Patents

Literature

78results about How to "High infrared transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

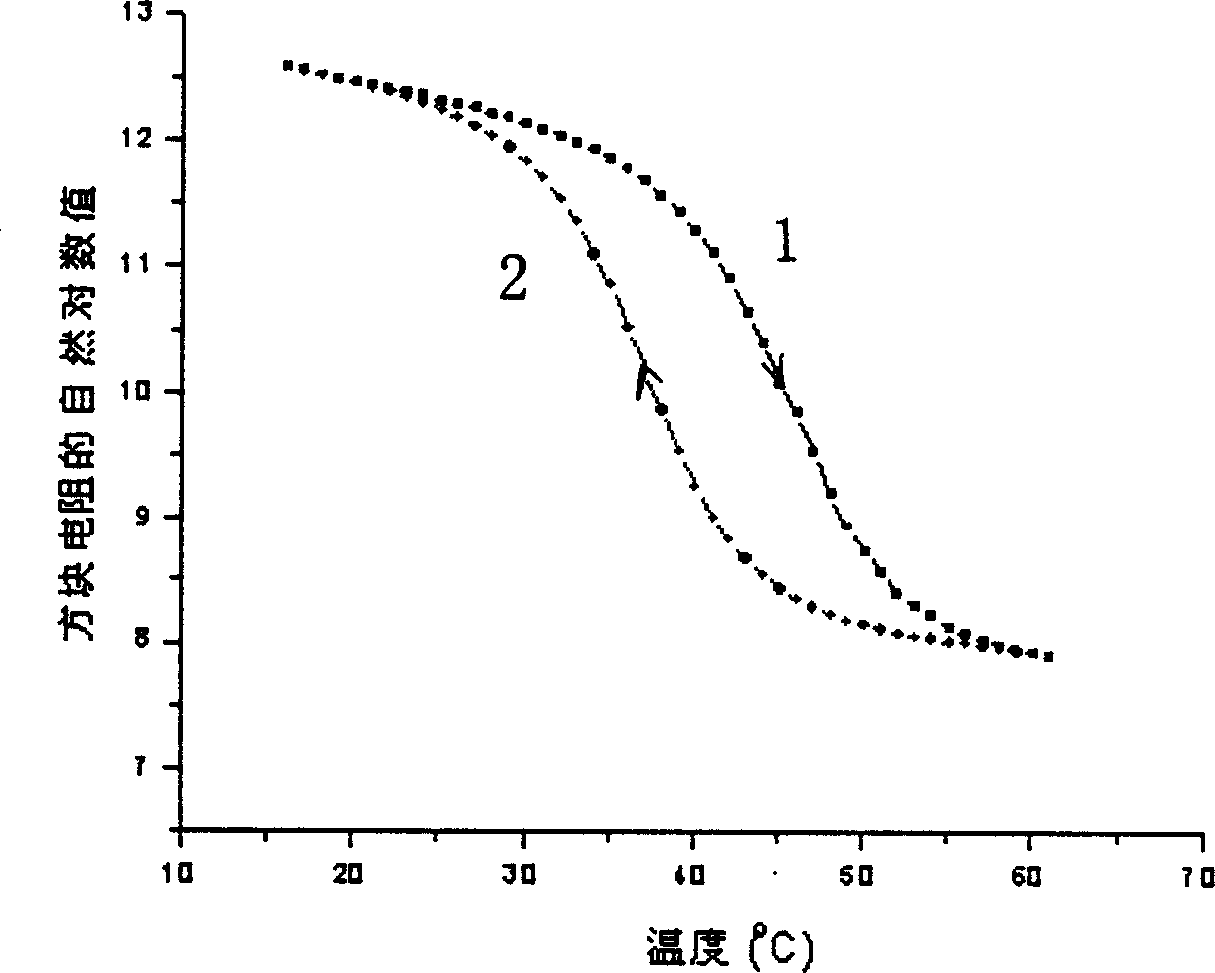

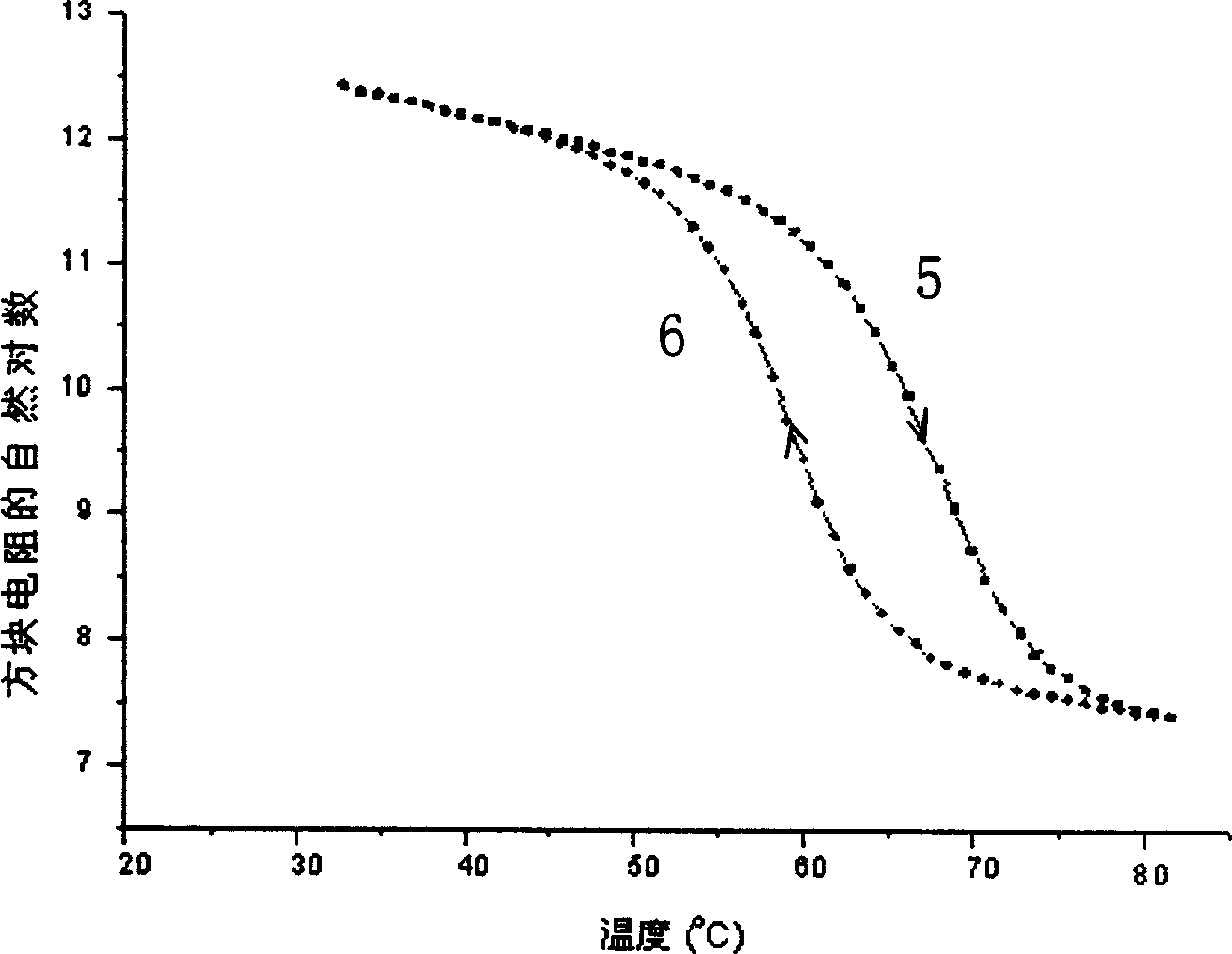

Process for preparing vanadium oxide film capable of regulating phase change temp.

InactiveCN1598040AEasy to moveReduce infrared transmittanceVacuum evaporation coatingSputtering coatingNitrogen gasVanadium oxide

This invention provides a preparation method of vanadium oxides film whose phase change temperature is variable. Siliconoxide film and silicon nitride film deposit on the silicon slice. The method of ion beam reactive sputtering is used to deposit vanadium oxide film. The processing conditions as followings: back bottom vacuum 4X10-4Pa-3X10-3Pa, oxygen pressure 6X10-4Pa-8X10-3Pa, argon gas pressure: 1X10-2Pa-2.3X10-2Pa,ion beam power: 8W-60W, substrate temperature: 120deg.C-450deg.C, sputter time: 10-45min, the vanadium target is butt material. The annealing treatment is for the sample. The processing conditions gas: argon or nitrogen gas, annealing temperature: 250deg.C-580deg.C, annealing time: 20-240 min, and then getting phase change vanadium oxide film.

Owner:HUAZHONG UNIV OF SCI & TECH

Glass plate and heater using same

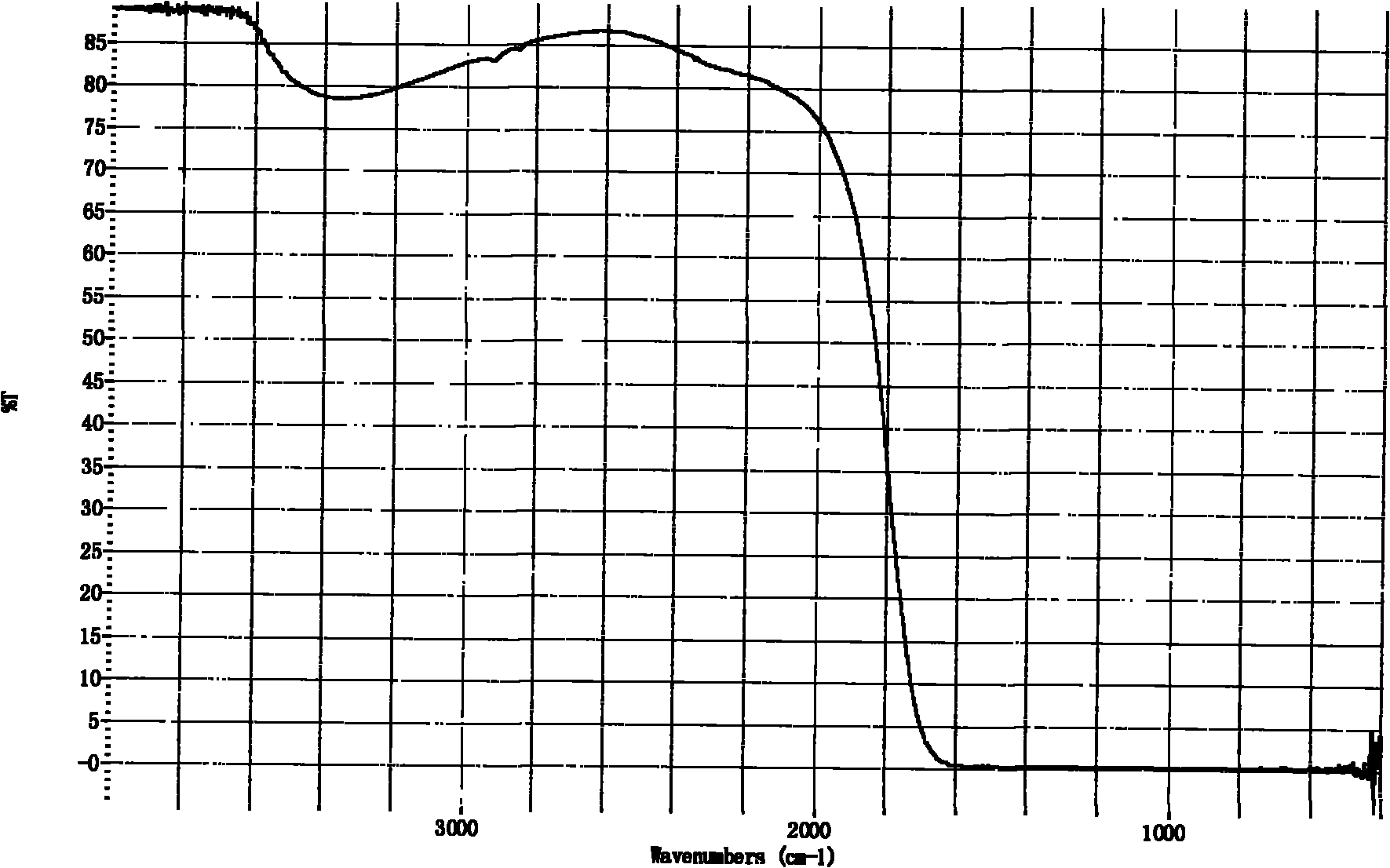

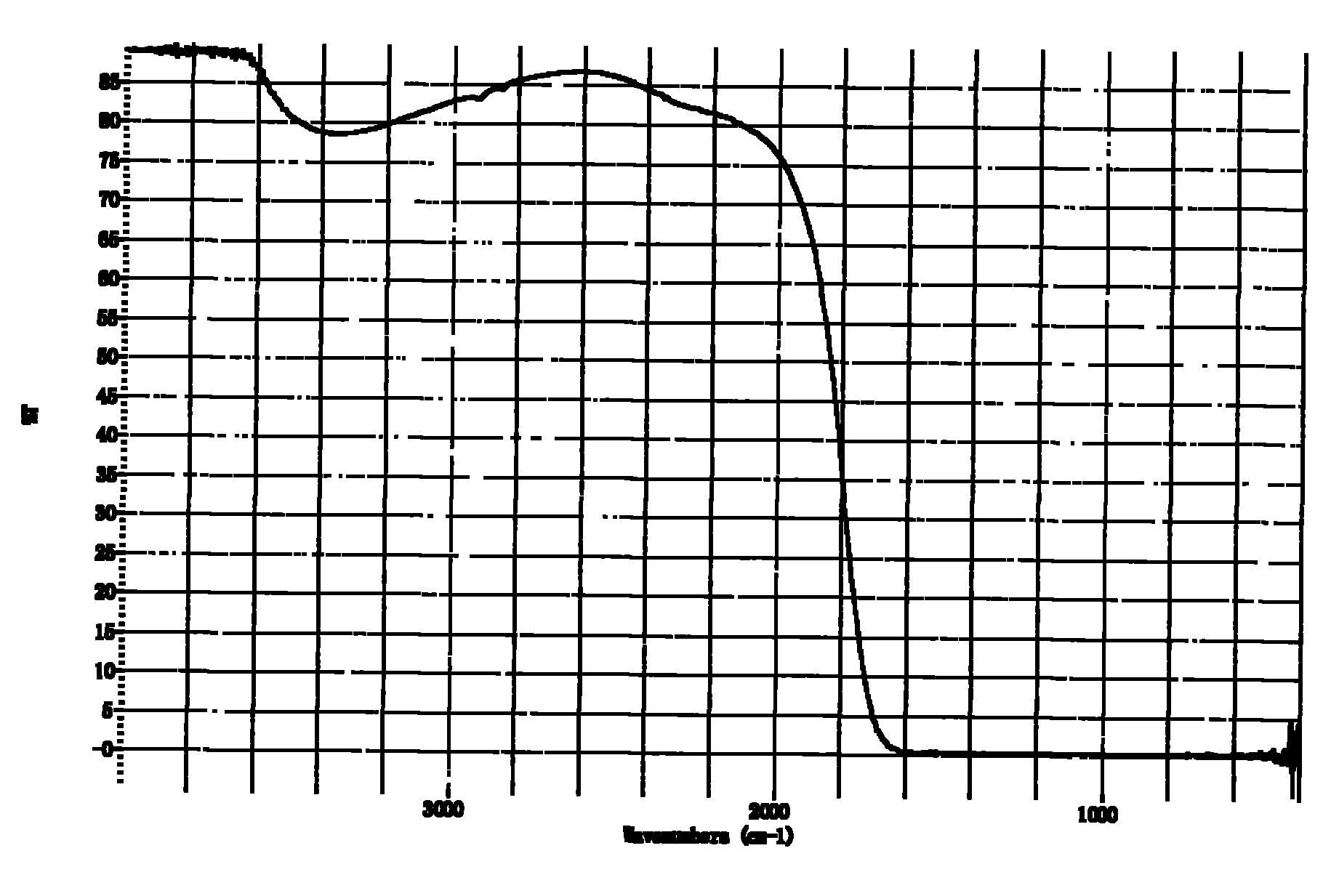

InactiveUS20170247284A1High infrared transmittanceEasy to optimizeStoves/ranges topsInduction heating apparatusTransmittanceThermal expansion

To provide a glass plate which is hardly broken and which has a high infrared transmittance.A glass plate, which has a thickness of from 1 to 8 mm, has an infrared transmittance T3000 at a wavelength of 3,000 nm of at least 4%, an average thermal expansion coefficient a at from 50 to 350° C. of from 15 to 35×10−7 / ° C., and a glass composition comprising, as represented by mol% based on oxides, from 50 to 85% of SiO2, from 0.1 to 25% of Al2O3, from 0.1 to 20% of B2O3, from 0 to 20% in total of at least one member selected from MgO, CaO, SrO, BaO and ZnO, and from 0 to 20% in total of at least one member selected from Li2O, Na2O and K2O.

