Patents

Literature

239results about How to "High output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

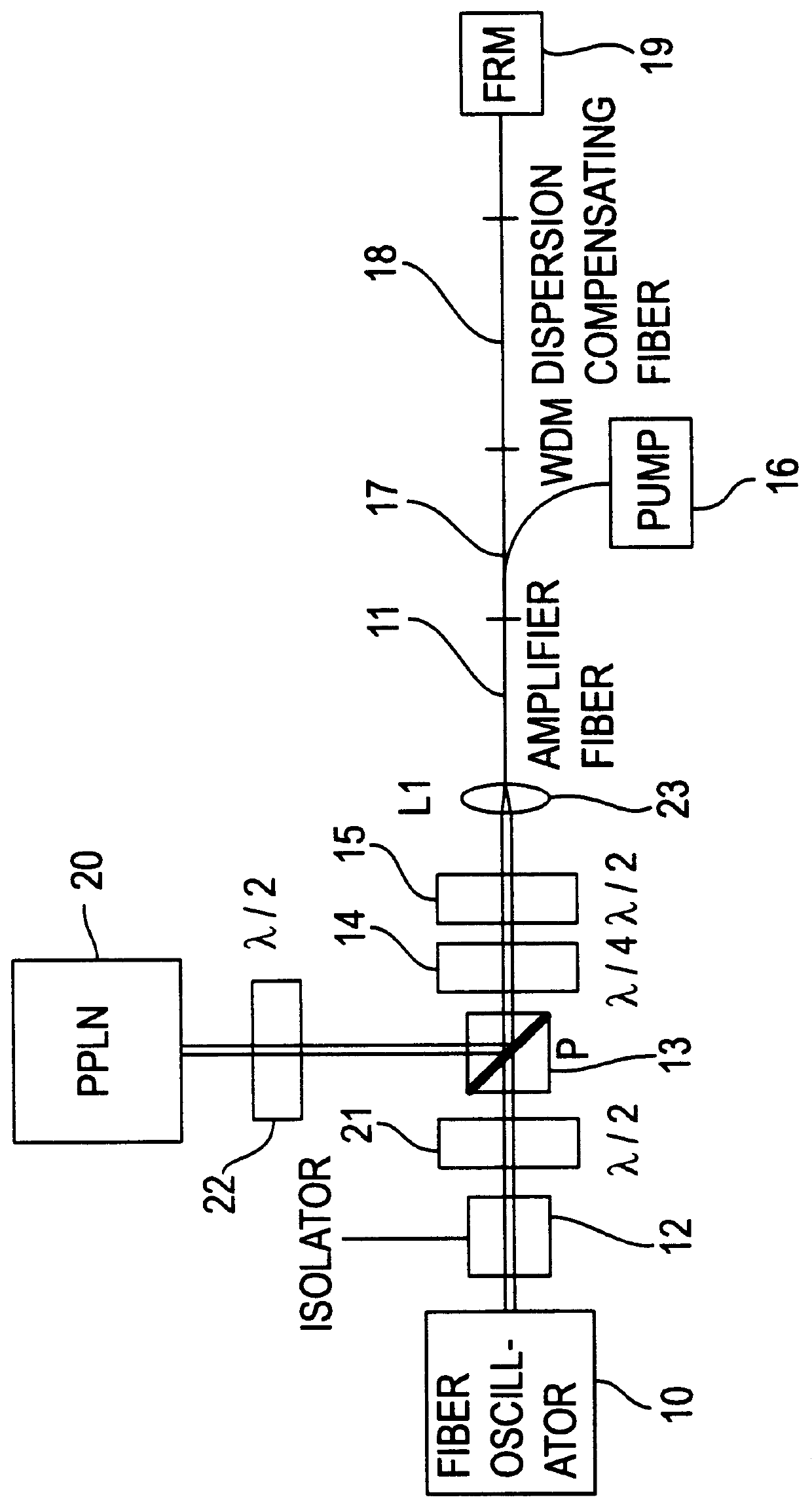

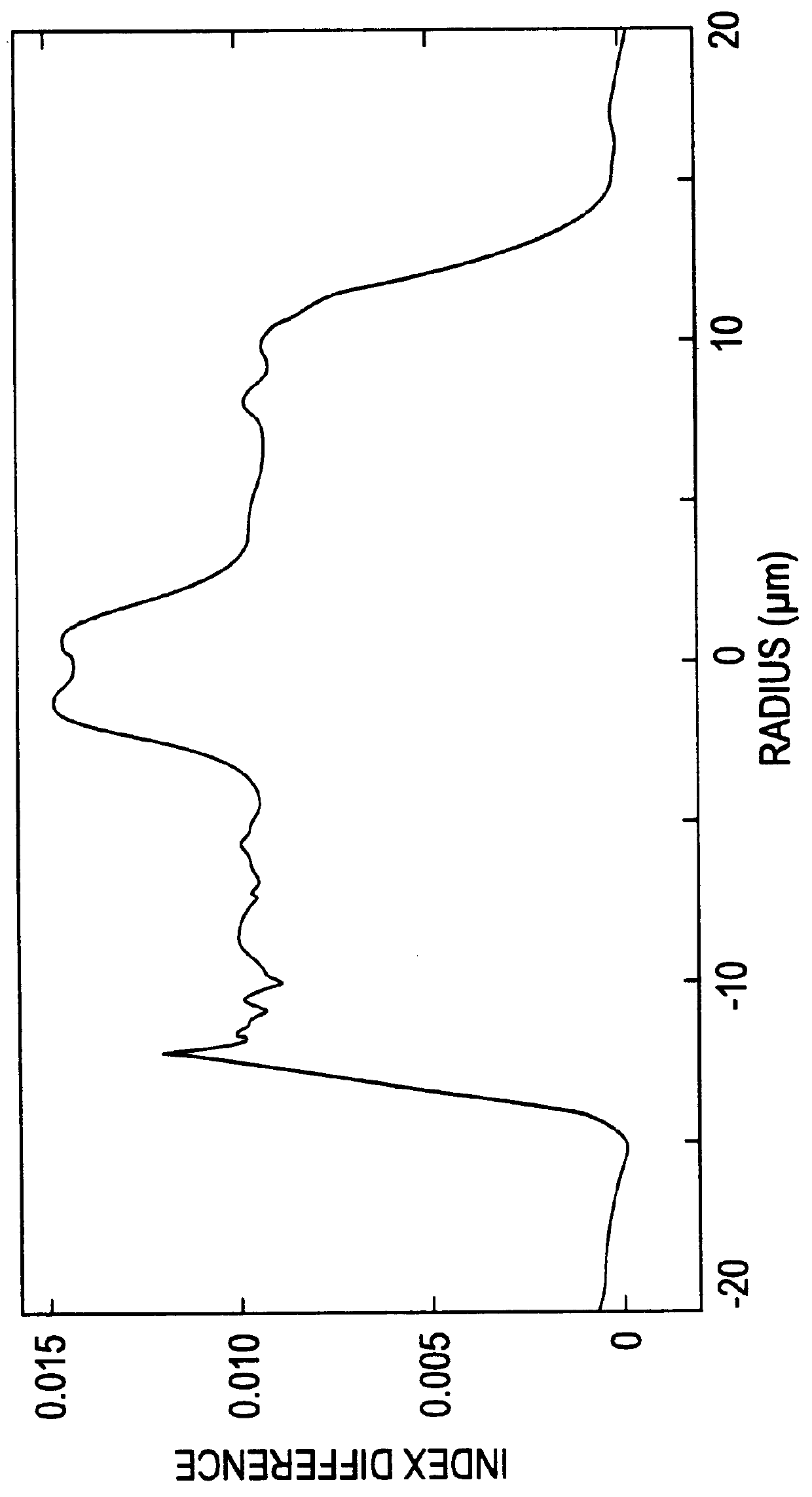

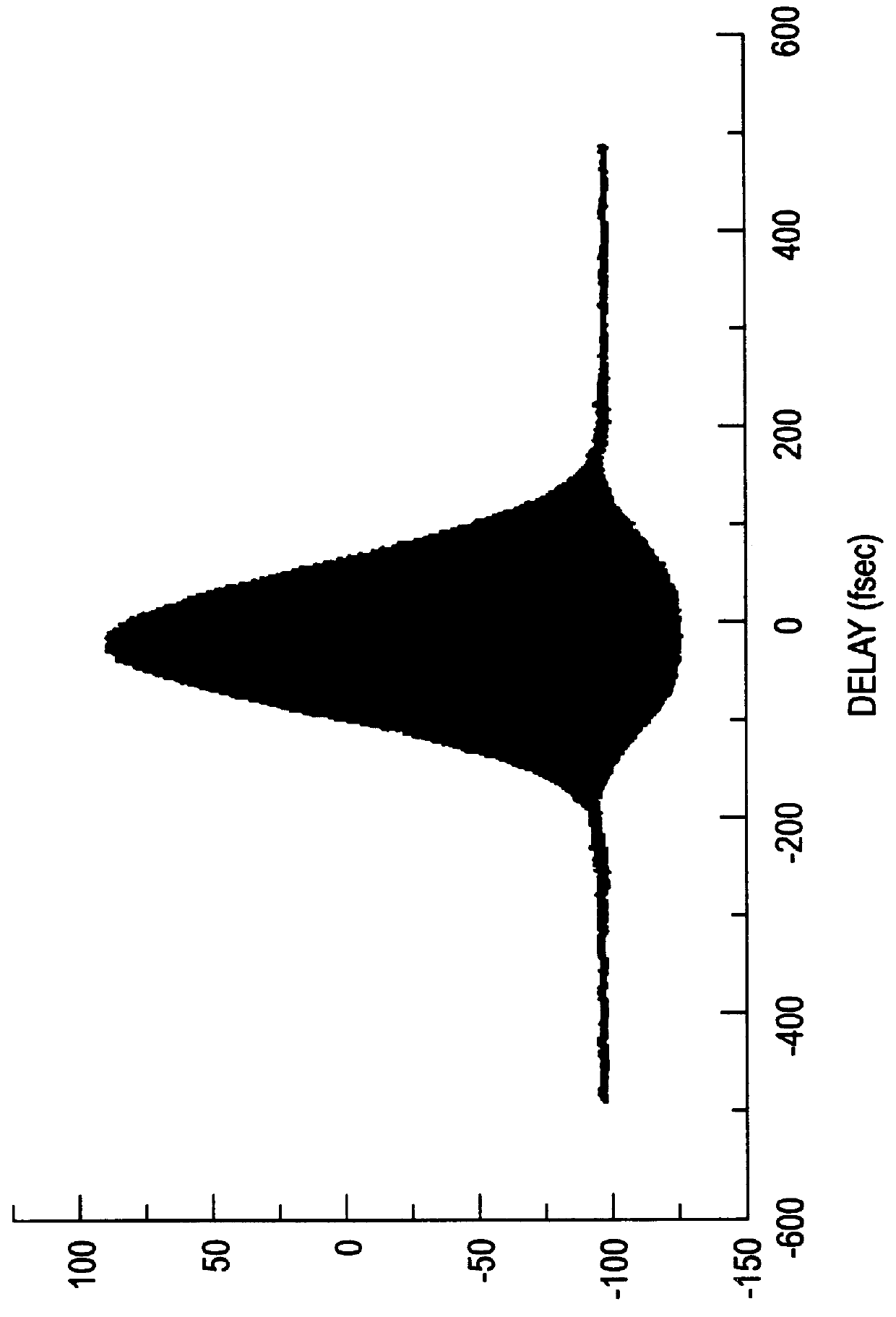

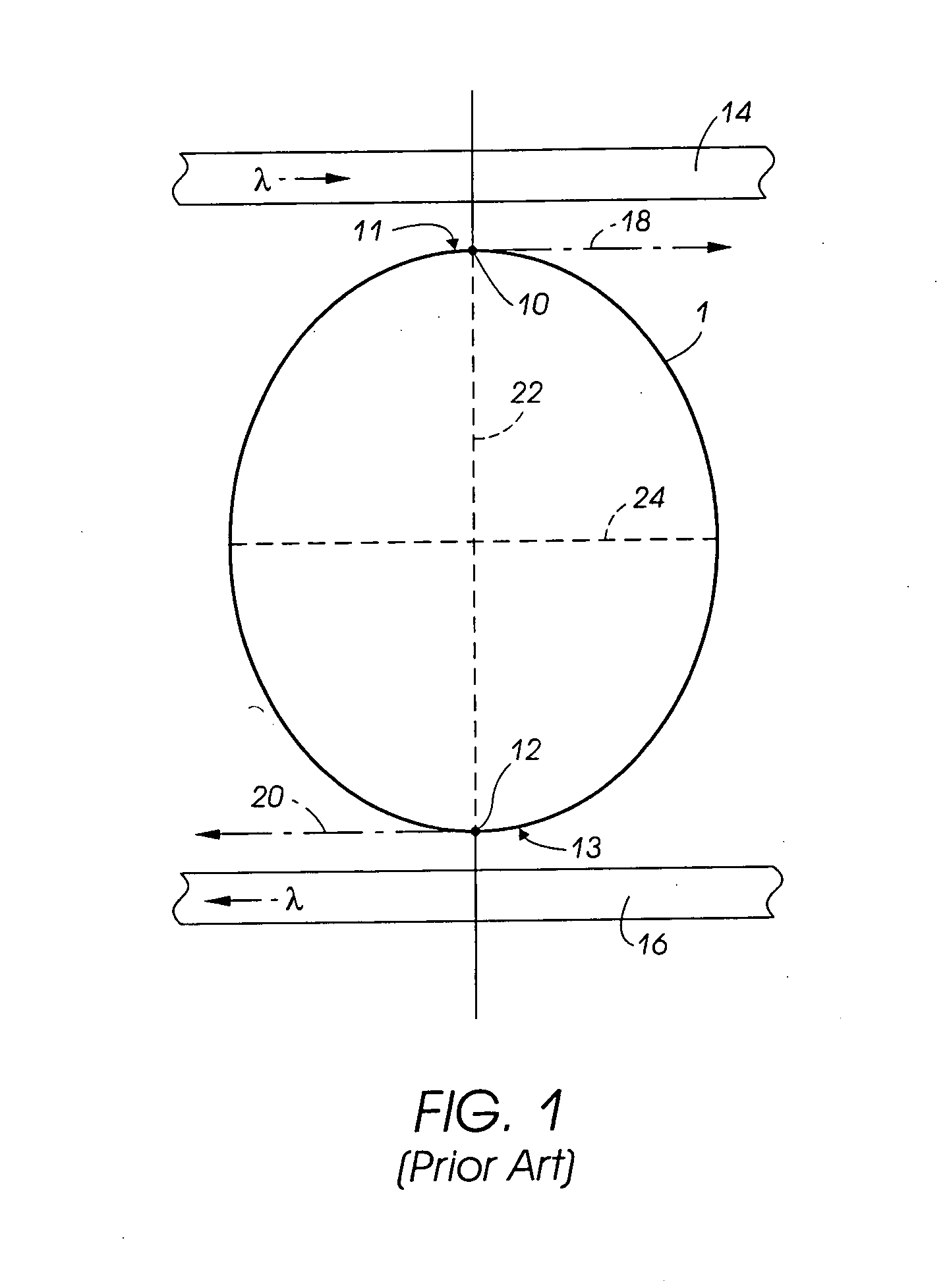

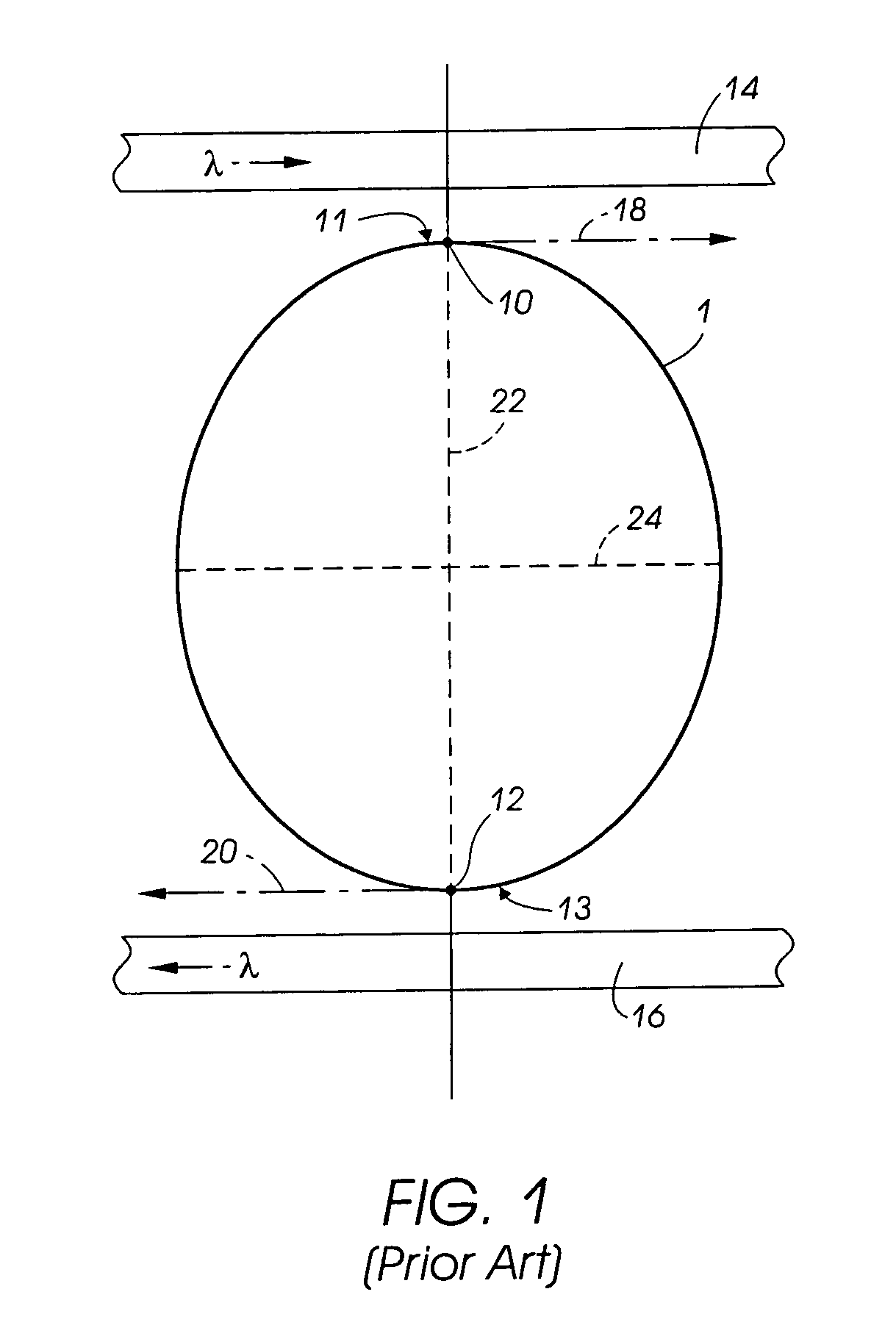

Apparatus and method for the generation of high-power femtosecond pulses from a fiber amplifier

InactiveUS6014249ALong pulse widthLow costLaser using scattering effectsLaser arrangementsFiberDouble-clad fiber

An apparatus generates femtosecond pulses from laser amplifiers by nonlinear frequency conversion. The implementation of nonlinear frequency-conversion allows the design of highly nonlinear amplifiers at a signal wavelength (SW), while still preserving a high-quality pulse at an approximately frequency-doubled wavelength (FDW). Nonlinear frequency-conversion also allows for limited wavelength tuning of the FDW. As an example, the output from a nonlinear fiber amplifier is frequency-converted. By controlling the polarization state in the nonlinear fiber amplifier and by operating in the soliton-supporting dispersion regime of the host glass, an efficient nonlinear pulse compression for the SW is obtained. The generated pulse width is optimized by utilizing soliton compression in the presence of the Raman-self-frequency shift in the nonlinear fiber amplifier at the SW. High-power pulses are obtained by employing fiber amplifiers with large core-diameters. The efficiency of the nonlinear fiber amplifier is optimized by using a double clad fiber (i.e., a fiber with a double-step refractive index profile) and by pumping light directly into the inner core of this fiber. Periodically poled LiNbO3 (PPLN) is used for efficient conversion of the SW to a FDW. The quality of the pulses at the FDW can further be improved by nonlinear frequency conversion of the compressed and Raman-shifted signal pulses at the SW. The use of Raman-shifting further increases the tuning range at the FDW. For applications in confocal microscopy, a special linear fiber amplifier is used.

Owner:IMRA AMERICA

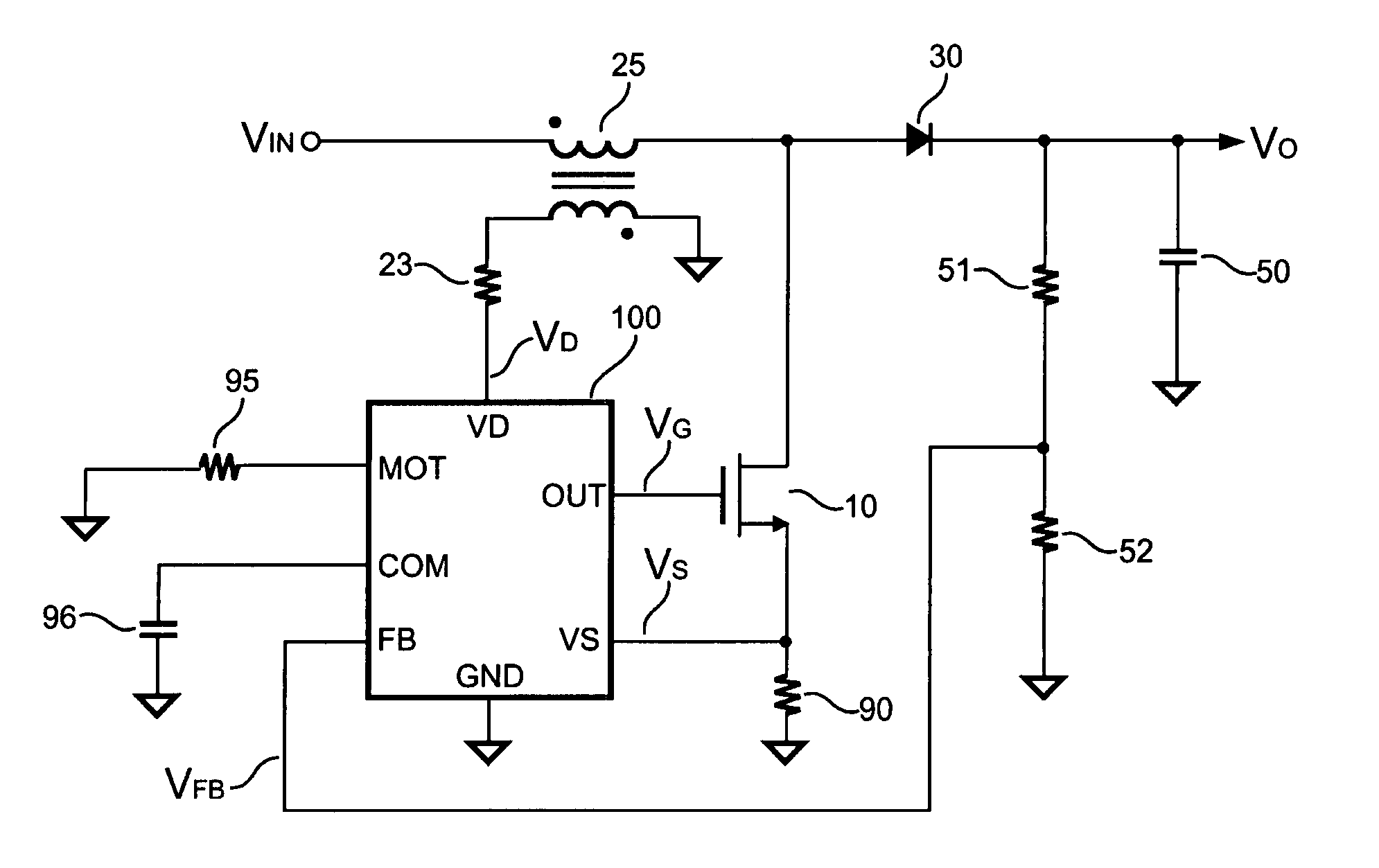

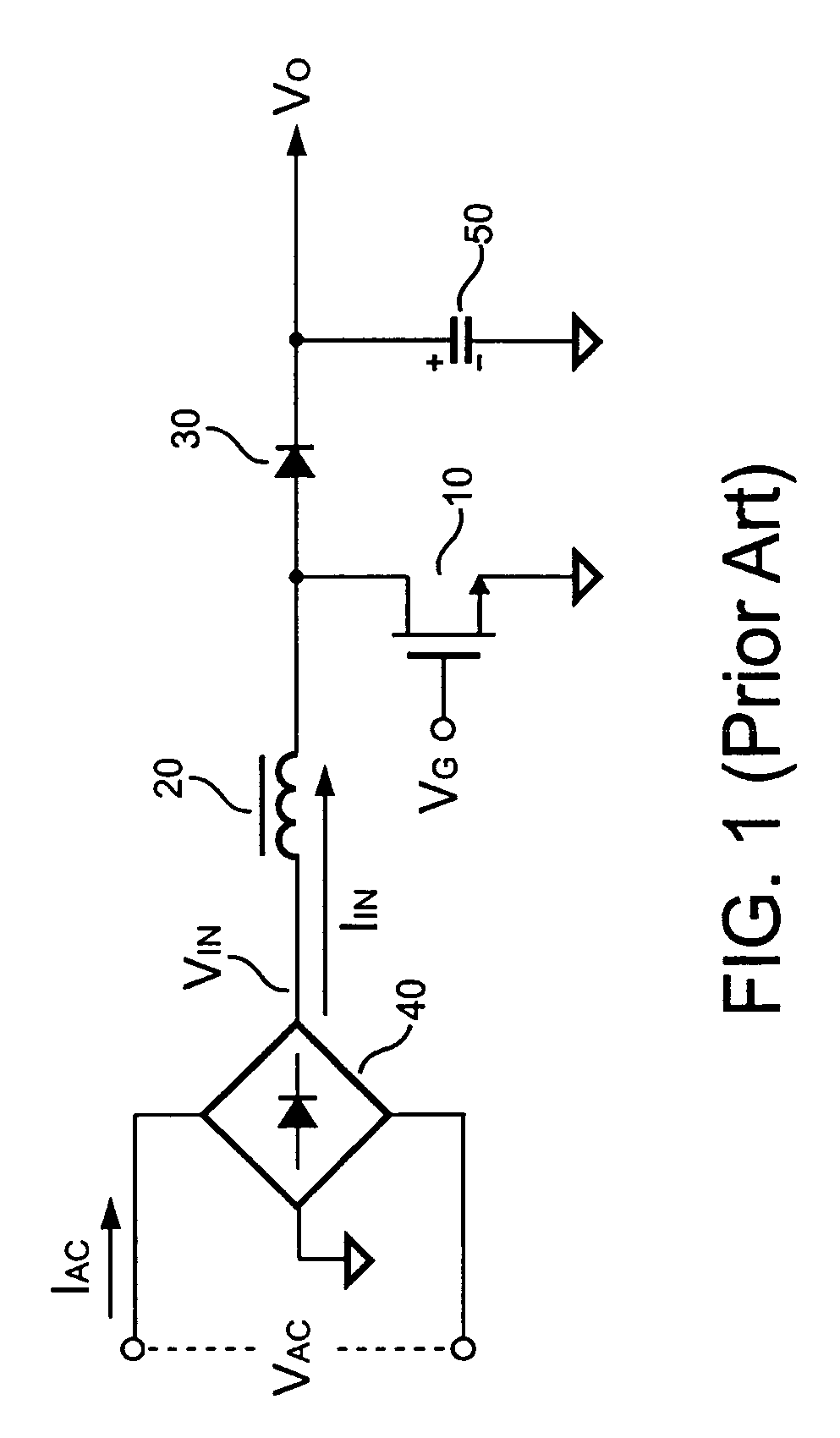

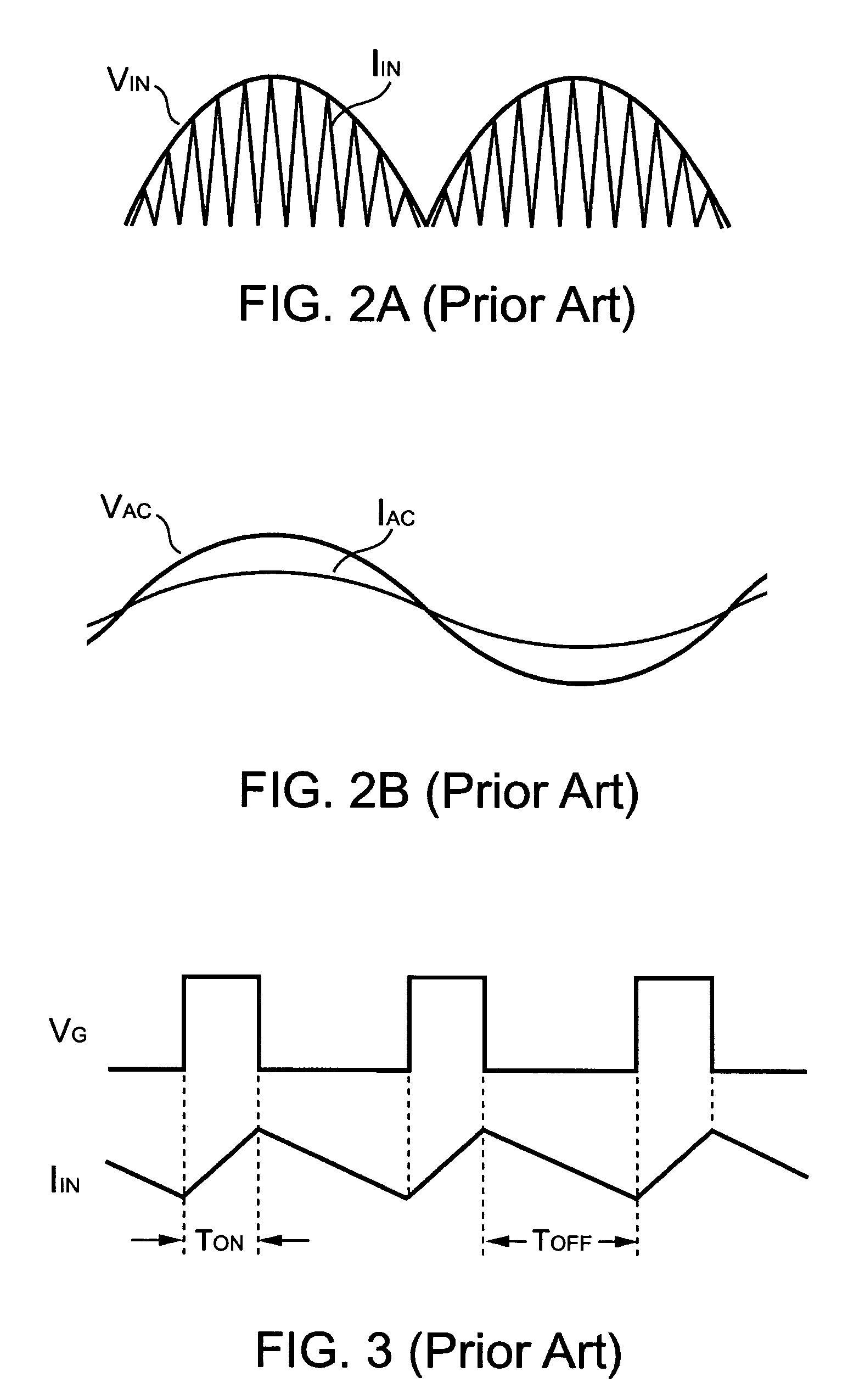

Switching control circuit for discontinuous mode PFC converters

ActiveUS7116090B1Reduce power consumptionDelay time increaseEfficient power electronics conversionElectric variable regulationInductorSlew rate

A switching control circuit having detection terminal, input terminal, ramp generator, program terminal, error amplifier, mix circuit, and delay circuit for power factor control is provided. The detection terminal generates a detection signal in response to the inductor discharge. An input terminal is connected for detecting a switching current signal. The program terminal determines the slew rate of the ramp signal and the maximum on-time of the switching signal. An error amplifier generates an error signal for regulating the output. A mix circuit generates a mixing signal proportional to ramp signal and the switching current signal. The switching signal is turned on in response to the detection signal, and is turned off based on the error signal. The slew rate of the mixing signal is increased in response to the increase of the input voltage. The on-time of the switching signal is increased inversely proportional to the input voltage.

