Patents

Literature

886results about How to "High repetition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

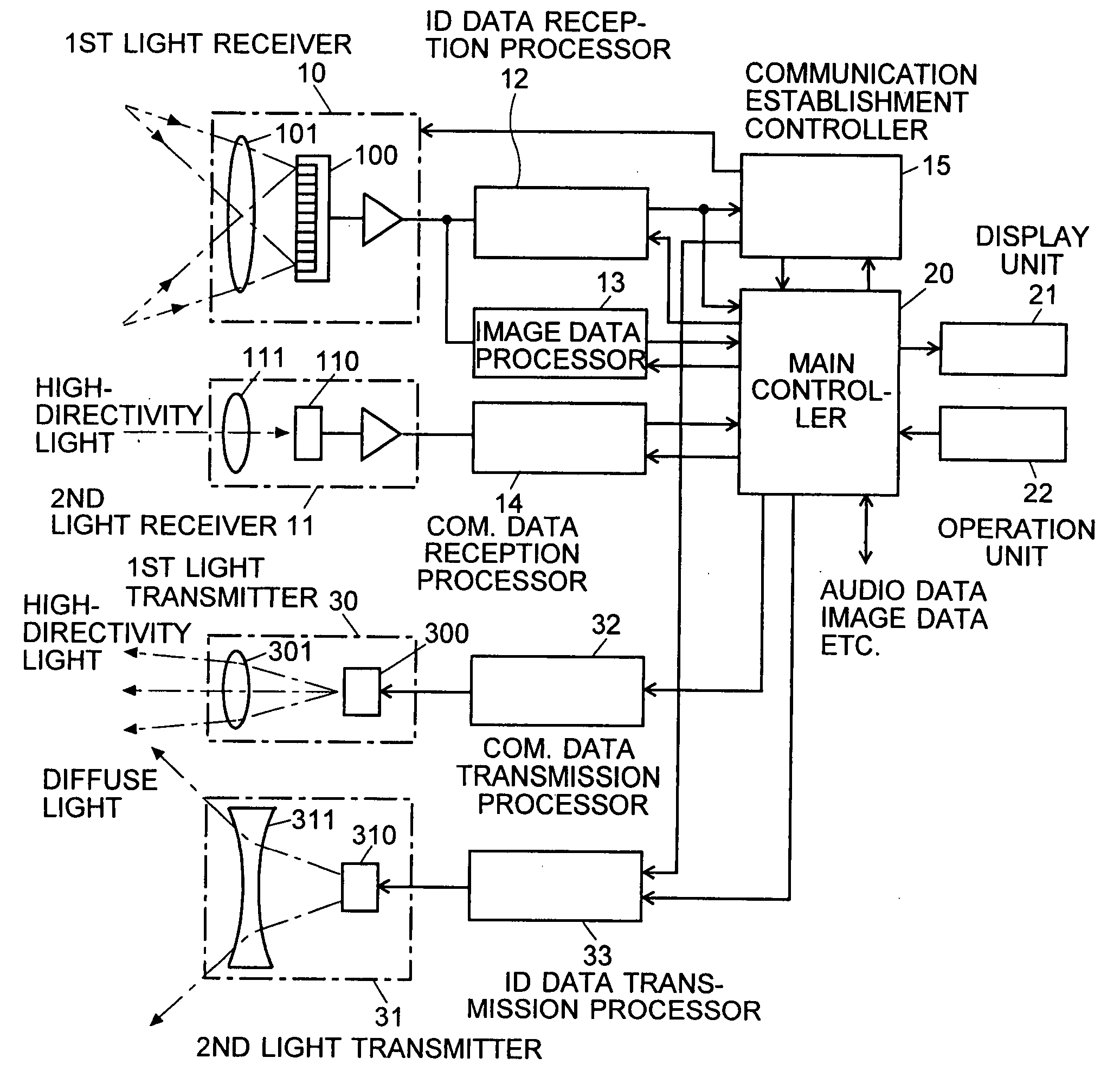

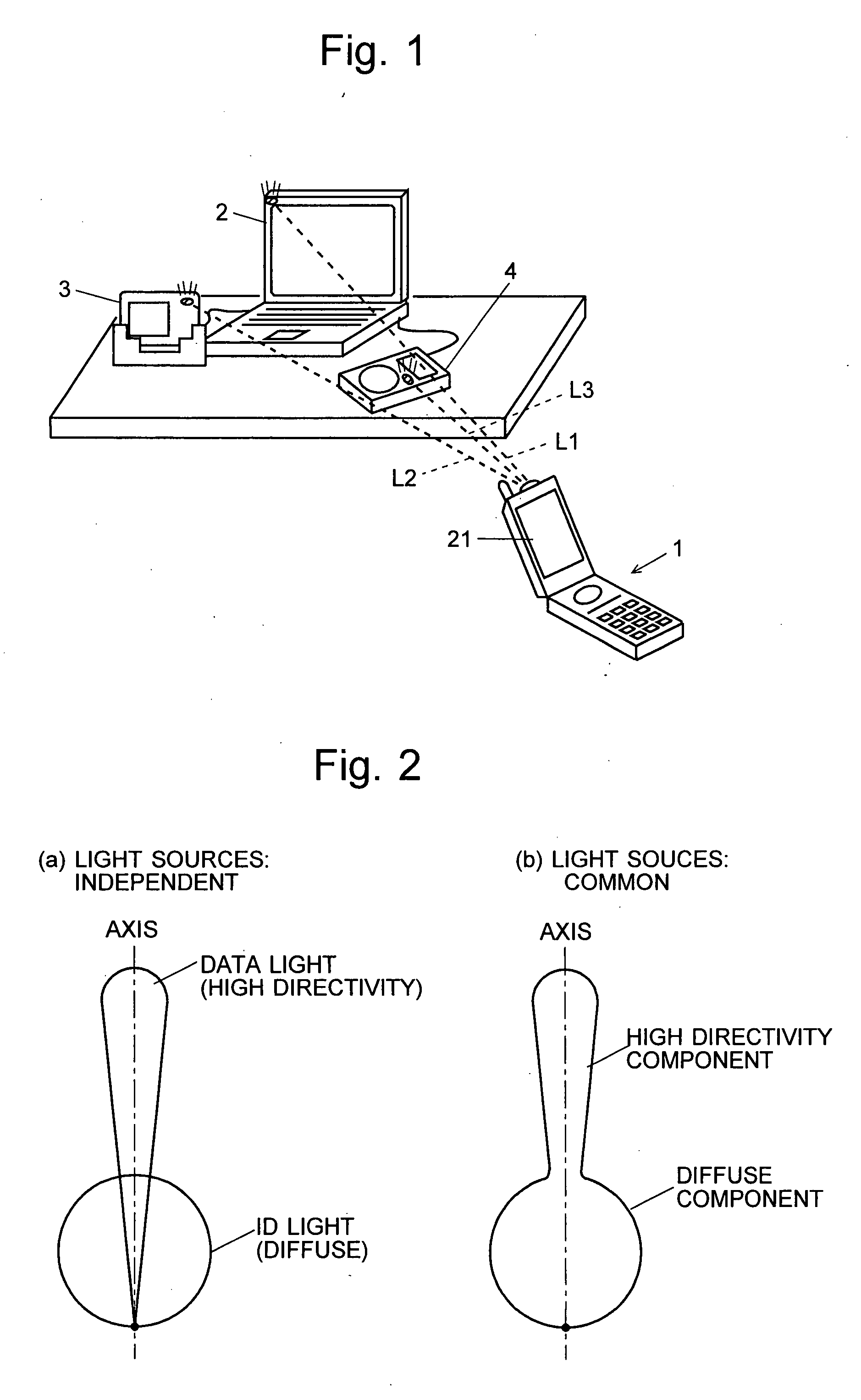

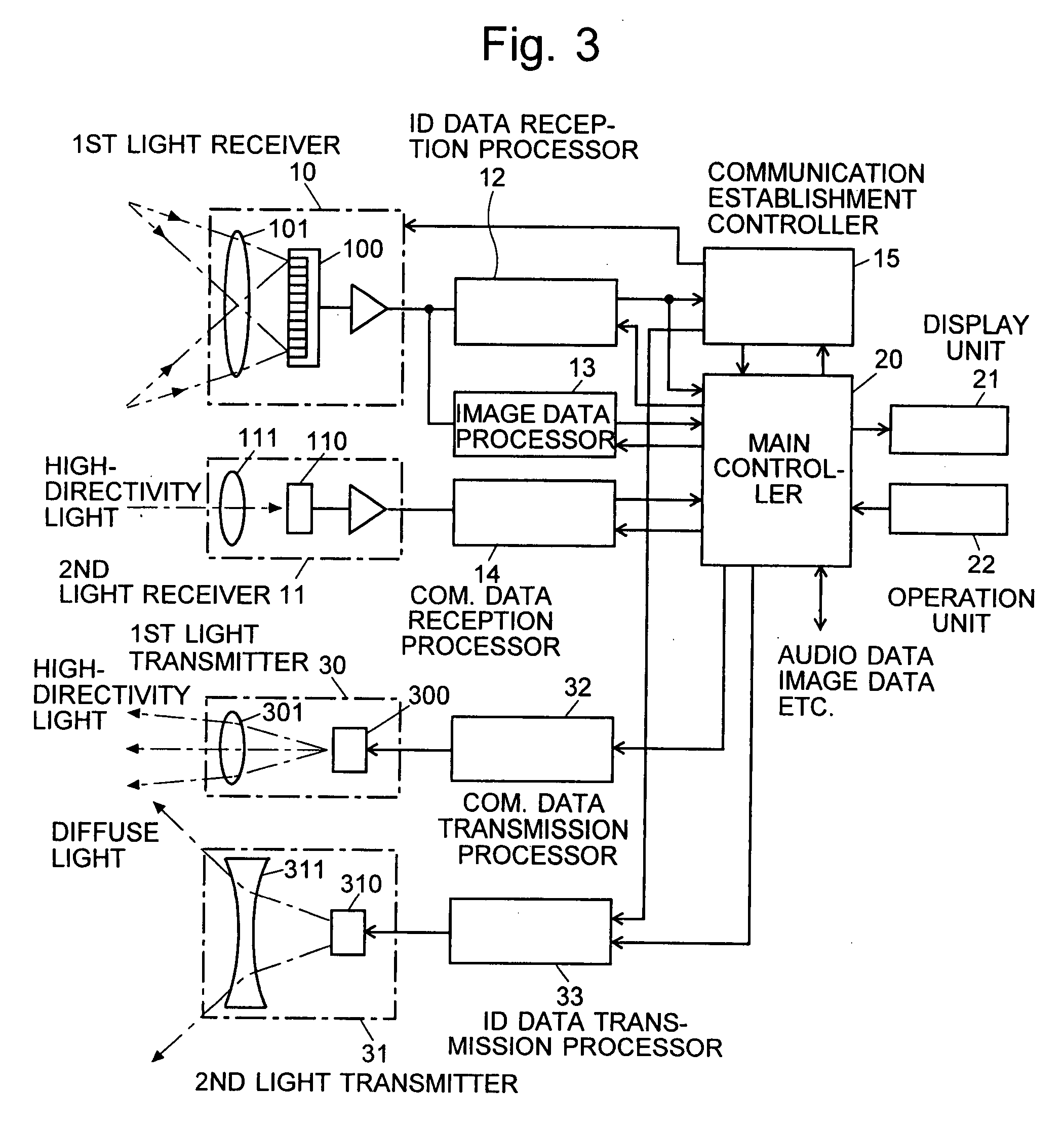

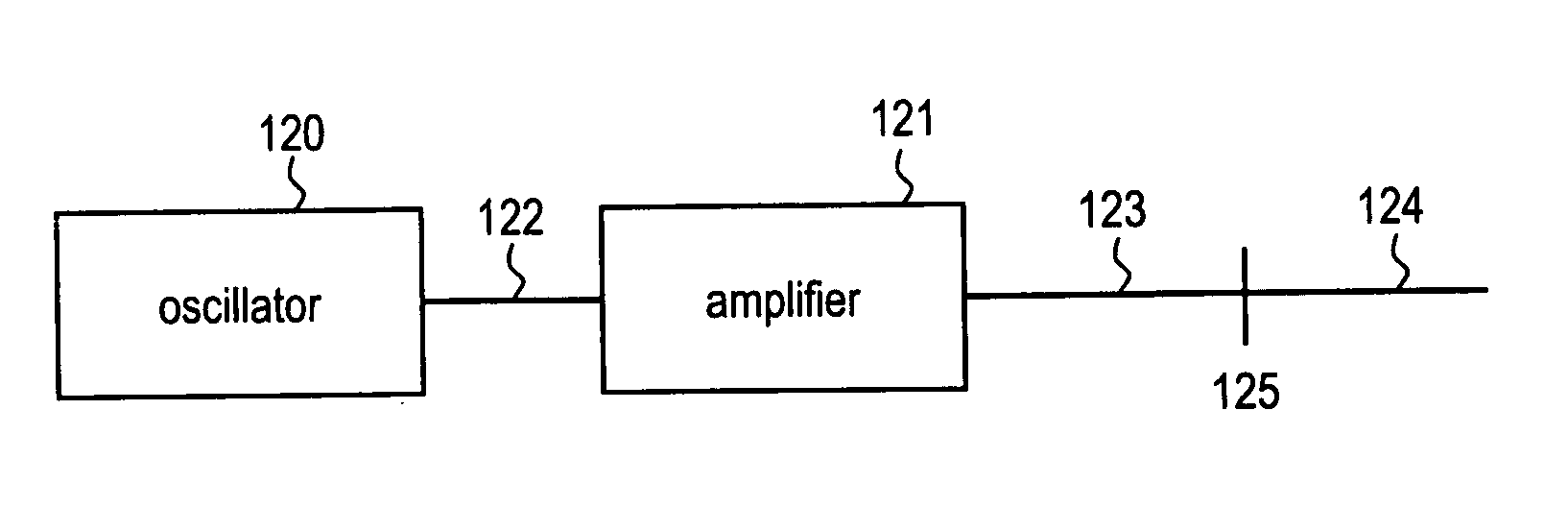

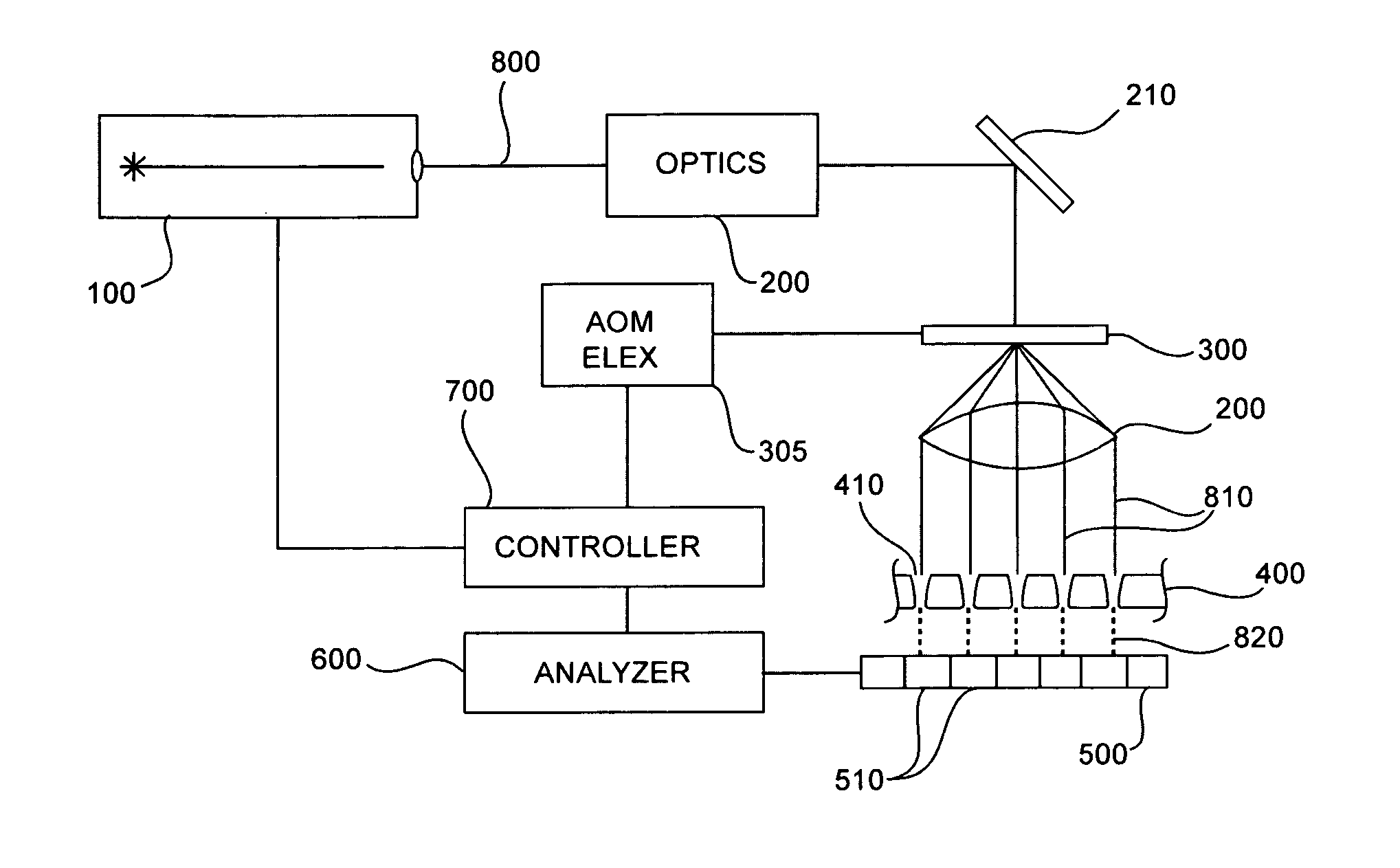

Information-Processing System Using Free-Space Optical Communication and Free-Space Optical Communication System

InactiveUS20080044188A1Suppress power consumptionSmall sizeNetwork topologiesConnection managementLight sourceHigh frequency

In a system for data communication between an information terminal to be operated by a user and remote communication nodes, the present invention intends to suppress the power consumption of the information terminal. For that purpose, communication nodes 2, 3 and 4 each emit diffuse light carrying a pilot signal blinking at a low frequency to notify the presence of the communication node and an ID signal belonging to a higher frequency range, the ID signal containing inherent address etc. for identifying each communication node. A mobile phone 1 as the information terminal captures an image and processes the image data to detect the pilot signal of each communication node. Then, determining the position of each node and setting a limited range for reading the pixels around that position, the mobile phone 1 reads the detection signals of the pixels within the limited range at high speed and obtains identification information. This information is used to identify each node and eliminate influences of any other light source that apparently resembles the pilot signal.

Owner:JAPAN SCI & TECH CORP +1

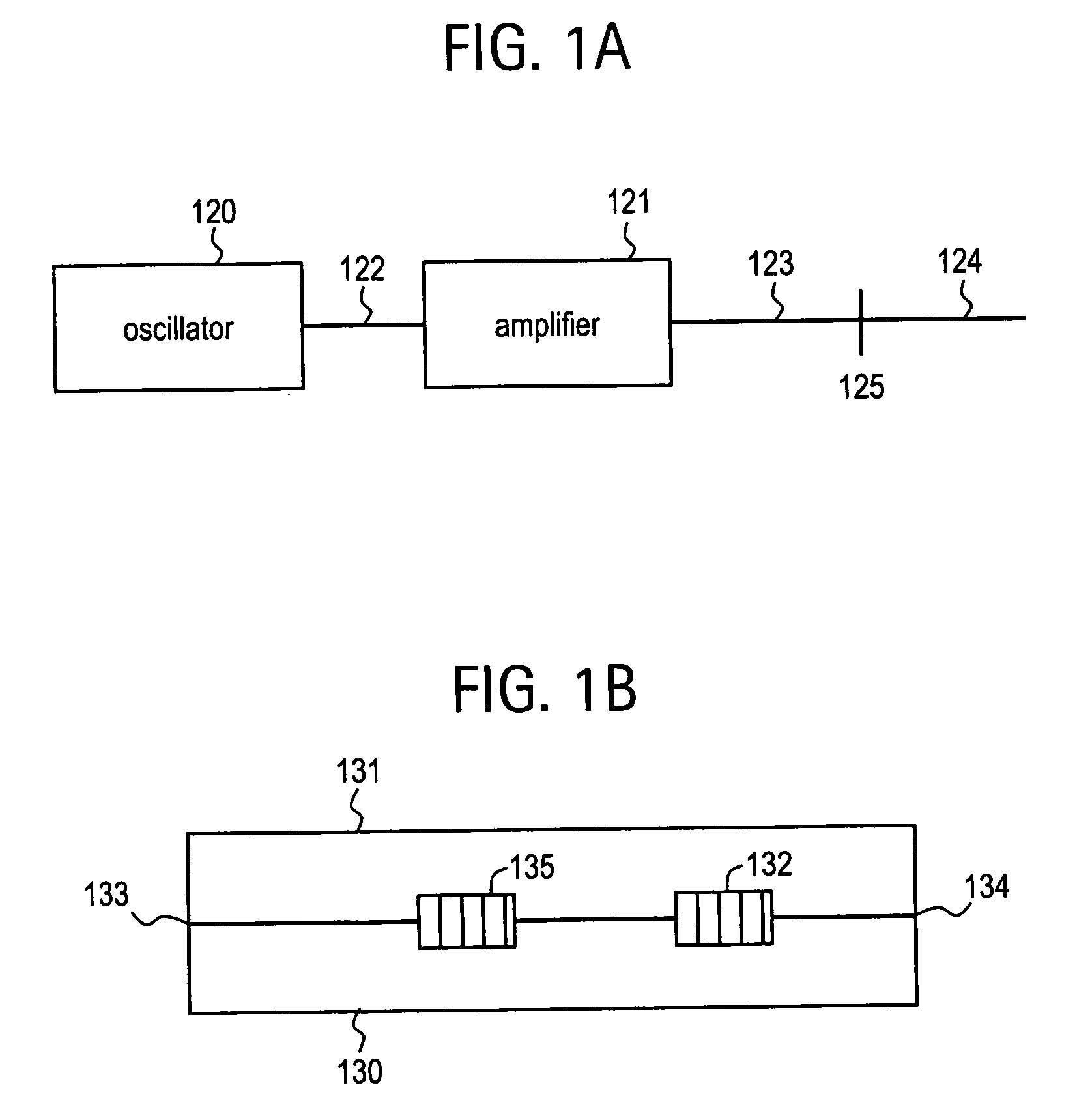

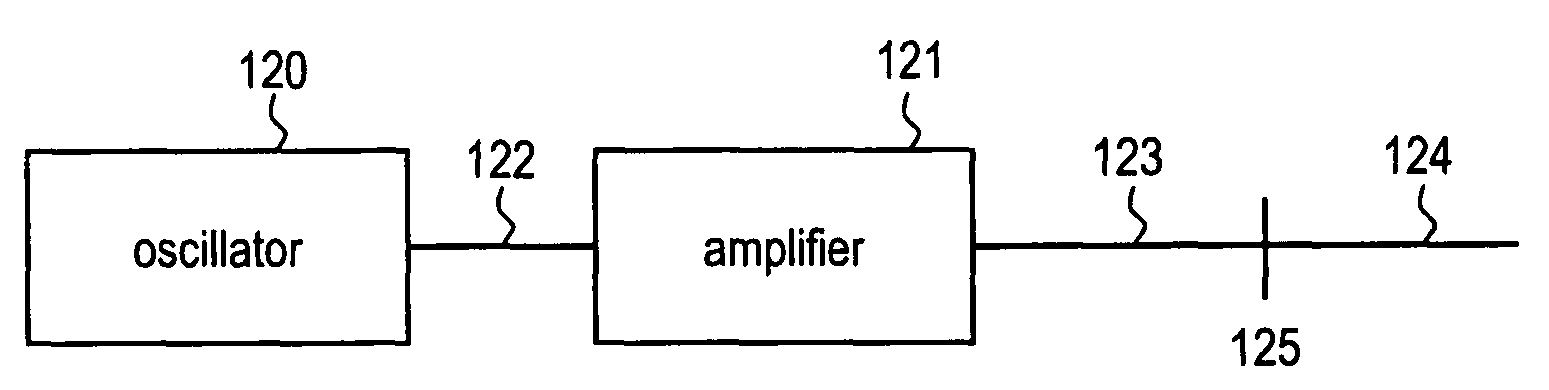

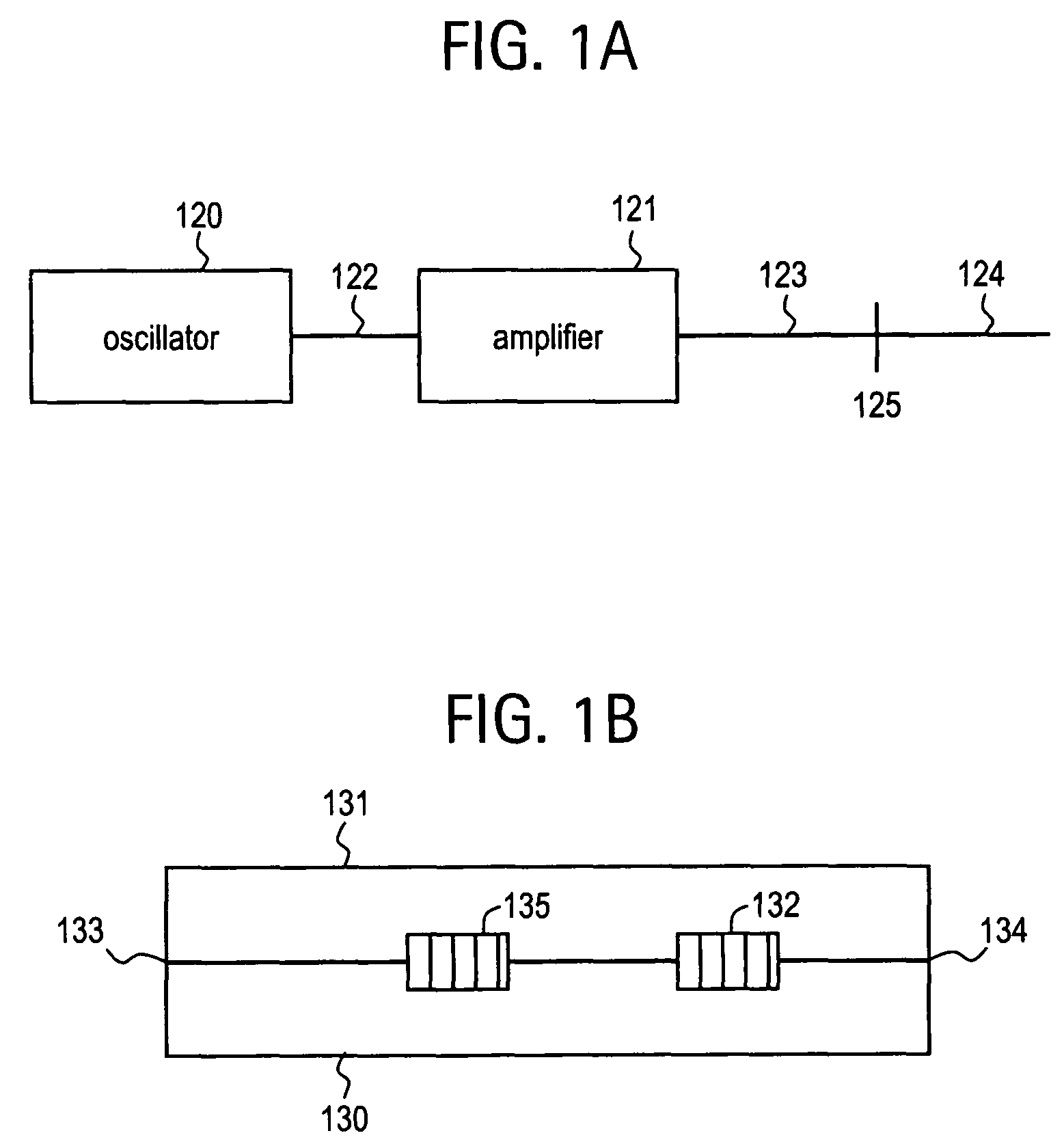

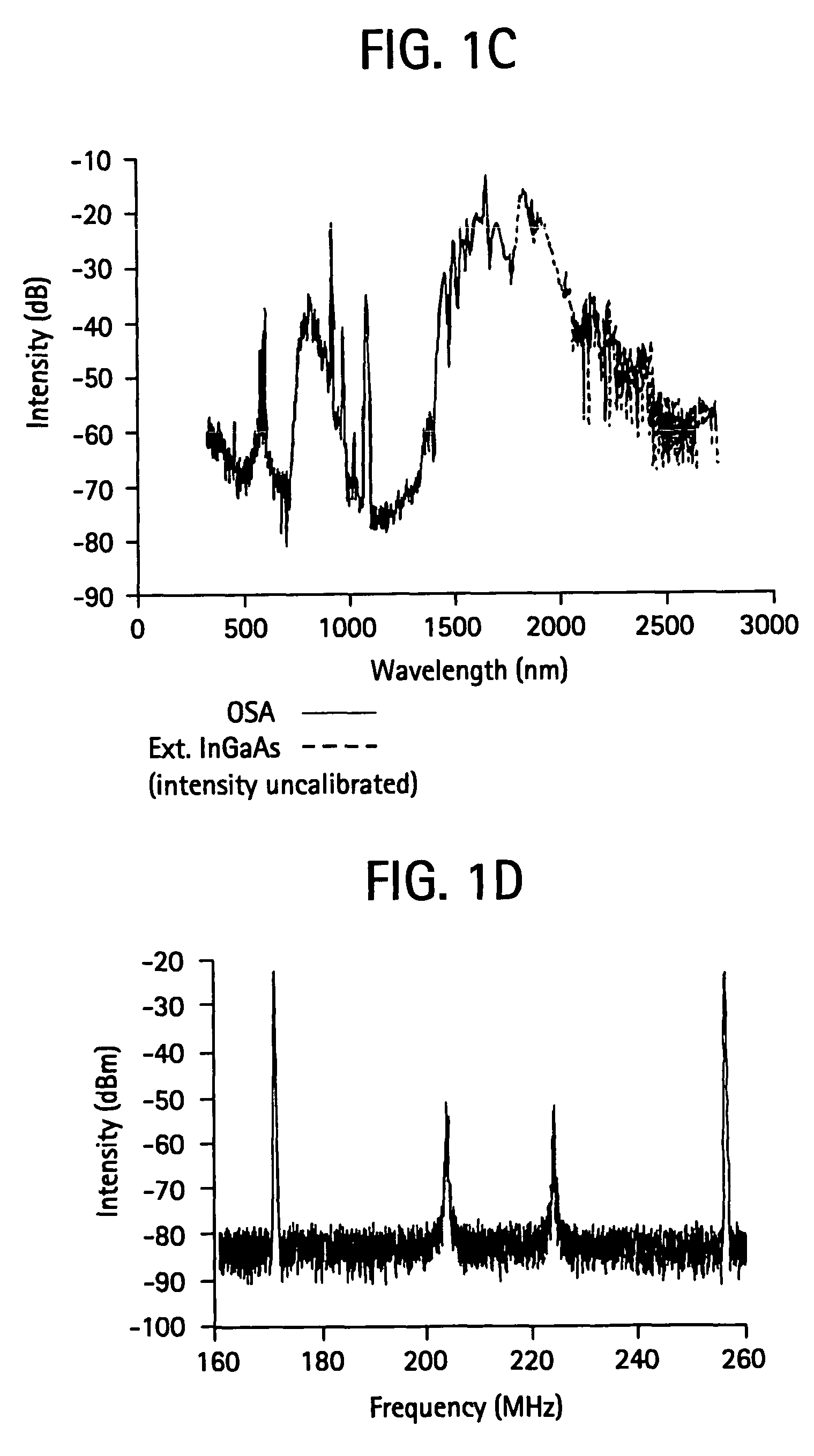

Laser based frequency standards and their applications

InactiveUS20070086713A1Minimize lossLow phase noiseLaser detailsCoupling light guidesFrequency standardLight source

Frequency standards based on mode-locked fiber lasers, fiber amplifiers and fiber-based ultra-broad bandwidth light sources, and applications of the same.

