Patents

Literature

1090results about How to "Ensure normal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

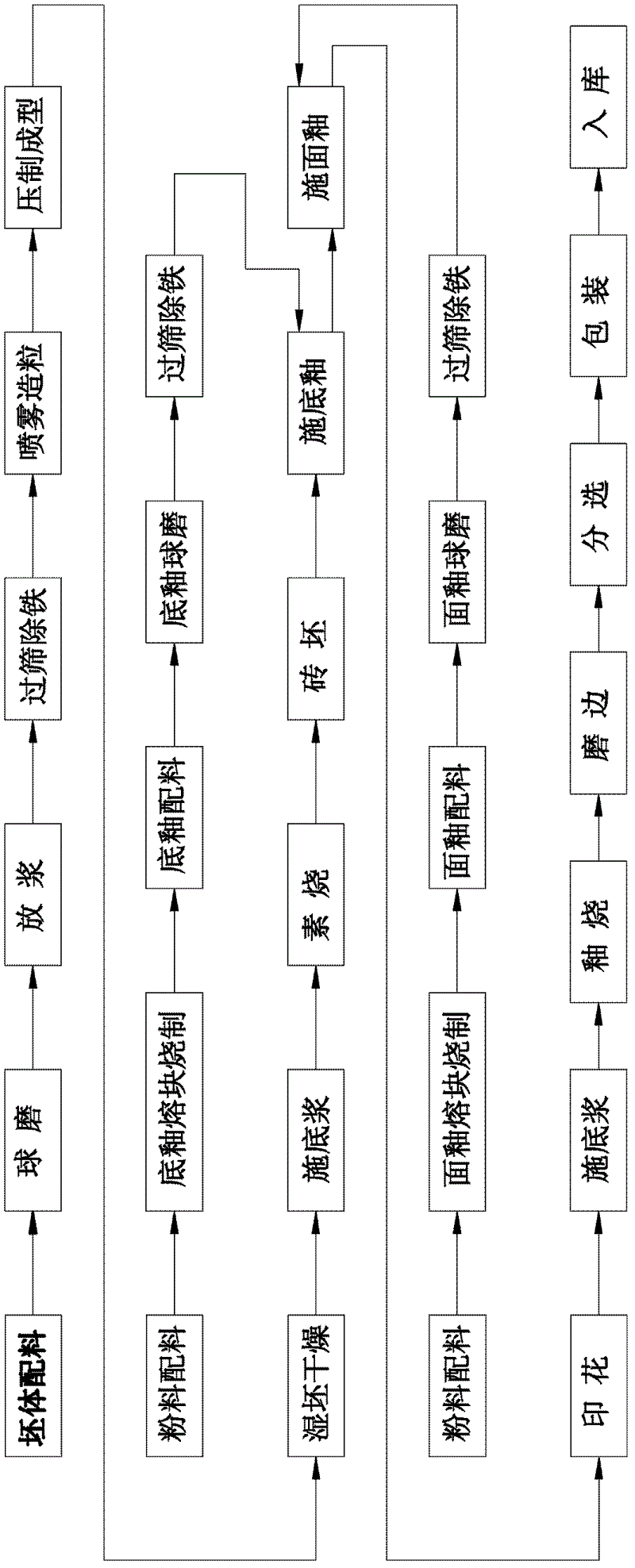

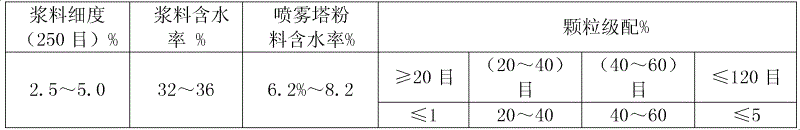

Formula and method for manufacturing ceramic tile blank bodies and glazed tiles by utilizing polished waste residues

The invention discloses a formula and a method for manufacturing ceramic tile blank bodies by utilizing polished waste residues. The formula adopts ingredients by weight portions: porcelain clays account for 18 to 40 parts, clays account for 20 to 30 parts, limestone grains account for 1 to 10 parts, wollastonite grains account for 3 to 15 parts, glazed tile sludge residues account for 3 to 10 parts, ceramic polished waste residues account for 15 to 45 parts, soluble glass accounts for 1 to 2 parts, thinners account for 0.15 to 0.4 parts, sodium tripolyphosphate accounts for 0.05 to 0.2 parts, and a proper amount of water is adopted. A manufacturing method of the ceramic tile blank bodies comprises the steps as follows: a. raw materials are put in a ball grinder for ball milling after being blended so as to form sizing agents with proper fineness and screen tailings through milling, and the sizing agents are processed through deferrization, sieving and spray drying so as to form powders; and b. the powders are put in a die cavity of a press forming machine to form waterish blanks through pressing, the waterish blanks are dried in a drying kiln, the dried waterish blanks are applied with base pulp and then enter a biscuit firing kiln, biscuit firing is carried out under the temperature ranging from 1080 to 1160 DEG C, heat preservation is carried out in an area with the temperature ranging from 1040 to 1060 DEG C, the sintering time of the area is prolonged, and the sintering process for oxidizing atmosphere can be enhanced at the same time so as to obtain the ceramic tile blank bodies.

Owner:GUANGDONG WINTO CERAMICS +1

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

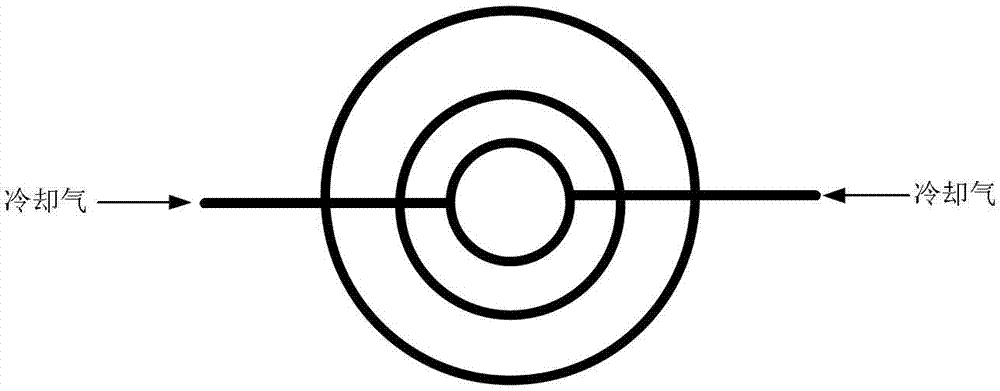

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Manufacturing technique and device for composite board

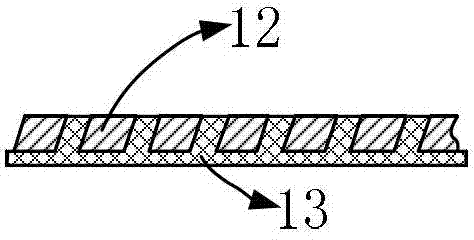

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

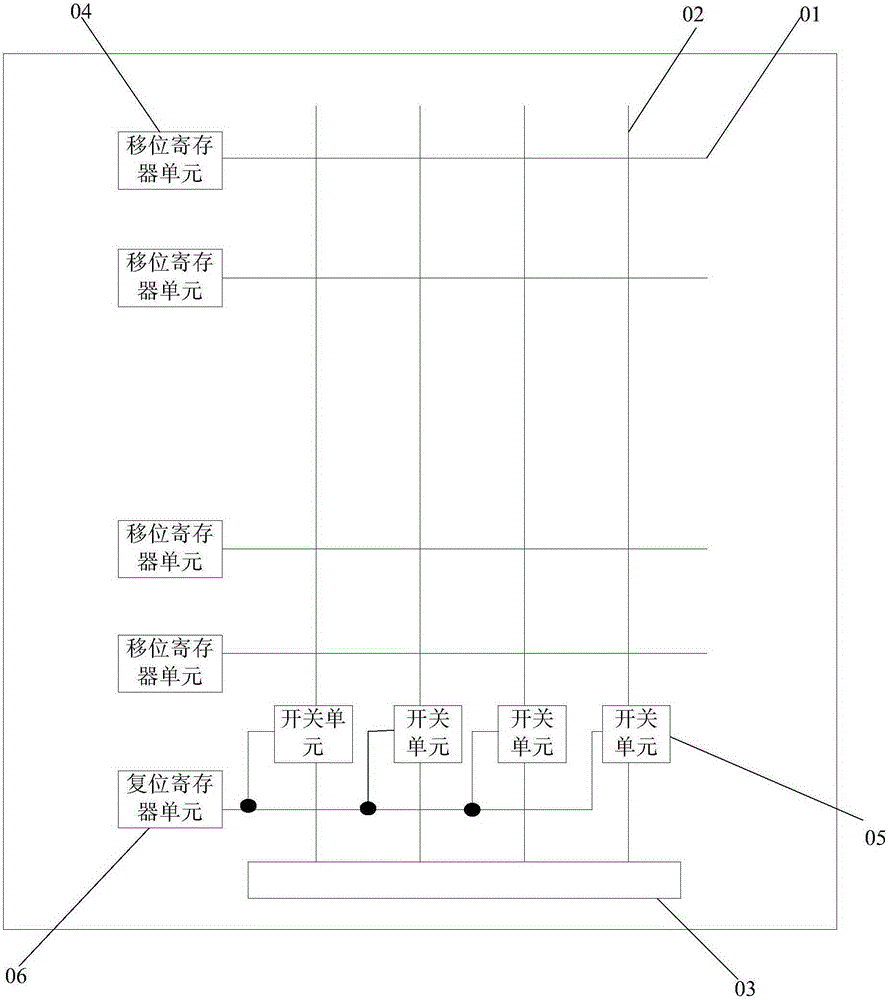

Display panel, driving method thereof, and display device

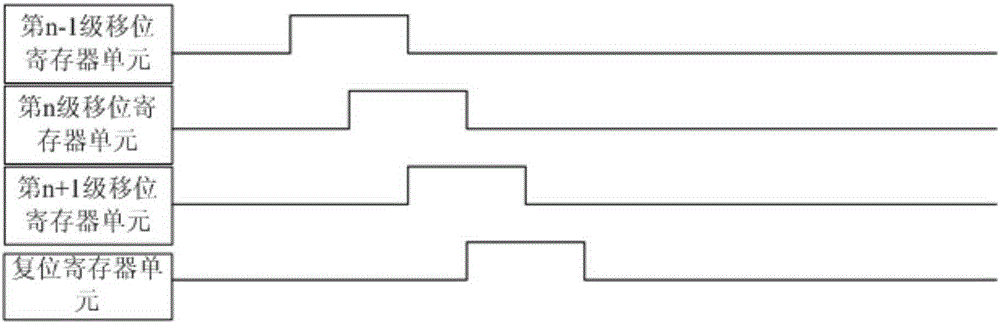

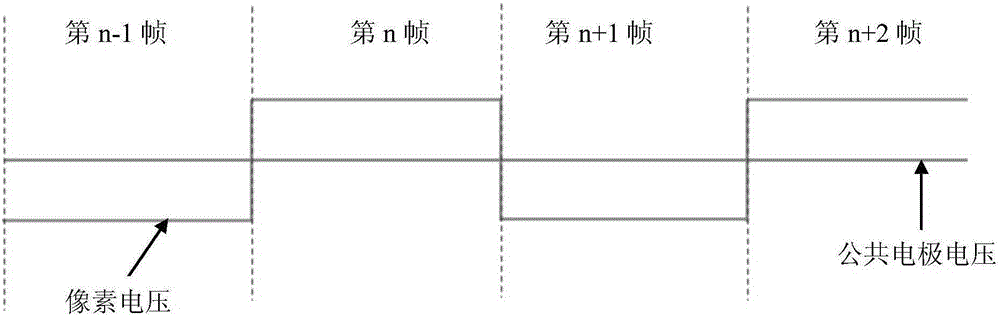

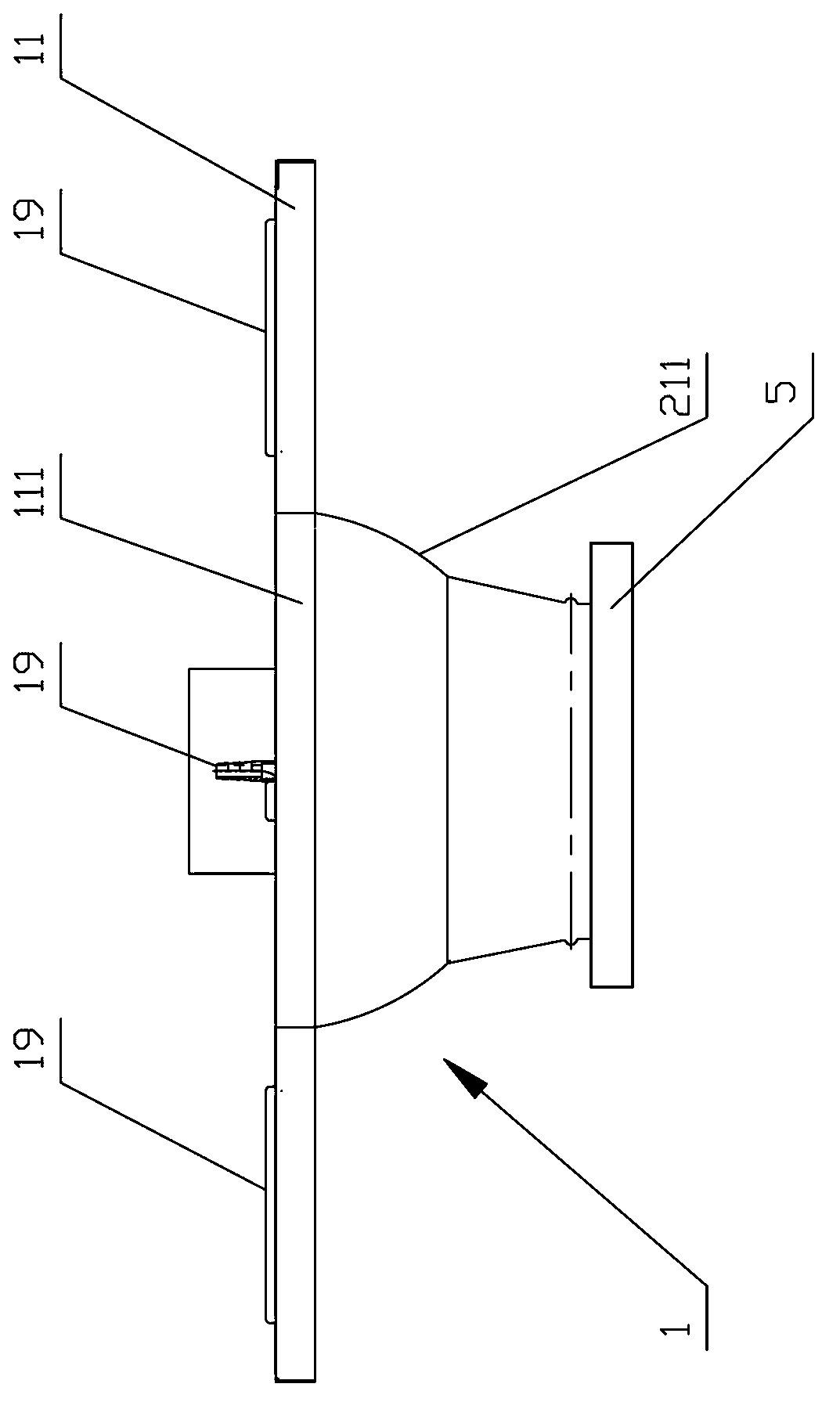

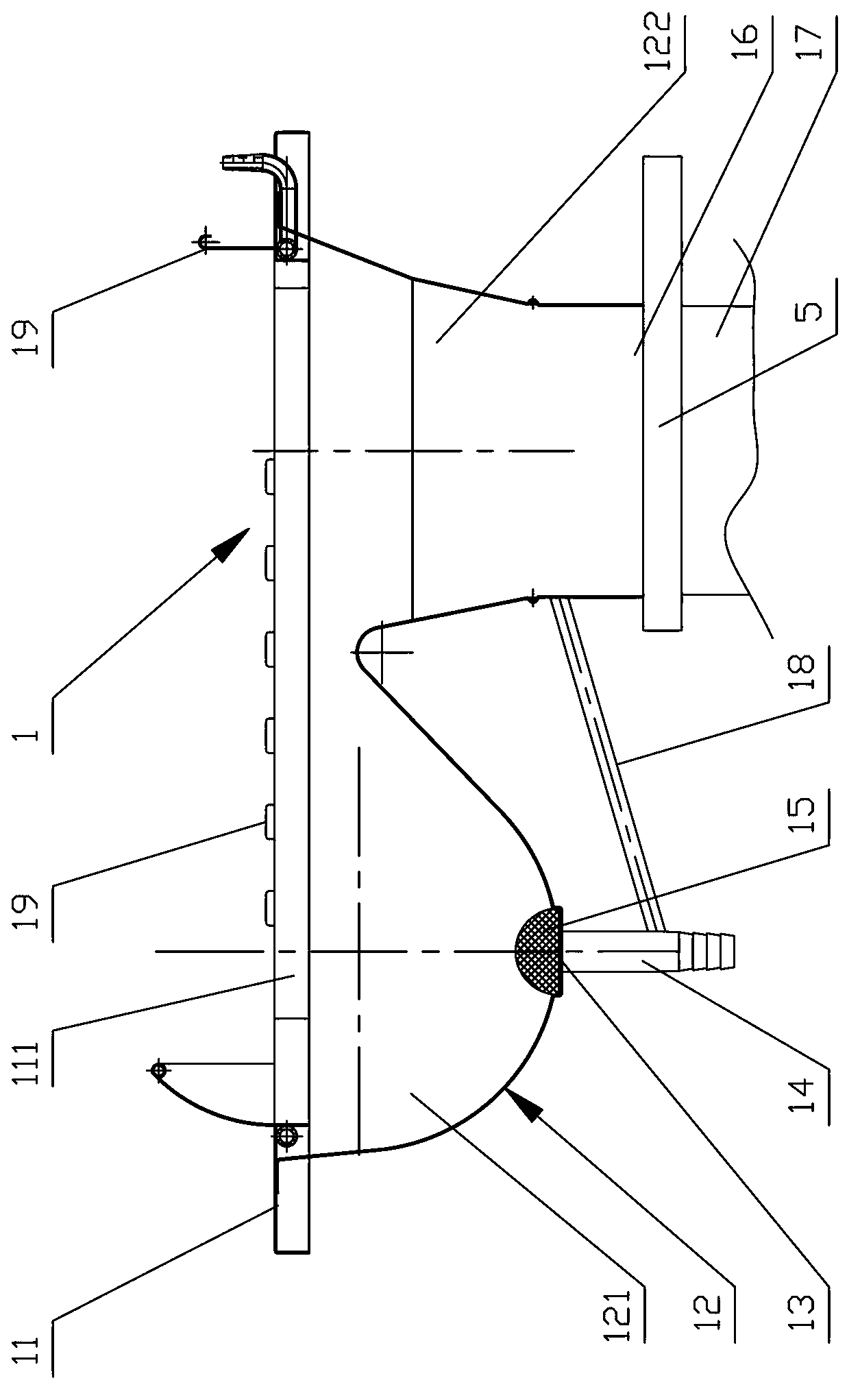

ActiveCN105185293ARealize progressive scanningPixel voltage has no effectStatic indicating devicesTime-sharingEngineering

The invention discloses a display panel, a driving method thereof, and a display device; when the display panel normally displays, each shift register unit inputs a scanning signal to a corresponding grid line in sequence in time sharing, thus realizing line-by-line scanning of the display panel; a reset register unit outputs a signal to a self-reset signal end, thus stopping outputting; in a power off moment, each shift register unit respectively inputs a scanning signal to the corresponding grid line, thus fully opening all pixels of the display panel; the reset register unit simultaneously inputs a control signal to a control end of a switch unit, so the switch unit is conducted, thus conducting each data line with a common electrode, and instantly discharging charges of all pixels to the common electrode, i.e., the display panel can realize inner self-discharging at the power off moment, thus ensuring complete discharging of the pixels, and effectively improving adverse phenomenon like display panel shutdown mura and power on screen scintillations.

Owner:BOE TECH GRP CO LTD +1

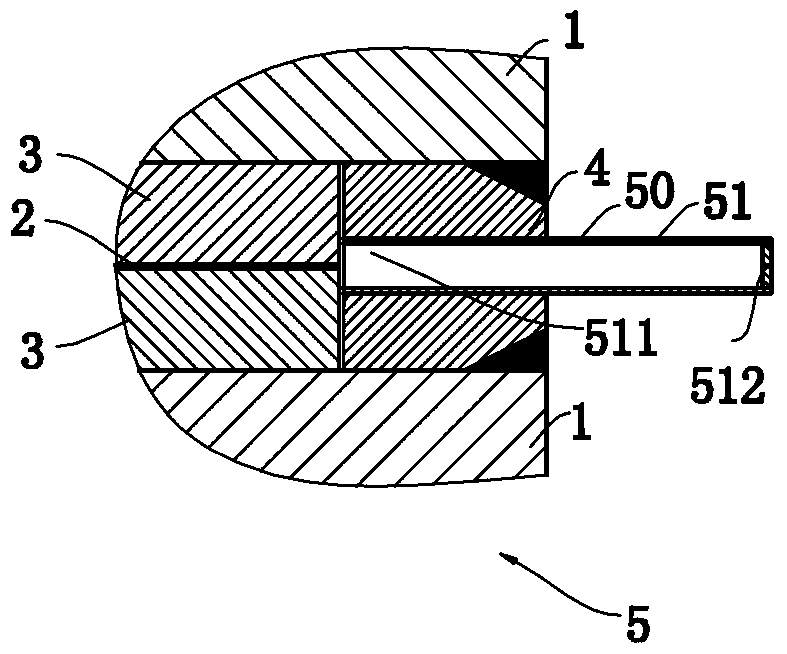

Solid-liquid separation toilet bowl and solid-liquid separation treatment system

InactiveCN102836866AReduce the possibility of mixingIncrease the amount of separationSolid waste disposalExcrement fertilisersUrine collectionEngineering

The invention provides a solid-liquid separation toilet bowl and a solid-liquid separation treatment system comprising the solid-liquid separation toilet bowl. The solid-liquid separation toilet bowl comprises a panel and a toilet bowl body, wherein the middle part of the panel is provided with a seat hole; the toilet bowl body is provided with a urine collection cavity and an excrement collection cavity; and the urine collection cavity and the excrement collection cavity are arranged with one in front of the other in longitudinal direction of the panel, are positioned below the seat hole and are opposite to the seat hole. Through the urine collection cavity and the excrement collection cavity formed in the toilet bowl body and by arranging the urine collection cavity and the excrement collection cavity with one in front of the other in the longitudinal direction of the panel, the urine collection cavity arranged at the front end is used for collecting urine, the excrement collection cavity arranged at the rear end is used for collecting the excrement, so that the urine and the excrement are effectively prevented from being mixed in the toilet bowl body; and thus, separation and recovery of the urine and the excrement are realized, further recycling of the excrement and the urine is realized respectively, and premise is provided for realizing the value of full utilization of the excrement and the urine.

Owner:张少岩 +2

Method for forming lithium ion secondary battery

InactiveCN101330158AAvoid ability to declineImprove thickness yieldFinal product manufactureElectrolyte accumulators manufactureLithiumEngineering

A method for forming a lithium ion secondary battery comprises the step of charging the lithium ion secondary battery, wherein the process of charging is at least partially carried out under a vacuum condition. The method ensures that the generated gas of the battery can be discharged at any time during the process of charging, so as to completely avoid the problems with the expansion and the deformation of the battery casing caused by the accumulation of the gas generated during the process of charging and with the performance reduction caused by the accumulation of the gas, so that the formed battery has the advantages of high capacity and good cycle performance.

