Ground spring device adopting electromagnetic damping

A technology of electromagnetic damping and floor springs, applied in the field of floor spring devices, to achieve high-quality products and services and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

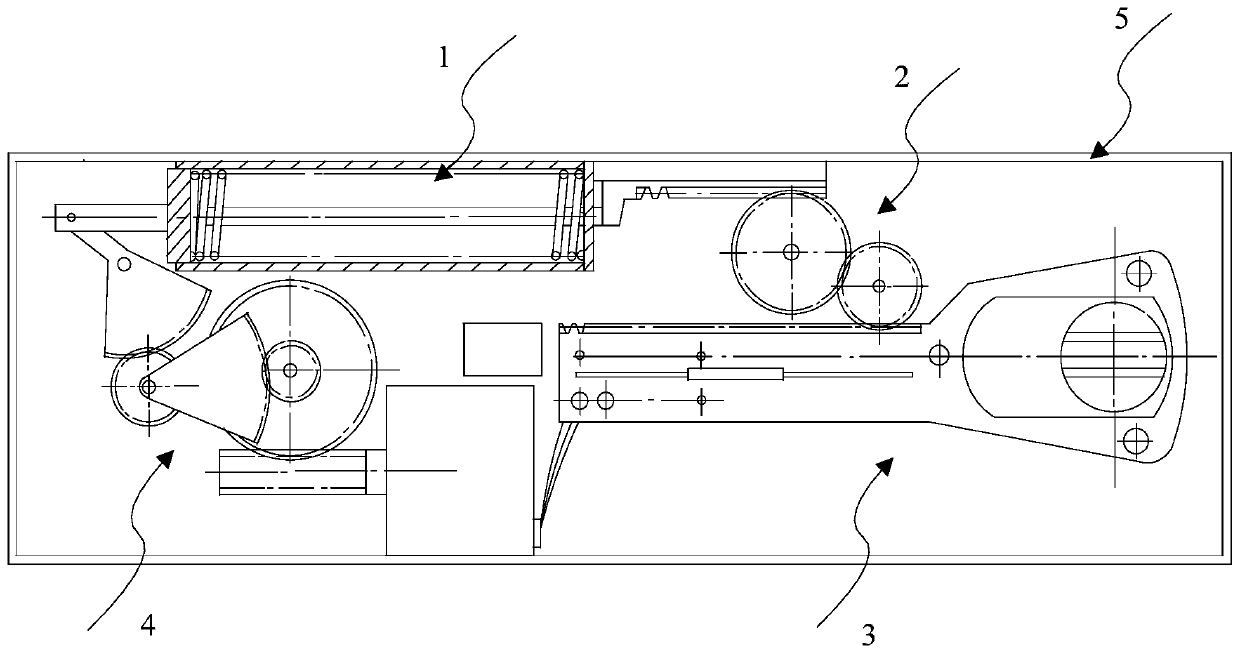

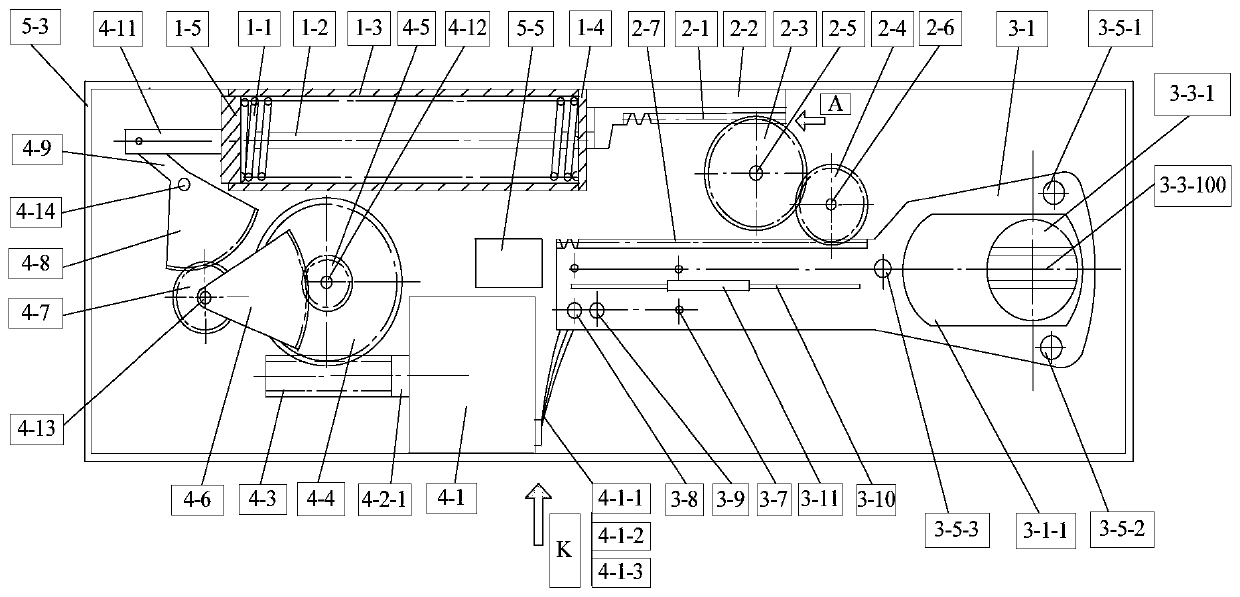

[0064] Such as Figure 1-Figure 21 , Figure 23 , Figure 24 , Figure 26 and Figure 27 As shown, a floor spring device using electromagnetic damping is composed of a spring mechanism (1), a rack and pinion speed regulating mechanism (2), an output shaft mechanism (3), a damping amplification mechanism (4) and a housing (5) .

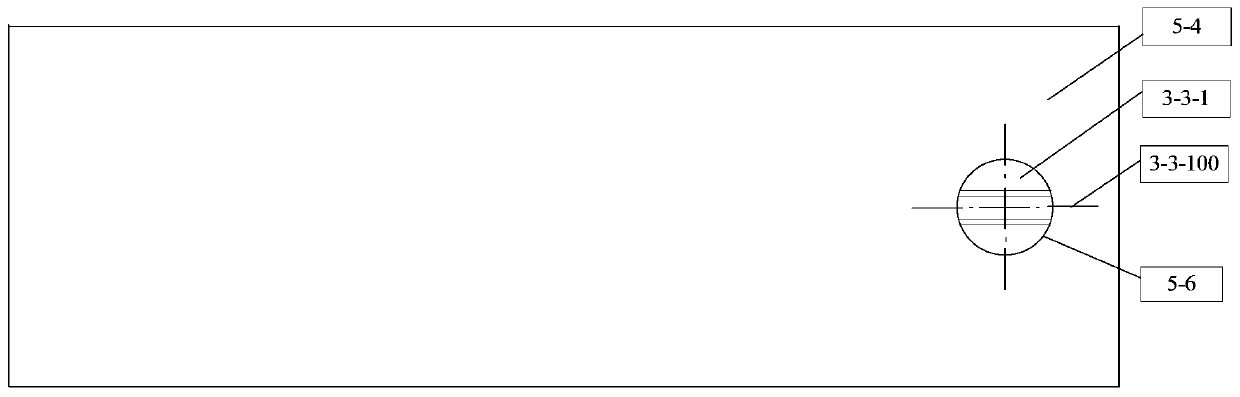

[0065] The spring mechanism (1), the rack and pinion speed regulating mechanism (2), the output shaft mechanism (3) and the damping amplification mechanism (4) are all fixedly installed on the upper tooling plate (5-1) and the bottom of the housing (5). Between the tooling plates (5-2); the upper part of the output shaft (3-3-1) of the cam output shaft integral part (3-3) of the output shaft mechanism (3) protrudes outside the housing (5); the spring One end of the mechanism (1) is connected to the output shaft mechanism (3) through the rack and pinion speed regulating mechanism (2), and the other end of the spring mechanism (1) is connected to th...

Embodiment 2

[0113] Such as Figure 1-Figure 20 , Figure 22 , Figure 23 , Figure 25 , Figure 26 and Figure 27 As shown, a floor spring device using electromagnetic damping is composed of a spring mechanism (1), a rack and pinion speed regulating mechanism (2), an output shaft mechanism (3), a damping amplification mechanism (4) and a housing (5) .

[0114] Other structures are exactly the same as embodiment 1, and the difference is that the reed switch device arranged on the slide table (3-13) is composed of two groups of parallel connected reed switch I (3-18) and dry reed switch II (3 -19) constitute, such as Figure 22 , Figure 23 , Figure 25 shown.

[0115] The first group of reed switch I (3-18) and dry reed switch II (3-19) are connected in parallel, and one end is connected to the winding wire I (4-1-1), and the second group of dry reed switch I (3-18 ) and dry reed switch II (3-19) connected in parallel, one end is connected to the winding wire (4-1-2), the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com