Owner:IMRA AMERICA

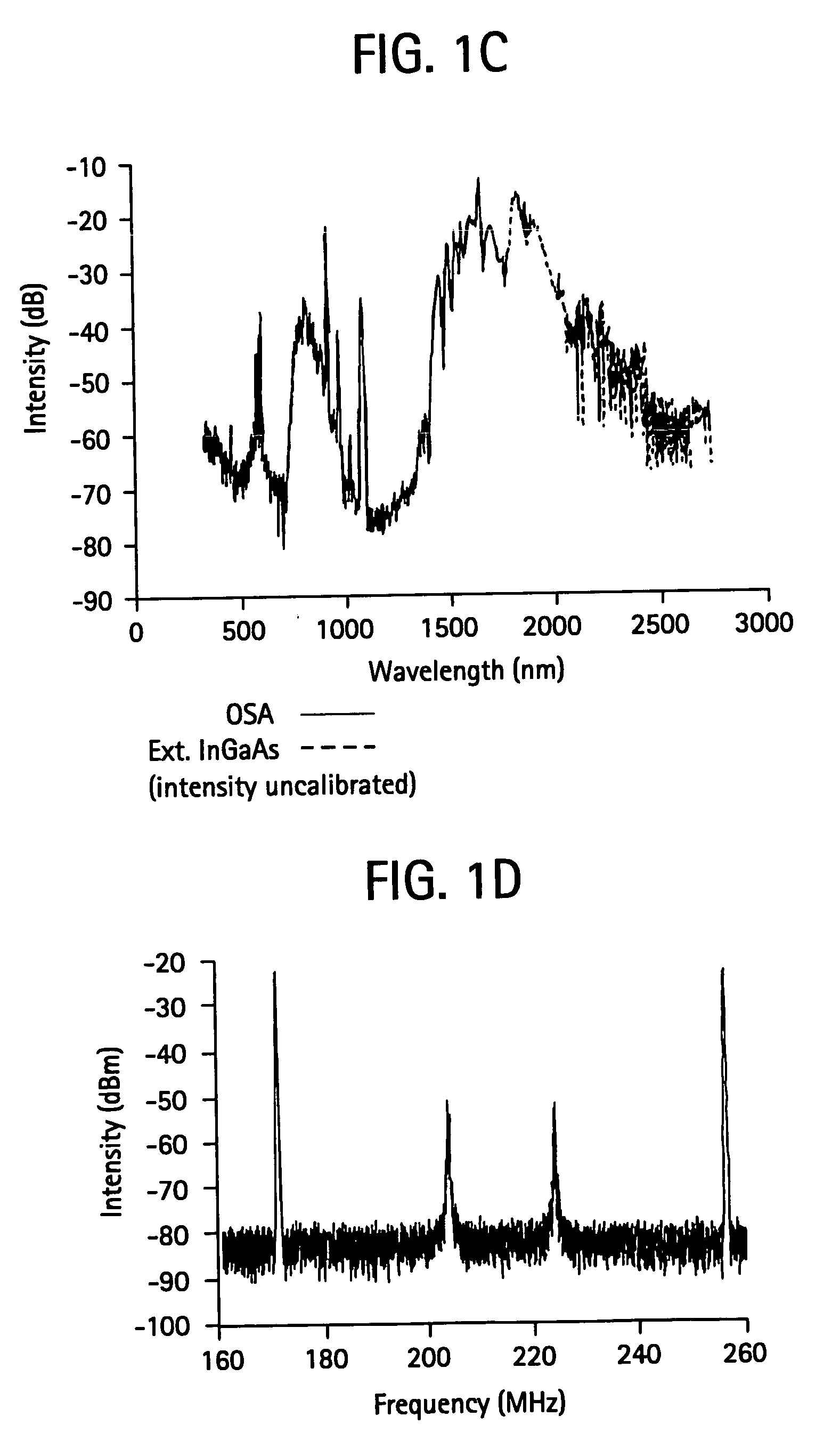

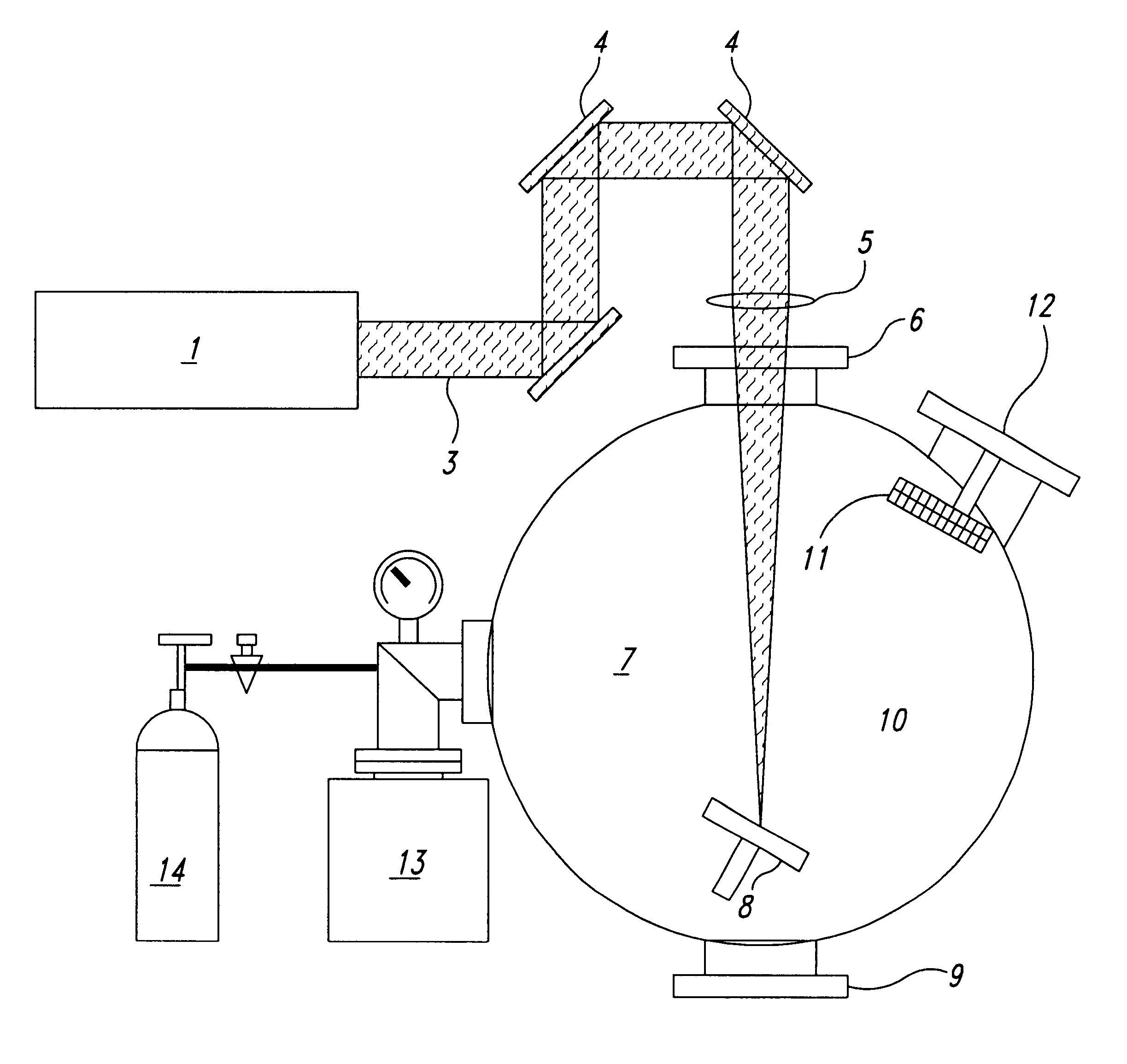

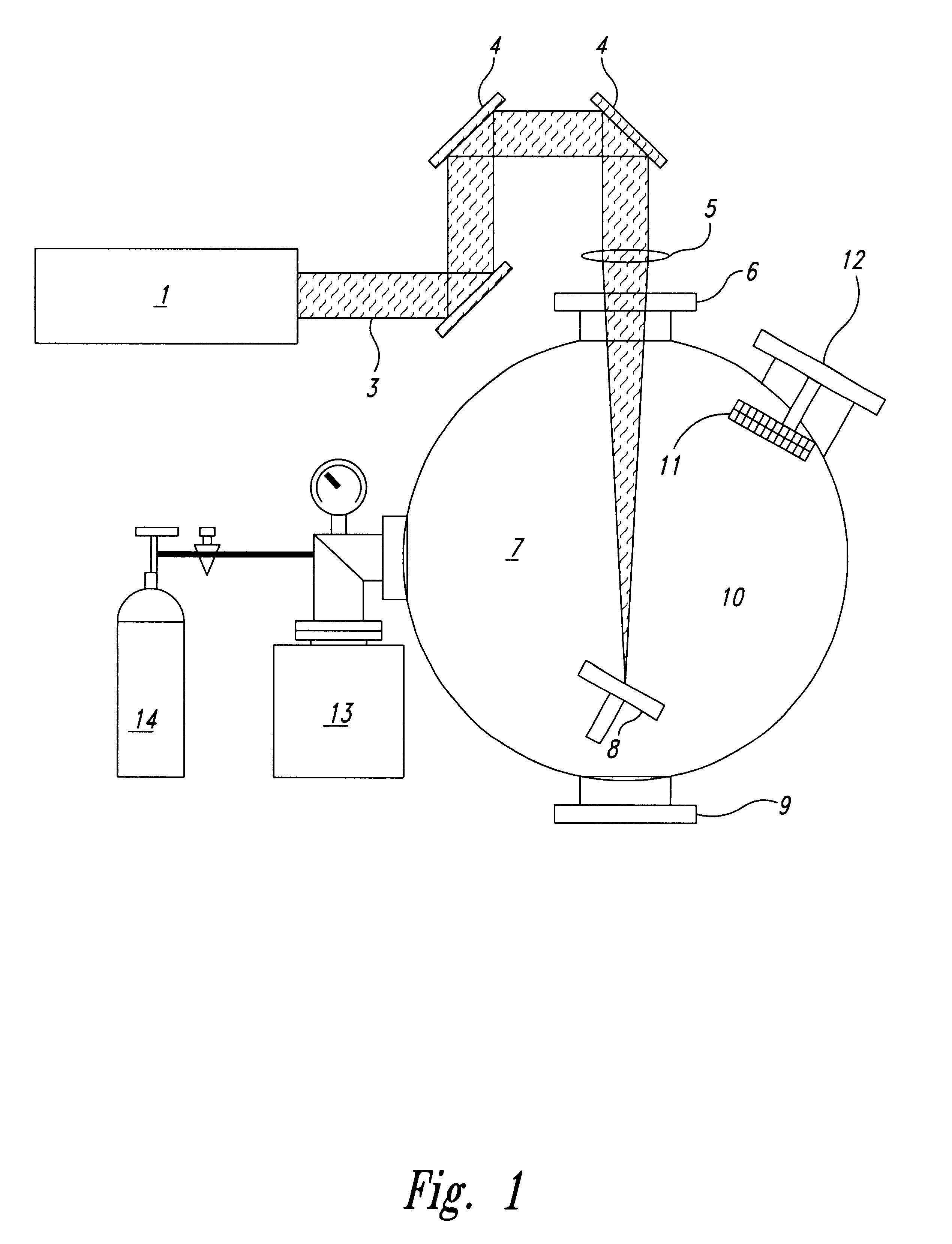

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

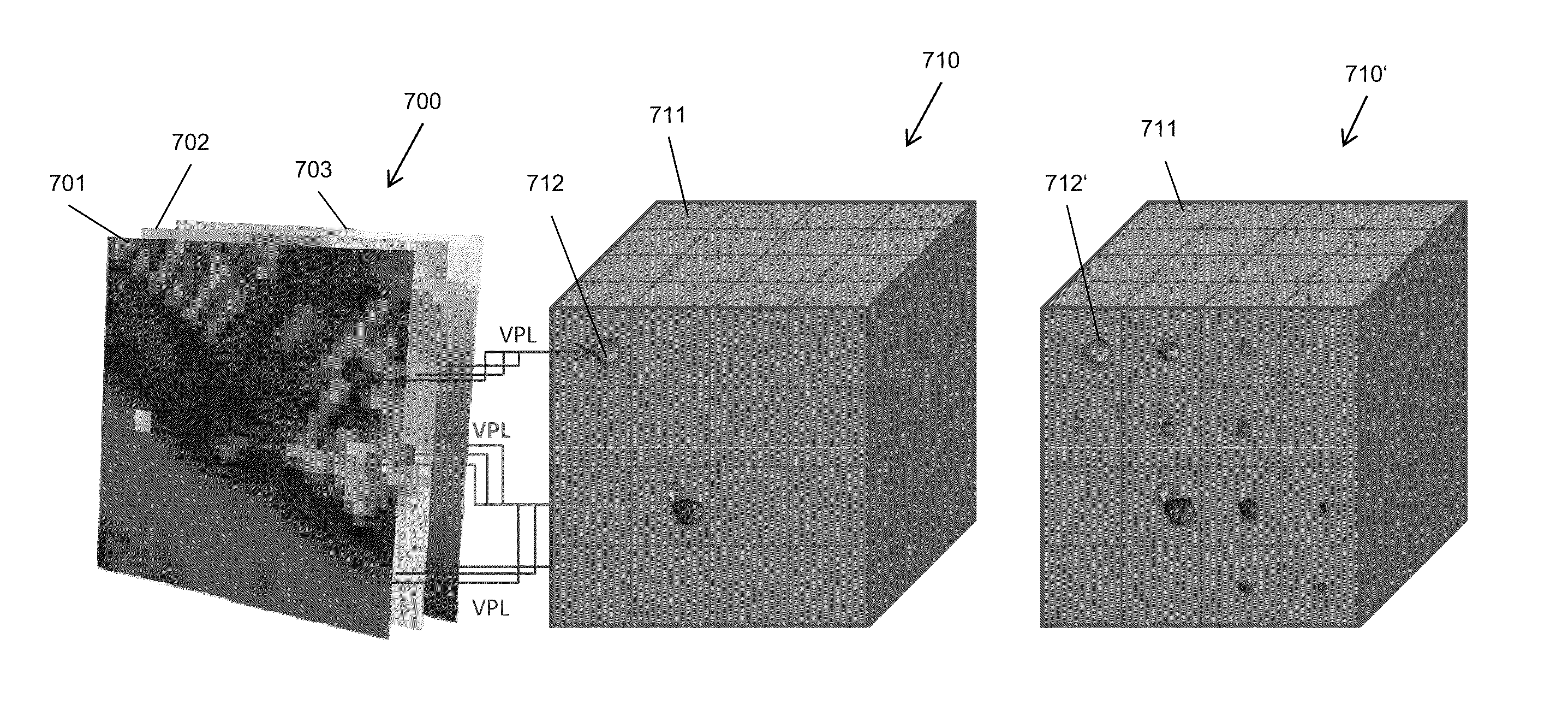

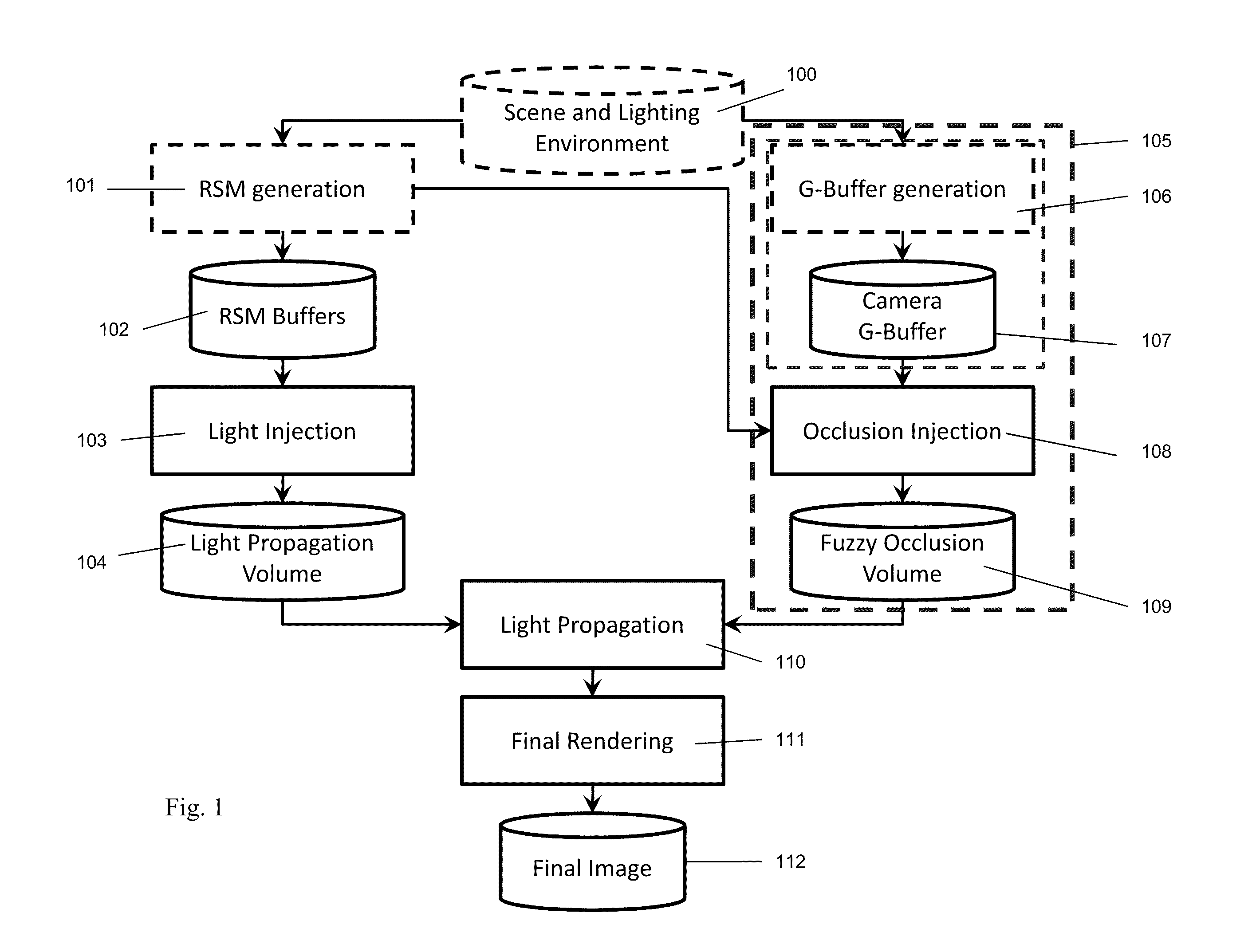

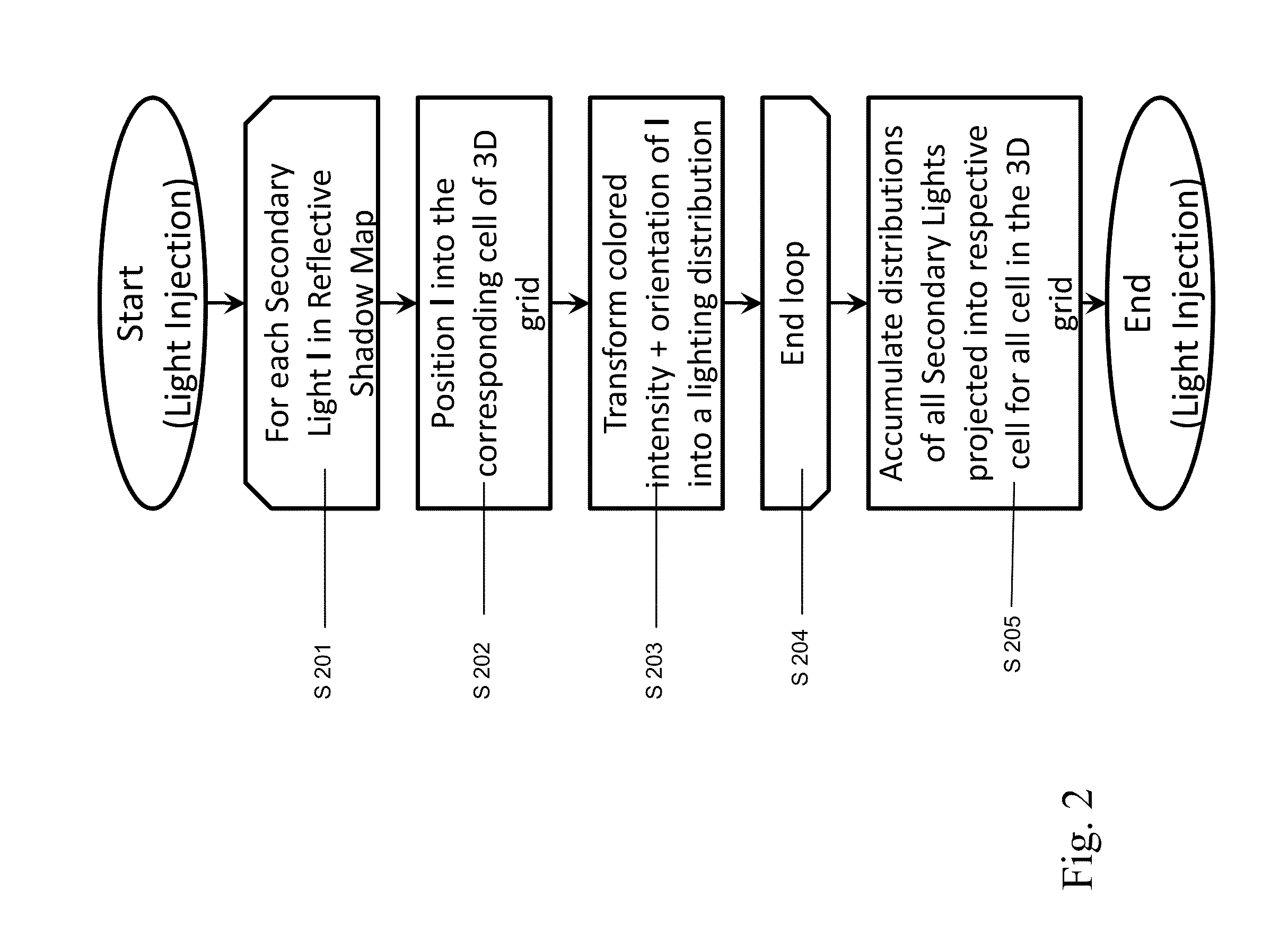

Method, computer graphics image rendering system and computer-readable data storage medium for computing of indirect illumination in a computer graphics image of a scene

ActiveUS20110012901A1High repetition rateQuality improvementCathode-ray tube indicators3D-image renderingGraphicsGrid cell

Method for real-time computing of indirect illumination in a computer graphics image of a scene, comprising: defining a light propagation volume as a three-dimensional grid consisting of a plurality of grid cells; allocating a plurality of secondary light sources to grid cells of said light propagation volume; accumulating directional, colored irradiance contributions of all secondary light sources in a respective grid cell and repeating this step of accumulating for all grid cells of the light propagation volume to thereby obtain an initial indirect light intensity distribution. The propagation of light in said light propagation volume is then iteratively computed starting with the initial indirect light intensity to obtain a final indirect light intensity distribution, which is used for rendering the scene illuminated by the final indirect light intensity distribution during a usual scene rendering process from a camera's point of view.

Owner:CRYTEK IP HLDG

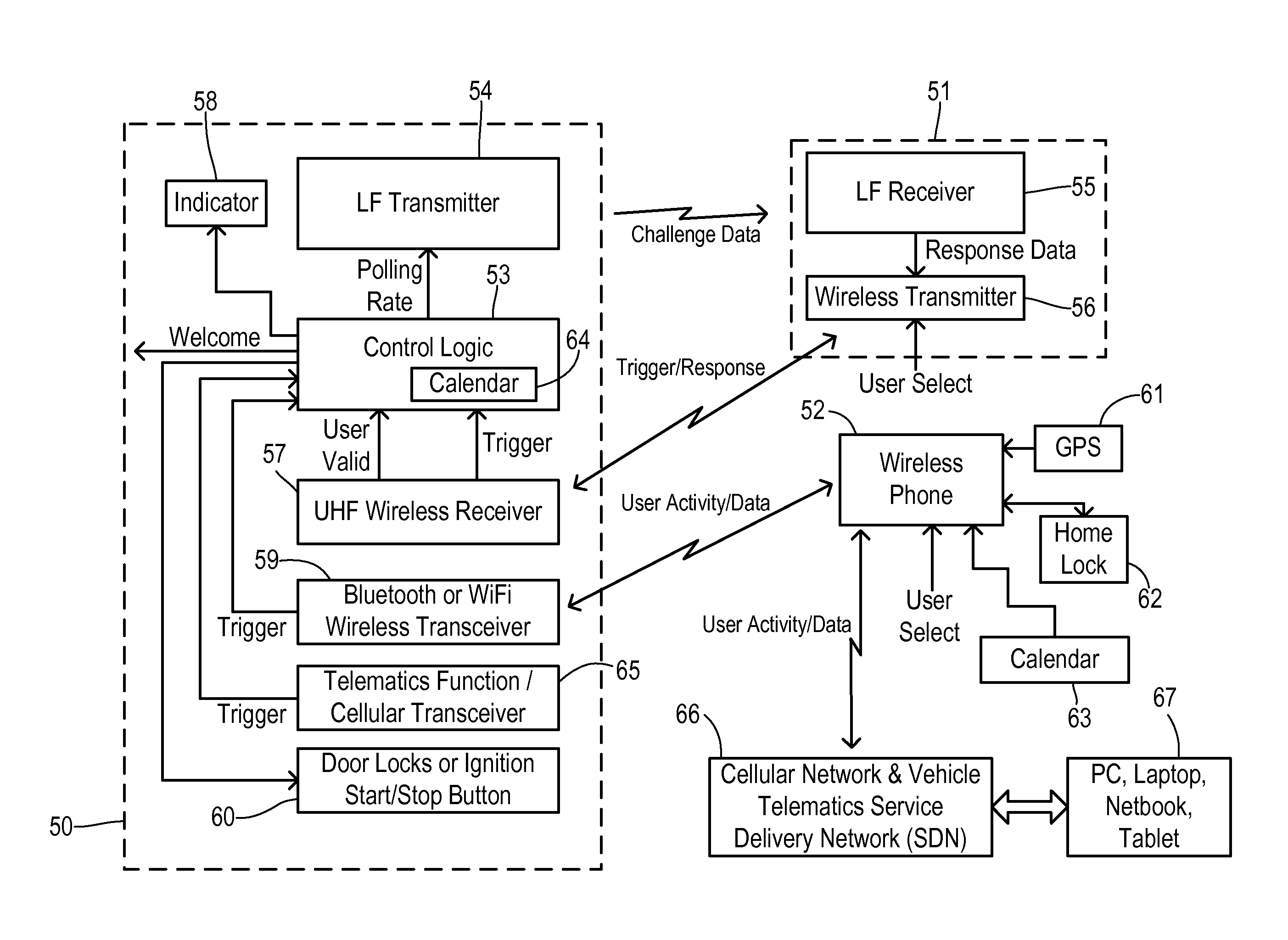

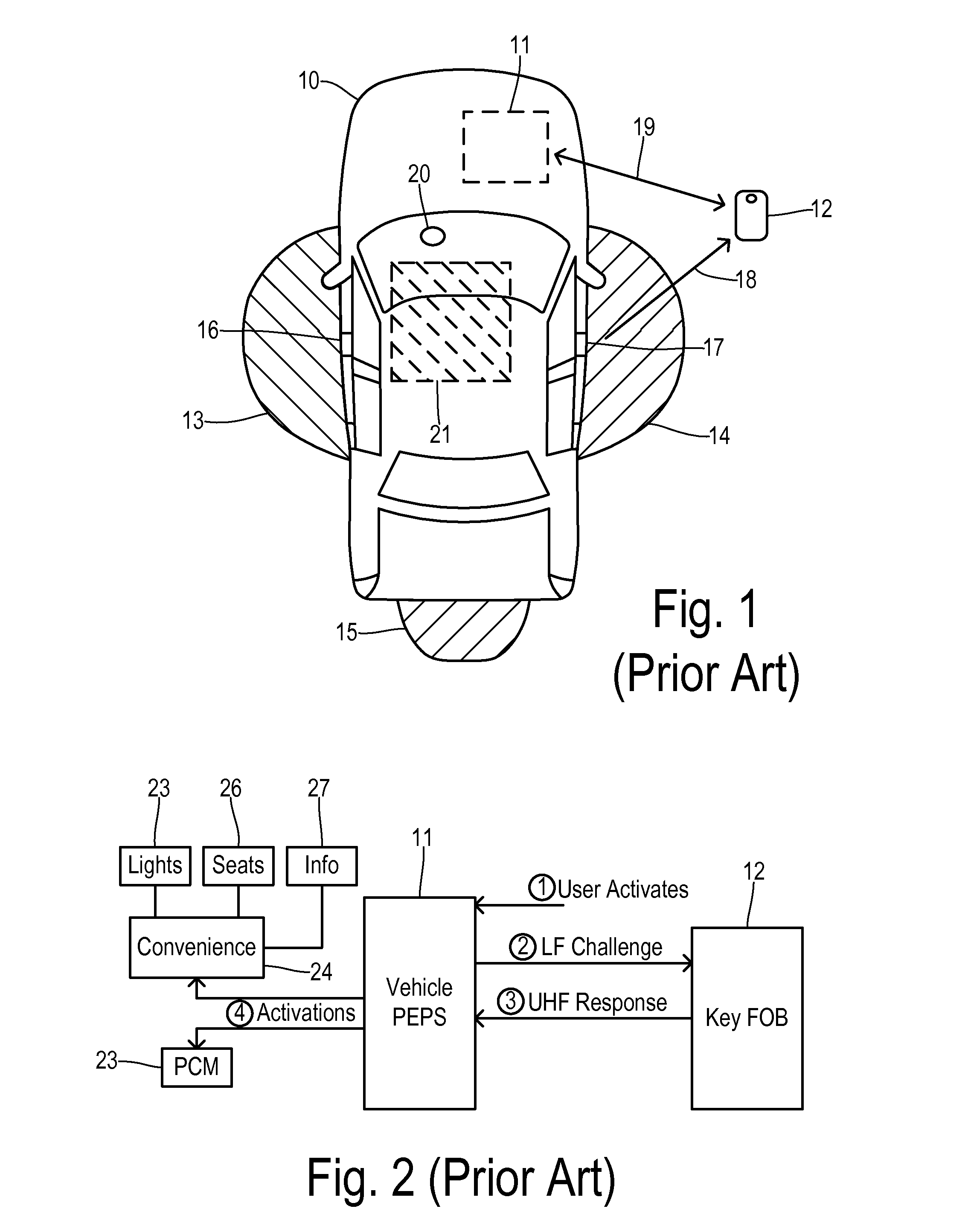

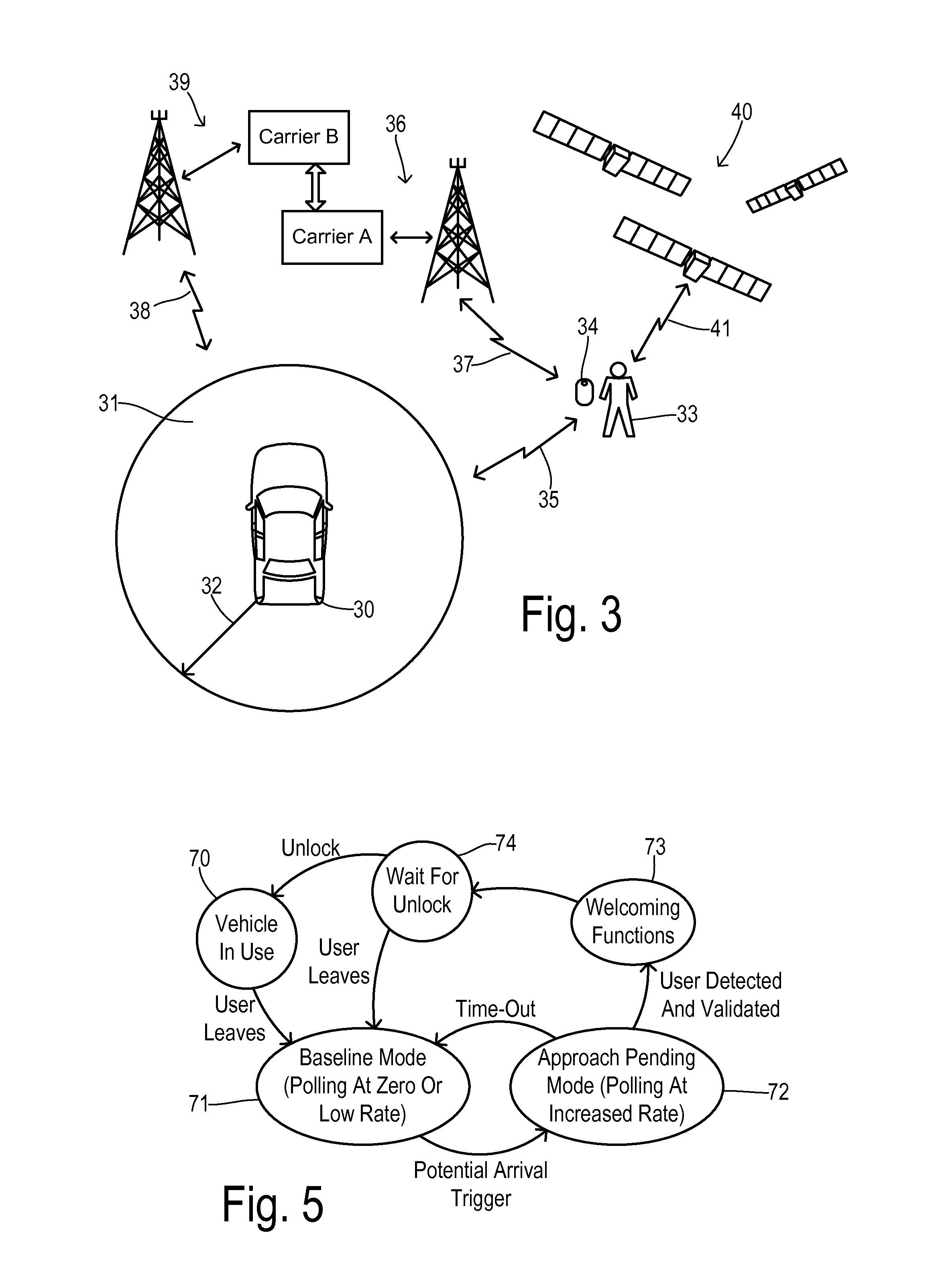

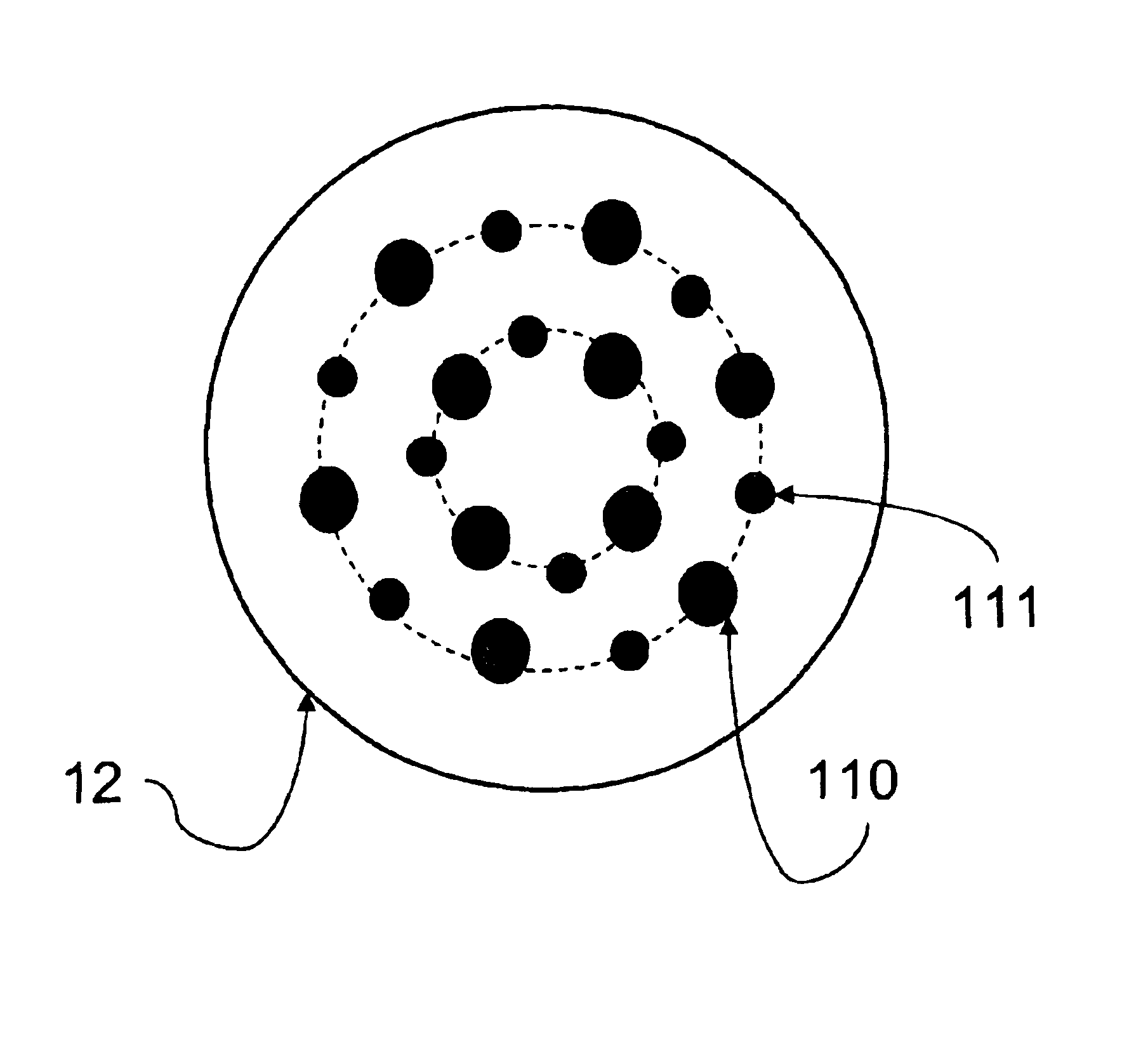

User proximity detection for activating vehicle convenience functions

ActiveUS20150161834A1Increase in overall average battery drainRaise the potentialElectric signal transmission systemsDigital data processing detailsPower flowCommunications system

A convenience controller activates a small zone high location precision welcoming detecting function (with high current utilization) in response to a detected arrival of an authorized user into a larger zone low location precision welcoming detecting function (with low current utilization) approach region around a vehicle. A short range transmitter broadcasts a polling signal covering the region. The short range transmitter has an approach pending mode wherein the polling signal is broadcast according to a first predetermined repetition and a baseline mode wherein the polling signal is broadcast according to a lower repetition. The short range transmitter has a first power drain in the approach pending mode. A wireless communication system is configured to monitor for user activity outside the approach region corresponding to a potential user entry into the approach region, wherein monitoring by the wireless communication system has a lower power drain. If the short range transmitter is in the baseline mode when the user activity is detected, then the short range transmitter switches to the approach pending mode.