Owner:BYD CO LTD

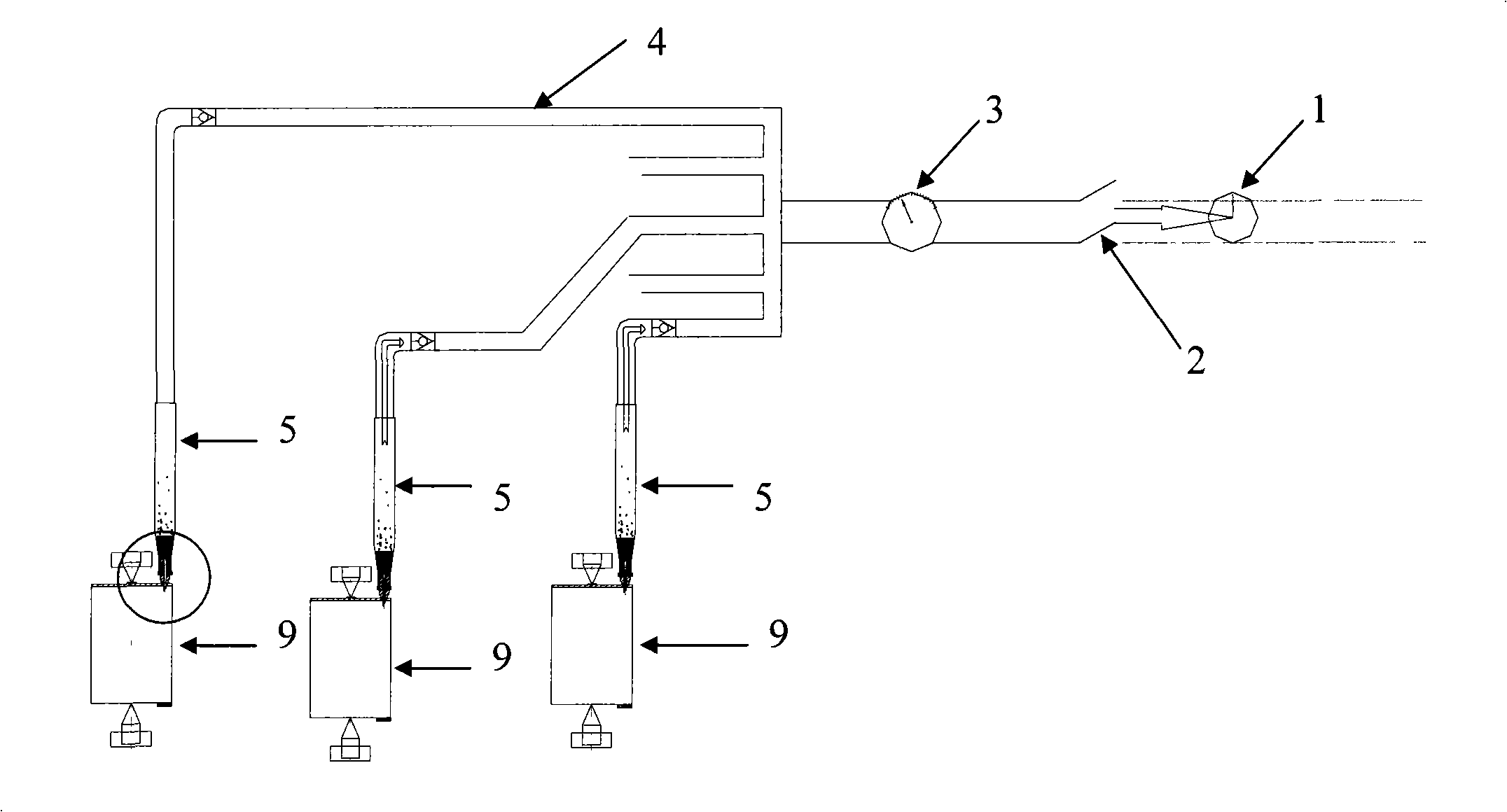

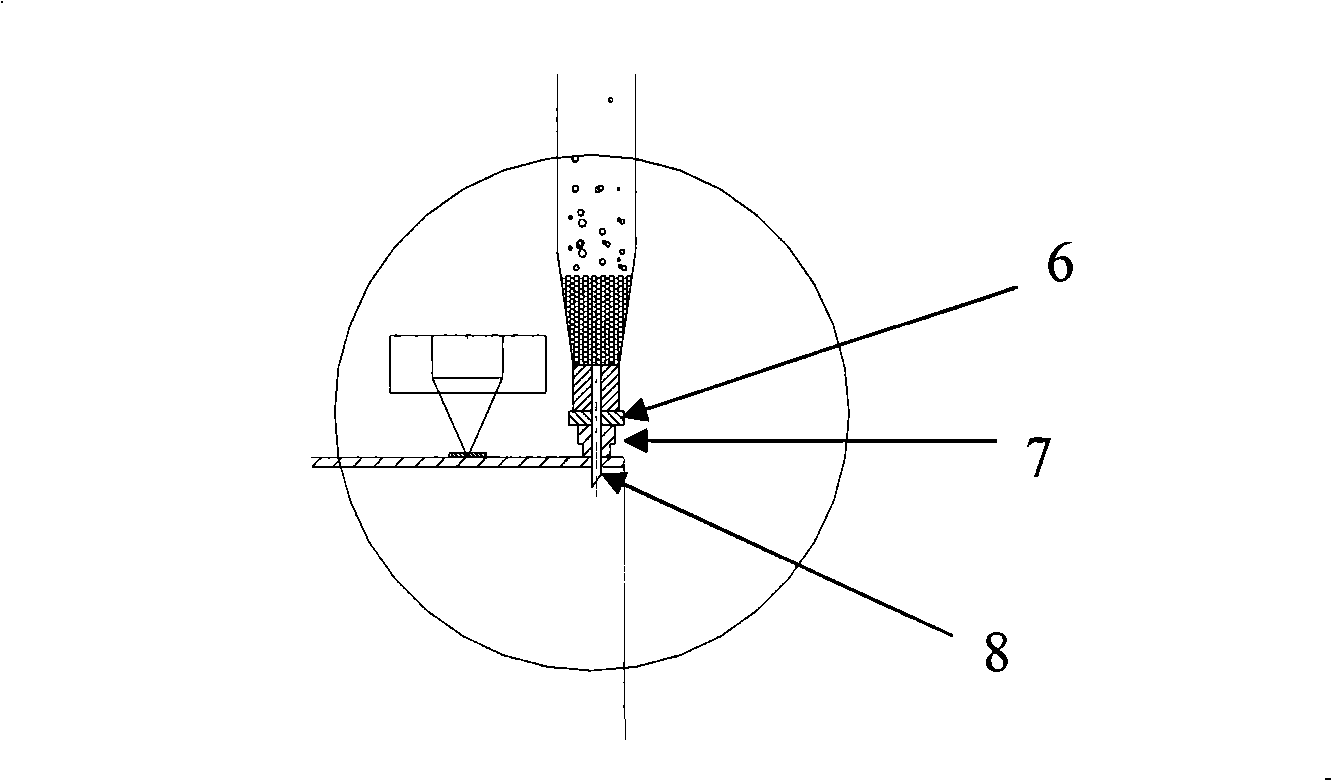

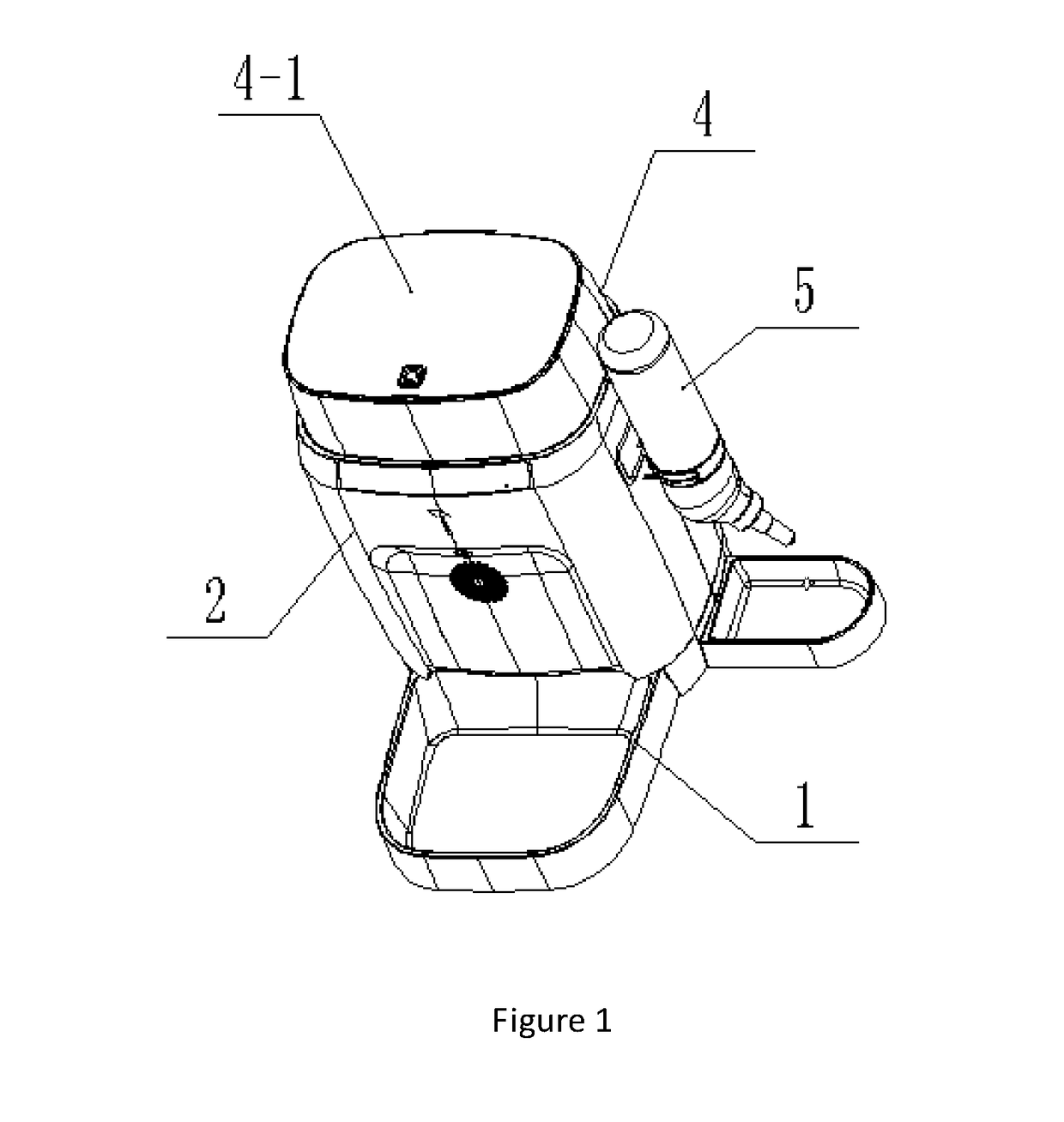

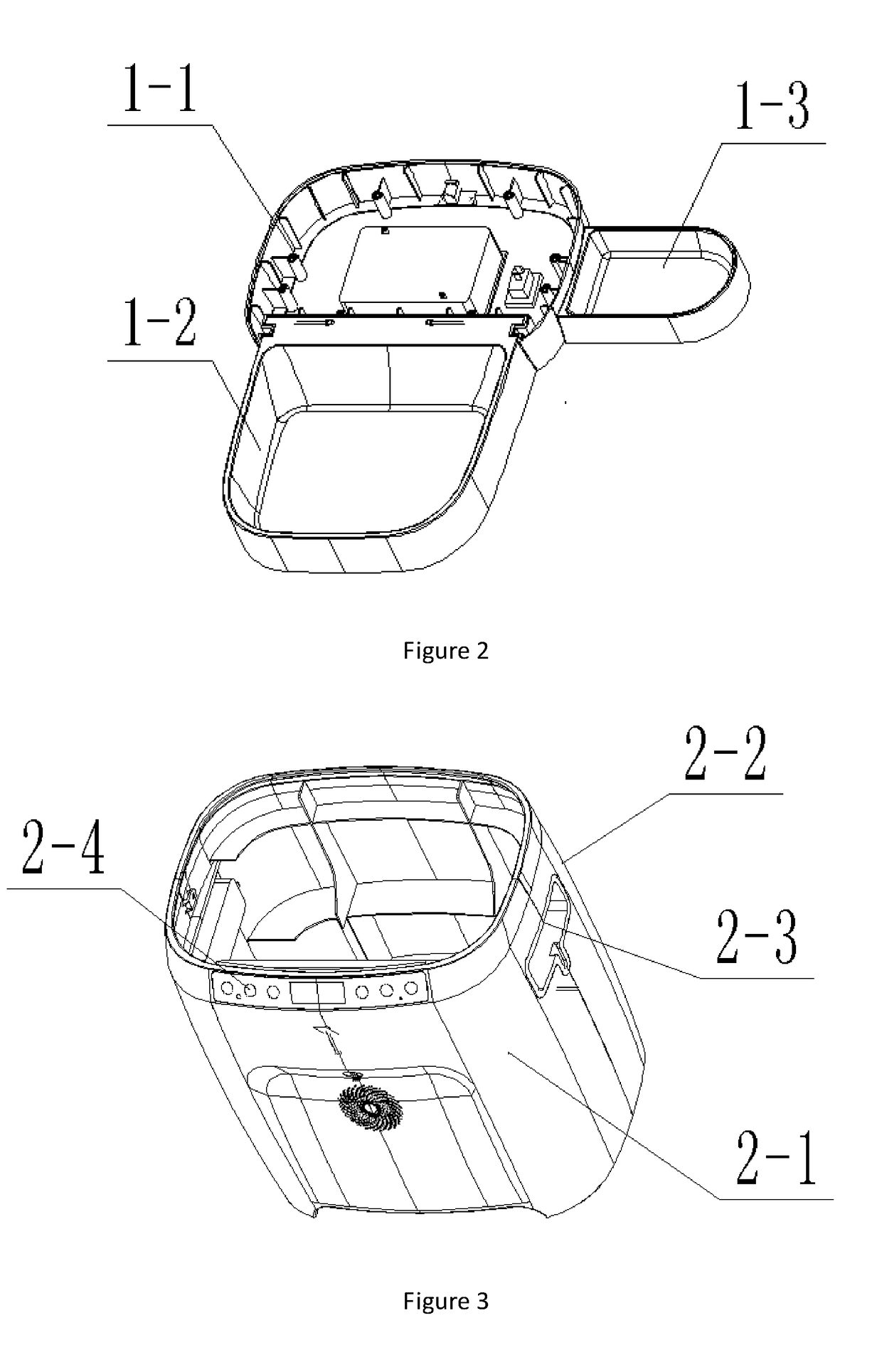

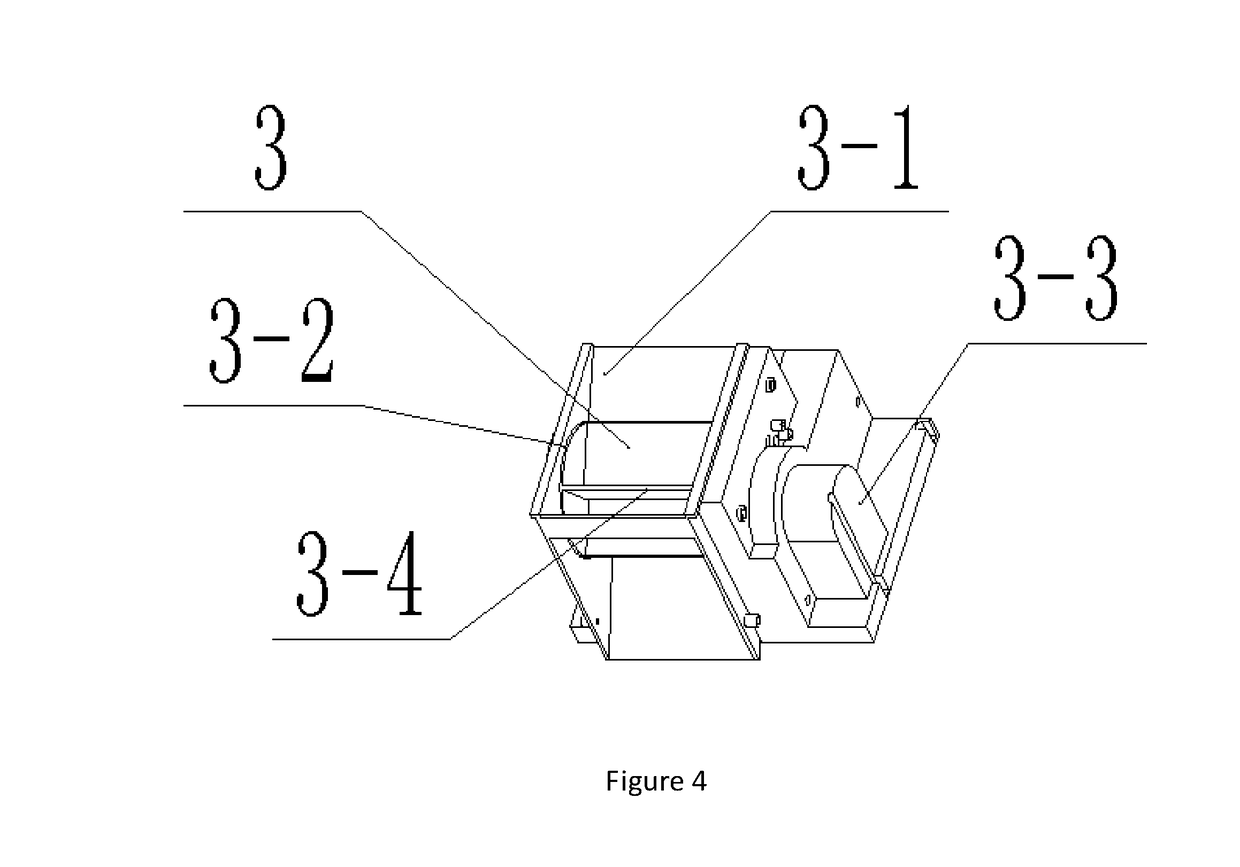

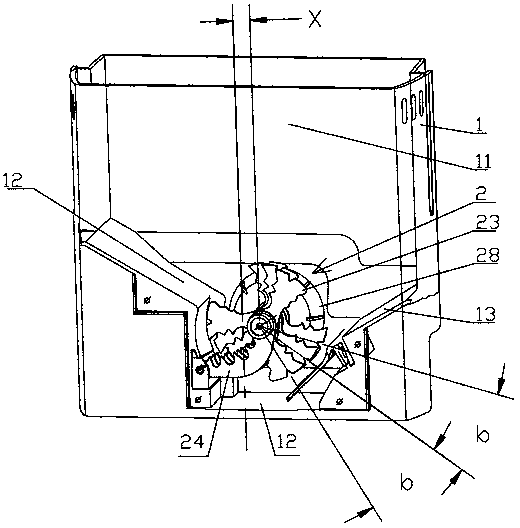

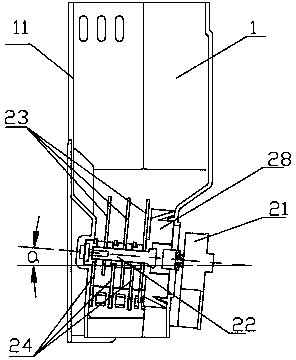

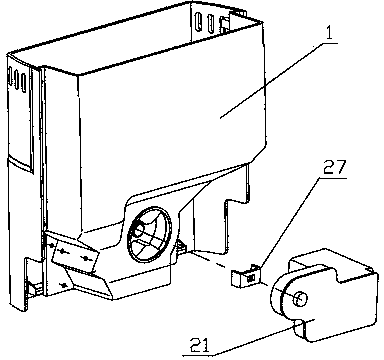

Novel pet feeder

InactiveUS20190059322A1Smooth entryFood lay off smoothlyAnimal watering devicesAnimal feeding devicesTerminal equipmentEngineering

The utility model discloses a novel pet feeder, comprising a base, a shell body, a discharging system, a material bucket, and a water bottle; the base consists of a base shell, a food disk and a water disk; the front side of base shell is provided with a buckle hook plugged in a chute arranged on the food disk; the shell body is fixed on the base; the shell body is composed of a front shell, a back shell, a handle and a control panel. The novel pet feeder can realize remote and accurate feeding control and instant video signaling of good vision by means of a terminal device; the grain discharging condition also can be monitored in real time and effectively controlled, The improved material stirring system makes food discharge more accurately. The effective anti-blocking mechanism can guarantee the normal discharge of food.

Owner:SHENZHEN BENKEI TECH CO LTD

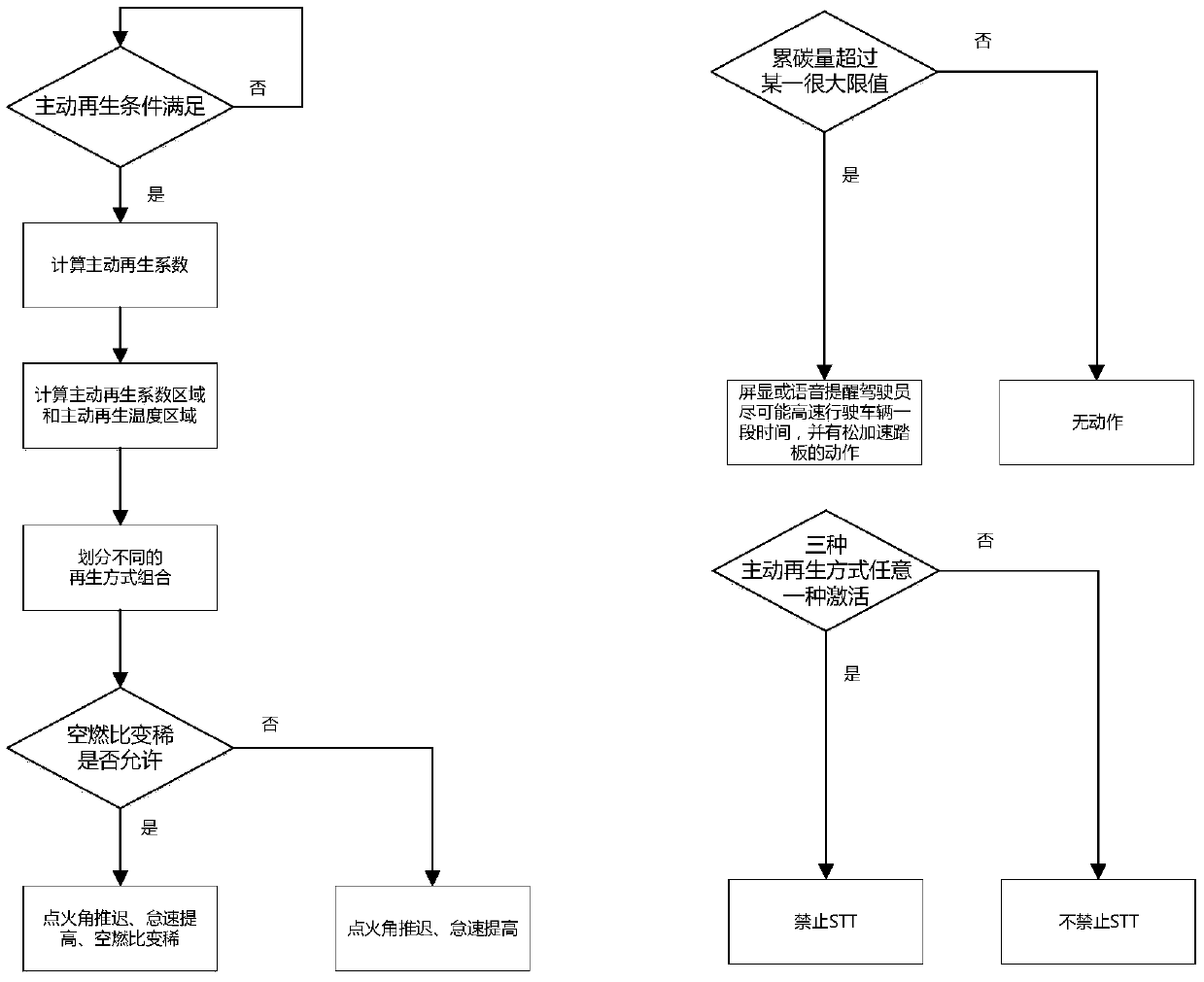

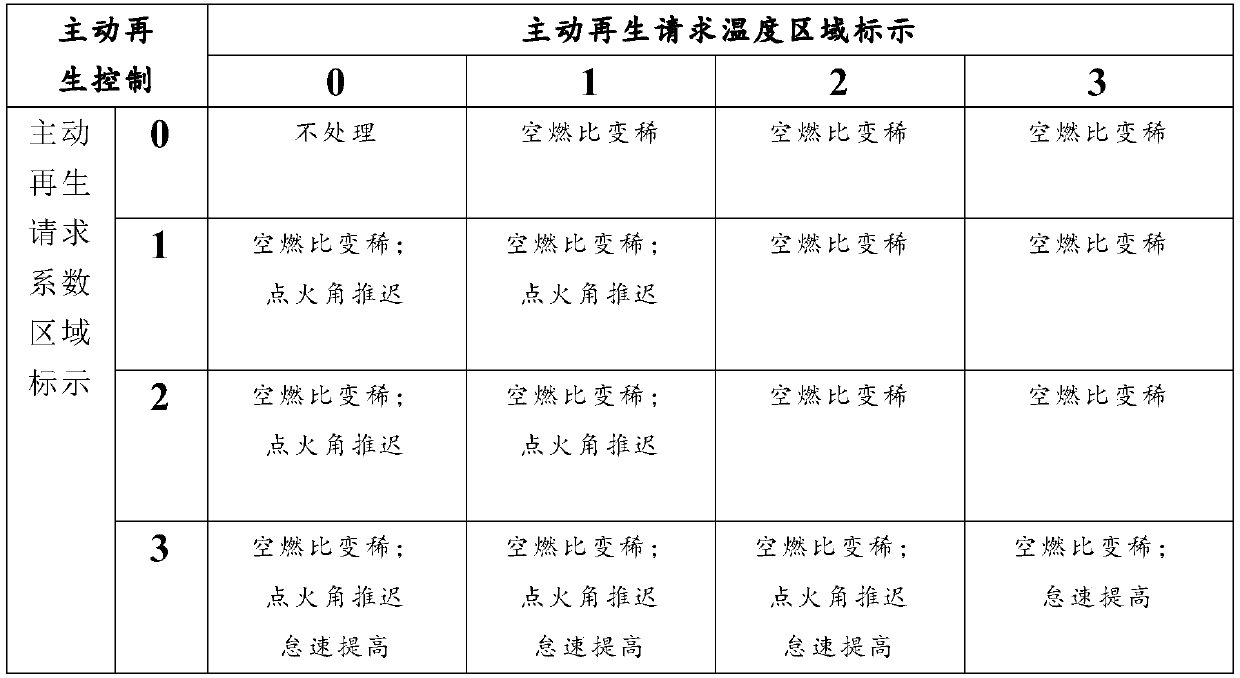

Active regeneration grading control method for particle trap

ActiveCN110925065AMonitor temperature in real timeReduce exhaust back pressureInternal combustion piston enginesExhaust apparatusParticle trappingEngineering

