Patents

Literature

31results about How to "Overcome lack of heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium battery

InactiveUS20090068563A1Suppression problemOvercome lack of heat resistanceFinal product manufactureElectrode carriers/collectorsSulfideVapor phase

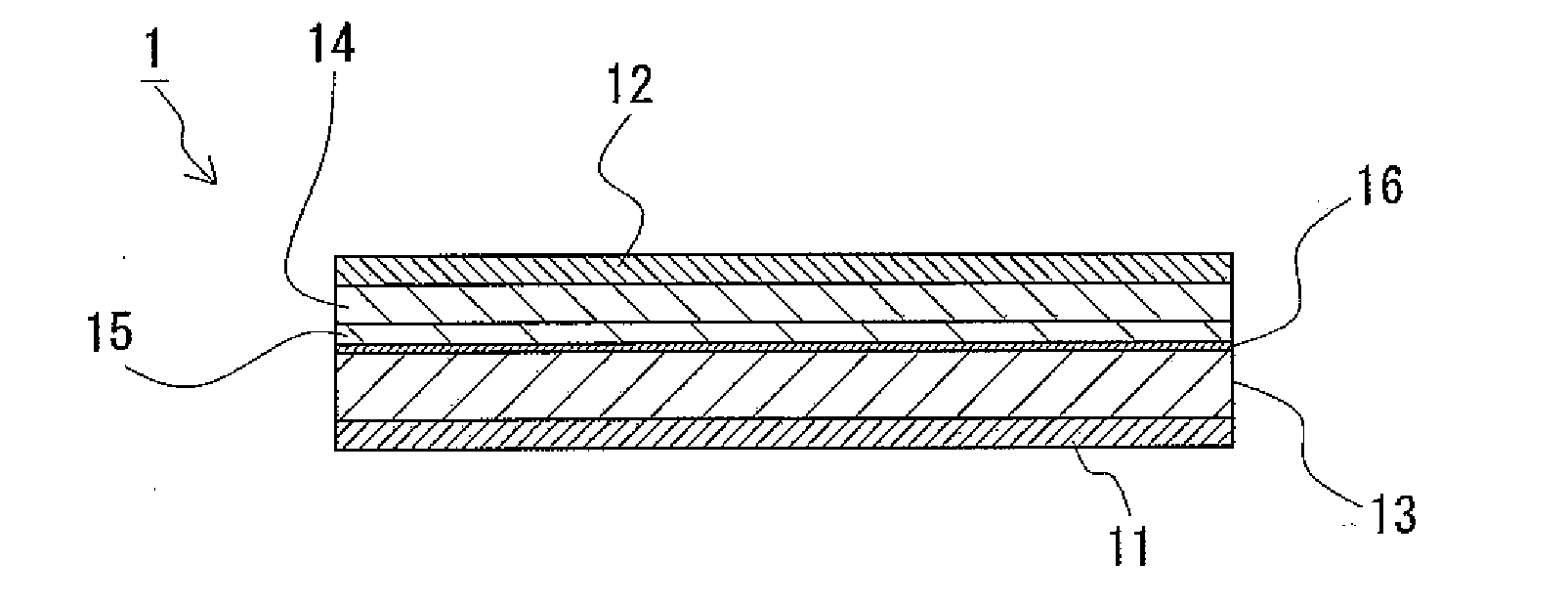

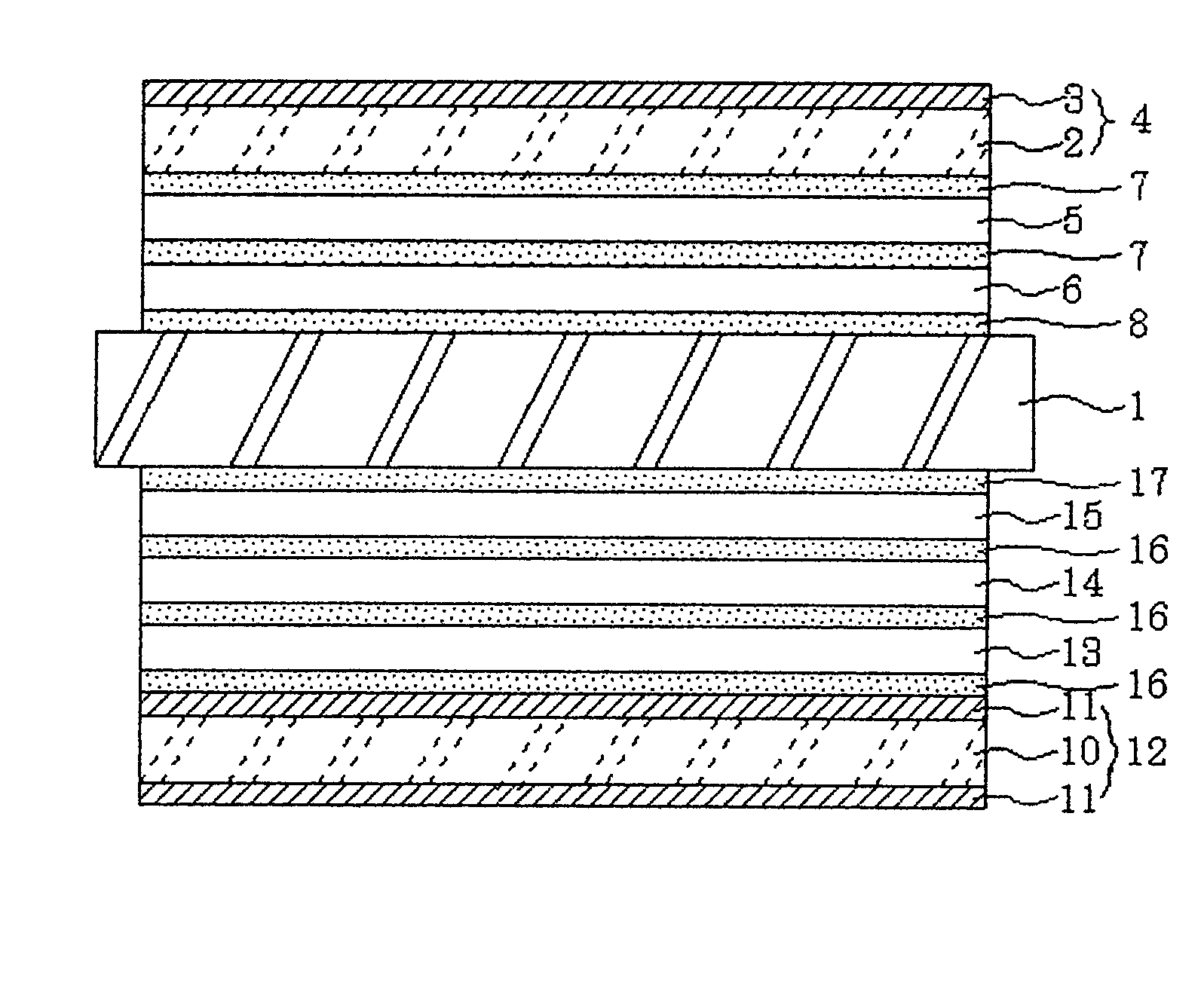

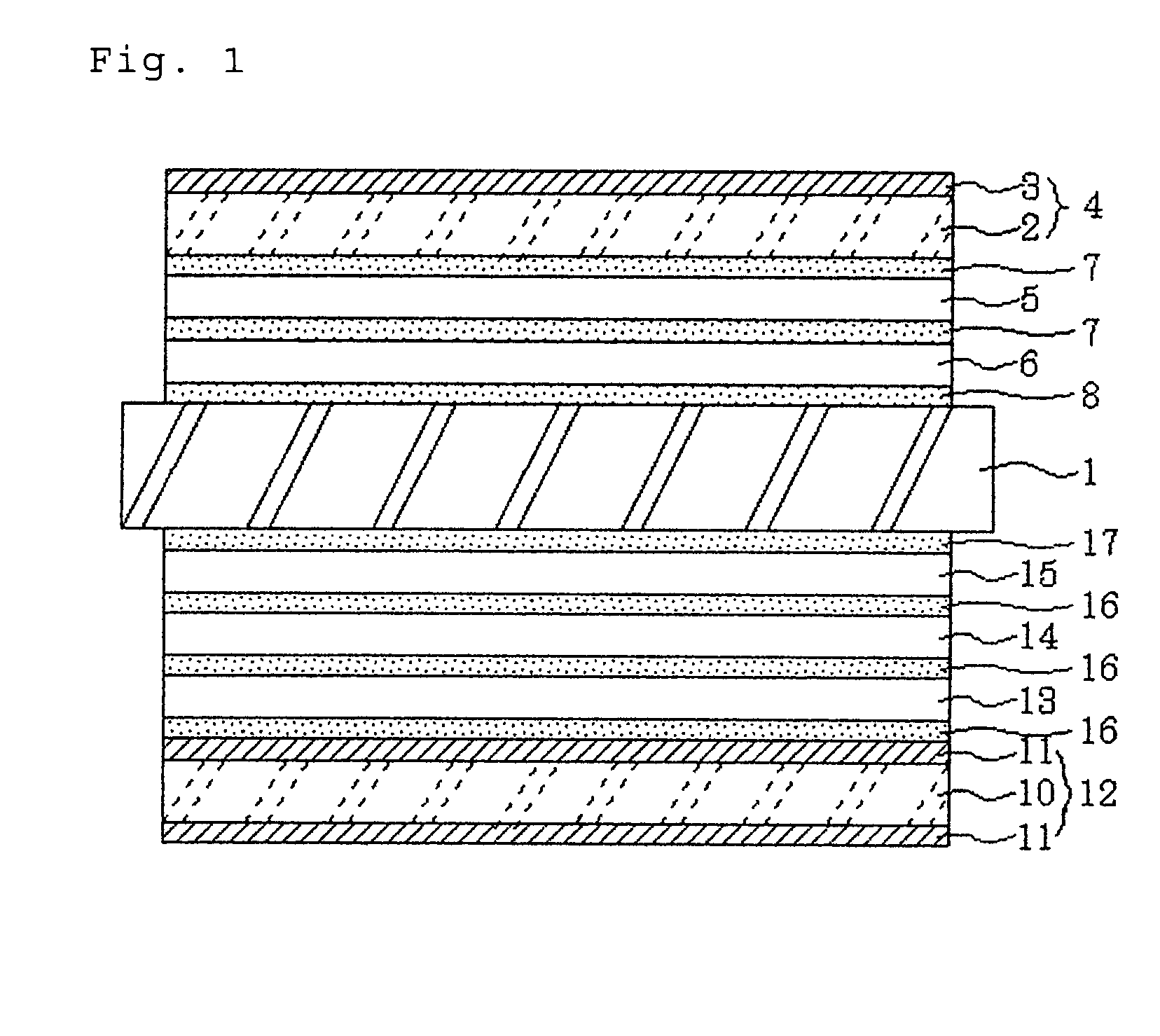

A lithium battery includes a substrate, a positive electrode layer, a negative electrode layer, and a sulfide solid electrolyte layer disposed between the positive electrode layer and the negative electrode layer, the positive electrode layer, the negative electrode layer, and the sulfide solid electrolyte layer being provided on the substrate. In this lithium battery, the positive electrode layer is formed by a vapor-phase deposition method, and a buffer layer that suppresses nonuniformity of distribution of lithium ions near the interface between the positive electrode layer and the sulfide solid electrolyte layer is provided between the positive electrode layer and the sulfide solid electrolyte layer. As the buffer layer, a lithium-ion conductive oxide, in particular, LixLa(2-x) / 3TiO3 (x=0.1 to 0.5), Li7+xLa3Zr2O12+(x / 2) (−5≦×≦3, preferably −2≦×≦2), or LiNbO3 is preferably used.

Owner:SUMITOMO ELECTRIC IND LTD

Naphthalene derivative, resist bottom layer material, and patterning process

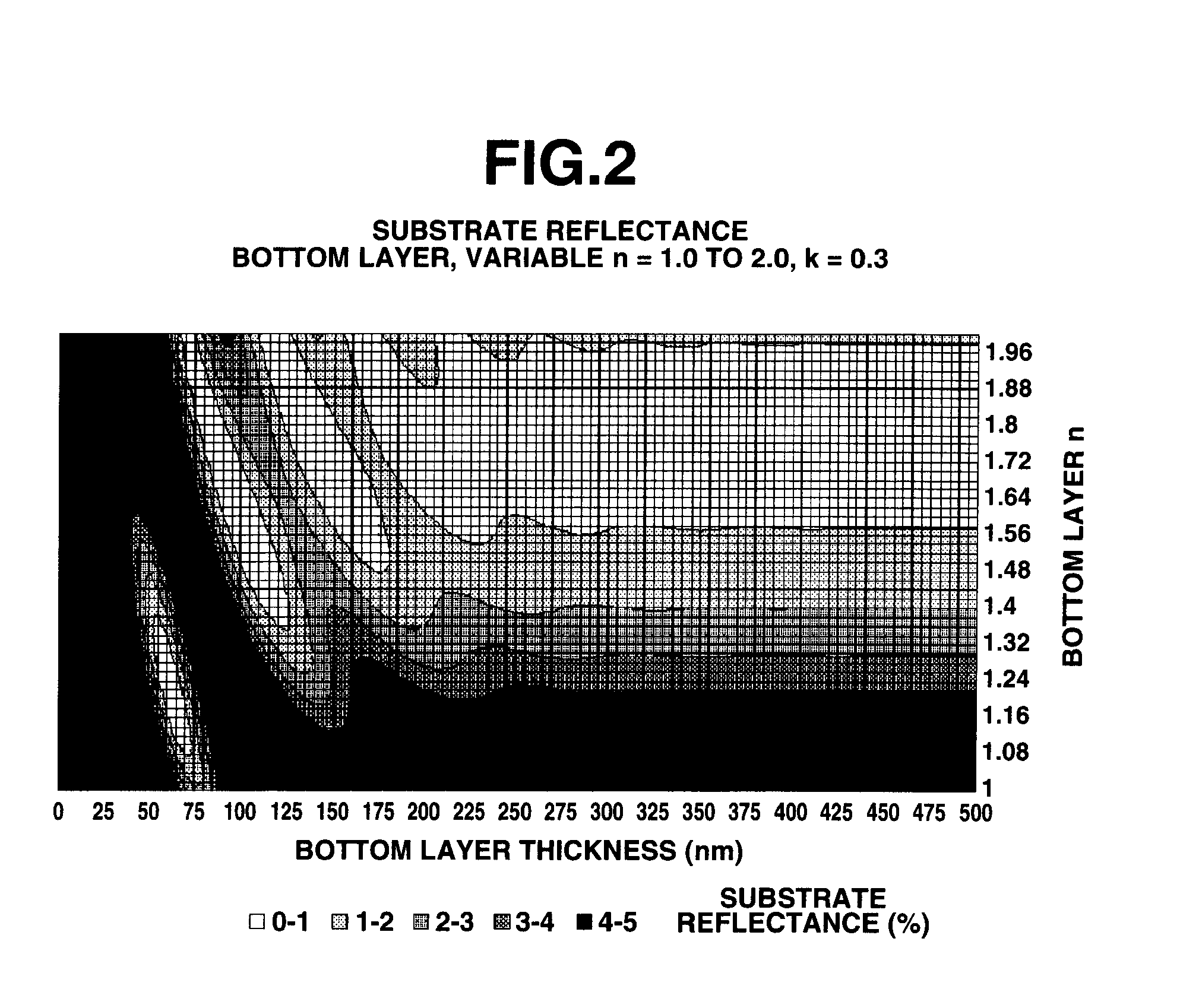

ActiveUS20120064725A1Excellent etch resistanceMinimizing outgassingOrganic chemistryOrganic compound preparationBenzeneResist

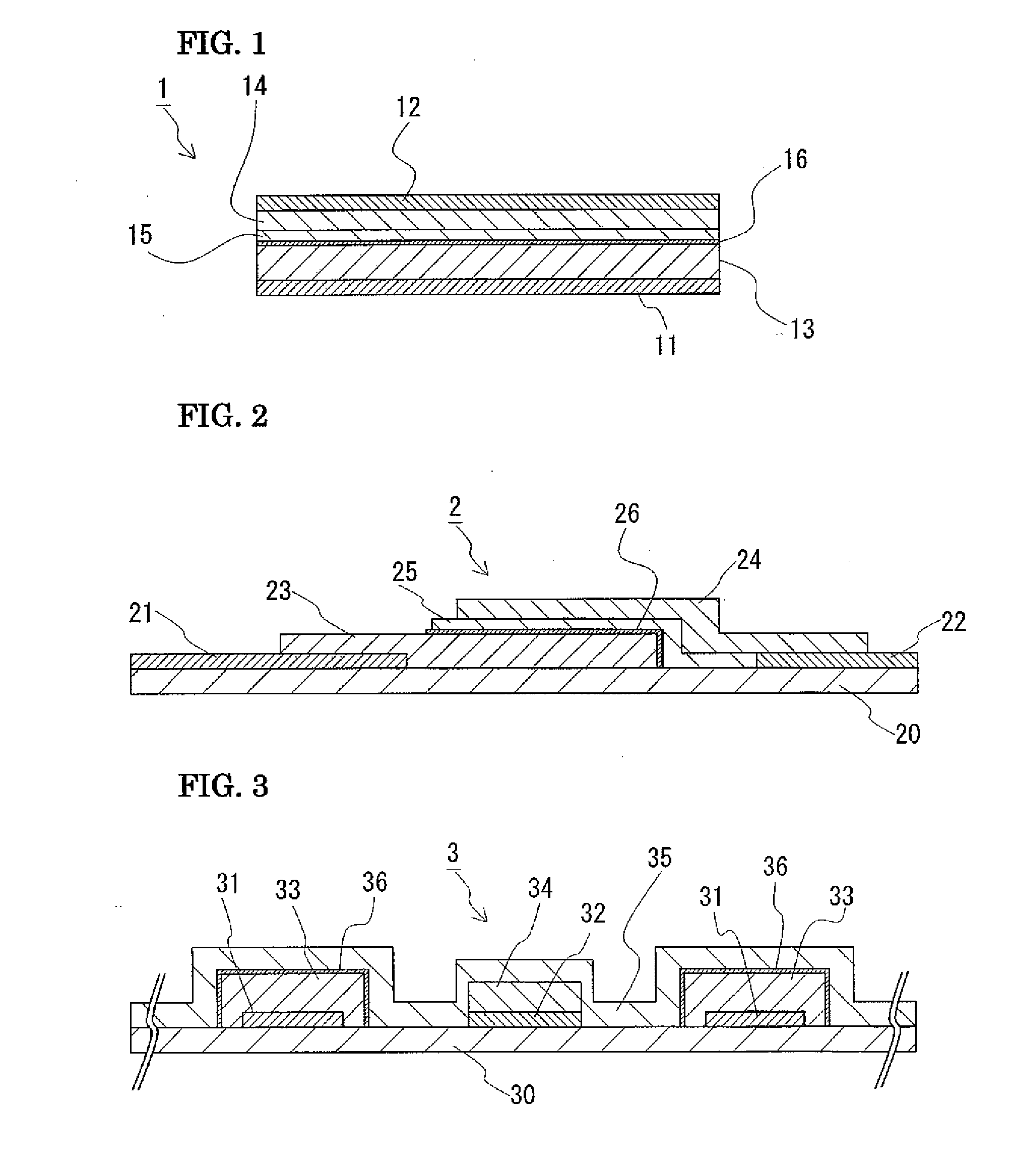

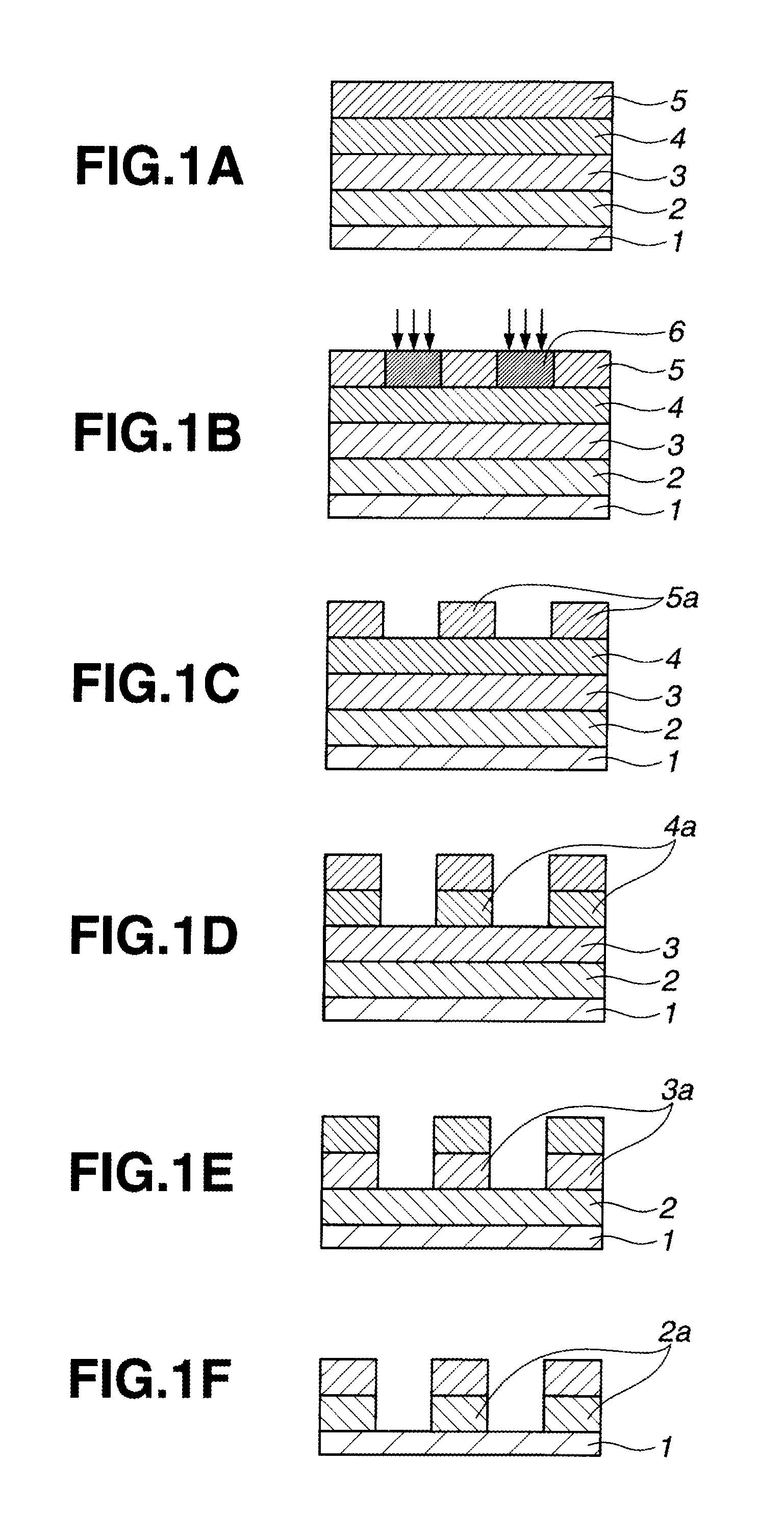

A naphthalene derivative having formula (1) is provided wherein An and Art denote a benzene or naphthalene ring, and n is such a natural number as to provide a weight average molecular weight of up to 100,000. A material comprising the naphthalene derivative or a polymer comprising the naphthalene derivative is spin coated to form a resist bottom layer having improved properties. A pattern forming process in which a resist bottom layer formed by spin coating is combined with an inorganic hard mask formed by CVD is available.

