Method for fermentation production of succinic acid by circulating utilization of recombinant Bacillus coli cells

A technology of recombinant Escherichia coli and cell fermentation, which is applied in the field of bioengineering, can solve the problems of decreased yield and production strength, decreased cell density, cell specific production strength, prolonged succinic acid production time, etc., so as to improve specific production strength. , the effect of prolonging the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

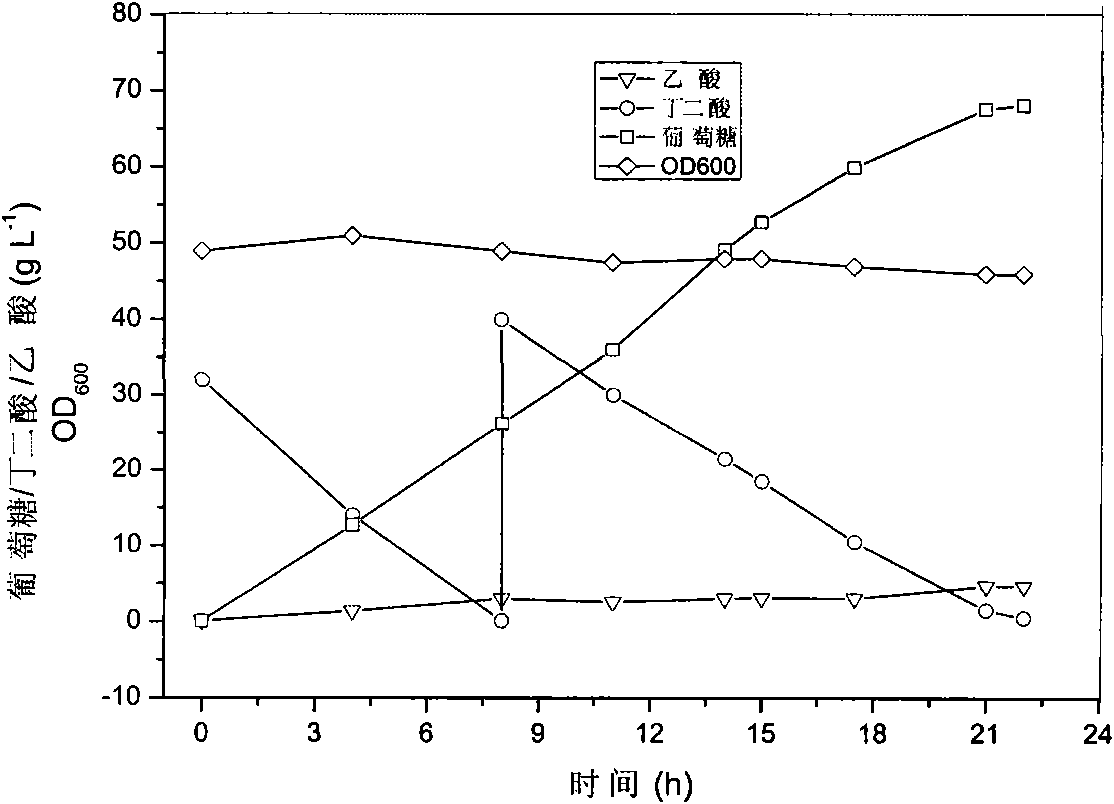

[0028] This example illustrates that Escherichia coli AFP111 can use metabolites (succinic acid, acetic acid, etc.) in the culture medium to maintain cell growth and function during the aerobic induction process after the two-stage fermentation. Its specific culture conditions and steps are as follows:

[0029] 1. Production of succinic acid by two-stage fermentation: first, LB culture medium activates the thallus, inserts the inoculum into the Erlenmeyer flask from the cryopreservation tube according to 1% (v / v), and cultivates the thallus for about 12 hours as the seed liquid; Inoculum size 3% was transferred to JSM fermentation medium, and glucose was added to an initial concentration of 25g L -1 , cultured aerobically until the dry weight of the cells was 10-12g·L -1 , the dissolved oxygen in the cultivation process was maintained above 40%; 2 Gas, for anaerobic fermentation to produce acid, adopt the method of adding glucose in batches, and the maximum concentration sha...