Owner:ASAHI GLASS CO LTD

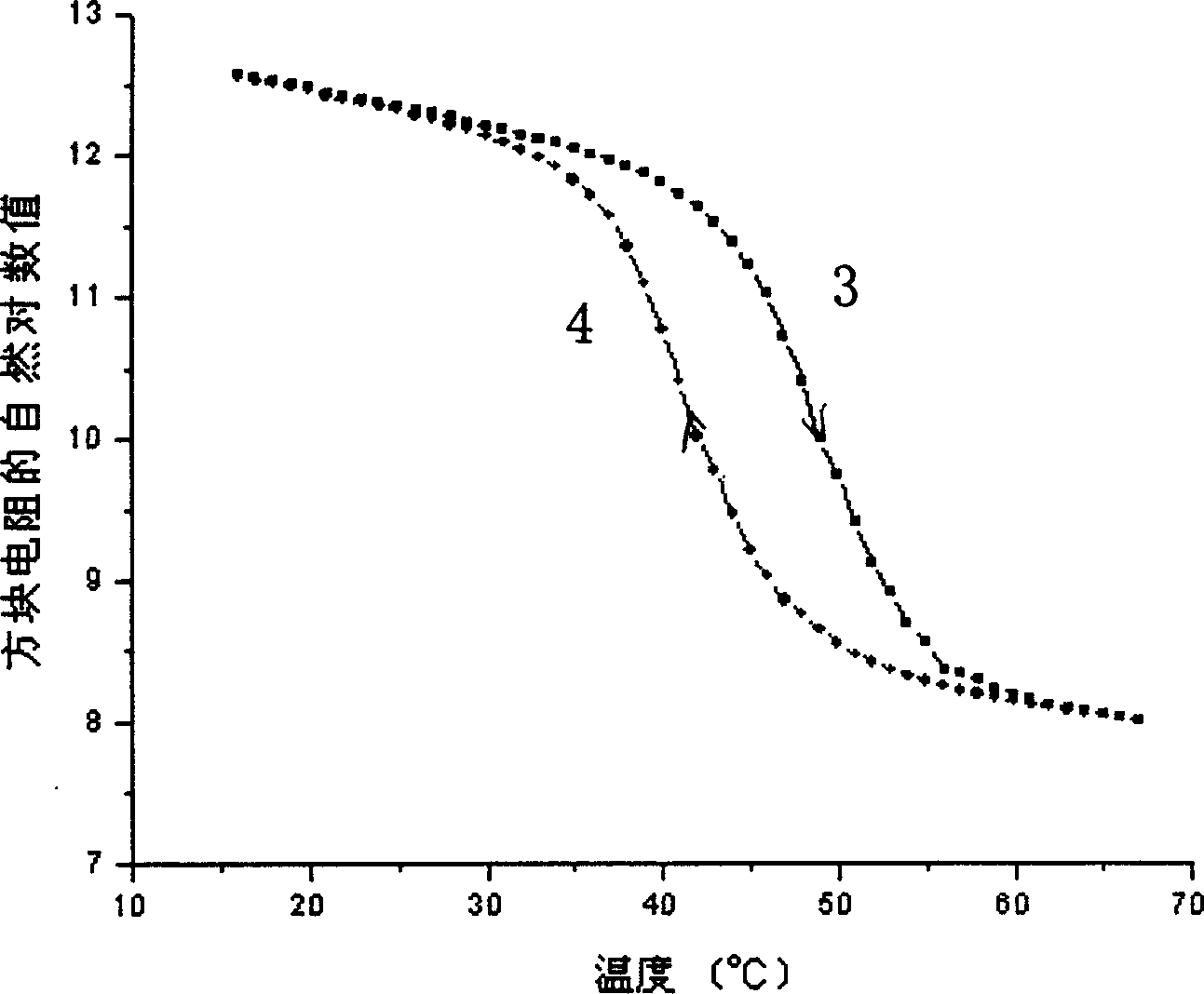

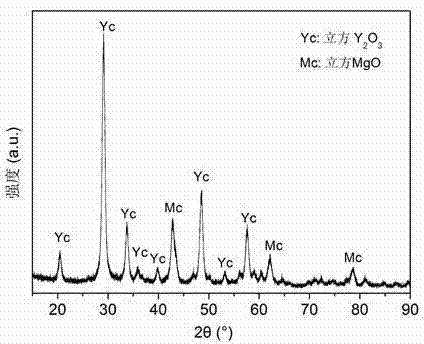

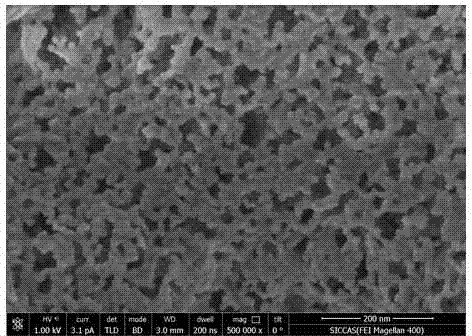

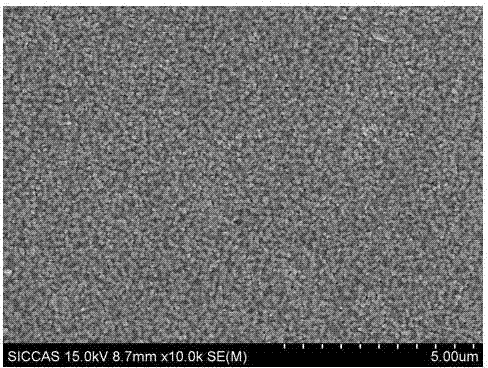

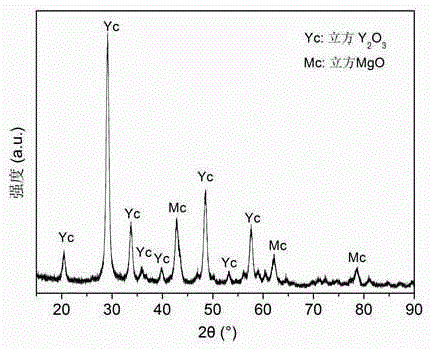

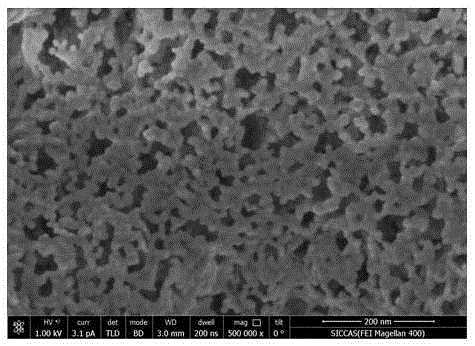

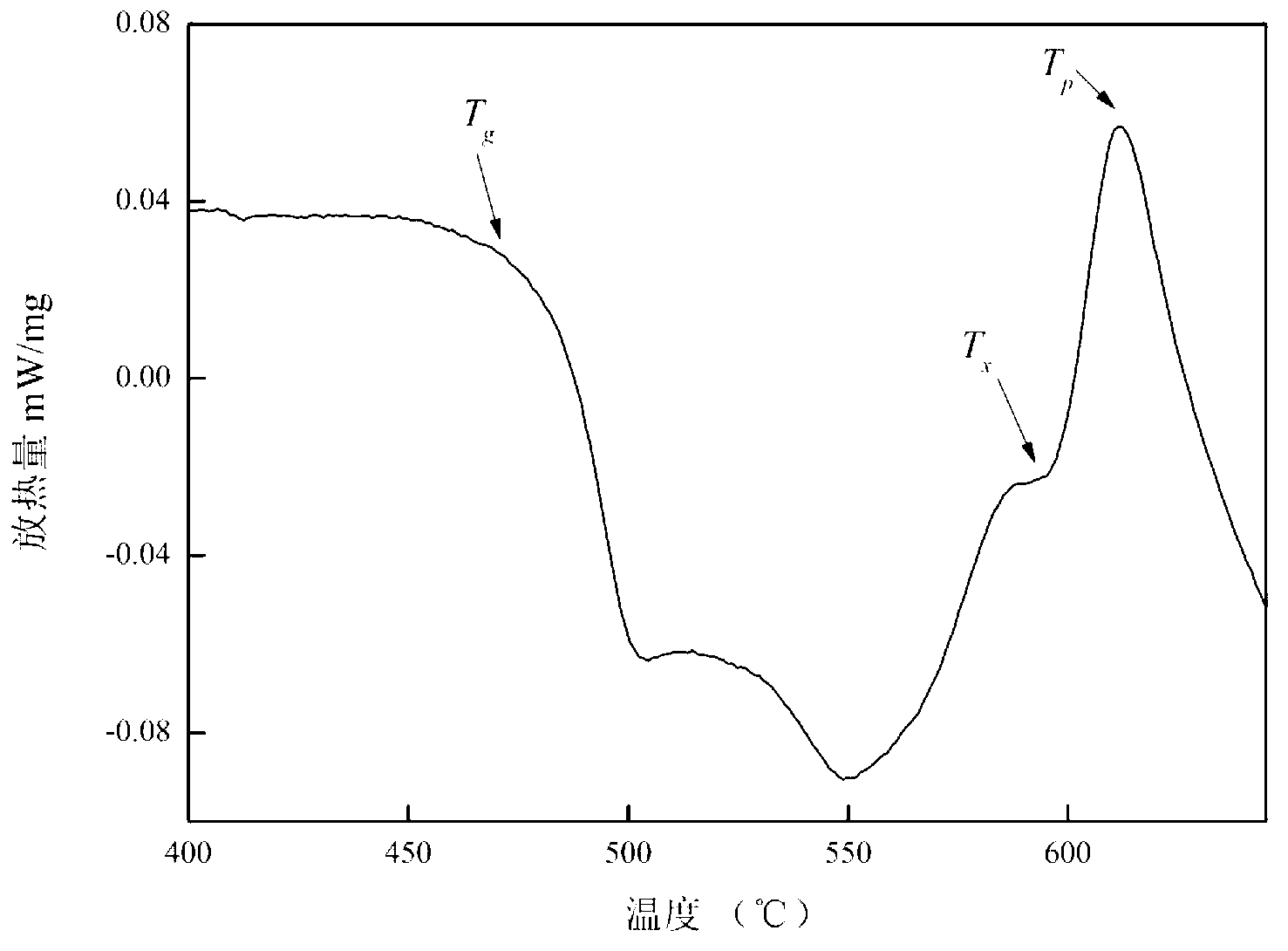

Y2O3-MgO nano-composite ceramic and preparation method thereof

The invention relates to a Y2O3-MgO nano-composite ceramic and a preparation method thereof. The Y2O3-MgO nano-composite ceramic is shown as xY2O3.(1-x)MgO, wherein x is the percentage of the mole number of Y2O3 to the total mole number of Y2O3 and MgO; the value of x is more than or equal to 0.01 and less than or equal to 0.99. The method comprises the following steps: preparing Y2O3-MgO nano-composite powder by adopting a sol-gel method; sintering the sieved composite powder by virtue of discharge plasma sintering or hot isostatic pressing sintering to obtain the infrared transparent Y2O3-MgO nano-composite ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

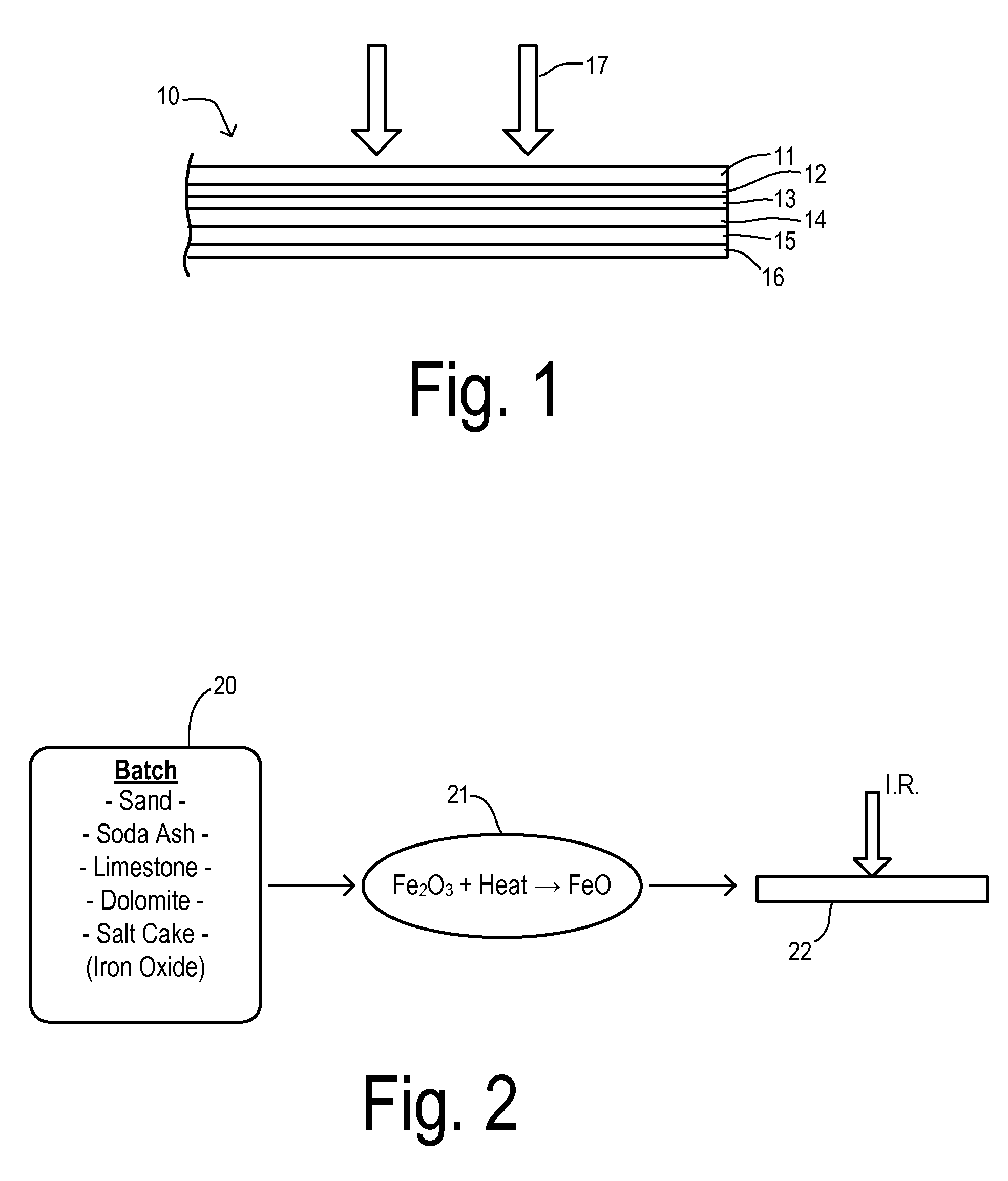

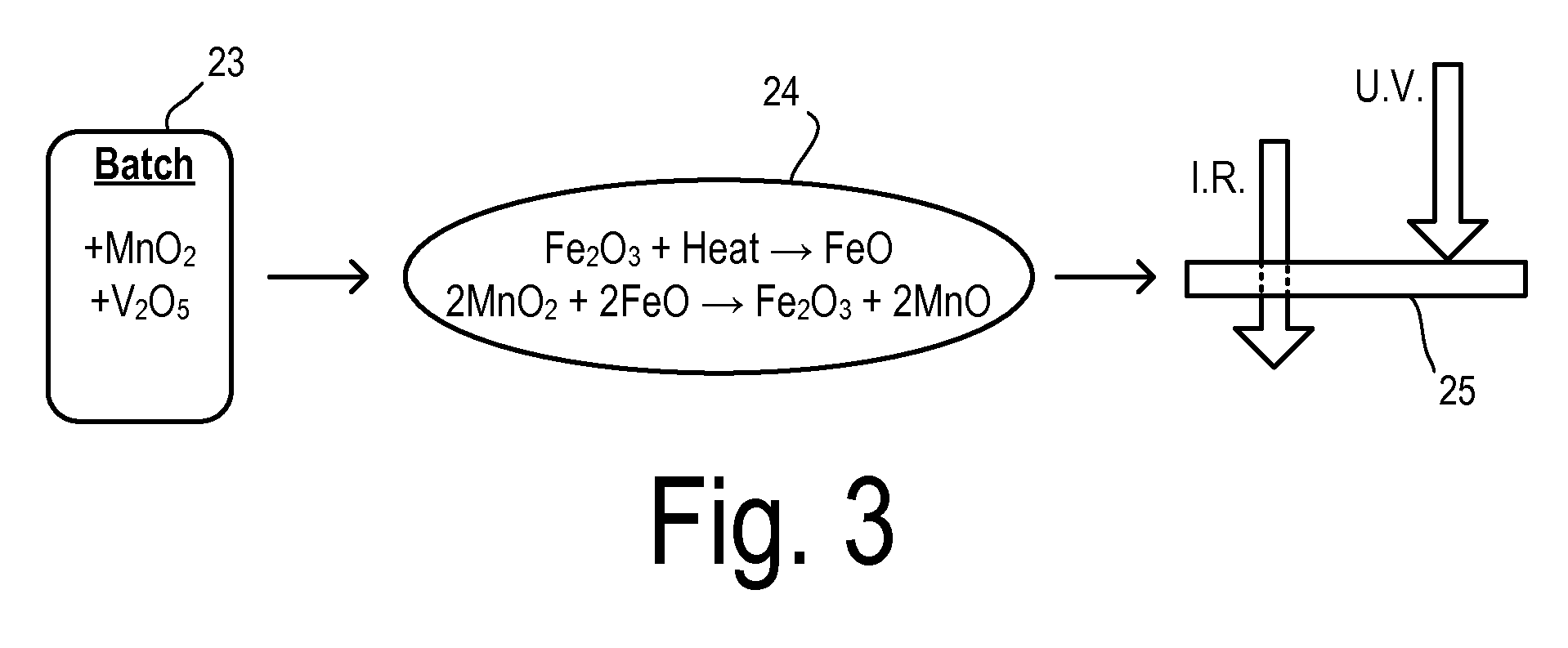

High Visible/Infrared Transmittance Glass Composition

InactiveUS20100252787A1Reduce amountHigh light transmittancePhotovoltaic energy generationSpectral modifiersFlat glassUltraviolet

A flat glass panel for use in applications requiring high visible and infrared transmittance (such as a solar panel) is made using lower cost batch materials containing iron oxide impurities. Iron oxide is known as an additive for decreasing infrared / visible transmittance of glass. Removal of iron oxide impurities from batch materials is very expensive. This invention uses common batch materials having iron oxide impurities to produce a glass with high transmittance by adding a clarifier comprised of 0.05 to 0.4 weight percent of manganese dioxide (MnO2). The optional addition of vanadium pentoxide (V2O5) enhances ultraviolet blocking of the glass for protecting coatings within a solar panel from ultraviolet-induced damage.

Owner:ZELEDYNE

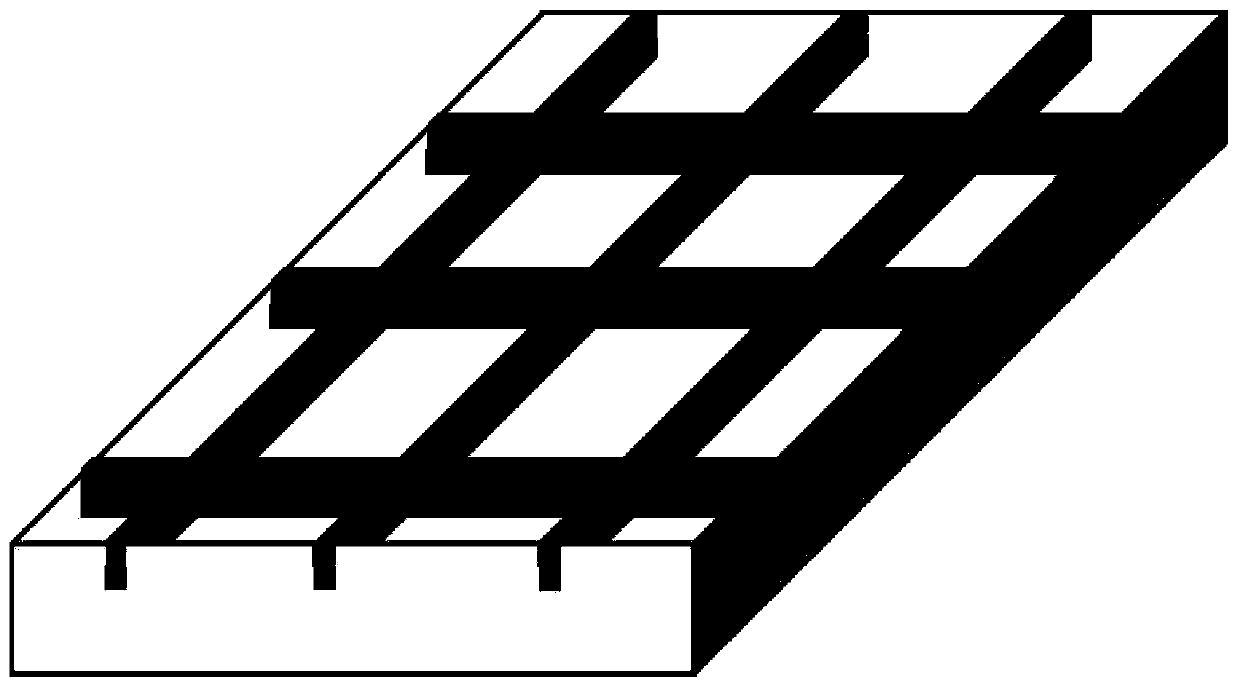

Multi-layer metal net grid electromagnetic shielding optical window employing femtosecond laser etching and fabrication method thereof

InactiveCN109769387AQuality improvementNot easy to fall offMagnetic/electric field screeningGrid patternDielectric substrate

In a multi-layer metal net grid electromagnetic shielding optical window employing femtosecond laser etching, a plurality of transparent dielectric plates etched with metal net grids are laminated, and a conductive metal net grid layer and a ferromagnetic metal net grid layer are etched on a surface of each transparent dielectric substrate from top to bottom. By a femtosecond laser direct-writingdeep-etching processing technology, metal net grid patterns such as lattices, round rings, diamonds and hexagonal shapes are etched on the surfaces of the transparent dielectric substrate coated withphotoresist, a layer of metal nickel or iron ferromagnetic metal thin film is plated on the etched substrate, a layer of gold or silver excellent conductive metal thin film is plated on the nickel layer, the conductive metal thin film is placed in an organic solvent to remove the photoresist and a metal part which is not needed to obtain a metal net grid. The fabricated metal net grid is difficultto scratch and fall off and is long in service lifetime. The ferromagnetic material and the conductive metal material are combined, a shielding effect can be developed at a wide band from a low-frequency electromagnetic band to a high-frequency electromagnetic band, and the multi-layer metal net grid electromagnetic shielding optical window has the characteristics of high electromagnetic shielding and high transmission of visible light and infrared light.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

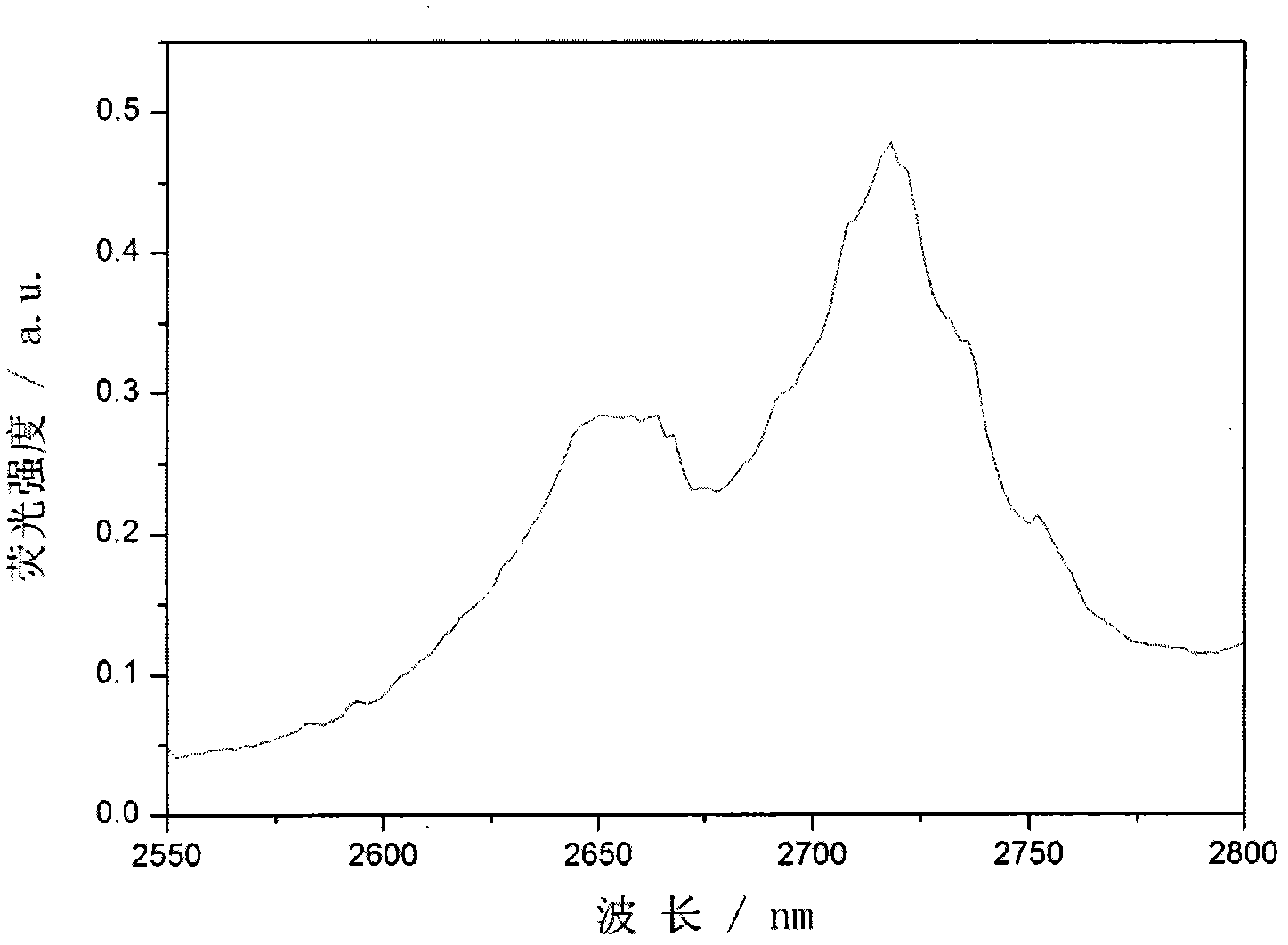

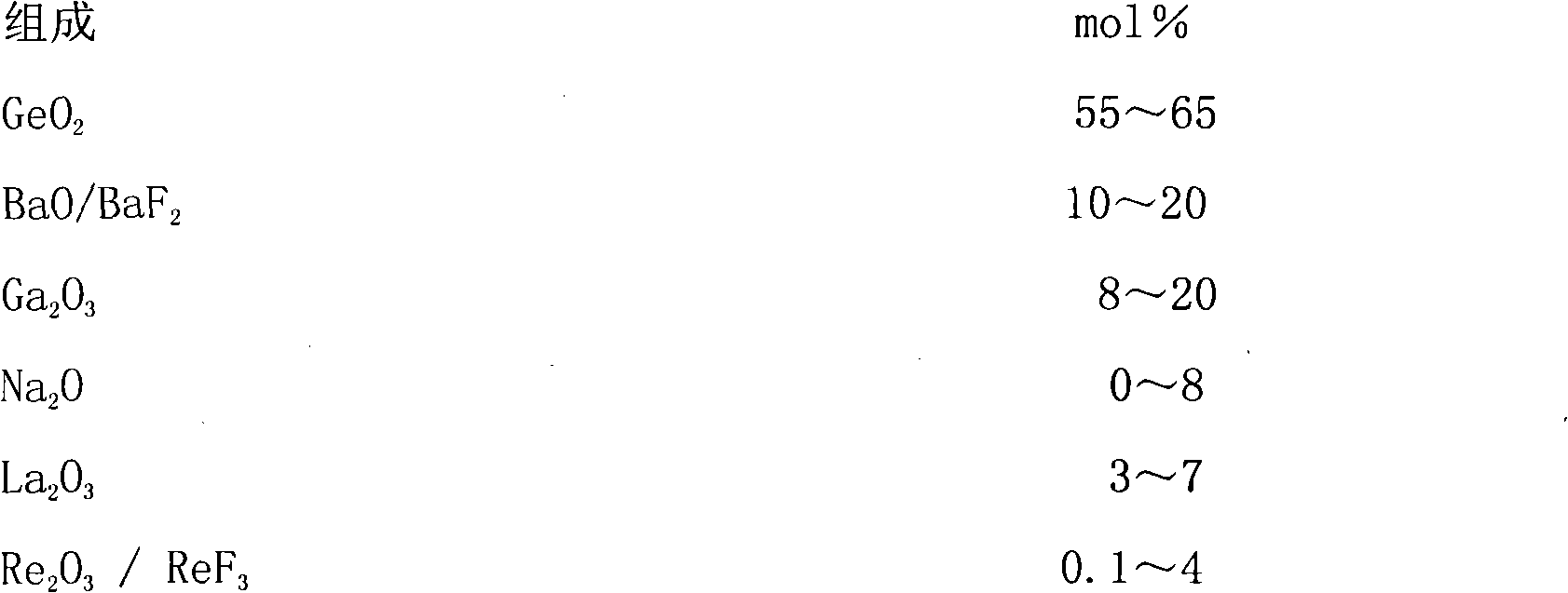

3mu m luminous rare-earth ion-doped fluogermanate laser glass and preparation method thereof

