Patents

Literature

31results about How to "Output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High power deep ultraviolet laser with long life optics

InactiveUS6904073B2Output powerBeam quality specificationOptical resonator shape and constructionLaser arrangementsPhysicsPulse energy density

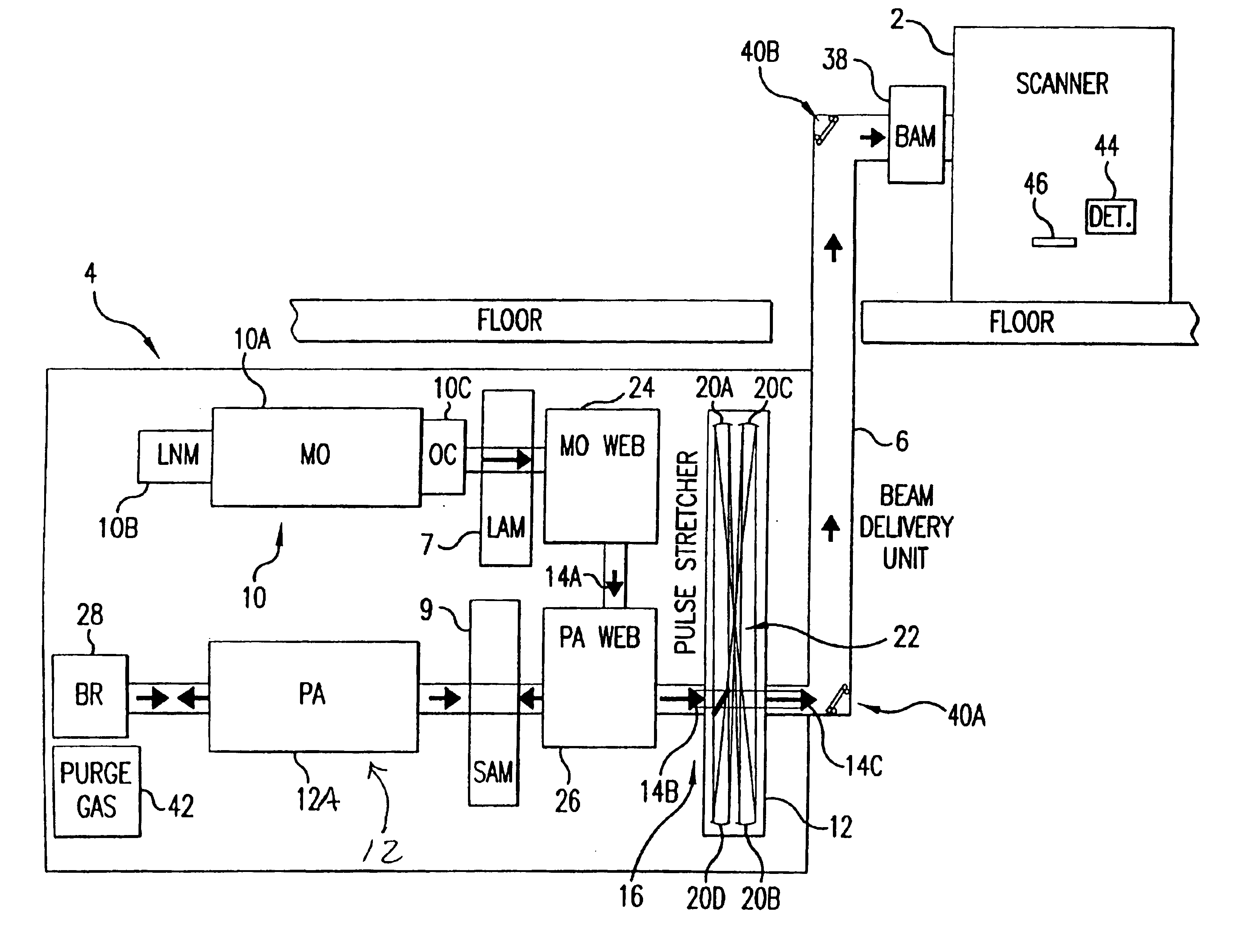

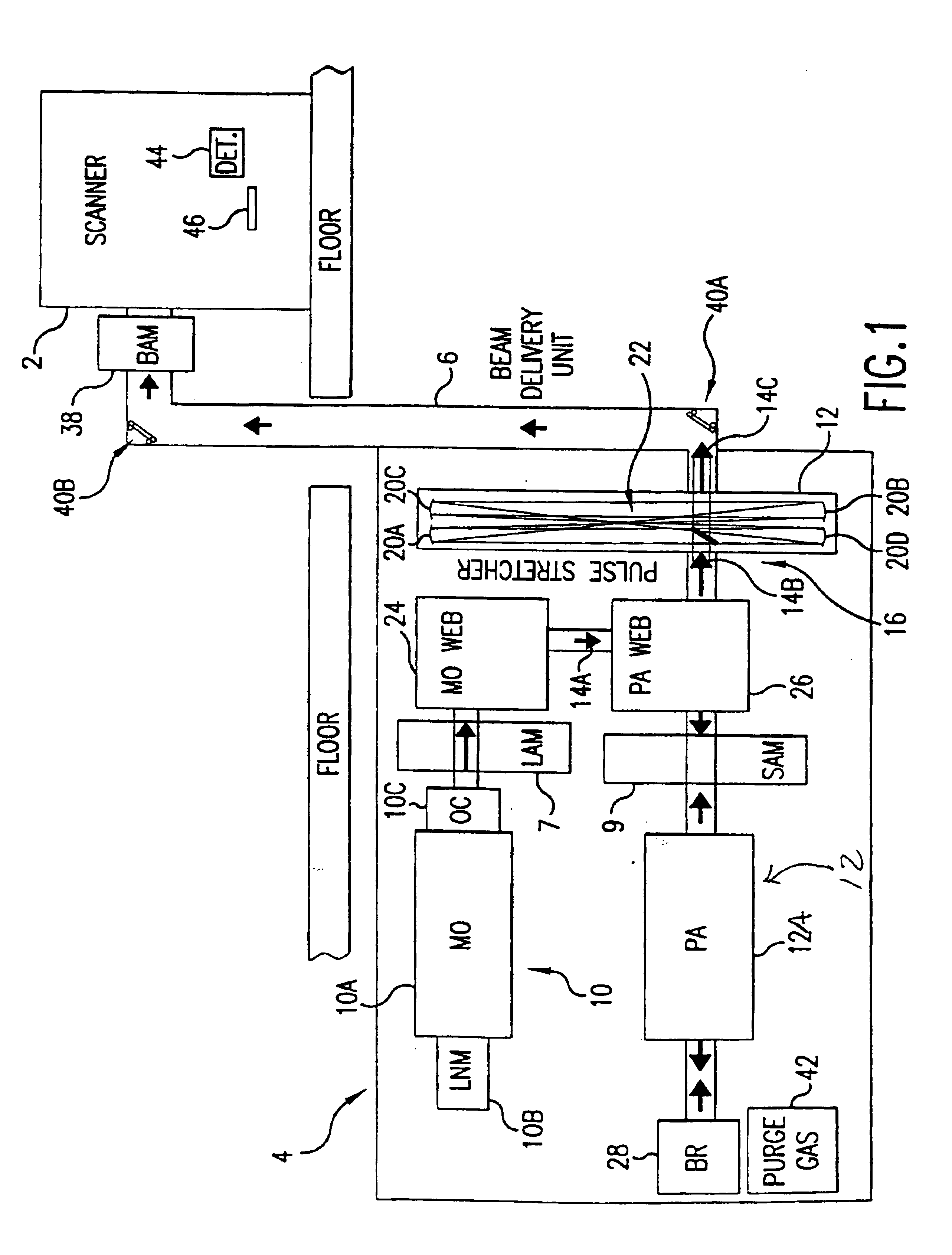

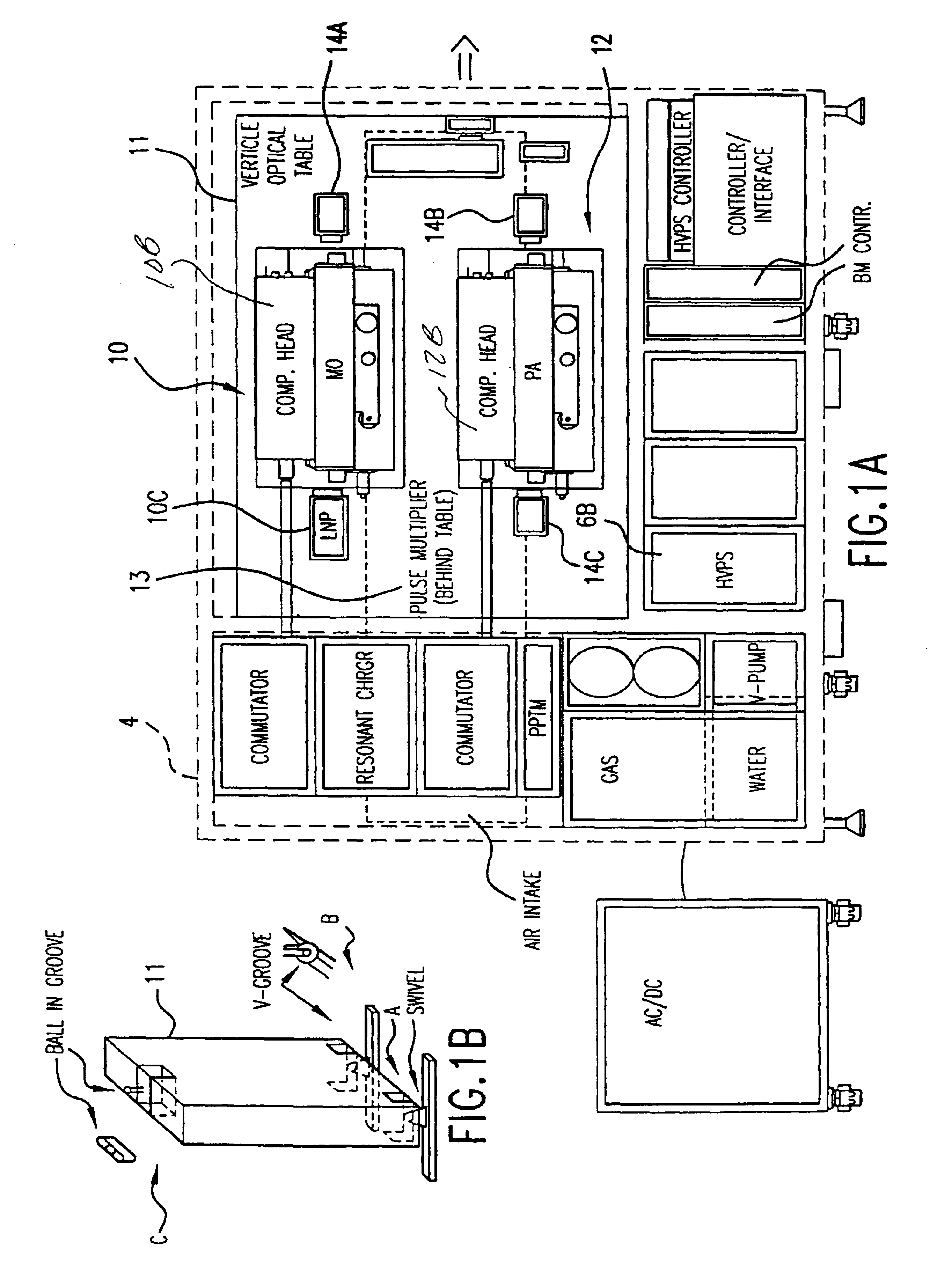

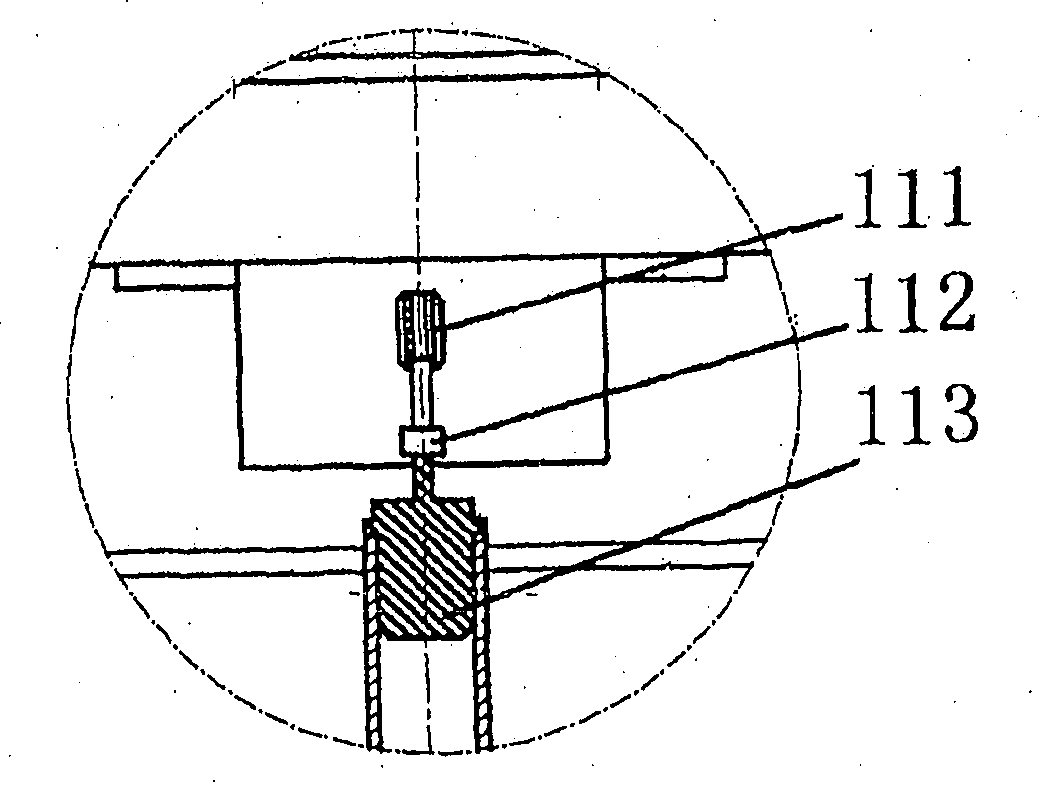

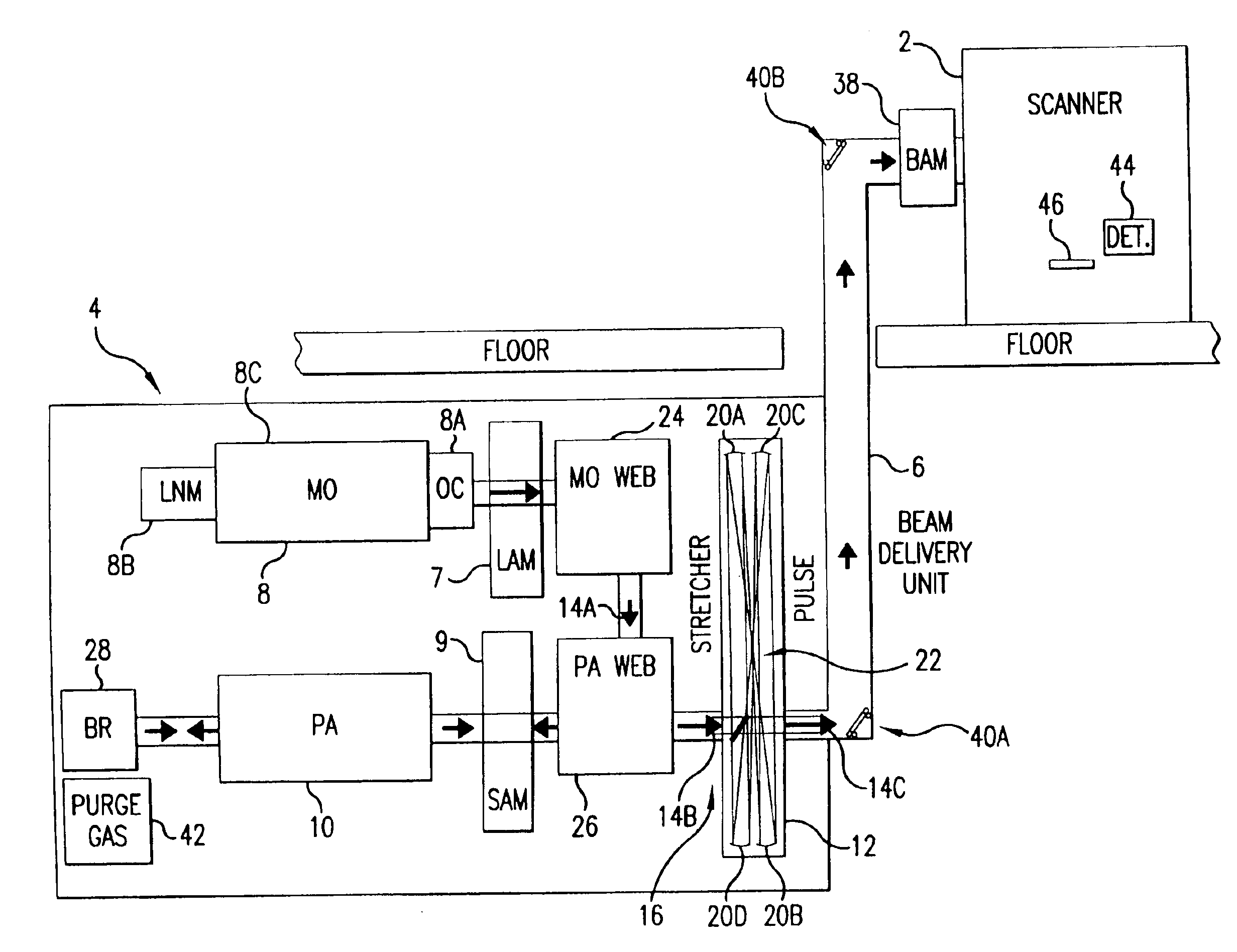

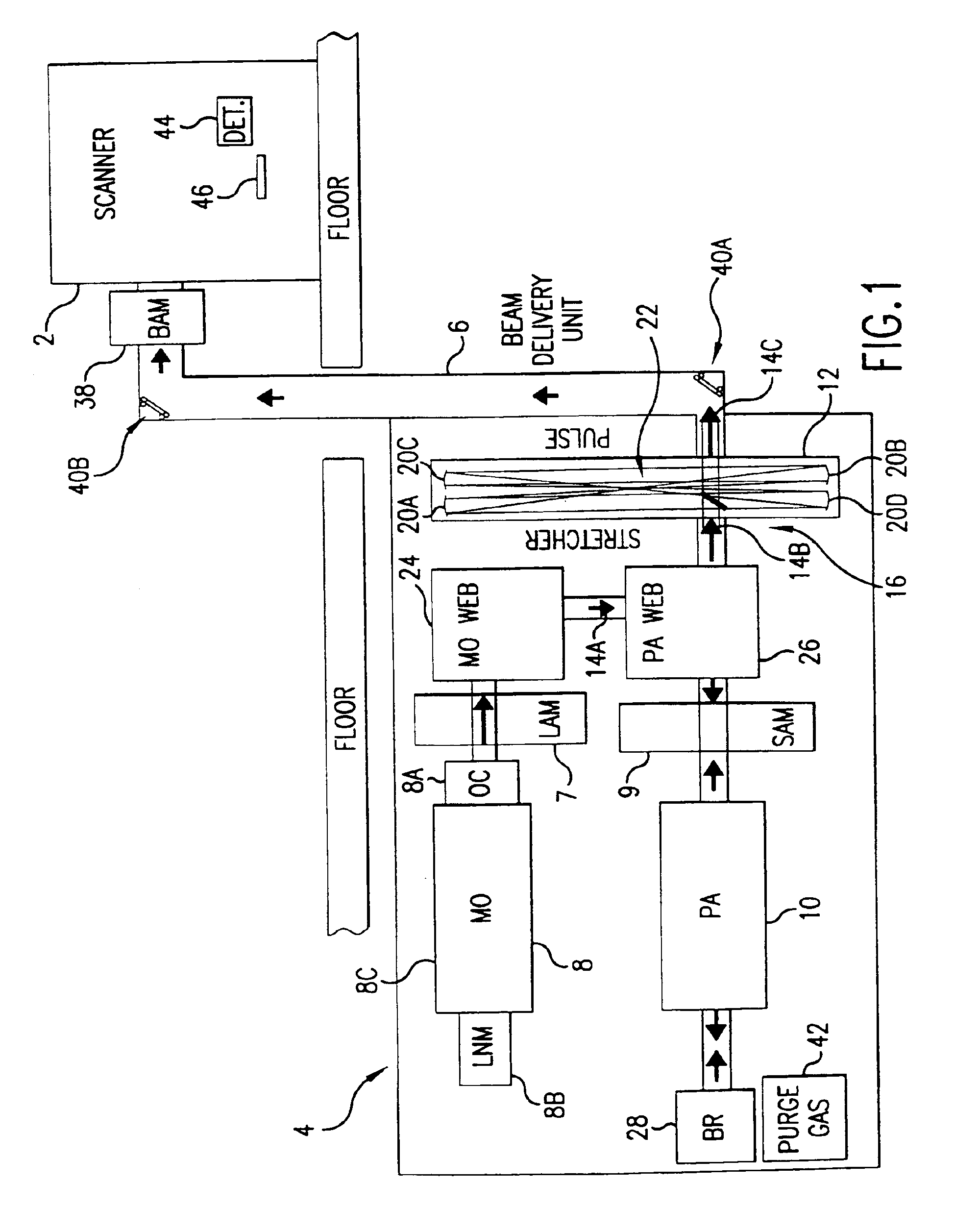

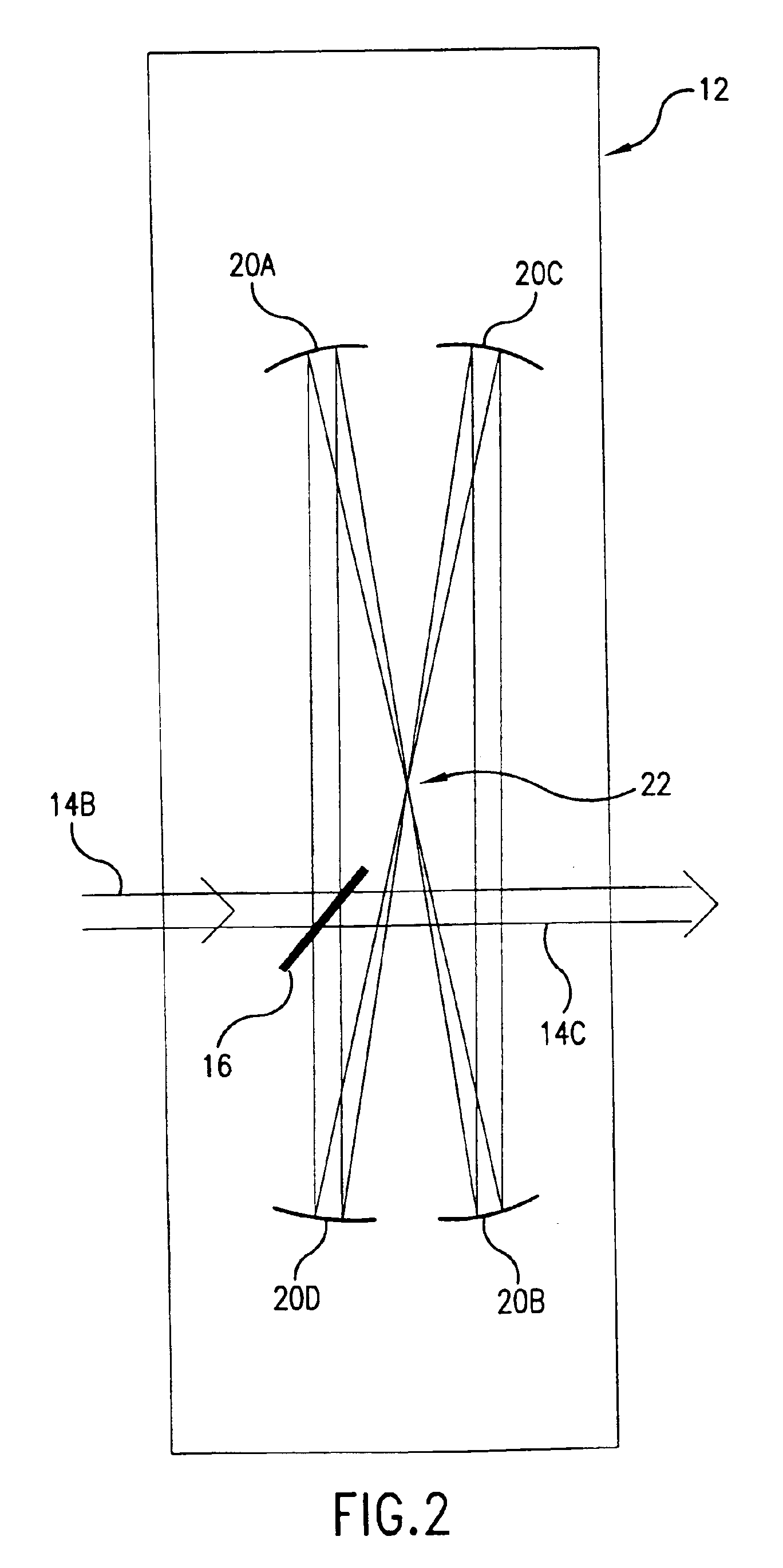

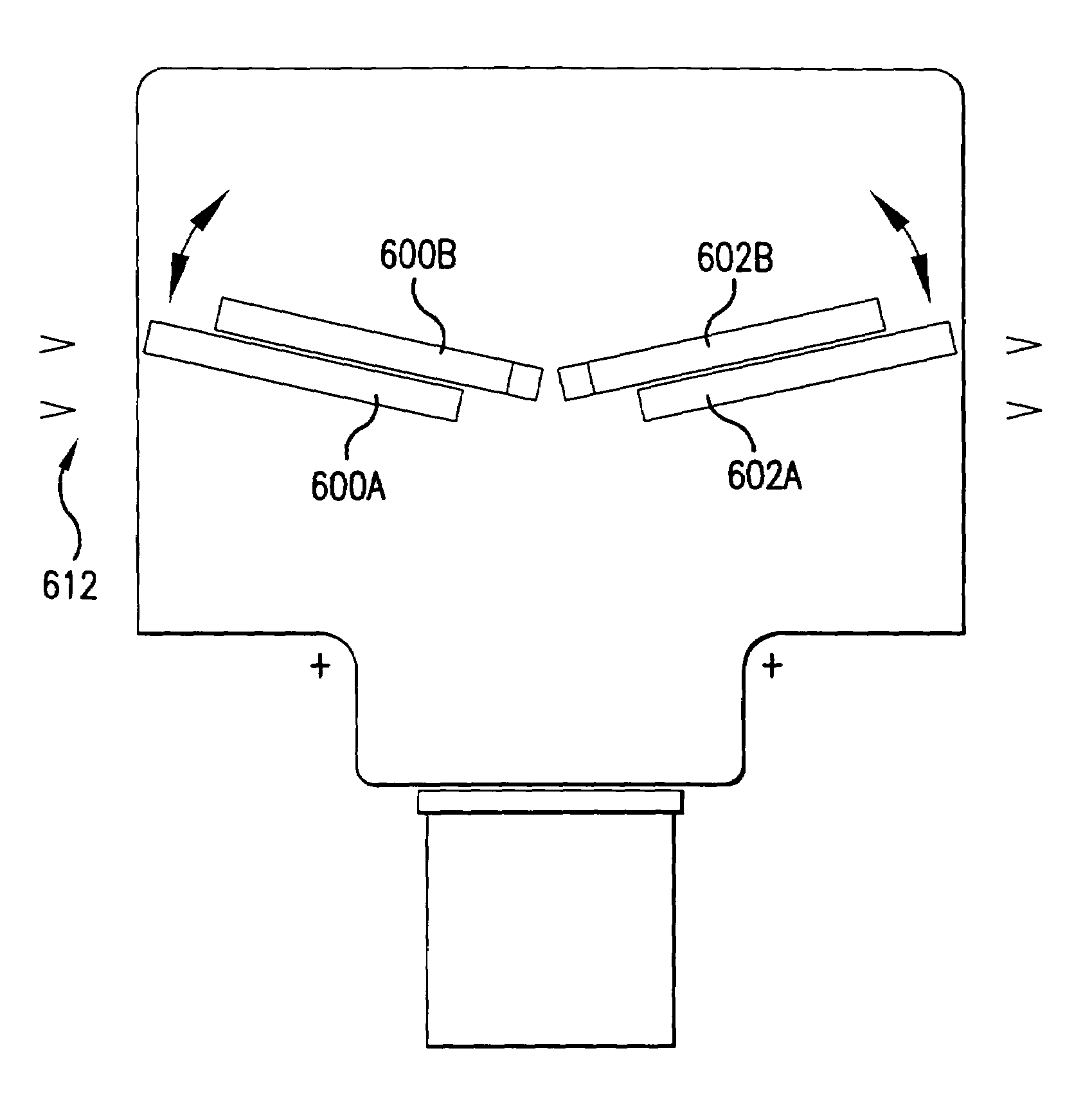

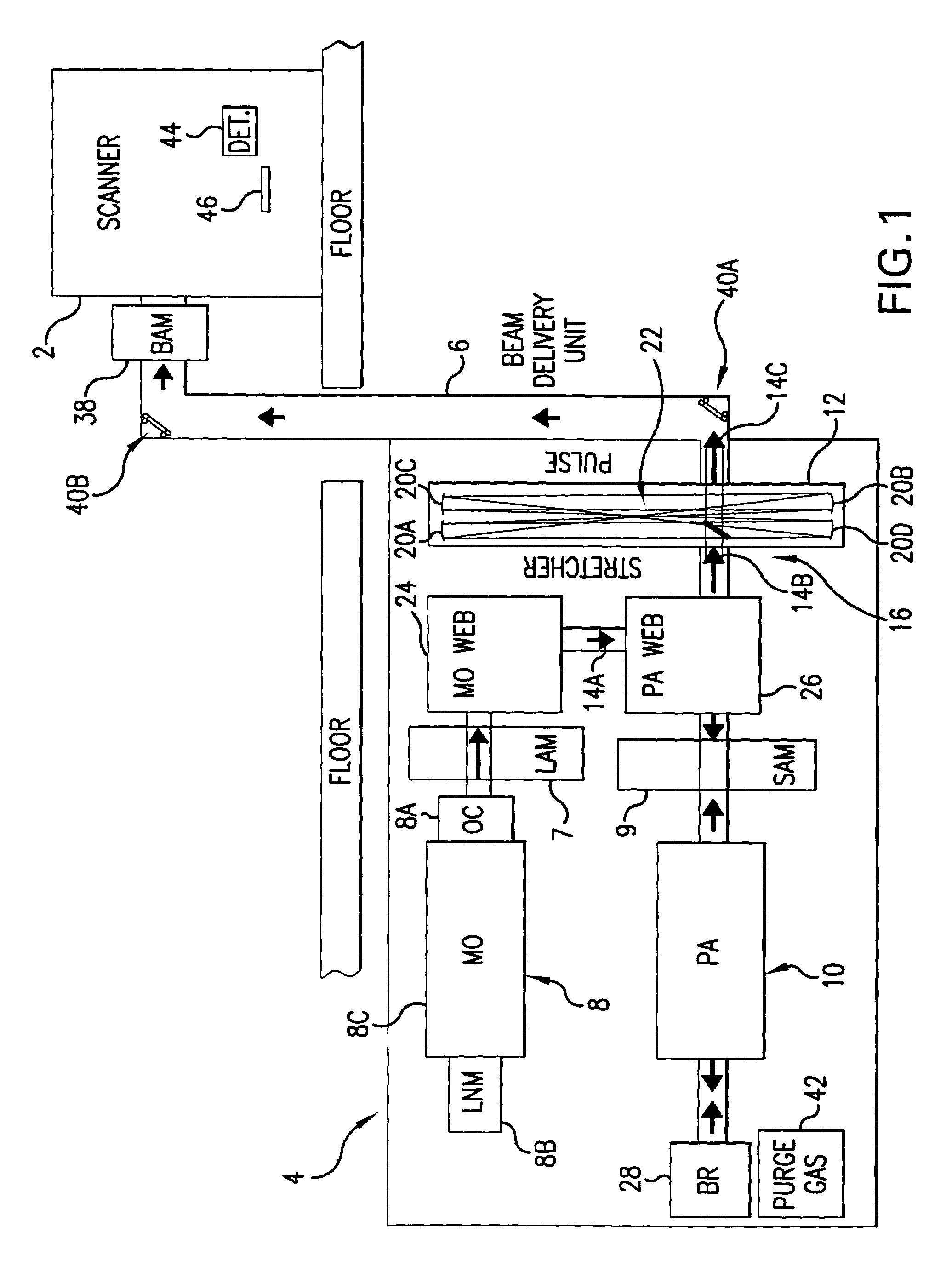

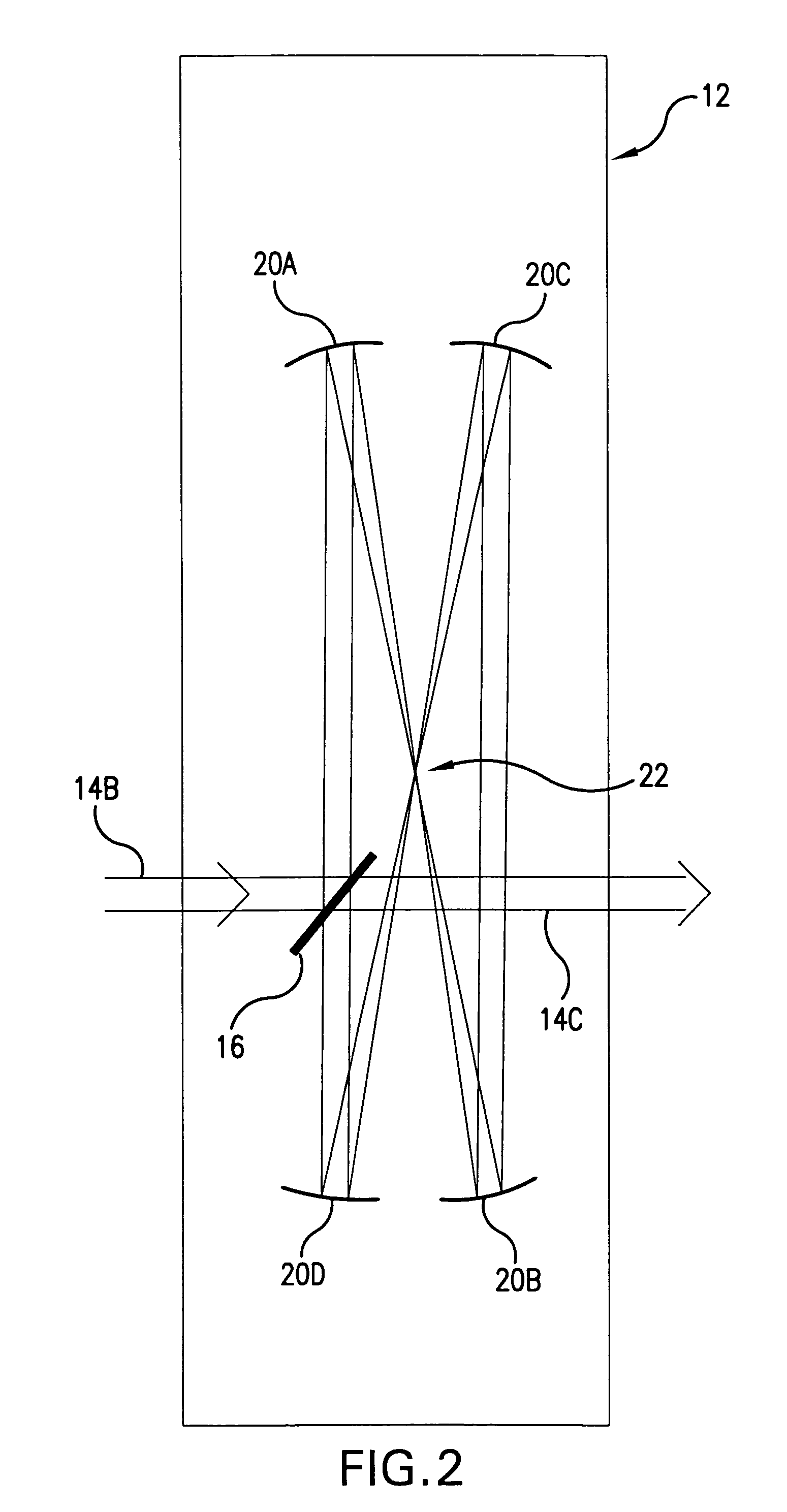

The present invention provides long life optics for a modular, high repetition rate, ultraviolet gas discharge laser systems producing a high repetition rate high power output beam. The invention includes solutions to a surface damage problem discovered by Applicants on CaF2 optics located in high pulse intensity sections of the output beam of prototype laser systems. Embodiments include an enclosed and purged beam path with beam pointing control for beam delivery of billions of output laser pulses. Optical components and modules described herein are capable of controlling ultraviolet laser output pulses with wavelength less than 200 nm with average output pulse intensities greater than 1.75×106 Watts / cm2 and with peak intensity or greater 3.5×106 Watts / cm2 for many billions of pulses as compared to prior art components and modules which failed after only a few minutes in these pulse intensities. Techniques and components are disclosed for minimizing the potential for optical damage and for reducing the pulse energy density to less than 100×10−6 J / cm3. Important improvements described in this specification have been grouped into the following subject matter categories: (1) Solution to CaF2 surface damage discovered by Applicants, (2) description of a high power ArF MOPA laser system, (3) description of beam delivery units, (4) polarization considerations (5) a high speed water-cooled auto shutter energy detector module and (6) other improvements.

