Patents

Literature

533results about How to "Avoid chalking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of continuous oxide fiber reinforced oxide ceramic based composite

ActiveCN105254320AAvoid Density GradientsAvoid fiber strength loss or pulverizationSolventOxide ceramic

The invention belongs to the preparation technology of a continuous fiber reinforced ceramic based composite, and relates to a preparation method of a continuous oxide fiber reinforced oxide ceramic based composite. The technology comprises the steps that an organic ceramic precursor solution is utilized to serve as solvent to prepare slurry with ceramic powder, the slurry is smeared on the surface of oxide fiber fabric to prepare oxide fiber prepreg, the technological processes of laminating, mold pressing and sintering are conducted on the prepreg, a low-porosity ceramic based composite preform is obtained, the repeated processes of soaking and splitting are conducted by adopting an organic ceramic precursor, and the continuous fiber reinforced ceramic based composite with the ideal density is obtained. According to the preparation method of the continuous oxide fiber reinforced oxide ceramic based composite, the organic ceramic precursor is adopted to serve as the solvent to prepare the ceramic slurry, the organic ceramic precursor can play a role of bonder for bonding the ceramic powder, low-temperature inorganic characteristics of the organic ceramic precursor can be utilized, fiber is protected against thermal damage caused by high temperature in the composite preparation process, and the composite strength is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

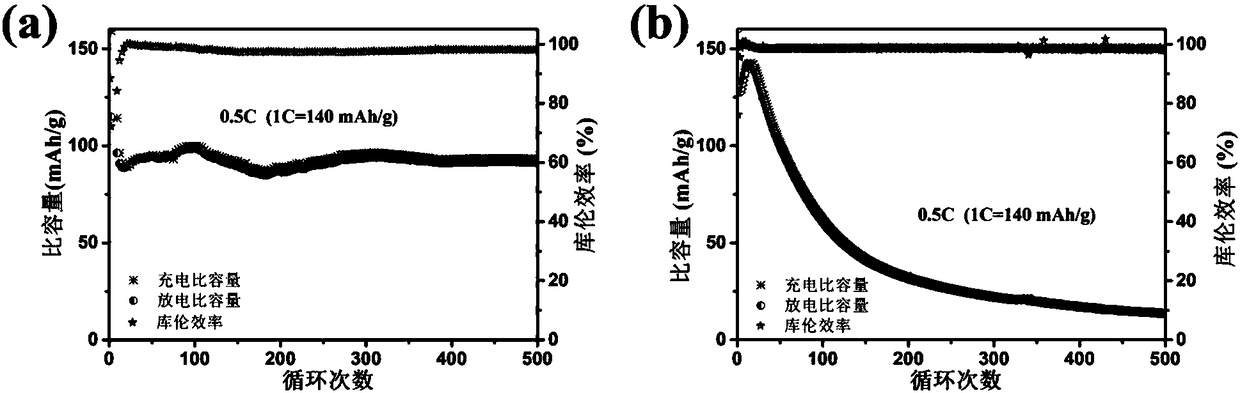

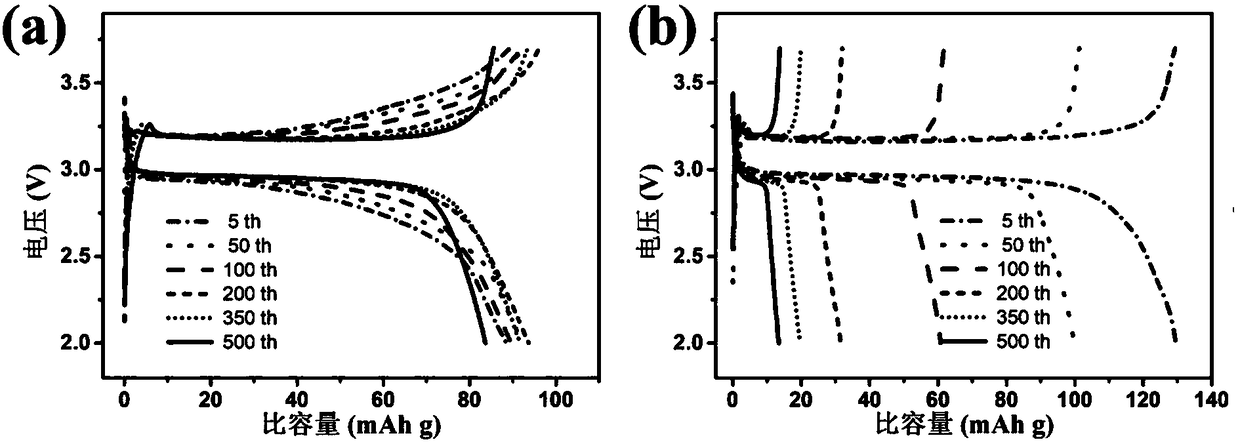

Positive pole material of lithium ion battery and preparation method of positive pole material

ActiveCN103441255AImprove long-term cycle stabilityAvoid crackingPositive electrodesNickel compoundsPhysical chemistrySodium-ion battery

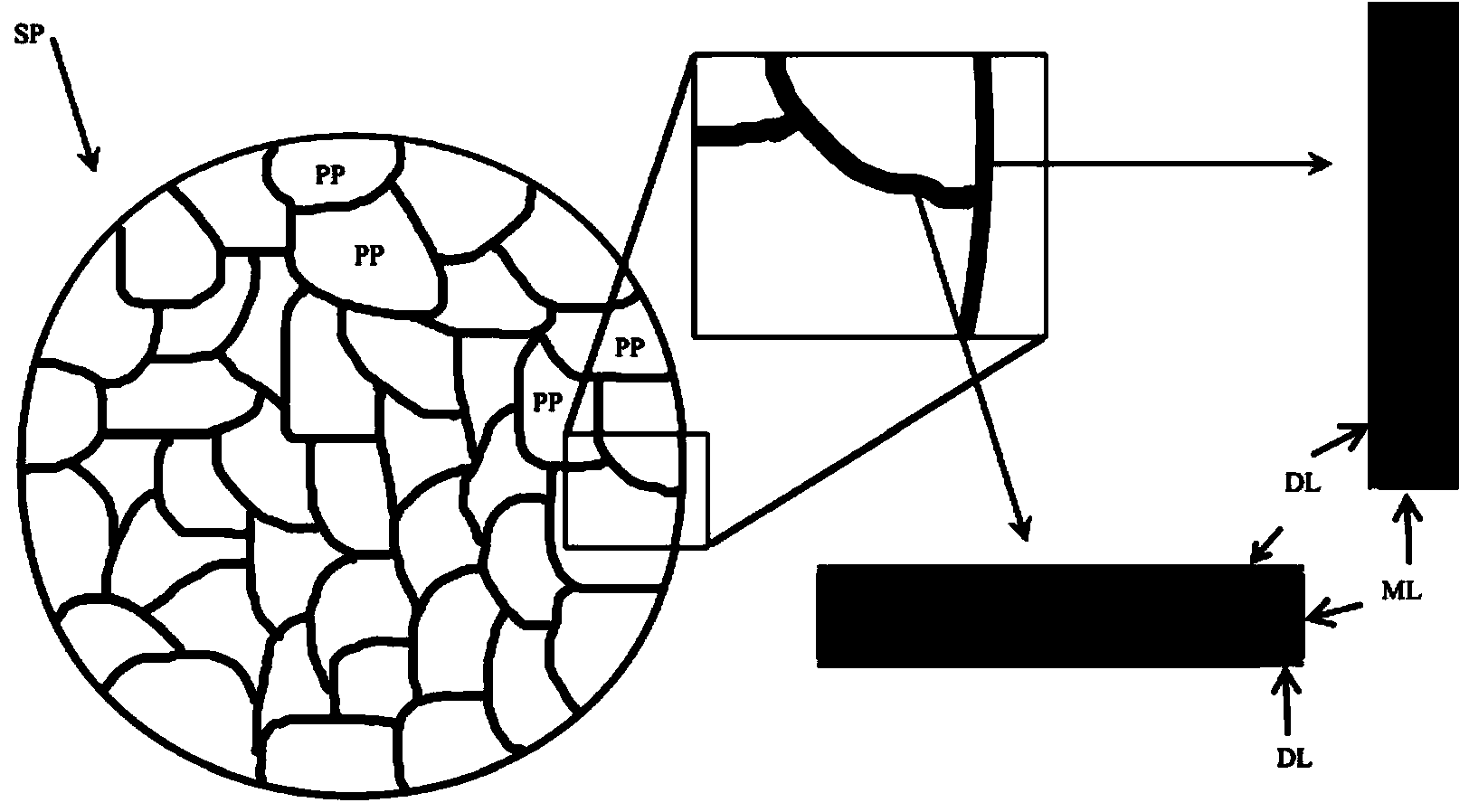

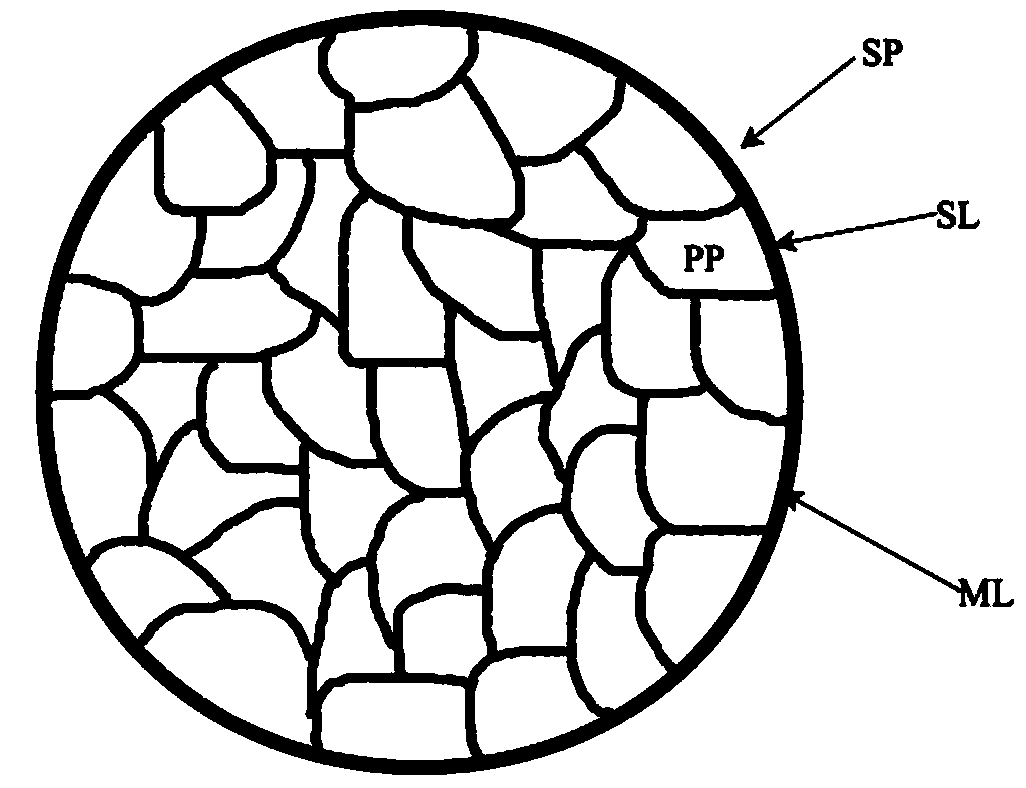

The invention provides a positive pole material of a lithium ion battery and a preparation method of the positive pole material. Secondary particles of the positive pole material of the lithium ion battery comprise primary particles of lithium-containing multi-transition metal oxide and second-phase materials; in a process of forming the secondary particles through the primary particles, the second-phase materials form second-phase material layers which are distributed on the surfaces of the primary particles, and are diffused with the lithium-containing multi-transition metal oxide through atoms to form diffusion layers so as to enable the second-phase material layers to be combined with the primary particles. Therefore, pulverization of the secondary particles of the positive pole material of the lithium ion battery along interfaces between the primary particles can be effectively suppressed, and the sizes of the primary particles and the secondary particles can be effectively controlled. When the positive pole material is applied to the lithium ion battery, the lithium ion battery is high in specific capacity, good in cycle performance and good in safety performance.

Owner:NINGDE AMPEREX TECH +1

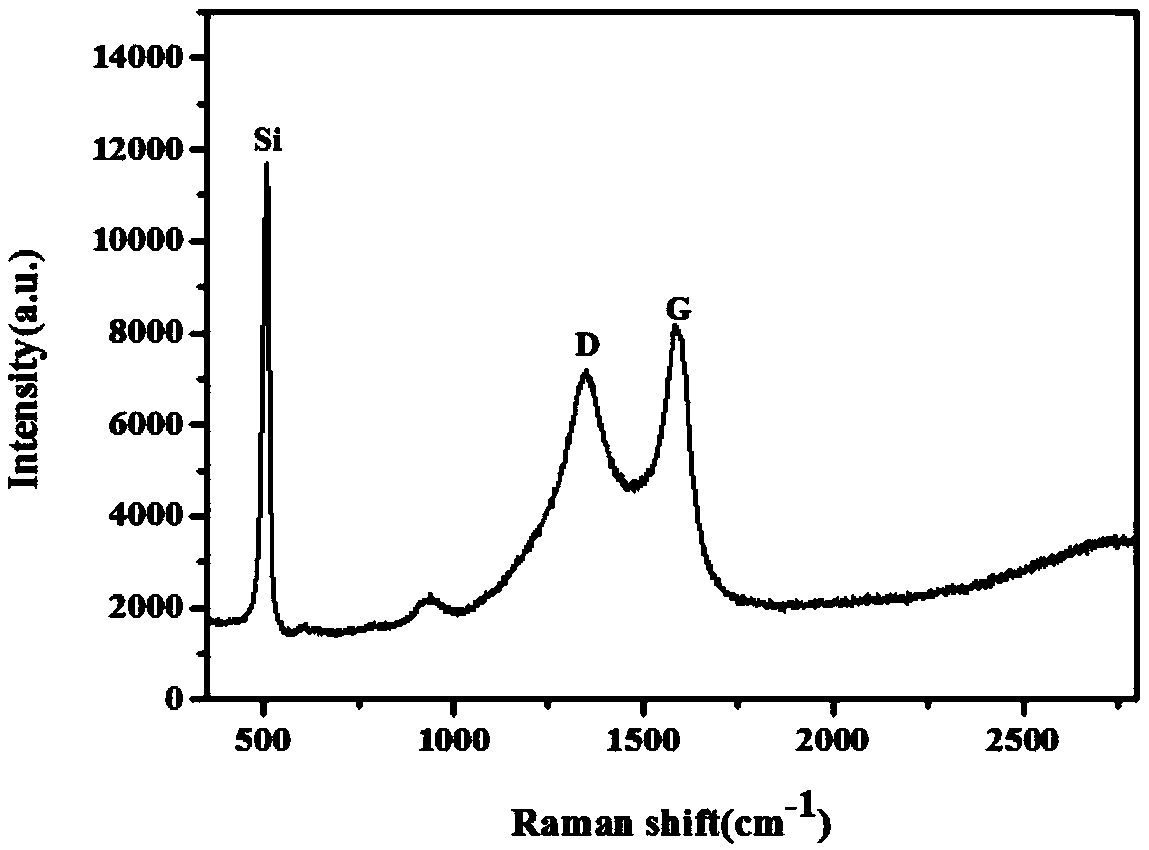

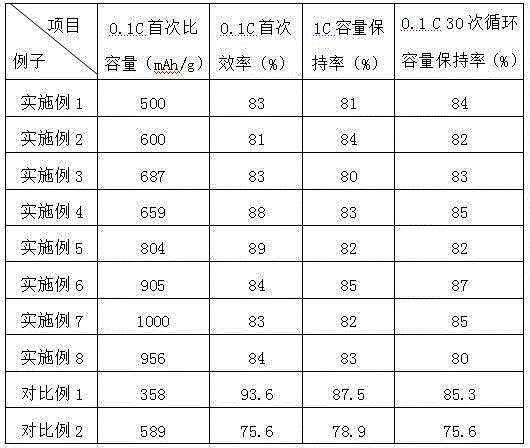

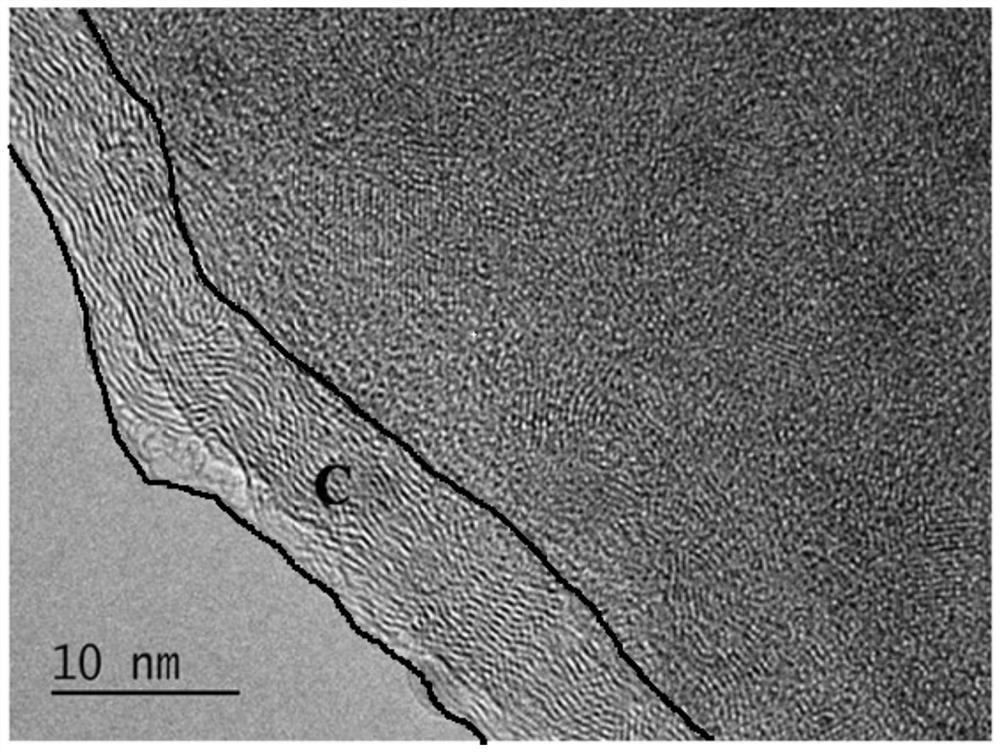

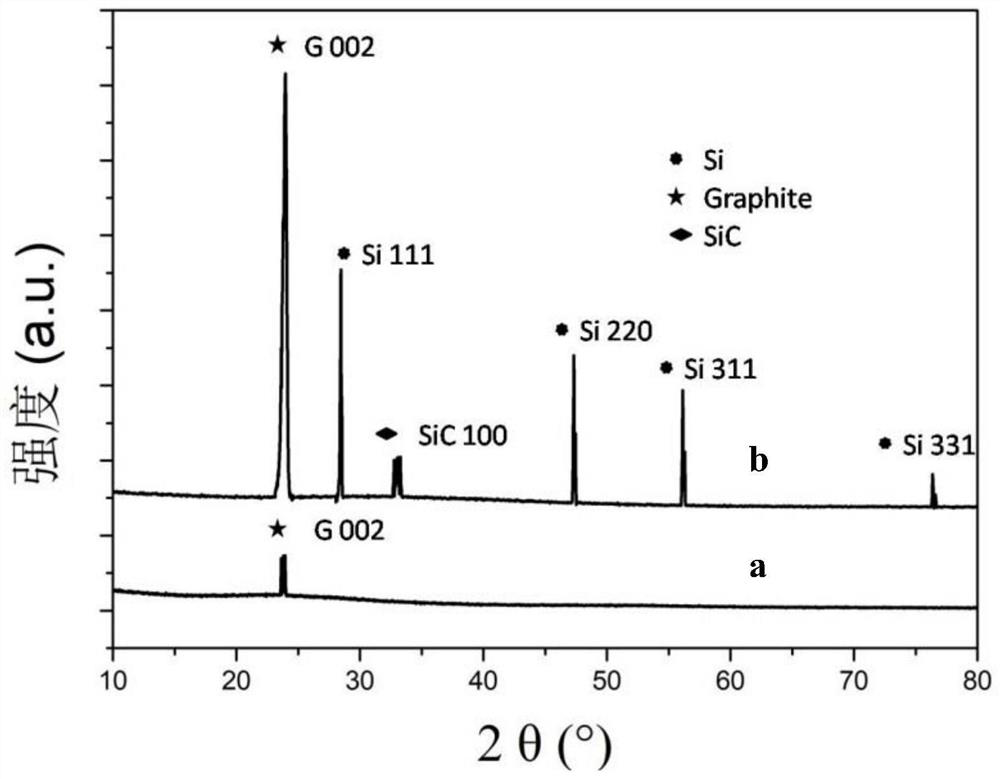

Silicon-carbon composite material for lithium ion battery and preparation method thereof

