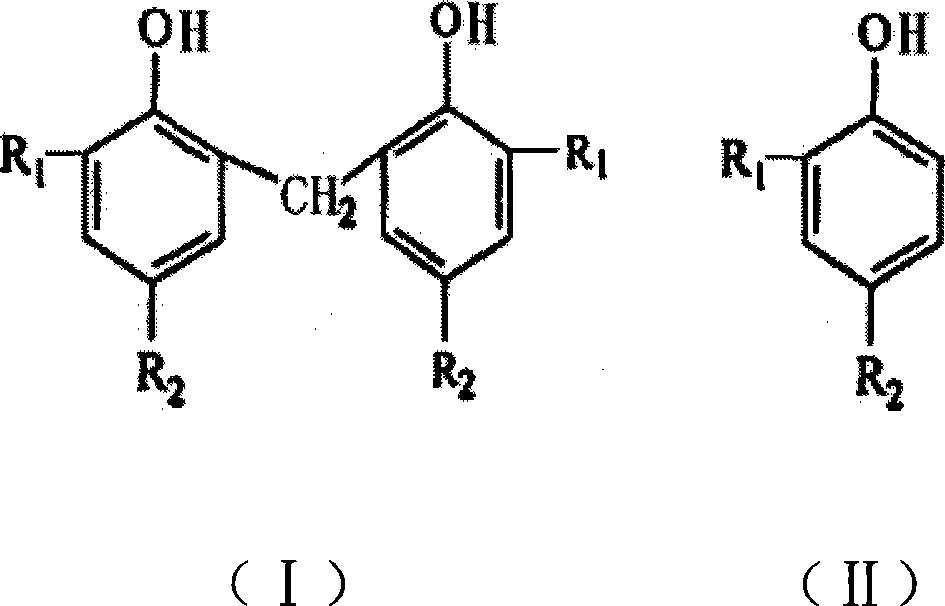

Preparation method for organic phosphate nucleating agent

The present invention relates to a method for preparing an organic compound, in particular to a method for preparing an organic phosphate nucleator, which includes the following steps: phosphorylation reaction, hydrolyzation and salification. Since the solvent for the phosphorylation reaction adopts halogenated hydrocarbon instead of benzene series compounds, which is cheap, the cost can be reduced, and since the yield of the organic phosphate synthesized with the halogenated hydrocarbon used as the solvent is higher, the yield of the final product, the organic phosphate, is greatly increased. Moreover, since the solvent does not adopt the benzene series compounds, toxicity is low, non-burning operation is safe, environment can be protected, recycling is convenient, and the diaryl-substituted organophosphate metal salt used as nucleator prepared by the method has obvious effect in the improvement of the processing property of resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

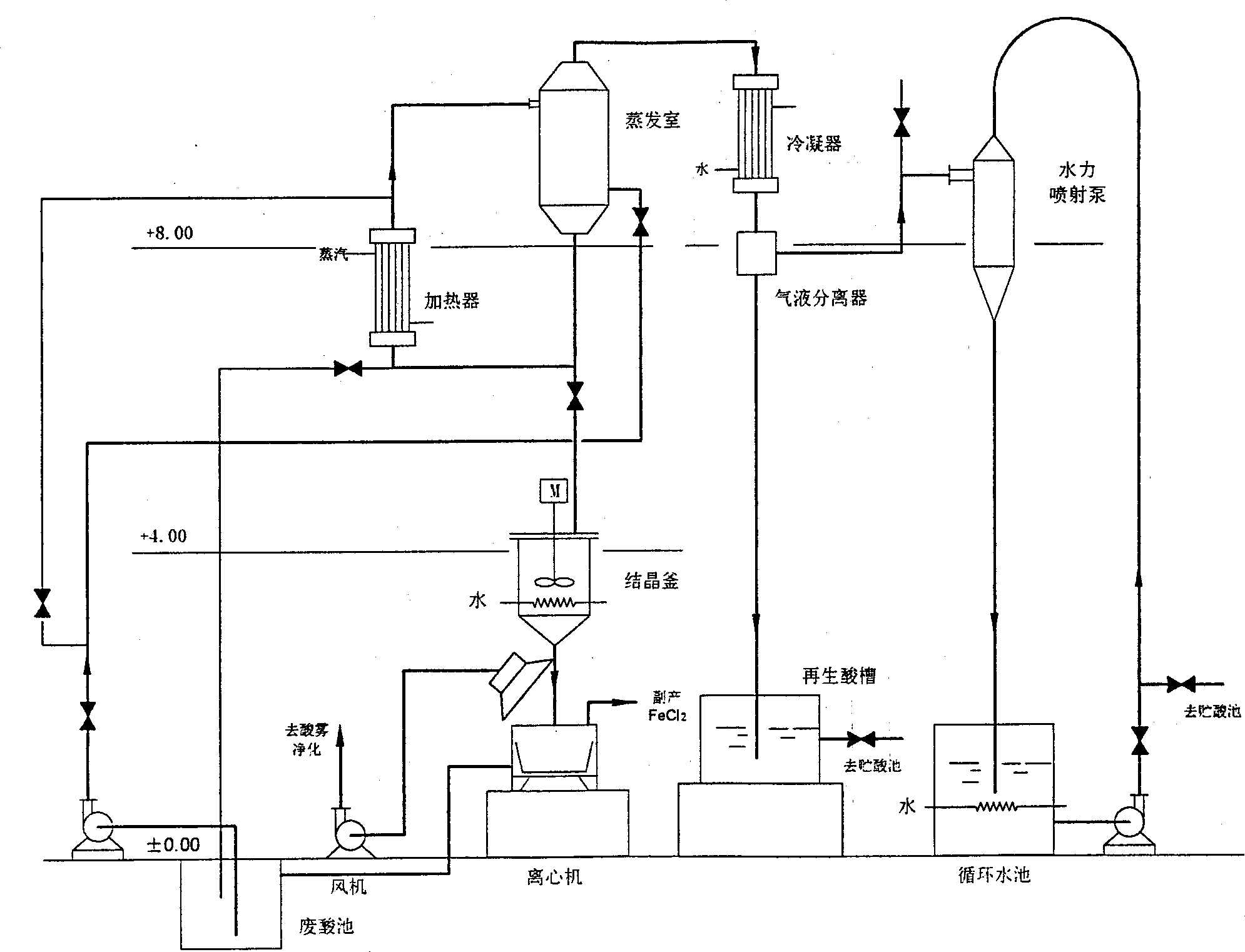

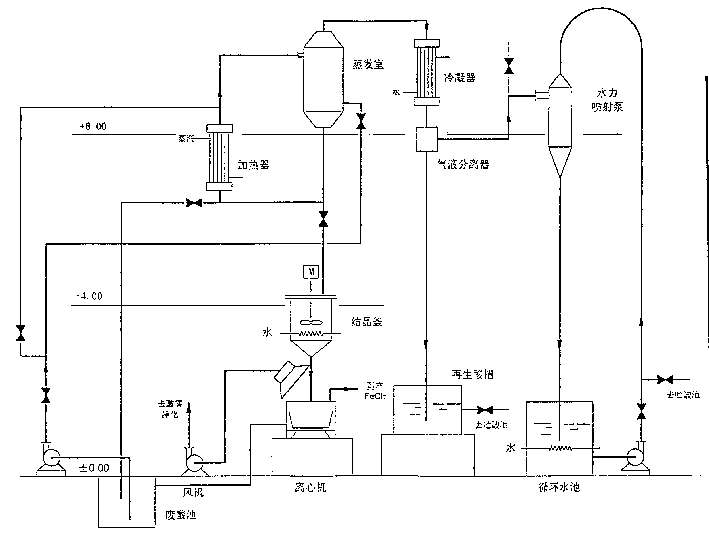

Process for treating waste pickling liquid of hydrochloric acid by negative-pressure external-circulation evaporation-concentrating crystallization method

InactiveCN1373243ALow boiling pointReduce leakageWater/sewage treatment by heatingLiquid wasteEvaporation

A process for treating used pickling liquid of hydrochloric acid includes pumping said waste liquid into evaporating chamber, heating it by steam heater while circulating the waste liquid between heater and evaporating chamber, evaporation concentrating to generate ferrous chloride crystal, centrifugal separation to obtain solid ferrous chloride crystal, and returning mother liquid back to waste acid pool. Its advantages are long service life and less leakage of hydrogen chloride.

Owner:NANCHANG UNIV

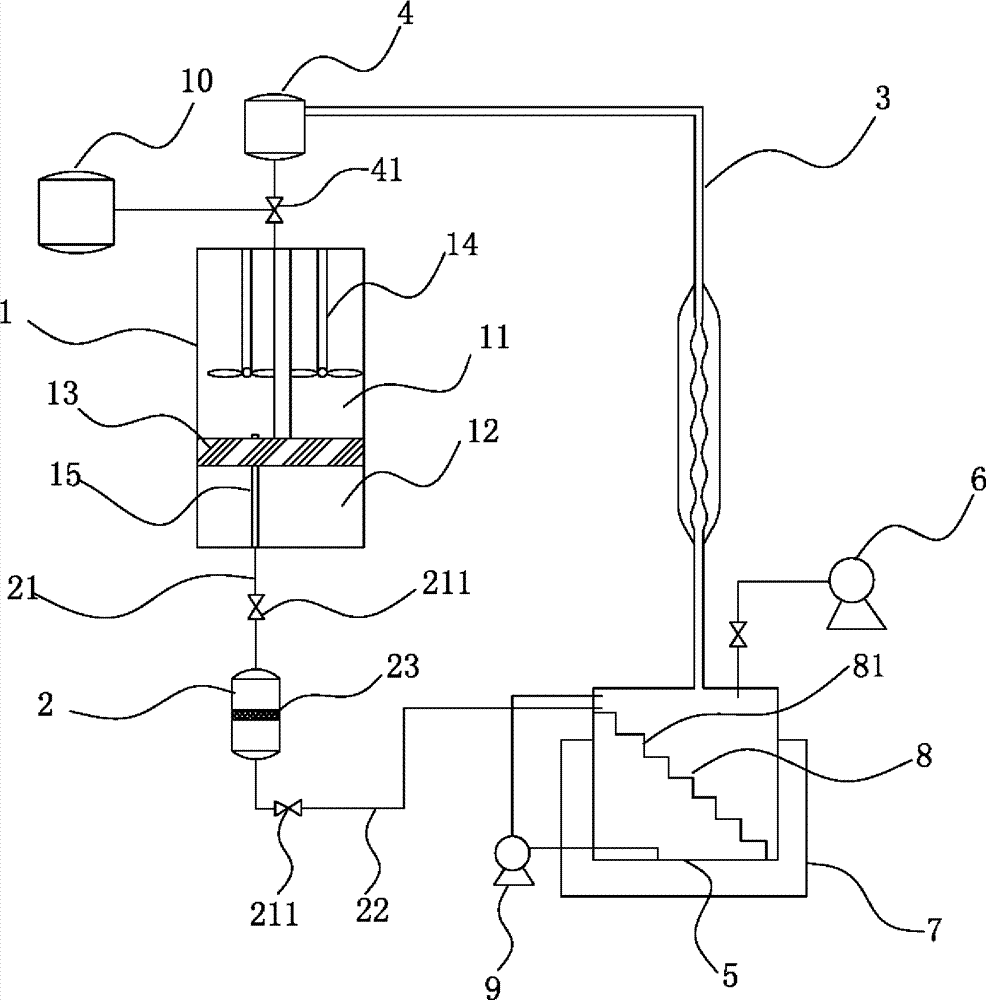

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614AIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

The invention relates to the technical field of extracting and concentrating of the traditional Chinese medicine, and in particular relates to a method and a device for extracting and concentrating the traditional Chinese medicine. The method for extracting and concentrating structurally comprises an extracting unit and a concentrating unit, wherein the extracting unit comprises an extracting tank and a liquid medicine storage tank, wherein a piston capable of moving up and down is arranged in the extracting tank; when the piston moves upwards under the action of the driving force, dredges of decoction in a pressurizing chamber are pressurized and further squeezed; the concentrating unit comprises a concentrating container, a vacuum pump and a heating device for heating up the concentrating container, wherein a step-shaped evaporation plate assembly of a liquid medicine thin film is formed in the concentrating container, so that the liquid medicine can be circulated and concentrated. Compared with the prior art, the extracting and concentrating efficiency is high, the heating time is short, and the damages to the active ingredients of the medicine are reduced.

Owner:GUANGDONG MEDICAL UNIV

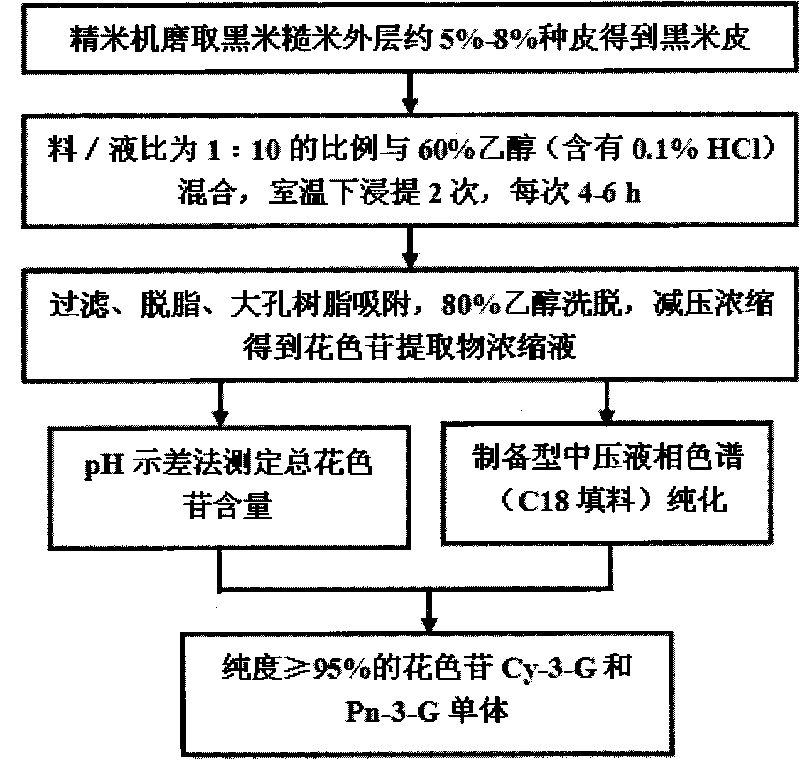

Method for separating high-purity anthocyanin monomers from black rice

ActiveCN101723996AGood choiceGood degreasing effectSugar derivativesSugar derivatives preparationFreeze-dryingEvaporation

The invention provides a method for separating high-purity anthocyanin monomers from black rice. The method comprises the following steps of: grinding 5 to 8 percent of episperm on the outer layer of black rice and brown rice to obtain black rice pericarp, leaching anthocyanin in the black rice pericarp by acidized ethanol, and extracting and defatting petroleum ether; performing primary purification of ethanol extracts of the black rice pericarp by using macroporous resin; separating the anthocyanin in coarse extracts of the anthocyanin of the black rice pericarp by the medium pressure preparation liquid phase chromatographic technique, collecting two leading anthocyanin components, which are cyanidin-3-glucoside and paeonidin-3-glucoside, in the black rice pericarp respectively according to the obtained chromatogram, and performing rotary evaporation of eluent at a temperature of below 45 DEG C until all methanol is gone, and performing freeze-drying to obtain powder of the anthocyanin monomers.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

