A noise reduction control method for a smoke machine

A control method and hood technology, applied in heating methods, oil fume removal, household stoves, etc., can solve the problems of poor active noise reduction effect, reduction of turbulence and resonance noise, interference, etc., to achieve good noise reduction and improvement Noise reduction effect, the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

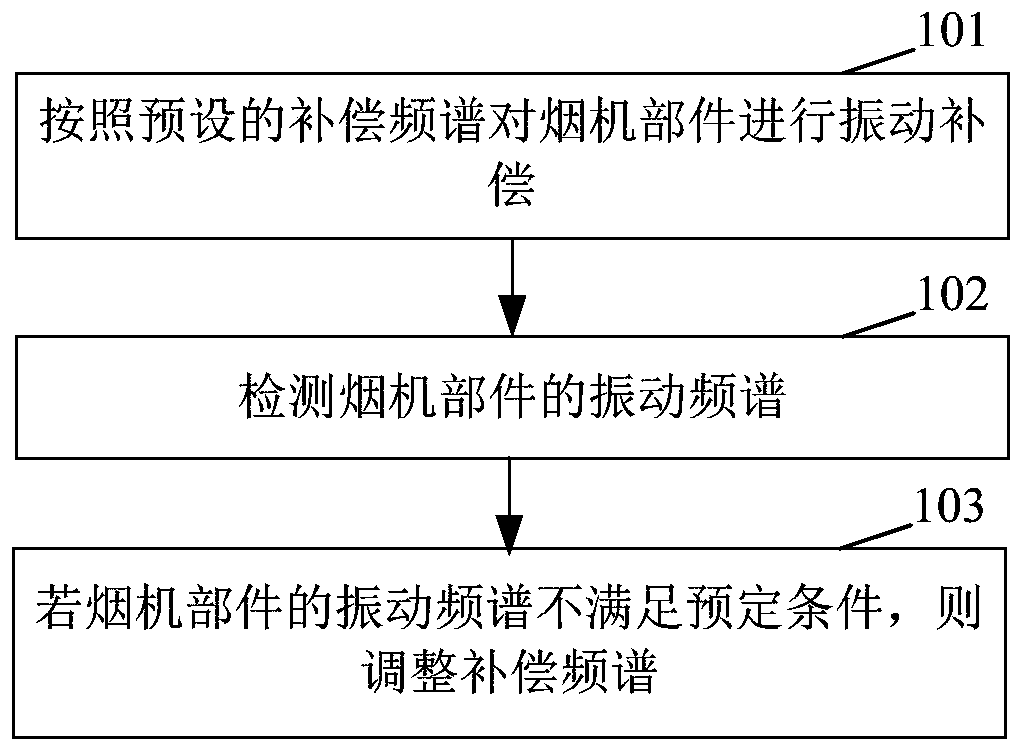

[0058] Such as figure 1 As shown, a noise reduction control method for a range hood may include: Step 101 to Step 103 .

[0059] Step 101: Vibration compensation is performed on the components of the hood according to the preset compensation frequency spectrum.

[0060] Step 102: Detect the vibration spectrum of the smoke machine components.

[0061] It should be noted that the vibration spectrum of the hood components includes: the vibration frequency of the hood components and the vibration amplitude of the hood components.

[0062] Step 101 includes: taking the vibration frequency of the components of the range hood as the frequency in the compensation spectrum, and taking the vibration amplitude of the components of the range range unchanged and the phase inversion as the amplitude in the compensation spectrum; components for vibration compensation.

[0063] Optionally, in step 102, the vibration spectrum of the components of the cigarette machine may be detected by a v...