ActiveCN102891297AImprove cycle performanceIncrease capacityCell electrodesCarbon compositesCarboxymethyl cellulose

The invention discloses a silicon-carbon composite material for a lithium ion battery and a preparation method for the silicon-carbon composite material, and belongs to the field of lithium ion batteries. The silicon-carbon composite material is characterized in that carboxymethylcellulose sodium is used as a bonding agent, a liquid phase coating technology is used for silicon-carbon compounding, and a spray drying technology is used for drying granulation to prepare the silicon-carbon composite material with uniform granularity and excellent performance for the lithium ion battery. The silicon-carbon composite material and the preparation method thereof have the advantages that 1, the composite material for the lithium ion battery is prepared through a silicon-carbon compounding technology, and the capacity of the composite material is higher than that of the conventional graphite cathode material, reaches over 500mAh / g, and can meet requirements on the growing of the market of lithium ion batteries; 2, carboxymethylcellulose is used as a bonding agent which can be effectively coated and bonded on the silicon-carbon material to prevent efflorescence caused by silicon during charging and discharging, so that the cycling performance of the silicon-carbon composite material is effectively improved; and 3, the liquid phase coating and spray drying granulation technologies are adopted, so that the silicon-carbon material can be uniformly coated and bonded, has uniform granules, and is small in specific area, and the cycling performance of the silicon-carbon composite material is further improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

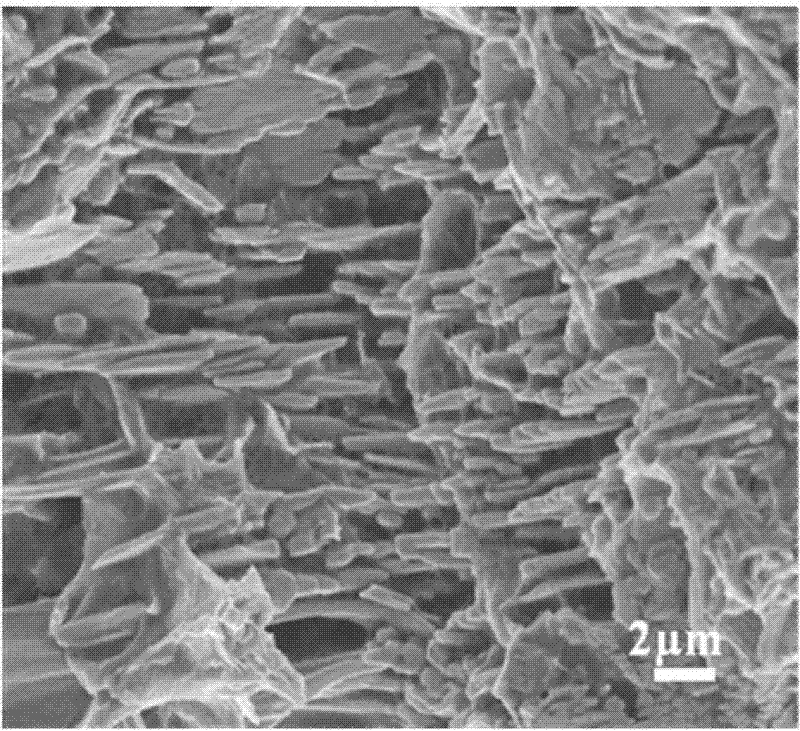

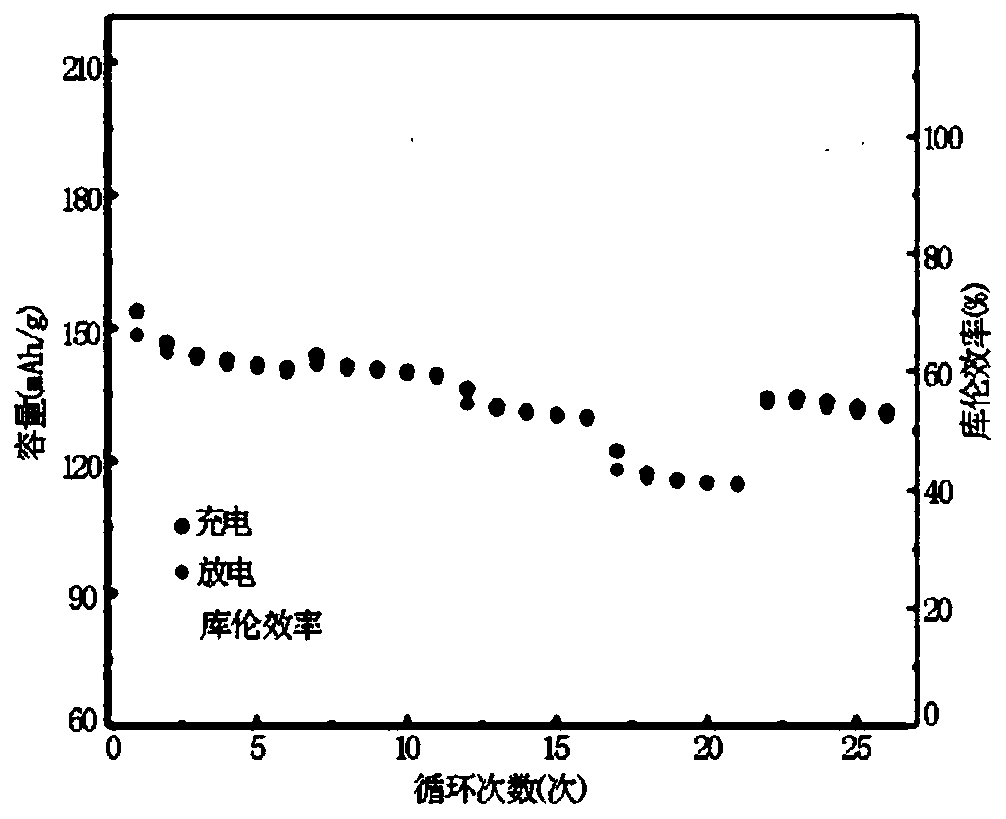

Graphene macroscopic body/tin oxide composite lithium ion battery anode material and process thereof

ActiveCN102244250AImprove conductivityLarge specific surface areaCell electrodesPorous grapheneElectrolytic agent

The invention relates to a graphene macroscopic body / a tin oxide composite lithium ion battery anode material and a process thereof. The anode material consists of a three-dimensional graphene macroscopic body and nano tin dioxide which grows in a pore of the three-dimensional graphene macroscopic body in an orientated way; and a volume is 500 to 2,000 mAh / g; the coulomb efficiency is 80 to 99.5 percent, wherein a mass ratio of the three-dimensional graphene macroscopic body to the tin dioxide is 1:(0.1-20). The characteristic of high electric conductivity of graphene is kept, the transfer and transport of charges are facilitated, and microscopic and macroscopic electric network structures are formed; meanwhile, the three-dimensional graphene macroscopic body has a big specific surface area and abundant pore spaces, so that the transfer of lithium ions is facilitated, and the contact area of the electrode material and electrolyte is enlarged; and the preparation process is environment-friendly, pollution-free and suitable for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Stain-resistant heat-insulation coating and preparation method thereof

InactiveCN104403465AImprove rigidityGood stain resistanceReflecting/signal paintsPhotopigmentCoating

The invention discloses a special electric stain-resistant heat insulation coating. The special electric stain-resistant heat insulation coating comprises the following components in parts by weight: 15-50 parts of a film formation emulsion, 5-30 parts of nano oxide powder, 10-20 parts of heat reflection pigment, 5-25 parts of hollow ceramic microbeads, 8-15 parts of a filler, 5-15 parts of additives and a proper amount of deionized water. The purposes of resisting stains and insulating heat can be achieved by introducing components such as nano oxide powder into the heat insulation coating. The invention also discloses a preparation method of the stain-resistant heat insulation coating. The preparation method of the stain-resistant heat insulation coating comprises the following steps: adding deionized water, part of the additives, the nano oxide powder, the hollow ceramic microbeads, the heat reflection pigment and filler into a grinder for grinding to obtain slurry; transferring the prepared slurry into a dispersing machine, adding the film formation emulsion and the rest of additives into the slurry, stirring and dispersing the slurry, filtering the slurry by a screen to obtain the stain-resistant heat insulation coating. The preparation method of the stain-resistant heat insulation coating is simple in process, easy to implement and simple and convenient to operate.

Owner:STATE GRID CORP OF CHINA +3

Application of high-molecular coating in aluminium negative electrode, aluminium negative electrode, preparation method thereof and secondary battery

ActiveCN108155363AAvoid erosionAvoid reactionCell electrodesSecondary cellsElectrochemistryElectrochemical energy storage

The invention discloses application of a high-molecular coating in an aluminium negative electrode, the aluminium negative electrode, a preparation method thereof and a secondary battery and relates to the field of electrochemical energy storage devices. For the application of the high-molecular coating in the aluminium negative electrode, the aluminium negative electrode is used as a negative current collector and a negative active material simultaneously. The aluminium negative electrode is used as the negative current collector and the negative active material simultaneously and is coated with the high-molecular coating; the secondary battery comprises the aluminium negative electrode. The application disclosed by the invention has the beneficial effects that the problems that the volume of the aluminium negative electrode used as the negative current collector and the negative active material is expanded and the capacity is attenuated due to an unstable solid electrolyte membrane are relieved; after the high-molecular coating is applied on the aluminium negative electrode, electrolytic solution and the aluminium negative electrode can be effectively isolated, the aluminium negative electrode can be prevented from being eroded and reacted, the coulombic efficiency is effectively improved, the irreversible capacity can be reduced, the cyclic stability of the battery can be improved, simultaneously certain role is played in inhibiting powdering of the aluminium negative electrode in the process of volume expansion, and the integrity of the aluminium negative electrode structure can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH

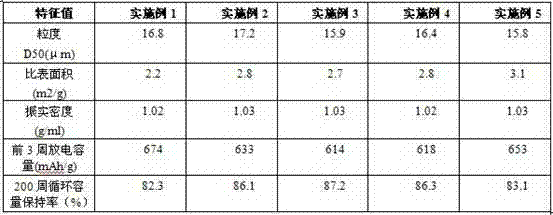

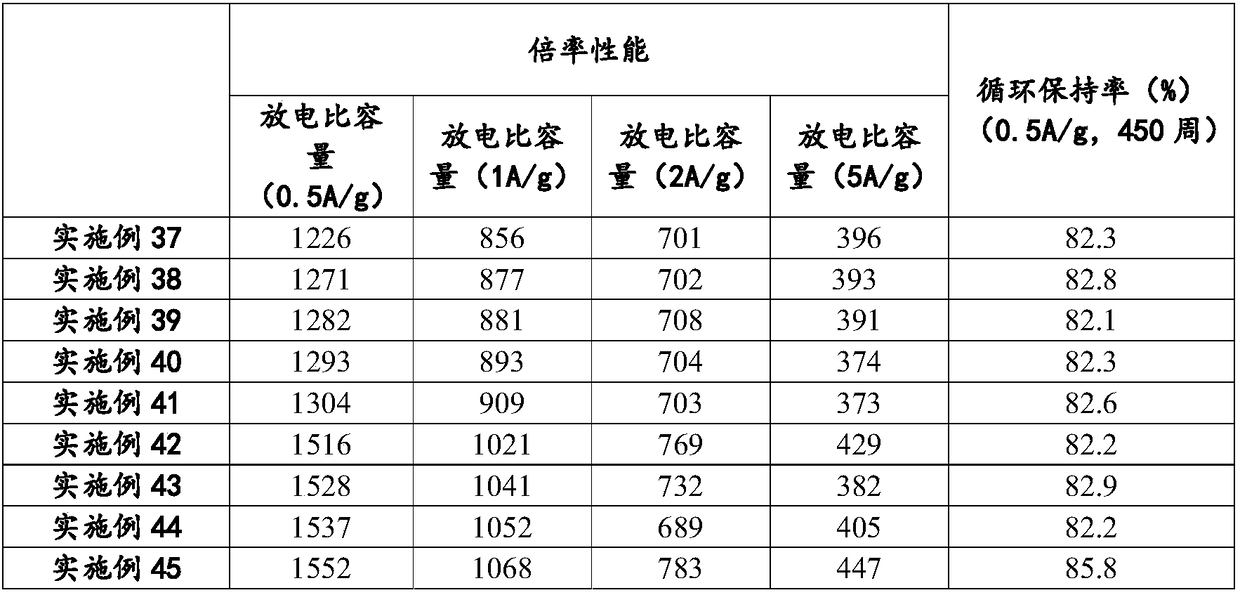

Silicon-carbon composite material and preparation method thereof

InactiveCN109802120AAvoid chalkingImprove cycle performanceMaterial nanotechnologyCell electrodesCyclic processCarbon coating

The invention discloses a silicon-carbon composite material which is a composite material similar to a dragon fruit structure. The silicon-carbon composite material comprises a base core, a silicon-carbon composite housing and a coating layer. The silicon-carbon composite housing is formed by uniformly dispersing a plurality of nano silicon particles in conductive carbon. The nano silicon particles are formed by pyrolysis of a silicon source. The conductive carbon is formed by pyrolysis of an organic carbon source. The coating layer is a carbon coating layer. At least one carbon coating layeris provided. The thickness of a single carbon coating layer is 0.2 to 3[mu]m. Compared with the prior art, a silicon-carbon composite material precursor is formed by using vapor phase synchronous deposition, and carbon coating is performed to form the silicon-carbon composite material similar to the dragon fruit structure. The silicon-carbon composite material has a high first effect, low expansion and long circulation, slows down the silicon material grain growth during the heat treatment process, avoids the powdering of the material during the cycle, alleviates the volume expansion effect ofthe silicon-based material, and is improved in the cycle performance, the electrical conductivity and the rate performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

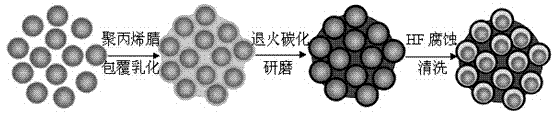

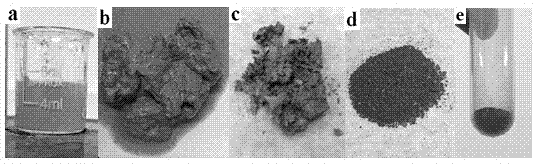

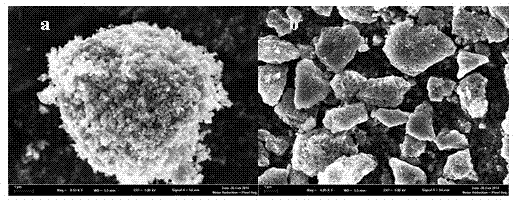

Pomegranate-like structured composite material preparation method

InactiveCN104300125AEasy to prepareThe preparation method is safeMaterial nanotechnologyCell electrodesMaterials preparationSilica particle

The invention discloses a pomegranate-like structured composite material preparation method which comprises the following steps: S1, taking a polyacrylonitrile solution, adding silica nanoparticles, and fully dispersing; S2, adding deionized water after stirring for emulsification to obtain a mud like precursor; S3, heating the mud like precursor obtained in the S2, and annealing to obtain a solid composite; and S4, grinding the solid composite obtained in the S3 into micron particles, adding a hydrogen fluoride solution for corrosion for a certain period of time, washing hydrogen fluoride, and drying to obtain a pomegranate-like structured composite material. According to the method, polyacrylonitrile is used for coating the silica particle surface, the polyacrylonitrile is emulsified when meeting water, so that the coated silicon particles are agglomerated, the coated silicon particles are carbonized and ground for formation of the pomegranate shaped structured silicon carbon composite material, HF is used for direct corrosion of the silicon nanoparticles in the material for preparation of the hollow pomegranate-like structured composite material, and detailed structure characterization and electrochemical performance testing of the material show that the material is good in performances.

