Patents

Literature

137 results about "Bismuthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuthate is an ion. Its chemical formula is BiO₃⁻. It has bismuth in its +5 oxidation state. It is a very strong oxidizing agent. It reacts with hot water to make bismuth(III) oxide and oxygen. It also reacts with acids. Sodium bismuthate is the most common bismuthate. It is one of the few sodium compounds that does not dissolve in water.

Compositions for control of drug abuse

InactiveUS20130295170A1Challenge can be overcomePrevent degradationBiocidePowder deliveryBenzodiazepinePersulfate

Opiates, amphetamines, barbiturates and other drugs such as benzodiazepines are extensively abused or misused and are frequently the cause of death by overdosing. These drugs are also prone to oxidation and the final degradation products depend on the reactants and the reaction conditions. This invention describes the use of inactivating agents such as permanganates, peroxides, persulfates, bismuthates, periodates or other oxidants in a dosage form as an approach to minimize abuse and overdose. The product is designed such that the inactivating agent is released if there is an attempt to extract the drug from the formulation or in cases of overdose. Once released, the inactivating agent quickly degrades the drug and converts it into inactive compounds. Since the reactants (drug and inactivating agent) are incompatible in situations of normal drug usage, they are kept separated within the vehicle of the invention, but released for interaction in case of misuse. A catalyst may be included in the formulation to facilitate the reaction.

Owner:KYDES PHARMA

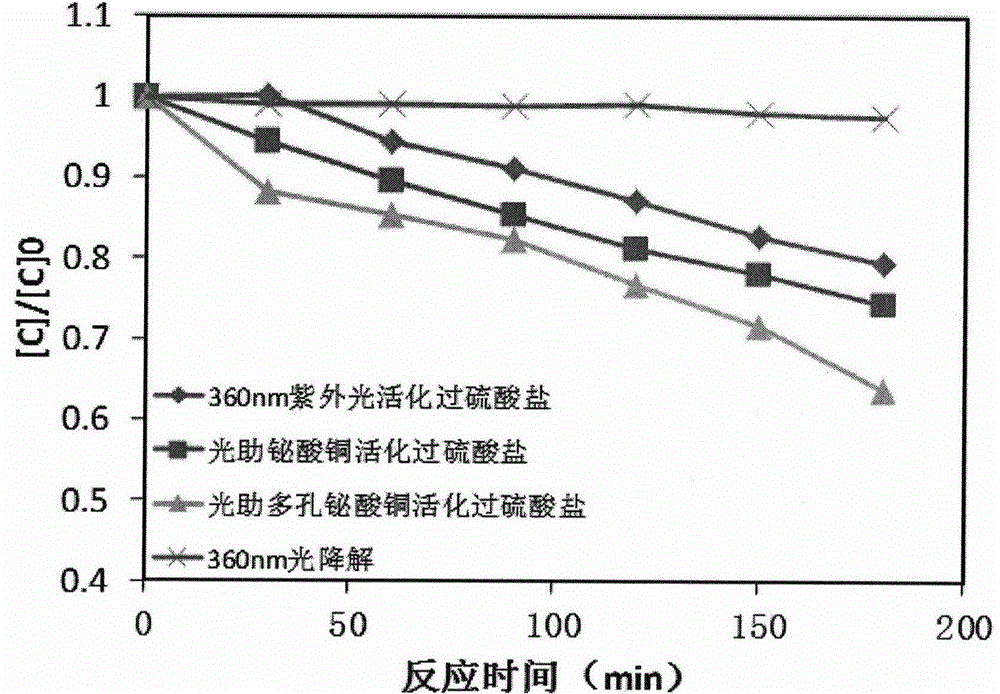

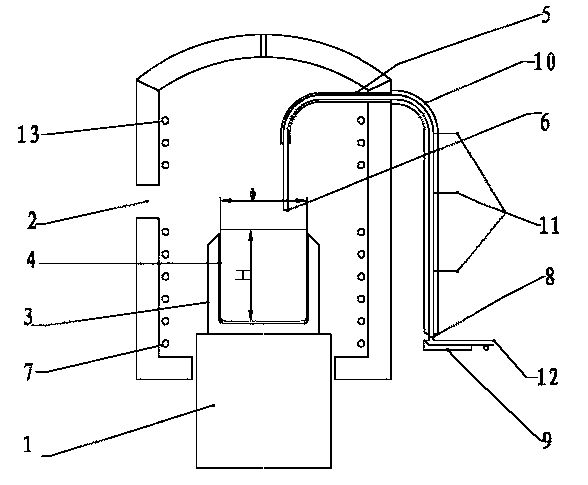

Construction and application method of photoassisted porous copper bismuthate activated persulfate water treatment high-grade oxidation technology

ActiveCN104909427AAchieve enhanced removalImprove efficiencyWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsCoumarin degradationWater quality

The invention provides a construction and application method of a photoassisted porous copper bismuthate activated persulfate water treatment high-grade oxidation technology, and belongs to the field of water treatment technologies and environmental functional materials. The shape of porous copper bismuthate can be powder or particles, and a porous copper bismuthate material with a high specific surface area is prepared by using bismuth nitrate, copper nitrate and polyvinylpyrrolidone as main materials, so the coumarin degradation ability of free radicals generated in the activation process of persulfate under photoassisted conditions is improved. The novel porous copper bismuthate is provided as a catalyst to solve the problem of poor coumarin removal effect of present routine sewage treatment, realizes successful application in a persulfate system, provides theoretic reference for coumarin compound removal technologies, and provides scientific basis and technical support for water safety and water environment improvement.

Owner:BEIJING FORESTRY UNIVERSITY

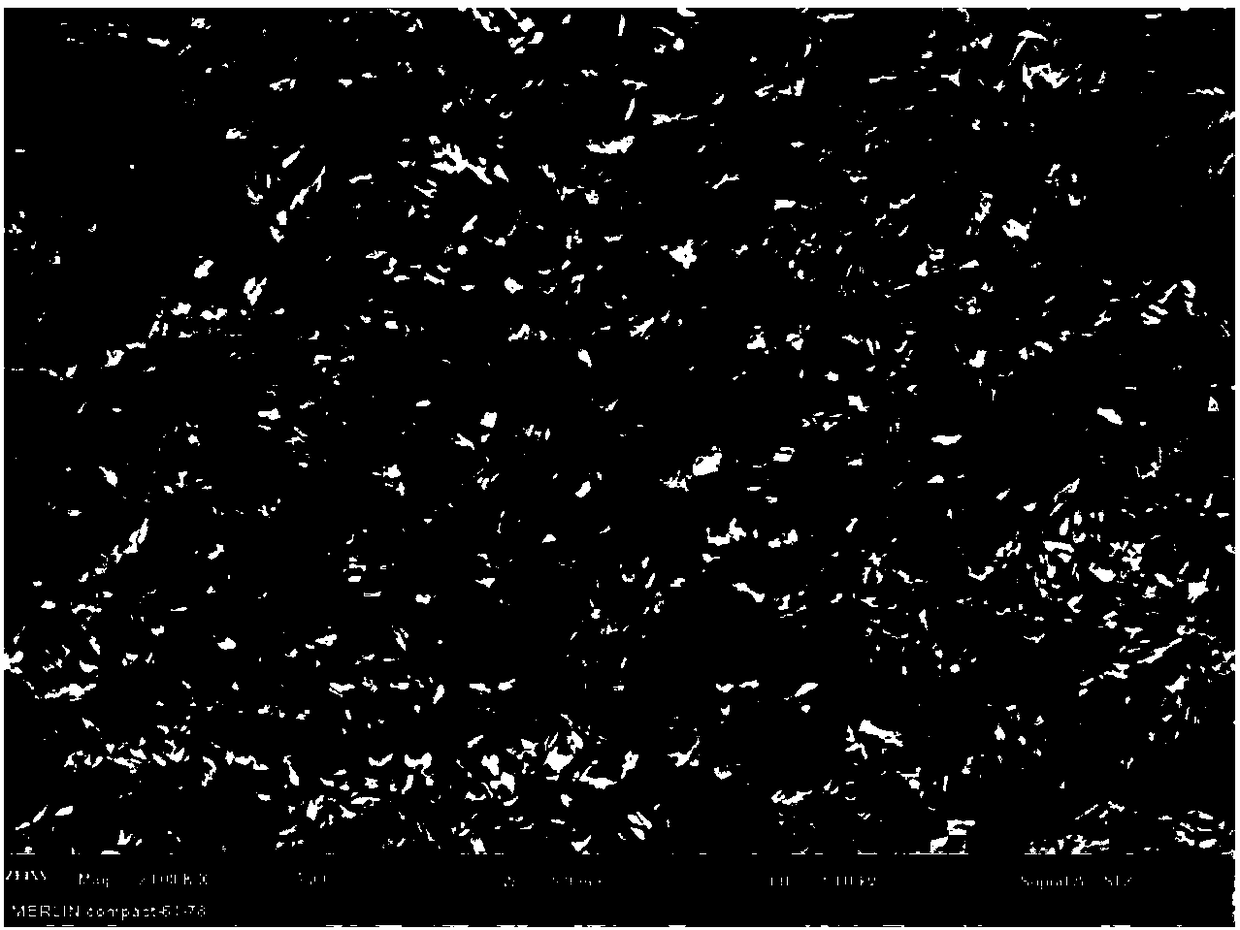

Preparation method and application of metal element doped BiOCl nanosheet material

ActiveCN108383160ASimple preparation processMild process conditionsNanotechnologyBismuth compoundsManufacturing technologyHigh energy

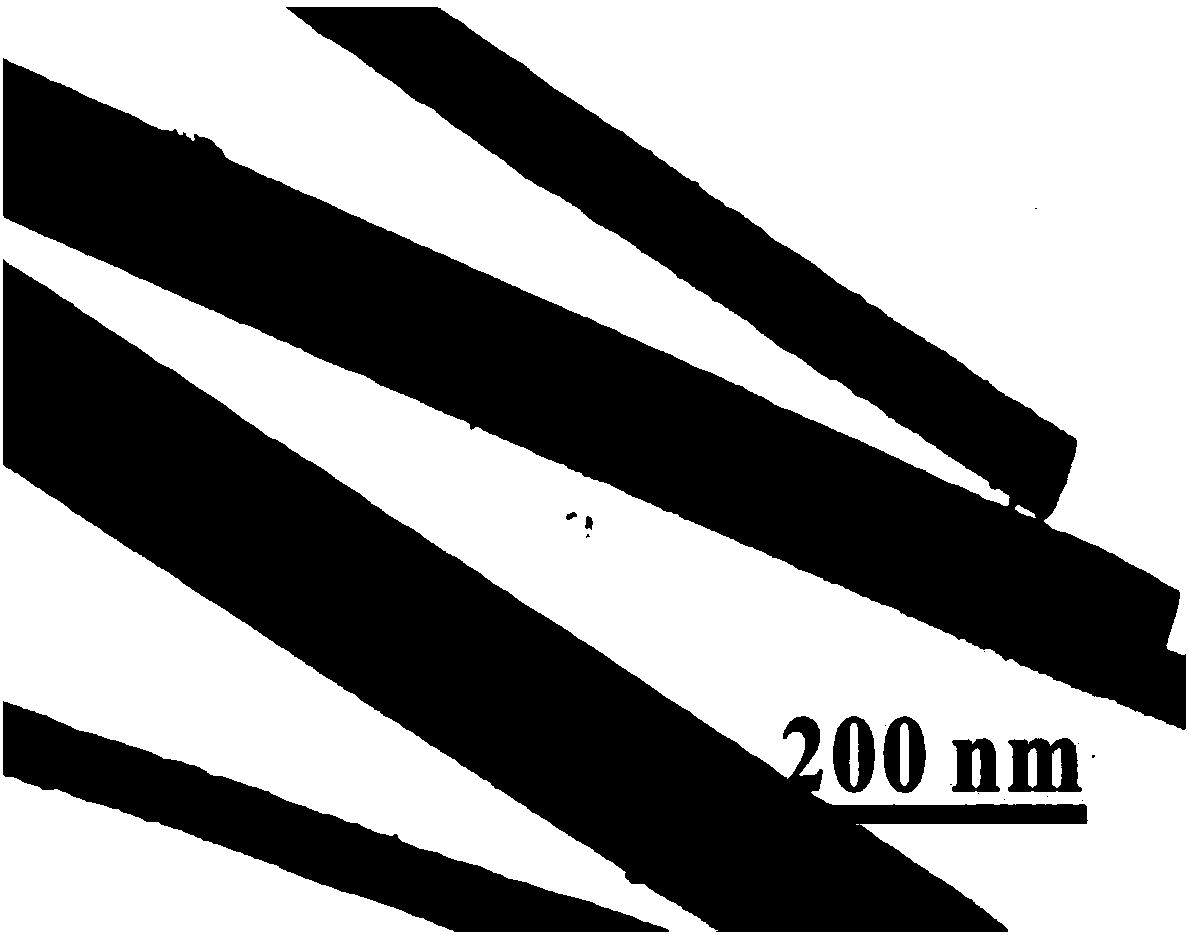

The invention relates to a preparation method and an application of a metal element doped BiOCl nanosheet material. The method comprises the steps of taking bismuthate, a doped source, a reducer, a chlorine source and an accessory ingredient as raw materials, synchronously applying a mechanical force of a high energy ball mill onto an oxidoreduction reaction, a doping reaction and a chlorination reaction, and performing heat treatment, washing, purification, solid-liquid separation and drying to form the metal element doped BiOCl nanosheet material. A mole ratio of a doped metal element to a bismuth element in the prepared material is (0.01-0.3):1; the material comprises a nanosheet that is 20-500 nm in planar size and 1-20 nm in thickness; the specific surface area of the material is 3-300 m<2> / g. The method is simple in technology, high in industrial production possibility, low in manufacturing technology cost and environmentally friendly; the prepared metal element doped BiOCl nanosheet material is widely applied to the fields of supercapacitors, alkaline secondary batteries, lithium ion batteries, photocatalysts, pearlescent pigments, medicines and the like.