Owner:SEMICON COMPONENTS IND LLC

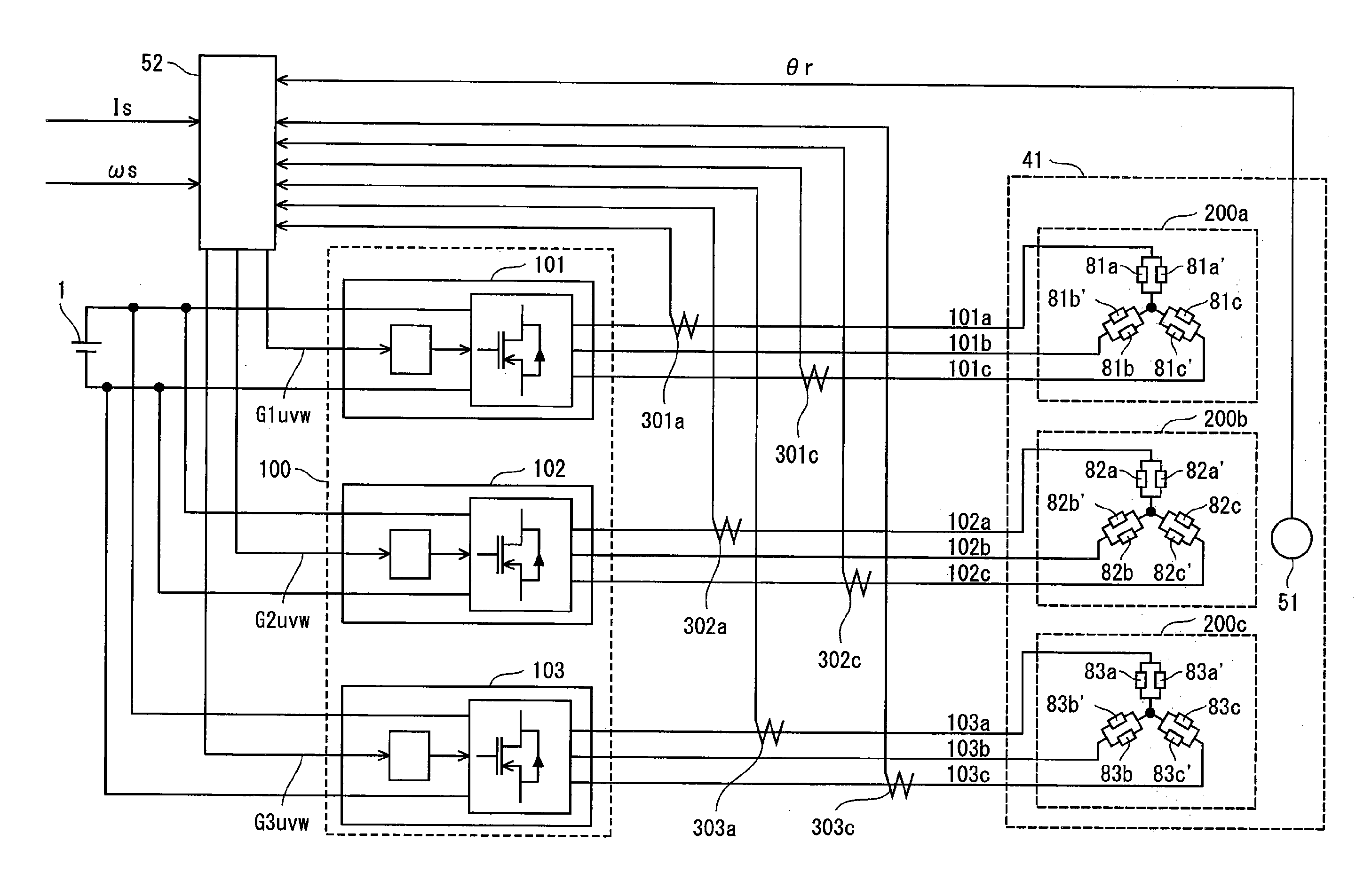

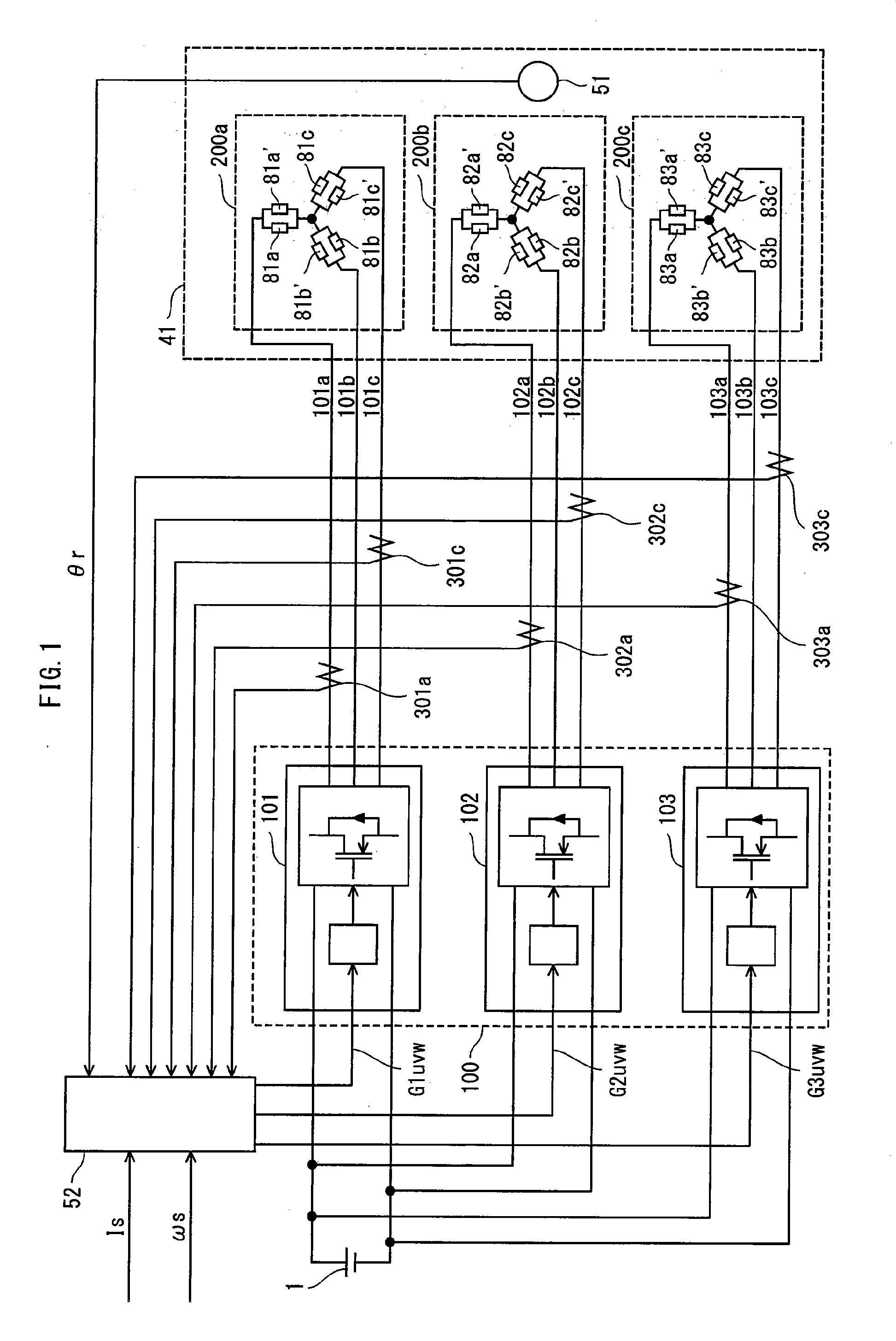

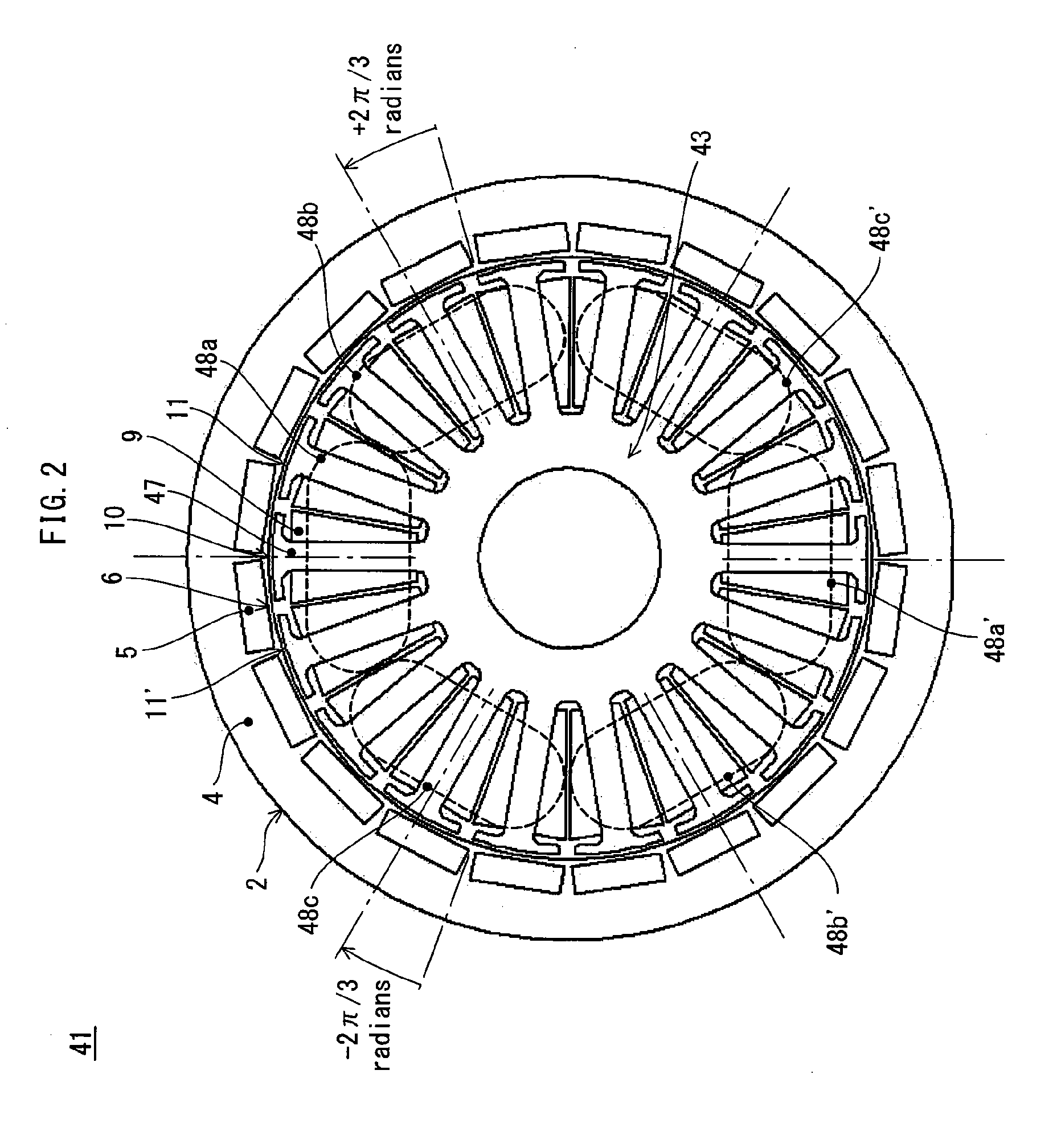

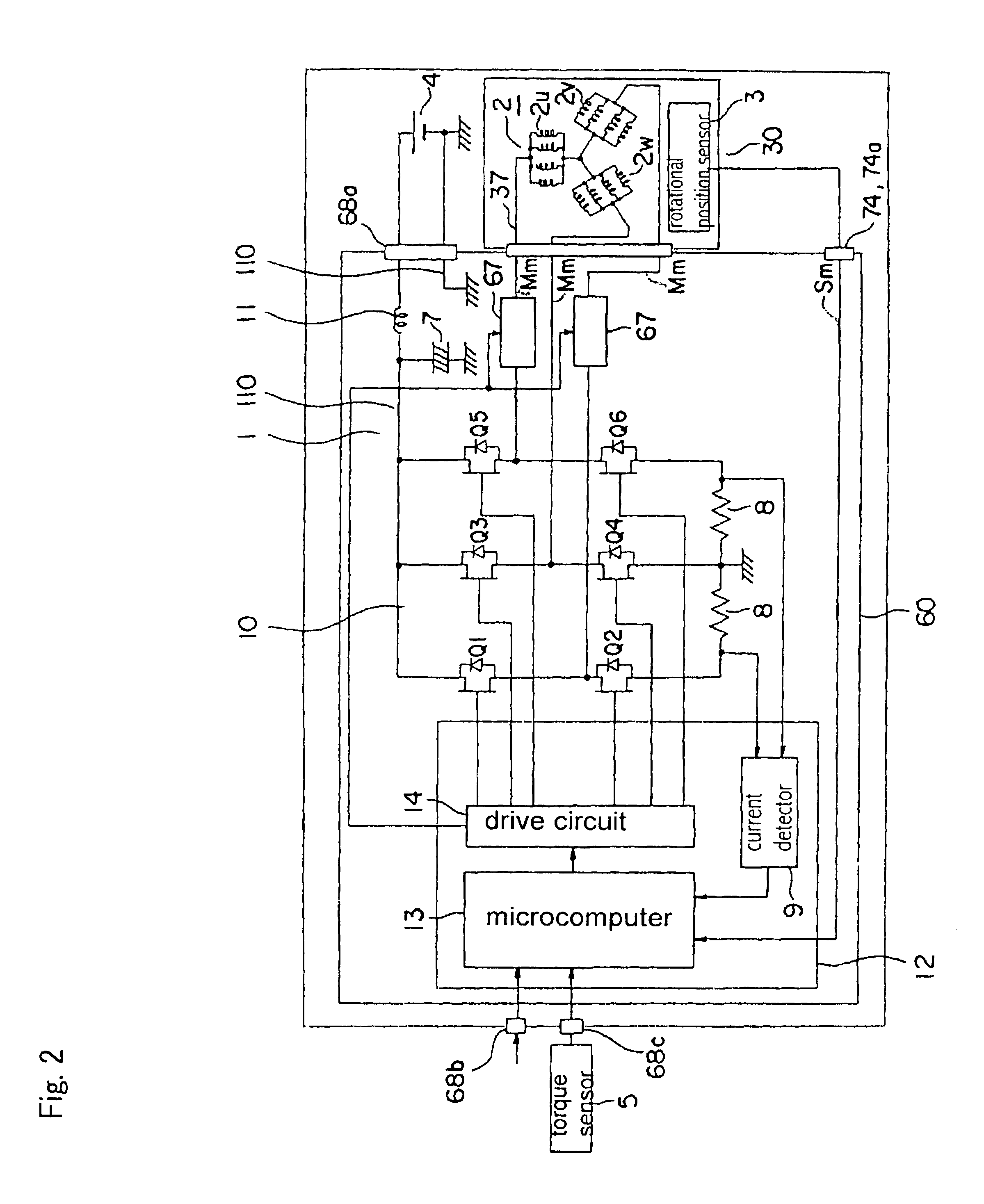

Synchronous electric motor drive system

ActiveUS20110057591A1Prevents degradation of inverter efficiencyPrevents an increase of iron lossesTorque ripple controlSynchronous motors startersSynchronous motorDC - Direct current

The present invention provides a synchronous motor drive system designed to realize reduced vibration and noise along with high output. The system includes: inverters 101, 102, and 103 for converting a direct current to a three-phase alternating current; a current application control unit 52 that controls operations of the three-phase inverters; and a synchronous motor 41 driven by three-phase alternating currents supplied from the three-phase inverters. The current application control unit 52 determines, for each three-phase inverter, a current phase angle and a current amount of a three-phase alternating current to output, and each inverter supplies a three-phase alternating current having the determined current phase angle and current amount to a different one of three-phase coil groups 200a to 200c.

Owner:PANASONIC CORP

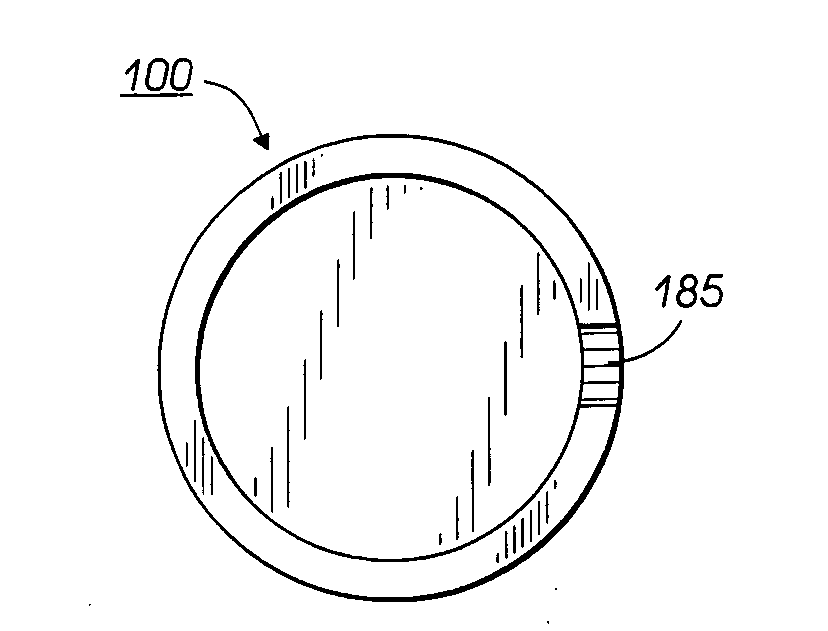

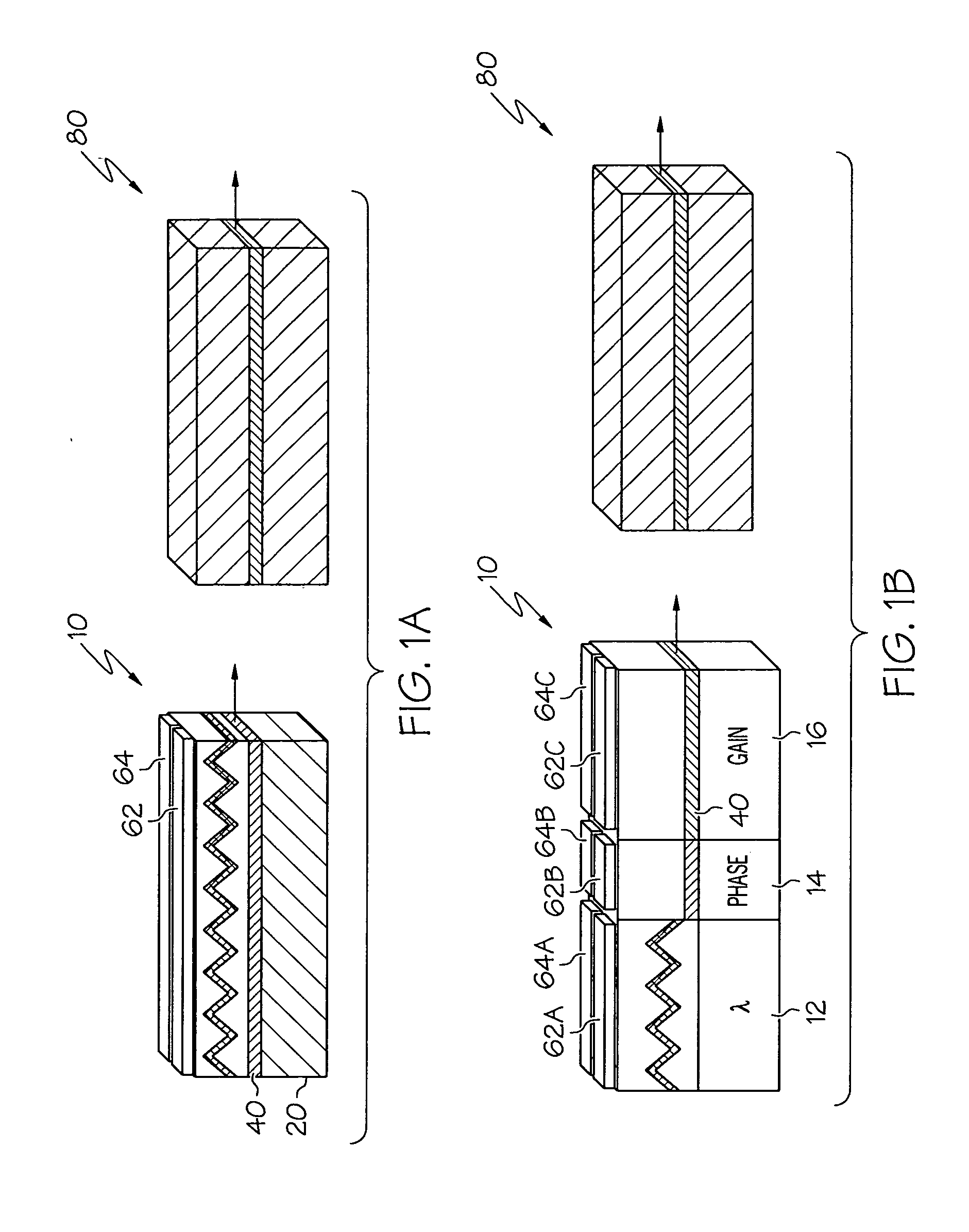

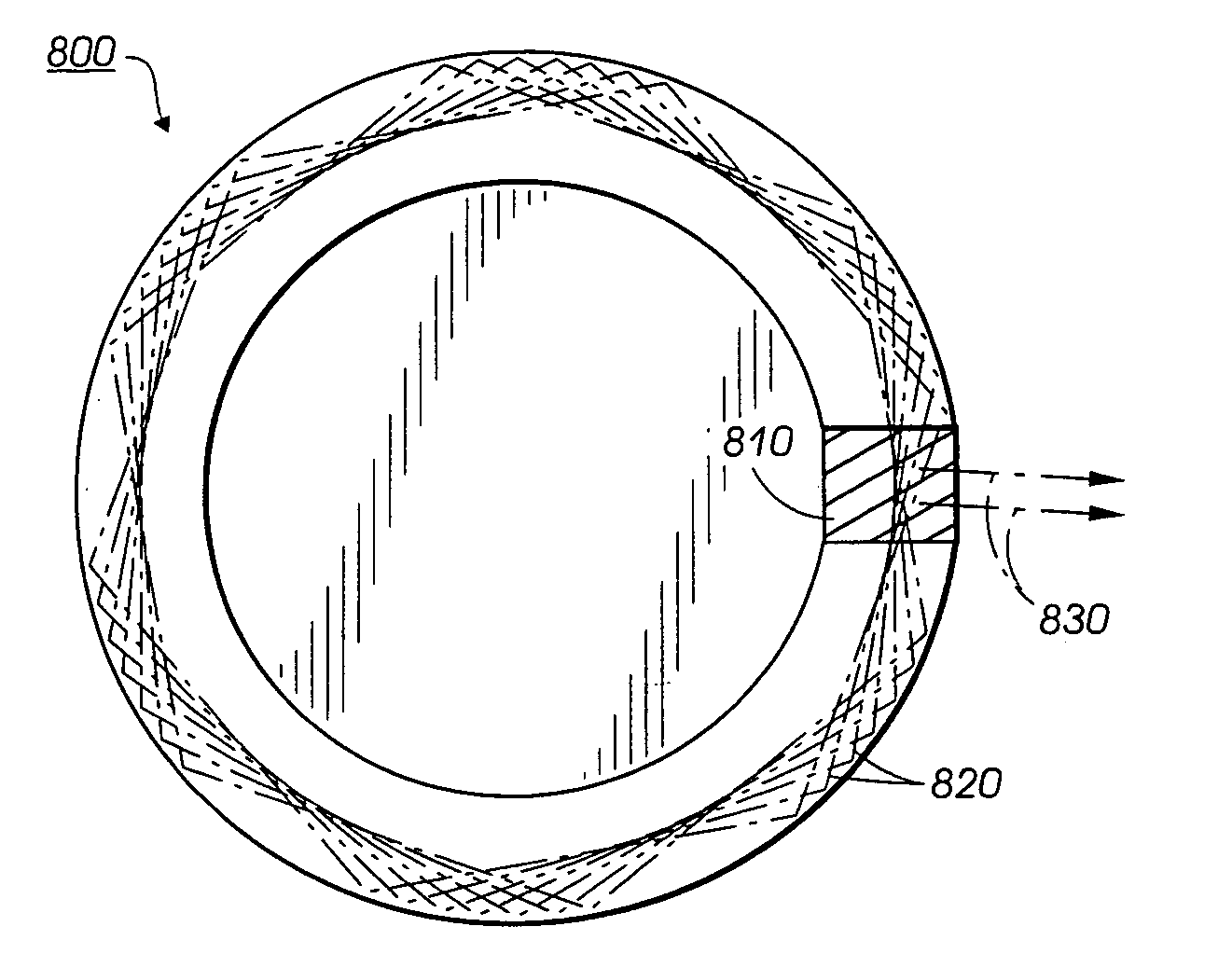

Grating-outcoupled cavity resonator having uni-directional emission

InactiveUS20050135453A1High output levelEasy to makeLaser optical resonator constructionSemiconductor laser structural detailsGratingWhispering gallery

A grating-outcoupled microcavity disk resonator has whispering gallery modes existing in a nearly circular resonator. Light is outcoupled by providing a grating region in the plane of the grating-outcoupled microcavity disk resonator. The grating region provides an outcoupling or lass mechanism that symmetrically interacts with the clockwise and counterclockwise whispering gallery modes, thereby making the resonator capable of surface emission.

Owner:PALO ALTO RES CENT INC

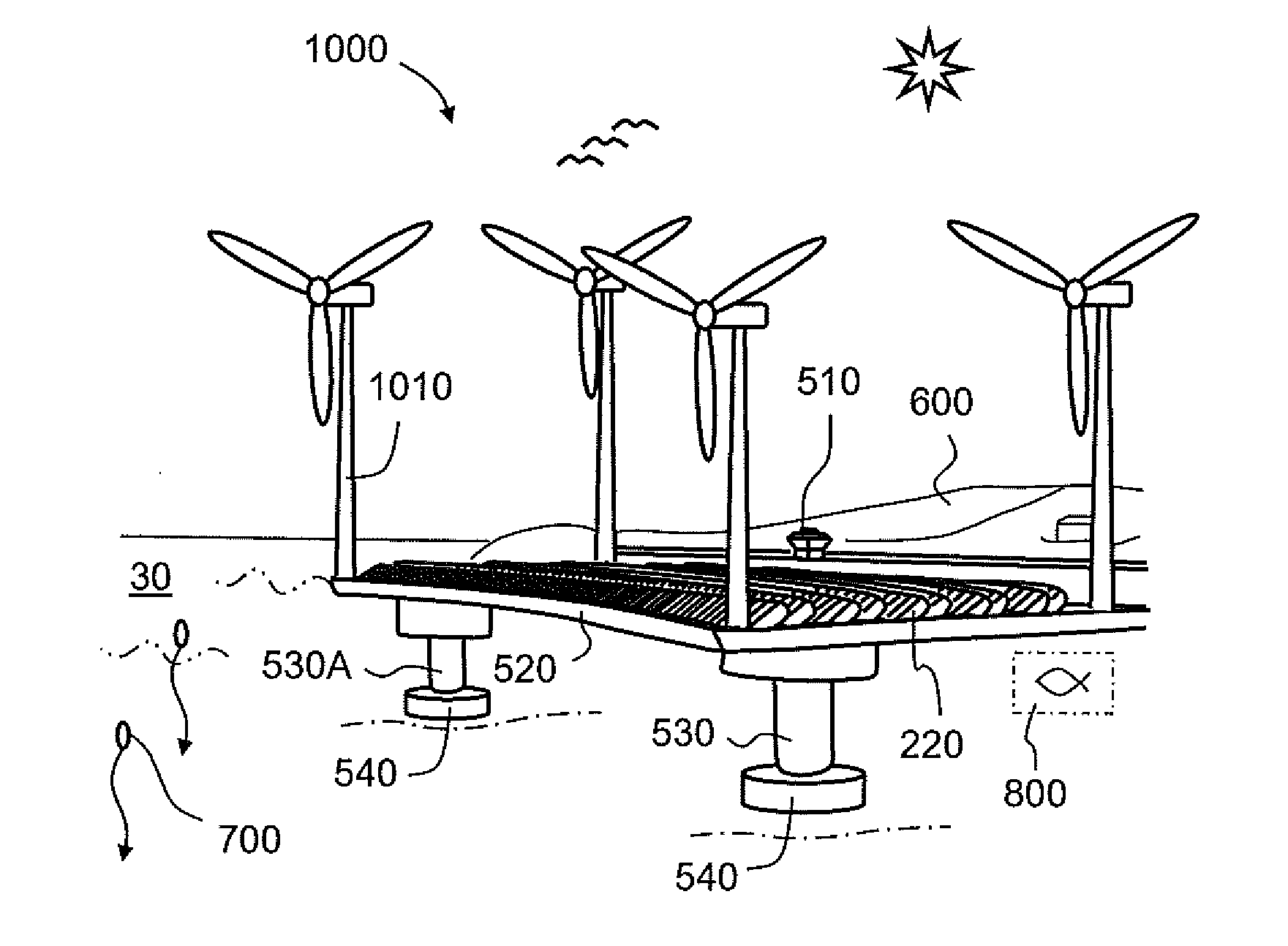

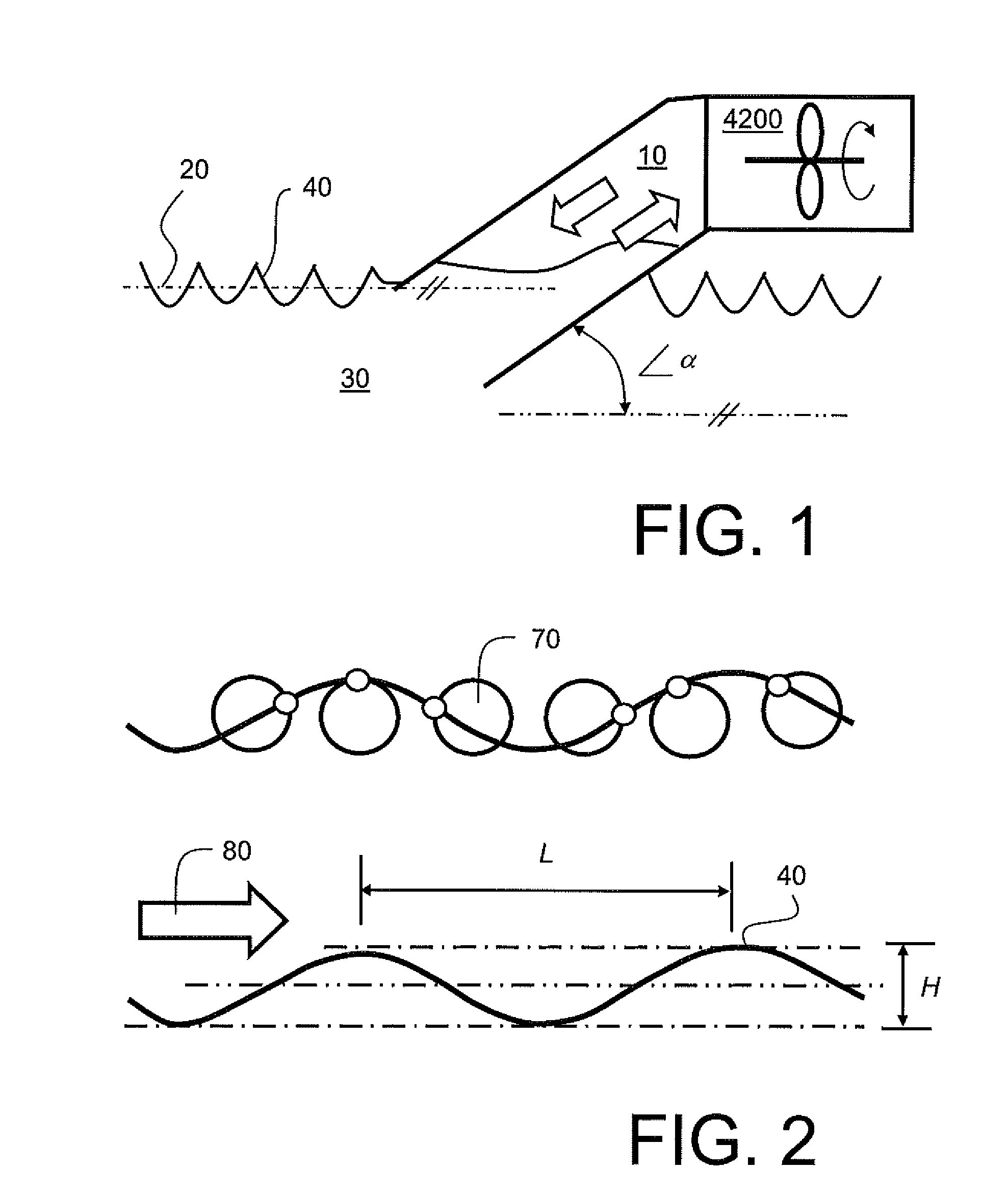

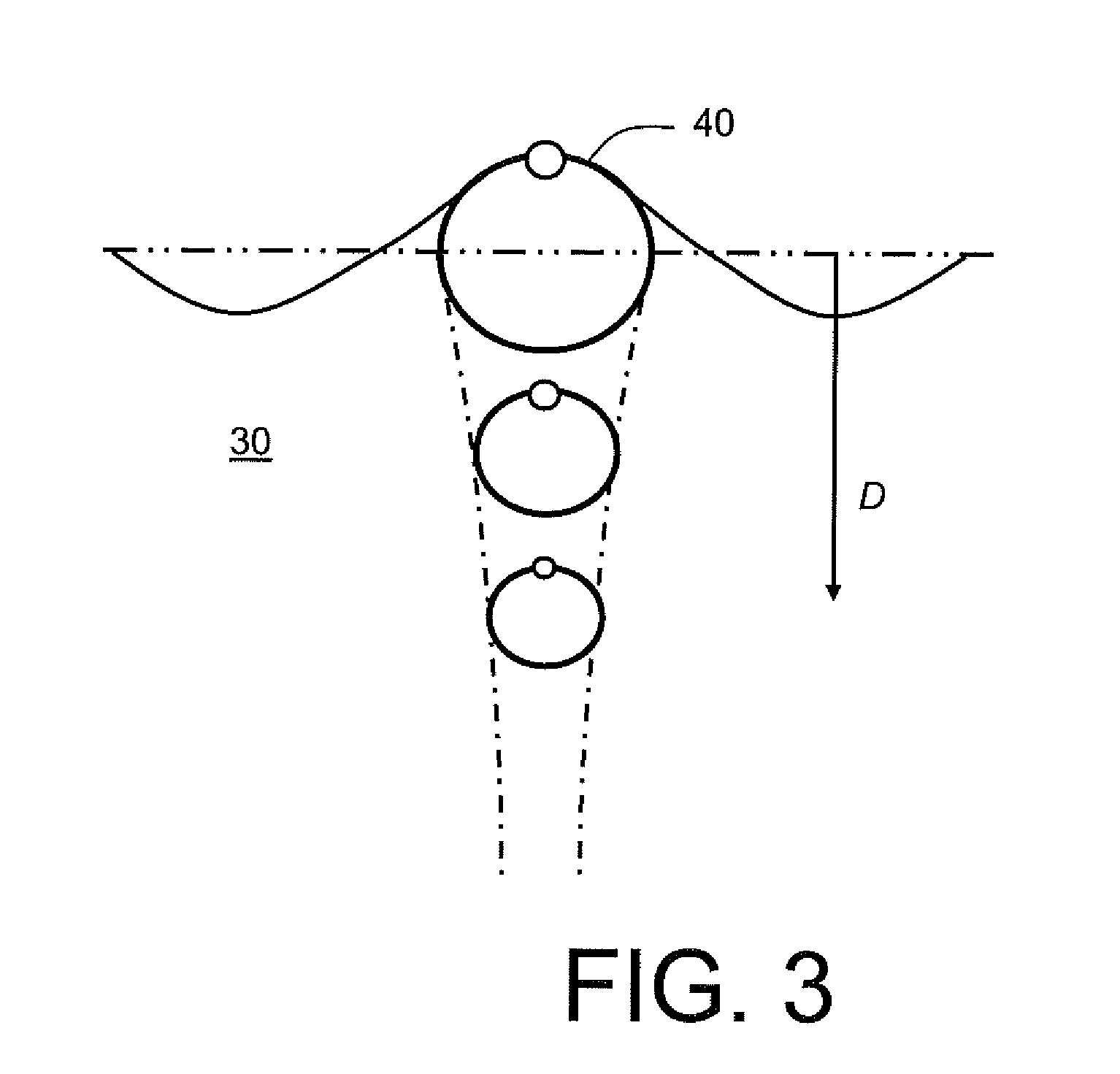

Ocean wave energy system

ActiveUS20130099496A1Improve efficiencyHigh output powerWind motor controlWorking fluid for enginesAir movementSea waves

An ocean wave energy system for generating power from ocean waves includes a platform supporting an array of hollow columns whose respective lower ends are in fluidic communication with ocean waves and whose respective upper ends are in air communication with a turbine arrangement such that wave motion occurring at the lower ends is operable to cause air movement within the columns for propelling the turbine arrangement to generate power output. The system further includes one or more position-adjustable and / or angle-adjustable submerged structures near the lower ends of the columns for forming ocean waves propagating in operation towards the lower ends of the columns to couple the waves in a controllable manner into the hollow columns.

