Patents

Literature

60results about How to "Reduce residual internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aviation aluminum alloy pre-stretching plate and production method thereof

InactiveCN101037747AAvoid deformationReduce residual stressTemperature control deviceAviationQuenching

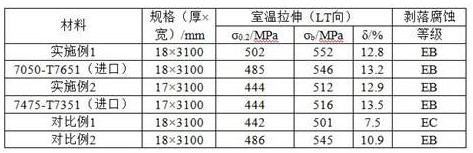

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention is steady without deforming in machining.

Owner:NORTHEAST LIGHT ALLOY CO LTD

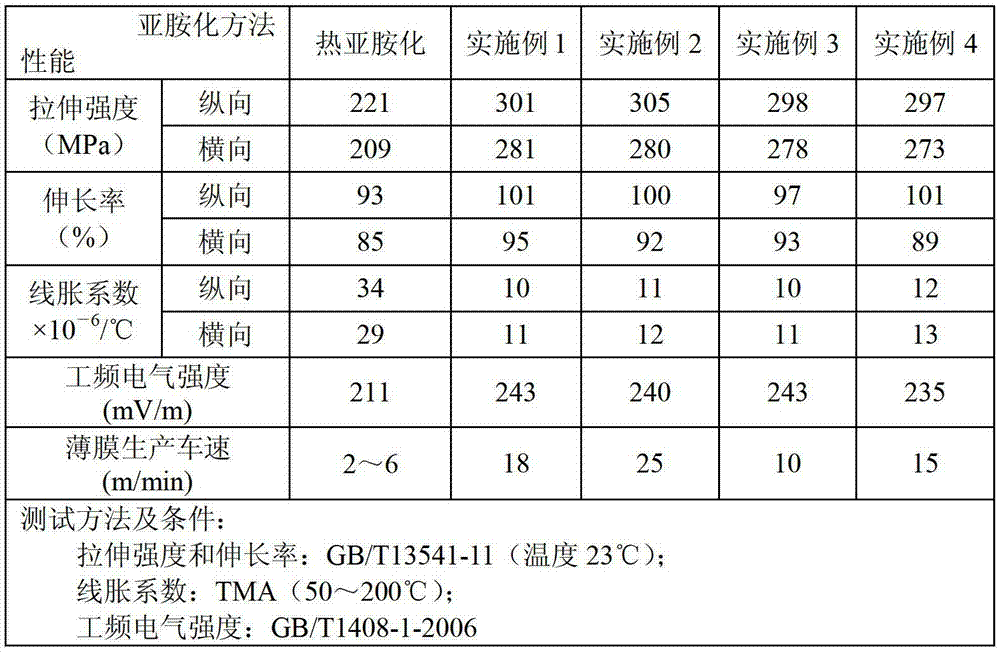

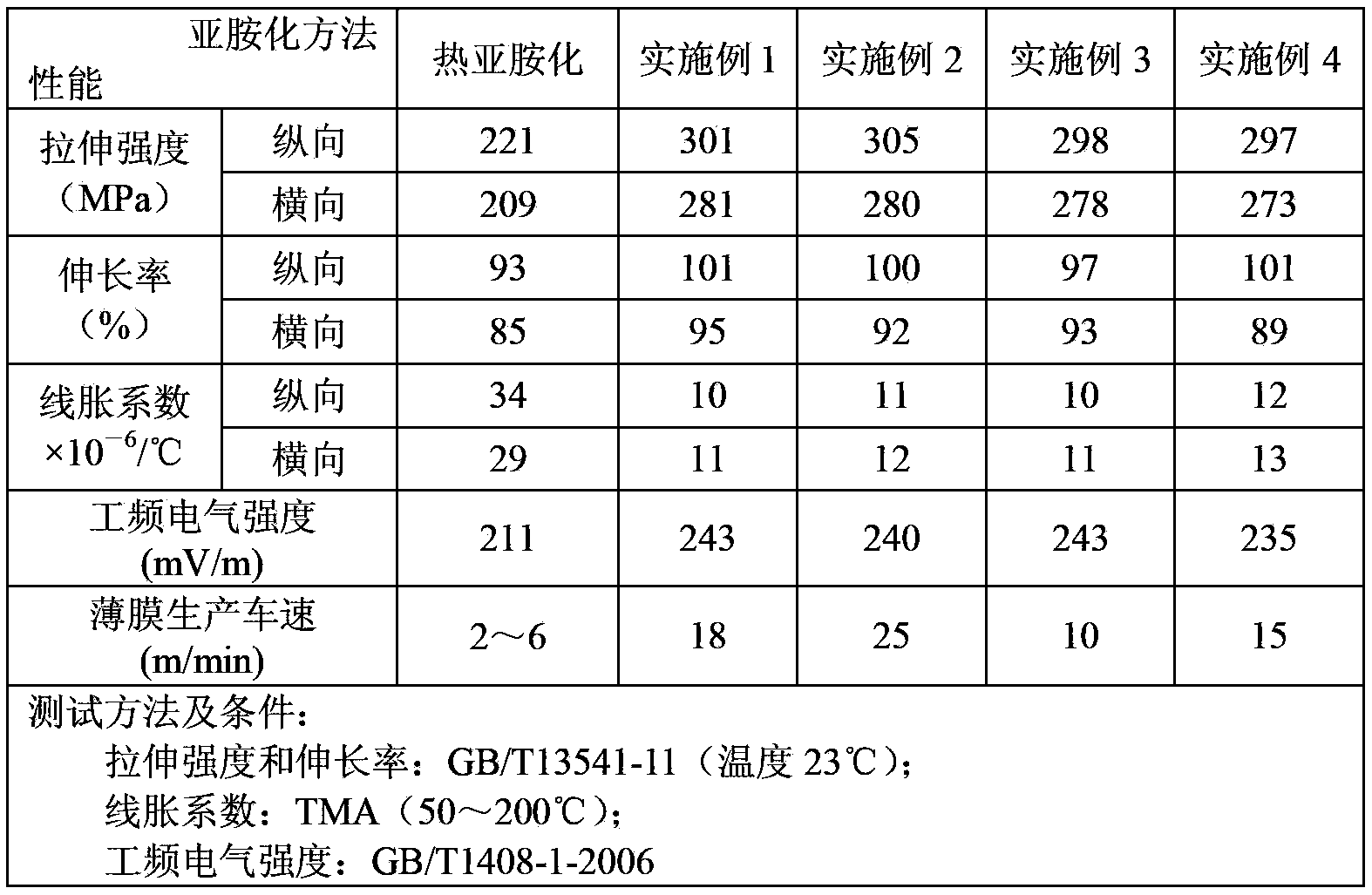

Method for preparing polyimide film by adopting chemical imidization in combined mode

ActiveCN103172891ASmall coefficient of linear expansionGood dimensional stabilityPolyamic acidMechanical property

The invention discloses a polyamic acid imidization catalyst composite and a method for preparing an electronic-grade polyimide film by adopting chemical imidization in a combined mode, and belongs to the technical field of the manufacture of electronic film insulating materials. The novel chemical imidization method of polyimide mainly comprises the following steps of: storing polyamic acid at a low temperature, and stretching to form a film in a casting way; and then producing high-quality electronic-grade polyimide film through a mixing type and bath type combined high-efficiency imidization method. Compared with a method firstly adopting thermal imidization, the method disclosed by the invention outstandingly improves the linear expansion coefficient, the mechanical property, and the like of the obtained polyimide film and is high in production efficiency, lower in preparation cost and suitable for large-scale chemical industrial production of the high-property polyimide film.

Owner:HUAWEI POLYIMIDE +1

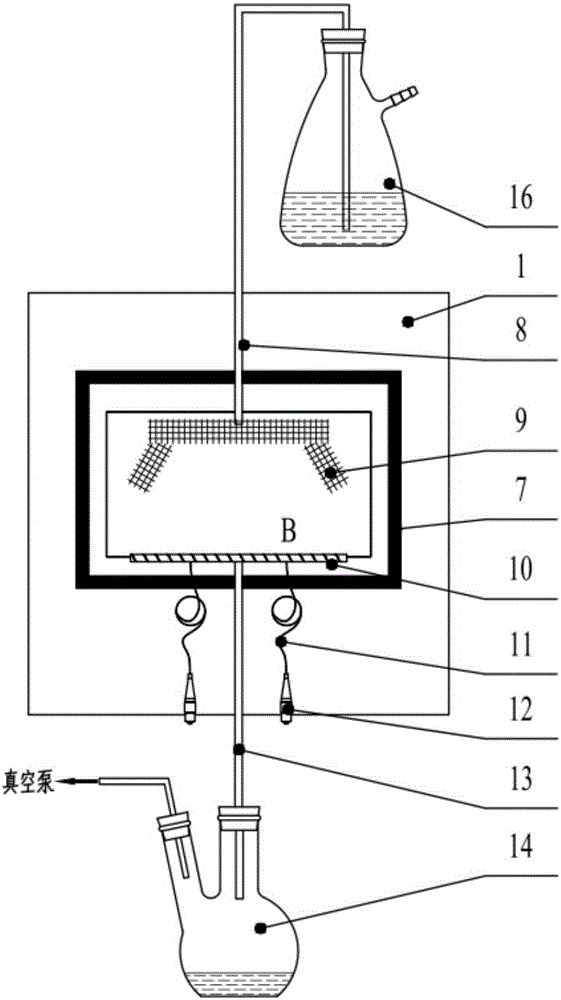

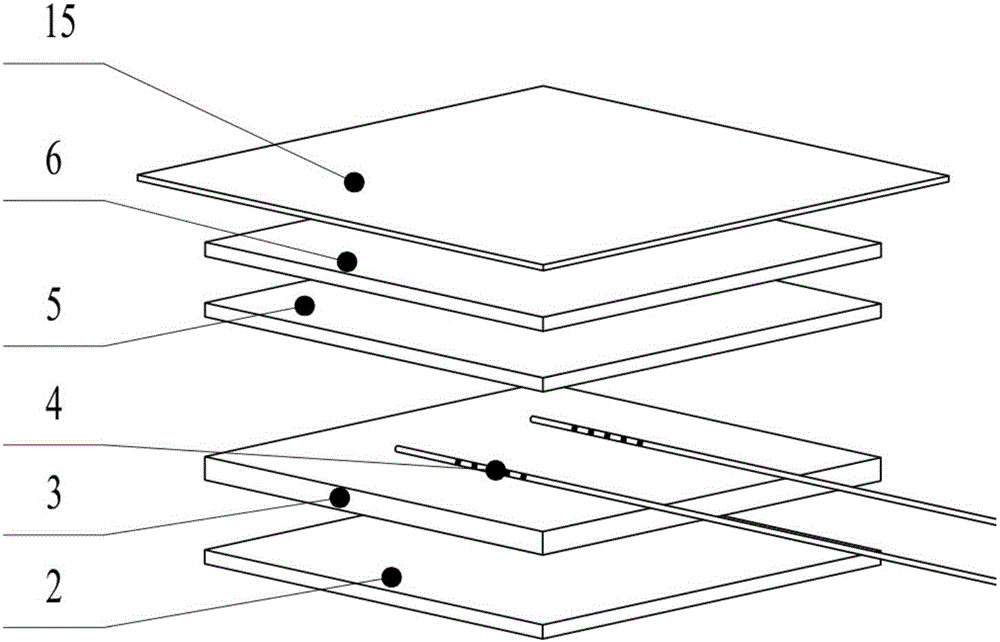

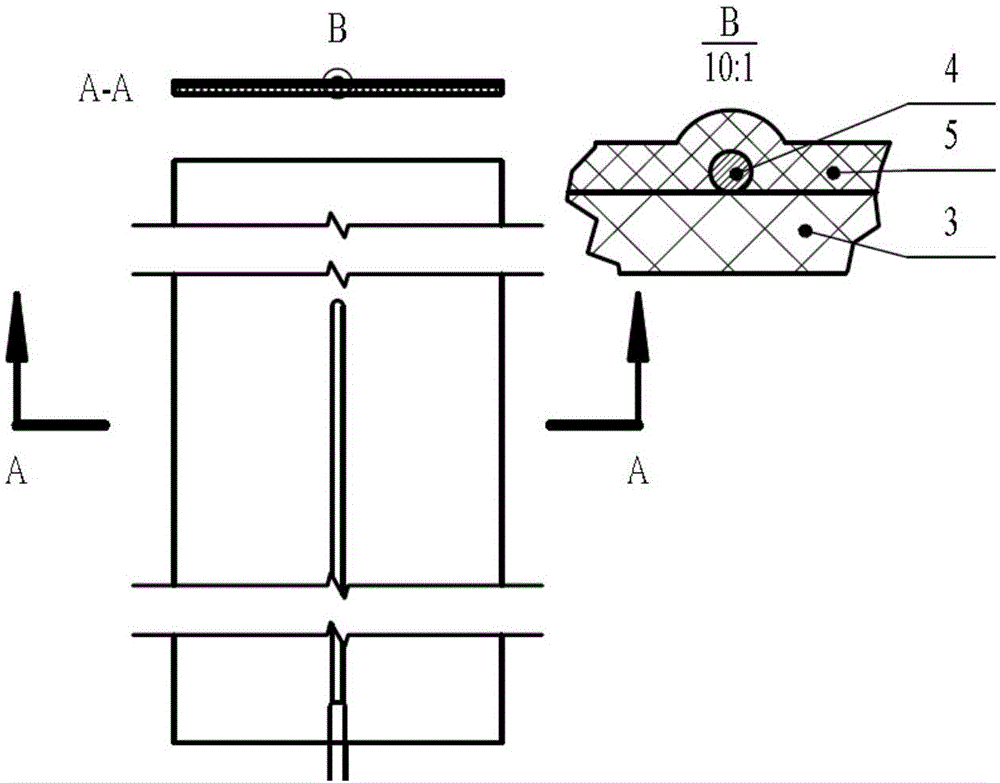

Manufacturing technology of glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

ActiveCN106633137AImprove performance and stabilityReduce internal stressMeasurement devicesOptical articlesFiberEpoxy

The invention discloses a manufacturing technology of a glass fiber / epoxy resin composite material substrate type fiber bragg grating sensor. The manufacturing technology comprises the steps that glass fiber / epoxy resin prepreg is procured to prepare a glass fiber / epoxy resin composite material substrate; a fiber bragg grating is fixed to the glass fiber / epoxy resin composite material substrate; the glass fiber / epoxy resin composite material substrate fixed with the fiber bragg grating is covered with a dry-state glass fiber cloth, vacuum aided filling of liquid epoxy resin is performed, and secondary curing molding is performed. The manufacturing technology adopts the secondary curing molding in the packaging process, the interlayer interface strength is remarkably improved, accordingly the testing precision and stability of the fiber bragg grating sensor are improved, batch production of the fiber bragg grating sensor can be achieved, and the manufacturing technology has wide market prospect and huge economic benefit.

