Intermediate infrared 2.7 mum luminous erbium ion-doped gallium germanium bismuthate glass

A technology of gallium bismuthate and erbium ions is applied in the field of ion-doped germanium gallium bismuthate glass to achieve the effects of high infrared transmittance and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

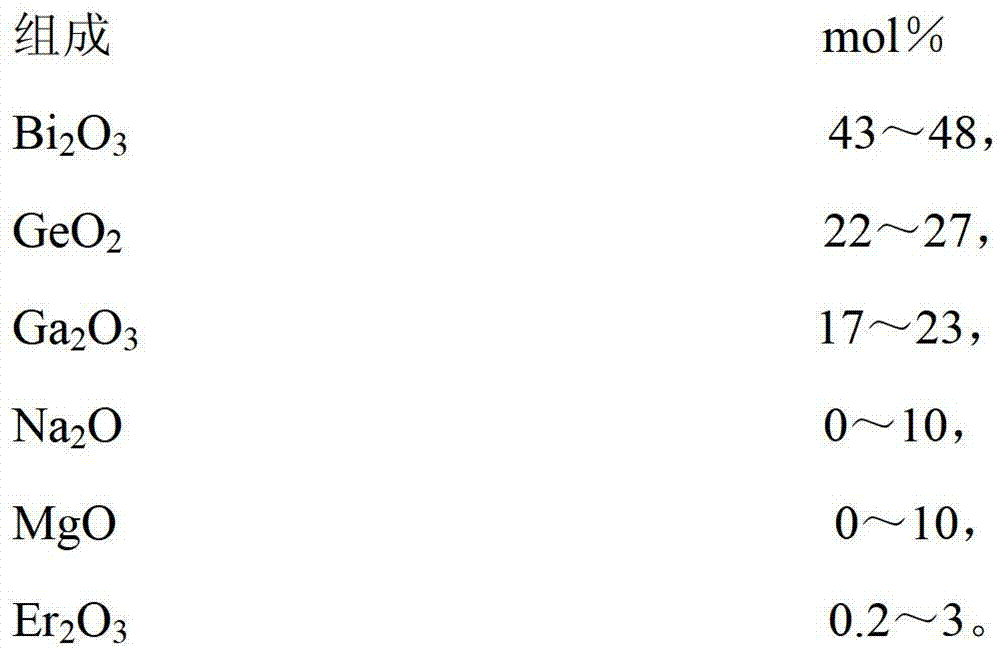

[0021] Composition as in Table 1 1 # As shown, the specific preparation process is as follows:

[0022] According to table 1 in 1 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and melt it into the completely melted glass after 15 minutes Oxygen is introduced into the liquid, and the temperature will reach 1150°C. Ventilate for 20 minutes, take out the oxygen tube, clarify for 15 minutes, pour the glass liquid into the preheated mold; quickly move the glass into the muffle furnace that has been heated to 420°C, Keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass sample after complete cooling.

[0023] The test results for this glass are as follows:

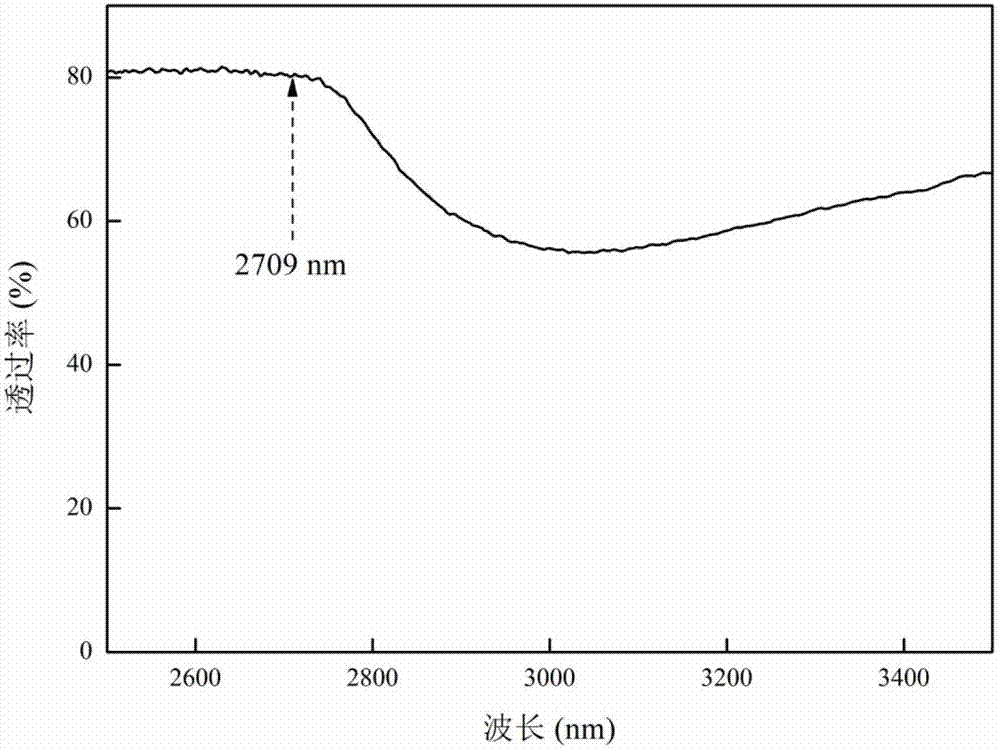

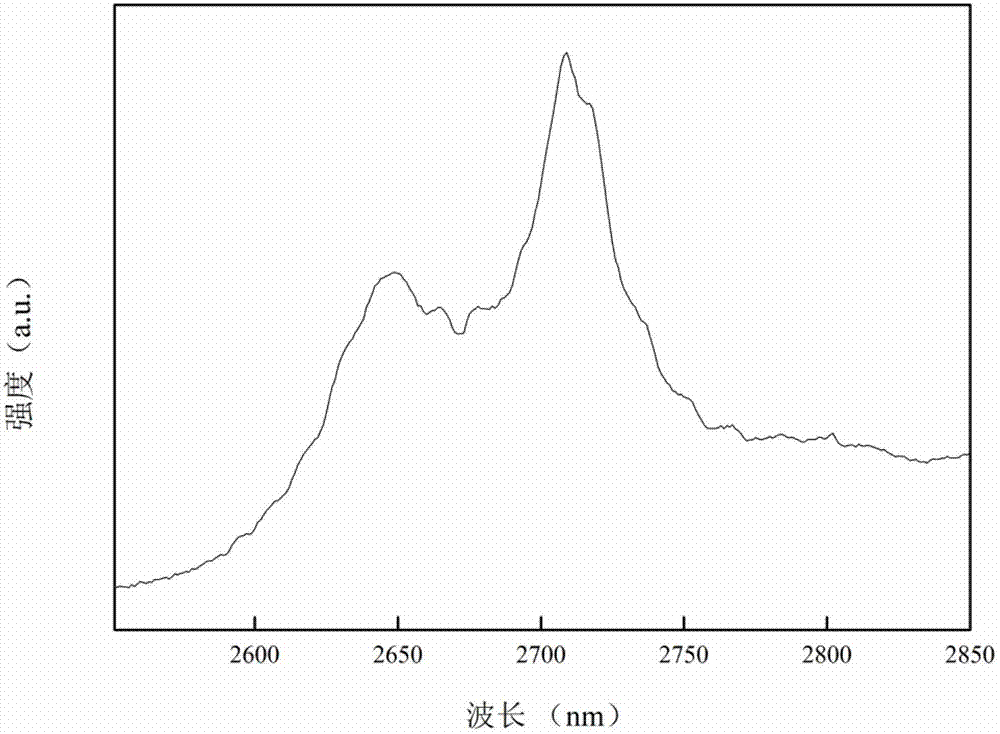

[0024] Process the annealed sample into a 20×10×1.0mm glass ...

Embodiment 2

[0026] Composition as in Table 1 2 # As shown, the specific preparation process is as follows:

[0027] According to table 1 in 2 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and melt it into the completely melted glass after 15 minutes Oxygen is introduced into the liquid, and the temperature will reach 1150°C. Ventilate for 20 minutes, take out the oxygen tube, clarify for 15 minutes, pour the glass liquid into the preheated mold; quickly move the glass into the muffle furnace that has been heated to 420°C, Keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass sample after complete cooling.

[0028] The test results for this glass are as follows:

[0029] Process the annealed sample into a 20×10×1.0mm glass ...

Embodiment 3

[0031] Composition as in Table 1 3 # As shown, the specific preparation process is as follows:

[0032] According to table 1 in 3 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh the raw materials and mix them uniformly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace at 1200 ° C, and melt it into the completely melted glass after 15 minutes Oxygen is introduced into the liquid, and the temperature will reach 1150°C. Ventilate for 20 minutes, take out the oxygen tube, clarify for 15 minutes, pour the glass liquid into the preheated mold; quickly move the glass into the muffle furnace that has been heated to 420°C, Keep it warm for 10 hours, then lower it to room temperature at a rate of 10°C / hour, and take out the glass sample after complete cooling.

[0033] The test results for this glass are as follows:

[0034] Process the annealed sample into a 20×10×1.0mm glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com