Patents

Literature

611results about How to "Extended production time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

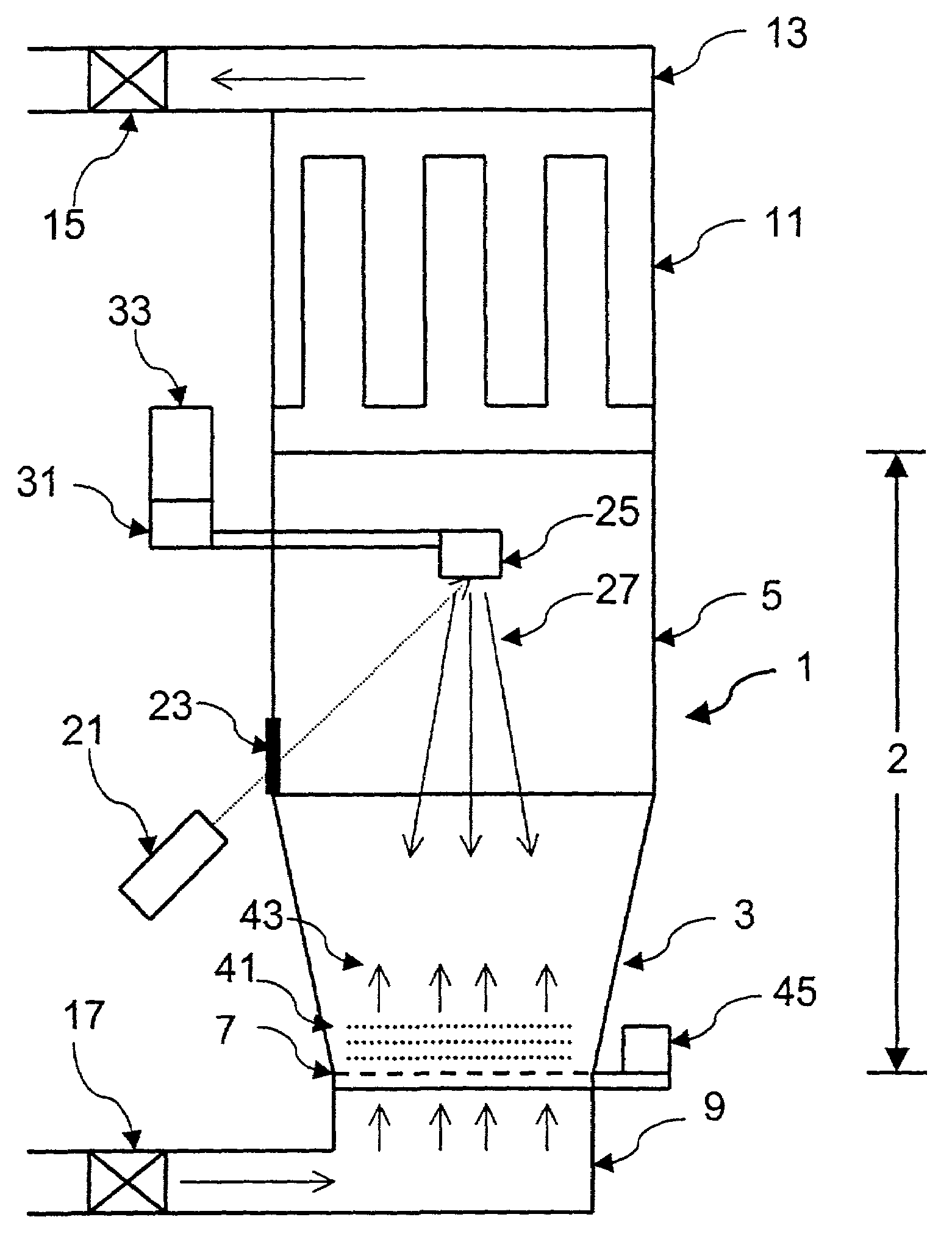

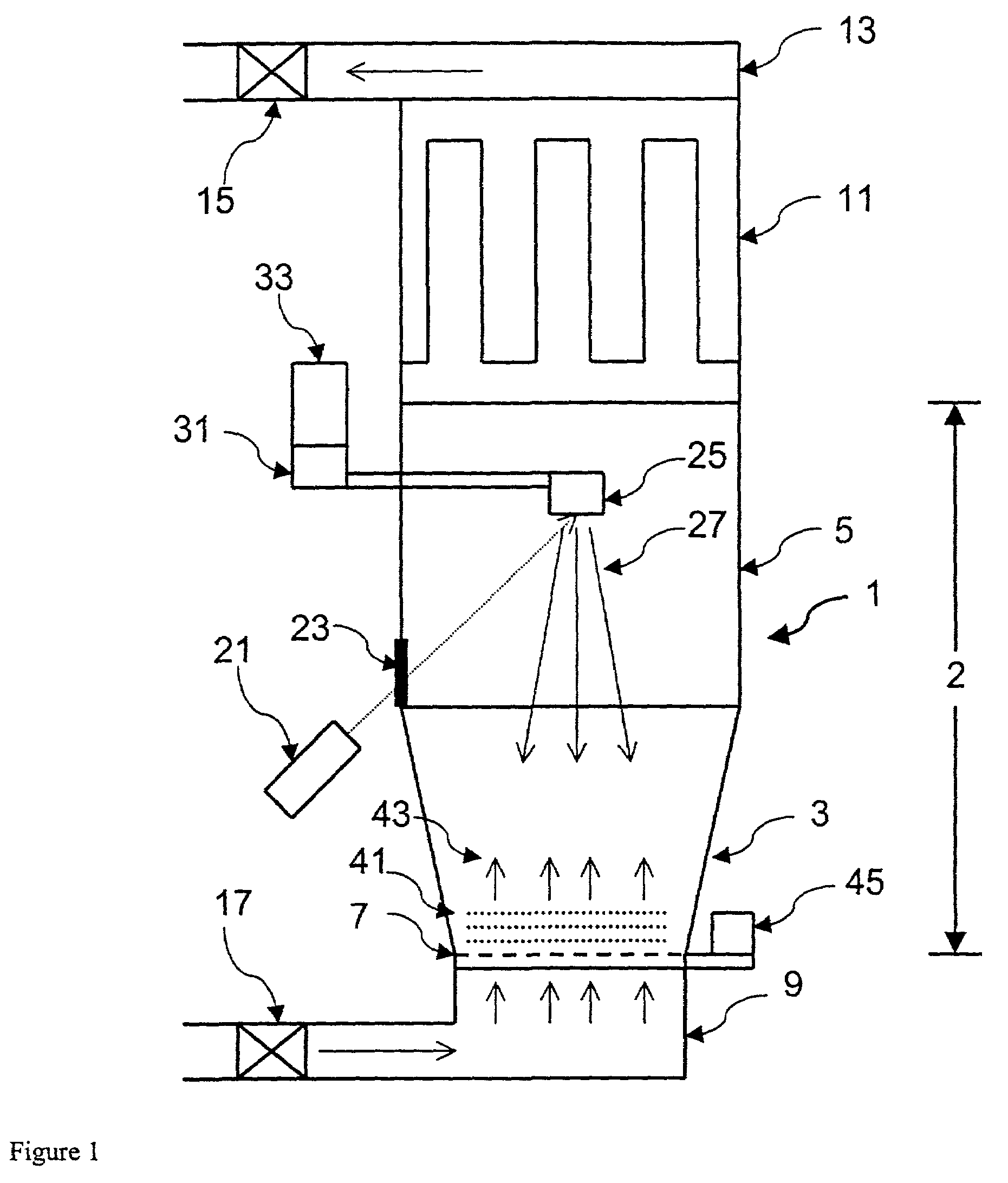

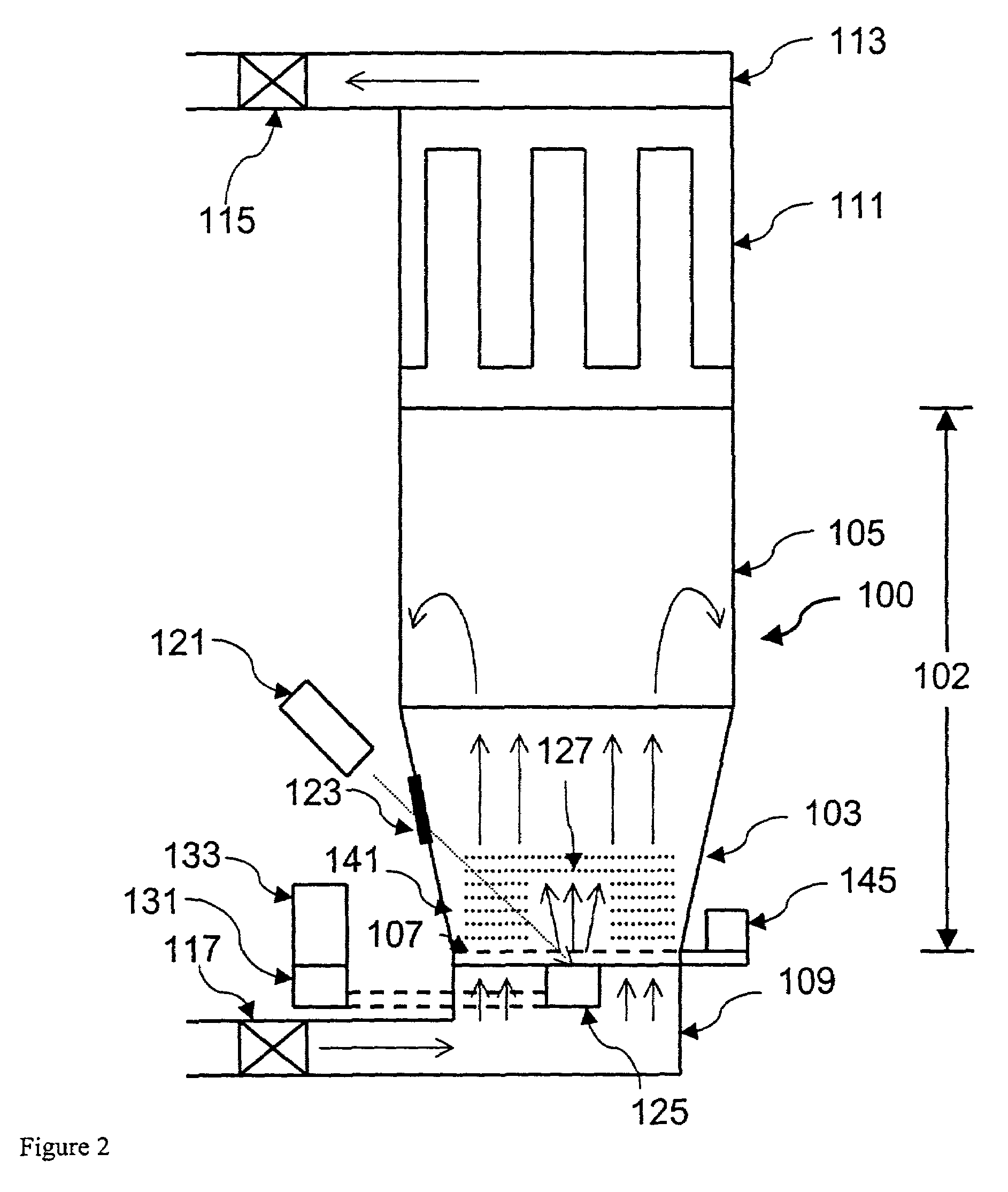

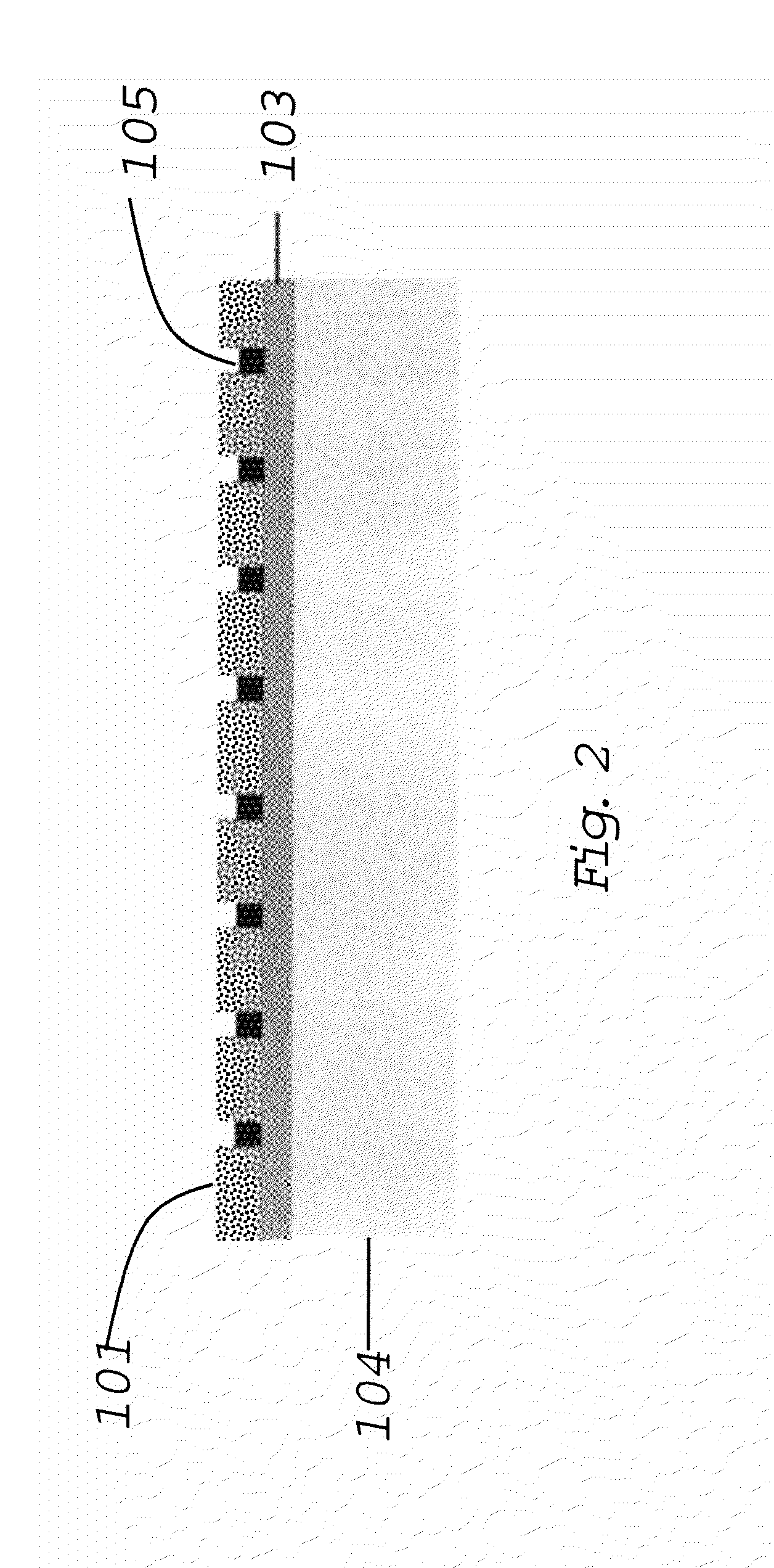

Methods for coating particles and particles produced thereby

InactiveUS7063748B2Improved pharmacokinetic profileExtended production timeLiquid surface applicatorsElectric discharge heatingParticulatesAtmospheric pressure

Methods of coating core materials by providing target materials and core materials; ablating the target materials to form ablated particulate target materials; and coating the core materials with said ablated particulate target materials; wherein the method is performed at a pressure of about 10 Torr or higher. Methods of coating particles with nanometer to multiple nanometer thick coatings in atmospheric pressure, and using pneumatic fluidization, are also provided.

