Preparation method of lanthanum bismuthate nanorod

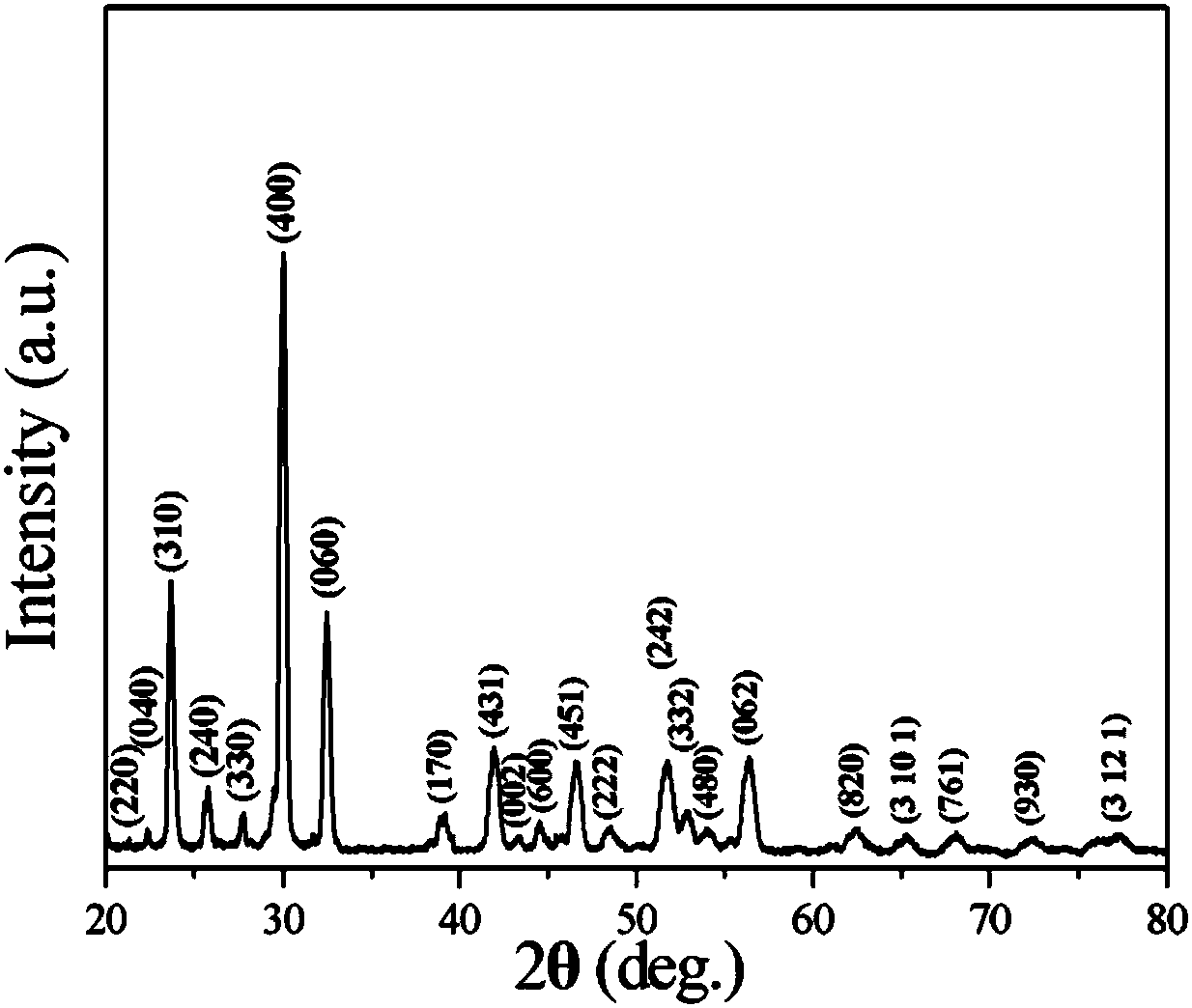

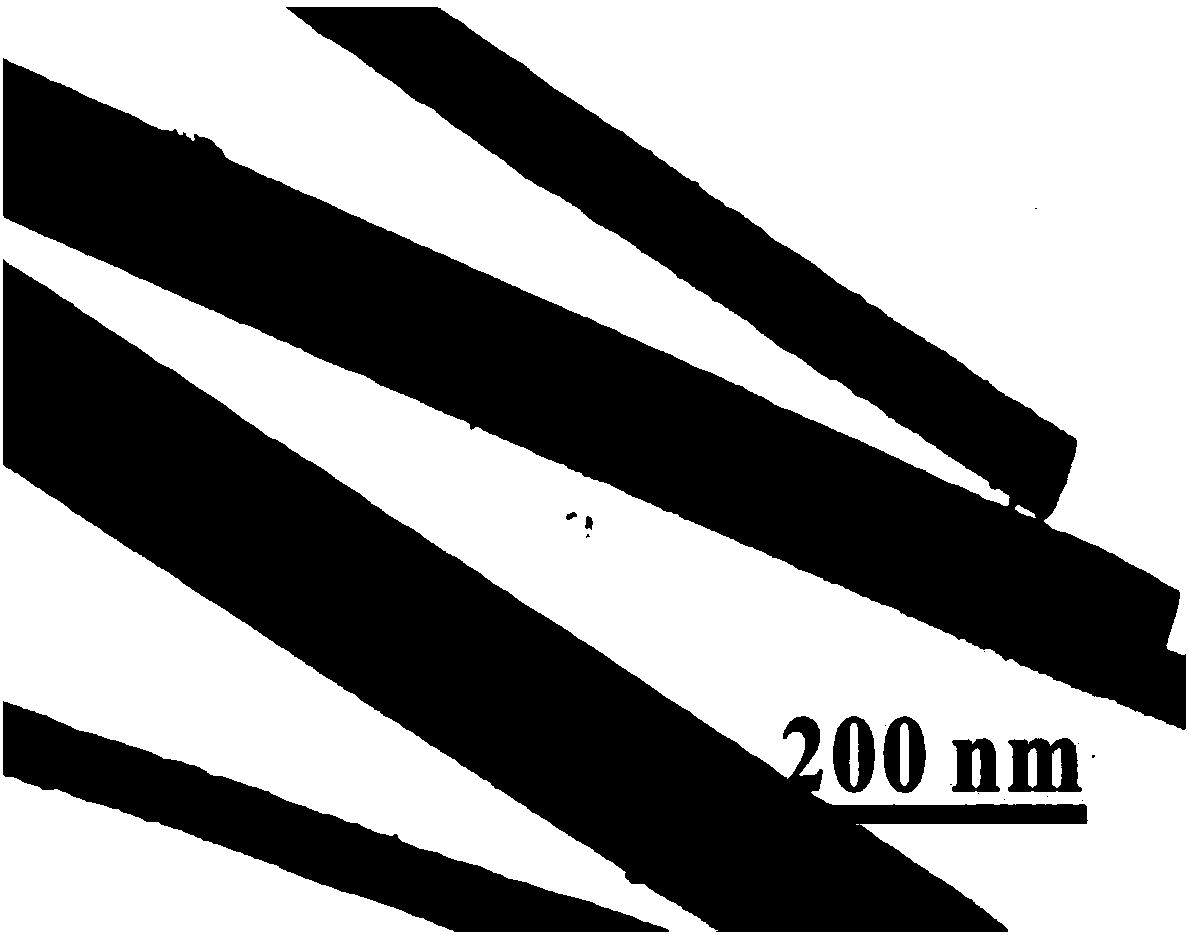

A nanorod, bismuth acid technology, applied in nanotechnology, chemical instruments and methods, bismuth compounds, etc., can solve the problem of no single-phase lanthanum bismuthate material, etc., and achieve the effects of simple preparation process, small size, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: first mix sodium bismuthate and lanthanum acetate evenly, wherein the molar ratio of sodium bismuthate and lanthanum acetate is 1:1, then place the mixed powder of sodium bismuthate and lanthanum acetate in the high temperature zone of the corundum tube reaction vessel, Place an alumina sheet with a size of 6×4cm in the low temperature zone of the corundum tube reaction vessel, seal the corundum tube, heat the high temperature zone to 1300°C, and the low temperature zone to 200°C, keep warm for 3 hours, and the argon flow rate is 50cm 3 / min, thus obtaining alumina flakes with white deposits on the surface.

[0029] Step 2: first fix the aluminum oxide sheet containing white deposits on the surface obtained in step 1 in the middle of the reaction vessel, then mix sodium bismuthate and lanthanum acetate that account for 30% of the water weight with water and place in the reaction vessel and seal it. Wherein the molar ratio of sodium bismuthate to lanthanum acetat...

Embodiment 2

[0031] Step 1: first mix sodium bismuthate and lanthanum acetate evenly, wherein the molar ratio of sodium bismuthate and lanthanum acetate is 1:1, then place the mixed powder of sodium bismuthate and lanthanum acetate in the high temperature zone of the corundum tube reaction vessel, Place an alumina