Patents

Literature

144 results about "Industrial premises" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

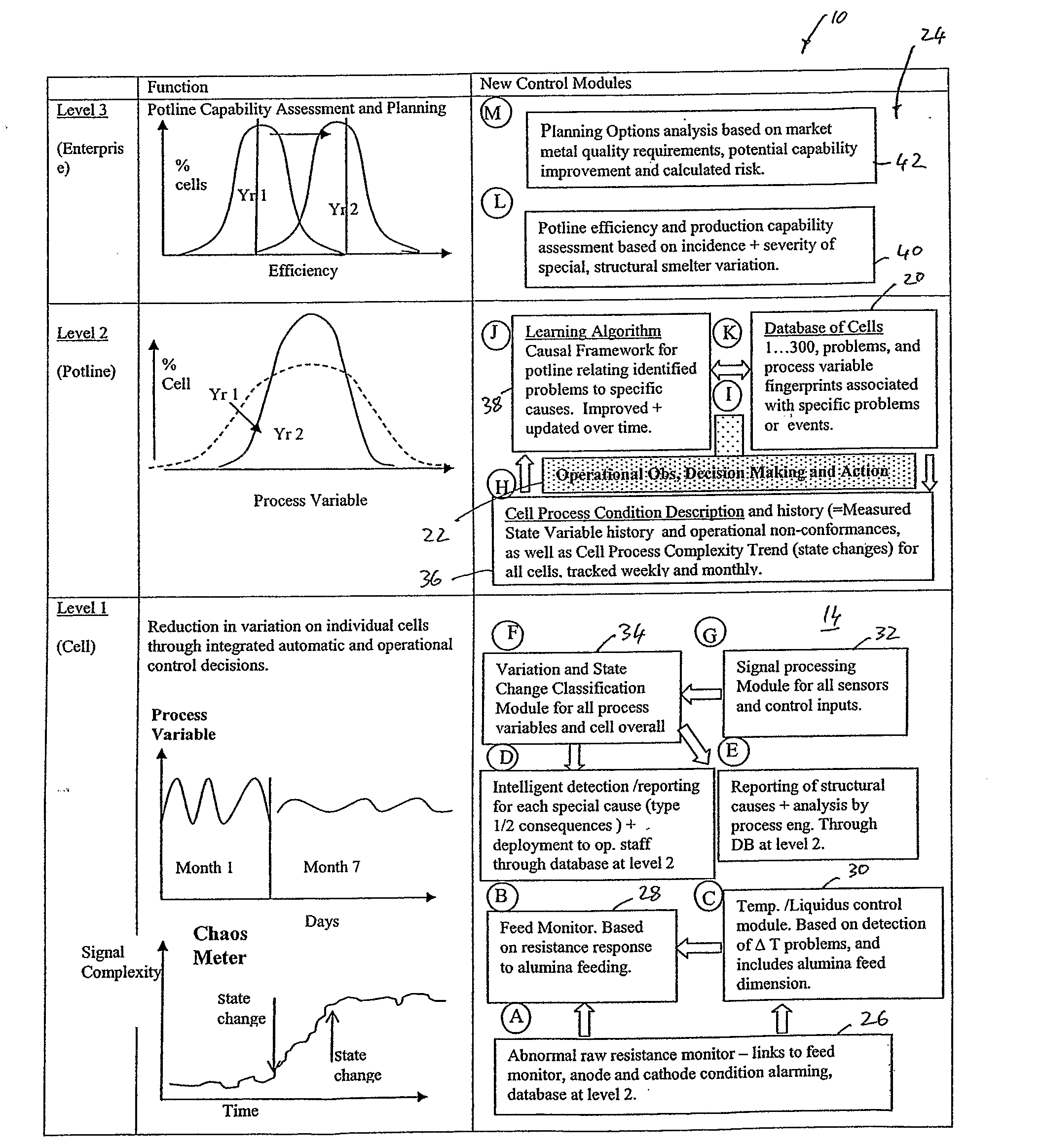

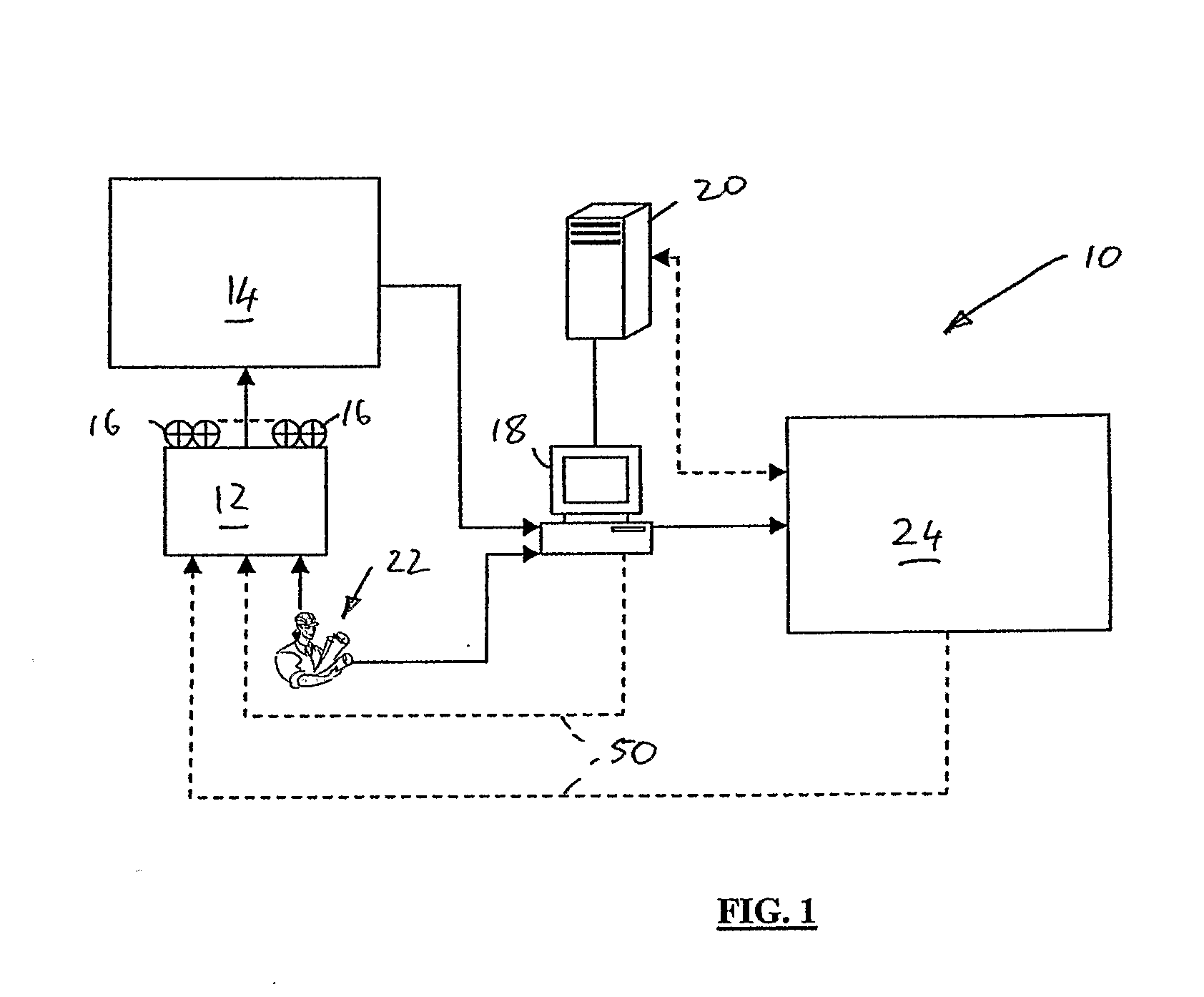

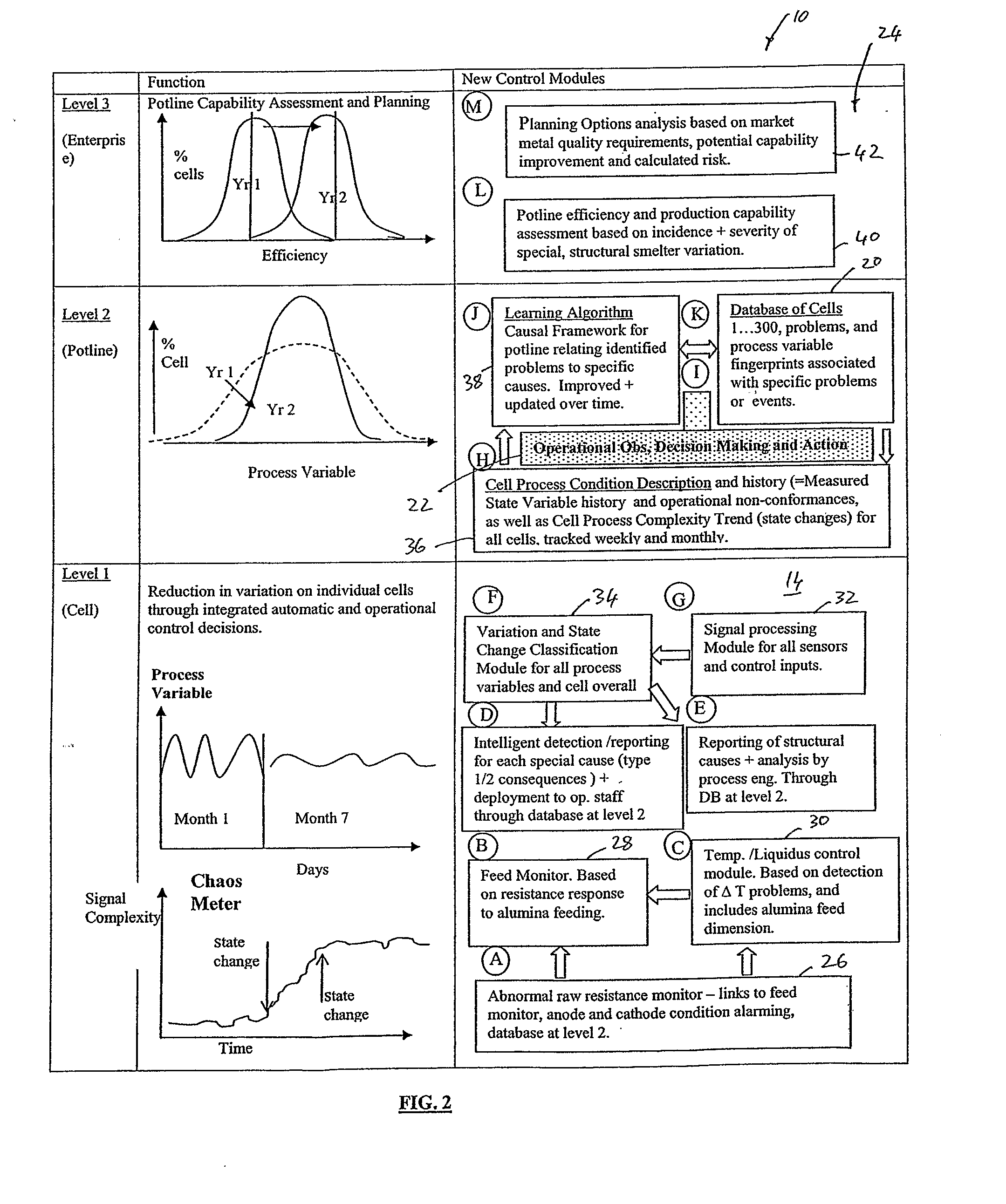

Process control of an industrial plant

ActiveUS20140316579A1Reduce variationExtension of timeSampled-variable control systemsComputer controlAutomatic controlProcess conditions

A system 10 for controlling an industrial plant 12 comprises automatic control equipment 14 comprising a plurality of measurement sensors 16 for sensing predetermined variables associated with components of the industrial plant 12. The sensors 16 generate measured data relating to operation of the components of the industrial plant 12. A database 20 contains operational data, including observational data, regarding the industrial plant 12. A processor 18 is in communication with the automatic control equipment 14 and the database 20 for receiving the measured data from the sensors 16 of the automatic control equipment 14 and the operational data from the database 20. The processor 18 manipulates the measured and operational data to provide an evolving description of a process condition of each component over time, along with output information relating to operational control of the industrial plant 12 and for updating the database 20.

Owner:AUCKLAND UNISERVICES LTD

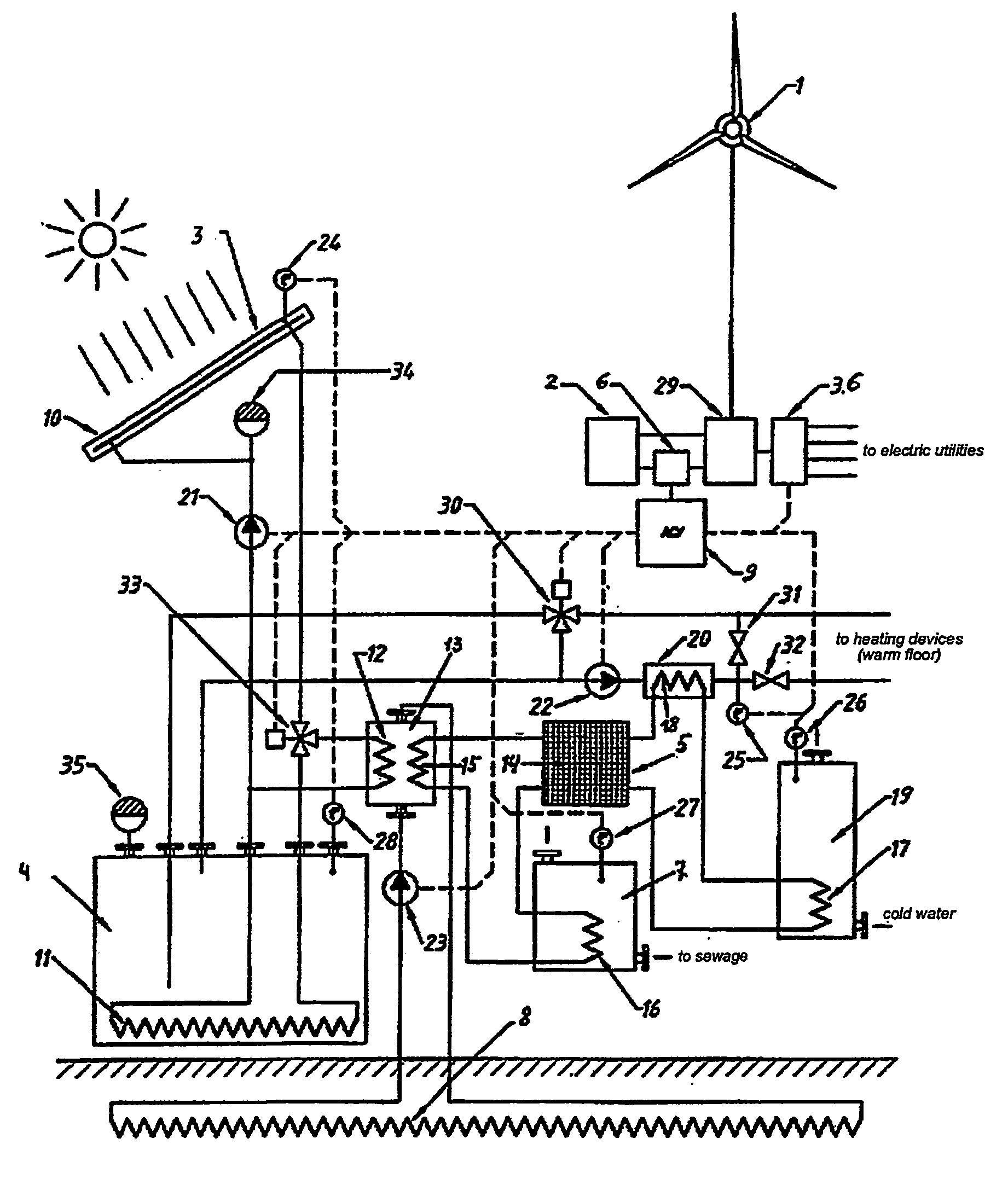

Independent system of energy and heat supply

InactiveUS20060168961A1Optimize load distributionImprove performanceAuxillary drivesPV power plantsThermal energyEngineering