Owner:CYMER INC

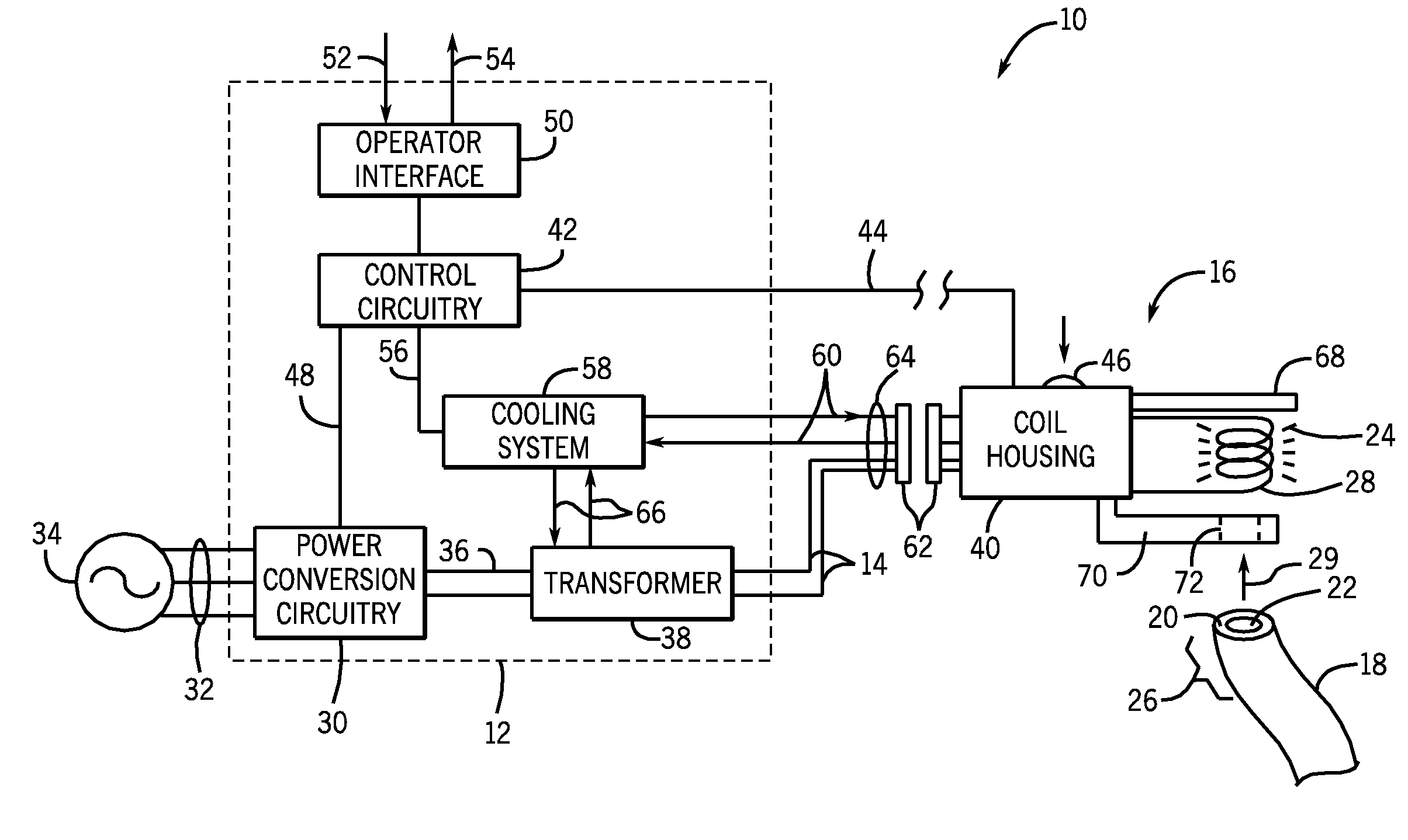

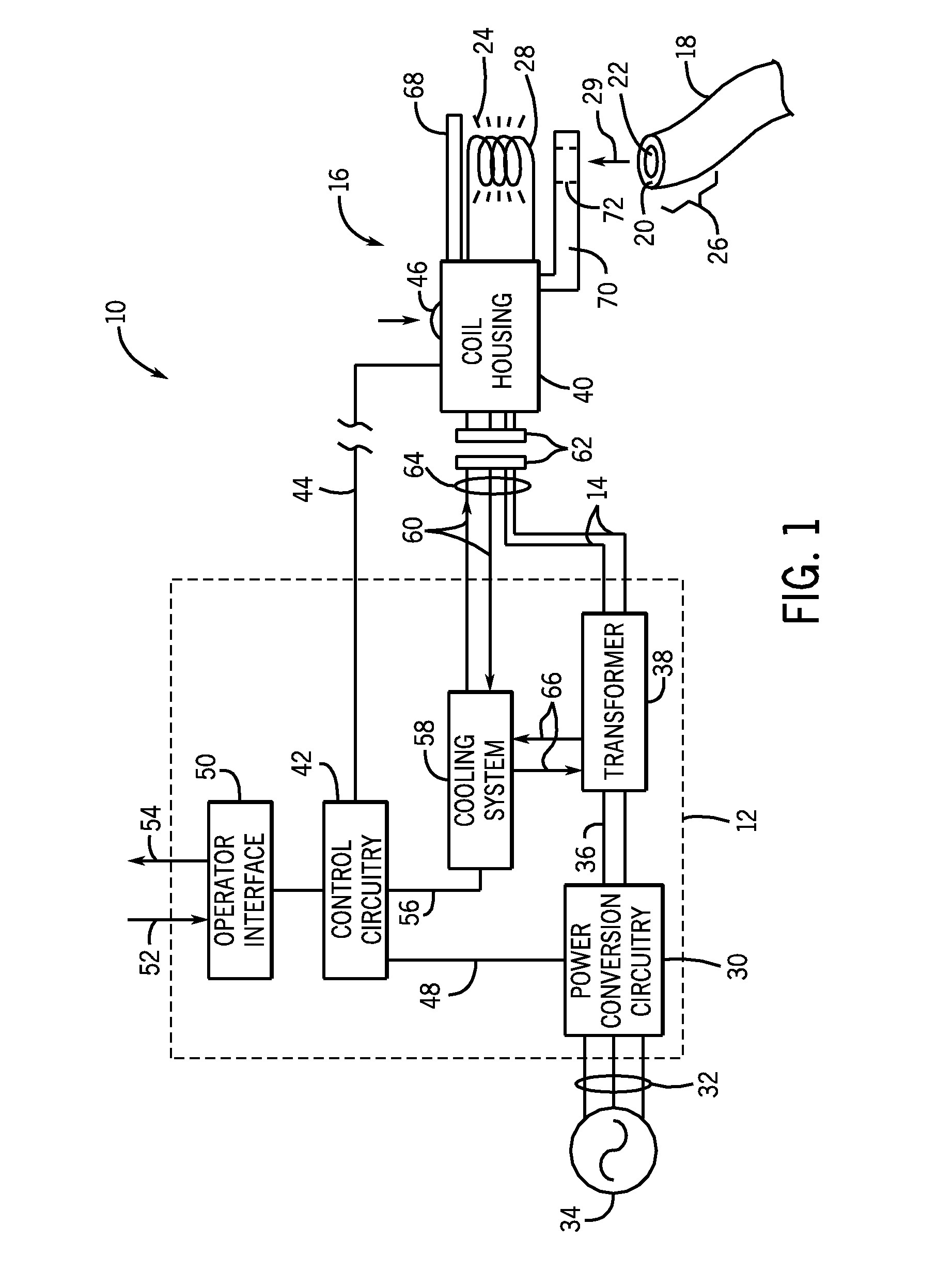

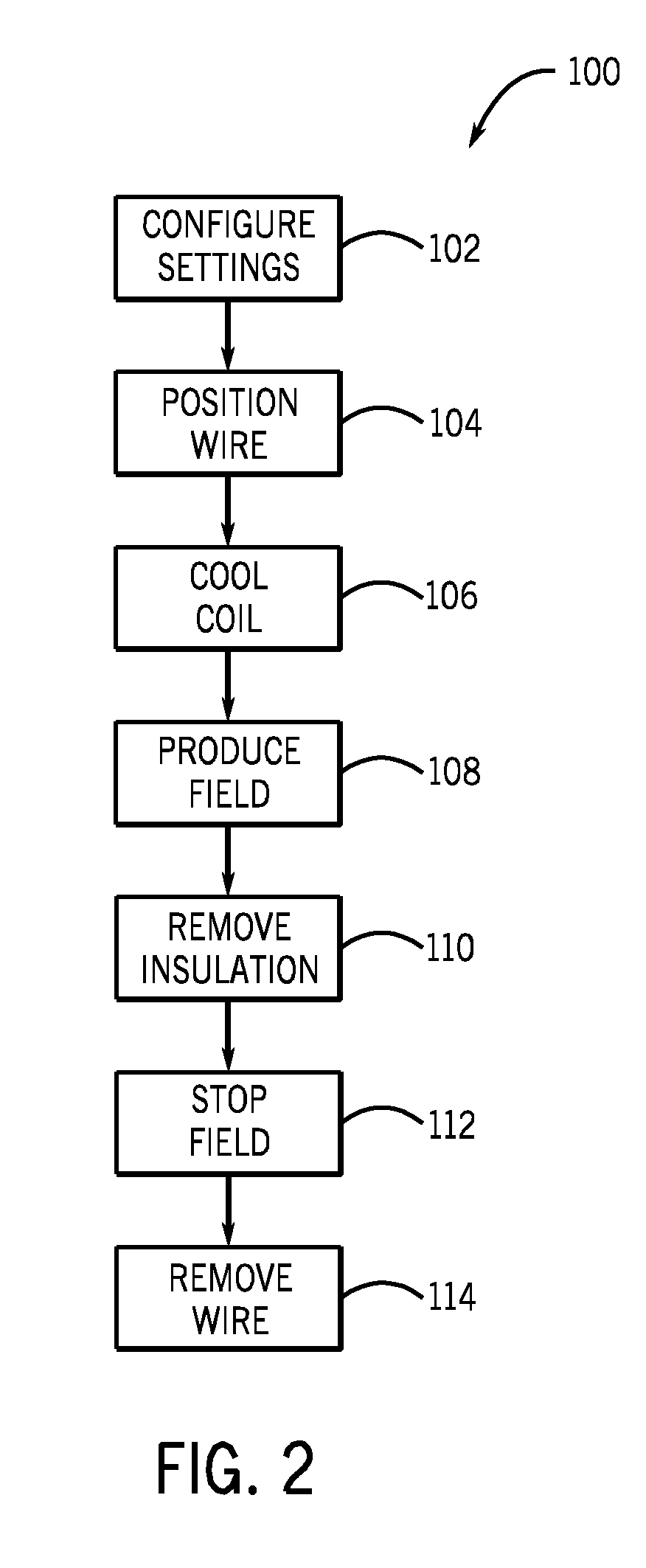

Induction heating wire insulation heating and removal

InactiveUS20120248093A1Output powerCable installation apparatusInduction heating apparatusHigh frequency powerEngineering

This disclosure relates generally to removing wire insulation. In an embodiment, a system for heating and removal of wire insulation includes a power supply configured to receive input power and to provide a high frequency power output to an induction coil. The induction coil is to be coupled to the power supply and dimensioned to receive an insulated wire therethrough. The induction coil is also to produce a field based upon the high frequency power output to heat the wire by induction and to condition insulation disposed on an outer surface of the wire for removal.

Owner:ILLINOIS TOOL WORKS INC

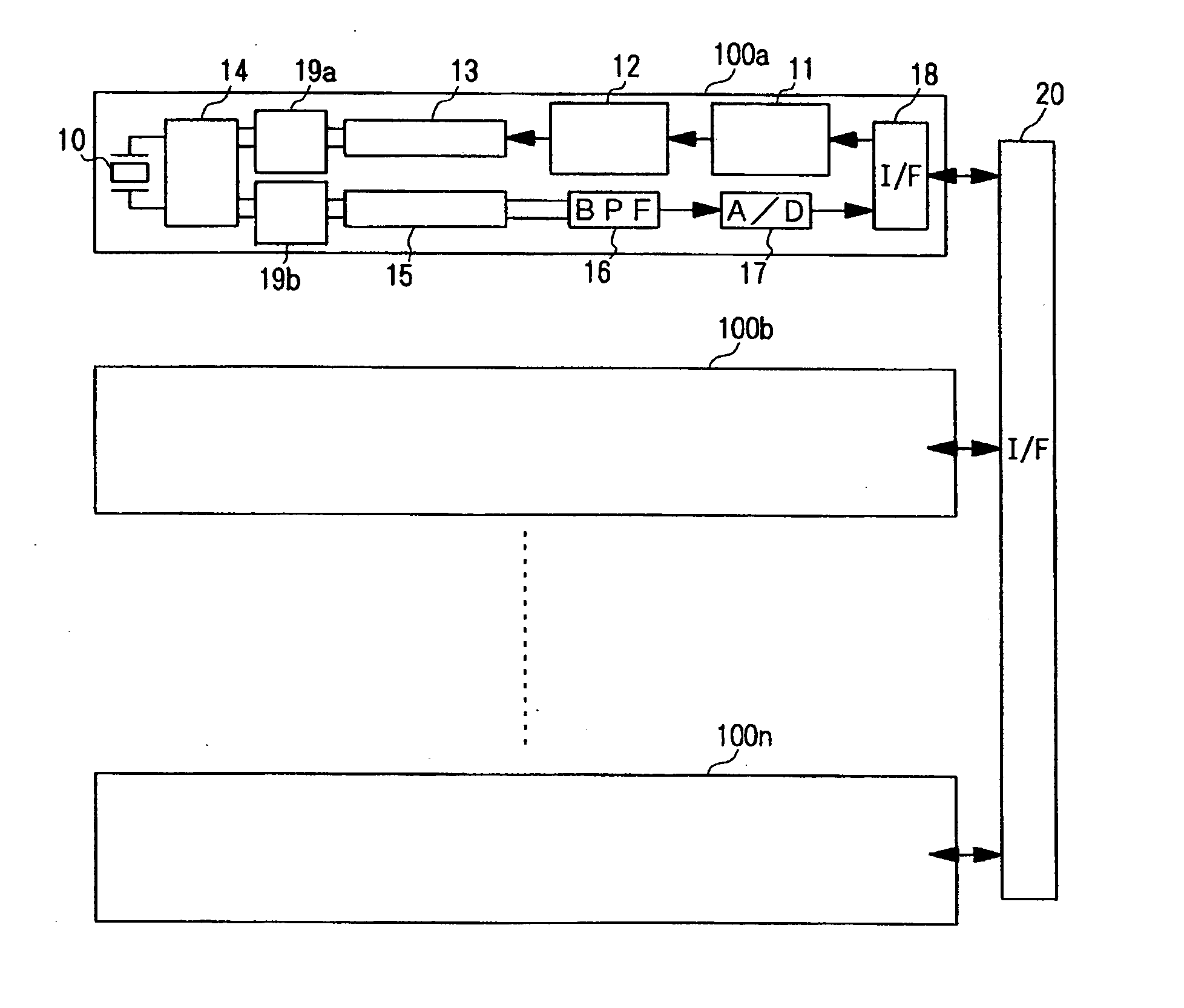

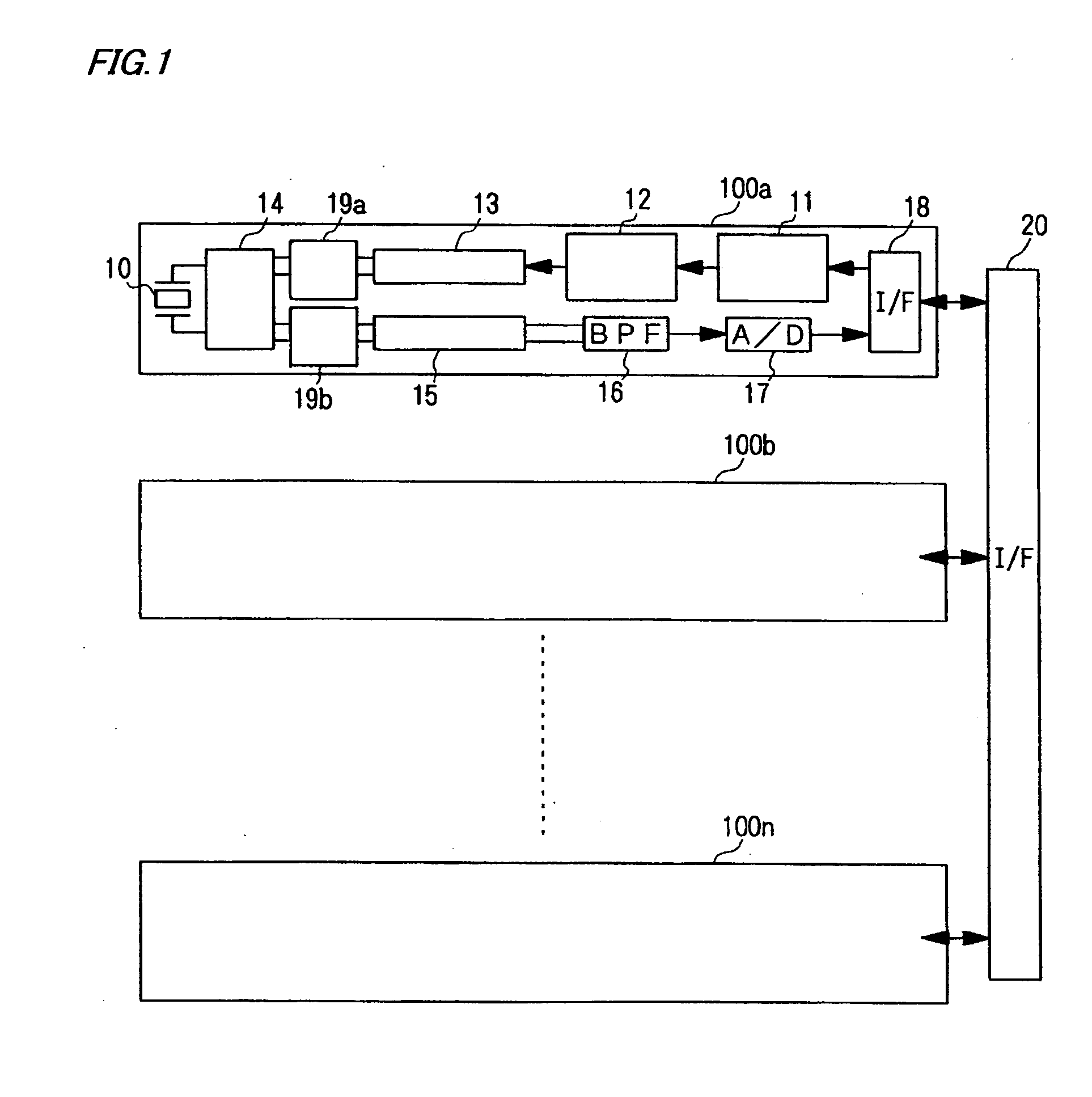

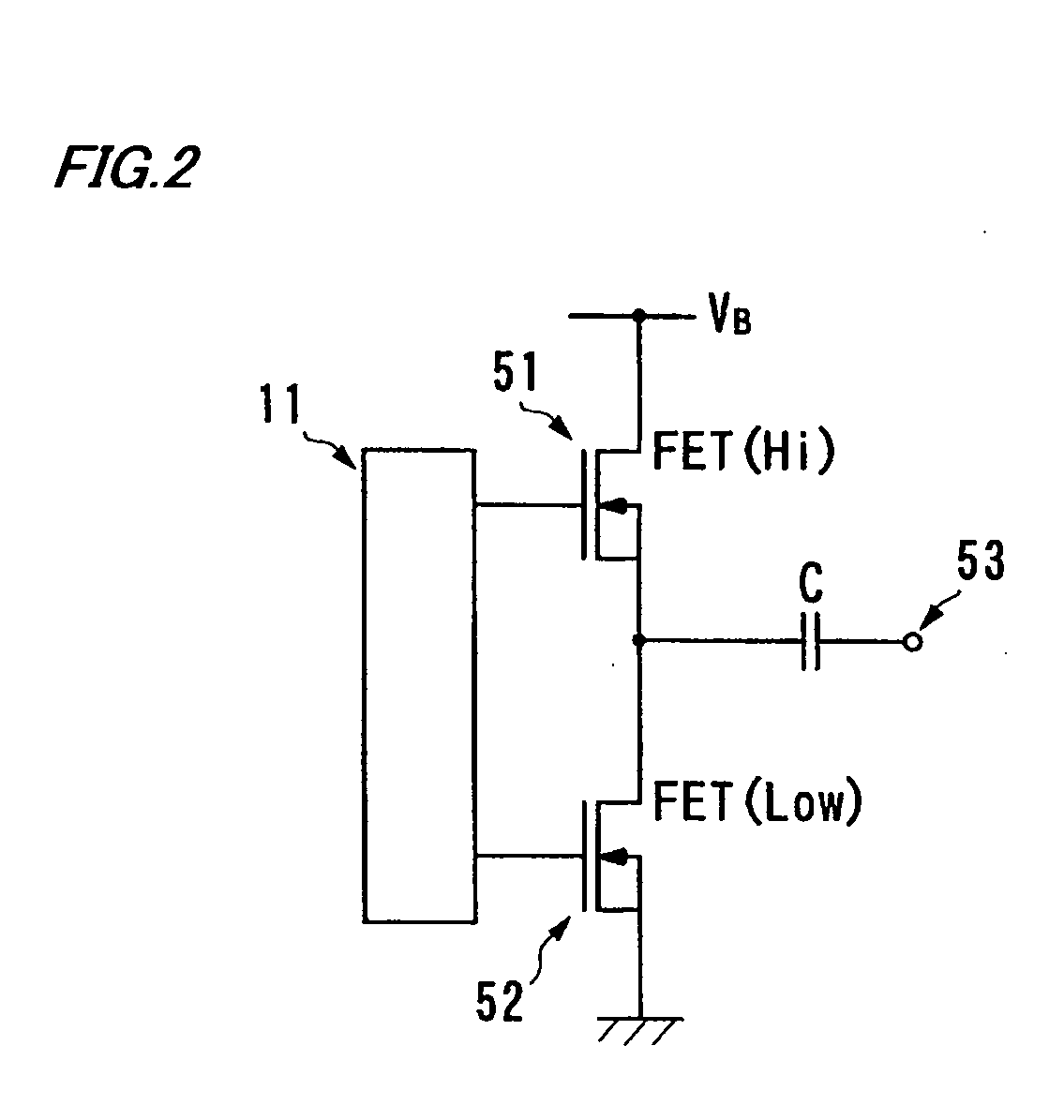

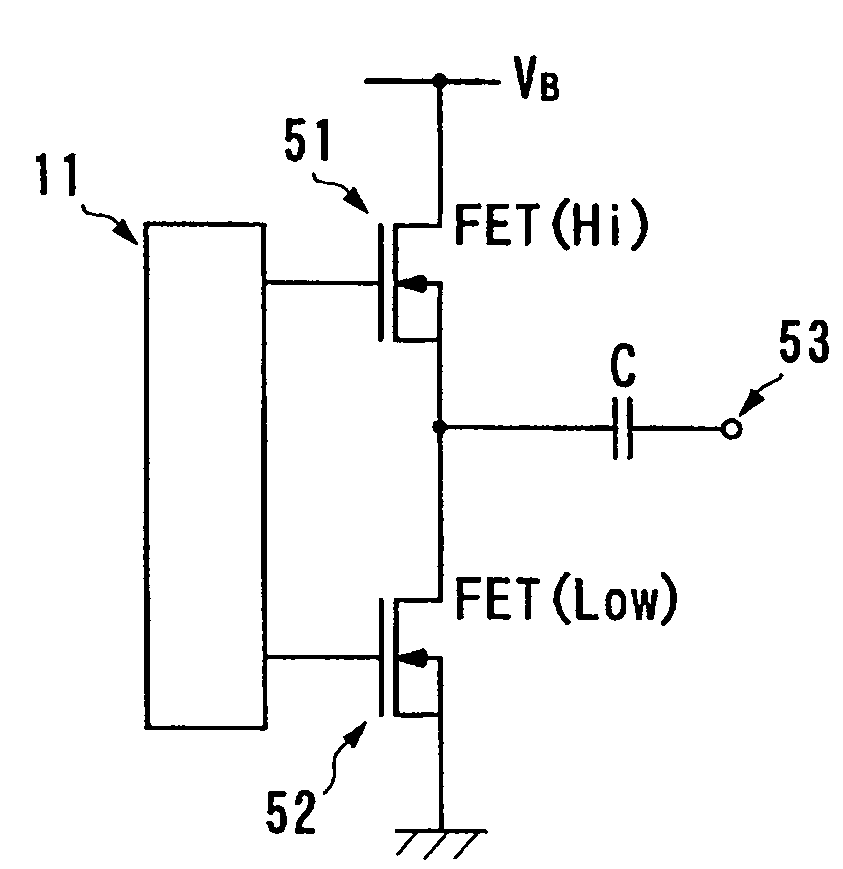

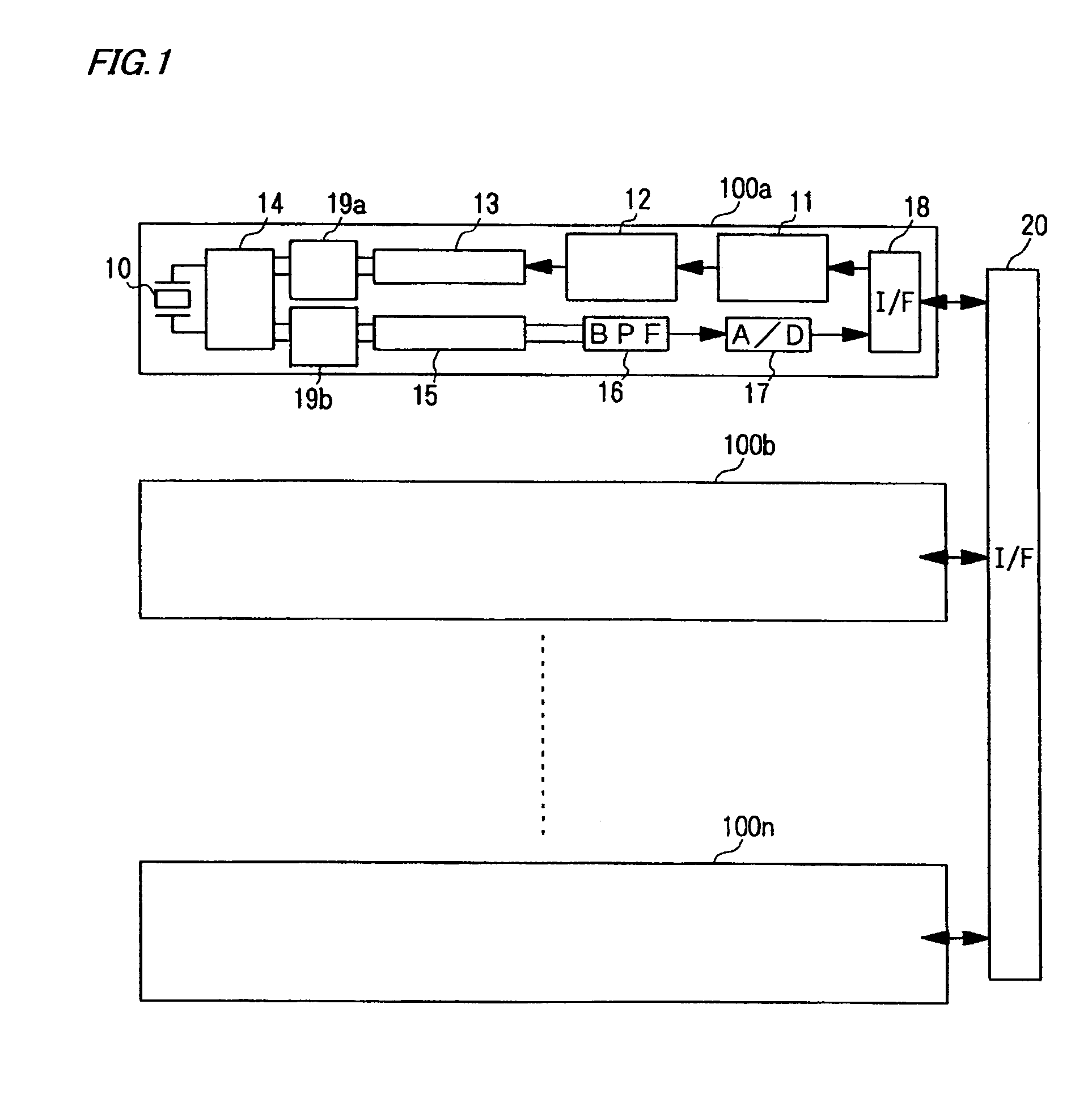

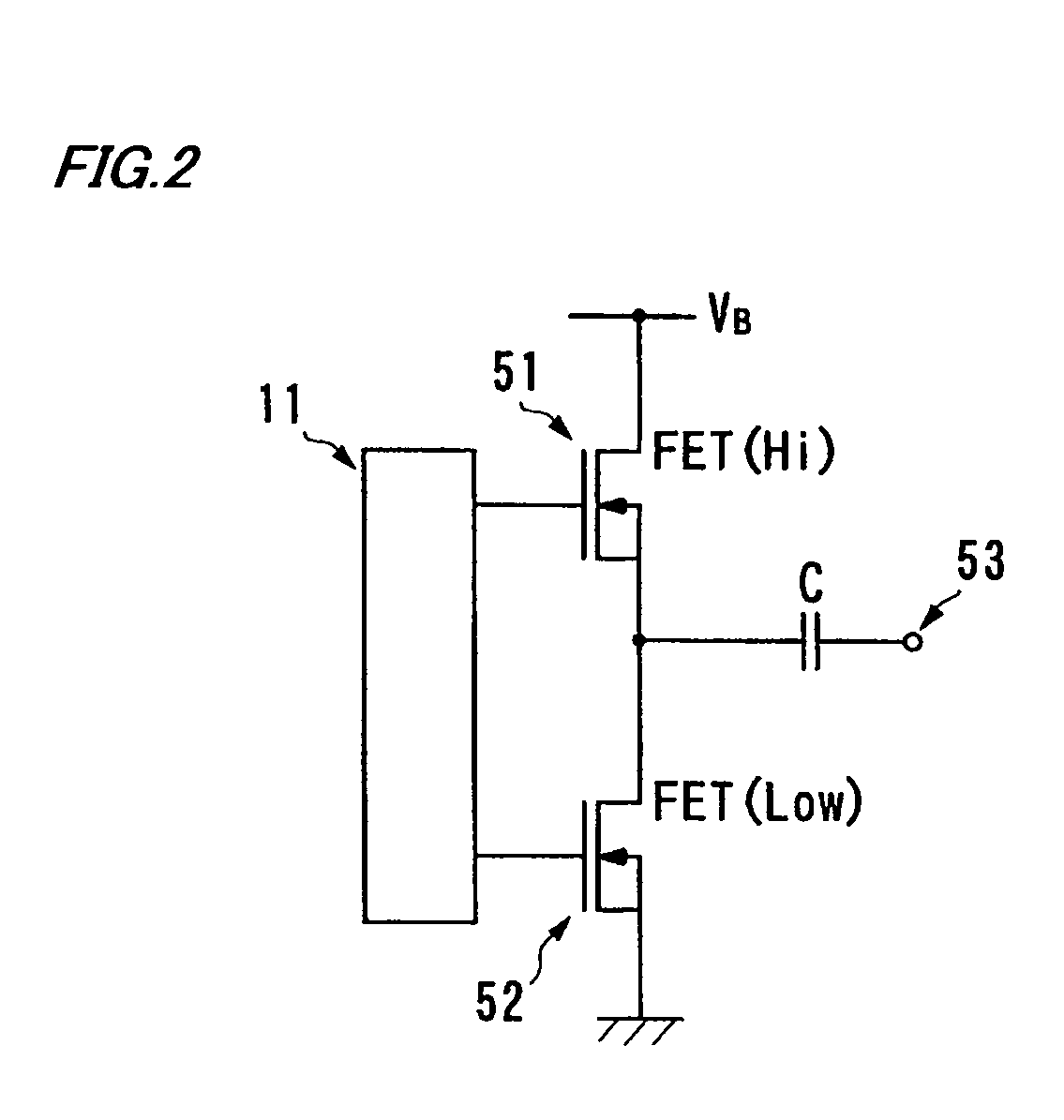

Ultrasonic transmitter, ultrasonic transceiver and sounding apparatus

InactiveUS20050007879A1Suppress emissionImprove efficiencySonic/ultrasonic/infrasonic transmissionMechanical vibrations separationDriver circuitTransceiver

A driver circuit for generating a driving signal by pulse-width modulation (PWM) includes a half-bridge circuit formed essentially of a pair of series-connected FETs. When the level of an ultrasonic signal, or of the driving signal, is to be maximized, the individual FETs are switched at a switching frequency matched to the frequency of the driving signal. When the level of the ultrasonic signal, or the driving signal is to be reduced, on the other hand, the individual FETs are switched with specific timing determined based on the frequency of a clock signal of which period is shorter than that of the driving signal.

Owner:FURUNO ELECTRIC CO LTD

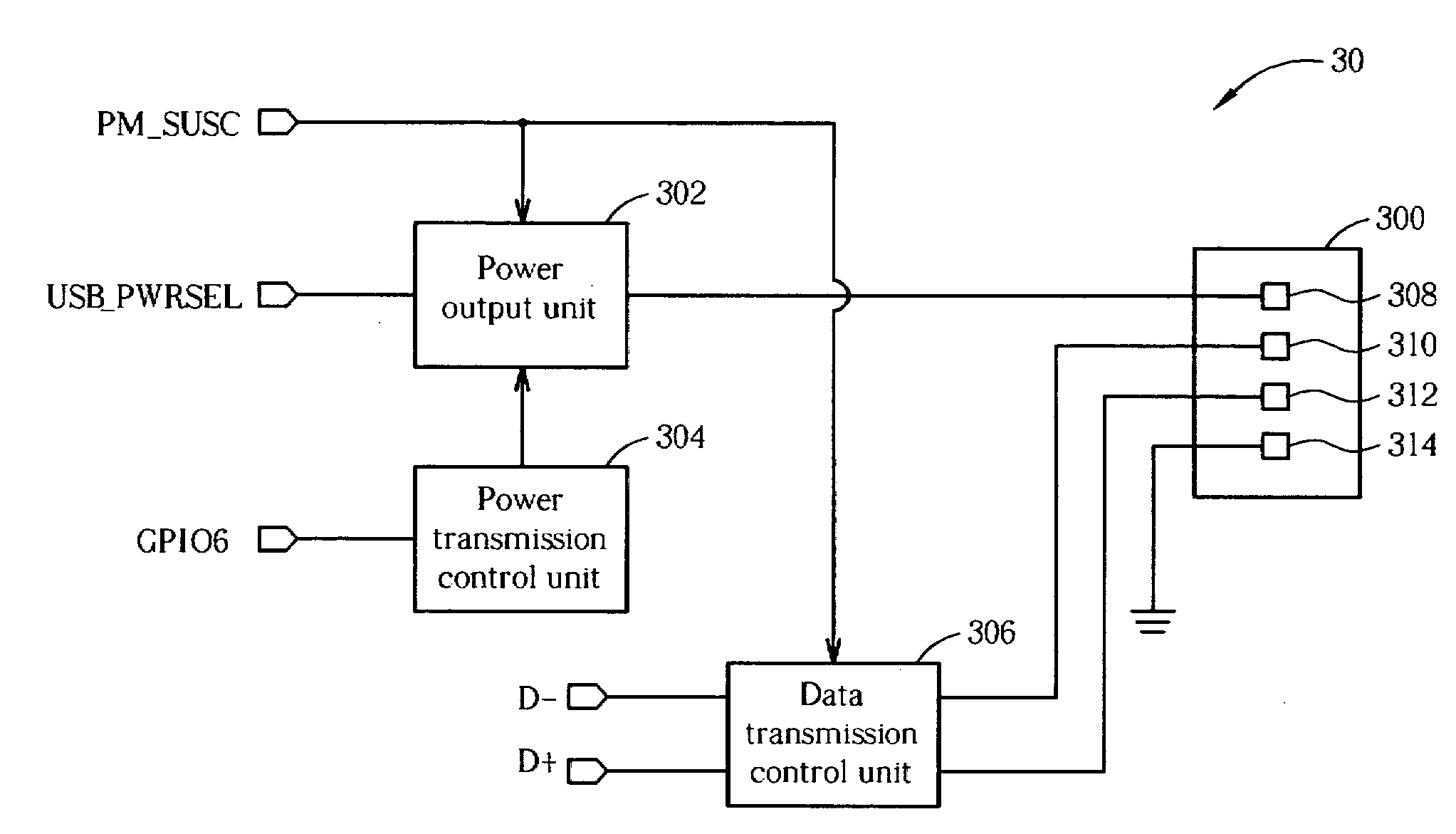

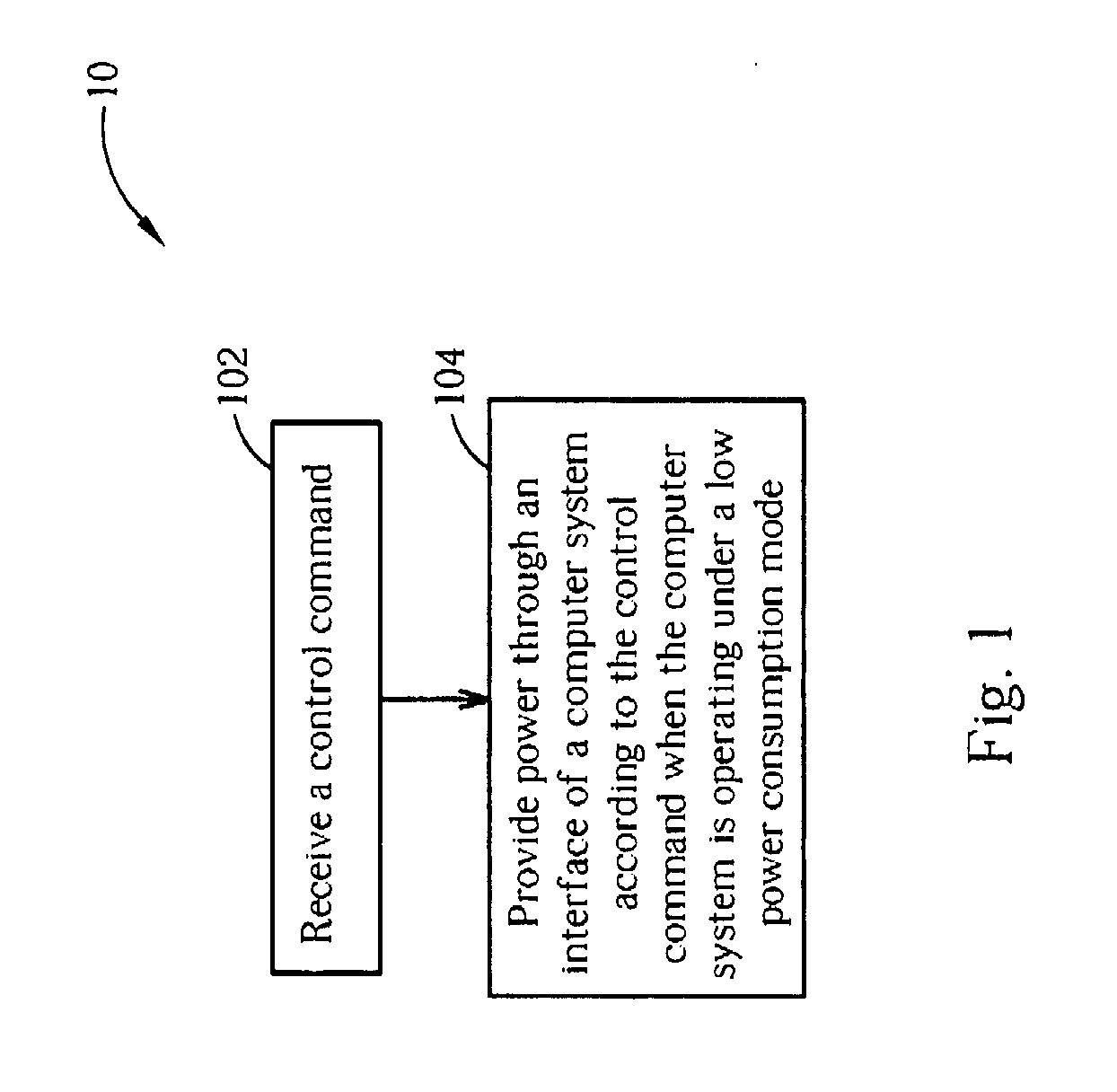

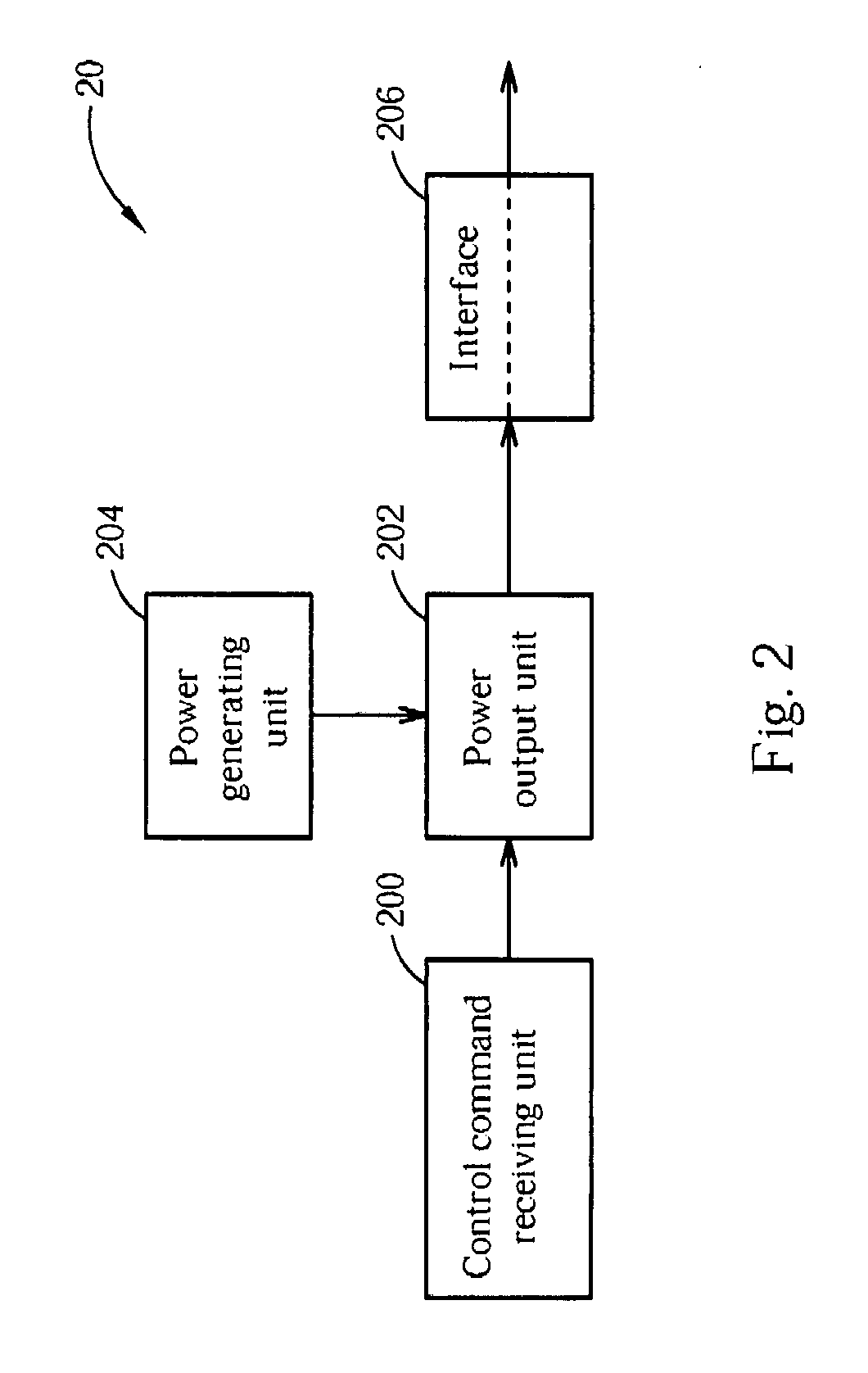

Method and apparatus for controlling power supply in a computer system

ActiveUS20070220290A1Output powerVolume/mass flow measurementPower supply for data processingControl powerComputerized system

A method for controlling power supply in a computer system includes receiving a control command, and providing power through an interface of the computer system when the computer system is operating in a low power consumption mode.

Owner:ASUSTEK COMPUTER INC

Control system for a two chamber gas discharge laser

InactiveUS7039086B2Output powerBeam quality specificationPhotomechanical apparatusLaser arrangementsTemperature controlProduction line

The present invention provides a control system for a modular high repetition rate two discharge chamber ultraviolet gas discharge laser. In preferred embodiments, the laser is a production line machine with a master oscillator producing a very narrow band seed beam which is amplified in the second discharge chamber.Novel control features specially adapted for a two-chamber gas discharge laser system include: (1) pulse energy controls, with nanosecond timing precision (2) precision pulse to pulse wavelength controls with high speed and extreme speed wavelength tuning (3) fast response gas temperature control and (4) F2 injection controls with novel learning algorithm.