sheet with a size of 6×4cm in the low temperature zone of the corundum tube reaction vessel, seal the corundum tube, heat the high temperature zone to 1100°C, and the low temperature zone to 100°C, keep warm for 0.5h, and the argon flow rate is 20cm 3 / min, thus obtaining alumina flakes with white deposits on the surface.

[0032] Step 2: first fix the aluminum oxide sheet containing white deposits on the surface obtained in step 1 in the middle of the reaction vessel, then mix sodium bismuthate and lanthanum acetate accounting for 5% of the water weight with water and place in the reaction vessel and seal it. Wherein the molar ratio of sodium bismuthate to lanthanum acetate is 1...

Embodiment 3

[0034] Step 1: first mix sodium bismuthate and lanthanum acetate evenly, wherein the molar ratio of sodium bismuthate and lanthanum acetate is 1:1, then place the mixed powder of sodium bismuthate and lanthanum acetate in the high temperature zone of the corundum tube reaction vessel, Place an alumina sheet with a size of 6×4cm in the low temperature zone of the corundum tube reaction vessel, seal the corundum tube, heat the high temperature zone to 1120°C, and the low temperature zone to 120°C, keep warm for 0.8h, and the argon flow rate is 25cm 3 / min, thus obtaining alumina flakes with white deposits on the surface.

[0035] Step 2: first fix the aluminum oxide sheet containing white deposits on the surface obtained in step 1 in the middle of the reaction vessel, then mix sodium bismuthate, lanthanum acetate and water that account for 7% of the water weight and place in the reaction vessel and seal it. Wherein the molar ratio of sodium bismuthate to lanthanum acetate is 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com