Owner:SHANDONG UNIV

Copper alloy frame material strip for etching and preparation method of strip

The invention relates to a copper alloy frame material strip for etching, and the copper alloy frame material strip is low in residual internal stress; the strip is prepared from the following alloy components: 2.2-4.2% of Ni, 0.25-1.2% of Si, 0.05-0.30% of Mg, 0.01-0.2% of Fe, 0.002-0.01% of Mn, 0.005-0.015% of Zn and the balance of Cu; the strip is prepared by the following steps: uniformly mixing the alloy components and casting; performing hot-rolling, cooling and quenching on an ingot, wherein the initial hot-rolling temperature is 850-1000 DEG C, the final temperature is 700-800 DEG C, and a rolled strip blank is quenched at a cooling speed of 10-30 DEG C / s; and then carrying out annealing, straightening and withdrawing, and low-temperature heat treatment for three times so as to obtain a finished product. By selecting an appropriate alloy component proportion as well as processes of controlling hot-rolling, quenching temperature, aging heat treatment system, straightening and withdrawing as well as low-temperature heat treatment, the purpose of reducing the internal residual stress of the strip can be achieved.

Owner:TAIYUAN JIN XI CHUNLEI COPPER CO LTD

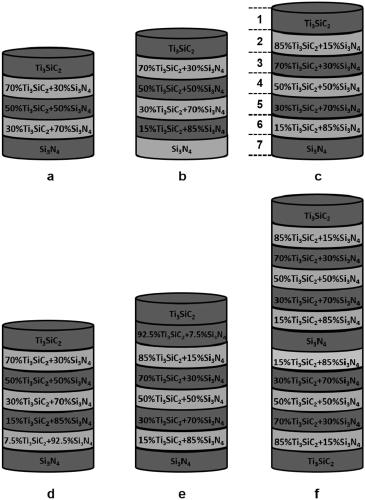

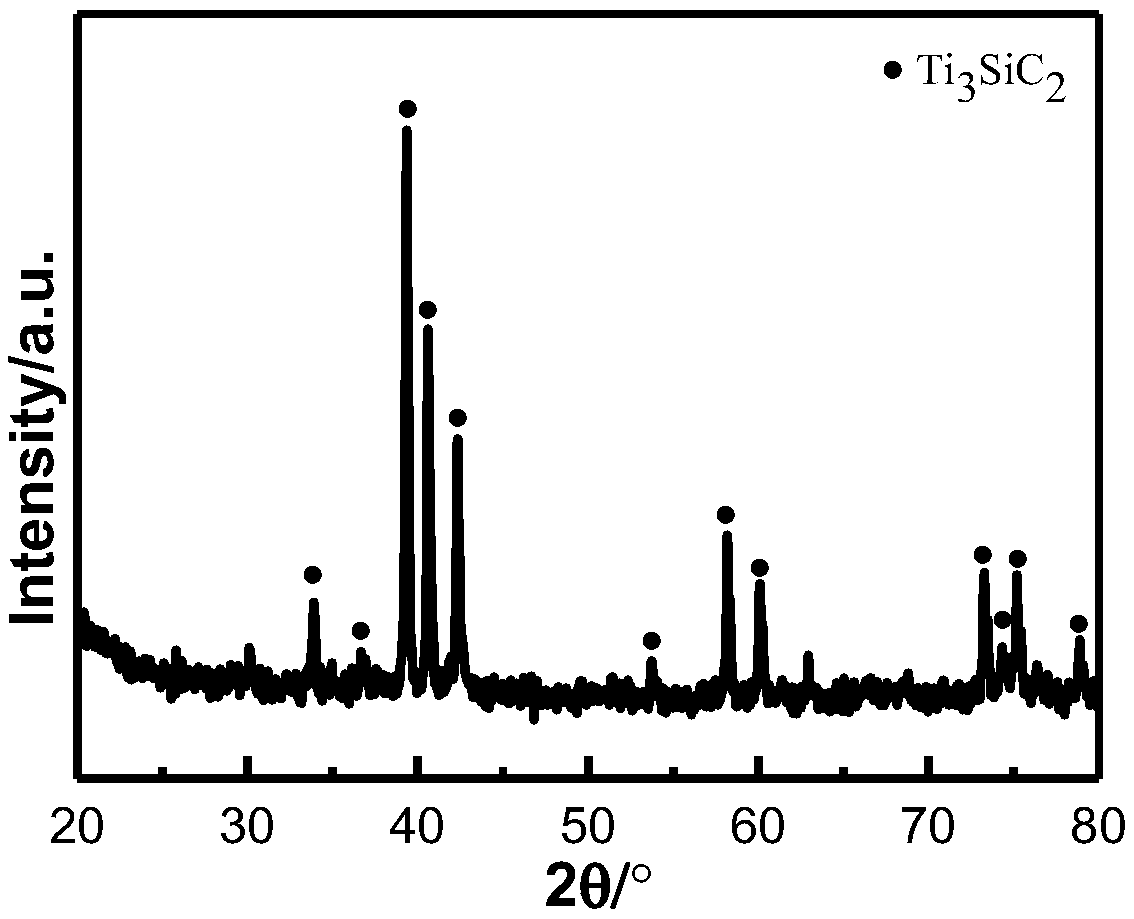

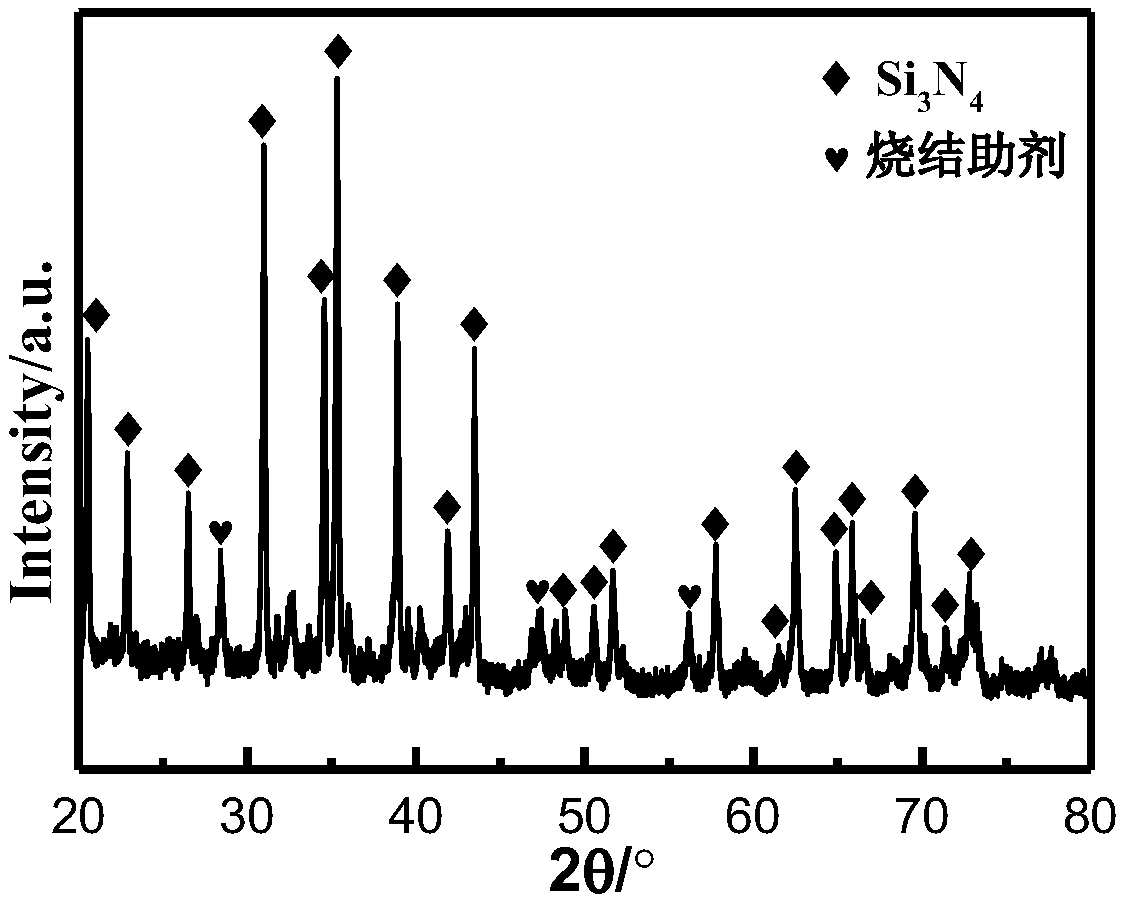

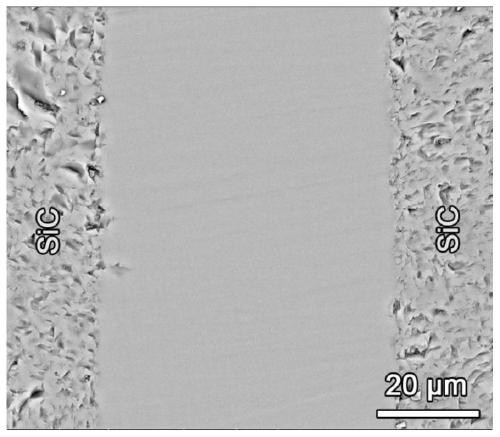

MAX phase/nitride ceramic laminated gradient composite material as well as rapid preparation method and application thereof

ActiveCN109400164AHigh temperature strengthImprove thermal shock resistanceCeramic layered productsHigh densityNitrogen

The invention discloses a MAX phase / nitride ceramic laminated gradient composite material as well as a rapid preparation method and application thereof, belonging to the technical field of preparationof ceramic matrix composite materials. The method adopts an SPS sintering technology to prepare the MAX phase / nitride ceramic laminated gradient composite material; the method introduces an electricfield on the basis of a temperature field and a pressure field, thus playing a role in plasma activation of raw materials, and further quickly preparing the dense multiphase ceramic material under theconditions of lower sintering temperature and shorter heat preservation time; furthermore, the activation of plasma also contributes to the diffusion of atoms, so that the interlayer bonding of a MAXphase and nitride is promoted, and the high-performance connection between the MAX phase and the nitride is realized; the method has the advantages of being high in heating rate, low in sintering temperature and short in heat preservation time. The method can be used for quickly preparing the MAX phase / nitrogen ceramic laminated gradient composite material with high density, low impurity contentand good interface bonding property.

Owner:XI AN JIAOTONG UNIV

Silicon carbide ceramic braze welding connection method

ActiveCN110330356AFirmly connectedImprove wettabilityWelding/cutting media/materialsSoldering mediaAdhesivePre treatment

The invention relates to a silicon carbide ceramic braze welding connection method. The invention aims to solve the problems in the traditional braze welding method that a metal brazing material has low wettability, the residual stress is large and a weldable workpiece is small. The method comprises the following steps: mixing Al2O3, SiO2 and CaO or CaCO3, drying after grinding, melting, performing water quenching, grinding again, sieving and drying to obtain a microcrystal glass brazing material; pretreating to-be-brazed silicon carbide ceramic to obtain pretreated silicon carbide ceramic; mixing the microcrystal glass brazing material and an adhesive uniformly and coating the pretreated silicon carbide ceramic with the mixture to obtain a silicon carbide ceramic to-be-welded connecting piece; and performing braze welding treatment on the silicon carbide ceramic to-be-welded connecting piece and performing furnace cooling to obtain silicon carbide ceramic after braze welding connection. The invention can obtain the silicon carbide ceramic braze welding connection method.

Owner:HARBIN INST OF TECH

Aviation aluminum alloy pre-stretching plate and production method thereof

ActiveCN101037752AAvoid deformationReduce residual stressTemperature control deviceAviationQuenching

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.2, Cu of 4.2, Mn of 0.70, Mg of 1.5, Ni of 0.6, Zn of 0.1, Ti of 0.1, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hot rolling and cutting; 5) quenching, straightening, and pretensioning, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention has steady properties, and the plates can not be deformed in machining, while the machining yield can be improved.

Owner:NORTHEAST LIGHT ALLOY CO LTD

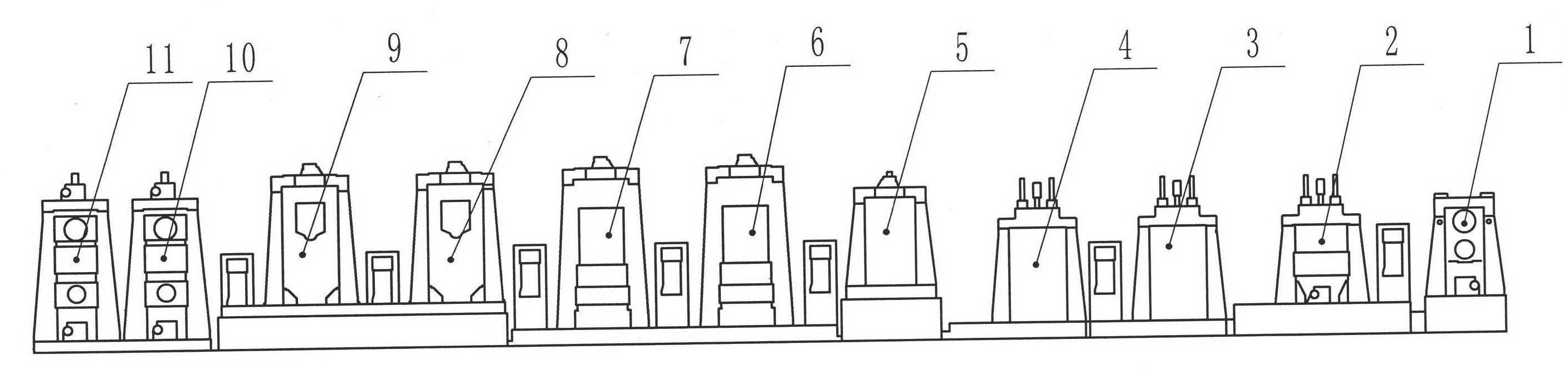

Method and equipment for flexible forming of straight seam submerged arc welded pipe

The invention discloses a method and equipment for flexible forming of straight seam submerged arc welded pipes, belonging to the technical field of straight seam submerged arc welded pipe forming; and provides a method for flexible forming of straight seam submerged arc welded pipes with low equipment price, easy forming, and little damage to steel pipes and equipment; the center is fixed and the edge is extruded. First, two curved edges are extruded through a flat roller frame, and then gradually extruded into a U shape through four four-roller frames, and then four C-shaped vertical The roll frame is extruded into a C shape, and finally it is extruded into an open O shape through two four-roller frames. It is a device made according to the above method. Its structure is: according to the order in which the steel coils enter: the first One flat roll frame, the first four-roll frame, the second four-roll frame, the third four-roll frame, the fourth four-roll frame, the first C-type vertical roll frame, the second C-type vertical roll machine frame, the third C-type vertical roll frame, the fourth C-type vertical roll frame, the fifth four-roller frame and the sixth four-roller frame; the present invention is applied in the technical field of longitudinal submerged arc welded pipe forming.