Owner:XIANGTAN UNIV

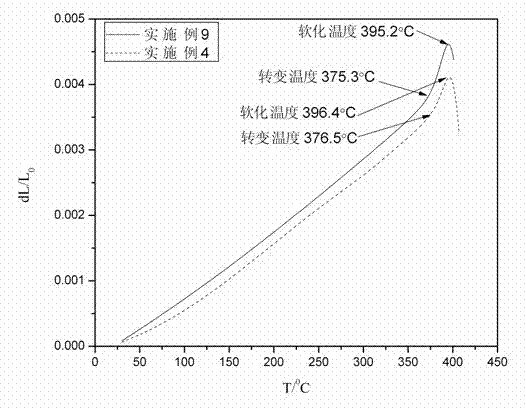

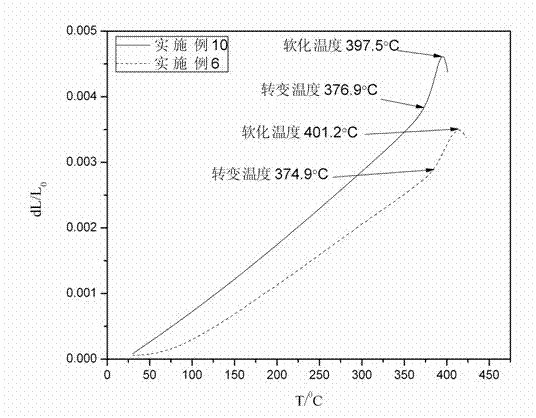

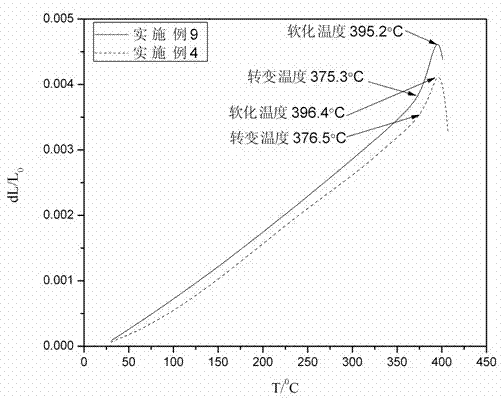

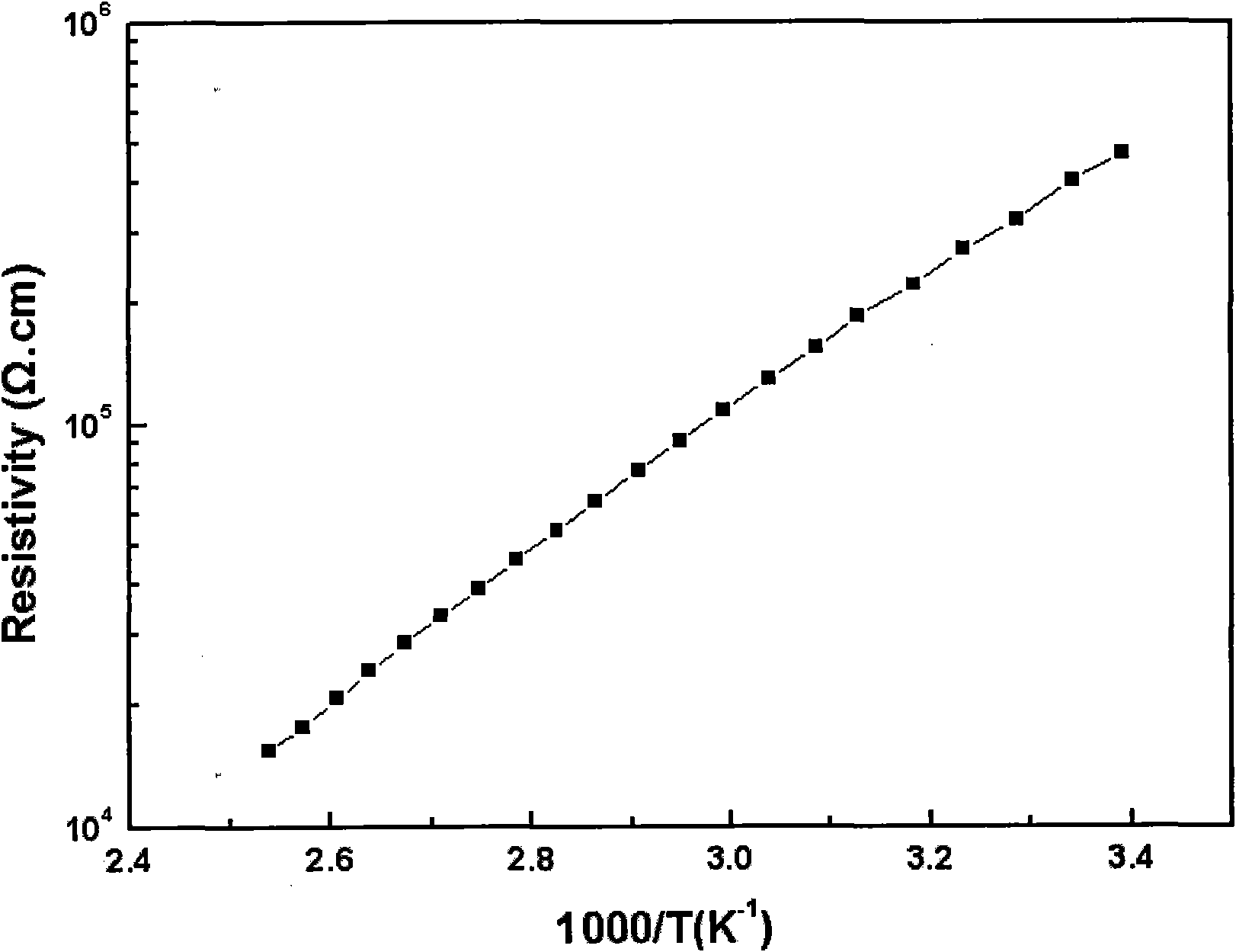

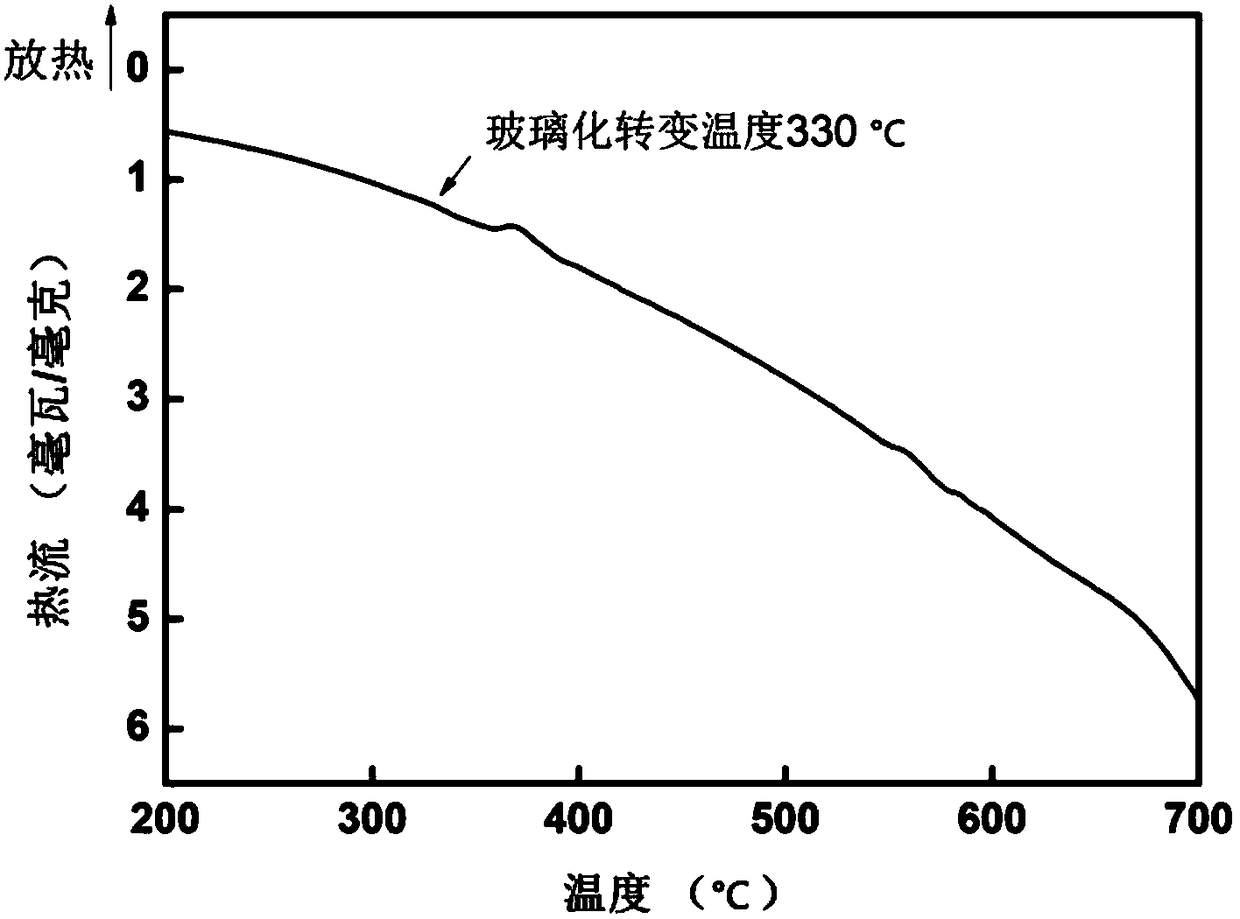

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

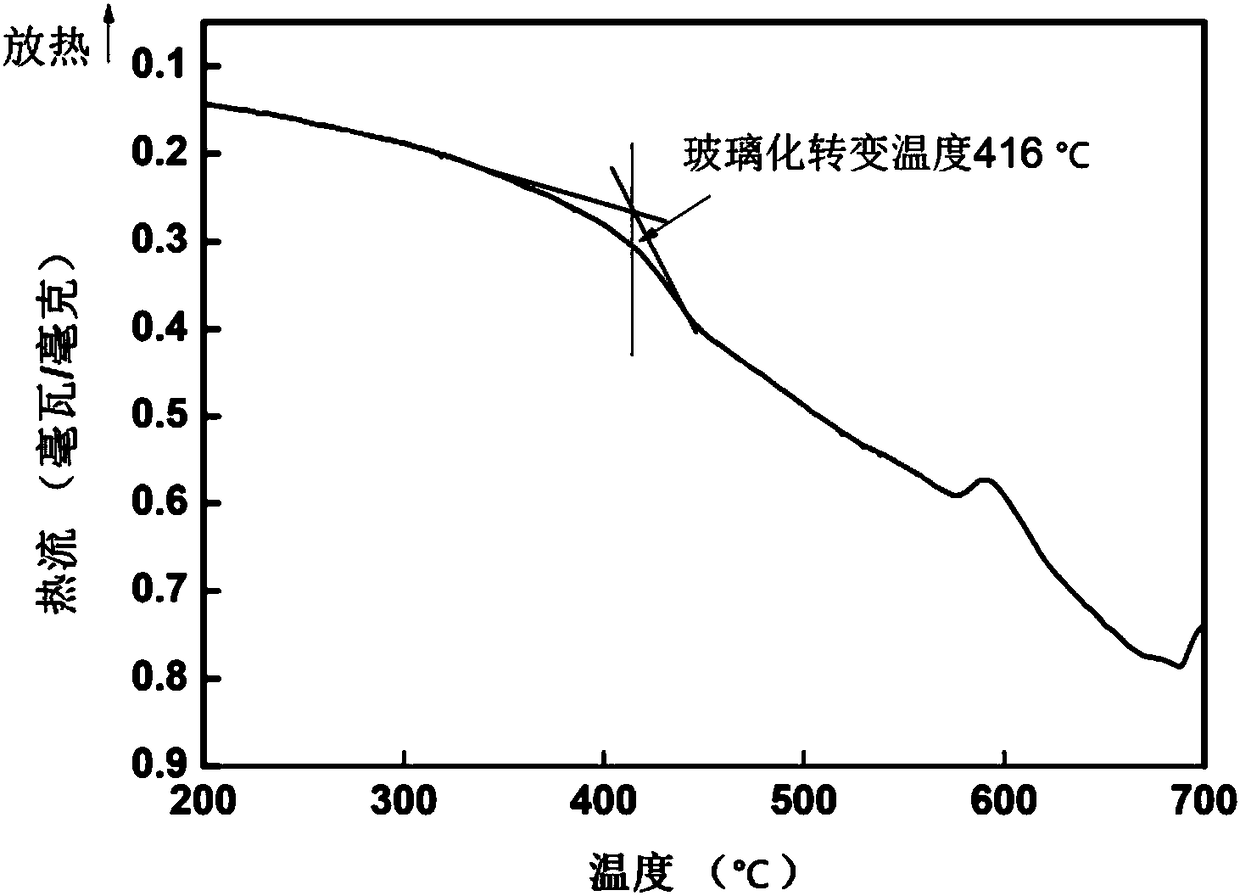

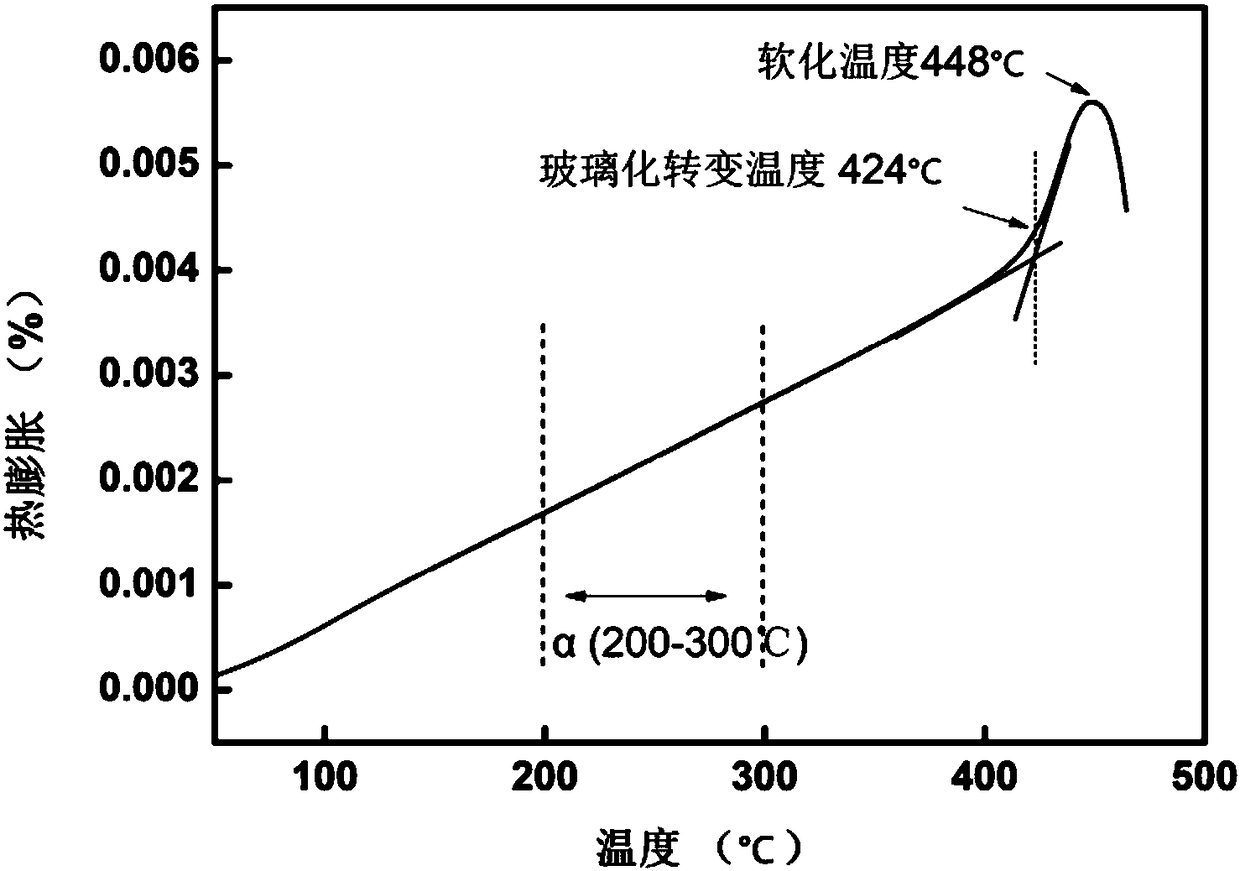

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Alumina ceramic low temperature brazing connection method

ActiveCN105418131ALow softening temperatureReduce residual internal stressThermal expansionSolder paste

The invention relates to an alumina ceramic low temperature brazing connection method and aims at solving the problems that existing brazing alumina ceramics are high in soldering temperature and low in connection strength of obtained joints. The brazing connection method comprises the following steps: 1, mixing Bi2O3, B2O3, ZnO and SiO2, and obtaining low-melting-point bismuthate glass powder; 2, conducting mechanical grinding on an alumina ceramic, conducting ultrasonic cleaning, and obtaining a pre-treated alumina ceramic; 3, preparing an alumina ceramic where aluminum borate whiskers grow; 4, applying glass soldering paste to the surface of the alumina ceramic where the aluminum borate whiskers grow; 5, making two alumina ceramic parts to be soldered be in contact and aligned with each other; 6, conducting brazing connection at the temperature of 480-650 DEG C. By means of the alumina ceramic low temperature brazing connection method, connection of the alumina ceramic is achieved at the low temperature, the thermal expansion coefficient of the adopted glass brazing material is matched with the alumina ceramic, the shearing strength of an obtained soldered joint can reach 60-100 MPa, and reliability of alumina connection is guaranteed.

Owner:HARBIN INST OF TECH

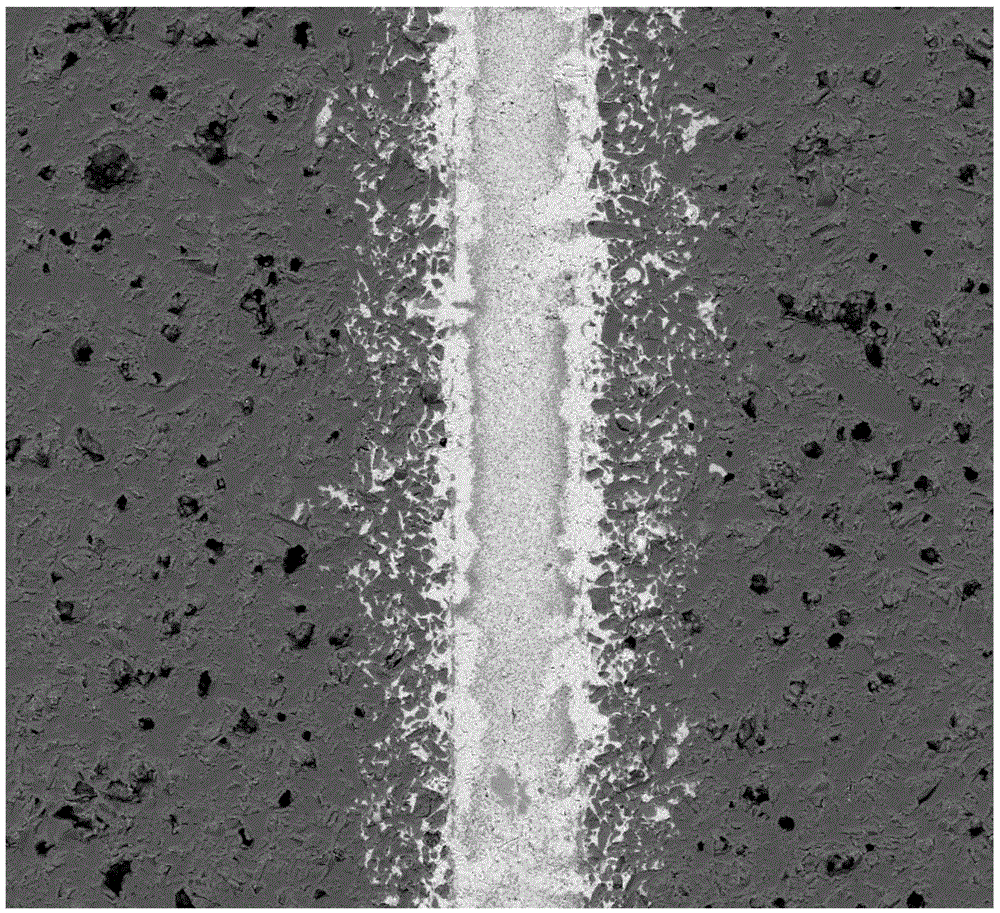

Thick film thermistor slurry, preparation method thereof and thick film thermistor

InactiveCN101826377AGood NTC characteristicsLow melting pointNegative temperature coefficient thermistorsNon-conductive material with dispersed conductive materialAdhesiveRare earth