The invention discloses an active regeneration grading control method for a particle trap. The active regeneration grading control method aims to acquire the real-time carbon loading amount and temperatures of the particle trap. According to the carbon loading amount, a plurality of carbon loading limit values are determined, a plurality of temperature limit values are determined according to thetemperatures, the real-time carbon loading amount and the carbon loading amount limit values of the particle trap are compared, the real-time particle trap temperatures and the temperature limit values are compared, an active regeneration mode is determined, and the active regeneration mode is one or a combination containing more than one of the conditions that an engine is controlled to defer theignition angle, the air-fuel ratio becomes lean, and the idle speed is increased. According to the active regeneration grading control method for the particle trap, the mode of active regeneration isdetermined according to the regions where different carbon loading amount and the temperatures of the particle trap are located and the marking of the region, so that the carbon deposition is effectively removed in time when the carbon loading amount is too high, and the exhaust back pressure is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

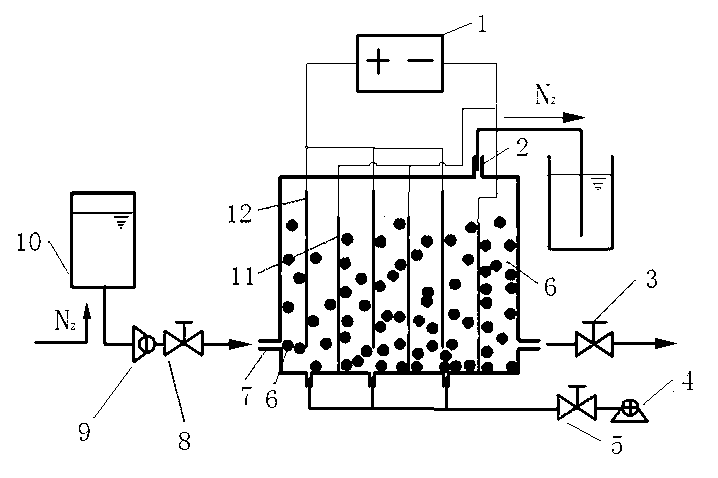

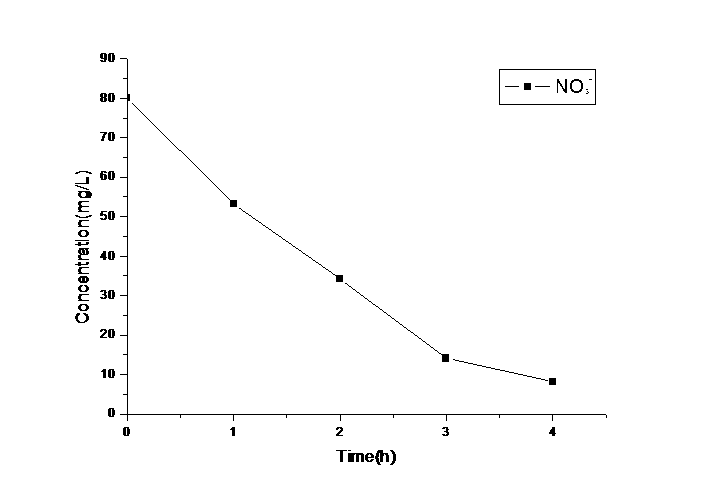

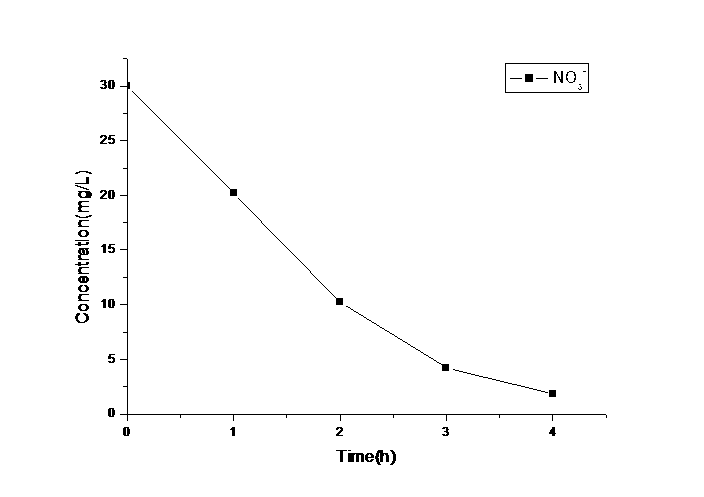

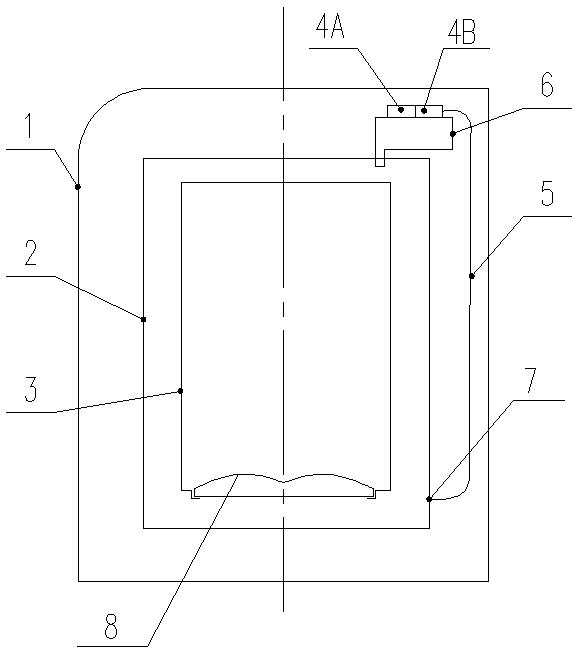

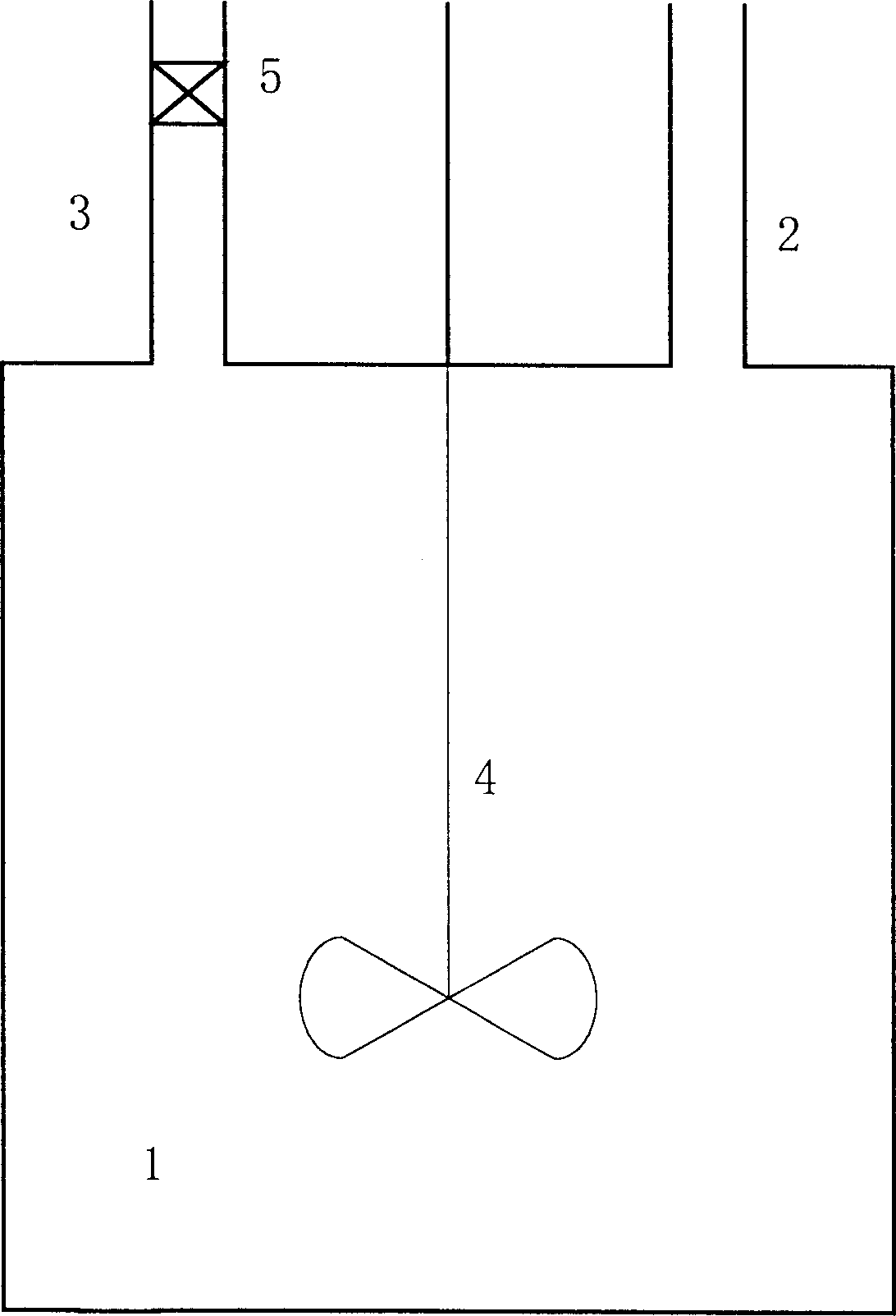

Electrochemical reactor for processing nitrogenous organic wastewater, and application and processing method thereof

InactiveCN103193301AEfficient removalAmmonium Oxide StrongWater contaminantsWater/sewage treatment by magnetic/electric fieldsElectrochemical responseChemical oxygen demand

The invention discloses an electrochemical reactor for processing nitrogenous organic wastewater, and an application and a processing method thereof, and belongs to the field of processing nitrogenous organic wastewater. The device comprises a reaction container, a power supply, a gas outlet pipe, a water outlet pipe, a water outlet pipe valve and a water inlet system, and further comprises a packing material, a negative plate and a positive plate, wherein the packing material is formed by mixing active carbon and magnet particles; the negative plate is connected with the negative electrode of the power supply; the negative plate is a silicon dioxide plate loaded copper-palladium coating electrode, and the coating material consists of Pd and Cu at a mass ratio of 6: 1; and the positive plate is a digital subtraction angiography (DSA) oxide coating electrode Ti / IrO2-PtO2. The reactor is a batch-type operation three-dimensional electrode reactor which adopts a mixture of active carbon particles and magnet particles with similar diameter as the packing material, and has the functions of efficiently removing nitrate nitrogen, ammonia nitrogen and COD (chemical oxygen demand), and is low in energy consumption; and the reactor is capable of achieving a purpose of removing nitrogen and COD in the nitrogenous organic wastewater.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