Owner:FORD GLOBAL TECH LLC

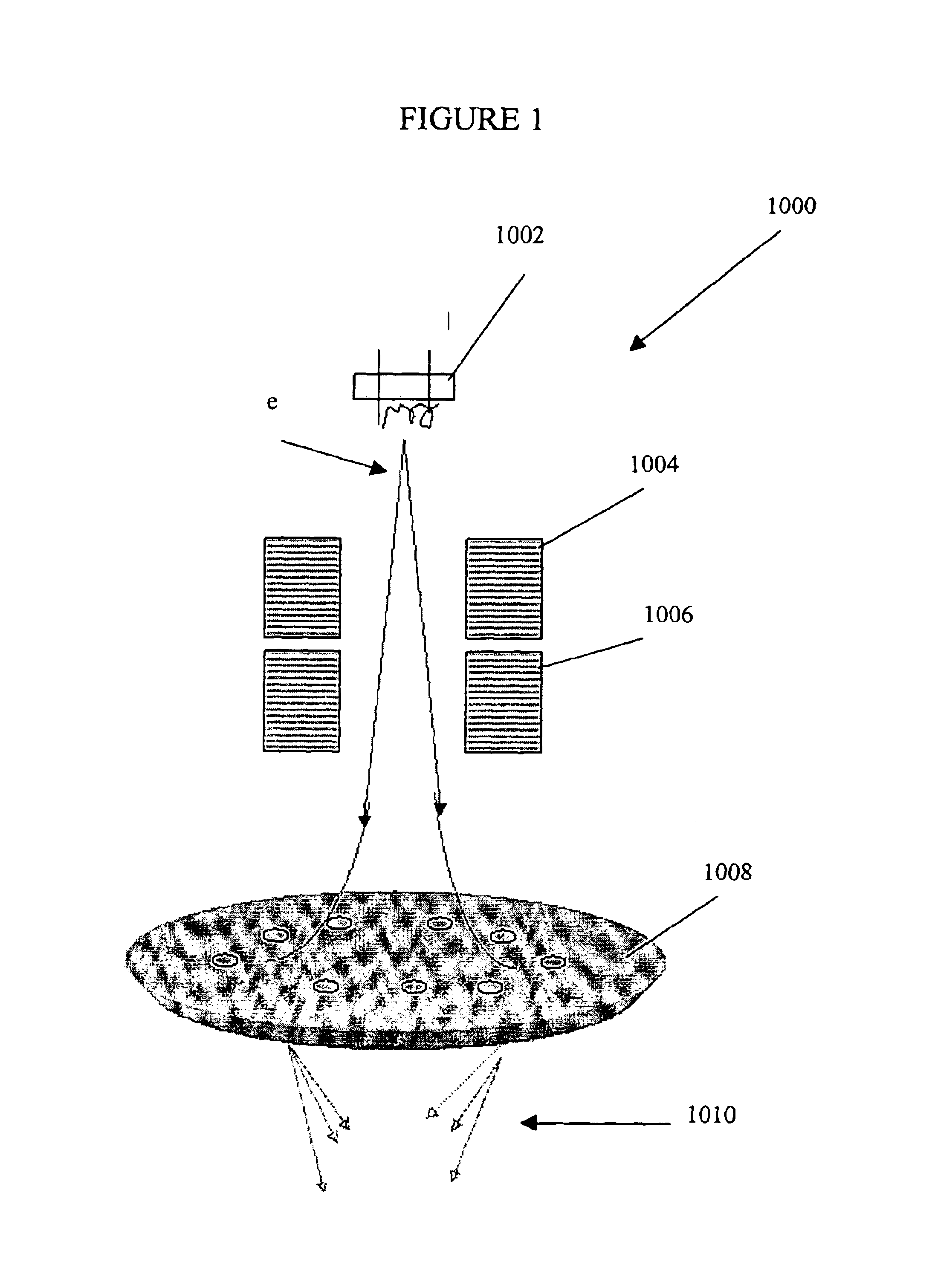

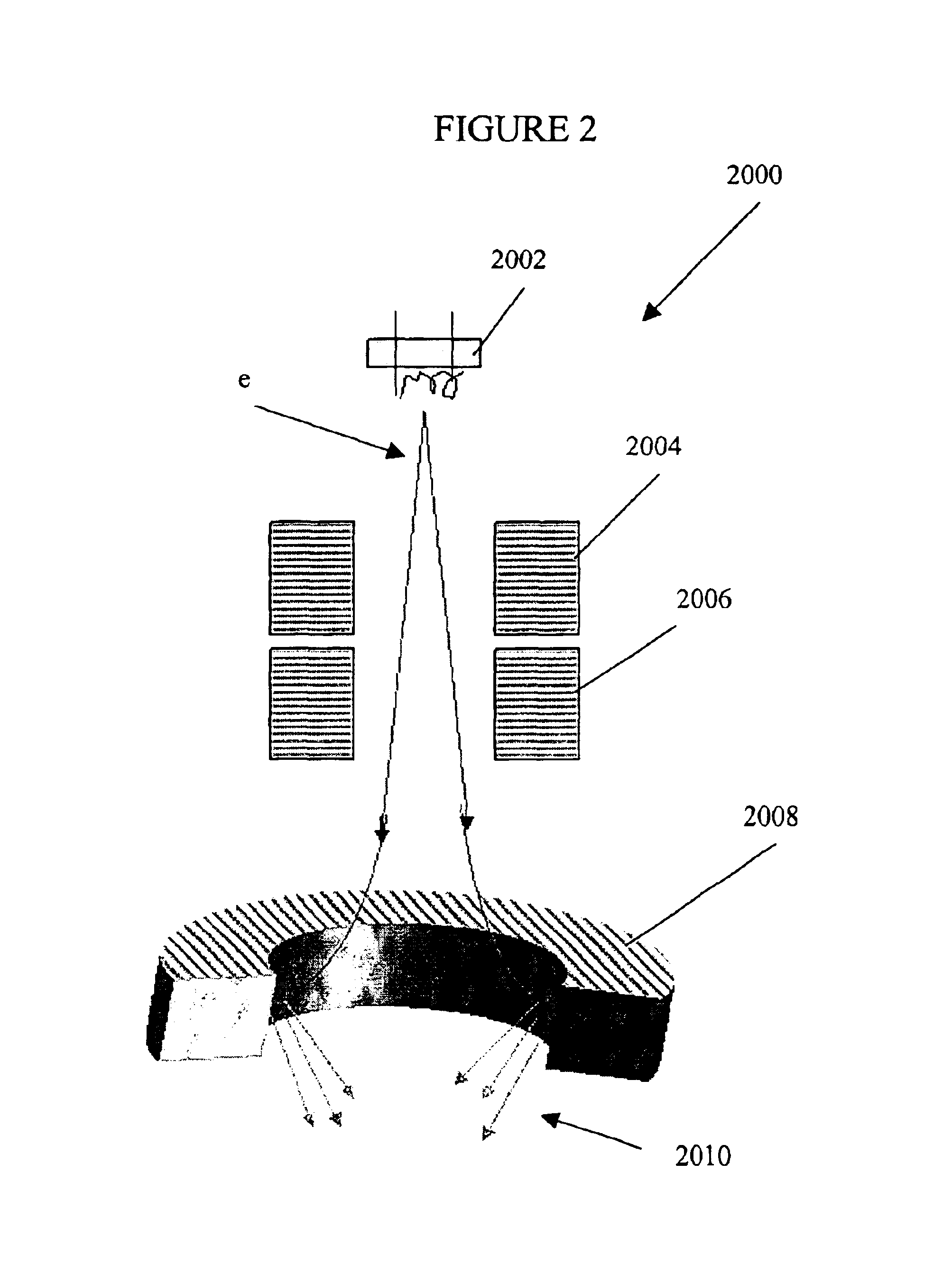

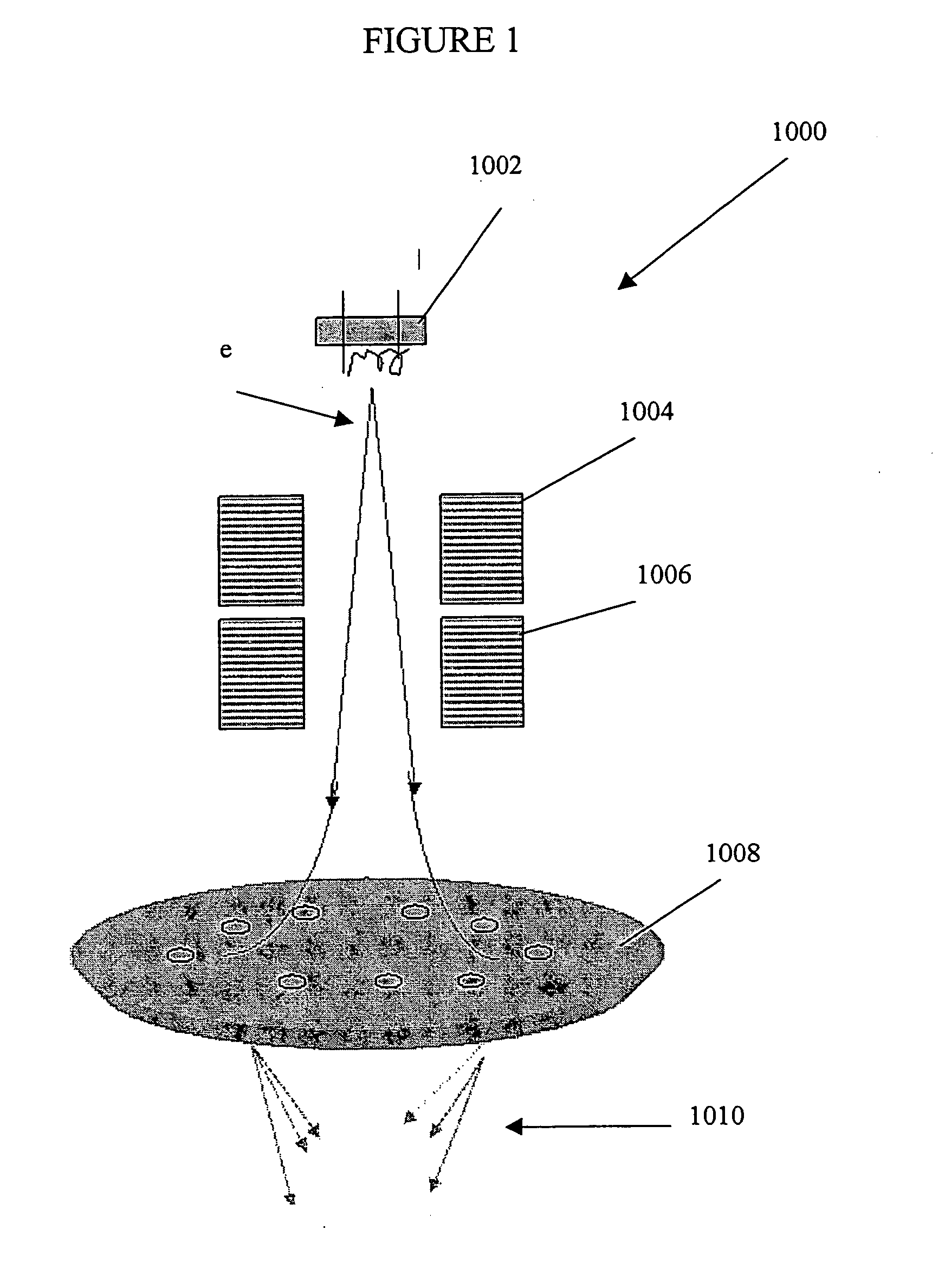

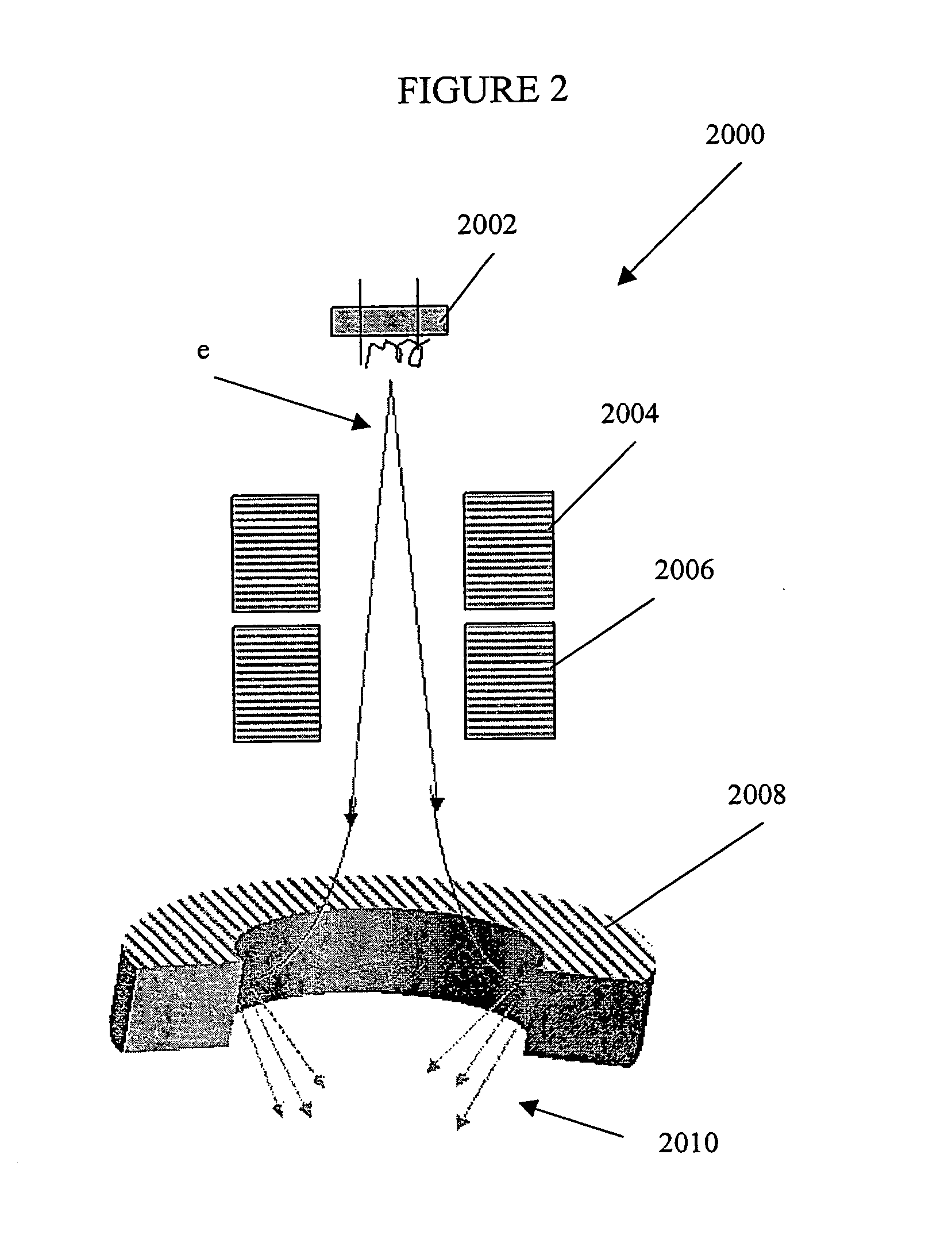

Devices and methods for producing multiple x-ray beams from multiple locations

InactiveUS6980627B2Efficient in producing multi-beamHighly integrated multiple functionX-ray tube electrodesNanoinformaticsX-rayCold cathode

An x-ray generating device includes at least one field-emission cold cathode having a substrate and incorporating nanostructure-containing material including carbon nanotubes. The device further includes at least one anode target. Associated methods are also described.

Owner:NURAY TECH

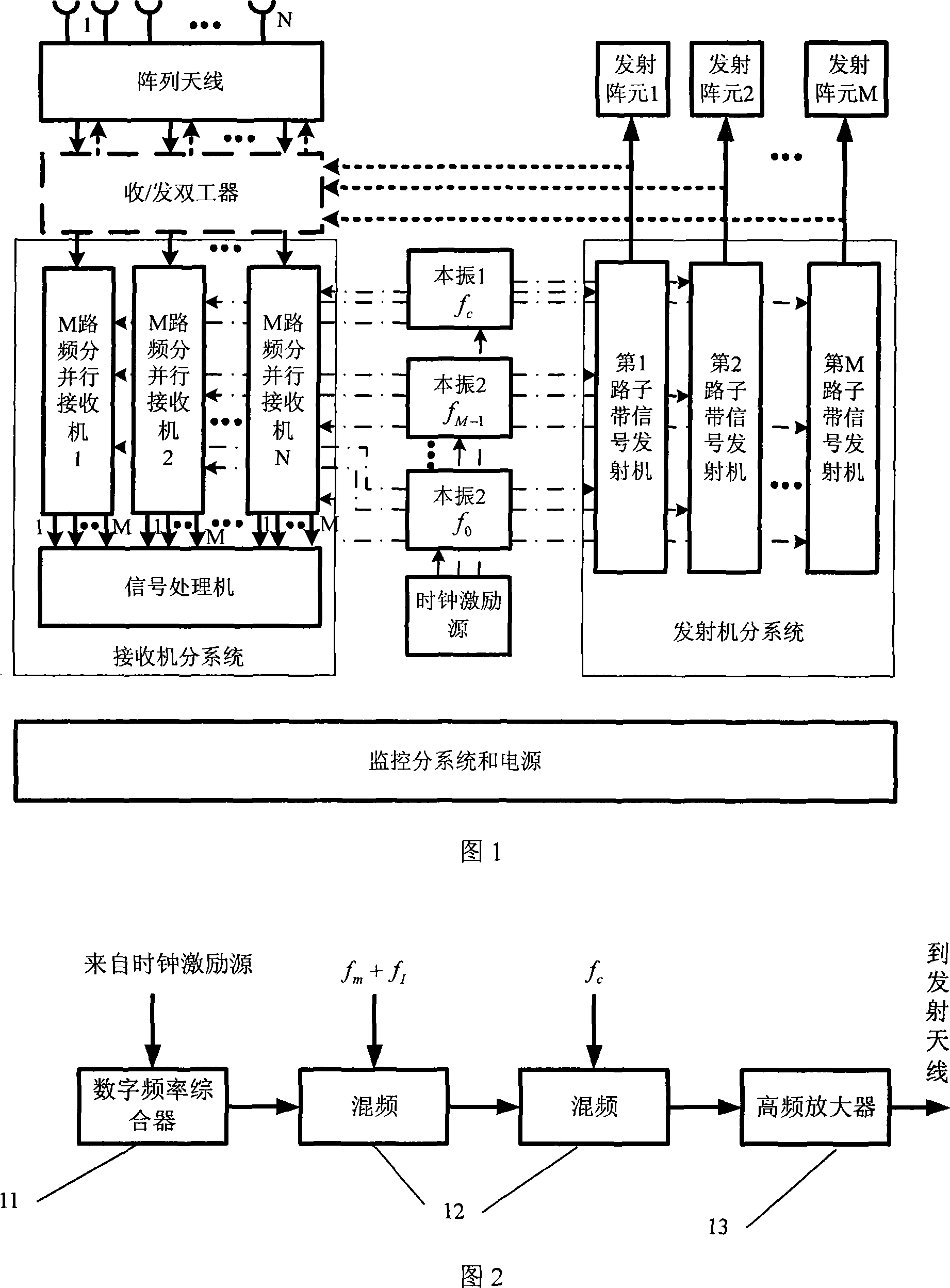

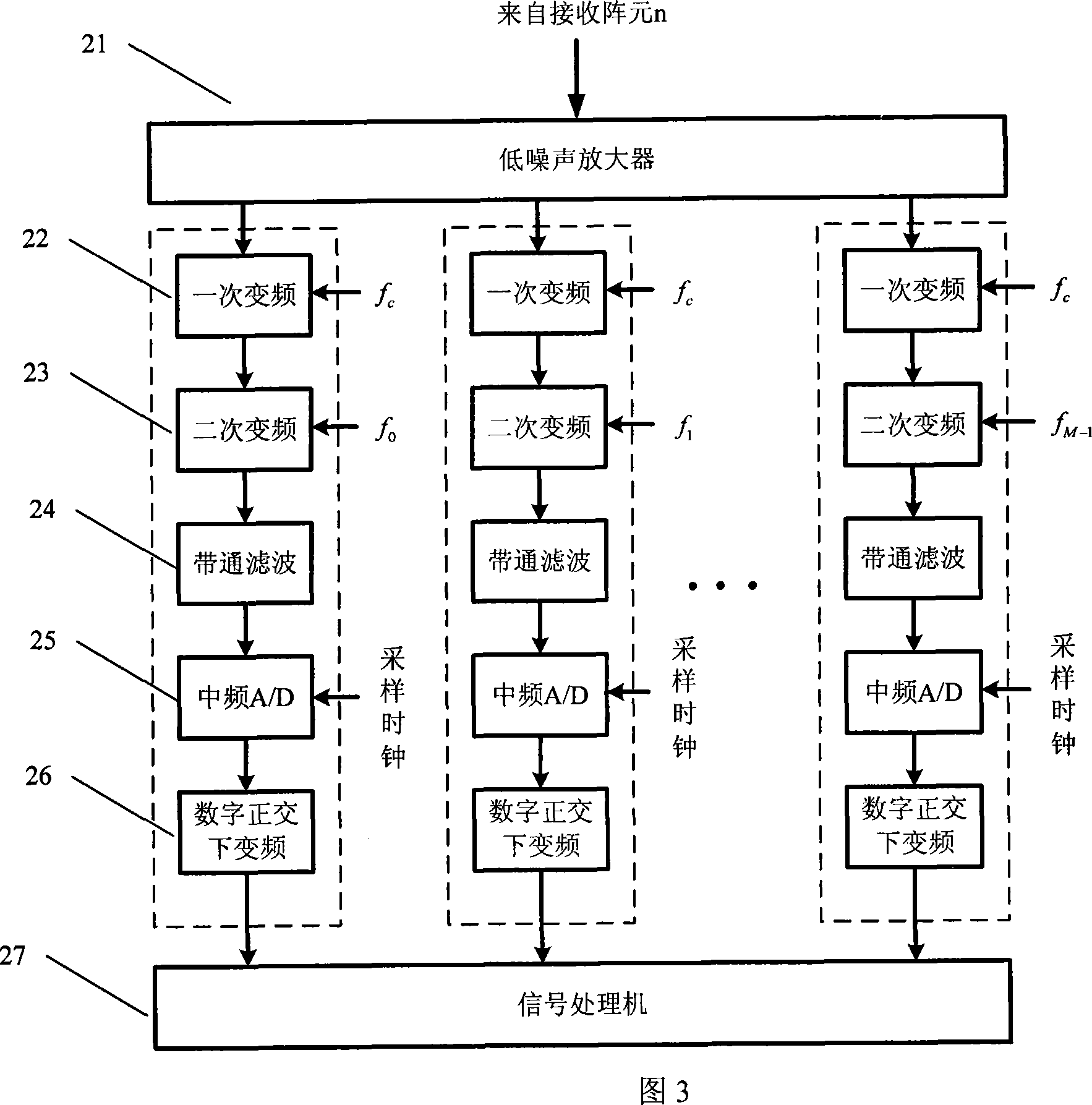

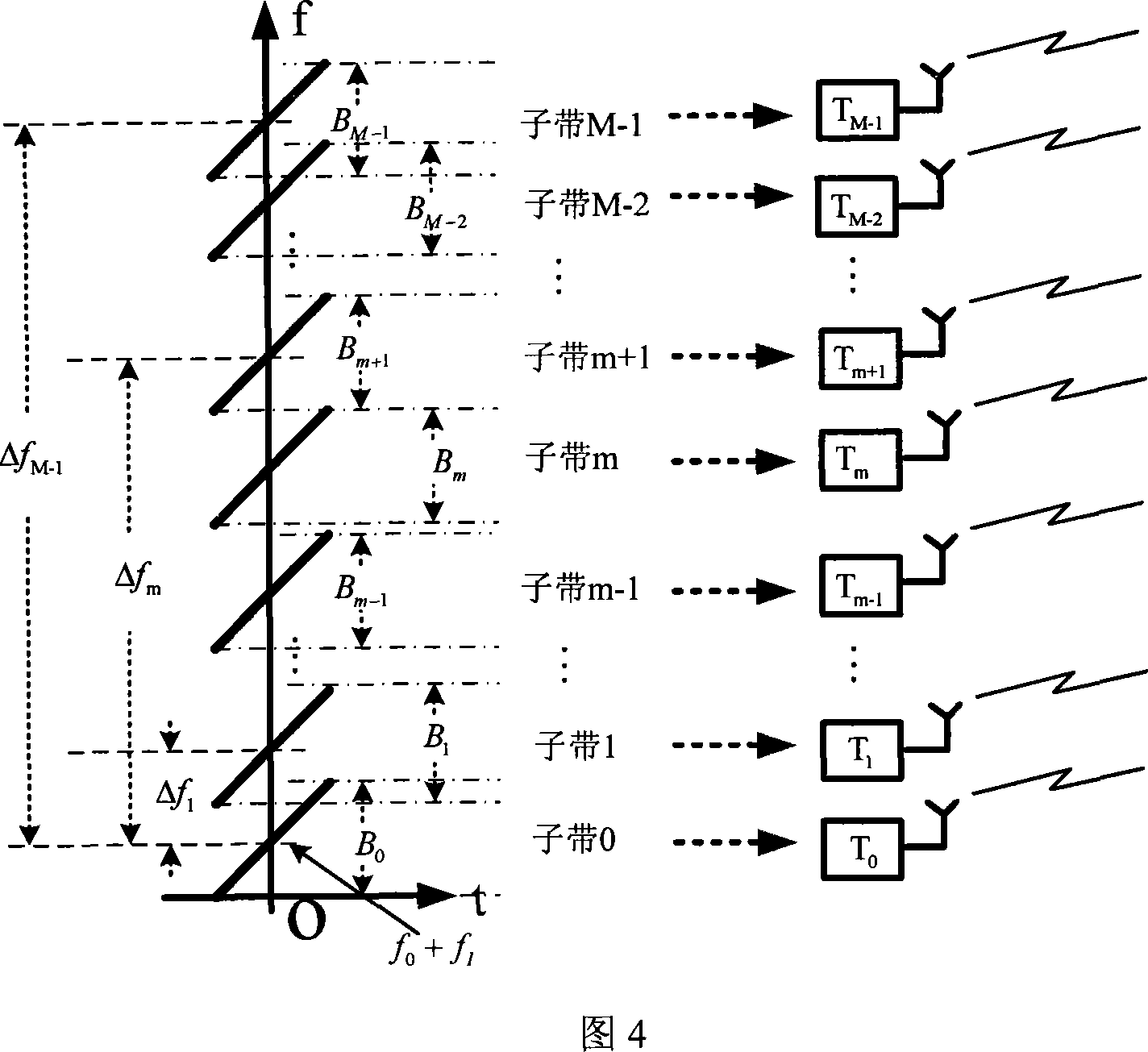

Wide band rader utilizing multi-transmitting and multi-receiving frequency division signal and imaging method thereof

InactiveCN101021561AReduced instantaneous bandwidth requirementsOvercoming Poor Image QualitySpatial transmit diversityRadio wave reradiation/reflectionPhysicsBroadband

The invention relates to a wide-band radar figure method used the multi-emitter and multi-receiver frequency molecular signal. It includes the below process: 1. the M array unit of the radar emitter emit M frequency molecular band signal; 2. the radar receiver is made up of N receiving array units which is set with M receiving channels matched to the M frequency molecular band signal, so it can get M*N channels of the echo signal; 3. disposing the M*N channels of the echo signal and finishing the object detection then it composes the many echoes into the high resolution figure in the object location and the distance. The invention has decreased the need of the radar to the instantaneous bandwidth; also the radar has the ability of the electronic scanning to complete the object detecting, tracking and figure.

Owner:TSINGHUA UNIV

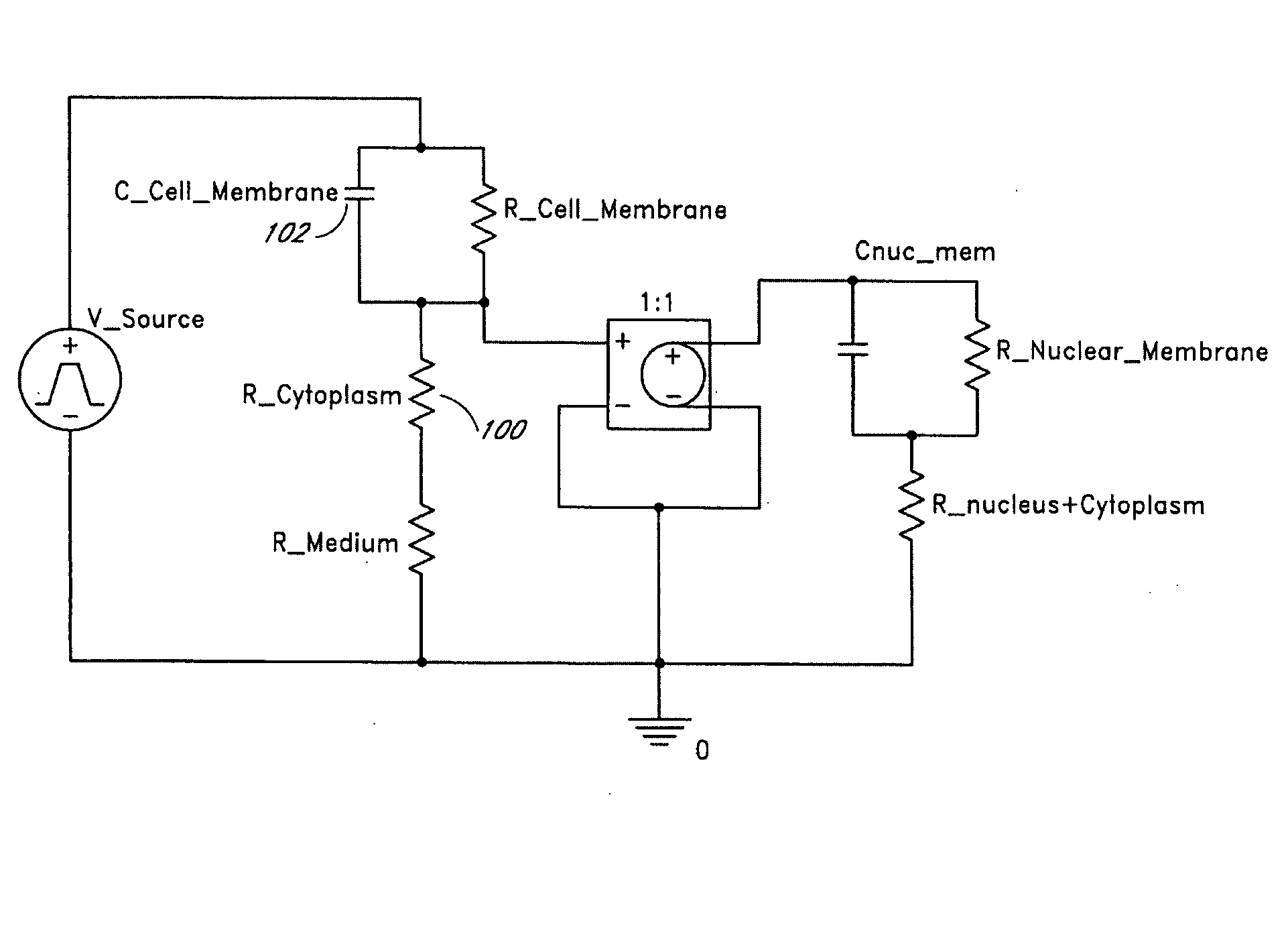

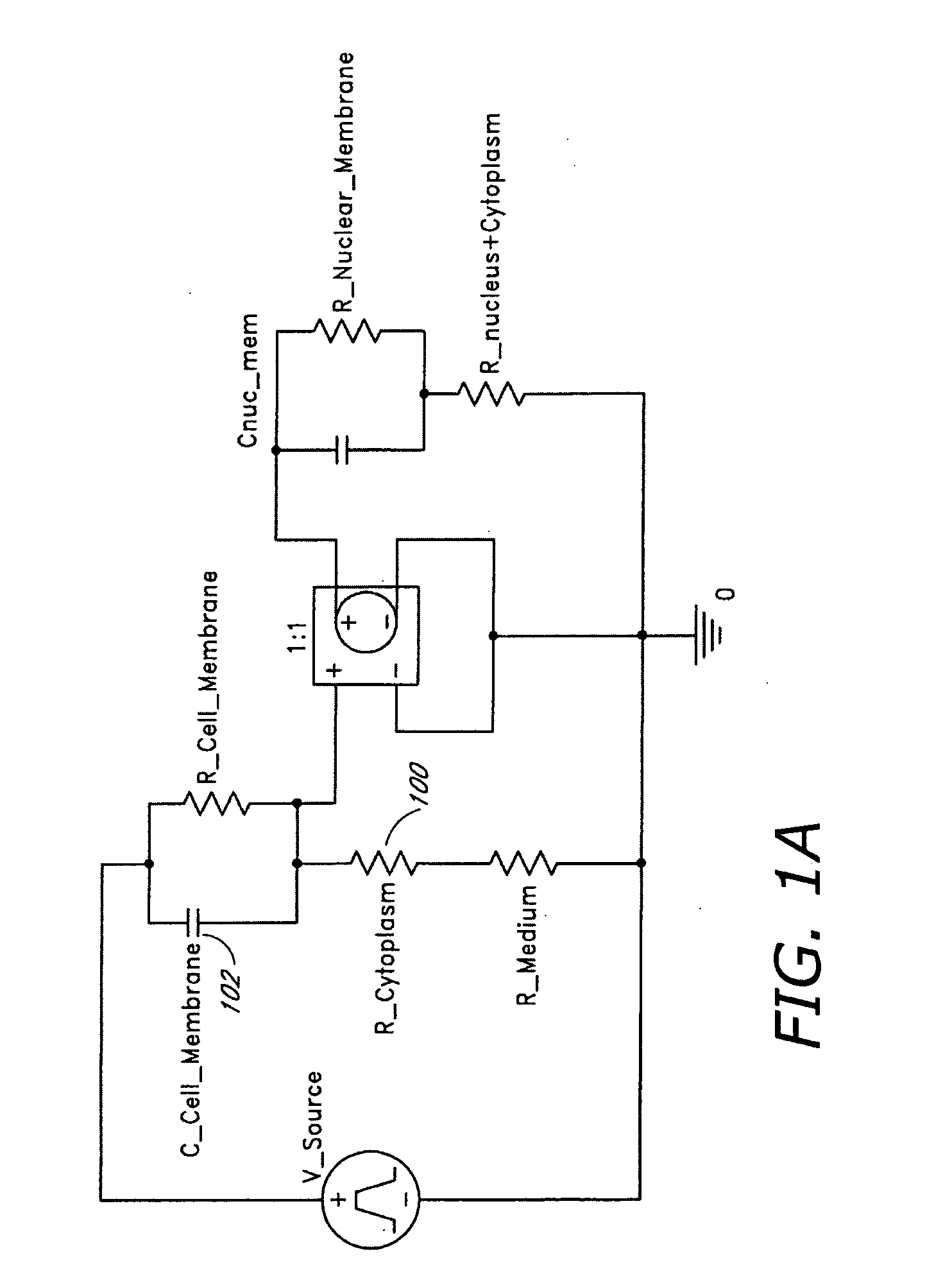

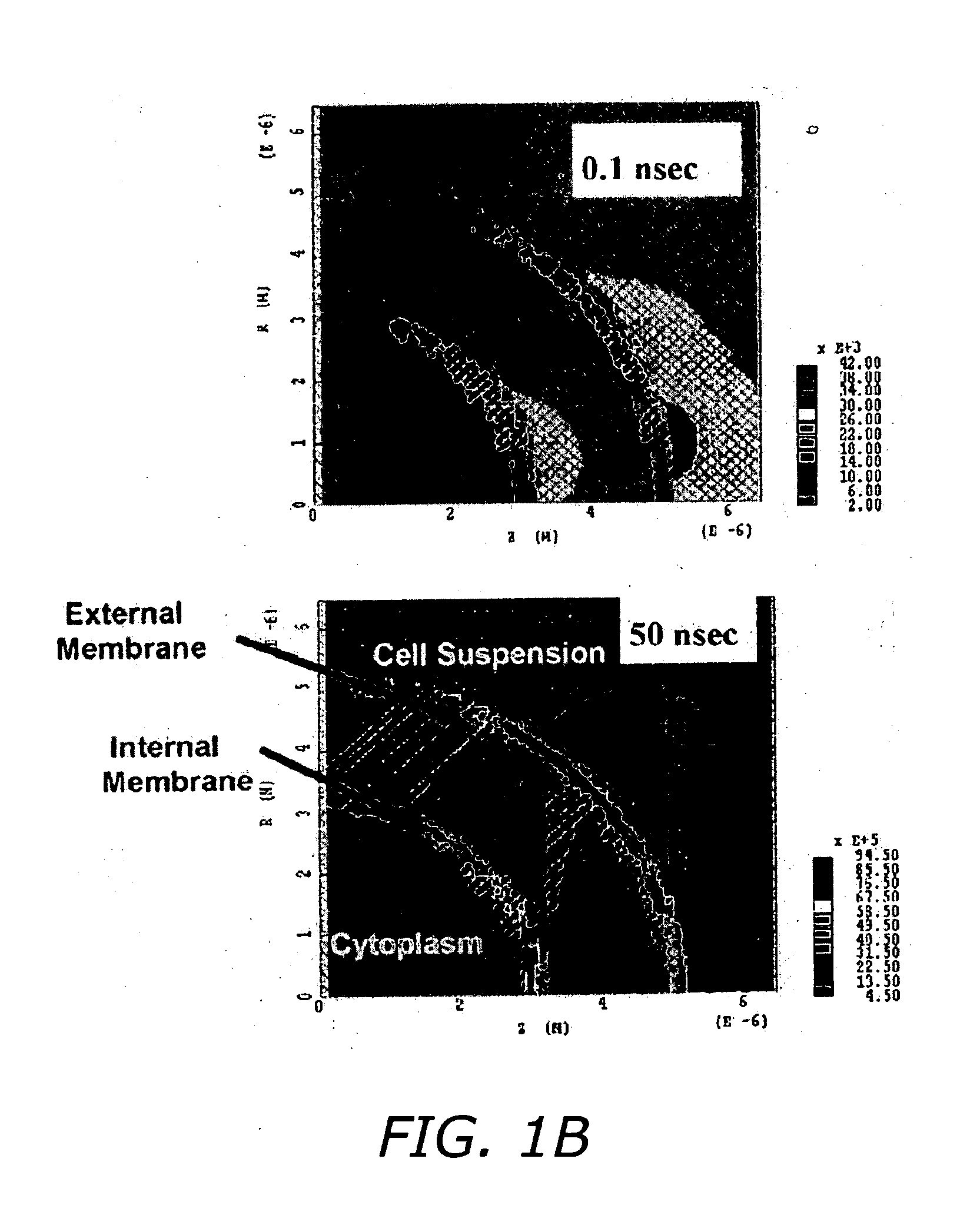

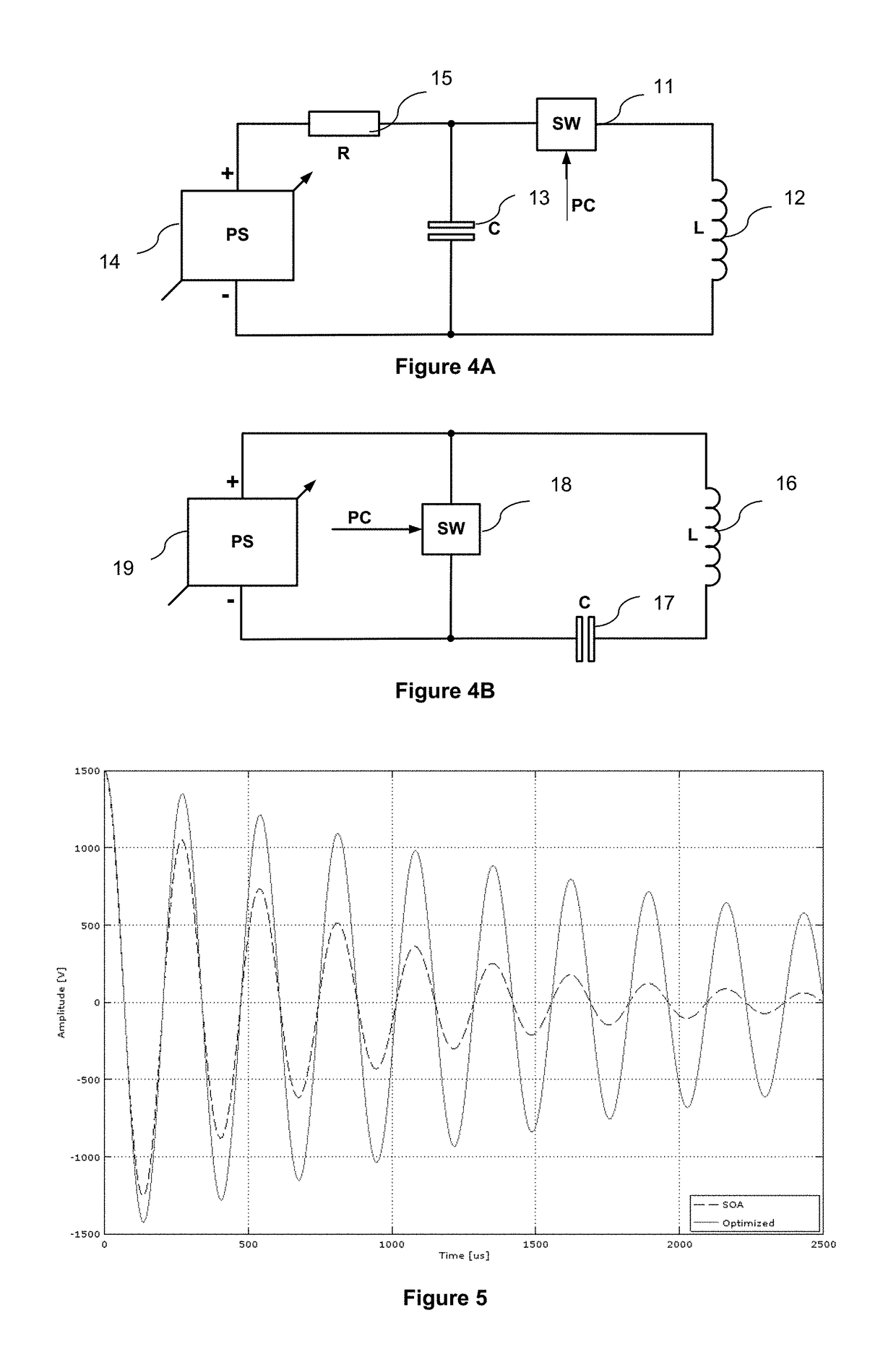

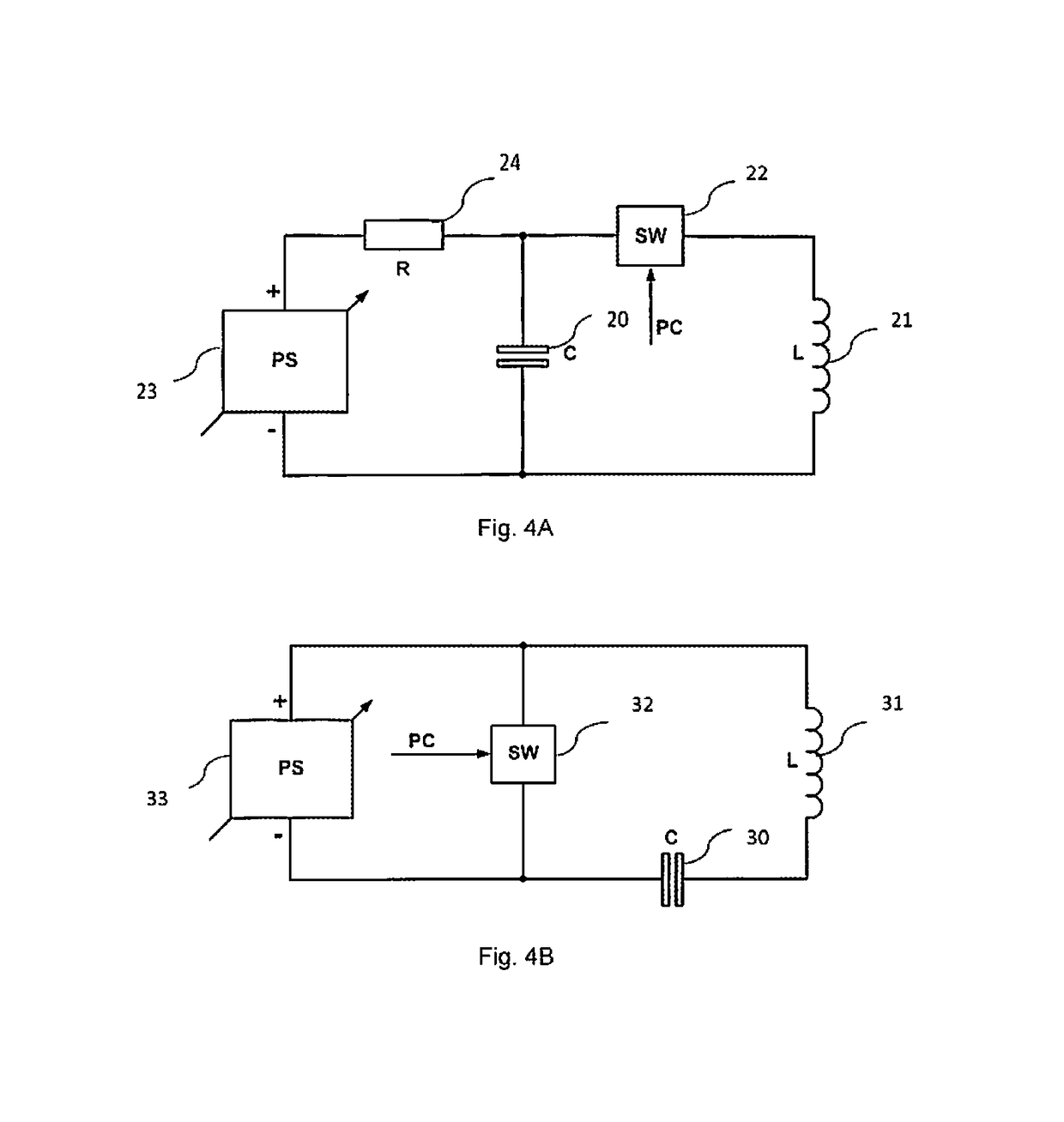

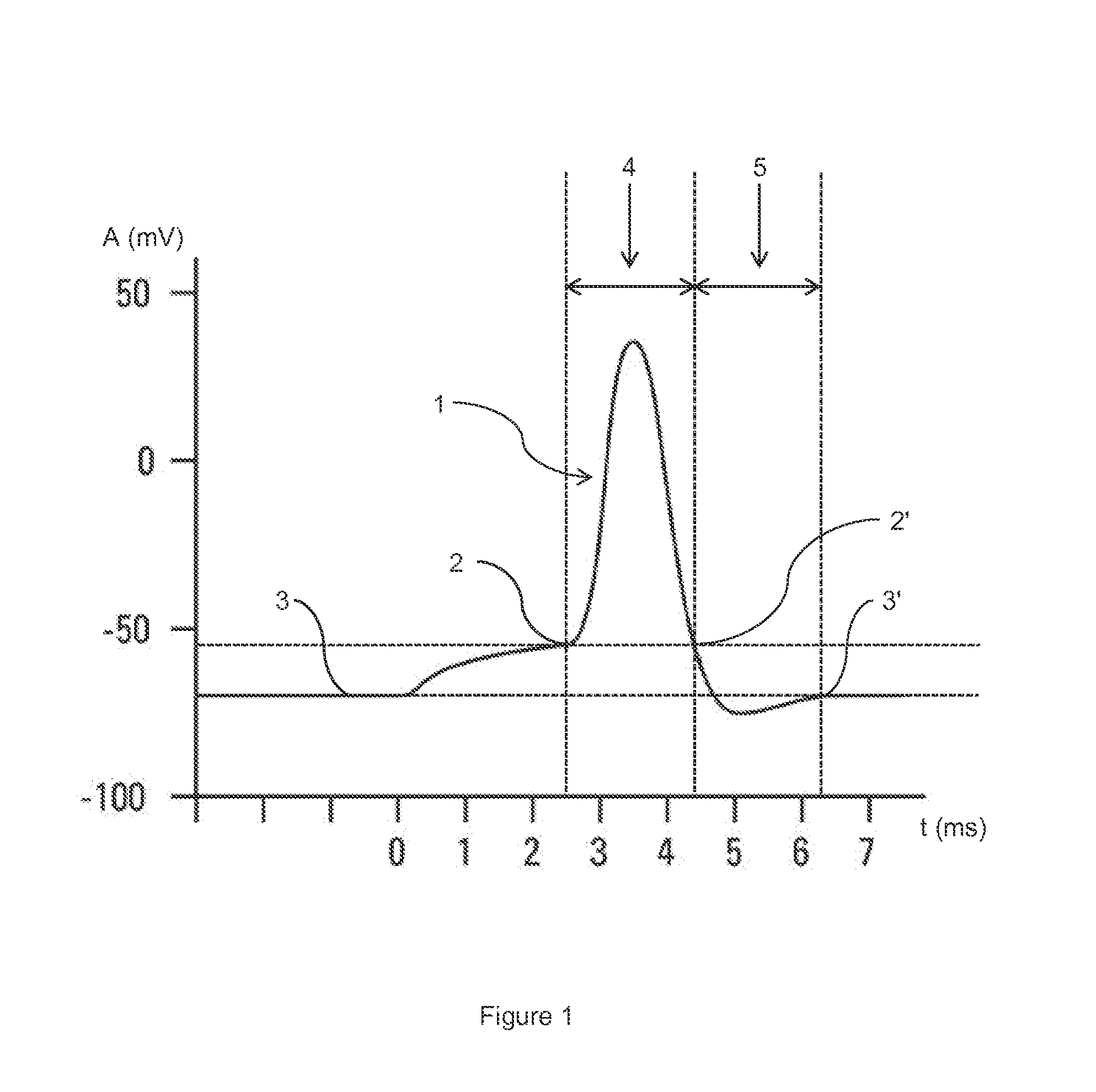

Compact subnanosecond high voltage pulse generation system for cell electro-manipulation

ActiveUS20080231337A1Good treatment effectGood effectElectrotherapyDelay line applicationsDistortionHigh bandwidth

Disclosed are methods and systems for subnanosecond rise time high voltage (HV) electric pulse delivery to biological loads. The system includes an imaging device and monitoring apparatus used for bio-photonic studies of pulse induced intracellular effects. The system further features custom fabricated microscope slide having micro-machined electrodes. A printed circuit board to interface the pulse generator to the micro-machined glass slide having the cell solution. An low-parasitic electronic setup to interface with avalanche transistor-switched pulse generation system. The pc-board and the slide are configured to match the output impedance of the pulse generator which minimizes reflection back into the pulse generator, and minimizes distortion of the pulse shape and pulse parameters. The pc-board further includes a high bandwidth voltage divider for real-time monitoring of pulses delivered to the cell solutions.

