Bending mode conversion type ultrasound wave torsional vibration energy converter

A mode conversion and torsional vibration technology, which is applied in the direction of material analysis using sound waves/ultrasonic waves/infrasonic waves, fluids that use vibrations, instruments, etc., can solve the problem of limiting the application range of ultrasonic torsional vibrations, small power and output amplitude of torsional transducers, and The manufacturing process is difficult to realize and other problems, and achieve the effect of simple structure, easy fabrication and bonding, and large vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

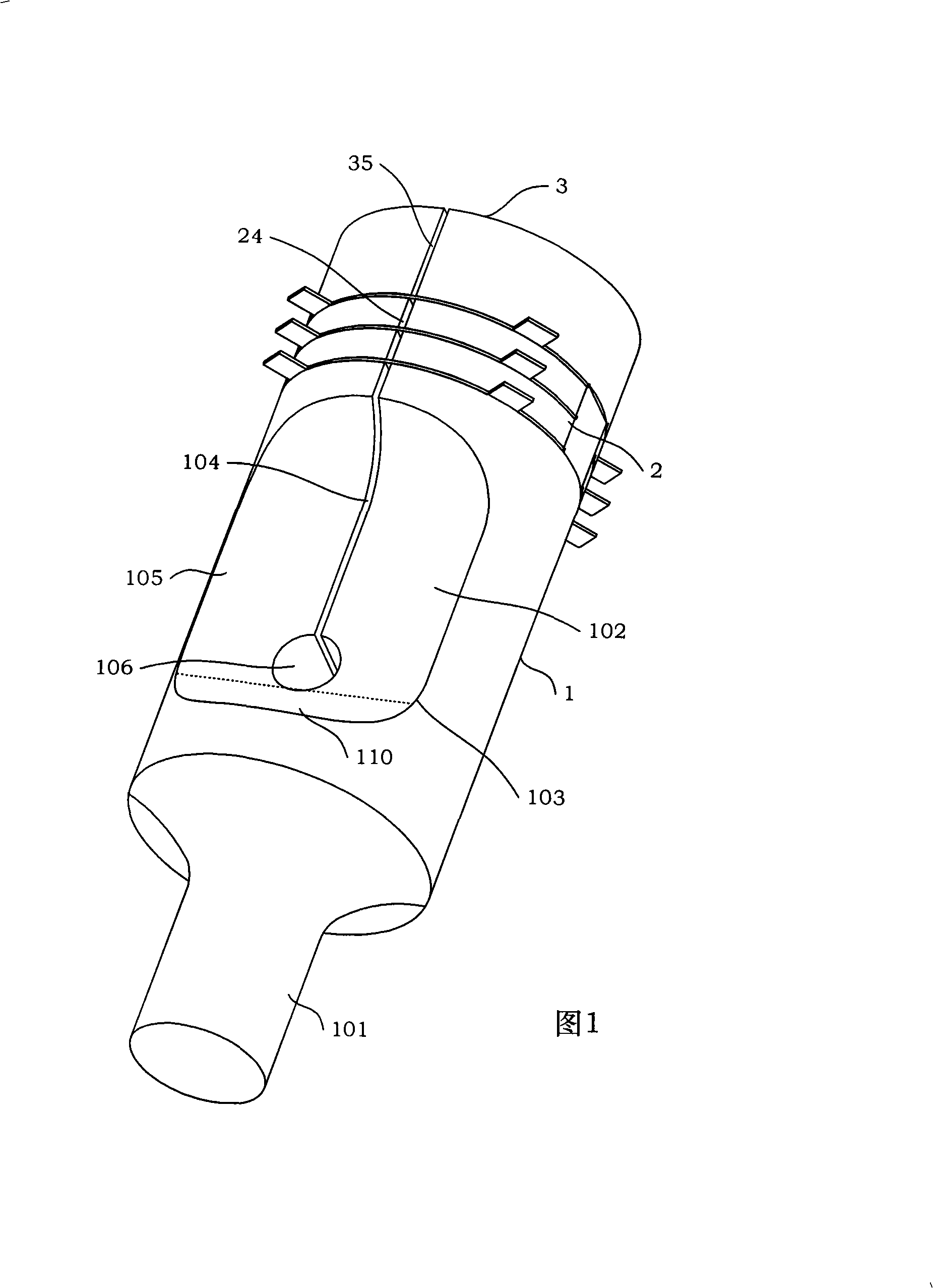

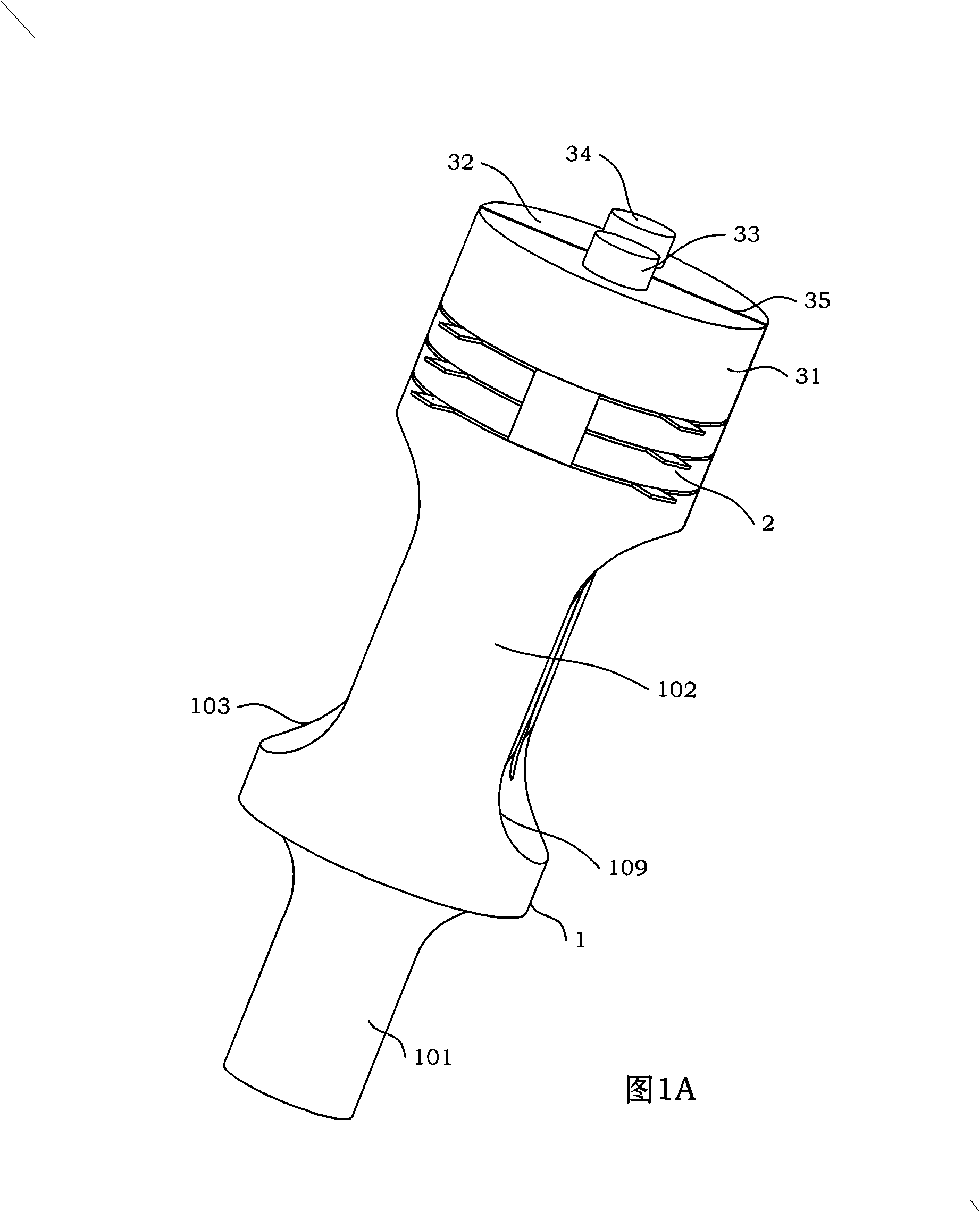

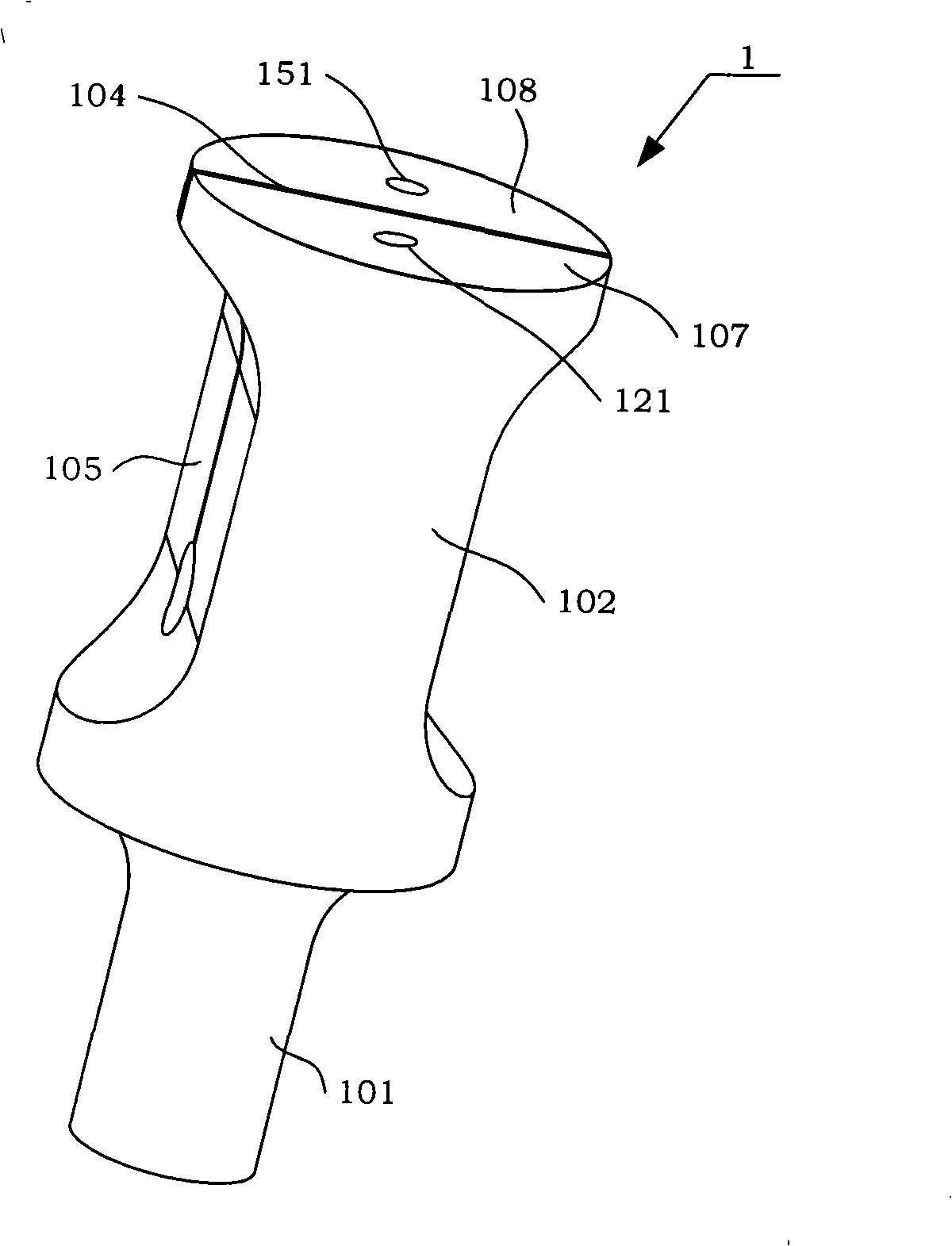

[0033] The present invention is a bending-torsion mode conversion ultrasonic torsional vibration transducer that can be used in multiple fields, which includes a bending-torsion vibrating body 1, a drive assembly 2, and a back cover 3 of the transducer.

[0034] Please refer to Figure 1, Figure 1A, figure 2 As shown, the drive assembly 2 is placed between the bending-torsion vibrating body 1 and the back cover 3 of the transducer, and passes through the through hole of the A end cover 31, the A through hole 22, and the A pre-tensioning screw 33 in sequence. Tighten the screw hole 121 to install the A end cover 31 and the insulating block 21 on the A top surface 107 of the bending-torsion vibrating body 1; pass the B pre-tightening screw 34 through the through hole of the B end cover 32 and the B through hole 23 in sequence , The B pre-tightening screw hole 151 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com