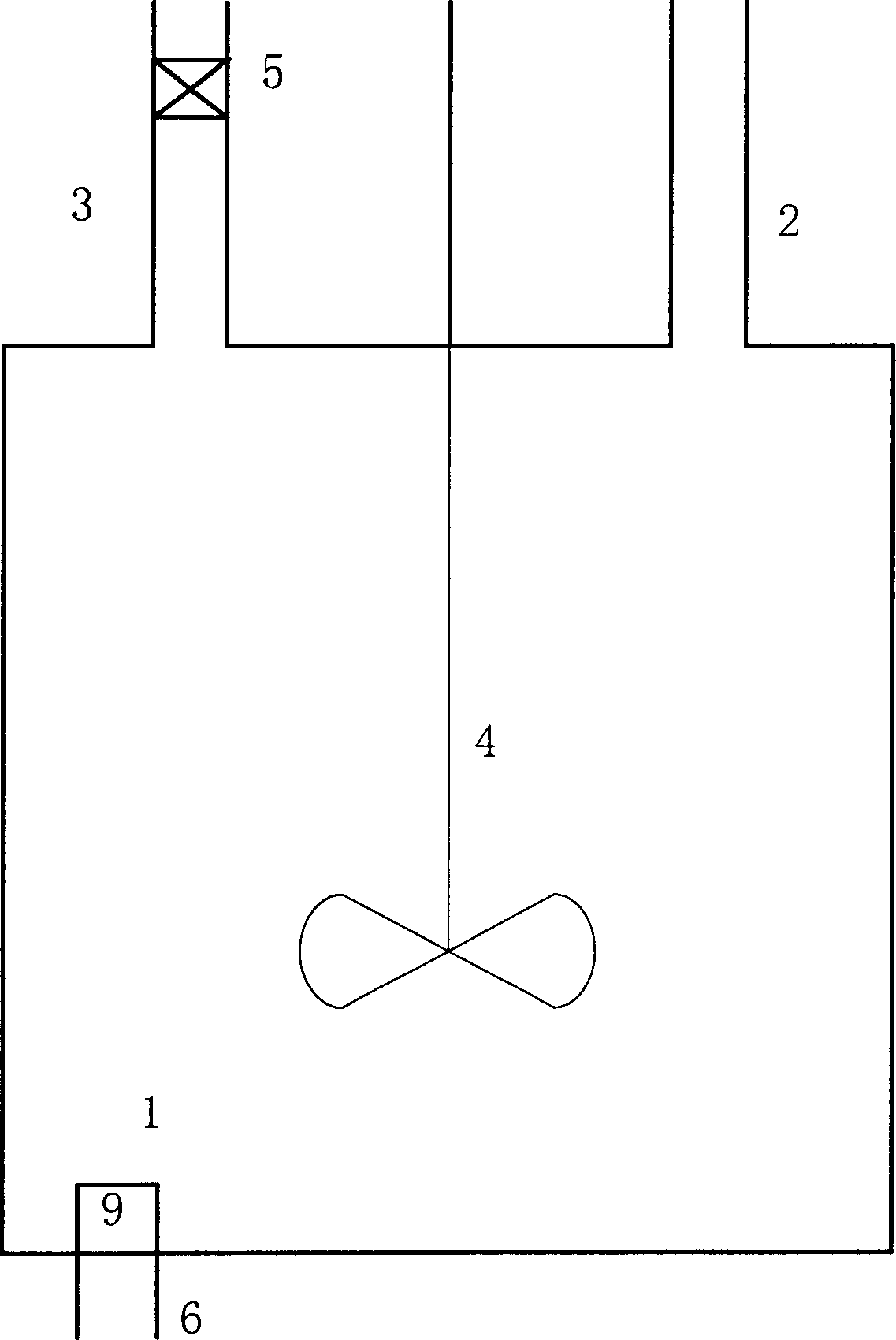

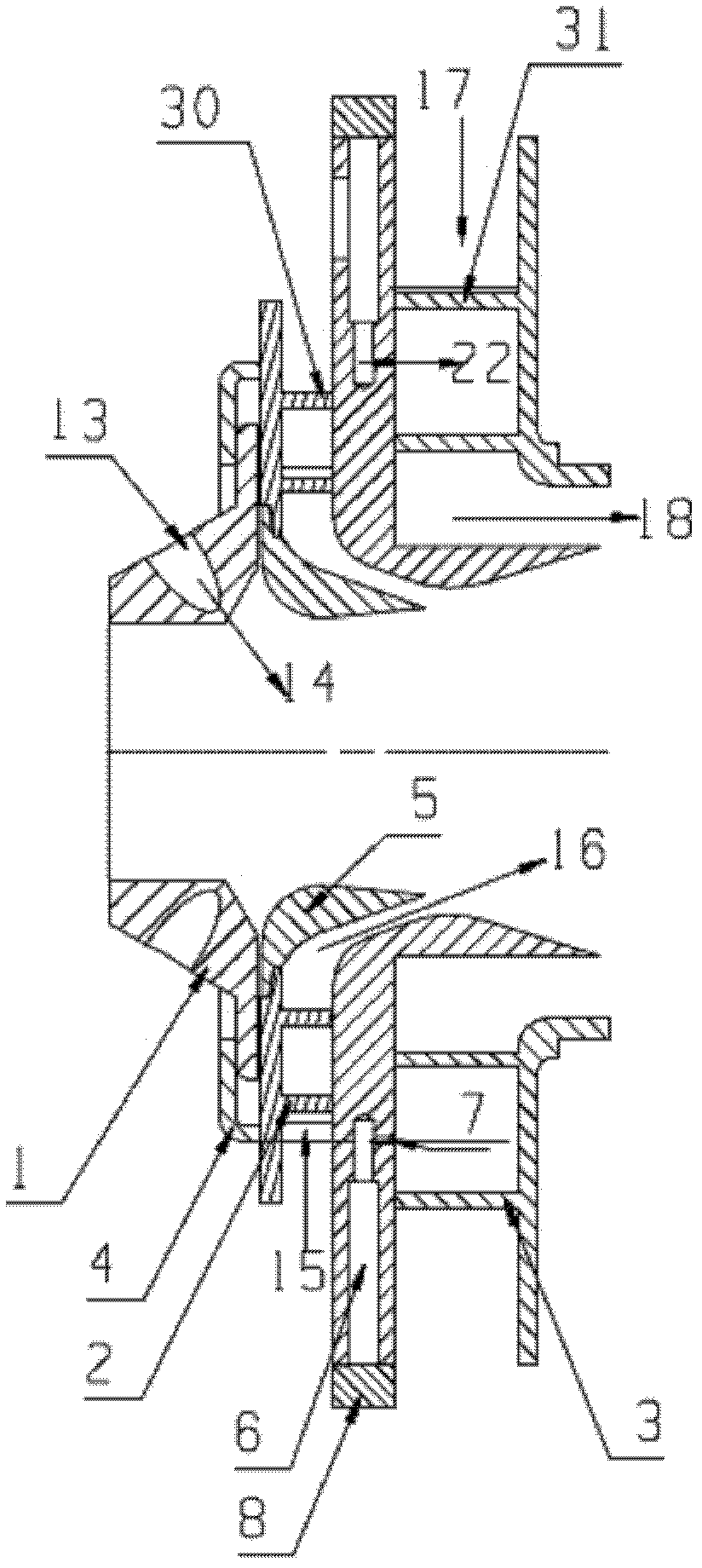

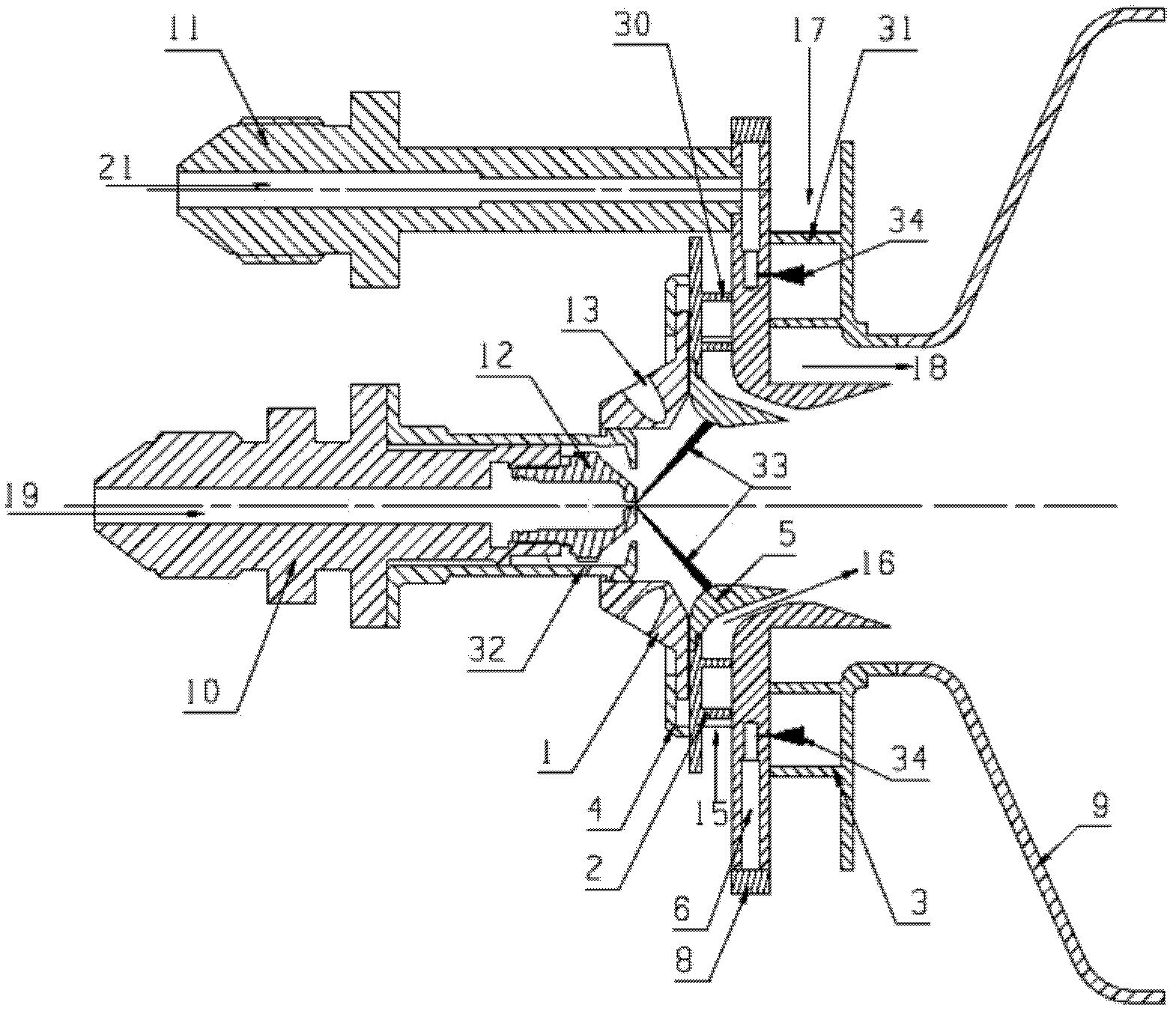

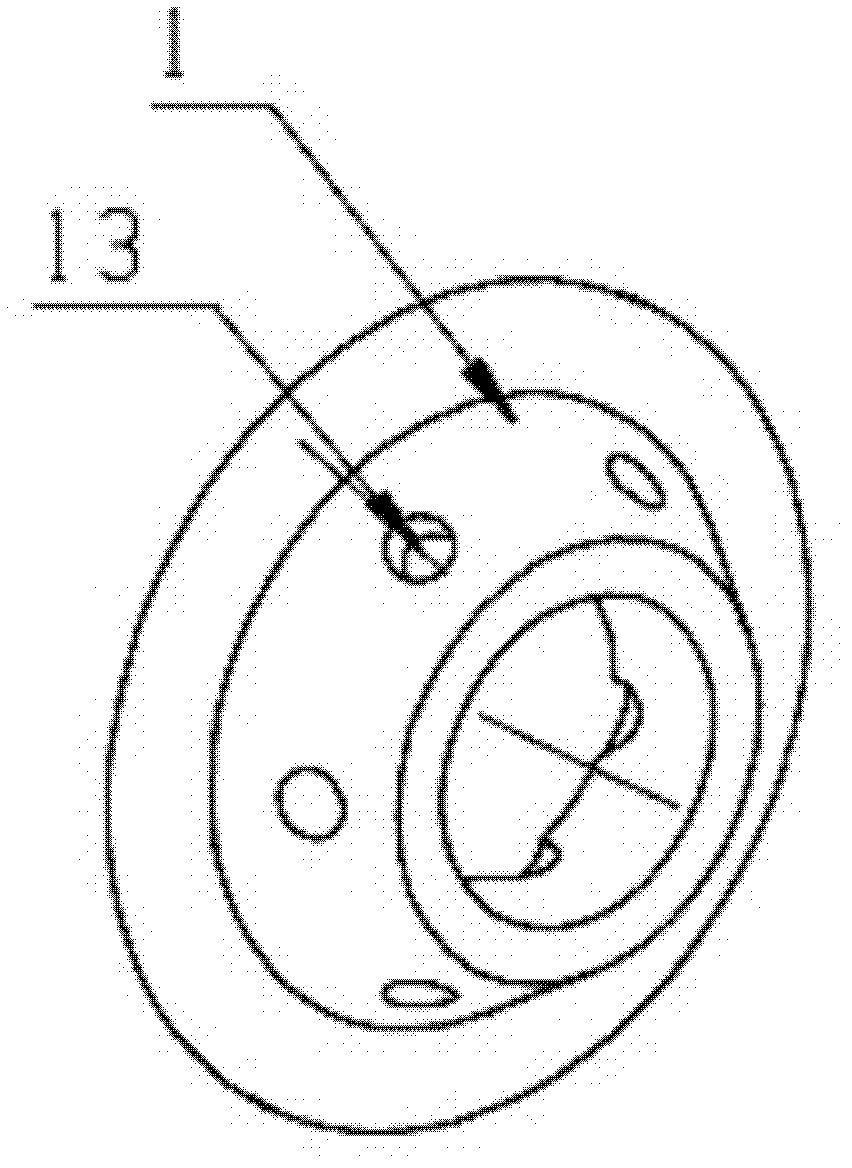

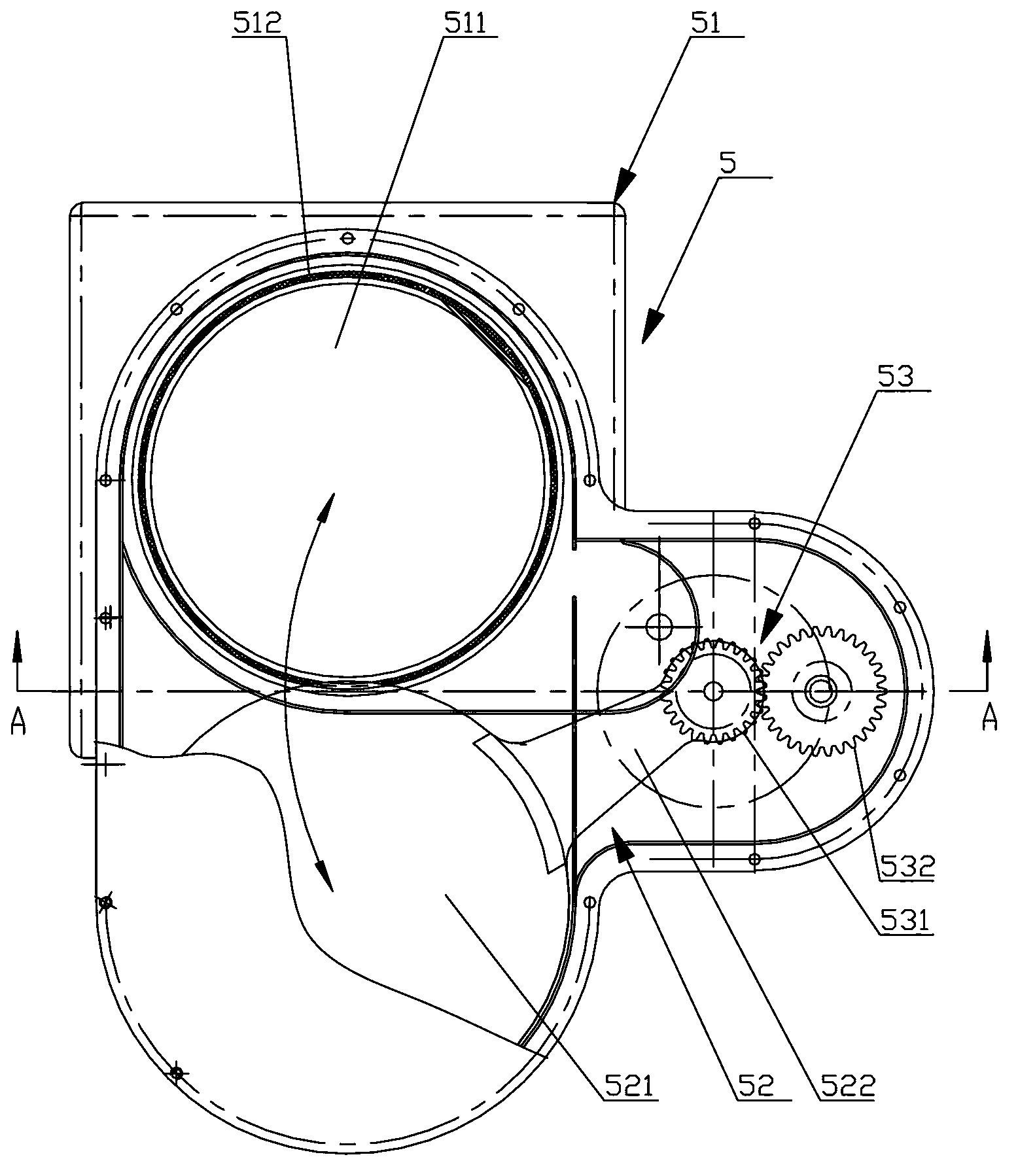

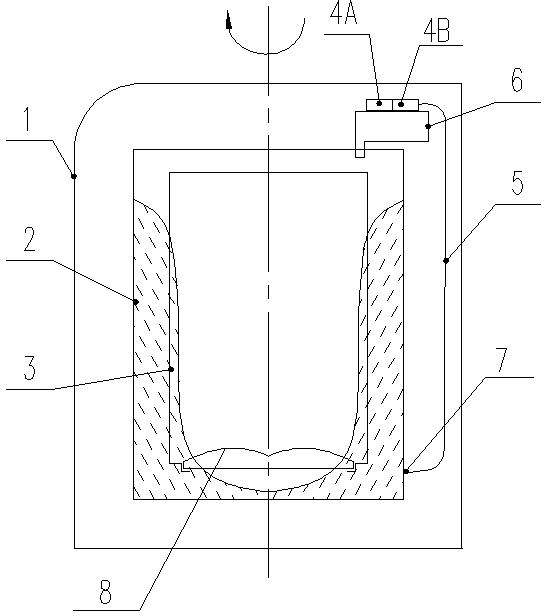

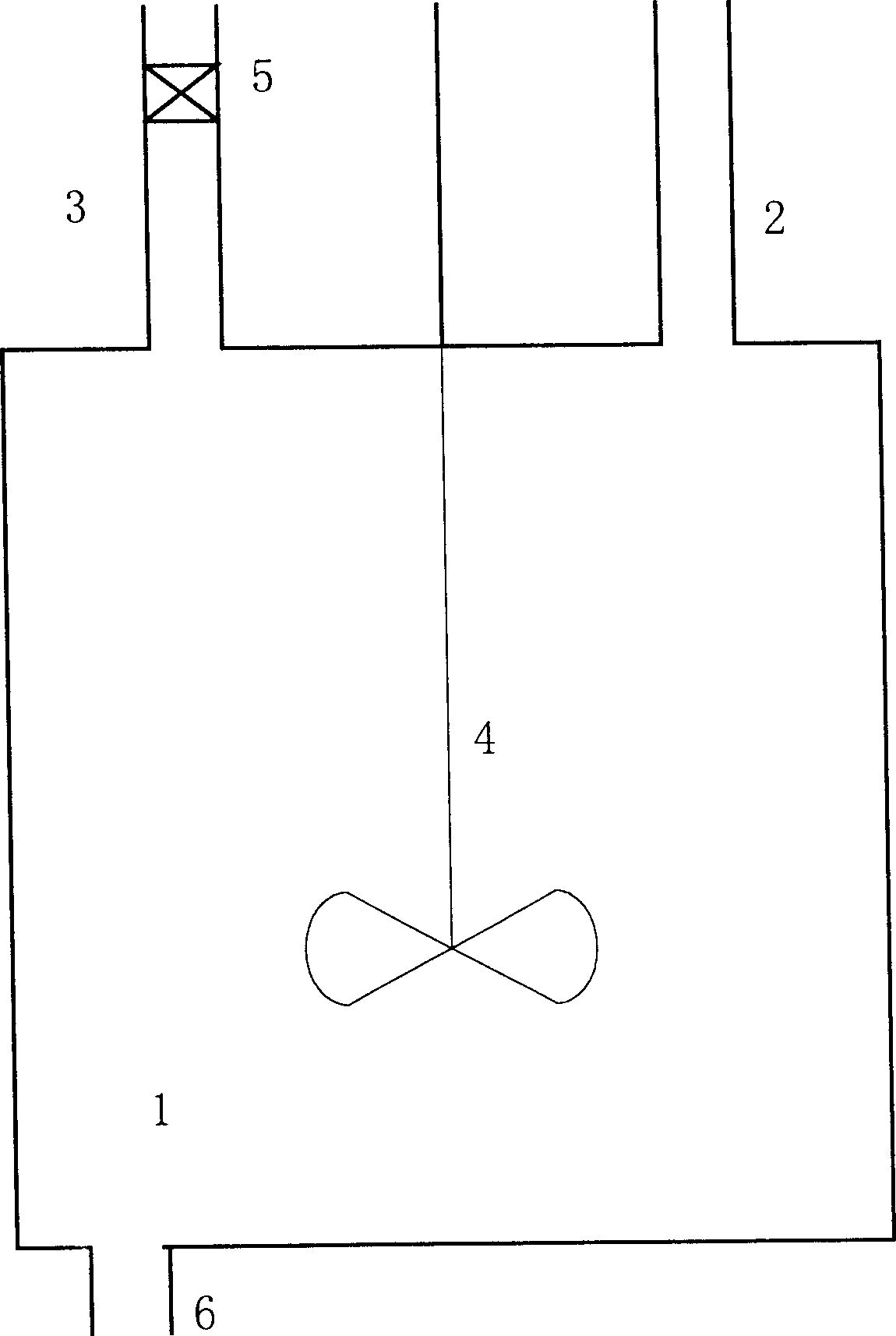

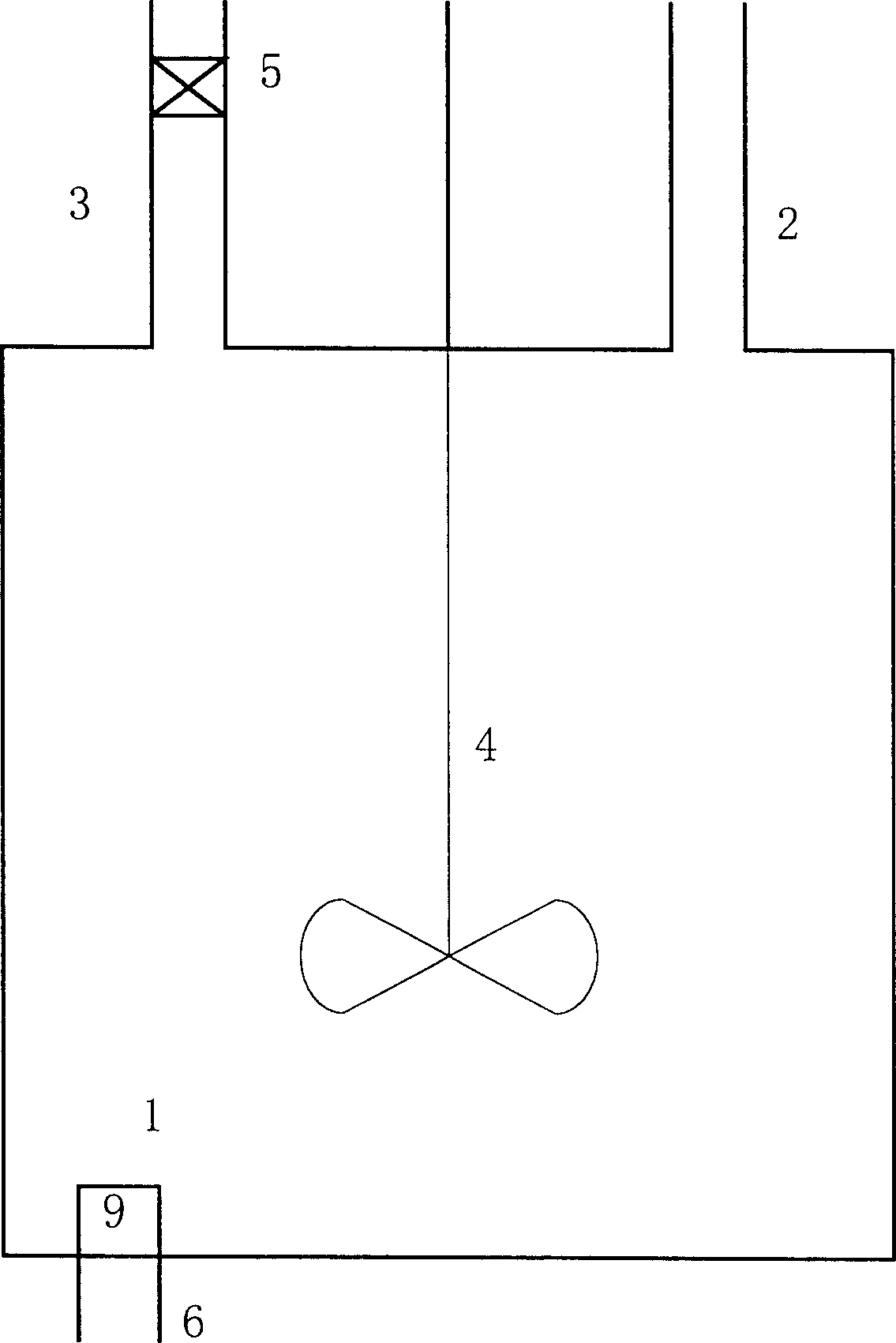

Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

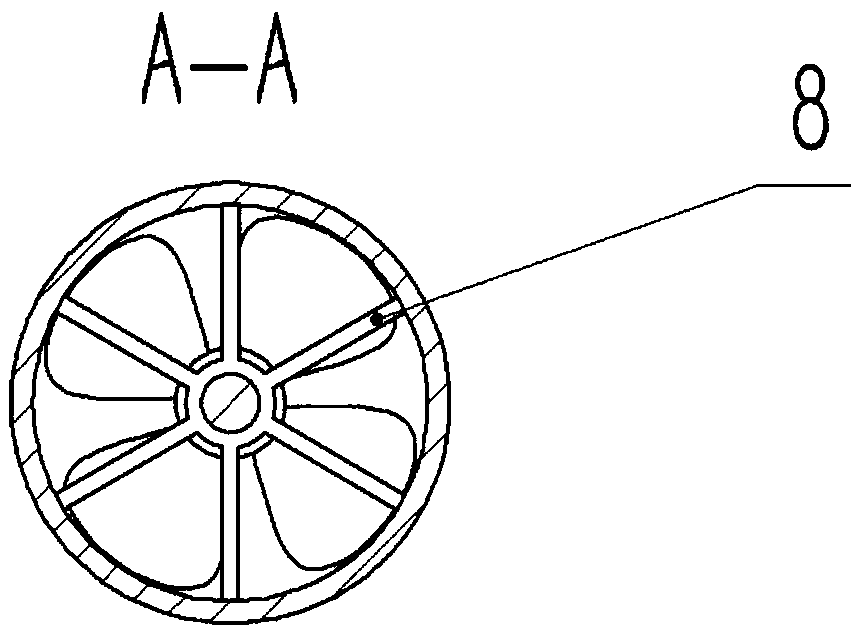

InactiveCN102628205AAvoid depositionEnsure normal dischargeOther washing machinesControl devices for washing apparatusImpellerInlet valve

The invention discloses a sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine which comprises a shell, wherein an external water-storing barrel and an internal washing barrel are arranged in the shell; a water inlet box, a draining valve, a clutch, a program controller and a power supply part are arranged in the shell; a water inlet valve is arranged on the water inlet box; an ozone generating device is mounted on the water inlet box; an air outlet end of the ozone generating device is communicated with the bottom of a side wall of the external barrel through an ozone pipeline; the ozone generating device is connected with the program controller and the power supply part; and the draining valve and the clutch are respectively arranged and are respectively controlled by the program controller. The invention also discloses a barrel-cleaning control method of the washing machine. The sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine is simple in structure and convenient in use; the internal barrel, the external barrel, the space between the internal and external barrels and the space under an impeller are cleaned and are sterilized and disinfected by using ozone; when water is discharged, the impeller is started to rotate positively and negatively by the washing machine so as to prevent line scraps and dirt in water from depositing at the bottom of the external barrel and internal barrel and on the impeller; the discharging of the line scraps and dirt is ensured; and the barrel-cleaning function is achieved.

Owner:HENAN XINFEI ELECTRICAL EQUIP

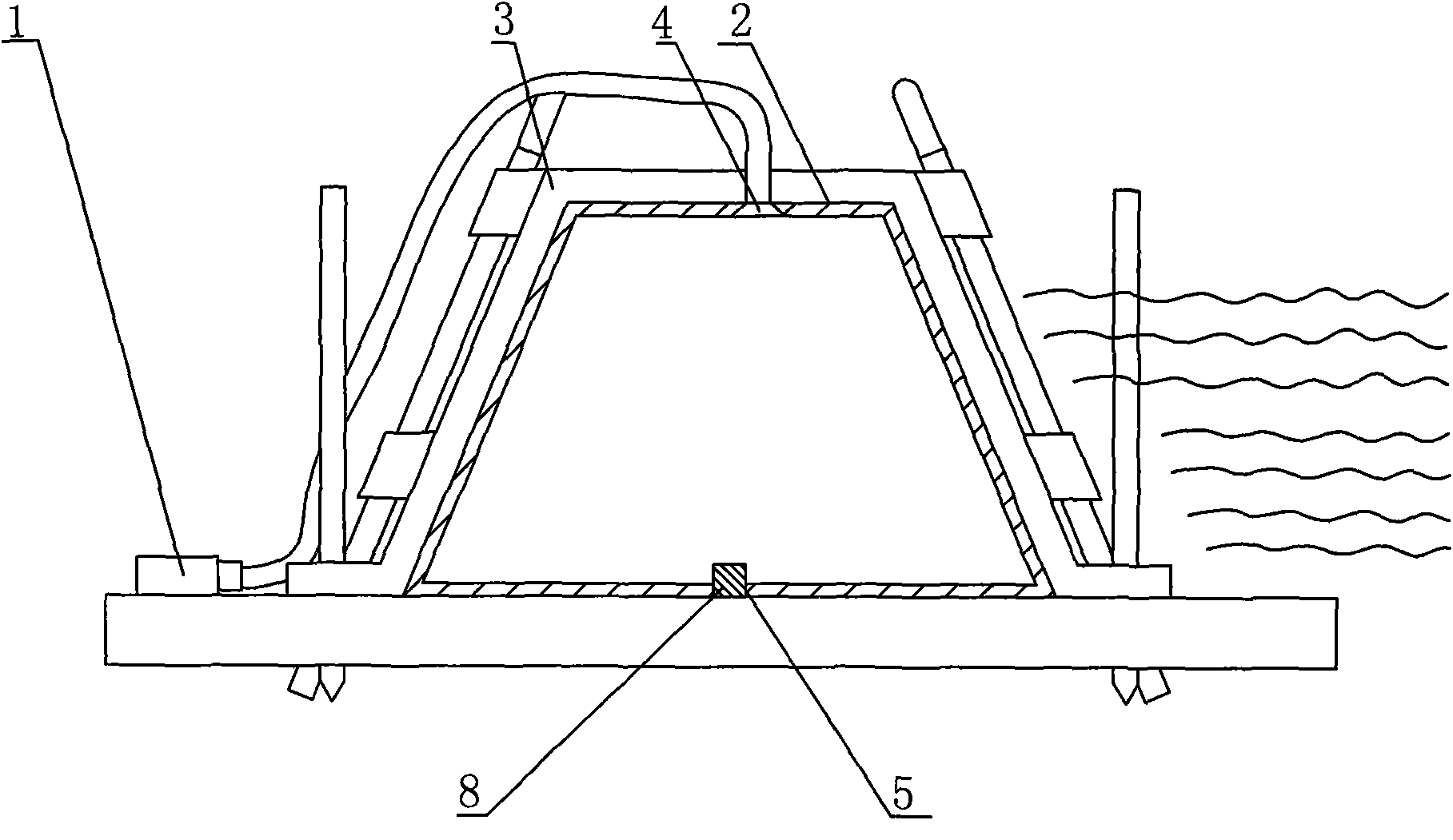

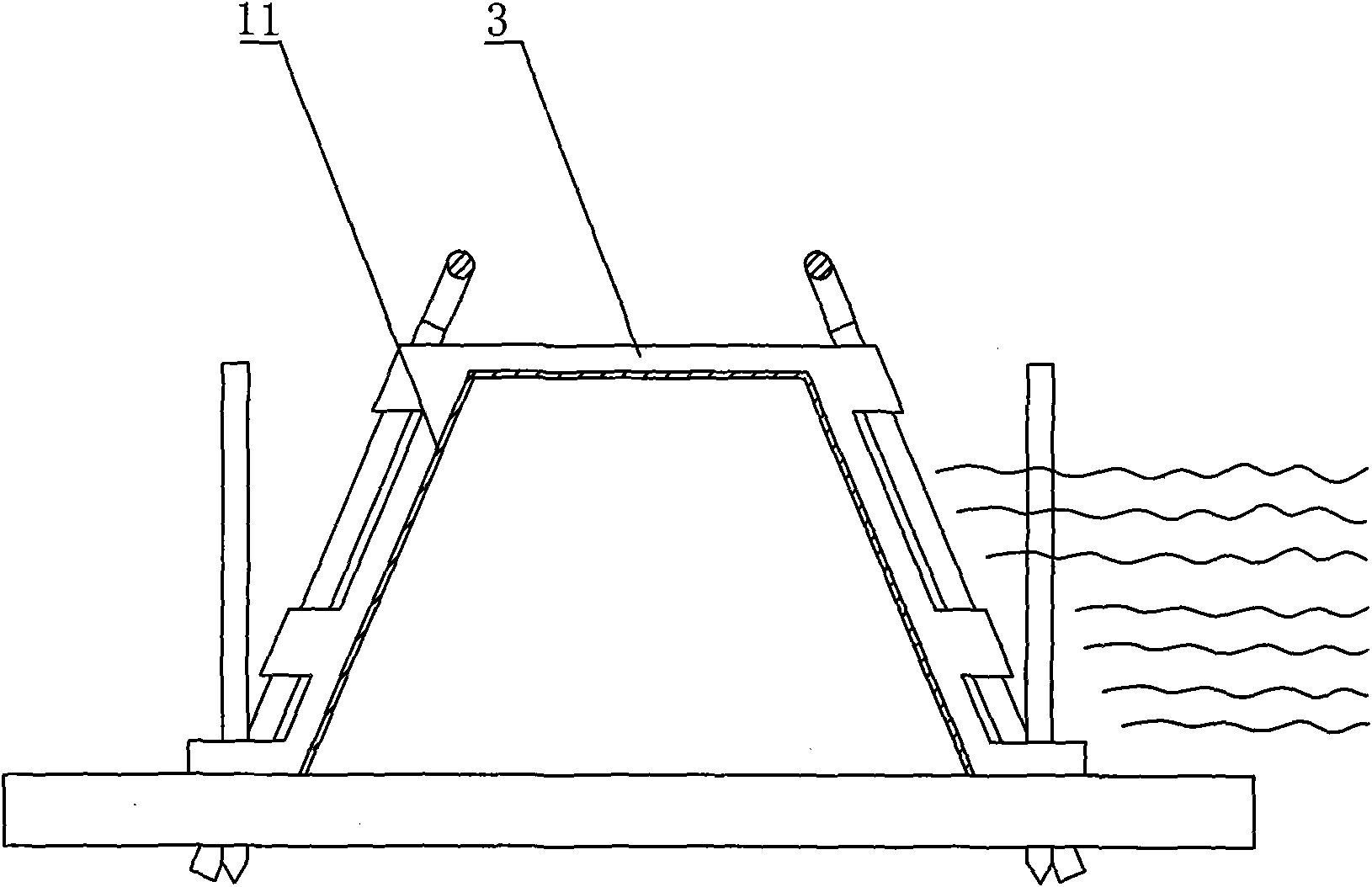

Water surface garbage cleaning device based on solar energy

PendingCN109024515AInflow guaranteeThe water flowing into the tank is discharged at a constant speed by the water pump to ensureBatteries circuit arrangementsWater cleaningElectricityWater flow

The invention discloses a water surface garbage cleaning device based on solar energy, and relates to the technical field of sanitation machinery. The garbage cleaning device is simple in structure and compact in size. A box body and a floating body module are fixedly connected by a support frame, and a top cover and the upper surface of the floating body module are embedded with solar panels, thefloating body module is used for floating the box body on the water surface and forming a certain position difference from a water inlet of the box body to the water surface, a collecting net bag isarranged in the box body, and a water pump is installed in the lower portion of the box body. By using the water level difference between the upper port on the box body and the water surface, floatingobjects are carried by the current into the collecting net bag of the box body for collection, the water which flows into the box body is discharged, and the function of cleaning water surface garbage is realized. According to the water surface garbage cleaning device based on the solar energy, the solar panels are used for generating electricity and used as power for driving the water pump, energy conservation and environment protection are achieved, wherein the electric energy generated by the solar panels is stored in a battery to supply power to the water pump through a motor, and the remained electric energy is stored, so that the function of cleaning water surface garbage is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

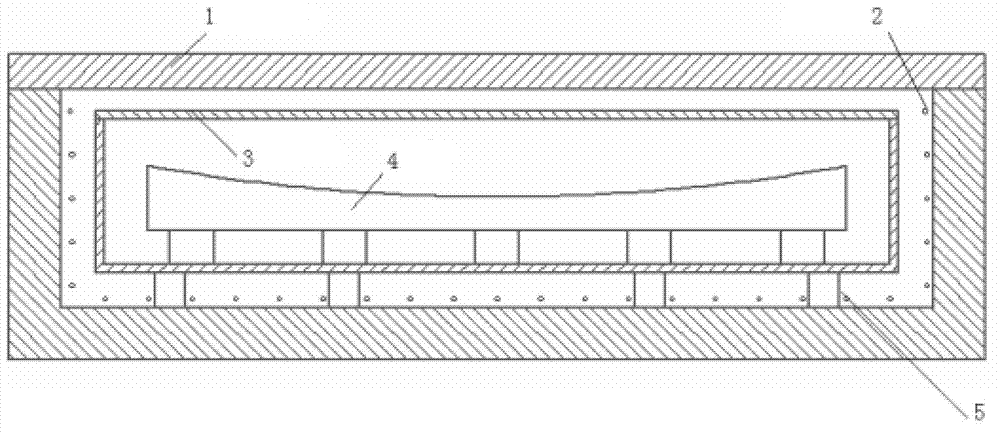

Superheat steam drying device

InactiveCN102914134AEasy accessEnsure normal dischargeDrying using combination processesDrying machine combinationsEngineeringProcess engineering

The invention provides a superheat steam drying device which comprises a steam drying mechanism, a vacuum drying mechanism, a first discharging valve, a second discharging valve and a steam heating part. A superheat steam drying and vacuum drying combined structure is adopted by the superheat steam drying device, namely, a full-closed belt pressing drying system is adopted; the structure is simple; the steam heat energy for drying and evaporating materials is fully recycled; a waste heat recovery device is simple or the waste heat is directly sent to the other heating device; the energy consumption is greatly reduced; the whole set of device is full-automatically controlled; the device can continuously produce; the operating flexibility is high; and the handling capacity is high.

