Patents

Literature

64 results about "Lattice tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lattice tower or truss tower is a freestanding framework tower.They can be used as electricity transmission towers especially for voltages above 100 kilovolts, as a radio tower (a self-radiating tower or as a carrier for aerials) or as an observation tower.. Before 1940, they were used as radio transmission towers especially for short and medium wave, occasionally lattice towers consisting ...

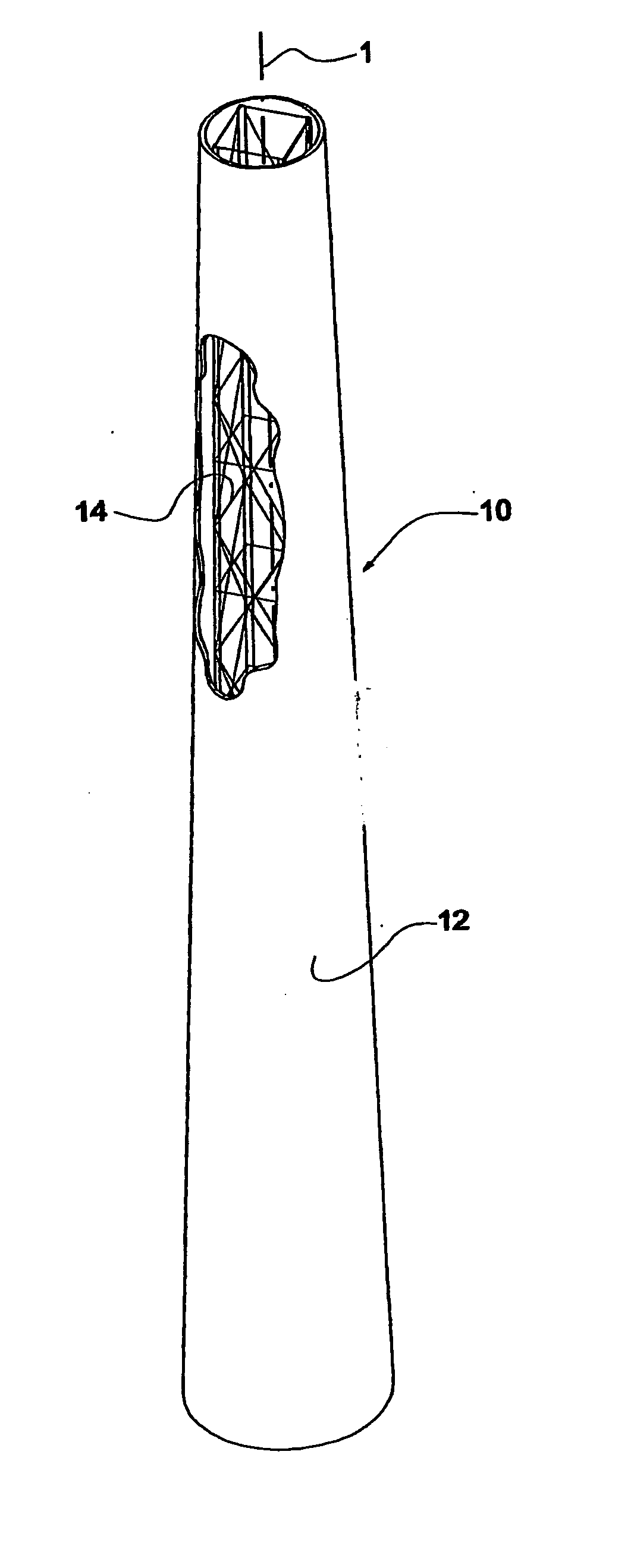

Lattice tower disguised as a monopole

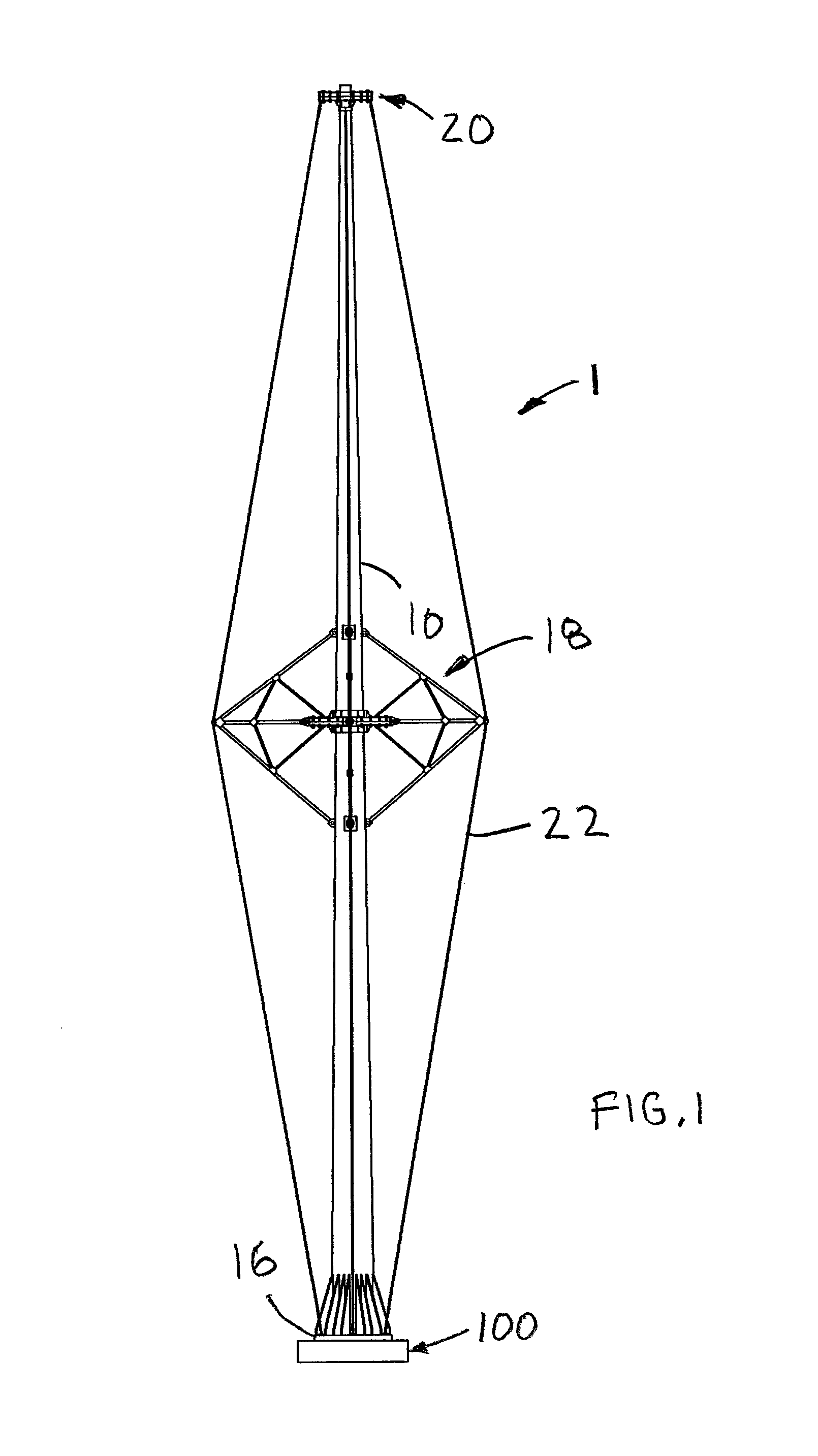

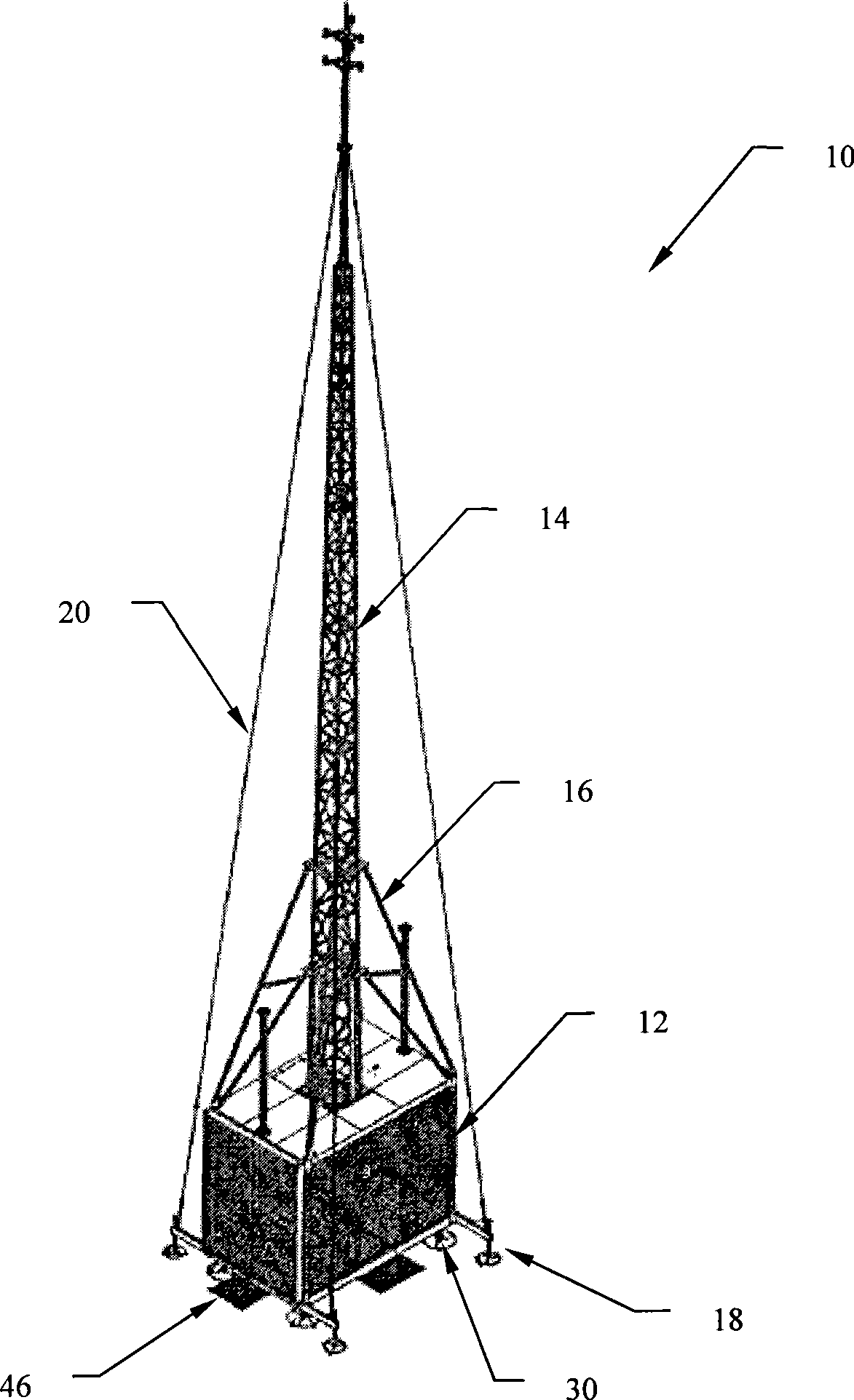

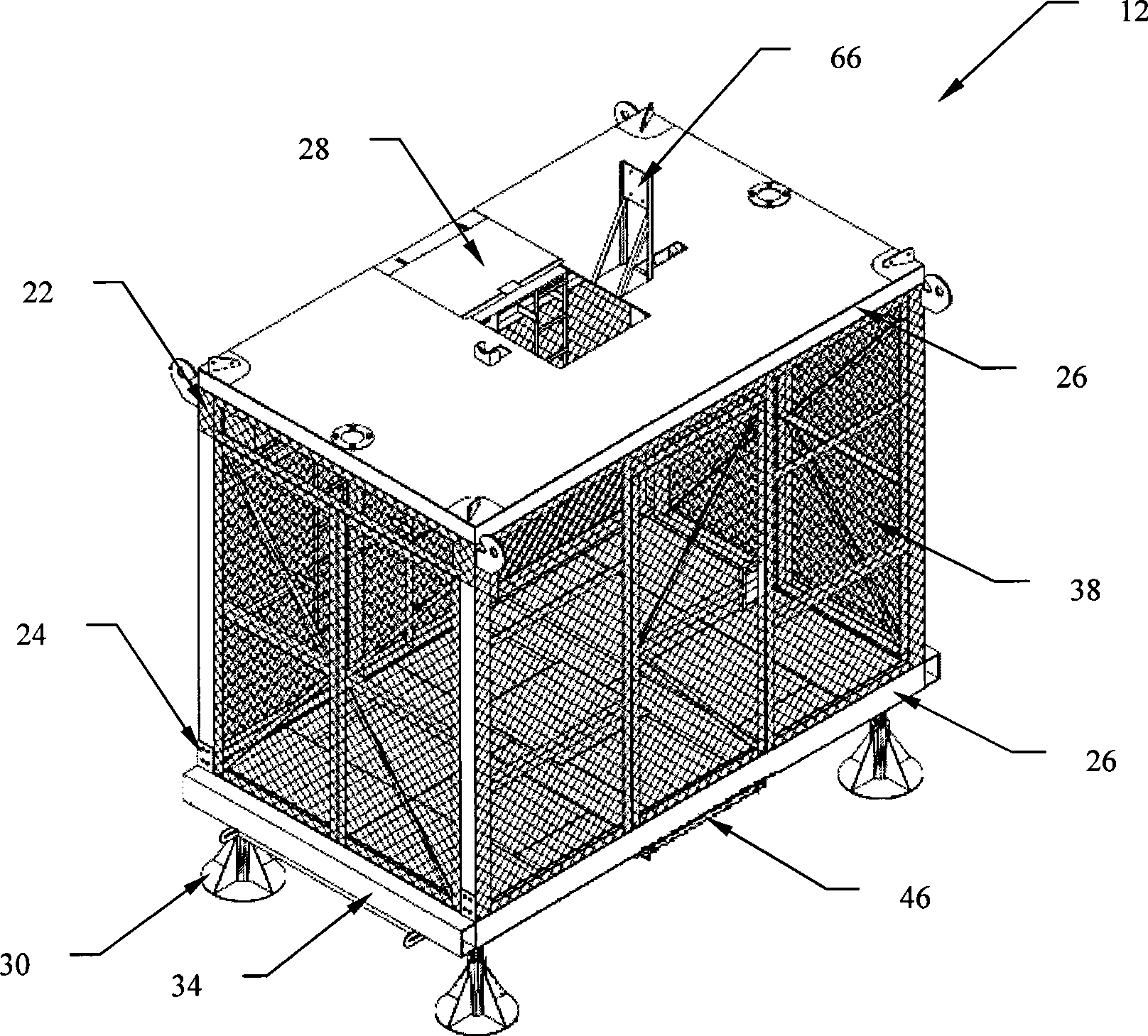

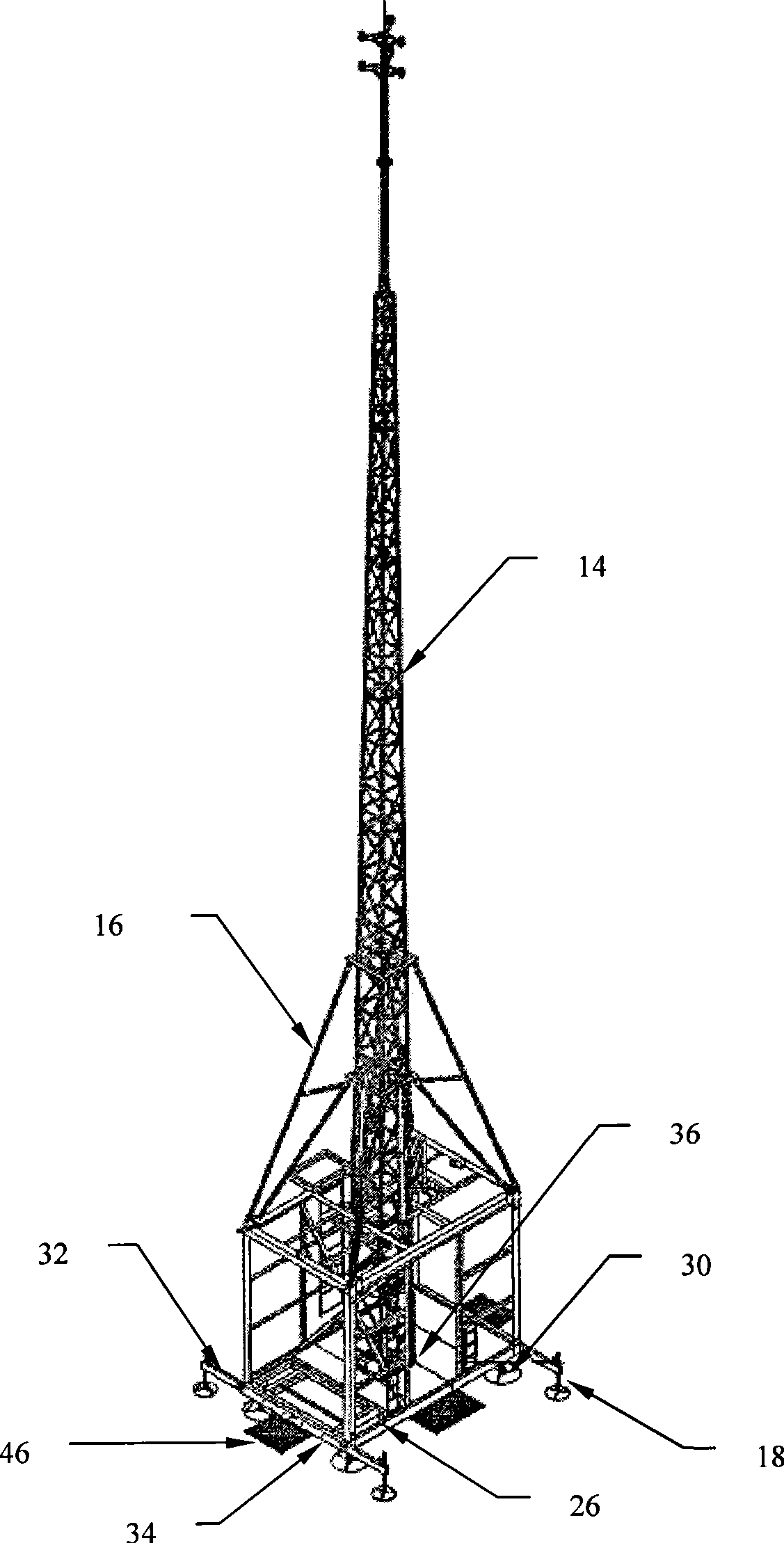

InactiveUS20050166521A1Efficient solutionTransmission of vertical forceFloorsGirdersEngineeringMetal lattice

A solution for a tower (10) that may be substantially tall, characterized by the appearance of a monopole, the capacity to support large objects and consequently sustain great lateral loads generated by wind or earthquake, the facility to conceal vertical access ladder and all other installations, such as antenna feeder cables, and the availability at an acceptable cost level. The heart of the invention is the basic concept of separation between the structurally functioning elements, which are kept concealed, and a non-structural shell (12) which provides the tower (10) the shape of a monopole. The tower (10) comprises, therefore, a tall metal lattice structure (14) having a central vertical axis (1) and certain apparatus for its anchoring to a foundation, concealed within a shell (12) concentric with said central vertical axis (1) and further characterized, at any given level, by a closed cross-section which is either circular or equi-sided polygonal, said shell (12) being internally secured to and supported by said lattice metal structure (14) in an appropriate density throughout its area, so as to maintain its shape when subjected to wind loads or any other likely loads.