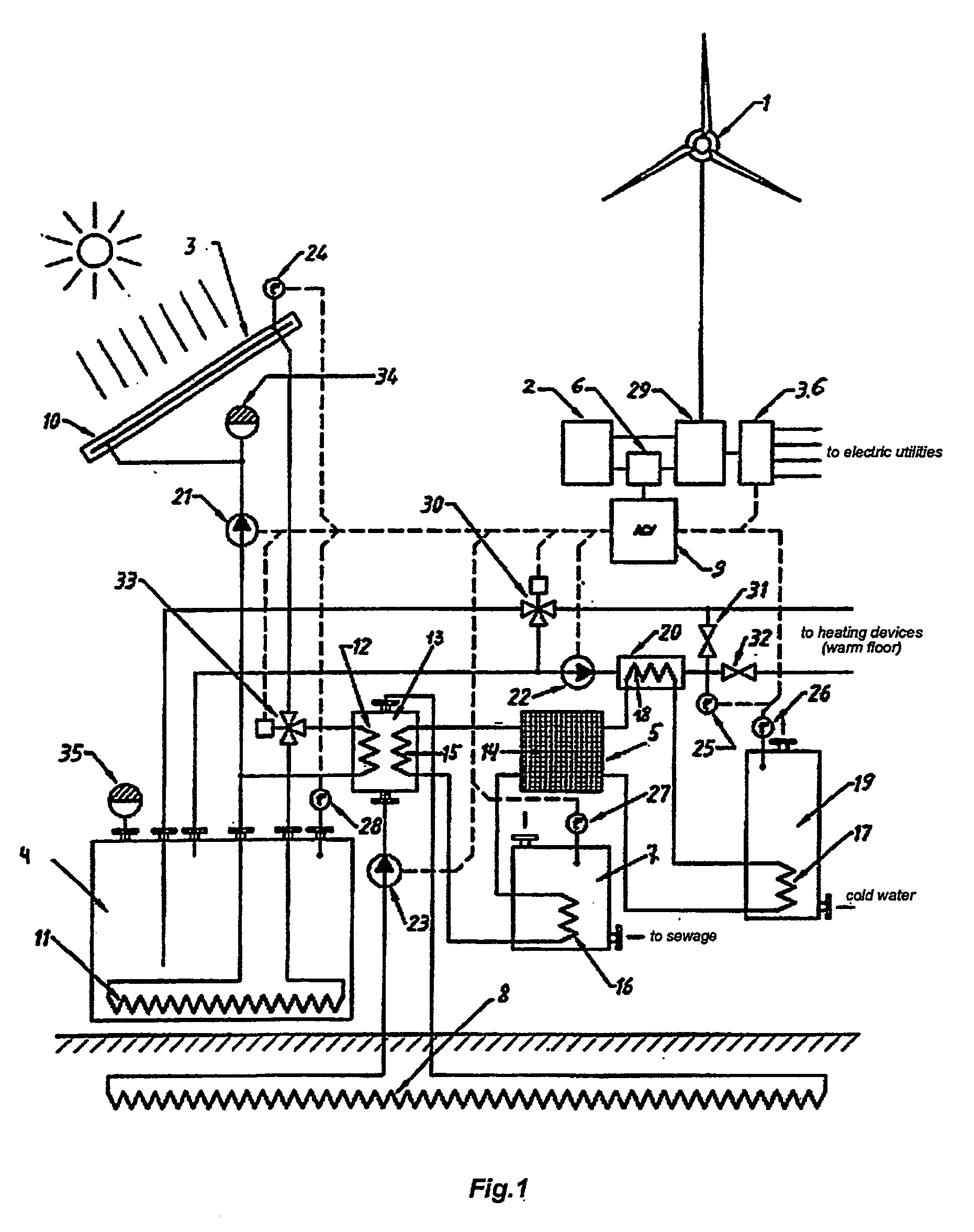

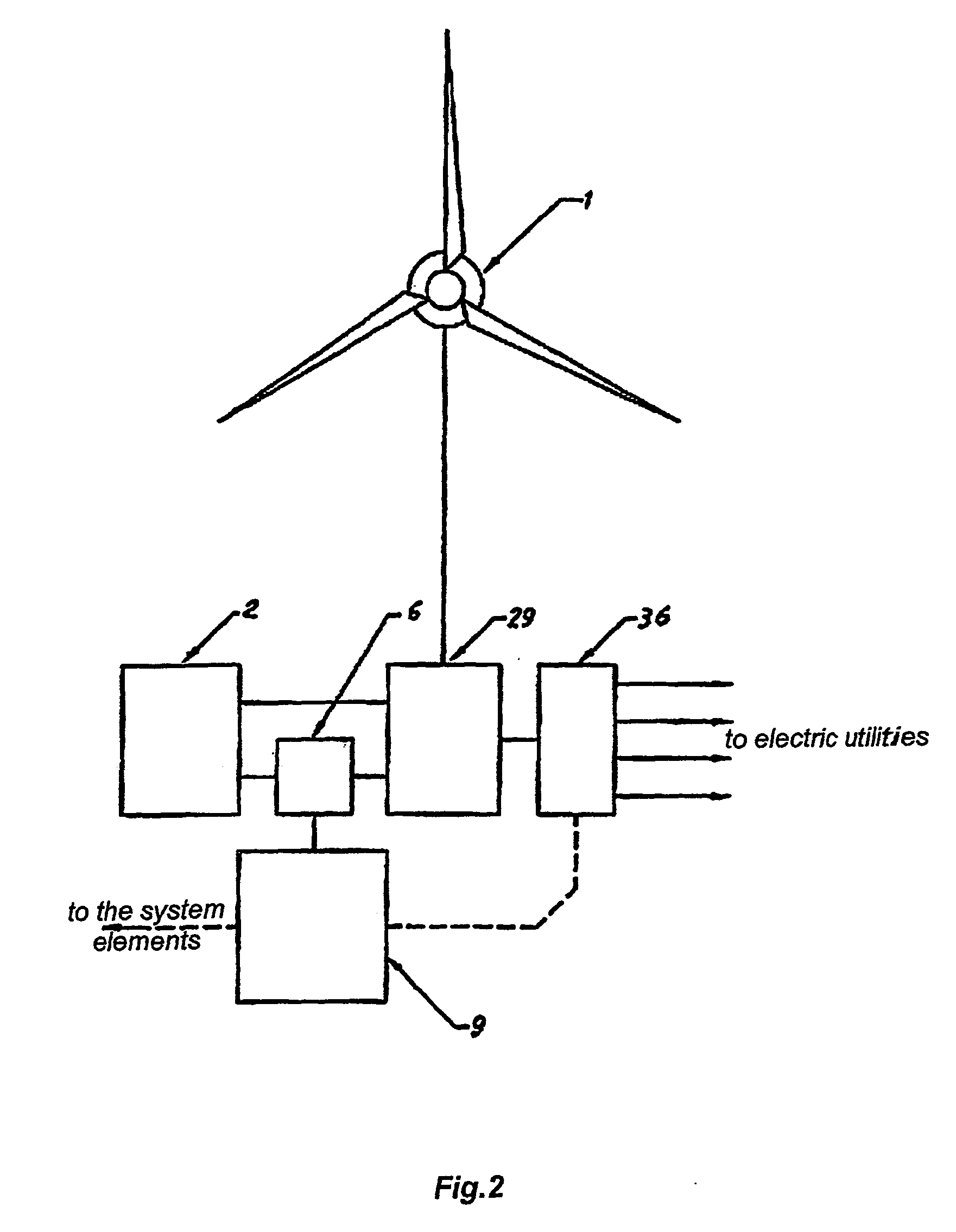

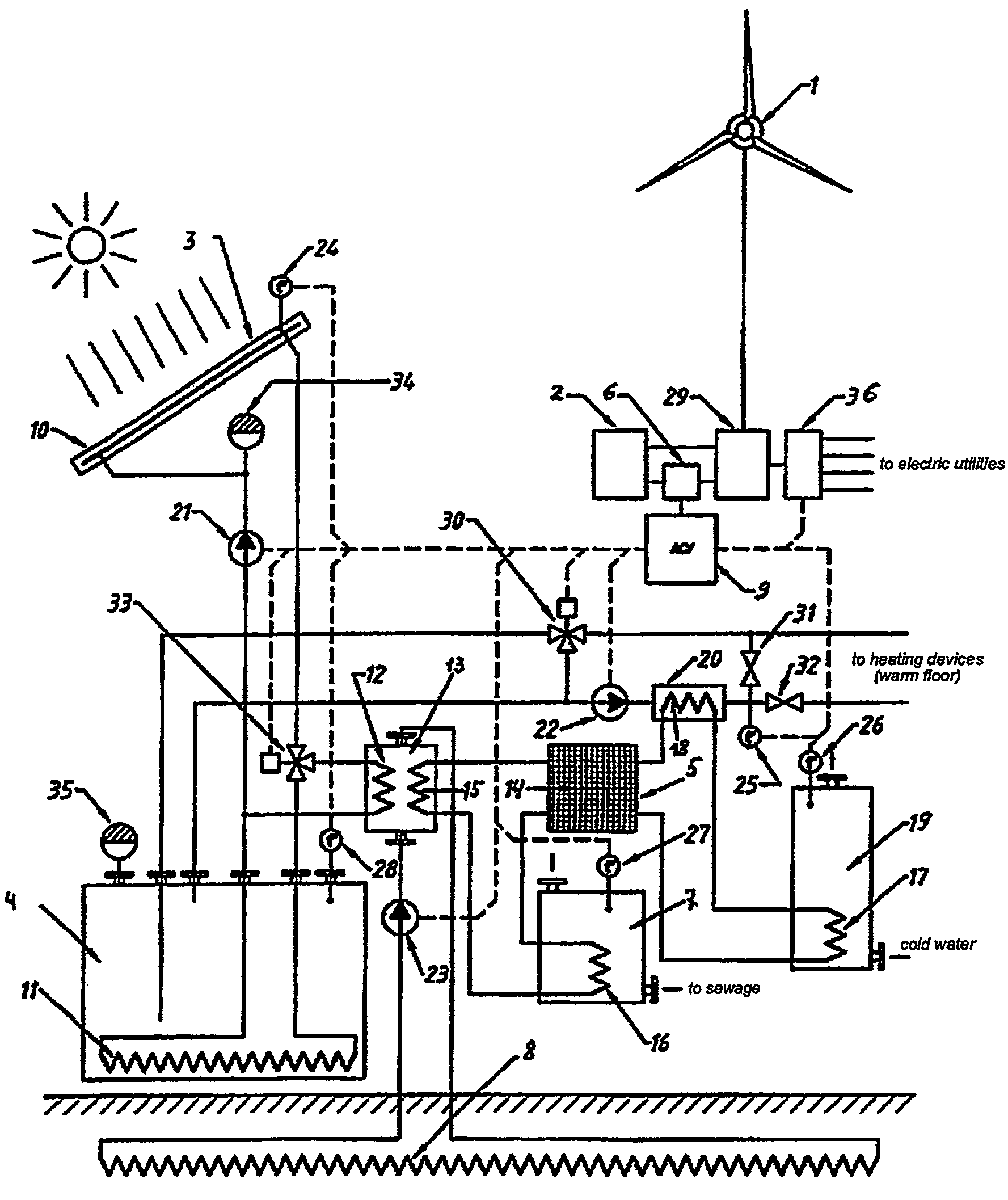

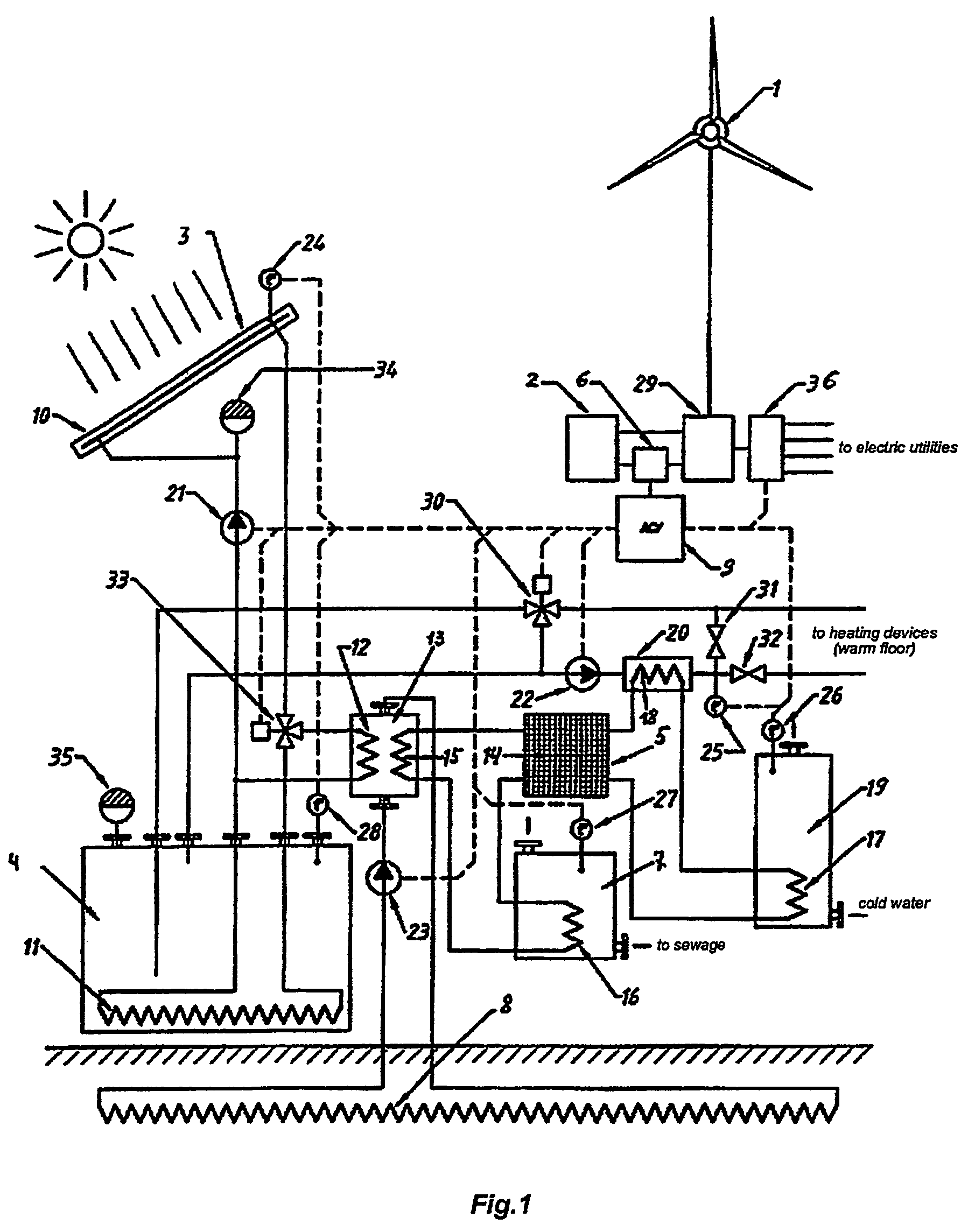

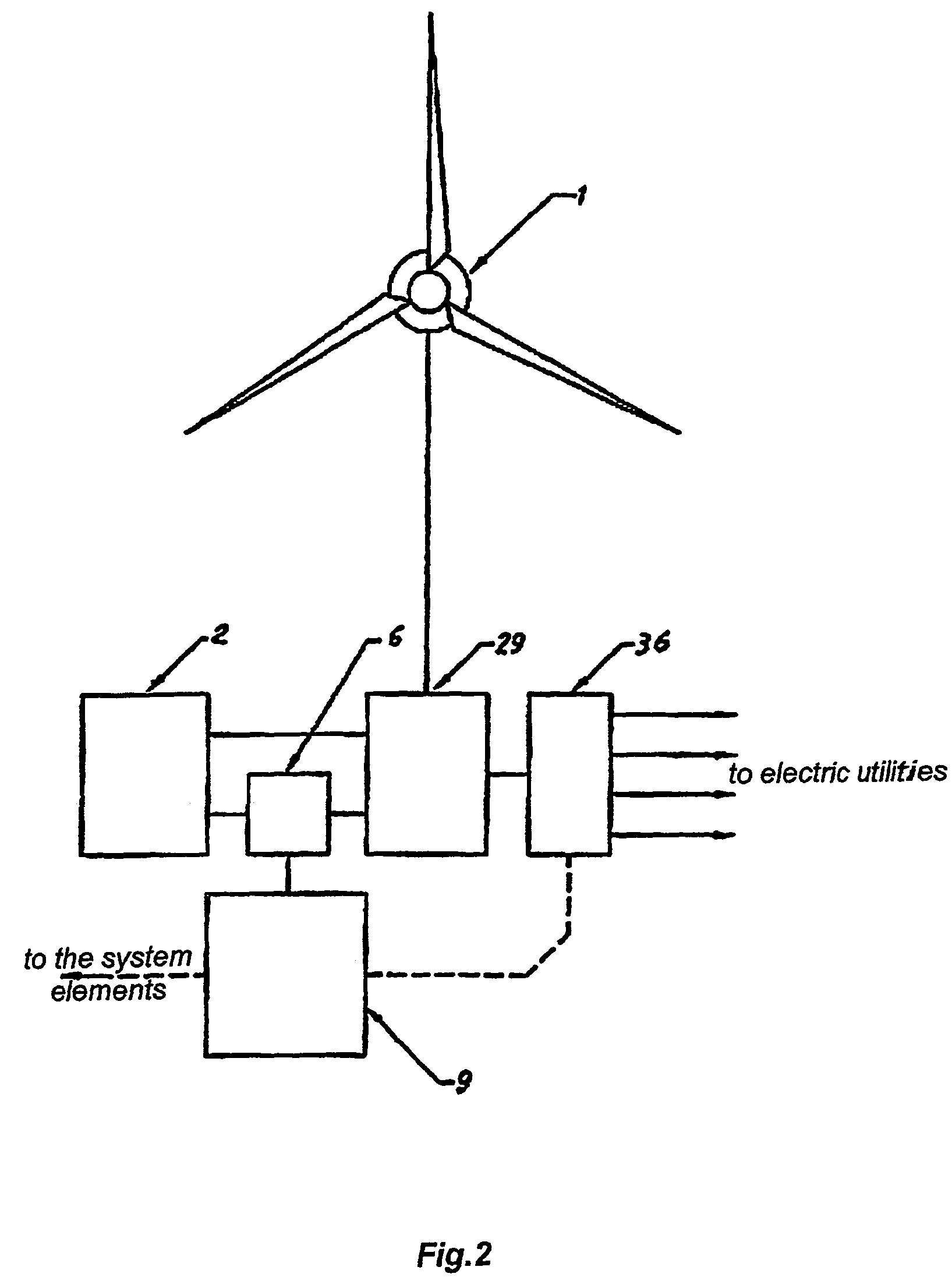

The invention concerns devices of power supply and is intended for independent energy, heat and hot water supply of living and industrial premises. The system of independent energy and heat supply of living and industrial premises contains wind generator setup for electric power production 1, connected with electric energy consumers; the electric energy accumulator 2 connected with the wind generator by setup 1 and electric energy consumers; setup for solar into thermal energy transformation 3 and the thermal accumulator 4, connected with thermal energy consumers.

Owner:GORDIN ALEKSANDER +1

Independent system of energy and heat supply

InactiveUS7555897B2Improve performanceImprove system performanceAuxillary drivesPV power plantsThermal energyEngineering

Owner:GORDIN ALEKSANDER +1

Communication process for elements composing a home or industrial electrical energy distribution network and devices for implementing the same

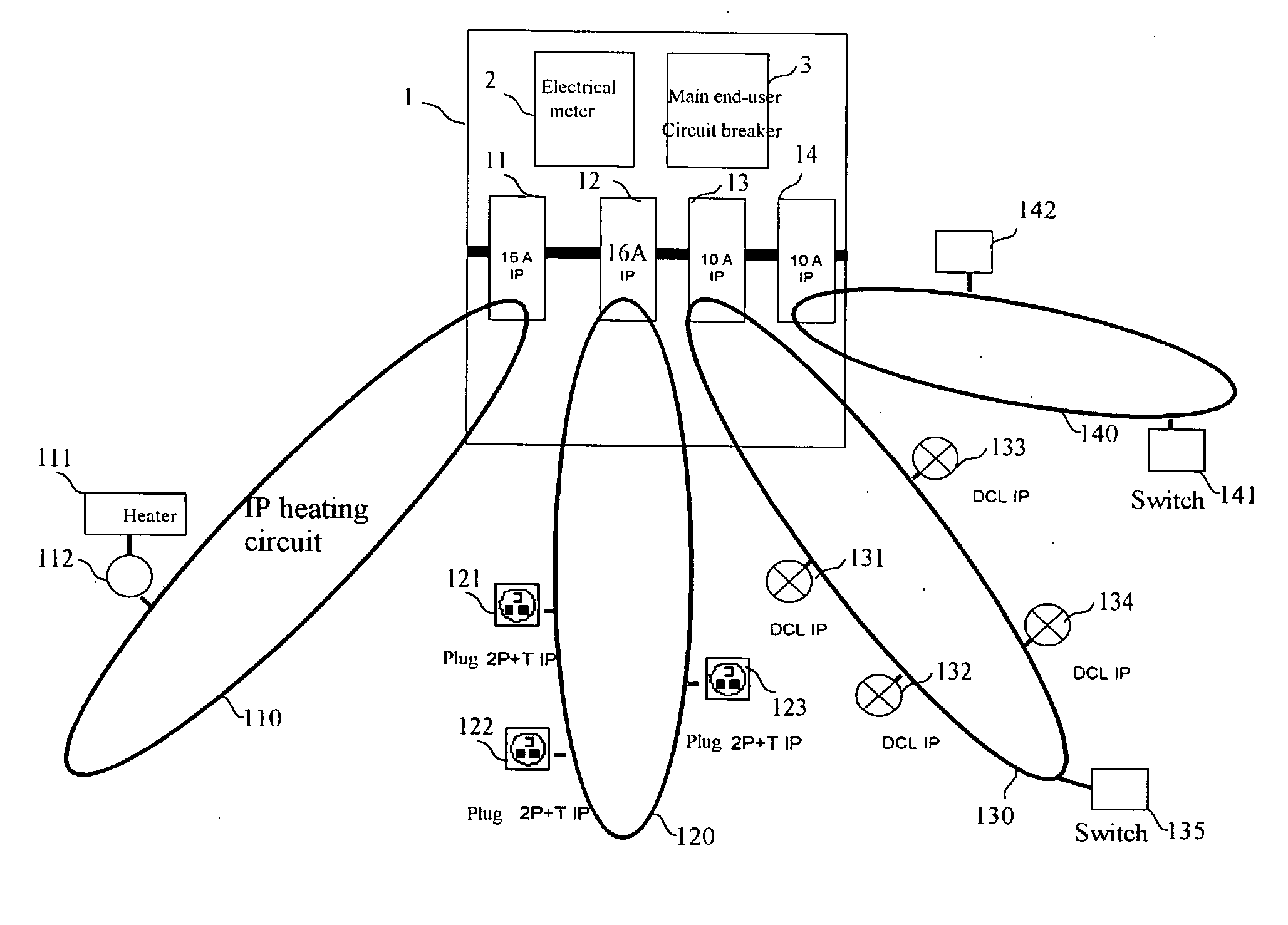

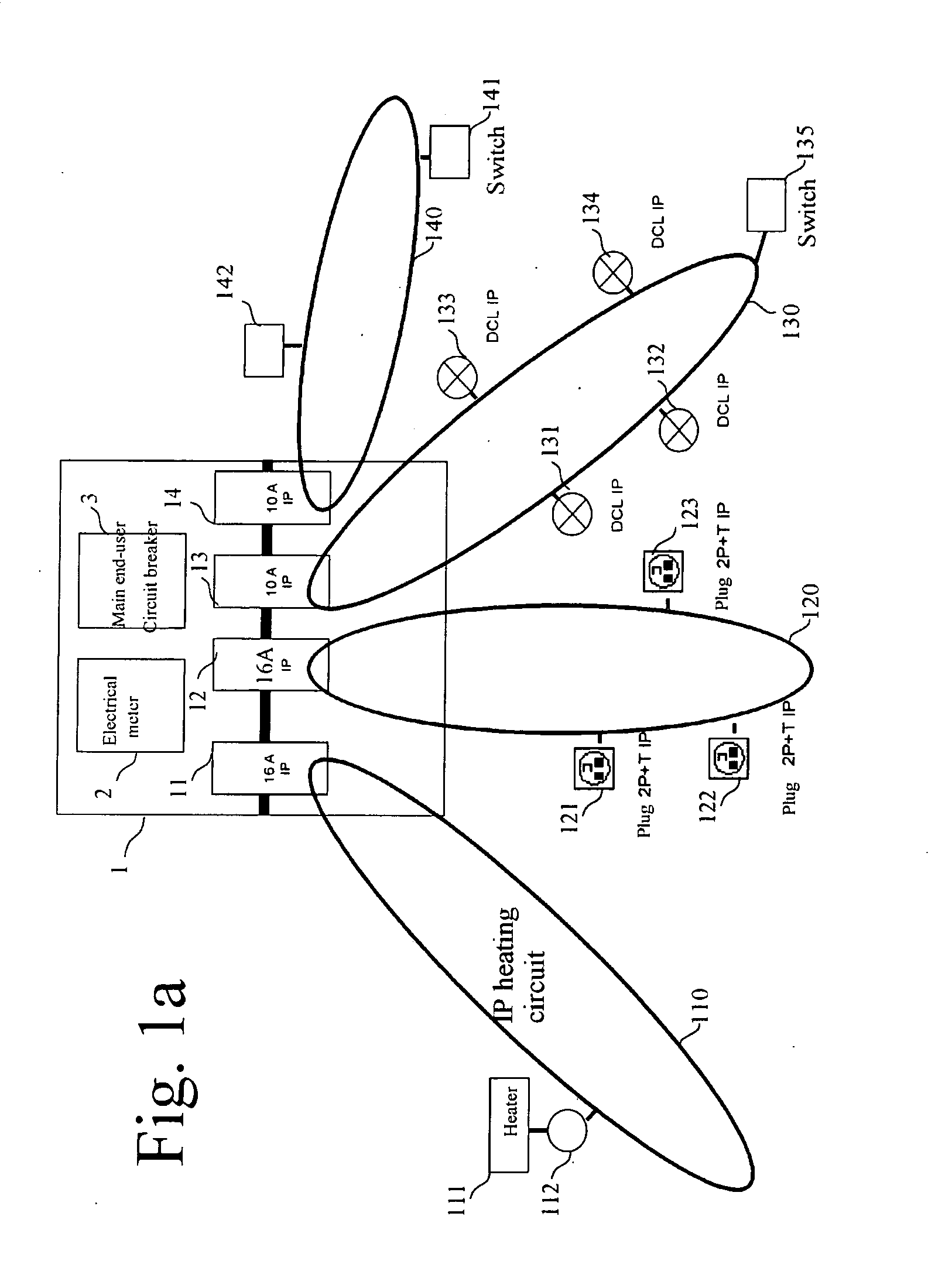

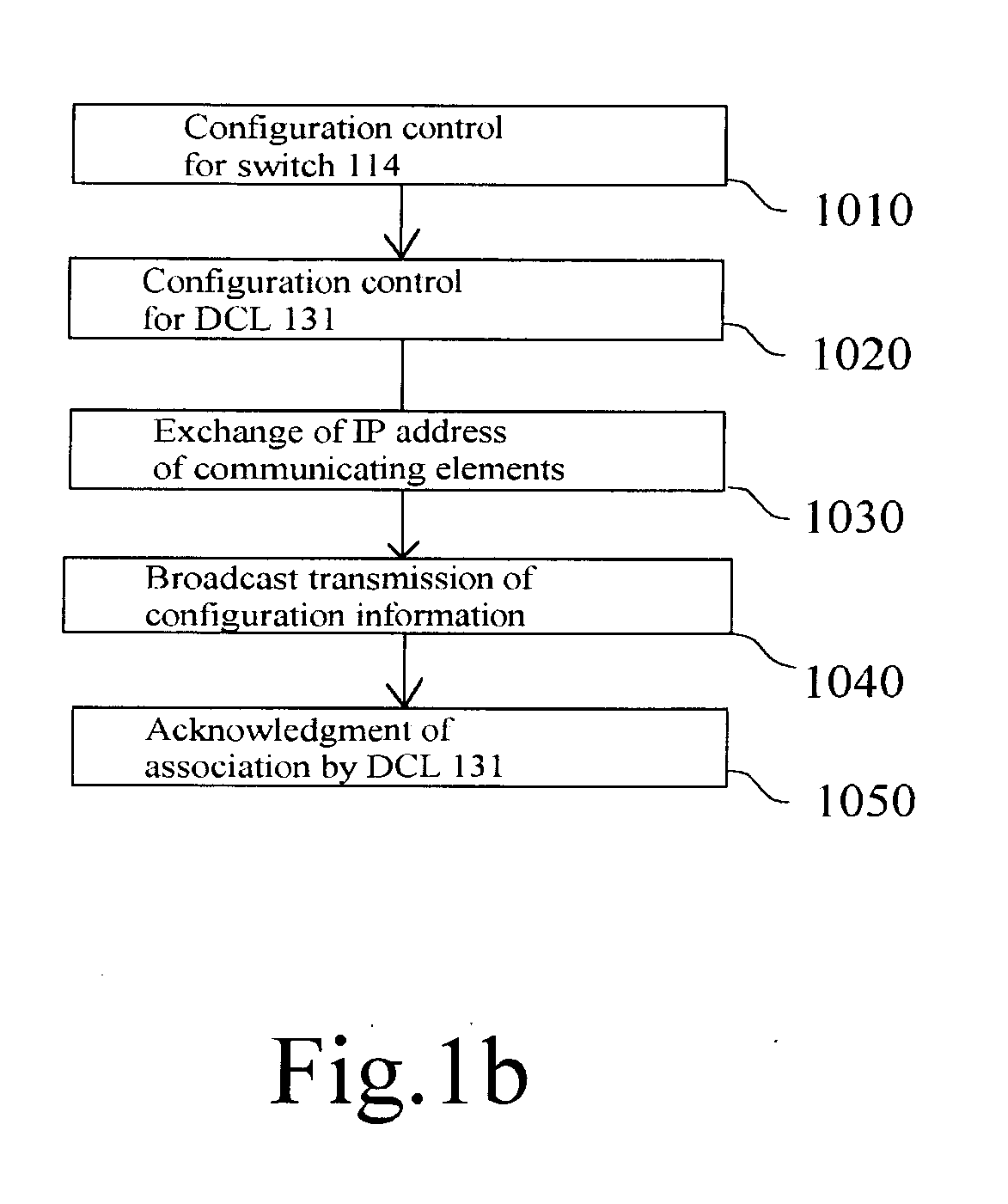

A communication process between two constitutive elements of the network of electricity distribution in a domestic or industrial premise including circuit breakers, electrical modules, switches, electrical plugs and light connection devices. The process including the following steps: assignment by a protocol such as DHCP, BootP or RARP of a first IP address to a first element of the power distribution network, assignment of a second IP address to a second element, and establishment of a communication between the first and second elements of the power distribution network.

Owner:KOGLER ROLAND +1

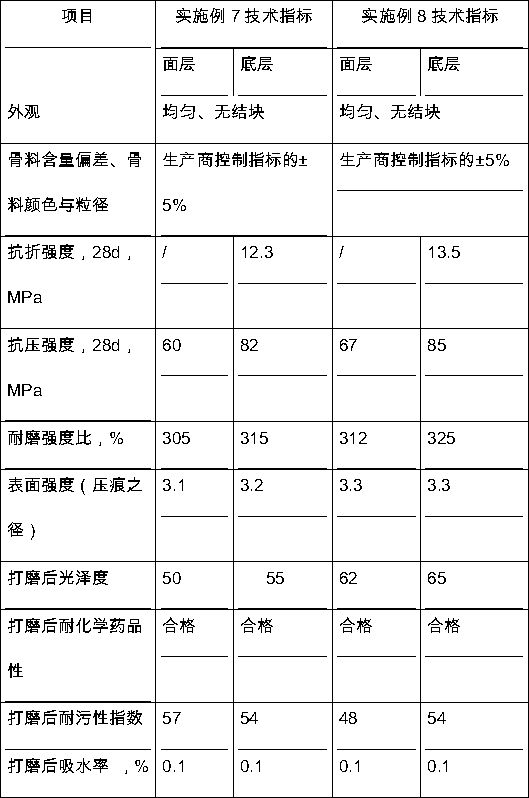

Multilayer radiation cooling coating and preparation method thereof

InactiveCN111574878AHigh solar reflectanceSimple processPolyurea/polyurethane coatingsEpoxy resin coatingsNear infrared reflectanceLight reflection

The invention discloses a multilayer radiation cooling coating and a preparation method thereof. The multilayer radiation cooling coating comprises an ultraviolet reflection surface coating, a visiblelight reflection floating coating and a near-infrared reflection base coating, wherein the ultraviolet reflection surface coating contains an ultraviolet reflection material, the visible light reflection middle coating contains a visible light reflection material, and the near-infrared reflection bottom coating contains a near-infrared reflection material. By utilizing the synergistic effect of the ultraviolet reflection surface coating, the visible light reflection floating coating and the near-infrared reflection base coating, extremely high sunlight reflectivity can be generated, the process is simple, the cost is low, and the coating is suitable for special shapes and planes and can be applied to occasions such as residential buildings, commercial buildings and industrial factory buildings and has a wide application prospect.

Owner:杭州净碳科技有限公司

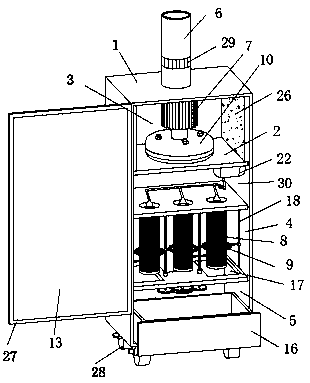

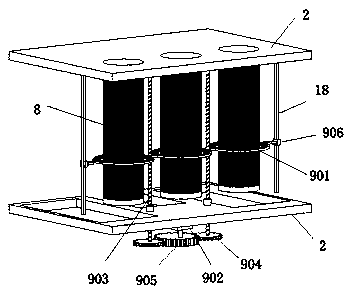

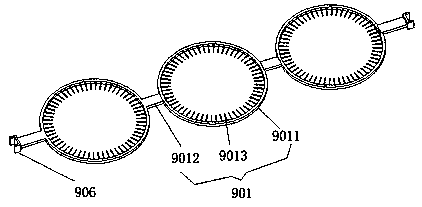

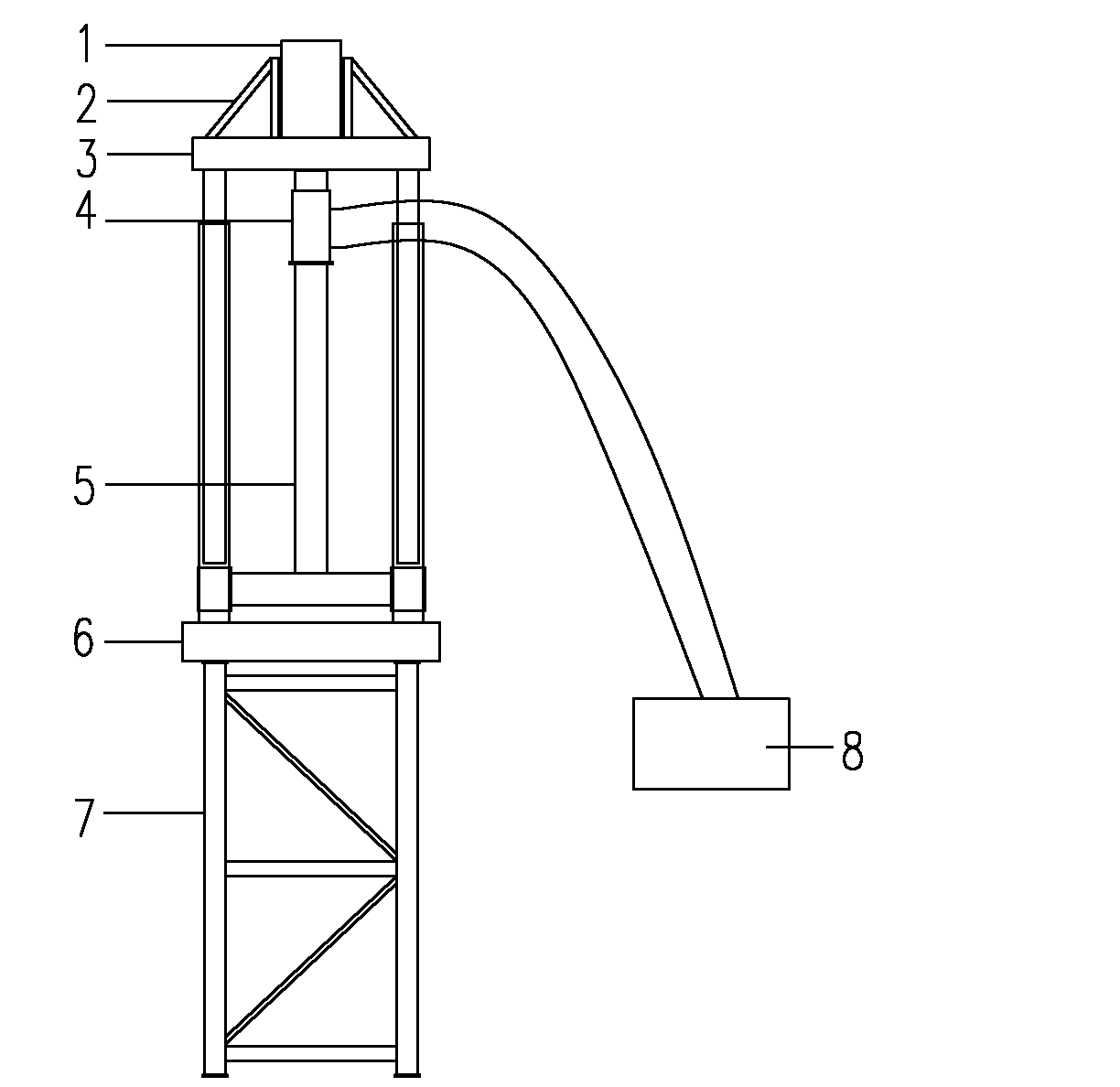

Movable dust removal equipment for industrial factory building

InactiveCN111346449AExtended service lifeFast cleaningDispersed particle filtrationTransportation and packagingActivated carbon filtrationDust control

The invention relates to the technical field of industrial factory building dust removal, and in particular, relates to movable dust removal equipment for an industrial factory building, wherein the movable dust removal equipment comprises a machine box body, the interior of the machine box body is sequentially divided into a power cavity, a reverse blowing cavity, a filtering cavity and a collecting cavity from top to bottom through two transverse partition plates, an air outlet pipe is arranged at the top of the power cavity, and an activated carbon filter is arranged on the air outlet pipe;a centrifugal fan communicated with the air outlet pipe is arranged in the power cavity, and the bottom end of the centrifugal fan is communicated with an air collecting disc; a filter cartridge typefilter and an ash removal device are arranged in the filter cavity, the left outer wall and the right outer wall of the filter cavity are communicated with air inlets, and electronic air valves are arranged in the air inlets; an ash collecting drawer is slidably mounted in the collecting cavity, and an ash falling hole is formed in the transverse partition plate between the collecting cavity andthe filtering cavity; walking wheels are fixedly mounted at four corners of the lower end surface of the bottom end of the machine box body; dust on the surface of the filter element can be cleaned while the filter element filters gas, and meanwhile, the filter element can be matched with the reverse blowing system to accelerate the cleaning speed of industrial dust.