Owner:NANOTHERAPEUTICS INC

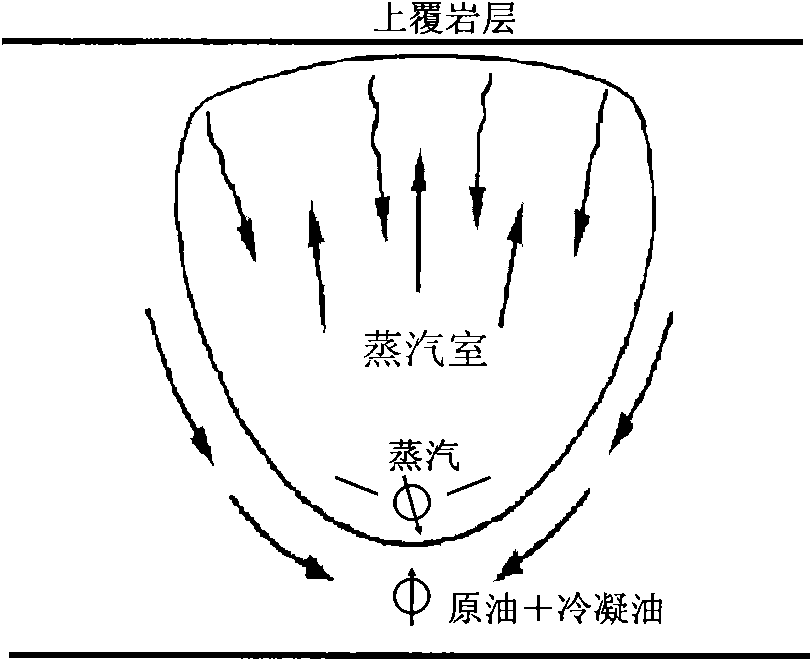

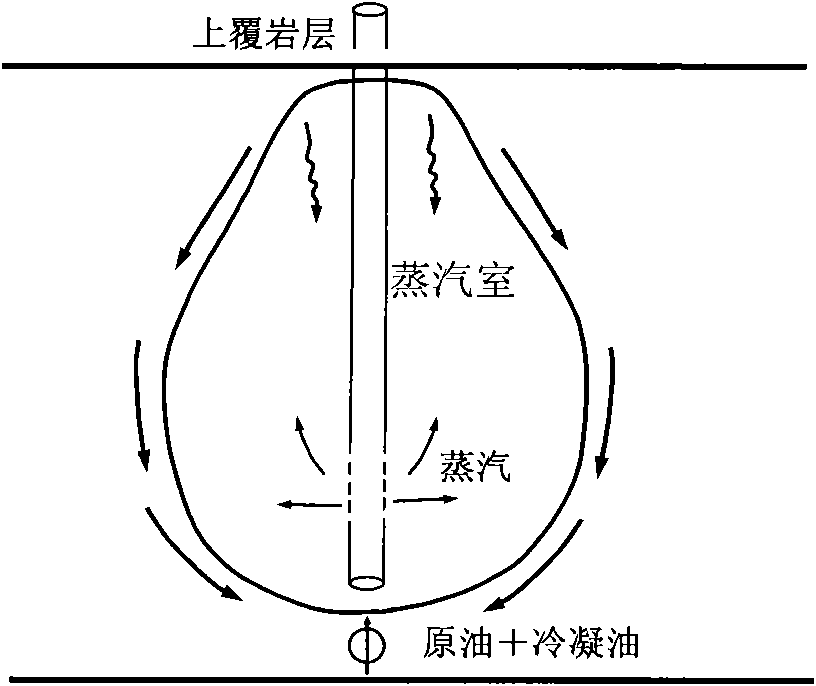

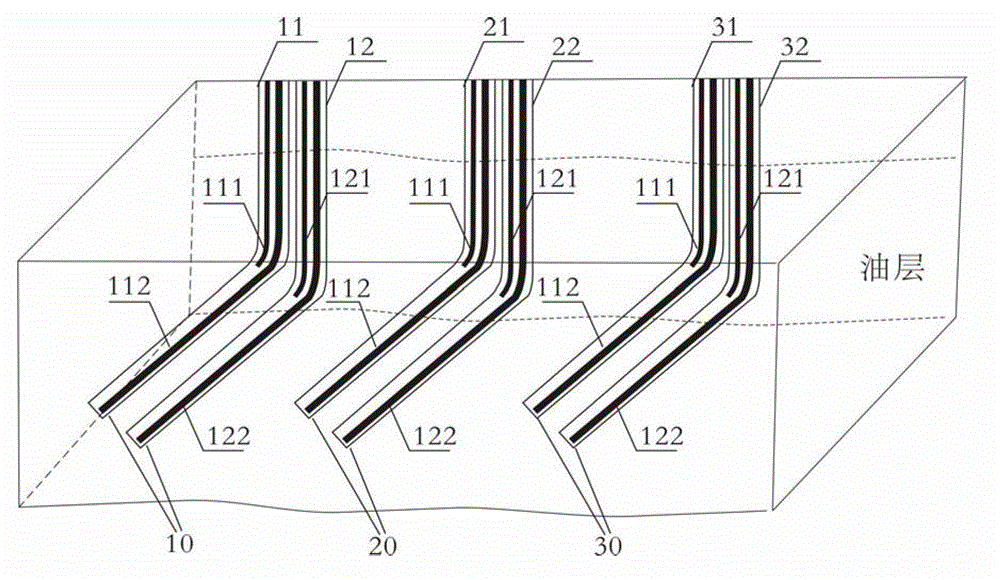

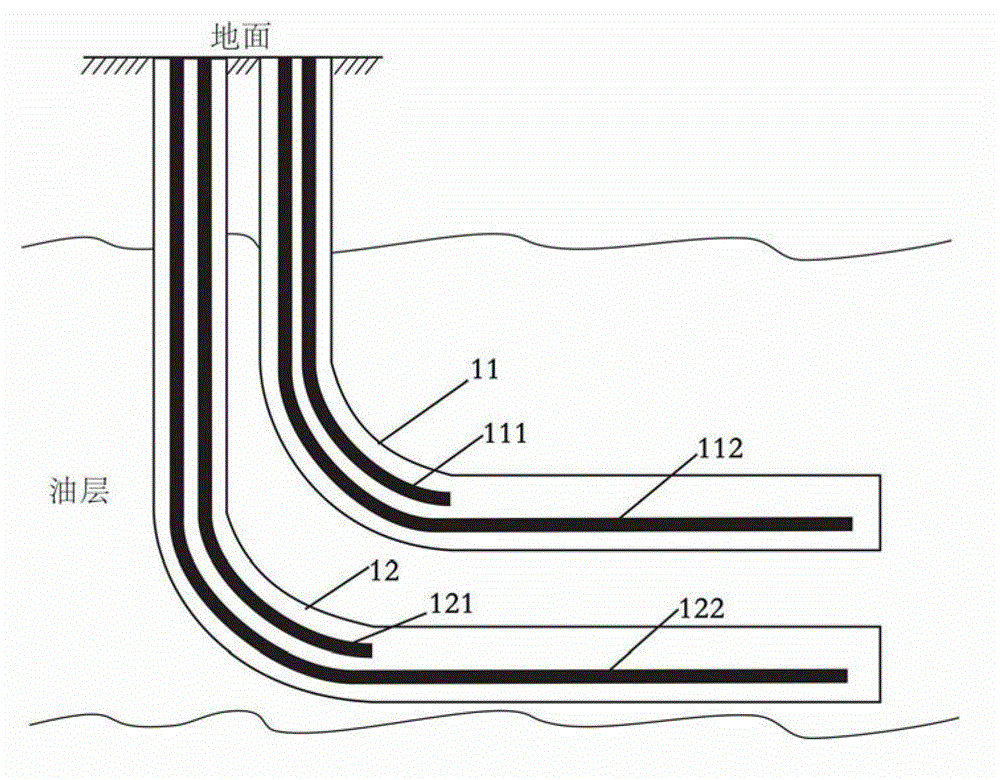

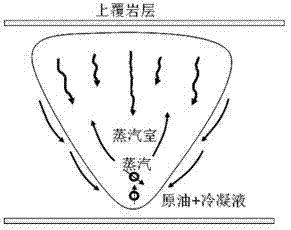

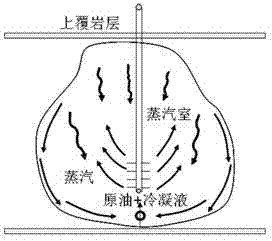

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

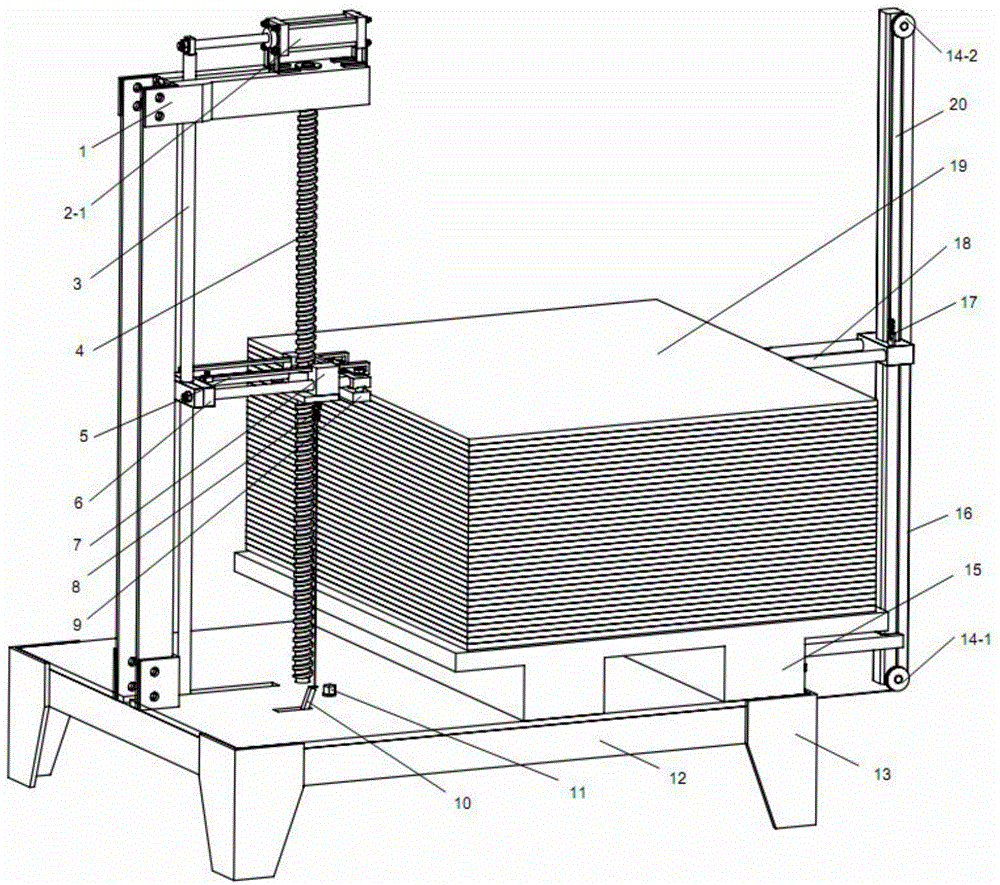

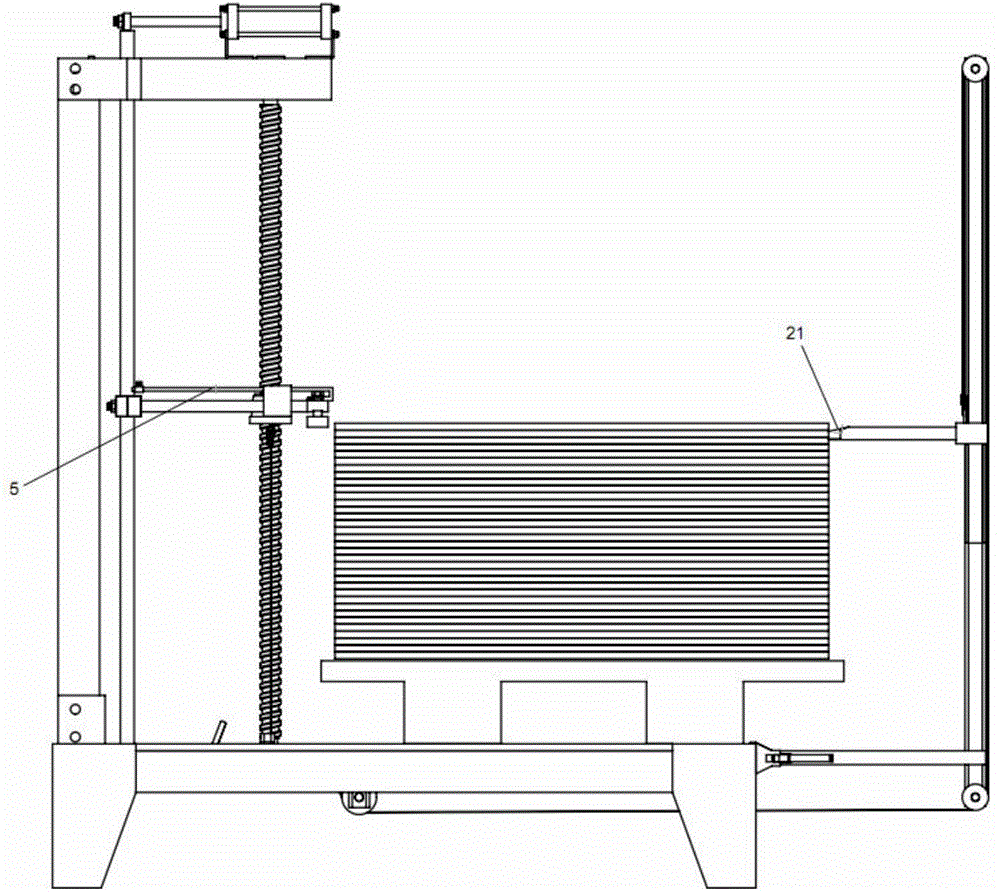

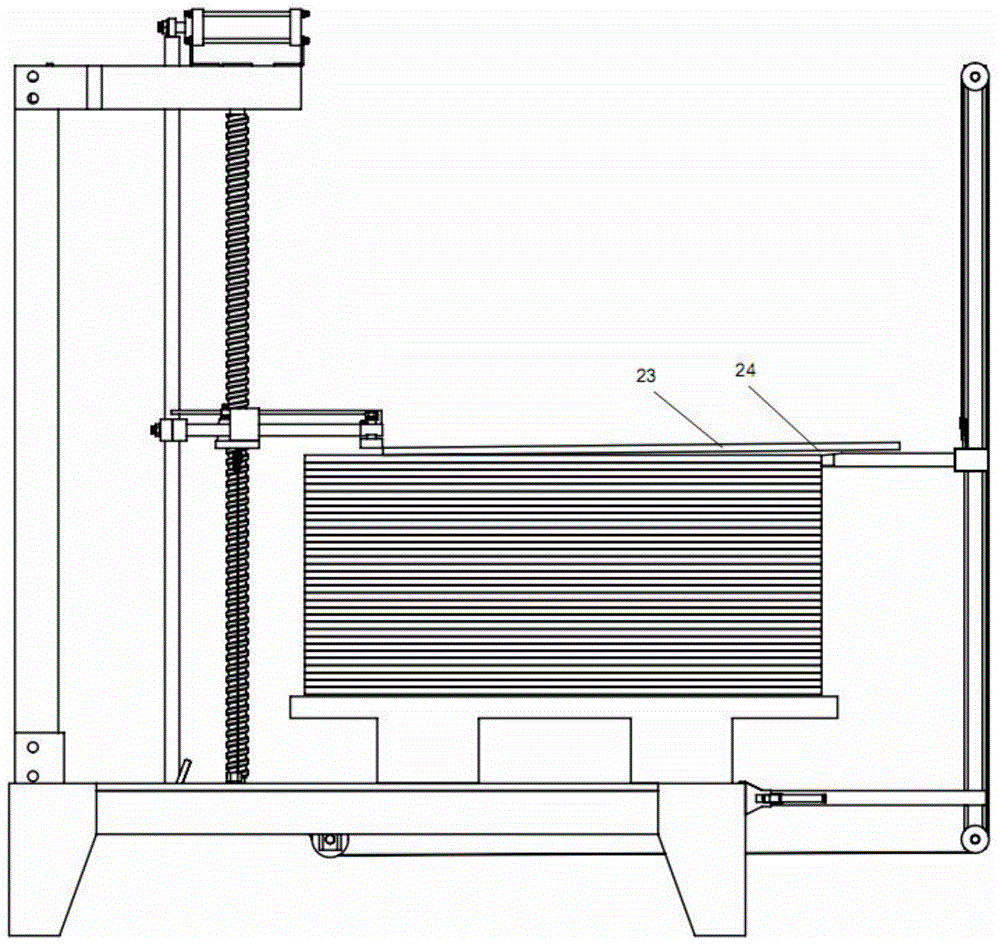

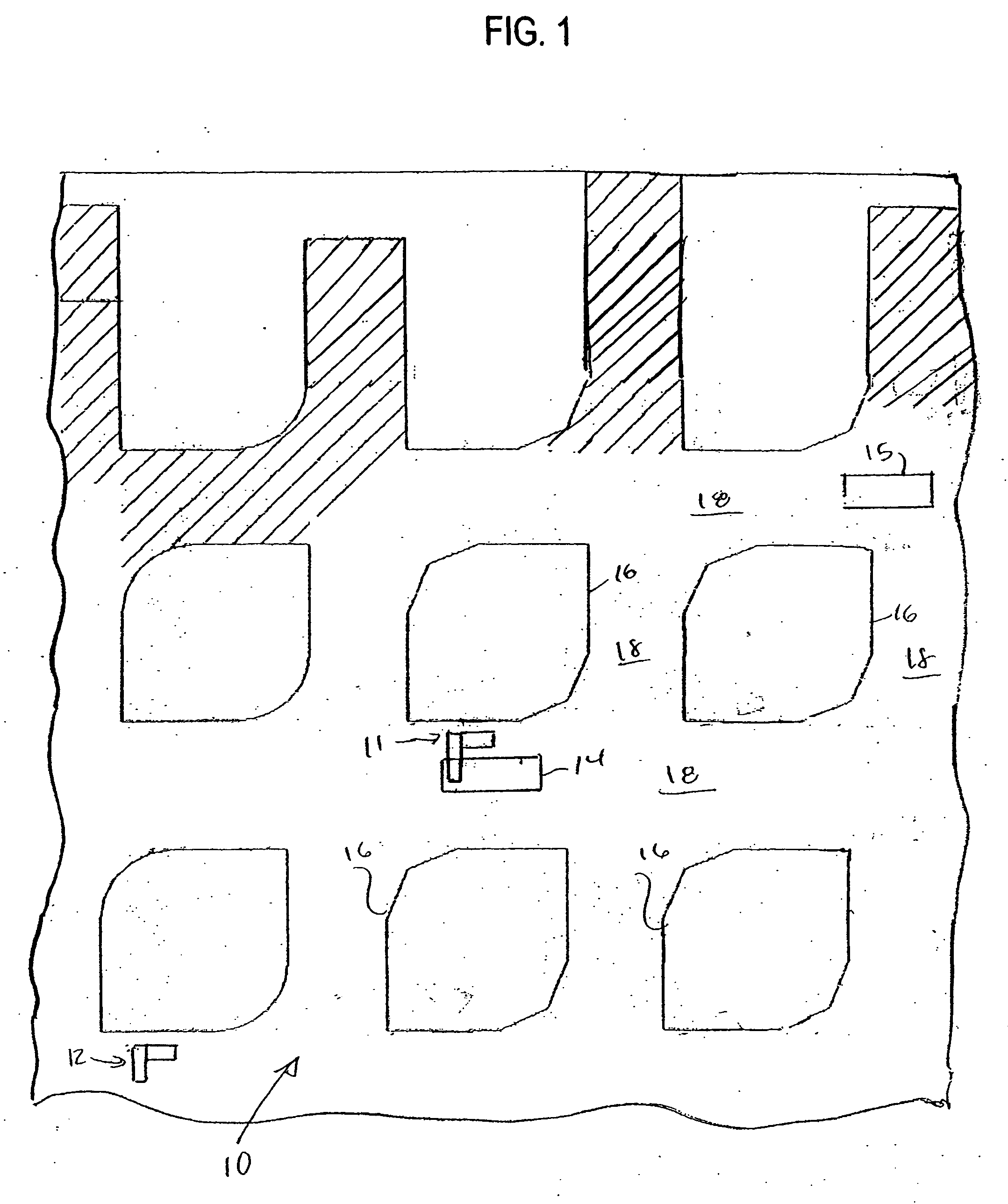

Separation device for detaching and stacking stamped sheet metal

A separation device for detaching and stacking stamped sheet metal comprises a driving mechanism, a pushing mechanism, a lifting mechanism, a separating mechanism and a sheet metal supporting base. The sheet metal supporting base is used for supporting the other mechanisms and stacking the sheet metal. The pushing mechanism allows a pushing assembly to slide linearly in the horizontal guide direction of a guide support through a vertical slide rod connected with a cylinder so that the effect of pushing out the sheet metal on the top layer can be achieved. The lifting mechanism controls the guide support to rise and fall by adjusting the number of rotation circles of a screw so that a push block can always keep aligned with the sheet metal on the top layer when starting to work. The separating mechanism is connected to the lifting mechanism when a steel wire rope is wound around a pulley so that the separating mechanism can synchronously rise and fall together with the lifting mechanism under the influences of the gravity of the separating mechanism. A separating rod can prevent the sheet metal on the top layer from absorbing the sheet metal on the lower layer and sliding together with the sheet metal on the top layer, and a separating inclined block makes a gap formed between the sheet metal on the top layer and a sheet metal stack. The intermittent movement of the pushing mechanism and the lifting mechanism is achieved through double ratchets by means of the driving device. The separation device is easy to operate, high in efficiency, good in separation effect, high in flexibility and wide in applicability.

Owner:GUANGXI UNIV

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

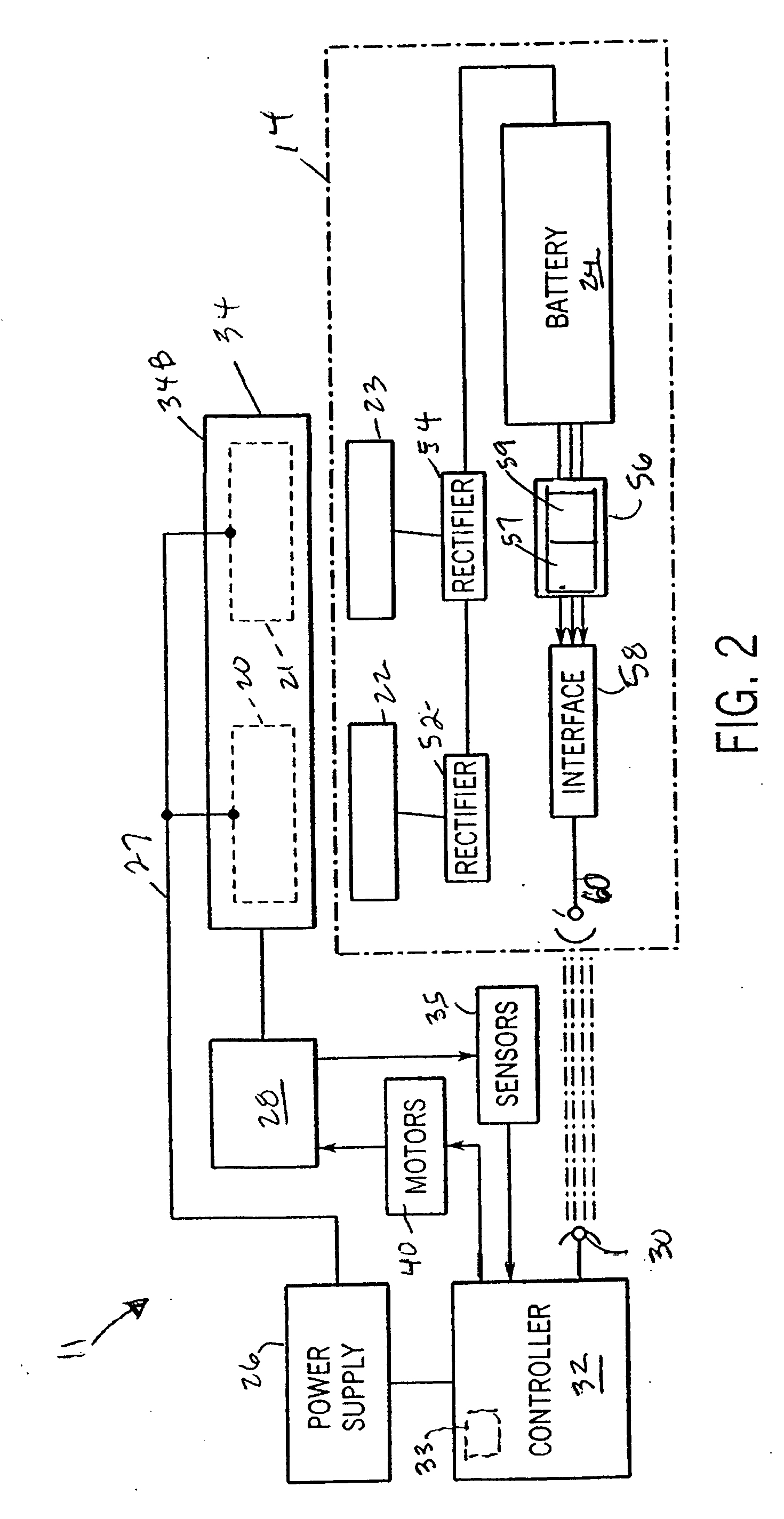

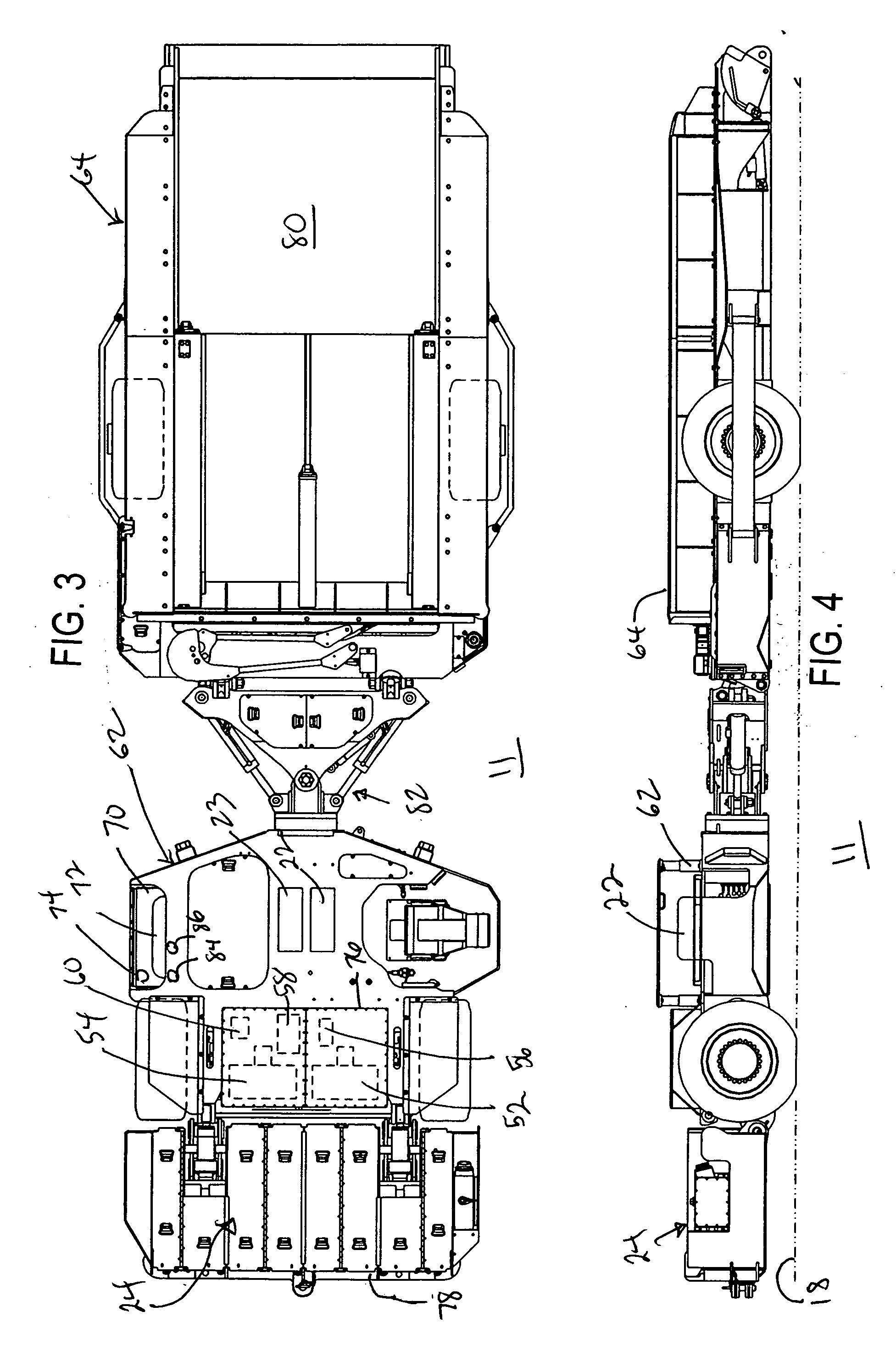

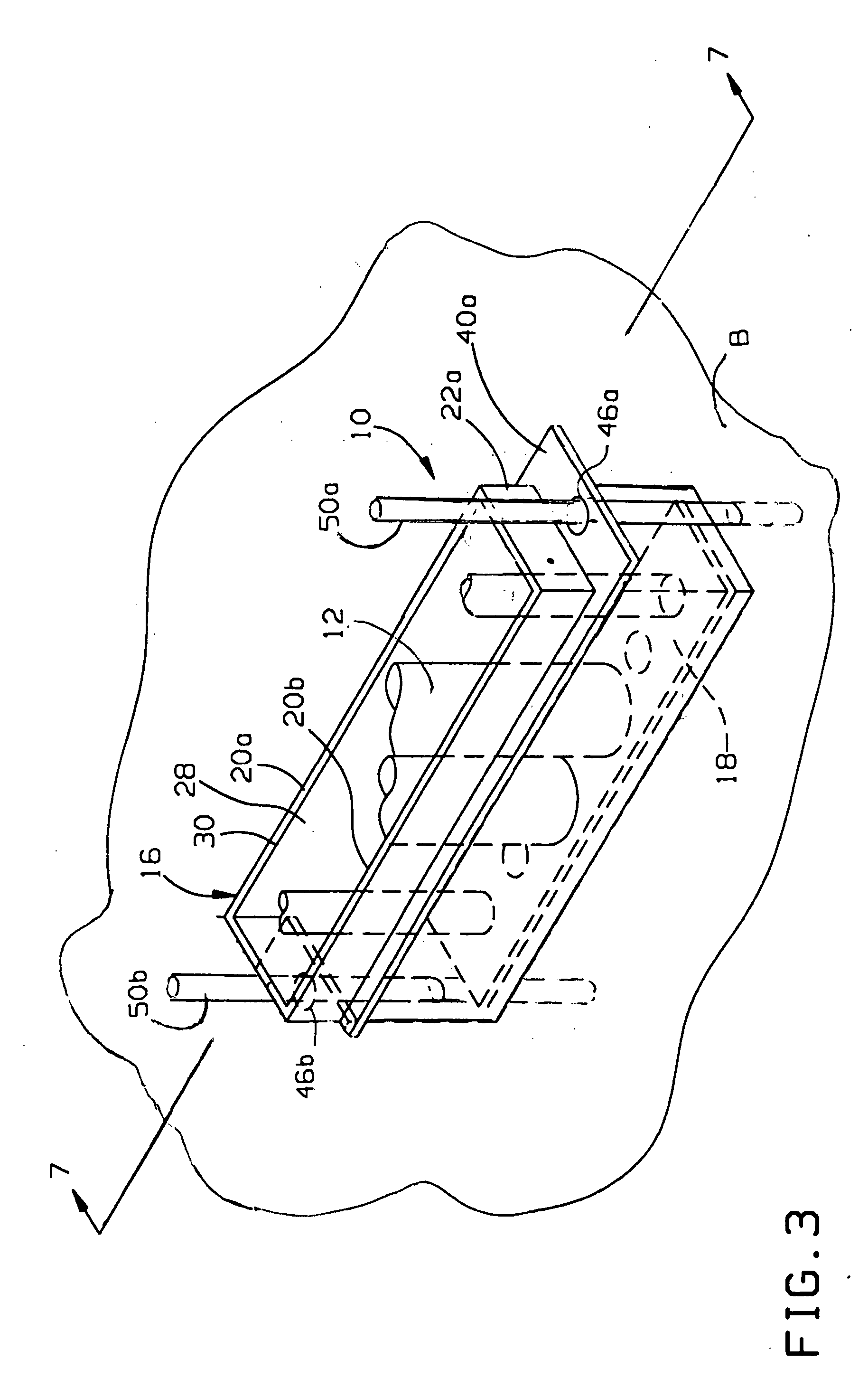

Opportunity charging system for battery powered mining equipment

InactiveUS20060273756A1Change timeFast chargingCharging stationsRailway vehiclesElectric power transmissionBattery charge

An opportunity charging system for a battery-powered, mobile mining machine employs inductive power transfer for transferring battery charging current produced by a rapid charging station to the battery of the machine. An alignment module of the charging station automatically aligns primary coils of the charging station with pick-up coils carried by the machine in response to detection of the presence of the machine at the charging station. The charging station is located along roadways of the mine normally traveled by production equipment.

Owner:JOY MM DELAWARE INC

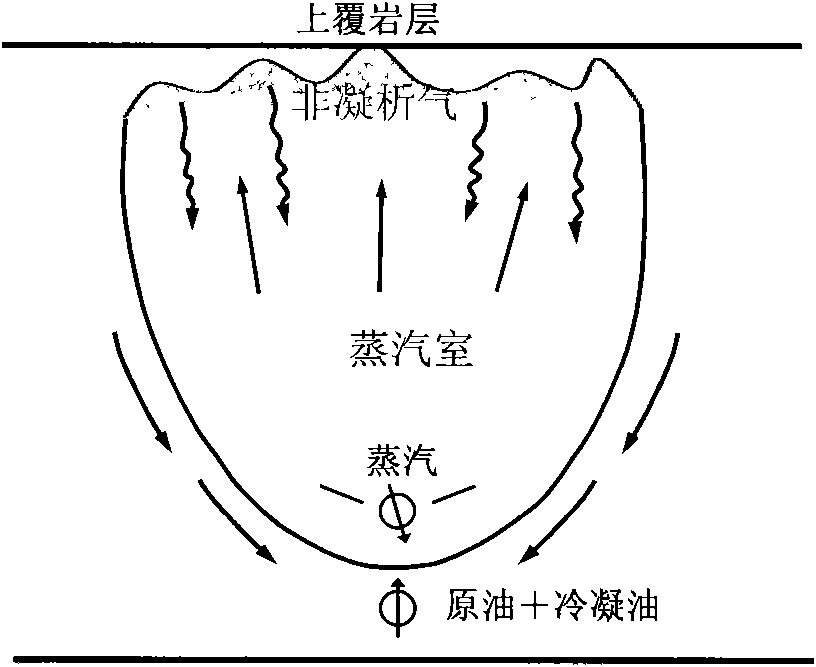

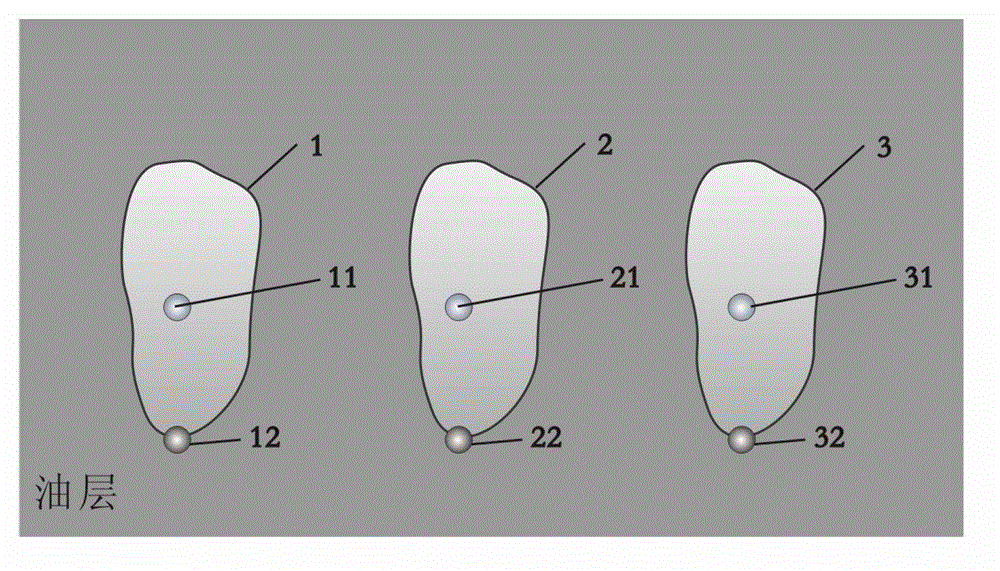

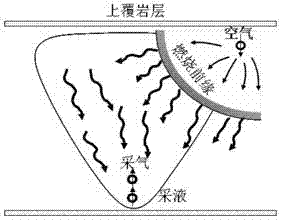

Fire-flooding exploitation method used in later period of steam assisted gravity drainage (SAGD) of heavy oil reservoir

ActiveCN102747997AExtended production timeIncrease profitFluid removalInjection wellSteam-assisted gravity drainage

The invention relates to a fire-flooding exploitation method used in a later period of steam assisted gravity drainage (SAGD) of a heavy oil reservoir. At a steam chamber expansion phase of the SAGD, when steam chambers of adjacent injection and production well pairs are subjected to coalescence, a injection and production well of the middle injection and production well pair is used for injecting air to ignite, a production well of the middle well pair and production wells of the left and right adjacent well pairs are used for producing, and injection wells of the left and right adjacent well pairs are converted into fire-flooding ventilation wells. The exploitation method can utilize a high-temperature fire-flooding front edge to effectively drive remaining reserves at the lower part of an oil layer between the adjacent SAGD well pairs, avoids the steam play of in the later period of the regular SAGD or the gas-assisted SAGD, prolongs the SAGD production time, and obviously improves the oil recovery. The method disclosed by the invention combines the advantages of the SAGD and fire flooding; the output at an SAGD production phase is high, and the oil exploitation speed is high; and the fire flooding is utilized at an output declination phase after the adjacent stream cavities are subjected to the coalescence, so that the injection cost can be reduced, and the heat energy utilization rate and the oil recovery are improved.