Owner:太原华科信冶金成套设备有限公司

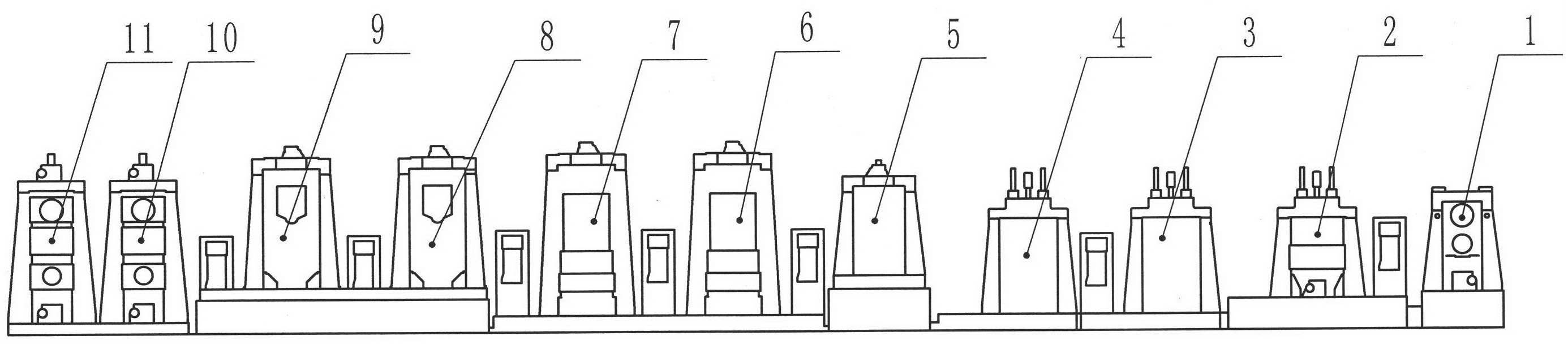

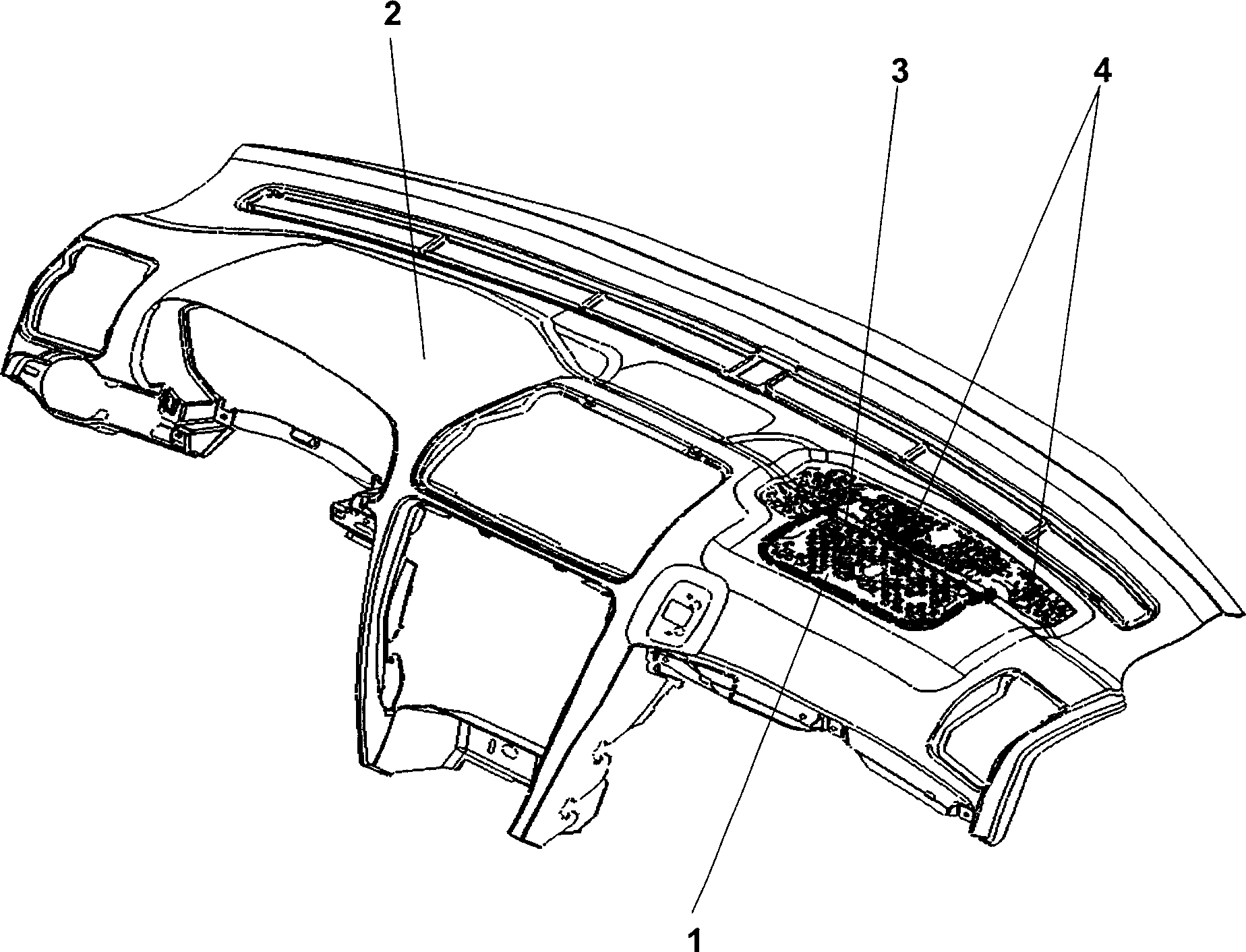

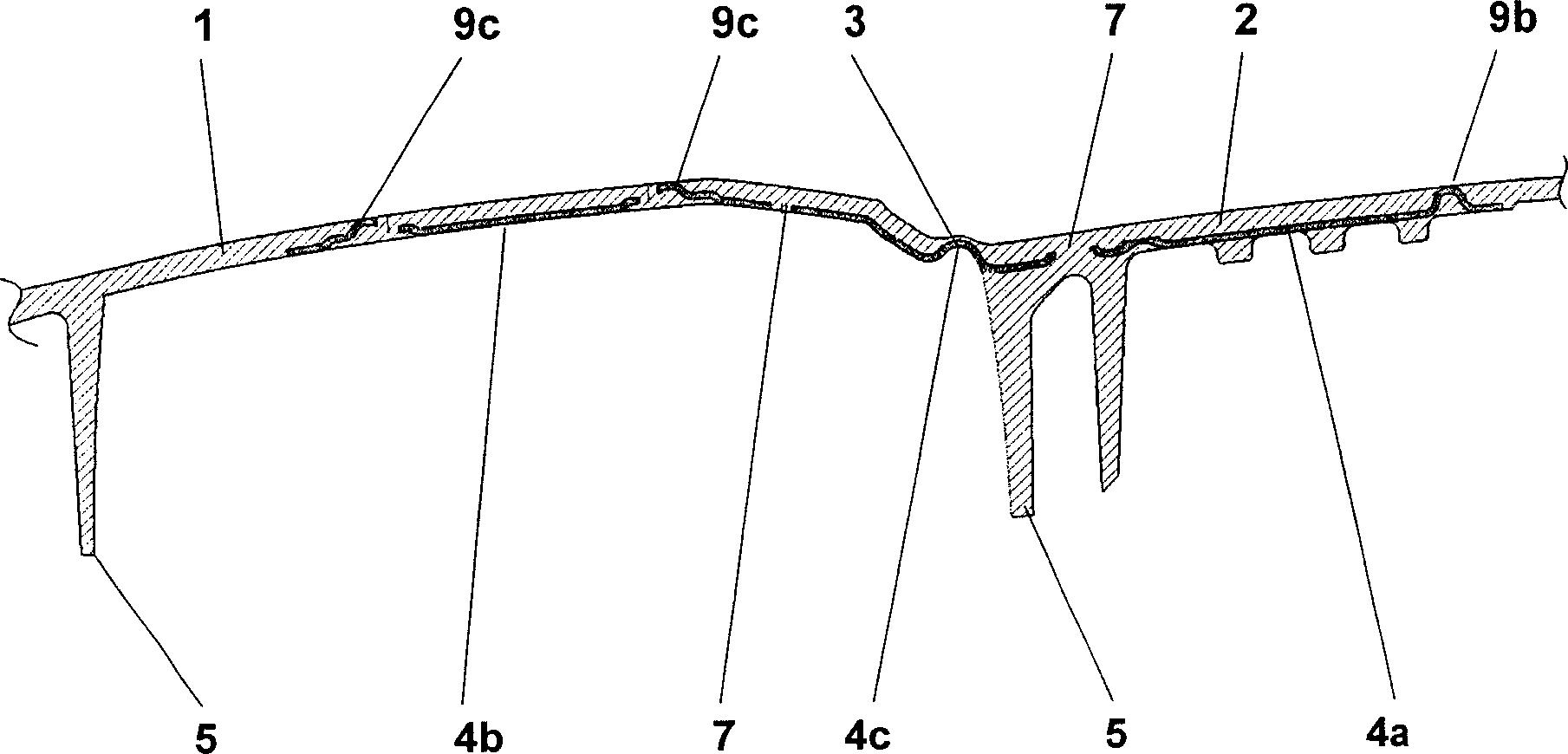

Dash board with integrated safety airbag cover

InactiveCN1915713AAvoid damageAvoid deformationPedestrian/occupant safety arrangementThermoplasticEngineering

Owner:佩格福尔姆波西米亚公司

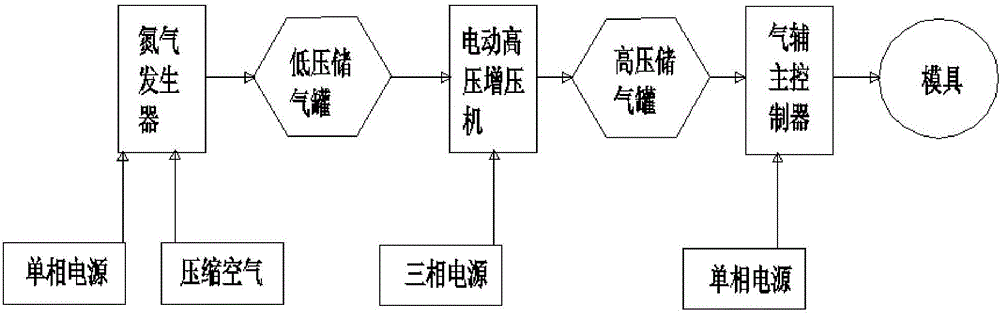

Multipoint nitrogen charging injection molding technology

InactiveCN105729716AEliminate sink marksImprove surface qualityCoatingsInjection molding processNitrogen

The invention discloses a multi-point nitrogen-filled injection molding process, which comprises the following steps: (1) making the plastic melt enter the mold cavity from the mold gate in the mold clamping state; (2) filling the mold cavity with the plastic melt When the cavity reaches 75% to 95% volume, the inert gas enters the molten plastic melt through the inlet of the air channel, and pushes the unsolidified plastic melt in the center into the mold cavity that has not yet been filled; (3) the inert gas in the plastic melt Form an air passage; (4) Under the pressure-holding state, the inert gas in the air passage compresses the plastic melt, replenishes the material to ensure the appearance of the part is complete, and continues to maintain pressure until the plastic melt cools down; (5) The plastic melt is cooled and formed Finally, the inert gas in the airway is exhausted to obtain plastic products. The invention solves the problem that the traditional injection molding process of plastic products is prone to produce inconsistent wall thickness shrinkage, uneven stress, easy deformation and warping of plastic parts, low precision, unsatisfactory appearance and color of products, and the solid injection molding process has high requirements for mold equipment and is expensive. material problem.

Owner:上海精卫模具有限公司

Aviation aluminum alloy pre-stretching plate and production method thereof

ActiveCN101037748AAvoid deformationReduce residual stressTemperature control deviceQuenchingInternal stress

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention has steady properties, flat surface, and low internal stress.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method of low-stress silicon carbide single crystal and apparatus of same

InactiveCN108103575AReduce the probability of crackingReduce residual internal stressPolycrystalline material growthFrom frozen solutionsSingle crystalCrystal growth

The invention belongs to the technical field of crystal growth and particularly relates to a preparation method of a low-stress silicon carbide single crystal and an apparatus of same. In the invention, crystal stress during the growth process is reduced by changing the shape of a heat preservation layer II on a graphite crucible and changing the temperature gradient in a growth thermal field; meanwhile, the method further includes in-situ annealing in a growth chamber after the growth is finished, and further reduction of internal stress of the crystal after the crystal growth is finished. Inthe method, by optimizing the temperature field, the source which introduces the internal stress of the crystal during the growth process is eliminated, thereby producing the low-stress silicon carbide single crystal, and reducing crystal cracking rate during the process and improving mechanical property of the substrate. In addition, by means of the in-situ high-temperature annealing continuousto the growth process, residual internal stress of the crystal is continuously reduced, annealing time being short and efficiency being high. In subsequent process, a long-time high-temperature annealing for stress removal is unnecessary, so that production efficiency is increased and production cost is reduced.

Owner:SICC CO LTD

Method for low-temperature connection of aluminum oxide ceramics through phosphate glass brazing filler

The invention relates to a method for low-temperature connection of aluminum oxide ceramics, in particular to a method for low-temperature connection of aluminum oxide ceramics through phosphate glass brazing filler and aims to solve the problem of higher welding temperature for existing brazing connection of the aluminum oxide ceramics. The connection method comprises steps as follows: 1, P2O5 powder, SnO powder and MgO or CaO powder are uniformly mixed, heated to be melted and subjected to water quenching and ball milling, and lead-free phosphate glass powder is obtained; 2, the lead-free phosphate glass powder is mixed with an adhesive, and glass soldering paste is obtained; 3, to-be-welded surfaces of the aluminum oxide ceramics are polished and washed; 4, the glass soldering paste is applied through silk-screen printing; 5, to-be-welded connecting parts are assembled; 6, the connecting parts are put in a muffle furnace, heated and subjected to heat insulation, and low-temperature connection of the aluminum oxide ceramics is completed. The aluminum oxide ceramics are connected at the low temperature ranging from 280 DEG C to 450 DEG C, the matching property of the thermal expansion coefficients of the aluminum oxide ceramics is good, and the shearing strength of a joint can reach 30-60 MPa.