Owner:SHIN ETSU CHEM IND CO LTD

Hydrogenated block copolymer having alkoxysilyl group and use therefor

InactiveUS20130244367A1High glass transition temperatureImprove heat resistanceNon-fibrous pulp additionAluminium compoundsHigh humidityPolymer science

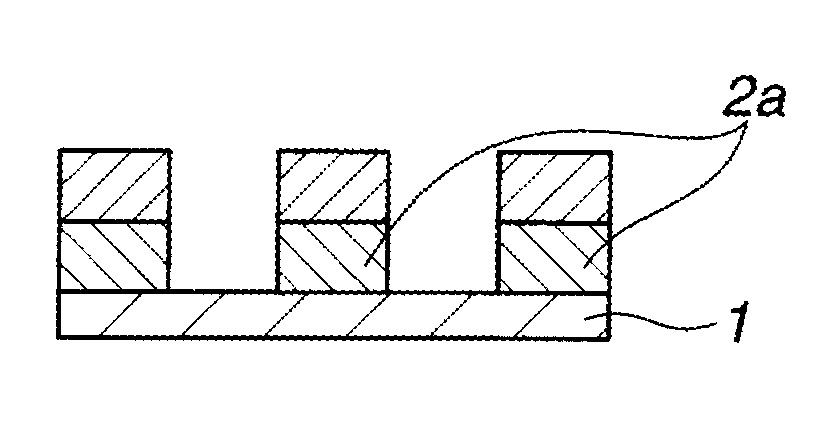

Provided are: an alkoysilyl group-containing hydrogenated block copolymer produced by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer that includes at least two polymer blocks [A] and at least one polymer block [B], the polymer block [A] including a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block [B] including a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer to a weight fraction wB of the polymer block [B] in the block copolymer being 20:80 to 60:40; a method for producing the same; a solar cell element encapsulating material; a sheet, a laminated sheet; a multilayer sheet; and a method for encapsulating a solar cell element. The alkoxysilyl group-containing hydrogenated block copolymer exhibits low hygroscopicity, a low water vapor permeability, transparency, weatherability, and flexibility, maintains excellent adhesion to glass even when exposed to a high-temperature / high-humidity environment for a long time, and can encapsulate a solar cell element without applying a special waterproof treatment.

Owner:ZEON CORP

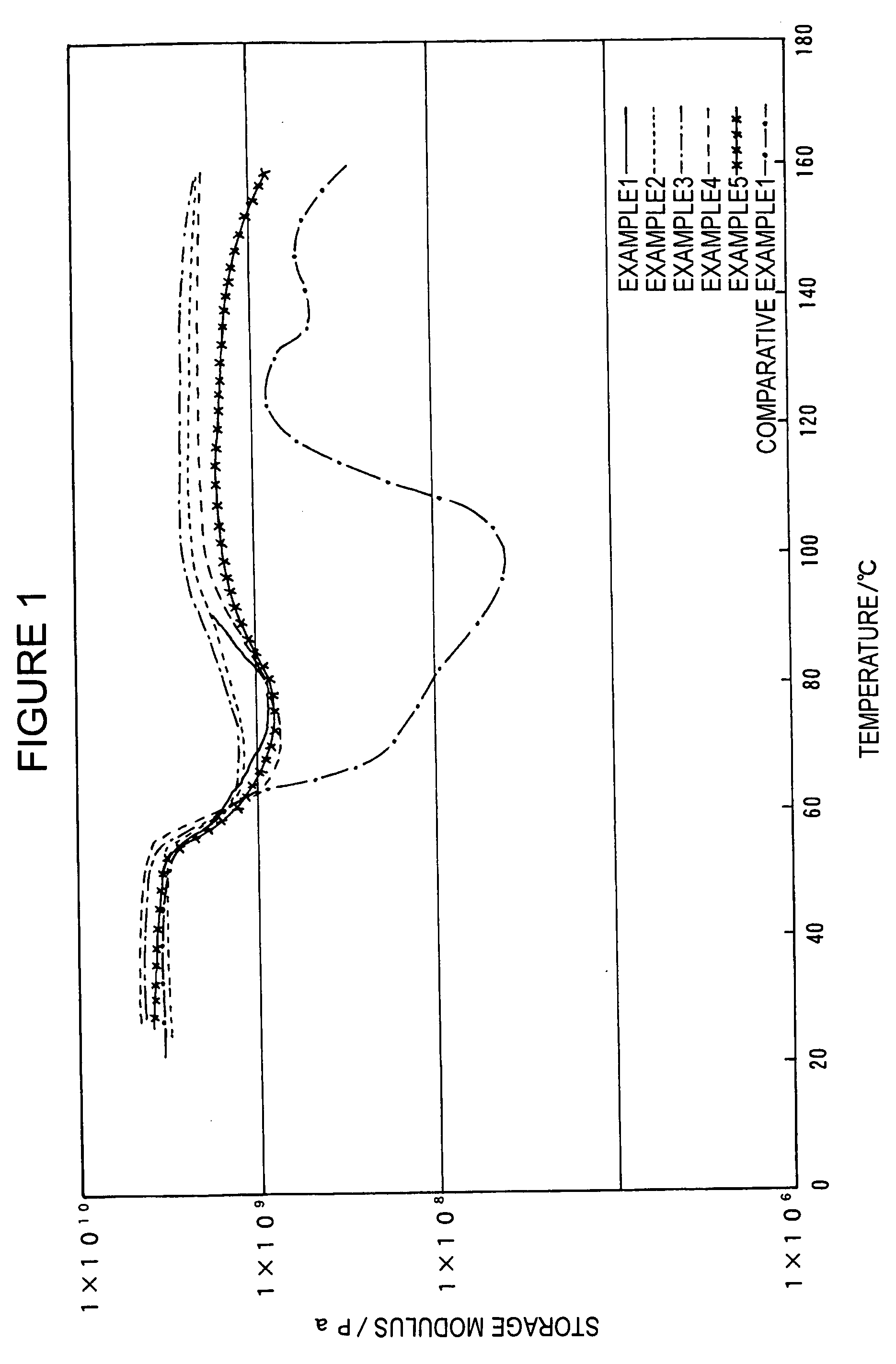

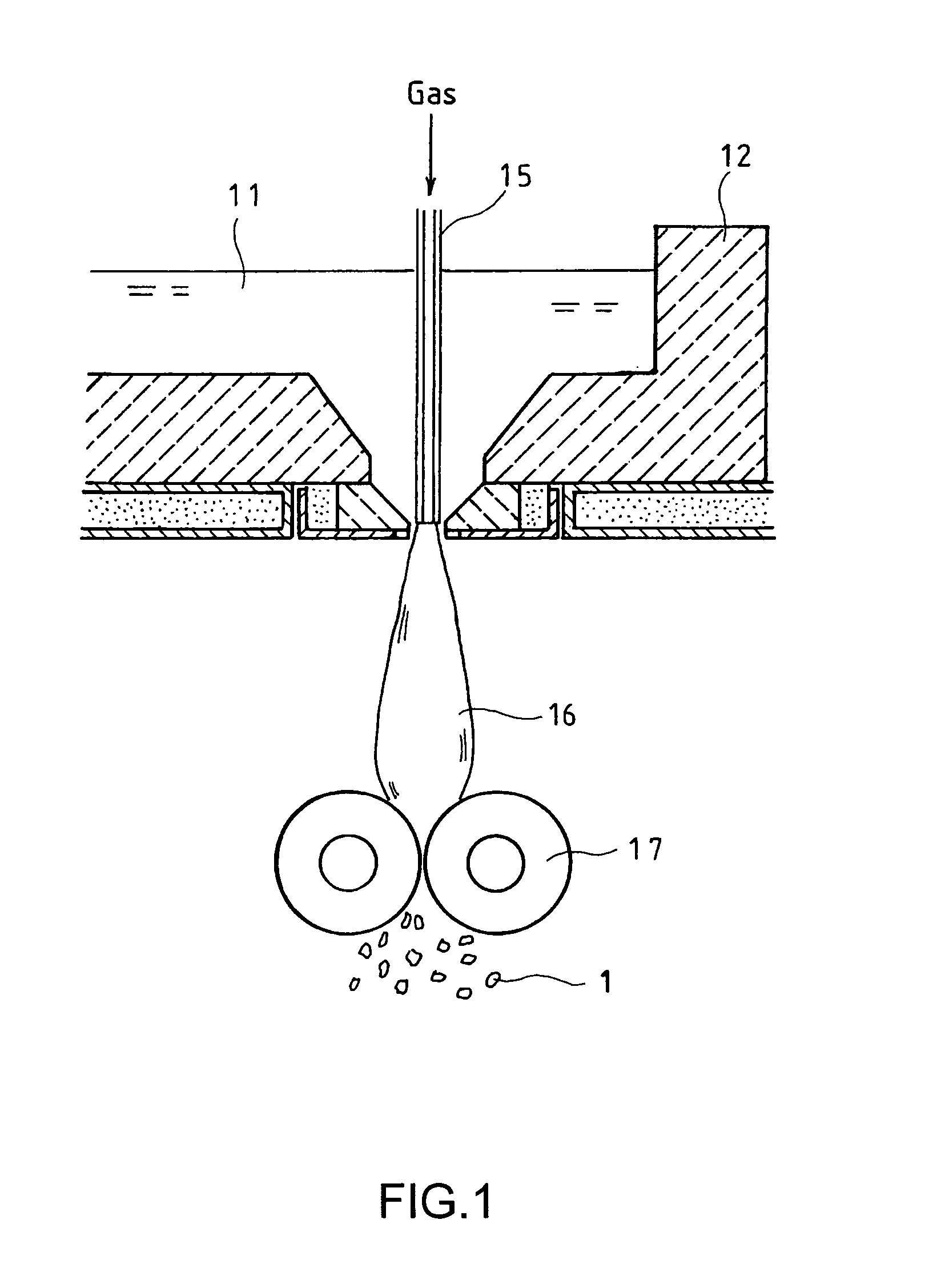

Polyamide composition

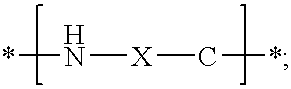

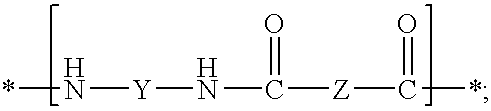

InactiveUS6887930B2Low water absorptionOvercome lack of heat resistanceCarboxylic acidTerephthalic acid

A polyamide composition comprising 50 to 90 parts by weight of (A) semiaromatic polyamides having dicarboxylic acid units containing 60 to 100 mole % of terephthalic acid units and diamine units containing 60 to 100 mole %, in total, of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 50 to 10 parts by weight of (B) aliphatic polyamides in which the average of total carbon atoms of dicarboxylic acid units and diamine units per one amide group is 7 to 12; having excellent moldability, toughness, light-weightness, hot water and steam resistance, heat resistance, mechanical characteristics, low water absorption, chemical resistance and melt stability; and are applicable for molding at low temperature with a conventional steam-heating or a conventional hot-water-heating type mold to give molded articles having sufficient heat resistance, rigidity at high temperature and dimensional stability.

Owner:KURARAY CO LTD

Composite composition and molding using the same

A composite composition includes at least one organic polymer compound having biodegradability, vegetable fibers, and a hydrolysis inhibitor for the organic polymer compound having biodegradability.

Owner:SONY CORP

Glass flake

InactiveUS20050049133A1Overcome lack of heat resistanceGood molding effectPigmenting treatmentOther chemical processesHeat resistanceBoron trioxide

The present invention provides a glass flake that is substantially free of boron trioxide (B2O3), barium oxide (BaO), zinc oxide (ZnO), and fluorine (F) and has sufficient heat resistance and good formability for glass flake. The glass flake of the present invention includes a glass composition that contains the following components, expressed in mol %; 50≦SiO2≦65; 4≦Al2O3<12; 5≦SrO≦25; 10<(MgO+SrO)≦30; 20≦(MgO+CaO+SrO)≦45; and 0<(Li2O+Na2O+K2O)<2; wherein the glass composition is substantially free of B2O3, BaO, ZnO, and F. This glass flake is useful for resin compositions, paints, cosmetics, ink compositions, and the like.

Owner:NIPPON SHEET GLASS CO LTD

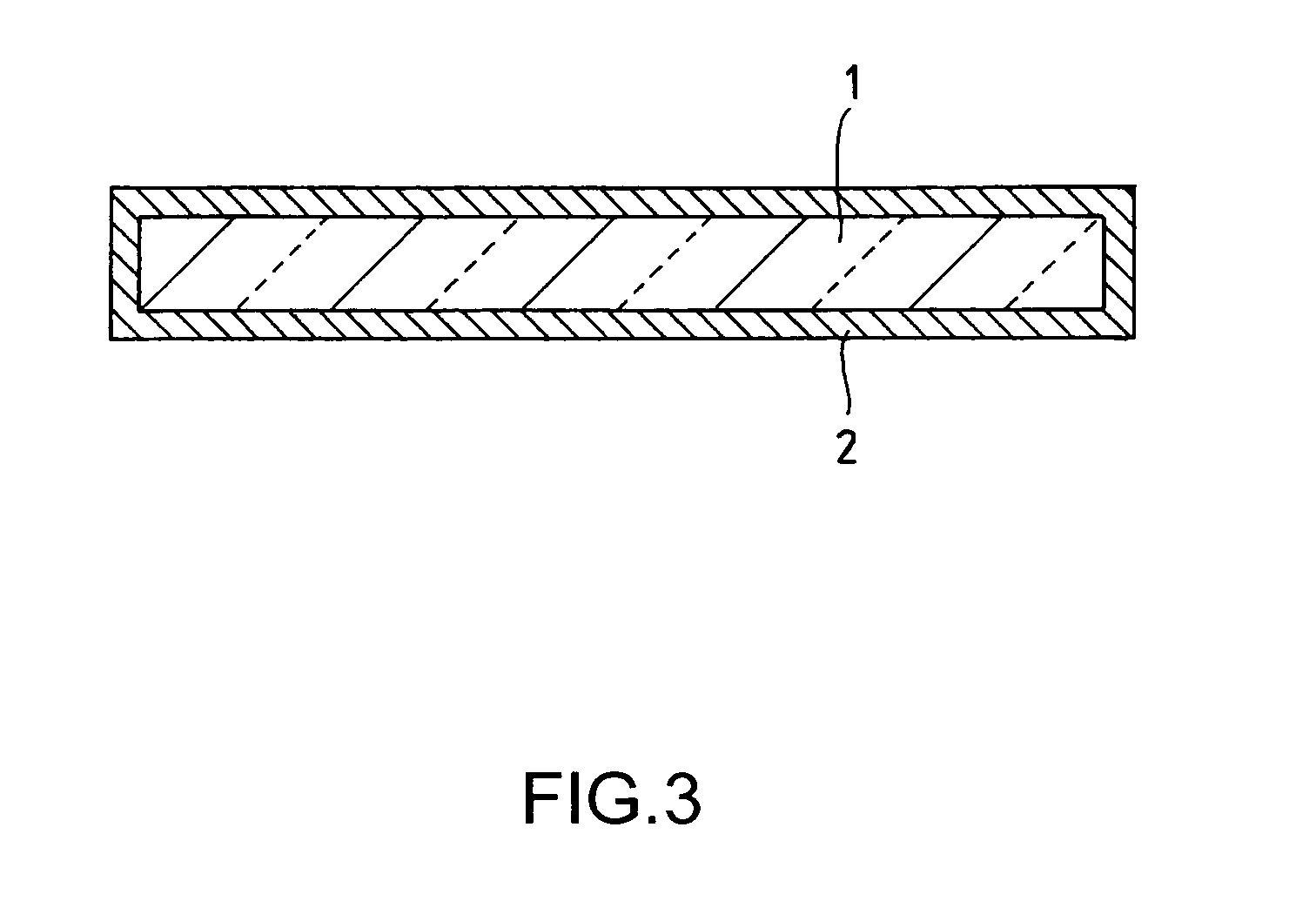

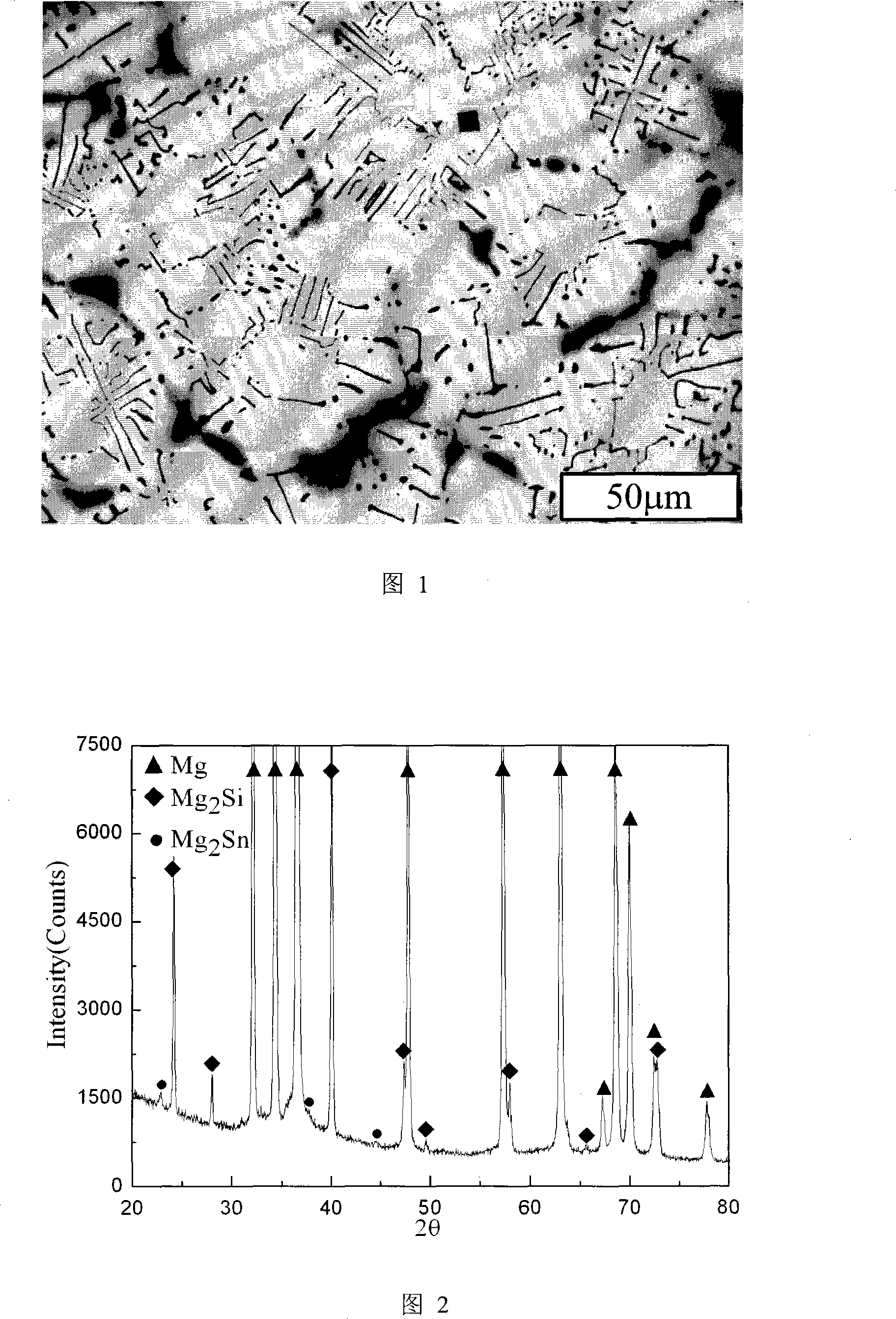

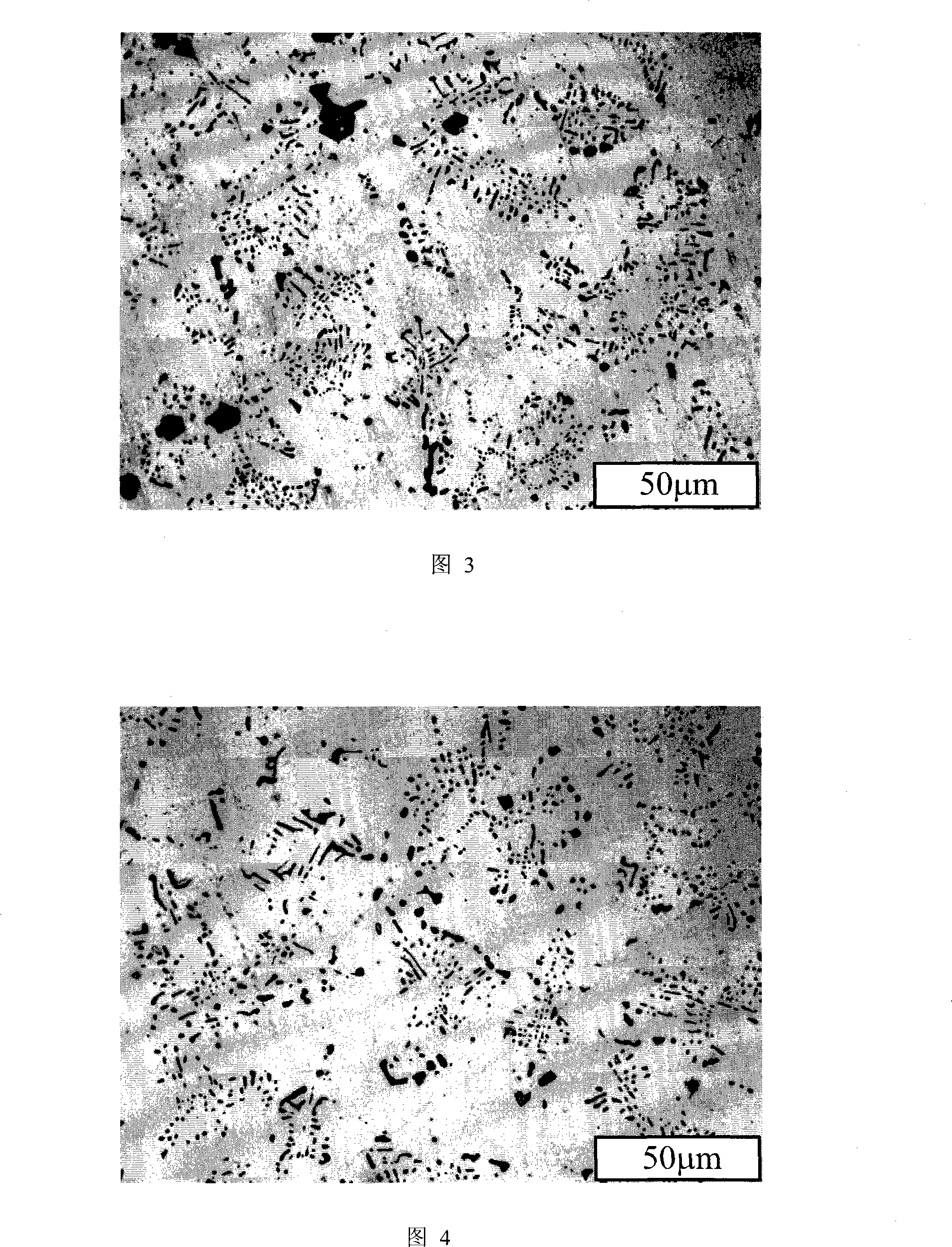

Mg-Si-Sn series magnesium alloy and heat treatment process for deteriorate Chinese character shaped eutectic Mg2Si phase therein