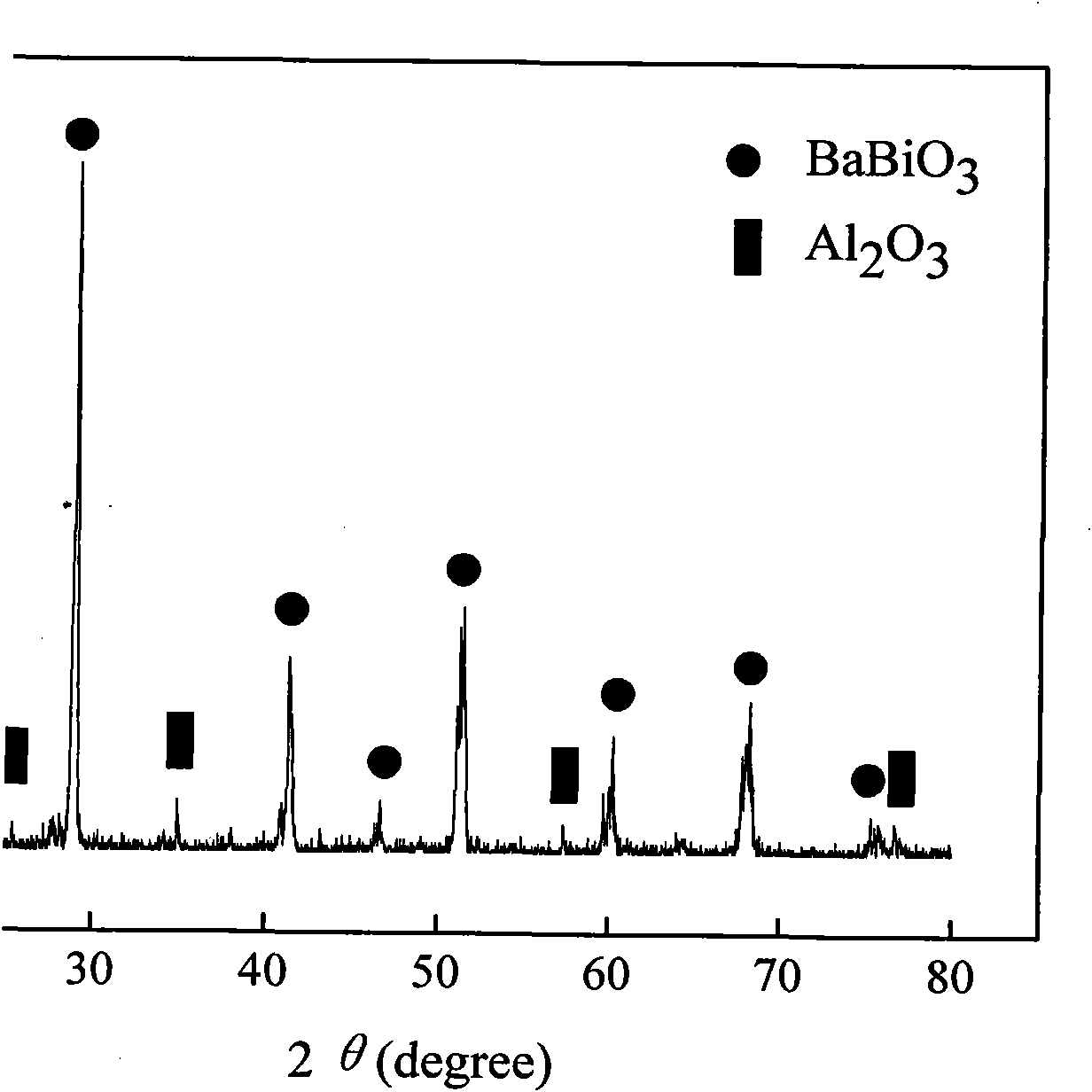

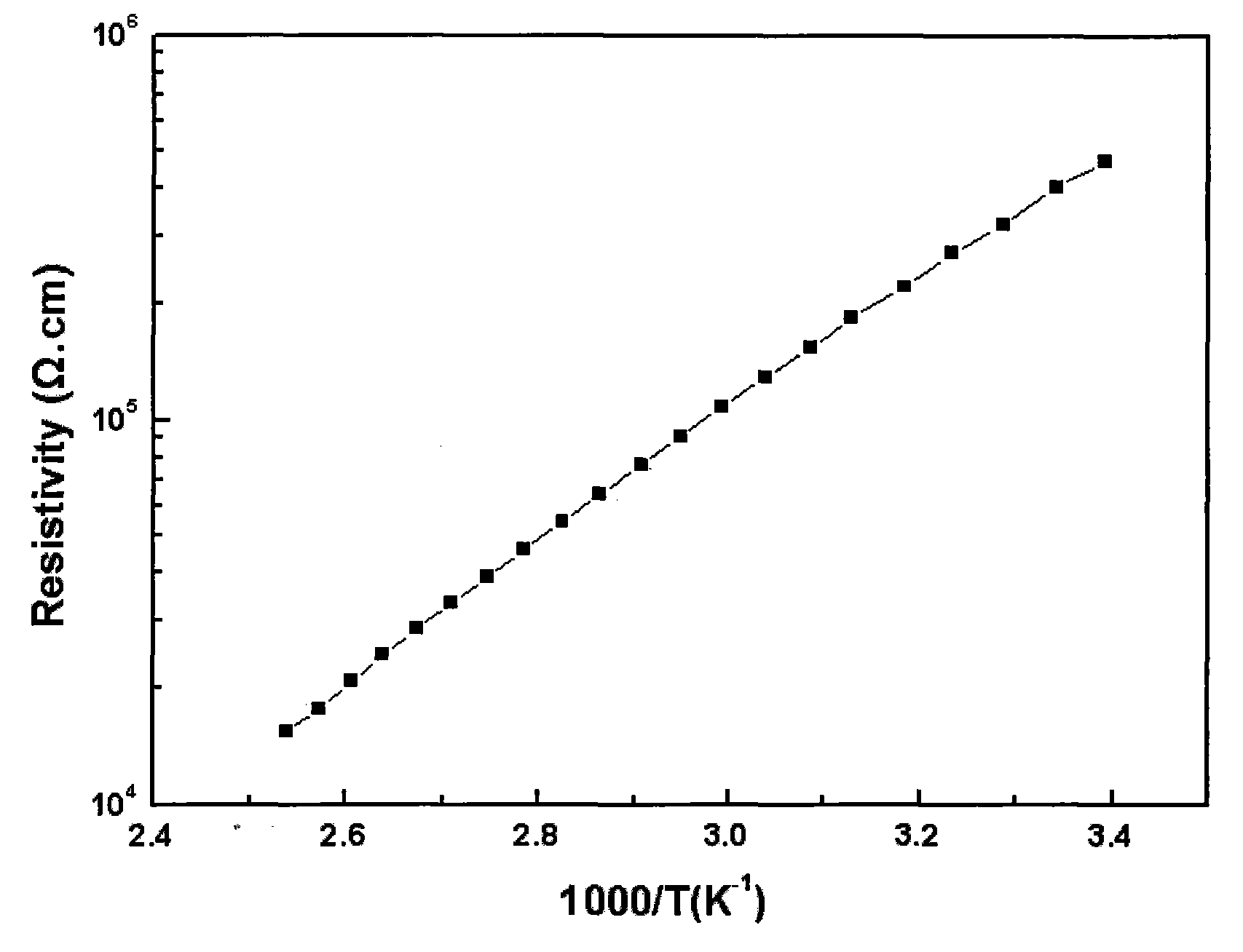

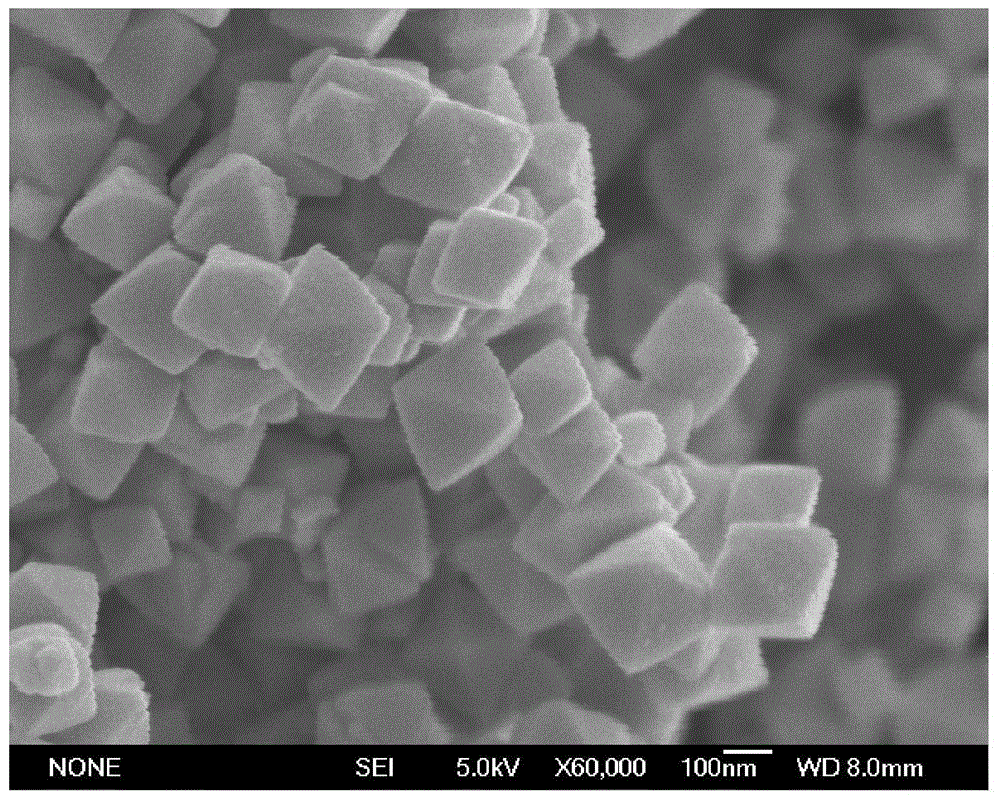

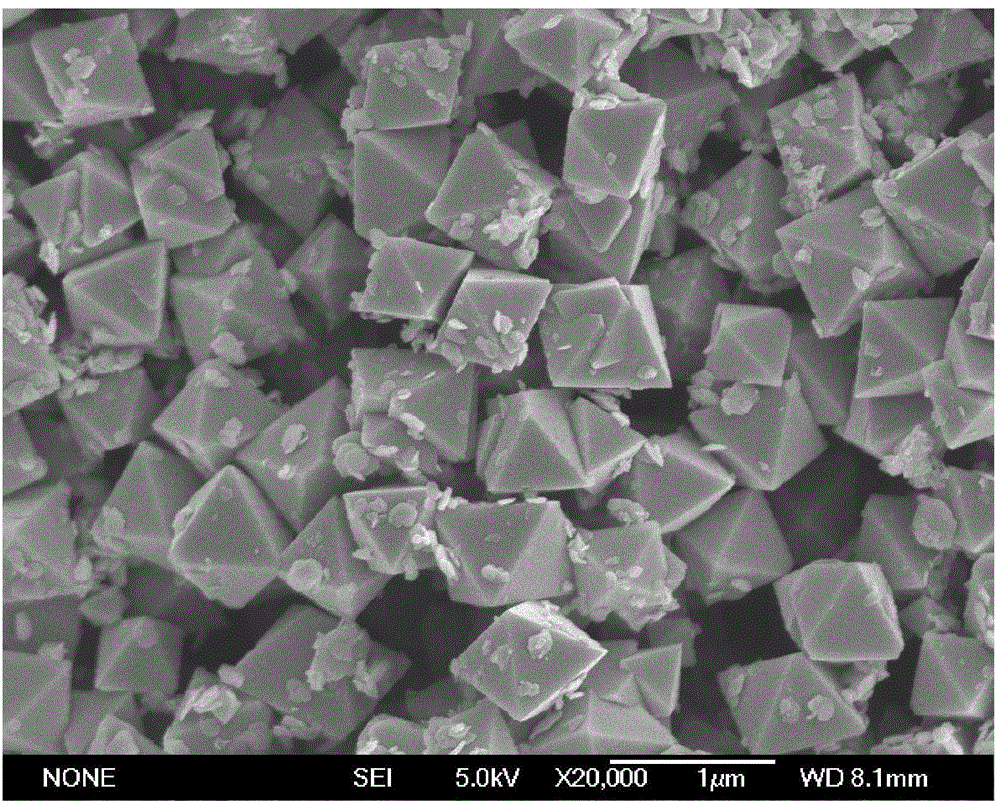

The invention relates to the technical field of a negative temperature thermistor material, in particular to thick film thermistor slurry taking a barium bismuthate base material as a functional phase, a preparation method thereof and a thick film thermistor prepared from the thick film thermistor slurry. The thick film thermistor slurry consists of the functional phase and an organic carrier solvent in a weight ratio of 60-80:20-40, wherein the functional phase is a compound of which the chemical formula is (Ba1-xAx)BiO3. In the formula, x is more than 0 or equal to 0 and less than 0.01; and A is a rare earth metal element and is selected from Y, La, Nd, Sm, Dy and Er. The preparation method comprises the following steps: 1), preparing the functional phase; 2), preparing the organic carrier; and 3), preparing the slurry. Compared with the prior art, the thick film thermistor slurry of the invention has the advantages of avoiding the use of adhesive and realizing low-temperature sintered thick film resistor, along with excellent resistance performance and simple preparation process.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Solar cell back face silver paste and preparing method thereof

InactiveCN104575669AImprove photoelectric conversion efficiencyLow melting pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolar cell

The invention discloses a solar cell back face silver paste and a preparing method thereof. The silver paste is used for producing back face electrodes of a solar cell. The silver paste comprises, by mass, 45-60% of electric conduction metal powder such as silver powder, copper powder, aluminum powder and nickel powder, 31-46% of organic bond, 1-6% of lead-free bismuthate glass powder and 0-3wt% of additive. The preparing method of the silver paste comprises preparation of the lead-free bismuthate glass powder, preparation of the organic bond, preparation of the additive and the processing technology of the sizing agent. According to the prepared back face electrode silver paste containing the additive, silver layers are compact after the prepared back face electrode silver paste is sintered, makes very good ohmic contact with a silicon wafer and has low series resistance and excellent electrical conductivity, the adhesive force between the back face electrode and the silicon wafer is improved, and the photoelectric converting efficiency is high.

Owner:ZHEJIANG ZHONGXI ELECTRONICS TECH

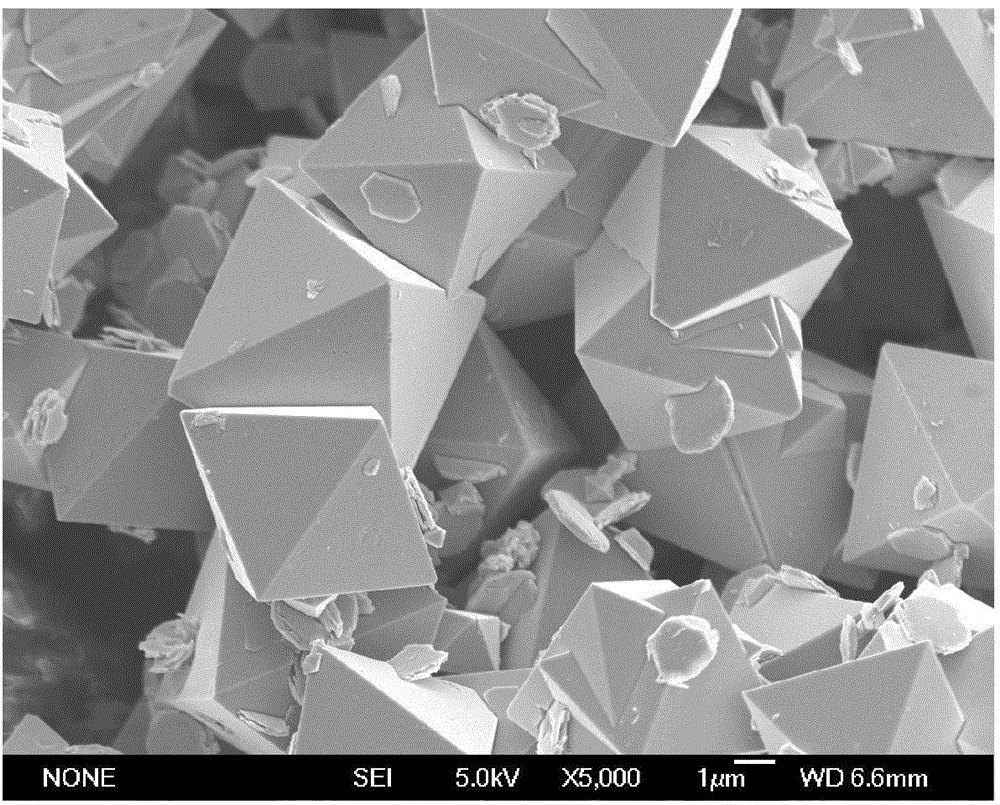

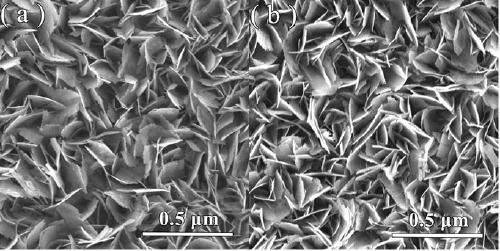

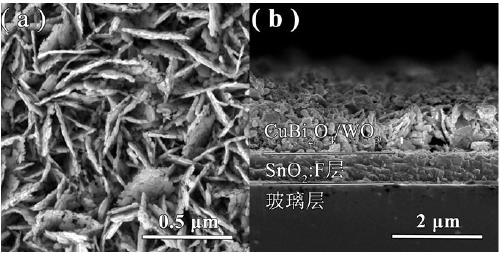

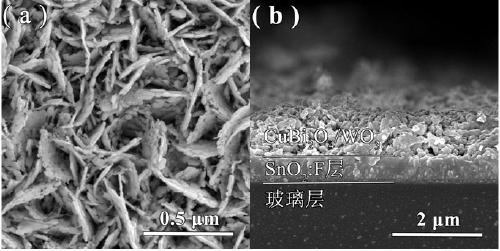

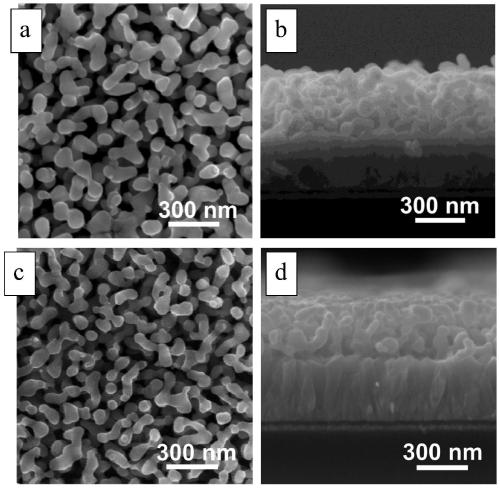

Copper bismuthate/ tungsten oxide composite film material, preparation method and application thereof in preparation of methane by photocatalytic carbon dioxide

ActiveCN109772357AEffective absorptionImprove solar utilizationHydrocarbon from carbon oxidesCatalyst activation/preparationReduction ActivityComposite film

The invention relates to a preparation method of a copper bismuthate / tungsten oxide composite film material, which comprises the following steps:1) the FTO loaded with tungsten oxide seed layer is ina tungstic acid solution for heat preservation at 180 DEG C to 200 DEG C for 8-10h, then the FTO is naturally cooled to room temperature and dried to obtain a sheet of WO3 film material on the FTO surface; 2) a mixed aqueous solution of copper nitrate and bismuth nitrate spin-coats on the flaky WO3 film material, then is placed the mixture in a muffle furnace at 550-650 DEG C for heat preservation for 10-24 hours, and naturally is cooled to obtain the CuBi2O4 / WO3 composite film material. The composite film material is cheap and can be obtained easily, the structure is stable, the visible light catalysis carbon dioxide reduction activity is high, the product selectivity is good, the circulation stability is good, the catalyst recovery rate is high, and the composite film material has wideapplication prospect in the fields of photocatalysis technology, CO2 energy conversion and the like.

Owner:HENAN INST OF SCI & TECH +1

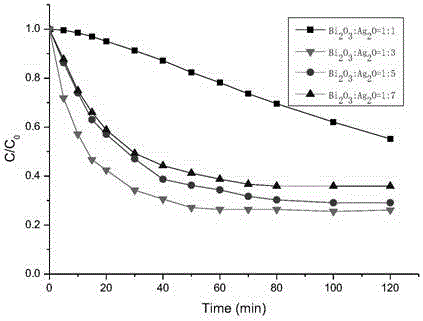

Simple method for preparing AgxBiOy visible-light responsive catalyst

InactiveCN105289598AEmission reductionOvercome operabilityMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSaturated water vapor

A provided simple method for preparing an AgxBiOy visible-light responsive catalyst comprises the following steps: A, at room temperature, respectively getting Bi2O3 and Ag2O, and preparing reactants according to the molar ratio of 1:1-7; B, grinding in a mortar for 0.5 h; C, transferring the ground powder into a culture dish, putting in a saturated water vapor environment at room temperature, and reacting for 24 h; and D, taking out the sample, and drying at 60 DEG C for 12 h, so as to obtain AgxBiOy, wherein x=3 or x=5, y=3 or y=5. The innovation point is that controllable preparation of the silver bismuthate is realized, in other words, the sample composition is controlled by changing the Bi / Ag ratio, and operation uneasiness and time consumption and energy consumption in a conventional preparation method are overcome. The reactants Bi2O3 and Ag2O are both obtained through market purchase, and the preparation method is simple, carbon discharge in the product production process is reduced, and the preparation method is suitable for large-scale industrialized production application.

Owner:SHIJIAZHUANG TIEDAO UNIV

Novel powder nanometer catalytic sulfur fixation agent for dry cement raw material, and preparation method thereof

InactiveCN107164013ALower activation energyEmission reductionSolid fuelsTitanium oxideFixation agent

The invention discloses a novel powder nanometer catalytic sulfur fixation agent for a dry cement raw material, and a preparation method thereof, wherein the novel powder nanometer catalytic sulfur fixation agent comprises nanometer lanthanum oxide, nanometer thorium oxide, nanometer praseodymium oxide, nanometer titanium oxide, nanometer nickel oxide, nanometer magnesium oxide, nanometer calcium oxide, nanometer calcium carbonate, hydroxyl calcium, potassium permanganate, potassium bismuthate, fly ash, carbon black, and the balance of a dispersion carrier. According to the technical scheme, by adding europium oxide and aluminum acetylacetonate, the sulfur fixation efficiency can achieve more than 98%. According to the present invention, the product is mixed into the raw material through the air chute in front of the homogenizing bin, and at the high temperature, the surface activity of the raw material is improved and the activation energy of the reaction with sulfur dioxide is sufficiently reduced through catalysis, oxidation and metal ion exchange, such that SO2 generated during the combustion process generates the sulfate-like solid material, and sulfate-like solid material is subjected to solid solution into the cement clinker so as not to cause corrosion and other side effects on the cement pre-heater, the kiln and other equipment.

Owner:严生

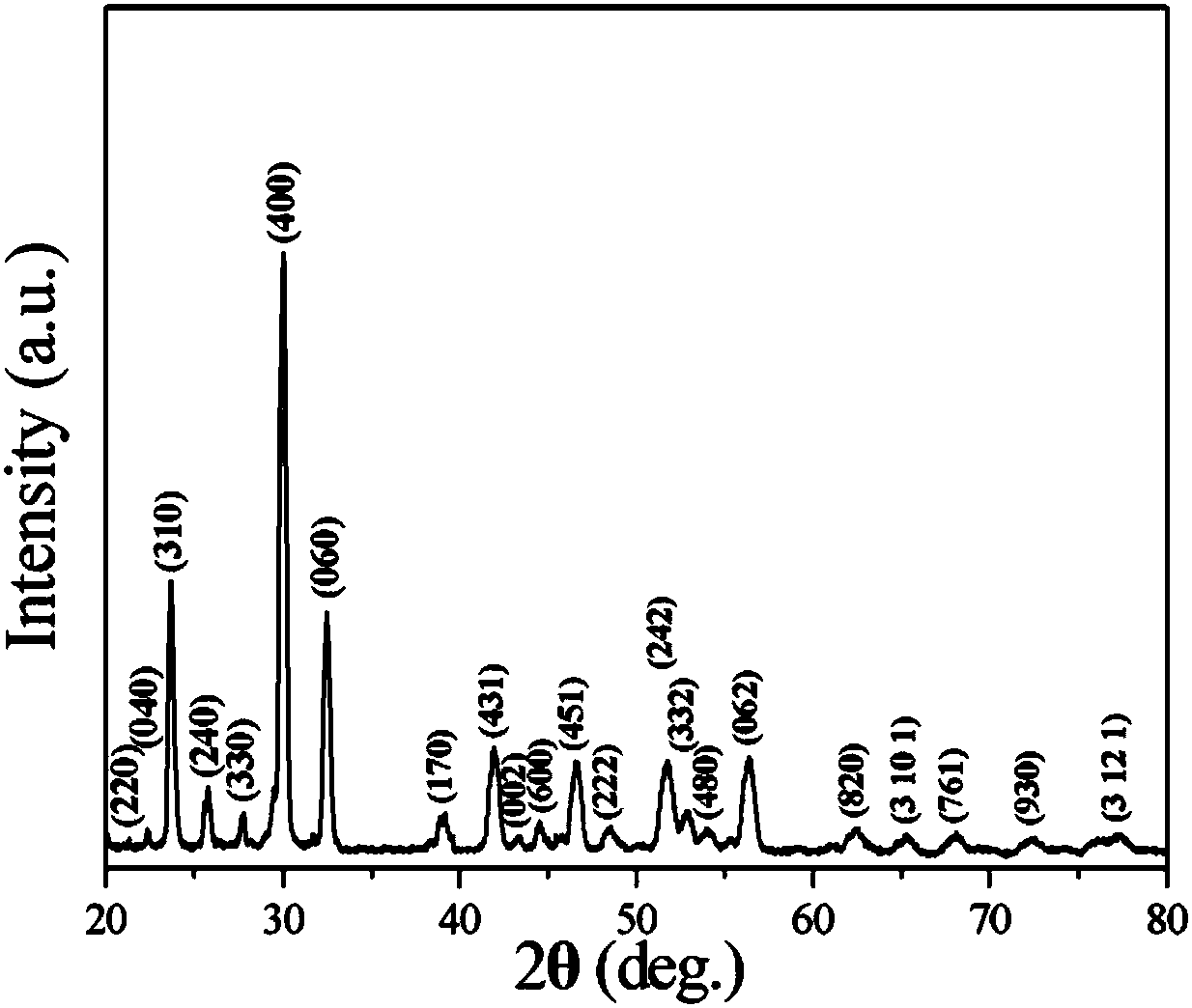

Visible-light response photocatalyst Sr2Bi3V3O14 and preparation method thereof

InactiveCN103495411AImprove catalytic performanceHas decomposed harmful chemicalsMetal/metal-oxides/metal-hydroxide catalystsChemical compositionIrradiation