Owner:HARBIN INST OF TECH

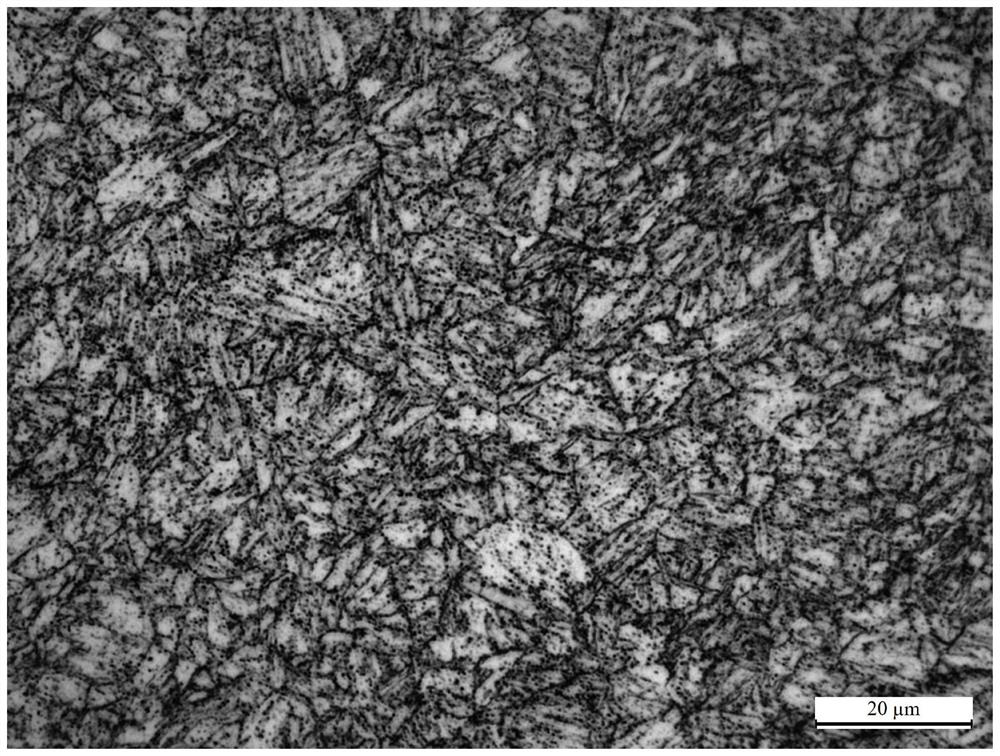

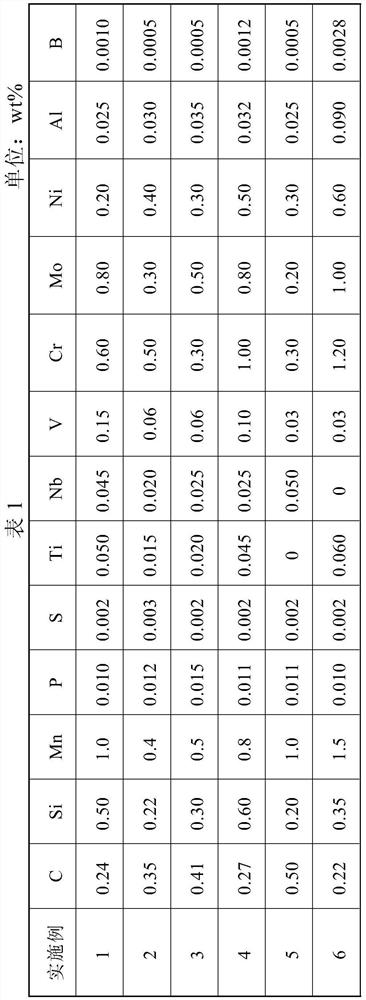

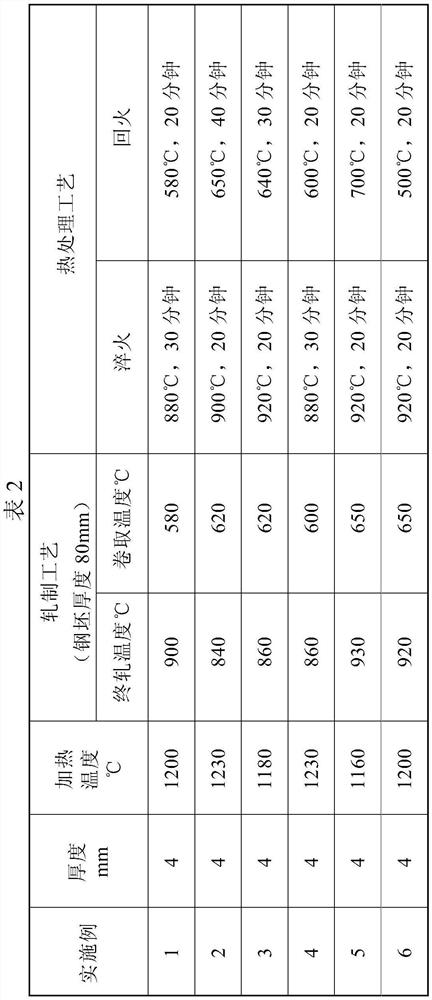

1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel and production method thereof

ActiveCN111748732AReduce lattice distortionReduce residual internal stressUltimate tensile strengthMagnetism

The invention discloses 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel and a production method thereof. The 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel is prepared from the following components in percentage by weight: 0.20 to 0.50 percent of C, 0.2 to 1.0 percent of Si, 0.5 to 1.5 percent of Mn, less than or equal to 0.015 percentof P, less than or equal to 0.005 percent of S, less than or equal to 0.06 percent of Ti, less than or equal to 0.05 percent of Nb, 0.20 to 1.0 percent of Mo, 0.20 to 1.20 percent of Cr, 0.20 to 0.60percent of Ni, 0.03 to 0.15 percent of V, 0.0005 to 0.003 percent of B, 0.015 to 0.10 percent of Al, less than or equal to 0.010 percent of N, less than or equal to 0.0080 percent of O, and the balance of Fe and other unavoidable impurities; and meanwhile Cr+Mo+Ni is larger than or equal to 0.80 percent; Nb+V+Ti is larger than or equal to 0.06 percent; carbon equivalent CEV is larger than or equal to 0.50 percent. The yield strength of the hot-rolled magnetic yoke steel is larger than or equal to 1000MPa, the tensile strength is larger than or equal to 1050MPa; the impact power KV<2> is larger than or equal to 40J at the temperature of 20 DEG C below zero; the magnetic induction performance B<50> is larger than or equal to 1.58T; B<100> is larger than or equal to 1.73T; B<200> is larger than or equal to 1.90T; and B<300> is larger than or equal to 1.93T. The 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel meets relevant requirements of the hydropower industry on rotor magnetic yoke steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for laser cladding of copper alloy powder on surface of copper substrate

ActiveCN112430811AQuality improvementHigh hardnessAdditive manufacturing apparatusMetallic material coating processesSurface cleaningSurface oxidation

A method for laser cladding of copper alloy powder on the surface of a copper base comprises the following steps: (1) , using a polishing tool for polishing the surface of a copper base workpiece to remove a surface oxide layer; cleaning the surface of the copper-based workpiece by using a detergent to obtain a copper-based surface with a clean surface; (2), fixing the copper-based workpiece on aworking platform; and (3), carrying out high-speed laser cladding on the copper-based workpiece by using laser cladding powder through a high-speed laser cladding optical fiber laser device. The lasercladding powder comprises the following chemical components in percentage by weight: 0.01%-0.25% of C, 0.5%-3% of B, 1%-4% of Si, 012% of Cr, 0.5%-14% of Fe, 10%-50% of Cu, 30%-80% of Ni, wherein a powder particle size interval is 25-150 microns and a sphericity degree is more than or equal to 80%. The method has the advantages that for specific laser cladding powder, a transition layer, a pre-coating layer and the like do not need to be added before cladding, a desired cladding layer is directly obtained through single-layer cladding in the mode that powder is fed from the center and the working included angle of the cladding head is controlled, and the process is simplified.

Owner:ZHEJIANG UNIV

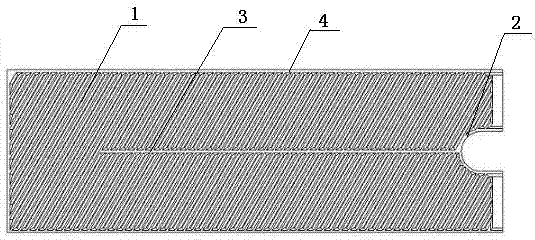

Built-in lamella heat exchanger of welding plate

InactiveCN104729330AIncrease contact areaAvoid askingLaminated elementsStationary plate conduit assembliesPlate heat exchangerWork performance

The invention discloses a built-in lamella heat exchanger of a welding plate in the field of heat exchange equipment. The heat exchanger is a rectangular sheet with trapezoid inclined grains. A U-shaped notch is arranged at the center on one side of the sheet, horizontal isolation ribs extending towards the corresponding side are arranged at the symmetrical center of the U-shaped notch, welding sealing edges are arranged on the other three sides on the periphery of the U-shaped notch and the sheet, a plurality of sheet pairs composed of the sheets, a water box and a pipe flange are welded to form a welding core body and fixed by a clamping plate, bolts and a fastening pulling plate. A U-shaped channel is formed in the sheet, the flowing channel length and the contact area with a medium are increased, and the heat exchange efficiency is effectively improved. Due to the fact that a chip body is integrally welded, a sealing gasket is not required to improve high temperature resistance, high pressure resistance and corrosion resistance, the sheet pairs are connected with the pipe flange through the water box, inner stress residue generated during welding of the pipe plate is reduced, cracking and deformation are avoided, and the heat exchanger has the advantages of being novel in conception, reasonable in structure design, stable in working performance, convenient to wash and maintain and suitable to be popularized.

Owner:SIPING VIEX HEAT EXCHANGE EQUIP

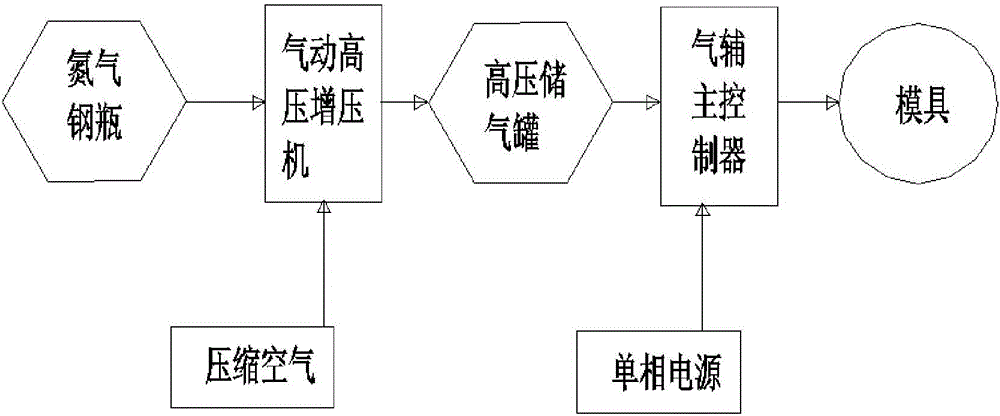

Gas auxiliary injection molding method of car roof handle

ActiveCN109624202APrevent warpageImprove injection molding efficiencyVehicle arrangementsInjection molding machineInjection moulding

The invention belongs to the technical field of car parts and particularly relates to a gas auxiliary injection molding method of a car roof handle. The method comprises the following steps that 1, molten plastic is injected into a die cavity through two or more pouring gates, and after injection of a die is full, pressure is maintained; 2, inert gas is injected into the molten plastic in the diecavity through two or more gas inlets, pressure of the injected inert gas is larger than storing pressure of injection molding, a part of the molten plastic in the die cavity returns to the pouring gates, and the hollow state is formed; and 3, the pressure is maintained, cooling is carried out, the die is opened, and a product is taken out.

Owner:NINGBO SHUAITELONG GRP CO LTD

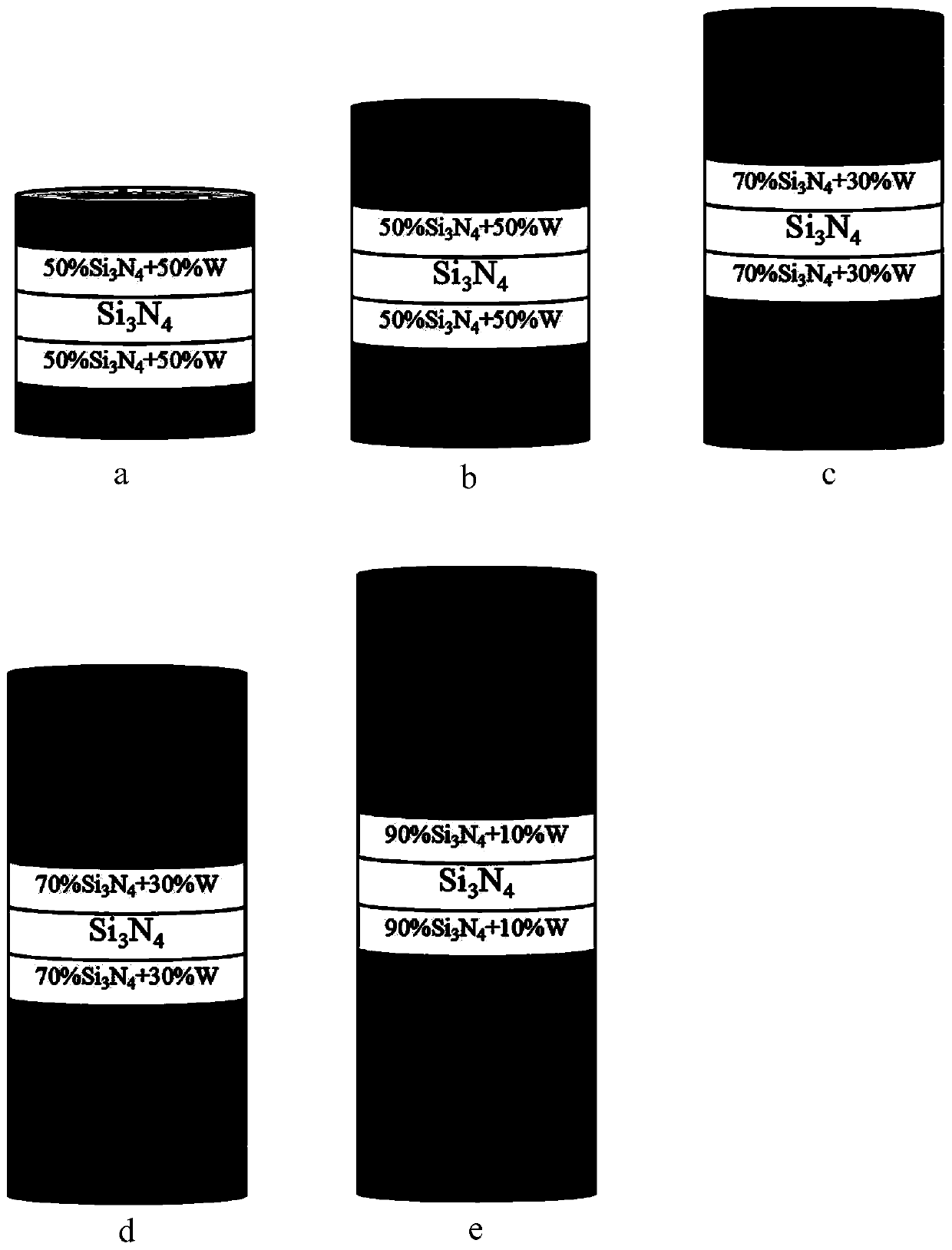

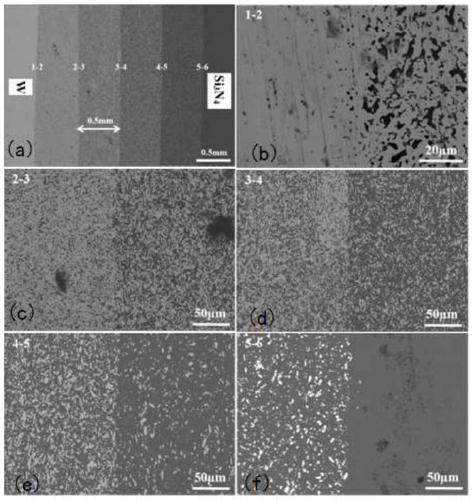

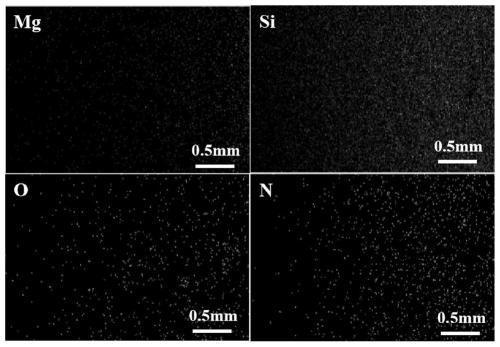

Tungsten/silicon nitride/tungsten symmetrical laminated gradient composite material as well as rapid preparation method and application thereof

ActiveCN111085688AExcellent high temperature mechanical propertiesImprove thermal shock resistanceIncreasing energy efficiencyCell sealing materialsComposite ceramicPlasma activation

The invention discloses a W / Si3N4 / W symmetrical laminated gradient composite material as well as a rapid preparation method and an application thereof, and belongs to the technical field of preparation for ceramic matrix composite materials. According to the tungsten / silicon nitride / tungsten symmetrical laminated gradient composite material as well as the rapid preparation method and the application thereof, the W / Si3N4 / W symmetrical laminated gradient composite material is prepared through an SPS sintering technology; in the method, an electric field is further introduced on the basis of a temperature field and a pressure field, a plasma activation effect on raw materials can be acted, so that a compact composite ceramic material can be rapidly prepared under the conditions of a low sintering temperature and a short heat-insulation time; and meanwhile, the activation effect of plasmas also contributes to the diffusion of atoms, then the interlayer bonding of W and Si3N4 can be promoted, and the high-performance connection between W and Si3N4 is realized. The method has the advantages of being high in heating speed, low in sintering temperature and short in heat-insulation time, and the W / Si3N4 / W symmetrical laminated gradient composite material with high compactness, low impurity content and good interface bonding can be rapidly prepared via the method.