Owner:PETROCHINA CO LTD

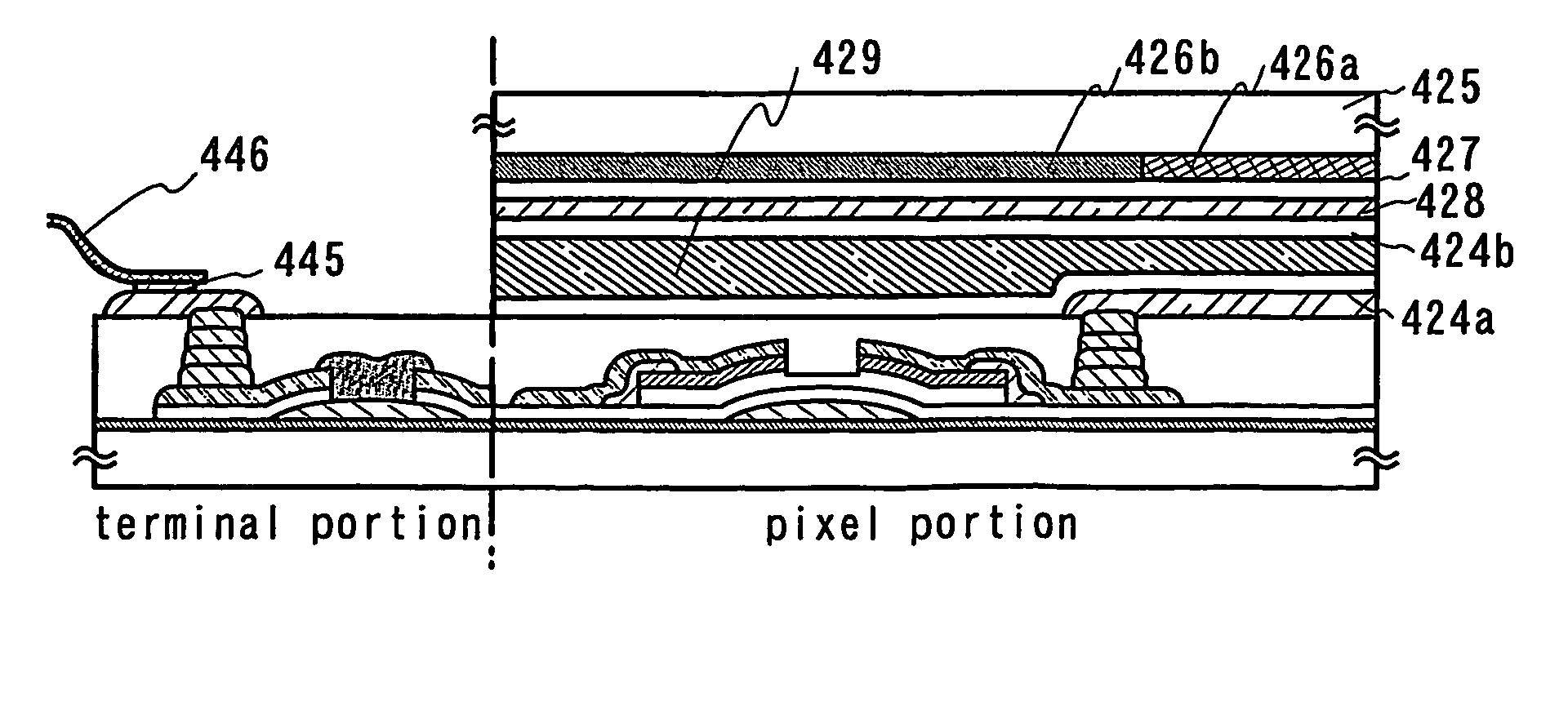

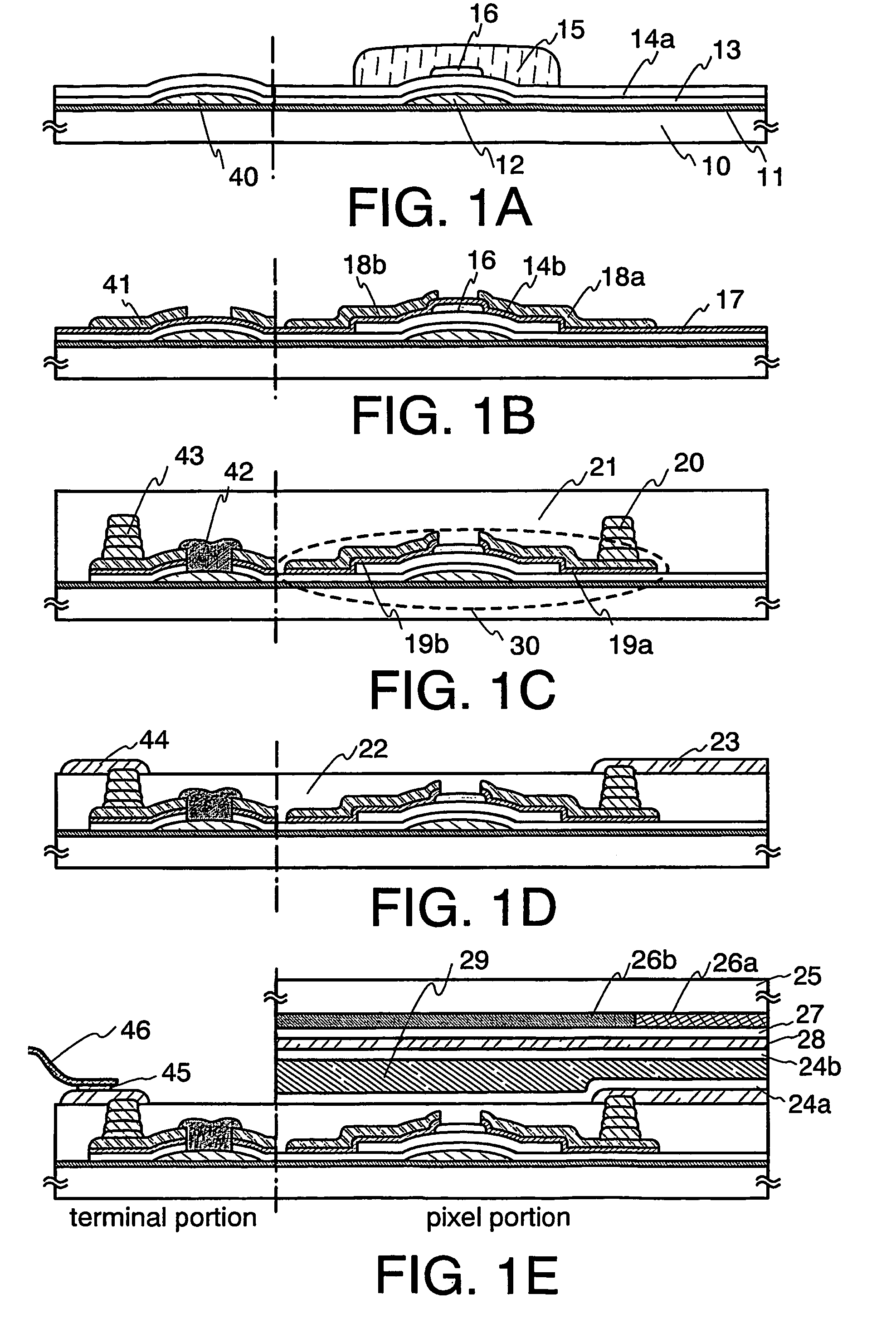

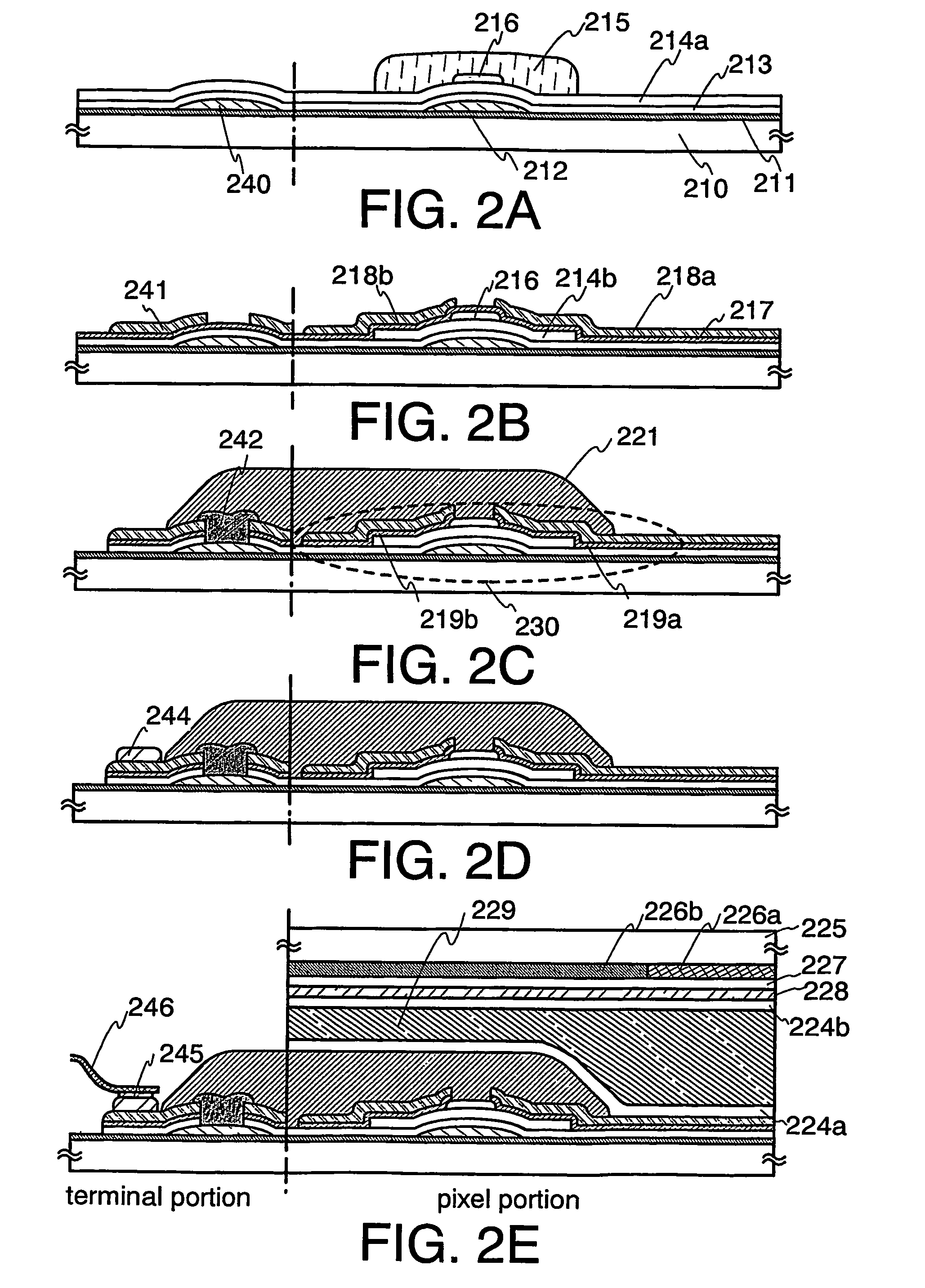

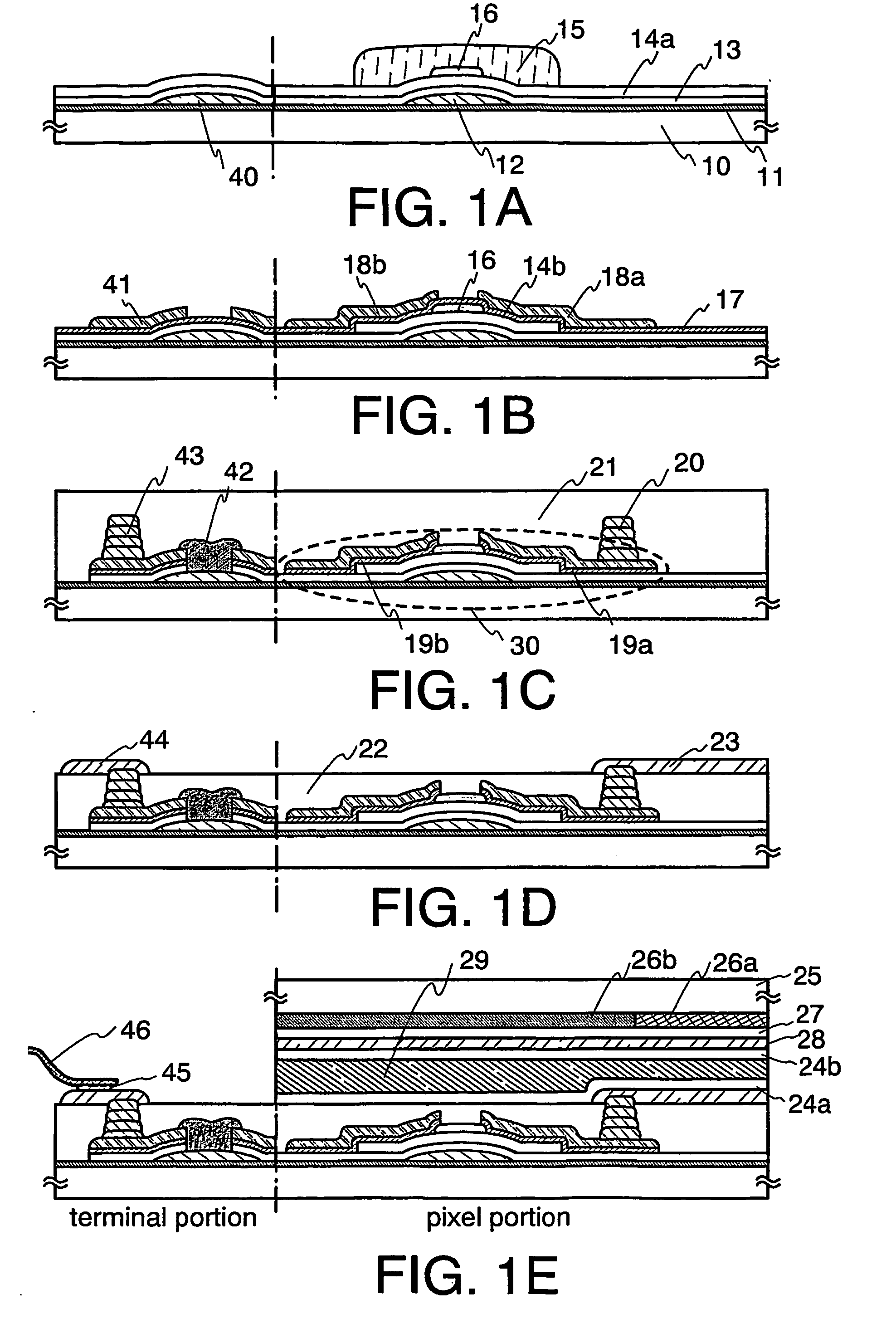

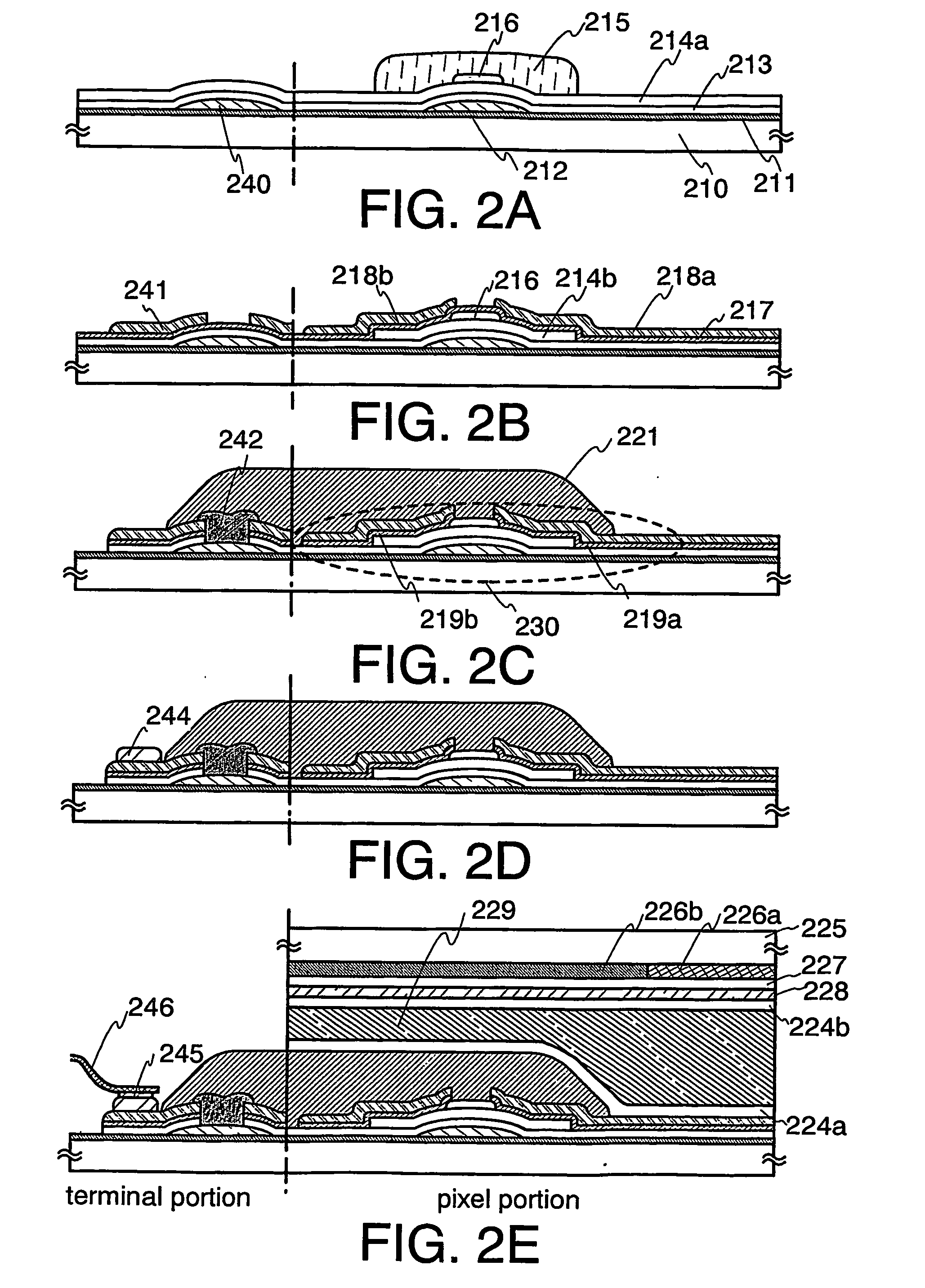

Liquid crystal display device and method for manufacturing the same

InactiveUS7795616B2Extended production timeIncrease wasteSolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

Owner:SEMICON ENERGY LAB CO LTD

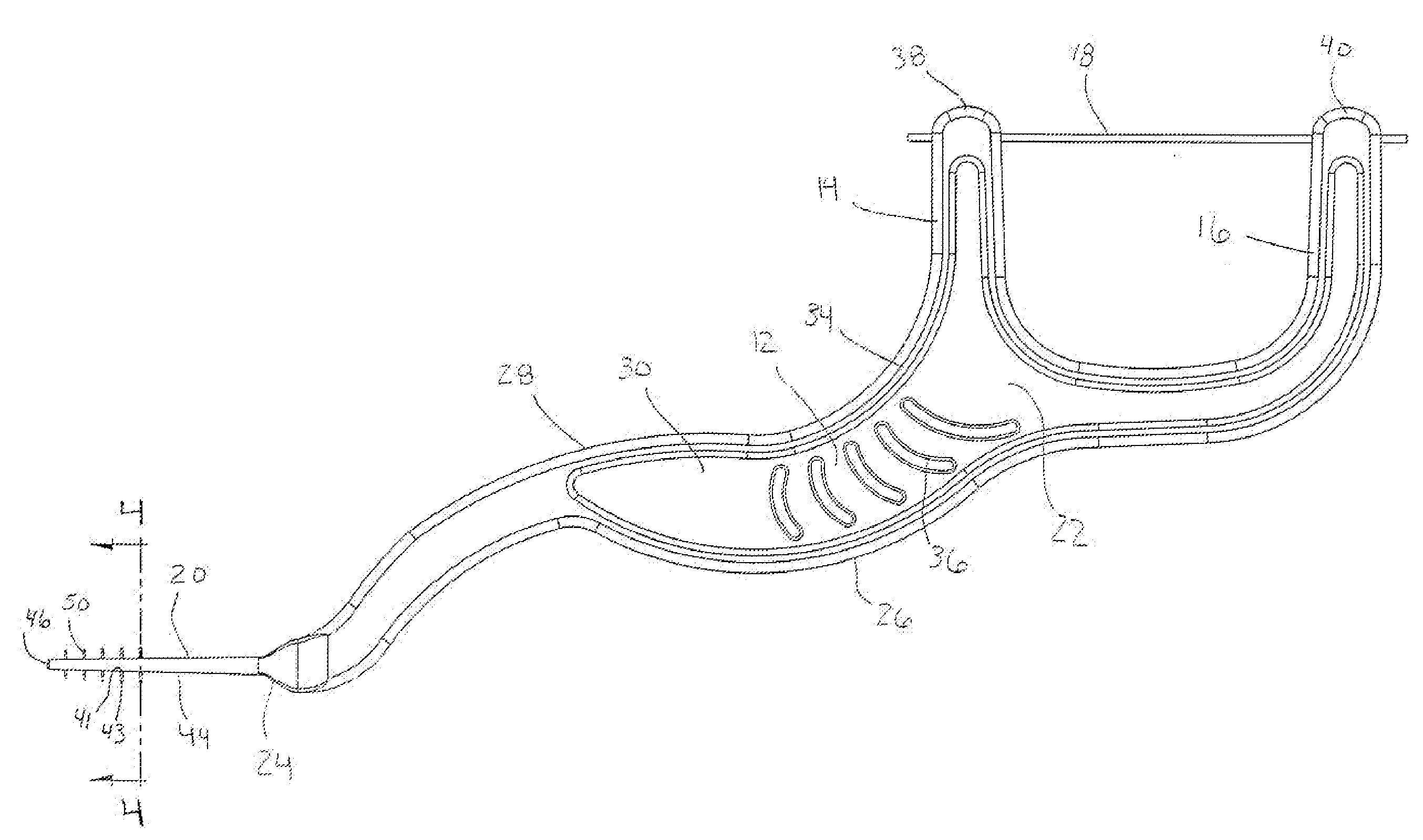

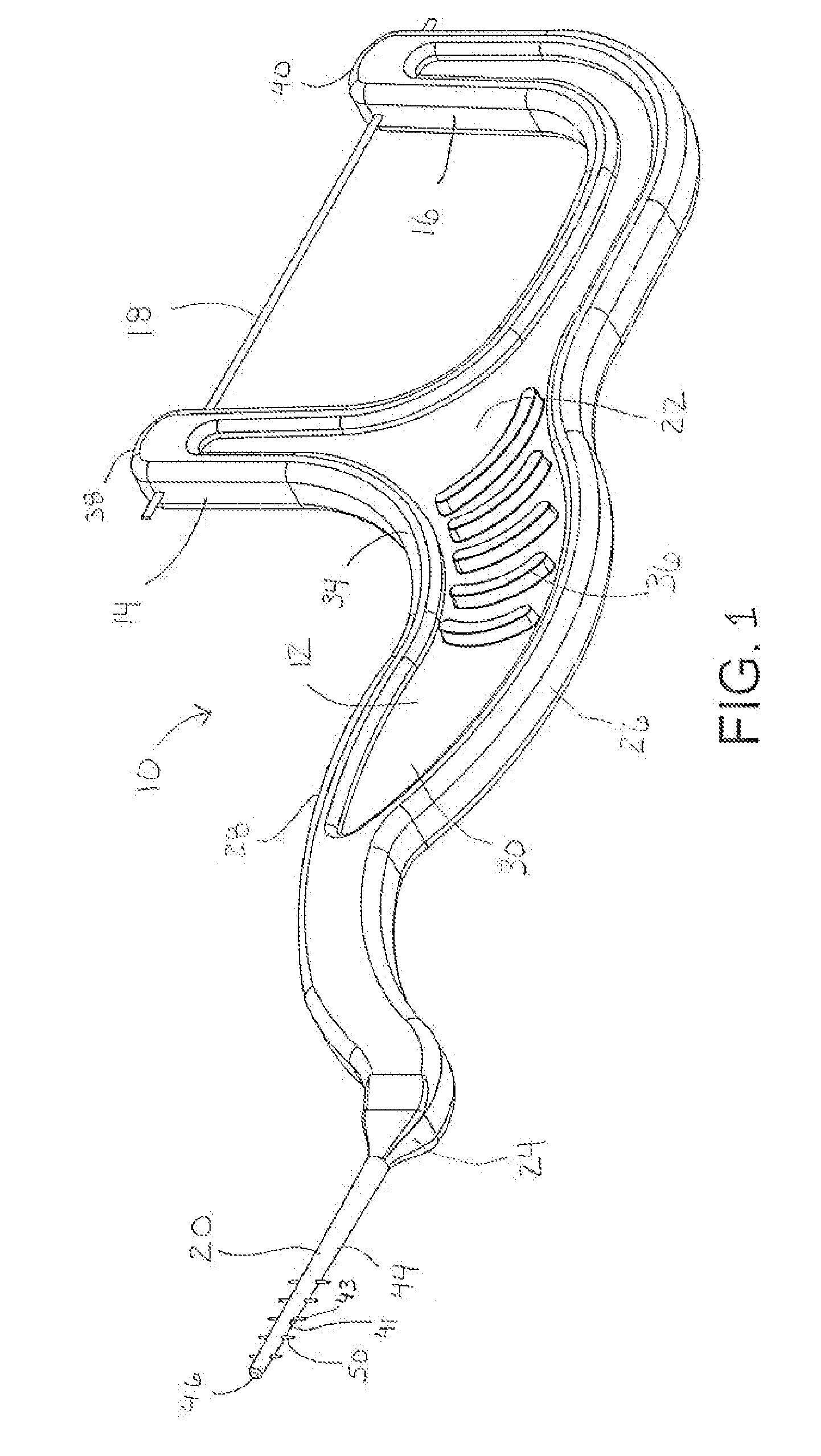

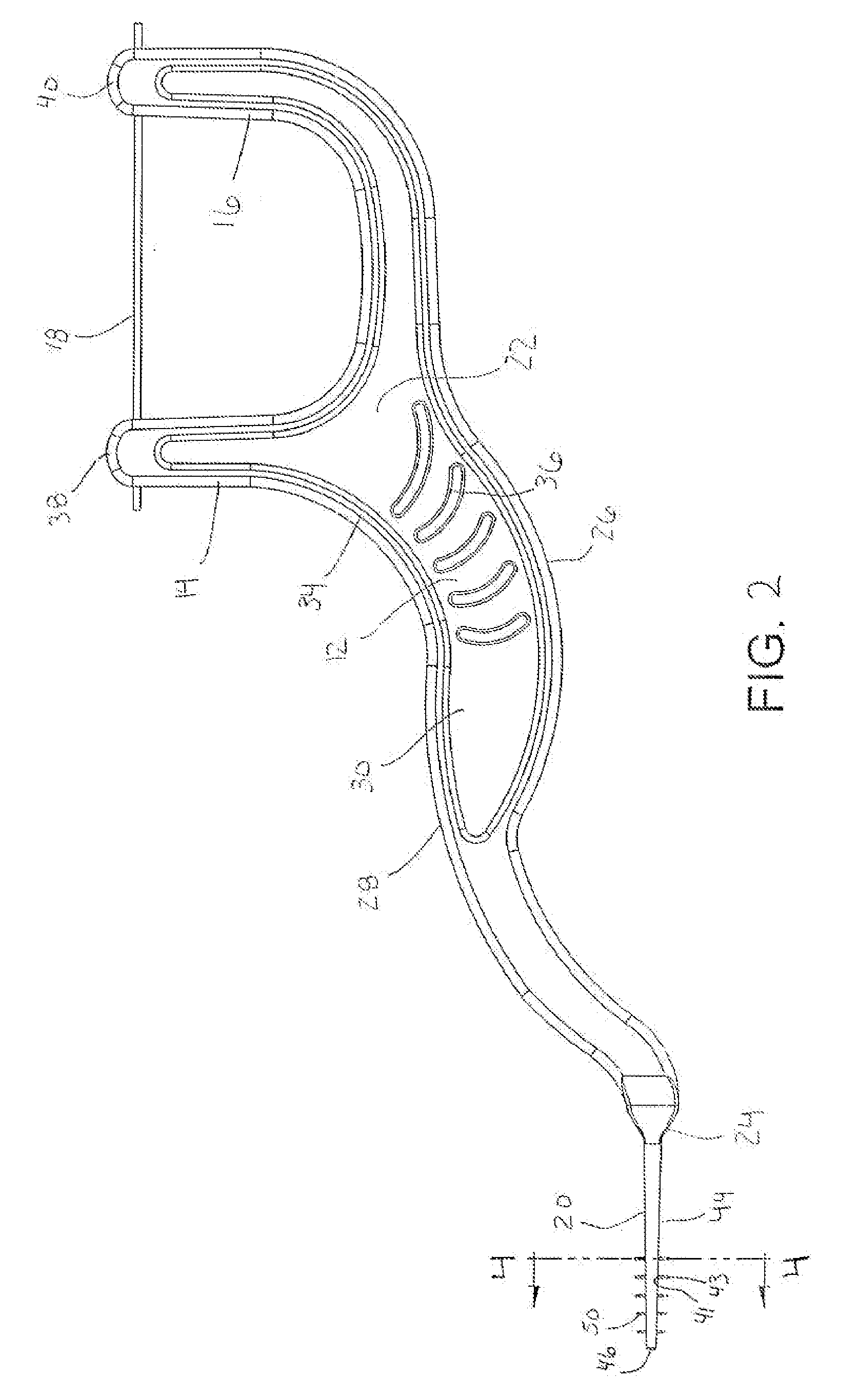

Dental floss holder

InactiveUS20080149134A1Easy to cleanLess harmful to a user's teeth and gumsGum massageDental flossDental flossEngineering

A dental floss holder includes an integral interproximal pick having a plurality of outwardly extending nubs. In one embodiment, the dental floss holder includes a handle having a first portion and a second portion. A pair of arms extend from the first portion with a strand of dental floss stretched therebetween. An interproximal pick extends from the second portion. The interproximal pick includes a plurality of nubs that extend outwardly from the pick. The handle, arms and interproximal pick may be a single, integrally molded piece.