Owner:UNIV OF SOUTHERN CALIFORNIA

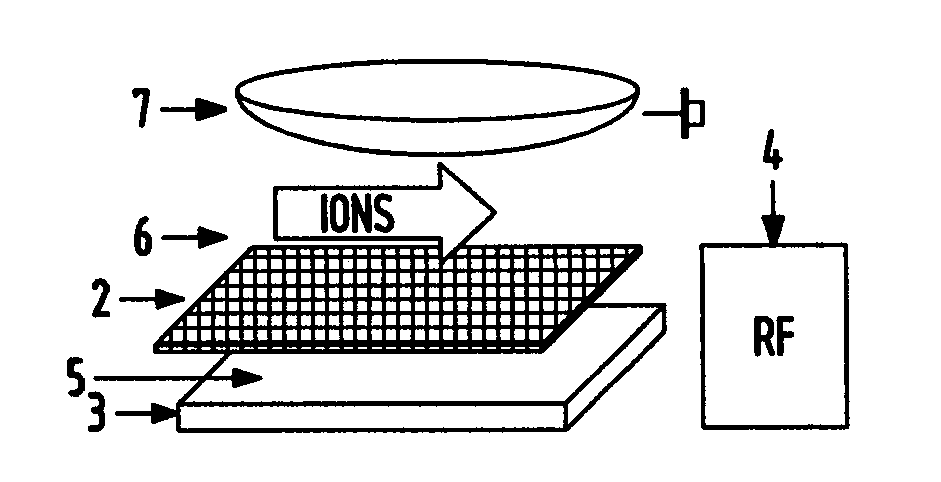

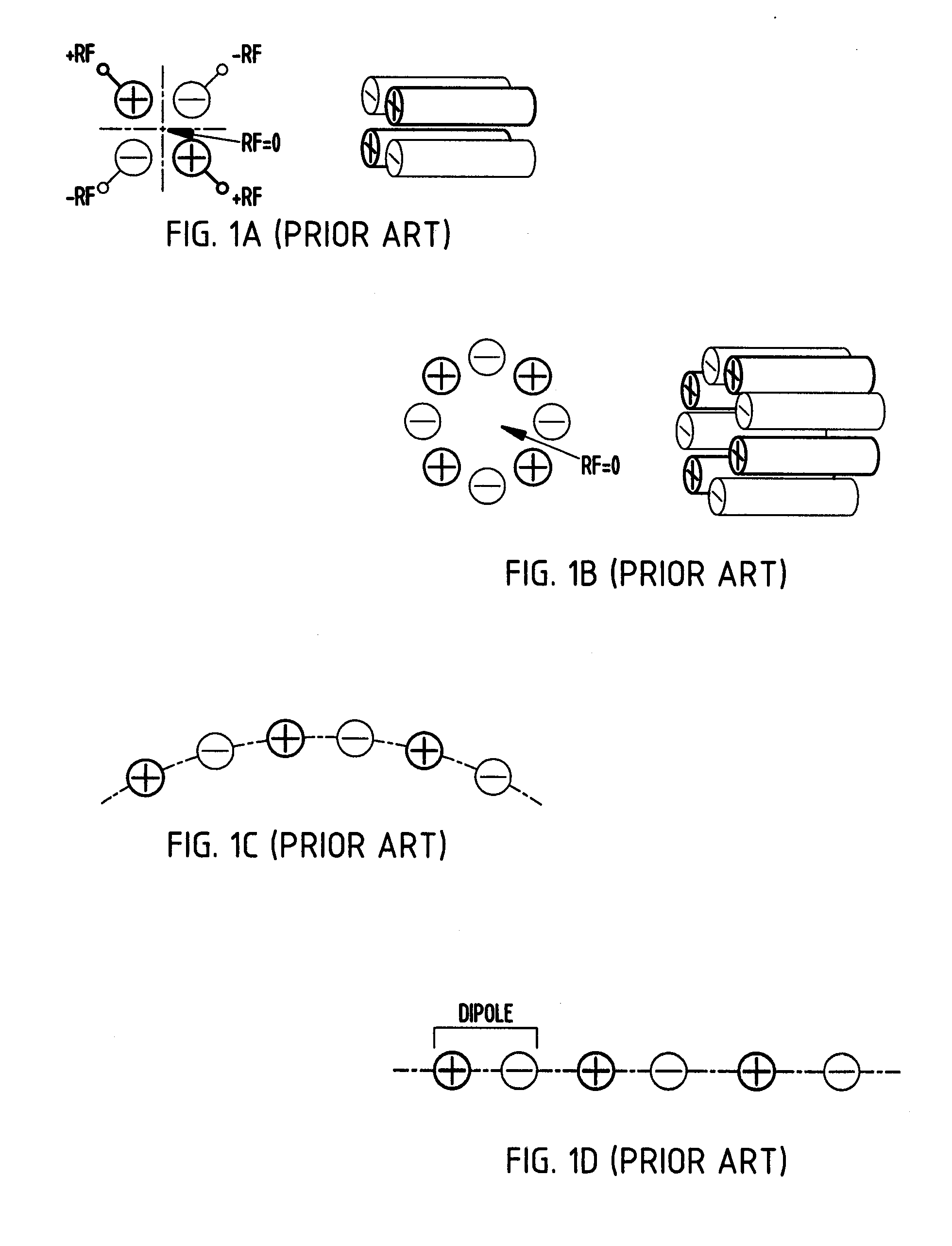

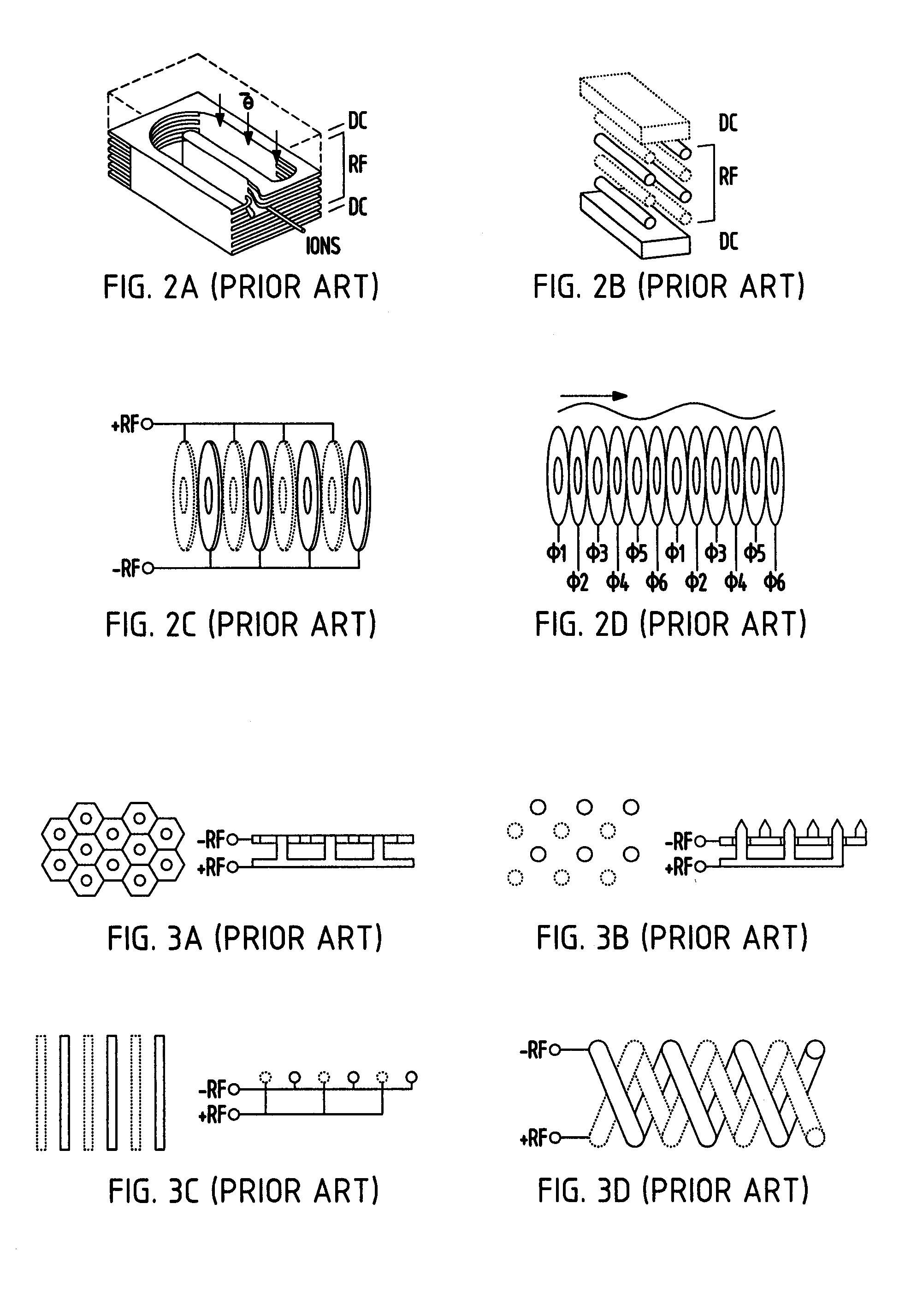

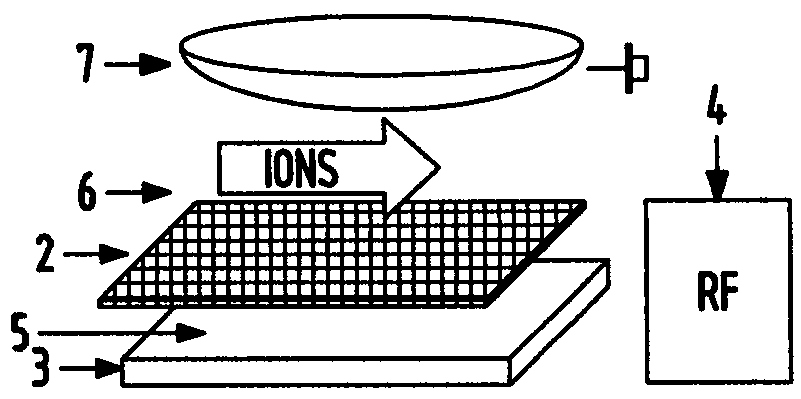

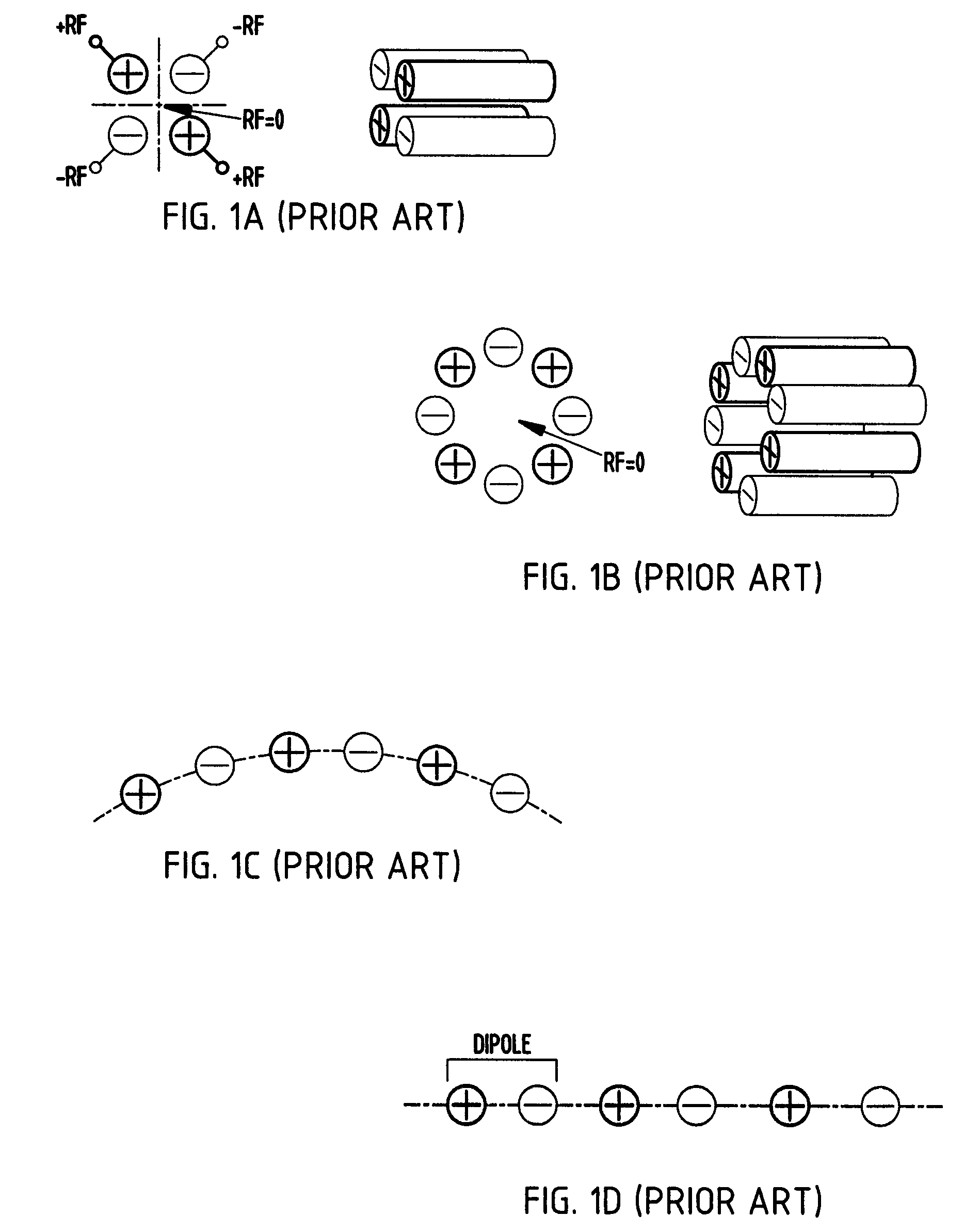

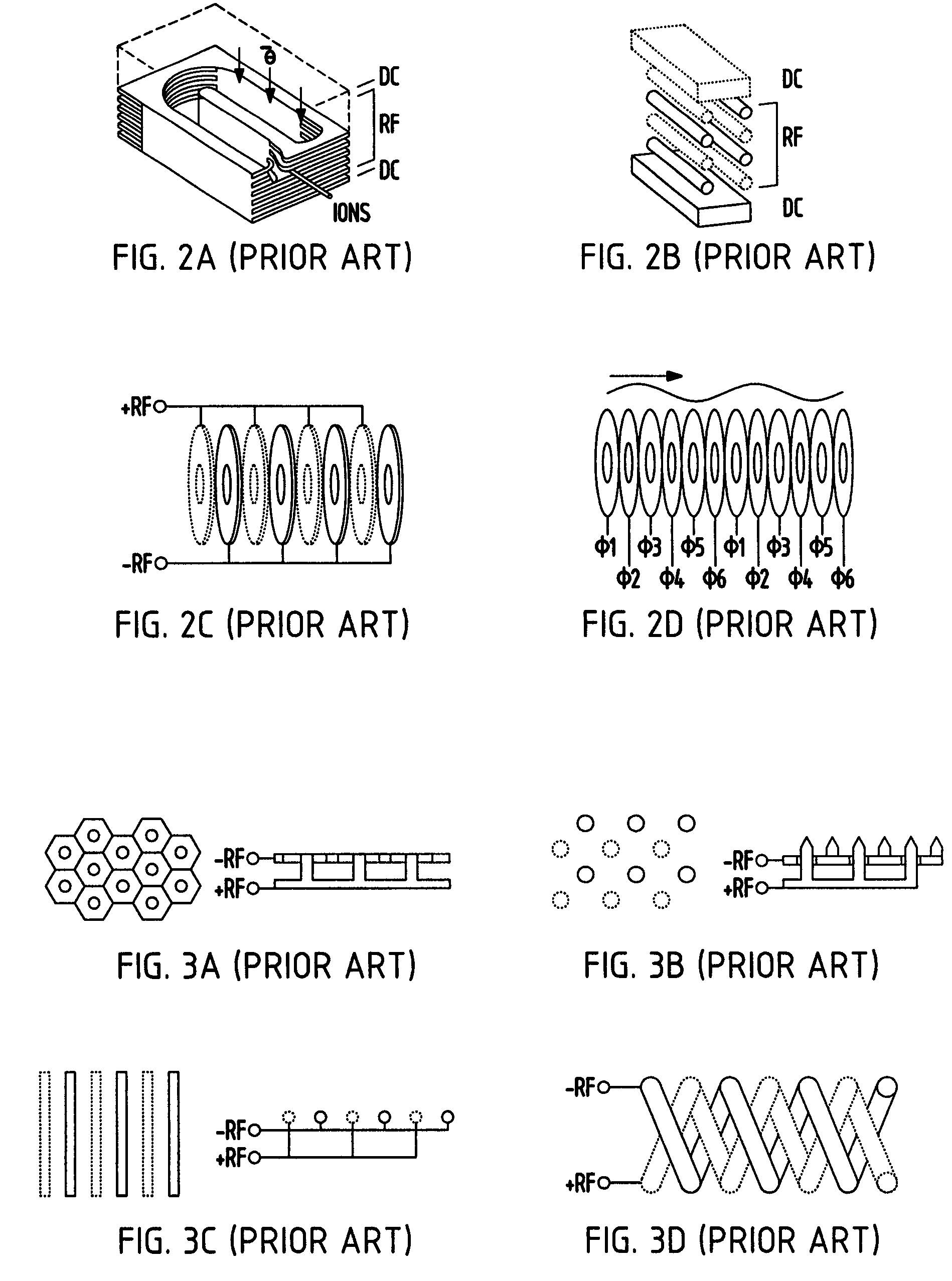

Method and apparatus for ion manipulation using mesh in a radio frequency field

ActiveUS20110192969A1Better wayEasy to buildTime-of-flight spectrometersIsotope separationIon chromatographyDesorption

Ion manipulation systems include ion repulsion by an RF field penetrating through a mesh. Another comprises trapping ions in a symmetric RF field around a mesh. The system uses macroscopic parts, or readily available fine meshes, or miniaturized devices made by MEMS, or flexible PCB methods. One application is ion transfer from gaseous ion sources with focusing at intermediate and elevated gas pressures. Another application is the formation of pulsed ion packets for TOF MS within trap array. Such trapping is preferably accompanied by pulsed switching of RF field and by gas pulses, preferably formed by pulsed vapor desorption. Ion guidance, ion flow manipulation, trapping, preparation of pulsed ion packets, confining ions during fragmentation or exposure to ion to particle reactions and for mass separation are disclosed. Ion chromatography employs an ion passage within a gas flow and through a set of multiple traps with a mass dependent well depth.

Owner:LECO CORPORATION

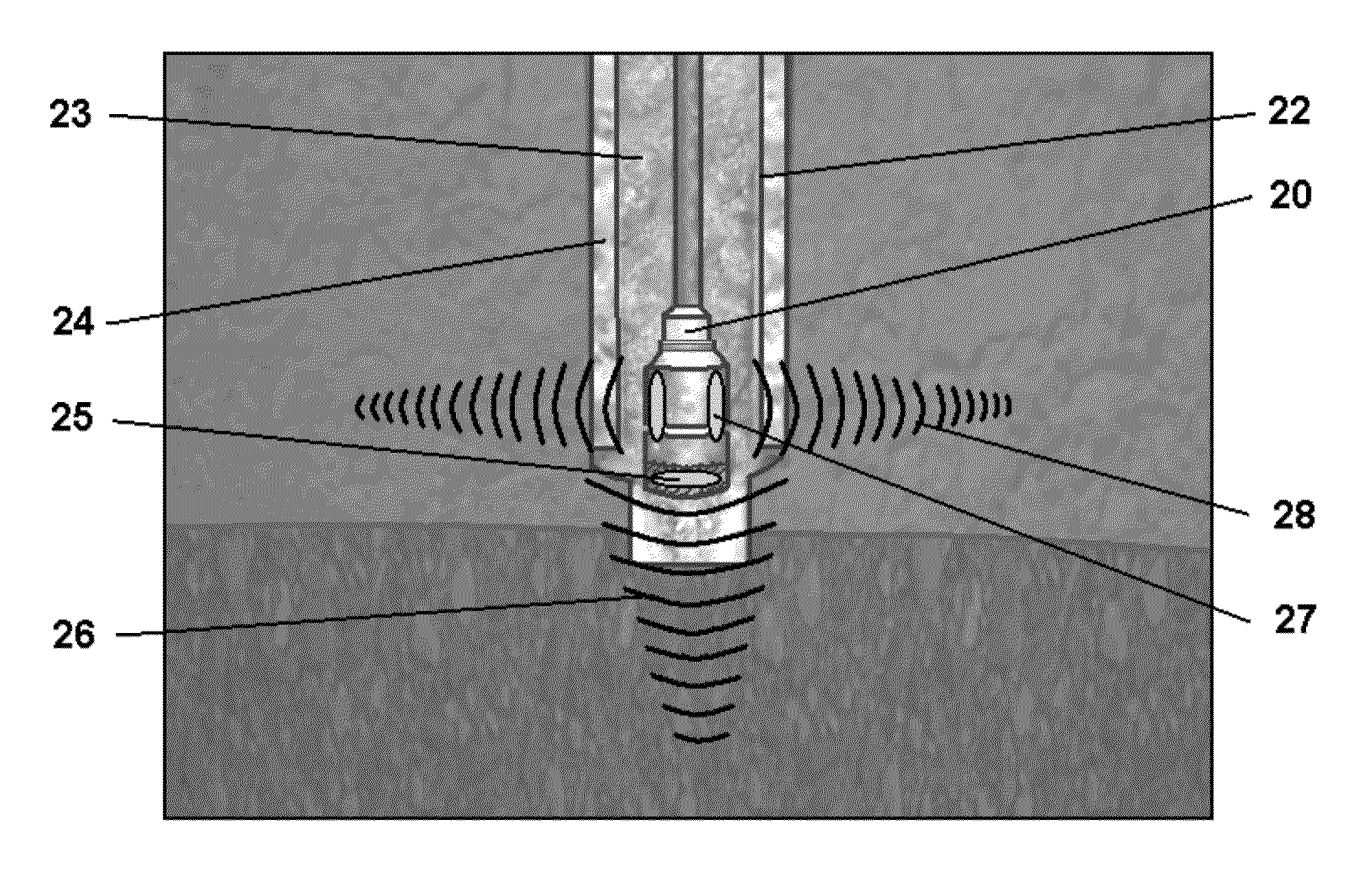

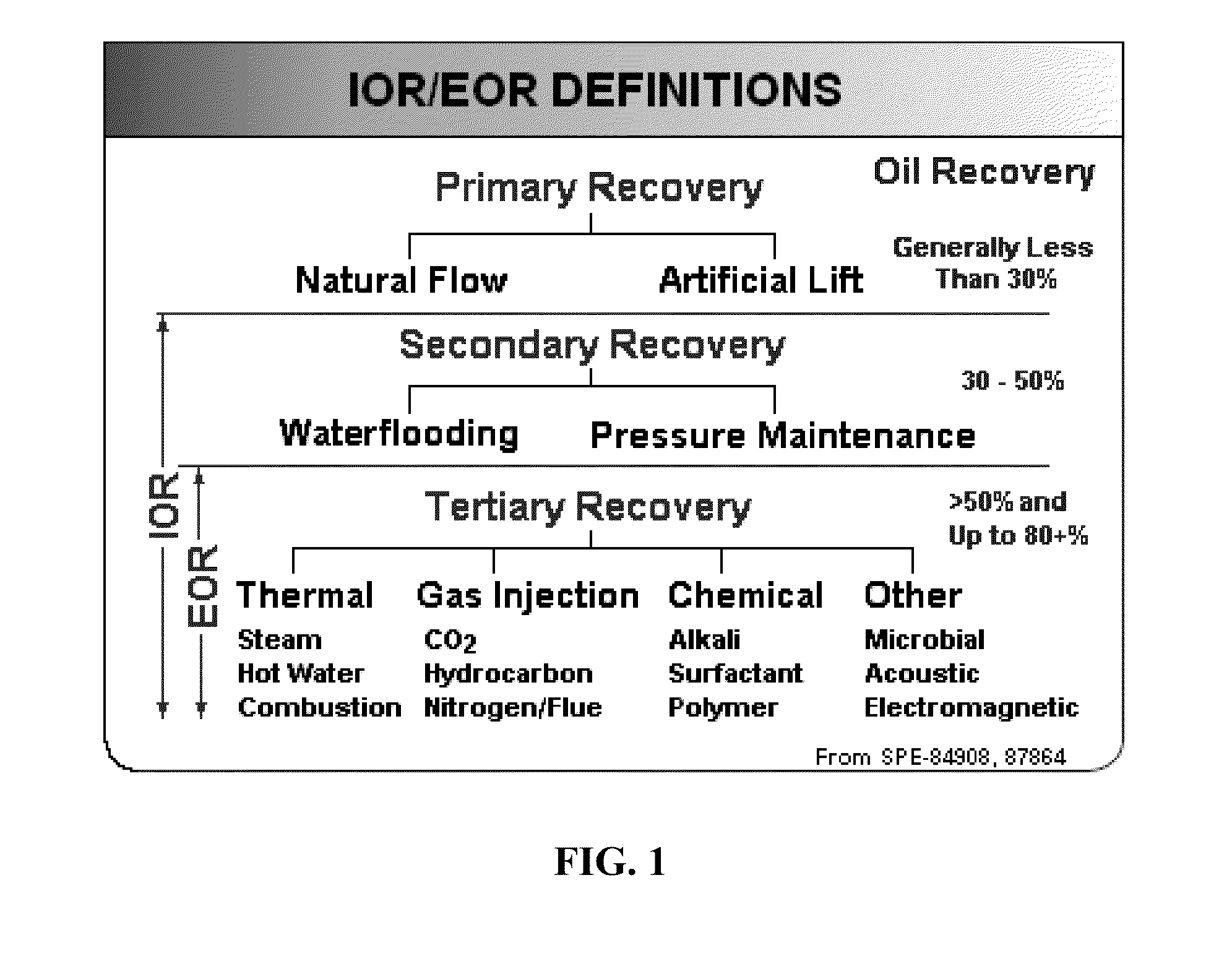

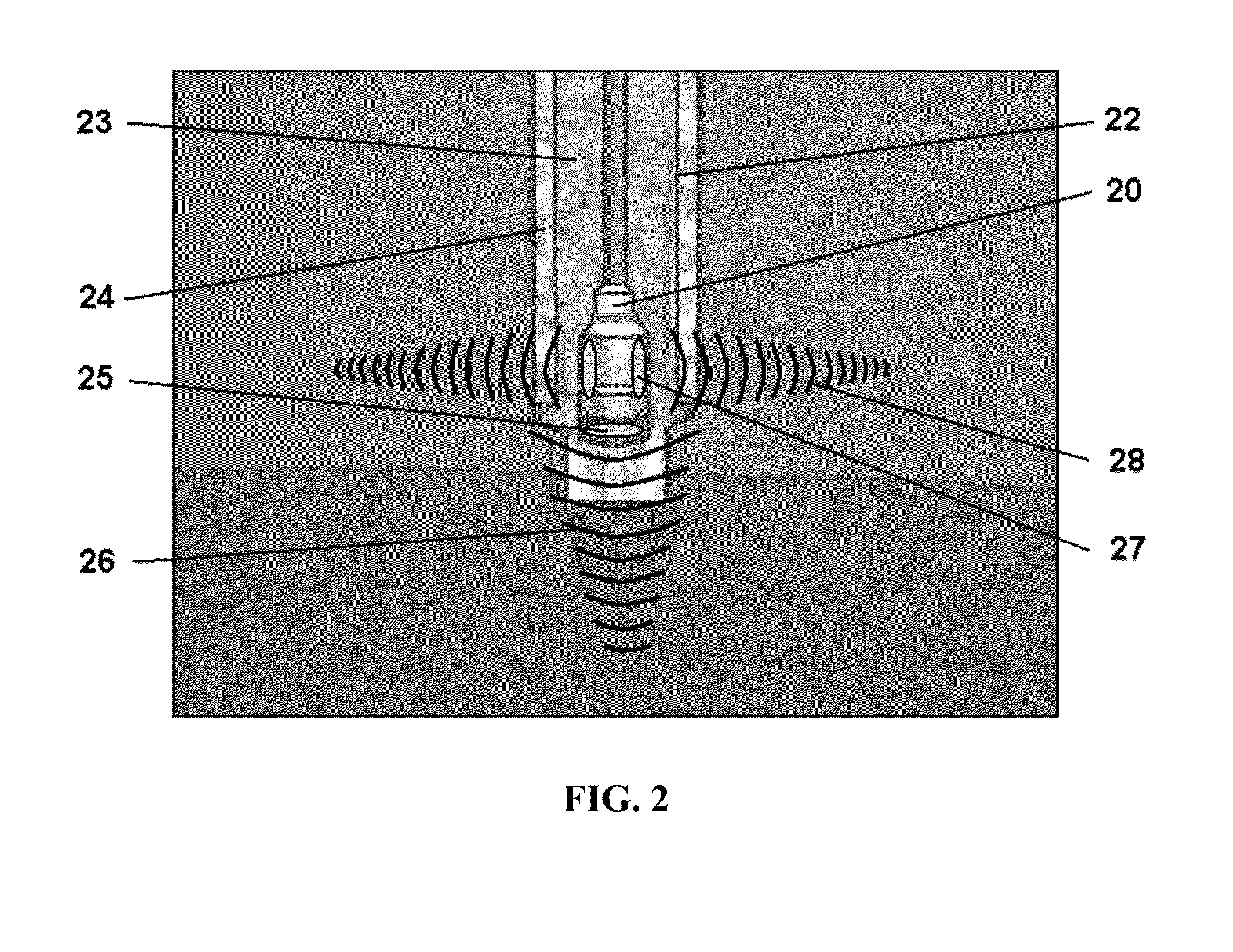

Apparatuses and methods for generating shock waves for use in the energy industry

ActiveUS20140305877A1Extend your lifeNeed can be fittedWaste water treatment from quariesFatty/oily/floating substances removal devicesShock waveFiber

Several methods and devices are provided herein to generate shock waves that are used in the oil industry for well drilling, hydrocarbon or gas exploitation, fracking process or improved oil recovery (IOR), enhanced oil recovery (EOR), cleaning of process waters, oil spills byproducts and oil pipes, which can be used as independent systems or as auxiliary systems concomitantly with other existing technologies. The different devices consist of generating shock waves utilizing either one or more laser sources, or a self-generated combustible gas supply, or a micro-explosive pellet, or piezocrystals, or a piezofiber composite structure.