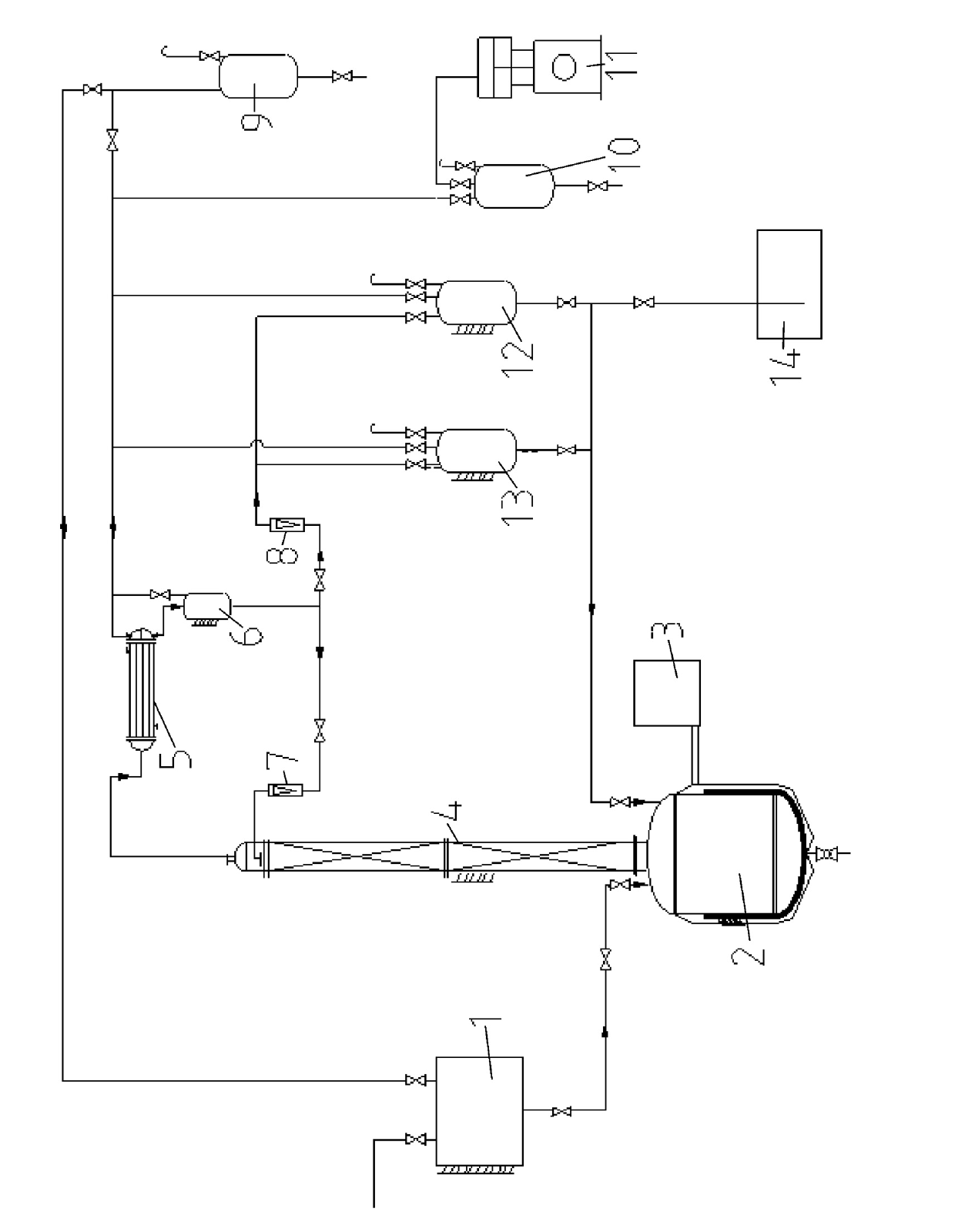

Method and device for performing refined separation on high-purity yellow phosphorous

ActiveCN101912691AImprove separation efficiencyLow boiling pointVacuum distillation separationPhosphorus compoundsBuffer tankBoiling point

The invention discloses a method and a device for performing refined separation on high-purity yellow phosphorous. A raw material storage tank is connected with a tower bottom; a rectifying tower is positioned above the tower bottom; one end of a condenser is connected with a tower top of the rectifying tower, while the other end is connected with a return tank; the return tank is connected with the tower top of the rectifying tower through a return flowmeter and connected with a front fraction tank and a product tank through a product flowmeter, and a discharge pipe of the product tank is connected with a product collecting tank; a vacuum pump is connected with the condenser, the return tank, the front fraction tank and the product tank through a buffer tank; and a nitrogen tank is connected with the raw material storage tank, the condenser, the return tank, the front fraction tank and the product tank. Through operation of performing rectification under reduced pressure and changinga reflux ratio, the method and the device reduce the boiling point of each component of the material greatly, change the relative volatility among the components, and have the advantages of uniform heating in the tower bottom, simple operation process, high separation efficiency and high purity of the product at the same time.

Owner:湖北兴福电子材料股份有限公司

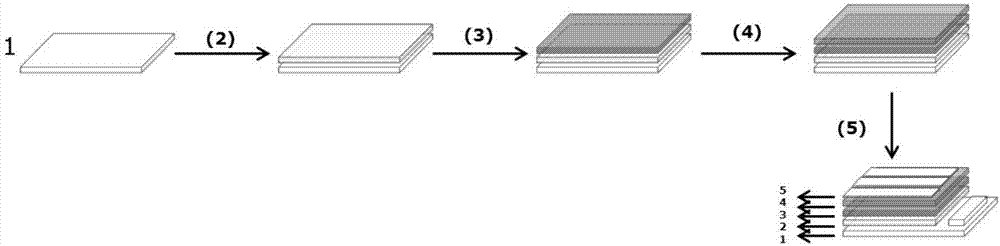

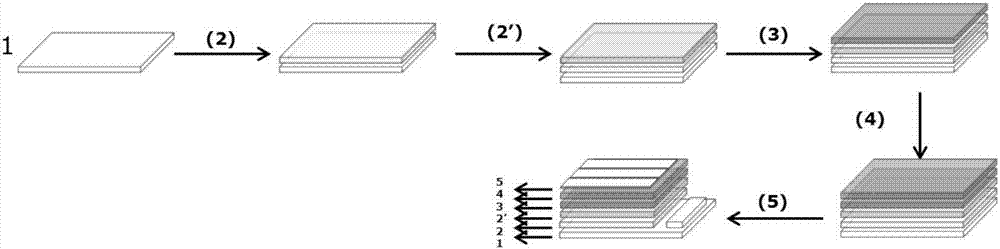

Solar energy cell with double-layer perovskite film structure and manufacturing method thereof

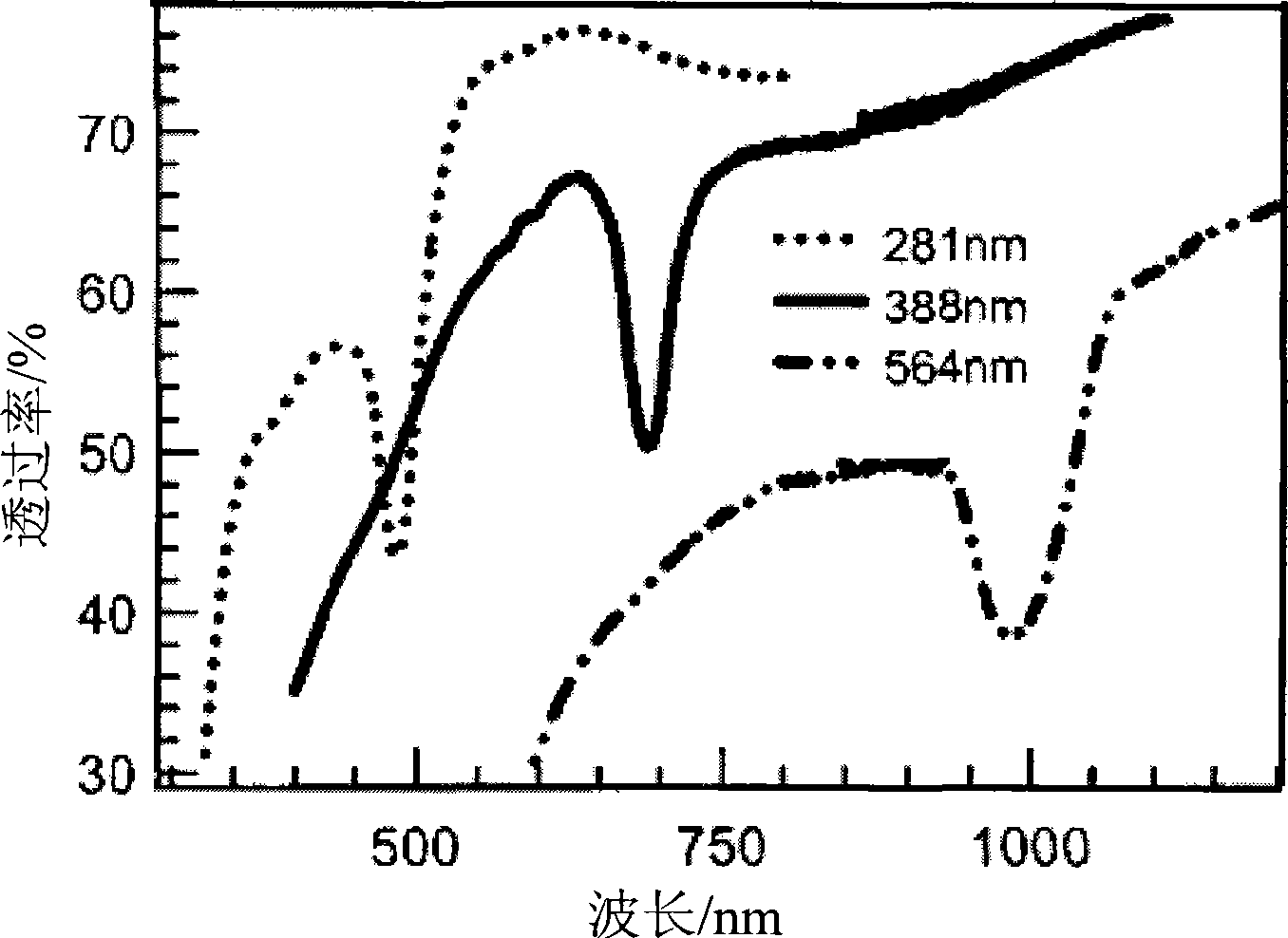

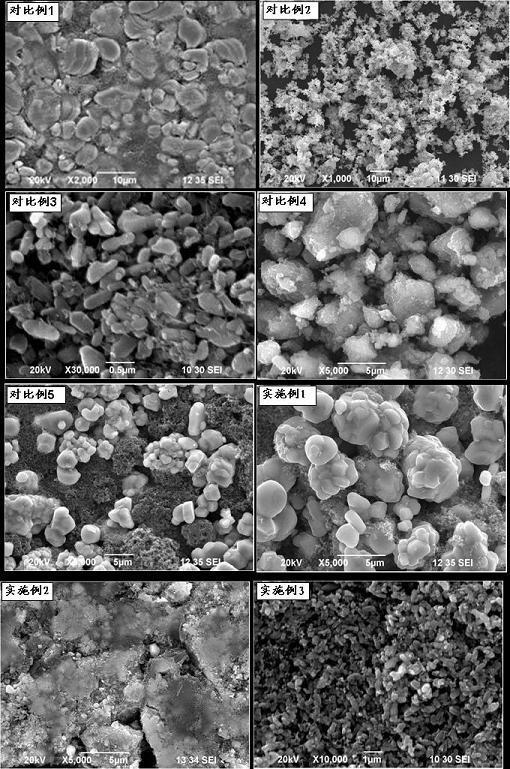

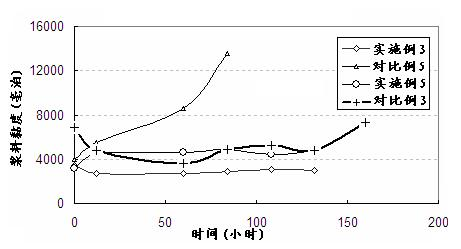

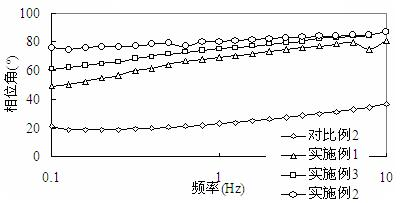

ActiveCN106910828AIncrease UV-Vis absorptionHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingSilver electrodeEngineering

The invention discloses a manufacturing method for the solar energy cell with double-layer perovskite film structure, and the method comprises the following steps: 1) selecting a conductive substrate; etching patterns on the conductive substrate and obtaining the etched conductive substrate; 2) preparing an electron transport layer or a hole transport layer; (3) preparing a film with a double-layer perovskite structure; 4) preparing a hole transport layer or an electron transport layer; and 5) hotly plating a gold or silver electrode on the hole transport layer or the electron transport layer to obtain an n-I-P-type or p-I-N-type solar cell with the double-layer perovskite thin film structure. The invention further discloses a solar energy cell manufactured and obtained from the above method. The manufacturing method is environmentally friendly, can change the morphology, the crystallinity and the interface of the perovskite film and increases the photoelectric performance of a device.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for purifying lutein esters

The invention discloses a method for purifying lutein esters and in particular relates to a method for extracting high-purity lutein esters from marigold ointment. The method is characterized by dissolving the marigold ointment into ethyl acetate at 25-80 DEG C and stirring the mixture for 1-6h; adding absolute ethyl alcohol to the liquid obtained through heat filtration and stirring the mixture at 20-70 DEG C for 0.5-5.0h to form uniform solution and then filtering the solution after cooling the solution at minus 5-30 DEG C for 5-20h; and then washing filter cakes with lower alcohol and drying the solid under vacuum to remove the solvent residues, thus obtaining the required high-purity lutein esters. The content of the lutein esters is 70-80%. The method is high in product yield, simple and convenient to operate and easy to realize large-scale industrial production.

Owner:YUNNAN RAINBOW BIO TECH

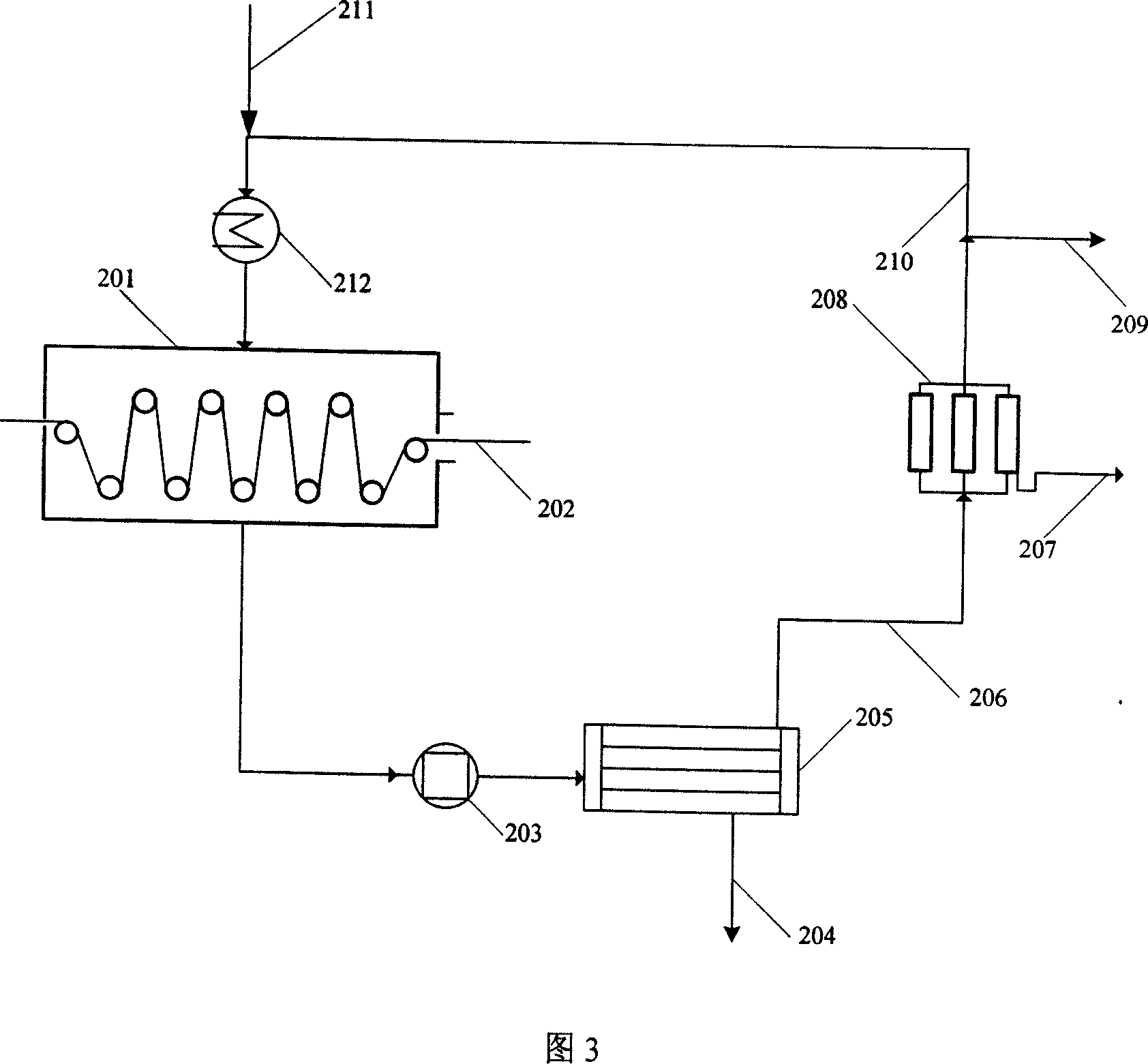

Pleietrepie counter current falling film evaporator of organic solvent recycle

InactiveCN101229449AControl circulation volumePromote circulationMultiple-effect evaporationSteam condensationGas phase