Owner:RANIR LLC

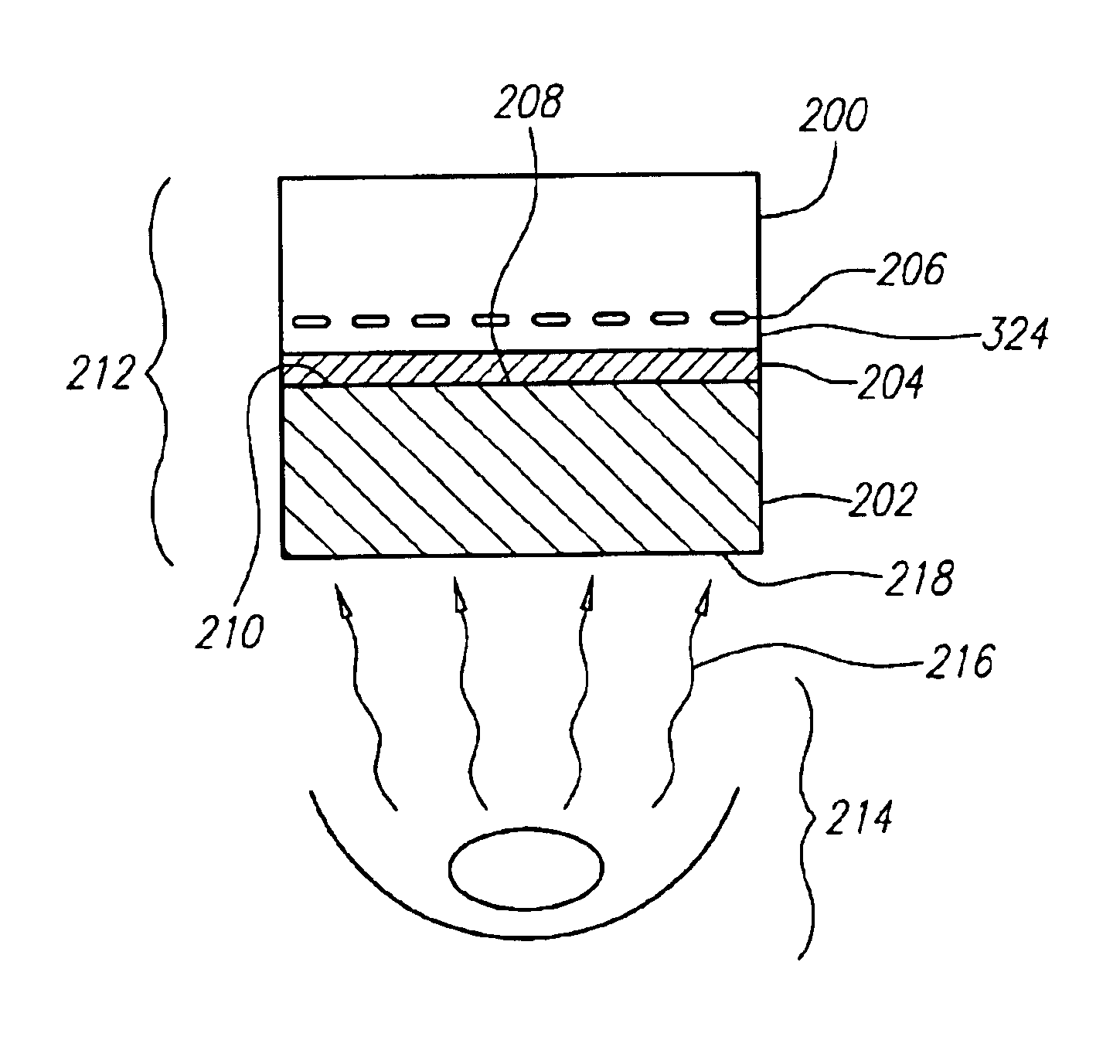

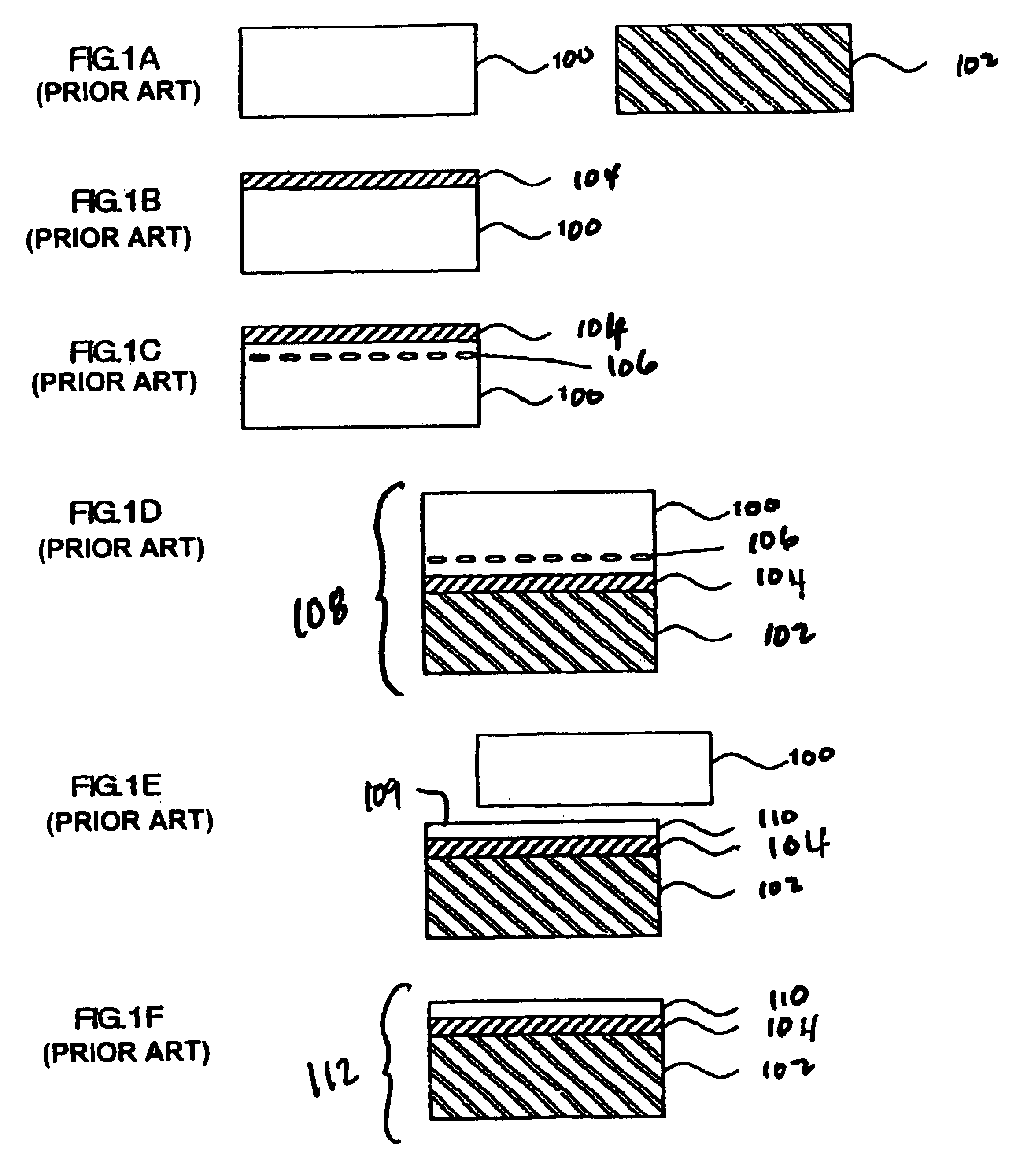

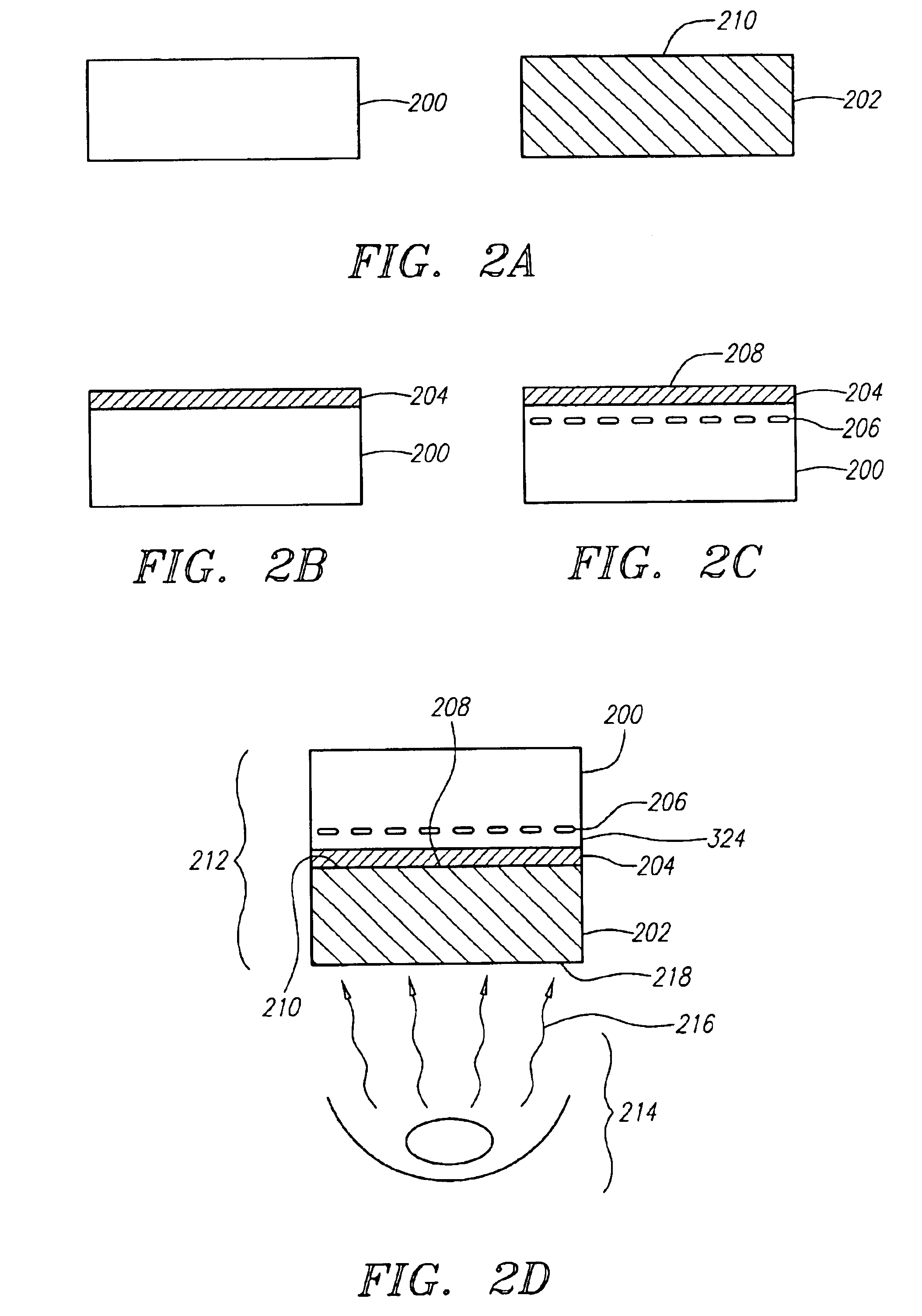

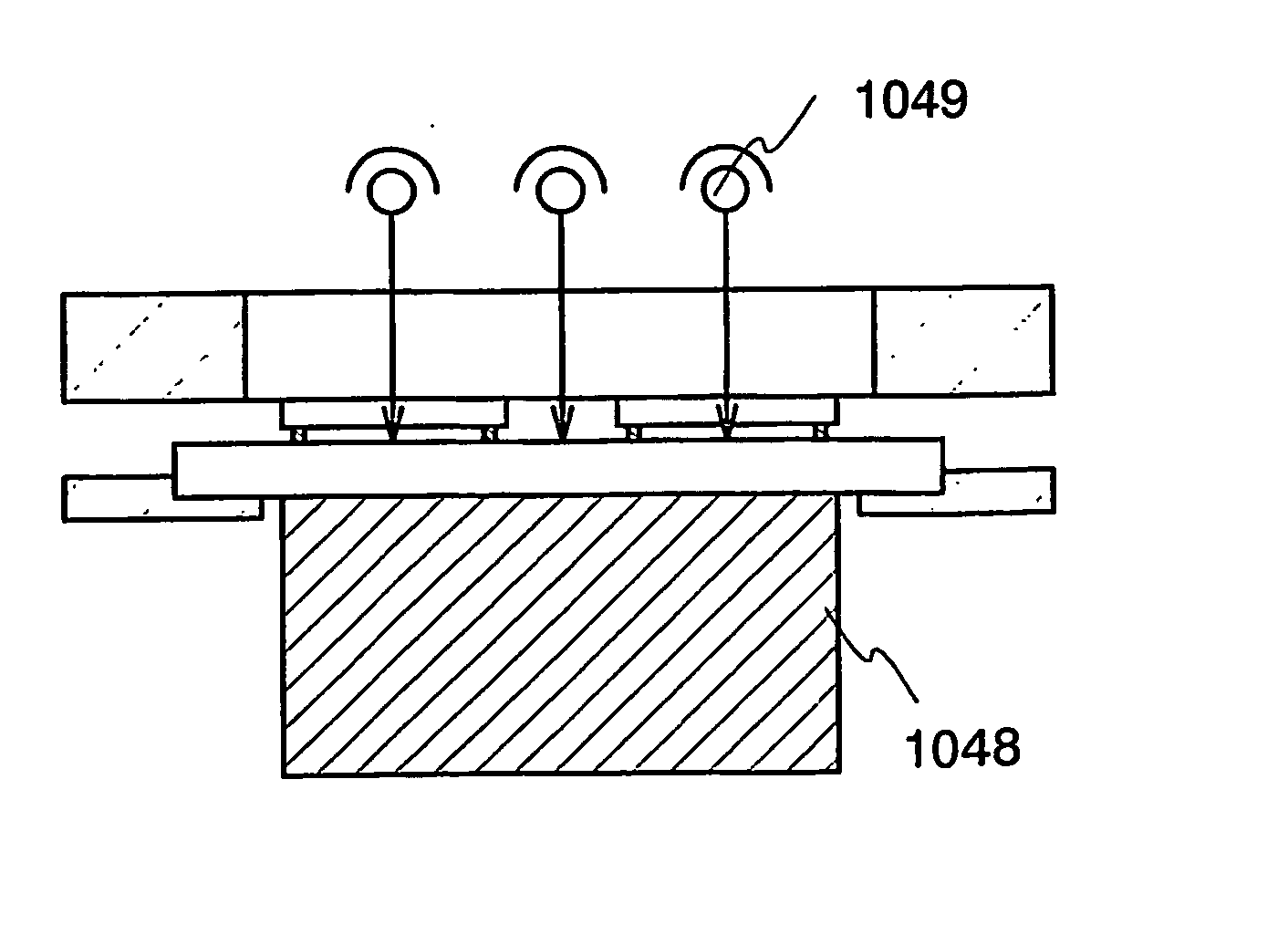

Selective heating using flash anneal

InactiveUS6911376B2Reduce breakageFaster rateSemiconductor/solid-state device manufacturingSemiconductor devicesHydrogenSilicon

Owner:WAFERMASTERS

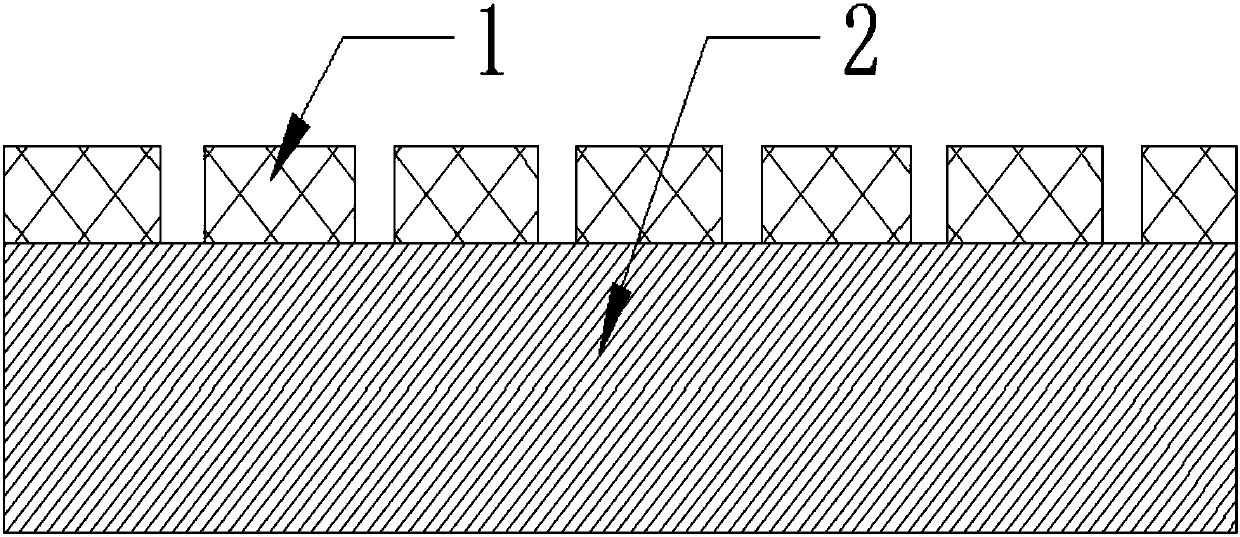

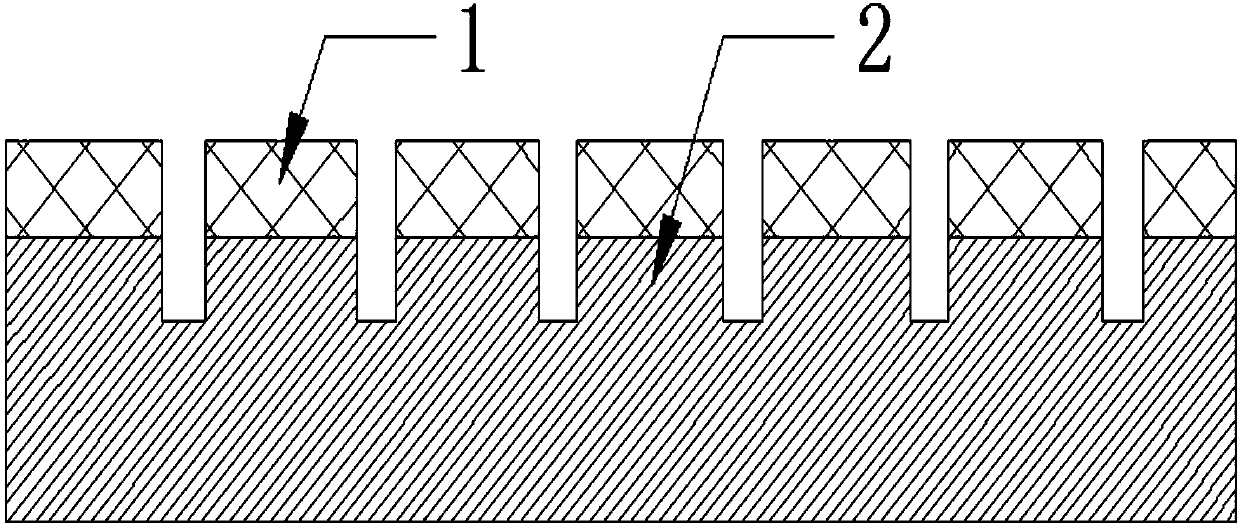

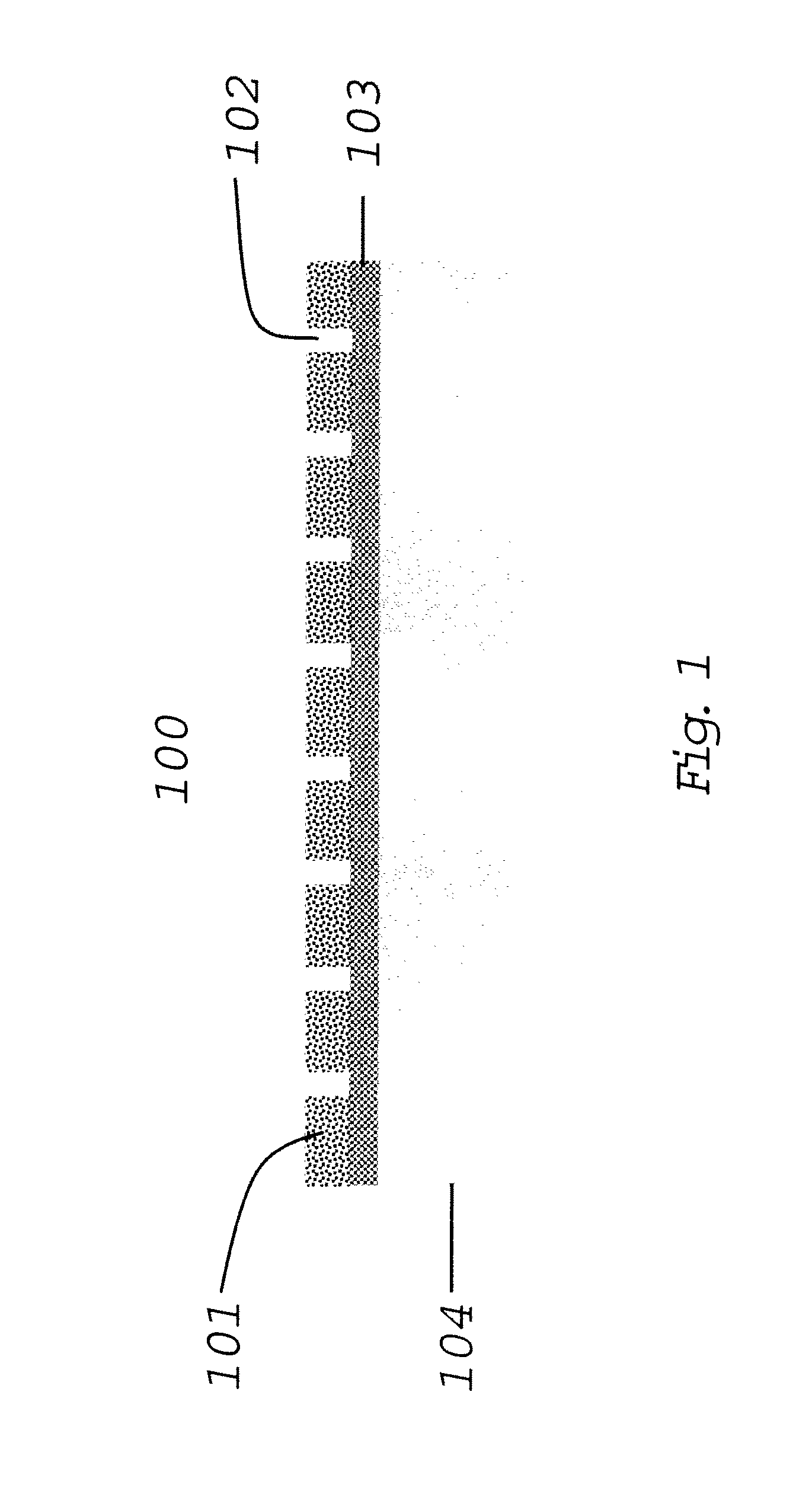

Method for preparing optical super-structure surface based on nanoimprinting

InactiveCN107561857ALow costShorten production timeNanoopticsPhotosensitive material processingEngineeringSuper structure

The invention discloses a method for preparing an optical super-structure surface based on nanoimprinting. According to the method, an adopted template is an impressing template with a super-structurefunctional element pattern. The method for preparing the optical super-structure surface based on the nanoimprinting, provided by the invention, can be used for replacing an electron beam lithographymethod when preparing a super-structure functional element, the cost is reduced by a large margin and the production time is shortened. According to the method provided by the invention, the production cost is remarkably reduced, and the production time is remarkably shortened, thus the low-cost and large-scale manufacturing of a super-structure surface optical element within a short time is realized, and good industrial prospect is realized.

Owner:深圳南科构彩科技有限公司

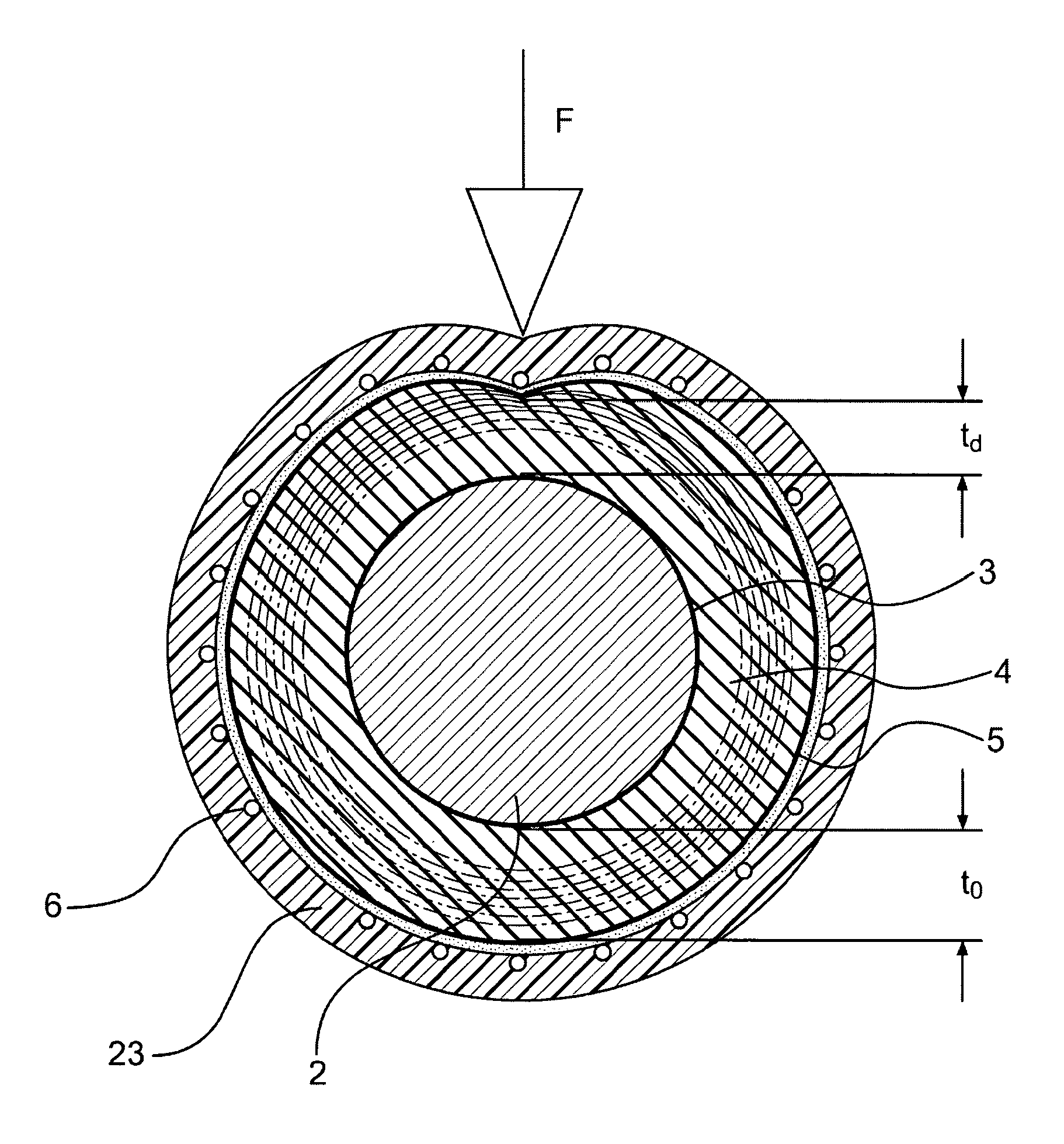

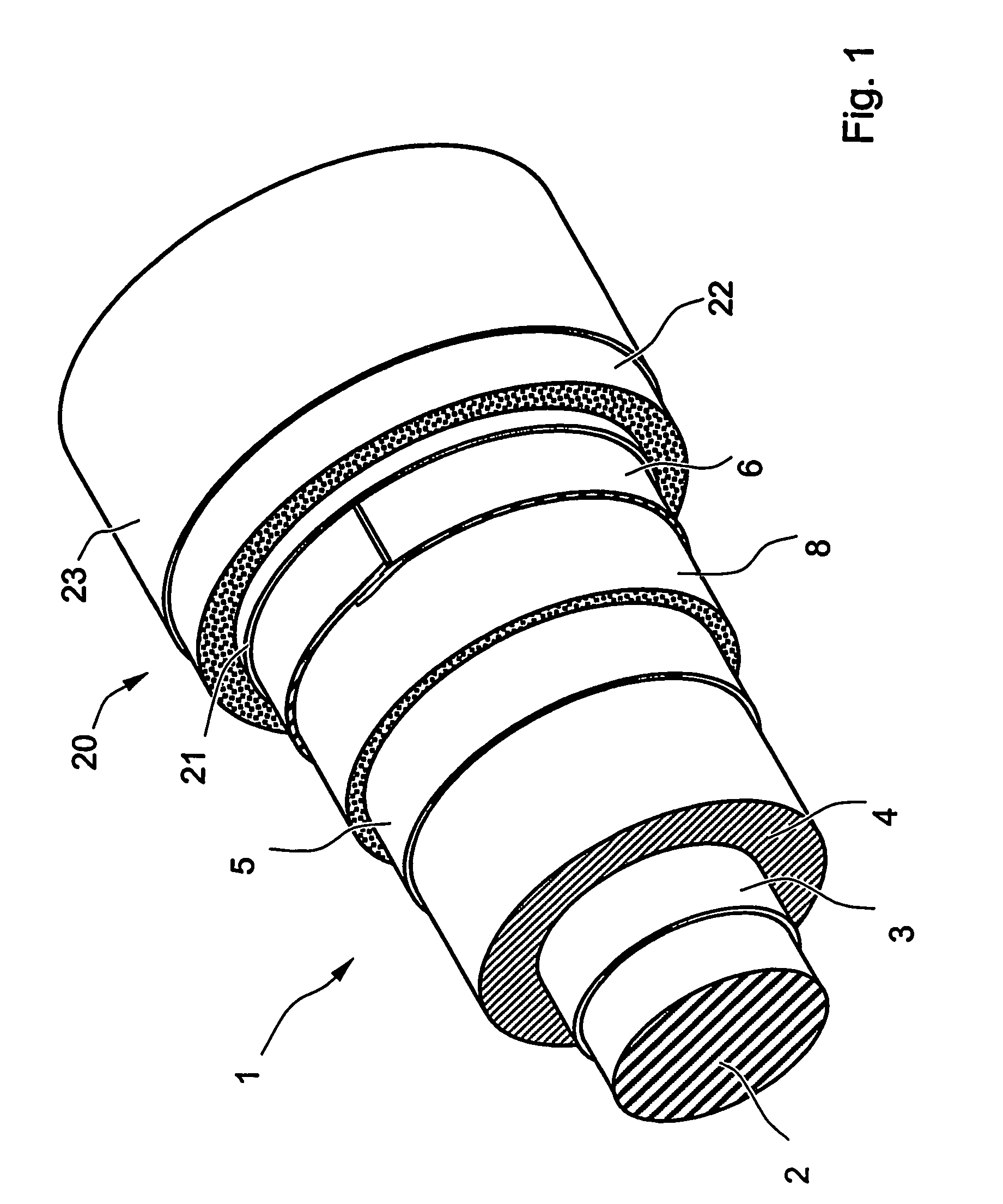

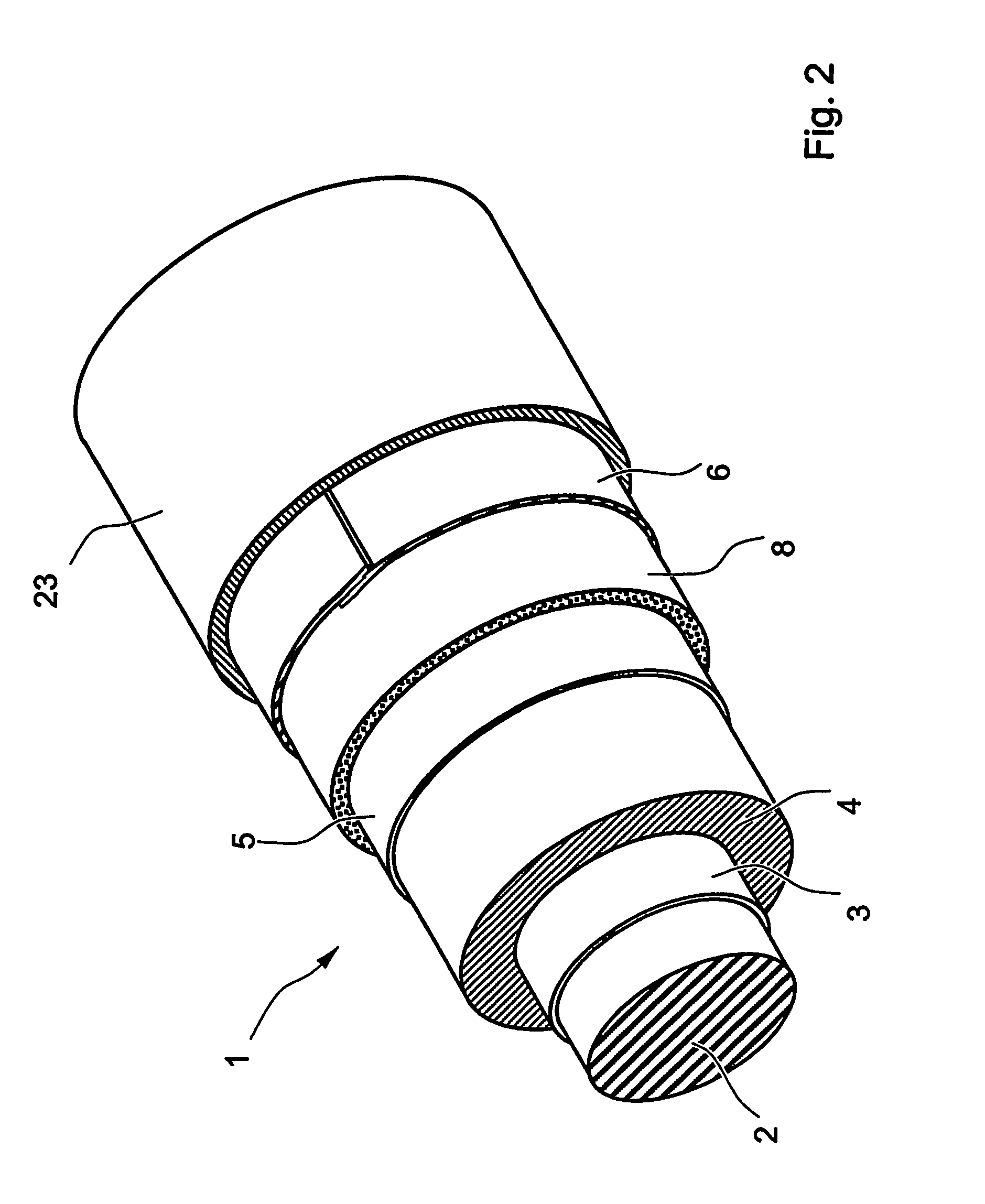

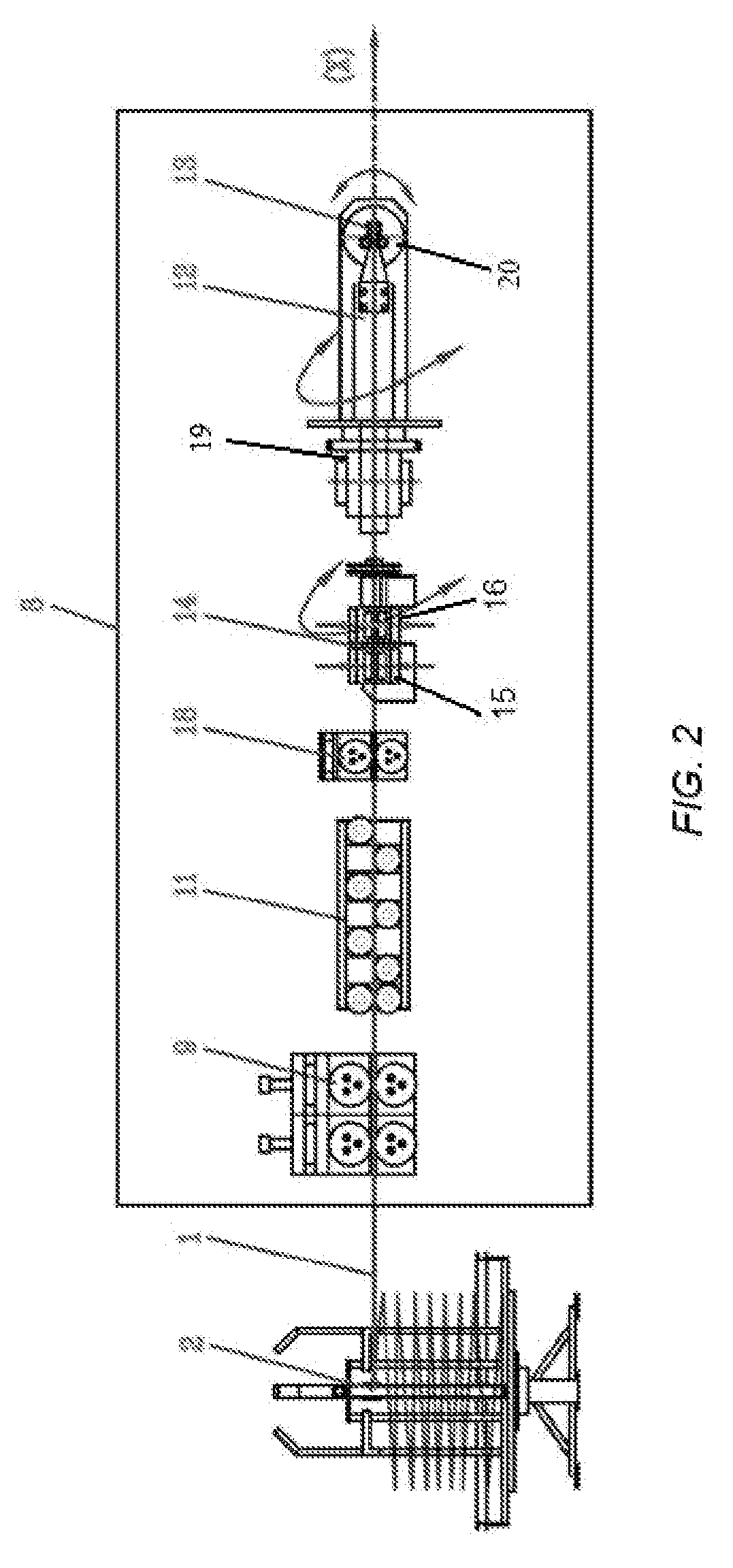

Continuous process for manufacturing electrical cables

InactiveUS7459635B2Increase in costExtended production timeNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorEngineering

A process for manufacturing an electric cable. In particular, the process includes the steps of: a) feeding a conductor at a predetermined feeding speed; b) extruding a thermoplastic insulating layer in a position radially external to the conductor; c) cooling the extruded insulating layer; and d) forming a circumferentially closed metal shield around the extruded insulating layer. The process may be carried out continuously, i.e., the time occurring between the end of the cooling step and the beginning of the shield forming step is inversely proportional to the feeding speed of the conductor.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Binder in use for jointing covering rubber on table tennis bat

InactiveCN101003711AImprove solubilityShort manufacturing timeNatural rubber adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceTennis racket

This invention discloses a pressure-sensitive adhesive for rubber layer on table tennis racket. The adhesive is composed of: solvent 60-90 wt. %, rubber 8-20 wt. %, and thickening resin 2-20 wt. %. The solvent is 1, 8-terpadiene, or a mixture of 1, 8-terpadiene and one or two of ethyl acetate, methanol and ethanol. The rubber is one or two of nonpolar rubbers such as natural rubber, and polar rubbers such as polychlorobutadiene, or rubber compound. 1, 8-terpadiene used as the solvent has high solvency for rubber layer on table tennis racket, and is harmless and environmentally friendly. The adhesive, when used on rubber layer on table tennis racket, has such advantages as rapid swelling, long elasticity-enhancing effect, and simple process.

