Movable dust removal equipment for industrial factory building

A technology for dust removal equipment and industrial plants, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of high effect, low noise and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

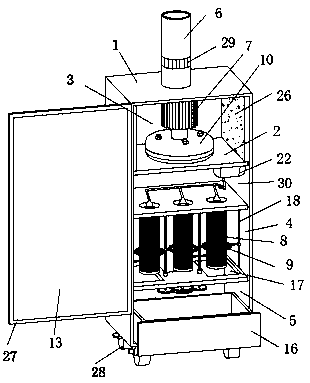

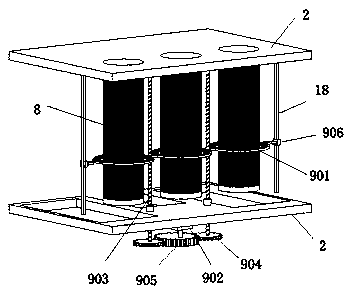

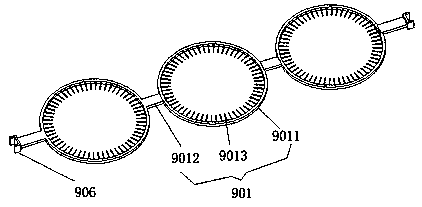

[0037] A kind of mobile dust removal equipment for industrial plants, such as figure 1 and Figure 6 As shown, including the chassis body 1, the inside of the chassis body 1 is divided into a power chamber 3, a blowback chamber 30, a filter chamber 4 and a collection chamber 5 through two transverse partitions 2 from top to bottom, and the inner wall of the power chamber 3 is fixed with Sound insulation board 26, thereby can reduce the noise that equipment produces when working, the top of power chamber 3 is provided with air outlet pipe 6, and the air outlet pipe 6 is provided with active carbon filter 29; The inside of power chamber 3 is provided with and air outlet pipe 6 connected centrifugal fans 7, the bottom of the centrifugal fan 7 is connected with a wind collecting disc 10; the inside of the filter chamber 4 is provided with a cartridge filter 8 and a dust removal device 9, and the cartridge filter 8 includes several filter cartridges Skeleton 801 and filter core 80...

Embodiment 2

[0042] On the basis of Example 1, as Figure 7 and Figure 8 As shown, several pressure sensors 23 are embedded on the upper surface of the bottom plate of the collection chamber 5 , and a buzzer 24 and a warning light 25 are installed on the outer wall of the collection chamber 5 .

[0043] When this embodiment is in use, when the average value of the pressure data monitored by all the pressure sensors 23 is greater than a certain value, the buzzer 24 and the warning light 25 will be powered on at this time, so that the operator can be reminded to gather The interior of the gray drawer is full of dust, easy to use and strong in practicability.

[0044] The invention has the remarkable characteristics of low energy consumption, low noise, stable operation, high filtration efficiency, good filtration precision, high cleaning effect of the filter cartridge, and continuous operation for a long time. The shape of the waste medium can be absorbed, and it can be reasonably matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com