The invention provides a multiple effective reflux falling film evaporation system used for recycling organic solvent. The invention is mainly used for recycling the solvent in water solution of the organic solvent during the concentration production process of plant extractions in food industry and biopharmaceutical industry. The invention adopts falling film evaporators with high heat transmission coefficient and small terminal temperature difference to form the multiple effective evaporation system. Each evaporator is provided with a solution circulating pump which increases down-flow quantity in a heat transfer tube and avoids dry wall of a heat transfer surface and enhances heat transferring, thus having great evaporation ability and high efficiency. The condensate of each evaporator enters into a corresponding condensate tank respectively and is discharged by the pump and recycled. A gas-phase communicating pipe is arranged between the condensate tank and a gas-liquid separator, which guarantees the discharge of noncondensable gas under vacuum operation condition, thus being beneficial for improving condensing and heat transferring efficiency. The invention is a new technique, new technology and new device used in concentration process of the extractions of the organic solvent and used for recycling solvent, which has high recycling rate, little energy consumption and convenient operation and can use a vacuum low temperature evaporation concentration production device in continuous and intermittent production operation.

Owner:DALIAN UNIV OF TECH

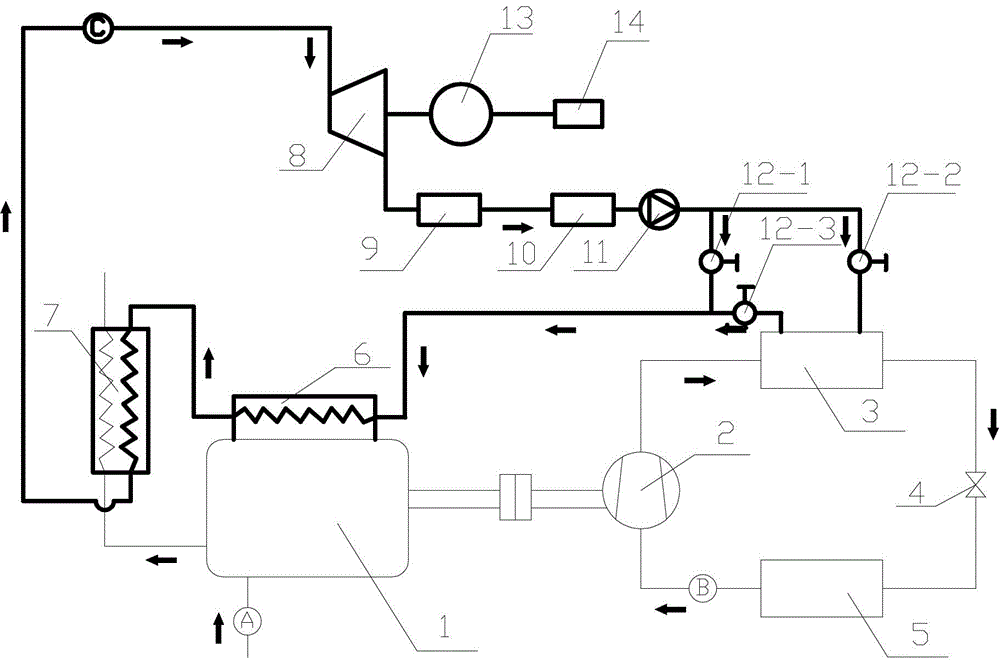

Gas heat-pump energy supplying system based on power generation of third working medium

InactiveCN102748895ALow boiling pointImprove system efficiencyInternal combustion piston enginesClimate change adaptationLiquid storage tankRecuperator

The invention discloses a gas heat-pump energy supplying system based on power generation of a third working medium. The principle and the structure of the gas heat-pump energy supplying system are as follows: a heat pump system formed by connecting a compressor, a condenser, an electric expansion valve and an evaporator in sequence is driven by a gas engine; and a waste heat recovery and circle power generation system comprises a gas-engine cylinder sleeve heat exchanger, a gas waste-heat heat exchanger, a turbine, an engine, a cooler, a liquid storage tank and a circulating pump and the like. The heat pump system and the waste heat recovery and circle power generation system are connected together by a second stop valve and a third stop valve. After absorbing the waste heat of the engine from the condenser, the gas-engine cylinder sleeve heat exchanger and the gas waste-heat heat exchanger, the third working medium enters into the turbine for doing work so as to drive a power generator to generate power. The gas heat-pump energy supplying system disclosed by the invention has the advantages that primary energy input of natural gas is adopted, and off-grid independent operation can be realized by the waste heat recovery and circle power generation system, so that the efficiency and the stability of the system are greatly improved, simultaneously the operating cost of the system is reduced, and the economic and energy-saving effects are achieved.

Owner:YANTAI UNIV

Method of recovery phenol from waste water and system thereof

InactiveCN1919818ALow boiling pointSmall latent heatOrganic chemistryOrganic compound preparationOrganic solventWastewater

The invention discloses a recycling method and system in the phenolwaste water, which comprises the following steps: adopting ketone organic solvent as extractant; adopting extracting tower, organic solvent recycling tower and stripping tower to extract; distilling; stripping to obtain the product. The system is composed of extracting tower, organic solvent recycling tower, stripping tower and corresponding connecting pipe.

Owner:TSINGHUA UNIV

Method for degrading and recycling unsaturated polyester resin material

ActiveCN104326907AImprove immersionEfficient fractureOrganic compound preparationPreparation from carboxylic acid anhydridesFiberPolyester

The invention provides a method for degrading and recycling an unsaturated polyester resin material. The method comprises the following steps: preparing a reaction solution by a catalyst and a reaction solvent; mixing the reaction solution with an unsaturated polyester material to prepare an unsaturated polyester degrading system; heating the prepared unsaturated polyester degrading system for degradation; adding a separation solvent into the cooled unsaturated polyester degrading system; filtering to obtain solids, namely enhanced fibers and a catalyst; drying and sieving, and recycling; adding water into filtrate so as to separate out a polymer degrading component containing a styrene structure, and filtering; drying and recycling the filtered polymer solids containing the styrene structure; and evaporating filtrate to obtain substances mainly comprising resin degraded products which do not contain the styrene structure. The method for degrading and recycling the unsaturated polyester resin material has the advantages of low cost, moderate recycling conditions and high degrading activity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