Owner:徐昊为

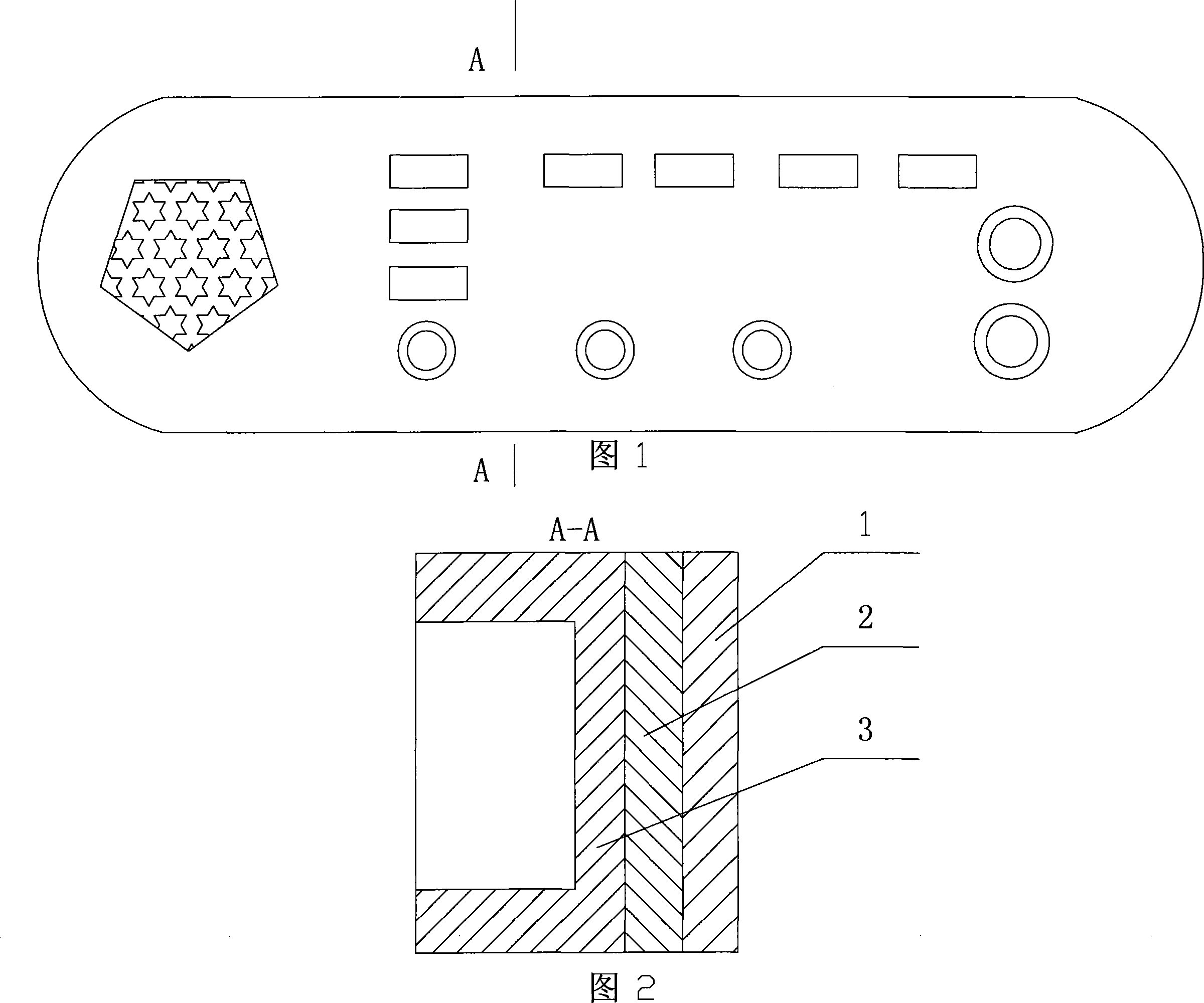

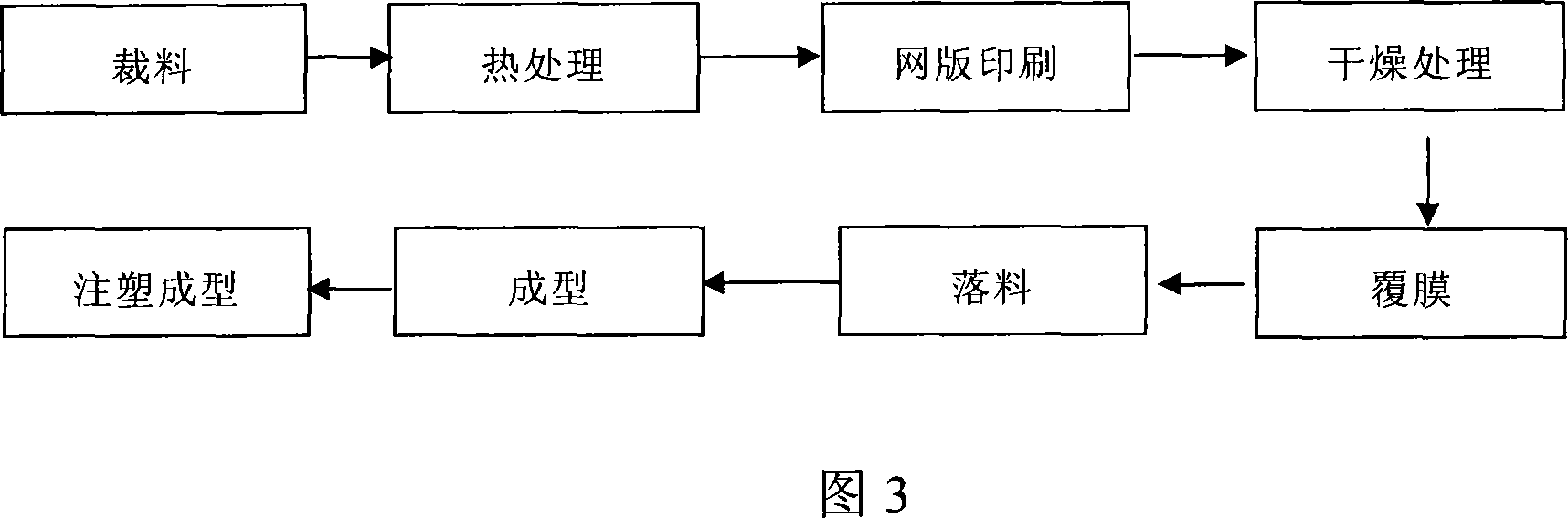

Surface decoration and process for making the same

InactiveCN101200156ABulb uniformAvoid cumbersome stepsSynthetic resin layered productsSpecial ornamental structuresScreen printingGraphics

The invention relates to a surface decoration piece (IMD) and the production process of the surface decoration piece, which is in particular widely used in the information technology products, household appliances, electronic products, personal computers, car accessories and so on and belongs to the technical field of injection molding decoration. The invention is characterized in that the screen-printing of ink patterns is adopted on the reverse side of a transparent sheet. The ink pattern is disposed between the injection molding layer sheet and the formed transparent sheet, which is integrated through the drying, cutting, molding and the injection molding. With the invention, the production time can be shortened and the costs can be reduced with the improvement of product quality and the enhancement of the scratch resistance of the products. With strong solvent resistance, excellent three-dimensional sense, the patterns are clear with excellent anti-light and moisture proof performance. The graphic, logo and color can be changed at any time without the need to replace the die. The convex bubbles of the function keys are uniform with good feel, in which the life expectancy can be up to one million times. The printing precision of the products with three-dimensional shapes is accurate and the error is small.

Owner:无锡市红光标牌有限公司

Later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation

The invention relates to a later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation. The method comprises the following steps of: newly drilling a straight well as an air injection well at a position where a steam cavity of the super heavy oil reservoir develops poorly; perforating on the upper part of the air injection well to complement a perforation section with the length of 2-3m; continuously injecting air by the air injection well at the speed of 20,000-80,000m<3> / day and firing to exploit; and stopping injecting the air when the volume percentage of the oxygen in the produced gas reaches 3 percent or the volume ratio of the volume of the injected air and the volume of the produced crude oil reaches over 3,000m<3> / m<3>. With the adoption of the method, the later-period heat loss is reduced by using the SAGD technology, and the stable production of the whole system is maintained by utilizing heat energy released by reacting substances in the oil reservoir.

Owner:PETROCHINA CO LTD

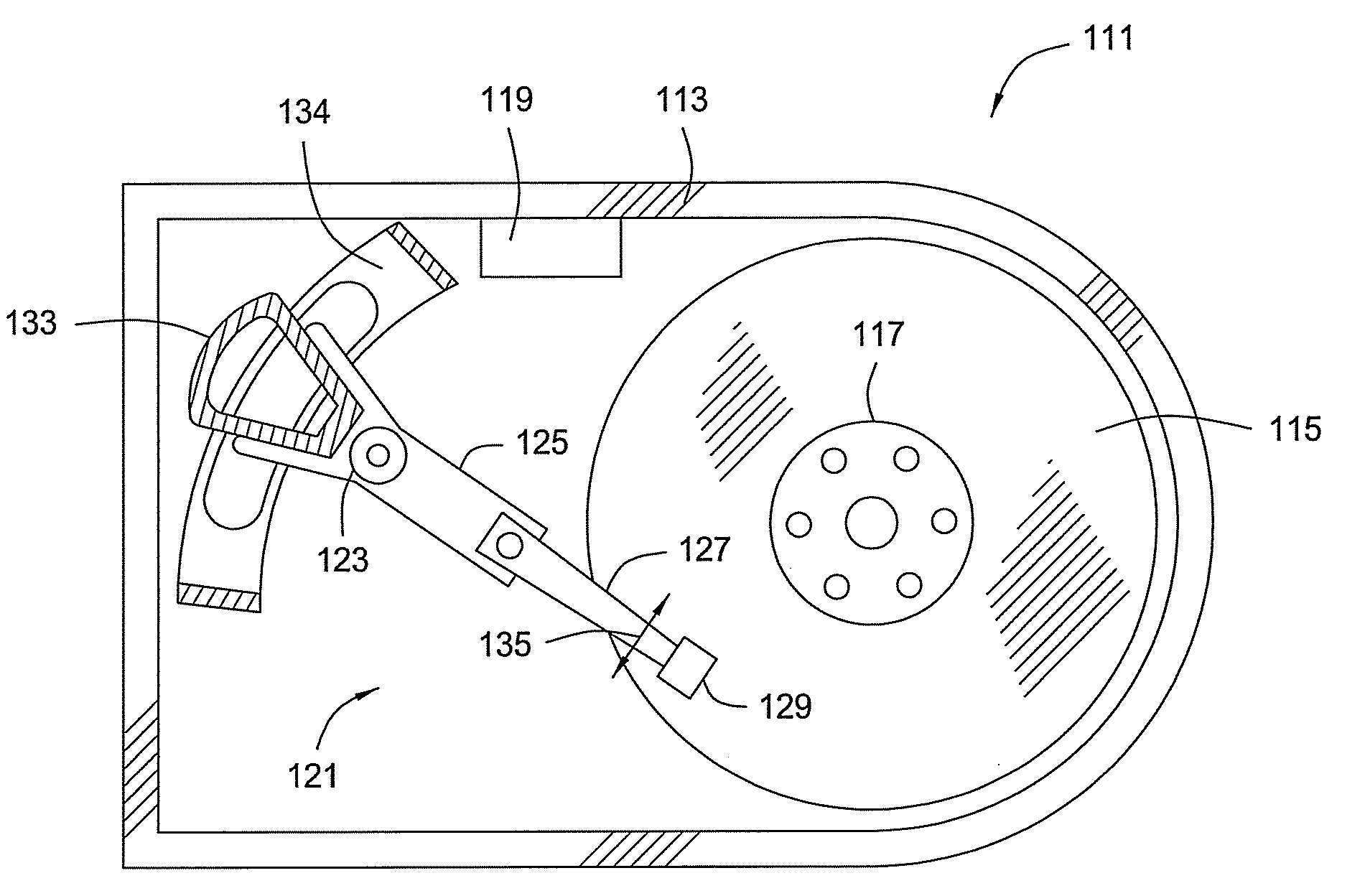

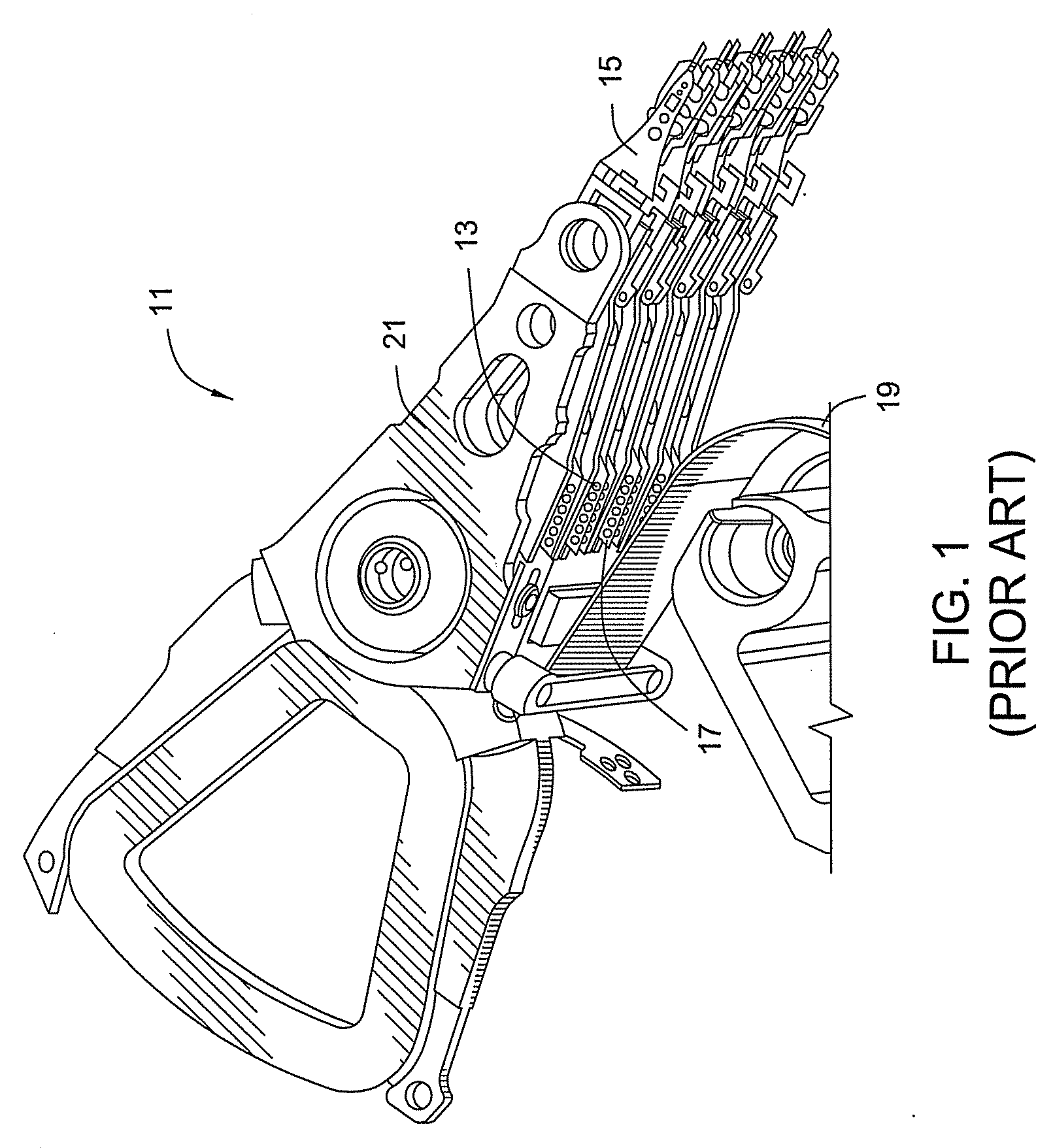

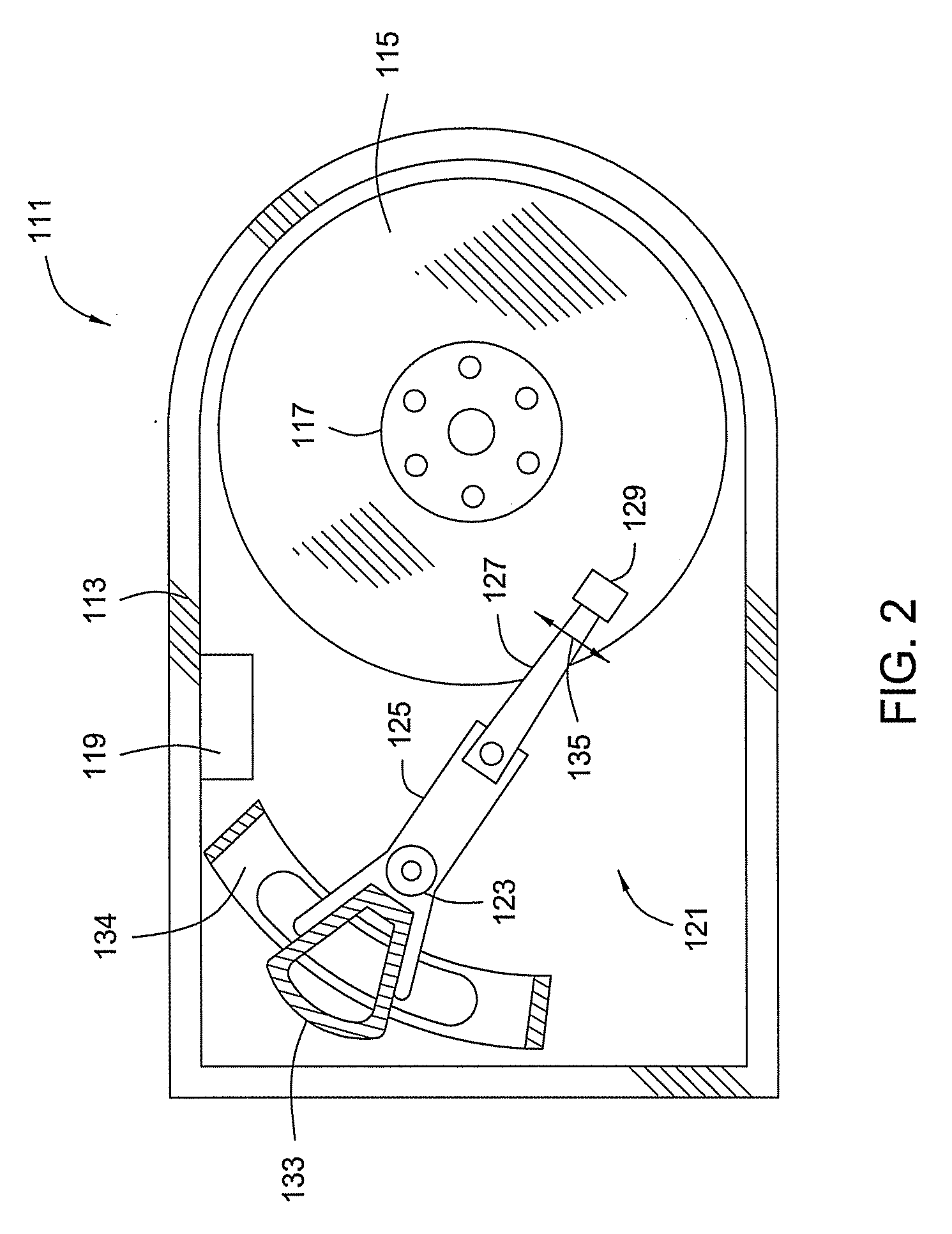

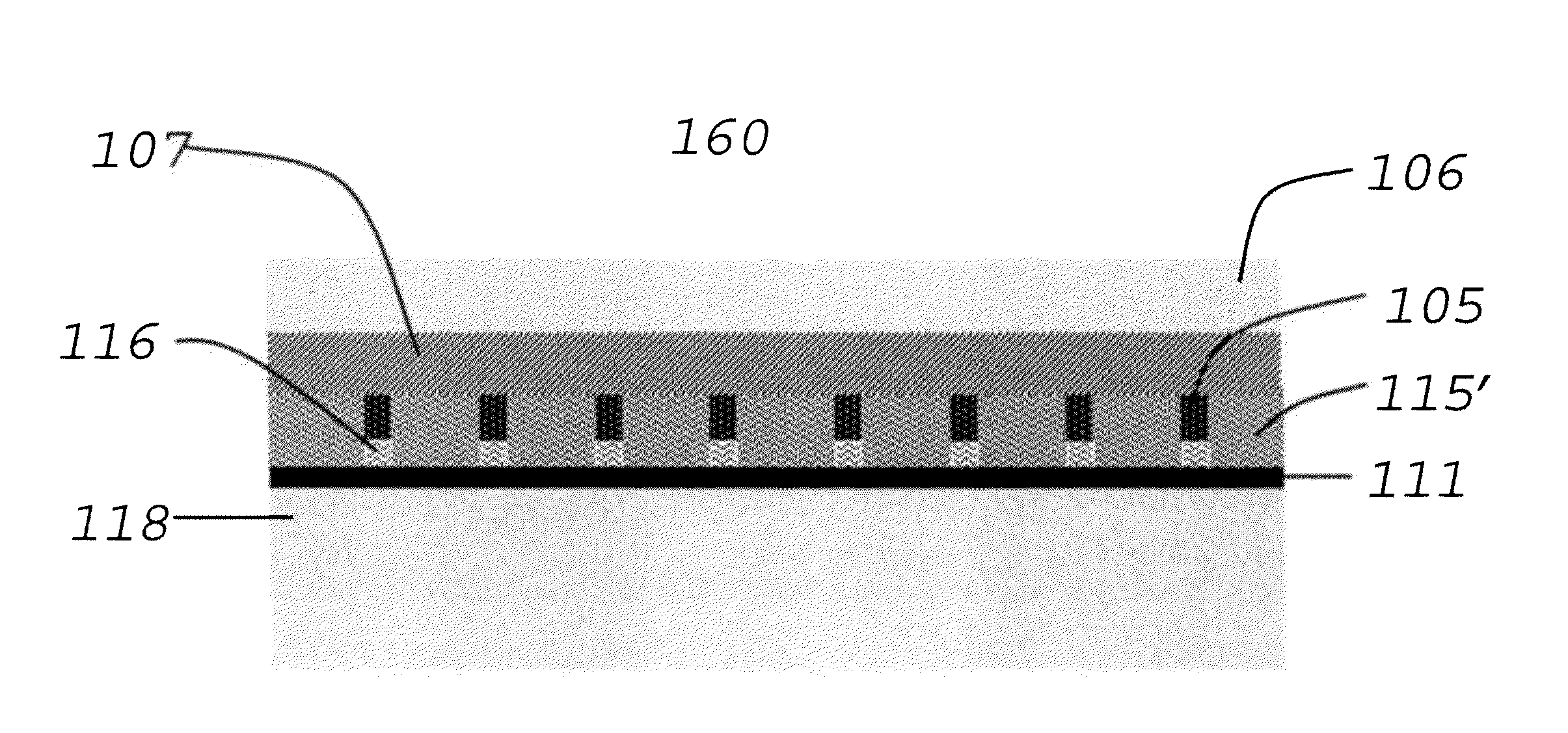

System and apparatus for vibration damping of integrated lead suspensions in high density magnetic storage devices

ActiveUS20080253028A1Reducing level of excitationReduce vibrationDisposition/mounting of recording headsUndesired vibrations/sounds insulation/absorptionHigh densityElectrical conductor

An integrated lead suspension (ILS) has a constrained layer damper (CLD) that attenuates vibration of the ILS. The CLD may be applied over an already assembled ILS such that the CLD is applied to the cover layer, to the base layer, or to both. Alternatively, the ILS may be encapsulated via a deposition process such that a damping layer is sandwiched between the conductor layer and the cover layer of the ILS, between the conductor layer and the dielectric layer of the ILS, or both.

Owner:WESTERN DIGITAL TECH INC

Tools and Methods for Forming Semi-Transparent Patterning Masks

ActiveUS20120125880A1High resolution patterningRapid and low-cost tool fabricationDecorative surface effectsConfectioneryManufacturing technologyImage resolution

Means, apparatus, systems, and / or methods are described for forming improved rigid or flexible semi-transparent imprinting templates. These templates can be used to produce patterning masks having improved resolution that do not require plasma etching for residue removal. The methods and apparatus are compatible with roll-to-roll manufacturing processes and enable roll-to-roll formation of a wide range of metal patterned films.

Owner:MICROCONTINUUM

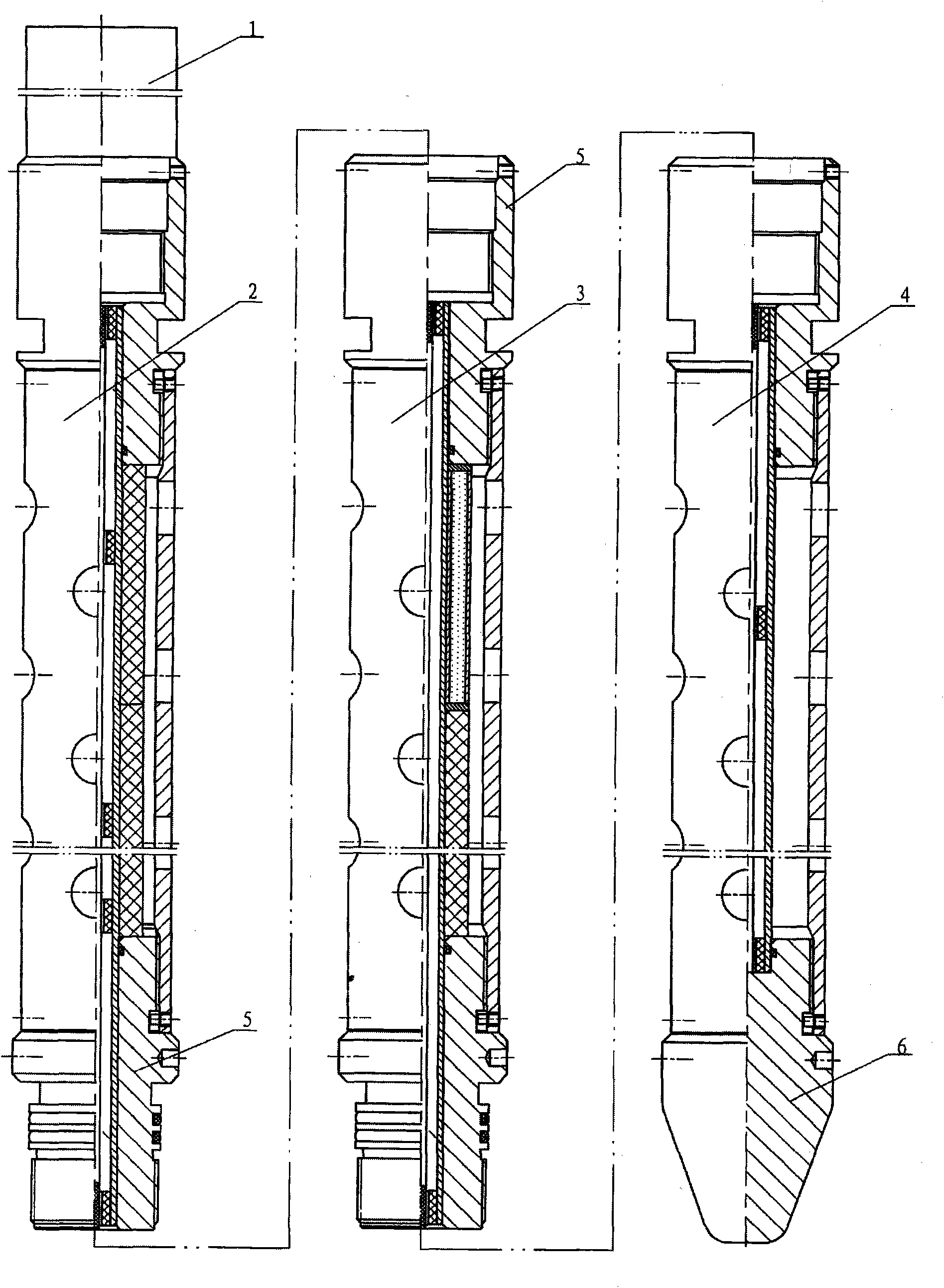

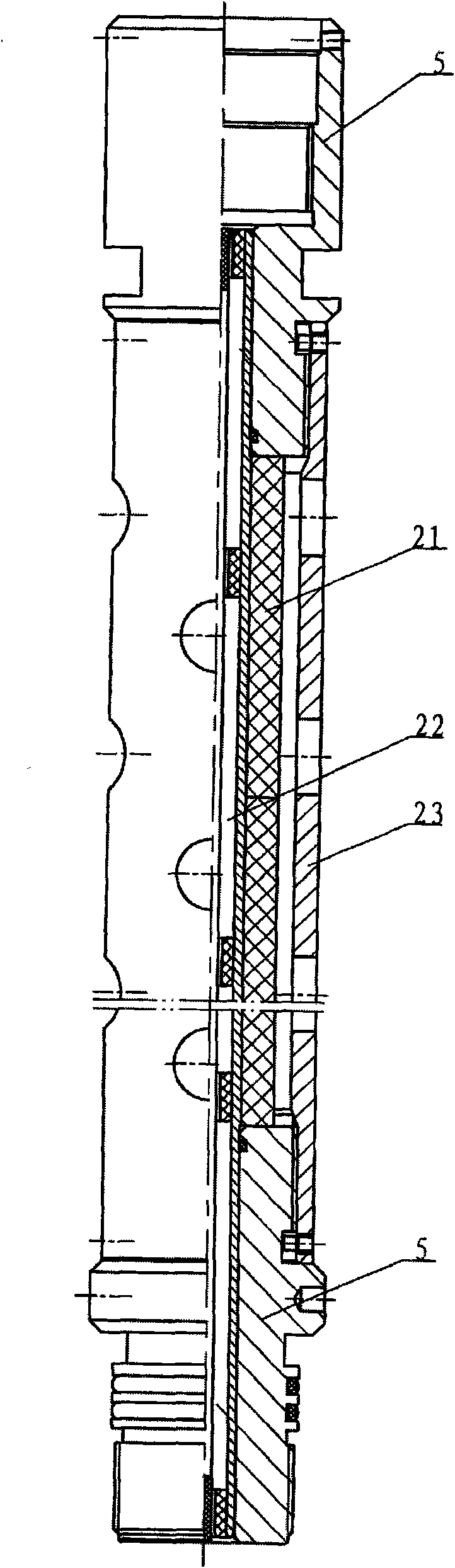

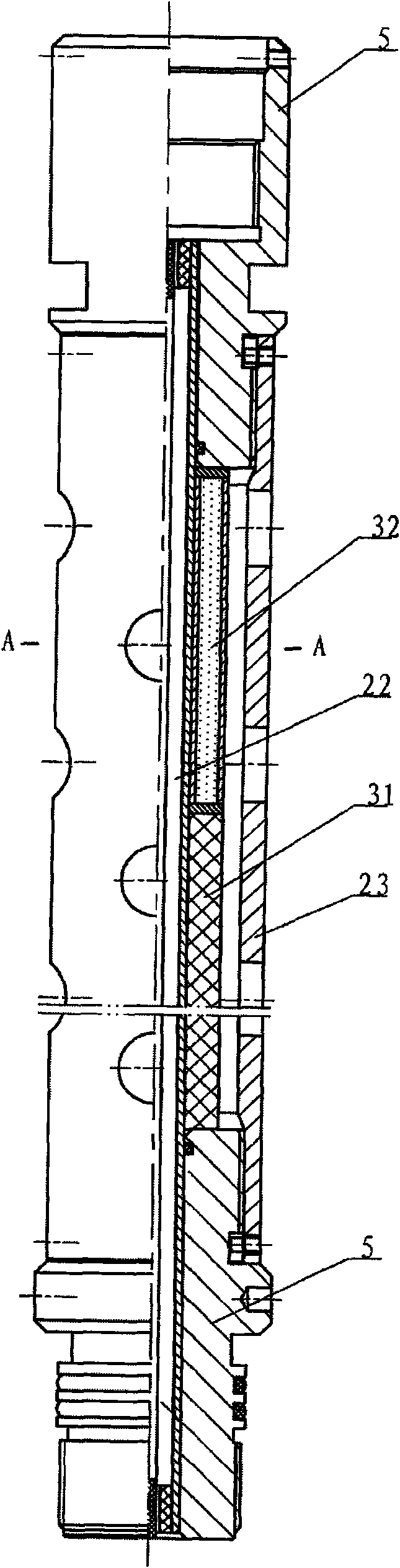

Pulse fracturing sand injector for horizontal wells

ActiveCN101619654AIncrease profitImprove stabilityFluid removalDirectional drillingHigh energyHorizontal wells

