Patents

Literature

337 results about "Industrial Factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

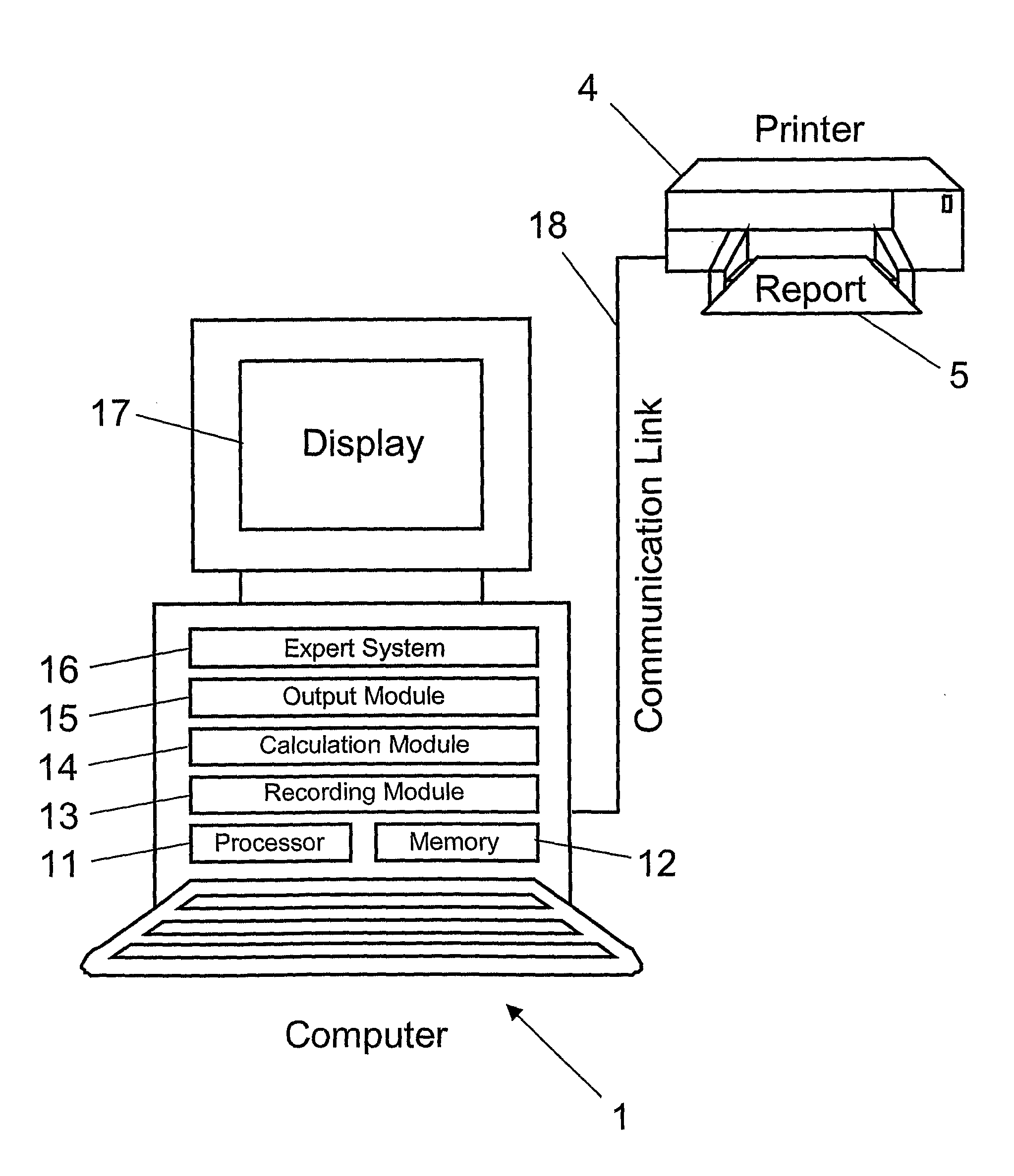

Industrial plant asset management system: apparatus and method

InactiveUS6421571B1Simple or very complex alarming schemesComputer controlElectric testing/monitoringGraphicsDatabase interface