Owner:SUN YAT SEN UNIV

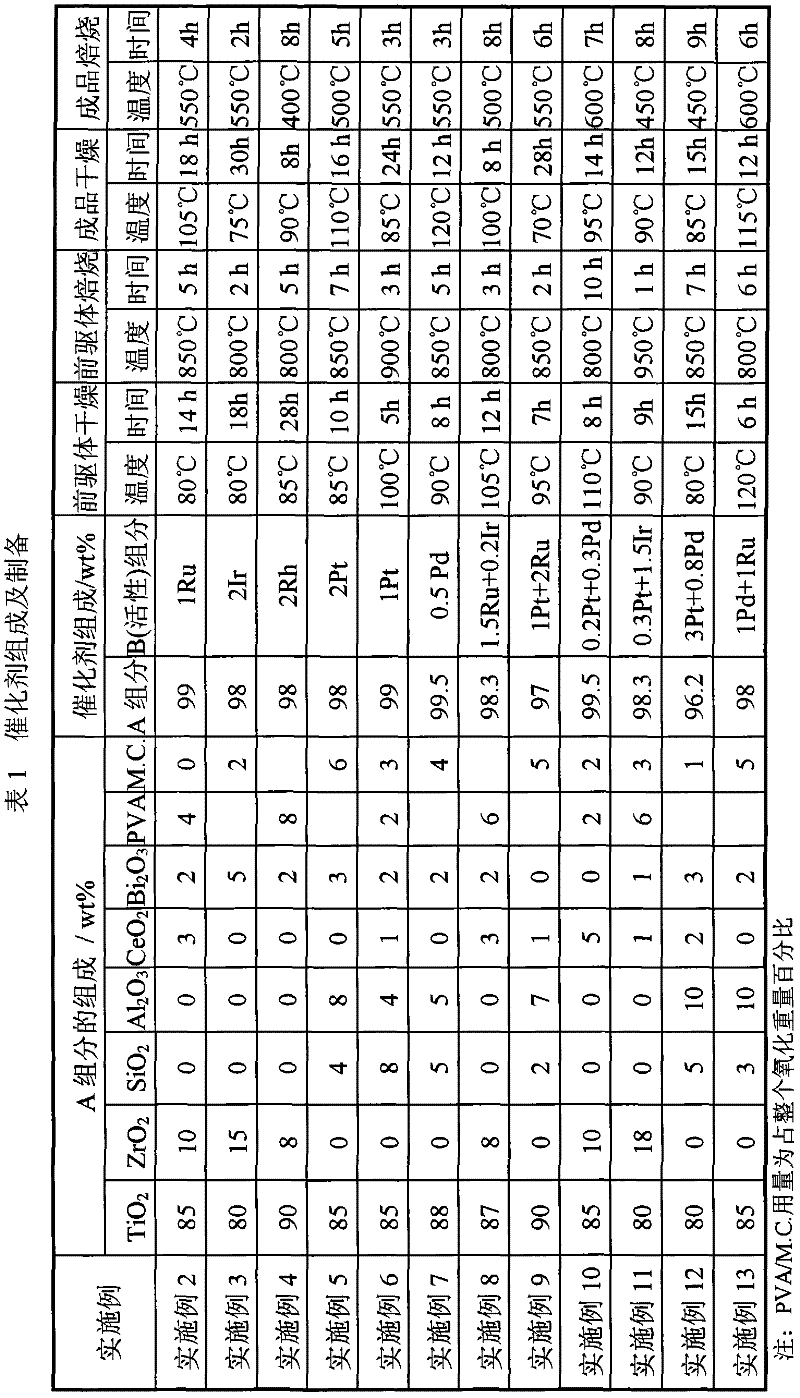

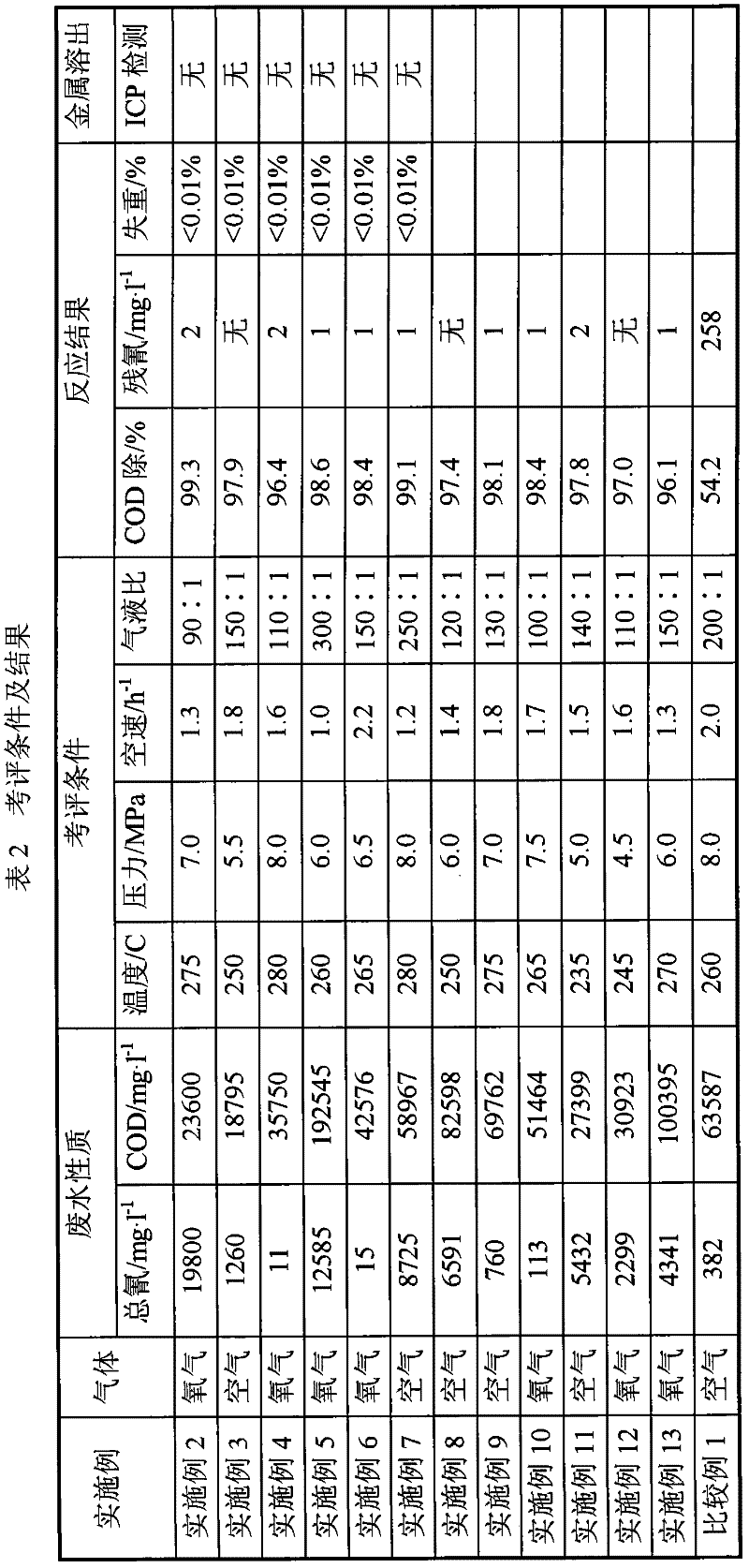

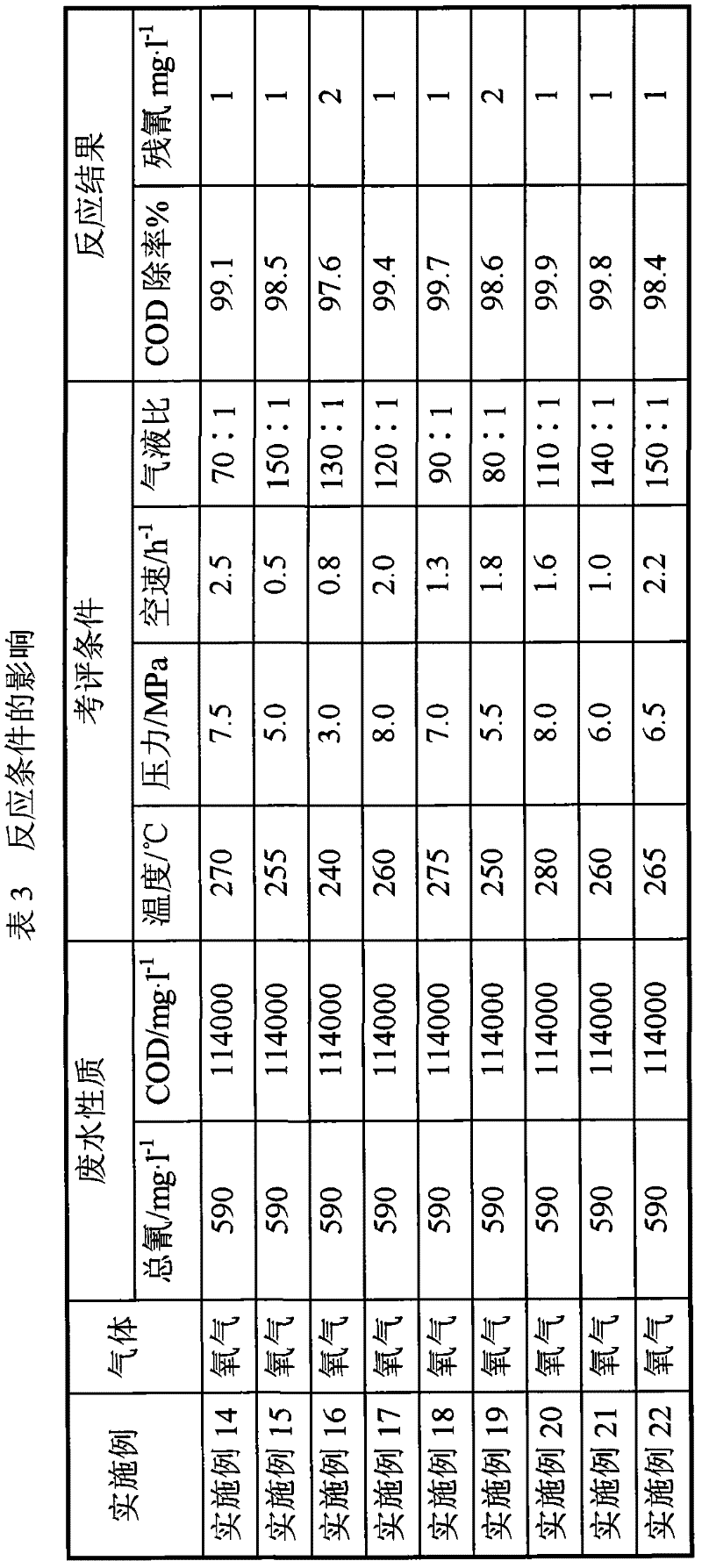

Catalytic wet oxidation method of cyanogen-containing industrial wastewater

ActiveCN102452710AHigh strengthAvoid crackingWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The invention relates to a catalytic wet oxidation method of cyanogen-containing industrial wastewater. With the method, problems of catalysts in existing technologies, such as difficult shaping, low activity, easy crushing, short service life, low COD removing rate, and complicated technology, can be solved. According to the invention, industrial wastewater and gas containing elementary oxygen are adopted as raw materials. Under a reaction temperature of 230-300 DEG C, a reaction pressure of 3-10MPa, and a liquid space velocity of 0.5-2.5h<-1>, the raw materials contact a catalyst, such tat a COD removing rate is higher than 95%. After the treatment, a total cyanogen content is smaller than 5ppm. The adopted catalyst is a composite carrier loaded with at least one metal selected from Pt,Pd, Ru, Ir, or Rh, or an oxide of the metals. With the method provided by the invention, the problem is well solved. The method can be used in industrial treatment of cyanogen-containing industrial wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

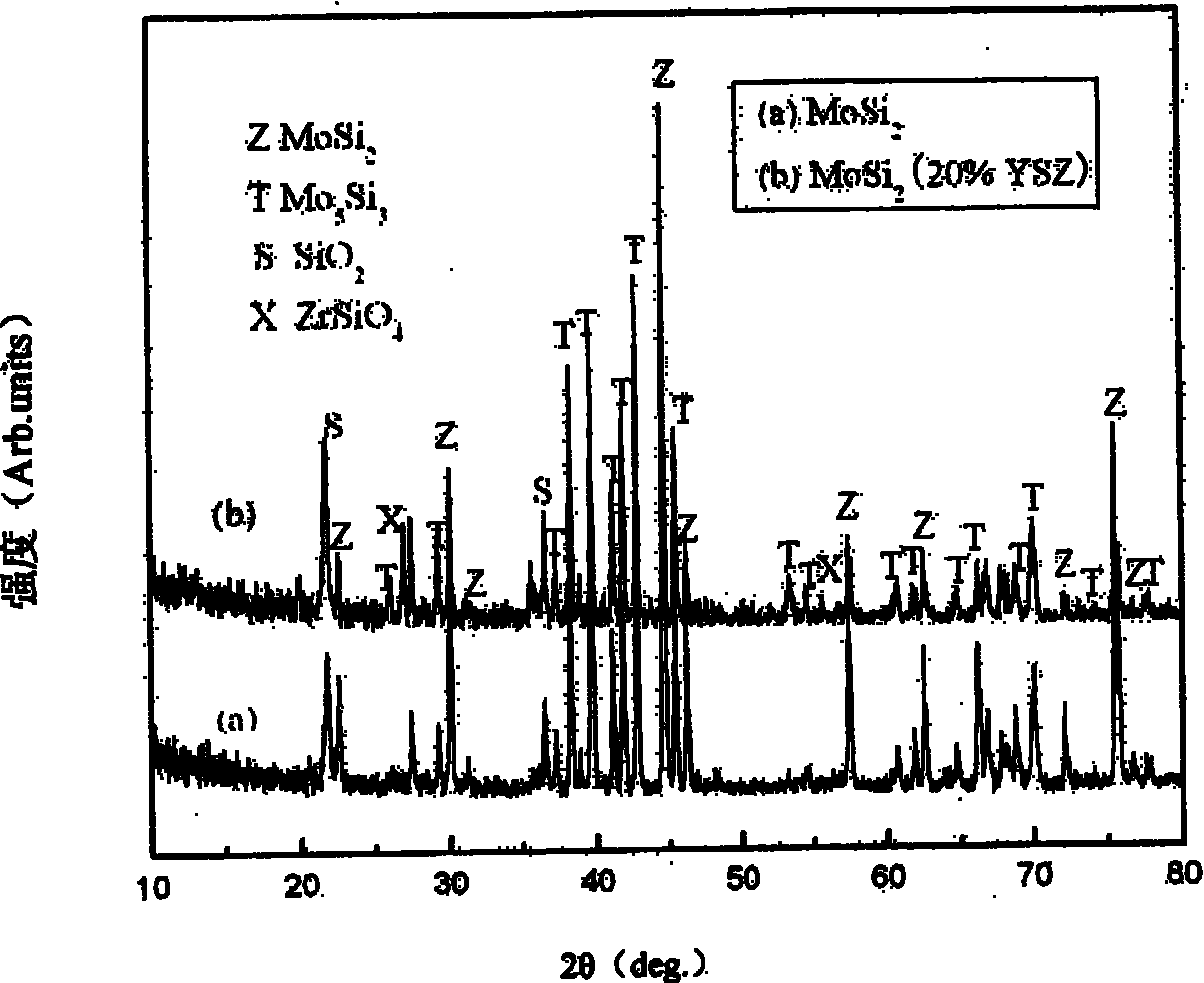

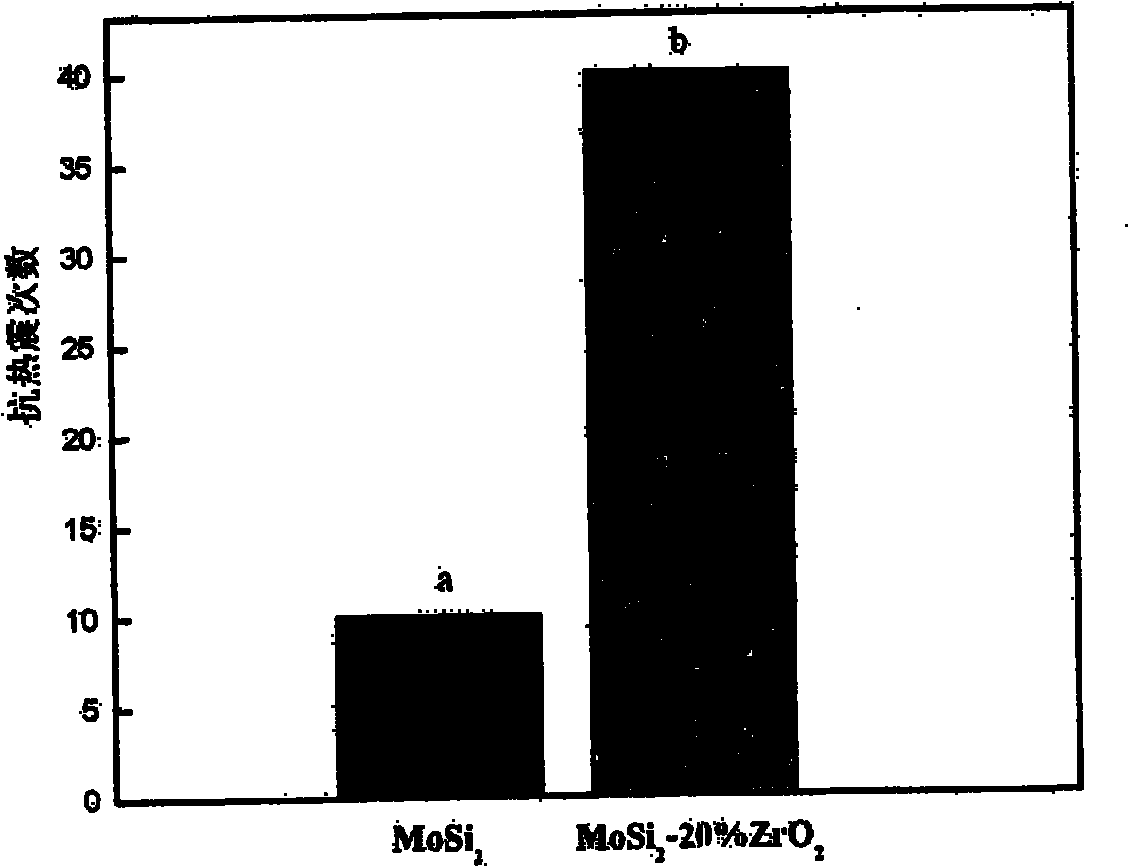

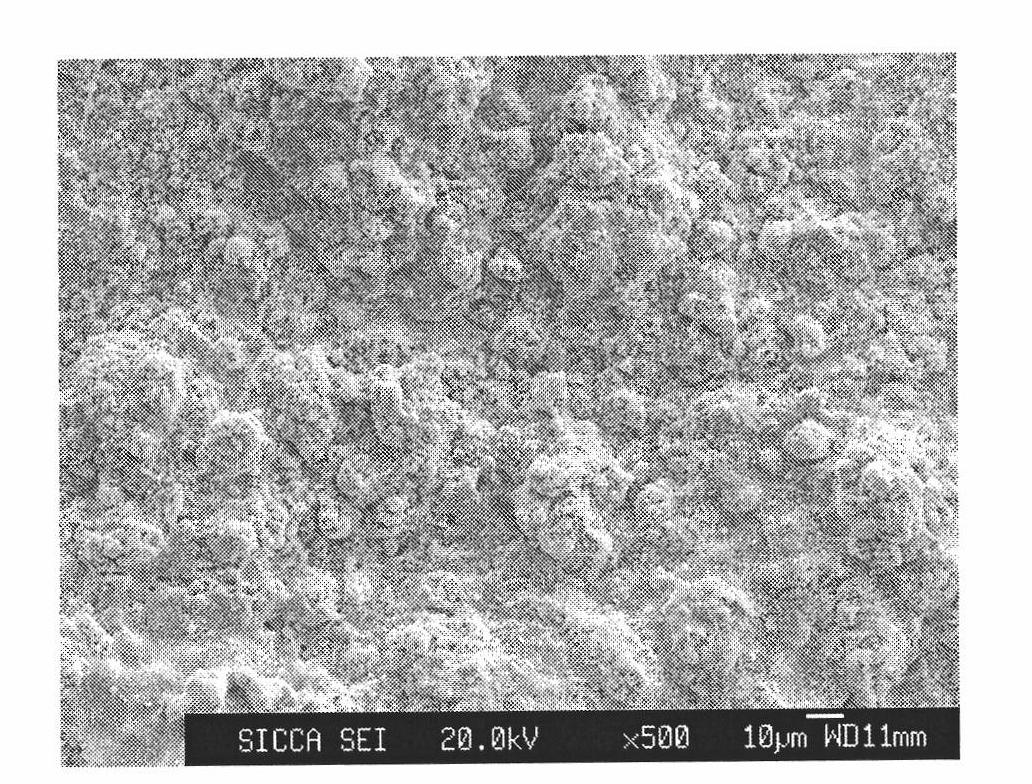

Molybdenum disilicide composite coating and preparation method thereof

InactiveCN102041499AImprove thermal shock resistanceExtended service lifeMolten spray coatingOxidation resistantThermal shock

The invention relates to a molybdenum disilicide composite coating and a preparation method thereof. In the invention, molybdenum disilicide powder (MoSi2) with certain particle size distribution and purity and zirconia powder (ZrO2) are mixed, and a MoSi2-ZrO2 composite coating is prepared on a high temperature alloy by adopting the plasma spraying technology, wherein the prepared composite coating has fine high temperature antioxidation property and thermal shock resistance superior to that of a MoSi2 coating. The molybdenum disilicide composite coating and the preparation method also have the advantages of simple process, high efficiency, suitability for large-scale production and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

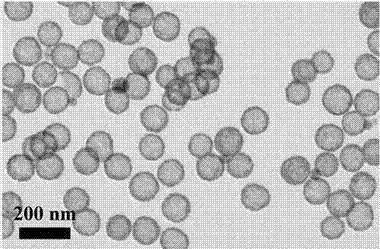

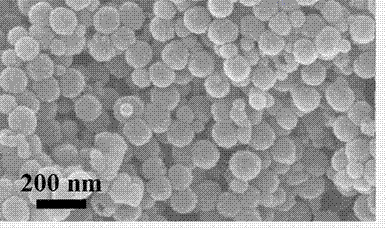

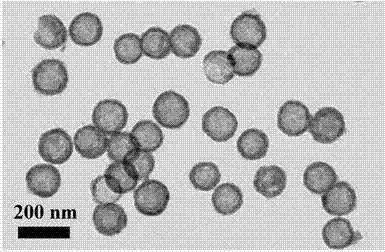

Preparation method and application of hollow SnO2@C nanosphere in lithium ion battery

InactiveCN103193263AThe synthesis method is simpleUniform particle sizeMaterial nanotechnologyCell electrodesCarbon layerElectrical battery

The invention belongs to the technical field of nanocomposites, and in particular relates to a preparation method of a hollow SnO2@C nanosphere with a core-shell structure and an application of the hollow SnO2@C nanosphere in a lithium ion battery. The preparation method comprises the following steps: synthesizing a hollow SnO2 nanosphere with high dispersibility and uniform particle diameter by taking silica as a template via one-step process; and wrapping a carbon layer on the hollow SnO2 nanosphere by taking PAA (Phenolic Aldehyde Amine) as a carbon source, thereby preparing the hollow SnO2@C nanosphere with the core-shell structure. According to the invention, the purpose of integrating the regulating effects of the nanoscale dispersion of nanoparticles to the volume expansion of SnO2, the absorbing effects of the hollow structure to the internal stress generated by volume changes and the restricting and buffering effects of the carbon wrapping layer to stannic oxide particles is achieved; and when the hollow SnO2@C nanosphere is applied to the lithium ion battery, the lithium ion battery can have a larger volume, better cycling stability and longer service life.

