Patents

Literature

302results about How to "Improve water removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

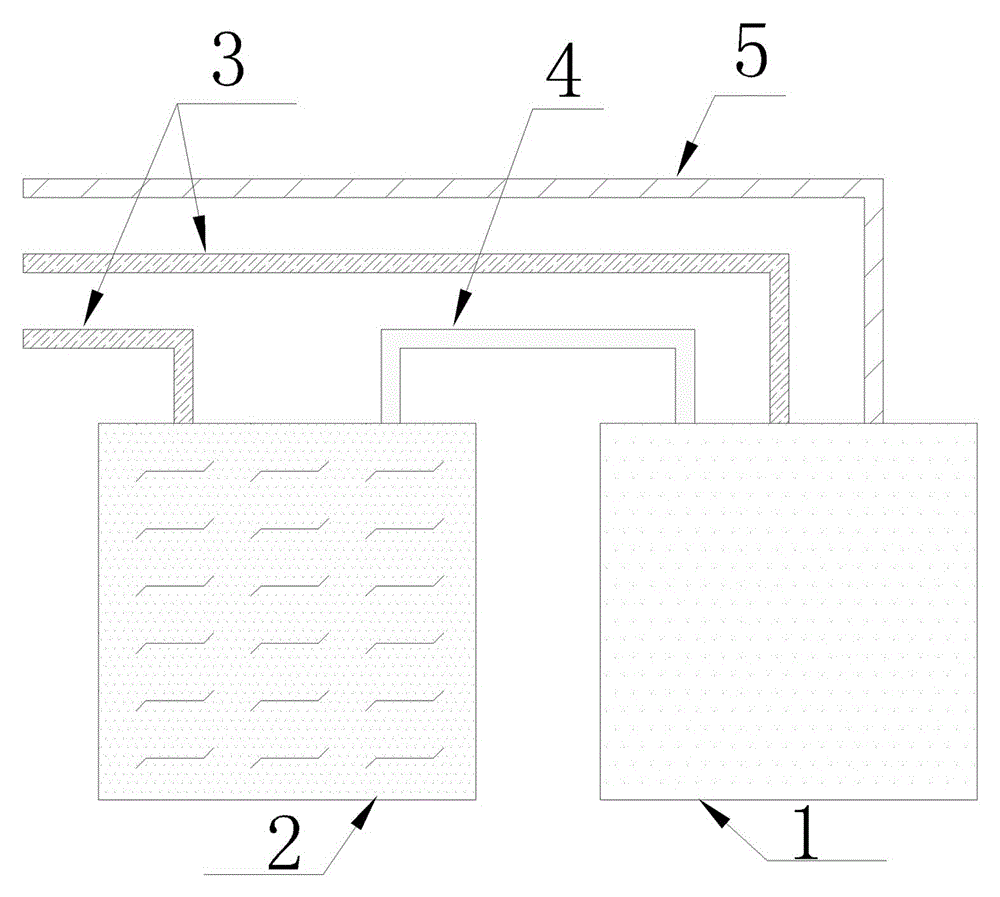

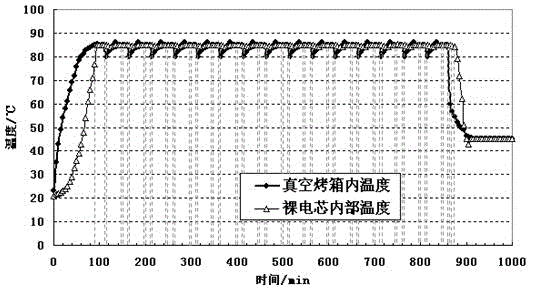

Rapid drying method for lithium ion battery cell

ActiveCN105115250ALow boiling pointImprove water removal effectDrying using combination processesBoiling pointNitrogen gas

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

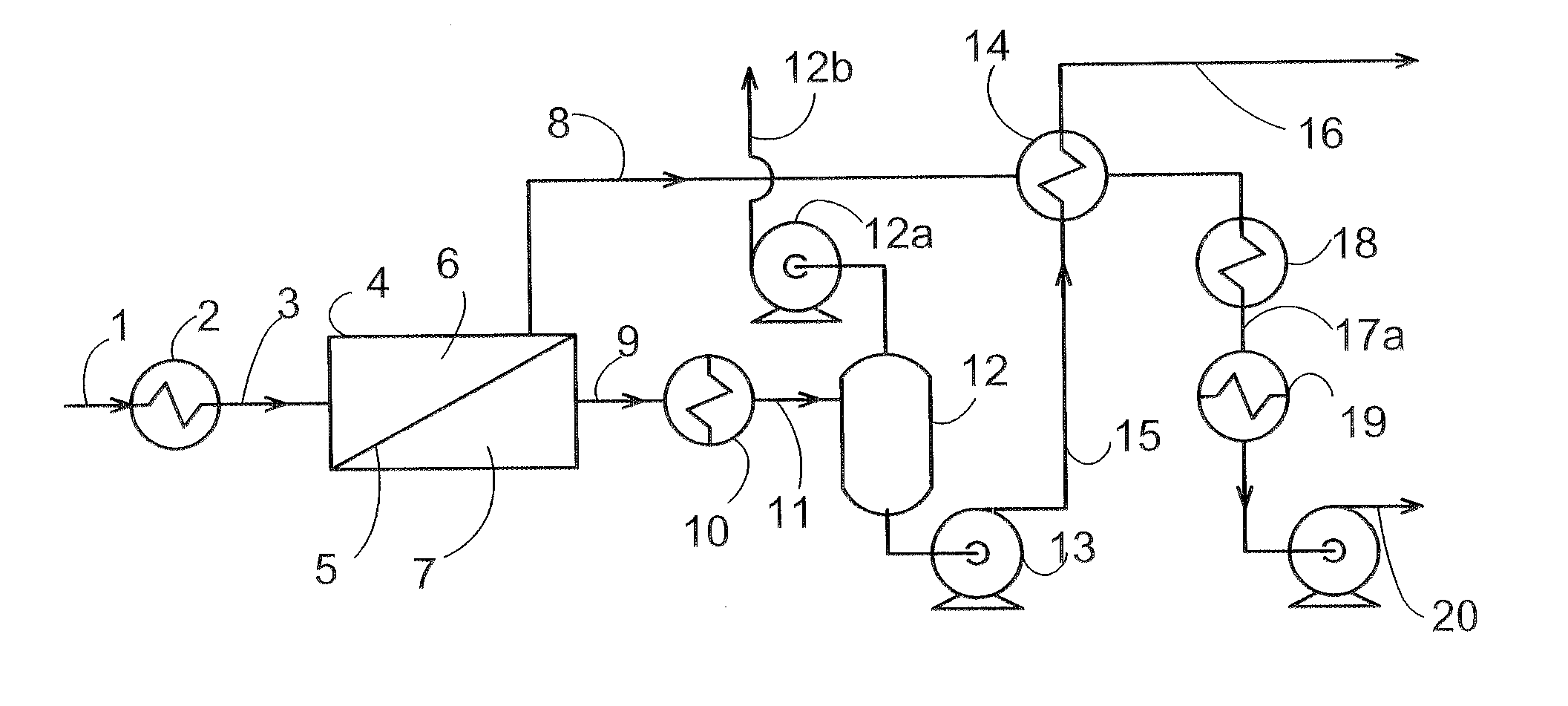

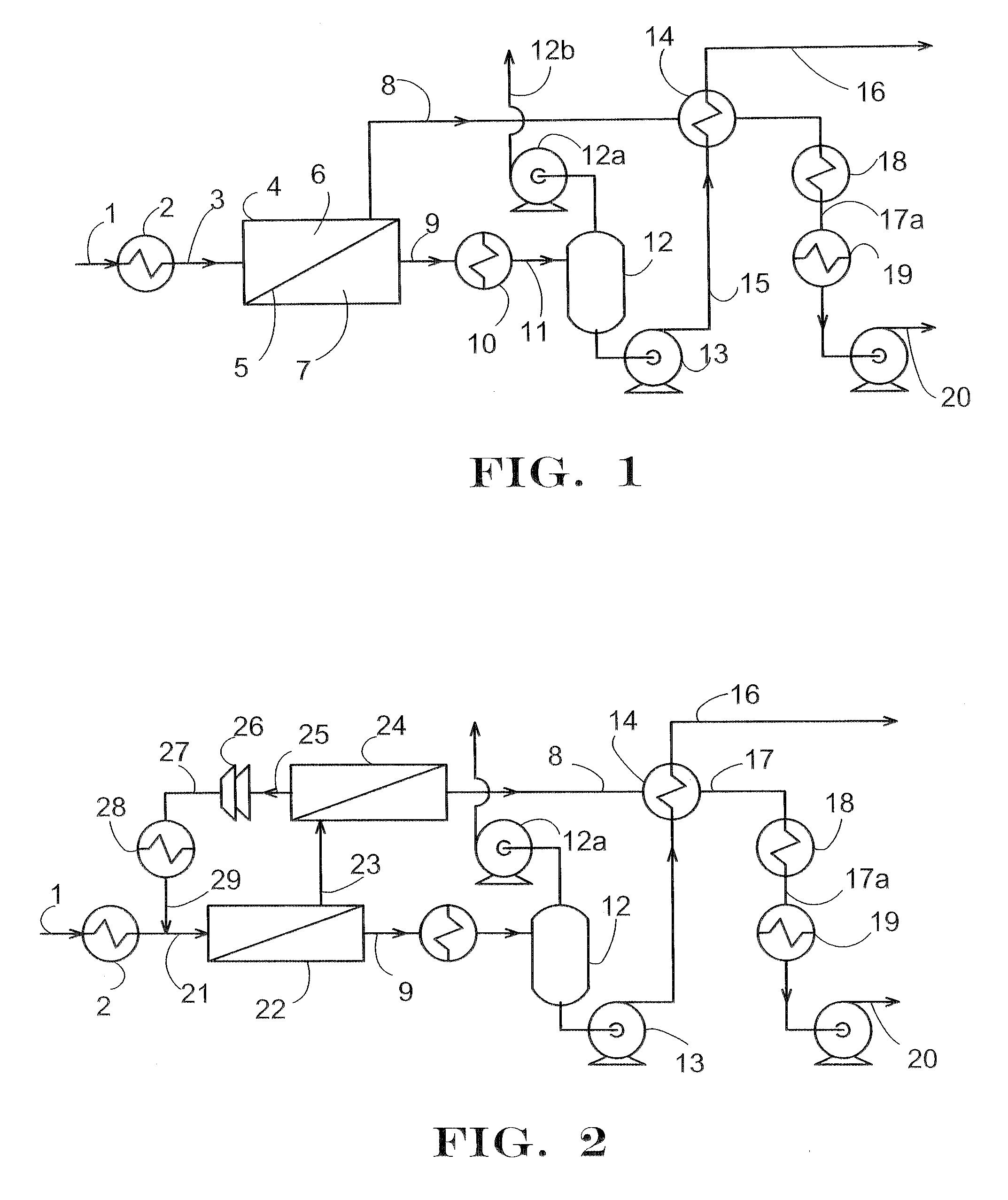

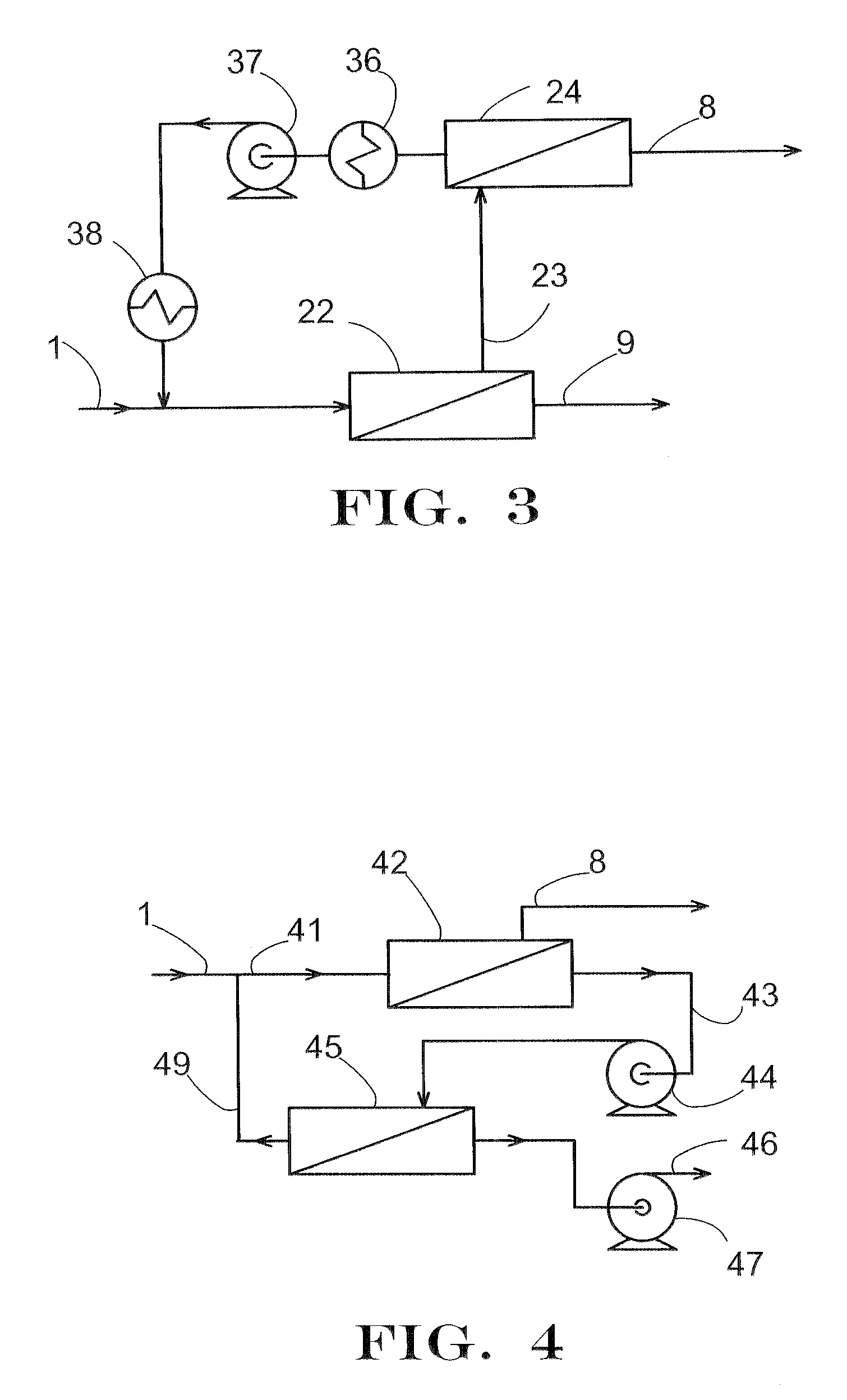

Removal of Water and Methanol from Fluids

ActiveUS20080099400A1Efficient separationPowerfulMembranesUltrafiltrationChemical reactionInternal combustion engine

A method of removing water and / or methanol from fluid mixtures of the water or methanol with other compounds uses vapor permeation or pervaporation of the water or methanol, as the case may be, from the mixture through a membrane having an amorphous perfluoropolymer selectively permeable layer. The novel process can be applied in such exemplary embodiments as (a) removing water or methanol from mixtures of compounds that have relative volatility of about 1-1.1 or that form azeotropic mixtures with water or methanol, (b) the dehydration of hydrocarbon oil such as hydraulic fluid to concentrations of water less than about 50 ppm, (c) removing water and methanol byproducts of reversible chemical reactions thereby shifting equilibrium to favor high conversion of reactants to desirable products, (d) drying ethanol to less than 0.5 wt. % water as can be used in fuel for internal combustion engines, and (e) controlling the water content to optimum concentration in enzyme-catalyzed chemical reactions carried out in organic media.

Owner:COMPACT MEMBRANE SYST INC

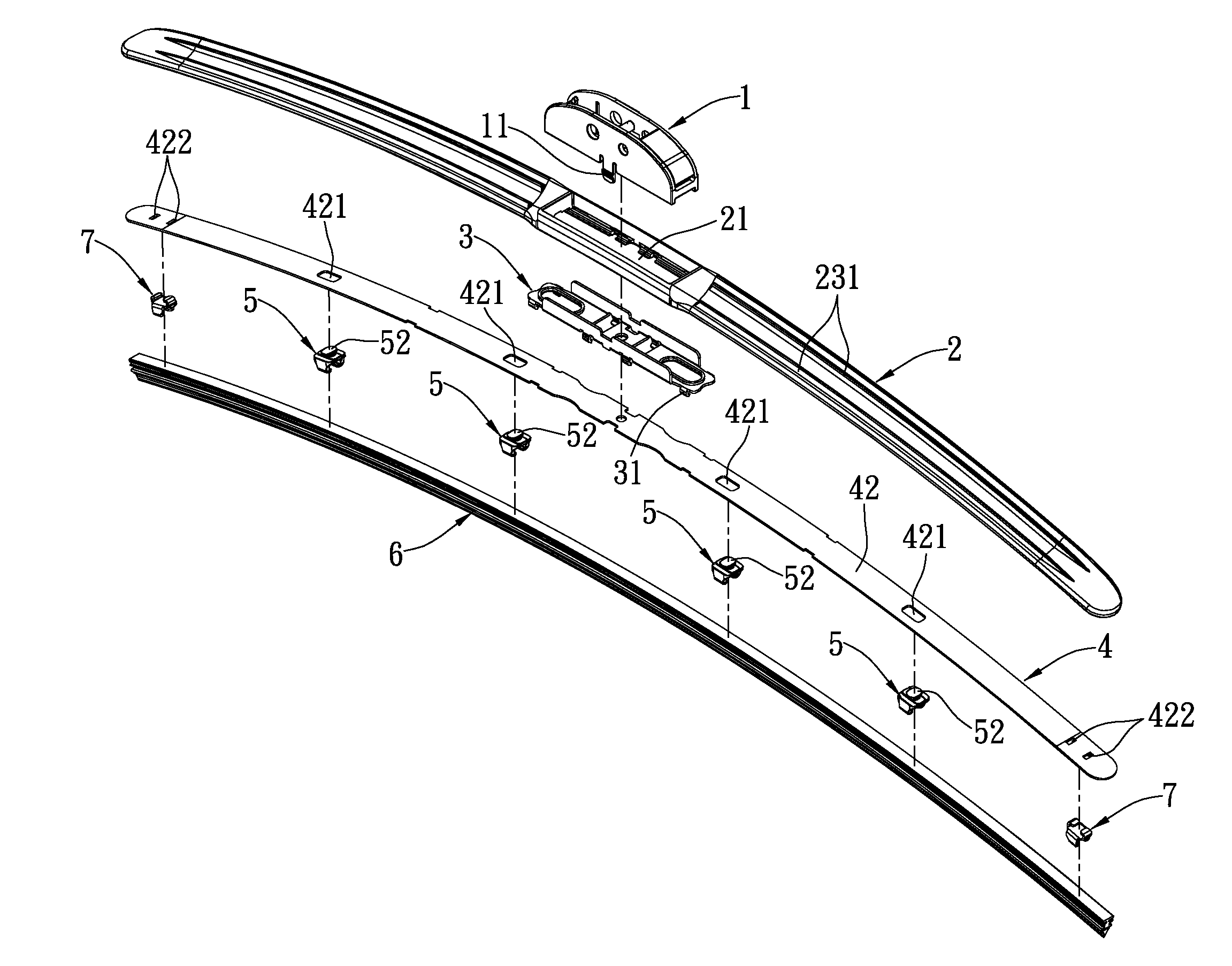

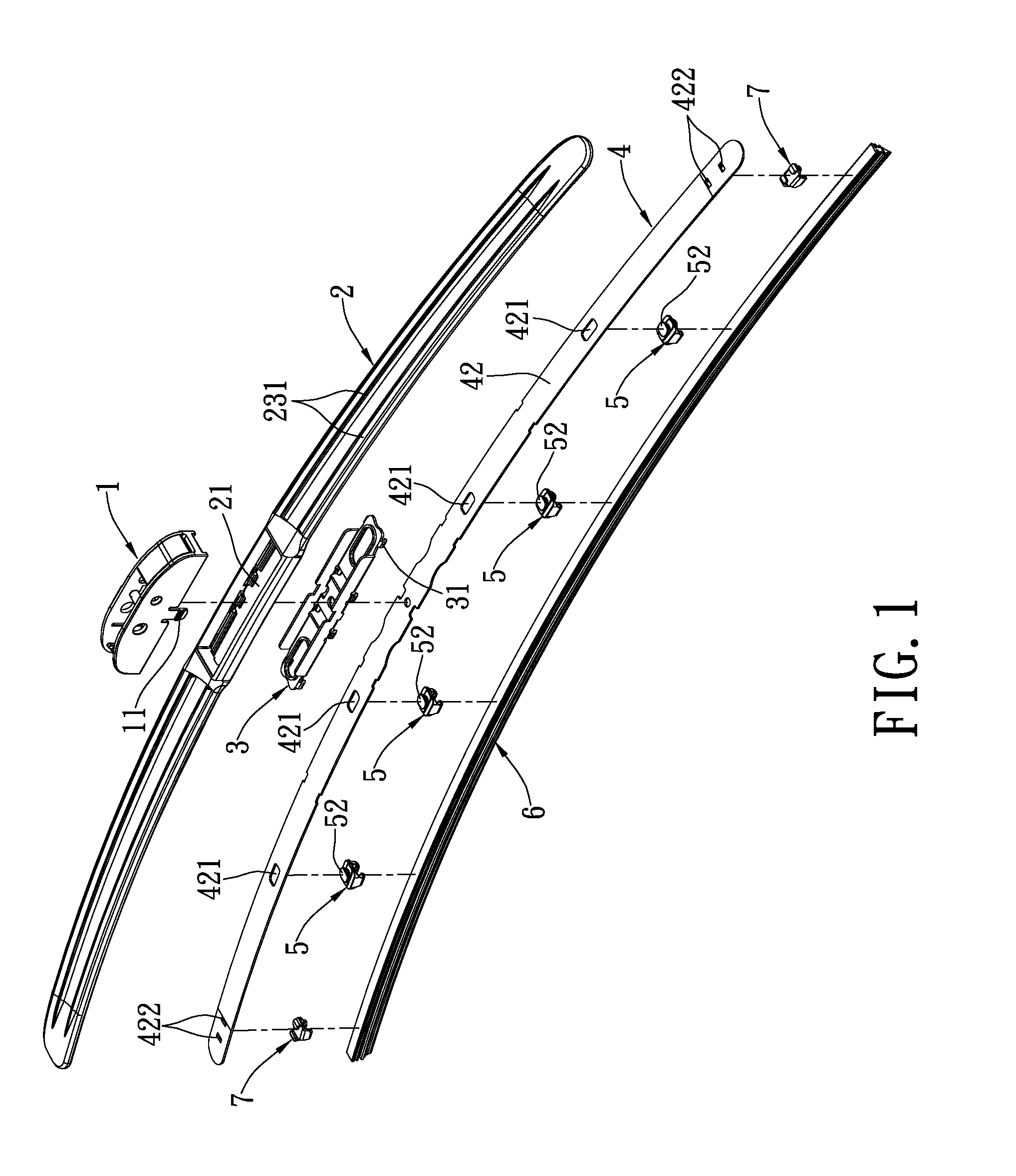

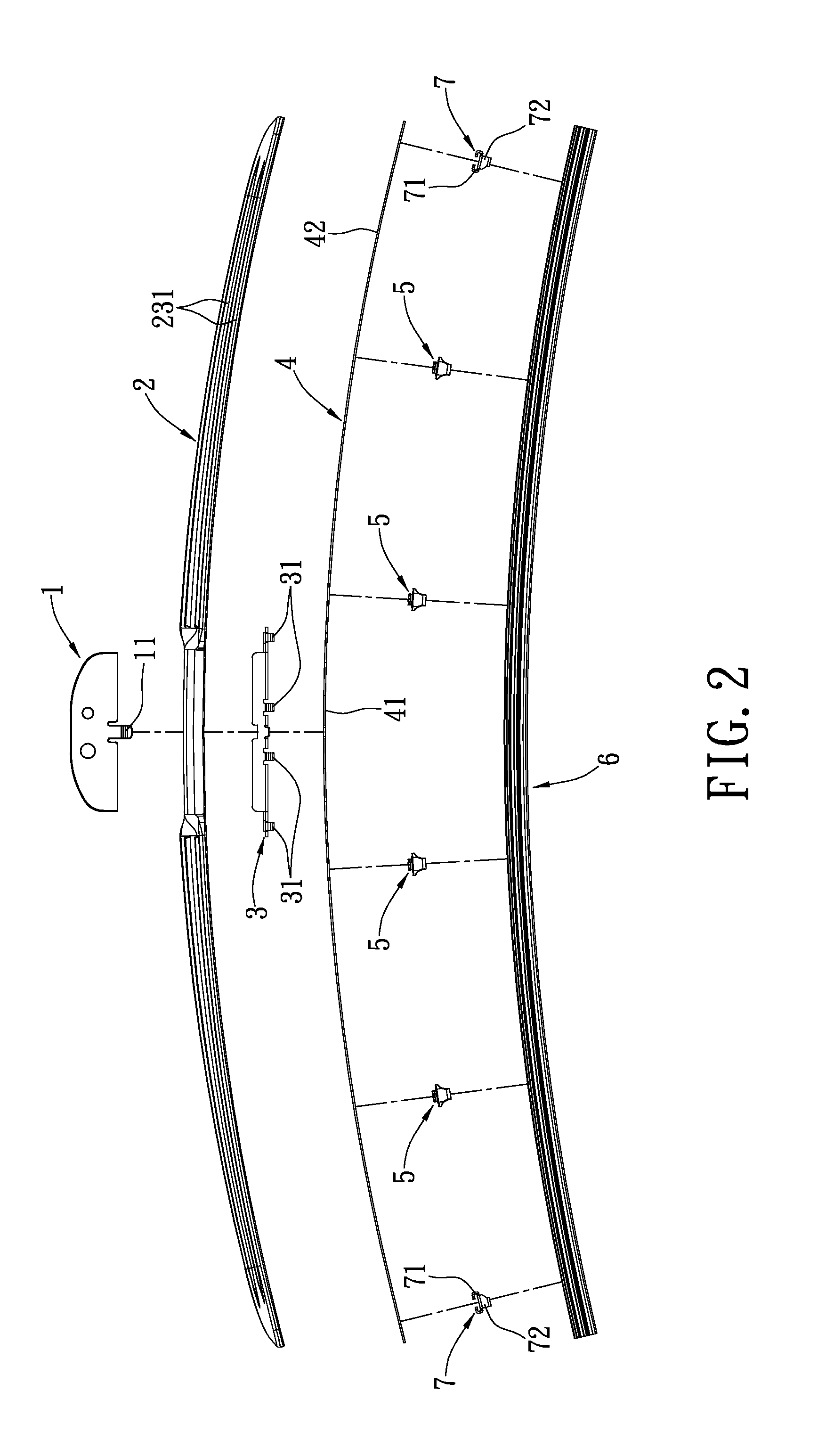

Windshield wiper

InactiveUS20130117957A1Improve conformityGood removal effectWindow cleanersVehicle cleaningEngineeringRigid frame

