Foam microcrystalline glass made of high-silicon iron tailings and production method of foam microcrystalline glass

A foamed glass-ceramic and high-silicon iron tailings technology is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., and can solve the problems of high cost, low thermal conductivity and high compressive strength of foamed glass-ceramic, and achieves The effect of solving the problem of pollution hazards, low production cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

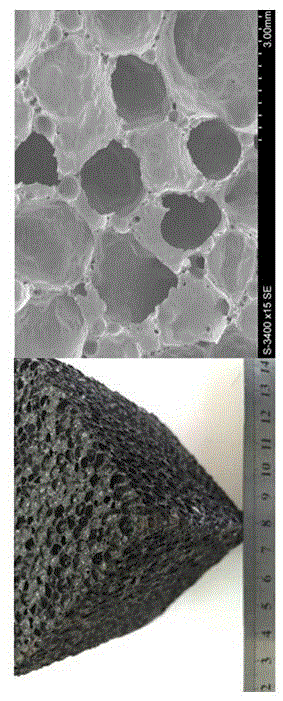

Image

Examples

Embodiment 1

[0037] Embodiment one: the method for producing foamed glass-ceramic by utilizing high-silicon tailings, comprises the following steps:

[0038] (1) Raw materials: Weigh 90wt% of high-silicon iron tailings, 1wt% of foaming agent, and 9wt% of additives; Talc is mixed at a mass ratio of 5:0.5;

[0039] (2) Put each raw material in a ball mill, and ball mill until the particle size of the mixture is 200 mesh;

[0040] (3) Spread the mixture into the mold for molding;

[0041] (4) Push the formed mixture into the tunnel kiln, and go through preheating, sintering, foaming, quenching, crystallization, and annealing processes to obtain a foamed glass-ceramic blank. The specific requirements are as follows:

[0042] 1) Preheating: Gradually raise the temperature of the formed mixture from room temperature to 600°C at a heating rate of 2°C / min, and keep it at this temperature for 30 minutes;

[0043] 2) Sintering: Gradually raise the temperature from 600°C to 1000°C at a heating rat...

Embodiment 2

[0049] Embodiment 2 The method for producing foamed glass-ceramics by using high-silicon tailings comprises the following steps:

[0050] (1) Raw materials: Weigh 80wt% of high-silicon iron tailings, 1wt% of foaming agent, and 19wt% of additives; Stone and talc are mixed at a mass ratio of 5:0.5;

[0051] (2) Put each raw material in a ball mill, and ball mill until the particle size of the mixture is 300 mesh;

[0052] (3) Put the mixture into the mold and press it into shape;

[0053](4) The formed mixture is pushed into the tunnel kiln, and after preheating, sintering, foaming, quenching, crystallization, and annealing processes, the foamed glass-ceramic blank is obtained. The specific requirements are as follows:

[0054] 1) Preheating: Gradually raise the temperature of the formed mixture from room temperature to 600°C at a heating rate of 5°C / min, and keep it at this temperature for 30 minutes;

[0055] 2) Sintering: Gradually raise the temperature from 600°C to 1000°...

Embodiment 3

[0061] Embodiment 3 The method for producing foamed glass-ceramics by utilizing high-silicon tailings comprises the following steps:

[0062] (1) Weigh 70wt% of raw material high-silicon iron tailings, 1wt% of foaming agent, and 29wt% of additives; Mixed with a mass ratio of 5:0.5;

[0063] (2) Put each raw material in a ball mill, and ball mill until the particle size of the mixture is 250 mesh;

[0064] (3) Put the mixture into the mold and press it into shape;

[0065] (4) Push the formed mixture into a tunnel kiln, and undergo preheating, sintering, foaming, quenching, crystallization, and annealing processes to obtain rough foamed glass-ceramics. The specific requirements are as follows:

[0066] 1) Preheating: Gradually raise the temperature of the molded mixture from room temperature to 600°C at a heating rate of 5°C / min, and keep it at this temperature for 30 minutes;

[0067] 2) Sintering: Gradually raise the temperature from 600°C to 1000°C at a heating rate of 5°...

PUM

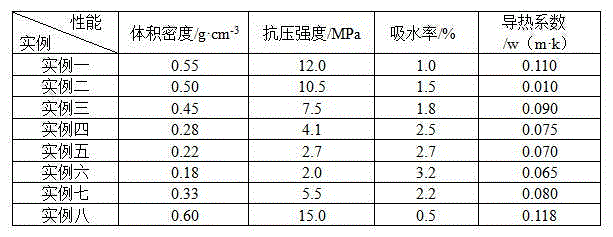

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com