Patents

Literature

63 results about "Material efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material efficiency is a description or metric which expresses the degree in which raw materials are consumed, incorporated, or wasted, as compared to previous measures in construction projects or physical processes. Making a usable item out of thinner stock than a prior version increases the material efficiency of the manufacturing process. Material efficiency goes hand in hand with Green building and Energy conservation, as well as any other ways of incorporating Renewable resource's in the building process from start to finish.

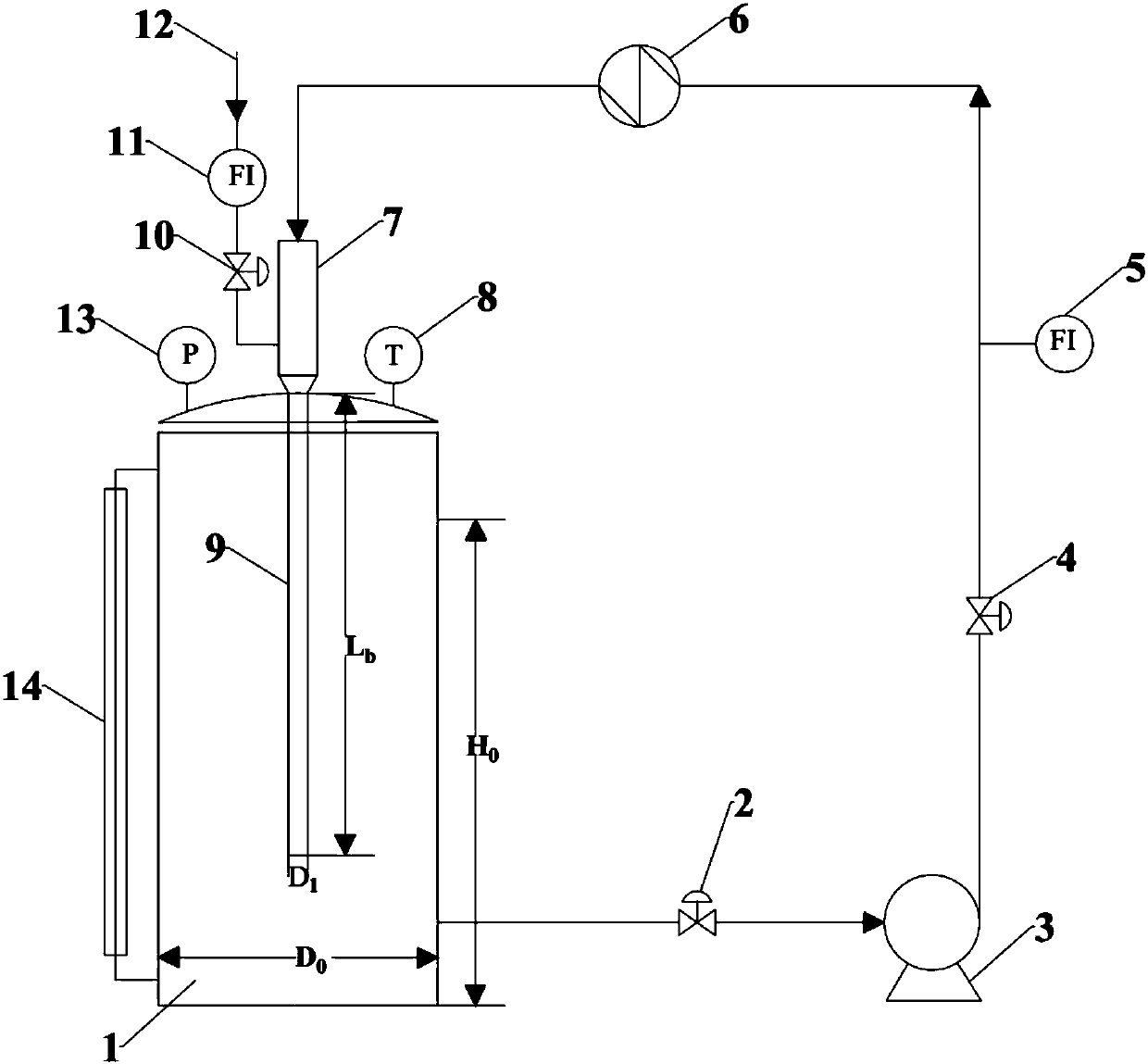

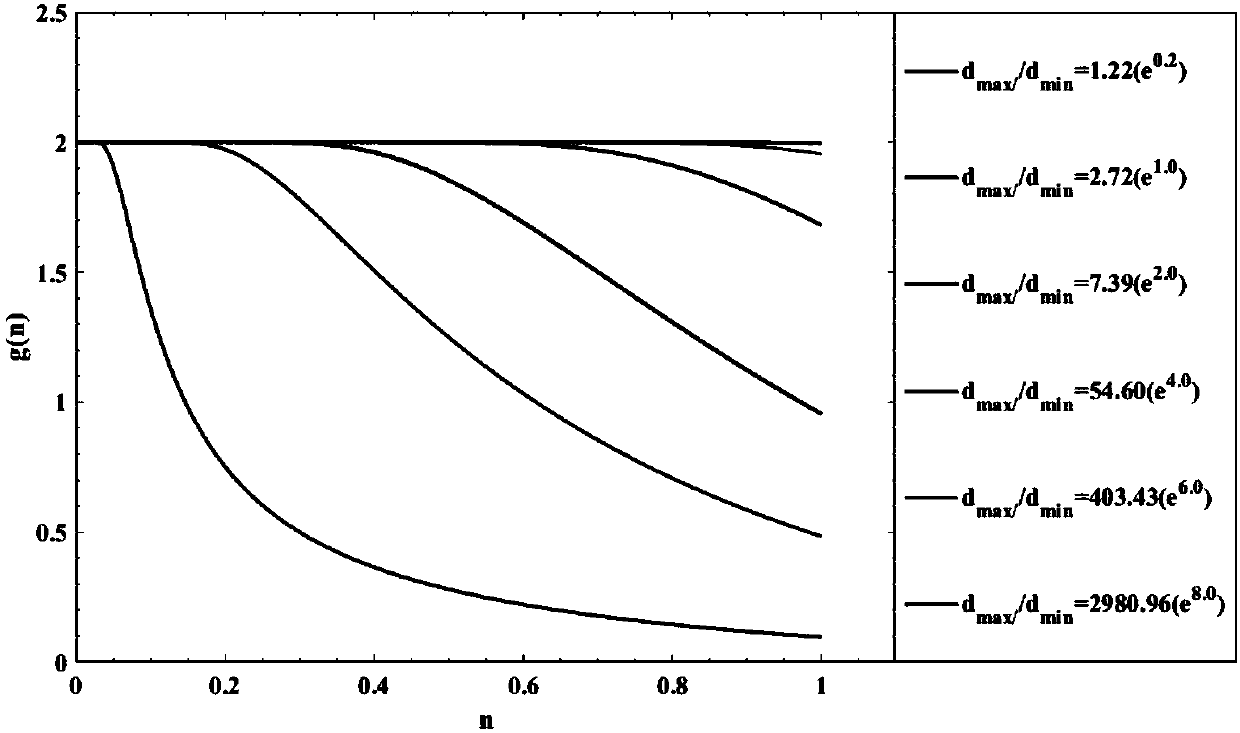

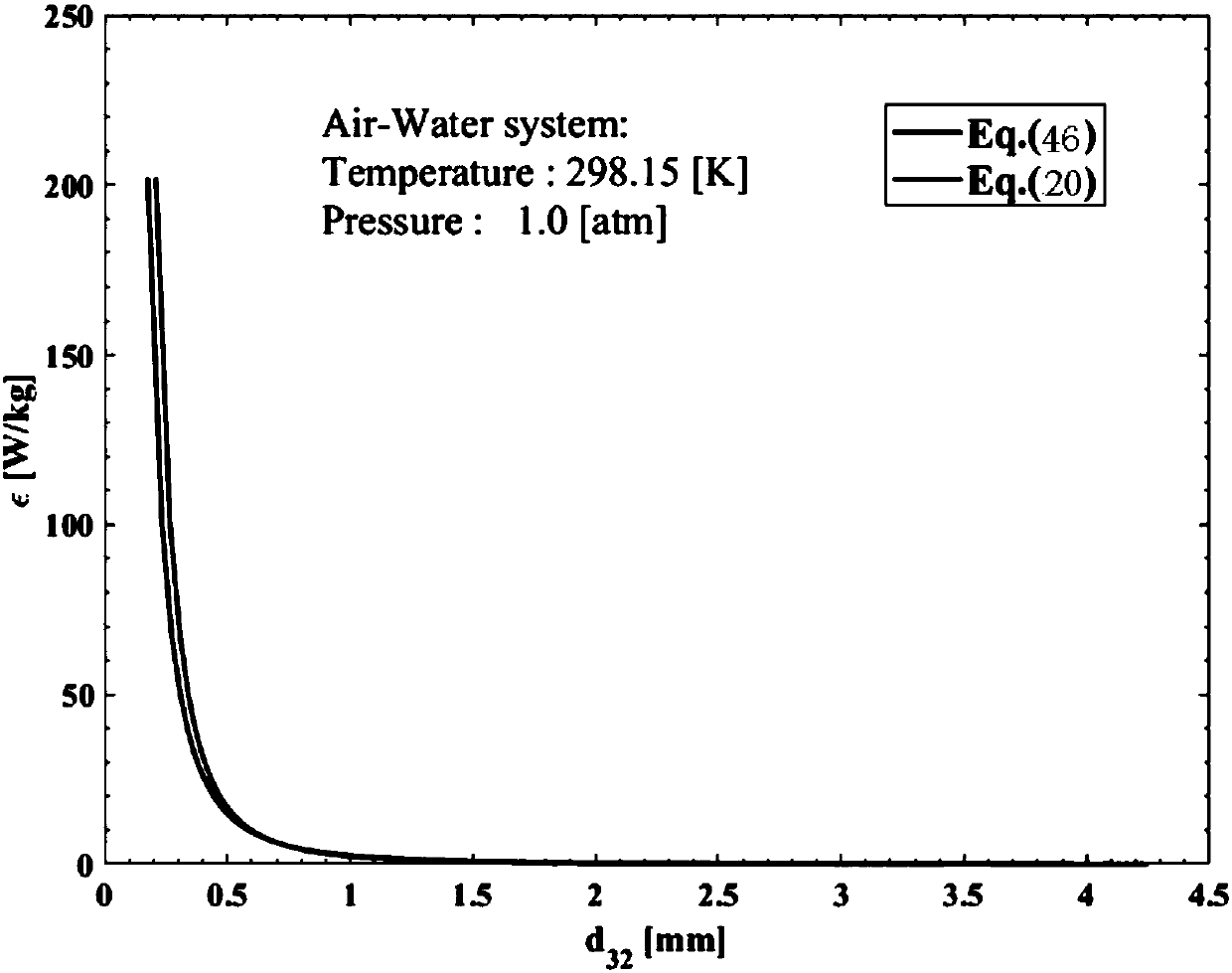

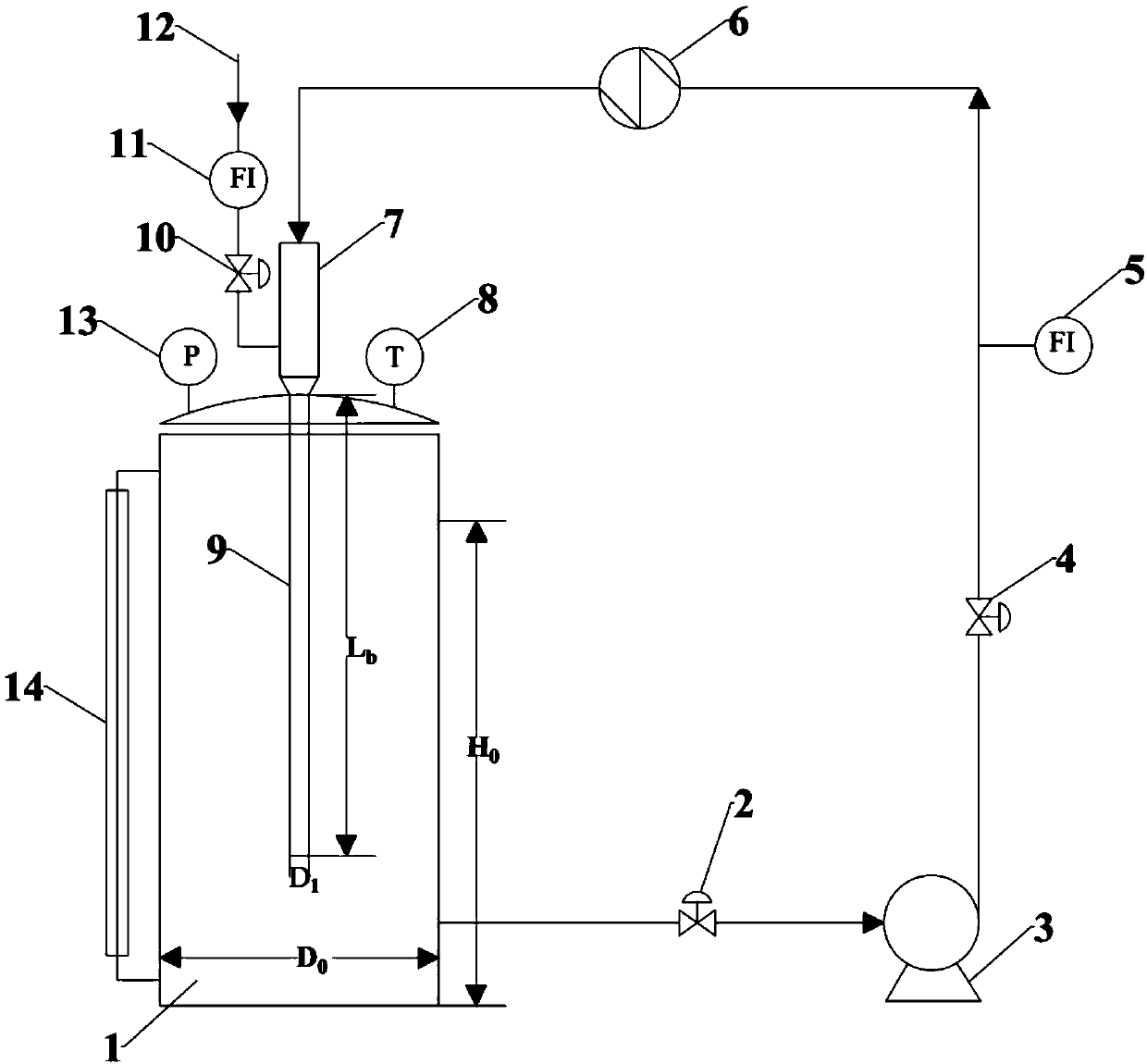

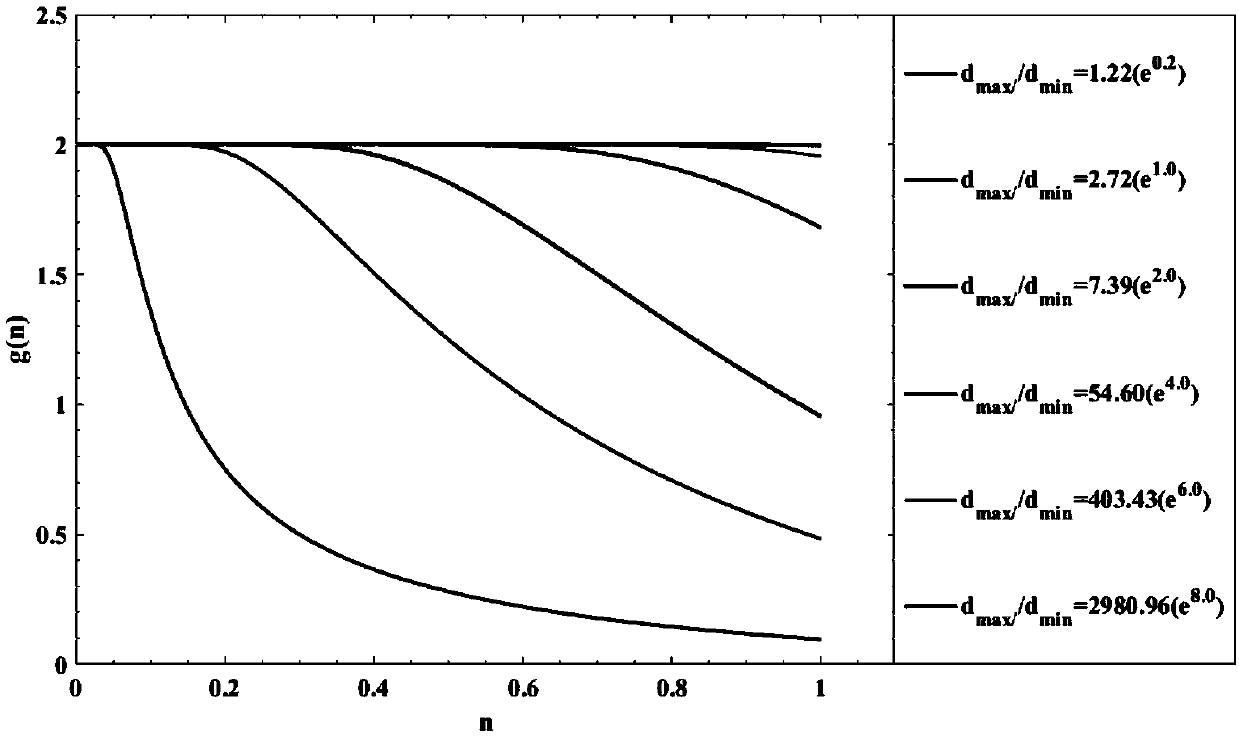

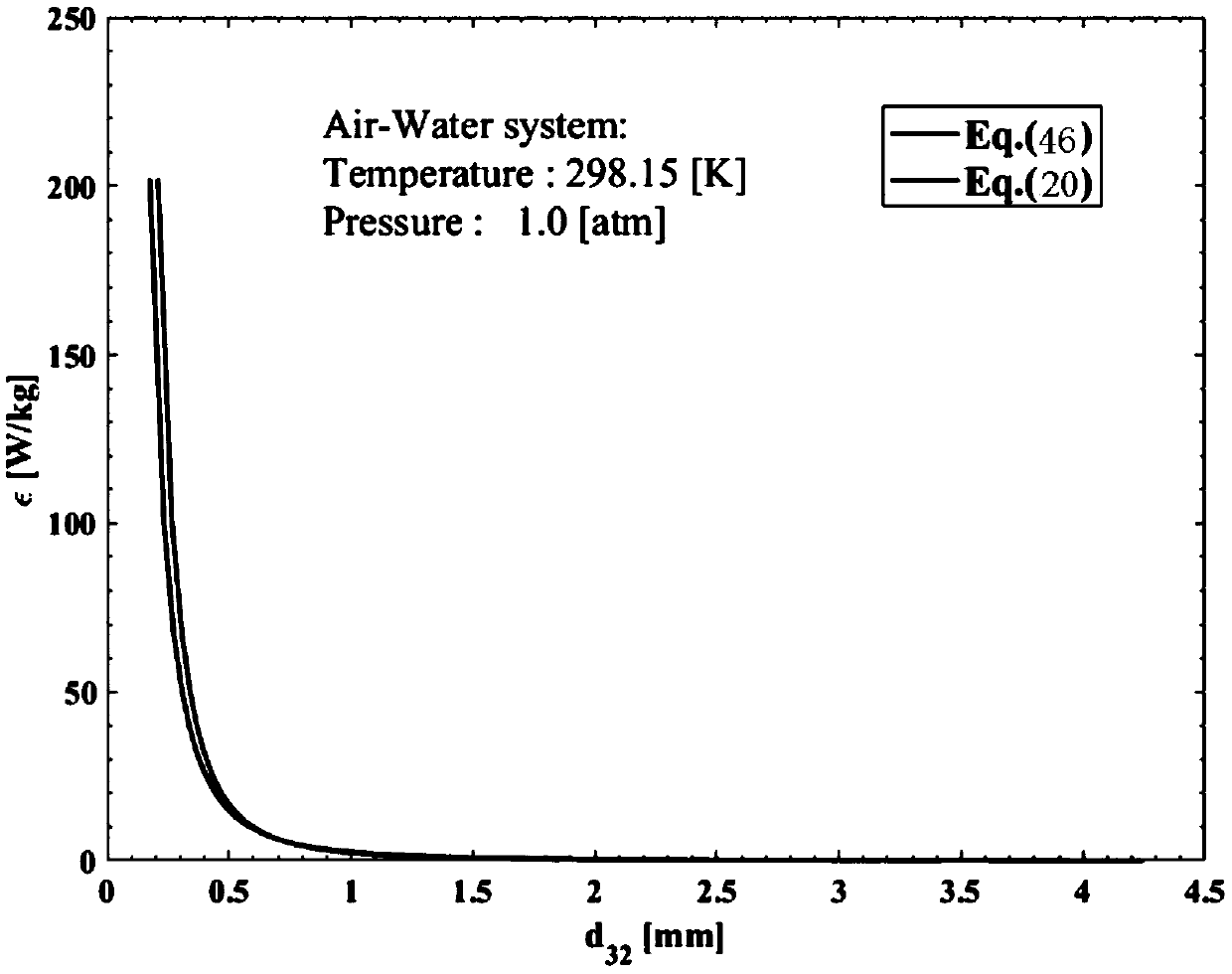

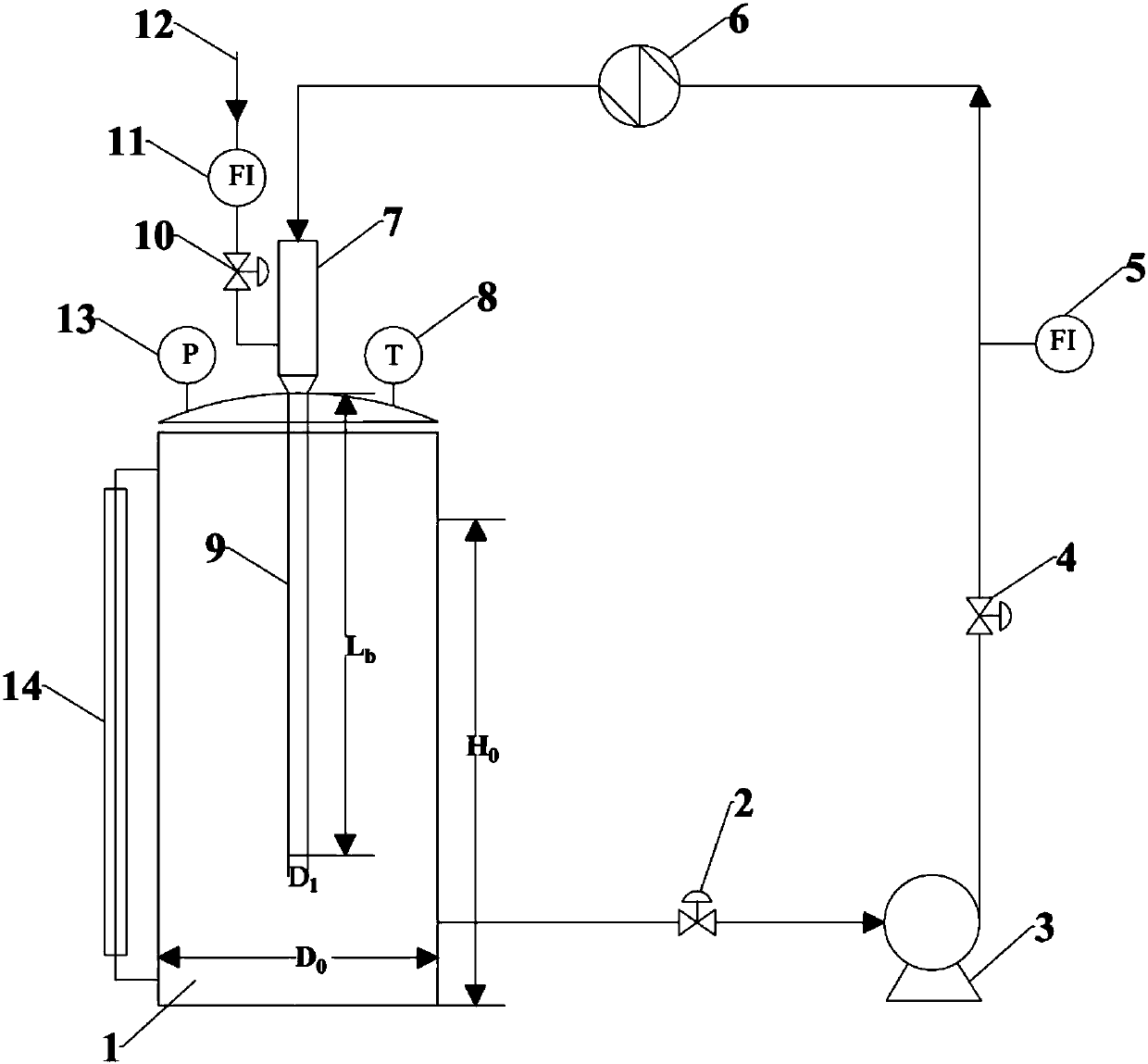

Micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method

ActiveCN107563051AReduce mistakesImprove versatilitySpecial data processing applicationsActivity regulationScale structure

The invention relates to a micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method. The diameter dmax of the largest bubble of a micro-interface enhanced reactor and the diameter dmin of the smallest bubble of the micro-interface enhanced reactor serve as independent variables, the average diameter d32 of the bubble Sauter serve as a dependentvariable, and a numerical relationship is built; based on the Kolmogorov-Hinze theory, the relationship between the diameter dmax of the largest bubble of the micro-interface enhanced reactor, the diameter dmin of the smallest bubble and the parameters of the reactor is built. According to the method, the reactor bubble scale is associated with the structural parameter, the operation parameter andthe physical property parameter of the reactor by using specific numerical relationship, the numerical relationship has the guiding significance for the design of the reactor and can be applied to avariety of reactors, the versatility is good, by means of a bubble scale regulation and control model built through the method, by adjusting the structural parameter and the operation parameter of thereactor, and the maximization of energy efficiency and material efficiency in the reaction process can be achieved, or under the condition that reaction targets, energy consumption and material consumption are given, a high-efficiency reactor structure is designed.