The instant disclosure provides a wiper, comprising a wiper connector, a flexible member, a reinforcing member, a rigid frame, a plurality of fastening members and a wiper blade. The flexible member includes a central loading portion and two distal loading portion extending symmetrically from two ends of the central loading portion, where the central loading portion has a zero curvature. The reinforcing member is sleevingly coupled to the flexible member. A front-facing side of the reinforcing member has at least one wind-deflecting rib formed thereon. The rigid frame is arranged on the central loading portion to connect the wiper connector. The fastening member is engaged to the second loading portion. The wiper blade is inserted through the plurality of fastening members. Thus, a better conformity can be achieved between the windshield and the wiper through the wind pressure while driving to provide a better water removal effect.

Owner:DONGGUAN HONGYI WIPER

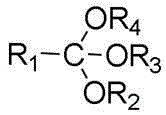

Method of increasing the elasticity of moisture-cured elastomers

The invention provides a method of increasing the elasticity of moisture-cured elastomers, which comprises adding to alkoxy-cross linking one-component compositions comprising an alkoxysilane-terminated polymer (A) containing end groups of the formula (1) -A-Si(R)a(CH3)3-a (1) a silane (B), of the general formula (2) X—CH2—Si(R)2(CH3) (2) where A is a divalent hydrocarbon radical, R is a methoxy or ethoxy group, X is a group R″O—, R″NH—, R′—O—CO—NH, R′—NH—CO—NH— or halogen, R″ is hydrogen, an optionally halogen-substituted C1-18 hydrocarbon radical or a radical R′—O—CO— or R′—NH—CO, R′ is an optionally halogen-substituted C1-8 hydrocarbon radical, and a is 1, 2 or 3.

Owner:WACKER CHEM GMBH

Method of increasing the elasticity of moisture-cured elastomers

The invention provides a method of increasing the elasticity of moisture-cured elastomers, which comprises adding to alkoxy-cross linking one-component compositions comprising an alkoxysilane-terminated polymer (A) containing end groups of the formula (1)-A-Si(R)a(CH3)3-a (1)a silane (B), of the general formula (2)X—CH2—Si(R)2(CH3) (2)whereA is a divalent hydrocarbon radical,R is a methoxy or ethoxy group,X is a group R″O—, R″NH—, R′—O—CO—NH, R′—NH—CO—NH— or halogen,R″ is hydrogen, an optionally halogen-substituted C1-18 hydrocarbon radical or a radical R′—O—CO— or R′—NH—CO,R′ is an optionally halogen-substituted C1-8 hydrocarbon radical, anda is 1, 2 or 3.