Owner:HAVKRAFT

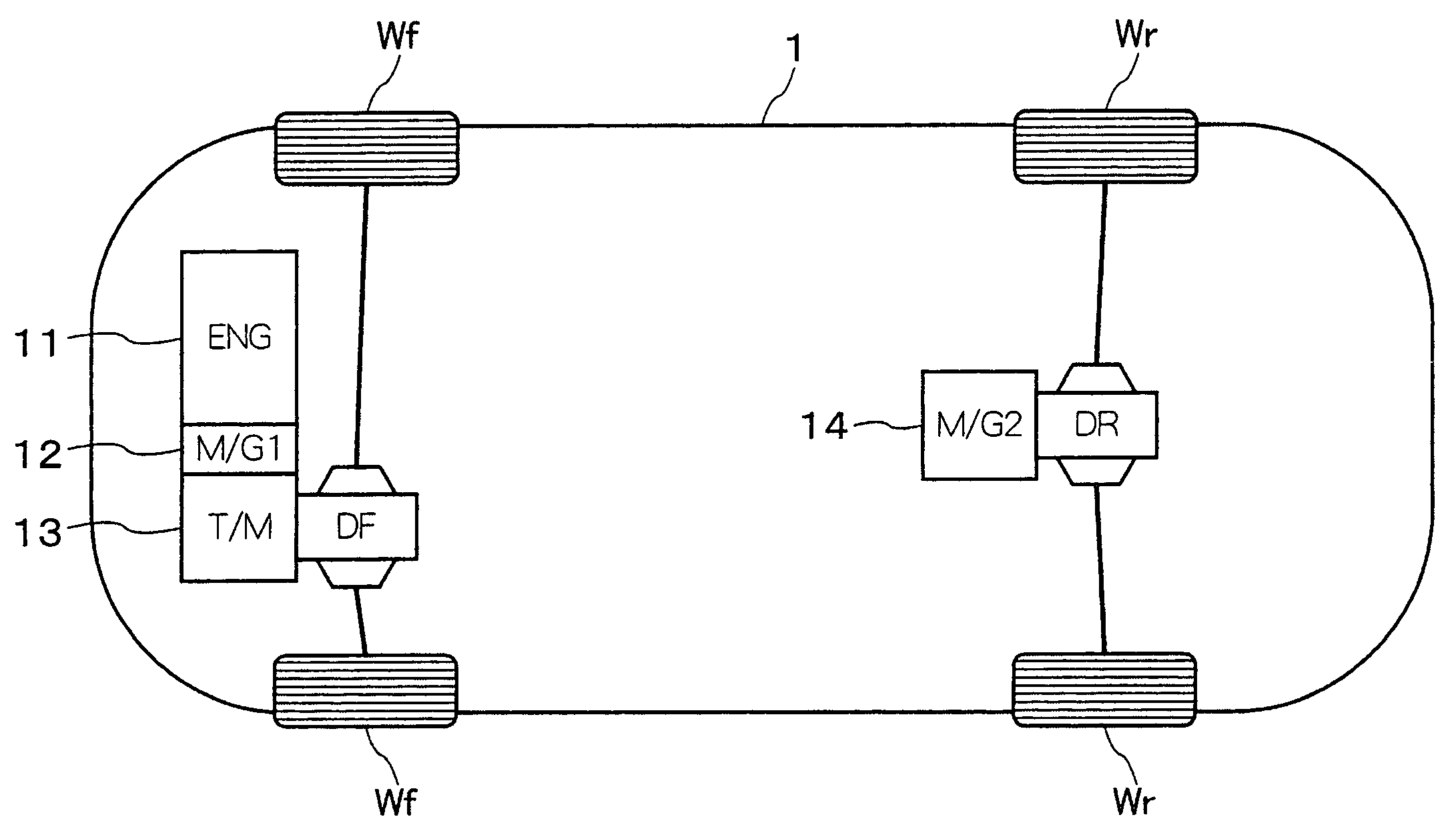

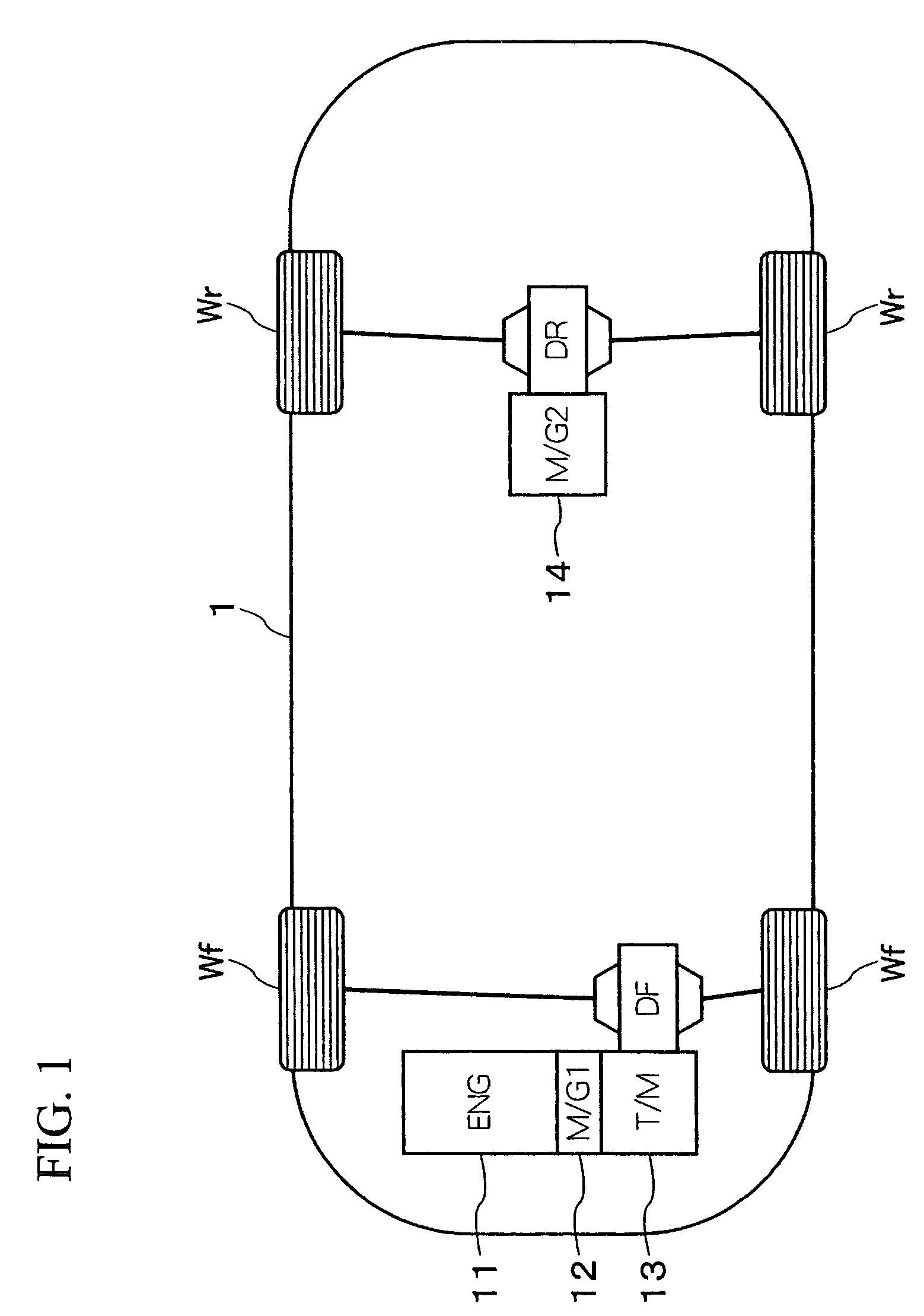

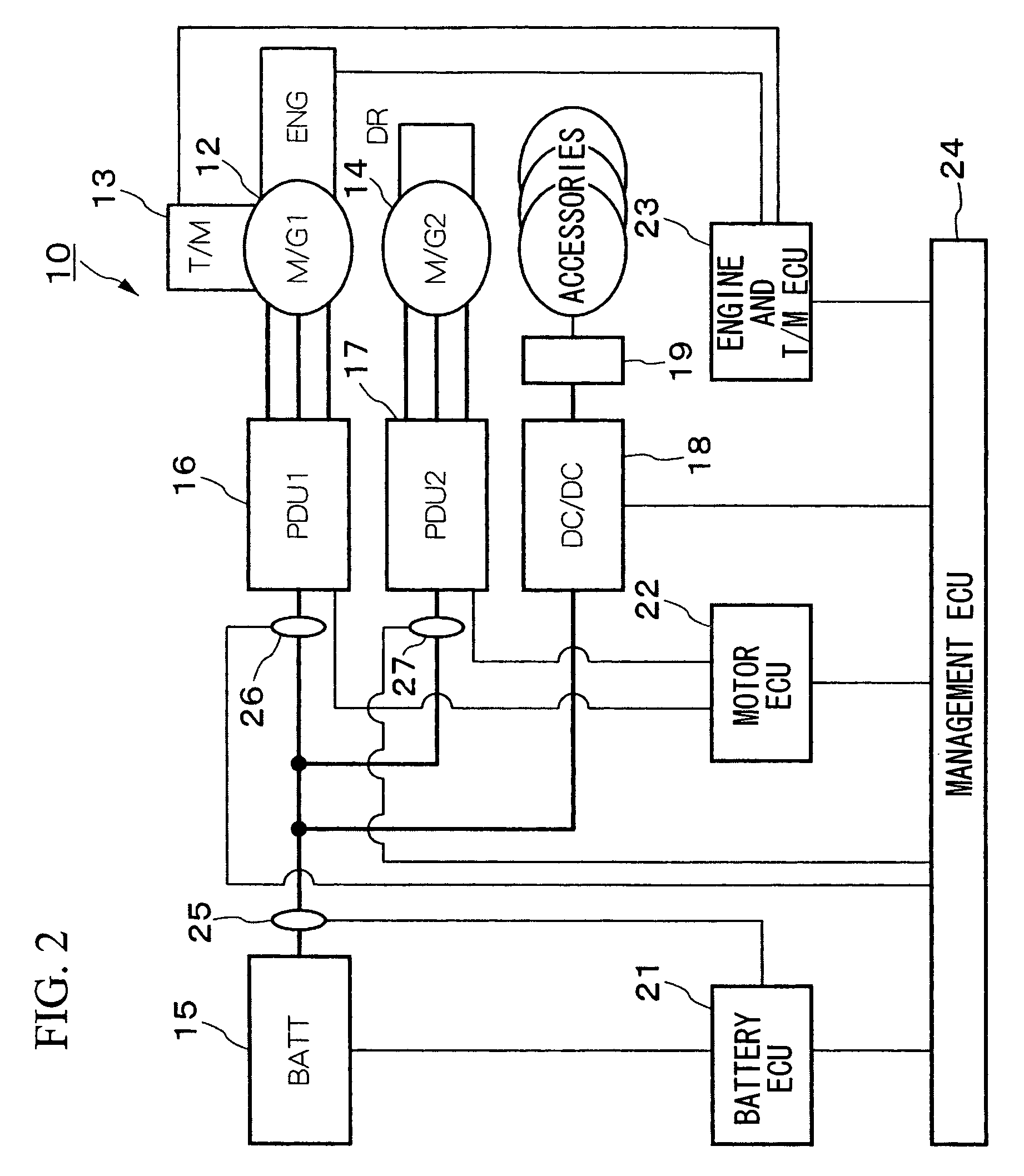

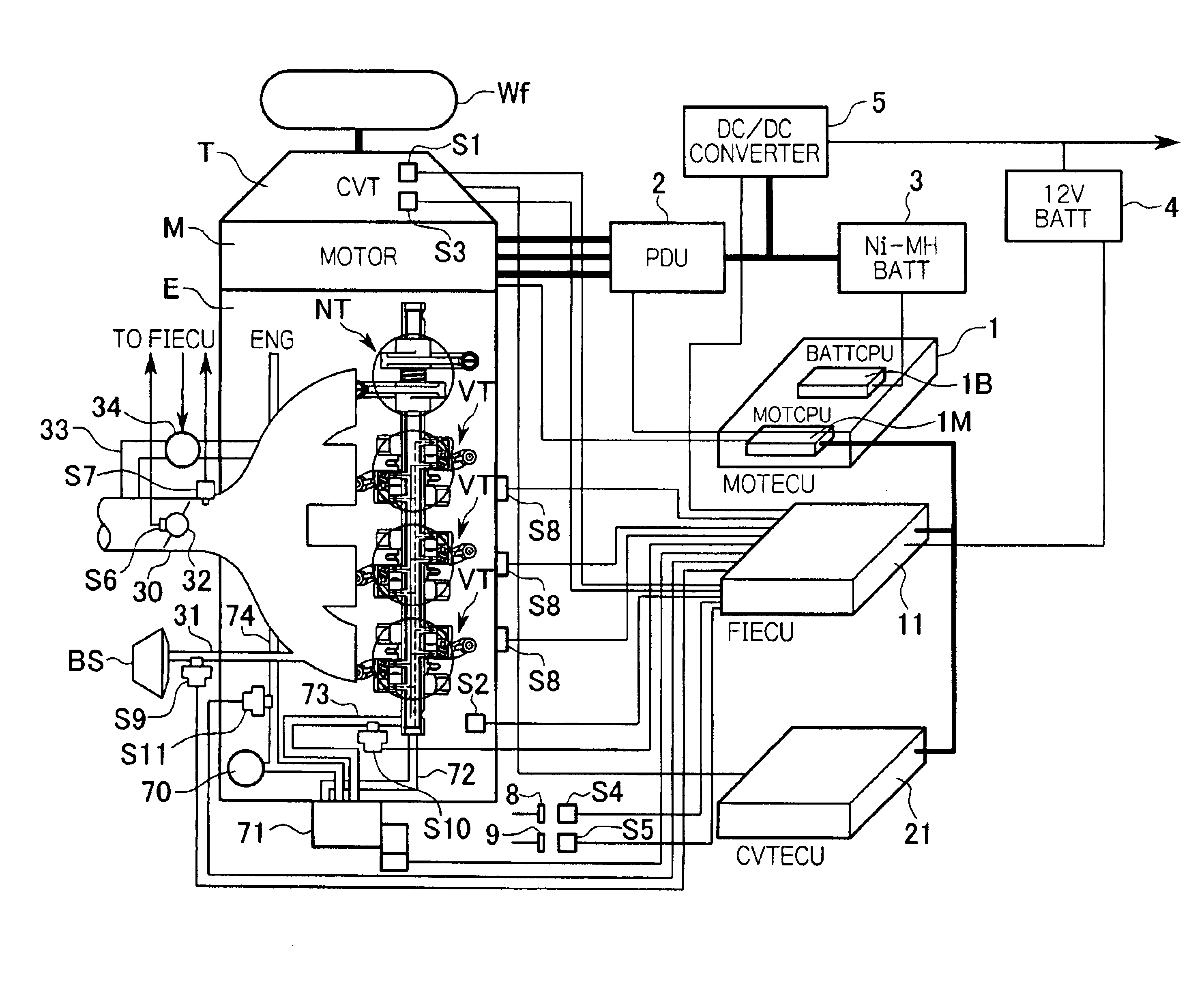

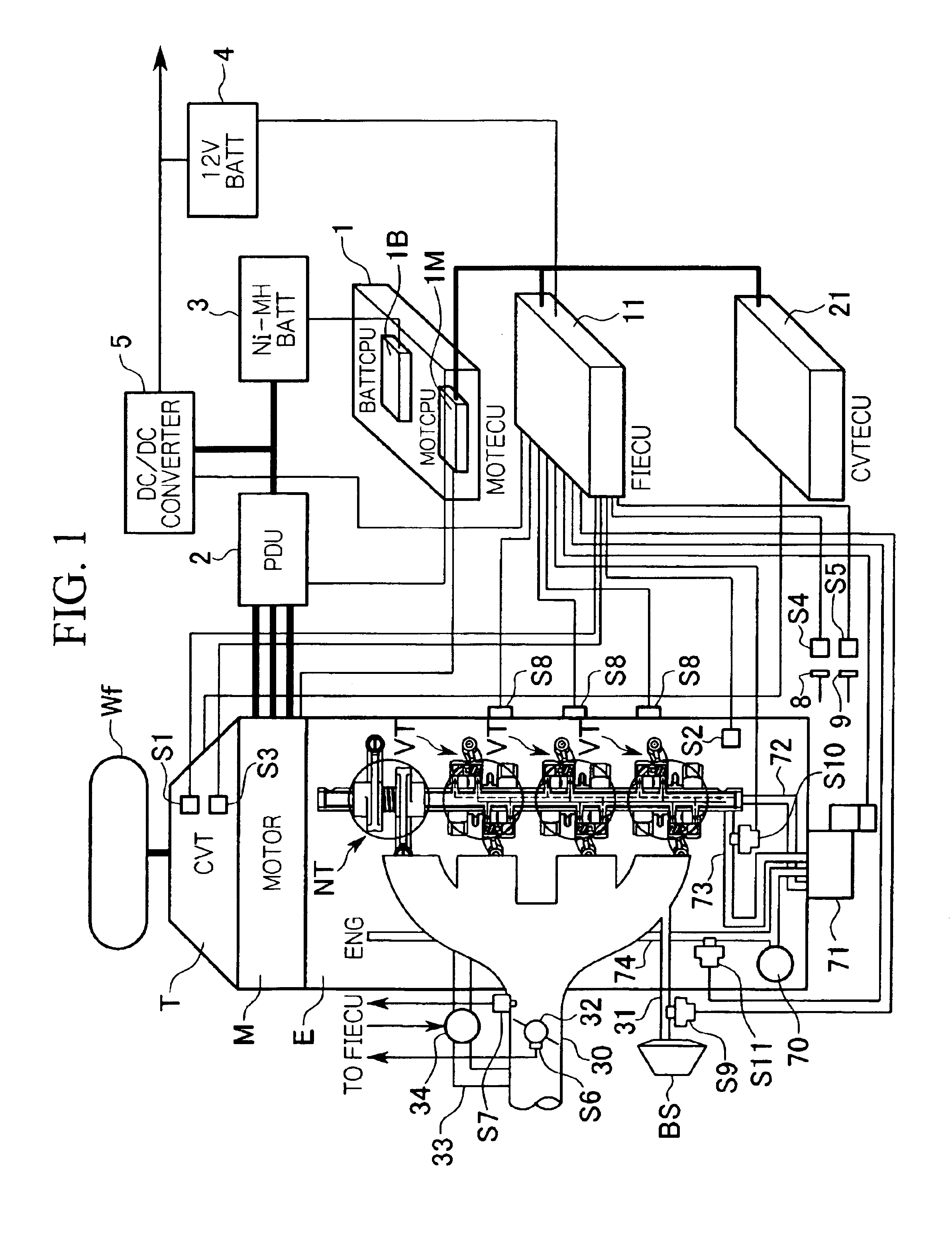

Power control apparatus for hybrid vehicle

A power control apparatus for a hybrid vehicle (1), the hybrid vehicle including an internal combustion engine (11), a front motor-generator (12), and a transmission (13) which are connected to front wheels (Wf), and a rear motor-generator (14) which is connected to rear wheels (Wr) via a rear differential gear box (DR). A calculated value, which is obtained by subtracting a front output power F_POWER and an accessory output power DV_POWER from a battery output power limit B_LimPow is set as an rear output power limit R_LimPow. The smaller of a rear drive command R_PowCmd (which is set depending on the running state of the vehicle) and a rear output power limit R_LimPow is set as a new rear drive command R_PowCmd. Accordingly, a demanded motor output power can be obtained without increasing the size of the main battery (15).

Owner:HONDA MOTOR CO LTD

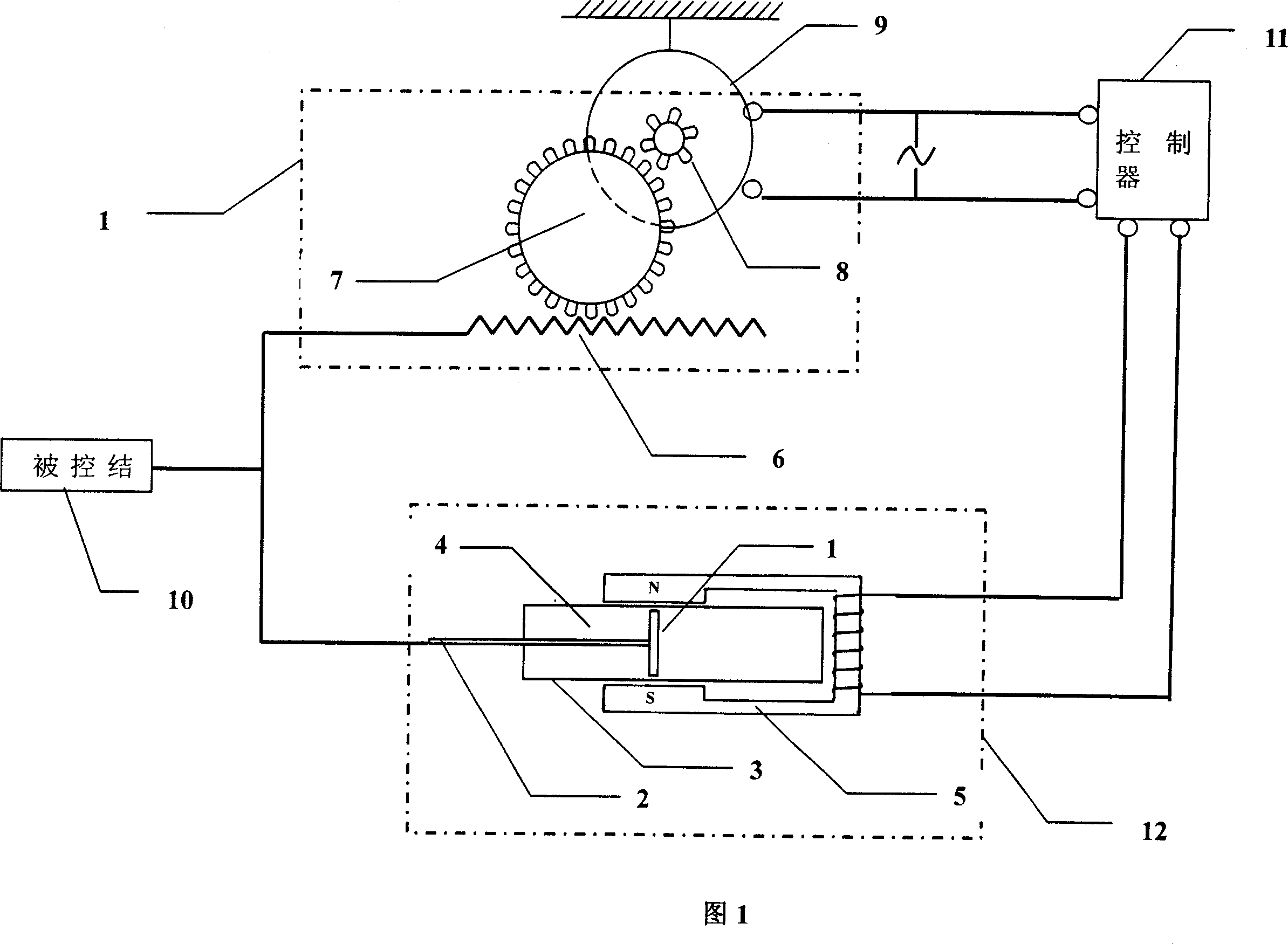

Self-power-supply magnetorheological intelligent vibration damping device

InactiveCN101086179AIncrease rotor speedSimplified semi-active damping systemNon-rotating vibration suppressionShock proofingSelf adaptiveMagnet

A self-power magnetic current changing intelligent vibration damping system consists of electromagnetic adjustable magnetic current changing damper, rack gear accelerator and permanent magnet DC generator, the piston rod of said damper is fixed and connected with the racks of accelerator, and the final pinion of accelerator is installed on said DC generator axle, the outlet end of the DC generator is connected with the electromagnetic coil receiving terminal of said damper, and controller is installed between the outlet end of said DC generator and the electromagnetic coil receiving terminal of the damper. The kernel technology of the invention is: it integrates the sensor of structure vibration and the power-supply source of magnetic current changing damper on small-sized permanent magnet DC generator. The invention applies to the vibration damping of civil engineering structure, it can realize semi-active real-time control without extraneous power source, reduce the system cost, and it is reliable, stable, simple and practical and has obvious self-adaptive characteristics.

Owner:HUNAN UNIV

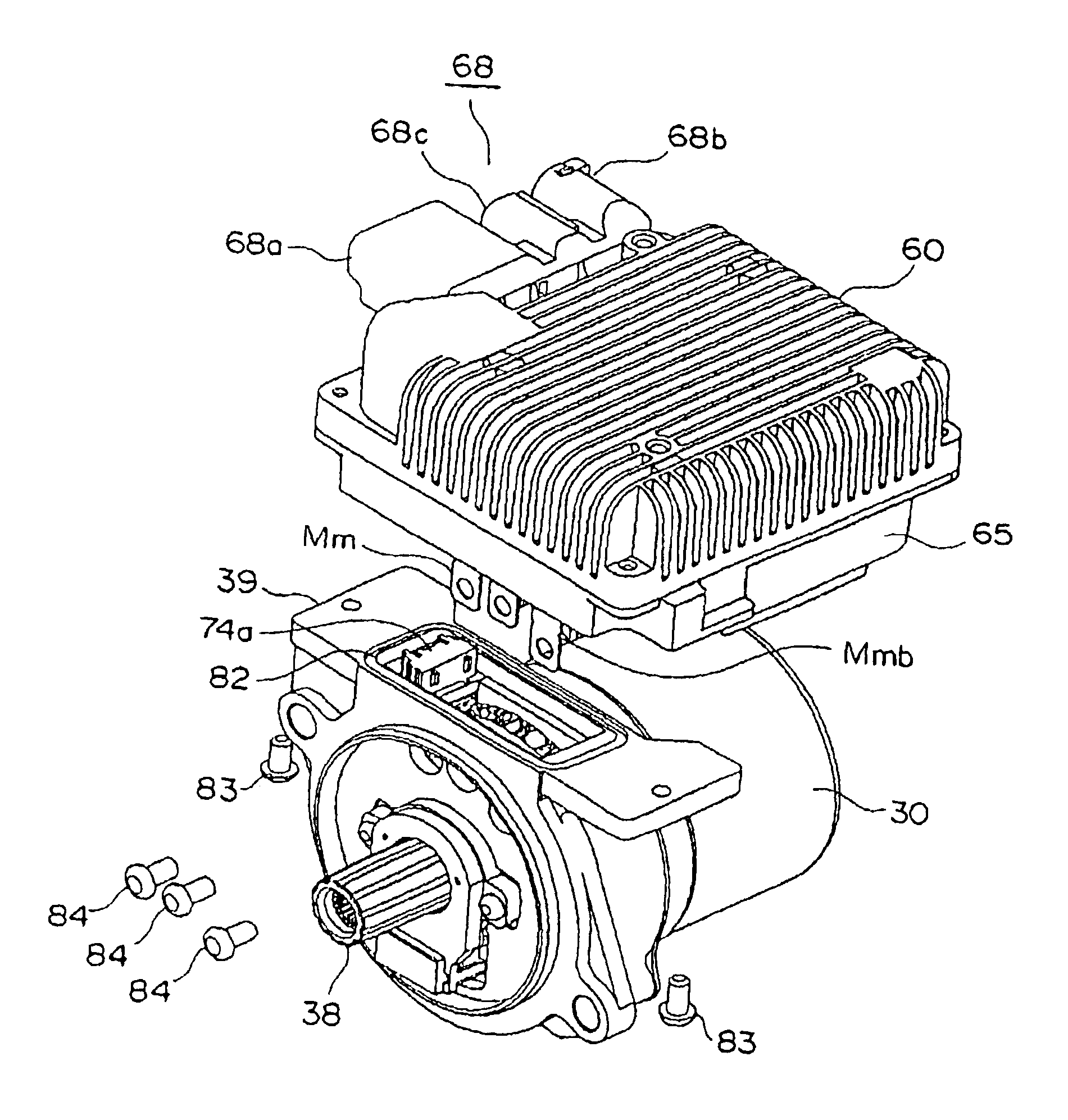

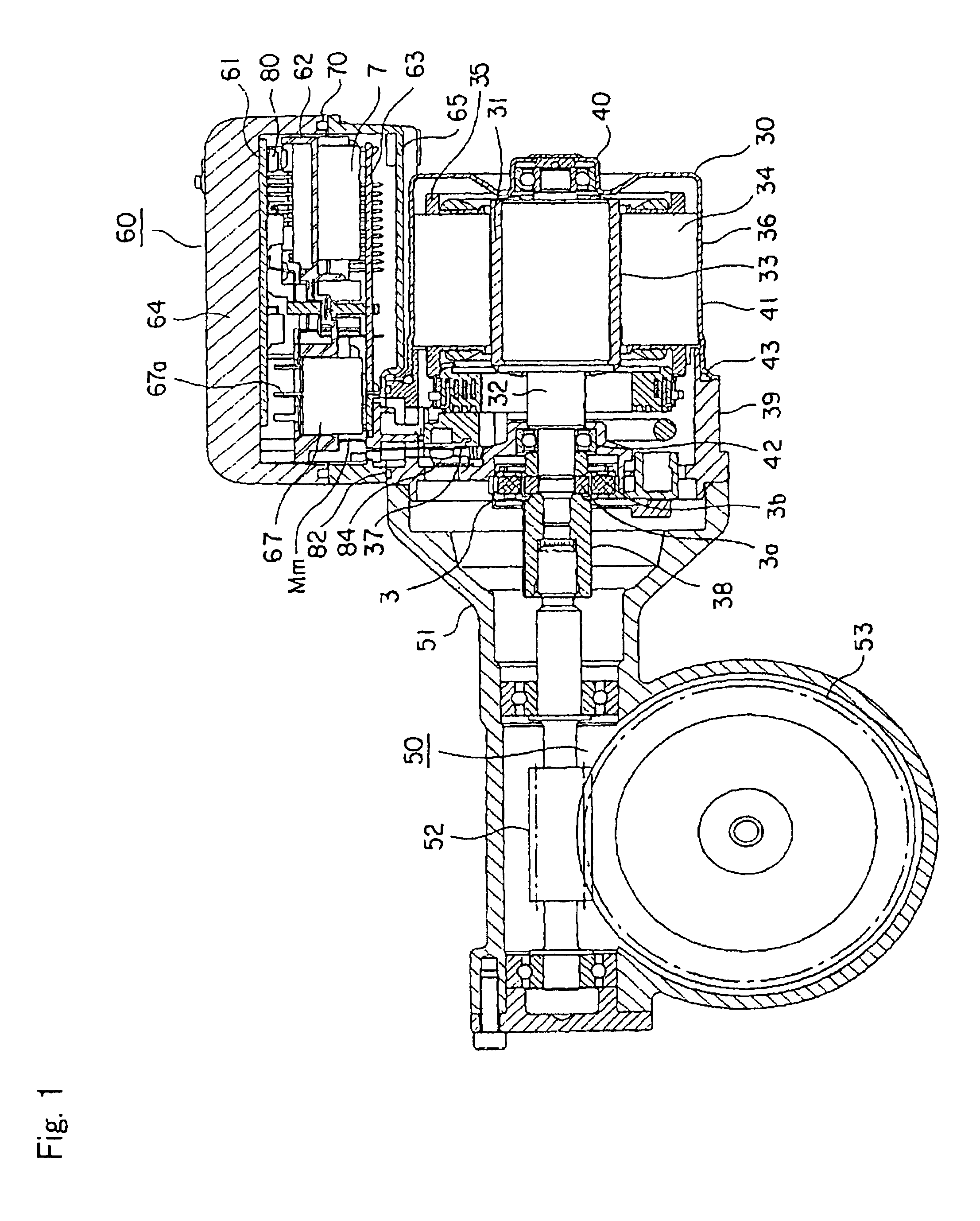

Electric power steering apparatus

InactiveUS6906483B2Reduce the impactLow costAssociation with control/drive circuitsDC motor speed/torque controlElectric power steeringElectric power system

An electric power steering removes external wiring connecting between an electric motor and a control unit, whereby the influence of radiation noise caused by a PWM operation can be reduced. In addition, the heat radiation and assemblability of the electric motor and the control unit can be improved, while achieving high power output. A housing 64 with a metal substrate 61 fixedly secured thereto is arranged at a side opposite to an electric motor 30. The cooling fins are formed on an outer side of a housing 64 and on an outer side and an inner side of a cover 65. A metal substrate 61, a large current substrate 62 and a control substrate 63 are arranged inside of the housing 64 and the cover 65 in a laminated structure.

Owner:MITSUBISHI ELECTRIC CORP

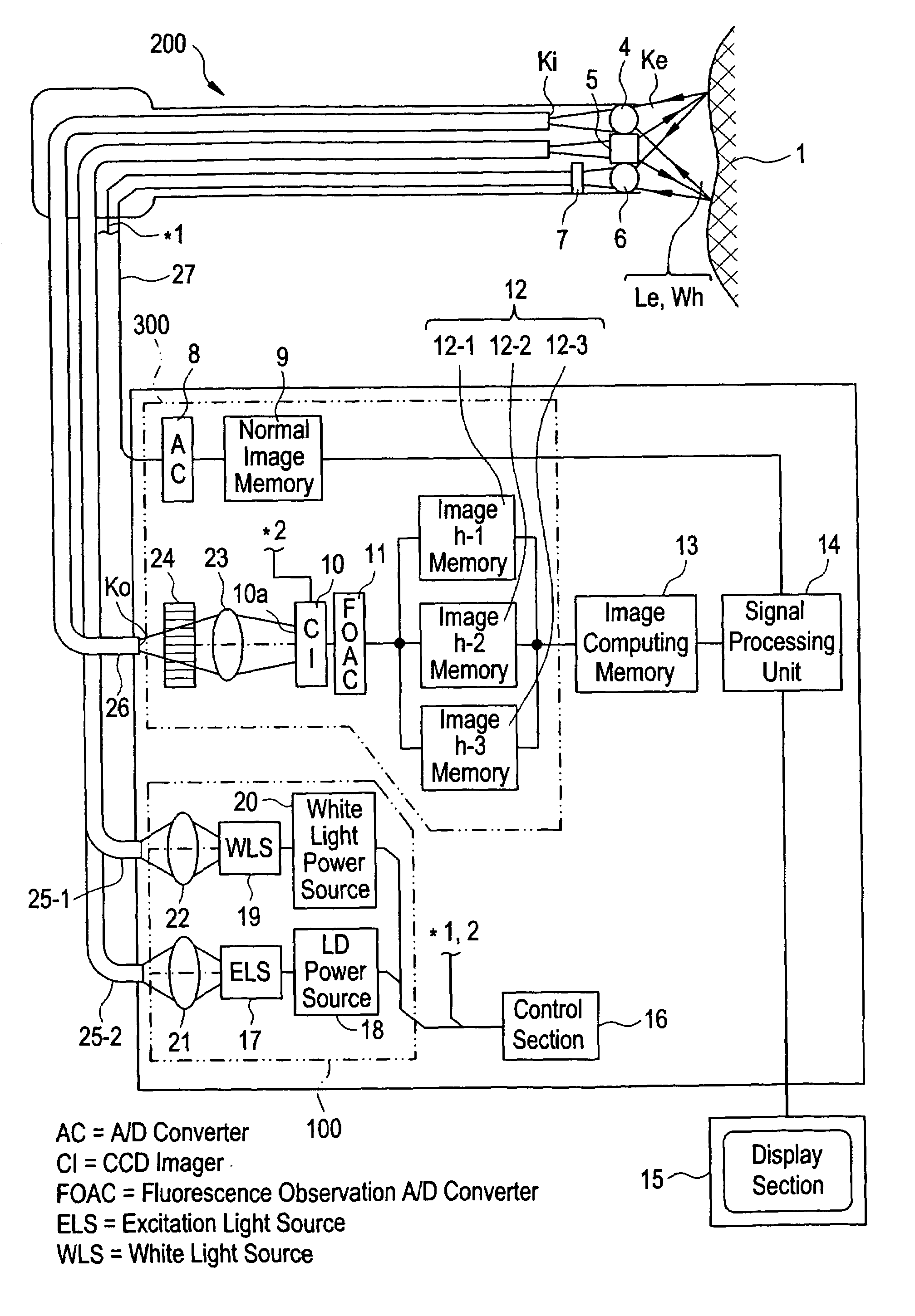

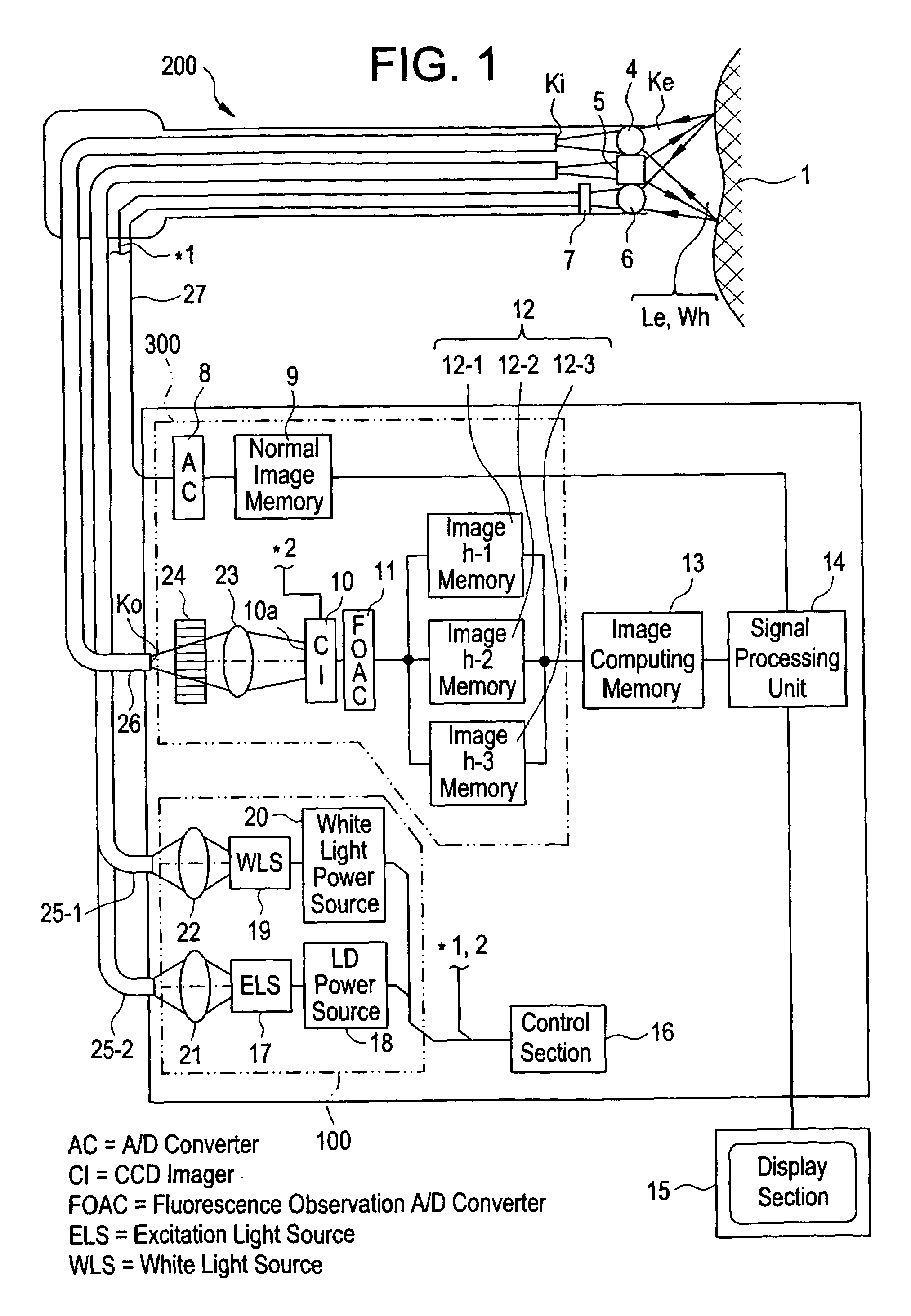

Fluorescence observing apparatus

InactiveUS7062311B1High output powerHigh peak powerOptical radiation measurementRadiation measurementLight irradiationFluorescence

A fluorescence observing apparatus including a light source for emitting excitation light, an excitation light irradiation section for irradiating the excitation light to a sample, and a fluorescence measurement section for measuring fluorescence emitted from the sample by the irradiation of the excitation light. In the fluorescence observing apparatus, a GaN semiconductor laser is employed as the light source.

Owner:FUJIFILM CORP +1

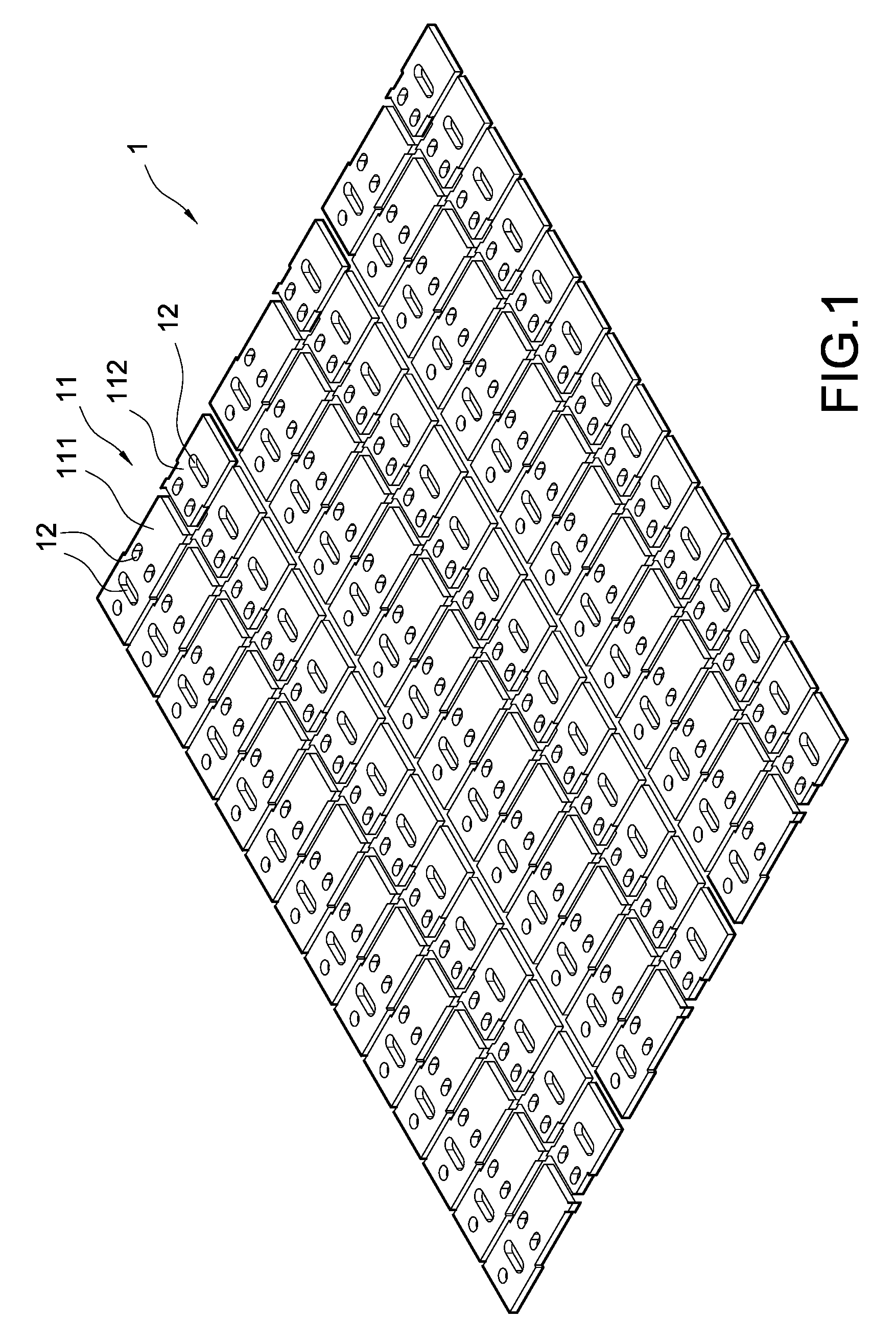

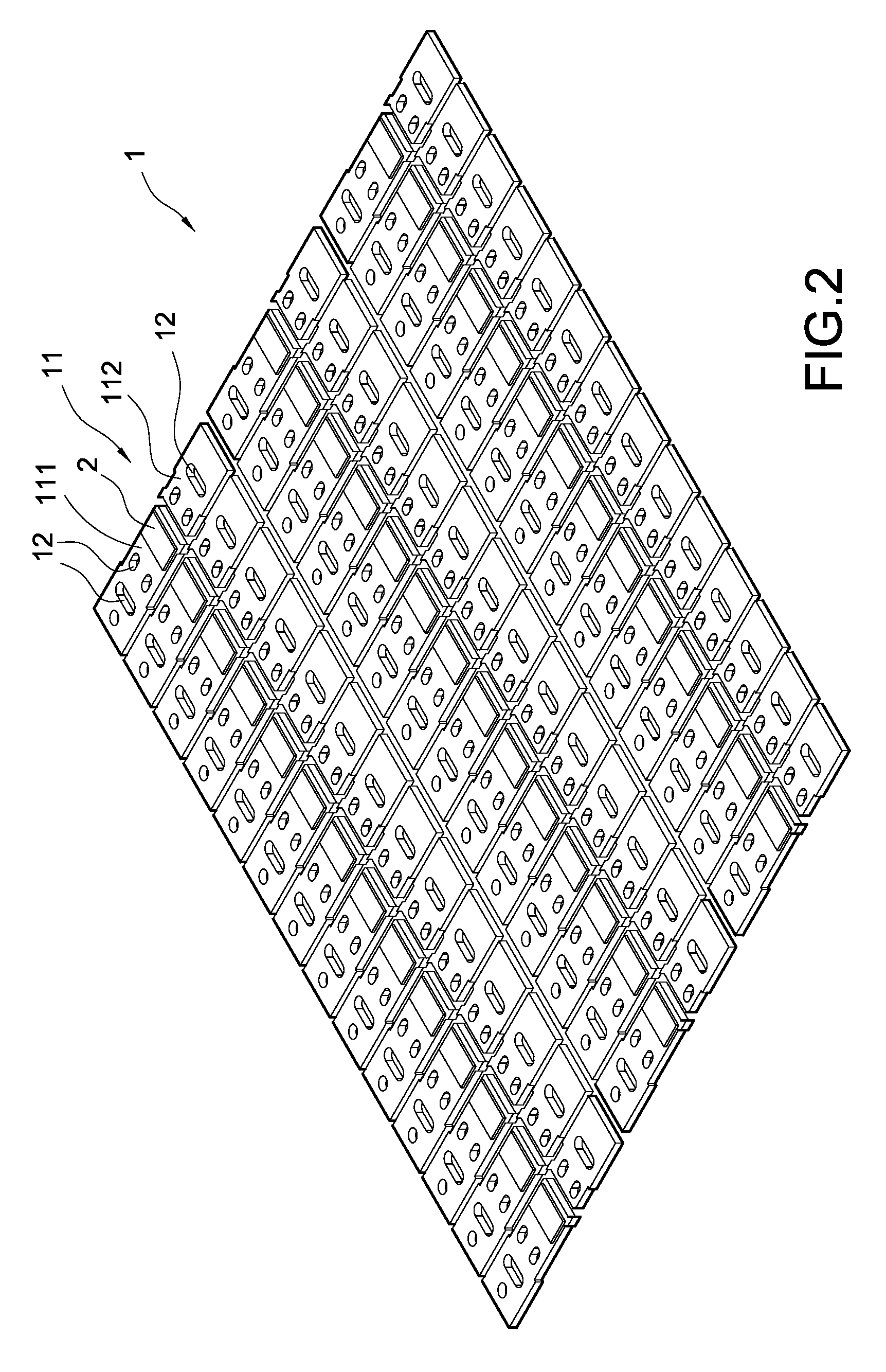

Bending mode conversion type ultrasound wave torsional vibration energy converter

InactiveCN101259465ALarge vibration amplitudeHigh output powerMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesTransformerTransducer

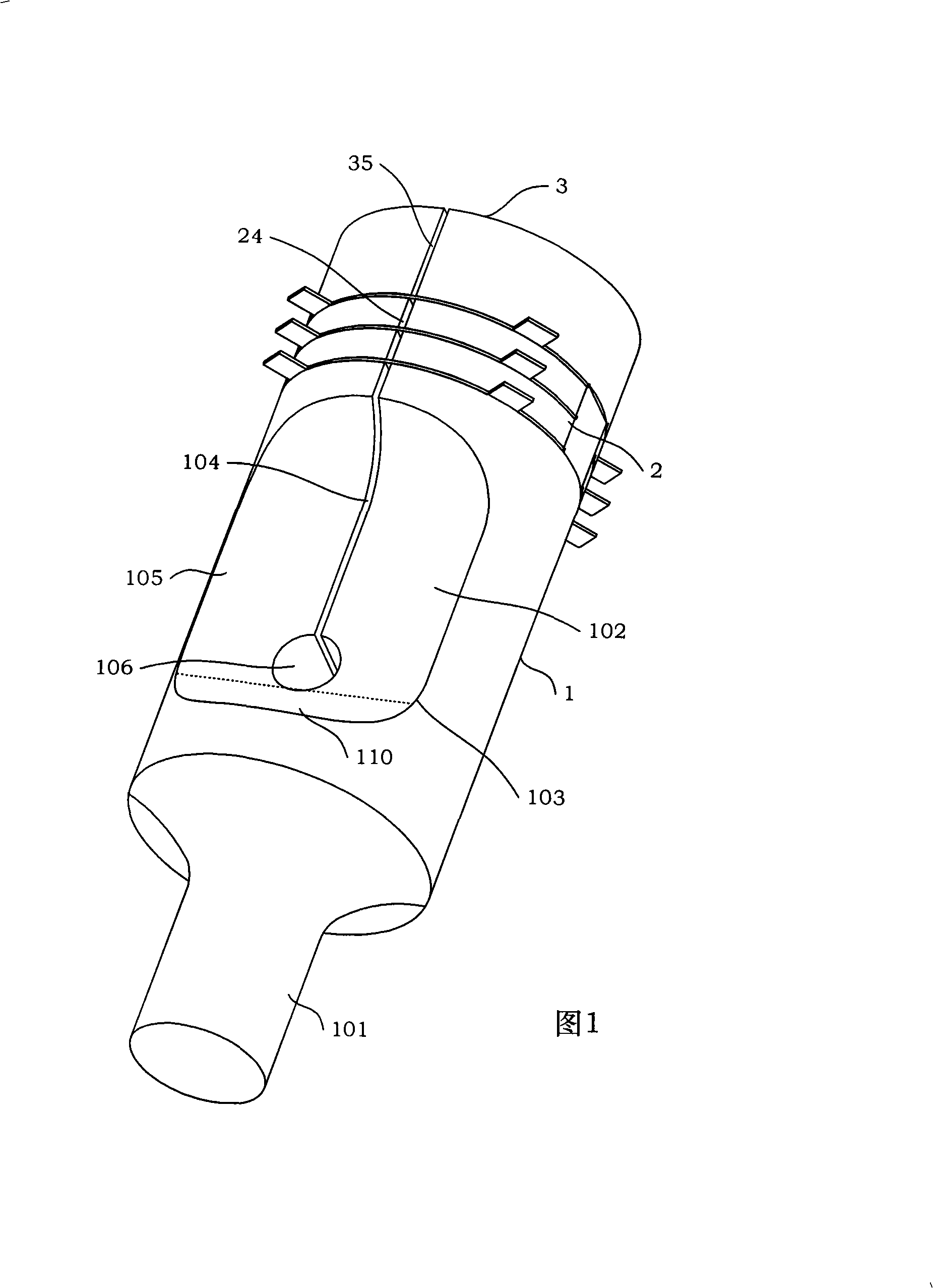

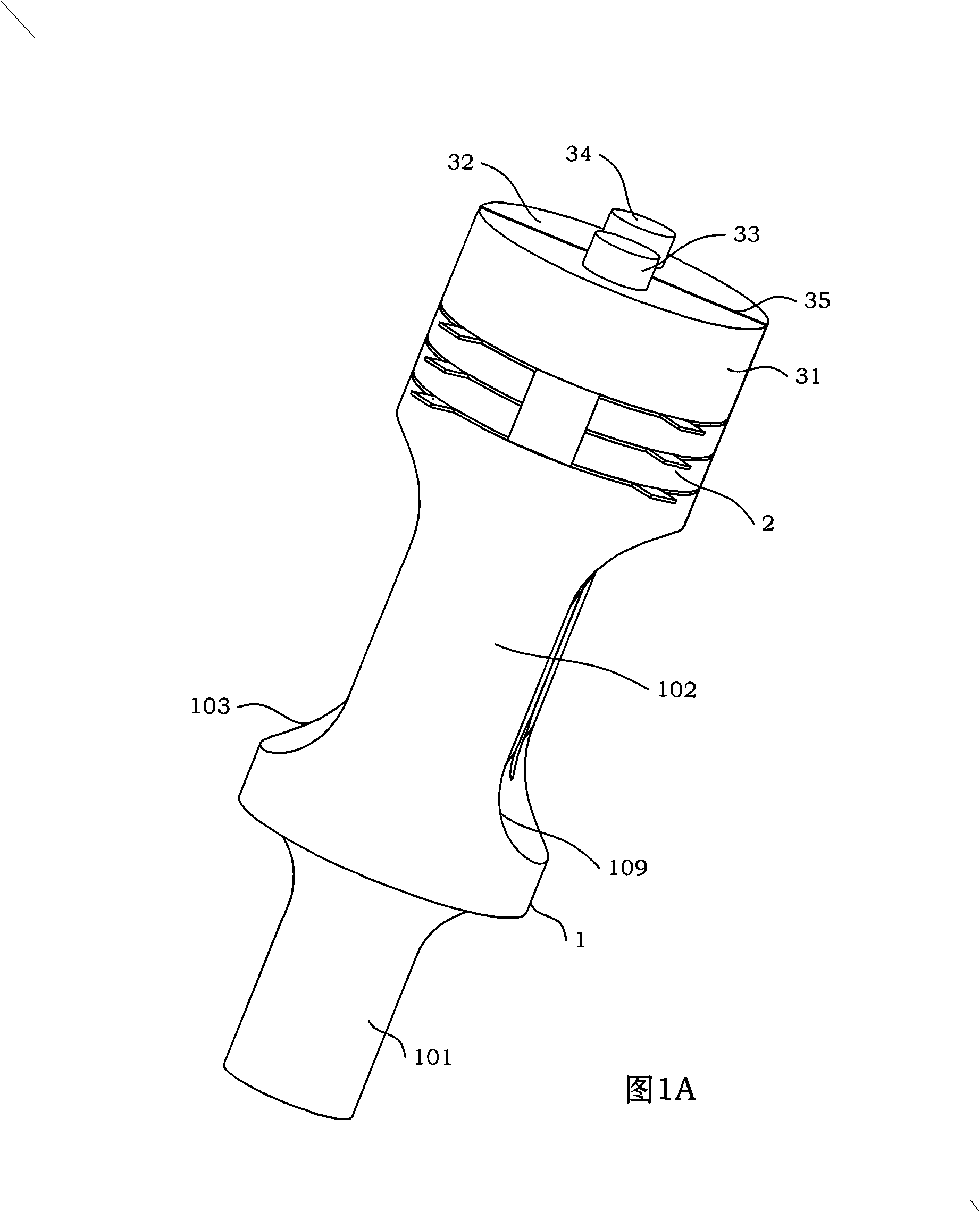

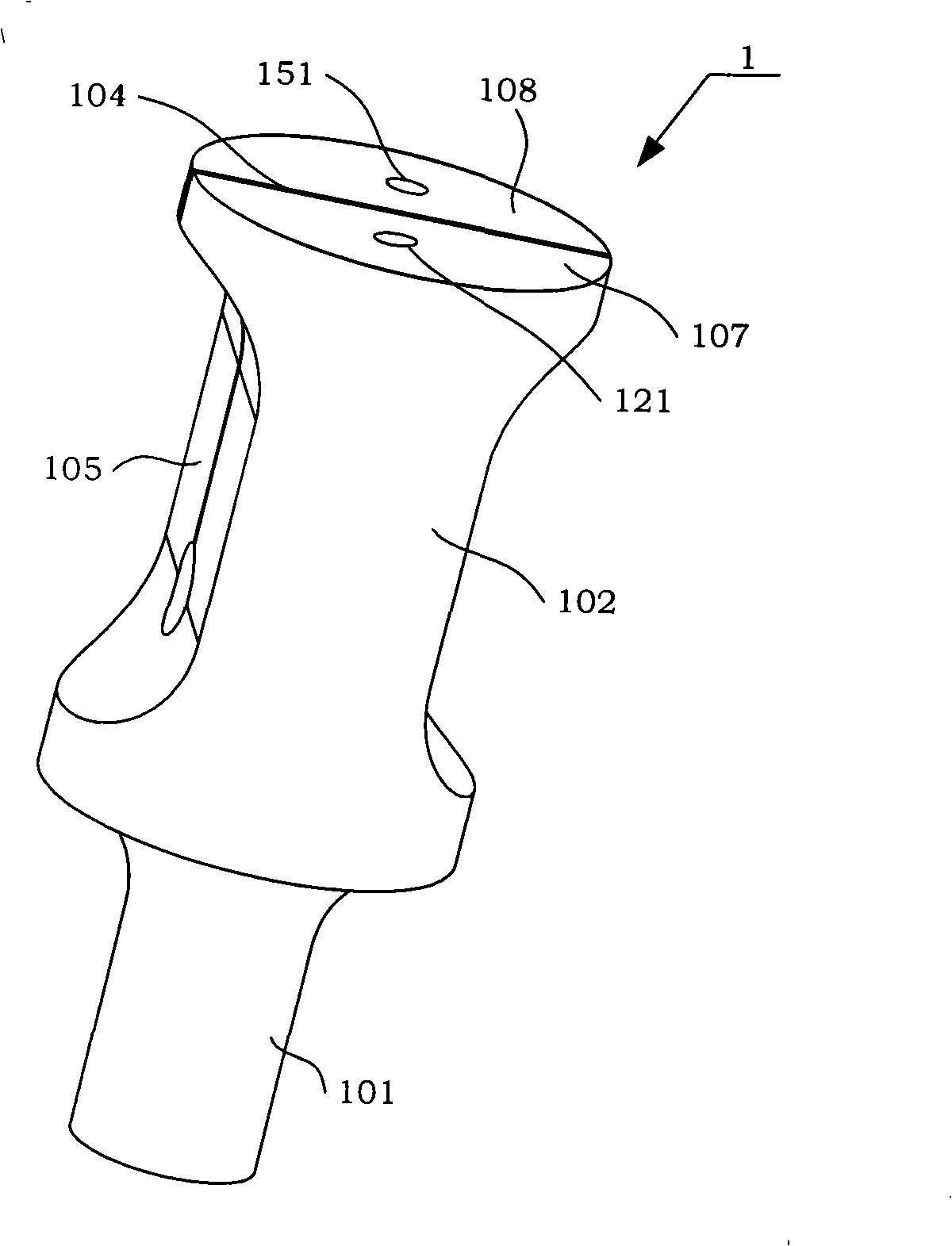

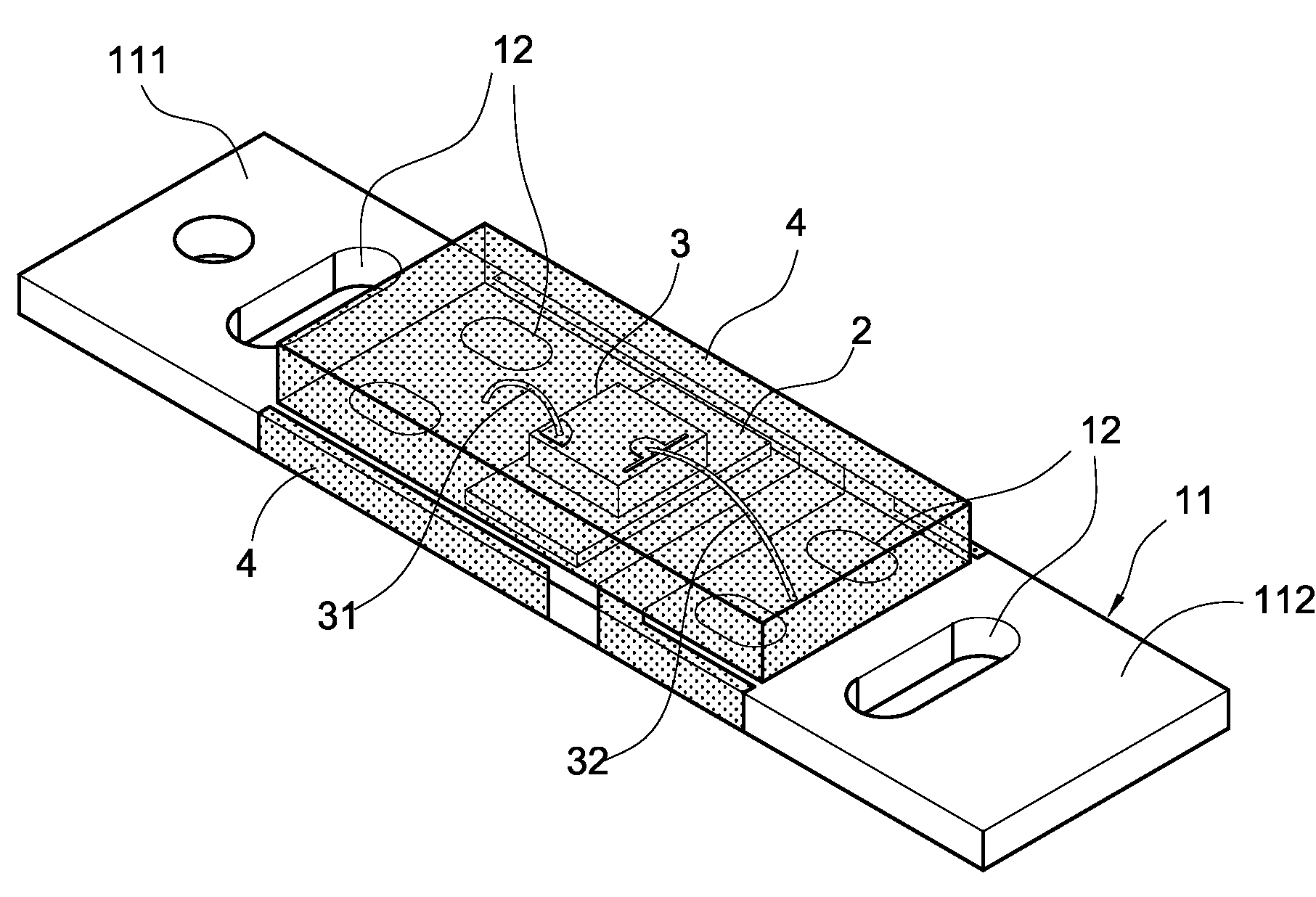

The invention discloses a bending-twisting conversion type ultrasonic torsion vibration transducer which comprises a bending-twisting vibrating body(1), a drive component (2) and a back cover (3) of the transducer; the drive component (2) is arranged between the bending-twisting vibrating body(1) and the back cover (3) of the transducer, and moreover, an A pretighting bolt (33) passes through the through hole of an A end cover (31), an A through hole (22) and an A pretighting screw hole (121) in turn through to arrange the A end cover (31) and an insulating block (21) on the A top surface (107) of the bending-twisting vibrating body(1); an B pretighting bolt (34) passes through the through hole of an B end cover (32), an B through hole (23) and an B pretighting screw hole (151) in turn to arrange the B end cover (32) and the insulating block (21) on the B top surface (108) of the bending-twisting vibrating body(1). A pair of bending vibrations with the same frequency swings and opposite vibrating directions generated by corresponding two groups of piezoelectric ceramics drive elements are amplified and transmitted to a converter by two bending arms; two bending vibrations are coupled and converted into a coupling torsion vibration (63) through a mode converter; a torsion vibration (64) is obtained and output after being amplified by an amplitude transformer (101), thus obtaining ultrasonic torsion vibration by a simpler mode.

Owner:BEIHANG UNIV

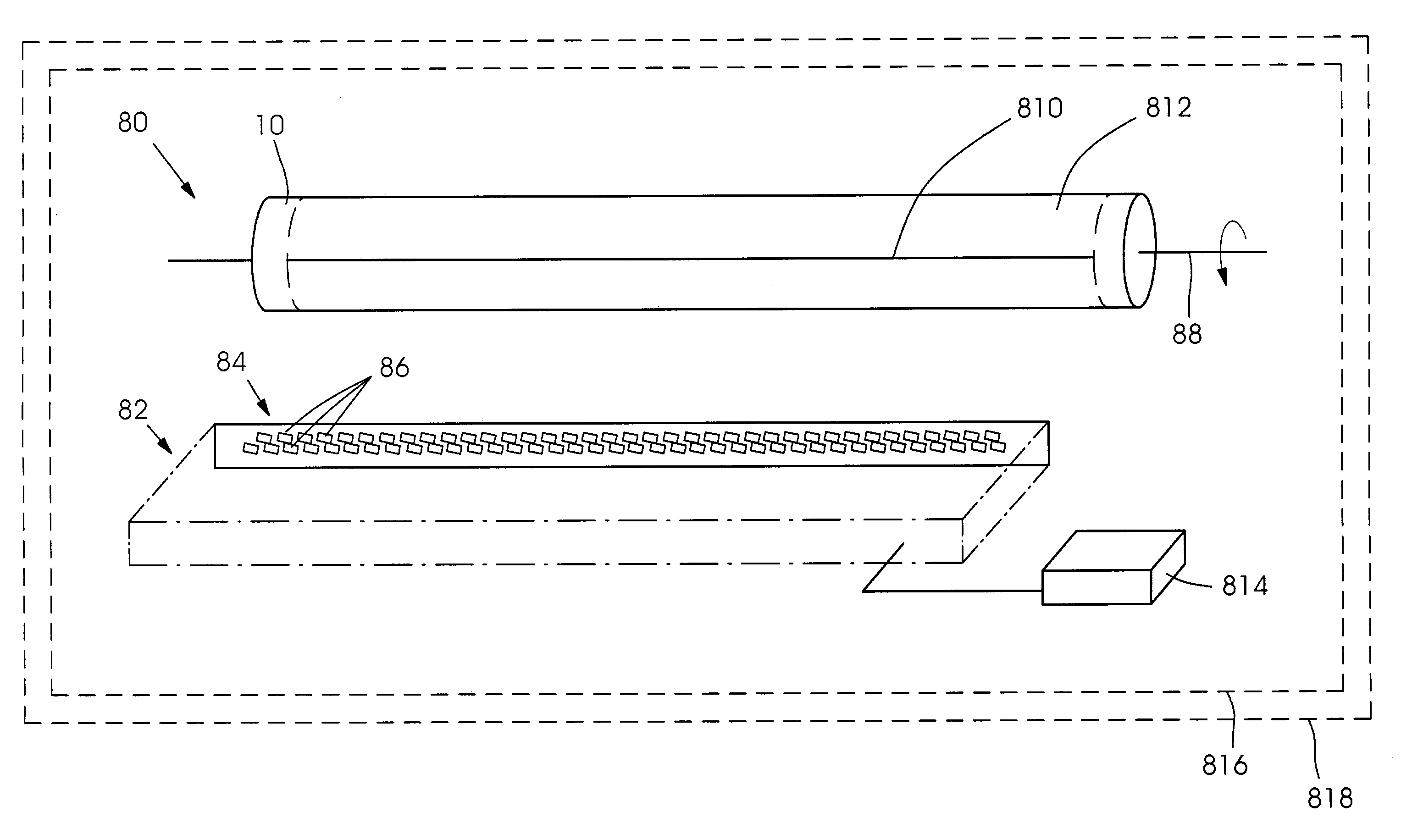

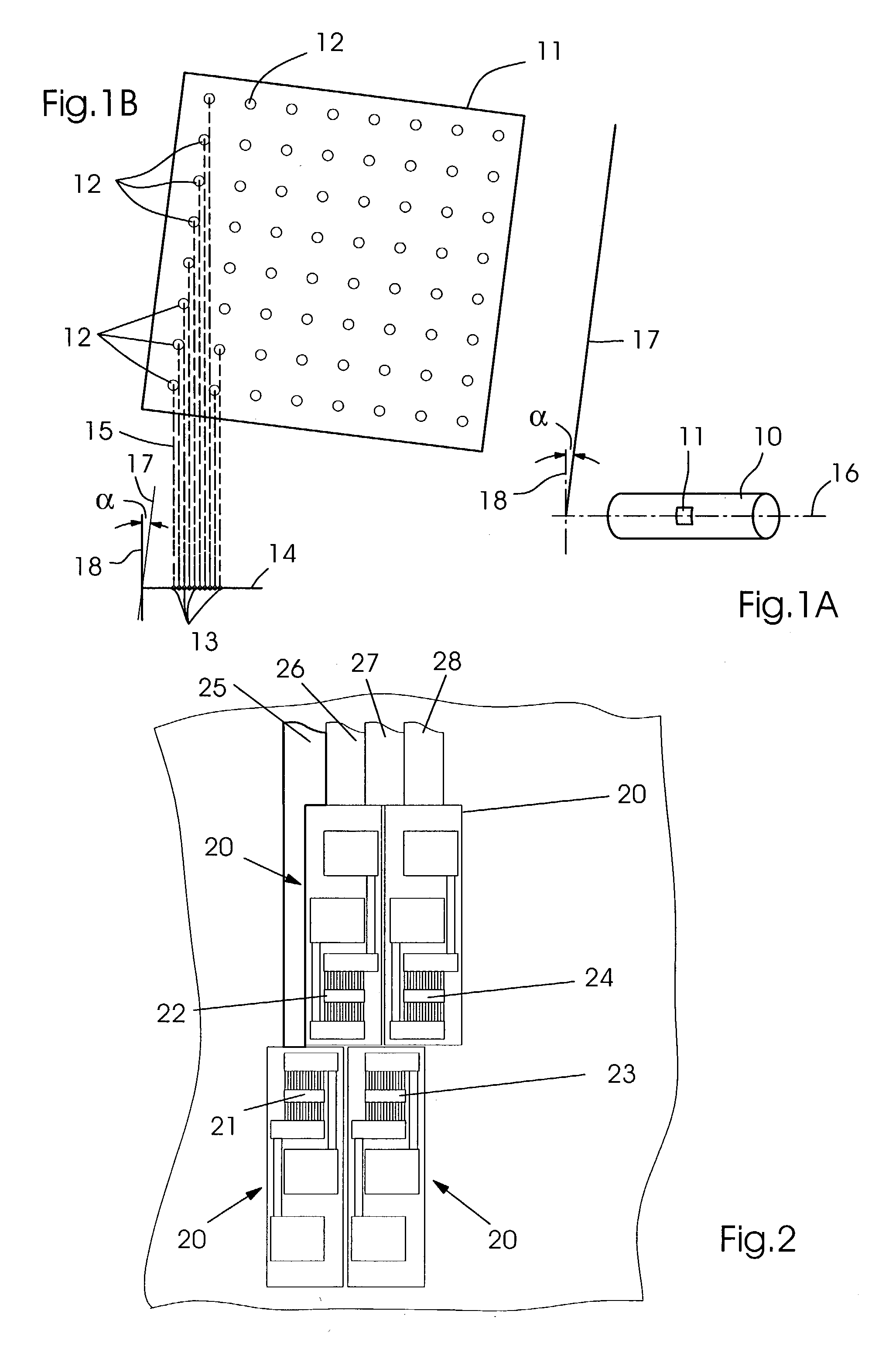

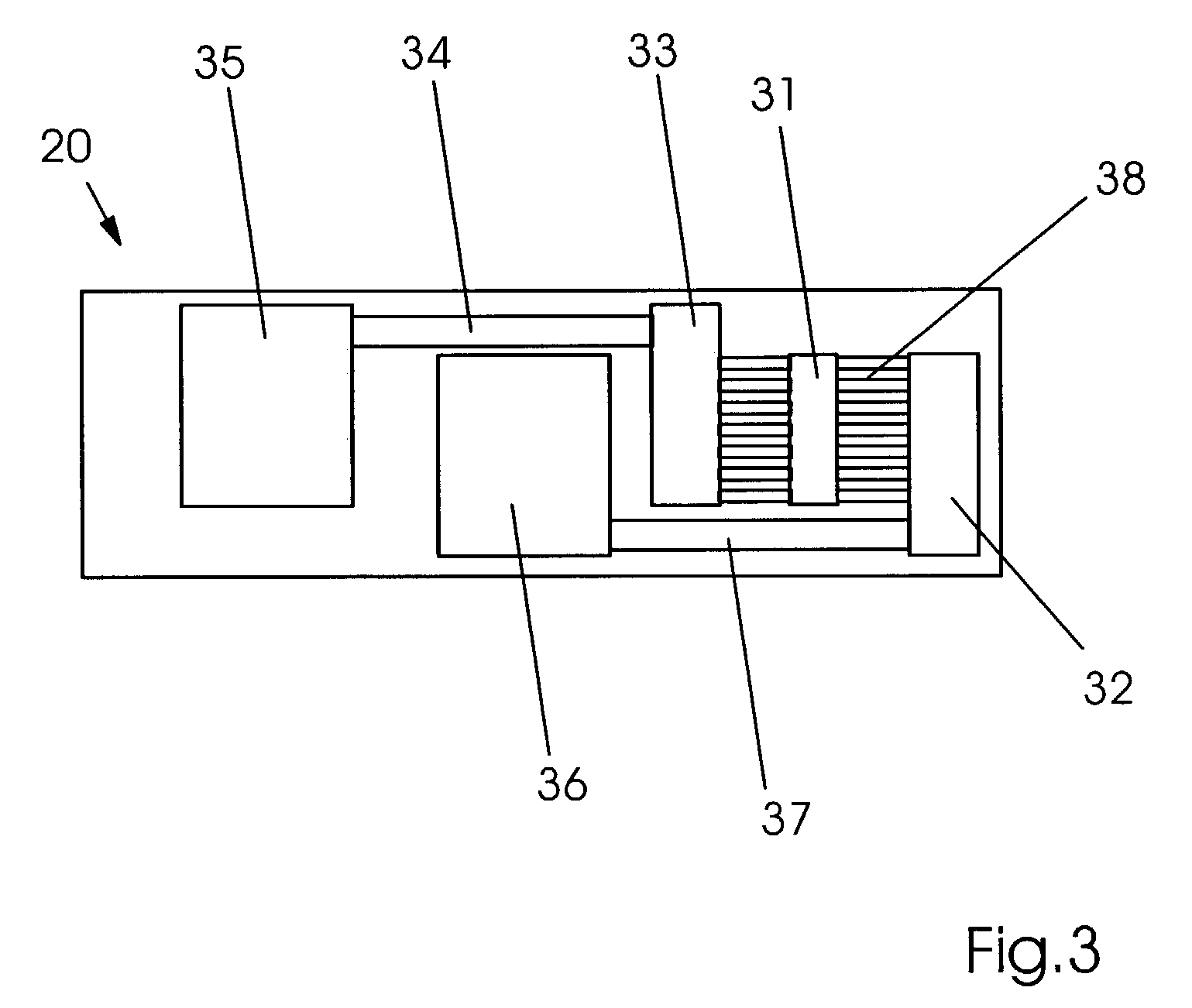

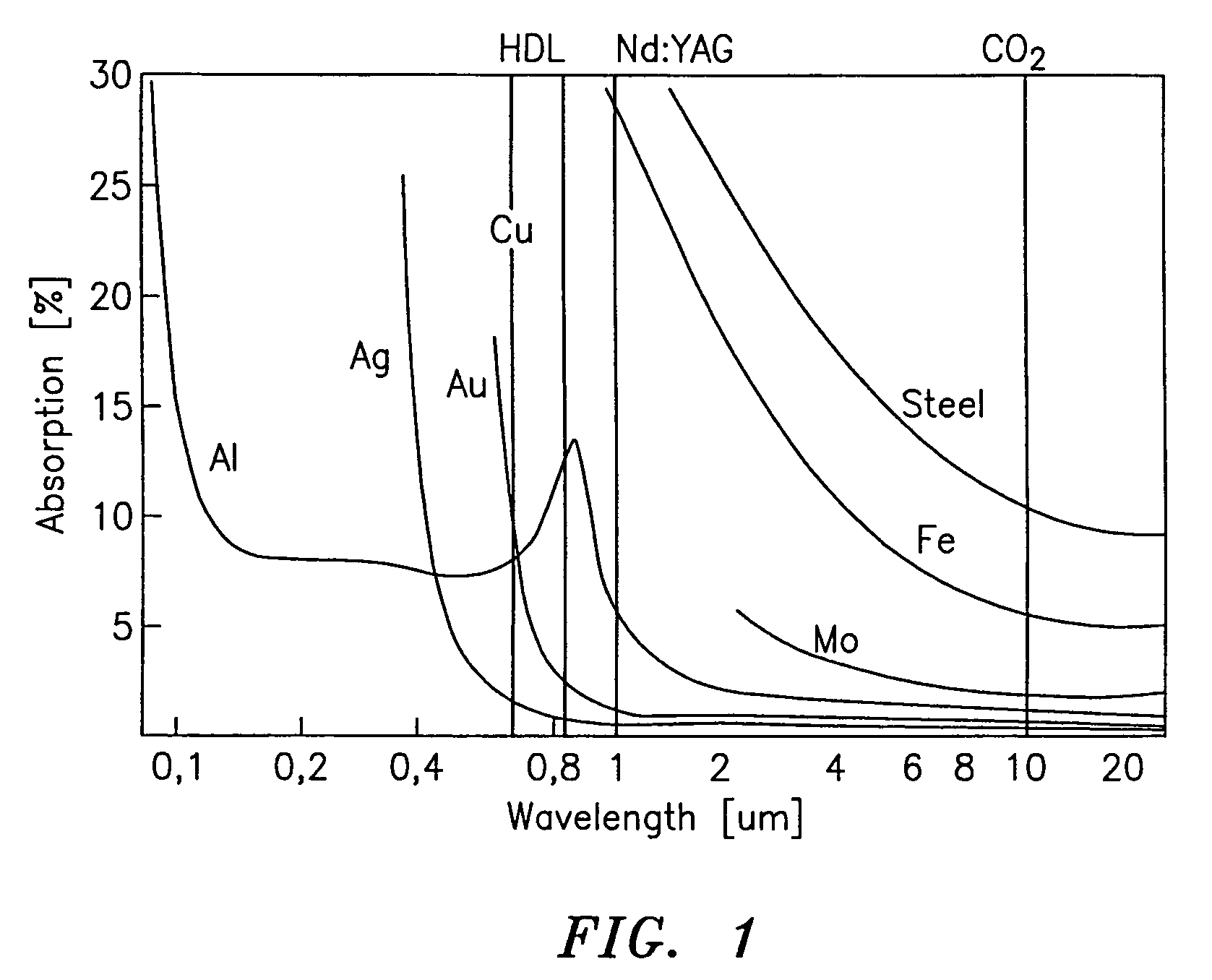

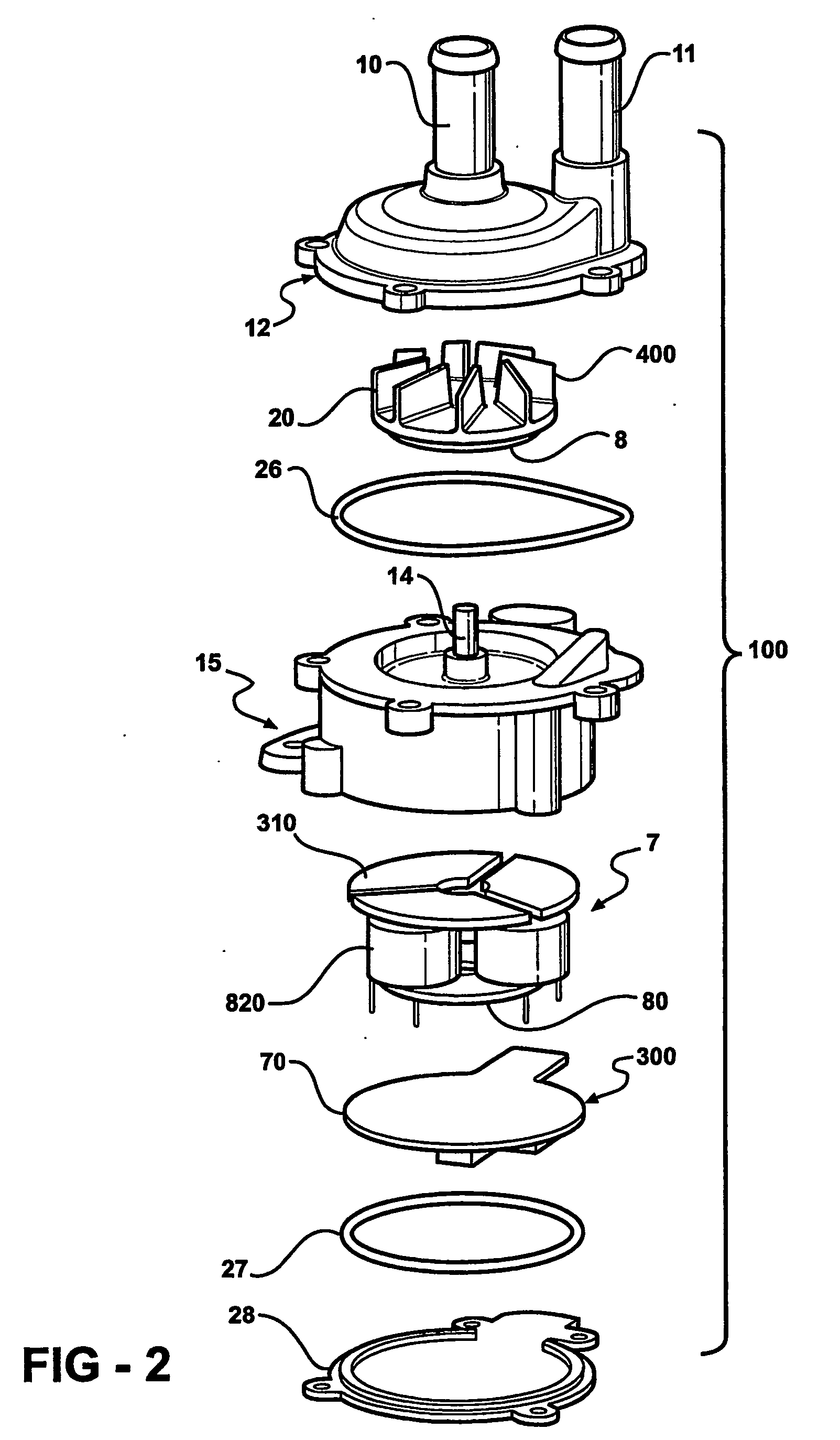

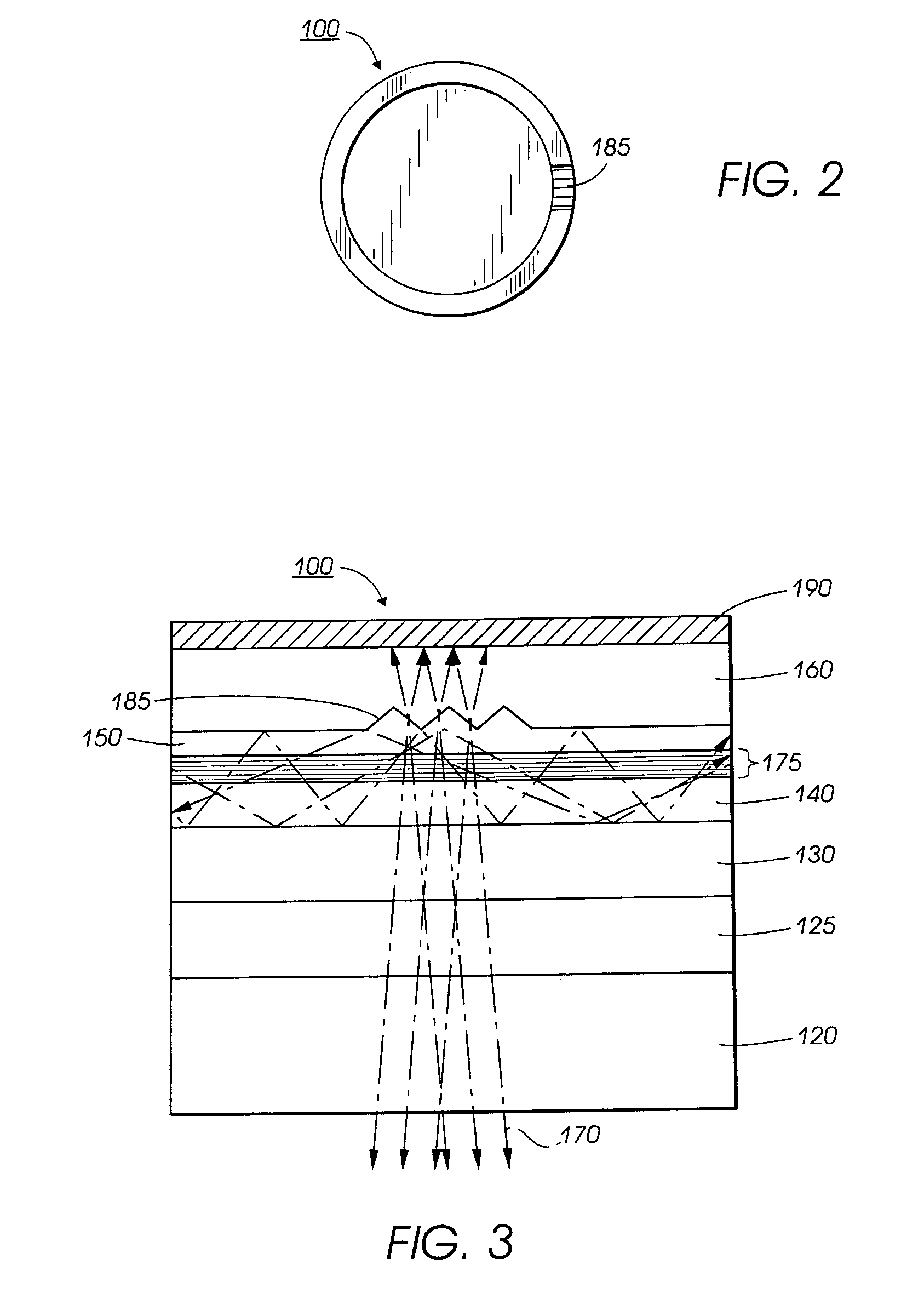

Method for printing an image on a printing substrate and device for inputting energy to a printing-ink carrier

InactiveUS7002613B2High output powerHigh reliabilityPrinting platesOther printing apparatusLaser lightPrinting ink

A method for printing an image on a printing substrate, a number of portions of fluid printing ink being produced on a printing ink carrier (10) through energy input by a number of image spots (810) of an array (84) of individually controllable VCSEL light sources, and the fluid printing ink being transferred to the printing substrate. A device for inputting energy (80) to a printing-ink carrier (10), includes a number (82) of individually controllable laser light sources which have a modular design consisting of subarrays (86) and are disposed in an array (84), and further includes printing-ink carrier (10) with which is associated an axis of rotation (88) and on the surface of which can be produced a number of image spots (810) of the laser light sources. The subarrays of laser light sources are VCSEL bars (84), and rows of image spots (12) of the VCSEL bars are inclined with respect to the axis of rotation (88).