Owner:NANJING UNIV

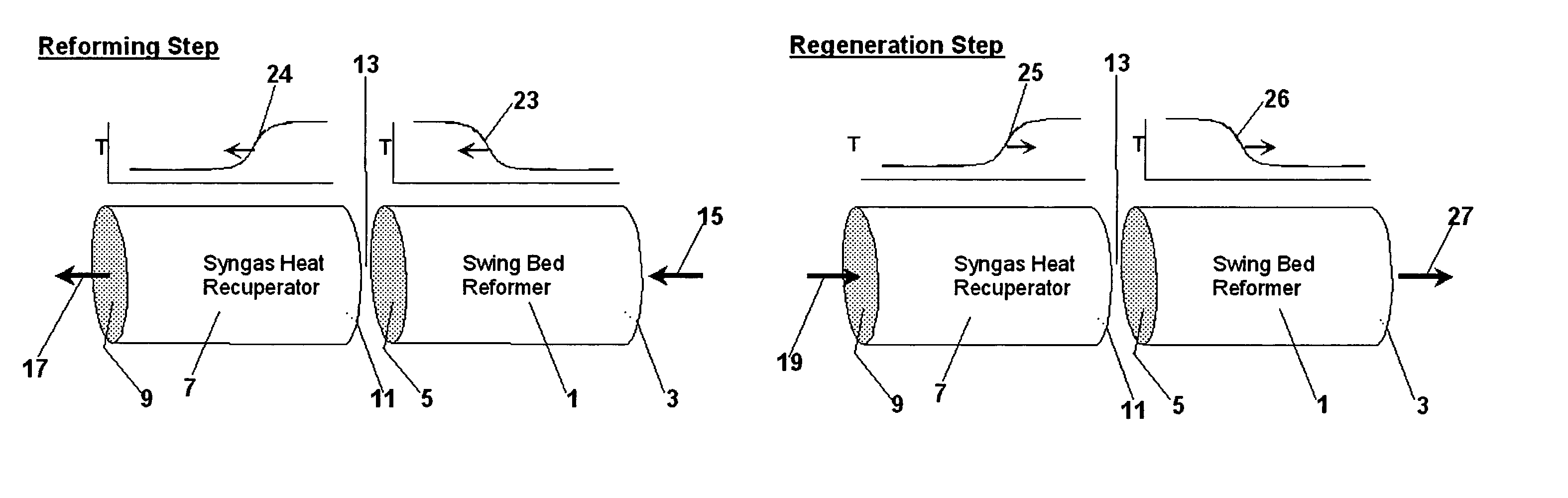

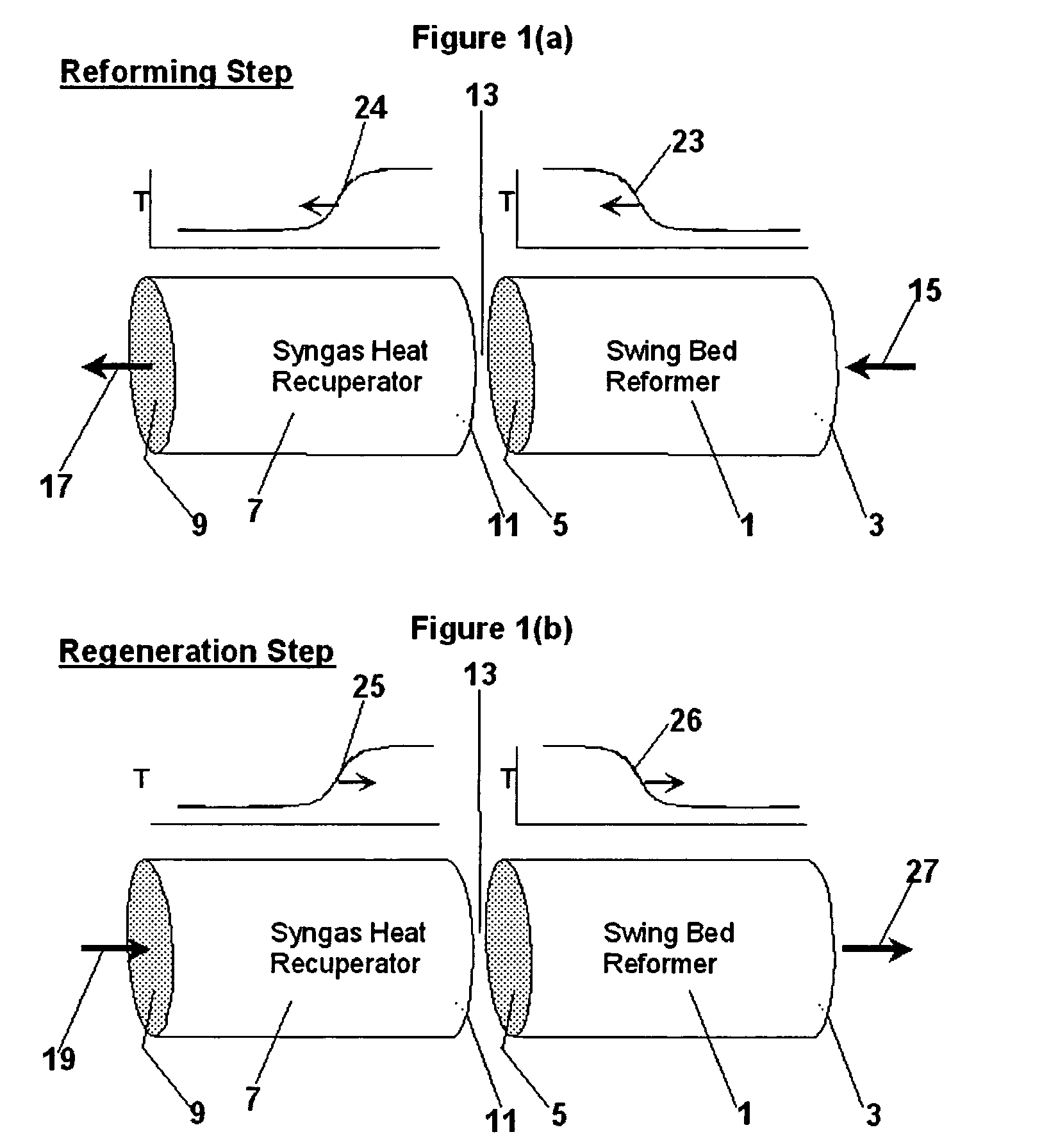

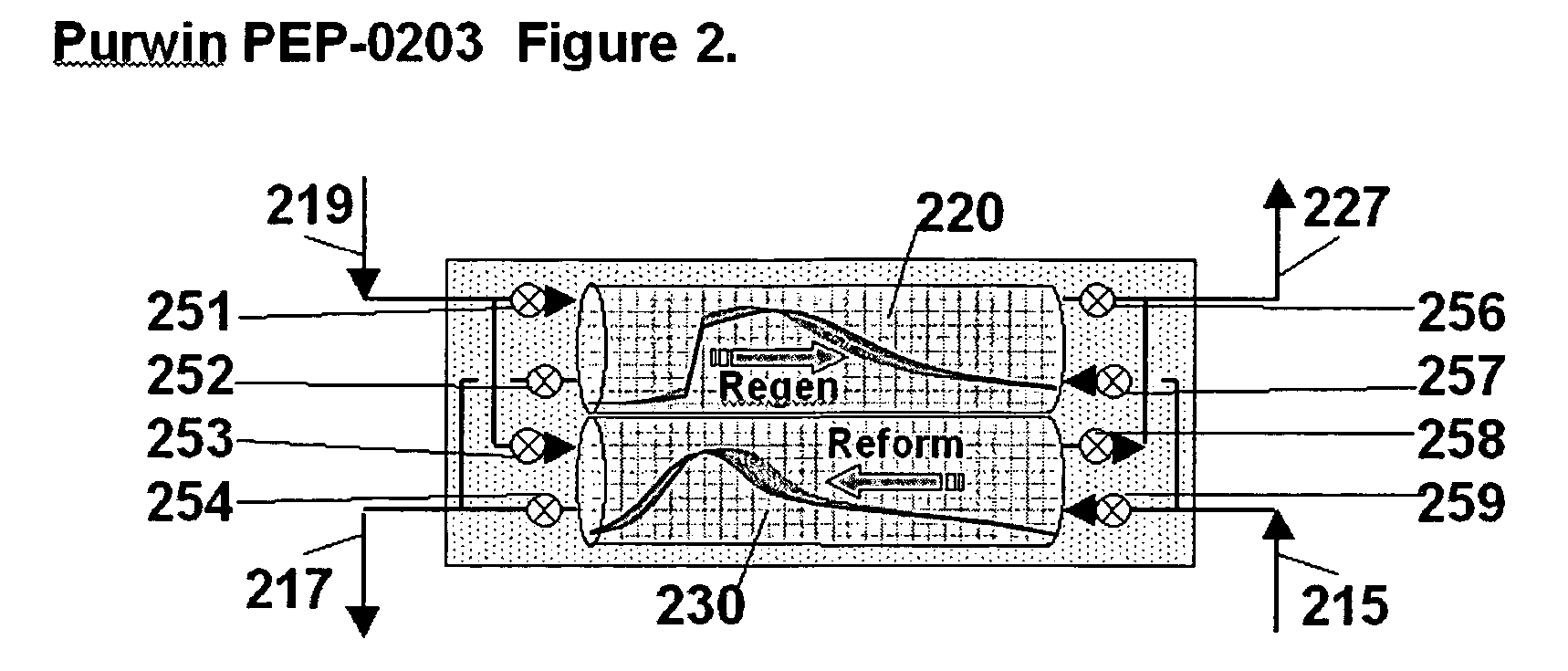

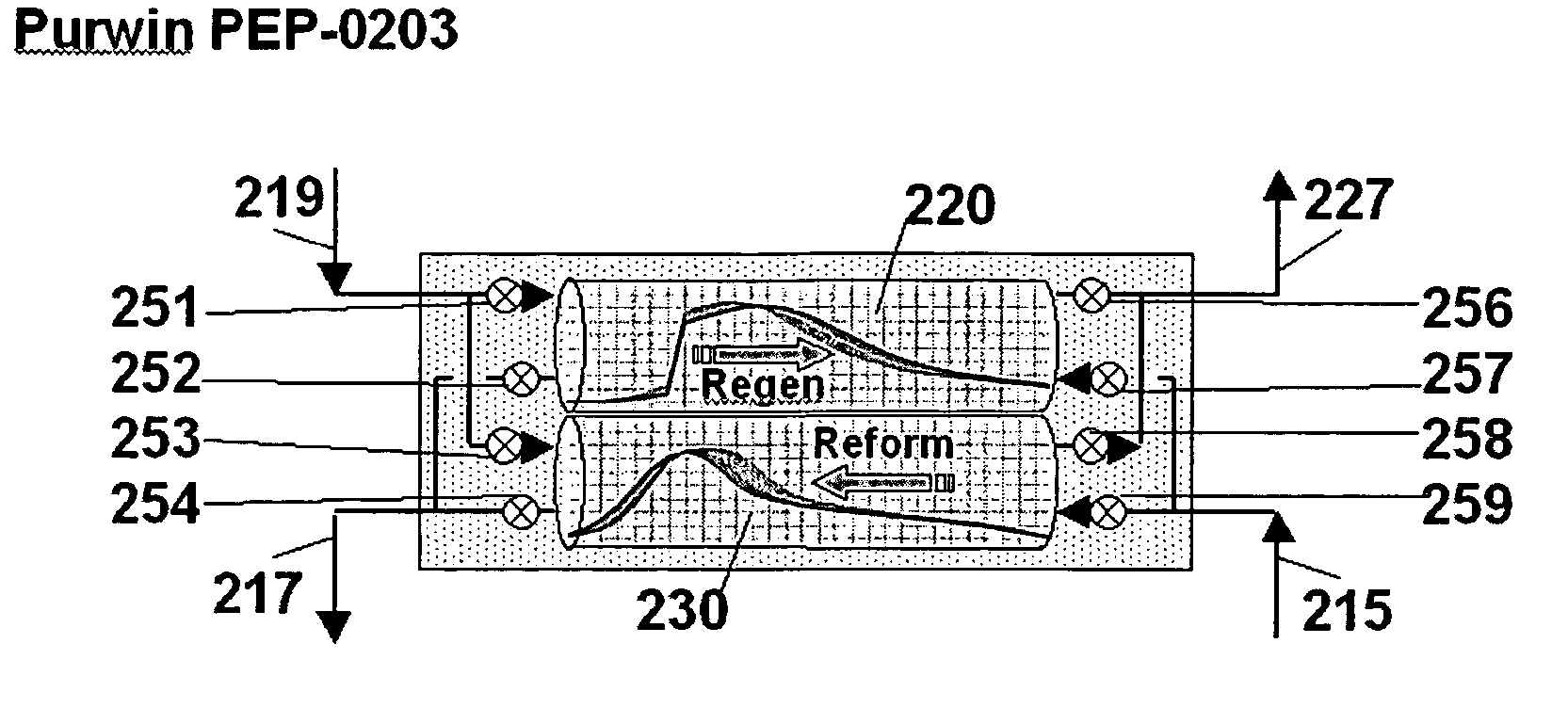

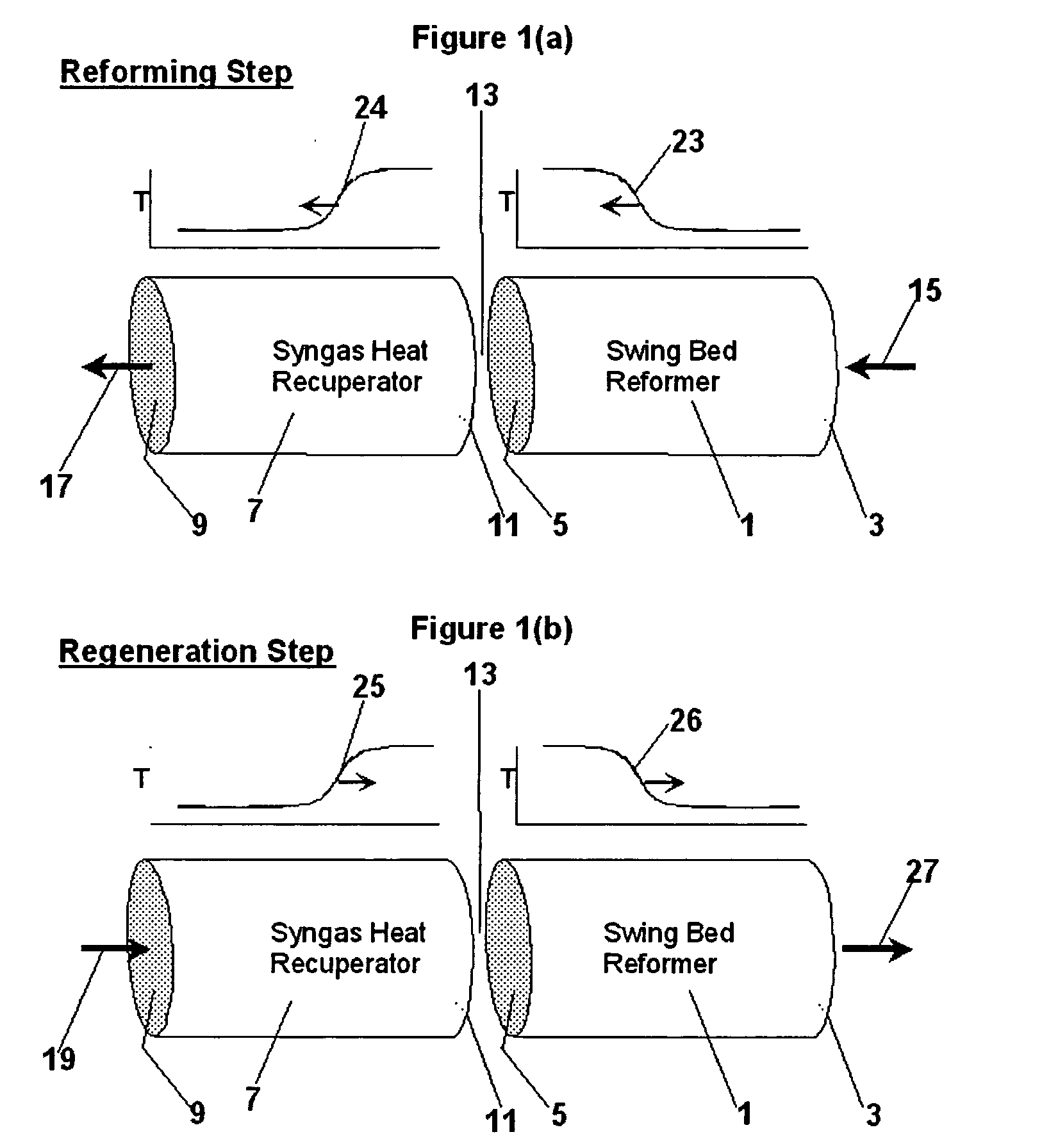

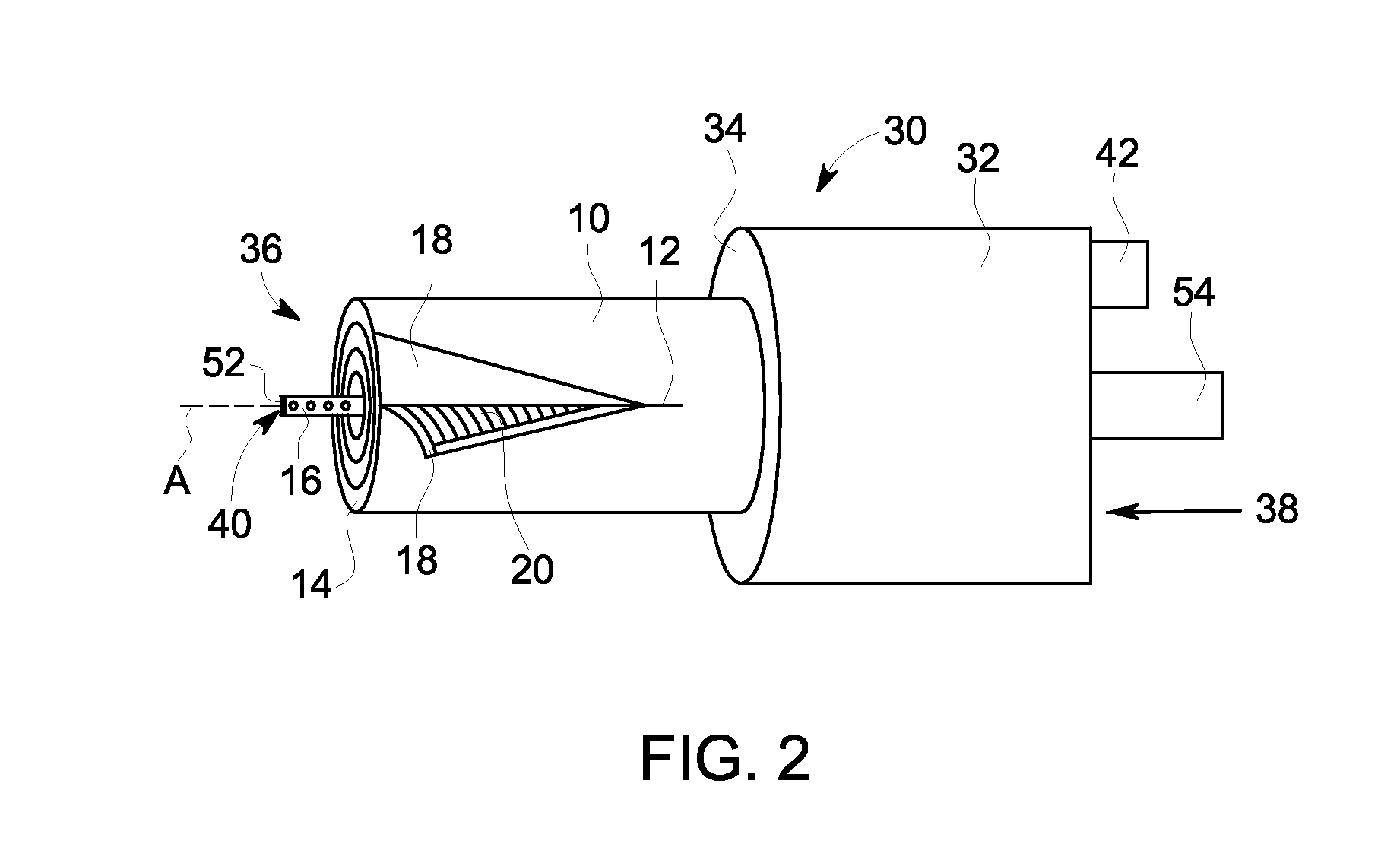

Pressure swing reforming for fuel cell systems

Owner:EXXON RES & ENG CO

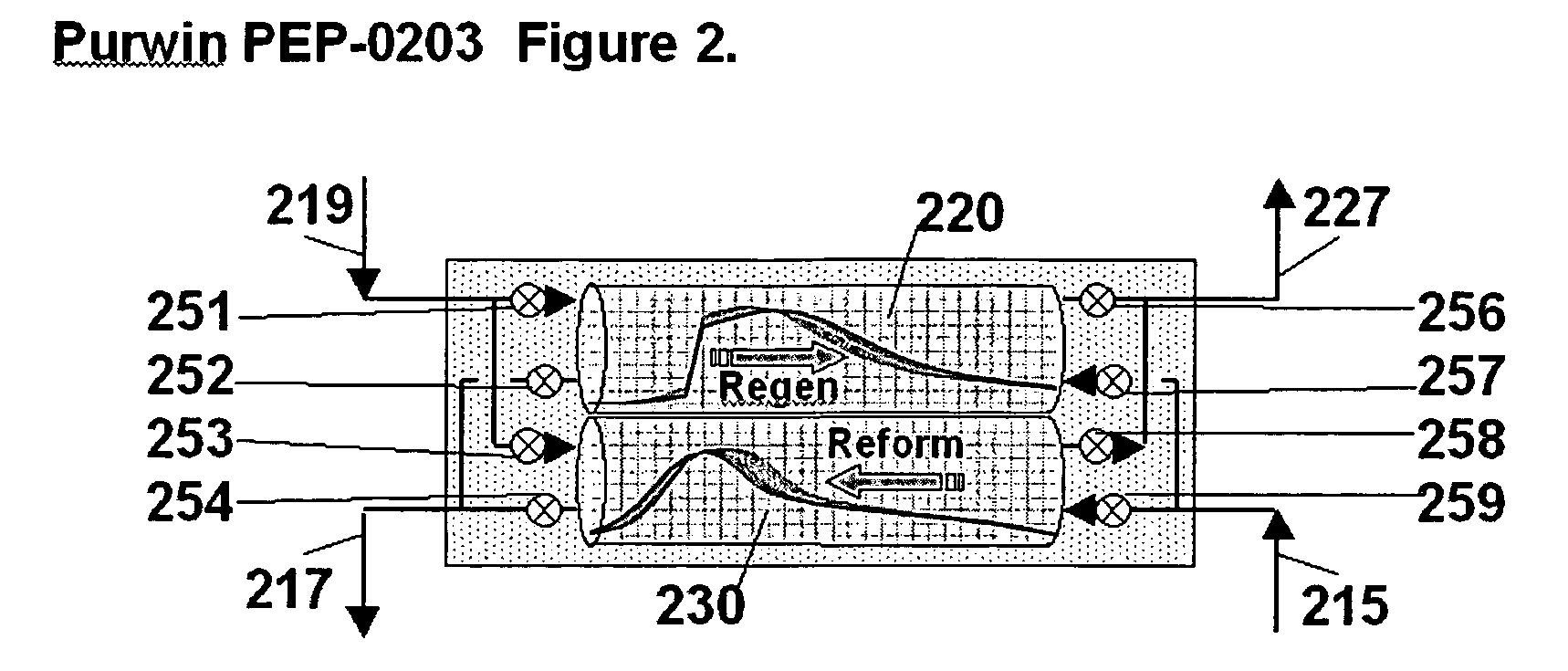

Pressure swing reforming for fuel cell systems

ActiveUS20040175326A1Efficient productionImprove permeabilityHydrogenChemical industrySyngasFuel cells

The present invention provides an improvement in the process of producing hydrogen from hydrocarbon-containing streams. A cyclic reforming process, referred to as pressure swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for fuel cell applications. Pressure swing reforming may be integrated with shift reactions, preferential oxidation, and membrane separation, achieving thermal and material efficiencies relative to conventional hydrogen production. In one embodiment, at least some synthesis gas which is first produced in the pressure swing reforming process is combusted with air to provide the heat for the regeneration step of the pressure swing reforming process.

