Tower cross arm member

A component and iron tower technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of damaged cross-arm silicone rubber, low mechanical strength, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0016] see figure 1 and figure 2 , the embodiment of the present invention includes:

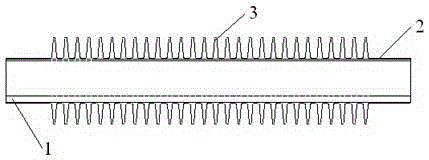

[0017] A steel tower cross-arm component, comprising: a skeleton 1, a protective layer 2 covering the outer surface of the skeleton 1, and an umbrella group 3 poured on the outer side of the protective layer 2.

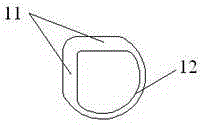

[0018] The cross-sectional shape of the skeleton 1 is D-shaped, consisting of two mutually perpendicular right-angled sides 11 and an arc 12, such as figure 2 shown.

[0019] The frame 1 is made by the process of pultrusion and winding, and the frame 1 is connected by angle steel or plates of composite materials. The connection method can be free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com