The invention discloses a pulse fracturing sand injector for horizontal wells, which is formed by connecting a fracturing gun component, a sand-injecting gun component and an interlayer gun component via intermediate joints, wherein, the fracturing gun component is loaded with fracturing gunpowder with various burning speeds; the interlayer gun component is applied to the interlay where oil gas is not produced and achieves the effect of igniting; the sand-injecting gun component is internally loaded with a sand collecting cylinder and sand-expelling gunpowder and used for conveying propping agent to the formation fracture, thereby forming the fracturing sand injector with the length ranging from dozens of meters to hundreds of meters for horizontal wells by proper combining the components according to the distribution of the production pay and the interlayer. By introducing the propping agent to the high-energy gas fracturing process, the fracturing sand injector can improve the stability of fracture and extend the stimulation time, and the fracturing sand injector has the characteristics of low cost, obvious stimulation effect, simple process and safe and reliable application. The invention is applicable to horizontal wells with different completion manners, vertical wells or inclined wells, such as cased wells, sieved wells or uncased wells.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

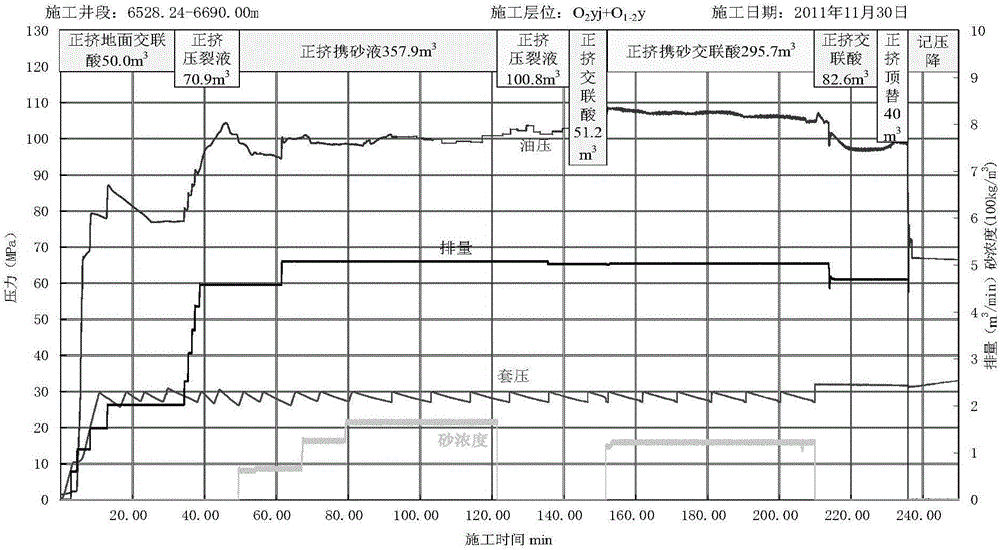

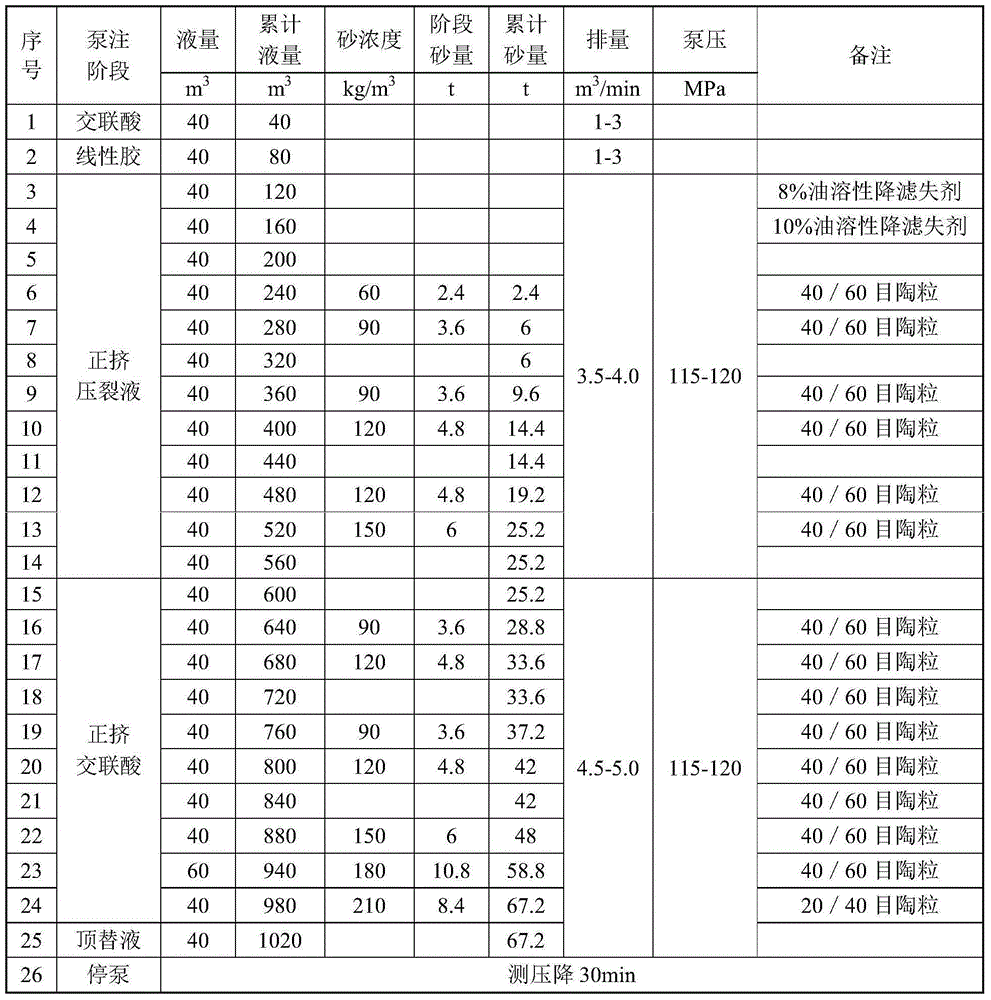

Proppant-carrying acid fracturing method for high-temperature ultra-deep carbonate reservoir

InactiveCN106321044ASimple processEasy to operateFluid removalDrilling compositionAcid fracturingFracturing fluid

The invention provides a proppant-carrying acid fracturing method for a high-temperature ultra-deep carbonate reservoir. The proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir comprises the following steps that (1) fracture forming is conducted through fracturing fluid; (2) ground crosslinked acid is adopted and is made to react with rock, so that an acid-etched fracture is generated in a formed fracture, and a proppant is carried with the ground crosslinked acid for supporting the acid-etched fracture; and (3) linear glue is used for replacement, and thus acid fracturing is completed. According to the proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir, the technique is simple, operation is convenient, and the construction effect is remarkable; and the proppant-carrying acid fracturing method is suitable for transforming construction of deep well carbonatite at the high temperature of 150-170 DEG C, a supporting fracture which has deep penetration and longer flow conductivity can be formed in a stratum, the productivity is increased and the production time is prolonged after acid fracturing and well fracturing, and the length of the formed fracture is larger than 120 m.

Owner:CHINA PETROLEUM & CHEM CORP +1

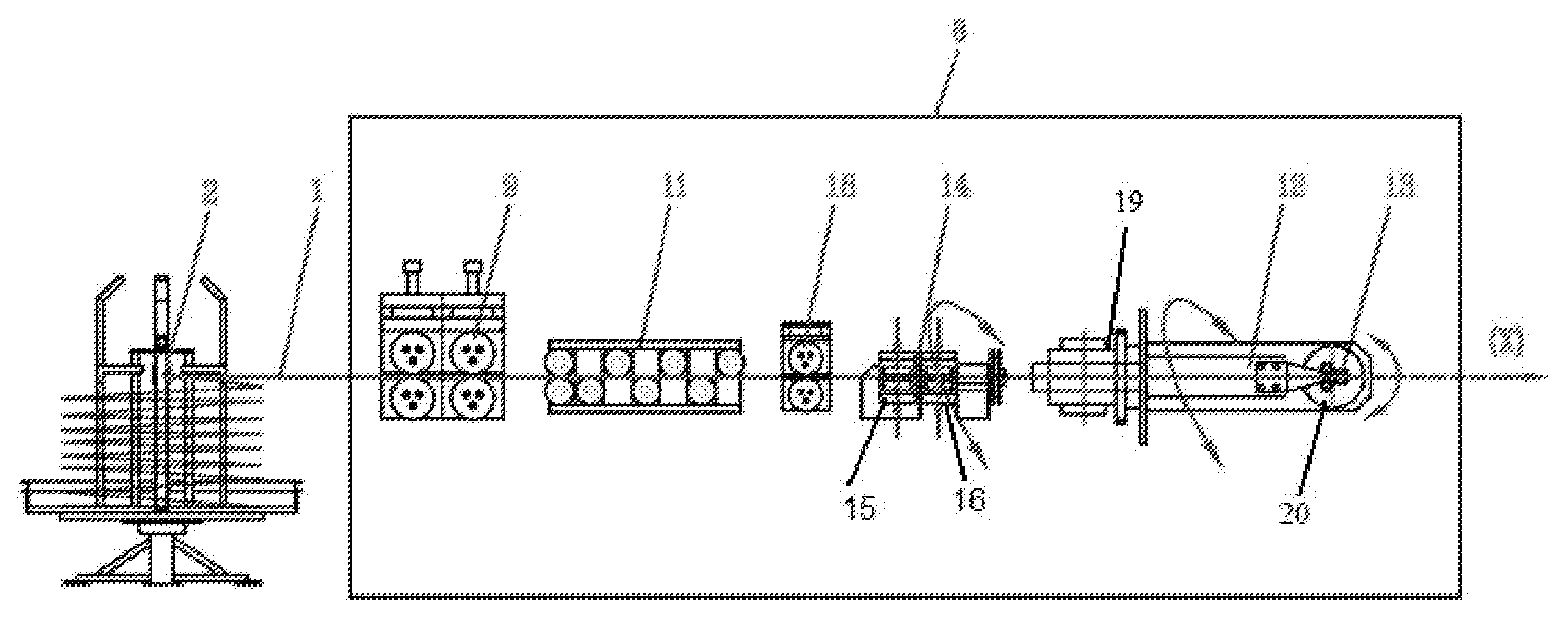

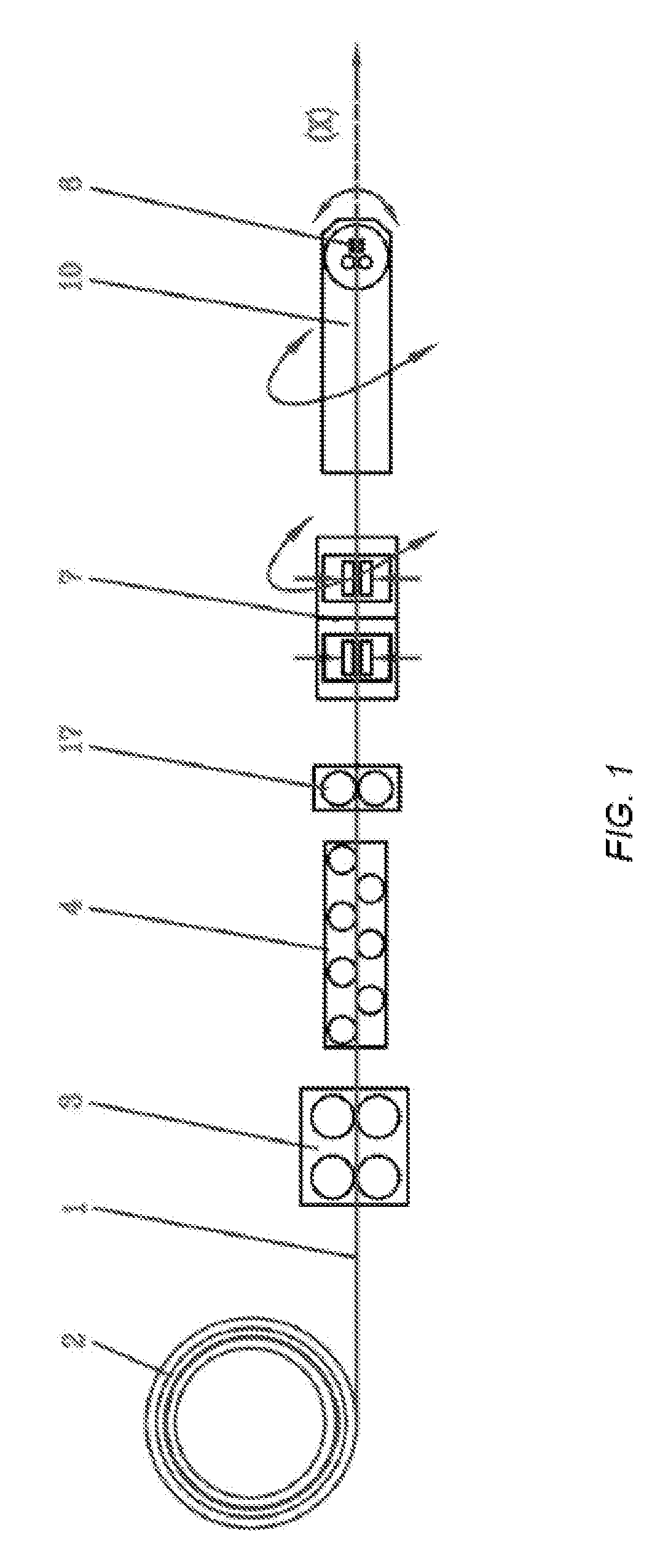

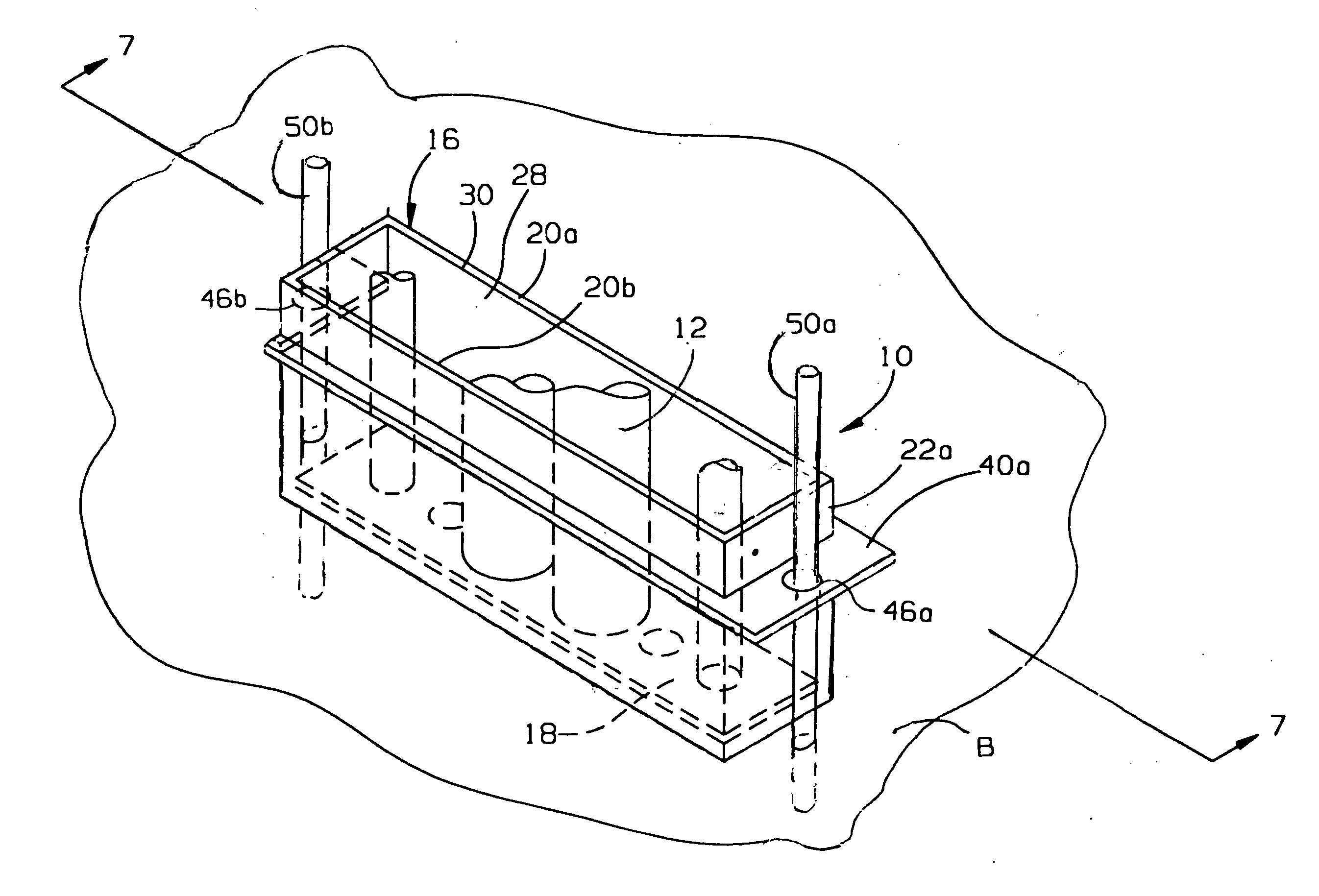

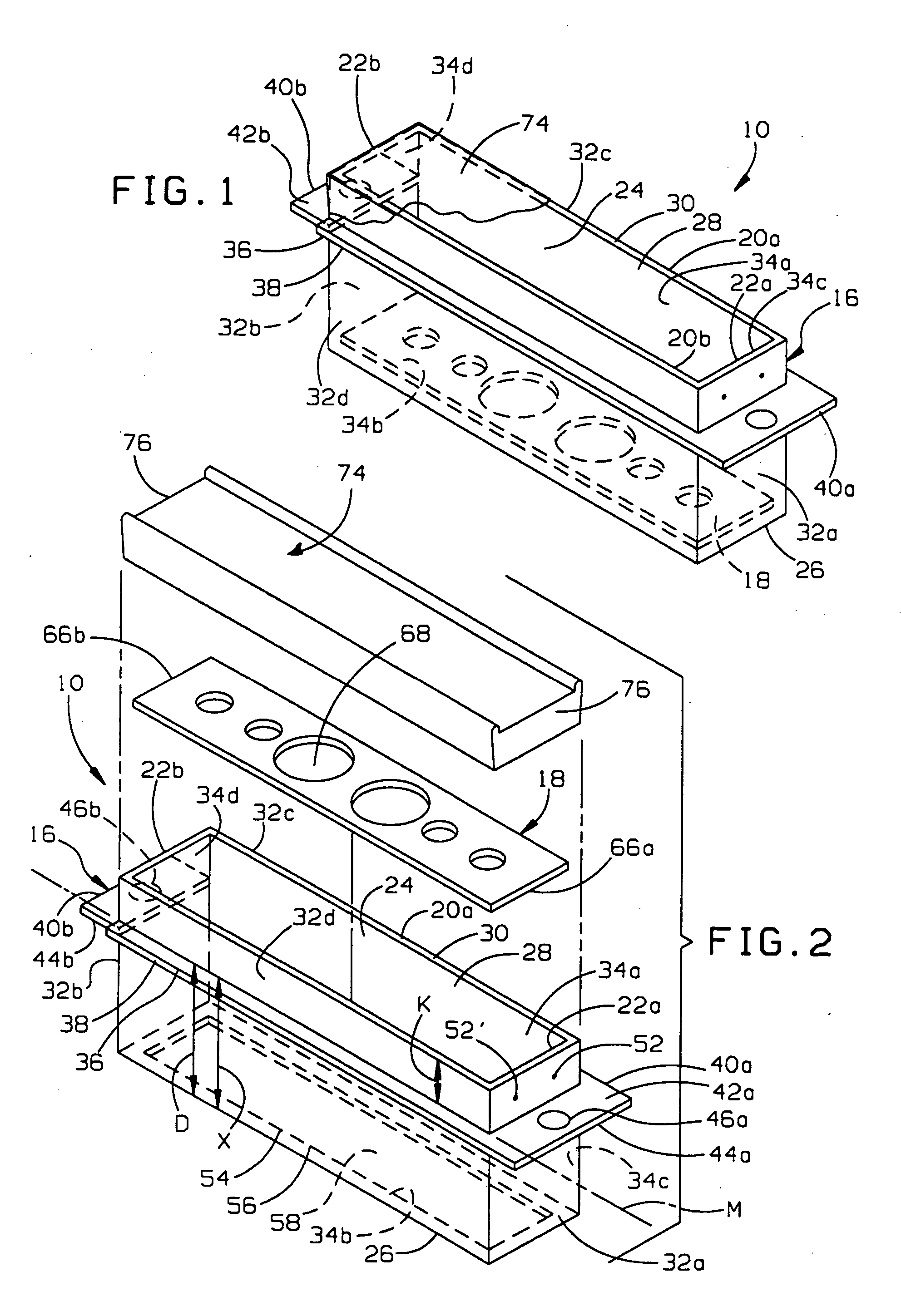

System and process for production of three-dimensional products from wire

InactiveUS20080078226A1Low production costLow costMetal-working feeding devicesPositioning devicesWire rodThree dimensional shape

A process of production of three-dimensional products from wire (1) or other suitable material, which process may be implemented in a system (8) that may include an advancement mechanism (9), a straightening mechanism (11), a length measuring arrangement (18) towards which advances the material (1), a gripper arrangement (14) suitable to hold the material with fixed grippers (15) and simultaneously with other grippers (16) to twist it to a desired angle around its longitudinal axis (X), and a rotatable bending mechanism (12) that can bend the material plastically in one plane and simultaneously can rotate at a desired angle around the longitudinal axis (X) of the wire (1) so that it may generate bends in different planes. The system (8) implementing the process may also carry a cutting arrangement (13). The process of production of three-dimensional products affords the ability of choosing and energizing within the same product shape either the gripper arrangement (14) or the bending mechanism (12) thus providing the flexibility of bettering the times of production of various three-dimensional shapes.

Owner:ANAGNOSTOPOULOS ANTONIOS

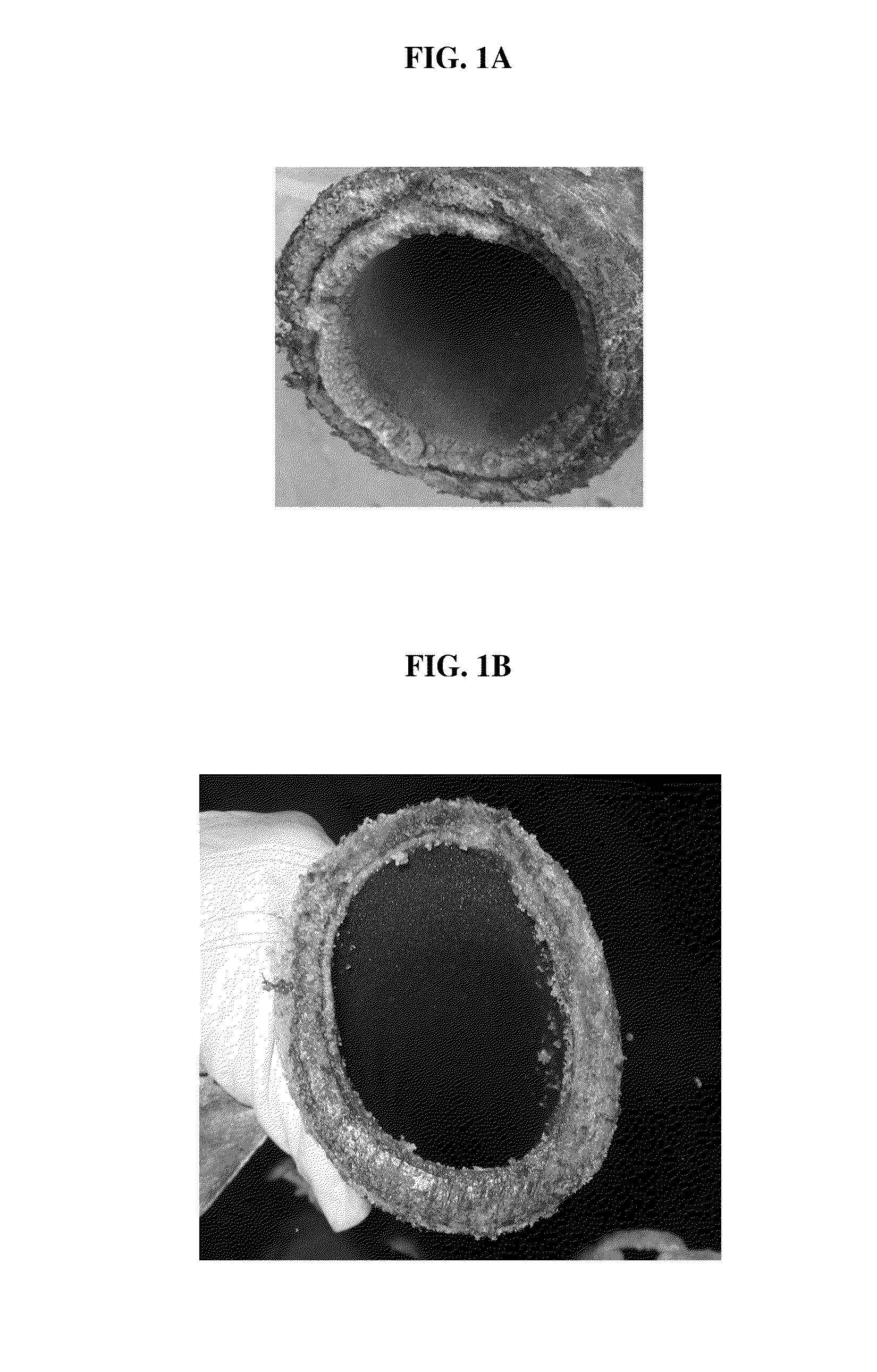

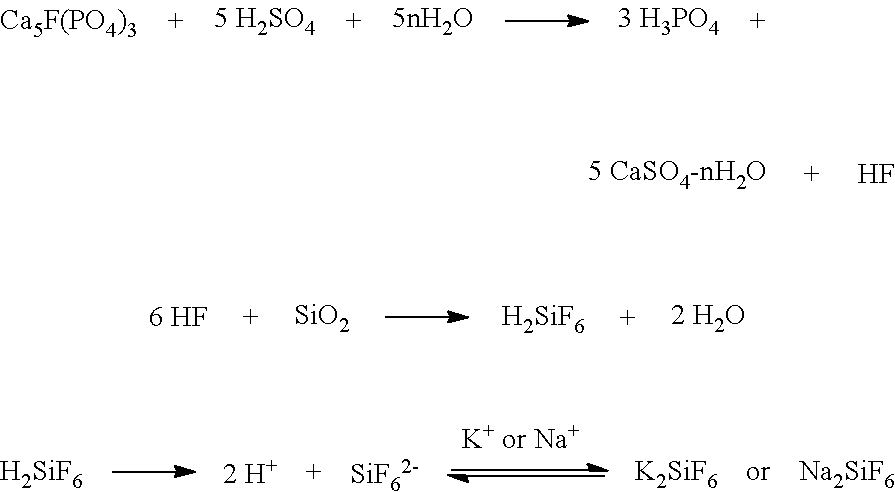

Process and Reagents for the Inhibition or Reduction of Scale Formation During Phosphoric Acid Production

ActiveUS20110076218A1Reduce and eliminate scalingLow treatment concentrationPhosphoric acidPhosphoric acidHydroxy group

Processes and reagents for inhibiting or eliminating scale formation during wet-process phosphoric acid production are provided and include adding to a wet-process phosphoric acid production stream a scale inhibiting amount of a reagent having an aliphatic or aromatic compound containing at least two hydroxy groups, and at least one amine.