Owner:EXXON RES & ENG CO

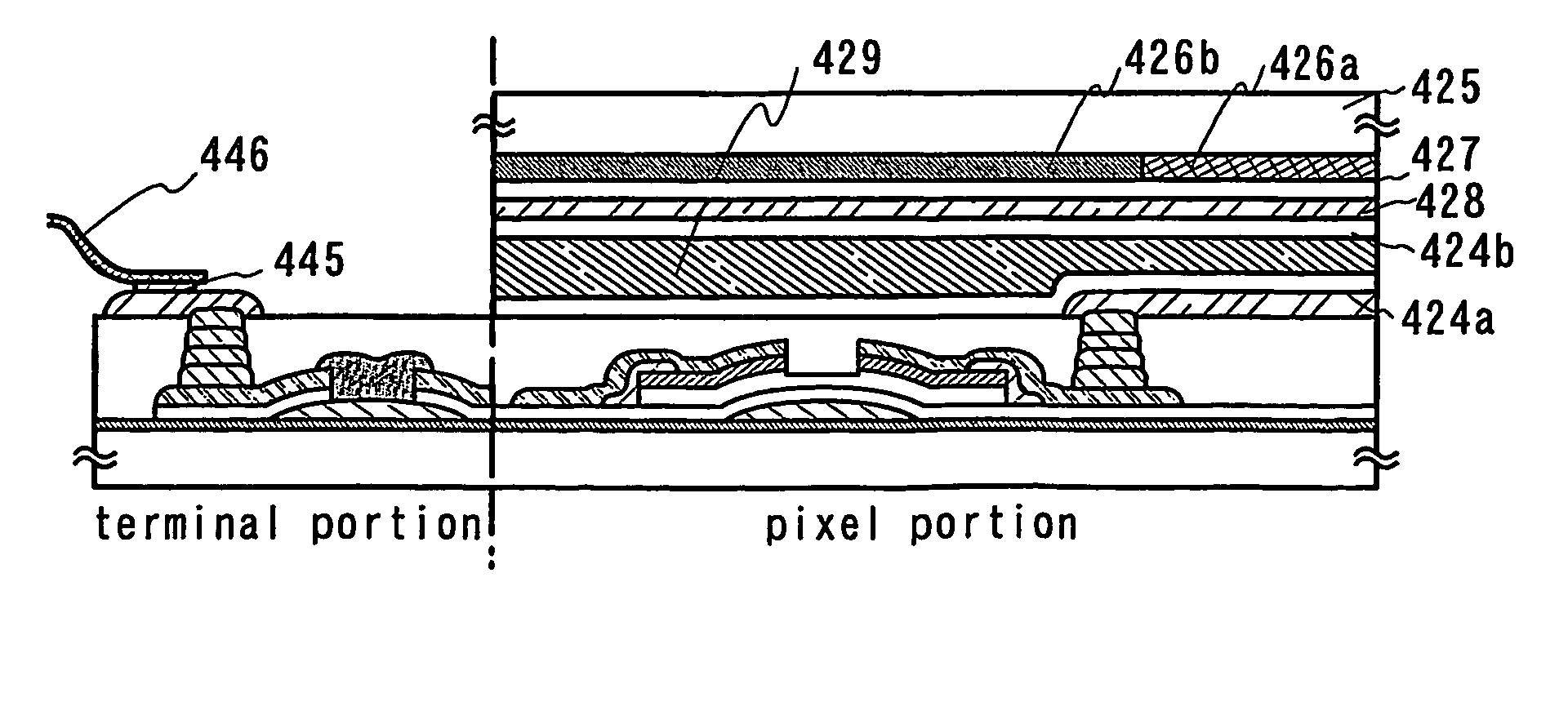

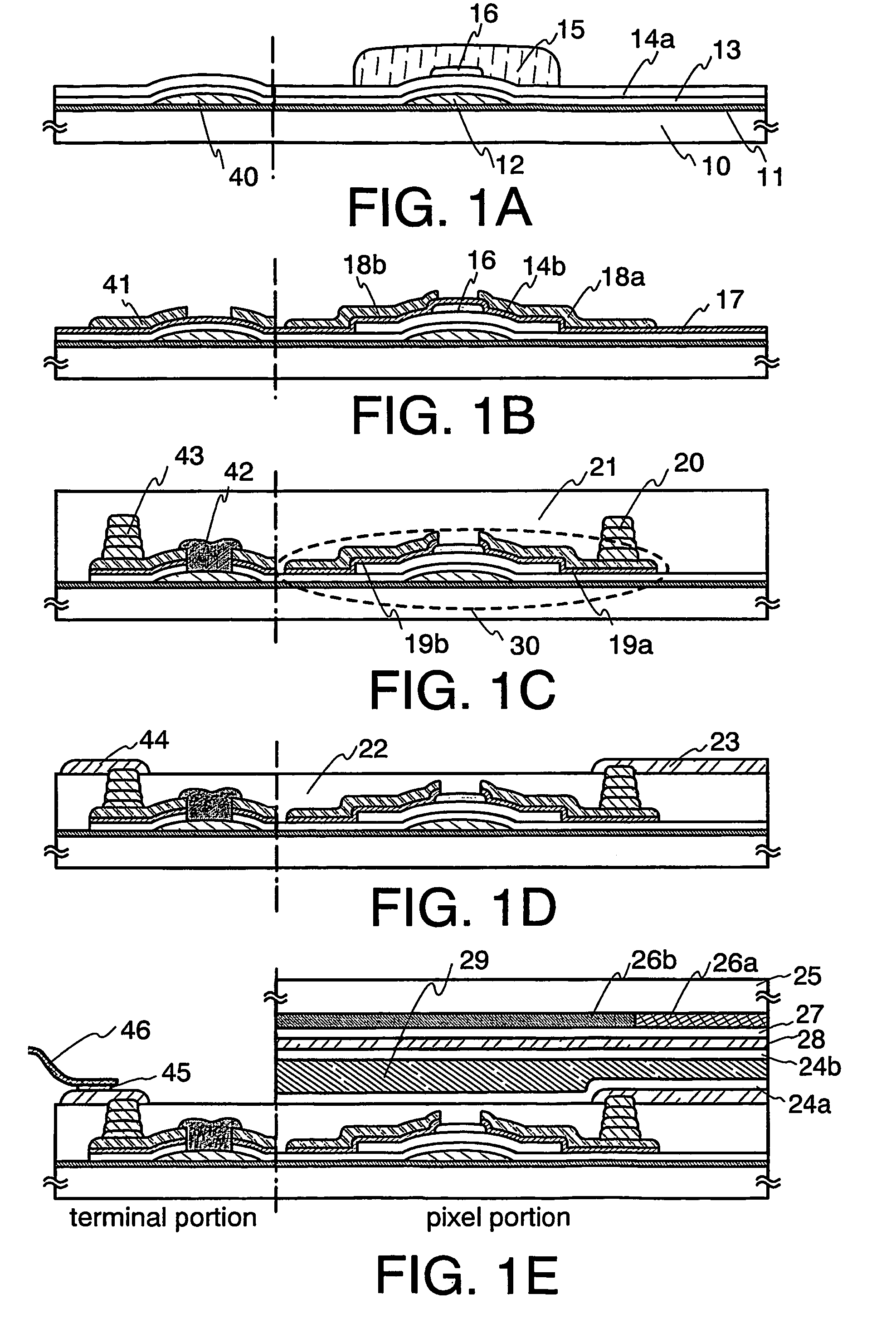

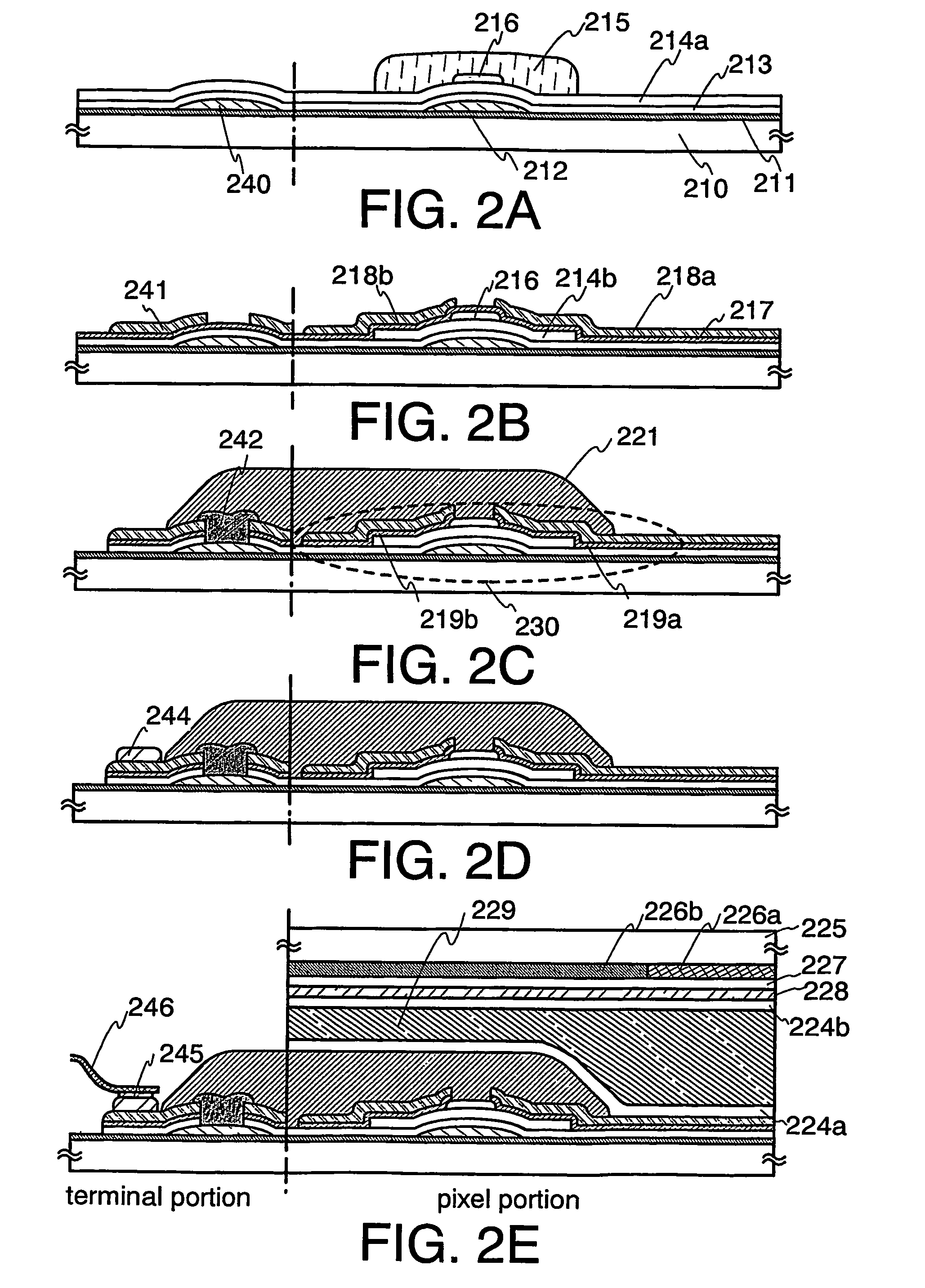

Semiconductor device and manufacturing method thereof

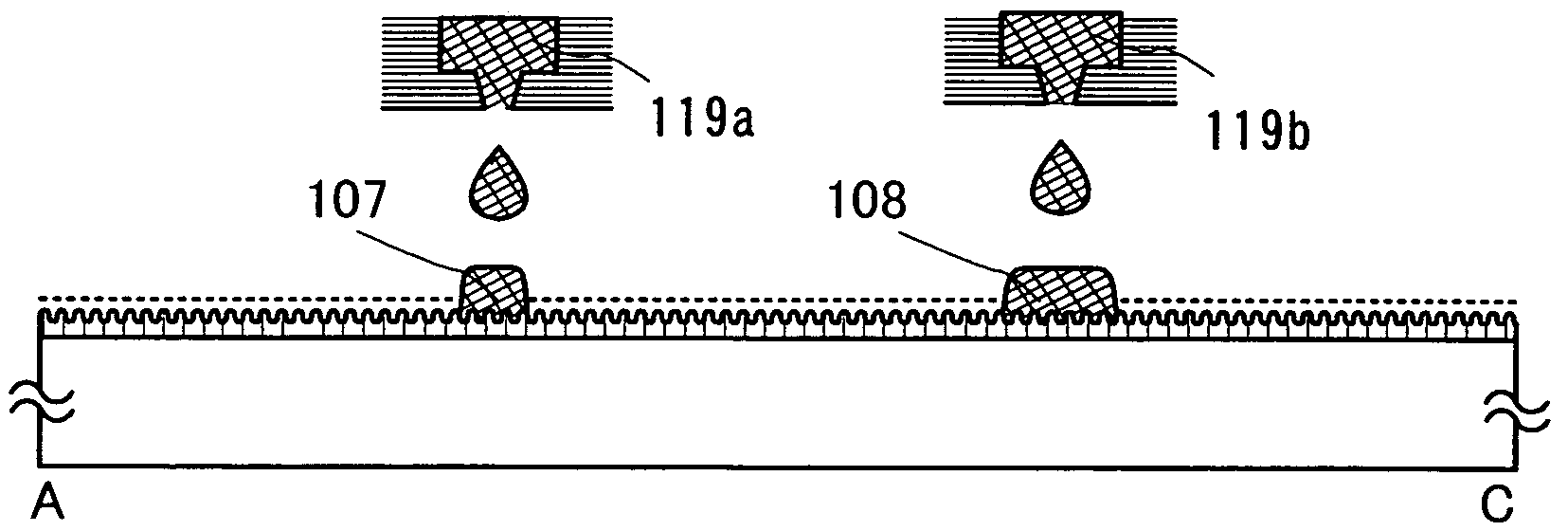

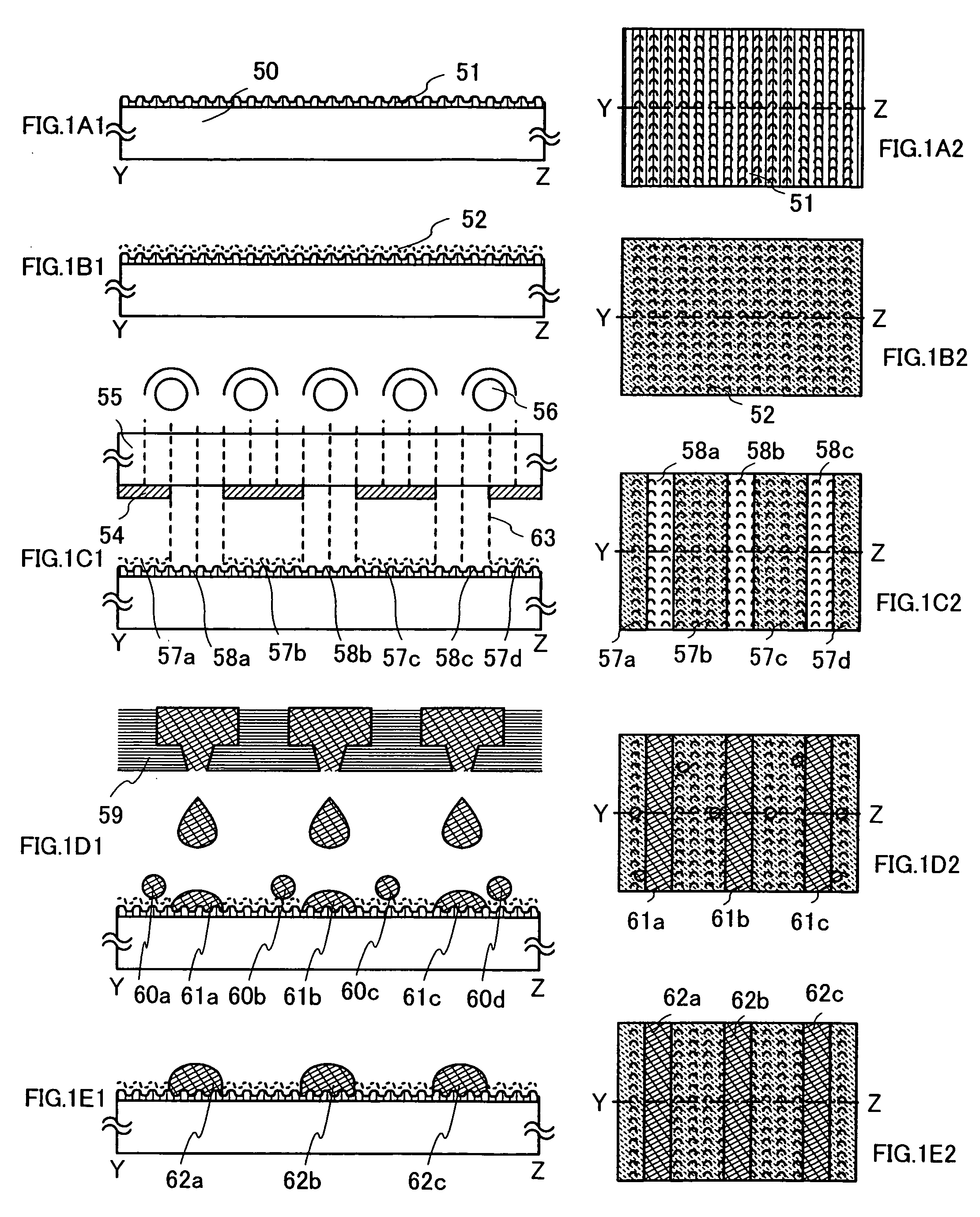

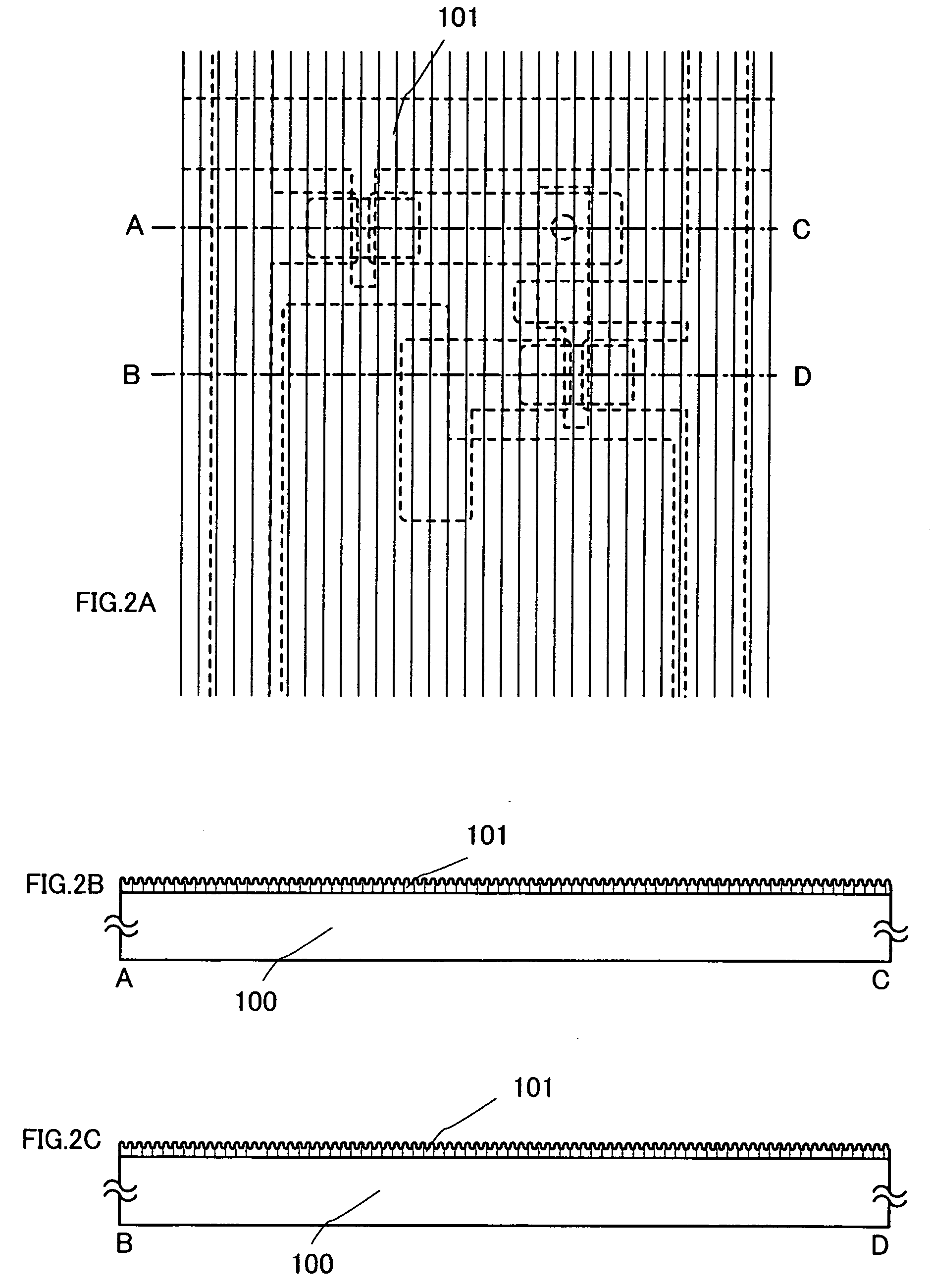

InactiveUS20060166411A1Improve adhesionLess material lossSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceManufacturing technology

An object of the invention is to provide a semiconductor device and a display device which can be manufactured with improved material efficiency through a simplified manufacturing process, and a manufacturing method thereof. Another object is to provide a technique capable of forming a pattern such as a wiring included in the semiconductor device or display device in a desired shape with good controllability. One feature of a method for manufacturing a semiconductor device is to comprise the steps of forming a layer having a rough surface, forming a region having low wettability by a composition containing a conductive material and a region having high wettability by the composition over the rough surface, and forming a conductive material using the composition in the region having high wettability. Since regions having largely different wettability (regions having a large difference in wettability) can be formed, a liquid conductive or insulating material is attached only to a formation region with precision. Accordingly, a conductive or insulating layer can be precisely formed in a desired pattern.

Owner:SEMICON ENERGY LAB CO LTD

Bubble-scale structure-effect control model modeling method for micro-interface strengthening reactor

ActiveCN107563051BReduce mistakesImprove versatilitySpecial data processing applicationsActivity regulationScale structure

The invention relates to a micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method. The diameter dmax of the largest bubble of a micro-interface enhanced reactor and the diameter dmin of the smallest bubble of the micro-interface enhanced reactor serve as independent variables, the average diameter d32 of the bubble Sauter serve as a dependentvariable, and a numerical relationship is built; based on the Kolmogorov-Hinze theory, the relationship between the diameter dmax of the largest bubble of the micro-interface enhanced reactor, the diameter dmin of the smallest bubble and the parameters of the reactor is built. According to the method, the reactor bubble scale is associated with the structural parameter, the operation parameter andthe physical property parameter of the reactor by using specific numerical relationship, the numerical relationship has the guiding significance for the design of the reactor and can be applied to avariety of reactors, the versatility is good, by means of a bubble scale regulation and control model built through the method, by adjusting the structural parameter and the operation parameter of thereactor, and the maximization of energy efficiency and material efficiency in the reaction process can be achieved, or under the condition that reaction targets, energy consumption and material consumption are given, a high-efficiency reactor structure is designed.

Owner:NANJING UNIV

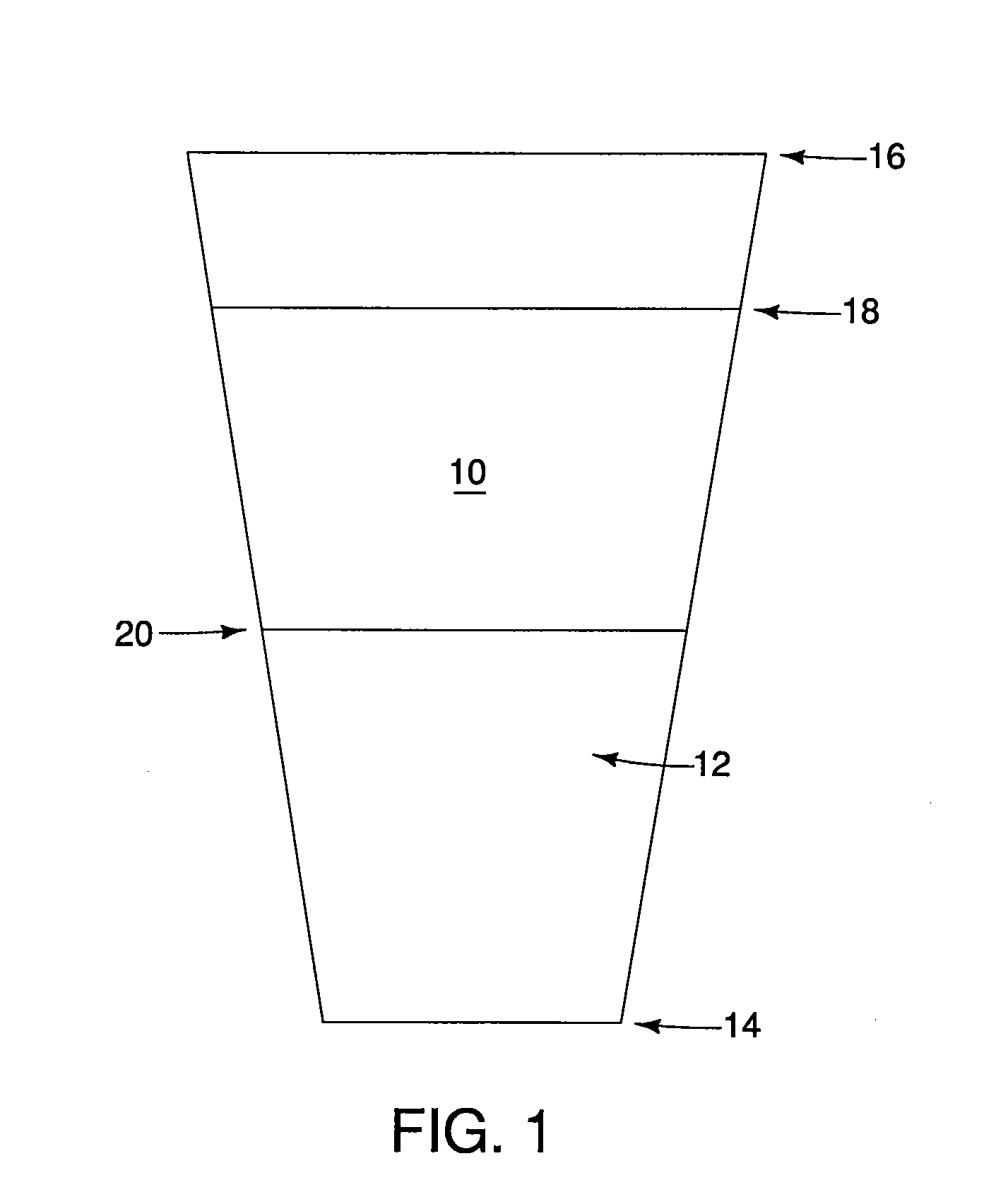

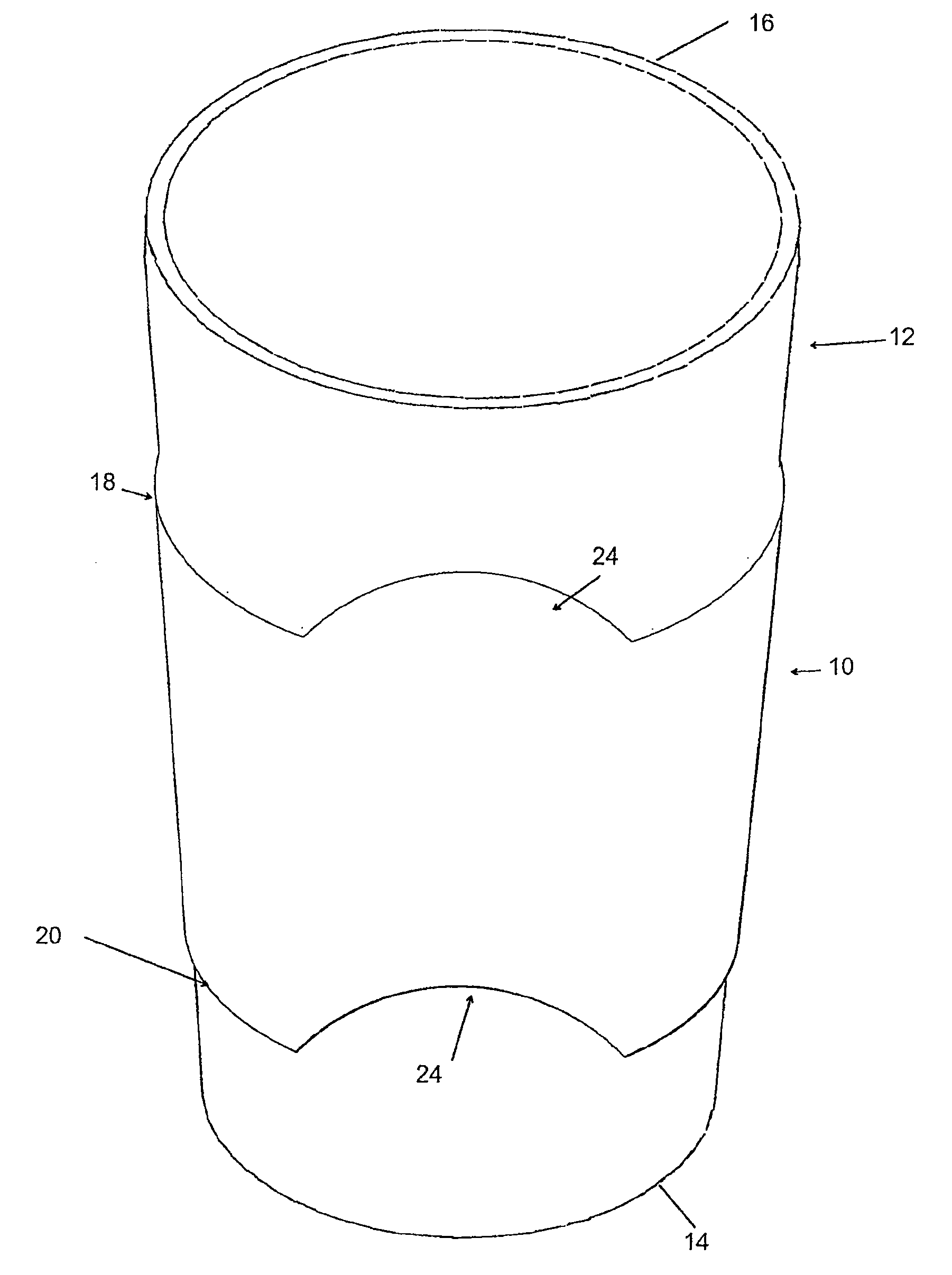

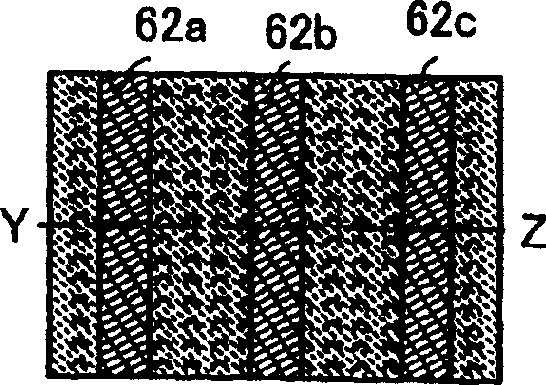

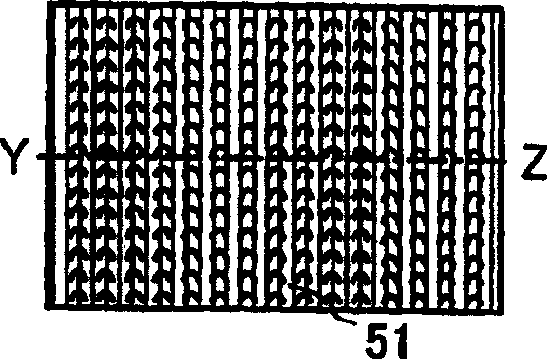

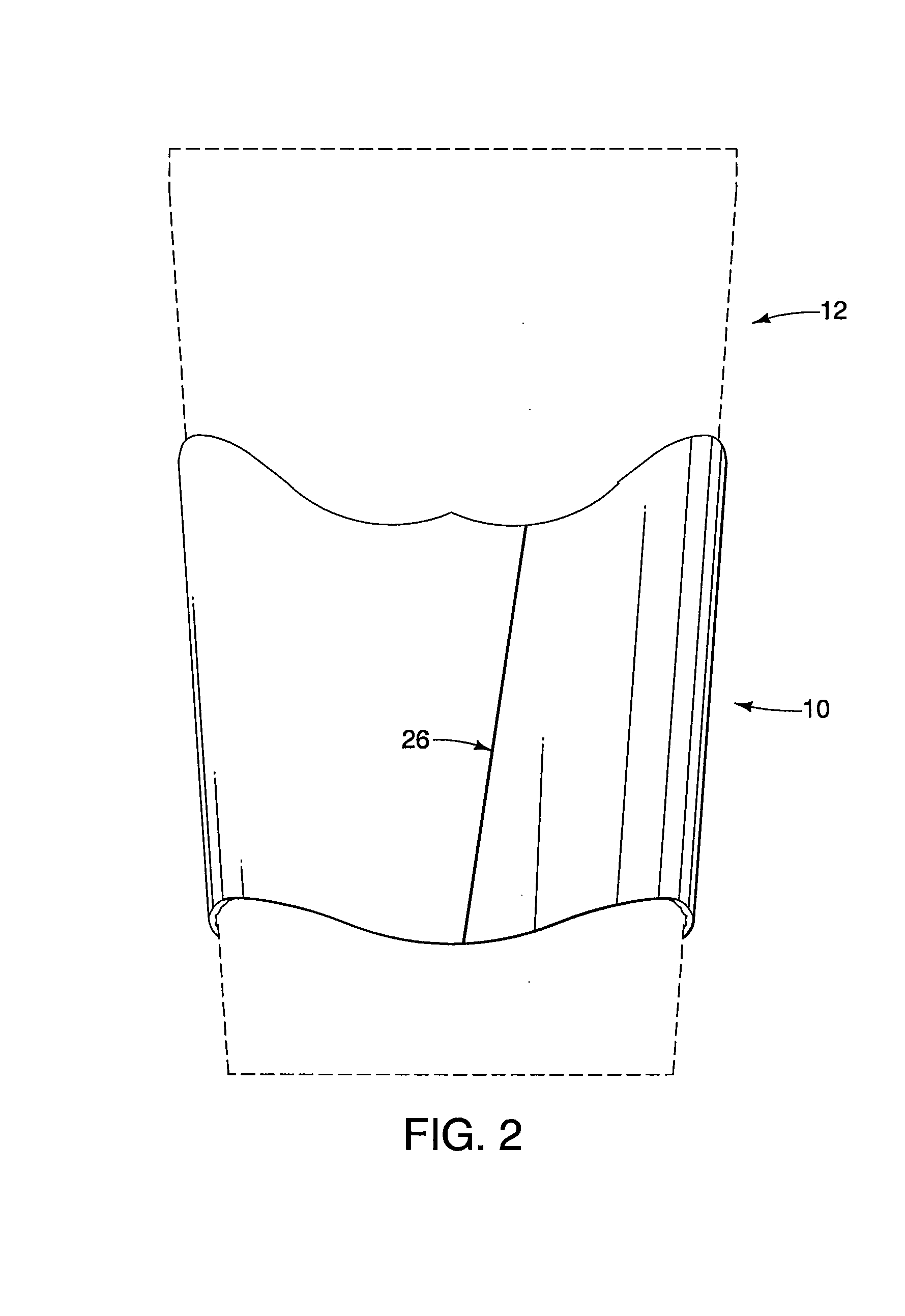

Protective sleeve

A container and a sleeve for a container are disclosed that employ unique air channels to divert heat from a hot beverage via hot air escaping upward and downward. The surface of the container and sleeve include raised images, depressed images, or a combination of both which are generally aligned in substantially vertical columns. The space between the columns defines the air channels. The air channels are substantially uninterrupted and facilitate the upward and downward escape of hot air. The images are applied, such as by embossing and / or debossing, which facilitates manufacturing material efficiency and therefore reduces material costs and environmental waste. A blank for a container or sleeve and a method of making a sleeve are also disclosed.