Owner:界首尚嘉工业设计有限公司

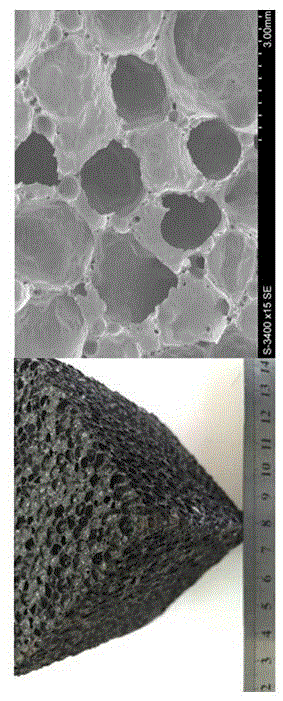

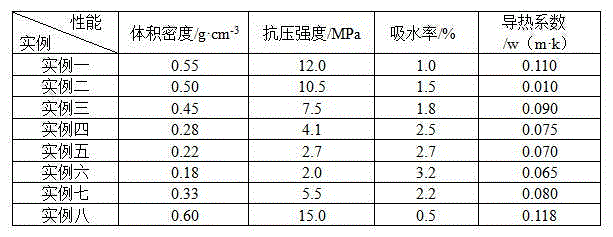

Foam microcrystalline glass made of high-silicon iron tailings and production method of foam microcrystalline glass

ActiveCN104788011AAddress pollution hazardsSave raw materialsGlass shaping apparatusCompressive resistanceFoaming agent

The invention relates to foam microcrystalline glass produced by using high-silicon iron tailings and a production method of the foam microcrystalline glass. Main raw materials of the foam microcrystalline glass comprise 70%-90% of the high-silicon iron tailings, 0.5%-5% of a foaming agent and 5%-30% of an additive, wherein the foaming agent is obtained by mixing carbon powder and calcium carbonate in a mass ratio being 2:1; the additive is obtained by mixing albite and talc in the ratio being 5: (0.5-1). During production, the raw materials are uniformly mixed, and the foam microcrystalline glass is prepared through preheating, sintering, foaming, crystallizing and annealing processes after forming. The foam microcrystalline glass has the advantages of small density, small heat conductivity coefficient, high compressive strength, easiness in processing and forming and the like and can be used for buildings such as a villa, a civic building, an industrial factory building and the like. The problems of high raw material production cost, complicated technology and the like of the foam microcrystalline glass are solved, pollution hazard of tailing accumulation to the environment is avoided, waste is turned into wealth, and energy saving and environmental protection are realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

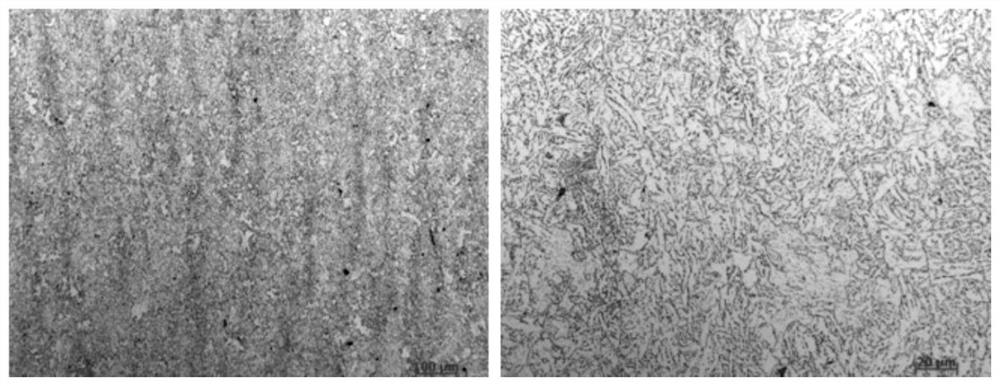

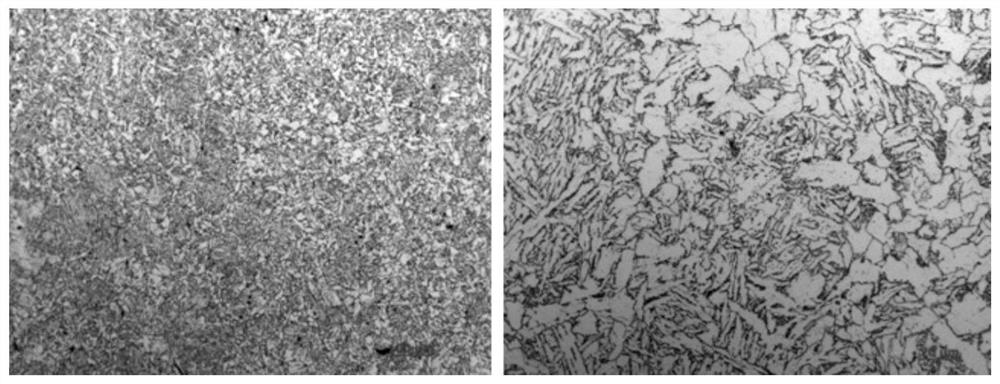

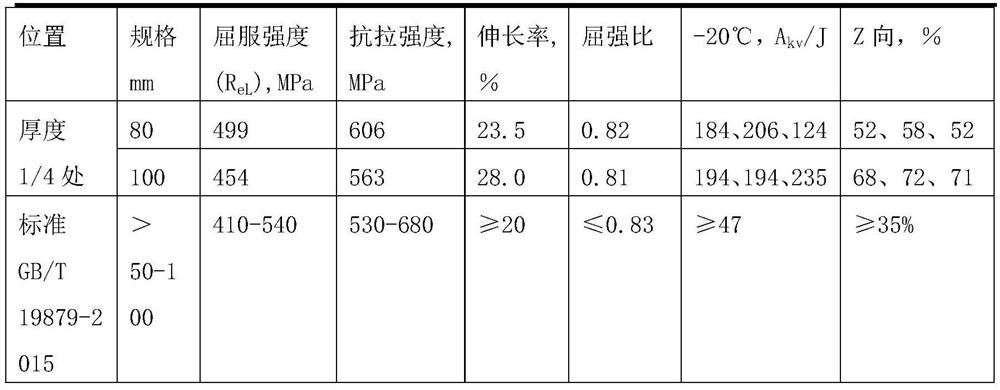

Quenched and tempered steel plate with yield strength being 420 MPa grade for building structure and production method of quenched and tempered steel plate

The invention relates to a quenched and tempered steel plate with the yield strength being 420 MPa grade for a building structure and a production method of the quenched and tempered steel plate. The component design that Nb and Ti microalloying treatment is conducted on the basis of a Fe-Mn-C system is adopted, and the steel plate material is prepared from the chemical components including 0.13%-0.18% of C, 0.20%-0.50% of Si, 1.40%-1.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, 0.020%-0.050% of Al, less than or equal to 0.015% of V, 0.025%-0.050% of Nb, 0.010%-0.020% of Ti, less than or equal to 0.006% of N and the balance Fe and inevitable impurity elements. The production process comprises the following steps that raw materials are smelted in a converter, refined outside the converter and refined in an RH furnace in sequence to obtain molten steel with higher purity, the molten steel is poured to form a steel billet being 370 mm-450 mm, then reasonable steel billet heating, rolling, on-line direct quenching and tempering heat treatment technologies are adopted, and the steel plate material with the yield strength being 420 MPa grade is suitable for large-scale steel structure constructional engineering such as high-rise buildings, large-span stadiums, airports, exhibition centers and industrial factory buildings is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

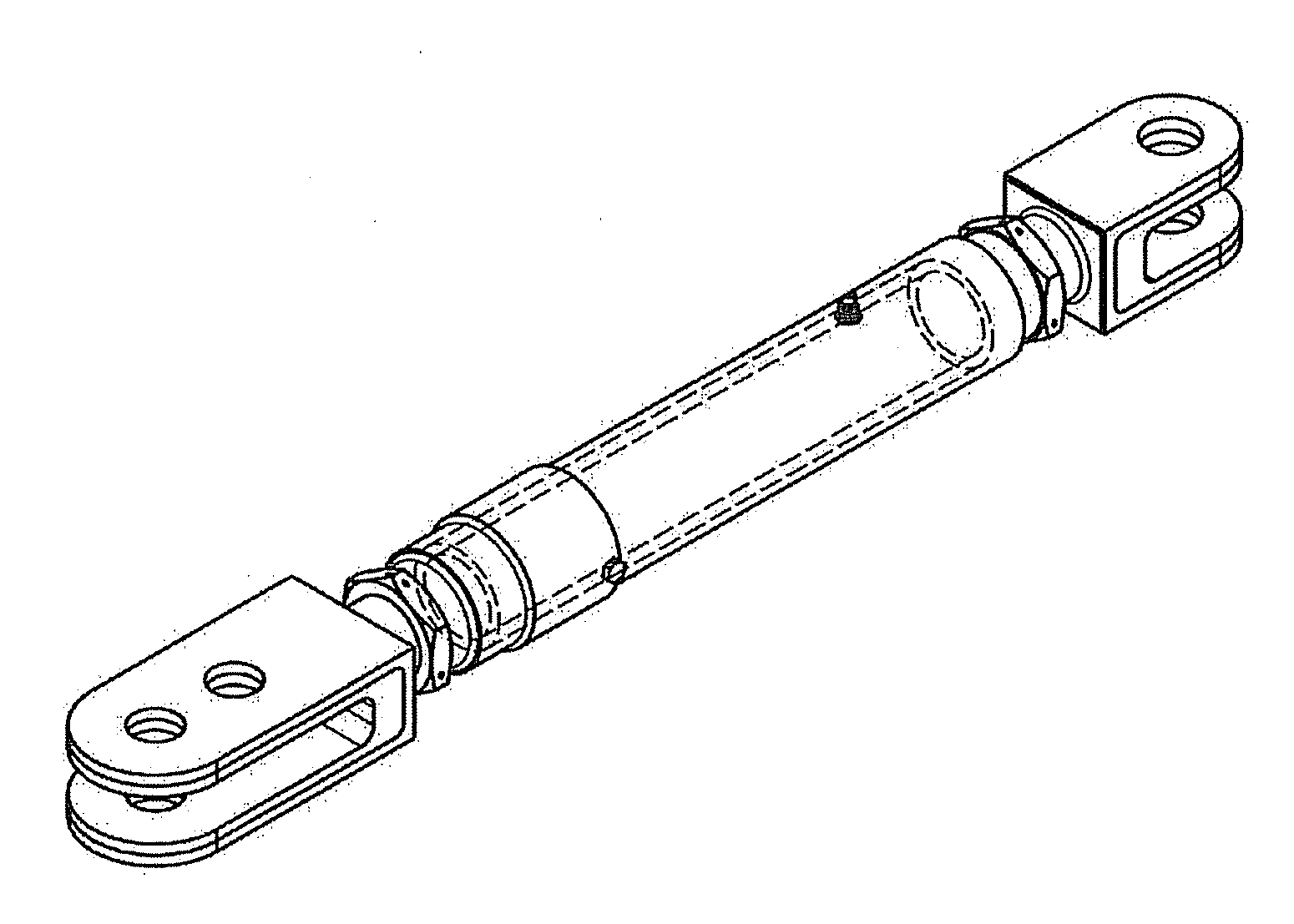

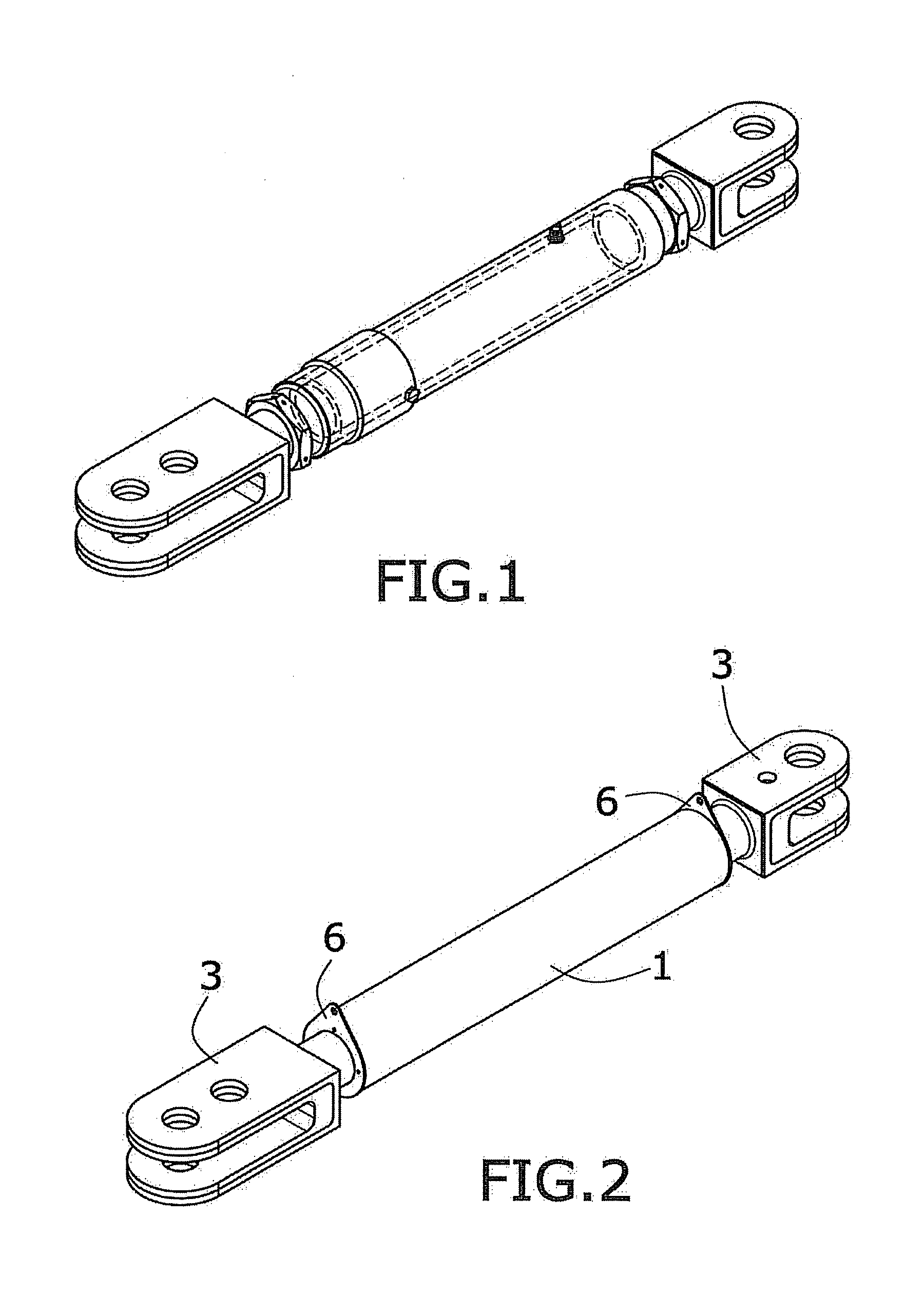

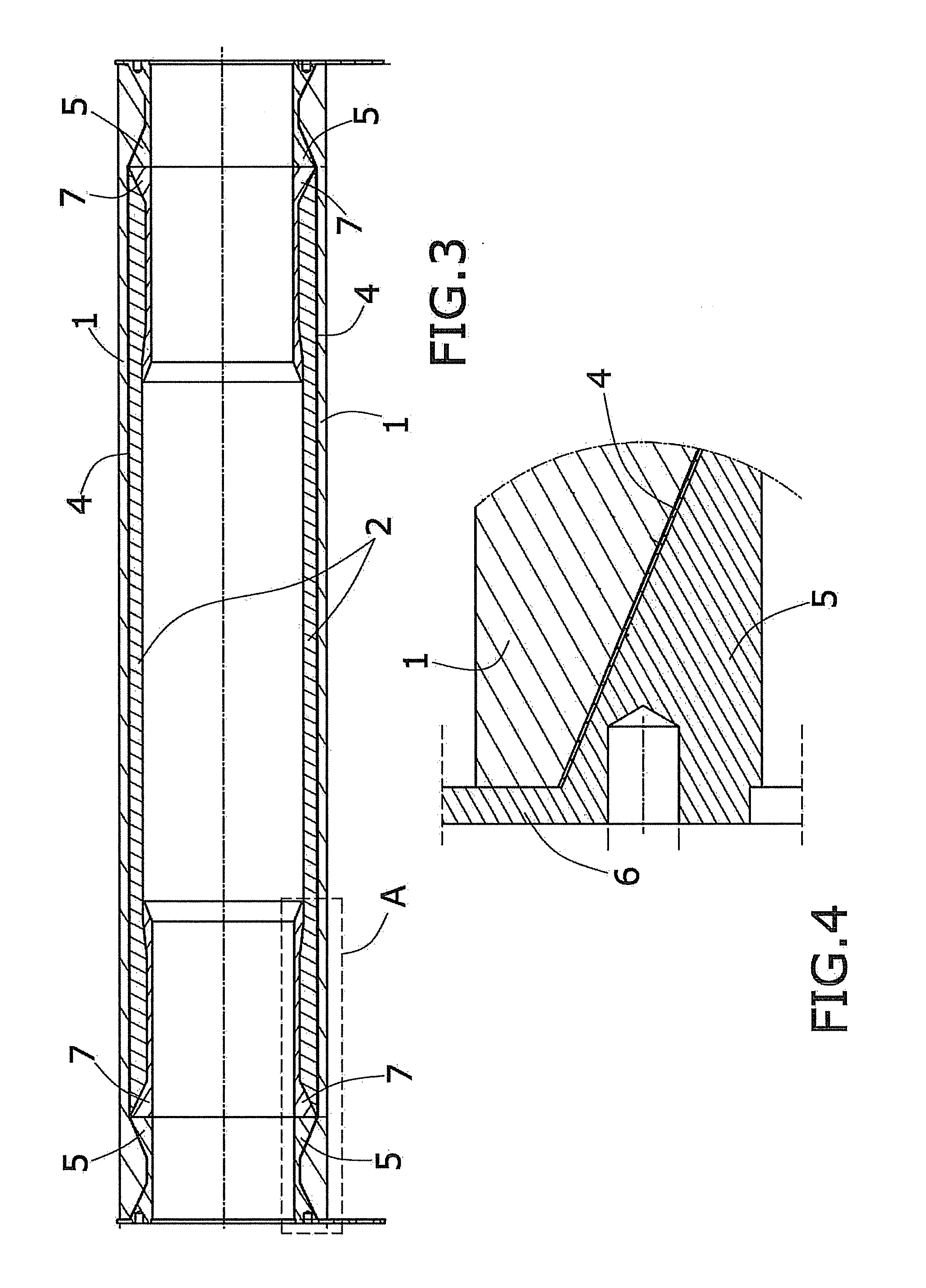

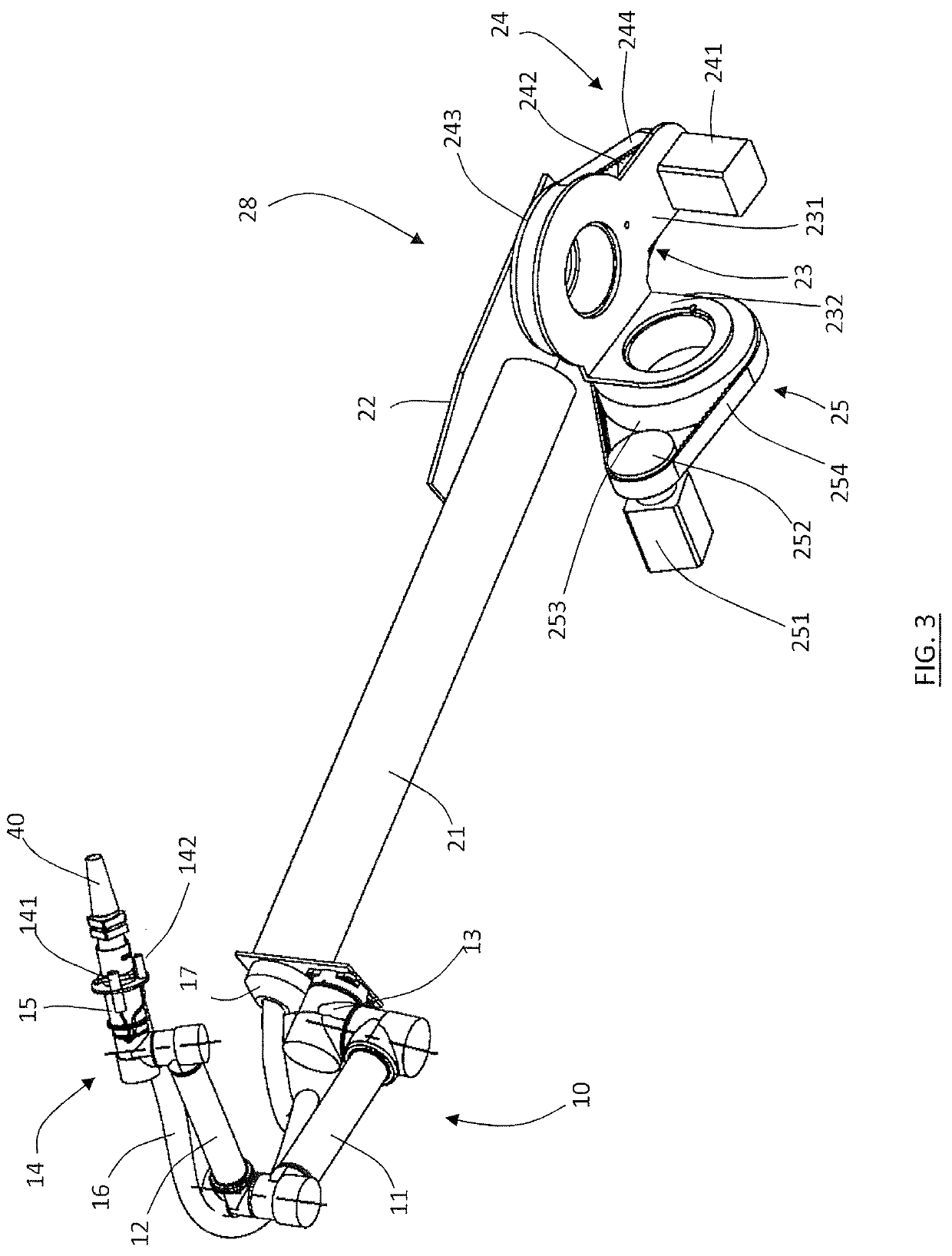

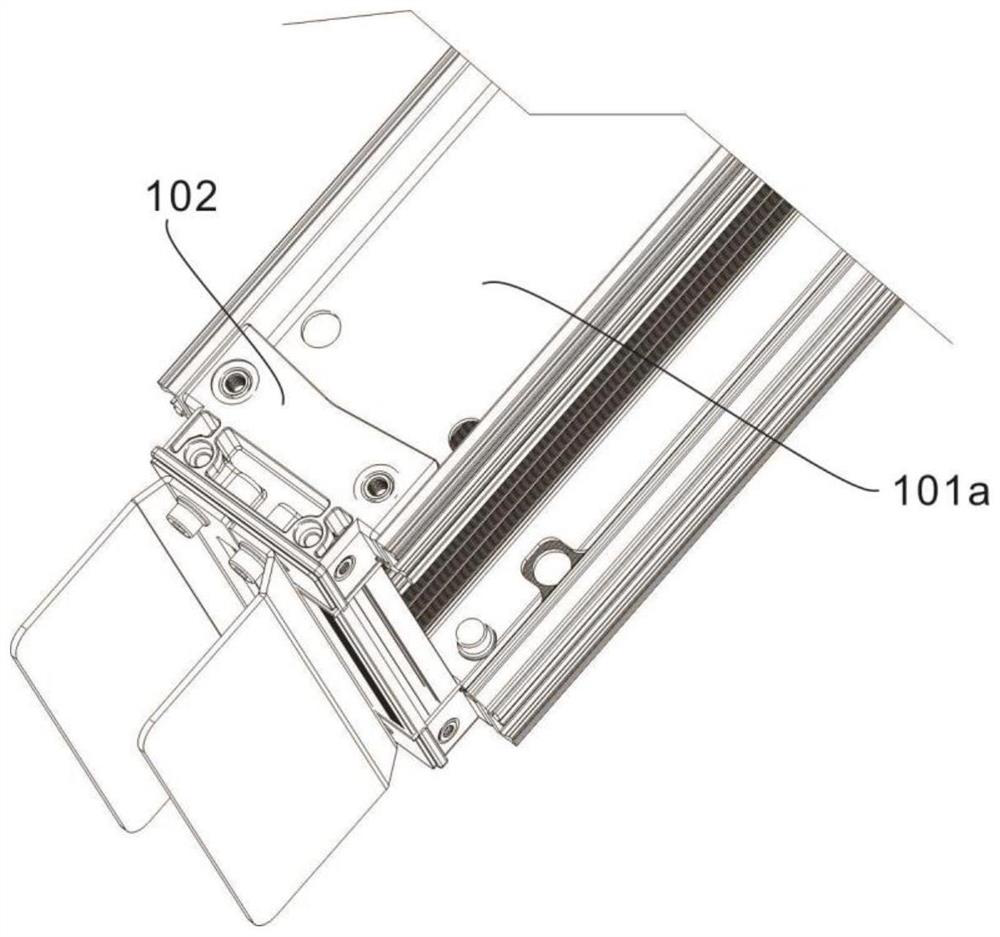

Composite rod, manufacturing method and tool

ActiveUS20130187015A1High currentMaintain dimensional stabilityFuselage framesConnecting rodsIndustrial premisesManufacturing engineering

The present invention describes composite rods keeping two elements apart a determined distance carrying the loads between them, such as railways, industrial premises, etc. Besides, the manufacturing method thereof and the tool involved in this process are also described.