Owner:CYMER INC

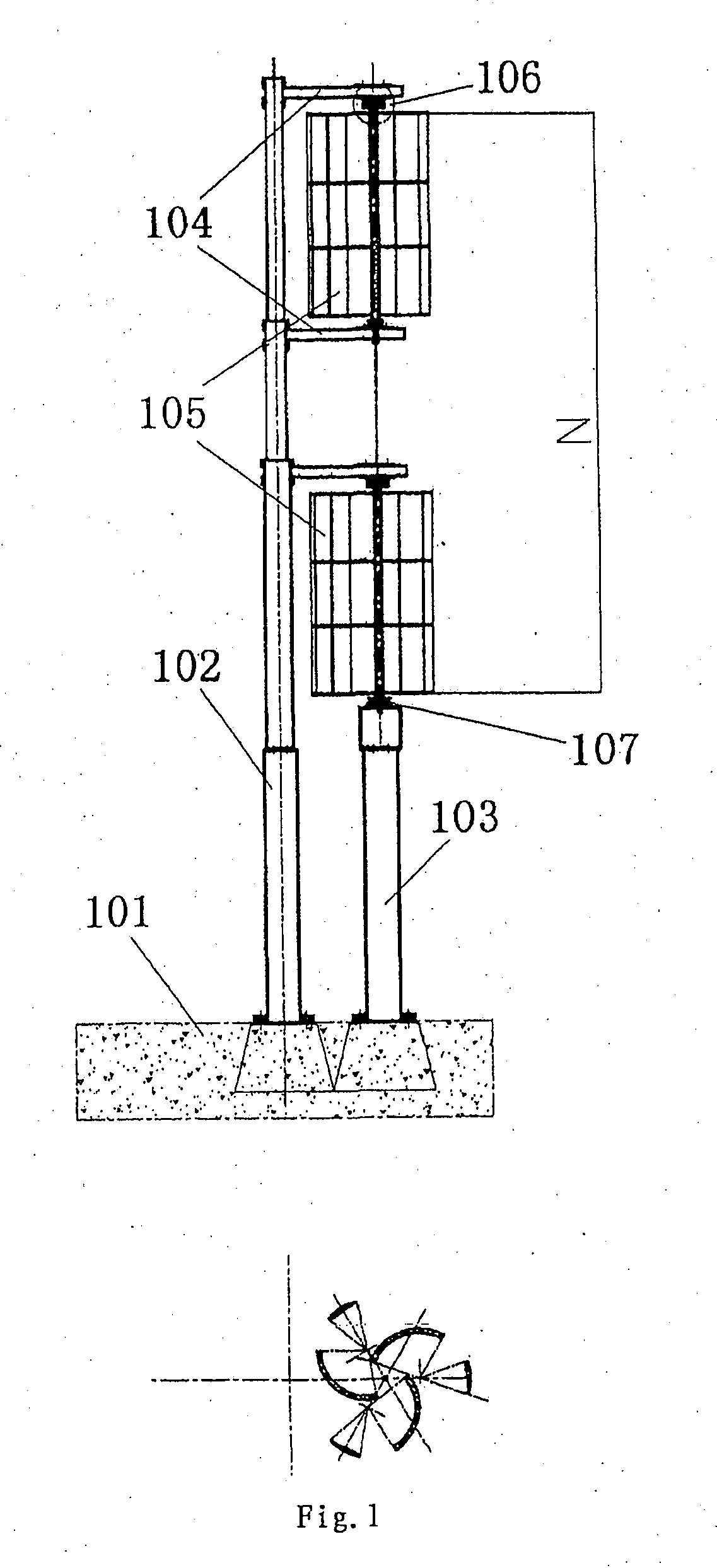

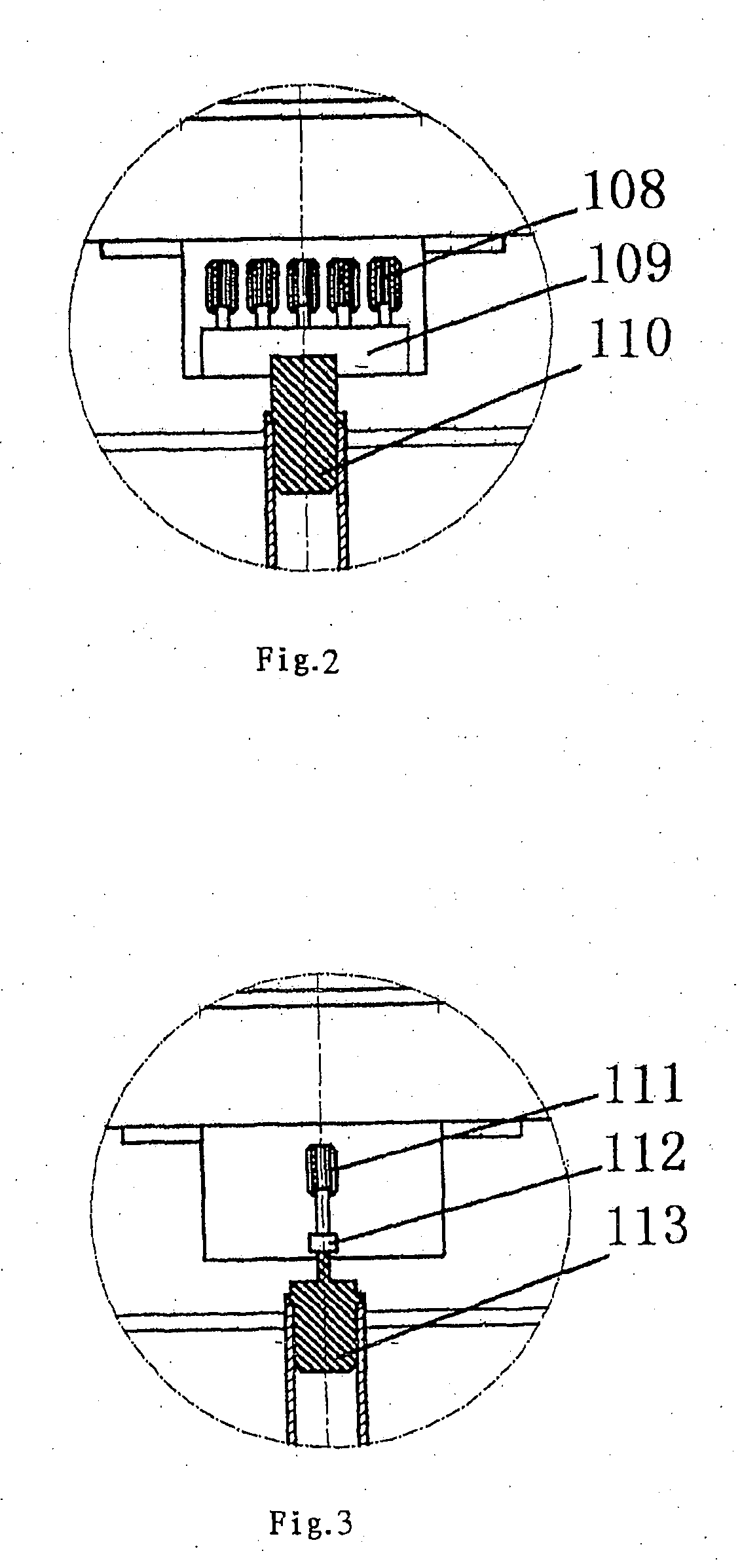

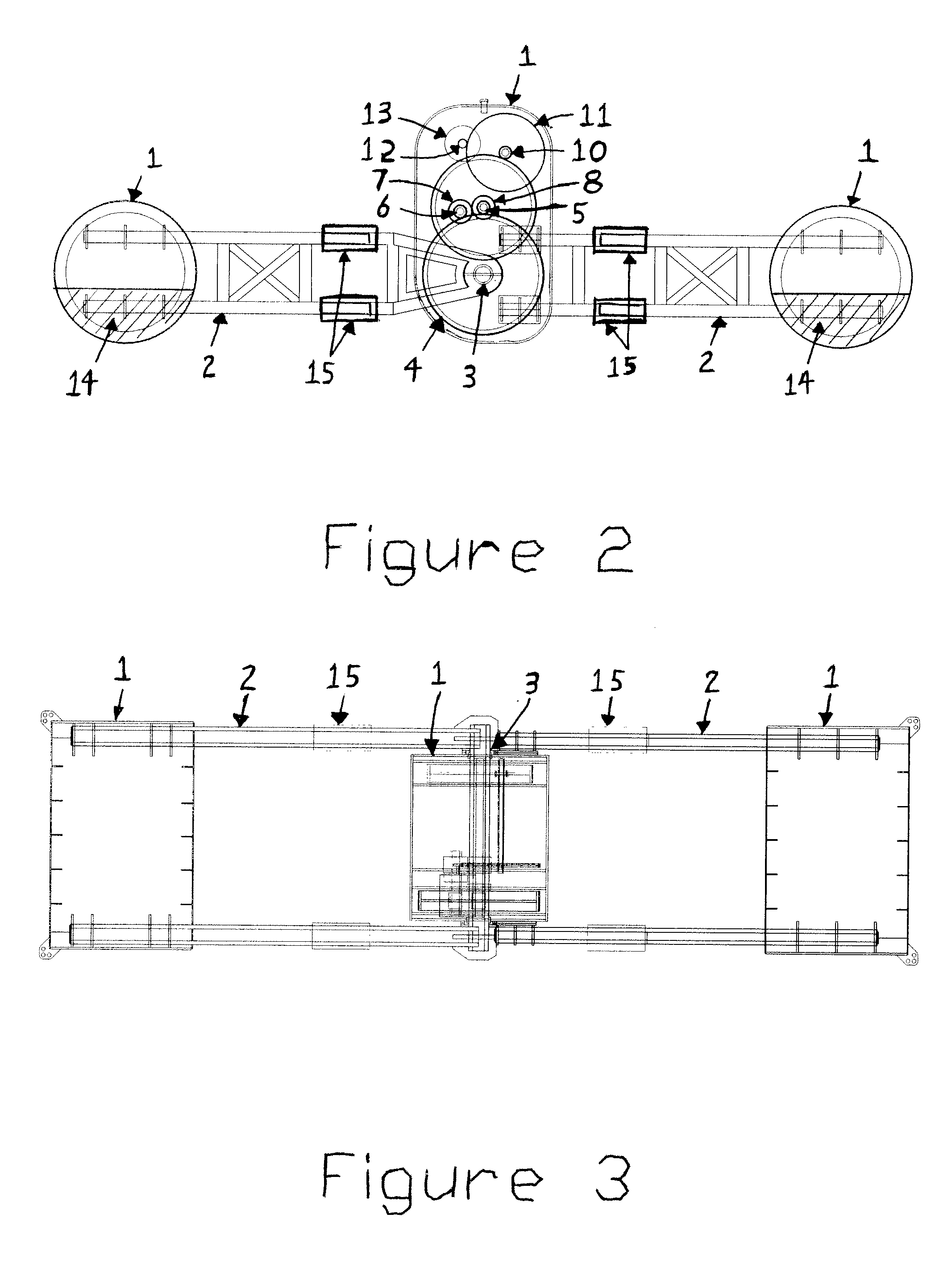

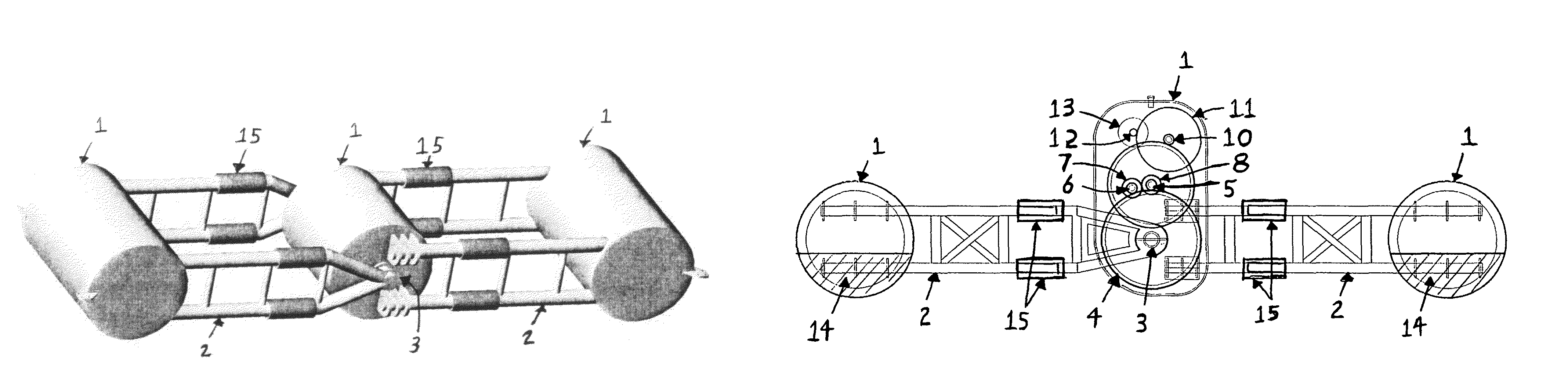

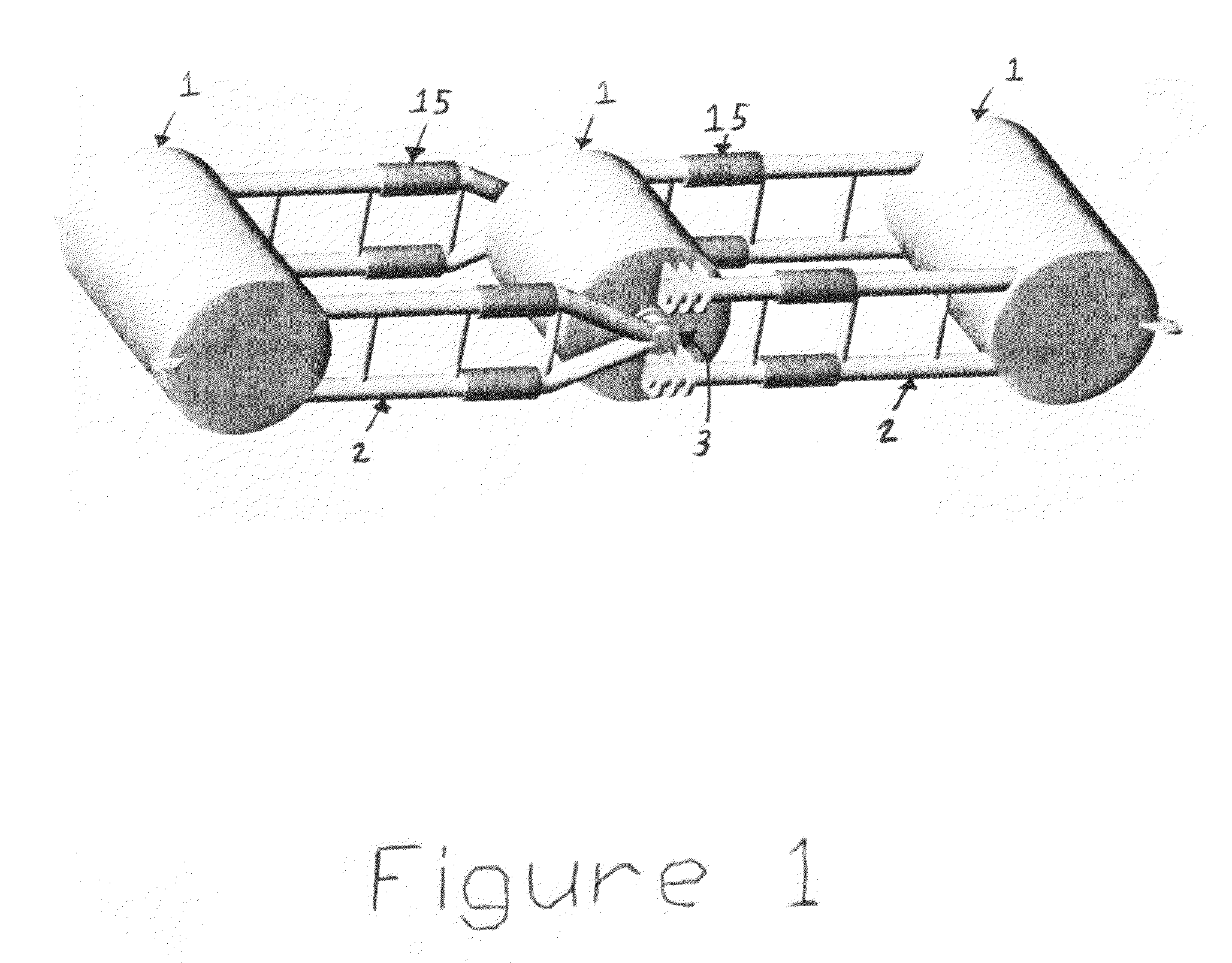

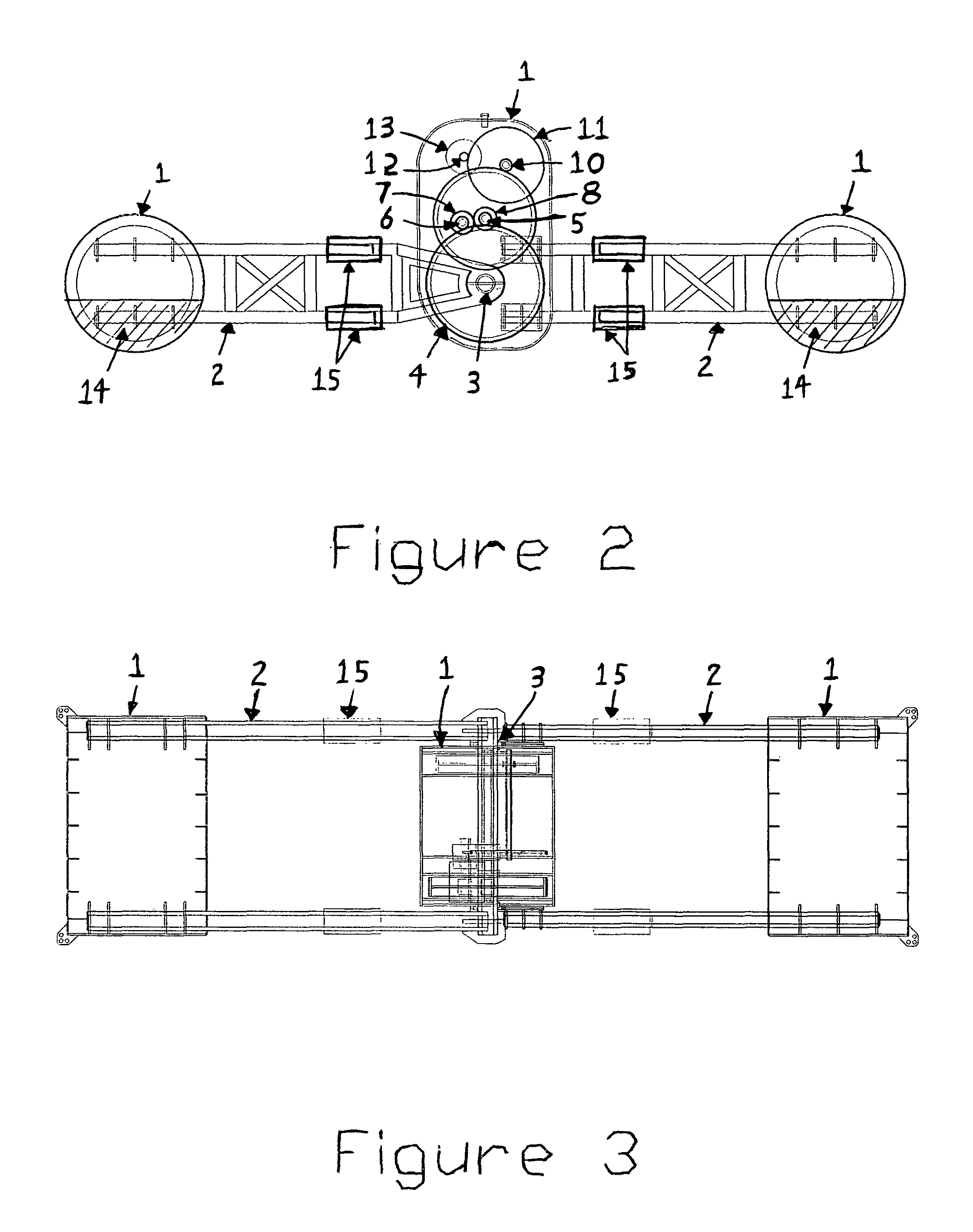

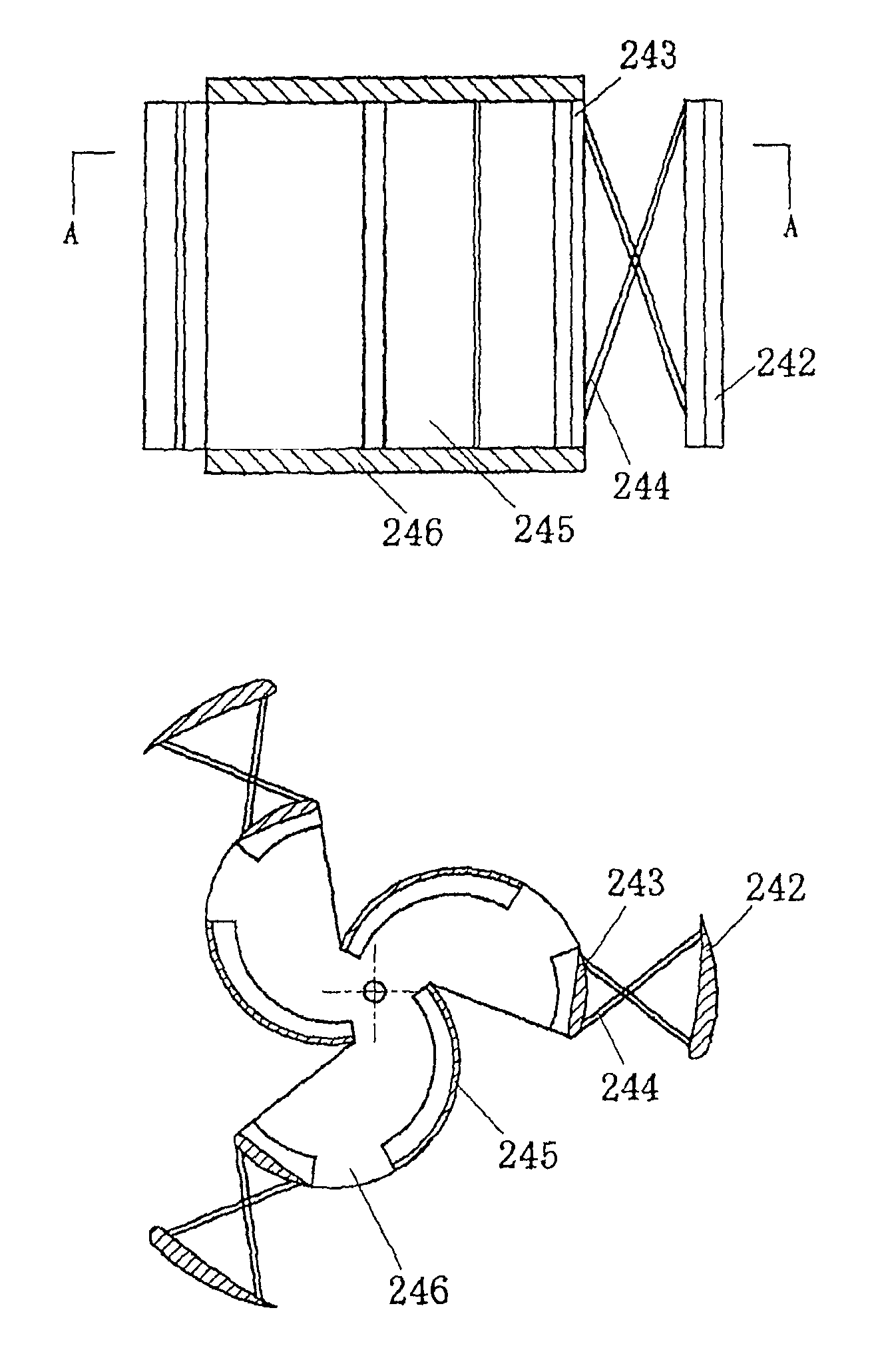

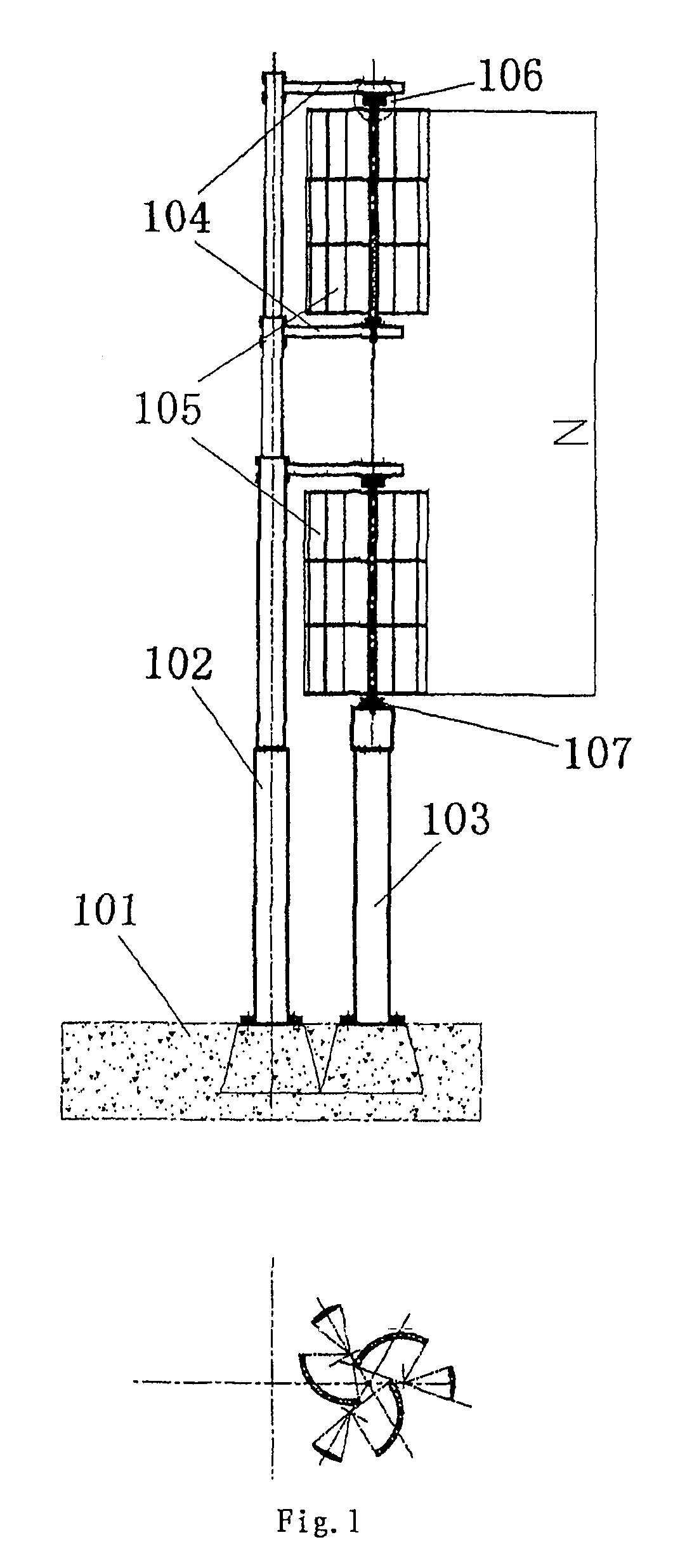

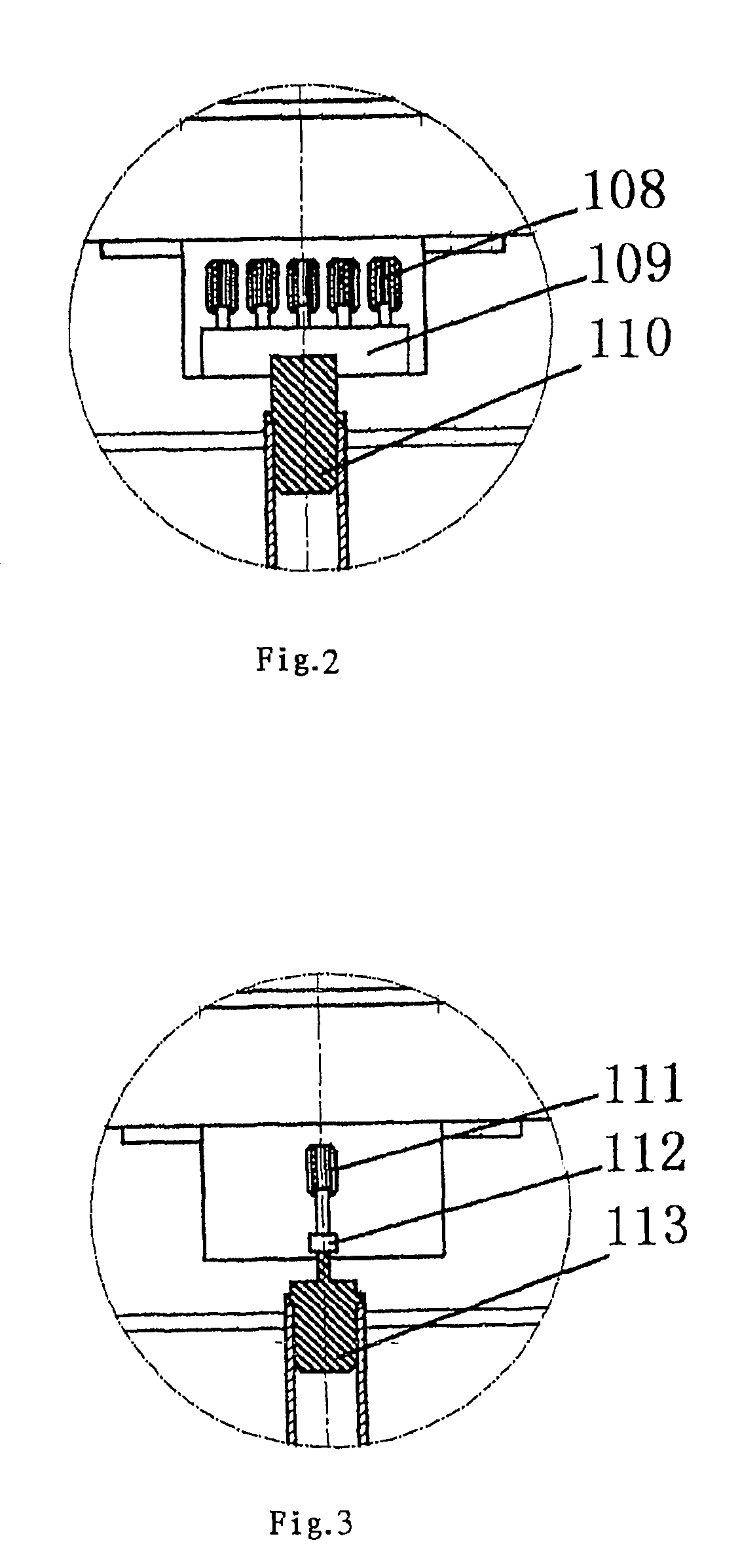

Wind power system

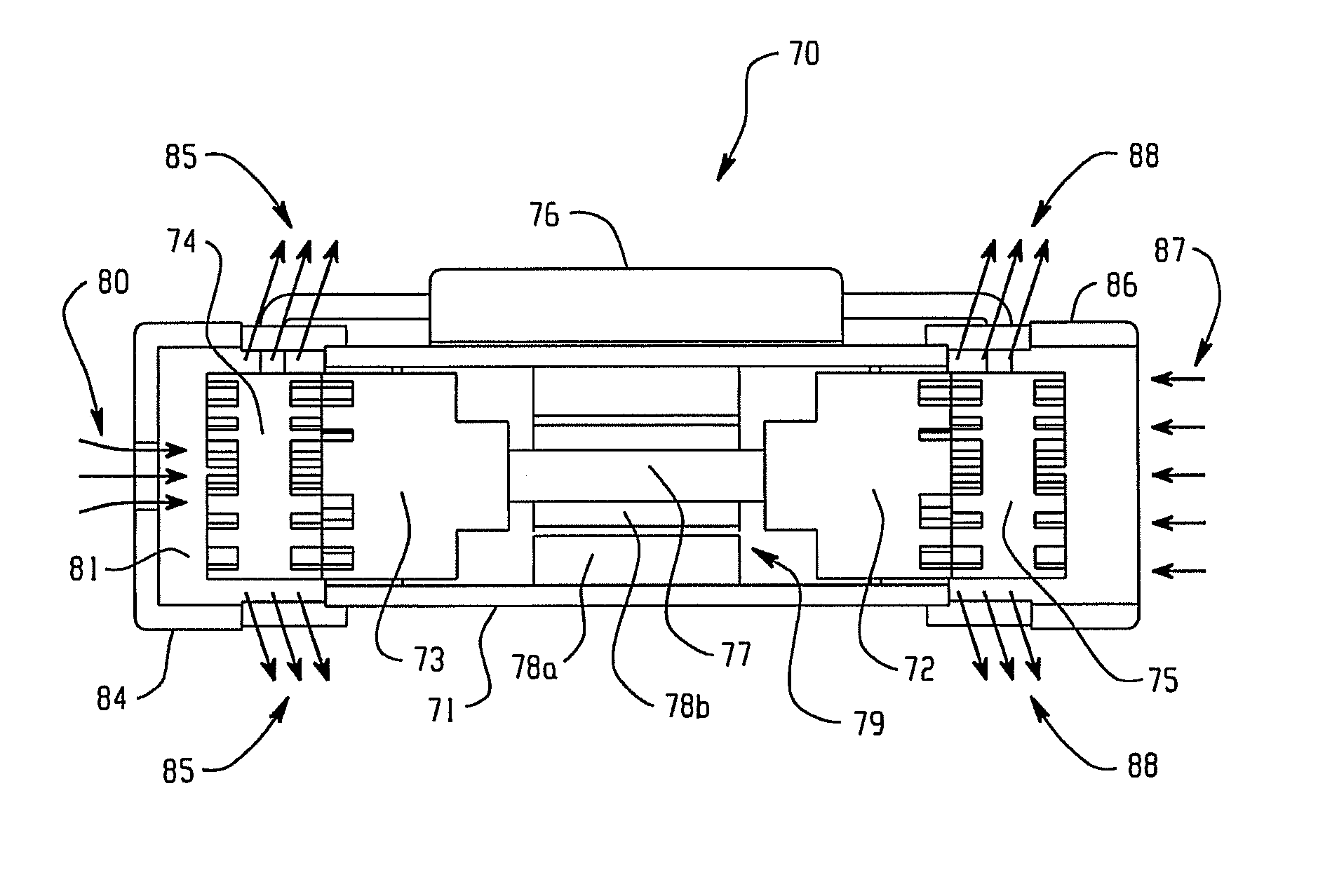

InactiveUS20110006543A1Reduce difficultyLowing in installationFinal product manufactureMachines/enginesWind fieldVertical axis wind turbine

The present invention relates to a wind power generation system. Said system is an array of a number of wind power generation units on the supporting tower, each wind power generation unit is formed by one vertical axis wind rotor and one or more power generation unit(s), in which the rotation shaft of the wind rotor is coupled with the rotor shaft of the single generator set through a connector, or the rotation shaft of the wind rotor is connected with the rotor shafts of multiple generator sets through the transmission mechanism. The present invention proposes a helical vertical axis wind rotor and a lineal vertical axis wind rotor constructed by the drag type blade and the lift type blade, and proposes a helical wind rotor with pure drag type blade as well as the disassembling and splicing design of the above wind rotor. The present invention is similar to a “building block” power generation unit whose design could be optimized according to the wind field to reach megawatts scale power output. Furthermore, by adjusting the number of the generator sets connected with the single wind rotor in the power generation unit, the starting load of the wind rotor can be lowered on the one hand, on the other hand this can load proper number of generator sets with small power by disengaging and engaging at real time according to the varying conditions of the wind speed. The manufacture, transportation, installation and maintenance of said power generation unit are relatively easier and it can resist larger wind disaster, thus being of higher safety.

Owner:NANJING YUNENG NEW ENERGY TECH

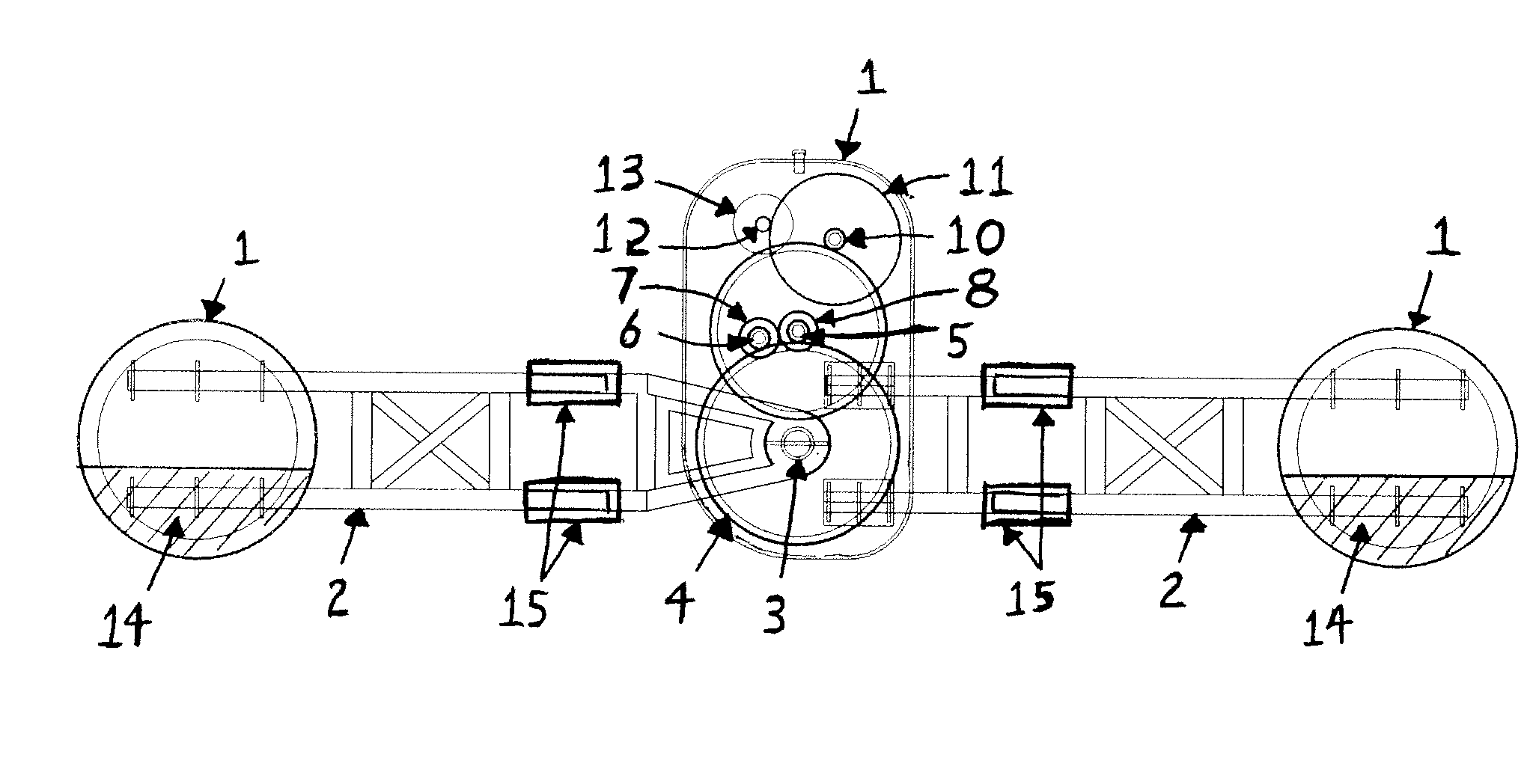

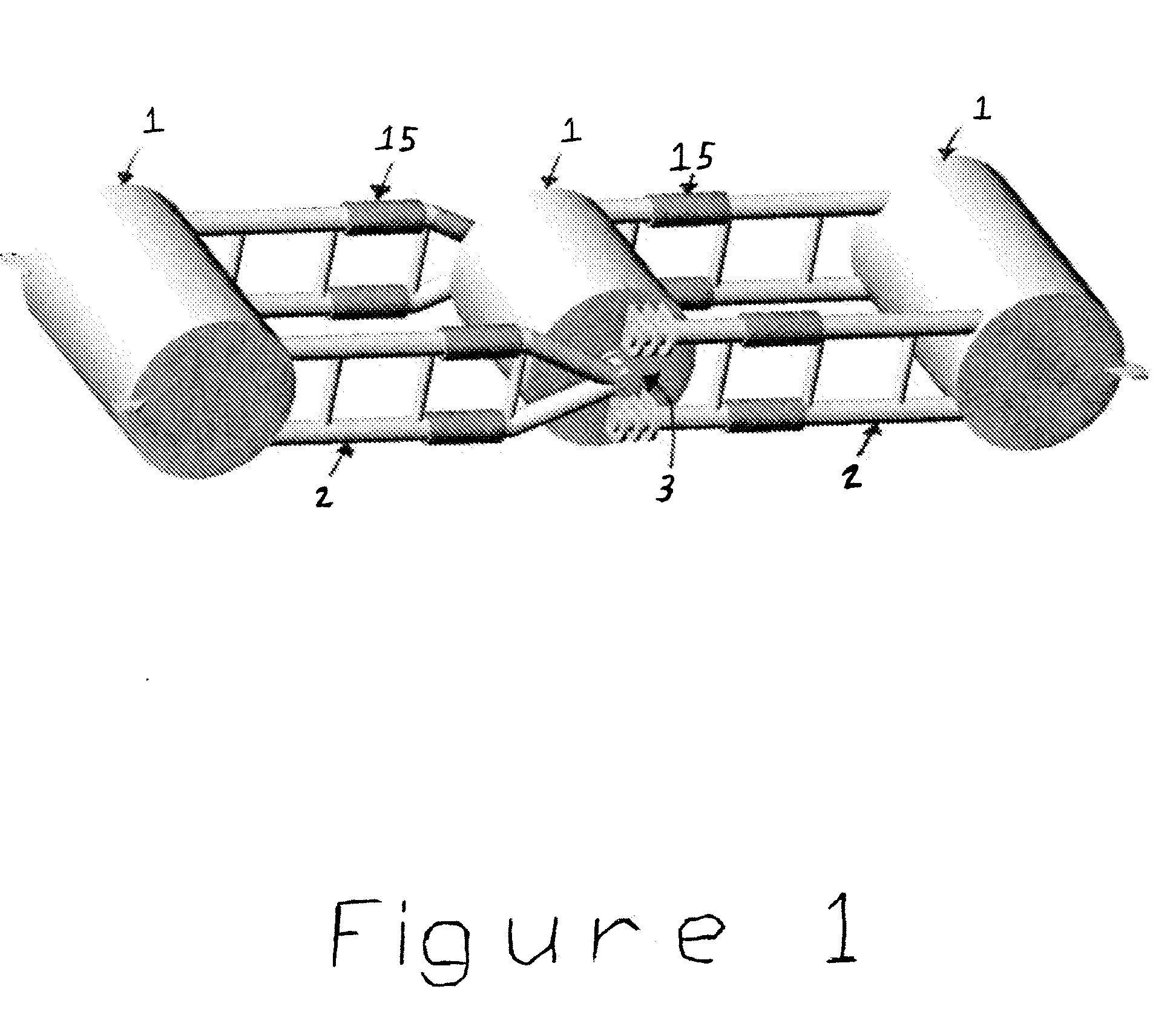

Energy Transformation Device

InactiveUS20090066085A1Efficiently and cost-effectively transformLittle and no environmental impactMachines/enginesEngine componentsEngineeringElectric generator

This invention is a device for transforming the energy of water waves into useable energy. The device comprises two or more floats, structural members connecting the floats, a means for transferring torque, and one or more generators.