Owner:LBP MANUFACTURING INC

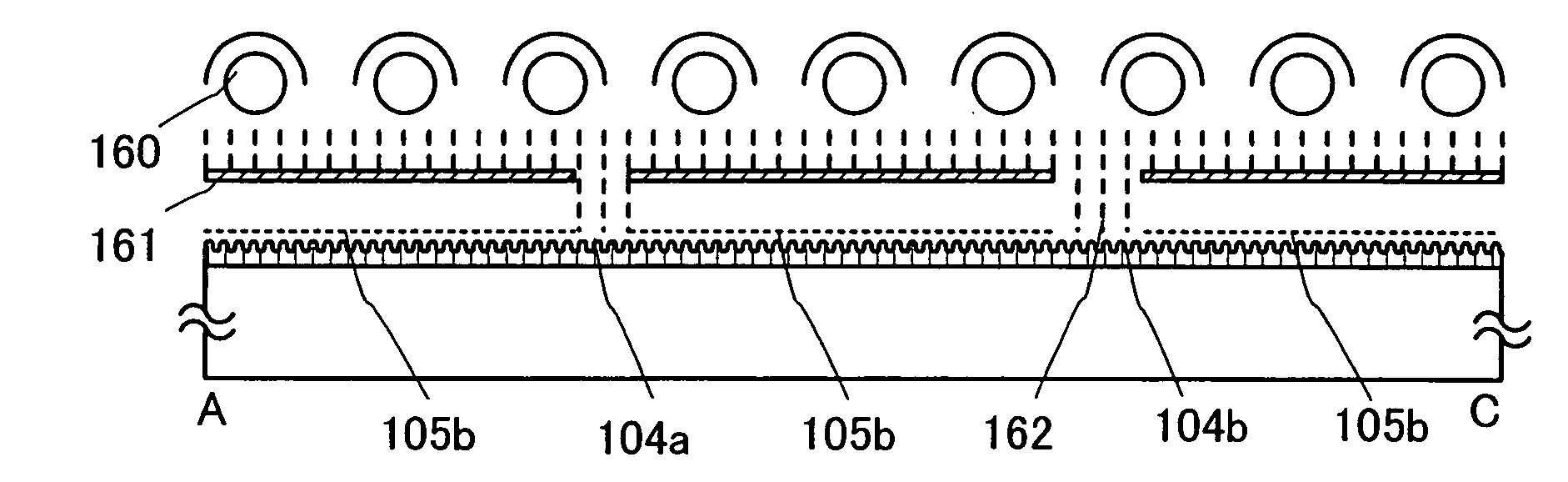

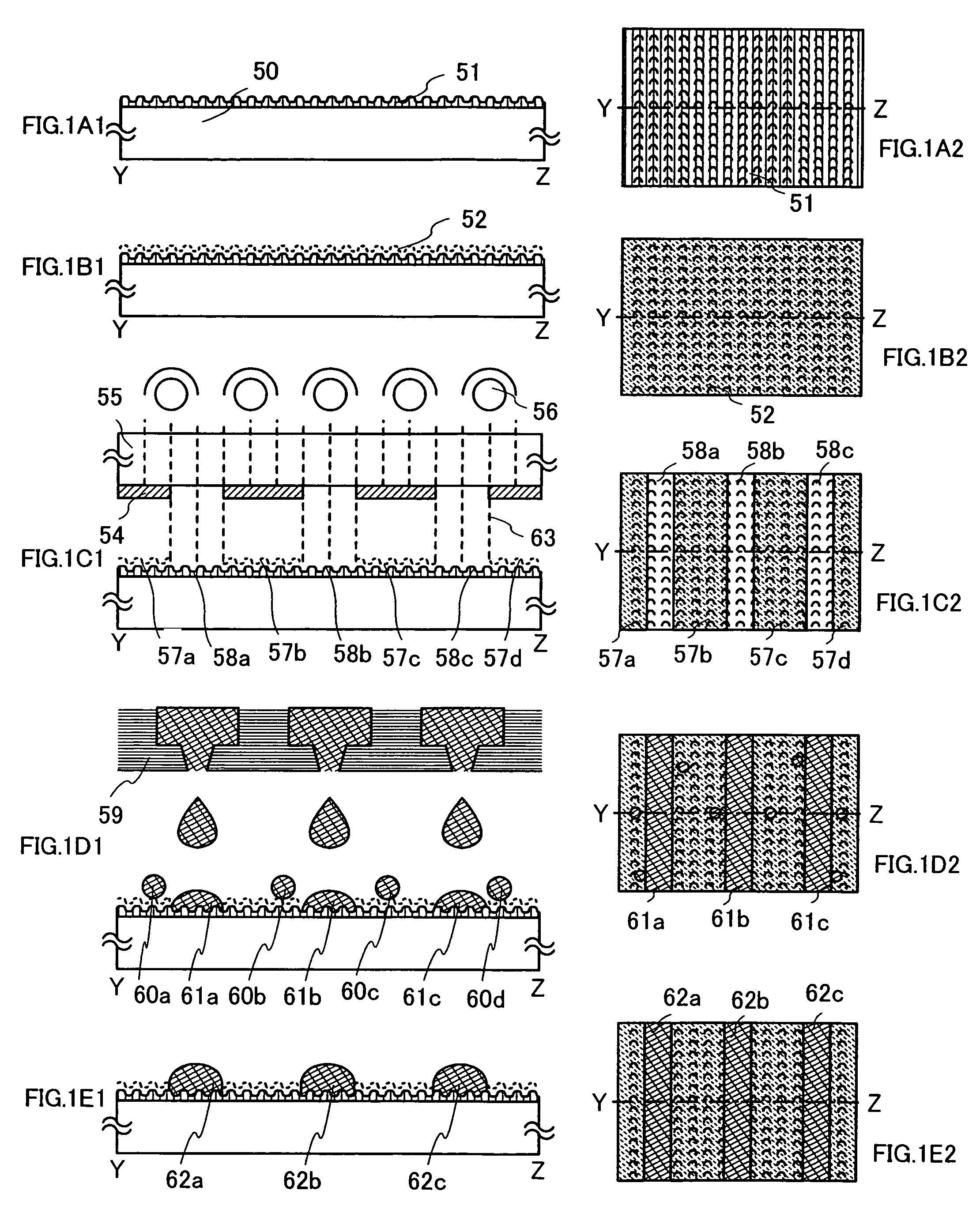

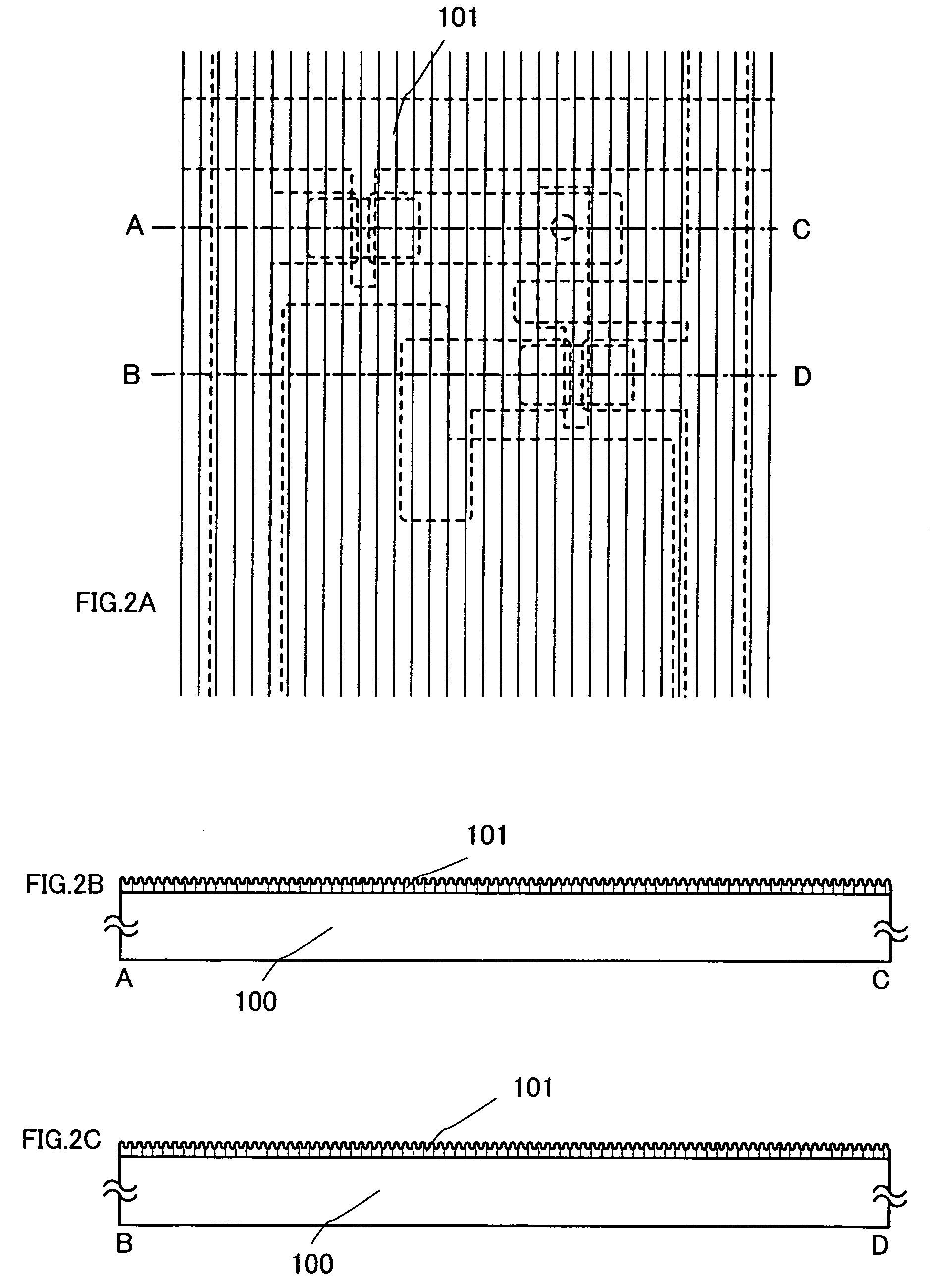

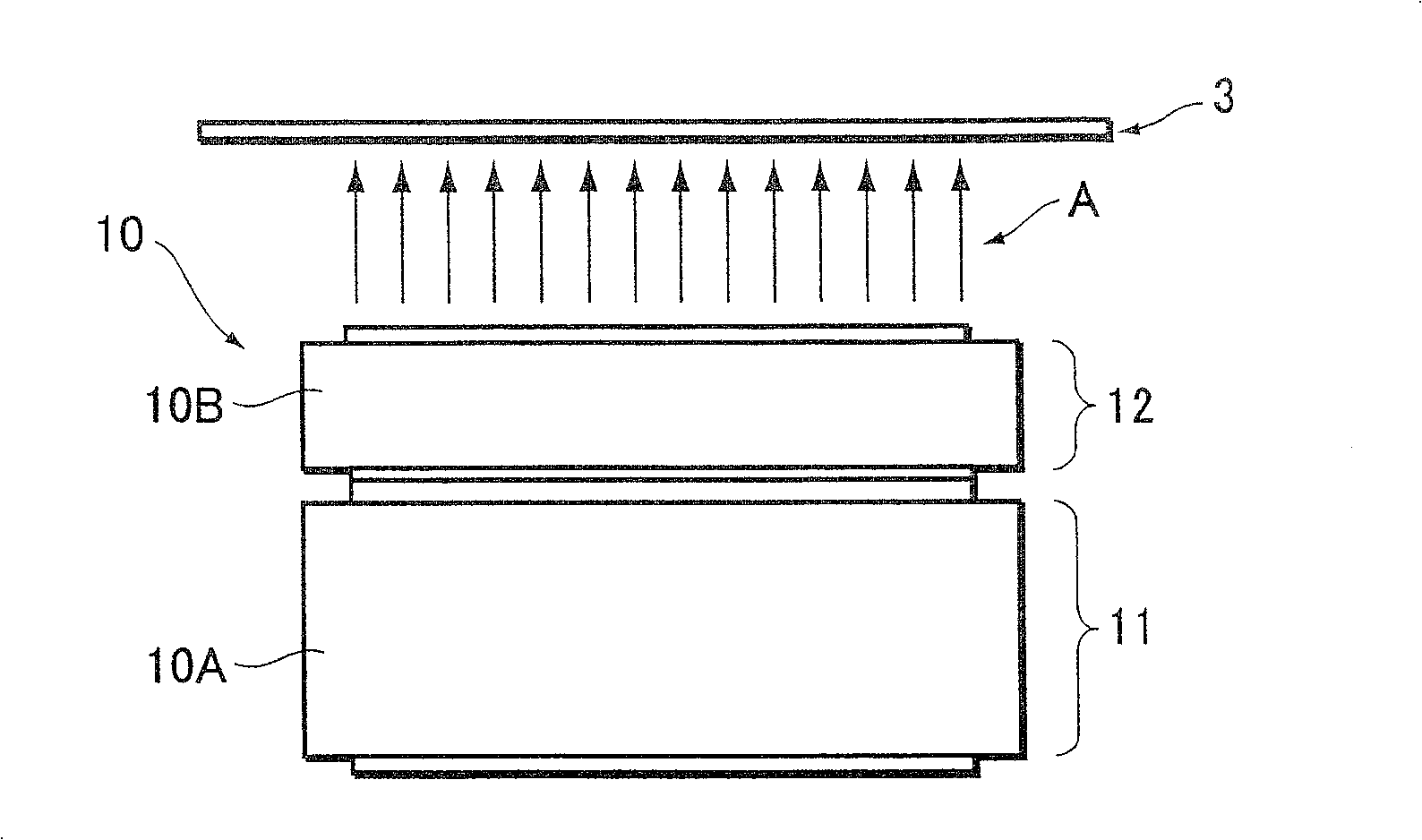

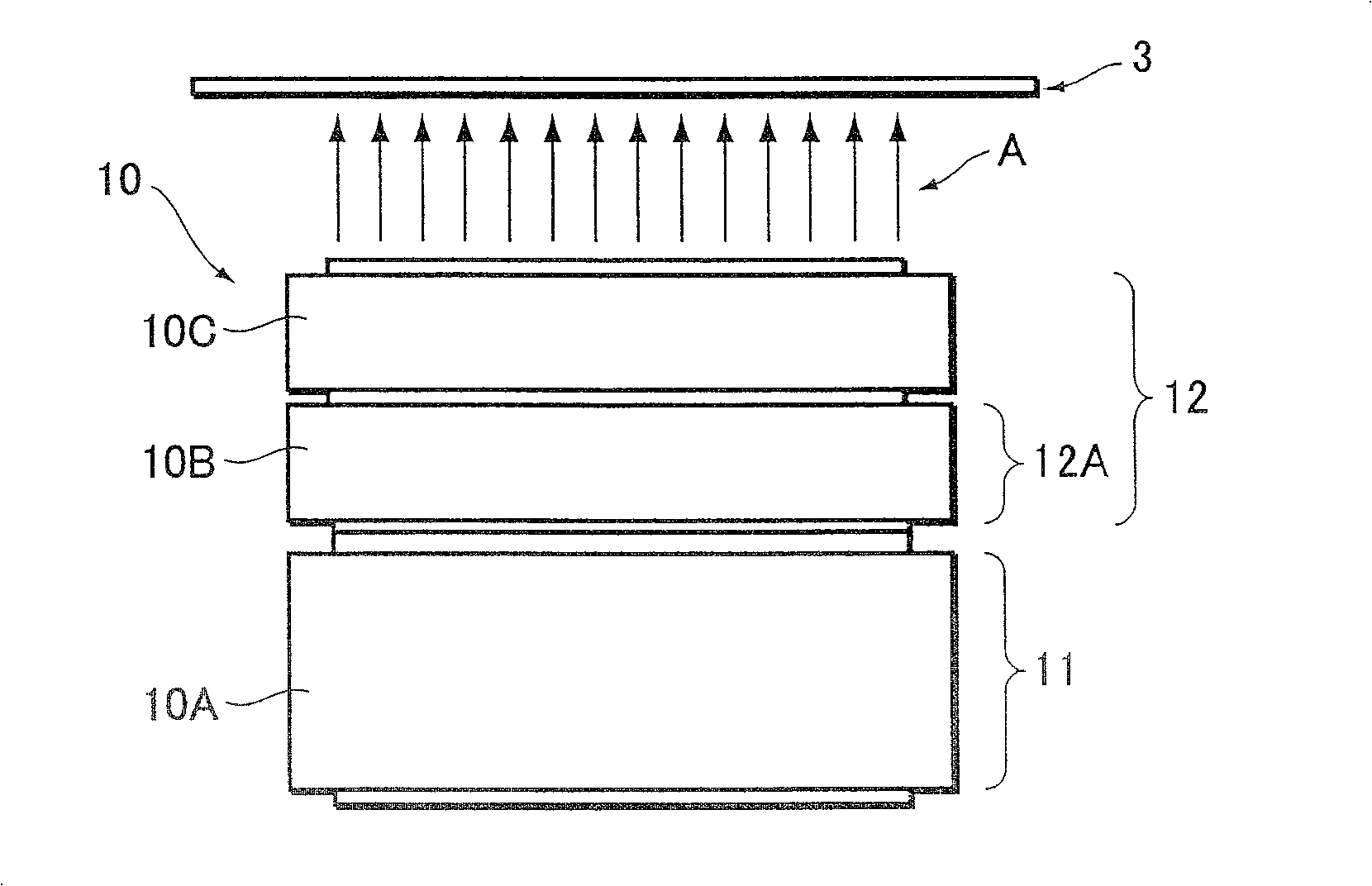

Liquid crystal display device and method for manufacturing the same

InactiveUS7795616B2Extended production timeIncrease wasteSolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

Owner:SEMICON ENERGY LAB CO LTD

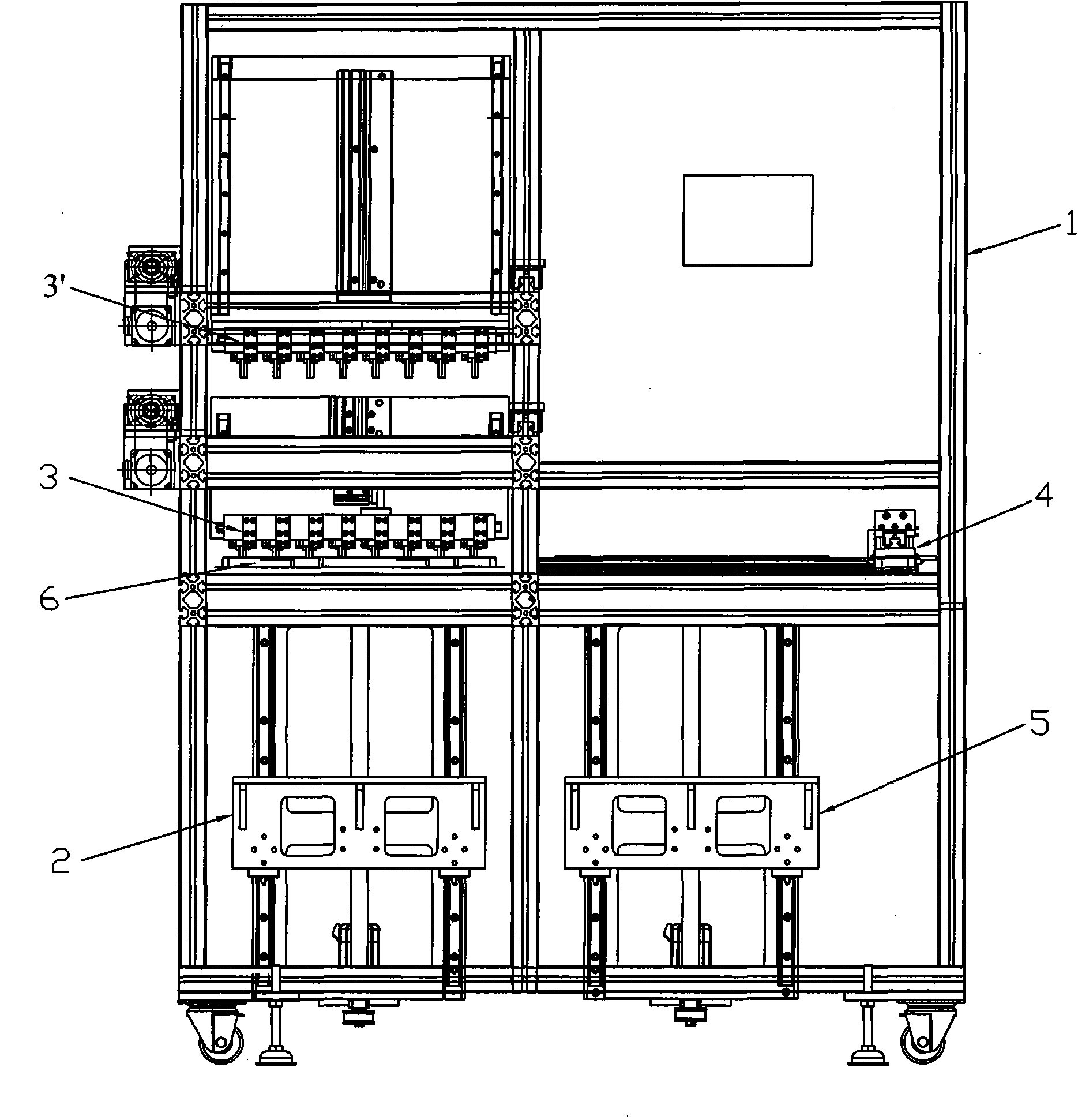

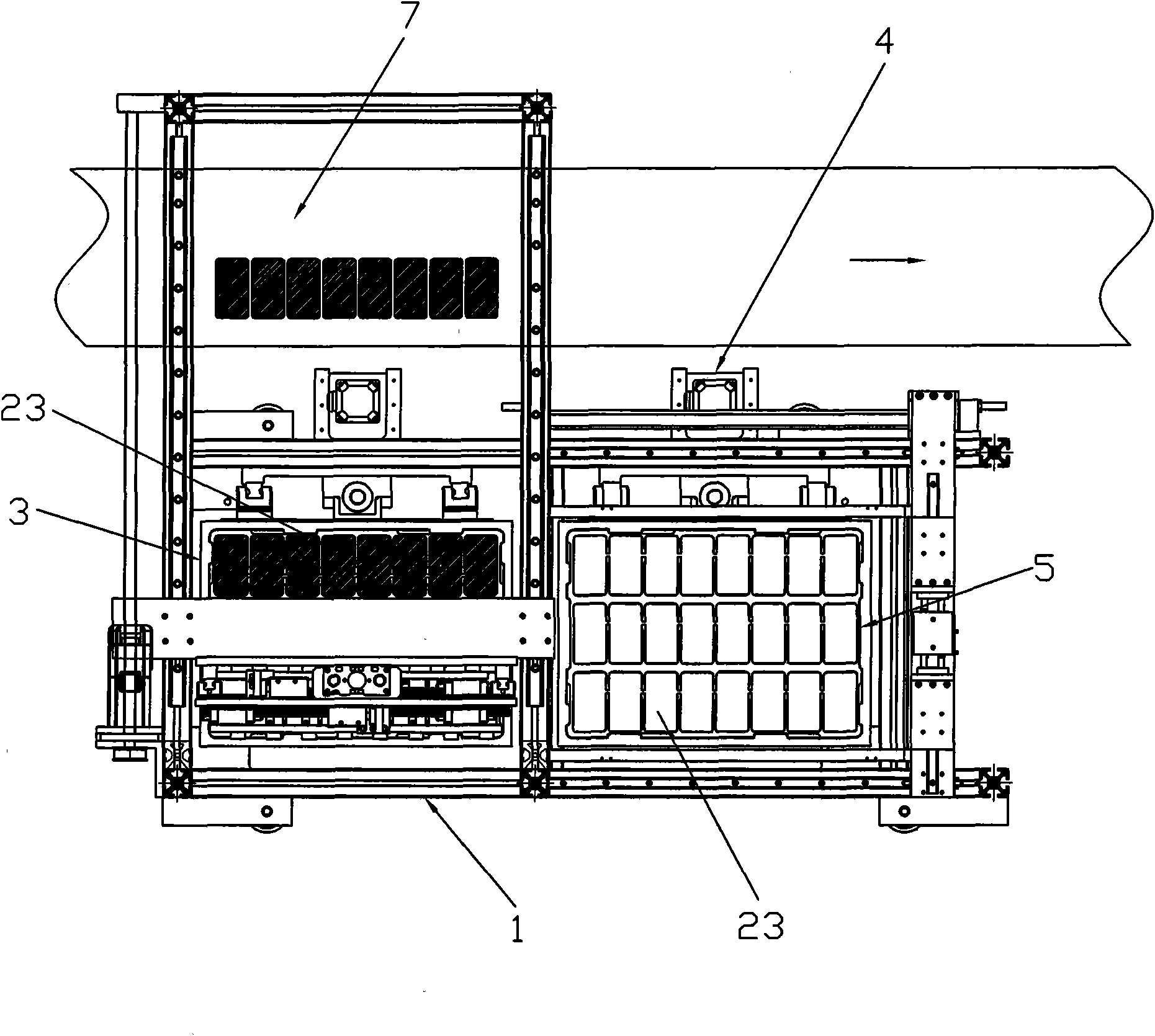

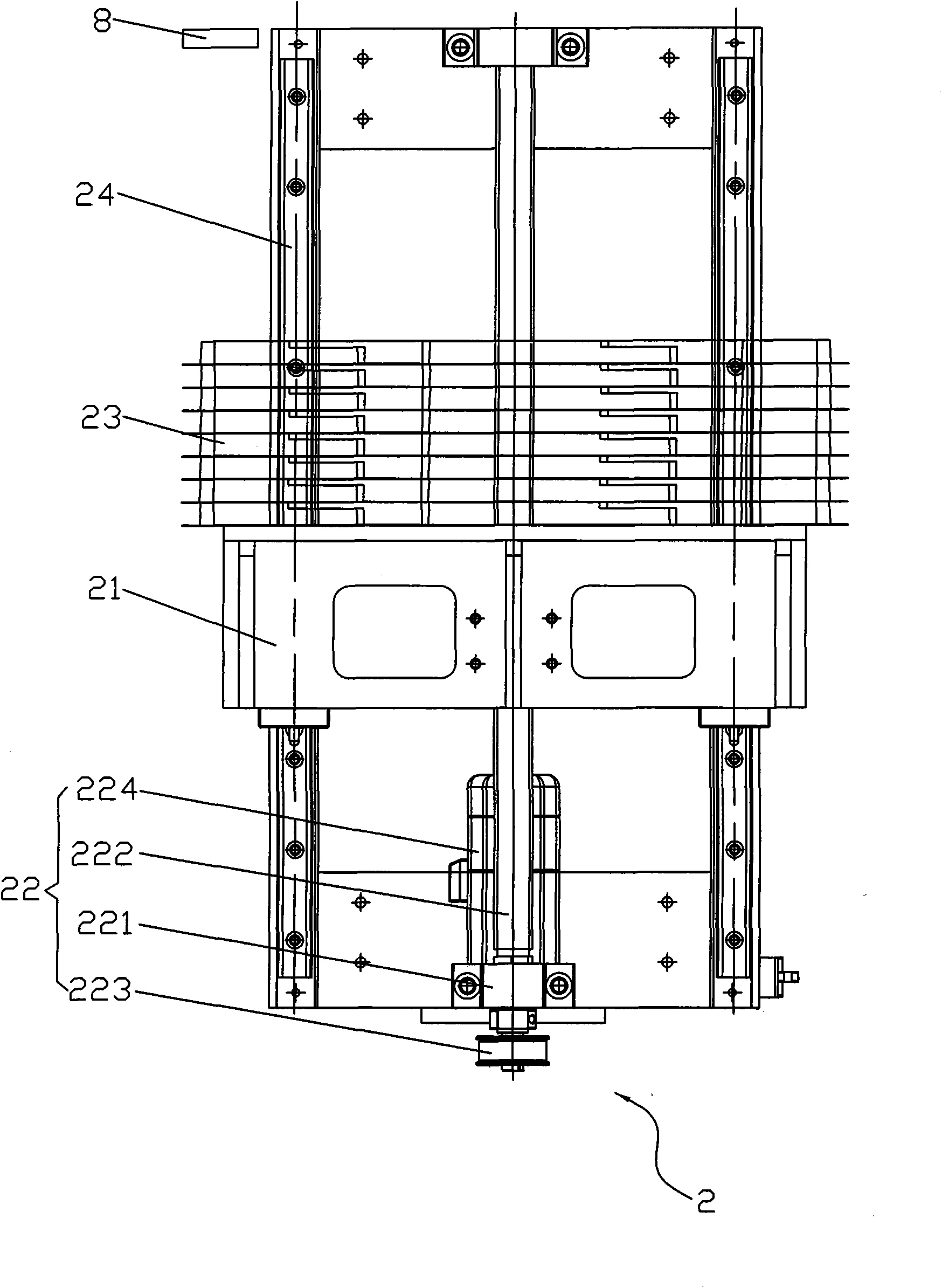

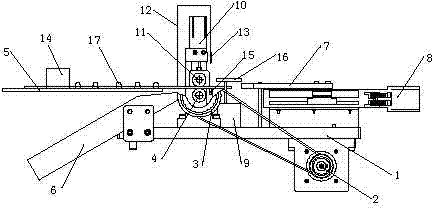

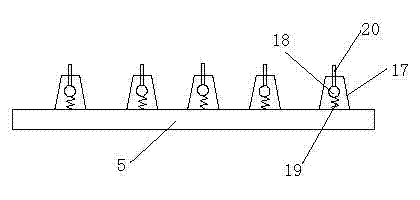

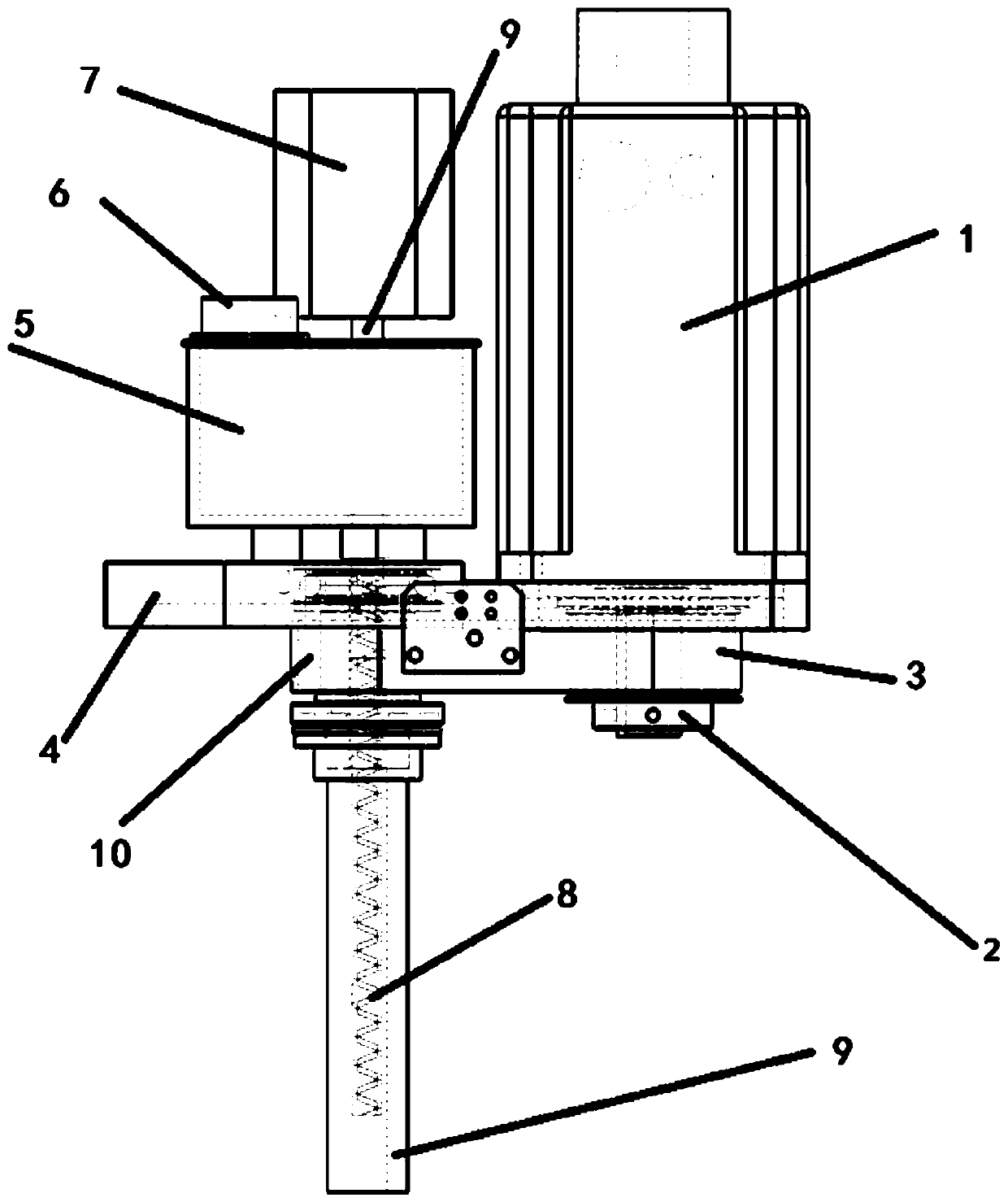

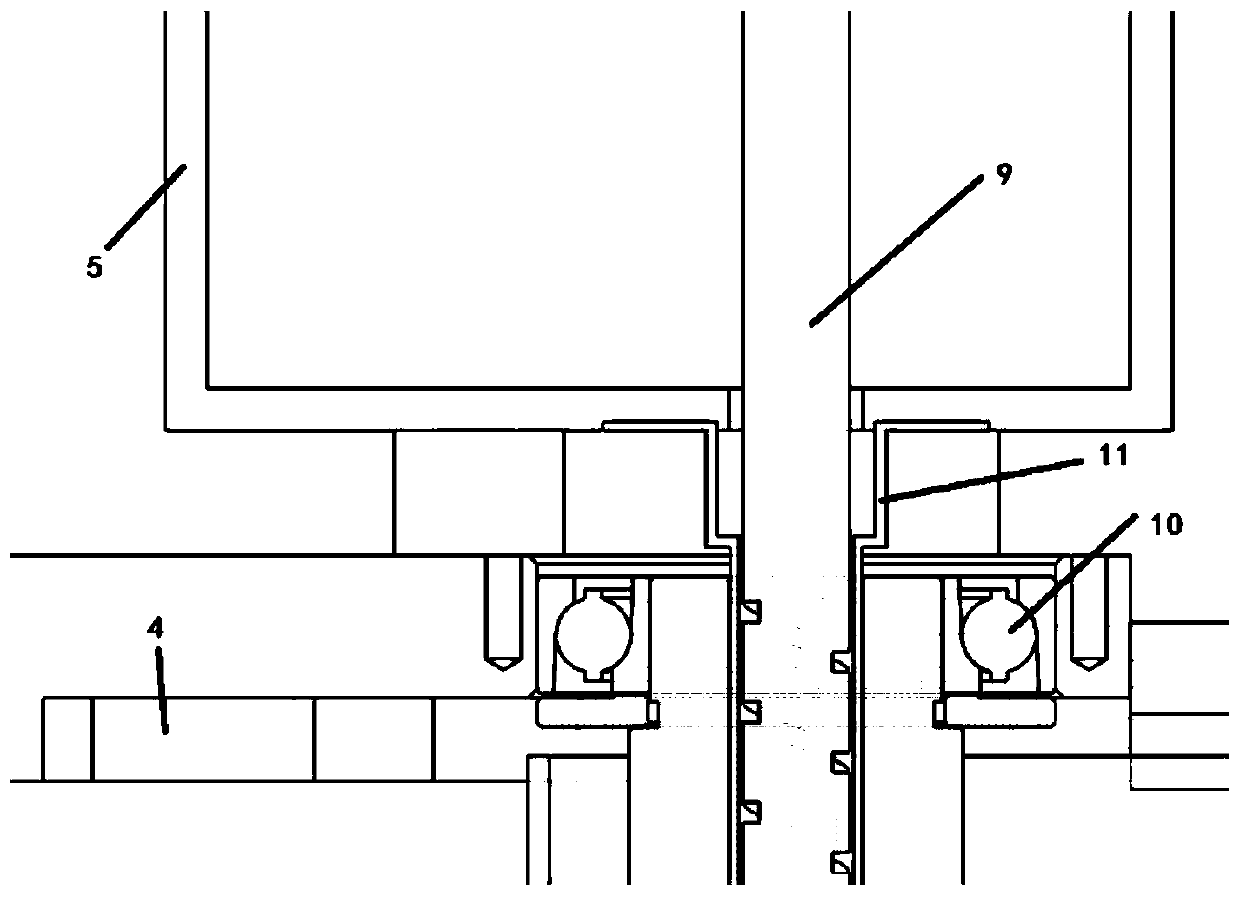

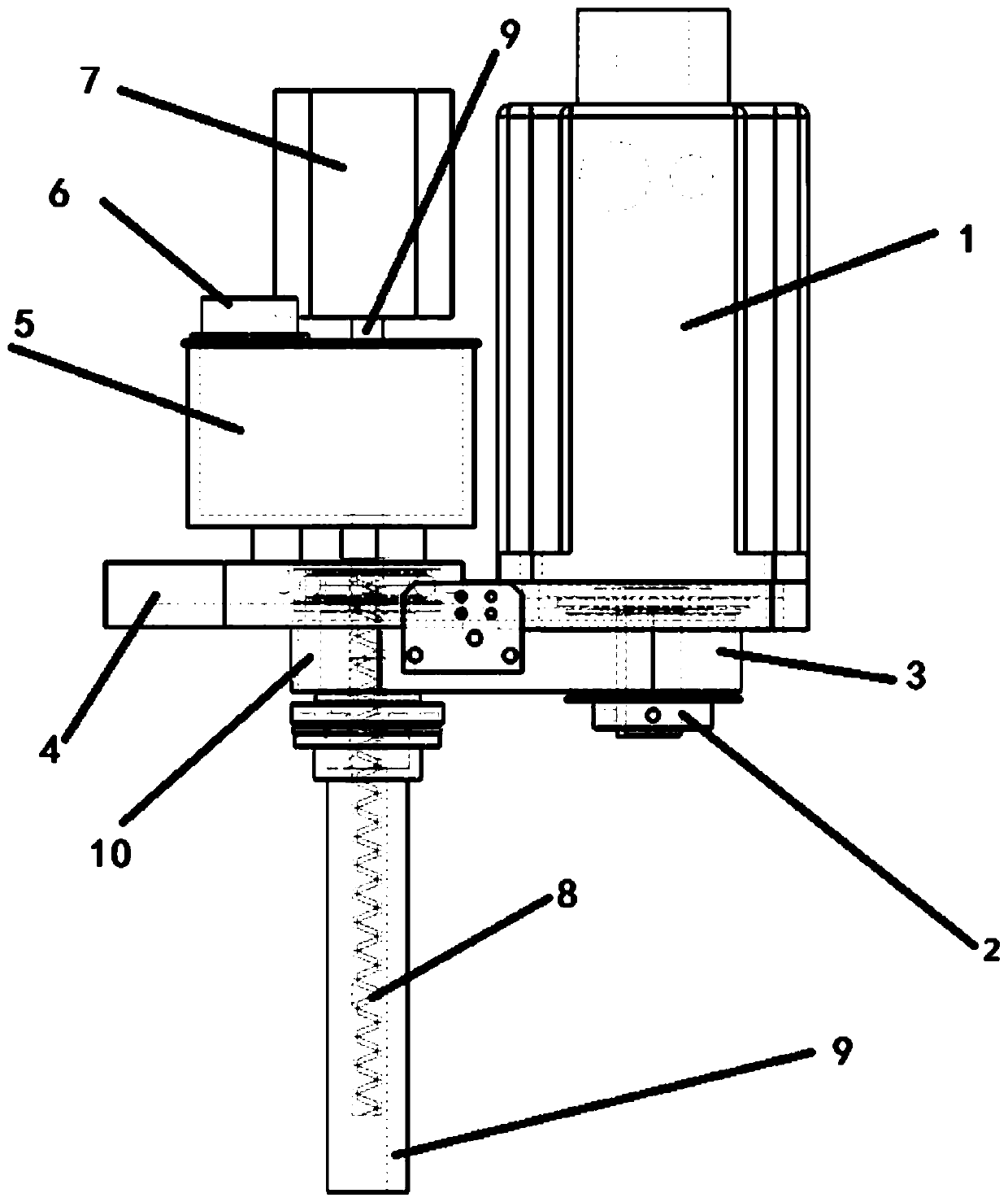

Automatic piece unloading device

InactiveCN102107771AImprove efficiencySolve the problem of declining production efficiencyProgramme-controlled manipulatorStacking articlesProduction lineEngineering

The invention provides an automatic piece unloading device which comprises a material disc sending device, a material taking device, a material disc taking device and a material disc collecting device. According to the invention, material discs filled with material are firstly stacked up and placed on the material disc sending device, and sent to a material taking area by the material disc sending device; after being sent in place, the material is taken down from the material discs and placed on a conveyer belt by the material taking device, and sent to a production line by the conveyor belt;and after the material is taken down, the empty material discs are taken out of the material taking area and placed on the material disc collecting device by the material disc taking device, so the material discs can be collected and overlaid one by one. Compared with the prior art, the automatic piece unloading device provided by the invention can once grab all material in the material discs, thereby remarkably improving the material taking efficiency; and after the material is taken down, the empty material discs are automatically sent to the material disc collecting device by the material disc taking device to be collected, thereby reducing the production cost of a product.

Owner:启东赫子新材料有限公司

Micro-interface enhancement reactor reaction rate structure-activity regulation and control model modeling method

ActiveCN107561938AReduce mistakesImprove versatilityAdaptive controlActivity regulationReaction rate

The invention discloses a micro-interface enhancement reactor reaction rate structure-activity regulation and control model modeling method. Based on the Levenspiel theory, a reaction rate structure-activity model suitable for a micro-interface enhancement reactor is constructed. According to the invention, the reaction rate structure-activity regulation and control model constructed through the method can intuitively make out the effects of the bubble diameter, gas-liquid mass transfer coefficients, the mass transfer resistance and the like on the reaction rate; the bubble diameter of a reaction system, the reaction efficiency (energy efficiency and material efficiency), the physical and chemical properties of the system, micro-interface characteristics, mass transfer characteristics andthe reactor structure are correlated through a mathematic method; the energy efficiency and material efficiency of a reaction process are maximized by adjusting structural parameters and operating parameters; and alternatively, a reaction target (mission), energy consumption and material consumption are given, the efficient reactor structure is designed.