InactiveCN101161840AImproved high temperature tensile and creep propertiesOvercome lack of heat resistanceMagnesium alloyHeat treated

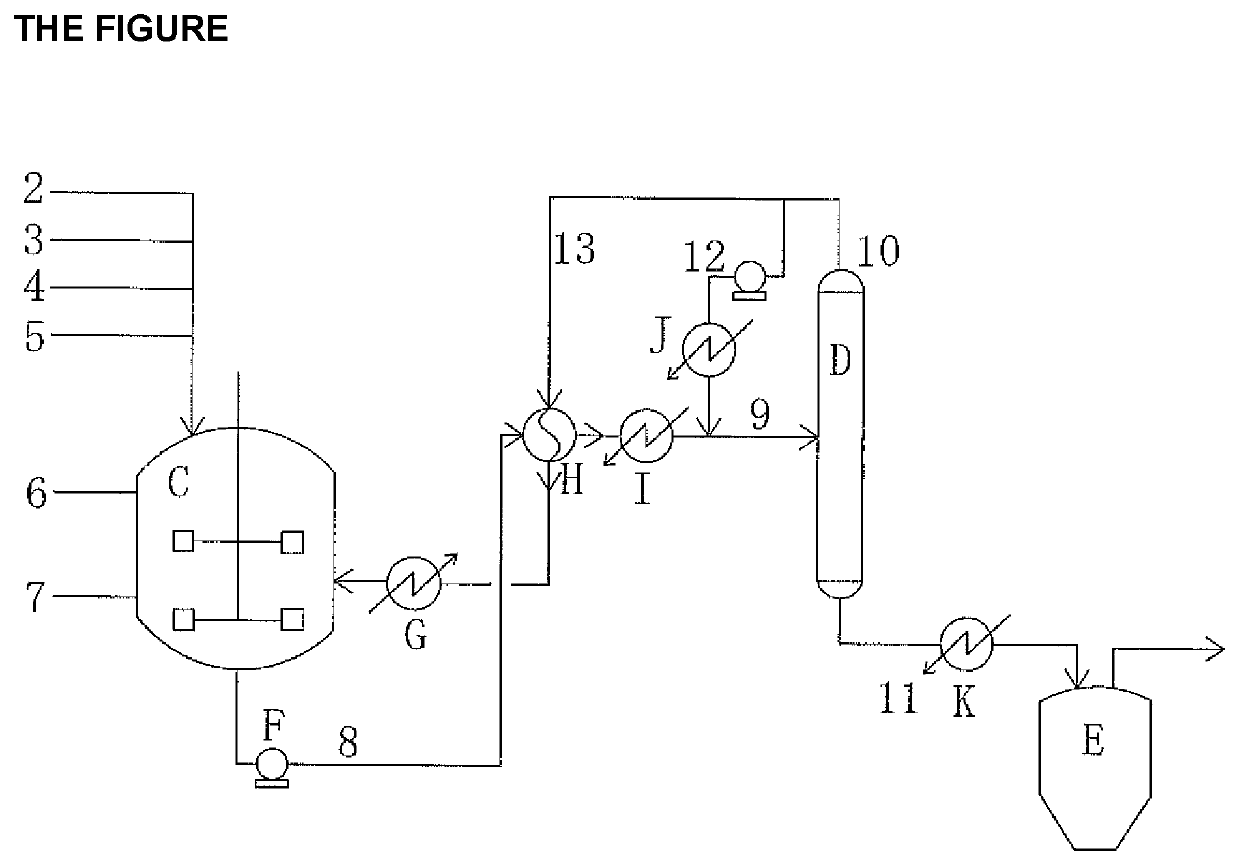

The invention proposes an Mg-Si-Sn series magnesium alloy and the heat treatment technics for changing the quality of eutectic crystal Mg2Si phase with a Chinese character shape. The preferred compositions and weight percentage of the Mg-Si-Sn series magnesium alloy are as follows: 3 percent of Sil, Sn of 1 percent to 3 percent of Sn and remaining Mg. The Mg-Si-Sn series magnesium alloy adopts industrial pure magnesium ingot, industrial polyeristalline silicon powder and pure tin ingot to melt and cast. The Mg-Si-Sn series magnesium alloy casting member which is melted according to ingredient formulation is placed into box type resistance furnace with protective atmosphere for preserving heat, in which the range of temperature is from 490 DEG C to 550 DEG C and the time of heat preservation is from 1 hours to 4 hours; and then the casting member is quickly taken out and put into water for quenching. The invention opens a novel path for developing cheap heat resistant magnesium alloy. The Mg-Si-Sn series magnesium alloy is thought as one of the cheap heat resistant magnesium alloys with the most developing potential and can be used to produce parts such as automobile engine tank cover, crankcase, gear box and the like.

Owner:HARBIN ENG UNIV

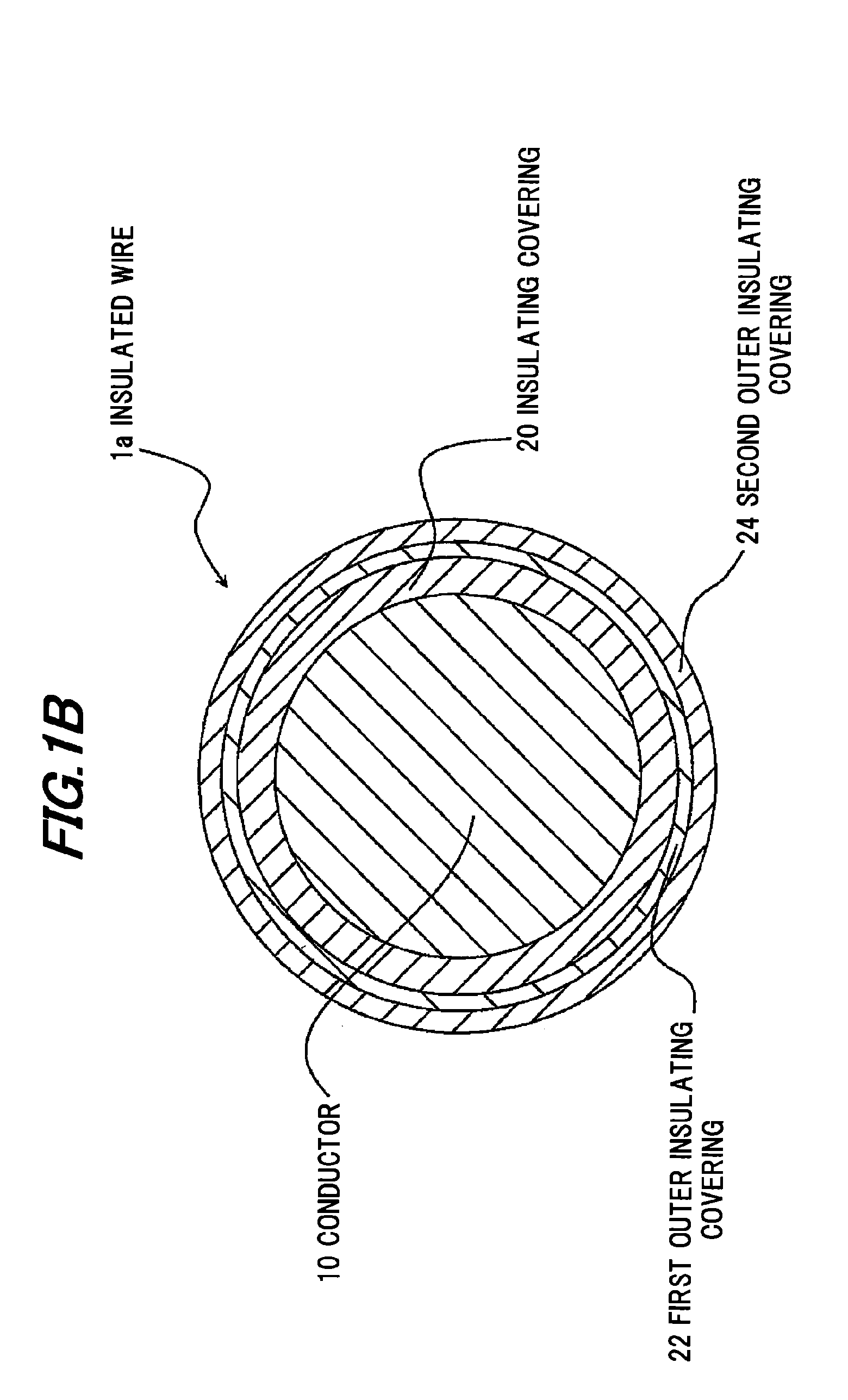

Non-Halogenous Insulated Wire and a Wiring Harness

InactiveUS20090057009A1Improve mechanical propertiesImprove coordinationPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorZinc compounds

A non-halogenous insulated wire possessing sufficient flame retardancy, wear resistance, flexibility and workability, and excellent coordination with a halogen-containing material, which includes a conductor, an inside coat formed of one or more layers and an outermost coat, wherein the outermost coat is in the range of 10-100 μm in thickness and made from a resin composition including one or more sorts of polyethylene such that an average density of the included polyethylene becomes 0.910 g / cm3 or more, and at least one of the layers is made from a resin composition including a resin ingredient which includes (A) polyethylene and (B) at least one sort of polymer, (C) a metallic hydrate, and (D) a zinc compound, in which at least one of (B) the polymer is modified by acid and / or (E) an organic functional coupling agent is further included.

Owner:AUTONETWORKS TECH LTD +2

Non-crosslinked flame-retardant resin compsition, and an insulated wire and a wire harness using the same

InactiveUS20070048524A1Sufficient flame retardancySolve the lack of flexibilityPlastic/resin/waxes insulatorsSpecial tyresAdditive ingredientPliability

To provide a non-crosslinked flame-retardant resin composition possessing sufficient flame retardancy, mechanical properties, flexibility and workability, and also delivering excellent heat resistance over a long period of time as it is hard to be molten when used under high temperature environment and its material is not deteriorated even if used in contact with a vinyl chloride resin material and the like, and an insulated wire and a wiring harness using the same. The composition includes (A) a non-crosslinked base resin which contains a propylene resin containing 50 wt % or more of propylene monomer and a thermoplastic resin of which a melting point is 180° C. or more, (B) a metallic hydrate, (C) a hindered phenolic antioxidant, (D) a sulfurous antioxidant, and (E) a metallic oxide. Polymethylpentene, an imidazole compound and an oxide of zinc are preferably utilized as the thermoplastic resin, the ingredients (D) and (E), respectively. The composition is used as an insulated covering material for a non-halogenous insulated wire, which is used in a wire bundle of the wiring harness.

Owner:AUTONETWORKS TECH LTD +2

Preparation technology of chlorobutyl rubber used for internal rubber layer of rubber tube of automobile air conditioning

InactiveCN101817958AMeet the requirements of the ELV directiveOvercome lack of heat resistancePolymer scienceAutomobile air conditioning

The invention discloses a preparation technology of chlorobutyl rubber used for an internal rubber layer of a rubber tube of an automobile air conditioning, comprising the process flows of making up a formula and preparing. In the invention, the technical scheme utilizing a heat-resisting modified formula to match with a corresponding preparation method is adopted, thus overcoming the problem of poor heat-resistant quality of the chlorobutyl rubber in the prior art. The provided preparation technology of the chlorobutyl rubber used for the internal rubber layer of the rubber tube of the automobile air conditioning prepares chlorobutyl rubber the application temperature of which is minus 30-135 DEG C, and the chlorobutyl rubber is used for manufacturing the inner rubber layer of the automobile air conditioning, thus reaching the purpose of improving heat-resistant property.