The invention discloses a visible-light response bismuthate photocatalyst Sr2Bi3V3O14 and a preparation method thereof. The chemical composition formula of the bismuthate photocatalyst is Sr2Bi3V3O14. The invention further discloses the preparation method of the photocatalyst. According to the photocatalyst and the preparation method of the photocatalyst, the preparation method is simple and is low in cost, and the prepared photocatalyst has excellent catalysis performance, plays a role in decomposing harmful chemical substances under the irradiation of visible light and is good in stability, thereby having good application prospects.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

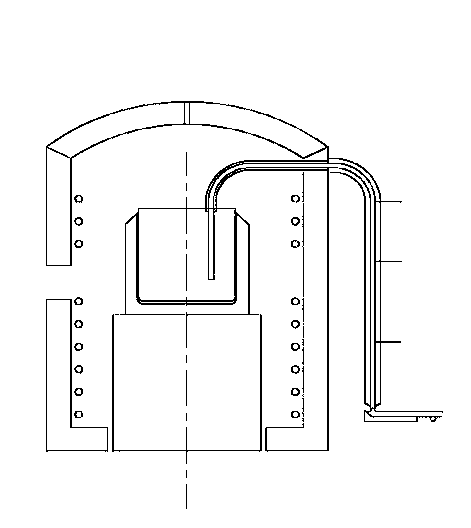

Optical glass melting method and optical glass melting device used for method

ActiveCN102849920AExtended service lifeNo pollution in the processPot furnacesGlass furnace apparatusPlatinumCrucible

The title of the invention is an optical glass melting method and an optical glass melting device used for the method. The invention belongs to the technical field of optical glass melting and mainly provides a method for melting glass and a device for controlling high quality of flowed molten glass. The melting method is mainly characterized in that: (1) putting optical glass raw materials of phosphatic, columbate and bismuthate into a crucible for high-temperature fusion, clarification and homogenization so as to obtain molten glass; (2) placing the above crucible together with the molten glass into an insulation area of a smelting furnace; and (3) leading out the molten glass at an intermediate area below the central surface layer and over the bottom of the crucible from the smelting furnace through a conduit so as to prepare an optical glass strip material. The furnace bottom is a liftable furnace bottom, and a guiding control device is a flow guide tube made of platinum or platinum alloy. The optical glass manufactured in the invention has high transmittance, and its refractive index nd is not less than 1.8. The optical glass has characteristics of no pollution of metal Pt and Au particles and no generation of streaks in the strip material, and is mainly used to manufacture phosphatic, columbate and bismuthate optical glass strip materials.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Photocatalyst Bi3Sb3Zn2O14 with visible light response

ActiveCN103521210AImprove catalytic performanceEasy to prepareAntimony compoundsMetal/metal-oxides/metal-hydroxide catalystsChemical compositionLight response

The invention discloses a bismuthate photocatalyst Bi3Sb3Zn2O14 with visible light response and a preparation method thereof. The chemical composition formula of the bismuthate photocatalyst is Bi3Sb3Zn2O14. The invention also discloses the preparation method of the material. The preparation method is simple and is low in cost. The prepared photocatalyst has excellent catalytic performance, has the function of decomposing harmful chemical substances when irradiated by visible light and has good stability and good application prospect.

Owner:东台城东科技创业园管理有限公司

Preparing method of silicon-based hydrogen production material

InactiveCN107188124AEasy to operateEase of industrial productionHydrogen productionHydrogen/synthetic gas productionBismuthateSodium oxide

The invention relates to a preparing method of a silicon-based hydrogen production material. Silicon alloy is adopted as a precursor, weak acid salt and basic oxide are mechanically mixed, and briquetting and high-temperature treatment are conducted to obtain the silicon-based hydrogen production material; silicon alloy is magnesium silicon, aluminum silicon and zinc silicon binary alloy, the mole ratio of silicon to other metal is 0.5-4, the mass of weak acid salt is 1-20wt% that of silicon alloy, and the mass of basic oxide is 0.1-20wt% that of silicon alloy; weak acid salt is one of sodium bismuthate, potassium bismuthate, sodium stannate and potassium stannate; basic oxide is one of sodium oxide, potassium oxide, calcium oxide, barium oxide, strontium oxide, lithium oxide and rubidium oxide. The silicon-based hydrogen production material reacts with water at a normal temperature, is high in hydrogen yield, and can be used in a miniature human chat battery portable hydrogen source.

Owner:CHINA JILIANG UNIV

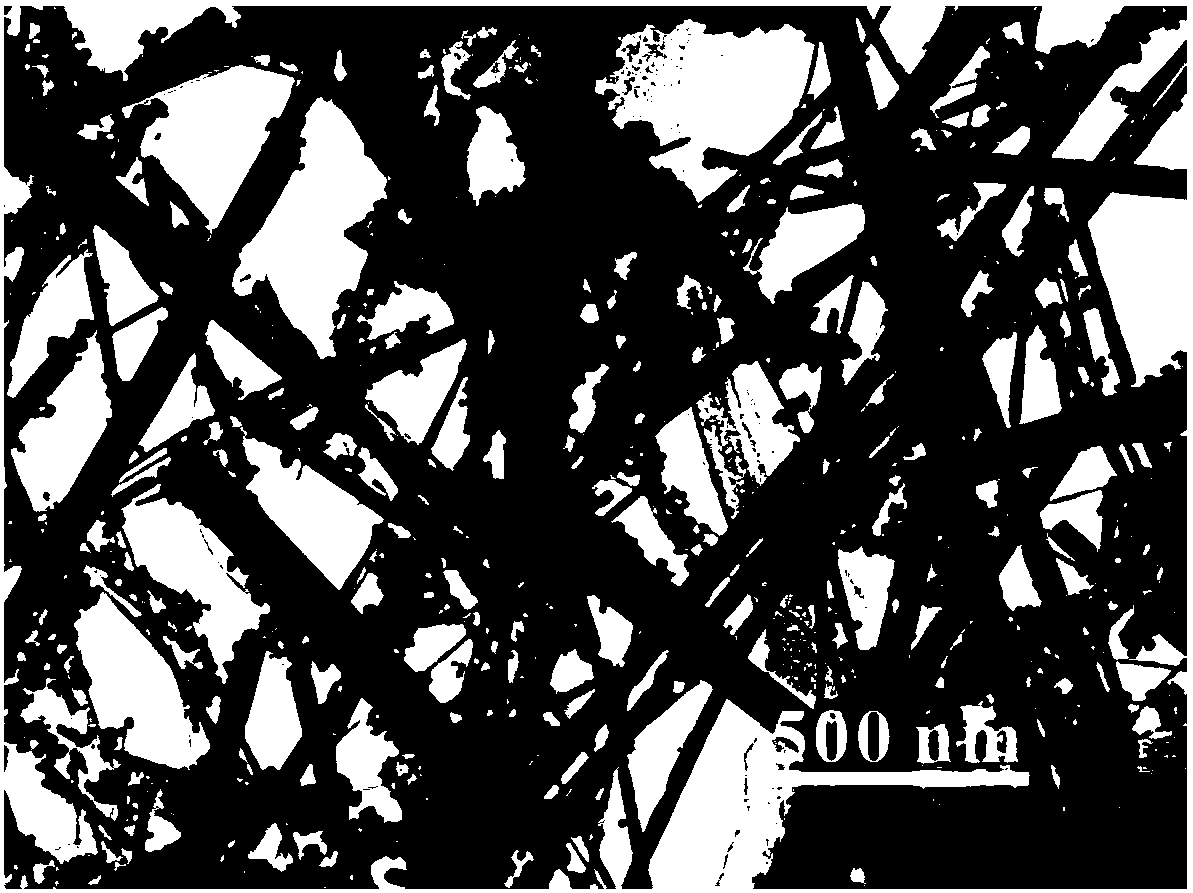

Preparation method of lanthanum bismuthate nanorod

ActiveCN107651706AEasy to makeEasy to controlNanotechnologyBismuth compoundsLanthanumLithium-ion battery

The invention discloses a preparation method of a lanthanum bismuthate nanorod, and belongs to the technical field of nanometer material preparation. The method is concretely characterized in that firstly, sodium bismuthate and lanthanum acetate are uniformly mixed; then, sodium bismuthate and lanthanum acetate mixed powder is put into a high-temperature region of an alundum tube reaction container; an alumina wafer is put into a low-temperature region of the alundum tube reaction container; the reaction container is sealed; the high-temperature region is heated to be 1100 to 1300 DEG C; the low-temperature region is heated to be 100 to 200 DEG C; heat insulation is performed for 0.5 to 3h; the alumina wafer containing white sediments on the surface is obtained; then, the alumina wafer isfixed in the middle of the reaction container; the sodium bismuthate, the lanthanum acetate and water are mixed and are then put into the reaction container to be sealed; heat insulation is performedfor 24 to 72h at the temperature of 300 to 500 DEG C. The two-step reaction process is used; the preparation process is simple; the control is easy; the obtained lanthanum bismuthate nanorod has goodapplication prospects in the aspects of photocatalysis, adsorption, lithium ion batteries, solid-oxide fuel batteries and the like.

Owner:山东艾兰药业有限公司

Colloidal bismuth tartrate medicine and preparation method and use thereof

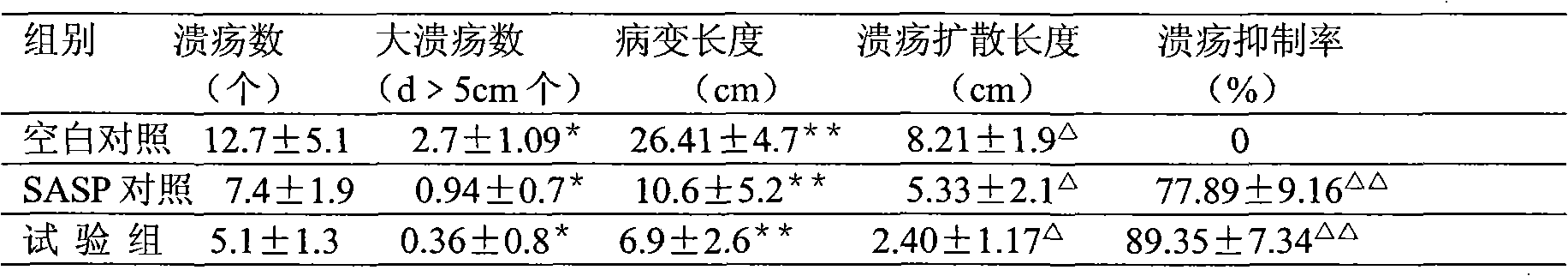

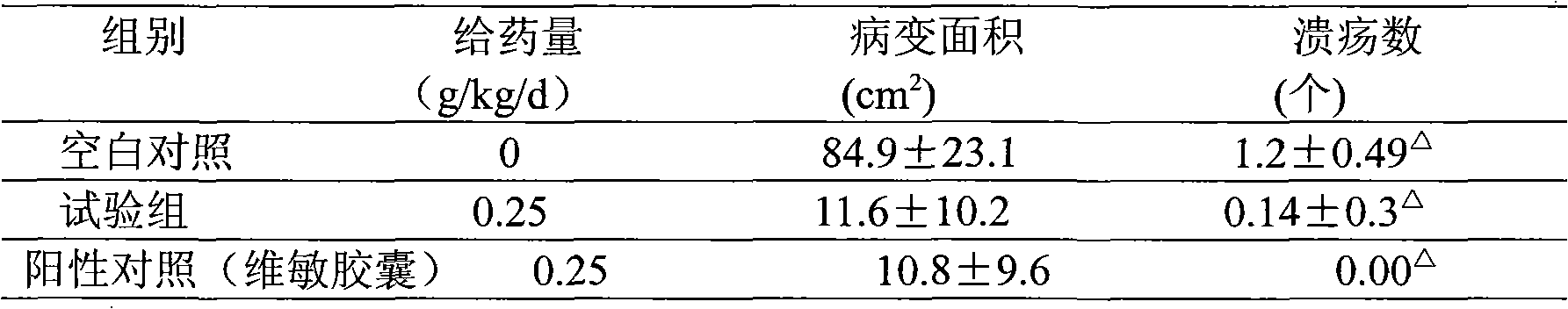

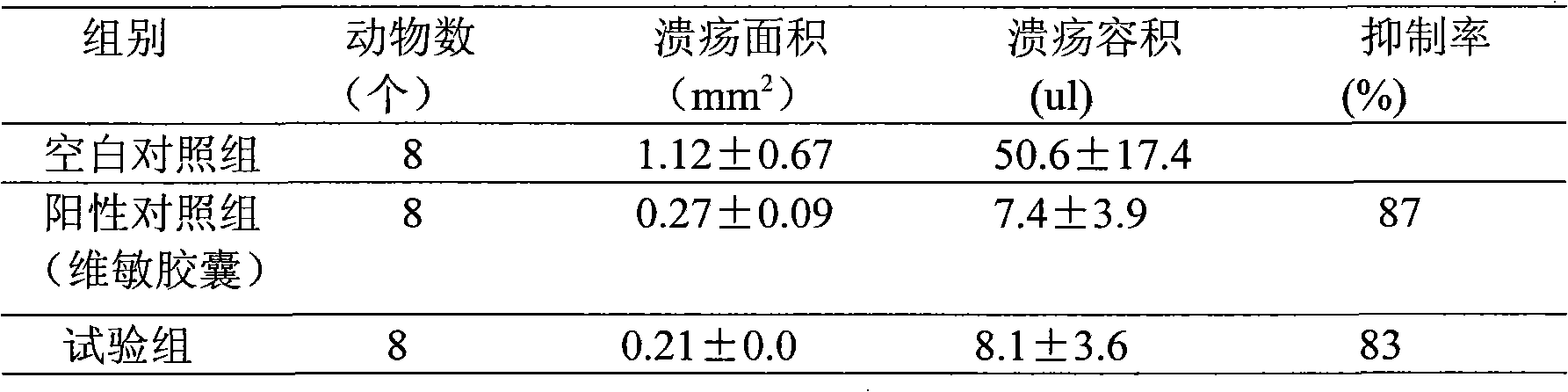

ActiveCN101491507AChemically stableSmall particle sizeHeavy metal active ingredientsDigestive systemTherapeutic effectGastroenterology department

The invention relates to a colloid tartro-bismuthate and a drug preparation, a preparation method and application of the colloid tartro-bismuthate. The colloid tartro-bismuthate consists of tartaric acid, trivalent metal bismuth ion oxide or salt and low methoxyl-D-polygalacturonase; and the colloid tartro-bismuthate is subjected to centrifugal spraying and drying by dissolution, mixing, precipitation and other methods to form microcrystalline fine powdery colloid tartro-bismuthate. The drug has obvious treatment effect on chronic nonspecific ulcerative colitis, irritable bowel syndrome and chronic colonic inflammation, has good treatment effect on chronic atrophic gastritis and other stomach diseases, has small toxicity and side effect and belongs to a safe, nontoxic and effective drug of a gastroenterology department.

Owner:山西双雁生物科技有限公司

Method for deep purifying organic toxicant and waste water by photocatalysis-oxidation and preparation method for used photocatalysis material

InactiveCN101838078AHas visible light absorption propertiesPromote degradationWater/sewage treatment by irradiationWater contaminantsLight irradiationToxicant