Owner:XI AN JIAOTONG UNIV

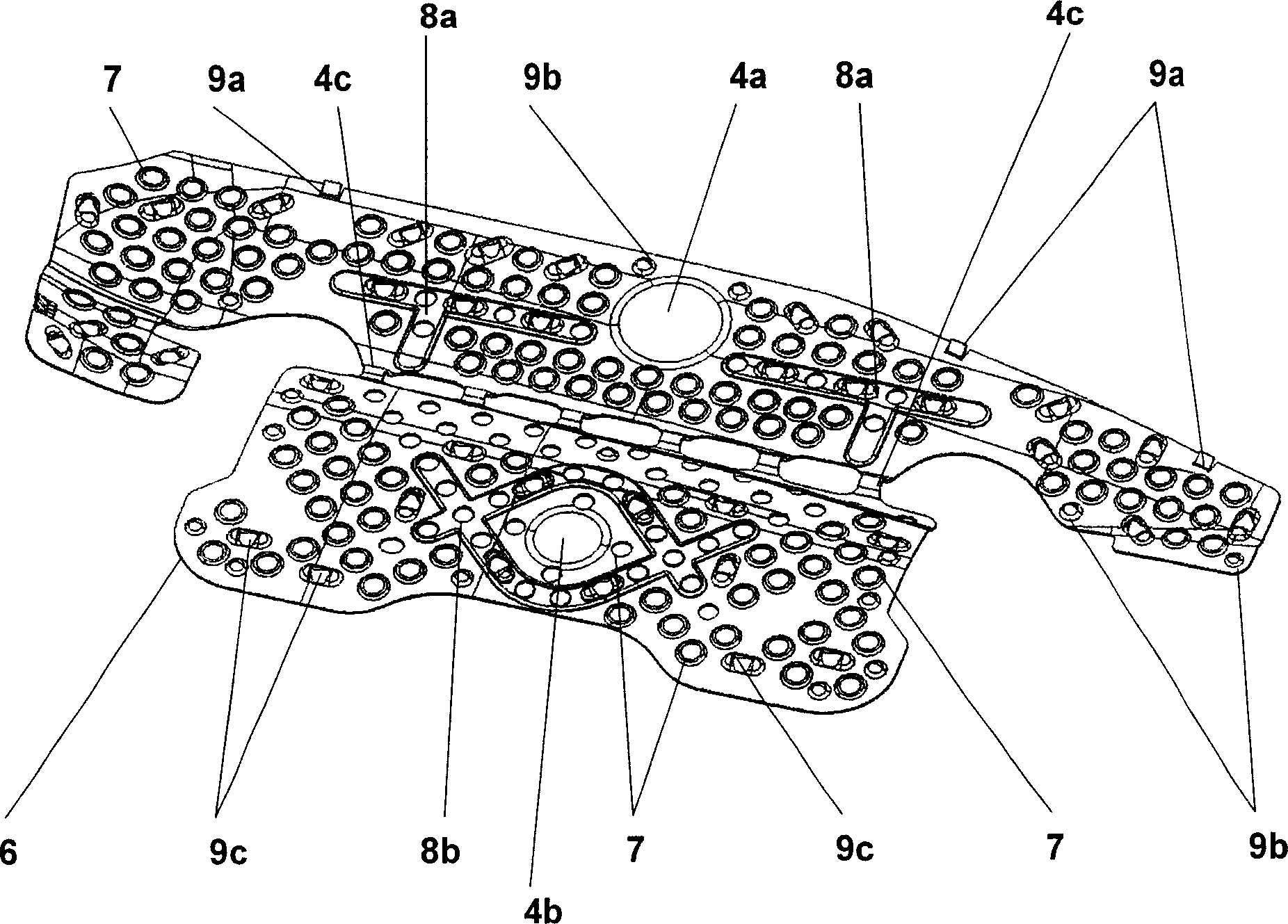

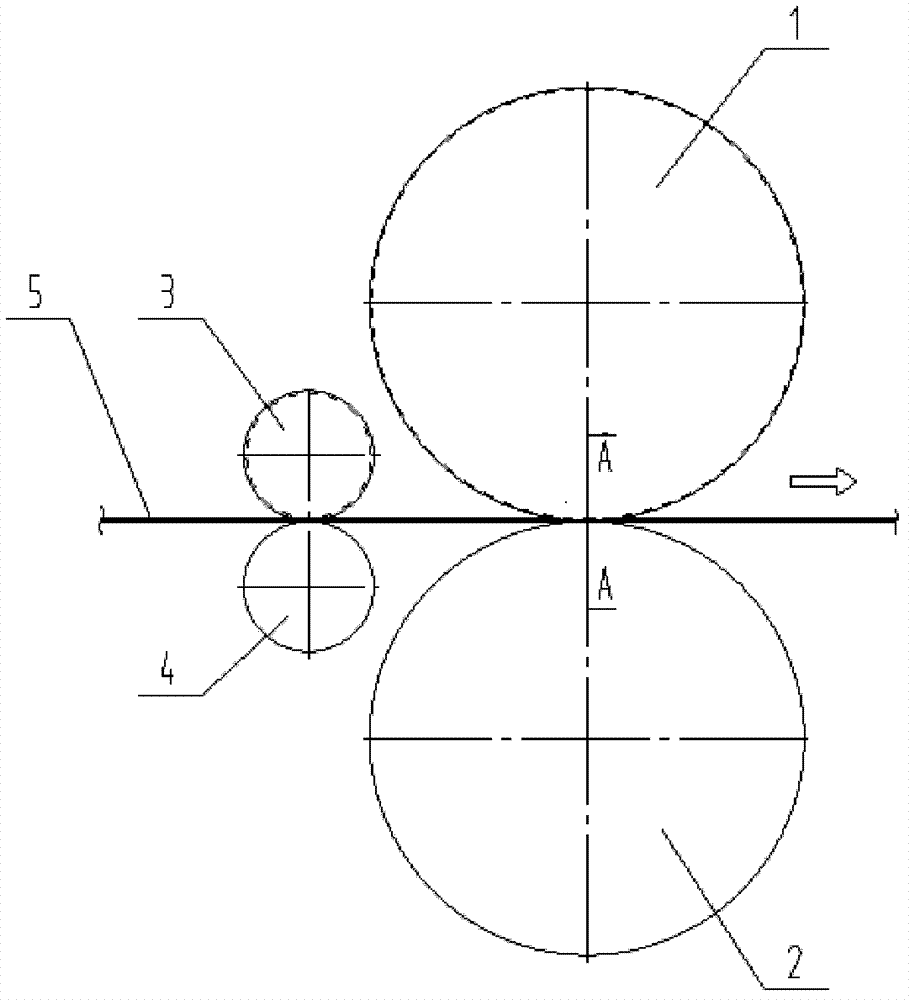

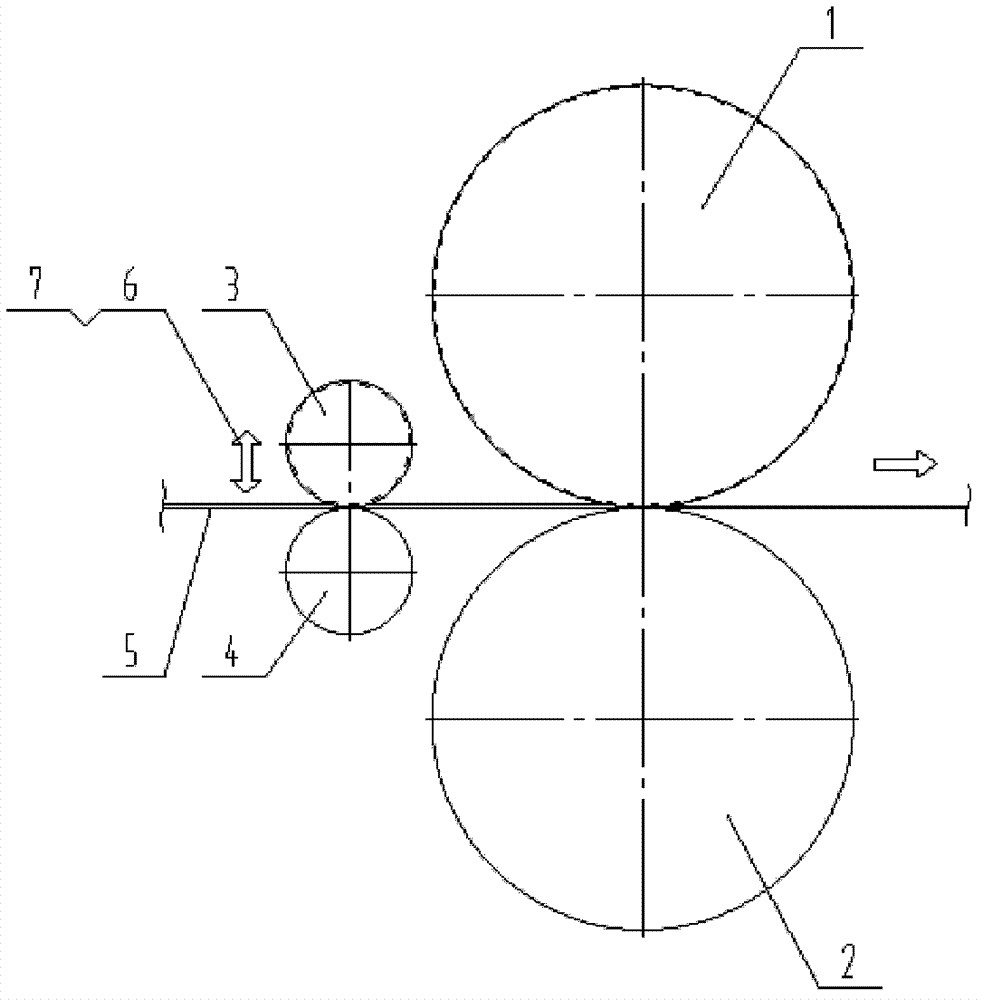

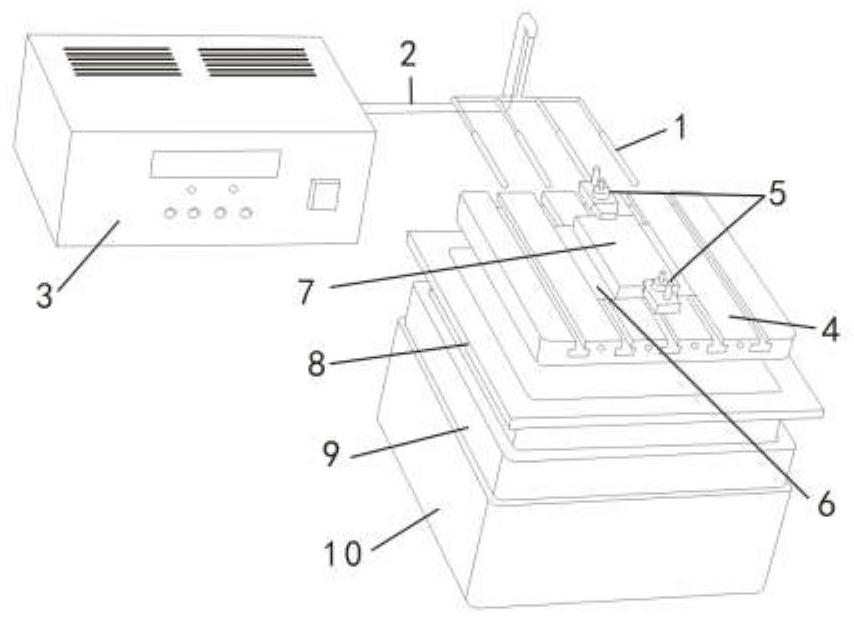

Stable rolling control device

InactiveCN102896157AImprove surface roughnessStable rolling processRoll mill control devicesMetal rolling arrangementsEngineeringAngle alpha

The invention relates to a stable rolling control device. The purpose of the stable rolling control device can be achieved by the technical scheme which includes that a guide device is lifted step by step during rolling and produces tension to enable a strip billet trapezoidal projection and a groove type hole of a hole type roll 1 to form a clinging segmental arc (see figures 4 and 5), a horizontal guide adjustment device 7 is used for horizontal micro-adjustment of alignment of the strip billet center and the roll pass center, left-right movement of a strip billet is quite effectively controlled as the trapezoidal projection and the groove type hole of the hole type roll 1 form the clinging segmental arc which is close to a rolling area. Additionally, the size A1 and the angle alpha of the strip billet trapezoidal projection are as same as those of a finished product trapezoidal projection, so that factors caused by excessive local machining rate at junctions of thick materials and thin materials are avoided, and rolling is stable and reliable.