The invention discloses 3mu m luminous rare-earth ion-doped fluogermanate laser glass and a preparation method thereof. The laser glass comprises the following components: 55 to 65 molar percent of GeO2, 10 to 20 molar percent of BaO / BaF2, 8 to 20 molar percent of Ga2O3, 0 to 8 molar percent of Na2O, 3 to 7 molar percent of La2O3, and 0.1 to 4 molar percent of Re2O3 / ReF3 (Re is a rare-earth element selected from Er, Pr, Yb, Tm, Ho and Nd). Experimental results show that the rare-earth ion-doped fluogermanate laser glass prepared by the method has high infrared transmittance and wide transmission range. The glass can obtain good near 3 mu m fluorescence emission under the action of a laser diode pump of which the wavelength is 980nm, so the glass is suitable for the preparation and application of near 3mu m luminous rare-earth ion-doped special glass and an optical fiber material.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

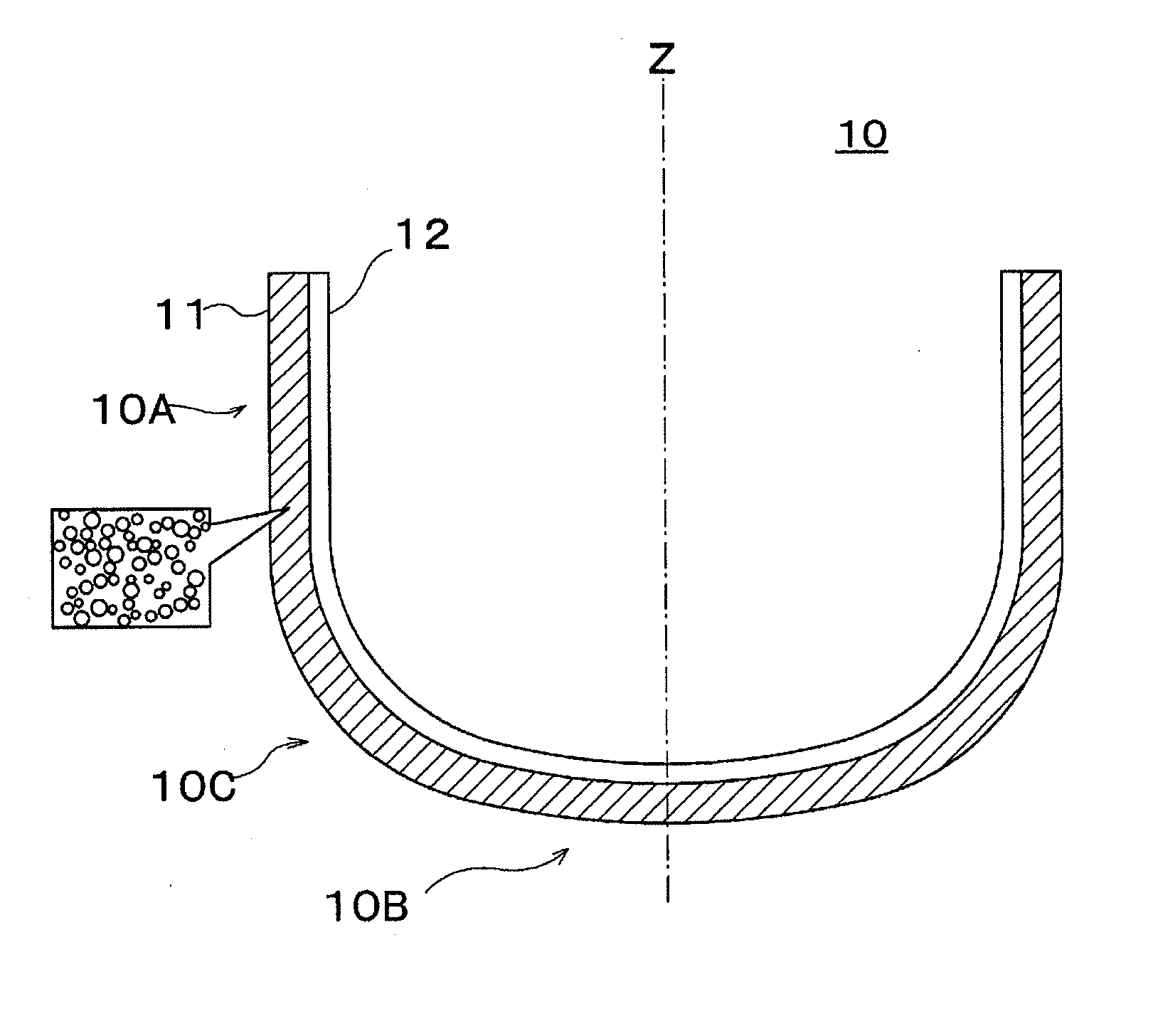

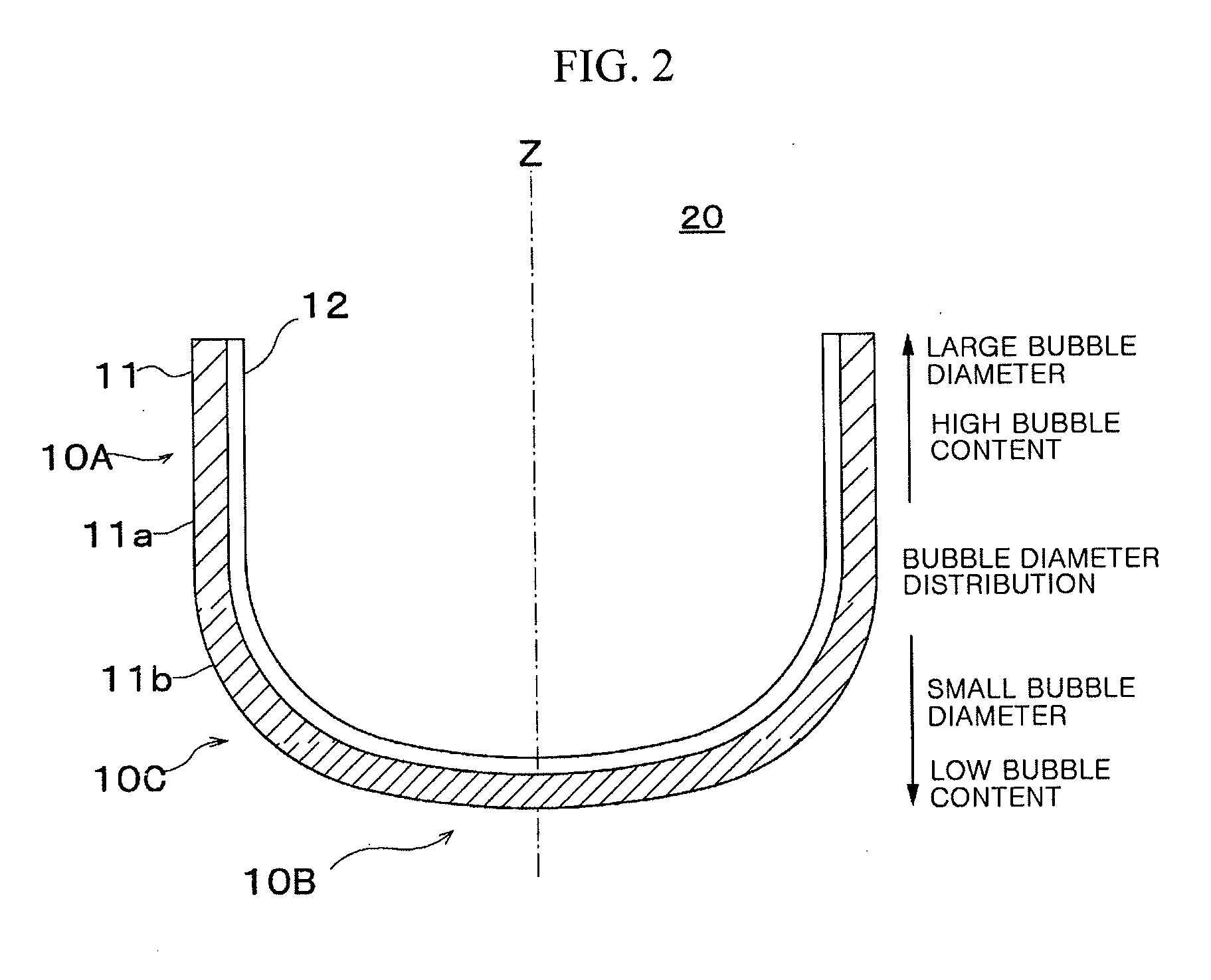

Vitreous silica crucible for pulling silicon single crystal

ActiveUS20100251959A1Improve production yieldShort timeAfter-treatment apparatusPolycrystalline material growthCrucibleRaw material

Provided is a vitreous silica crucible for pulling silicon single crystals, which can melt a silicon raw material in a short time and improve production yield of silicon single crystals by temporal change of an opaque vitreous silica layer. The vitreous silica crucible includes an opaque vitreous silica layer(11) provided on an outer surface thereof and containing plural bubbles, and a transparent vitreous silica layer(12) provided on an inner surface and not containing bubbles substantially. The opaque vitreous silica layer(11) has a bubble diameter distribution in which the content of bubbles having a diameter of less than 40 μm is 10% or more and less than 30%, the content of bubbles having a diameter of 40 μm or more and less than 90 μm is 40% or more and less than 80%, and the content of bubbles having a diameter equal to or more than 90 μm is 10% or more and less than 30%. Relatively small bubbles contained in the opaque vitreous silica layer(11) contribute to the thermal conductivity of a crucible at an initial pulling stage, and relatively large bubbles contained in the opaque vitreous silica layer are expanded through a long-term pulling process to thereby largely contribute to the warmth retaining property of the crucible at a later pulling stage.