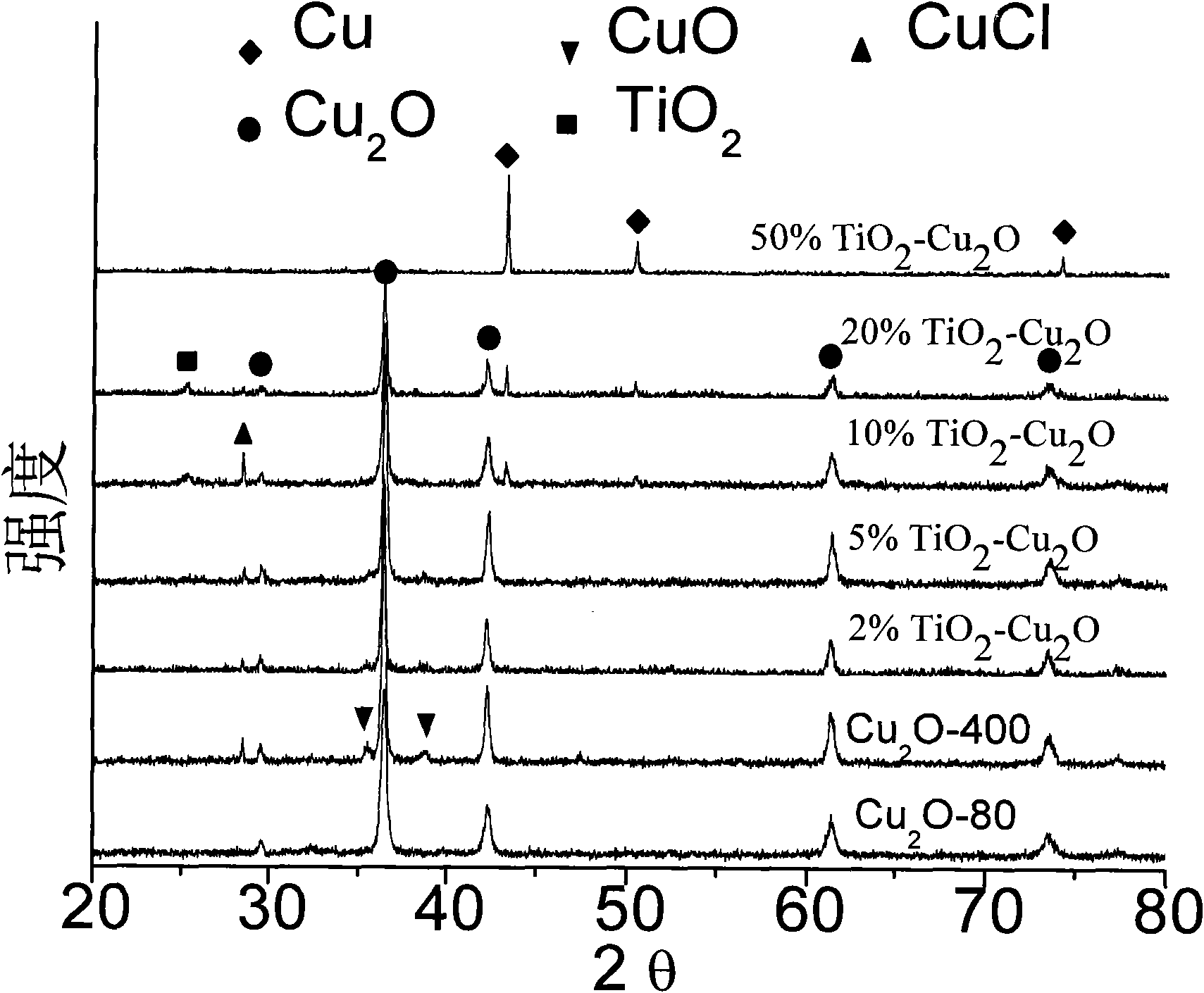

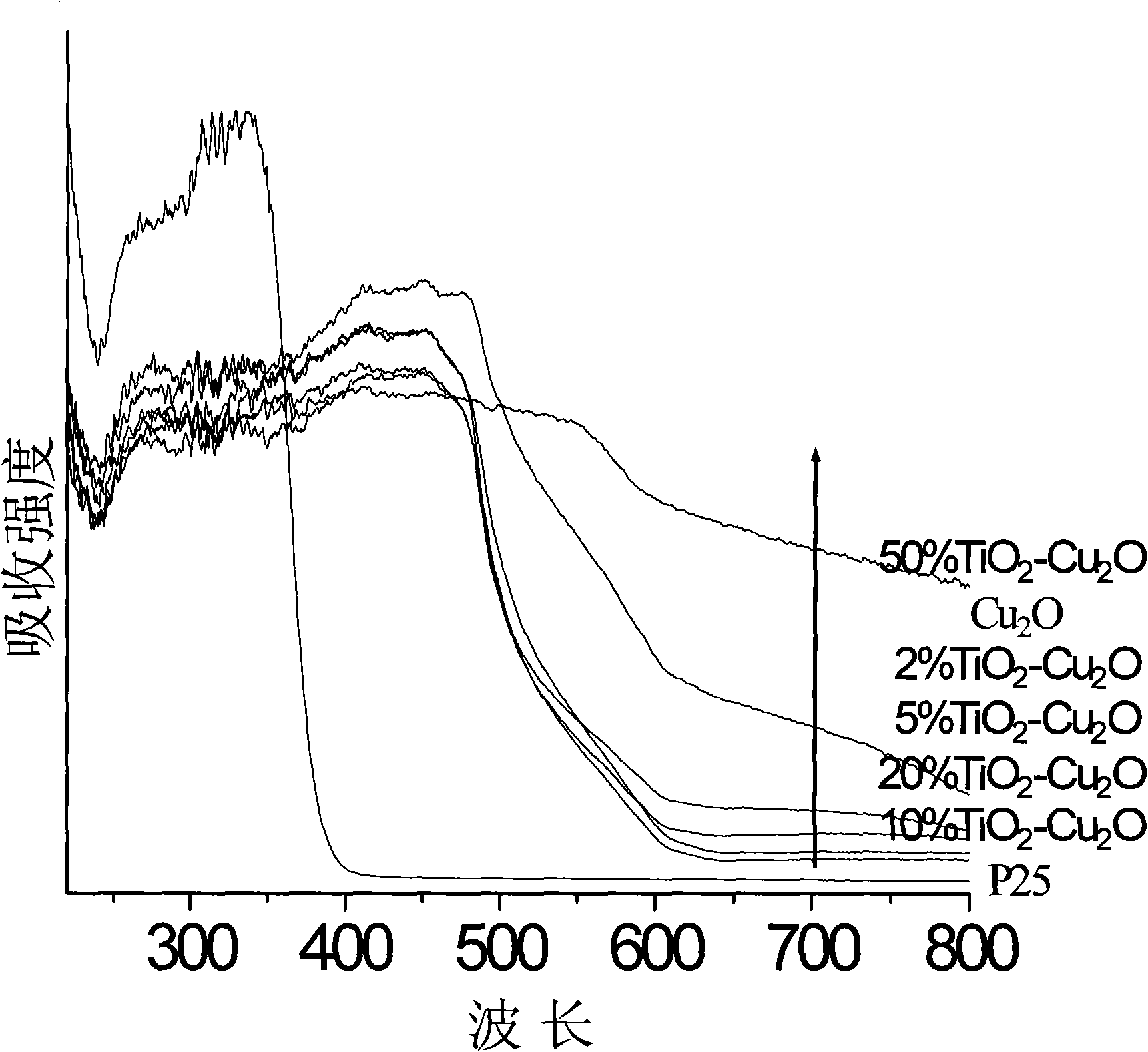

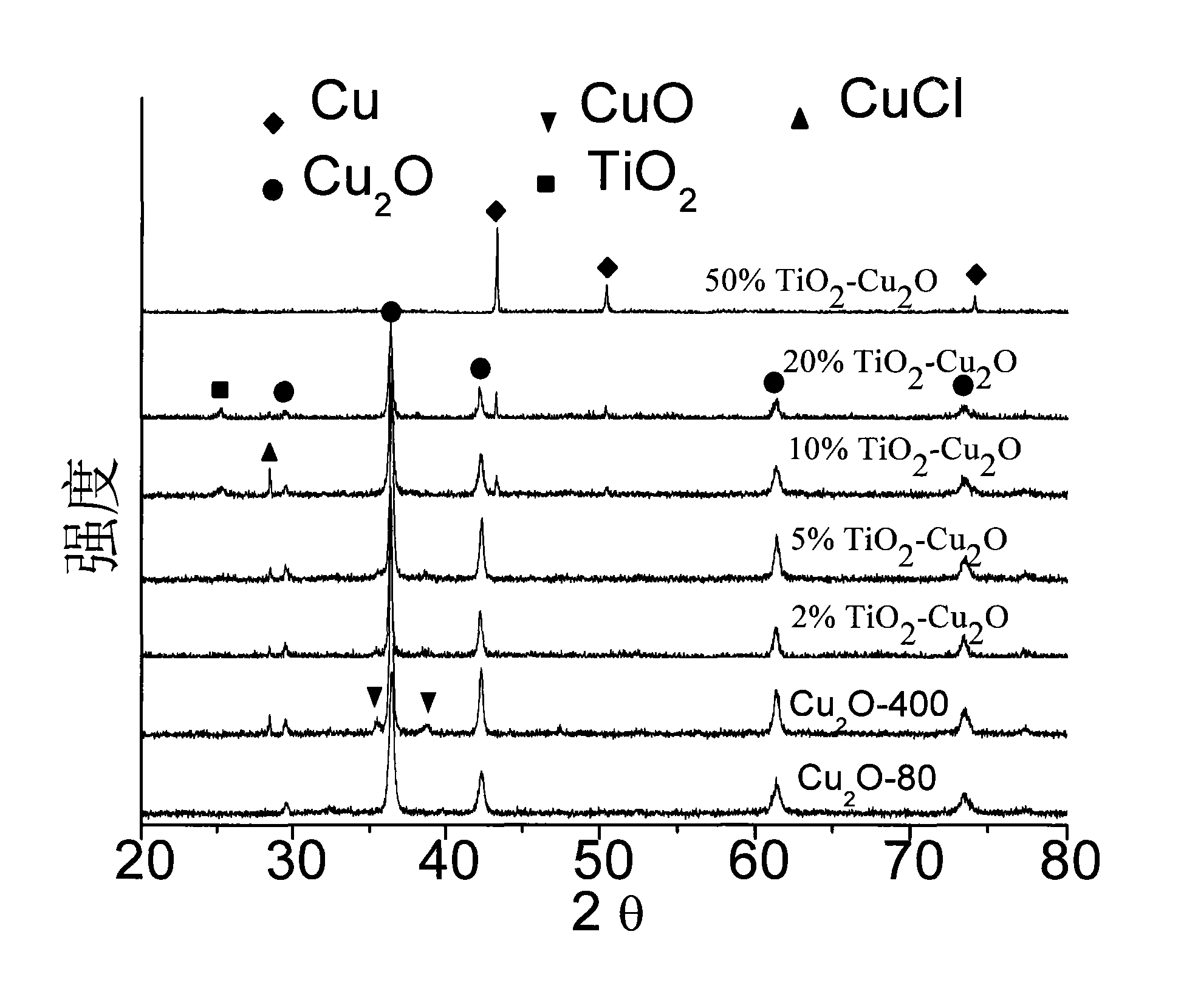

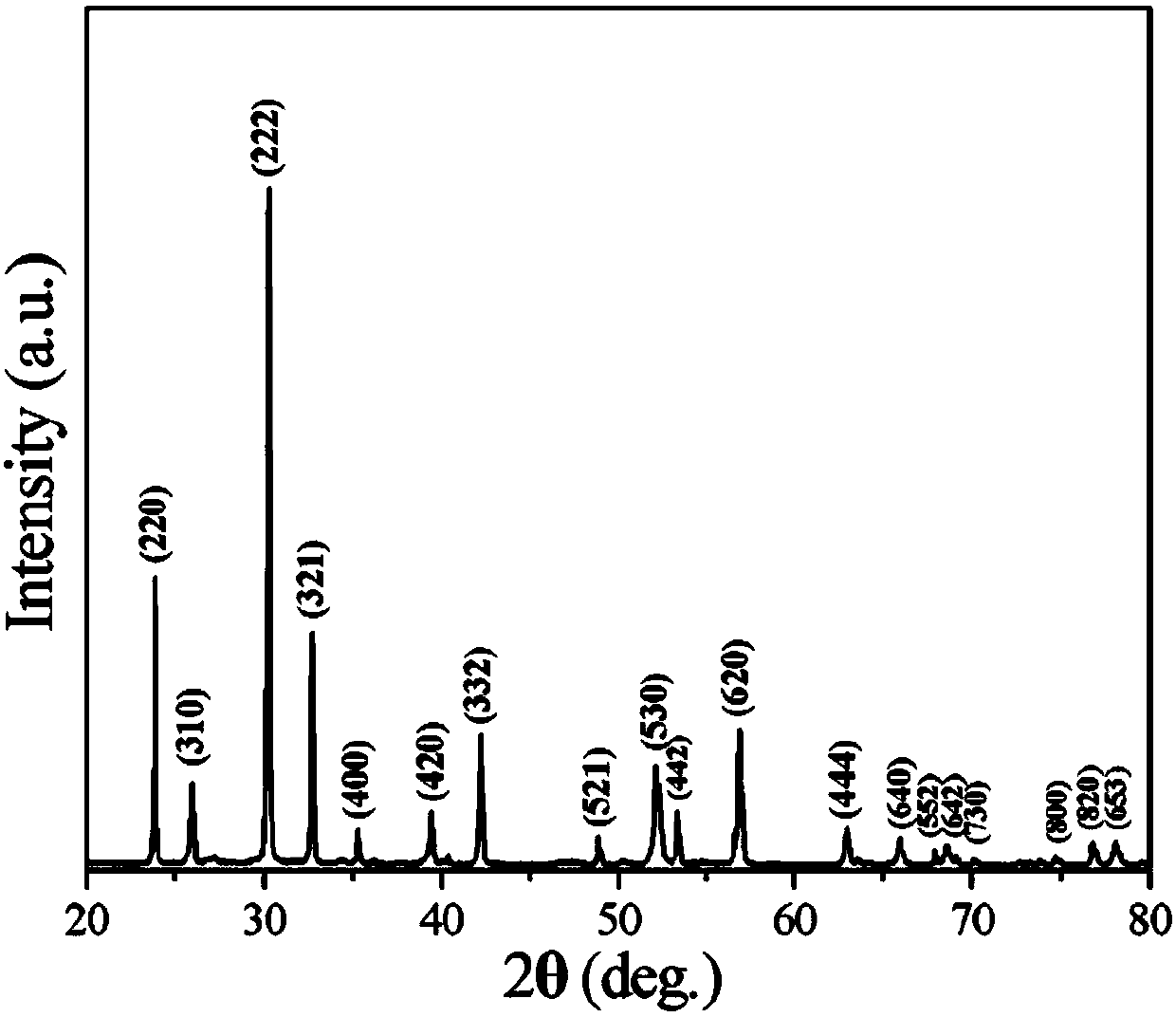

The invention discloses a method for deep purifying organic toxicant and waste water by photocatalysis-oxidation and a preparation method for the used photocatalysis material; under the light irradiation, a core-shell type Cu2O-TiO2 photocatalysis material and a photo-oxidant bismuthate coupling technique are used for deep purifying the organic waste water. In the core-shell type Cu2O-TiO2 photocatalysis material, the mole percentage of TiO2 / Cu2O+TiO2 is 0.1 / 100-50 / 100; the characteristic molecular thereof is (TiO2) x (Cu2O), wherein in the formula, X is larger than 0.0010 and less than or equal to 0.500. The invention uses the core-shell type Cu2O-TiO2 photocatalysis material and the photo-oxidant bismuthate coupling technique for purifying the organic waste water. Since the photocatalysis material has visible light absorption characteristics, therefore, the clean energy-sunlight can be utilized for achieving the purpose of environment purification; simultaneously, the coupling combination technique is adopted, therefore, the invention can well mineralize the pollutant, realizes the deep purification and has very good using prospect.

Owner:NANJING UNIV

Low-temperature connecting method for K9 glass and titanium metal

ActiveCN104961357ASolve the strength problemSmall coefficient of thermal expansionTitanium metalRoom temperature

The invention relates to connection of glass and metal, in particular to a low-temperature connecting method for K9 glass and titanium metal. The low-temperature connecting method is characterized by comprising the following steps: (I) preparing powdered composite solder of bismuthate containing an active element Ti; (II) placing the composite solder between the titanium metal and the K9 glass; (III), getting out a sample and then putting the sample into a vacuum connecting furnace, wherein direct-current electric fields with voltage of 100 to 700V are arranged in the vacuum connecting furnace, the temperature of the vacuum connecting furnace is 300 to 600 DEG C, pressure of 5 to 40Pa perpendicular to the sample plane is applied, and the degree of vacuum is 10<-3> to 10<-2> Pa; and keeping the temperature not more than 120 minutes to realize an effective connection of the K9 glass and the titanium metal, cooling the sample to the room temperature along with the furnace, then, getting out the sample, thereby completing low-temperature connection of the K9 glass and the titanium metal. The low-temperature connecting method has the advantages of being simple to operate, green and environmentally-friendly, high in working efficiency, stable in process, and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

Preparation method of polyaniline compounded zinc bismuthate nano-rods

ActiveCN107804871AEasy to makeEasy to controlMaterial nanotechnologyBismuth compoundsLithium-ion batteryZinc Acetate Dihydrate

The invention discloses a preparation method of polyaniline compounded zinc bismuthate nano-rods, and belongs to the technical field of preparation of functional materials. According to the preparation method, sodium bismuthate, zinc acetate and polyaniline are used as raw materials, and argon is used as carrier gas. The preparation method comprises the following specific steps: uniformly mixing the sodium bismuthate with the zinc acetate at first; and then placing mixed powder of the sodium bismuthate and the zinc acetate in a high-temperature region of an alundum tube reaction container, placing the polyaniline in a low-temperature region of the alundum tube reaction container, sealing the reaction container, heating the high-temperature region to the temperature of 1,200-1,400 DEG C, heating the low-temperature region to the temperature of 200-300 DEG C, and insulating for 12-24 hours, wherein the flow speed of the argon is 100-200 cm<3> / min. A preparation process is simple and is easy to control, and the polyaniline compounded zinc bismuthate nano-rods have good application prospect in the fields of electronic devices, optical devices, electrochemical devices, lithium ion batteries and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

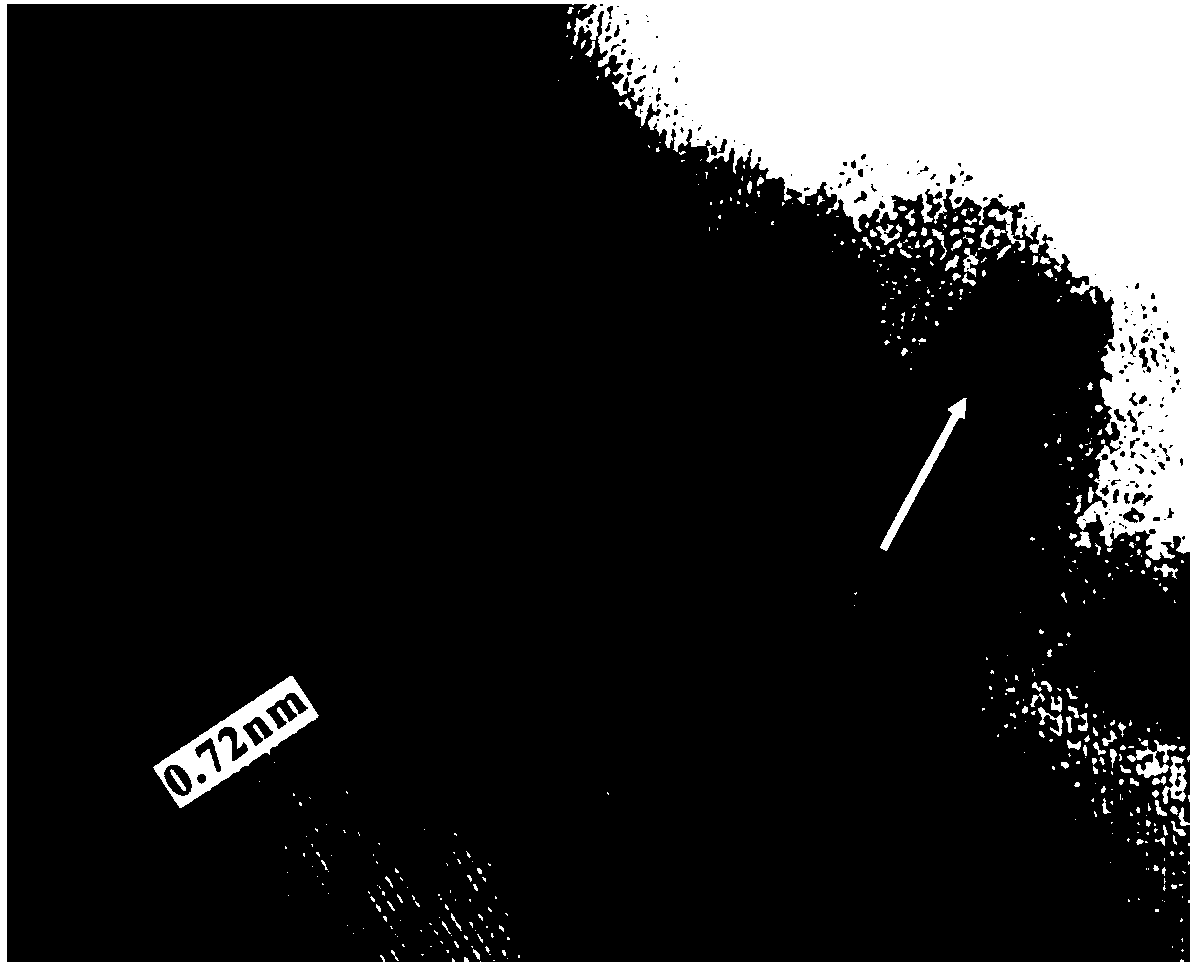

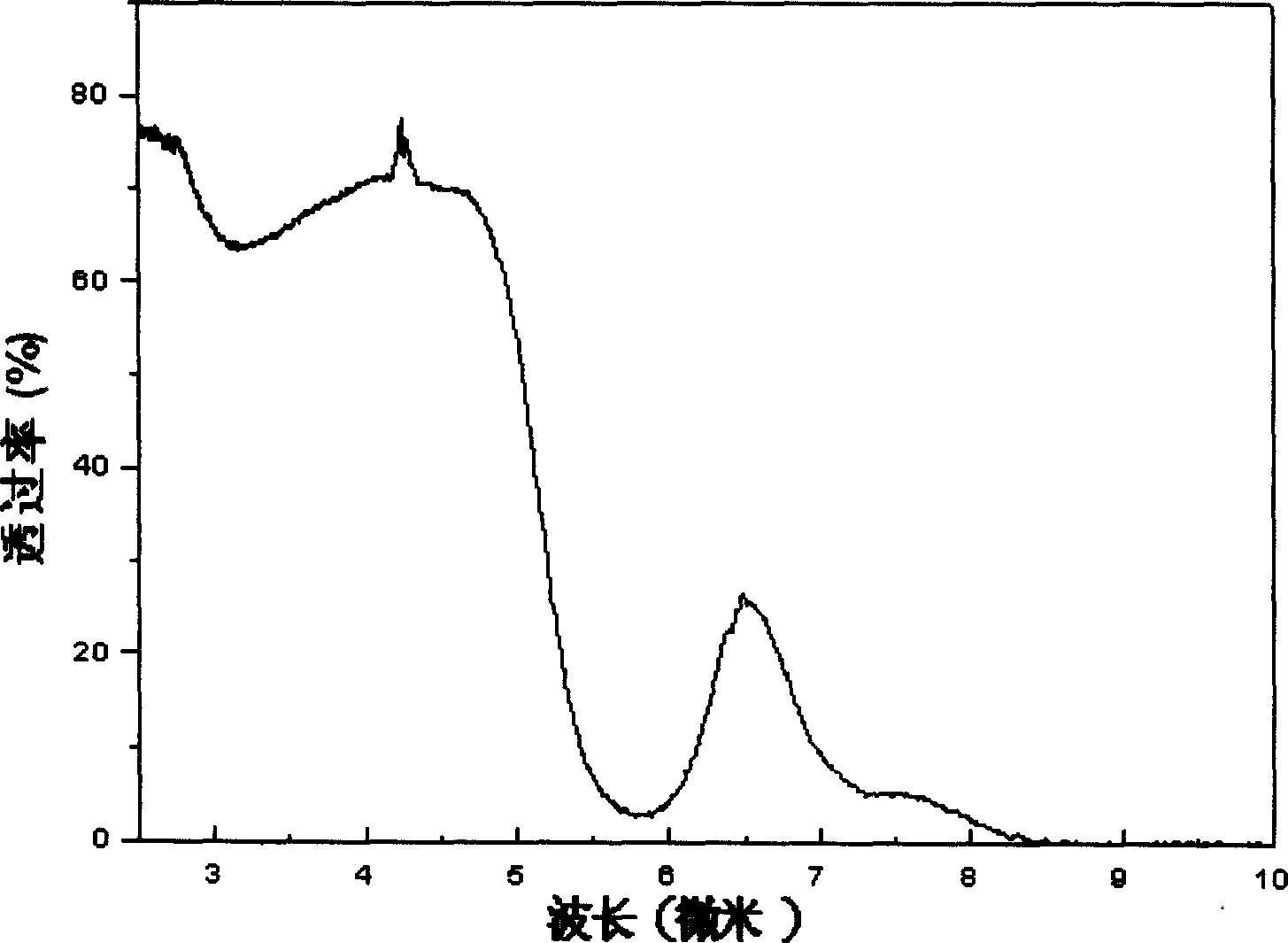

Bismuthate glasls and preparing method thereof

InactiveCN1583626ARaise the transition temperatureImprove stabilityHost materialStability coefficient