Owner:宁波市天普橡胶科技股份有限公司

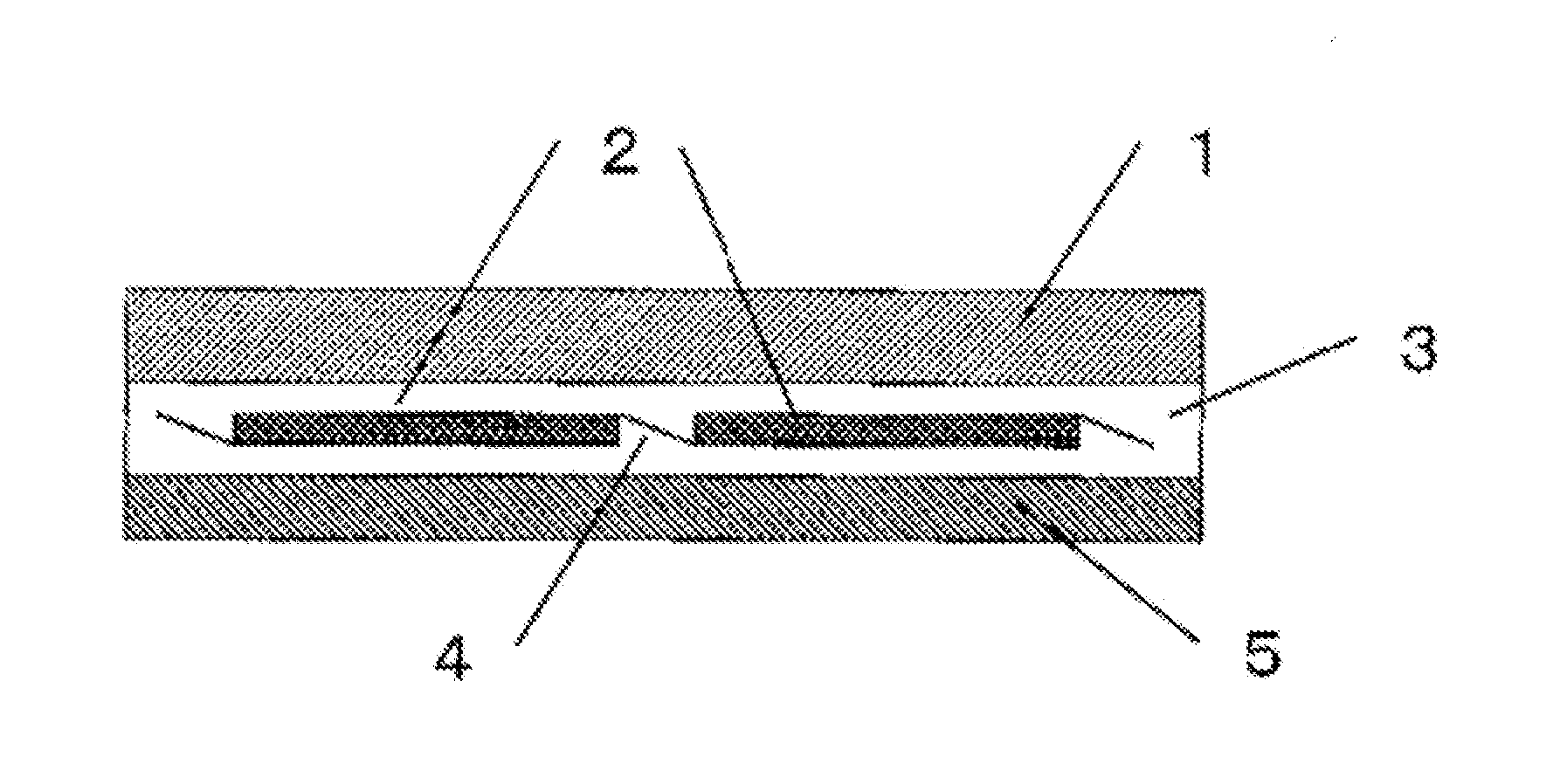

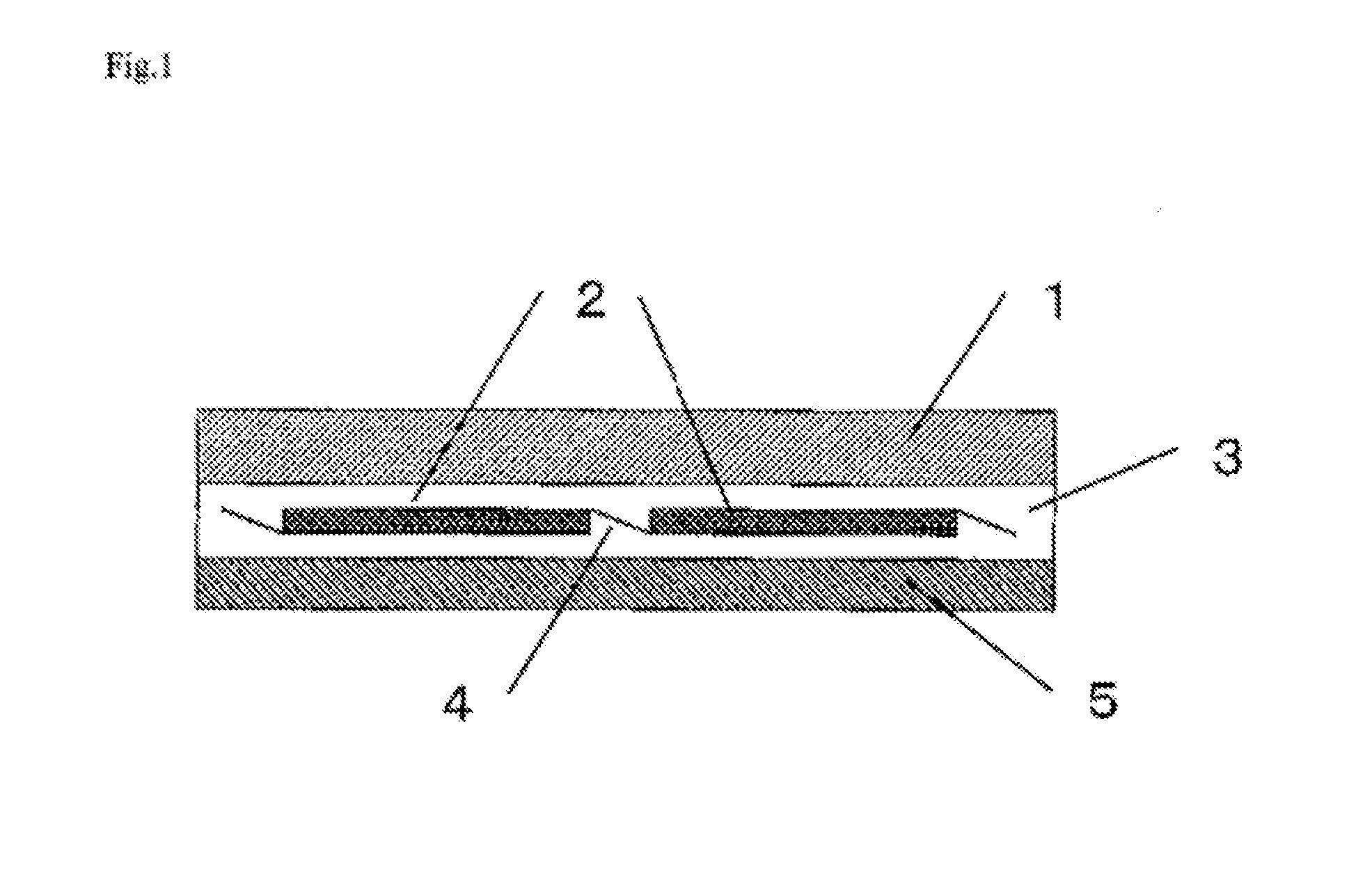

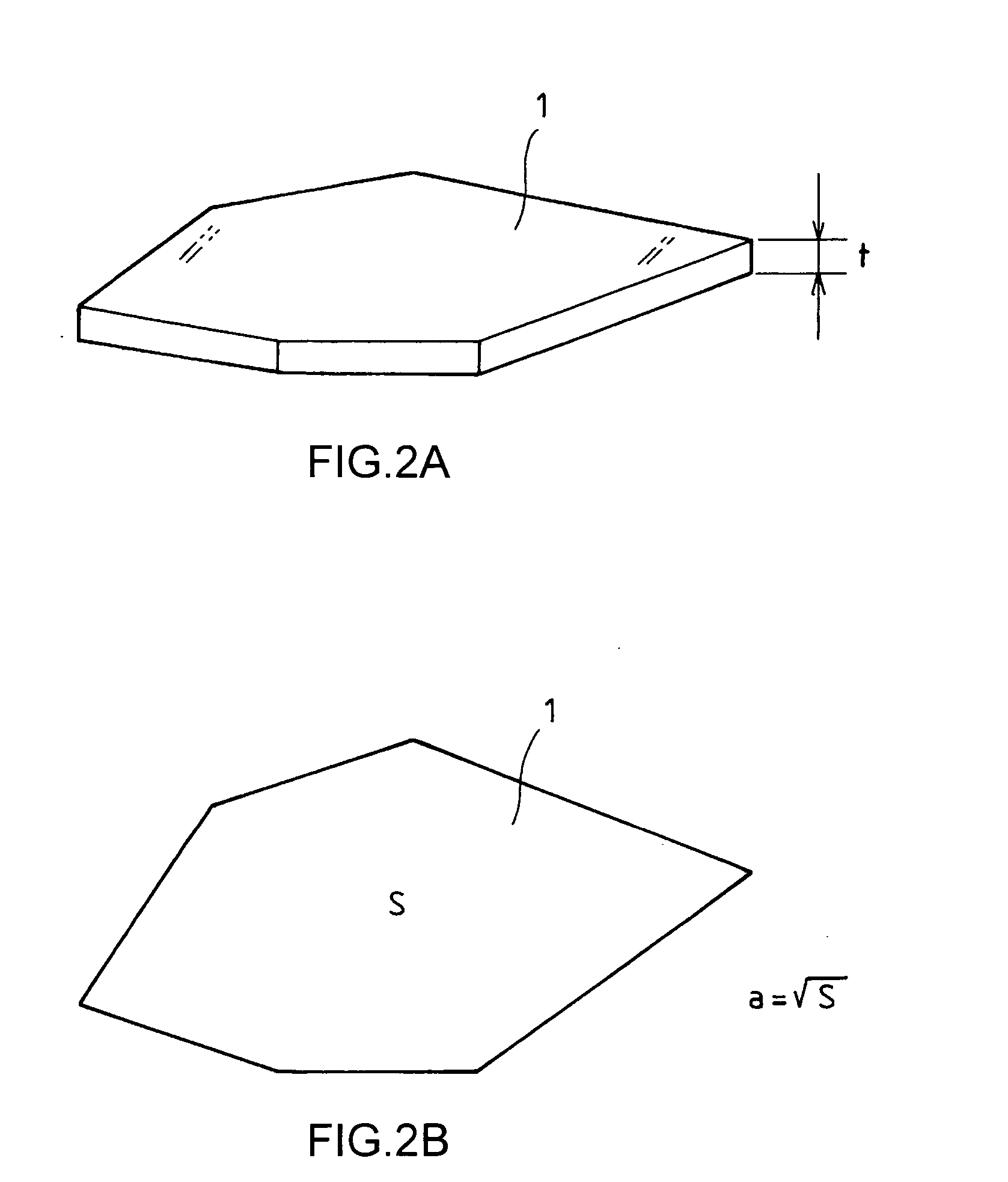

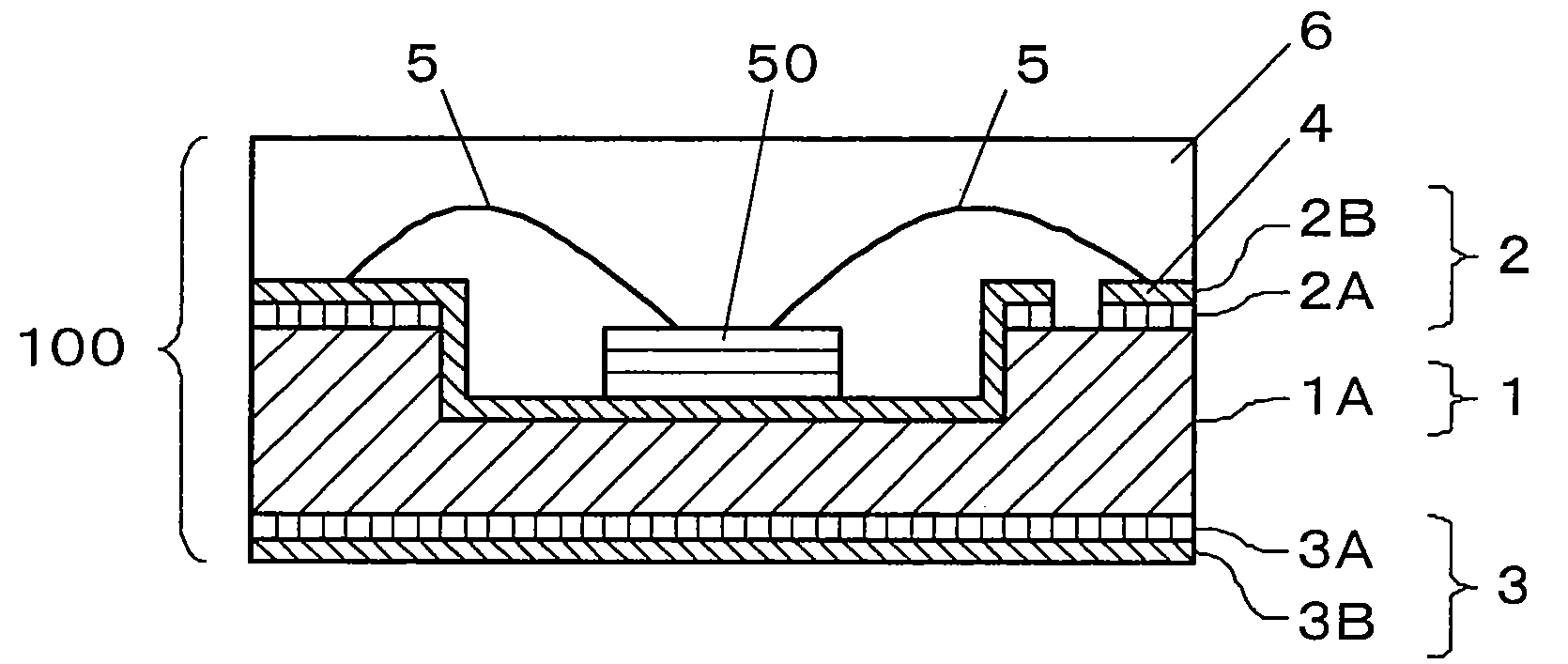

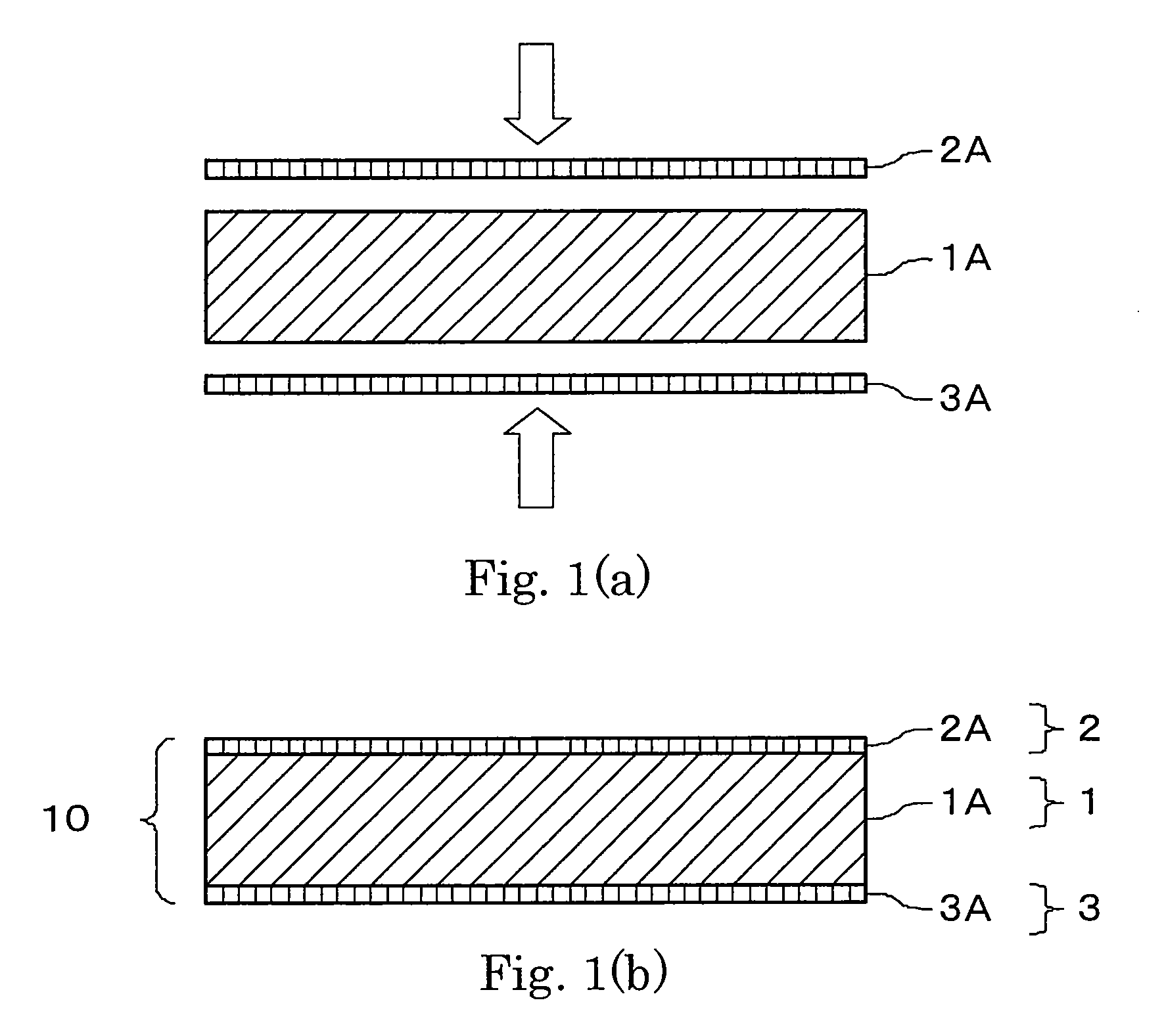

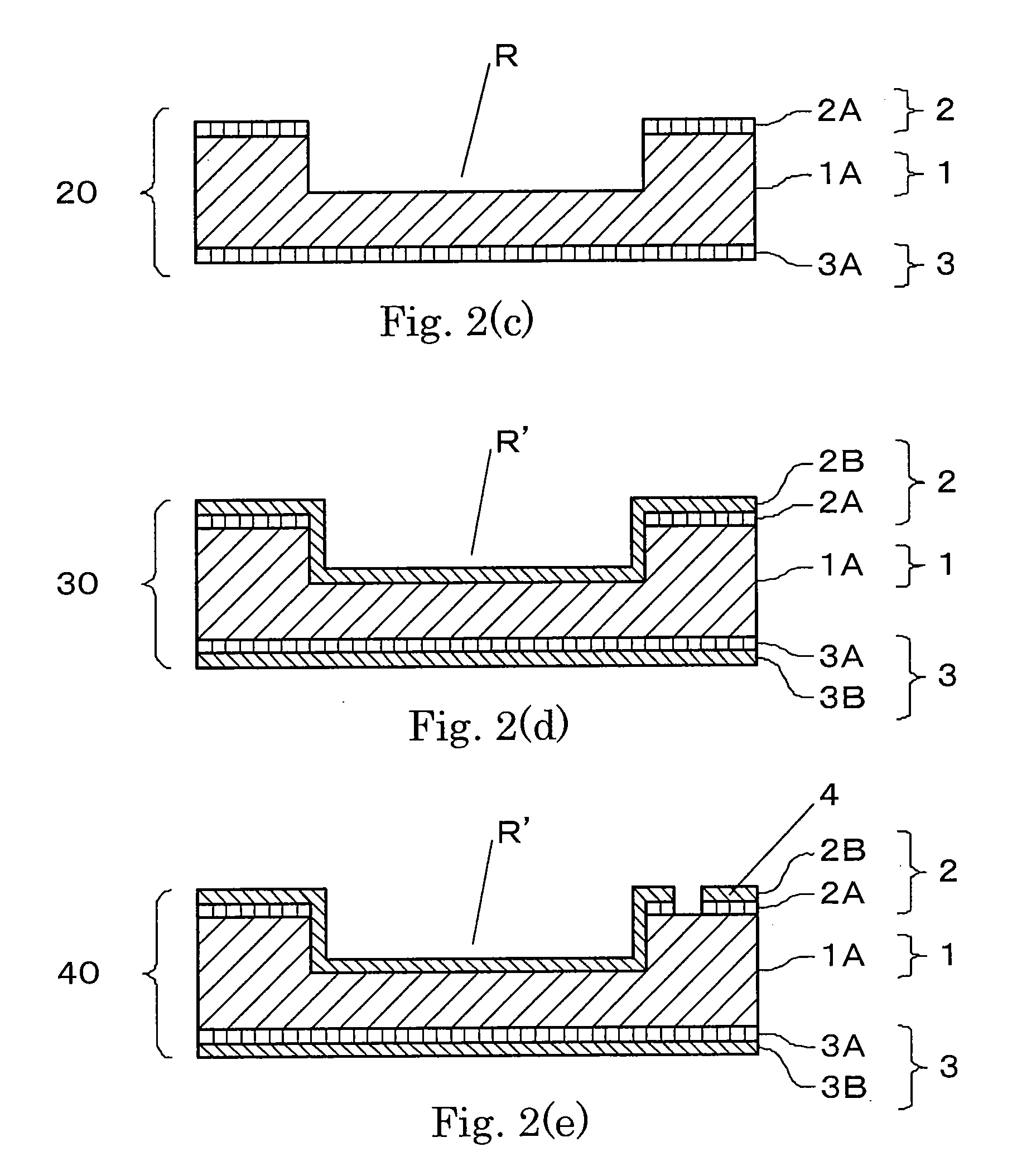

Substrate applicable in chip LED package

InactiveUS20100084167A1Small coefficient of linear expansionOvercome lack of heat resistancePrinted circuit aspectsSolid-state devicesPolyesterFiber

The present invention provides a substrate applicable in a chip LED package, the substrate having a conductive layer, an insulation layer and a heat-dissipation plate in this order, wherein the insulation layer comprises a liquid crystal polyester soluble in a solvent and a sheet comprising inorganic fibers and / or organic fibers. The substrate has a small linear expansion coefficient of the insulation layer in the surface direction and is extremely useful for production of a chip LED package while having a practical heat resistance.

Owner:SUMITOMO CHEM CO LTD

Multicolored thermally recording medium

InactiveUS20060072429A1Sharp thermal sensitive characteristicImprove heat resistanceMechanical record carriersRecord information storageBenzenePolymer

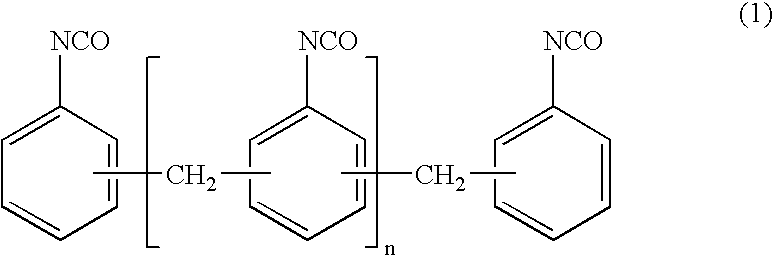

In the multi colored thermally sensitive recording medium, at least one kind of dye precursor is contained in complex fine particles which contain dye precursor and polymer of multi valence isocyanate compound, further contain 4,4′-diisocyanate-3,3′-dimethyl-1,1′biphenyl and / or polymethylene.polyphenyl.polyisocyanate.

Owner:NIPPON PAPER IND CO LTD

Polyacetal resin molded article having excellent acid resistance

InactiveUS20090143508A1Improve acid resistanceOvercome lack of heat resistanceFibre treatmentSynthetic resin layered productsPolymer scienceFatty acid

Provided is a polyacetal resin molded article having an excellent acid resistance, used for parts contacting with a liquid containing an acidic substance. Specifically, a molded article having excellent durability under direct contact with a liquid containing an acidic component is obtained by molding the composition of (A) 100 parts by weight of a polyacetal resin, (B) 0.01 to 5 parts by weight of an antioxidant, and (C) 0.01 to 10 parts by weight of a metal salt of fatty acid.

Owner:POLYPLASTICS CO LTD

Composite ceramic particles as well as preparation method and application thereof

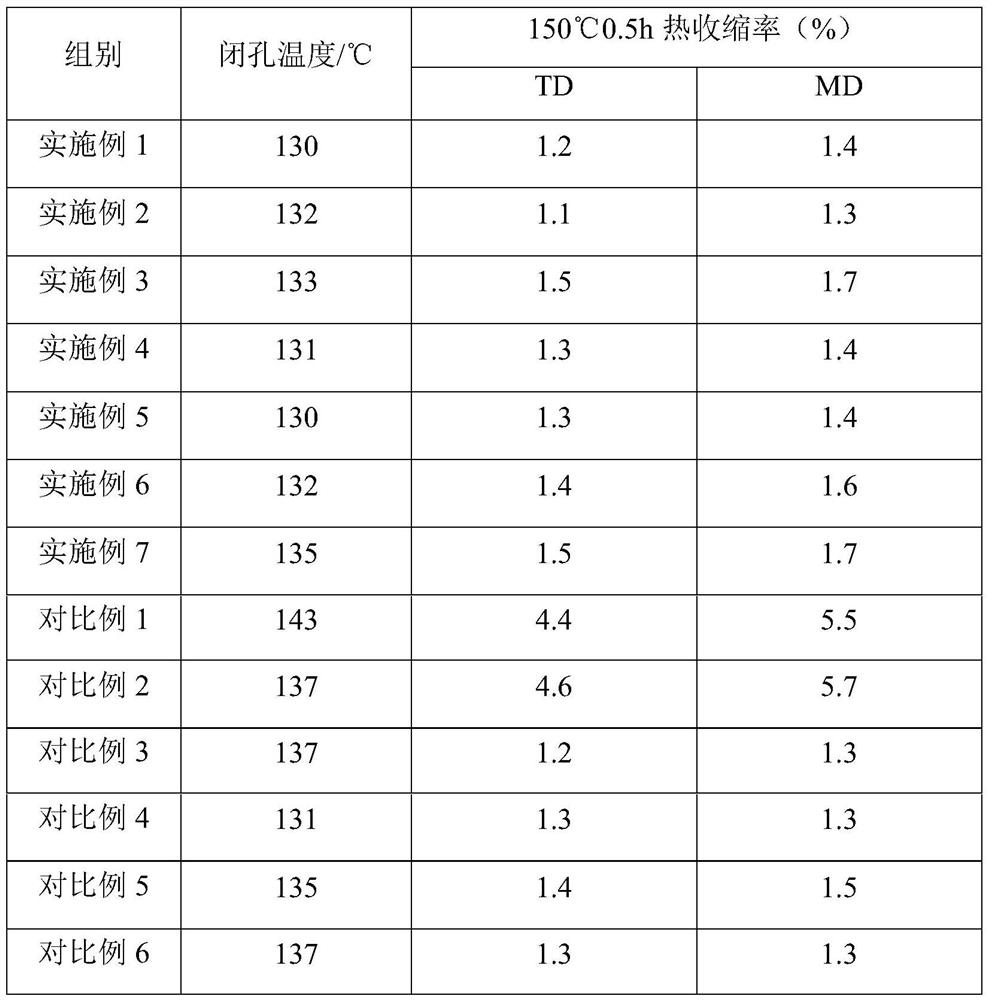

ActiveCN113278310AOvercome lack of heat resistanceImprove heat resistance deficiencySecondary cellsCell component detailsCeramic coatingComposite ceramic

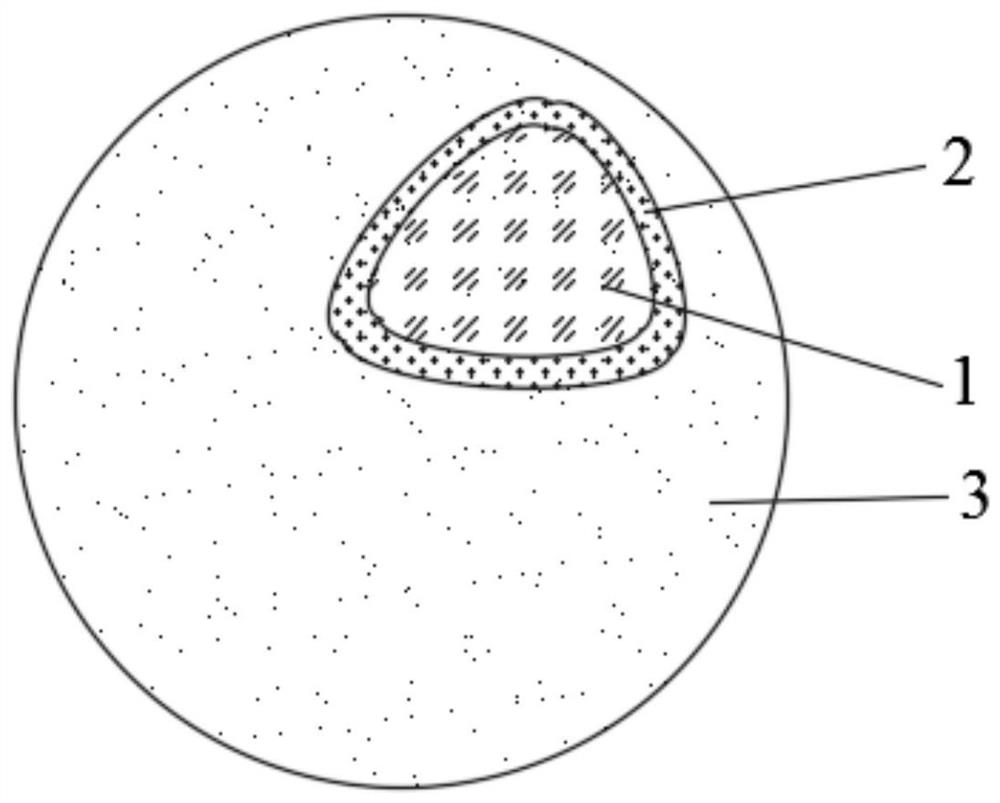

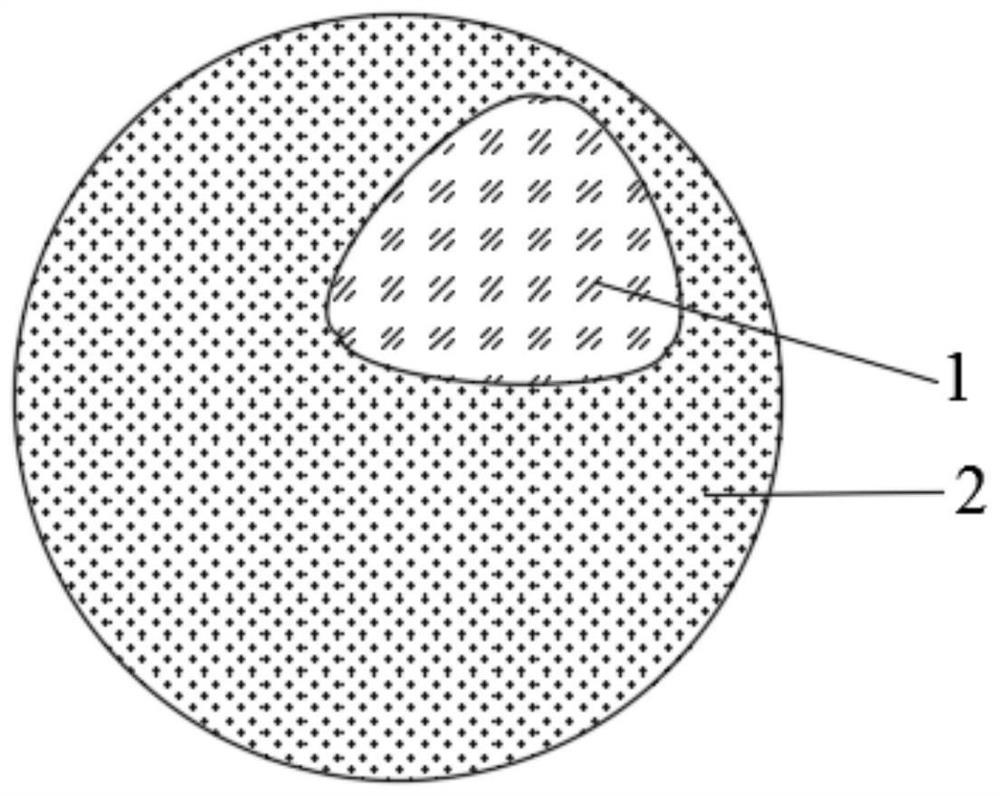

The invention provides composite ceramic particles as well as a preparation method and application thereof. The composite ceramic particles comprise phase change particles, ceramic particles and a material easy to form a film after being heated, wherein the phase change particles are used as inner cores of the composite ceramic particles, the ceramic particles are used as middle layers of the composite ceramic particles, the ceramic particles are of mesoporous hollow sphere structures, the phase change particles fill in the ceramic particles, the material easy to form a film after being heated is used as shells of the composite ceramic particles and coats the surfaces of the ceramic particles; the melting point of the material easy to form the film after being heated is 80-150 DEG C. Compared with a conventional ceramic coating prepared from ceramic particles, a ceramic coating prepared from the ceramic particles with the three-layer core-shell structure has high heat resistance. Thus, with the structural design of the composite ceramic particles adopted, the problem that the existing ceramic coating is insufficient can be effectively solved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