Owner:SILBER MEIR

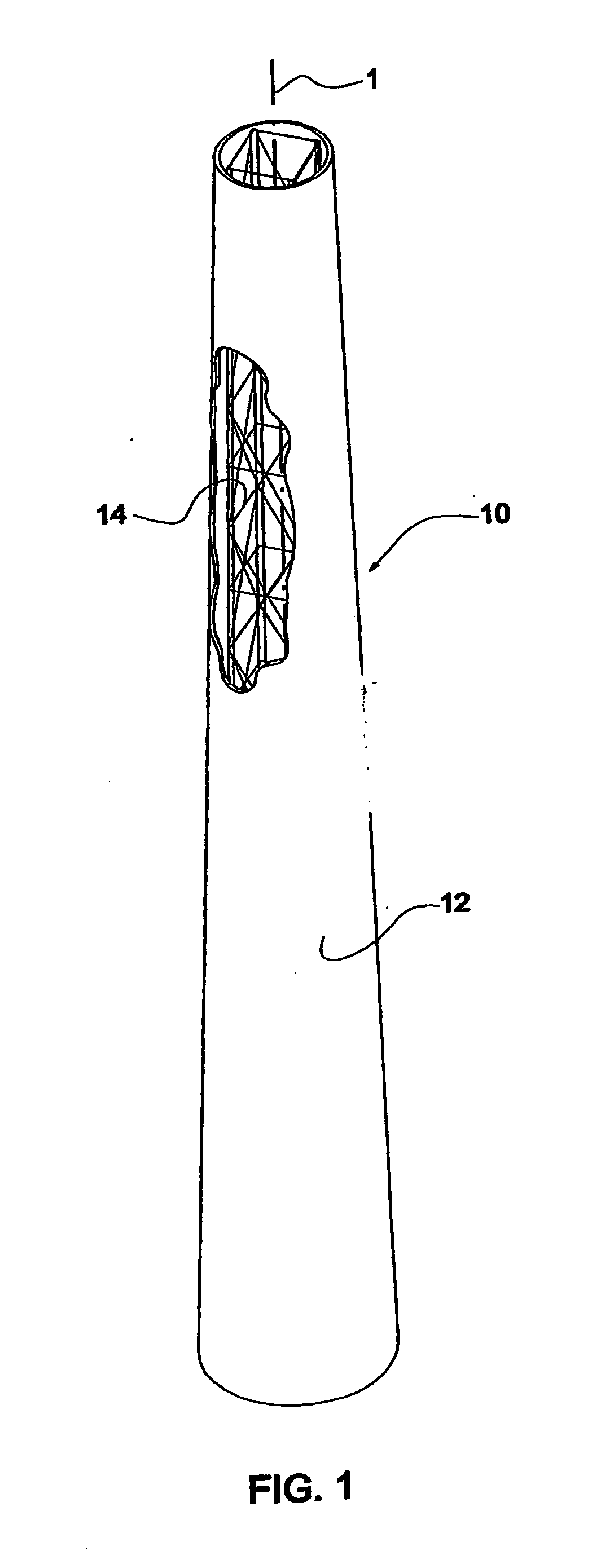

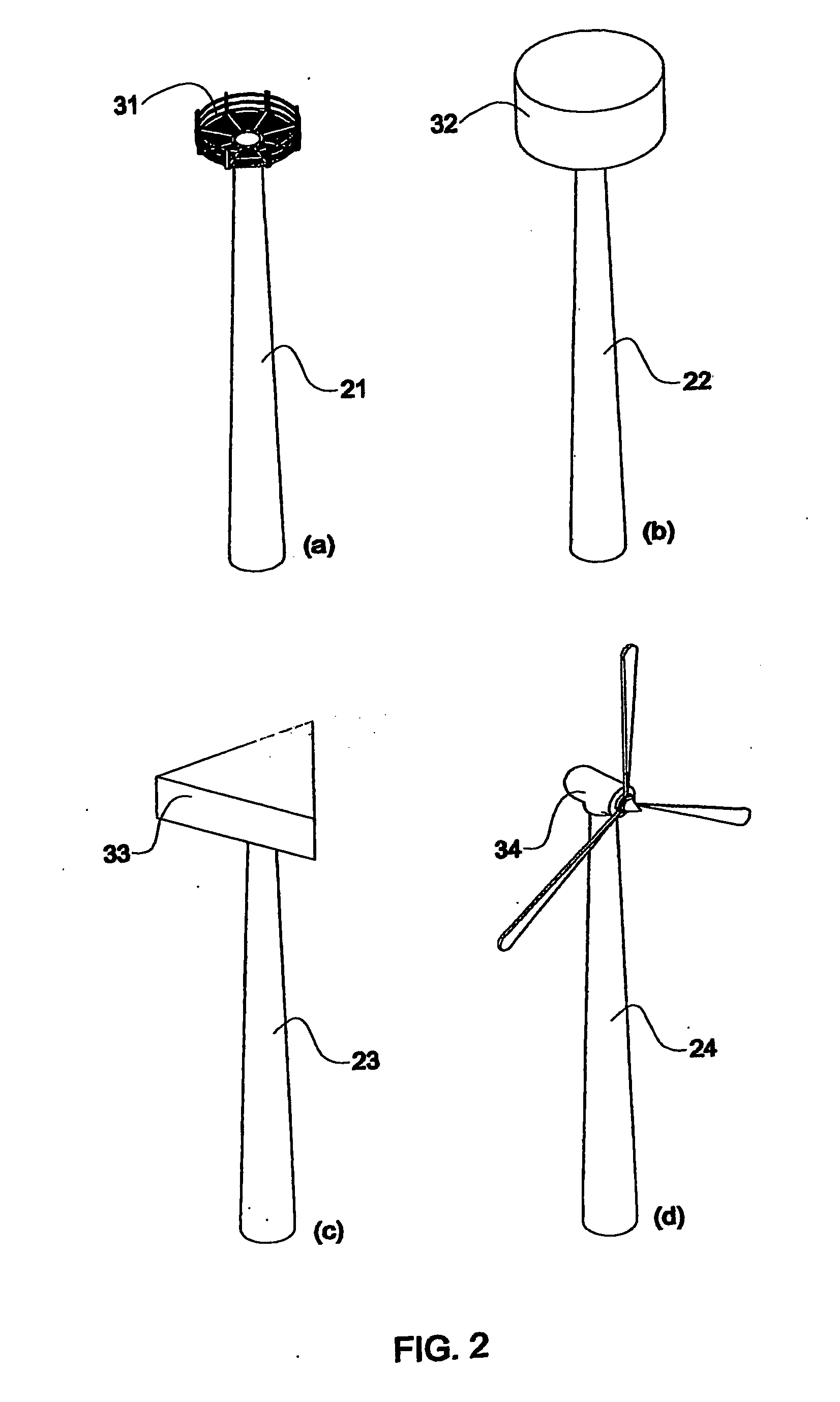

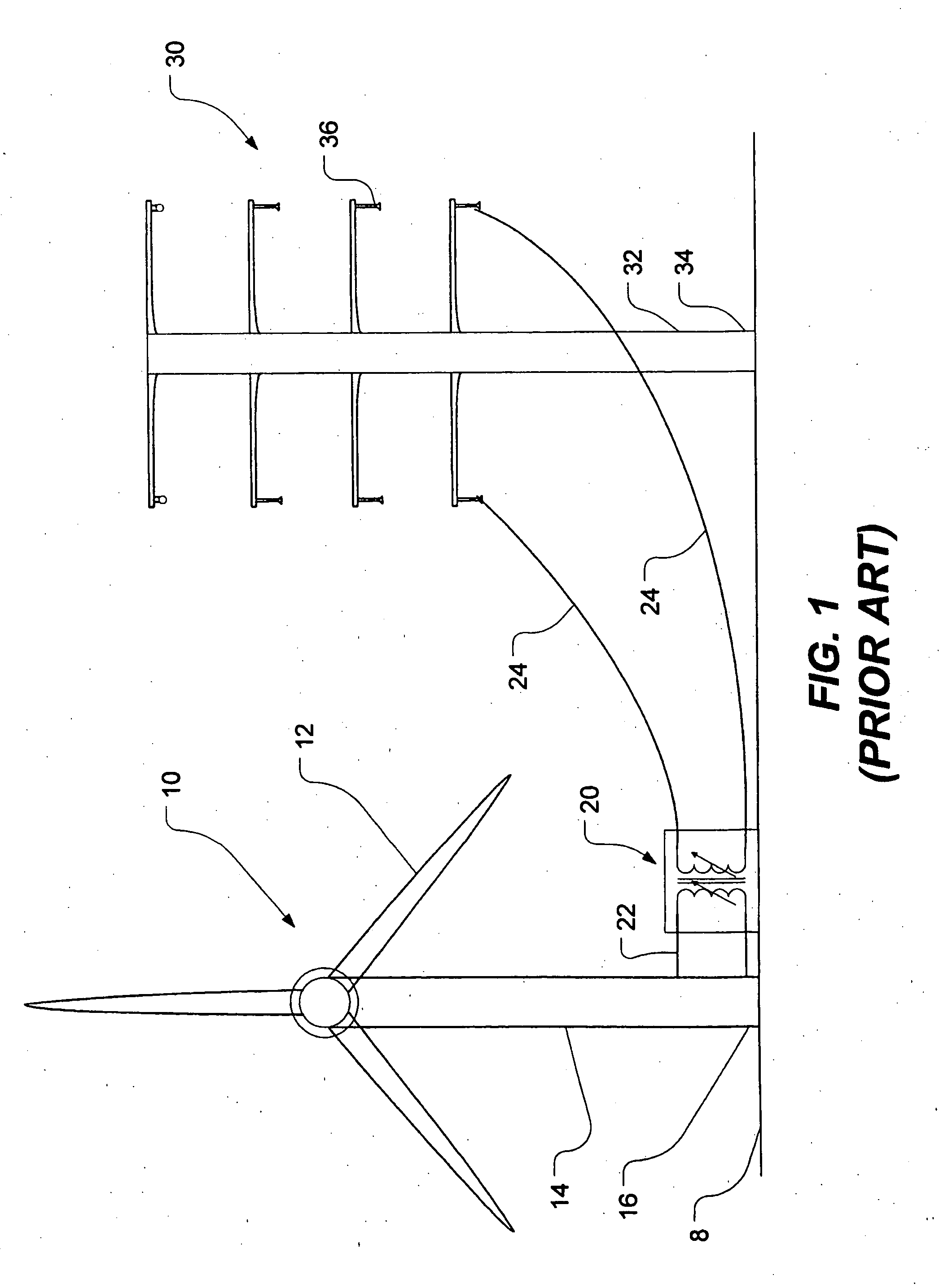

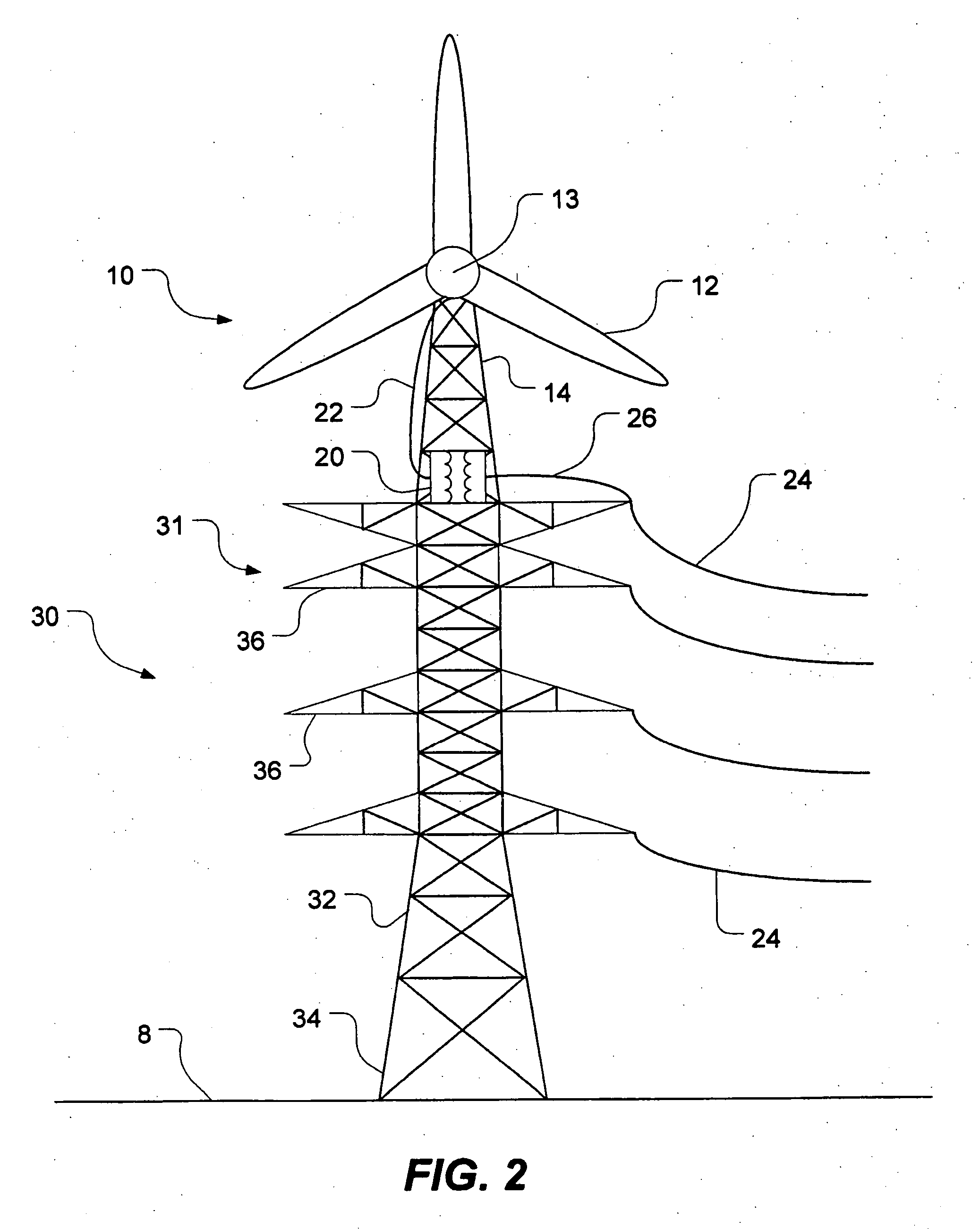

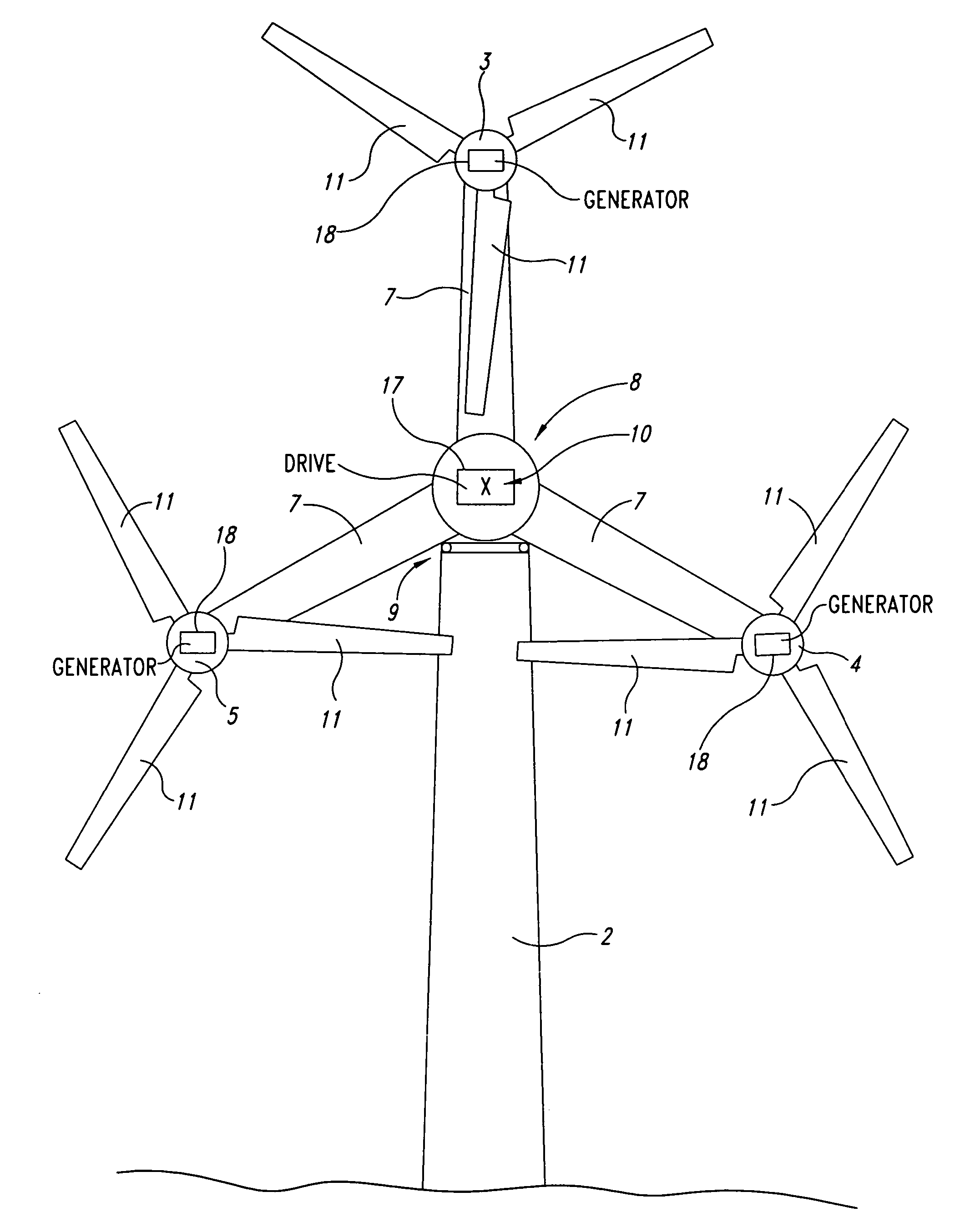

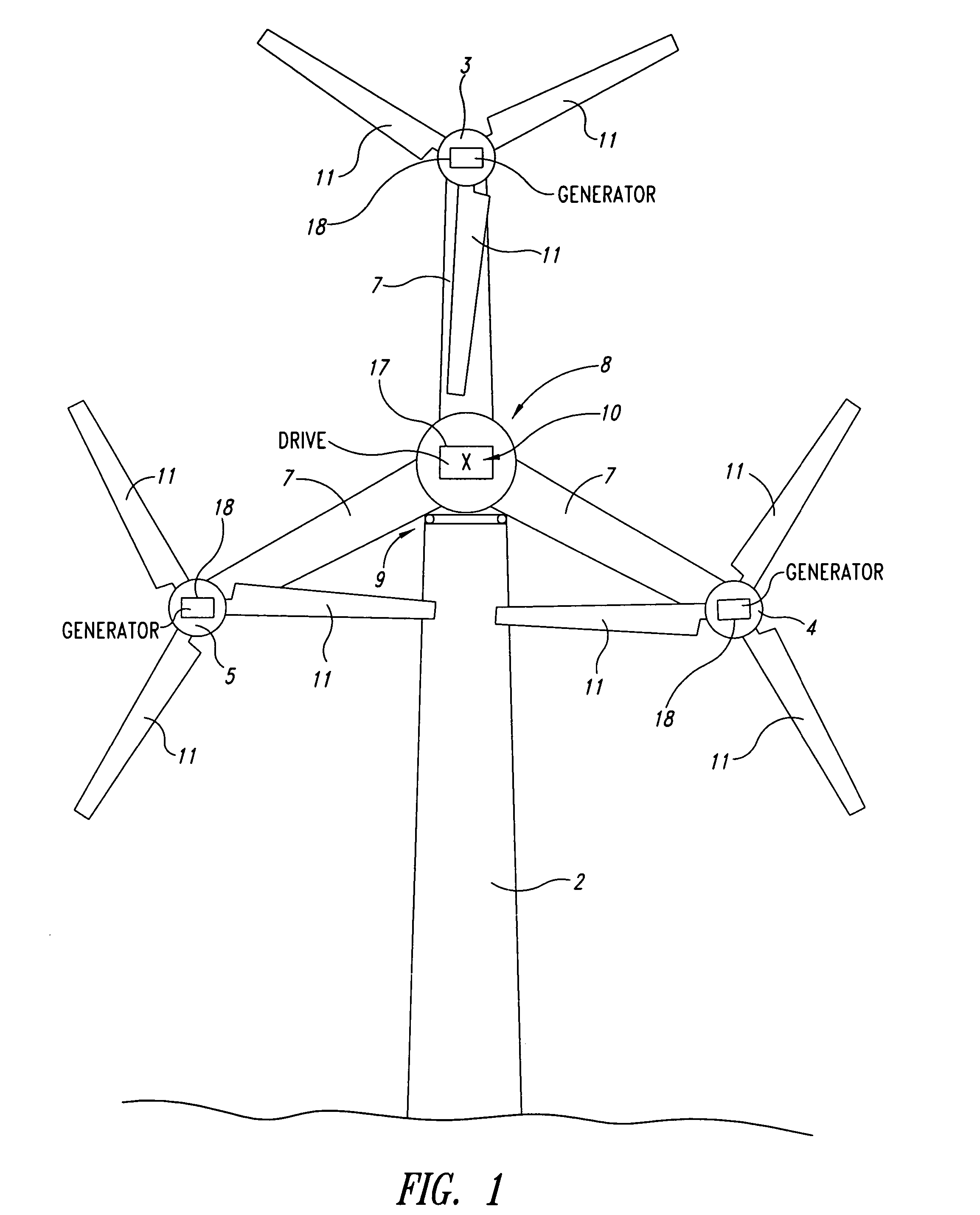

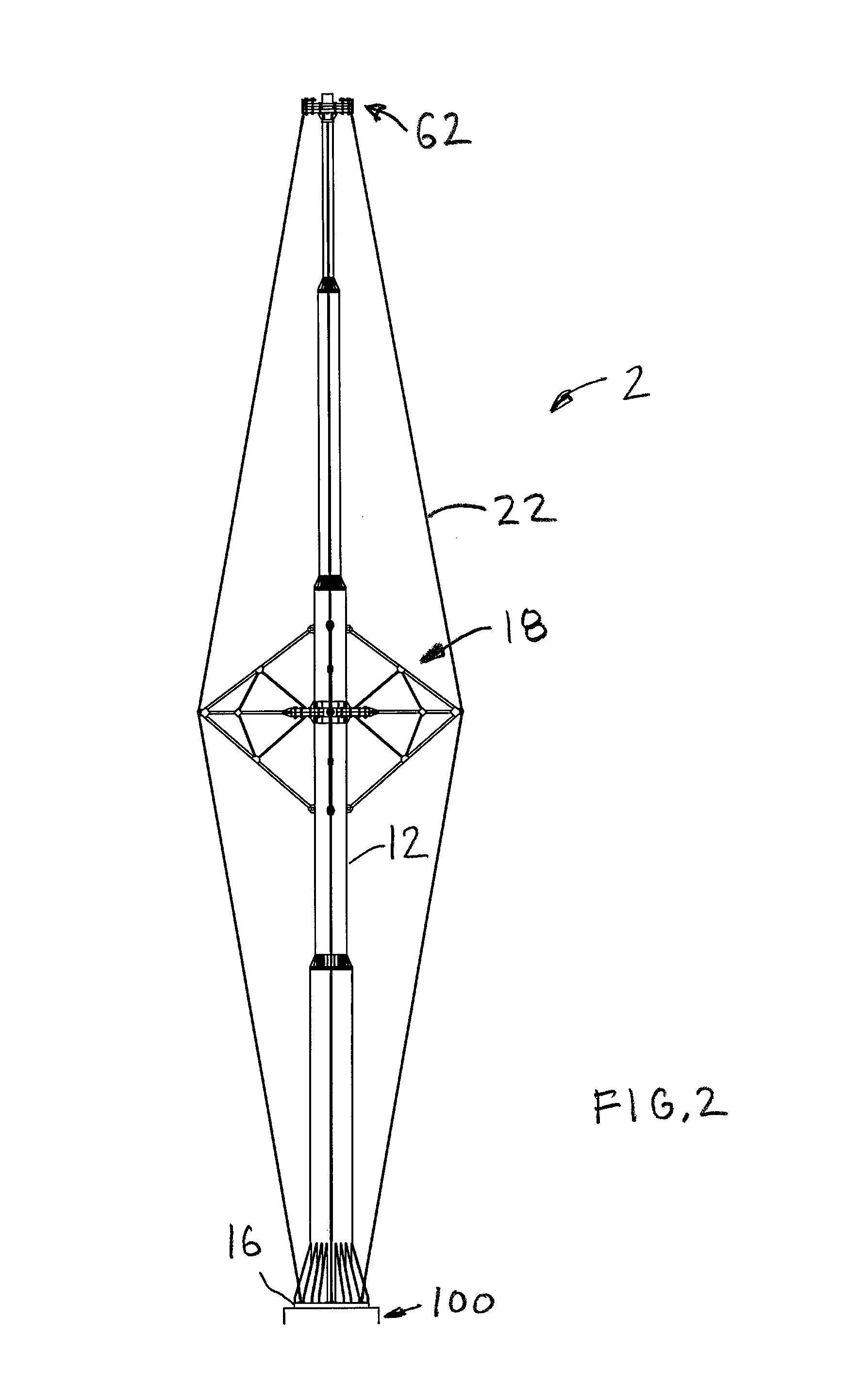

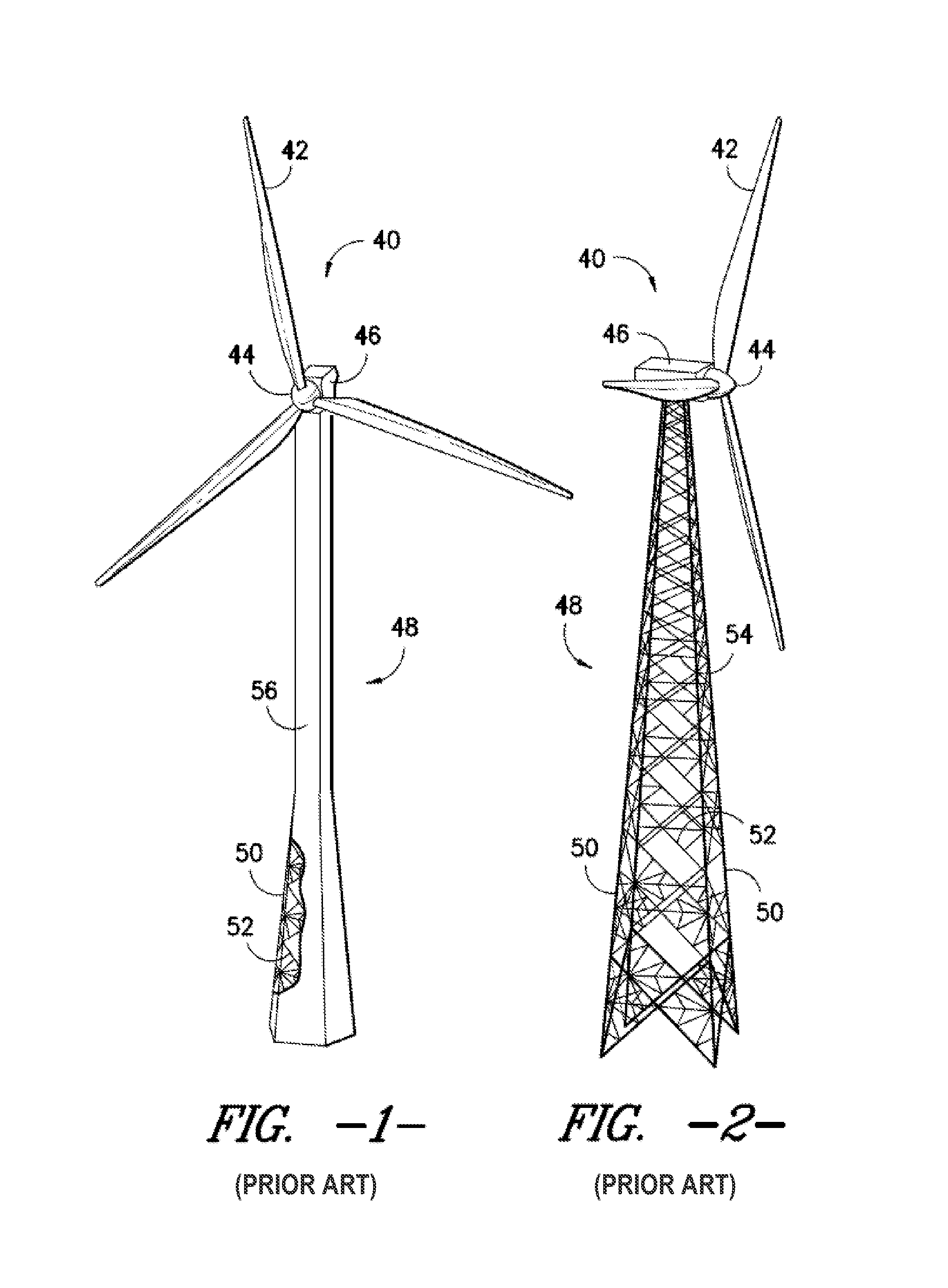

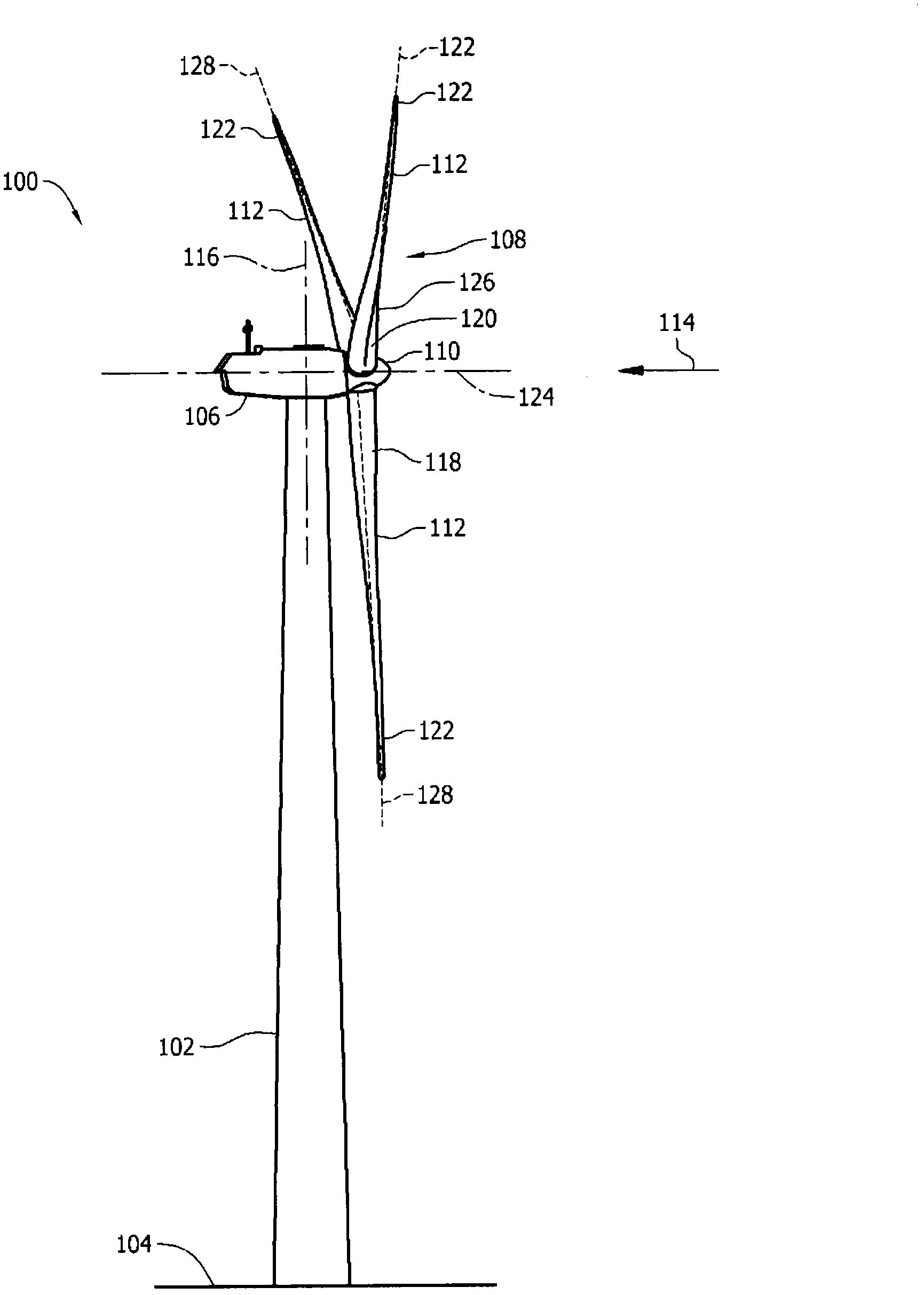

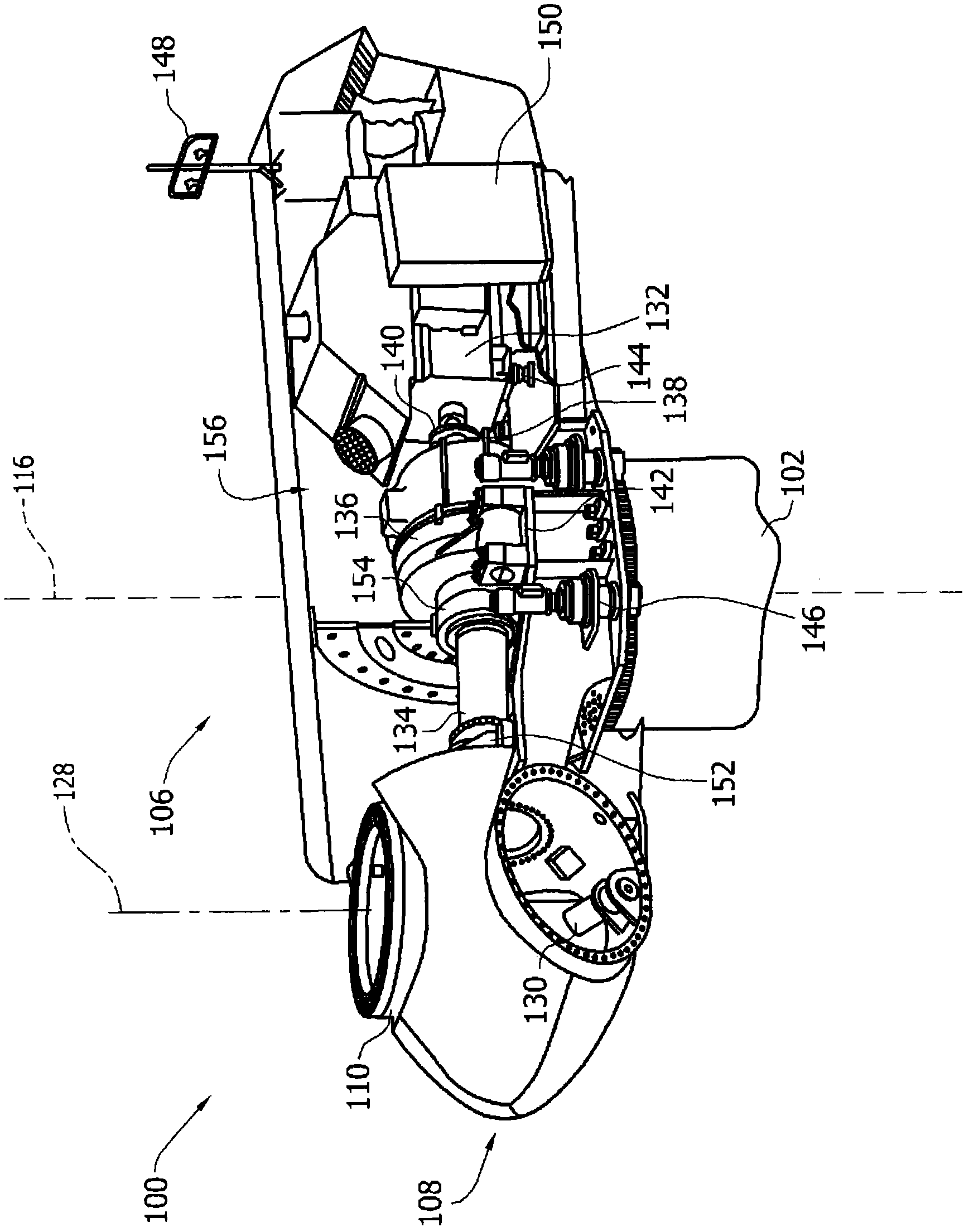

Wind turbine mounted on power transmission tower

InactiveUS20050230980A1Reduce construction costsMinimises aesthetic impactWind motor supports/mountsWind motor combinationsTransformerHorizontal axis

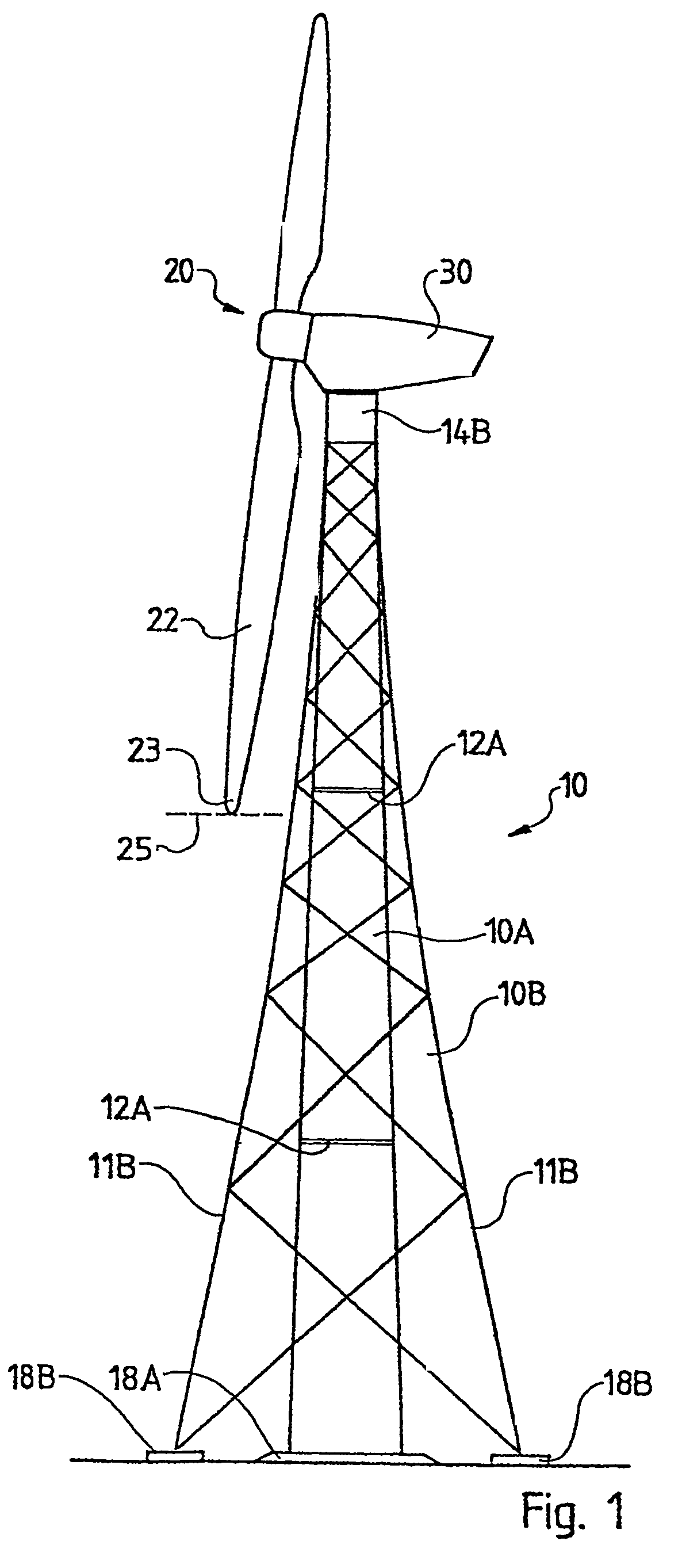

A power transmission tower carrying power lines has a wind turbine mounted to an upper portion of the tower. The wind turbine has a rotor which drives a generator for generating electric power. The generated power is stepped up using a transformer before being fed into one of the power lines. Optionally, electric power generated by a plurality of such wind turbines could be accumulated downstream and then transformed and fed into the grid at multiple-tower intervals. The wind turbine can be mounted on a lattice tower, a monopole tower or a hybrid tower. The wind turbine has either a fixed horizontal axis or a variable (but non-vertical) axis. Alternatively, a vertical-axis wind turbine may be used provided the generator is mounted at or near the top of the tower. Using existing infrastructure, the present invention supplements the capacity of a power grid with environmentally friendly power generation.