A sort of glass with bismuthate and method of preparation. Percents of every part is as follow, BiO3, 20-80mol%; PbO, 10-70mol%; Sum of SrO and M2O(M is Li or Na), 10-20mol%, stability coefficient is as follow, delta T=80deg.C, delta Tmax=195deg.C, infrared cut-off wavelength>8.1mum and reaching max at 8.5mum. Host material for upconversion and infrared transmitting material.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Attapulgite-loaded full-spectrum response photocatalyst material and preparation method thereof

ActiveCN107243350ALittle changeIncrease contact areaGas treatmentPhysical/chemical process catalystsBismuth oxybromideUltraviolet lights

The invention discloses an attapulgite-loaded full-spectrum response photocatalyst material and a preparation method thereof. The material is prepared from an attapulgite matrix, and bismuth oxychloride, bismuth oxybromide, bismuth oxyiodide and copper bismuthate which are loaded in a gap and on the surface of the matrix, wherein the content of the bismuth oxychloride is 1.0 weight percent to 10 weight percent; the content of the bismuth oxybromide is 1.0 weight percent to 10 weight percent; the content of the bismuth oxyiodide is 1.0 weight percent to 10 weight percent; the content of the copper bismuthate is 1.0 weight percent to 10 weight percent; the composite material disclosed by the invention has full-spectrum photocatalytic response on ultraviolet light, visible light and near-infrared light. The attapulgite-loaded full-spectrum response photocatalyst material provided by the invention can be used for preparing an air purification net and has relatively strong adhesion force; changes, caused by the environment, of the material are relatively small and the contact area between the material and the air is large; the attapulgite-loaded full-spectrum response photocatalyst material has strong permeability, an attached compound photocatalyst is used for fully absorbing sunlight, the utilization rate of solar energy is improved and the catalysis efficiency is enhanced, so that air pollutants can be effectively degraded.

Owner:苏州尼普环境科技有限公司

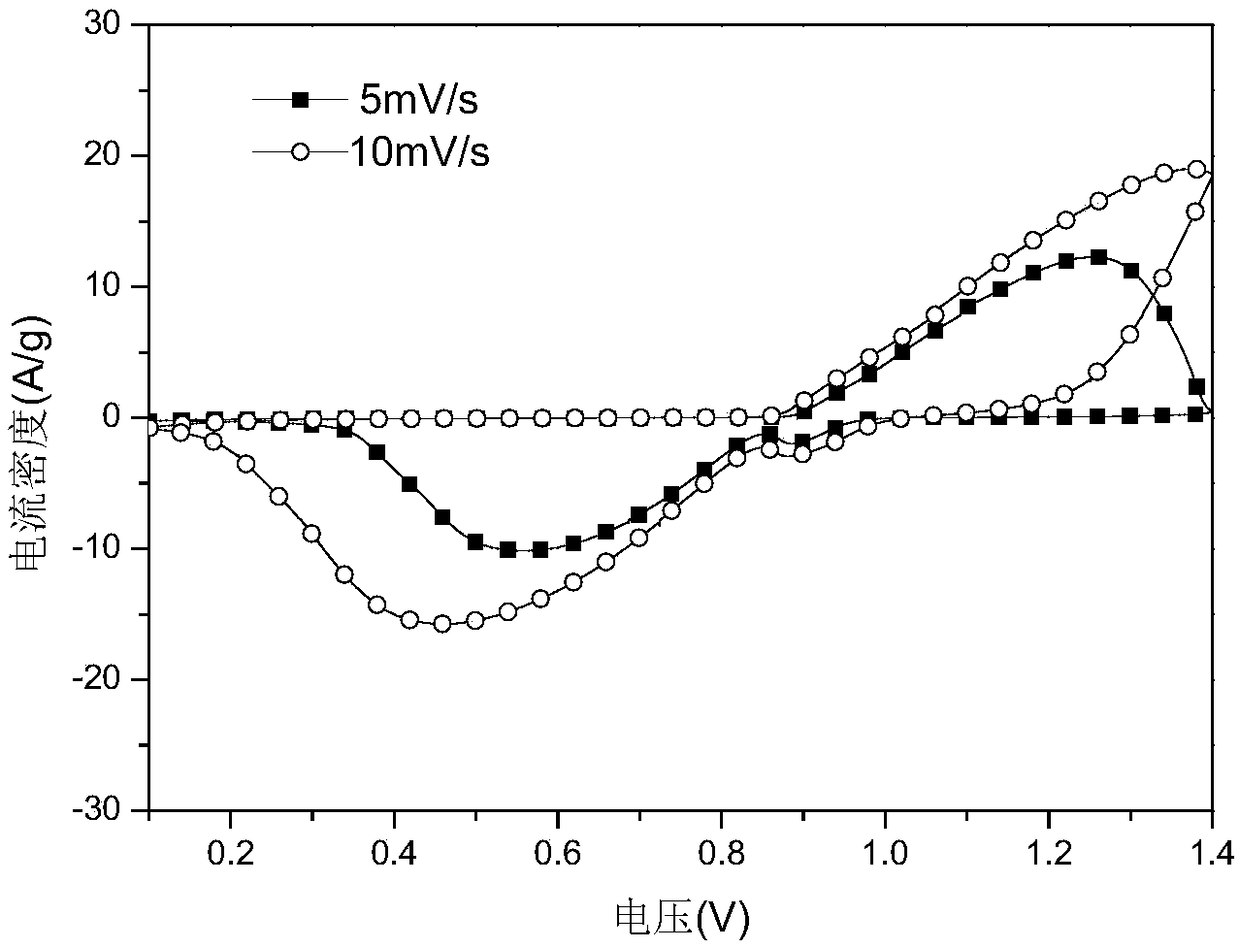

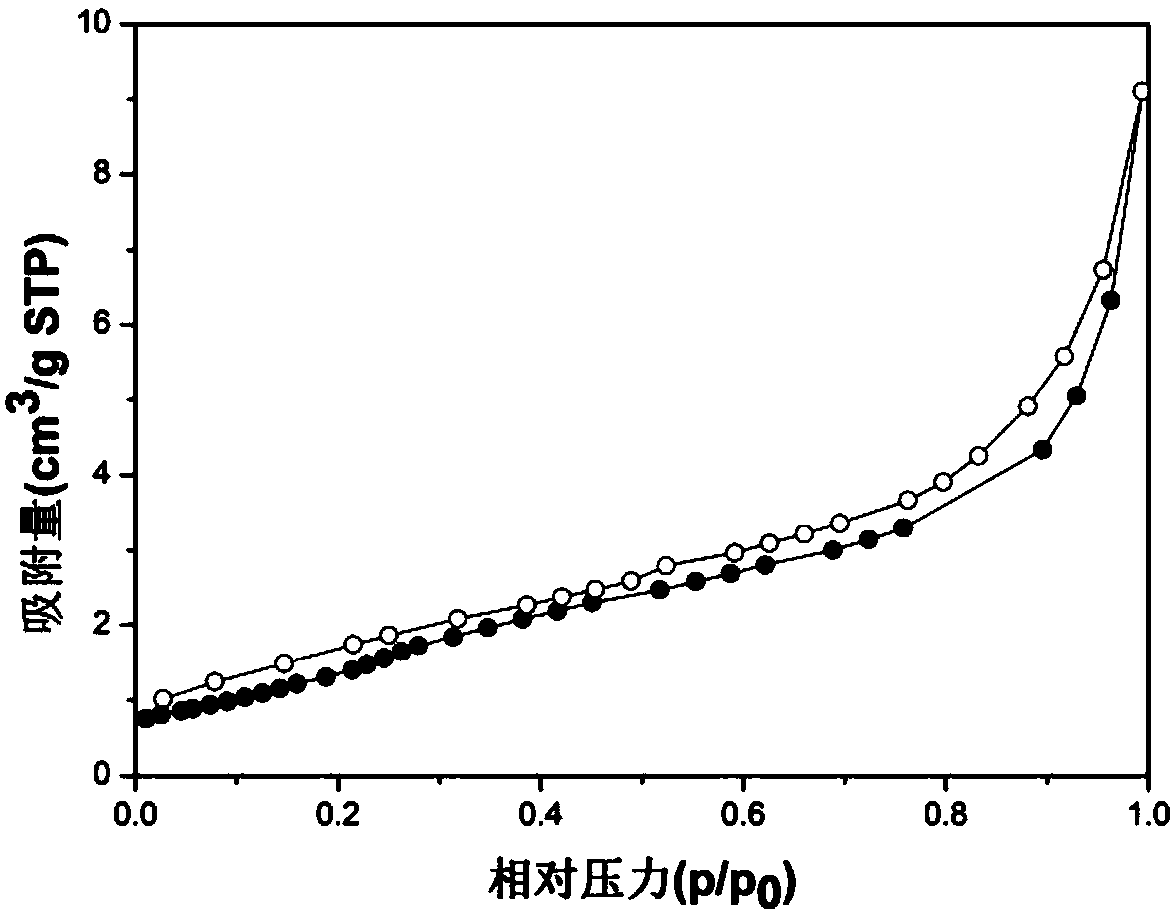

Lithium bismuthate/nickel hydroxide secondary alkaline battery and preparation method thereof

ActiveCN106532143ALarge capacityImprove cycle lifeCell electrodesFinal product manufactureCapacitanceLithium

The invention relates to a lithium bismuthate / nickel hydroxide secondary alkaline battery and a preparation method thereof. The preparation method utilizes a lithium bismuthate material as a negative electrode active material of the battery, a nickel hydroxide material as a positive electrode active material of the battery and an alkaline solution as an electrolyte solution. The battery has a voltage window of 0.2 to 1.4V. A preparation method of the lithium bismuthate material comprises preparing a mixed solution from a lithium raw material and NaBiO3 according to a certain molar ratio, and carrying out a reflux reaction process at 90 to 110 DEG C for 2 to 72 hours, or carrying out hydrothermal treatment on the mixed solution in a reactor at 120 to 200 DEG C for 2 to 96 hours. The prepared battery has a capacitance of 166 mAh / g at current density of 0.5 A / g and a capacitance of 143 mAh / g at current density of 5 A / g, has characteristics of large capacitance, good cycle stability and environmental friendliness, and is a novel electrochemical power source with a wide application prospect.