Owner:NORTHEAST NORMAL UNIVERSITY

Hollow/porous structure silicon-based composite material and preparation method thereof

InactiveCN109449423AAlleviate volume effectAvoid chalkingMaterial nanotechnologySiliconCarbon compositesCarbon coating

The invention discloses a hollow / porous structure silicon-based composite material. The composite material comprises a hollow / porous structure, a silicon-carbon composite layer and a coating layer, the silicon-carbon composite layer is formed by evenly dispersing nano silicon or silica in a conductive carbon network, the conductive carbon network in the silicon-carbon composite layer is formed with binder through pyrolysis, the coating layer is a carbon coating layer, and at least one carbon coating layer is provided. The composite material provided by the invention is prepared through a method of evenly mixing the nano silicon / silica, the binder and salt, then, performing spray granulation, high temperature sintering, water desalination and coating treatment. The composite material provided by the invention is a lithium ion battery silicon-carbon cathode material with the advantages, such as high first effect, low expansion and long cycle; grain growth of the silicon material in a thermal treatment process is slowed, powdering of the material in a cycle process is avoided effectively, volume expansion effect of the silicon-based material is remitted, cycle performance is promoted,and conductivity and rate capability of the material are improved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Preparation method of silicon-based negative electrode active material, silicon-based negative electrode active material, lithium ion battery negative electrode material and lithium ion battery

InactiveCN108598413ASmall volume changeAvoid pulverization and electrode collapseCarbon compoundsCell electrodesCarbon coatingCvd graphene

The invention provides a preparation method of a silicon-based negative electrode active material, the silicon-based negative electrode active material, a lithium ion battery negative electrode material and a lithium ion battery, and relates to the technical field of lithium ion batteries. The preparation method comprises the steps of adding a macromolecule protection agent during the process of coating a silicon dioxide layer outside nanometer silicon, coating a grapheme oxide layer outside the silicon dioxide layer, add finally, performing hydrofluoric acid etching to obtain a Si / void / SiO2 / void / Graphene composite material which takes the nanometer silicon as a core and which the silicon dioxide layer and the graphene layer are sequentially coated from inside to outside, and the technicalproblem that the silicon-based negative electrode active material with greatly-improved performance is difficult to obtain by traditional methods of single silicon nanocrystallization or carbon coating and porous structure preparation is reduced; and with the silicon-based negative electrode active material prepared by the method provided by the invention, the volume change of the nanometer coreduring the charge-discharge process can be reduced, and moreover, the conductivity and the dynamic flexibility of the silicon-based negative electrode active material can be improved.

Owner:桑德新能源技术开发有限公司 +1

High strength energy saving heat insulation material for use outside external wall

InactiveCN1458112AImprove workabilityAvoid chalkingConstruction materialSolid waste managementFoaming agentPolystyrene

The heat insulation material consists of cement 50-55 wt%, granular polystyrene 10-15 wt%, flyash 20-25 wt%, light calcium carbonate 1-5 wt%, heavy calcium carbonate 5-10 wt%, flyash 10-20 wt%, cellulose fiber 0.1-0.5 wt%, methyl cellkulose 0.1-0.3 wt%, amylase 0.1-0.2 wt%, foaming agent 0.1-0.2 wt% and air entraining agent 0-0.2 wt%. The present invention is a kind of green furnishing and decorating material and is suitable for use as heat insulating material outside the outer wall and roof.

Owner:王胜怀

Method for preparing lithium battery silicon carbon anode material

InactiveCN103022448AImprove volume effectAlleviate volume effectCell electrodesCarbon compositesCopper foil

The invention discloses a sodium alginate bonding agent used in a lithium battery silicon carbon anode, particularly discloses a method for preparing a silicon carbon anode material by the bonding agent. The method comprises the steps that: step one, micron-grade silica powder is added into a ball milling tank, and a solvent is added to perform ball milling; step two, natural graphite is added into the industrial silicon powder subjected to the ball milling in the step one to continuously perform the ball milling; step three, substances subjected to the ball milling in the step two are dried, and the dried substances are finely ground; step four, 70-80 parts by weight of the silicon carbon composite material, 5-20 parts by weight of sodium alginate and 5-20 parts by weight of acetylene black are weighed, defined amount of deionized water is added, and the materials are uniformly stirred, then coated on a copper foil and dried to obtain the silicon carbon anode material. The novel bonding agent adopted by the invention can effectively improve the cycling performance of the silicon carbon anode material and prolong the cycling service life of the anode material.

Owner:TIANJIN B&M SCI & TECH

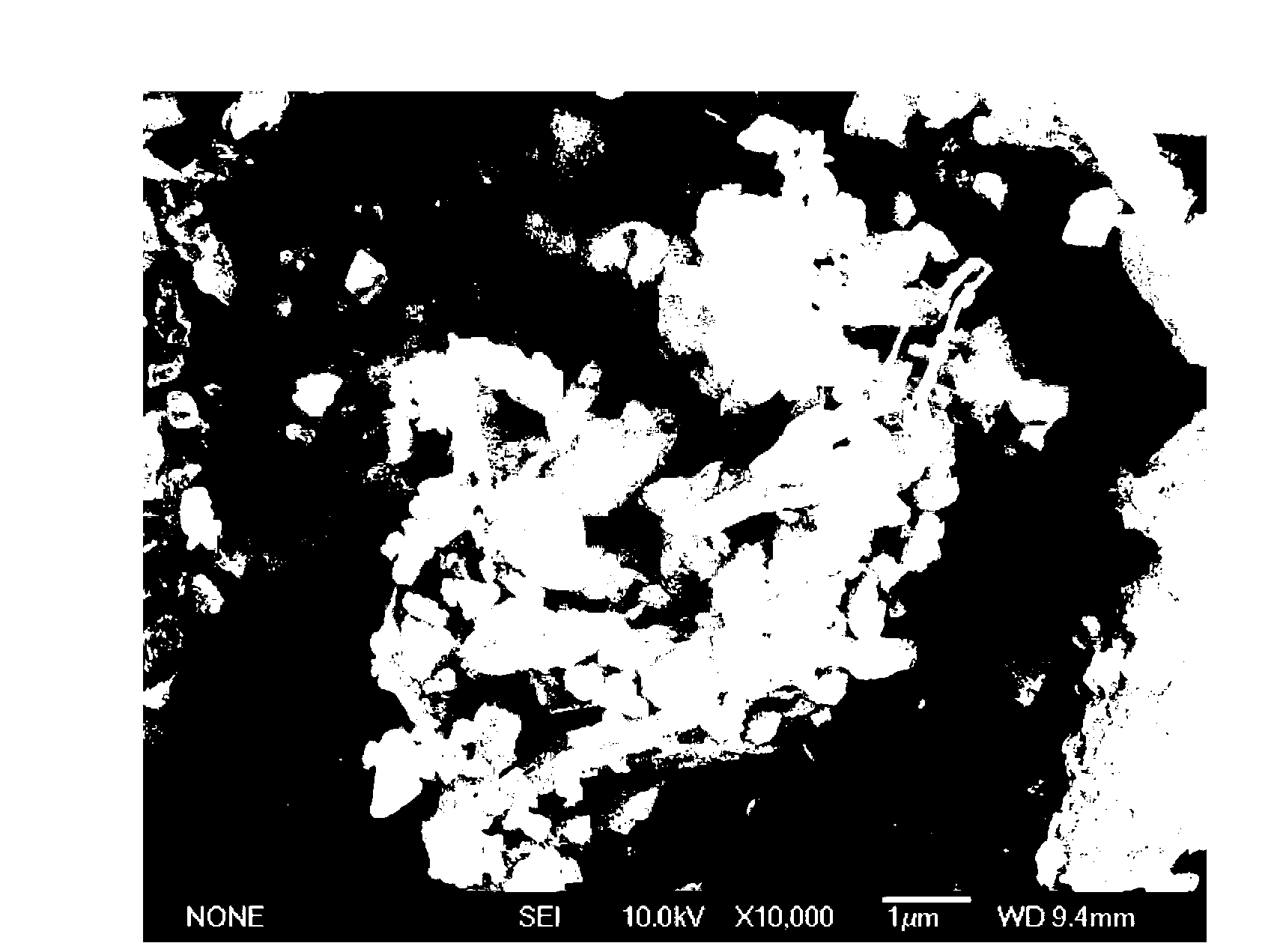

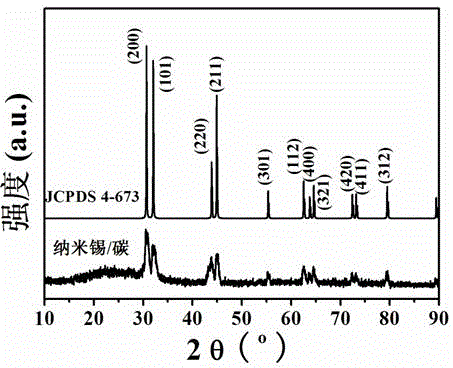

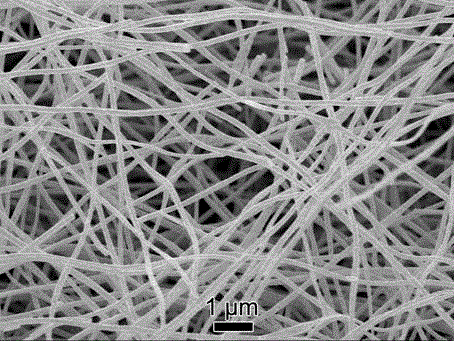

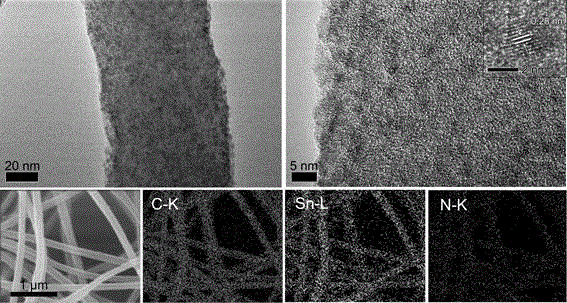

Method for preparing nano tin/carbon composite nanofibers through electrospinning technology

ActiveCN104466140AIncrease contentImprove volume changeCell electrodesCarbon compositesPorous carbon

The invention discloses a method for preparing nano tin / carbon composite nanofibers through the electrospinning technology. The method includes the steps that first, stannous chloride, polymethyl methacrylate and polyacrylonitrile are prepared into composite nanofibers through the electrospinning technology; then calcination is conducted under the nitrogen atmosphere, so that the polyacrylonitrile is carbonized, SnCl2 is decomposed, the polymethyl methacrylate is subjected to pyrolysis, accordingly, a porous structure is formed, and the nano tin / carbon composite nanofibers are obtained. The method has the advantages that the preparation technology is simple, the reaction condition is easy to control, and the repetitive rate is high; obtained Sn particles are only 1-2 nm and are evenly inlaid N-doped porous carbon nanofibers, and the mass percent of the Sn can reach 60-65%. The composite material is of a three-dimensional net structure which is formed by interweaving nanofibers from the microcosmic view, the composite material can be directly used as the negative electrode of a sodium-ion battery without a binding agent, high electrochemistry sodium storage reversible capacity can be achieved, excellent rate capability and cycling stability are achieved, and the application prospect is very bright.

Owner:NANKAI UNIV

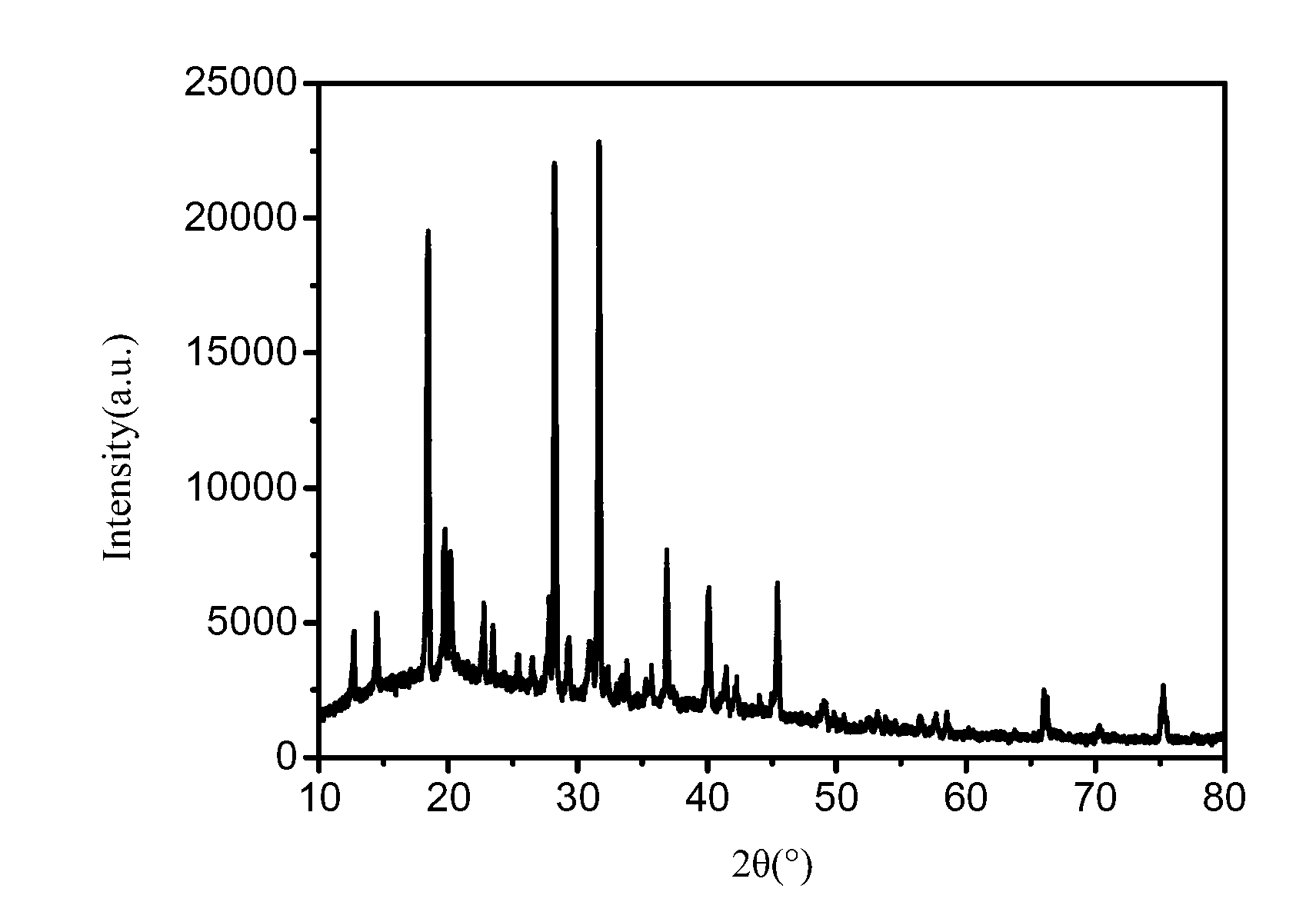

Method for preparing tin dioxide/graphene-compounded anode material of lithium ion battery

ActiveCN103078095AExcellent electrochemical performanceRaw ingredients are simpleCell electrodesCvd grapheneLithium electrode

The invention discloses a method for preparing a tin dioxide / graphene-compounded anode material of a lithium ion battery. The method comprises the following steps: uniformly mixing choline chloride, ethylene glycol and graphene oxide to obtain a mixed solution, adding stannous chloride to the mixed solution, performing ultrasonic oscillating reaction, and performing post-processing to obtain the product. According to the method for preparing the tin dioxide / graphene-compounded anode material of the lithium ion battery, a normal-pressure and normal-temperature one-step method is adopted, the adopted raw materials are simple in components and common and easy to obtain, the reaction conditions are mild and controllable, the reaction can be performed at normal temperature and normal pressure, and the preparation process is simple and practicable, has low requirements for equipment so as to be free from geographical restrictions, and is suitable for large-scale industrial production. The prepared tin dioxide / graphene-compounded anode material of the lithium ion battery has excellent electrochemical properties, and can be used as an active electrode substance for preparing an anode of the lithium ion battery so as to have a wide market application prospect.