Owner:SANUWAVE INC

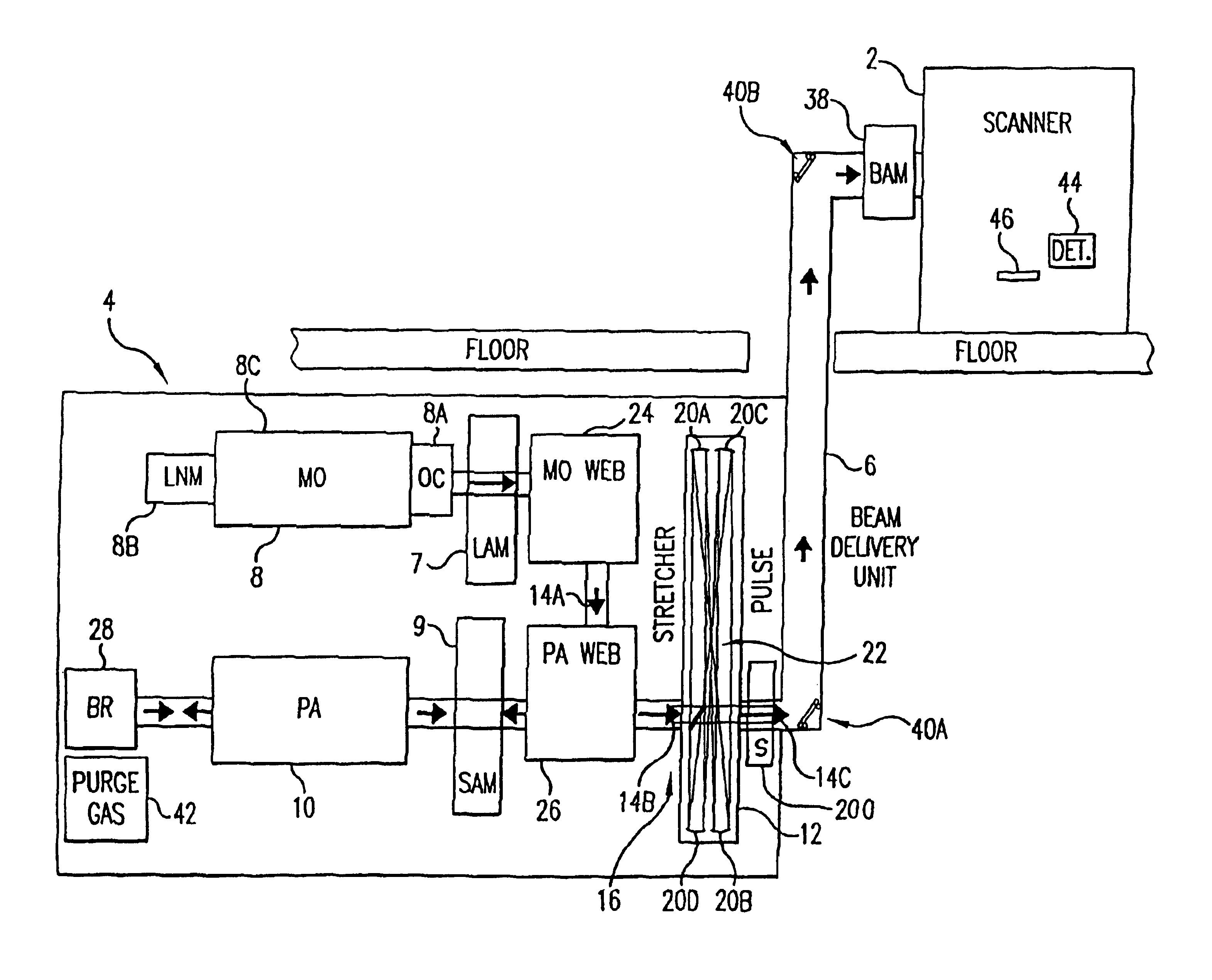

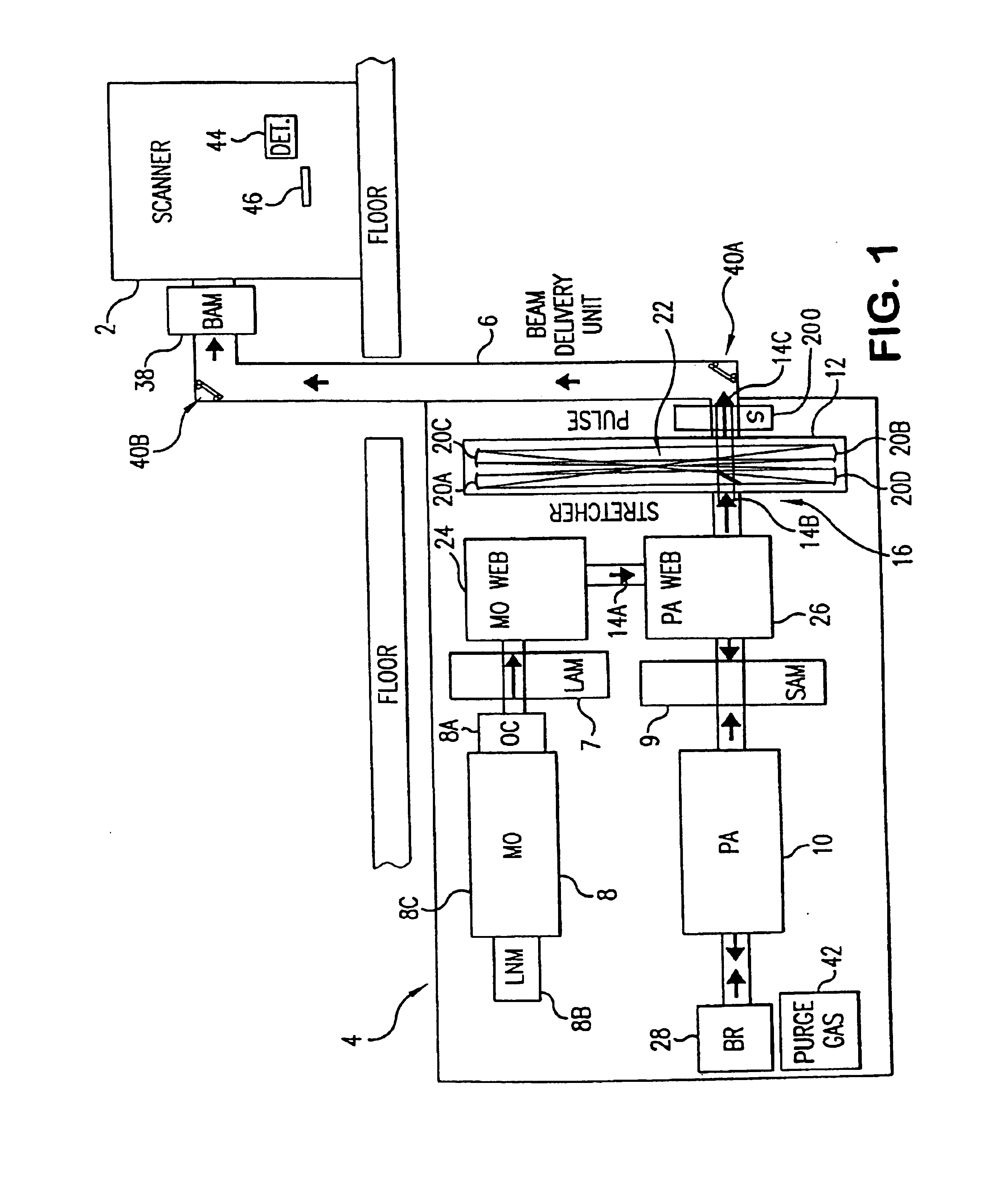

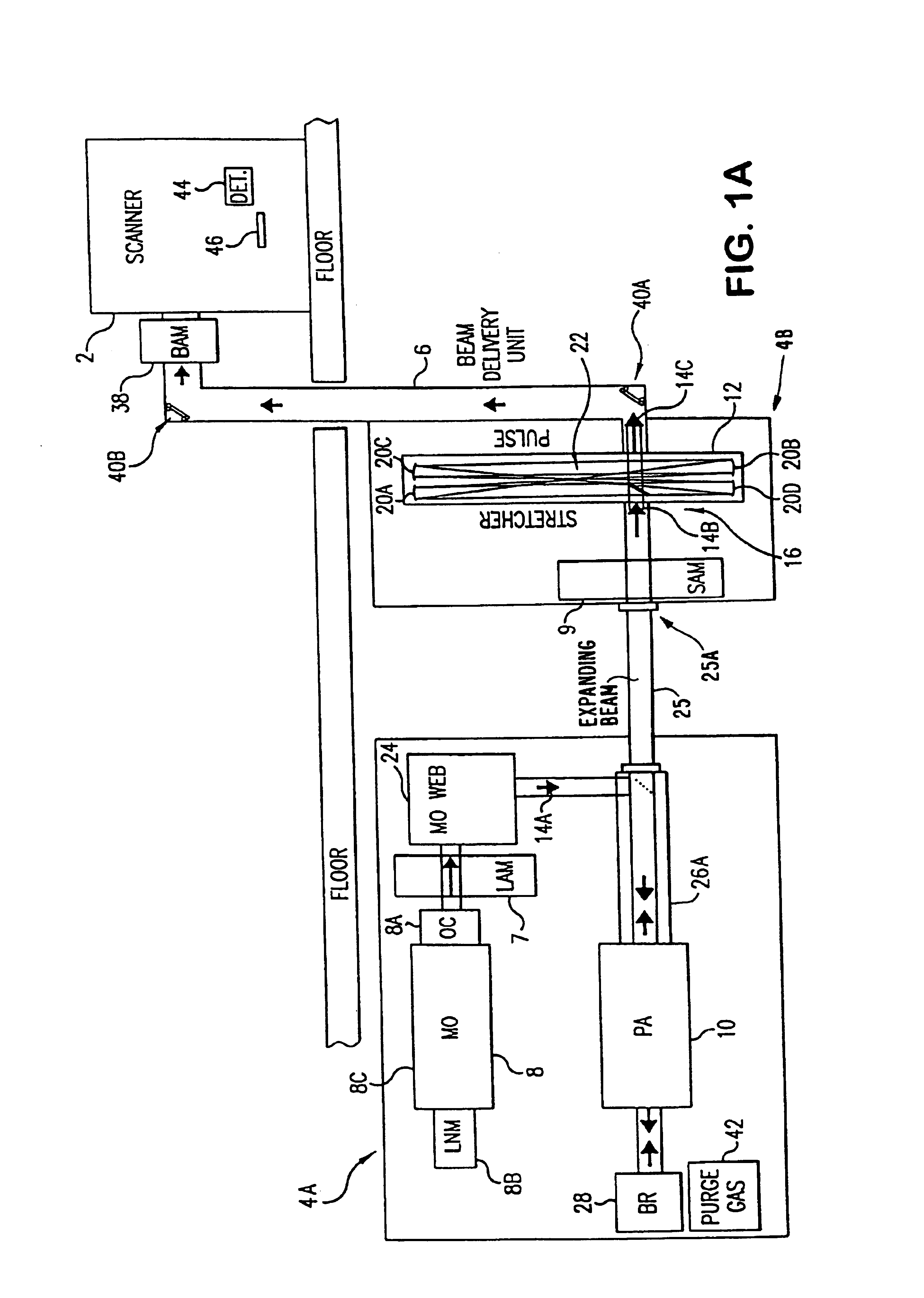

High power deep ultraviolet laser with long life optics

InactiveUS6904073B2Output powerBeam quality specificationOptical resonator shape and constructionLaser arrangementsPhysicsPulse energy density

The present invention provides long life optics for a modular, high repetition rate, ultraviolet gas discharge laser systems producing a high repetition rate high power output beam. The invention includes solutions to a surface damage problem discovered by Applicants on CaF2 optics located in high pulse intensity sections of the output beam of prototype laser systems. Embodiments include an enclosed and purged beam path with beam pointing control for beam delivery of billions of output laser pulses. Optical components and modules described herein are capable of controlling ultraviolet laser output pulses with wavelength less than 200 nm with average output pulse intensities greater than 1.75×106 Watts / cm2 and with peak intensity or greater 3.5×106 Watts / cm2 for many billions of pulses as compared to prior art components and modules which failed after only a few minutes in these pulse intensities. Techniques and components are disclosed for minimizing the potential for optical damage and for reducing the pulse energy density to less than 100×10−6 J / cm3. Important improvements described in this specification have been grouped into the following subject matter categories: (1) Solution to CaF2 surface damage discovered by Applicants, (2) description of a high power ArF MOPA laser system, (3) description of beam delivery units, (4) polarization considerations (5) a high speed water-cooled auto shutter energy detector module and (6) other improvements.

Owner:CYMER INC

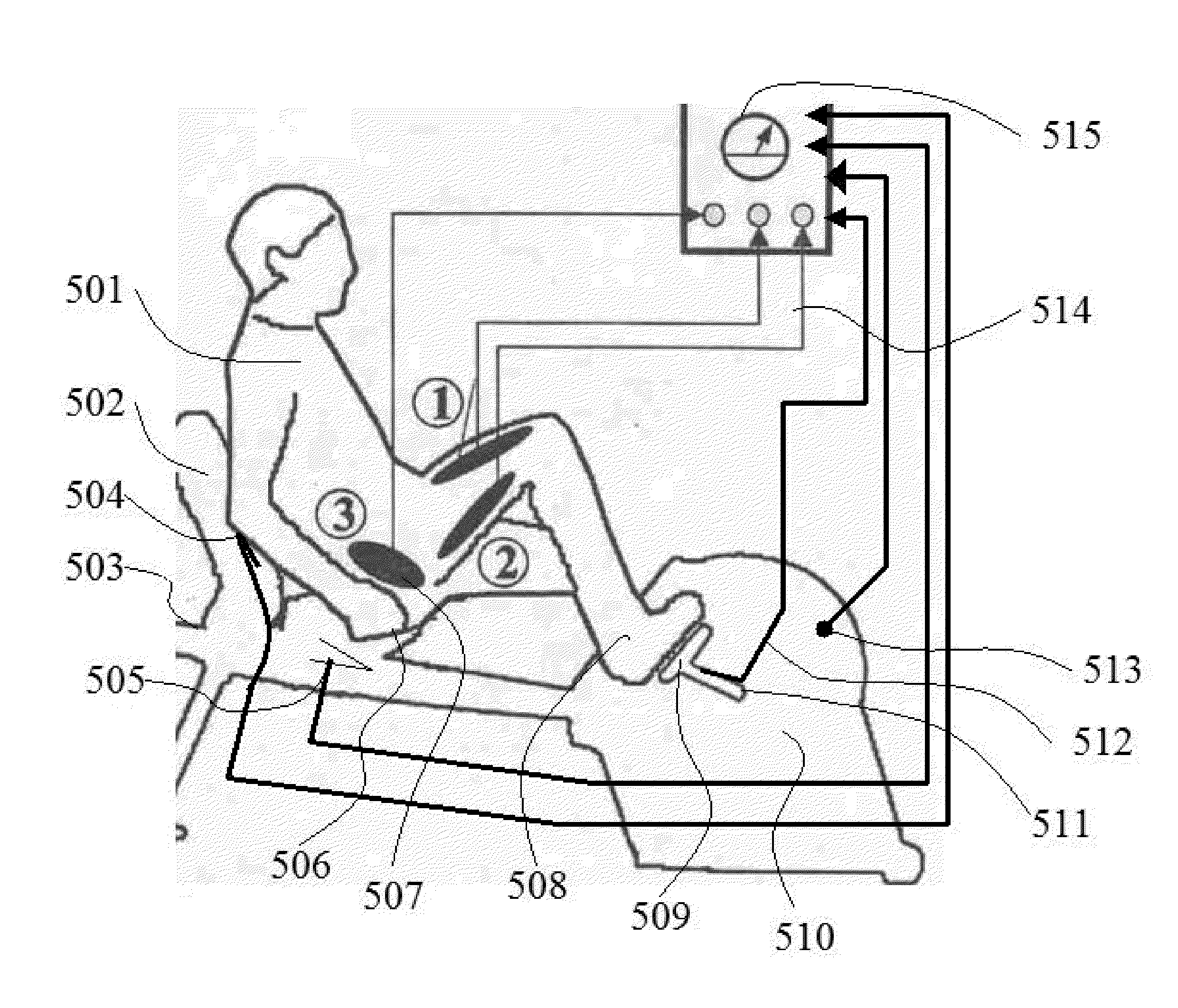

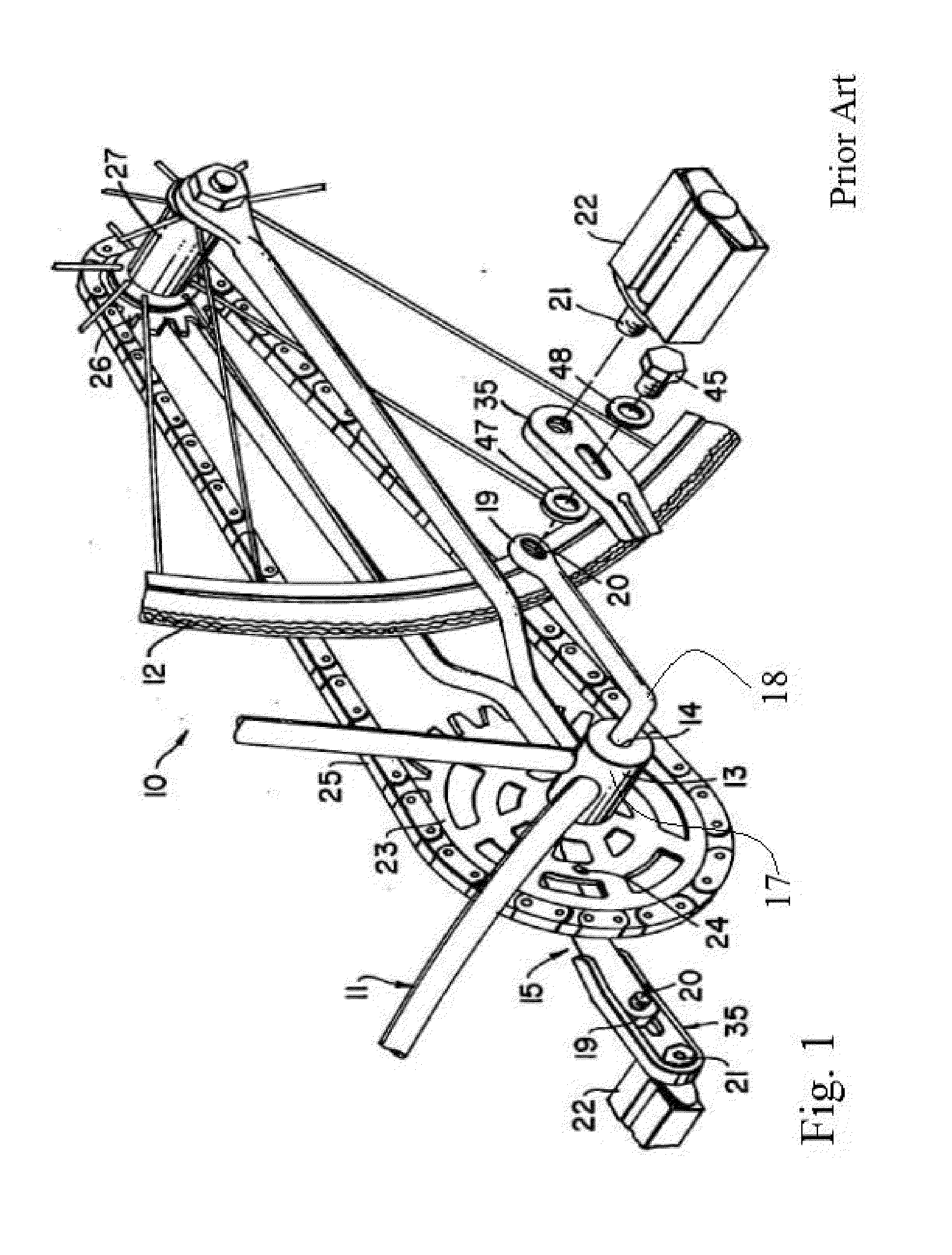

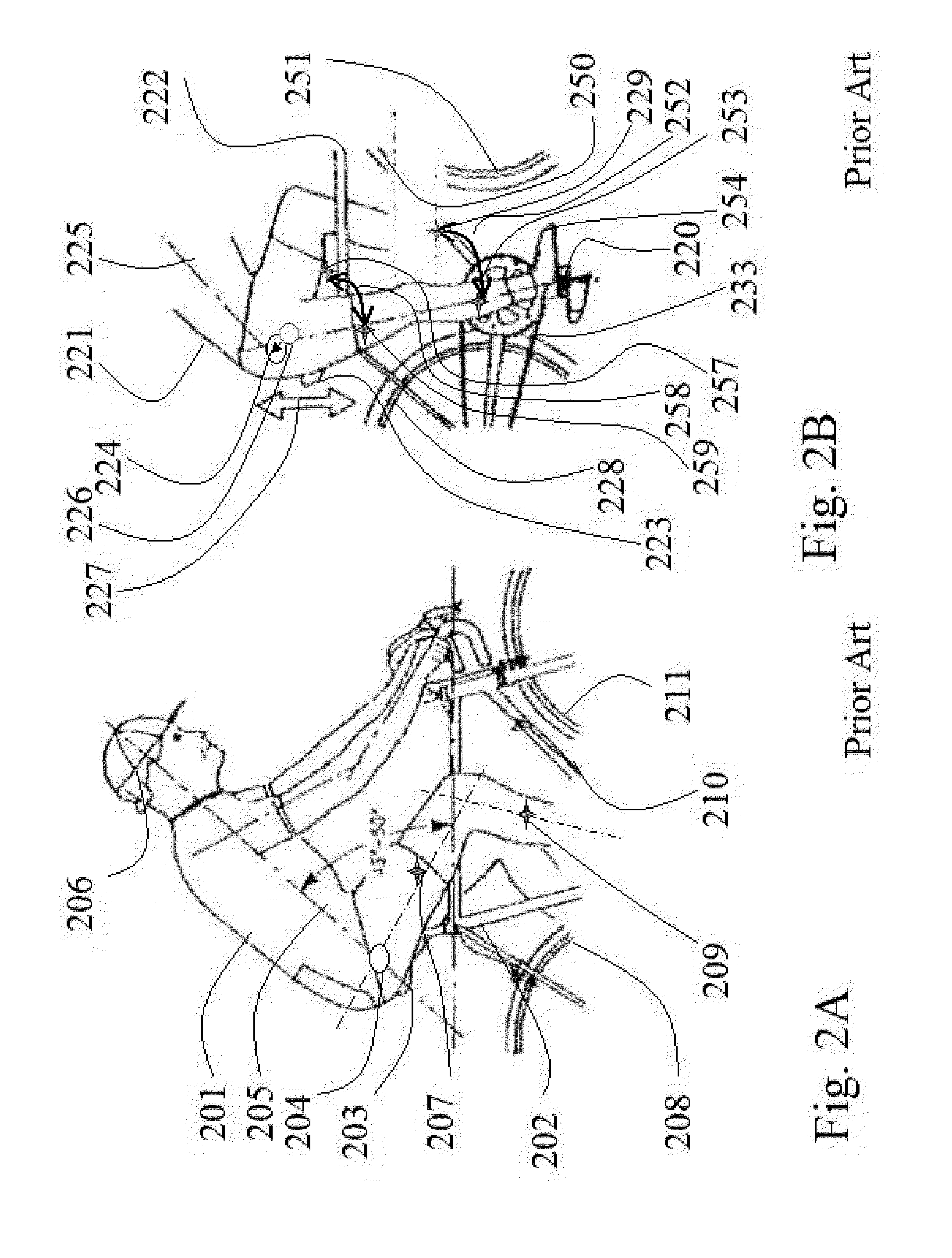

Method and accessories to enhance riding experience on vehicles with human propulsion

InactiveUS20160023081A1Improve indoor experienceMore experienceVehicle cranksCycle equipmentsReciprocating motionThe Internet

A set of accessory devices and a method that improves riding experience indoors and outdoors on devices using human propulsion and reciprocating motion. A mechanical accessory device that adds the stepping and reciprocating motion to a pedaling system, like those used on bicycles, tricycles, boats, individual power generators used indoors and outdoors with various positions, and movement range adjustments. A set of electronic accessories added gradually, that measures, records, transmits, processes and shares a large range of the parameters, generically called “riding experience” force and displacements, giving effort and work, GPS, accelerations, movie, etc. giving the path and rider vital and functional parameters, giving medical and exploratory results. A system that uses a code to process these information and transmits on the Internet, used on their indoors devices to reproduce the experience in their terms, transforming their devices in simulators, enabled to remotely control outdoors devices.

Owner:POPA SIMIL LIVIU +2

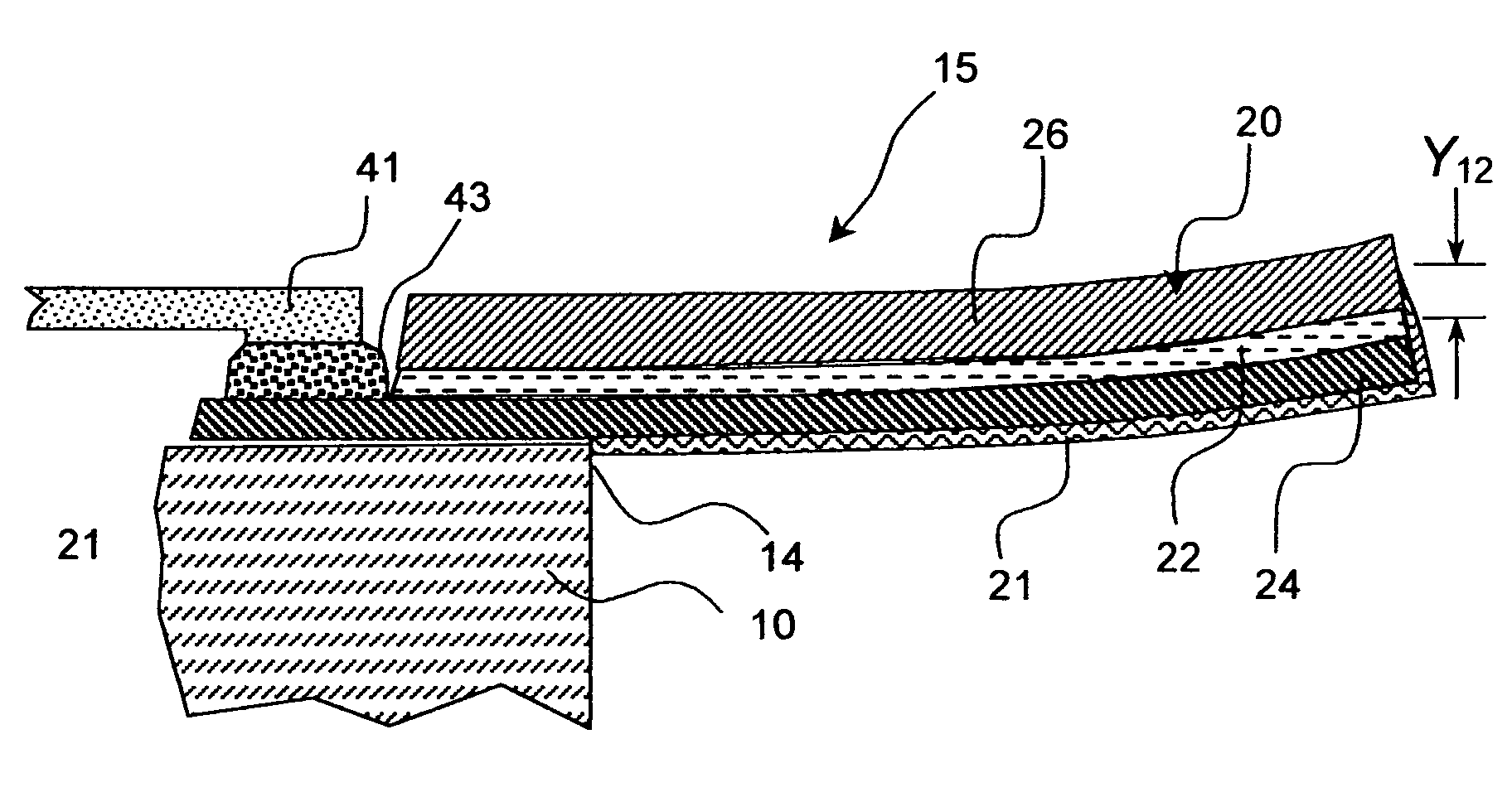

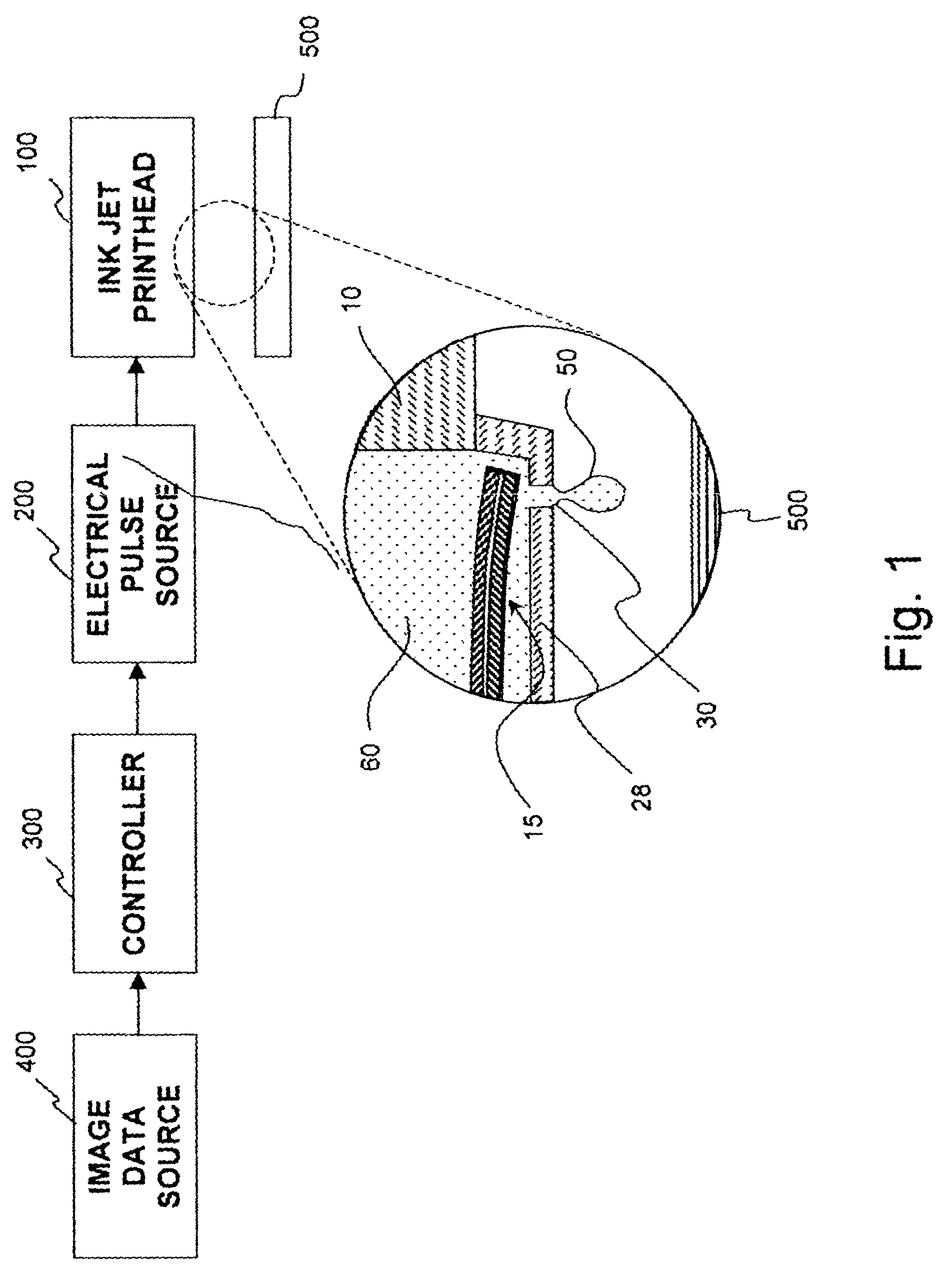

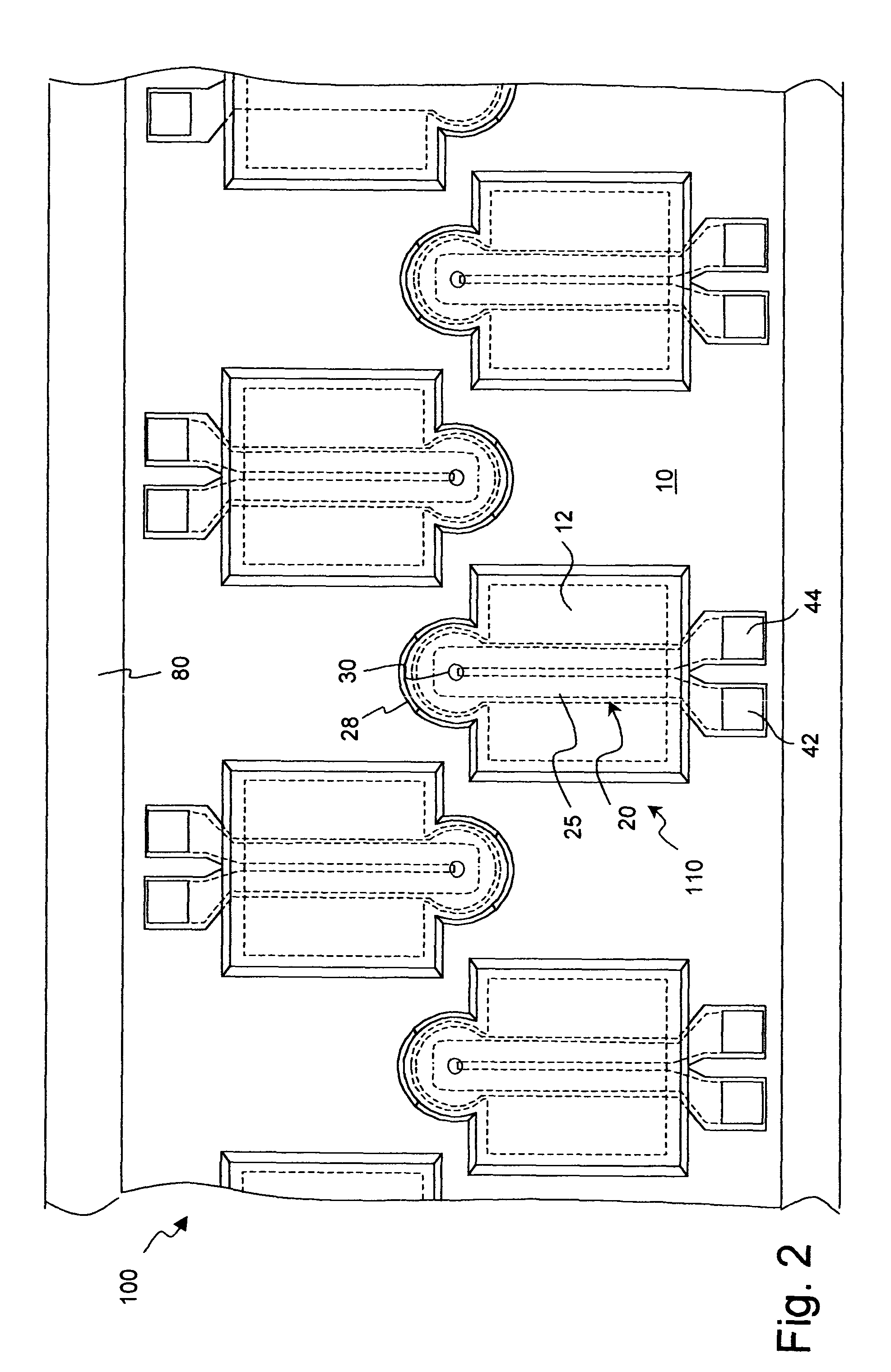

Thermally conductive thermal actuator and liquid drop emitter using same

ActiveUS7073890B2Reduce frequencyWithout excessive riseInking apparatusInfluence generatorsYoung's modulusEngineering

A thermal actuator for a micro-electromechanical device is disclosed. The thermal actuator includes a base element and a movable element extending from the base element and residing at a first position. The movable element includes a barrier layer constructed of a barrier material having low thermal conductivity material, bonded between a first layer and a second layer; wherein the first layer is constructed of a first material having a high coefficient of thermal expansion and the second layer is constructed of a second material having a high thermal conductivity and a high Young's modulus. An apparatus is provided adapted to apply a heat pulse directly to the first layer, causing a thermal expansion of the first layer relative to the second layer and deflection of the movable element to a second position.

Owner:EASTMAN KODAK CO

Laser based frequency standards and their applications

InactiveUS7809222B2Increase powerReduced Power RequirementsLaser detailsCoupling light guidesFiberMode locked fiber laser

Frequency standards based on mode-locked fiber lasers, fiber amplifiers and fiber-based ultra-broad bandwidth light sources, and applications of the same.

Owner:IMRA AMERICA

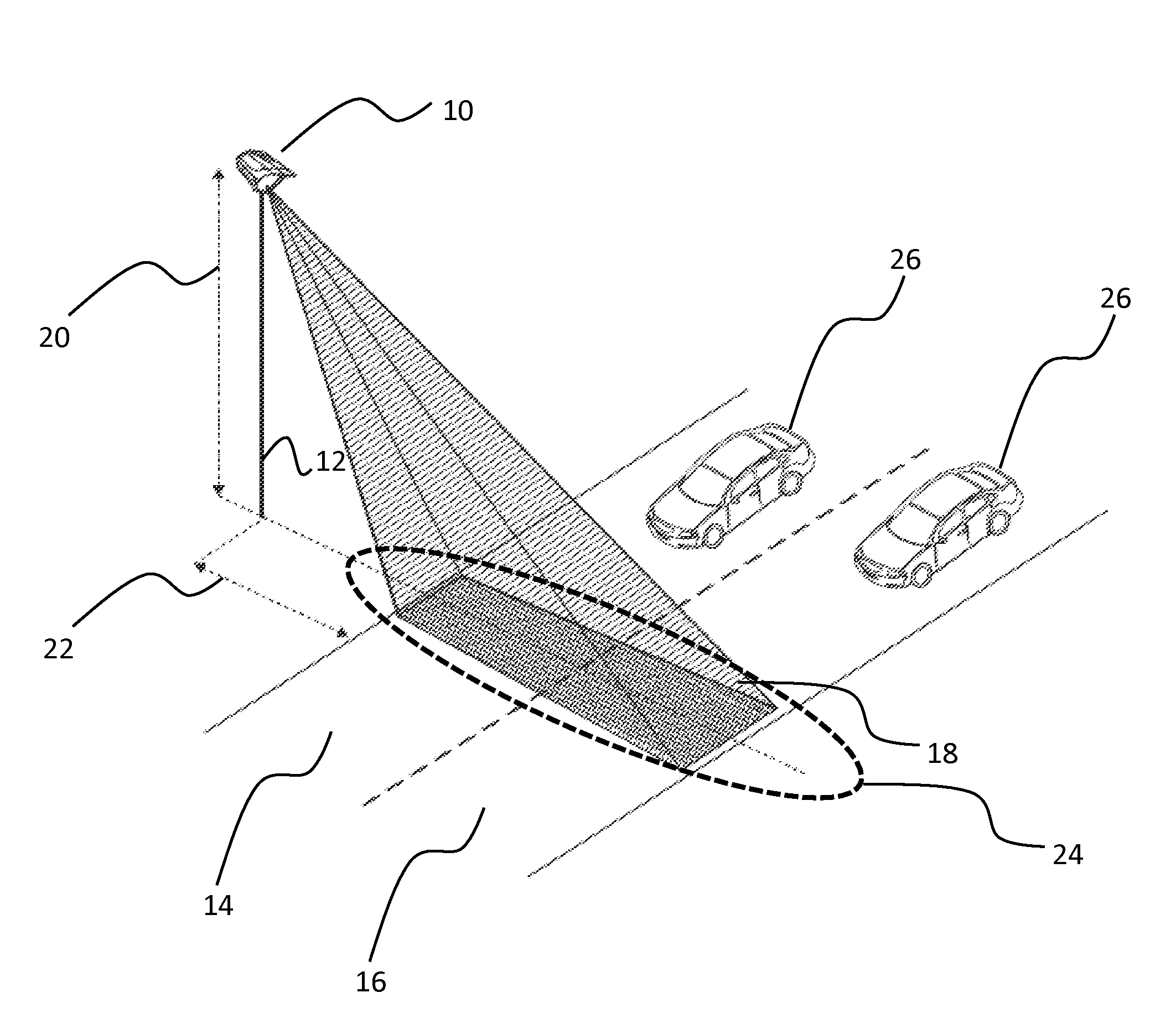

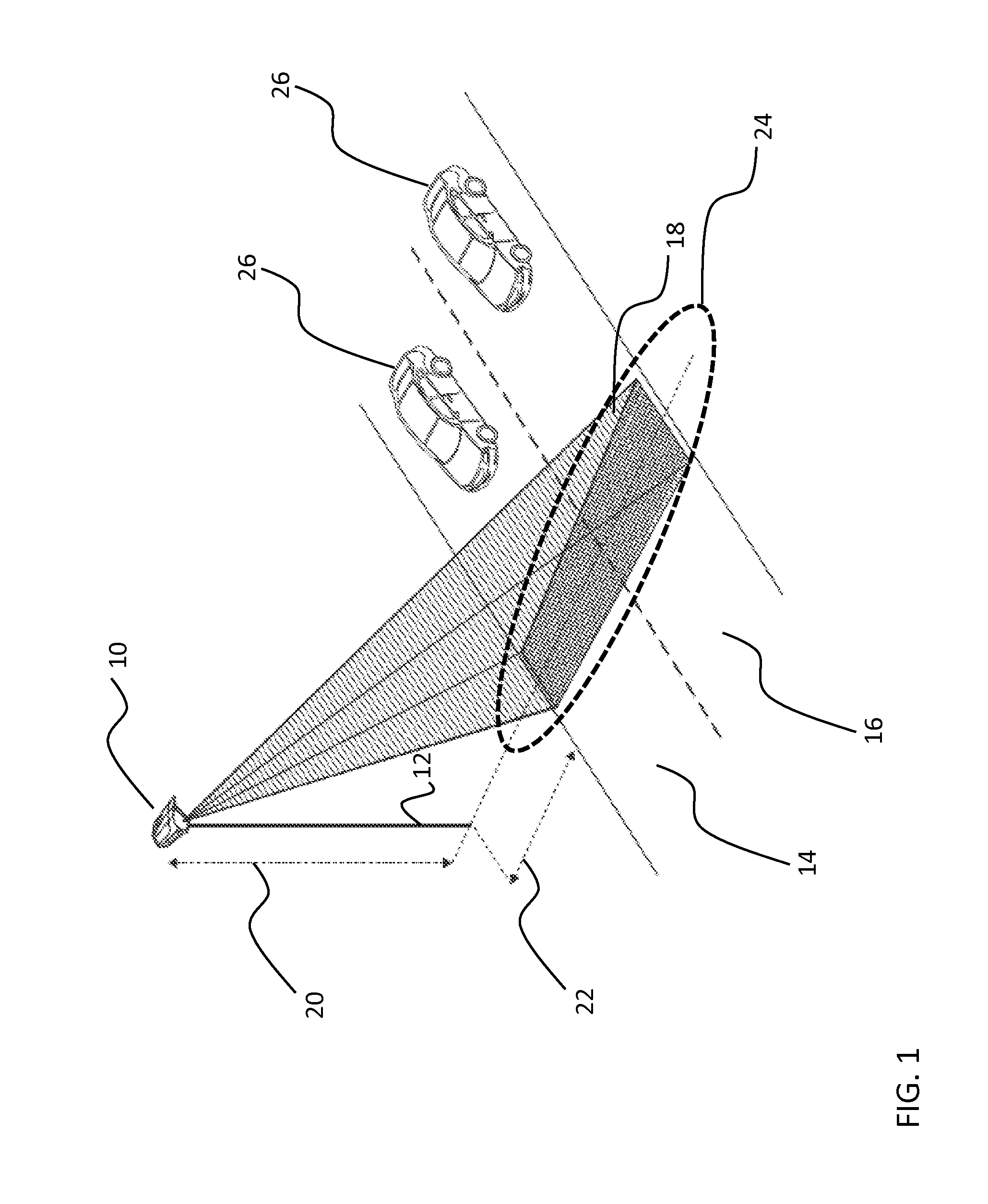

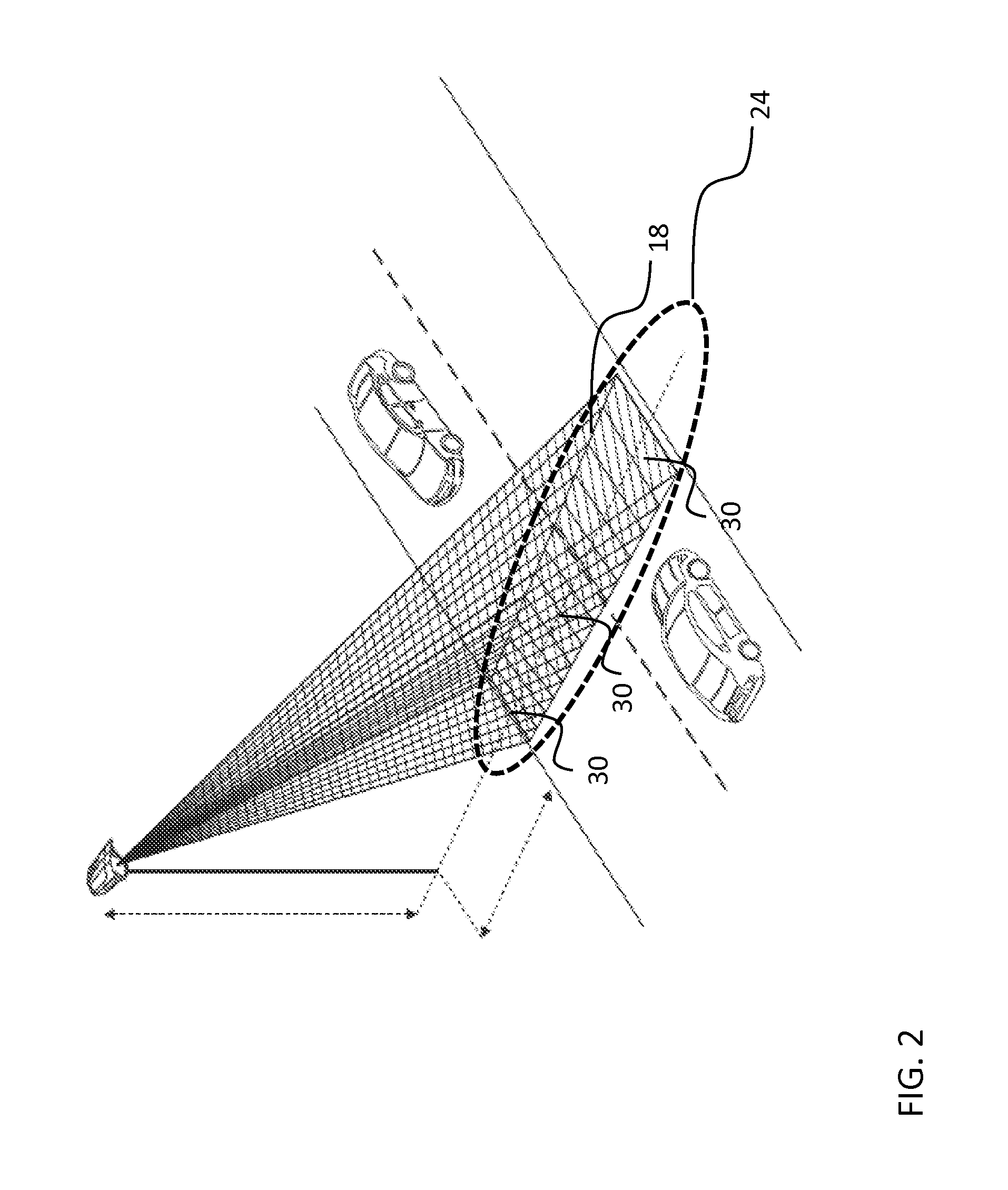

System and method for traffic side detection and characterization

ActiveUS20140232566A1High repetition rateDetection of traffic movementCharacter and pattern recognitionRadarFull waveform

A method for detecting a vehicle comprising: providing a multi-channel scannerless full-waveform lidar system operating in pulsed Time-Of-Flight operation oriented towards a surface of the roadway to cover the detection zone; providing at least one initialization parameter; emitting pulses at an emission frequency; receiving reflections of the pulses from the detection zone; and acquiring and digitalizing a series of individual complete traces at each channel of system; identifying at least one detection in at least one of the traces; obtaining a height and an intensity for the detection; determining a nature of the detection to be one of an environmental particle detection, a candidate object detection and a roadway surface detection; if the nature of the detection is the candidate object detection, detecting a presence of a vehicle in the detection zone.