Owner:GRAY DENNIS

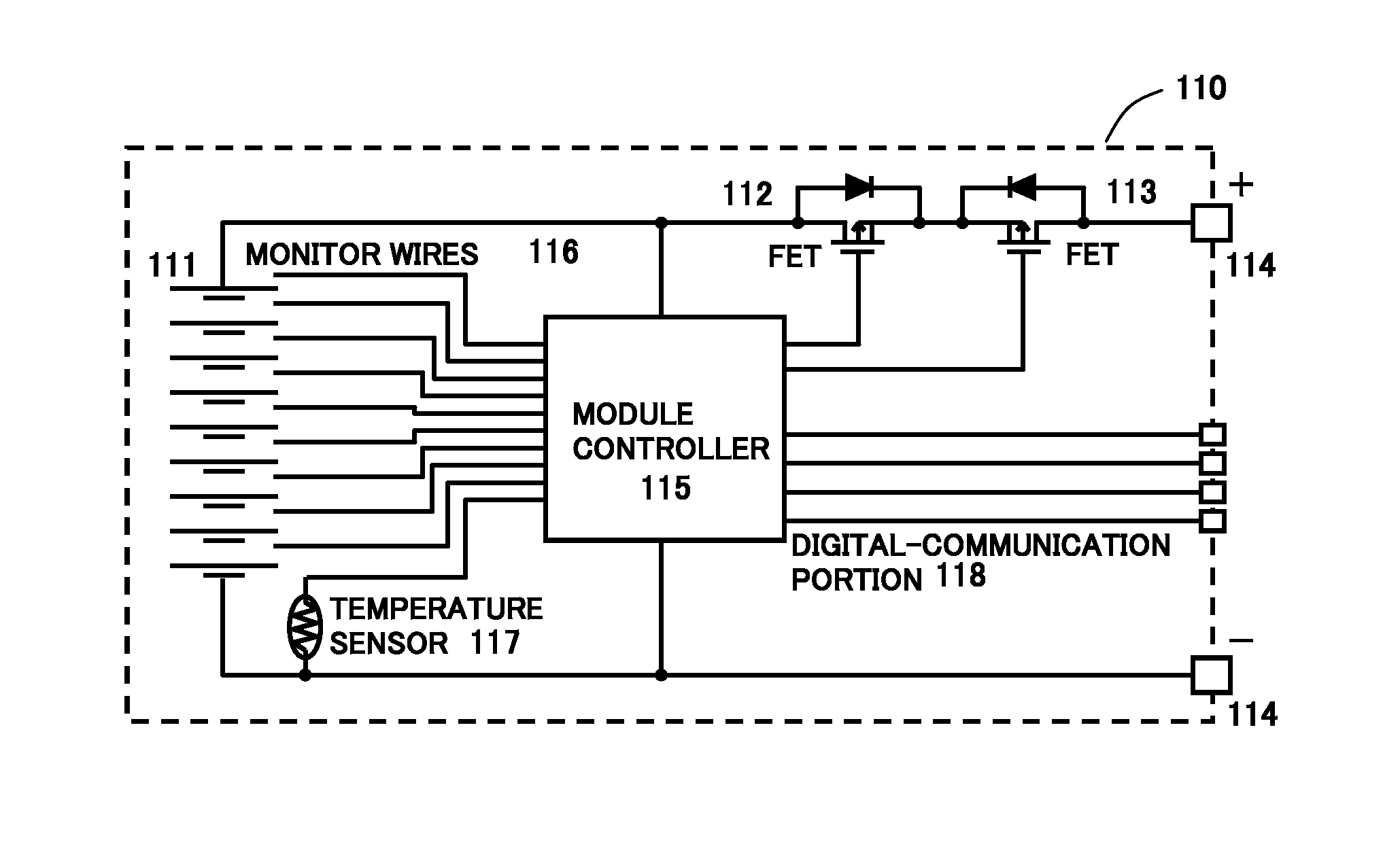

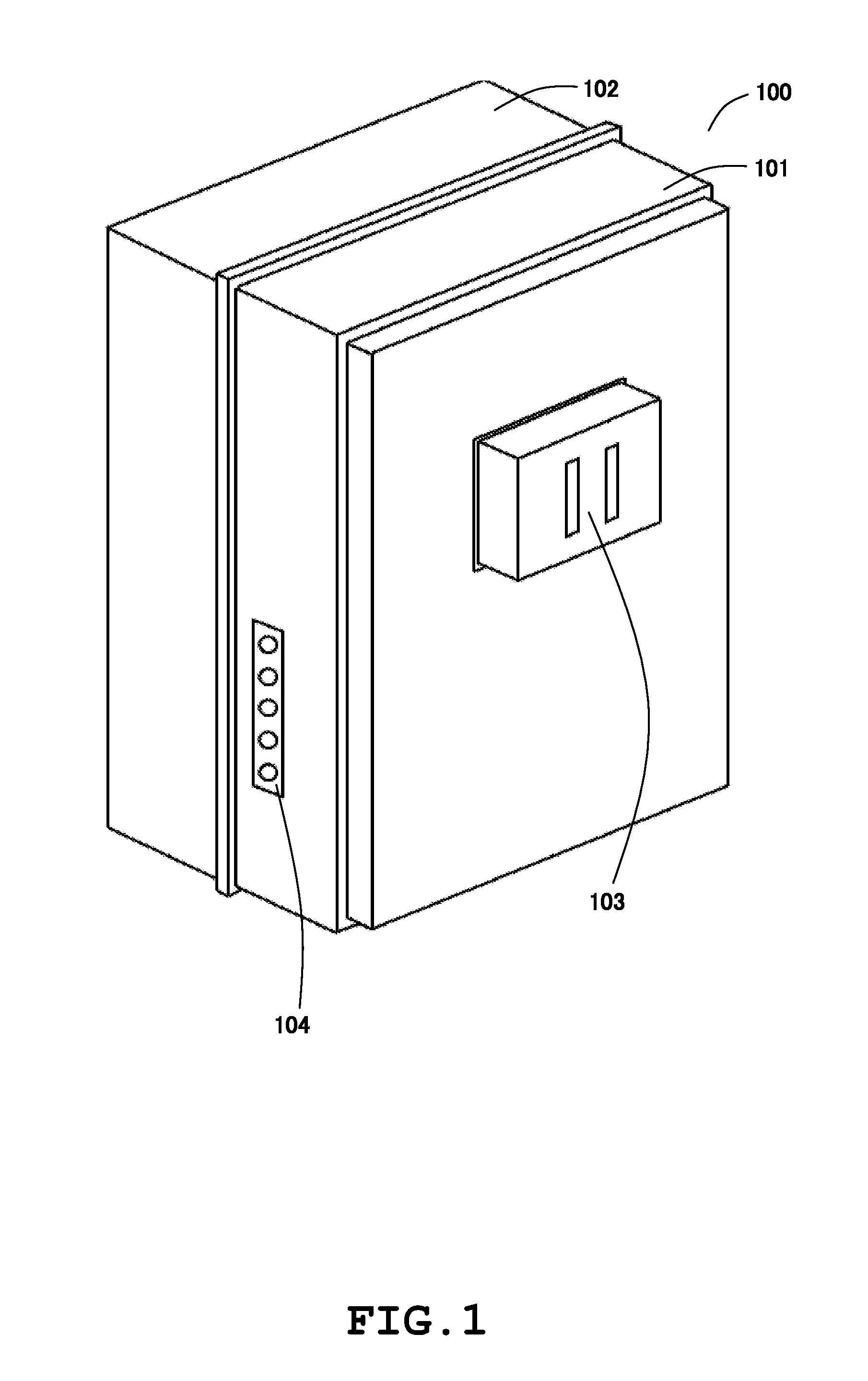

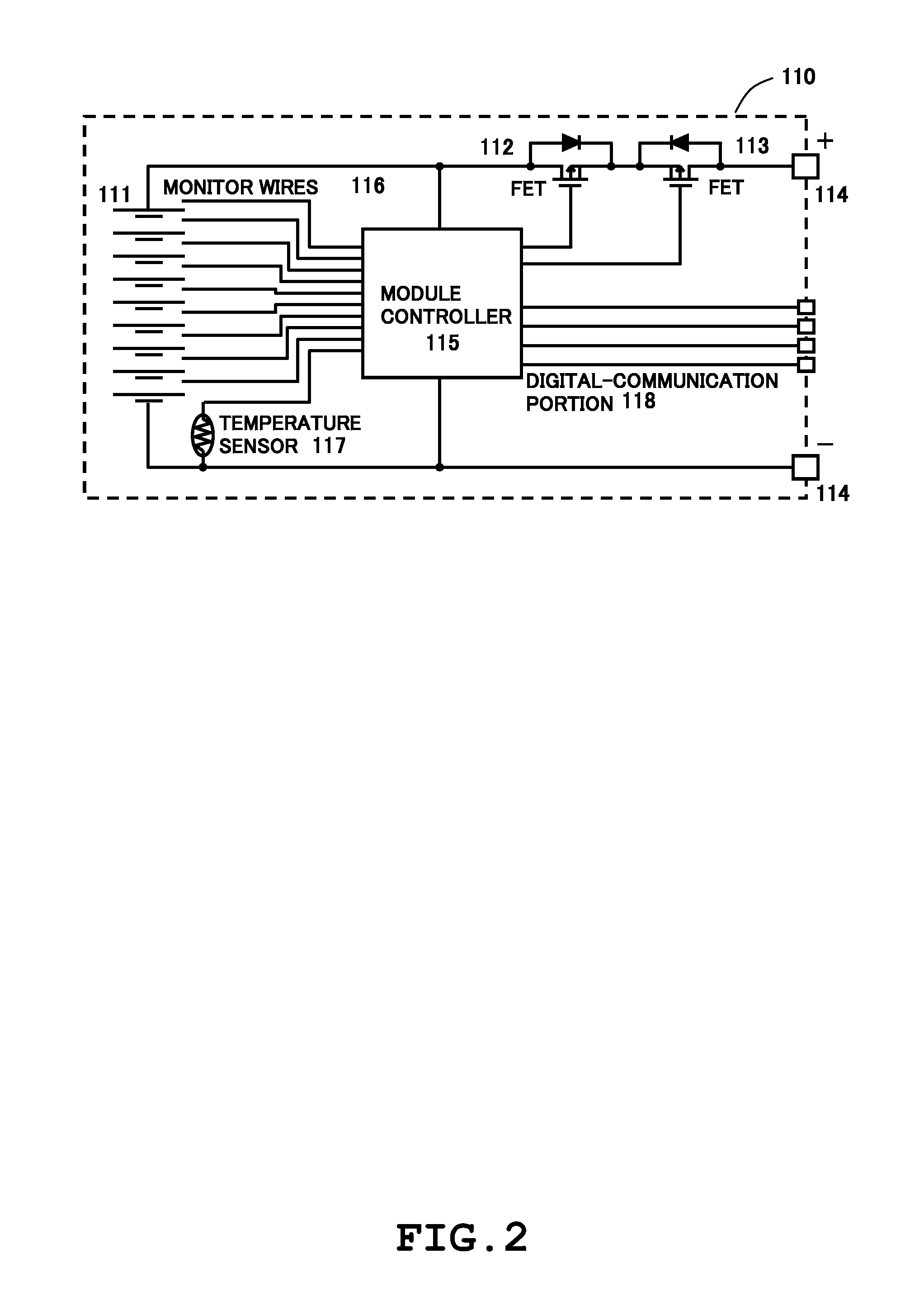

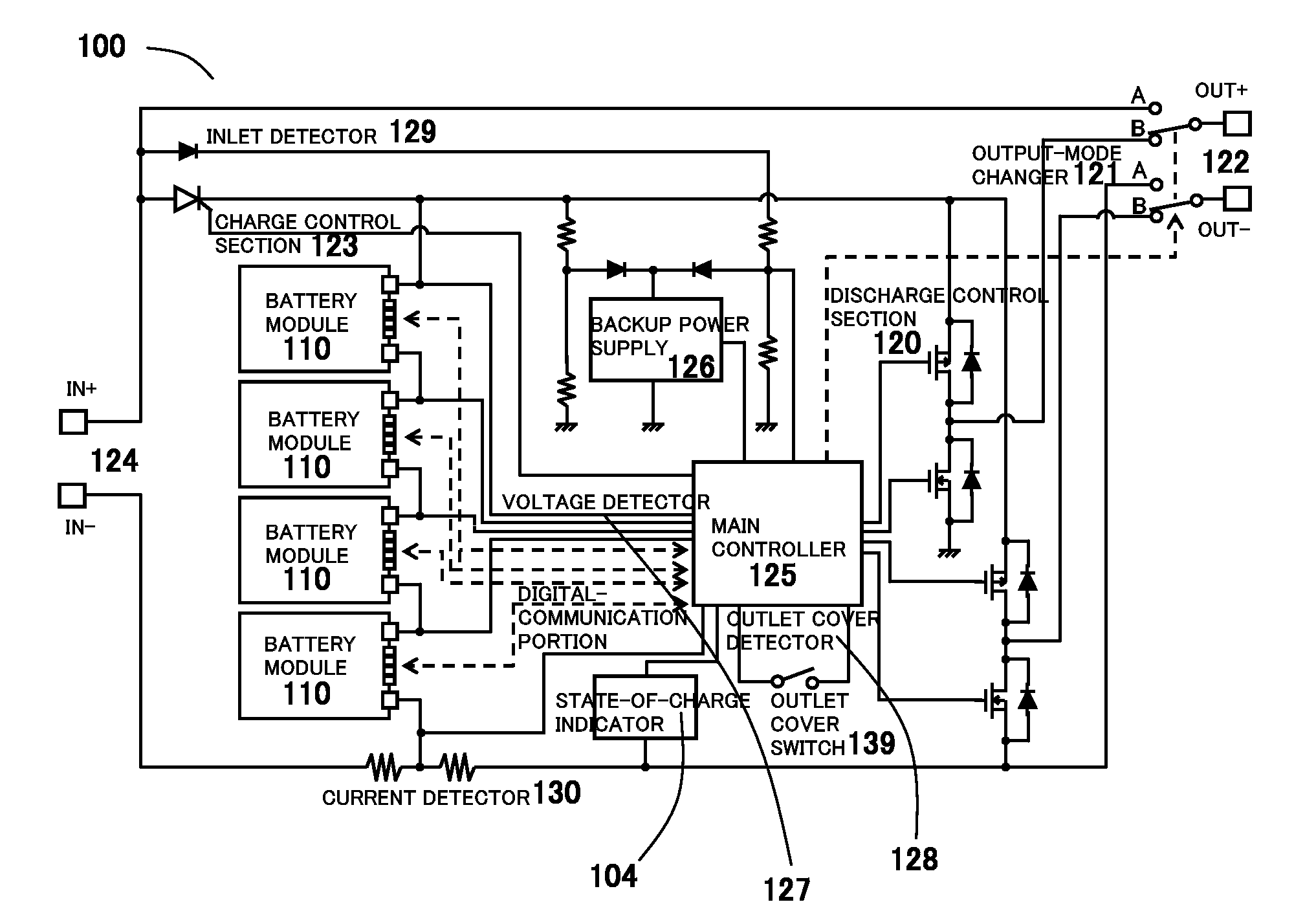

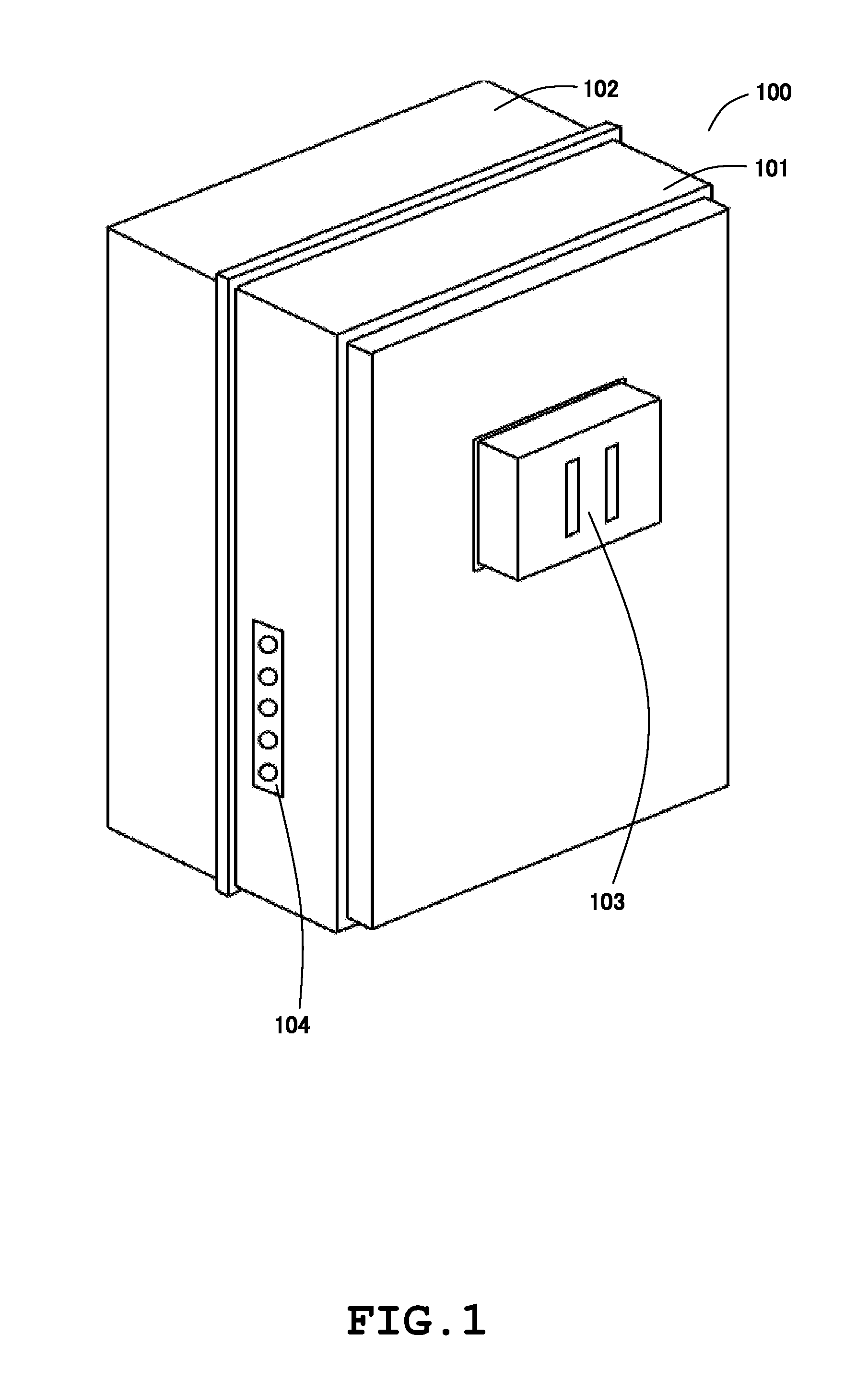

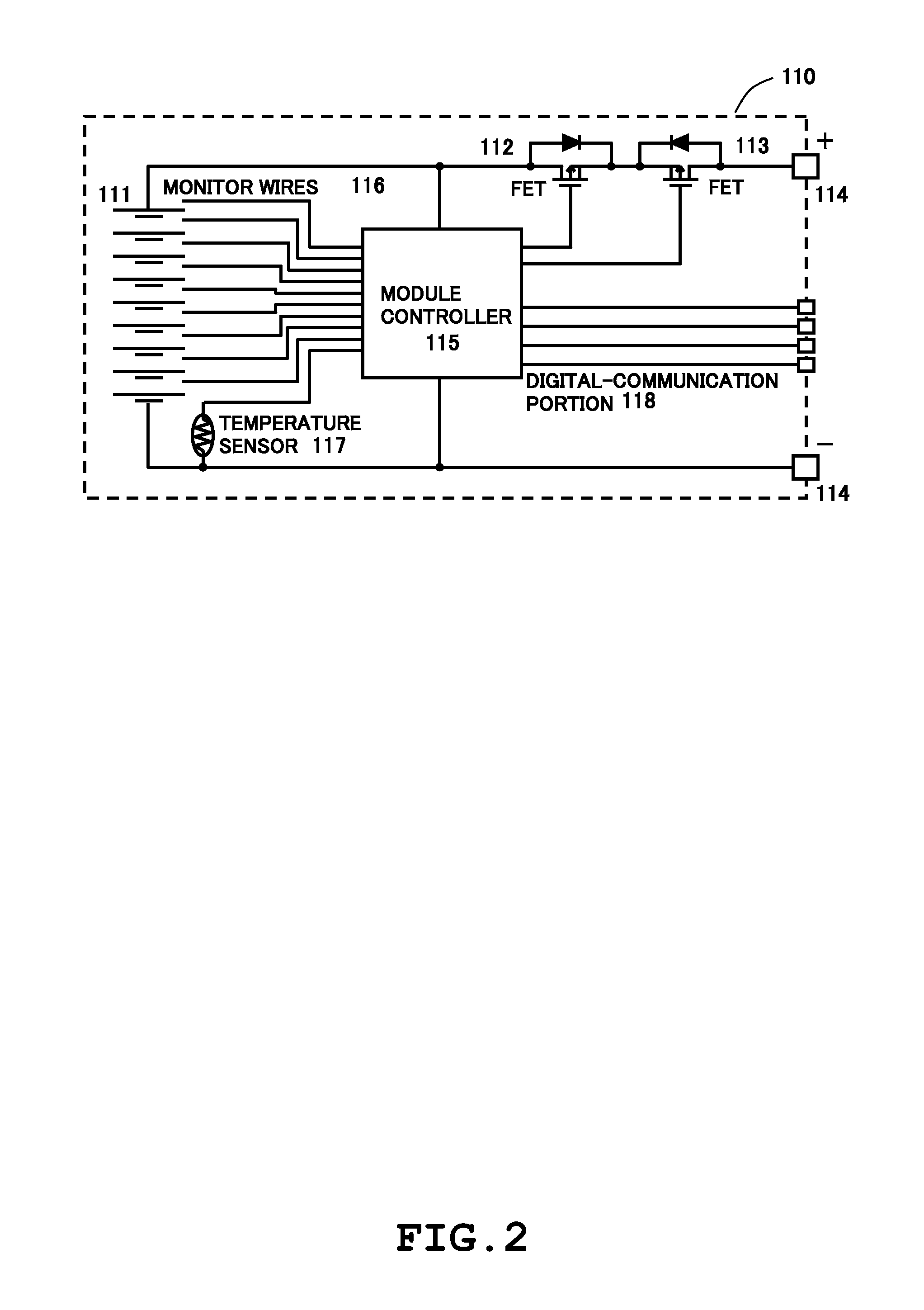

Battery pack

InactiveUS20100244769A1Easy to handleOutput powerBatteries circuit arrangementsCells structural combinationElectric power systemCharge control

A battery pack for an electric device is disclosed which includes: a group of battery cells interconnected in series; discharge control circuitry for converting DC voltage of the group into AC voltage; an AC-output terminal through which an output of the discharge control circuitry is supplied to the device; charge control circuitry for converting AC voltage of a commercial power source into DC voltage, to thereby charge the group; and a charging terminal through which electric power of the source is supplied into the group, wherein the AC-output terminal is connectable with a power-input connector of the device, and the charging terminal is connectable with a charging connector of the source, the pack further comprising a detector for detecting insertion of the power-input connector into the AC-output terminal, wherein the discharge control circuitry initiates a discharge control sequence for the group, if the insertion is detected, and does not initiate the discharge control sequence, in response to non-detection of the insertion.

Owner:SAKAKIBARA KAZUYUKI

Battery pack

InactiveUS8222863B2Easy to handleOutput powerBatteries circuit arrangementsCells structural combinationElectric power systemNon detection

Owner:SAKAKIBARA KAZUYUKI

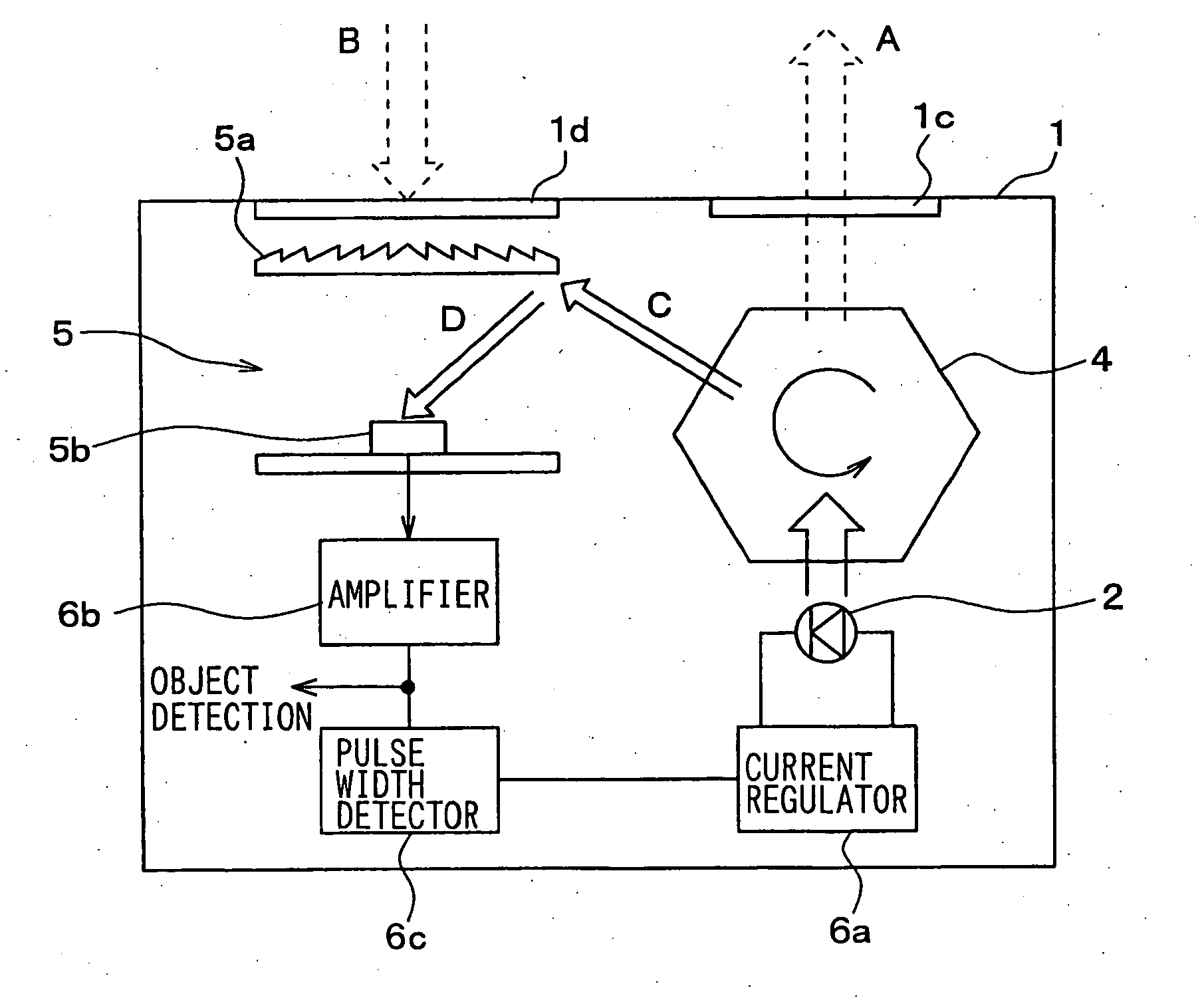

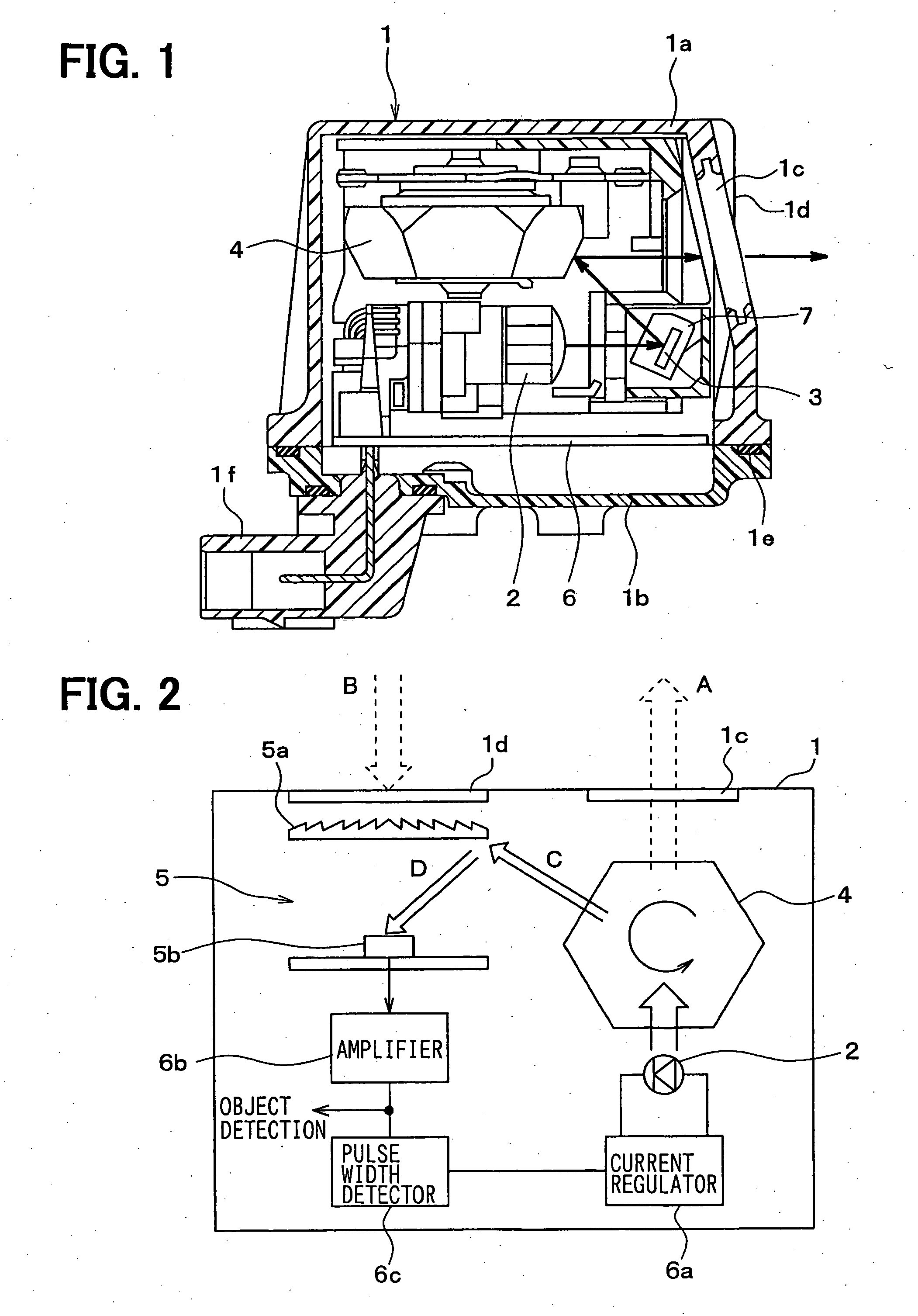

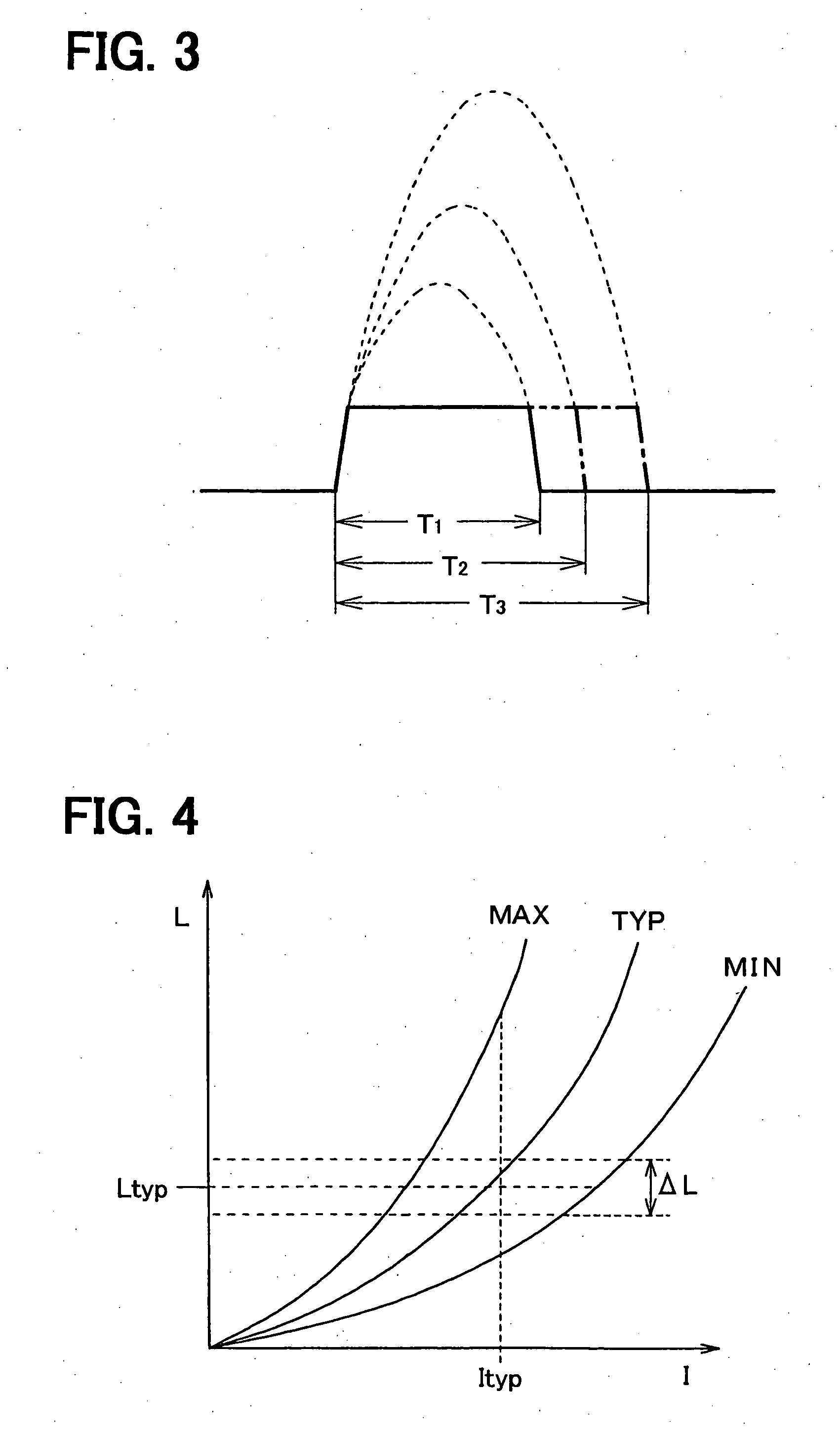

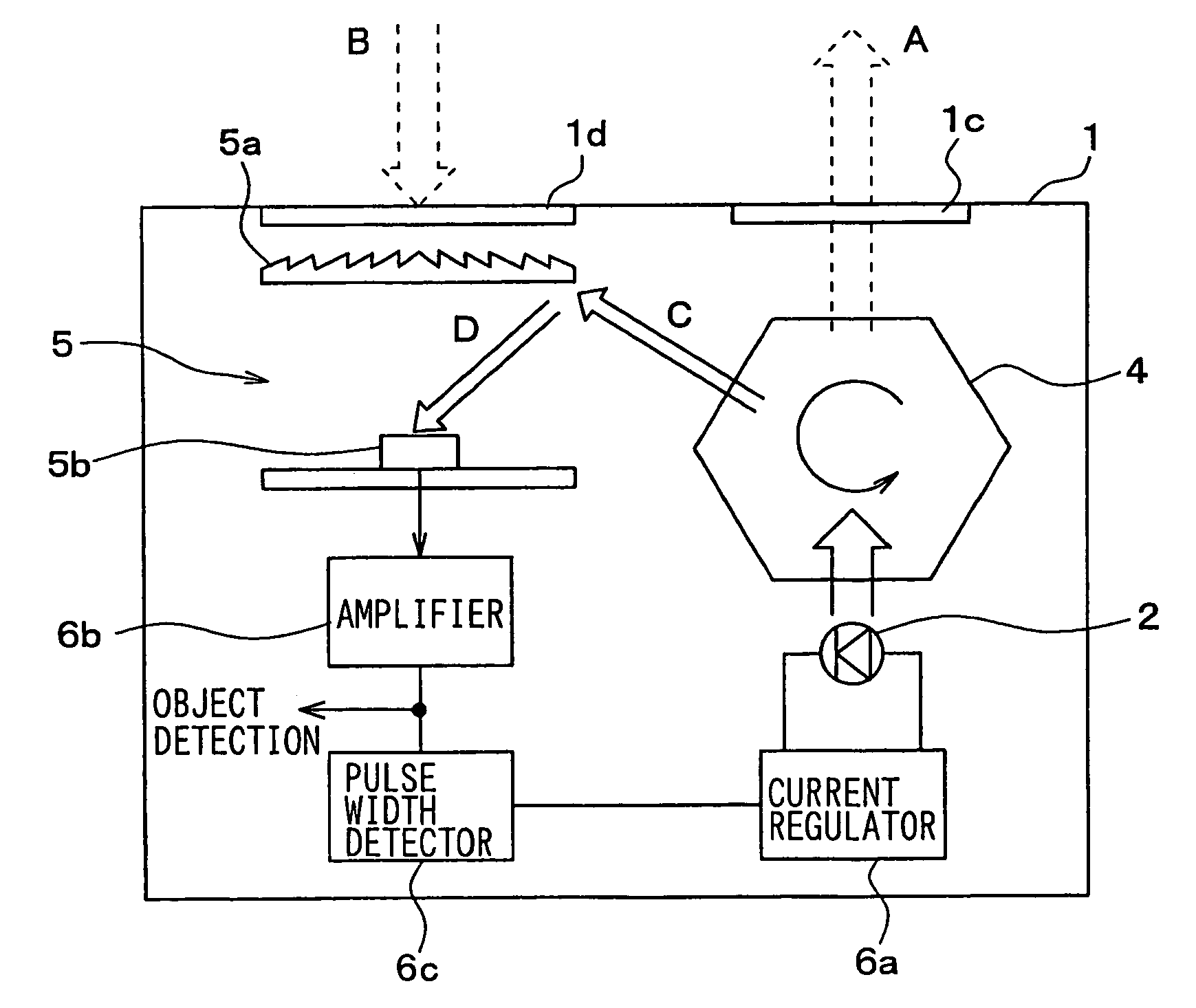

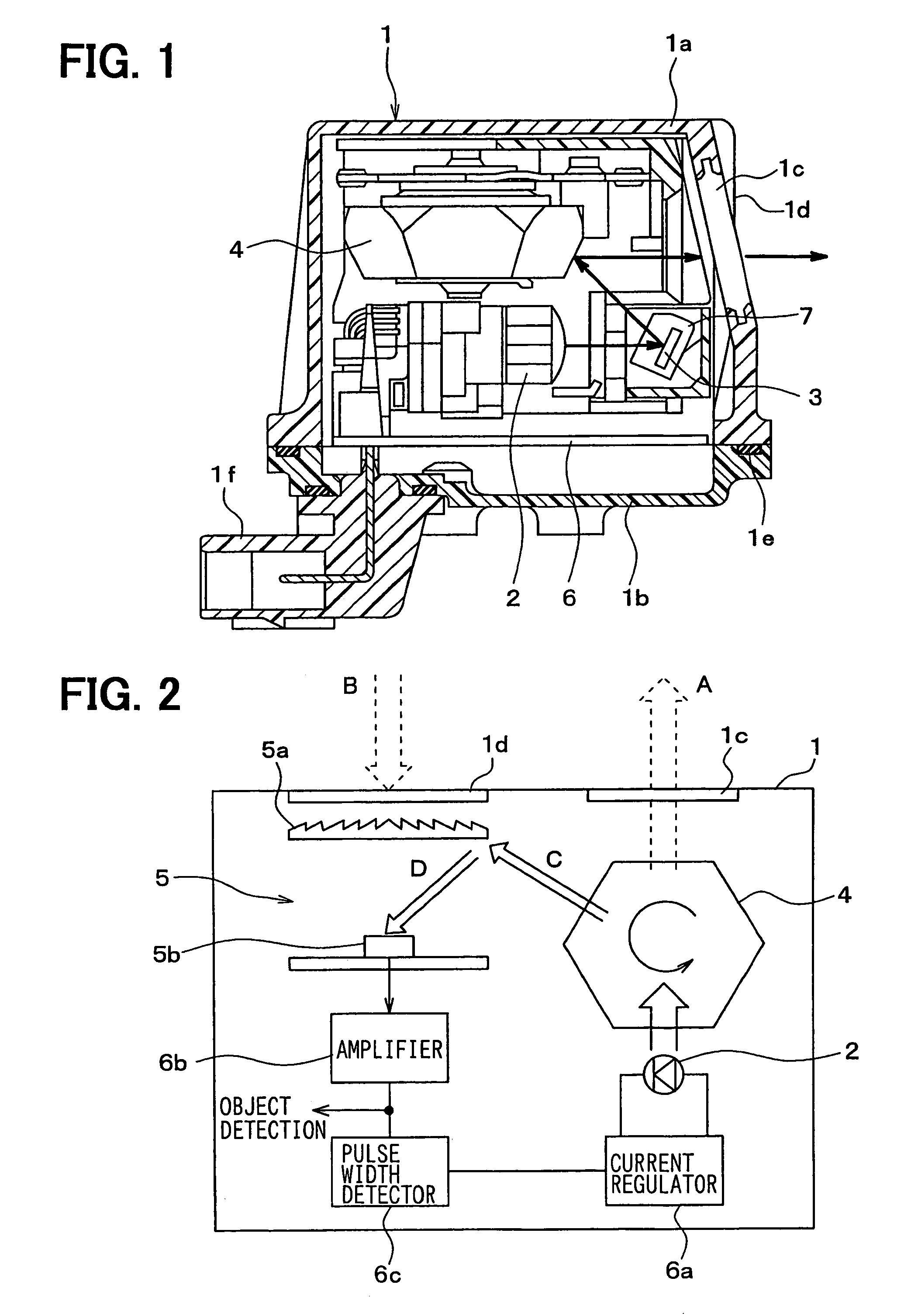

Object detecting apparatus having light radiation power regulating function

InactiveUS20050200832A1Improve accuracyImprove precision controlOptical rangefindersUsing optical meansAudio power amplifierDetector circuits

An object detecting apparatus for a vehicle has a light radiation unit and a light receiver unit disposed in a case for detecting an object or a distance to the object. When a vehicle is at a stop, the apparatus detects an output power of a laser light radiated from the light radiation unit by the light receiving unit and feedback-controls the output power of the laser light to a predetermined level based on the detected output power of the laser light. The feedback control is effected by an amplifier circuit, a pulse width detector circuit and a current regulator circuit. Thus, the output power of the laser light is reduced not to damage human eyes when the vehicle is at a stop.

Owner:DENSO CORP

Energy transformation device

InactiveUS8008792B2Efficiently and cost-effectively transformBig impactMachines/enginesAlarmsEngineeringEnergy conversion devices

This invention is a device for transforming the energy of water waves into useable energy. The device comprises two or more floats, structural members connecting the floats, a means for transferring torque, and one or more generators.