Owner:JAPAN SUPER QUARTZ CORP

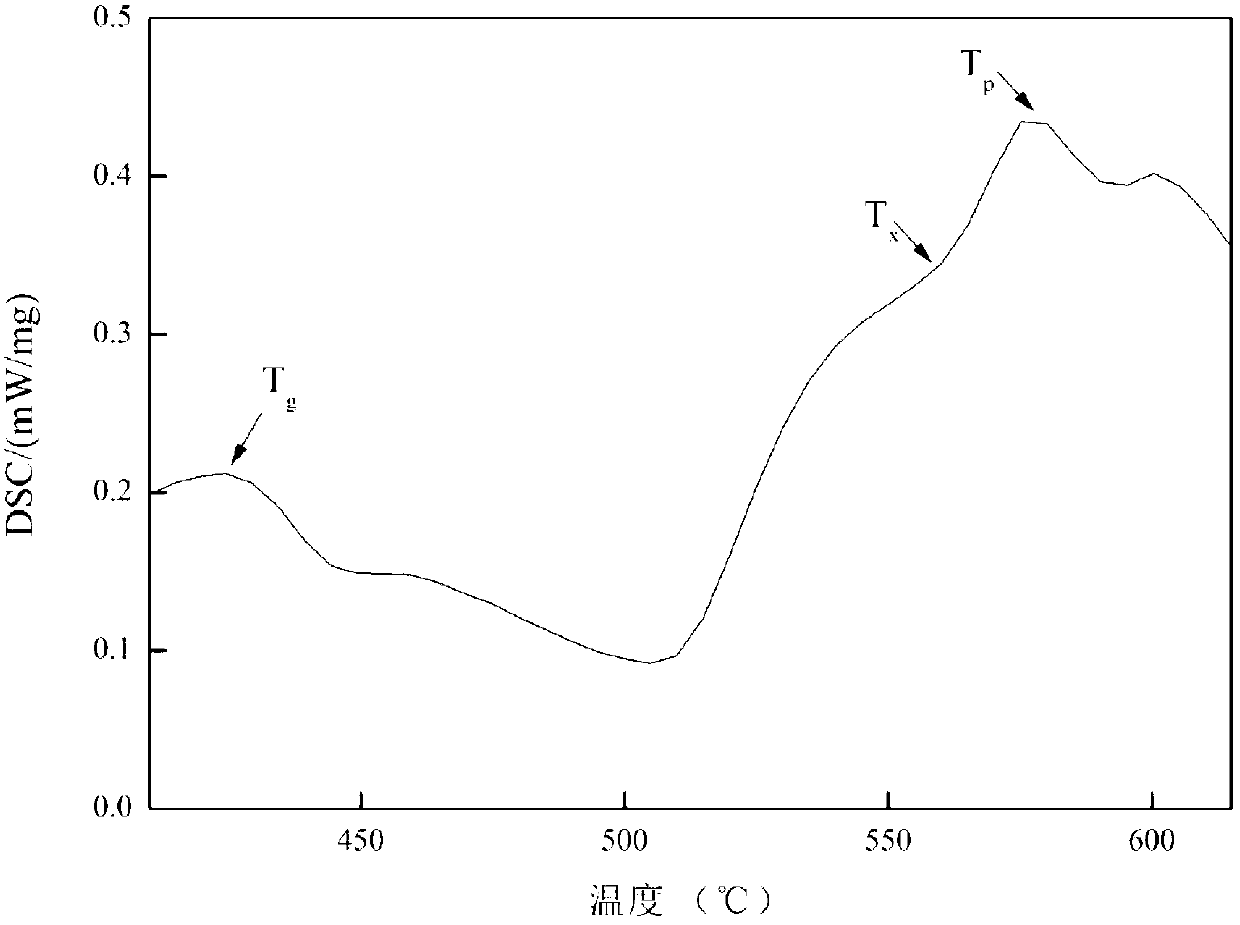

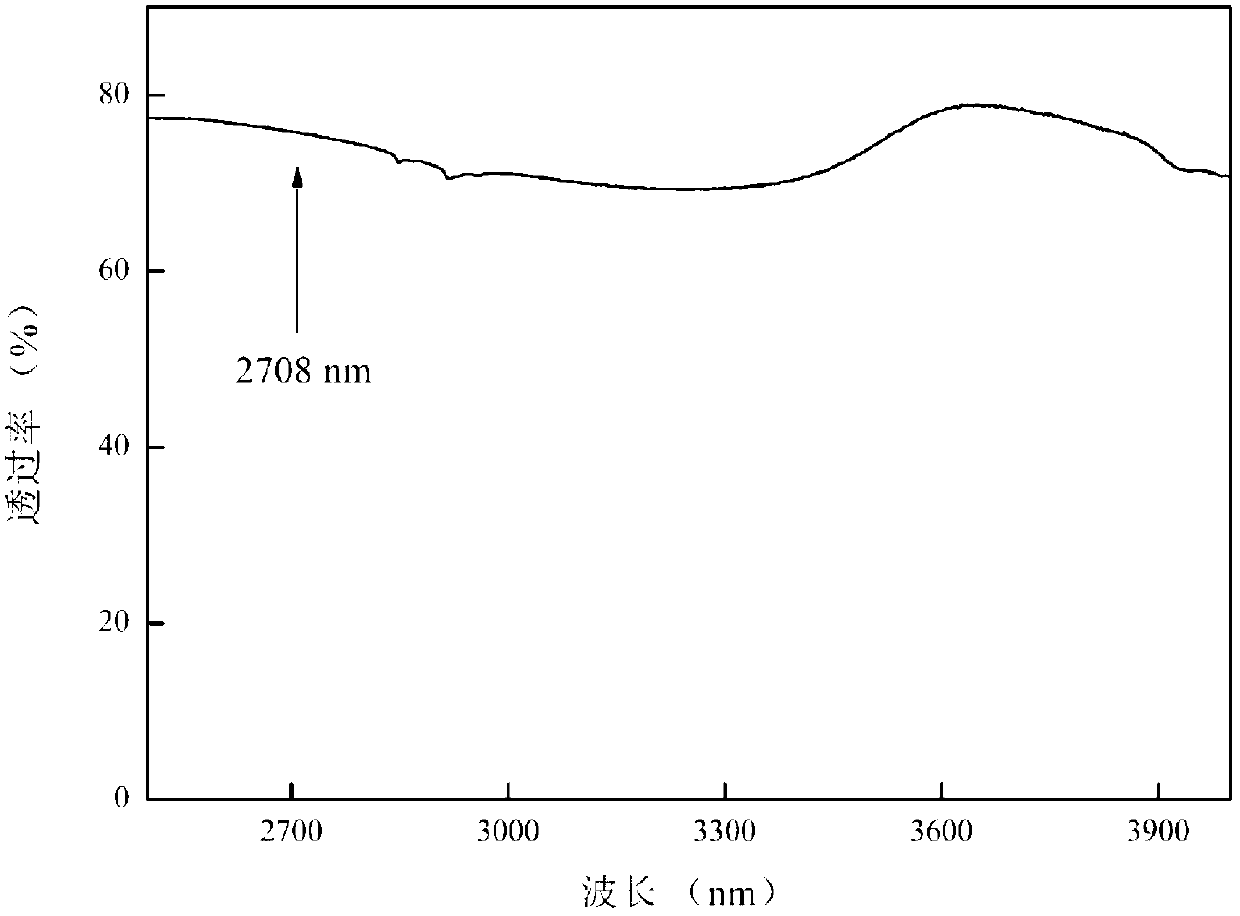

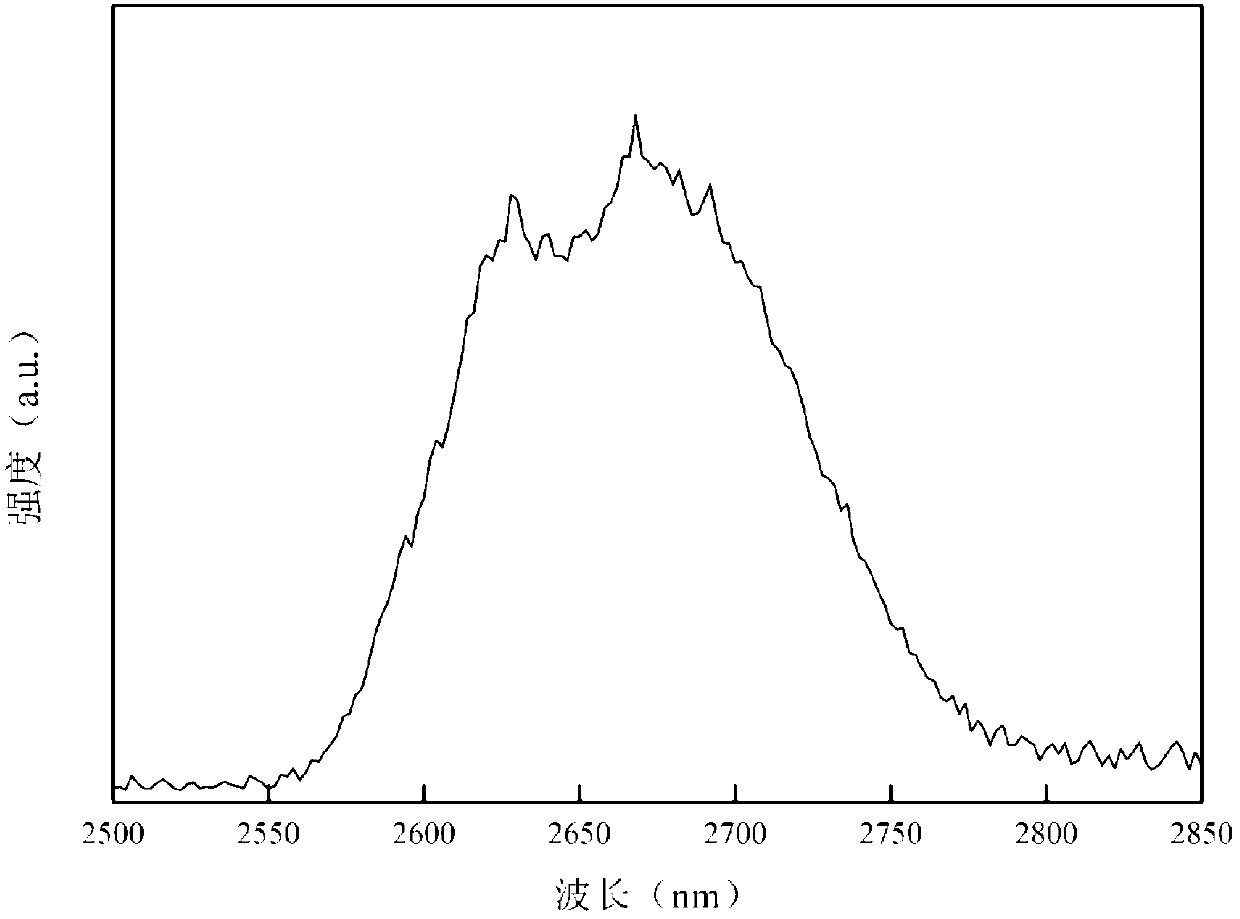

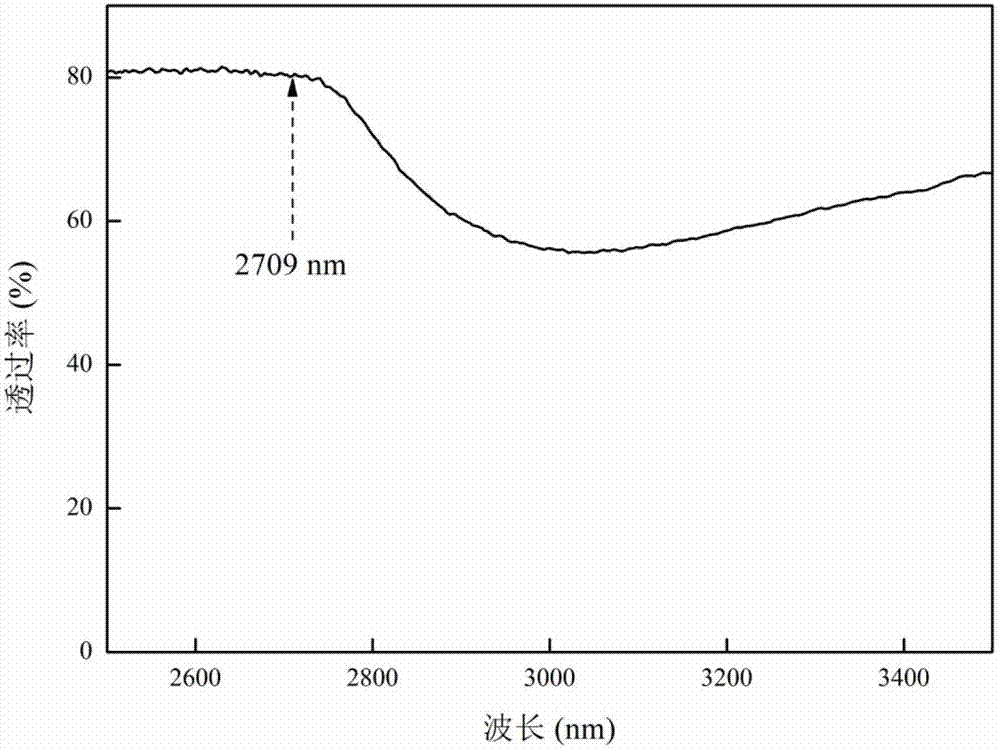

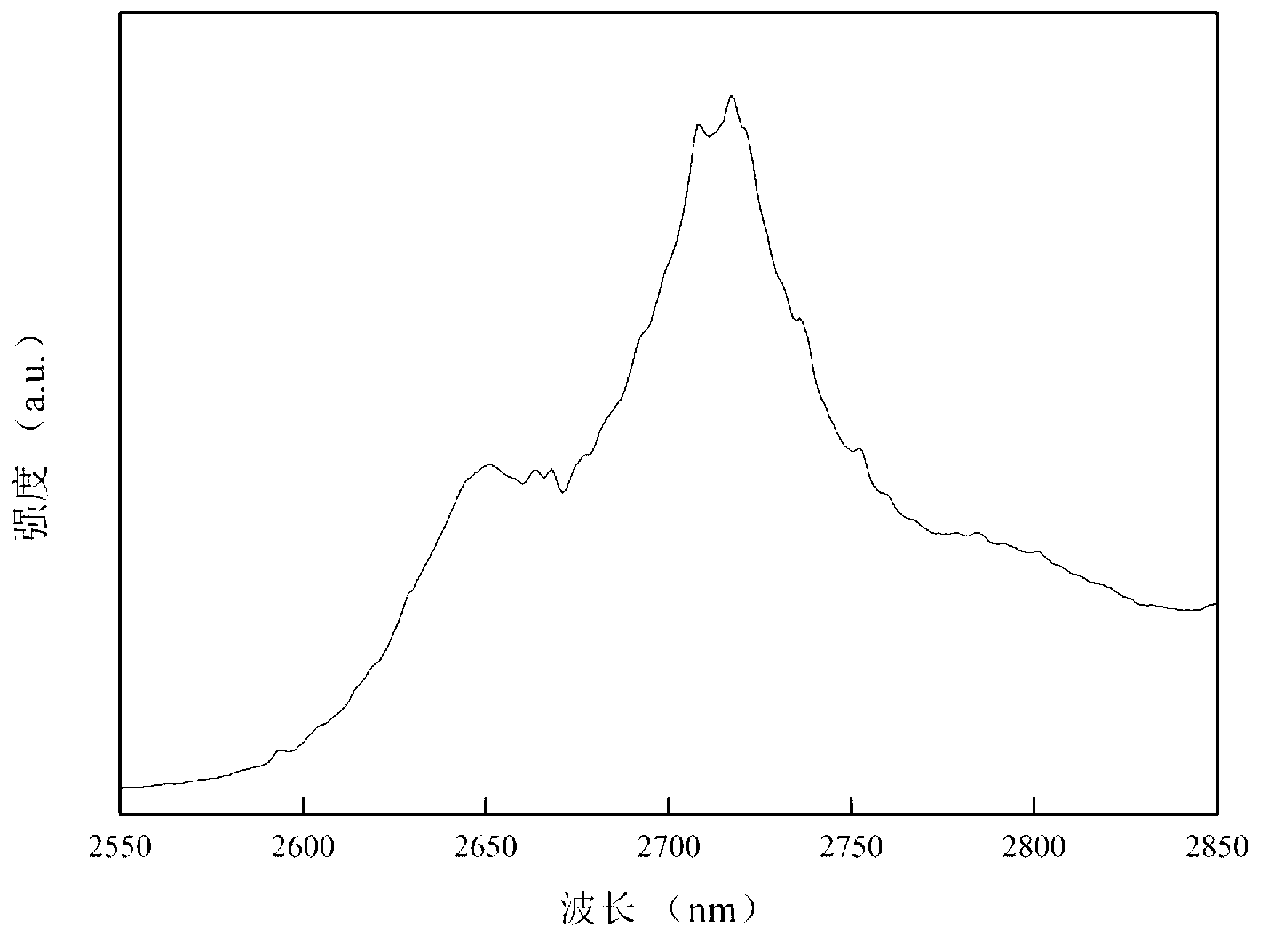

Erbium neodymium ion co-doped tellurium fluoride glass for emitting 2.7 microns of intermediate infrared light

InactiveCN103011593AImprove transmittanceExcellent physical and chemical propertiesRare-earth elementTransmittance

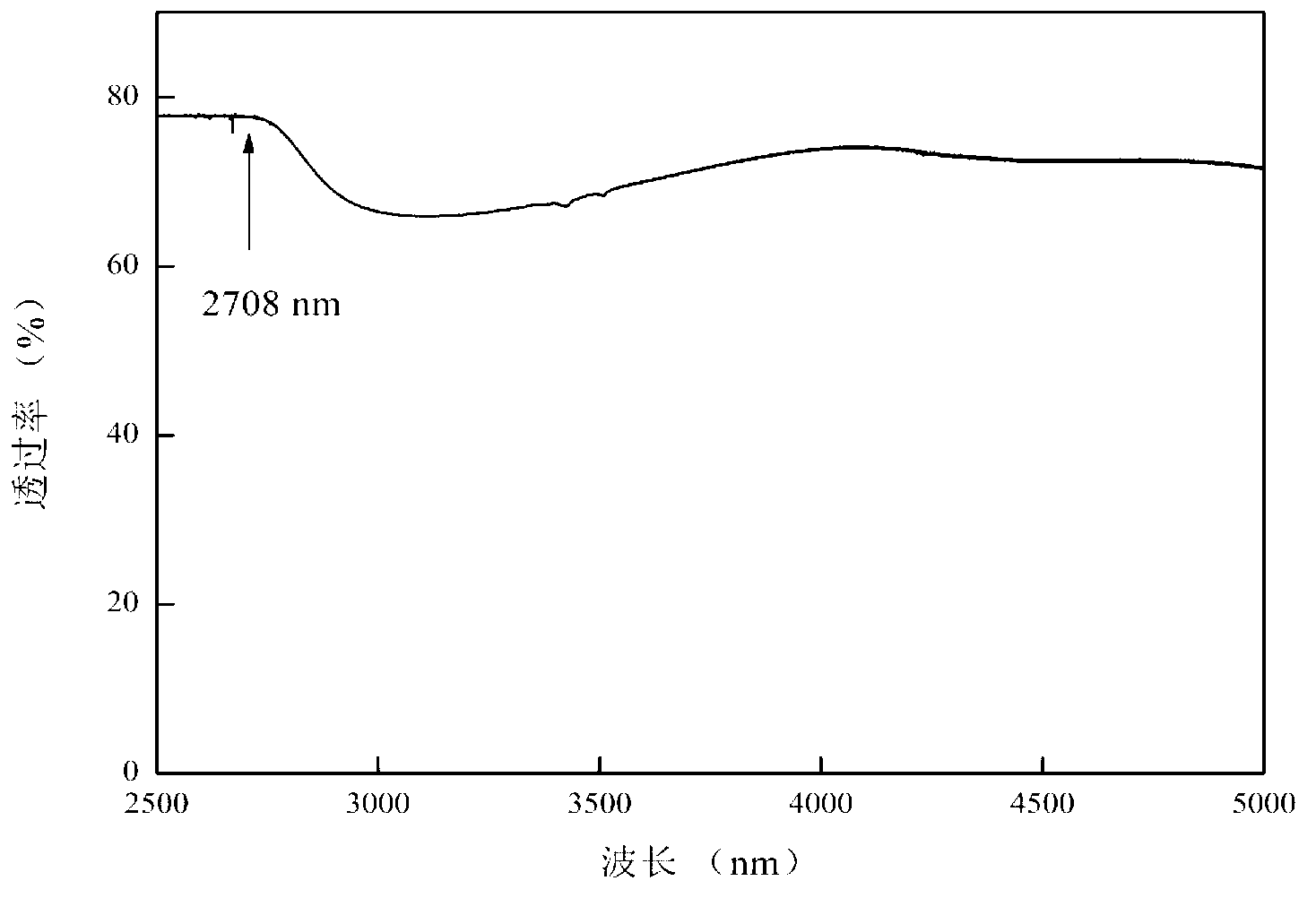

The invention discloses erbium neodymium ion co-doped tellurium fluoride glass for emitting 2.7 microns of intermediate infrared light. The glass comprises the following components in the range of mole percent: 55-65% of TeO2, 10-20% of GeO2, 0-20% of ZnO, 0-5% of Na2O, 0-20% of ZnF2, and 0-5% of NaF, and 0.5-1% of RE2O3, (RE is rare earth elements Er and Nd). The glass is prepared by a melting method of a corundum crucible and a silicon carbide rod electric furnace. The glass is transparent, not easy to devitrify, high in near infrared transmittance near 2708nm, and excellent in physical and chemical properties; the stability parameter delta T is greater than or equal to 140 DEG C; a strong 2.7 microns of intermediate infrared fluorescence can be obtained under pumping of a laser diode with 808nm of wavelength; and the glass is suitable for preparation and application of special glass doped with erbium ion for emitting 2.7 microns of intermediate infrared light and an optical fiber material.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A method of preparing gamma-La2S3 infrared transparent ceramic having a high infrared transmittance

The invention relates to a method of preparing gamma-La2S3 infrared transparent ceramic having a high infrared transmittance. The gamma-La2S3 infrared transparent ceramic which is in a cubic phase at a temperature ranging from room temperature to 1300 DEG C and is stable in structure can be prepared under conditions of a low preparing temperature, a low vacuum degree, low pressure and short temperature maintaining time. Technical problems that a liquid phase is difficult to generate, ceramic microstructure uniformity is poor and optical transmittance in the prior art is low are overcome. The gamma-La2S3 infrared transparent ceramic the average transmittance of which in a waveband of 8-14 [mu]m is not less than 50% can be prepared. Compared with the prior art, the prepared gamma-La2S3 hot-press infrared transparent ceramic has characteristics of good thermal stability, a simple process and the high infrared transmittance.

Owner:陕西智航昱铠新材料有限责任公司

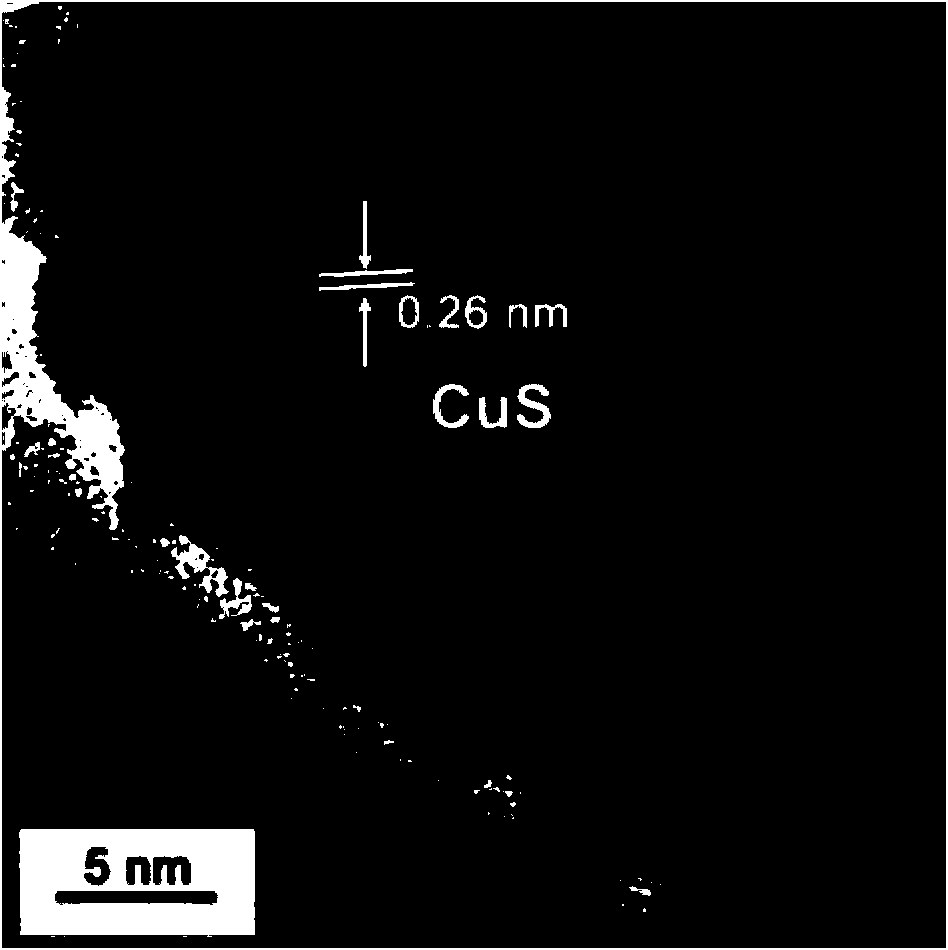

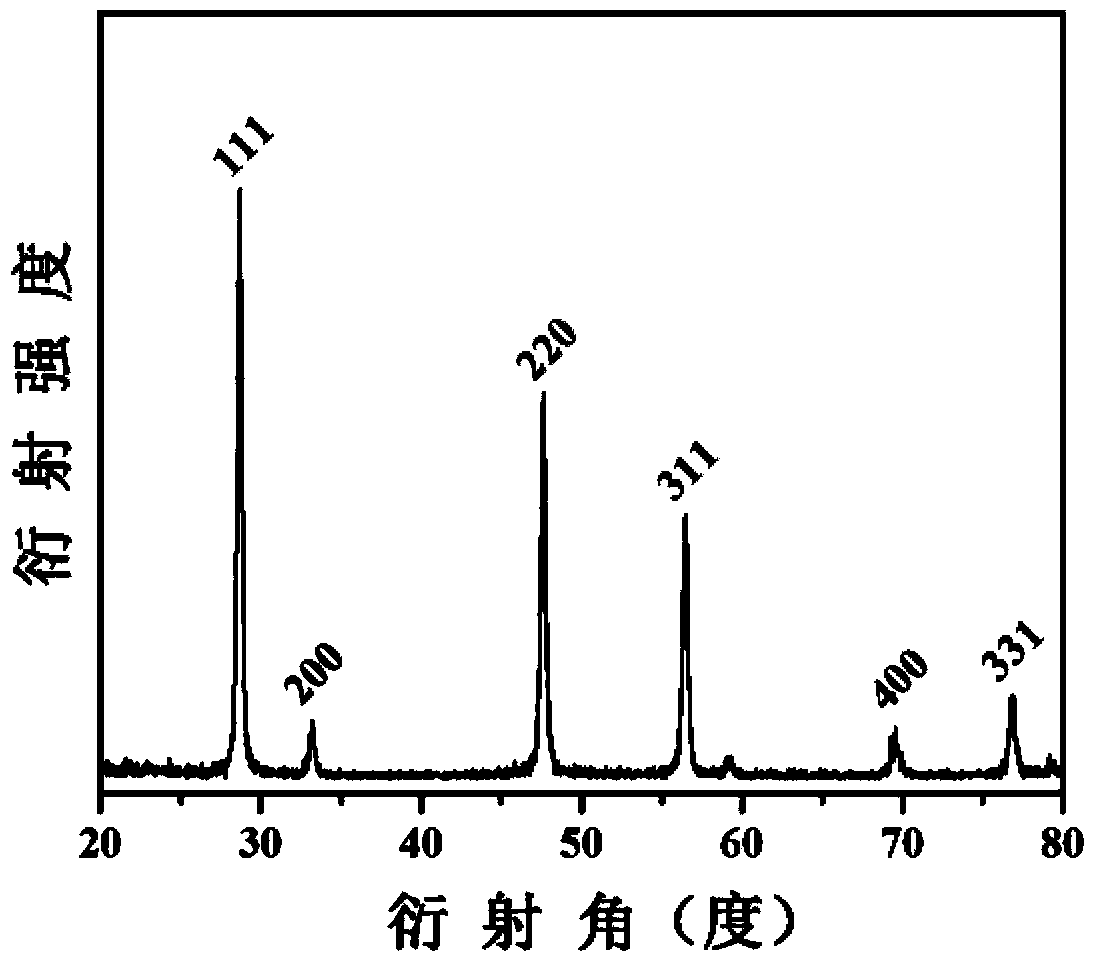

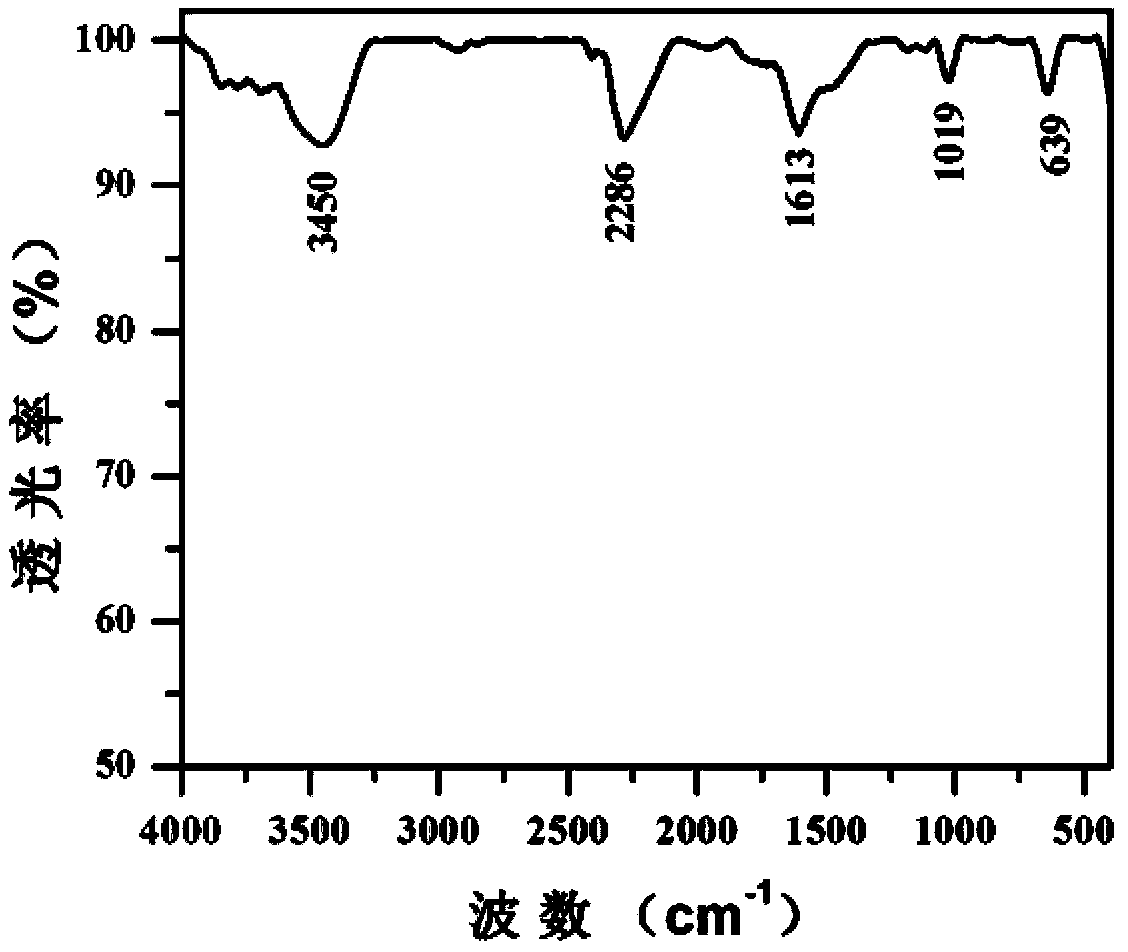

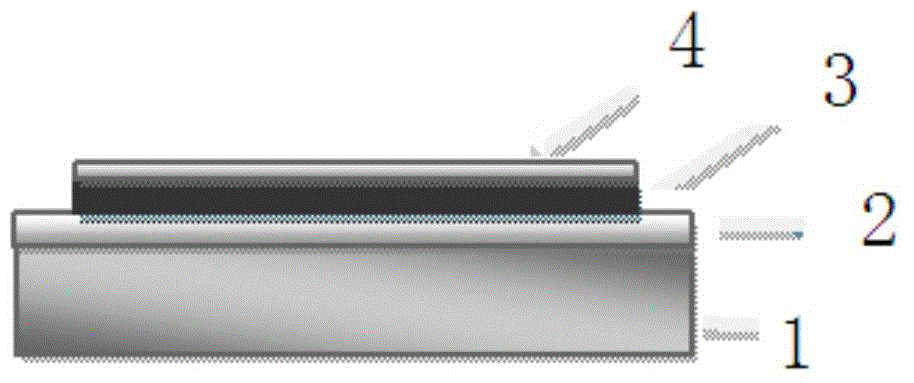

Copper sulphide-doped cubic crystal zinc sulfide material and preparation method thereof

InactiveCN103382576ASimple processLow costPolycrystalline material growthFrom normal temperature solutionsTransmittanceNucleation

The invention provides a copper sulphide-doped cubic crystal zinc sulfide material and a preparation method thereof. According to the invention, a small amount of CuS is doped in ZnS, CuS is uniformly dispersed in ZnS particles, and the mass percentage of CuS is 0.02 to 1.0%. The infrared transmittance of the material is more than 85% in a wavelength range of 2.5 to 25 mu m (400 to 4000 / cm); after the material is roasted at a temperature of 800 to 1000 DEG C for 1 to 2 h, the infrared transmittance of the material reaches 95% in a same range, and the crystal form of ZnS / CuS maintains unchanged after roasting. A nucleation / crystallization isolation method is used for preparation of the material, and the preparation method has the advantages of simple process, low cost and easily practicable reactions. CuS doped in the ZnS / CuS material is uniformly dispersed in the Zns particles, so an effect of stabilizing the crystal form of ZnS is produced, it is ensured that ZnS maintains a cubic phase crystal form after high temperature roasting, and infrared transmission performance of ZnS is not influenced.