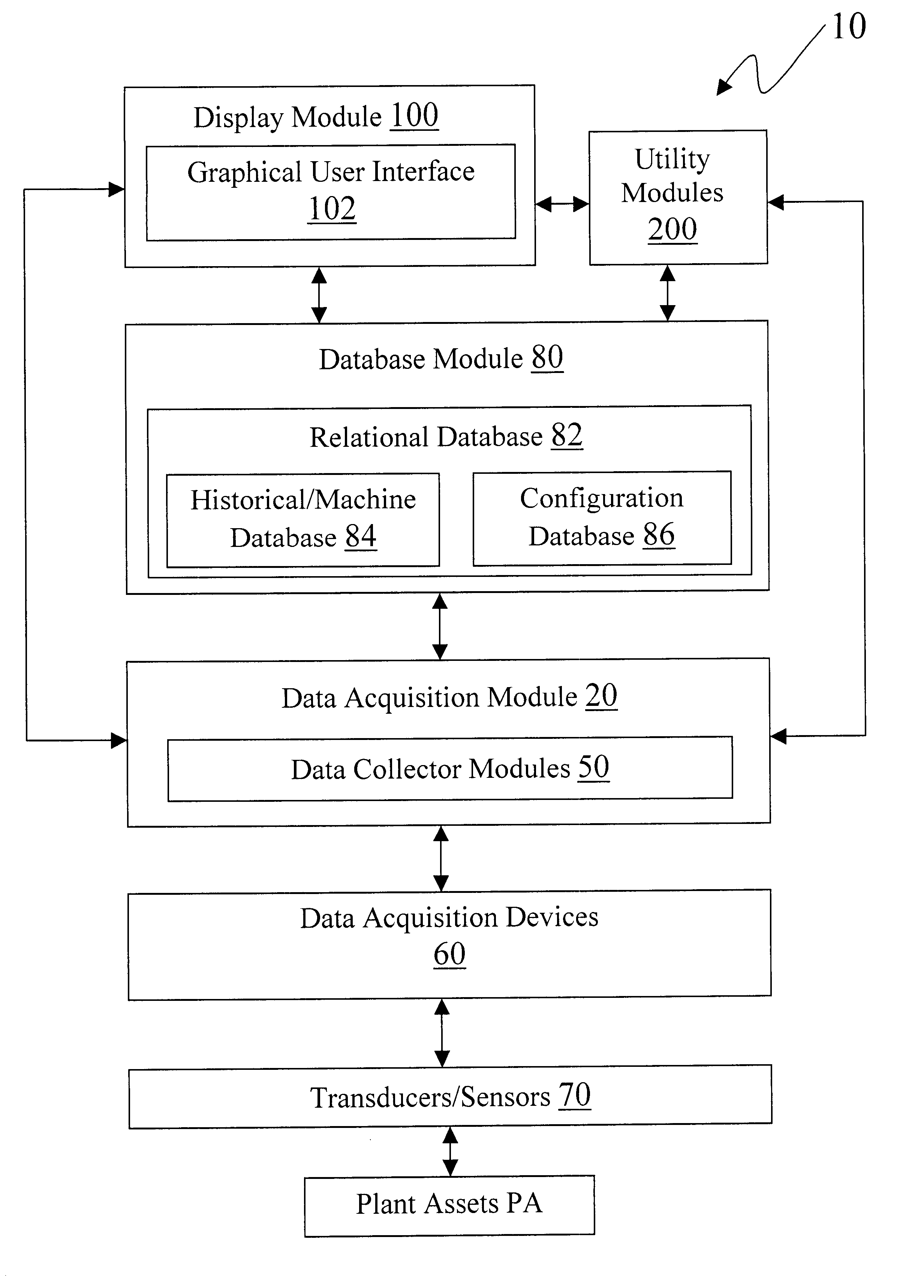

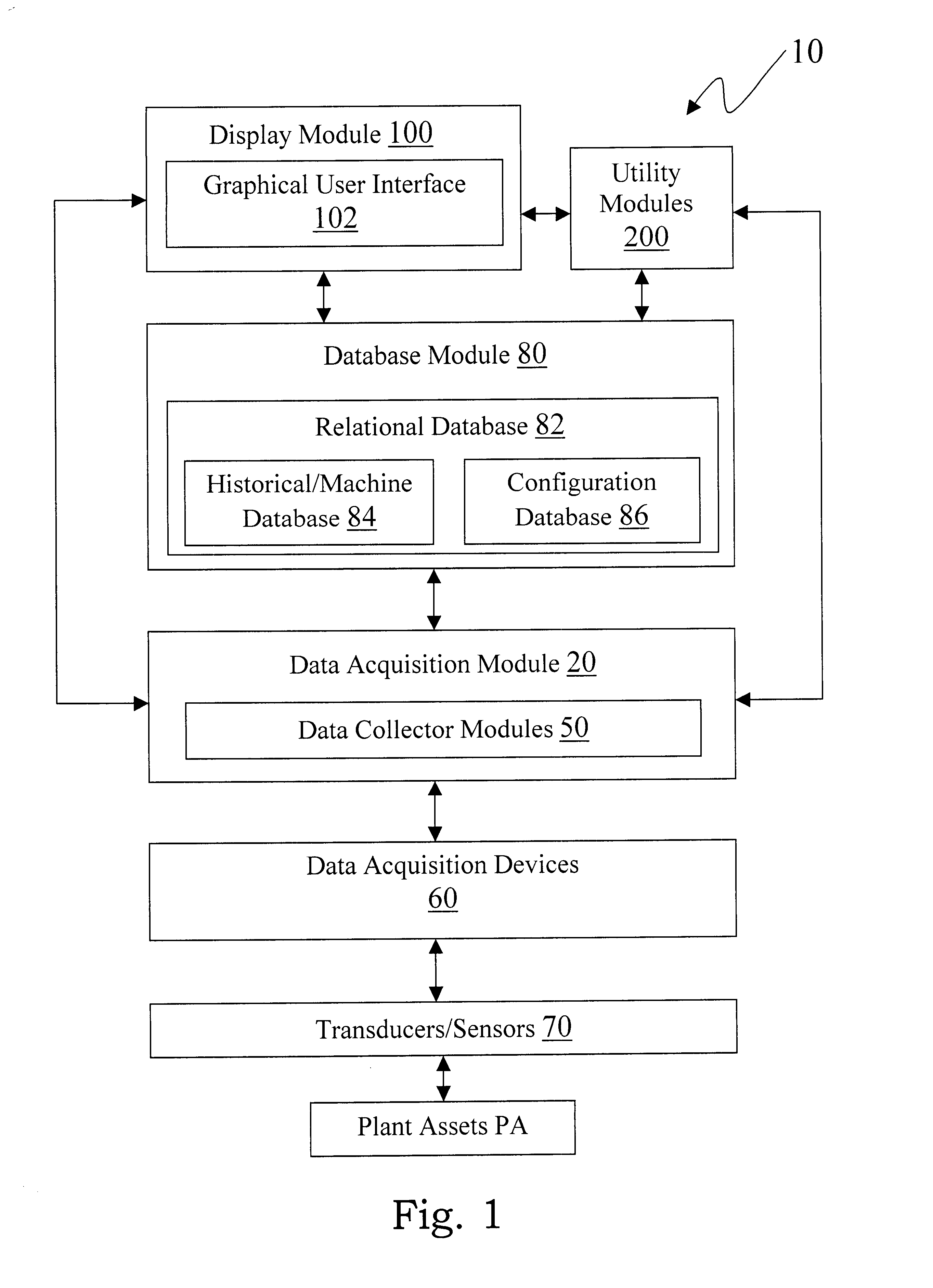

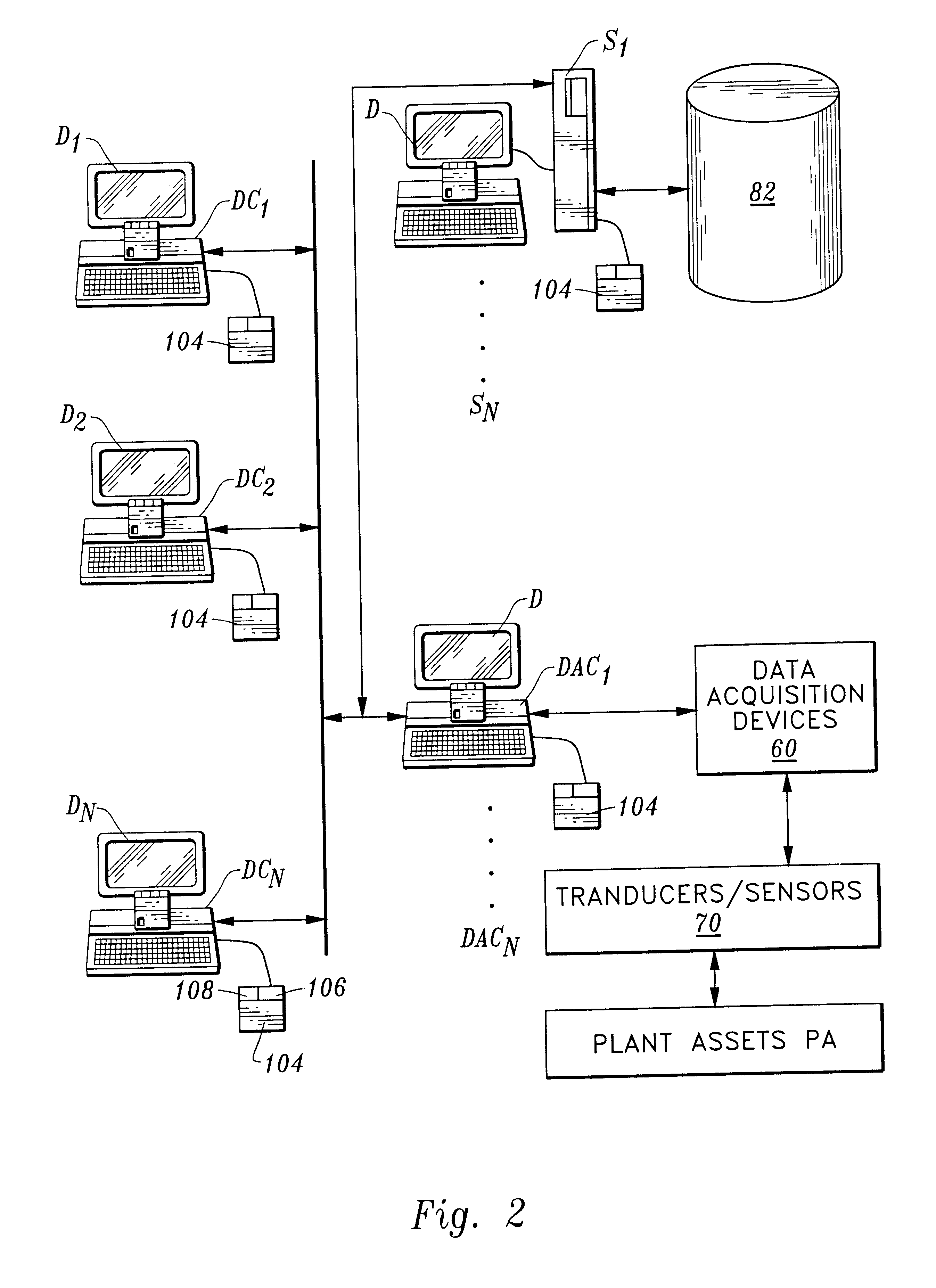

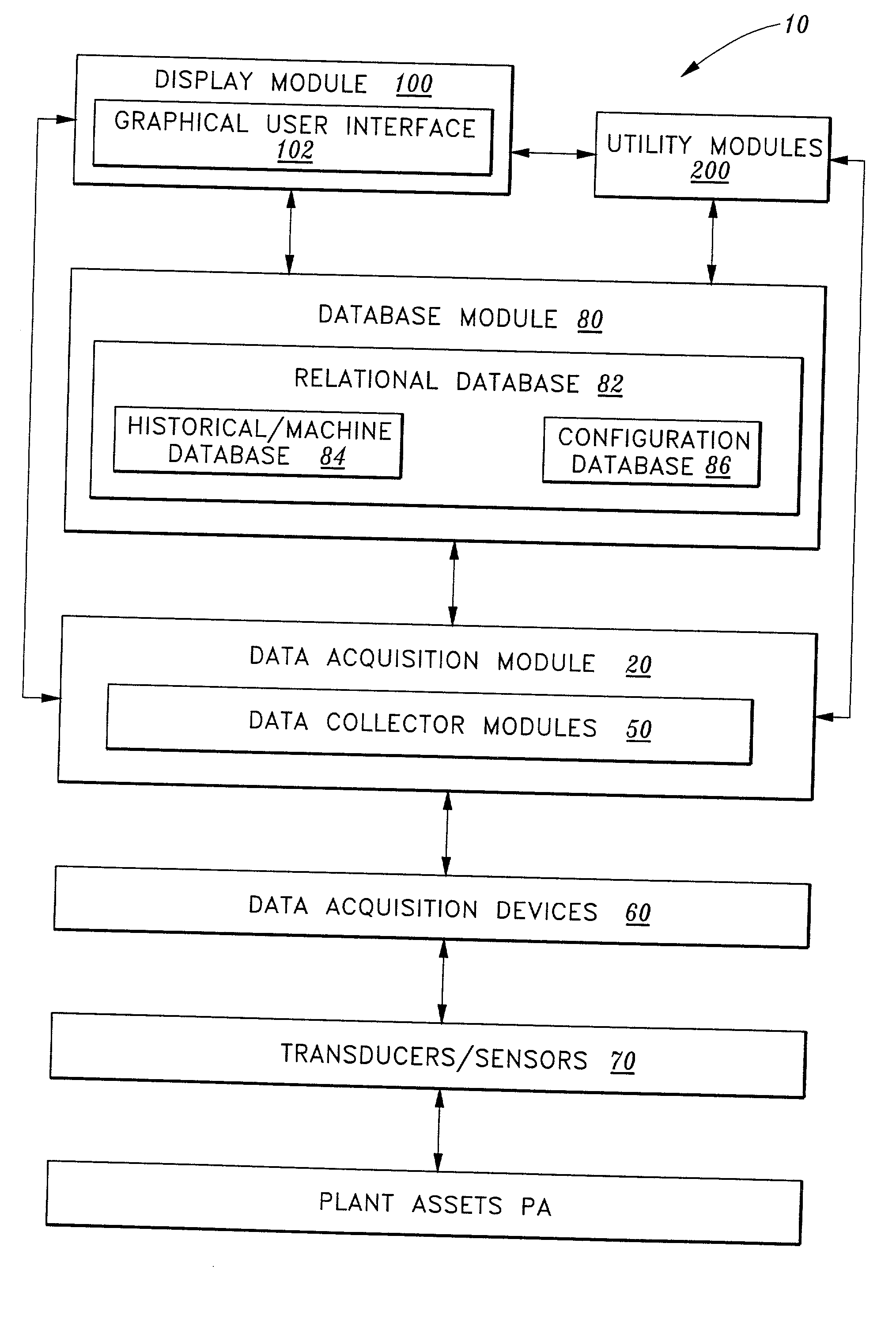

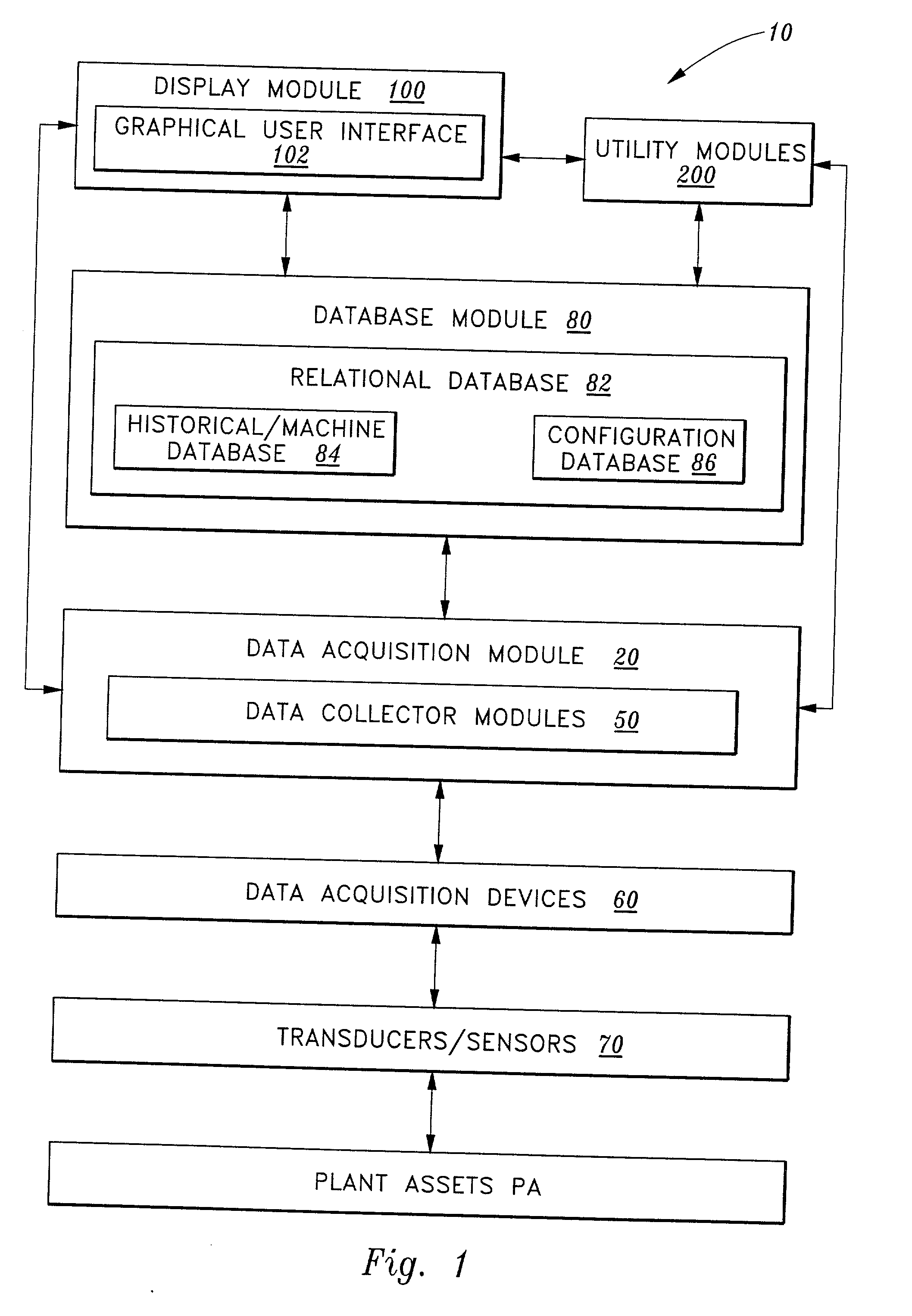

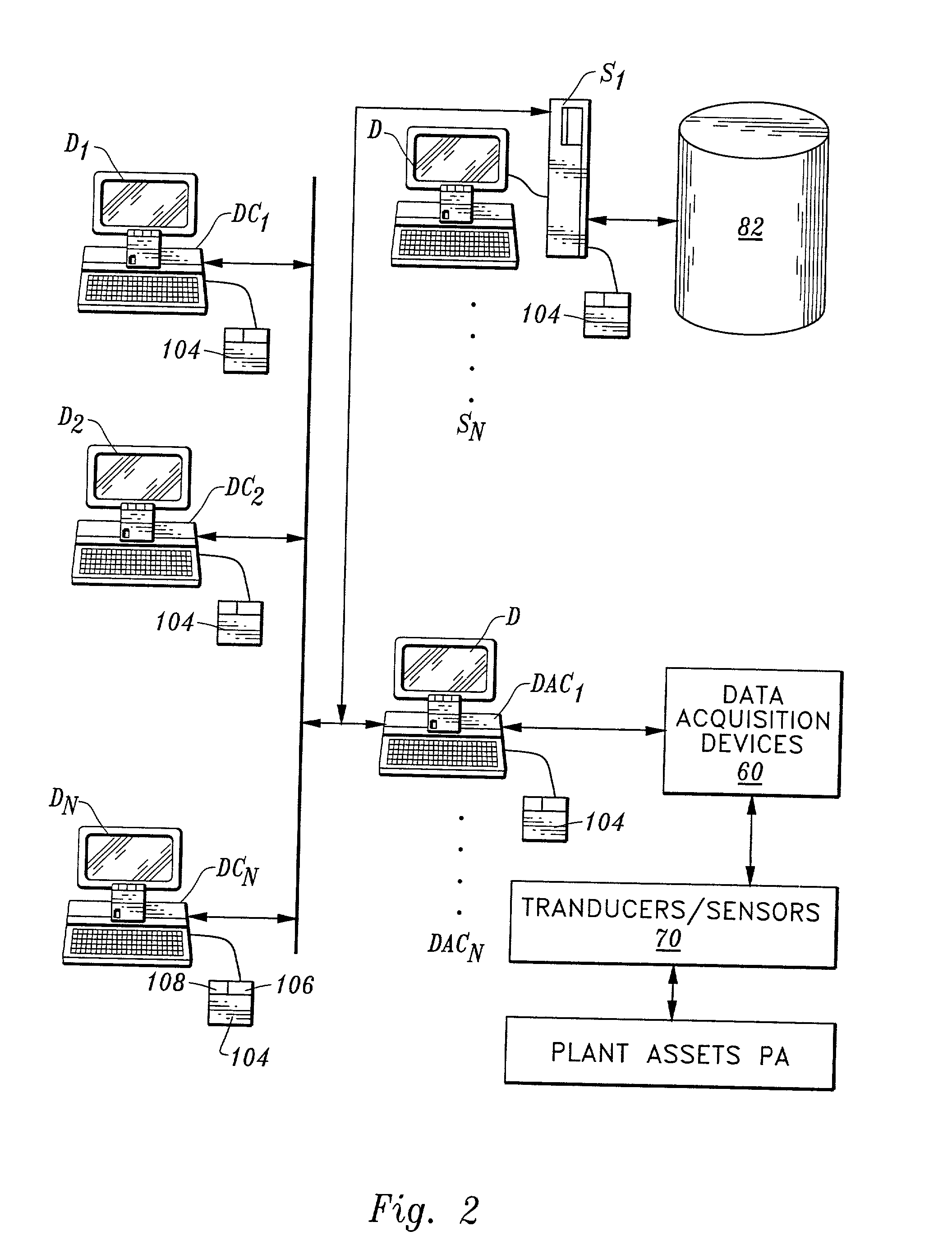

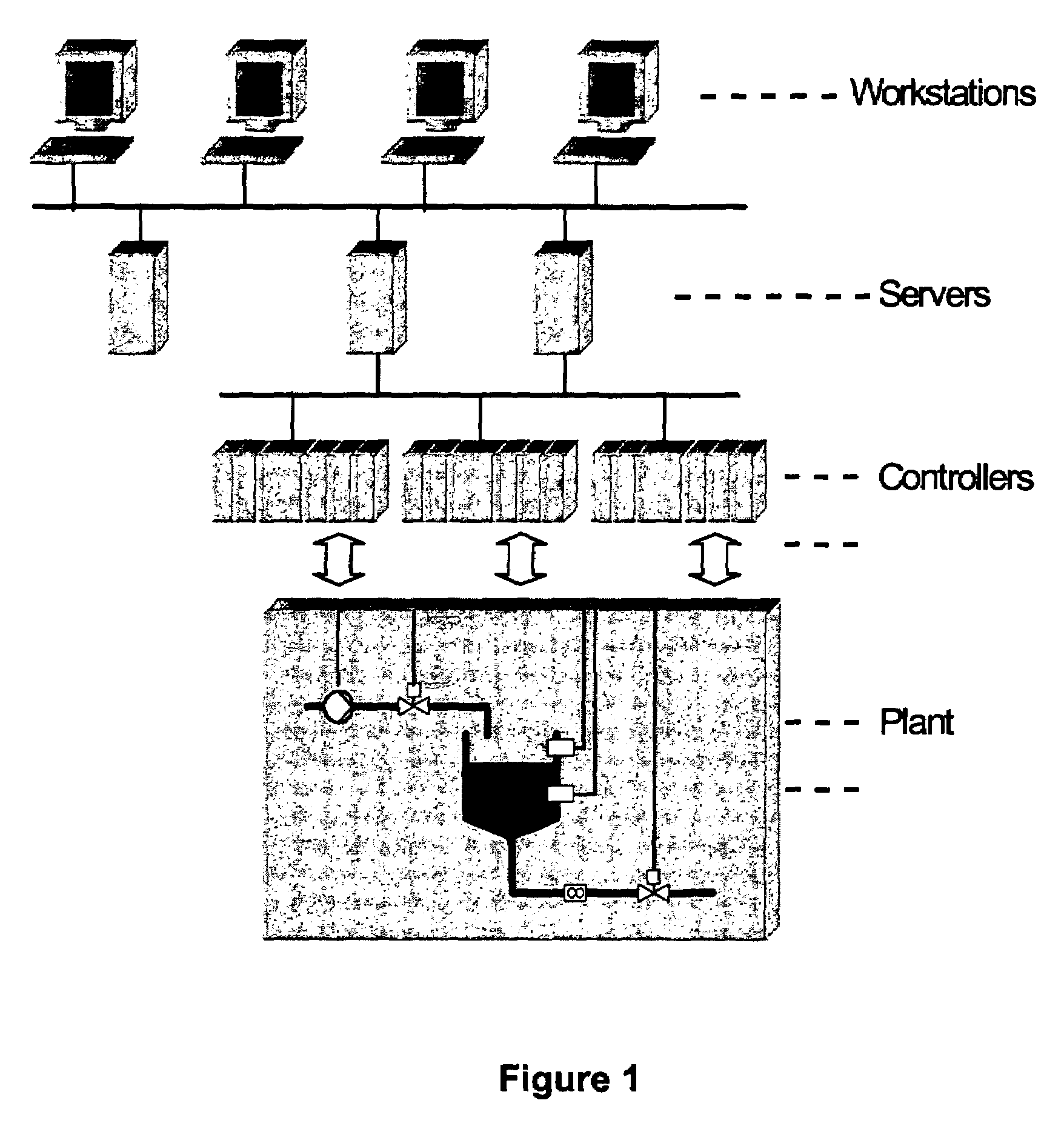

An industrial plant asset management system comprising of a synchronized multiple view graphical user interface combining simultaneous real time and database display capability, a database including a knowledge manager and having input and output interfaces, a normalizing data acquisition module with real time and database interfaces, and a variety of device dependent data collector modules with associated signal conditioning and processing devices for providing an environment for development and deployment of visual models for monitoring plant assets.

Owner:BENTLY NEVADA INC

Industrial plant asset management system: apparatus and method

InactiveUS20030023518A1Low costReduce installationComputer controlElectric testing/monitoringGraphicsDatabase interface

An industrial plant asset management system comprising of a synchronized multiple view graphical user interface combining simultaneous real time and database display capability, a database including a knowledge manager and having input and output interfaces, a normalizing data acquisition module with real time and database interfaces, and a variety of device dependent data collector modules with associated signal conditioning and processing devices for providing an environment for development and deployment of visual models for monitoring plant assets.

Owner:BENTLY NEVADA INC

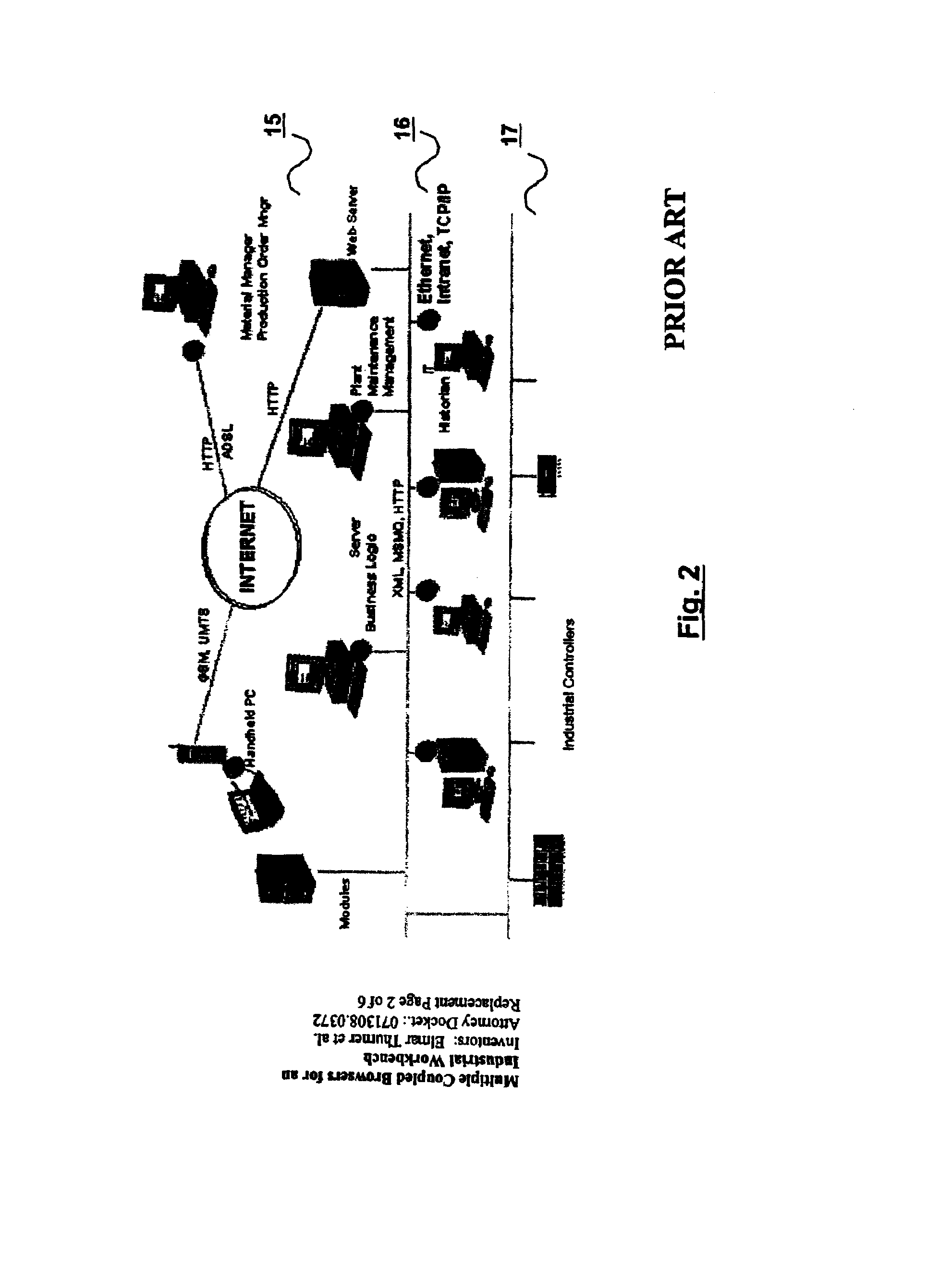

Multiple coupled browsers for an industrial workbench

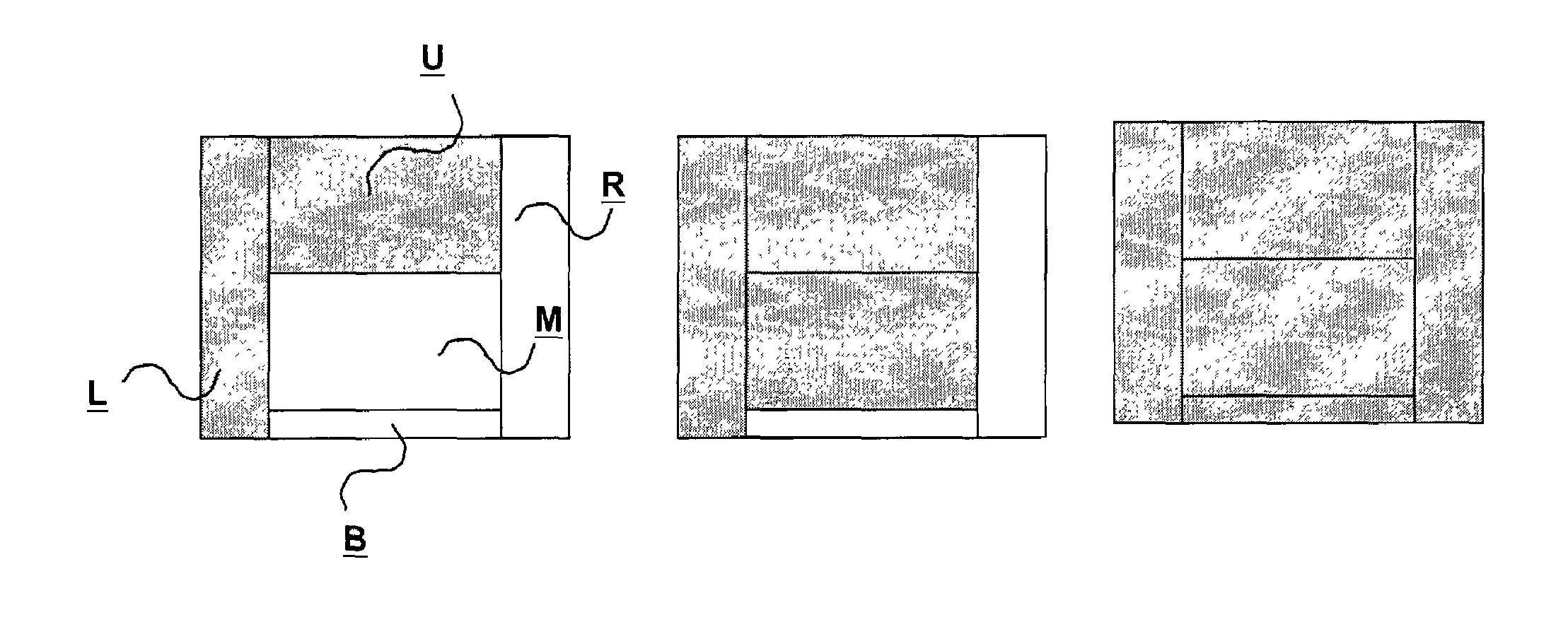

Multiple Views of an Industrial Plant are graphically displayed and viewed. A graphical user interface displays the views in corresponding panes or windows of the graphical user interface. The views, being graphical representations of systems of the Industrial Plant, are coupled by a coupler according to a predetermined relationship between the underlying systems of the Industrial Plant represented by the coupled views. The coupler automatically refocuses the panes to display different views of the Industrial Plant based on a selection of an object in any of the panes or on a manual refocus of one view and on the predetermined relationship for coupling the views. The Coupled views represent different domains of the Industrial Plant or Industrial Network e.g. real-time monitoring and operation, configuration, debugging, maintenance, scheduling, asset management, documentation, training, simulation, physical construction, material flow monitoring, programming, interconnecting function blocks, performance analysis. The analysis may be provided at different points in time (now, past, predicted future) and with a different spatial focus (parts, whole). Coupling different views greatly reduces handling effort for building and operating Industrial Plants.

Owner:SIEMENS AG

Preparation method and application method of water-based epoxy resin emulsion

ActiveCN102161731AGood water solubilityReduce manufacturing costCoatingsWater basedEnvironmental resistance

The invention relates to a preparation method and application method of a water-based epoxy resin emulsion, which comprises the following steps: (1) adding a proper amount of solvent into a bisphenol A epoxy resin, and evenly mixing; (2) heating, slowly and dropwisely adding grafted monomer and an initiator, and keeping the temperature to react; (3) at room temperature, slowly and dropwisely adding organic amine to neutralize so as to obtain salt, adding a certain amount of deionized water, and sufficiently stirring to obtain the epoxy resin emulsion; and (4) mixing the epoxy resin emulsion with a proper amount of curing agent, evenly stirring, coating a film, and curing at room temperature. The product has the main characteristics of no organic solvent volatilization and no peculiar smell in the construction process, and belongs to environment-friendly products. The construction technique of the product provided by the invention is similar to that of the traditional epoxy terrace series products. The product is applicable to the floor of various industrial factory buildings and offices, can be used in room-temperature and moist environments, and overcomes the defect that the solvent-type terrace paint is water-sensitive.

Owner:山东斯泰普力高新建材有限公司 +1

Acoustic absorption, noise insulation, thermal insulation, condensation resistant building material, preparation method and application thereof

The invention discloses a construction material with the effects of sound absorption, sound insulation, heat preservation, anti-condensation, etc., a preparation method and the application thereof. The construction material consists of the following independent constituents: constituent I, constituent II and constituent III; wherein, the constituent I is a water-base interfacial agent; the constituent II mainly consists of the following constituents according to certain weight portion: 55 to 65 portions of plant fiber and 35 to 45 portions of caking agent; the constituent III is a sealing agent. The construction material of the invention is made of wood fiber by chemical treatment and the construction material is sprayed on the base surface of buildings, which has the effects of sound absorption, sound insulation, heat preservation and anti-condensation, fire protection, moulding prevention, etc. The construction material of the invention is completely suitable for being used on a base surface configuration of any building, such as arc form, waveform, etc., and also is suitable on large-scale public places needing sound absorption, sound insulation, heat preservation, anti-condensation, fire protection, etc. such as a gymnasium, a natatorium, an opera house, a cinema, an exhibition center, an airport, tunnel, an industrial factory building, a machinery room, etc.