Embodiment 2

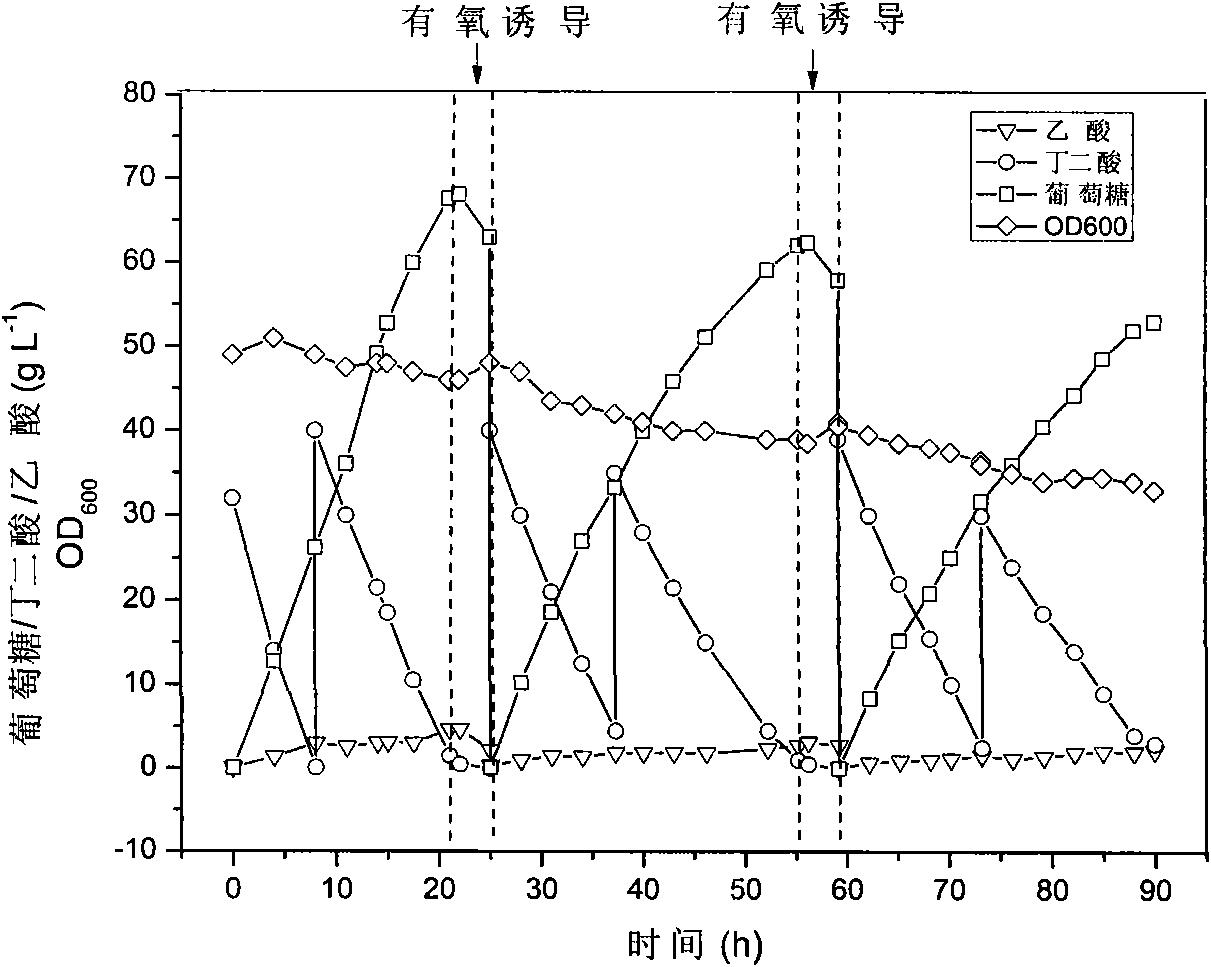

[0041] In this example, Escherichia coli AFP111 cells that have been induced to increase the activity of key enzymes in the pathway of succinic acid synthesis were used to ferment and produce succinic acid in fresh medium. The specific steps are as follows:

[0042] 1. Production of succinic acid by two-stage fermentation: first, LB culture medium activates the thallus, inserts the inoculum into the Erlenmeyer flask from the cryopreservation tube according to 1% (v / v), and cultivates the thallus for about 12 hours as the seed liquid; Inoculum size 3% was transferred to JSM fermentation medium, and glucose was added to an initial concentration of 25g L -1 , cultured aerobically until the dry weight of the cells was 10-12g·L -1 , the dissolved oxygen in the cultivation process was maintained above 40%; 2 Gas, for anaerobic fermentation to produce acid, adopt the method of adding glucose in batches, and the maximum concentration shall not exceed 50g L -1 , while basic magnesiu...