Owner:上海格林赛高新材料有限公司

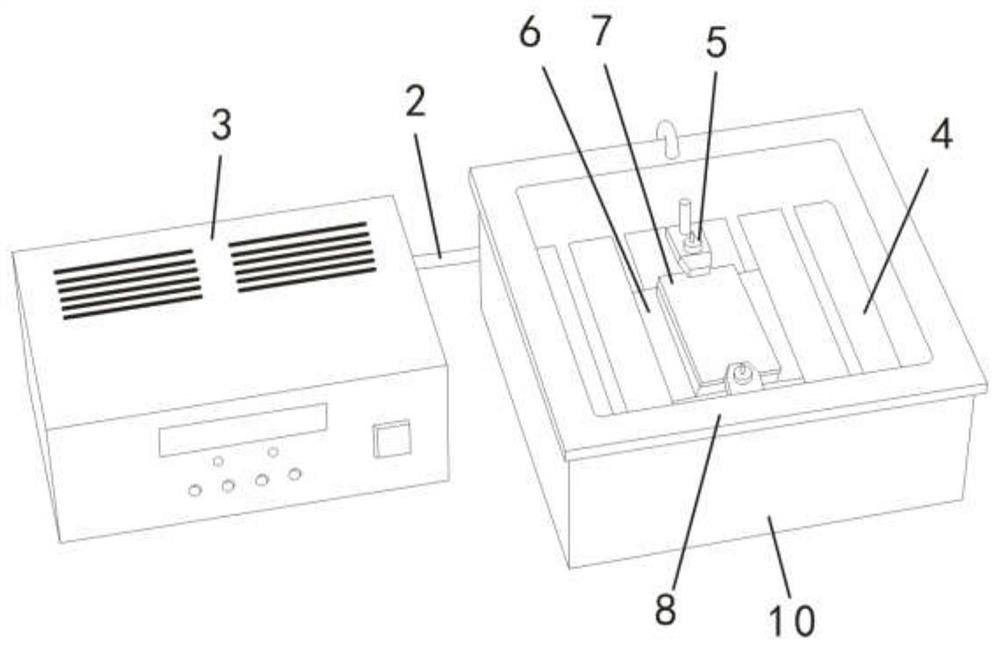

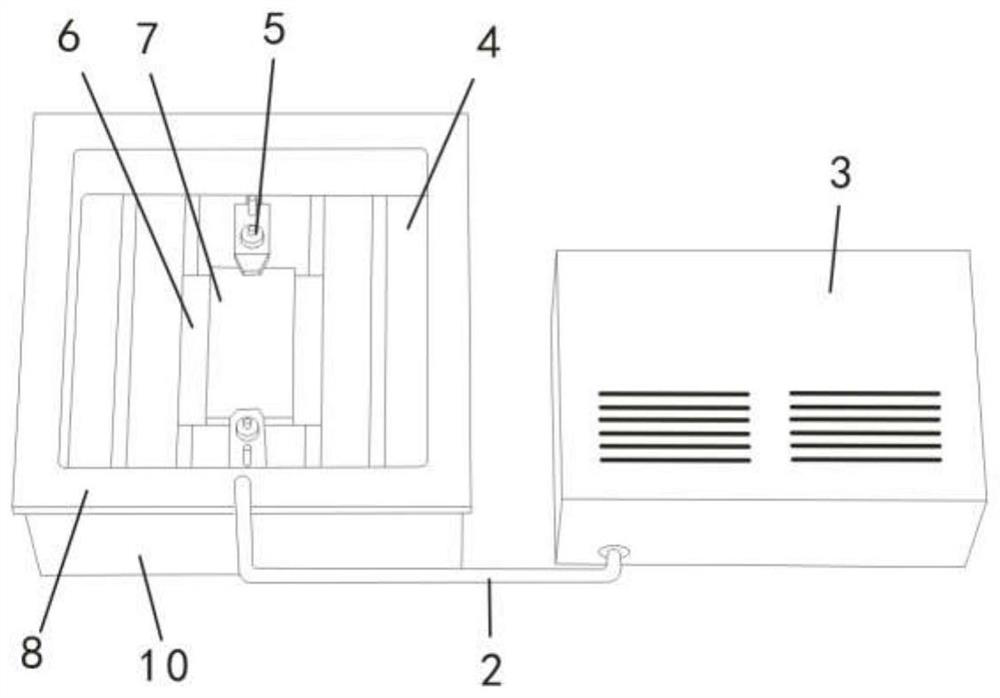

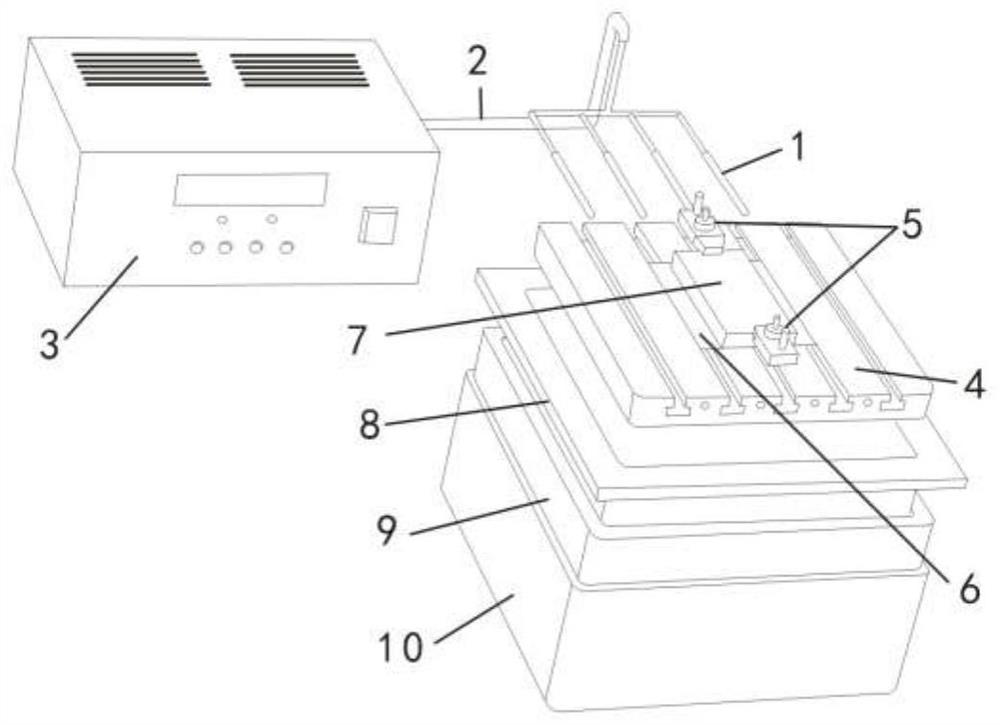

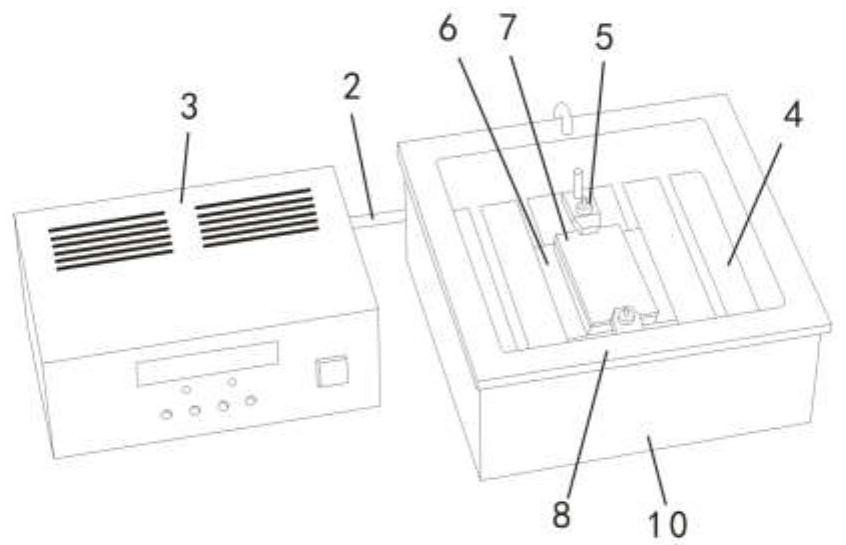

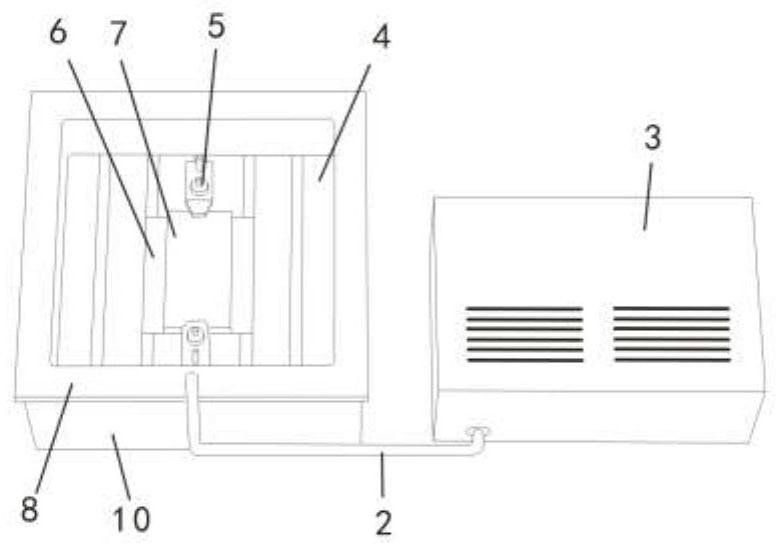

Preheating heat preservation device for laser additive manufacturing

ActiveCN112427658AQuality improvementHigh hardnessAdditive manufacturing apparatusMetallic material coating processesThermodynamicsProcess engineering

The invention discloses a preheating heat preservation device for laser additive manufacturing which is arranged on a cladding workbench of a laser additive. The preheating heat preservation device isprovided with a heat preservation cavity, wherein a heating temperature control unit and a workpiece clamping unit are arranged in the heat preservation cavity, an opening is formed in the top of theheat preservation cavity to allow laser to act on the additive material, and a cover is arranged at the opening. The preheating heat preservation device has the advantages that the blank of the preheating and heat preservation integrated equipment for experiments in the field of laser additive manufacturing research is filled up, an equipment solution is provided for controlling the key process of the working temperature in the laser additive manufacturing technology, and a foundation is laid for promoting research progress.

Owner:ZHEJIANG UNIV

Sn-based brazing filler metal used for SiC ceramic braze welding and preparation method thereof

ActiveCN111151912AReduce residual internal stressProcess equipment is simple and easy to operateWelding/cutting media/materialsSoldering mediaInternal stressFiller metal

The invention relates to Sn-based brazing filler metal used for SiC ceramic braze welding and a preparation method thereof. The Sn-based brazing filler metal used for SiC ceramic brake welding consists of the following components in percentage by mass: 5.30%-61.20% of a foam aluminum alloy framework, 0.65%-13.00% of pure aluminum, 24.70%-86.00% of Sn-9Zn alloy, 0.20%-16.50% of Zn-5Al alloy, and 0.002%-0.10% of a silver nanowire. The composite brazing filler metal takes the foam Al as a framework, and takes an Sn alloy as filling metal, so that so that residual internal stress of a braze-welding joint can be effectively reduced, and the stress problem due to the fact that the SiC ceramic welding joint uses high-temperature brazing filler metal to perform high-temperature welding is overcome.

Owner:NORTHEAST GASOLINEEUM UNIV

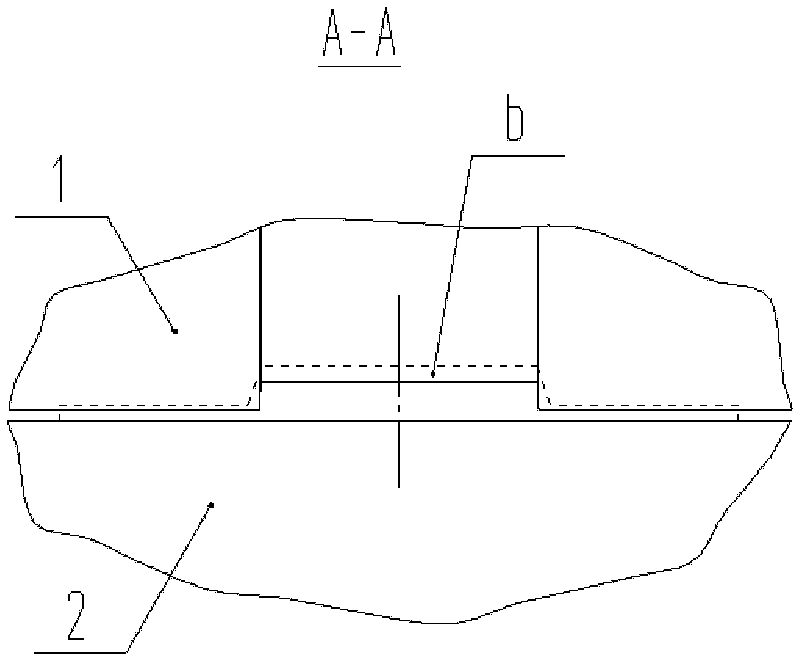

Seamless steel pipe formed by cold rolling and manufacturing method thereof

The invention relates to a seamless steel pipe formed by cold rolling and a manufacturing method thereof. The seamless steel pipe is processed and manufactured by carrying out diameter reduction rolling on the outer surface of a seamless steel pipe blank with uniform wall thickness and smooth inner and outer surfaces via at least two rollers in the environment at 5-40 DEG C. The outer diameter and the inner diameter of the rolled pipe blank are compressed and reduced to form a seamless steel pipe with helical grooves formed in the outer surface and convex-concave ripples in the inner surface. A cold rolling forming process is characterized in that rollers of rolling equipment are symmetrically arranged along the axis of the pipe blank; the rollers rotate along self axes and compress the outer diameter of the steel pipe; the inner diameter and the outer diameter of the pipe blank are subjected to plastic deformation; a plurality of spaced protrusions are formed in the outer circle of a middle section and a rear section of each roller; when the outer diameter of the pipe blank is reduced and the appropriate-sized helical grooves are formed in the surface of the pipe blank, the inner diameter of the pipe blank is also reduced and the convex-concave ripples are formed; the seamless steel pipe is further process and manufactured into a grouting connection sleeve of an FRP rib or a steel rib applied to buildings; the seamless steel pipe is low in mechanical cutting processing amount, low in cost and high in performance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Method for machining ultra thin-walled middle ring

The invention relates to a method for machining an ultra thin-walled middle ring. The method includes the following steps of (1) turning of an internal cone and an external cone, (2) boss milling, (3) heat treatment, (4) coarse grinding of the internal cone and the external cone, (5) aging treatment and (6) accurate grinding of the internal cone and the external cone. Manufacturing and machining are easy and fast. Residual internal stress of parts is effectively reduced, the deformation degree of the parts is also reduced, machining precision can be controlled easily, and the method is suitable for meeting the small-batch and fast production development requirements of the ultra thin-walled middle ring.

Owner:CHANGZHOU KUNMAO MACHINERY

Method for preparing polyimide film by adopting chemical imidization in combined mode

ActiveCN103172891BSmall coefficient of linear expansionGood dimensional stabilityPolyamic acidMechanical property

The invention discloses a polyamic acid imidization catalyst composite and a method for preparing an electronic-grade polyimide film by adopting chemical imidization in a combined mode, and belongs to the technical field of the manufacture of electronic film insulating materials. The novel chemical imidization method of polyimide mainly comprises the following steps of: storing polyamic acid at a low temperature, and stretching to form a film in a casting way; and then producing high-quality electronic-grade polyimide film through a mixing type and bath type combined high-efficiency imidization method. Compared with a method firstly adopting thermal imidization, the method disclosed by the invention outstandingly improves the linear expansion coefficient, the mechanical property, and the like of the obtained polyimide film and is high in production efficiency, lower in preparation cost and suitable for large-scale chemical industrial production of the high-property polyimide film.