Embodiment 2

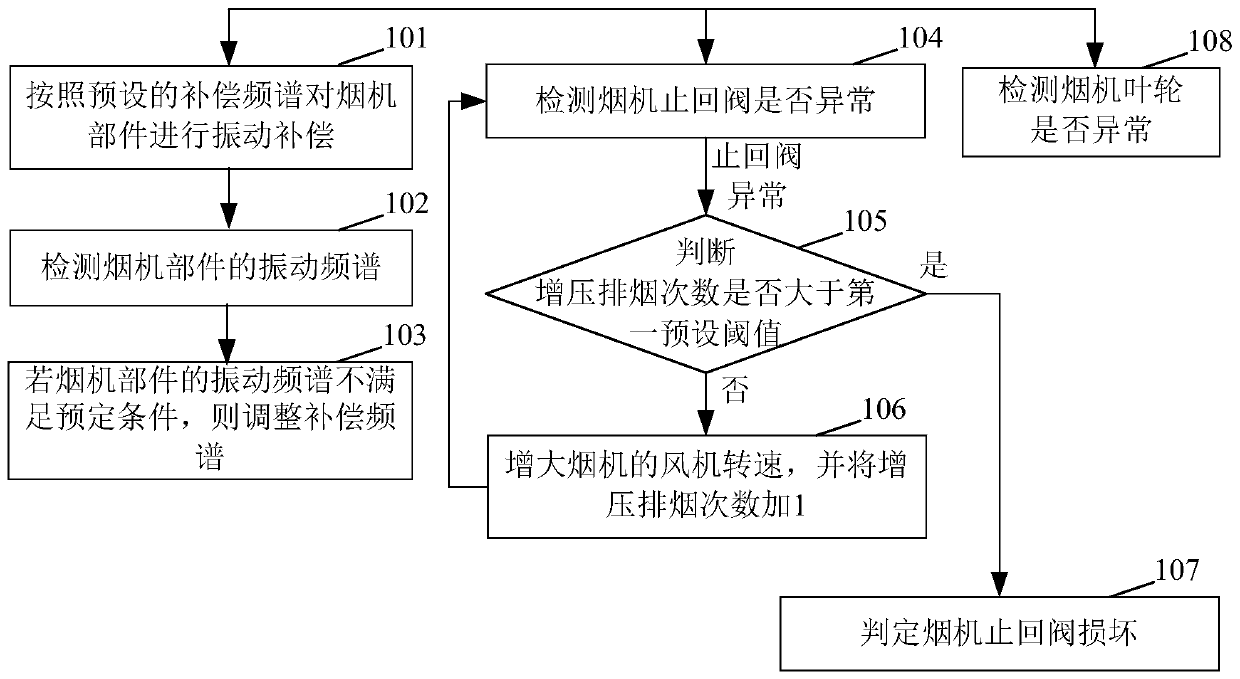

[0075] On the basis of the first embodiment, the embodiment of the present invention adds the detection of the check valve of the hood and the detection of the impeller of the hood. Such as figure 2 As shown, in addition to steps 101 to 103, the noise reduction control method for a hood may also include steps 104 to 108.

[0076] Step 104: Detect whether the check valve of the hood is abnormal, and execute step 105 when the check valve of the hood is detected to be abnormal.

[0077] Optionally, in step 104, it may be detected whether the check valve of the smoke machine is abnormal according to the vibration frequency spectrum of the check valve of the smoke machine.

[0078] For example, if the vibration frequency of the hood check valve is in the range of 100 Hz-500 Hz, and / or the vibration amplitude of the hood check valve is greater than 0.3 mm / S, it can be detected that the hood check valve is abnormal.

[0079] The vibration spectrum of the check valve of the hood ca...