Owner:HEIDELBERGER DRUCKMASHINEN AG

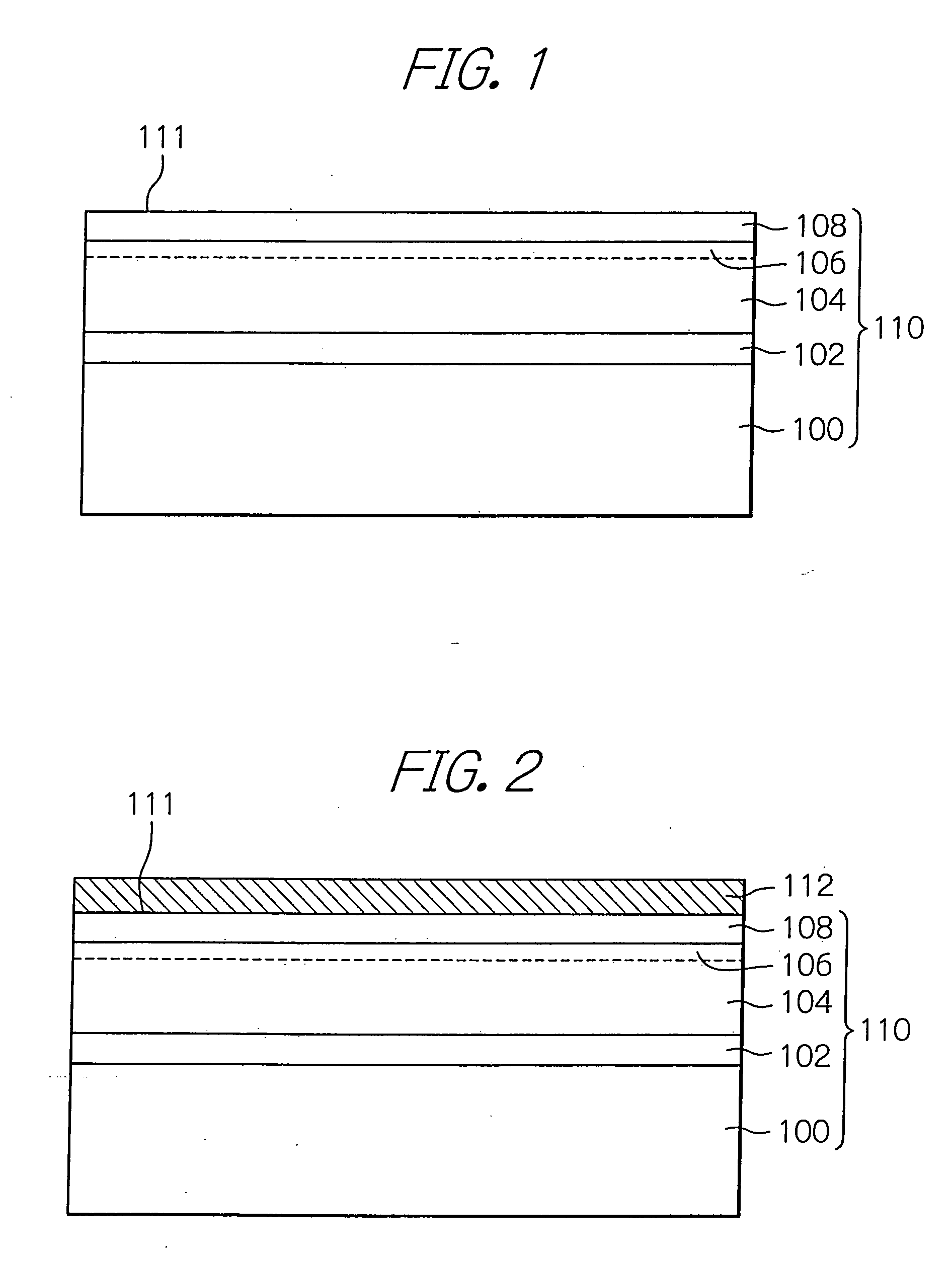

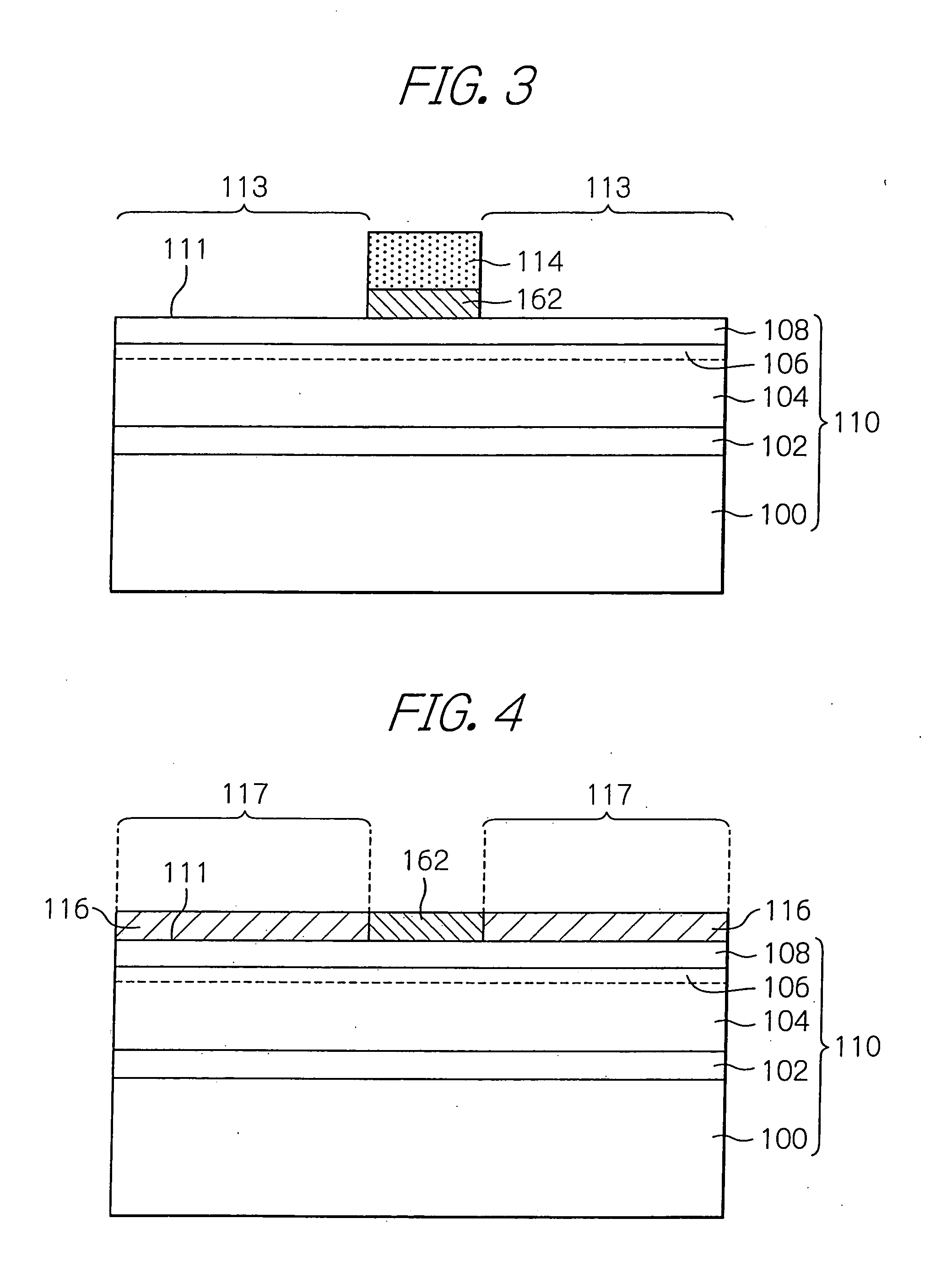

Method for fabricating AIGaN/GaN-HEMT using selective regrowth

InactiveUS20080176366A1Reduce generationReduce manufacturing stepsSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactContact resistance

A semiconductor body includes, on a substrate, a stack of buffer layer, UID-GaN layer overlying the buffer layer, and UID-AlGaN layer overlying the UID-GaN layer. On the surface of the UID-AlGaN layer, an insulation film is deposited and patterned. An n+-GaN layer is selectively regrown directly on a region of the surface of the semiconductor body other than the insulation film using the patterned insulation film as a mask without etching the surface of the semiconductor body. A portion of the selectively regrown n+-GaN layer corresponding to a region reserved for an ohmic contact electrode is defined and the ohmic contact electrode is formed on the region. An opening exposing a region reserved for a gate electrode is defined and formed within the insulation SiO2 layer, and a gate electrode is formed in the region. An AlGaN / GaN-HEMT or MIS type of AlGaN / GaN-HEMT has lower contact resistance and uniform device characteristics.

Owner:OKI ELECTRIC IND CO LTD

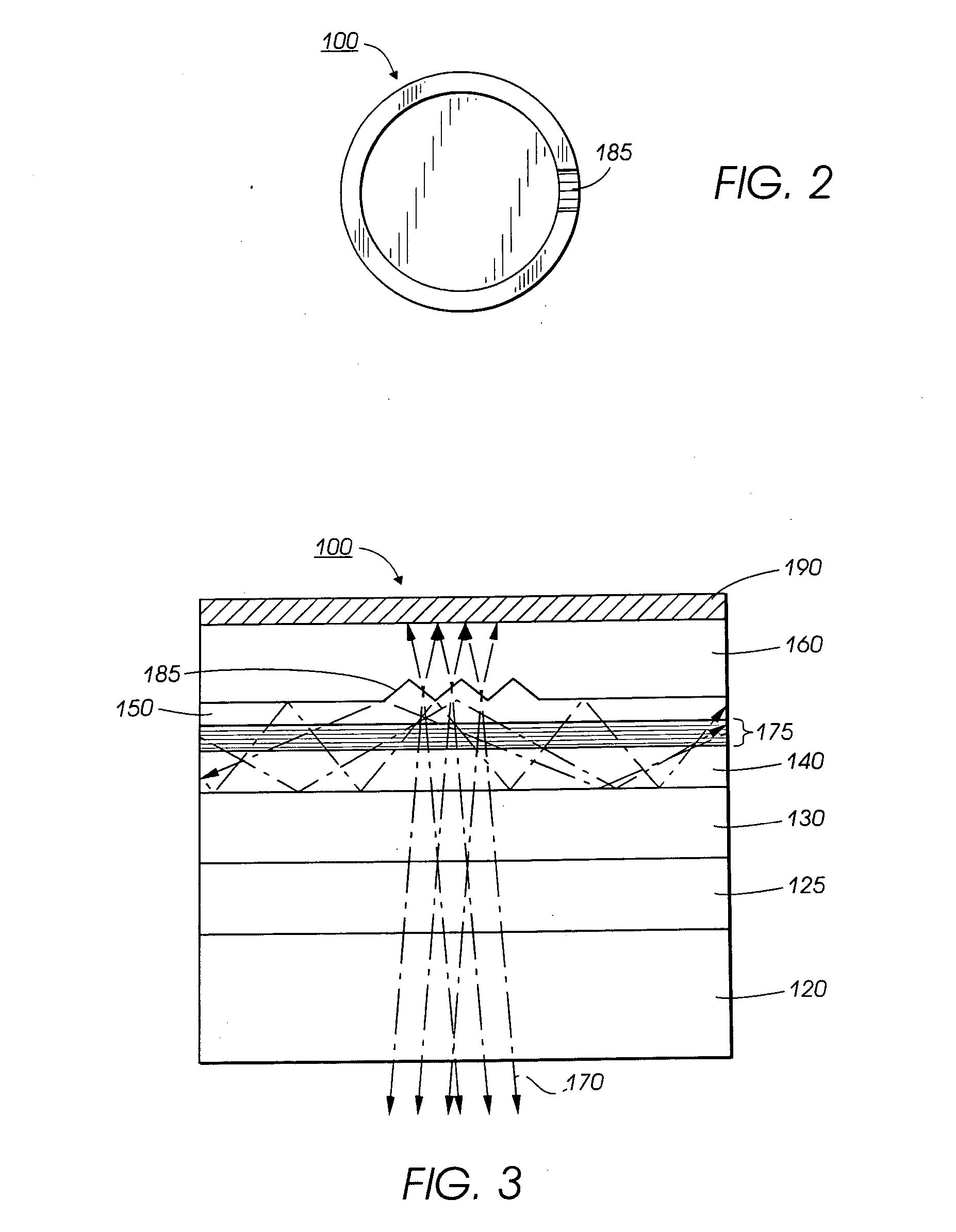

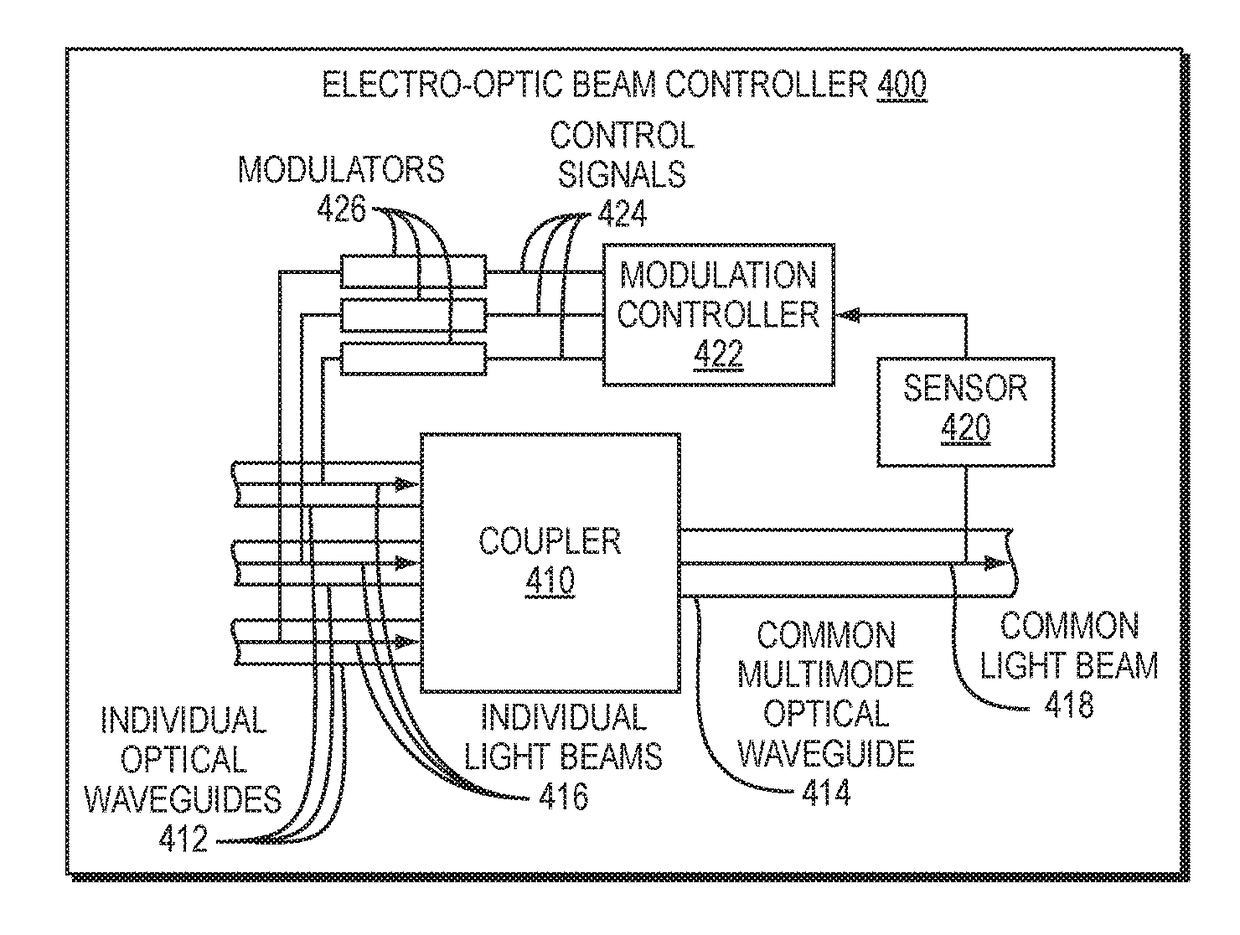

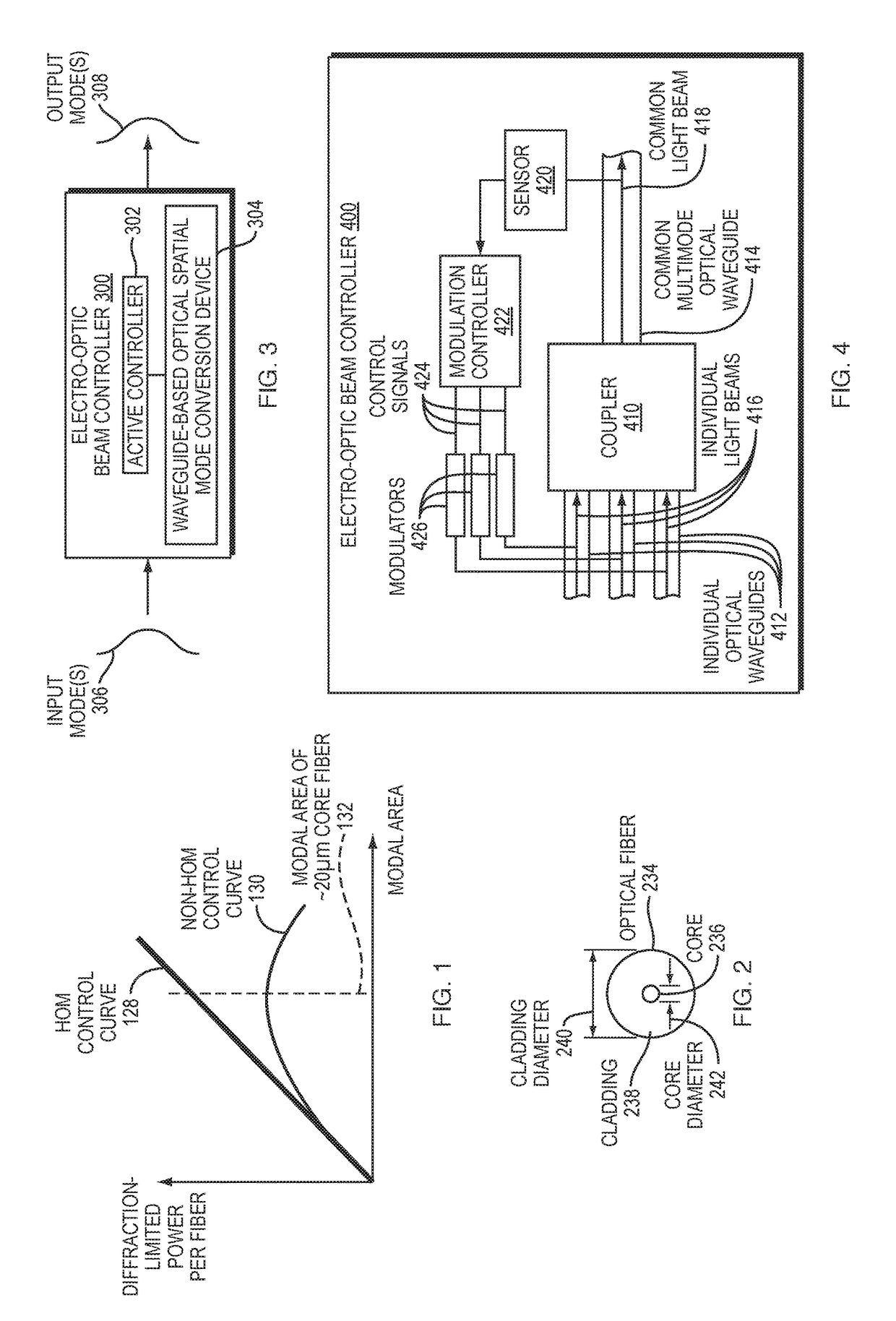

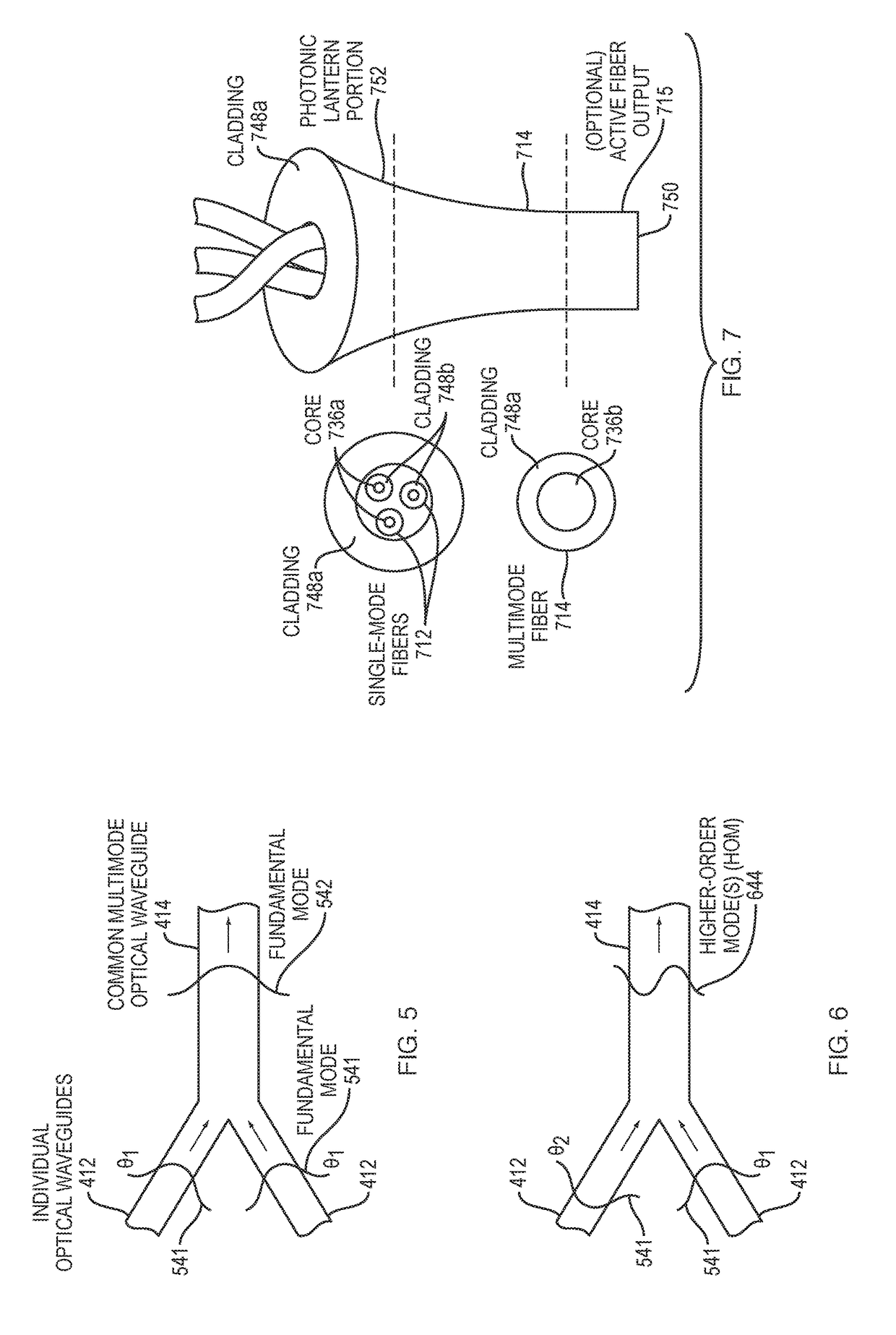

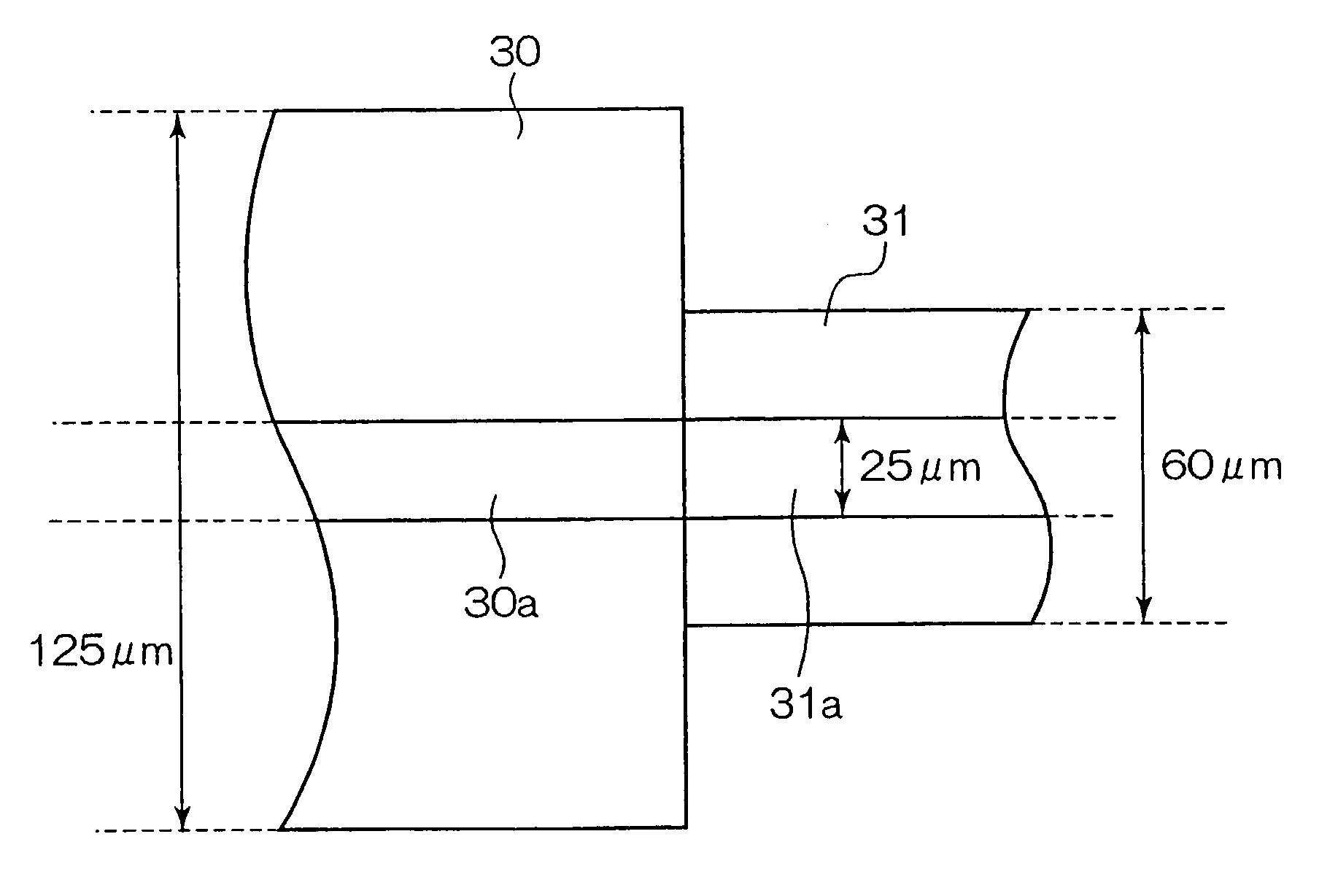

Devices and Methods For Optical Spatial Mode Control

ActiveUS20170299900A1Improve robustnessHigh output powerOptical light guidesOptical devices for laserMode controlHandling system

An electro-optic beam controller, material processing apparatus, or optical amplifier, and corresponding methods, can include an actively controlled, waveguide-based, optical spatial mode conversion device. The conversion device can include a coupler, which can be a photonic lantern, configured to combine light beams into a common light beam; a sensor configured to measure at least one characteristic of the common light beam; and a controller configured to modulate optical parameters of the individual, respective light beams to set one or more spatial modes of the common light beam. Actively controlled and modulated devices can be used to maintain a stable, diffraction-limited beam for use in an amplification, communications, imaging, laser radar, switching, or laser material processing system. Embodiments can also be used to maintain a fundamental or other spatial mode in an optical fiber even while scaling to kilowatt power.

Owner:MASSACHUSETTS INST OF TECH

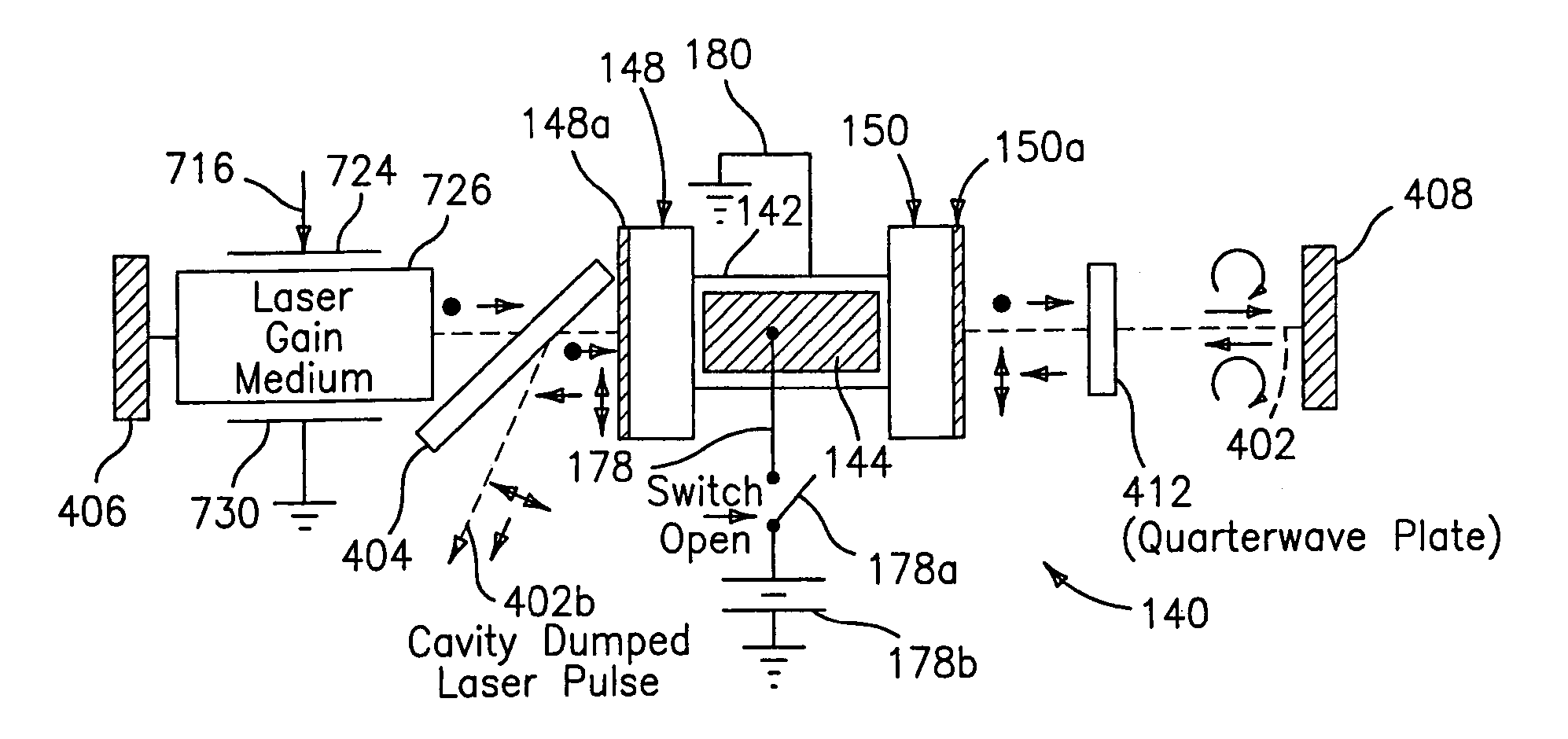

Q-switched, cavity dumped laser systems for material processing

InactiveUS7058093B2High strengthLow powerActive medium materialGas laser constructional detailsEngravingPeak value

This disclosure discusses techniques for obtaining wavelength selected simultaneously super pulsed Q-switched and cavity dumped laser pulses utilizing high optical damage threshold electro-optic modulators, maintaining a zero DC voltage bias on the CdTe electro-optic modulator (EOM) so as to minimize polarization variations depending on the location of the laser beam propagating through the CdSe EOM crystal, as well as the addition of one or more laser amplifiers in a compact package and the use of simultaneous gain switched, Q-switched and cavity dumped operation of CO2 lasers for generating shorter pulses and higher peak power for the hole drilling, engraving and perforation applications.

Owner:COHERENT INC

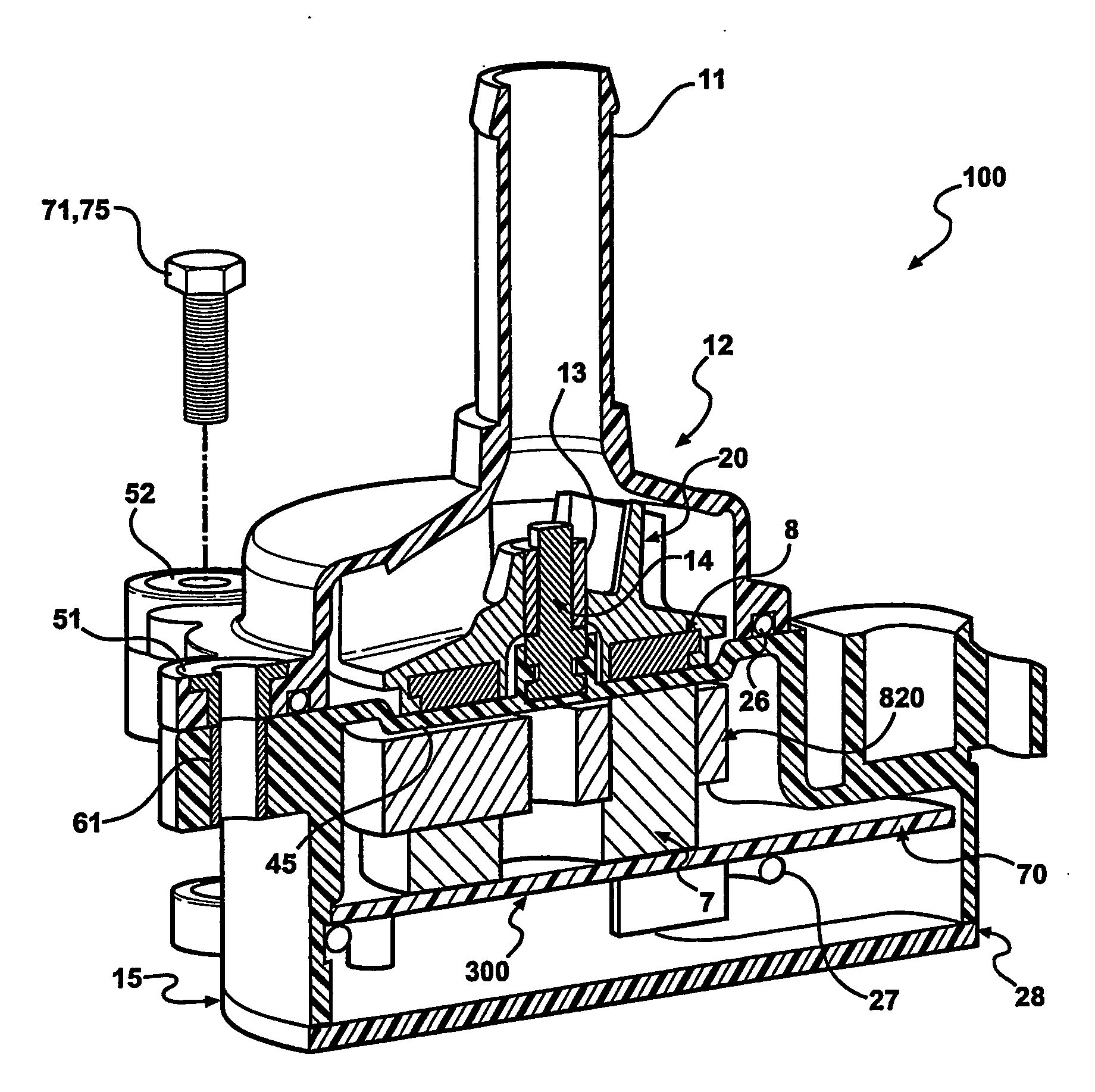

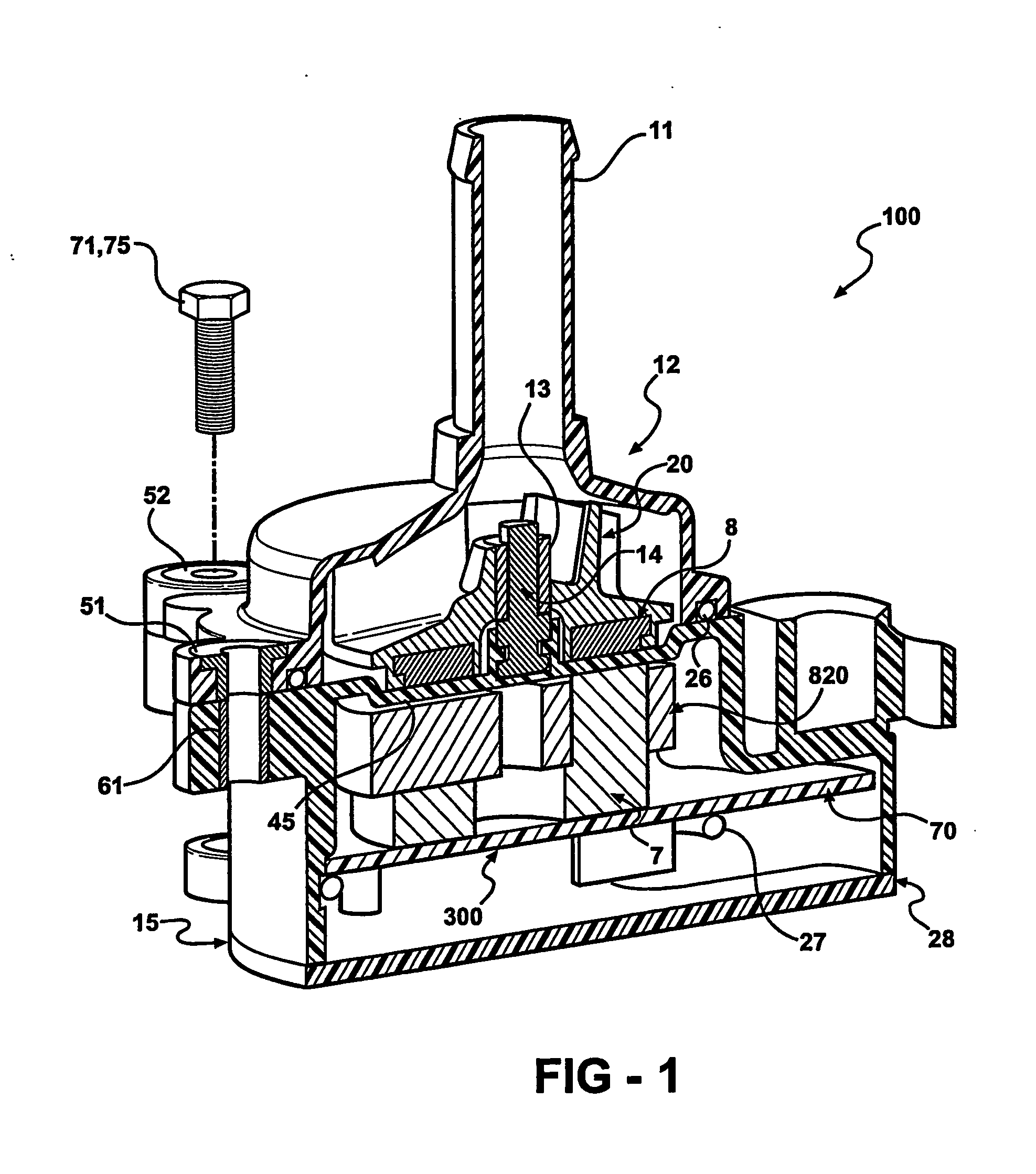

Electric fluid pump

InactiveUS20060245956A1Reduce numberGreat efficiencyPiston pumpsMechanical energy handlingImpellerStator

An electric fluid pump includes an upper housing having a fluid inlet and outlet. An impeller is seated within the upper housing for pumping fluid between the inlet and the outlet. The impeller includes at least one magnet secured thereto. A lower housing mates with the upper housing. The lower housing has an upper wall for closing the upper housing and a shaft extending from the upper wall for rotatably supporting the impeller. A stator is seated within the lower housing and spaced from the impeller by the upper wall. The stator includes a plurality of pillars supporting a winding of coils for producing a magnetic field to energize the magnet and rotate the impeller, and a plurality of top plates covering each of the coils and spaced apart by a predetermined gap for maintaining the magnetic field between the stator and the impeller. An end cap closes the stator within the lower housing.