Embodiment 3

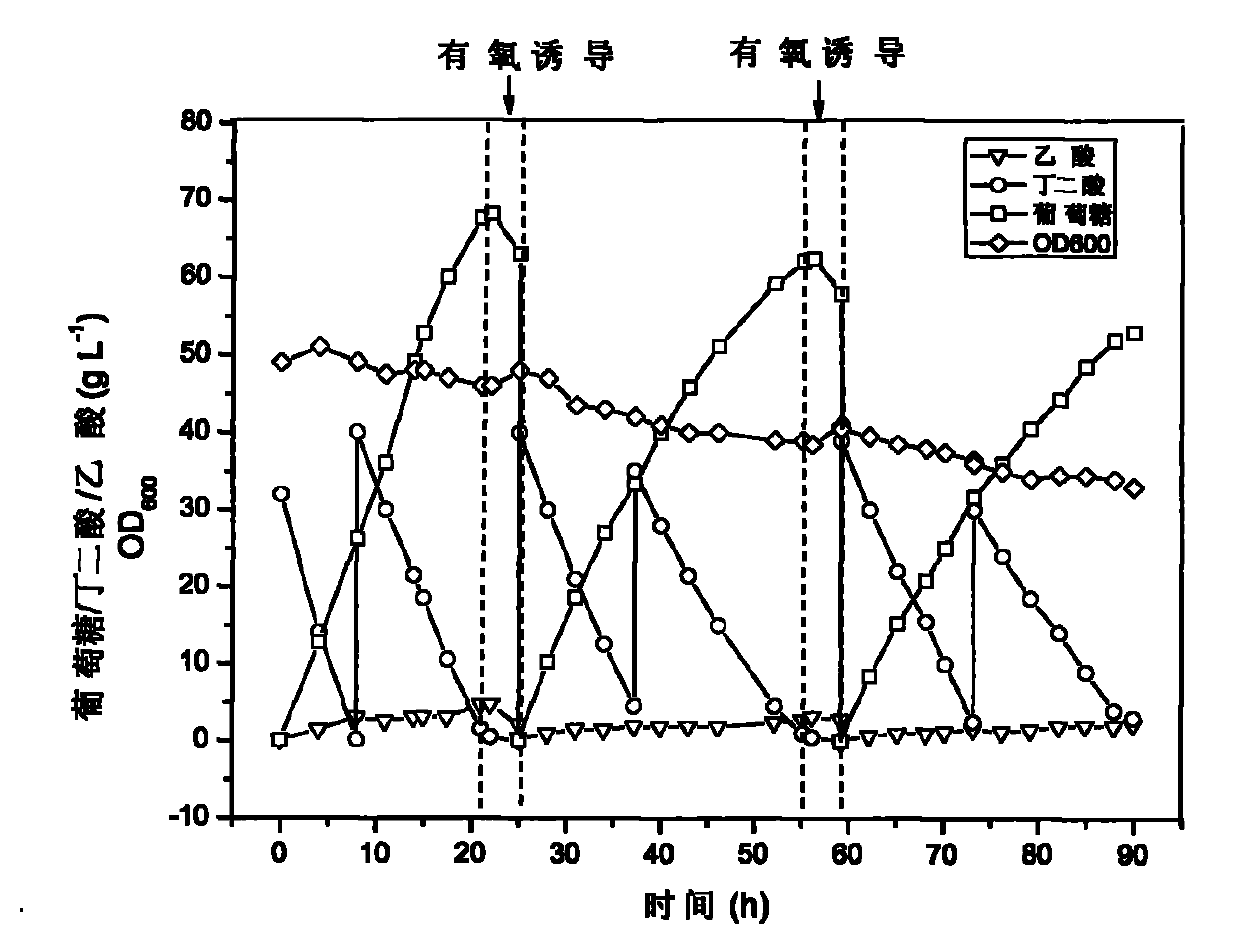

[0046] In this example, Escherichia coli AFP111 cells that have been induced to increase the activity of key enzymes in the pathway of succinic acid synthesis were used to recycle the cells to ferment and produce succinic acid in fresh medium. The specific steps are as follows:

[0047] 1. Production of succinic acid by two-stage fermentation: first, LB culture medium activates the thallus, inserts the inoculum into the Erlenmeyer flask from the cryopreservation tube according to 1% (v / v), and cultivates the thallus for about 12 hours as the seed liquid; Inoculum size 3% was transferred to JSM fermentation medium, and glucose was added to an initial concentration of 25g L -1 , cultured aerobically until the dry weight of the cells was 10-12g·L -1 , the dissolved oxygen in the cultivation process was maintained above 40%; 2 Gas, for anaerobic fermentation to produce acid, adopt the method of adding glucose in batches, and the maximum concentration shall not exceed 50g L -1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com