Owner:NANJING UNIV

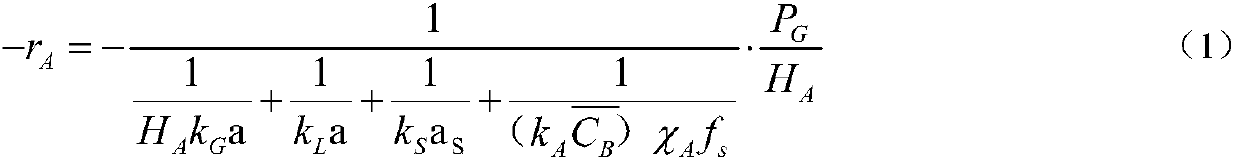

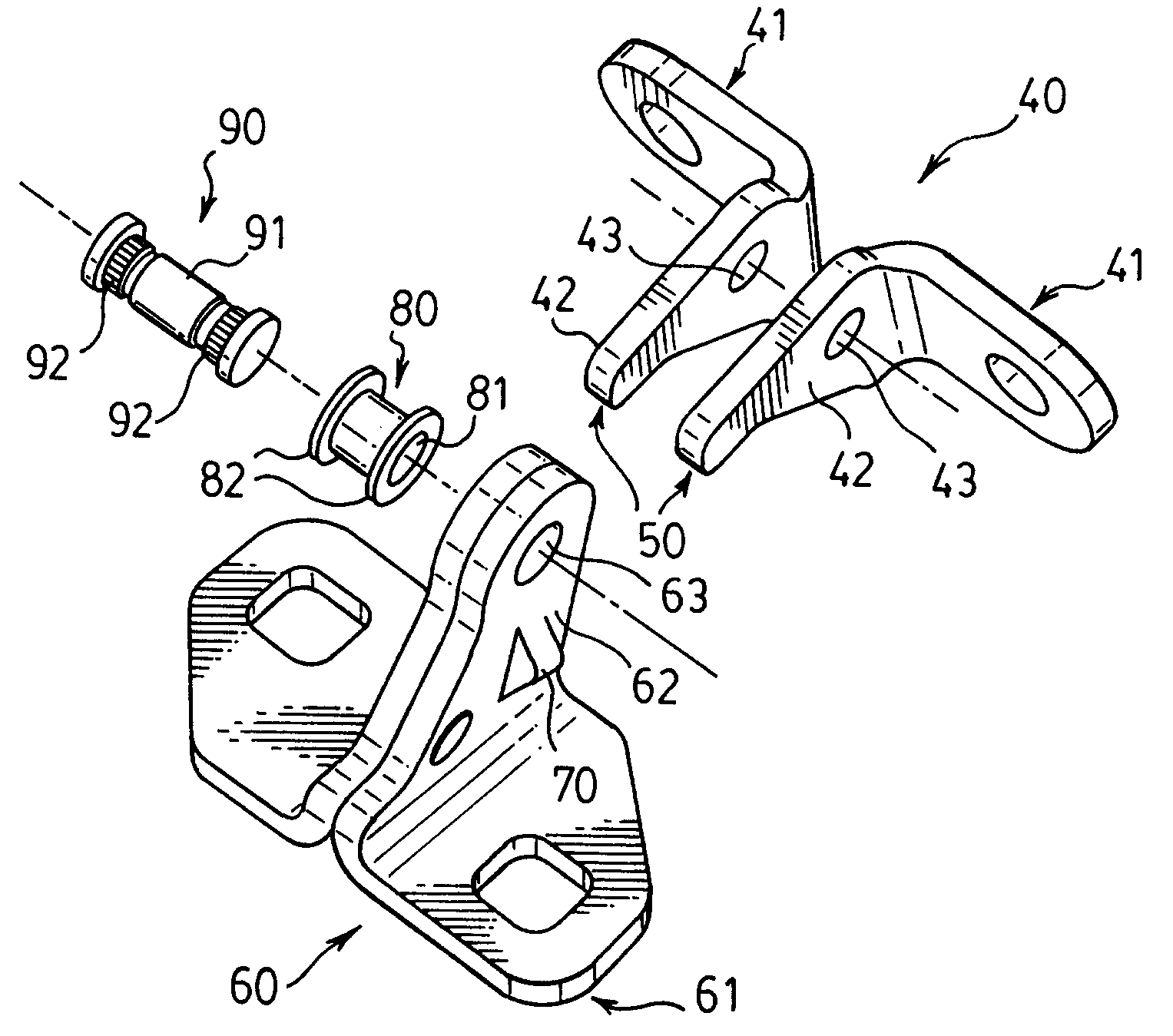

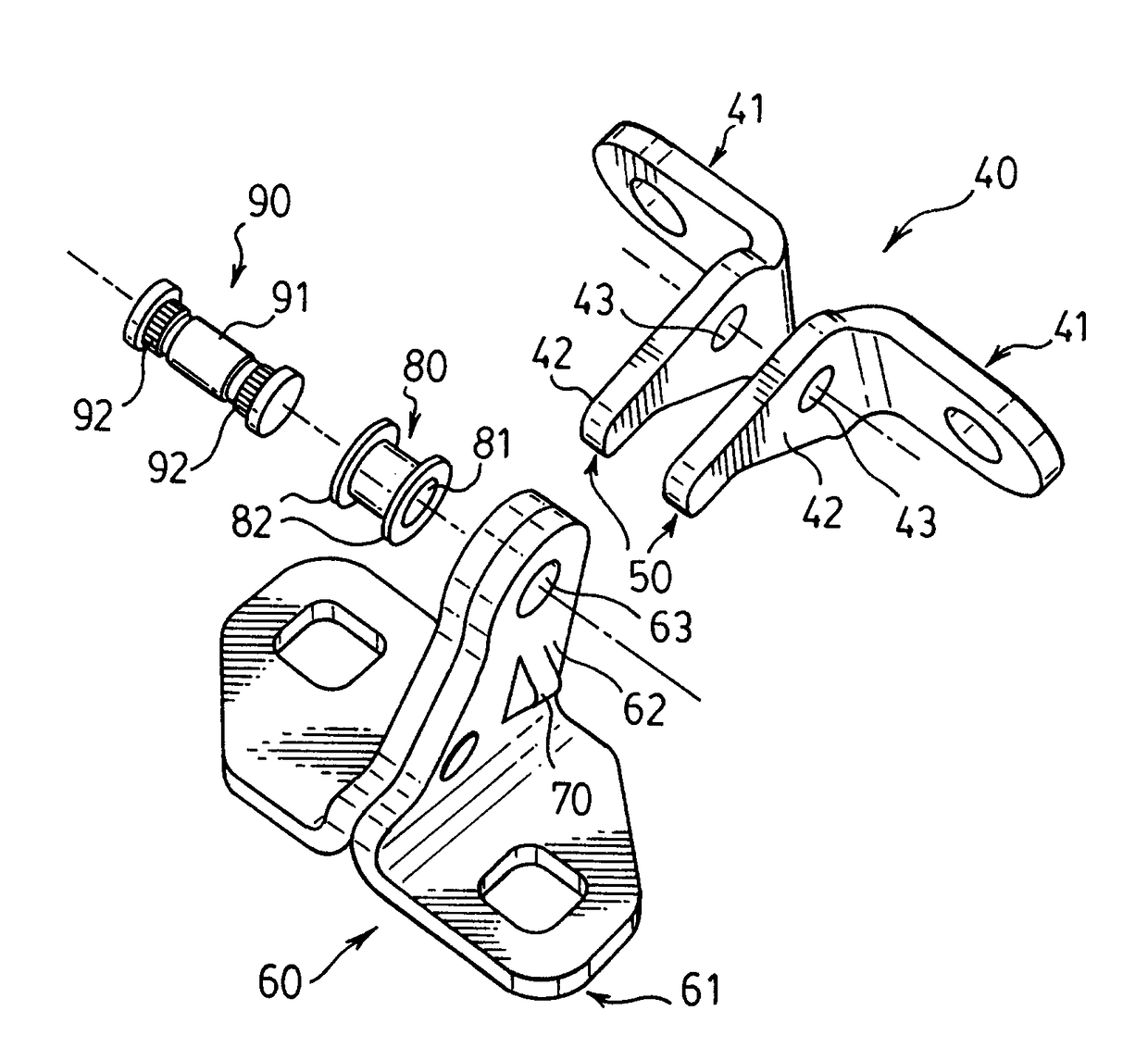

Multiple Piece Construction Automotive Door Hinge

ActiveUS20080295290A1Reduces and eliminates scrapWing accessoriesPin hingesEngineeringMaterial efficiency

An automotive hinge assembly adapted to facilitate motion of a closure panel relative to a fixed body structure comprises a door component constructed from two press formed angle brackets structurally connected via a pivot pin and adapted to be mounted to a vehicle closure panel, a body component constructed from two press formed angle brackets structurally connected via a simple formed feature and the pivot pin and adapted to be mounted to a vehicle body structure, such that the pivot pin structurally assembles the two hinge components, facilitates relative rotary motion between them and structurally connects the multiple press formed angle brackets so that the resulting assembly achieves a much higher material efficiency than the prior art with an associated significant cost reduction.

Owner:MULTIMATIC INC

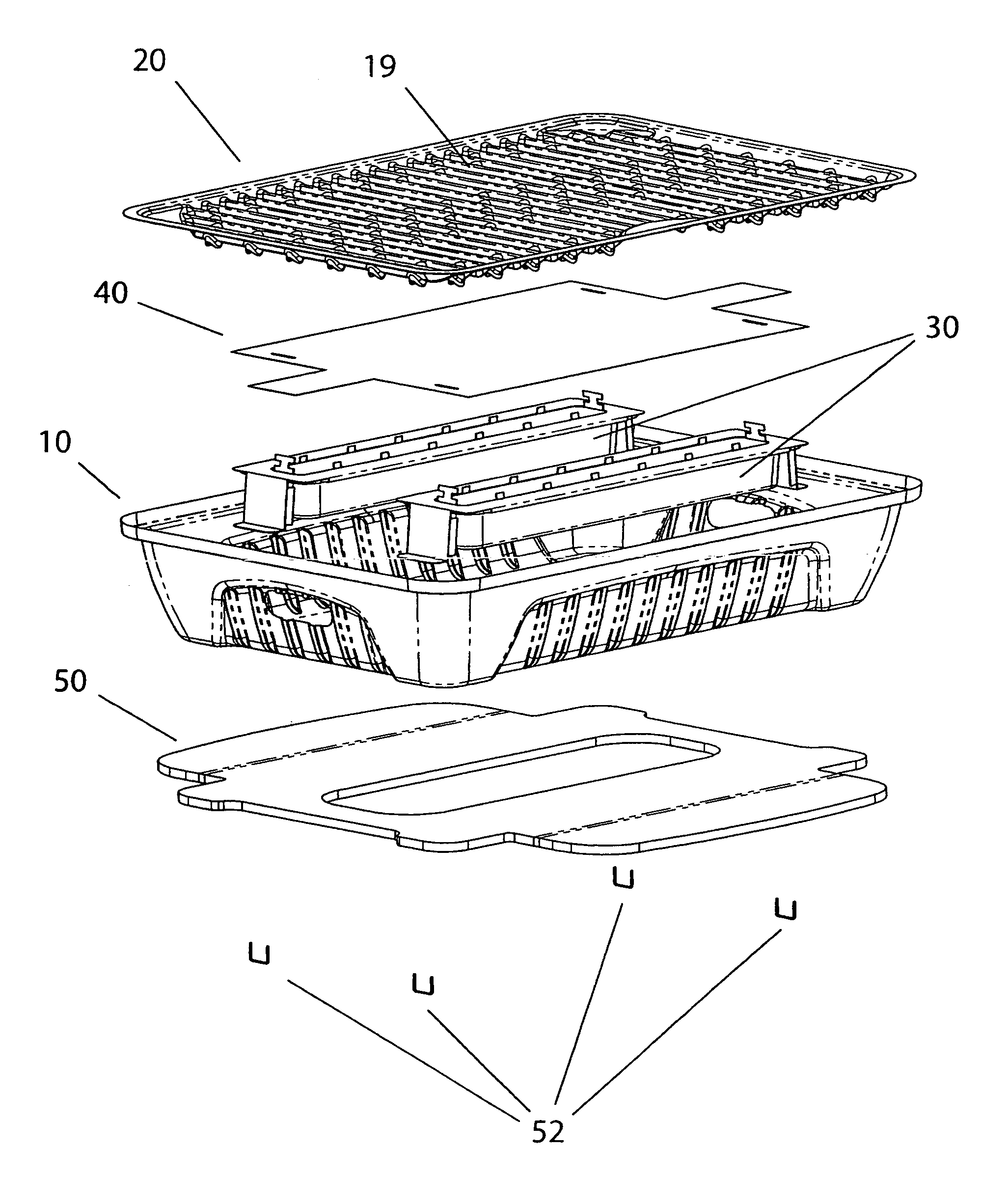

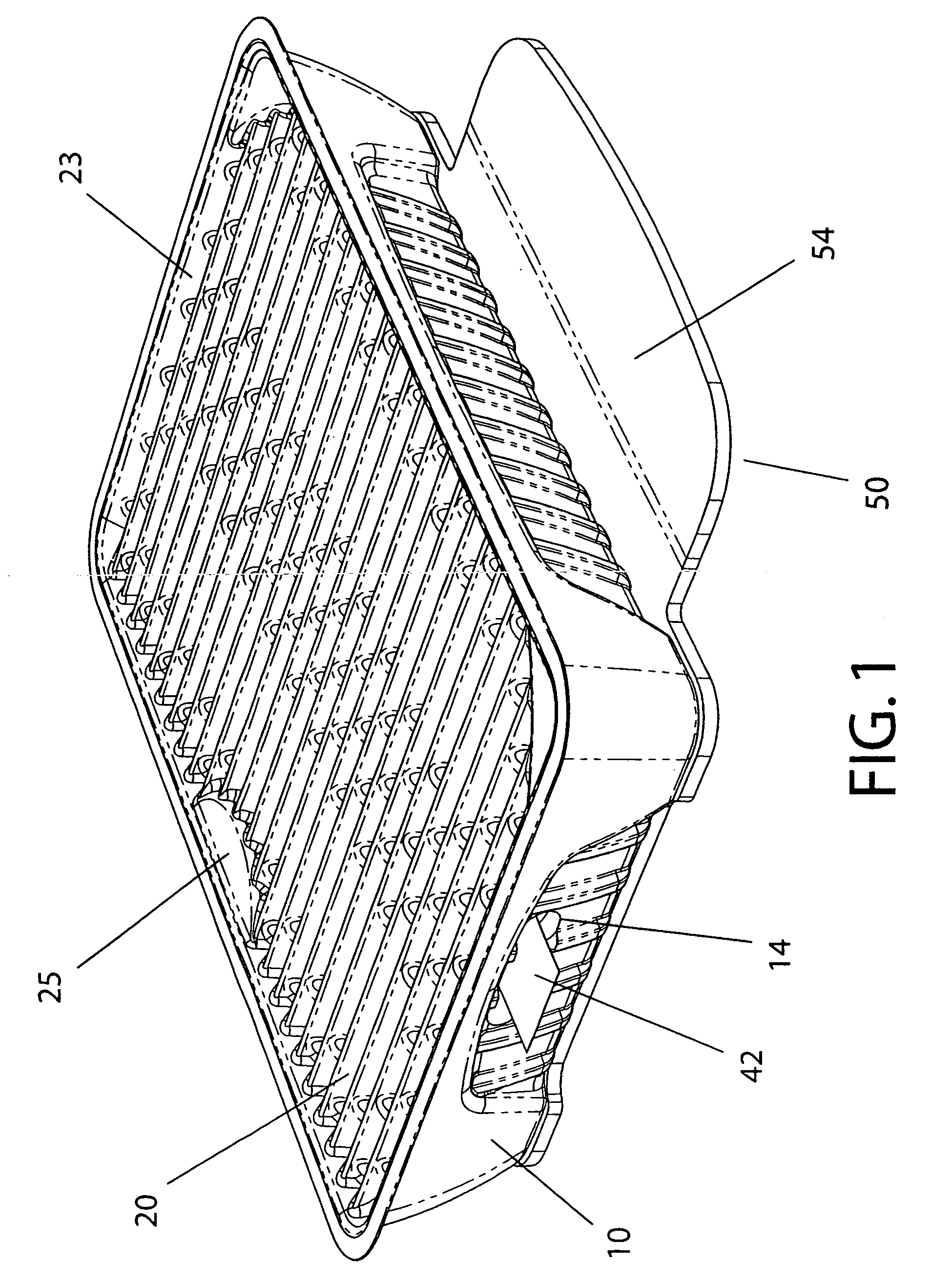

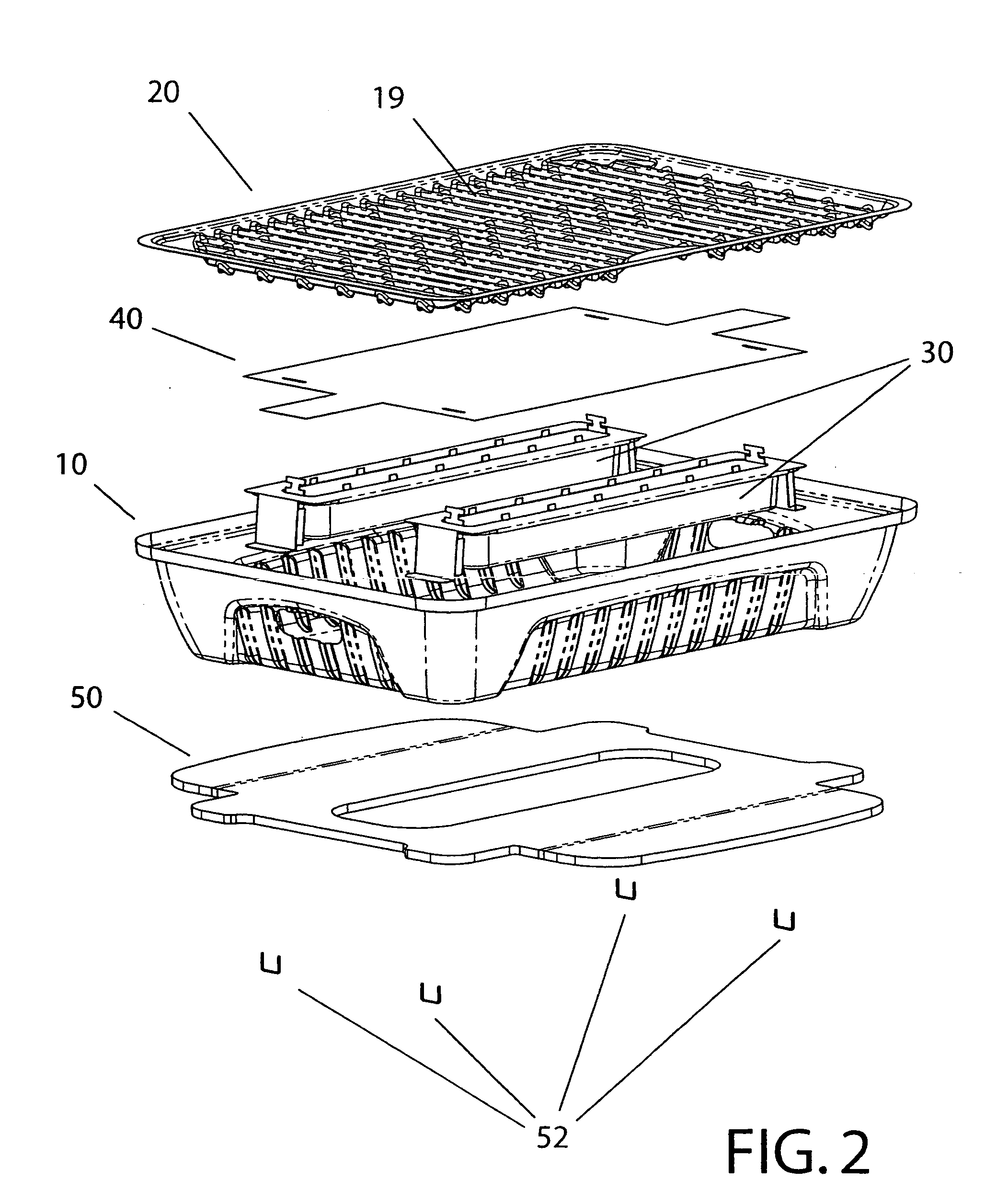

Inclusive single-use cooking apparatus

InactiveUS20060219233A1Large aperturePrevents wickingDomestic stoves or rangesLighting and heating apparatusAlcohol fuelProcess engineering

A single-use cooking apparatus utilizing a non-charcoal fuel source that is all-inclusive in nature; providing all tools, accessories and ignition means necessary for a complete cooking session. The cooking apparatus may be suitably fueled with a semi-solidified or gelled alcohol fuel, which provides immediate and controlled heat, a finite and predictable cooking time period, and rapid cool-down due to the invention's minimal mass and high material efficiency. The device is manufactured with sufficient economy to justify complete discard at the conclusion of the cooking session.

Owner:SOLOGEAR

Semiconductor device and manufacturing method thereof

InactiveUS7687326B2Reduce in quantitySimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceDisplay device

An object of the invention is to provide a semiconductor device and a display device which can be manufactured with improved material efficiency through a simplified manufacturing process, and a manufacturing method thereof. Another object is to provide a technique capable of forming a pattern such as a wiring included in the semiconductor device or display device in a desired shape with good controllability. One feature of a method for manufacturing a semiconductor device is to comprise the steps of forming a layer having a rough surface, forming a region having low wettability by a composition containing a conductive material and a region having high wettability by the composition over the rough surface, and forming a conductive material using the composition in the region having high wettability. Since regions having largely different wettability (regions having a large difference in wettability) can be formed, a liquid conductive or insulating material is attached only to a formation region with precision. Accordingly, a conductive or insulating layer can be precisely formed in a desired pattern.

Owner:SEMICON ENERGY LAB CO LTD

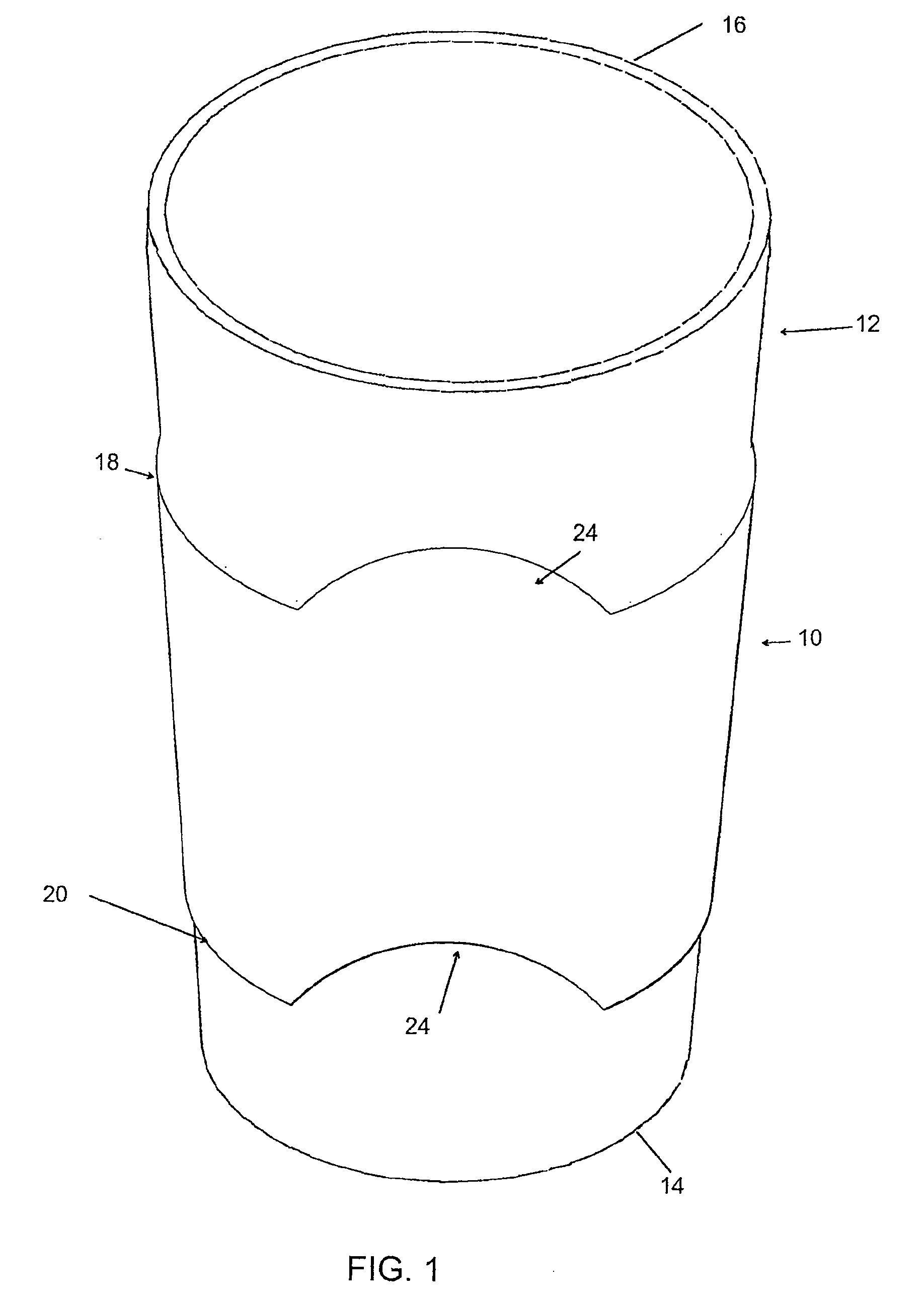

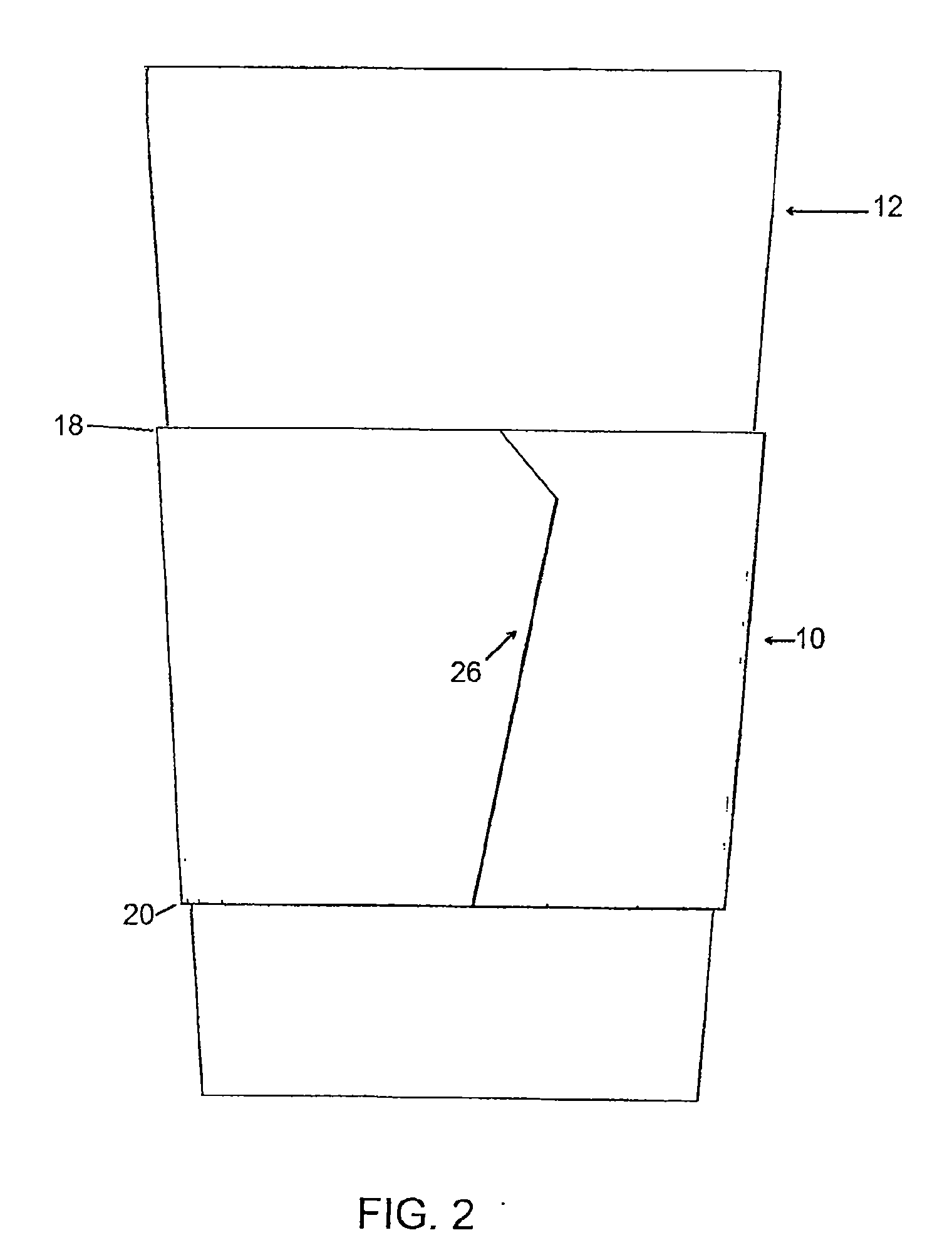

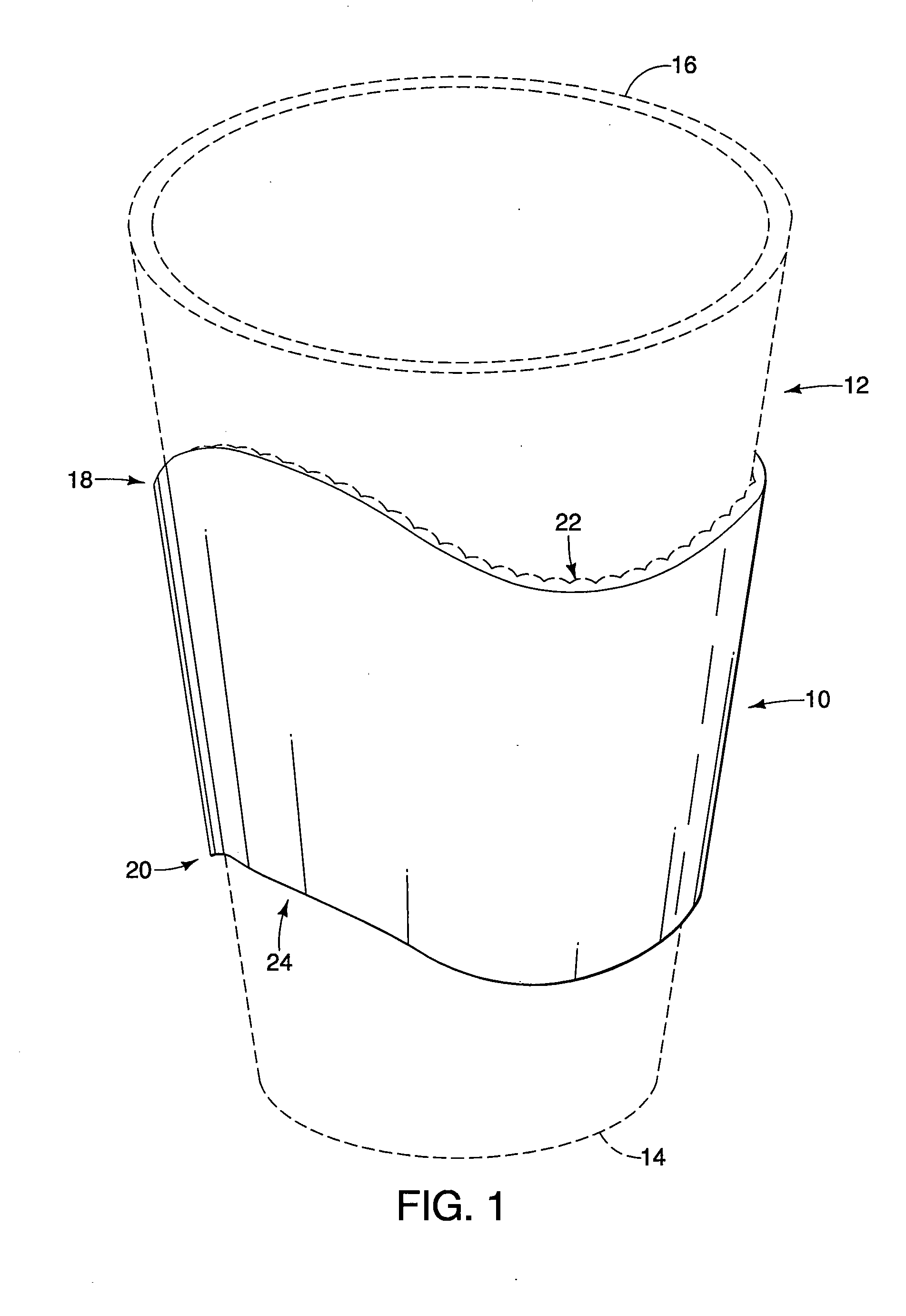

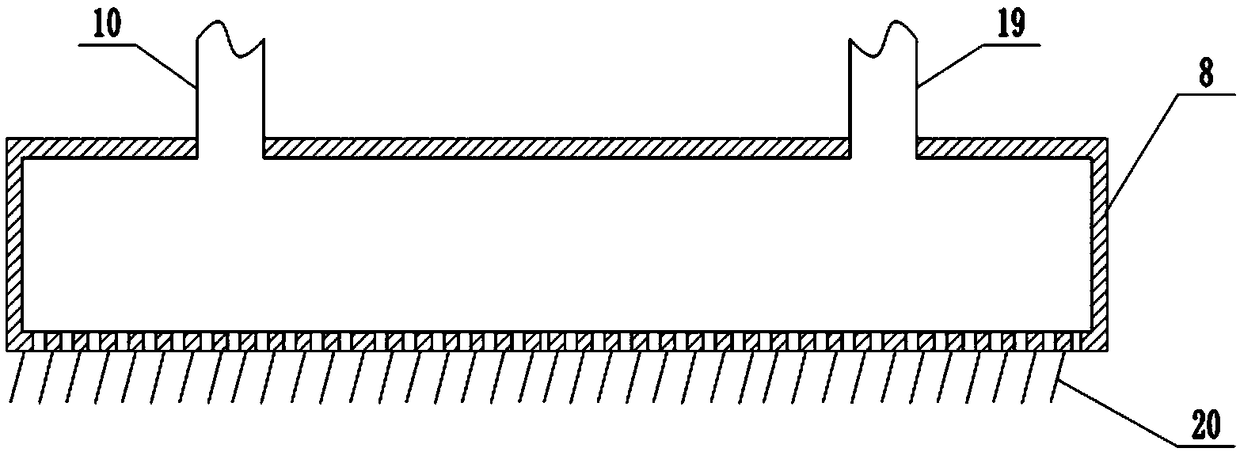

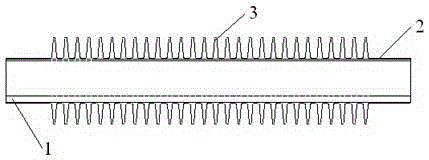

Protective sleeve

InactiveUS20100019023A1Supplement thermal insulating propertyReduce heat transfer rateMechanical working/deformationBoxes/cartons making machineryManufactured materialEngineering

A sleeve is disclosed having a unique arch-like shape that facilitates manufacturing material efficiency and therefore reduces material costs and environmental waste. A blank for a sleeve and a method of making a sleeve are also disclosed. The sleeve, when unassembled and laid flat, is a blank with top and bottom edges. The top and bottom edges have an arch-like formation created by peaks and troughs.