Owner:GRAY DENNIS

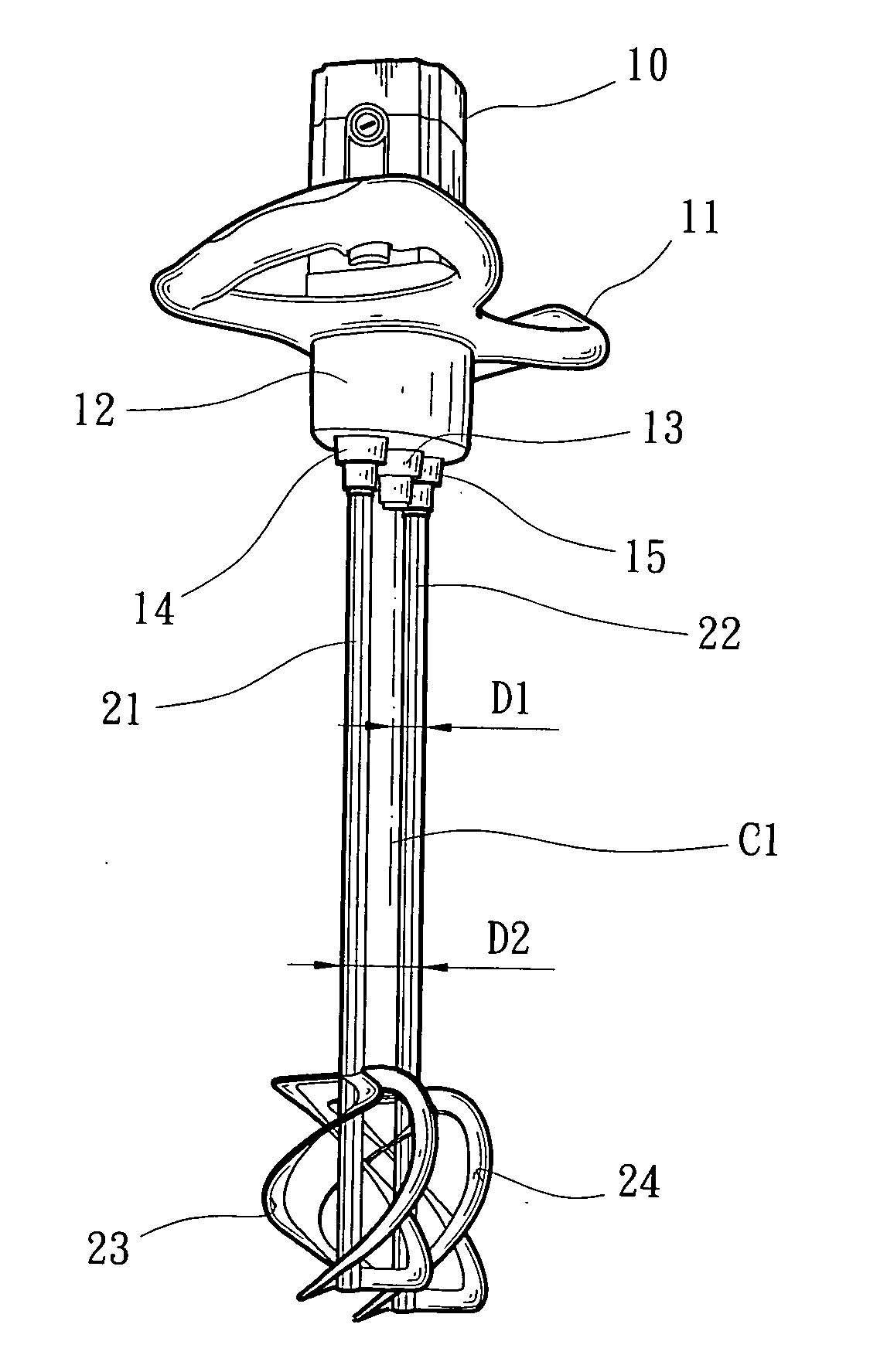

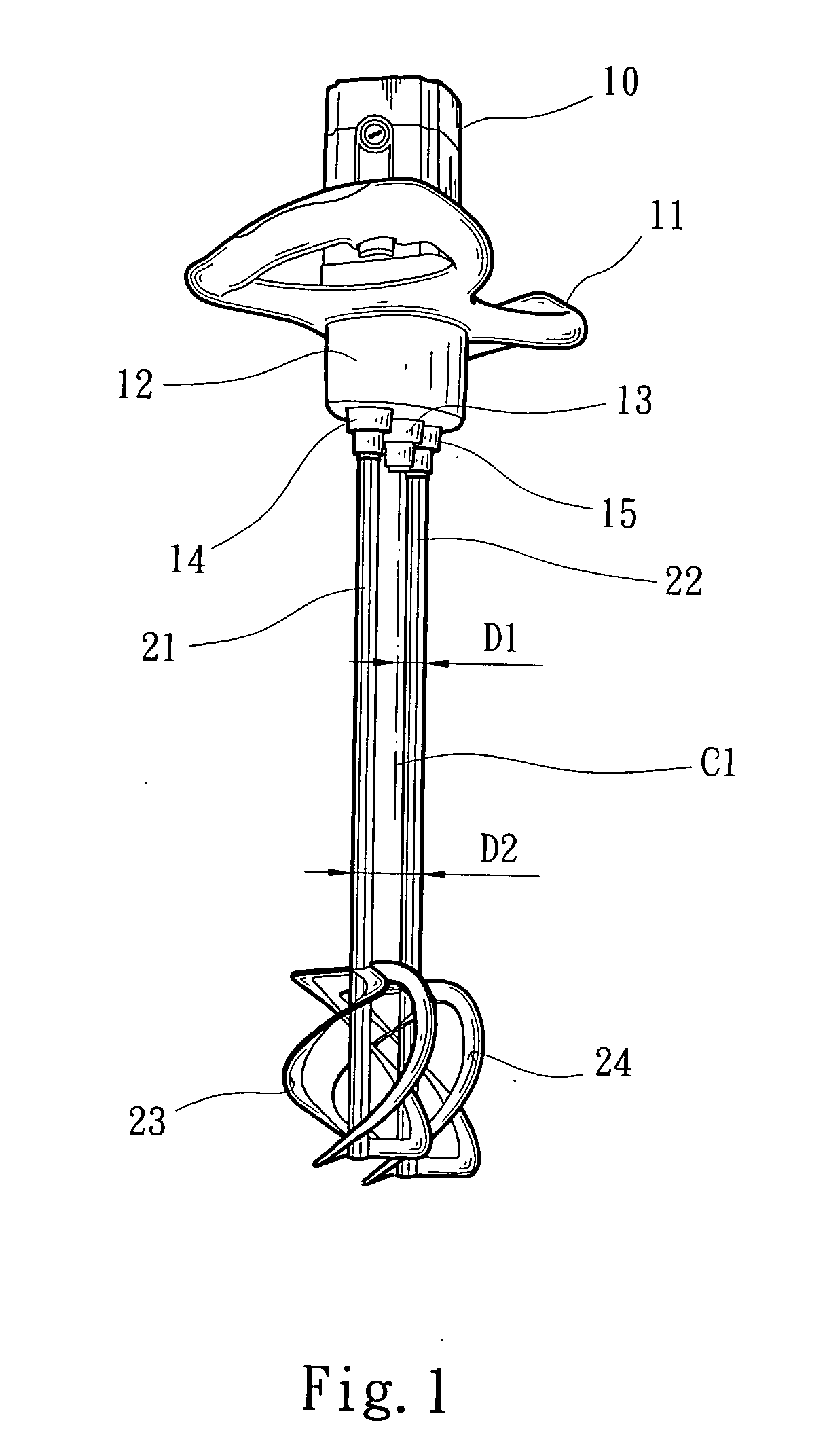

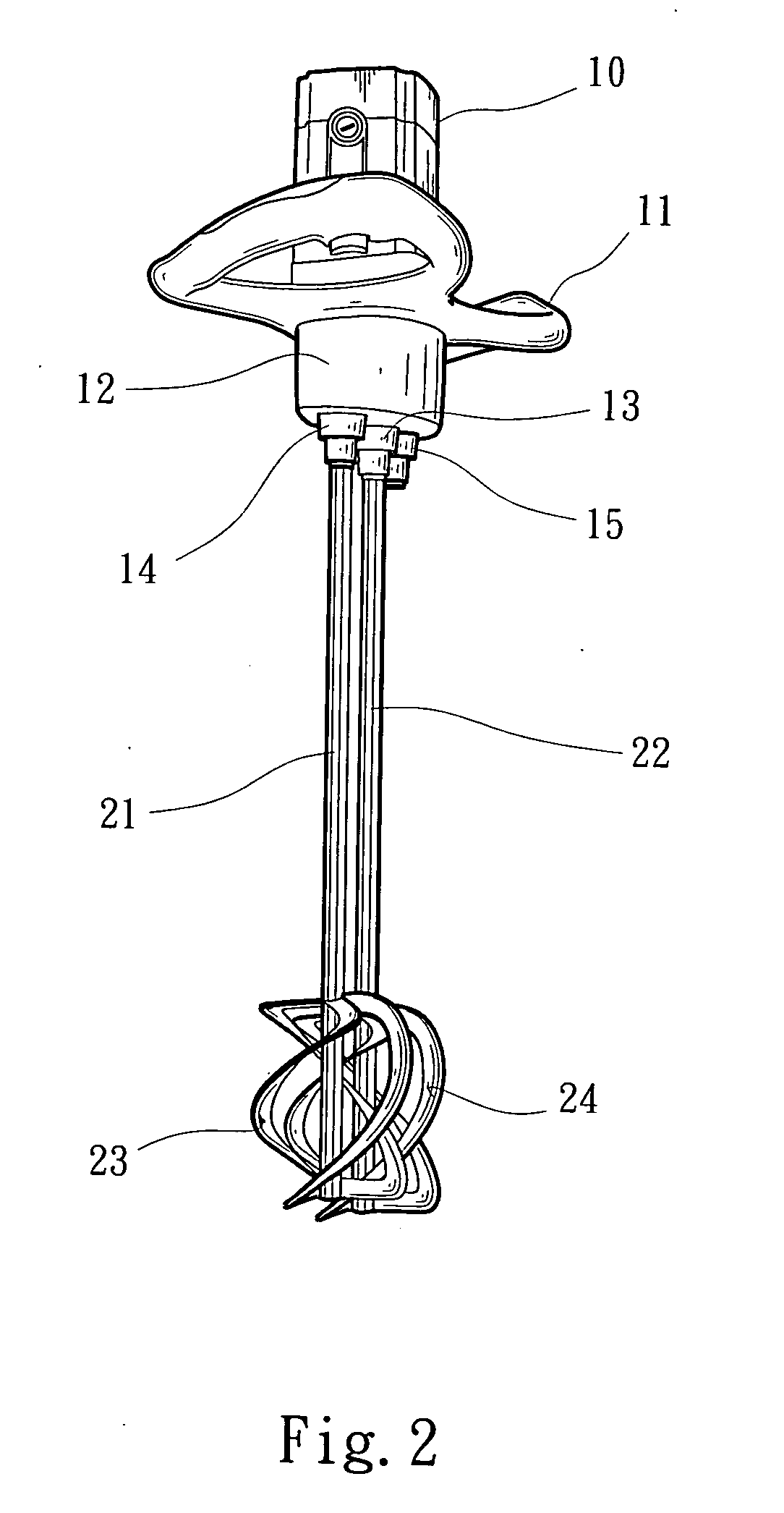

Electric mixer

InactiveUS20050281130A1Output powerRotary stirring mixersTransportation and packagingEngineeringElectrical and Electronics engineering

An electric mixer including a driving mechanism and a transmission mechanism. A first connecting tube, a second connecting tube and a third connecting tube which are parallelly arranged under the transmission mechanism at intervals. The first connecting tube is positioned in the middle of the electric mixer for connecting with and driving a mixing rod and a paddle. The second and third connecting tubes are respectively disposed on two sides of the first connecting tube. Each of the second and third connecting tubes serves to connect with and drive another mixing rod and another paddle. A smaller first gap is defined between the first middle connecting tube and any of the second and third lateral connecting tubes. A larger second gap is defined between the second and third connecting tubes. One mixing rod and paddle thereof can be connected with any of the first, second and third connecting tubes to form a single-paddle electric mixer. Alternatively, two mixing rods and paddles thereof can be respectively connected with the second and third connecting tubes to form a twin-paddle electric mixer with the larger gap. Still alternatively, two mixing rods and paddles thereof can be respectively connected with the first middle connecting tube and any of the second and third connecting tubes to form a twin-paddle electric mixer with the smaller gap.

Owner:LEE YEONG IND

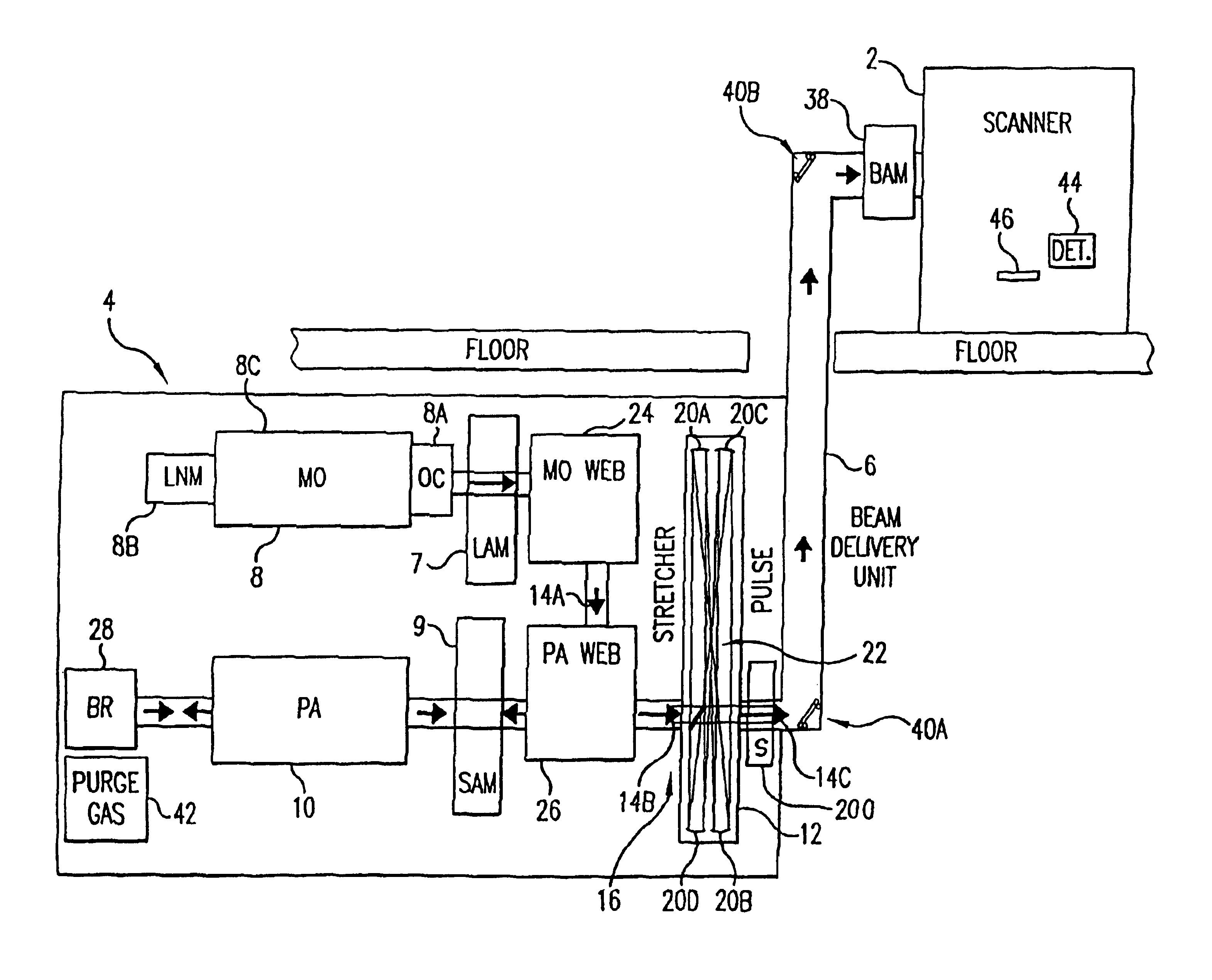

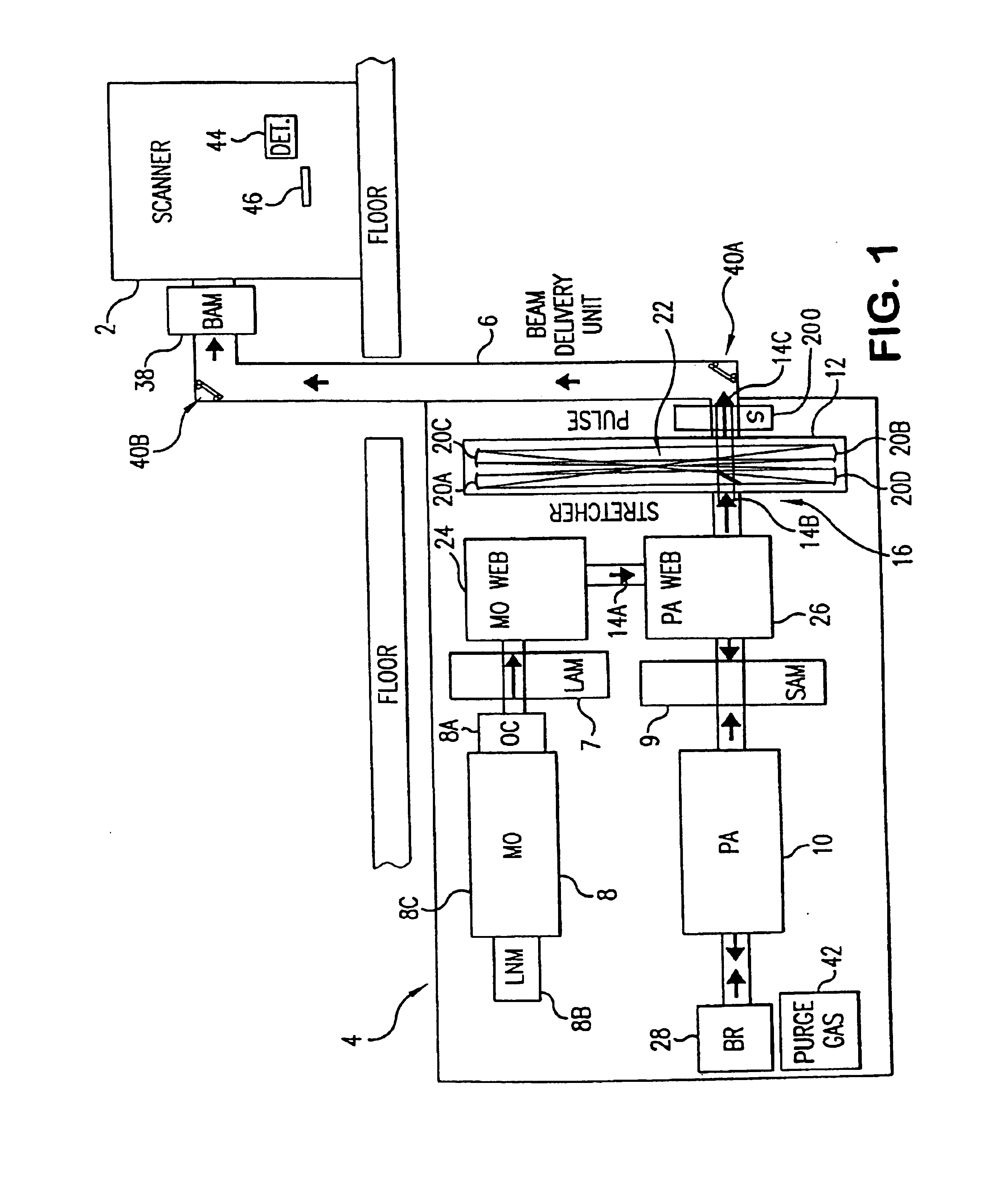

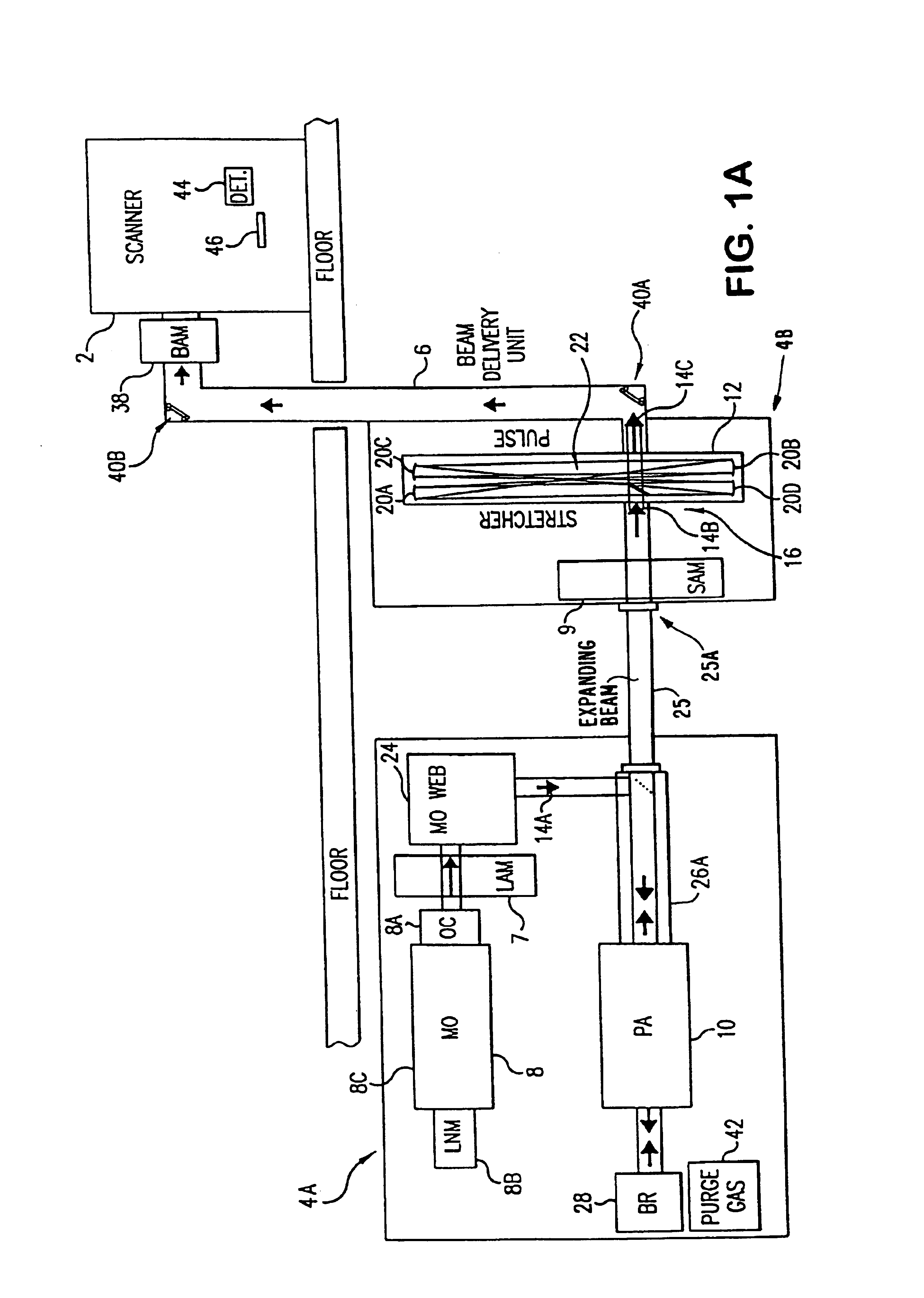

Laser lithography light source with beam delivery

InactiveUS7016388B2Output powerBeam quality specificationPhotomechanical apparatusLaser arrangementsPulse energyLight source

The present invention provides a modular high repetition rate ultraviolet gas discharge laser light source for a production line machine. The system includes an enclosed and purged beam path for delivery the laser beam to a desired location such as the entrance port of the production line machine. In preferred embodiments, the production line machine is a lithography machine and two separate discharge chambers are provided, one of which is a part of a master oscillator producing a very narrow band seed beam which is amplified in the second discharge chamber. This MOPA system is capable of output pulse energies approximately double the comparable single chamber laser system with greatly improved beam quality. A pulse stretcher more than doubles the output pulse length resulting in a reduction in pulse power (mJ / ns) as compared to prior art laser systems. This preferred embodiment is capable of providing illumination at a lithography system wafer plane which is approximately constant throughout the operating life of the lithography system, despite substantial degradation of optical components.

Owner:CYMER INC

Lithography laser with beam delivery and beam pointing control

InactiveUS7230964B2Output powerBeam quality specificationSemiconductor/solid-state device manufacturingLaser arrangementsUltravioletLaser light

The present invention provides a modular high repetition rate ultraviolet gas discharge laser light source with a beam delivery to a production line machine. The system includes an enclosed and purged beam path with beam pointing control for delivery the laser beam to a desired location such as the entrance port of the production line machine. Preferred embodiments include equipment for beam attenuation, equipment for automatic feedback beam alignment and equipment for accurate optics module positioning at installation and during maintenance. In preferred embodiments, the production line machine is a lithography machine and two separate discharge chambers are provided, one of which is a part of a master oscillator producing a very narrow band seed beam which is amplified in the second discharge chamber. This MOPA system is capable of output pulse energies approximately double the comparable single chamber laser system with greatly improved beam quality. A pulse stretcher more than doubles the output pulse length resulting in a reduction in pulse power (mJ / ns) as compared to prior art laser systems. This preferred embodiment is capable of providing illumination at a lithography system wafer plane which is approximately constant throughout the operating life of the lithography system, despite substantial degradation of optical components.

Owner:CYMER INC

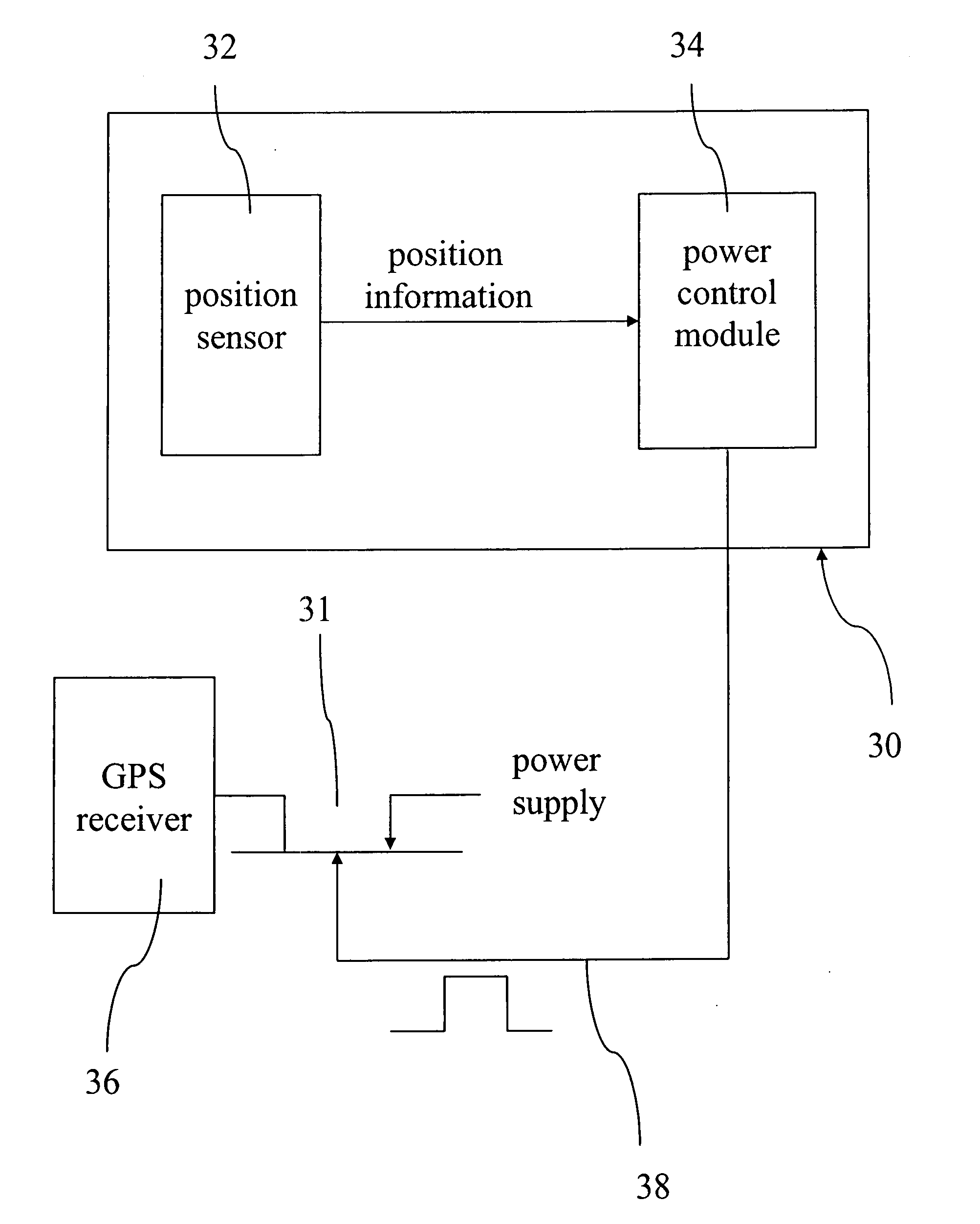

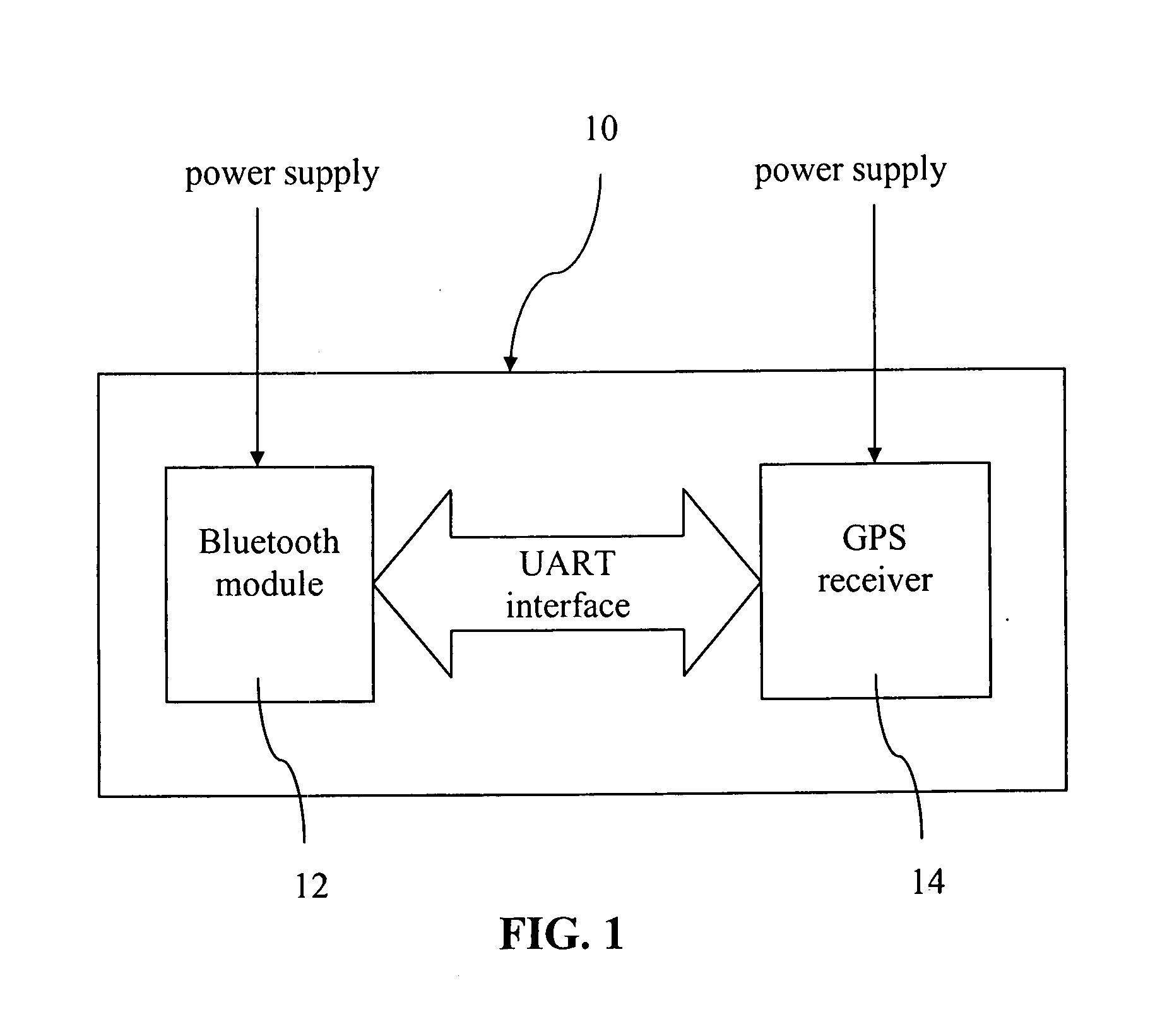

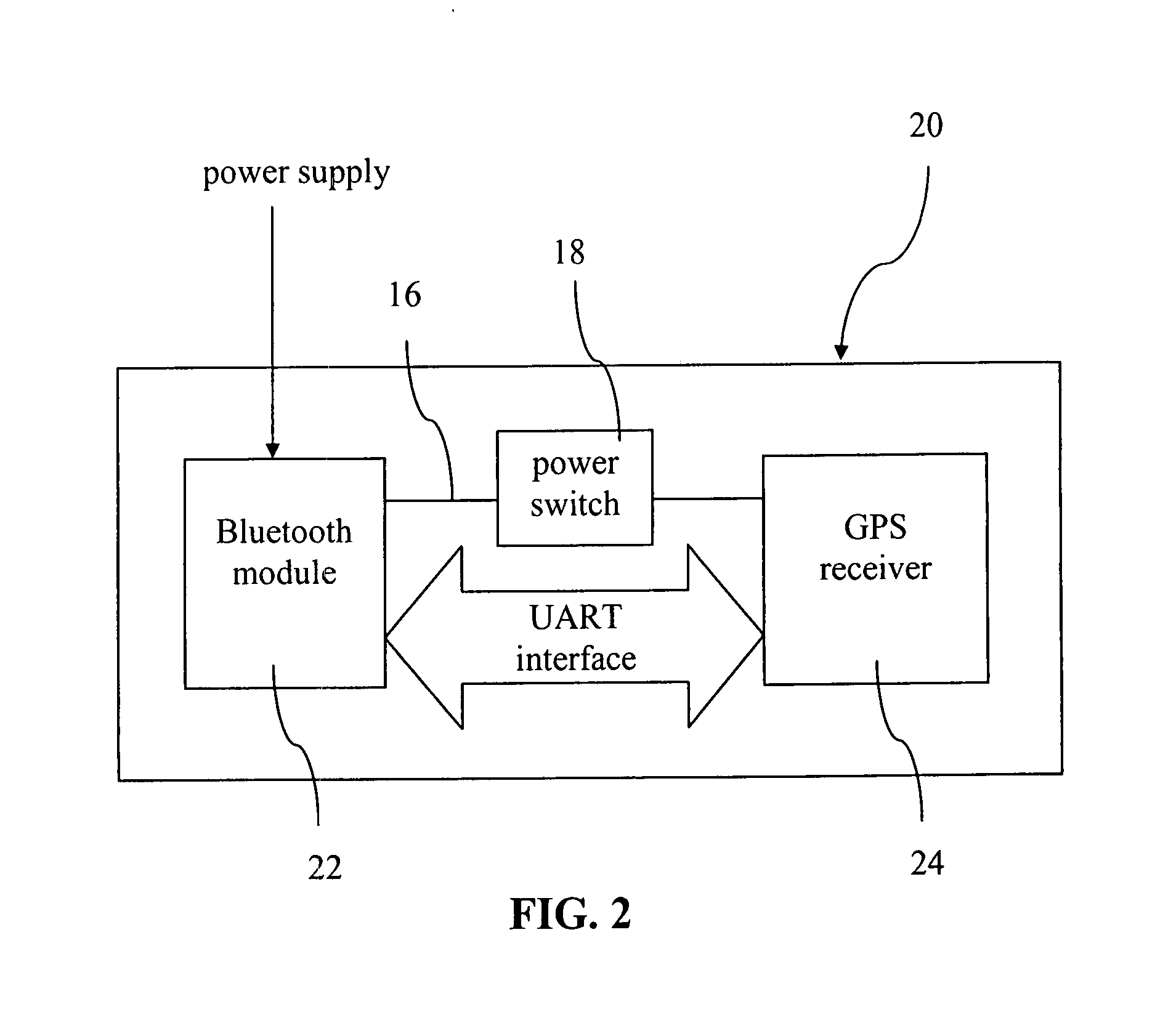

Power control device for GPS receiver and method of controlling power thereof

A power control device for selectively outputting power to a GPS receiver includes a position sensor and a power control module. The power control module determines whether to output power to the GPS receiver according to the variation quantity of the position information after receiving the position information. Therefore, as long as the GPS receiver remains still, the GPS receiver can be turned off since there is no need to receive the position information.