Owner:BRUNET ANDRE

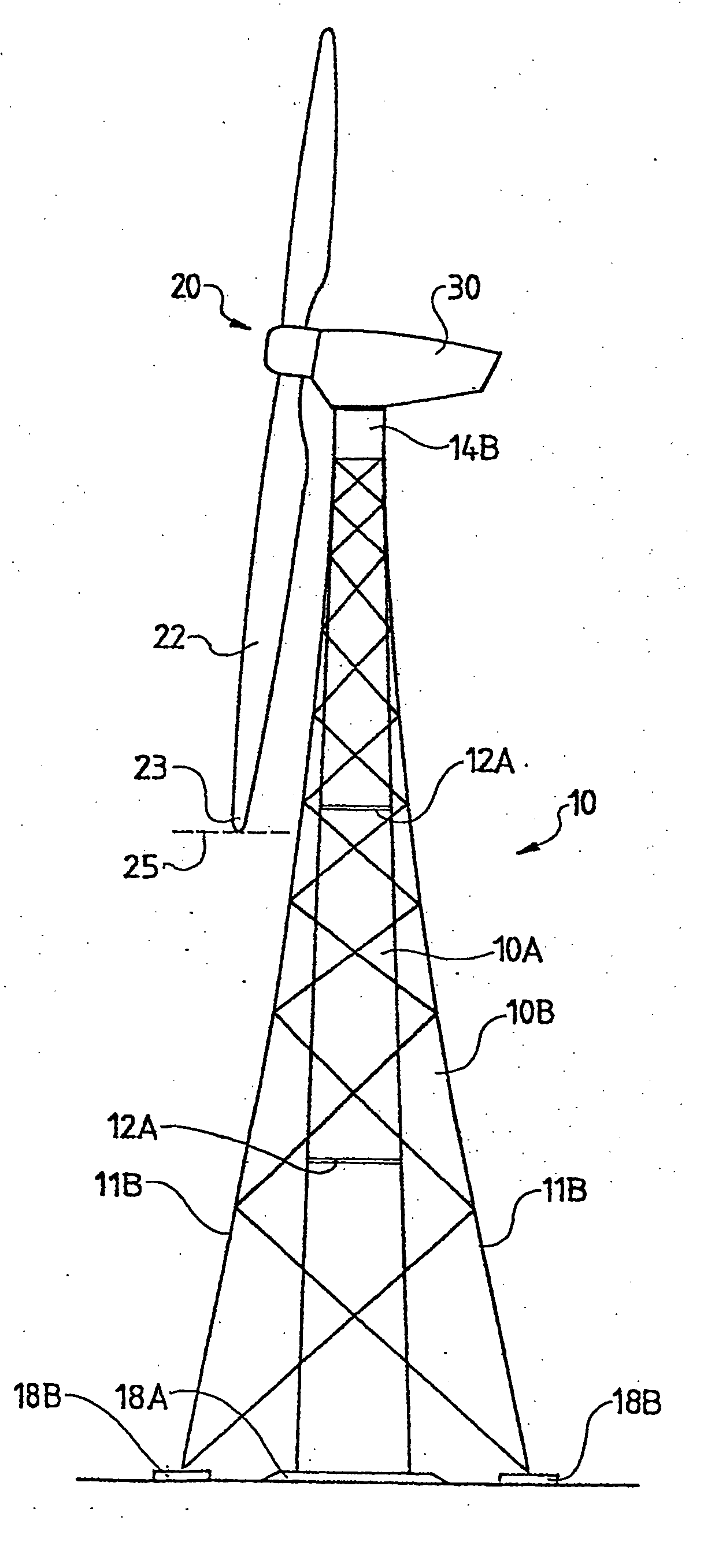

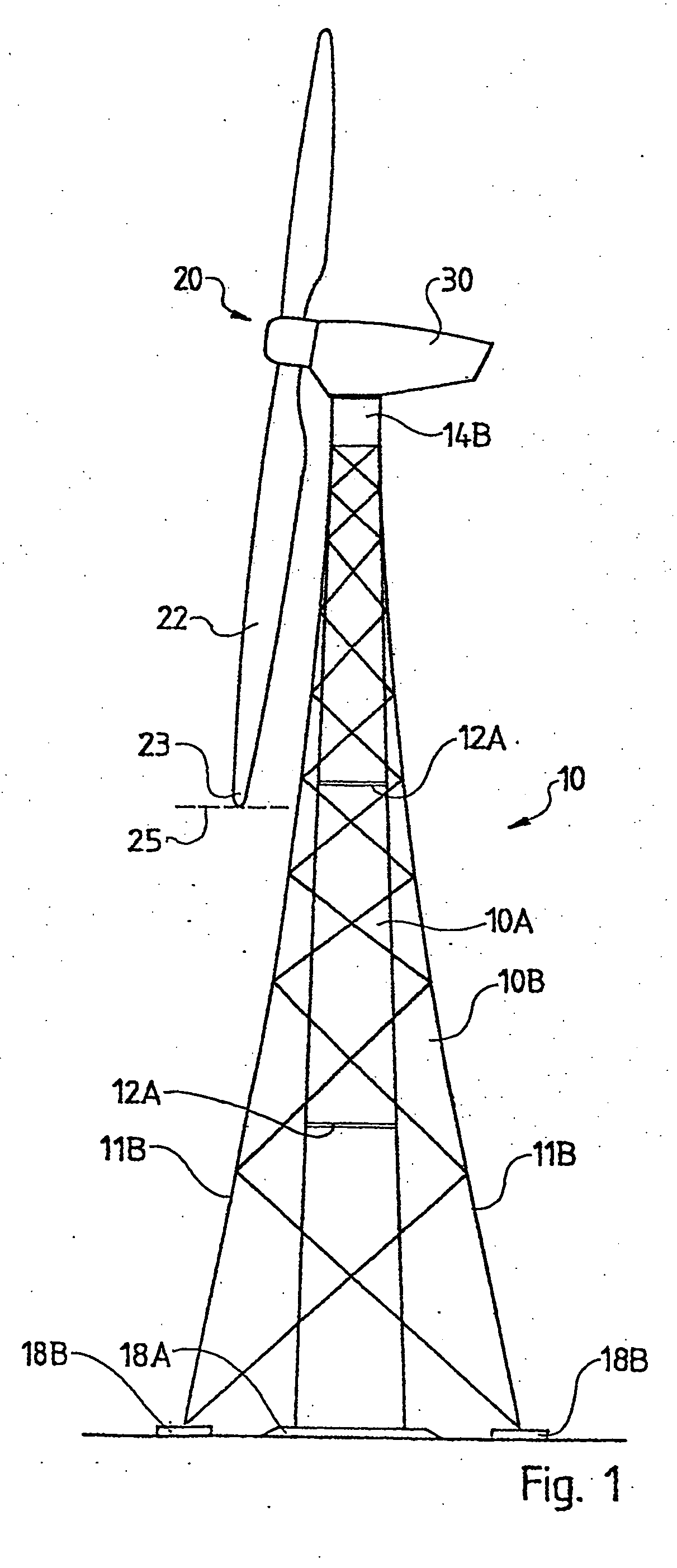

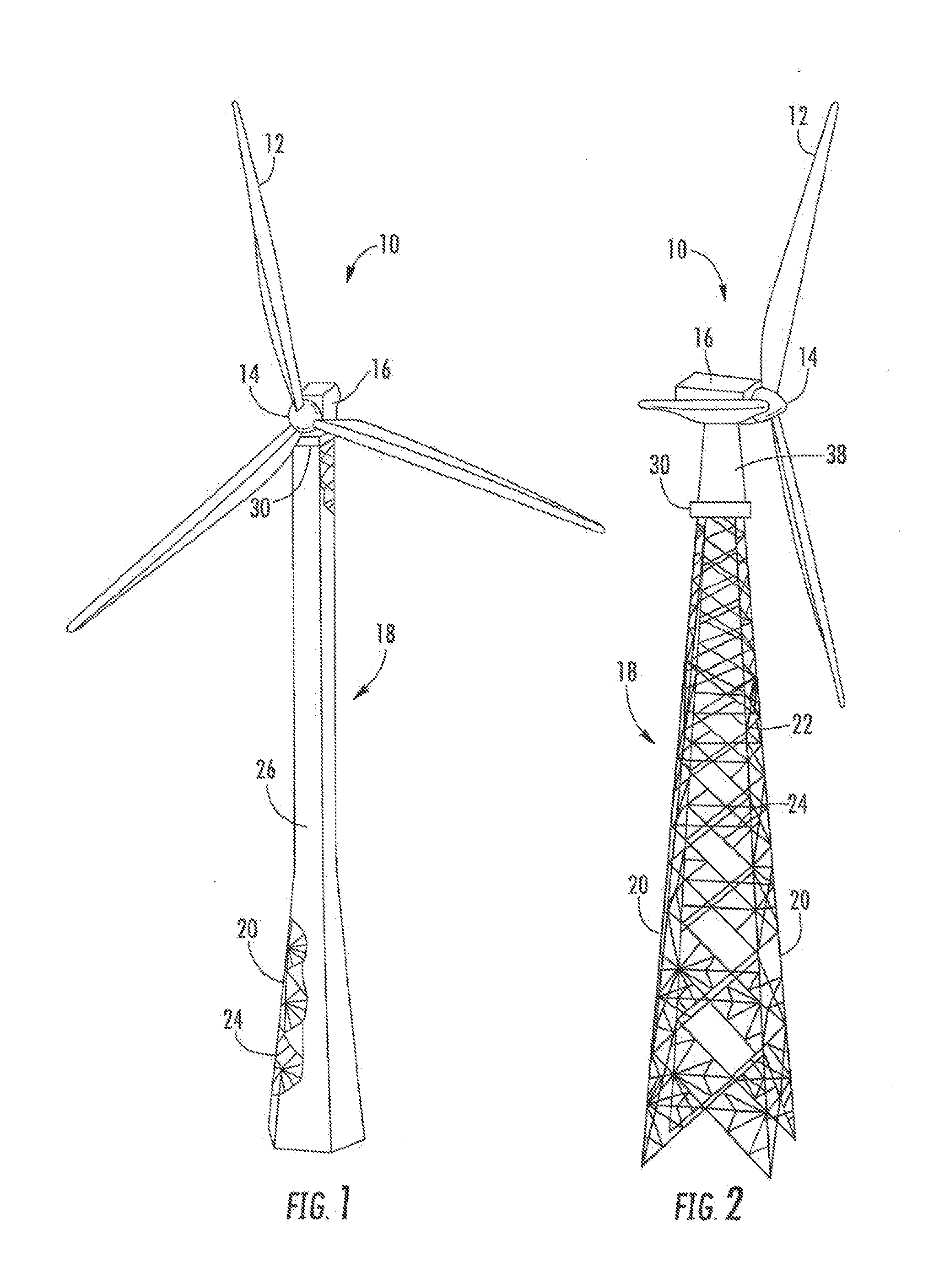

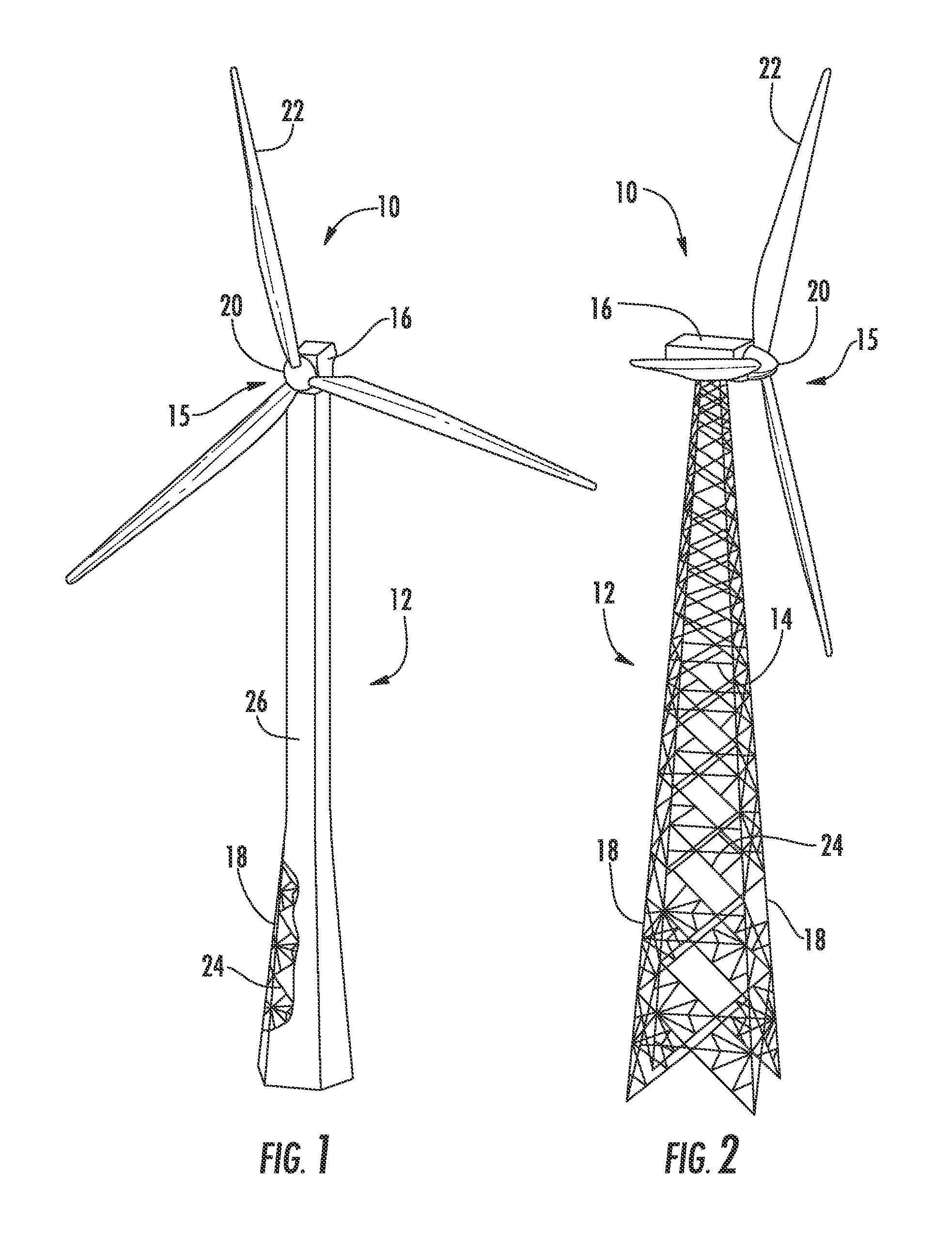

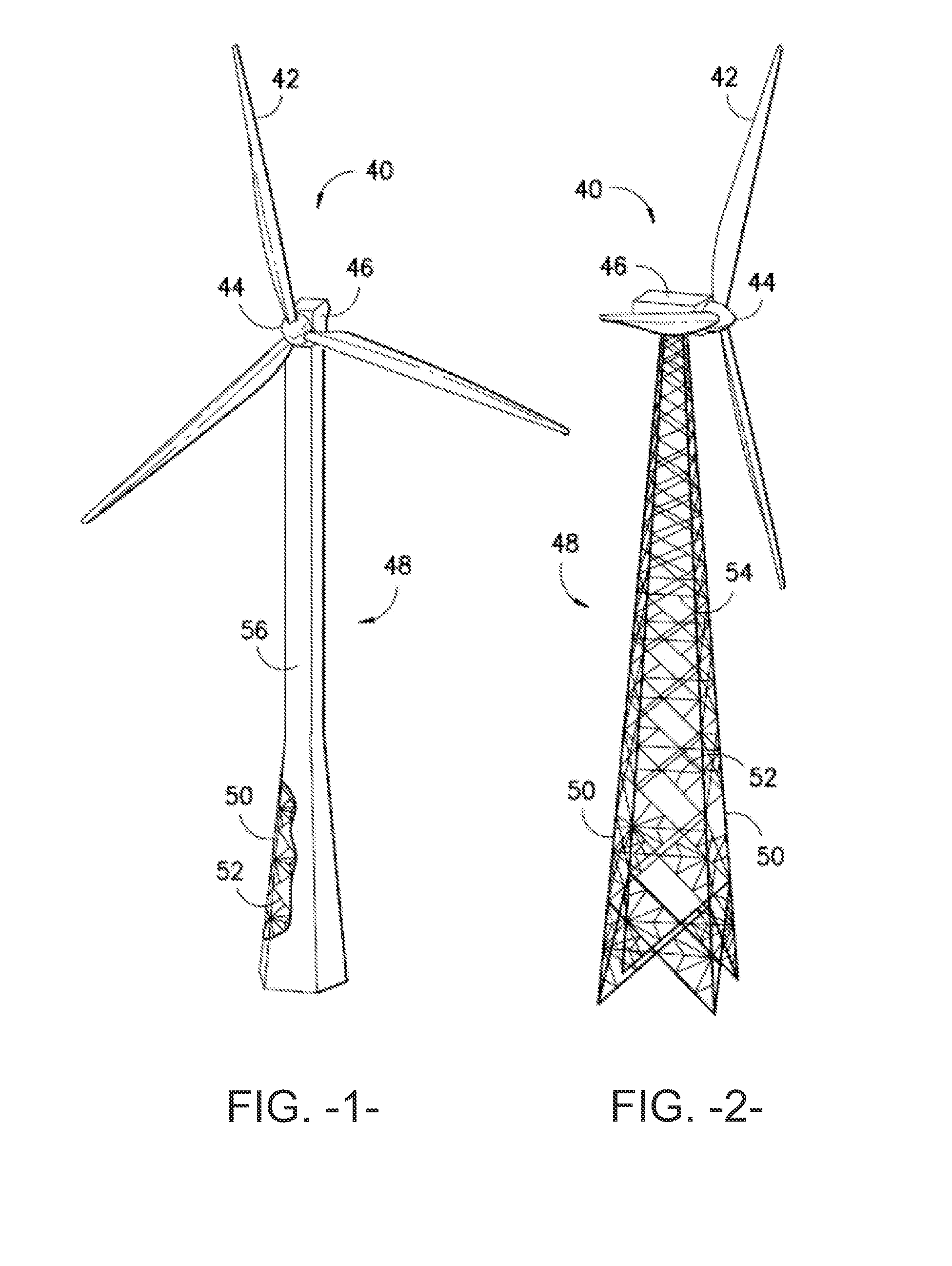

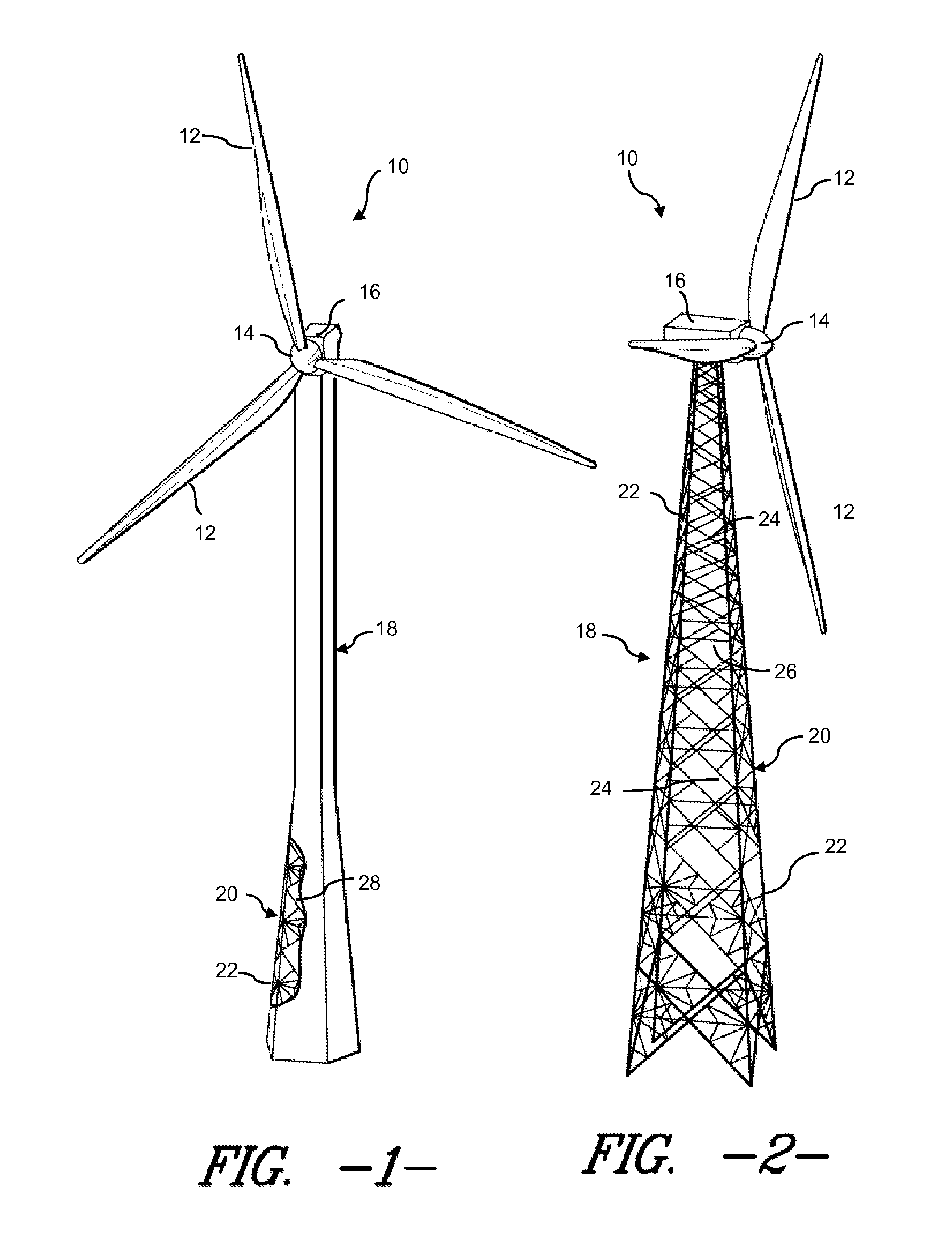

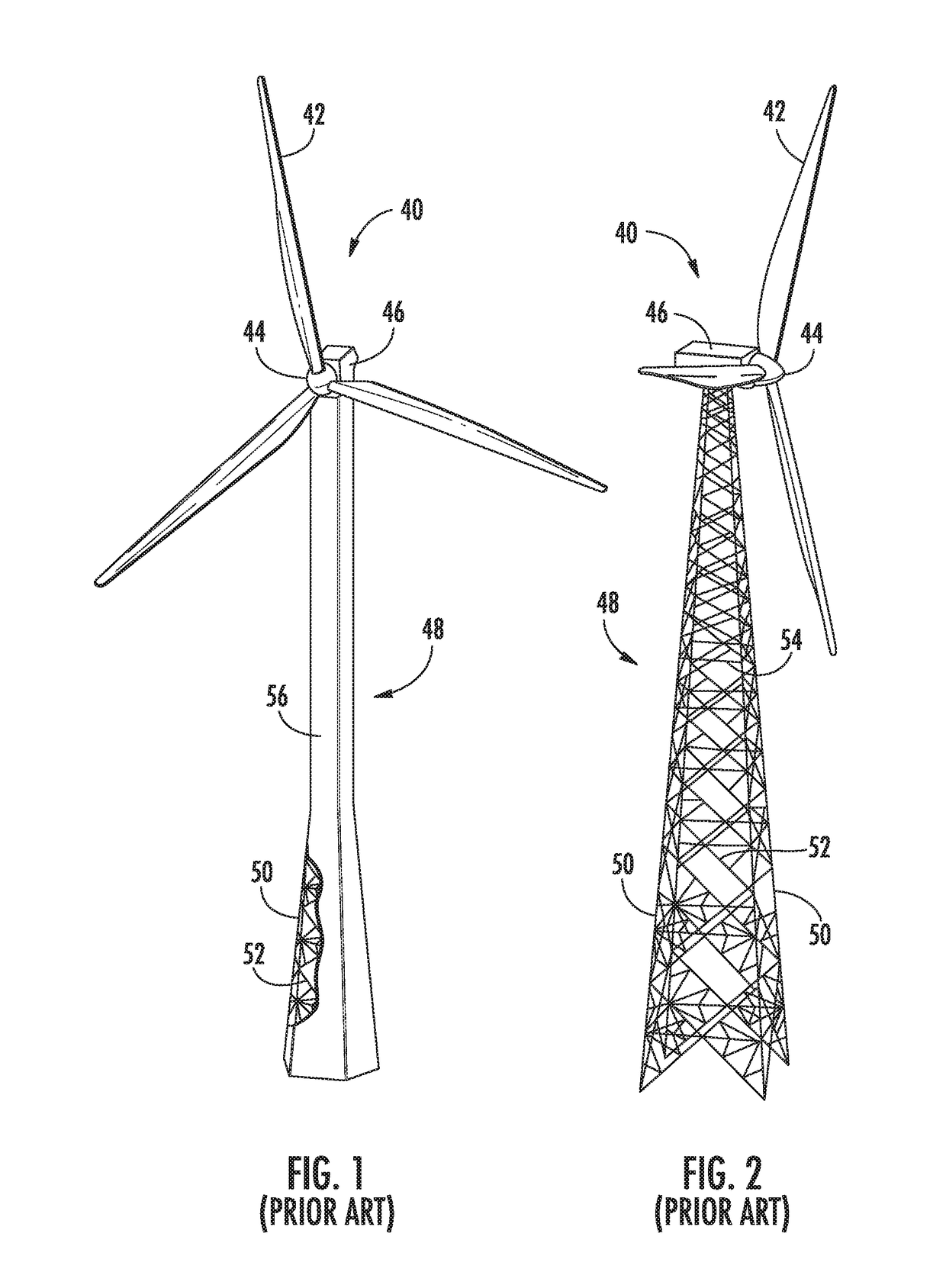

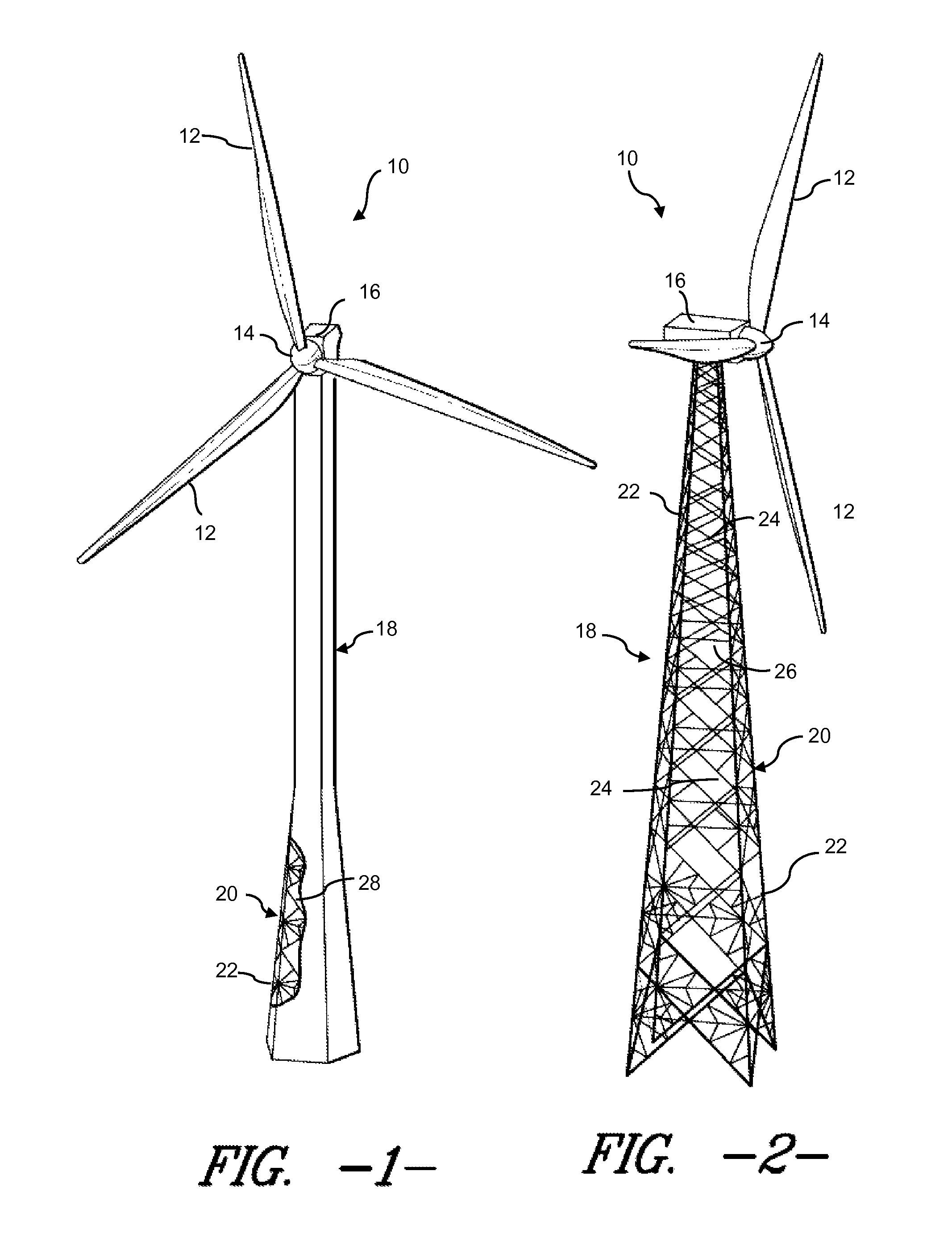

Tower for a wind power station

ActiveUS20060267348A1Drawback can be obviatedArtificial islandsWind motor supports/mountsPower stationHorizontal axis