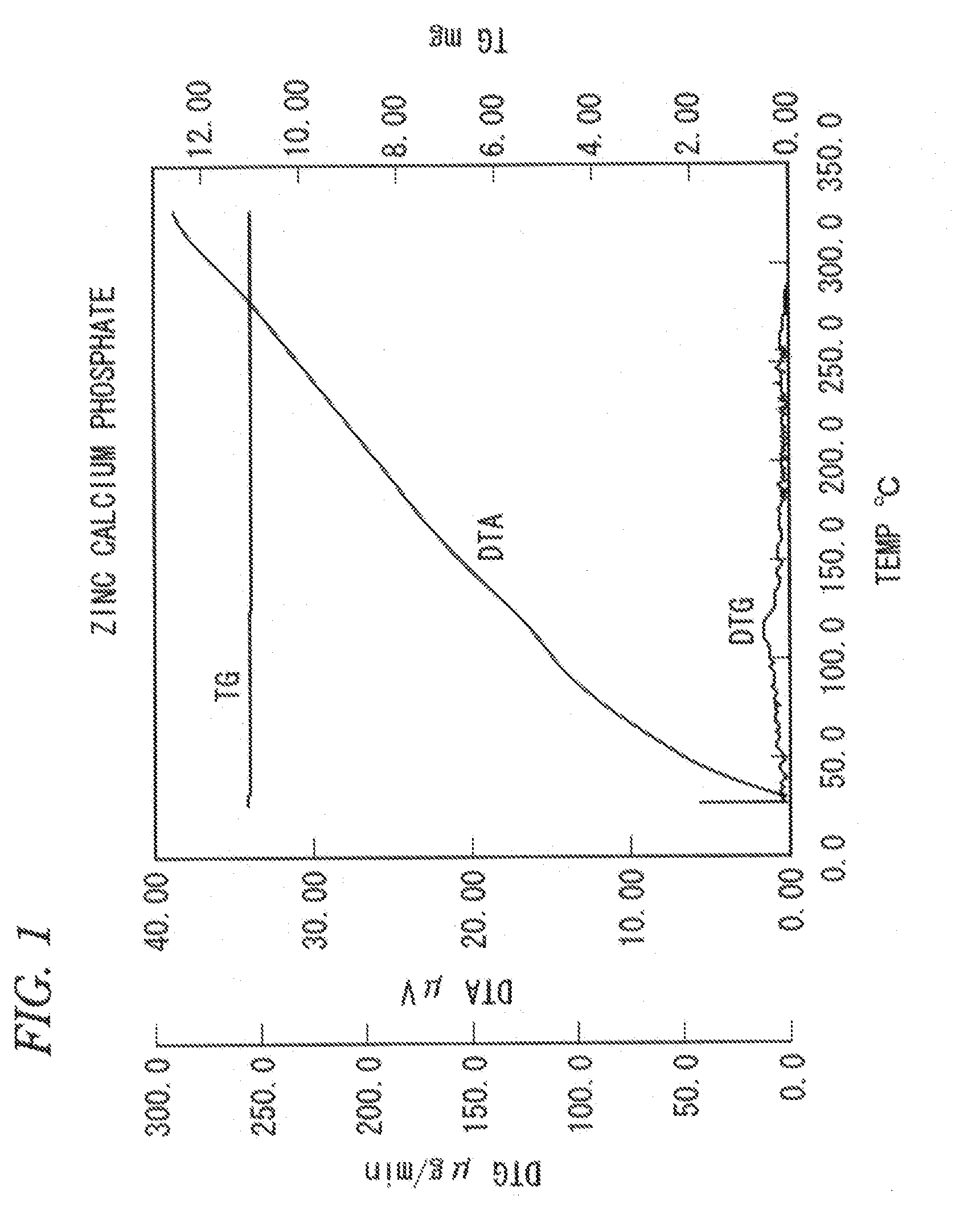

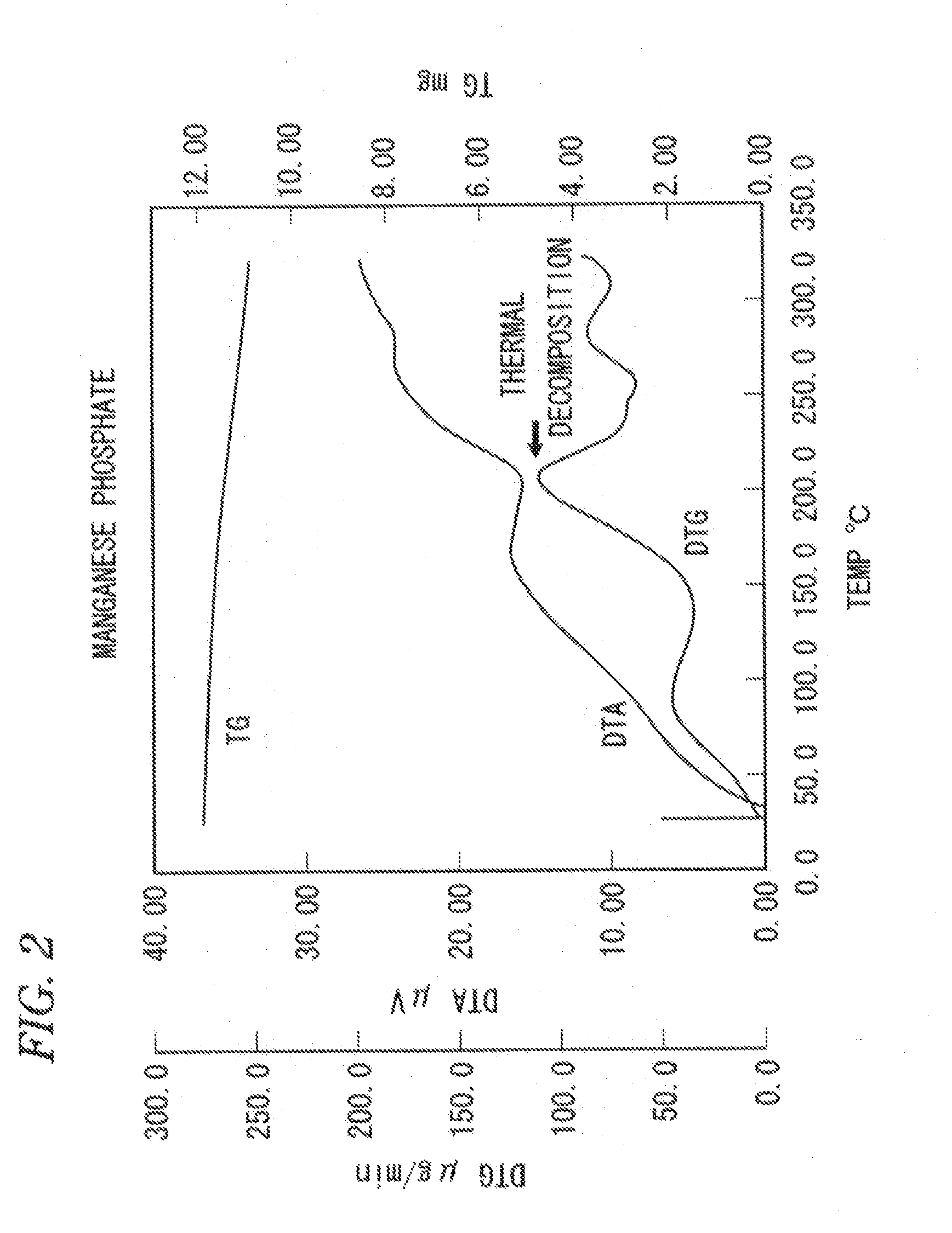

Sliding member for thrust bearing

InactiveUS20110052112A1Overcome lack of heat resistanceIncrease surface areaPretreated surfacesBearing componentsCalcium biphosphateInter layer

The present invention aims to provide a highly heat-resistant sliding member for thrust bearing which can be manufactured at a low cost through formation of an intermediate layer by a conversion treating method for cost reduction, includes a chemical conversion coating formed on an iron-base member and a resin film containing a thermosetting resin and a solid lubricant which is formed on the chemical conversion coating, and can resist to high temperatures of 200° C. or higher. And the invention is concerned with the sliding member for thrust bearing, characterized by including an iron-base member performed shot blast treatment on which the chemical conversion coating of zinc calcium phosphate is formed and a resin film containing a thermosetting resin requiring baking at temperatures of 200° C. or higher and the solid lubricant is further formed.

Owner:TAIHO INDUSTRIES CO LTD

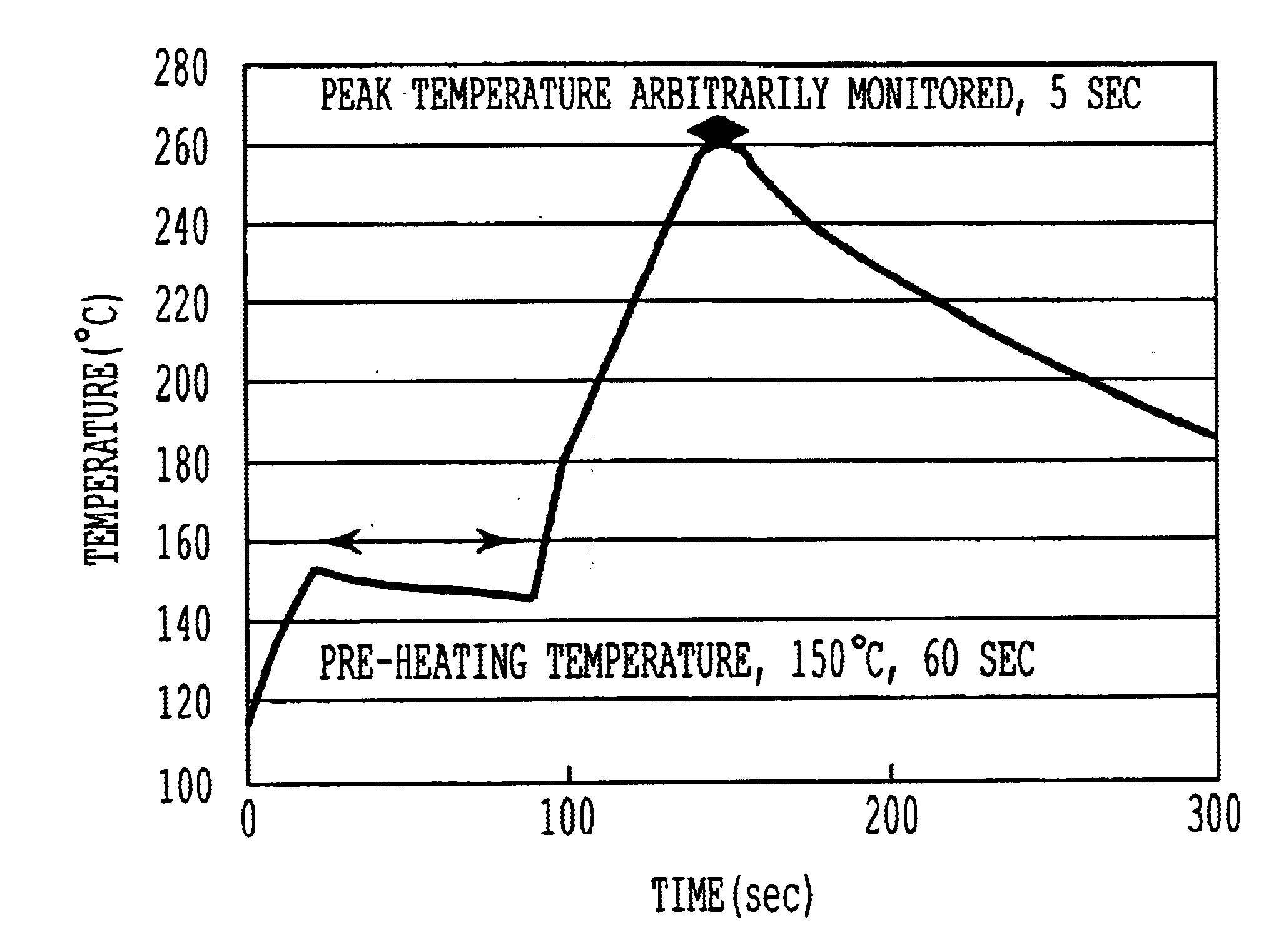

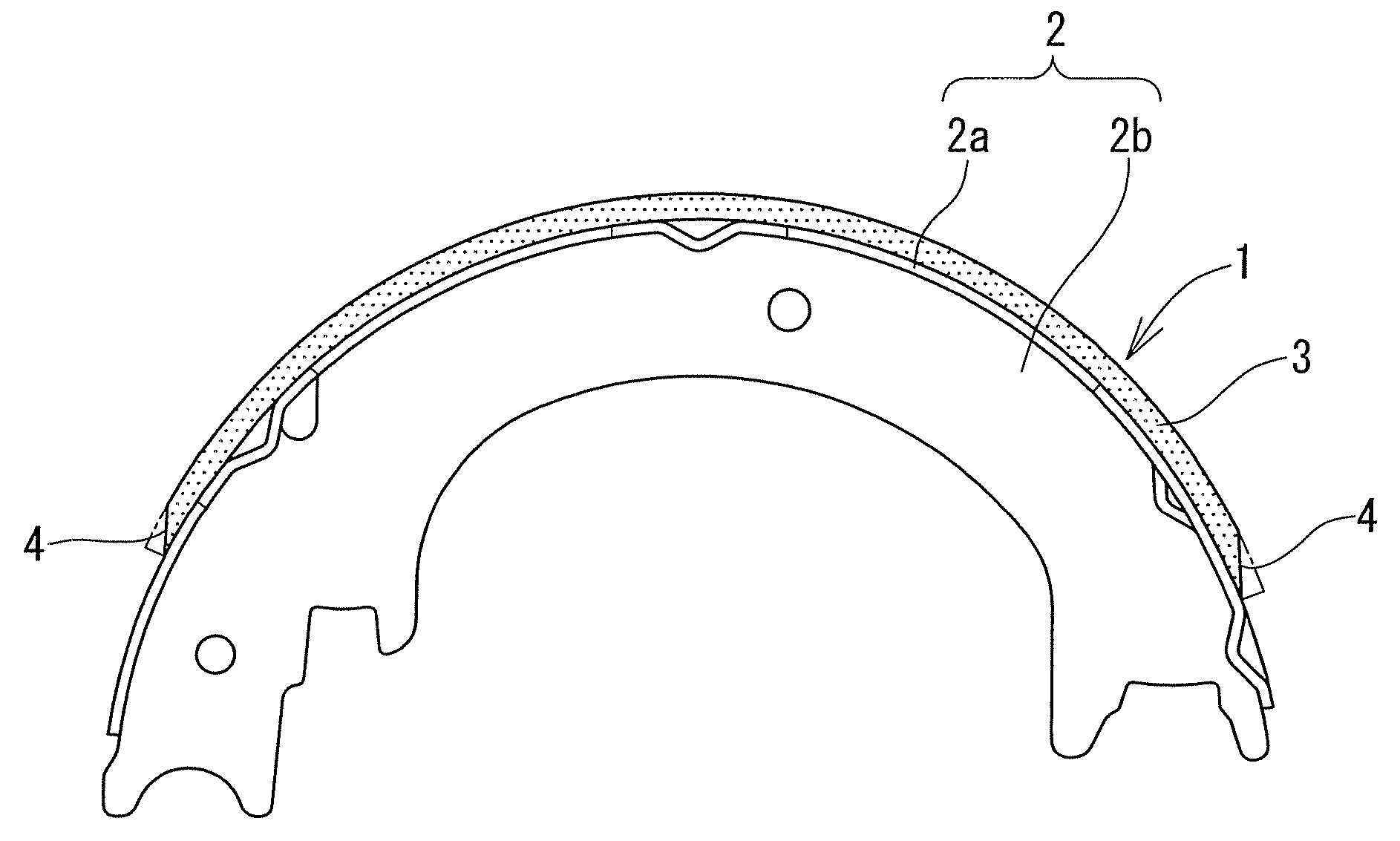

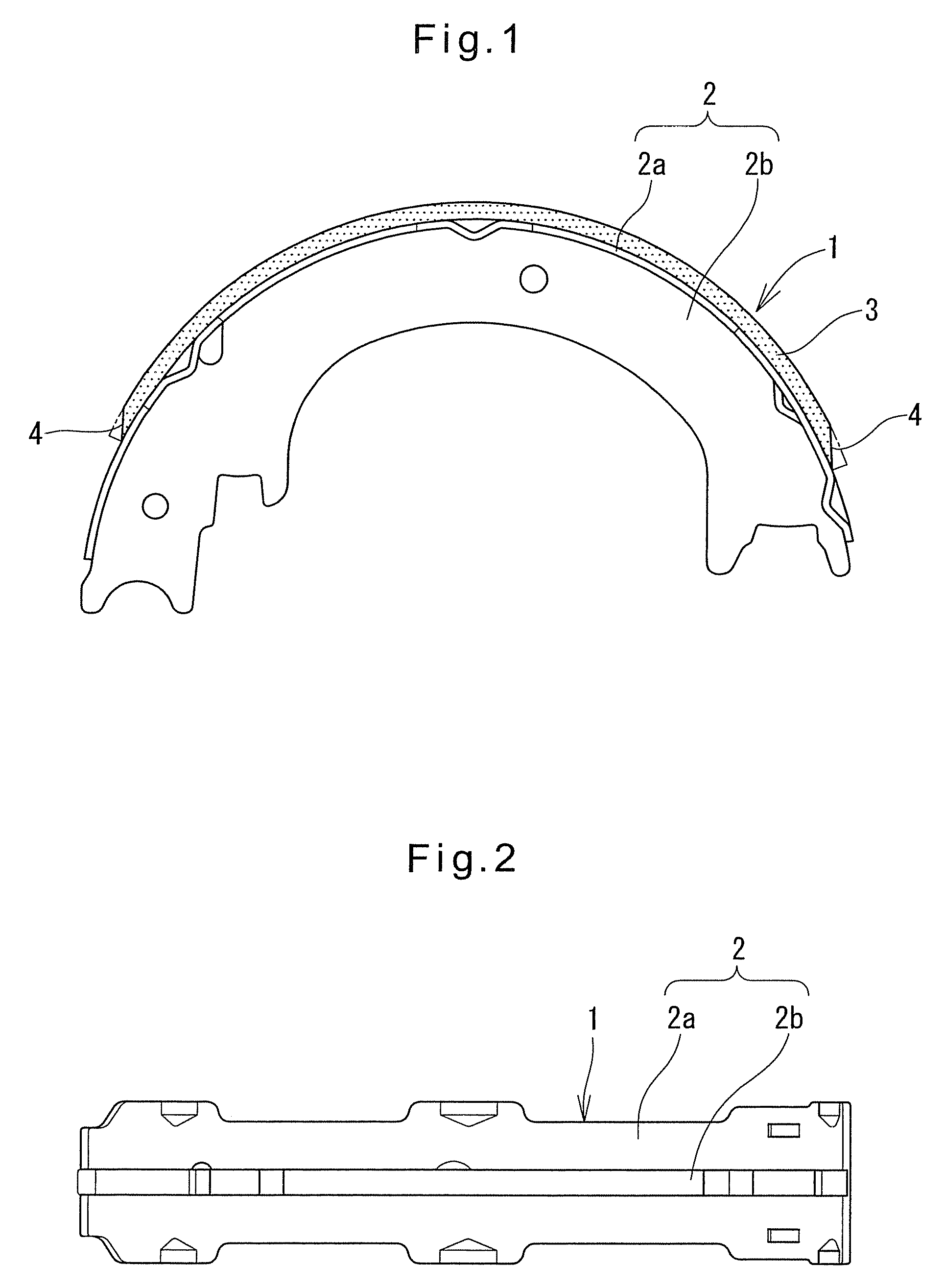

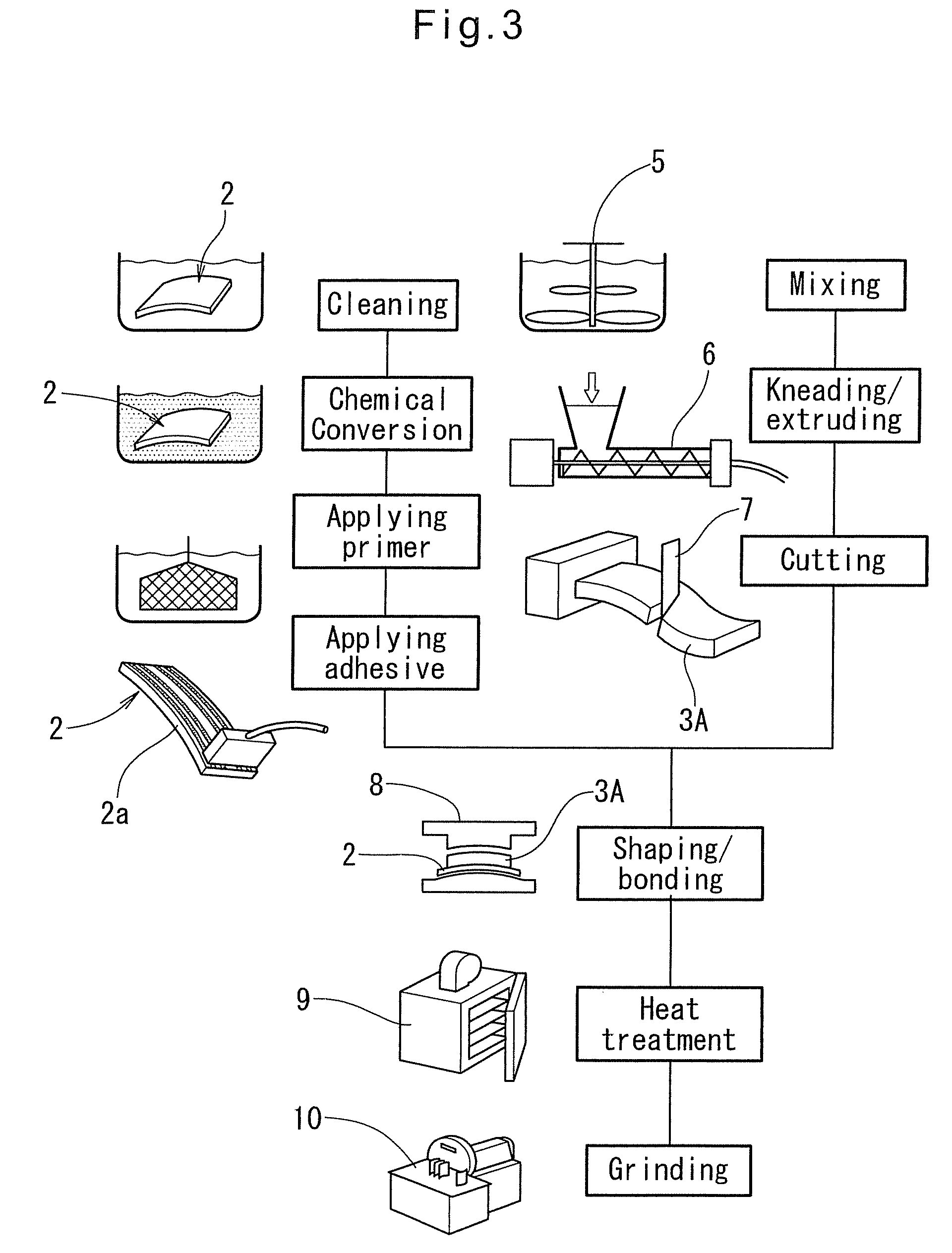

Brake Shoe and Method of Manufacturing the Same

InactiveUS20090159380A1Improve productivityReduce manufacturing stepsBraking membersFriction liningVulcanizationEngineering

An object is to provide a brake shoe which can be manufactured by a method comprising a reduced number of manufacturing steps, and such a method. A brake shoe 1 is manufactured by cutting a sheet blank formed by extrusion or calender sheeting into strips having a predetermined length, laying the strips on the shoe body 2, pressing and bonding the strips to the shoe body 2 and hardening the strips. The lining 3 is formed with tapered surfaces 4 at both ends thereof for facilitating release of the lining from a die. The lining 3 preferably contains as a binder a rubber that turns into ebonite when subjected vulcanization.