Owner:HUAWEI POLYIMIDE +1

High-density metal target material preparation process

InactiveCN111004993AReduce oxygen contentLow densityMolten spray coatingMaterials preparationHigh density

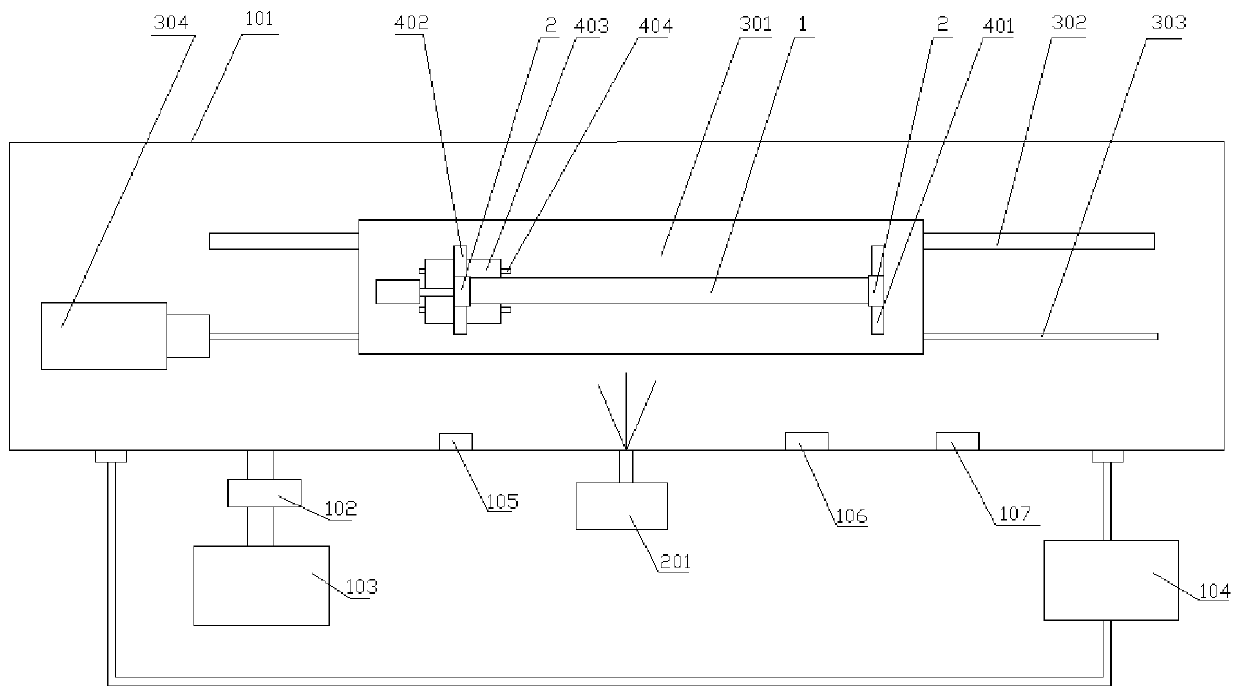

The invention relates to a high-density metal target material preparation process, which comprises the steps that a target material (1) is placed on a target material driving assembly, then a sprayingsealed cabin (101) is vacuumized to form a sealed vacuum environment with a pressure of 2Pa in the cabin; then the target material driving assembly is started to drive the target material to horizontally move left and right while rotating, and meanwhile, a spray gun of a plasma spray gun system (201) starts to spray the target material (1); and in the spraying process, an infrared temperature sensor (106) monitors the surface temperature of the target material (1) in real time, and when the temperature deviates from a set point, the power of the plasma spray gun system (201) and the wire supply speed of the plasma spray gun system (201) are adjusted accordingly, so that the surface of the target material (1) is kept in a micro-melting state all the time. According to the high-density metal target material preparation process, spraying can be carried out in a vacuum environment, so that the spraying quality of the target material is guaranteed.

Owner:SOLERAS ADVANCED COATINGS (JIANGYIN) CO LTD

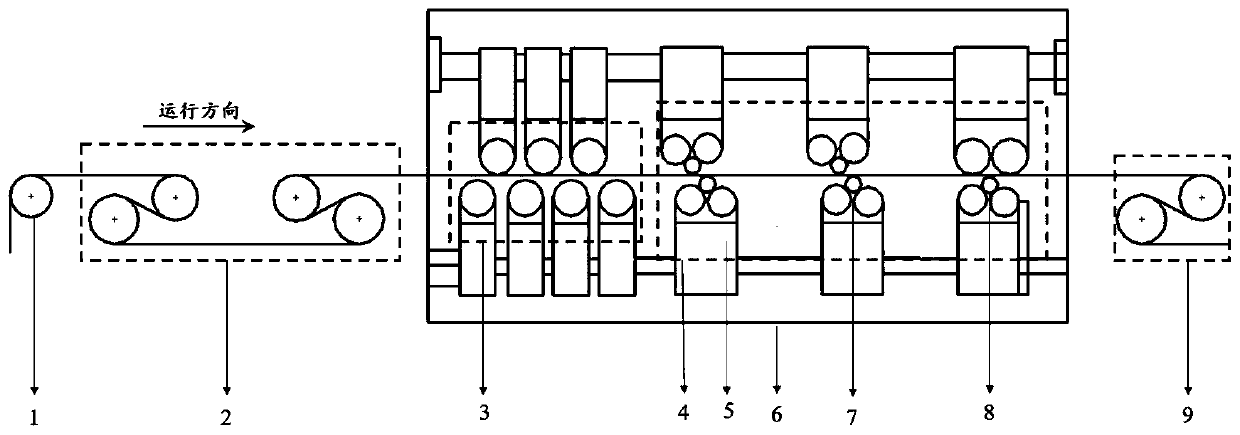

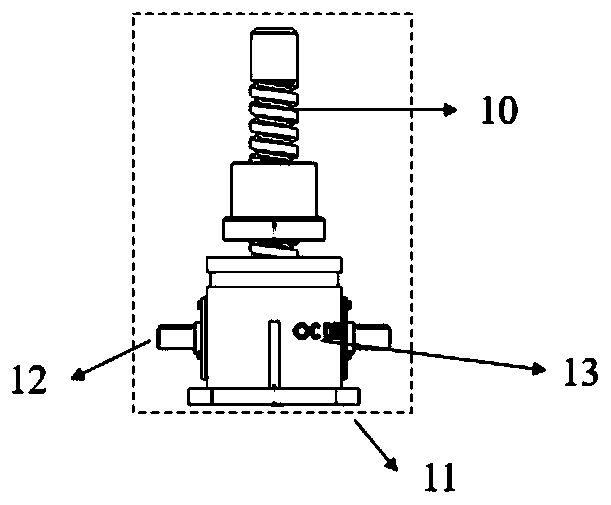

Combined type cold-rolled stretching-bending straightener

ActiveCN111185481AImprove scale breaking effectImprove flatnessWork treatment devicesMetal rolling arrangementsStructural engineeringStrip steel

The invention provides a combined type cold-rolled stretching-bending straightener, and belongs to the technical field of withdrawal and straightening equipment. The combined type cold-rolled stretching-bending straightener comprises a turning roller, an inlet tensioning roller set, a multi-roller straightening system, a stretching and straightening roller system, roller boxes, a machine frame, abending roller set, a straightening roller set, an outlet tensioning roller set and an elevator. The turning roller, the inlet tensioning roller set, the multi-roller straightening system, the stretching and straightening roller system, the bending roller set, the straightening roller set and the outlet tensioning roller set are sequentially arranged in the conveying direction of strip steel, themulti-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are installed on the machine frame, and the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are provided with the roller boxes and the lower parts of the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are connected with the elevator through lifting synchronous connecting rods.The combined type cold-rolled stretching-bending straightener can improve the scale breading effect on the surface of the strip steel, improve the acid pickling efficiency, reduce the acid consumptionamount in an acid pickling technology, can effectively improve the wear degree, reduce the risk of excessive withdrawal and straightening of welding lines, reduce the enterprise cost, and improve thesafety of equipment operation.

Owner:UNIV OF SCI & TECH BEIJING

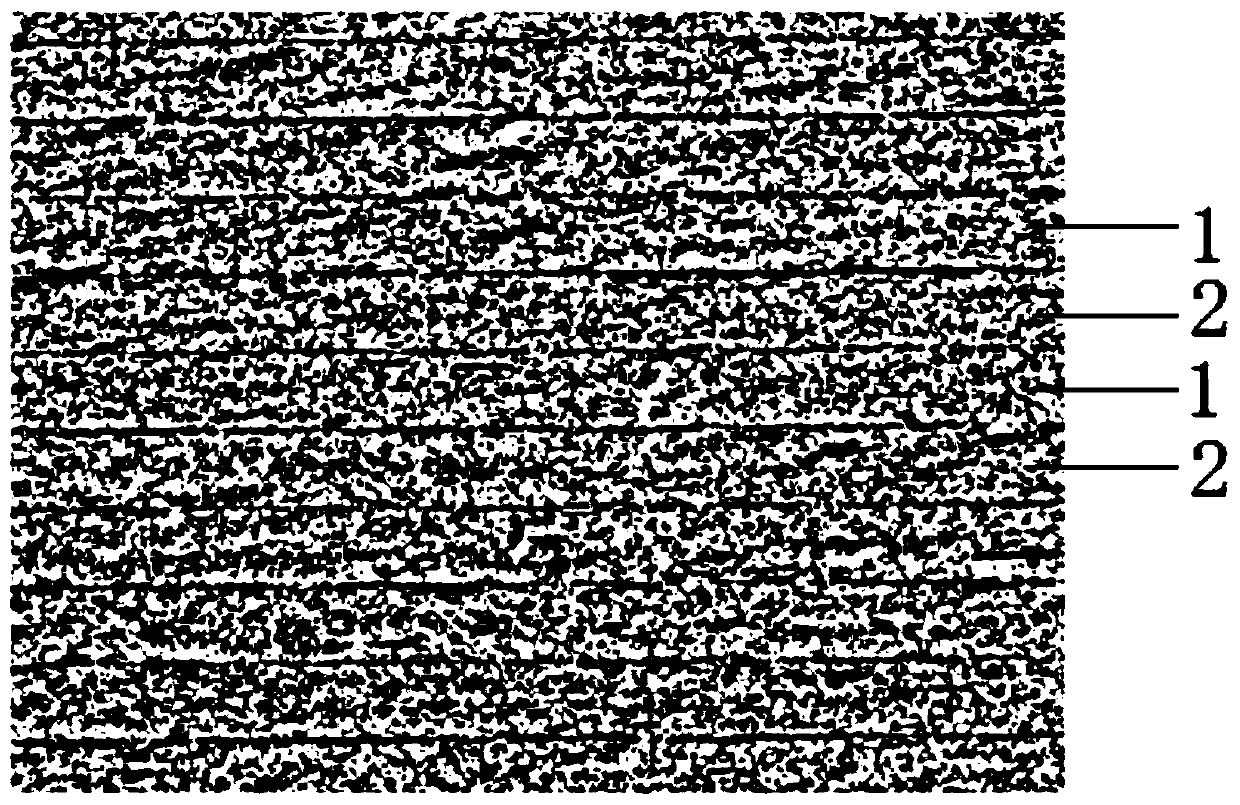

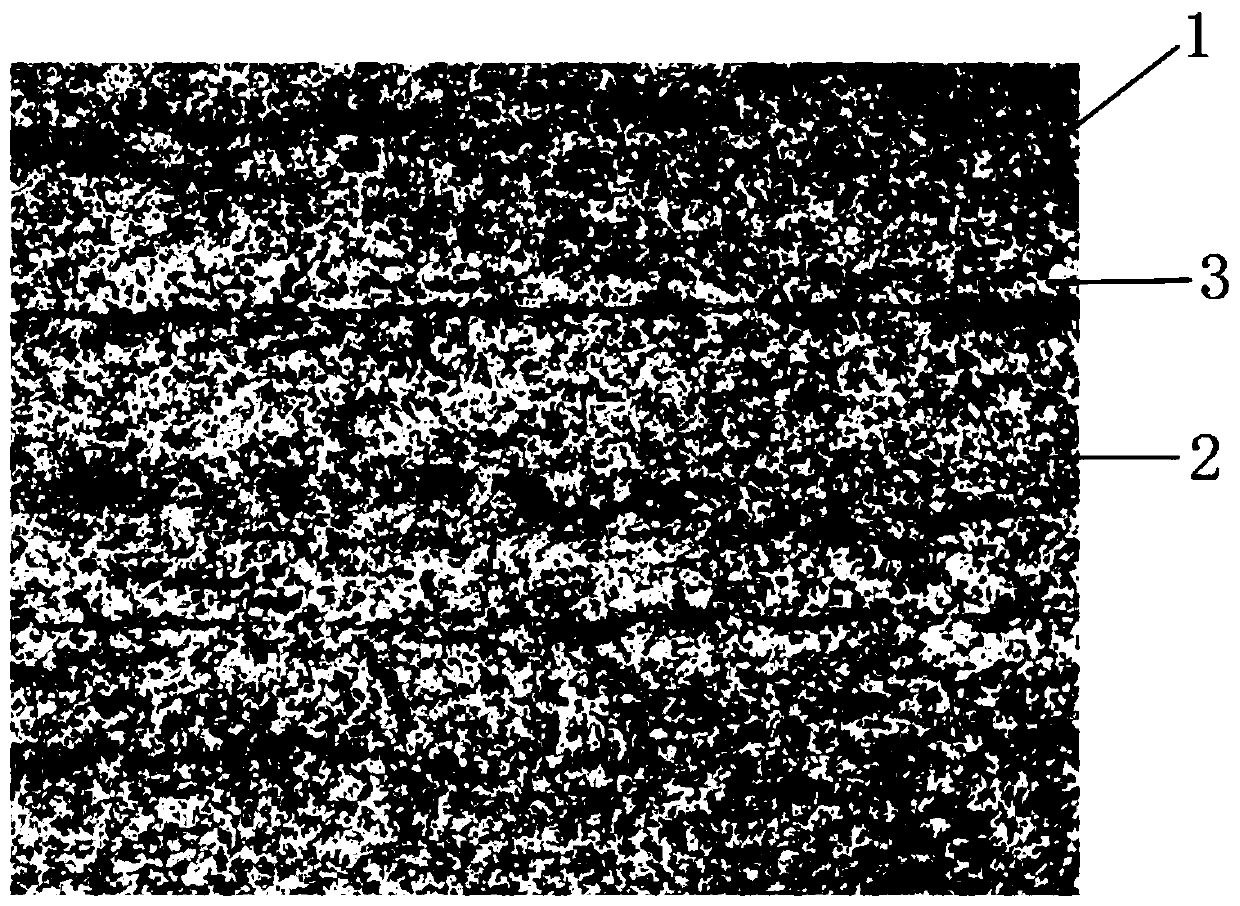

Ultra-wide aluminum alloy plate and preparation method thereof

ActiveCN113564502AReduce residual internal stressHigh strengthSolution treatmentUltrasonic vibration