Owner:傅梅

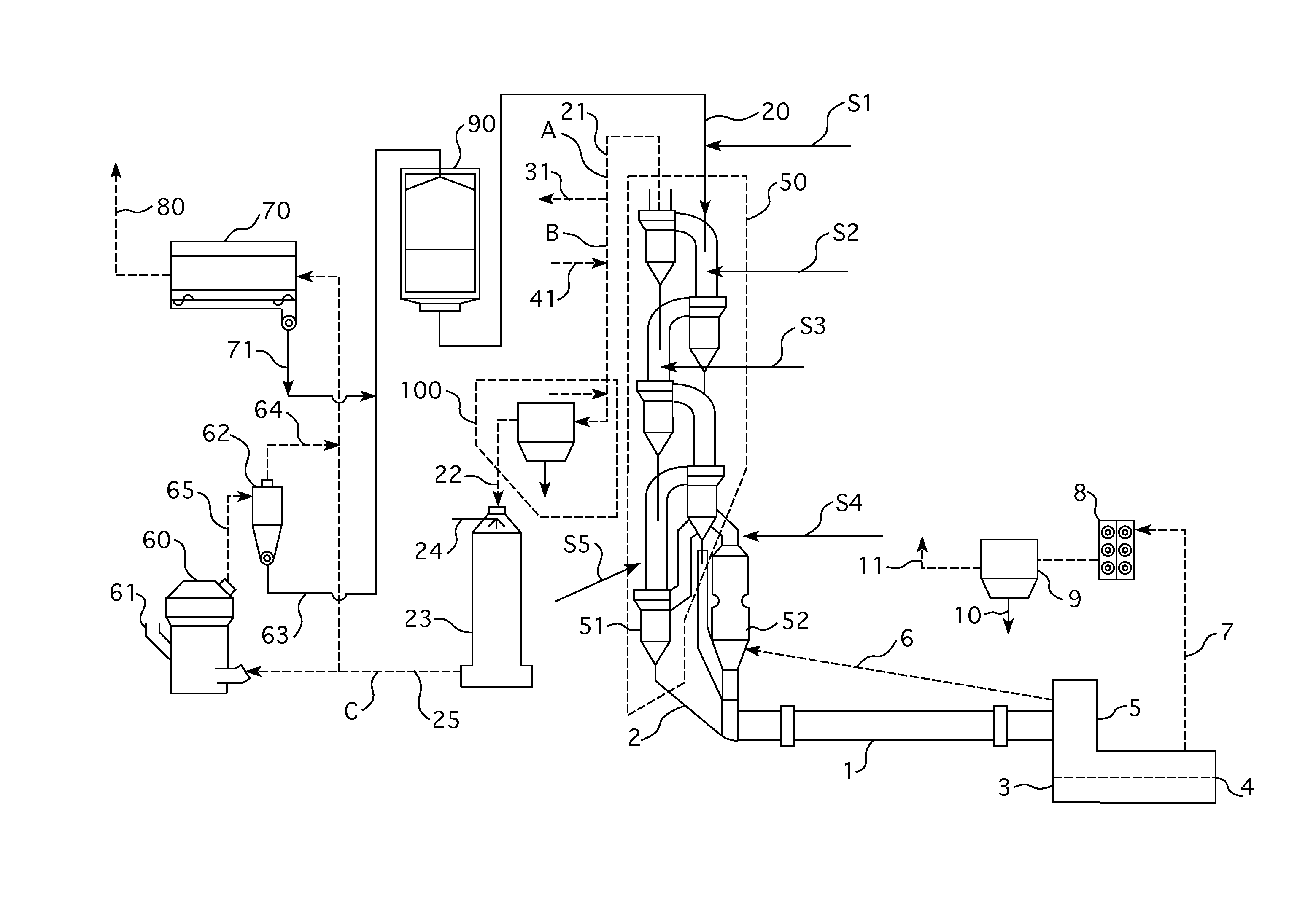

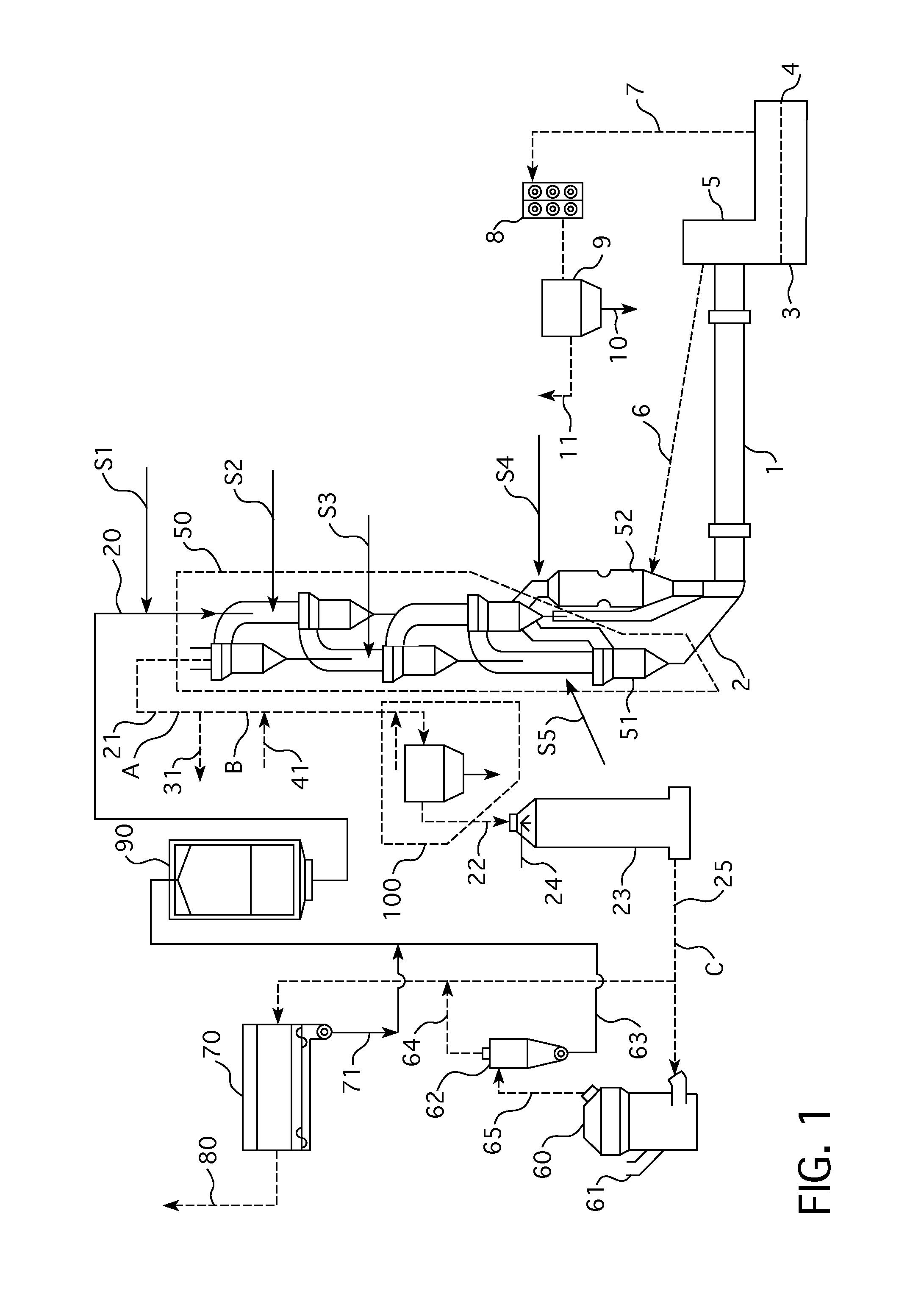

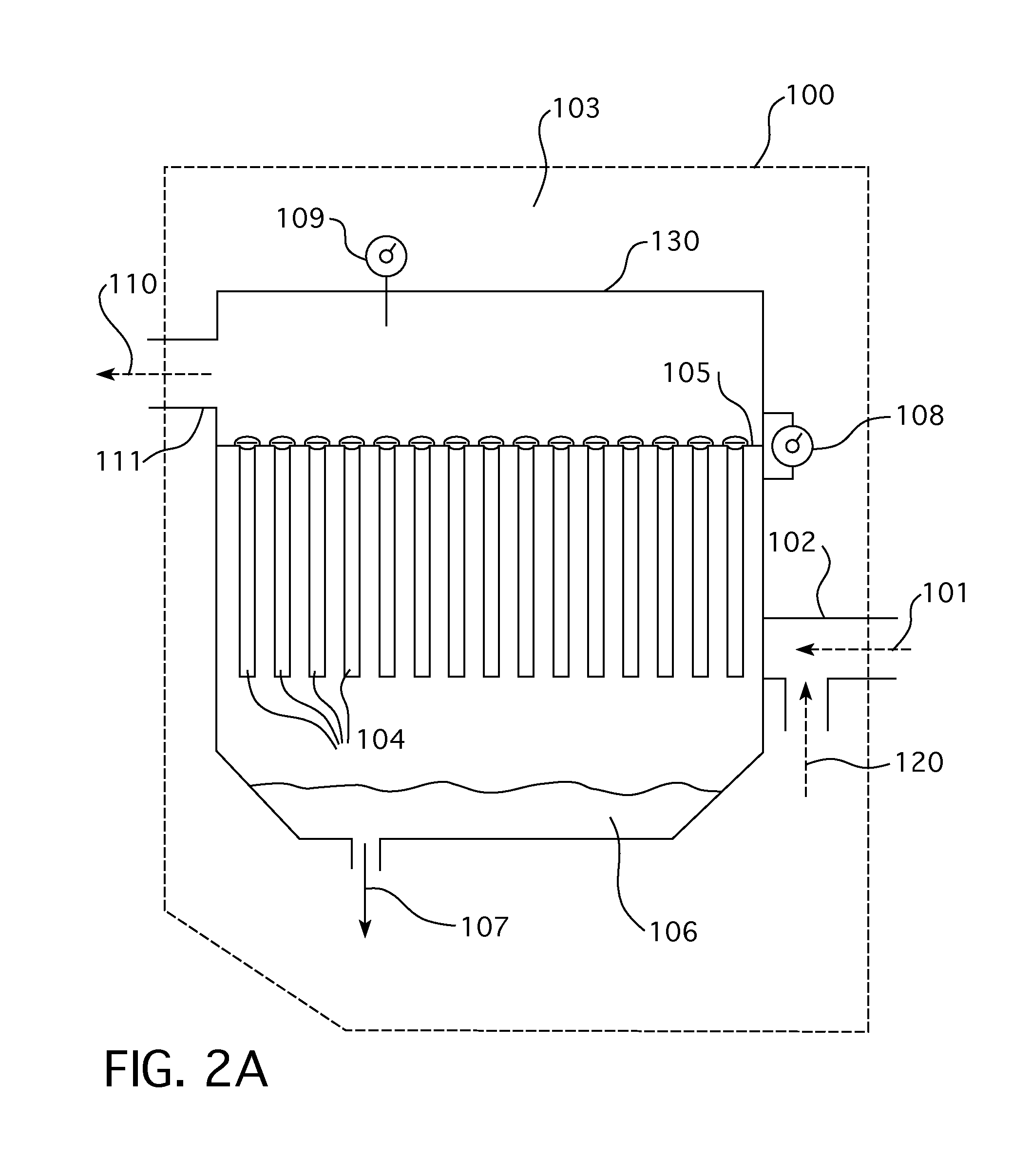

Pollution control system for kiln exhaust

InactiveUS20140170046A1Reduction of organic compound and other emissionAvoid cloggingGas treatmentOrganic chemistryPtru catalystPorous medium

Disclosed is a method and apparatus for the reduction of organic compounds and other emissions from an industrial plant utilizing a cement or minerals kiln that has a high level of organic compound emissions. The invention consists of a filter for the control of particulate emissions which has been treated with a catalyst to provide catalytic destruction of gaseous emissions as process gases are passed through the porous medium of the filter.

Owner:F L SMIDTH & CO AS

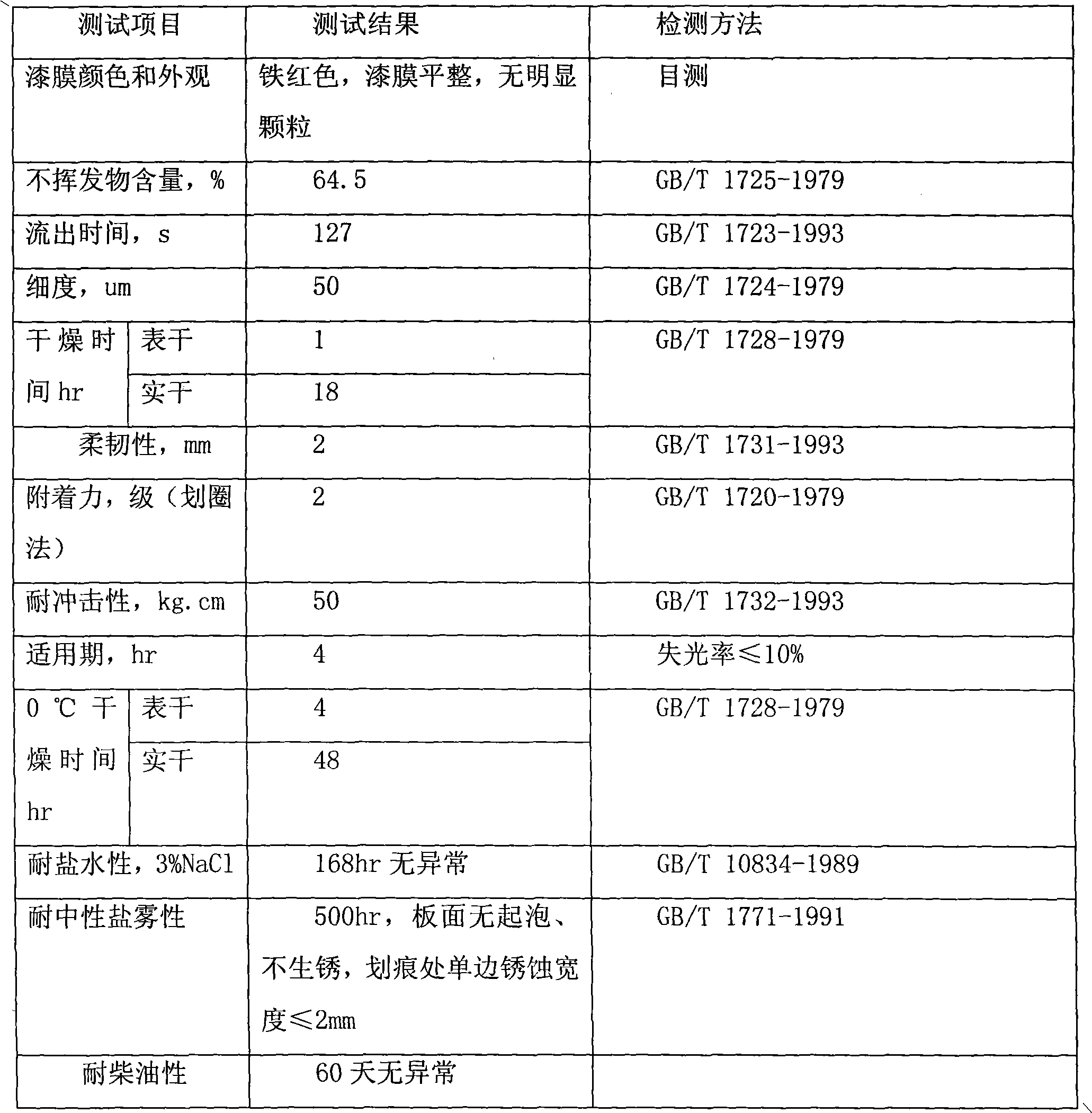

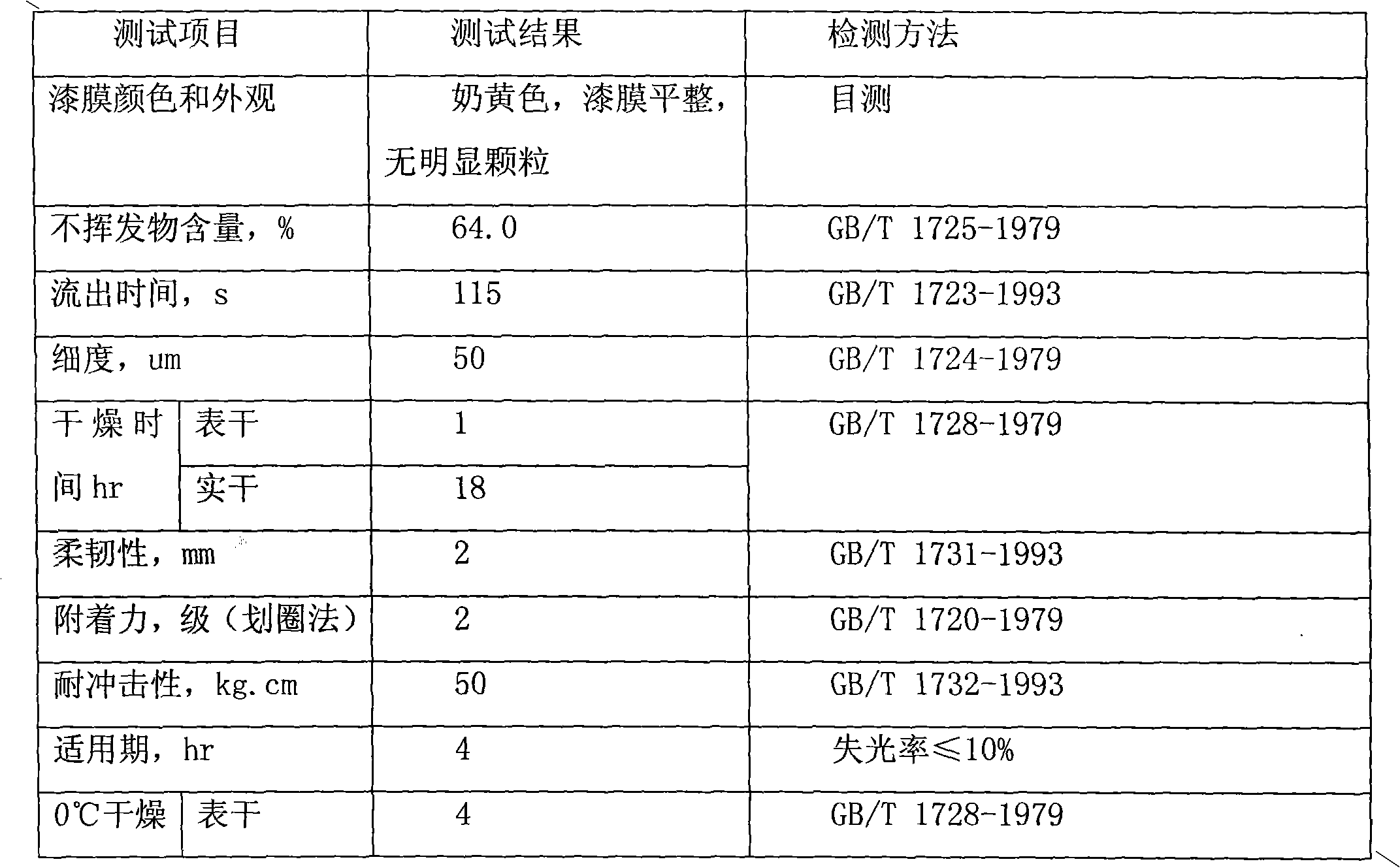

Waterborne polyester modified epoxy polyurethane anticorrosive paint and preparation method thereof

InactiveCN102108245AGood water and oil resistanceLow coating adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterEpoxy

The invention relates to a waterborne polyester modified epoxy polyurethane anticorrosive paint and a preparation method thereof. The preparation method of the paint is as follows: a component A is composed of 25-50 parts by weight of waterborne polyester modified epoxy dispersion and other raw materials, a component B is composed of waterborne polyisocyanates dispersion, the component A and the component B are mixed in a ratio range of 7:1-3:1 to form the main film-forming material; 0-30 parts by weight of rustproof pigment, 0-20 parts by weight of coloring pigment and 5-20 parts by weight of filler are further added. The paint of the invention has the advantages similar to that of the common waterborne paint, overcomes some defects of the waterborne anticorrosive paint, combines the advantages of polyester paint, epoxy paint and polyurethane paint, has excellent low temperature fast curing property, oil resistance, chemical medium and anticorrosive properties and has wide application prospect in various steel structure fields such as bridges, pipes, storage tanks and industrial factory buildings.

Owner:SHENZHEN ZHONGKE LITAO TECH

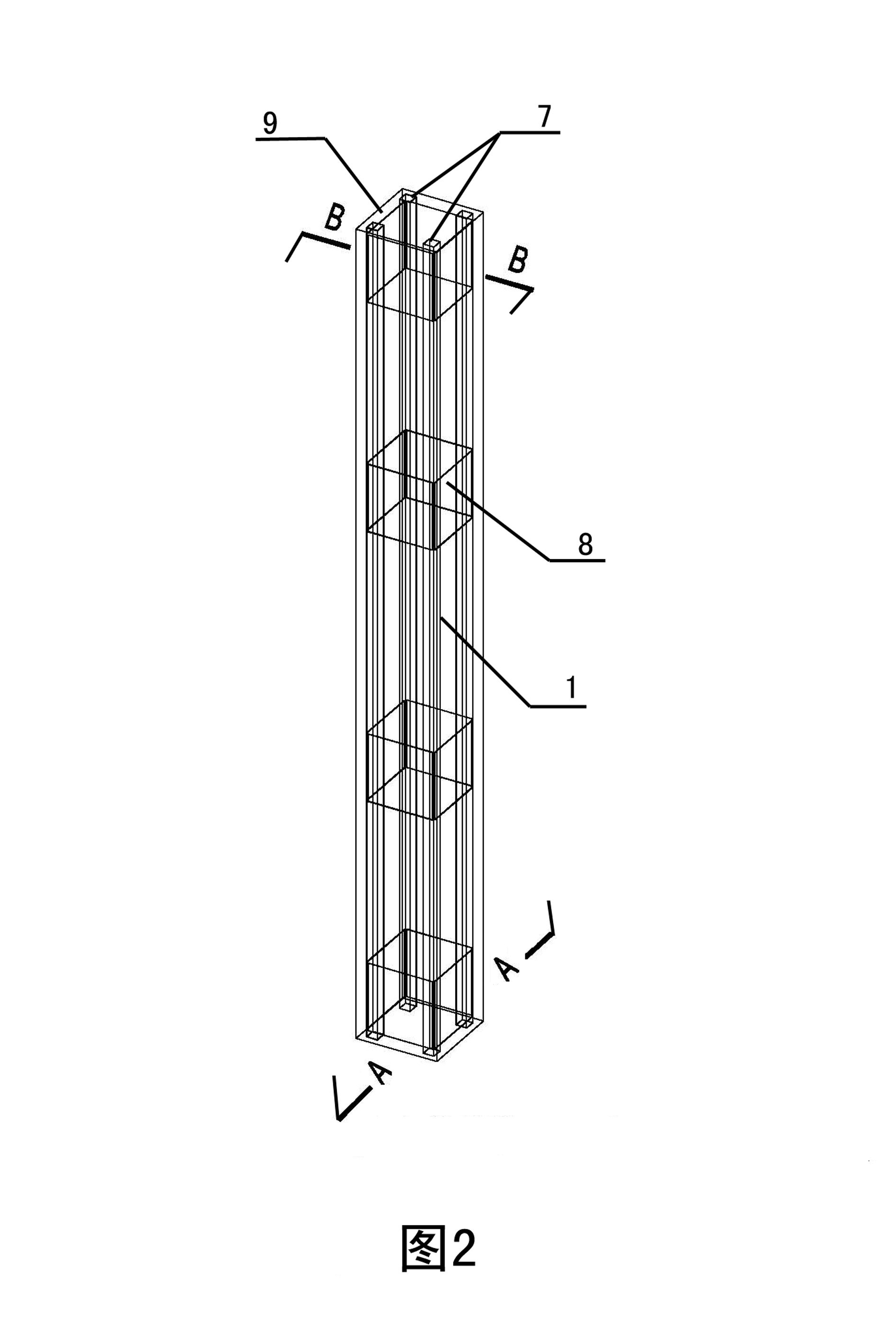

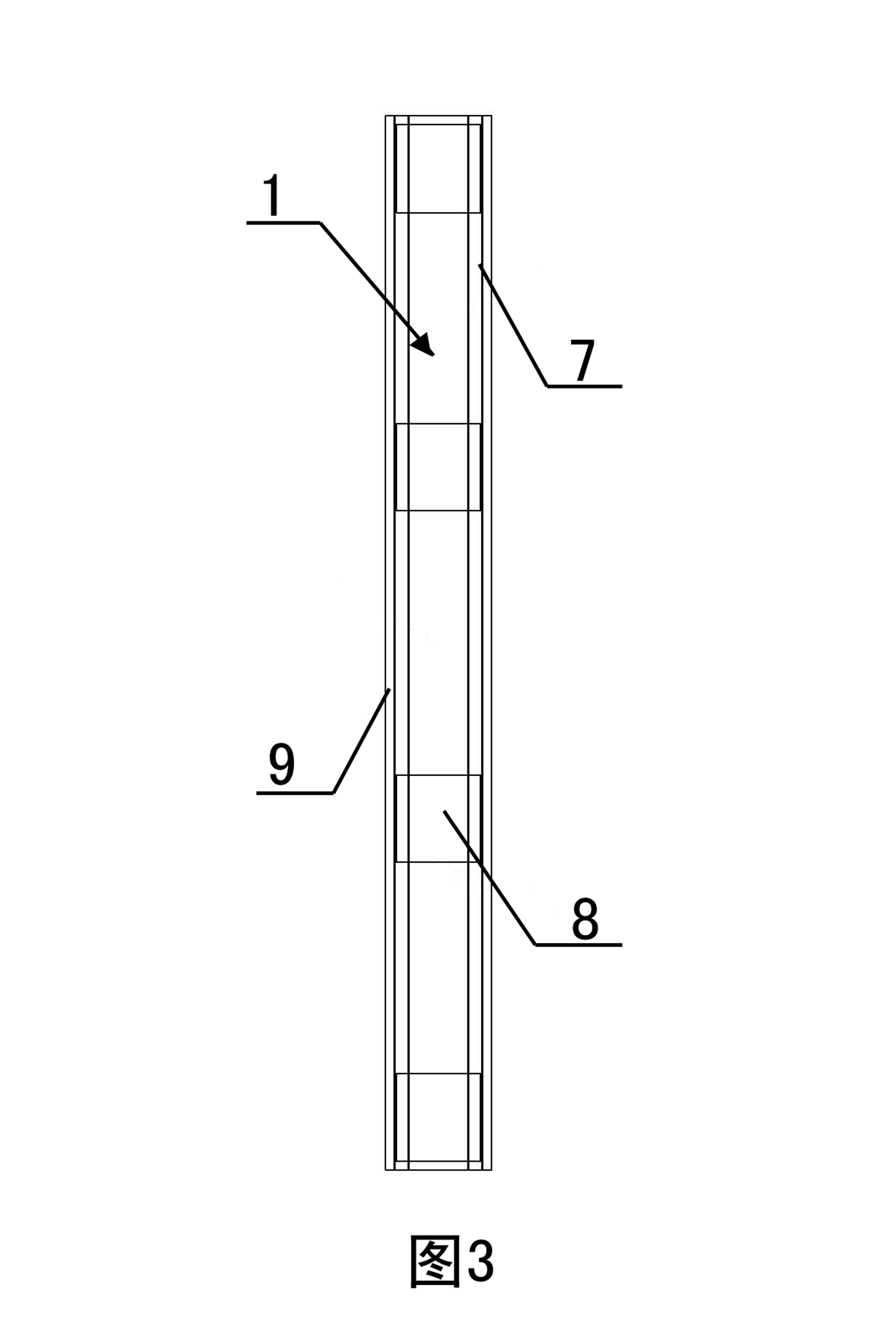

Light-steel light-concrete structural system and construction method thereof

ActiveCN101845852AImprove insulation effectImprove insulation performanceBuilding constructionsFloor slabThermal insulation

The invention relates to a light-steel light-concrete structural system and a construction method thereof. The structural system consists of pillars, beams, walls, floor plates and a roof panel; the pillars, the beams, the walls, the floor plates and the roof panel are formed by casting light steel and light concretes in situ; and the light-steel pillars and the light-steel walls are formed by connecting light-steel section bars and connecting sheets, and the floor plates and the roof panel are formed by connecting light steel, connecting sheets and steel meshed sheets. The structural system has light dead weight, good aseismicity, integrity and waterproofness and favorable thermal insulation and sound insulation performances, solves the problems of waterproofing, fireproofing and rust-proofing of the traditional light-steel structure, has the advantages of high industrialized degree, low overall cost, convenient construction and environmental protection, and is suitable for common civil buildings and light industrial factory buildings.