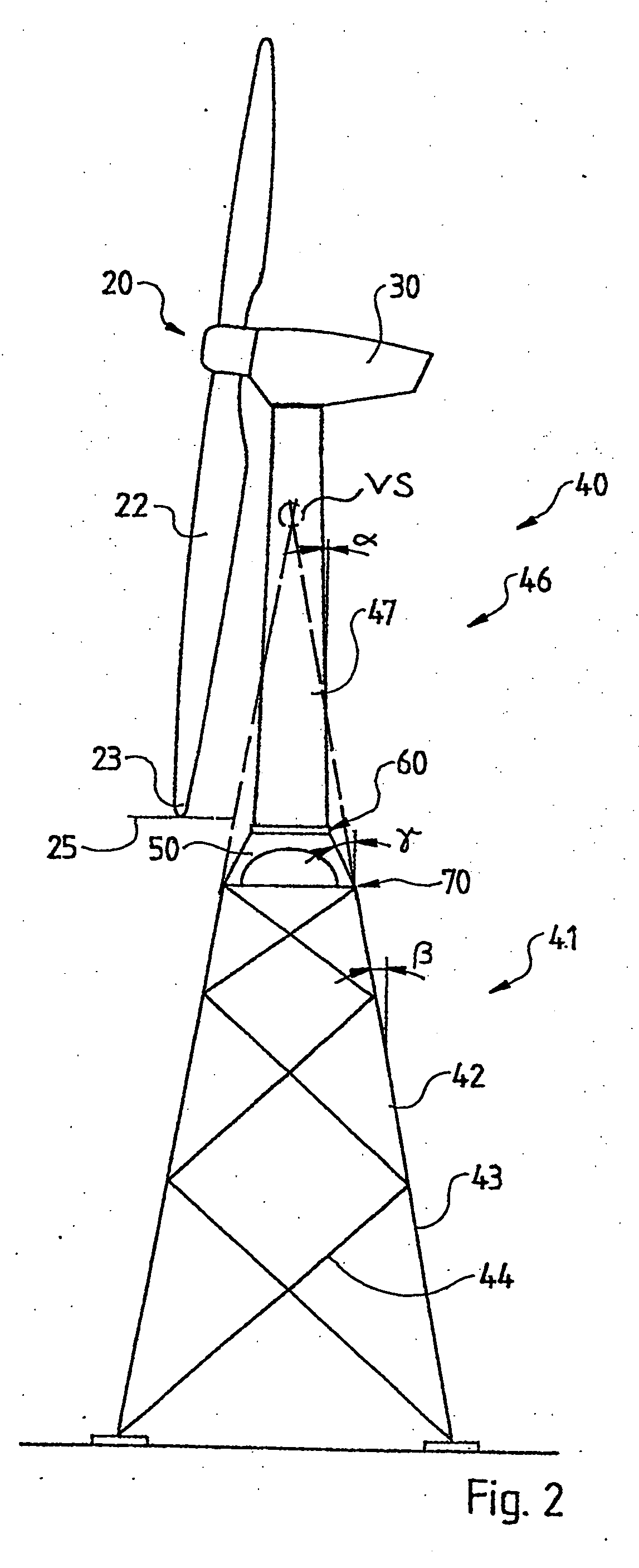

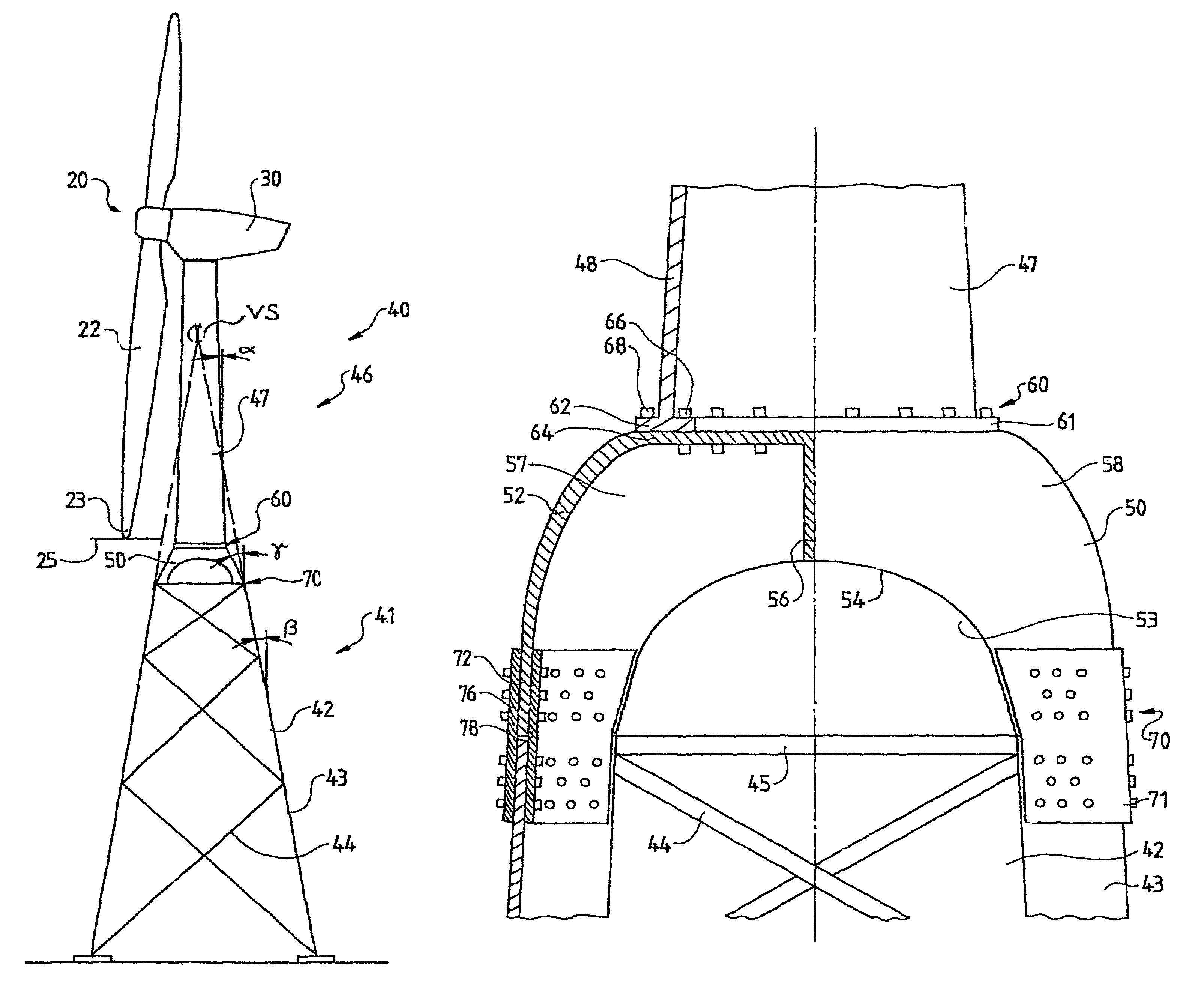

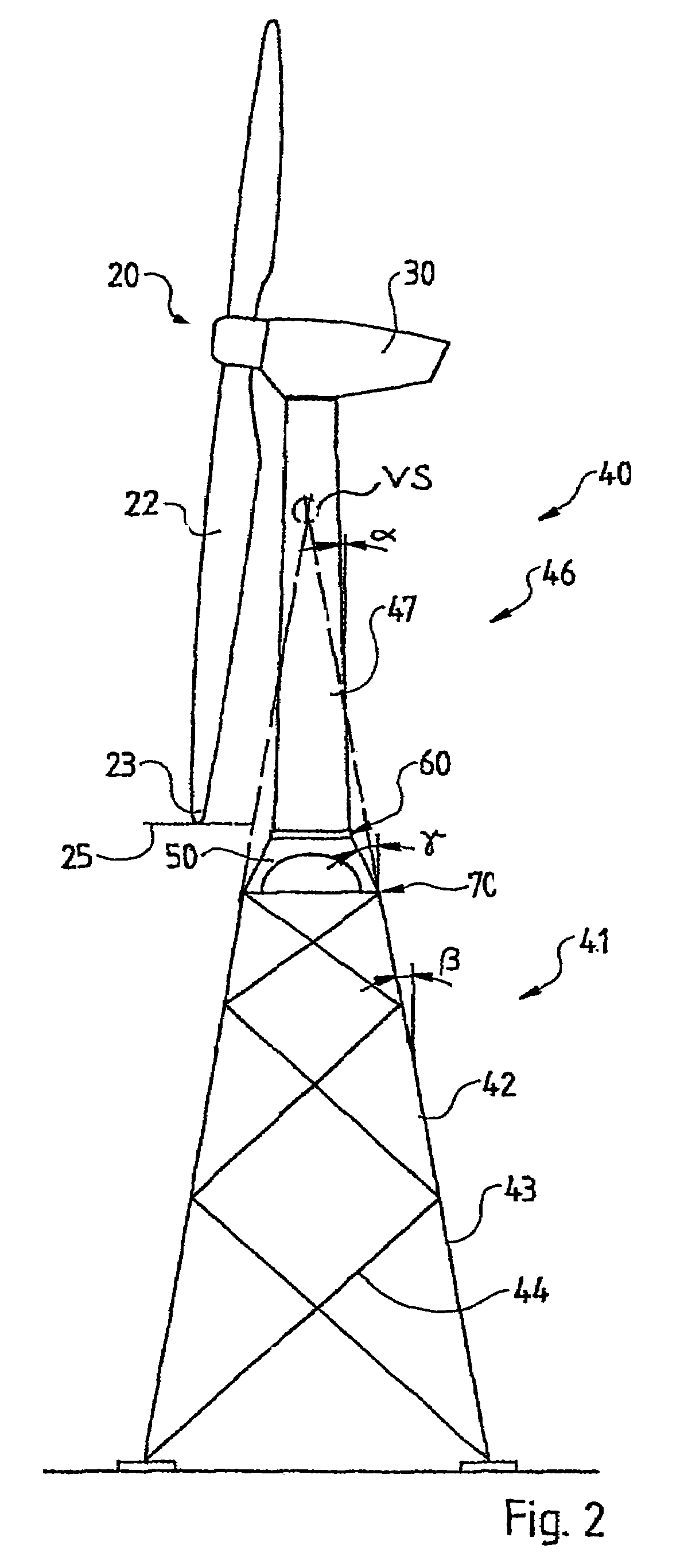

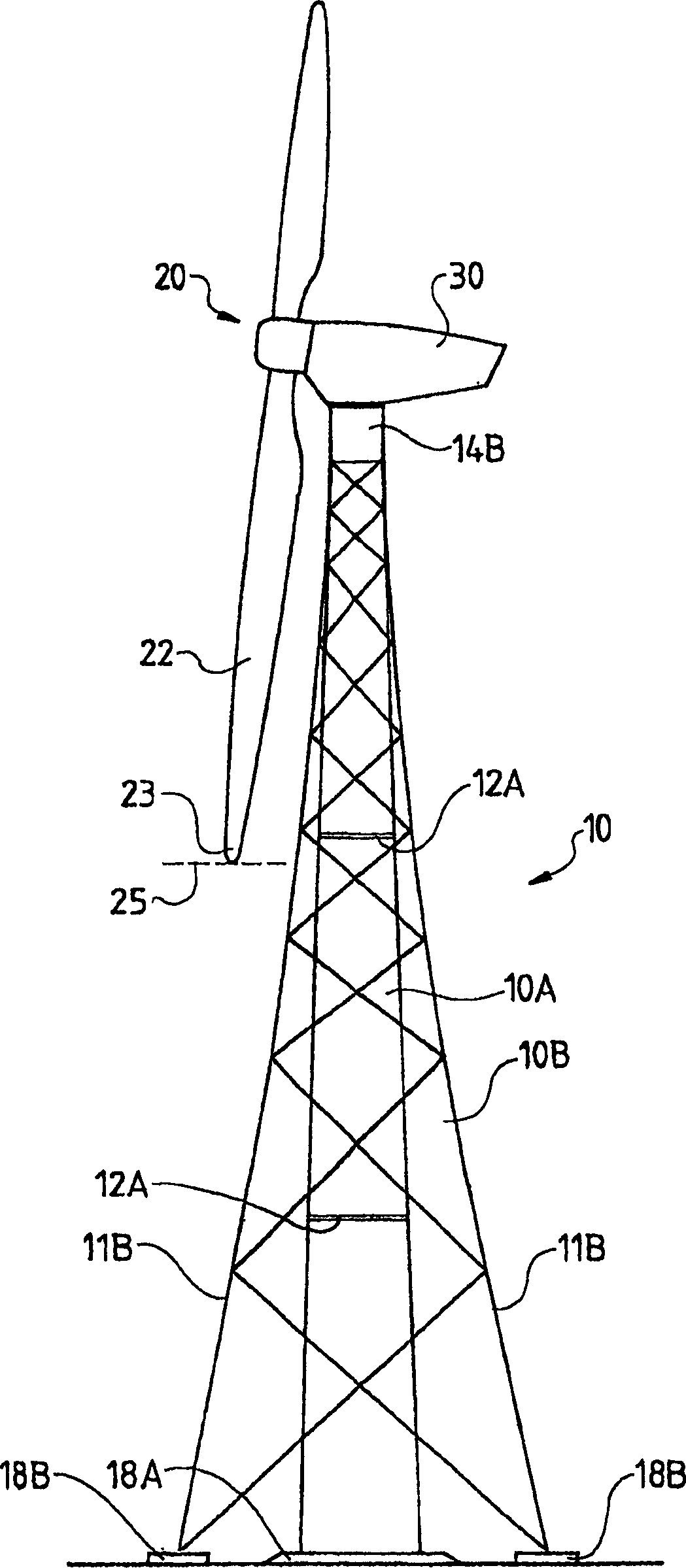

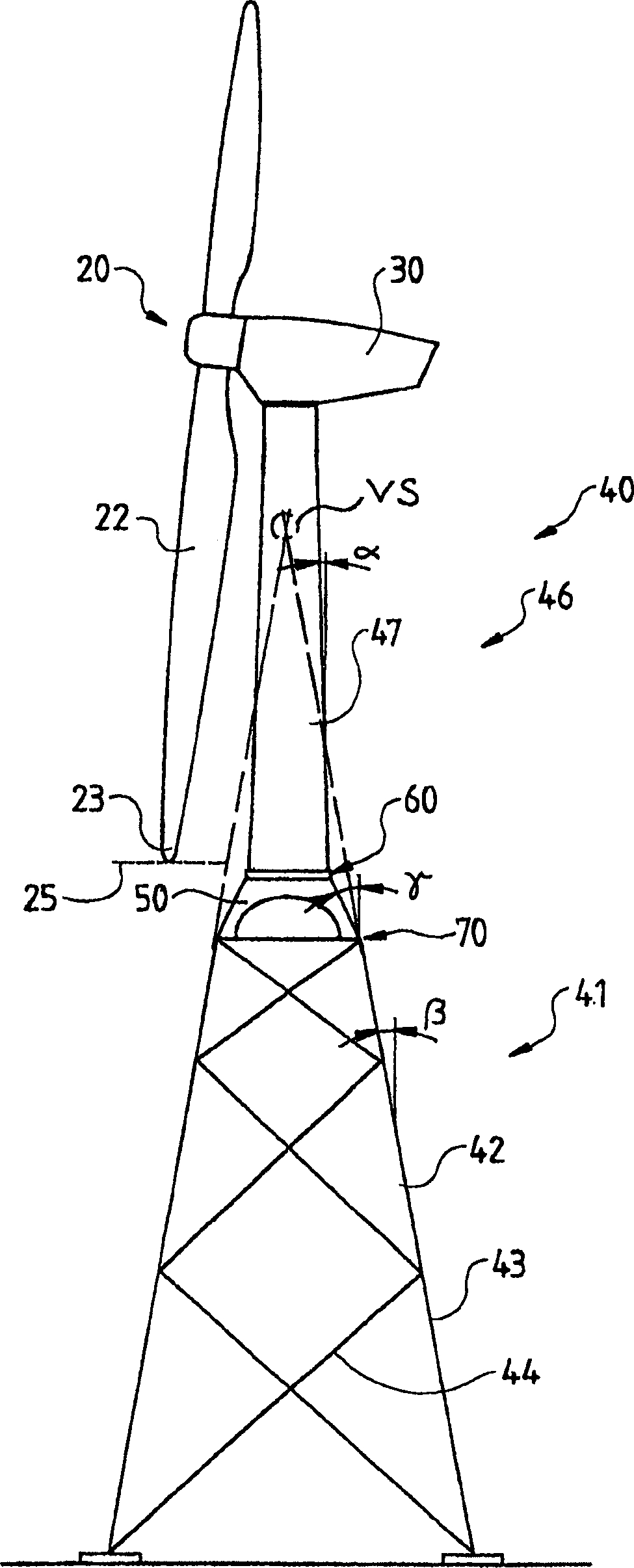

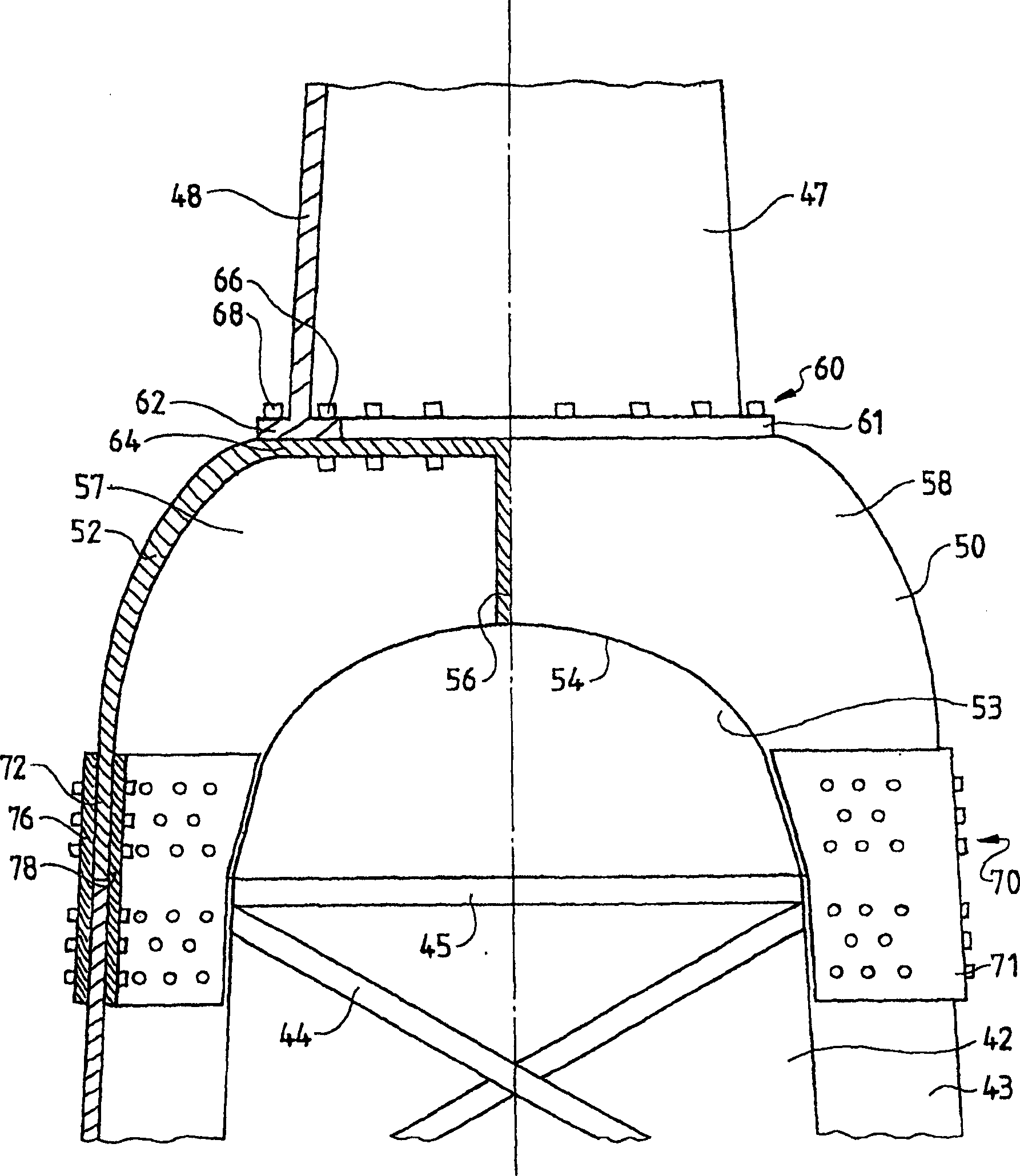

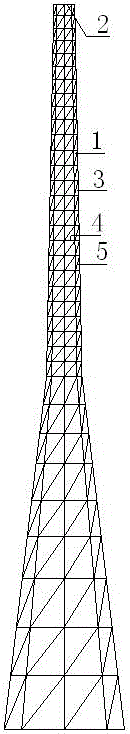

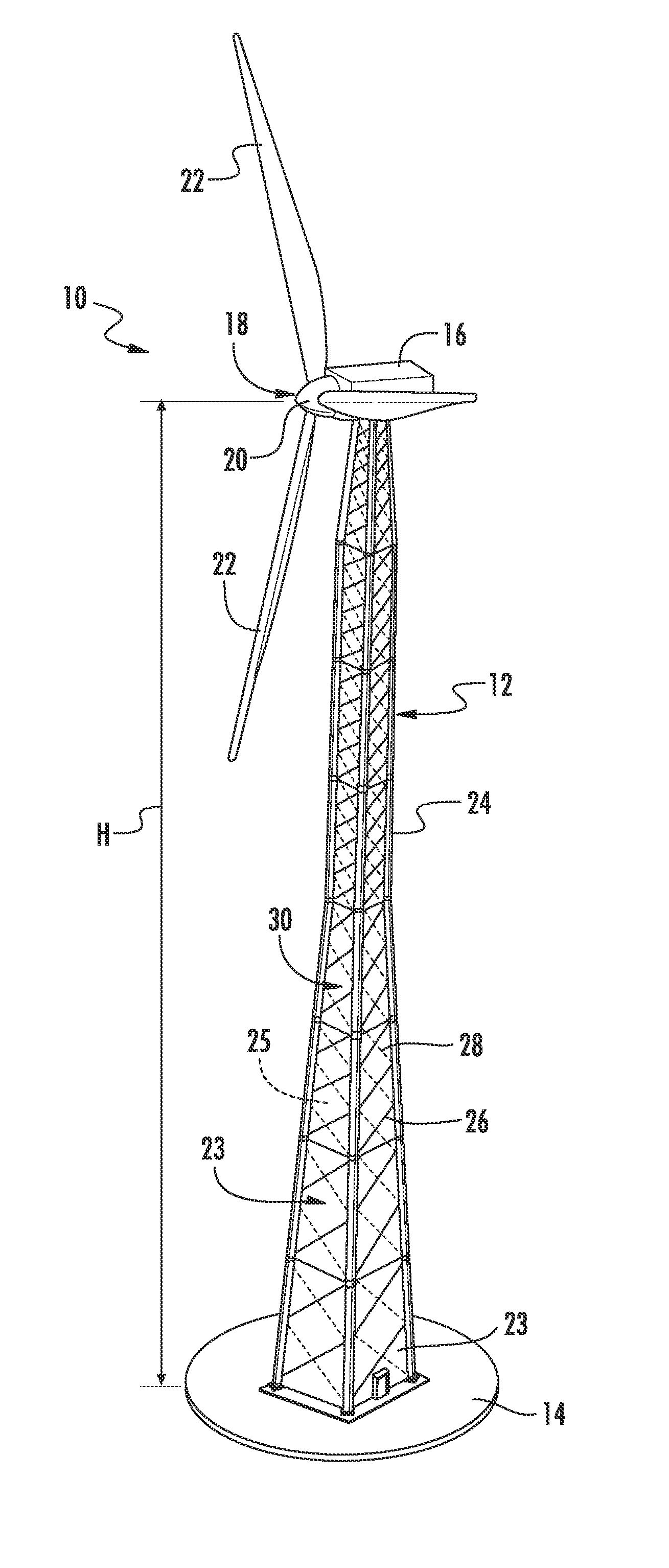

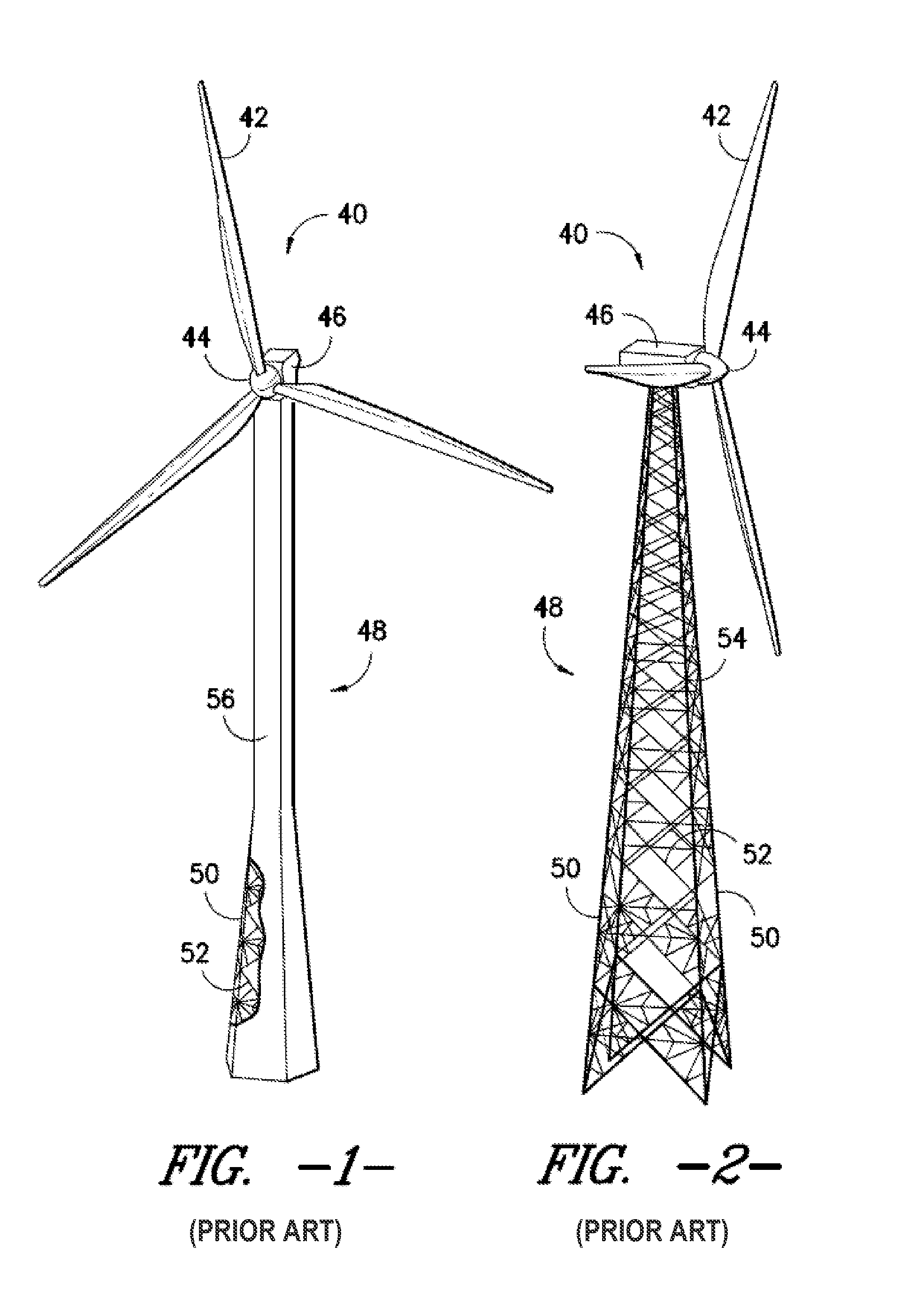

Disclosed is a tower for a wind power station comprising a machine pod disposed on the tower and a rotor mounted on the machine pod so as to be rotatable about an essentially horizontal axis. Said rotor is provided with at least one blade. The tower is composed of a tubular upper section that is connected to a lower section which is embodied as a lattice tower in a transition zone. The lattice tower encompasses at least three corner posts. The upper tower section forms at least one sixth of the entire tower. The cross section of the lower tower section below the transition zone is greater than the cross section of the upper tower section while the transition zone is configured such that the cross section of the lower tower section is adjusted to the cross section of the upper tower section so as to optimize power flux.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

Tower for a wind power station

ActiveUS7276808B2Drawback can be obviatedArtificial islandsWind motor controlPower stationHorizontal axis

Disclosed is a tower for a wind power station comprising a machine pod disposed on the tower and a rotor mounted on the machine pod so as to be rotatable about an essentially horizontal axis. Said rotor is provided with at least one blade. The tower is composed of a tubular upper section that is connected to a lower section which is embodied as a lattice tower in a transition zone. The lattice tower encompasses at least three corner posts. The upper tower section forms at least one sixth of the entire tower. The cross section of the lower tower section below the transition zone is greater than the cross section of the upper tower section while the transition zone is configured such that the cross section of the lower tower section is adjusted to the cross section of the upper tower section so as to optimize power flux.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

Tower for a wind power station

ActiveCN1842632AReduce workloadLow costArtificial islandsWind motor supports/mountsPower stationPower flux

Disclosed is a tower for a wind power station comprising a machine pod disposed on the tower and a rotor mounted on the machine pod so as to be rotatable about an essentially horizontal axis. Said rotor is provided with at least one blade. The tower is composed of a tubular upper section that is connected to a lower section which is embodied as a lattice tower in a transition zone. The lattice tower encompasses at least three corner posts. The upper tower section forms at least one sixth of the entire tower. The cross section of the lower tower section below the transition zone is greater than the cross section of the upper tower section while the transition zone is configured such that the cross section of the lower tower section is adjusted to the cross section of the upper tower section so as to optimize power flux.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

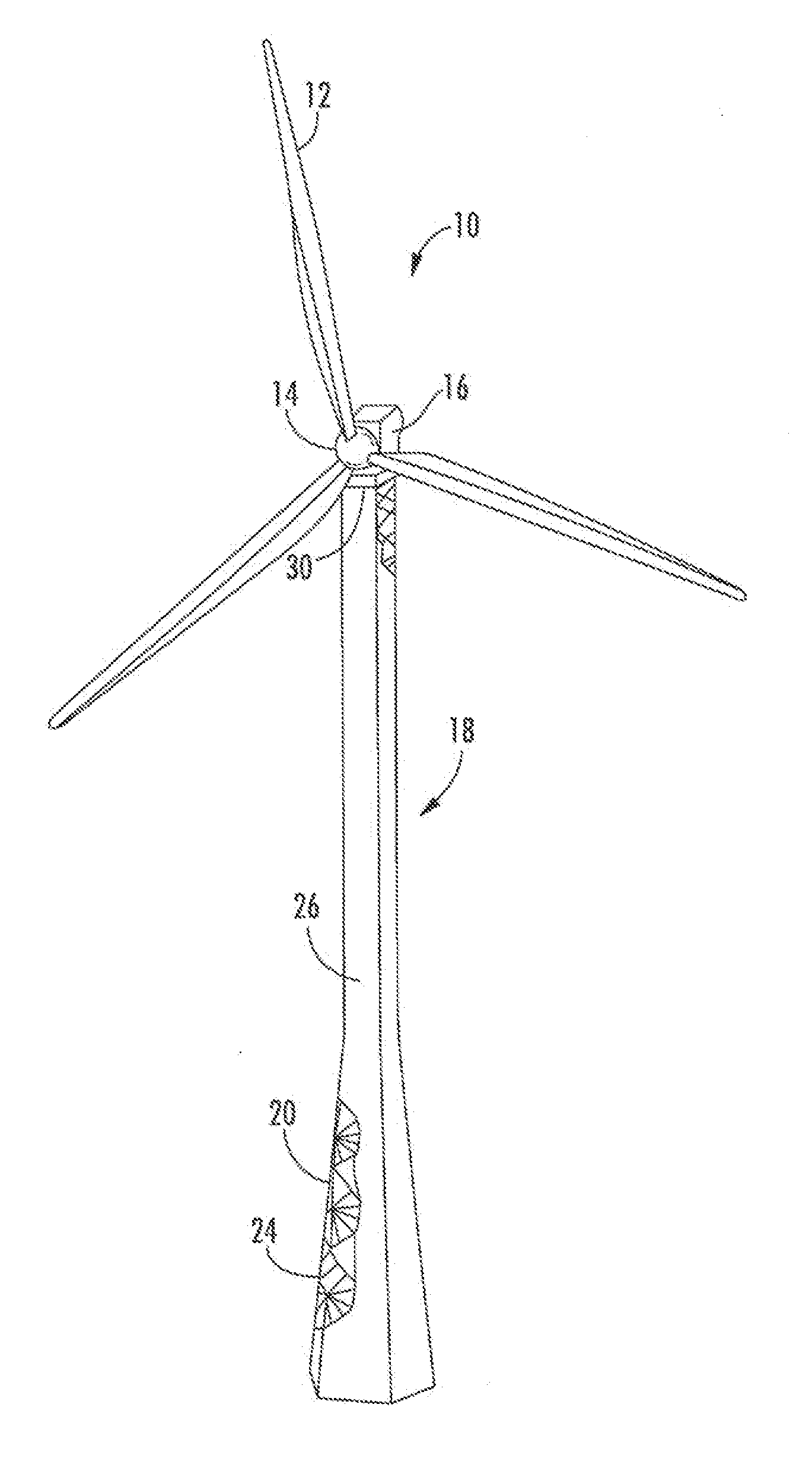

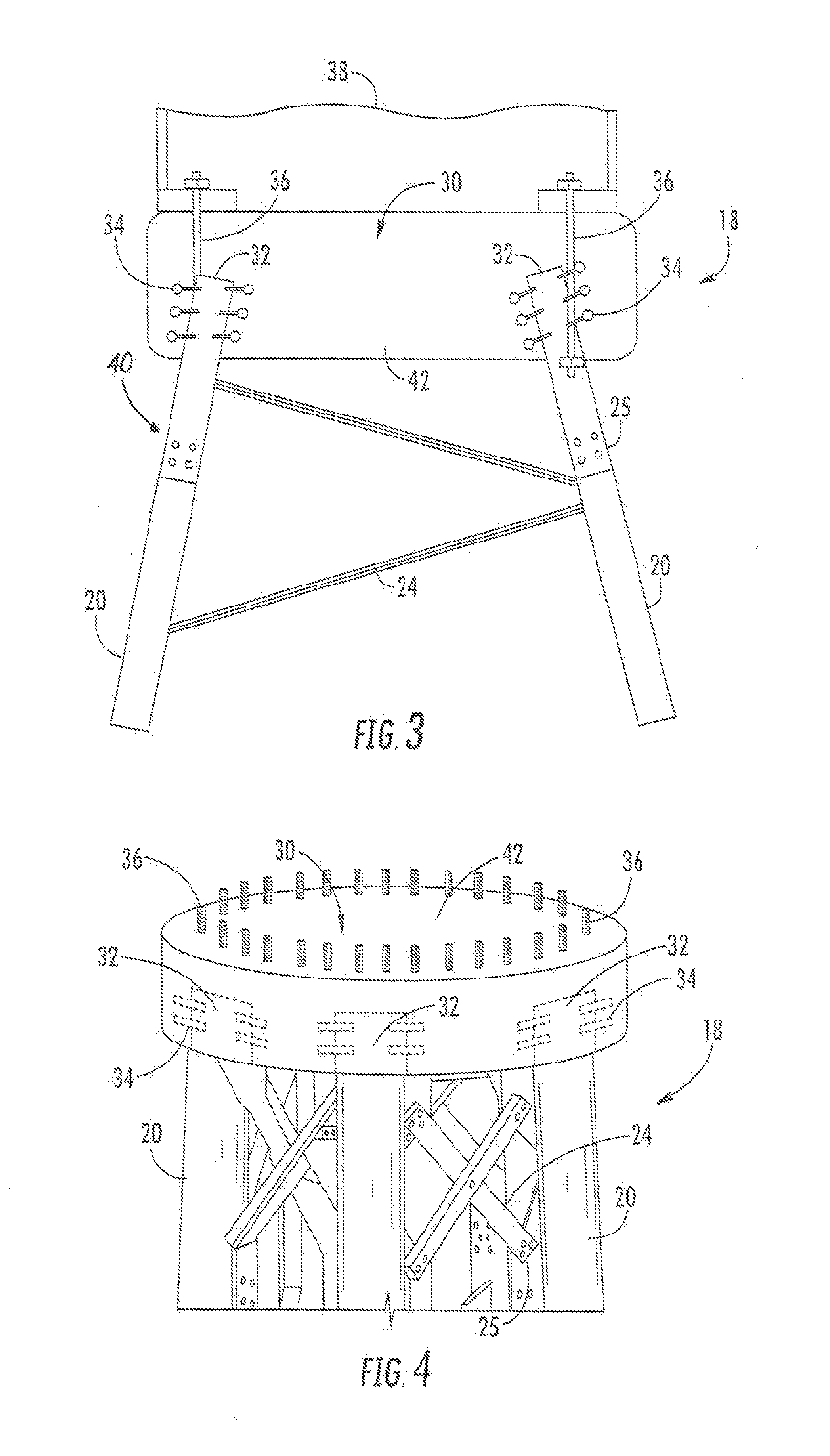

Adapter Configuration for a Wind Tower Lattice Structure

A wind turbine tower includes a lattice tower structure having a plurality of vertically oriented columns and cross-brace members. An adapter is molded onto a top of the lattice tower structure such that top portions of the columns are embedded into the adapter. The adapter may be a concrete member molded onto the lattice tower structure.