Owner:曾应祥

Treatment process of antibiotic wastewater

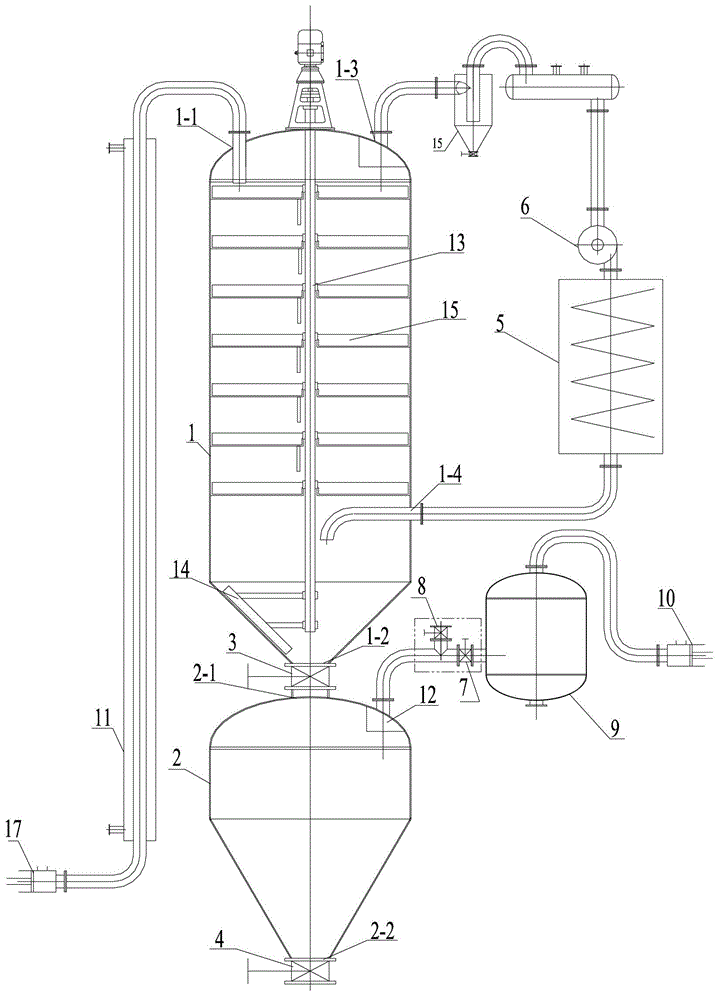

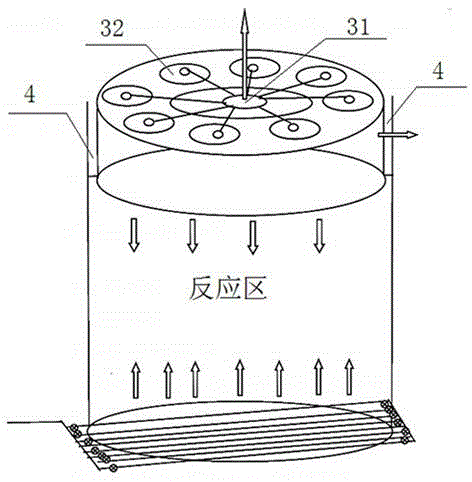

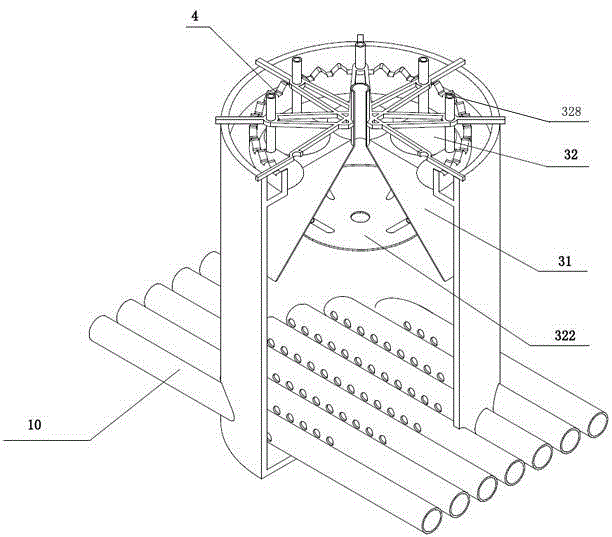

ActiveCN104671597ASimple facilitiesSimple and fast operationMultistage water/sewage treatmentEmission standardOxygen

The invention discloses a treatment process of antibiotic wastewater. The treatment process comprises the following steps: firstly carrying out coagulating sedimentation pretreatment on wastewater, and adding acidized supernate into a hydrolysis acidification pool; mixing returned sludge, anaerobic effluent and hydrolysis acidification effluent in proportion in a water distribution pool, and simultaneously regulating the pH value; feeding the regulated wastewater into a anaerobic treatment stage, converting most pollutants into water and carbon dioxide, simultaneously producing marsh gas, carrying out gas-solid-liquid separation by virtue of a three-phase separator, collecting marsh gas in a gas chamber, returning the sludge to a reaction region, returning partial supernate to the water distribution pool, and sequentially feeding rest supernate into an aerobic treatment stage and an advanced treatment stage. The antibiotic wastewater treated by virtue of the treatment process can thoroughly reach the emission standard, and the removal rate of various pollutants reaches above 99%; furthermore, facilities are simple and are easy and convenient to operate.

Owner:PUCHENG CHIA TAI BIOCHEM

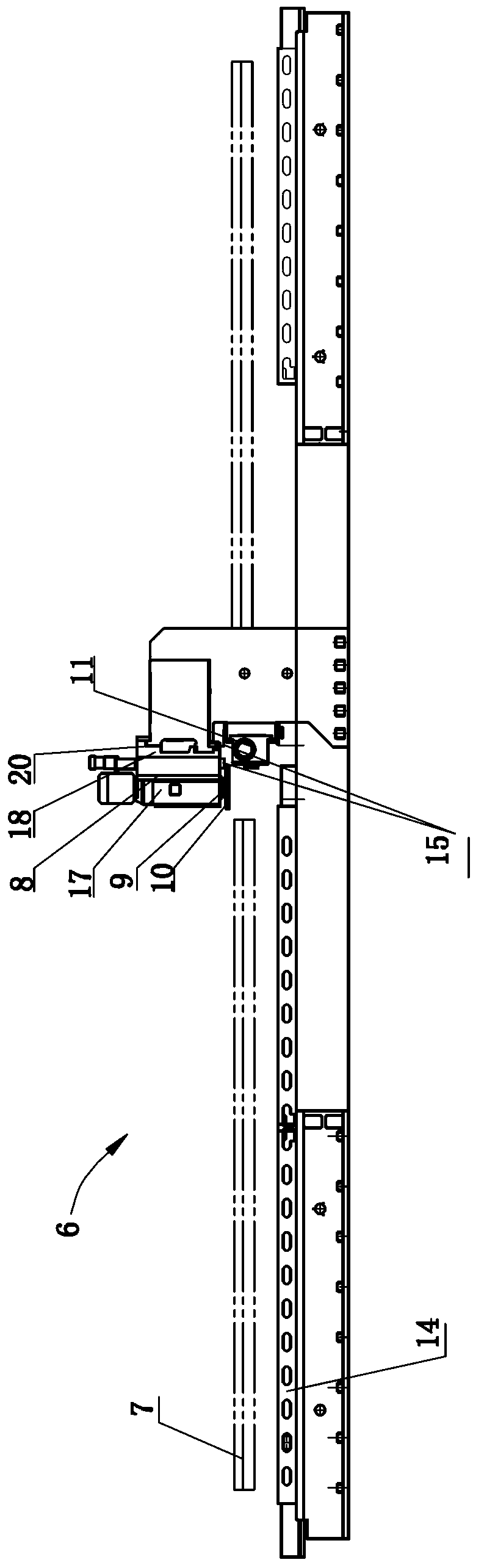

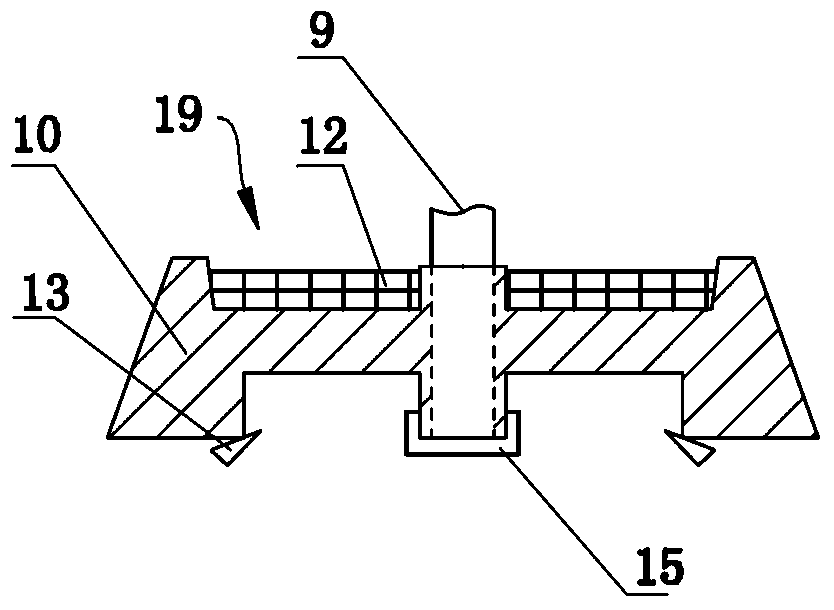

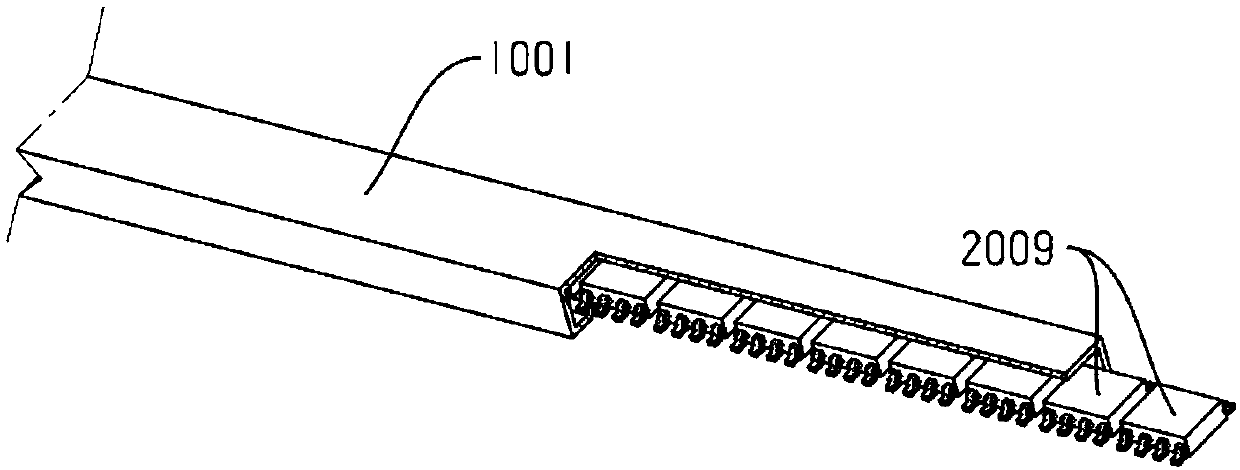

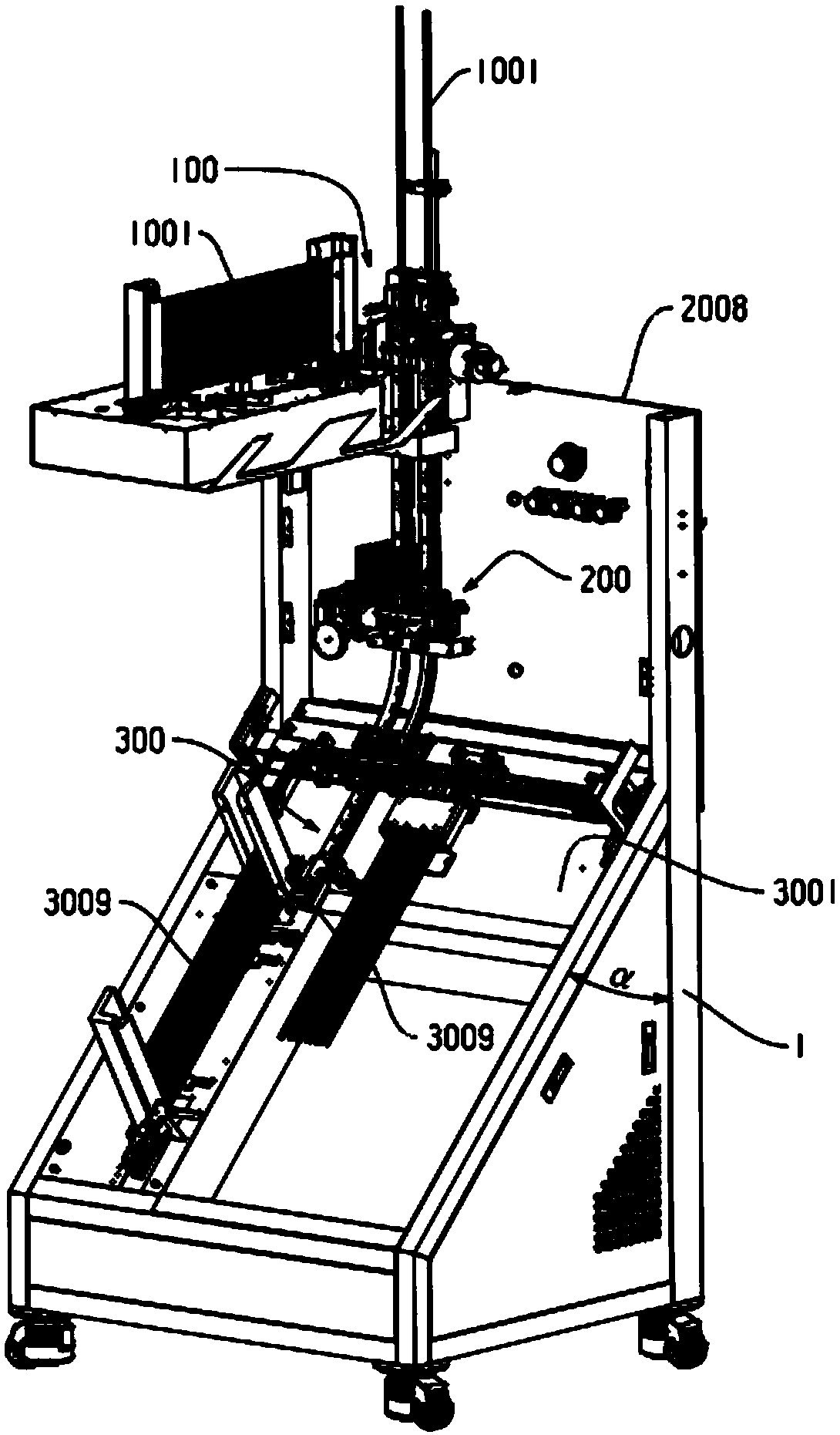

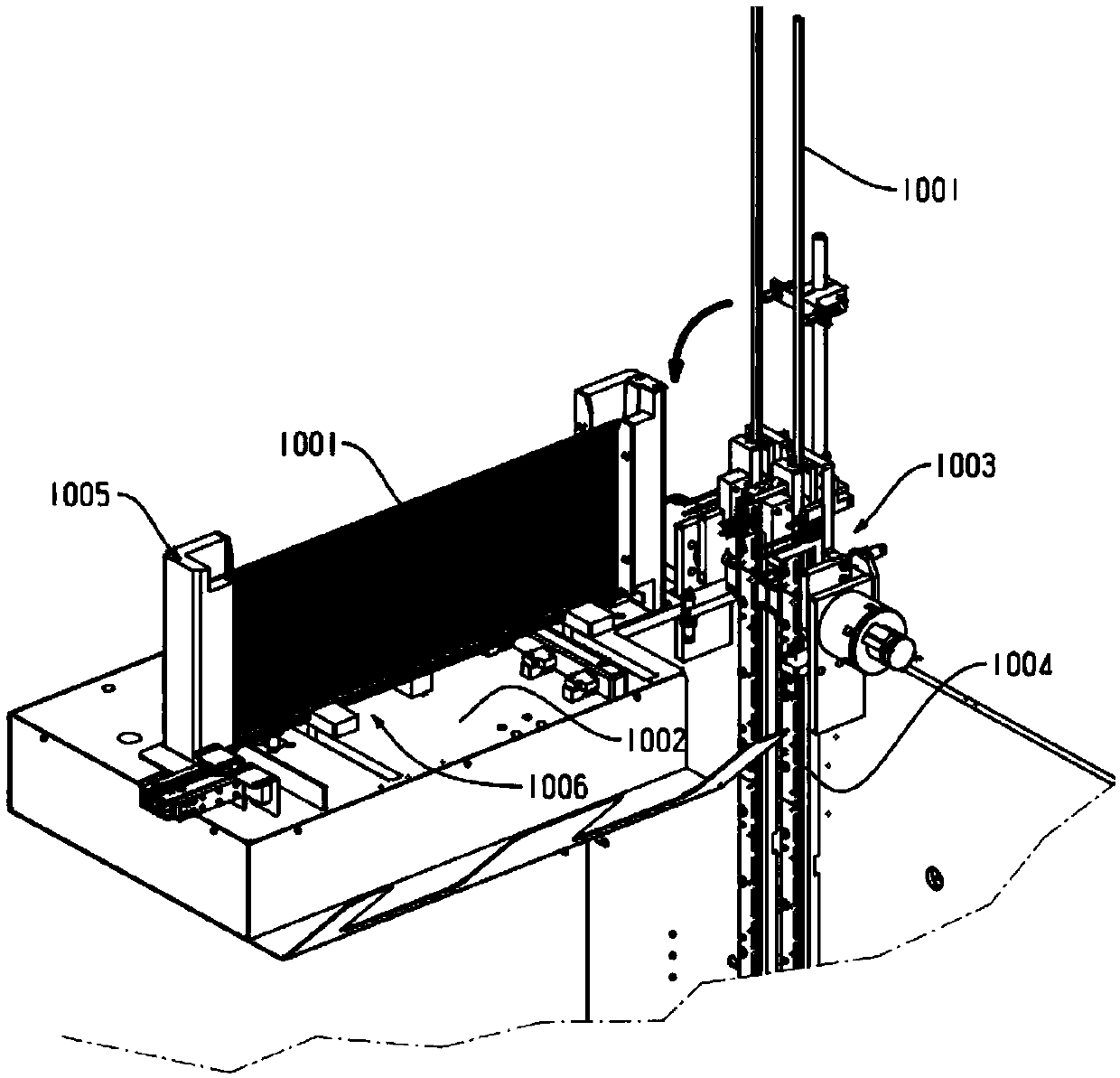

Automatic IC testing and sorting device

The invention discloses an automatic IC testing and sorting device. The device comprises a feeding device, a testing device and a sorting and storing device which are arranged on a machine frame; andthe machine frame comprises a first mounting plate and a second mounting plate, wherein the first mounting plate is vertically arranged, and the second mounting plate is connected with the bottom of the first mounting plate and is obliquely arranged. An IC material tube is clamped on the feeding device, IC chips which are not tested in the IC material tube are supplied to the testing device for testing through the feeding device, after the testing is finished, the chips are classified through the sorting and storing device and are stored in a plurality of empty material tubes. According to thedevice, a clamping mechanism with the IC material tube clamped is turned over, so that the IC material tube is changed into a vertical state, and the IC chips in the IC material tube slide out and get to a vertical material channel; the IC chips can be controlled by a blocking and pressing mechanism to be fed to the testing device one by one, testing chucks clamp the IC chips and push the IC chips to a testing PCB for testing, the IC chips are received through a material receiving table after the test is completed and are classified and placed to a first material storing mechanism or a second material storing mechanism, so that the speed of sorting and storing is increased, and the labor cost is saved.