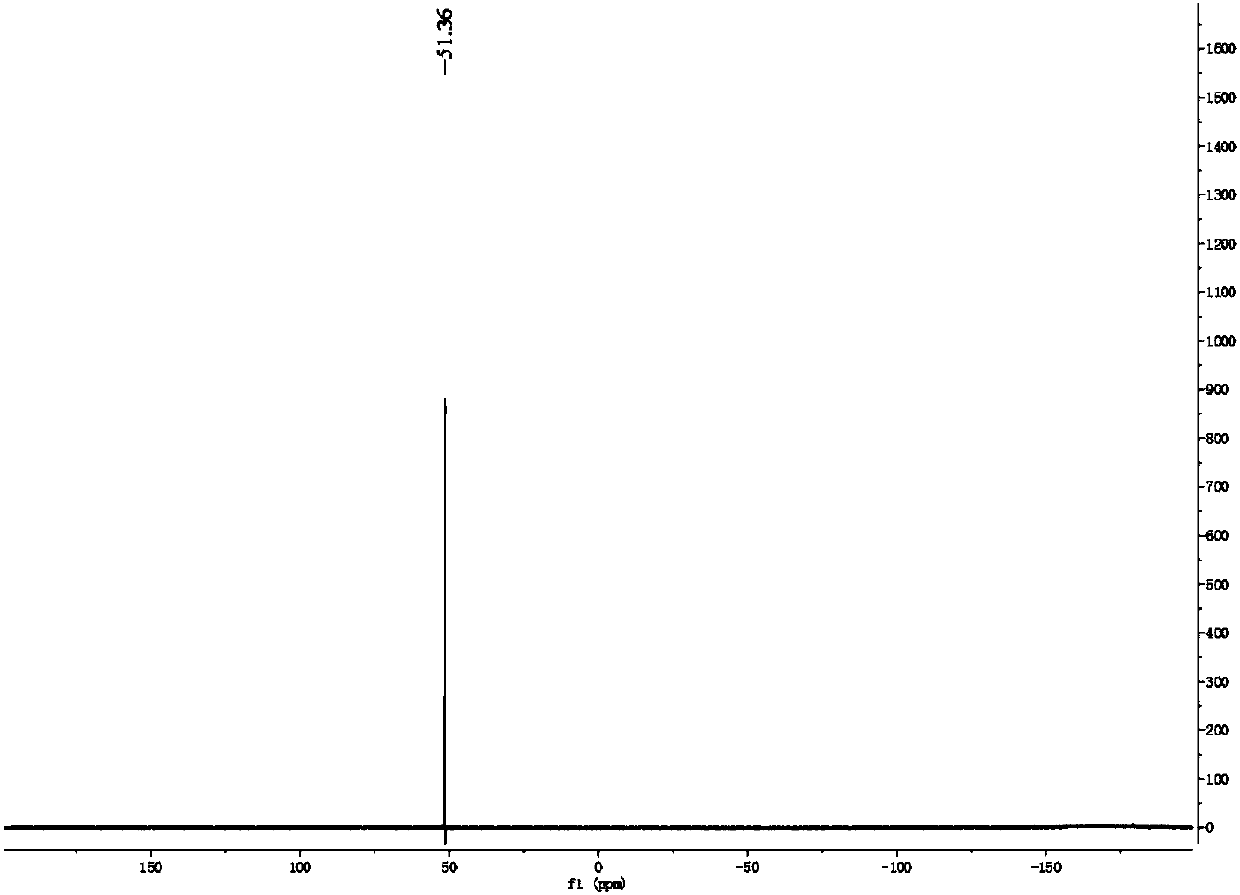

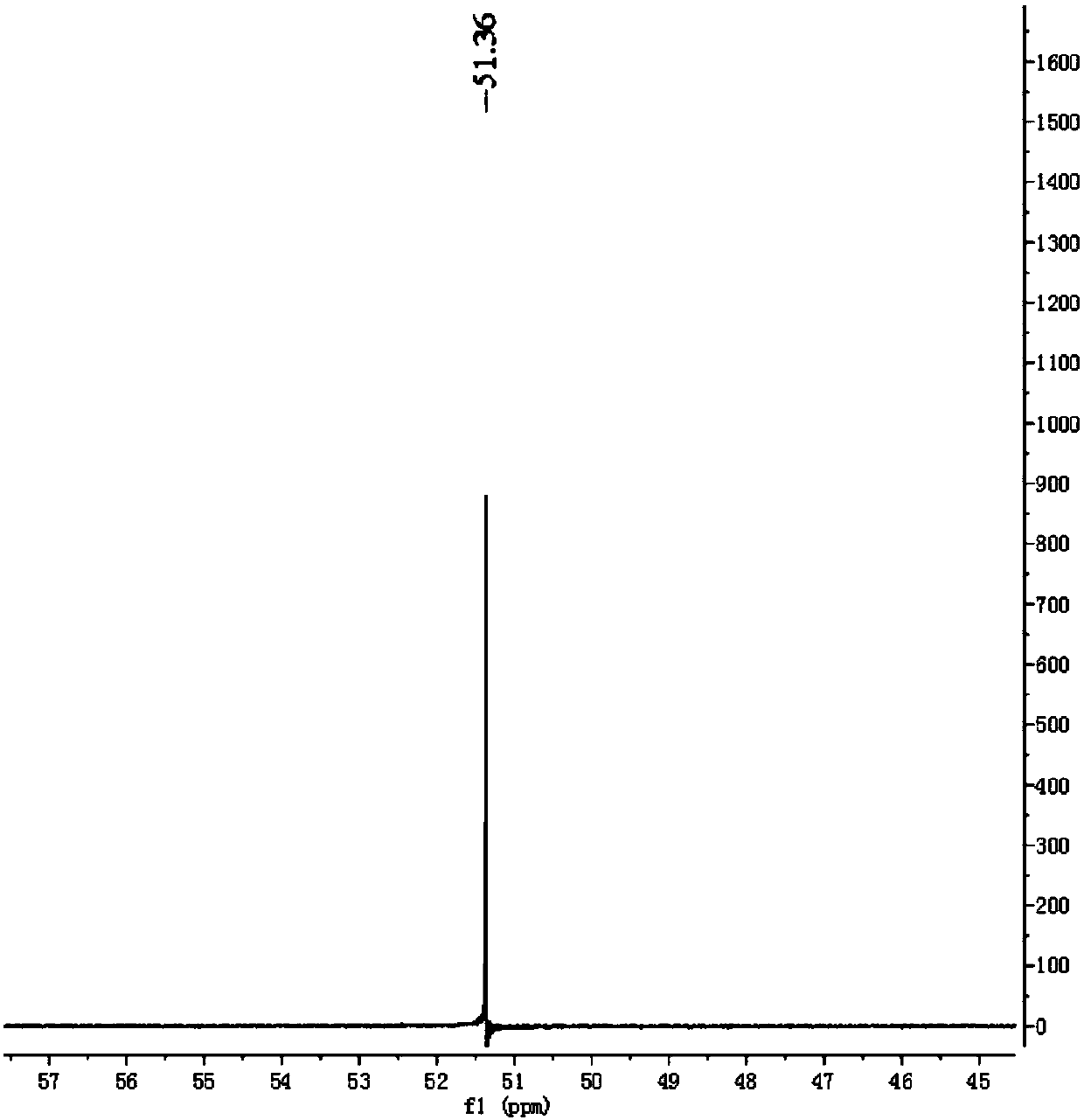

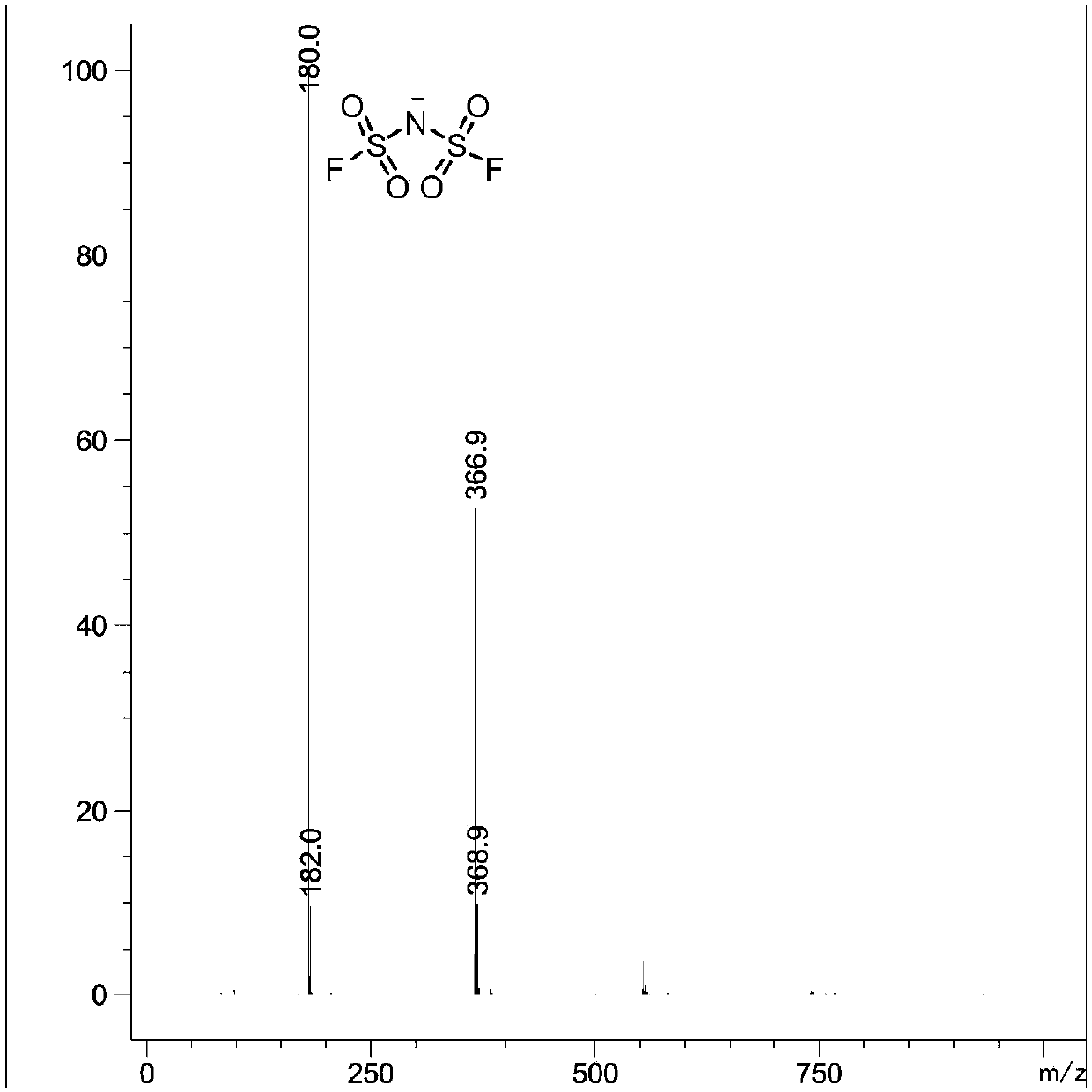

Method for preparing imidodisulfuryl fluoride lithium

The invention provides a method for preparing imidodisulfuryl fluoride lithium. The method comprises the following steps: (1) reacting imidodisulfuryl fluoride with antimony trifluoride under a solvent free condition, and distilling to obtain imidodisulfuryl fluoride lithium intermediate; (2) reacting metal lithium with anhydrate low alcohol, and concentrating and drying to obtain anhydrate low alcohol lithium; and (3) reacting the imidodisulfuryl fluoride lithium with lithium alkoxide, concentrating, pulping, filtering and drying to obtain a high-purity imidodisulfuryl fluoride lithium product. The method for preparing the imidodisulfuryl fluoride lithium has the characteristics of low cost, high purity and simple operation, and is suitable for industrial production.

Owner:JIANGSU LEE & MAN CHEM +2

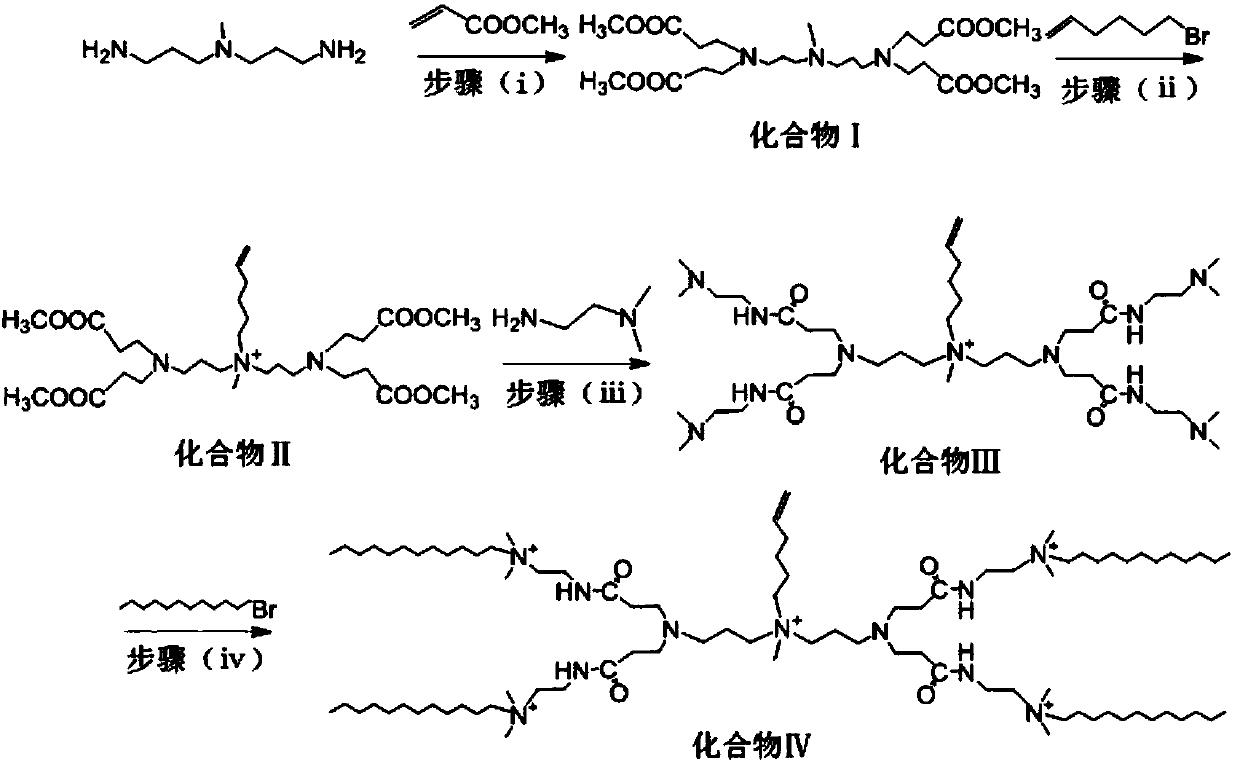

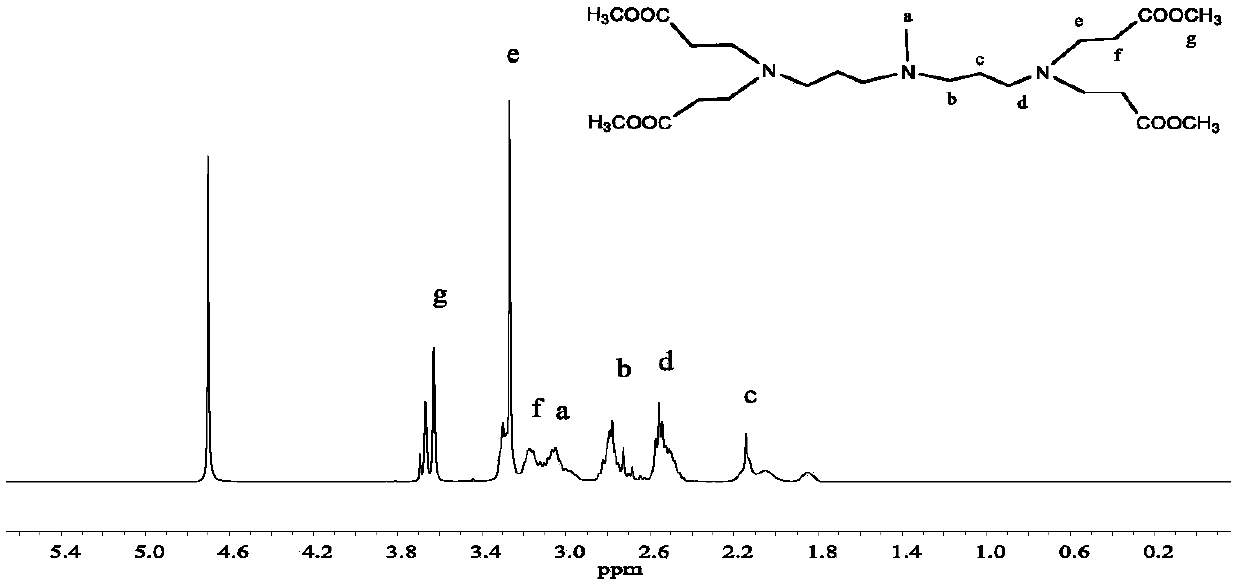

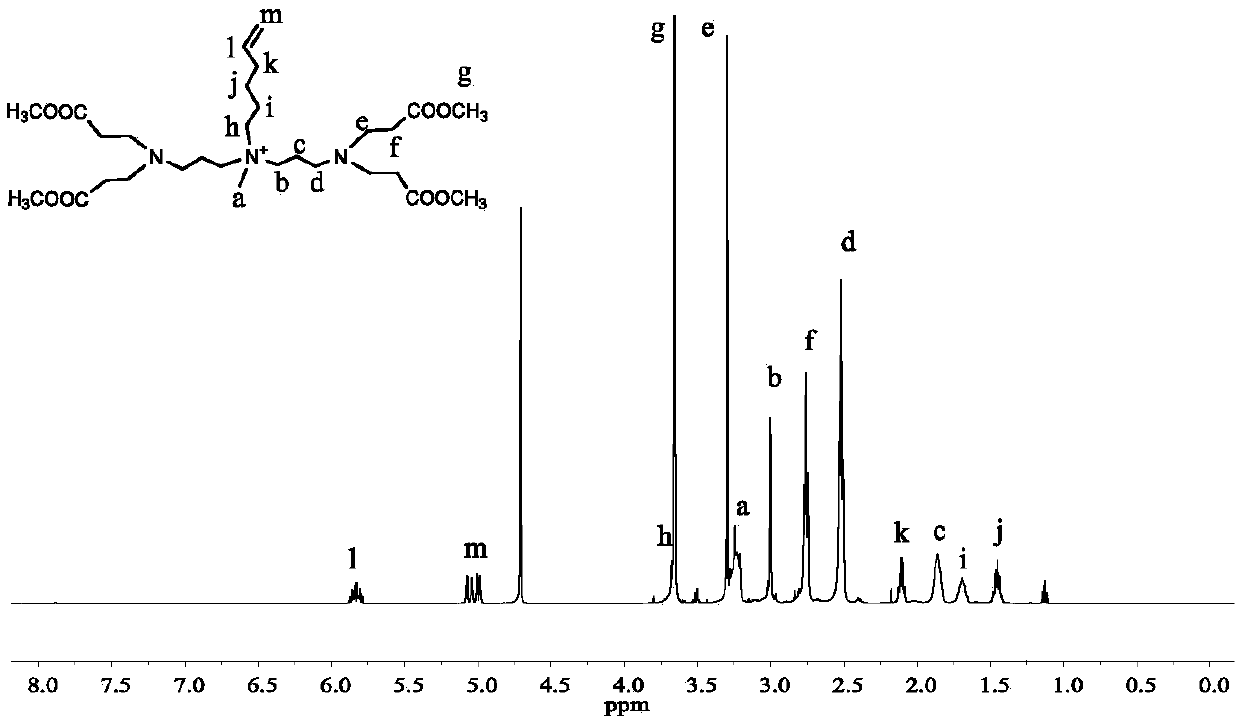

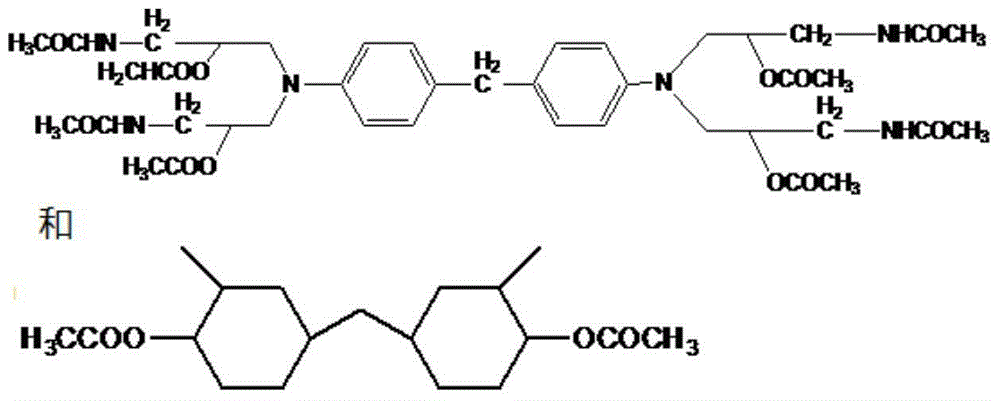

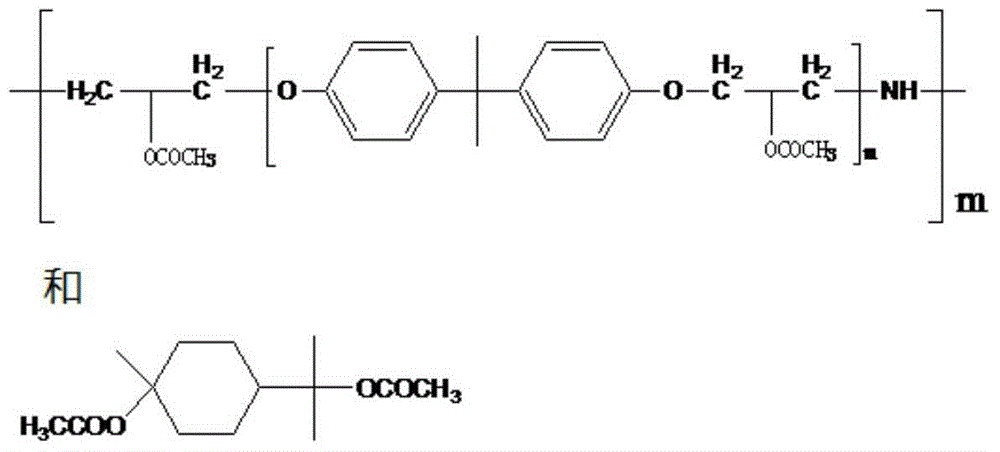

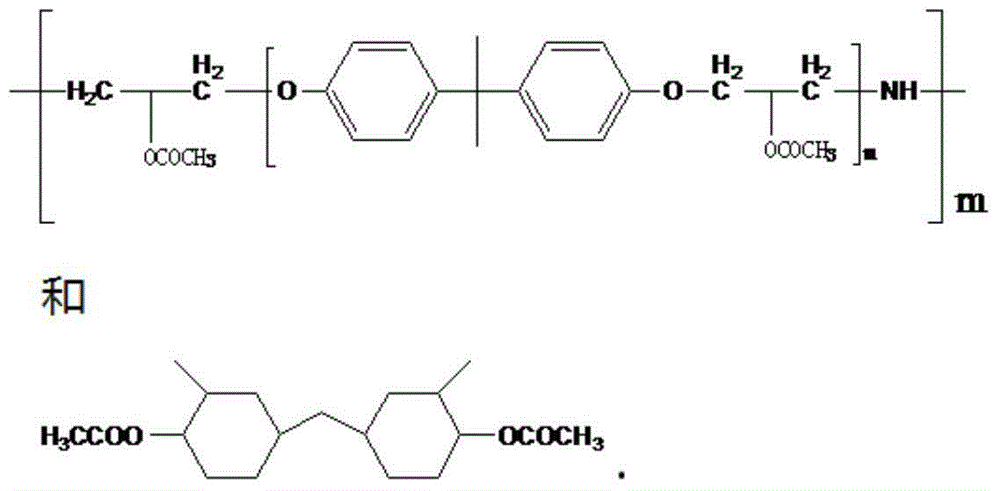

Preparation method of dentritic tetrameric cationic quaternary ammonium surface activity monomer

InactiveCN108033895AEasy to purifyRaw materials are easy to getOrganic compound preparationTransportation and packagingSolvent1-Hexene

The invention relates to a preparation method of a dentritic tetrameric cationic quaternary ammonium surface activity monomer, which includes steps of fully mixing methyl acrylate and monomer 3, 3-diamido-N-methyldipropylamine and then performing addition reaction; adding 6- bromine-1-hexene to perform quaternization reaction; depressurizing and removing solvent; then adding absolute ether as precipitator to wash for three times; adding N, N-dimethyl-1, 3-propane diamine to perform amidation; depressurizing and removing excessive N, N-dimethyl-1, 3-propane diamine to perform amidation; addinglong-chained monomer 1-dodecyl bromide to perform quaternary amination reaction; after finishing the reaction, repeatedly washing for over three times to obtain the pure dentritic tetrameric cationicquaternary ammonium surface activity monomer. The preparation method is easy to obtain raw materials, simple in synthesis step and product purification, high in yield, safe in use, convenient to store, low in temperature required by the process, simple and easy-controlled operation, low in energy consumption, wide in application prospect; the preparation method is applicable to the industrial production.