Owner:CHINA BUILDING TECHN GROUP +2

Application of black soldier fly larvae as oil-crop insect

InactiveCN101880593ARelieve stressHigh nutritional valueBiofuelsFatty-oils/fats productionChemical industryBiodiesel

The invention belongs to the fields of foods or bioenergy and develops a new oil source, i.e. black soldier fly larvae as an oil-crop insect. Oil can be obtained by using a compression method (larvae is fed into a screw-type press while hot to press oil out) after black soldier fly adult and larvae are dried by hot wind or microwave. The oil can be used as raw oil for eating, chemical industry and biodiesel. The oil content of the black soldier fly larvae is 30-35 percent, through analyzing the nutritious components of the oil, and oil extracted from the black soldier fly larvae contains various unsaturated fatty acids needed by human bodies, thereby being high-quality health oil. The black soldier fly larvae has short growth period which is only 20-30 days and very small floor area, can be cultured under the condition of high density, reaches the oil production per mu of 4t / mu.year, can be carried out in an industrial factory building without occupying land area, contains no toxin, is safe and reliable, and has simple extraction process.

Owner:SUN YAT SEN UNIV

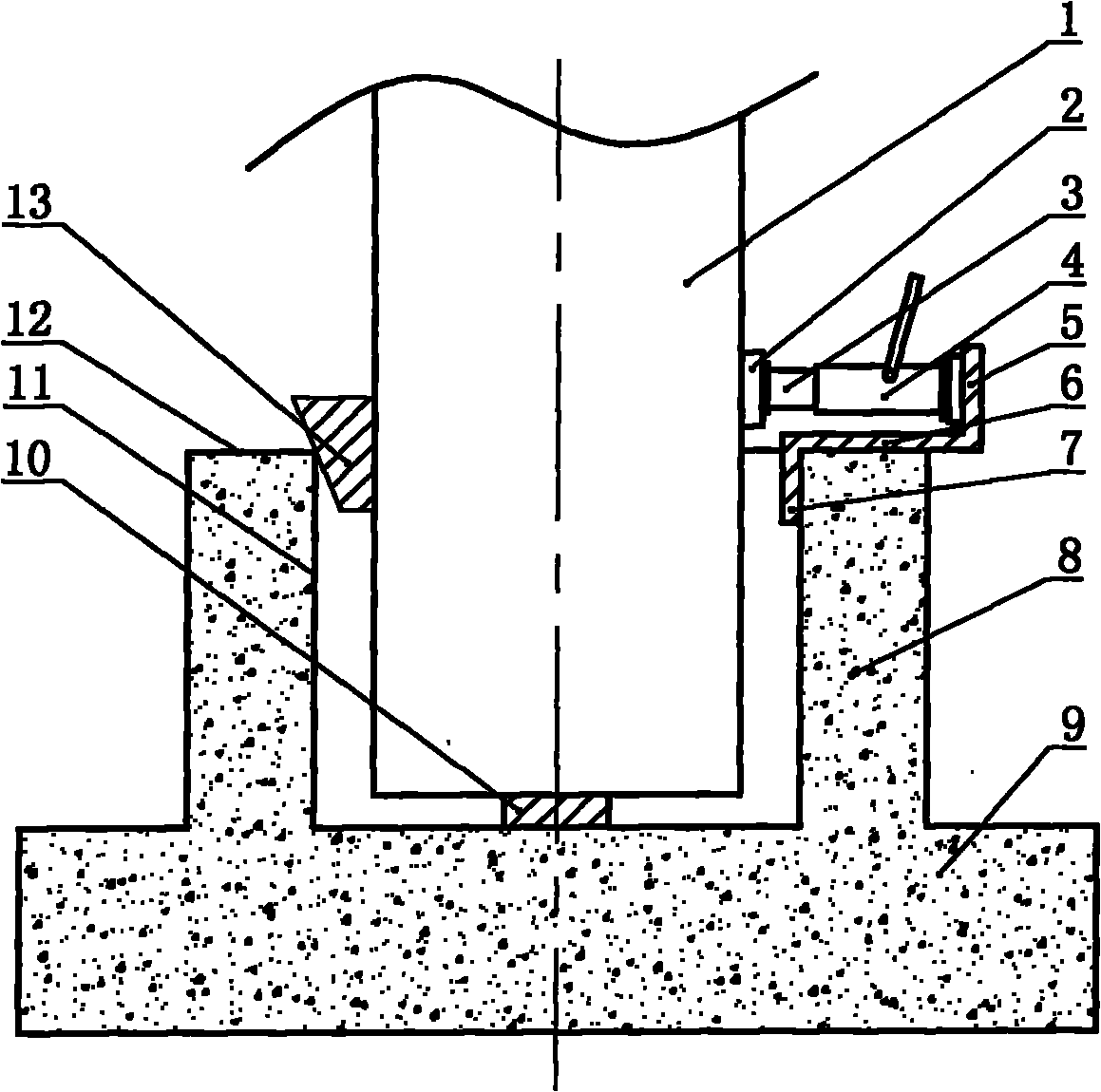

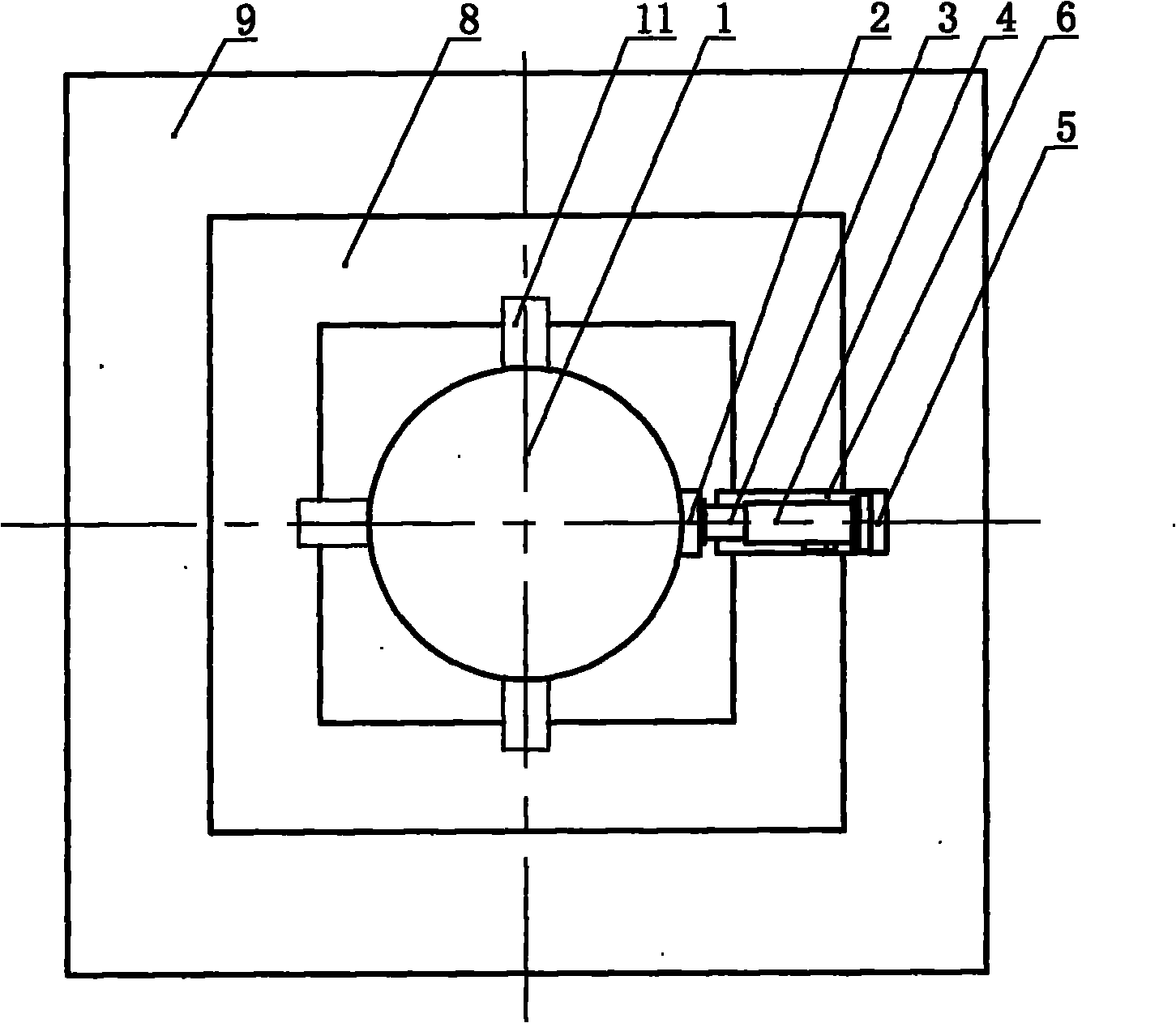

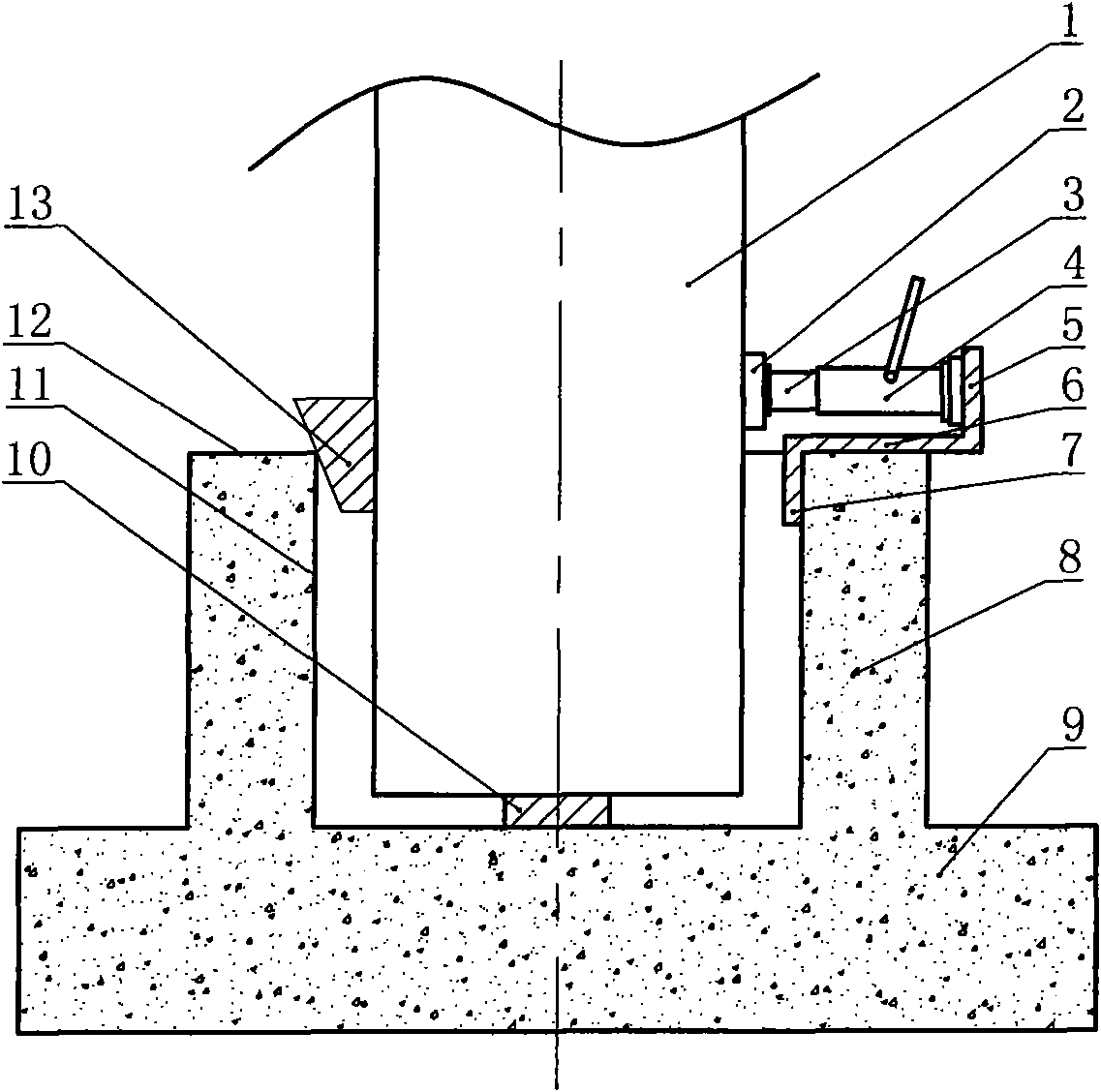

Method for adjusting axis deviation of industrial factory building edge foundation heavy column

The invention relates to a method for adjusting the axis deviation of an industrial factory building edge foundation heavy column, which comprises the following steps of: (1) hoisting a heavy column into an edge foundation; (2) measuring the verticality and the axis deviation of the heavy column by using a theodolite; and (3) adjusting the axis deviation of the heavy column. The axis deviation adjustment of the heavy column comprises the following steps of: firstly, vertically and fixedly installing vertical steel plates on both ends of the heterotopic surfaces of a horizontal rectangular steel plate respectively for forming a base; reclining the vertical steel plate at one end of the base and the horizontal steel plate to the inner wall and the top surface of the convex part of the edge foundation; reclining a jack base on the vertical steel plate at the other end of the base and attaching the end part of a push rod of a jack to the outer wall of the heavy column; controlling the jack to finish the axis deviation adjustment of the heavy column; and fixing by using a steel wedge with corresponding size. The adjusting method has the advantages of simple and easy operation, high operating safety, attractive edge foundation appearance, higher precision, effective improvement on the construction quality, shortening of the construction time and improvement on the construction efficiency.

Owner:MCC TIANGONG GROUP

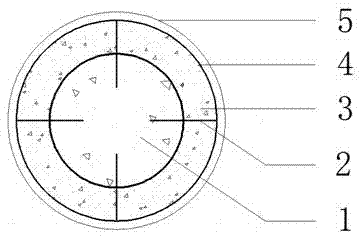

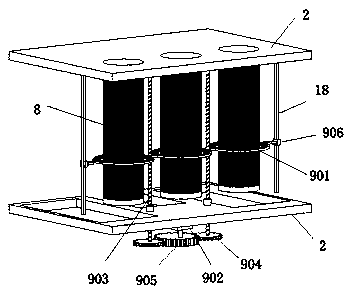

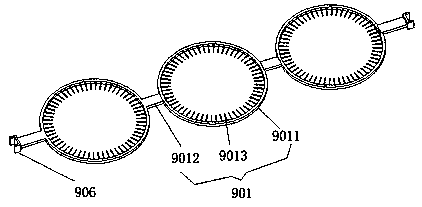

Local reinforcing method of circular reinforced concrete column

InactiveCN105442864AReduce wasteImprove bearing capacityBuilding repairsReinforced concrete columnButt welding

The invention discloses a local reinforcing method of a circular reinforced concrete column. The method mainly includes the steps that symmetrical embedded steel bars are arranged at the positions, needing to be reinforced, of an existing reinforced concrete column, an outer sleeve thin-walled steel pipe 3-10 mm thick is arranged on the periphery of the reinforced concrete column, the outer sleeve thin-walled steel pipe is a sleeve formed by conducting on-site butt welding on two semicircular rolled steel sheets, FRP cloth is wound outside the outer sleeve thin-walled steel pipe, and after adhesives of the FRP cloth are cured, self-compact concrete is poured in the space between the outer sleeve thin-walled steel pipe and the reinforced concrete column. By means of the method, compared with a newly-built project, the circular reinforced concrete column reinforced through the method has the advantages that waste of natural resources and social resources can be reduced, the bearing capacity and anti-seismic performance can be improved, the service life of the column is prolonged, the construction period is short, expenses are low, and the column is suitable for local reinforcing and the like of high-rise and super-high-rise buildings, large-span bridge piers and large industrial factories.

Owner:WUHAN UNIV

Phosphor-nitrogen ultrathin expansion type steel structure fire-resistant coating

ActiveCN101418158ASmall molecular weightGood film formingFireproof paintsPolyurea/polyurethane coatingsSolventIndustrial Factory

The invention discloses a fire-retardant coating with a phosphor-nitrogen ultra-thin intumescent steel structure. The compositions of the fire-retardant coating with the phosphor-nitrogen ultra-thin intumescent steel structure in portion by weight are 40 to 75 portions of base resin which consists of modified acrylic acid resin, urethane resin and alkyd resin, 50 to 70 portions of intumescent fire retardant, 8 to 12 portions of titanium pigment powder, 8 to 12 portions of calcium carbonate and 18 to 35 portions of mixed solvent which consists of xylene and butyl aetate. The base resin is formed by mixture of a plurality of types of resin and the intumescent fire retardant used is a substance which integrates a charring agent, a foaming agent and char forming catalyst, so that the coating has good fluidity and is convenient in construction; a coating formed is thin and has strong adhesion and high hardness; a charring layer formed after foaming has large thickness and high strength and is uniform and dense; and the phosphor-nitrogen ultra-thin intumescent steel structure fire-retardant coating has strong cementitiousness with a steel structure, can not be broken or dropped off by flame, has superior limit of fire resistance, and can be used for fireproof protection of steel structure buildings such as industrial factory buildings, gymnasiums and highrise.

Owner:应急管理部四川消防研究所

Multilayer radiation cooling coating and preparation method thereof

InactiveCN111574878AHigh solar reflectanceSimple processPolyurea/polyurethane coatingsEpoxy resin coatingsNear infrared reflectanceLight reflection

The invention discloses a multilayer radiation cooling coating and a preparation method thereof. The multilayer radiation cooling coating comprises an ultraviolet reflection surface coating, a visiblelight reflection floating coating and a near-infrared reflection base coating, wherein the ultraviolet reflection surface coating contains an ultraviolet reflection material, the visible light reflection middle coating contains a visible light reflection material, and the near-infrared reflection bottom coating contains a near-infrared reflection material. By utilizing the synergistic effect of the ultraviolet reflection surface coating, the visible light reflection floating coating and the near-infrared reflection base coating, extremely high sunlight reflectivity can be generated, the process is simple, the cost is low, and the coating is suitable for special shapes and planes and can be applied to occasions such as residential buildings, commercial buildings and industrial factory buildings and has a wide application prospect.

Owner:杭州净碳科技有限公司

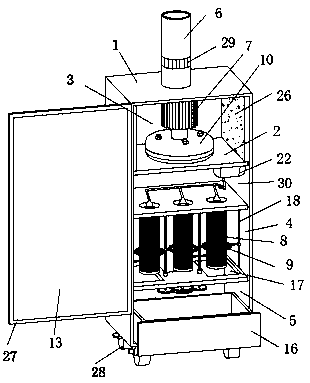

Movable dust removal equipment for industrial factory building

InactiveCN111346449AExtended service lifeFast cleaningDispersed particle filtrationTransportation and packagingActivated carbon filtrationDust control

The invention relates to the technical field of industrial factory building dust removal, and in particular, relates to movable dust removal equipment for an industrial factory building, wherein the movable dust removal equipment comprises a machine box body, the interior of the machine box body is sequentially divided into a power cavity, a reverse blowing cavity, a filtering cavity and a collecting cavity from top to bottom through two transverse partition plates, an air outlet pipe is arranged at the top of the power cavity, and an activated carbon filter is arranged on the air outlet pipe;a centrifugal fan communicated with the air outlet pipe is arranged in the power cavity, and the bottom end of the centrifugal fan is communicated with an air collecting disc; a filter cartridge typefilter and an ash removal device are arranged in the filter cavity, the left outer wall and the right outer wall of the filter cavity are communicated with air inlets, and electronic air valves are arranged in the air inlets; an ash collecting drawer is slidably mounted in the collecting cavity, and an ash falling hole is formed in the transverse partition plate between the collecting cavity andthe filtering cavity; walking wheels are fixedly mounted at four corners of the lower end surface of the bottom end of the machine box body; dust on the surface of the filter element can be cleaned while the filter element filters gas, and meanwhile, the filter element can be matched with the reverse blowing system to accelerate the cleaning speed of industrial dust.