The invention belongs to the technical field of aluminum alloys, and particularly relates to an ultra-wide aluminum alloy plate and a preparation method thereof. According to the preparation method, ultrasonic treatment is carried out in the hot rolling process, vacancies are continuously injected into materials through ultrasonic vibration, a large number of fine and dispersed nanometer precipitated phases are dynamically precipitated from the materials, and a pre-stretching procedure is added before solution treatment, so that the residual internal stress of the aluminum alloy plate is reduced, the strength and the extension performance of the aluminum alloy plate are improved, the produced aluminum alloy plate is stable in performance, high in surface flatness, low in residual internal stress and not prone to deformation during machining.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

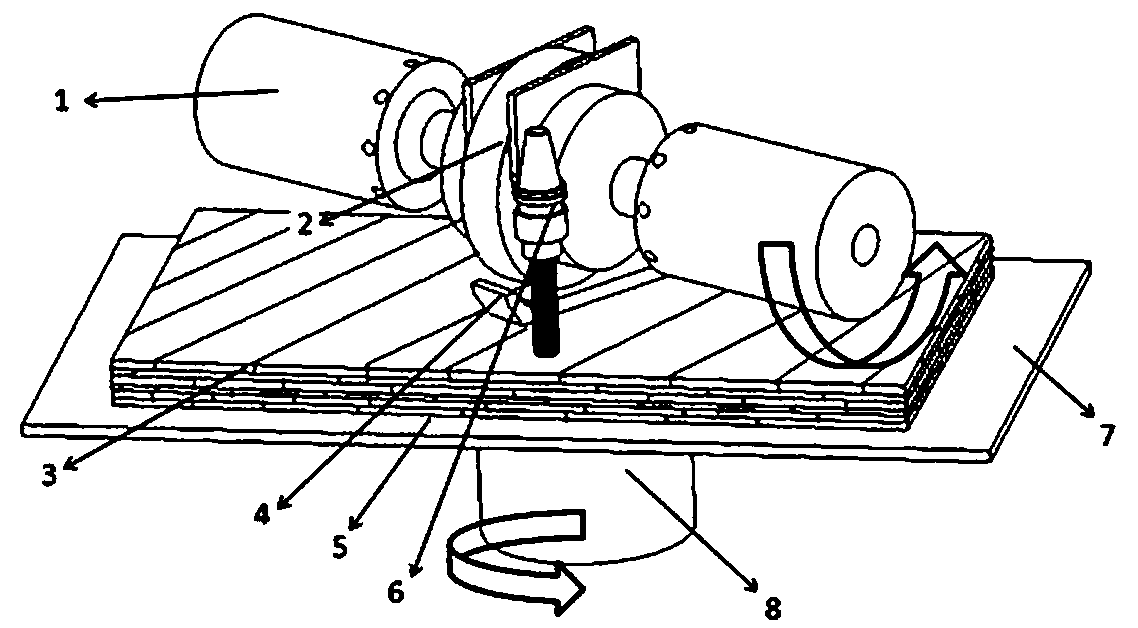

Method for preparing micro-laminated composite material by using ultrasonic additive and hot isostatic pressing and application thereof

InactiveCN110744184AHigh densityImprove uniformityWelding/soldering/cutting articlesNon-electric welding apparatusHigh densityUltrasonic welding

The invention belongs to the technical field of preparation of micro-laminated composite materials, and particularly relates to a method for preparing a micro-laminated composite material by using ultrasonic additive and hot isostatic pressing and application thereof. The method comprises the following steps that (1) a first metal layer is fixed on a preheated substrate, then a second metal layeris placed on the first metal layer, and after the second metal layer is placed on the first metal layer, an ultrasonic generator rolls on the surface of the second metal layer, so that the first metallayer and the second metal layer are welded under the action of rolling pressure and ultrasonic vibration; and (2) the laminated material obtained in the step (1) is subjected to hot isostatic pressing heat preservation treatment, and then the micro-laminated composite material is obtained. According to the method, the low-temperature forming characteristic of ultrasonic welding is utilized, so that metal atoms are diffused on the contact interface between the metal layers through the action of vibration, friction and the like, and solid-state metallurgical bonding is realized; and the hot isostatic pressing technology is adopted to apply pressure to the upper surface and the lower surface of the laminated composite material, so that the preparation of the micro-laminated composite material with high density, good uniformity and excellent performance is realized.

Owner:SHANDONG UNIV

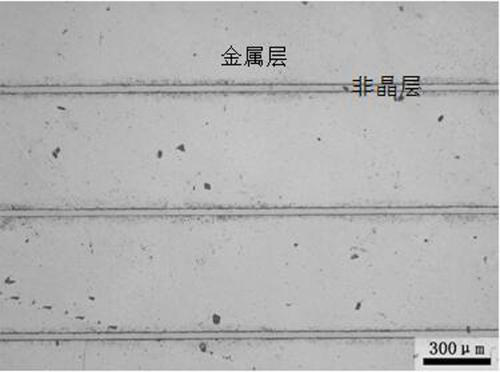

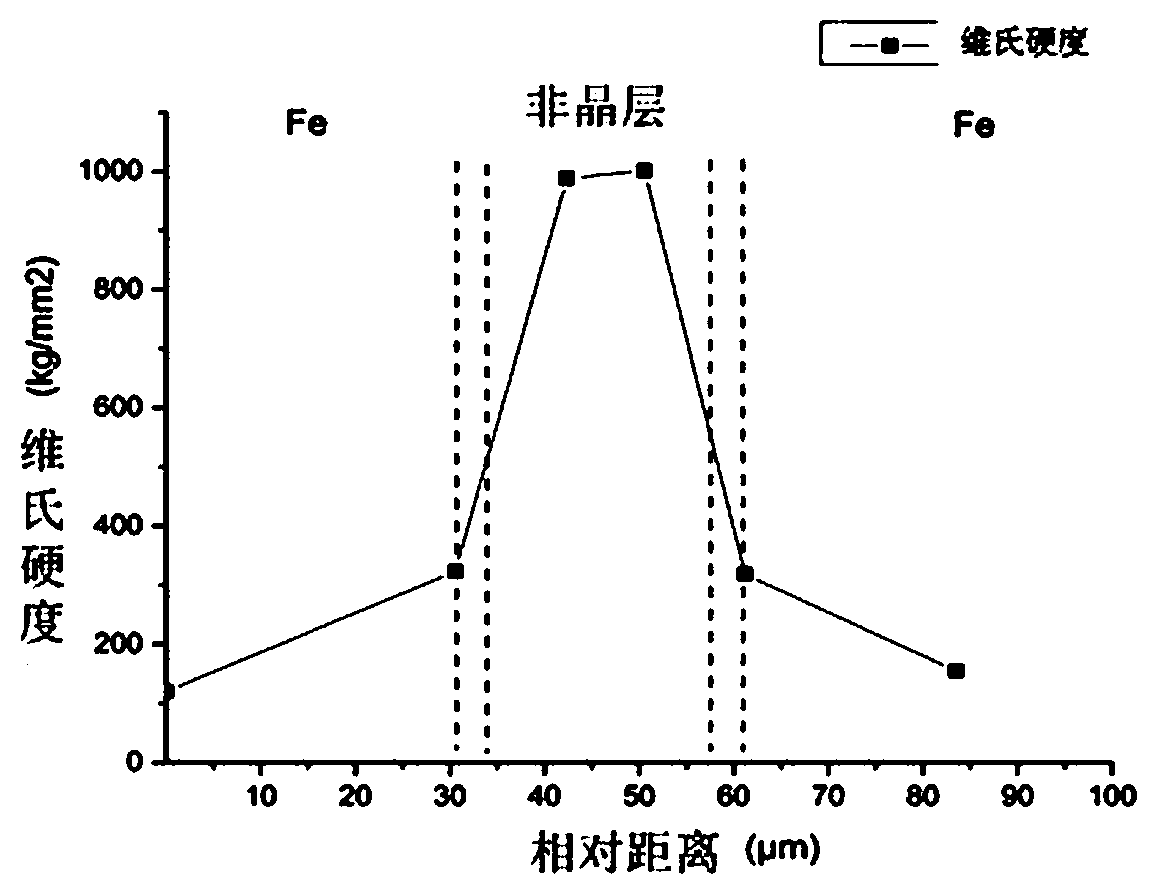

Ultrasonic accumulation manufacturing method of amorphous/metal micro-laminated composites

InactiveCN106862748BReduce residual internal stressEliminate stress relief annealing processWelding/soldering/cutting articlesNon-electric welding apparatusMetal foilAmorphous matrix

The invention relates to an ultrasonic accumulation preparation method for an amorphous / metal micro-laminated composite. The preparation method comprises the steps that laminating data of a part are extracted, amorphous / metal foil is welded onto a metal foil substrate layer by layer through the ultrasonic solidification technique, the welded amorphous / metal micro-laminated composite is cut layer by layer according to a set part contour, and finally the part composed of the amorphous / metal micro-laminated composite is obtained. By adoption of the method, manufacturing of the three-dimensional complex-shaped part composed of the amorphous / metal micro-laminated composite and manufacturing a large-size amorphous-matrix micro-laminated composite can be achieved easily. The micro-level multi-interface effect of the composite can overcome the disadvantages of poor indoor-temperature plasticity and low breaking tenacity of amorphous alloy, and low residual internal stress and good structural stability of the interior of the formed three-dimensional part can be guaranteed through the ultrasonic solidification technique.

Owner:ZHONGBEI UNIV

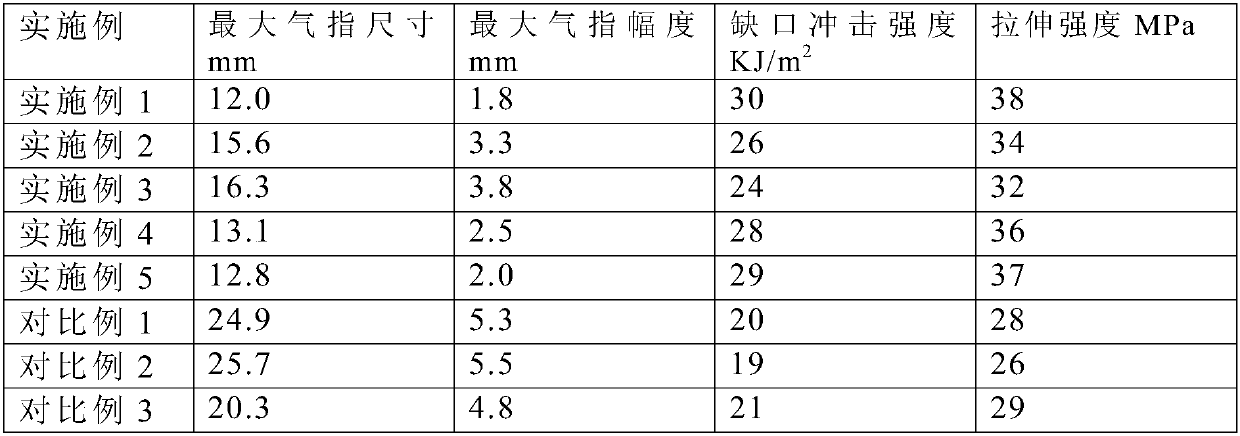

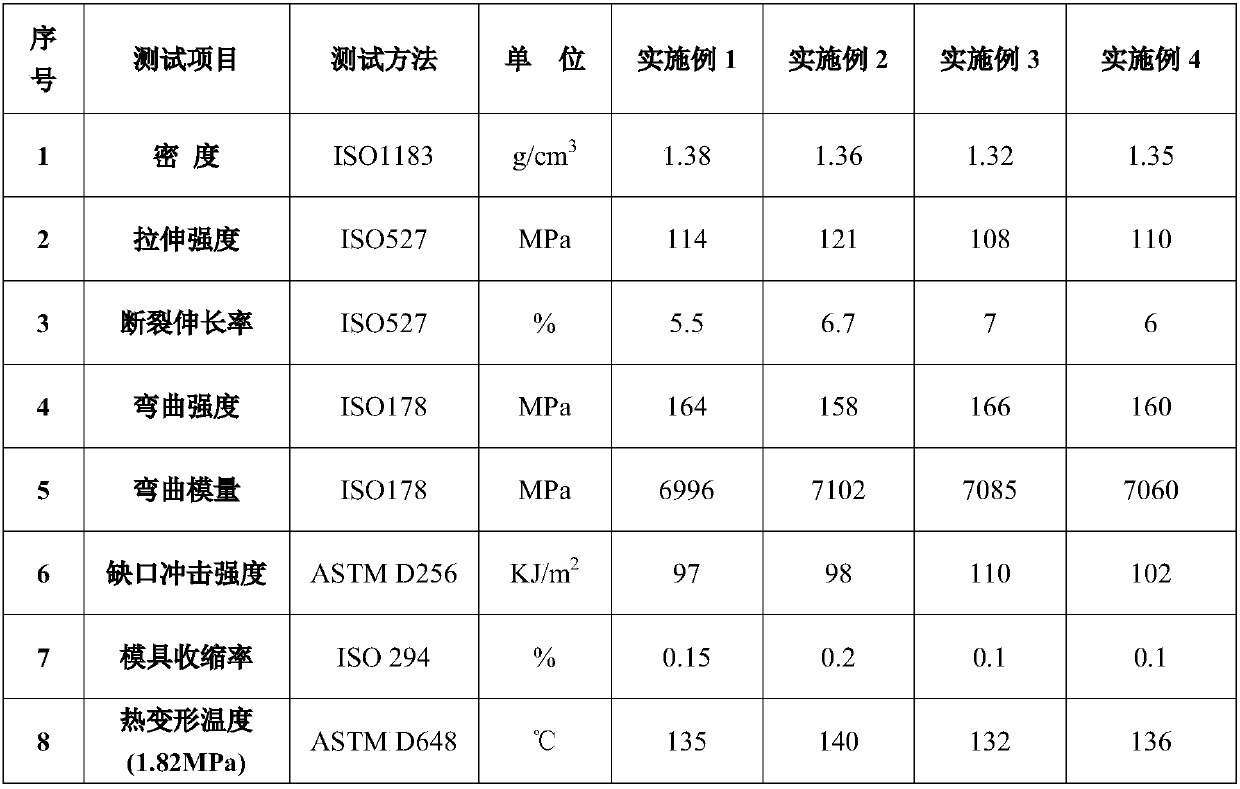

30% mineral reinforced electroplating PC/ABS alloy material and preparation method thereof

The invention discloses a 30% mineral reinforced electroplating PC / ABS alloy material, wherein the components of the formula of the PC / ABS alloy material comprise: a PC resin, an ABS resin, an internal stress improver, modified mineral fibers, a toughening agent, a compatilizer, a lubricant and an antioxidant. The preparation method comprises the following steps: sequentially putting a main material PC, an ABS resin, an internal stress improver and a lubricant into a mixing mill, and mixing for 4-8 minutes to obtain a mixture; then adding a toughening agent, a compatilizer and an antioxidant into the mixture, and mixing for 6-10 minutes; adding the obtained mixture into the main feeding port of a double-screw extruder, adding modified mineral fibers into the side feeding port, and finallycarrying out extruding, water-cooling and granulating in the double-screw extruder. The obtained PC / ABS alloy material is small in residual internal stress, excellent in physical performance, good inelectroplating performance, low in preparation cost and suitable for industrial production.

Owner:宁波优索高分子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com