Owner:SHANDONG UNIV

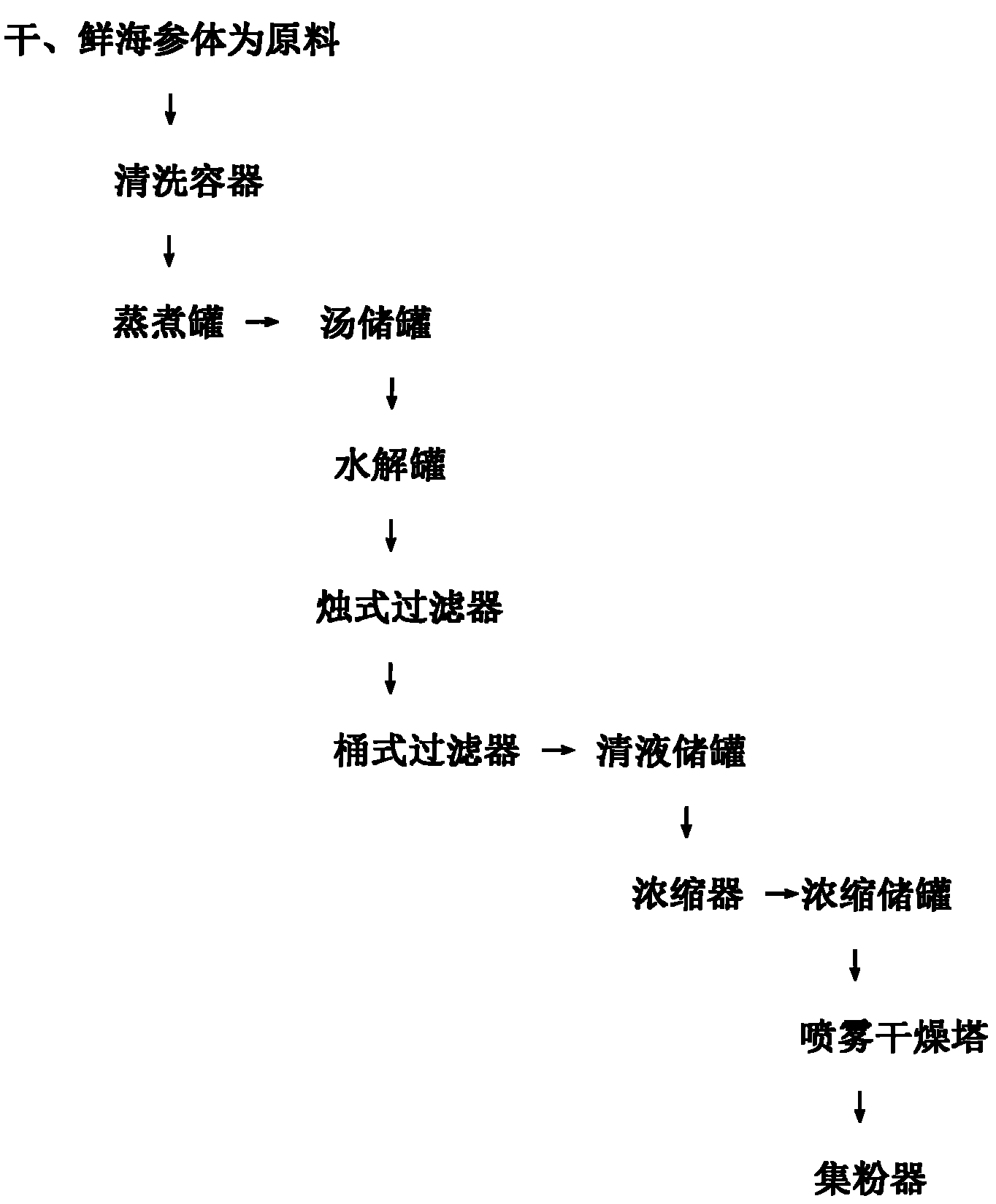

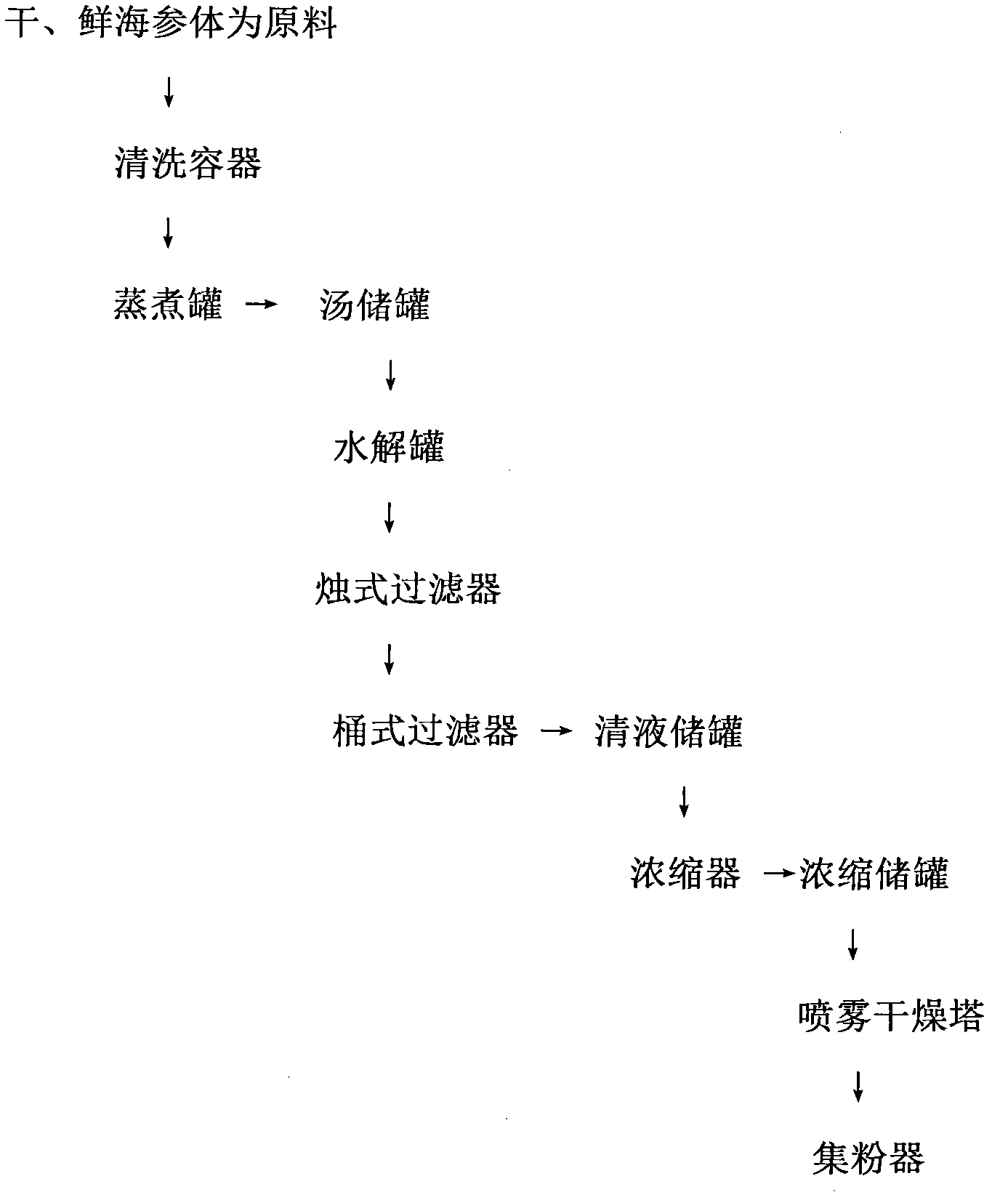

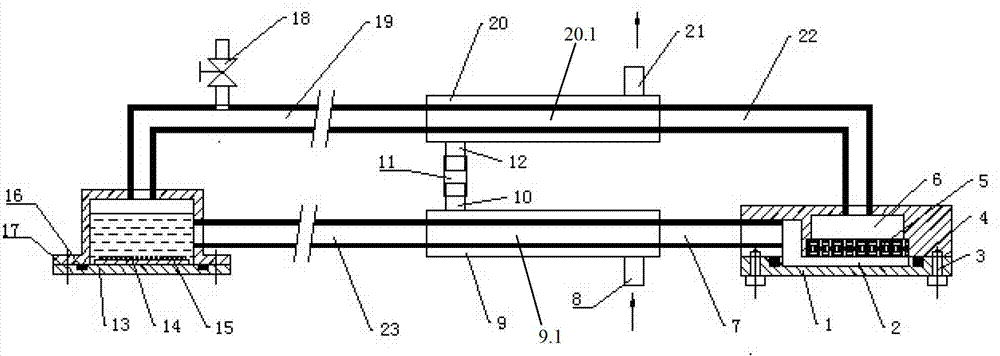

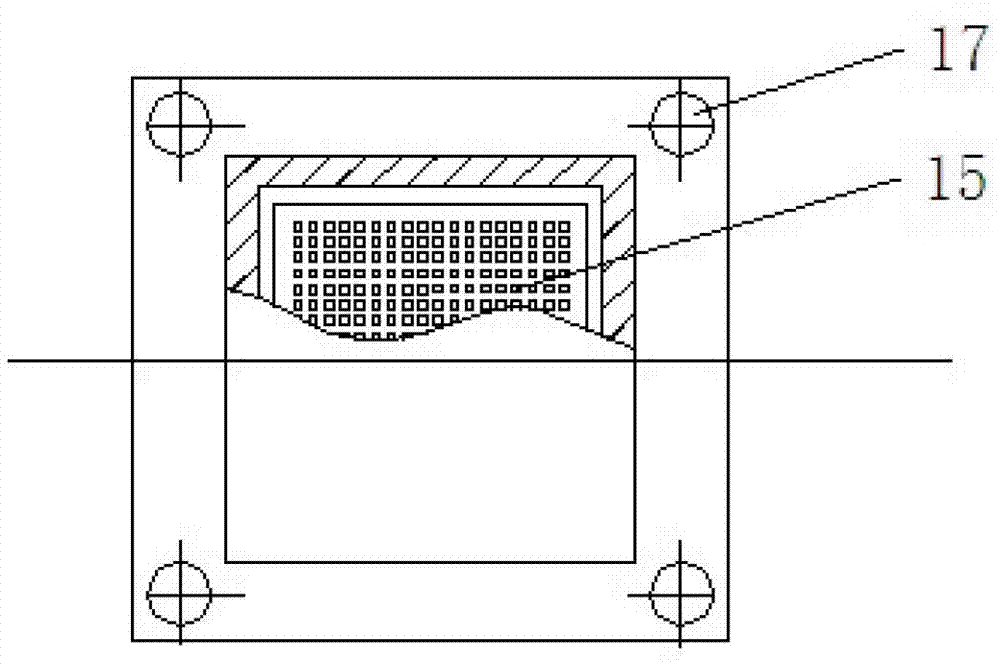

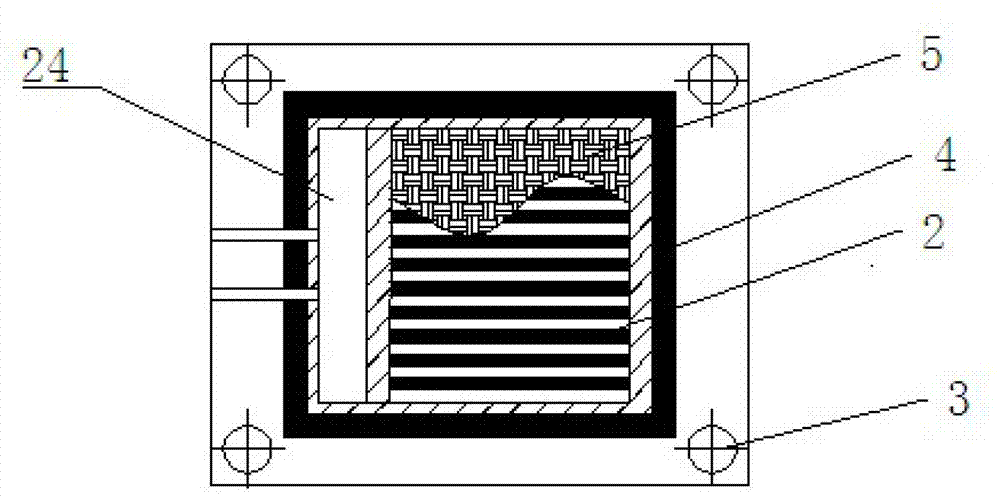

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

Loop heat pipe cooling device with pool boiling function

InactiveCN103200803ASmall sizeSimple structureCooling/ventilation/heating modificationsSuction forceEngineering

The invention discloses a loop heat pipe cooling device with a pool boiling function. The loop heat pipe cooling device comprises a flat plate type evaporator, a first condenser, a pool boiling evaporator and a second condenser, wherein a compensator is arranged on the top most portion of a metal cavity of the flat plate type evaporator, and an outlet of the flat plate type evaporator is connected to an outlet of the pool boiling evaporator through a first connecting pipeline. The first condenser is a casing pipe type condenser and is mounted on the first connecting pipeline in a sleeved mode. The outlet of the pool boiling evaporator is connected with the compensator through a second connecting pipeline. The second condenser is also a casing pipe type condenser and is mounted on the second connecting pipeline in a sleeved mode. A condensate outlet of the first condenser is connected with a condensate inlet of the second condenser through a pipeline. The loop heat pipe cooling device with the pool boiling function fully combines the advantages of a square column microstructural pool boiling device, wherein the advantages includes that the heat dissipation efficiency is high, the temperature fluctuation is small, the occupied space is small, and a loop heat pipe can be used for long-distance transmission; capillary suction force generated by a capillary core is used for providing motive power for a system; and the effect that electronic parts and components can be cooled high efficiently is guaranteed.