Owner:LBP MANUFACTURING INC

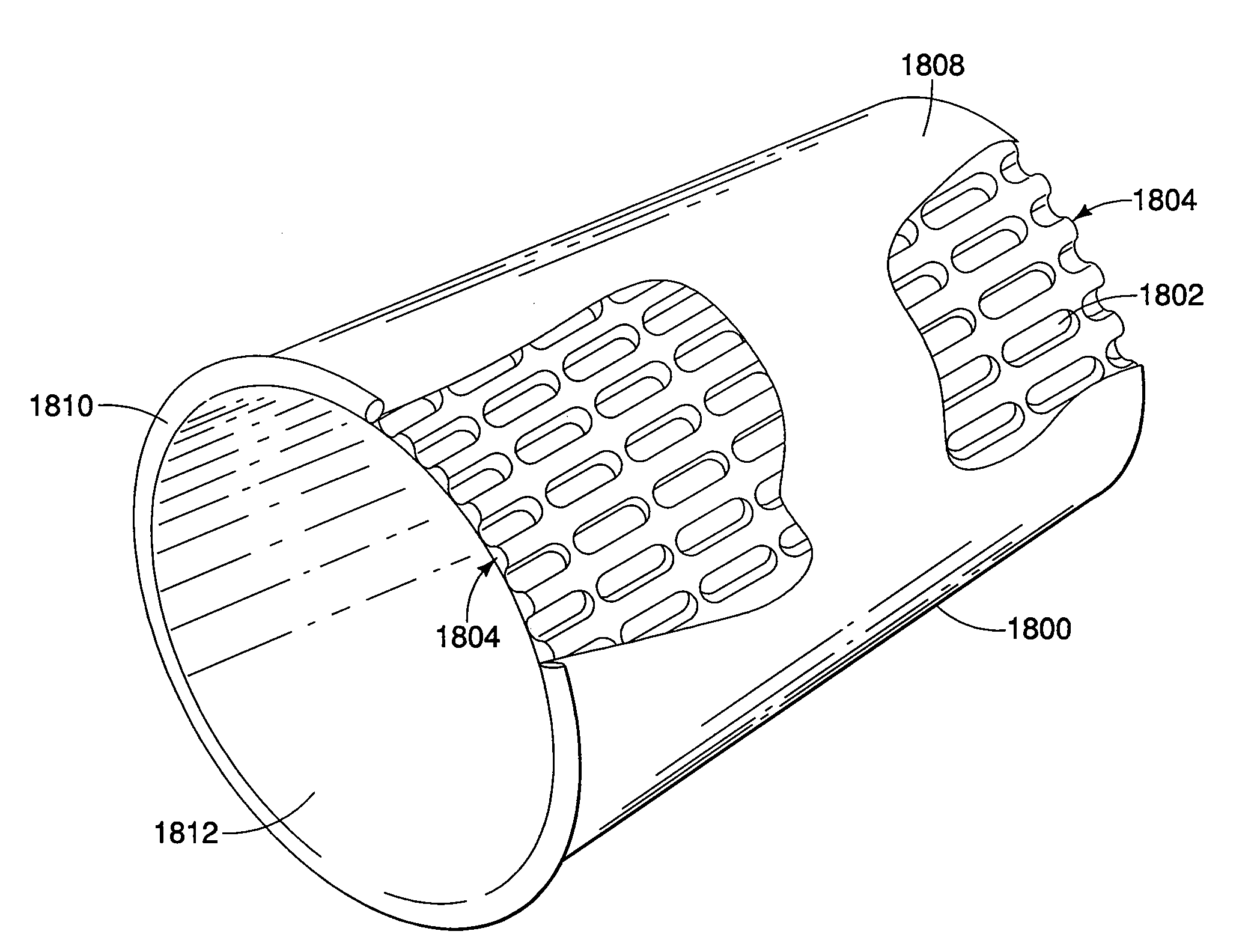

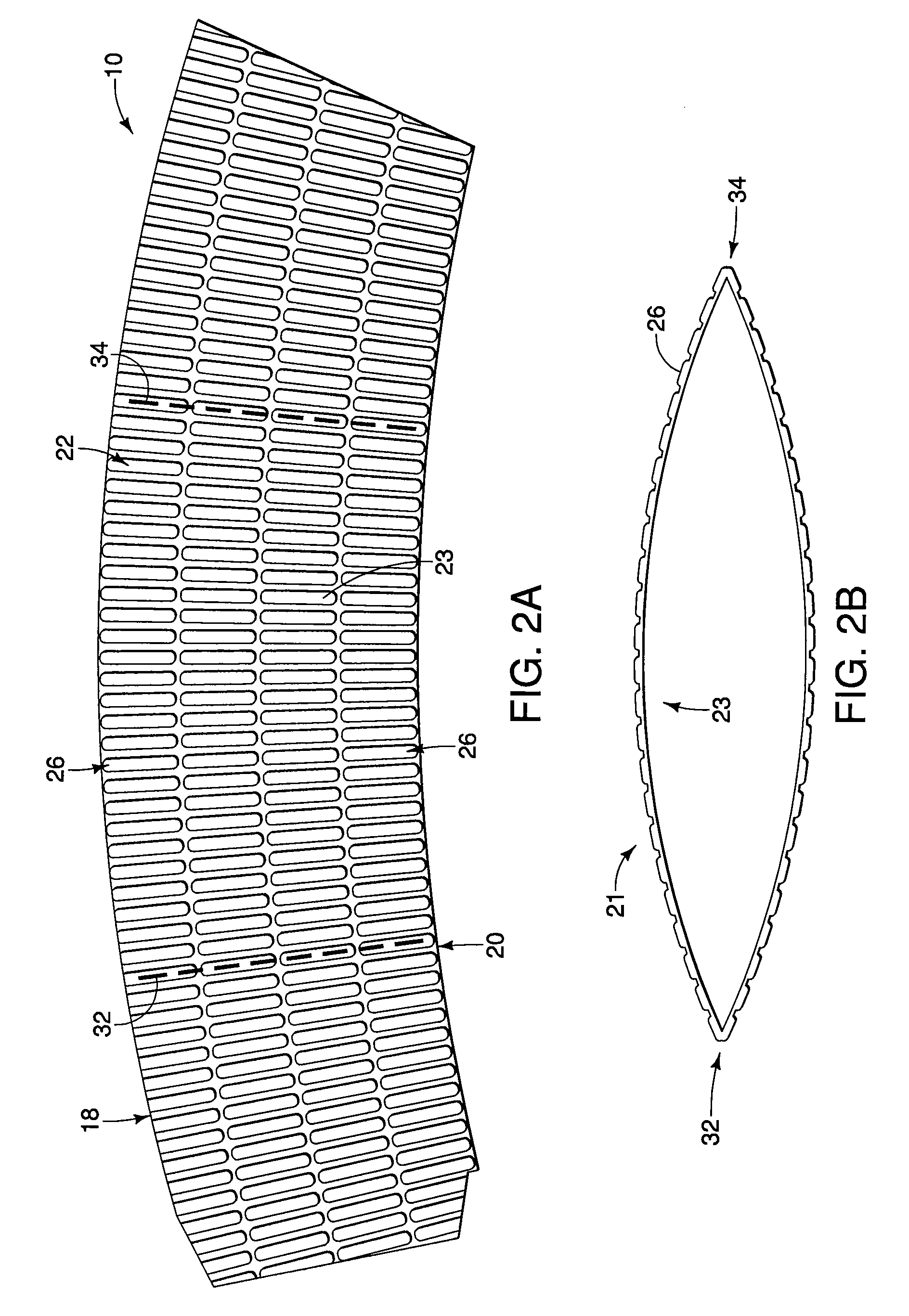

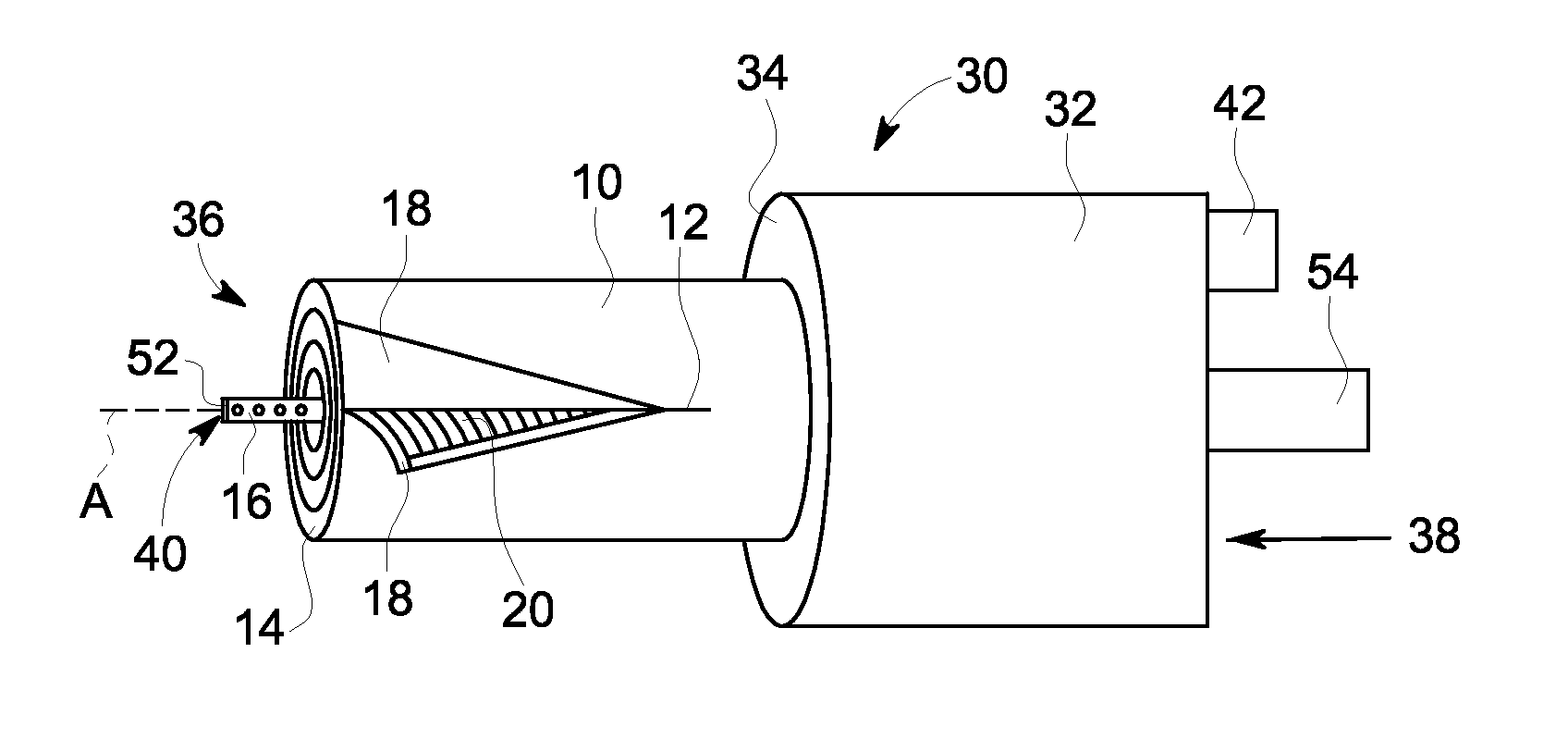

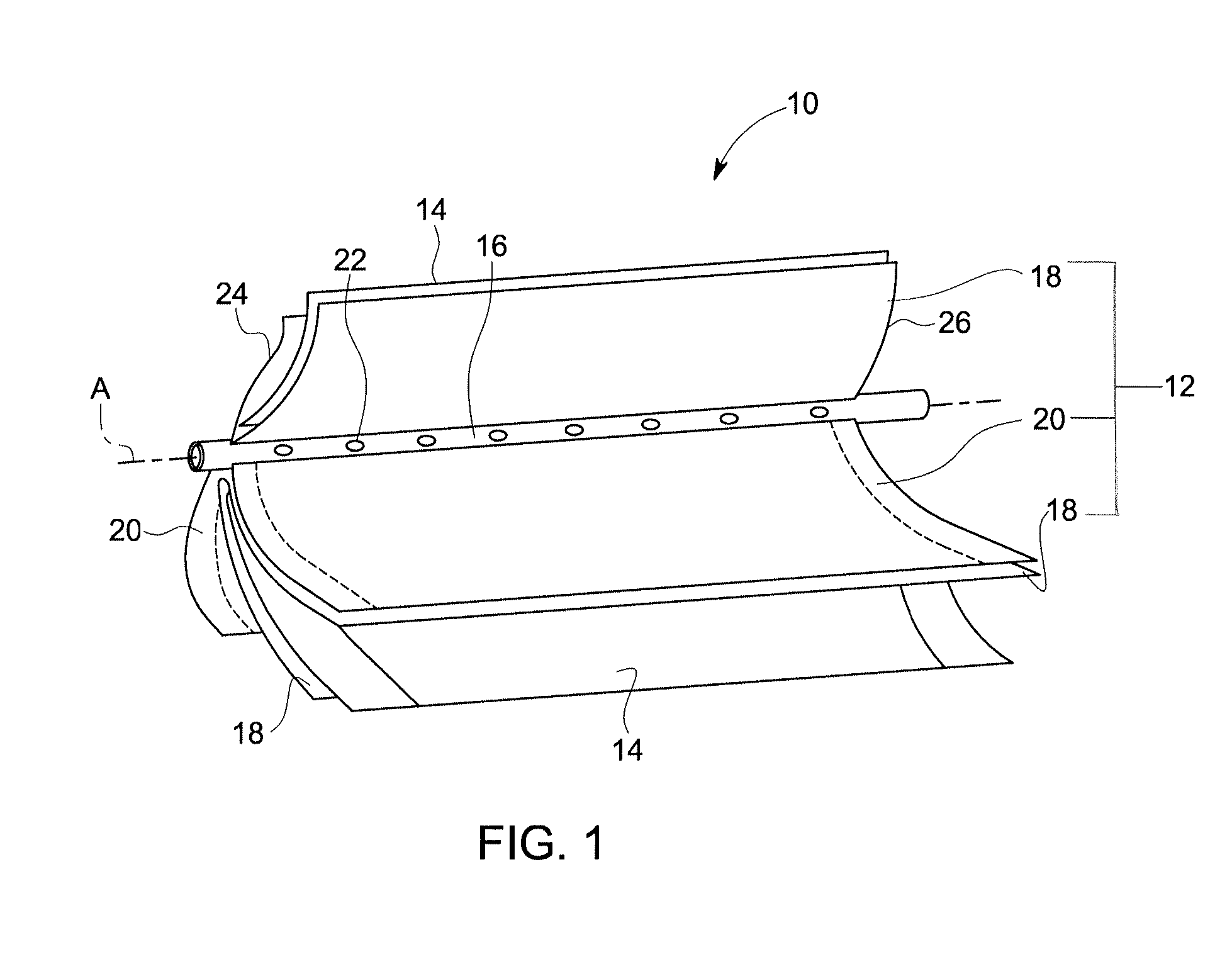

Material efficiency and fabrication of membrane elements

ActiveUS20130098831A1Reduce probabilityReduce delaysMembranesSemi-permeable membranesAdhesiveMaterial efficiency

Membrane elements that use multiple membrane leaves may have a limited total active membrane area due to an increased diameter at the ends of the element. Membrane leaves may comprise a permeate carrier positioned between one or more membrane sheets. Adhesive may be used to seal one or more edges of the membrane leaf. The membrane sheets, permeate carrier and the adhesive contribute to the thickness of the edges of the membrane leaf and the diameter at the ends of the element. A reduced thickness of the edges of the permeate carrier may reduce the diameter at the ends of an element. Another permeate carrier sheet may also be used that is distanced from at least one edge of the membrane sheet so the permeate carrier sheet does not contribute towards the increased diameter at the ends of the element.

Owner:BL TECH INC

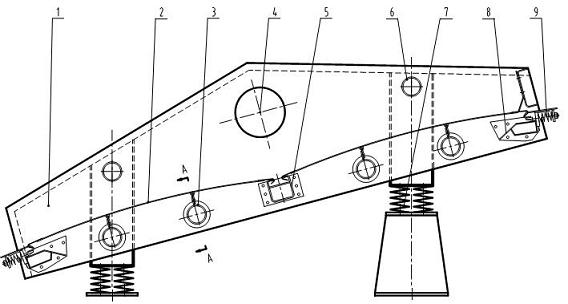

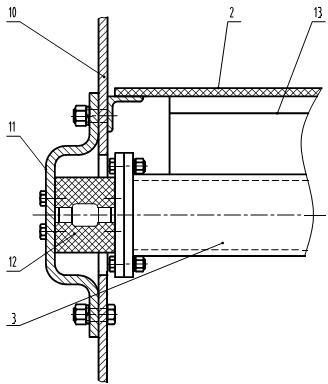

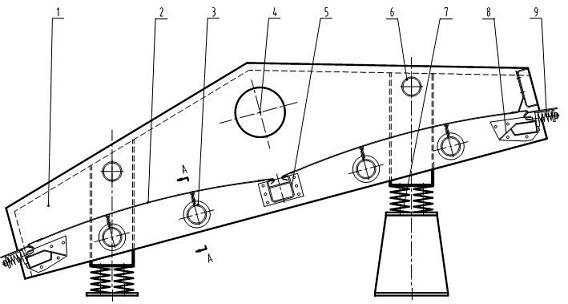

Floating screen vibrating screen

A floating screen surface vibrating screen belongs to the field of vibrating screening machinery. It solves the problems that the screen surface has no secondary vibration, the material is easy to get stuck and the screening efficiency is improved. It is mainly composed of screen frame, screen surface, vibrator, vibration damping support device and motor transmission device. The beams supporting the screen surface include fixed support beams and floating support beams, and the floating support beams are arranged between the corresponding two fixed support beams; the screen surface tensioned along the material flow, both ends are tensioned and fixed on the fixed support beams, and the middle is fixed by the fixed support beam. The floating support beam is supported and has an upward convex arc; both ends of the floating support beam are installed on the side plates of the screen frame through springs. The springs that mount the floating support beams can be rubber shear springs, composite springs or coil springs. The screen surface can be connected and combined by multiple sections of tensioned screen surface. It has the characteristics of long life and good elasticity of the screen surface, the material is not easy to get stuck and the screening efficiency is high. It can be applied to the vibrating screen for screening various materials.

Owner:鞍山重型矿山机器股份有限公司

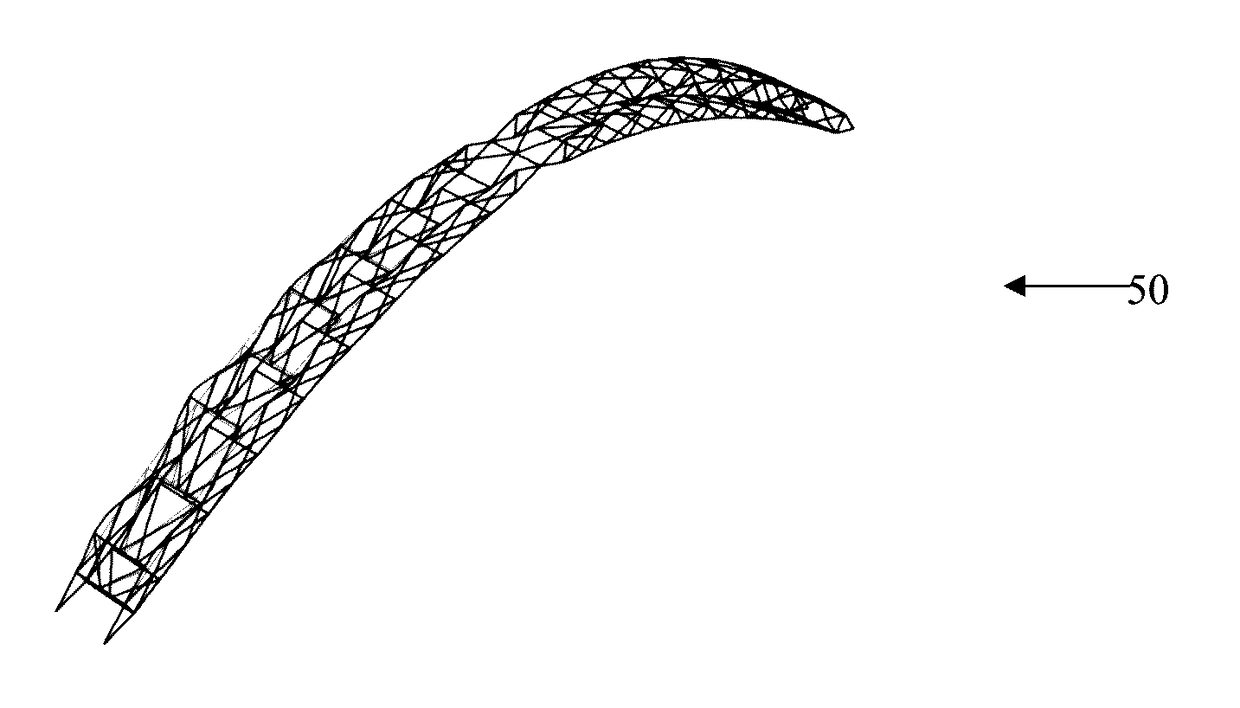

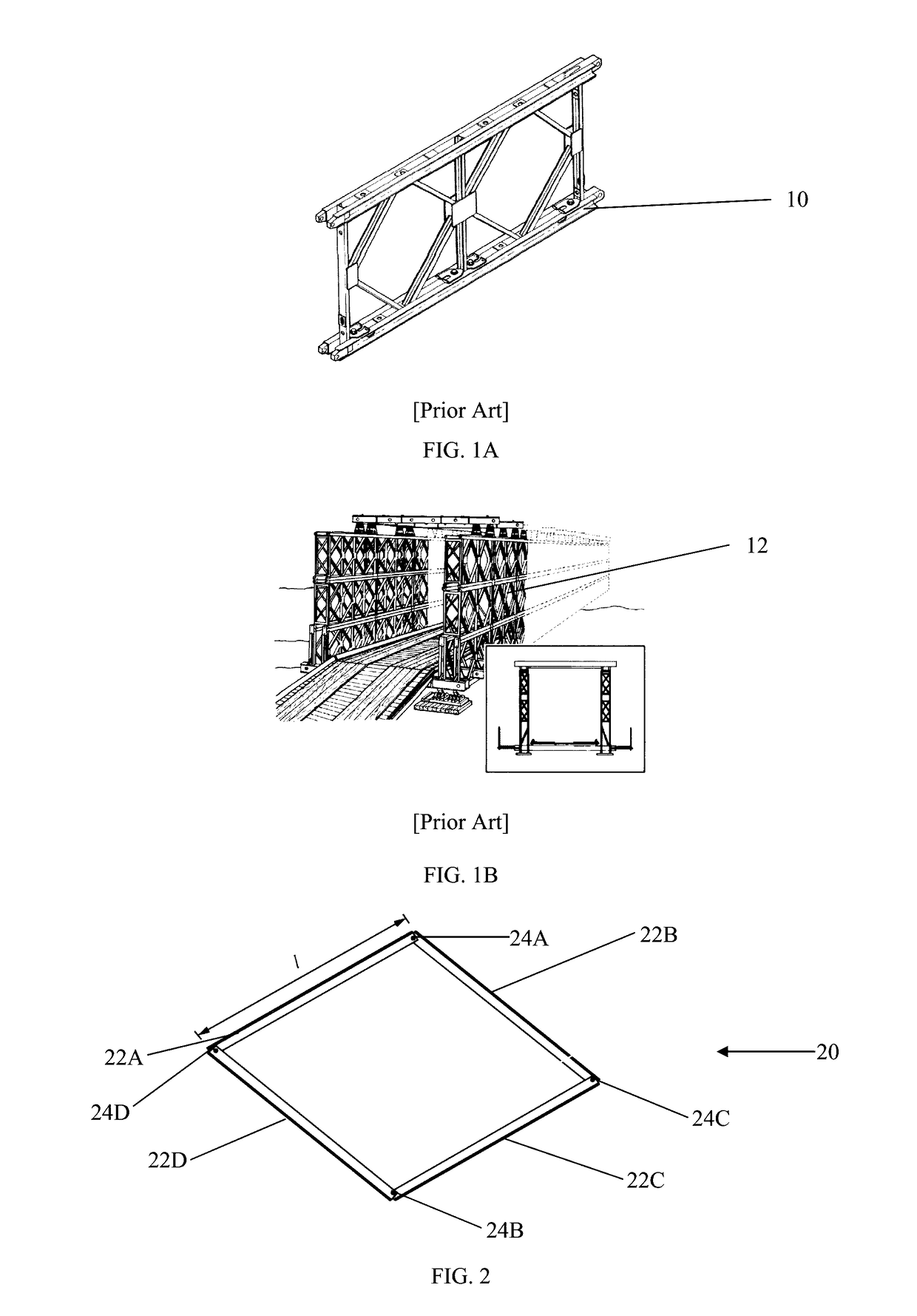

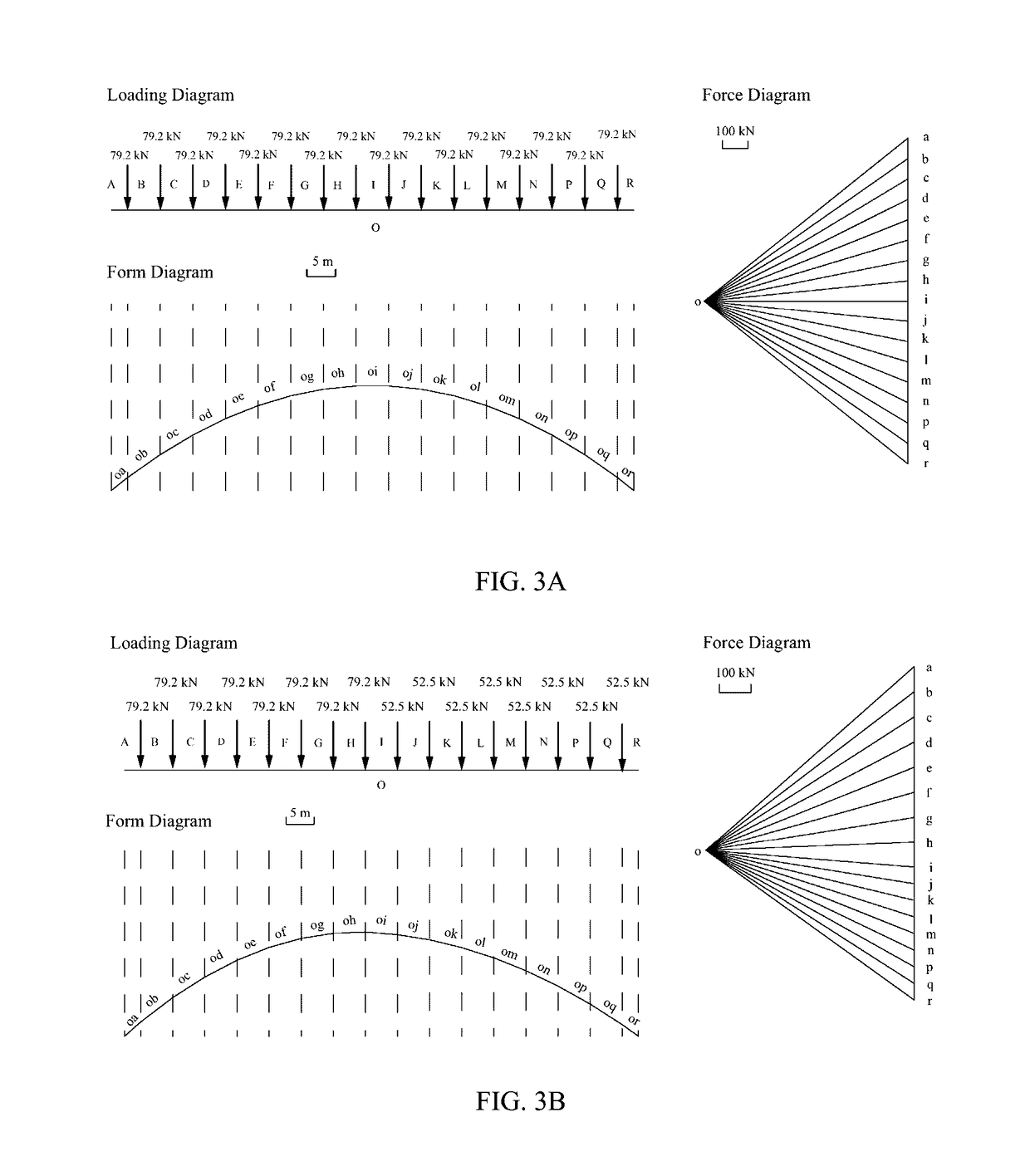

Adjustable Modules for Variable Depth Structures

This disclosure presents a new strategy for modular construction: an adjustable module. This disclosure develops a new adjustable module comprised of a four-bar linkage which can form more efficient variable depth structures. Applications can include rapidly erectable bridges, roofs, buildings, and grid shells, among others. This disclosure provides specific detail related to rapidly erectable bridge applications for variable depth arch forms. Existing rapidly erectable, steel panelized bridge systems have limited material efficiency as they are comprised of rigid modules in a girder-type configuration. This disclosure shows that the module can form variable depth three- and two-hinged arches which increase the material efficiency. The module and other arch components can be made of standard rolled steel sections, thereby forming a versatile, kit-of-parts systems.

Owner:UNIV OF NOTRE DAME DU LAC +1

Semiconductor device and manufacturing method thereof

InactiveCN1815686AAccurate attachmentReduce lossSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceDisplay device

An object of the invention is to provide a semiconductor device and a display device which can be manufactured with improved material efficiency through a simplified manufacturing process, and a manufacturing method thereof. Another object is to provide a technique capable of forming a pattern such as a wiring included in the semiconductor device or display device in a desired shape with good controllability. One feature of a method for manufacturing a semiconductor device is to comprise the steps of forming a layer having a rough surface, forming a region having low wettability by a composition containing a conductive material and a region having high wettability by the composition over the rough surface, and forming a conductive material using the composition in the region having high wettability. Since regions having largely different wettability (regions having a large difference in wettability) can be formed, a liquid conductive or insulating material is attached only to a formation region with precision. Accordingly, a conductive or insulating layer can be precisely formed in a desired pattern.

Owner:SEMICON ENERGY LAB CO LTD

Automatic stock cutter

InactiveCN103112047AImprove material cutting efficiencyEasy to useMetal working apparatusArticle deliveryMechanical engineeringMaterial efficiency

The invention belongs to the technical field of pen point automatic stock cutter appliances. The invention discloses an automatic stock cutter which comprises a machine frame and a feeding motor. A revolving wheel is connected with the feeding motor. A driving rolling is connected with the revolving wheel. A placing rod plate arranged on one side of the driving rolling is arranged on the machine frame. A waster material groove is arranged below the driving rolling. A sliding limiting plate on the other side of the driving rolling is arranged on the machine frame. The sliding limiting plate is connected with a limiting motor. A discharging groove is arranged between the driving rolling and the limiting plate. An air cylinder arranged at two ends of the driving rolling is arranged on the machine frame. The air cylinder is connected with a driven rolling. A pressing device is arranged on the machine frame. The pressing device is connected with a cutter. The cutter is arranged above the position between the driving rolling and the limiting plate. The feeding motor, the limiting motor, the air cylinder and the pressing device are connected with a controlling device. By means of the automatic stock cutter, automatic cutting material mechanization operation is achieved. Cutting material efficiency is greatly improved, thus the automatic stock cutter is safe to use.