Owner:WACKER CHEM GMBH

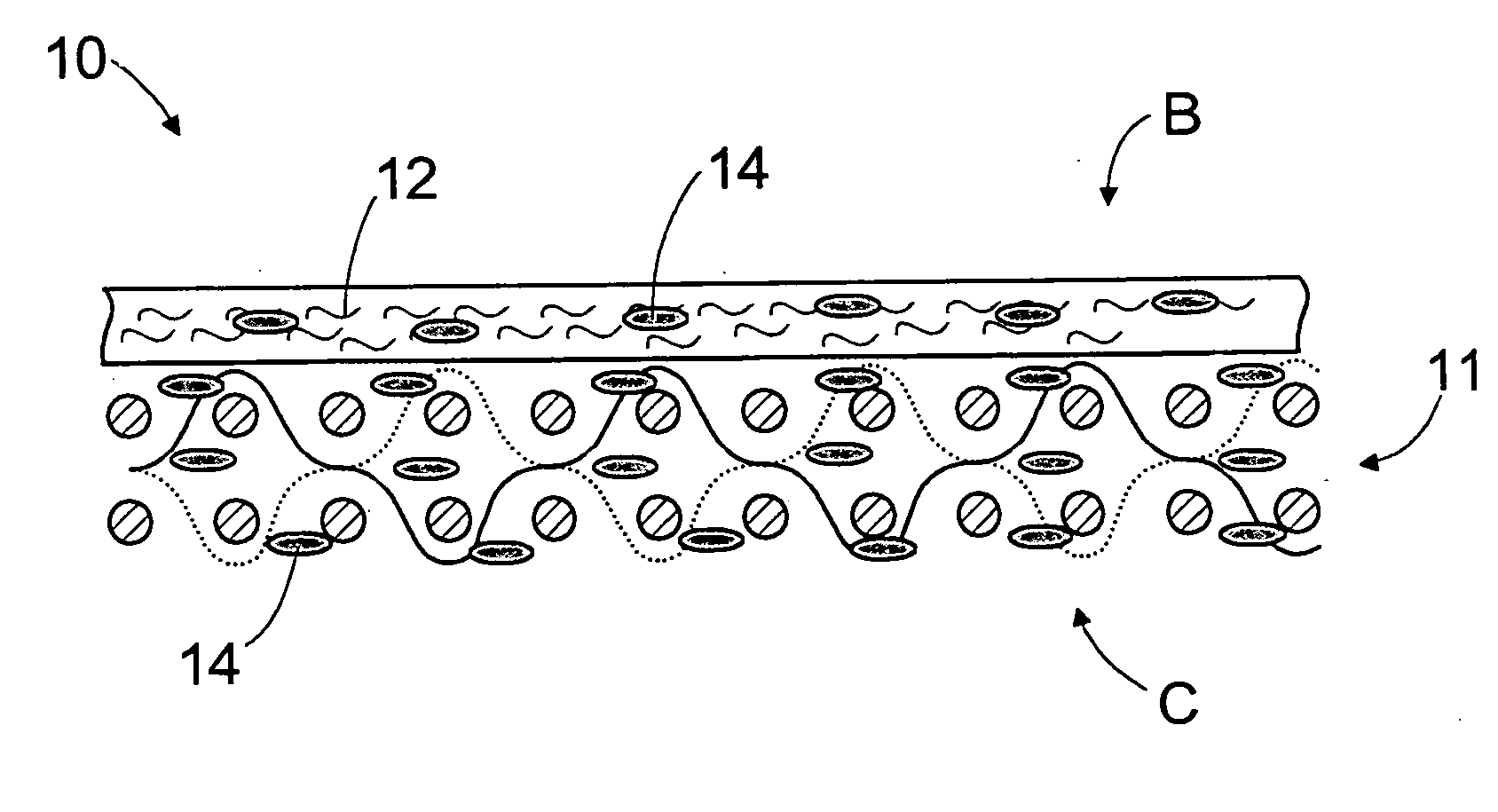

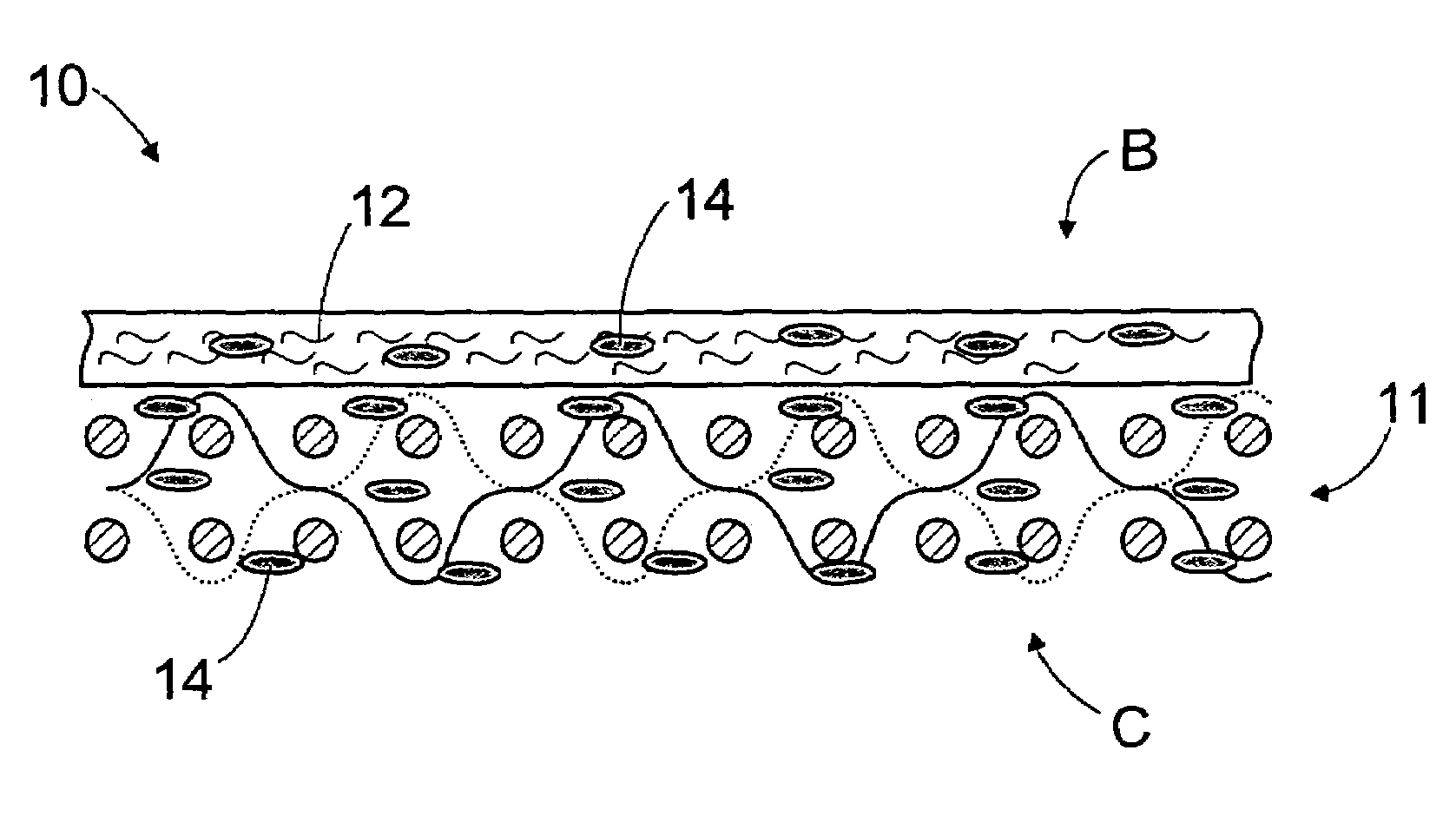

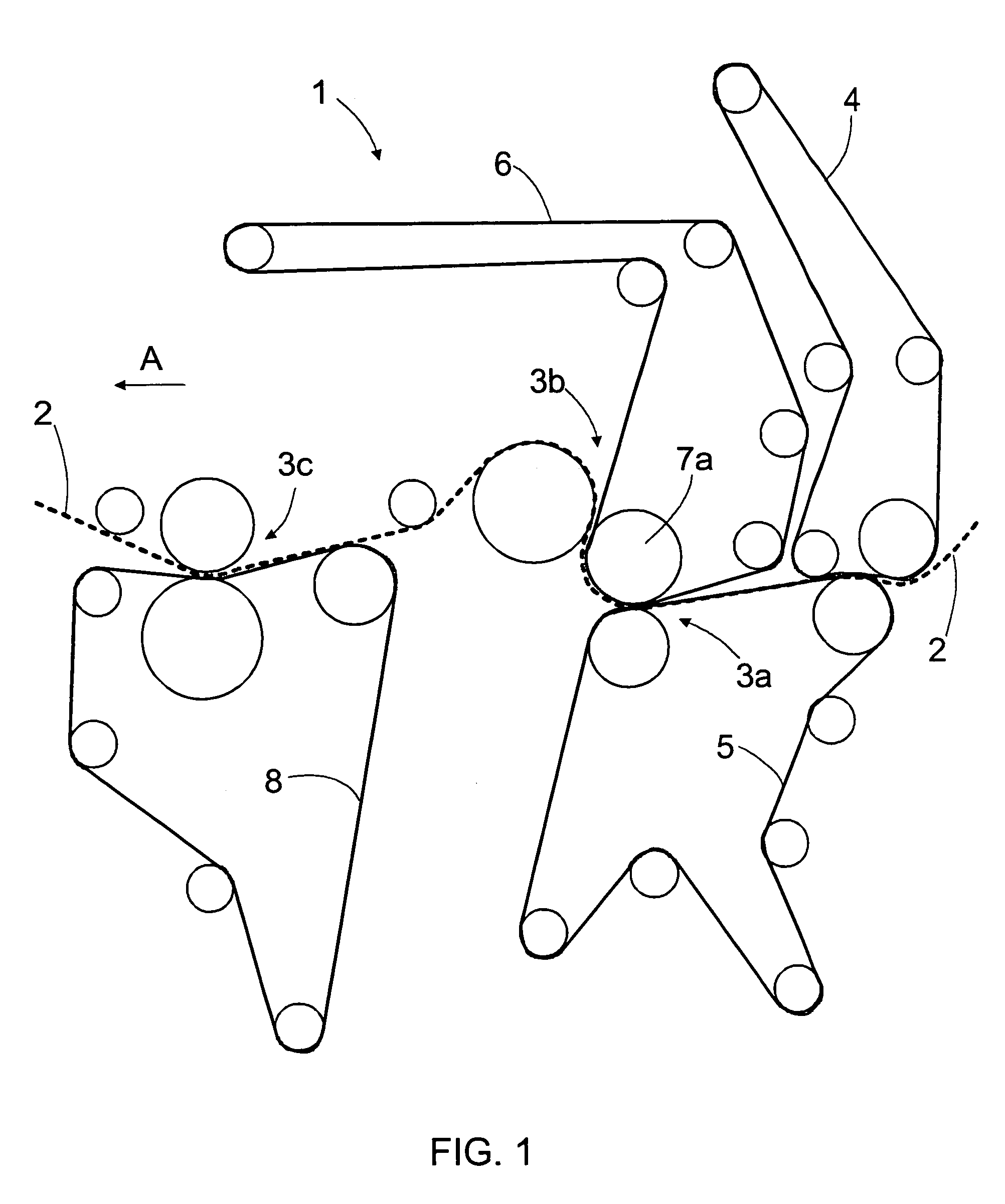

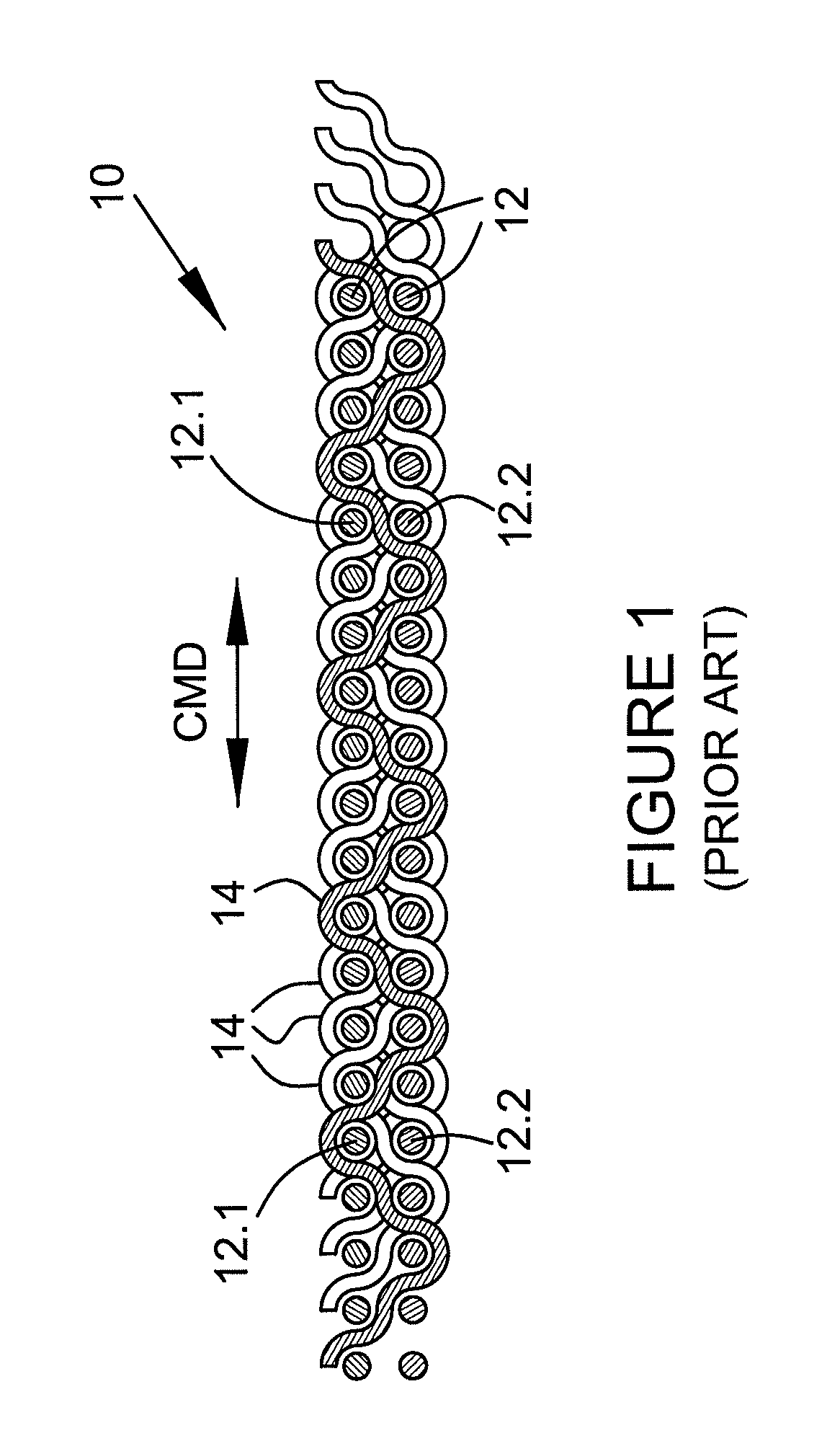

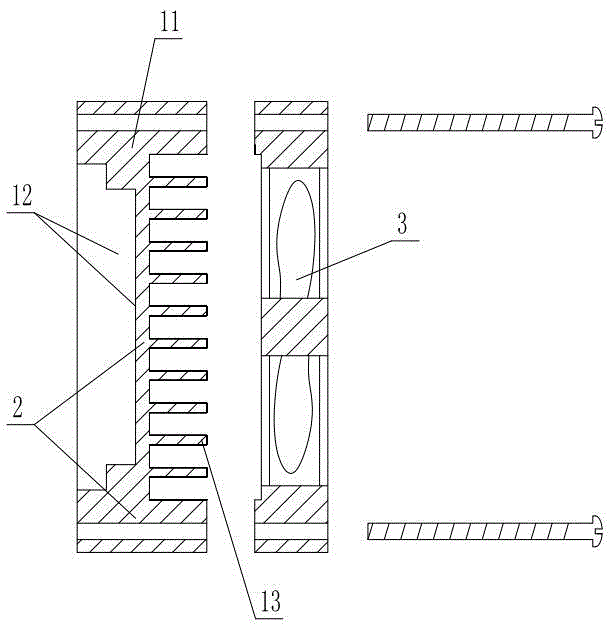

Press felt

InactiveUS20050124248A1Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

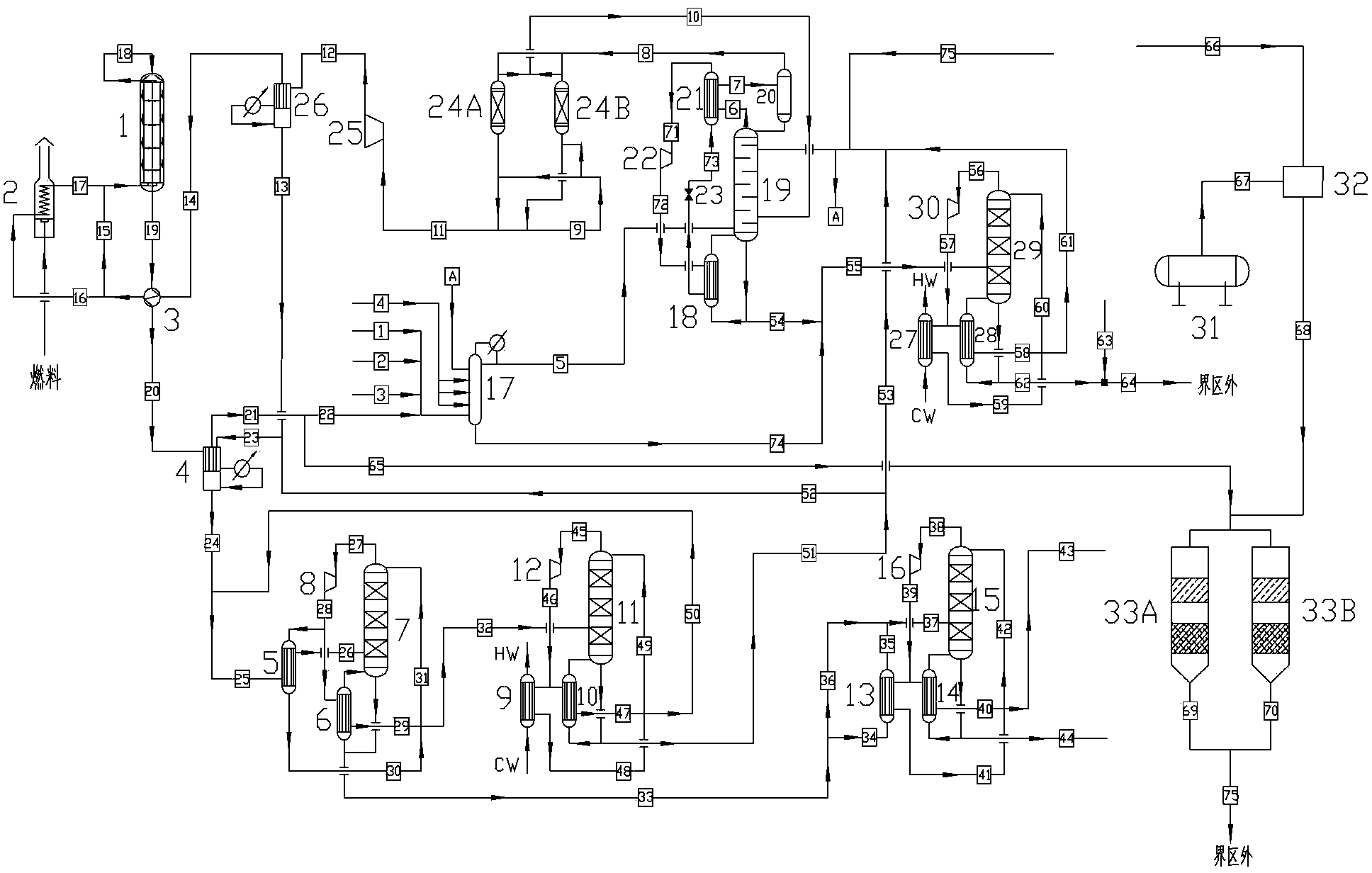

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

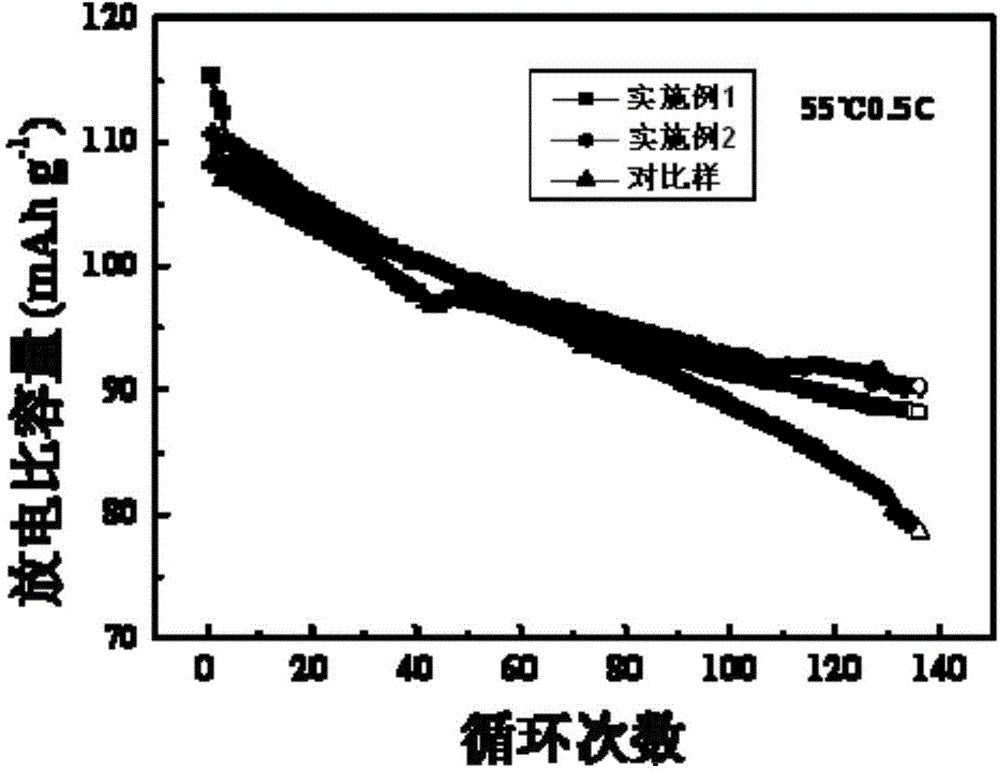

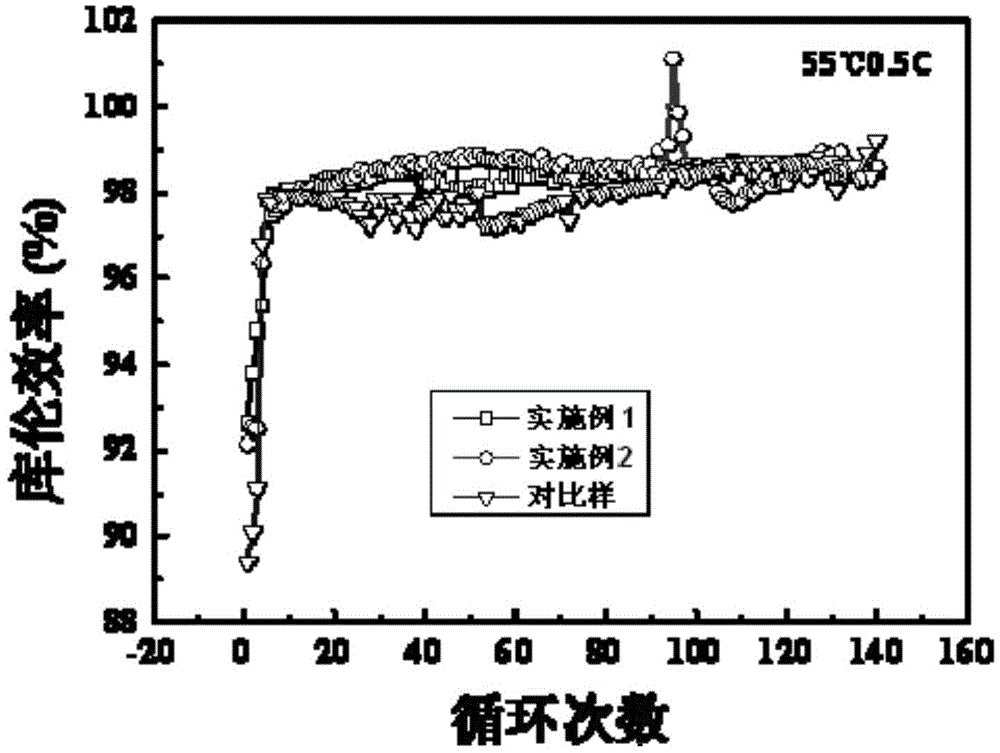

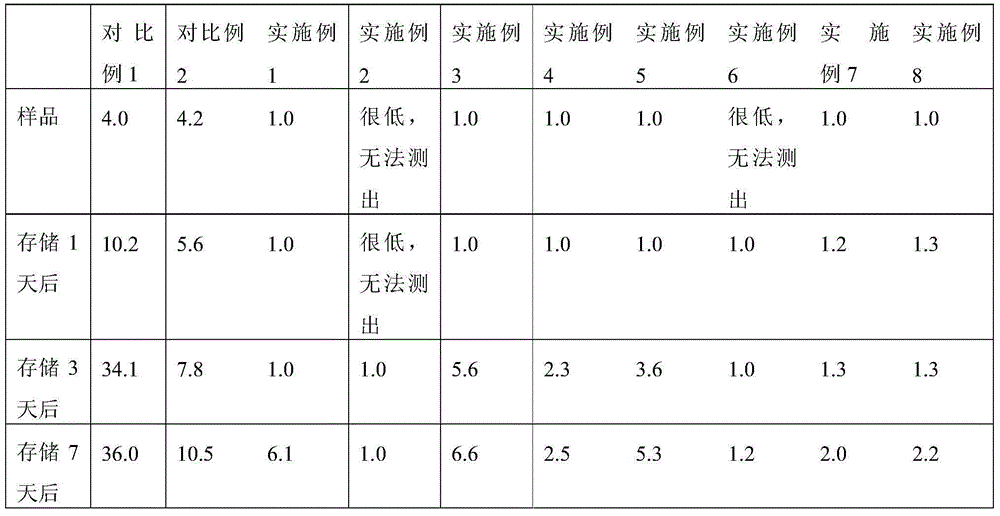

Electrolyte for improving high temperature performance of lithium manganate power battery and lithium manganate power battery

InactiveCN103985903AImprove high temperature cycle performanceImprove high temperature performanceSecondary cells servicing/maintenanceOrganic electrolytesPower batteryElectrolyte

The invention provides an electrolyte for improving high temperature performance of a lithium manganate power battery and the lithium manganate power battery. The electrolyte comprises the following components: 75wt%-88wt% of non-aqueous organic solvent, 10wt%-17wt% of lithium salt, 0.5wt%-6wt% of film forming additive, 0.5wt%-5wt% of high temperature additive, 0.5wt%-3wt% of surfactant and 0.001wt%-1wt% of stabilizing agent; the electrolyte is capable of inhibiting the capacity reduction of spinel LiMn2O4 under high temperature through control of proportion of non-aqueous organic solvent, application of combination of LiPF6 and novel lithium salt, and addition of the film forming additive, the high temperature additive, the surfactant and the stabilizing agent which have cooperative effect. The high temperature cycle performance of the lithium manganate power battery by using the electrolyte can be obviously increased.

Owner:CENT SOUTH UNIV

Press felt

InactiveUS7306704B2Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

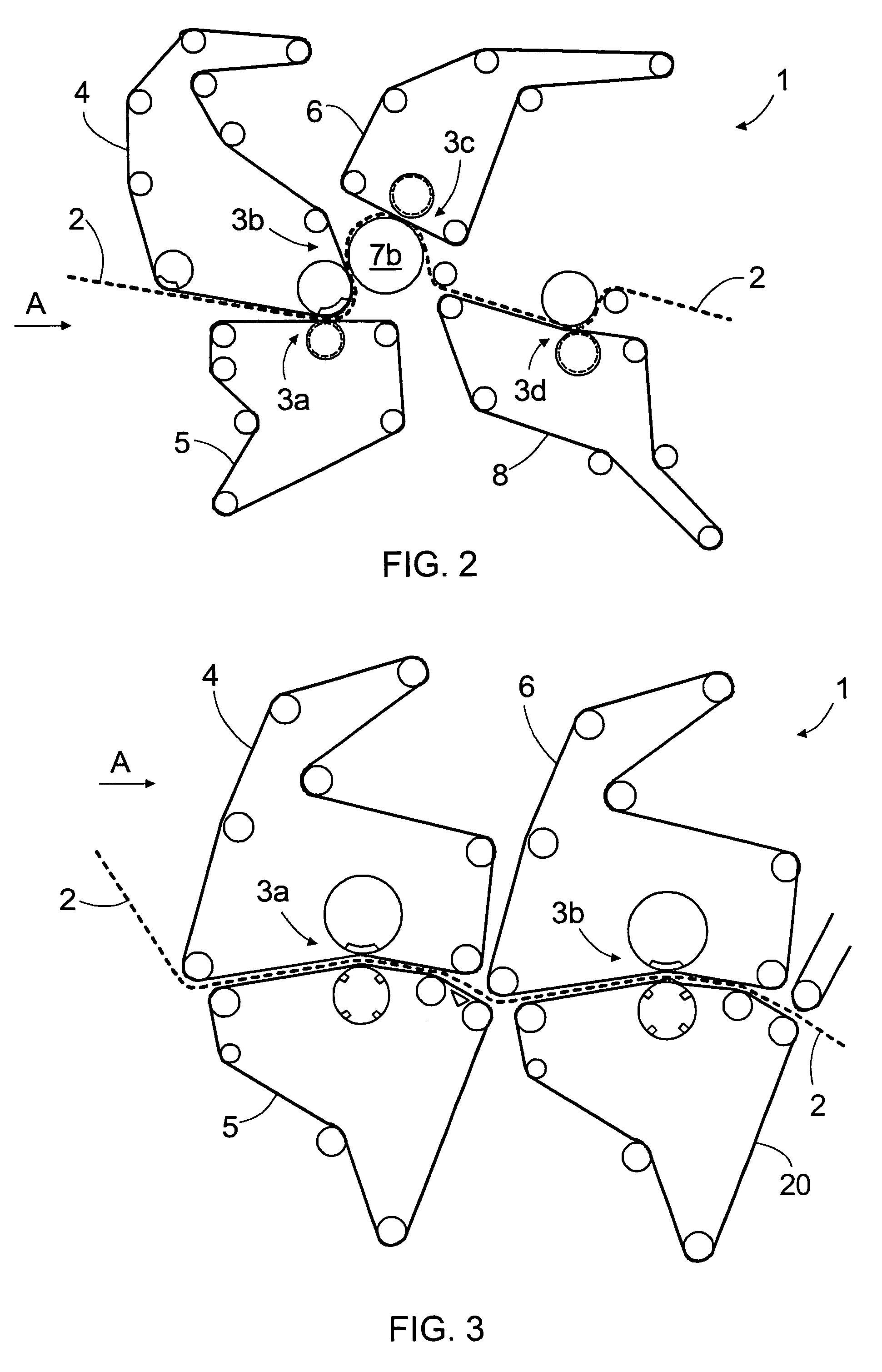

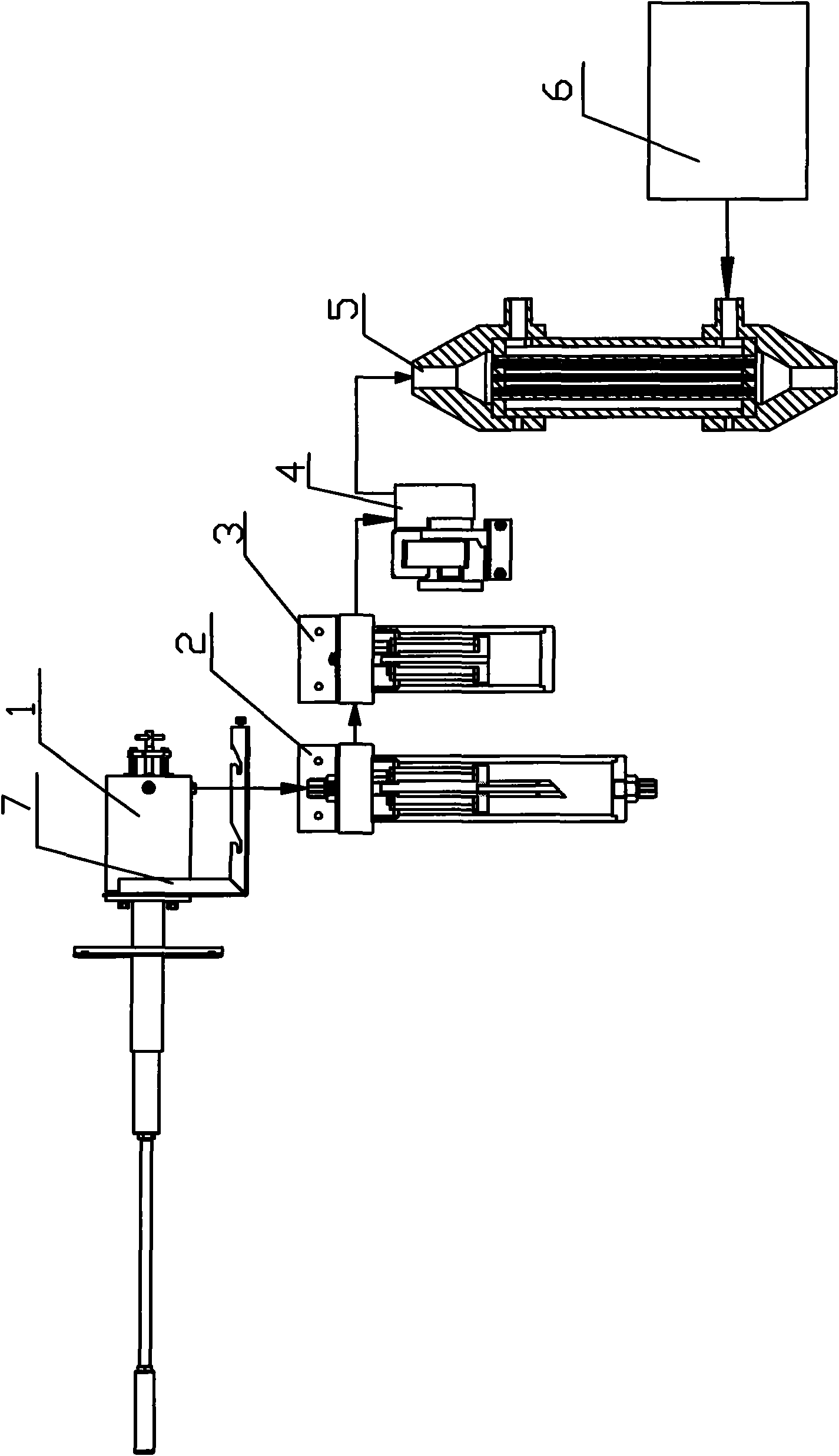

Method for removing moisture in gases by a Nafion tube

InactiveCN101524617ALow costImprove water removal effectDispersed particle separationGas analysisProduct gas

The invention discloses a gas drying method, in particular to a method for removing moisture in gases by a Nafion tube. The method is characterized in that the moisture is absorbed by adopting the permeability of the Nafion tube on the moisture and flow velocity of different gases on both sides of the Nafion tube to finally realize the aim of removing the moisture in processed gases inside the Nafion tube. The method has the advantages of low cost, high moisture removal property, small volume and the like. The method can be applied to such industries as atmospheric environment monitoring, pollution resource on-line monitoring, various gases analysis and rapid emergency command vehicles, etc.

Owner:陈明

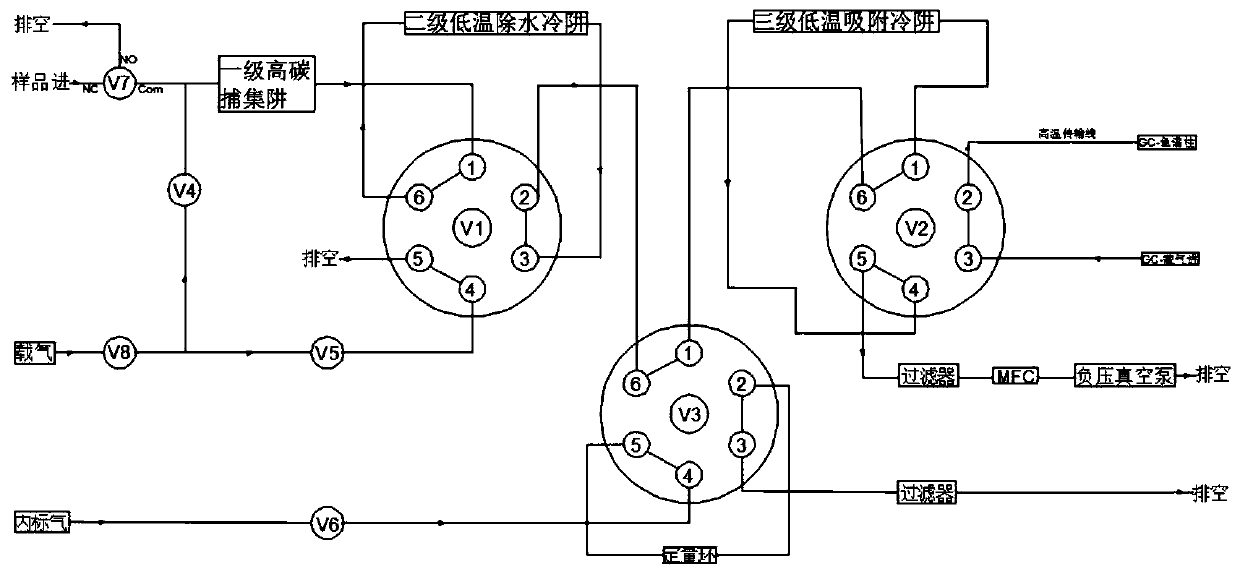

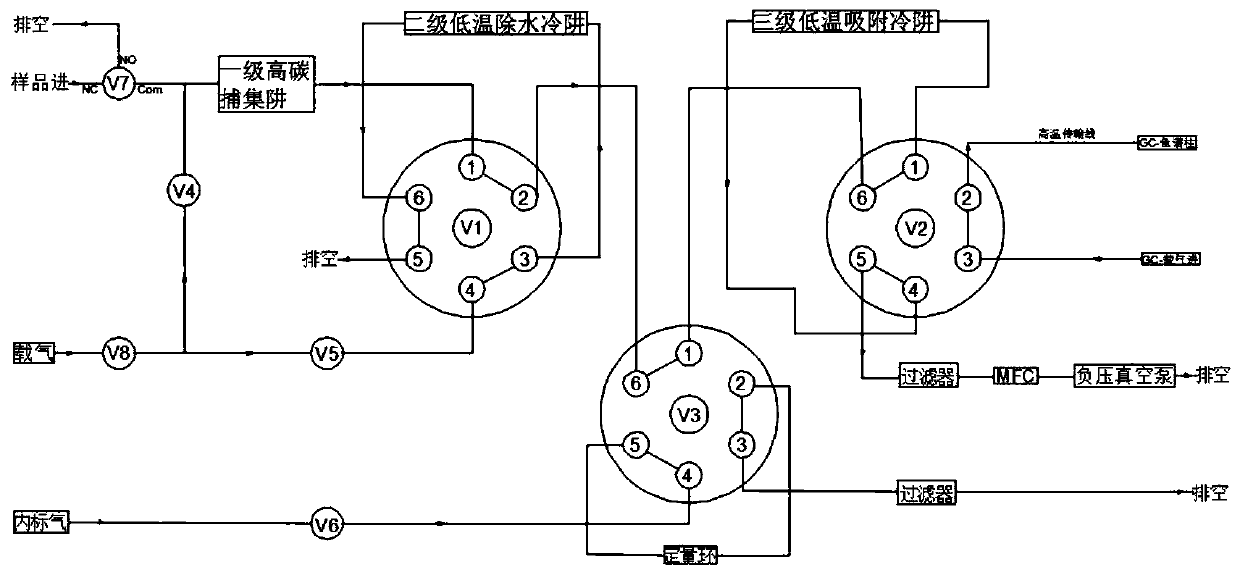

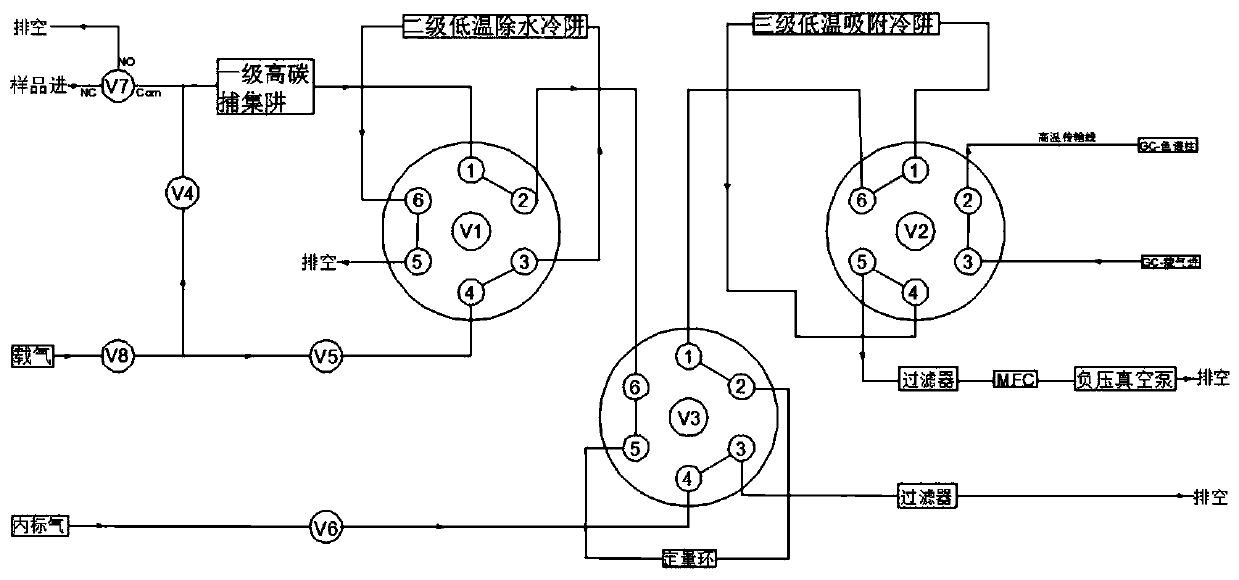

Dehydration and concentration gas circuit system and method for volatile organic compounds in atmosphere

PendingCN111007188AHigh recovery rateIncrease authenticityComponent separationWater vaporDehydration

The invention discloses a water removal and concentration gas path system and a method for volatile organic compounds in atmosphere. The system comprises a first-stage high-carbon trap, a second-stagelow-temperature water removal cold trap and a third-stage low-temperature adsorption cold trap, the first-stage high-carbon trap, the second-stage low-temperature water removal cold trap and the third-stage low-temperature adsorption cold trap are fixedly communicated through six-way valves; the method is scientific and reasonable, safe and convenient use, the gas path passes through a first-stage high-carbon trap; high boiling components are trapped, water vapor is removed through a secondary low-temperature water removal cold trap; then the gas enters a third-stage low-temperature adsorption cold trap to adsorb and trap the gas penetrating through the second-stage cold trap; according to the method, high-boiling-point components intercepted by the first-stage high-carbon trapping trap can be transferred into the third-stage low-temperature adsorption cold trap along with carrier gas; according to the method, the condensation of the high-carbon component in the water removal cold trap is avoided while water is removed, the recovery rate of the high-boiling-point component is improved, and the content of the tested high-boiling-point component is closer to an actual value, so thatthe authenticity and the accuracy of data are greatly improved.