Owner:昆山宇辰光通自动化科技有限公司

Refrigerator ice-storage box assembly and refrigerator therewith

ActiveCN104006595AAvoid stickingTo solve the adhesion,Domestic cooling apparatusLighting and heating apparatusIceboxElectric machinery

The invention relates to the technical field of refrigerator, and particularly discloses a refrigerator ice-storage box assembly and a refrigerator therewith. The refrigerator ice-storage box assembly includes an ice-storage box and an ice-crushing device. The ice crushing device includes a motor, a rotating shaft, a fixed blade, a movable blade which is installed on the rotating shaft and a stirring disk. The rotating shaft is drivingly connected to the motor. The fixed blade is installed, on a position opposite to the movable blade, in the ice-storage box and can rotate relative to the movable blade. The fixed blade, the stirring disk and the movable blade are arranged between two opposite inner walls in the ice-storage box. Both the fixed blade and the movable blade are arranged at the same side of the stirring disk. When the assembly is used, the motor drives the rotating shaft to rotate, the rotating shaft drives the movable blade and the stirring disk to rotate, an ice cube falls on the ice-crushing device, the movable blade and the fixed blade crush the ice cube through an interaction, and then the ice cube is discharged from an ice-discharging opening for use. With the stirring disk, capability of driving the ice cube of the ice-crushing device itself is enhanced. Clingy ice cubes can be scattered. Problems that the ice cubes are clingy due to a long-time storage and cannot be discharged through rotation of a blade are solved.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

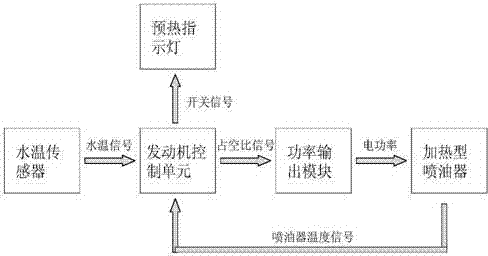

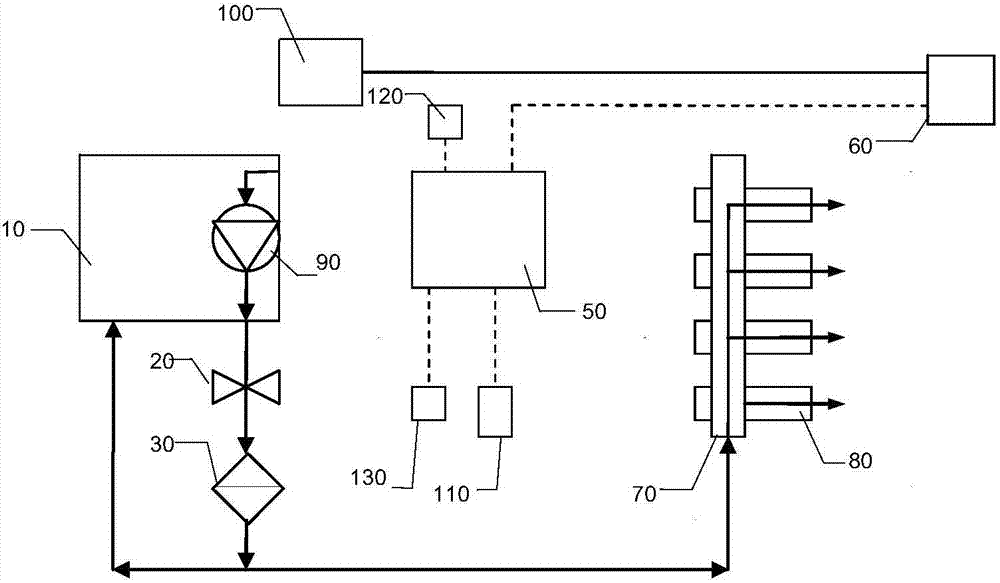

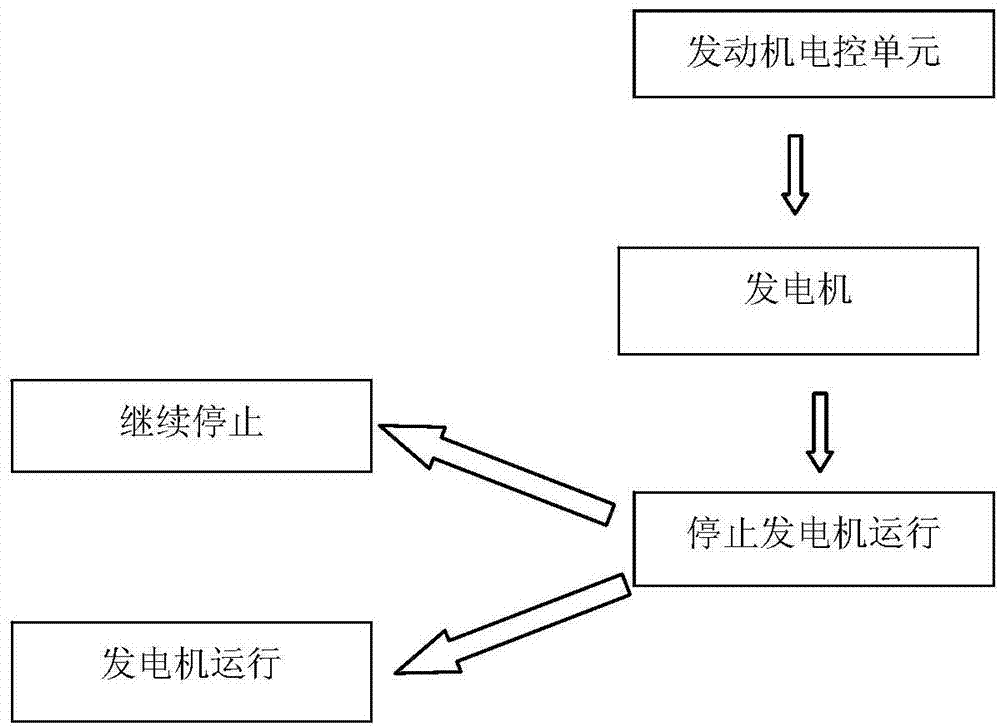

Cold start system and start method for flexible fuel vehicle

ActiveCN103615345AAchieve jet ignitionReduce manufacturing costFuel injection apparatusEngine controllersFuel oilFlexible-fuel vehicle

The invention relates to a cold start system and start method for a flexible fuel vehicle. The cold start system comprises an engine control unit, a fuel system and a fuel oil preheating module. The fuel oil preheating module comprises a water temperature sensor, a preheating indicator light, a power output module and a heating type oil sprayer. When a start switch is turned on, the preheating indicator light is firstly lightened, the water temperature sensor transmits a cooling water temperature signal to the engine control unit, the engine control unit calculates a duty ratio signal and judges whether the power output module needs to output power or not, the power output module outputs a current to the heating type oil sprayer, and the heating type oil sprayer heats ethanol fuel and feeds back a temperature signal of the heating type oil sprayer to the engine control unit at the same time so as to judge the preheating finish time.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

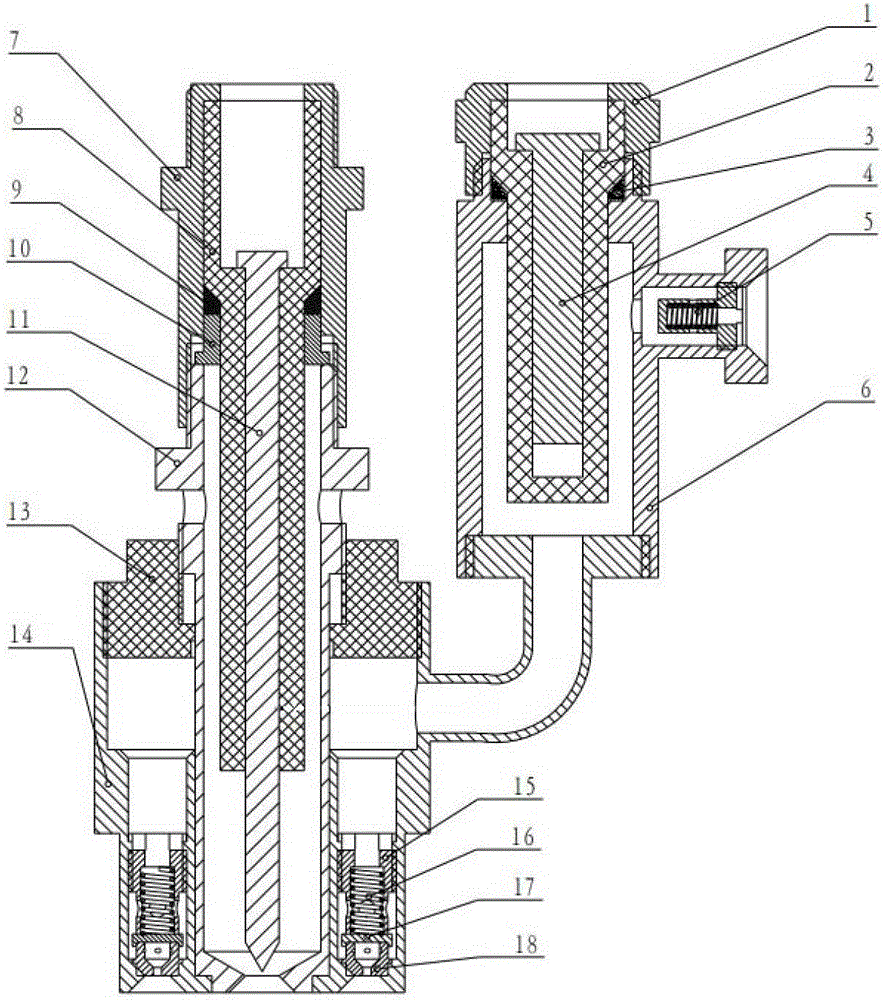

Plasma catalysis ignition integrated nozzle

InactiveCN102980209AGood drop spectrumLower activation energyContinuous combustion chamberPlasma jetCombustion chamber

The invention provides a plasma catalysis ignition integrated nozzle which is a plasma assisted atomization and plasma ignition integrated nozzle formed by a low-temperature plasma discharge assembly, a fuel pressure atomization nozzle assembly and a high-energy plasma ignition assembly. A barrier medium uniformly discharges to ensure that a liquid fuel partially pyrolyzes to generate a large quantity of gas activated components, so that a gas-liquid coexisting plasma microcell is formed, fuel activation energy and ignition energy are reduced, physical conditions of gas assisted atomization are formed, and atomization effect is improved. A plasma ignitor is arranged on the middle of a multi-point nozzle and is positioned in a combustion chamber low-pressure region, plasma and fuel atomized particles are well mixed to generate a chemical reaction, and a stable high-temperature ignition core is easily formed. Ignition is directly carried out by adopting a plasma jet, and because the plasma jet has special discharge characteristics and larger discharge energy and is highly concentrated in energy, the ignition reliability and the ignition concentration limit of a gas turbine are greatly improved. The plasma catalysis ignition integrated nozzle can be applied to a combustion chamber of the gas turbine.

Owner:三亚哈尔滨工程大学南海创新发展基地

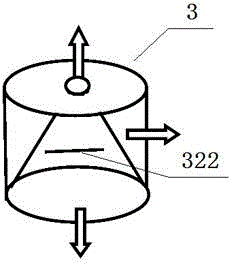

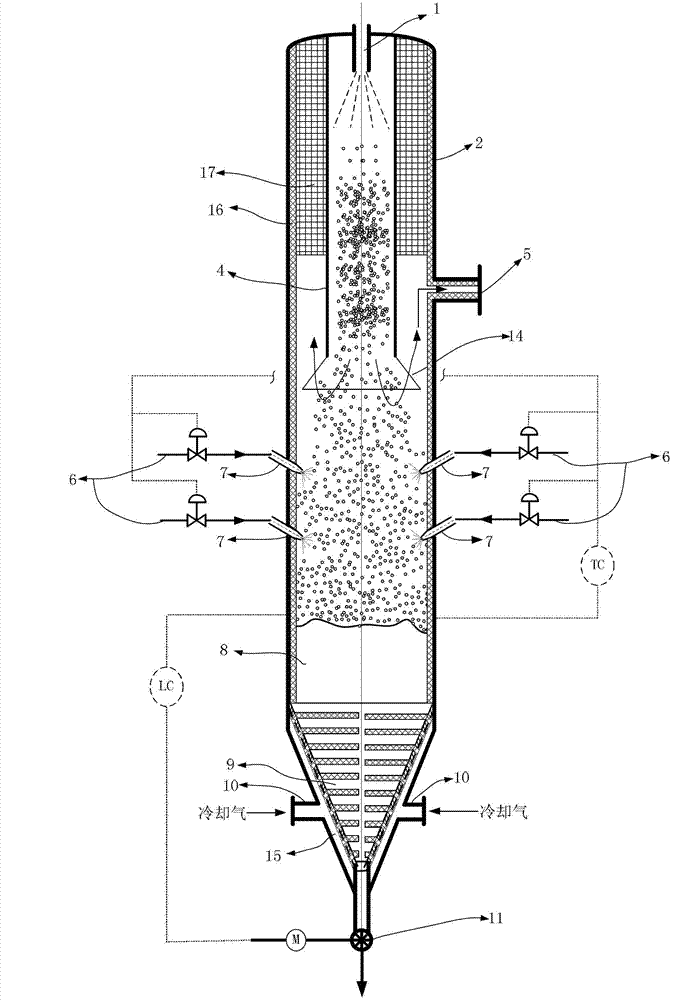

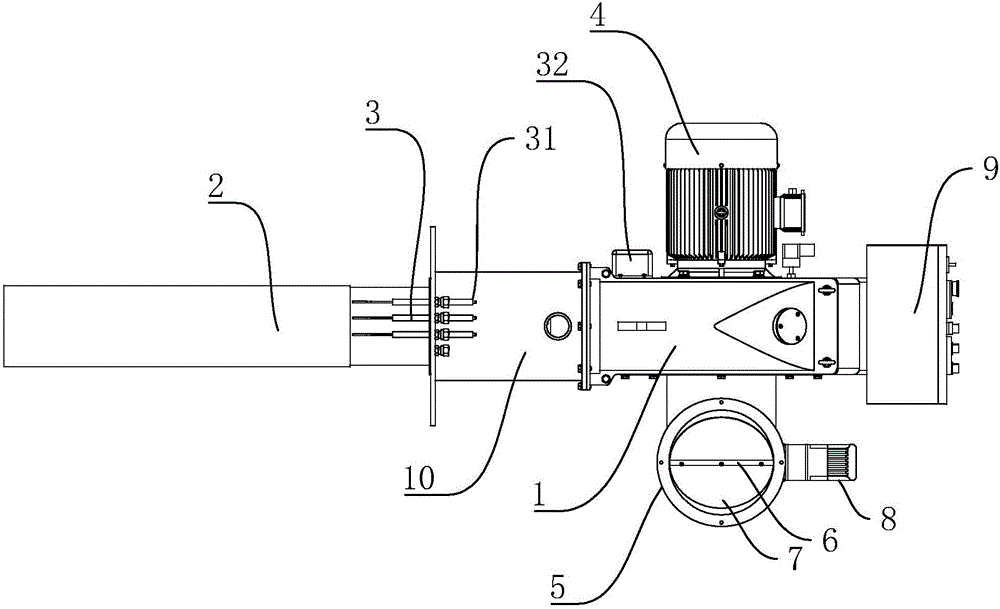

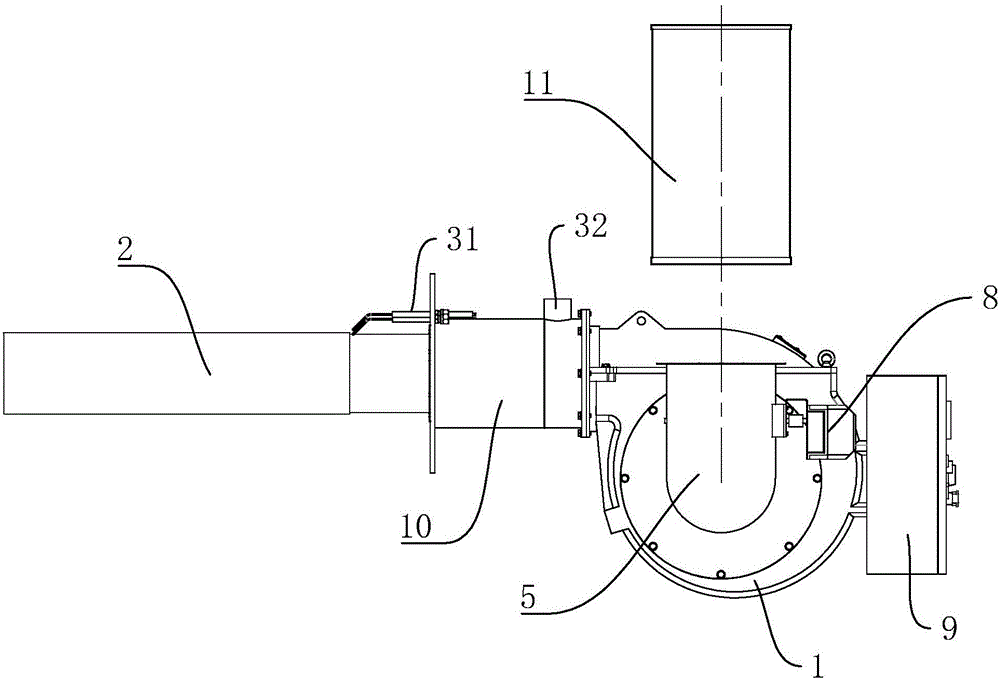

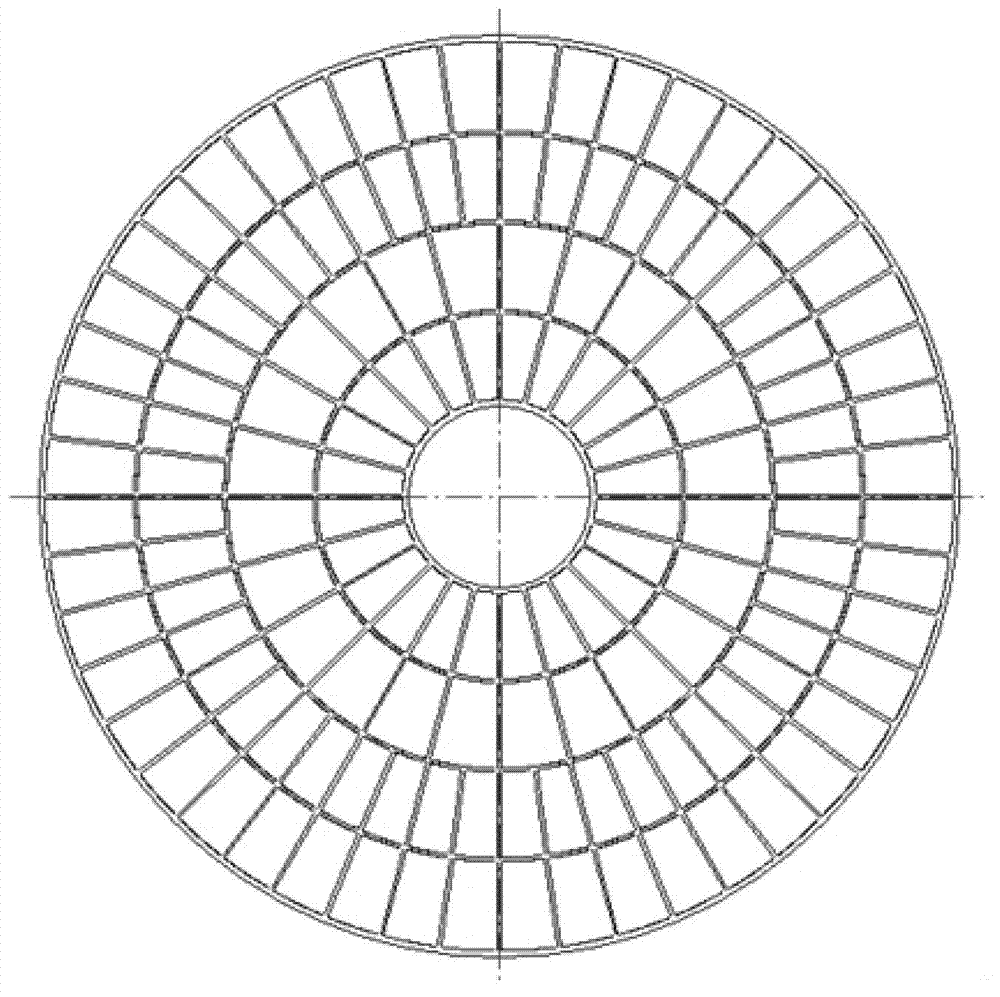

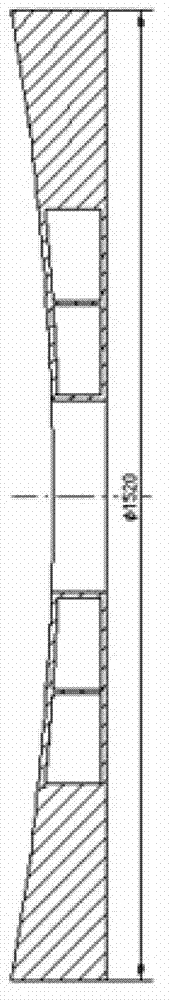

Dry-process slag discharge device and method for entrained flow bed

ActiveCN103031156AAchieving Clean TransformationMeet cooling requirements to different temperaturesGranular/pulverulent flues gasificationWater dischargeSlag

The invention relates to a dry-process slag discharge device and method for an entrained flow bed. The device is sequentially divided into a reaction section, a cooling section and a slag discharge section from top to bottom, wherein the reaction section comprises an inner barrel; the inner barrel is fixed on the top wall of the reaction section, and is opened downwards; the top wall of the reaction section is provided with a feed nozzle in a penetrating mode, which is opened to the internal space of the inner barrel; and the side wall of the reaction section is provided with a product gas outlet. According to the invention, gas flow deflection is utilized to implement primary separation of the gas product and solid product, and the solid coke slag and gas product are respectively cooled to satisfy the requirements of cooling the solid product and gas product to different temperatures; and the entrained flow bed operation and moving bed operation are combined to substitute the slag tank on the lower part of the entrained flow bed to further cool the coke slag, thereby effectively reducing the black water discharge amount and implementing clean conversion of coal resources.

Owner:ENN SCI & TECH DEV

Low-nitrogen burner

The invention discloses a low-nitrogen burner. According to the technical scheme, the low-nitrogen burner is characterized in that a mixer of the low-nitrogen burner comprises a barrel and a gas inlet, wherein an inner barrel and burning-supporting air swirling pieces arranged on the inner wall of the inner barrel are arranged at the gas inlet front end inside the barrel; an air inlet barrel located on the back side of the burning-supporting air swirling pieces in the air inlet direction is arranged at one end, close to the gas inlet back side, of the inner barrel; the air inlet barrel, the inner barrel and the inner wall of the barrel are connected in a sealed manner to form a gas sub-cavity; inclined flow guiding holes are formed in the air inlet barrel; a primary swirling impeller is arranged in the position, located on the air inlet back side of the inner barrel, inside the barrel; and the primary swirling impeller and the air inlet barrel form a primary mixing chamber. Through the arrangement, gas is ejected via the gas sub-cavity from the inclined flow guiding holes, the ejected gas can form multiple single, short and powerful gas flows, air flows sent by a fan pass through the burning-supporting air swirling pieces to form short and powerful rotating air flows, and the rotating air flows are circular and impact the multiple single gas flows, so that the air and the gas of the primary mixed gas reach the air-fuel ratio in the complete burning theory.

Owner:BEIJING SHENKEBOSI THERMAL ENERGY ENG TECH CO LTD

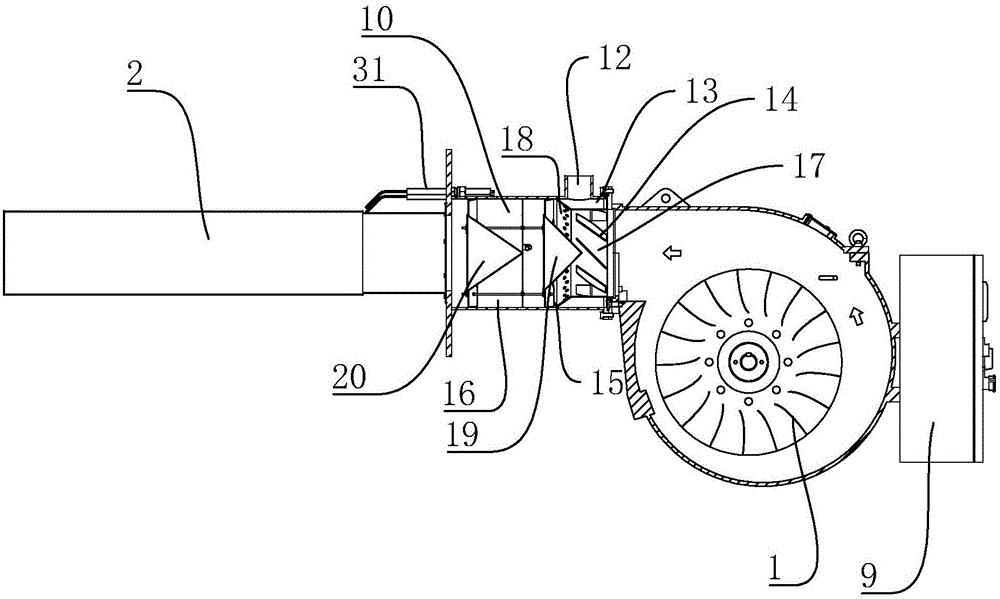

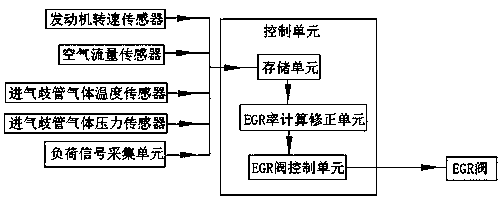

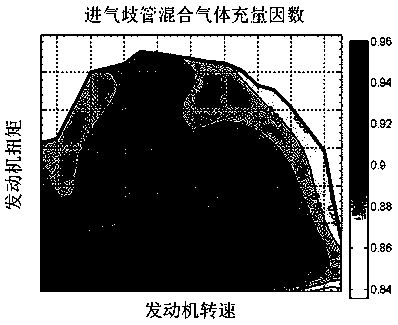

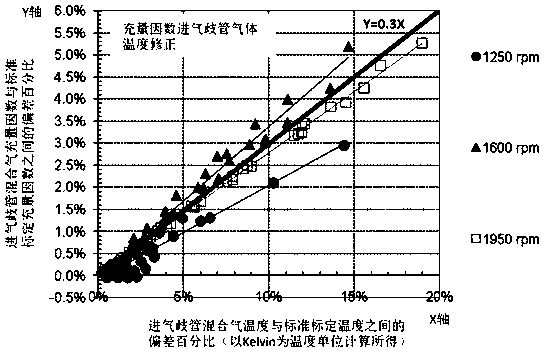

EGR rate correction system and method based on filling factor of internal combustion engine

ActiveCN109209659AAccurate calculationEnsure normal dischargeElectrical controlMachines/enginesClosed loop feedbackExternal combustion engine

The invention relates to an EGR rate correction system and method based on the filling factor of an internal combustion engine, and belongs to the field of engines. The method is based on the fillingfactor calibration pulse spectrum in the laboratory standard environment. The strong correlation between the filling factor and the inlet manifold gas temperature is adopted to conduct temperature correction to the filling factor. The actual EGR rate is calculated with the definition equation of filling factor. The actual EGR rate is compared with the target EGR rate calibration value or modifiedvalue to complete closed loop feedback control of the EGR valve opening. The EGR rate correction system and method can accurately determine the EGR rate of the engine in practical use when the EGR system and an intercooler deviate from laboratory calibration conditions due to the operation reasons such as fouling or efficiency change; additional sensors in addition to standing sensors are not required to added; and the characteristics of rich functions and being suitable for promotion are achieved.

