Solar cell back face silver paste and preparing method thereof

A technology on the back of solar cells, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low contact resistance of silver paste on the back, non-environmental protection, environmental pollution, etc., to improve photoelectric conversion efficiency, optimization and stability performance, high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

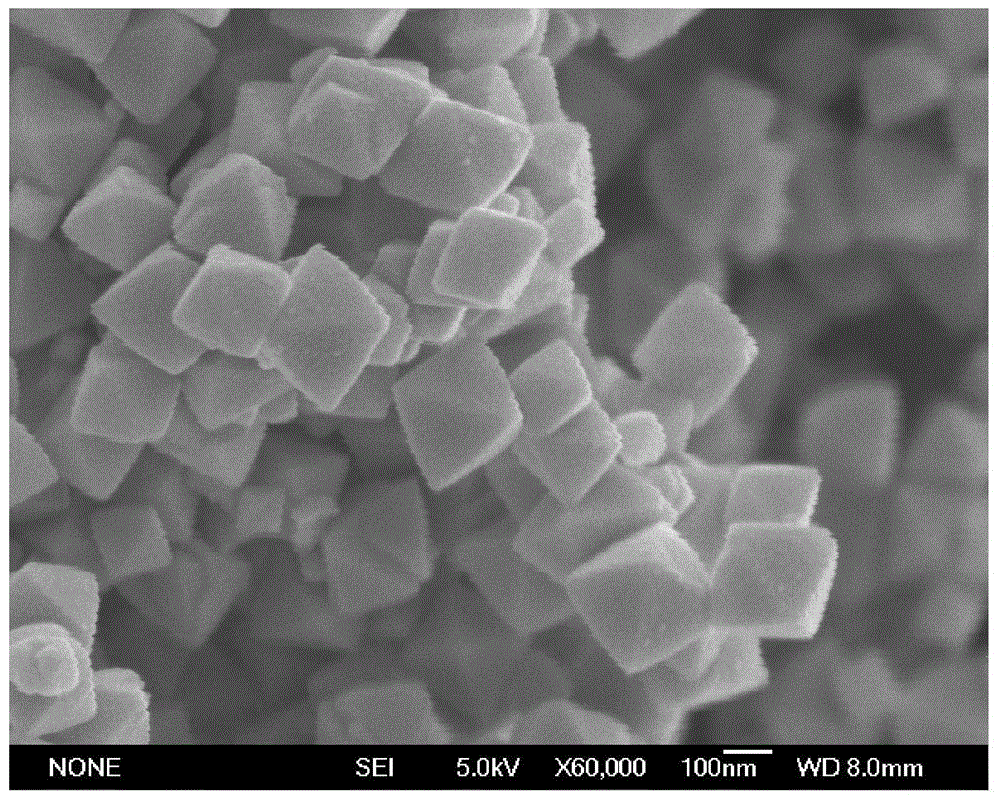

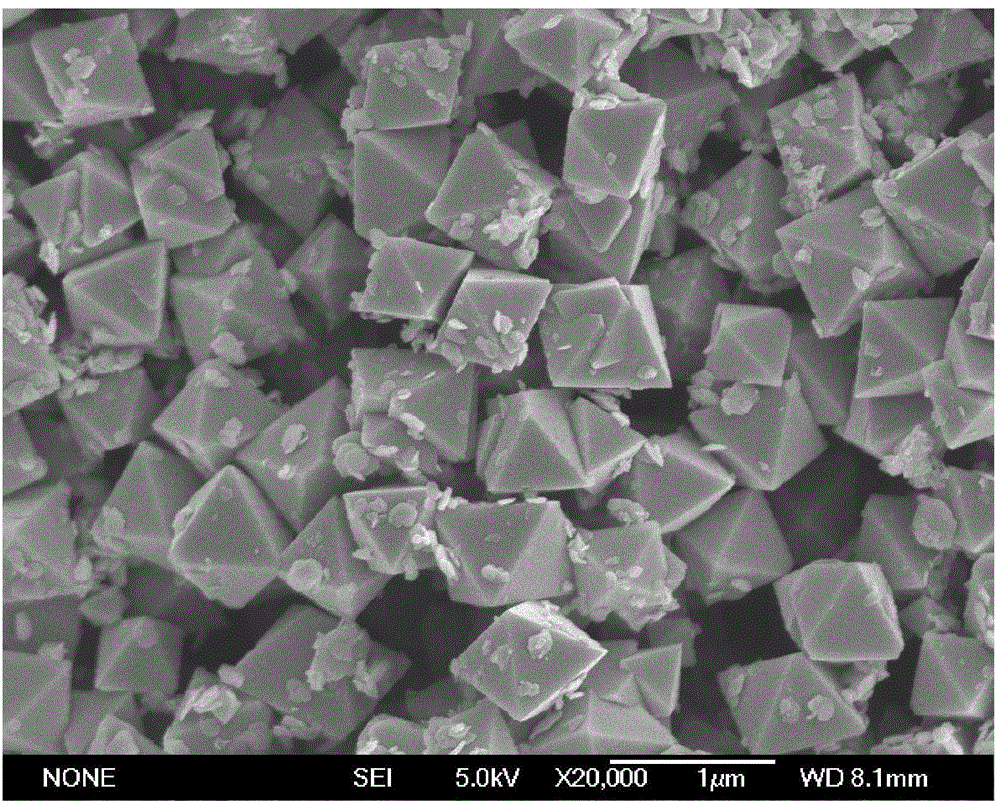

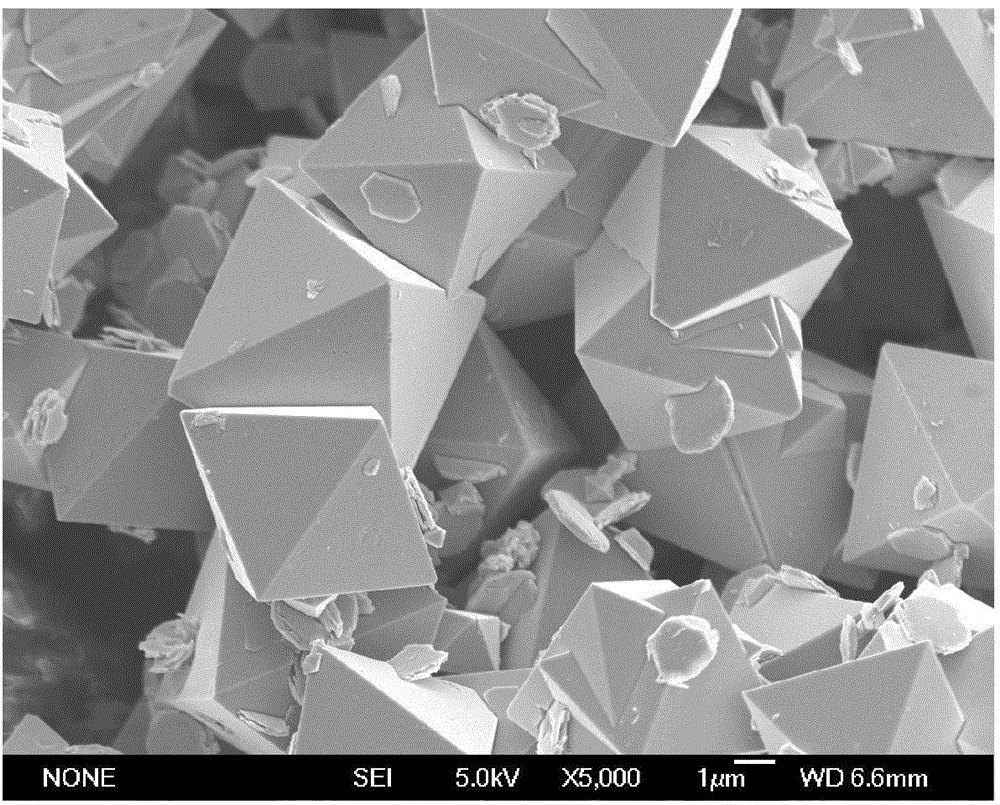

[0024] A specific embodiment of the present invention is a silver paste on the back of a solar cell, and its composition and weight percentage are as follows: 45-60wt% metal powder, 1-6wt% lead-free bismuth salt glass powder and 31-46wt% organic binder, 0 %~3wt% additives, the metal powder mainly includes silver powder, followed by at least one of copper powder, aluminum powder and nickel powder, lead-free bismuth salt glass powder includes 50~85wt% Bi 2 o 3 , 1~25wt% ZnO, 1~10wt% B 2 o 3 , 1~5wt% Al 2 o 3 , 1~5wt% BaO, 1~3wt% SiO 2 , 0~2wt% Sb 2 o 3 , the organic binder includes 1-15wt% organic vehicle and 5-98wt% organic solvent, the organic vehicle is at least one of acrylic resin, ethyl cellulose, butyl cellulose; the organic solvent is castor oil, terpineol , diethylene glycol monobutyl ether, diethylene glycol monobutyl ether acetate, sorbitan monostearate; additives are zinc oxide, titanium oxide, nickel oxide, nickel selenide and tellurium at least one of nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com