Owner:常州磐宇仪器有限公司

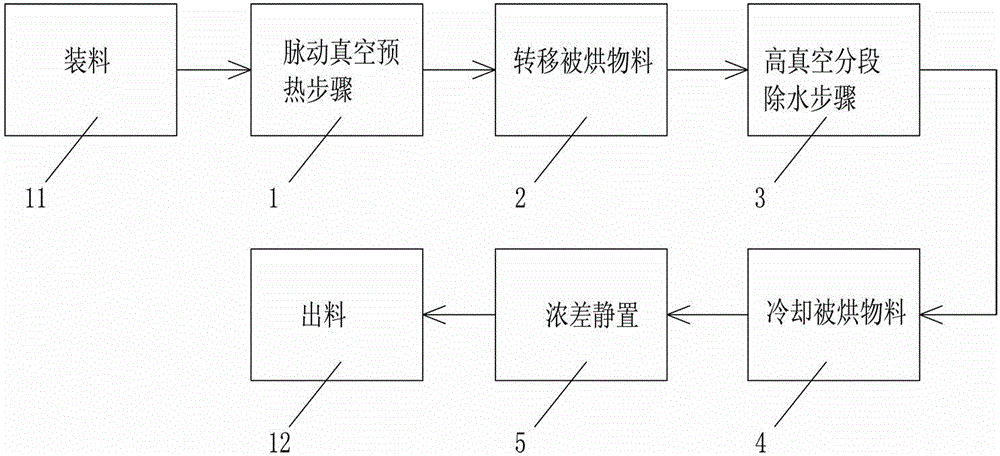

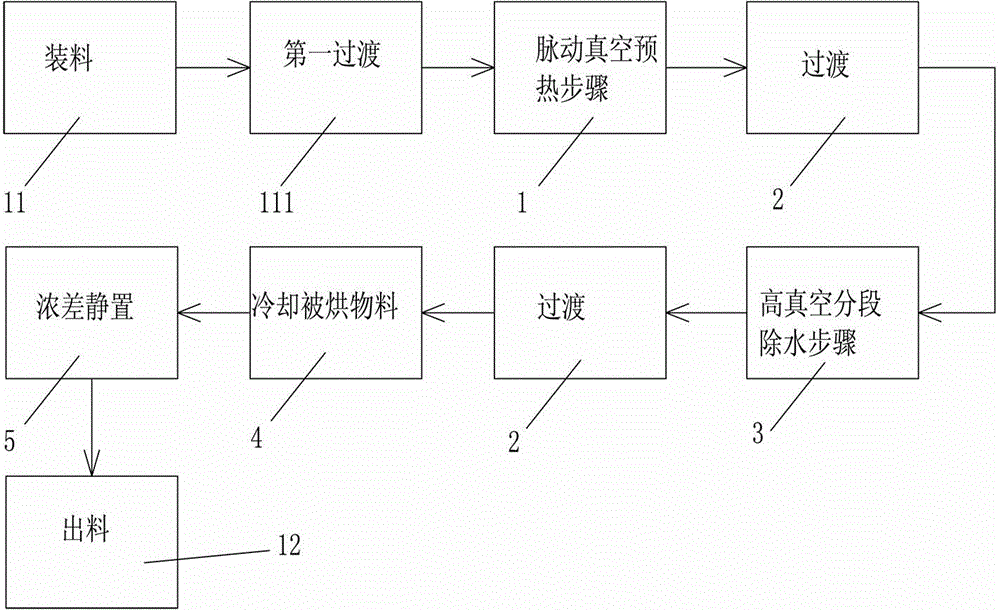

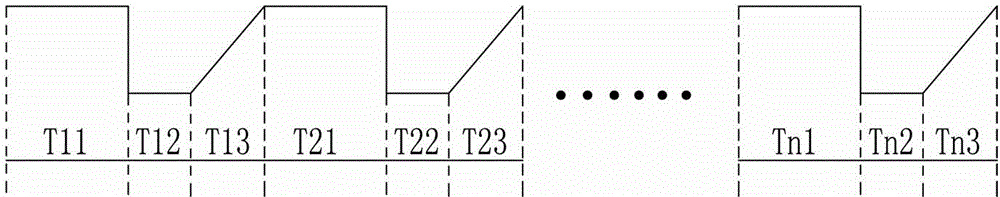

Method for baking lithium ion battery or battery pole piece in tunnel mode

InactiveCN104913601AGood water removal effectShorten water removal timeDrying using combination processesElectrical batteryManufacturing line

A method for baking a lithium ion battery or a battery pole piece in a tunnel mode at least includes the step of pulsation vacuum preheating, wherein the temperature in a preheating box is made to rise to first preset temperature within first preset time, a part of water in the preheating box is drained through a vacuumizing method within second preset time, and the preheating box is refilled with dry air; the temperature in the preheating box is made to rise to second preset temperature within third preset time, a part of water in the preheating box is drained through the vacuumizing method within fourth preset time, and the preheating box is refilled with dry air; the step is circulated in this way until the temperature of the lithium ion battery or the battery pole piece in the preheating box reaches technological design temperature. Compared with the mode of single temperature rise in the preheating box in the prior art, most water in the lithium ion battery or the battery pole piece can be removed in the preheating stage, the water removal effect is excellent, and the water removal time of a speed bar production line can be greatly shortened.

Owner:SHENZHEN XINYUREN TECH

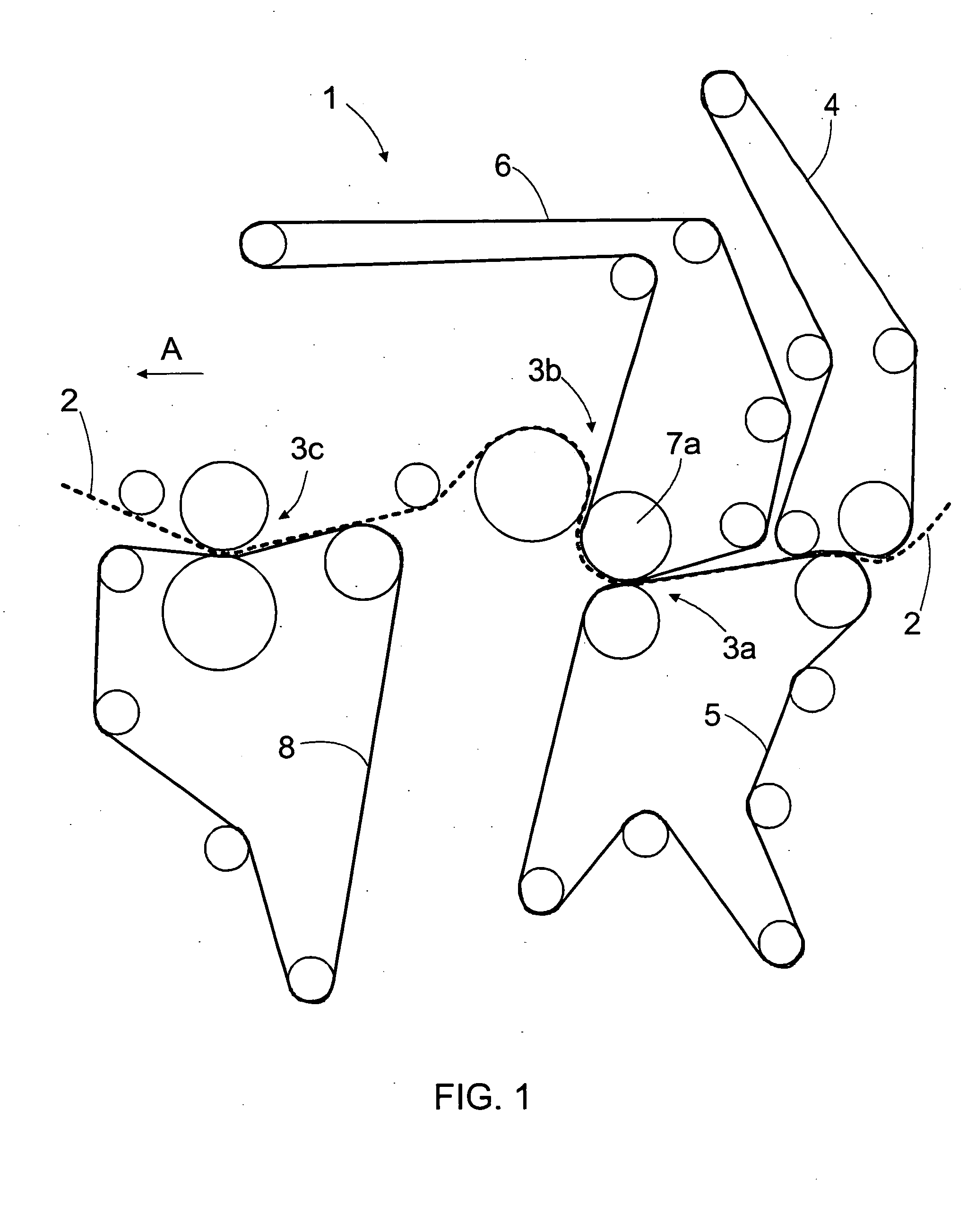

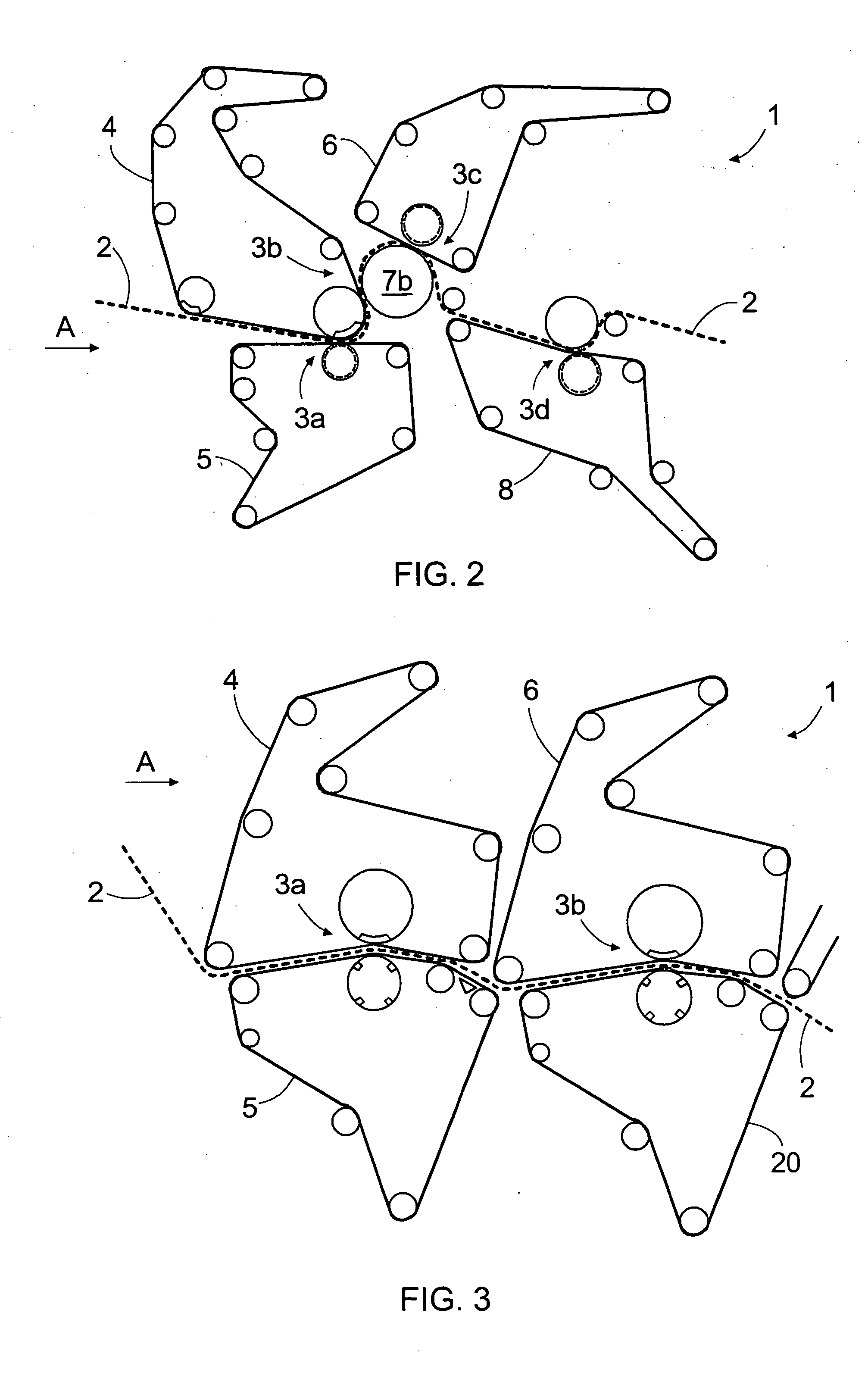

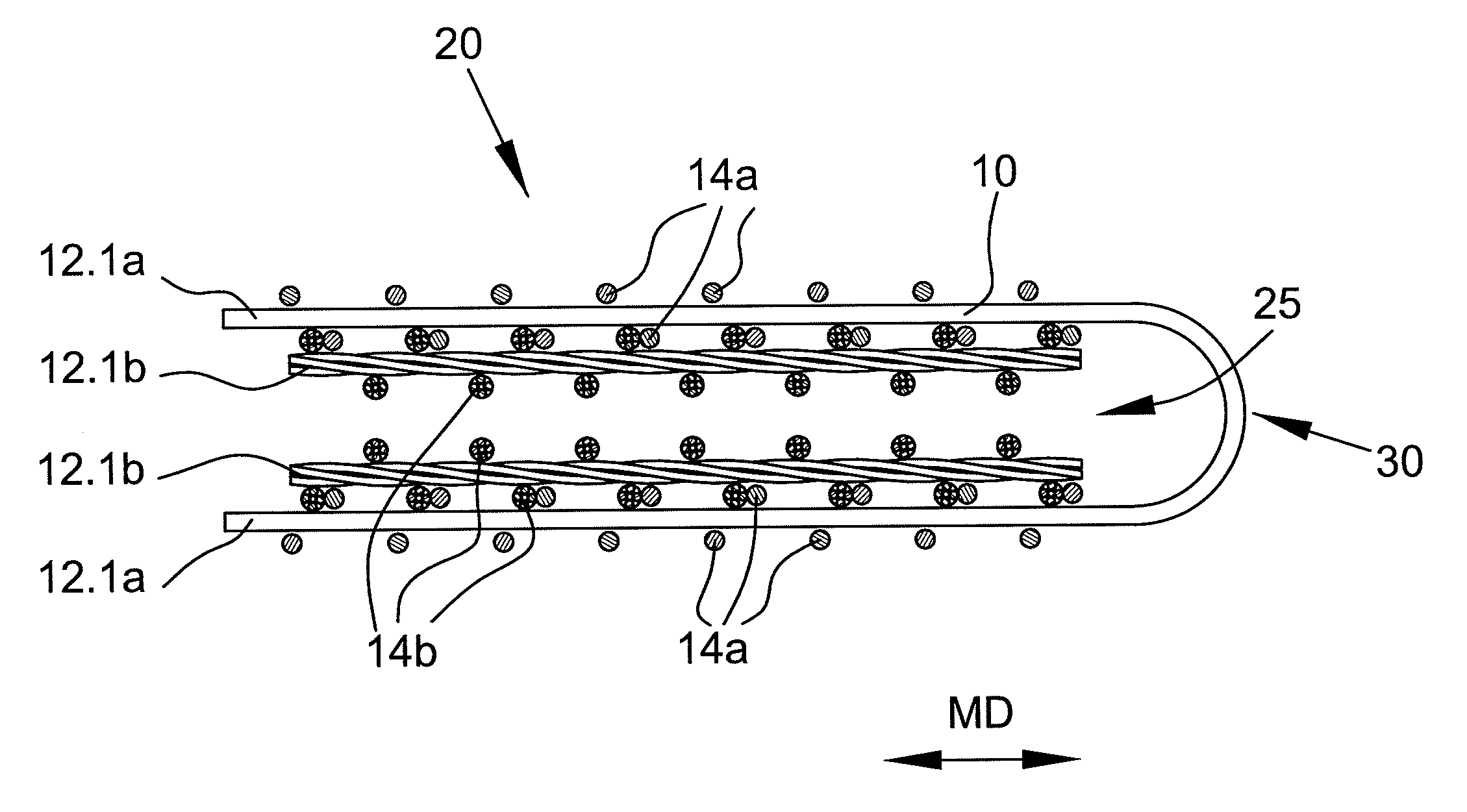

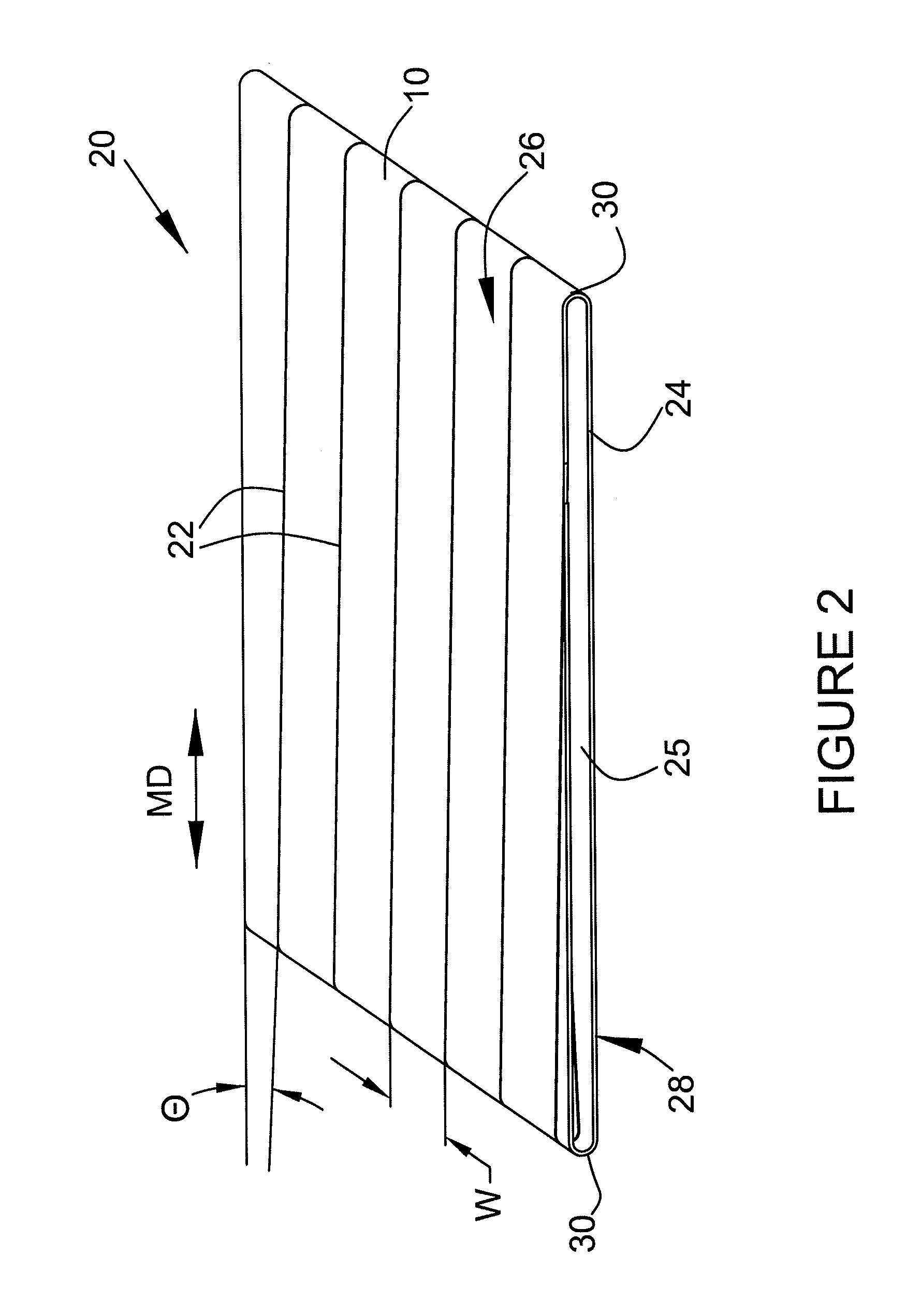

Multiaxial press felt base fabric including cabled monofilaments

ActiveUS20130020043A1Maintain volumeUniform qualityPaper/cardboardPress sectionPapermakingEngineering

A multiaxial press felt base fabric construction is provided in which the base fabric is formed from a spirally wound precursor textile strip having a width that is less than an overall width of the assembled papermaking fabric and which is joined together along neighboring adjacent edges to form a fabric tube. At least one of: 100% of the MD yarns located on one surface of the precursor textile strip are comprised of cabled yarns or from 50% to 100% of the CD yarns are a cabled yarn. The MD yarns are arranged as vertically stacked pairs for compression resistance to provide void volume, and the vertically stacked arrangement is maintained by interweaving with one system of CD weft yarns.

Owner:ASTENJOHNSON

Water removal method of dichloromethane

InactiveCN104857742AReduce energy consumptionEasy to operateHalogenated hydrocarbon separation/purificationLiquid separationMicrometerPollution

The invention relates to a water removal method of dichloromethane, which comprises the steps of filtering dichloromethane having a water content of 2-20% with a hydrophobic and oleophylic film having a pore size of 0.001-20 micrometers, collecting filtrate, and obtaining dichloromethane with a water content of less than 0.5%. The method is low in energy consumption, convenient to implement and good in water removal effect and cannot produce the problem of secondary pollution.