Owner:界首尚嘉工业设计有限公司

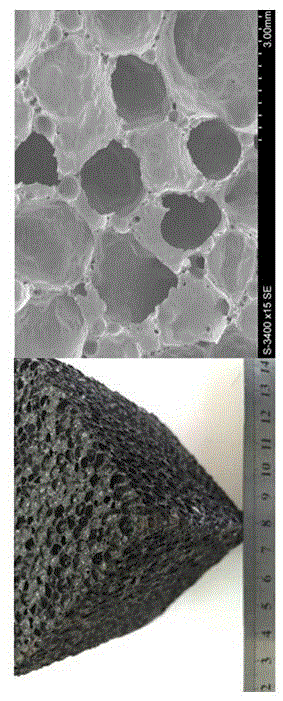

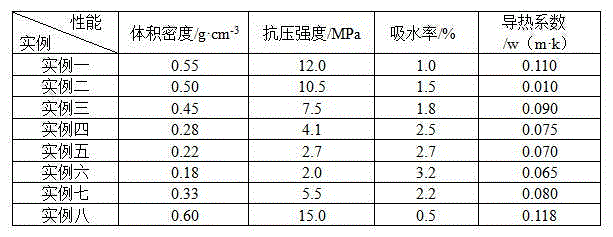

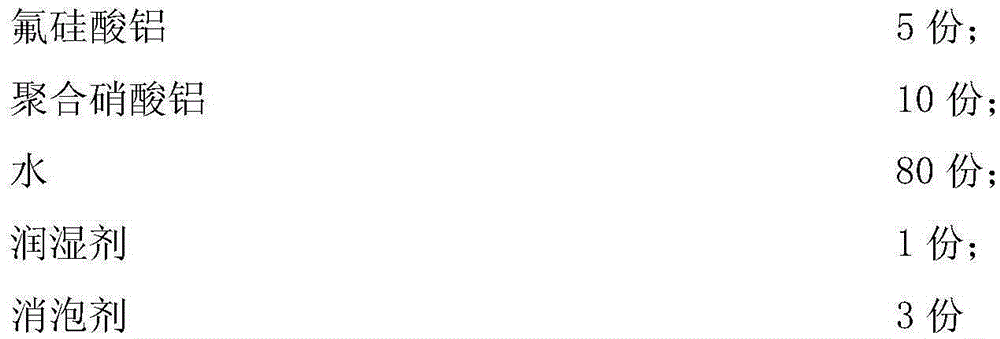

Foam microcrystalline glass made of high-silicon iron tailings and production method of foam microcrystalline glass

ActiveCN104788011AAddress pollution hazardsSave raw materialsGlass shaping apparatusCompressive resistanceFoaming agent

The invention relates to foam microcrystalline glass produced by using high-silicon iron tailings and a production method of the foam microcrystalline glass. Main raw materials of the foam microcrystalline glass comprise 70%-90% of the high-silicon iron tailings, 0.5%-5% of a foaming agent and 5%-30% of an additive, wherein the foaming agent is obtained by mixing carbon powder and calcium carbonate in a mass ratio being 2:1; the additive is obtained by mixing albite and talc in the ratio being 5: (0.5-1). During production, the raw materials are uniformly mixed, and the foam microcrystalline glass is prepared through preheating, sintering, foaming, crystallizing and annealing processes after forming. The foam microcrystalline glass has the advantages of small density, small heat conductivity coefficient, high compressive strength, easiness in processing and forming and the like and can be used for buildings such as a villa, a civic building, an industrial factory building and the like. The problems of high raw material production cost, complicated technology and the like of the foam microcrystalline glass are solved, pollution hazard of tailing accumulation to the environment is avoided, waste is turned into wealth, and energy saving and environmental protection are realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

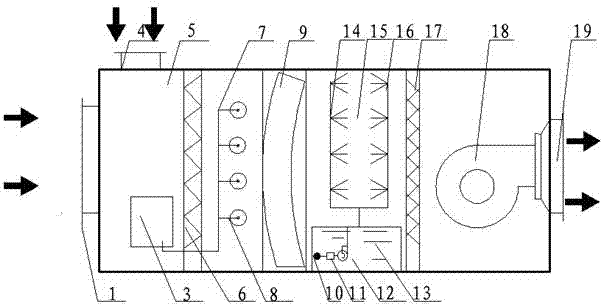

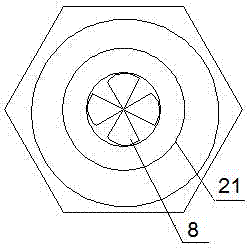

High pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit

InactiveCN102230651AIncrease jet expansion entrainmentIncrease expansion entrainmentLighting and heating apparatusEnergy industryCooling effectHigh pressure

The invention relates to a high pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit which is characterized in that the side wall opposite to the shell of the unit is respectively provided with an air inlet and an air supply outlet; the shell of the unit is internally provided with a primarily efficient filter, a high pressure air injection cooling air device, a rotation type air flow equalization plate, a fluid power type water spraying device, a weir plate and an air feeder in turn in an air inlet direction; a novel air returningmixed section is arranged between the air inlet and the primarily efficient filter; and the side wall of the unit shell on the novel air returning mixed section is provided with an air returning port. According to the invention, high pressure air injection and fluid power type water spraying chambers are organically combined, and two direct evaporative cooling sections are used, thus the unit hasan obvious cooling effect on places in which indoor air needs to be cooled in quantity, such as industrial factory buildings and workshops based on high sensible heat, especially, mines.

Owner:XI'AN POLYTECHNIC UNIVERSITY

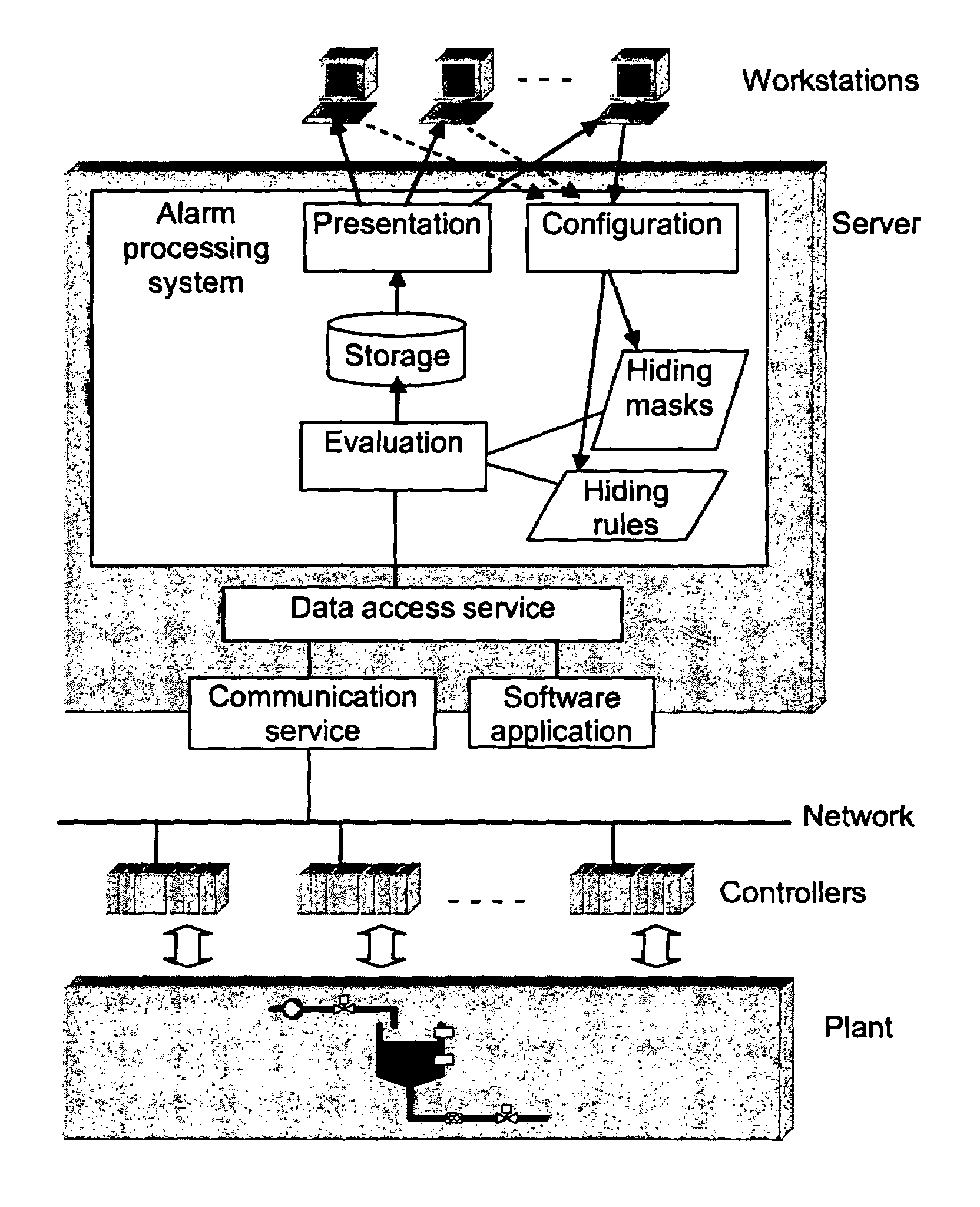

Method and system for automatically deciding what alarm, generated in an industrial plant, to hide or to present to an operator

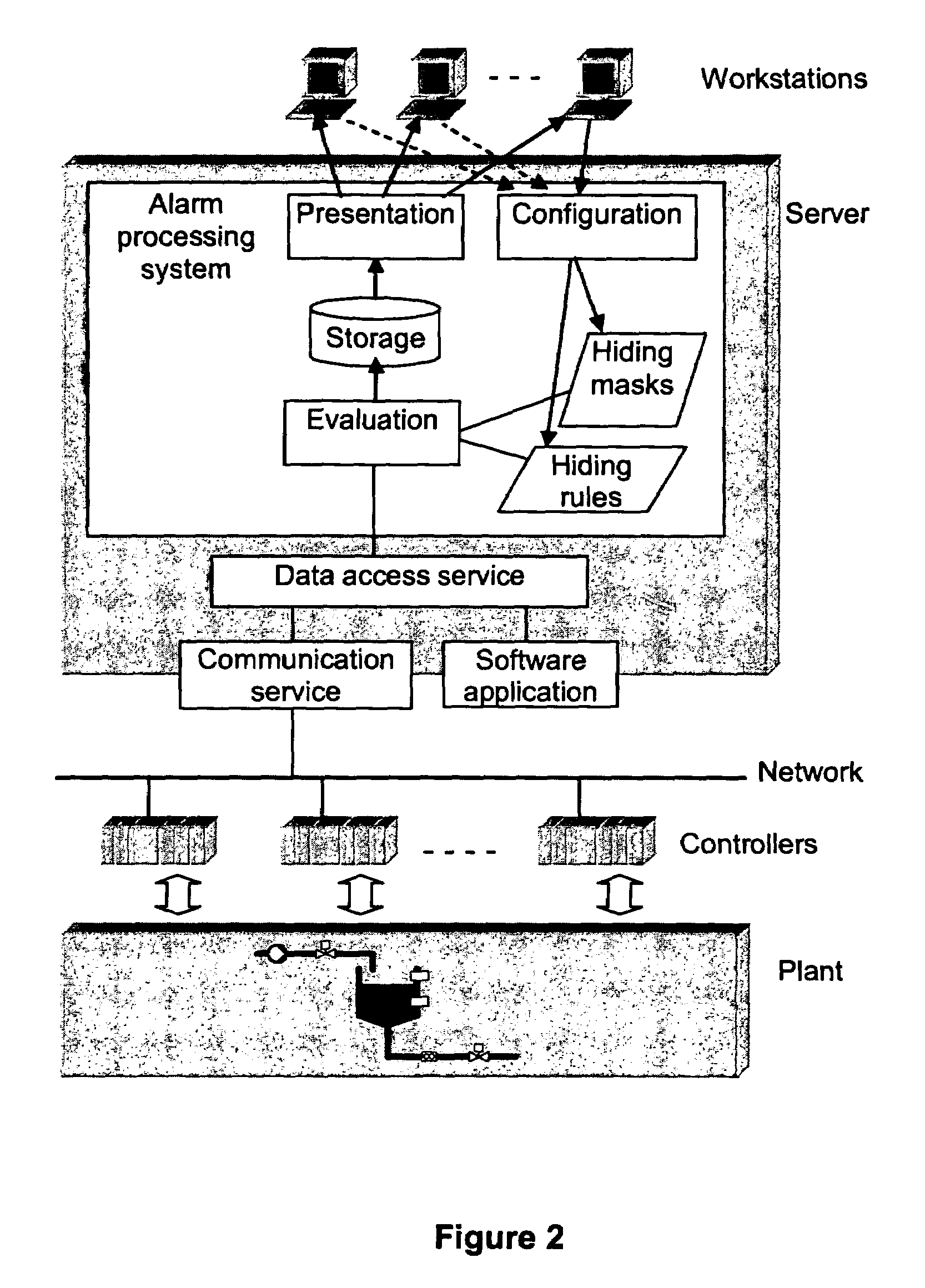

ActiveUS7692537B2Relieves operatorProgramme controlTesting/monitoring control systemsIndustrial FactoryComputer science

A method and an alarm processing system for deciding what alarm, out of a number of alarms generated in an industrial plant or process, to present to a system operator. The method includes creating hiding rules, associating each hiding rule with a real-world object, storing these rules in a storage means, receiving an alarm related to a real-world object, determining if a hiding rule is associated with the real-world object evaluating the hiding rule, deciding from the hiding rule whether to present or hide the alarm, selectively and actively hide such alarms that are decided to be hidden and not presenting the alarm to the system operator. The invention also includes an alarm processing system and a computer program for carrying out the method.

Owner:ABB (SCHWEIZ) AG

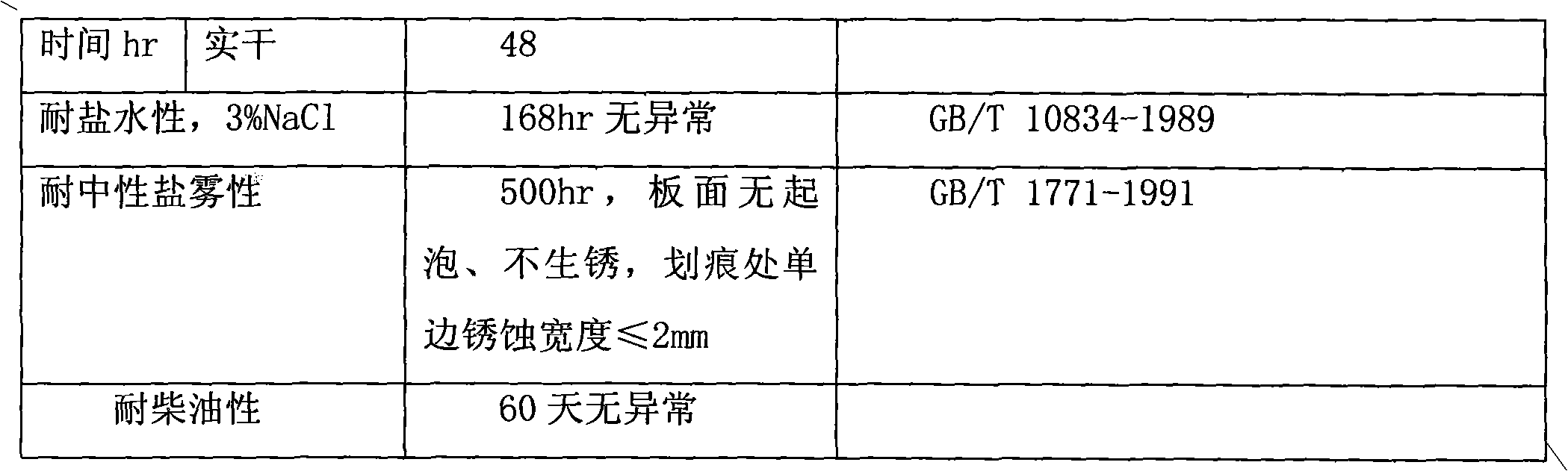

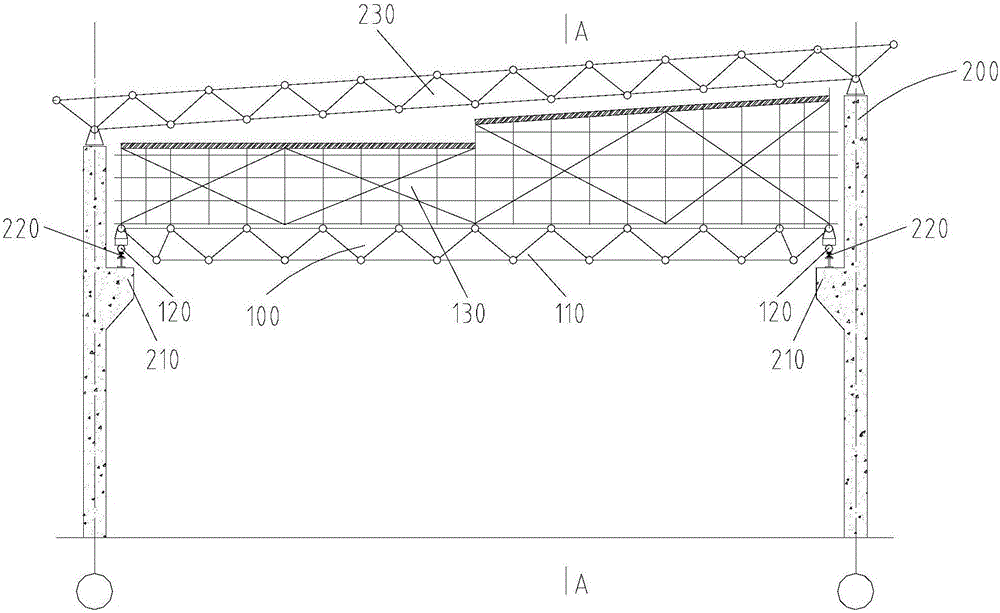

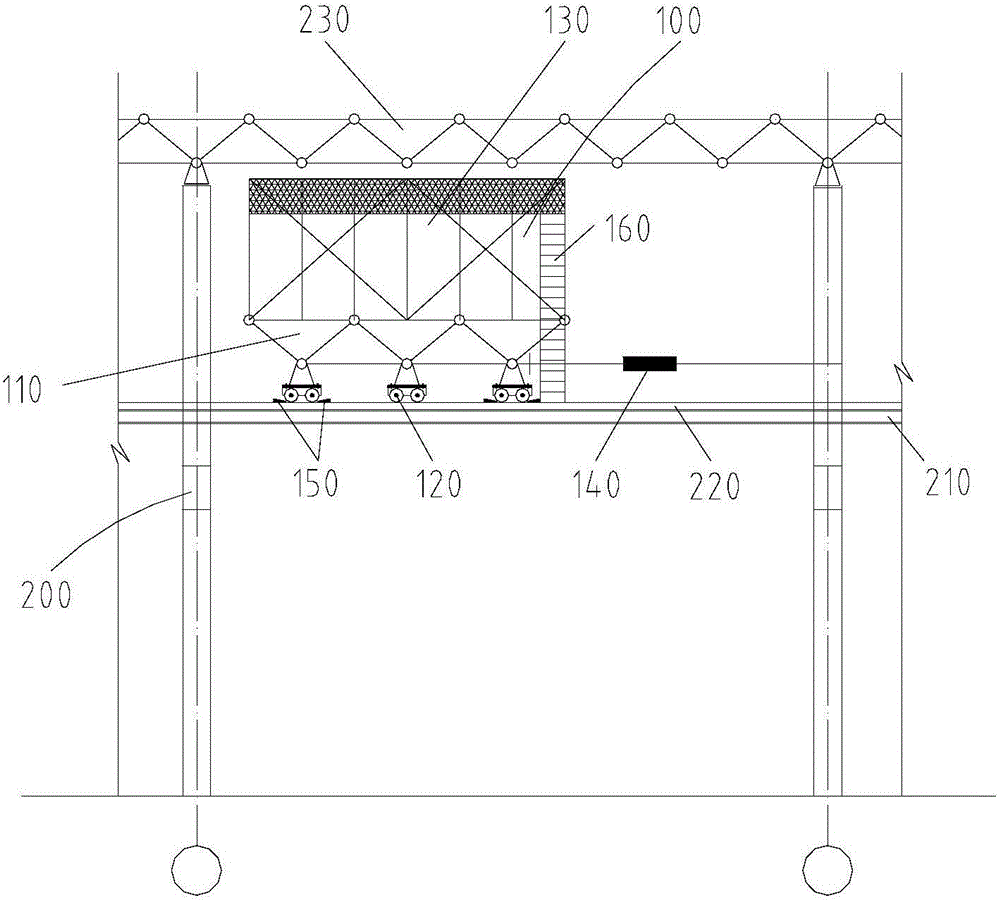

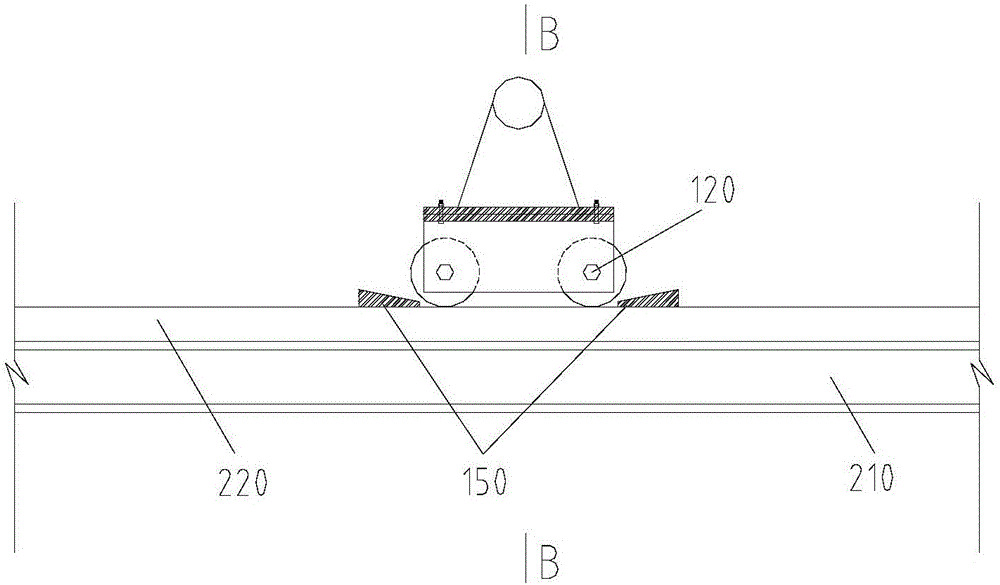

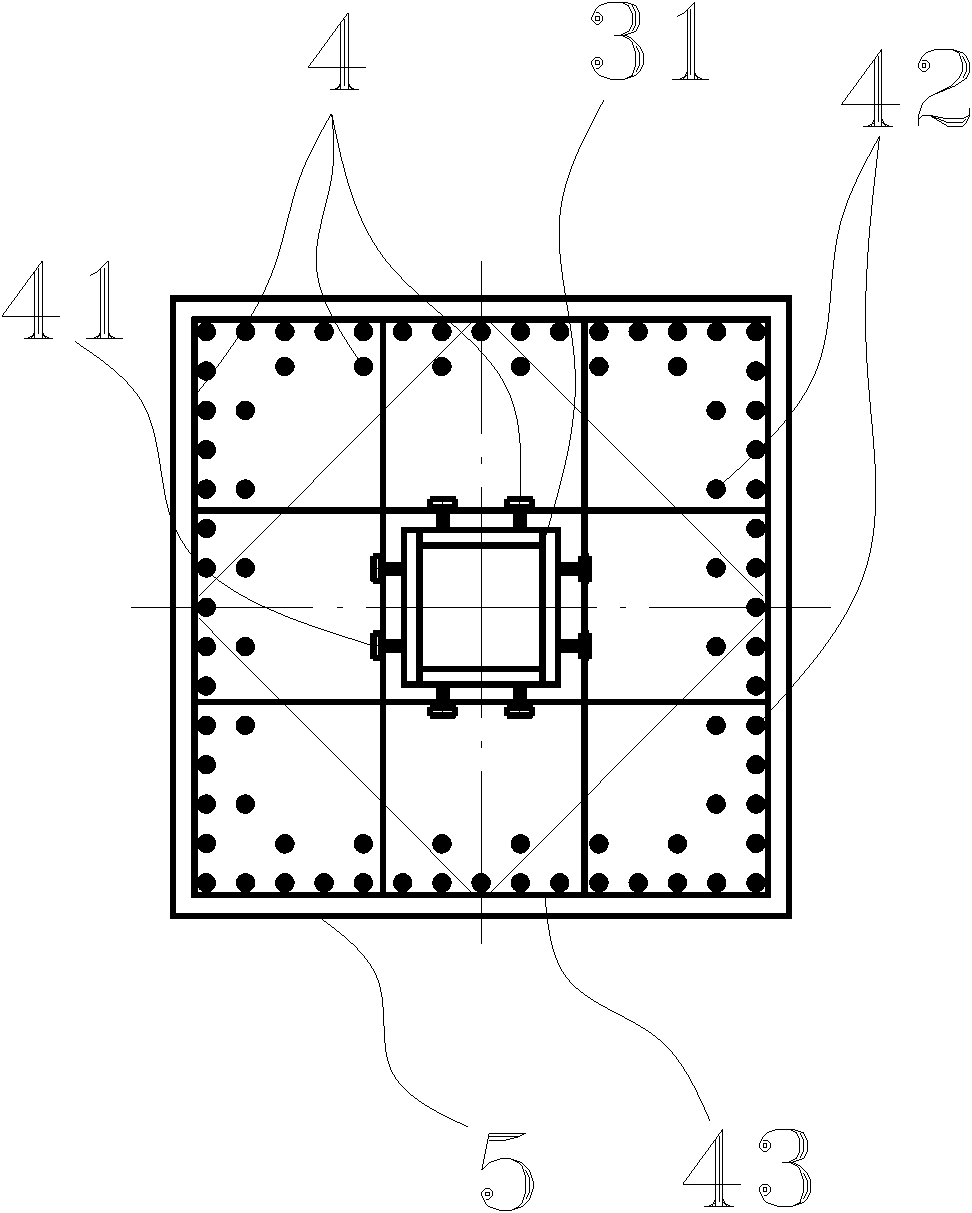

Sliding platform and construction method for separately mounting grid structures on high altitudes