Owner:AIRBUS OPERATIONS SL

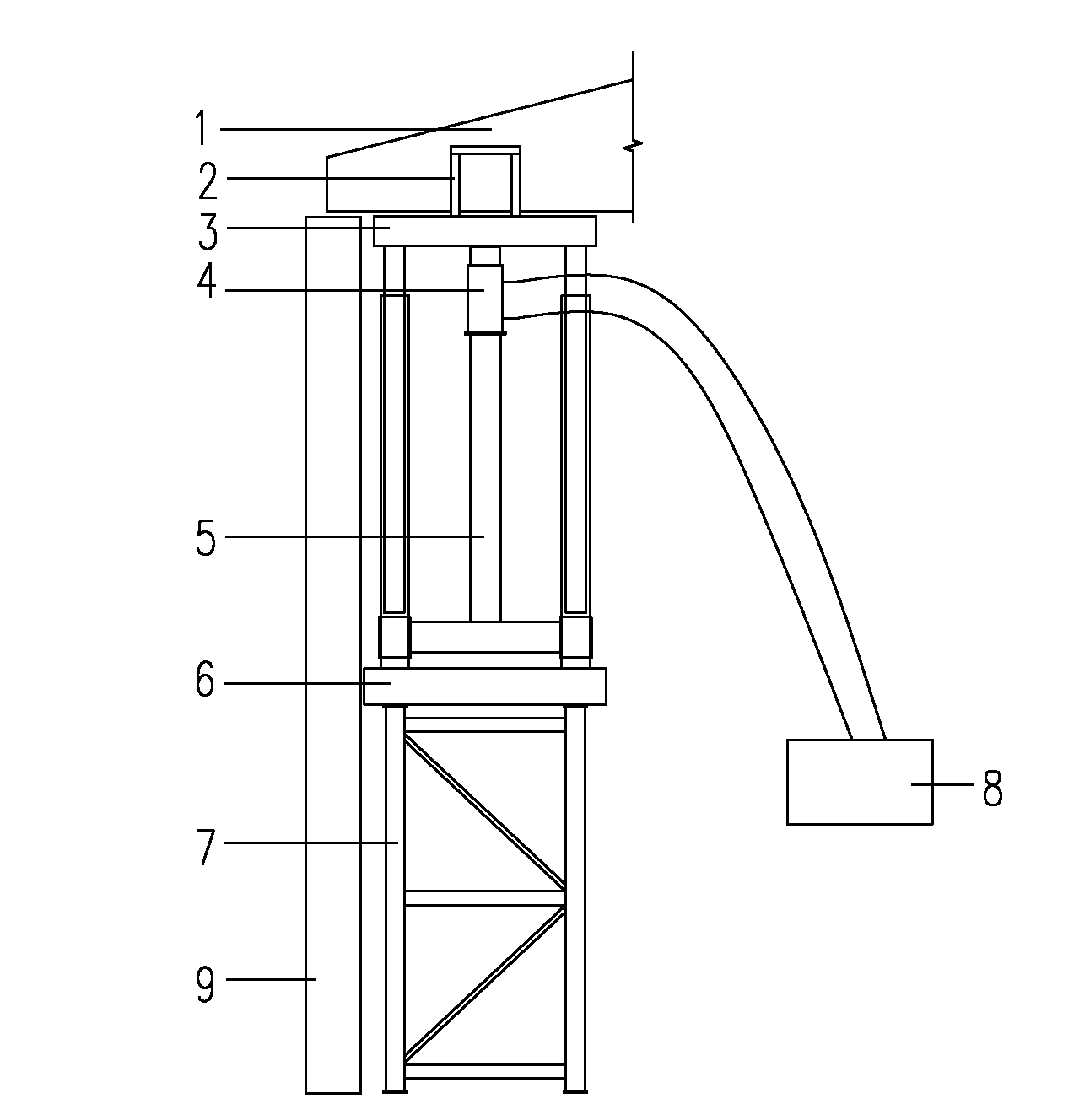

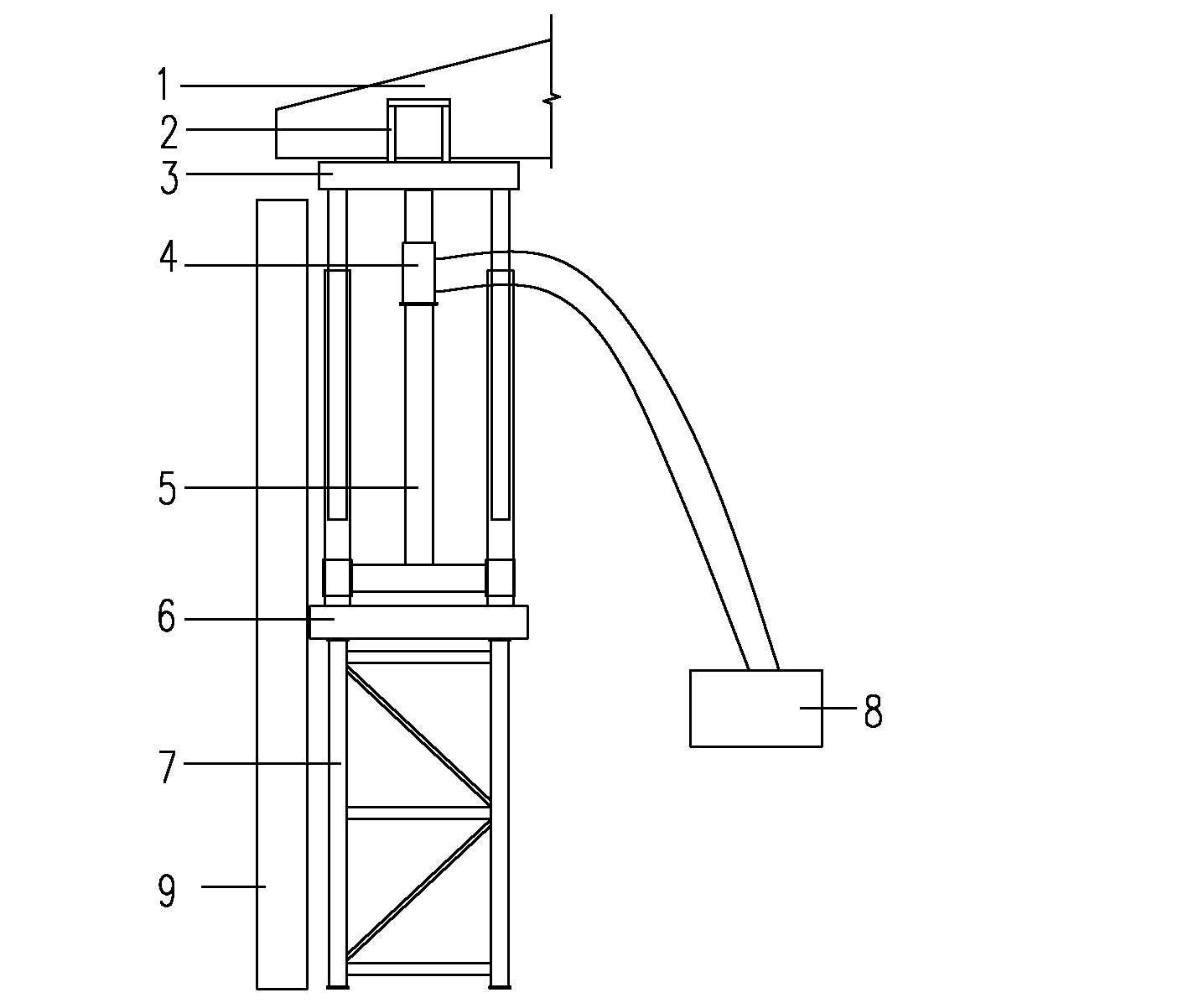

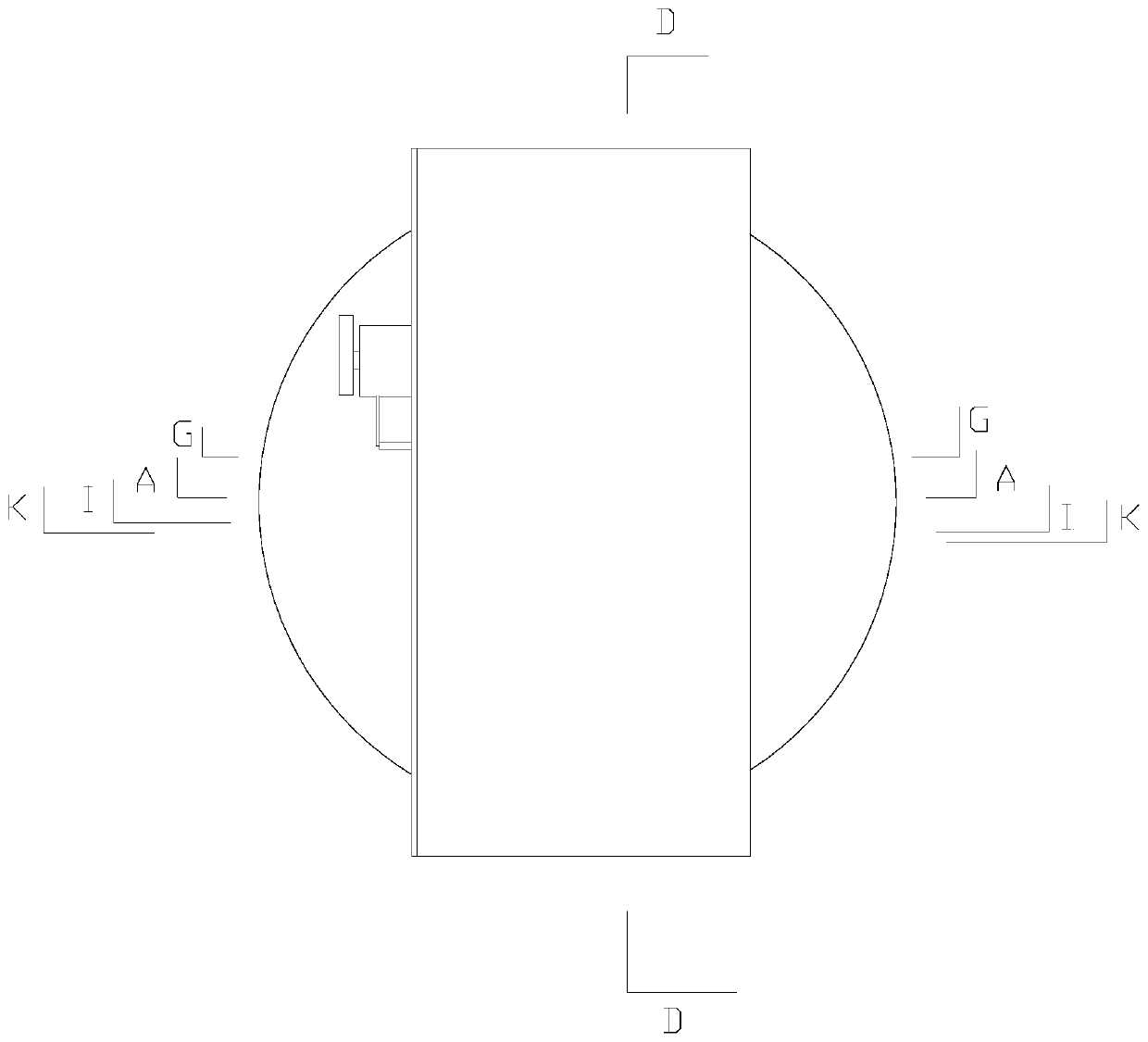

Device and construction method for overall lifting of single-story industrial factory roof

The invention relates to a device for integrally jacking a roof of a single-layer industrial factory building. The device is characterized by comprising three parts, namely a jacking device, a vertical force transfer device and a synchronous control device, wherein the vertical force transfer device is arranged on the ground of the factory building; and the jacking device is fixed above the vertical force transfer device and is connected with the synchronous control system. The construction method comprises the following steps of: enabling an upper section of an adjustable steel support column to be positioned in a freely-retractable state; fixing an inverted T-shaped counterforce cross beam, starting the synchronous control system and jacking a conventional shot-travel hydraulic jack to one travel height; fixing the upper section of the adjustable steel support column to enable the inverted T-shaped counterforce cross beam to be positioned in a freely-retractable state, starting the synchronous control system, retracting the jack and upwards hoisting the inverted T-shaped counterforce cross beam to be a travel height; and repeating the step (1) and the step (2) until an original roof frame beam is jacked to the designed elevation and realizing integral jacking of the roof of the single-layer industrial factory building. In the jacking process, an inserting pin of the adjustable steel column and an inserting pin at the end part of the counterforce cross beam are extracted out or inserted into conveniently and quickly by just arranging constructors according to the sequenceof jacking cycle.

Owner:HOHAI UNIV +1

Fire-proof insulation coating

InactiveCN102977647AExcellent physical and chemical propertiesDry fastFireproof paintsCarbide siliconBoride

The present invention relates to a coating, and particularly relates to a fireproof coating for constructions with fire-proof and insulation properties. The present invention is composed of, by weight, 30-40% of silicate; 10-20% of silicon nitride; 10-15% of silicon carbide; 5-10% of mica powder; 6-10% of titanium dioxide; 1-3% of boride; 0.5-2% of an additive; and the balance being water. When the fire is fired to expand, a compact and uniform fire-proof insulation layer is formed, and the fire-proof insulation effect is remarkable. The coating has excellent physical and chemical properties, and is fast to dry, moisture-resistance, anti-acid and base, and water-tolerant. The coating can be widely used for fire-proof protection of places with high requirements such as industrial plants, stadiums, and high-rise buildings.

Owner:SHENYANG XINDA INFORMATION SCI & TECH

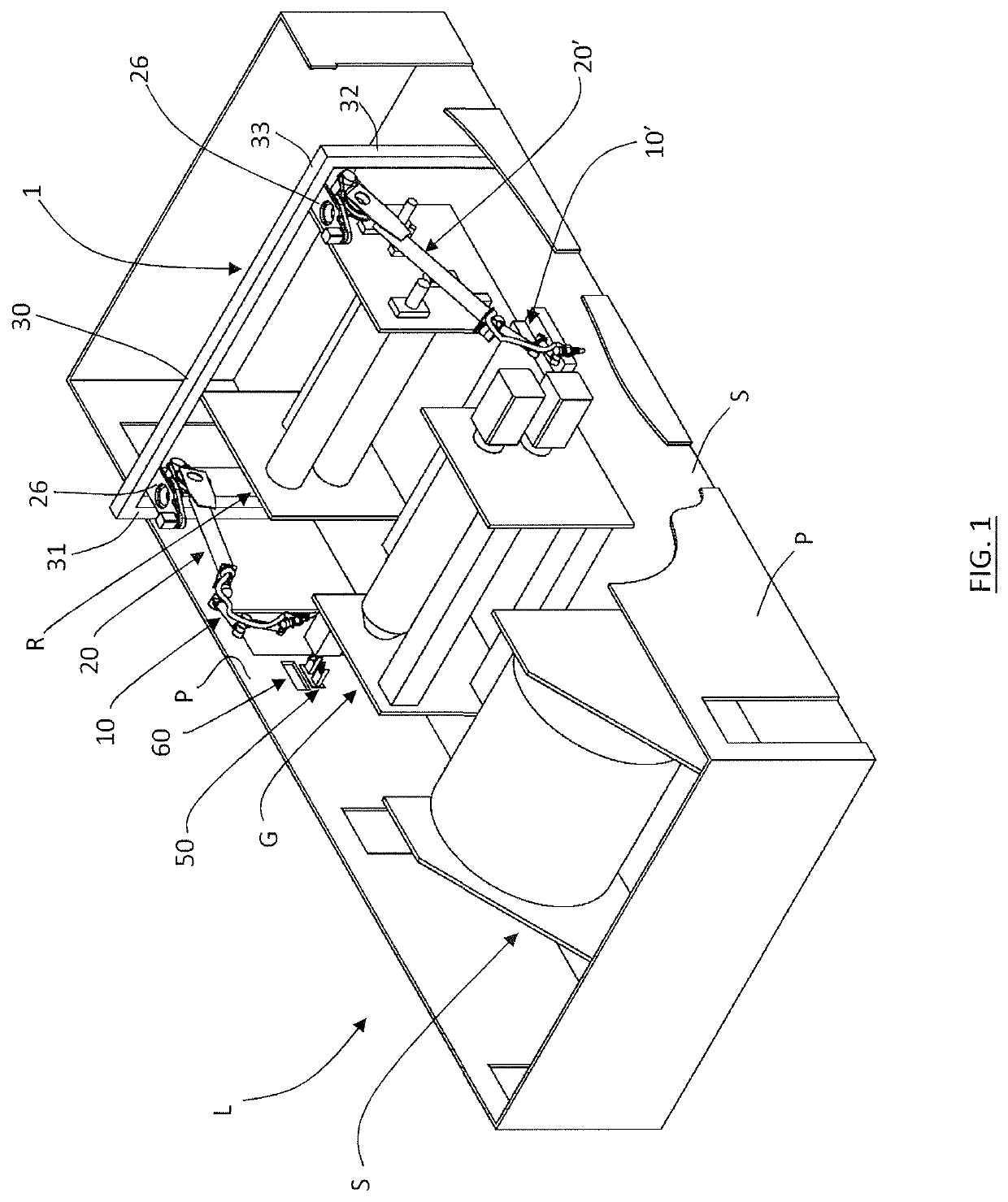

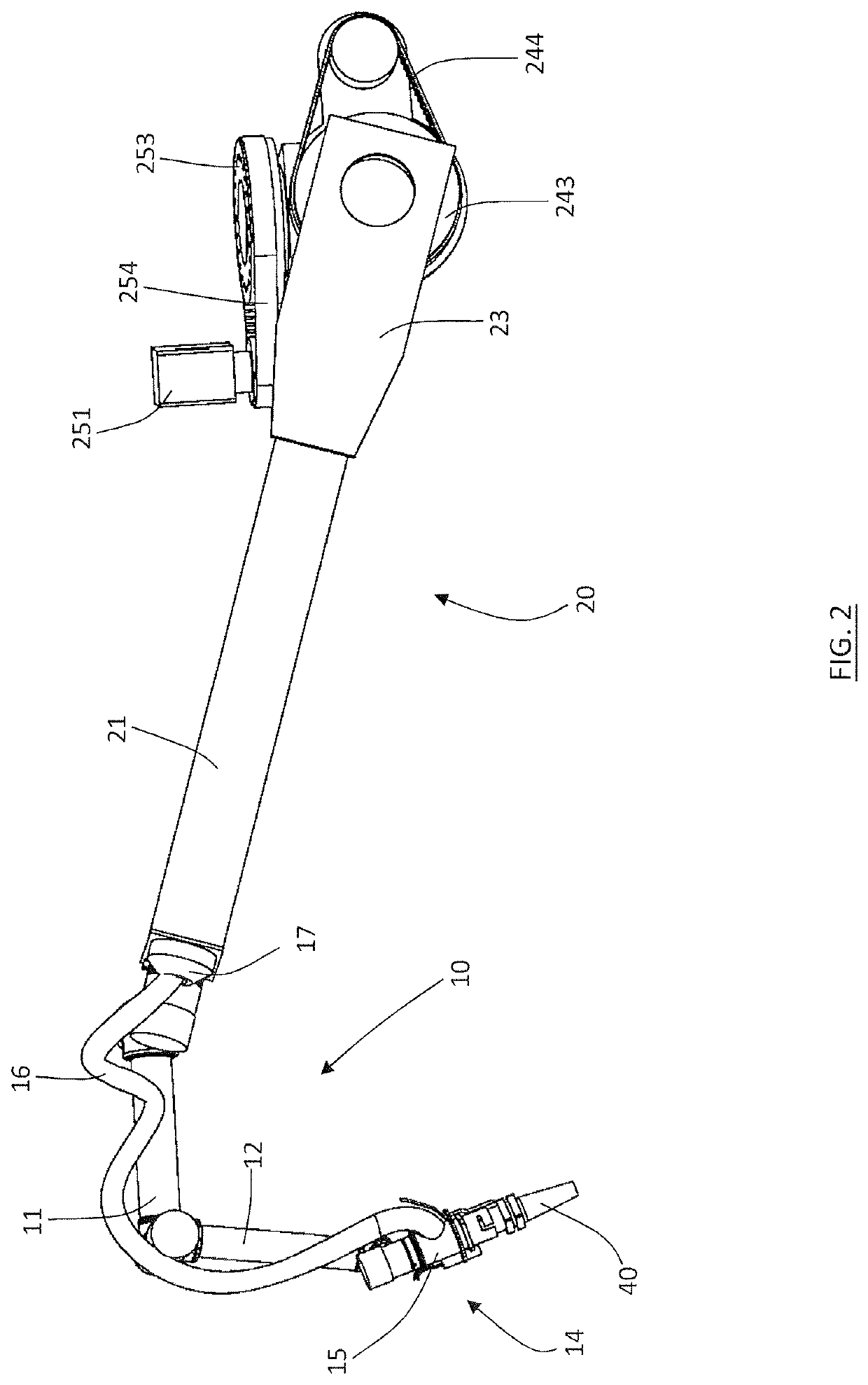

Apparatus for Cleaning Industrial Plants

InactiveUS20200139555A1Precision cleaningImprove efficiencyProgramme-controlled manipulatorGripping headsRobotic armIndustrial equipment

An apparatus (1) for cleaning industrial plants comprises a robotic arm to a working head of which are associated suction members suitable for sucking powders and working fragments inside a working volume in which a processing industrial plant is installed (L). The working head comprises an extensible manifold for moving the suction mouth (40) away from the end of the robotic arm thus allowing to reach remote positions and moreover the robotic arm (10) is mounted on moving members, for example a portal, which allow the robotic arm to be moved at different useful working volumes so that an accurate cleaning can be performed on a very large overall volume.

