Technique for reducing hydroxyl group content in glass

A technology of medium hydroxyl and content, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reducing the service life of silicon molybdenum rods, the danger, and the scrapping of the furnace, so as to improve the infrared transmittance and remove water. Significant effect, the effect of reducing hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

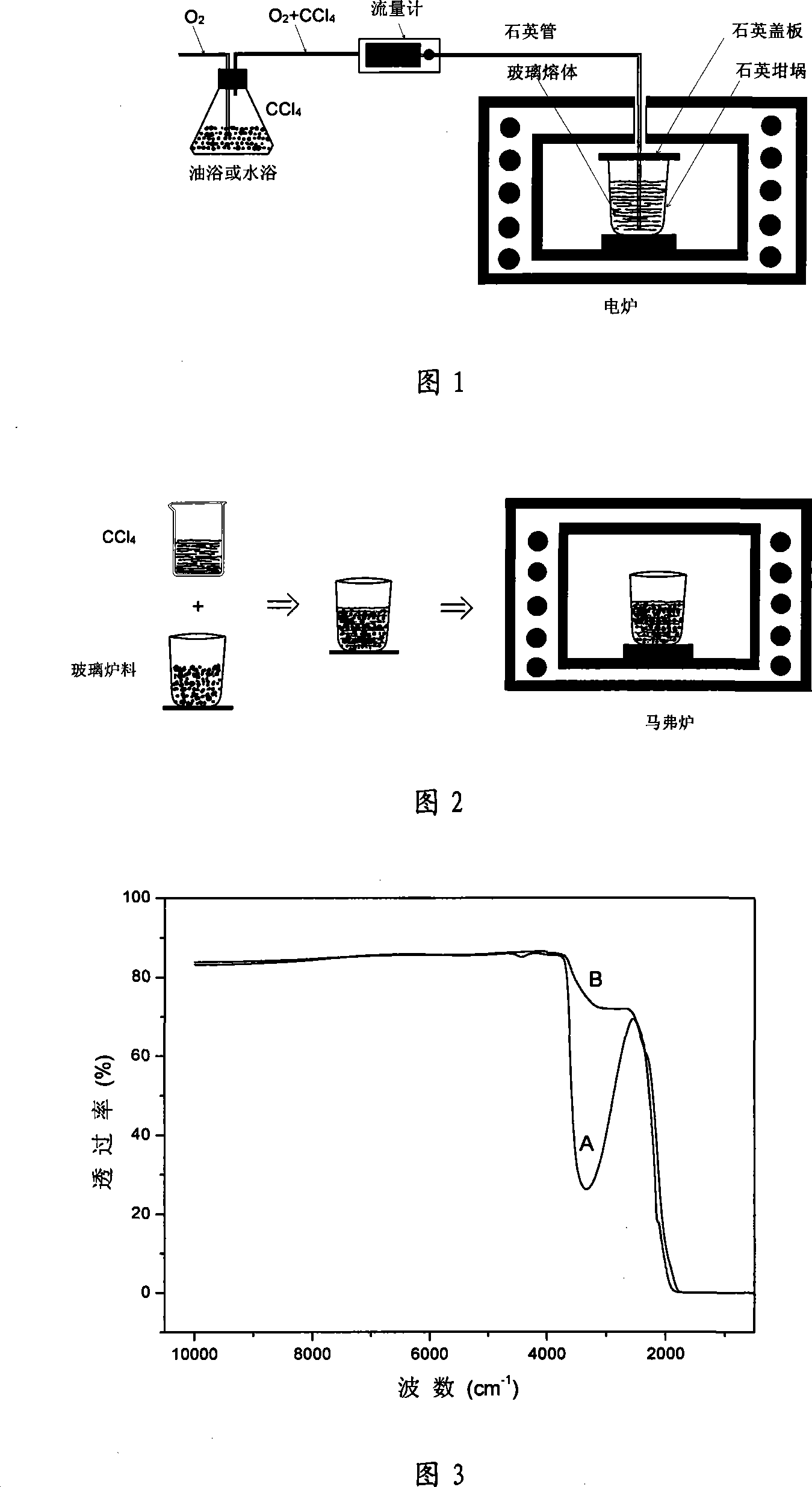

Method used

Image

Examples

Embodiment

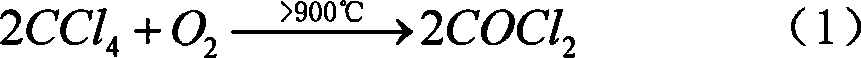

[0024] CCl as a scavenger 4 Slowly pour into the well-mixed charge until all the charge is soaked in CCl 4 In the liquid, after standing in a dry and ventilated environment for 8-15min, put it into a low-temperature muffle furnace while maintaining a ventilated environment to exclude CCl 4 decomposition products. Slowly heat the muffle furnace to 600°C and keep it for 1 hour, then transfer the charge to a high-temperature silicon-molybdenum rod electric furnace and continue to heat up to the target temperature to melt the glass. 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com