Owner:CYTEC TECH CORP

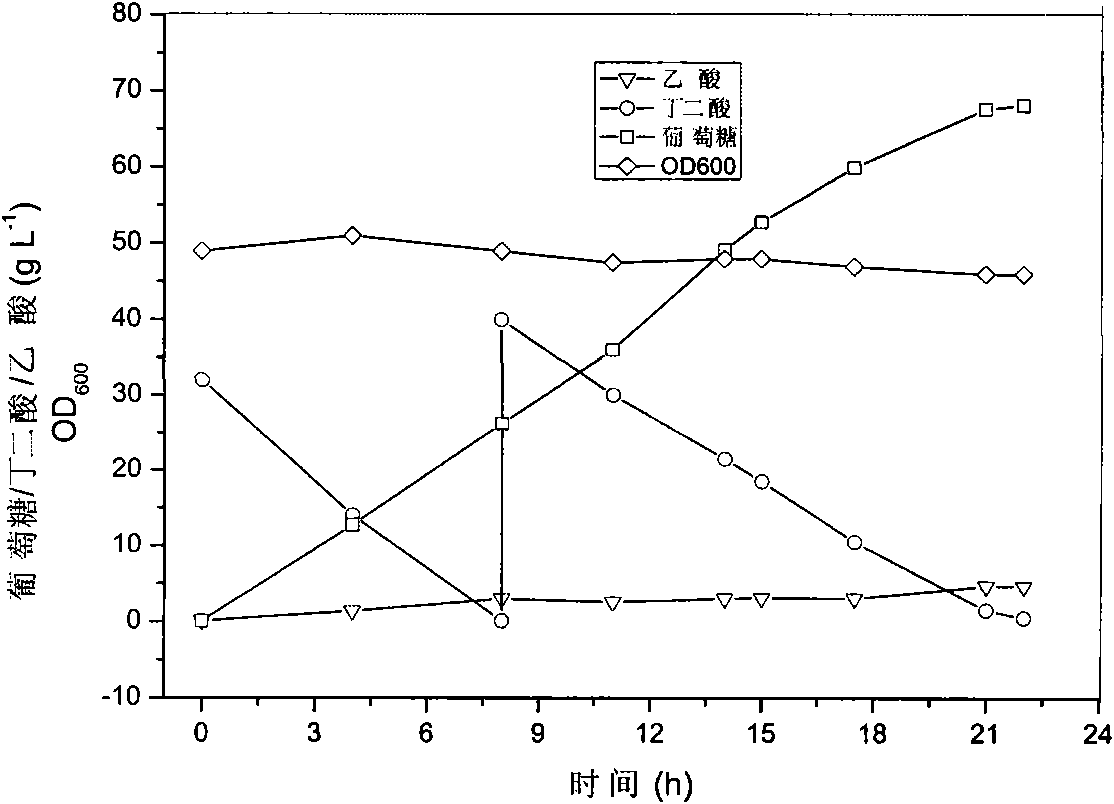

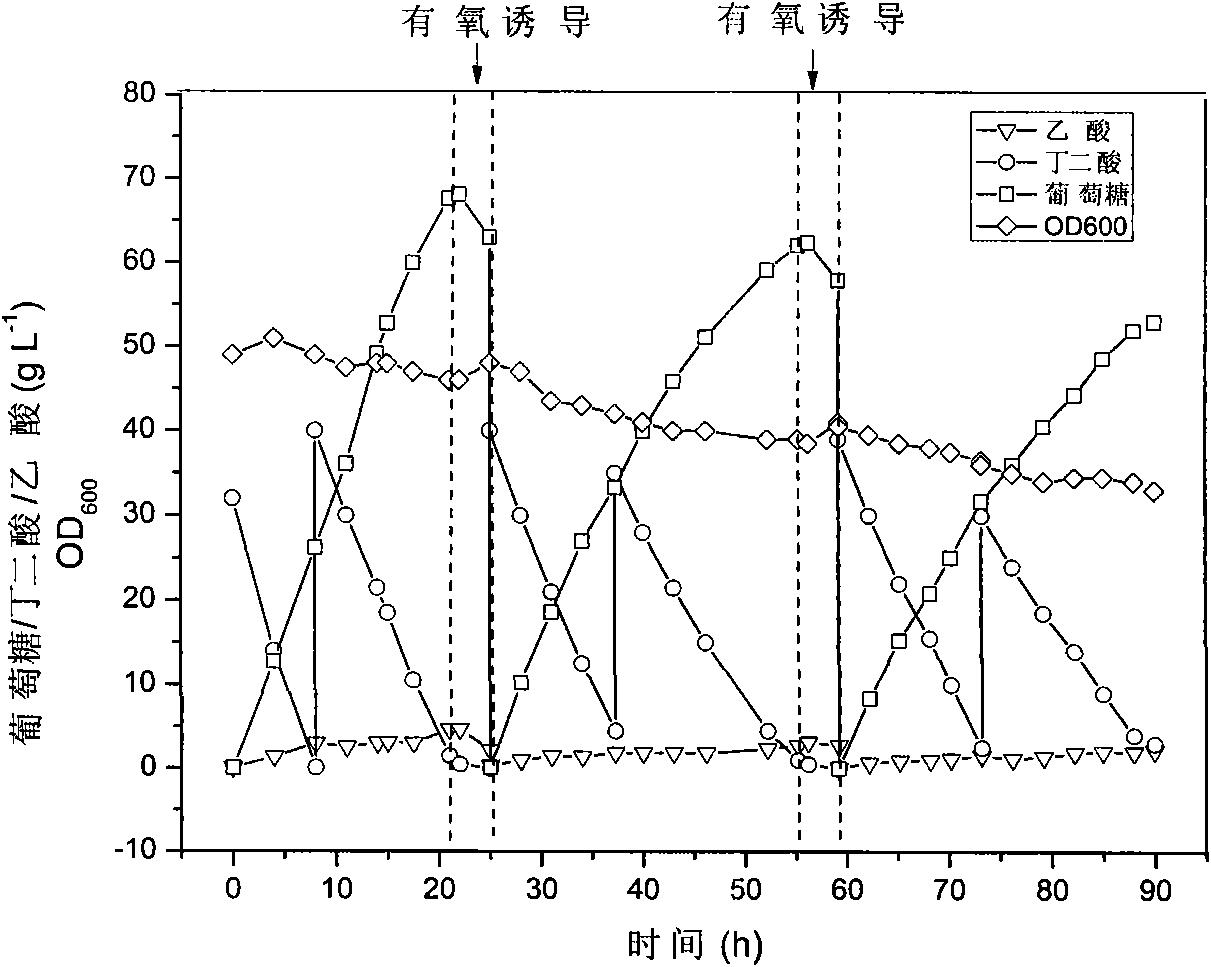

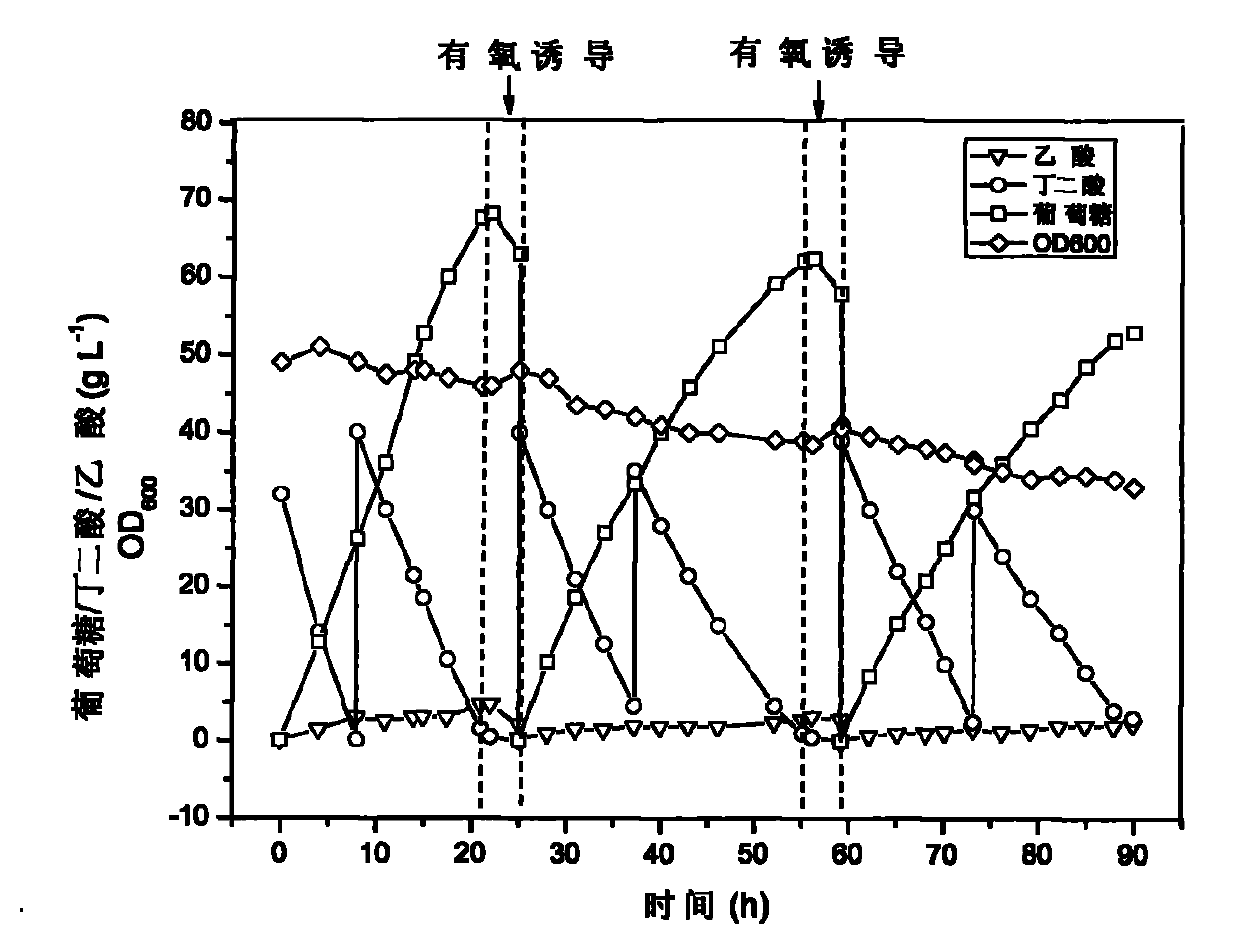

Method for fermentation production of succinic acid by circulating utilization of recombinant Bacillus coli cells

InactiveCN101792778AIncreased activity of key enzymesIncrease specific production intensityProductsReagentsEscherichia coliAcetic acid

The invention relates to a method for the fermentation production of succinic acid by the circulating utilization of recombinant Bacillus coli cells, which is characterized by comprising the following steps: adopting the two-stage fermentation mode of first aerobic culture of Bacillus coli and later anaerobic acid production to produce succinic acid by utilizing Bacillus coli for producing succinic acid; when the two-stage fermentation is finished, utilizing metabolites (succinic acid, acetic acid, pyruvic acid and the like) produced in the fermentation process to aerobically induce cells; aseptically collecting Bacillus coli cells, and anaerobically biotransforming and synthesizing the succinic acid in a fresh culture medium; after finishing the anaerobic biotransformation and synthesis,aerobically inducing again, and recovering the cells to continue to biotransform and synthesize the succinic acid in the fresh culture medium, and achieving the purpose of circulatingly utilizing thecells to biotransforme and synthesize the succinic acid. The technical scheme of the invention solves the problems that the yield and production intensity of the succinic acid is on the low side in the whole process of two-stage fermentation due to the consumption of a great deal of carbon sources and time in the process of aerobic Bacillus coli culture.

Owner:NANJING UNIV OF TECH

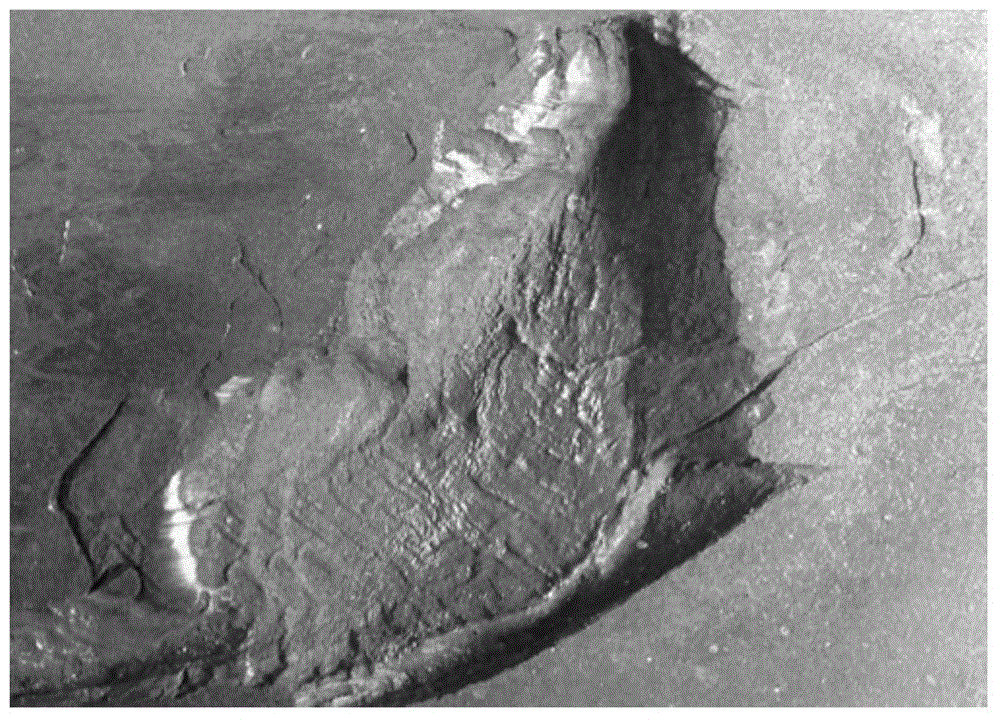

On-line detection method of machine vision system to photovoltaic glass flaws

InactiveCN101696945AReduce testing labor intensityIncrease productivityMaterial analysis by optical meansUsing optical meansImaging algorithmControl signal

The invention discloses an on-line detection method of a machine vision system to photovoltaic glass flaws. The diameter of an in-built air bubble, the length of an open air bubble and the length of a nick are set as detection parameters; the detection precision and the qualified range of the different detection parameters are set according to the requirements of a user; a camera is started by outer triggering and control signals for shooting an image of on-line running photovoltaic glass in real time; the shot image is transmitted to a computer for detection; the computer is used for extracting an image with the photovoltaic glass with flaws by image algorithm processing and computing three flaw sizes to judge whether products are qualified products or discarded products by the computed flaw sizes; and two kinds of products are separated from different discharge holes by the outer triggering and control signals. The method has the advantages of high detection precision and high direction speed of the photovoltaic glass and can effectively ensure the qualified ratio of the products.

Owner:WUXI ZHONGWANG 4D TECH

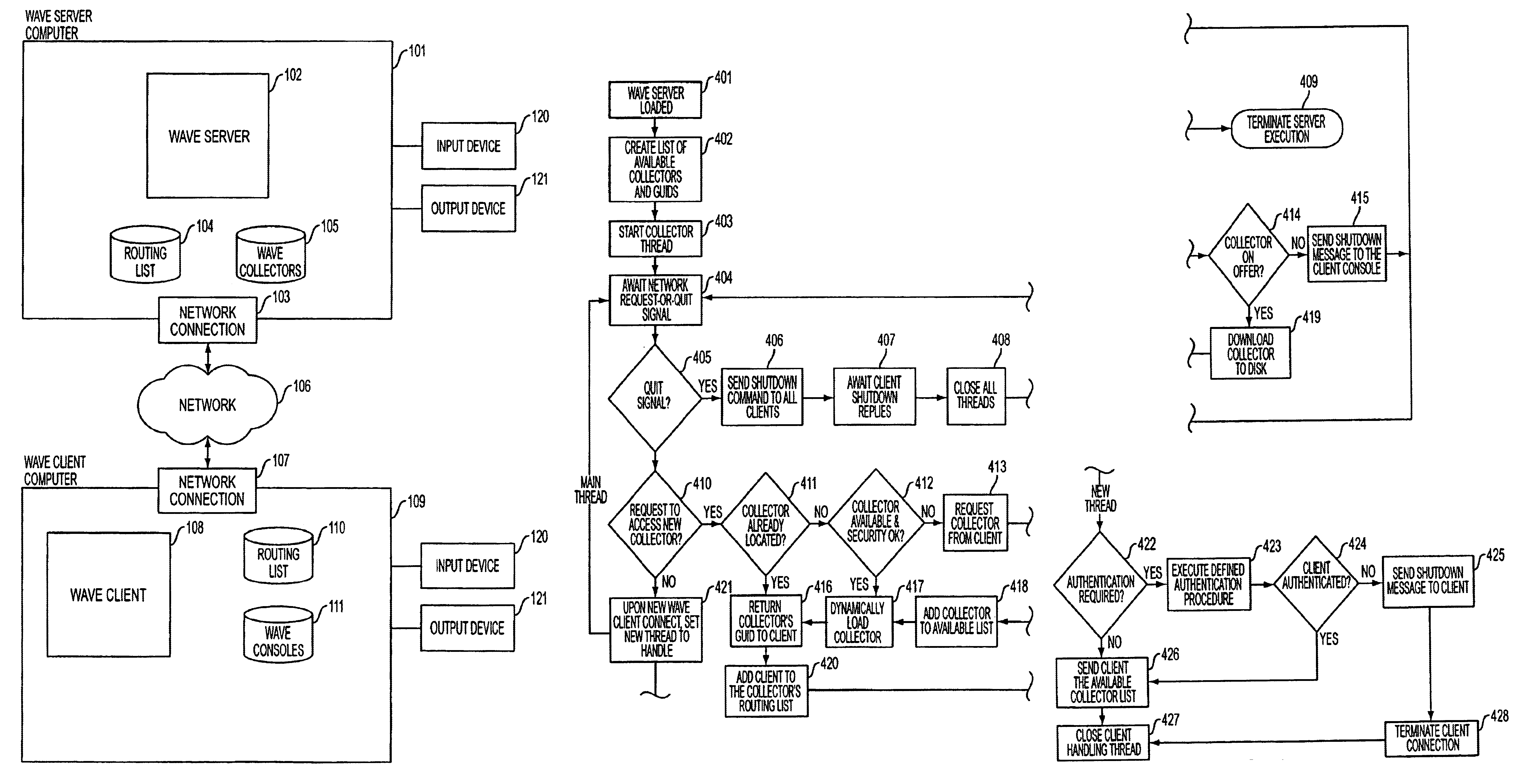

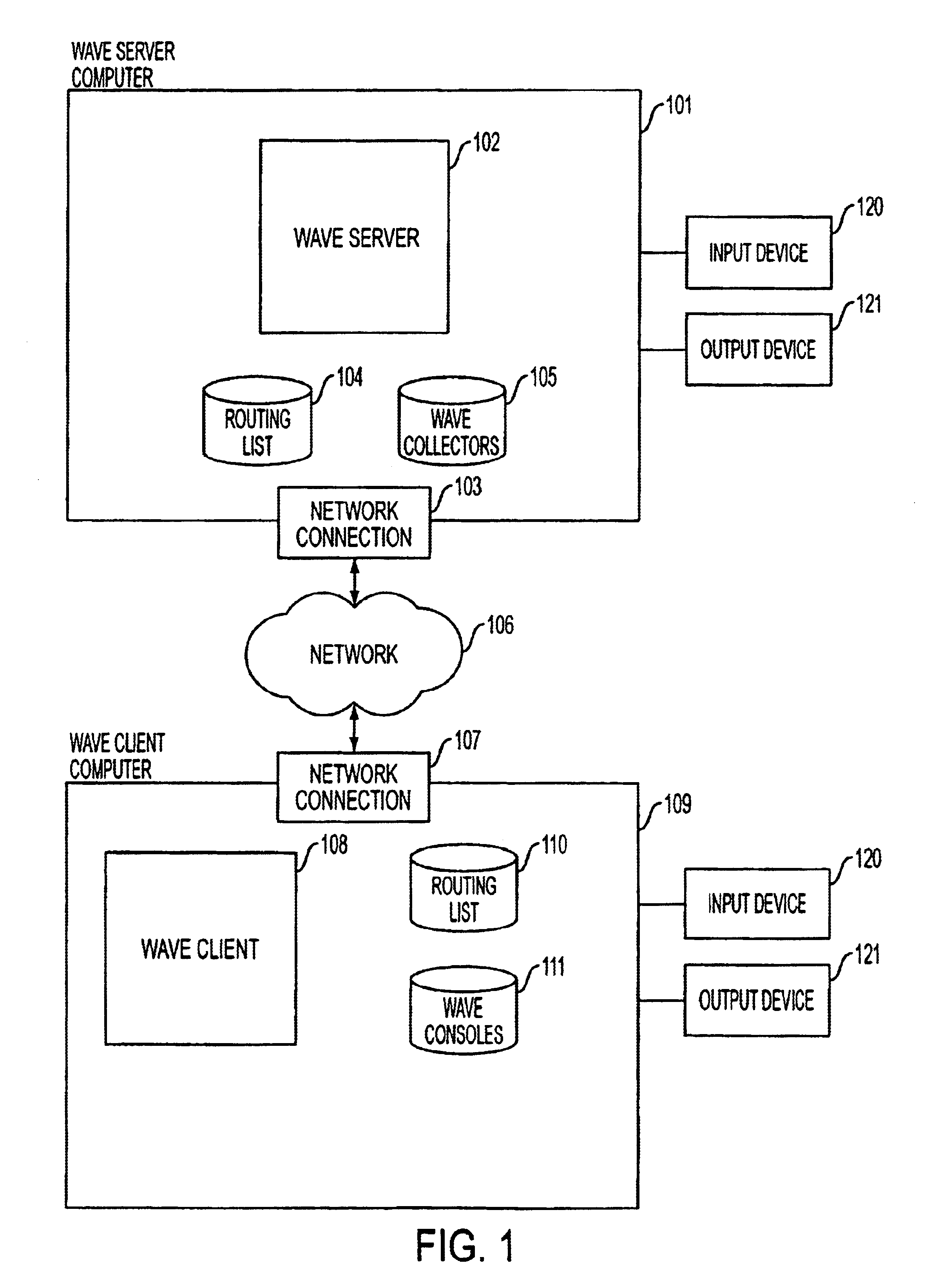

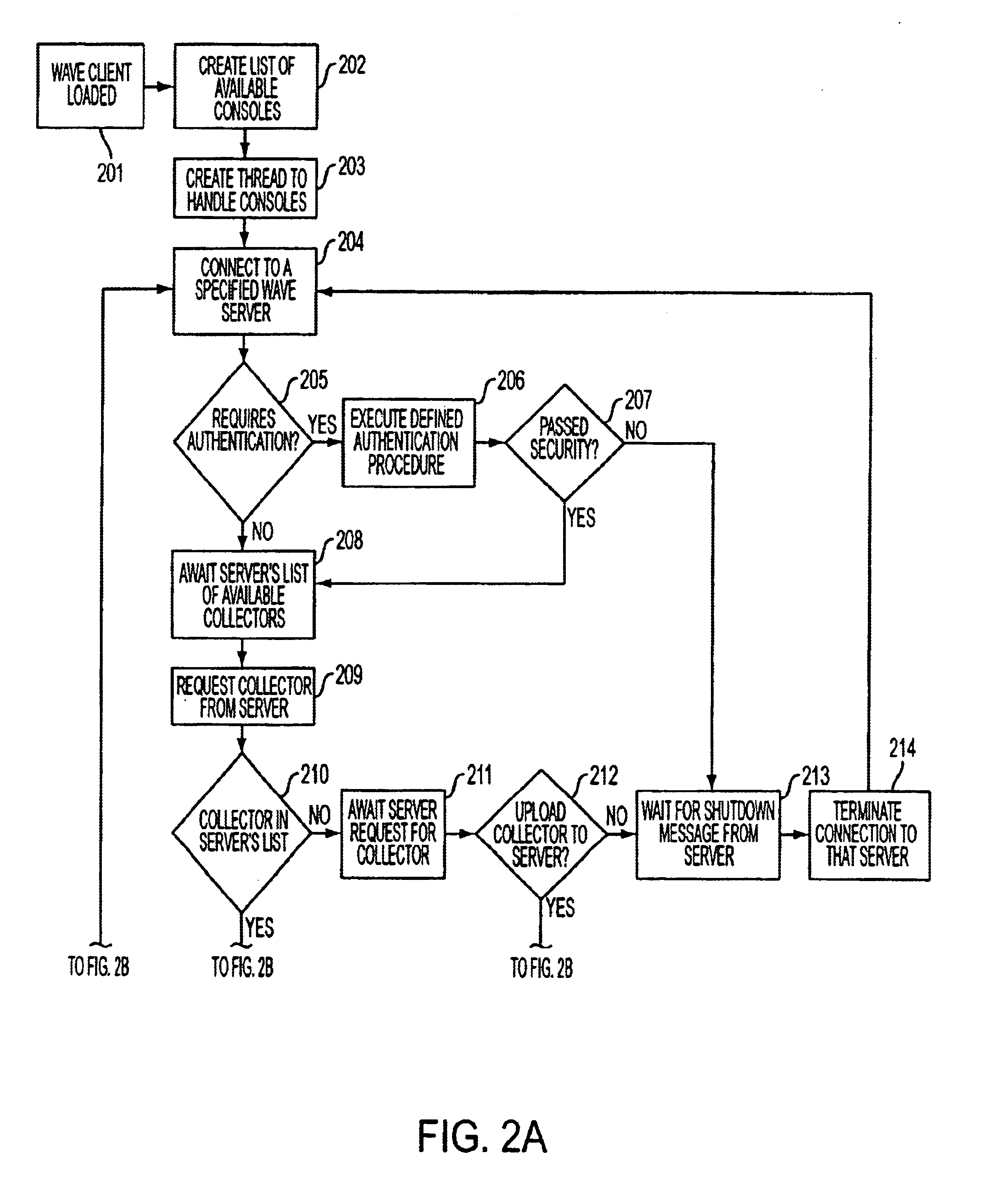

Wide area real-time software environment

InactiveUS6866587B1Easy to controlIncreased modificationVideo gamesSpecial data processing applicationsWide areaApplication software

A system for the remote monitoring or modification, whether temporary or permanent, of a running application's attributes. These attributes include, for example, art, sound, music, text, environmental variables or artificial intelligence parameters, program source code, program pseudo code, program compiled code or any other computerized attributes. The application is enabled so that there is the ability to dynamically monitor an application's internal data, components and functionality via a remote station and / or dynamically save application usage data while that application is executing. Further, this program has the ability to temporarily or permanently change internal settings and attributes of the application and add extra functionality to the application. If charges or added functionality are permanent, they can be used when the application is executed.

Owner:UNWIRED BROADBAND INC

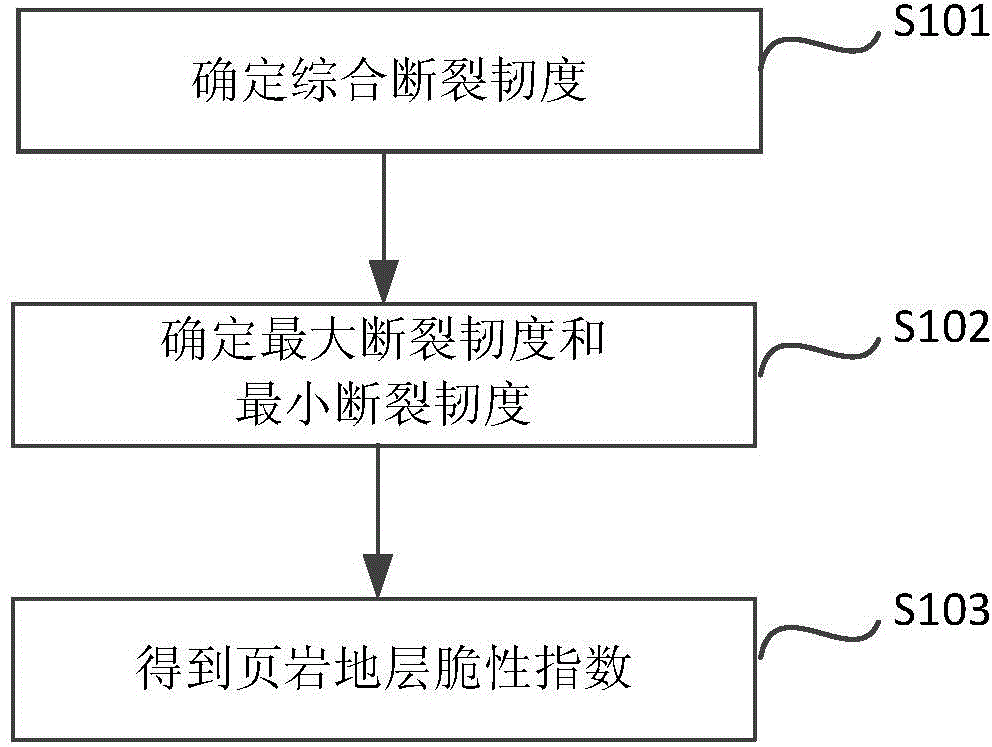

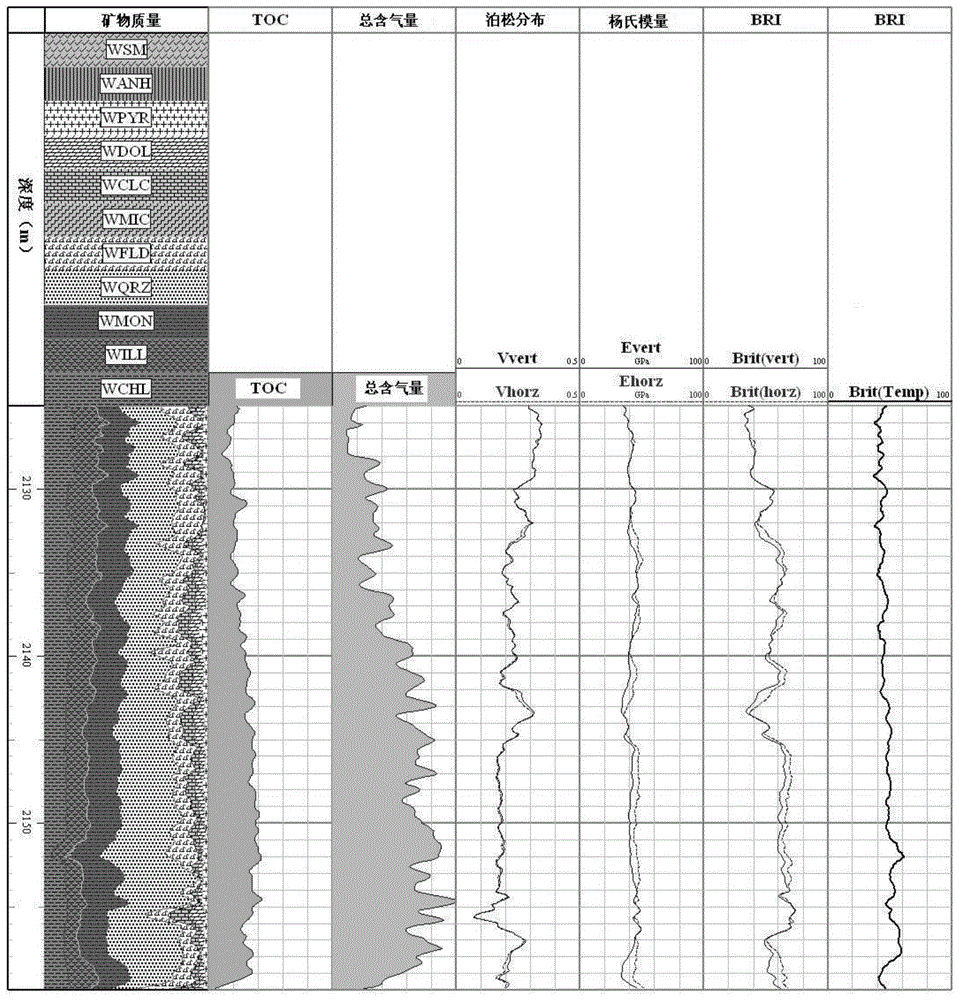

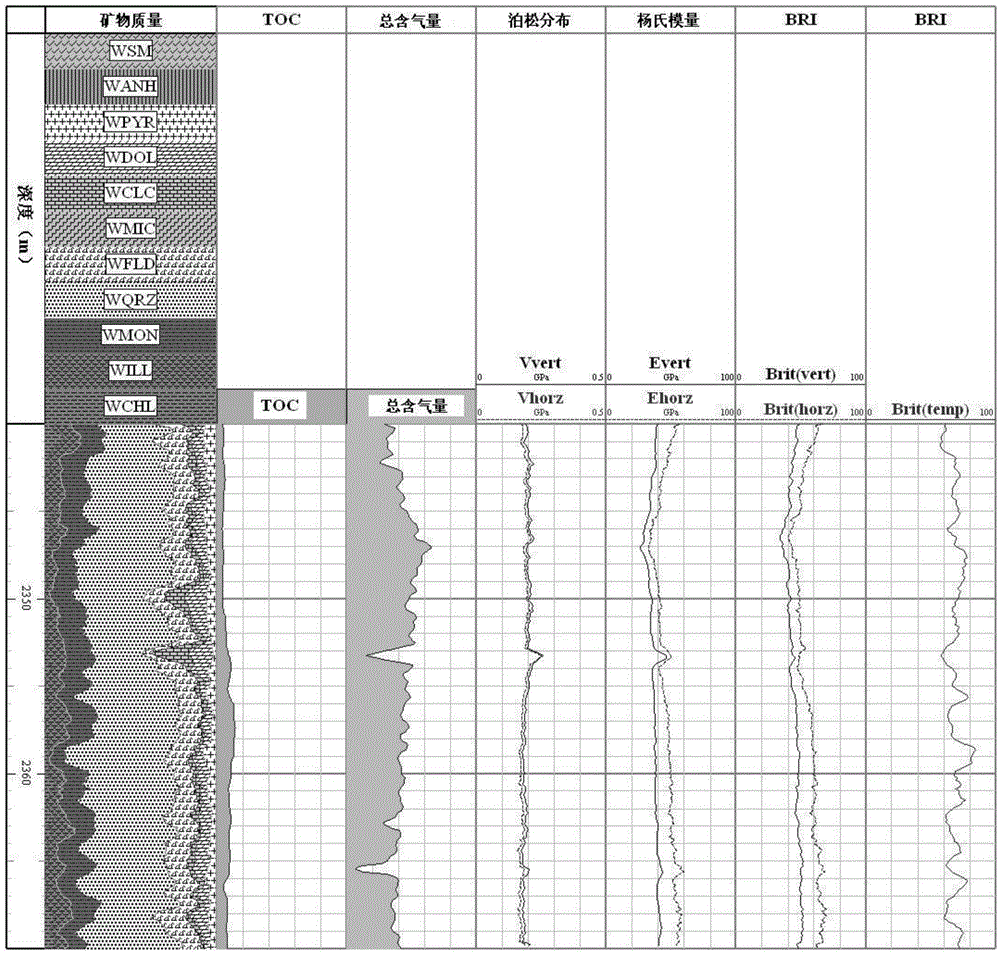

Method used for determining shale formation brittleness index

ActiveCN105277671AThe brittleness index is accurately determinedImprove development efficiencyEarth material testingMineralogyFracture toughness

The invention discloses a method used for determining shale formation brittleness index. The method comprises following steps: comprehensive fracture toughness is determined based on forming situations of shale formation in geological zones; the maximum fracture toughness and the minimum fracture toughness of each single kind mineral shale formation are determined; and the shale formation brittleness index is obtained based on the comprehensive fracture toughness, and the maximum fracture toughness and the minimum fracture toughness of each single kind mineral shale formation. According to the method, influences of minerals are taken into consideration, and initiation toughness of each mineral is taken into consideration, so that the obtained shale formation brittleness index is more accurate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid crystal display device and method for manufacturing the same

InactiveUS20070069210A1Material efficiency be improveSimplify manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEtchingMaterial efficiency

As a substrate gets larger, time of manufacture is increased due to the repetition of film formations and etchings; waste disposal costs of etchant and the like are increased; and material efficiency is significantly reduced. A base film for improving adhesion between a substrate and a material layer formed by a droplet discharge method is formed in the invention. Further, a manufacturing method of a liquid crystal display device according to the invention includes at least one step for forming the following patterns required for manufacturing a liquid crystal display device without using a photomask: a pattern of a material layer typified by a wiring (or an electrode) pattern, an insulating layer pattern; or a mask pattern for forming another pattern.

