Fire-flooding exploitation method used in later period of steam assisted gravity drainage (SAGD) of heavy oil reservoir

A technology for assisting gravity and heavy oil reservoirs, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve problems that have not been elaborated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

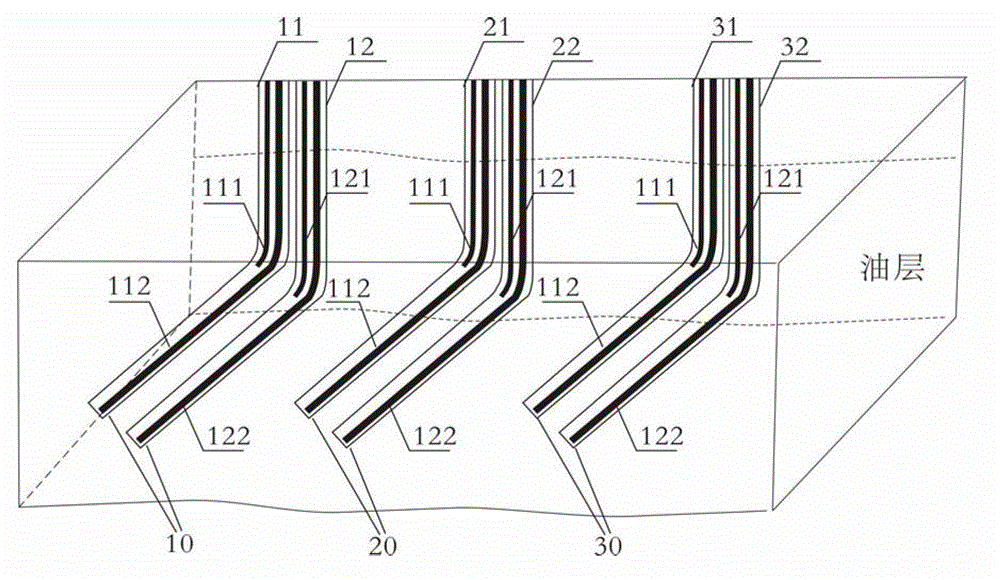

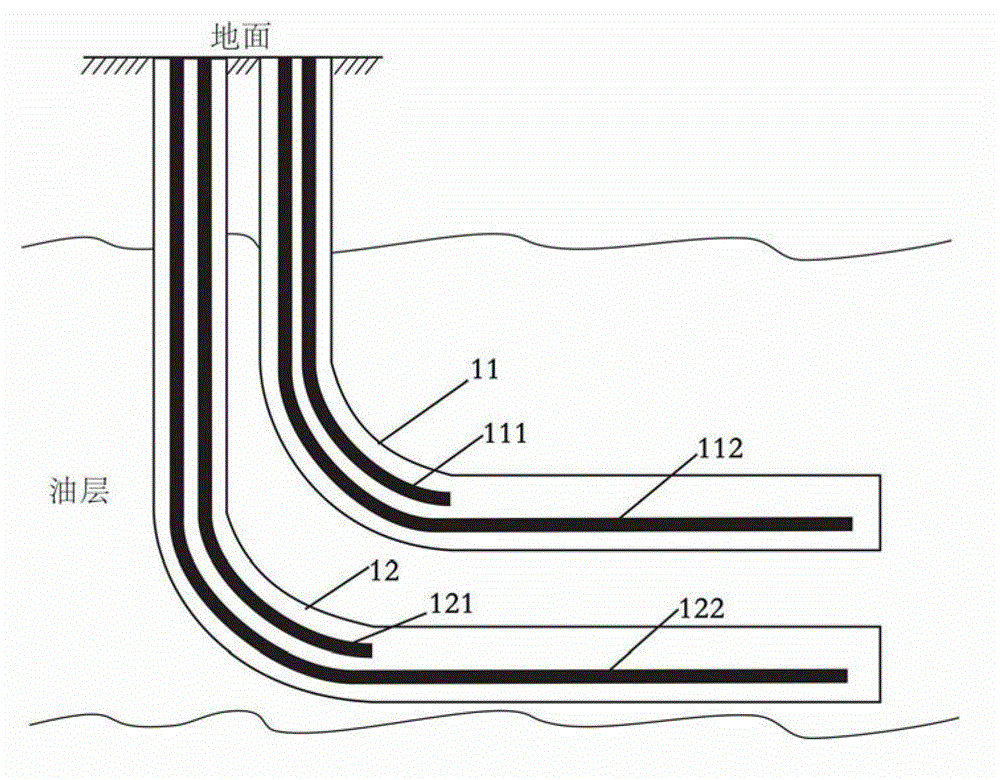

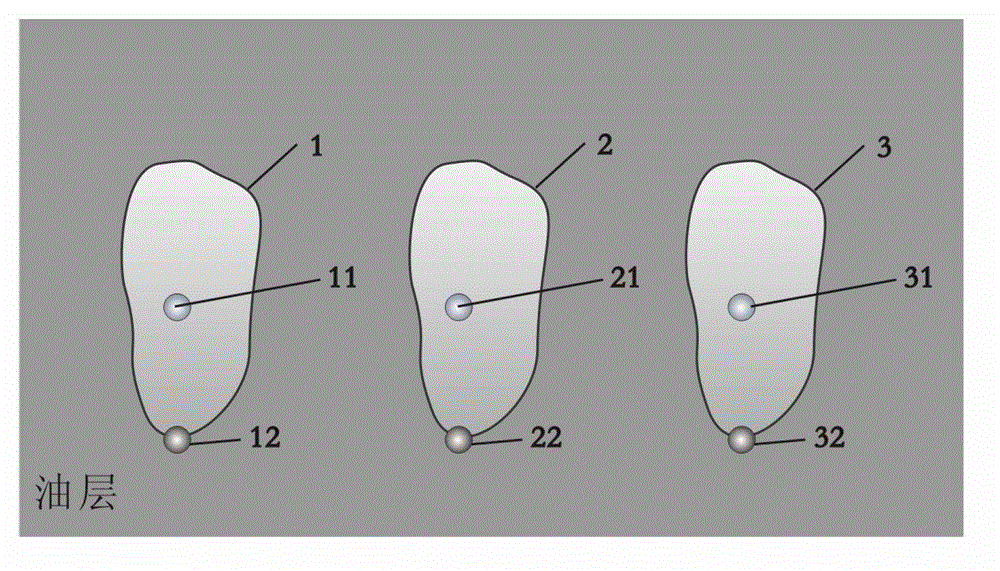

[0058] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0059] The present invention proposes a fire-flooding recovery method in the later stage of steam-assisted gravity drainage of heavy oil reservoirs. During the steam chamber expansion stage of steam-assisted gravity drainage, when the steam chambers of adjacent injection-production well pairs are merged, the intermediate The injection well of the injection-production well pair injects air to ignite, the production well of the well pair and the production wells of the two adjacent well pairs on the left and right produce, and the injection wells of the two adjacent well pairs on the left and right turn into exhaust wells for fire flooding; The production method can use the high temperature fire flooding front to effectively drive a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com