Owner:深圳环境能源研究院有限公司

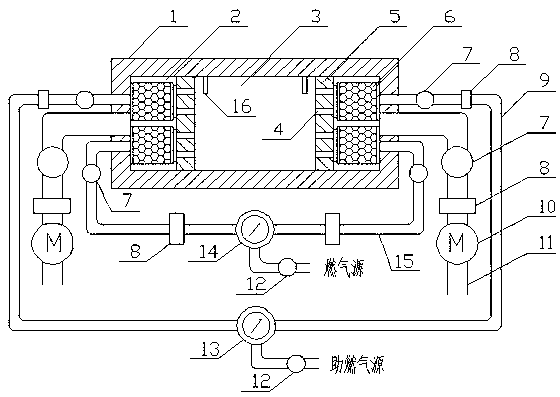

High thermal efficiency regenerative heating furnace

The invention discloses a high thermal efficiency regenerative heating furnace which is used for solving the problem that an existing regenerative heating furnace is low in thermal efficiency. The high thermal efficiency regenerative heating furnace comprises a furnace body, a partition wall divides an inner cavity of the furnace body into a combustion chamber and regenerative chambers arranged at two sides of the combustion chamber, the partition wall is provided with at least one combustion channel used for communicating the regenerative chambers with the combustion chamber. A heat accumulator is arranged inside each regenerative chamber, and is connected with a fuel combustion assisting pipeline and a fuel pipeline, and the fuel combustion assisting pipeline and the fuel pipeline are respectively connected with a combustion assisting gas source and a fuel source. The heat accumulator is further connected with a check valve capable of enabling fuel combustion assisting gas to enter the furnace body. The fuel pipeline is provided with a check valve capable of enabling the fuel to enter the furnace body. The high thermal efficiency regenerative heating furnace is capable of preventing burning smoke from entering the fuel combustion assisting pipeline and the fuel pipeline, and therefore ratio of the fuel and the fuel assisting gas is effectively controlled, and combustion efficiency is improved.

Owner:PANZHIHUA DUOSHI MACHINERY MFG

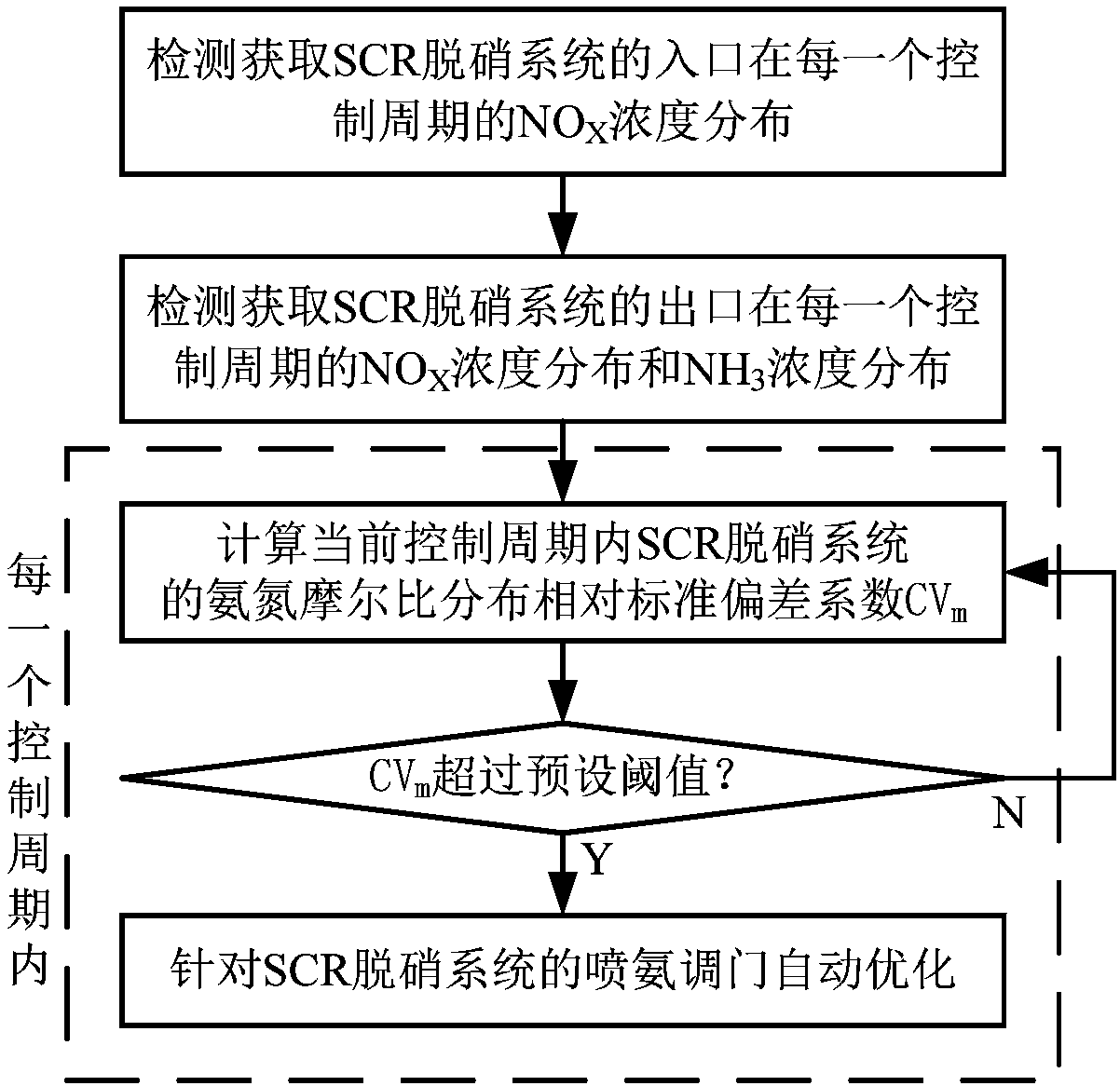

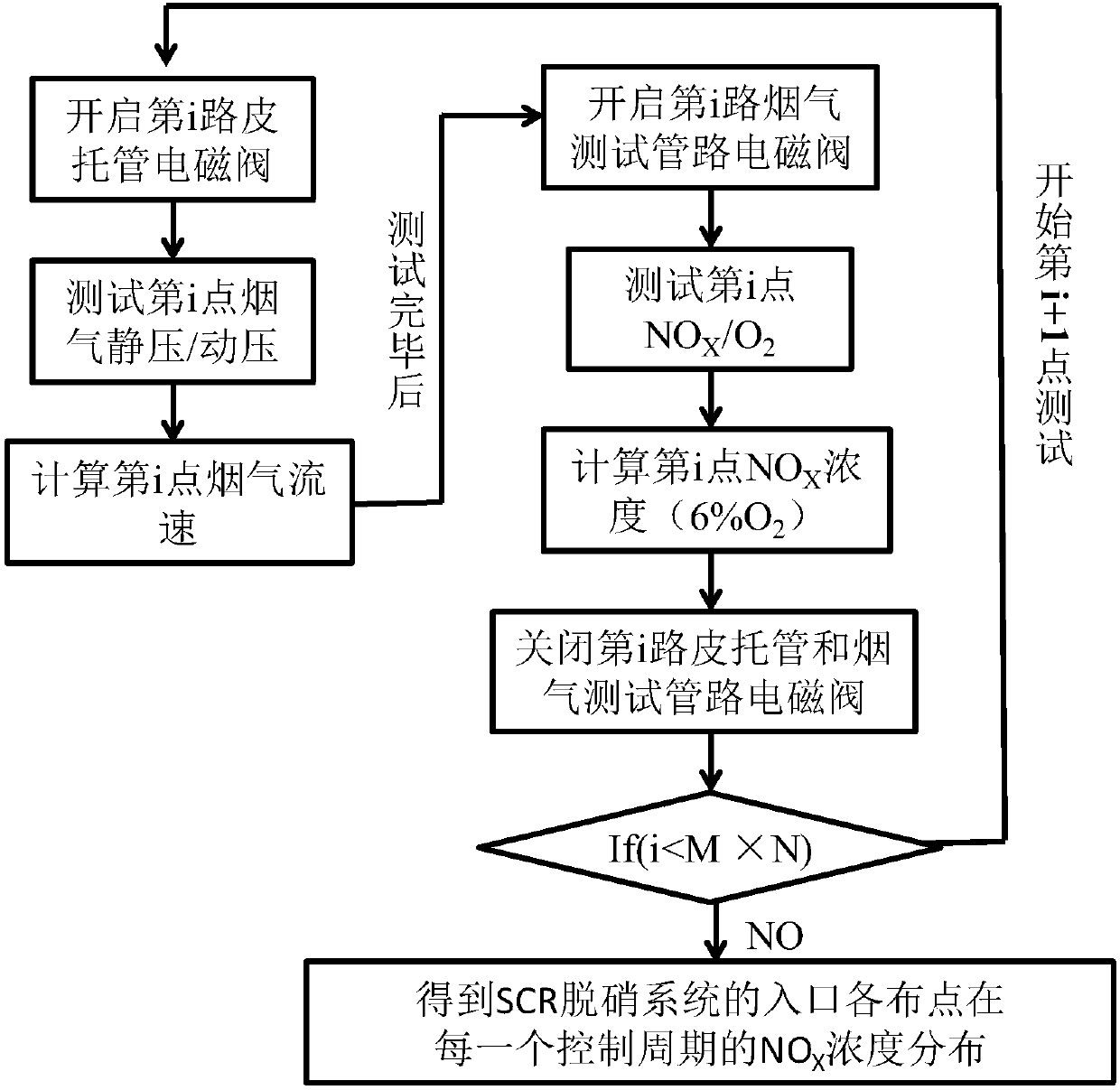

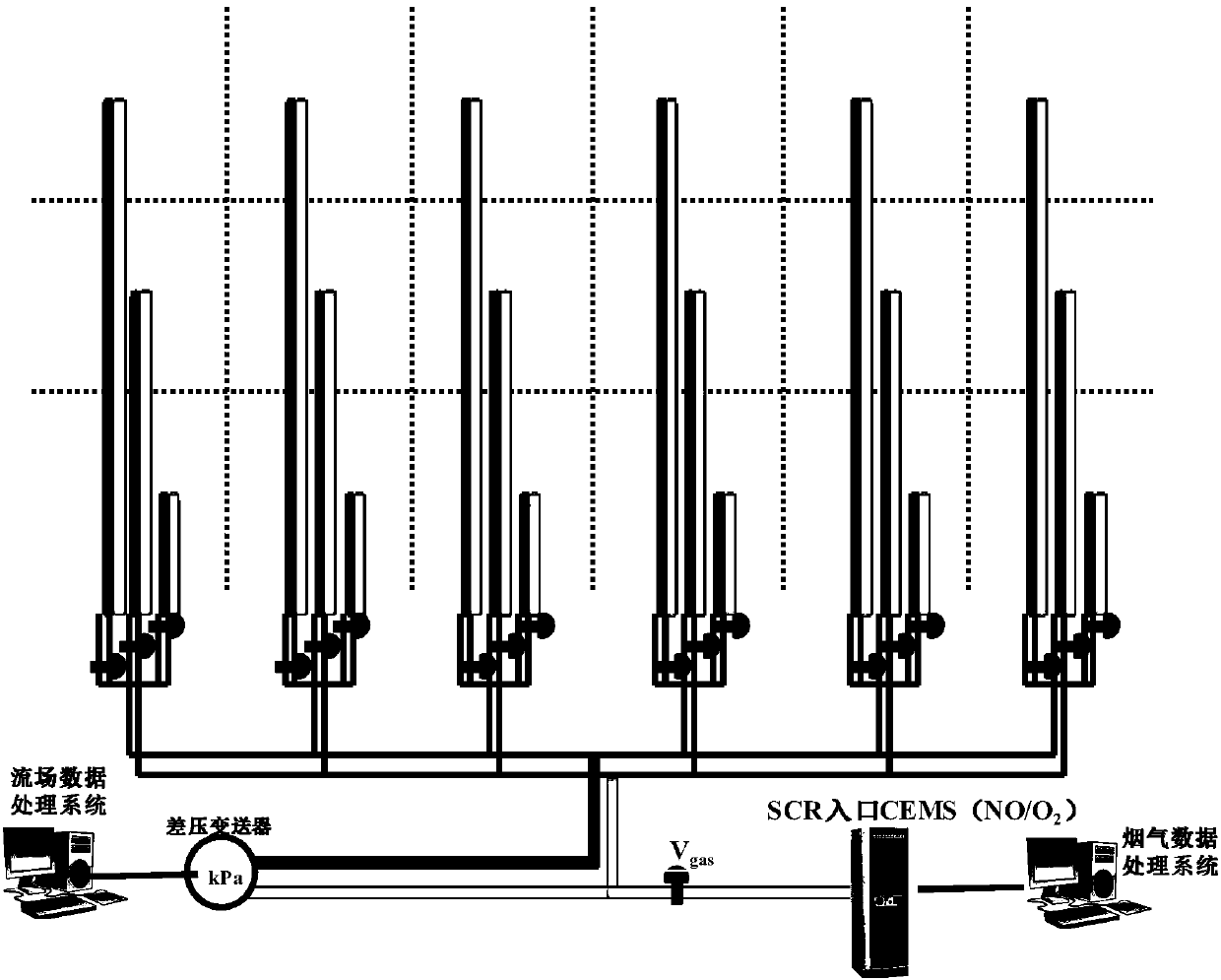

Method for optimizing ammonia nitrogen mole ratio distribution of SCR denitration system

ActiveCN107252630AAmmonia nitrogen molar ratio distribution adjustmentImproved ammonia nitrogen molar ratio distributionDispersed particle separationFluid speed measurementRelative standard deviationEscape rate

The invention discloses a method for optimizing ammonia nitrogen mole ratio distribution of an SCR denitration system. The method comprises the following implementation steps: detecting to obtain NOX concentration distribution within each control period at the inlet of the SCR denitration system and NOX concentration distribution and NH3 concentration distribution within each control period at the outlet; within each control period, calculating an ammonia nitrogen mole ratio distribution relative standard deviation factor CVm of the SCR denitration system within the current control period, and while the ammonia nitrogen mole ratio distribution relative standard deviation factor CVm exceeds a preset threshold value, automatically optimizing in allusion to an ammonia spraying control valve of the SCR denitration system, ending and quitting the automatic optimization while the ammonia nitrogen mole ratio distribution relative standard deviation factor CVm does not exceed the preset threshold value. The method is capable of effectively regulating the ammonia nitrogen mole ratio distribution of the SCR denitration system, solving the problems that the outlet ammonia escape rate of the SCR denitration system is high, the outlet NOX concentration distribution is not uniform and the produced ammonium bisulfate blocks an air pre-heater, remarkably improving the flow field distribution in an SCR reactor, and effectively improving the availability ratio of the SCR denitration system.

Owner:STATE GRID CORP OF CHINA +2

Drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit

The invention provides a drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit, which belongs to the field of ceramic drying technology and solves the shortcomings of easily cracking of and deformation of green bodies by adopting the existing ceramic wet green drying process. The process provided by the invention firstly prepares liquid ethanol and deionized water into drying solution with different concentration, then puts the SiC wet green into the bottom of a drying tank, respectively adds drying solution obtained by the step one into the drying tank for soaking to obtain the contracted SiC green body, and finally puts the contracted SiC green body in a drying oven for drying. The drying process provided by the invention greatly reduces the drying difficulty of large-sized and complex-shaped SiC biscuit, and achieves the non-defect drying of 1.5m-magnitude SiC ceramic biscuit prepared by a gelcasting process.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

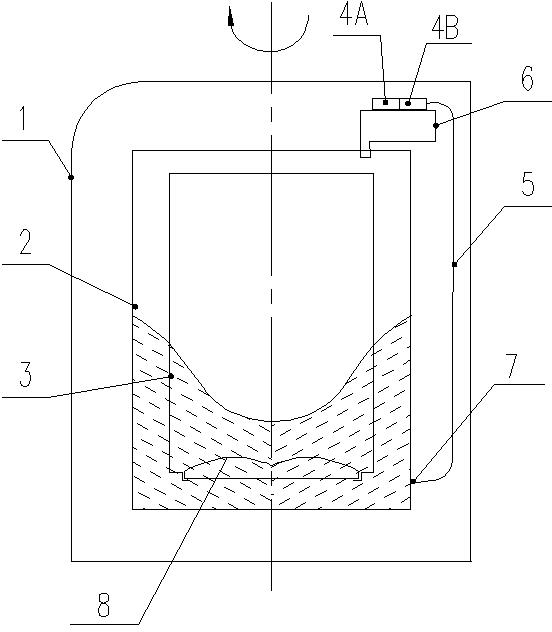

Gas phase aluminium extracting and silicon supplementing method of molecular sieve

ActiveCN1286721CEasy to unloadEasy to separateTobacco devicesCrystalline aluminosilicate zeolitesGas solidMolecular sieve

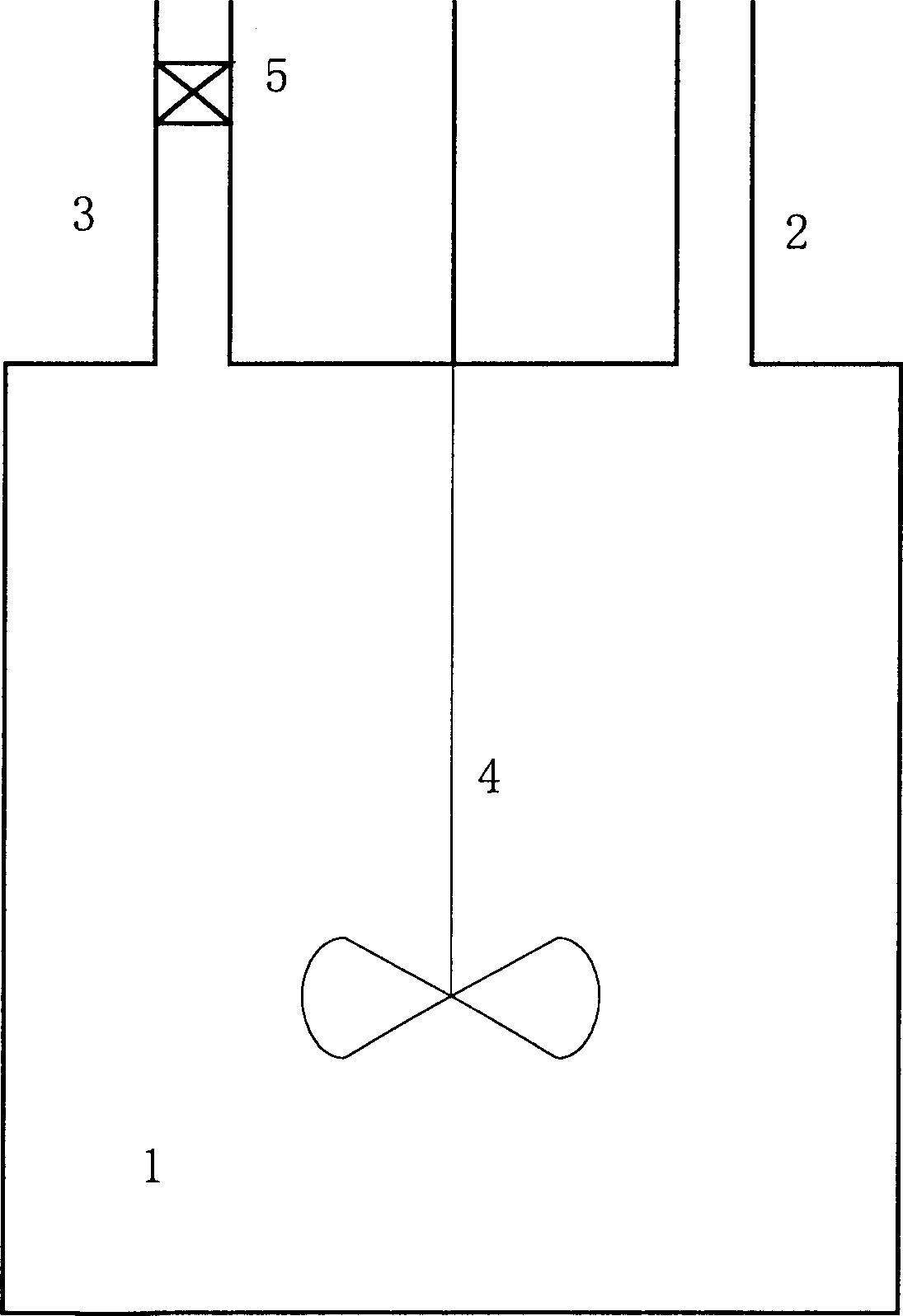

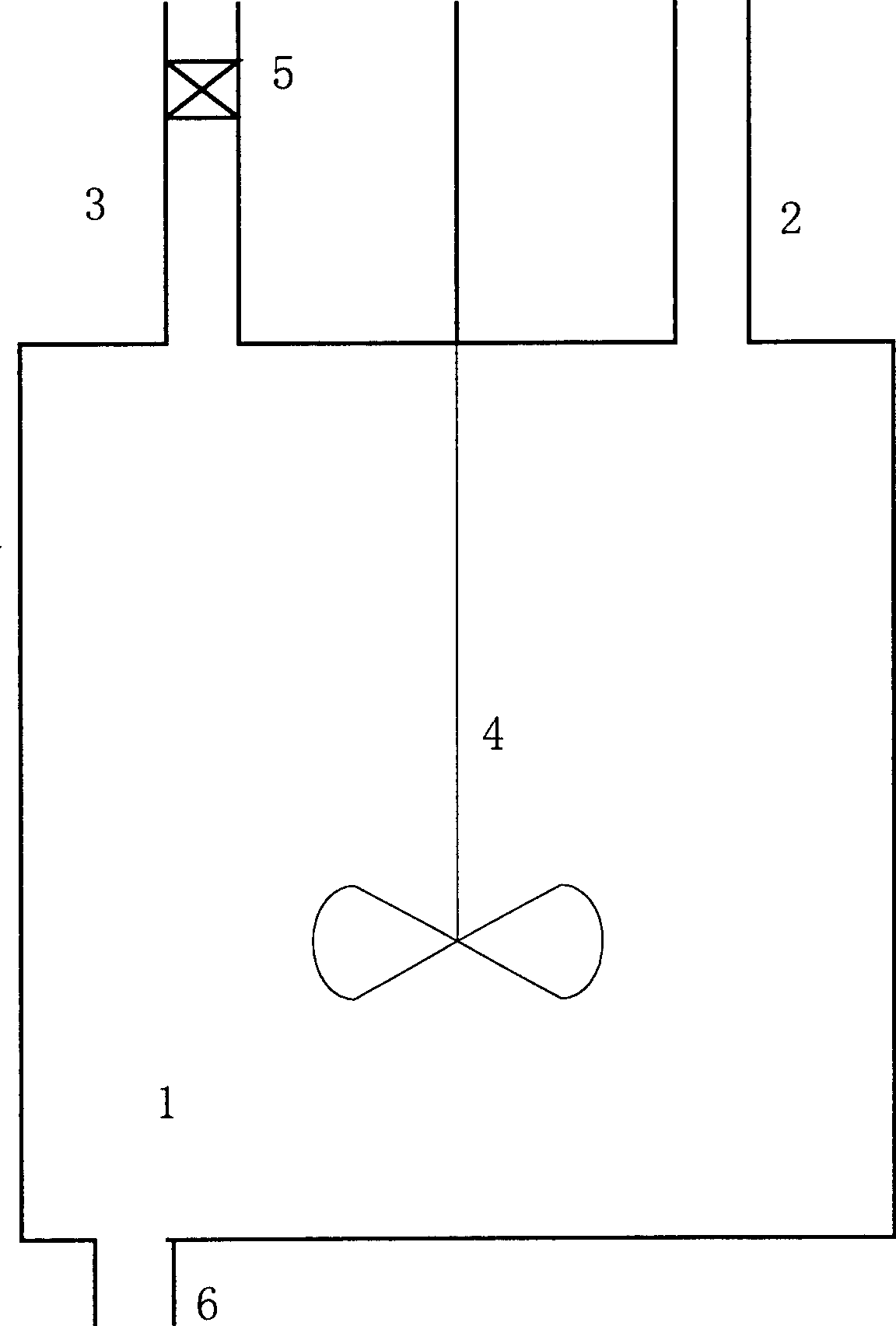

The gas phase method of extracting aluminum from and supplementing silicon to molecular sieve is to contact molecular sieve with silicon tetrachloride inside one reaction apparatus. The reaction apparatus includes one reactor with material inlet, gas outlet and stirrer, and one gas-solid separator in the gas outlet. The gas-solid separator has suck pore diameter and porosity that the gas can pass through and the solid particle can not. The stirrer has stirring rod extending beyond the reactor hermetically. The contact under stirring has contact temperature of 100-500 deg.c and time of 5-10 min, and the weight ratio between the molecular sieve and silicon tetrachloride is 1 to 0.05-0.5. The said method homogeneous contact reaction between gaseous silicon tetrachloride and solid molecular sieve, no coagulation of solid molecular sieve, less environmental pollution, lowered production cost and other advantages, and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