Owner:SHENZHEN KEXIN COMM TECH

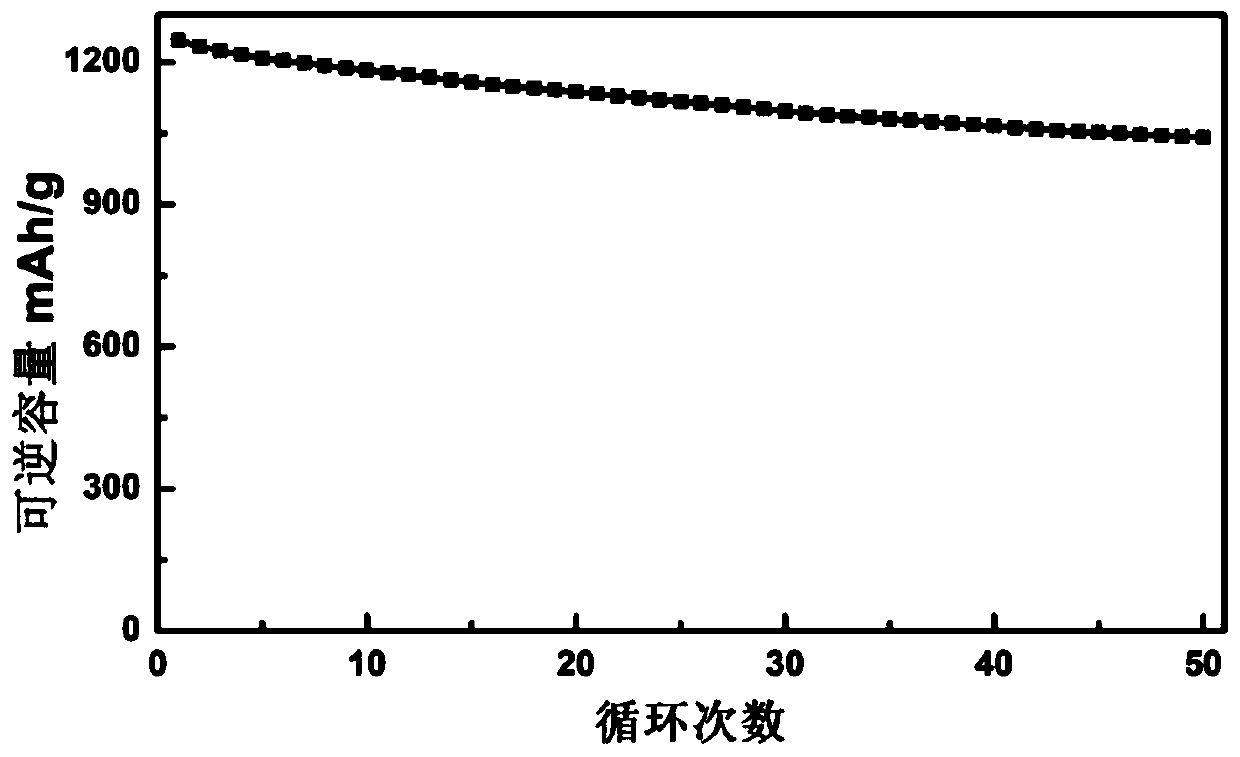

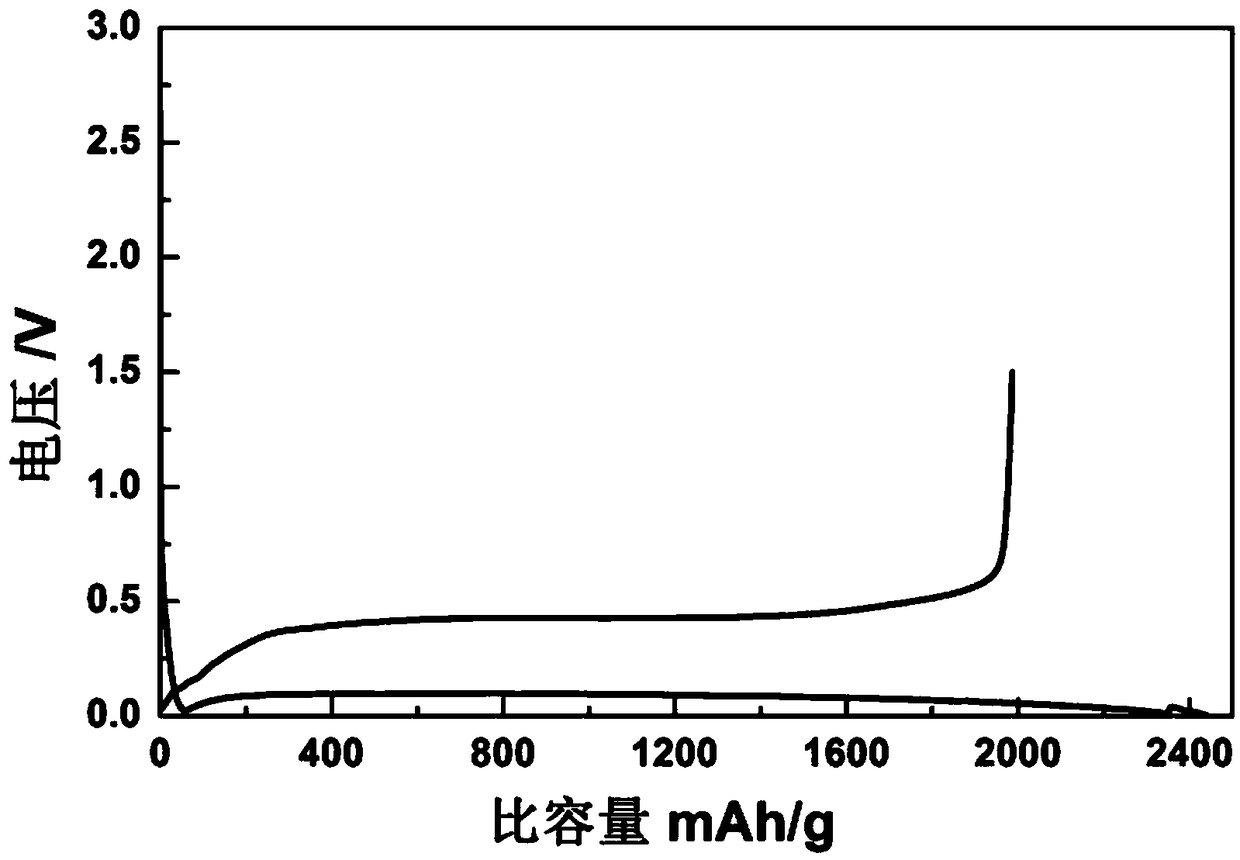

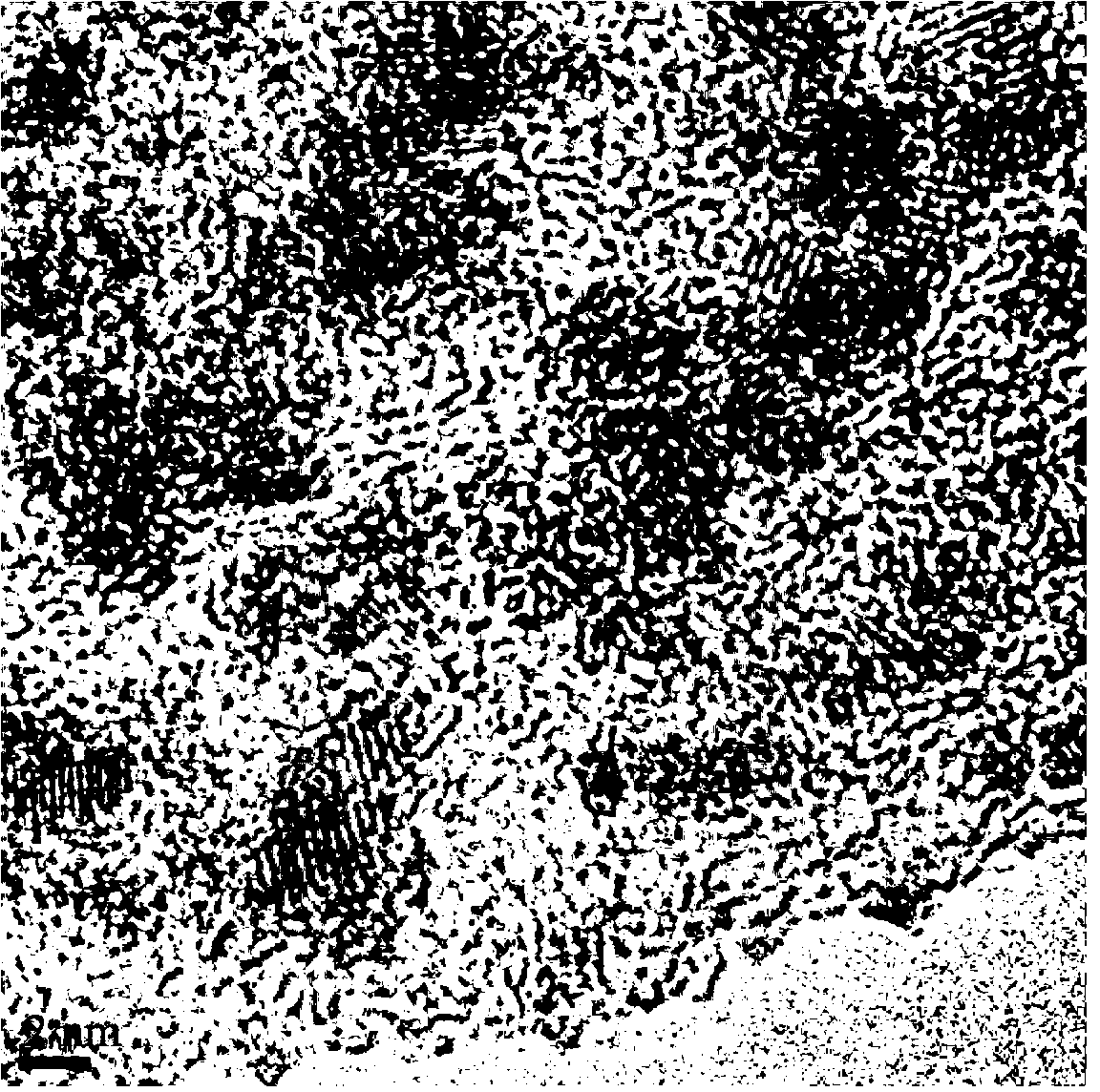

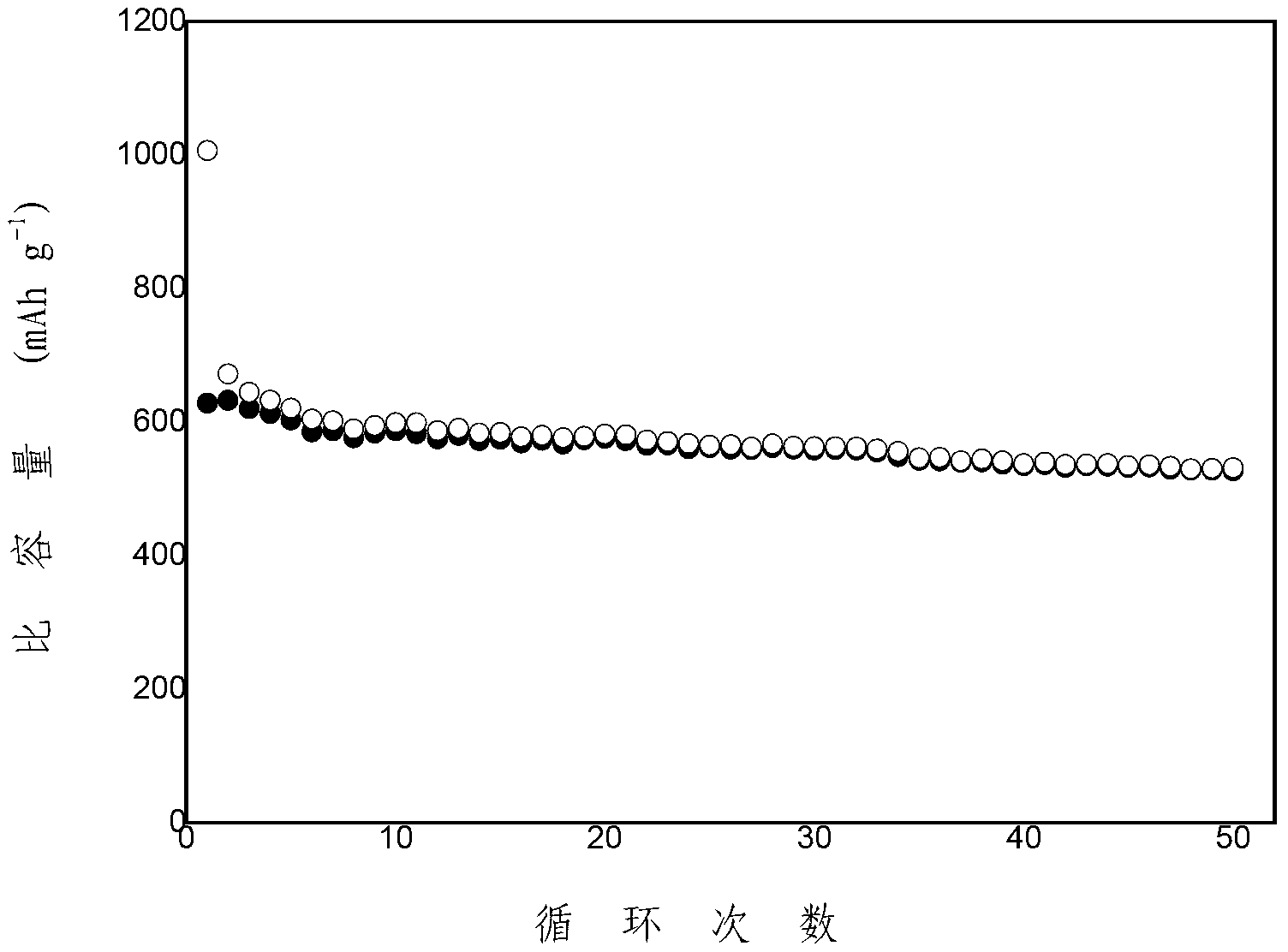

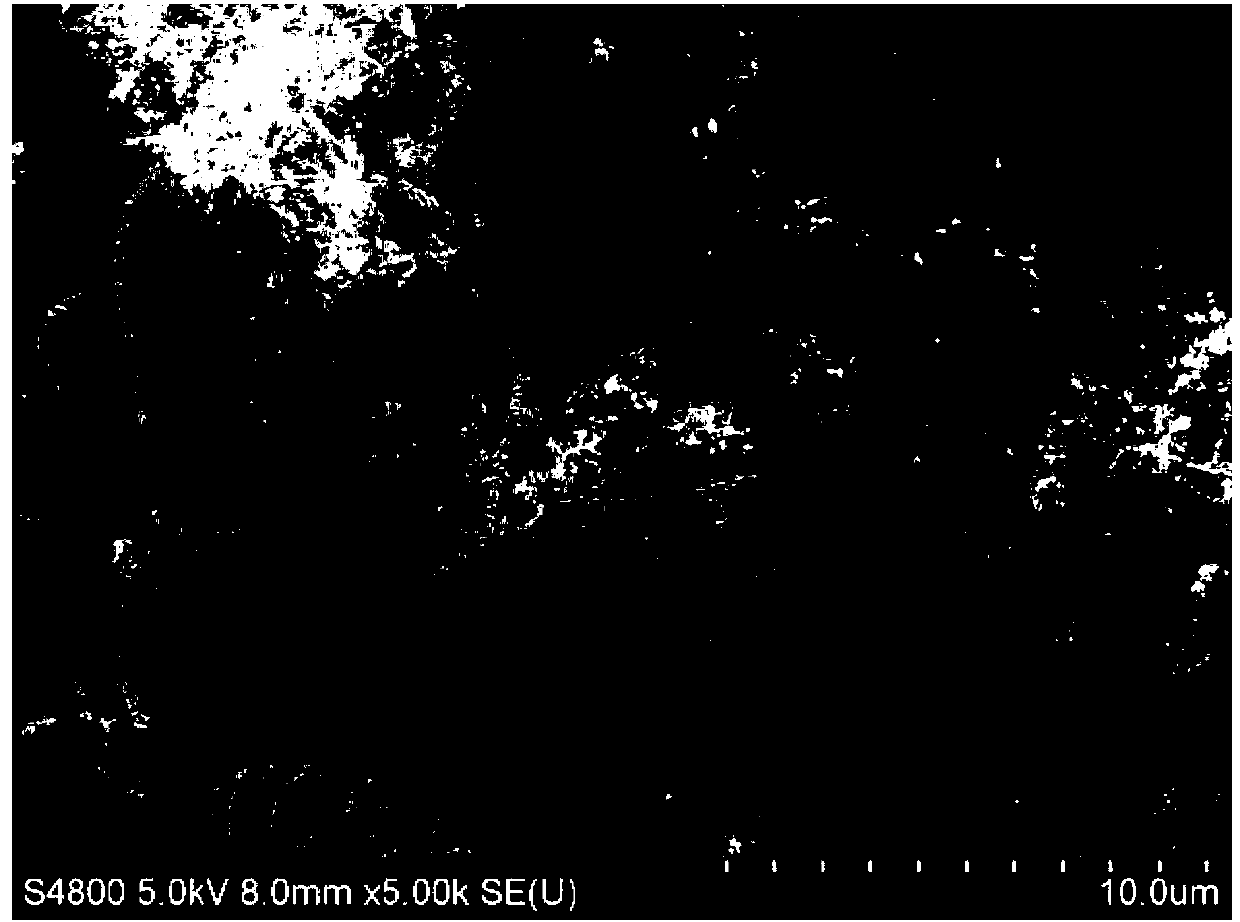

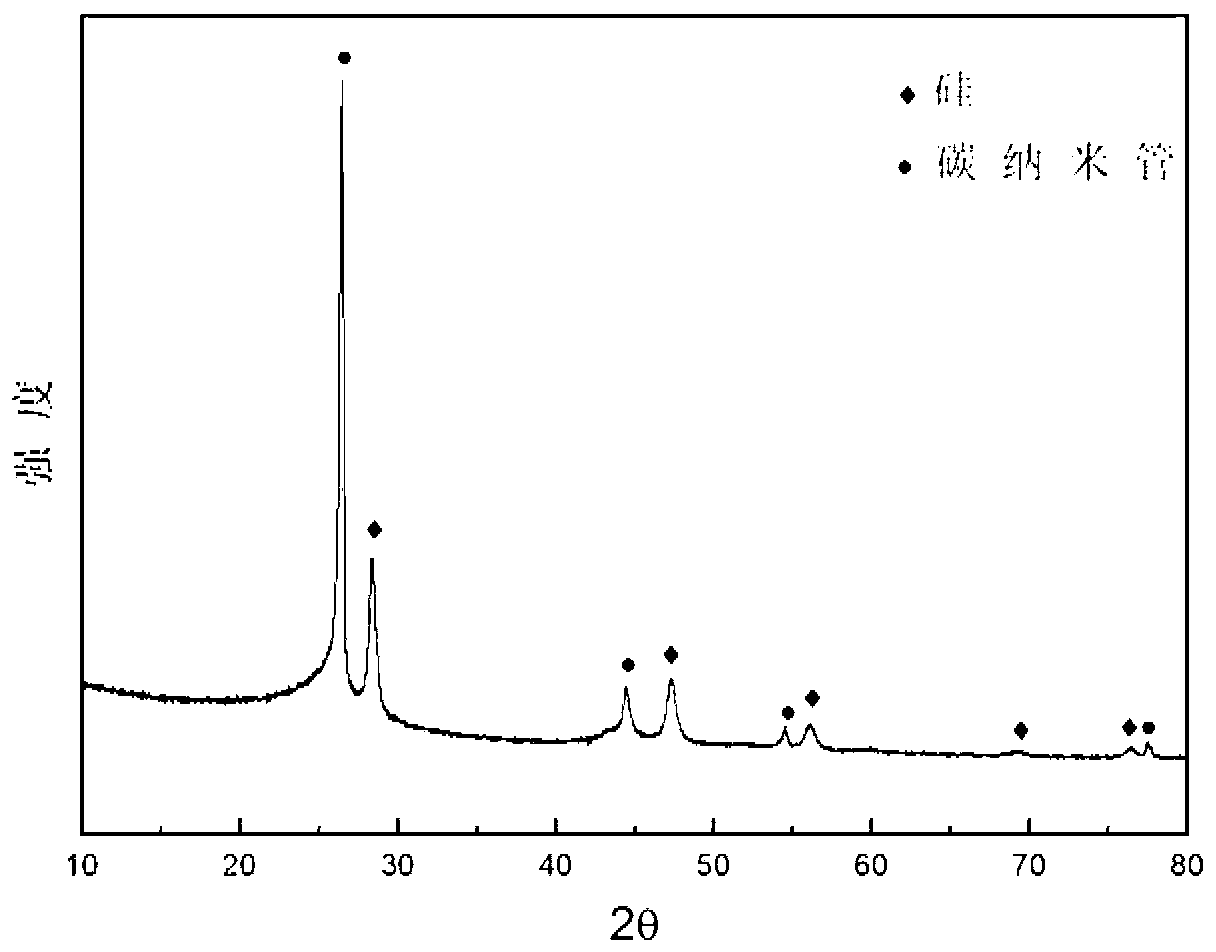

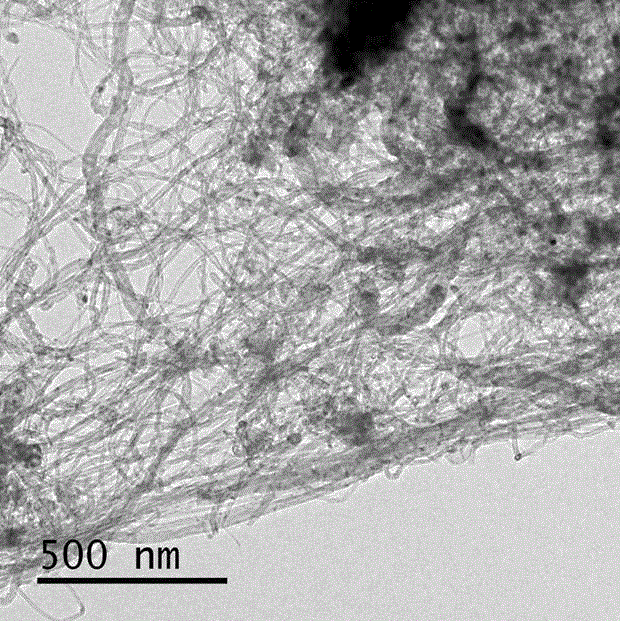

Lithium battery silicon-carbon nanotube composite cathode material as well as preparation method and application thereof

InactiveCN103346302ASolution volumeSolve efficiency problemsMaterial nanotechnologyCell electrodesCarbon nanotubeSlurry