Owner:PNP DISCOVER SRL

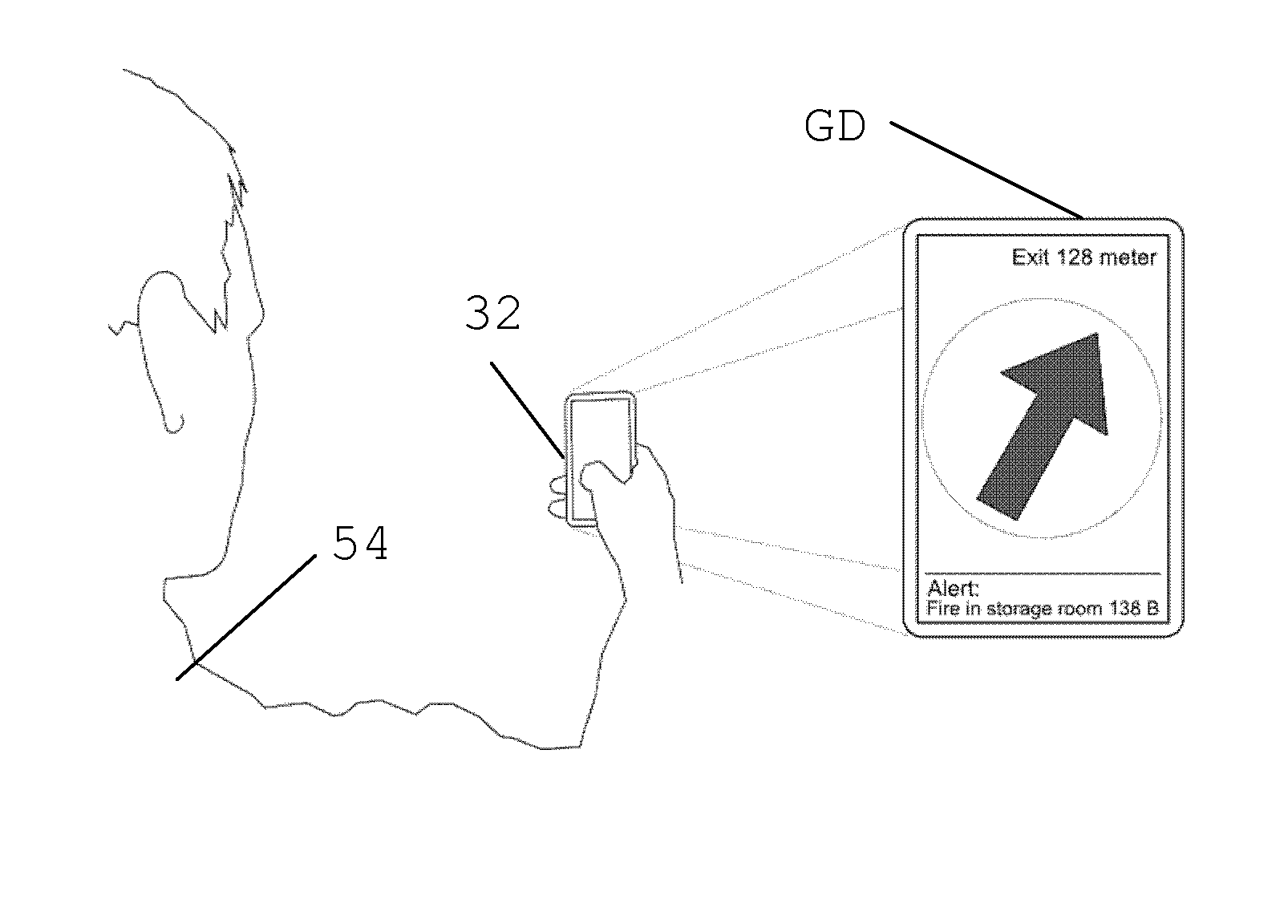

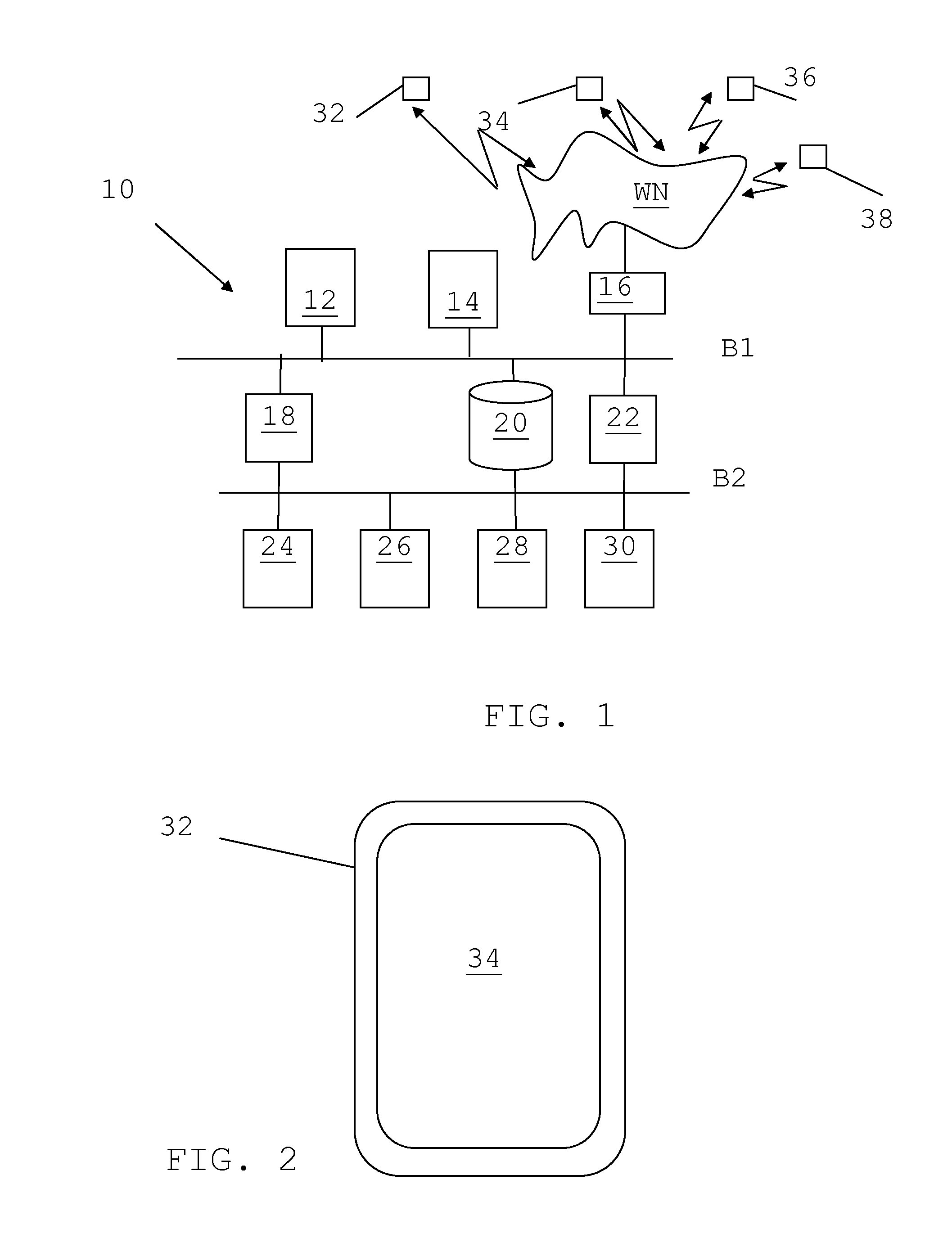

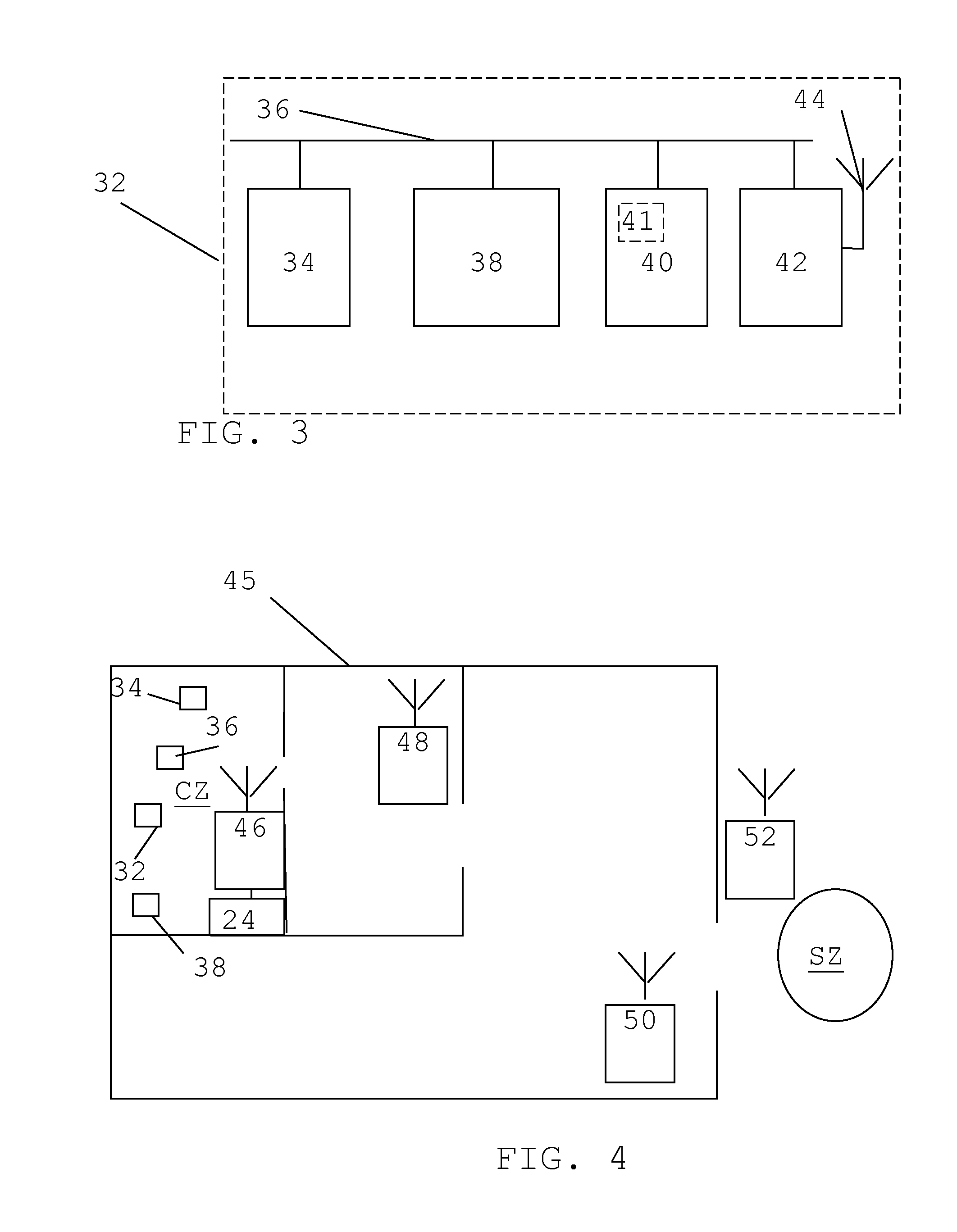

Guiding a user to safety from the premises of an industrial plant

ActiveUS20150102936A1Effective securitySignalling system detailsVisible signalling systemsComputer networkIndustrial premises

A method, safety route guiding device and a computer program product enables users in the premises of an industrial plant to reach safety in case of an emergency, where said users are equipped with mobile terminals, where the safety route guiding device includes a guiding unit that receives alarm data concerning an emergency in a clearance zone of the premises, the alarm data being relevant for a user of a mobile terminal, obtains data of a set of other users affected by the emergency, guides the user from the clearance zone to a security zone outside the premises, obtains status data concerning the other users in the set, and presents the status data to the user via the mobile terminal.

Owner:ABB (SCHWEIZ) AG

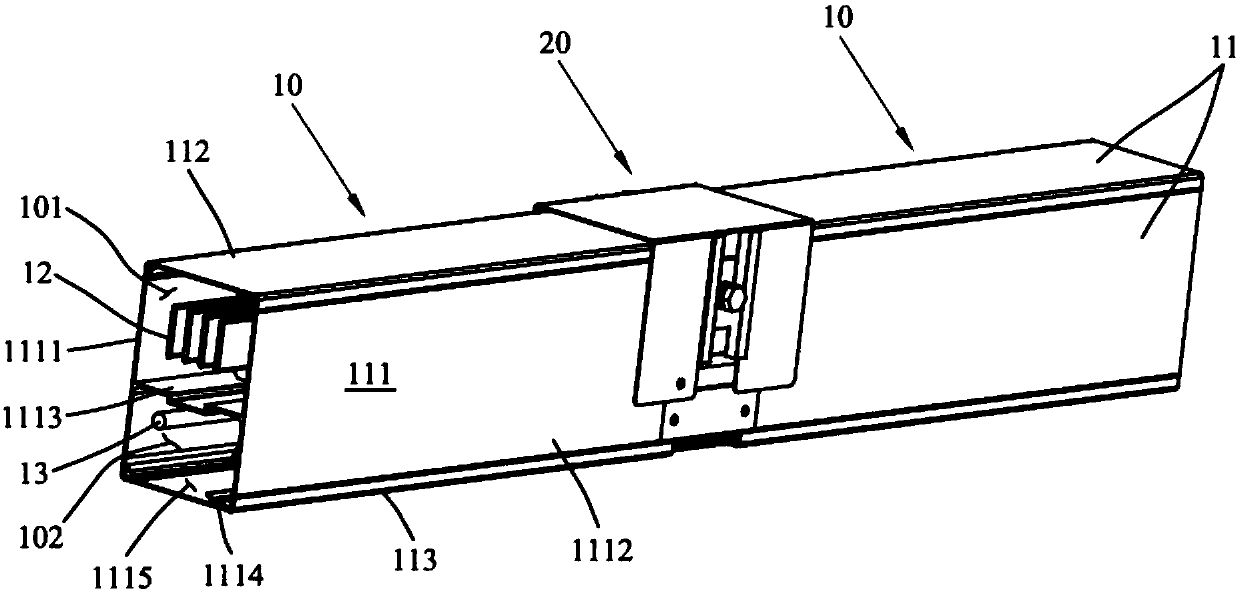

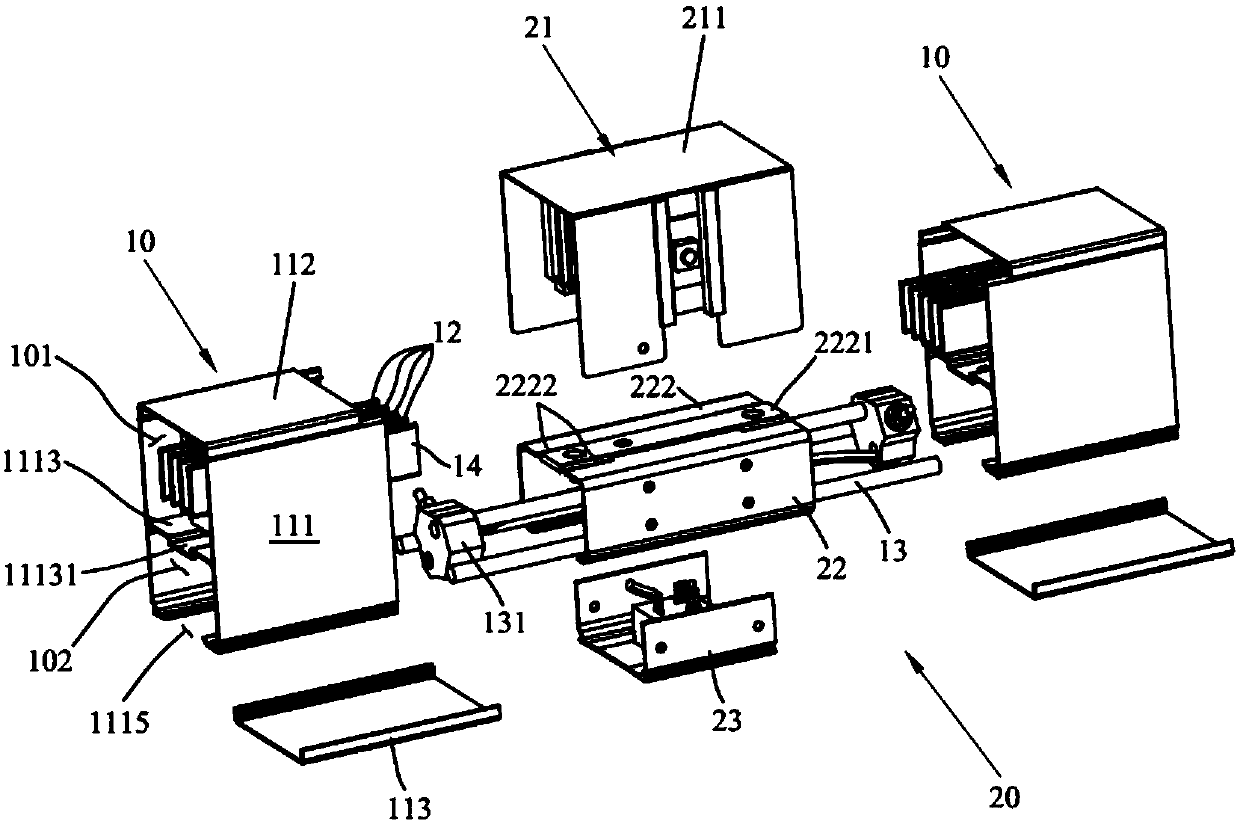

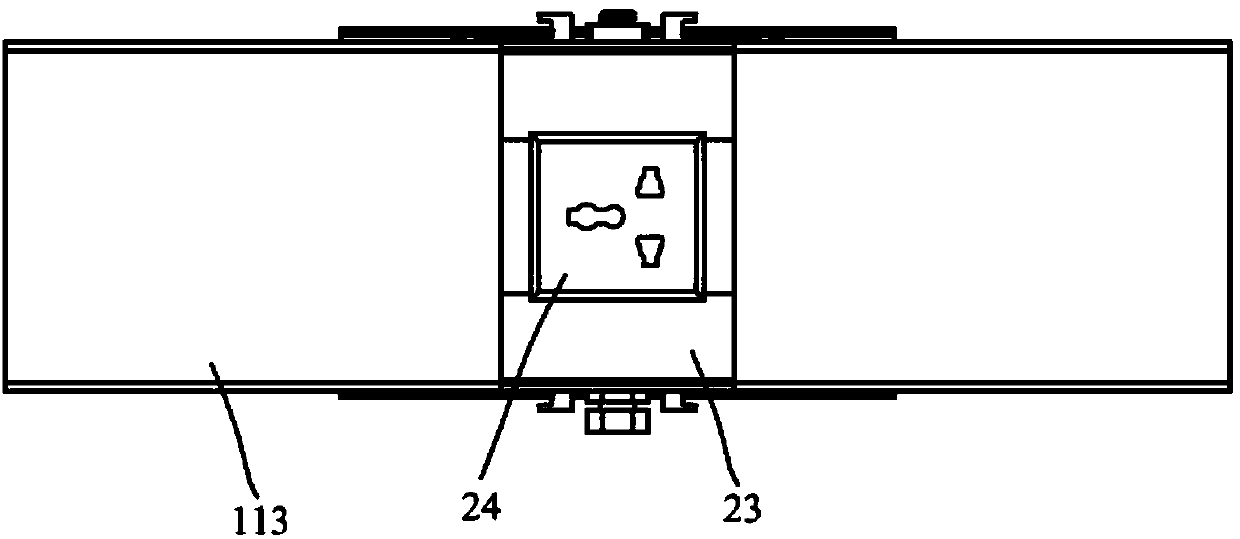

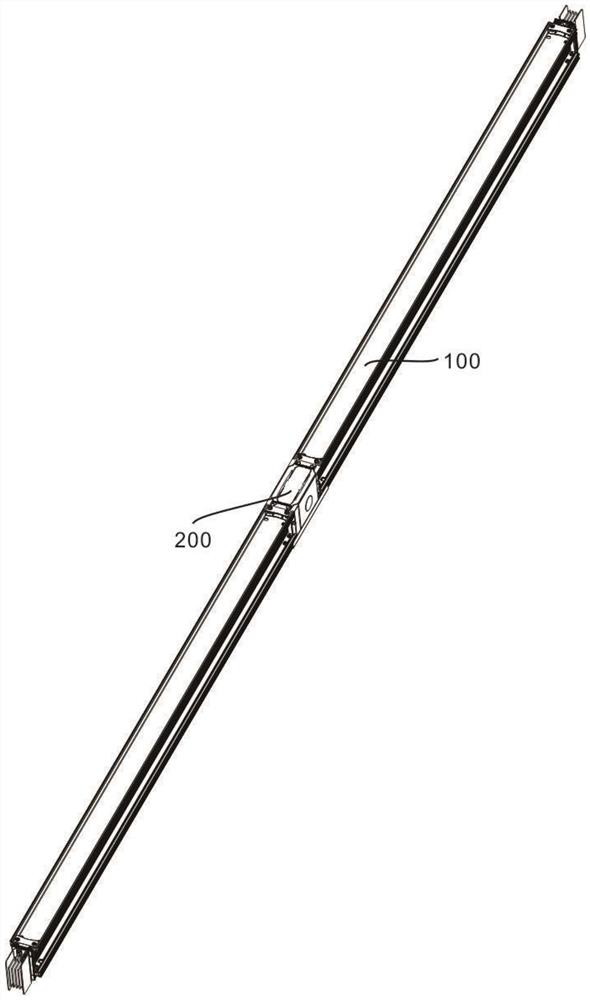

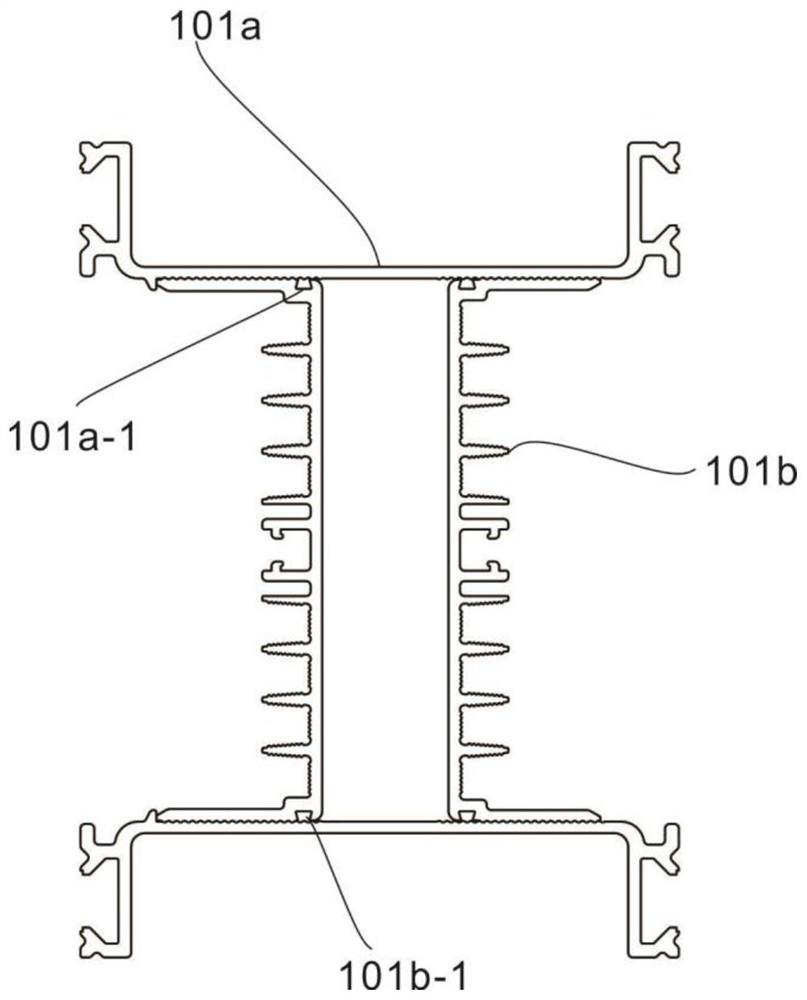

Single dual-circuit bus duct capable of combining bus and cable

PendingCN107706860AImprove securityExtended service lifeTotally enclosed bus-bar installationsMonomer compositionElectrical conductor

The invention relates to a single dual-circuit bus duct capable of combining a bus and a cable. The single dual-circuit bus duct comprises a shell, wherein a busbar accommodating space on the upper part and a cable accommodating space on the lower part are formed in the shell; multiple busbar conductors are arranged in the busbar accommodating space; the multiple busbar conductors are electricallyinsulated by insulating and phase-separating blocks; and multiple cables are arranged in the cable accommodating space. The bus duct provided by the invention combines the busbar conductors capable of forming a power circuit and the cables capable of forming an illumination circuit in the single shell, so that the bus duct is particularly suitable for occasions needing power and illumination distributing lines at the same time, such as an industrial factory building and a track traffic tunnel.

Owner:珠海光乐电力母线槽有限公司

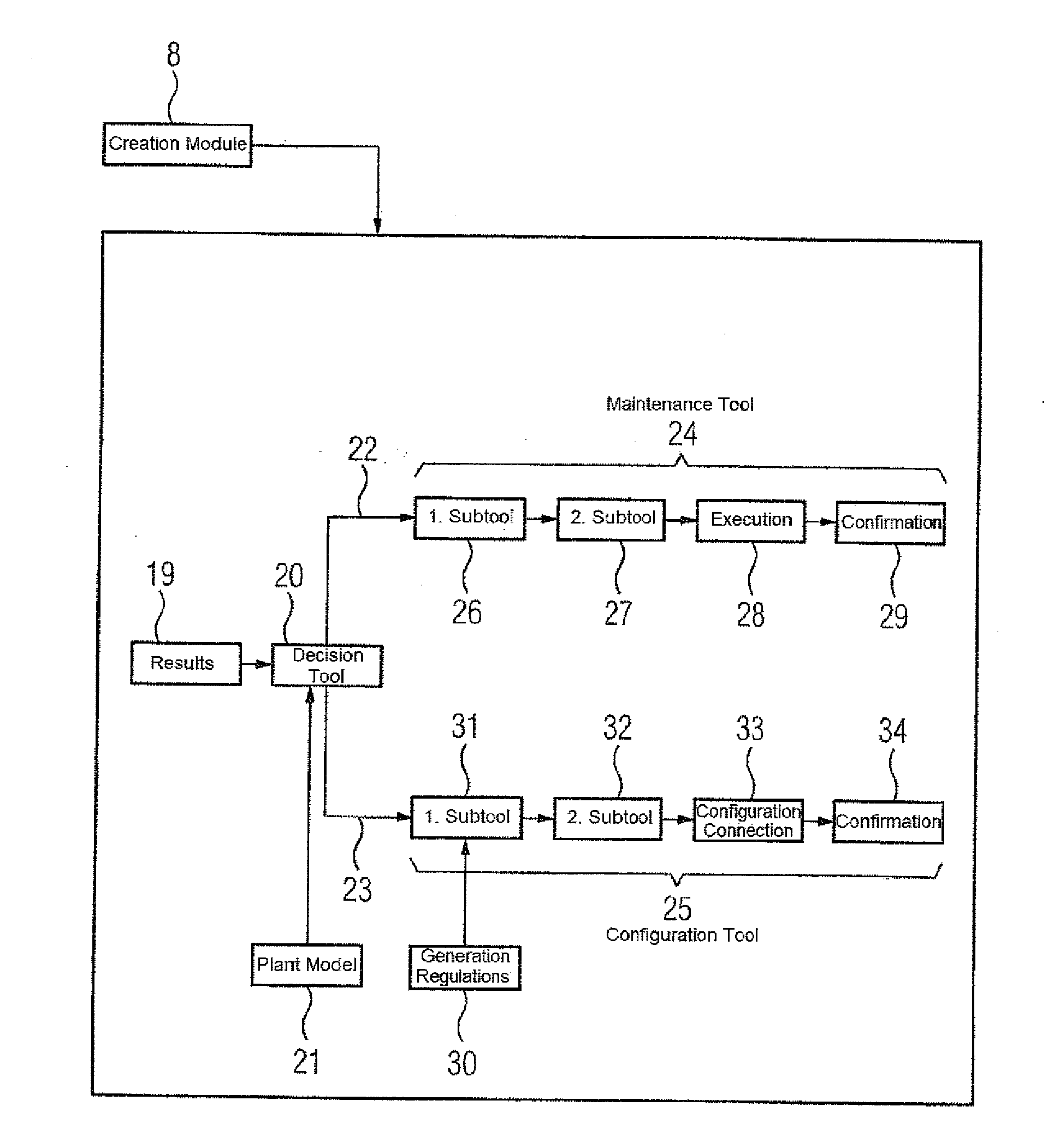

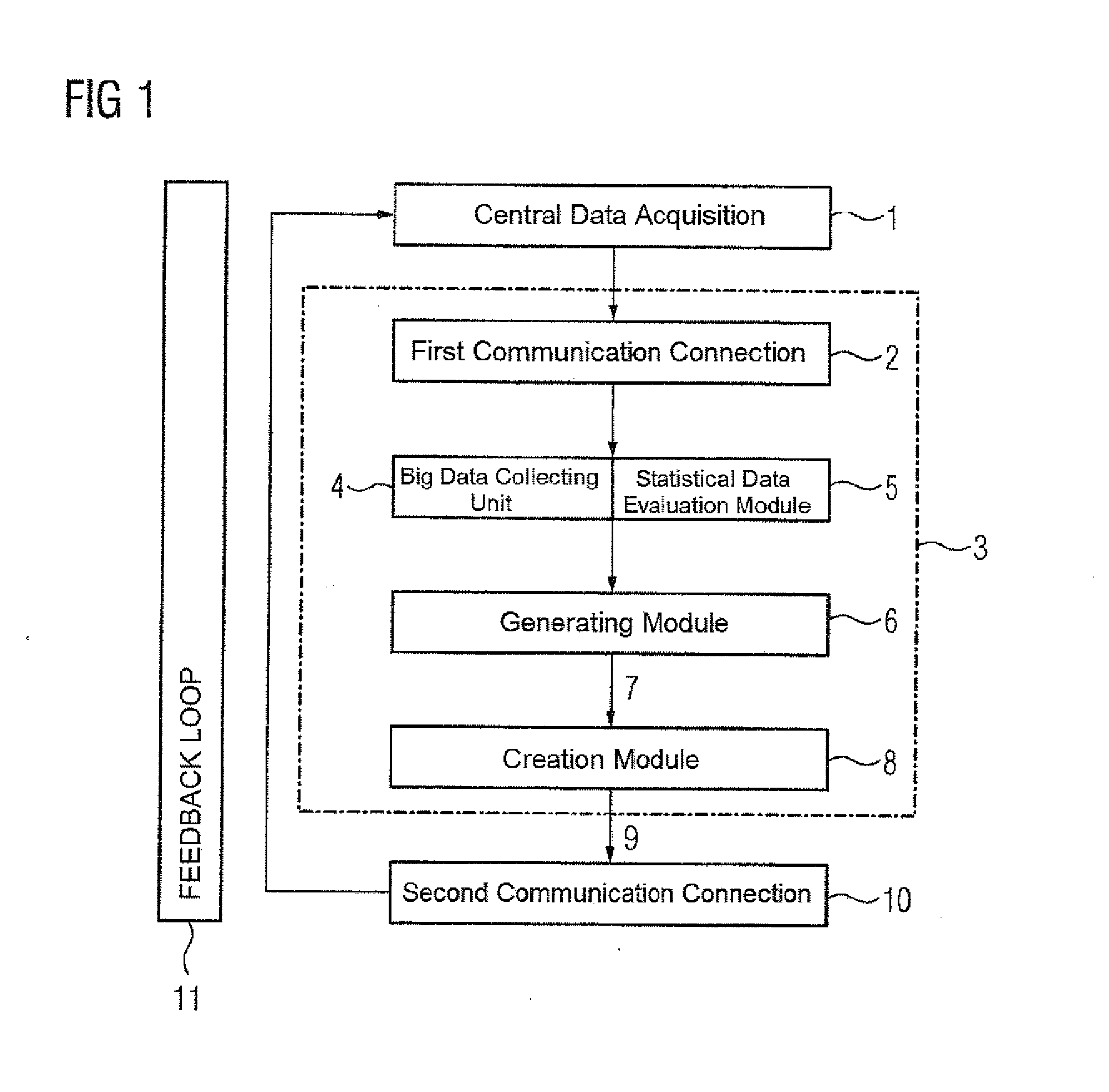

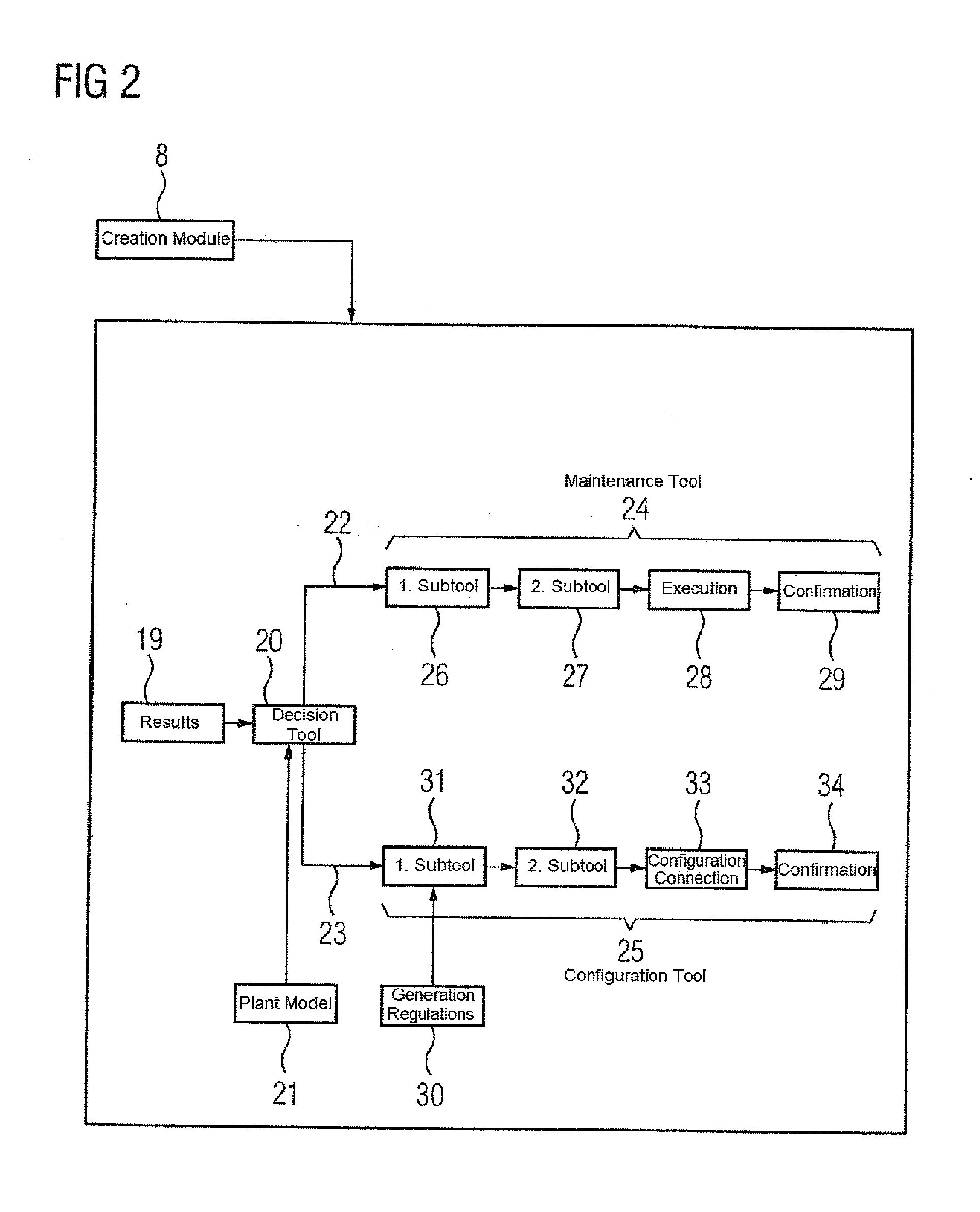

System for controlling, monitoring and regulating processes in industrial plants and a method for operating such a system