Owner:CHONGQING UNIV OF TECH

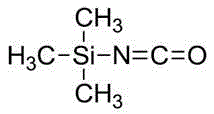

Non-aqueous electrolyte and lithium ion battery containing same

ActiveCN105990605AHigh cathode stabilityGood anode film-forming performanceSecondary cellsSilyleneOrthoester

The invention provides a non-aqueous electrolyte including: lithium salt, a non-aqueous solvent and an additive which includes trimethsilane isocyanate and orthoester. The invention also provides a lithium ion battery containing the non-aqueous electrolyte. The trimethsilane isocyanate and the orthoester serve as special additives in the electrolyte, which effectively improve high-temperature performance of the battery. The non-aqueous electrolyte with equal-amount addition of the special additives, compared with non-aqueous electrolytes with other common additives in the prior art, can greatly improve the high-temperature performance of the produced battery.

Owner:BYD CO LTD

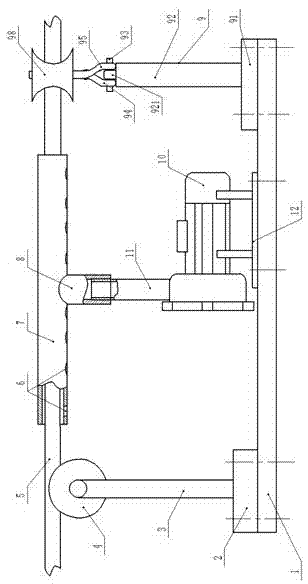

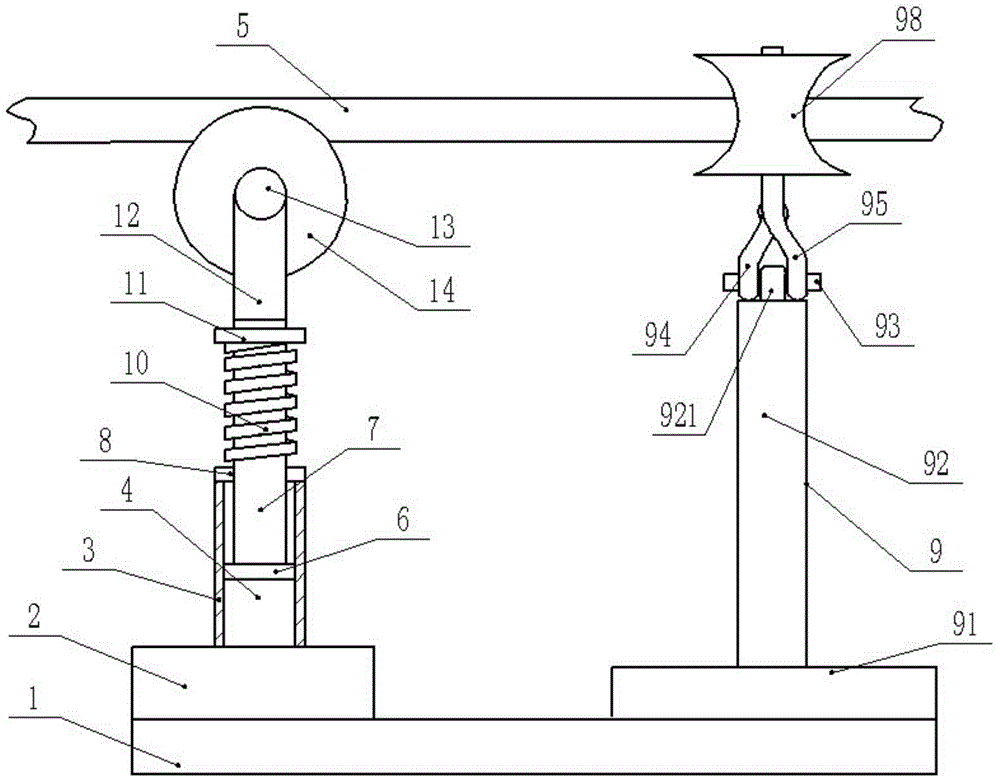

Cable drying device

InactiveCN104505199AImprove cleanlinessAvoid damageCable/conductor manufactureAgricultural engineeringIdler-wheel

The invention discloses a cable drying device, which comprises a bottom plate, a cable, a blower and a dehydrating device, wherein the top left of the bottom plate is fixedly connected with an idler wheel base through a bolt, an idler wheel support rod is vertically arranged at the upper end of the idler wheel base, the upper end of the idler wheel support rod is in rotating connection with an idler wheel, an annular groove is arranged in the middle of the idler wheel, the blower is arranged at the right side of the idler wheel, the lower end of the blower is fixed on a draught fan base, which is fixedly arranged on the bottom plate through the bolt, the upper end of the blower is connected with an air hose, the upper end of the air hose is connected with a shunt pipe through threads, an air duct is welded at the upper end of the shunt pipe, the cable is arranged in the air duct, and a plurality of drainage exits are arranged at the bottom of the air duct. The cable drying device has a simple structure, is convenient to use, and keeps the surface of the cable clearer; and the air duct further improves the dehydration capacity of the device, and protects a spark machine from being damaged by water on the cable.

Owner:江苏辰宇电气有限公司

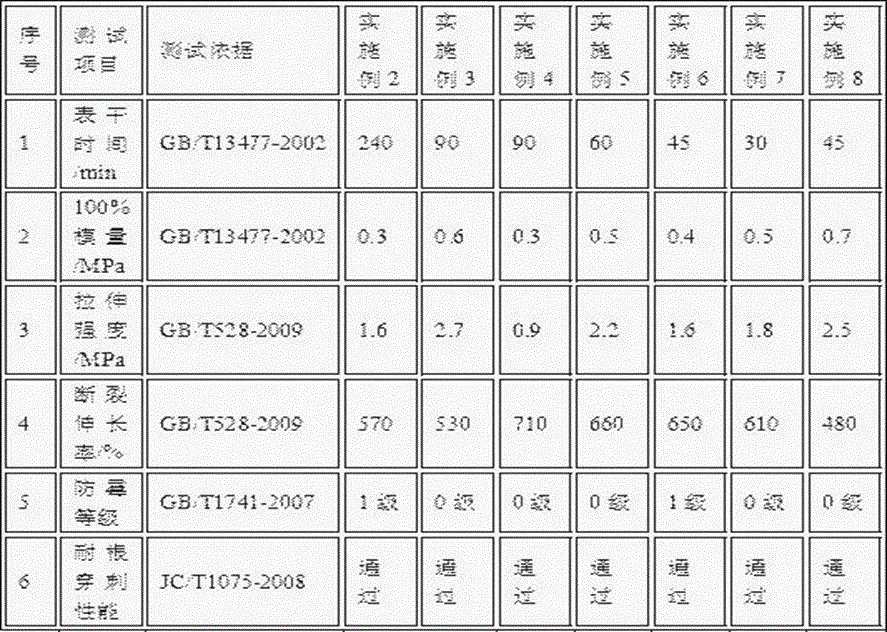

Single-component mildewproof negative-radical polyurethane building sealant and preparation method thereof

ActiveCN105482763AMildew proofWith resistive rootNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesVegetationSilanes

The invention relates to the technical field of sealants, particularly a single-component mildewproof negative-radical polyurethane building sealant and a preparation method thereof. The single-component mildewproof negative-radical polyurethane building sealant comprises a polyurethane prepolymer, a mildew preventive, a chemical negative-radical agent, a filler, a silane bonding accelerator, a catalyst and a moisture remover. The polyurethane prepolymer comprises polyoxypropylene diol, polyoxypropylene triol, polyisocyanate and a plasticizer. The single-component mildewproof negative-radical polyurethane building sealant simultaneously comprises the mildew preventive and chemical negative-radical agent, and thus, has the dual functions of mildew resistance and negative radical. The single-component mildewproof negative-radical polyurethane building sealant is especially suitable for node treatment of the vegetation roofing waterproofing structure, and can prevent the plant root system from piercing into the sealant, which can cause inactivation of the additional waterproof layer. The preparation method is simple, and is suitable for industrialized large-scale production.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

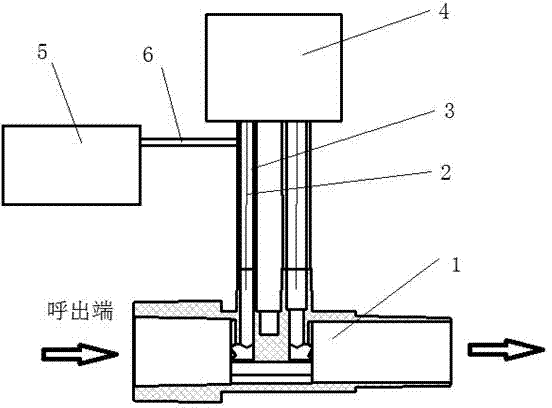

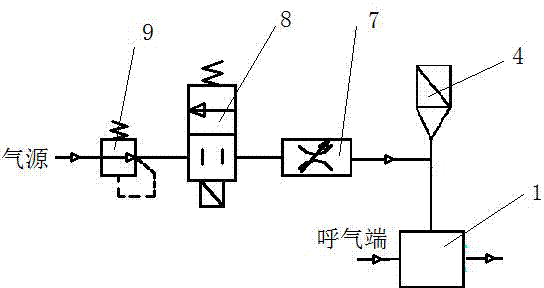

Breathing machine sampling pipe water removing method and device

The invention discloses a breathing machine sampling pipe water removing method and device. An air blowing device is arranged on the part, close to the breathing end of a breathing machine air flow pipe, of a sampling pipe, in the breathing machine inhalation stage, the air blowing device blows air to the sampling pipe for a time. By means of the breathing machine sampling pipe water removing method and device, water vapor in the sampling pipe is removed through the simple and practical air blowing method, the problem of water vapor condensation in the breathing machine sampling pipe is quite effectively solved, the water removing air blowing device is simple, effective, low in using cost and obvious in water removing effect, the service life of a breathing machine differential pressure transducer is greatly prolonged, the accuracy of breathing parameter monitoring is ensured, and the working efficiency of medical personnel is improved.

Owner:NANJING SUPERSTAR MEDICAL EQUIP

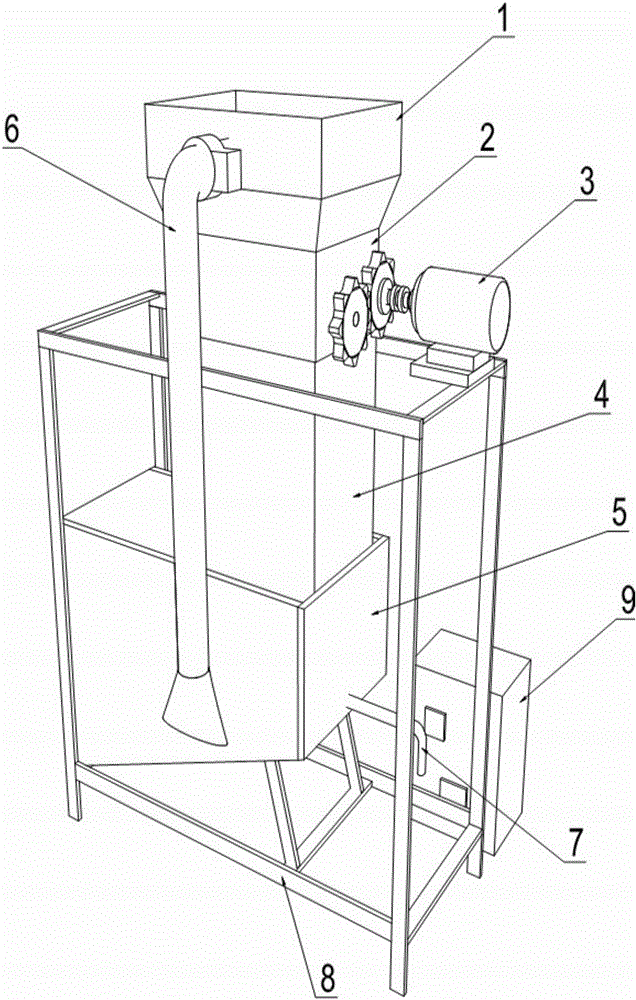

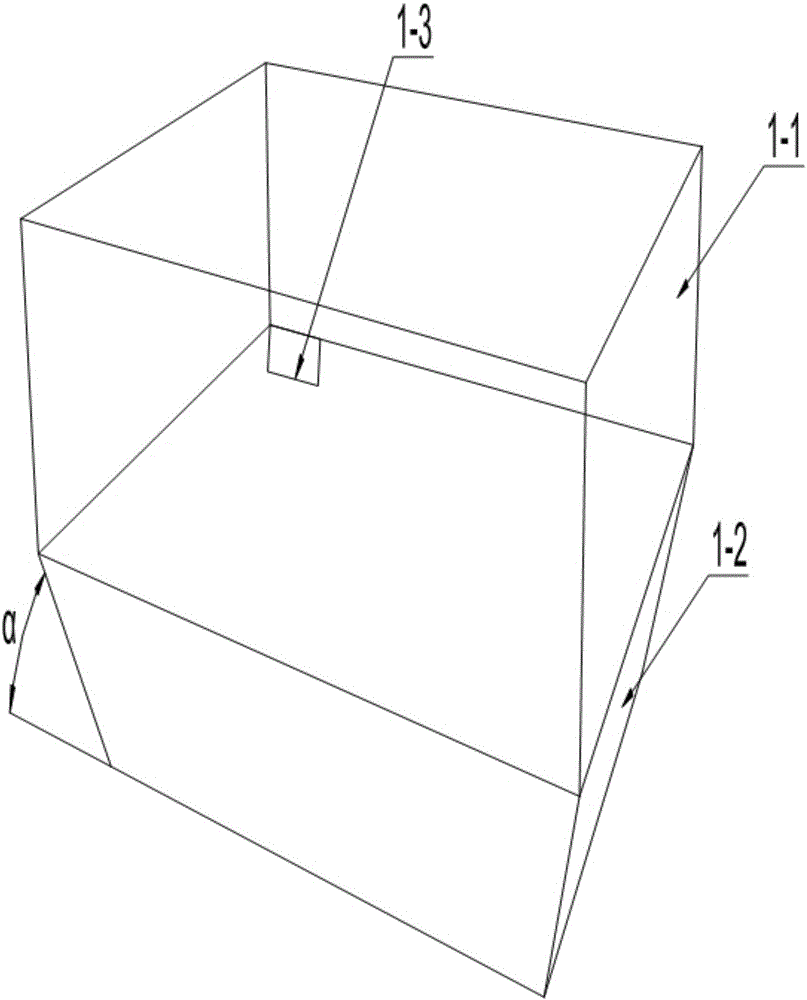

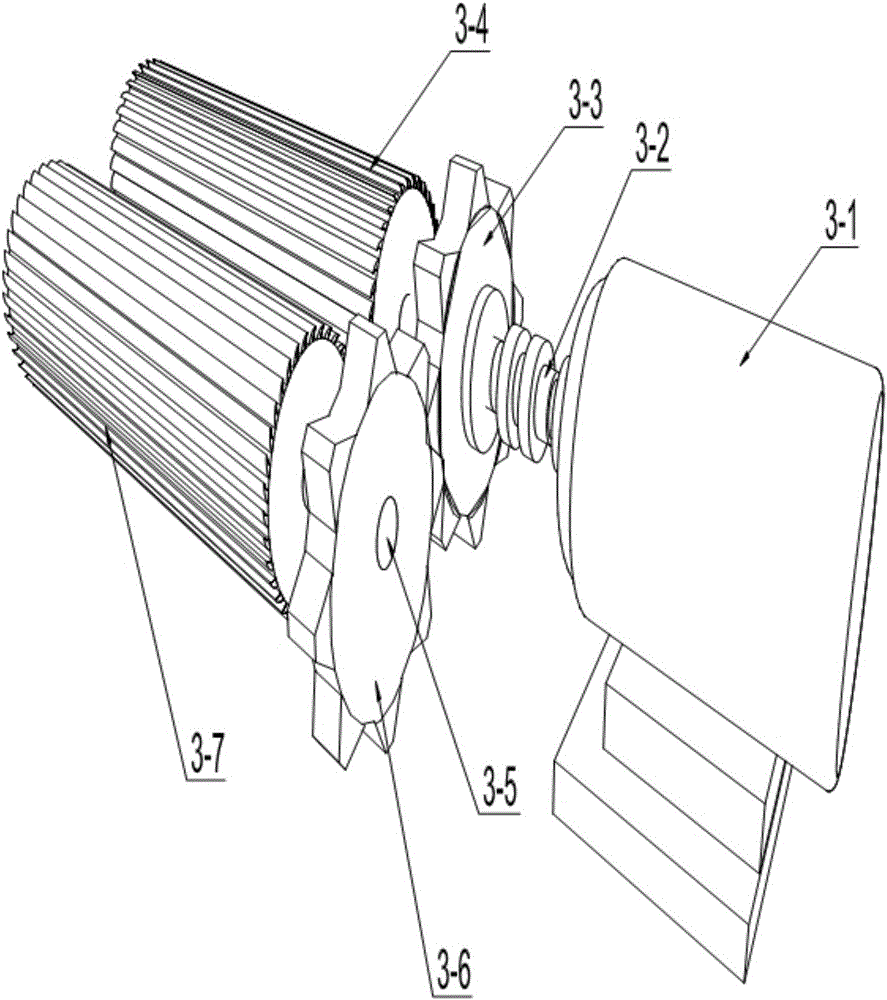

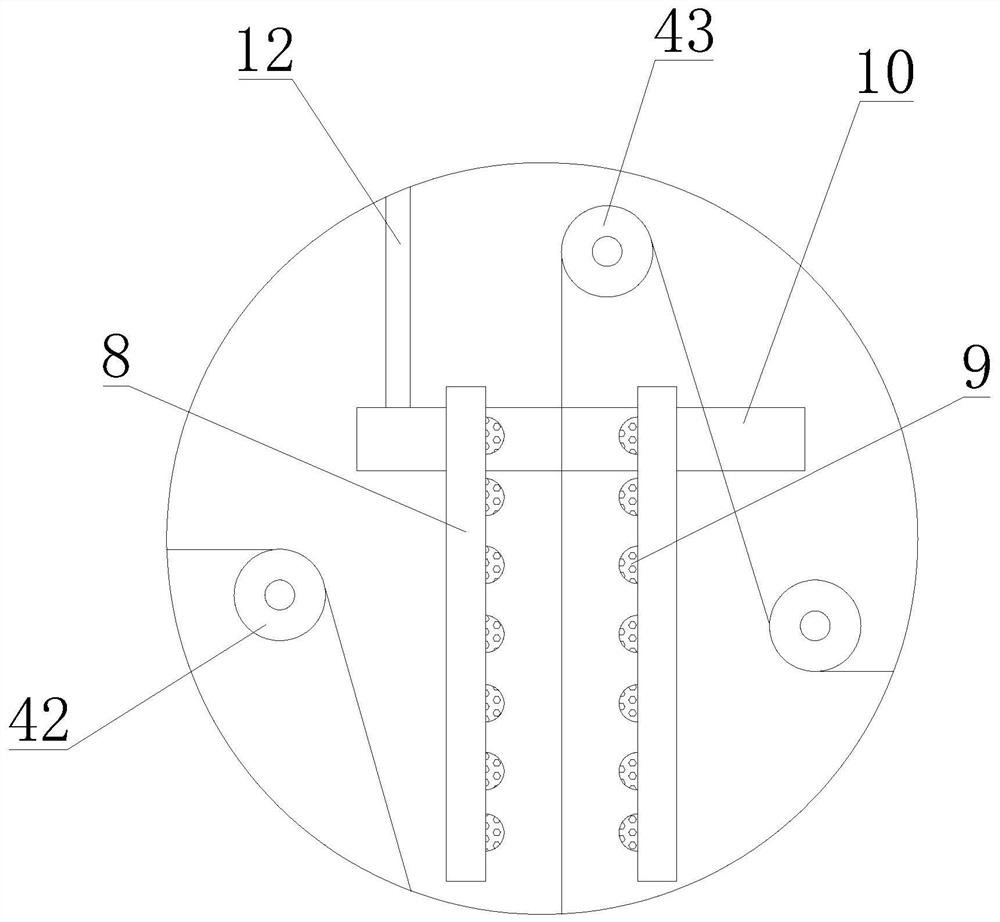

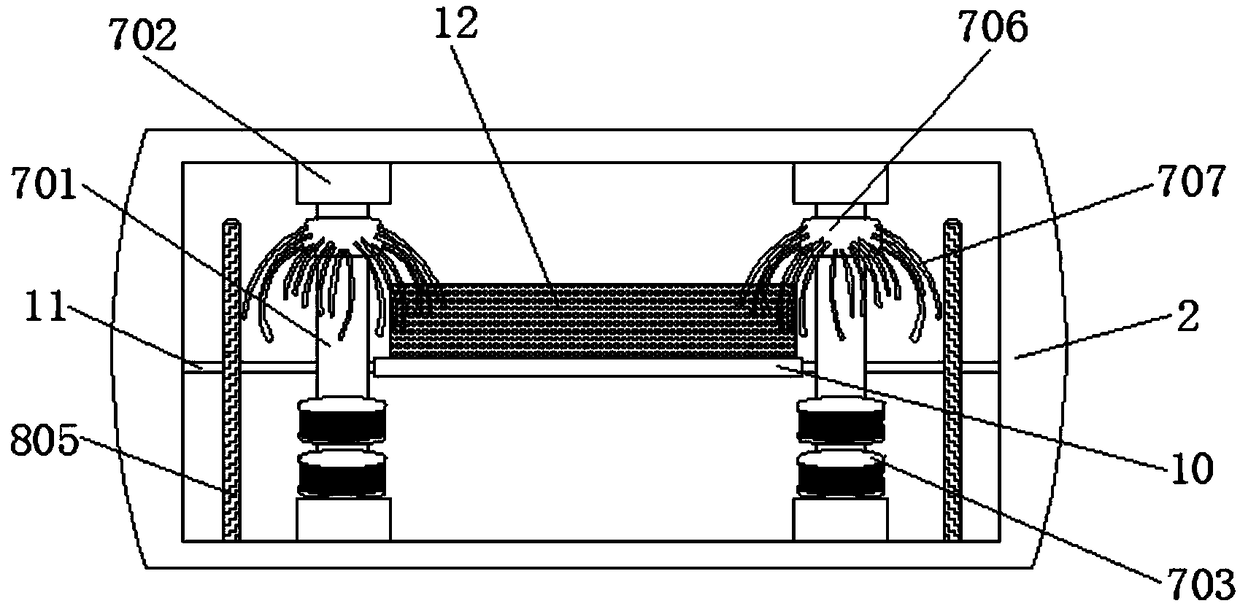

Crushing, compression and dehydration integrated device and working method thereof

ActiveCN105728100AImprove crushing precisionHigh degree of automationDrying solid materials without heatGrain treatmentsControl systemDehydration

The invention discloses a crushing, compression and dehydration integrated device. The crushing, compression and dehydration integrated device consists of a feed bin, a crushing bin, a crushing device, a screening bin, a compression dehydration bin, an automatic sucking device, a drain pipe, a bracket and a control system; raw materials enter the feed bin through the automatic sucking device to drop into the crushing bin; fragments, crushed by the crushing device, vertically enter the screening bin, and are screened by the screening bin; the screened fragments enter the compression dehydration bin, and are discharged out of a bin body after compression; and compressed water is drained out of the device by the drain pipe. The crushing, compression and dehydration integrated device is novel and reasonable in shape, is convenient and fast in automatic sucking structure, is simple and practical in compression mechanism, is excellent in dehydration effect, and is wide in application range.