Owner:XI AN JIAOTONG UNIV

Method for degrading and recycling thermosetting epoxy resin material

The invention discloses a method for degrading and recycling a thermosetting epoxy resin material. The method comprises the following steps: adding a catalyst into a solvent to prepare a reaction solution, wherein the solvent is a low-carbon organic acid or a mixed solution of a low-carbon organic acid and water; dipping epoxy resin material in the reaction solution, and degrading at 100-280 DEG C for 10min-72min; adding a separating agent to the reaction solution obtained after degradation so as to separate inorganic packing out of the catalyst and the resin, filtering, and drying and recycling the solid; and drying filtrate by distillation to obtain a resin degradation product. The method has the advantages of high efficiency and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Chip cooling system

ActiveCN104851857AReduce the temperatureLow boiling pointSemiconductor/solid-state device detailsSolid-state devicesHeat fluxEngineering

The invention relates to a chip cooling system, which comprises a chip heat conduction plate used for primary heat exchange, and an annular heat pipe used for secondary heat exchange, wherein a plurality of micro-channels are arranged on the chip heat conduction plate side by side, the micro-channels are connected with a circulating pipeline provided with a pump simultaneously to form a circulating loop, and the circulating loop is filled with liquid I; and the annular heat pipe is sleeved in the circulating loop to form a sleeving structure, the annular heat pipe is filled with liquid II and gas, and the pressure intensity of the gas is always less than the atmospheric pressure intensity. The chip cooling system combines the micro-channels with the annular heat pipe to form a two-stage heat exchange system, the micro-channels can provide large radiating heat flux and can absorb heat on the chip timely, the annular heat pipe fully utilizes effects such as phase change and gravity as a driving force, the radiating efficiency is high, and the cost is low; and the heat passes through the circulating loop and the annular heat pipe from the chip and is radiated to the environment, the radiating power is high, and the effect is good.

Owner:东营慧达科技创业服务有限公司

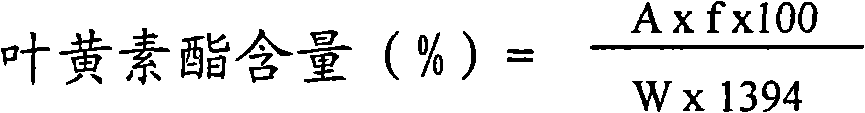

Method for separating and purifying fatty acid ester of lutein in high content from resin of marigold oil

ActiveCN1872839ASolvent with low boiling pointLow solvent residueOrganic chemistryNatural dyesSolventChemistry

This invention discloses a method for separating and purifying high-content xanthophyl fatty acid ester from tagetes oleoresin. The content of xanthophyl fatty acid ester obtained is 70-80%, wherein the content of all-trans xanthophyl ester is 90-95%. The method has such advantages as low solvent residue, high yield and simple operation, and is suitable for mass production.

Owner:浙江可明生物医药有限公司

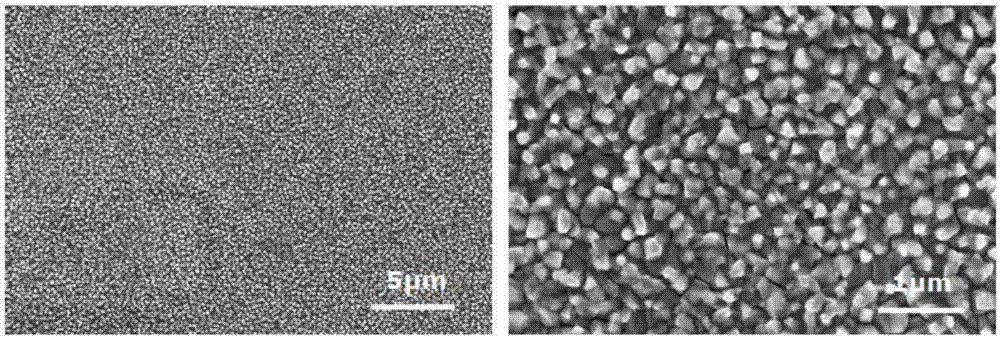

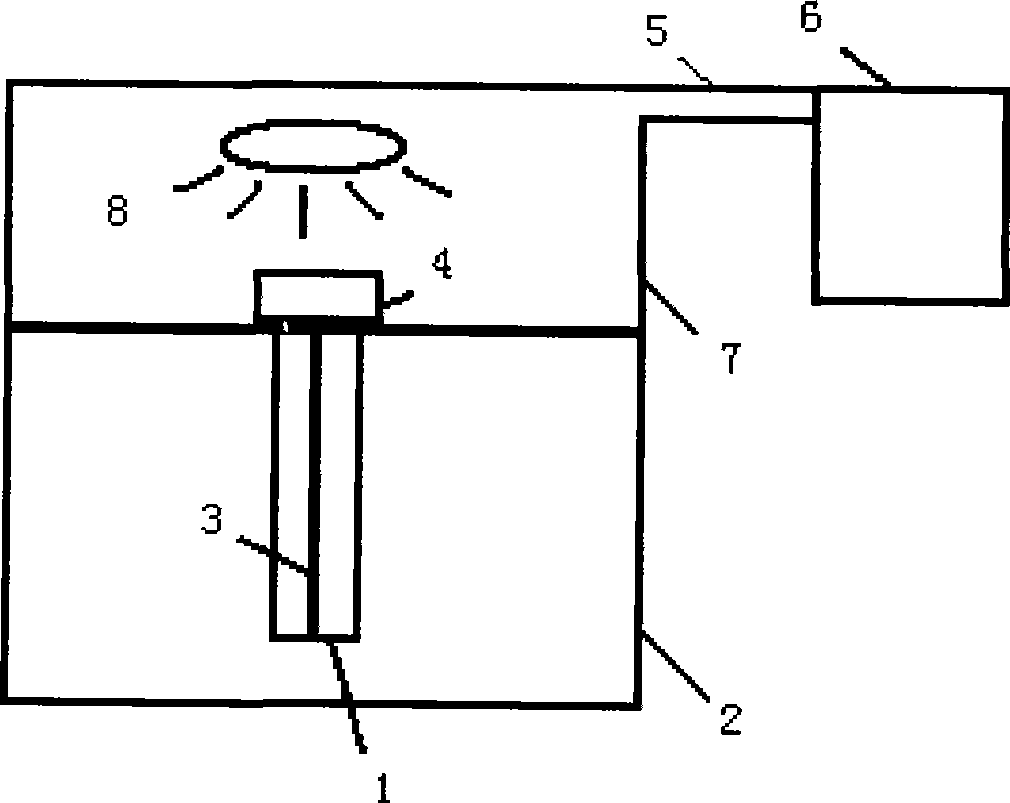

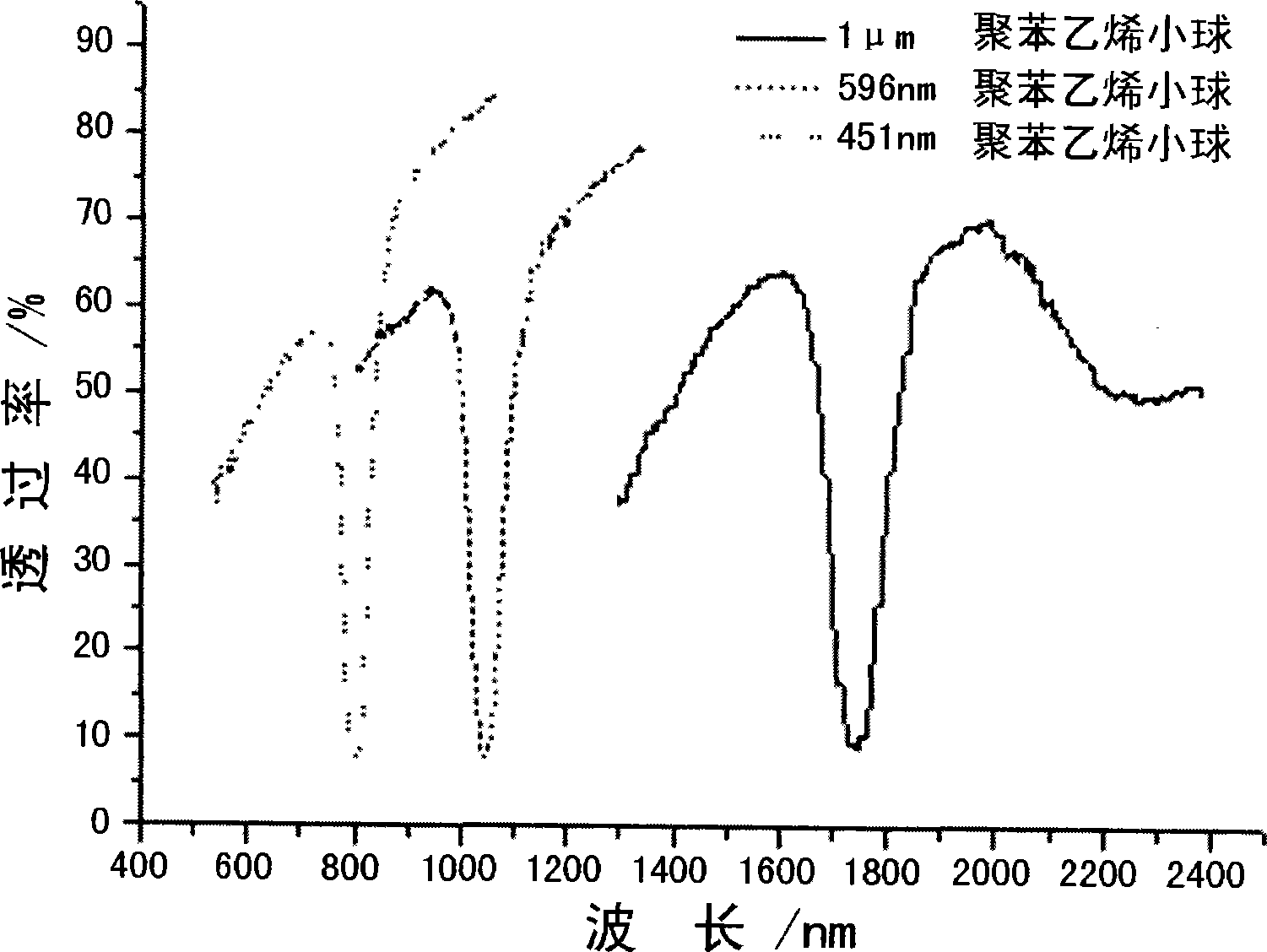

Method for self-assembly growth of three-dimensional ordered polyporous material

ActiveCN101429049AOvercoming the disadvantage of not being able to self-assemble large-size colloidal spheres synergisticallyWill not affect the flowCeramicwareEvaporationSolvent

The invention relates to a method for self-assembly growth of three-dimensional orderly porous materials, which is a method for self-assembly growth of multi-component material colloid crystals with single structures or composite structures and three-dimensional orderly porous membranes by combining assistant acceleration of evaporation through characteristic infrared light and the control of the boiling temperature of a solvent by decompression. The method basically overcomes the defect that the prior method is not suitable for the situations of overlarge colloid particles, overhigh boiling point of the solvent in a colloidal solution system, no high temperature resistance of the colloid particles, incapability of completing crystal growth and so on when the prior method is applied to cooperated self-assembly growth of the multi-component colloid crystals and three-dimensional orderly porous materials of the multi-component colloid crystals. The method has the characteristics of high efficiency, easy control, simple operation and good repeatability, can grow the high-quality multi-component colloid crystals and the three-dimensional orderly porous membranes, and is suitable for self-assembly and cooperated self-assembly of multi-component colloid particle mixed systems with various particle diameters and various varieties.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Water-based positive pole slurry of lithium ion battery and preparation method thereof

InactiveCN102130338ALow boiling pointImprove electrochemical performanceNon-aqueous electrolyte accumulator electrodesWater basedSlurry

The invention relates to the field of preparation of slurry of a lithium ion battery and discloses water-based positive pole slurry of the lithium ion battery. The slurry is prepared from 40-80 parts by weight of active substance, 25-50 parts by weight of solvent, 1-5 parts by weight of surfactant, 1-3 parts by weight of thickener, 2-6 parts by weight of conducive agent and 2-4 parts by weight of binding agent, wherein the solvent is one or two of deionized water and isopropanol, the surfactant is an anionic surfactant, the thickener is one or two of sodium carboxymethyl cellulose and polyacrylamide, and the binding agent is one or more of styrene-butadiene rubber latex, polyvinyl alcohol and polyacrylate. Compared with the prior art, the water-based positive pole slurry does not use the organic solvent which can pollute the environment and is difficult to recycle any more, thereby being environment-friendly; and furthermore, the boiling point of a water-based system is lower, the preparation process can save more energy, the cost is reduced, and the production efficiency is improved.