Embodiment 3

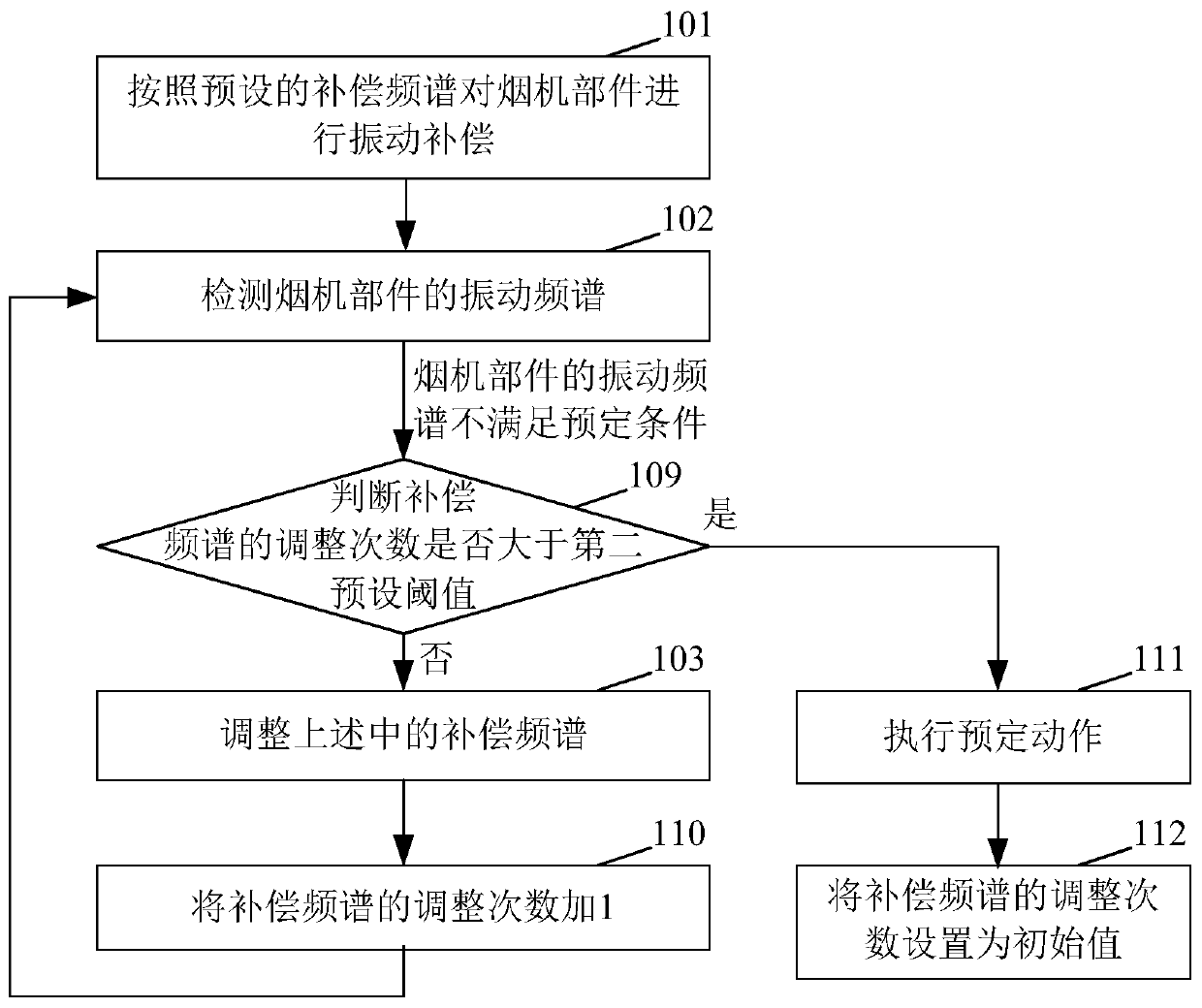

[0095] In the embodiment of the present invention, on the basis of the first embodiment, a step of judging the number of adjustments of the compensation spectrum is added after step 102 and between step 103 . Such as image 3 As shown, in addition to steps 101 to 103, the noise reduction control method for a hood may also include steps 109 to 112.

[0096] Step 109: After step 102, and when the vibration spectrum of the hood components does not meet the set conditions, determine whether the number of adjustments to the compensation spectrum is greater than the second preset threshold, where the initial value of the number of adjustments to the compensation spectrum is Y, and Y is Integer (such as Y=0). When it is determined that the number of adjustments of the compensation spectrum is greater than the second preset threshold, step 111 is performed;

[0097] Step 110: Add 1 to the adjustment times of the compensation spectrum, and return to step 102.

[0098] Step 111: Exec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com