Owner:XUZHOU UNIV OF TECH

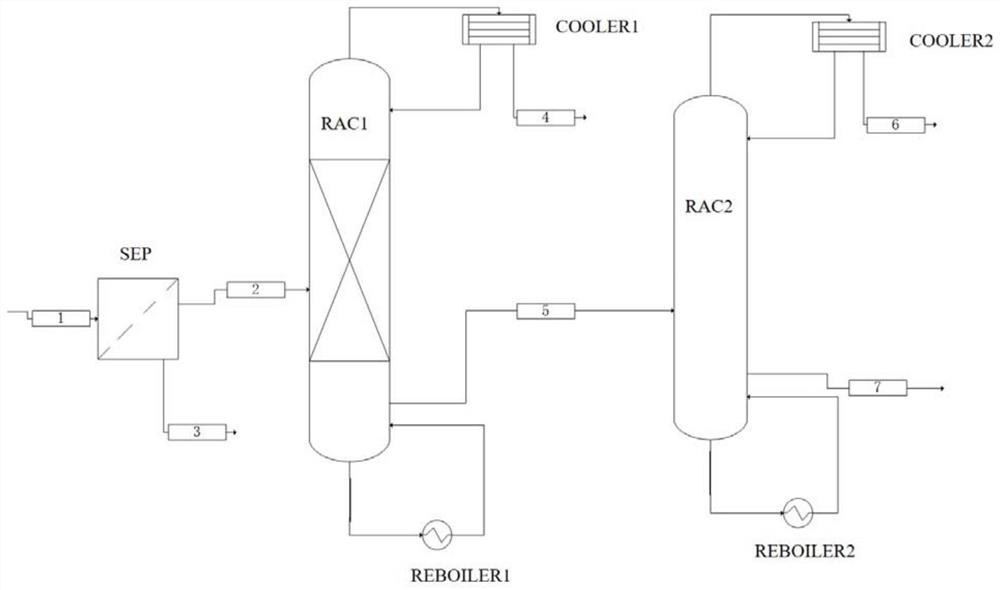

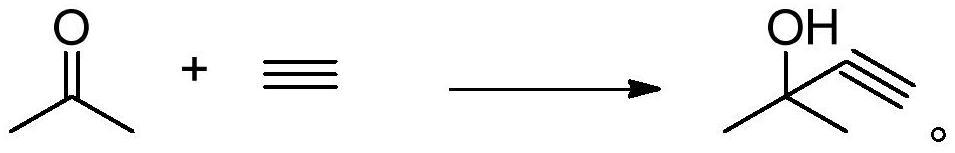

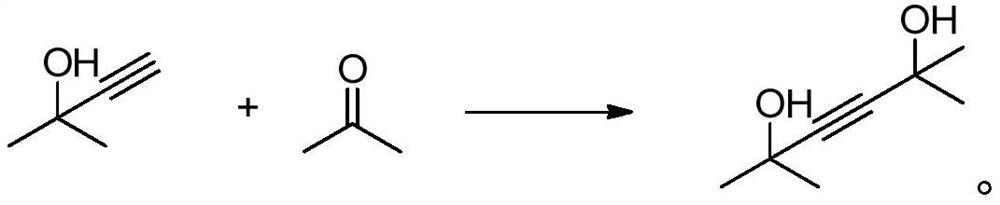

Separation method of 2-methyl-3-butyn-2-ol

ActiveCN111807929AHigh purityImprove conversion rateOrganic compound preparationHydroxy compound separation/purificationHexyneDistillation

The invention belongs to the technical field of acetylene alcohol production, and particularly relates to a separation method of 2-methyl-3-butyn-2-ol, which comprises the following steps: pretreatinga reaction solution containing 2-methyl-3-butyn-2-ol to remove unreacted acetone and contained salt from the reaction solution to obtain a 2-methyl-3-butyn-2-ol crude product, with the content of 2,5-dimethyl-3-hexyn-2,5-diol in the reaction solution containing 2-methyl-3-butyn-2-ol being not higher than 0.1 wt%; separating and purifying the 2-methyl-3-butyn-2-ol crude product by virtue of membrane separation treatment and reduced pressure distillation treatment, so as to obtain a 2-methyl-3-butyn-2-ol product. According to the method disclosed by the invention, water in the product can be removed and the content of the 2,5-dimethyl-3-hexyn-2,5-diol can be reduced under the condition that the investment and the energy consumption are reduced, so that the 2-methyl-3-butyn-2-ol with relatively high purity and conversion rate is obtained.

Owner:WANHUA CHEM GRP CO LTD

Synthesis process of hydroxyl pinacolone retinoate

ActiveCN113880797AFast absorptionStable esterification reactionOrganic chemistryChemical recyclingPtru catalystTretinoin

The invention belongs to the field of synthesis, and particularly relates to a synthesis process of hydroxyl pinacolone retinoate, the synthesis process comprises the following steps: carrying out condensation reaction on tretinoin and hydroxyl pinacolone under the action of a water absorption catalyst to obtain hydroxyl pinacolone retinoate, wherein the water absorption catalyst adopts a shell-core catalyst, vermiculite is used as an inner core, and titanium aluminum oxide is used as a mesoporous shell layer. According to the synthesis process, the defects in the prior art are overcome, distilled water generated in the reaction process is rapidly absorbed by utilizing the water absorption catalyst, and stable esterification reaction is formed under the catalytic action of titanium oxide.

Owner:南京先达医药科技有限公司

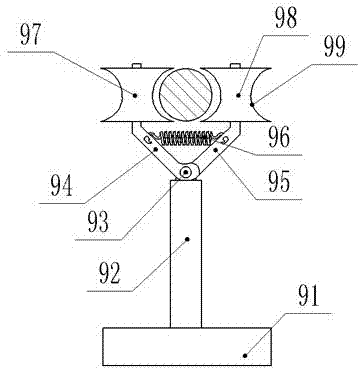

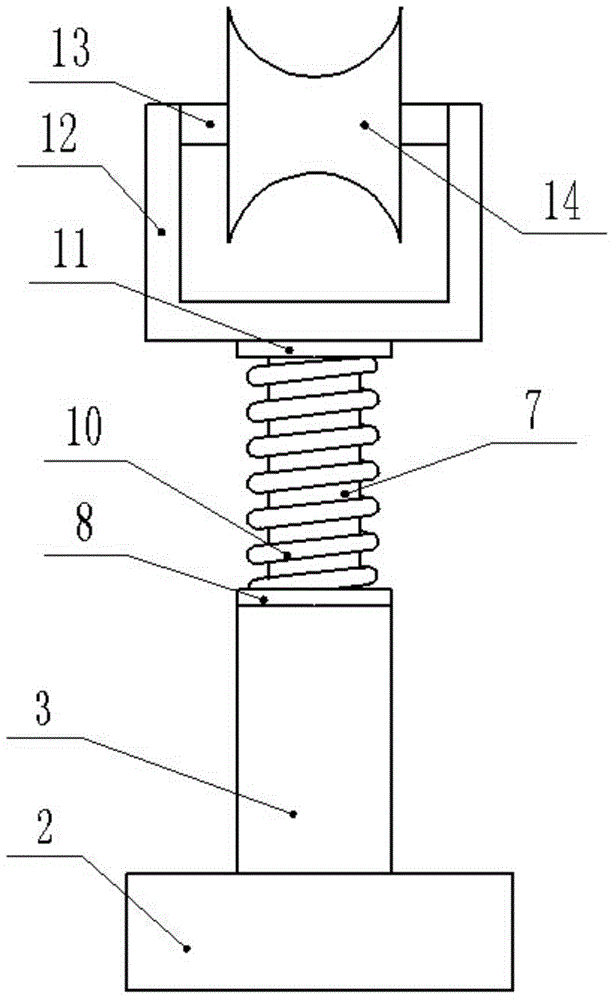

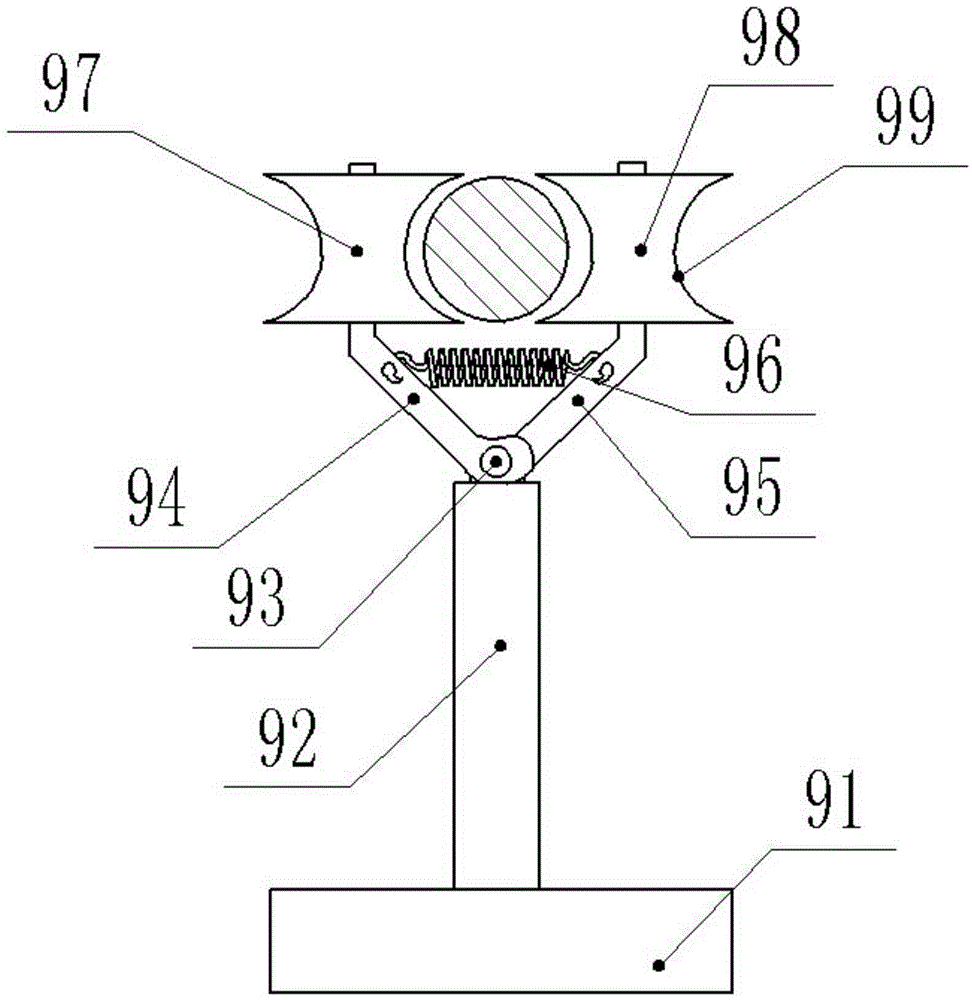

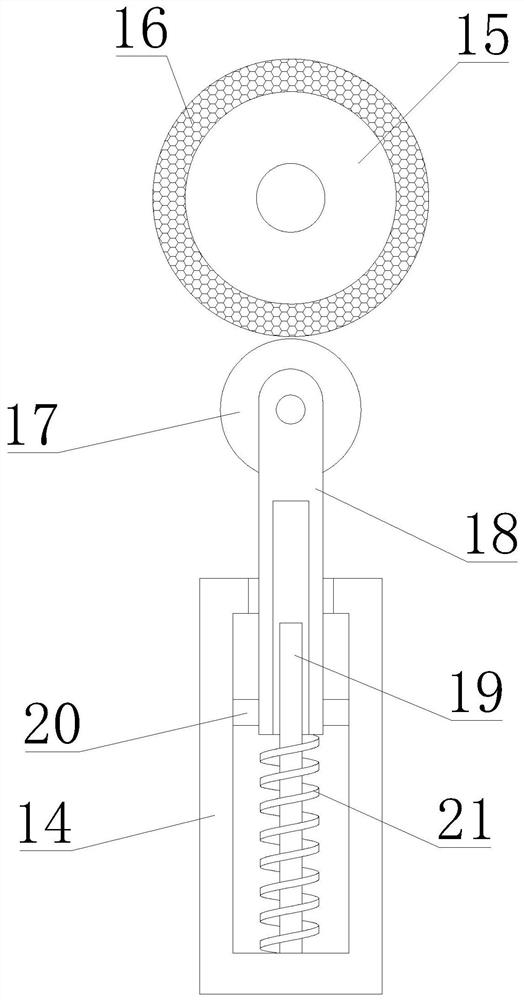

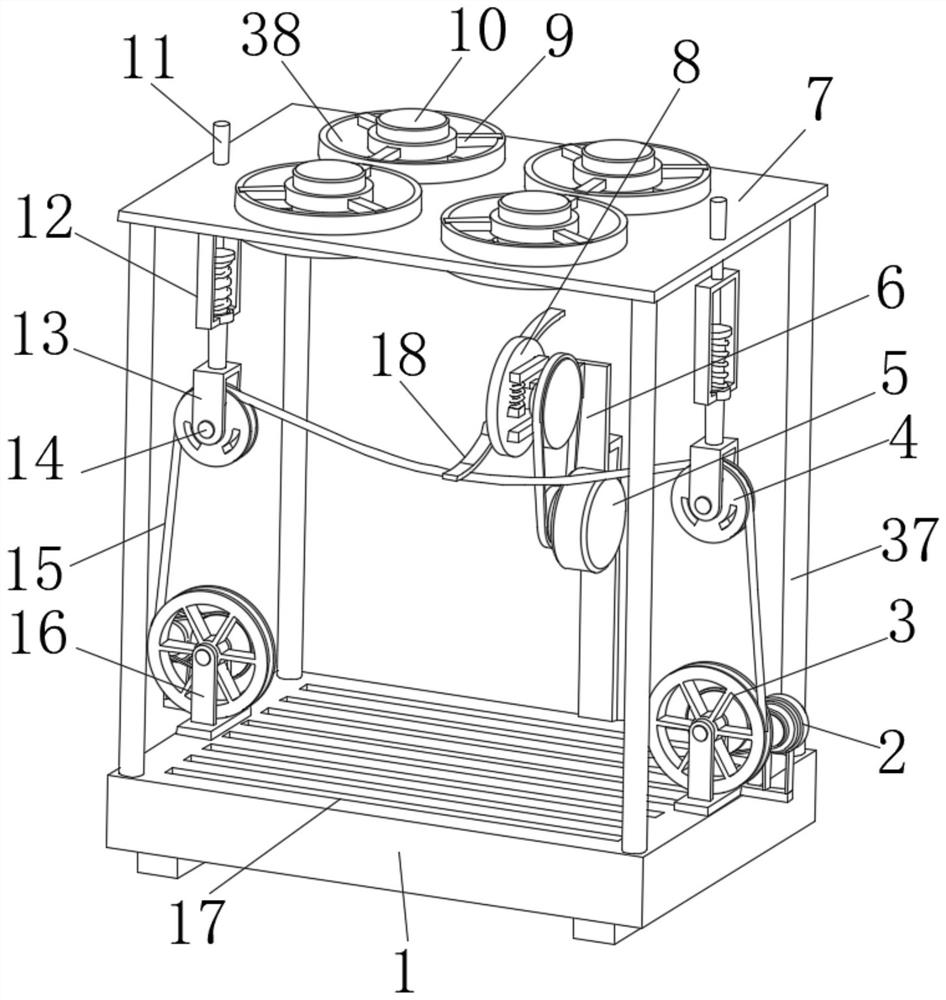

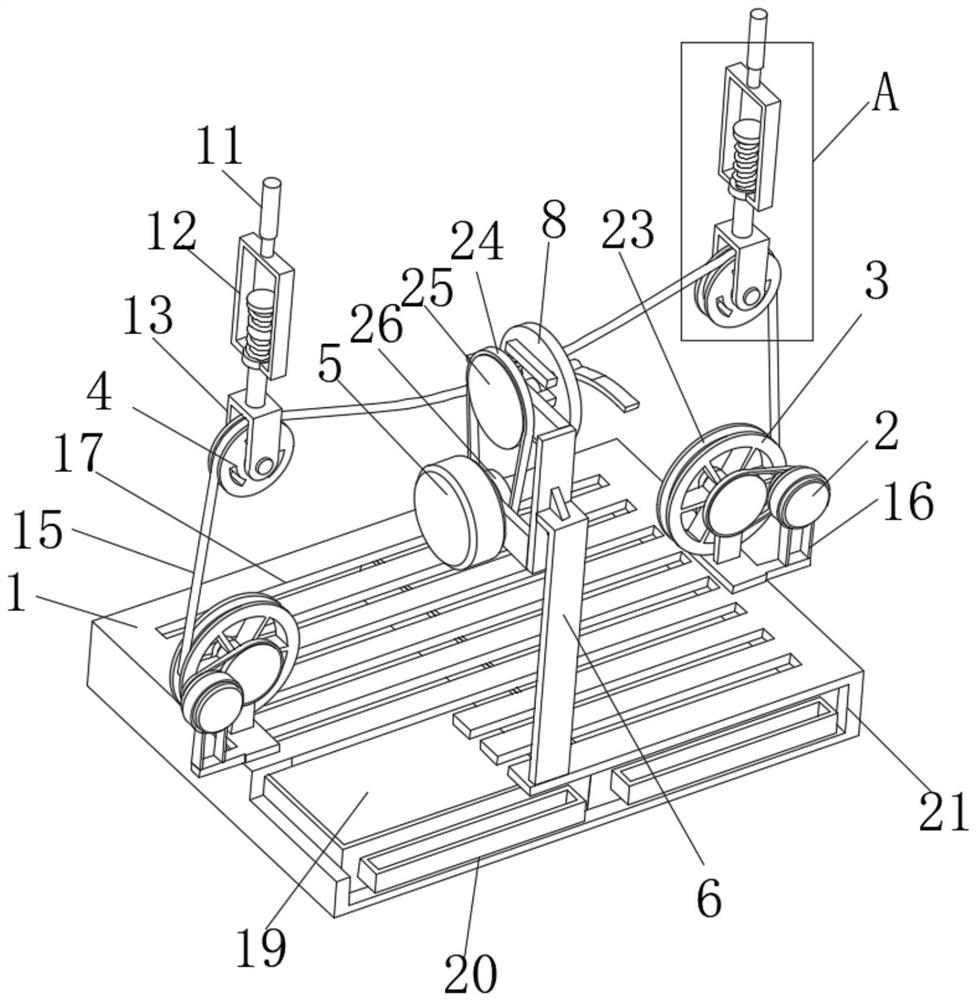

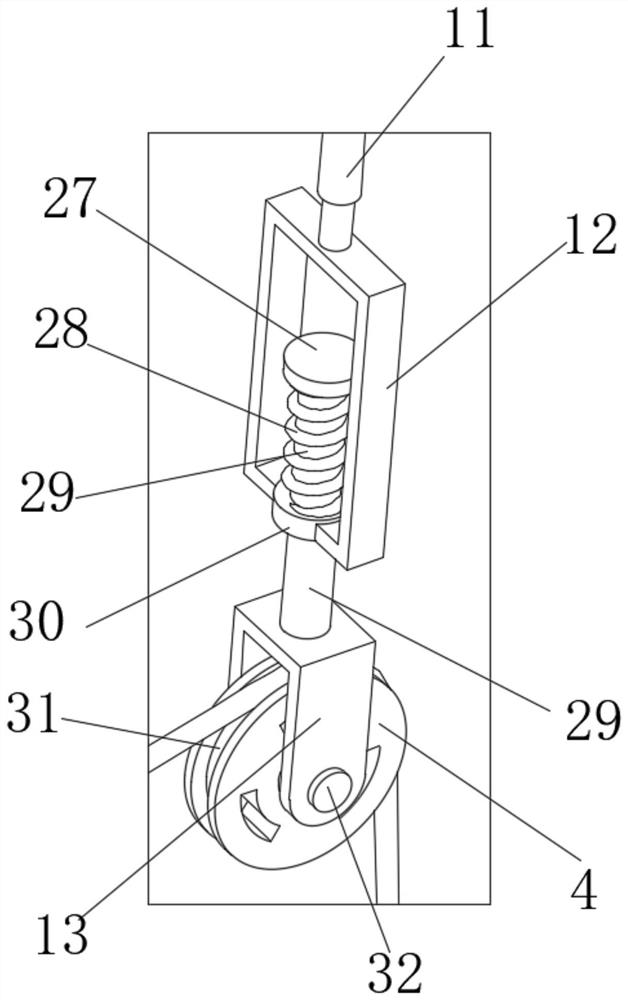

Cable drying and dewatering device

The invention discloses a cable drying and dewatering device. The cable drying and dewatering device comprises a bottom board, a cable and a dewaterer, wherein a cable support mechanism is fixedly connected to a position above the left side of the bottom plate through a bolt, a support base, a first dewatering wheel and a spring are arranged in the cable support mechanism, the support base is fixed at the upper end of the left side of the bottom plate through a bolt, a sliding bush is vertically arranged at the upper end of the support base, a cylindrical sliding cavity is formed in the sliding bush, an annular lower catch spring board is arranged at the upper end of the sliding bush, a rotating shaft is arranged in the axle center of the first dewatering wheel, an annular groove is formed in the middle of the first dewatering wheel, both ends of the rotating shaft are fixed on a framework in a rotating manner, and an upper catch spring board is fixedly connected to the middle part of the lower end surface of the framework. The cable drying and dewatering device disclosed by the invention is simple in structure, is convenient to use, and further improves the cleanliness of the surface of a cable wire; the dewaterer is arranged, so that the dewatering capacity is further enhanced, and the situation that water spots reserved on the cable wire damage a spark machine is avoided.