Owner:BEIJING UNIV OF CHEM TECH

South Pole infrared telescope sealing window capable of preventing and removing frost and manufacturing method thereof

InactiveCN104570166AHigh infrared transmittanceSolve the problem that it cannot be applied in the infrared spectral regionTransparent/reflecting heating arrangementsOptical elementsFrostTransmittance

The invention discloses a South Pole infrared telescope sealing window capable of preventing and removing frost and a manufacturing method thereof. An optical medium film system is arranged on a substrate of sealing window glass; the optical medium film system contains a transparent conductive film layer; the South Pole infrared telescope sealing window is characterized in that the transparent conductive film layer is divided into two layers, namely a planar transparent conductive film and a linear transparent conductive film; an insulating dielectric antireflective film layer is arranged between the planar transparent conductive film and the linear transparent conductive film; two electrodes are arranged on the edge of the upper surface of the transparent conductive film layer; the linear transparent conductive film and the planar transparent conductive film are connected in parallel. The invention is applicable to sealing window defrosting of a sealing window-type South Pole infrared telescope; the problem that the conventional transparent conductive film cannot be applied to an infrared spectral zone is solved; the infrared transmittance of the sealing window is improved to a great extent.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Preparation method of zinc selenide with high optical quality

ActiveCN101759161AHigh infrared transmittanceSmall absorption coefficientBinary selenium/tellurium compoundsAbsorption factorZinc selenide

The invention discloses a preparation method of zinc selenide with high optical quality, which belongs to the technical field of inorganic block body material preparation. The method comprises the following steps: putting zinc into a deposition furnace; pumping the vacuum; raising the temperature in a deposition chamber; using argon as carrying gas of reaction raw material gas; introducing H2Se gas and the argon into the deposition chamber through a mass flowmeter (the mol ratio of zinc to H2Se is between 0.8 and 1.2, the deposition reaction is carried out on the inner wall of the deposition chamber, and the zinc selenide begins to grow); maintaining the unchanged mol ratio of zinc to H2Se and the constant pressure in the furnace; carrying out deposition for 15 to 25 days; and then, lowering the temperature to the room temperature to obtain the zinc selenide with high optical quality. The invention effectively solves the problem of powder generation in the process of preparing the zinc selenide through chemical vapor deposition, the impurities mixed in products are eliminated, the materials have high infrared transmission rate and low absorption factor, and the optical quality is greatly improved.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

Infrared transparent conductive film and preparation method thereof

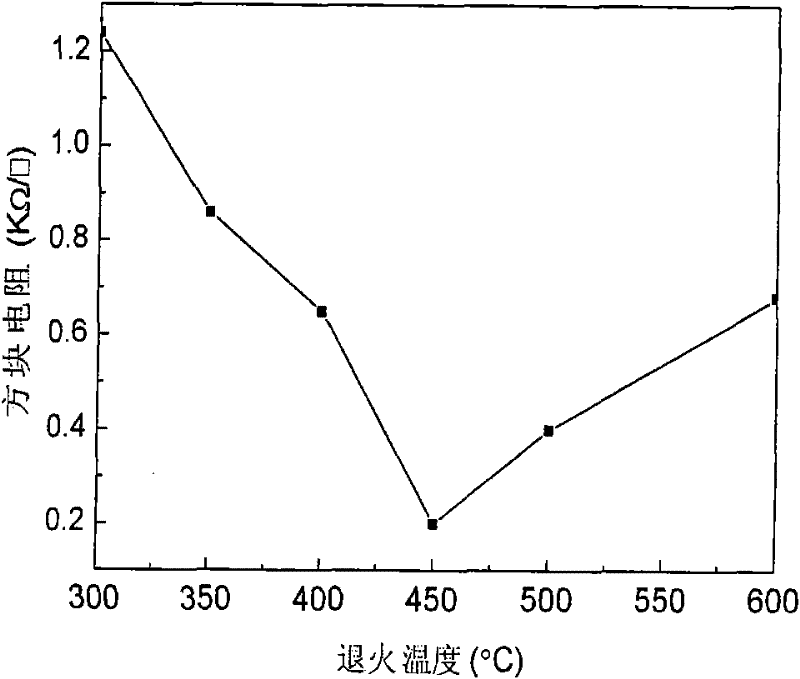

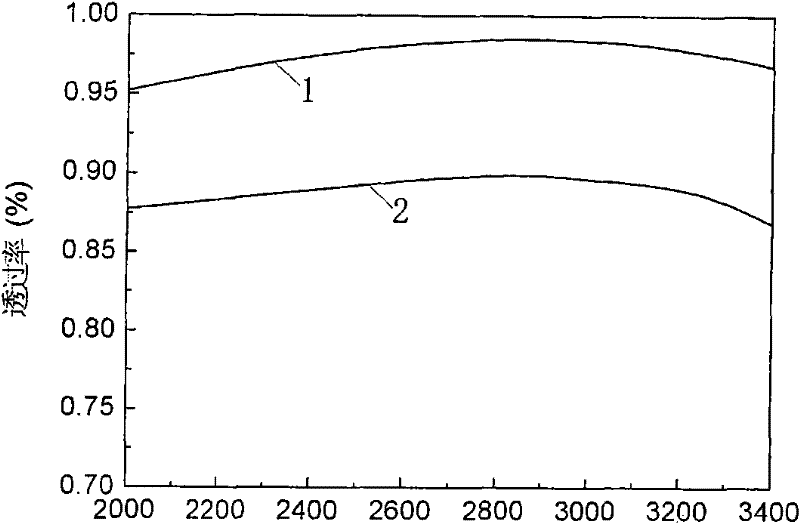

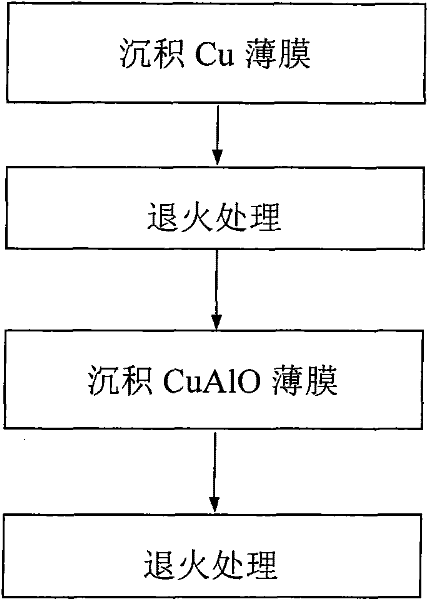

InactiveCN101752026AReduce infrared transmittanceGood infrared transmittanceConductive layers on insulating-supportsVacuum evaporation coatingOptical propertyRadio frequency magnetron sputtering

The invention discloses an infrared transparent conductive film and a preparation method thereof. The infrared transparent conductive film is prepared by covering Cu film and CuAlO film on sapphire substrate in turn. The thickness of the Cu film is 300-360nm, the refractive index is 1.07-1.13; and the thickness of the CuAlO film is 100-170nm and the refractive index is 1.70-2.00. During preparation, the radio frequency magnetron sputtering method is used to deposit Cu film on sapphire substrate, then annealing is performed, then the radio frequency magnetron sputtering method is used again to deposit CuAlO film on the sapphire with Cu film and then the annealing is performed. The prepared infrared transparent conductive Cu / CuAlO film of the invention has good infrared transmitting performance and conductivity, and can be used for improving the optical property and anti-electromagnetic interference performance of the infrared detector window / hood material.

Owner:NANTONG ZHONGLING INSULATION MATERIALS +1

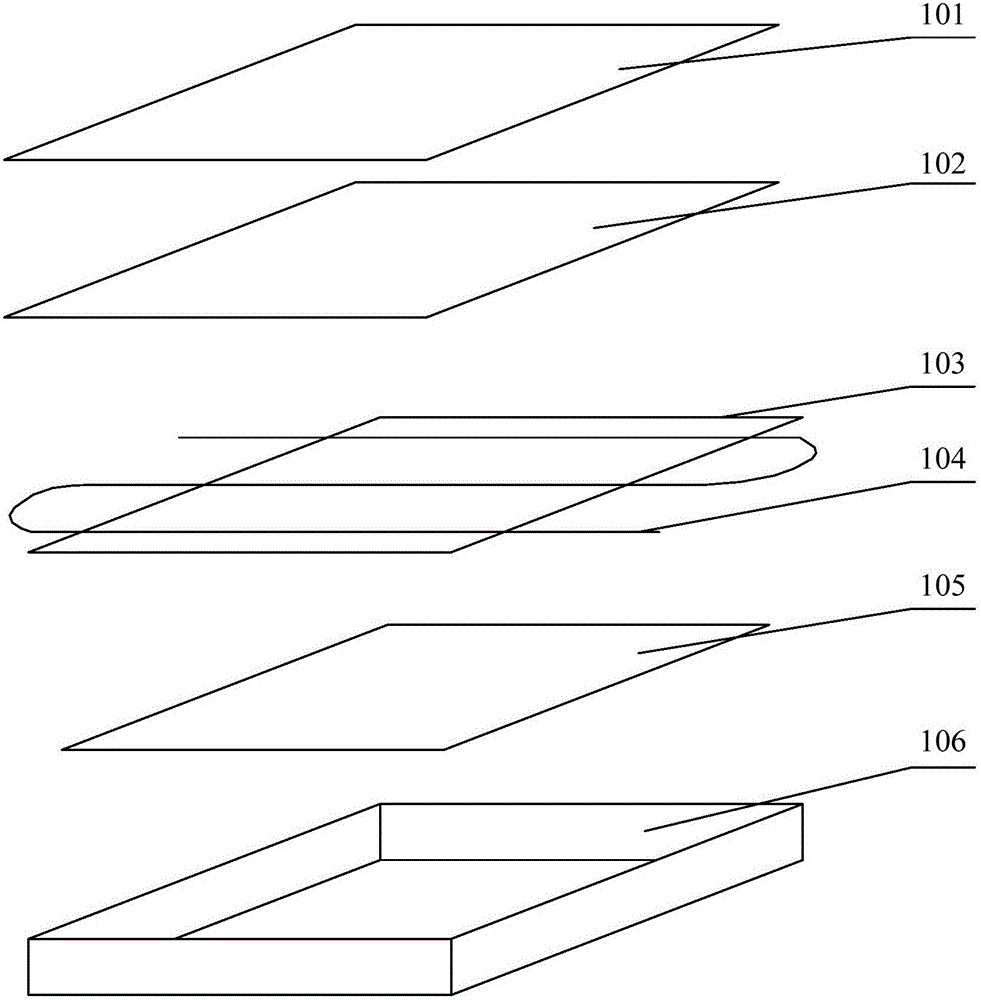

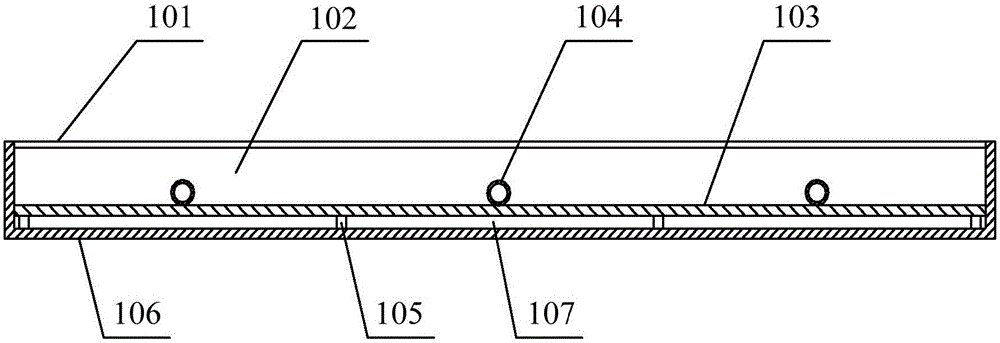

Radiation heat exchange board assembly

InactiveCN104990175ARadiant heat transfer effect is remarkableLow costLighting and heating apparatusSpace heating and ventilation detailsTransmittanceEngineering

The embodiment of the invention discloses a radiation heat exchange board assembly which comprises a veneer and a heat exchange component and further comprises supporting pieces arranged between the veneer and the heat exchange component. A hollow layer is formed between the veneer and the heat exchange component through the supporting pieces, or a heat exchange base of the heat exchange component is of a box-type structure with a hollow layer. According to the radiation heat exchange board assembly, the hollow layer is formed between the veneer and the heat exchange component, or the hollow layer is directly formed in the heat exchange base of the heat exchange component. The hollow layer replaces a nonmetal heat conducting layer in the prior art, the infrared transmittance of the hollow layer is higher than that of a PVC crystal board, and the radiation heat exchange effect is more obvious; the PVC material is omitted, cost can be lowered, the mass can be reduced, and deformation cannot happen along with changing of temperature.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Infrared optical window with double-sided anti-reflection structure

The invention discloses an infrared optical window with a double-sided anti-reflection structure, belonging to the technical field of infrared optical windows. The infrared optical window with the double-sided anti-reflection structure comprises an infrared optical window, wherein anti-reflection structures are etched on an incidence face and an exit face of the infrared optical window. By utilizing the structure, the transmissivity of the infrared window can be significantly increased, and the sensitivity of an infrared device can be improved. According to the infrared optical window disclosed by the invention, the average transmissivity measured in a wave band range of 8-14 um achieves 65 percent and is improved by 20 percent, wherein the maximum transmissivity achieves 73 percent.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

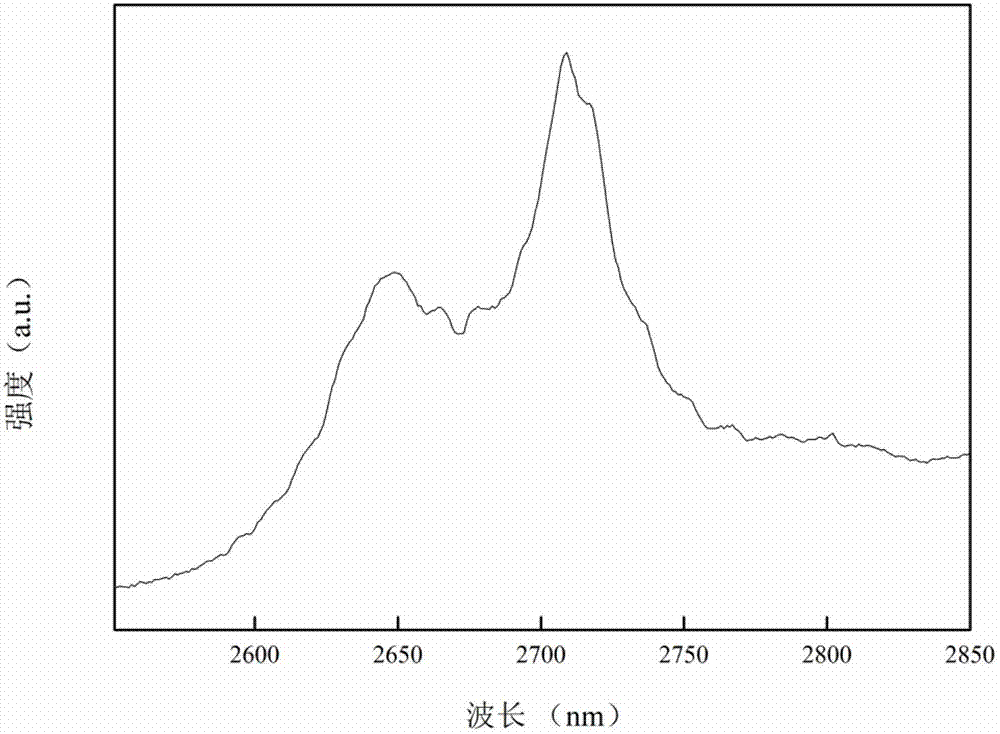

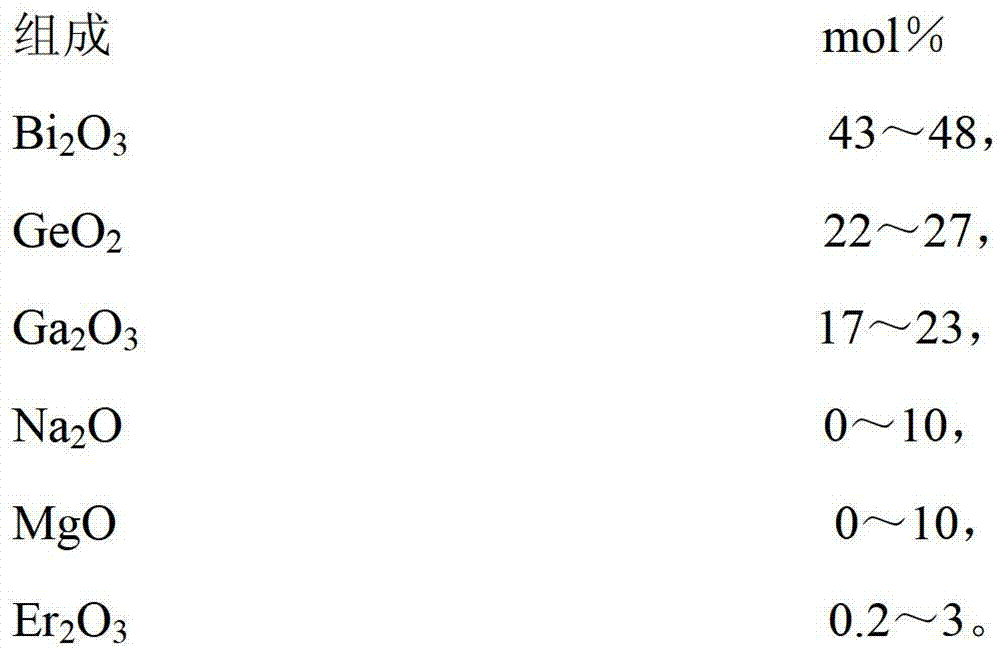

Intermediate infrared 2.7 mum luminous erbium ion-doped gallium germanium bismuthate glass

InactiveCN103030274AHigh infrared transmittanceExcellent physical and chemical propertiesTransmittanceHeavy metals

The invention relates to intermediate infrared 2.7 mum luminous erbium ion-doped gallium germanium bismuthate glass. The molar percentage composition range of the glass is shown as follows: 43-48 percent of Bi2O3, 22-27 percent of GeO2, 17-23 percent of Ga2O3, 0-10 percent of MgO, 0-10 percent of Na2O and 0.2-3 percent of Er2O3. The glass is prepared by adopting a corundum crucible and silicon carbide rod electric furnace melting method. The glass has high infrared transmittance nearby intermediate infrared 2.7 mum and excellent physical and chemical property, and the stability parameter delta t is more than or equal to 160 DEG C; and strong intermediate infrared 2.7 mum fluorescent light can be obtained under the pumping of a laser diode with a wavelength of 980 nm. The glass is suitable for the preparation and the application of intermediate infrared 2.7 mum luminous erbium ion-doped heavy metal oxide glass and optical fiber materials.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A kind of y2o3-mgo nanometer composite ceramics and preparation method thereof

The invention relates to a Y2O3-MgO nano-composite ceramic and a preparation method thereof. The Y2O3-MgO nano-composite ceramic is shown as xY2O3.(1-x)MgO, wherein x is the percentage of the mole number of Y2O3 to the total mole number of Y2O3 and MgO; the value of x is more than or equal to 0.01 and less than or equal to 0.99. The method comprises the following steps: preparing Y2O3-MgO nano-composite powder by adopting a sol-gel method; sintering the sieved composite powder by virtue of discharge plasma sintering or hot isostatic pressing sintering to obtain the infrared transparent Y2O3-MgO nano-composite ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Temperature-adjustable fabric based on carbon nano tube and preparing method of fabric

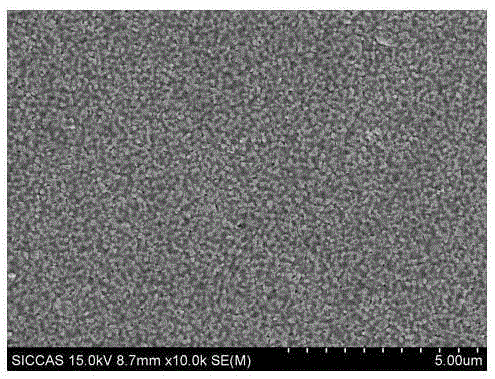

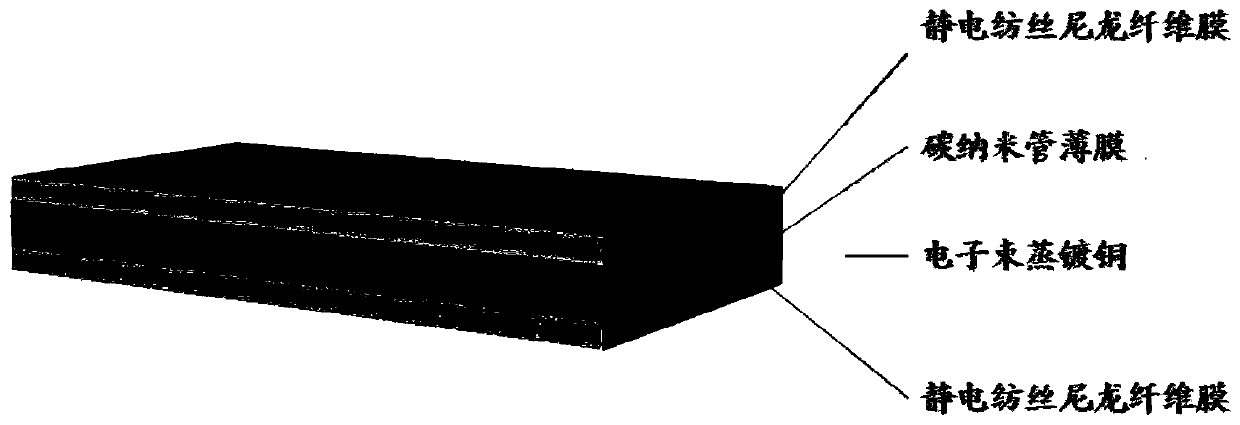

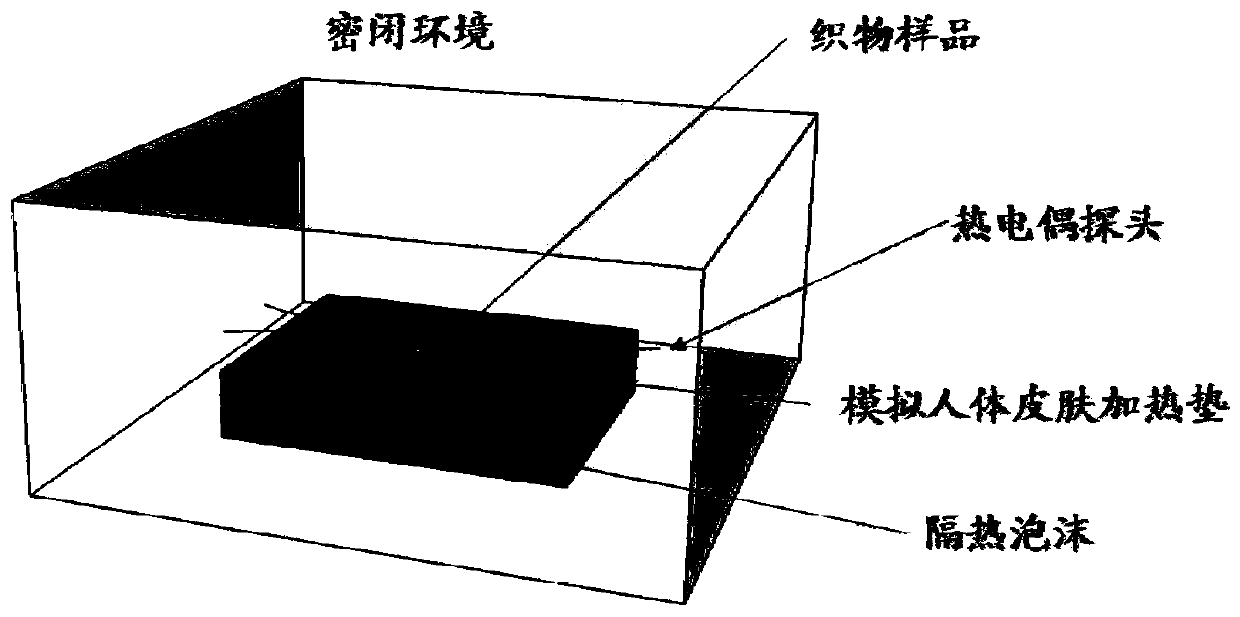

ActiveCN110565176AComposite effect is goodImprove the shortcomings of thickSynthetic resin layered productsElectro-spinningPlant TubersCarbon nanotube

