Galloping power generation device

A technology of power generation device and vibrator, which is applied in the fields of ocean energy power generation, engine components, machines/engines, etc., can solve problems such as failure to realize complex ocean conditions, development and utilization still to be studied, etc., and achieve the effect of efficient utilization of hydrodynamic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

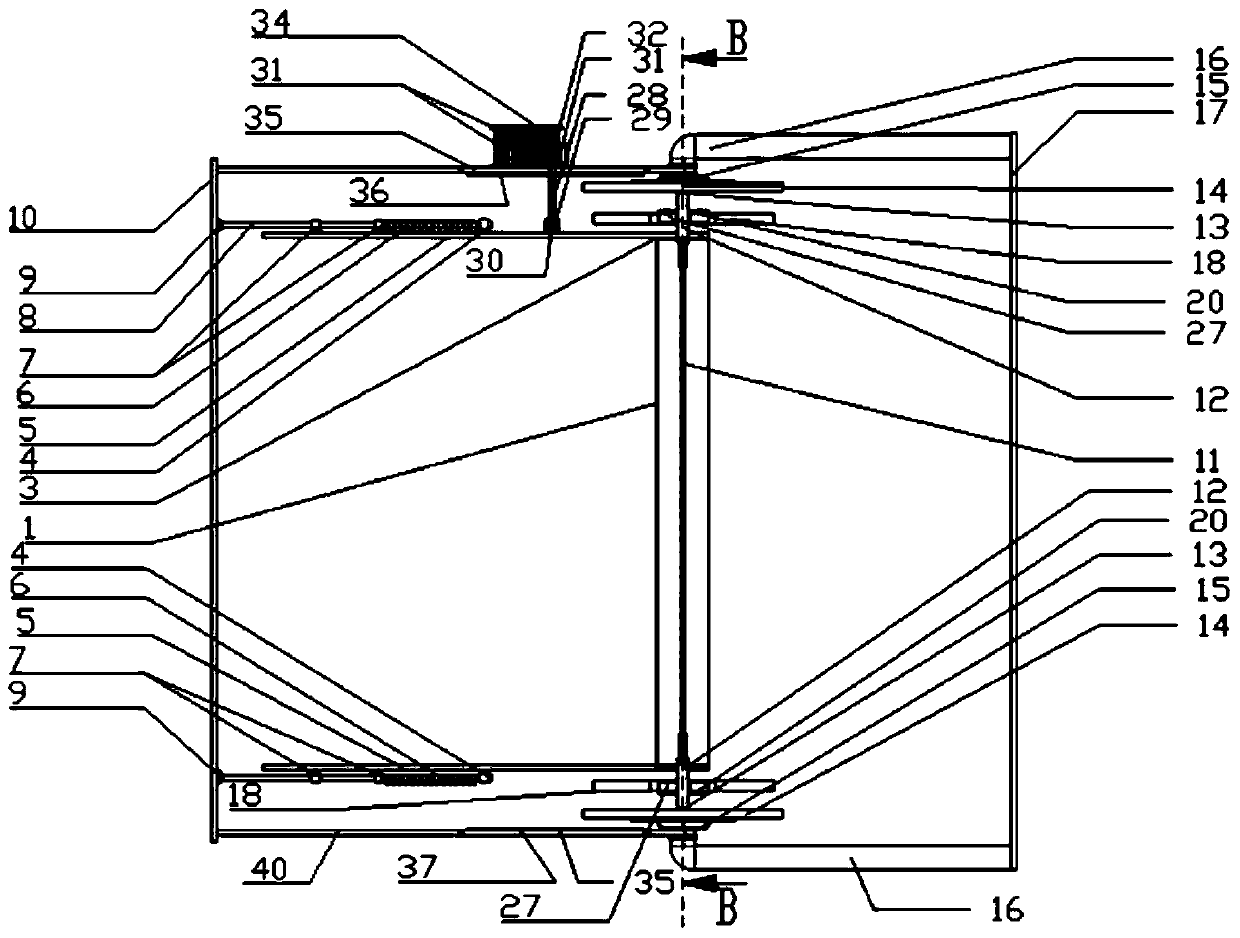

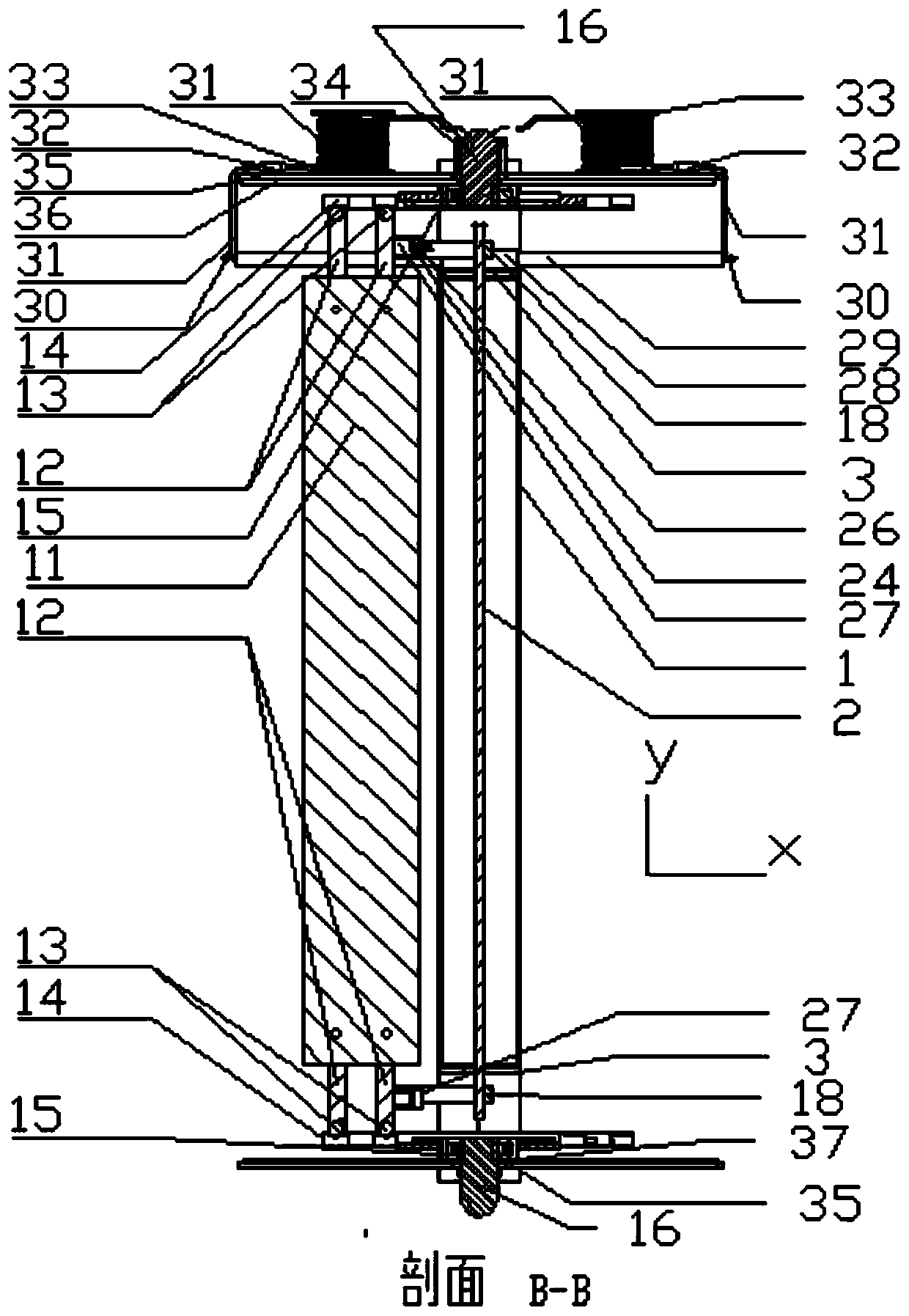

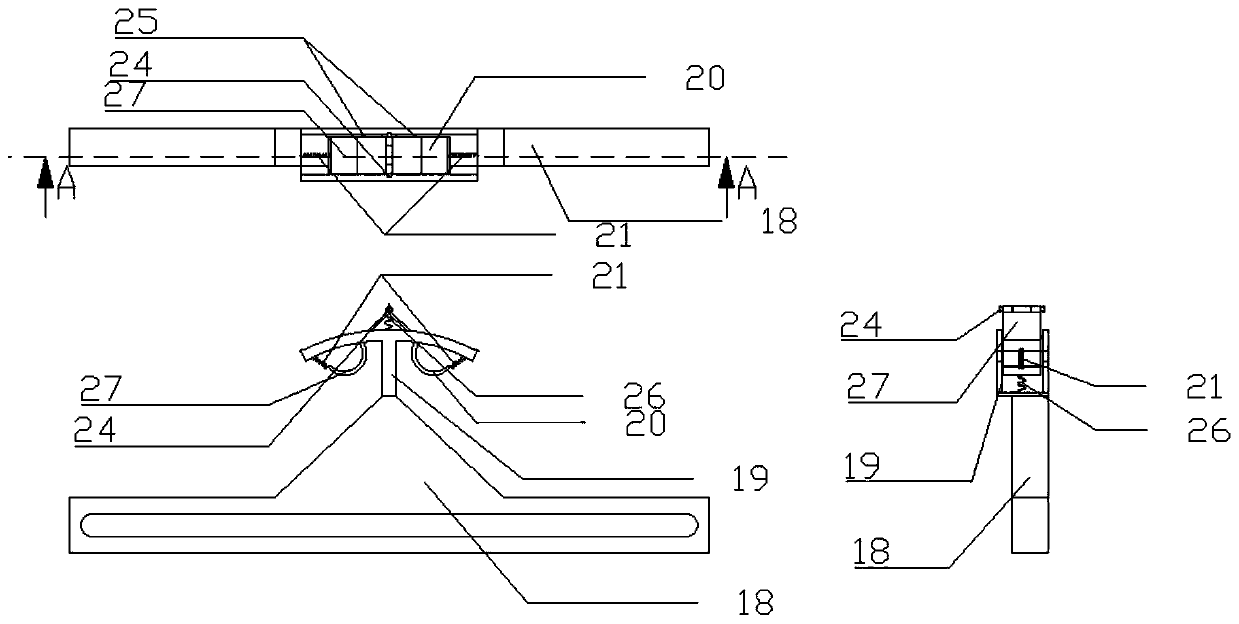

[0068] The galloping power generation device uses a cylindrical vibration exciter 1. Compared with other shapes of the vibration exciter 1, the cylindrical itself has relatively stable physical shape and other characteristics under real sea conditions, and has better resistance to asymmetrical sections. Seawater erosion and anti-microbial adhesion performance; In addition, in terms of processing technology, the cylindrical shape is also simpler and more economical than the excitation member 1 with other cross-sectional shapes. The galloping power generation device is mainly divided into four parts, that is, the rotatable elastic vibrator part, the double rotatable separation disc mechanism, the vertical straightener 38 and the electromagnetic induction mechanism. The arrangement of the elastic vibrator part and the separation plate mechanism converts the hydrodynamic force into the vibration kinetic energy of the vibration excitation part 1, and then drives the iron column 29 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com