Owner:STATE GRID CORP OF CHINA +2

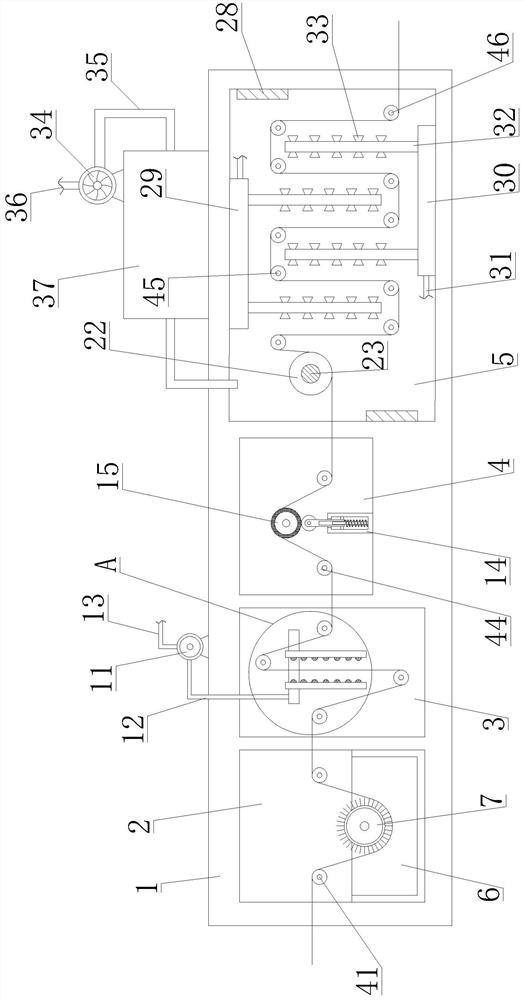

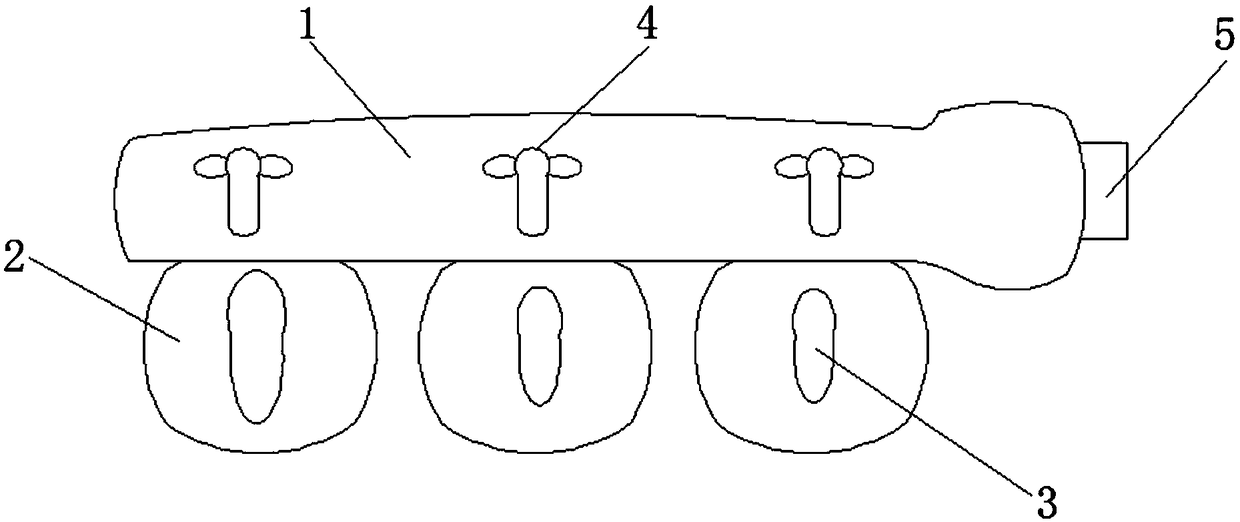

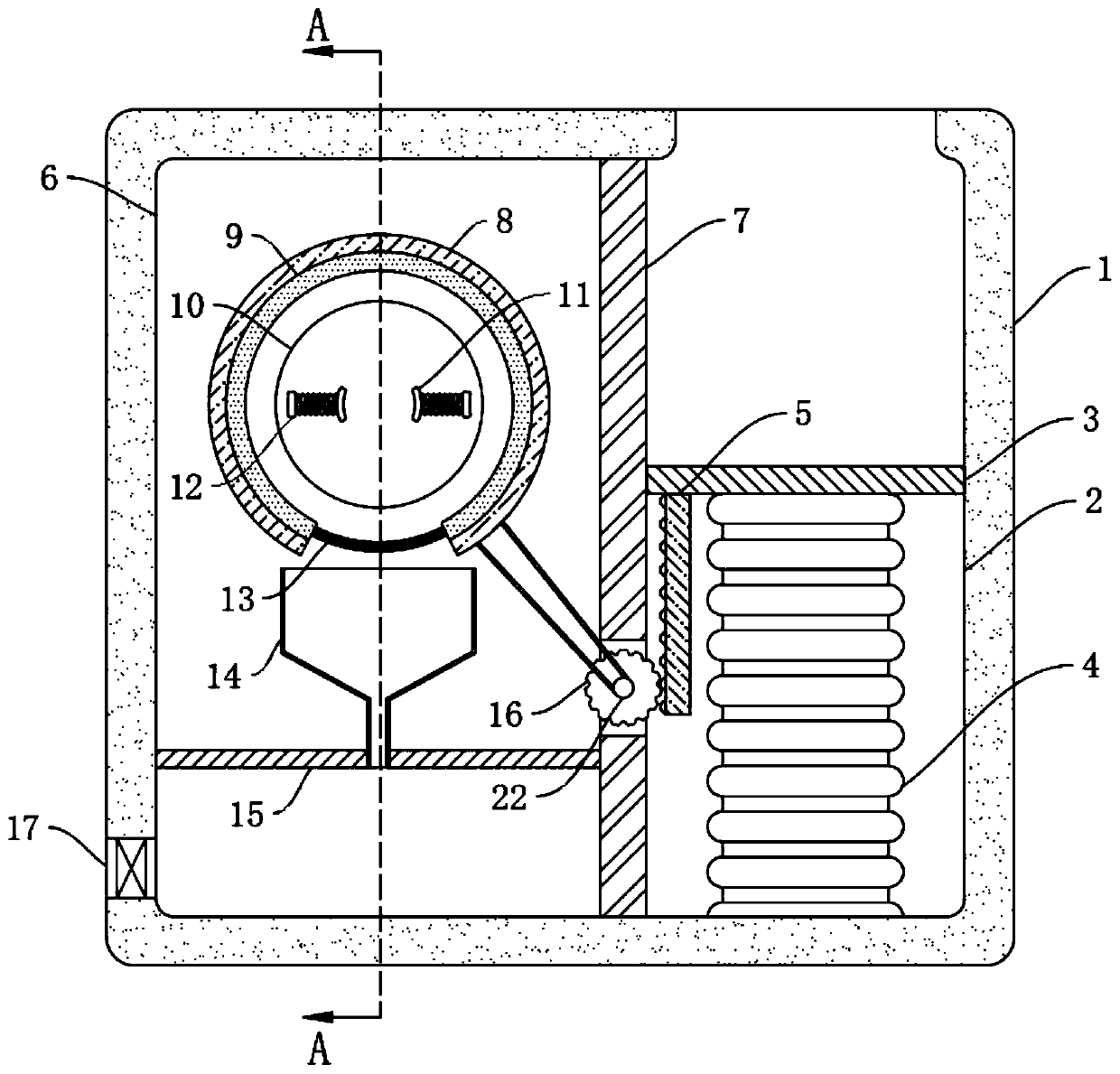

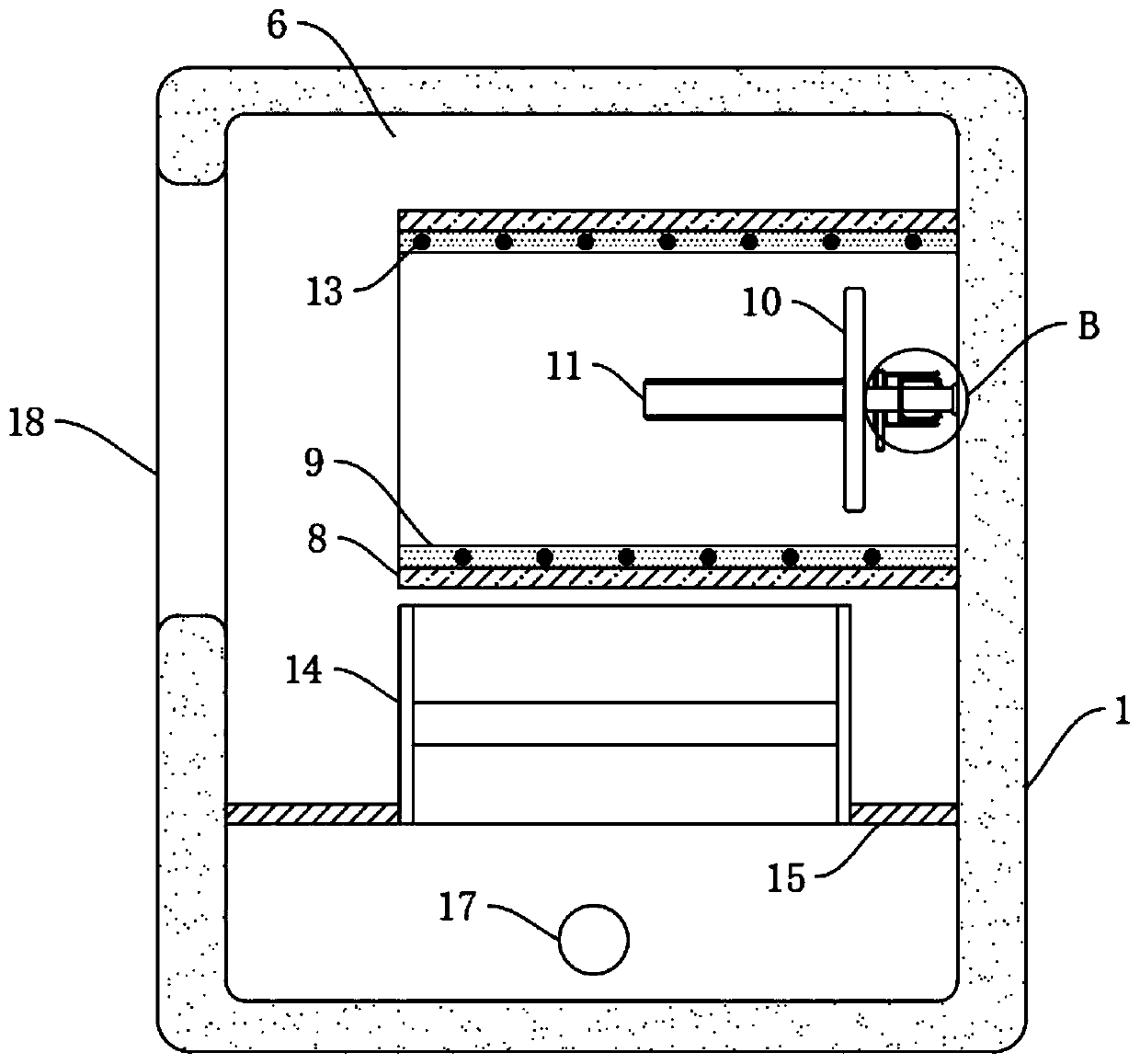

Textile fabric cleaning device for textile equipment

InactiveCN112430925AAchieve preliminary cleaningAchieve secondary cleaningLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsMechanical engineeringManufacturing engineering

The invention discloses a textile fabric cleaning device for textile equipment. The cleaning device comprises a cleaning box; a cleaning chamber, a spraying chamber, a water squeezing chamber and a drying chamber are arranged in the cleaning box; a cleaning pool is arranged in the cleaning chamber; a brushing roller is arranged in the cleaning pool; liquid distribution pipes are vertically arranged in the spraying chamber; spray heads are arranged on the liquid distribution pipes; a liquid collecting pipe is arranged in the spraying chamber, communicates with the two liquid distributing pipesand is provided with a liquid conveying pipe; a bearing roller is arranged in the water squeezing chamber; a water absorption sponge layer is arranged on the peripheral surface of the bearing roller;an extrusion roller is rotationally connected with two movable pieces and abuts against the water absorption sponge layer; the movable pieces are inserted into limiting cylinders downwards; a spring is connected with the movable pieces and the limiting cylinders; and a heating device is arranged in the drying chamber, a drying roller is rotationally connected with a fixed shaft, and an electric heating pipe is arranged on the fixed shaft and located in the drying roller. The textile fabric cleaning device can effectively clean a textile fabric, remarkably improves the cleaning effect and the cleaning efficiency, also can quickly dry the textile fabric, is excellent in drying effect, and is beneficial to use.

Owner:SUZHOUBIDAER INNOVATION MATERIALS TECH CO LTD

Two-force combined and air-drying shopping mall sole water removal device

The invention provides a two-force combined and air-drying shopping mall sole water removal device, and relates to the mechanical field. The device solves the problem that the rainy day shopping mallfloor is easy to fall due to the wet and slippery water on the customer's shoes. The Two-force combined and air-drying shopping mall sole water removal device comprises a movable empty shell. A bloweris welded on the right side of the interlocking empty shell, and an air outlet of the air blower faces the interlocking empty shell and communicates with the inside thereof, and the front side of theinterlocking empty shell is welded with a linkage split box. And the inside of the linkage bin is provided with a surrounding circumferential cleaning mechanism. The two-force combined and air-dryingshopping mall sole water removal device uses a coating mechanism to drive the sponge and the silica gel particles to wrap the shoes during the pressing process of the sponge. The airflow heating anddrying mechanism is arranged to dry and remove the moisture on the sponge and the silica gel particles, absorbing the moisture on the shoes, and evaporating the internal moisture to recycle, thereby the device can be used for a big crowd in a shopping mall.

Owner:王文元

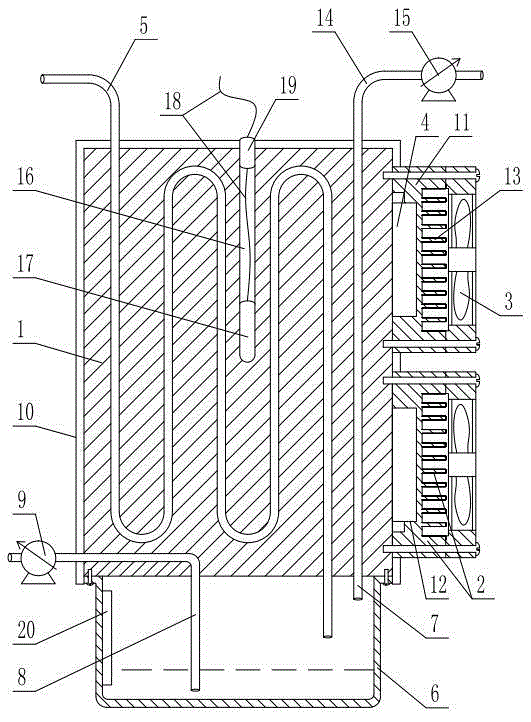

High-efficiency device for water removal from flue gas

InactiveCN106031840AIncrease profitImprove cooling efficiencyDispersed particle separationWater storageFlue gas

The invention discloses a high-efficiency device for water removal from flue gas. The device includes refrigeration block; the outer wall of the refrigeration block is provide with a fan through an installation piece; a semiconductor refrigeration piece is installed between the outer wall of the refrigeration block and the installation piece in clamping arrangement; the refrigeration surface of the semiconductor refrigeration piece is tightly against the side wall of the refrigeration block; the heating surface of the semiconductor refrigeration piece is arranged towards a fan; an airway is arranged in the refrigeration block; the lower end of the refrigeration block is tightly connected with a water storage bottle communicated with an output end of the airway; an air outlet pipe is communicated with the upper part of the water storage bottle; the bottom of the water storage bottle is communicated with a water drainage pipe; and the water drainage pipe is provided with a water drainage mechanism. The high-efficiency device for water removal from flue gas has the advantages of moderate volume, effective removal by filtration of the moisture in the flue gas, high water removal speed, good water removal efficiency and simple operation.

Owner:QINGDAO MINGHUA ELECTRONICS INSTR

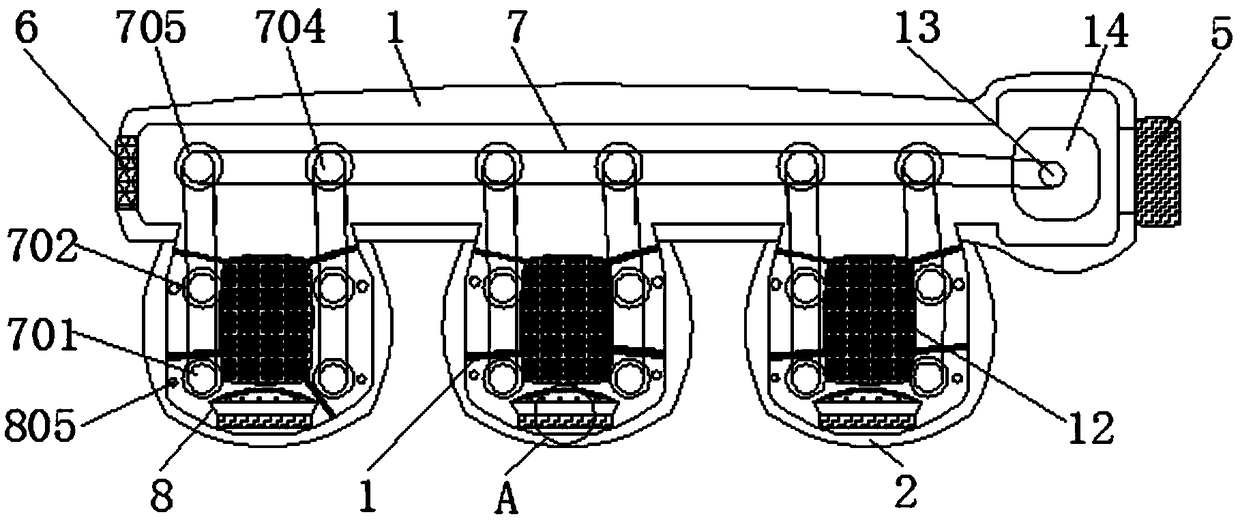

Cable surface dewatering device for cable production line

ActiveCN111696731AReduce consumptionHigh speedCable/conductor manufactureHydraulic cylinderWinding machine

The invention relates to the technical field of cable production, in particular to a cable surface water removing device for a cable production line. The device comprises a drying oven, wherein winding mechanisms are arranged on the two sides of the top of the drying box correspondingly. The winding mechanism comprises a second rotating support fixed to one side of the top of the drying box. A first motor is fixedly mounted on the second rotating support; the first motor drives a reel to rotate around the center of the reel through a belt transmission mechanism. A winding wheel is rotationallymounted on the second rotating support; a cable is connected between the reels of the two winding mechanisms; a top plate is horizontally arranged above the drying box; a plurality of supporting rodsare vertically connected between the bottom of the top plate and the drying box; and guide wheel mechanisms are arranged on the two sides of the bottom of the supporting rod correspondingly, each guide wheel mechanism comprises a hydraulic cylinder, the hydraulic cylinders are vertically fixed to the top plate, the lower ends of the hydraulic cylinders are fixedly connected with connecting frames, and therefore energy consumption of cable surface water removal can be reduced, and efficiency can be improved.

Owner:SHANDONG KUNYU CABLE

Water shedding device for umbrellas

InactiveCN111271942AQuick water removalEasy to useDrying solid materials without heatDrying chambers/containersWater storageStructural engineering

The invention discloses a water shedding device for umbrellas. The water shedding device comprises a shell, wherein the inner walls of the shell are fixedly connected to a baffle plate; the interior of the shell is divided into a left operating cavity and a right control cavity by the baffle plate; a connection opening is formed in the upper wall of the control cavity; a placement opening is formed in the side wall of the operating cavity; a control mechanism is arranged inside the control cavity; an operating mechanism and a water storage mechanism are arranged inside the operating cavity; the operating mechanism comprises a mounting plate which is fixedly connected to the inner wall of the operating cavity; a water-absorbing sponge is arranged on the side wall of the mounting plate; theinner wall of the operating cavity is rotatably connected to a placement plate through a first rotating shaft; the placement plate is provided with a clamping part; and a water squeezing mechanism isarranged in the operating cavity. The water shedding device can quickly shed water on the umbrellas without using plastic bags, does not cause wasting, and can also prevent water on shoe soles from being stained onto the ground to make the ground slippery and cause people to slip.