Owner:GENERAL ELECTRIC CO

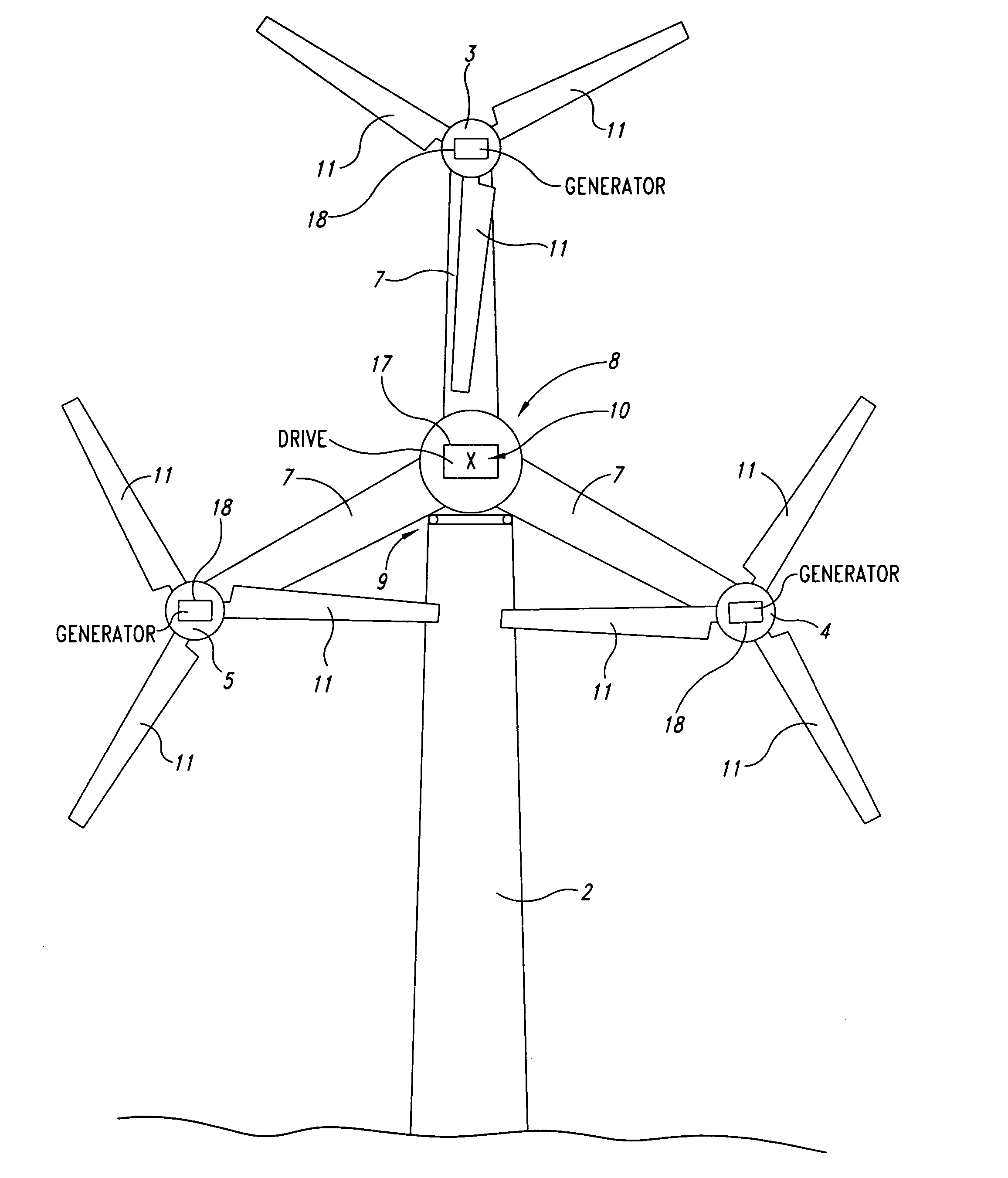

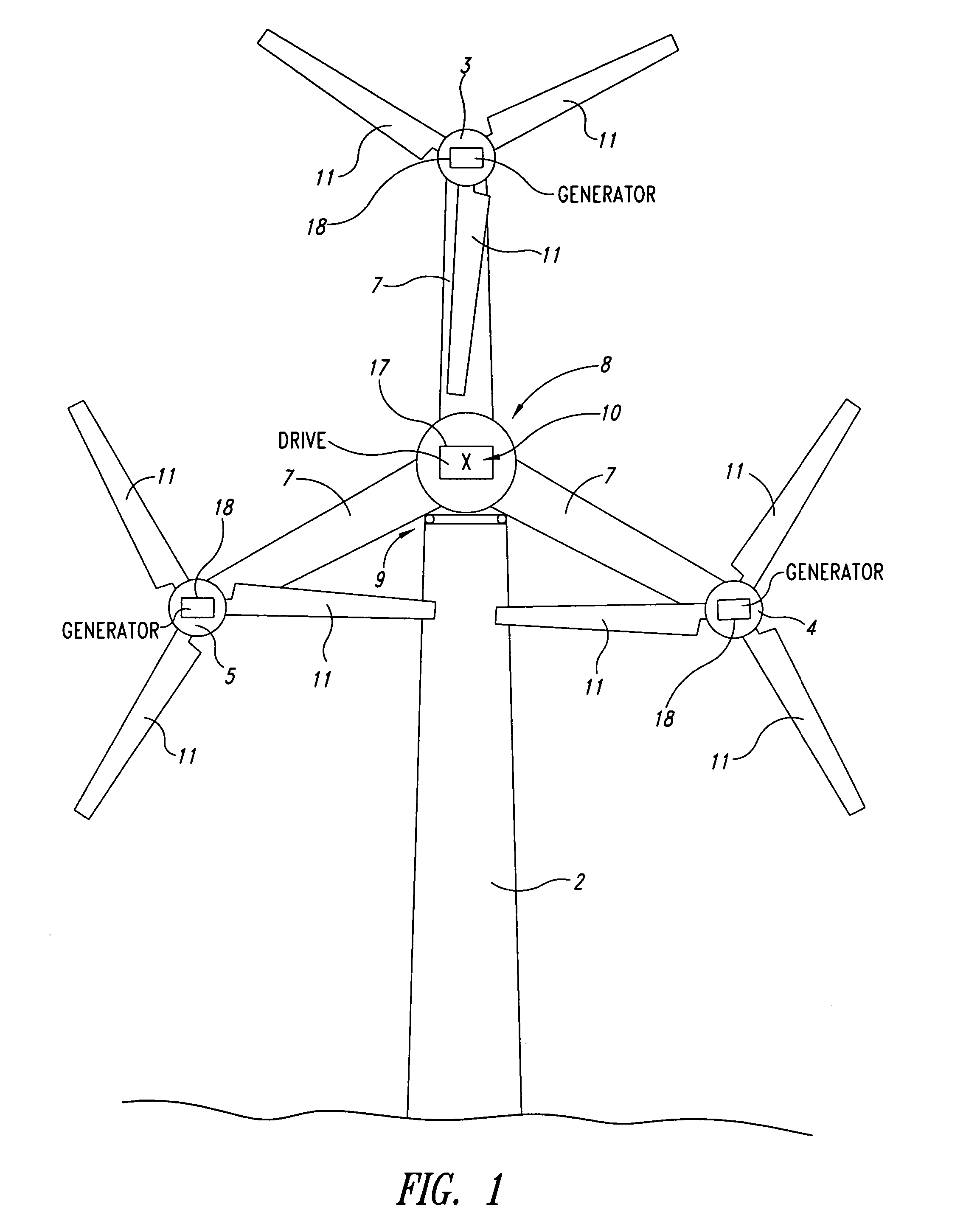

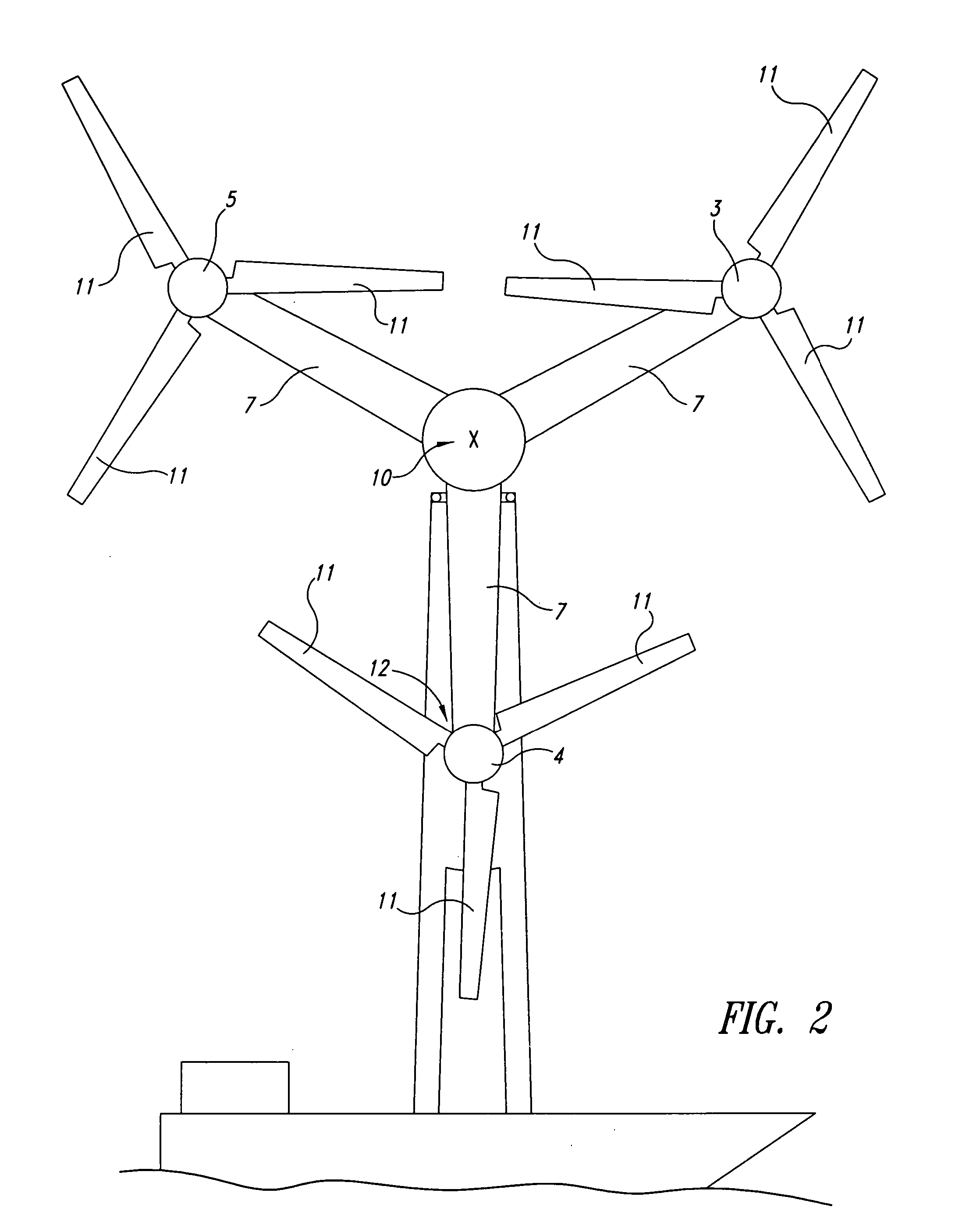

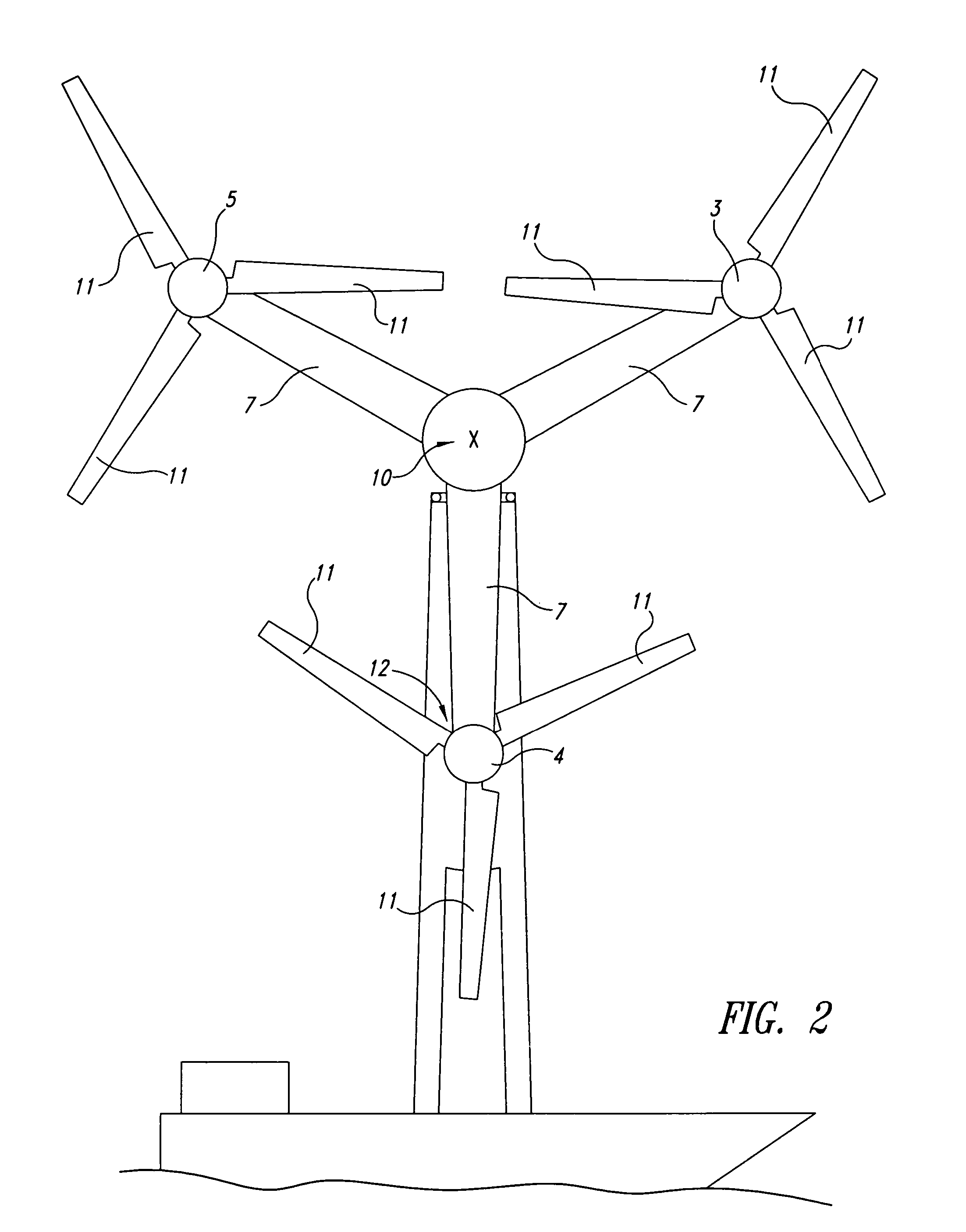

Wind energy turbine

InactiveUS20050218656A1Low costInstallation economyArtificial islandsFinal product manufactureNacelleLattice tower

The invention relates to a wind turbine and to the installation of such a wind turbine, particularly offshore. When wind turbines are installed in the previously known manner, a tower of the wind turbine is firstly manufactured, said tower being a steel tower, a concrete tower or a lattice tower. After the tower has been erected, a machine house is mounted on the top of the tower and said machine house then consists of the entire nacelle, the generator, the rotor and other parts. Such a machine house with rotor blades attached thereto and a generator connected thereto is referred to in the following as a rotor unit. The object of the present invention is to provide technical measures enabling the installation of offshore wind turbines in almost any weather, even when waves are small or moderate in height. Wind turbine with a tower that receives a rotatably mounted support, wherein the support receives at least one and preferably a plurality of rotors that are in a plane offset from the tower, and the support is positioned such that the centre of the rotors is lower than the top of the tower.