Owner:DONGGUAN AMPEREX TECH +2

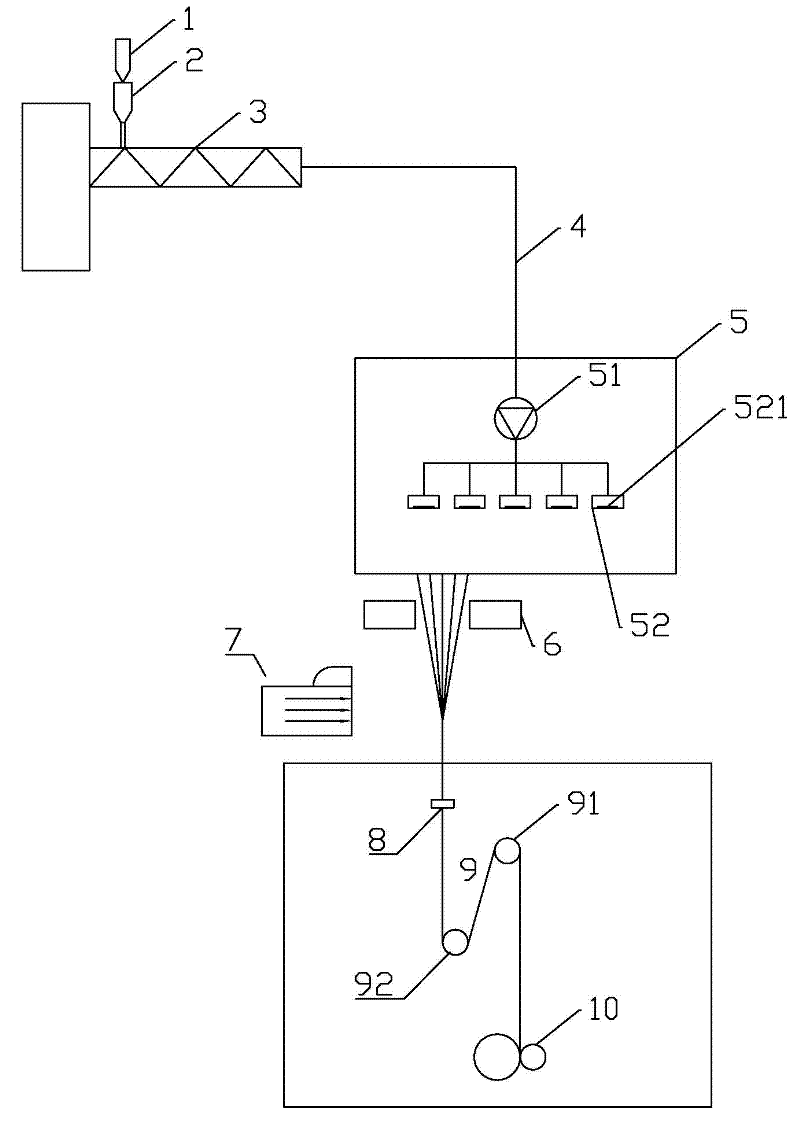

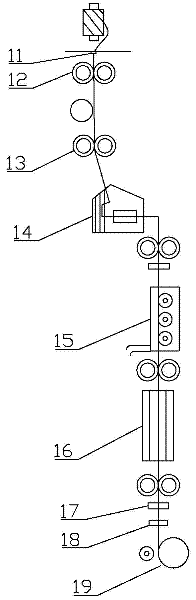

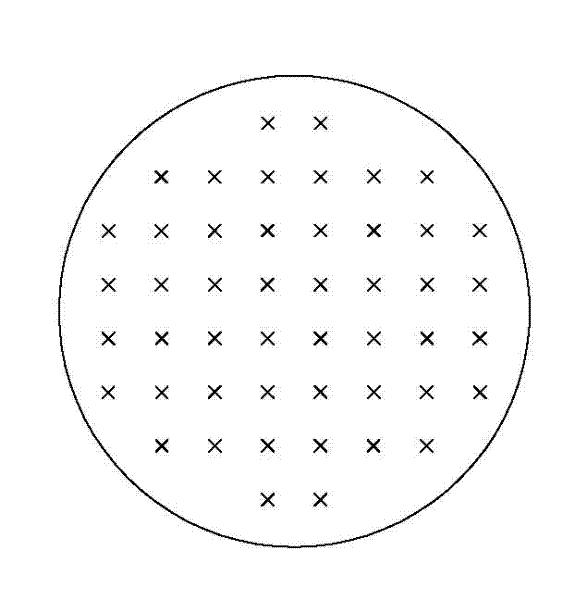

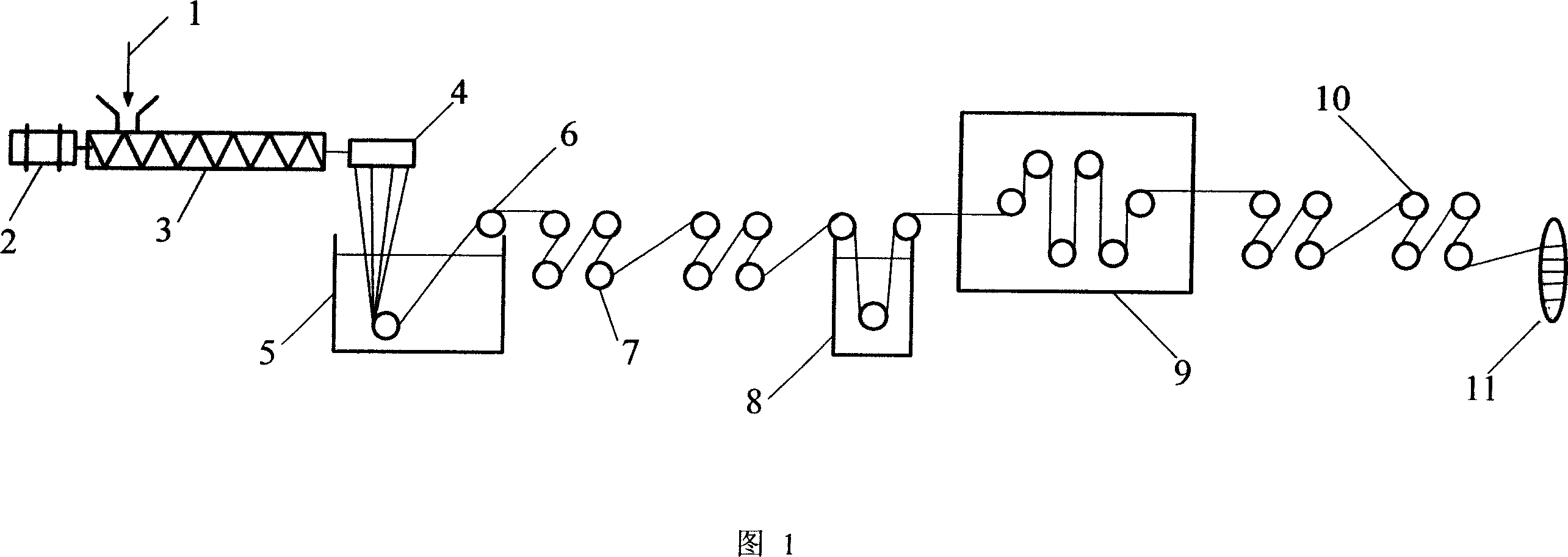

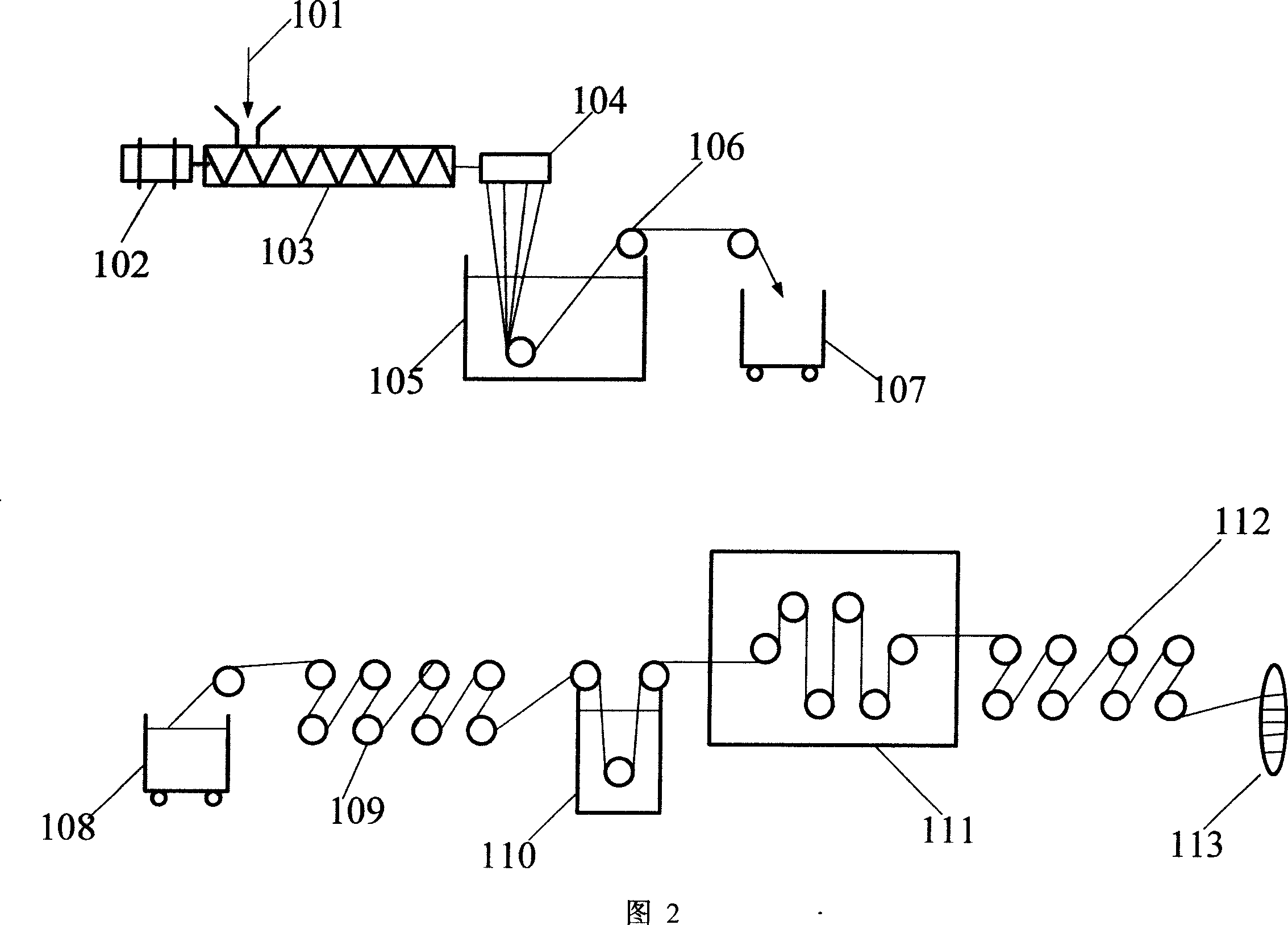

Production process of polyamide 6 special-shaped air-textured yarns with high strength and low boiling shrinkage

ActiveCN102251324AHigh strengthLow boiling pointHollow filament manufactureArtificial filament heat treatmentPolyamideYarn

The invention discloses a production process of polyamide 6 special-shaped air-textured yarns with high strength and low boiling shrinkage. The process comprises the following steps of: 1) adding polyamide 6 slices into an extruder through a slice hopper; 2) delivering the molten material to a metering pump in a spinning beam through a melt distribution duct in the extruder, accurately injecting the material into a spinning assembly in the spinning beam through the metering pump, and making the material form melt streamlet through a spinning plate; 3) making the melt streamlet pass through a temperature controller, gradually solidifying the melt streamlet into threads under the condition of lateral blowing cooling, oiling, stretching the threads by a GR1 thermal roller and a GR2 thermal roller, and forming drawn yarns through a winding device; and 4) feeding the drawn yarns into a first roller through a yarn breaker, making the drawn yarns pass through a second roller, an air nozzle and a stable thermal box, sizing the yarns in a sizing box, detecting the yarns by a yarn detector, oiling the yarns by an oil nozzle, and finally winding the yarns into the air-textured yarns through the winding device. The air-textured yarns produced by the process have the characteristics of high strength and low boiling water shrinkage.