Owner:SEMICON ENERGY LAB CO LTD

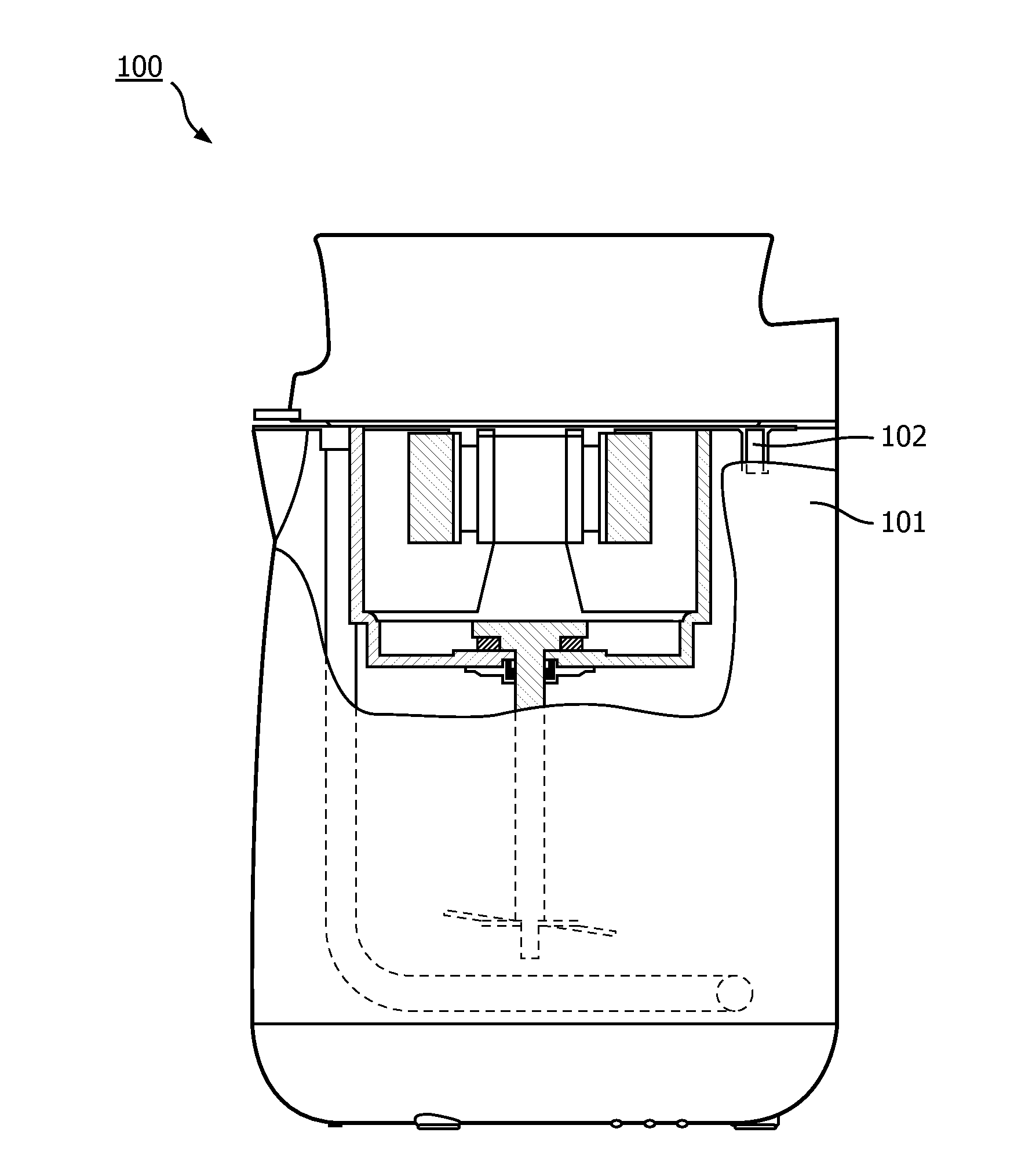

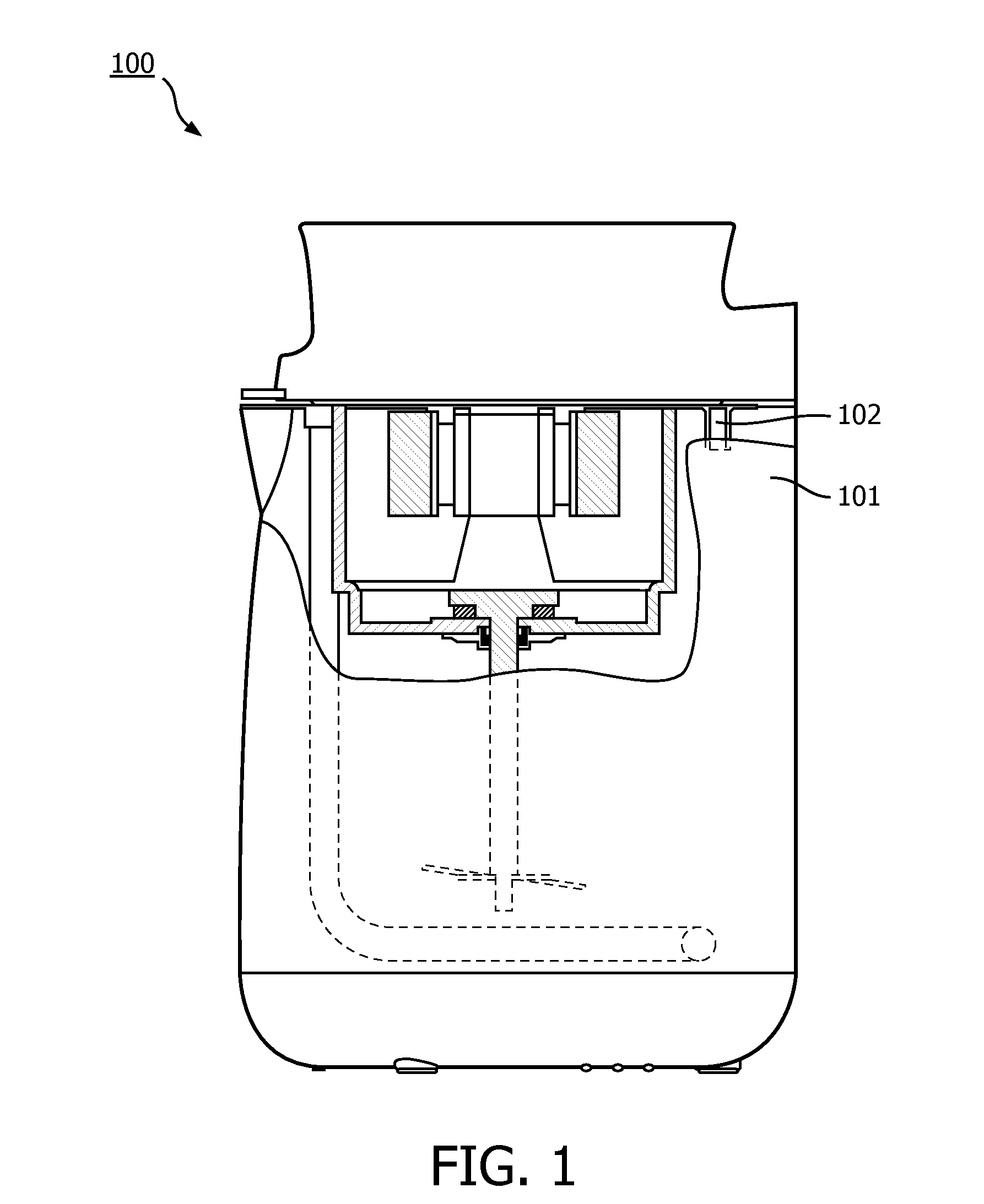

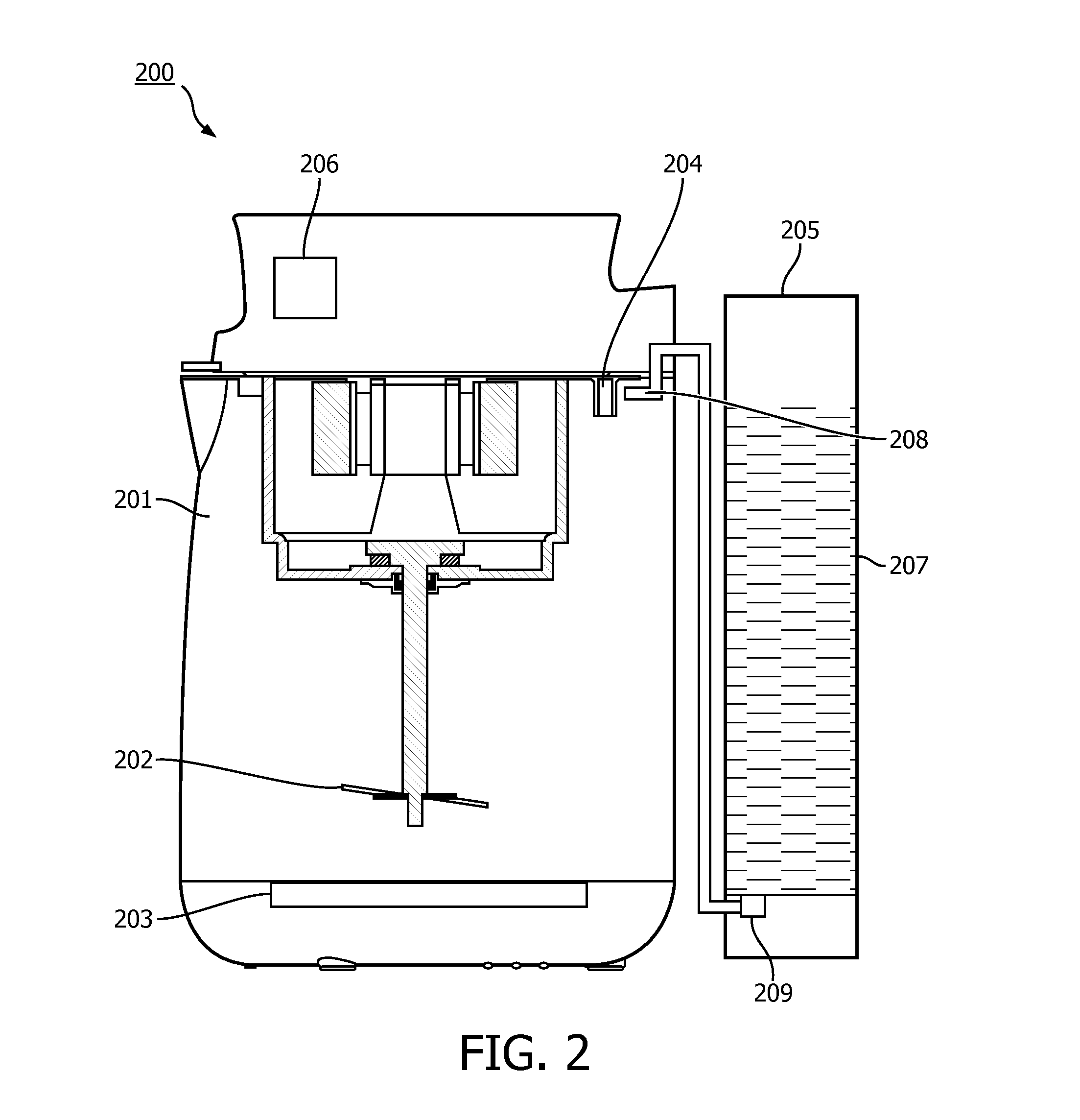

Soymilk maker and method of making soymilk

InactiveUS20150264954A1Shorten production timeExtended production timeBoiling over preventionAvicultureTime segmentLevel sensor

A method of making soymilk using a soymilk maker (200, 300), said soymilk maker comprising: a container (201, 301), a grinding device (202), a heating device (203), a level sensor (204, 304) set at the upper part of said container for detecting the liquid level of the material in said container, and a water injection device (205, 305) for injecting water into said container; which method comprises the steps of: a) grinding the material, and heating the material in said container (201, 301) by applying a first power; b) during a preset period, performing a first detection using said level sensor (204, 304); and, if said level sensor is triggered by the foam generated in the process of making soymilk, heating the material in said container (201, 301) by applying a second power, said second power being lower than said first power; c) after said first detection, performing a second detection by means of said level sensor (204, 304) after a predetermined time interval; and, if said level sensor is triggered by the foam generated in the process of making soymilk, injecting water into said container, and heating the material in said container by applying said first power; if the production time does not exceed said preset period, returning to step b); if the production time is equal to or exceeds said preset period, heating the material in said container by applying a third power. The method performs detections before and after said predetermined time interval respectively; a procedure for determining and eliminating “false” triggering is in place; under secure

Owner:KONINKLJIJKE PHILIPS NV

Devices and methods for protecting exposed pipe ends during construction

InactiveUS20060096195A1Suitable protectionLow production costPipe elementsBuilding componentsRigid bodyBuilding construction

Devices and methods are provided for protecting pipe ends that project upwardly during building construction and for reducing the safety hazard posed by such pipe ends. The devices include a rigid body suitable for positioning on a base on which concrete will be poured, having two opposed end walls, two opposed side walls, a recess therebetween, a top end, a bottom end, and a lateral tab extending from at least one end wall. A shield is securable to at least one side wall for protecting the pipe ends during later construction. In two embodiments, a plate positioned at the bottom end has an opening dimensionally and spatially configured to correspond to each pipe end requiring protection. The method comprises: (a) positioning a device in accordance with the invention on the base so the pipe ends project into the recess and the body forms a barrier between the pipe ends and the concrete slab to be formed; (b) securing the device to the base by inserting a securing structure through each lateral tab; and (d) after the concrete layer has been formed, removing any securing structure from above the surface of the concrete to continue with the construction of the building.

Owner:ZIERER INVESTMENT ENTERPRISES

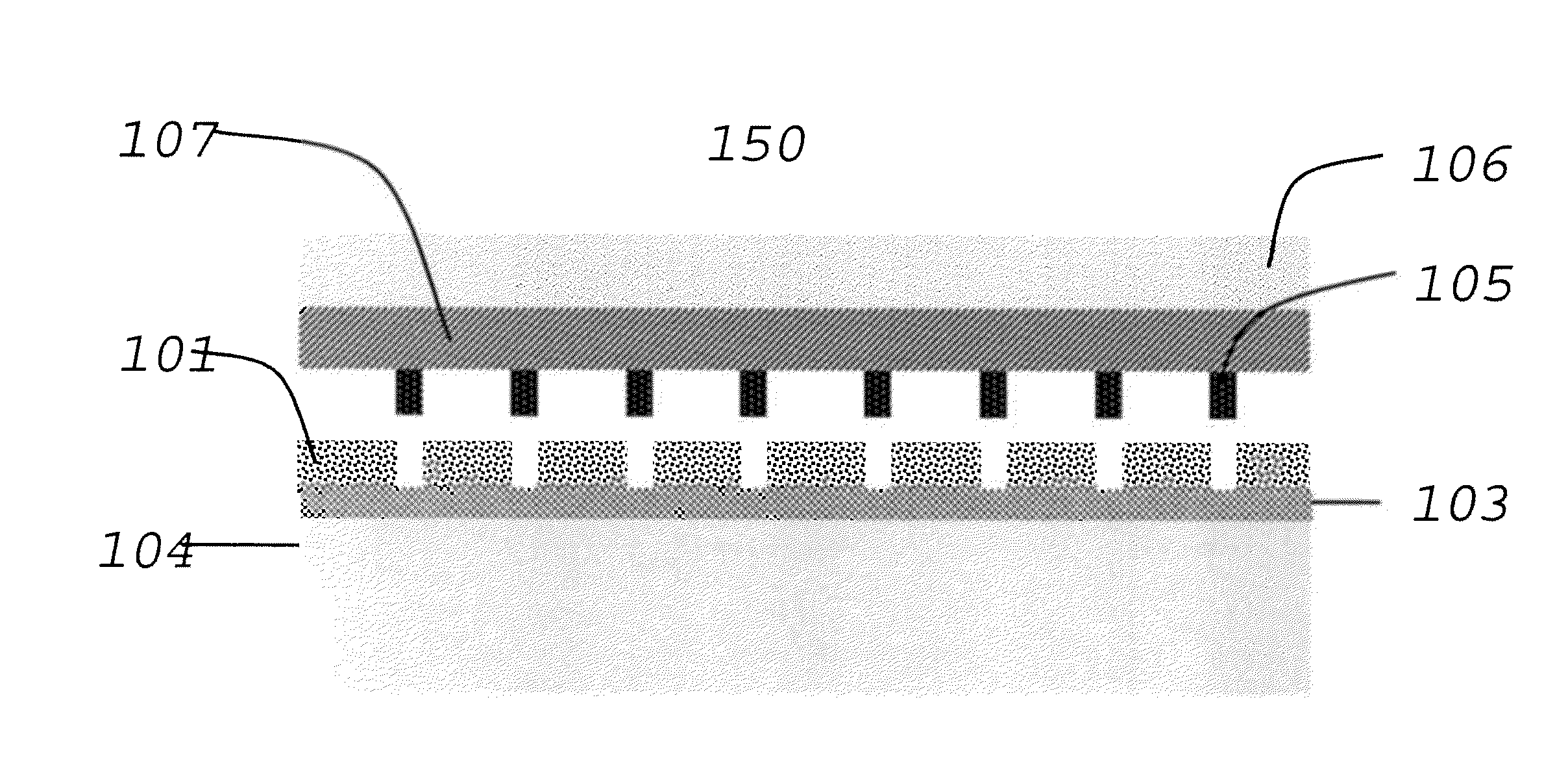

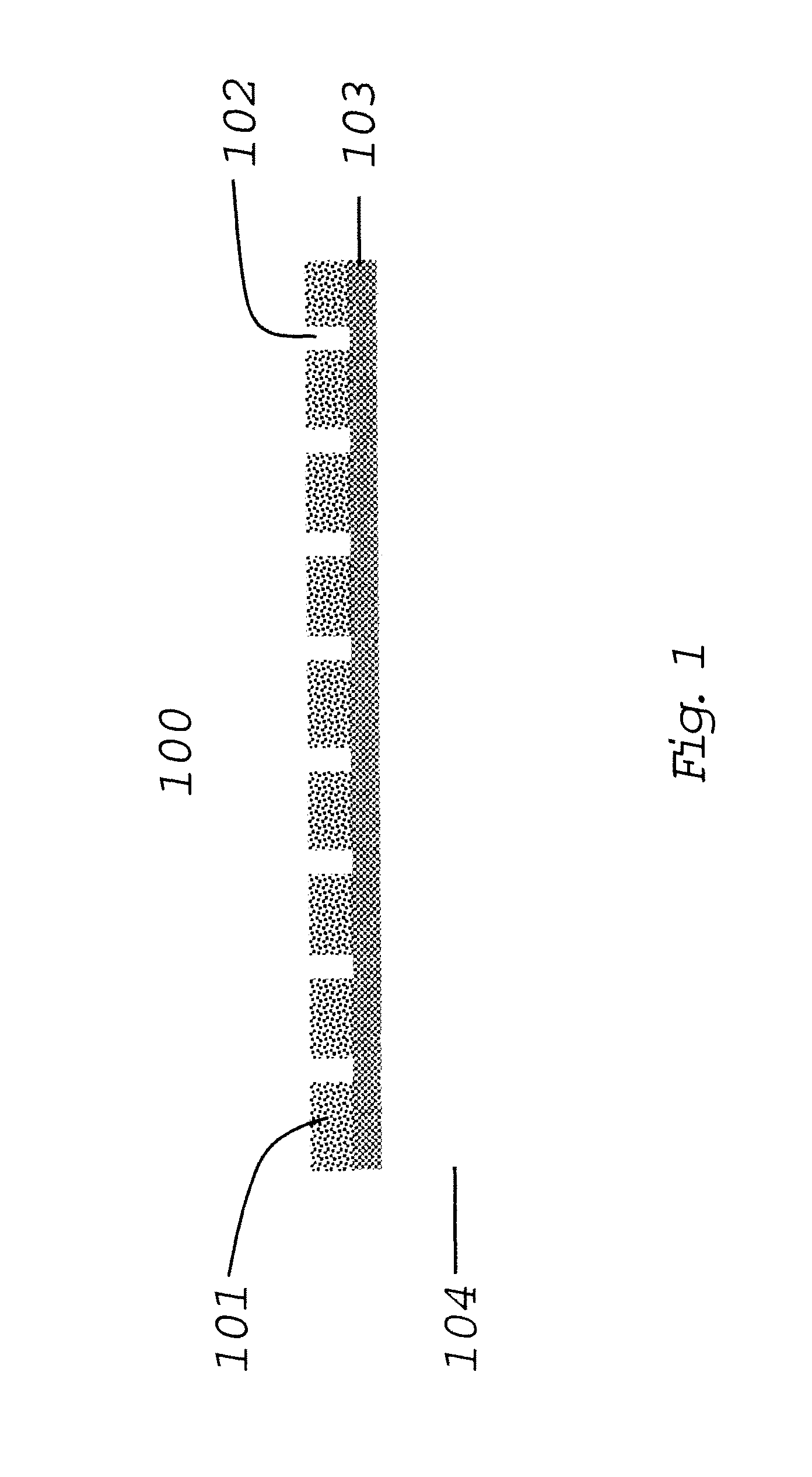

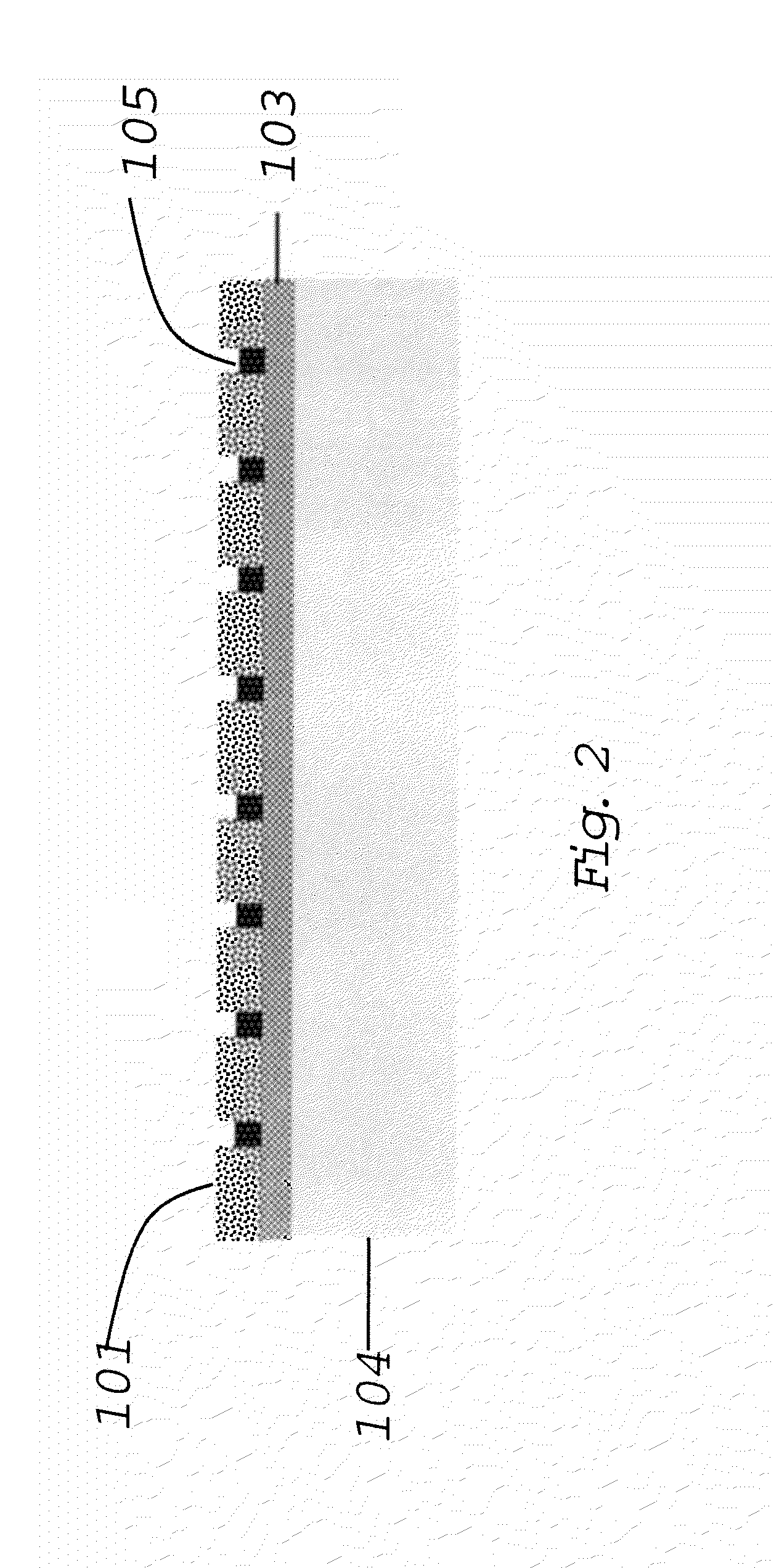

Tools and methods for forming semi-transparent patterning masks

ActiveUS8845912B2High resolutionFast preparationDecorative surface effectsSolid-state devicesImage resolutionEngineering

Means, apparatus, systems, and / or methods are described for forming improved rigid or flexible semi-transparent imprinting templates. These templates can be used to produce patterning masks having improved resolution that do not require plasma etching for residue removal. The methods and apparatus are compatible with roll-to-roll manufacturing processes and enable roll-to-roll formation of a wide range of metal patterned films.

Owner:MICROCONTINUUM

Processing method of water-retention ready-to-eat natural rhopilema esculentum

InactiveCN102726770ACrisp tasteLong shelf life at room temperatureFood preparationAcetic acidReady to eat

The invention discloses a processing method of water-retention ready-to-eat natural rhopilema esculentum, wherein the processing method comprises the following working procedures: salting rhopilema esculentum and cutting into shreds; blanching for 20-30 seconds at 60-70 DEG C; rinsing for 3-8 minutes by use of running water; rinsing for 20-40 minutes by use of running water; rinsing by four stilling basins successively, and rinsing for 20-40 minutes for each basin; immersing by use of an immersing liquid containing calcium chloride and treholose; immersing by use of an immersing liquid containing potassium sorbite and acetic acid; and leaching water and carrying out vacuum packaging, thereby obtaining the water retention ready-to-eat natural rhopilema esculentum. The water retention ready-to-eat natural rhopilema esculentum prepared by the processing of the technology has reduced salt and vitriol content, is crisp in mouthfeel, is long in quality guarantee period, moreover is low in production cost, and is short in production time.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com