Owner:WOBBEN ALOYS

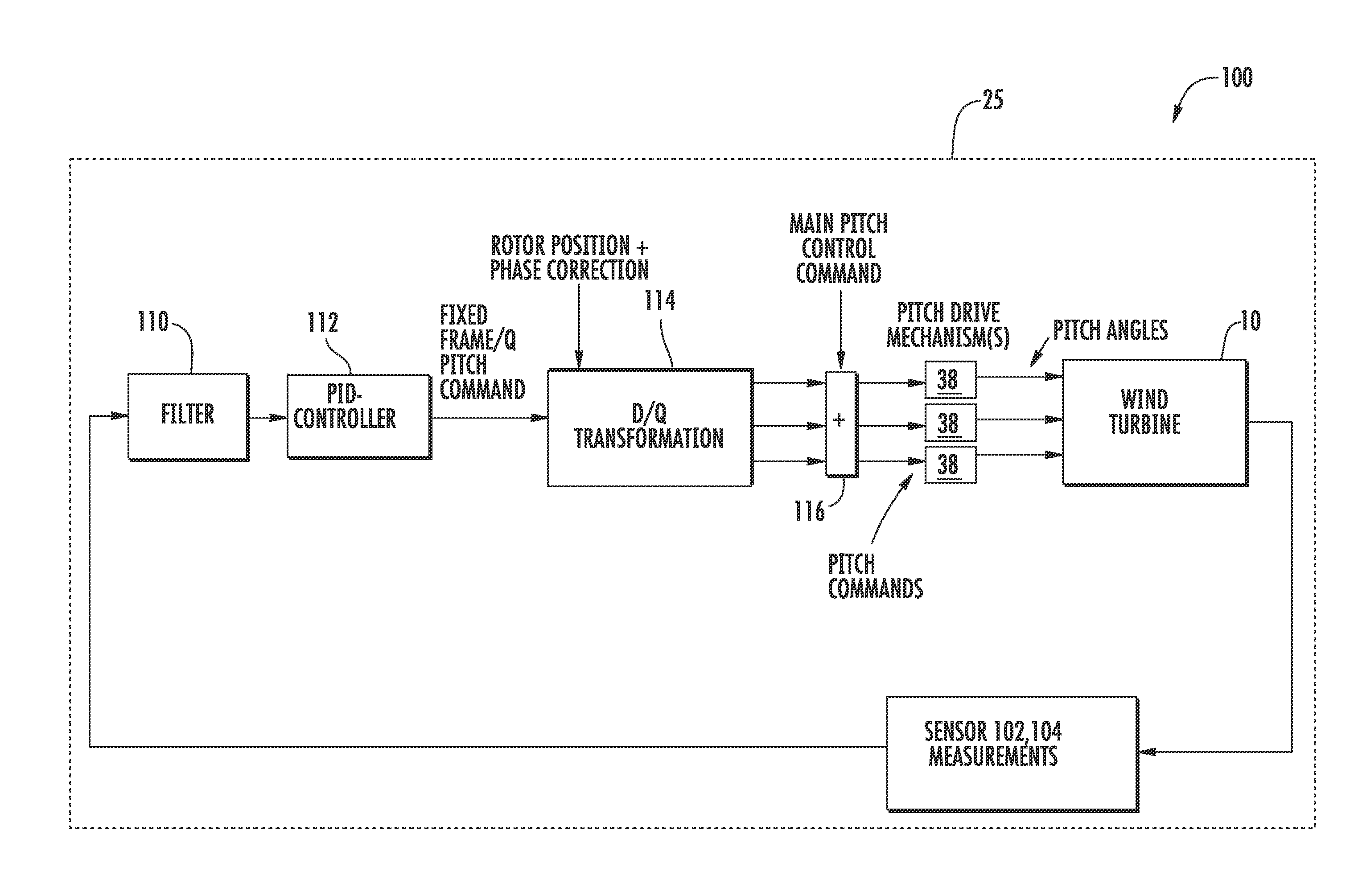

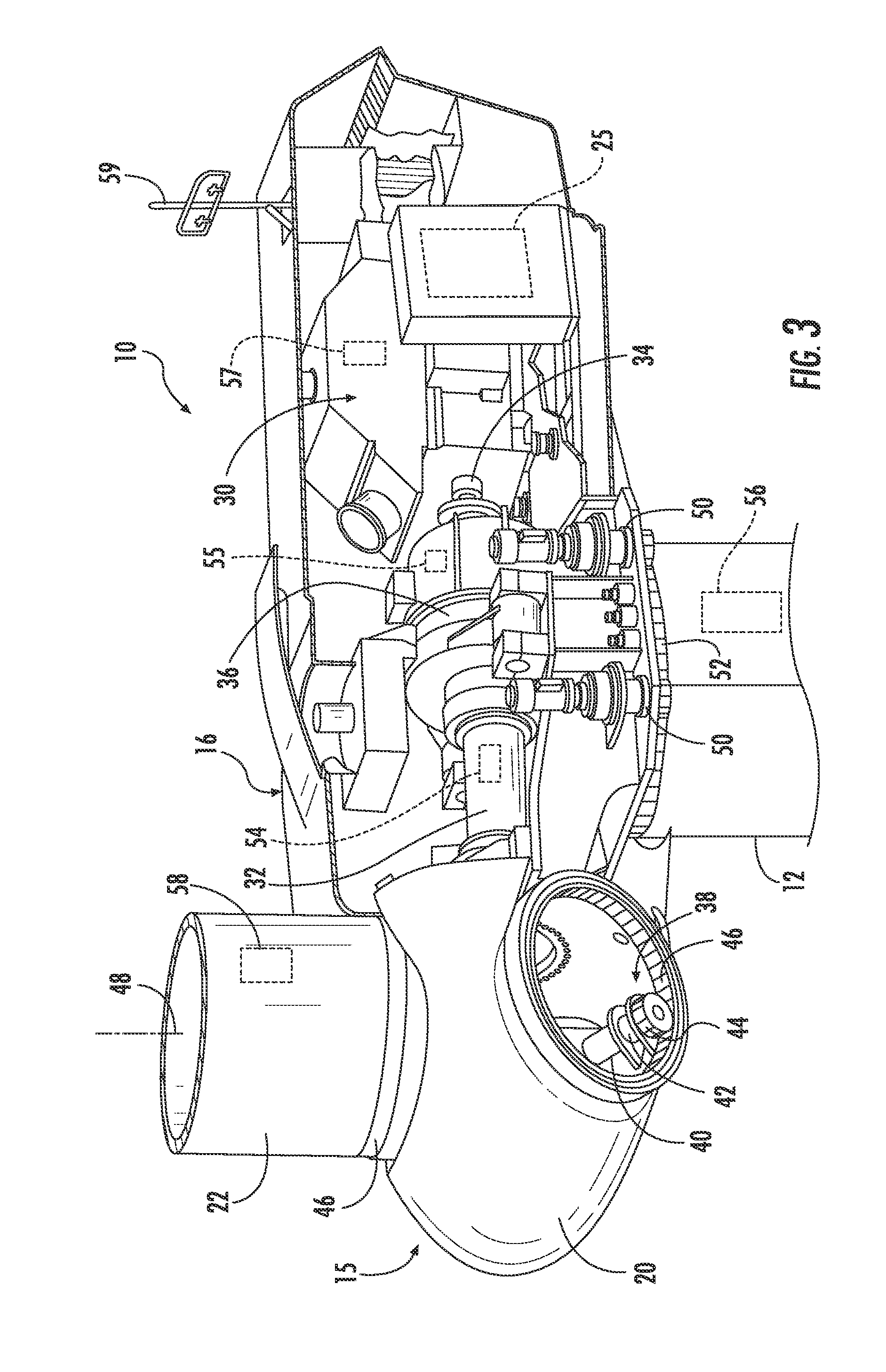

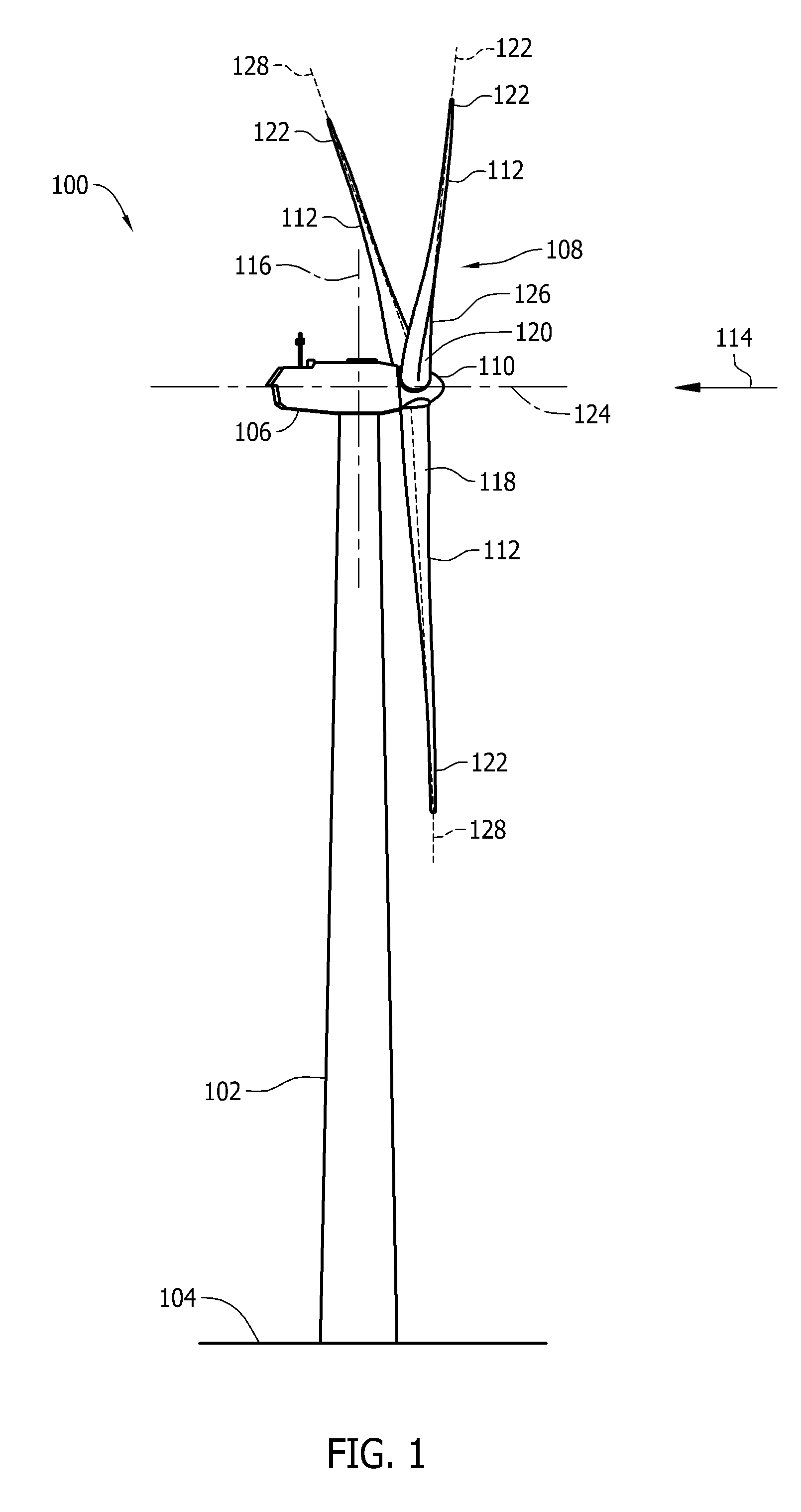

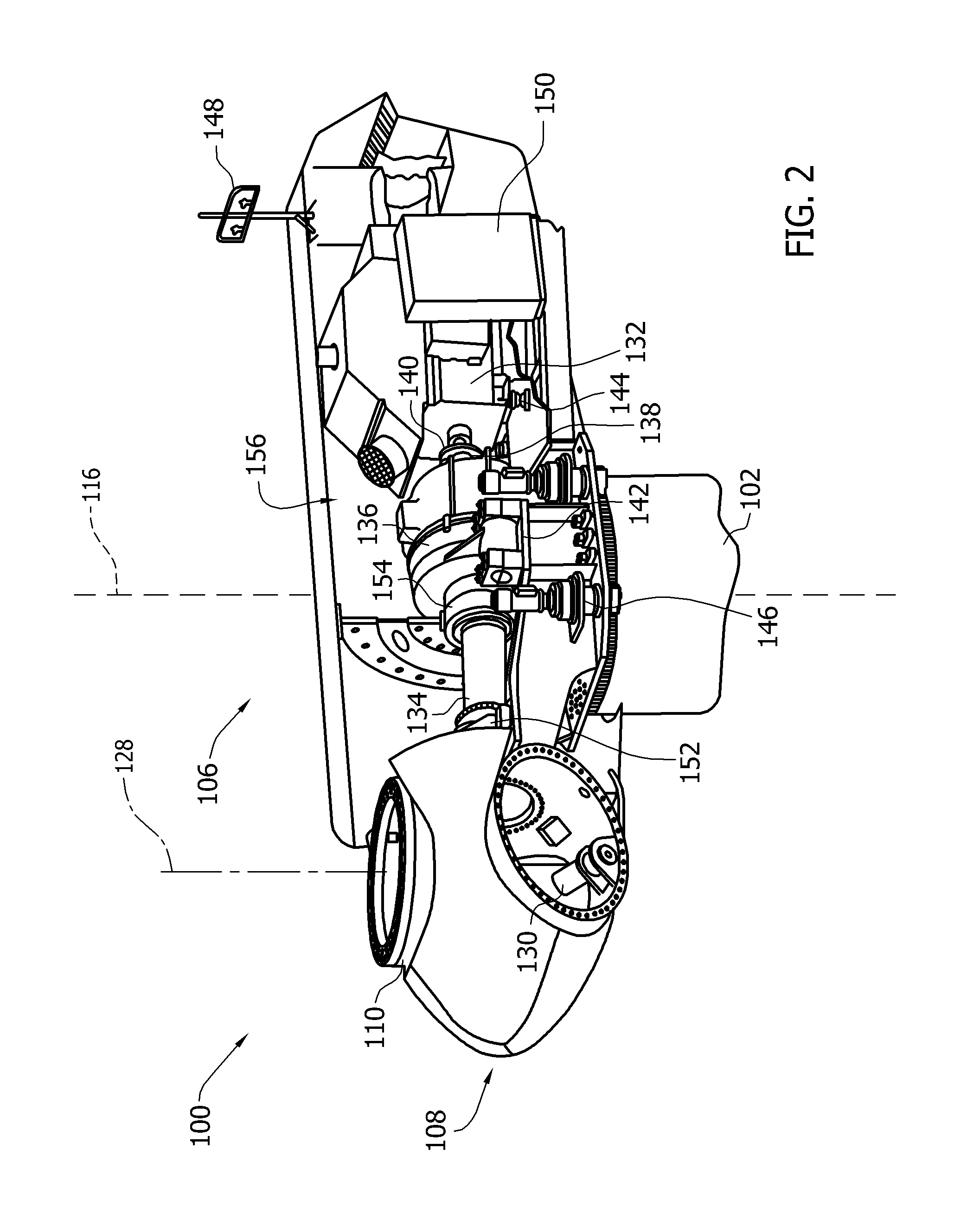

System and Method for Reducing Torsional Movement in a Wind Turbine Tower

InactiveUS20160356266A1Reduce vibrationDampen torsional movementWind motor controlEngine fuctionsTurbineLattice tower

The present disclosure is directed to a system and method for reducing vibrations of a tower (e.g. a tubular steep tower or a lattice tower structure) of a wind turbine. The method includes continuously determining a torsional movement of the tower based at least in part on measurements obtained from one or more sensors. Another step includes continuously determining, via a controller, a control command for one or more pitch drive mechanisms of the wind turbine based on the torsional movement. Thus, the method also includes operating the one or more pitch drive mechanisms based on the control command so as to dampen the torsional movement of the tower.

Owner:GENERAL ELECTRIC CO

Wind energy turbine

The invention relates to a wind turbine and to the installation of such a wind turbine, particularly offshore. When wind turbines are installed in the previously known manner, a tower of the wind turbine is firstly manufactured, said tower being a steel tower, a concrete tower or a lattice tower. After the tower has been erected, a machine house is mounted on the top of the tower and said machine house then consists of the entire nacelle, the generator, the rotor and other parts. Such a machine house with rotor blades attached thereto and a generator connected thereto is referred to in the following as a rotor unit. _The object of the present invention is to provide technical measures enabling the installation of offshore wind turbines in almost any weather, even when waves are small or moderate in height. _Wind turbine with a tower that receives a rotatably mounted support, wherein the support receives at least one and preferably a plurality of rotors that are in a plane offset from the tower, and the support is positioned such that the centre of the rotors is lower than the top of the tower.

Owner:WOBBEN ALOYS

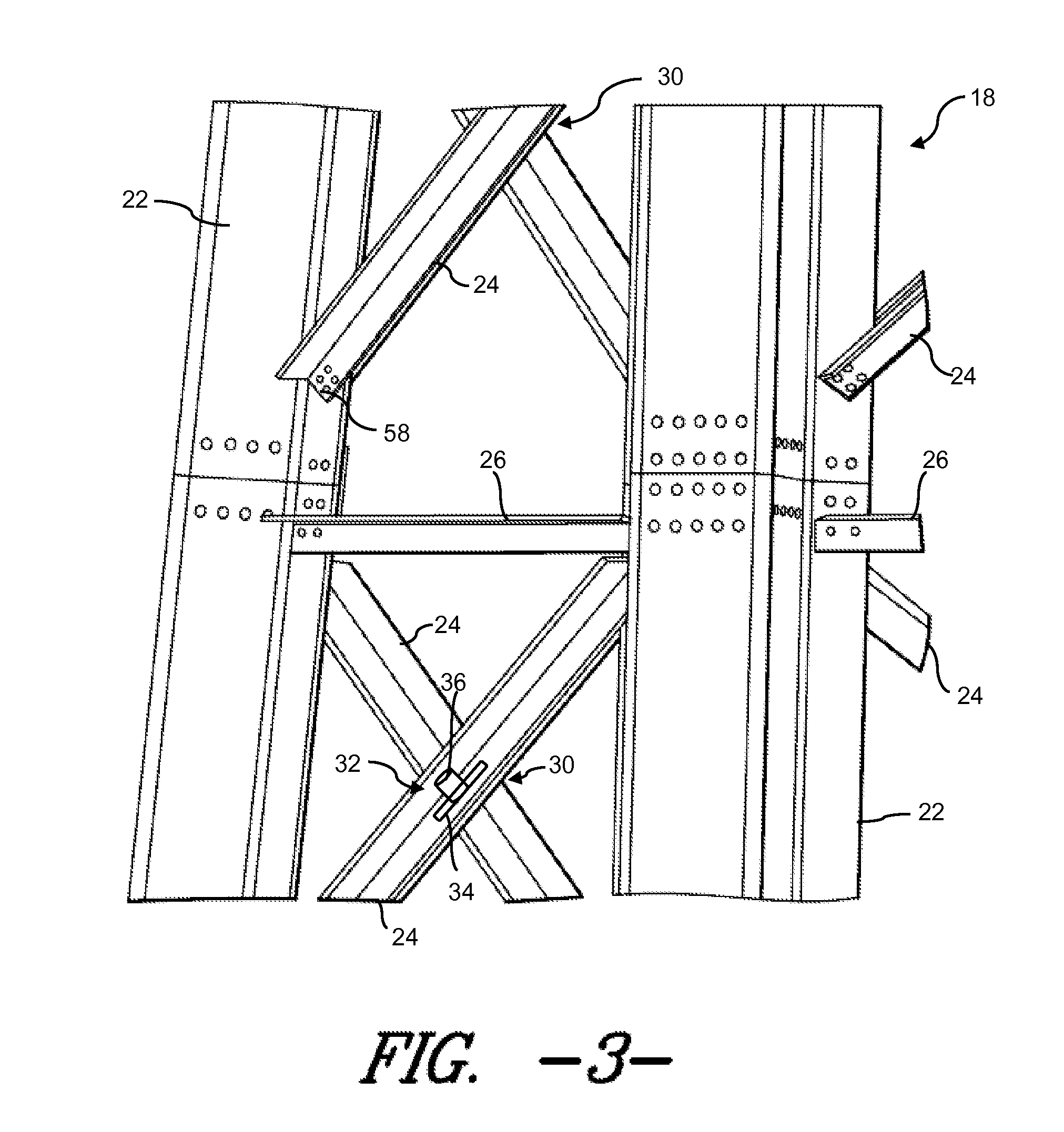

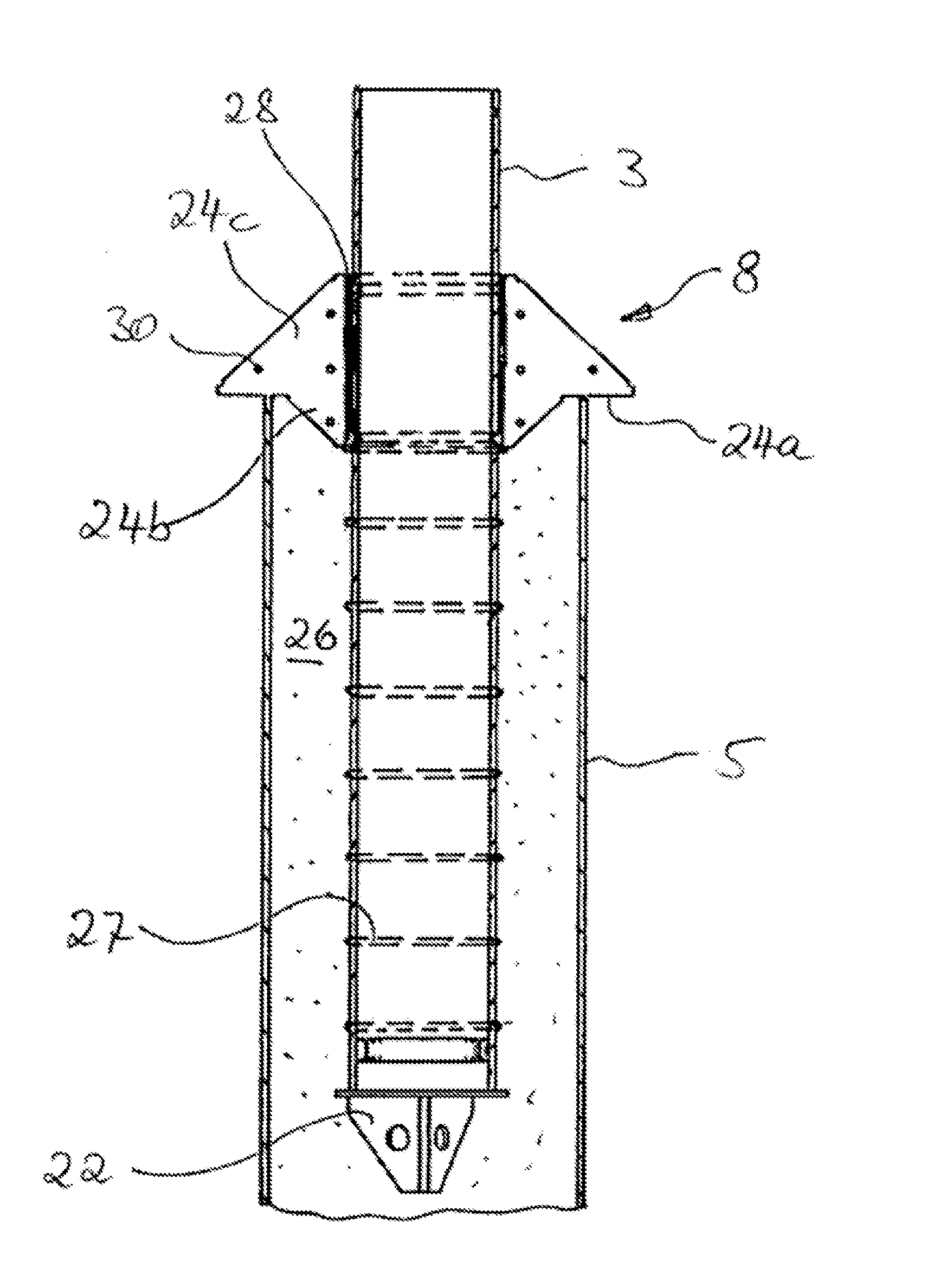

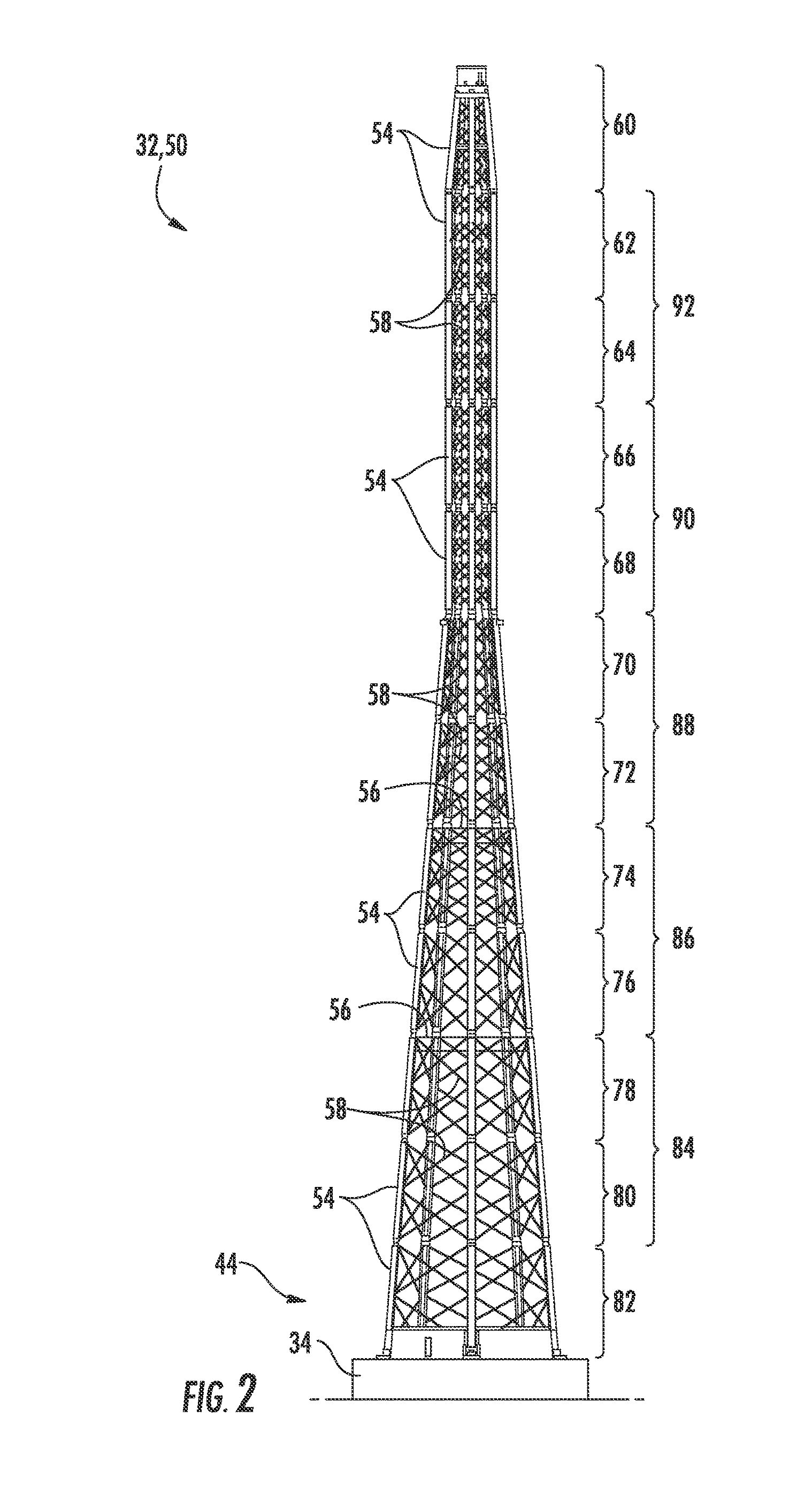

Support tower for use with a wind turbine and system for designing support tower

InactiveUS20110133475A1Facilitate local distortionWind motor supports/mountsMachines/enginesEngineeringTurbine

A lattice tower for use with a wind turbine. The lattice tower includes at least one support extending from a supporting surface. At least one cross-support member is coupled to the support to form the lattice tower. A reinforcement assembly is coupled to the support to transfer at least a portion of a bending load and a torsional load induced to the support to the reinforcement assembly to facilitate reducing a local distortion of the support.