Owner:XIANGTAN UNIV

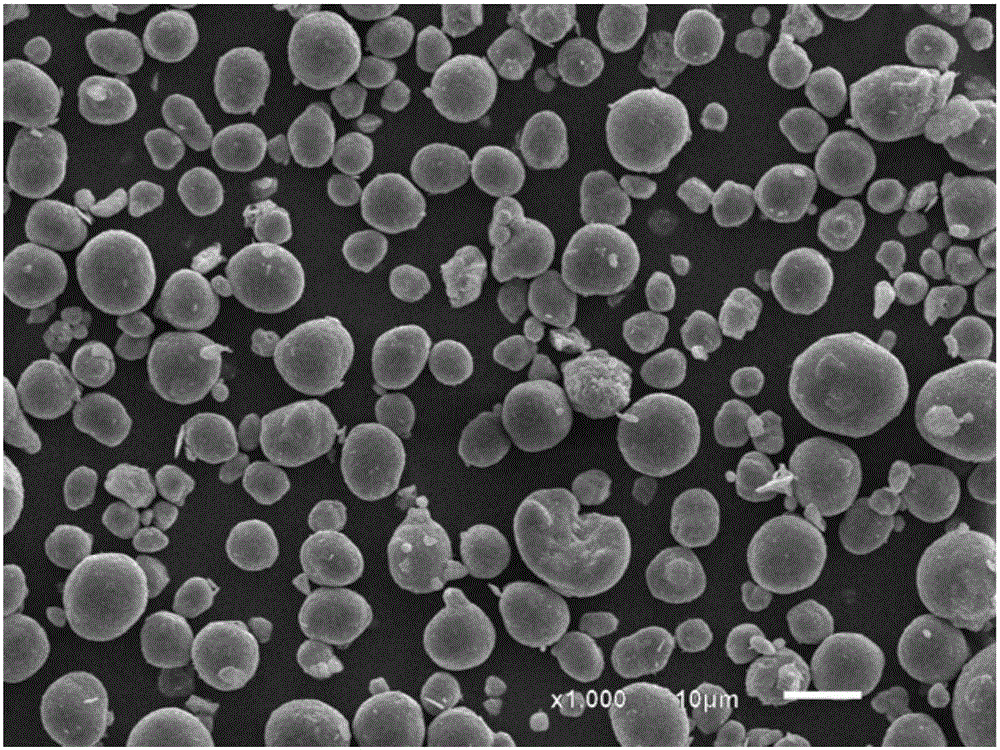

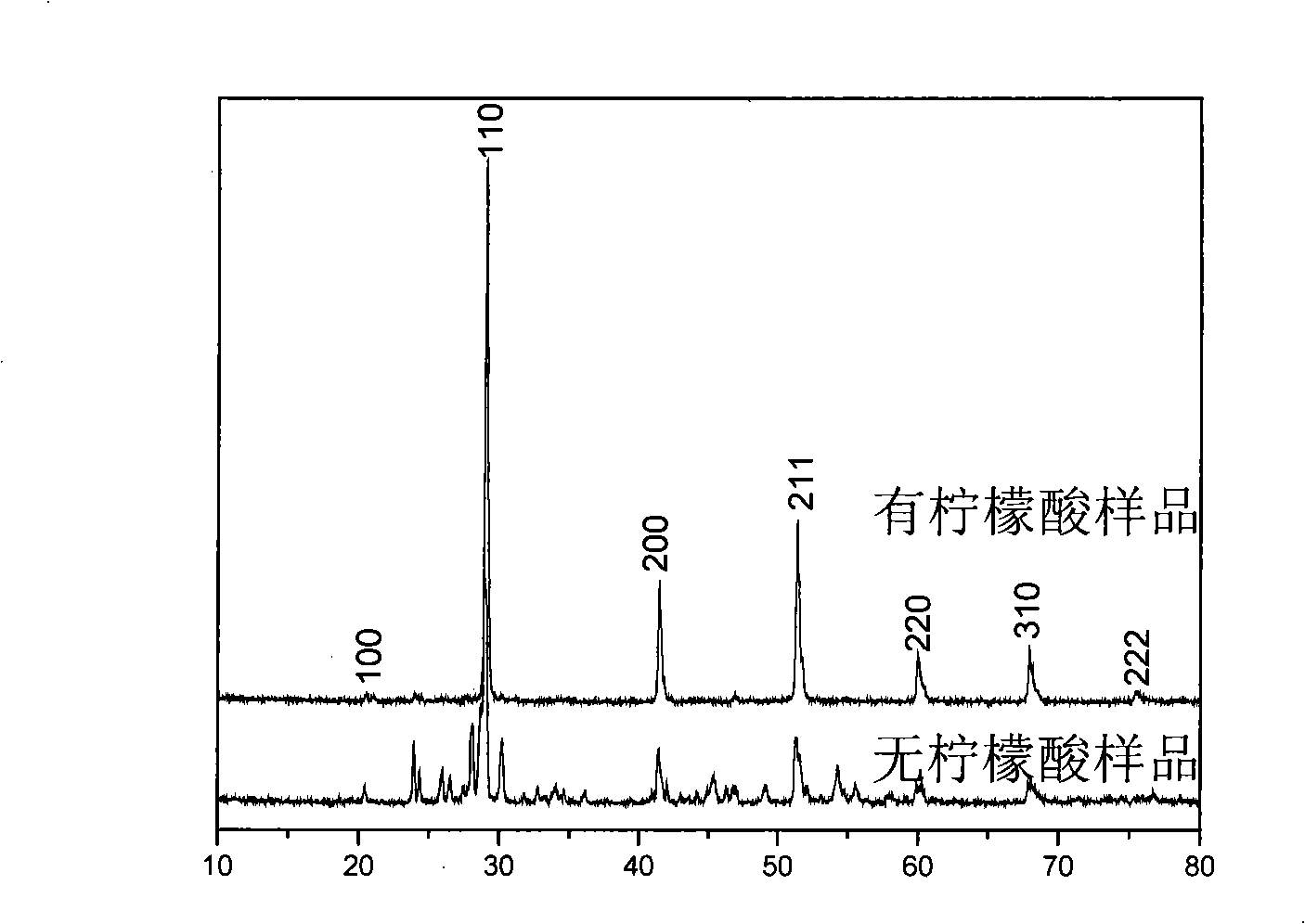

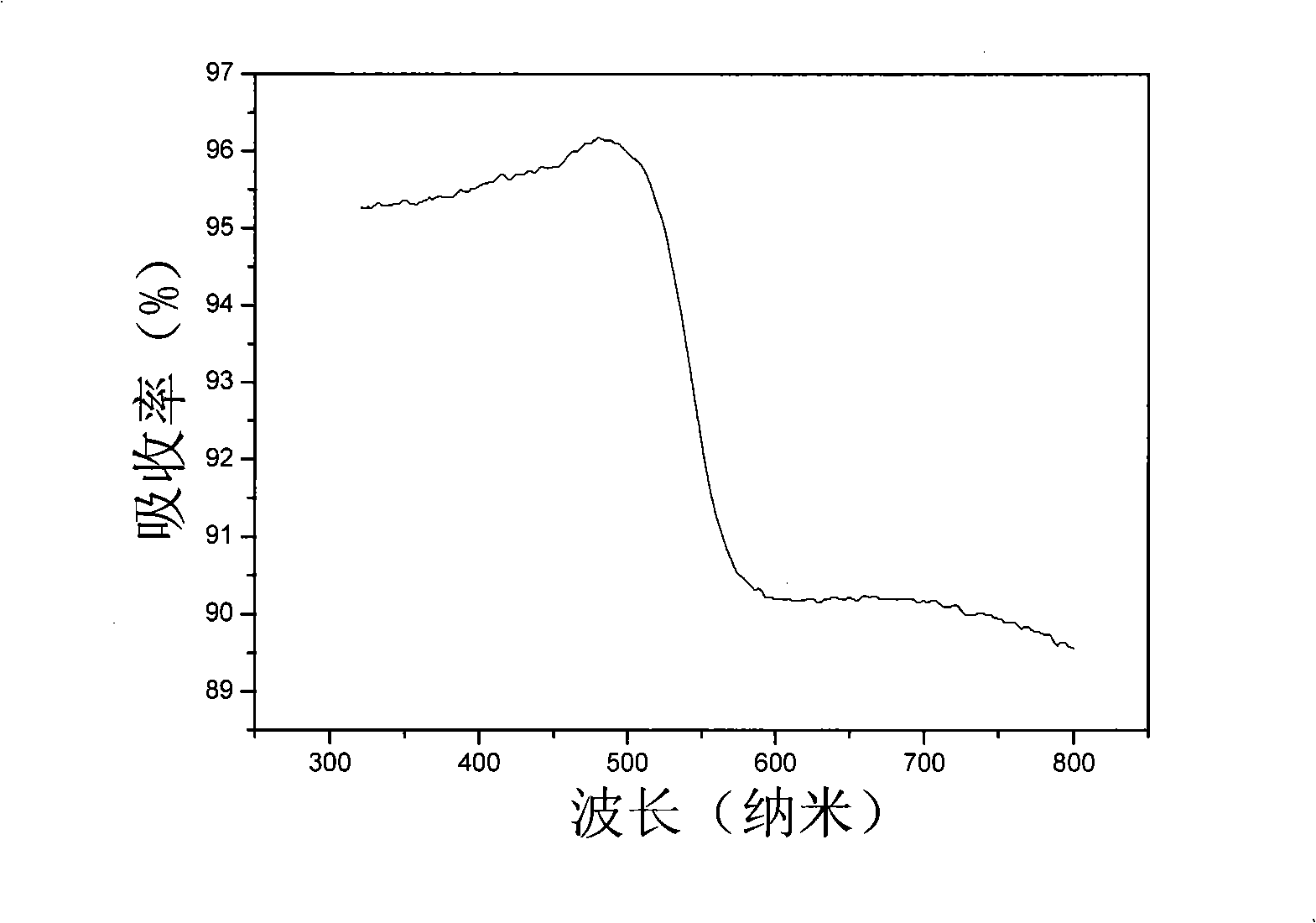

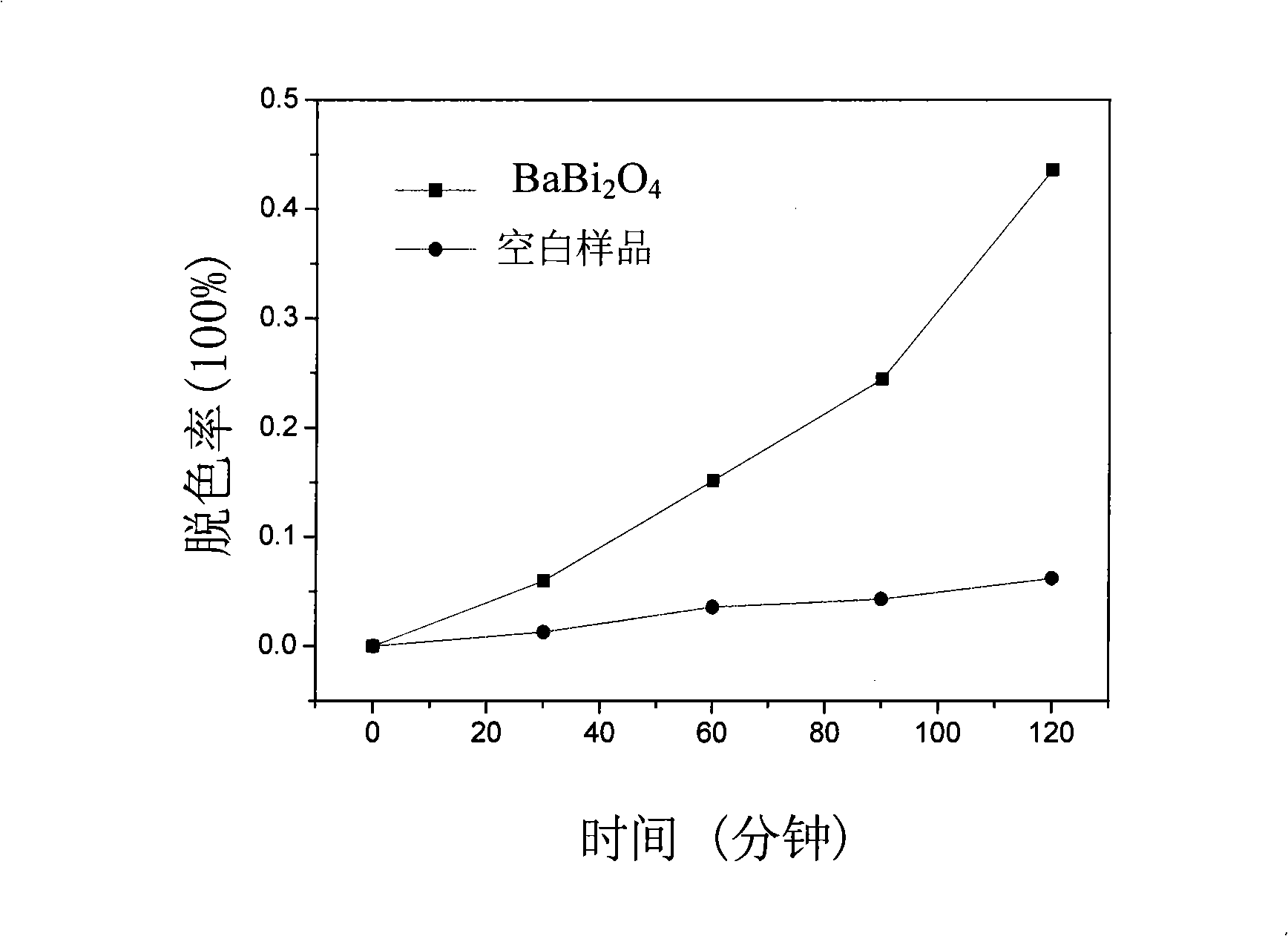

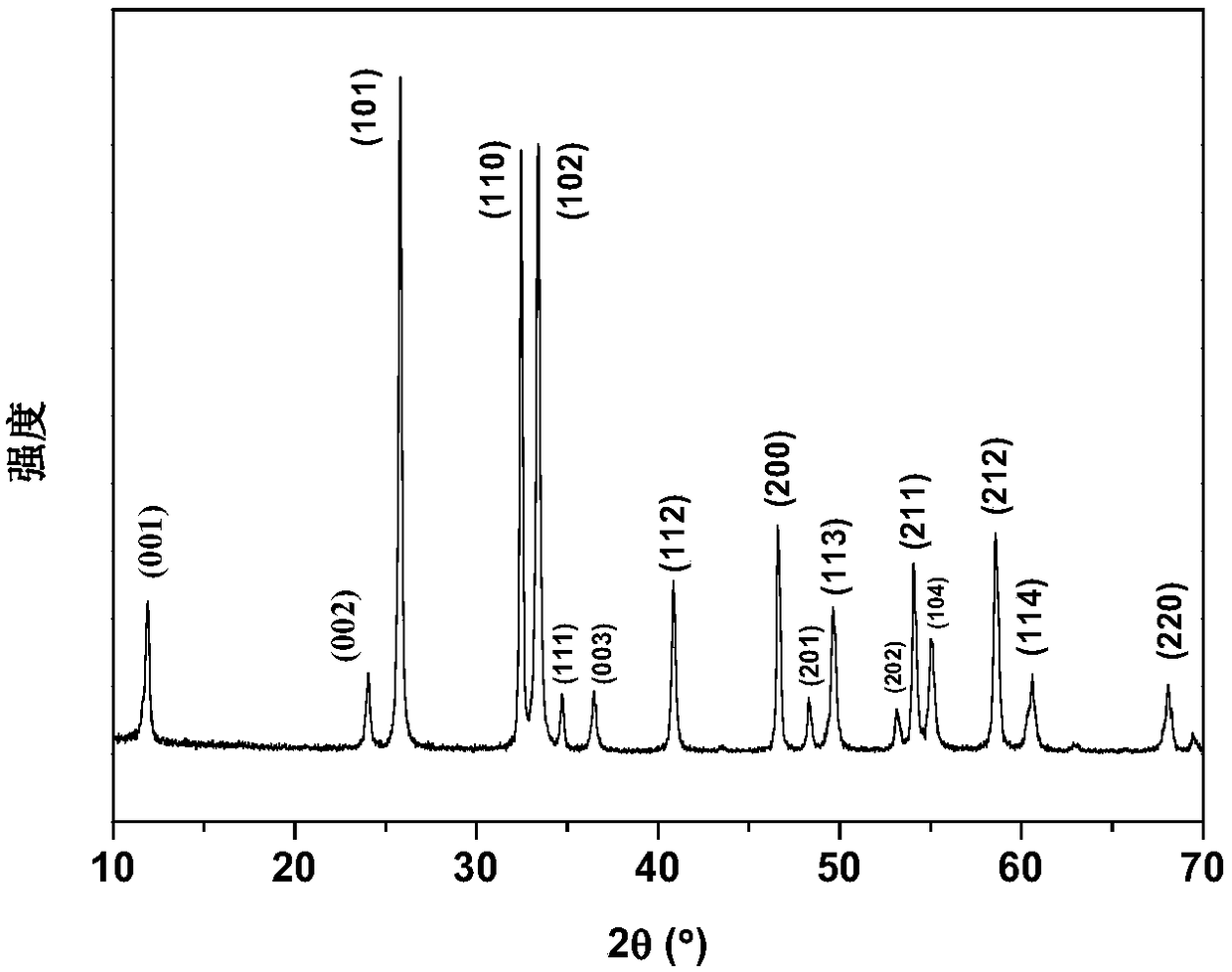

Visible light responding photocatalyst and low temperature combustion synthesis method

InactiveCN101306360AWell mixedImprove relationshipMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsDissolution

The invention relates to a visible light responding photo-catalyst as well as the low temperature combustion synthetic method thereof. The invention is characterized in that the provided photo-catalyst is barium bismuthate, wherein the mol ratio of barium ions to bismuth ions is 1-6:2, the method is characterized in that the amine solution of bismuth nitrate and ethylene diamine tetraacetic acid is mixed with citric acid solution according to the stoichiometric proportion, so as to form a transparent solution which is then added with barium nitrate, stirring is carried out for dissolution, thereby obtaining a transparent precursor solution; then the low temperature combustion heat treatment is carried out in three stages, according to the photo-catalyst provided by the invention, photo-response exists from the ultraviolet region to the visible region, and the invention has photo catalytic degradation effect on methylene blue under the visible light irradiation.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

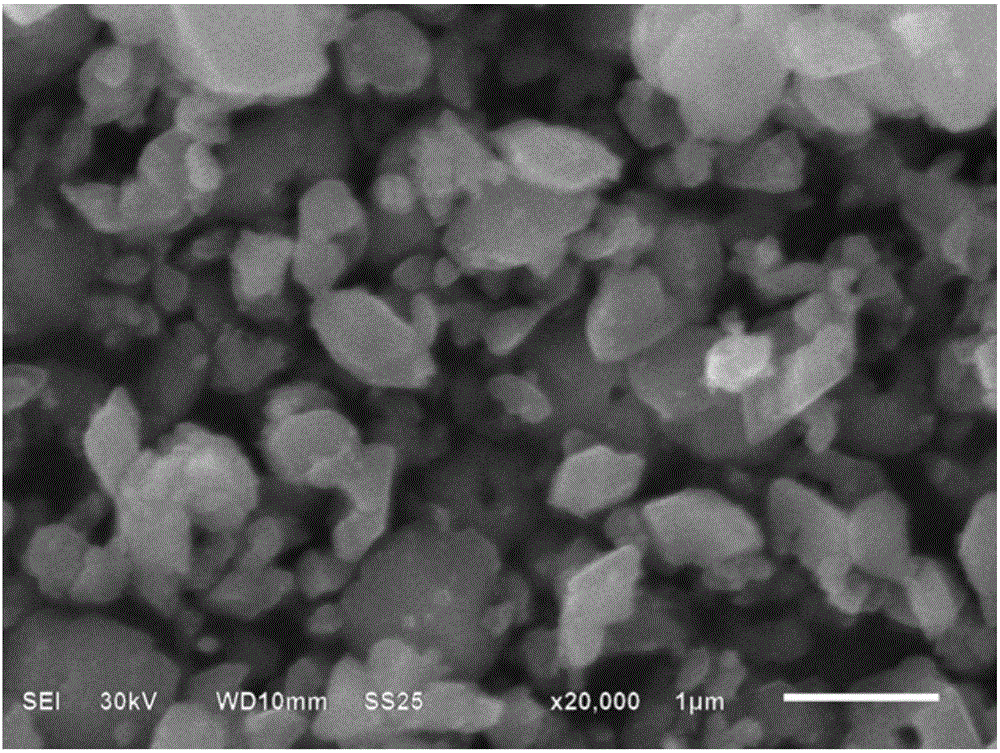

BiOCl material preparation method and application of BiOCl material

ActiveCN108408773ASimple preparation processMild process conditionsBismuth compoundsManufacturing technologyHigh energy

The invention relates to a BiOCl material preparation method and application of a BiOCl material. The BiOCl material preparation method comprises the following steps of by taking bismuthate, a reducing agent, a chlorine source and a dispersant as raw materials, synchronously applying the mechanical force of high energy ball milling on redox reaction and chlorination reaction, and then performing heat treatment, washing for impurity removal, solid-liquid separation and drying to prepare the BiOCl material. The prepared BiOCl material is formed by a nanosheet with a plan view size being 0.1-5 microns and the thickness being 2-20nm and has the specific surface area of 3-300m<2> / g. The BiOCl material preparation method has the advantages of simpleness in technology, easiness in industrial production, low cost in manufacturing technology, environmental protection and the like; and the prepared BiOCl material has a wide application in the fields of supercapacitors, alkaline rechargeable batteries, lithium ion batteries, photocatalysts, pearlescent pigments, medicines and the like.

Owner:XIANGTAN UNIV

Heterostructure photocatalyst for enhancing visible light response and preparation method thereof

InactiveCN111545225AHigh visible light absorption responseChemically stablePhysical/chemical process catalystsBismuth compoundsCalcium nitrate tetrahydrateLight response

The invention discloses a CaBi2O4 / BiOCl heterojunction composite photocatalyst and a preparation method thereof, and belongs to the technical field of photocatalytic materials. The preparation methodcomprises the following steps: dissolving calcium nitrate tetrahydrate in deionized water, dissolving barium nitrate pentahydrate in dilute nitric acid, and uniformly mixing the calcium nitrate tetrahydrate and barium nitrate pentahydrate; dropwise adding dilute ammonia water and the mixed solution into deionized water at the same time, and continuously stirring until the pH value is 6-8 to obtainwhite turbid liquid; stirring and aging the obtained precipitate suspension for 30 minutes, carrying out solid-liquid separation by using a centrifugal machine to obtain a white precipitate, washing,diluting, putting into a reaction kettle, carrying out heating treatment at 180-260 DEG C for 6 hours, and cooling and drying to obtain calcium bismuthate; roasting Calcium bismuthate for 4 h, and then adding absolute ethyl alcohol and deionized water for ultrasonic treatment; and adding hydrochloric acid with required volume according to different molar fractions, stirring, filtering, washing and drying to obtain a series of CaBi2O4 / BiOCl heterojunction photocatalysts with different BiOCl contents. The method has the characteristics that the preparation temperature is low, the process is simple, the absorption of the prepared CaBi2O4 / BiOCl heterojunction photocatalyst to visible light is enhanced, and the degradation performance to rhodamine B is also obviously superior to that of CaBi2O4.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

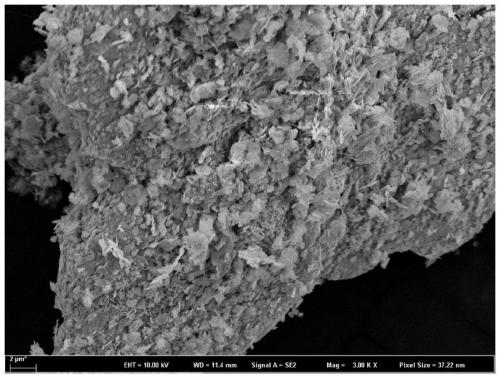

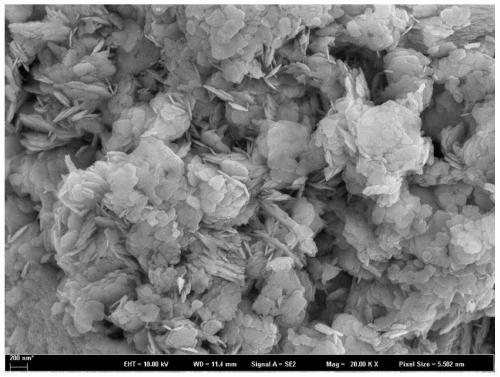

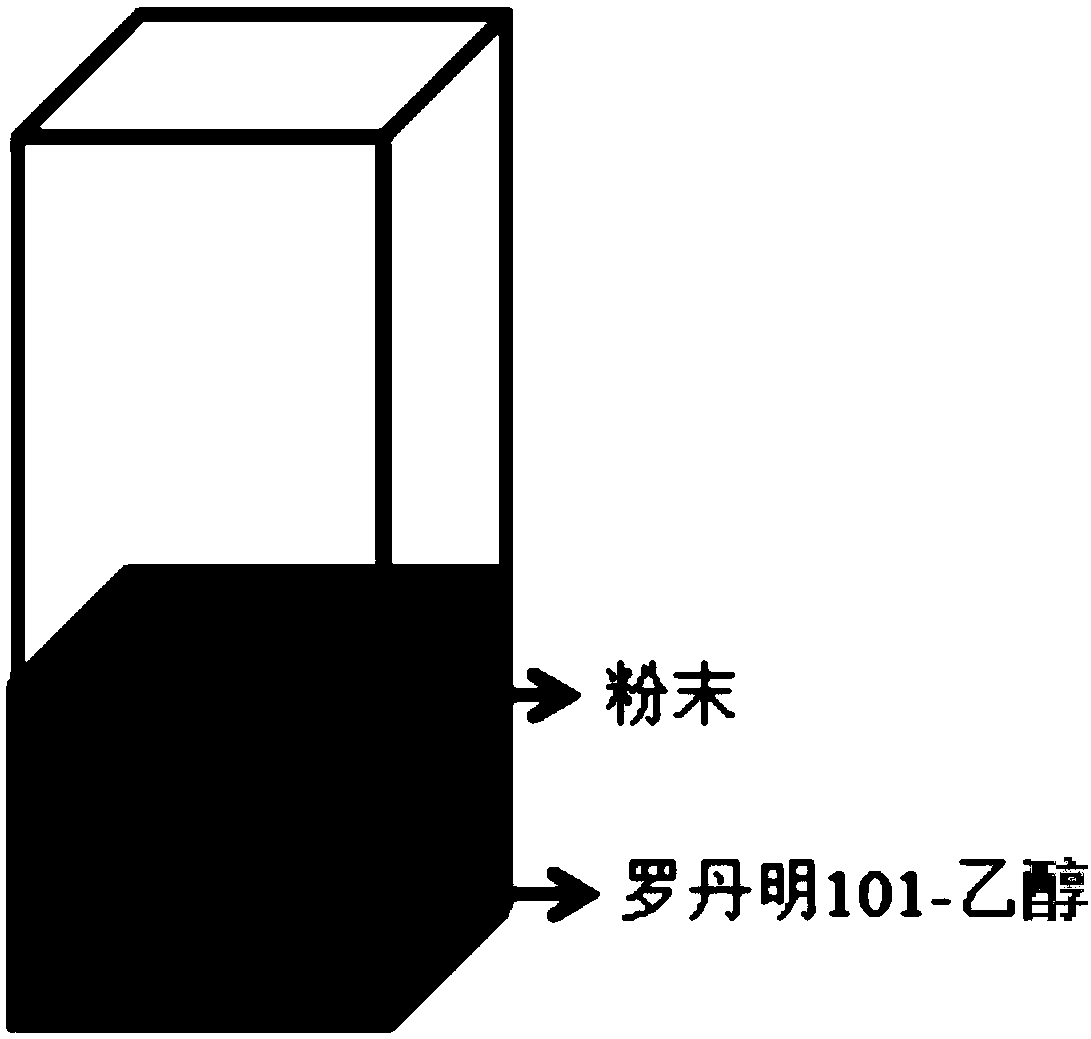

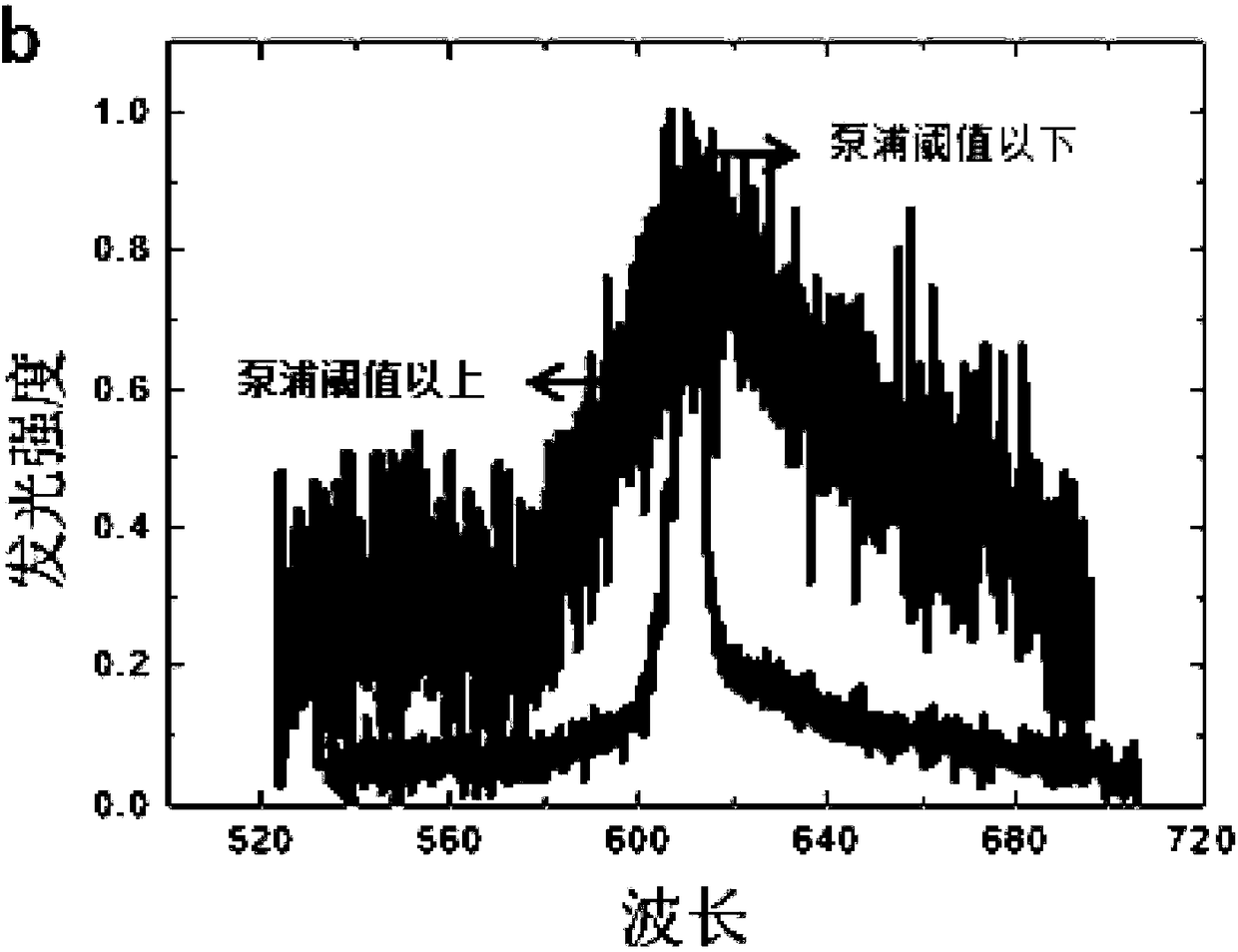

Ultra-wideband random laser scattering material based on amorphous bismuthate, laser device and preparation and application