Owner:TESMA INT INC

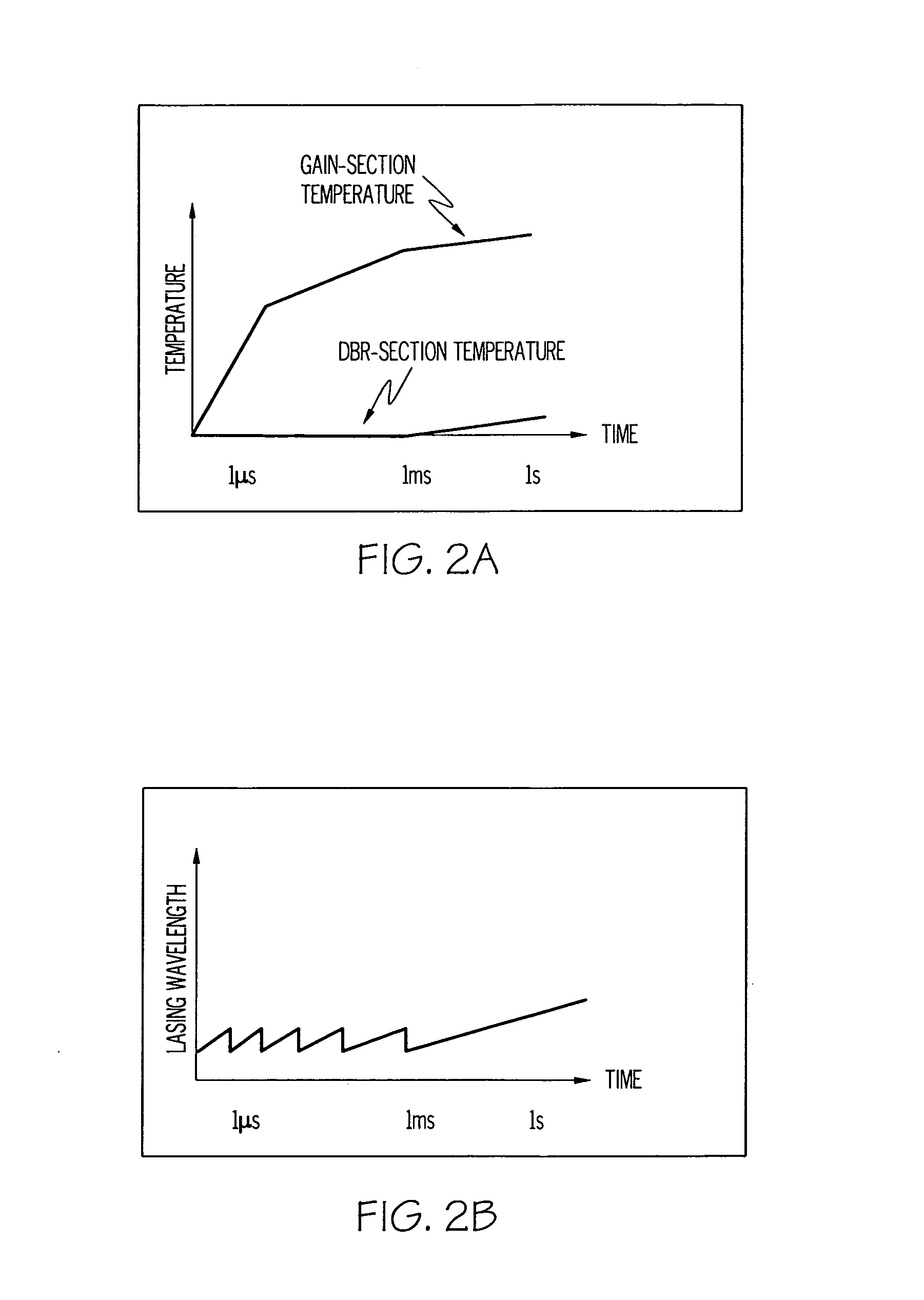

Thermal compensation in semiconductor lasers

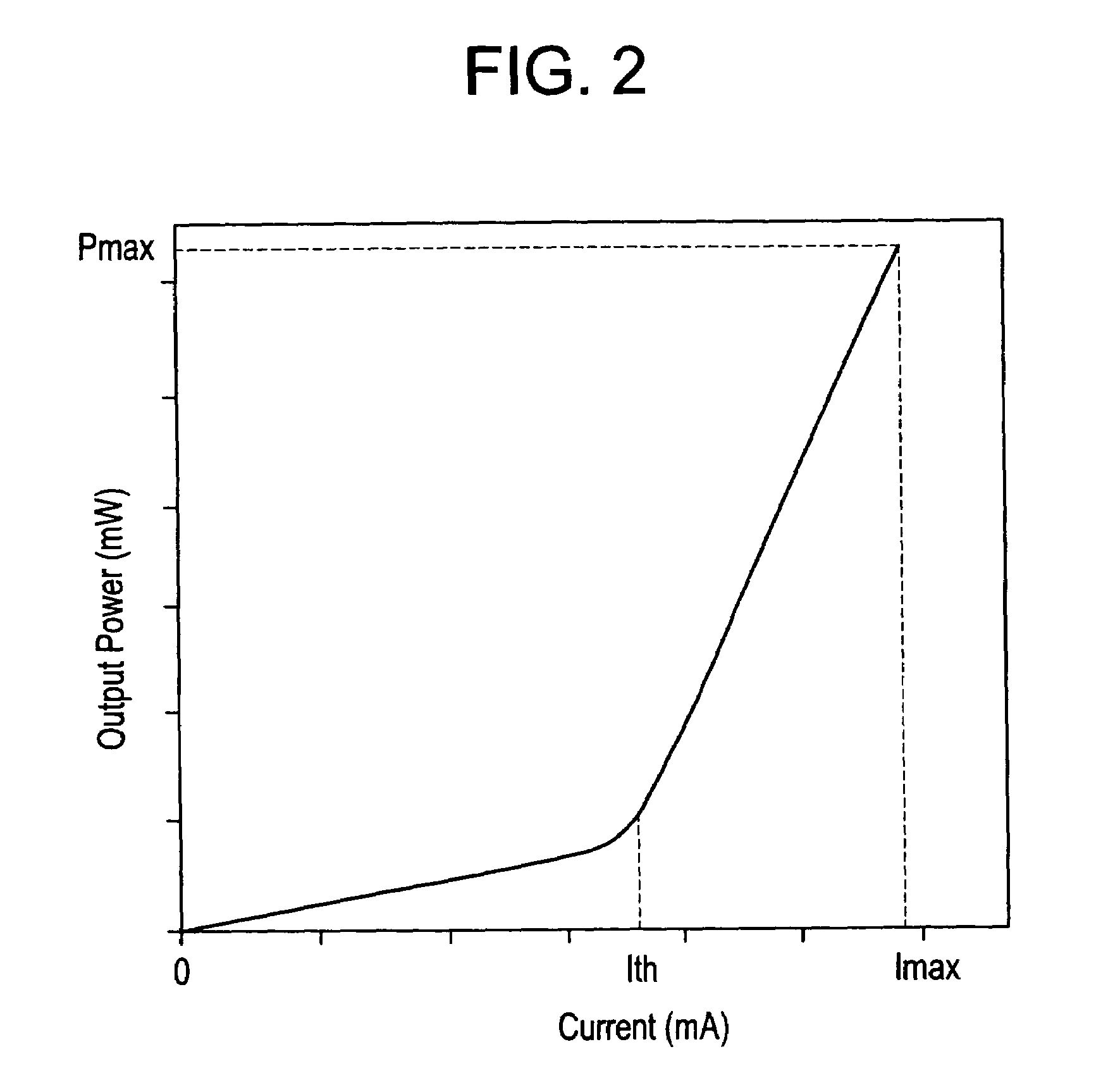

InactiveUS20080063016A1High output powerWithout excessive noiseOptical wave guidanceLaser cooling arrangementsDriving currentHarmonic

The present invention relates to methods for modulating a semiconductor laser and wavelength matching to a wavelength converter using monolithic micro-heaters integrated in the semiconductor laser. The present invention also relates to wavelength matching and stabilization in laser sources in general, without regard to whether the laser is modulated or whether second harmonic generation is utilized in the laser source. According to one embodiment of the present invention, a method of compensating for thermally induced patterning effects in a semiconductor laser is provided where the laser's heating element driving current IH is set to a relatively high magnitude when the laser's driving current ID is at a relatively low magnitude. Additional embodiments are disclosed and claimed.

Owner:CORNING INC

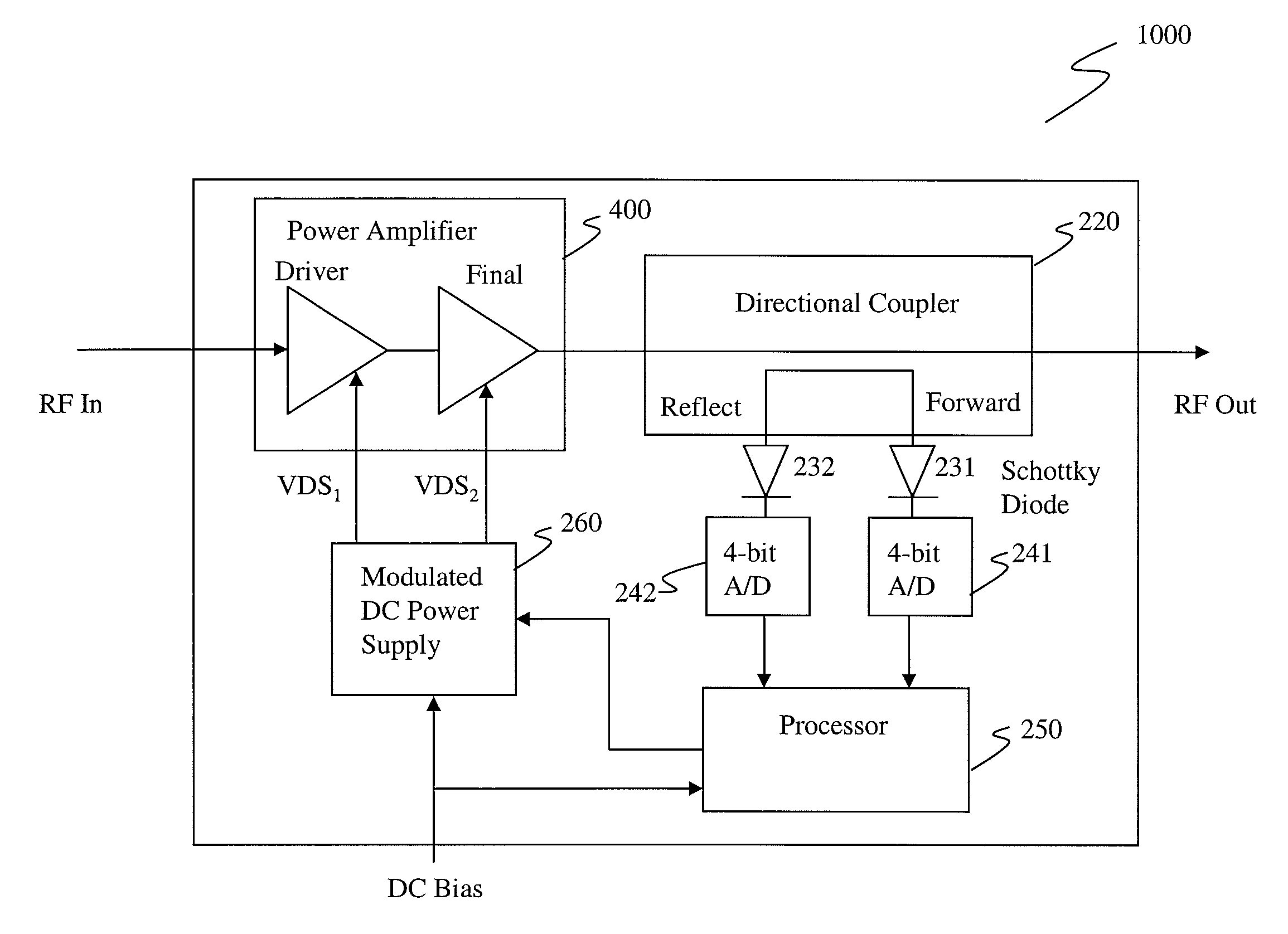

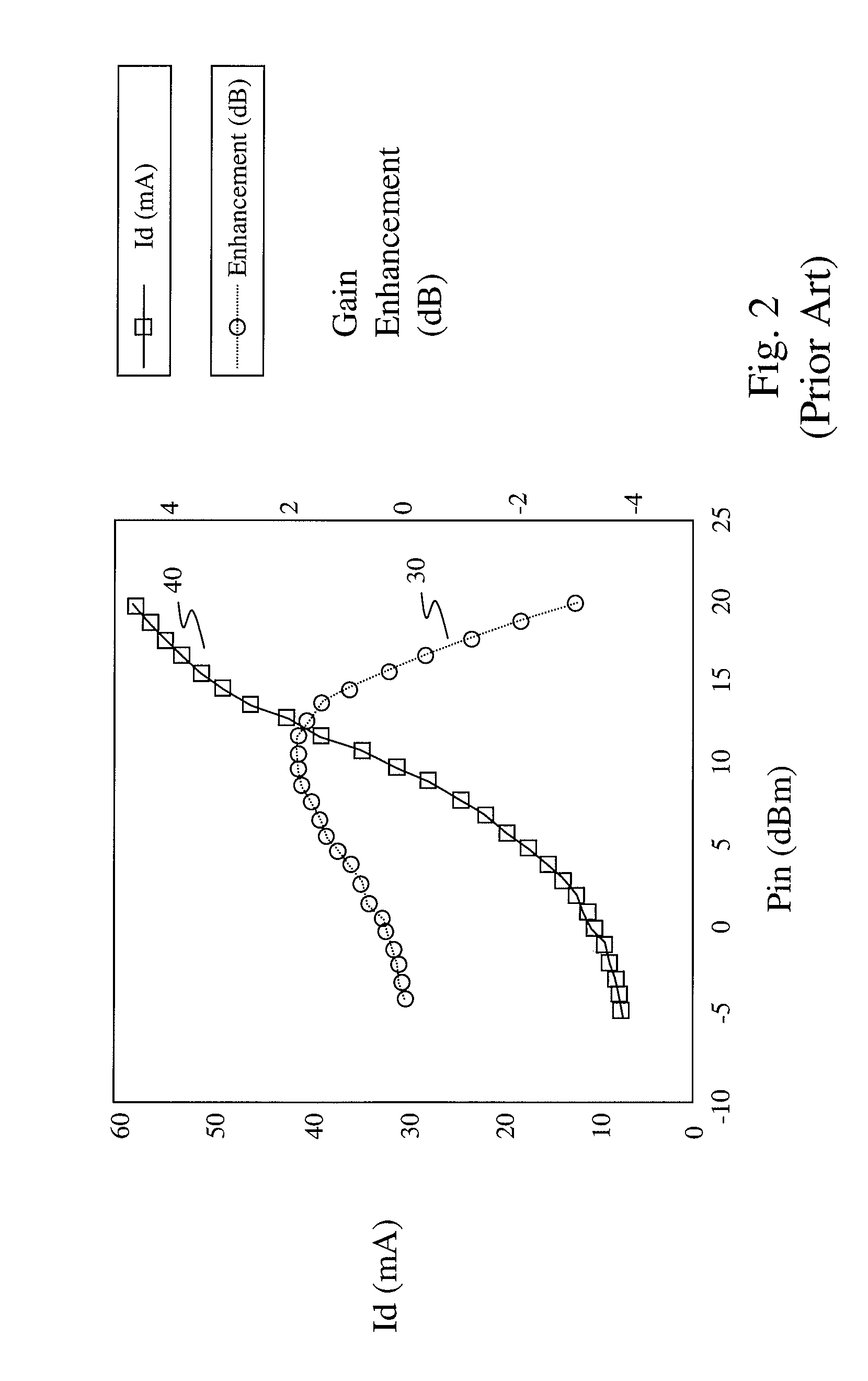

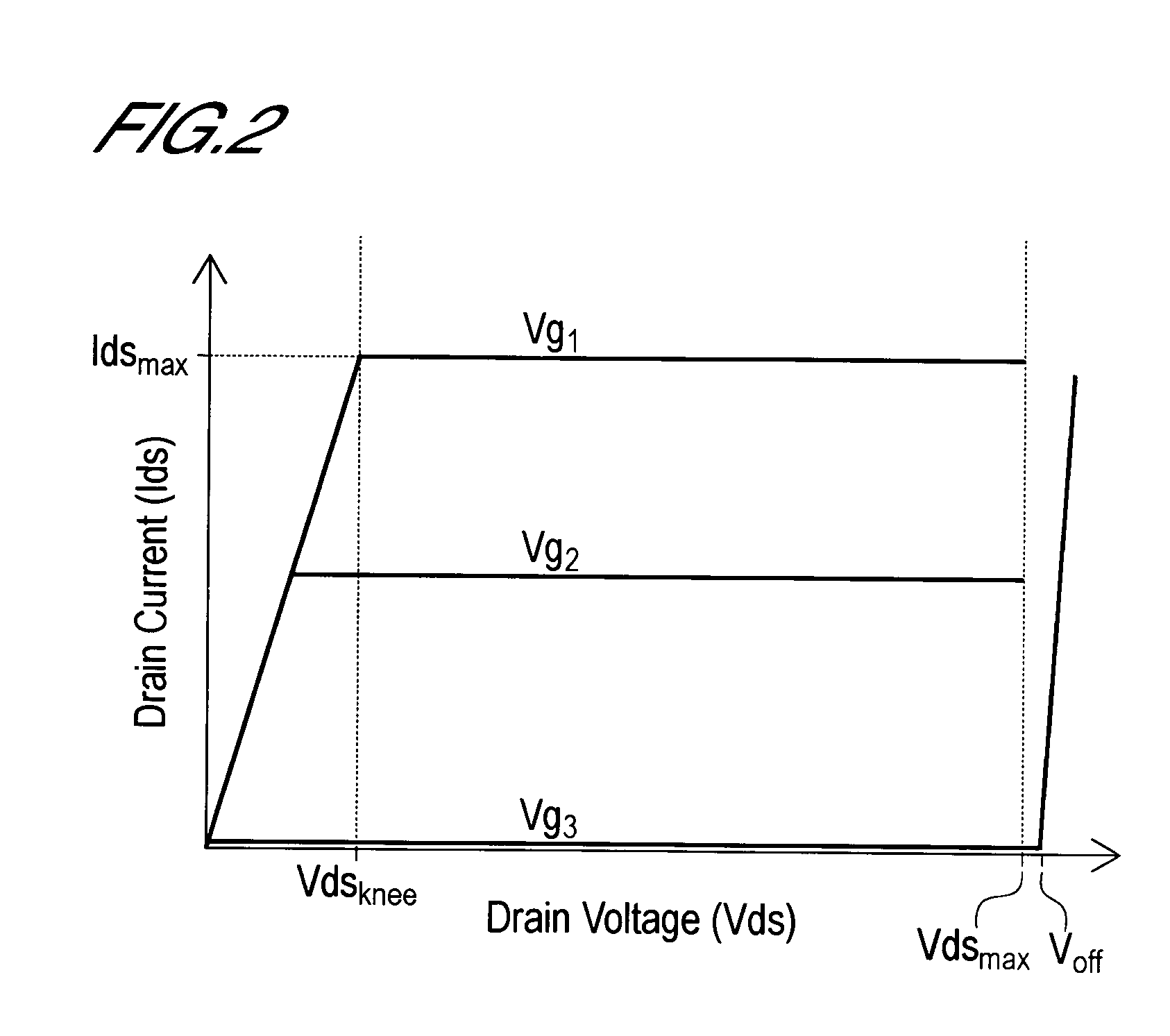

High efficiency linear microwave power amplifier

ActiveUS7477102B1High efficiencyHigh output powerHigh frequency amplifiersSupply voltage varying controlMicrowave power amplifiersEngineering

A post-distortion method for cascading amplifier stages in a two-stage microwave power amplifier and a dynamic biasing method using back-end processing for correcting nonlinearity in the power amplifier output. A first or driver stage biased in a near-A region with low distortion is cascaded with a second or power stage biased in a near-C region with high efficiency. The amplitude and phase responses of the two stages compensate another to yield a more linear overall gain for the overall power amplifier. The dynamic biasing scheme modulates the source to drain voltages of the transistors used in the amplifier stages based on the harmonics in amplifier output in order to minimize the harmonics and correct non-linearity in the output.

Owner:HRL LAB

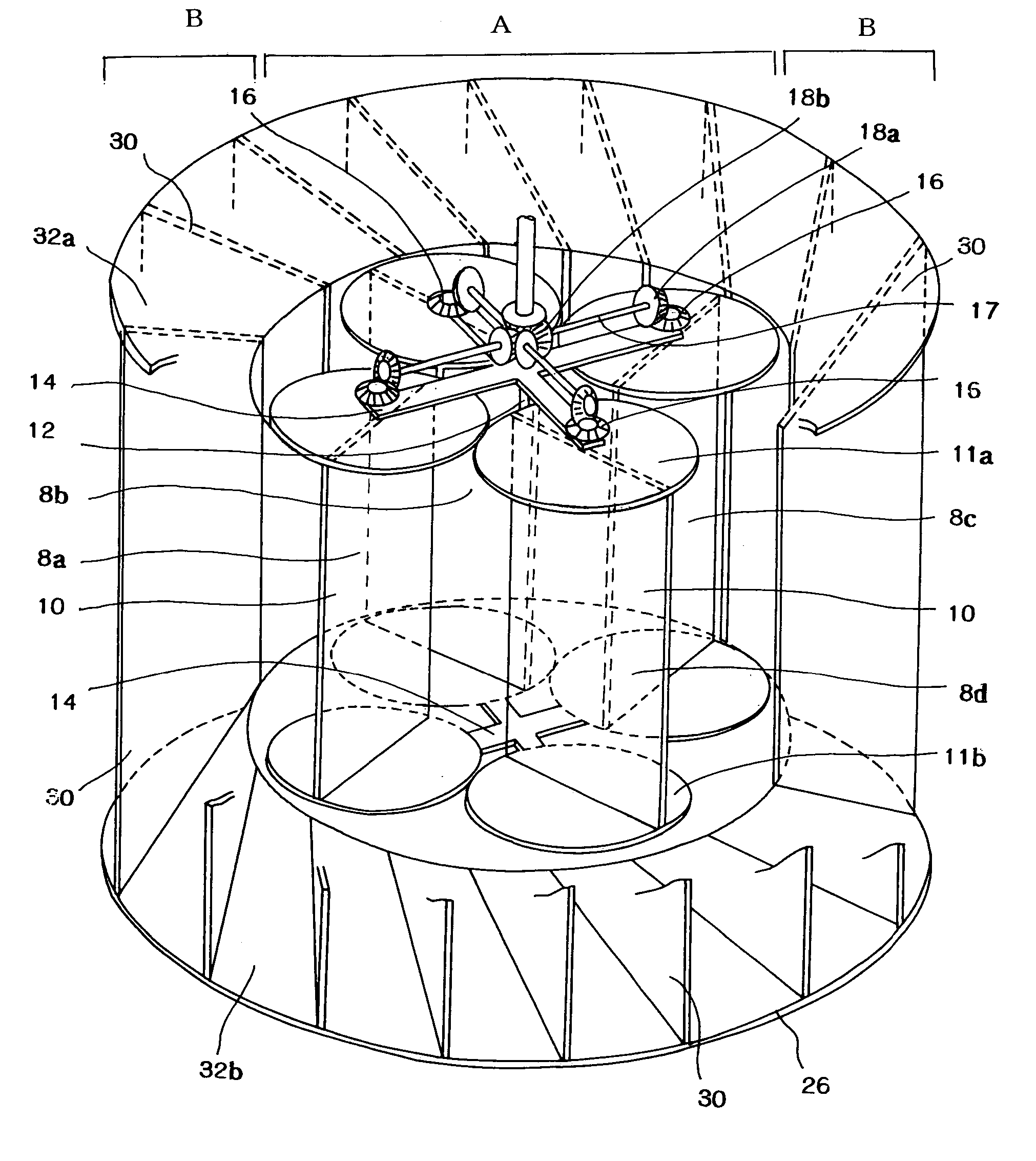

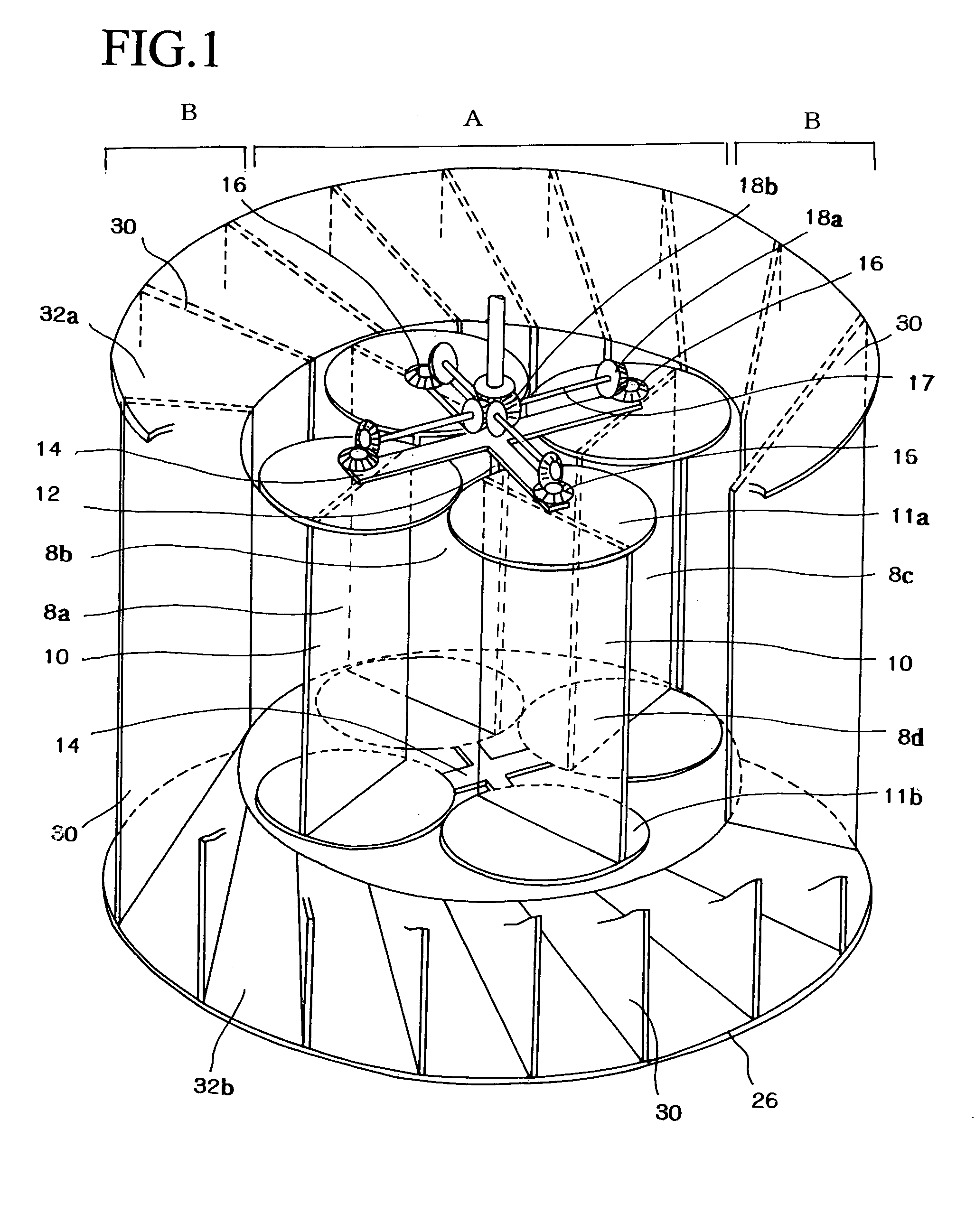

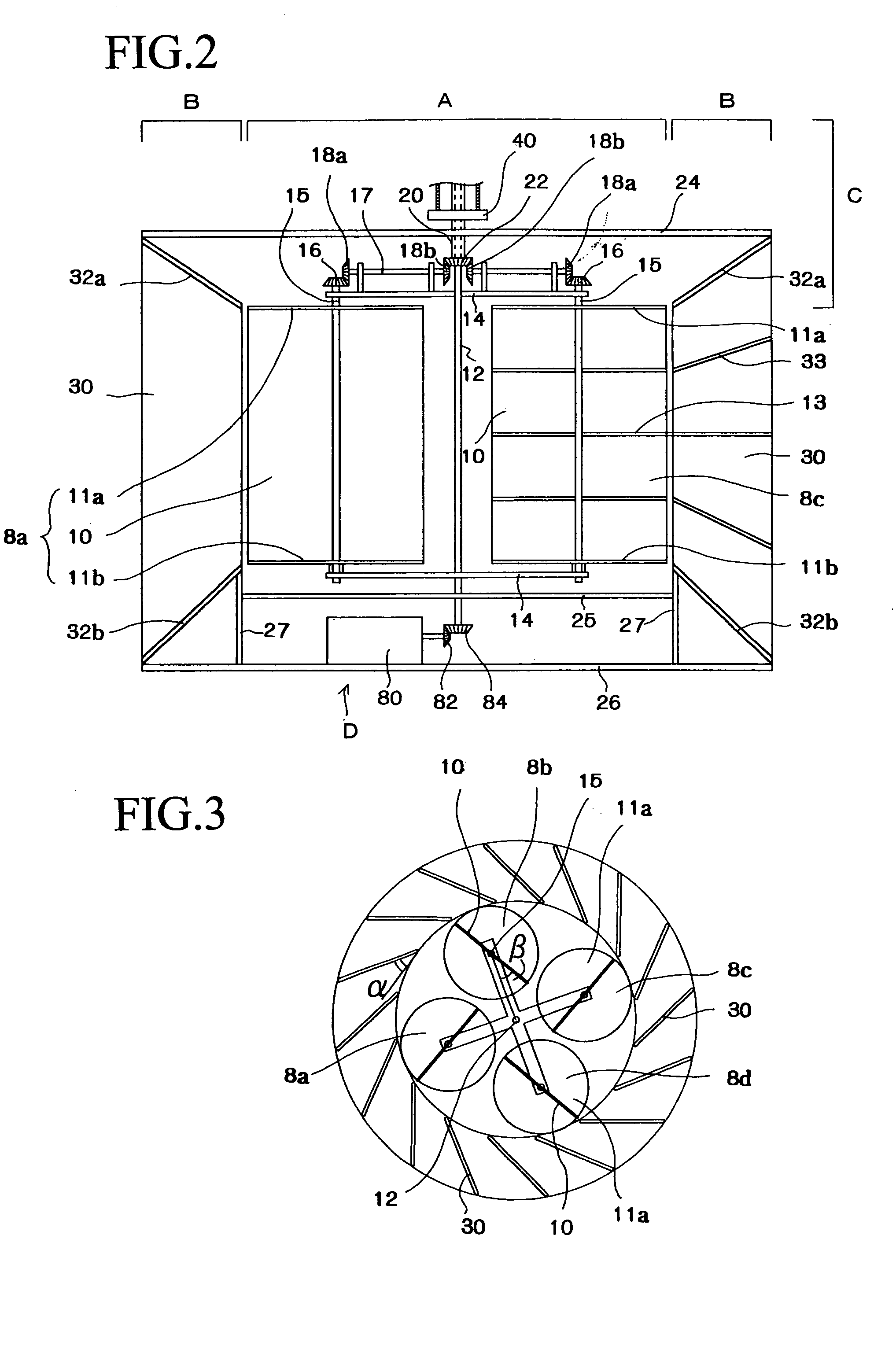

Vertical shaft driving device for vertical wind mills or the like and electric power generator using the same

InactiveUS7094017B2High output powerIncrease wind speedPropellersPump componentsClassical mechanicsWater flow

Owner:LEDERER YURIKO +1

Grating-outcoupled cavity resonator having uni-directional emission

InactiveUS7242705B2Broaden the spectral widthHigh output powerLaser optical resonator constructionSemiconductor laser structural detailsWhispering galleryGrating

A grating-outcoupled microcavity disk resonator has whispering gallery modes existing in a nearly circular resonator. Light is outcoupled by providing a grating region in the plane of the grating-outcoupled microcavity disk resonator. The grating region provides an outcoupling or loss mechanism that symmetrically interacts with the clockwise and counterclockwise whispering gallery modes, thereby making the resonator capable of surface emission.

Owner:PALO ALTO RES CENT INC

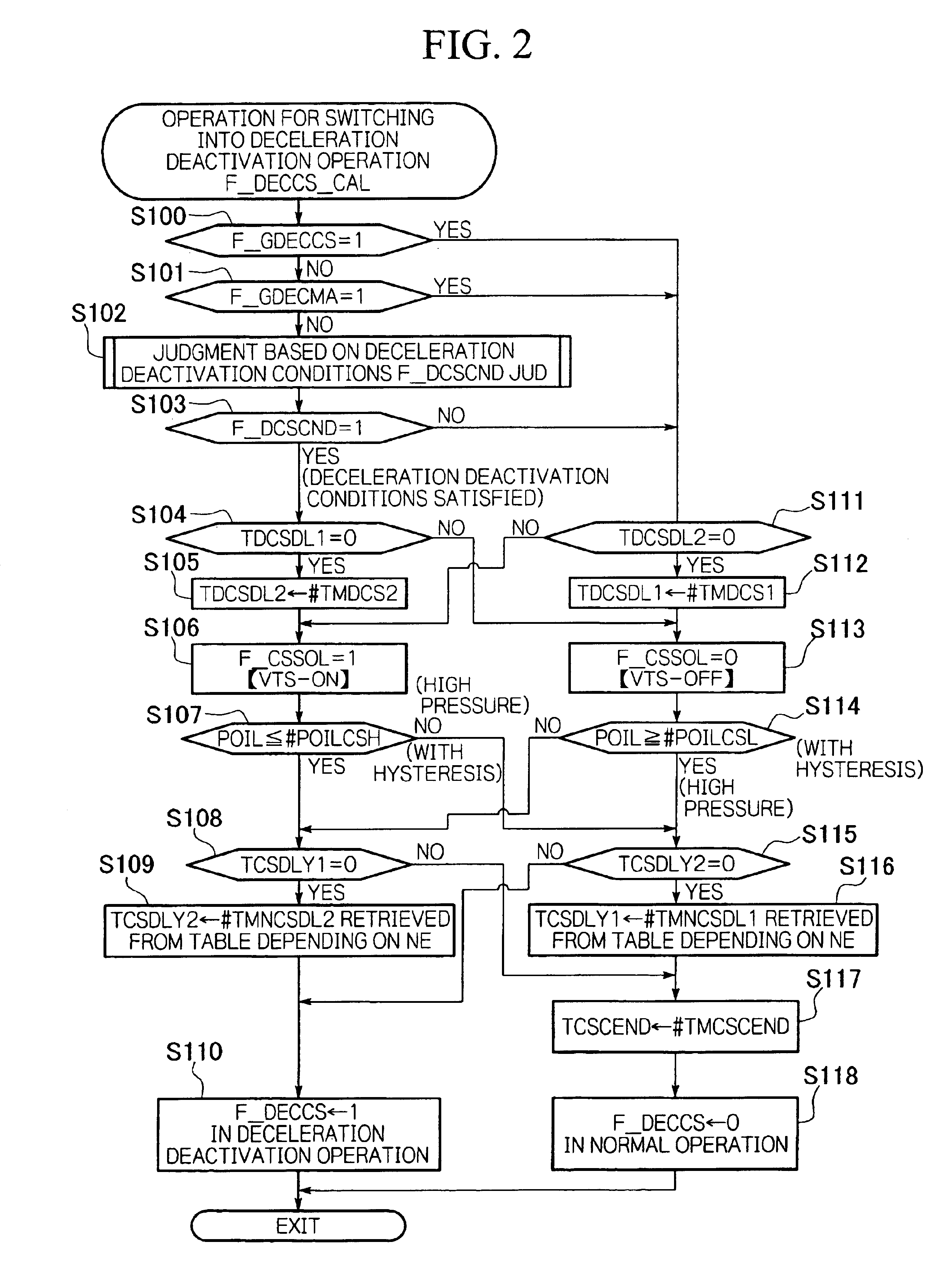

Motor controller of deceleration idling-cylinder engine vehicle

InactiveUS6950739B2Improve efficiencyHigh output powerAnalogue computers for vehiclesValve arrangementsStaringMotor controller

A motor control device for a vehicle having a deceleration deactivatable engine which includes at least one deactivatable cylinder which is deactivated during a deceleration traveling of the vehicle, and which is started by a motor when the operation thereof transitions from a deceleration deactivation operation to a normal operation. The motor control device comprises a cylinder deactivation state determining section (S202) for determining whether or not the engine is in a cylinder deactivation state, a cylinder deactivation executing section, a cylinder deactivation operation detecting section (S201) for detecting whether or not the cylinder deactivation executing section is activated, and a starting torque setting section (S201-S204) for setting staring torque for starting the engine by the motor. When it is determined, by the cylinder deactivation state determining section, that the engine is in a cylinder deactivation state, and it is determined, by the cylinder deactivation operation detecting section, that the engine is to return to the fuel supply operation, the starting torque setting section sets a smaller staring torque than in the case of a normal operation. Accordingly, the output of the motor is optimally set when the operation transitions from the cylinder deactivation operation to the normal operation; thus, a smooth drivability and an improved fuel consumption efficiency can be obtained.