Owner:ADVICS CO LTD

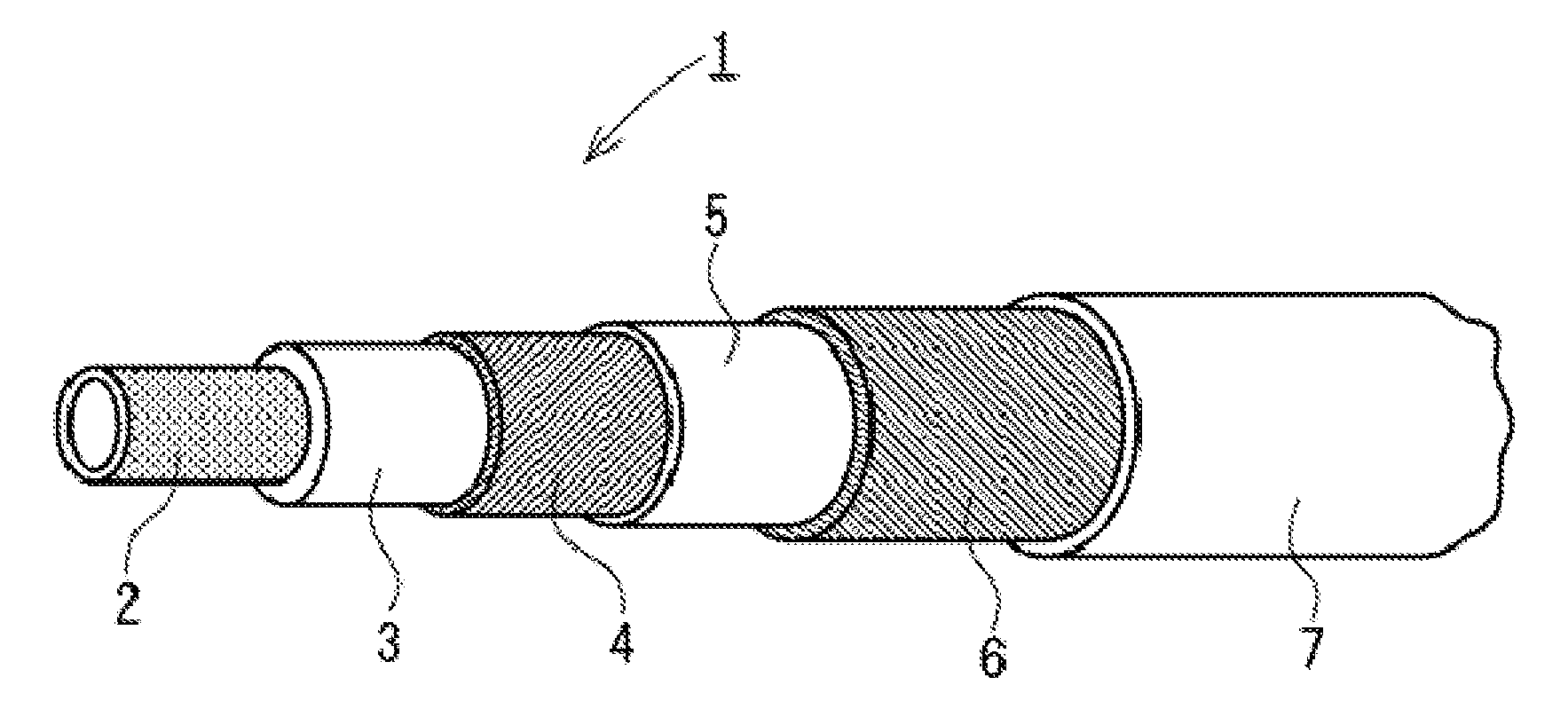

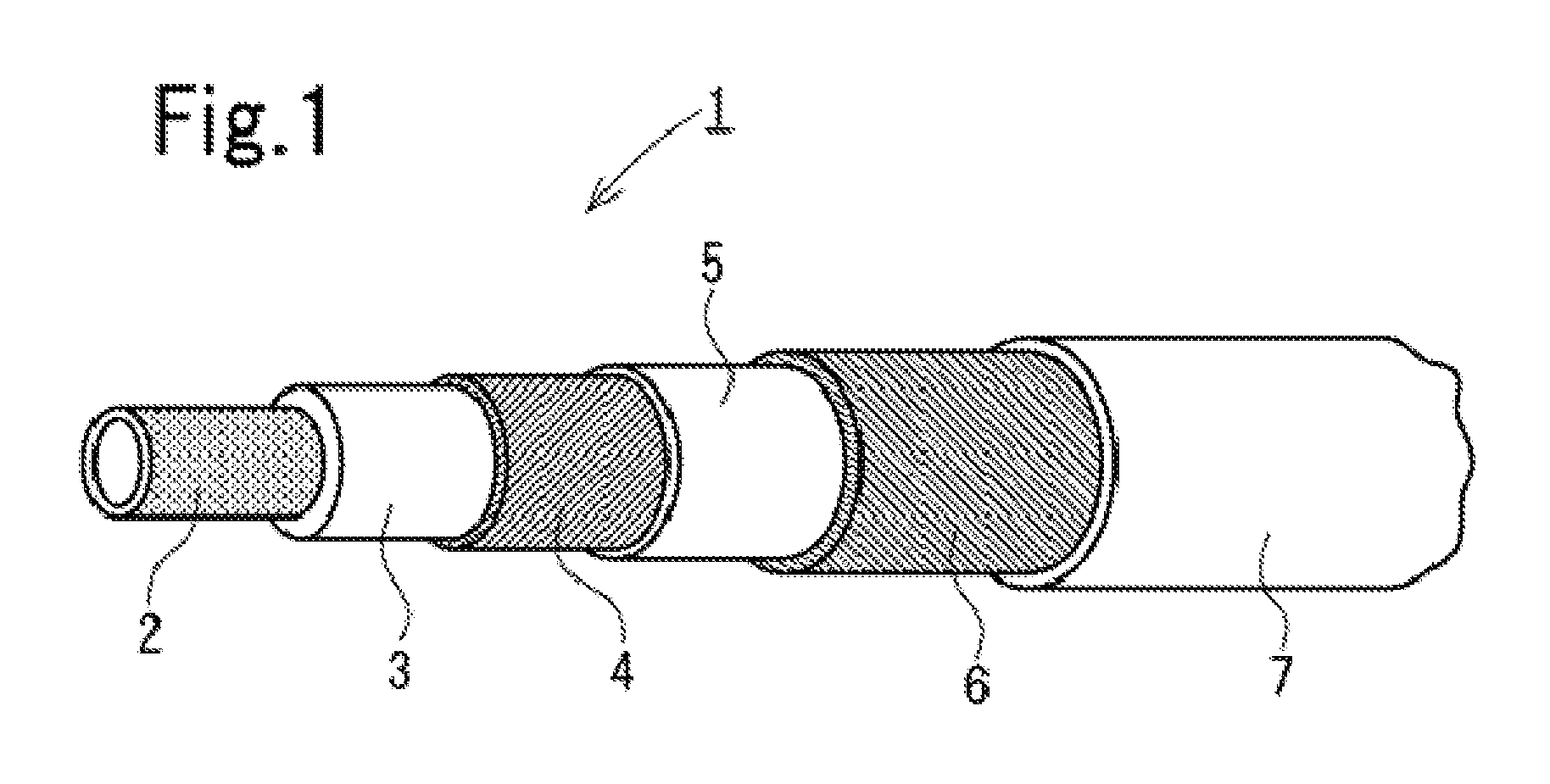

Polyamide resin composition, method for producing the same and refrigerant transporting hose

ActiveUS20130327434A1Good dispersionInhibitionSynthetic resin layered productsFlexible pipesElastomerPolymer science

A polyamide resin composition is provided which contains an anti-aging agent together with a deterioration inhibitor, such as a metal compound or a silica-based inorganic compound, for preventing deterioration caused by, for example, an acid component or a halogen component contained in a refrigerant or an oil, and which satisfactorily produces an anti-aging effect expected by adding the anti-aging agent. For producing a polyamide resin composition containing an (a) polyamide resin, a (b) polyolefin-based elastomer, at least one (c) deterioration inhibitor selected from the group consisting of hydroxides, oxides and basic salts of divalent or trivalent metals, and silica-based inorganic compounds, and a (d) anti-aging agent, a mixture prepared by mixing and kneading the (c) deterioration inhibitor and (b) polyolefin-based elastomer and a mixture prepared by mixing and kneading the (a) polyamide resin and the (d) anti-aging agent are mixed and kneaded.

Owner:BRIDGESTONE CORP

Graft copolymer and thermoplastic resin composition

ActiveUS20170037175A1Ameliorate abrasion resistanceAmeliorate sliding characteristicEthyleneVinyl polymer

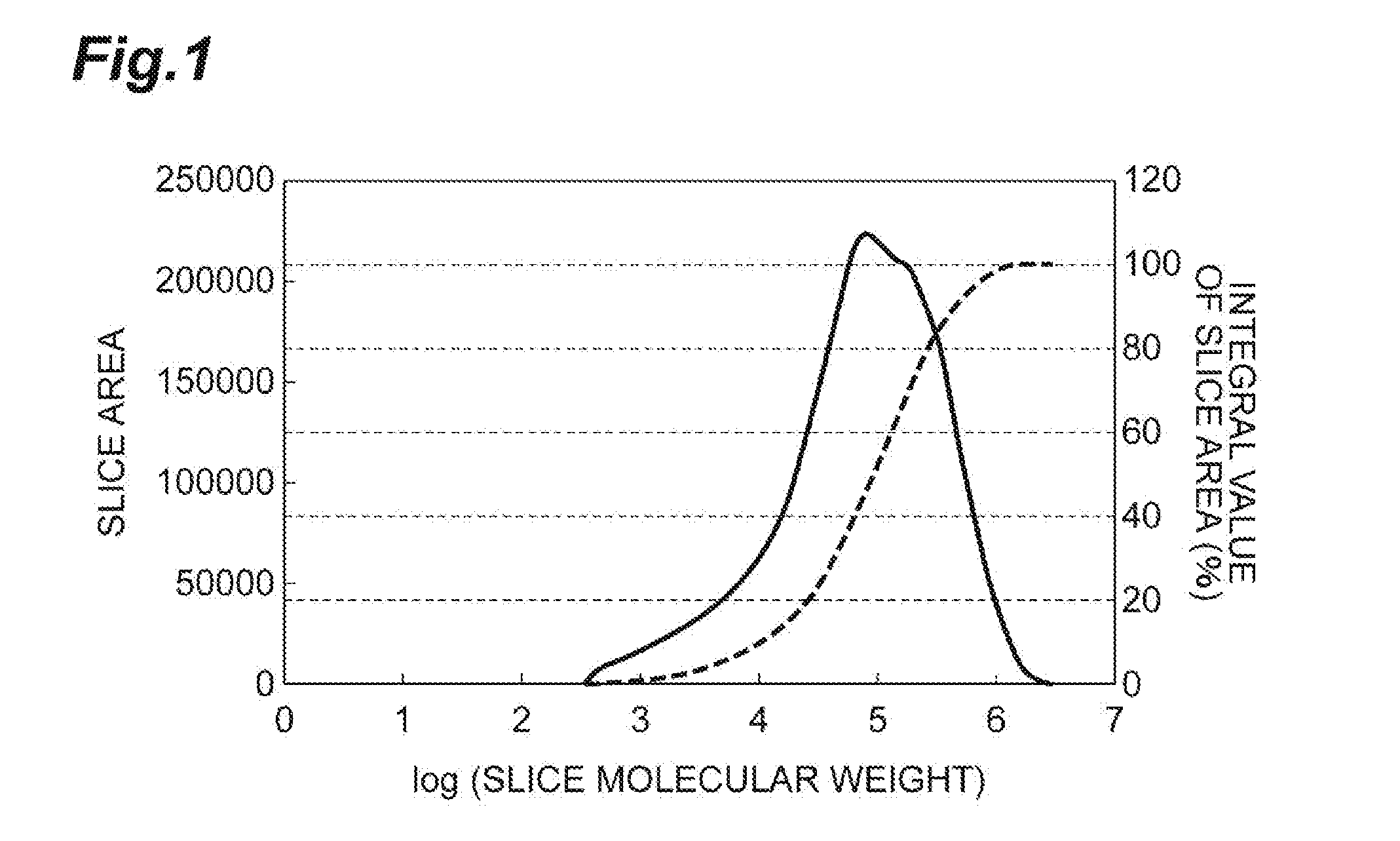

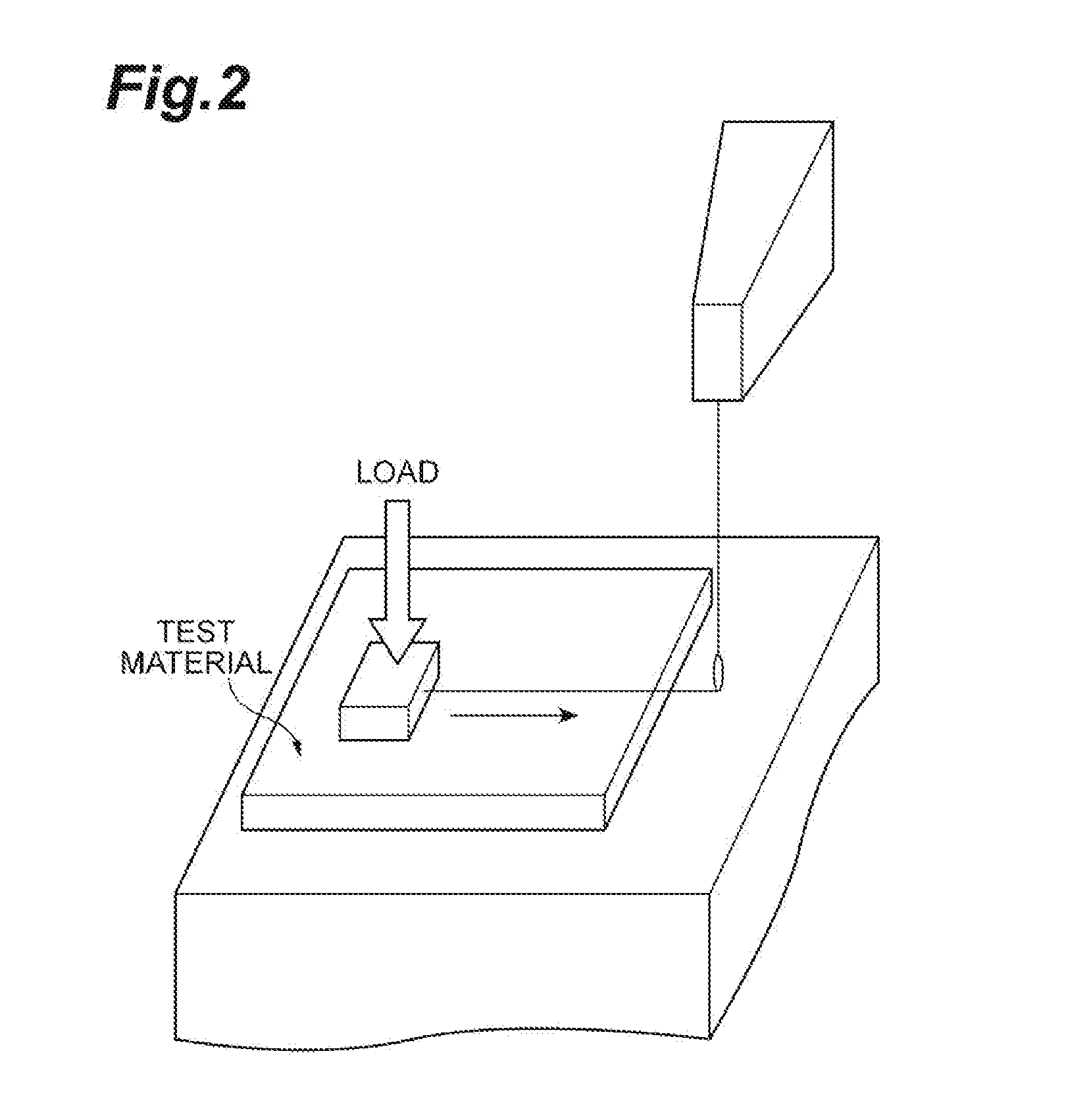

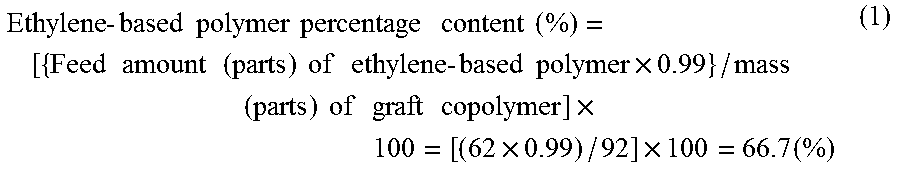

Provided is a graft copolymer (A) obtainable by graft-polymerizing, in the presence of 30 to 80 parts by mass of an ethylene-based polymer (a), an aromatic vinyl-based monomer (b) and, if necessary, another vinyl-based monomer (c) copolymerizable with the aromatic vinyl-based monomer (b) in a total amount of 20 to 70 parts by mass (provided that the sum of the components (a), (b) and (c) is 100 parts by mass), in which the ethylene-based polymer (a) has a density of 0.900 g / cm3 or more and less than 0.966 g / cm3, a number average molecular weight of 10,000 to 50,000, and a molecular weight distribution of 5 to 15, and the proportion of the ethylene-based polymer (a) molecules having a molecular weight of 10,000 or less is 5.5% or more.