The invention discloses a temperature-adjustable fabric based on a carbon nano tube and a preparing method of the fabric. The temperature-adjustable fabric comprises an inner structure layer and an outer structure layer. The inner structure layer comprises a carbon nano tube layer and a metal layer covering the carbon nano tube layer, and the infrared ray emitting rate of the metal layer is lowerthan that of the carbon nano tuber layer; the outer structure layer at least covers a first surface and a second surface of the inner structure layer, the first surface and the second surface are oppositely arranged in the thickness direction of the inner structure layer, and the outer structure layer has a pore structure and can allow infrared rays to pass through. The preparing method comprisesthe steps of depositing the metal layer on the surface of a carbon nano tube thin film to form the inner structure layer; at least covering the first surface and the second surface of the inner structure layer with the outer structure layer. According to the temperature-adjustable fabric, no other energy sources are consumed, the difference of the infrared emitting rates of the front and reverse directions of the inner structure layer is utilized, the temperature can be automatically adjusted according to the changes of the environment temperature, and meanwhile, the effect of heat preservation or cooling is achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

High-concentration erbium ion doped tellurium tungstate glass capable of emitting light at mid-infrared 2.7 microns

InactiveCN103058516AIncrease the doping concentrationPreparation strongStability parameterHigh concentration

The invention discloses a high-concentration erbium ion doped tellurium tungstate glass capable of emitting light at mid-infrared 2.7 microns. The glass comprises the following components by molar percent: 58-70% of TeO2, 15-25% of WO3, 0-15% of La2O3, 0-15% of LaF3 and 2-4% of Er2O3. The glass is prepared by adopting an electric furnace melting method of a corundum crucible and a silicon carbide rod. The glass is high in doping concentration of erbium ion, high in infrared transmittance near to the mid-infrared 2.7 microns and good in physicochemical properties; and the stability parameter delta T is not less than 180 DEG C. Strong mid-infrared 2.7 microns fluorescence is obtained under pumping of a laser diode with a wavelength of 980 nm; and the glass is suitable for preparation and application of erbium ion doped special glass and optical fiber materials capable of emitting light at mid-infrared 2.7 microns.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

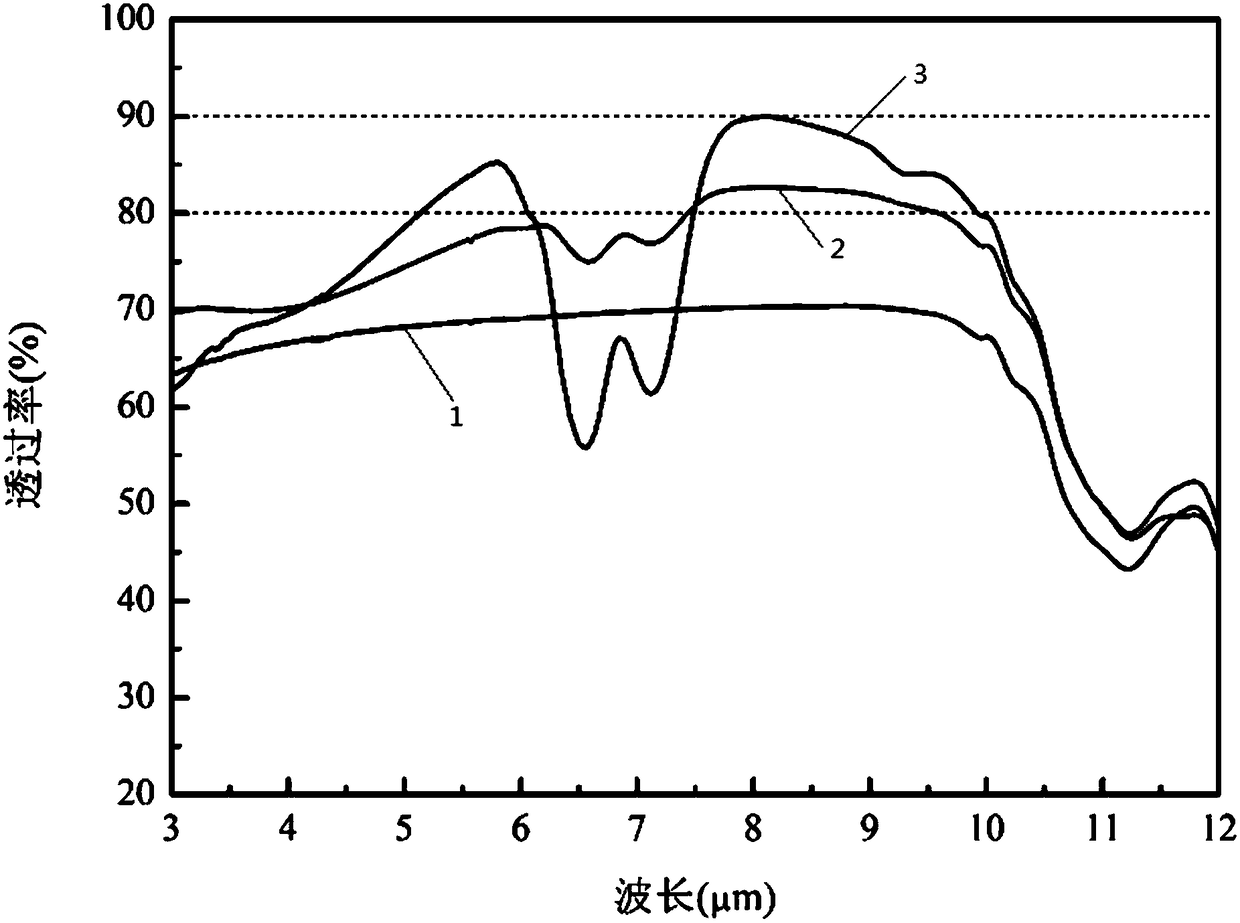

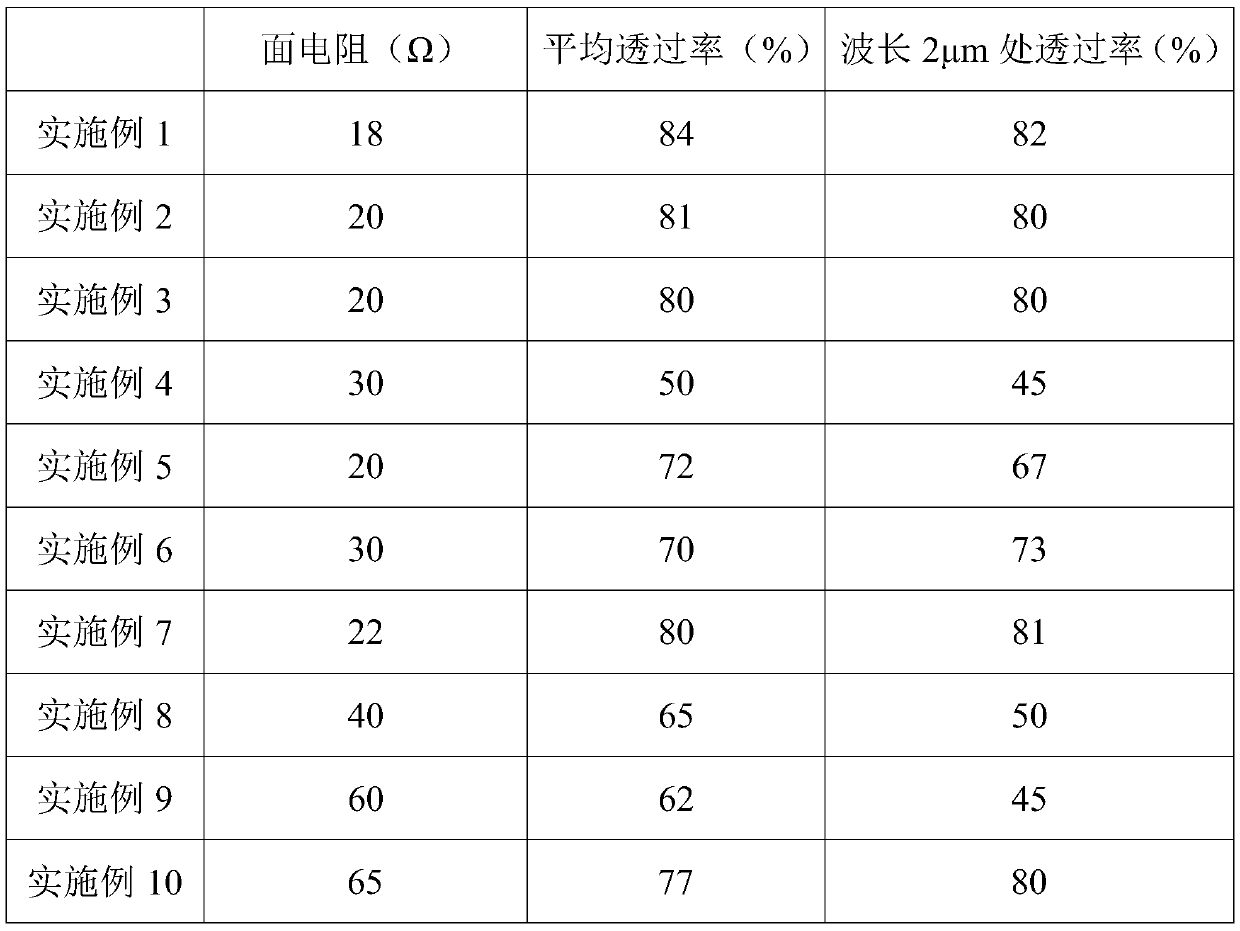

Window with infrared transparent conductive function

ActiveCN111276277AHigh hardnessPromote growthConductive layers on insulating-supportsVacuum evaporation coatingElectrical resistance and conductancePhysical chemistry

The invention discloses a window with an infrared transparent conductive function, and belongs to the field of infrared optical materials and the field of electronic materials. The invention aims to solve the technical problem that an existing window with an infrared transparent conductive function cannot give consideration to electromagnetic shielding and high infrared transmittance. The window with the infrared transparent conductive function is composed of a substrate, a transparent conductive layer and an infrared anti-reflection layer, wherein the transparent conductive layer and the infrared anti-reflection layer sequentially grow on the substrate. The transmittance of the window with the infrared transparent conductive function is not lower than 80% within the wavelength range of 0.78 mu m to 2.5 mu m; the transmittance is not lower than 75% within the wavelength range of 2.5-5 microns, the square resistance is not larger than 100 ohm / sq, and the shielding efficiency for 1GHz-18GHz electromagnetic waves is larger than 10dB. The preparation method is applied to preparation of the window with the infrared transparent conductive function.

Owner:HARBIN INST OF TECH

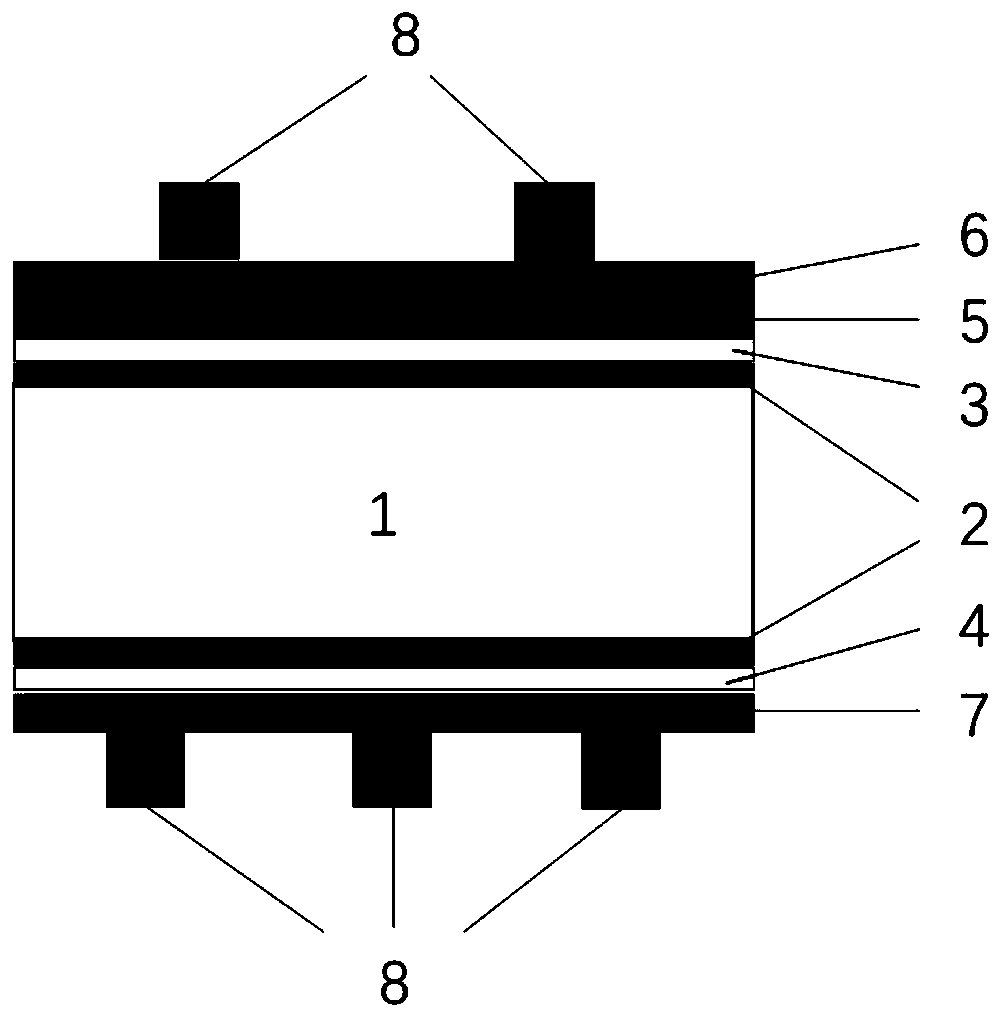

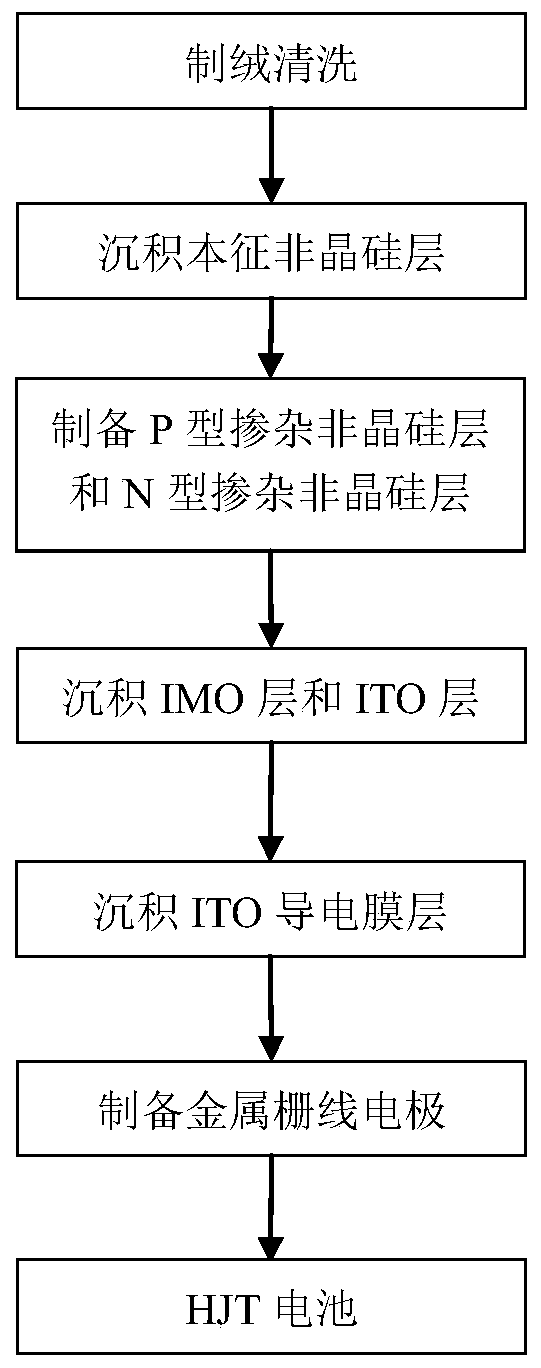

HJT battery and preparation method thereof

InactiveCN110416328ARaise the built-in potentialImprove performanceFinal product manufacturePhotovoltaic energy generationHeterojunctionLow volume

The invention discloses an HJT battery and a preparation method thereof. The battery comprises an N-type silicon wafer, wherein intrinsic noncrystalline silicon layers are arranged on the illuminatedface and shady face of the N-type silicon wafer respectively; a P-type doped noncrystalline silicon layer and an N-type doped noncrystalline silicon layer are arranged on the intrinsic noncrystallinesilicon layers respectively; an IMO layer and an ITO layer are arranged on the P-type doped noncrystalline silicon layer in sequence; an ITO conducting film layer is arranged on the N-type doped noncrystalline silicon layer; and metal gate electrodes are arranged on the ITO layer and the ITO conducting film layer respectively. The preparation method comprises the following steps: carrying out texturing cleaning on the N-type silicon wafer; and carrying out deposition / preparation of the intrinsic noncrystalline silicon layers, the P-type doped noncrystalline silicon layer, the N-type doped noncrystalline silicon layer, the IMO layer, the ITO layer, the ITO conducting film layer and the metal gate electrodes. The HJT battery has excellent electrochemical performance, and has extremely important meanings for improving the application range of heterojunction batteries, and the preparation method has the advantages of simple technology, low volume production threshold, low preparation cost,high production efficiency and the like.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Method for preparing long-wave infrared antireflective protective film

ActiveCN108149210AHigh infrared transmittanceImprove accuracyVacuum evaporation coatingSputtering coatingTectorial membraneOptical property

The invention provides a method for preparing a long-wave infrared antireflective protective film, and relates to a method for preparing for an antireflective protective film. The problems to be solved are that an existing infrared detection system window material antireflective protective film has the serious performance degradation during the service process, so that the optical properties of athin film are decreased; or due to the poor adhesion between the antireflective protective film and a substrate, a transition layer need deposit, and the complexity of technology is increased; and orthe hardness of the antireflective protective film is lower. The method includes the steps of firstly, cleaning of a target and a window; secondly, preparatory work before coating; thirdly, preparation of Gd2O3 thin films by a reactive sputtering mode; fourthly, finish and shutdown; and fifthly, double-sided coating. The method for preparing the long-wave infrared antireflective protective film isfinished. The method is used for preparing the long-wave infrared antireflective protective film.

Owner:HARBIN INST OF TECH

Infrared window protective film material, use thereof and preparation method thereof