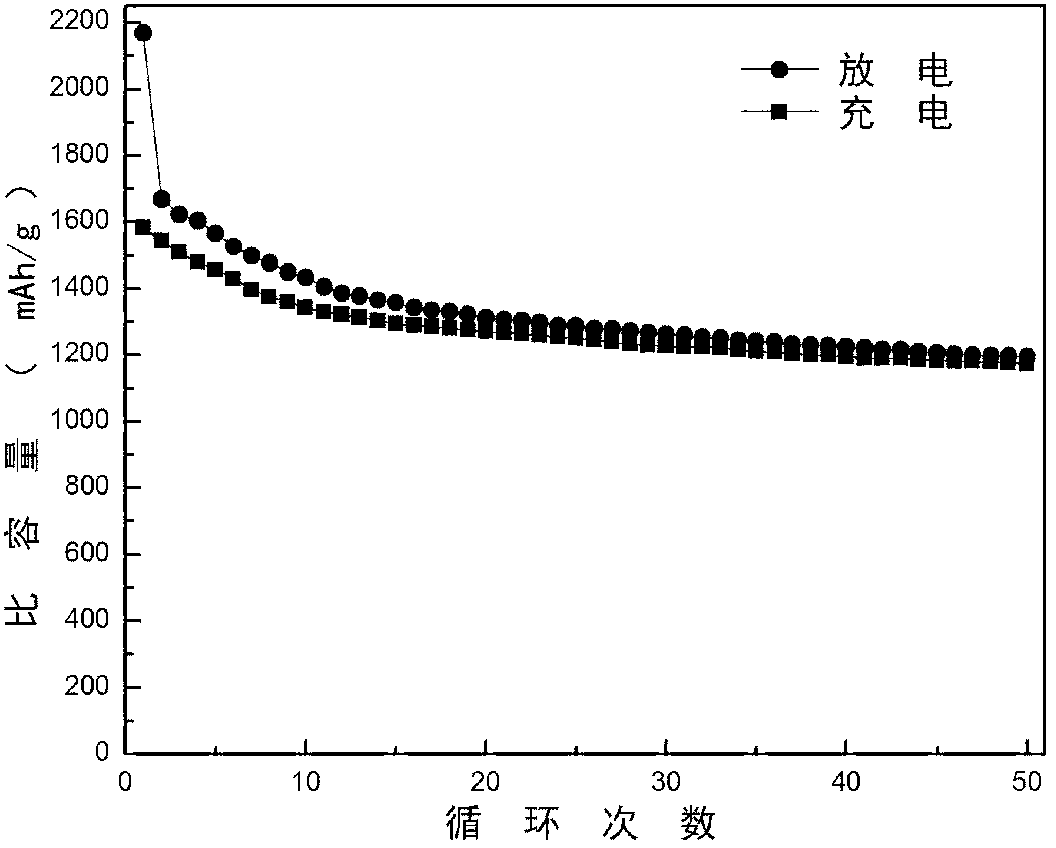

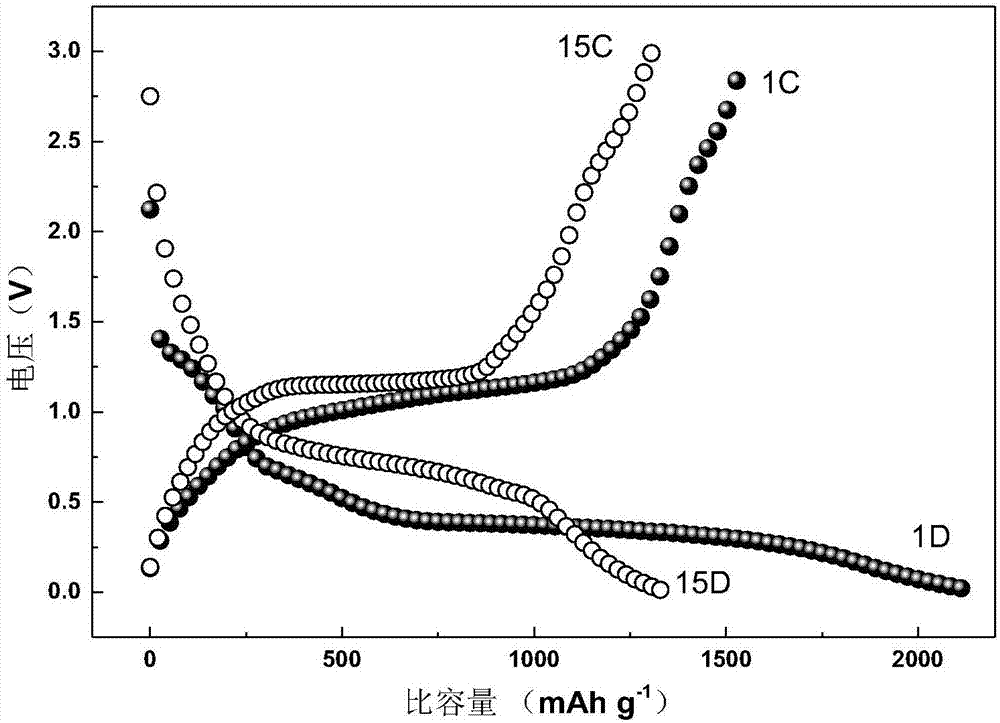

The invention discloses a lithium battery silicon-carbon nanotube composite cathode material as well as a preparation method and application of the lithium battery silicon-carbon nanotube composite cathode material. The preparation method of the lithium battery silicon-carbon nanotube composite cathode material comprises the following steps of: mixing and uniformly stirring an organic carbon source and nanometer silicon based on the mass ratio of (0.4-9): 1, adding a catalyst to obtain mixed slurry, drying by a closed circulation spray dryer to obtain a precursor, insulating the precursor for 1-5 hours at the temperature of 300-700 DEG C to obtain a sample, feeding the sample in a tube furnace, increasing the temperature to 500-900 DEG C under the mixed gas of gaseous organic carbon source and N2 and Ar2, and naturally cooling to obtain the lithium battery silicon-carbon nanotube composite cathode material. The lithium battery silicon-carbon nanotube composite cathode material has excellent electrochemical properties, high first charge-discharge efficiency up to more than 2000mAh / g, reversible specific capacity of about 1100mAh / g after cycle of 50 weeks, and good specific capacity and cycle performance, and the problems of low first efficiency, large irreversible capacity loss and poor conductivity of silicon when being used to prepare a lithium ion battery cathode are successfully solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

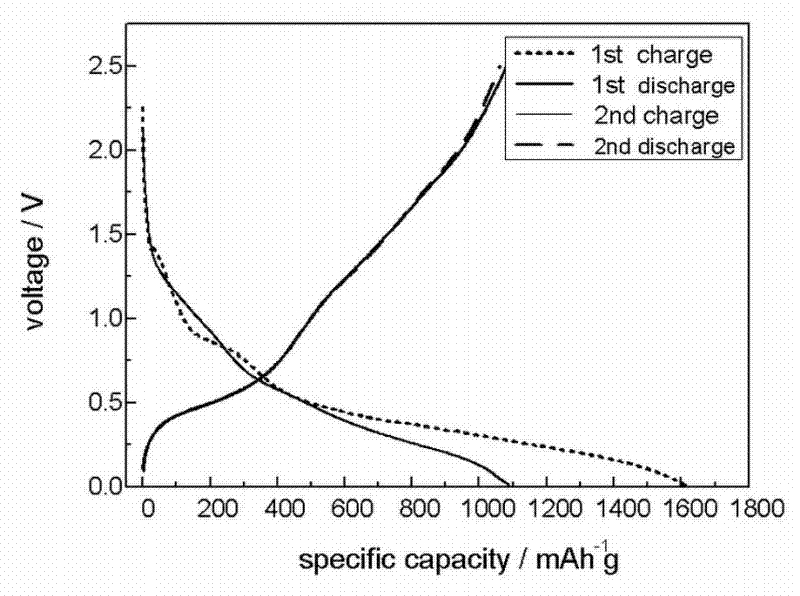

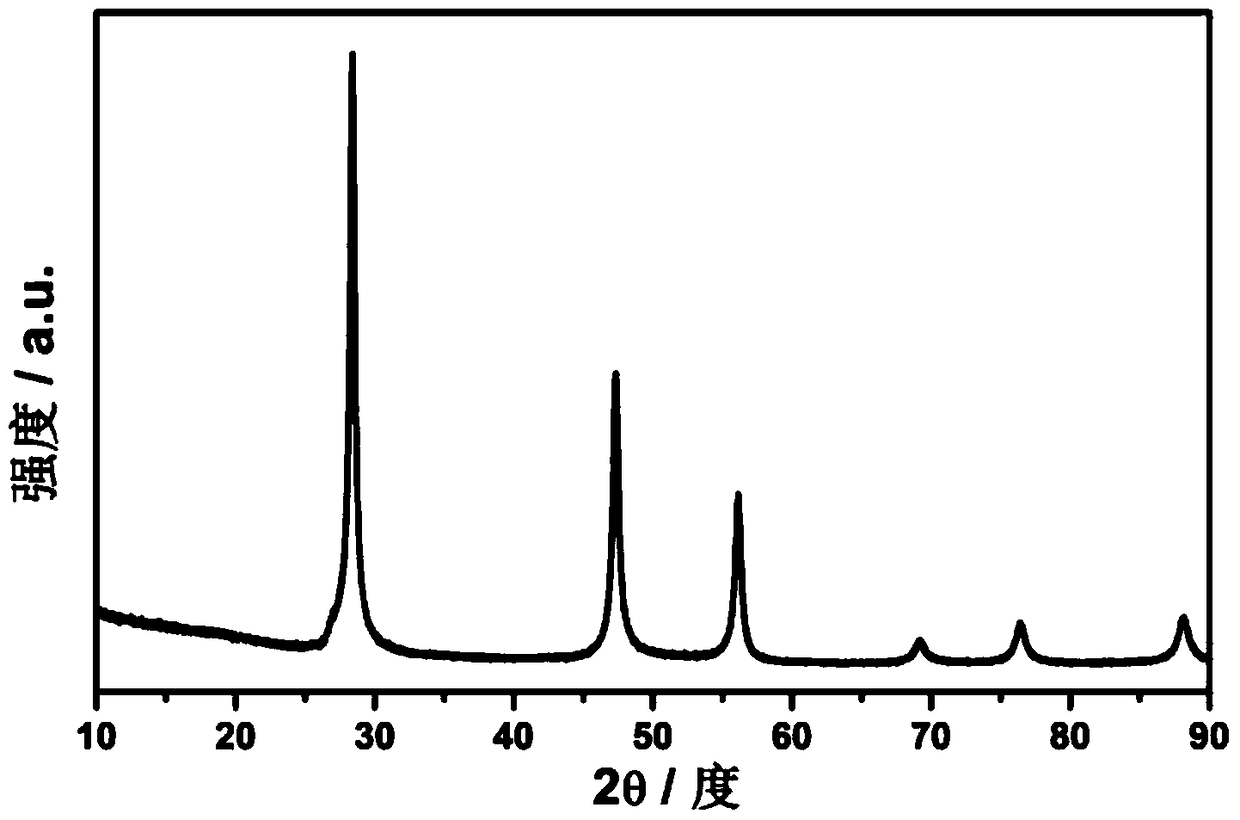

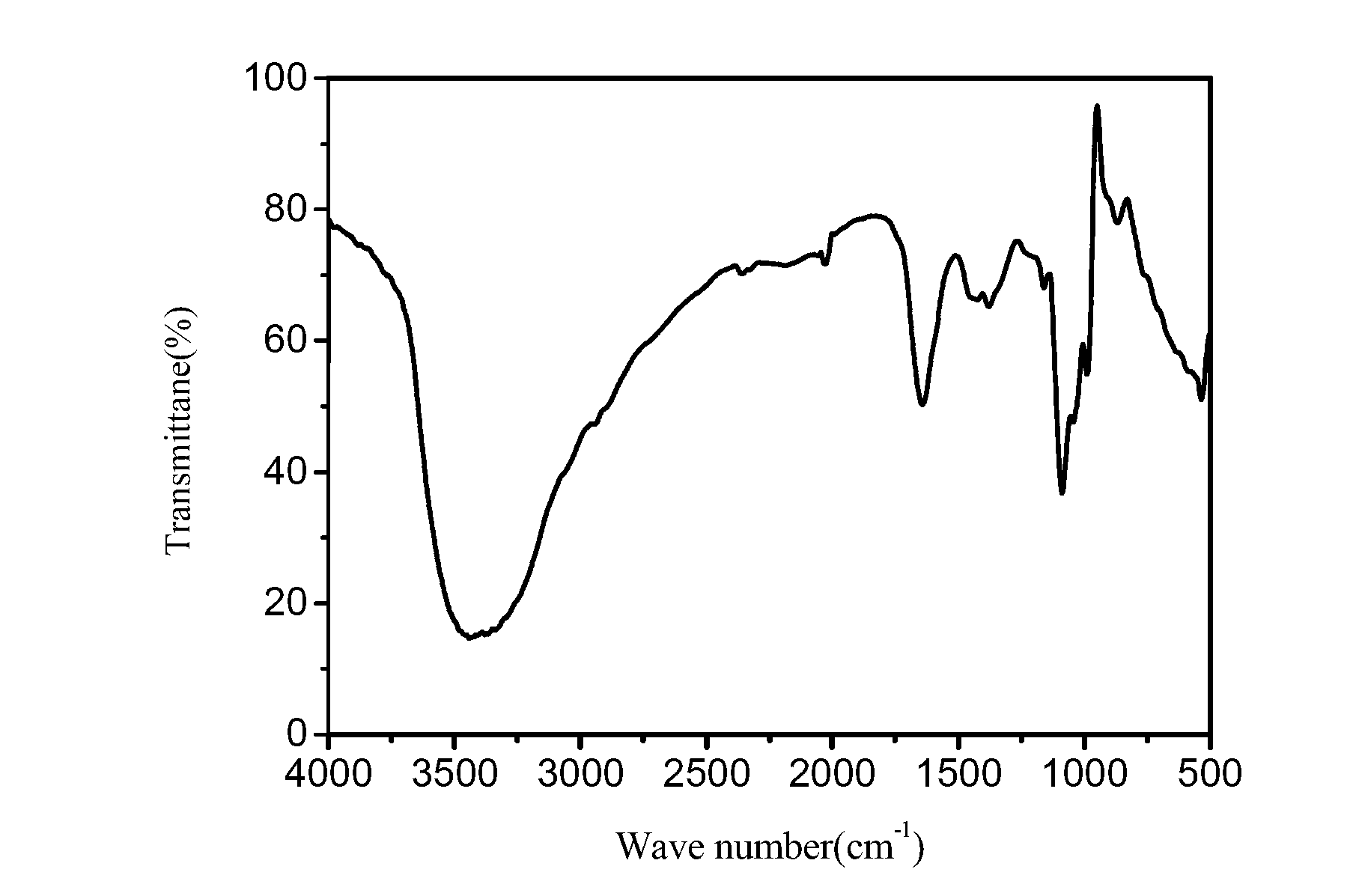

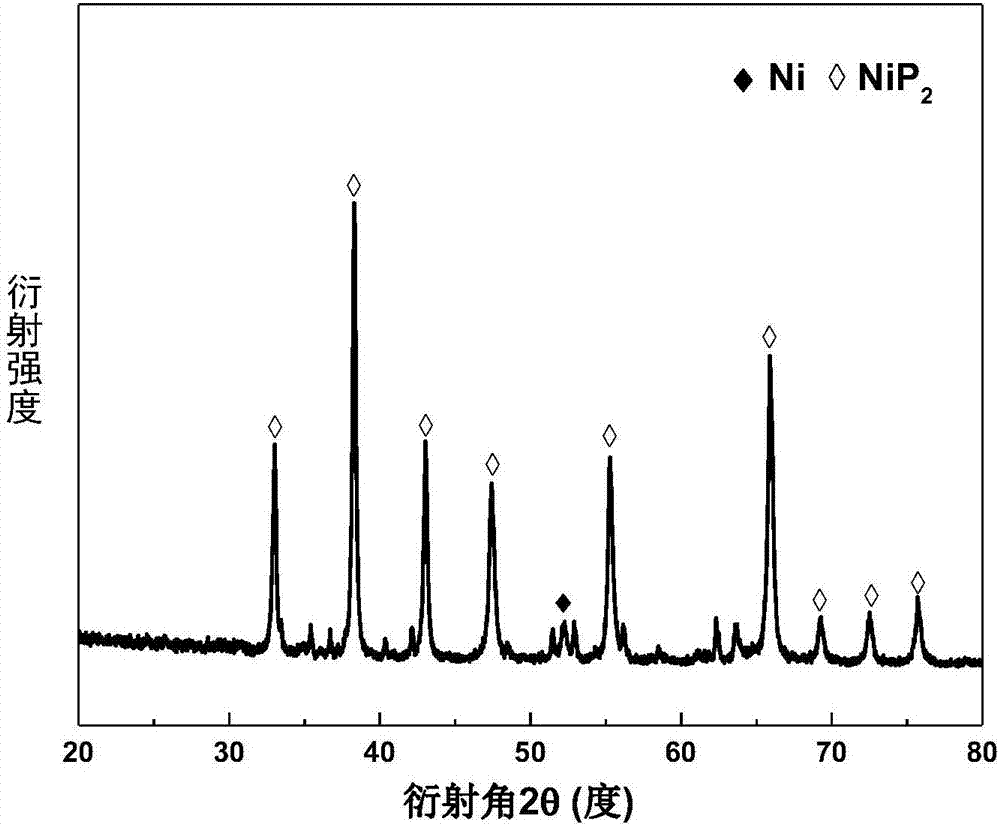

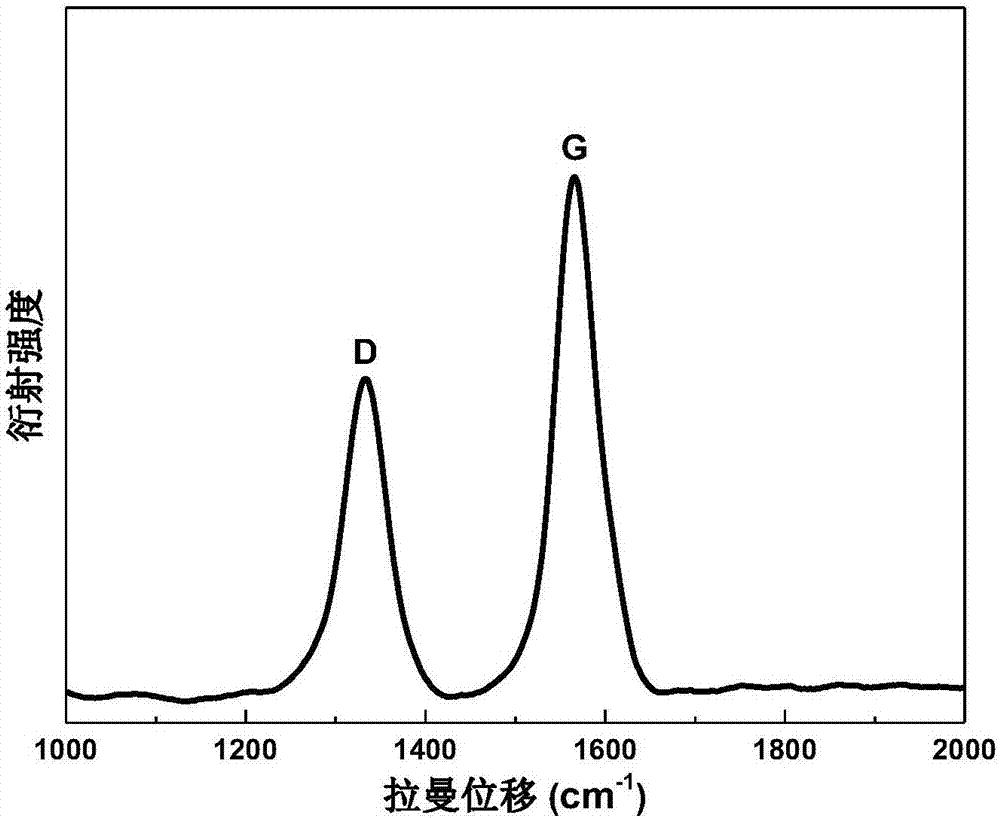

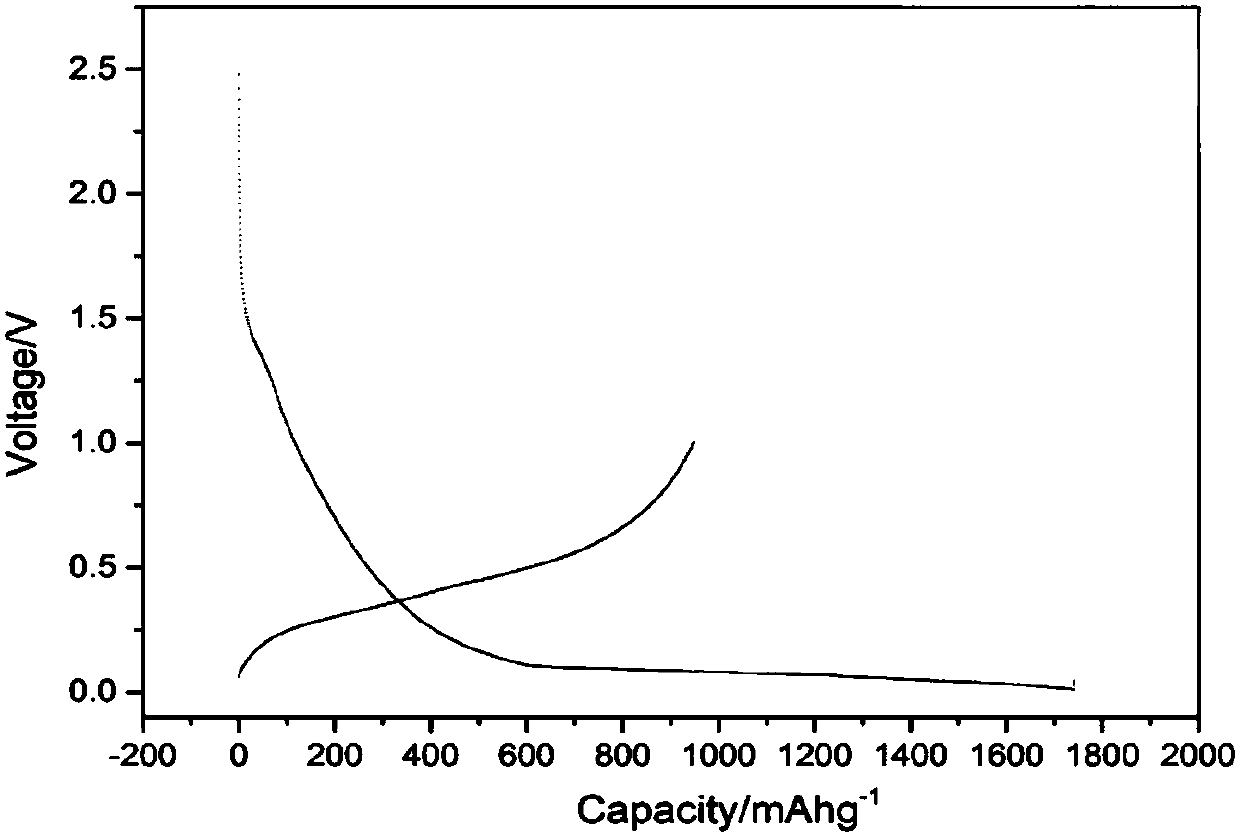

Preparation method and application of shell-core carbon-coated metal phosphide nanometer composite particle