Owner:NIPPON A & L INC

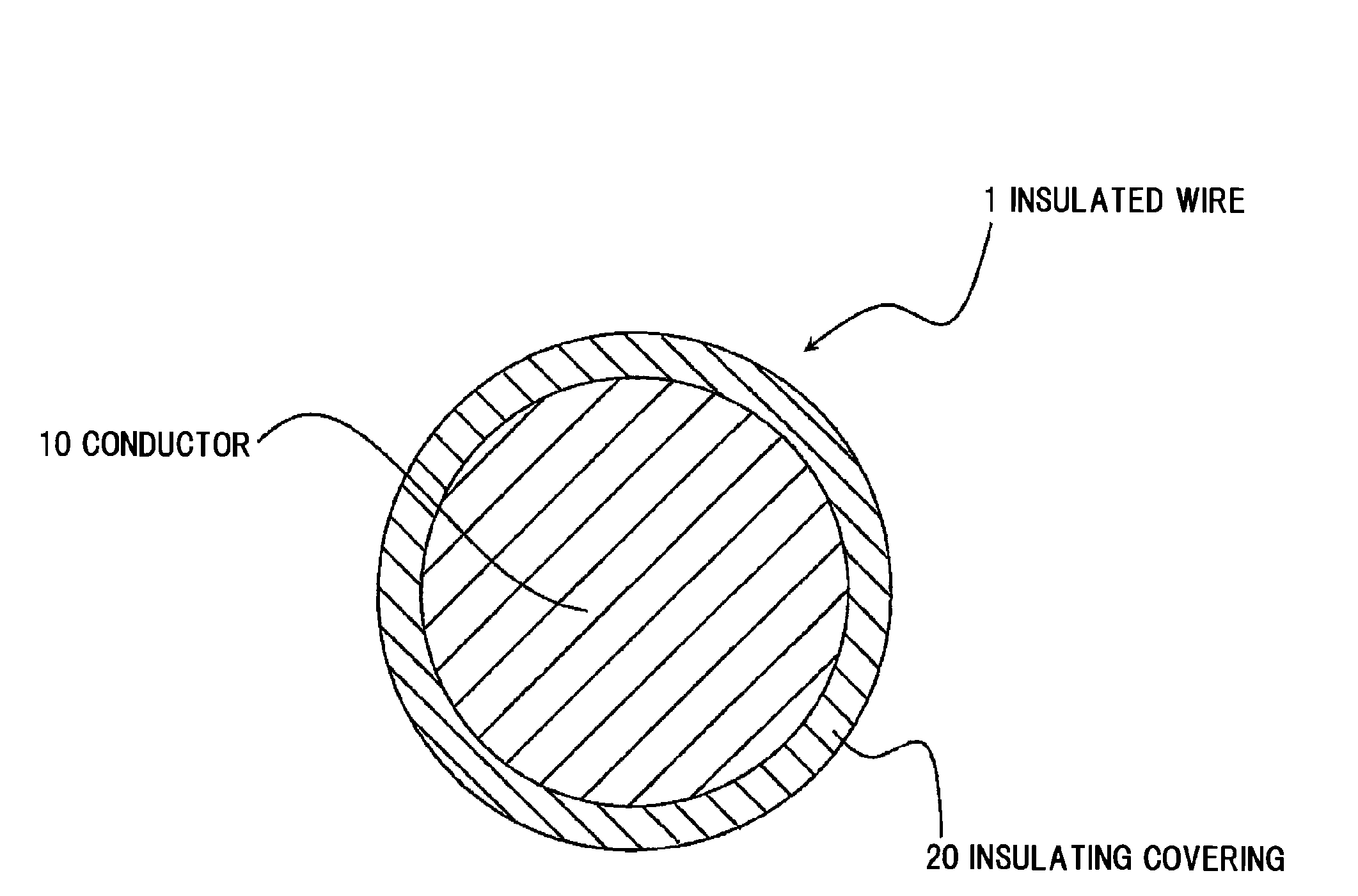

Polymerizable liquid crystal composition

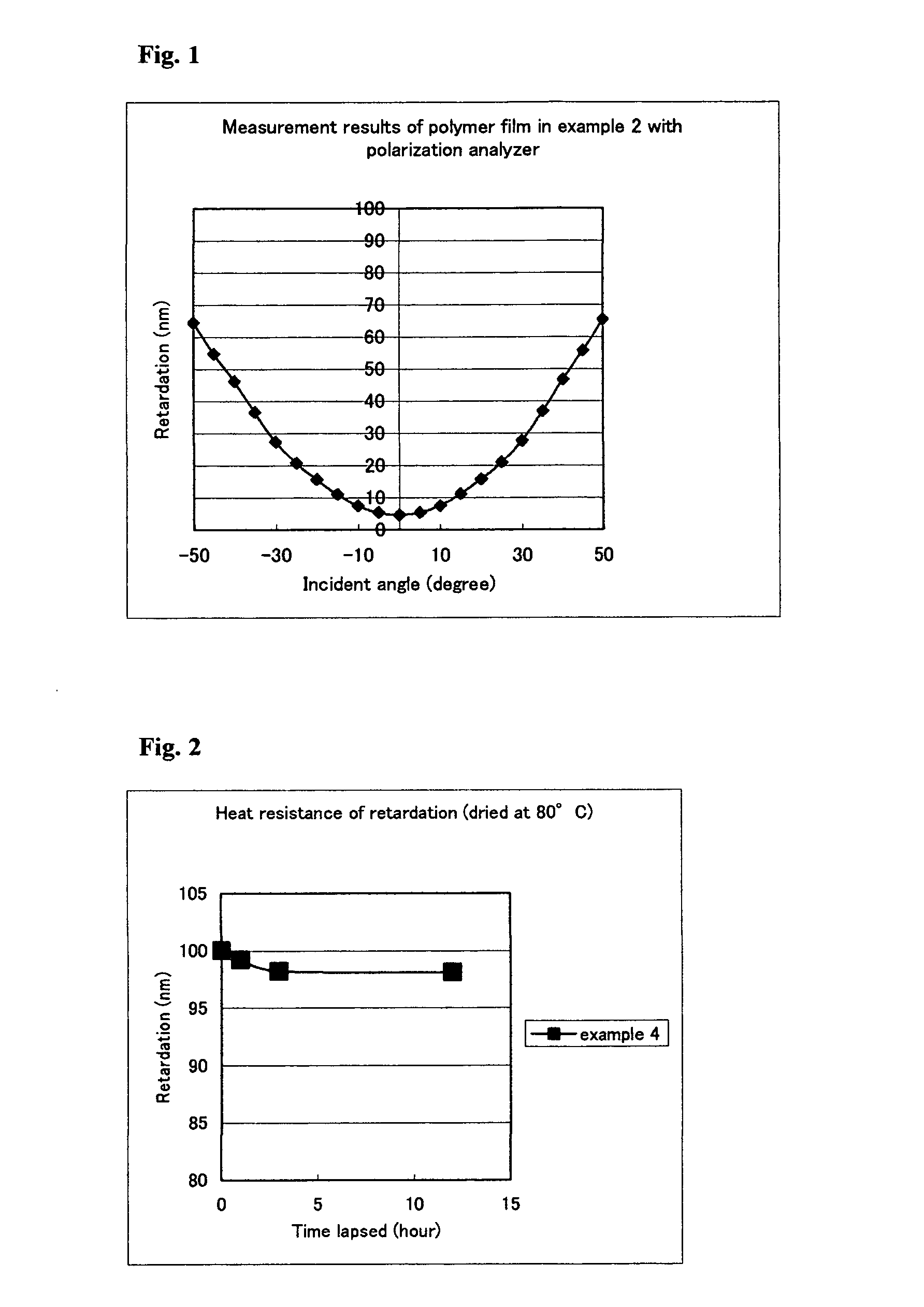

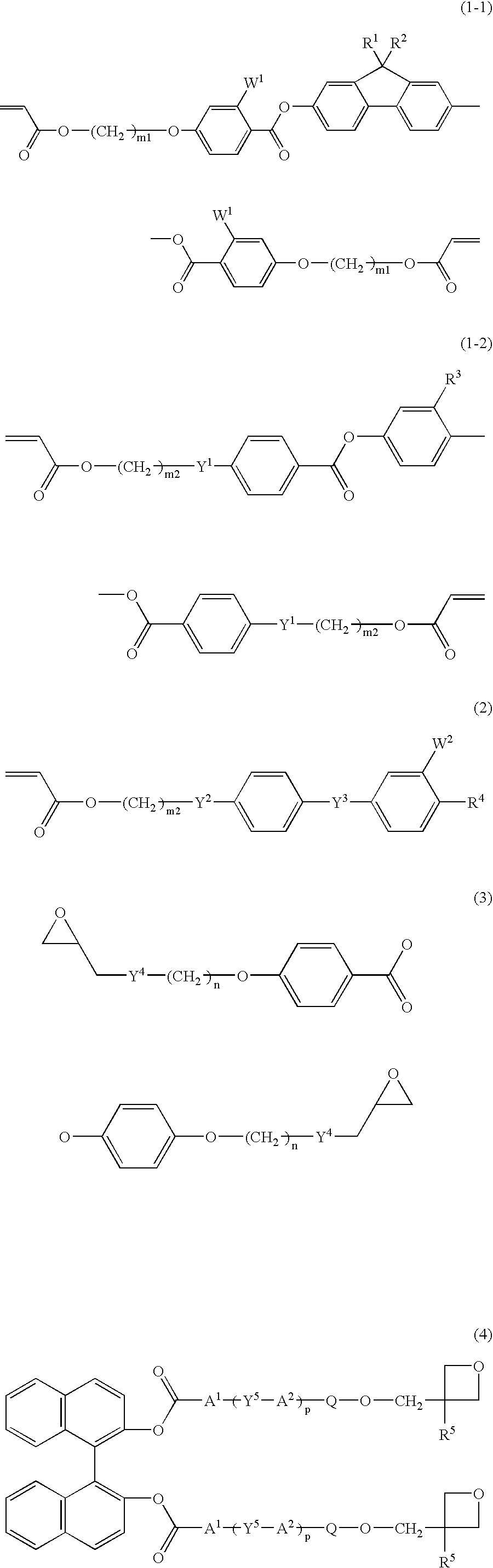

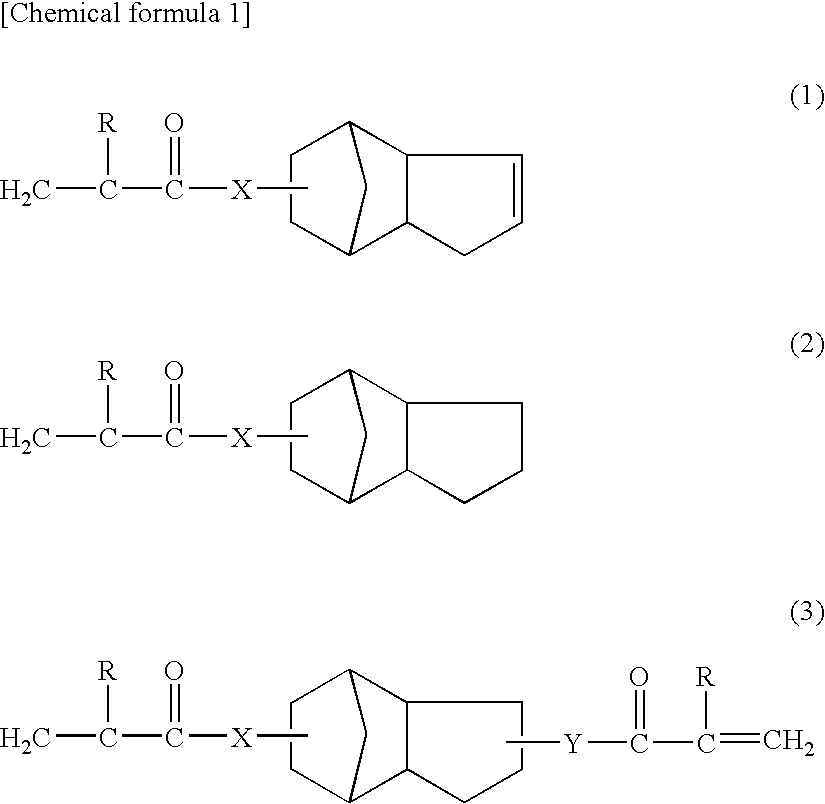

InactiveUS20080152844A1Good storage stabilityOvercome lack of heat resistanceLiquid crystal compositionsSynthetic resin layered productsUV curingCompound (substance)

A cholesteric polymerizable liquid crystal composition excellent in UV curing property and alignment property is provided. The polymerizable liquid crystal composition contains at least one liquid crystal compound selected from compounds represented by Formula (1-1) and Formula (1-2), at least one liquid crystal compound selected from compounds represented by Formula (2), and 5 to 15% by weight of at least one optically active compound selected from compounds represented by Formula (4) and may contain at least one liquid crystal compound selected from compounds represented by Formula (3). The meanings of the symbols in the Formulae are described in the specification.

Owner:JNC CORP +1

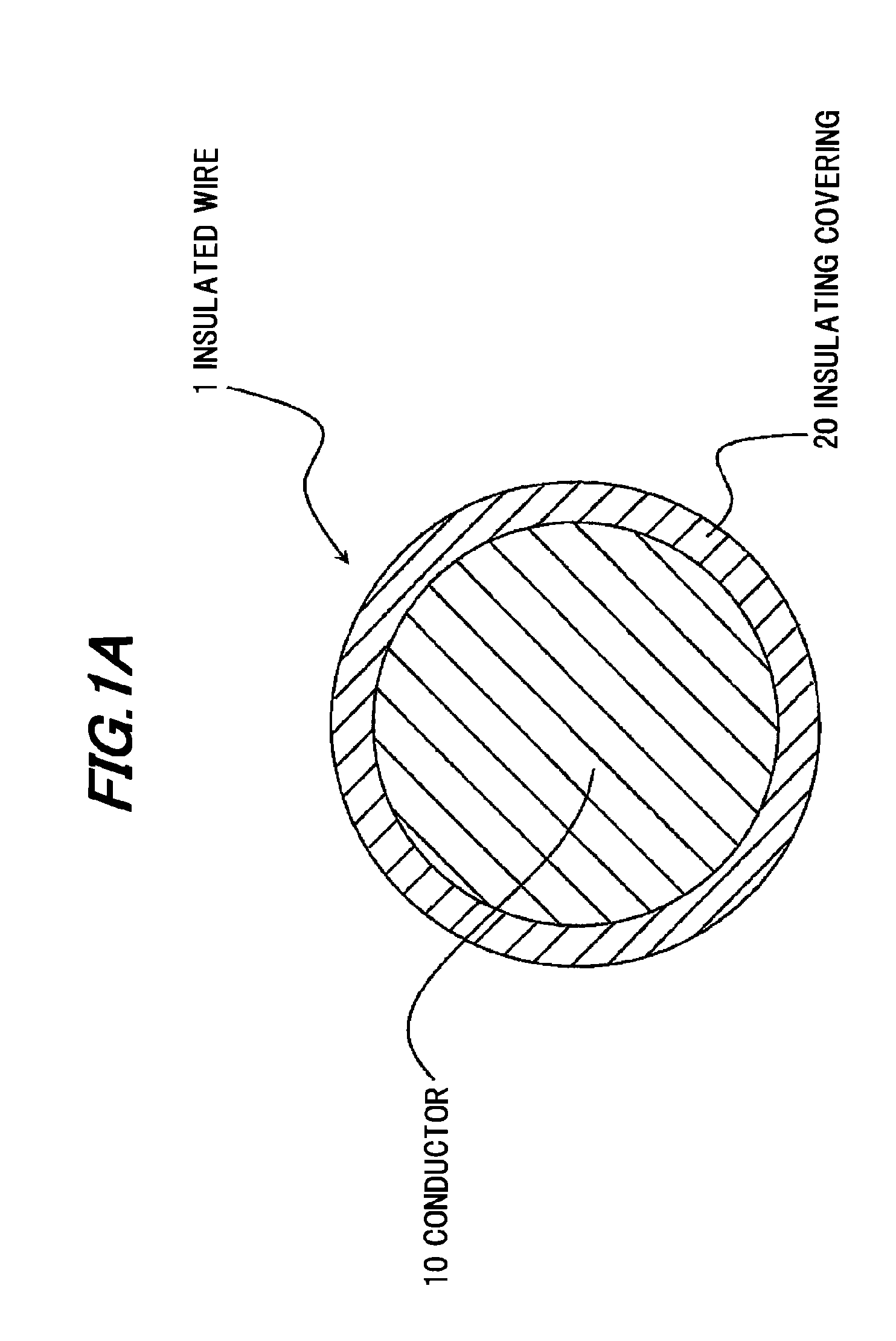

Insulating varnish and insulated wire

InactiveUS20100206611A1Improve adhesionLow dielectric constantPlastic/resin/waxes insulatorsSynthetic resin layered productsElectrical conductorEther

An insulating varnish for forming an insulating covering on a conductor includes a polyimide resin including a repeat unit represented by a general formula (1):where X1 includes a tetravalent aromatic group including an aromatic ether structure represented by a formula (3):and Y1 includes a bivalent aromatic group including an aromatic ether structure, and a repeat unit represented by a general formula (2):where X2 includes a tetravalent alicyclic group and Y2 includes a bivalent alicyclic group including an alicyclic structure.

Owner:HITACHI CABLE

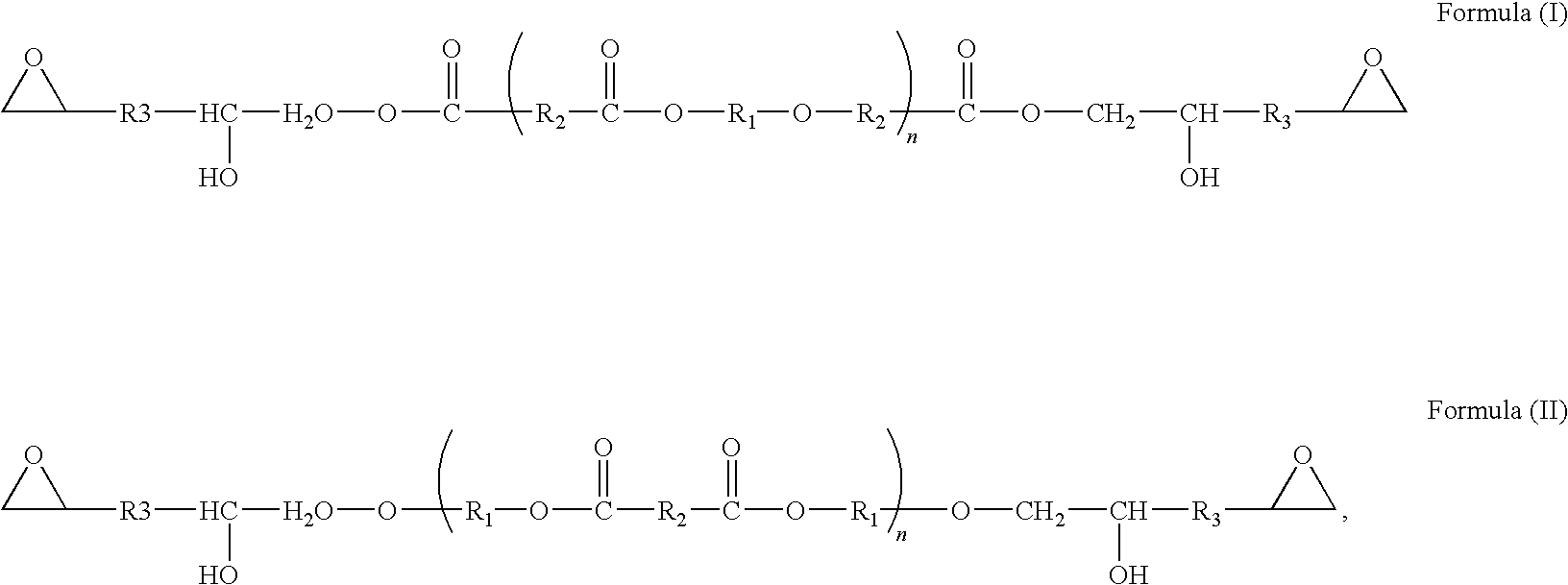

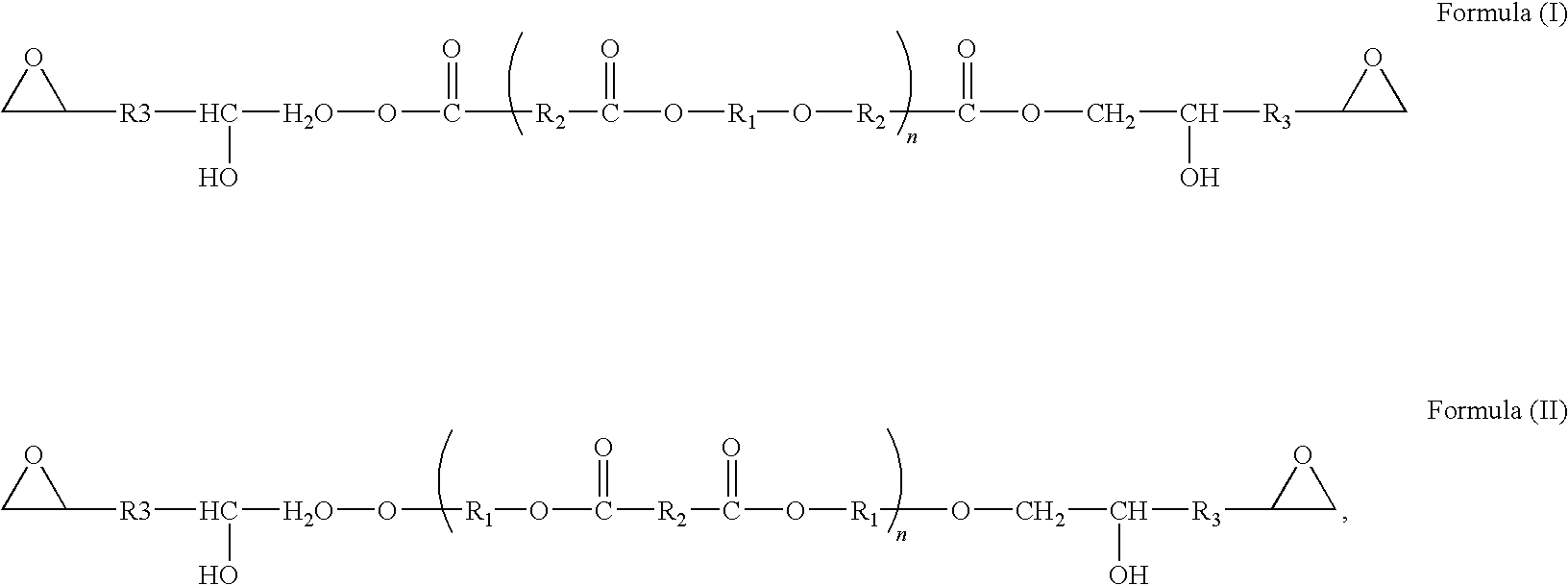

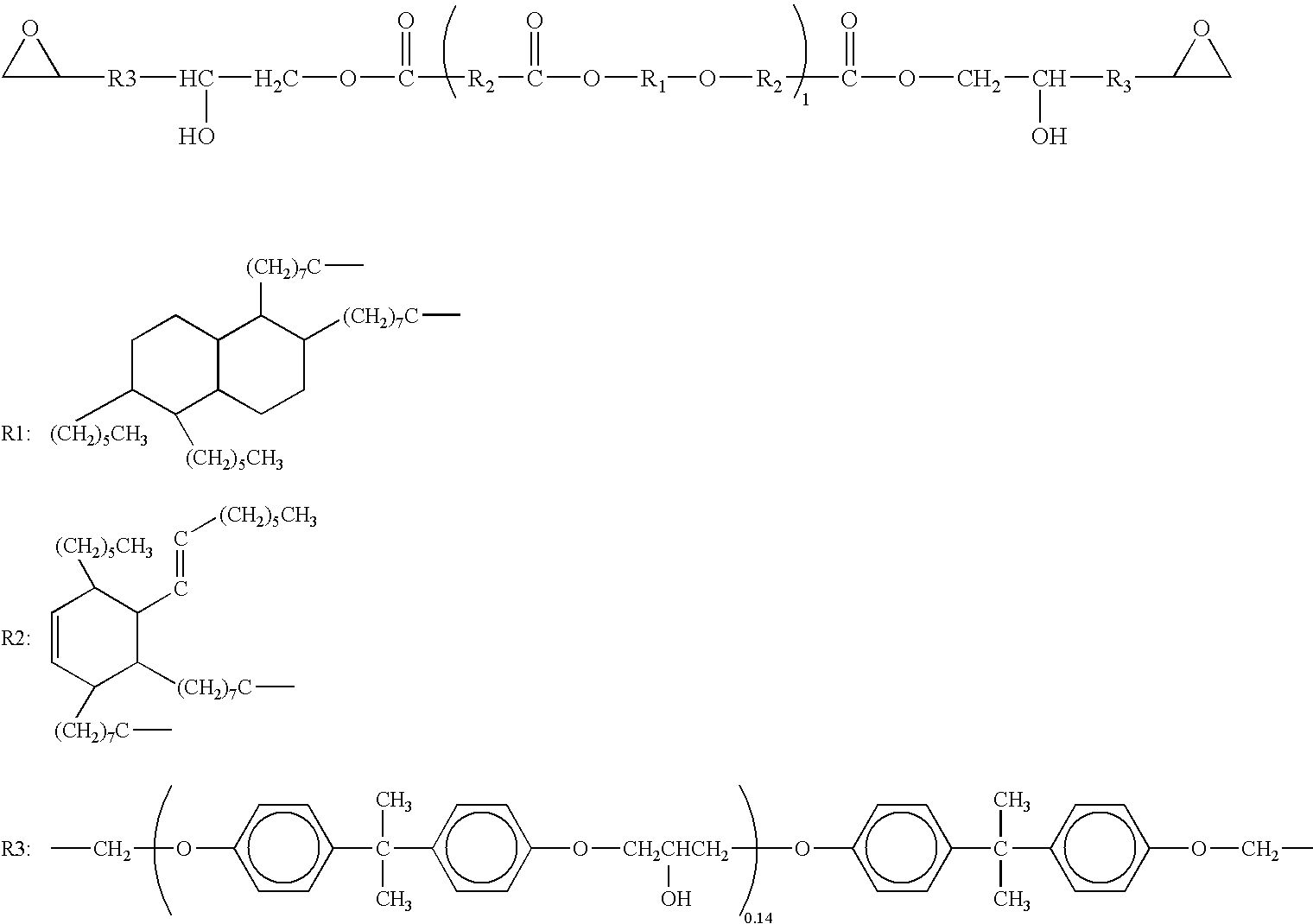

Thermally curable solder resist composition

InactiveUS20100167205A1Sufficient flexibilityOvercome lack of heat resistancePhotosensitive materialsPrinted circuit aspectsResistEpoxy

A thermally curable solder resist composition for a flexible printed circuit board is provided. The solder resist composition includes (a) 50-100 parts by weight of an epoxy resin, wherein the epoxy resin includes at least an aliphatic polyester modified epoxy resin having formula (I) or (II), in which, each of R1 and R2, independently, is a C6-38 saturated or an unsaturated carbon chain, R3 is ether, phenyl, a C6-38 heterocyclic or C6-38 saturated carbon chain, n is an integer of 1-10 and the aliphatic polyester modified epoxy resin had a molecular weight of 1000-5000; (b) 1-10 parts by weight of a curing agent; and (c) 1-10 parts by weight of a catalyst.