InactiveUS20170052532A1Little effortImprove efficiencyTesting/monitoring control systemsTotal factory controlData acquisitionComputer module

A system for controlling, monitoring and regulating a process in an industrial plant includes a closed feedback loop which includes an automatically configurable central data acquisition for acquiring an operating parameter generated by the industrial plant on a customer side in a field, and a central data evaluation unit. The central data evaluation unit includes a centralized data collecting unit, a generating module configured to generate a result for plant optimization, process extension, optimization of necessary maintenance works, or any combination thereof, and a creation module configured to create a new target parameter via automated adaptation of the operating parameter. A first communication connection transmits data from the field to the central data evaluation unit, and a second communication connection transmits data in response to the target parameter from the central data evaluation unit back to the field and adjusts the industrial plant as a function of the target parameter.

Owner:SIEMENS AG

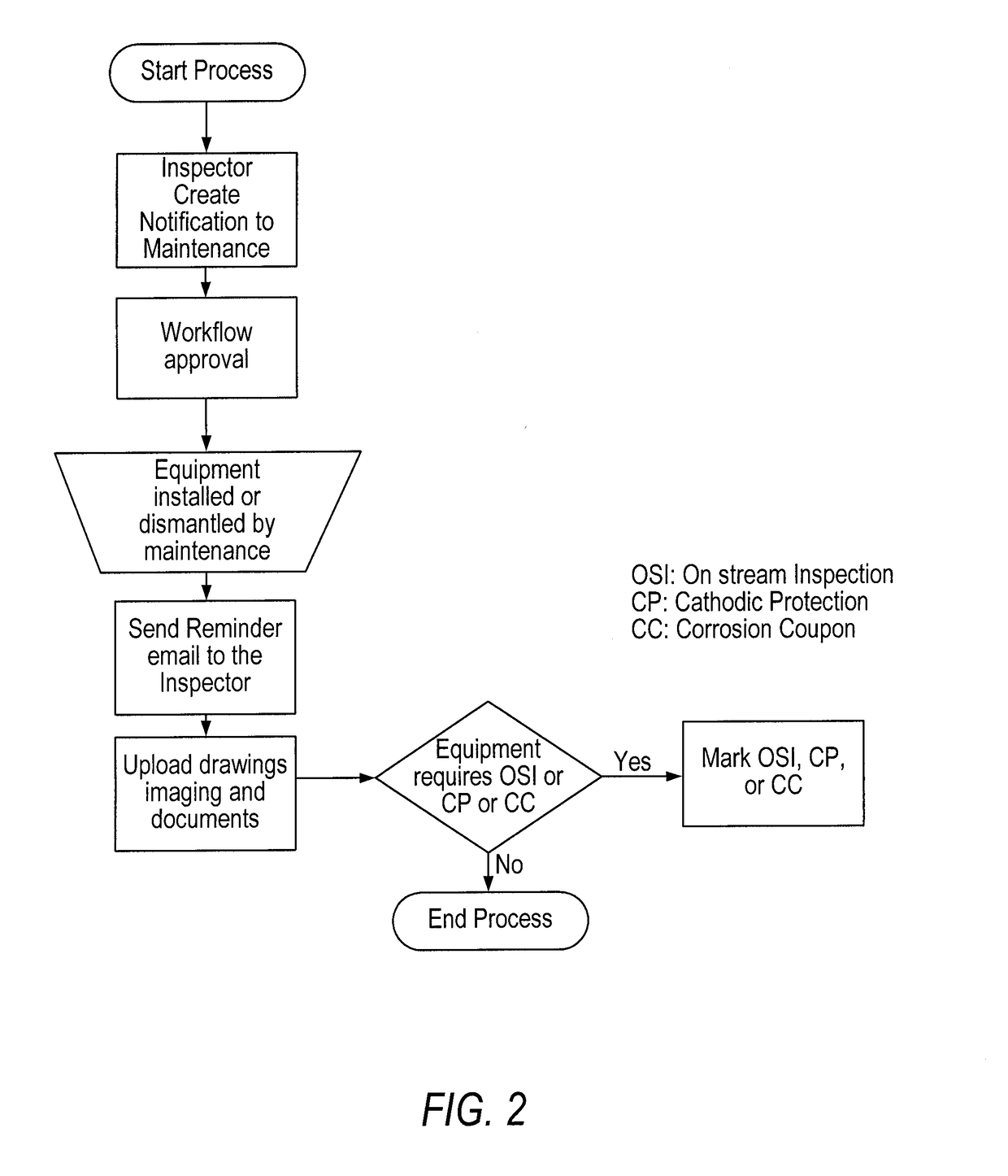

System for inspection and maintenance of a plant or other facility

InactiveUS20170228702A1More accurate, systemComputer controlTesting/monitoring control systemsSoftware modulesMaintenance system

Owner:SAUDI ARABIAN OIL CO

Hydrophilic radiation cooling coating, and preparation method and application thereof

ActiveCN112126260AHigh solar reflectanceLong-term radiation cooling functionAntifouling/underwater paintsAlkali metal silicate coatingsIndustrial premisesMineralogy

The invention discloses a hydrophilic radiation cooling coating, and a preparation method and application thereof. The hydrophilic radiation cooling coating is prepared from, by weight, 15-30 parts ofalkali metal silicate, 5-10 parts of a hydrophilic silicon material, 20-40 parts of a sunlight reflecting material, 20-40 parts of an infrared radiation material, 3-5 parts of auxiliaries and 60-100parts of deionized water through high-speed dispersion and uniform mixing and filtering using a filter screen. A base material is coated with the hydrophilic radiation cooling coating, micropores contained in a hydrophilic coating layer formed after drying cooperate with a sunlight reflection material to generate 0.93-0.97 sunlight reflectivity, and the sunlight reflection function can be recovered through clear water washing after pollution. The radiation cooling coating is simple in process and low in cost, is suitable for special shapes and planes, is suitable for occasions such as residential buildings, commercial buildings and industrial factory buildings, and has a wide application prospect.

Owner:杭州净碳科技有限公司

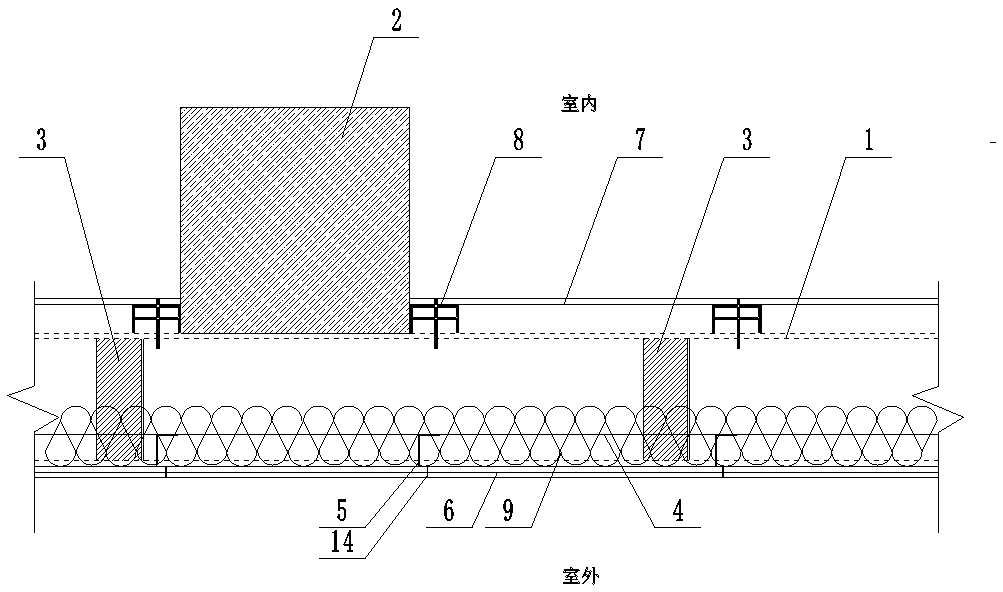

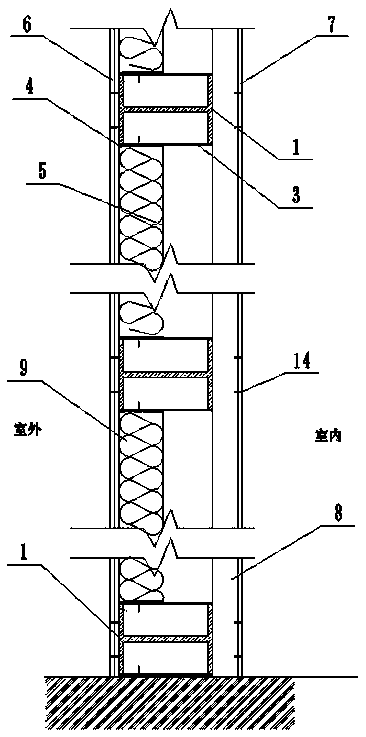

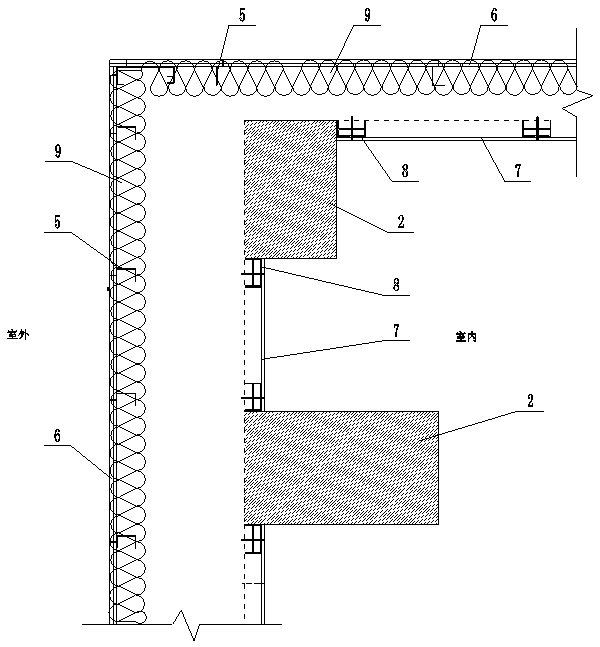

Anti-explosion pressure-relief wall construction method for large-scale industrial factory building

ActiveCN110670798AImprove quality and efficiencyImprove construction efficiencyBuilding componentsLine tubingArchitectural engineering

The invention relates to an anti-explosion pressure-relief wall construction method for a large-scale industrial factory building. Purlines are welded and fixed to embedded parts of a framework structure, outer-side-of-wall horizontal keels are connected with the purlines through angle iron, and welded and fixed to the upper and lower sides of the purlines; a outer-side-of-wall vertical keel is fixed to each span of the outer-side-of-wall horizontal keel, the inner side of the wall is only provided with inner-side-of-wall vertical keels, the inner-side-of-wall vertical keels are connected withthe purlines, and inner wall boards are fixed to the inner-side-of-wall vertical keels; the outer-side-of-wall vertical keels are filled with thermal preservation materials; anti-explosion pressure-relief boards at the two sides of the wall are fixed to the corresponding vertical keels as wall boards respectively. By conducting construction according to the method, the improvement of the engineering construction quality and construction efficiency is facilitated, and particularly, the method is suitable for construction for operation platforms of pressure gasification large-scale chemical factory buildings and the like, equipment, pipelines, doors and windows, holes and the like of inlet and outlet frames, and building outer walls under irregularity and other complicated conditions.

Owner:CHINA CHEM ENG SECOND CONSTR

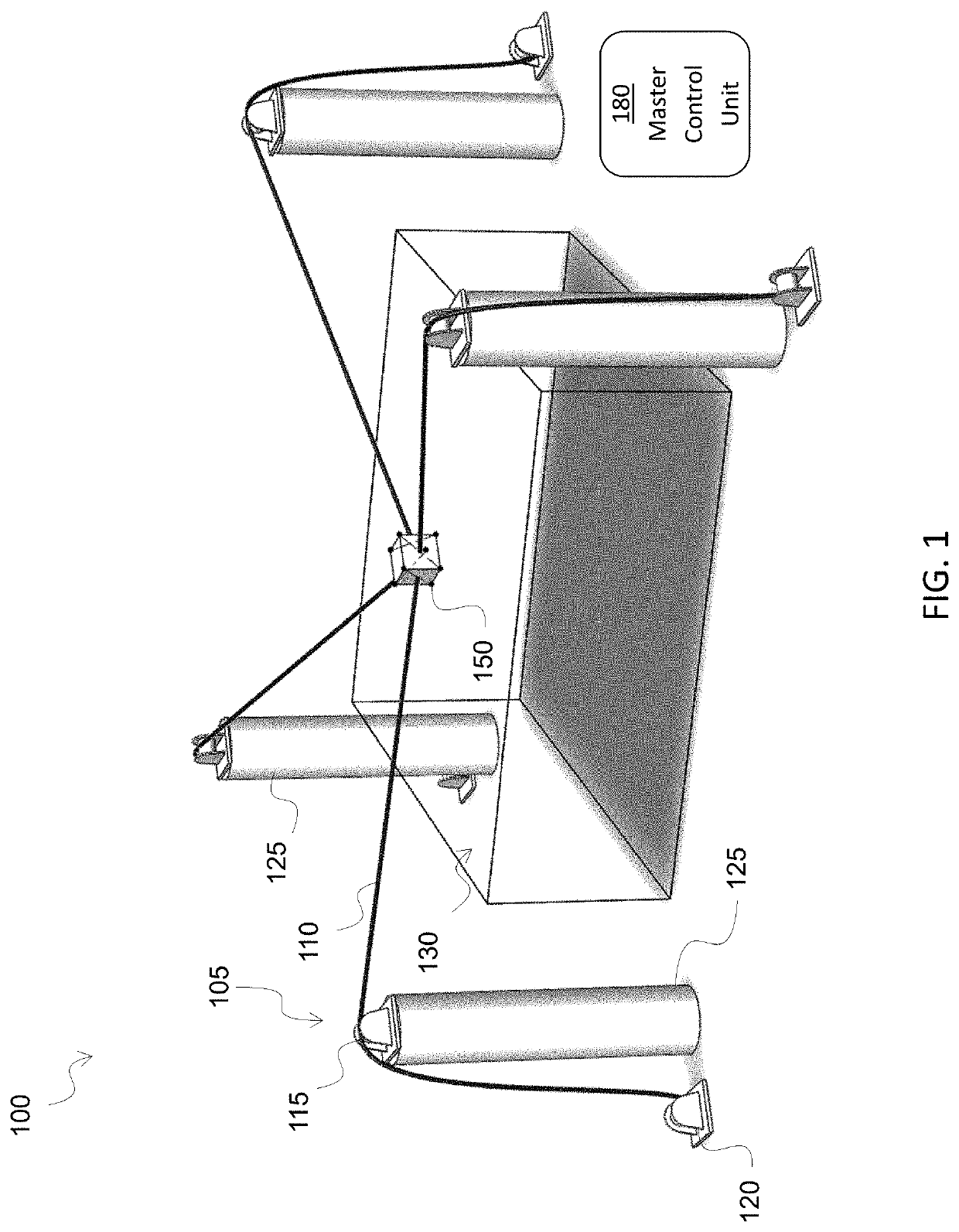

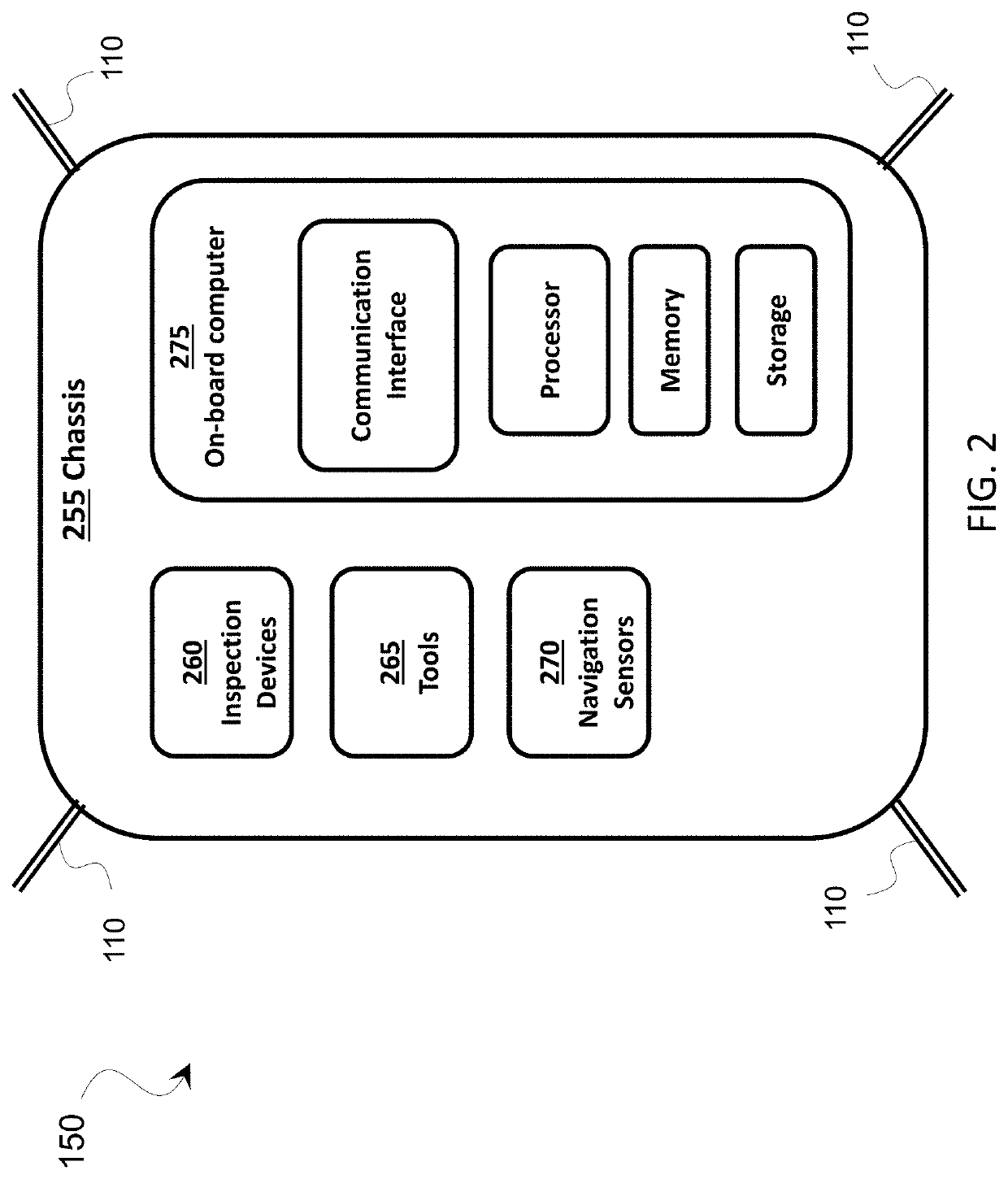

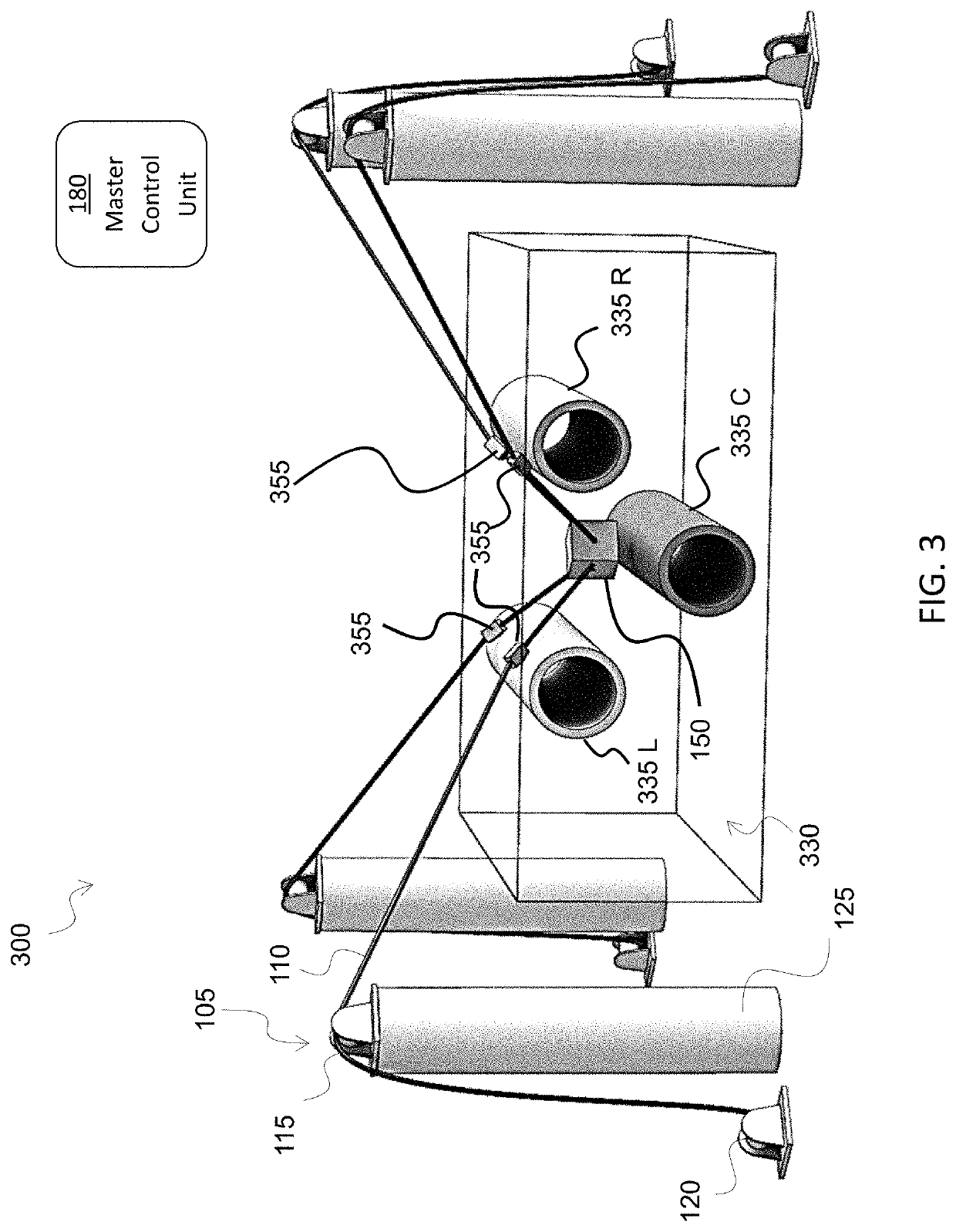

Cable suspended robot for industrial plants

ActiveUS20220024031A1Programme controlProgramme-controlled manipulatorAerial cableControl engineering

Cable-driven robotic platform systems and methods of operation are disclosed. The system includes a robotic platform suspended by a system of overhead cables, motorized cable reels and pulleys. A master control computer coordinates operation of the motorized cable system as a function of sensor data captured by navigation sensors on-board the platform so as to move the robotic platform inside an industrial plant. The system is configured to maneuver around pipings and avoid obstacles in the plant in order to maximize the effective workspace that the robotic platform can reach to perform operations including inspection or repair. Additionally, a robotic “wire jacket” device can be attached to suspension cables and configured to crawl along a cable. The wire-jacket can be selectively positioned on a cable to provide an intermediate cable suspension point that improves platform mobility within congested spaces and avoids obstacles.