Owner:LEDDARTECH INC

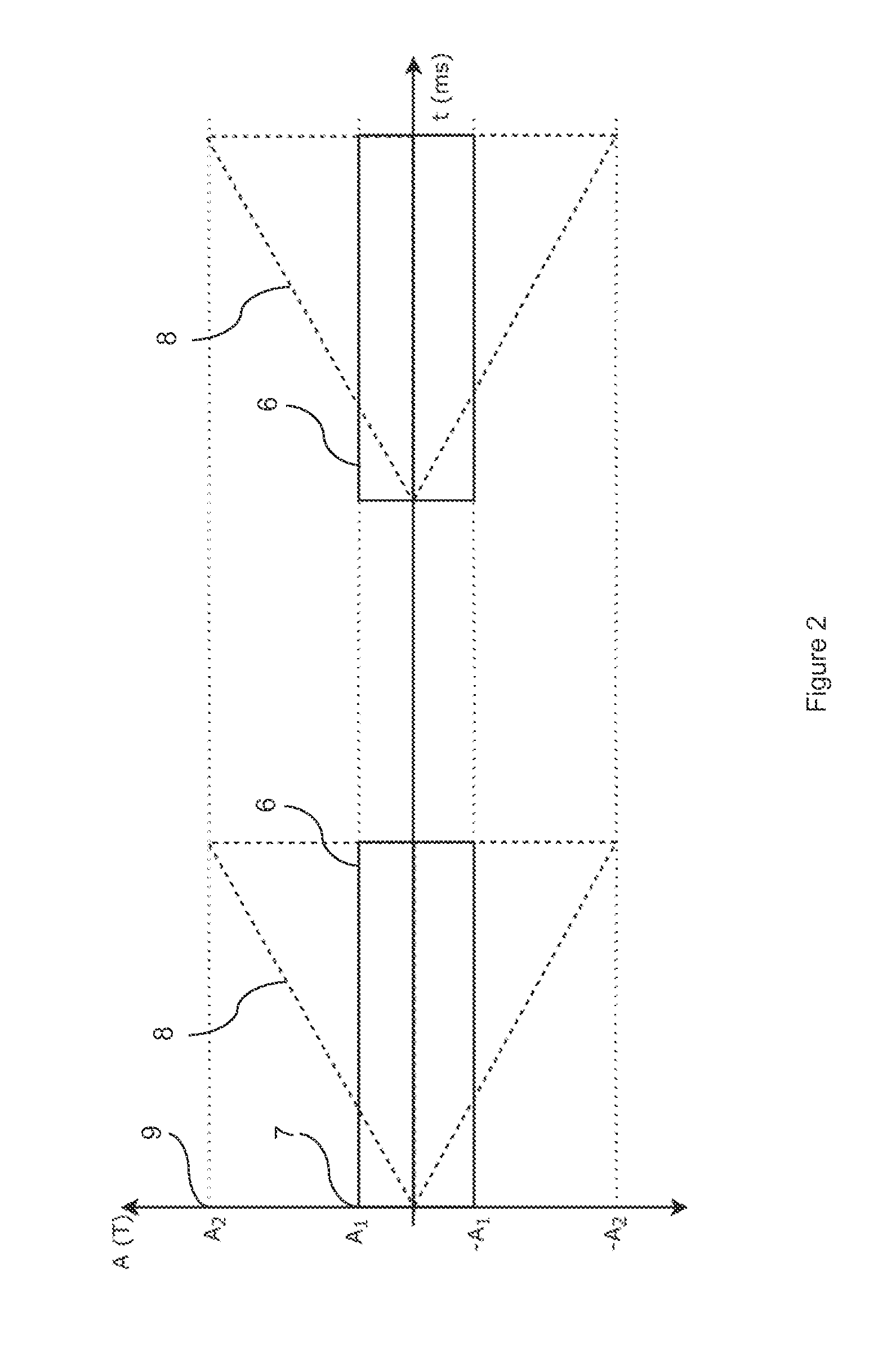

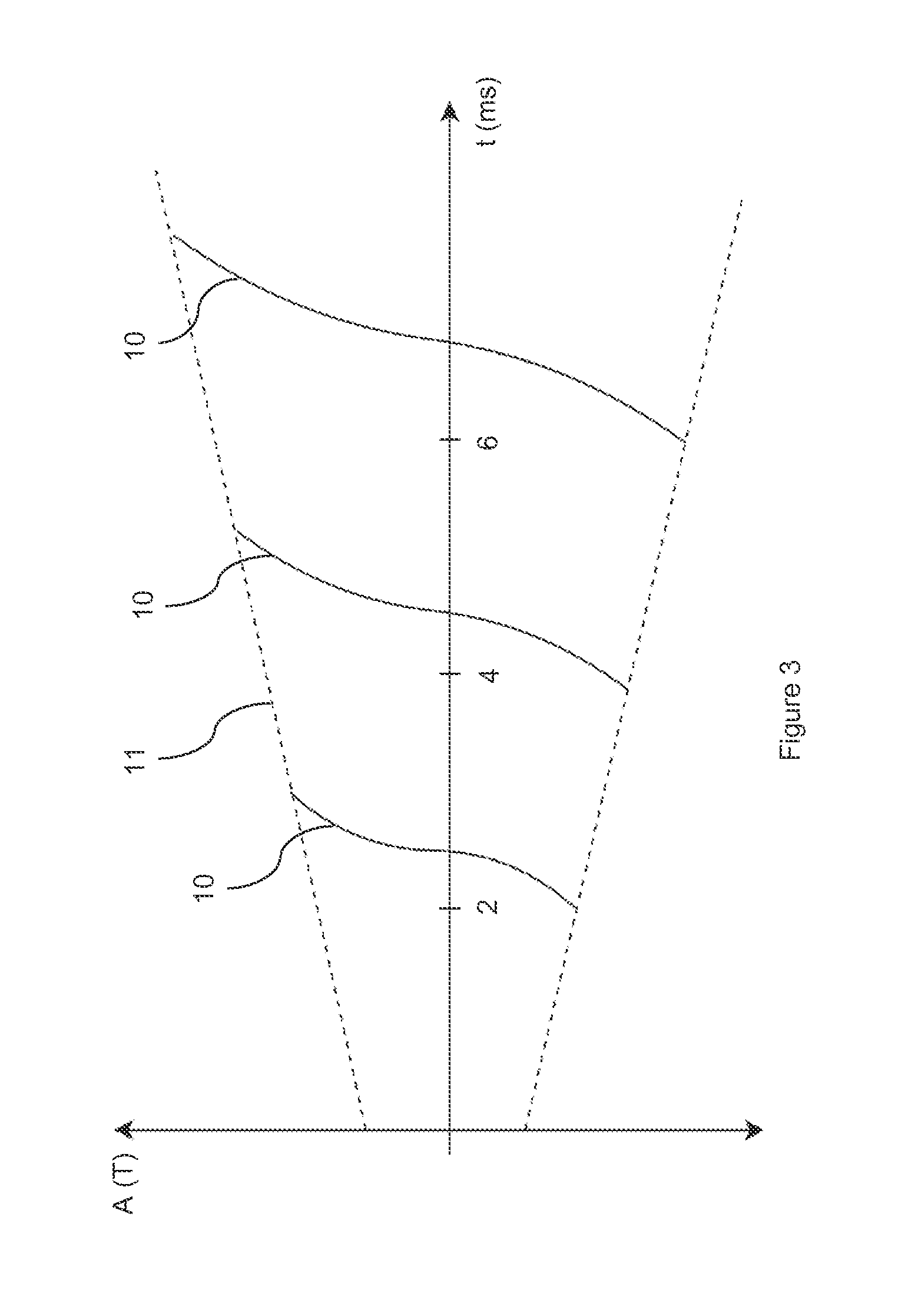

Aesthetic method of biological structure treatment by magnetic field

ActiveUS20180001106A1Improve effectivenessReduce self-heatingElectrotherapyMagnetotherapy using coils/electromagnetsMuscle contractionAdipose tissue

In methods for treating a patient, a time varying magnetic field is applied to a patient's body and causes a muscle contraction. The time-varying magnetic field may be monophasic, biphasic, polyphasic and / or static. The method may reduce adipose tissue, improve metabolism, blood and / or lymph circulation. The method may use combinations of treatments to enhance the visual appearance of the patient.

Owner:BTL MEDICAL SOLUTIONS AS +1

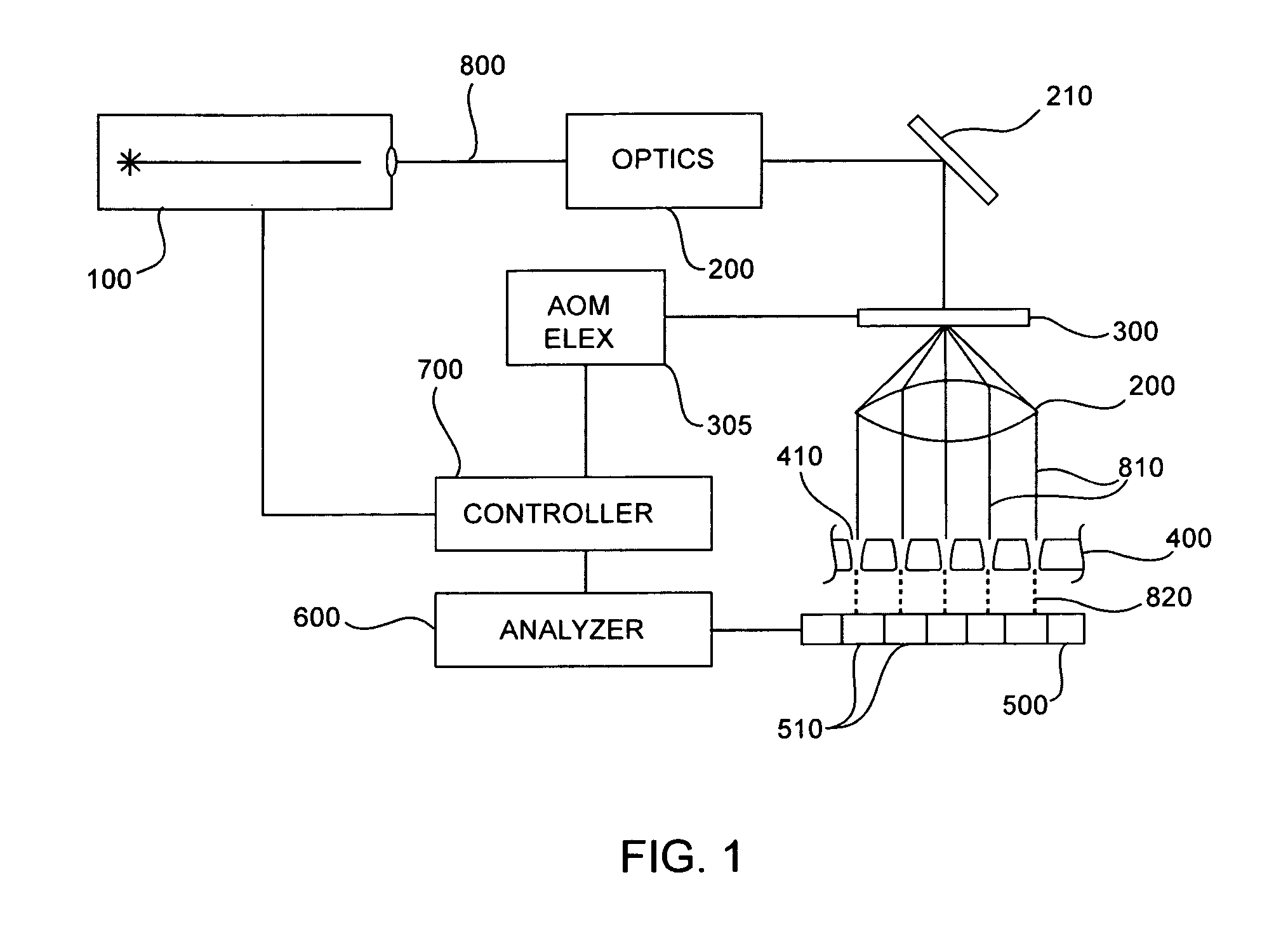

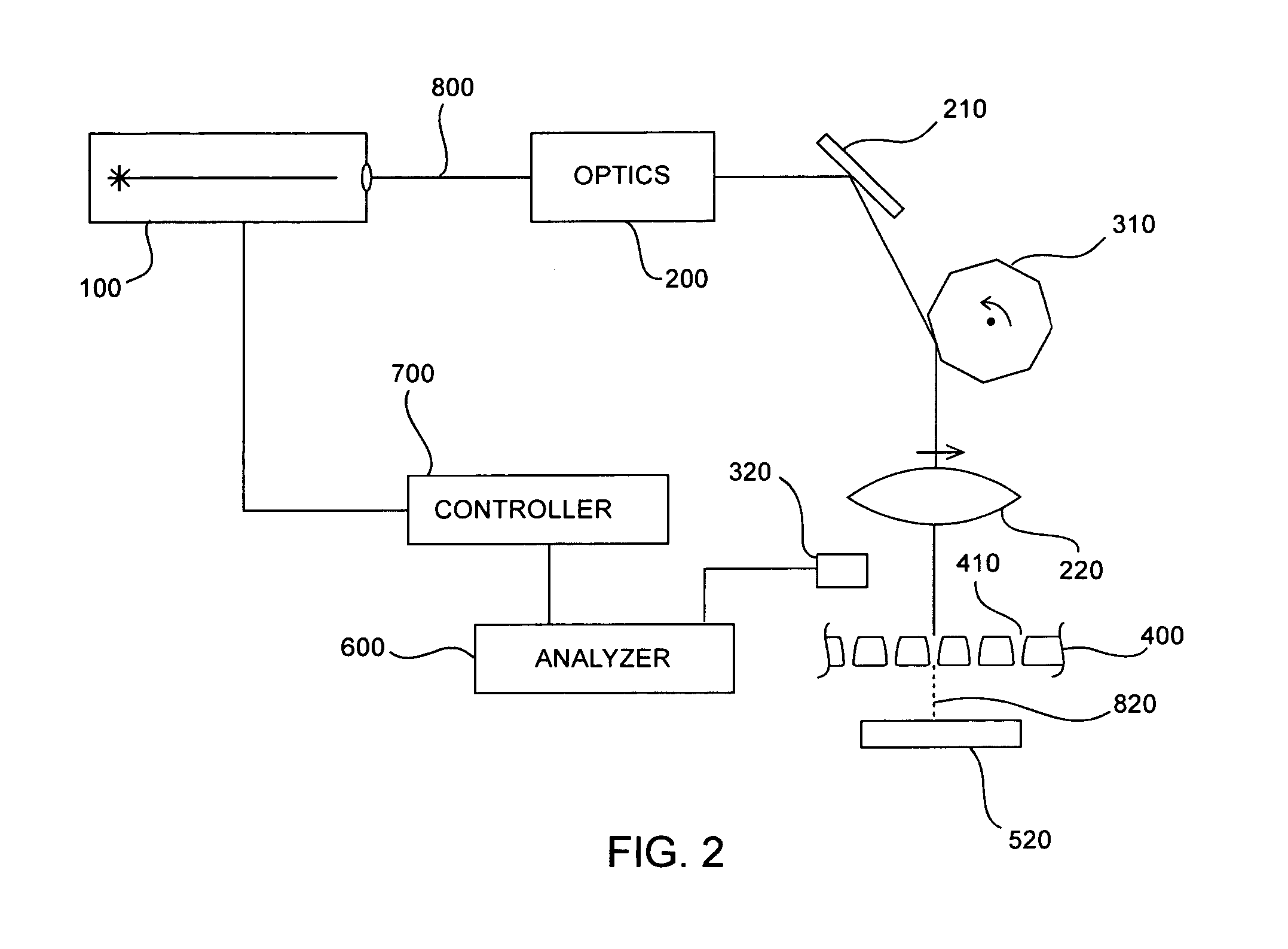

Method and system for LASER machining

InactiveUS20070075063A1Shorten the timeIncrease powerWelding/soldering/cutting articlesMetal working apparatusLaser processingLight beam

The invention provides a method of rapidly machining multiple, often similar or nearly identical, features using a LASER machining system. During LASER machining, light of a wavelength and intensity that will modify the workpiece to be machined is directed at the workpiece and interacts to produce the desired change. If several features are to be machined, the processing speed can be increased by operating on a multiplicity of features at once. In one embodiment of the invention, this is achieved by separating the LASER beam into multiple beams and machining the desired features simultaneously.

Owner:DAIMAY NORTH AMERICA AUTOMOTIVE +1

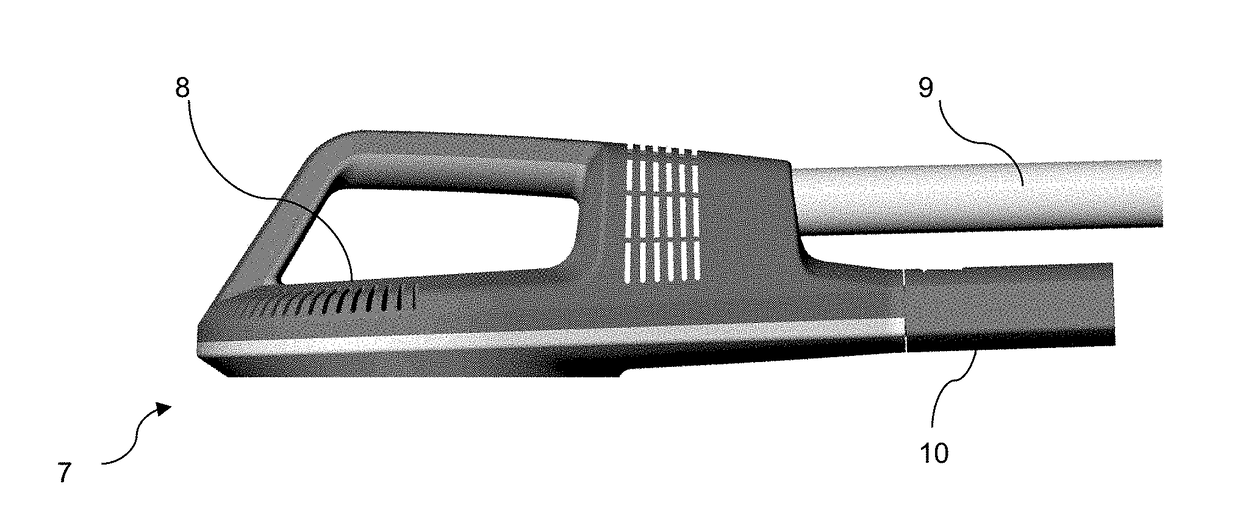

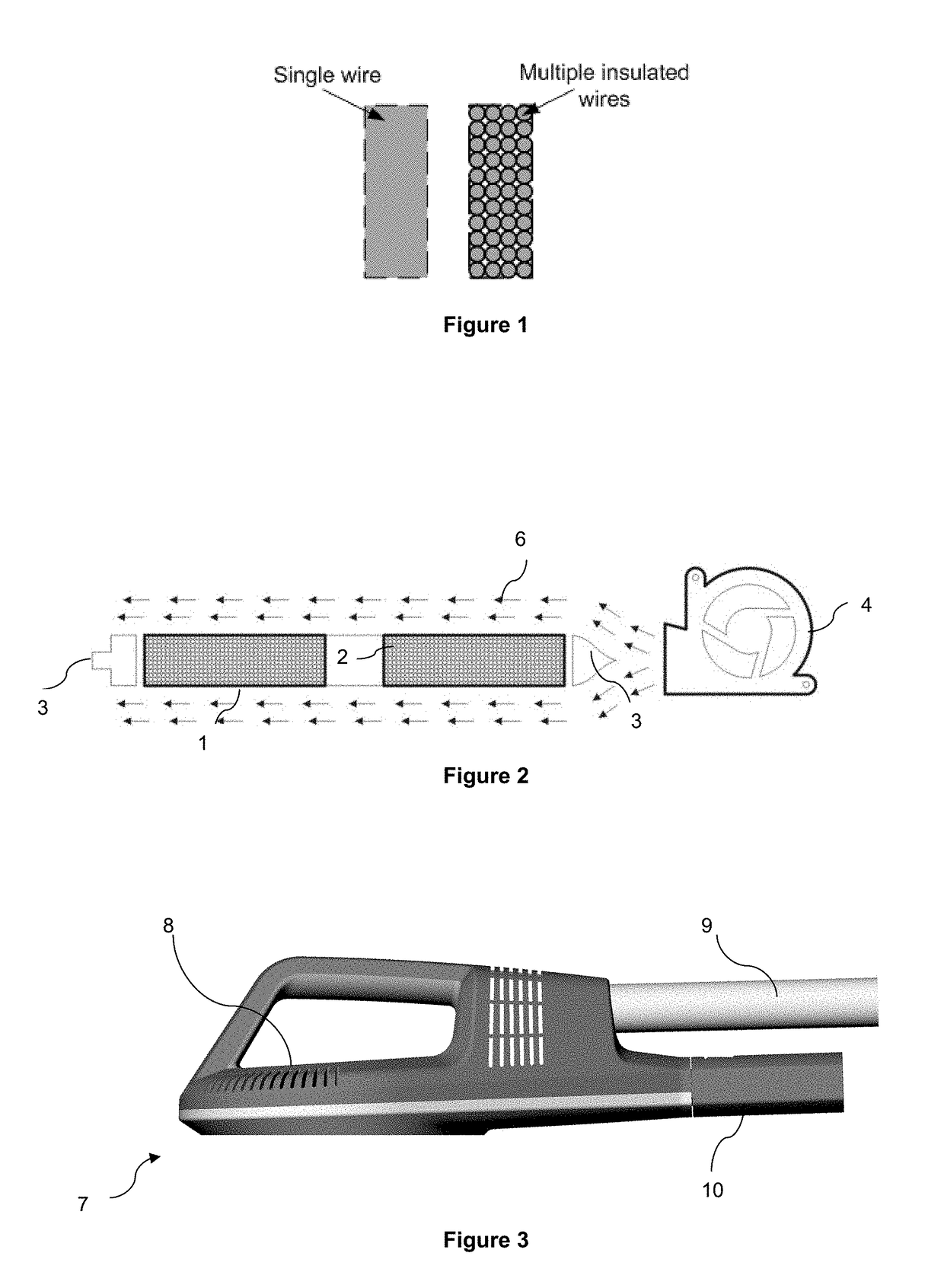

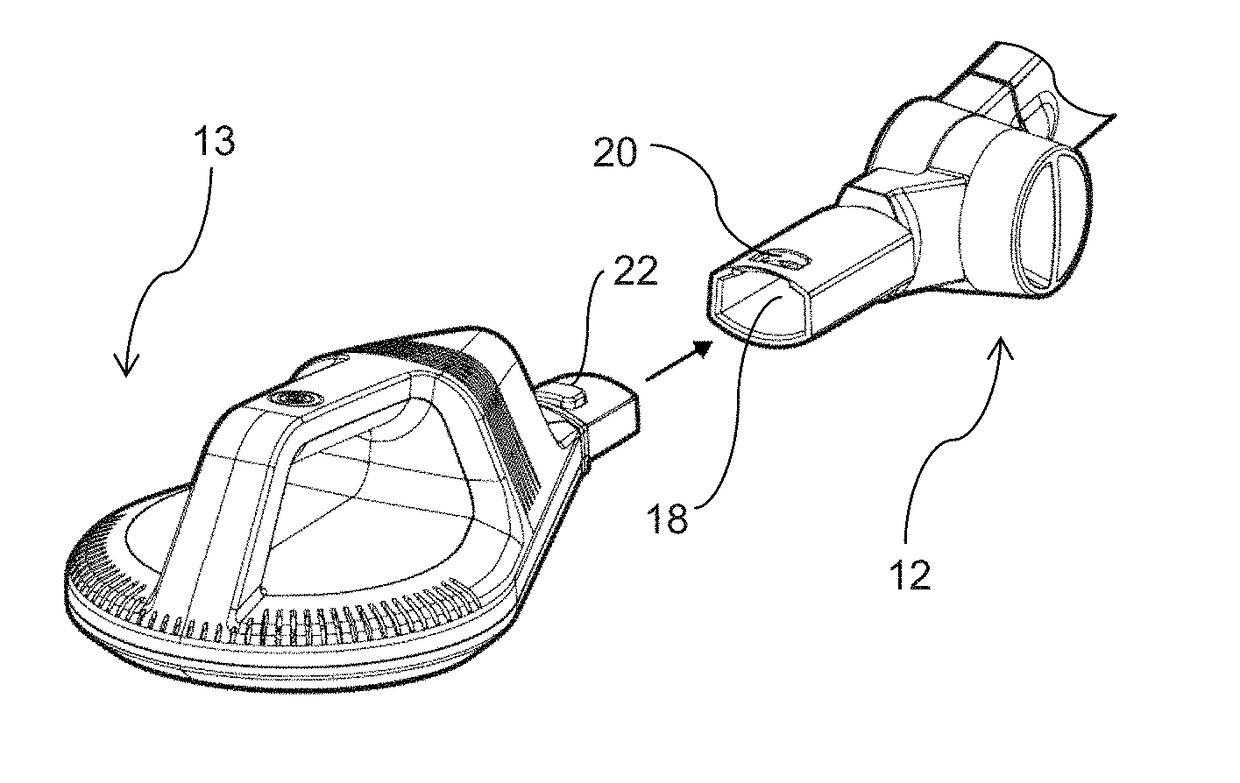

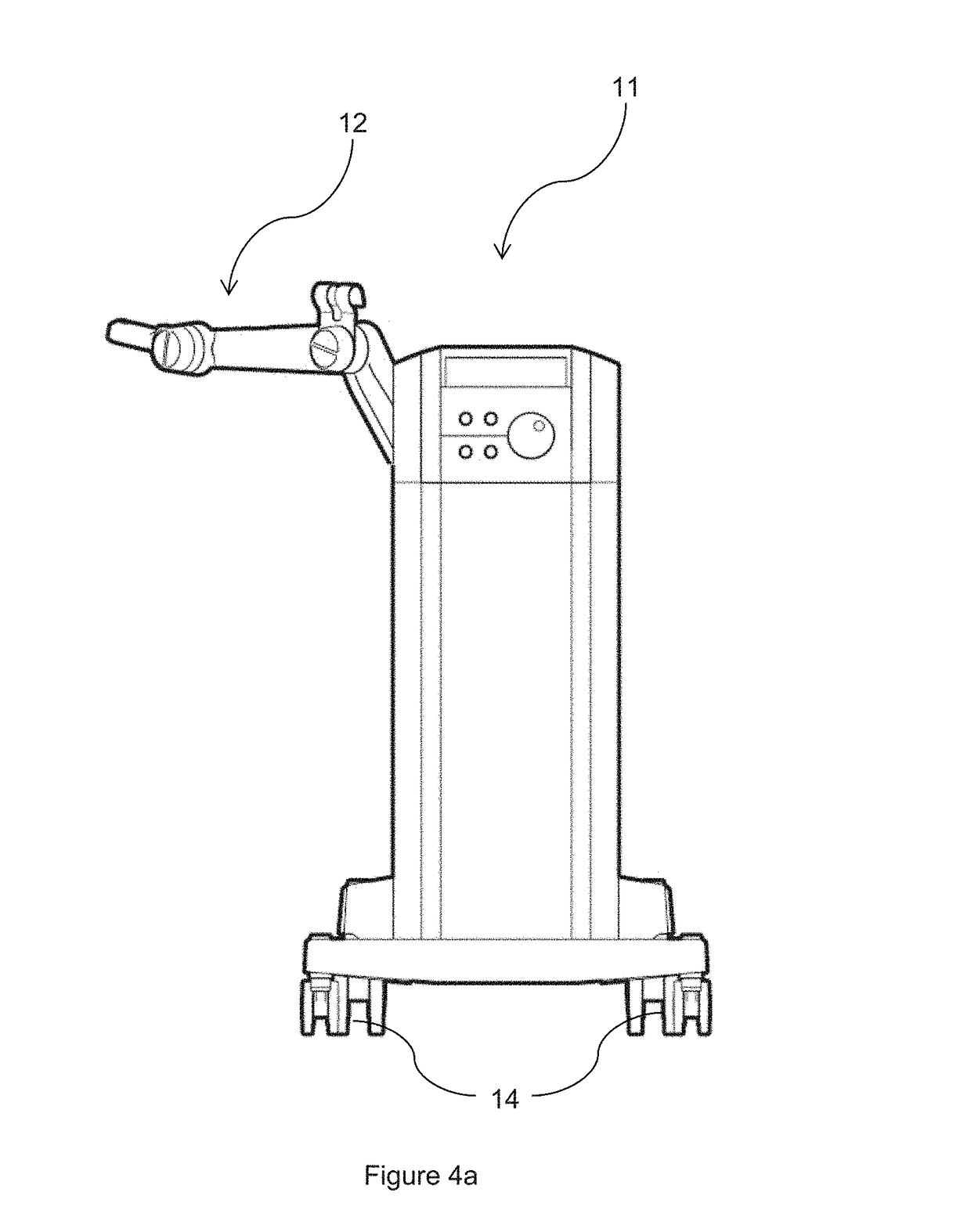

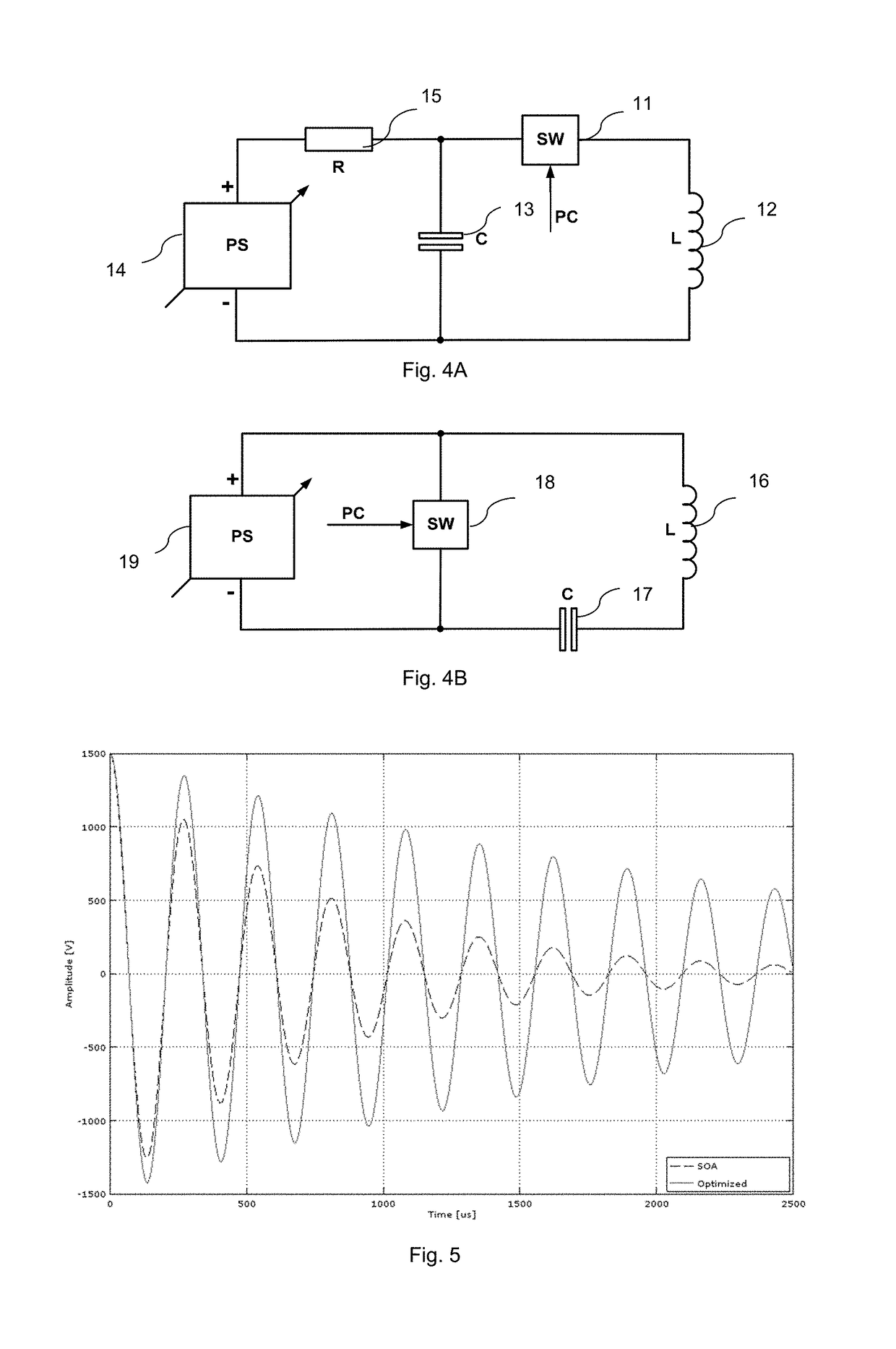

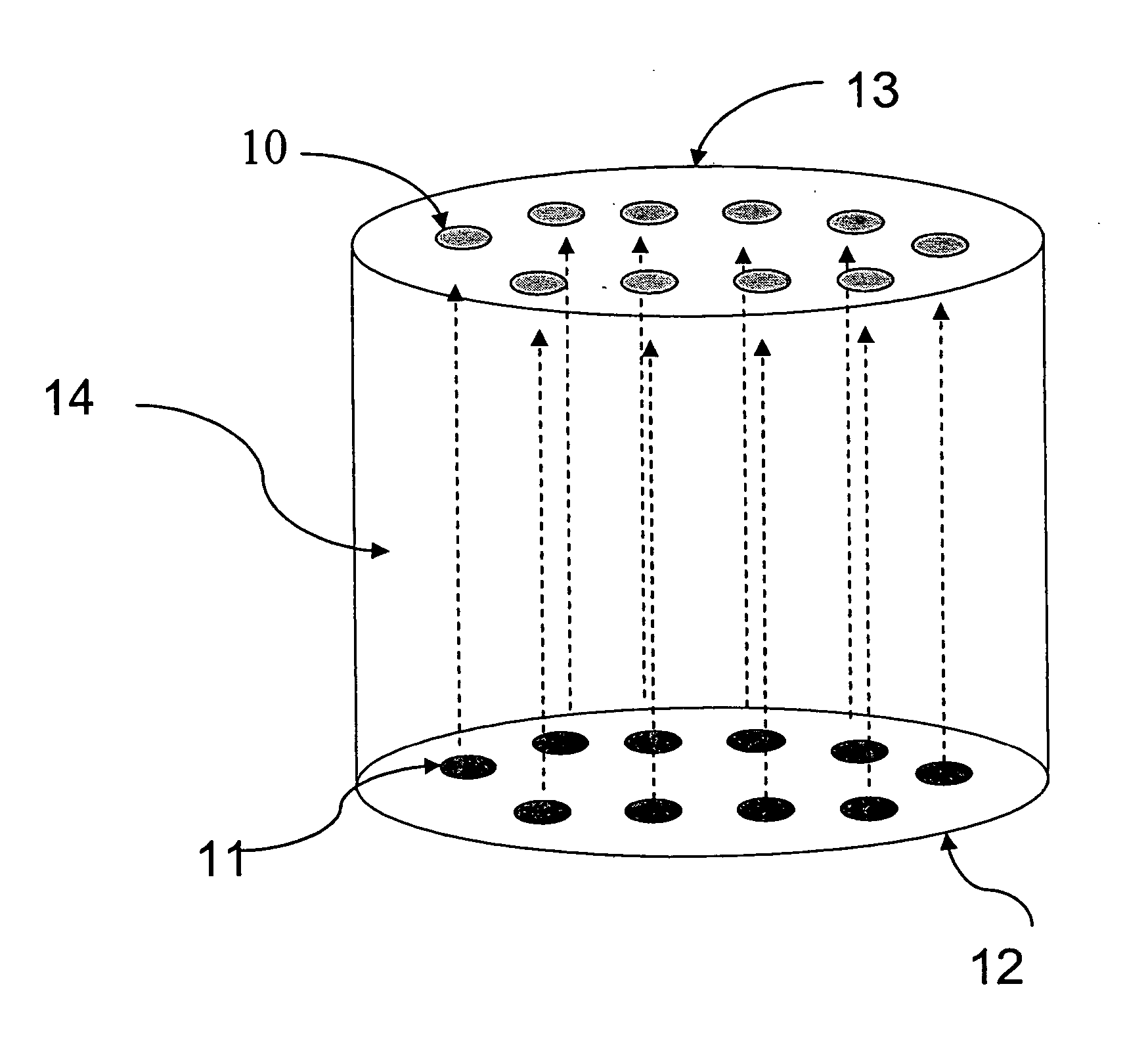

Aesthetic methods of biological structure treatment by magnetic field

ActiveUS9937358B2Enhancing visual appearanceHigh repetition rateElectrotherapyMagnetotherapy using coils/electromagnetsMuscle contractionMedicine

In a method for stimulation and treatment of a biological structure of a patient, the biological structure is treated by high power time-varying magnetic field. The treatment is followed by at least a partial muscle contraction. The method may be used in applications for non-invasive aesthetic medicine.