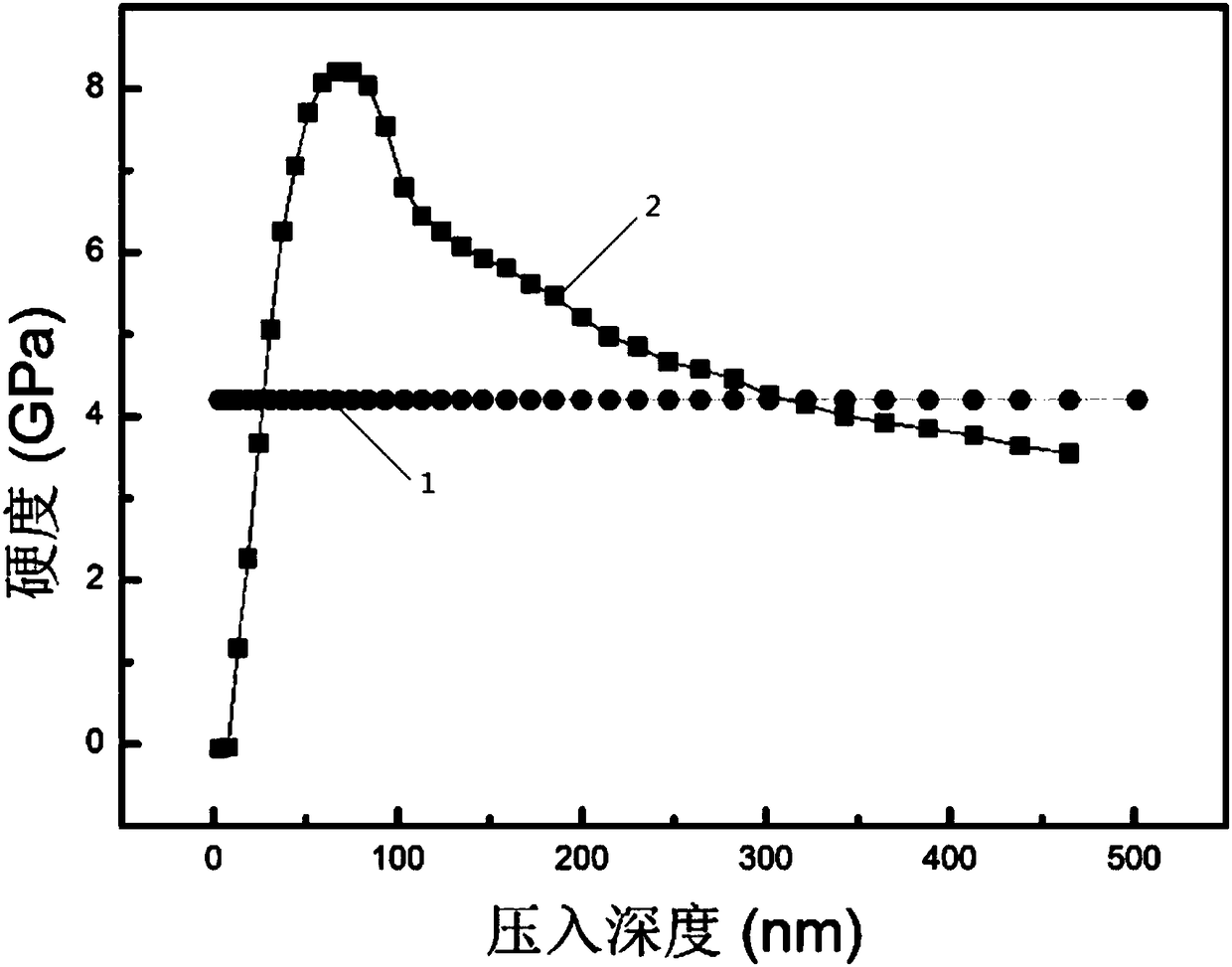

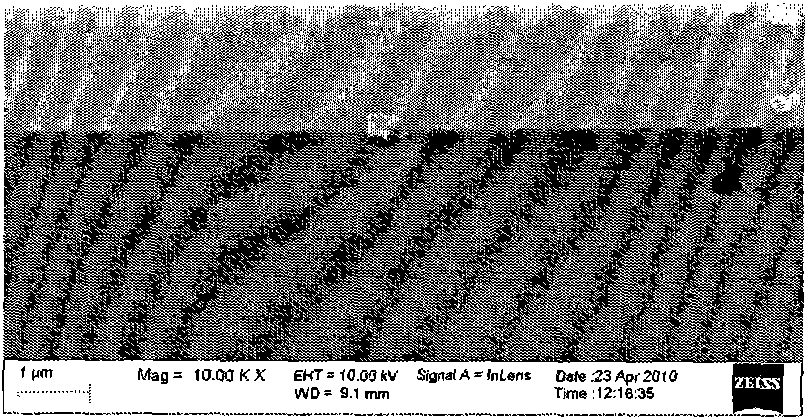

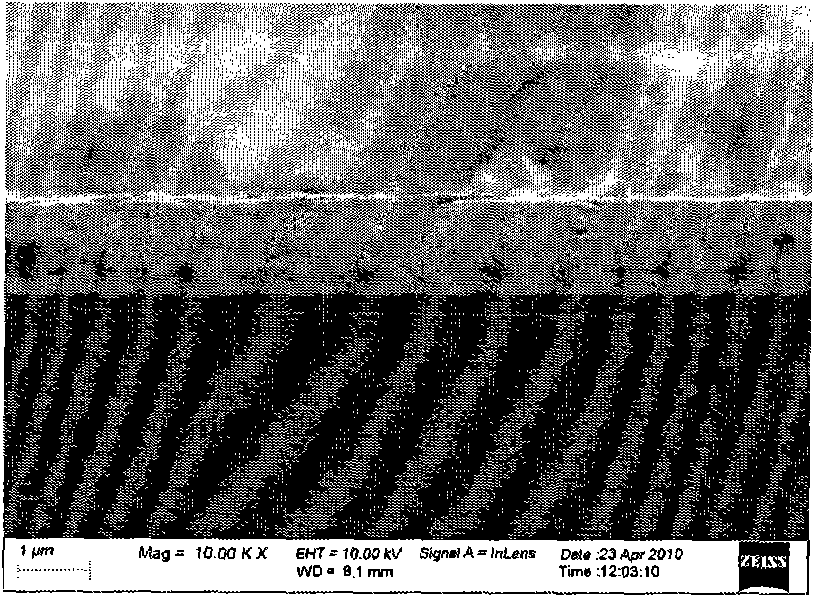

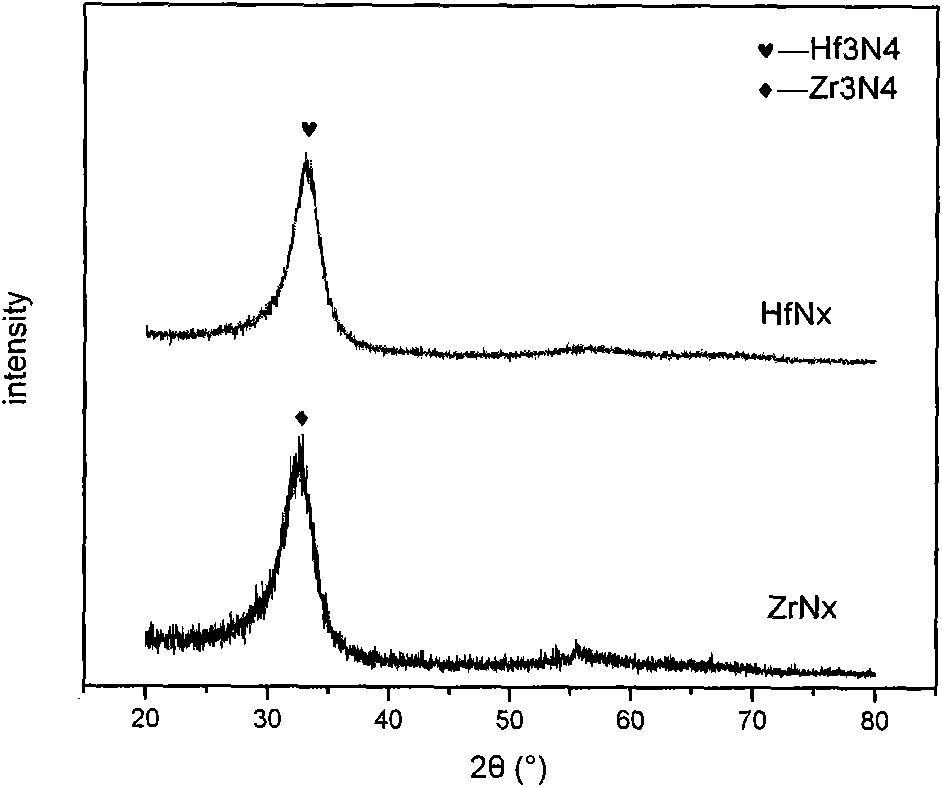

InactiveCN101887134AGood performanceGood application prospectVacuum evaporation coatingSputtering coatingInfrared windowFilm material

The invention belongs to the technical field of infrared optical thin films and particularly relates to novel transitional metal Zr and Hf nitride optical thin films, use thereof and a preparation method thereof. The infrared window protective film material consists of transitional metal Zr and Hf nitrides and can be expressed as (Zr, Hf)Nx, wherein x represents the nitrogen content; and the value of the x ranges from 1.0 to 1.5. The material is particularly suitable to be used for manufacturing far-infrared band ZnS and ZnSe infrared window protective films which have high transmissivity, high hardness and low internal stress. The films can be made by various methods such as physical gas-phase deposition or chemical gas-phase deposition and have a promising prospect.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of zinc selenide with high optical quality

ActiveCN101759161BSolve build problemsHigh infrared transmittanceBinary selenium/tellurium compoundsPhysical chemistryChemical vapor deposition

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

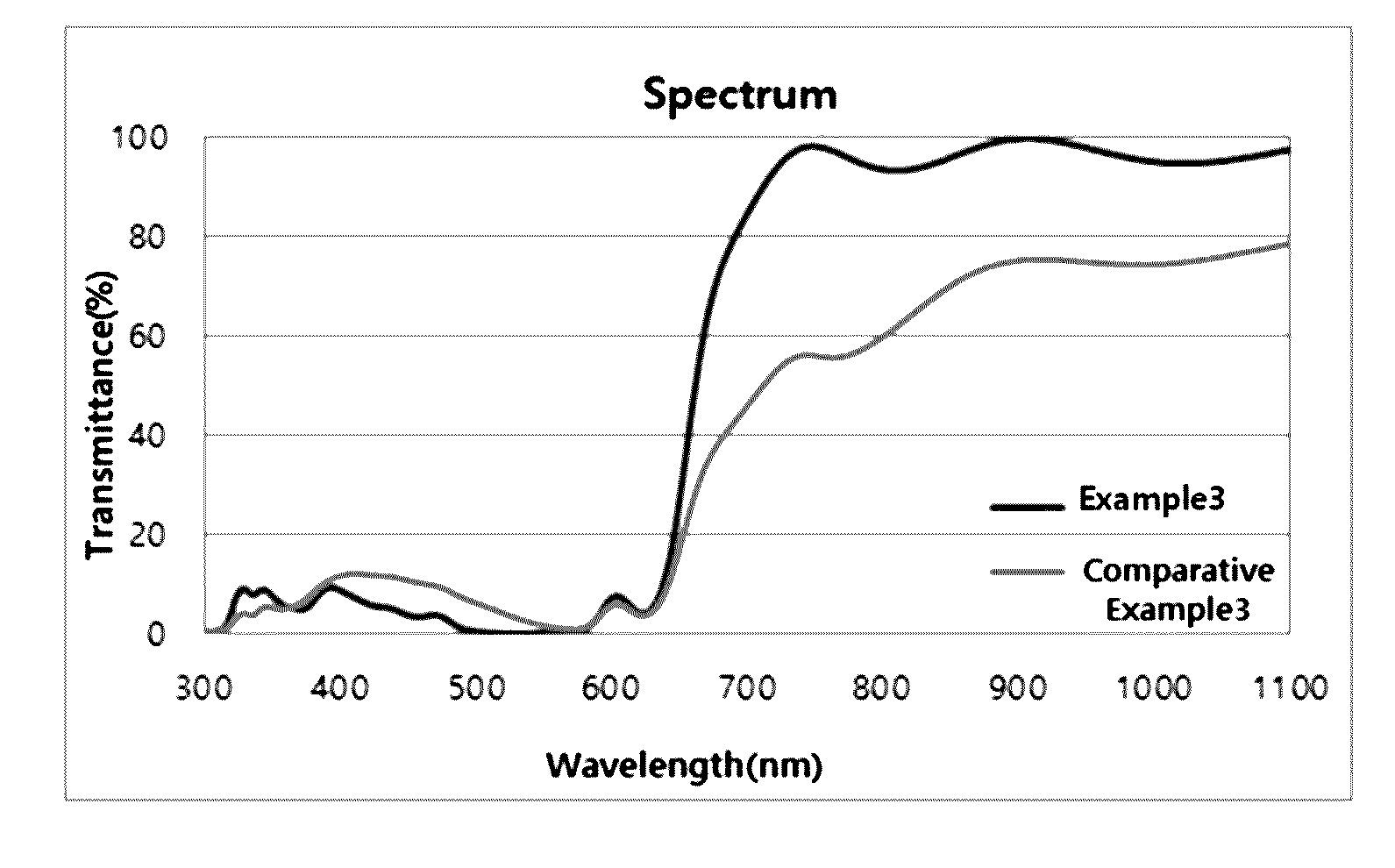

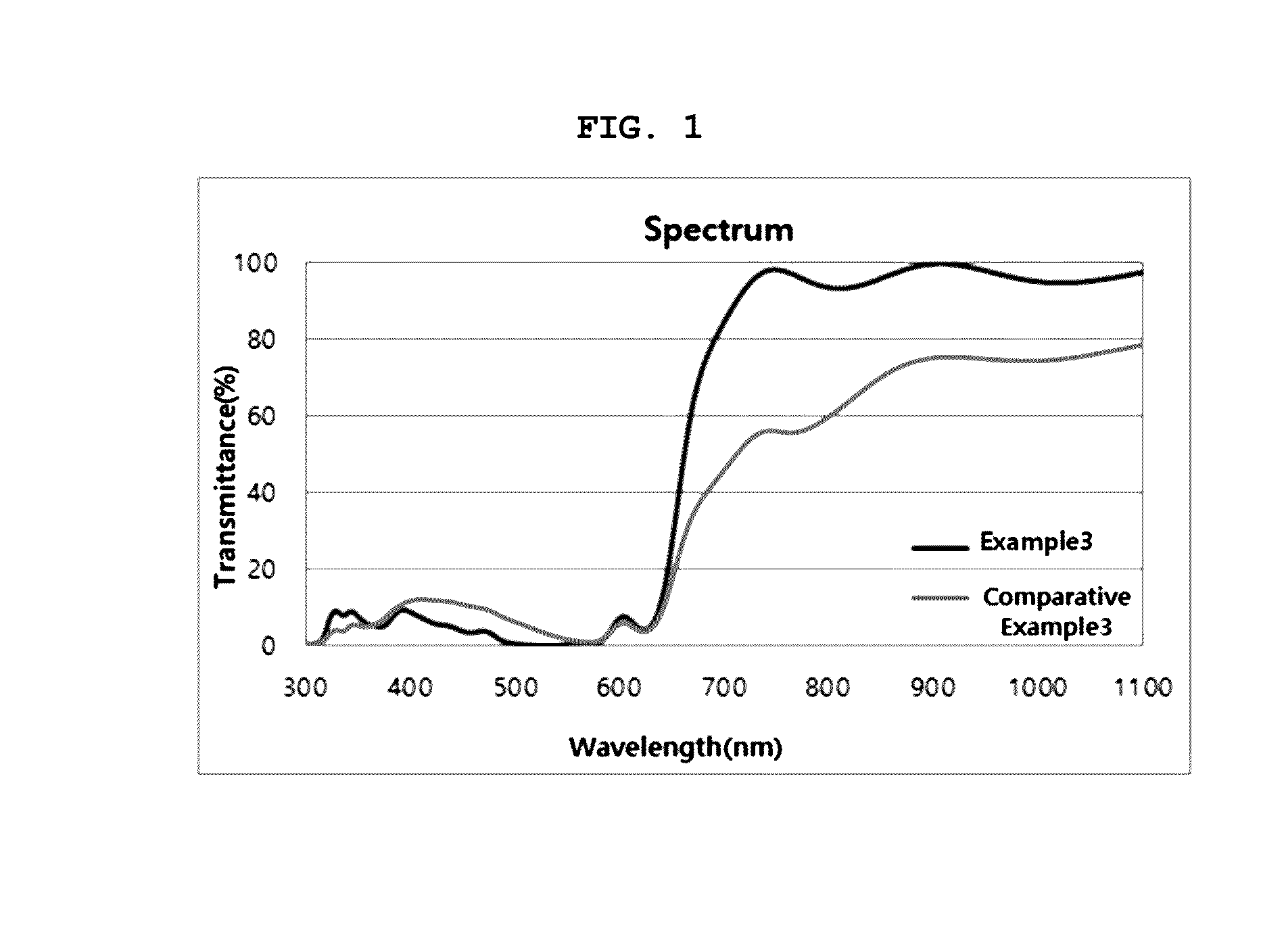

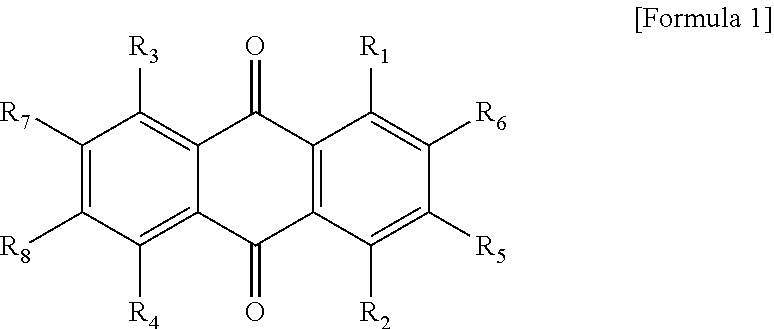

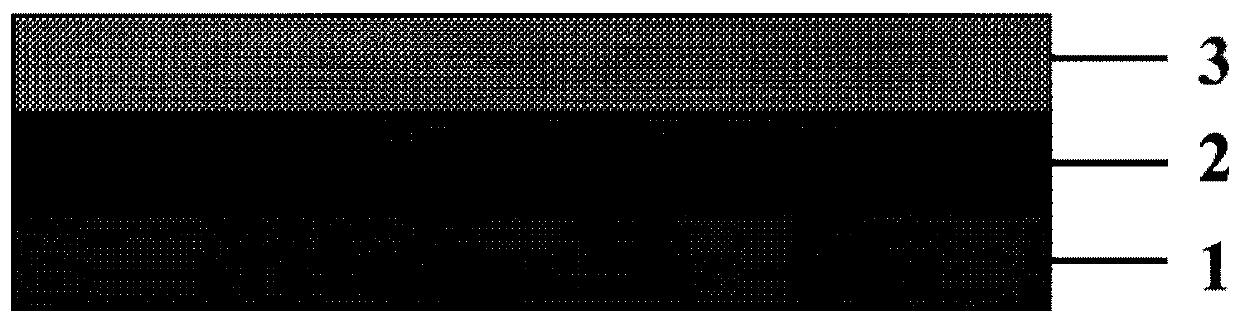

Infrared transmission photosensitive resin composition

ActiveUS20160282716A1Improve image qualityHigh infrared transmittanceOptical filtersPhotomechanical apparatusImaging qualityPhotopigment

An infrared transmission photosensitive resin composition includes (A) a pigment dispersion composition including a coloring agent (a1); (B) an alkaline soluble resin; (C) a photo-polymerizable compound; (D) a photo-polymerization initiator; and (E) a solvent, wherein the coloring agent (a1) includes a blue pigment, a red pigment and a yellow pigment. Thereby, the infrared transmission photosensitive resin composition may form an infrared transmission pixel which exhibits a high transmittance in an infrared region while having a very low transmittance in a visible light region, so as to be used in an image sensor for obtaining an image having excellent image quality at a place where the quantity of light is insufficient.

Owner:DONGWOO FINE CHEM CO LTD

Infrared transparent conductive film, and preparation method and application thereof

InactiveCN109872835AImprove photoelectric performanceHigh hardnessConductive layers on insulating-supportsOxide conductorsIndiumTransmittance

The invention relates to an infrared transparent conductive film, and a preparation method and an application thereof. The infrared transparent conductive film comprises a substrate and a seed layer and a conductive layer sequentially arranged on the substrate; the seed layer is made from material of a square iron ferromanganese ore cubic crystal structure; the conductive layer is an indium oxide-doped IIIB compound. According to the infrared transparent conductive film, and the preparation method and the application thereof, the material of the square iron ferromanganese ore cubic crystal structure is used as the seed layer, the indium oxide-doped IIIB compound is used as the conductive layer, the crystal structure of the seed layer is the same as that of indium oxide, so that the acquired infrared transparent conductive film has the good photoelectric property, compared with the prior art adopting the metal mesh and the ITO film mesh, the infrared transparent conductive film has theadvantages of high film hardness, strong adhesive force and high infrared transmittance.

Owner:SHENZHEN PLANCK INNOVATION TECH CO LTD

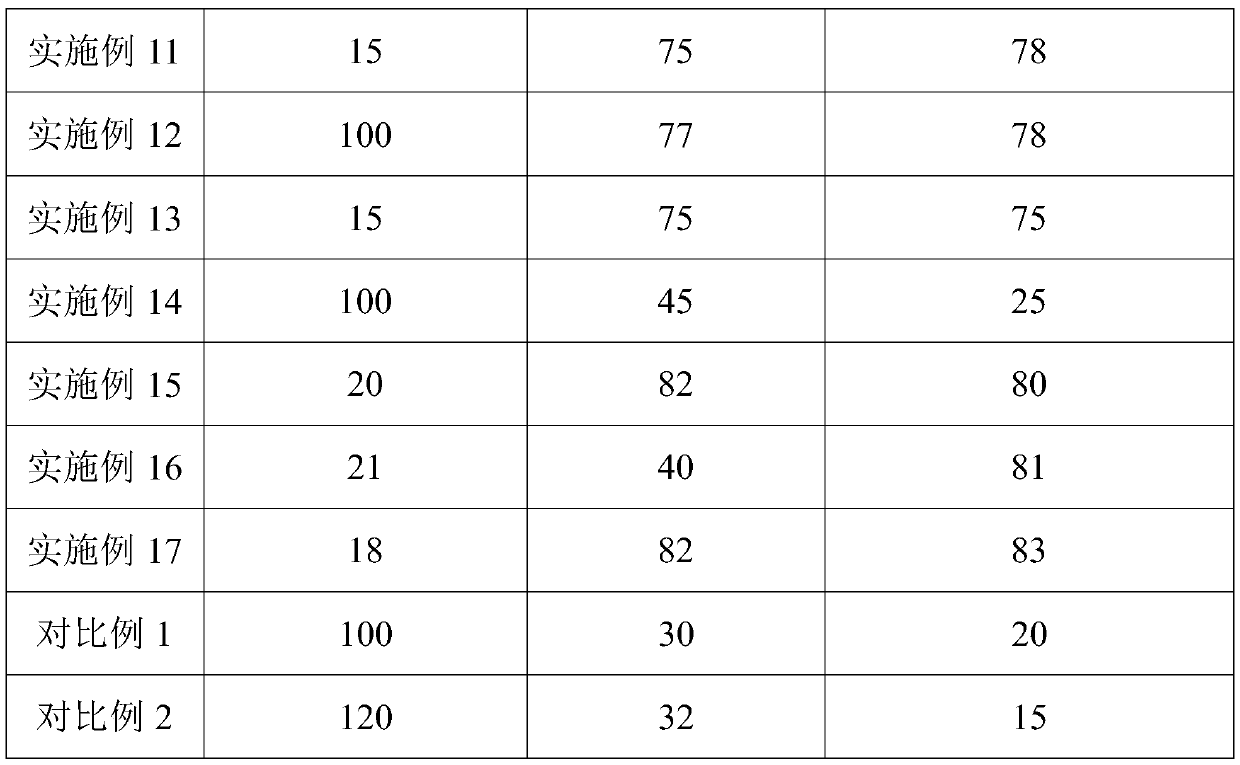

Intelligent B-pillar trim panel assembly of automobile and identity recognition method

PendingCN112061078AAccurate identificationIncrease coverageAnti-theft devicesAcquiring/recognising eyesIdentity recognitionStructural engineering

The invention discloses an intelligent B-pillar trim panel assembly of an automobile and an identity recognition method. The intelligent B-pillar trim panel assembly comprises an infrared recognitionmodule, a base, a trim panel body which is used for being connected with a B pillar and has high infrared transmittance, and a hidden layer which is matched with the trim panel body and has high infrared transmittance; the hidden layer and the base are sequentially arranged on one side of the trim panel body so that the hidden layer can cover the base; and the infrared recognition module is arranged on the side, facing the trim panel body, of the base and electrically connected with a BCM of the automobile. According to the intelligent B-pillar trim panel assembly of the automobile and the identity recognition method, the appearance integration of the B-pillar trim panel assembly of the automobile is achieved, and the B-pillar trim panel assembly has functionality.