ActiveCN106223595AMeet the requirements of continuous installationGood sliding safetyBuilding support scaffoldsOverhead craneIndustrial Factory

The invention discloses a sliding platform and a construction method for separately mounting grid structures on high altitudes. The sliding platform for separately mounting the grid structures on the high altitudes is arranged in an industrial factory building. The industrial factory building is provided with crane beams, and overhead crane tracks are arranged on the crane beams. The sliding platform for separately mounting the grid structures on the high altitudes comprises a grid structure type sliding platform, a scaffold operating platform and pulling equipment. The grid structure type sliding platform is slidably arranged on the overhead crane tracks via a plurality of sliding rollers; the scaffold operating platform is arranged on the upper surface of the grid structure type sliding platform; the pulling equipment is connected onto the grid structure type sliding platform, so that the grid structure type sliding platform can slide along the overhead crane tracks. The mounting quality of the grid structures, with bolt-sphere joints, of the industrial factory building can be sufficiently guaranteed, the time and labor can be saved, and the safety of staffs for constructing the grid structures on the high altitudes and the safety of construction staffs below the staffs can be guaranteed. The sliding platform and the construction method have the advantages of flexibility, convenience, speediness and low cost. Besides, merits can become obvious along with increase of ratios of the longitudinal lengths to the span of the grid structure.

Owner:CHINA IPPR INT ENG

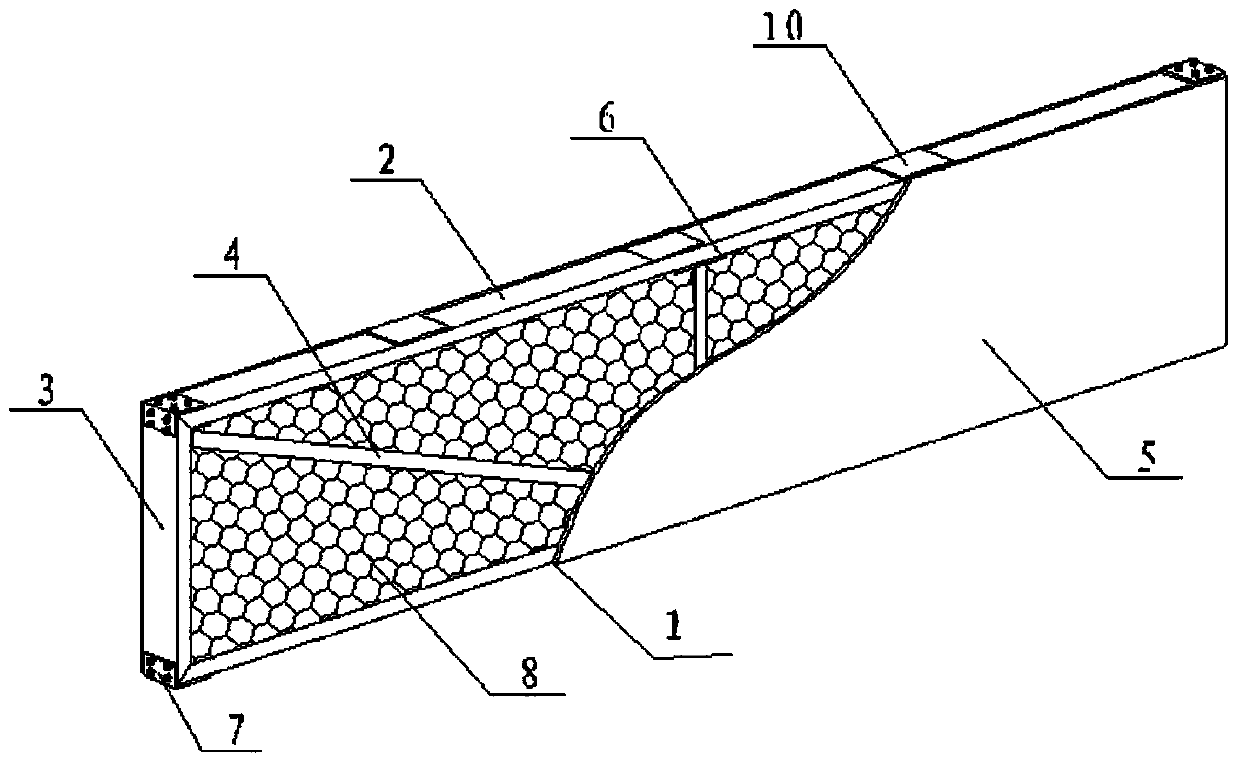

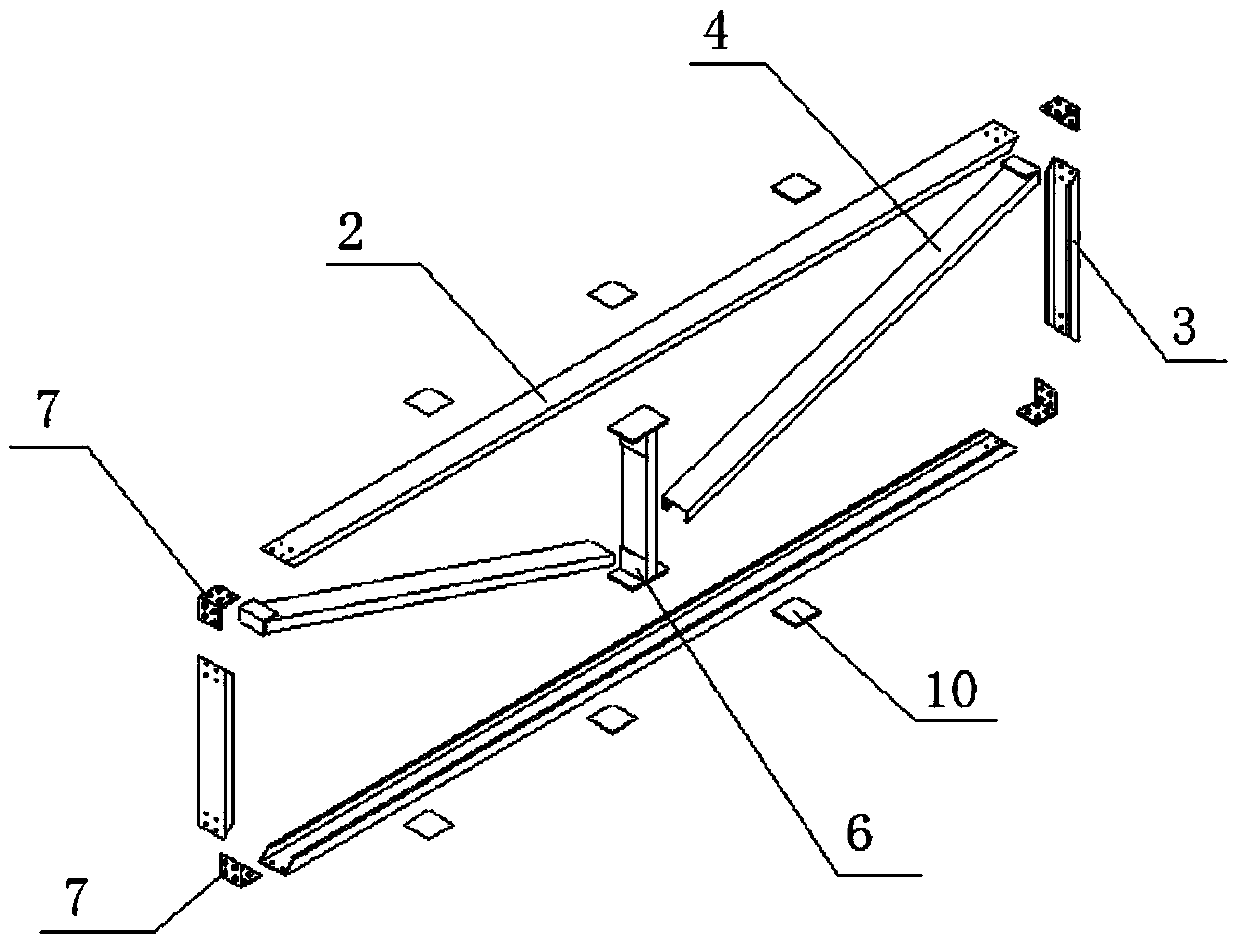

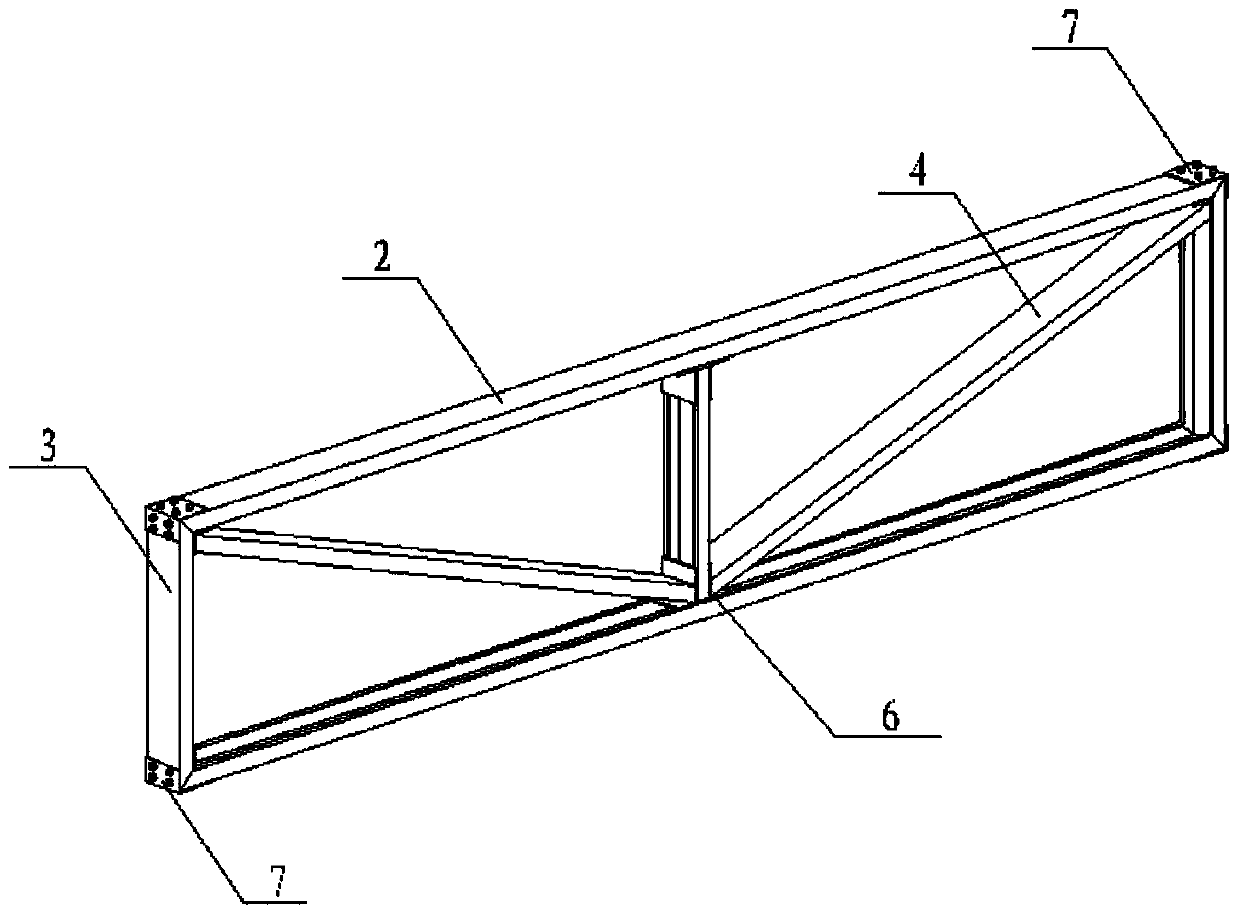

Novel prefabricated wall plate and building external wall assembled by same

ActiveCN103938791AStable structureIncreased load-bearing capacityWallsShock proofingIndustrial FactoryWall plate

The invention belongs to the field of buildings, and in particular relates to a novel prefabricated wall plate and a building external wall assembled by the novel prefabricated wall plate. The novel prefabricated wall plate comprises a wall plate steel framework, wherein the wall plate steel framework comprises main ribs, auxiliary ribs and reinforcement ribs; the auxiliary ribs are perpendicular to the main ribs; two ends of the auxiliary ribs are respectively connected with the upper main ribs and the lower main ribs; two ends of the reinforcement ribs are connected with the main ribs and the auxiliary ribs; panels are mounted on two sides of the wall plate steel framework; a heat preservation layer is arranged between the panels and is provided with a core material. According to the novel prefabricated wall plate and the building external wall assembled by the novel prefabricated wall plate, on the basis of the structure, the wall plate is light in weight, can preserve the heat and can be assembled, the transportation cost is saved, and the structure of the wall plate is stable, durable and reasonable; an external wall, which is assembled by the wall plate, of an industrial factory is strong in durability and bearing property.

Owner:包头市兼强轻型板业有限责任公司

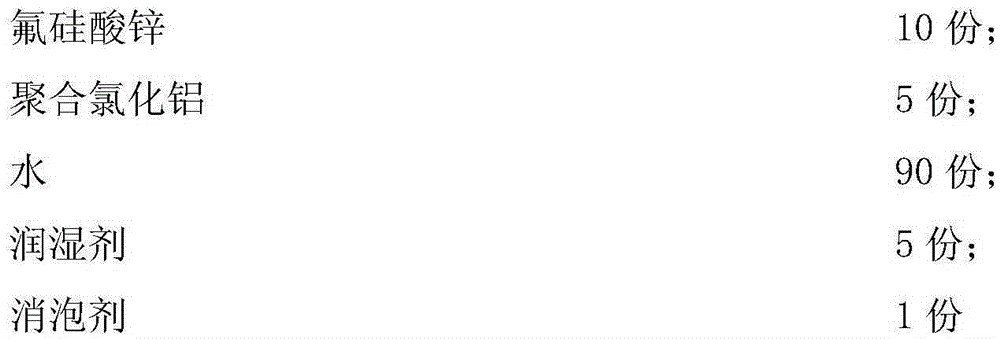

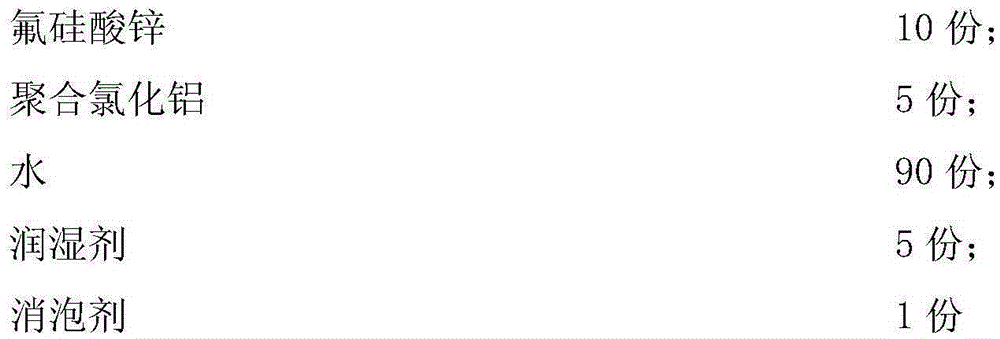

High-permeability liquid hardening agent

The invention relates to the technical field of cement-based building materials, and aims at providing a high-permeability liquid hardening agent. The high-permeability liquid hardening agent is prepared from, by weight, 5-20 parts of fluosilicate, 5-10 parts of polymeric hydroxy aluminum salt, 70-90 parts of water, 1-5 parts of wetting agent and 1-5 parts of antifoaming agent. Fluosilicate and polymeric hydroxy aluminum salt are adopted as main ingredients, and the hardness and abrasion resistance of cement can be remarkably improved. Meanwhile, a preparation method is simple, raw materials are cheap, and industrial production cost can be reduced. The preparation process is simple and easy to implement, operation is easy and convenient, industrial large-scale production is facilitated, the industrial production cost is reduced, the high-permeability liquid hardening agent is especially suitable for cement-based floors such as industrial factory buildings and parking lots, and wide application prospects are achieved.

Owner:ZIGONG GELING NEW MATERIAL TECH CO LTD

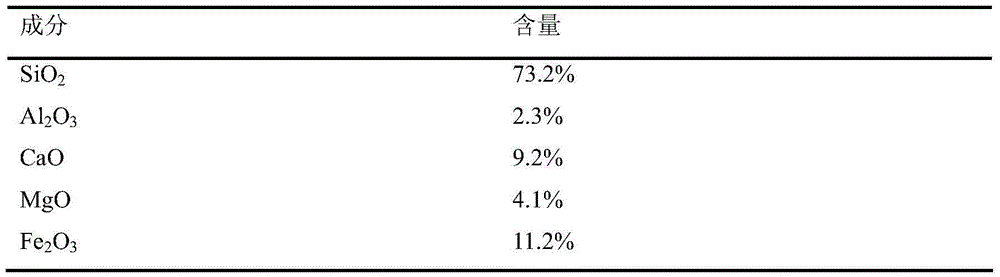

Energy-saving open-cell foamed glass and preparation method thereof

The invention discloses energy-saving open-cell foamed glass and a preparation method thereof. The energy-saving open-cell foamed glass is characterized by taking waste glass, ground calcium carbonate, coarse borax and a small amount of zinc white as raw materials. The preparation method comprises the following steps: smashing and mixing the raw materials by a ball mill to obtain a mixed material and filling the mixed material into a die; and then, firing the die in a furnace according to a preset program to obtain the open-cell foamed glass. The method which applies a lot of solid wastes, namely waste glass and natural stone materials can greatly lower the production cost and effectively save the energy source. The volume density of the open-cell foamed glass prepared by the method disclosed by the invention is 144-150kg / <m3>, the compressive strength is 0.6-0.7MPa, and the opening porosity is 60-70%. The acoustical absorption coefficients measured by a tube detecting method are respectively: 0.37-0.46 at low frequency (100-125HZ) and 0.52-0.61 at high frequency (125-1600HZ). The prepared open-cell foamed glass has the advantages of low density, high strength, attractive appearance, good acoustical absorption effect and the like, and can be used for acoustical absorption and noise reduction of occasions such as substation rooms, swimming pools, metro and various industrial factory buildings.