Owner:SAUDI ARABIAN OIL CO

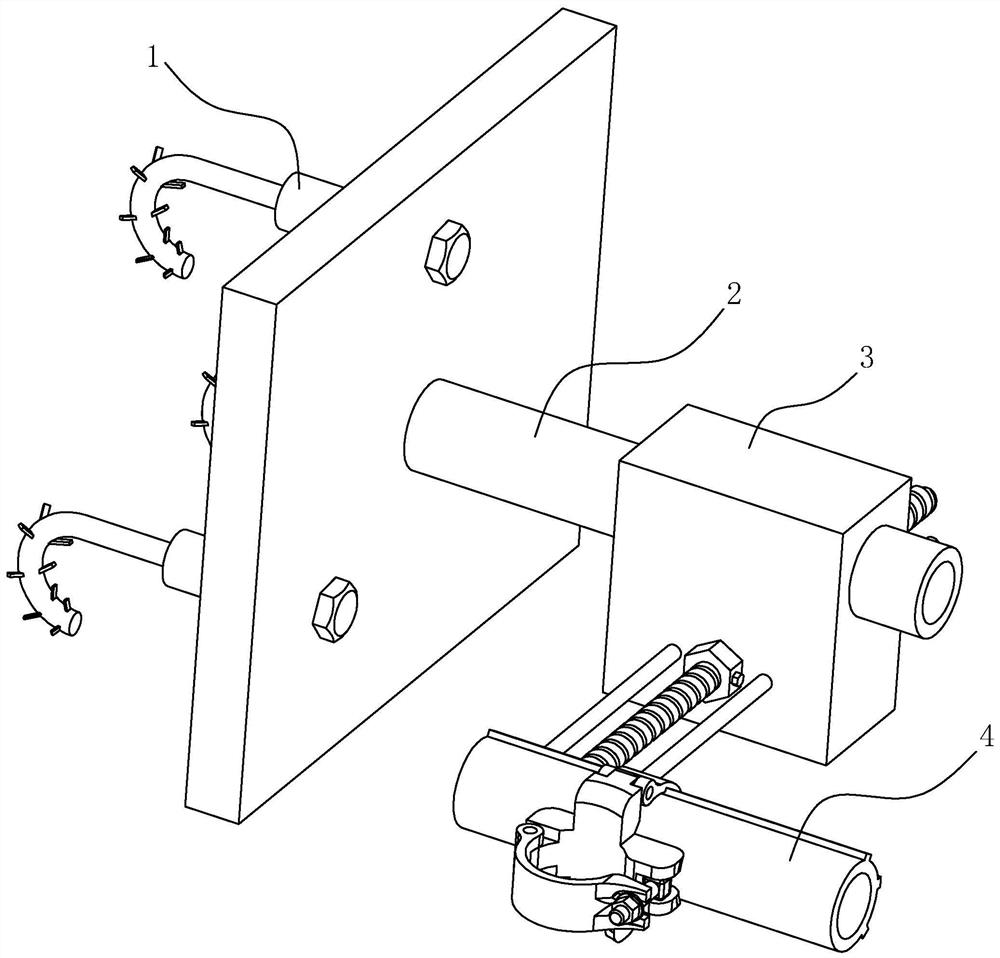

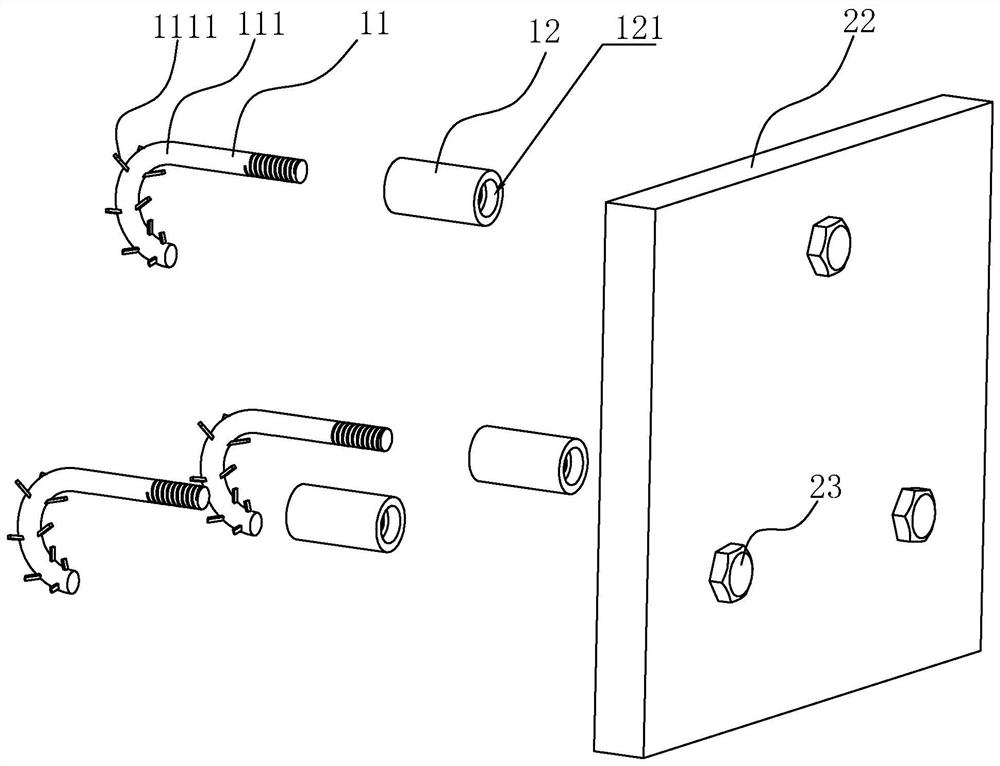

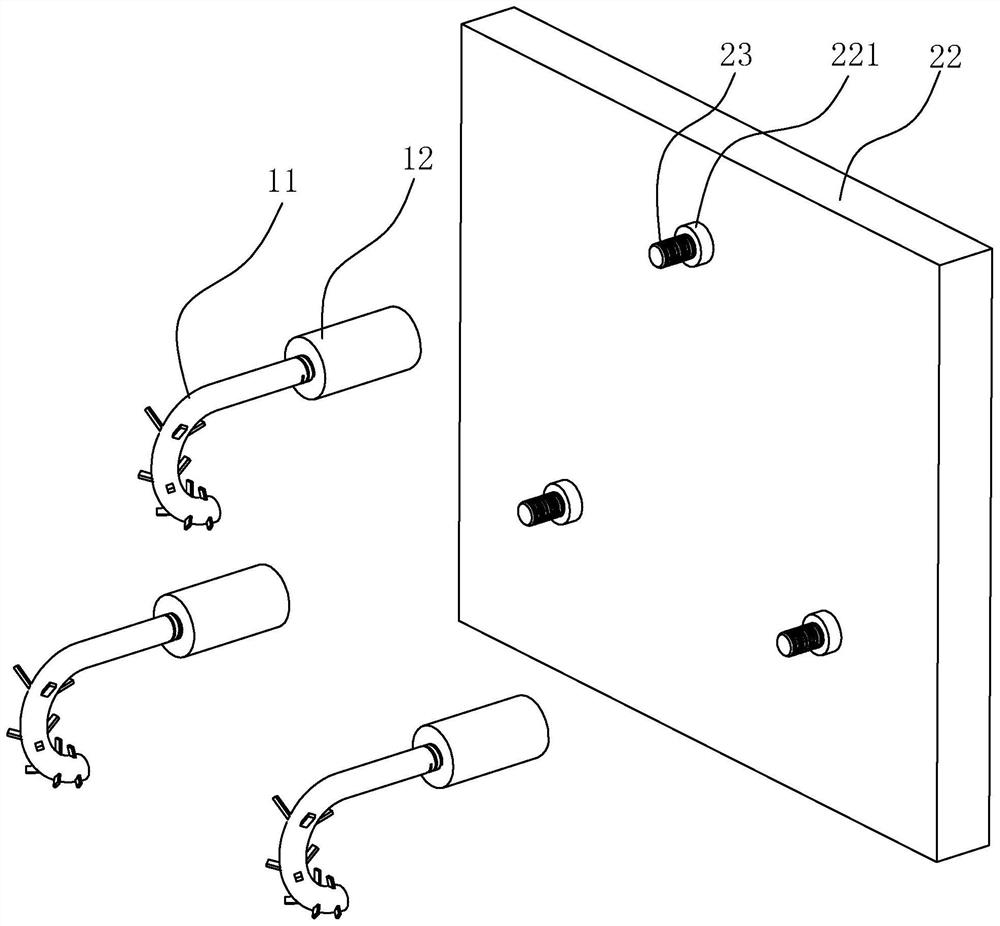

Wall connecting device used for industrial factory building outer wall scaffold and use method thereof

InactiveCN111608385AImprove stabilityEasy alignmentScaffold accessoriesConstruction engineeringIndustrial premises

The invention relates to a wall connecting device used for an industrial factory building outer wall scaffold and a use method thereof, and belongs to the field of building construction. The device comprises a pre-embedding part and a connecting part, the pre-embedding part comprises a pre-embedding part and a pre-embedding casing pipe, the end, close to the outside of a wall, of the pre-embeddingrod is provided with an outer thread, an inner thread is formed on the inner wall of the pre-embedding casing pipe, the inner wall of the pre-embedding casing pipe sleeves the pre-embedding rod in athreaded manner, the connecting part comprises a connecting pipe, one end of the connecting pipe is provided with a connecting plate, the connecting plate is provided with a positioning bolt, the positioning bolt penetrates through the connecting plate to be inserted into the pre-embedding casing pipe, the end, away from the connecting plate, of the connecting pipe is fixedly provided with a connecting block, a through hole is formed in the connecting block, a fastening assembly is mounted in the through hole, the fastening assembly comprises a fastening pipe, one end of the fastening pipe isprovided with a right-angle fastening part, an inserting rod is fixed to the fastening pipe, and is mounted in the connecting block in a penetrating manner, and a positioning part enabling the inserting rod and the connecting block to be oppositely fixed is arranged on the inserting rod. The wall connecting device has the advantages of conveniently improving the alignment effect of the wall connecting device and a scaffold so as to improve the connecting stability.

Owner:成都市天柱建筑工程有限公司

Gel type radiation cooling coating, and preparation method and application thereof

ActiveCN112126287AWith radiation cooling functionLong-term stabilitySpecial surfacesReflecting/signal paintsIndustrial premisesIndustrial Factory

The invention discloses a gel type radiation cooling coating, and a preparation method and application thereof. The gel type radiation cooling coating is prepared from, by weight, 5-30 parts of a water-based polymer, 20-40 parts of a sunlight reflecting material, 20-40 parts of an infrared radiation material, 3-5 parts of an auxiliary agent and 60-100 parts of deionized water through high-speed dispersion and uniform mixing, and filtration by a filter screen. A base material is coated with the gel type radiation cooling coating according to the thickness of 200-800 [mu]m, a hydrogel coating layer formed by cross-linking after sealed packaging has the sunlight reflectivity of 0.92-0.96, and the sunlight reflection function can be recovered through clear water washing after pollution. The radiation cooling coating is simple in process and low in cost, is suitable for special shapes and planes, is suitable for occasions such as residential buildings, commercial buildings and industrial factory buildings, and has a wide application prospect.

Owner:杭州净碳科技有限公司

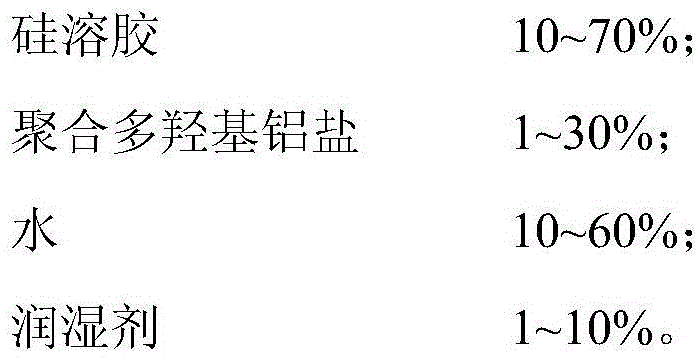

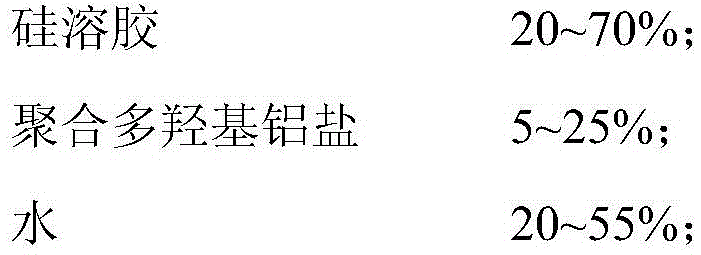

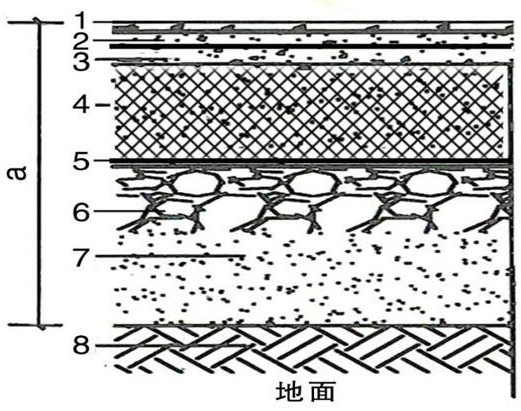

Permeable liquid hardener and preparation method thereof

The invention relates to a permeable liquid hardener and a preparation method thereof. The hardener comprises raw materials in percentage by mass as follows: 10%-70% of silica sol, 1%-30% of polymerized polyhydroxyl aluminum salt, 10%-60% of water and 1%-10% of a wetting agent. Meanwhile, the preparation method is simple, raw materials are cheap, and the industrial production cost is reduced. According to the preparation method, paint can be prepared after the raw materials are mixed and dispersed, the preparation technology is simple, easy to implement and convenient to operate, industrial mass production is facilitated, the industrial production cost is reduced, and the hardener is particularly applicable to cement-based floors such as industrial plants, parking lots and the like and has broad application prospect.

Owner:苏州纳固新材料有限公司

Water-based radiation cooling coating as well as preparation method and application thereof

PendingCN114790350AReduce pollutionShorten the transmission pathCovering/liningsReflecting/signal paintsCooling effectEngineering

The invention discloses a water-based radiation cooling coating as well as a preparation method and application thereof. The water-based radiation cooling coating is prepared from the following components in parts by mass: 10-25 parts of water-based film-forming resin with infrared radiation, 35-42 parts of a sunlight reflecting material, 1-9 parts of an auxiliary agent and 30-42 parts of water. After being prepared into a coating, the water-based radiation cooling coating disclosed by the invention is dried to form numerous micro-gaps, and cooperates with a sunlight reflecting material to generate air-resin, air-filler and resin-filler multi-interfaces, so that the transmission path of light is shortened, the scattering effect of light is enhanced, the temperature of the back of the coating can be about 5 DEG C lower than the ambient temperature, and the service life of the coating is prolonged. And the cooling effect is obvious. In addition, the coating is good in high-temperature-resistant and anti-aging effects, is suitable for outer wall surfaces of occasions such as residential buildings, commercial buildings and industrial factory buildings, and has a wide application prospect.

Owner:WUHAN UNIV OF TECH

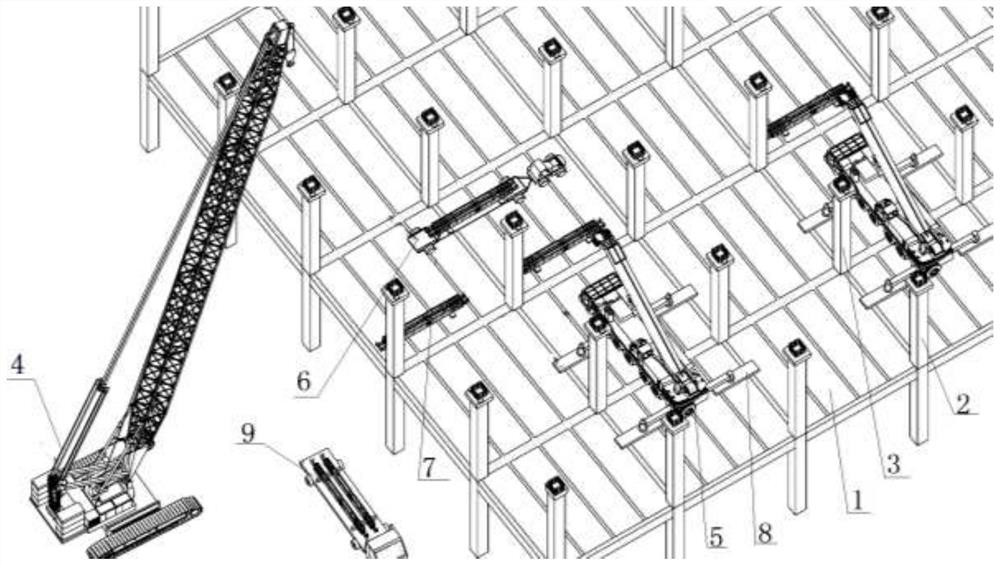

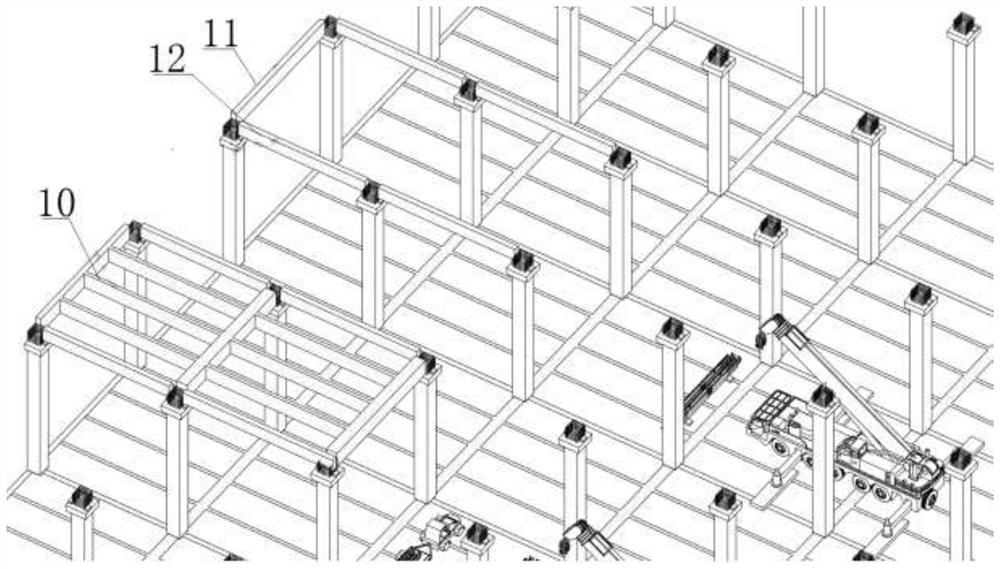

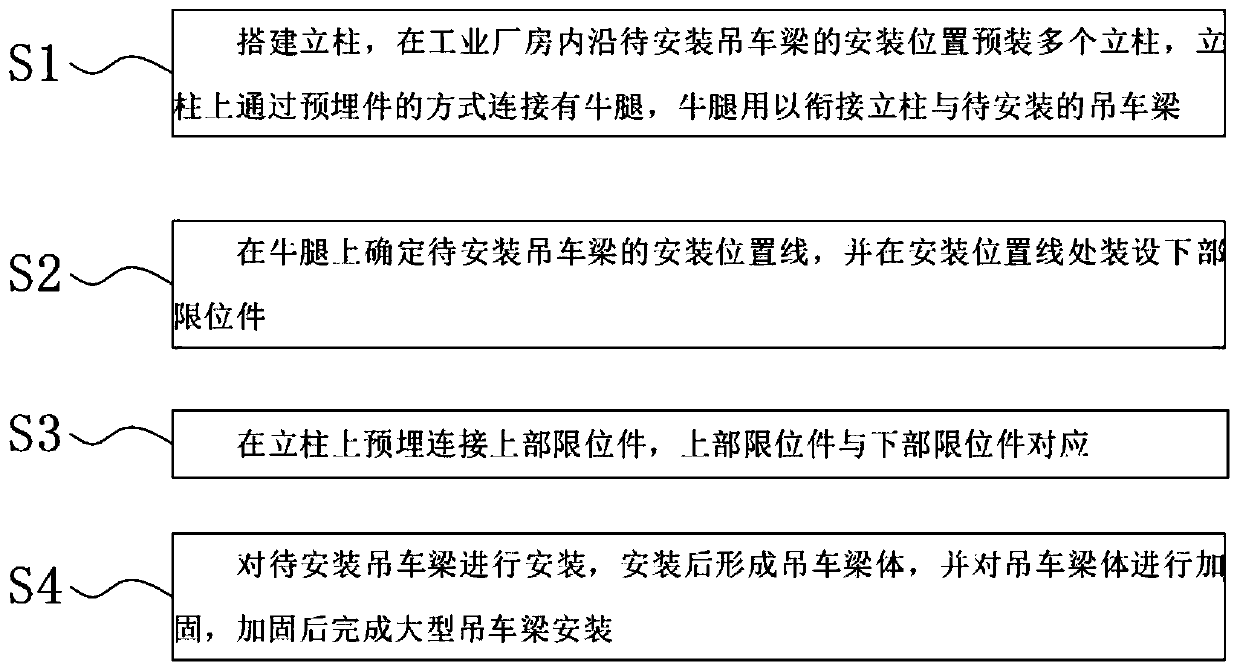

Step-by-step hoisting construction method for prefabricated beam of multilayer fabricated industrial factory building

InactiveCN112443040AShorten the lifting periodExtended production timeFloorsBuilding material handlingArchitectural engineeringIndustrial premises

The invention discloses a step-by-step hoisting construction method for a prefabricated beam of a multilayer fabricated industrial factory building. The step-by-step hoisting construction method comprises the following steps that (1), at least one truck crane is hoisted to a second floor; (2), at least one short barge truck is hoisted to the second floor; (3), the prefabricated beam is conveyed toa prefabricated beam placing position in front of each truck crane through a crawler crane and the short barge trucks; (4), a prefabricated beam is installed at the third floor by the truck cranes, after hoisting is completed, the crawler crane correspondingly hoists the truck cranes and the short barge trucks to the ground, and then the crawler crane hoists part of the prefabricated beams whichare not hoisted to the side span position; and (5), third-layer floor and column construction is carried out, and then the hoisting work from the step (1) to the step (4) is repeated till hoisting ofthe prefabricated beams of all floors is completed. The hoisting method can shorten the hoisting period of the prefabricated beams.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

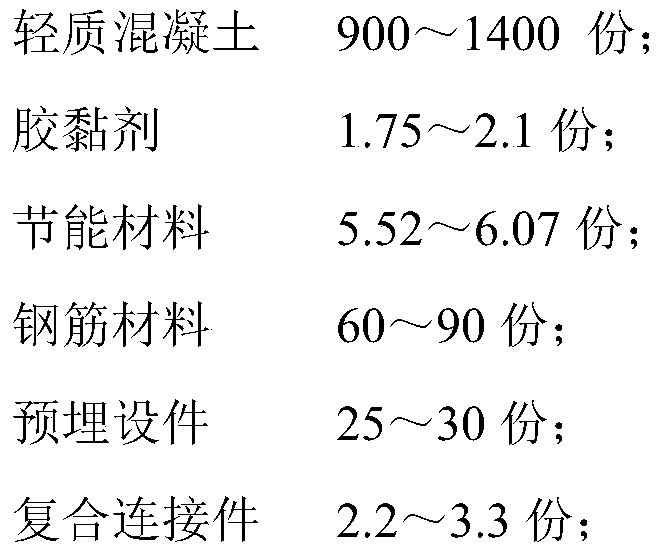

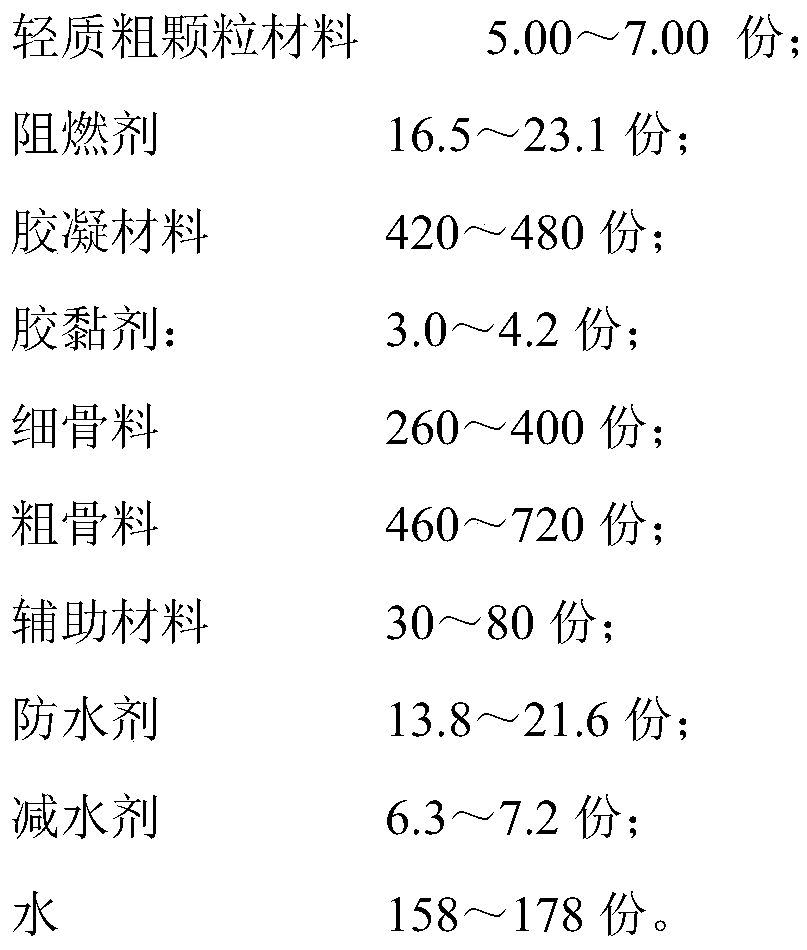

Environment-friendly and energy-saving water-proof wall material for assembly-type building and production method for wall material

The invention relates to the field of wall materials for construction such as industrial plants, civil housing, hotels and schools, in particular to an environment-friendly and energy-saving and water-proof wall material for an assembly-type building and a production method for the wall material. The wall material comprises the followings: 900-1400 parts of light concrete, 1.75-2.1 parts of an adhesive, 5.52-6.07 parts of energy-saving materials, 60-90 parts of rebar materials, 25-30 parts of pre-buried pieces, and 2.2-3.3 parts of composite pieces. A decorative material comprises the followings: 4.2-5.2 parts of inner wall putty, 5.2-7.0 parts of outer wall putty, and 10.5-14 parts of waterproof latex paint. A lightweight coarse particle material is the particle made of one or more of waste polyphenyl foam, polyurethane foam and waste phenolic resin foam, the particle size is 5-15 mm, and the stacking density is 10 kg / m3. The wall material has the advantages of being low in water absorption rate, poisonless, harmless, energy-saving, heat-insulation and long in service life.