Owner:FUYAO GLASS IND GROUP CO LTD

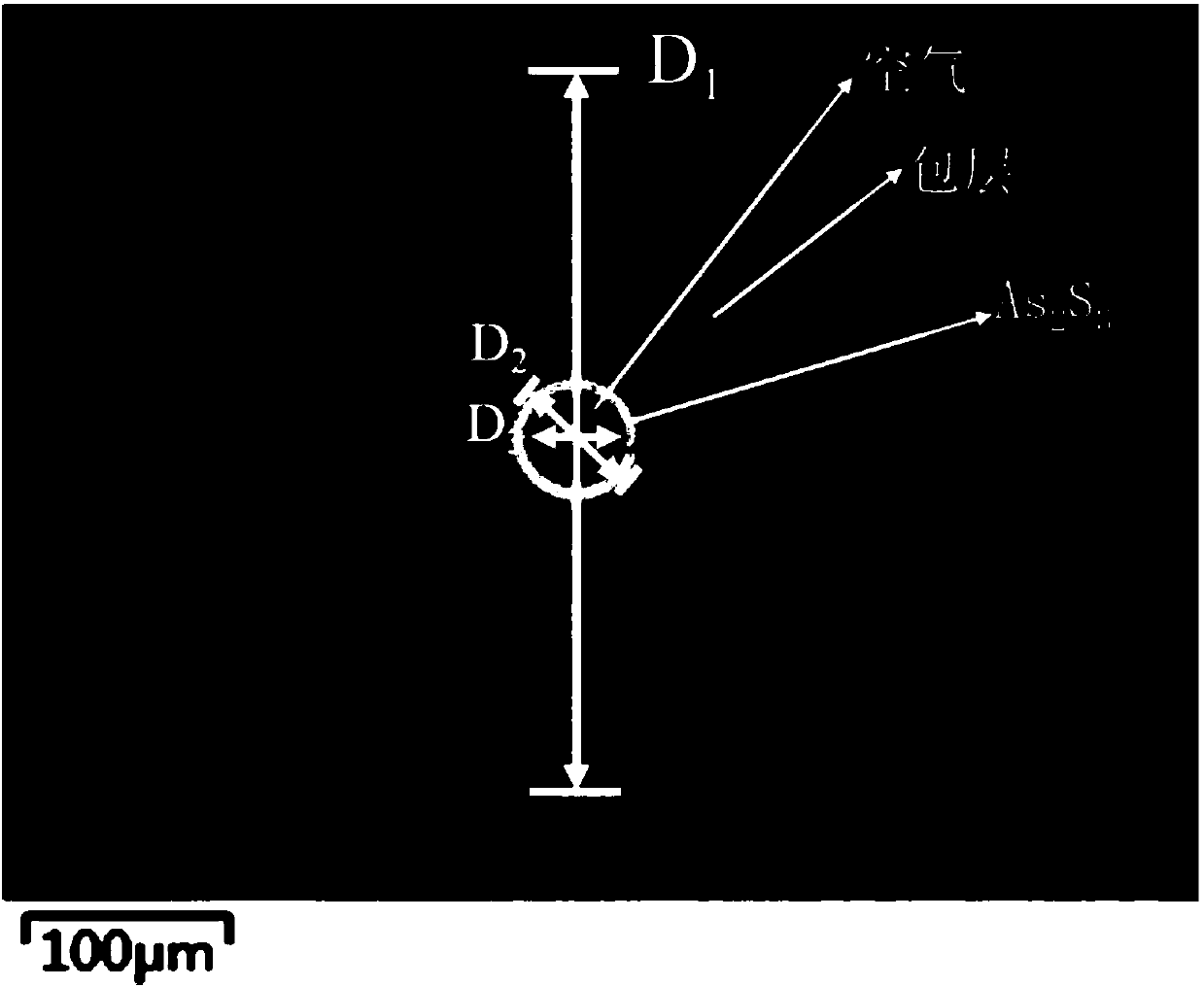

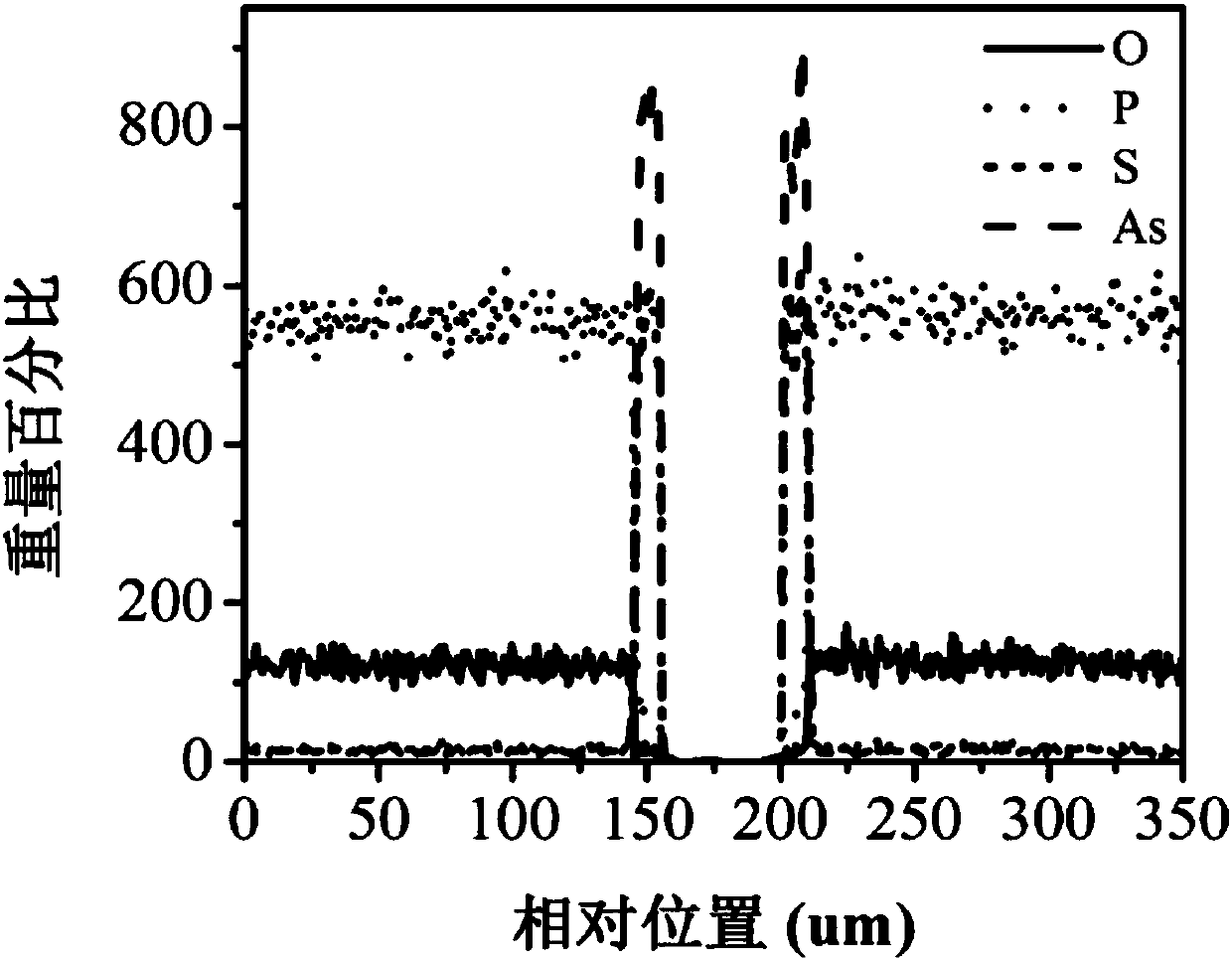

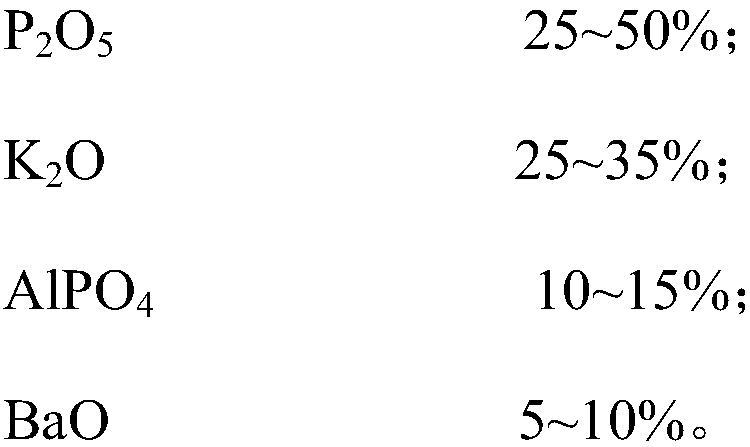

Hollow-core composite glass optical fiber and preparation method thereof

ActiveCN107894629AHigh infrared transmittanceHigh nonlinear coefficientGlass making apparatusOptical light guidesFiberRefractive index

The invention discloses a hollow-core composite glass optical fiber and a preparation method thereof. The cladding of the hollow-core composite glass optical fiber is phosphate glass. The fiber core is composed of a thin high-refractive-index sulfur-based semiconductor layer and a central air hole. The optical fiber consists sequentially from the outer layer to the inner layer of the phosphate glass cladding, the sulfur-based semiconductor layer and the air hole. The hollow-core composite glass optical fiber of the invention has the characteristics of being high in infrared transmittance, large in non-linear coefficient, large in photoconductivity, capable of producing a mid-infrared supercontinuum, and low in loss in the mid- and far-infrared, and stably supports vortex optical transmission. The preparation method of the invention fully utilizes the wettability of the phosphate glass and the sulfur-based semiconductor fiber core material, and obtains the hollow-core composite glass optical fiber by hot-melting the sulfur-based semiconductor core material in the non-through hole in the phosphate glass under high temperature conditions to spontaneously form a ring-shaped fiber coreand, then, using a simple traditional drawing method.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of ZnS polycrystal

ActiveCN107747128AHigh infrared transmittanceLower requirementPolycrystalline material growthSingle crystal growth detailsHeating furnaceZinc sulfide

The invention provides a preparation method of a ZnS polycrystal. The preparation method comprises the following steps: putting zinc sulfide into a tubular heating furnace; after introducing hydrogensulfide for 20min to 30min, raising the temperature; after raising the temperature to first temperature of 500 DEG C to 600 DEG C, keeping heat for 2h to 4h; after raising the temperature to the firsttemperature, adjusting an introducing speed; then cooling to obtain pre-treated zinc sulfide, wherein the ratio of the mass of the zinc sulfide to the introducing starting speed of the hydrogen sulfide to the adjusted introducing speed of the hydrogen sulfide is (0.0001kg to 15kg) to (1.5L / min to 2.3L / min) to (0.5L / min to 1L / min); mixing the pre-treated zinc sulfide and Al2S3 according to the mass ratio of 100 to (0.3 to 0.8) to obtain a mixture; after pre-pressing the mixture to 50MPa to 55MPa, vacuumizing; after raising the vacuum degree to 4Pa to 10Pa and raising the temperature to secondtemprature of 800 DEG C to 1000 DEG C, keeping the heat for 6h to 8h; after raising the temperature to the second temprature for 3h to 5h, pressurizing to 70MPa to 90MPa; keeping the pressure until the temperature is 10 DEG C to 40 DEG C to obtain the ZnS polycrystal.

Owner:昆明先导新材料科技有限责任公司

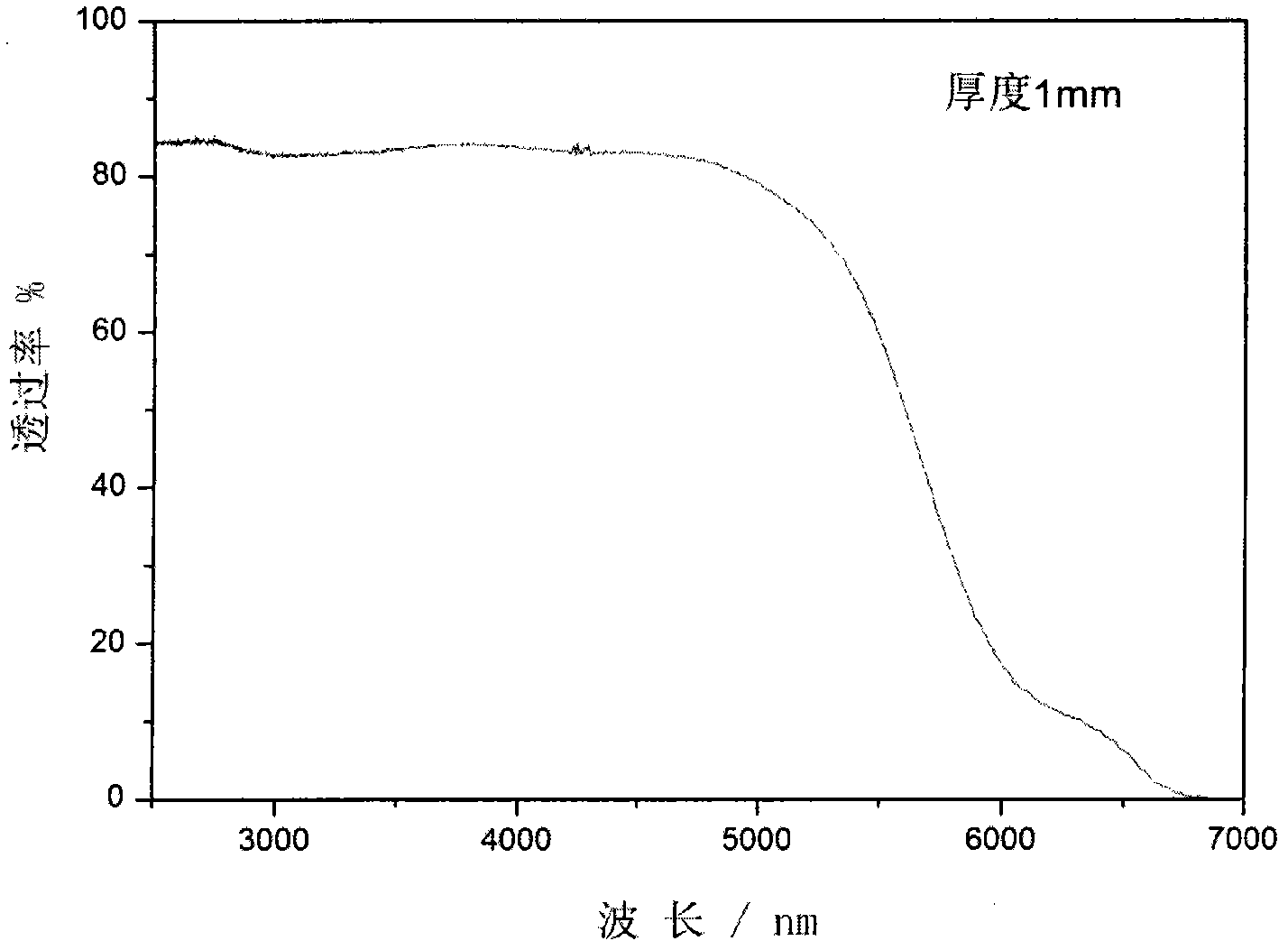

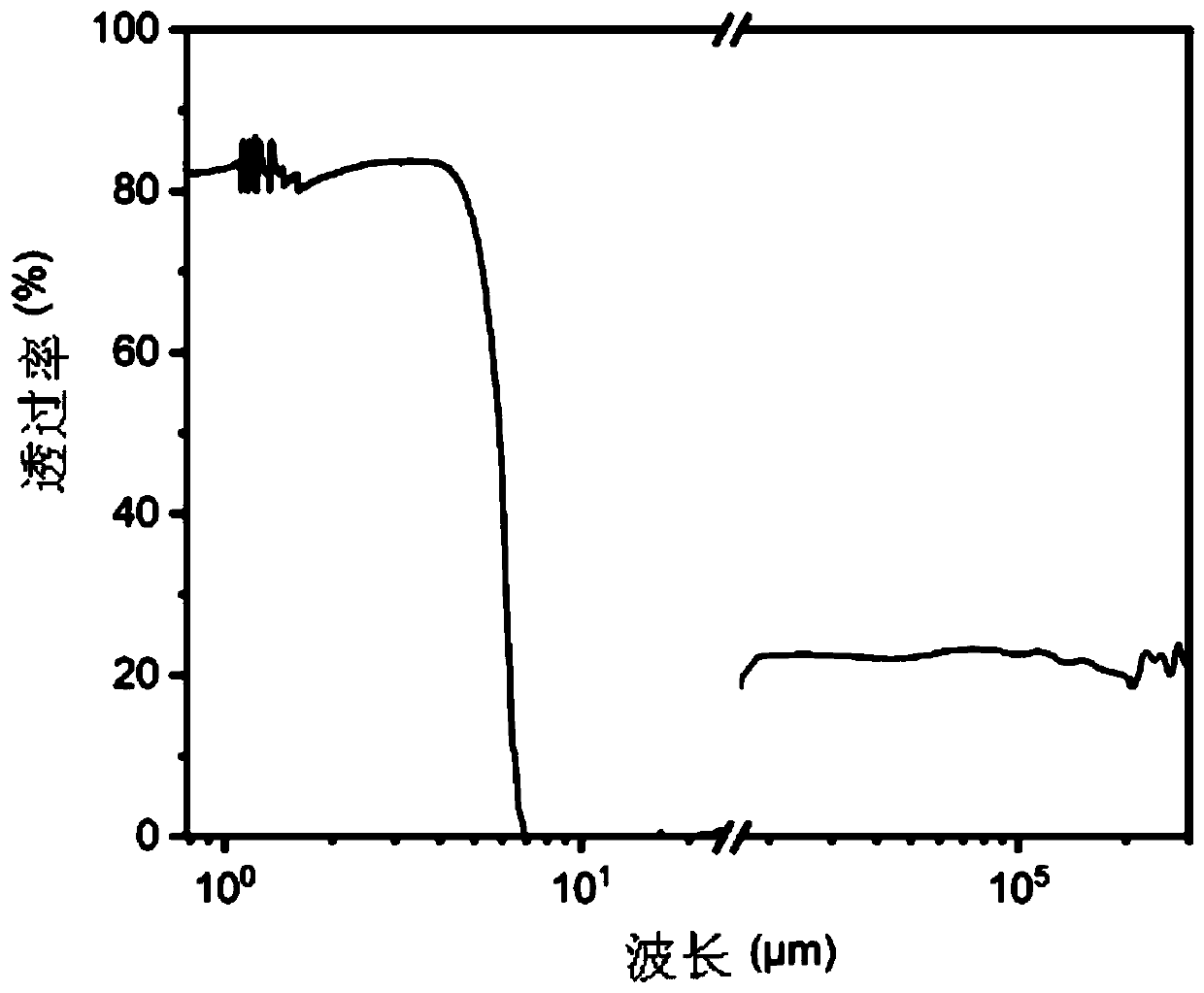

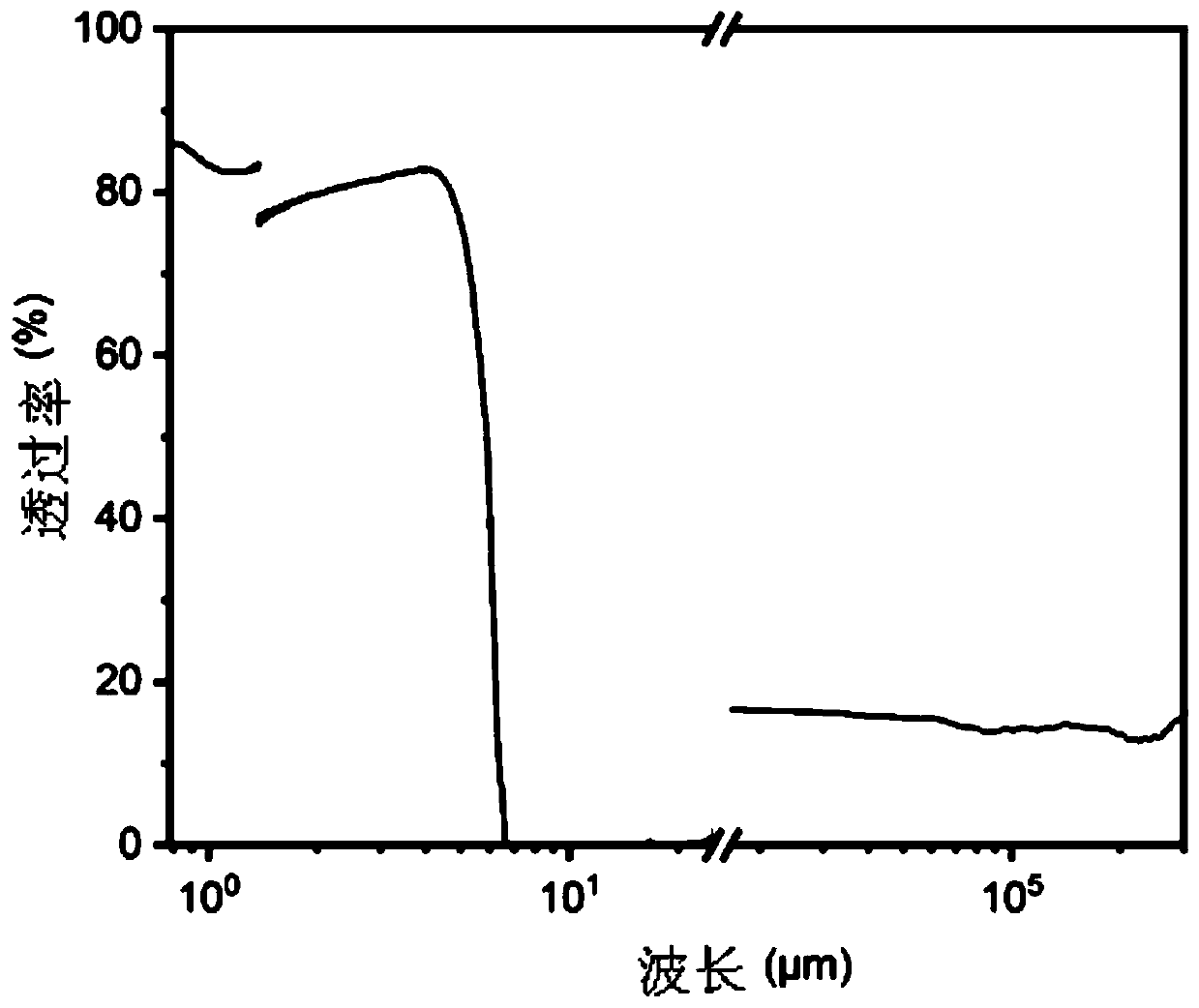

Infrared transmitting germanate glass and preparation method thereof

The invention relates to infrared transmitting germanate glass and a preparation method thereof, and belongs to the technical field of germanate glass. The invention mainly provides infrared transmitting germanate glass with excellent physiochemical performance and infrared transmitting performance and a preparation method thereof. The germanate glass comprises the following components of: 35 to 45 percent of GeO2, 15 to 30 percent of M2O3, 25 to 40 percent of M'O, 0 to 15 percent of M''O2 and 0 to 5 percent of La2O3, wherein M2O3 is Al2O3, Ga2O3 and the like; M'O is MgO, CaO, BaO and the like; and M''O2 is ZrO2, TiO2 and the like. The preparation method comprises the following steps of: a, weighing raw materials, and mixing uniformly in a ball-milling tank; b, melting in a platinum crucible; c, after melting, introducing dry gas on the surface of glass liquid to remove moisture in the glass liquid, and stirring, homogenizing and clarifying by using a platinum stirrer simultaneously; d, homogenizing and clarifying the liquid, and forming in a die; and e, annealing. The infrared transmitting germanate glass has the excellent physiochemical and infrared performance, the transformation temperature is between 650 and 750 DEG C, the infrared cut-off wavelength is more than 6 micrometers, the ultraviolet cut-off wavelength is less than 400 nanometers, and the vickers hardness is more than 650 kgf / mm<2>. The invention is mainly used for the infrared transmitting germanate glass and the preparation method thereof.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com