InactiveCN107317008ALow costEasy to makeCell electrodesSecondary cellsAutomatic controlCarbon source

The invention provides a preparation method of a shell-core carbon-coated metal phosphide nanometer composite particle. The obtained composite particle is used as a lithium ion battery negative electrode material to be applied to the field of a lithium ion battery. The preparation method comprises the steps of adding a certain proportion of a substance containing a carbon source and inert gas into automatic control DC arc metal nanometer powder production equipment, and evaporating a metal raw material to obtain a carbon-coated metal nanometer particle precursor; mixing and placing the precursor and red phosphorus powder in a high-pressure sealing reaction kettle for thermal treatment to obtain a carbon-coated metal phosphide nanometer composite material; and fabricating a lithium ion electrode plate by taking the carbon-coated nickel phosphide nanometer composite material as an active substance. The preparation method has the advantages that the carbon-coated nickel nanometer particle synthesized in an in-situ way is used as the precursor, the carbon-coated nickel phosphide nanometer composite particle is obtained by low-temperature phosphorization, and the composite particle has relatively high intercalation / de-intercalation lithium capacity density and cycle stability, is low in raw material cost and simple in process, can be prepared on a large scale and is suitable for industrial production.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

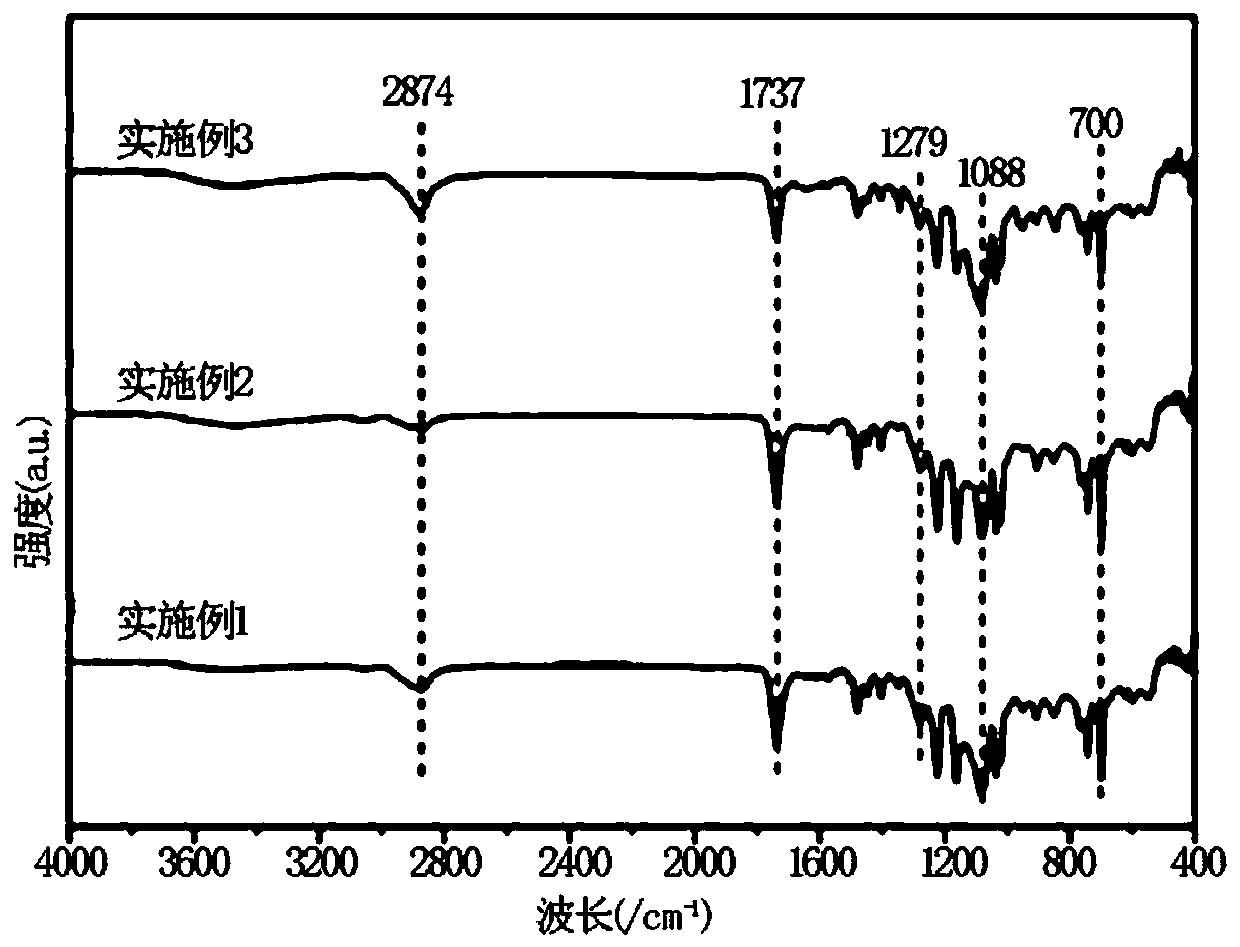

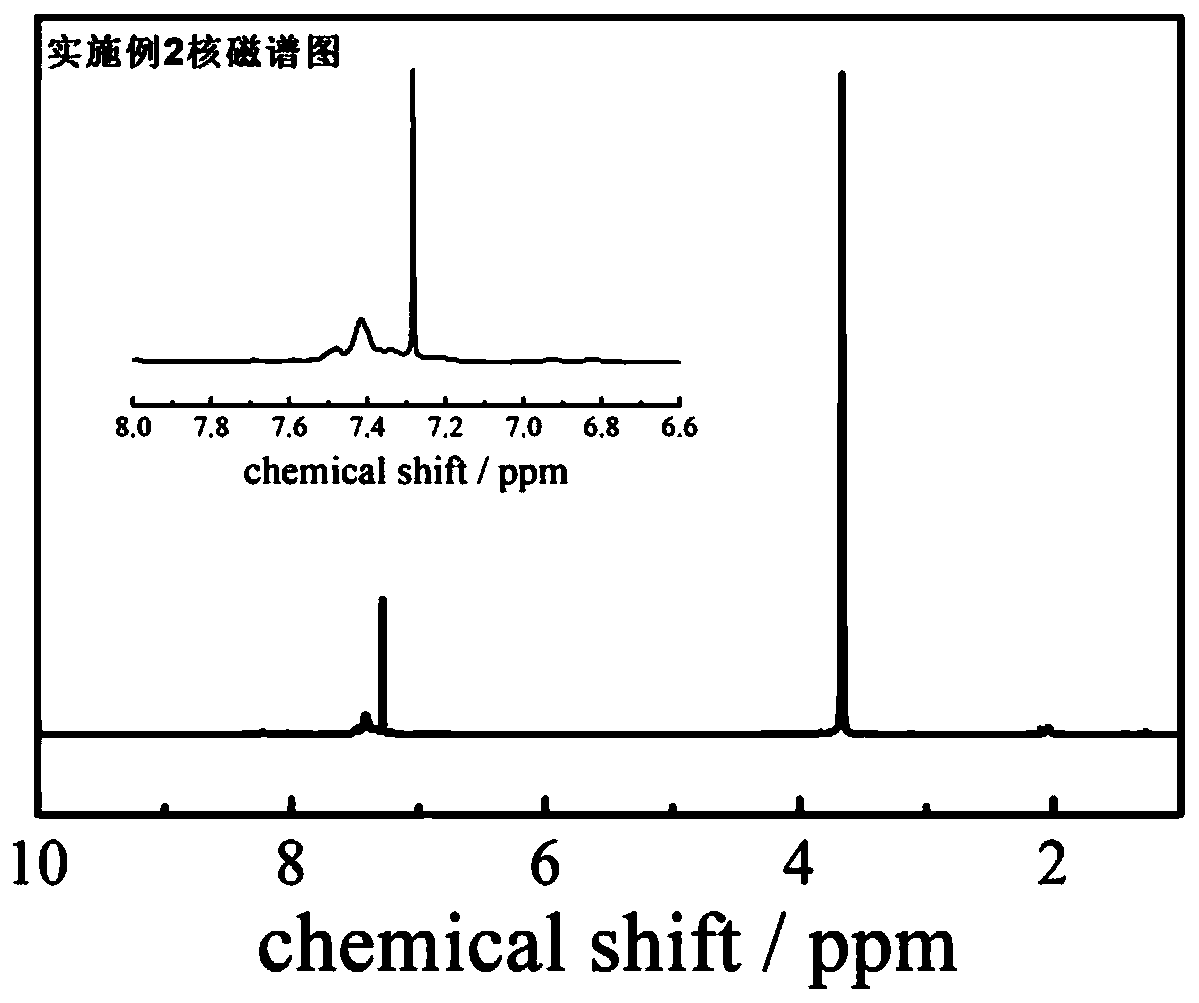

All-solid-state polymer electrolyte, preparation method thereof, and all-solid-state lithium ion battery

The invention relates to the technical field of lithium ion batteries, in particular to an all-solid-state polymer electrolyte, a preparation method thereof, and an all-solid-state lithium ion battery. The all-solid-state polymer electrolyte comprises lithium salt and a polymer, wherein the polymer is provided with a structure as shown in the general formula (I). The all-solid-state polymer electrolyte provided by the invention achieves high compatibility with the lithium salt, excellent film-forming performance, a Young modulus of 3.9GPa, and a breaking strength of 140MPa, and can effectivelyinhibit the growth of cathode lithium dendrites and pulverization; the ionic conductivity at the room temperature is (0.1-3) x 10<-5>S / cm; and when the all-solid-state polymer electrolyte is used asan electrolyte for the all-solid-state lithium ion battery, the possible safety problems of a liquid-state electrolyte can be avoided, so that the safety performance of the lithium ion battery can begreatly improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Light alkane dehydrogenation catalyst with good hydrothermal stability and preparation method thereof

InactiveCN104128175AImproves hydration resistanceAvoid chalkingHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention relates to a light alkane dehydrogenation catalyst with good hydrothermal stability and a preparation method thereof. The catalyst comprises the following components, by weight, 5-40% of Cr2O3, 30-85% of Al2O3, 0.1-30% of MO and 0.5-5% of Me2O, wherein M is Mg, Zn or a mixture of Mg and Zn; and Me is one of alkalis or a mixture of more than two of alkalis. The light alkane dehydrogenation catalyst has advantages of good hydrothermal stability, high activity and high selectivity, and is used in a dehydrogenation reaction of C3-C5 alkane.

Owner:YANTAI UNIV

Negative electrode composite material of lithium ion battery and preparation method thereof

ActiveCN107623116ANovel structureControl volume expansionSecondary cellsNegative electrodesNano siliconSilicon monoxide

The invention relates to a negative electrode composite material of a lithium ion battery. The material comprises a core body, an intermediate layer that is coated outside the core body and has pores,and an outer layer coated outside the intermediate layer, wherein the core body is nano silicon, the intermediate layer is silicon monoxide compounded with graphite, and the outer layer is amorphouscarbon. According to the scheme of the invention, a negative electrode composite material with a novel structure is obtained through the improvement of a preparation method, the negative electrode composite material can control the volume expansion of silicon in a certain space, effectively prevent silicon electrodes from being pulverized, and improve the cycling stability, and can be used as a negative electrode material of a high-capacity lithium battery. The preparation method has a simple process and is suitable for industrial production.

Owner:SUZHOU GINET NEW MATERIAL TECH CO LTD

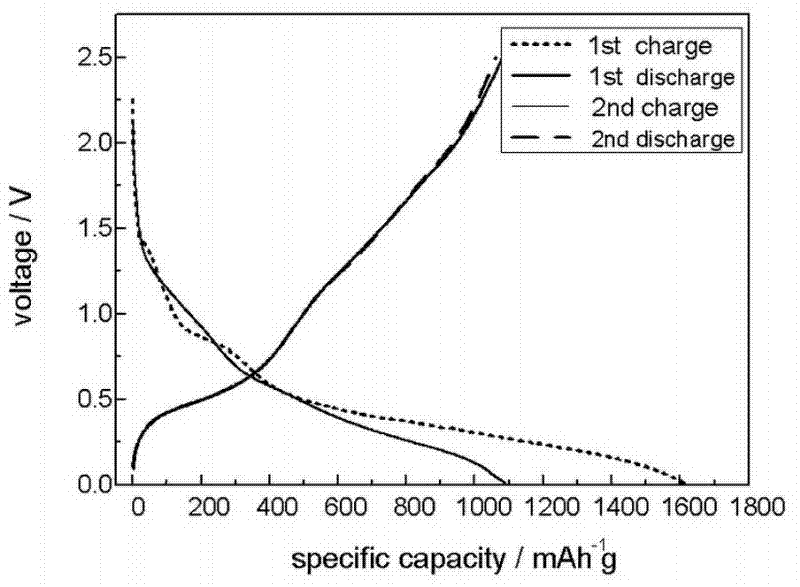

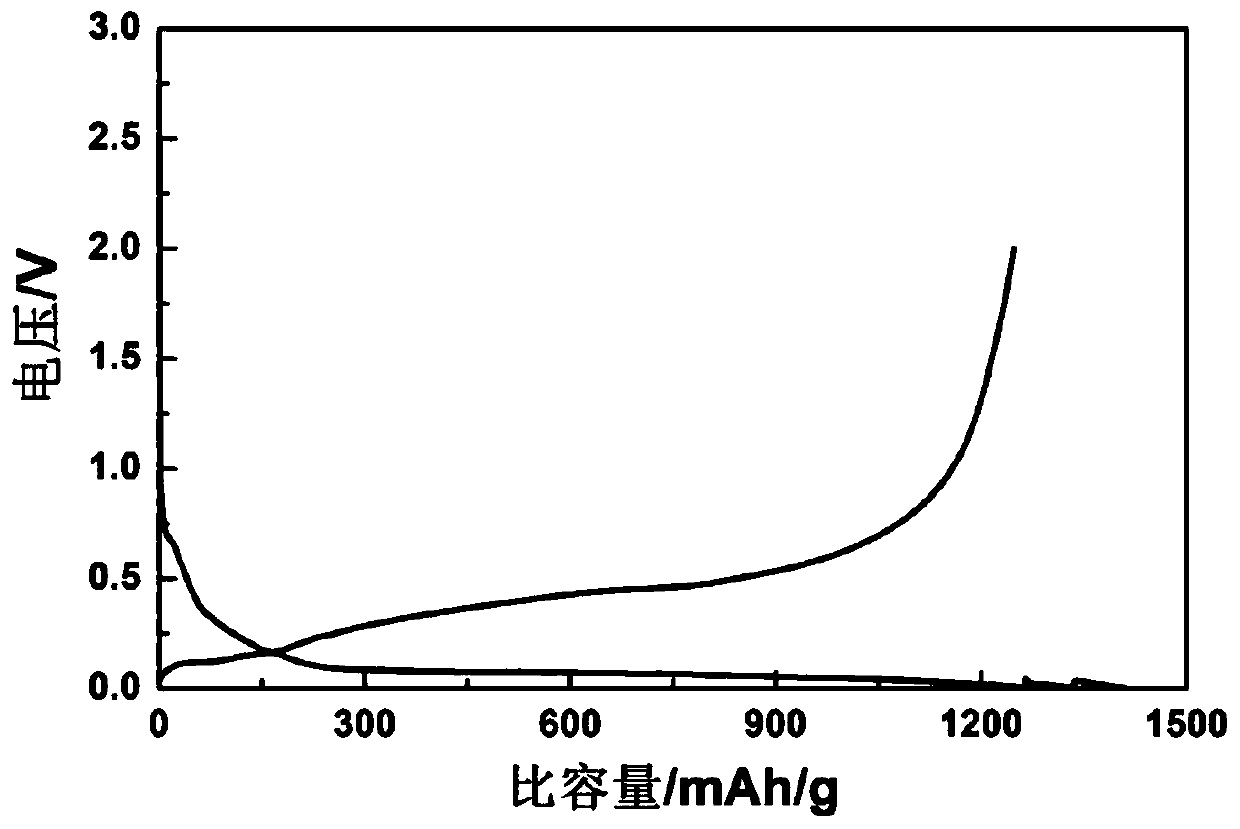

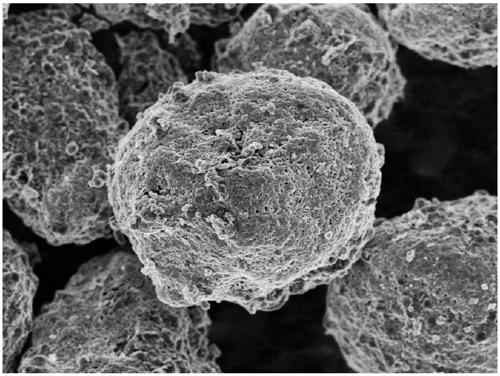

Phosphorus-carbon composite material and preparation method and application thereof

ActiveCN105702939AIncrease contactAvoid chalkingCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention provides a phosphorous-carbon composite material and a preparation method and application thereof. The phosphorus-carbon composite material is prepared from red phosphorus, a carbon material and an additive through simple and high-efficiency mass production at a large scale and is of a porous spherical structure, wherein the red phosphorous is uniformly dispersed in the spherical phosphorous-carbon composite material in a form of nanometer phosphorous. The phosphorous-carbon composite material has the advantages of high first-circle coulombic efficiency, high cycle stability and the like when used for a sodium ion battery. The preparation method of the phosphorous-carbon composite material is simple, is cheap and available in raw materials, is easy for commercial production, and has very wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