Owner:UNIV OF SCI & TECH OF CHINA

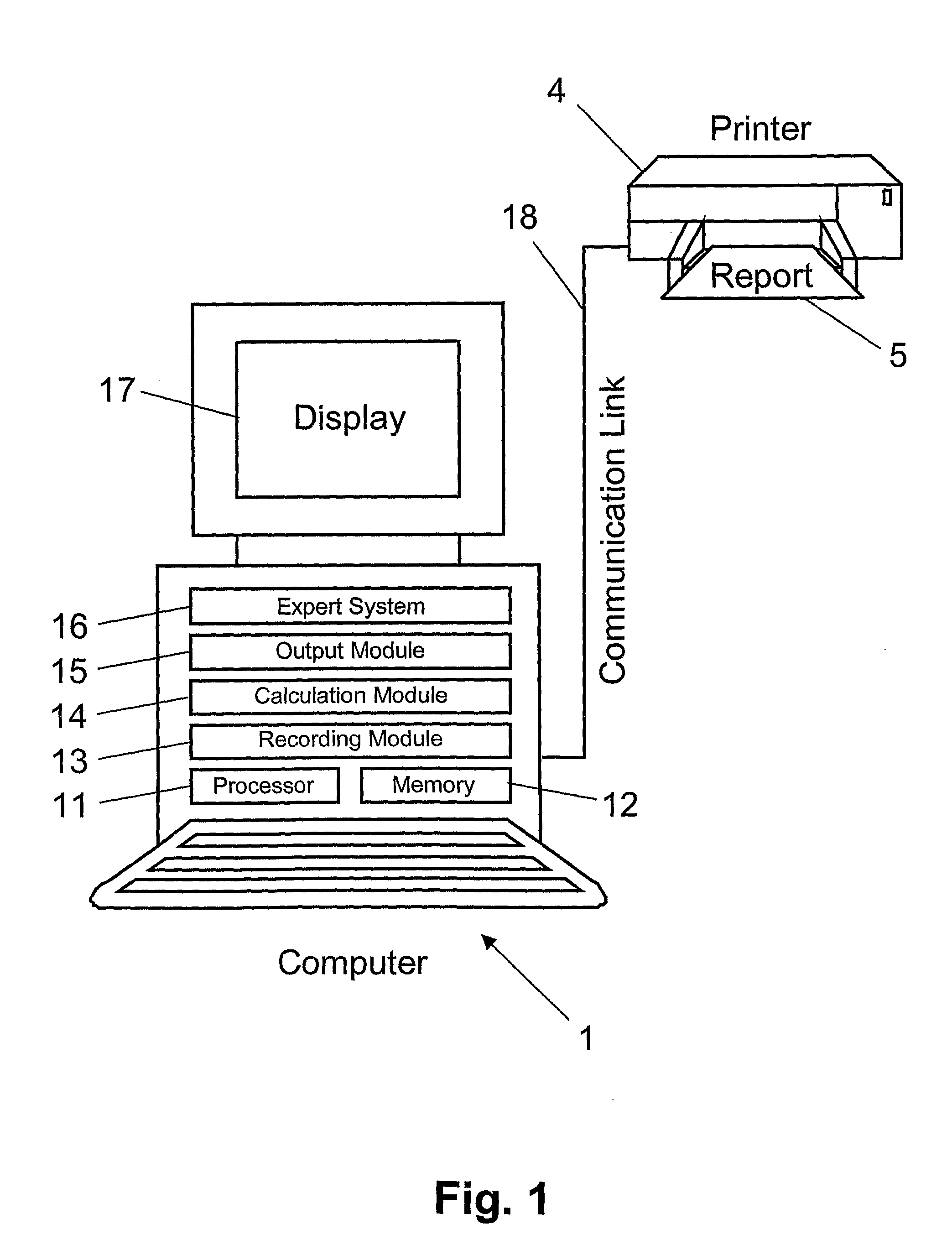

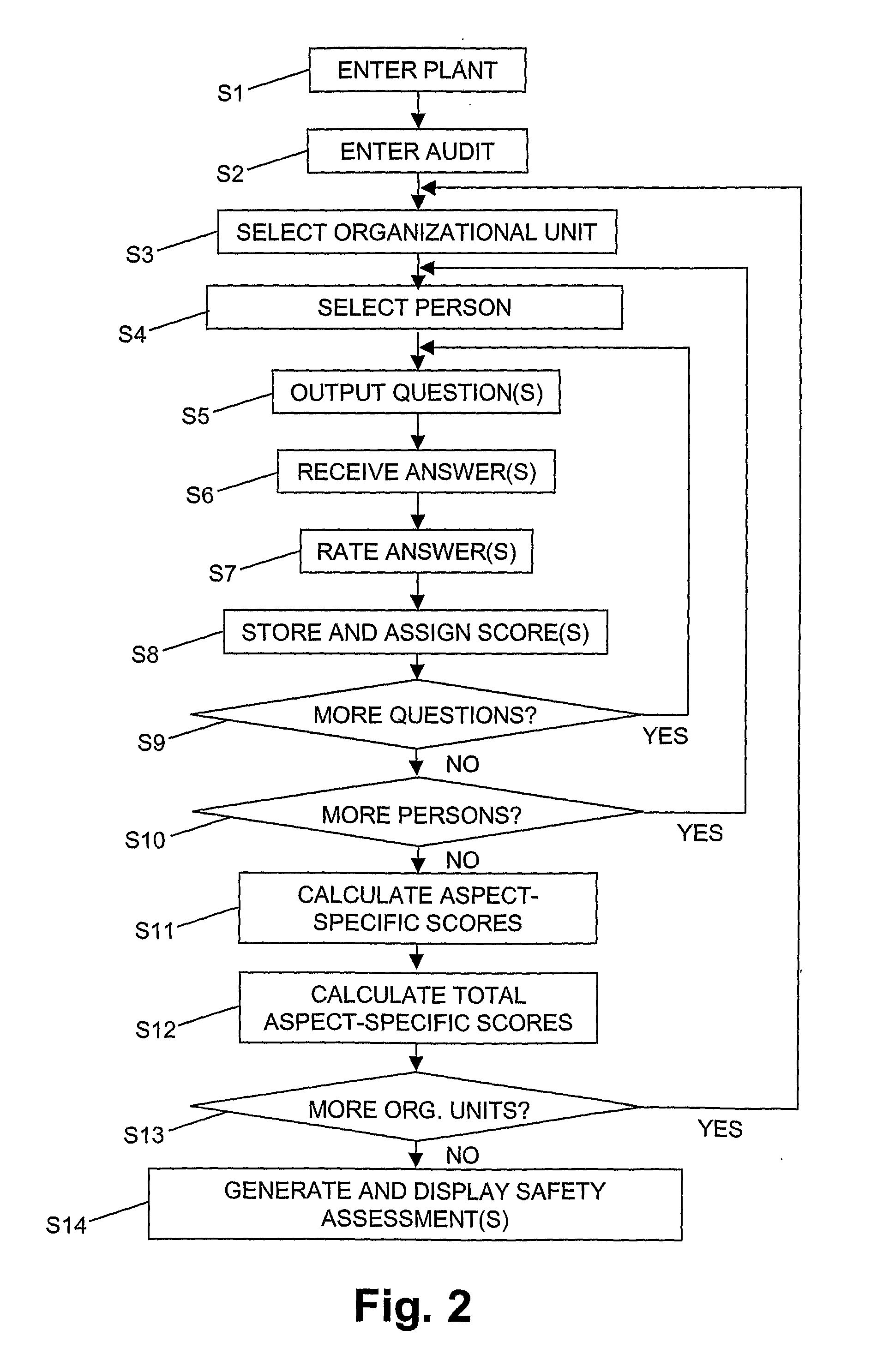

Computer system and computer-based method for assessing the safety of a process industry plant

ActiveUS20090073171A1Improve efficiencyImprove consistencyDrawing from basic elementsFinanceProcess industryKnowledge management

A method and system to establish a safety assessment of a process industry plant including multiple organizational units. The method and system store scores relating to a rating of one of an inspection, undertaken in one of the organizational units regarding an aspect of the plant, and an answer, given by a human representative of one of the organizational units in response to defined questions relating to one of the aspects. The scores are assigned to respective of the organizational units and respective of the aspects. Aspect-specific scores are then calculated. Safety assessment can then be established from the aspect-specific scores of the organizational units.

Owner:SWISS REINSURANCE CO LTD

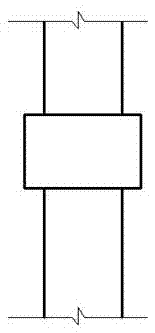

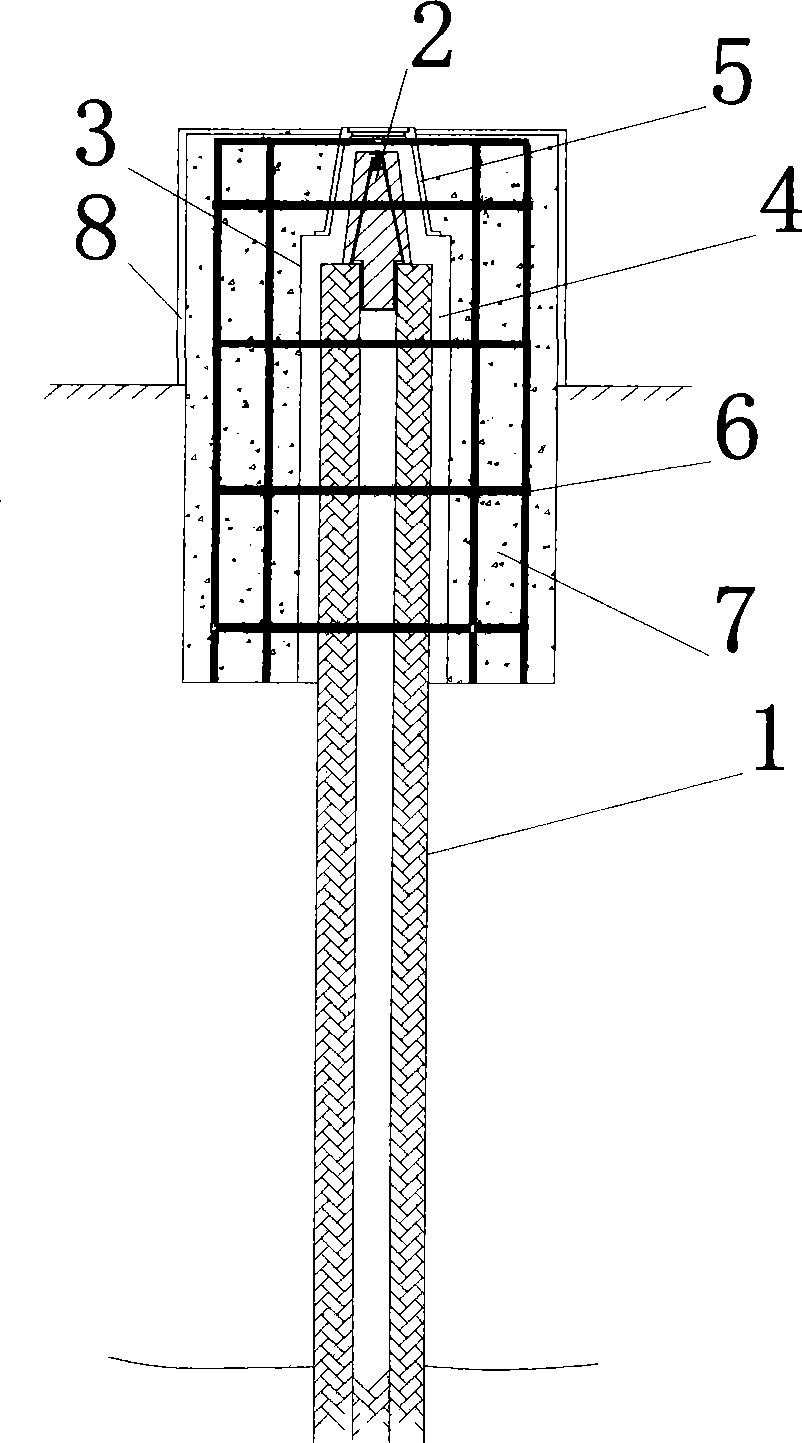

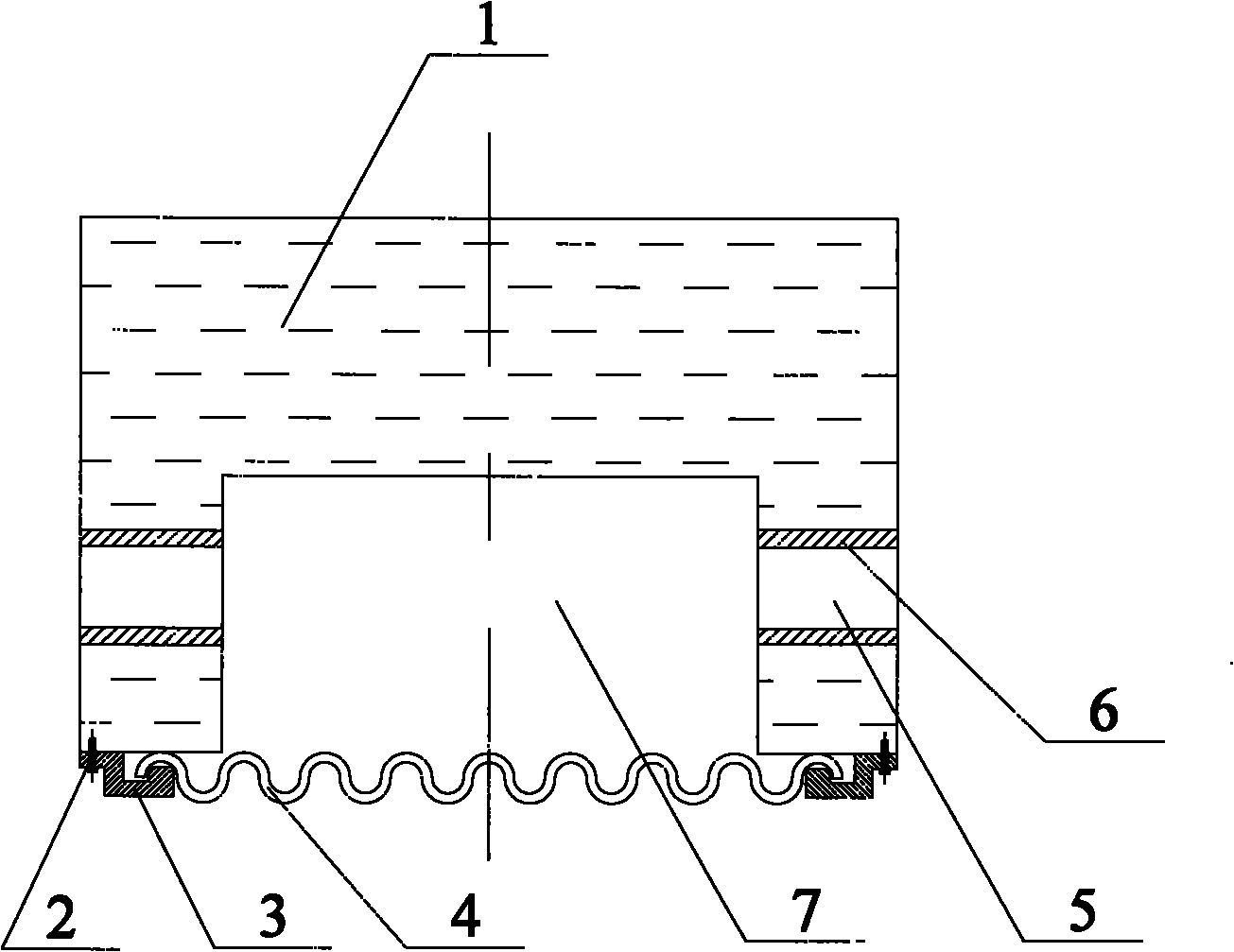

Deep pile survey mark burying method

ActiveCN101397800AImprove stabilityGuarantee the reliability of measurement resultsFoundation testingStable stateEmbedment

The invention discloses a method for embedding a deep pile survey marker, which includes the follow steps: (1) the embedding depth of a deep pile (1) is designed; (2) marker embedment is carried out; (3) the top of the deep pile (1) is embedded into a stainless steel survey marker core (2) and the upper part of the deep pile (1) is sheathed with a steel outer sleeve (3); (4) silver sand (4) is filled between the steel outer sleeve (3) and the deep pile (1) so as to separate the steel outer sleeve (3) and the deep pile (1); (5) the top of the steel outer sleeve (3) is connected with the bottom of a protection pot (5) which is sheathed outside the stainless steel survey marker core (2); and (6) a concrete reinforcing bar is installed outside the steel outer sleeve (3), and then concrete (7) is poured; and after the concrete is well maintained, a ground part of a platform outside the concrete (7) is decorated by marble (8). The method has the advantages that: silver sand is filled between an upper platform and the deep pile so as to separate the upper platform and the deep pile to ensure that the deadweight of the upper platform is not transferred to the deep pile, namely that the deep pile is in a stable state without any load. When the upper platform is bumped by an external force, the stainless steel survey marker core is not influenced, which is of significance to construction survey with high precision in industrial factories.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

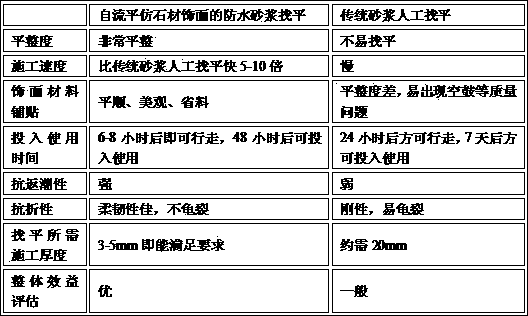

Self-leveling waterproof mortar of imitated stone facing and construction process of waterproof mortar

InactiveCN103936370AFast constructionRapid deployment for high construction speedFlooringCelluloseFiber

The invention discloses a self-leveling waterproof mortar of an imitated stone facing and a construction process of the waterproof mortar. The self-leveling cement mortar is composed of the following components in parts by weight: 250-300 parts of cement, 50-80 parts of ground calcium carbonate, 900-1000 parts of natural color sand, 2-8 parts of cellulose ether, 3-8 parts of wood fibers, 1-3 parts of PP (Poly Propene) fibers, 18-25 parts of latex powder and 2-8 parts of special natural rock slices for really stone paint; a water-to-material ratio is 4.2L-4.5l / 25kg. The construction process of the waterproof mortar comprises the steps of base surface treatment, interface treatment, material stirring and material construction. The self-leveling waterproof mortar is a dry-blending type powdery material composed of a plurality of active ingredients, and can be mixed with water in field to be use. The self-leveling waterproof mortar is slightly spread by using a scraper knife and then a high-level base surface can be obtained. The self-leveling waterproof mortar is hardened quickly, and after 4-8 hours, people can walk on the hardened mortar or subsequent work can be carried out on the hardened mortar; the self-leveling waterproof mortar is quick, simple and convenient in construction and can be applied to industrial factory buildings, workshops, commercial stores and the like.

Owner:南通苏宝建筑节能科技有限公司

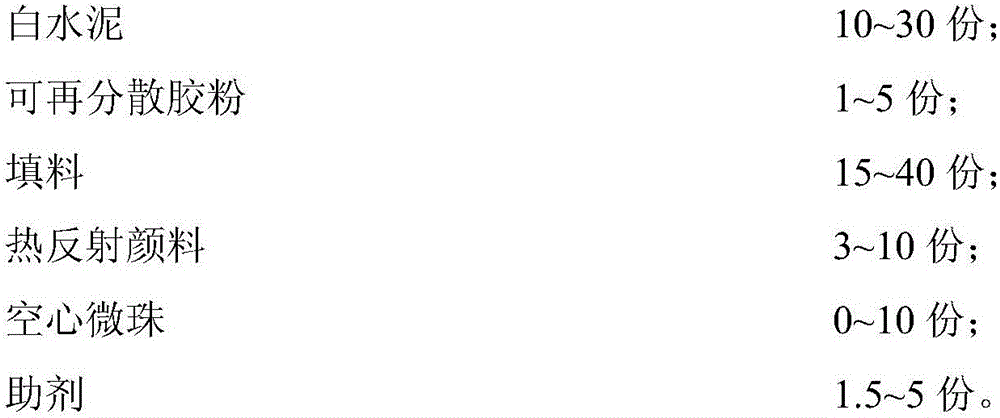

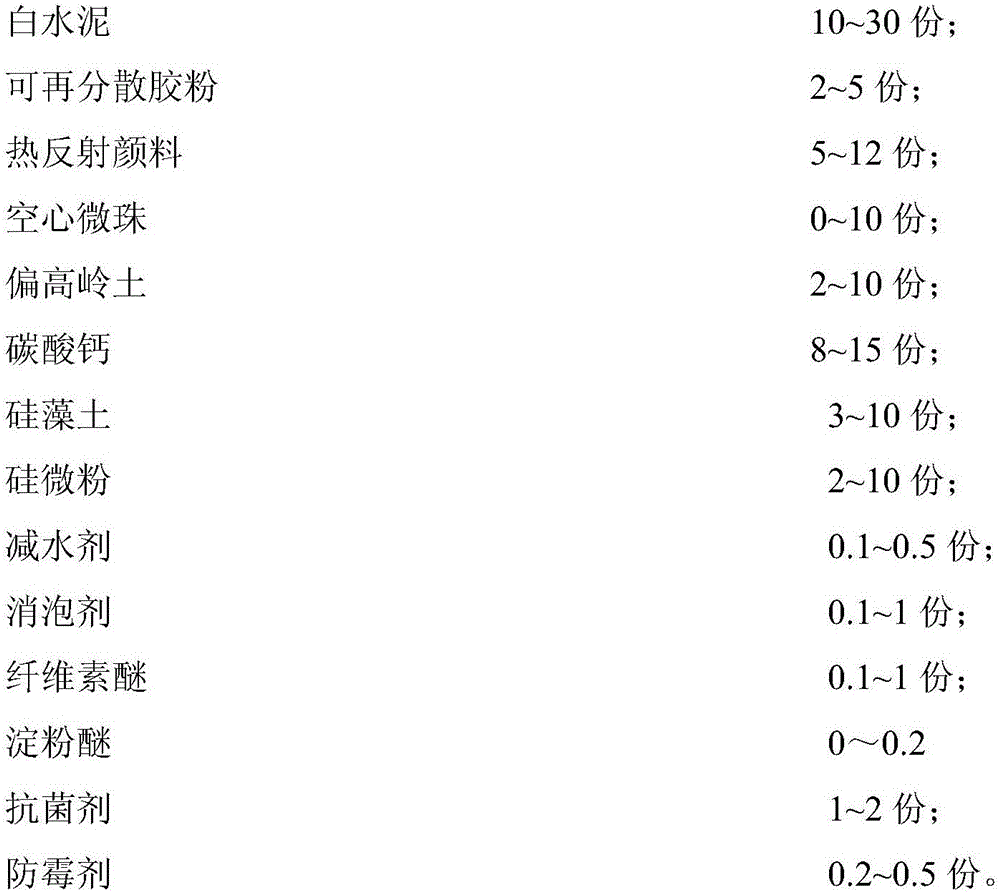

Inorganic dry powder heat insulation paint

InactiveCN106007571AGood heat insulationImprove stain resistanceAdditive ingredientFilling materials

The invention belongs to the field of building materials, and aims at providing inorganic dry powder heat insulation paint. The inorganic dry powder heat insulation paint is prepared from the following ingredients in parts by weight: 10 to 30 parts of white cement, 2 to 5 redispersible adhesive powder, 15 to 40 parts of filling materials, 5 to 12 parts of heat reflection pigments, 0 to 10 parts of hollow micro beads and 1.5 to 5 parts of auxiliary agents. The inorganic dry powder heat insulation paint uses white cement as a film forming substance; the degradation caused by external factors can be resisted; the heat reflection pigments are used as color adjusting pigments; near infrared rays in sun light can be reflected. Through the mutual cooperative effect of the non-dense-stacking gathering of non-absorption filling materials and high durability, the inorganic dry powder heat insulation paint finally achieves good heat insulation effect and excellent stain-resistant performance; the heat insulation performance is stable and can be maintained for a long time. The VOC (volatile organic compound) content is low; the environment pollution can be reduced to the maximum degree; the environment-friendly effect is achieved. The inorganic dry powder heat insulation paint is particularly applicable to occasions such as civil buildings, commercial buildings and industrial factory buildings, and has wide application prospects.

