Method for preparing polyimide film by adopting chemical imidization in combined mode

A technology of polyimide film and chemical imidization, which is applied in the field of polyamic acid chemical imidization manufacturing and combined chemical imidization manufacturing of polyamic acid, which can solve the problems of poor performance of finished products, low production efficiency, Lack of market competitiveness and other issues, to achieve the effect of small internal stress, good dimensional stability, and small linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

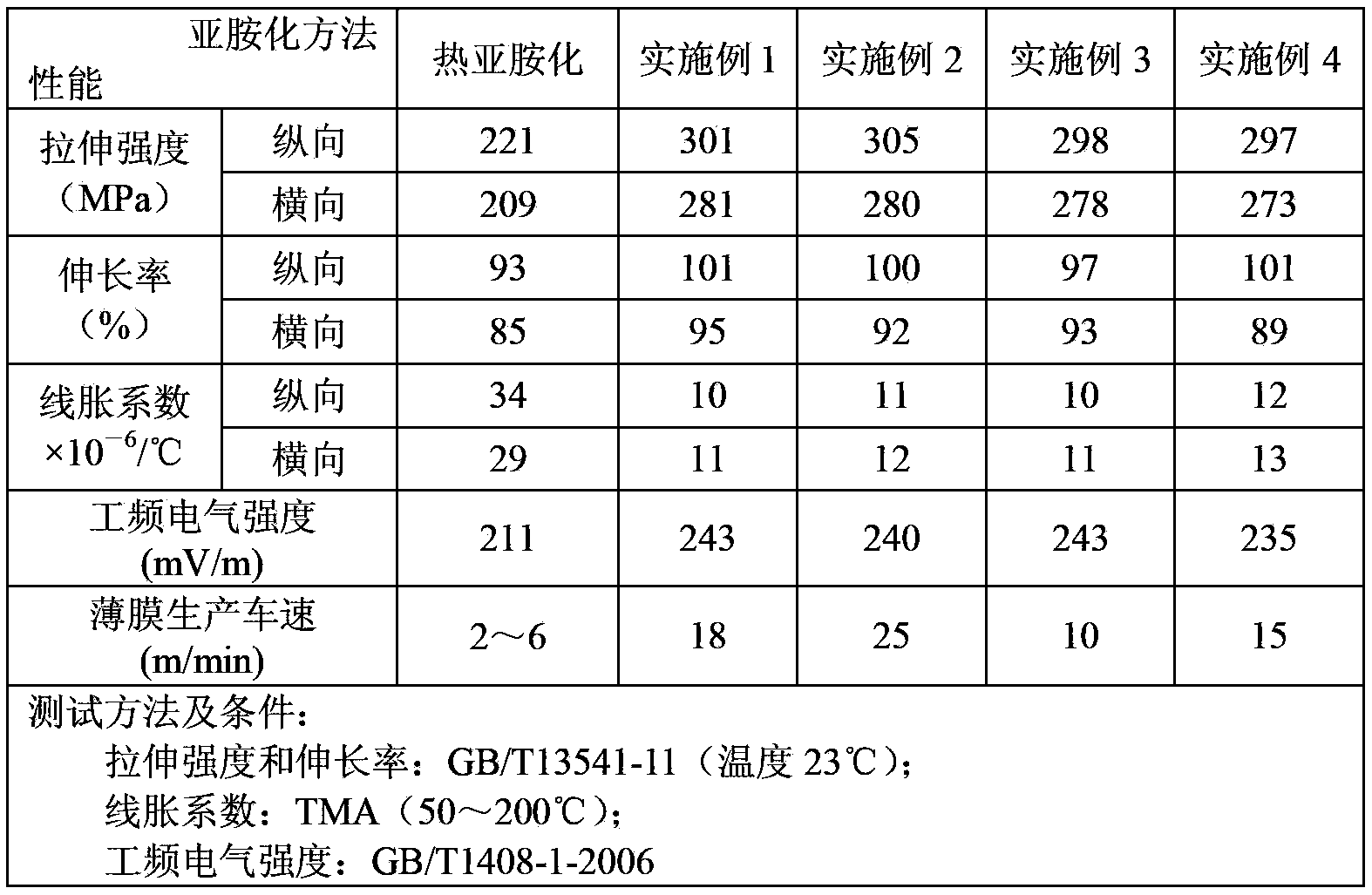

Examples

Embodiment 1

[0030]Take 600kg of polyamic acid solution with a solid content of 20% and a viscosity of 245,100 centipoise, and keep the temperature below 0°C, quickly mix it with dehydrating agent and catalyst (dehydrating agent: thionyl chloride 11kg, 1,3-dichlorohexyl Carbodiimide 17kg, catalyst: N,N-dimethylaminopyridine 19kg, triethylenediamine 25kg), after mixing and defoaming, cast the film immediately, pay attention to the casting die lip During the whole process of the mouth, the temperature of the glue solution is always kept below 0°C. When the extrusion die device flows from the gap of the casting nozzle to the closed clean system running below it, the endless stainless steel belt running at a speed of 18m / min is cast into a film of uniform thickness, and the chemical sublimation is carried out at 75°C. Amination, after one week of circulation, the preliminary chemically imidated gel film is peeled off the endless steel strip by the peeling roller, and then sent to the bath tank...

Embodiment 2

[0032] Take 650kg of a polyamic acid solution with a solid content of 21% and a viscosity of 255,300 centipoise, and keep the temperature below 0°C, and quickly mix it with a dehydrating agent and a catalyst (dehydrating agent: 18kg of acetic anhydride, 1,3-dichlorohexyl carbonization Diimine 22kg, catalyst: N,N-dimethylaminopyridine 21kg, triethylenediamine 24kg), after mixing and defoaming, cast the film immediately, pay attention to the casting die lip During the whole process, the glue temperature is always kept below 0°C. When the extrusion die device flows from the gap of the casting nozzle to the closed clean system running below it, it is cast on the endless stainless steel belt running at a speed of 25m / min to form a film of uniform thickness, and the chemical sublimation is carried out at 65°C. Amination, after one week of circulation, the preliminary chemically imidated gel film is peeled off the endless steel strip by the peeling roller, and then sent to the bath t...

Embodiment 3

[0034] Take 600kg of a polyamic acid solution with a solid content of 19% and a viscosity of 233,600 centipoise, and keep the temperature below 0°C, quickly mix it with a dehydrating agent and a catalyst (dehydrating agent: thionyl chloride 11kg, N,N-dicyclohexyl Carbodiimide 30kg, catalyst: quinoline 15kg, triethylenediamine 31kg), after mixing and defoaming, cast the film immediately, pay attention to the glue in the whole process of entering the lip of the casting die The temperature is always kept below 0°C. When the extrusion die device flows from the gap of the casting nozzle to the closed clean system running below it, the endless stainless steel belt running at a speed of 10m / min is cast into a film of uniform thickness, and the chemical sublimation is carried out at 85°C. Amination, after one week of circulation, the preliminary chemically imidated gel film is peeled off the endless steel strip by the peeling roller, and then sent to the bath tank with a length of 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com