Owner:HONDA MOTOR CO LTD

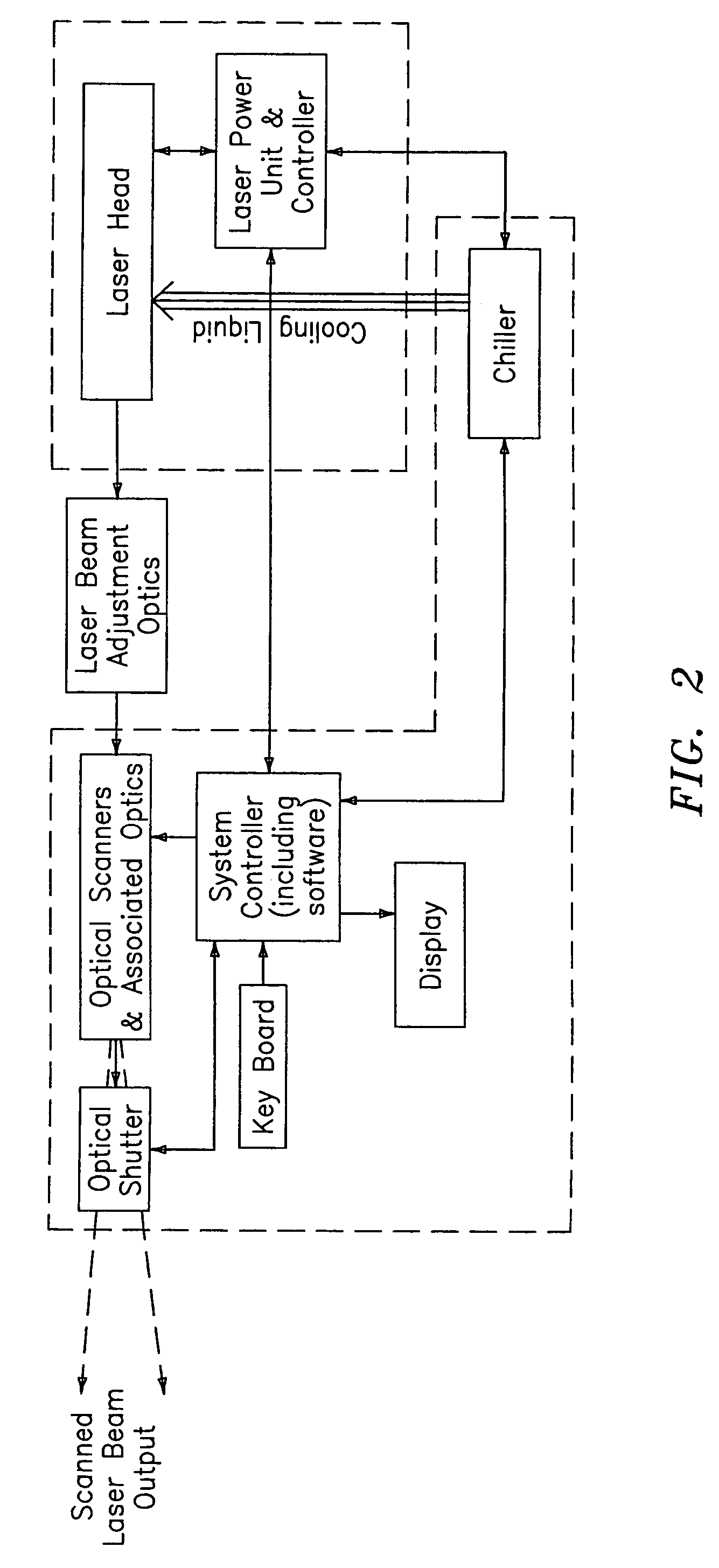

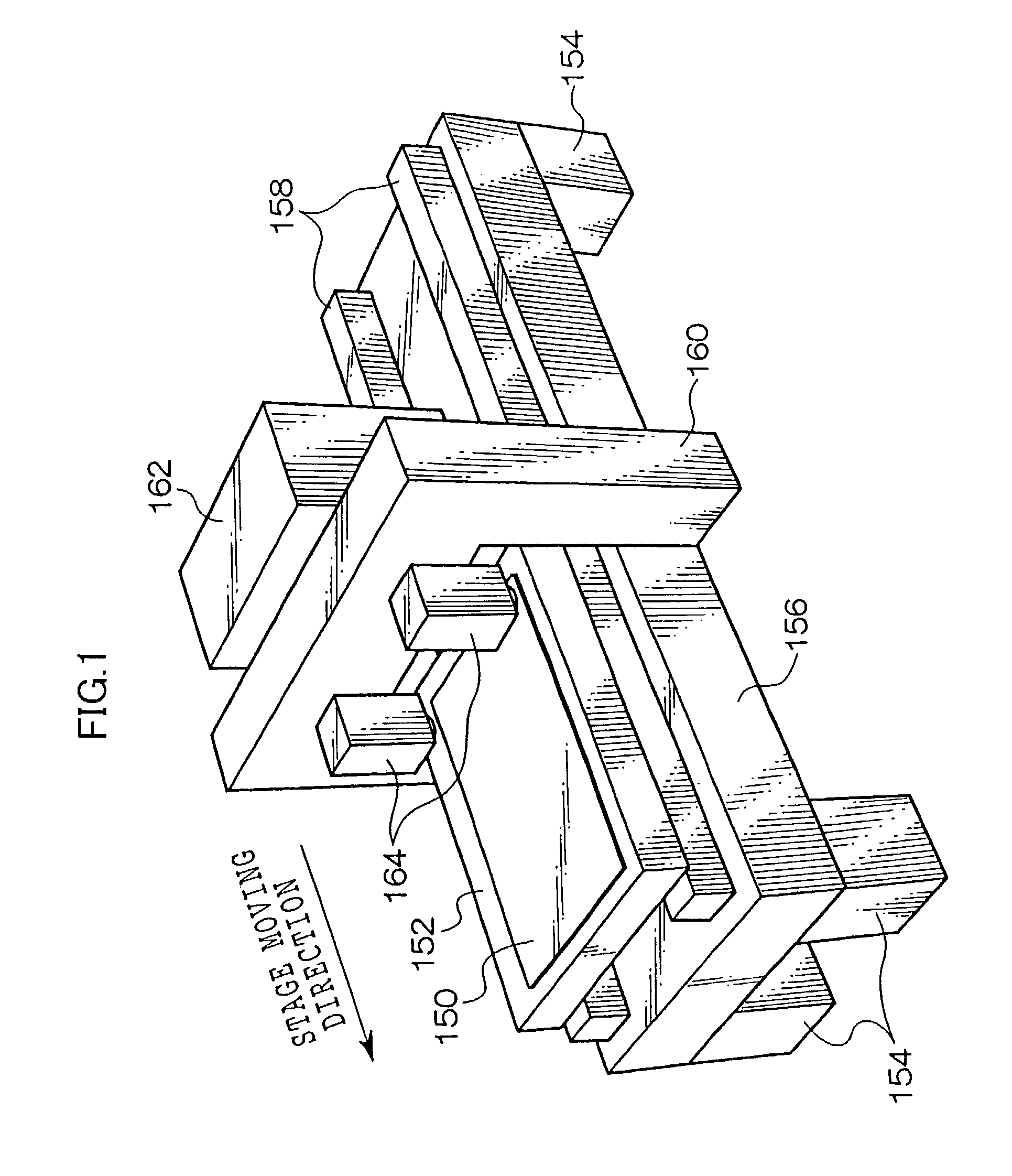

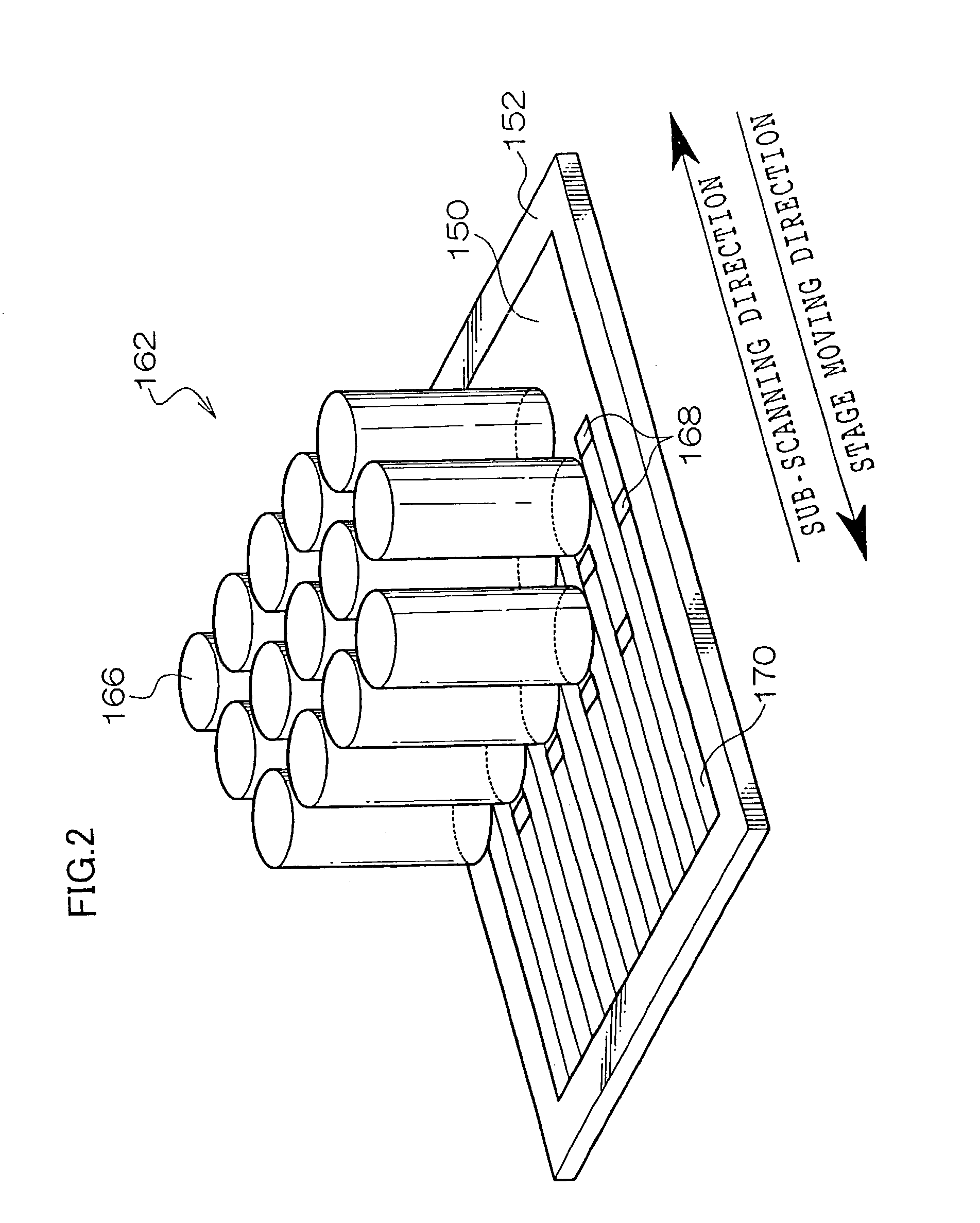

Laser annealer and laser thin-film forming apparatus

InactiveUS7112760B2Increase speedGood crystal characteristicLaser using scattering effectsVacuum evaporation coatingSpatial light modulatorControl signal

A laser annealer has a laser light source with at least one GaN-type semiconductor laser and is configured so as to form emission points that emit laser beams having a wavelength of 350 to 450 nm, and a scanning device for scanning an annealing surface with the laser beams. The laser annealer may have a spatial light modulator for modulating the laser beams, and in which pixel portions whose light modulating states change in accordance with control signals are arranged on a substrate. The invention is applied to a laser thin-film forming apparatus. The apparatus has a laser source that has at least one semiconductor laser and is configured so as to form emission points, and an optical system for focusing laser beams into a single beam in the width direction of a substrate.

Owner:FUJIFILM HLDG CORP +1

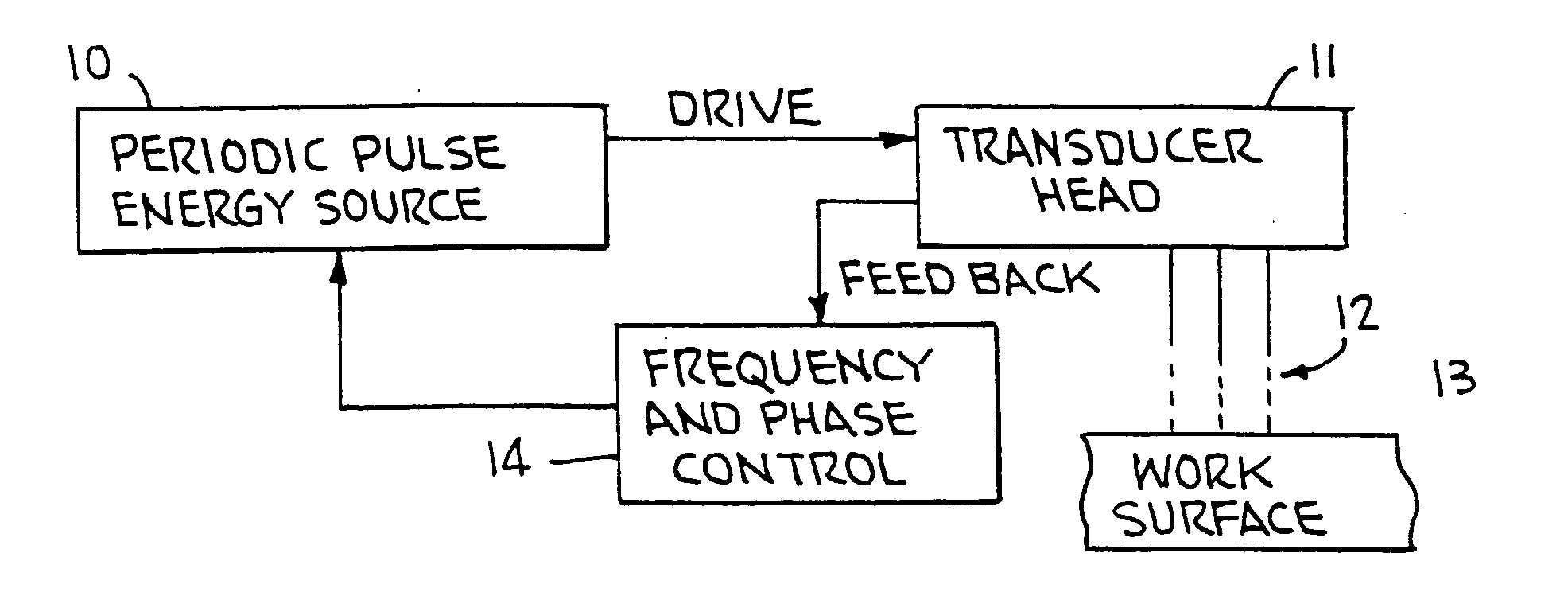

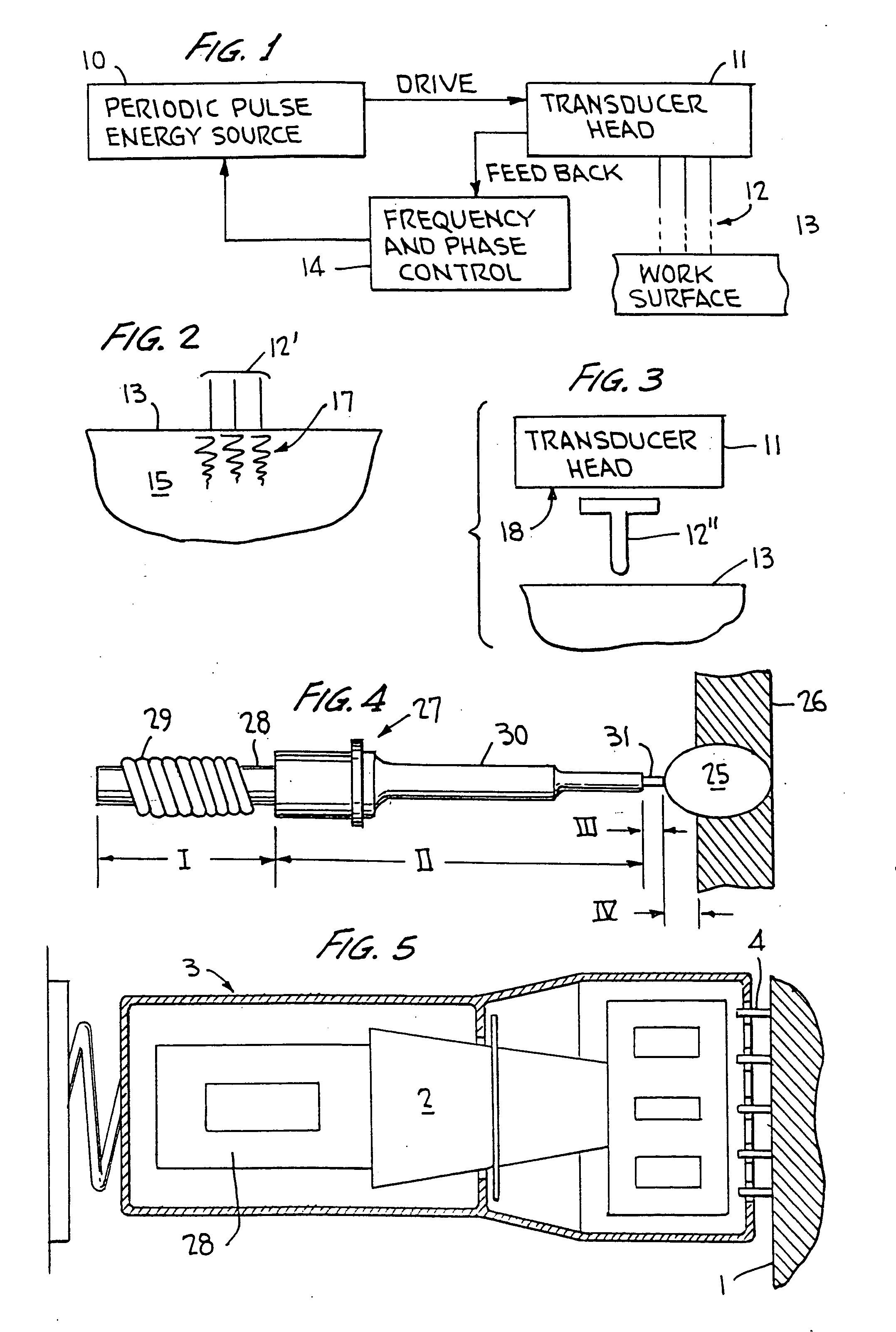

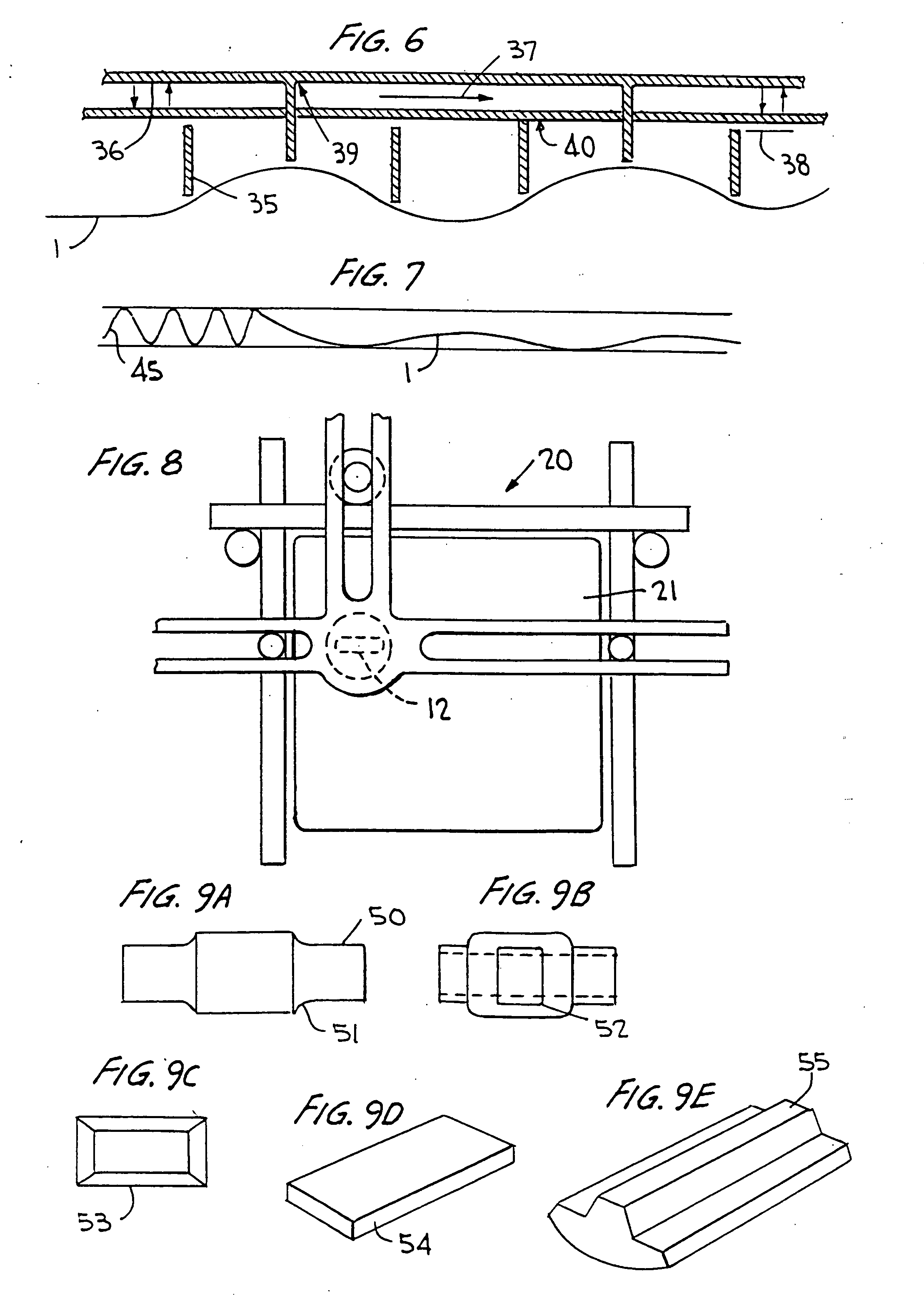

Ultrasonic impact machining of body surfaces to correct defects and strengthen work surfaces

InactiveUS20060237104A1Increase speedHigh energyFurnace typesMechanical vibrations separationUltrasonic sensorPeriodic oscillation

Metallic workpieces of diverse shapes having work surfaces which are deformed at the surface and adjacent sub-surface layers by surface impact from ultrasonic transducers employing freely axially moving impacting elements propelled and energized by a transducer oscillating surface vibrating periodically at an ultrasonic frequency. The impacting elements are propelled in a random aperiodic and controlled impact mode at different phases of the periodic oscillation cycles. The transducer may be portable and provides a series of mechanically interconnected stages having mechanical resonances harmonically related as a multiple of the primary ultrasonic frequency and have matched stage resistances under instantaneous loading when the impact elements are driven by the transducer oscillating surface into the surface of the workpiece. This mode of operation produces Q-factor amplification of the input ultrasonic power oscillator energy at the impact needles and high propulsion velocities making it possible to machine metallic workpiece bodies to greater depths for compressing the metal to increase compressive strength of the workpiece work surfaces to substantially the ultimate material strength. The impact machining is done at ambient temperatures.

Owner:APPLIED ULTRASONICS INT PTY LTD

Intermetallic compounds for use as catalysts and catalytic systems

InactiveUS20040126267A1Large powerDecrease in levelActive material electrodesAqueous electrolyte fuel cellsHydrogen fuelCompound (substance)

The invention is directed to intermetallic compounds for use as catalysts for chemical reactions and catalytic systems. The structure of ordered intermetallic compounds enables such compounds to function as highly efficient catalysts. The ordered intermetallic compounds may be used to catalyze reactions in fuel cells (e.g., hydrogen fuel cells), amongst numerous other applications.

Owner:CORNELL RES FOUNDATION INC

Manufacturing method of white light LED and structure thereof

InactiveUS20080246397A1Output powerPoor colorDischarge tube luminescnet screensLamp detailsFluorescenceEngineering

A manufacturing method of white light LED and a structure thereof include first, a substrate being prepared to be formed as a consecutively connected holder, on a first electrode of which non-conductive fluorescent glue is coated to form a fluorescent layer, on which a blue light chip is fixed; second, two conducting wires being welded onto the chip and electrically connected to both the first electrode and the second electrode of the holder respectively, finally, glue body encapsulating the holder, the fluorescent layer, the chip, and the two conducting wires to form a photic zone, over which a frame body encloses; furthermore, a window being formed on the frame body and provided for making the photic zone exposed. When blue light chip is excited to generate blue light, which will further excite the fluorescent layer to emit yellow light, then both blue light and yellow light will be dispersed through the photic zone to generate a uniform light source, which may output light longitudinally and collectively, making the output power promoted notably and the lightness enhanced significantly.

Owner:HARVATEK CORPORATION

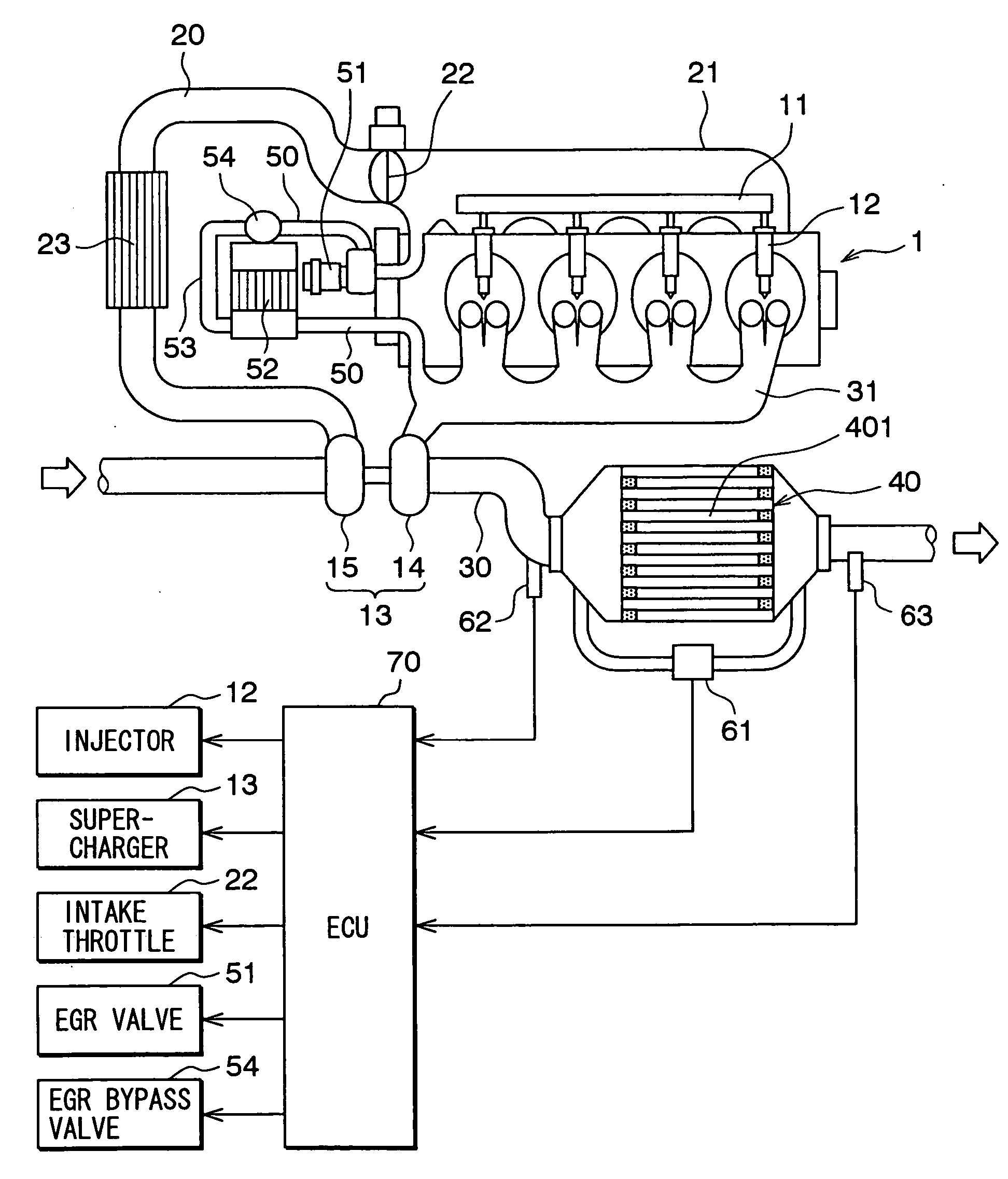

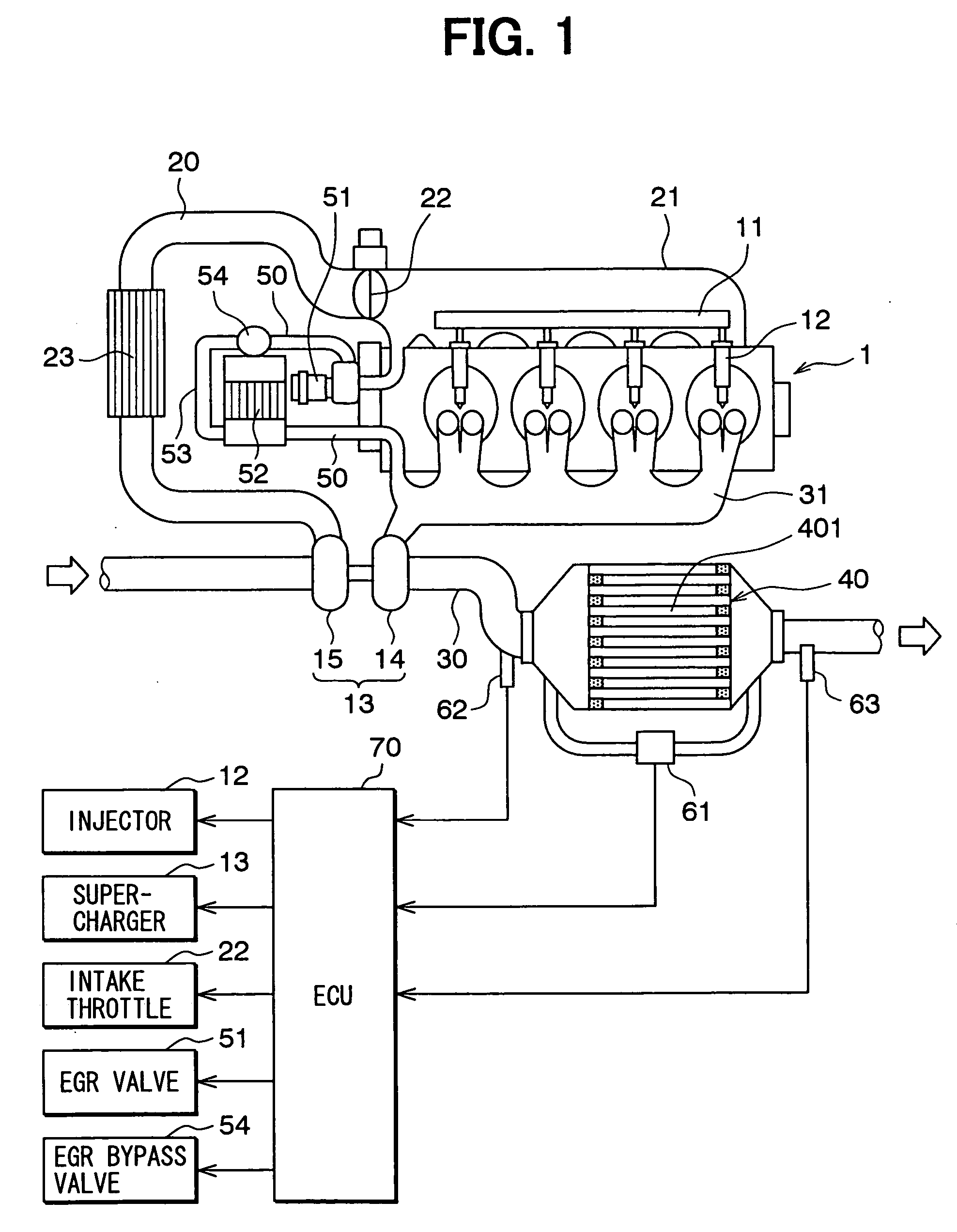

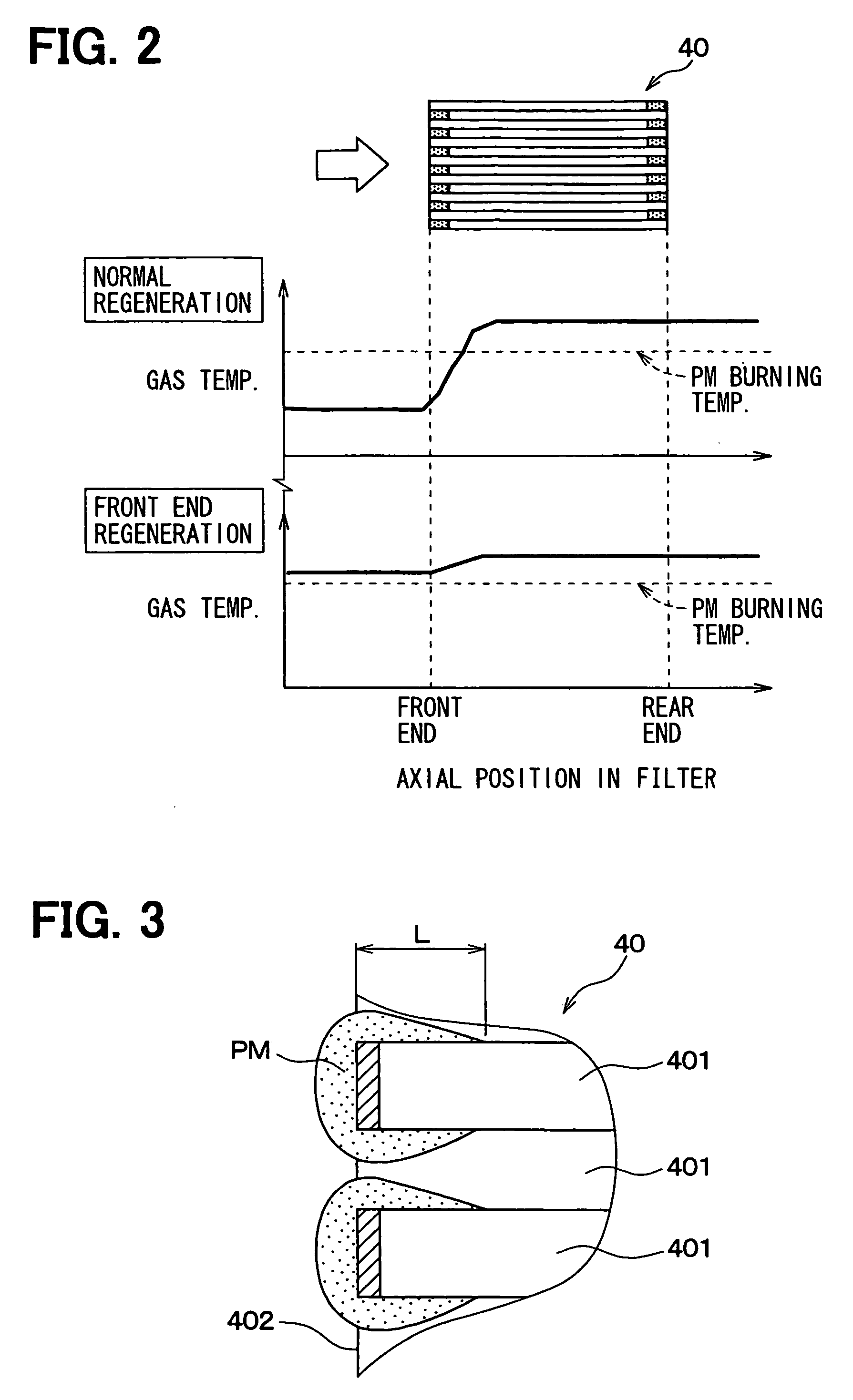

Exhaust emission control system for internal combustion engine

InactiveUS20070012034A1High output powerElectrical controlNon-fuel substance addition to fuelControl systemEnvironmental engineering

In an exhaust emission control system for a vehicular internal combustion engine, a particulate filter collects particulate matters in an exhaust gas of the internal combustion engine. A filter regenerator regenerates the particulate filter by burning the particulate matters accumulated in the particulate filter. A filter front clogging detector determines whether a front end portion of the particulate filter is clogged by the particulate matters. A filter regeneration controller that controls the filter regenerator to perform a front regeneration to remove the particulate matters accumulated in the front end portion of the particulate filter when the filter front clogging detector determines that the front end portion of the particulate filter is clogged.