Owner:ZIGONG GELING NEW MATERIAL TECH CO LTD

Production method for separating high-speed steel electric furnace slag

ActiveCN102605169ASolve pollutionRecycling and recovery technologiesMagnetic separationWater useBrick

The invention discloses a method for separating high-speed steel electric furnace slag, which is characterized by comprising the following steps in sequence: 1) breaking and sorting; 2) performing watermill grinding; 3) washing; 4) carrying out primary strong magnetic separation; 5) carrying out secondary strong magnetic separation; 6) purifying; 7) separating by a method of specific gravity; 8) precipitating; 9) preparing a cement raw material; and 10) processing tailings. According to the invention, refined particles steel of which product grade can reach over 90% can be used as a scrap steel raw material, and can be directly fed into a converter for melting into a high-quality finished product special steel; iron refined powder of which the product grade can reach over 55% can be fed into the converter for melting into a high-quality finished product special steel; the produced waste slag micro powder can be used for manufacturing cement and baking-free bricks; and parts of particle slag is used for laying paint grounds of industrial factory buildings. The market demand is considerable. The water used in the technical production is precipitated to form a closed cycle for reutilization, so that zero emission is achieved.

Owner:张文钦

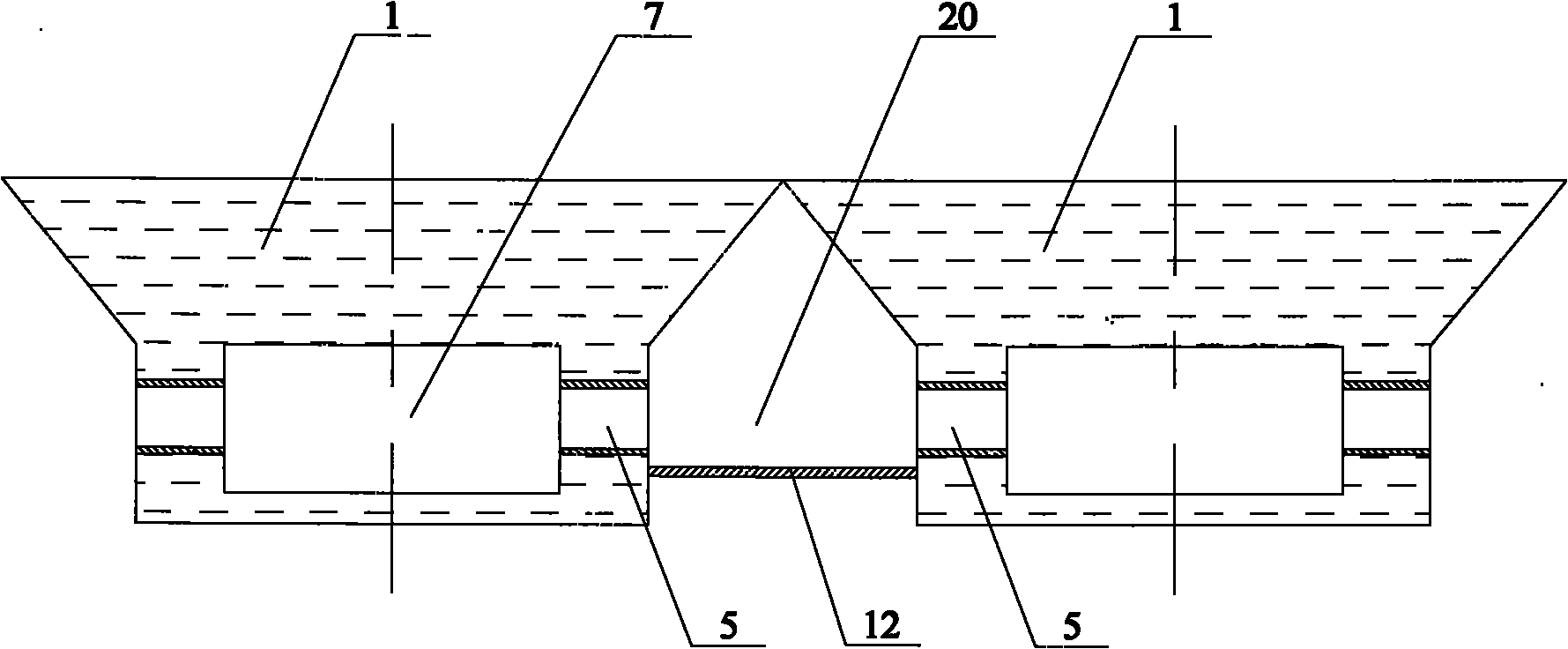

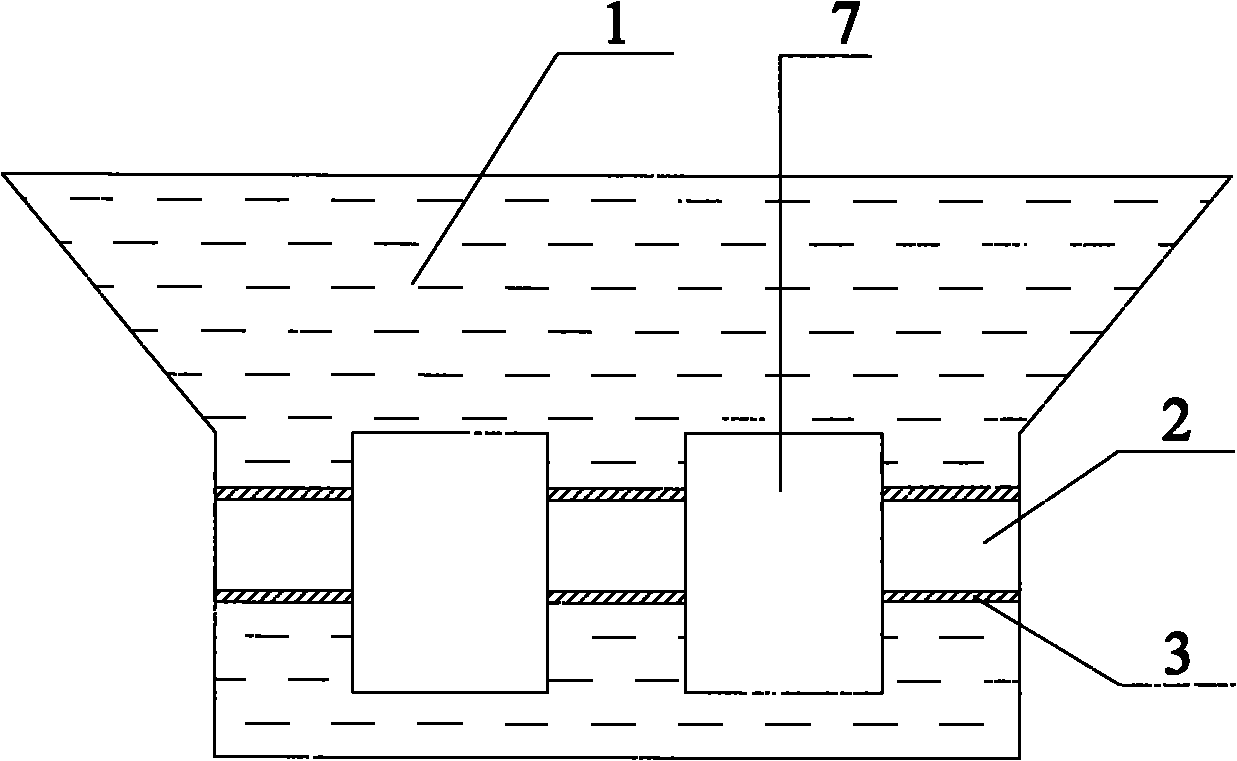

Large-span prestressed concrete beam plate as ventilating channel and ventilating channel system

ActiveCN102116065ASimple structureEasy constructionLighting and heating apparatusFloorsPrestressed concrete beamConcrete beams

Owner:青岛颐丰瑞和商贸有限公司

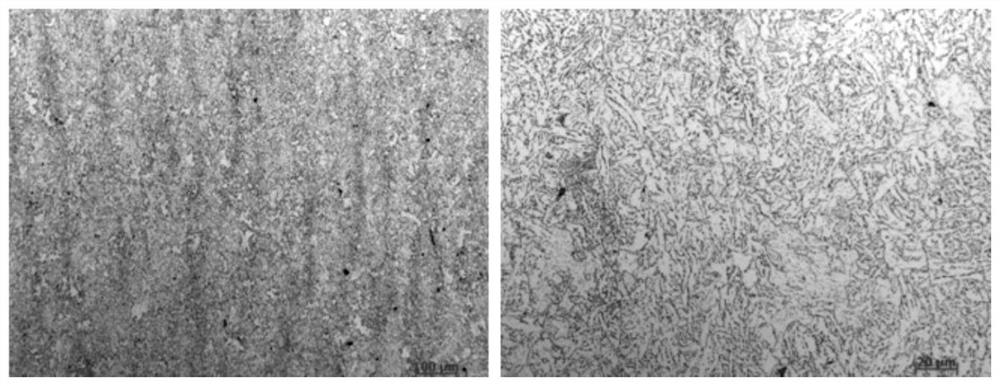

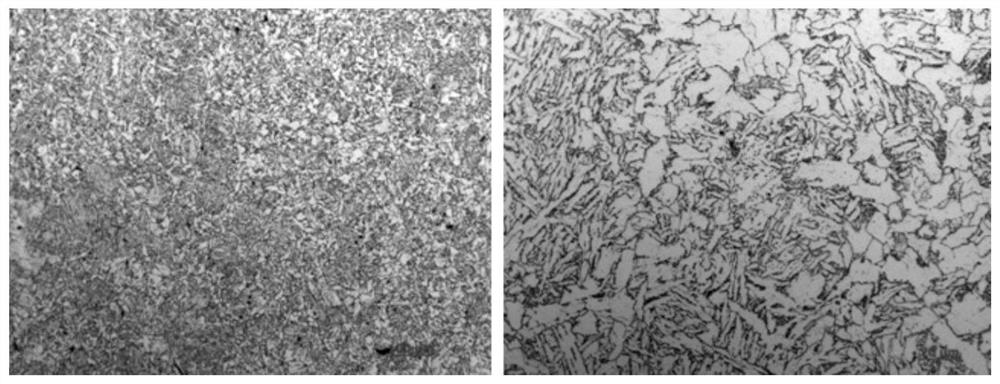

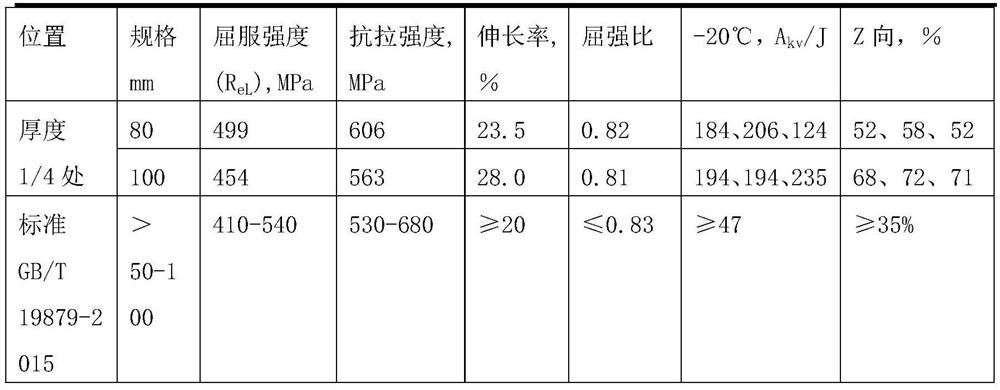

Quenched and tempered steel plate with yield strength being 420 MPa grade for building structure and production method of quenched and tempered steel plate

The invention relates to a quenched and tempered steel plate with the yield strength being 420 MPa grade for a building structure and a production method of the quenched and tempered steel plate. The component design that Nb and Ti microalloying treatment is conducted on the basis of a Fe-Mn-C system is adopted, and the steel plate material is prepared from the chemical components including 0.13%-0.18% of C, 0.20%-0.50% of Si, 1.40%-1.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, 0.020%-0.050% of Al, less than or equal to 0.015% of V, 0.025%-0.050% of Nb, 0.010%-0.020% of Ti, less than or equal to 0.006% of N and the balance Fe and inevitable impurity elements. The production process comprises the following steps that raw materials are smelted in a converter, refined outside the converter and refined in an RH furnace in sequence to obtain molten steel with higher purity, the molten steel is poured to form a steel billet being 370 mm-450 mm, then reasonable steel billet heating, rolling, on-line direct quenching and tempering heat treatment technologies are adopted, and the steel plate material with the yield strength being 420 MPa grade is suitable for large-scale steel structure constructional engineering such as high-rise buildings, large-span stadiums, airports, exhibition centers and industrial factory buildings is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for preparing high-permeability liquid hardening agent

The invention relates to the field of wood processing and protecting, and aims at providing a method for preparing a high-permeability liquid hardening agent. The method comprises the steps that water and polymeric hydroxy aluminum salt are added to a high-speed dispersion machine for low-speed stirring; fluosilicate continues to be added for high-speed dispersion; a wetting agent and an antifoaming agent continue to be added under low-speed stirring, and the high-permeability liquid hardening agent is obtained. Fluosilicate and polymeric hydroxy aluminum salt are adopted as main ingredients, and the hardness and abrasion resistance of cement can be remarkably improved. Meanwhile, the preparation method is simple, raw materials are cheap, and industrial production cost can be reduced. According to the preparation method, after the raw materials are stirred and dispersed, paint can be prepared, the preparation process is simple and easy to implement, operation is easy and convenient, large-scale industrial production is facilitated, the industrial production cost can be reduced, the high-permeability liquid hardening agent is especially suitable for cement-based floors such as industrial factory buildings and parking lots, and wide application prospects are achieved.

Owner:ZIGONG GELING NEW MATERIAL TECH CO LTD

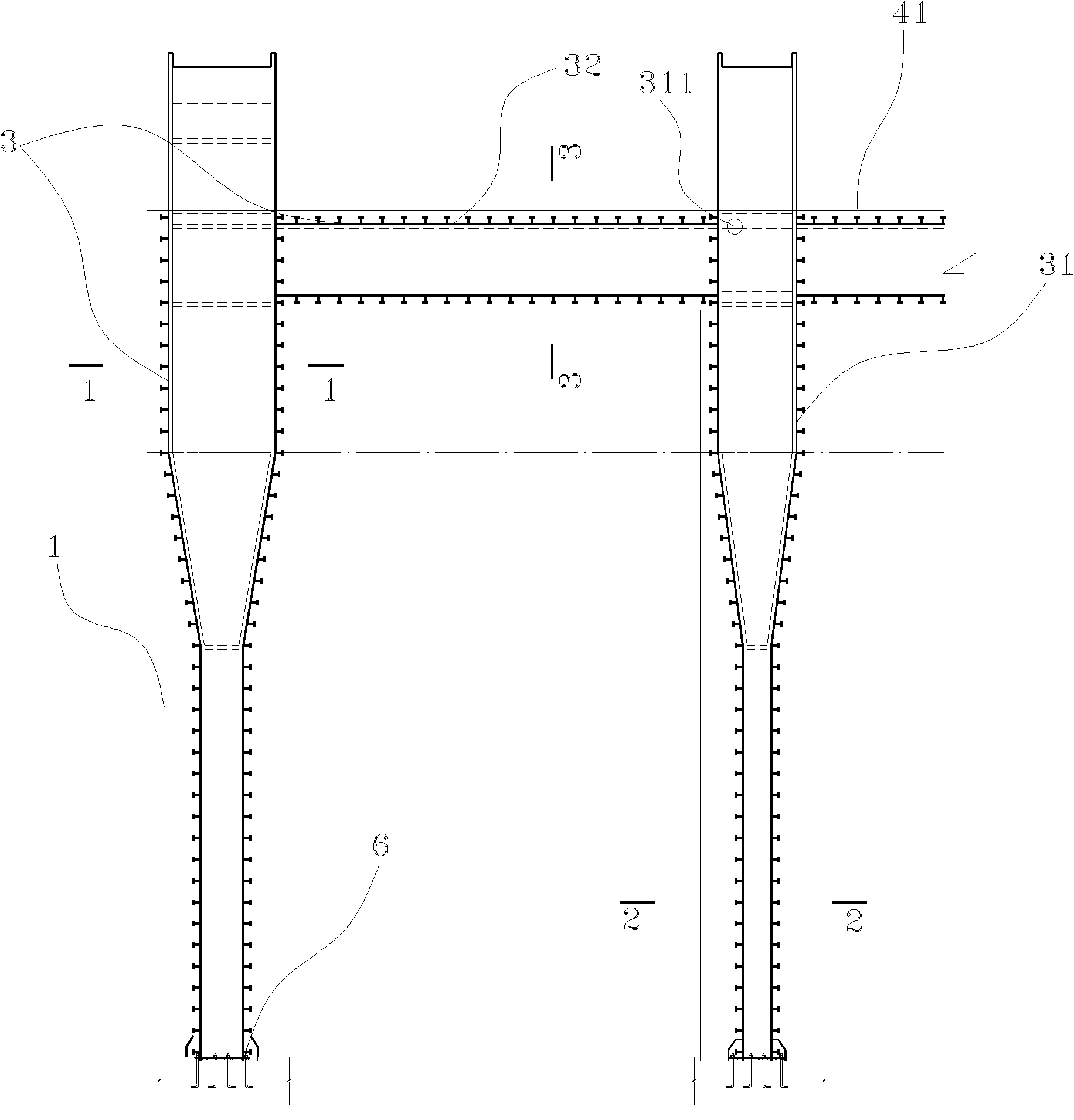

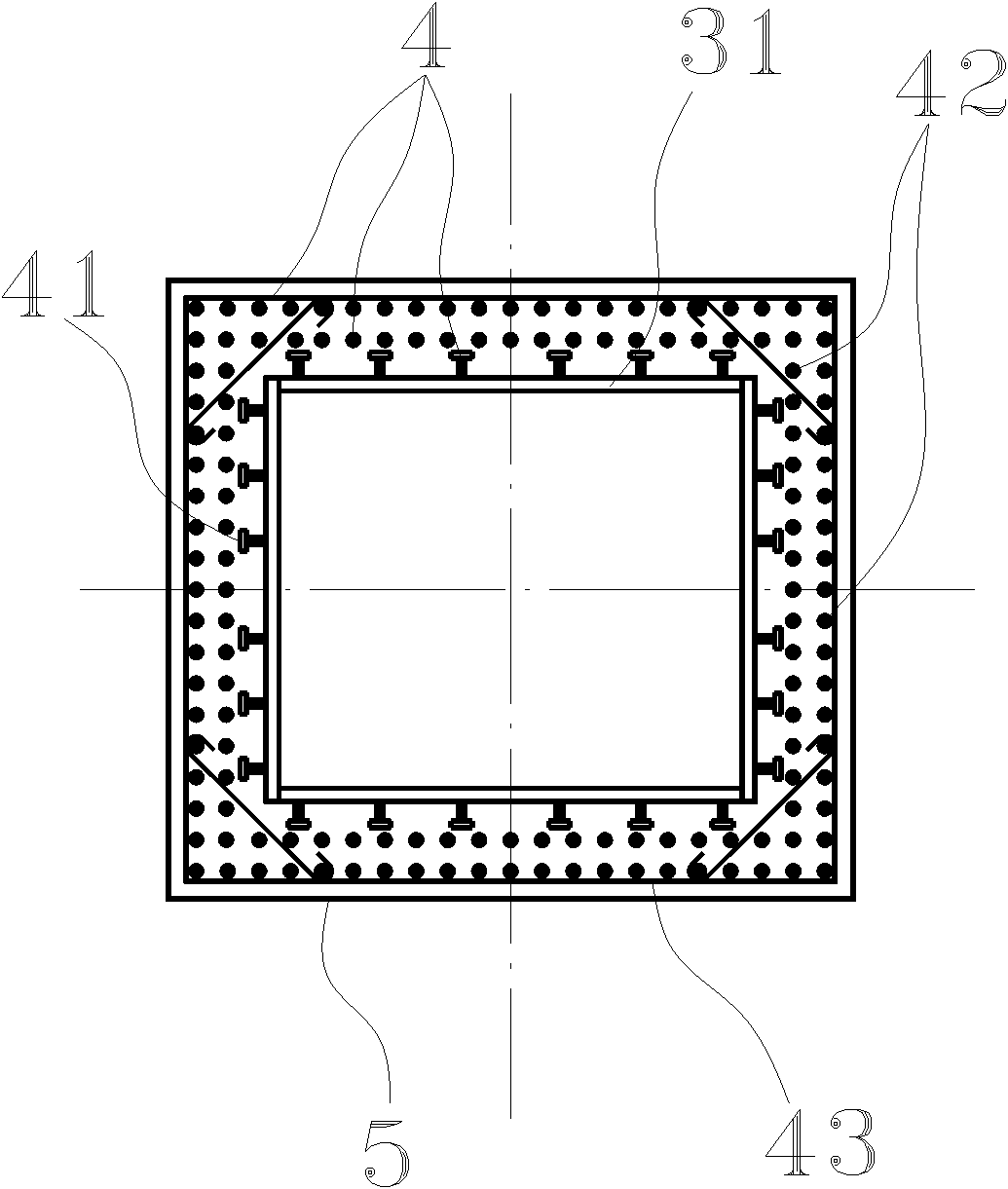

Method for constructing combined steel and concrete column of large metallurgy industrial factory building

ActiveCN102102443AEasy to installGuaranteed installation qualityBuilding material handlingSteel columnsRebar

The invention discloses a method for constructing a combined steel and concrete column of a large metallurgy industrial factory building, belongs to the technical field of factory building construction and production, and provides a method for constructing the combined steel and concrete column of the large metallurgy industrial factory building, which can guarantee the manufacturing quality of the combined steel and concrete column. The method for constructing the combined steel and concrete column of the large metallurgy industrial factory building comprises the following steps of: firstly, arranging a steel framework which consists of a steel column and a steel beam on the basis of arrangement, and regulating the arrangement quality of the steel column by arranging a regulation base plate and a cable wind rope; secondly, arranging the outer side of the steel column and the outer side of the steel beam on the steel framework sequentially; then arranging concrete reinforcement on the connection part between the steel column and the steel beam sequentially, and supporting a concrete casting template of the steel column on the outer side of the concrete reinforcement of the steel column, wherein the concrete on the inner side and the outer side of the steel column box body are cast by a high toss and vibrating casting method and a fixed point positioning vibrating casting method; and finally, removing casting template curing concrete after the concrete strength meets the design requirement.

Owner:CHINA 19TH METALLURGICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com