Owner:IND TECH RES INST

Polarizing Plate

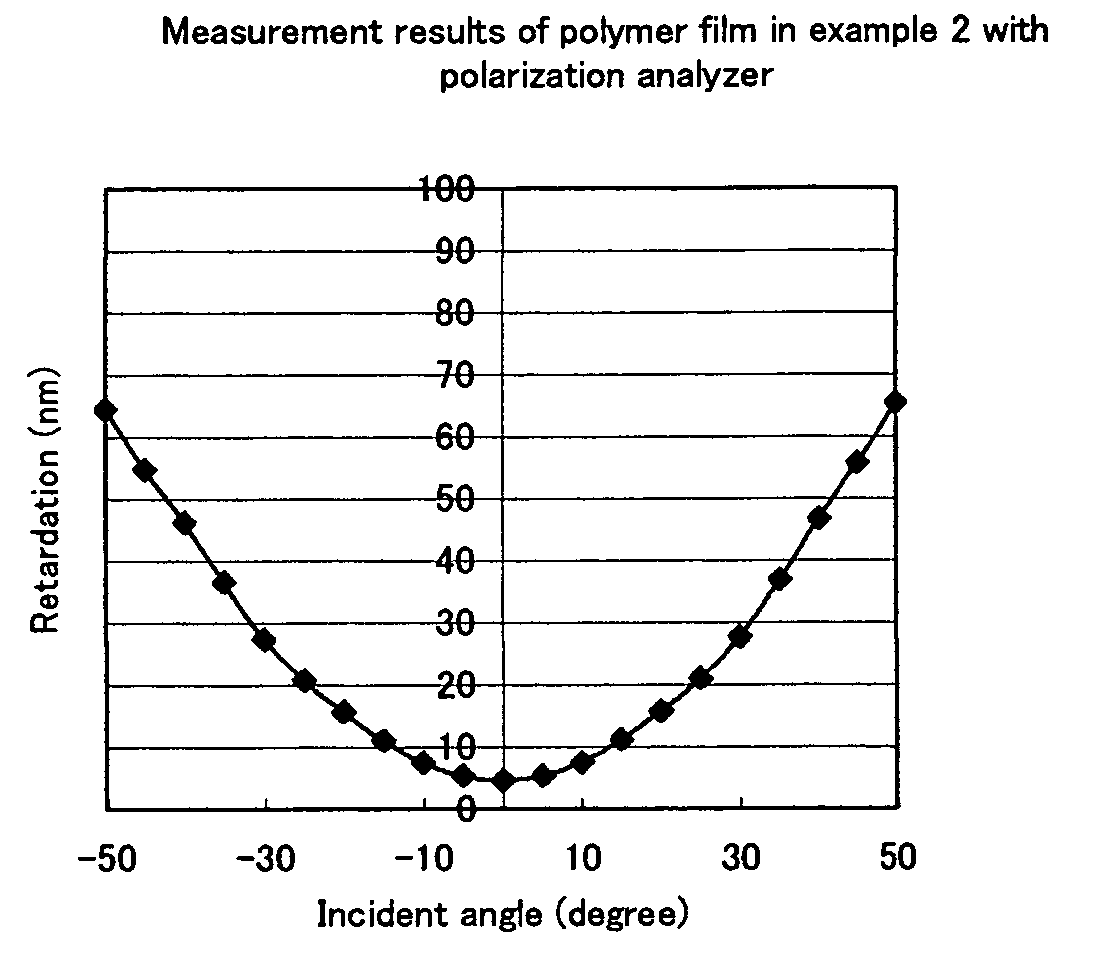

InactiveUS20090269514A1Overcome lack of heat resistanceAvoid insufficient moisture resistanceLiquid crystal compositionsThin material handlingTectorial membranePolarizer

A polarizing plate is provided in which adhesion properties between a polarizer and a protection film are improved and in which the optical properties of the polarizer are stable under the influence of moisture and the like. Specifically, in polarizing plates 4 and 12, protection films 3 and 11 are formed on at least one side of polarizers 2 and 10, respectively, by curing an energy ray-curable composition. The energy ray-curable composition contains (1) an energy ray-polymerizable compound having a bridged hydrocarbon group, a bisphenol group, a neopentyl glycol group, a trimethylolpropane group, or a pentaerythritol group and (2) a hydrolysate of a silane-based coupling agent. At least one of the polarizing plates 4 and 12 is provided on at least one side of a liquid crystal panel 1, whereby a liquid crystal device 9 is constituted.

Owner:DEXERIALS CORP

ETHYLENE/alpha-OLEFIN/NON-CONJUGATED POLYENE COPOLYMER, METHOD FOR PRODUCING THE SAME, AND USE THEREOF

PendingUS20210009730A1Low long-chain branching contentGood curing propertiesSpecial tyresPolymer scienceAlkene

An object of the present invention is to provide a novel ethylene / α-olefin / non-conjugated polyene copolymer containing a certain non-conjugated polyene such as VNB as a copolymerization component, having a low long-chain branching content, excellent in cure characteristics in the case of crosslinking by using peroxide, and having good processability. The ethylene / α-olefin / non-conjugated polyene copolymer according to the present invention has constitutional units derived from ethylene (A), an α-olefin (B) having 3 to 20 carbon atoms, and a non-conjugated polyene (C) having a total of two or more partial structures selected from the group consisting of the following general formulas (I) and (II) in a molecule, and satisfies certain requirements.

Owner:MITSUI CHEM INC

Molded article and process for producing the same

InactiveUS20090197079A1Promote degradationImprove the immunityGlass/slag layered productsThin material handlingLignin degradationInjection moulding

In a molded article containing a plant material and a thermoplastic resin, and formed by injection molding, the thermoplastic resin is contained in an amount of 5 to 50% by mass, and the plant material is contained in an amount of 50 to 95% by mass when the total amount of the thermoplastic resin and the plant material is taken as 100% by mass, and a material containing lignin in an amount of 10% by mass or more when the total amount of the plant material is taken as 100% by mass is used as the plant material. And, a process for producing a molded article includes the mixing step of mixing a plant material, water and a thermoplastic resin to obtain a molding material, and the injecting and molding step of injecting the molding material in a molding die and molding the molding material with the molding die to obtain the molded article. In the mixing step, a material containing lignin in an amount of 10% by mass or more when the total amount of the plant material is taken as 100% by mass is used as the plant material, the thermoplastic resin is mixed in an amount of 5 to 50% by mass and the plant material is mixed in an amount of 50 to 95% by mass when the total amount of the thermoplastic resin and the plant material is taken as 100% by mass, water is mixed in an amount of 5 to 200% by mass based on 100% by mass of the plant material, and the plant material, water and the thermoplastic resin are mixed while thermofusing the thermoplastic resin.

Owner:TOYOTA BOSHOKU KK

Preparation method for aromatic polyester or aromatic nylon

InactiveCN103159942AHigh melting pointOvercome lack of heat resistanceOrganic compound preparationHydroxy compound preparationFiberNylon material

The invention discloses a preparation method for aromatic polyester or aromatic nylon. During the preparation of the aromatic polyester or the aromatic nylon, a terephthalic acid unit is prepared and obtained by biological original methyl alcohol. According to the terephthalic acid unit in the components of the aromatic polyester or the aromatic nylon, the component of carbon is from biological materials instead of petroleum raw materials, the quantity of carbon dioxide (CO2) emitted during smelting of petroleum is greatly reduced, and the preparation method for the aromatic polyester or the aromatic nylon has a good environment-friendly effect, and is capable of being widely applied to the fields such as resin, fibers and film.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Electro-rheological composition

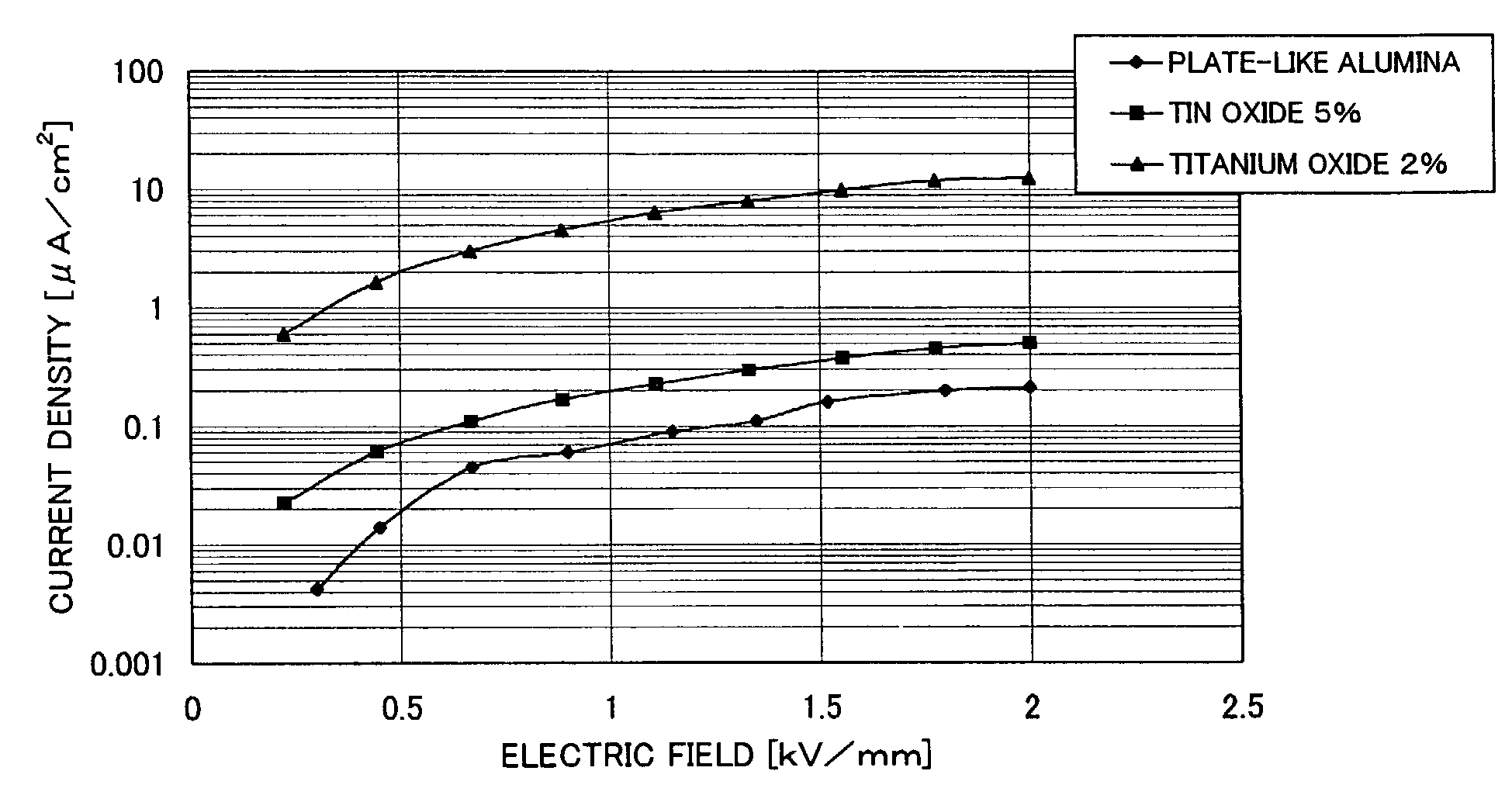

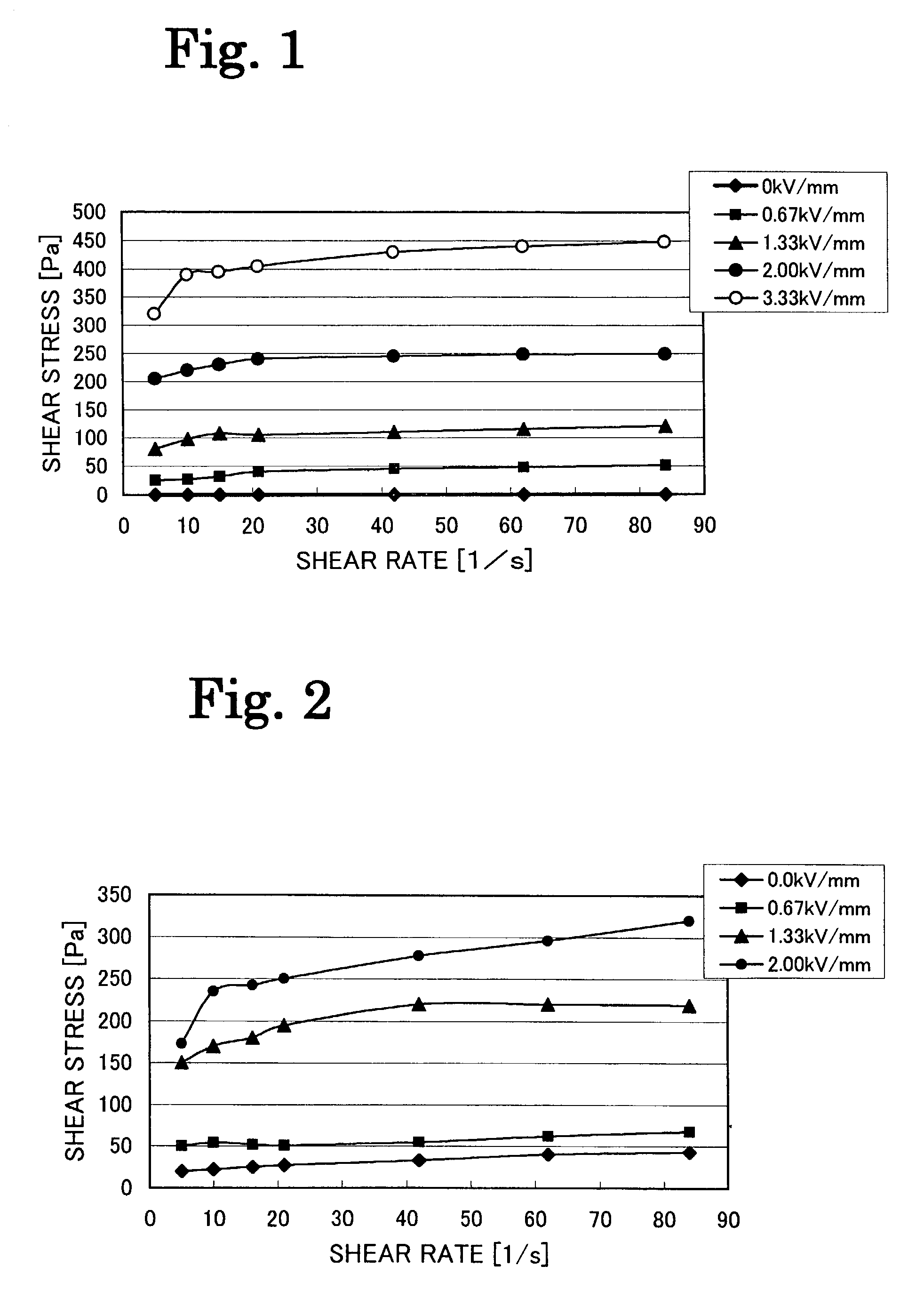

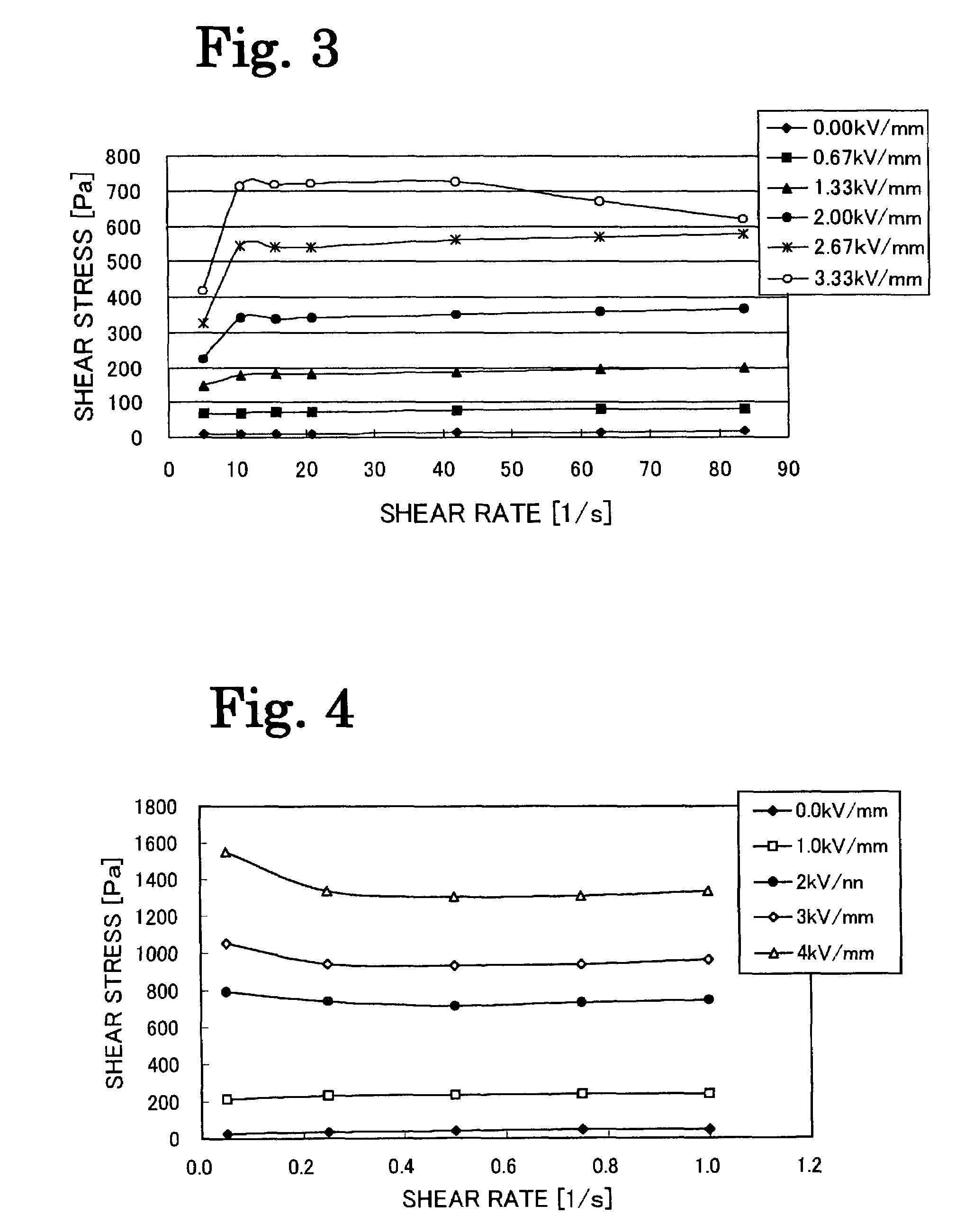

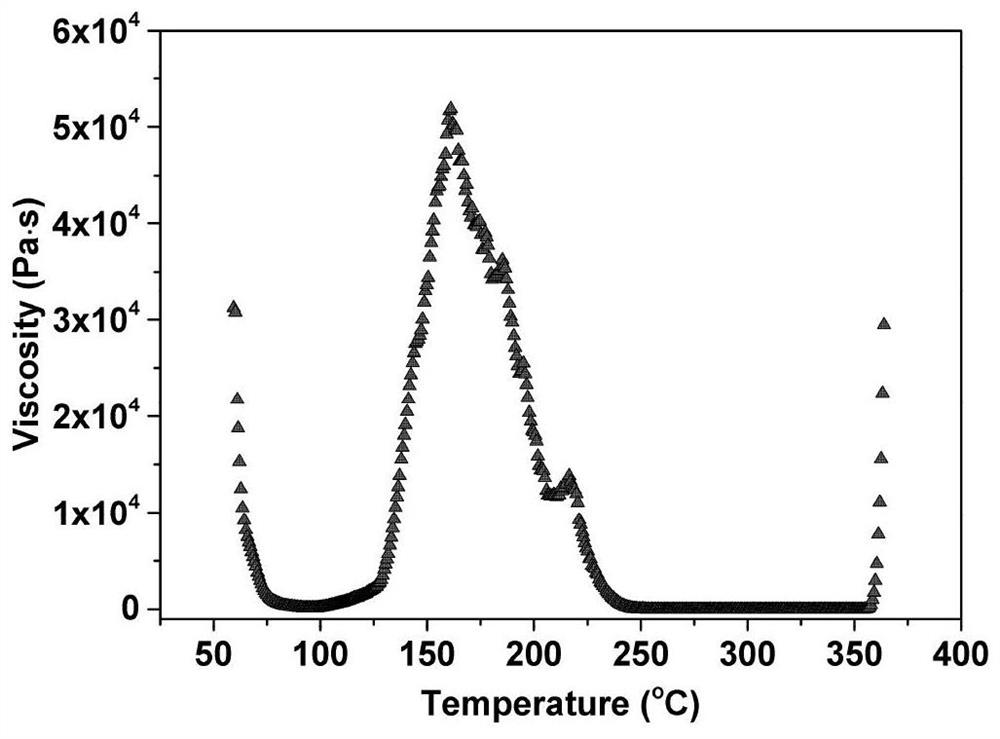

InactiveUS7001532B2Excellent ER effectOvercome lack of heat resistanceConductive materialOxide conductorsChemical compositionSolid particle

In an electro-rheological composition comprising an electrical insulating medium and solid particles dispersed therein, insulating solid particles possessed of morphological anisotropy are used as the solid particles. In a preferred embodiment, the insulating solid particles mentioned above are plate-like insulating solid particles, preferably plate-like insulating solid particles having a diameter (particle diameter) not less than 1 μm, more preferably plate-like aluminum oxide particles having a diameter not less than 1 μm. In another preferred embodiment, the insulating solid particles which have undergone a surface treatment with organic molecules or a semiconducting inorganic material, particularly the insulating solid particles having a metal oxide such as tin oxide and titanium oxide adhered to the surfaces thereof are used as the particles. Still another preferred embodiment is the ER composition of which electrical insulating medium is gelled.

Owner:KINSEI MATEC +1

Base fabric for coated airbag, manufacturing method therefor, and coating composition used for said manufacturing method

ActiveUS20210024029A1Overcome lack of heat resistanceSolve the lack of resistanceFibre treatmentPedestrian/occupant safety arrangementFoaming agentAirbag

An object of this invention is to provide a coated fabric for airbags that achieves sufficient heat resistance without relying on the amount or type of resin in a coating layer.Provided is a coated fabric for airbags, comprising a coating layer disposed on at least one surface of a woven fabric directly or with one or more other layers interposed therebetween, the coating layer containing a thermally responsive foaming agent.

Owner:TOYO TOYOBO CO LTD

High temperature-resistant ethylene propylene rubber

InactiveCN110564066AImprove heat resistanceOvercome lack of heat resistanceTemperature resistanceStearic acid

The invention provides high temperature-resistant ethylene propylene rubber. The ethylene propylene rubber is composed of the following components by mass: 50-150 parts of ethylene propylene diene monomer, 60-100 parts of carbon black, 5-20 parts of inorganic filler, 3-11 parts of paraffin oil, 5-12 parts of zinc oxide, 1-3 parts of stearic acid and 5-12 parts of dicumyl peroxide. The invention can manufacture ethylene propylene rubber resistant to a high temperature of 160DEG C, and through optimization of the formula, the heat resistance of ethylene propylene rubber is improved, the formulacan be widely applied to engine peripheral rubber parts with high temperature resistance requirement, and solves the problem of insufficient heat resistance of ethylene propylene rubber manufactured from common materials.

Owner:WUHU JITUO RUBBER TECH

A low-viscosity high-heat-resistant polyimide fiber sizing agent and its preparation method

ActiveCN109162101BEasy to operateImprove efficiencyCarbon fibresHeating/cooling textile fabricsImidePolymer science

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation technology of chlorobutyl rubber used for internal rubber layer of rubber tube of automobile air conditioning

InactiveCN101817958BMeet the requirements of the ELV directiveOvercome lack of heat resistancePolymer scienceAutomobile air conditioning

The invention discloses a preparation technology of chlorobutyl rubber used for an internal rubber layer of a rubber tube of an automobile air conditioning, comprising the process flows of making up a formula and preparing. In the invention, the technical scheme utilizing a heat-resisting modified formula to match with a corresponding preparation method is adopted, thus overcoming the problem of poor heat-resistant quality of the chlorobutyl rubber in the prior art. The provided preparation technology of the chlorobutyl rubber used for the internal rubber layer of the rubber tube of the automobile air conditioning prepares chlorobutyl rubber the application temperature of which is minus 30-135 DEG C, and the chlorobutyl rubber is used for manufacturing the inner rubber layer of the automobile air conditioning, thus reaching the purpose of improving heat-resistant property.

Owner:宁波市天普橡胶科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com