Method for preparing nano tin/carbon composite nanofibers through electrospinning technology

An electrospinning technology and nanofiber technology are applied in the field of preparation of negative electrode materials for sodium ion batteries, which can solve the problems of unreported, high price, uneven distribution, etc., so as to alleviate volume changes and facilitate reversible de-intercalation. , the effect of easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

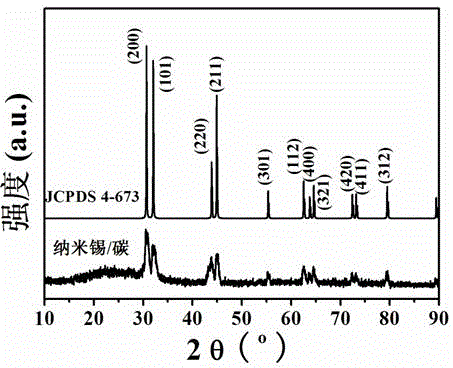

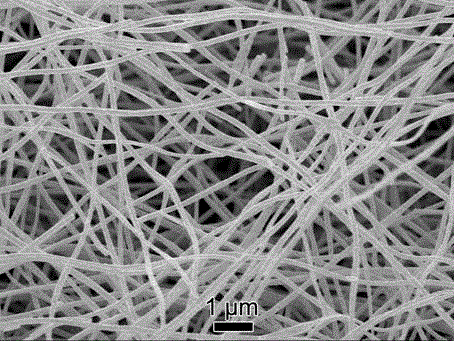

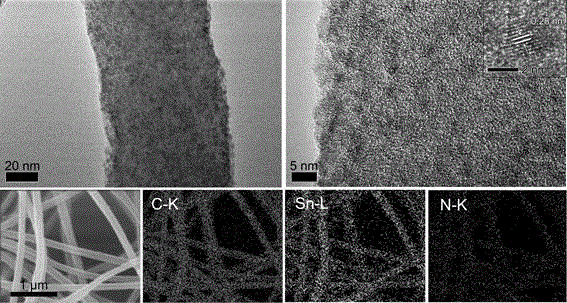

[0025] A method for preparing nano-tin / carbon composite nanofibers by electrospinning technology, the steps are as follows:

[0026] 1) Add 0.6 g of polyacrylonitrile (PAN) and 0.4 g of polymethyl methacrylate (PMMA) into 12 mL of N,N-dimethylformamide (DMF), stir at 80°C for 24 h to obtain a solution ;

[0027] 2) 1.33 g stannous chloride (SnCl 2 ) was dissolved in the above solution, and stirred at 60°C for 12 h to obtain a mixed solution;

[0028] 3) Transfer the above mixture to a syringe, with 10 μL min -1 The propulsion speed is injected to the receiving copper foil, the distance between the injector and the receiving copper foil is 18cm, and a high-voltage electrostatic field of 15 kV is applied between the injector and the receiving copper foil, the spinning time is 12 hours, and the electrospun film is collected The thickness is about 40 μm;

[0029] 4) The electrospun film collected above was calcined at 250 °C for 5 h in a nitrogen atmosphere to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com