Owner:南京溧水高新产业股权投资有限公司

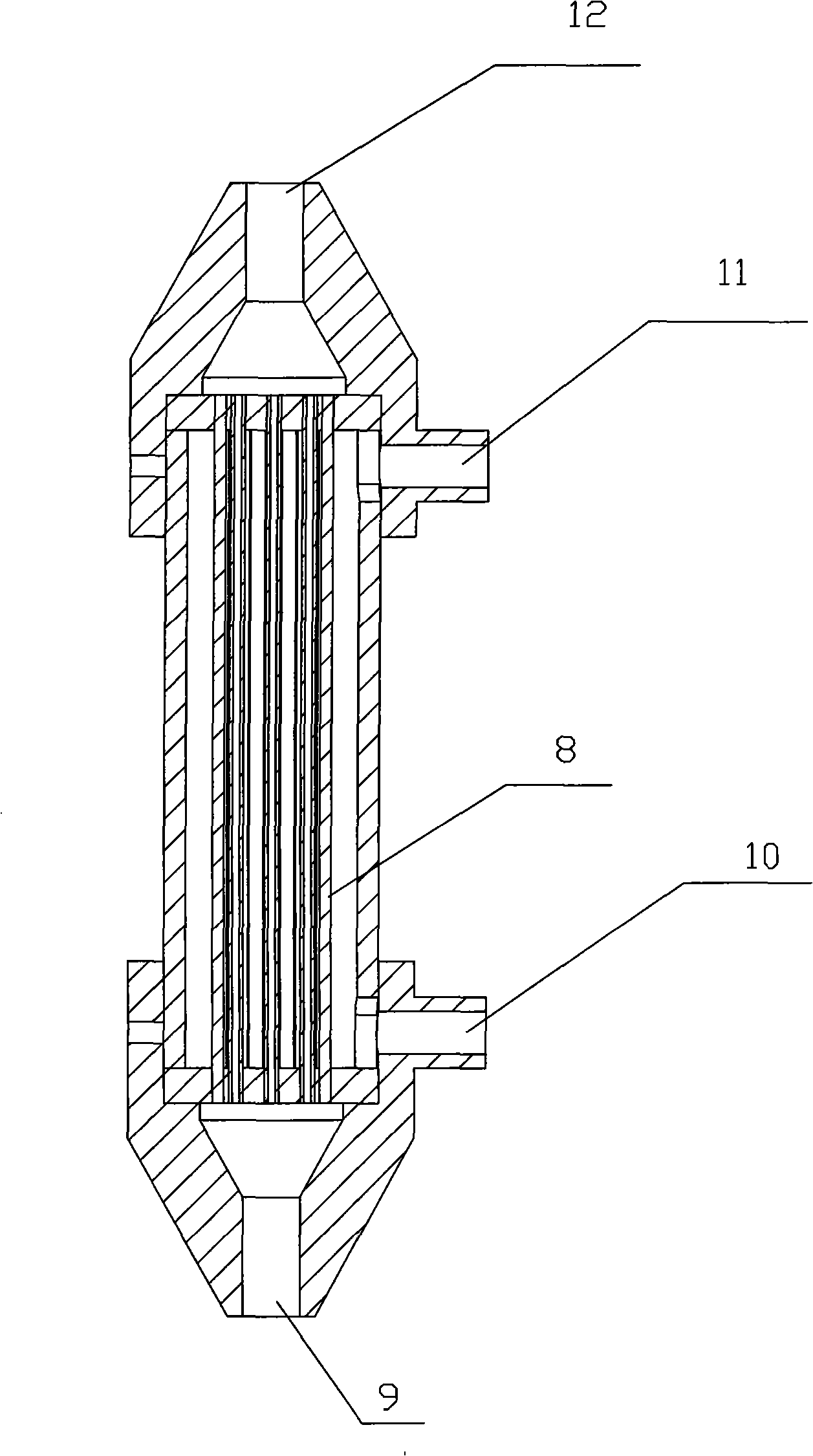

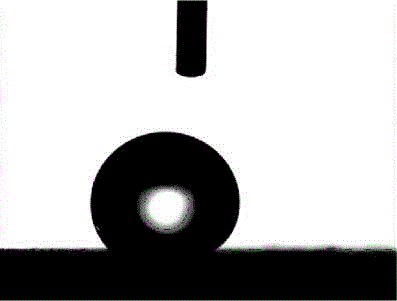

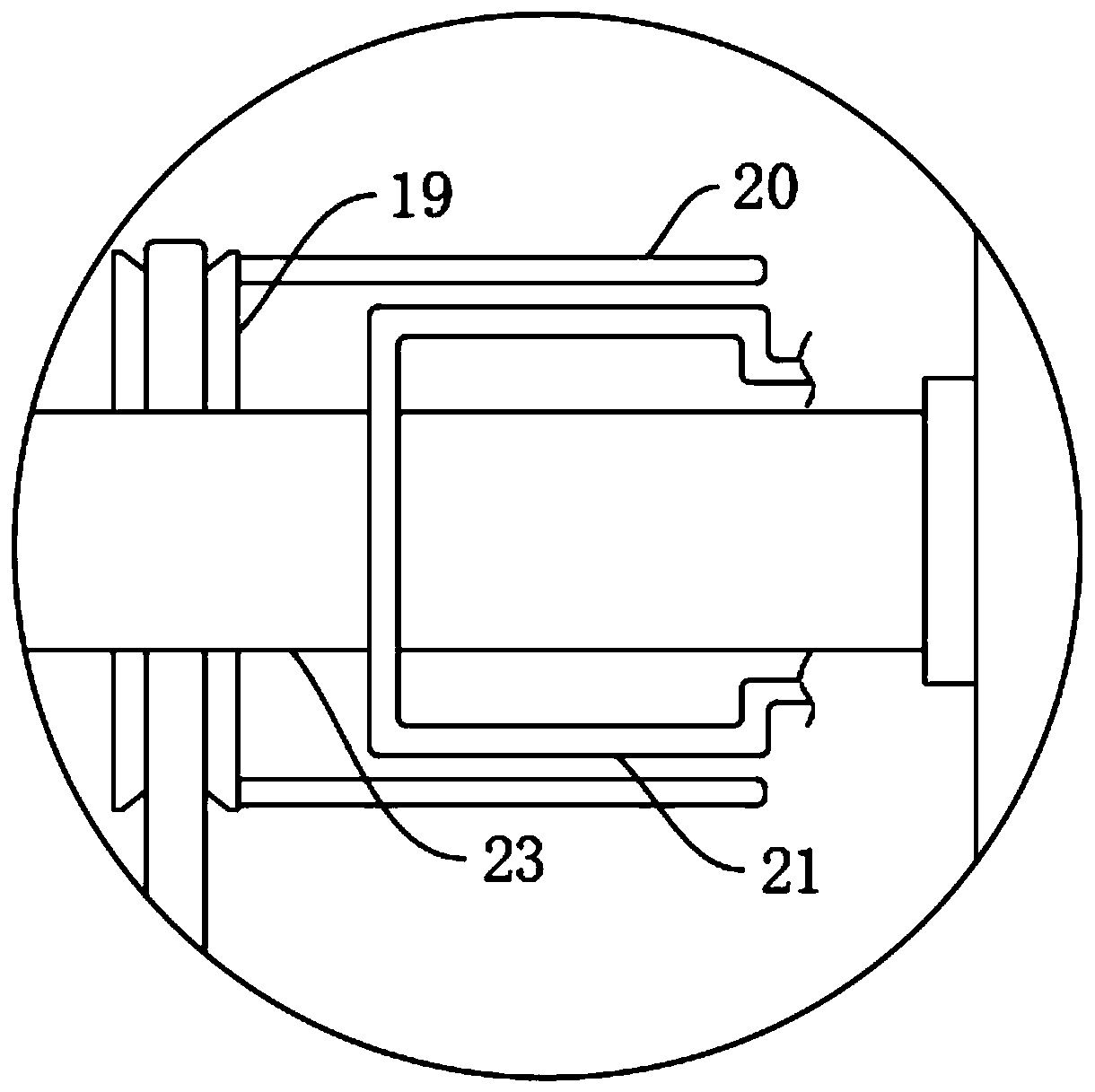

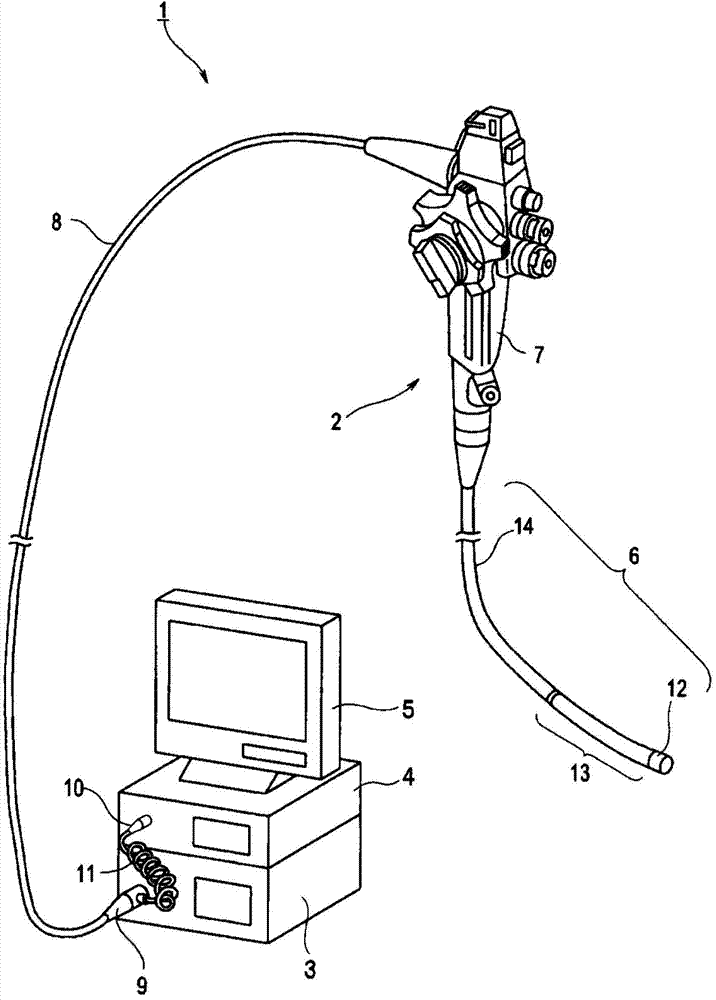

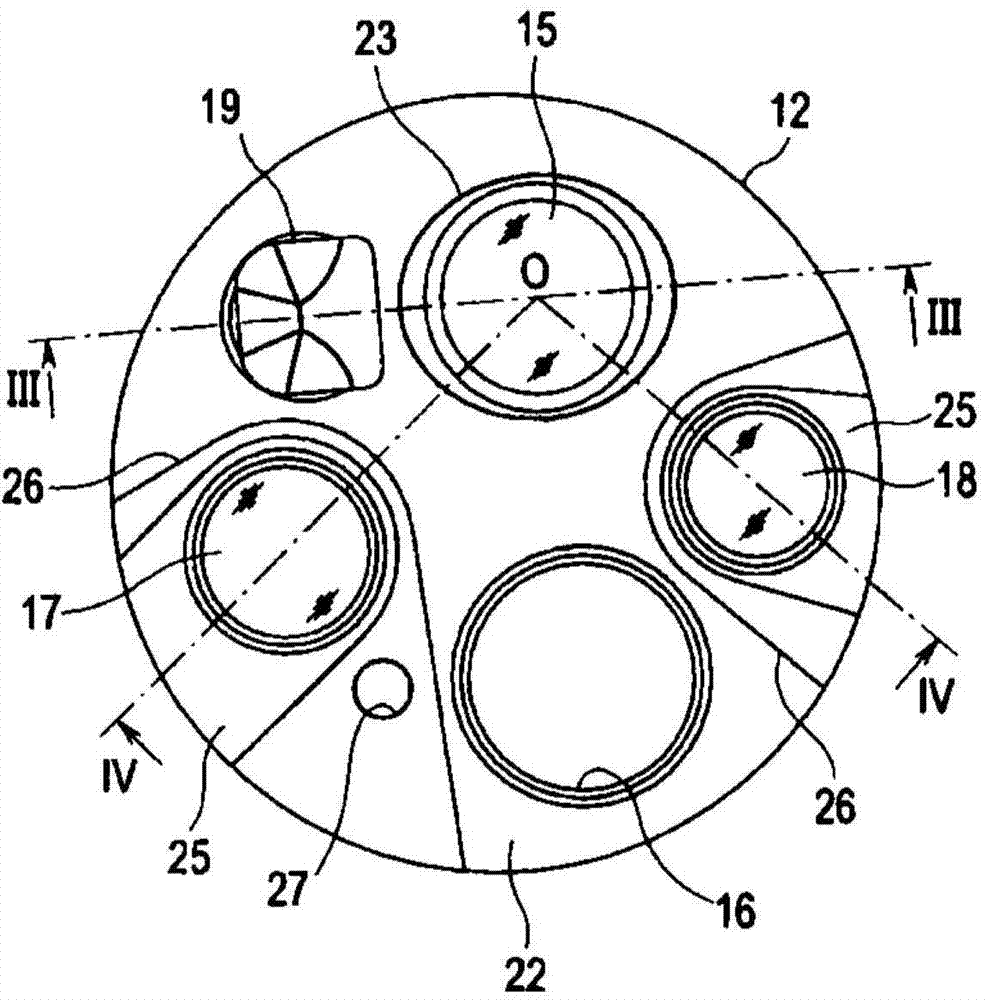

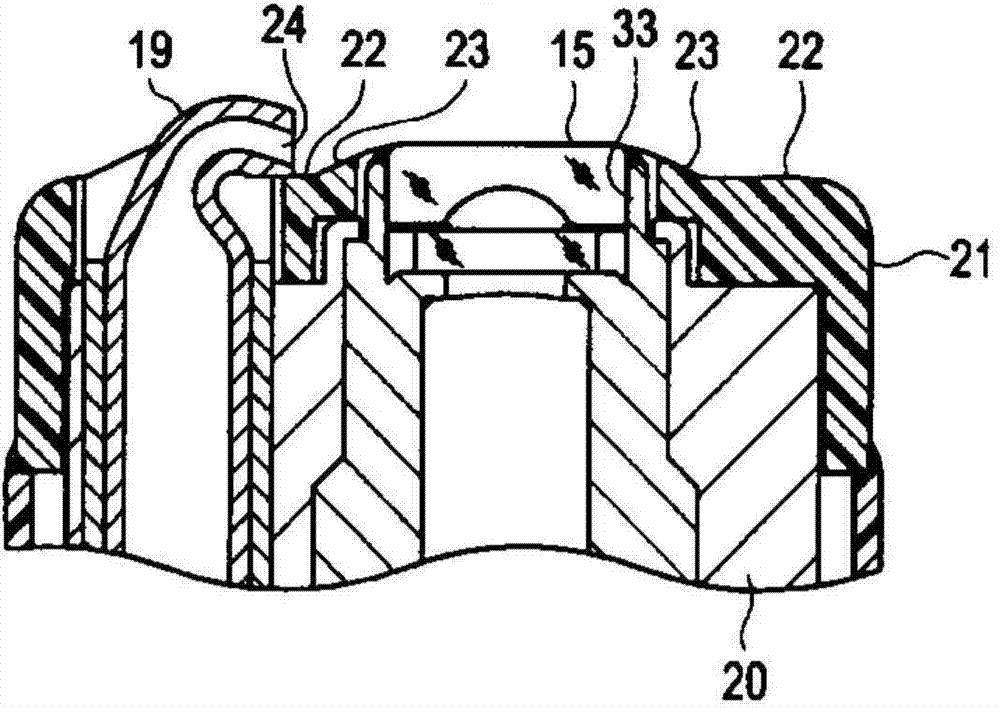

Endoscope

ActiveCN103813744AEasy to cleanImprove water removal effectSurgeryEndoscopesStructural engineeringEngineering

An endoscope (2) comprises: a window part (15) which protrudes at a prescribed height from a flat part (22); an air supply / water supply nozzle (19) which is disposed from the flat part (22) in opposition to the window part (15) and discharges a fluid toward the surface of the window part (15); and an oblique part (23) which is formed in a peripheral edge part of the window part (15). In an oblique angle of the oblique part (23) to the flat part (22), a second angle of elevation (theta2) is made greater than a first angle of elevation (theta1), said first angle of elevation (theta1) of a direction along a first axis which passes through the center of the window part (15) of the discharge direction of the fluid which is discharged from the air supply / water supply nozzle (19) and said second angle of elevation (theta2) of a direction along a second axis which is orthogonal to the first axis at the center of the window part.

Owner:OLYMPUS CORP

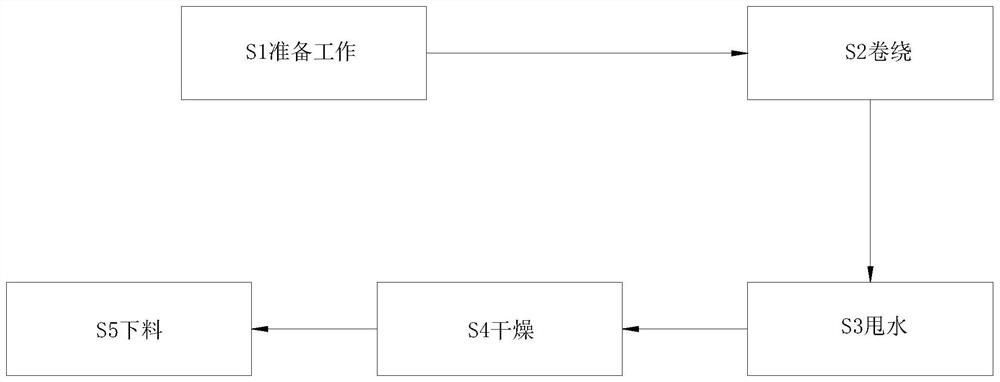

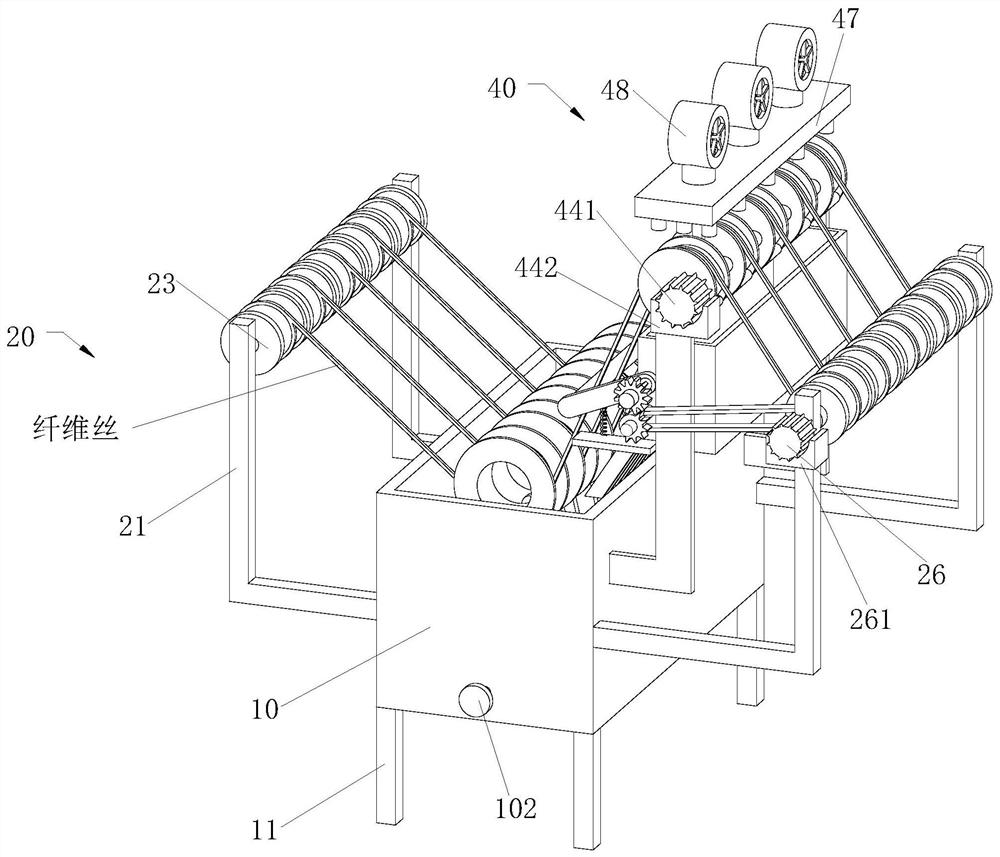

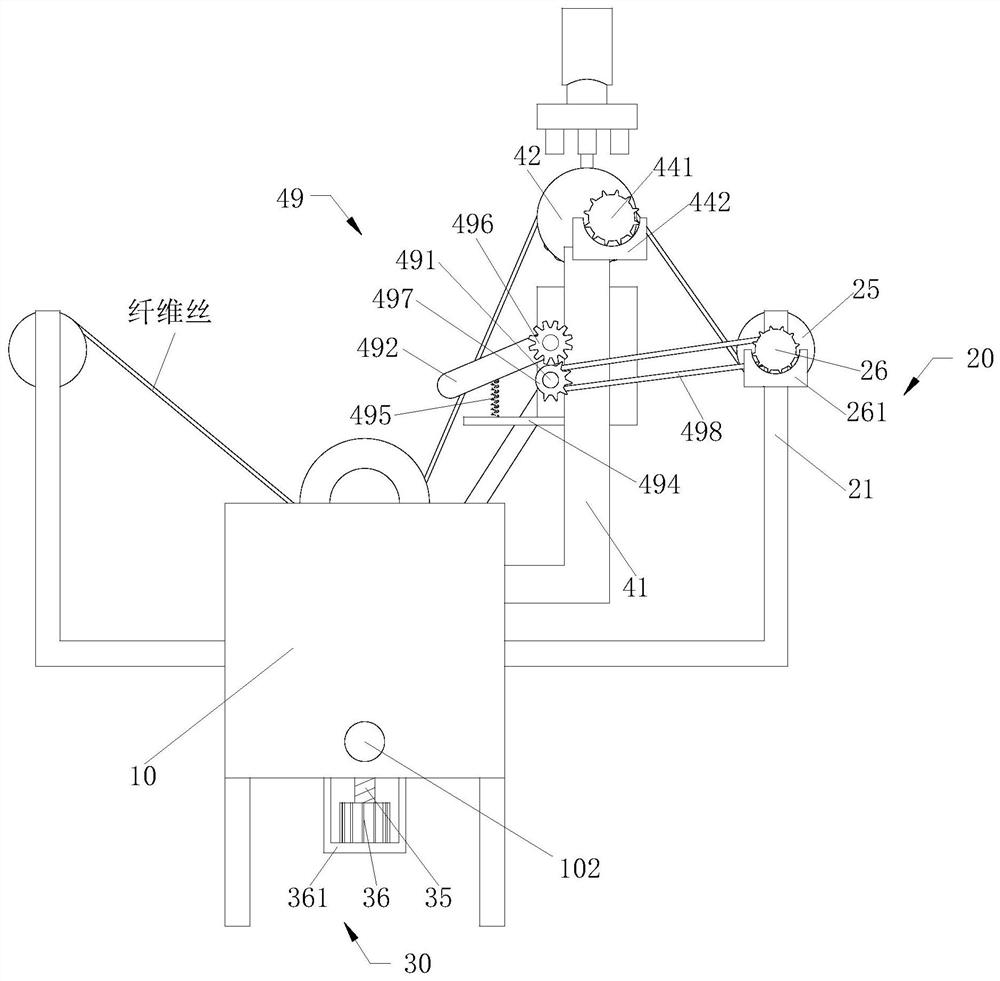

Carbon fiber yarn production process

InactiveCN112877947AAdjustable tensionVibrating screenLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersYarnFiber

The invention relates to a carbon fiber yarn production process. The carbon fiber yarn production process uses carbon fiber yarn processing and manufacturing equipment, wherein the equipment comprises a water tank and a tensioning device arranged in the water tank, and a drying device is arranged on the outer side of the water tank. Through cooperation of a gear, an incomplete gear, a rotating plate, a flapping column and a telescopic spring, the incomplete gear can drive the gear to rotate intermittently, the gear drives the rotating plate to swing, the rotating plate can return to the original position under the action of the elastic force of the telescopic spring, and therefore water-washed carbon fibers are flapped; vibration is generated on the surfaces of the washed carbon fibers, so that moisture on the surfaces of the washed carbon fibers can be vibrated and sieved, and the surfaces of the washed carbon fibers can be conveniently dried in the later period; and through cooperation of a first transmission belt, cotton cloth and extrusion rollers, the first transmission belt can drive the cotton cloth to rotate together, and therefore secondary water removal can be carried out on the carbon fiber yarns obtained after vibration screening.

Owner:合肥曹秀化工科技有限公司

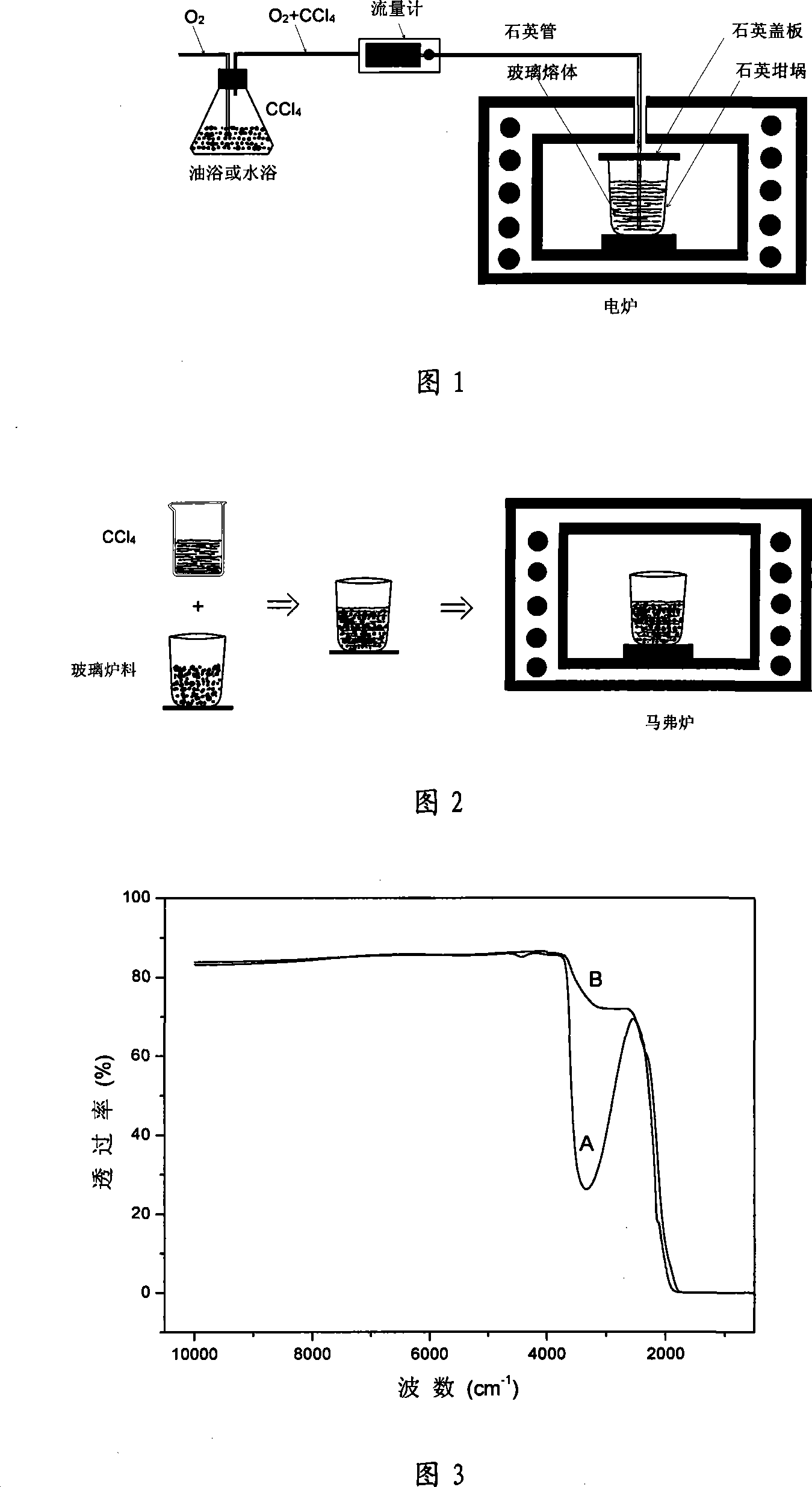

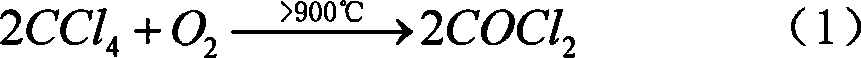

Technique for reducing hydroxyl group content in glass

InactiveCN101215073ALow costGood water removal effectGlass furnace apparatusGlass meltingMuffle furnace

Disclosed is a technology for reducing hydroxyl group content in glass. Adding hydroxyl group remover CCI4 to a glass burden until all burden is immersed in the CCI4 liquid, resting the burden in aeration-drying environment, then puting the glass burden in a low-temperature muffle furnace, simultaneously keeping aerating environment to remove decay products of CCI4, the muffle electric stove is slowly heated up to 500-700 DEG C and the heat preservation time is 0.5-3 hours, and then the glass burden in the muffle furnace is transferred into a high-heat glass-melting furnace for melting. Glass with low hydroxyl group content prepared by the technology of the invention has the advantages of low costs, simplicity and easy operation, prominent de-watering effects and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com