Owner:BEHAVIOR TECH COMPUTER

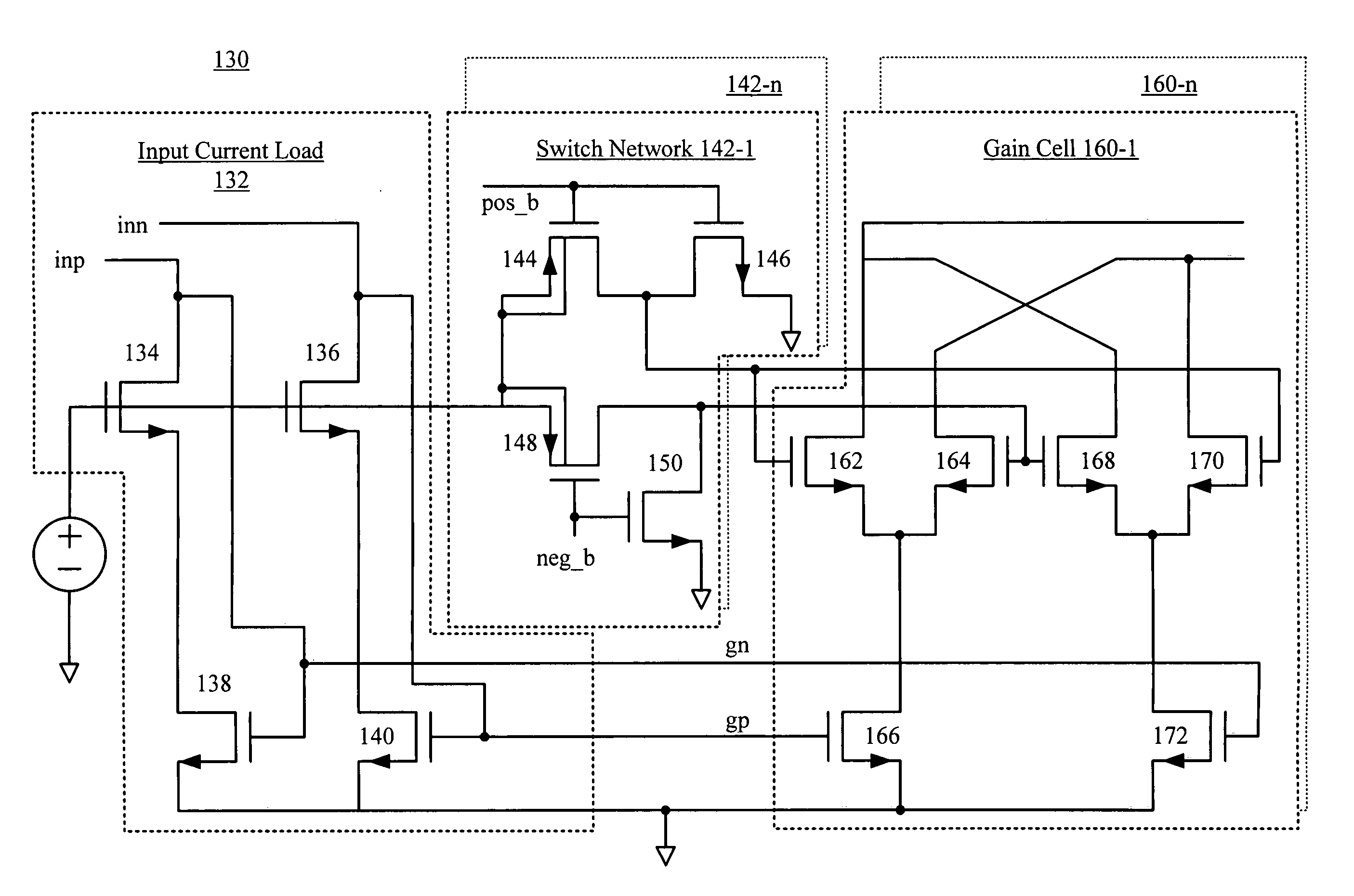

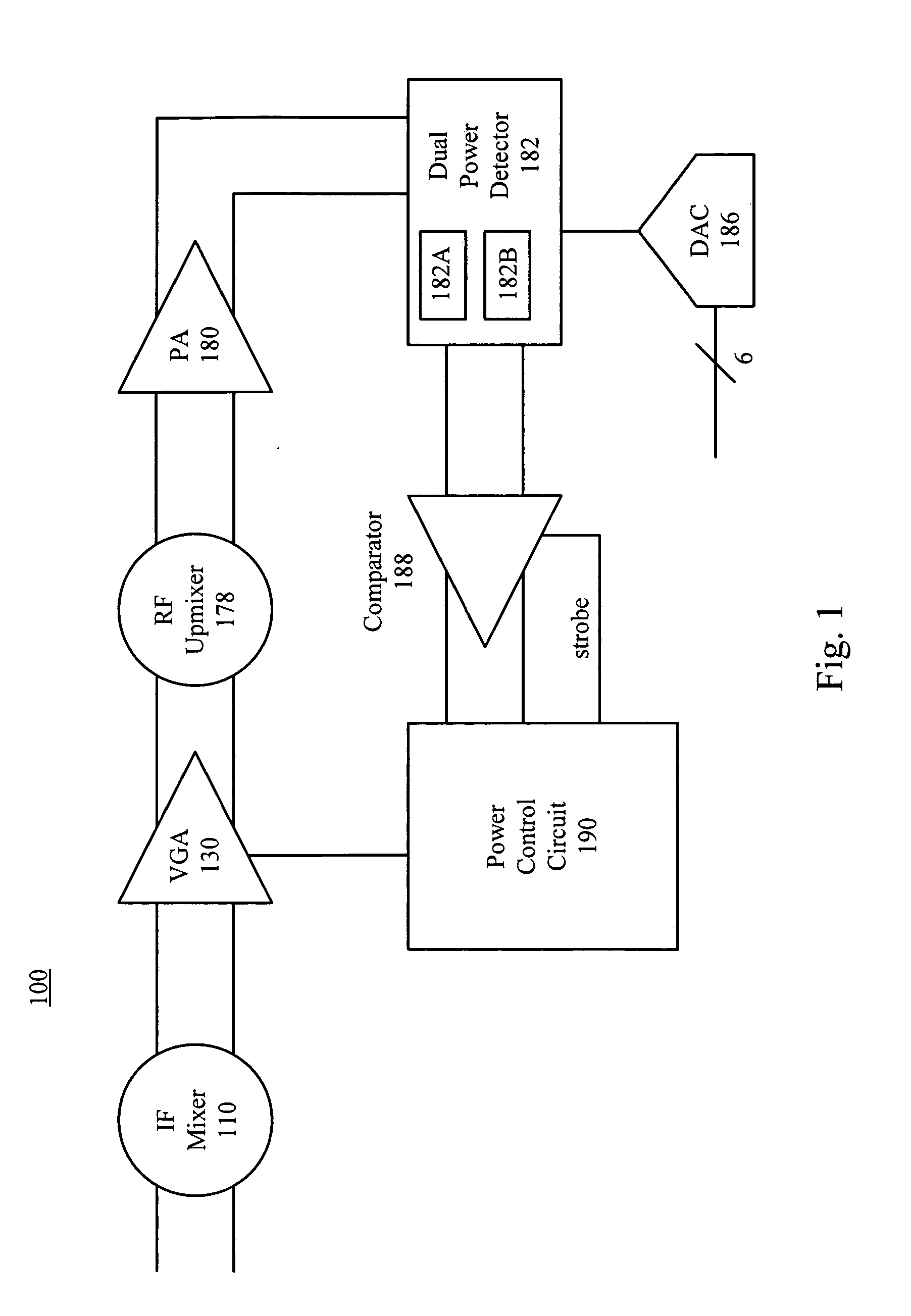

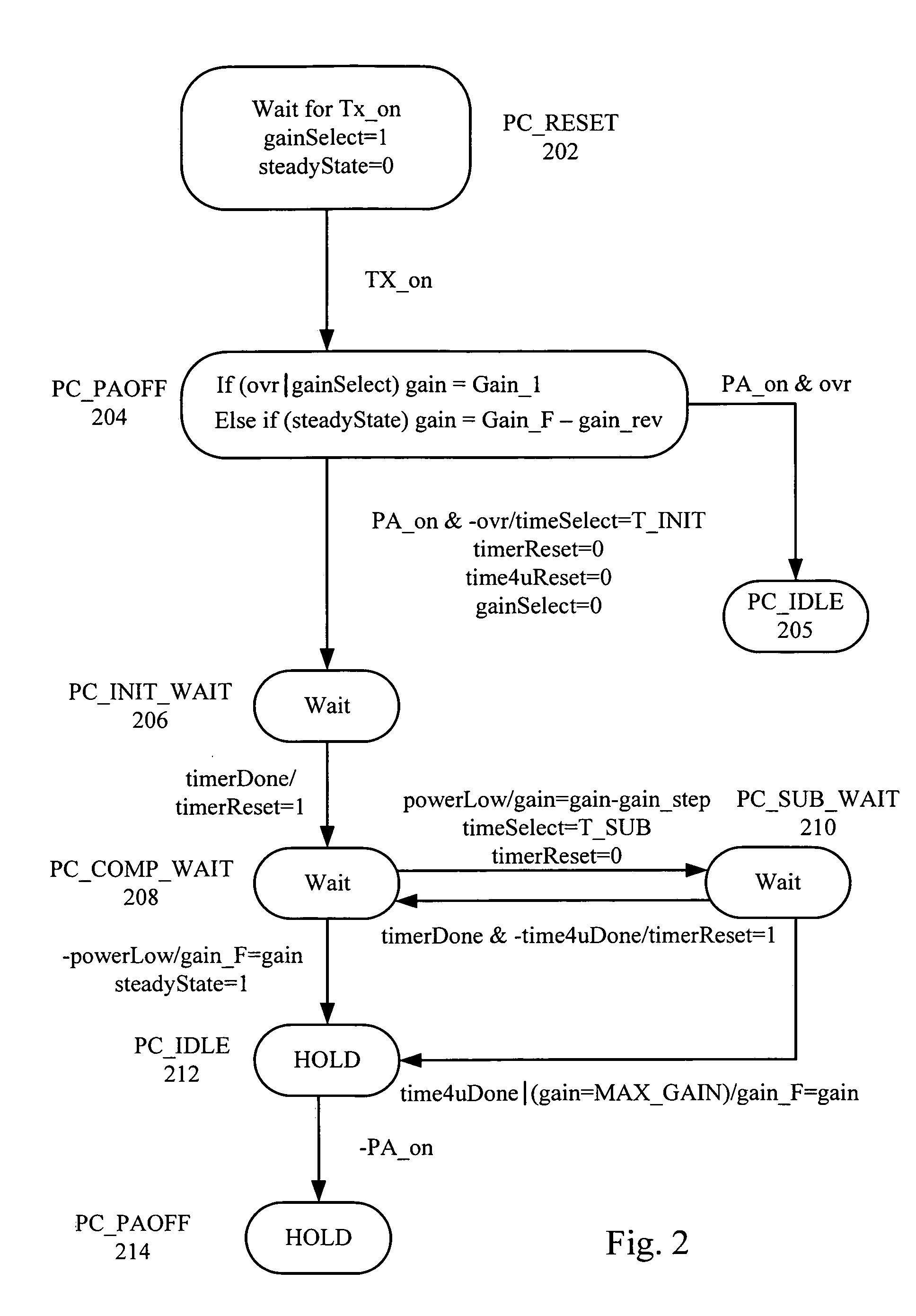

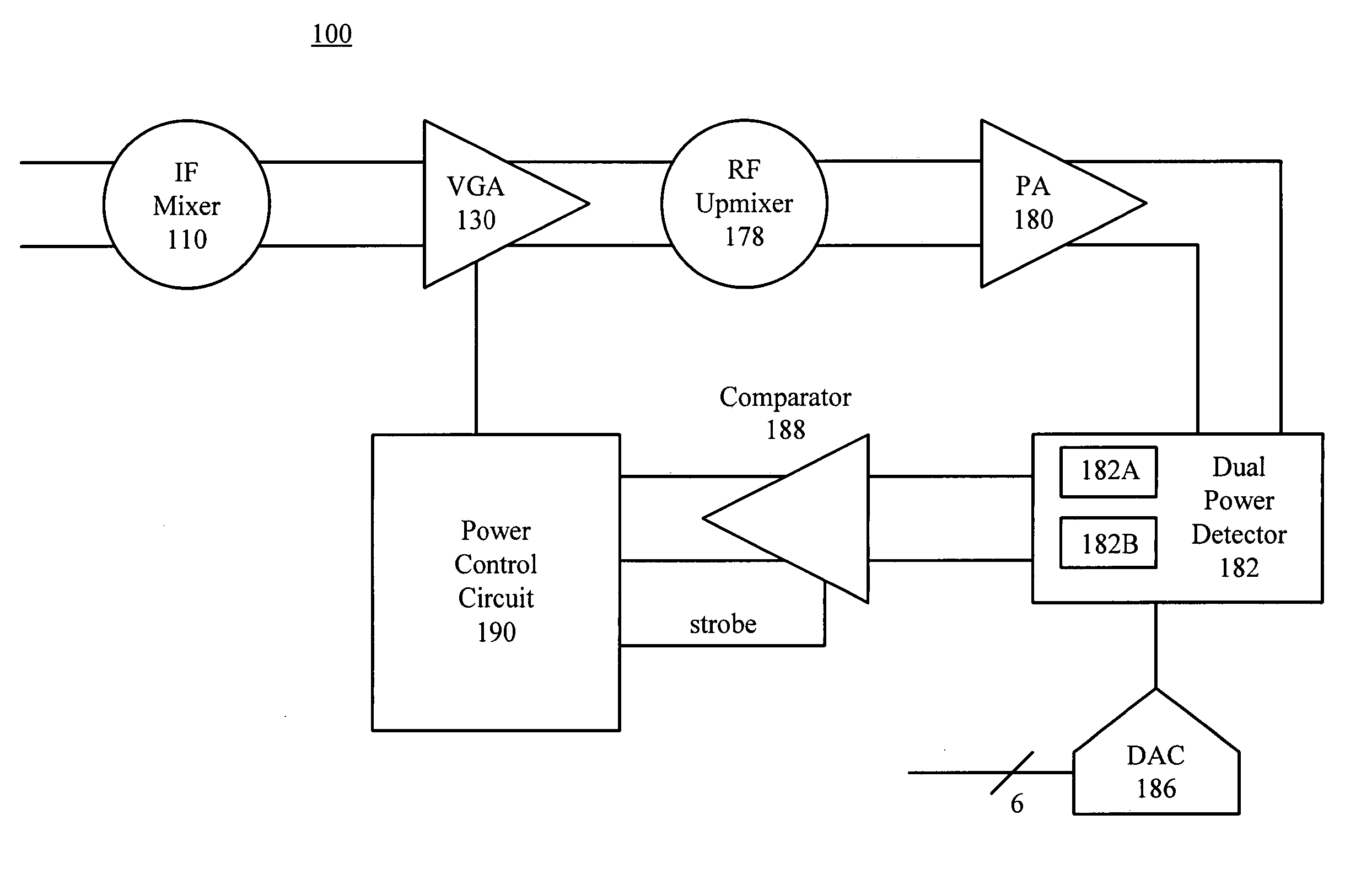

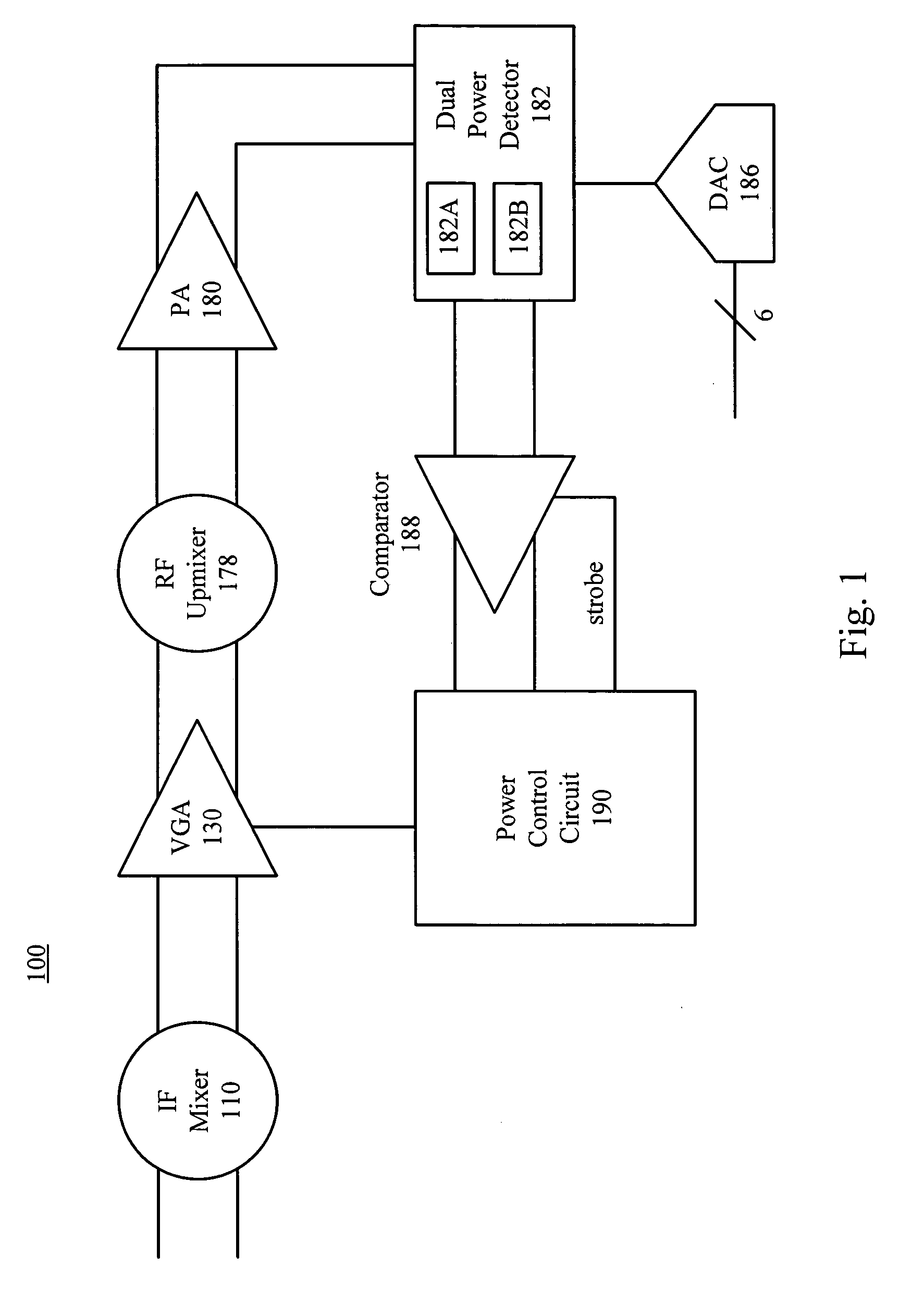

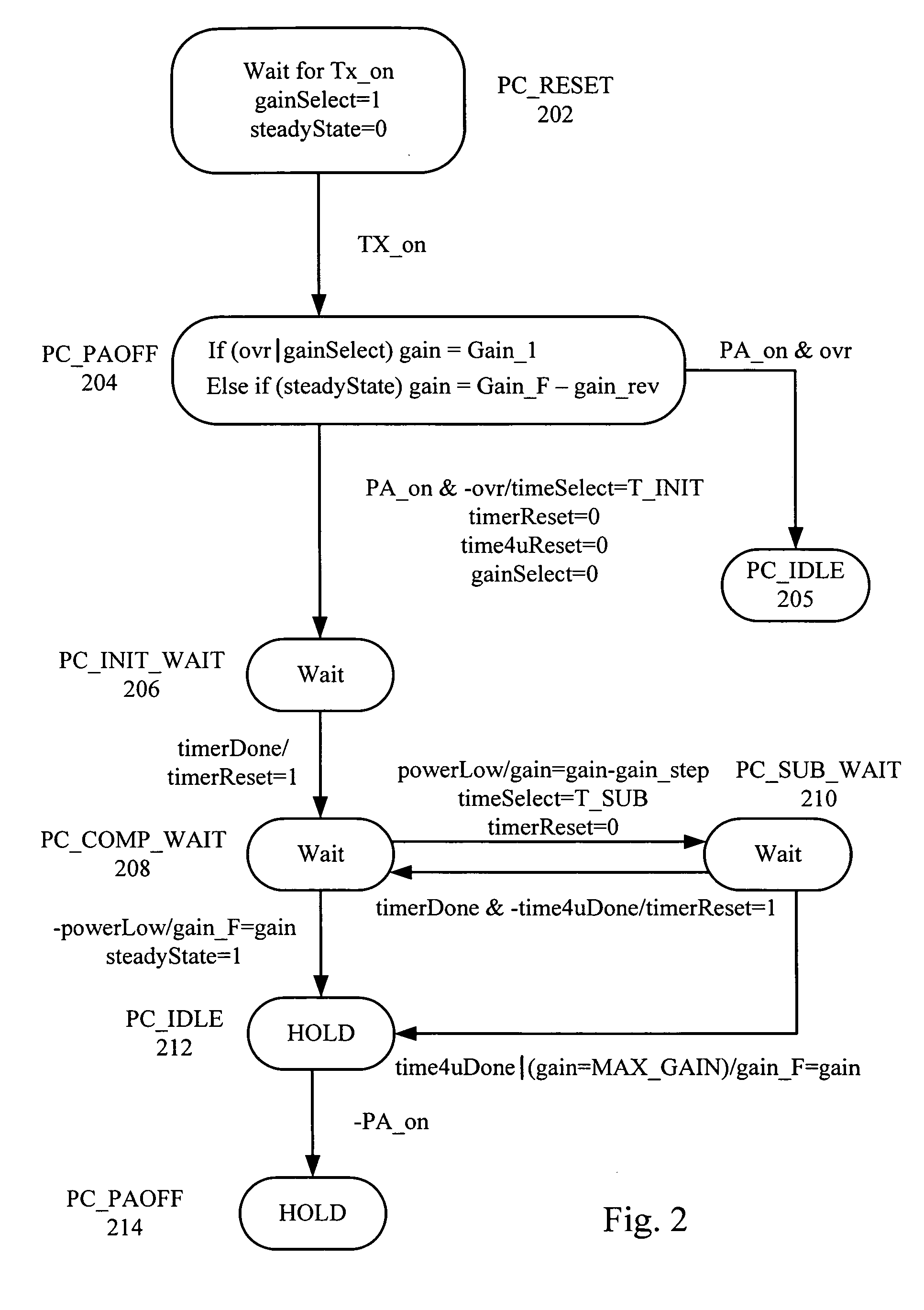

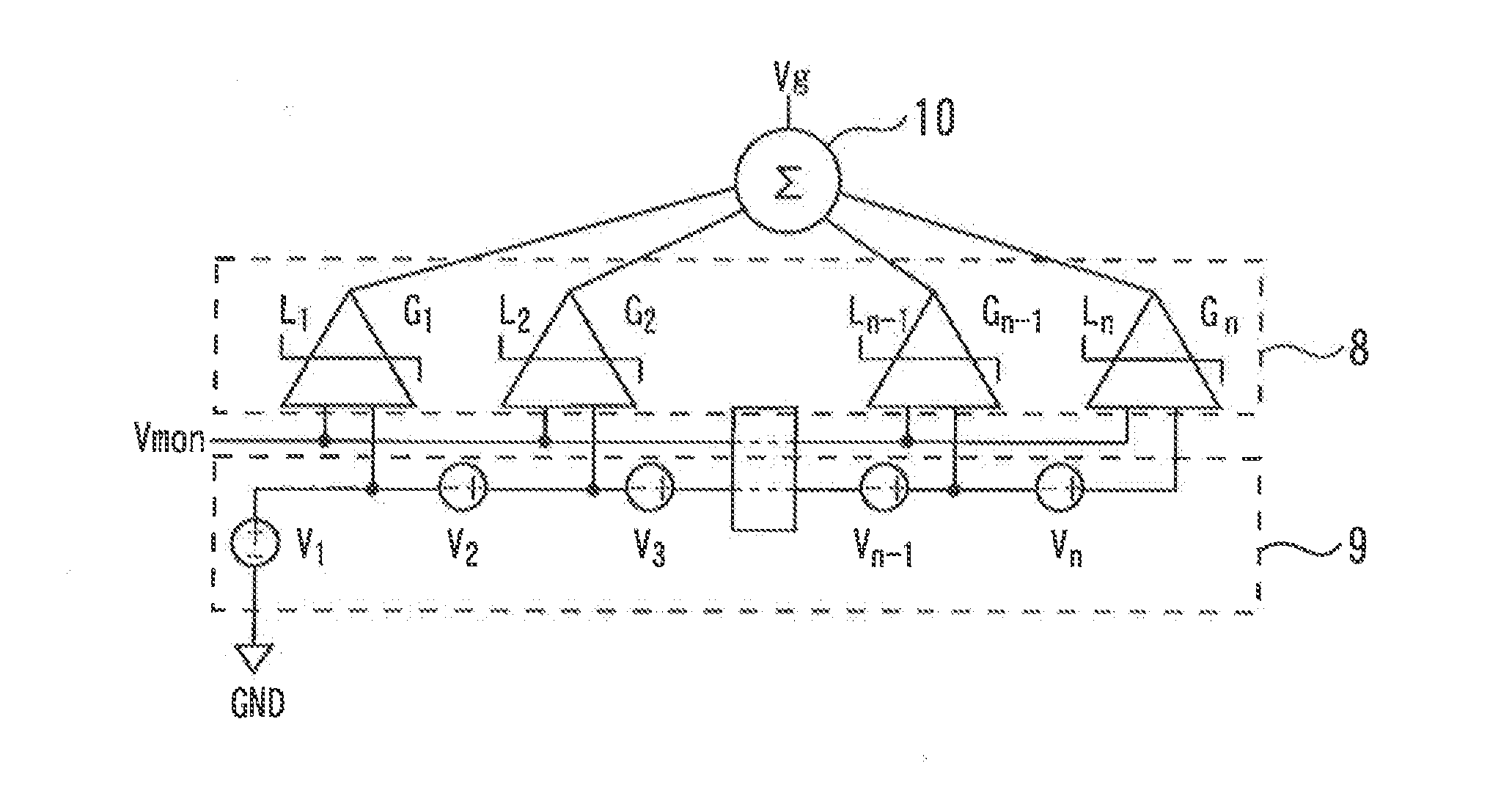

Method and apparatus for a transceiver having a constant power output

InactiveUS7065155B2High output powerAvoid powerPower managementResonant long antennasTransceiverConstant power

The present invention includes a transceiver and a method of operating the same that includes in the transmitter a power control circuit that operates on an analog differential signal containing data packets individually. The power control circuit initially transmits a series of data symbols with known values, periodically strobes the transceiver system for correct power levels and incrementally increases the power level of the transceiver until the optimal gain is reached, without exceeding the maximum output power.

Owner:THE CONNECTIVITY PATENT TRUST

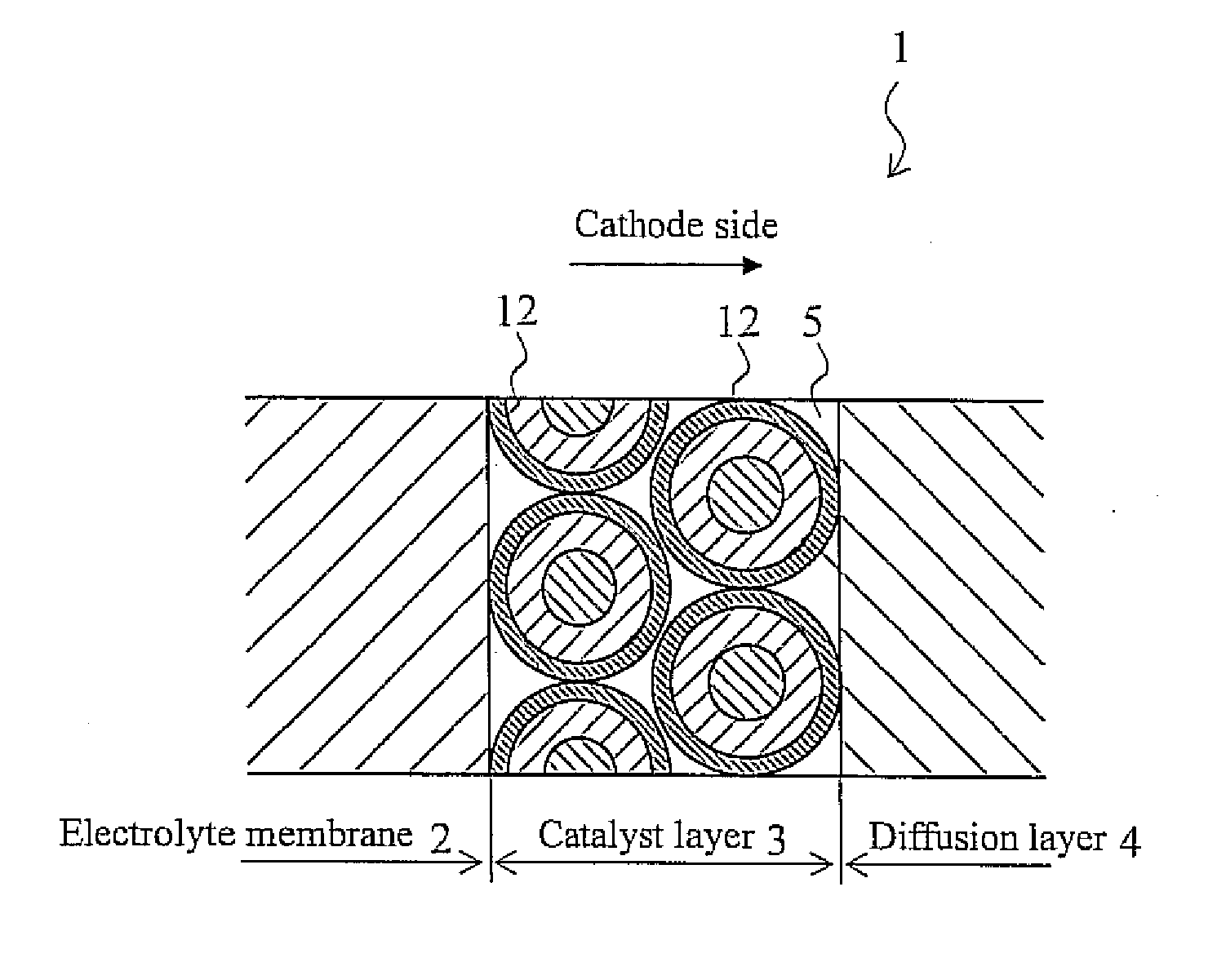

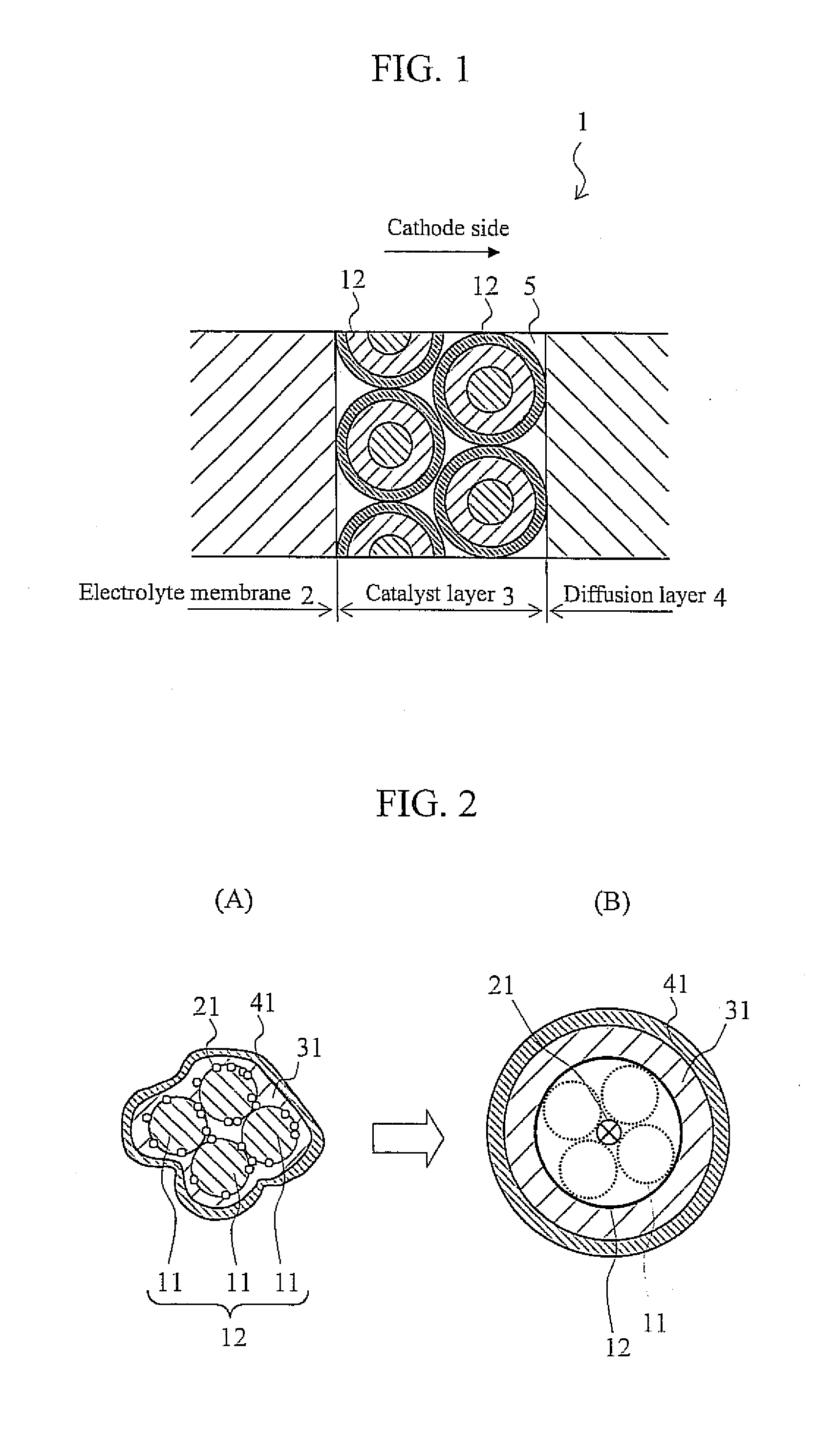

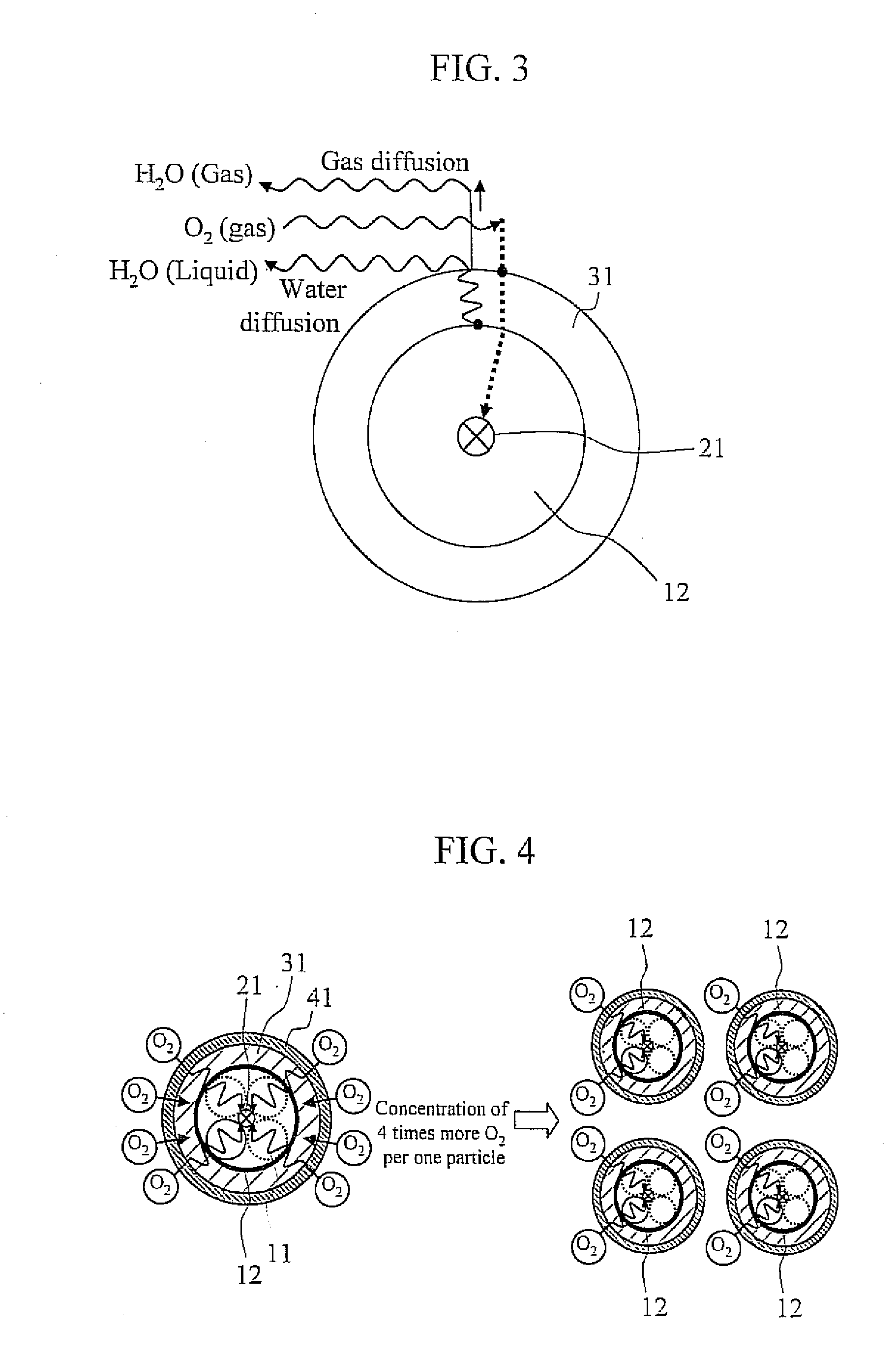

Catalytic layer structure for fuel cell

InactiveUS20110200916A1Reduce the amount requiredAvoid concentrationActive material electrodesFuel cellsHigh current densityIonomer

An object according to the present invention is to provide a catalyst layer for a fuel cell, which prevents the lowering of the performance due to the lack of oxygen in a high current density region and can provide a desired power, even when containing a small amount of catalyst particles. The catalyst layer for a fuel cell has a structure including: an electroconductive carrier made of a secondary particle which is formed by agglomerating a plurality of primary particles; catalyst particles which are dispersed on and carried by the electroconductive carrier; and an ionomer which covers the electroconductive carrier and the catalyst particles, wherein the catalyst particles have the particle quantity in a range of 0.05 mg / cm2 to 0.15 mg / cm2, the electroconductive carriers have the average secondary particle size in a range of 100 nm to 180 nm, and the ionomer has the film thickness in a range of 6 nm to 16 nm. Thereby, the catalyst layer for a fuel cell can reduce the amount of oxygen per one piece of the secondary particles to inhibit oxygen from concentrating on the surface of the ionomer, and shortens the diffusion distance of oxygen in the ionomer to alleviate a rate-controlled condition by the concentration diffusion process of oxygen in the catalyst layer.

Owner:TOYOTA JIDOSHA KK

Wind power system

InactiveUS8698340B2Output powerReduce difficultyWind motor controlFinal product manufactureEngineeringVertical axis wind turbine

A wind power generation system is presented that includes a number of wind power generation units on the supporting tower, each wind power generation unit is formed by one vertical axis wind rotor and one or more power generation unit(s). The rotation shaft of the wind rotor is coupled with the rotor shaft of the single generator set through a connector, or the rotation shaft of the wind rotor is connected with the rotor shafts of multiple generator sets through a transmission mechanism. A helical vertical axis wind rotor and a lineal vertical axis wind rotor constructed by a drag type blade and a lift type blade is incorporated having a disassembling and splicing design. With this configuration, the number of the generator sets connected to the single wind rotor in the power generation unit may be adjusted in real time in accordance to different conditions.

Owner:NANJING YUNENG NEW ENERGY TECH

Object detecting apparatus having light radiation power regulating function

InactiveUS7382441B2Improve accuracyOutput powerOptical rangefindersUsing optical meansDetector circuitsAudio power amplifier

An object detecting apparatus for a vehicle has a light radiation unit and a light receiver unit disposed in a case for detecting an object or a distance to the object. When a vehicle is at a stop, the apparatus detects an output power of a laser light radiated from the light radiation unit by the light receiving unit and feedback-controls the output power of the laser light to a predetermined level based on the detected output power of the laser light. The feedback control is effected by an amplifier circuit, a pulse width detector circuit and a current regulator circuit. Thus, the output power of the laser light is reduced not to damage human eyes when the vehicle is at a stop.

Owner:DENSO CORP

Method and apparatus for a transceiver having a constant power output

InactiveUS20060083331A1Output power is preventedReduce gainPower managementResonant long antennasTransceiverConstant power

The present invention includes a transceiver and a method of operating the same that includes in the transmitter a power control circuit that operates on an analog differential signal containing data packets individually. The power control circuit initially transmits a series of data symbols with known values, periodically strobes the transceiver system for correct power levels and incrementally increases the power level of the transceiver until the optimal gain is reached, without exceeding the maximum output power.

Owner:THE CONNECTIVITY PATENT TRUST

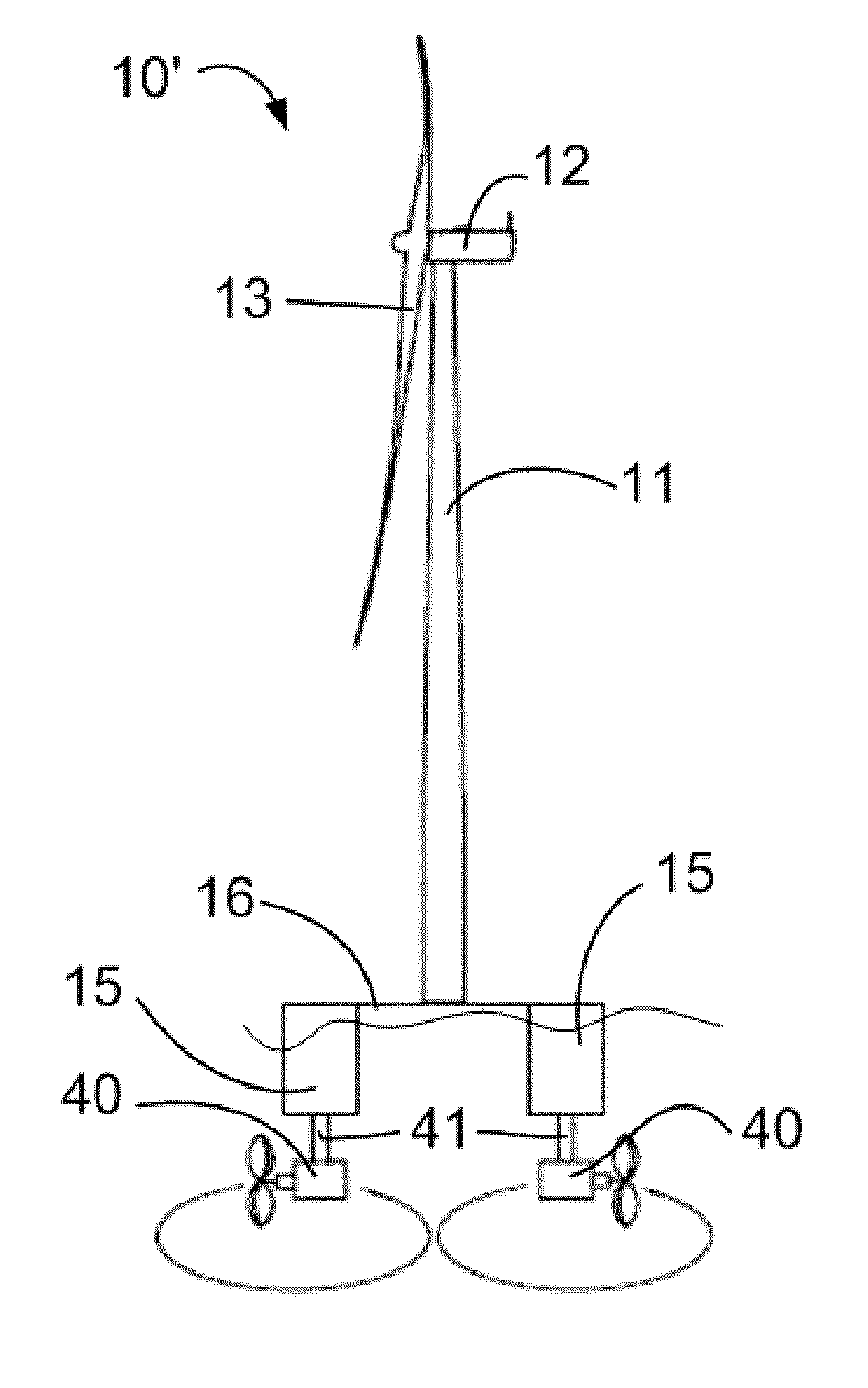

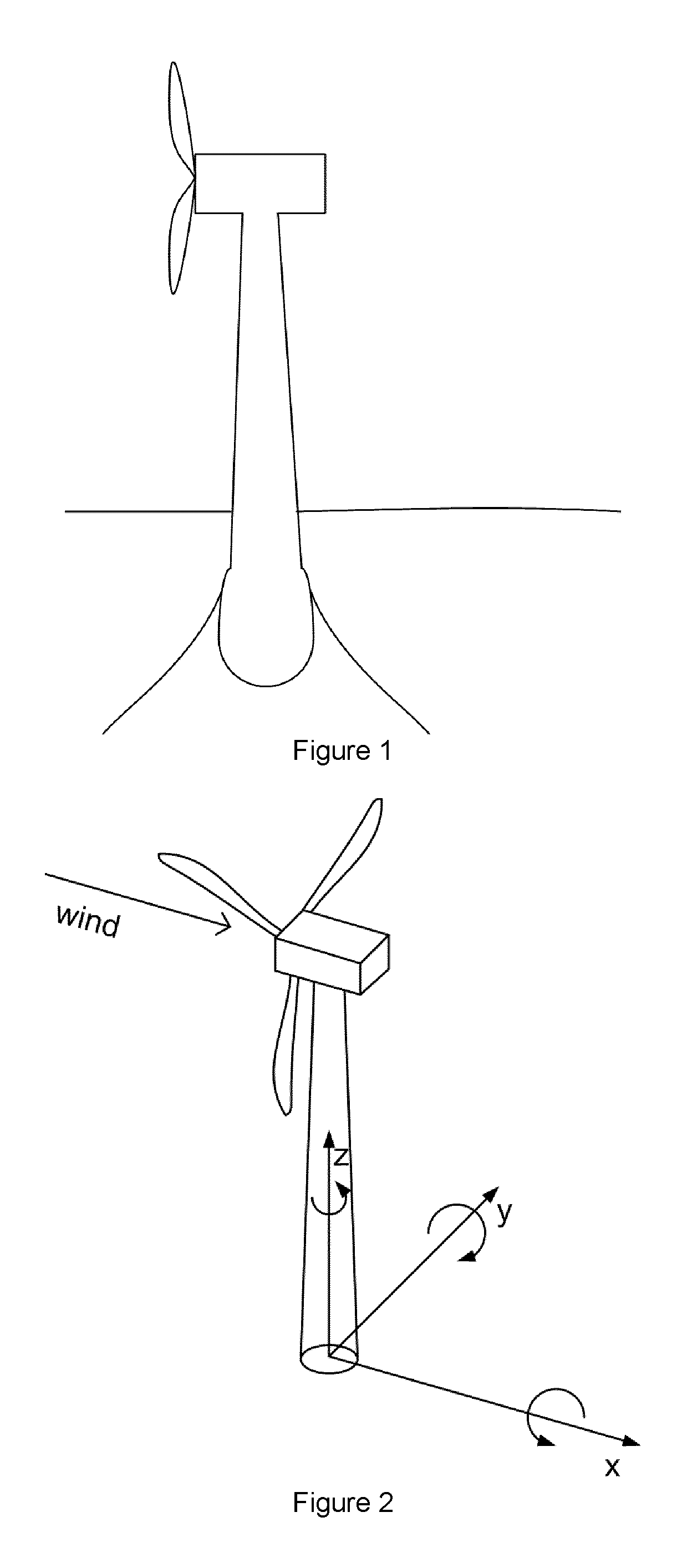

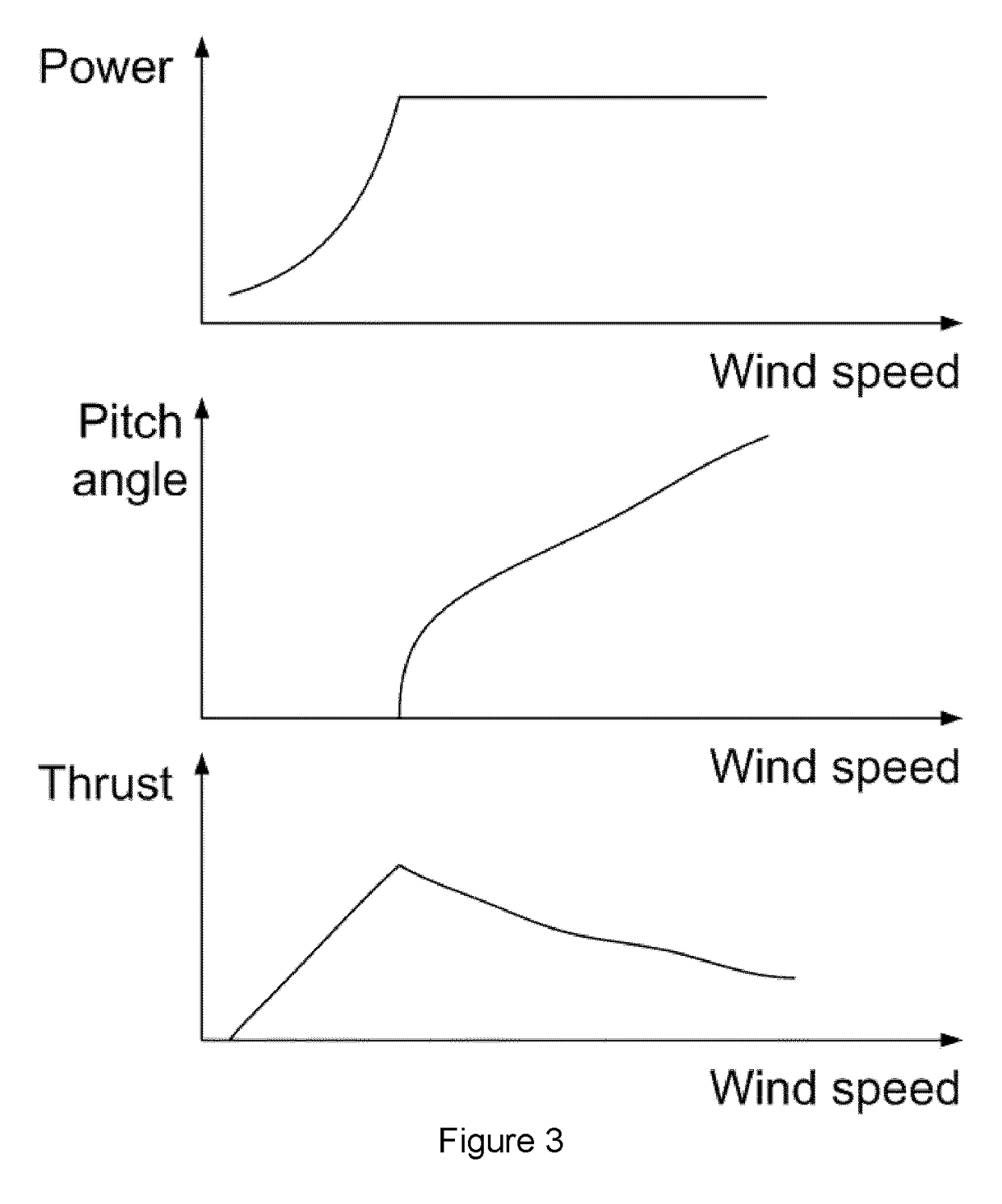

Method for reducing oscillations in offshore wind turbines

The invention relates to a method of reducing oscillations in an offshore wind turbine comprising one or more thrusters, the method comprising determining an oscillation of the offshore wind turbine and operating the one or more thrusters such that the oscillation is reduced. The invention further relates to an offshore wind turbine comprising one or more underwater thrusters, oscillation determination system for determining an oscillation of the wind turbine and a control system for operating the underwater thrusters in response to signals received from the oscillation determination system.