Owner:BTL MEDICAL SOLUTIONS AS

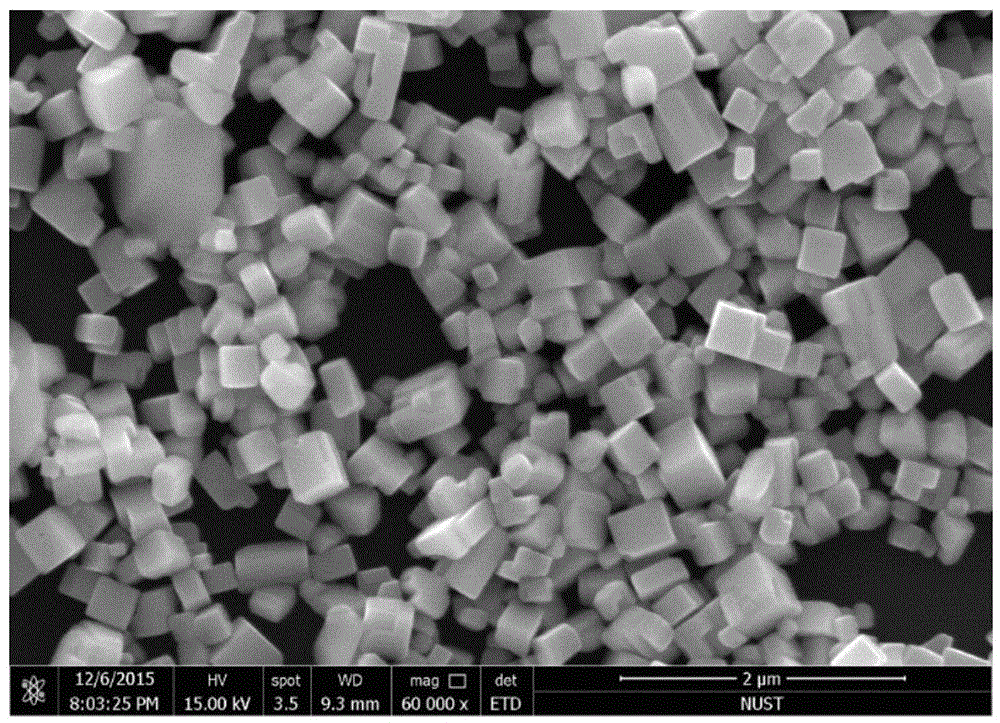

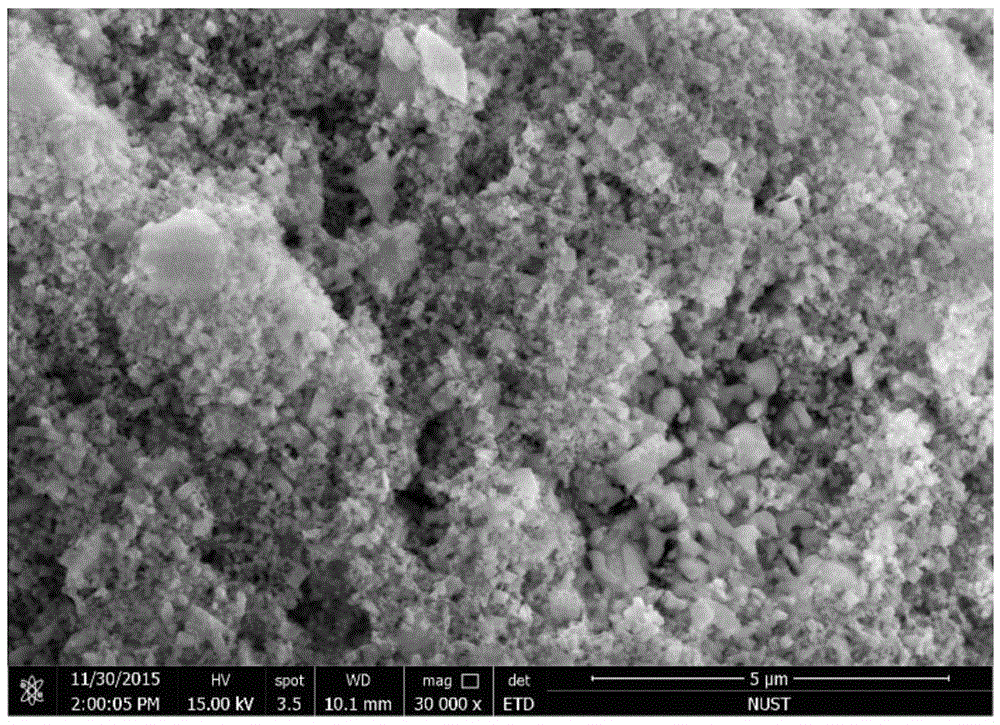

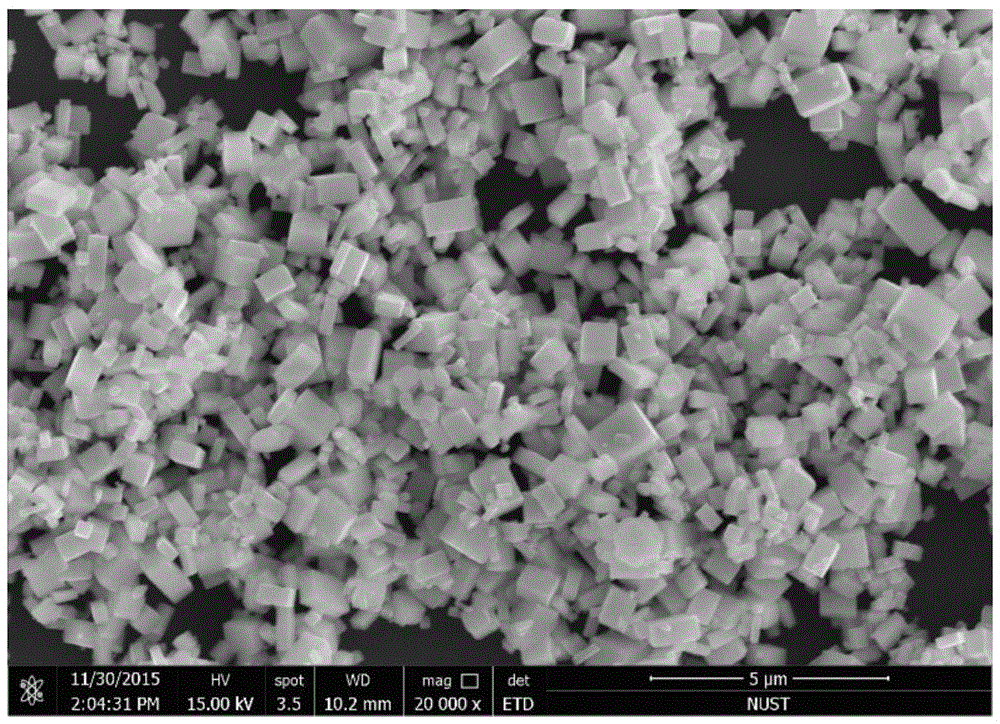

Preparation method of metal halide inorganic perovskite quantum dots

The invention discloses a preparation method of metal halide inorganic perovskite quantum dots. The method includes the steps of firstly, dissolving metal halide salt BX2 and AX in DMSO, and adding surface active agents; secondly, rapidly injecting the mixed liquid in reaction solvent; thirdly, making BX2 and AX rapidly react under the effect of the surface active agent to generate the ABX3 type metal halide inorganic perovskite quantum dots of different morphologies. According to the method, in the low-temperature solution method system, by using different surface active agents and reaction solvent for changing the morphologies of the metal halide inorganic perovskite quantum dots, the performance of the metal halide inorganic perovskite quantum dots is regulated and controlled, and the method has profound significance in constructing high-performance full-solution photoelectric devices.

Owner:NANJING UNIV OF SCI & TECH

Aesthetic method of biologoical structure treatment by magnetic field

ActiveUS9974519B1Improve the effectiveness of treatmentReduce self-heatingAnti-cellulite devicesOrgan movement/changes detectionMedicineVisual perception

Methods for treating a patient using time varying magnetic field are described. The treatment methods combine various approaches for aesthetic treatment. The methods are focused on enhancing a visual appearance of the patient. In one embodiment, the method is performed by switching on a device which includes a connection to an energy source, an energy storage device, a switching device and a magnetic field generating device including a core, and applying a time-varying field with a maximal value of magnetic flux density derivative of at least 300 T / s to a muscle of the patient. The diameter of the core is up to 80% of an outer diameter of the magnetic field generating device.

Owner:BTL MEDICAL SOLUTIONS AS

Aesthetic method of biological structure stimulation by magnetic field

InactiveUS20170001025A1High repetition rateReduce the numberElectrotherapyMagnetotherapy using coils/electromagnetsMuscle contractionMedicine

In a method for stimulation and treatment of a biological structure the biological structure is stimulated by high power time-varying magnetic field. The stimulation is followed by at least a partial muscle contraction. The method may be used e.g. in applications for non-invasive aesthetic medicine.

Owner:BTL MEDICAL SOLUTIONS AS

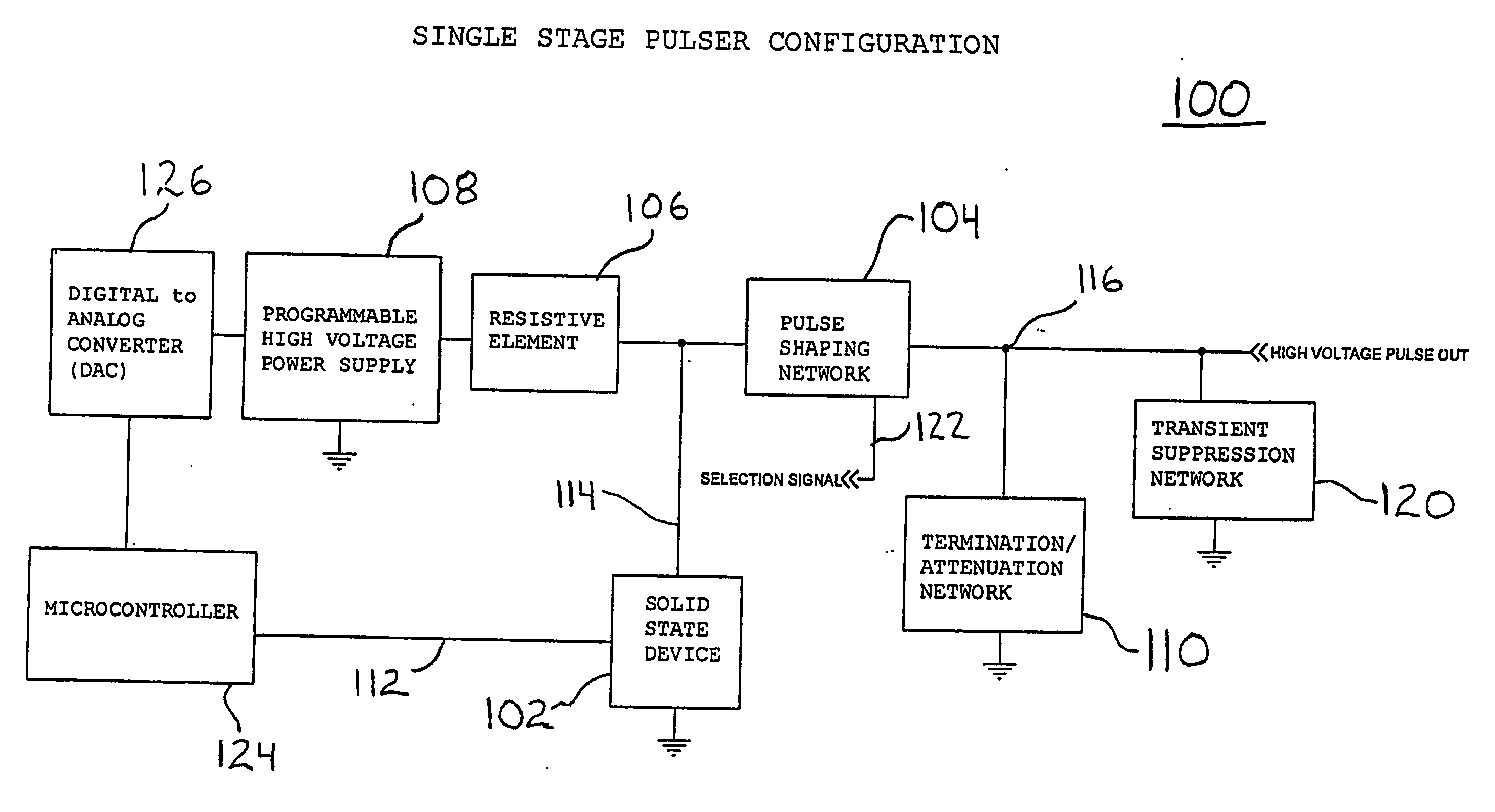

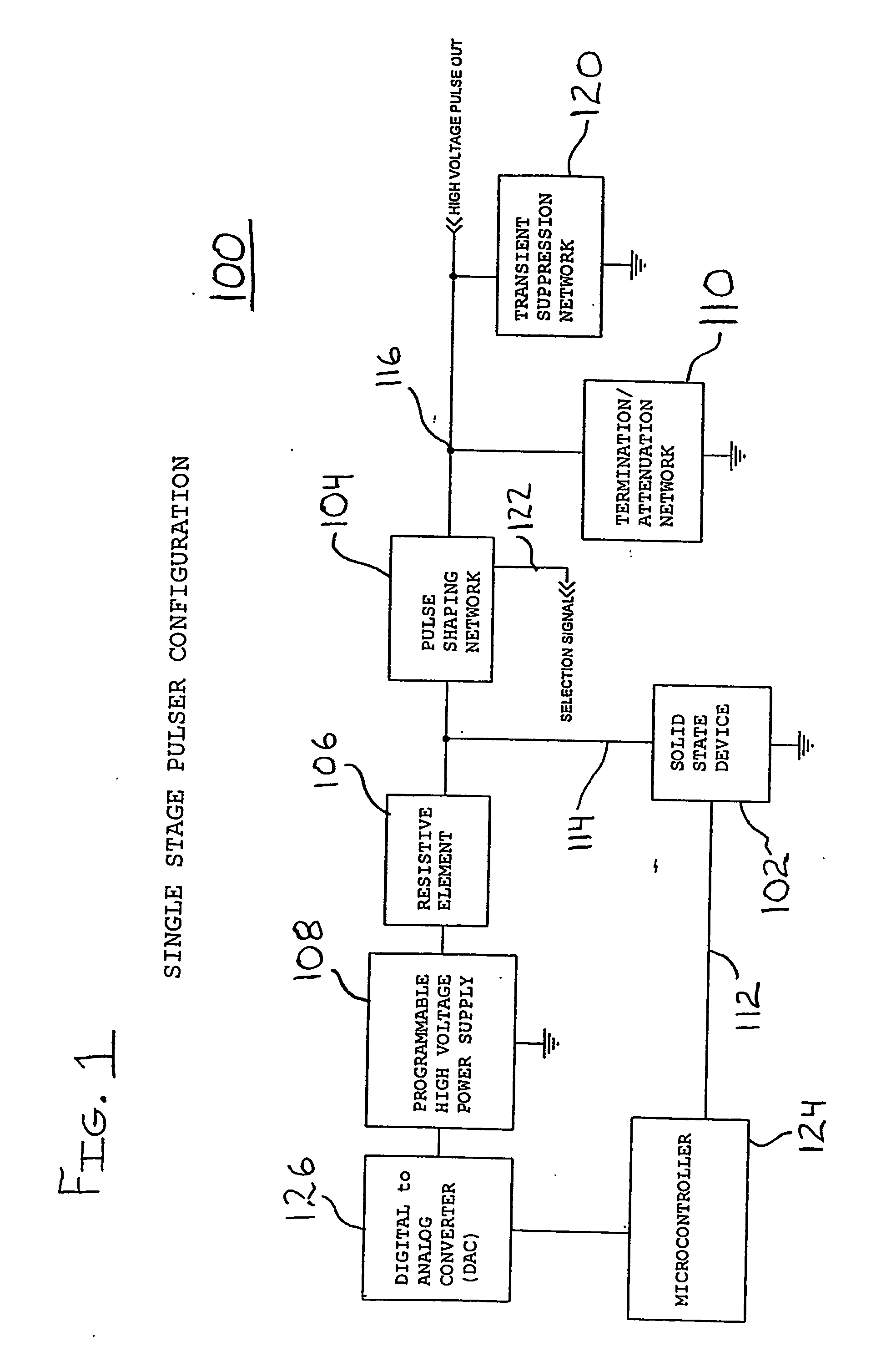

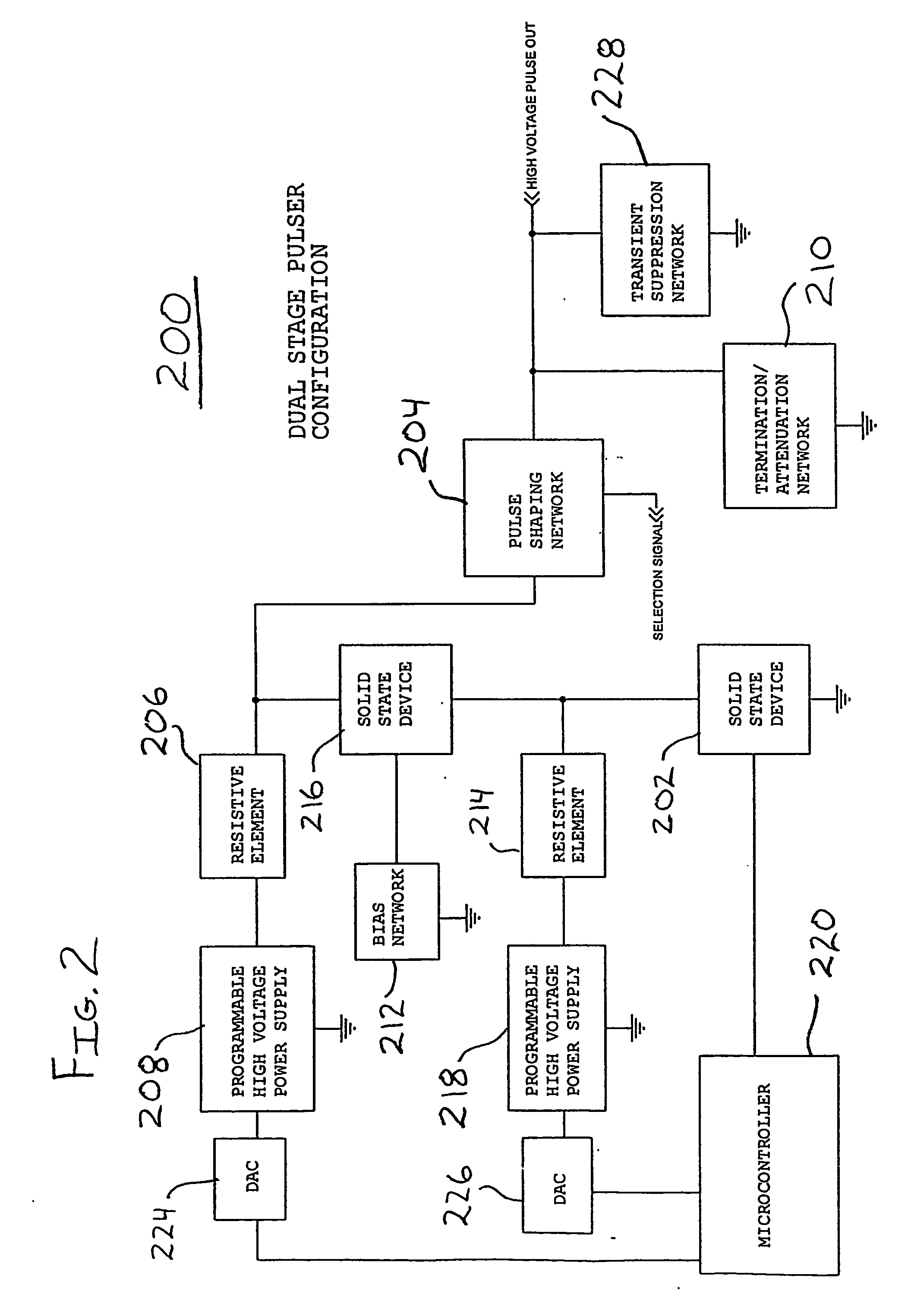

Short duration variable amplitude high voltage pulse generator

InactiveUS20070018504A1Wide range of useImprove accuracyElectric discharge tubesDigital data processing detailsMOSFETHigh voltage pulse

An improved electrical pulse generator incorporating MOSFET components, a programmable high voltage power supply, and a shaping network for generating short duration signals having narrow pulse widths and short rise times.

Owner:WIENER SCOTT ALBERT +1

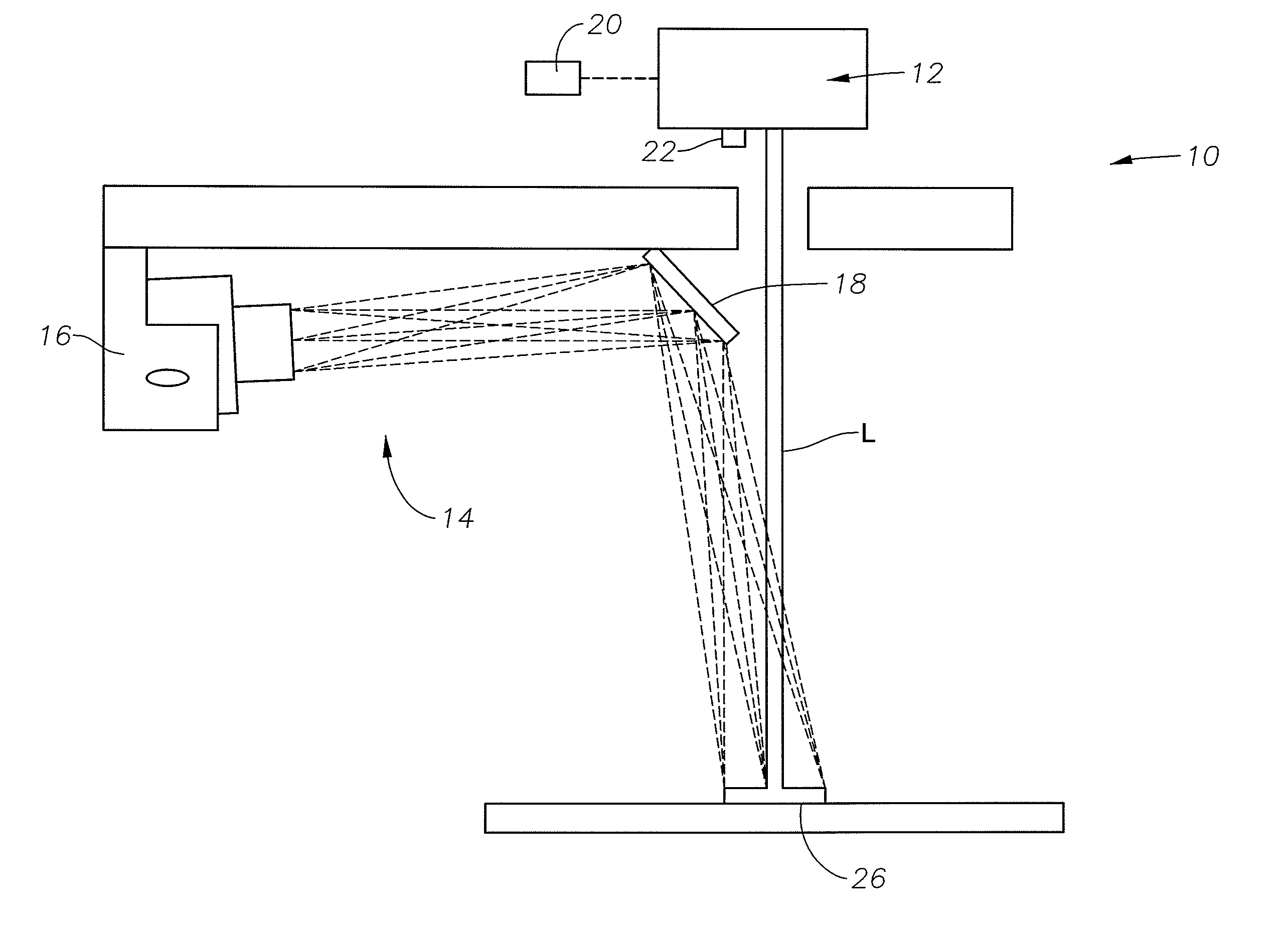

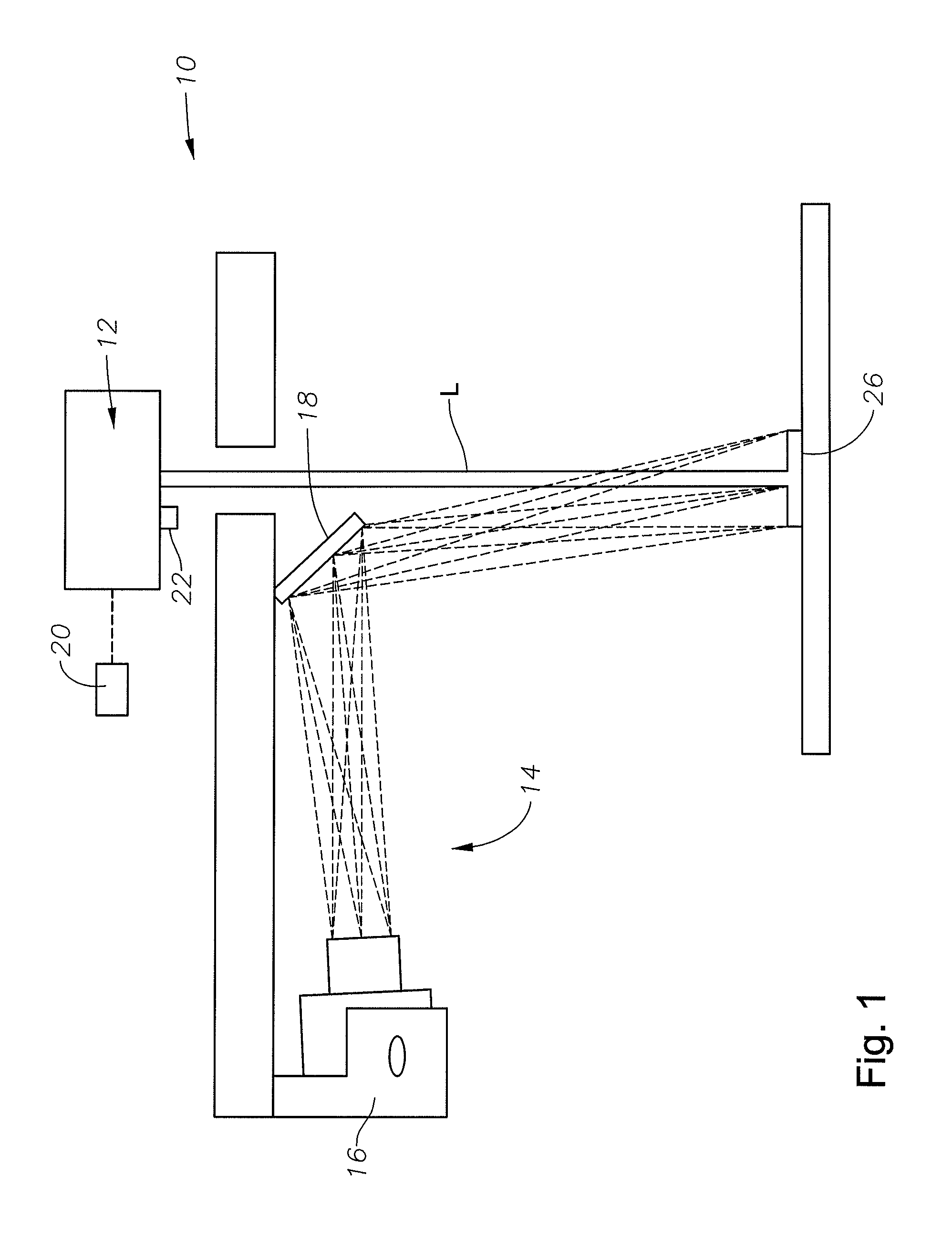

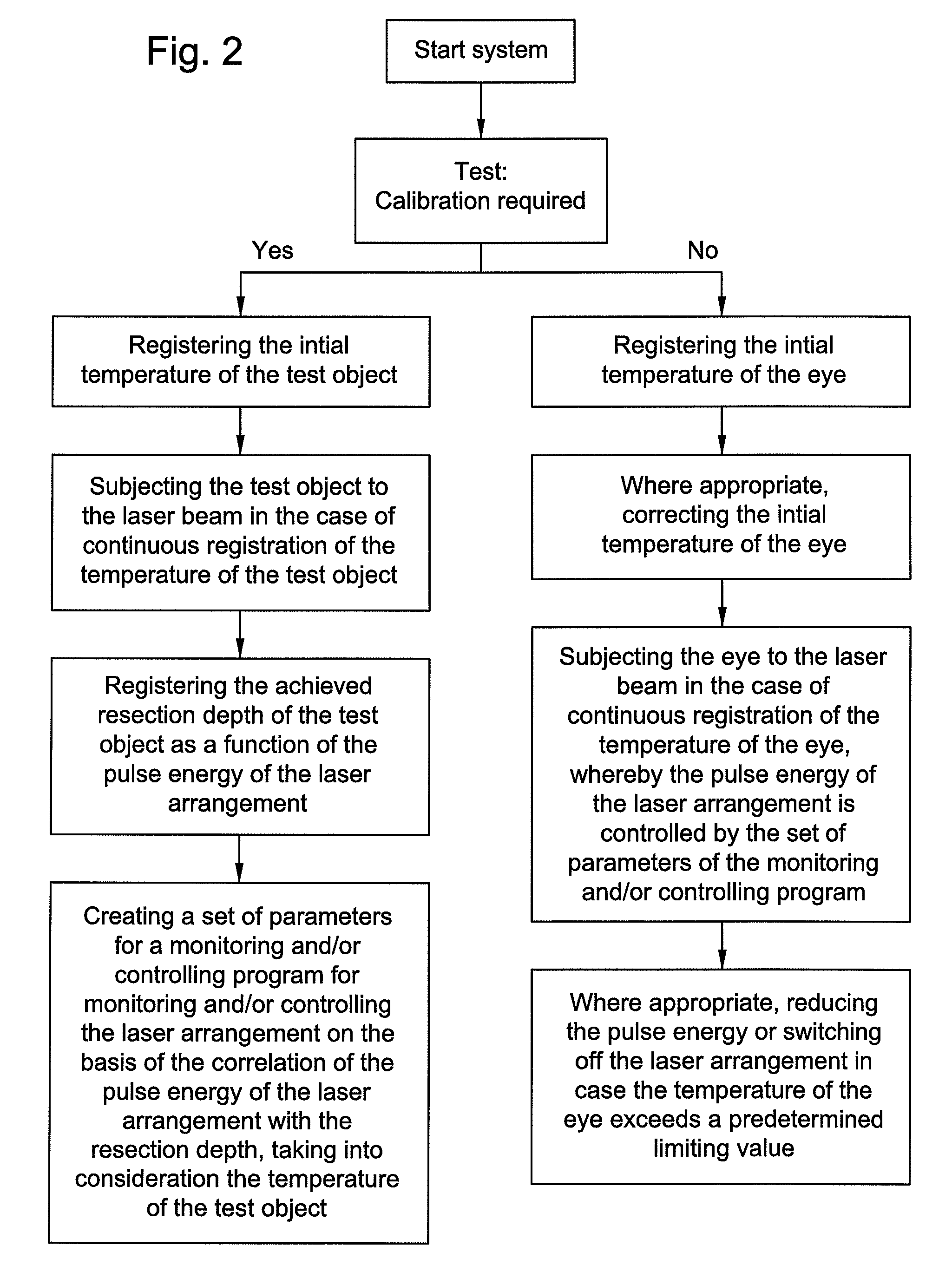

System and process for surgical treatment of an eye as well as process for calibrating a system of such a type

ActiveUS20120296318A1Increase temperatureHigh altitudeLaser surgerySurgical instrument detailsOphthalmologyLaser

A system for surgical treatment of an eye includes a laser arrangement that is adapted to emit light with a wavelength and repetition-rate suitable for surgical treatment of the eye. The system further includes a temperature-registration device that is adapted to register the temperature of an object that is to be subjected to the light of the laser arrangement.