Owner:吴鸣寰

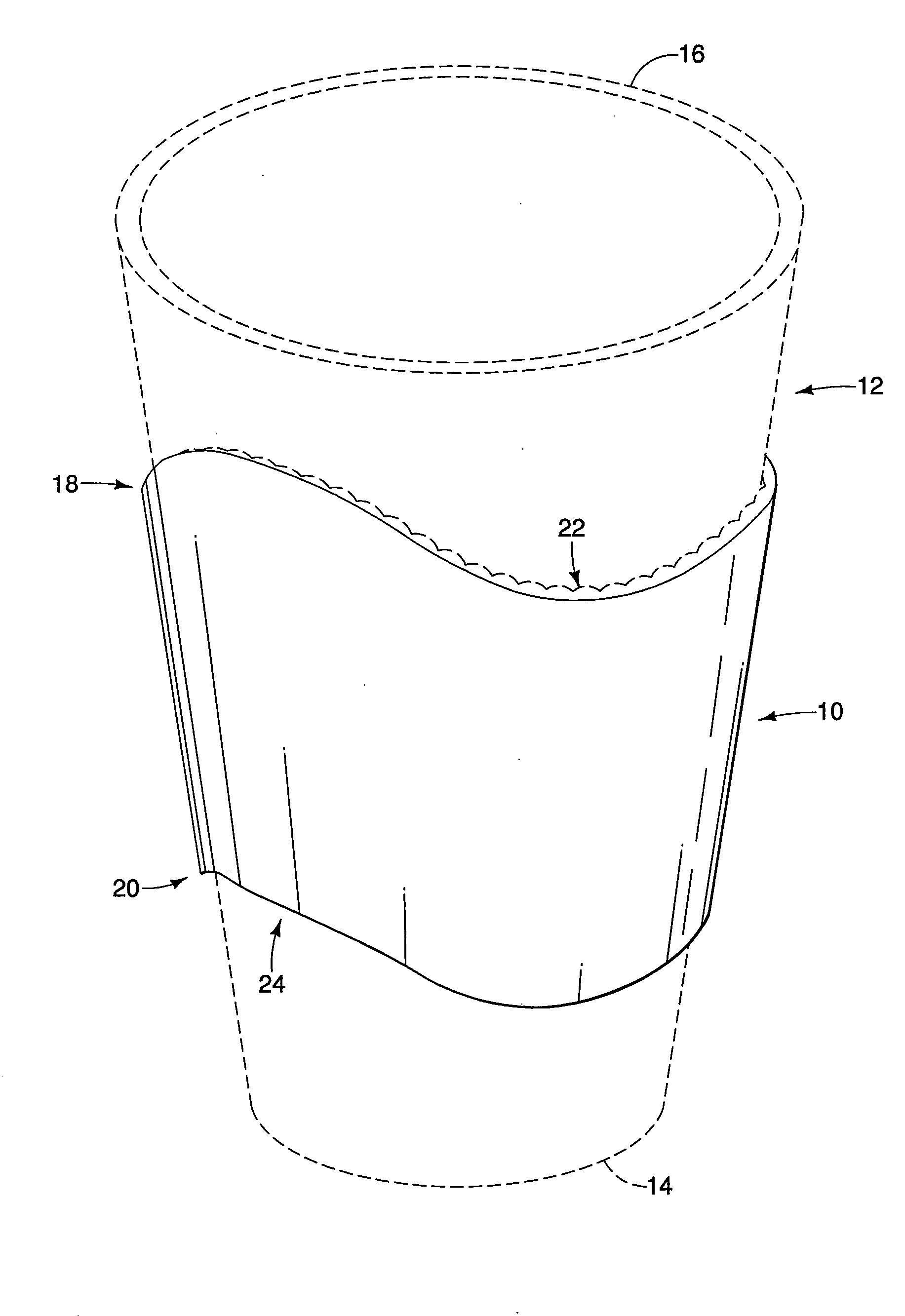

Protective Sleeve

InactiveUS20090283537A1Supplement thermal insulating propertyReduce heat transfer rateBoxes/cartons making machineryContainer/bottle contructionManufactured materialEngineering

A sleeve is disclosed having a unique wave-like shape that facilitates manufacturing material efficiency and therefore reduces material costs and environmental waste. A blank for a sleeve and a method of making a sleeve are also disclosed. The sleeve, when unassembled and laid flat, has a top and bottom edge. The top and bottom edges have a wave-like formation created by peaks and troughs.

Owner:LBP MANUFACTURING INC

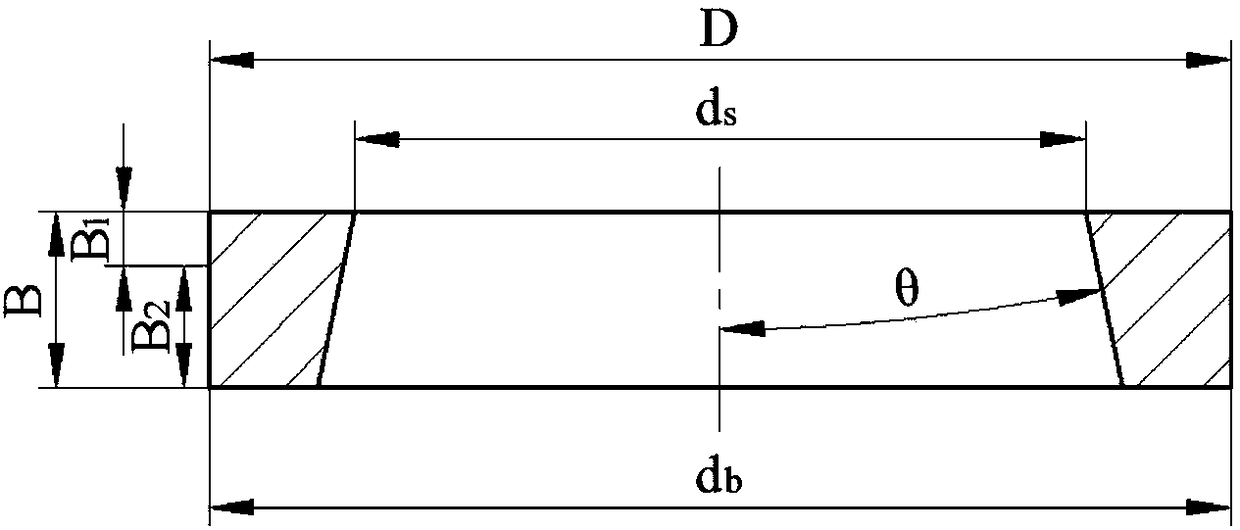

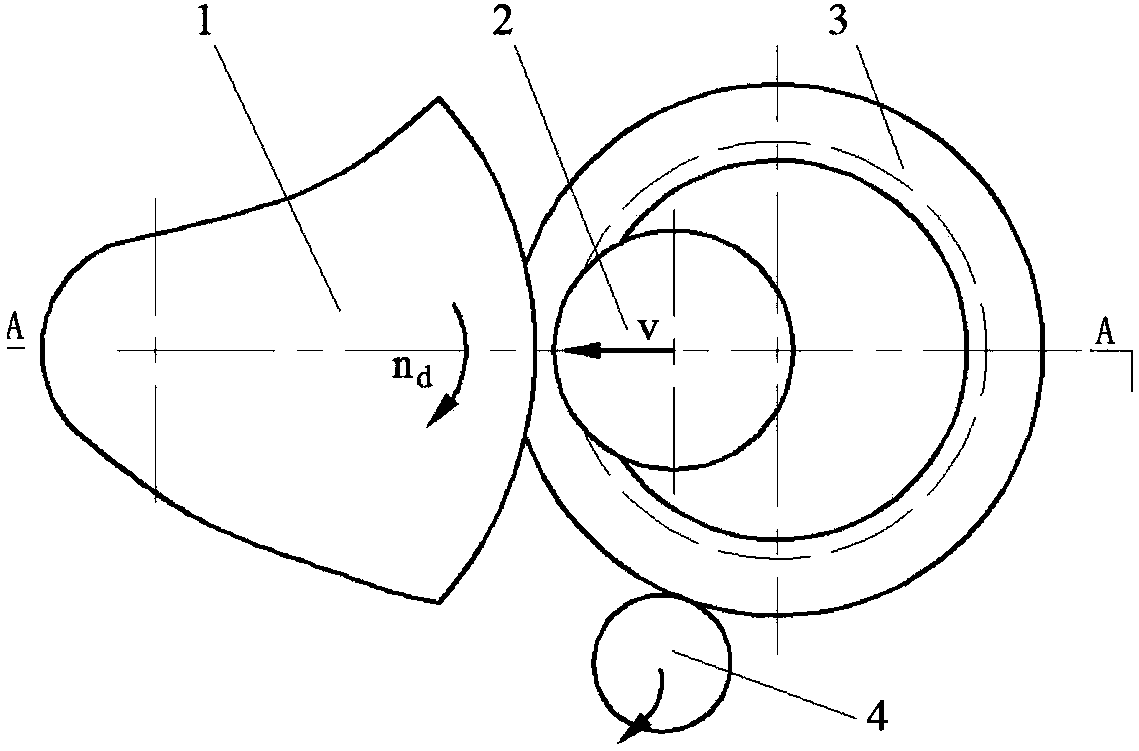

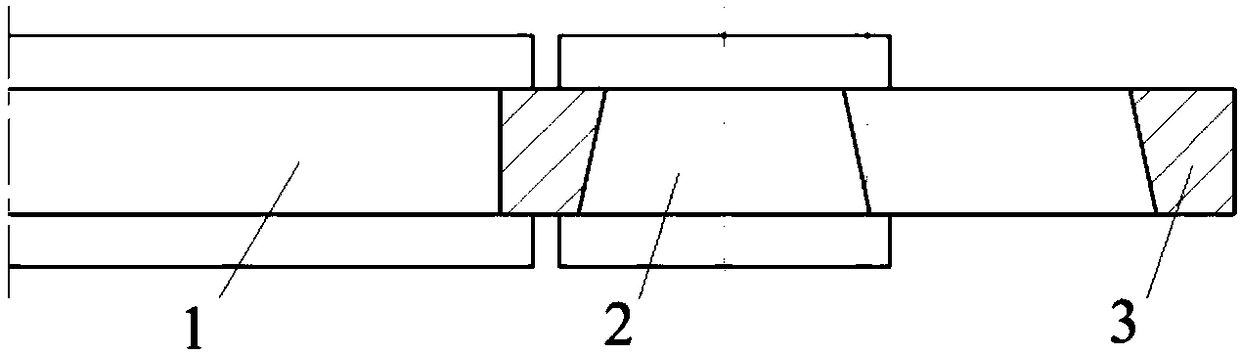

Method for precisely cold-rolling and forming outer ring of tapered roller bearing

InactiveCN108568489AAvoid damageReduce man-hour consumptionMetal rollingEngineeringMechanical engineering

The invention discloses a method for precisely cold-rolling and forming an outer ring of a tapered roller bearing. The method comprises the following steps: S1, designing a ring blank: a ring blank tapered hole and a ring blank cylindrical hole are coaxially arranged in the ring blank, the small-diameter ends of the ring blank tapered hole and the ring blank cylindrical hole are connected, the diameter of the ring blank cylindrical hole is less than the diameter of the small-diameter end of the ring blank tapered hole; S2, cold-rolling and forming: a cold-rolling hole pattern comprises workingsurfaces of a driving roll and core roll, the shape of the working surface of the driving roll and the shape of the outer surface of an outer ring piece are consistent, the shape of the working surface of the core roll and the shape of the inner surface of the outer ring piece are consistent, the driving roll and the core roll are both designed to I-shapes, the ring blank is put between the driving roll and the core roll, the upper end and the lower end of the driving roll and the core roll axially constraint the ring blank, the driving roll does rotating motion, meanwhile, the core roll doesradial feeding motion, and then the ring blank is cold-rolled and formed. The method has the advantages that the forming precision is high and the product quality, the material efficiency and the processing efficiency are improved.

Owner:WUHAN UNIV OF TECH

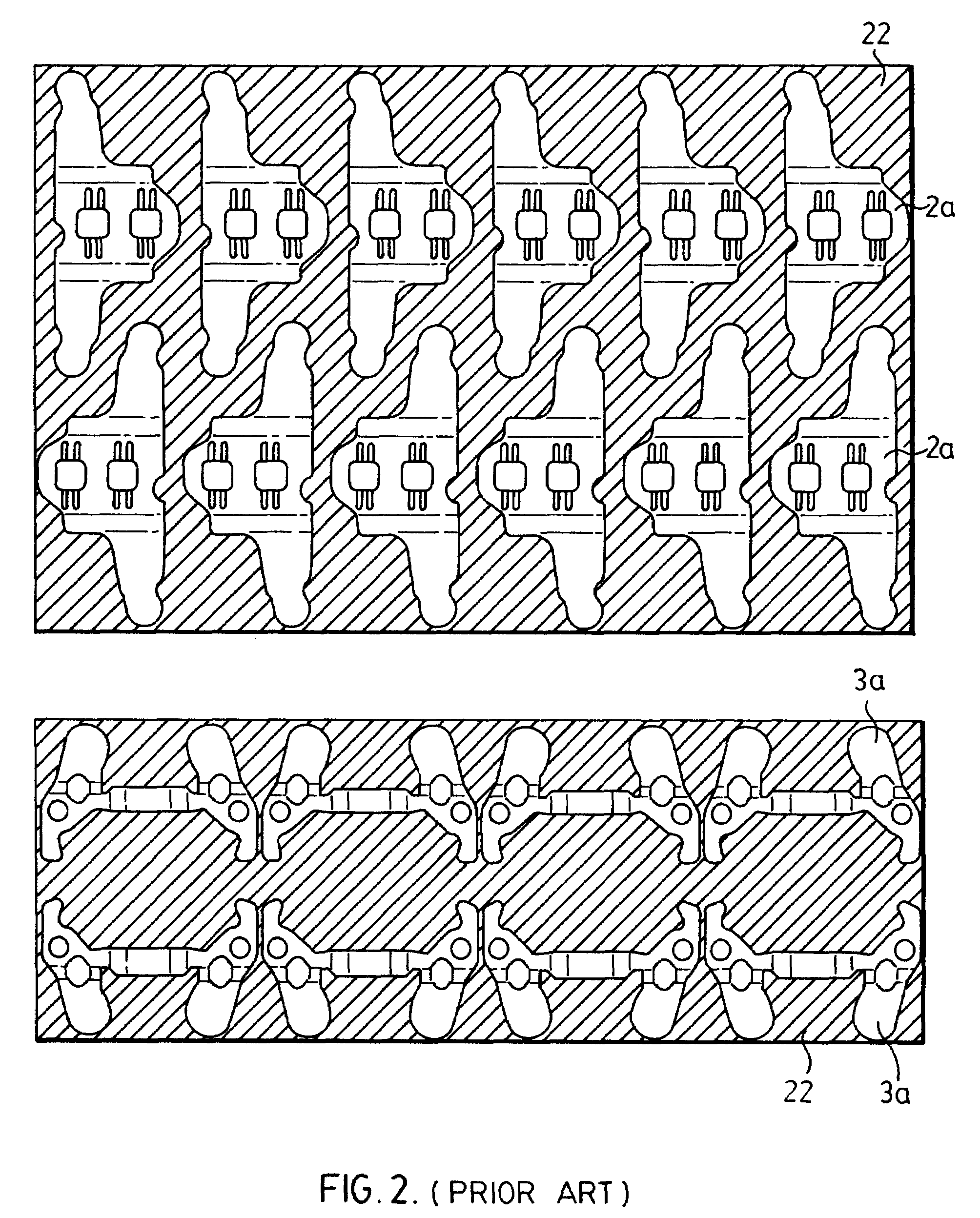

Multiple piece construction automotive door hinge

ActiveUS9863175B2Reduces and eliminates scrapLow material utilizationWing accessoriesPin hingesEngineeringMaterial efficiency

An automotive hinge assembly adapted to facilitate motion of a closure panel relative to a fixed body structure comprises a door component constructed from two press formed angle brackets structurally connected via a pivot pin and adapted to be mounted to a vehicle closure panel, a body component constructed from two press formed angle brackets structurally connected via a simple formed feature and the pivot pin and adapted to be mounted to a vehicle body structure, such that the pivot pin structurally assembles the two hinge components, facilitates relative rotary motion between them and structurally connects the multiple press formed angle brackets so that the resulting assembly achieves a much higher material efficiency than the prior art with an associated significant cost reduction.

Owner:MULTIMATIC INC

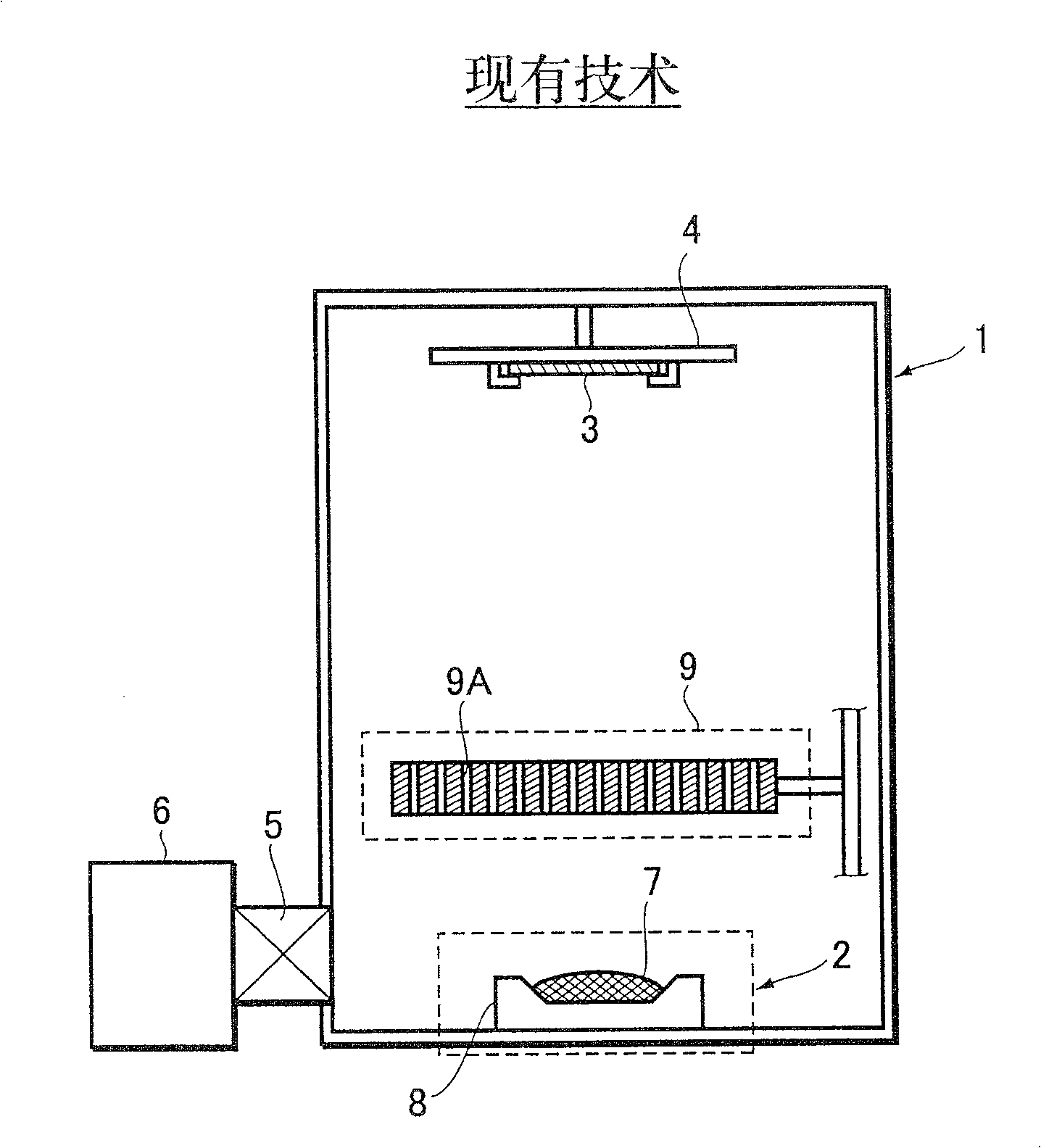

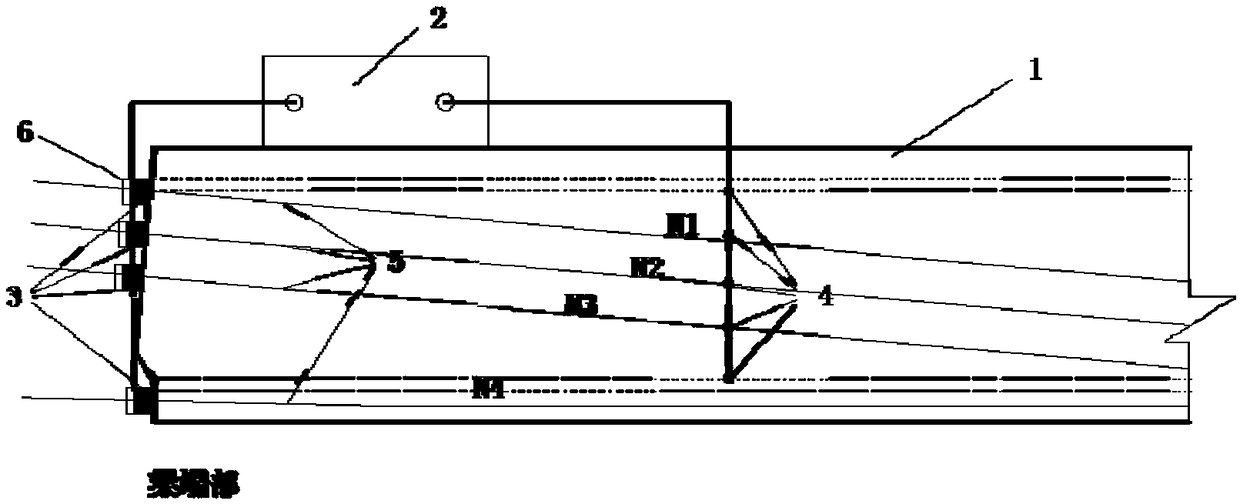

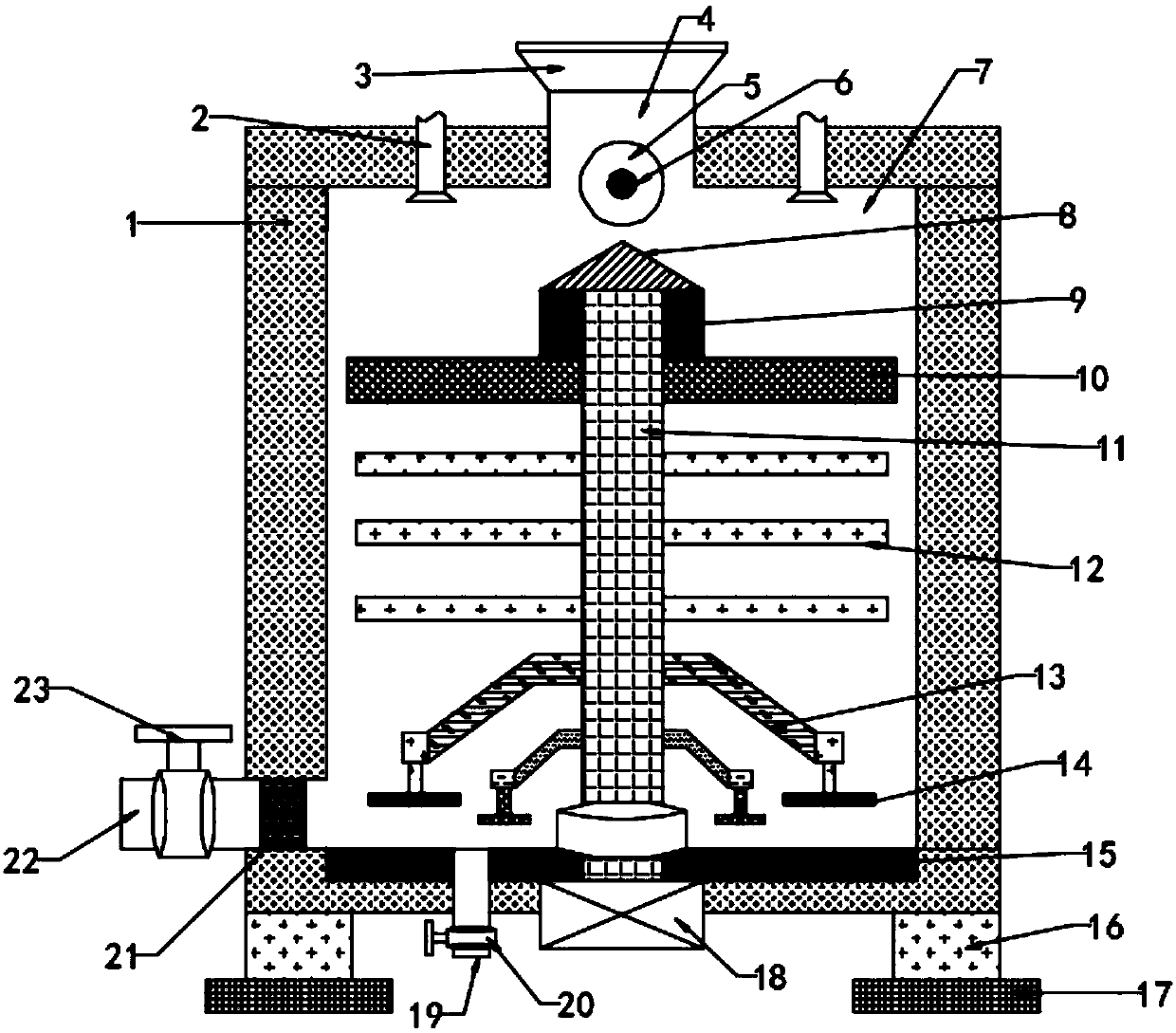

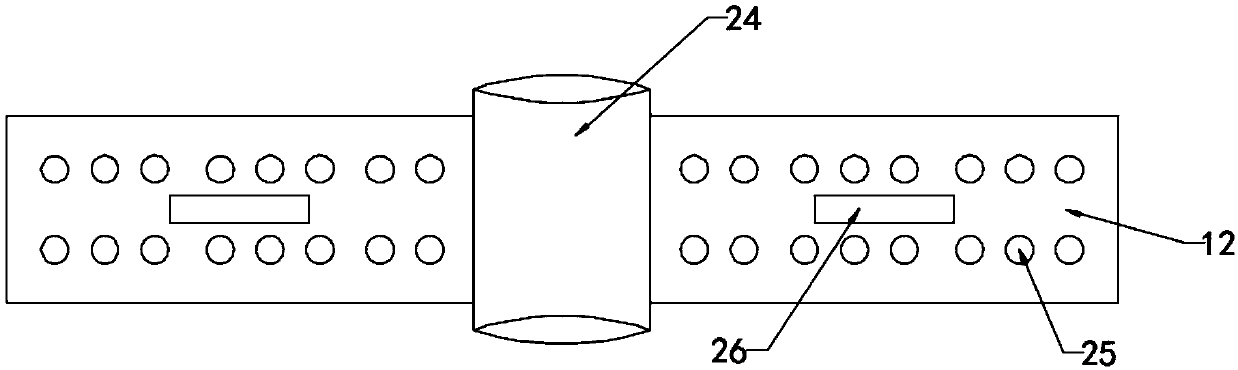

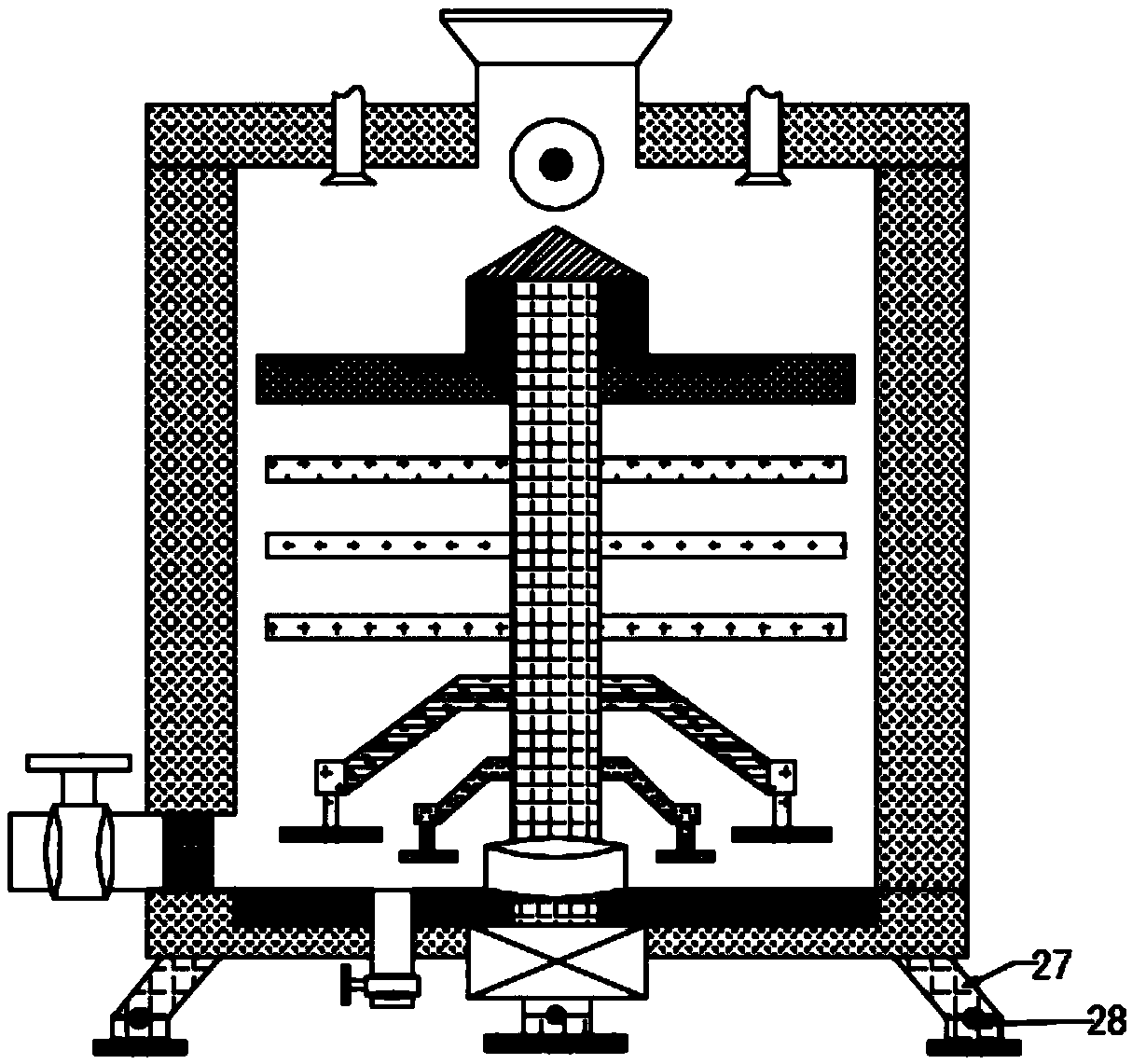

Vacuum evaporator and method for manufacturing organic el display panel using the same

InactiveCN100535175CUniform qualityImprove qualityElectroluminescent light sourcesVacuum evaporation coatingOrganic layerEvaporation