Owner:GUANGDONG XINHUI MEIDA NYLON

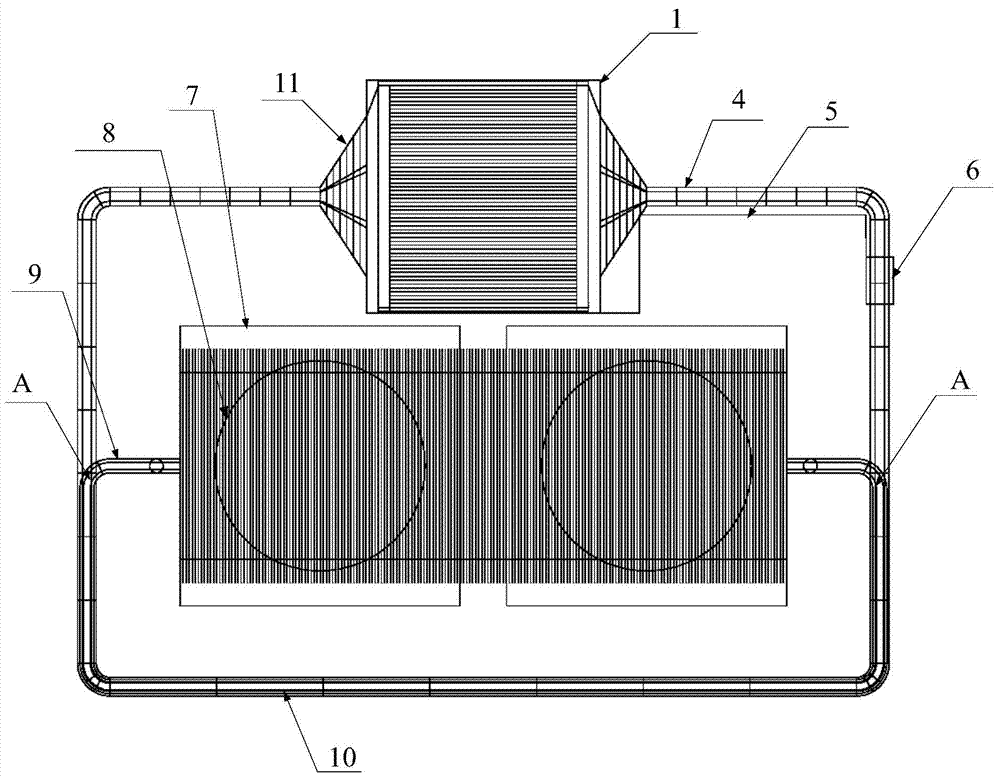

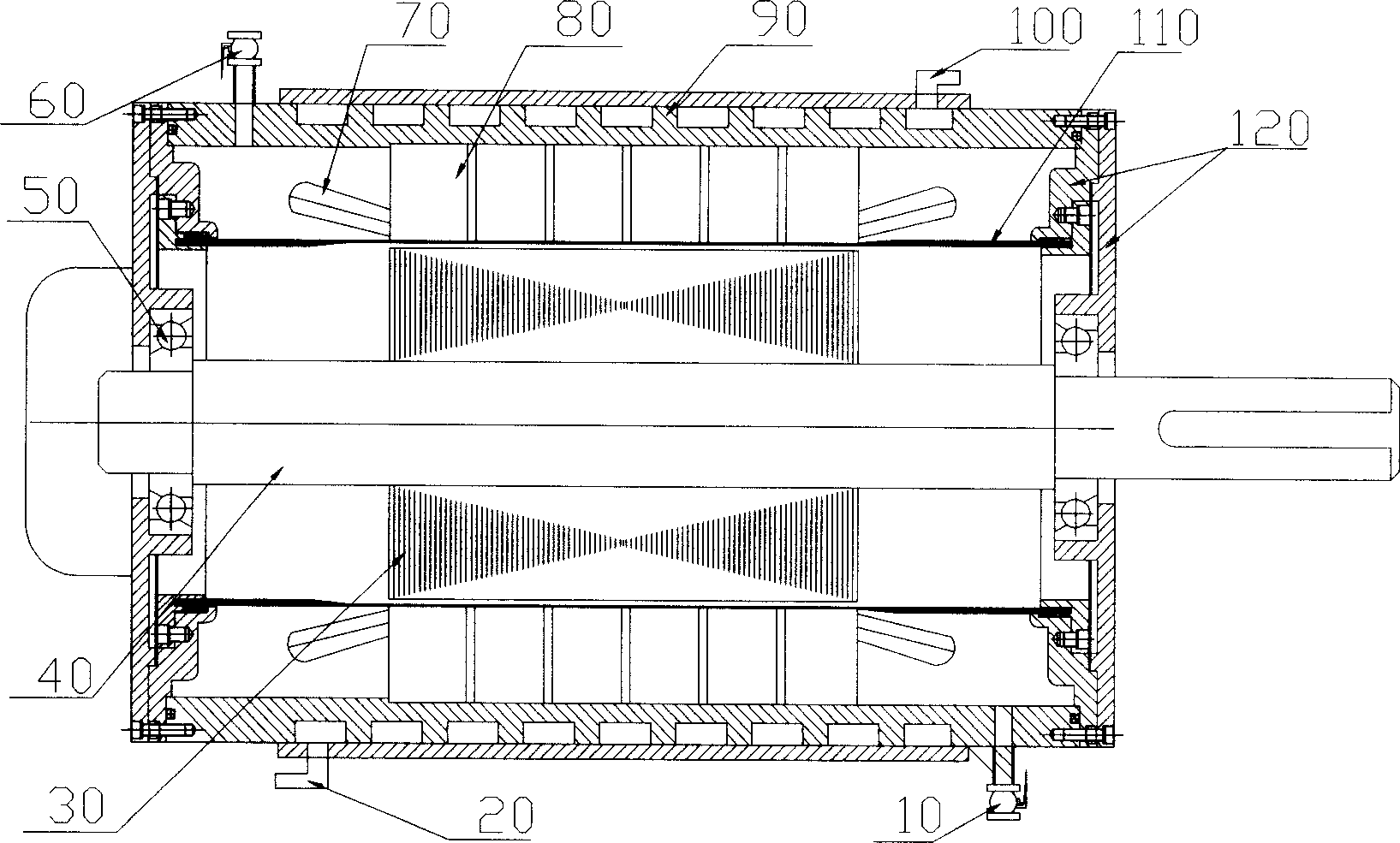

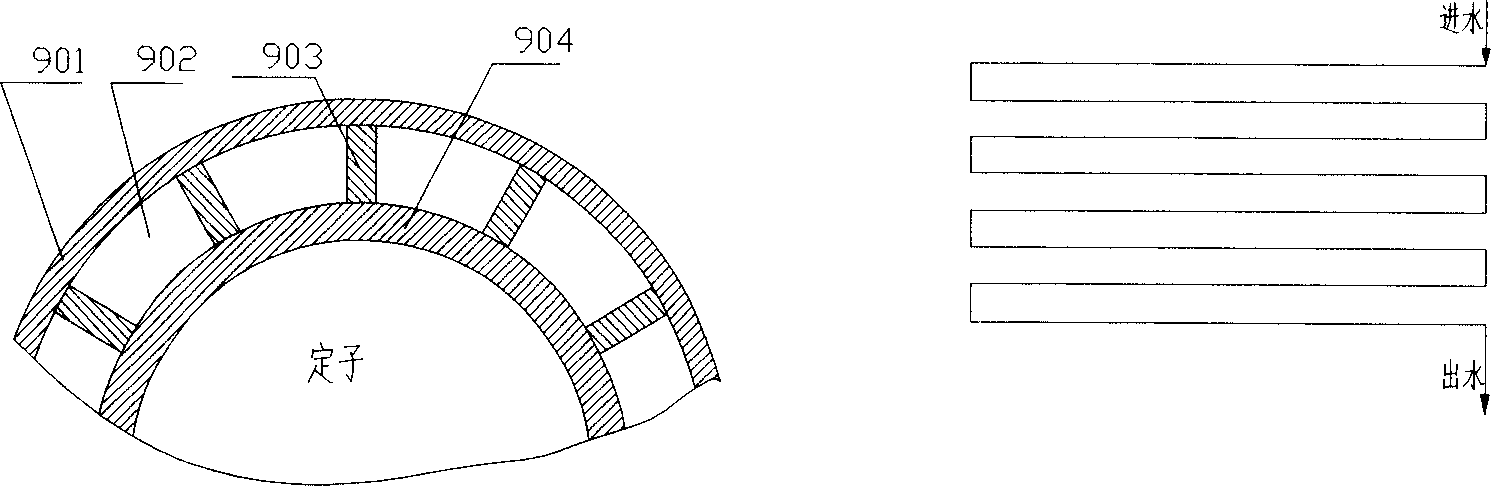

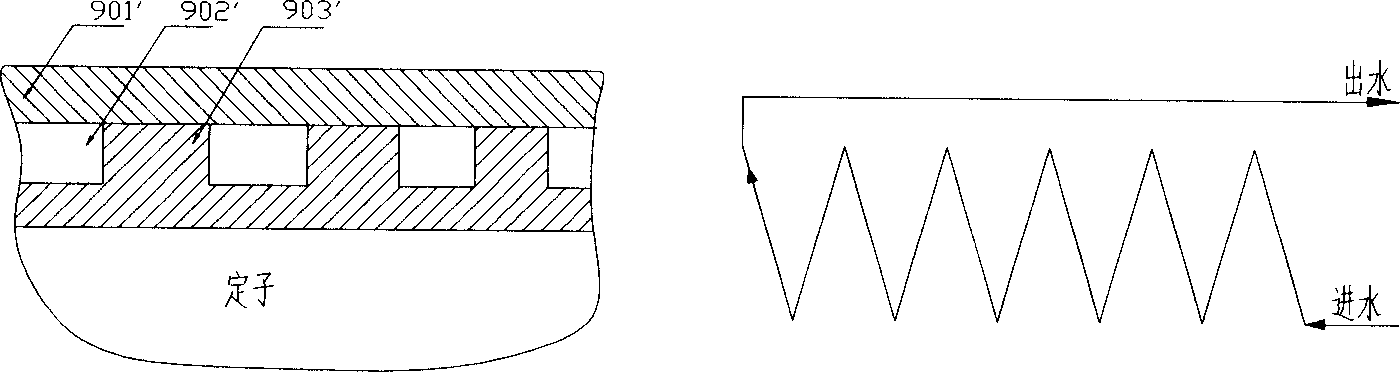

External water channel evaporative cooling horizontal motor

InactiveCN1889334ACompact structureUniform temperatureMagnetic circuit stationary partsManufacturing stator/rotor bodiesHeat sinkFree flow

A outside watercourse evaporative cooling horizontal motor features adopting sealing between stator housing and front rear endplate, inner sleeve two ends and front rear endplate, constituting inclosed stator cavity to seal whole stator in stator cavity, evaporative cooling media implanting in stator cavity. Evaporative cooling media free-flow in stator cavity and can penetrate into stator core interior. Stator winding and stator core etc heating part generated heat quantity is conducted evaporative cooling media, when evaporative cooling media main unit temperature rises to corresponding pressure saturation temperature, media bubble and generate phase transition heat sink and vapour. Vapour is condensed and liquefied by flowing in water jacket cylinder inner wall in stator cavity upper part, then flowing back in stator cavity bottom evaporative cooling media, forming non - external power stator evaporative cooling self -circulation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN101012577AReduce oil contentHigh strengthArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

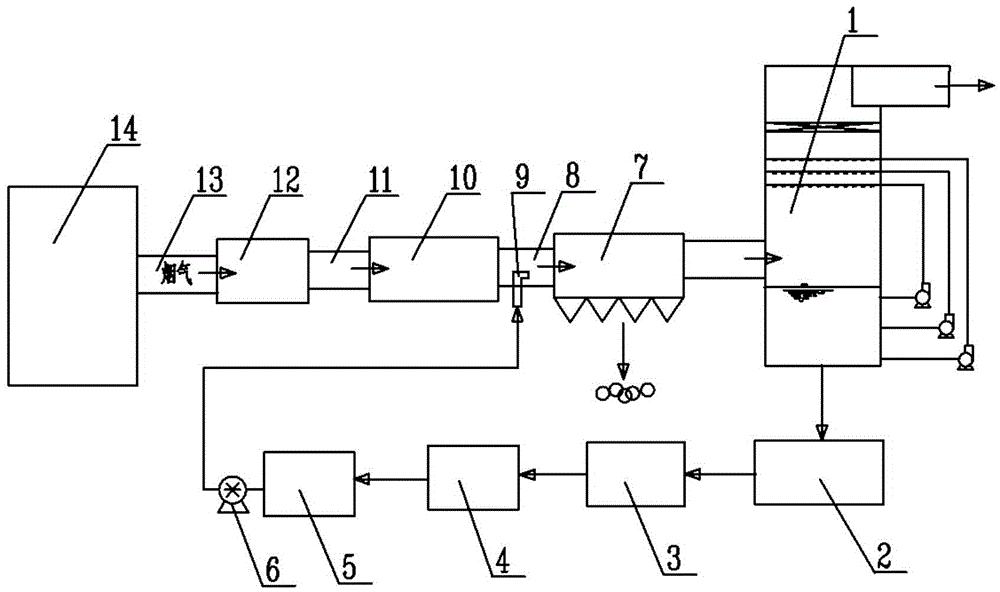

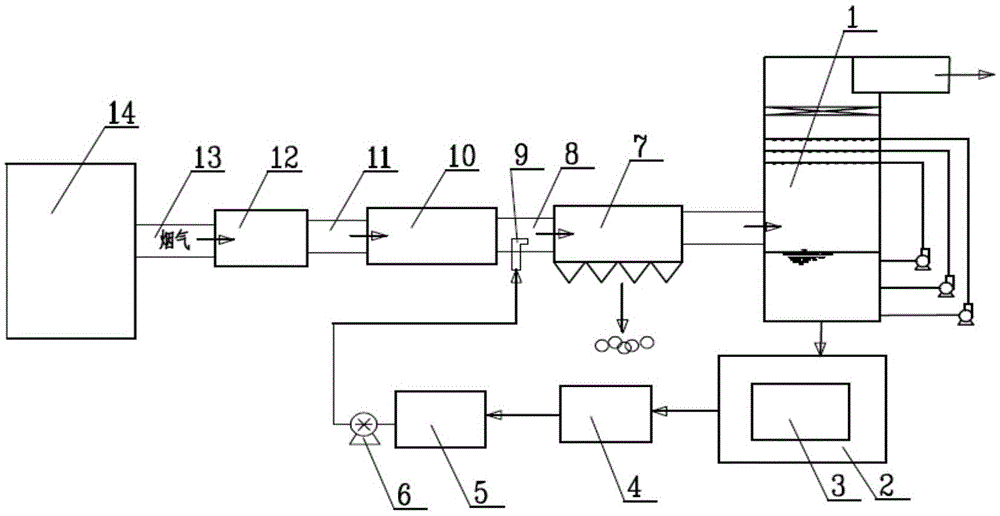

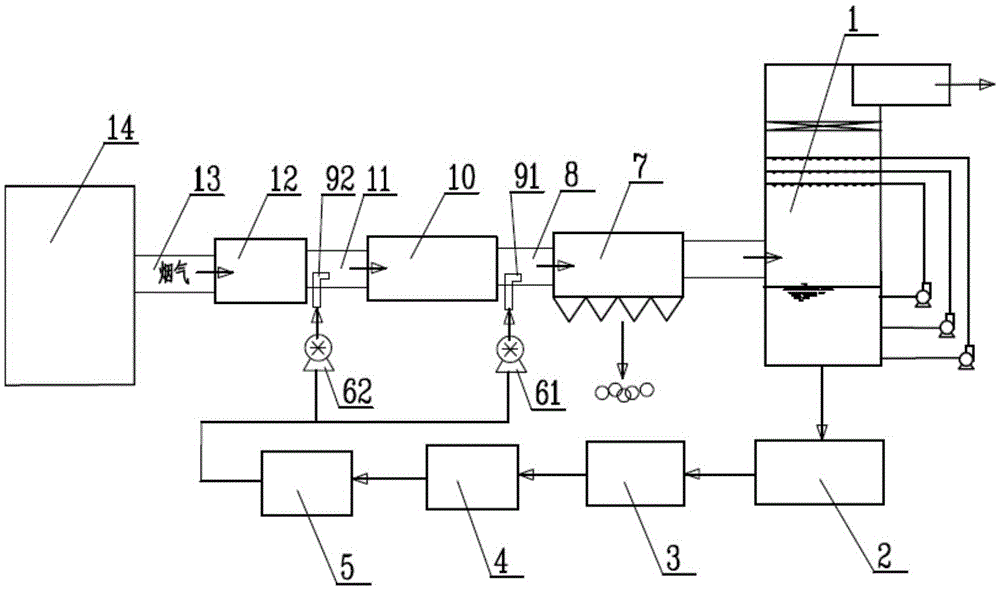

System and method for treating high salinity wastewater

ActiveCN105417817AEconomical and efficient processingAchieving zero emissionsWater contaminantsWaste water treatment from gaseous effluentsBoiling pointSalt water

The invention discloses a treatment system and evaporating treatment method for high salinity wastewater. The treatment system comprises a desulfurization waste water conventional treatment device, a high-salinity water concentration device, a concentrated high-salinity water storage pool and an atomizer which are connected in sequence. The treatment system further comprises a high-salinity water boiling point reducing device which is arranged at any appropriate position in front of the concentrated high-salinity water storage pool. The water spraying amount of concentrated high-salinity water sprayed out of the atomizer can be adjusted. The treatment method comprises the steps that 1, after desulfurization waste water is subjected to conventional treatment, upper-layer clear water, namely, high-salinity water is collected, the high-salinity water is concentrated to be reduced, and concentrated high-salinity water is formed and stored in the concentrated high-salinity water storage pool; 2, the concentrated high-salinity water in the concentrated high-salinity water storage pool is sprayed into a flue between a hearth and a dust remover and / or the hearth through the atomizer and subjected to atomization and evaporation, and crystal substances are mixed into coal ash to be removed together, wherein the water spray amount of the concentrated high-salinity water sprayed into the flue between the hearth and the dust remover and / or the hearth is adjusted according to flue gas temperature.

Owner:高境 +1

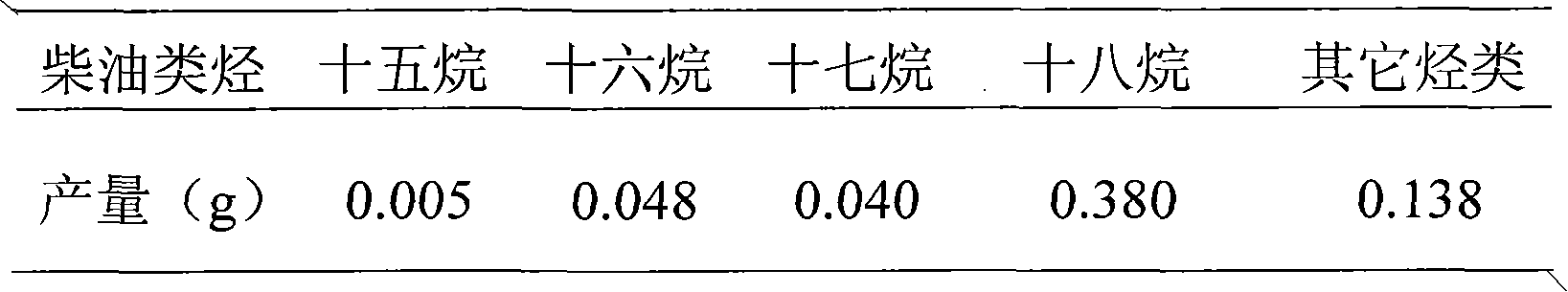

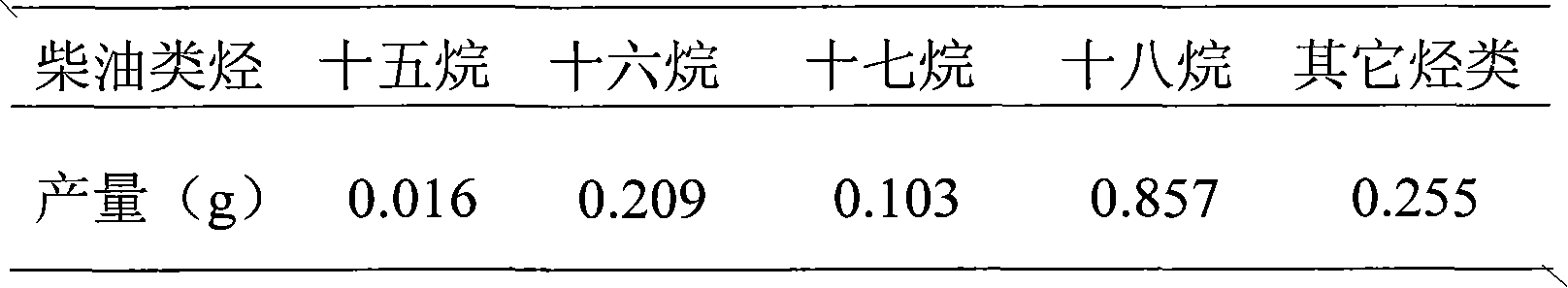

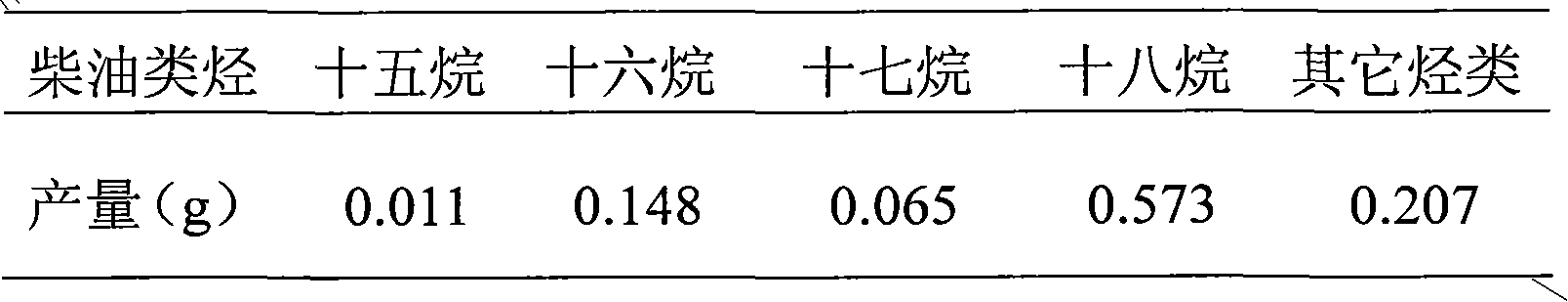

Method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation

InactiveCN101899318AReduce manufacturing costConducive to large-scale industrialization promotionBiofuelsLiquid hydrocarbon mixture productionAlkaneHydrogen

The invention discloses a method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation, is a method for preparing alkane with a high calorific value from vegetable fat through catalytic hydrogenation and deoxygenation, and adopts a one-pot method reaction process, comprising the following steps: adding a molybdenum carbide catalyst, vegetable fact and solvent in a reactor, filling hydrogen in the reactor, stirring and heating, reacting for 3-10h with the reaction pressure of 1-10MPa and the reaction temperature of 250-350 DEG C, stopping reaction, cooling to room temperature, filtering and separating the catalyst out to obtain the diesel hydrocarbons with alkane at a high calorific value. By adopting the technical scheme in the invention, the method has low production cost and high product combustion value, is favor of large-scale industrialized popularization and is a clean and regenerative diesel alternative fuel.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com