Owner:GE RENEWABLE TECH WIND BV

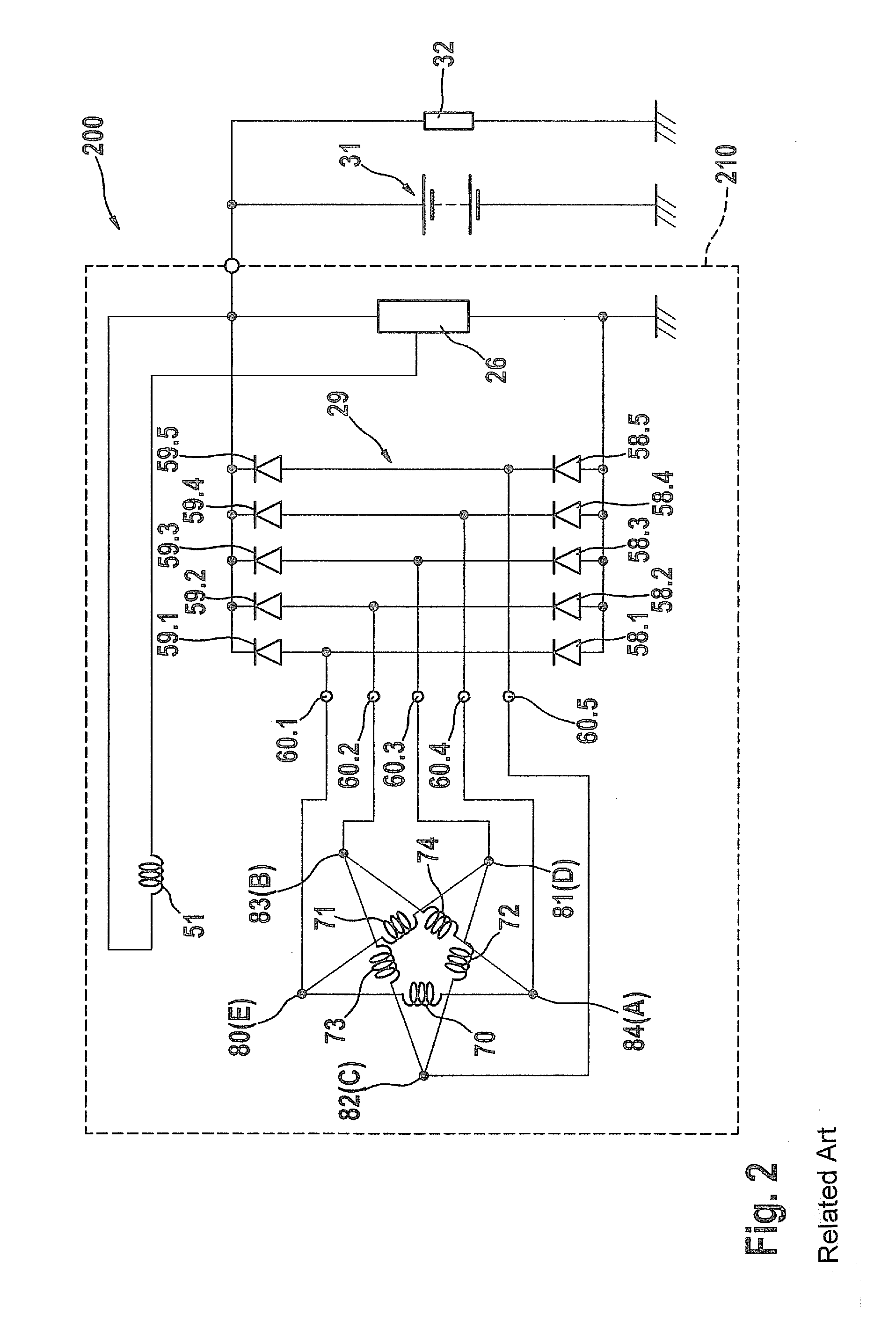

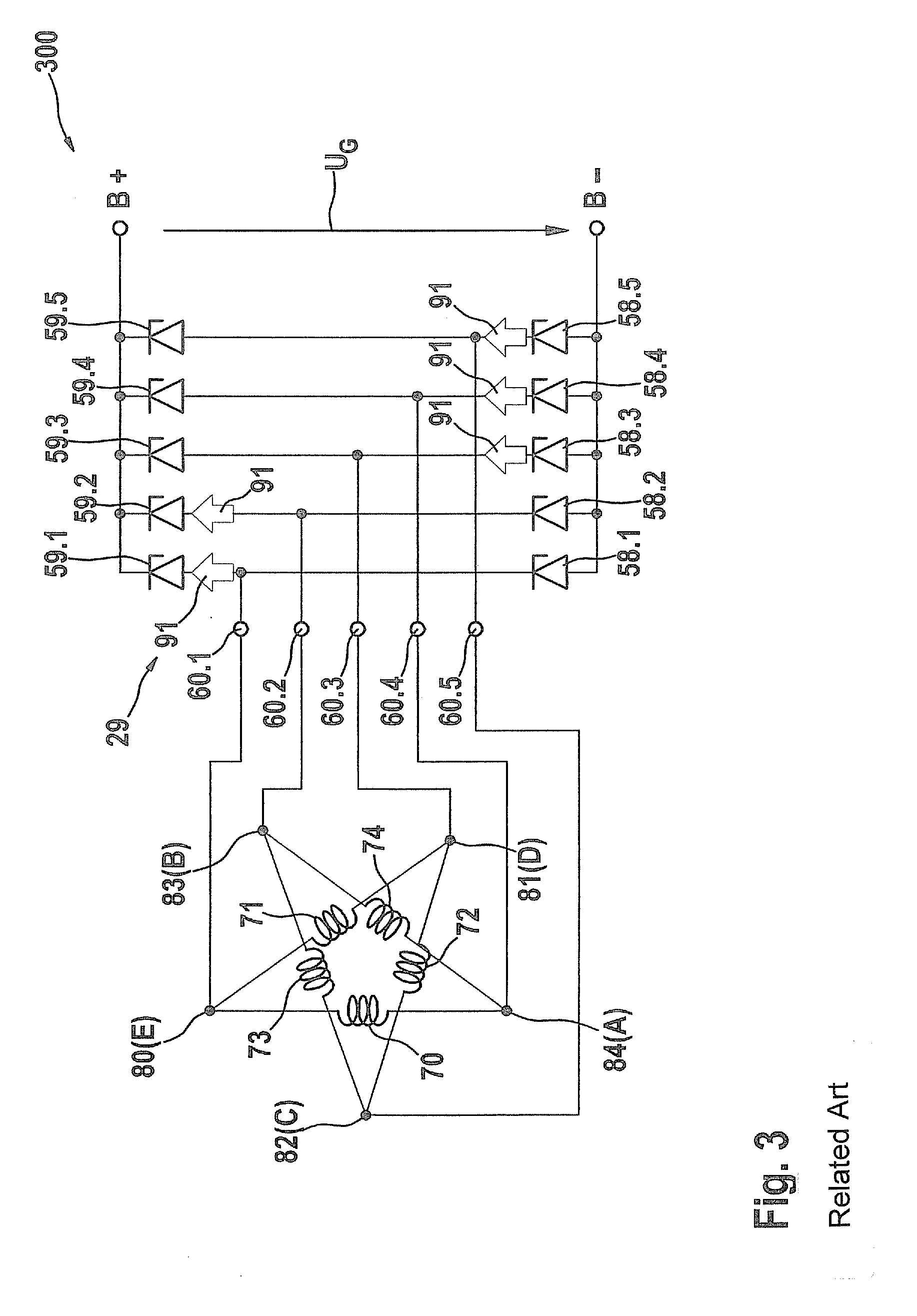

Preventing load dump overvoltages in synchronous rectifiers,

InactiveUS20120281446A1Executable very easily and reliablyPromote activationAc-dc conversion without reversalElectric motor controlOvervoltageControl engineering

In a method for reducing load dump overvoltages during operation of a synchronous rectifier for a polyphase alternating current having a number of inputs which correspond to the number of alternating current phases of the alternating current, and having at least two outputs for providing a direct current, an alternating current phase is connected to each of the inputs, and each of the inputs are electrically optionally connected via active switching elements to either the first or the second output in accordance with a control unit.

Owner:ROBERT BOSCH GMBH

Ultrasonic transmitter, ultrasonic transceiver and sounding apparatus

InactiveUS7269098B2Improve efficiencySuppress emissionSonic/ultrasonic/infrasonic transmissionMechanical vibrations separationDriver circuitTransceiver

Owner:FURUNO ELECTRIC CO LTD

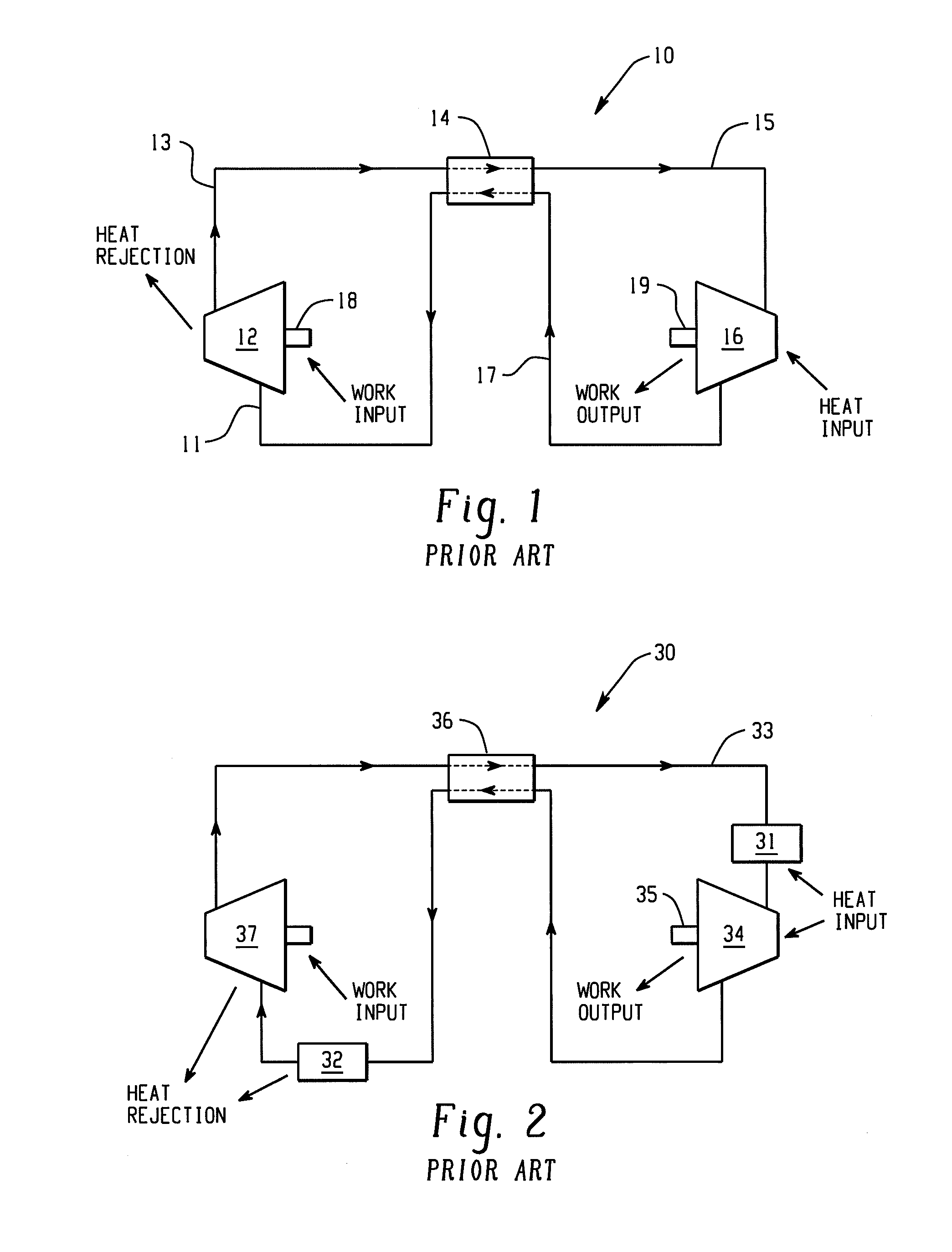

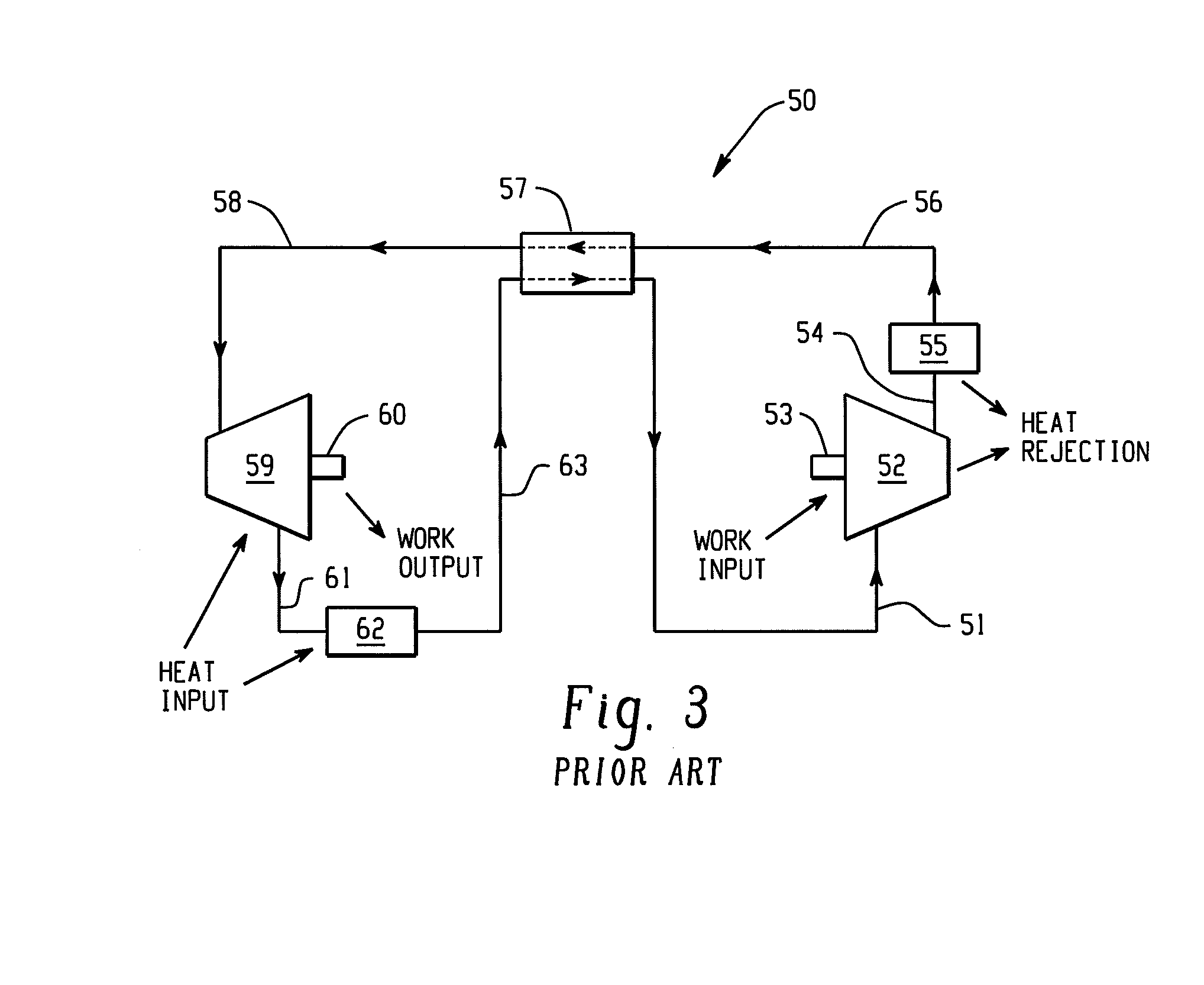

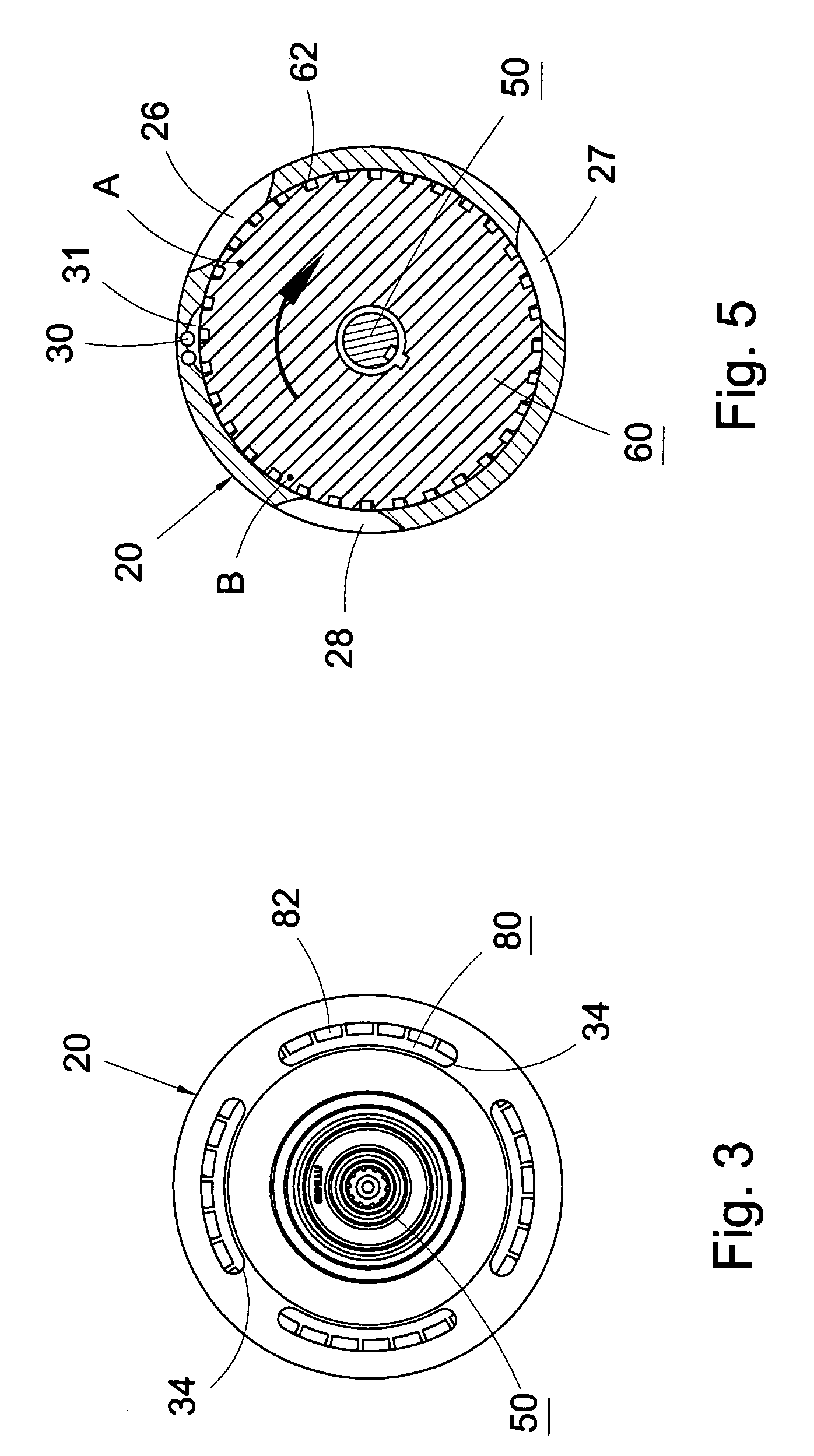

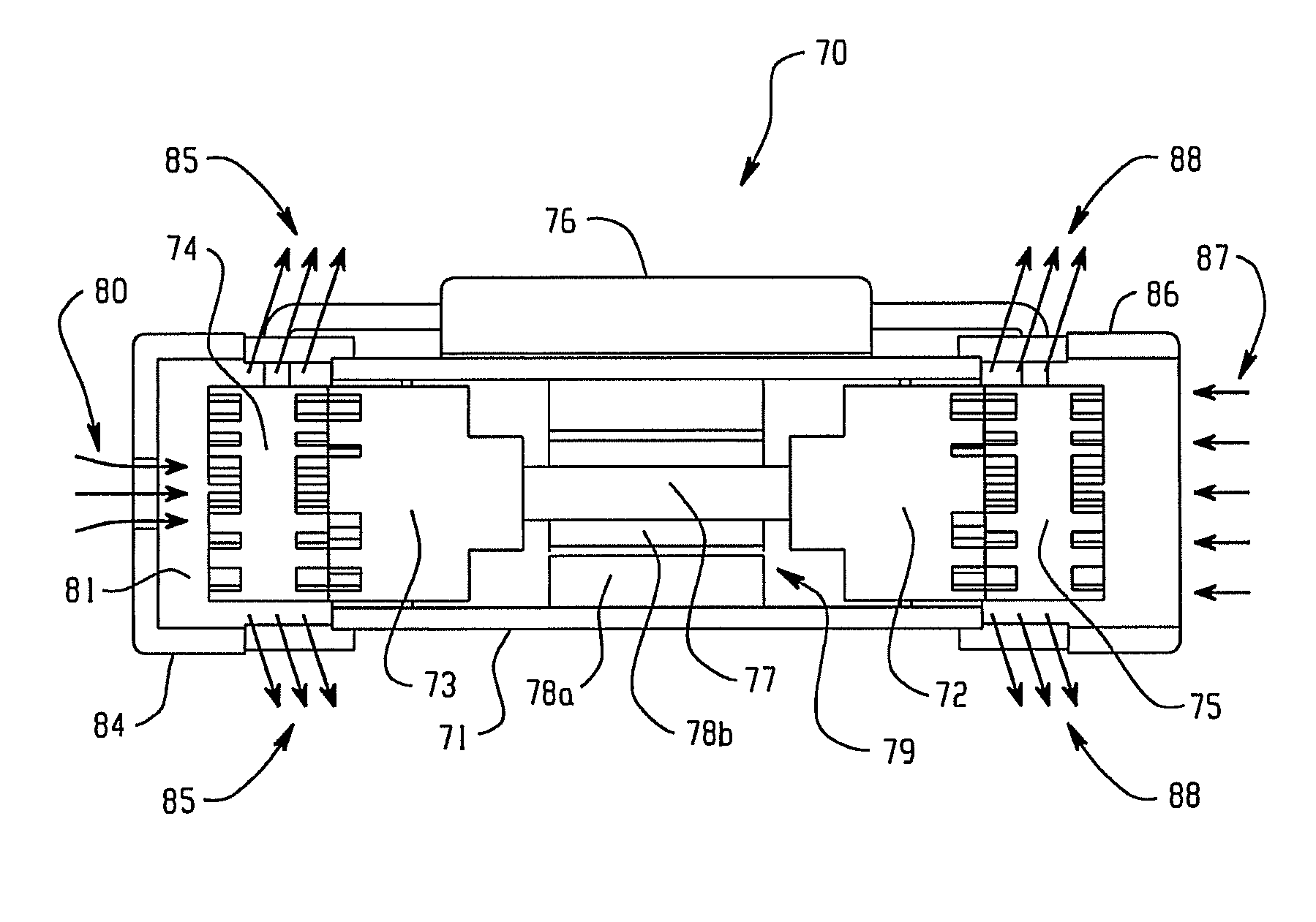

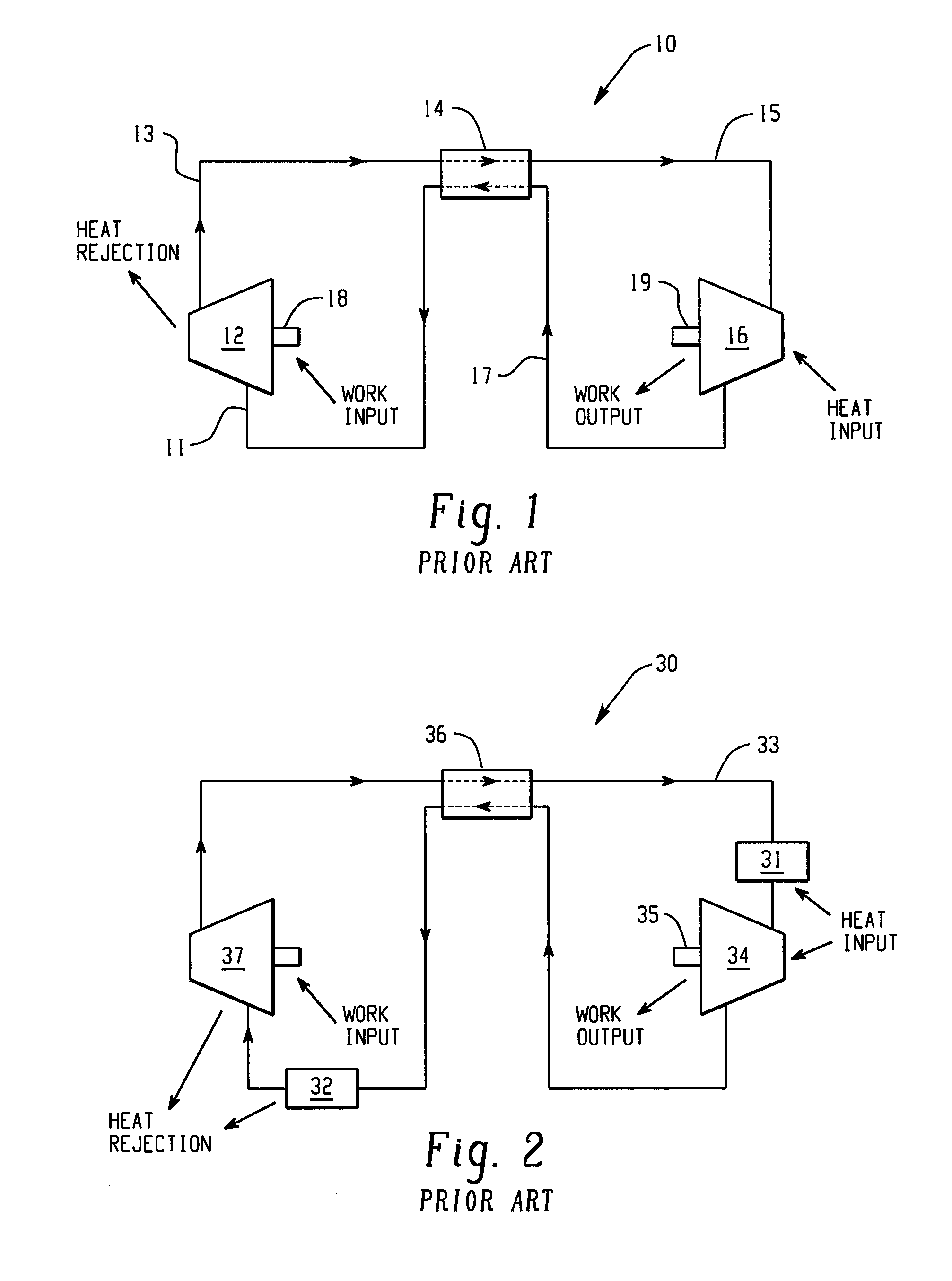

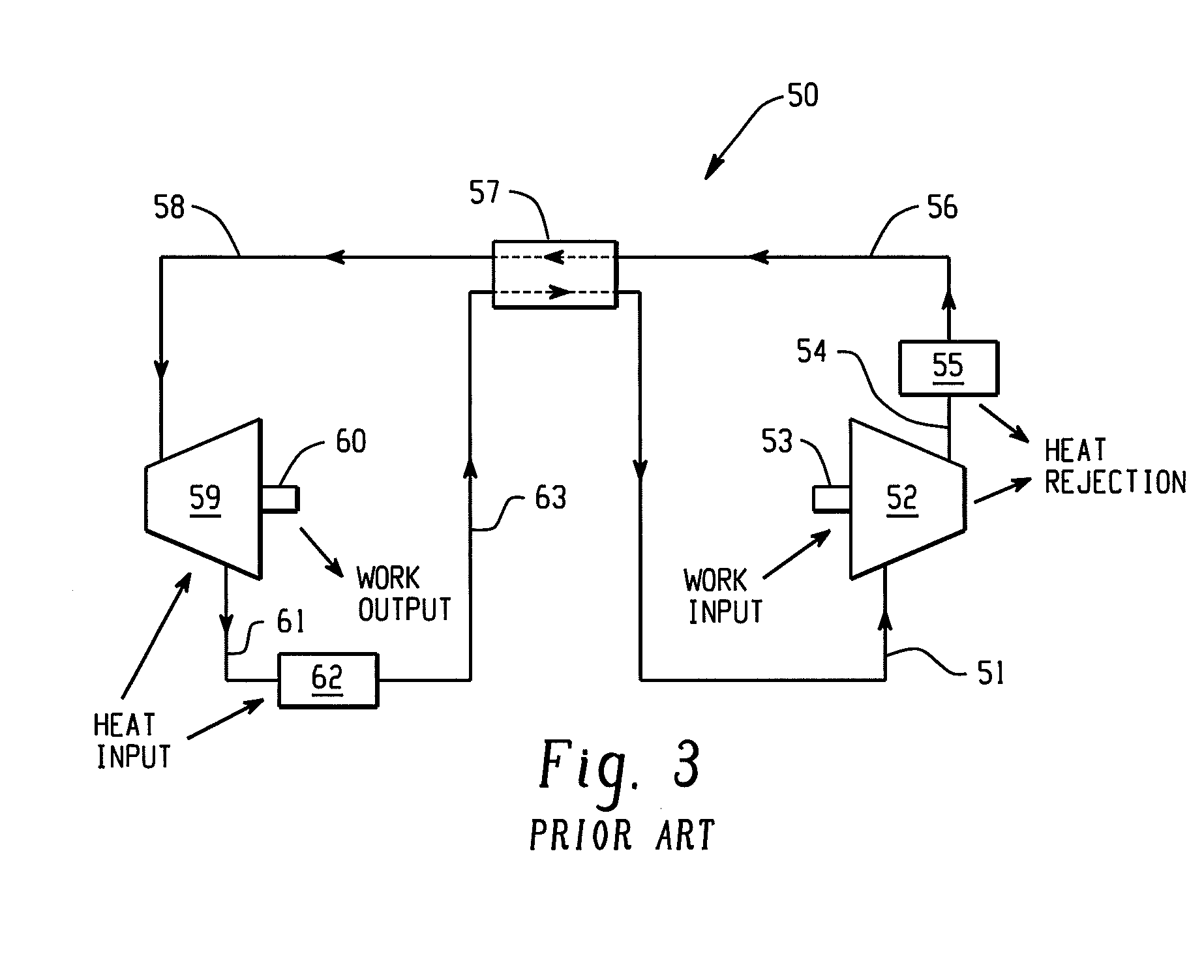

Ericsson cycle device improvements

ActiveUS20140311167A1Reduce output powerIncrease output powerCompression machinesRefrigeration componentsBrayton cycleEricsson cycle

The present disclosure relates to improvements to thermodynamic devices that approximate the Ericsson cycle, Brayton cycle, or regenerated Brayton cycle. These cycles and various ways of implementing them are known in the art. They can operate as engines or refrigerators. The Ericsson cycle is attractive since it can theoretically operate at the Carnot efficiency, which is the maximum possible efficiency for a heat engine or refrigerator.