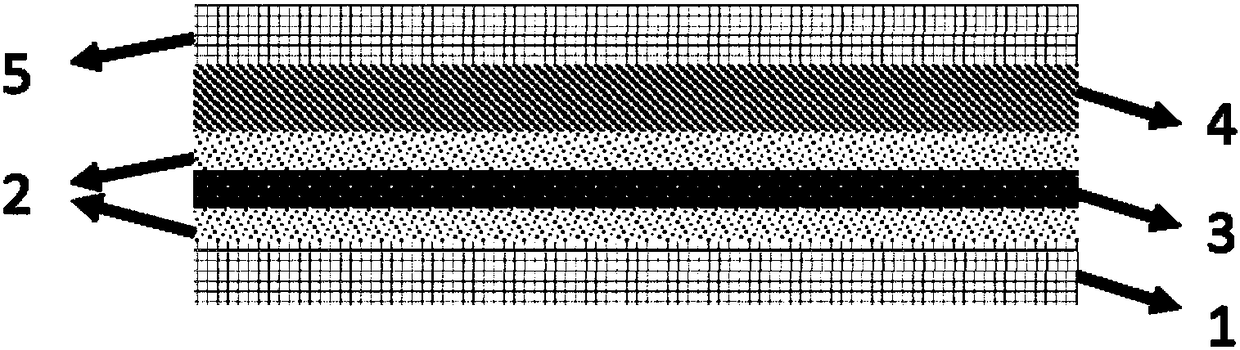

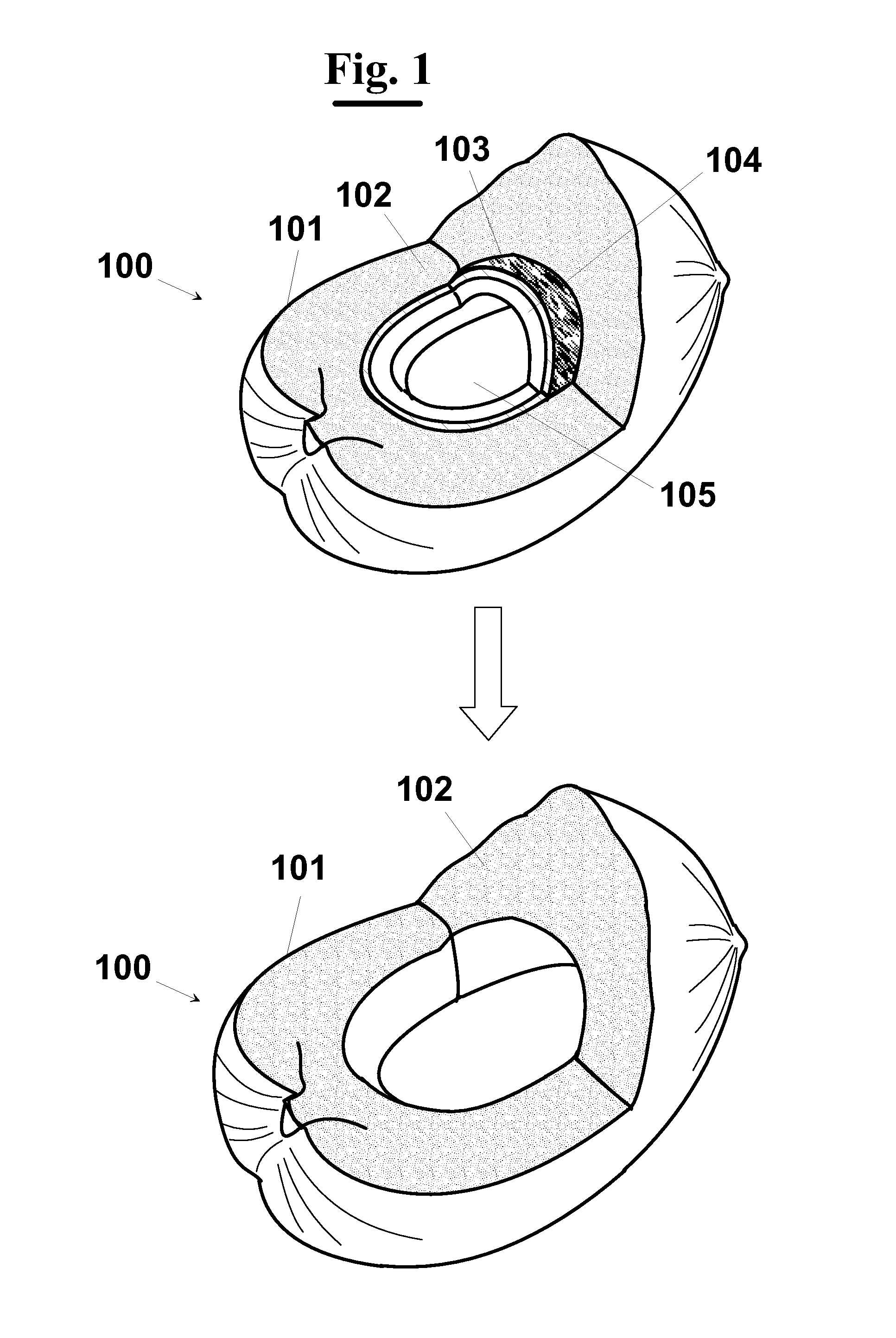

Safe lithium ion battery with good cyclic performance

InactiveCN103606699AAvoid chalkingAvoid crackingElectrode carriers/collectorsSecondary cellsFiberComposite film

The invention discloses a safe lithium ion battery with a good cyclic performance. The safe lithium ion battery comprises a positive pole piece, a negative pole piece, and a diaphragm and electrolyte arranged between the positive pole piece and the negative pole piece; polymer carrier coatings are coated on the surfaces of the positive pole piece and the negative pole piece; a negative pole is made of a carbon and tin nano fiber composite thin film material. According to the safe lithium ion battery with good cyclic performance, the pulverization, the cracking and the reunion of pole materials are inhibited greatly so that the cyclic performance of pole materials can be improved and the stability of the poles can be kept; the negative pole material with good reversible specific capacity and cyclic performance is obtained; the separation is generated by the polymer carrier coatings so as to prevent a positive pole and the negative pole from being contacted to cause short circuit.

Owner:JIANGSU TENPOWER LITHIUM

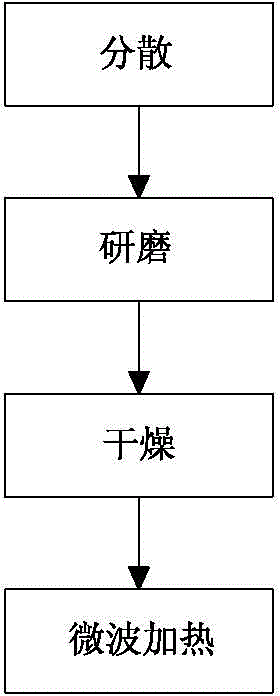

Method for preparing composite cathode material of silicon-carbon nanotube of lithium ion battery

ActiveCN104617261AAlleviate the volume expansion effectImprove conductivityNegative electrodesNanotechnologyDischarge efficiencyCarbon nanotube

The invention discloses a method for preparing a composite cathode material of a silicon-carbon nanotube of a lithium ion battery. According to the method, firstly, the surface of nano silicon is coated with a carbon source, carbon nanotubes are generated in microwave treatment, and furthermore the surface of silicon is also coated with an introduced catalyst, so that the carbon nanotubes which are coated with the carbon source and are generated through catalytic cracking are very uniformly distributed on the surface of nano silicon, the problems that in the prior art the nano silicon is high in volume expansion effect, low in first charge / discharge efficiency and poor in circulation stability are solved, and both the conductivity and the mechanical property of the composite cathode material prepared by using the method disclosed by the invention are greatly improved and the circulation property, the multiplying power charge and discharge performance and the initial charge-discharge efficiency of the composite cathode material as a lithium lion battery cathode material are all greatly improved when being compared with those of a silicon-carbon nanotube cathode material which is mixed in a mechanical ball-milling manner as silicon and carbon nanotubes are compounded in an in-situ manner in the method disclosed by the invention. In addition, the method disclosed by the invention is simple in process, and the energy consumption is greatly reduced due to the adoption of a simple and efficient microwave chemical method.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Nano-silver wallpaper primer and preparation method thereof

InactiveCN102757672AImprove antibacterial propertiesImprove permeabilityAntifouling/underwater paintsPaints with biocidesAdjuvantAdhesive

The invention belongs to the field of wallpaper accessories and particularly relates to a nano-silver wallpaper primer which is prepared by mixing the following raw materials in part by weight: 350 to 415 parts of deionized water, 10 to 15 parts of ethylene glycol, 0.5 to 1 part of nano-silver, 0.5 to 1 part of pH control agent, 100 to 200 parts of transparent adhesive, 250 to 350 parts of odorless latex, 8 to 10 parts of film-forming adjuvant, and 6 to 8 parts of alkali-swelling thickener. The nano-silver wallpaper primer product can inhibit the growth of bacteria on the surface of a wall body and prevent mildew of wallpaper, increases the density of the wall surface, solves the problems of wall body chalking and water molecule lateral seepage, and keeps the pH of the wall body balanced to ensure that the pH value of the wall surface trends to be neutral.

Owner:杭州嘉力丰化工有限公司

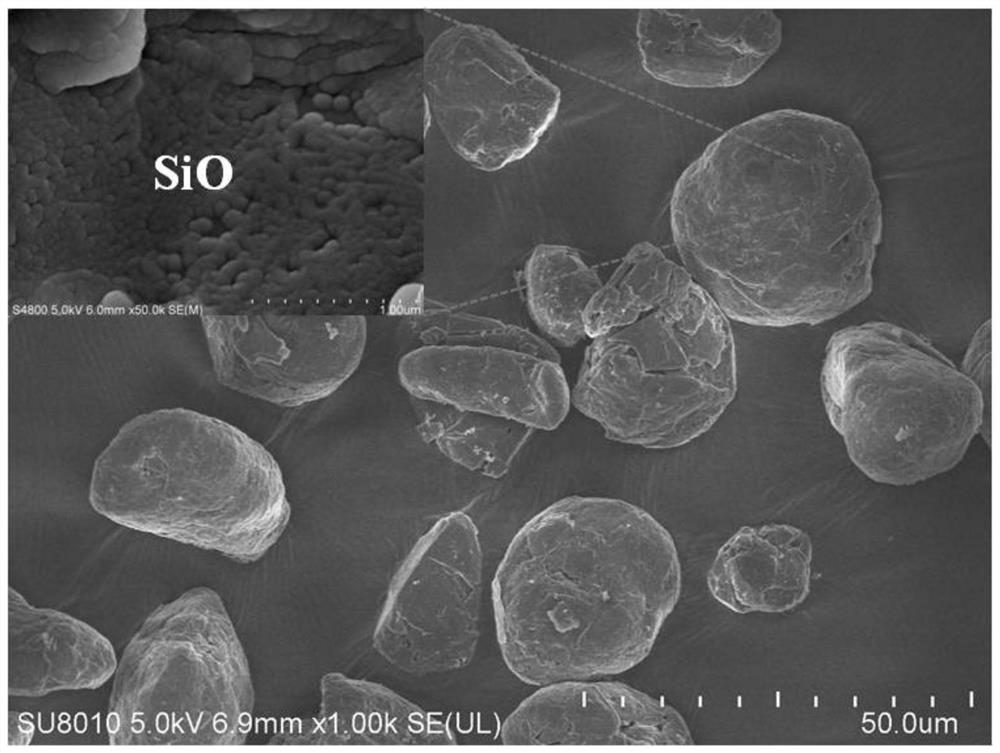

Preparation method of silicon monoxide composite negative electrode material and product thereof

ActiveCN112086630ASmall volume expansionInhibit sheddingSecondary cellsNegative electrodesCarbon coatingCarbon layer

The invention discloses a preparation method of a silicon monoxide composite negative electrode material, which comprises the following steps: by using elemental silicon and silicon dioxide as initialraw materials, carrying out a neutralization reaction to generate silicon monoxide; vaporizing silicon monoxide, introducing the vaporized silicon monoxide into a chemical vapor deposition furnace filled with a carbon material, and carrying out chemical vapor deposition to obtain a primary product; and finally, carrying out carbon coating to obtain the silicon monoxide composite negative electrode material. The prepared composite negative electrode material has a sandwich type sandwich structure, a carbon material is taken as a core, the outer surface of the carbon material is uniformly coated with silicon monoxide, and the outermost layer is coated with a uniform carbon layer. The lithium ion battery assembled by the composite negative electrode material has relatively high capacity andrelatively good cycling stability, and particularly has ultrahigh initial coulombic efficiency, and the highest initial coulombic efficiency can reach 90%.

Owner:云南锂宸新材料科技有限公司

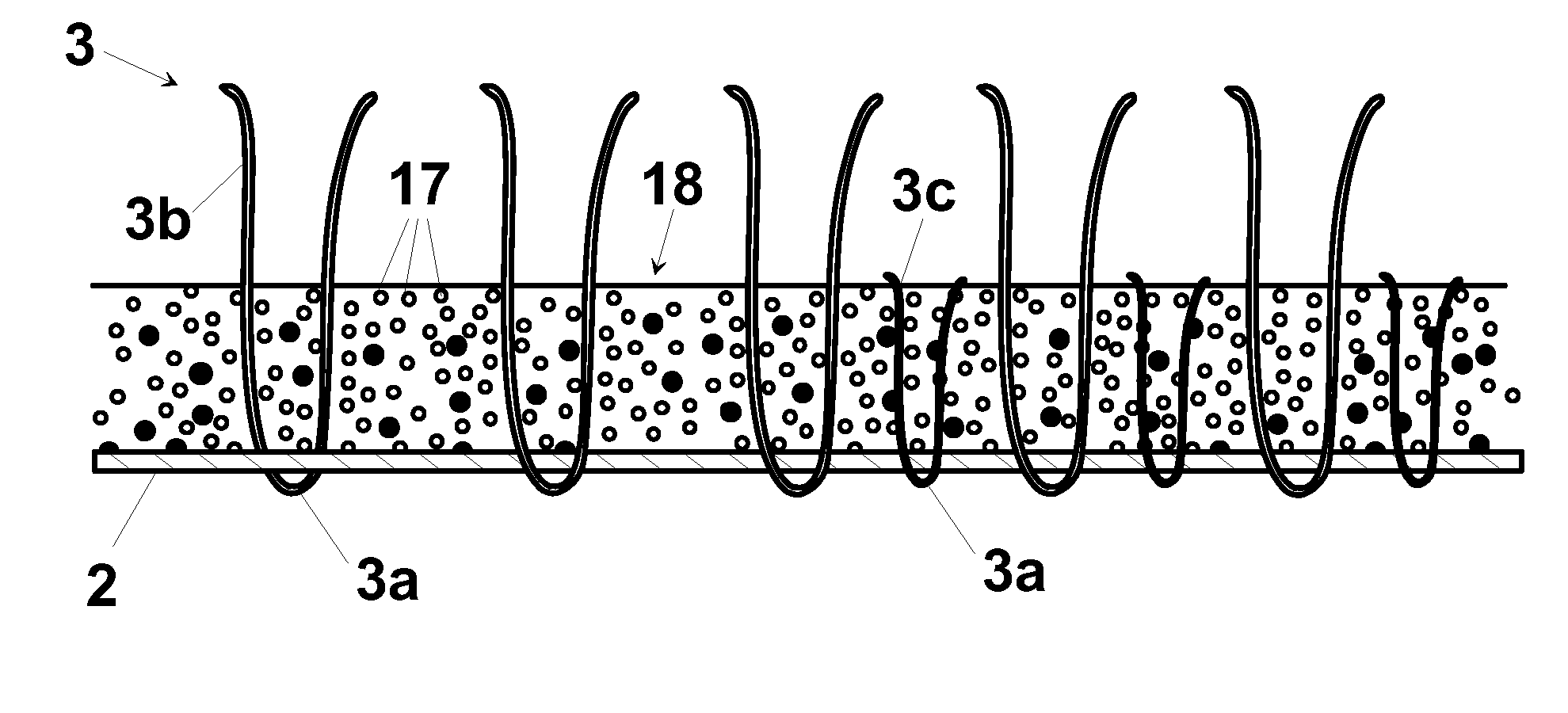

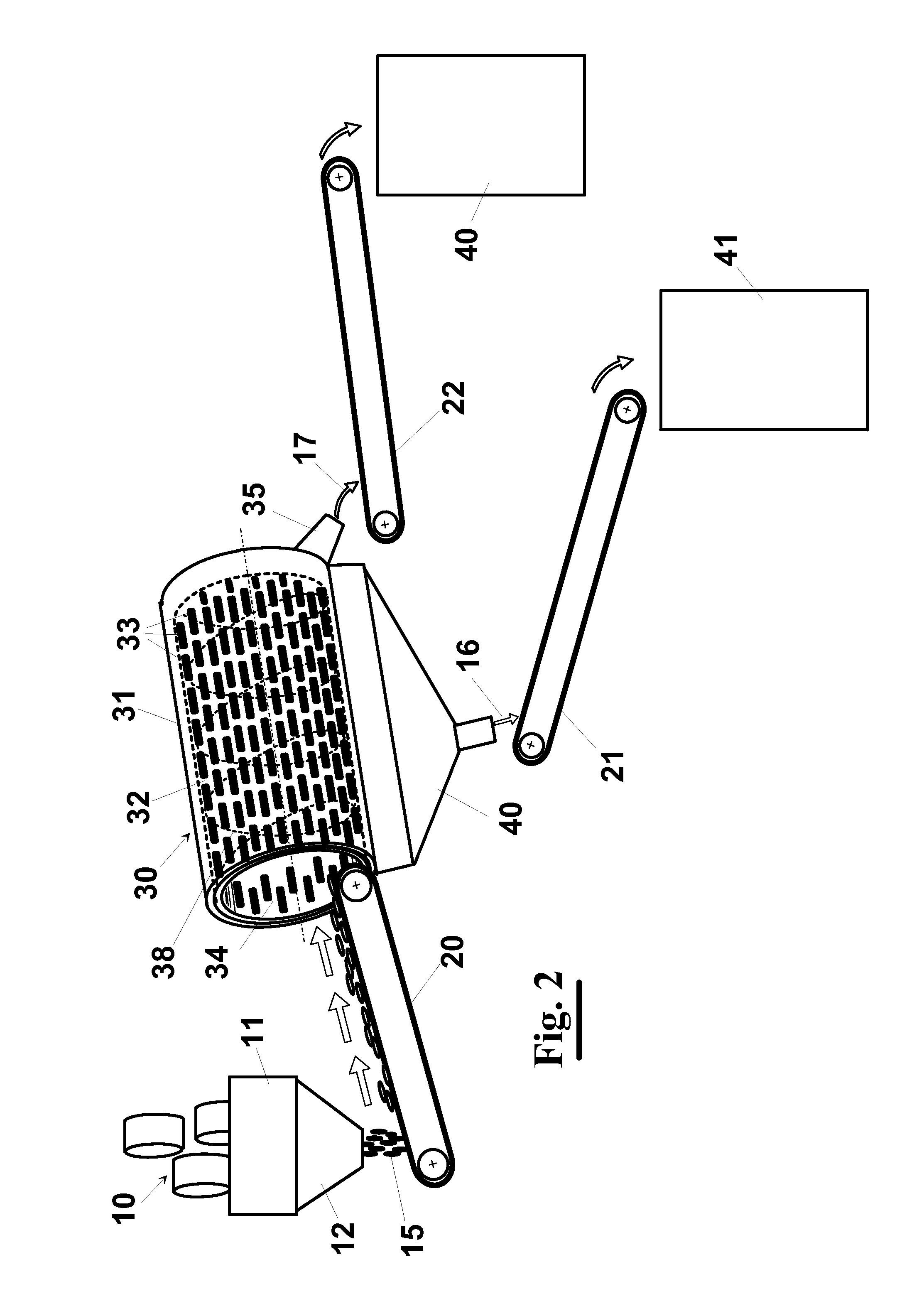

Method for producing synthetic turfs

ActiveUS20100166984A1Cheaply and easilyAvoid chalkingDead plant preservationArtificial flowers and garlandsInfillFilling materials

Method for making a synthetic turf comprising laying a turf (1) consisting of a mat (2) on which a plurality of blades (3, 3a, 3b, 3c) of synthetic material is woven. An infill material (18) is obtained using the granular and fibrous part (17) of a loose product based on ground coconut, alone or with addition of other material such as rubber in granules or sand or other loose vegetable material such as cork. The raw material based on coconut, having a heterogeneous granulometry set between about 500 micron and several mm, is obtained loading a loose product based on ground coconut by a hopper on a conveyor belt for being fed in a sieve, for example a rotating screen that separates the powder part from the granular and fibrous part. In particular, the powder part of the raw material, is gathered on a conveyor belt and from here sent to a storage reservoir. The granular and fibrous part of the raw material, which represents the main product of the process, is, instead, sent by a conveyor belt to a storage, reservoir from where it is taken for the process to provide infill material for a synthetic turf.

Owner:LIMONTA SPORT SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com