Composite ceramic particles as well as preparation method and application thereof

A technology of composite ceramics and ceramic particles, used in coatings, electrical components, electrochemical generators, etc., can solve the problems of inability to provide mechanical strength, melting collapse, powdering of external ceramic coatings, etc., to improve heat resistance. , Avoid excessive shrinkage, improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

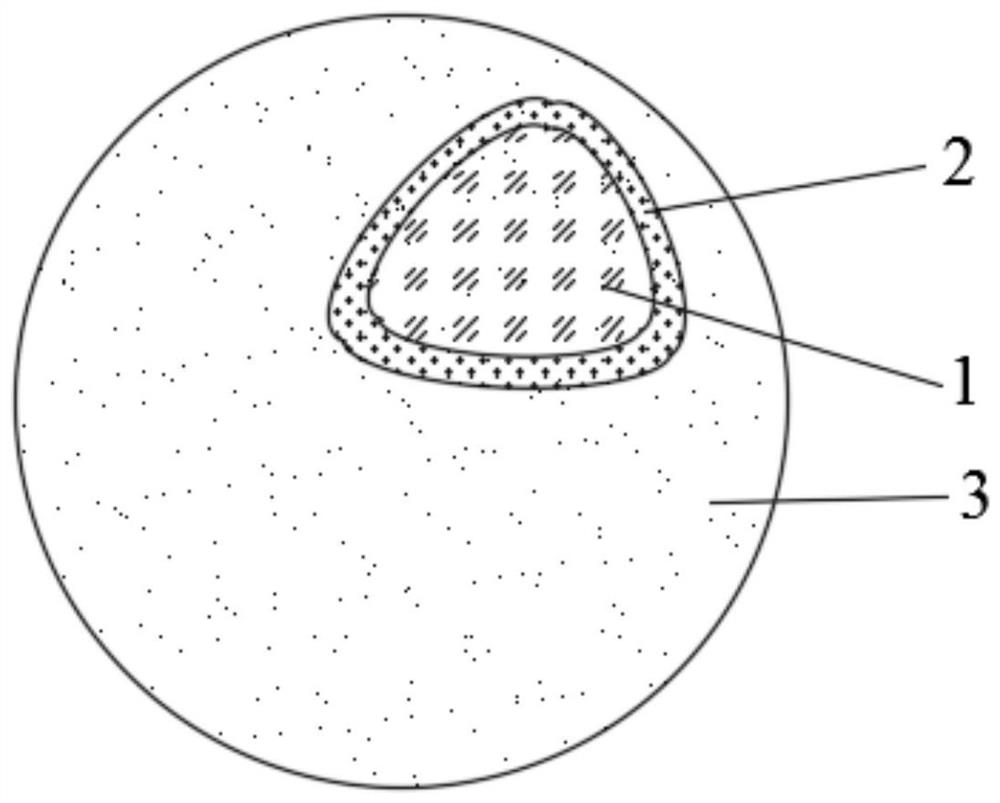

[0044] 2. A method for preparing composite ceramic particles, comprising the following steps:

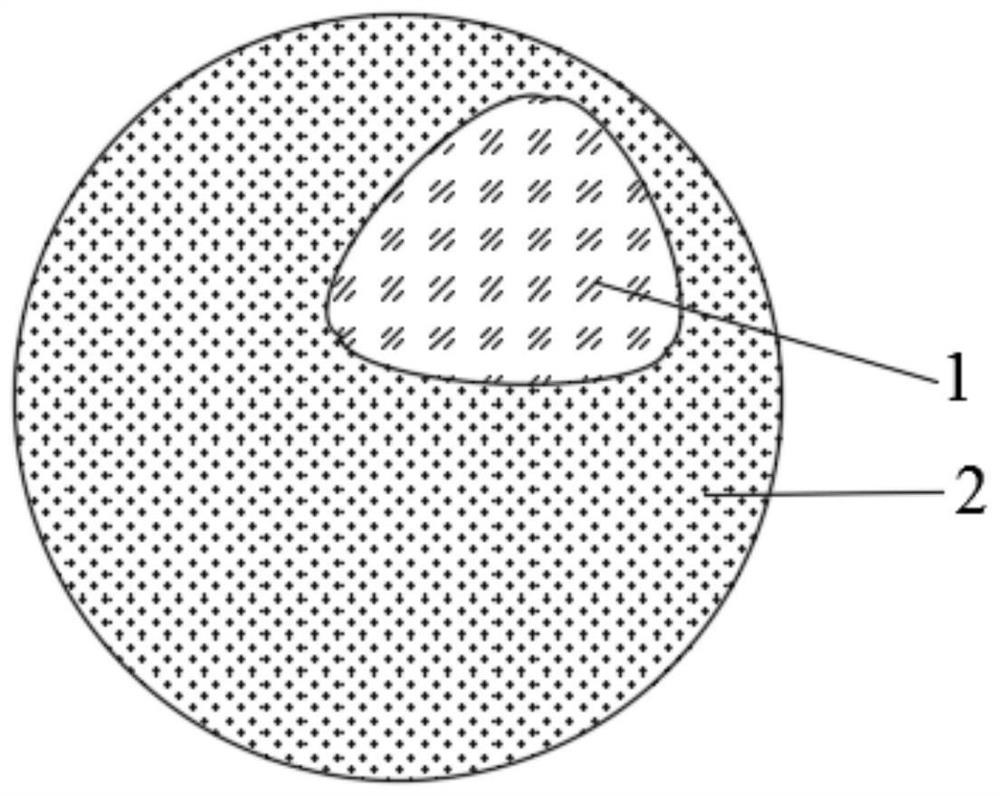

[0045] mixing phase change particles 1 and ceramic particles 2, so that the phase change particles 1 are filled in the ceramic particles 2, and ceramic particles filled with phase change particles are obtained;

[0046] The ceramic particles filled with phase-change particles are mixed with the heated film-forming material 3, so that the heated film-forming material 3 is coated on the surface of the ceramic particles filled with phase-change particles; wherein, the heated The melting point of the film-forming material 3 is 80-150°C;

[0047] The preparation of composite ceramic particles is completed.

[0048] Further, when the phase-change particles 1 are mixed with the ceramic particles 2, the phase-change particles 1 should be ground into powder first, and the particle diameter of the phase-change particles 1 is smaller than the inner diameter of the ceramic particles 2, so as t...

Embodiment 1

[0069] A kind of composite ceramic particles, including phase change particles 1, ceramic particles 2 and heated film-forming material 3; wherein, the phase change particles 1 are used as the inner core of the composite ceramic particles; the ceramic particles 2 are used as the middle layer of the composite ceramic particles; the The ceramic particles 2 have a mesoporous hollow sphere structure, and the phase change particles 1 are filled in the ceramic particles 2; the heated film-forming material 3 is used as the shell of the composite ceramic particles, and is coated on the ceramic particles 2. Surface; the melting point of the heated film-forming material 3 is 80-150°C.

[0070] Specifically, copper sulfate pentahydrate is used as the phase change particles 1 , alumina with a mesoporous hollow sphere structure is used as the ceramic particles 2 , and polyethylene wax is used as the film-forming material 3 easily heated by heat.

[0071] The preparation method of the compos...

Embodiment 2

[0084] Different from Example 1, the phase change particle 1 of this example is potassium sulfate.

[0085] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com