Owner:INVENTHERM LLC

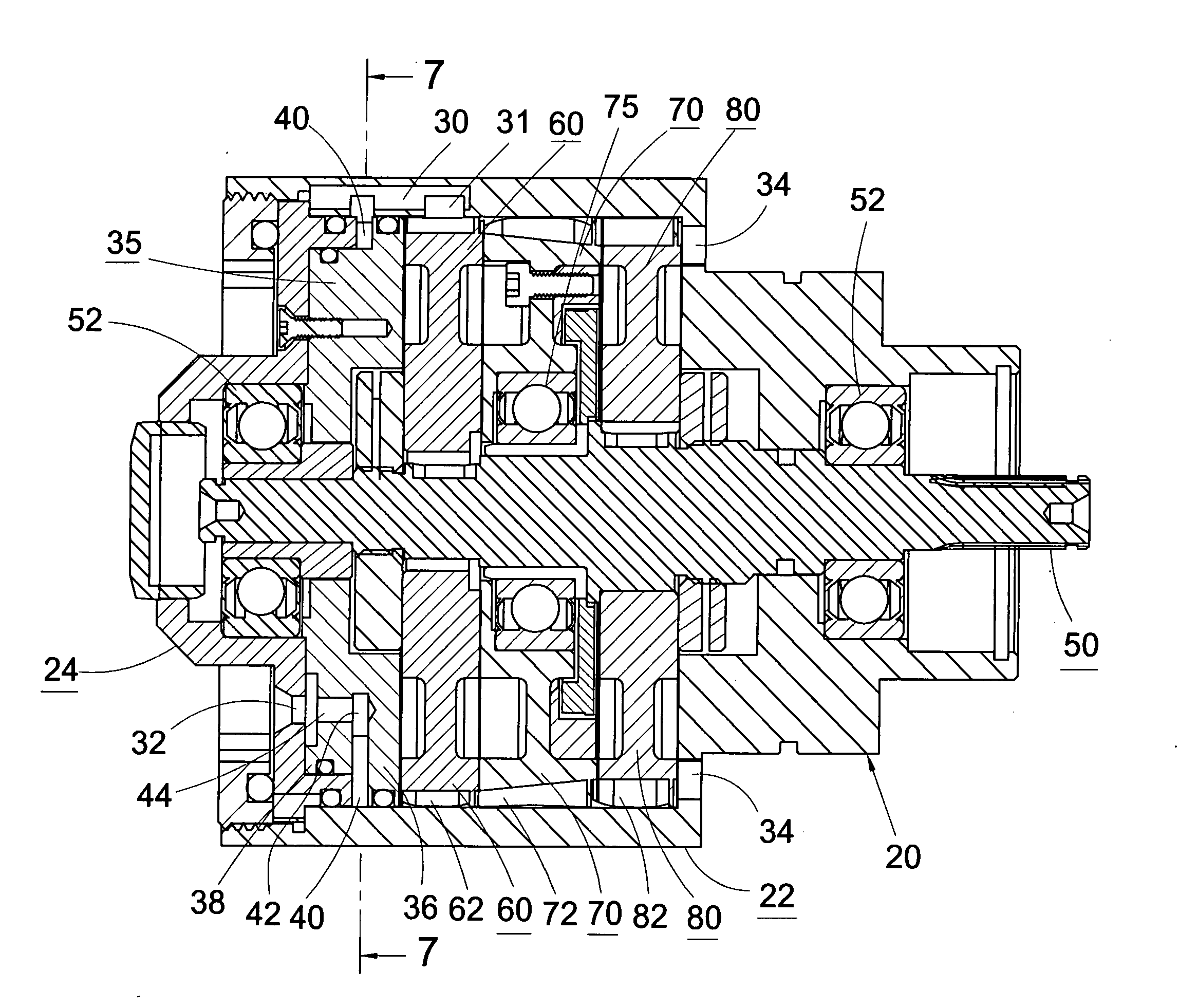

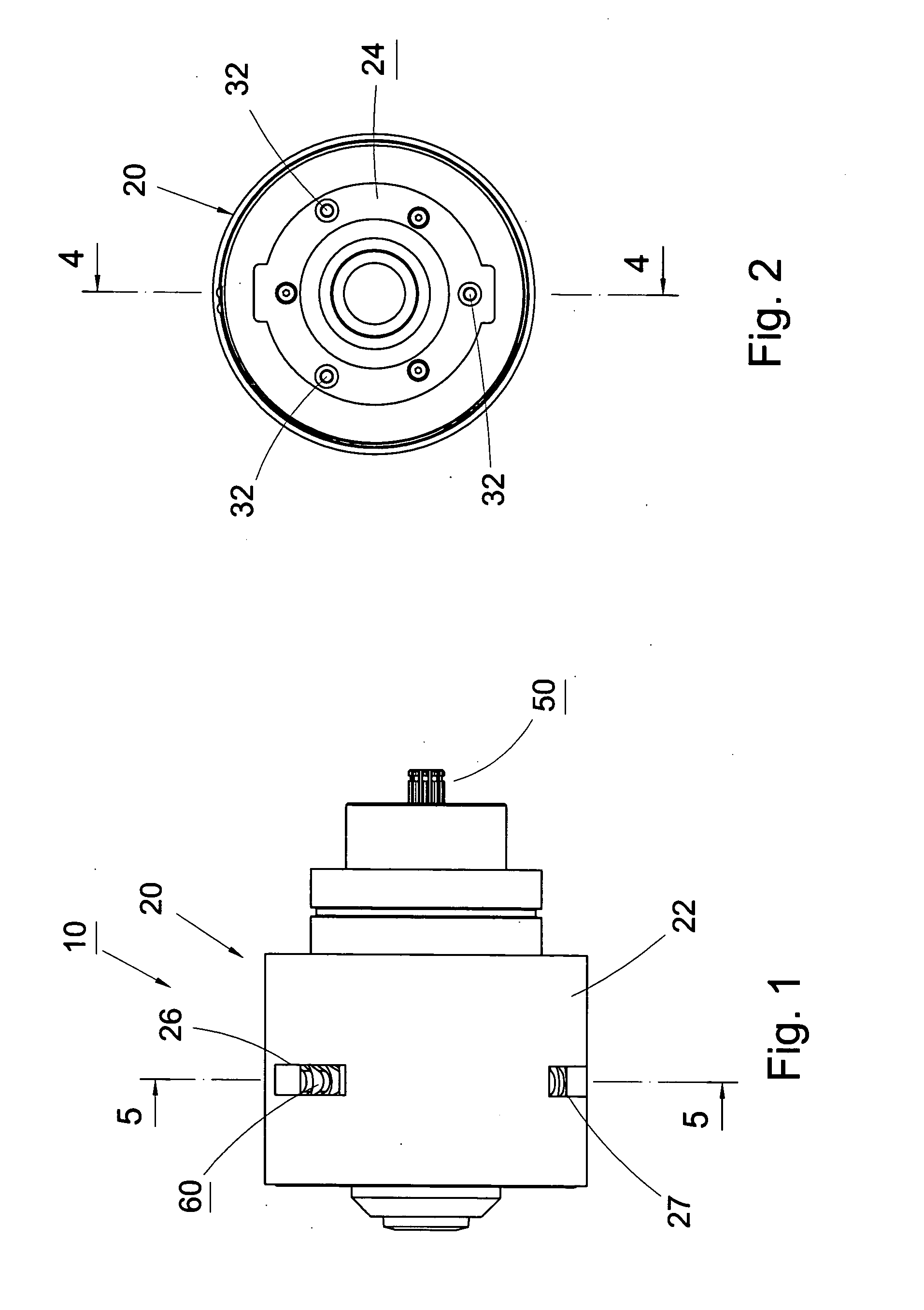

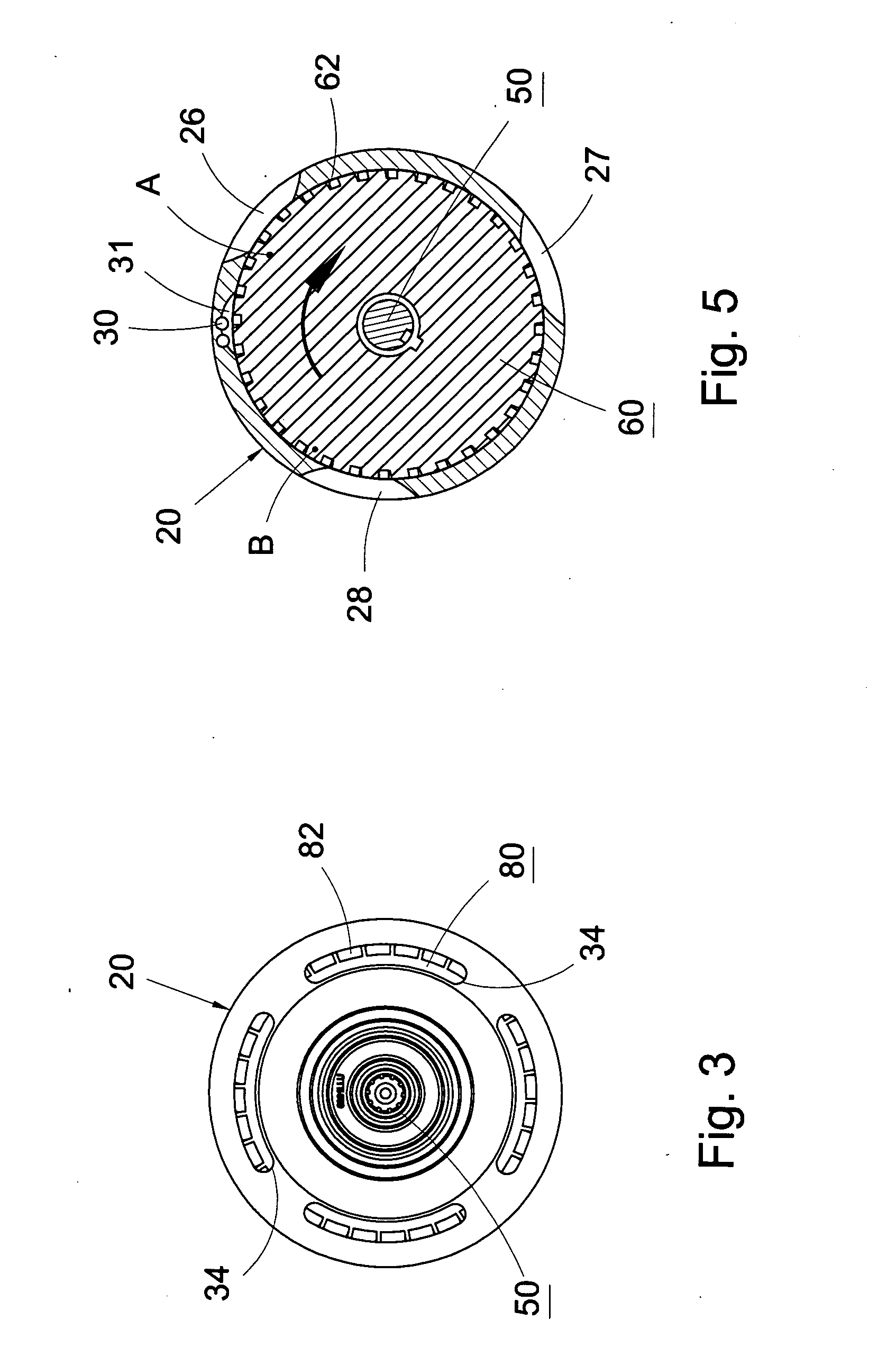

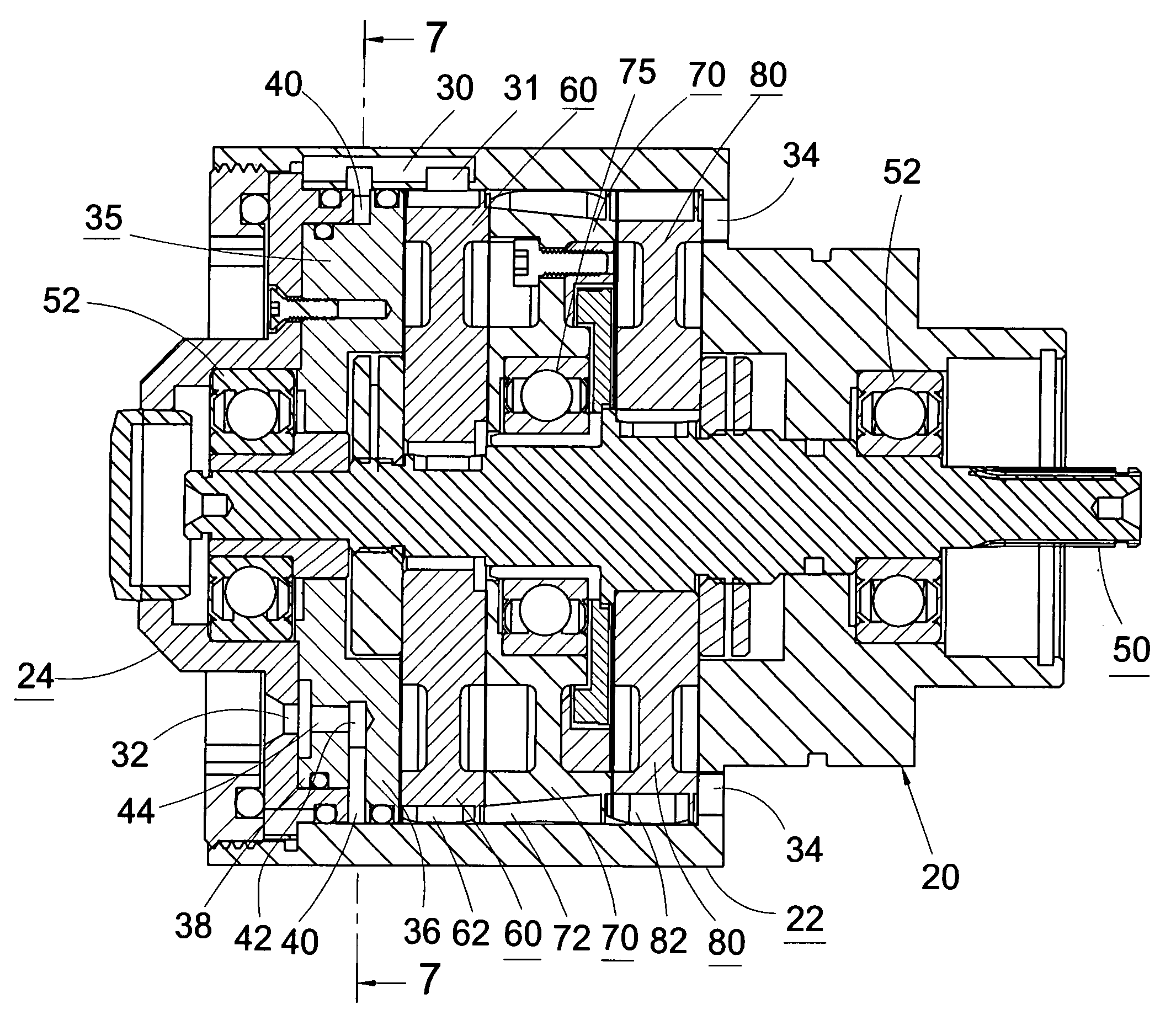

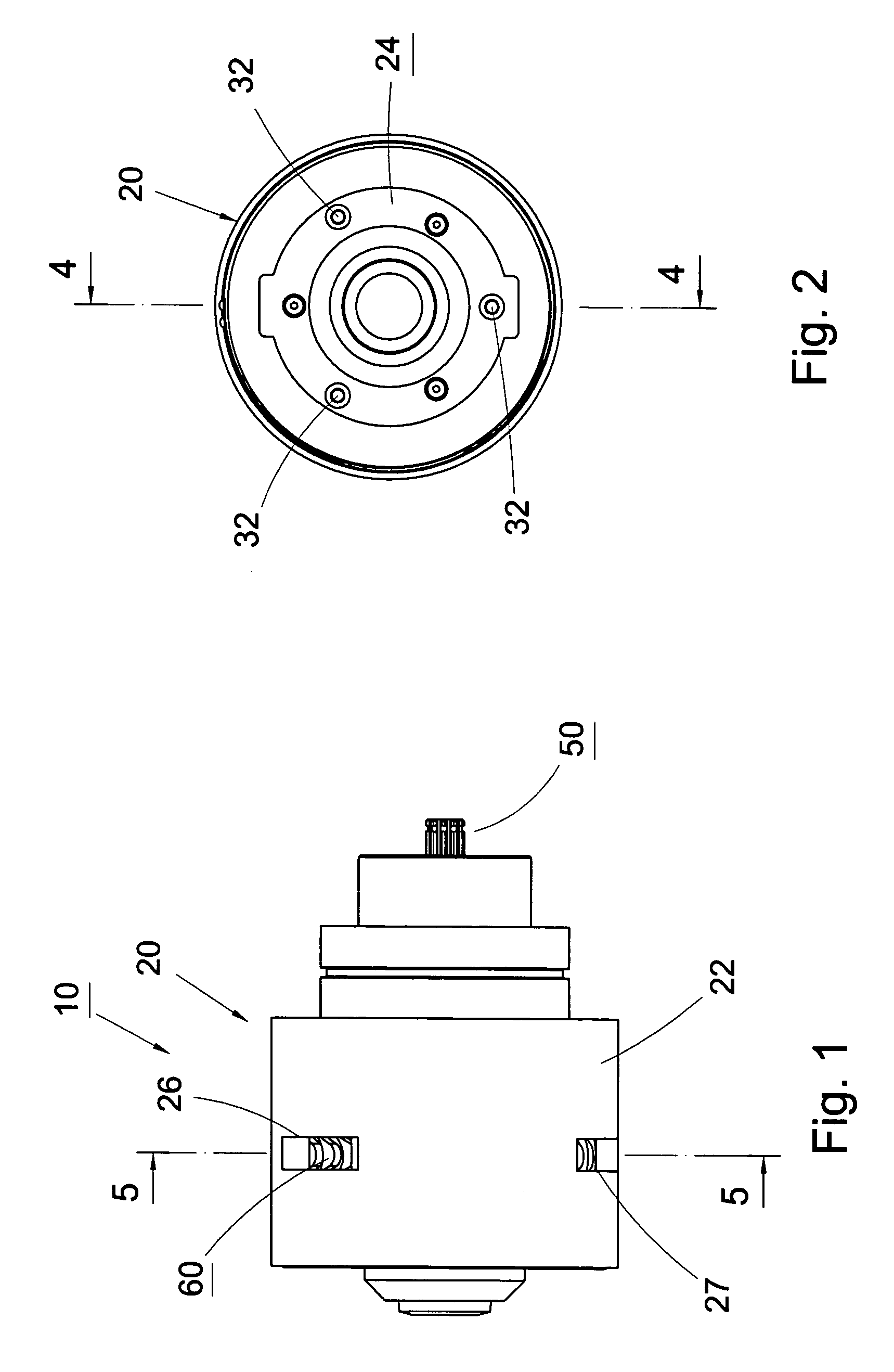

Turbo pneumatic cylinder of pneumatic tool

InactiveUS20080014086A1Large outputLow gas consumptionPropellersPump componentsPneumatic cylinderRotational axis

A turbo pneumatic cylinder of a pneumatic tool, including a front turbine, a one-way rotatable inverse turbine and a rear turbine. The front and rear turbines are mounted on the rotary shaft of the pneumatic cylinder. The inverse turbine is one-way rotatably fitted on the rotary shaft between the front and rear turbines. Multiple blades are arranged on the circumferences of the front and rear turbine and the inverse turbines. The blades of the inverse turbine are directed in a direction reverse to the direction of the blades of the front and rear turbines. The front and rear turbines and the rotary shaft rotate in the same direction, while the inverse turbine rotates in a direction reverse to the direction of the front and rear turbines. As a result, the efficiency of the pneumatic cylinder is enhanced and the twisting of the pneumatic cylinder is avoided when it is in operation.

Owner:GISON MASCH CO LTD

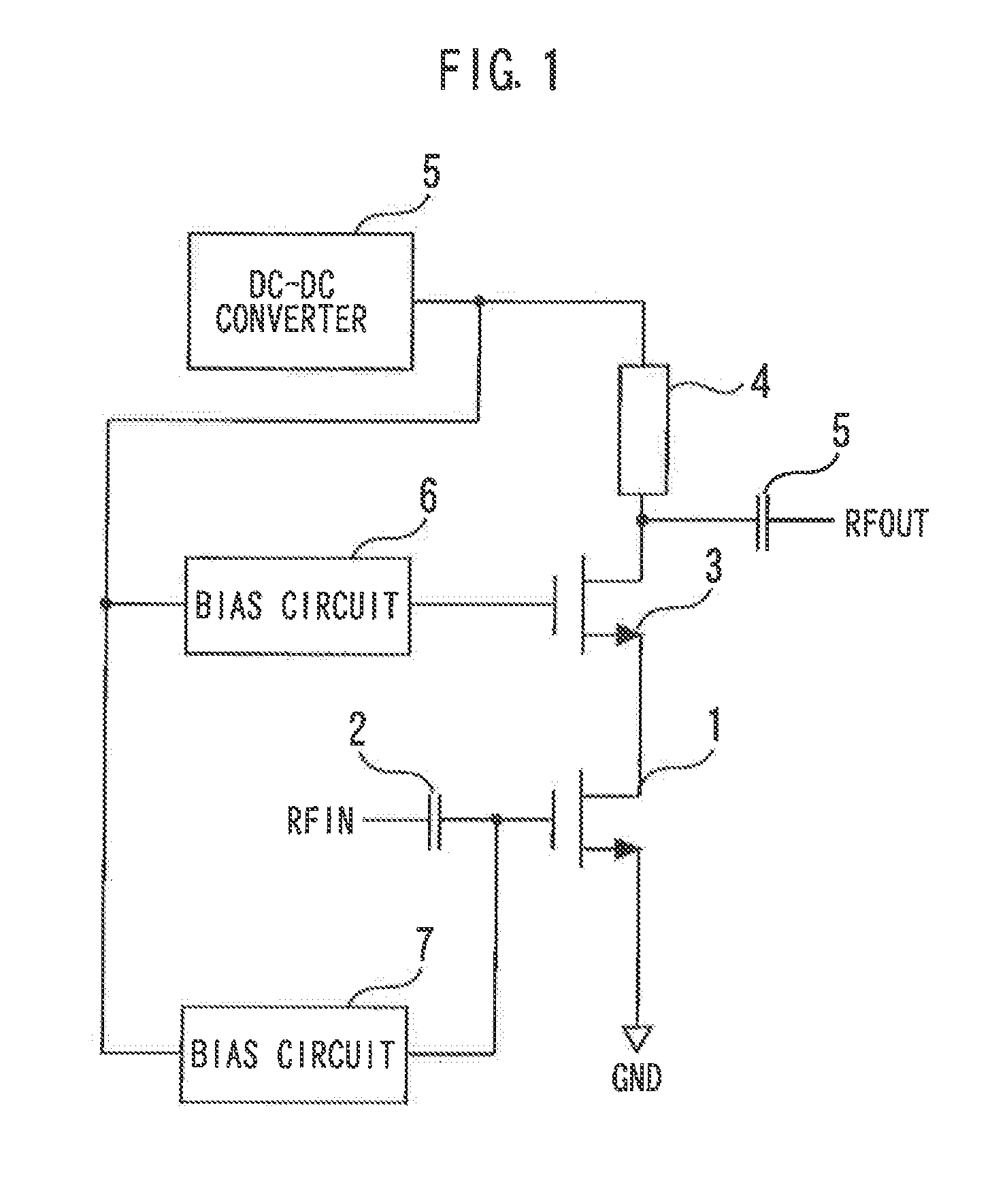

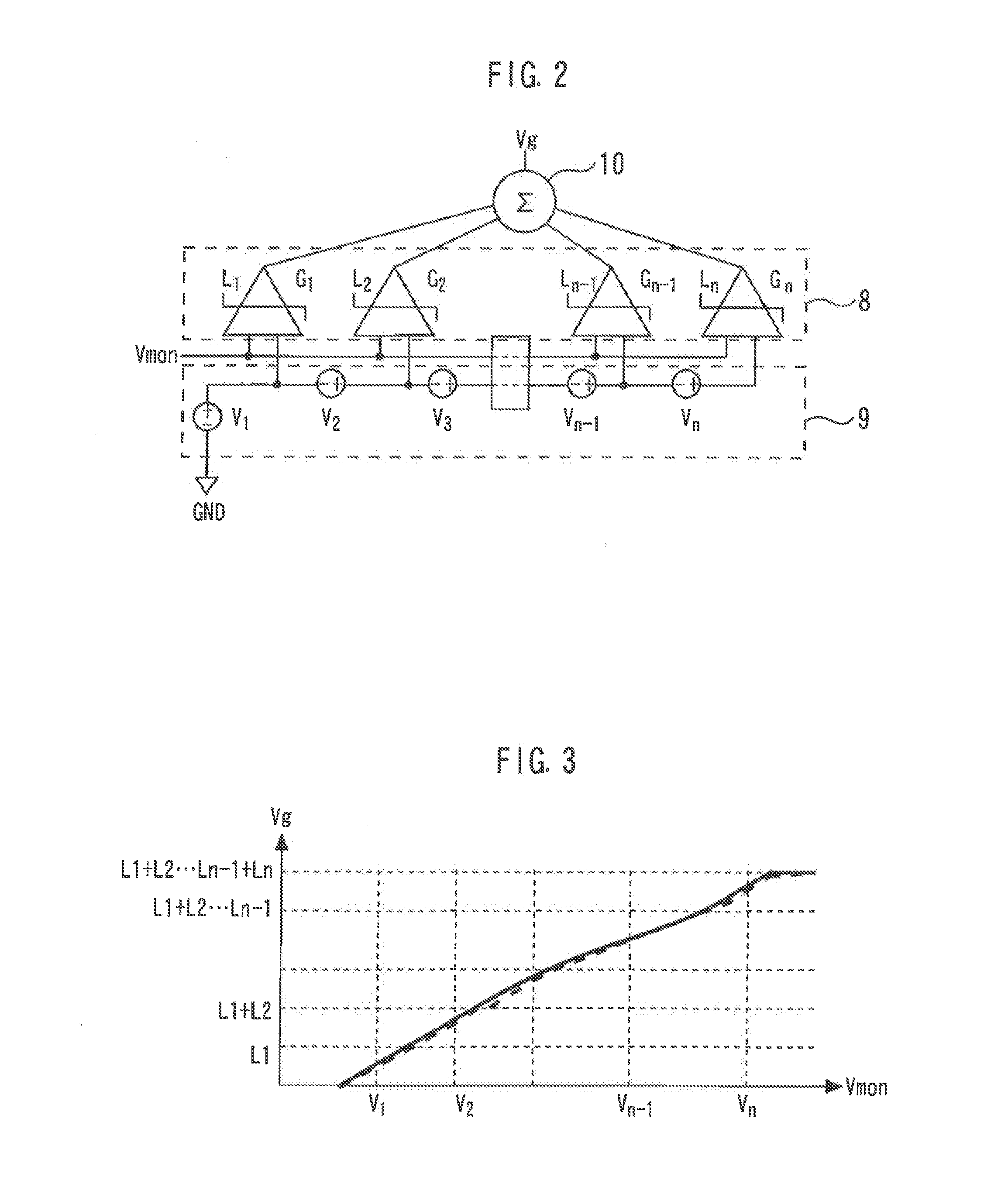

Cascode amplifier

ActiveUS20150171794A1Prevent deterioration of power add efficiencyOutput powerPower amplifiersAmplifier modifications to raise efficiencyCascode amplifierElectrical and Electronics engineering

A cascode amplifier includes: a first transistor having a gate to which a signal is input, a grounded source, and a drain; a second transistor having a gate, a source connected to the drain of the first transistor, and a drain; a load connected to the drain of the second transistor; a DC-DC converter supplying a supply voltage, which is variable according to output power, to the drain of the second transistor via the load; and a first bias circuit supplying a voltage, which is a function of the supply voltage, to the gate of the second transistor.

Owner:MURATA MFG CO LTD

Turbo pneumatic cylinder of pneumatic tool

A turbo pneumatic cylinder of a pneumatic tool, including a front turbine, a one-way rotatable inverse turbine and a rear turbine. The front and rear turbines are mounted on the rotary shaft of the pneumatic cylinder. The inverse turbine is one-way rotatably fitted on the rotary shaft between the front and rear turbines. Multiple blades are arranged on the circumferences of the front and rear turbine and the inverse turbines. The blades of the inverse turbine are directed in a direction reverse to the direction of the blades of the front and rear turbines. The front and rear turbines and the rotary shaft rotate in the same direction, while the inverse turbine rotates in a direction reverse to the direction of the front and rear turbines. As a result, the efficiency of the pneumatic cylinder is enhanced and the twisting of the pneumatic cylinder is avoided when it is in operation.

Owner:GISON MASCH CO LTD

Ericsson cycle device improvements

ActiveUS9482450B2Output powerCompression machinesRefrigeration componentsBrayton cycleEricsson cycle

The present disclosure relates to improvements to thermodynamic devices that approximate the Ericsson cycle, Brayton cycle, or regenerated Brayton cycle. These cycles and various ways of implementing them are known in the art. They can operate as engines or refrigerators. The Ericsson cycle is attractive since it can theoretically operate at the Carnot efficiency, which is the maximum possible efficiency for a heat engine or refrigerator.

Owner:INVENTHERM LLC

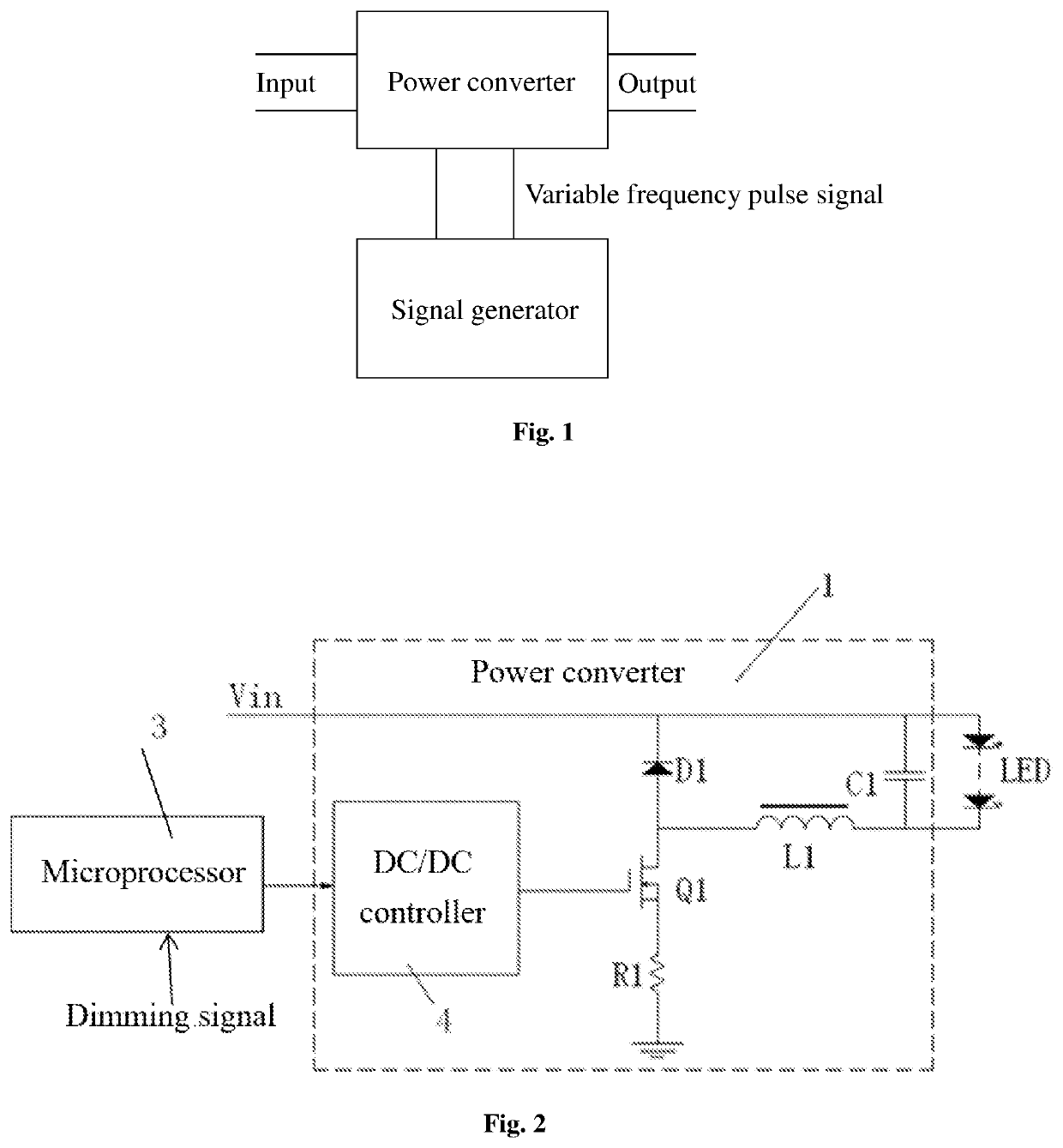

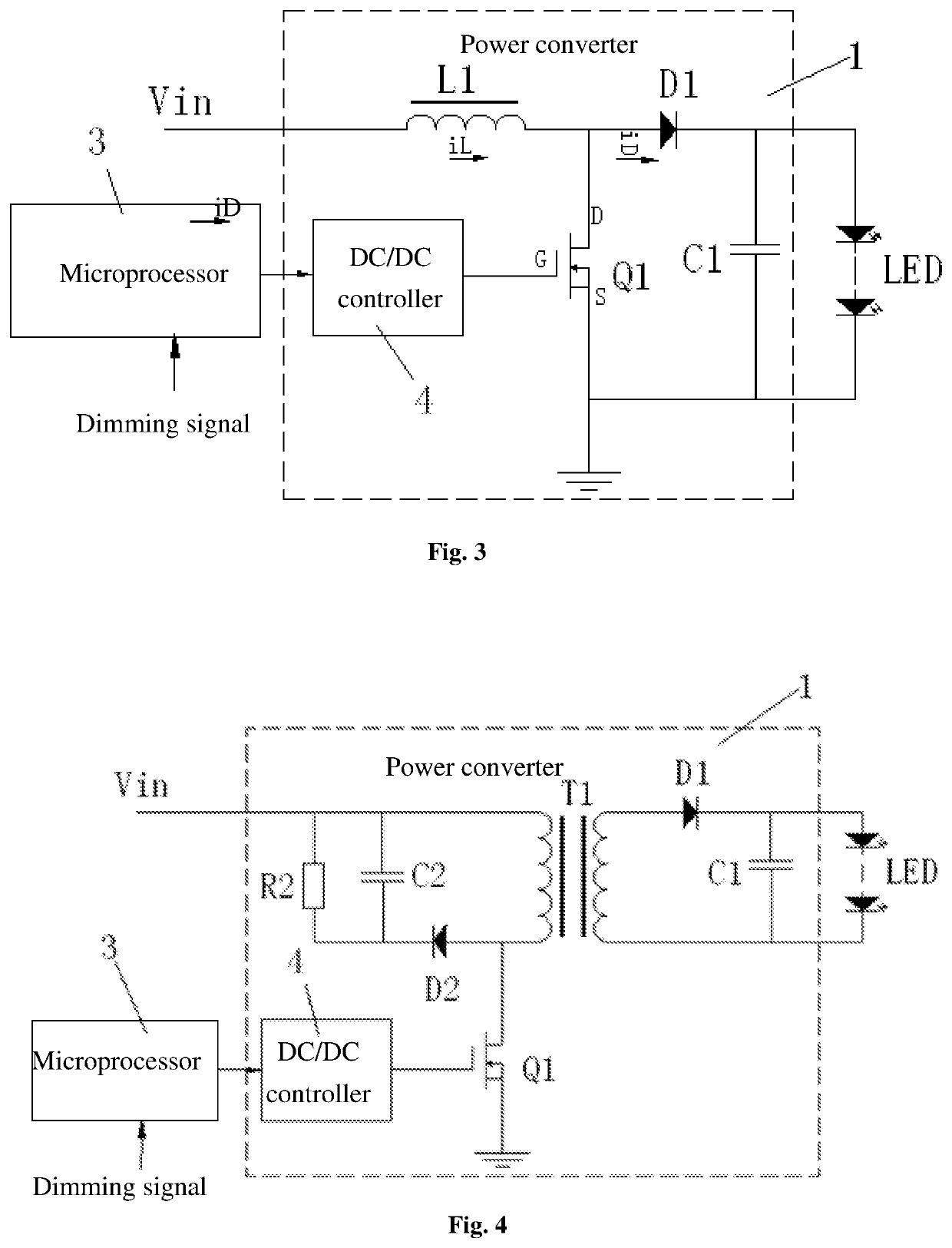

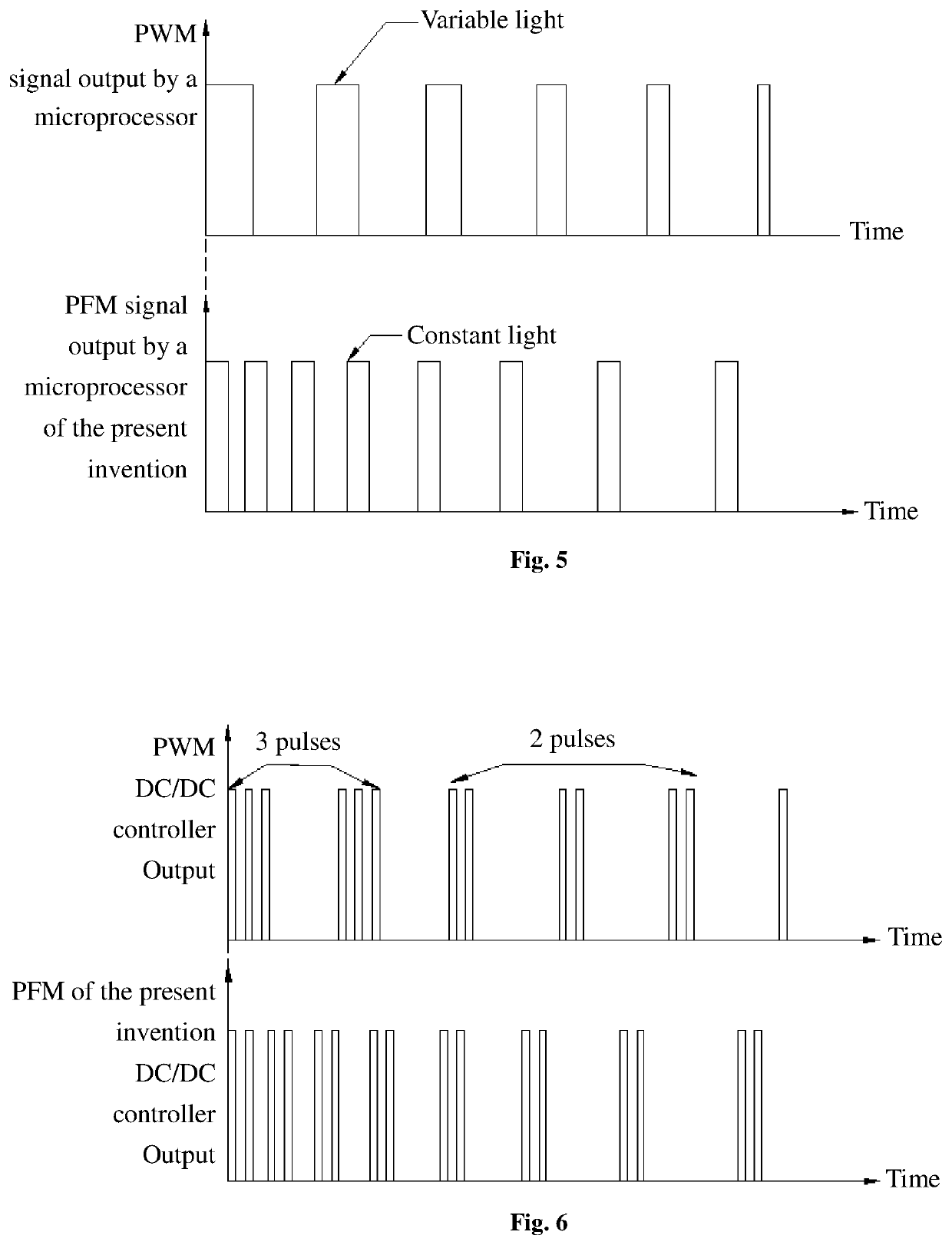

Constant current dimming apparatus for LED lamp

InactiveUS20200275539A1Wide dimming rangeImprove conversion efficiencyElectrical apparatusElectroluminescent light sourcesConvertersSignal generator

A constant current dimming apparatus for an LED lamp includes a signal generator and a power converter, where an input end of the signal generator is externally connected to a dimming device; an output end of the signal generator is connected to the power converter; an input end of the power converter is connected to an input voltage; and an output end of the power converter is connected to a positive electrode end and a negative electrode end of the LED lamp. The signal generator is used for transmitting a variable frequency pulse signal to the power converter upon receipt of a dimming signal of the dimming device. According to the present invention, a wide dimming range is achieved, and a dimming depth can reach 1‰ of a rated voltage or rated current.

Owner:ADPOWER TECH WUXI

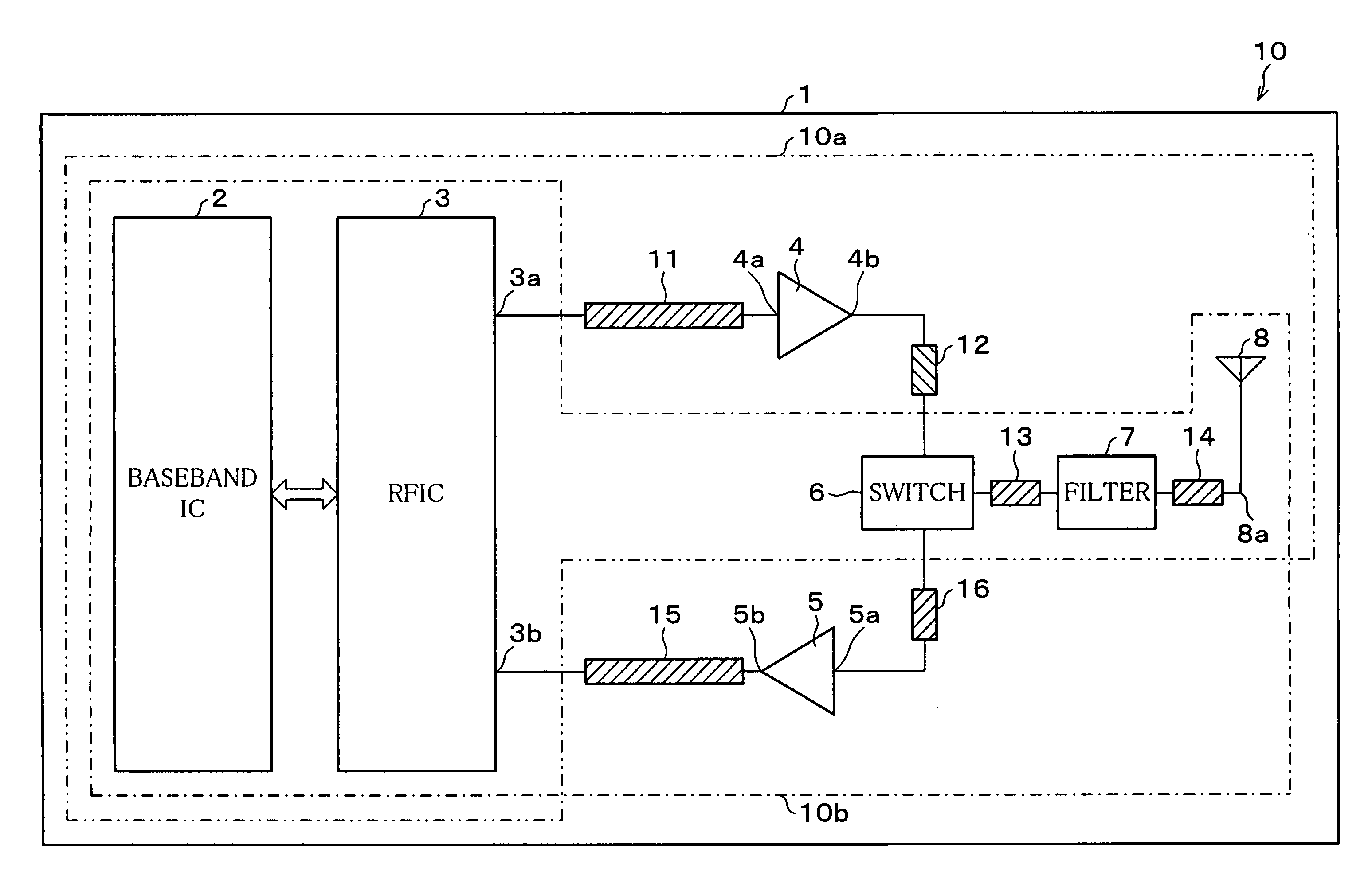

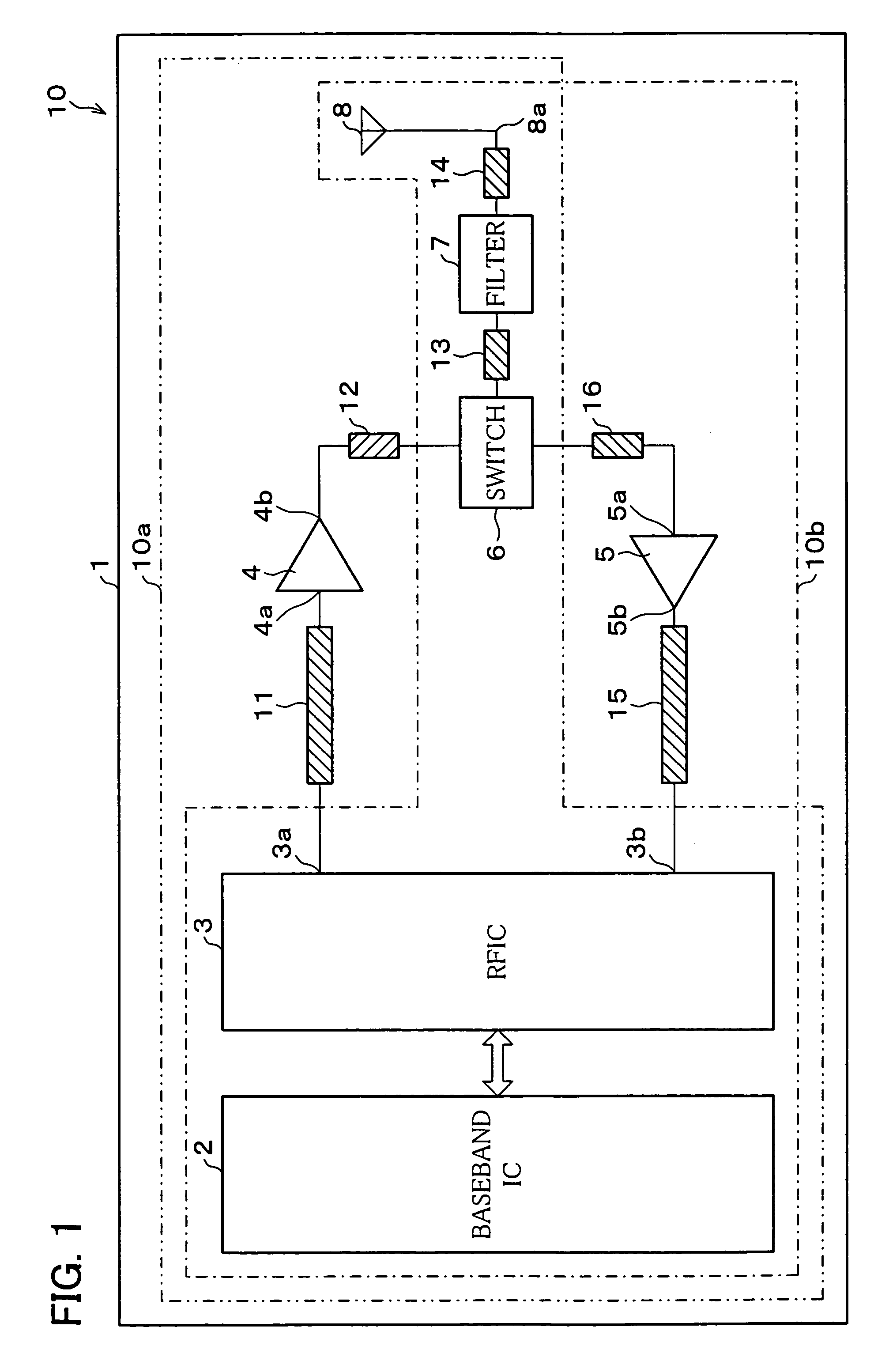

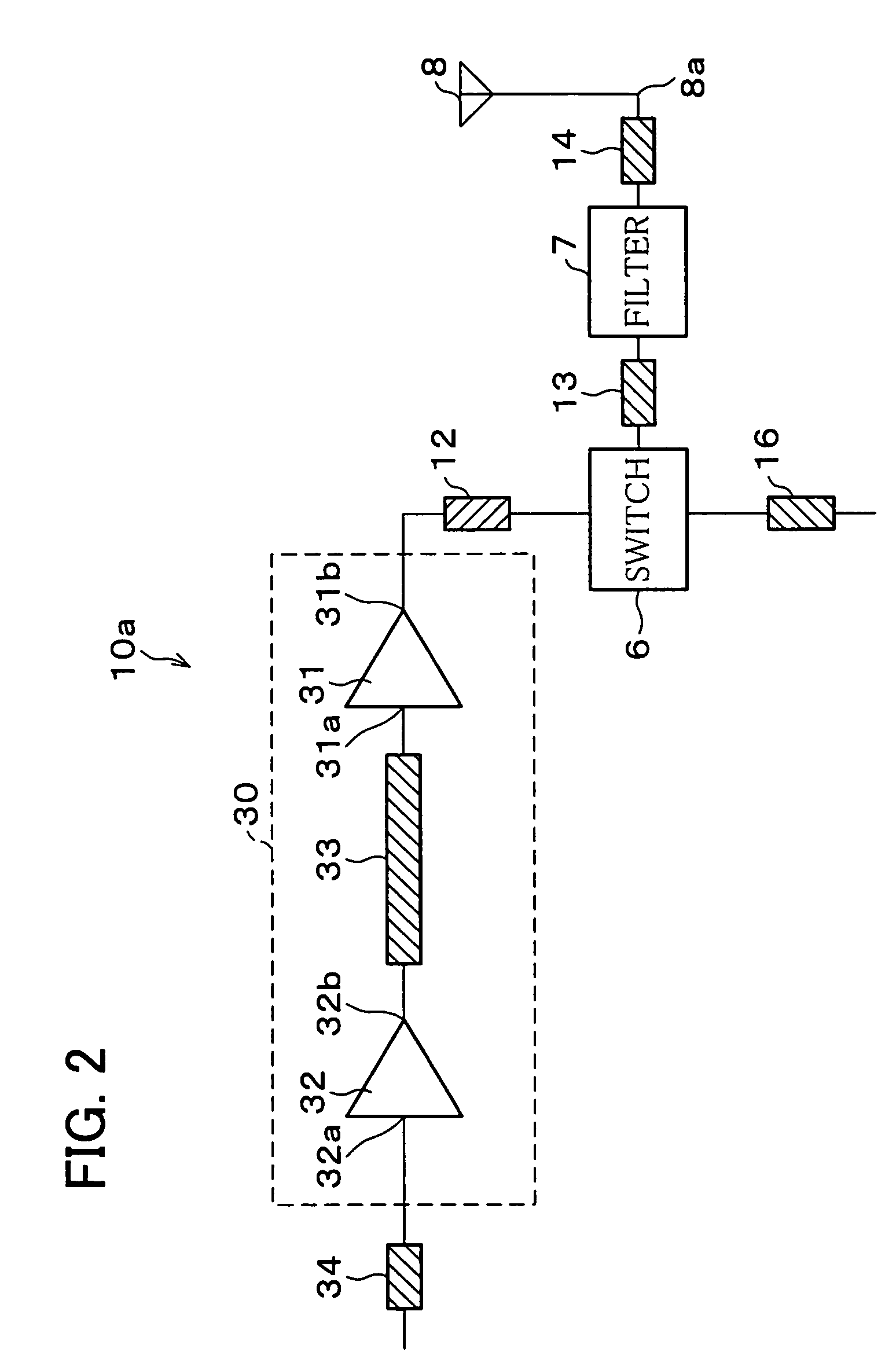

Wireless communication apparatus and information processing terminal apparatus with a wireless application

InactiveUS7636024B2Improve wireless performanceReduce transmission lossMultiple-port networksTransmissionInformation processingAudio power amplifier

A wireless communication apparatus is made up of a transmission circuit block including an antenna that is laid out such that the transmission lines, i.e., the sum of the distance connecting respective circuit blocks between an output terminal of the transmission power amplifier to an input / output terminal of the antenna is shorter than the transmission line, i.e., the sum of the distance connecting respective circuit blocks between an input terminal of a transmission power amplifier and an output terminal of a RFIC disposed at a preceding stage of the transmission power amplifier. This arrangement realizes a wireless communications apparatus ensuring improvement of overall performance of the wireless application without reducing the total transmission loss or improving the performance of individual circuits.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com