Owner:NIPPON STEEL CHEMICAL CO LTD

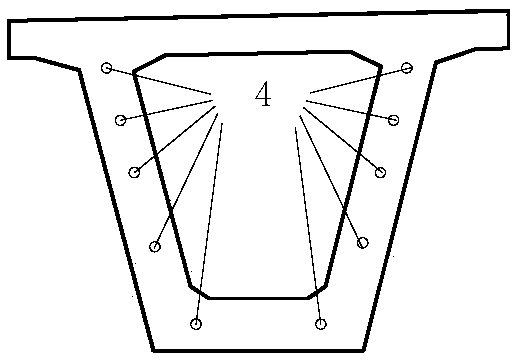

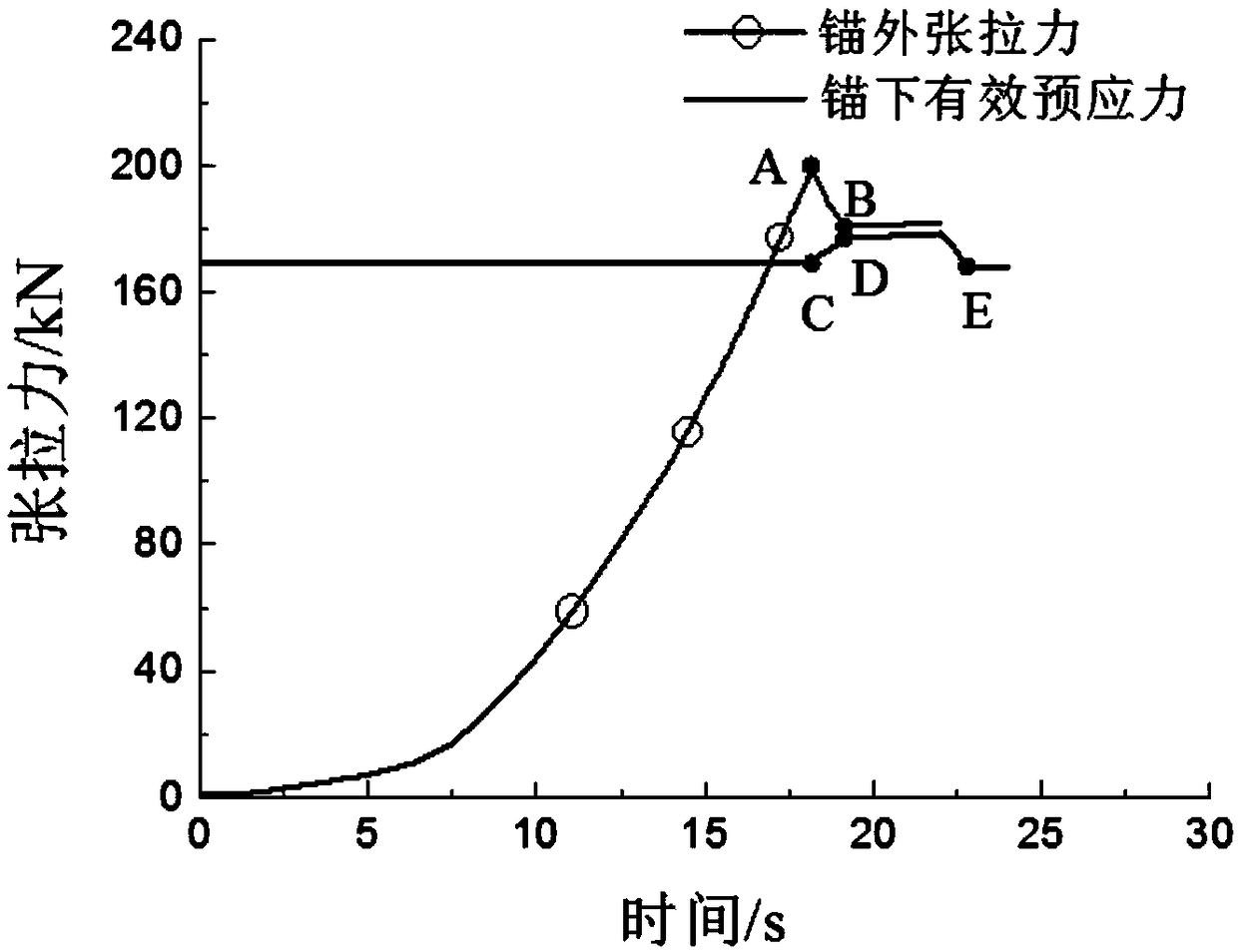

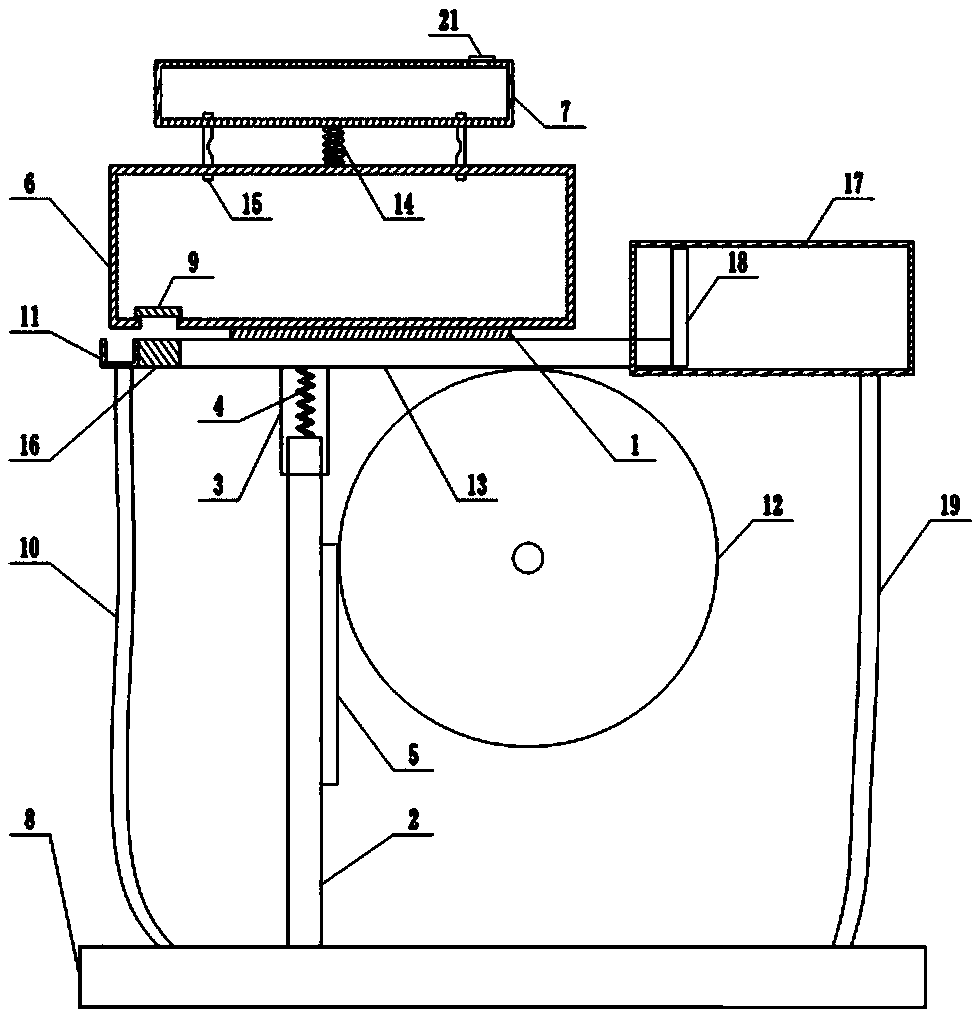

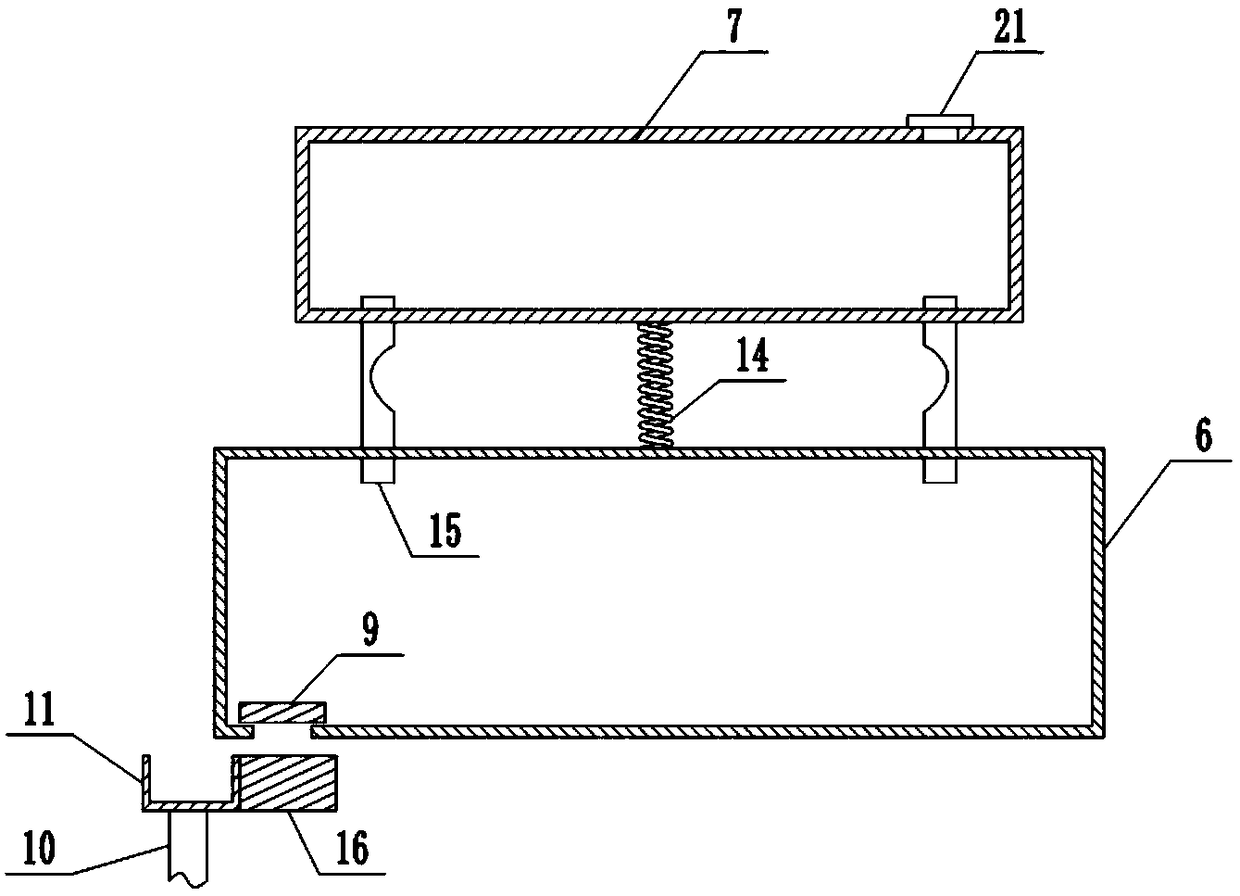

A method and a system for judging the time and temperature effect correction of the pull-out test result

ActiveCN109299498AImprove detection efficiencyImprove detection accuracyDesign optimisation/simulationSpecial data processing applicationsPre stressPre stressing

The invention discloses a method and a system for judging the time and temperature effect correction of the pull-out test result. By performing the temperature effect and the pre-stress change test under the time effect, a typical curve of the effective pre-stress under the anchor with time and temperature effect is drawn. The influence rule of temperature on prestress under anchor is analyzed, and the influence of temperature is eliminated. The variation of prestress under anchor with time is analyzed. A mathematical regression model of effective prestress unde anchor under that influence oftemperature effect and time effect is obtain by data fitting regression of the temperature-corrected test curve. It can quickly and accurately determine whether the stranded wire is qualified, which is conducive to improve the detection efficiency and accuracy of the prestressed stranded wire, give full play to the material efficiency, good economy, and also improve the engineering quality of theactual bridge.

Owner:SHANDONG UNIV +1

An automobile waxing device capable of automatically supplying materials

The invention relates to the technical field of automobile maintenance, Disclosed is an automobile waxing device capable of automatically supplying materials, comprises a frame, wherein the frame is fixedly connected with a support plate, a storage box is arranged on the support plate, a connecting pipe is fixedly connected on the lower surface of the support plate, a jacking rod is slidably connected inside the connecting pipe, a first spring is fixedly connected between the jacking rod and the lower surface of the support plate, the jacking rod is fixedly connected with a brush plate, a plurality of bristles are connected on the lower surface of the brush plate, and a plurality of through holes are arranged on the lower surface of the brush plate; A first rack is fixedly connected to theejector rod, The first rack meshes with a gear, the gear meshes with a second rack, the bottom plate of the storage tank is provided with a feeding port, the bottom plate of the storage tank is slidably connected with the first magnet, the second rack is fixedly connected with the second magnet, the second magnet is fixedly connected with a material receiving groove on the side away from the second rack, and the material receiving groove and the brush plate are communicated with a first hose. The automobile waxing device capable of automatically supplying materials effectively solves the problems that the waxing machine in the prior art needs artificial waxing material in the waxing process, the waxing material efficiency is low, and the working efficiency is affected.

Owner:浙江信基科技有限公司

Additive material device and method

ActiveCN111151742AReduce distortionReduce porosityAdditive manufacturing apparatusProcess engineeringMechanical engineering

The invention provides an additive material device and method, and relates to the technical field of solid-phase additive materials. The device comprises a supply part, a stirring piece and a bearingpiece. The supply part comprises a storage box and a supply rod which are in communication. The stirring piece is provided with a stirring shaft, the stirring shaft is provided with a first hollow cavity, the supply rod and the stirring shaft are coaxially arranged, and a discharging port of the supply rod communicates with the first hollow cavity. The storage box and the stirring piece are connected with the bearing piece and can move along with movement of the bearing piece, and accordingly, after materials extruded by the supply rod are rubbed and ground through the stirring shaft, an additive material layer is formed. By means of the device, the stirring friction additive material automatic process can be achieved, the additive material efficiency is improved, and the additive materialprocess is simplified. The additive material method adopts the above additive material device and is conducted mainly according to the following steps that the materials in the storage box are conveyed out through the supply rod, and the stirring shaft conducts friction grinding on the conveyed-out materials. The method has the advantages that the material application range is wide, efficiency ishigh, the structure performance of the additive material layer is excellent, high efficiency and green are achieved, pollution is avoided, and deformation is little.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

Rapid part prototyping method for refractory materials

InactiveCN105798294AImprove compactnessArbitrarily increasing complexityIncreasing energy efficiencySelective laser meltingMicrometer

Provided is a rapid part prototyping method for refractory materials. The technical defects that a powder metallurgy (PM) forming mode is complex and wastes time, and the liquid phase amount cannot reach the technical index of compactness and the comprehensive performance of alloy cannot be given to full play by means of a selective laser melting (SLM) method can be overcome. The rapid part prototyping method includes the steps that 1, a CAD model for a part is designed through three-dimensional modeling software, then multi-layer slicing information is generated through slicing processing software and stored as an STL file, and data of the STL file are transmitted to an SLM rapid prototyping system; 2, a layer of metal powder (with the particle size being about 50 micrometers) to be machined is laid on a working platform through a powder feeding mechanism, and the thickness of the layer of metal powder is 0.52 mm; and 3, a fiber laser is adopted for scanning and slicing, the metal powder to be machined which is laid in the step 2 is molten, and the scanning speed is 800 mm / s. The rapid part prototyping method has the beneficial effects that the powder is alloyed, the binding force of alloy is increased, liquid filling and prototyping compaction are better facilitated, and therefore the comprehensive performance of the alloy is improved. According to the method, time is saved, and material efficiency is higher.

Owner:HARBIN RUNDE WEIYE TECH DEV

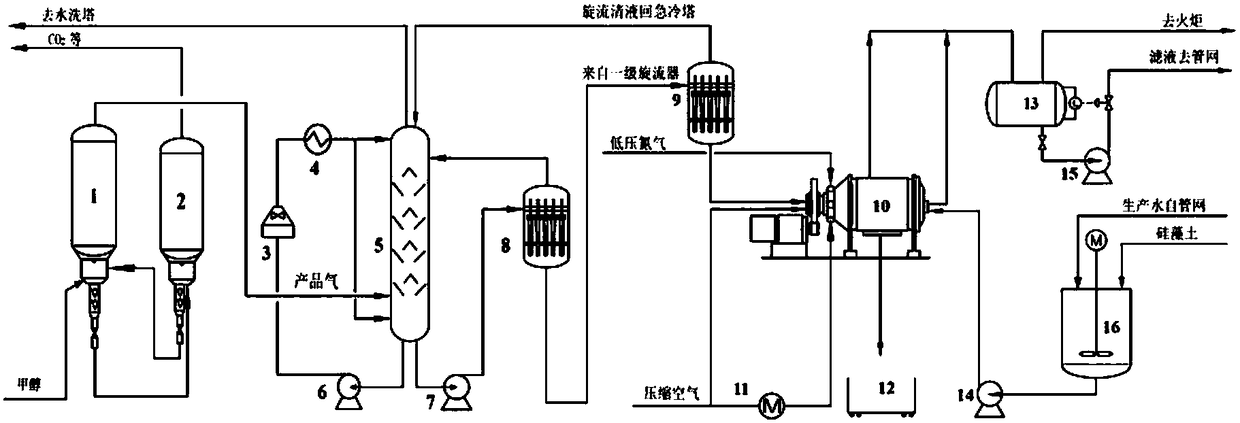

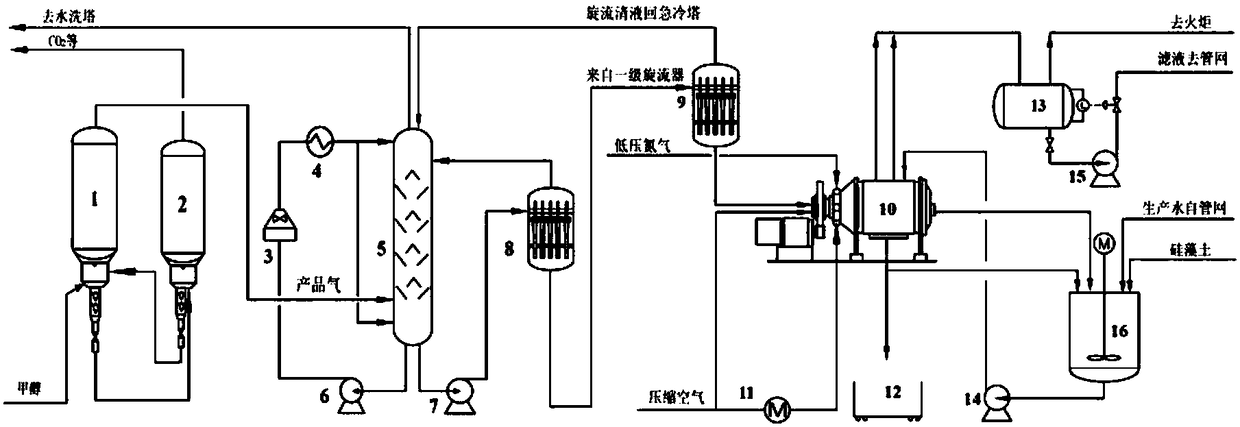

Pre-coating material efficiency increasing and consumption reducing method and pre-coating material efficiency increasing and consumption reducing apparatus in MTO quenching water pre-coating pressure filtration separation system

InactiveCN108325273ASave industrial waterLow solid contentHydrocarbon from oxygen organic compoundsFiltration separationCycloneFilter press

The present invention relates to a pre-coating material efficiency increasing and consumption reducing method and a pre-coating material efficiency increasing and consumption reducing apparatus in anMTO quenching water pre-coating pressure filtration separation system, and provides a pre-coating material efficiency increasing and consumption reducing method in an MTO quenching water pre-coating pressure filtration separation system, wherein the pre-coating material efficiency increasing and consumption reducing method comprises that (i) an auxiliary filtration agent is added to an auxiliary filtration agent stirring tank (16), the obtained material is fed into to the pre-coating unit chamber of a filter press (10), and a pre-coating is formed on a filtration cloth; (ii) a catalyst suspension concentrated by a two-stage cyclone (9) enters the filter press (10), and filtering is performed on the pre-coating; (iii) at the early stage of filtration, the filter cake returns to the auxiliary filtration agent stirring tank (16), and is mixed with the auxiliary filtration agent so as to be used as the new auxiliary filtration agent, and the new auxiliary filtration agent enters the next cycle of the auxiliary filtration process; (iiii) the filtration specific resistance of the pre-coating is increased after the cycle is performed for a certain time, and when the pressure of a filtrateinlet is increased to achieve a set value, a material discharge port is switched to a filter cake collection tank (12) so as to discharge the filter cake. The invention further provides a pre-coatingmaterial efficiency increasing and consumption reducing apparatus in an MTO quenching water pre-coating pressure filtration separation system.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

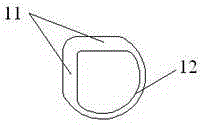

Tower cross arm member

The invention discloses a tower cross arm member, comprising a frame, a protective layer covering the outer surface of the frame, and a shed group cast outside the protective layer. The section of the frame is D shaped, formed of two mutually perpendicular right-angle sides and an arc. The frame is formed by connecting steel angels or plates. The tower cross arm member according to the above manner has the advantages such as high mechanical strength, high rigidity, low deformation, weatherability, stressing reasonableness, material efficiency and cost efficiency and is applicable to 500 kV overhead transmission lines.

Owner:CHANGSHU FENGFAN POWER EQUIP

Efficient chemical raw material stirring cylinder

InactiveCN109647277APracticalImprove stirring efficiencyRotary stirring mixersTransportation and packagingChemical industryEngineering

The invention discloses an efficient chemical raw material stirring cylinder, and belongs to the field of chemical industry. The efficient chemical raw material stirring cylinder comprises a shell anda stirring cylinder inner cavity. The upper end of the shell is provided with a water inlet pipe and a feeding structure. Supporting legs are arranged at the lower end of the shell. A waste materialchannel and a servo motor are sequentially installed between the supporting legs from left to right. The upper end of the servo motor is connected with a rotating shaft. The upper side of the lower end of the shell is provided with a thickened material layer. The upper end of the rotating shaft penetrates through the thickened material layer and extends into the stirring cylinder inner cavity. Therotating shaft is sequentially provided with a shaft cover, a bearing, a filter screen, a stirring bar and a stirring rack from top to bottom. The efficient chemical raw material stirring cylinder isreasonable in structural design and high in practicability; due to the unique structural design of the stirring bar of the stirring cylinder, the chemical material even mixing and stirring efficiencyis enhanced, the resistance of the chemical materials to the stirring bar is reduced, and the efficient chemical raw material stirring cylinder is high in chemical material stirring and mixing efficiency and worthy of use and popularization in the chemical production field.

Owner:张磊

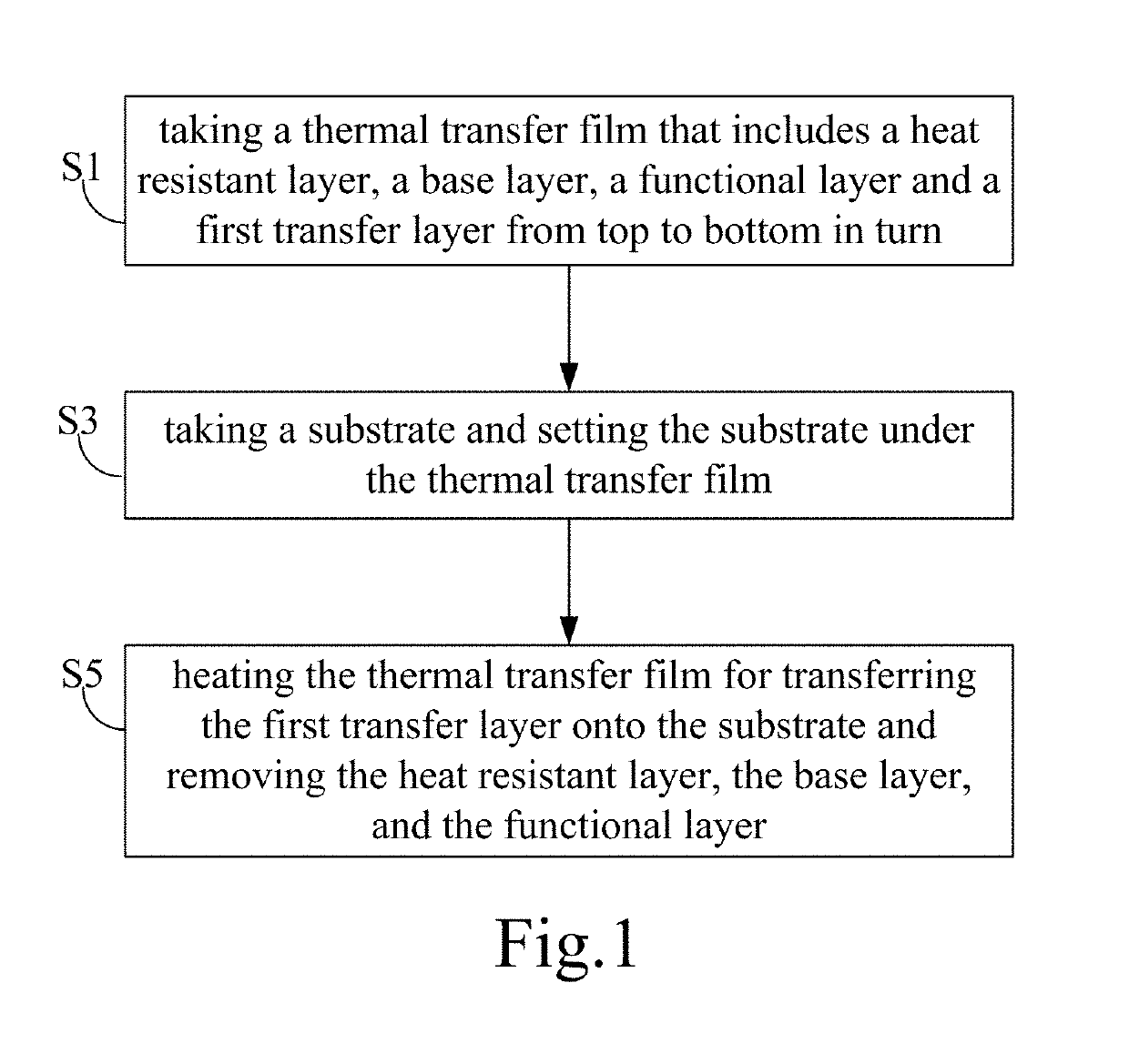

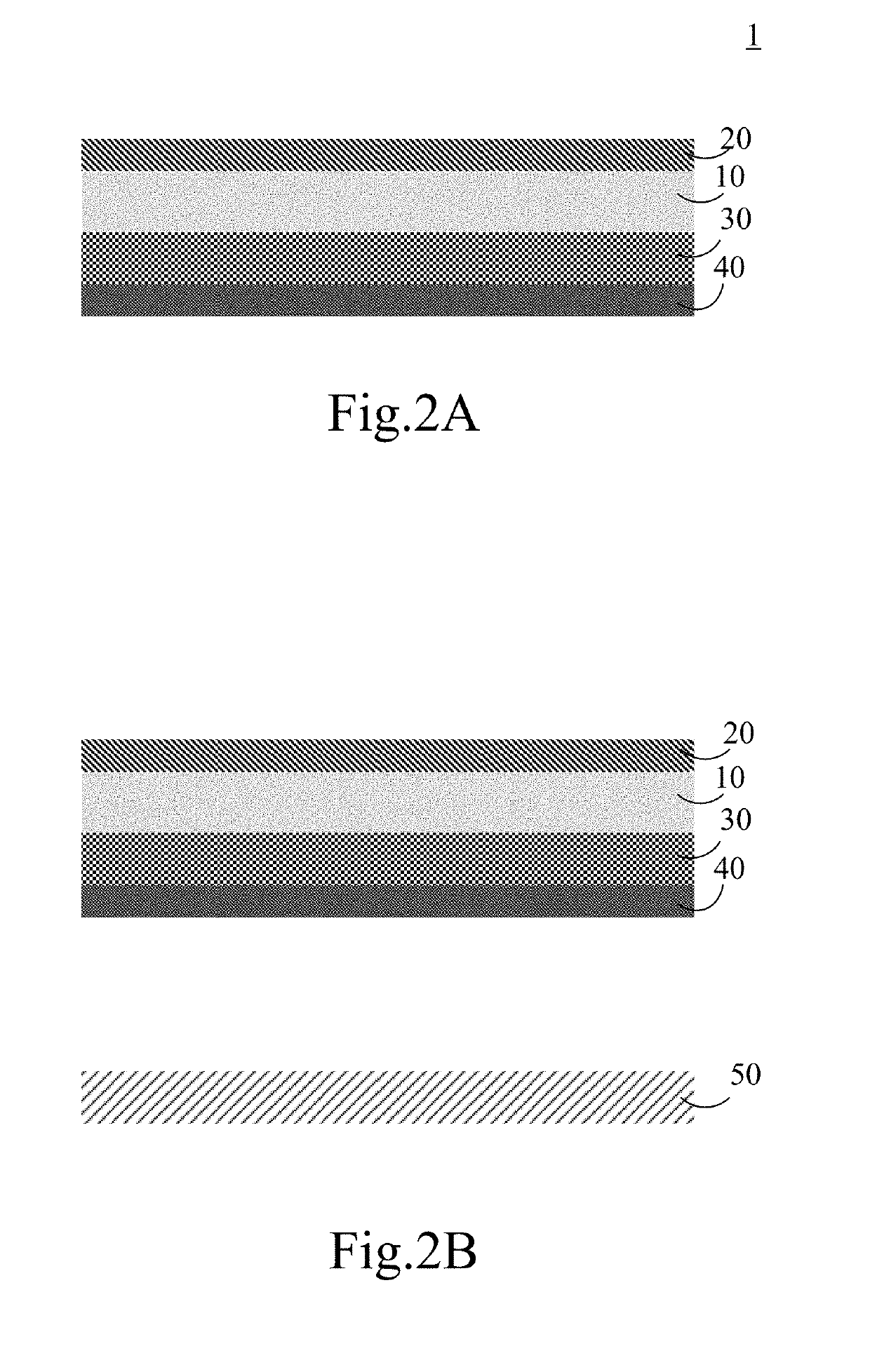

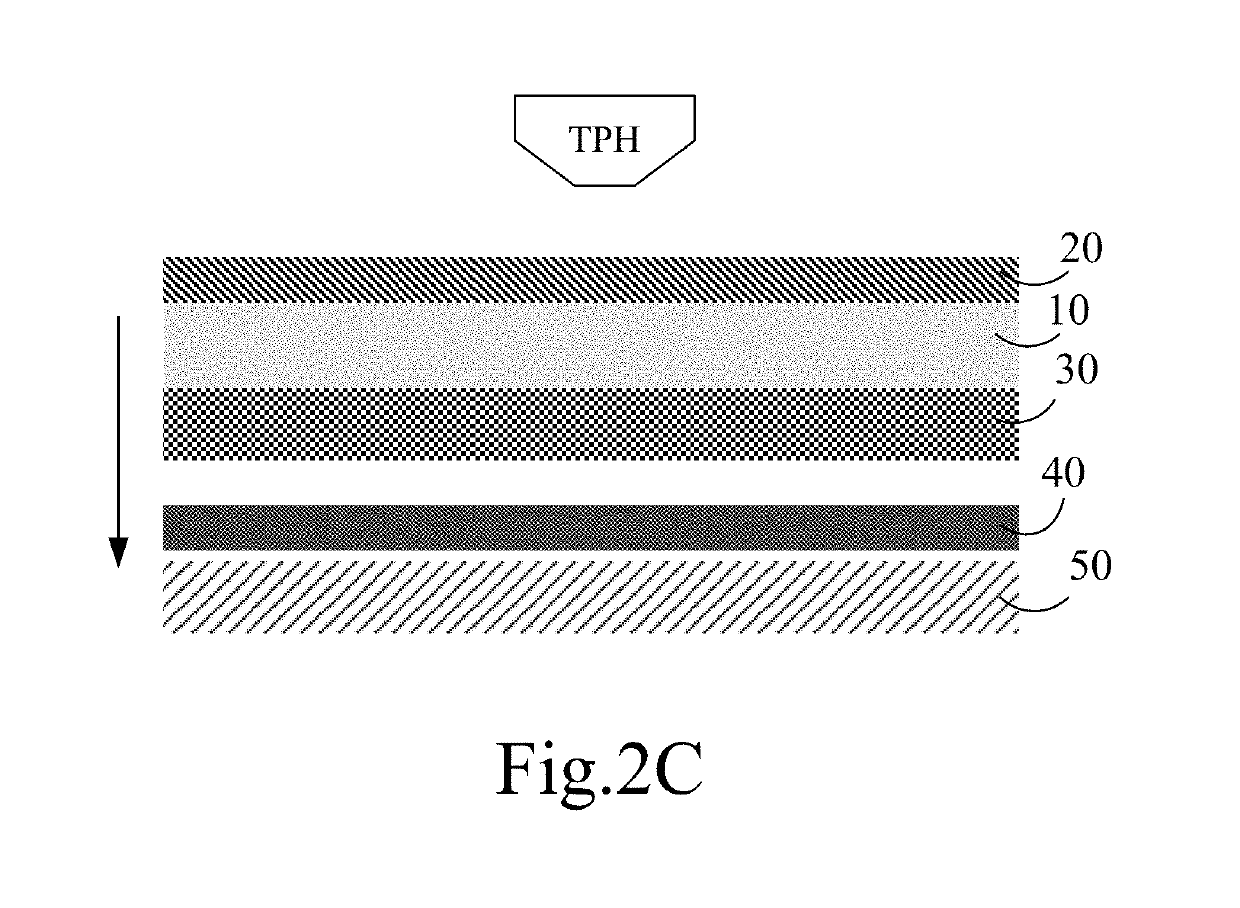

Method for preparing organic light emitting diode by using thermal transfer film

InactiveUS20190288242A1Efficiency of material is lowLow efficiencySolid-state devicesSemiconductor/solid-state device manufacturingVacuum evaporationLight-emitting diode

A method for preparing organic light emitting diode (OLED) by using thermal transfer film is revealed. A first transfer layer on a thermal transfer film is transferred onto a substrate by thermal transfer printing for overcoming shortcomings of the conventional vacuum evaporation including complicated processes and low material efficiency. Only less than 50% material reaches the substrate after the vacuum evaporation.

Owner:CHIEN HWA COATING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com