Owner:ALCON INC

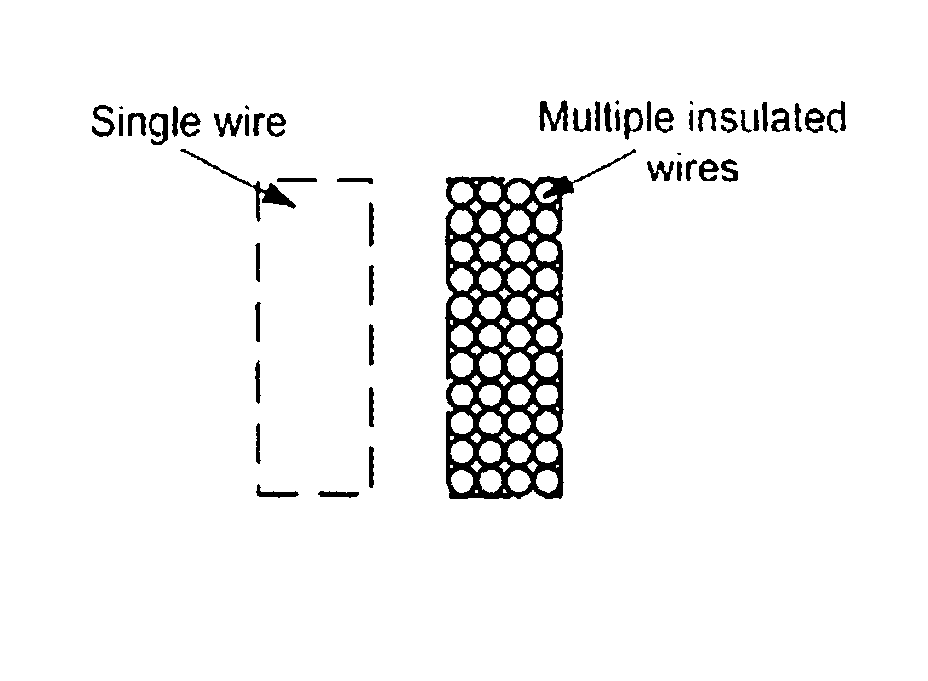

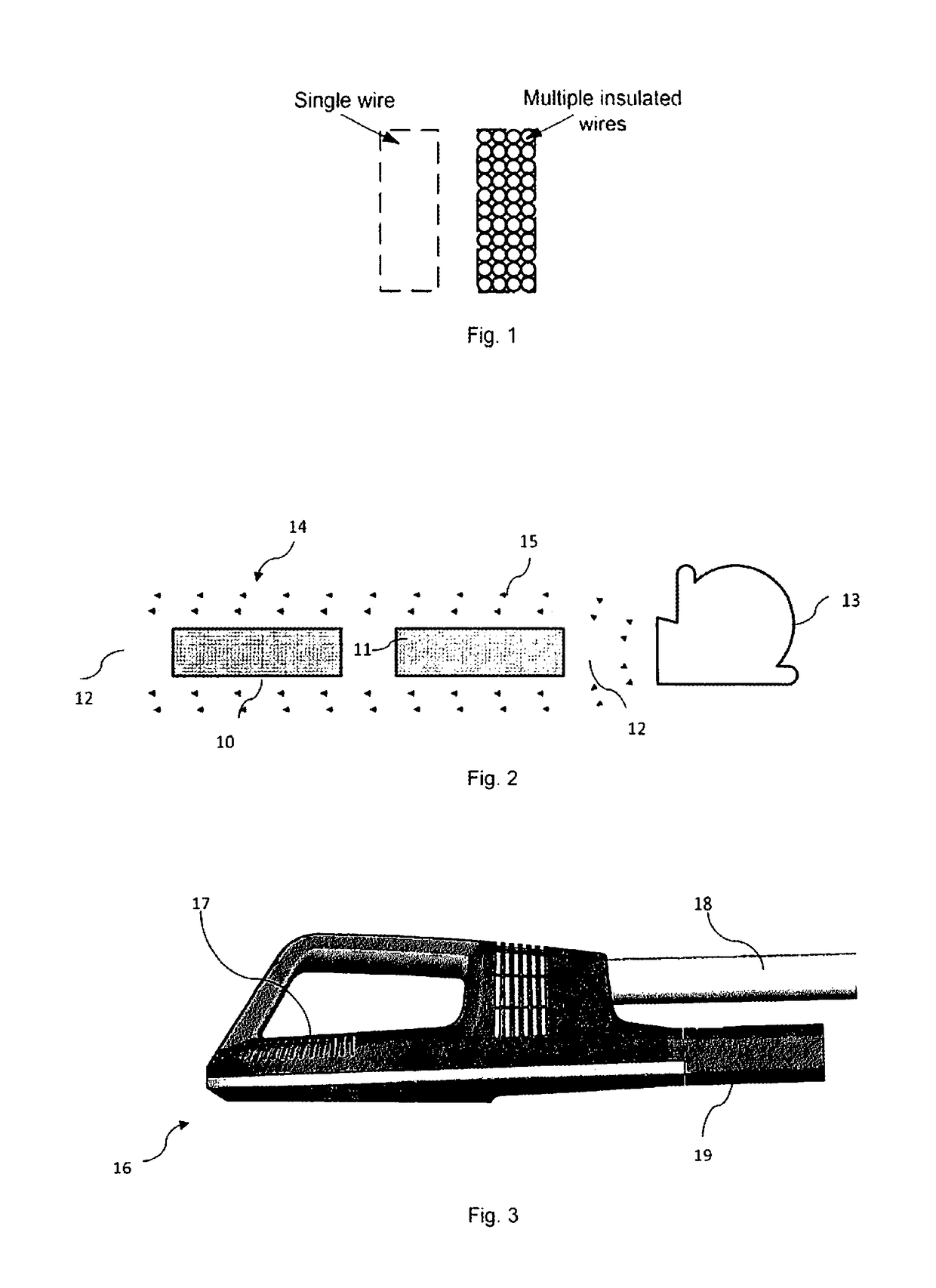

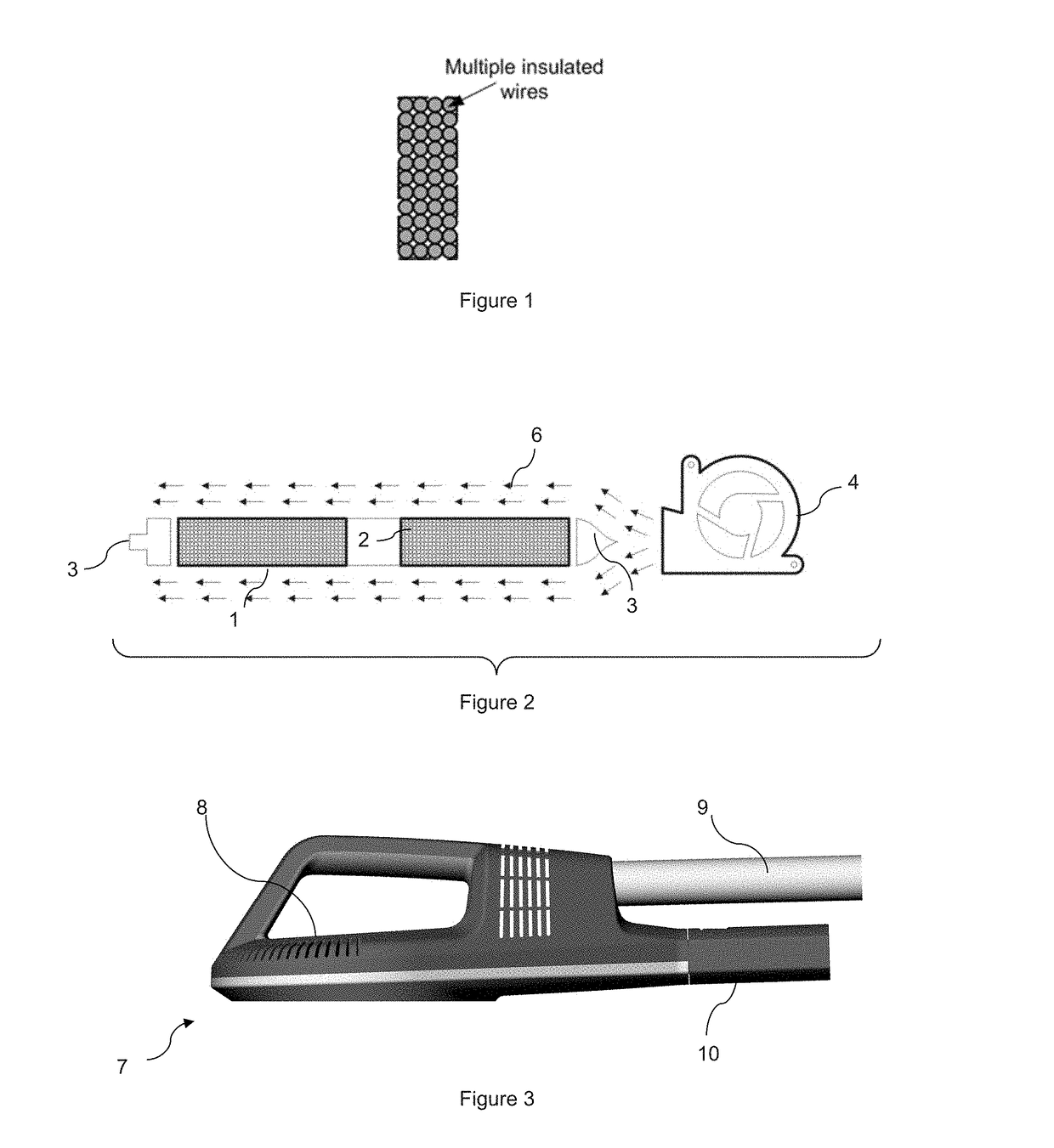

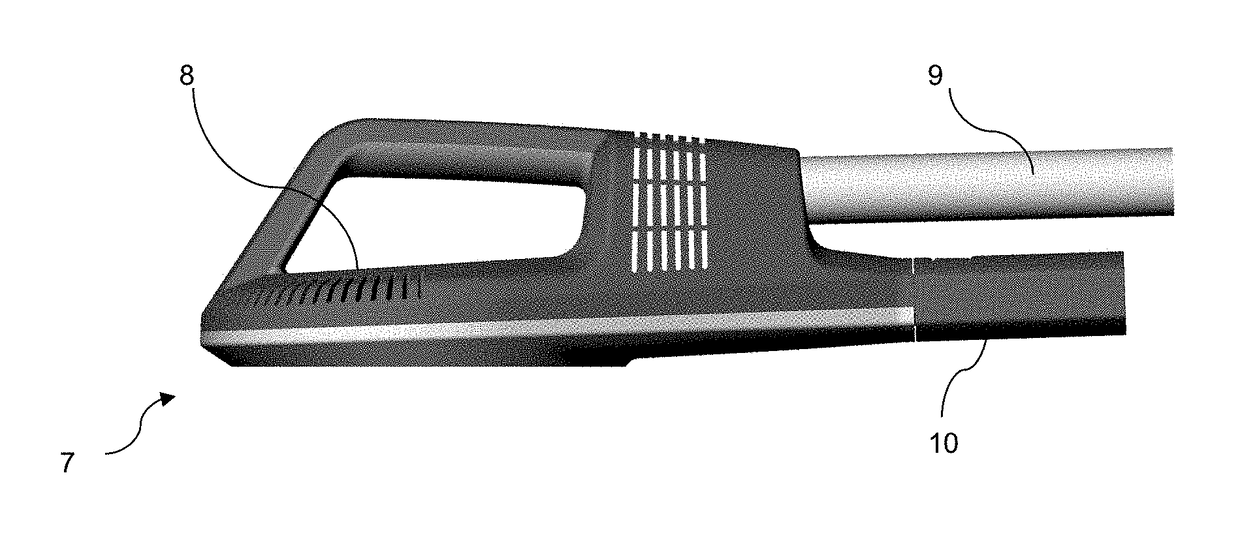

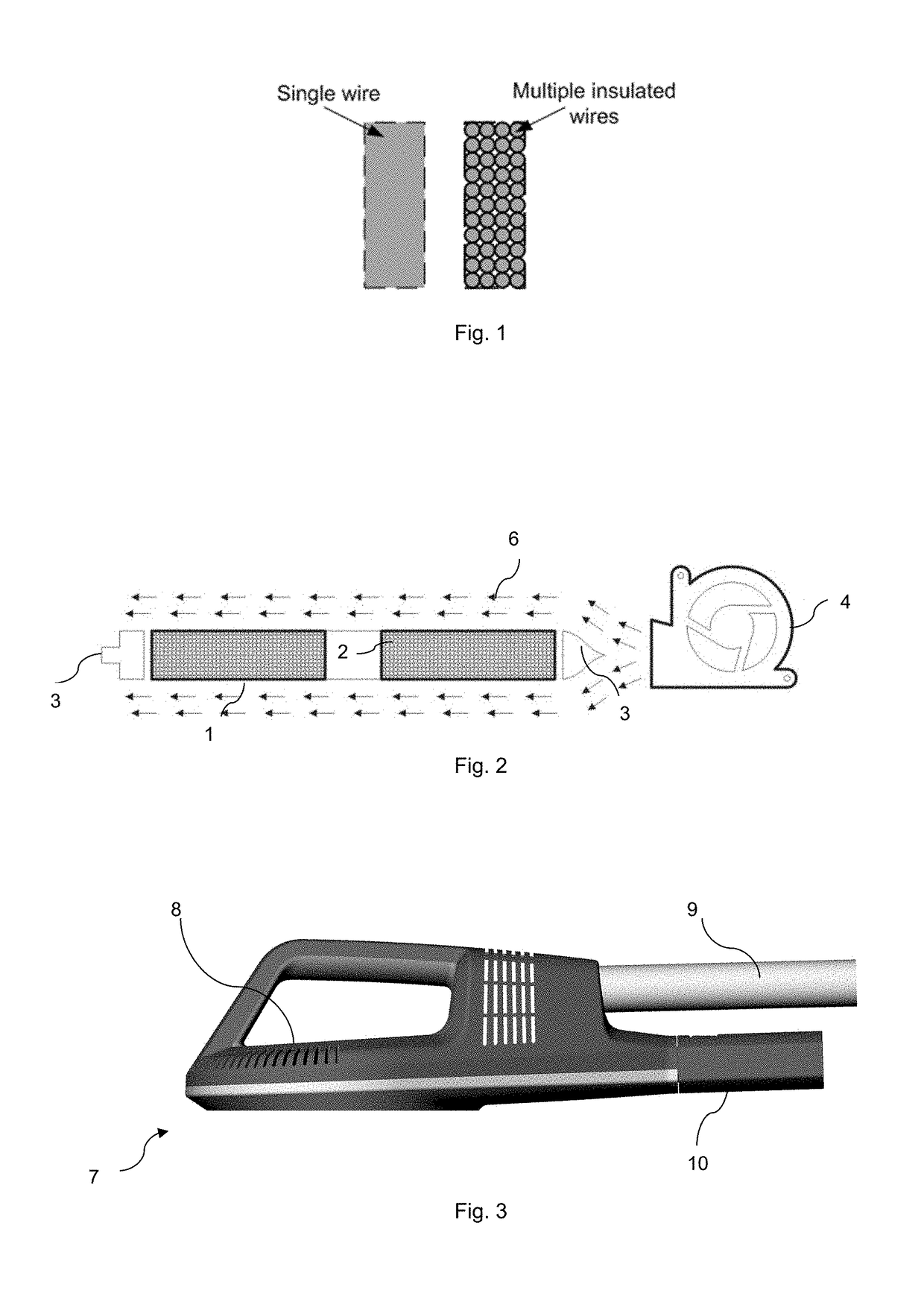

Aesthetic method of biological structure treatment by magnetic field

InactiveUS20180001107A1Improve the effectiveness of treatmentReduce self-heatingElectrotherapyMagnetotherapy using coils/electromagnetsEngineeringUrology department

Methods and devices producing time varying magnetic field treats a patient. The device contains a coil made of insulated wires, an energy storage device, an energy source and a switch. The coil is flexibly attached in a case. The device has at least one blower for cooling the coil. The methods and devices can be used in for example in physiotherapy, neuropsychiatric therapy, aesthetic therapy, urology or urogynecology.

Owner:BTL MEDICAL SOLUTIONS AS

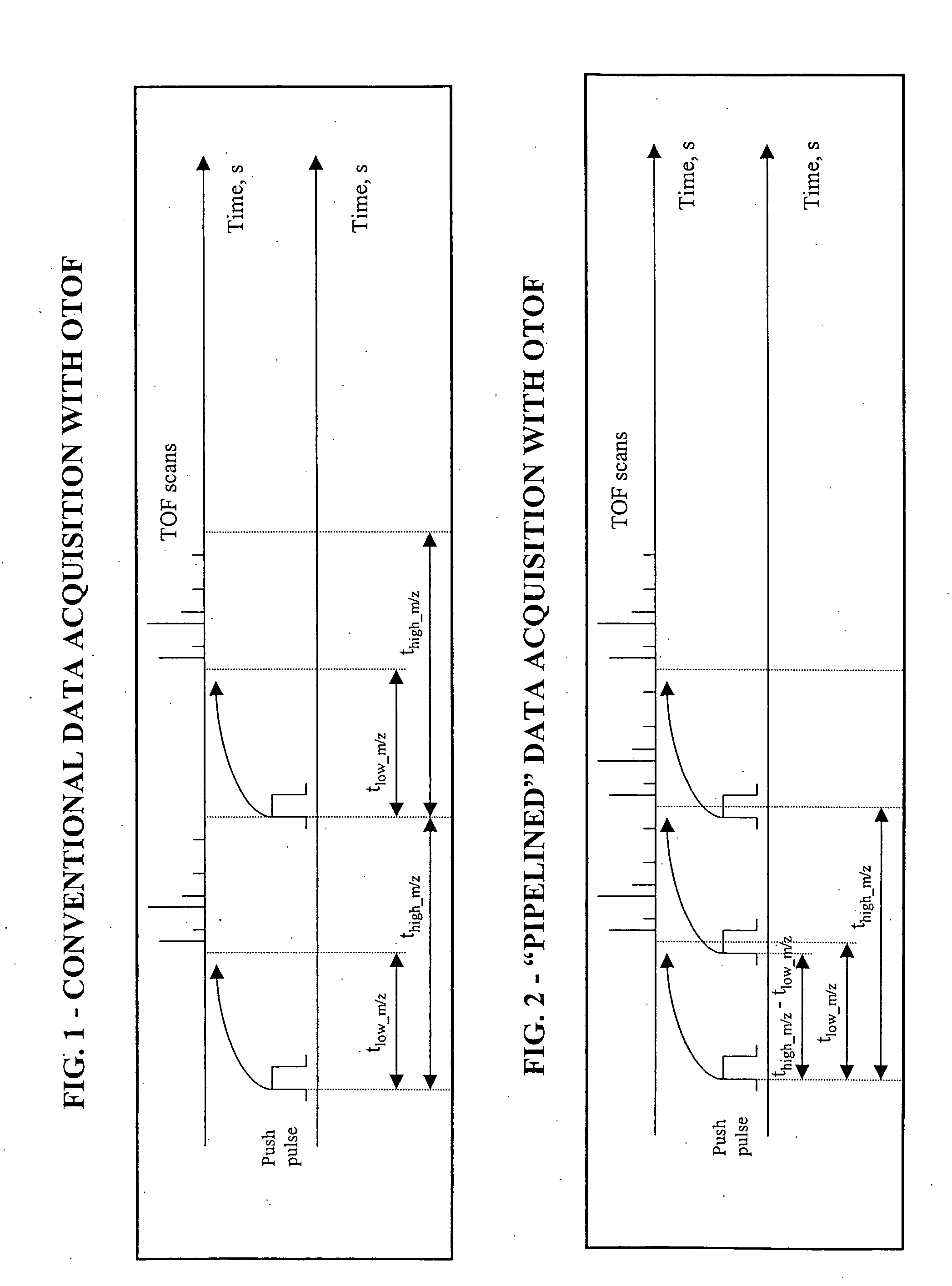

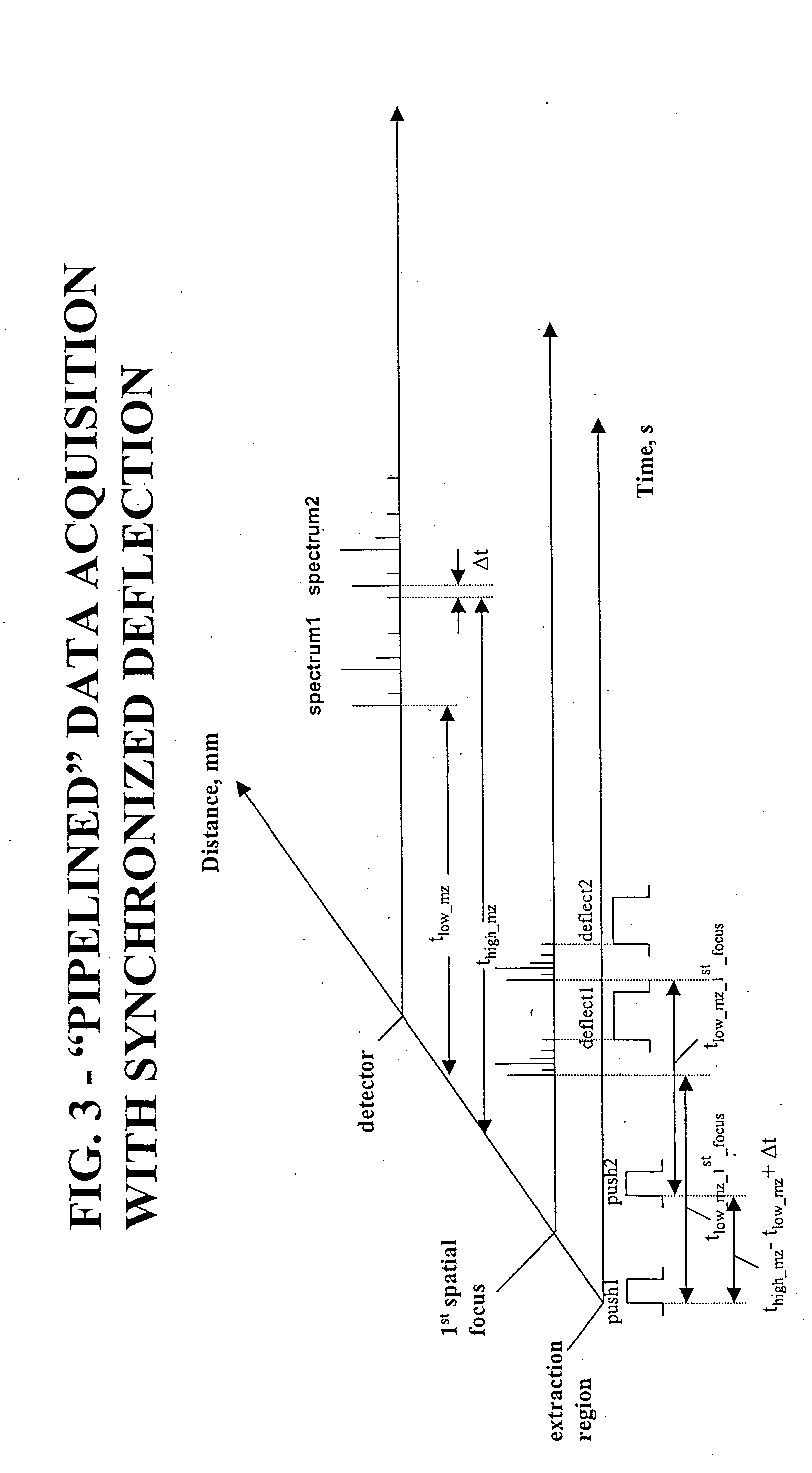

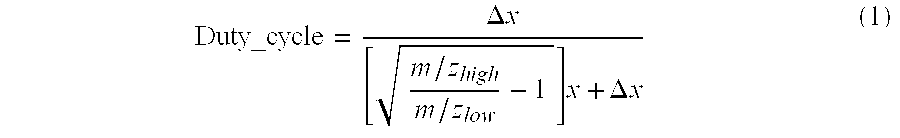

Scan pipelining for sensitivity improvement of orthogonal time-of-flight mass spectrometers

InactiveUS20050133712A1Improve device performanceImprove sensitivity performanceTime-of-flight spectrometersIsotope separationData acquisitionMass spectrometric

Methods and apparatus for analyzing ions by pipelining data acquisitions with an orthogonal time-of-flight (OTOF) mass spectrometer. A predetermined push sequence is established for launching packets of ions from a source region into a flight tube towards a detection region within the OTOF mass spectrometer such that ions which are launched in adjacent packets do not overlap prior to reaching the detection region. These discrete packets of ions do not intermingle and are launched in accordance with the predetermined push sequence along a propagation path from the source region toward the detection region such that portions of the packets of ions are simultaneously in-flight within the flight tube of the OTOF mass spectrometer. The times of arrival of ions are detected at the detection region to produce time-of-flight scans with signals corresponding to times of arrival for the ions in the launched packets of ions to provide a mass spectrum derived from pipelined data acquisitions.

Owner:NORVIEL VERN

High power time varying magnetic field therapy

InactiveUS20170001024A1High repetition rateIncrease muscle strengthElectrotherapyMagnetotherapy using coils/electromagnetsBiological structureLow magnetic field

In a method for stimulation and treatment, a biological structure is stimulated by a high power time-varying magnetic field. The stimulation is followed by at least a partial muscle contraction. The methods can be used e.g. in physiotherapy, urology or urogynecology.

Owner:BTL MEDICAL SOLUTIONS AS

Devices and methods for producing multiple x-ray beams from multiple locations

InactiveUS20050281379A1Efficiently produceFlexible controllabilityX-ray tube electrodesNanoinformaticsPhysicsCarbon nanotube

An x-ray generating device includes at least one field-emission cold cathode having a substrate and incorporating nanostructure-containing material including carbon nanotubes. The device further includes at least one anode target. Associated methods are also described.

Owner:NURAY TECH

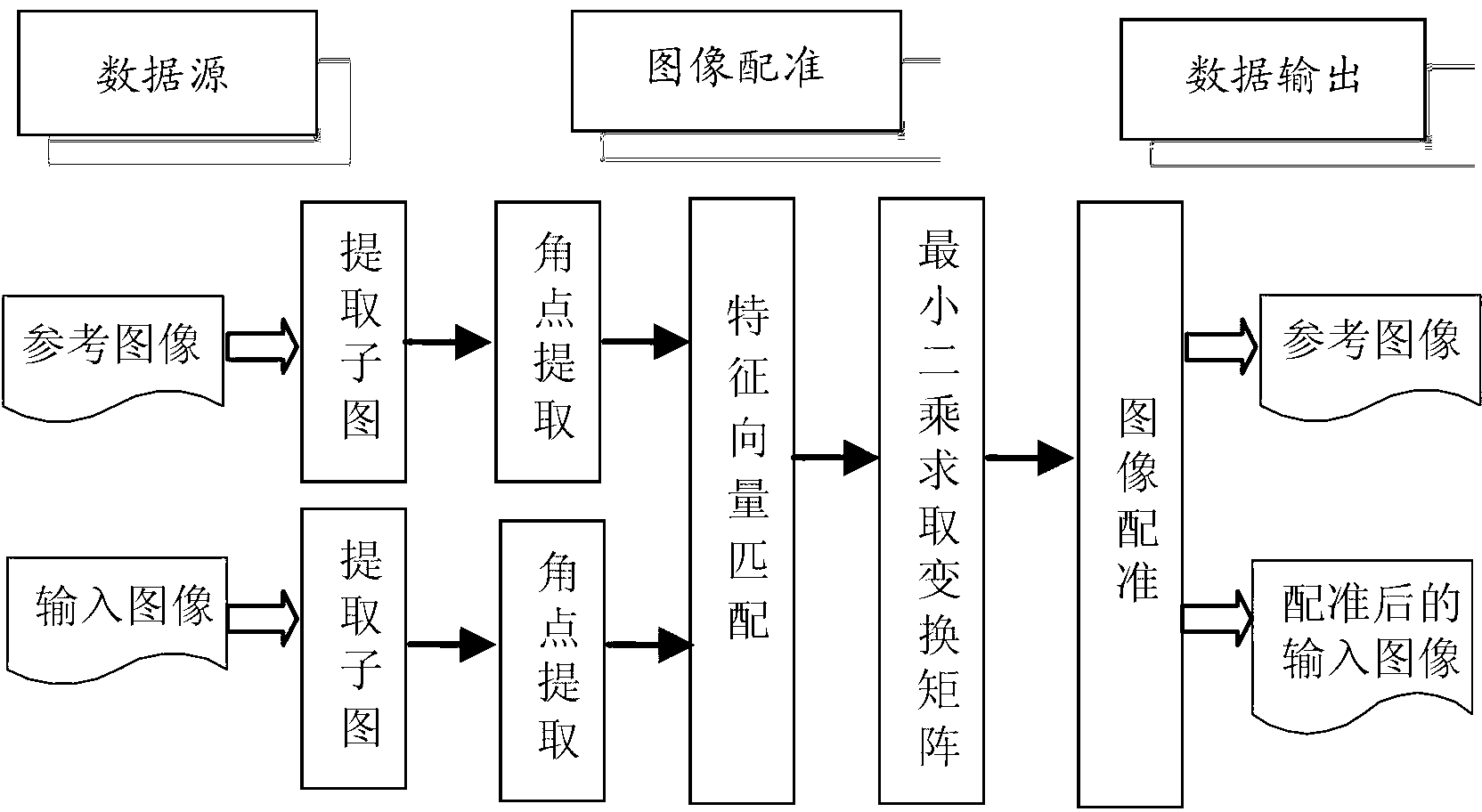

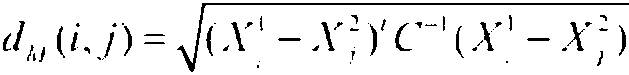

Rapid image registration method based on sub-image corner features

InactiveCN103310453AQuick matchExact matchImage analysisSpecial data processing applicationsFeature vectorReference image

The invention discloses a rapid image registration method based on sub-image corner features. The method includes the specific steps: firstly, selecting a reference sub-image and a to-be-registered sub-image, selecting one sub-image from a reference image as the reference sub-image, and selecting one sub-image with the same coordinate space as the reference sub-image from a to-be-registered image as the to-be-registered sub-image; secondly, extracting corners of the reference sub-image and the reference sub-image; thirdly, performing feature description on the corners extracted from the reference sub-image and the reference sub-image to obtain a feature vector of each corner; fourthly, performing similarity measurement and feature matching on the feature vectors of the corners on the reference sub-image and the reference sub-image to obtain K matching point pairs; and fifthly, adopting a least square method to compute a transformation matrix H between the reference image and the to-be-registered image based on the K matching point pairs, and registering the to-be-registered image onto the reference image based on the transformation matrix H. By the method, the requirement for image matching precision can be met, and image matching speed is increased greatly.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

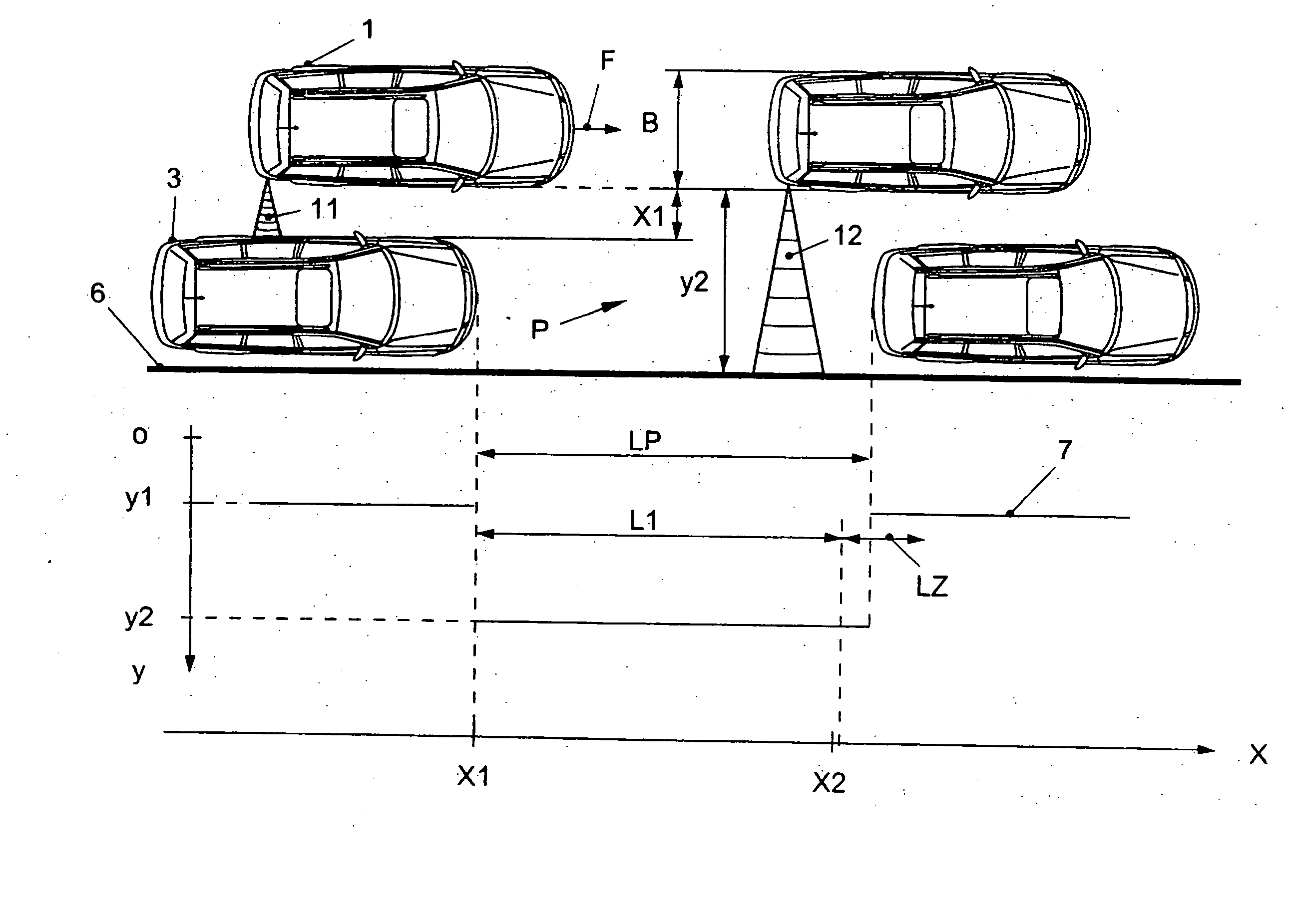

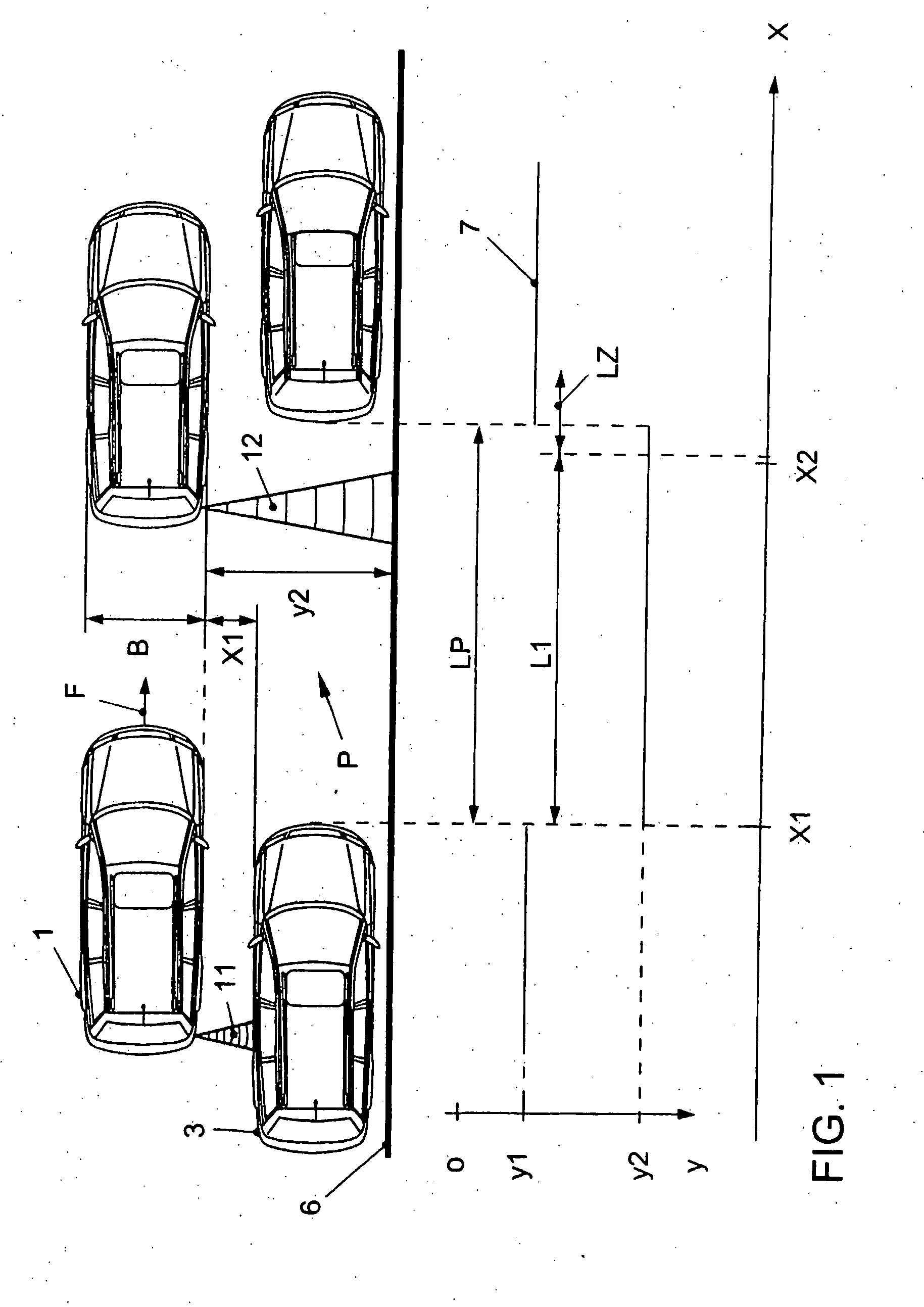

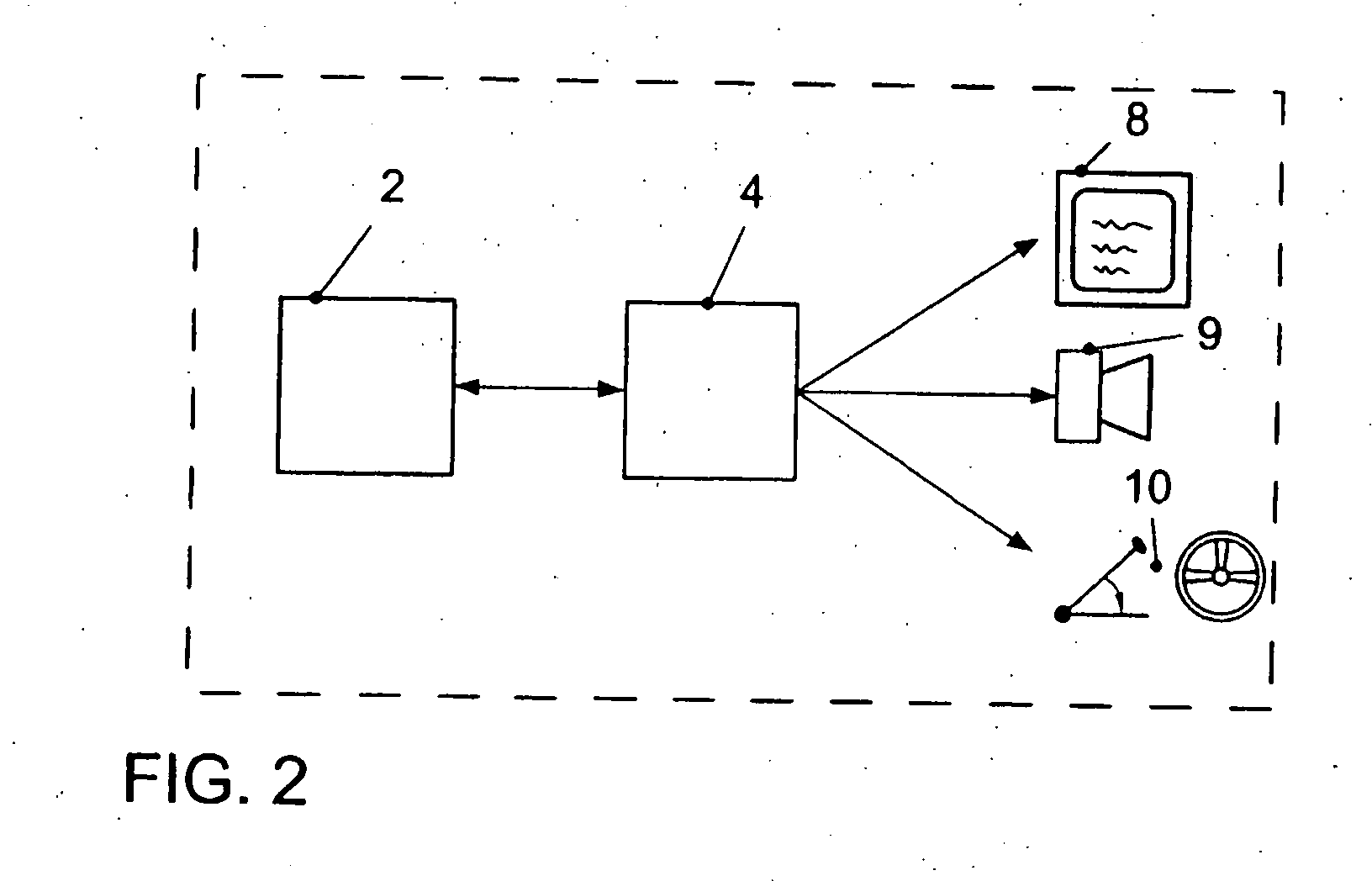

Device For A Motor Vehicle

ActiveUS20080033647A1Easy to measureRapid repetitionComplex mathematical operationsPosition/course control in two dimensionsEngineeringBiological activation

A device for a motor vehicle includes at least one distance sensor for recording a predominantly lateral clearance between the motor vehicle and objects, and a control device for controlling the distance sensor, the distance sensor emitting measuring signals during an activation time, and receiving measuring signal reflected by at least one object during a measurement receiving time. In the process, the measurement receiving time of the distance sensor is modifiable by the control device.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com