Owner:ANGANG CONSTR CONSORTIUM

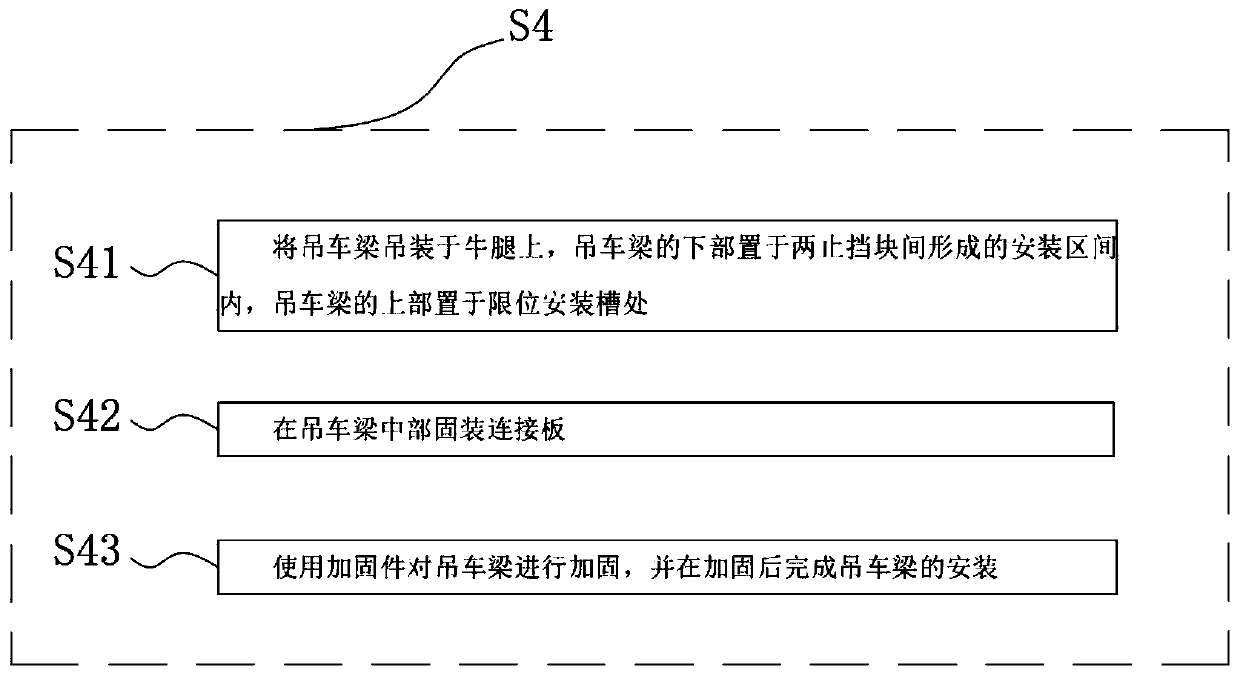

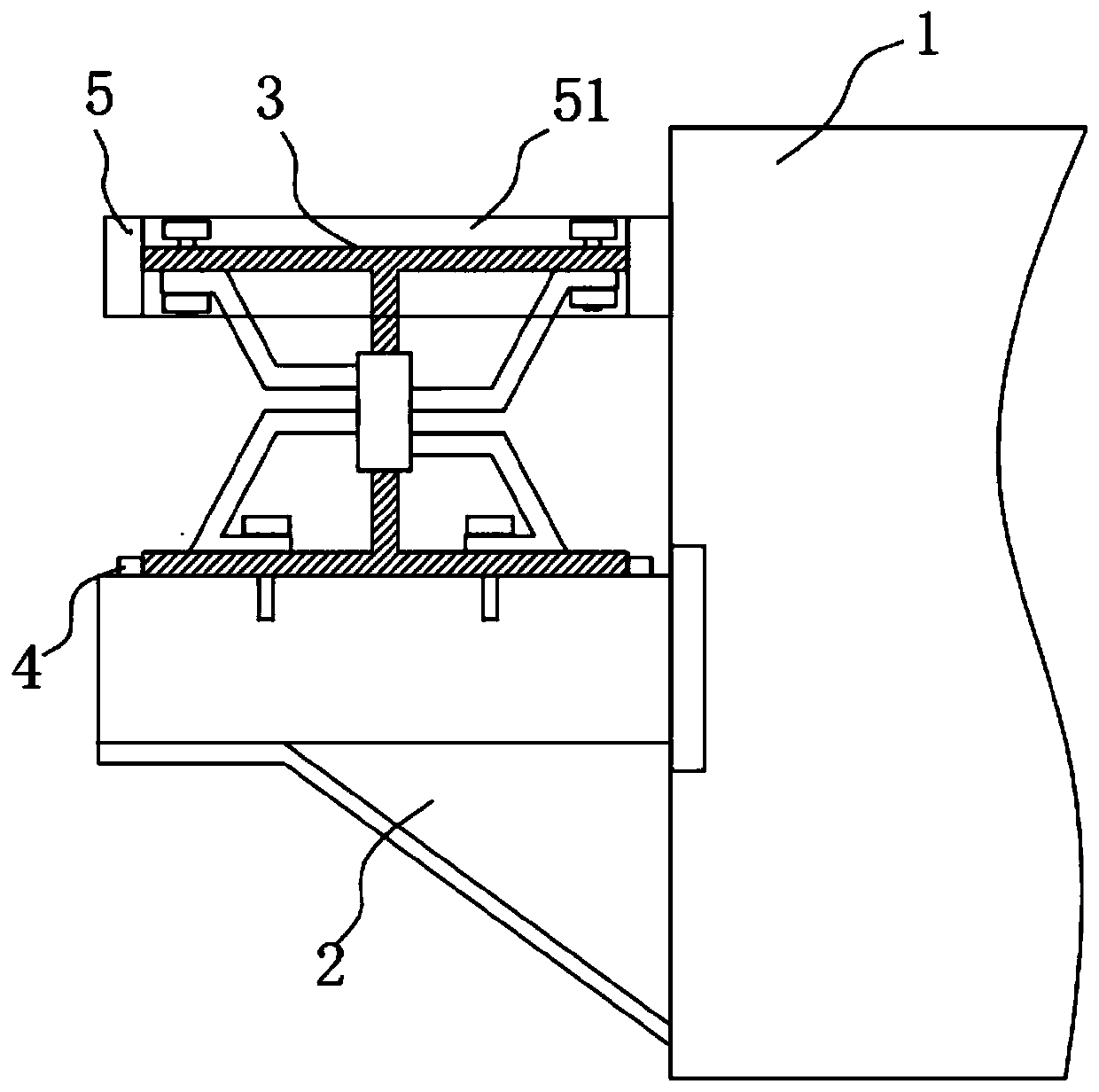

Installation method of large crane beam

InactiveCN111591882AGuaranteed stabilityGuaranteed positioning accuracyLoad-engaging girdersIndustrial premisesCrane Equipment

The invention belongs to the field of crane equipment, and particularly relates to an installation method of a large crane beam. The installation method of the large crane beam includes the followingsteps that a plurality of stand columns are established, the stand columns are preloaded along the installation position of crane beams to be installed in an industrial factory building, corbels are connected to the stand columns by the way of embedded parts, and the corbels are used for connecting the stand columns with the crane beams to be installed; installation position lines of the crane beams to be installed are determined on the corbels, and lower part limit members are arranged at the installation position lines; upper part limit members are pre-buried and connected to the stand columns, and the upper part limit members correspond to the lower part limit members; the crane beams to be installed are installed, a crane beam body is formed after installation, the crane beam body is strengthened, and the large crane beam is installed after reinforcement. The installation method of the large crane beam can ensure the position of the crane beams to the installation position, the position accuracy of the crane beams to be installed is ensured, the crane beams are limited through the lower part limit members and the upper part limit members, the stability of the crane beams to beinstalled is ensured, and the pressure resistance of the crane beams is improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

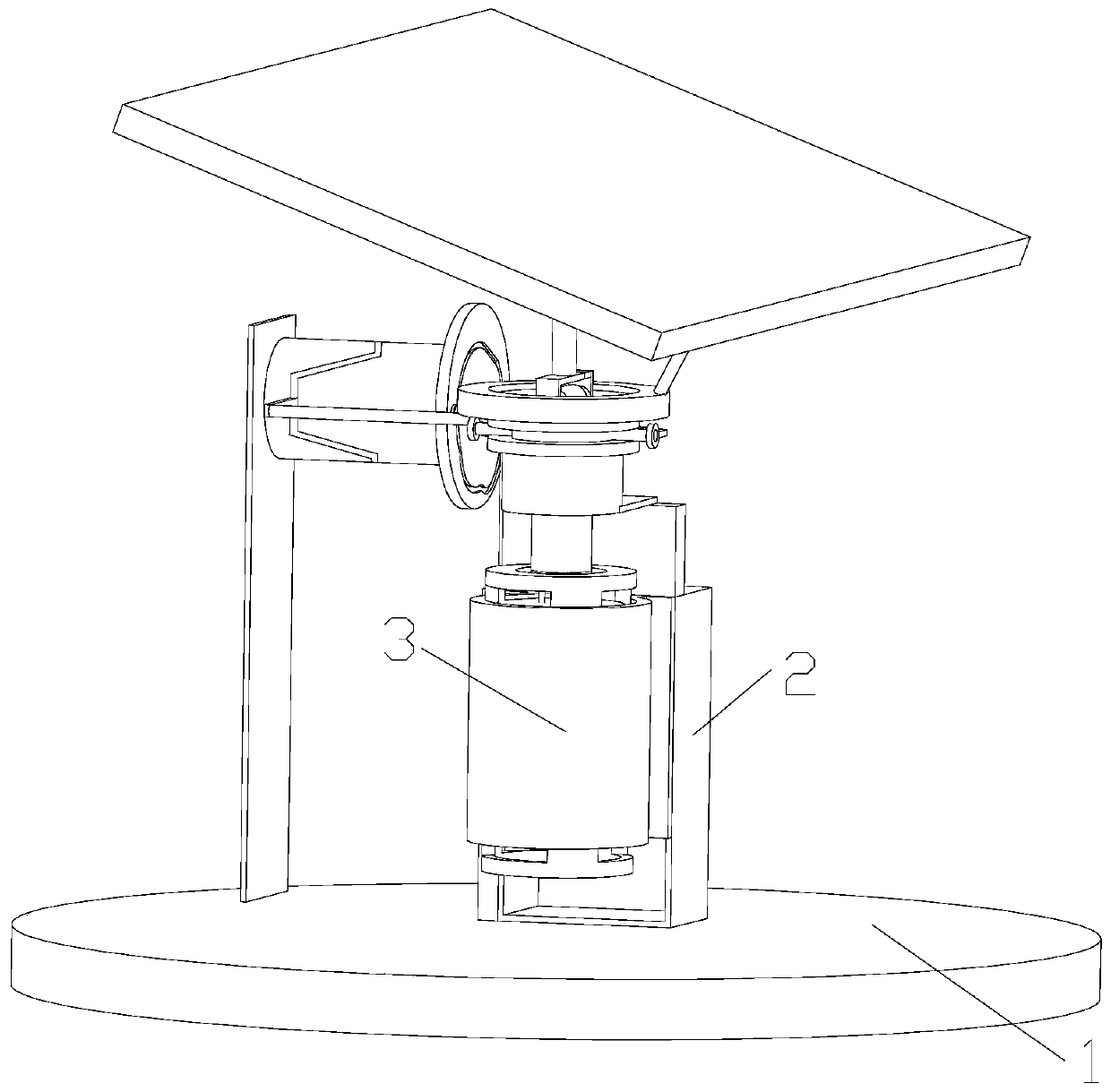

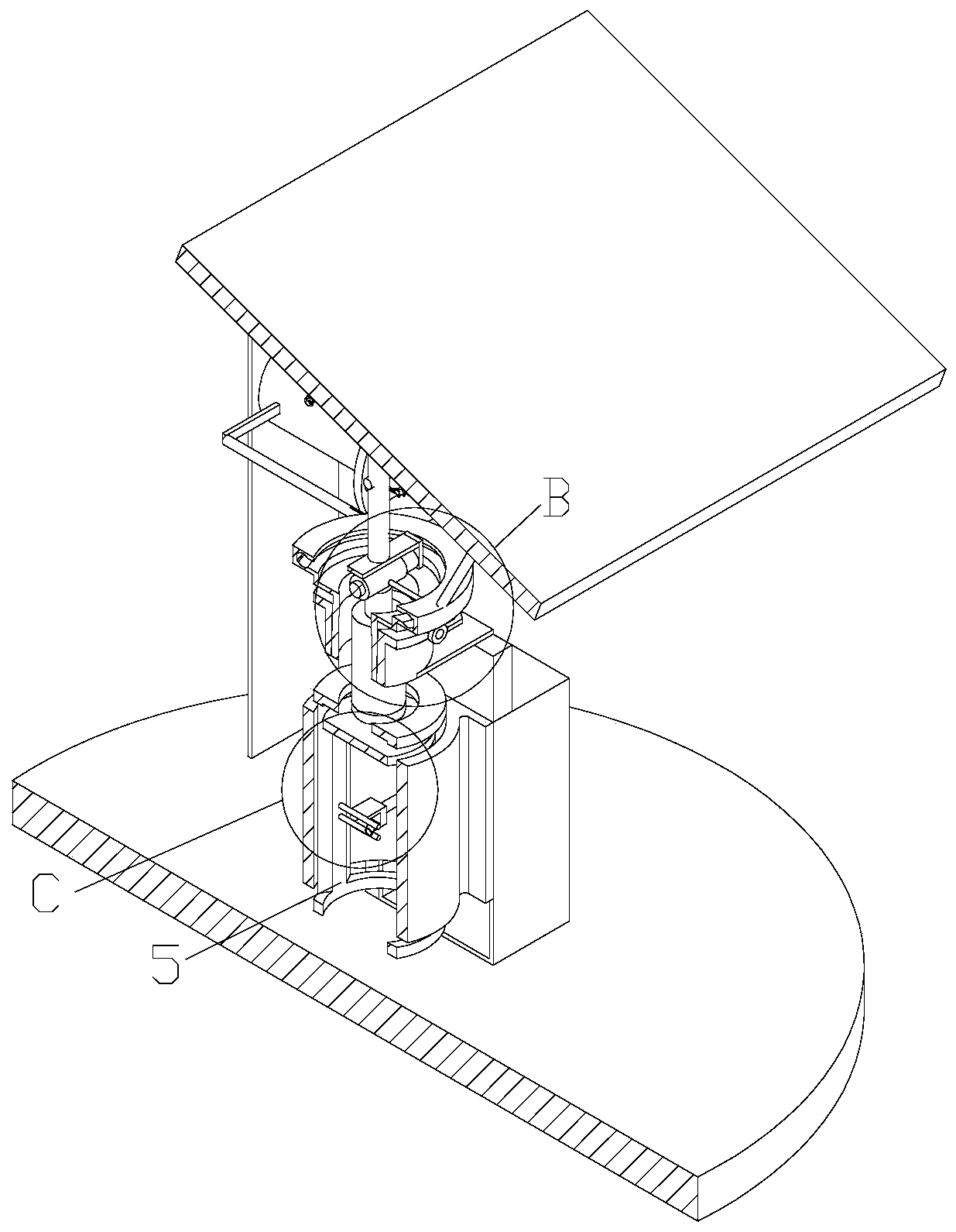

Solar photovoltaic power generation system for industrial factory building

ActiveCN111030585AImprove absorption rateSimple structurePhotovoltaic supportsSolar heating energyIndustrial premisesIndustrial Factory

The invention discloses a solar photovoltaic power generation system for an industrial factory building. The solar photovoltaic power generation system comprises a base, a fixed shell fixedly arrangedon the upper end face of the base, a fixed shell space arranged in the fixed shell, a motor fixedly arranged on the front end wall of the fixed shell space, a lifting device arranged on the motor anda supporting device arranged on the lifting device; the lifting device comprises a cylindrical shell fixedly arranged on the front end face of the fixed shell, a first turning plate fixedly arrangedat the output end of the motor, and two second turning plates fixedly arranged on the upper sides and the lower sides of the front end face of the first turning plates respectively.

Owner:山东蓝迪照明科技有限公司

Bus duct end connection device

ActiveCN112838541AImprove waterproof performanceCooling bus-bar installationsTotally enclosed bus-bar installationsTemperature controlIndustrial premises

A bus duct end connection device disclosed by the present invention comprises a connection unit and a temperature control unit. The connection unit comprises a protection assembly and connection assemblies located at the two ends of the protection assembly, the protection assembly comprises symmetrically arranged first protection shells, and the connection assemblies comprise clamping shells located at the two ends of the first protection shells; and the temperature control unit comprises a temperature control assembly located between the connecting assemblies, and the temperature control assembly comprises a second protective shell fixed to the clamping shell through screws. Heat generated by circuit operation is absorbed through a temperature control assembly in the temperature control unit, so that the temperature of circuit operation is controlled to be within a normal range, and the situation that a bus duct end often causes circuit burnout due to poor heat dissipation performance, power failure of a large commercial plaza, a building, a gymnasium, a hospital, an industrial factory building and the like is caused, and economic loss is caused.

Owner:鼎圣集团有限公司

Wear-resistant hardening agent for concrete TWF application system

InactiveCN112479655ASolve the problem of wear-resistant hardener crackingSolve crackingFlooringPortland cementStructural engineering

The invention relates to the technical field of constructional engineering materials, in particular to a wear-resistant hardening agent for a concrete TWF (The Whole Floor, also called as an integralterrace) application system. The wear-resistant hardening agent is mainly composed of Portland cement, an expansion component, quartz sand, aggregate, silica fume, a water reducing agent and the like.The concrete base layer and the concrete TWF application system wear-resistant hardening agent are firmly and tightly combined, the concrete TWF application system wear-resistant hardening agent is attractive in color, free of fading, small in shrinkage, good in decoration effect, high in wear resistance and good in corrosion resistance, the use requirements of industrial plants and workshops canbe met, the novel workshop decoration effect can also be met, and meanwhile, the wear-resistant hardening agent can be applied to newly-built floors with design requirements, such as underground parking lots, shopping malls, hotels and buildings.

Owner:斯泰普力(东营)地坪科技有限公司

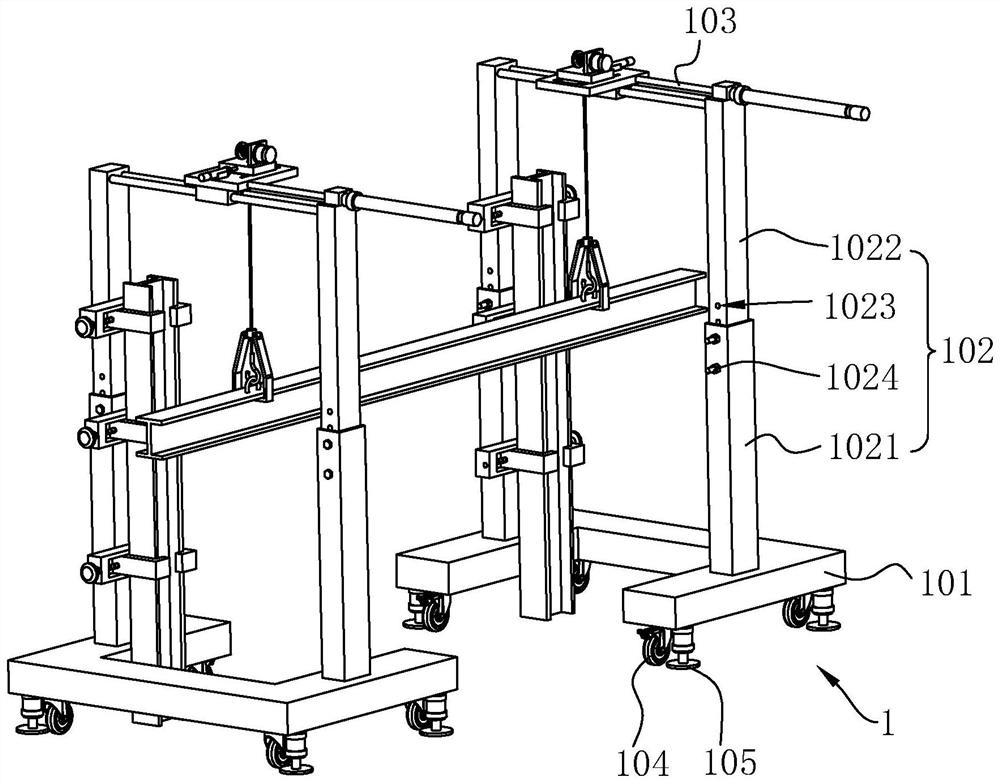

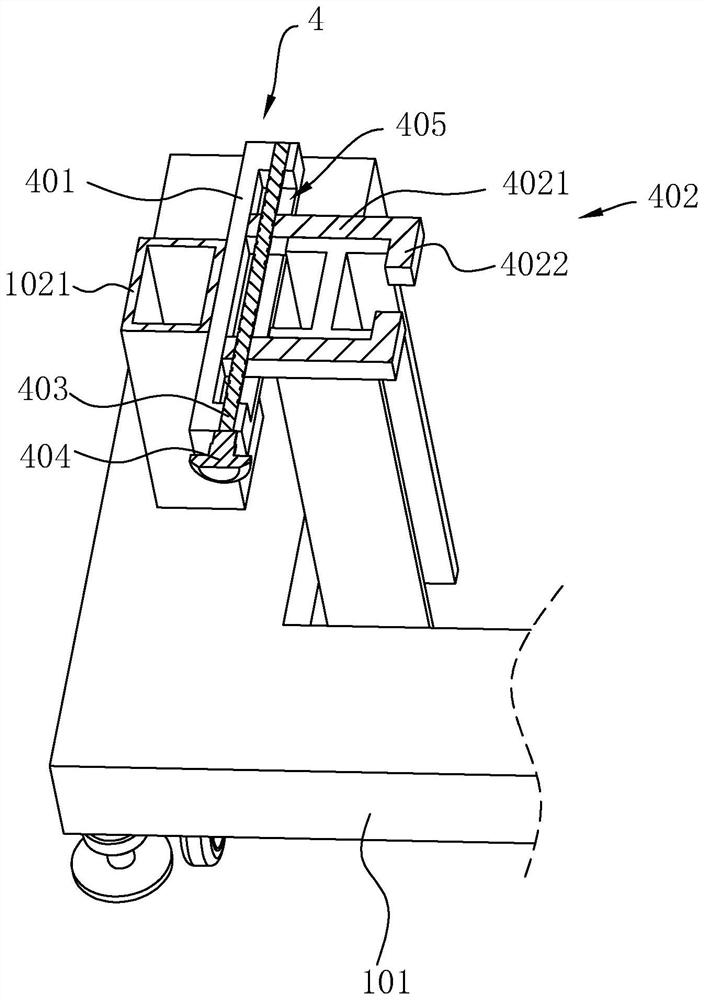

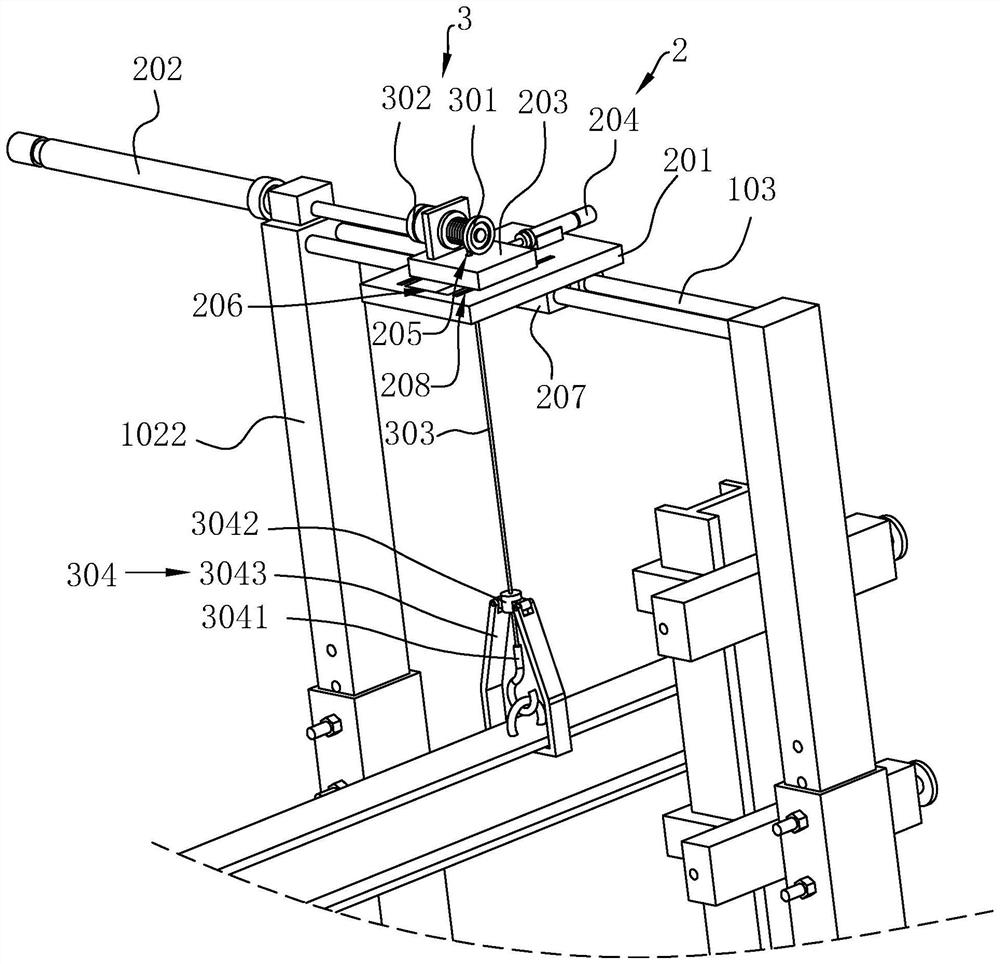

Industrial factory building steel structure hoisting device and construction method thereof

PendingCN114560385AAvoid shakingAvoid shaking and dumpingBase supporting structuresBraking devices for hoisting equipmentsElectric machineryEngineering

The invention relates to the technical field of hoisting equipment, in particular to an industrial factory building steel structure hoisting device and a construction method thereof, and the industrial factory building steel structure hoisting device comprises a base, a stabilizing mechanism for connecting a steel column, a hoisting mechanism for hoisting a steel beam and an adjusting mechanism for adjusting the position of the steel beam; the base comprises a base body, two vertical rods and two transverse rods, the two vertical rods are fixed on the base body, and the two transverse rods are fixed between the two vertical rods; the adjusting mechanism comprises a mounting plate, a first hydraulic push rod used for driving the mounting plate to slide, a sliding plate and a second hydraulic push rod used for driving the sliding plate to slide, the mounting plate is slidably connected to the two cross rods, the sliding direction of the mounting plate is in the length direction of the cross rods, and the sliding plate is slidably connected to the mounting plate. The hoisting mechanism comprises a winding drum, a motor, a steel wire rope and a hoisting pendant used for hanging the steel beam, the winding drum is rotationally connected to the sliding plate, one end of the steel wire rope is wound around the winding drum, and the other end of the steel wire rope is connected with the hoisting pendant. The steel beam mounting structure has the effect of facilitating steel beam mounting.

Owner:中和华丰建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com