ActiveCN108512029AFacilitate interactionEffective laser resonanceLaser using scattering effectsUltra-widebandDigital storage

The invention relates to an ultra-wideband random laser scattering material based on amorphous bismuthate, a laser device and preparation and application. The scattering material comprises the chemical compositions in following mole percents: 45-65% of Bi2O3, 20-35% of B2O3, and 0-20% of Ga2O3; the preparation method comprises the following steps: mixing required raw materials, melting at a high temperature, annealing the high-temperature melt near by the glass transition temperature after the compression molding, and then ball-milling a bulk material into powder, wherein the prepared powder can be used for constructing suspension, solid tablet, substrate spinning film and various construction capable of providing random laser resonant optical feedback; and the ultra-wideband random lasercan be observed in the wide spectrum range of 530-870nm by changing the variety of the gain medium and exciting by the laser in different wavelengths. The preparation method is simple and flexible inform, and can be well used for the optical communication, the digital storage, the energy conversion and other fields.

Owner:QILU UNIV OF TECH

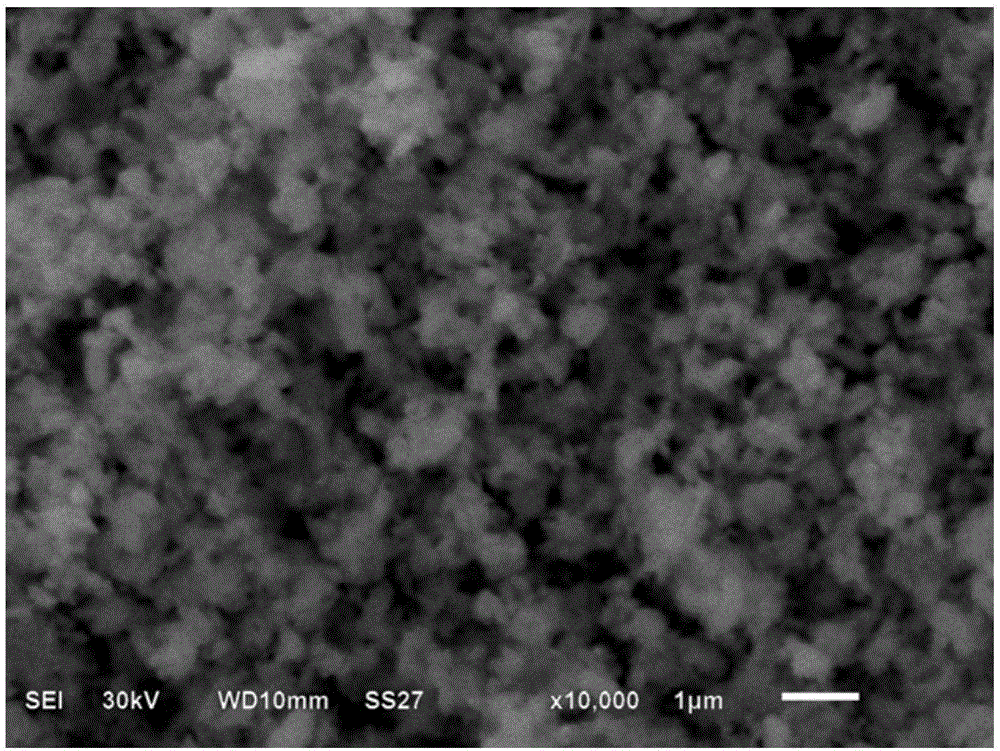

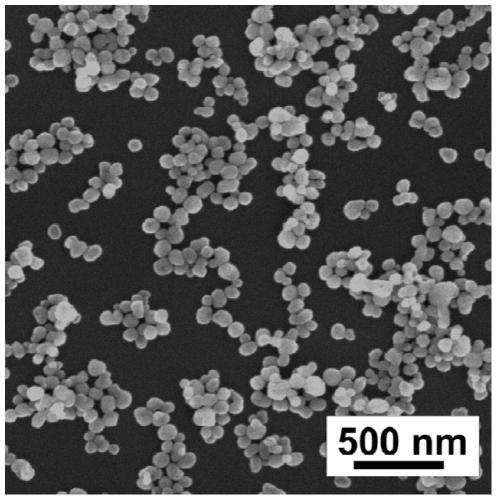

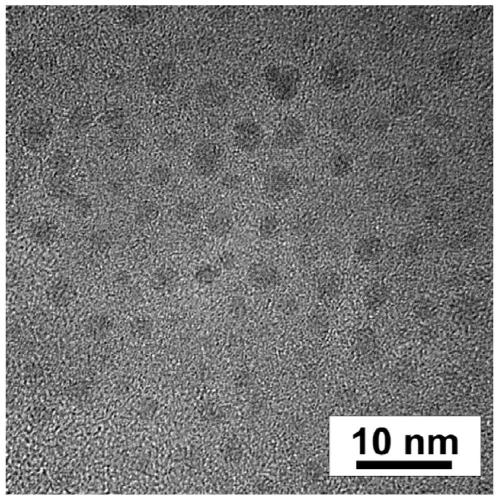

Copper bismuthate film embedded with ligand-free quantum dots, and preparation method and application thereof

InactiveCN110201676AEasy to prepareMild conditionsHeterogenous catalyst chemical elementsCatalyst activation/preparationLiquid mediumVolumetric Mass Density

The invention discloses a copper bismuthate film embedded with ligand-free quantum dots, and a preparation method and an application thereof. The preparation method comprises the following steps: dispersing a semiconductor oxide or a metal material in a liquid medium to obtain a mixed solution; irradiating the mixed solution under a laser beam to obtain a ligand-free quantum dot colloid solution;and mixing the ligand-free quantum dot colloid solution with a copper bismuthate precursor solution, forming a film, and sintering the film to obtain the copper bismuthate film embedded with ligand-free quantum dots. The ligand-free quantum dots are uniformly embedded in the copper bismuthate film by a liquid phase pulse irradiation technique, so that the carrier separation efficiency of the copper bismuthate film is significantly improved; and results of photocurrent density test of films shows that the photocurrent density of the copper bismuthate film not embedded with ligand-free quantum dots is 2.0 mA / cm<2>, and the photocurrent density of the copper bismuthate film embedded with ligand-free quantum dots is increased to about 3.0 mA / cm<2>, so the photoelectric performances are remarkably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bismuth borate glass-based Ce:YAG glass ceramic for white light LED and preparation method thereof

ActiveCN109592907AImprove thermal stabilityGood chemical stabilityCoatingsSpectral modifiersSlurryBismuth borate

The invention belongs to semiconductor blue light chip optical excitation and white light transmission, and discloses boron bismuthate glass based Ce:YAG glass ceramic for white light LED and a preparation method thereof. The glass ceramic is prepared from matrix red light glass sheet and printing slurry through silk-screen printing and sintering, wherein the printing slurry is prepared from low-melting-point fine glass powder, organic mixture and YAG:Ce <3+> fluorescent powder; the matrix red light glass sheet has a chemical general formula of x1B2O3.x2Bi2O3.x3Mo.x4Eu2O3; the low-melting-point fine glass powder has a chemical general formula of x5B2O3.x6Bi2O3.x7Al2O3.x8M'O; and the organic mixture contains terpilenol C10H18O and ethyecellulose C23H24N6O4. The glass ceramic has good thermal stability, good chemical stability, excellent color rendering and luminescence property; and the preparation method has low cost, and can be produced in batches.

Owner:JIANGXI UNIV OF SCI & TECH +1

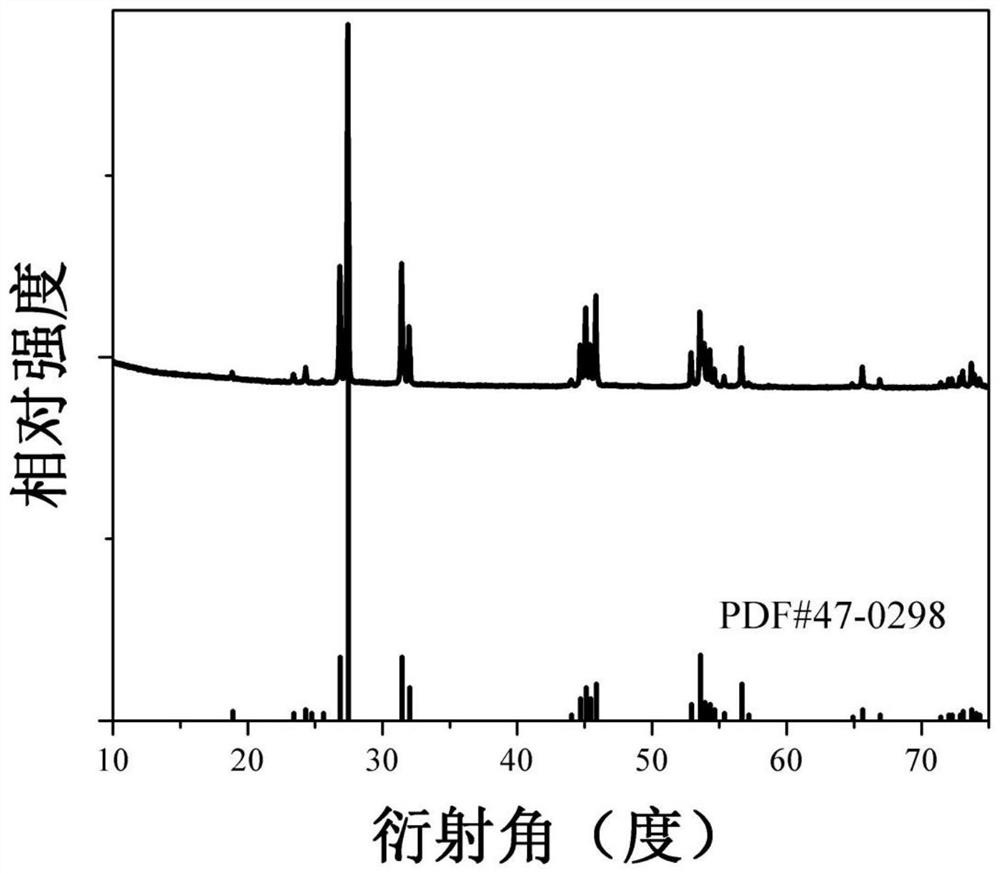

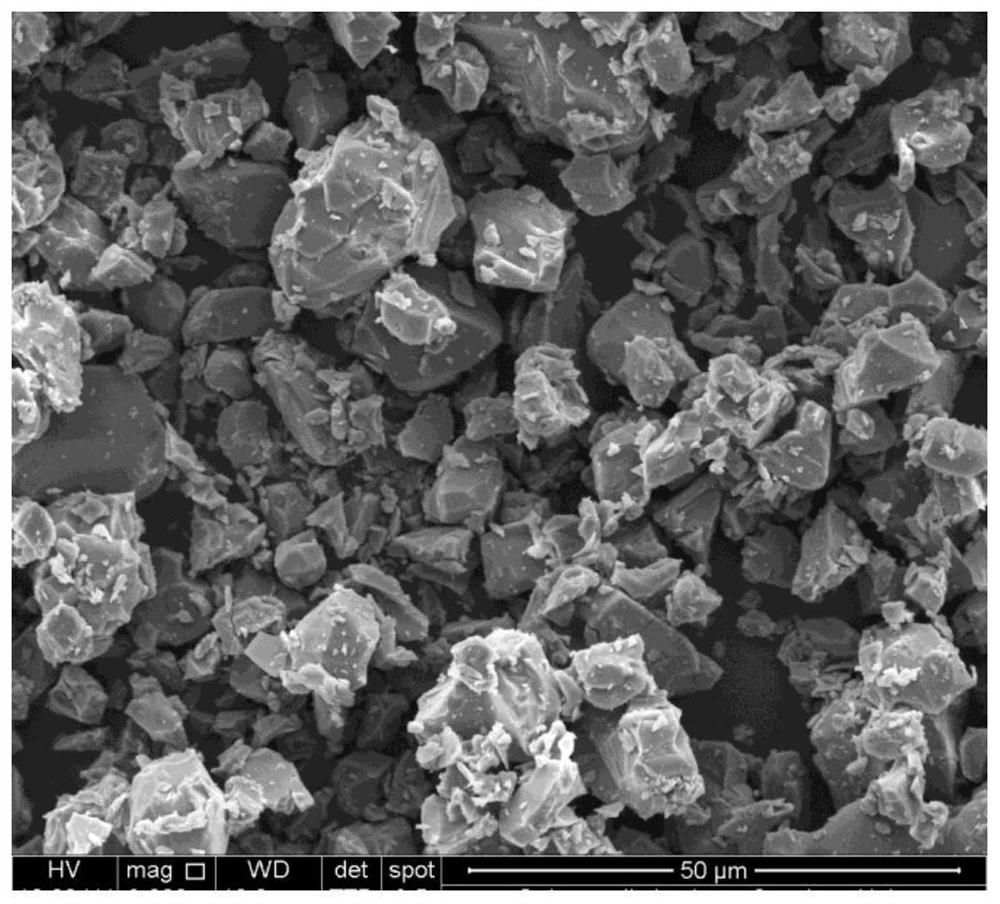

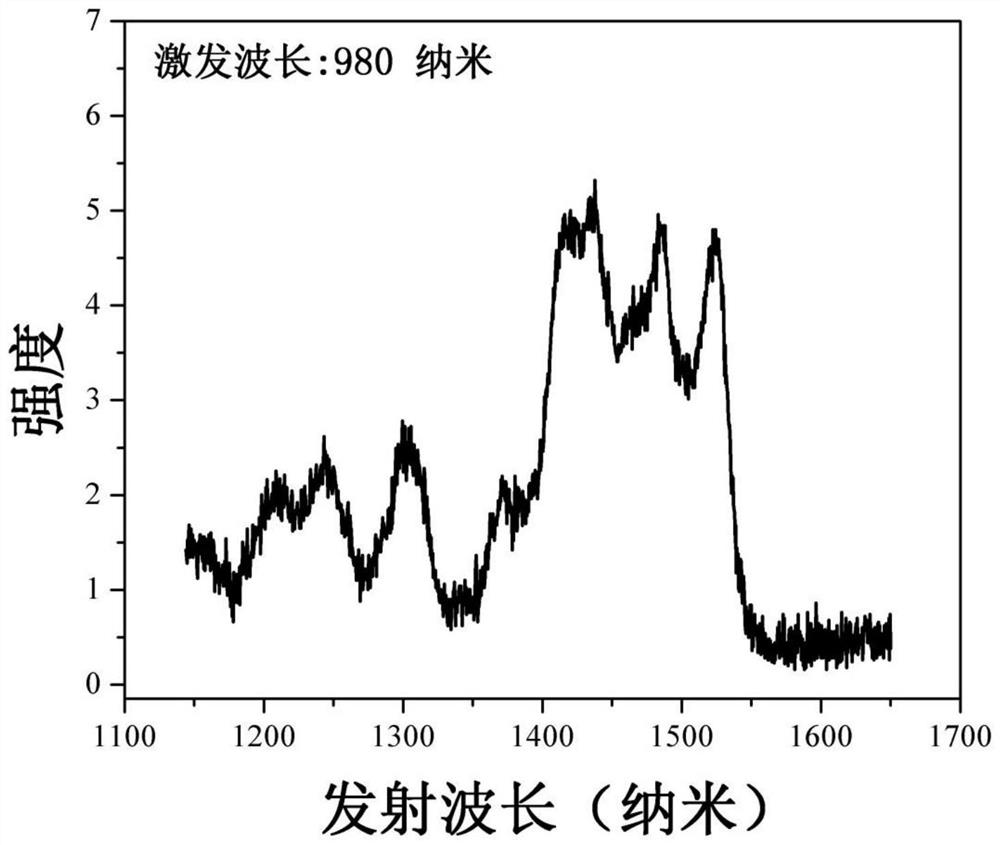

Pr<3+> ion activated near-infrared luminescent material and preparation method thereof

ActiveCN112111273AImprove polarization performanceHigh space-occupying disorderLuminescent compositionsBismuth compoundsPolarizabilityNear infrared luminescence

The invention discloses a Pr<3+> ion activated near-infrared luminescent material and a preparation method thereof. The matrix of the luminescent material is rare earth bismuthate oxide, Bi<3+> ions enhance the polarization performance of crystal lattices, and positive ions in the crystal lattices have very high occupied disorder, so that a structural basis is provided for effective luminescence of Pr<3+> ions; the luminescent material has the strongest emission intensity in the wavelength range of 1.4-1.56 mum, belongs to 1D2-to-1G4 transition luminescence from Pr<3+> ions, and the emission waveband is mainly suitable for being applied to an E-band extension waveband and an S-band short wavelength waveband in an optical amplifier; the matrix crystal lattice of the luminescent material hasvery strong rigidity, so that the prepared near-infrared luminescent material has very high stability; the preparation method of the near-infrared luminescent material is simple in overall preparation process, easy to operate, low in production cost, free of environmental pollution and high in implementation feasibility.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Lead-free bismuthate system low-melting-point glass powder and preparation method thereof

InactiveCN108298823ANo pollution in the processImprove performanceGlass shaping apparatusMetallurgyGlass particle

The invention relates to lead-free bismuthate system low-melting-point glass powder and a preparation method thereof. The glass powder comprises components including a glass main body and an additive;the mass ratio of the glass main body to the additive is 100:(0-17). The preparation method comprises the steps of weighing each component, and conducting stirring and grinding to obtain a mixture; melting the mixture to obtain a glass liquid, and then performing quenching treatment to obtain glass particles; drying and grinding the glass particles to obtain the glass powder. The glass powder does not contain lead and has a low melting point, glass transition temperature of 330-430 DEG C and a wide sintering temperature range.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com