Owner:DENSO CORP

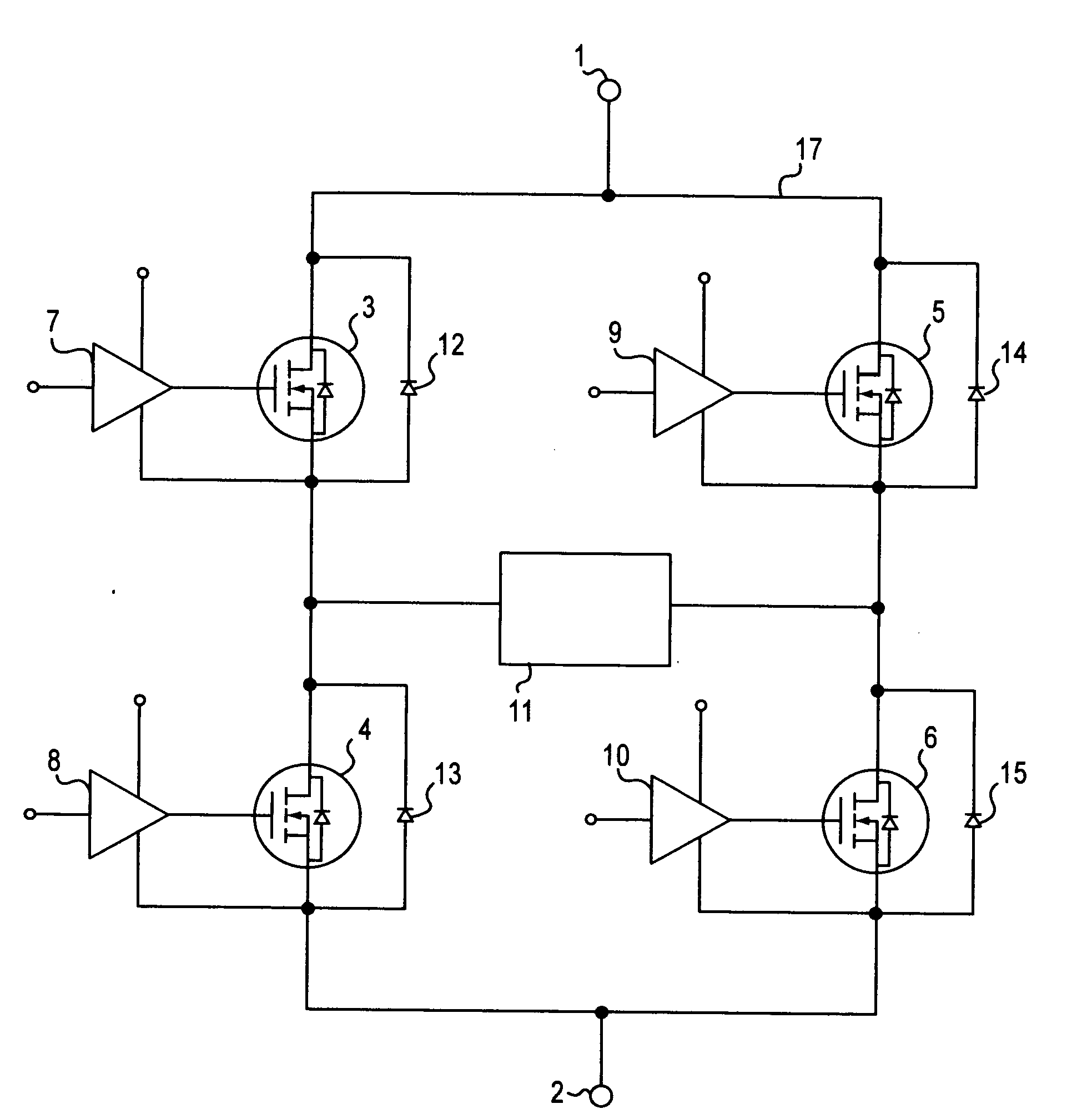

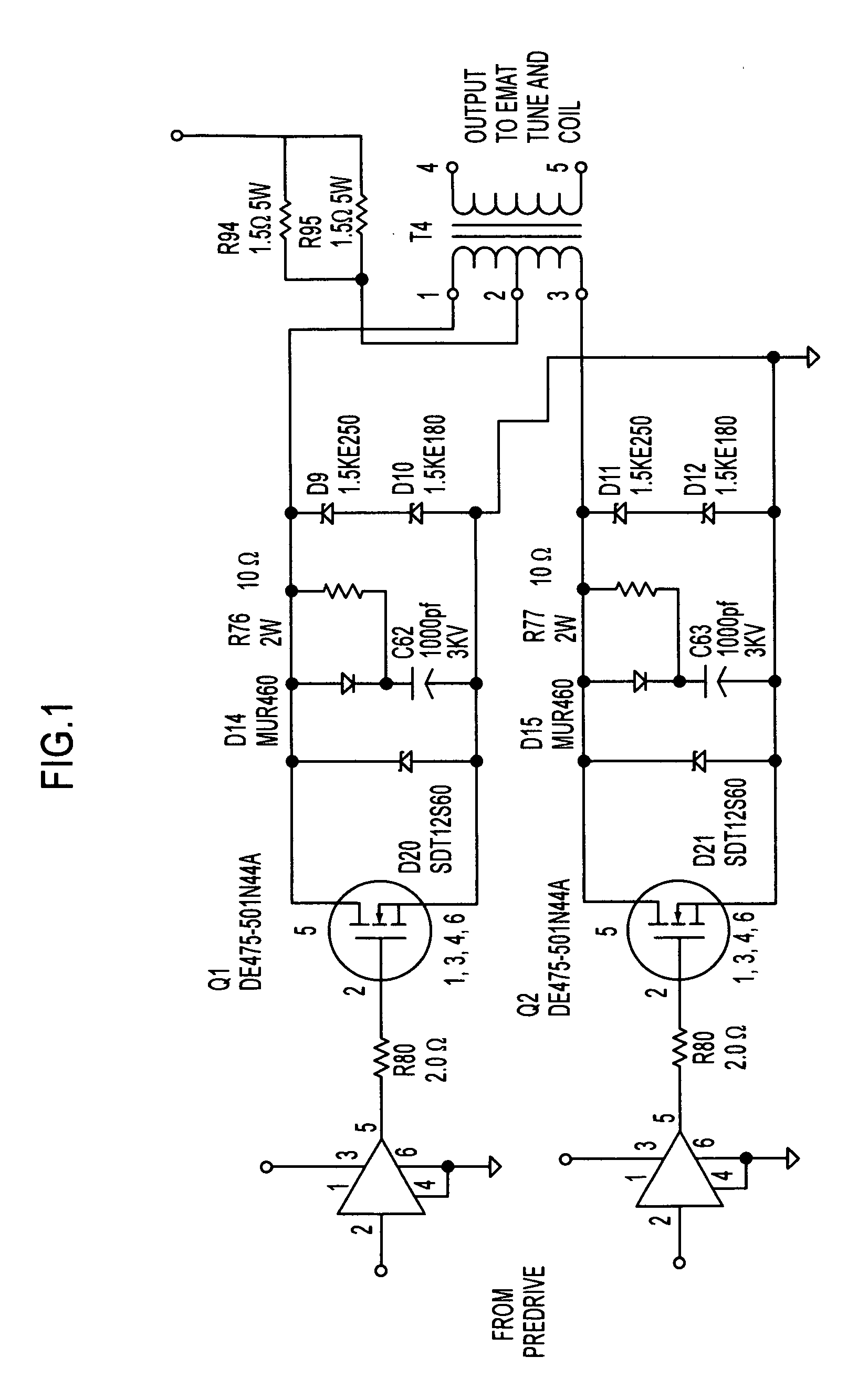

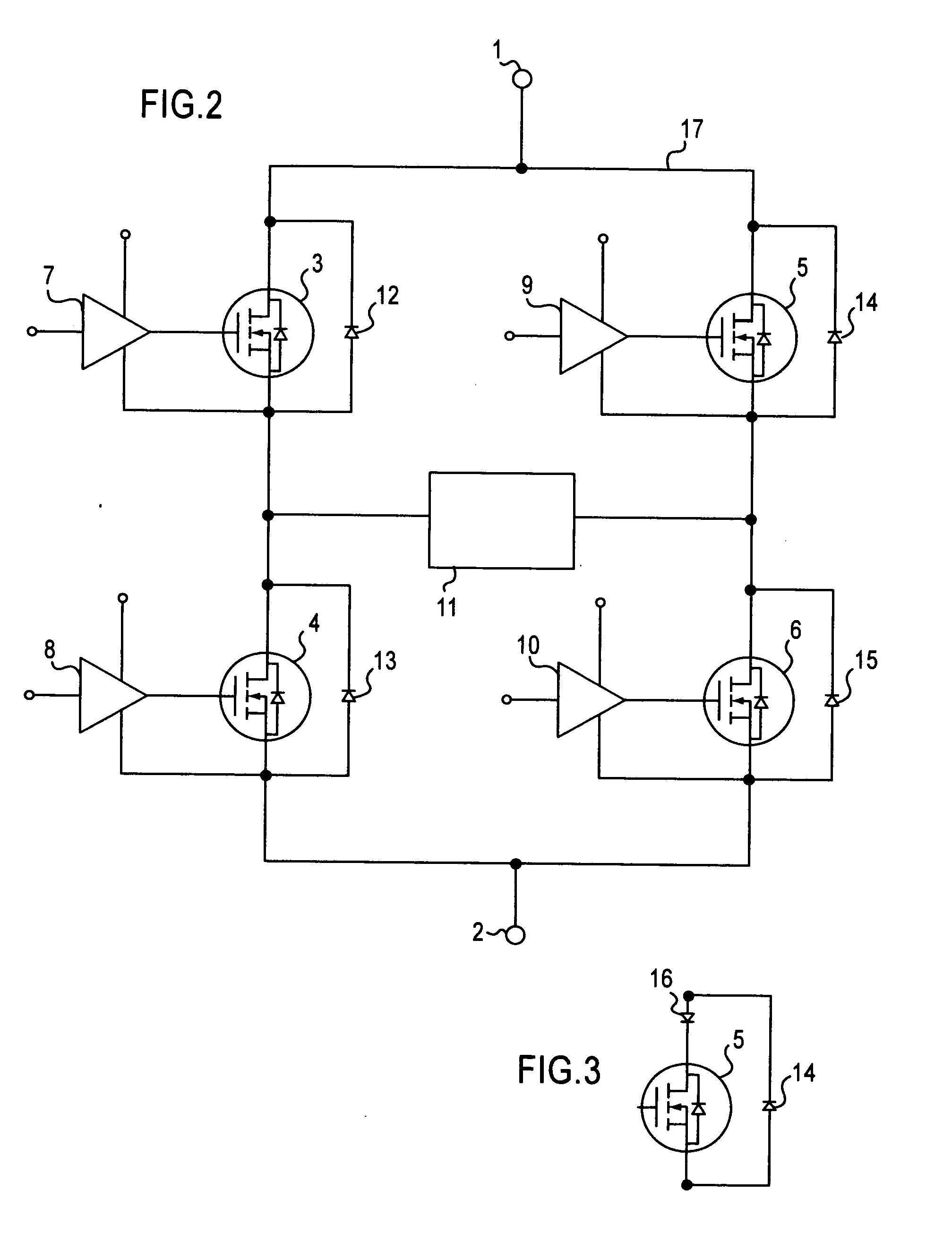

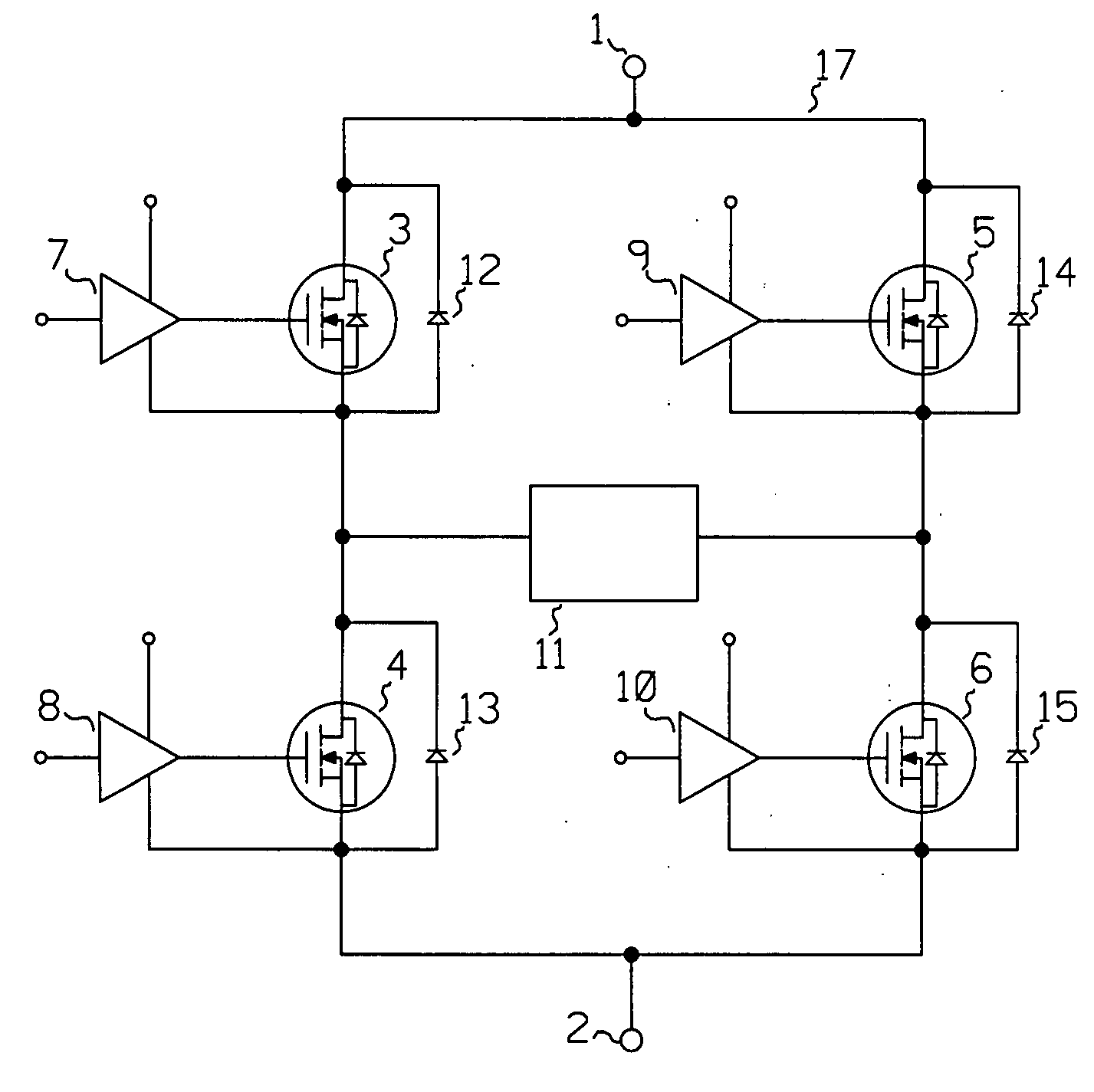

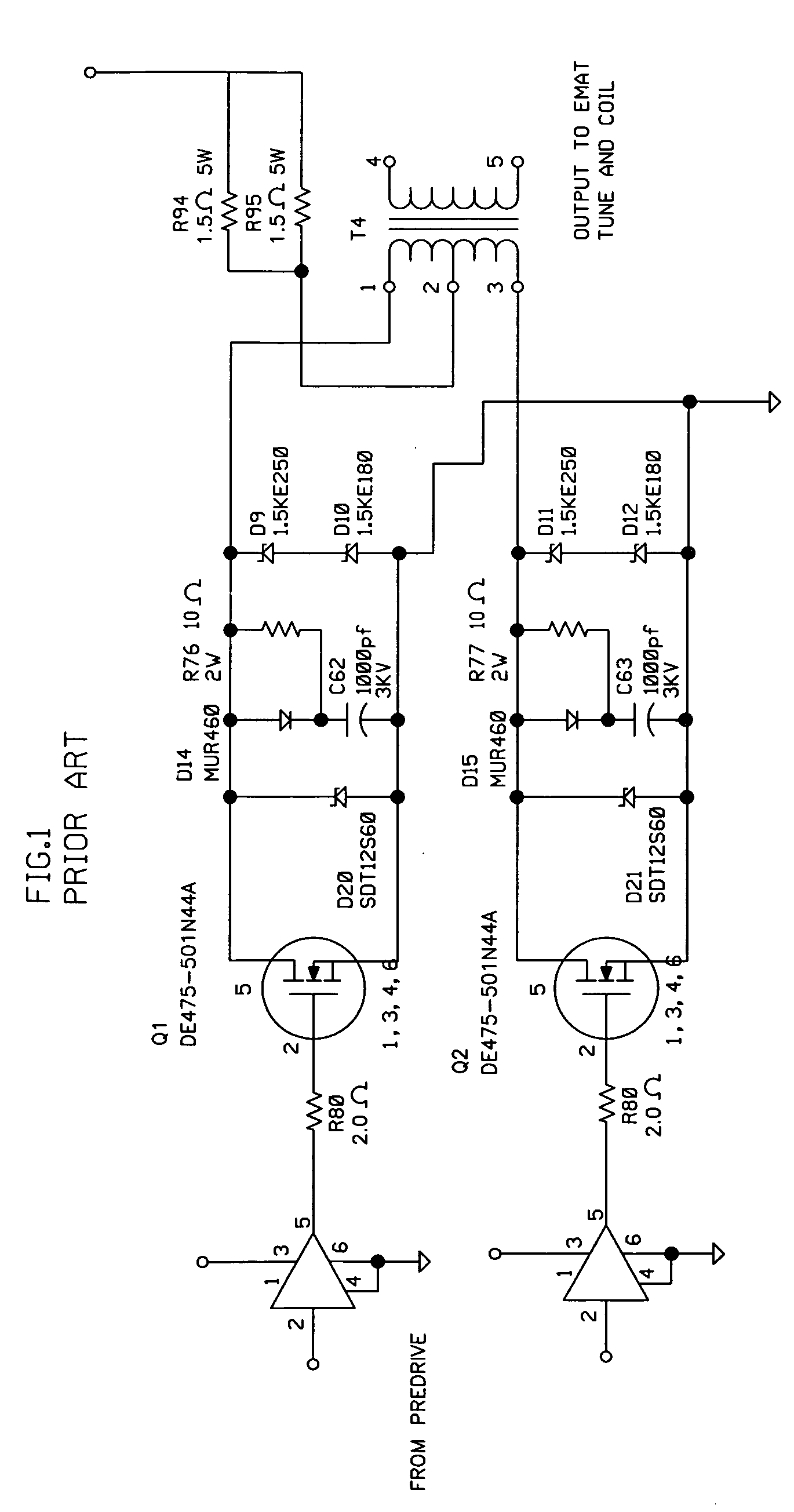

H-bridge pulse generator

InactiveUS20090102443A1High output powerImprove efficiencyMechanical vibrations separationElectric variable regulationMOSFETTransformer

A new type of circuit for driving an electromagnetic acoustic transducer (EMAT) which does not employ push-pull technology using a transformer but instant uses a novel circuit employing a series of Mosfet switches to correct all the disadvantages of using a transformer.

Owner:SMITH STEPHEN

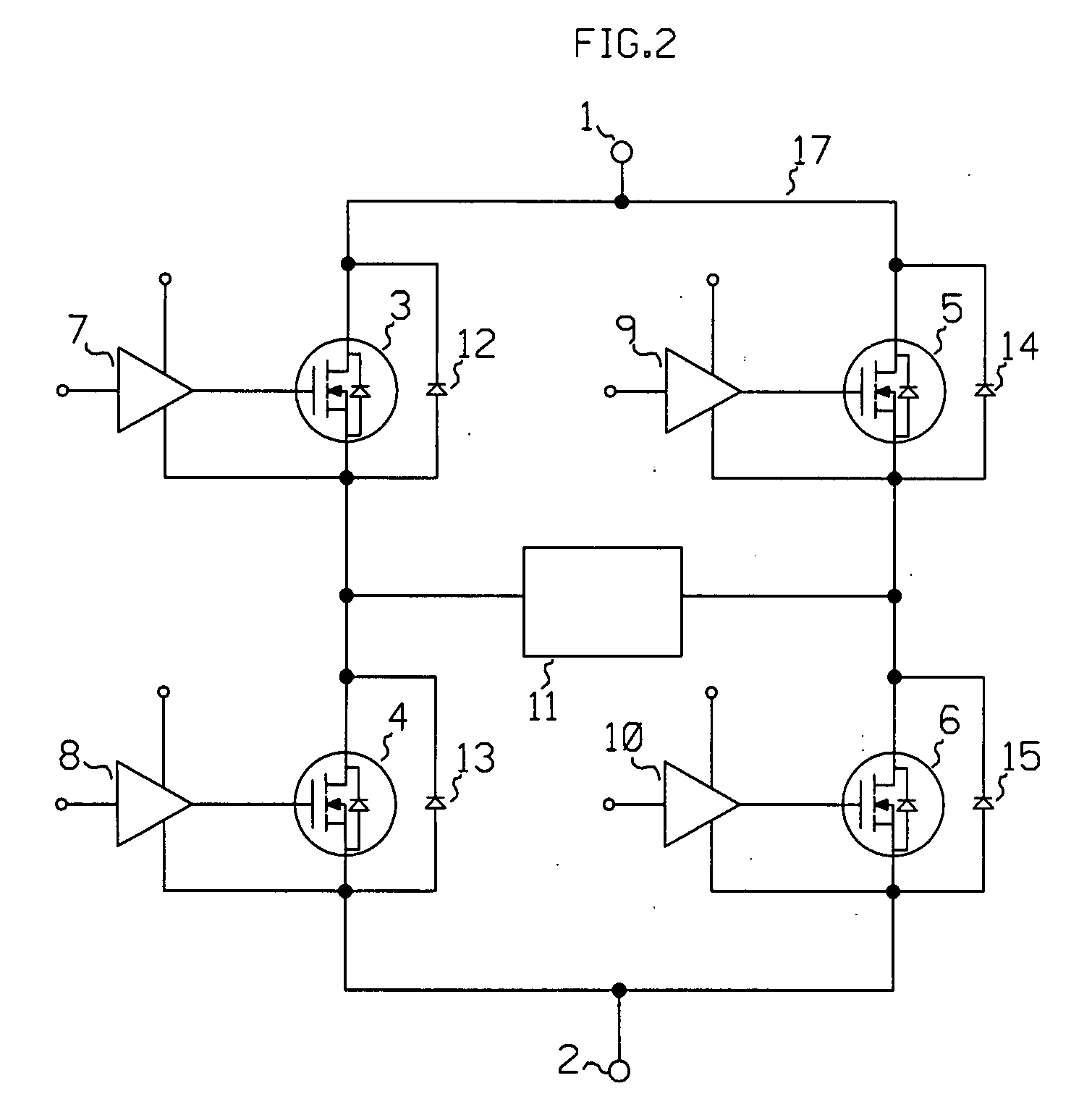

H-Bridge pulse generator

InactiveUS20100254221A1Reduce Propagation DelayAvoid failureMechanical vibrations separationTransmissionOutput transformerPeak value

Electronic circuitry for high-power, high-frequency excitation of electromagnetic acoustic transducers (EMAT) without the use of a matching transformer is described. This circuit contains a least 4 switching devices such as power Mosfet transistors, arranged in an H-Bridge configuration that are designed to drive various EMATs over a wide range of frequencies. The switching devices can be connected in parallel with respect to the H-Bridge and switched in sequence for greater power output and variety of wave forms. This circuit configuration can provide a many excitation waveforms including, Churp, Hemming window tone burst, rectangular tone burst and Barker Code wave forms.An improved electronic pulser circuit based on the H-bridge topology is designed for driving the sensor coils of an electromagnetic acoustic transducer (EMAT) to correct the disadvantages of conventional H-bridge pulsers and pulsers that require the use of an output transformer. A plurality of switching devices, primarily power Mosfets, are connected in parallel and augmented with support circuitry to provide improved performance in terms of increased power output, stability, reduced noise and complex output wave forms. This improved design provides for the application of modulated pulses such as multi-pulse, multi-frequency tone bursts of peak power outputs in excess of 20 thousand watts and frequencies in excess of 10 thousand Hertz.

Owner:SMITH STEPHEN

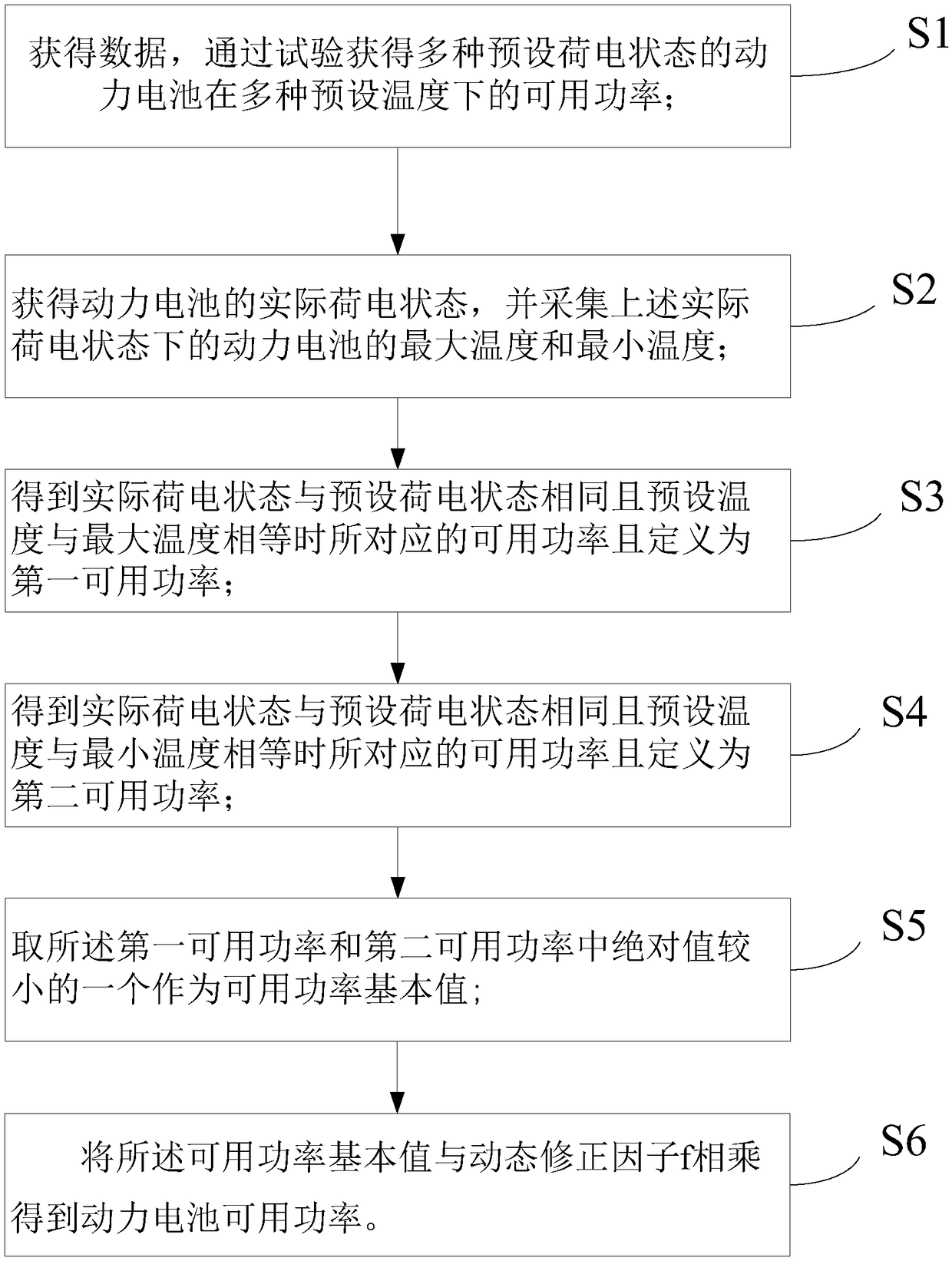

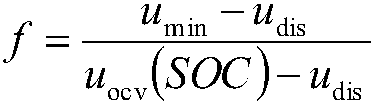

Method for estimating available power of vehicle power battery

ActiveCN108072844AAvoid sharp drops in voltageAvoid triggering battery protectionElectrical testingElectrical batteryPower battery

The invention discloses a method for estimating the available power of a vehicle power battery, and the method comprises the steps: obtaining the data; obtaining an actual charge state of the power battery, and collecting the maximum temperature and minimum temperature of the power battery in the actual charge state; obtaining a corresponding available power when the actual charge state is the same as a preset charge state and the preset temperature is equal to the maximum temperature, and defining the available power as first available power; obtaining a corresponding available power when theactual charge state is the same as a preset charge state and the preset temperature is equal to the minimum temperature, and defining the available power as second available power; taking the power with the smaller absolute value in the first and second available power as an available power basic value, multiplying the available power basic value by a dynamic correcting factor f, and obtaining the available power of the power battery. The method can effectively prevent the sharp drop of a voltage from triggering battery protection and remarkably reducing the output power.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

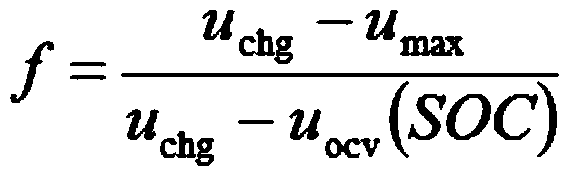

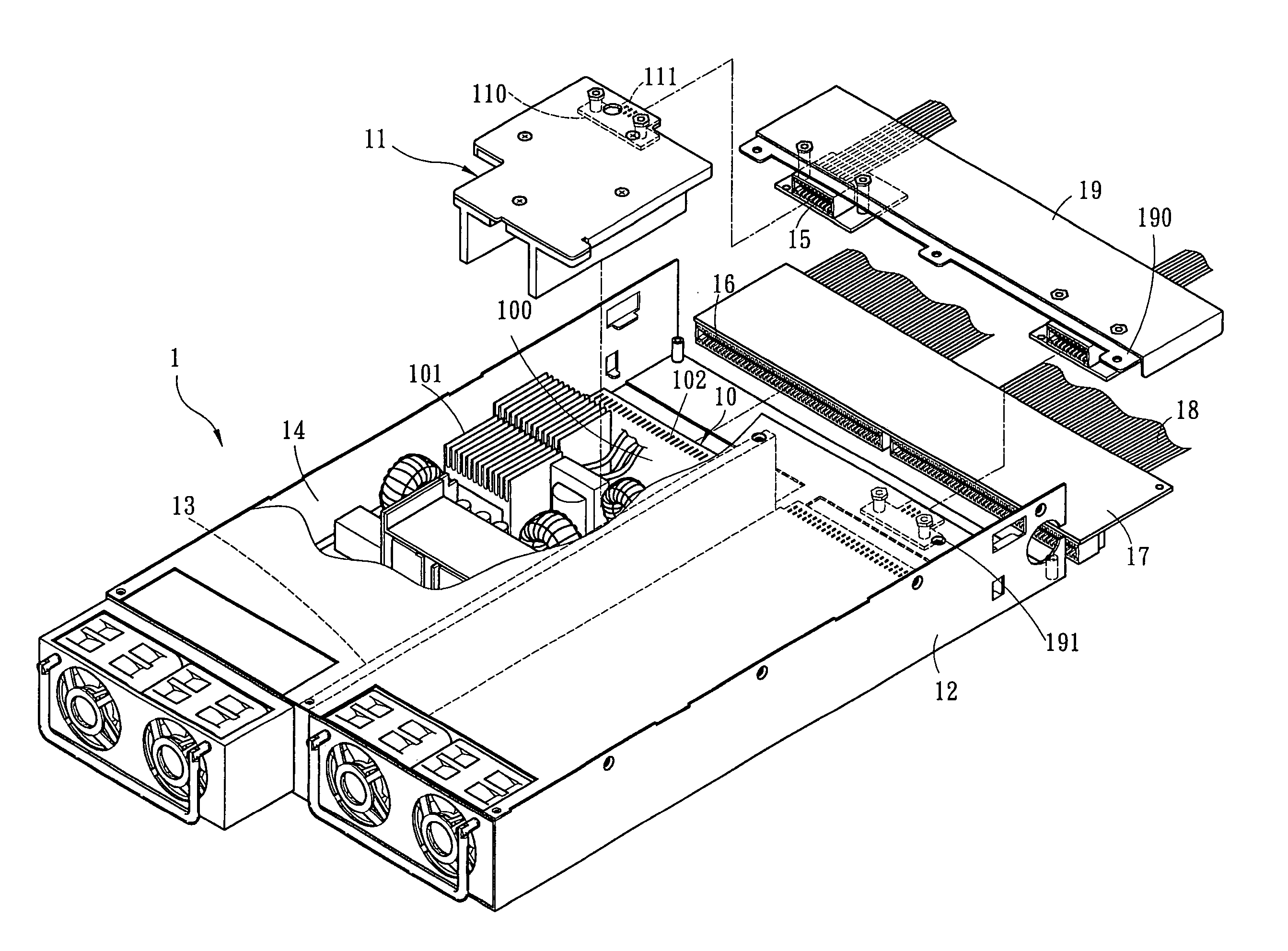

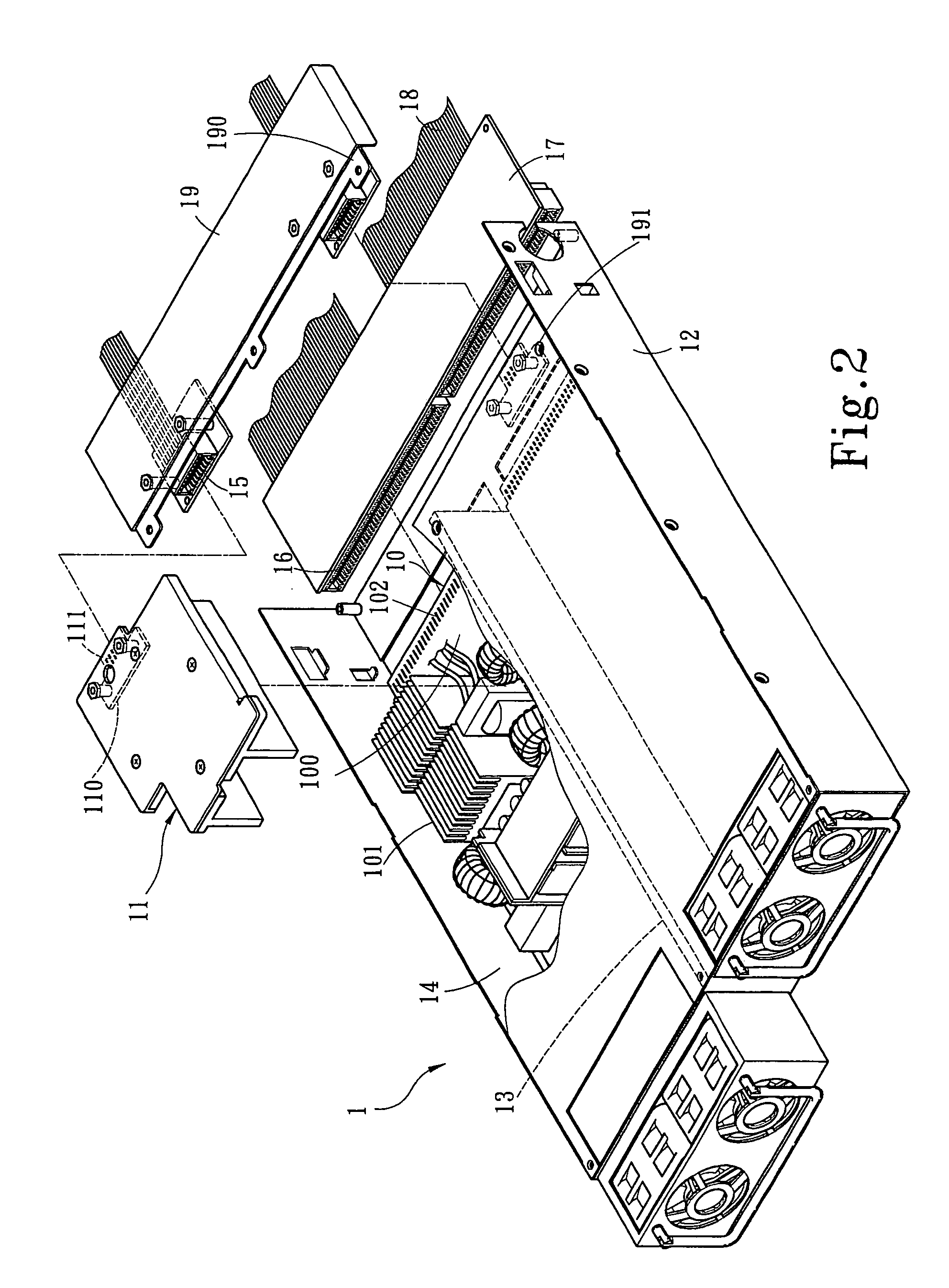

Power supply device, power supply module and retrieval power supply device equipped with AC and DC connection structures

InactiveUS7397670B2High output powerImprove effectivenessConversion constructional detailsCouplings bases/casesEngineeringElectrical and Electronics engineering

Owner:ZIPPY TECH

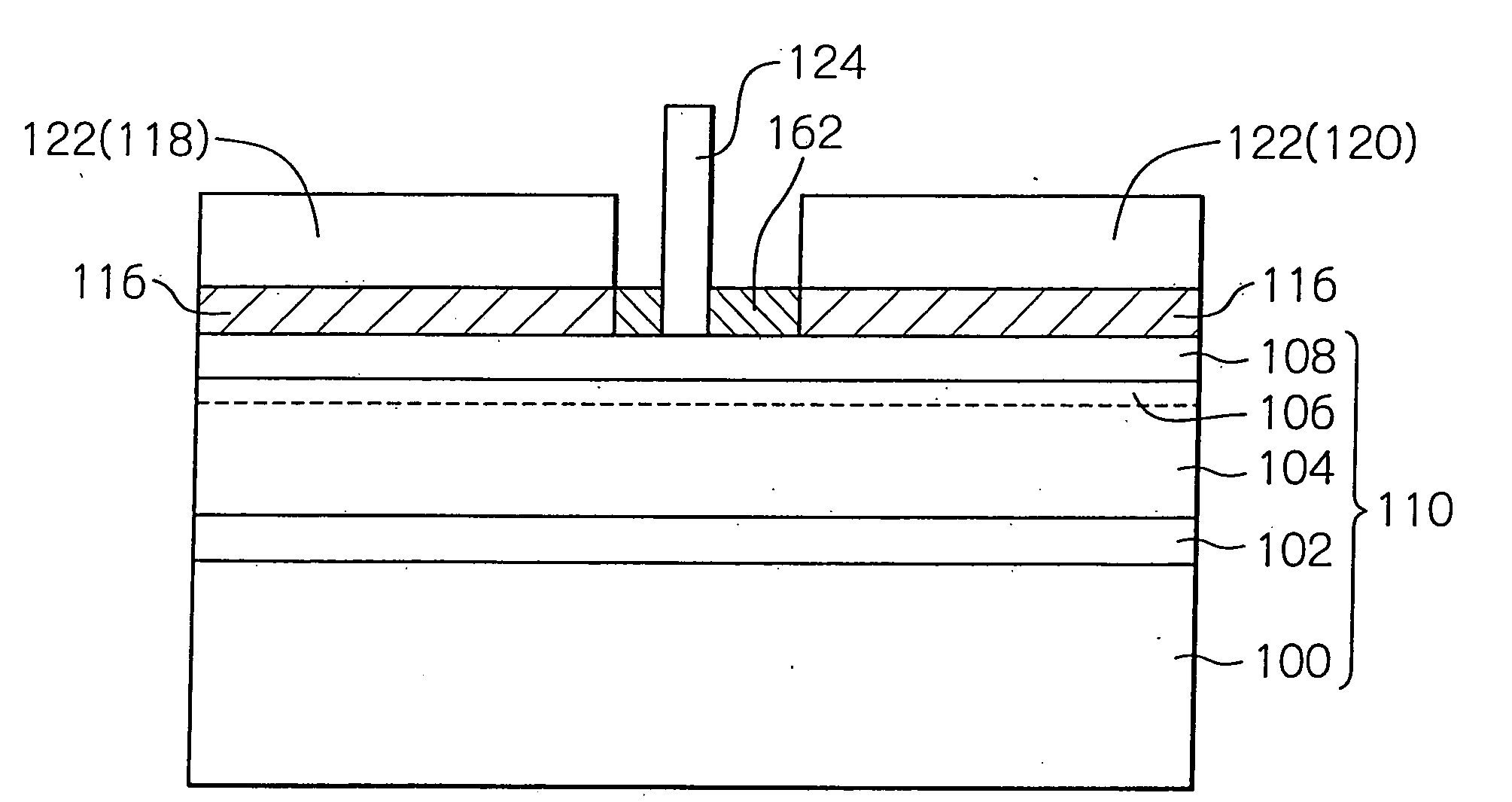

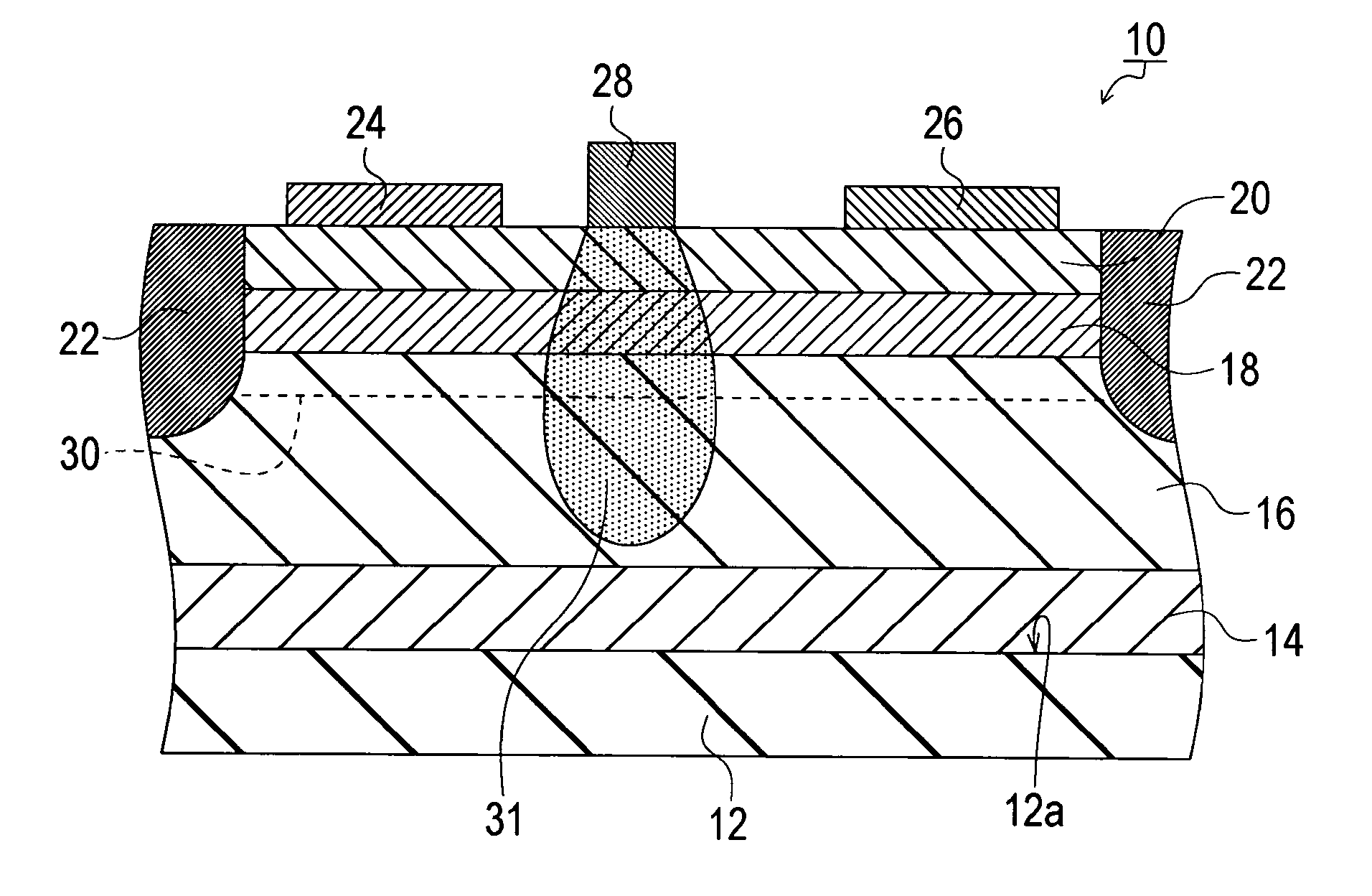

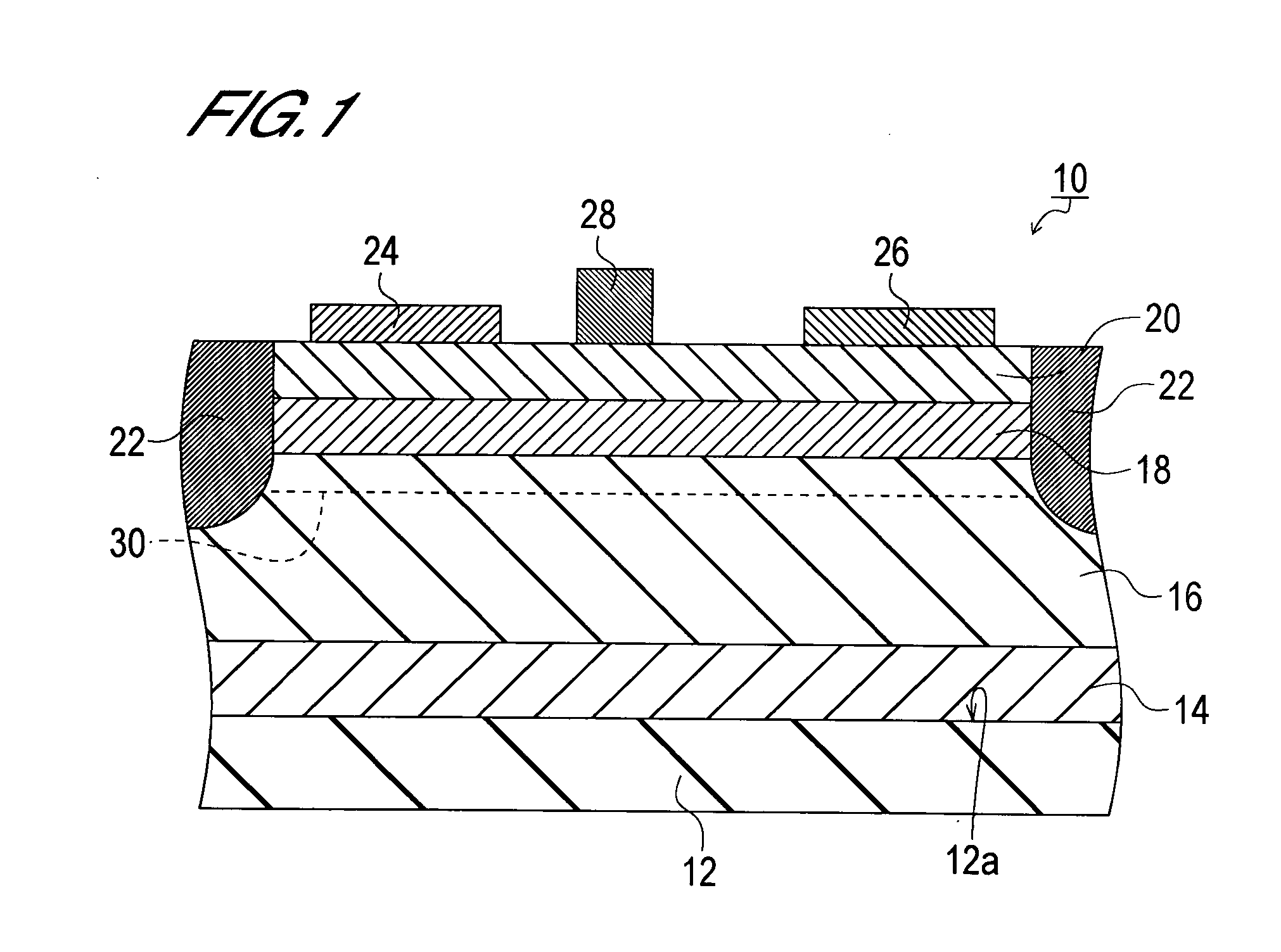

Wafer for semiconductor device fabrication, method of manufacture of same, and field effect transistor

InactiveUS20060214187A1Manufactured very thinImprove off-state breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorSemiconductor

A wafer for semiconductor device fabrication, from which large output power can be obtained by making the off-state breakdown voltage higher than in the prior art. The wafer for semiconductor device fabrication comprises a substrate, GaN electron transit layer formed on the side of the principal surface of the substrate, and AlGaN electron supply layer formed on the electron transit layer. The thickness of the electron transit layer is from 0.2 to 0.9 μm.

Owner:OKI ELECTRIC IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com