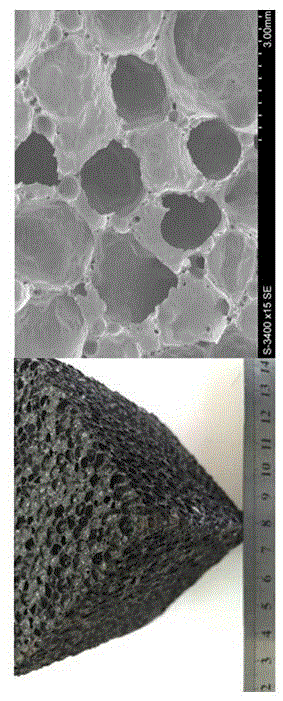

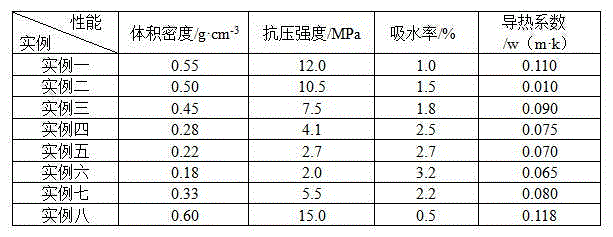

Foam microcrystalline glass made of high-silicon iron tailings and production method of foam microcrystalline glass

ActiveCN104788011AAddress pollution hazardsSave raw materialsGlass shaping apparatusCompressive resistanceFoaming agent

The invention relates to foam microcrystalline glass produced by using high-silicon iron tailings and a production method of the foam microcrystalline glass. Main raw materials of the foam microcrystalline glass comprise 70%-90% of the high-silicon iron tailings, 0.5%-5% of a foaming agent and 5%-30% of an additive, wherein the foaming agent is obtained by mixing carbon powder and calcium carbonate in a mass ratio being 2:1; the additive is obtained by mixing albite and talc in the ratio being 5: (0.5-1). During production, the raw materials are uniformly mixed, and the foam microcrystalline glass is prepared through preheating, sintering, foaming, crystallizing and annealing processes after forming. The foam microcrystalline glass has the advantages of small density, small heat conductivity coefficient, high compressive strength, easiness in processing and forming and the like and can be used for buildings such as a villa, a civic building, an industrial factory building and the like. The problems of high raw material production cost, complicated technology and the like of the foam microcrystalline glass are solved, pollution hazard of tailing accumulation to the environment is avoided, waste is turned into wealth, and energy saving and environmental protection are realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

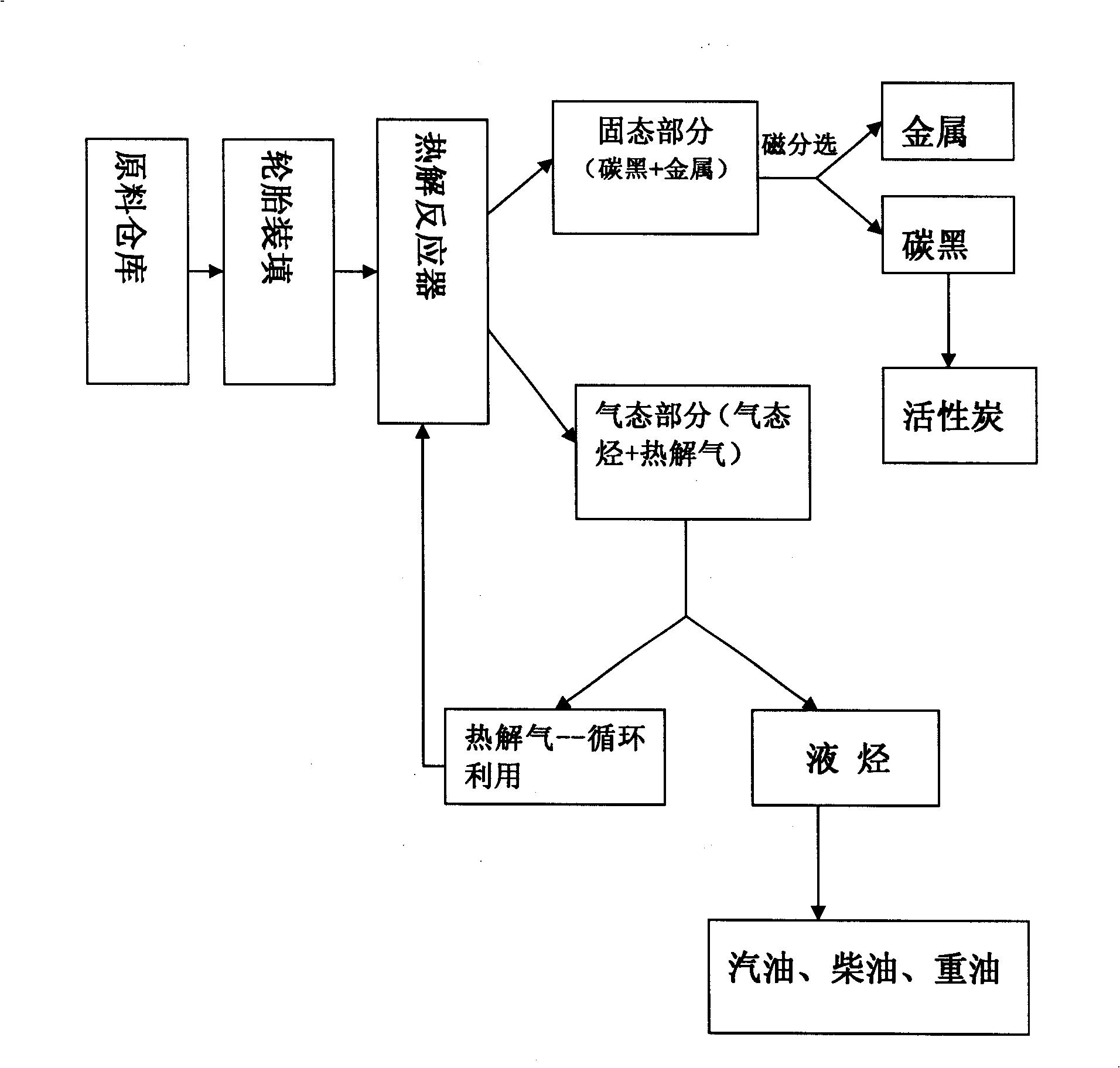

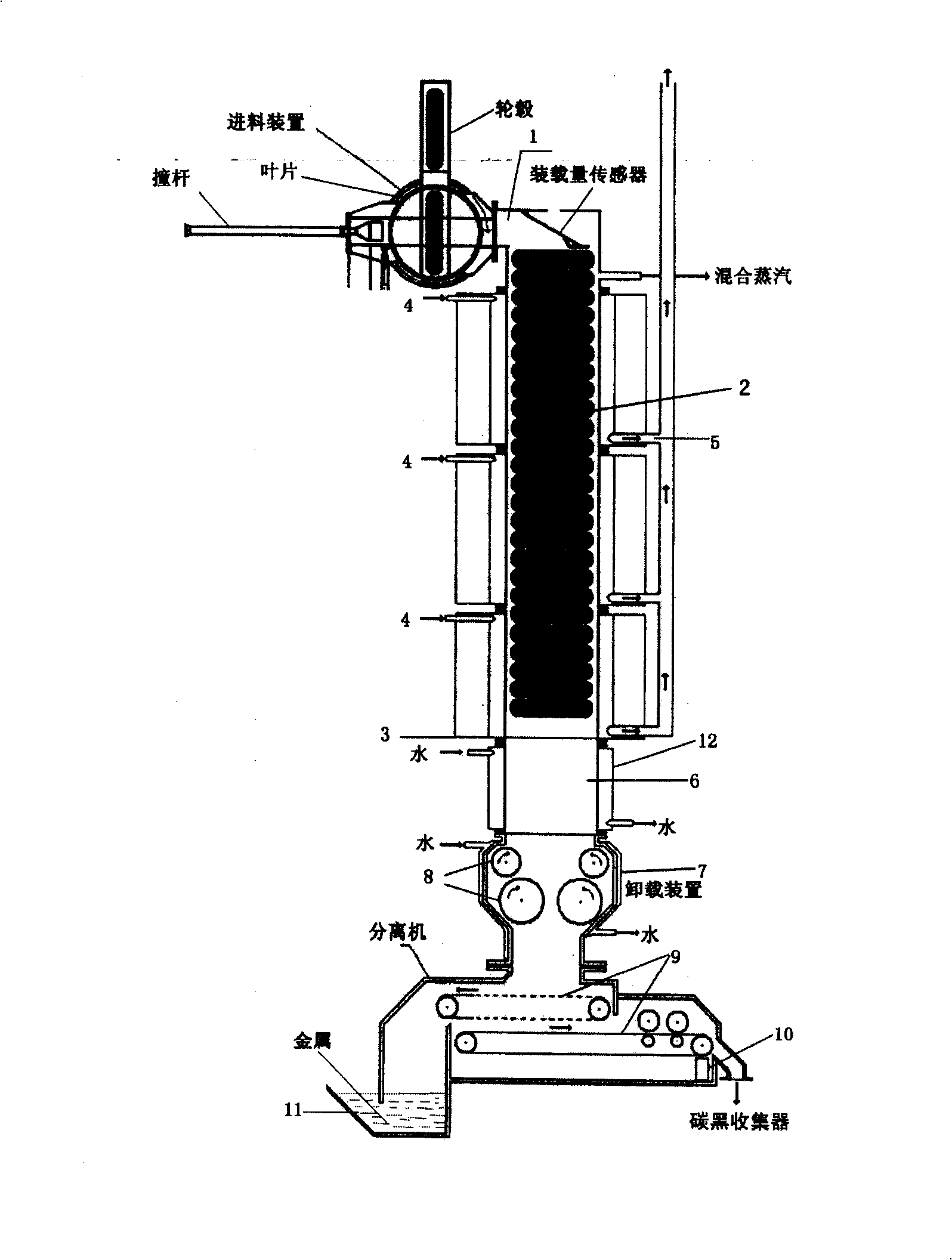

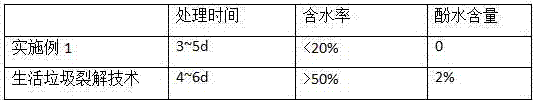

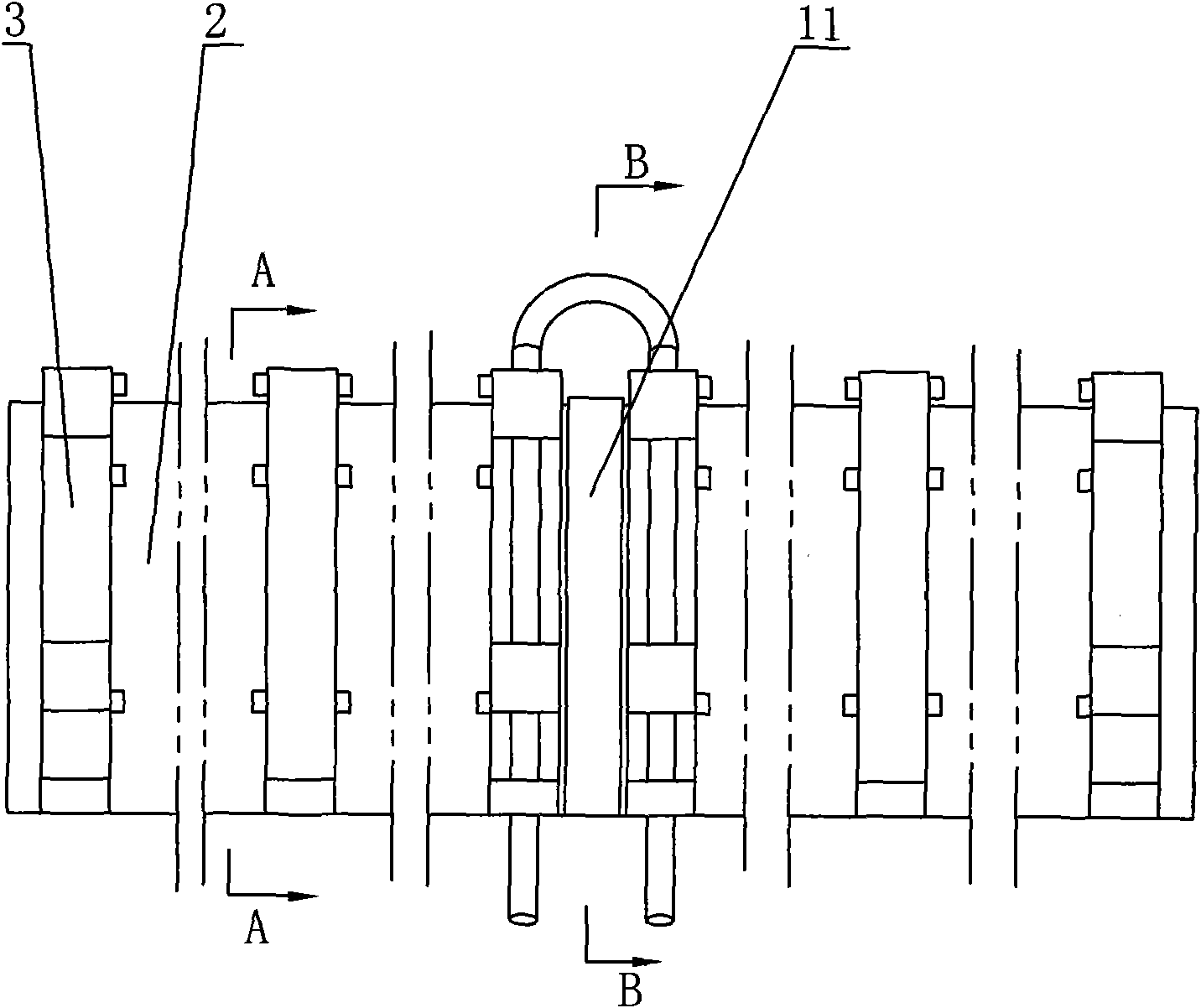

Apparatus for treating waste and old tyres

InactiveCN101307151AImprove sealingEnsure normal dischargePlastic recyclingLiquid hydrocarbon mixture productionPollutant emissionsWaste tires

The invention relates to a device for processing waste tires, belonging to the waste tire recovery processing technical field. The device comprises a feeding device, a reactor and a discharging device and is characterized in that: the discharging device comprises a condenser (6), a shell (7), a hub (8) / separator (9), a carbon black gatherer (10), a metal gatherer (11) and so on; a discharge opening of the condenser (6) is connected with a feed opening of the shell (7); the hub (8) and the separator (9) are arranged inside the shell (7); a conveyer belt of a conveyer on the upper part of the separator (9) is a reticular conveyer belt and can make carbon black powder fall off on the conveyer belt of the conveyer on the lower part and leave steel wires on the upper part; the metal gatherer (11) and the shell are sealed through liquid; and the carbon black gatherer (10) and the shell (7) are sealed through a sealed valve. The discharging device can continuously discharge materials and be sealed, and guarantee that no pollutant is discharged; the device for processing the waste tires is water and energy saving, safe and environment-friendly, and can realize production process automation.

Owner:BEIJING TIANHAIYUAN TECH +1

Municipal solid waste pyrolysis and gasification process

InactiveCN107008735AGuaranteed treatment effectLow bulk densitySolid waste disposalTransportation and packagingMicrobial agentWaste treatment

The invention discloses a municipal solid waste pyrolysis and gasification process. The municipal solid waste pyrolysis and gasification process comprises the following steps of a, crushing, wherein the size of crushed waste ranges from 2 cm to 2.5 cm; b, drying dehydration, wherein the crushed municipal solid waste is conveyed into a biology drying bin to be subjected to microorganism dehydration, and a microbial agent is used for treatment; c, sorting, wherein the dried waste is sorted into three classes, inorganic matter, gasifiable matter and waste metal; d, respective treatment; and e, waste gas treatment. According to the process, the municipal solid waste is crushed into the specified particle size and then put into the biology drying bin to be treated through the aerobiotic high-temperature-resisting microbial agent, the municipal solid waste is subjected to drying dehydration, the water content is reduced, waste drying is ensured, and sorting treatment of the next step is facilitated; the gasifiable matter is combusted to be used for power generation and heat supply, and energy consumption and treatment cost are further reduced; and by means of the process, large-scale treatment can be achieved, no dioxin gas is generated, the occupied area is not large, the additional value of the municipal solid waste can be increased, and the process is worth of application and popularization.

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

Folding water-storing water-retaining water wall

The invention relates to a folding water-storing water-retaining water wall, comprising more than one water bag units; the water bag unit comprises a flexible water bag and more than two skeletons; the flexible water bag forms an enclosed water storage space; the inner wall of the flexible water bag is provided with a silica gel layer; the skeletons are arranged on the flexible water bag and tightly connected and fixed with the flexible water bag; the water bag unit is provided with a fixing device; a connecting ring is arranged on the skeletons of the two ends of the flexible water bag in the water bag unit; a connecting piece is arranged between the adjacent connecting rings on the adjacent water bag units; the water bag unit is provided with a locking device; the flexible water bag is provided with a water inlet and a water outlet; and a sealing device is arranged between the water bag units. The structure of the folding water-storing water-retaining water wall can fast build and dismantle the water-storing water-retaining water wall, is convenient to transport and carry and has reliable water retaining.

Owner:黄文勇

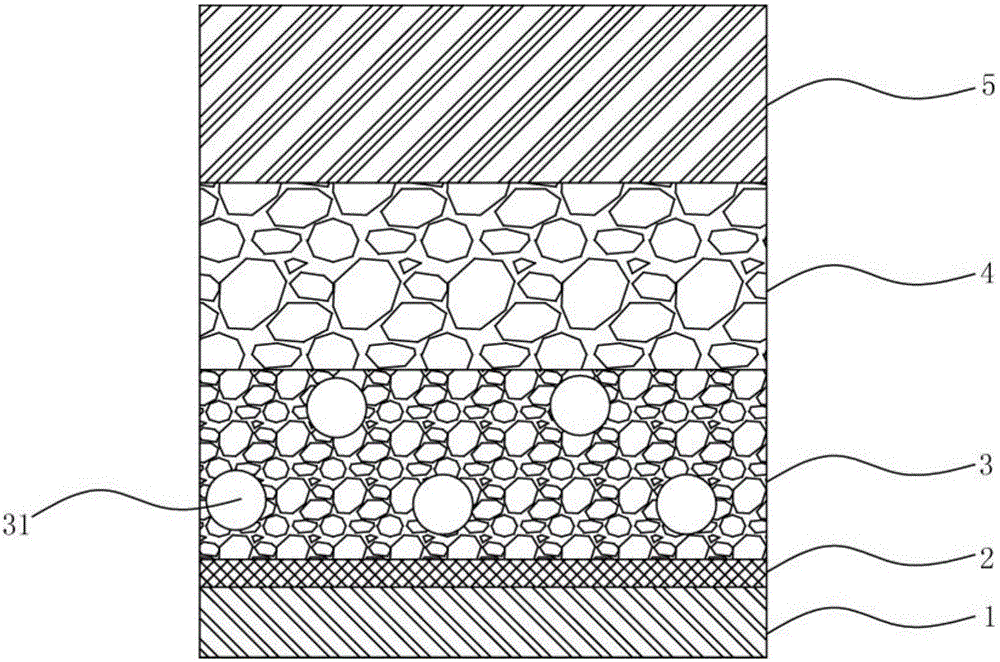

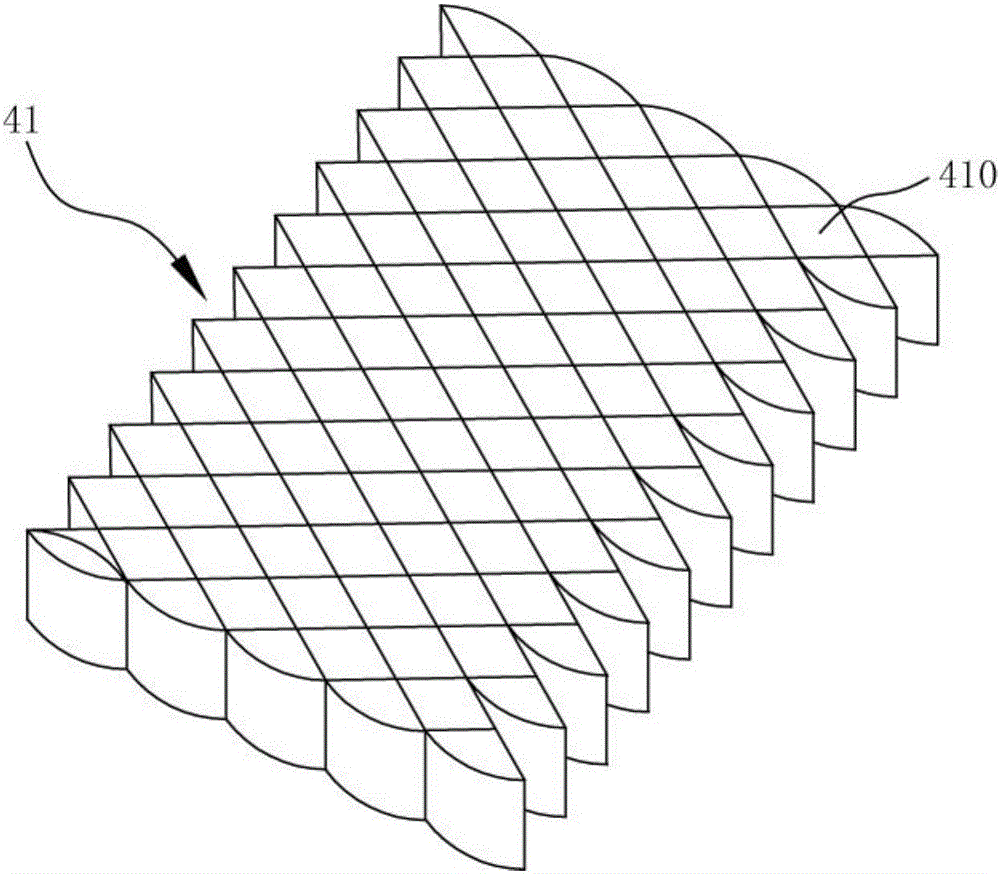

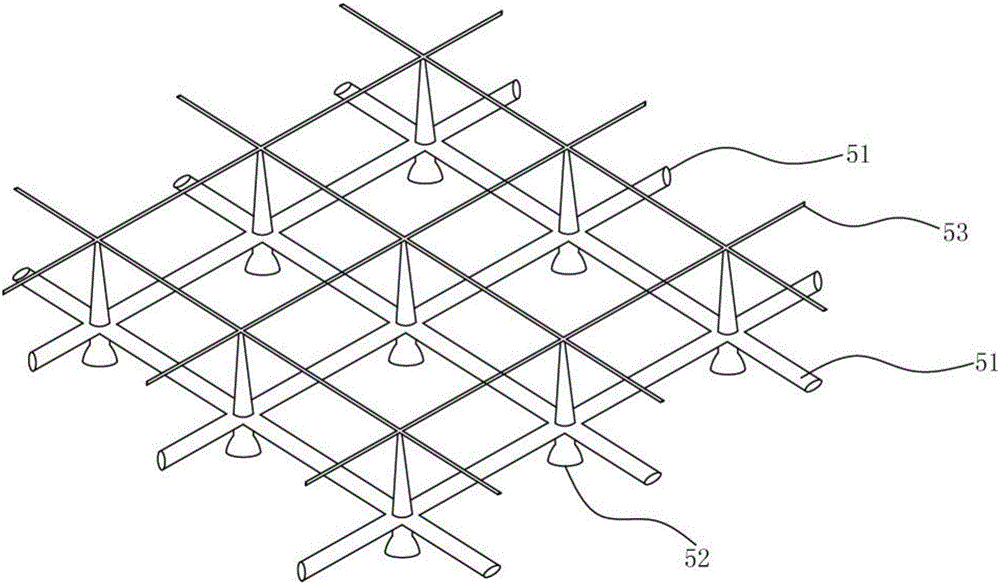

Permeable pavement structure with high strength and high permeability and paving method thereof

ActiveCN106351103AHigh strengthImprove permeabilityIn situ pavingsPaving gutters/kerbsChipsealHigh density

The invention discloses a permeable pavement structure with high strength and high permeability. The permeable pavement structure comprises a water isolating seal layer, a base layer and a surface layer which are sequentially arranged on a soil matrix; the surface layer comprises a permeable framework, and concrete positioned among pores of the permeable framework; the permeable framework comprises transverse vent pipes which are communicated with one another and vertical osmosis pipes vertically arranged on the transverse vent pipes; the base layer comprises rubble layer at the upper layer and a sand mat at the lower layer; and the water isolating seal layer comprises a water isolating membrane. The high-density concrete in the surface layer has the advantages of high strength and high durability, and the permeable framework in the concrete can guide rainfall into the base layer so as to prevent accumulation of rainfall on the pavement. Rubbles in the rubble layer are overlapped so as to form a flowing passage for rainfall, thus playing the role in delivering water and improving the strength of the base layer. Macadams in the sand mat can decelerate infiltration of the rainfall, thus playing the roles in storing water, discharging water and improving the strength of the base layer; and the water isolating membrane can prevent the rainfall from permeating into the soil matrix.

Owner:苏谦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com