Owner:GENERAL ELECTRIC CO

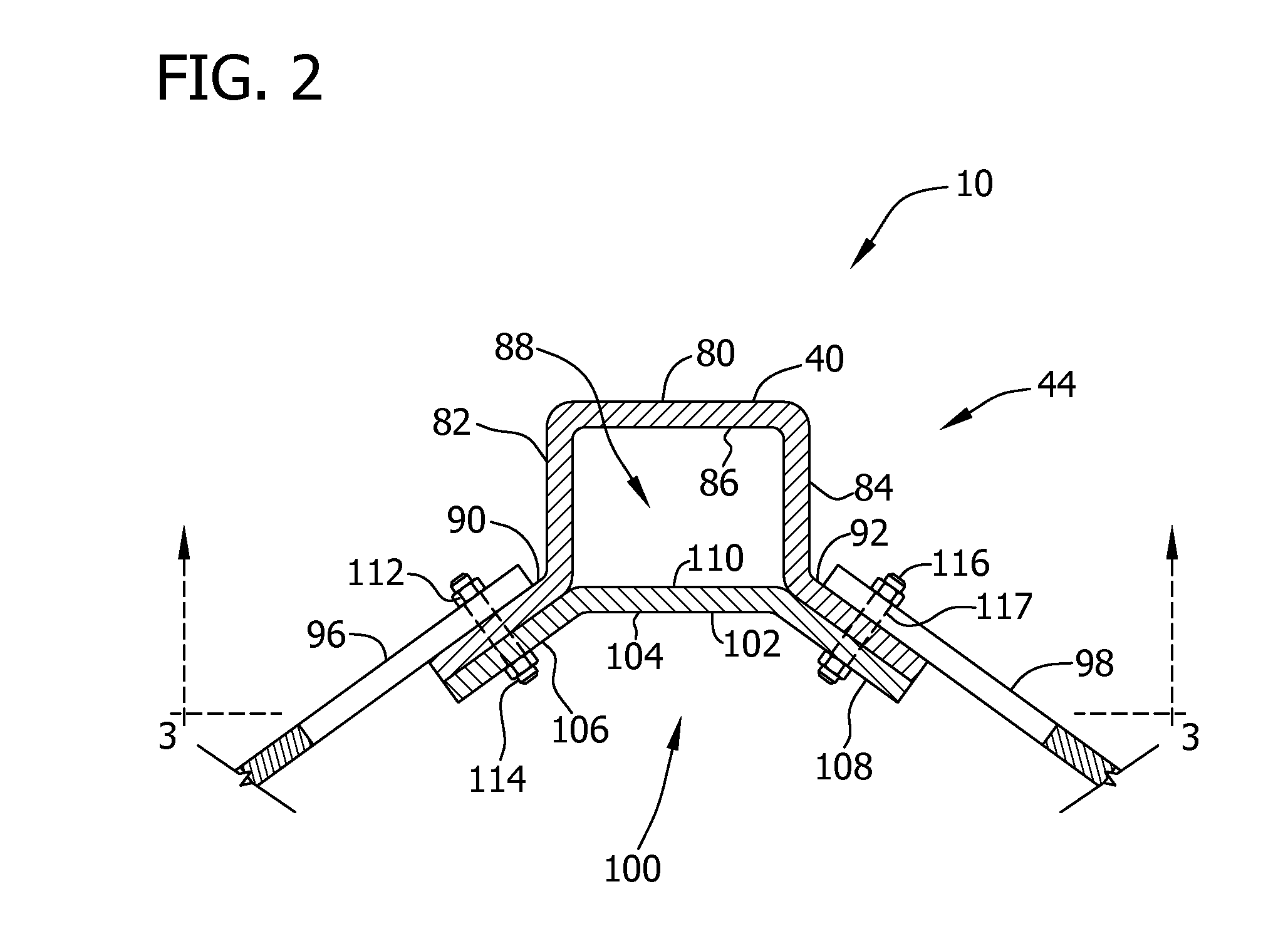

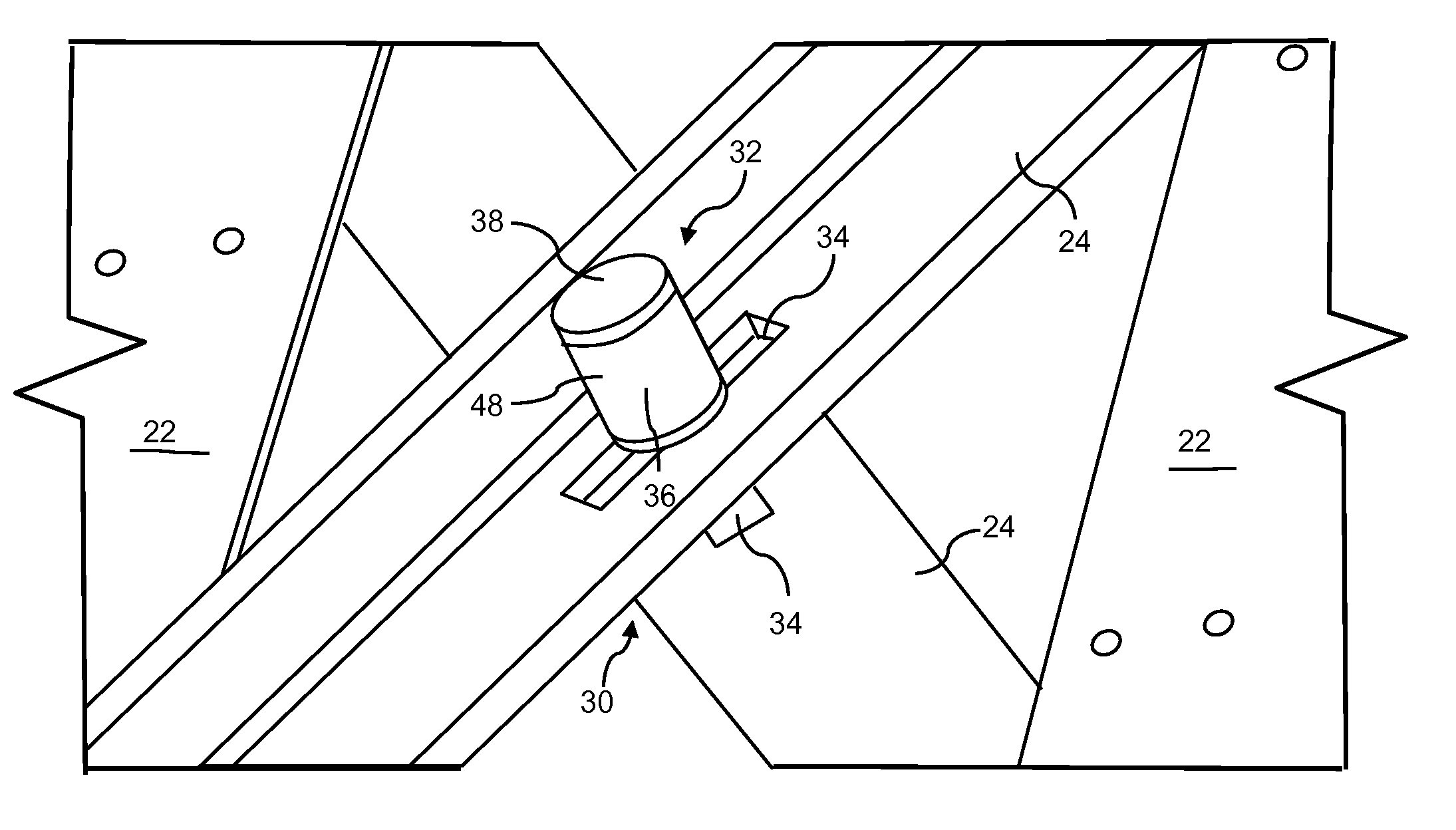

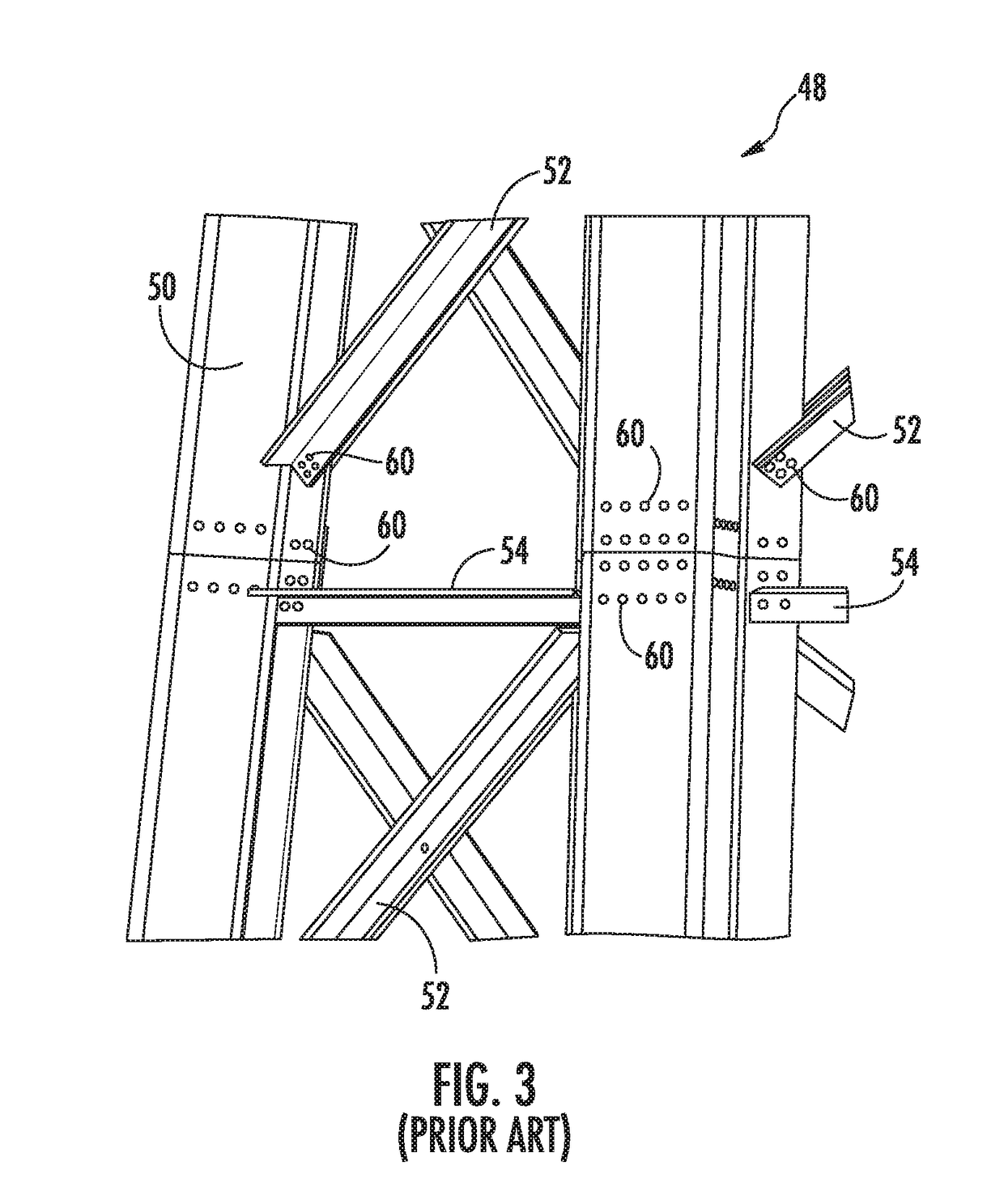

Bolt connection assembly for a wind turbine lattice tower structure

InactiveUS20140331568A1Improve joint reliabilityEvenly loadedEngine manufactureFinal product manufactureEngineeringTurbine

A bolt connection assembly is provided that is particularly well-suited for connecting structural members of a lattice tower structure for a wind turbine. The bolt connection assembly includes a bolt component having a head and a shaft and a structural bore component having a bore defined therethrough for receipt of the bolt component. The shaft includes a knurled surface such that the knurled surface defines an outermost shaft diameter. Moreover, the knurled surface includes a plurality of knurls, each defining a non-arcuate edge. The bore defines a bore diameter, wherein the outermost shaft diameter is greater than the bore diameter. In an assembled state of the bolt component and the structural bore component, the bolt component may be inserted within the bore such that the knurled surface may be deformed to friction fit within the bore diameter.

Owner:GENERAL ELECTRIC CO

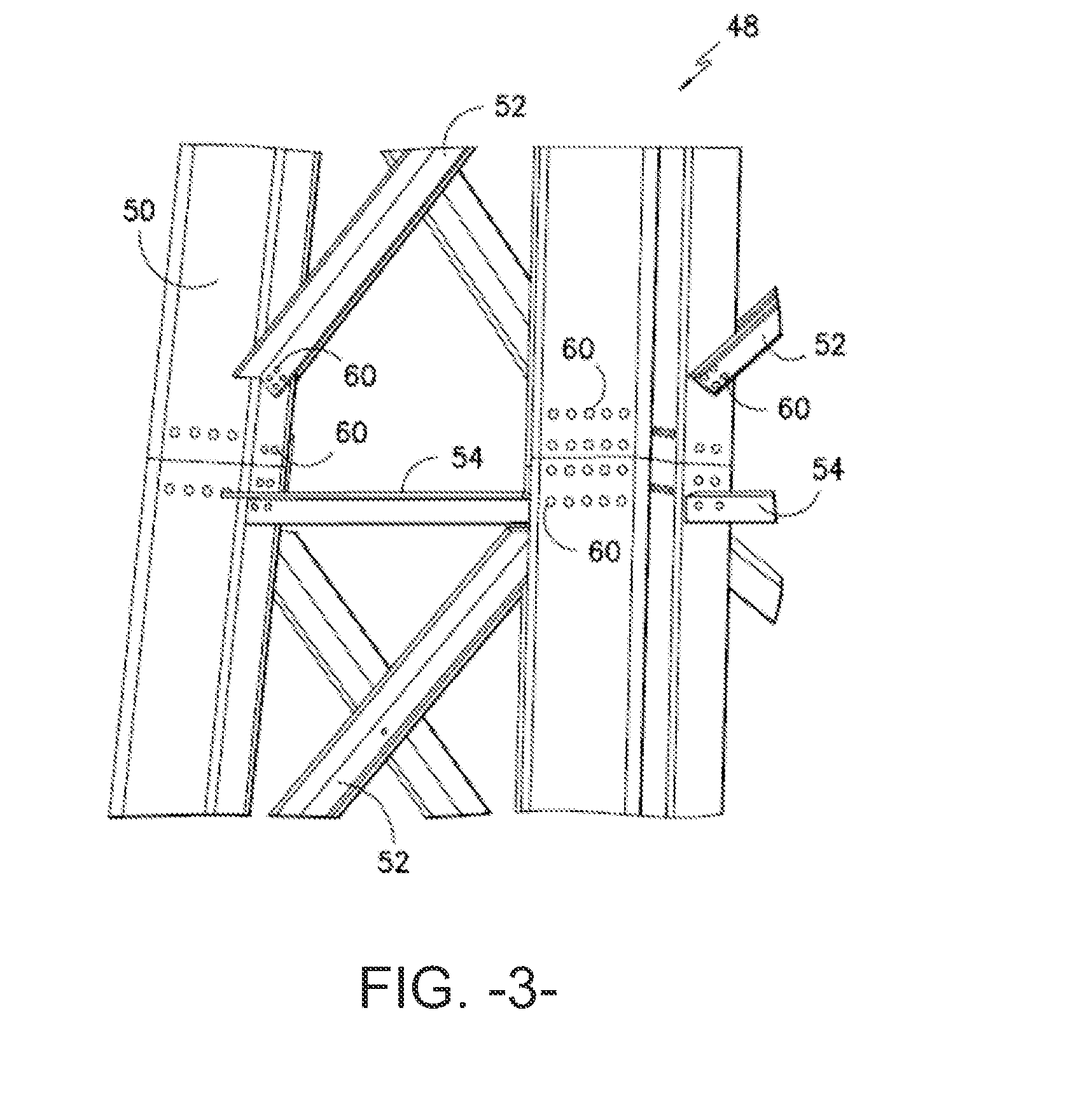

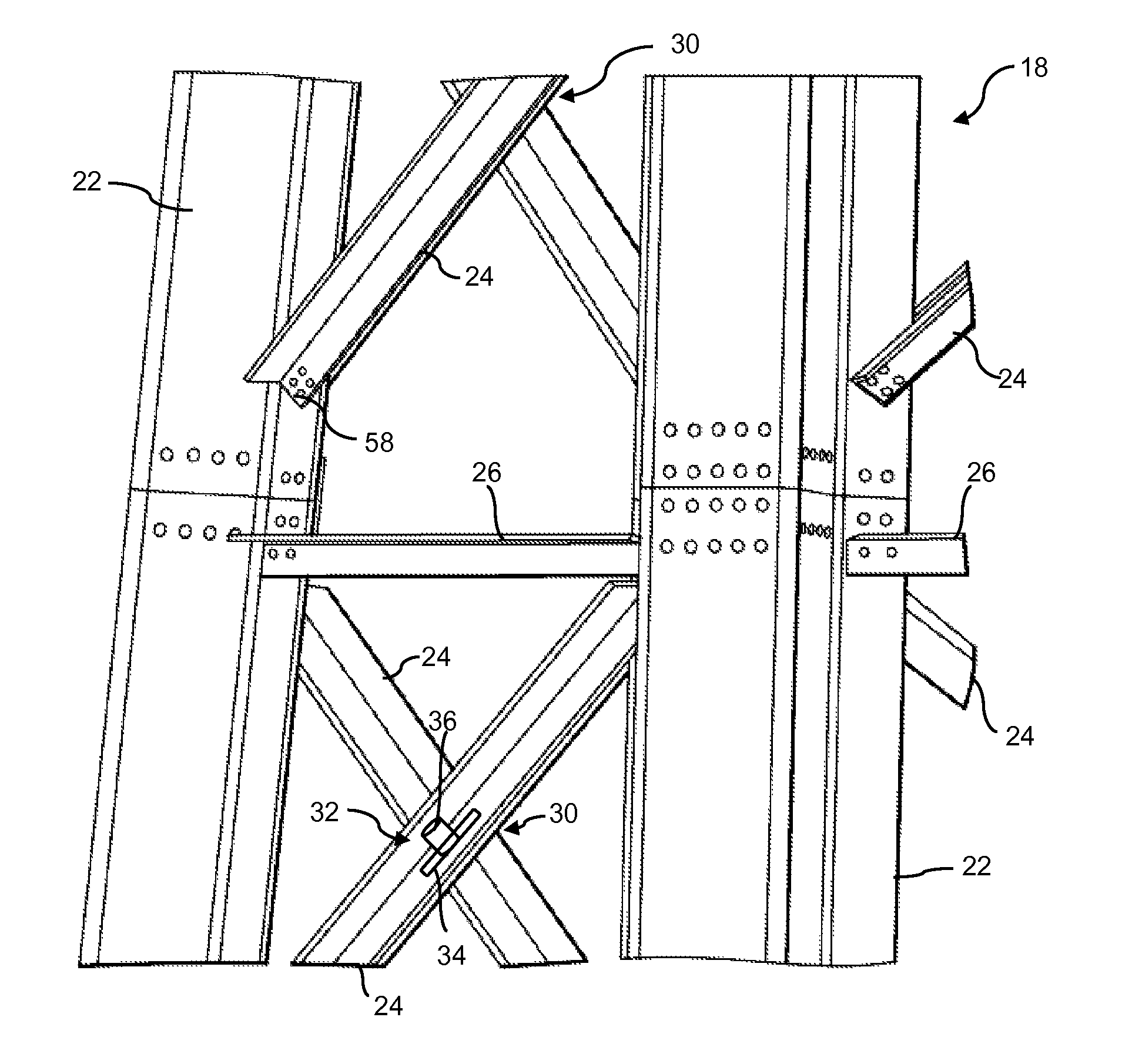

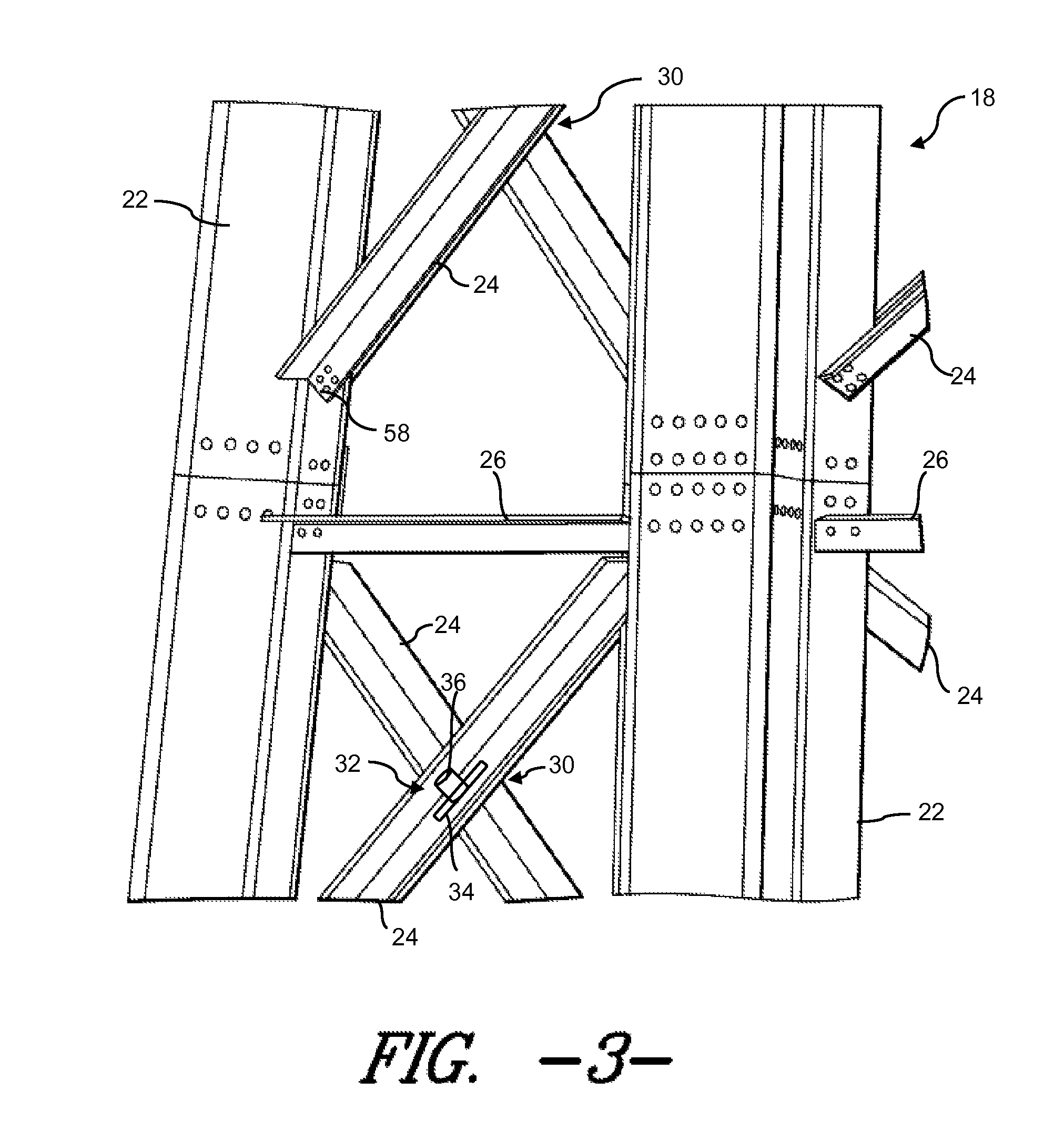

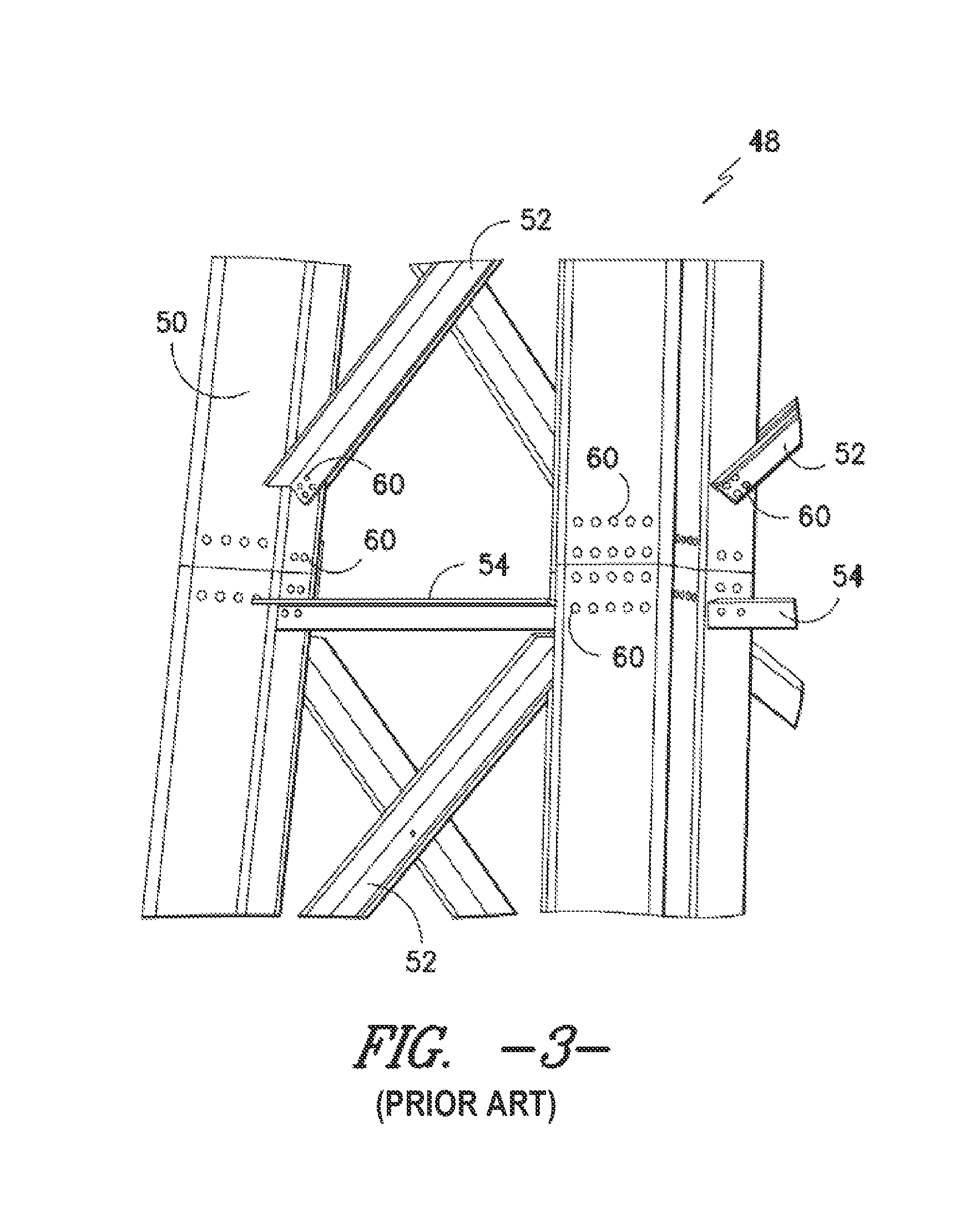

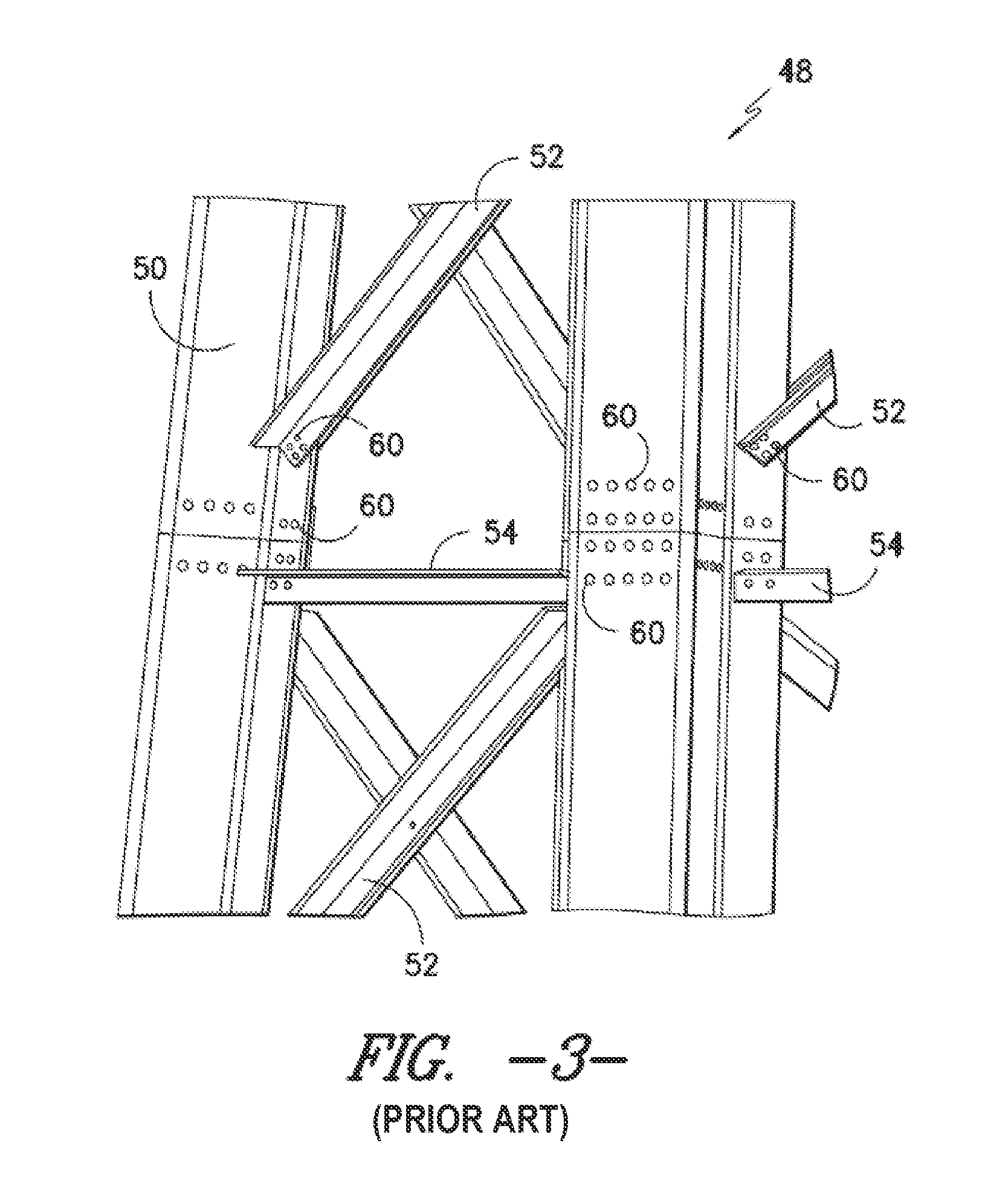

Friction damping bolt connection for a wind tower lattice structure

InactiveUS20120131877A1Increase sliding frictionImprove vibrationTowersProtective buildings/sheltersRelative motionTurbine

A wind turbine lattice tower structure includes a plurality of structural members connected together to define an open lattice tower, with the structural members including vertical leg members and diagonal braces extending between the vertical leg members. Pairs of the diagonal braces form cross braces having an intersection point therebetween. A damping bolt connection assembly is provides at the intersection point of the cross braces and is configured to attach the cross braces together at the intersection point while providing for relative movement of each individual cross brace along a defined longitudinal section of the other respective cross brace.

Owner:GENERAL ELECTRIC CO

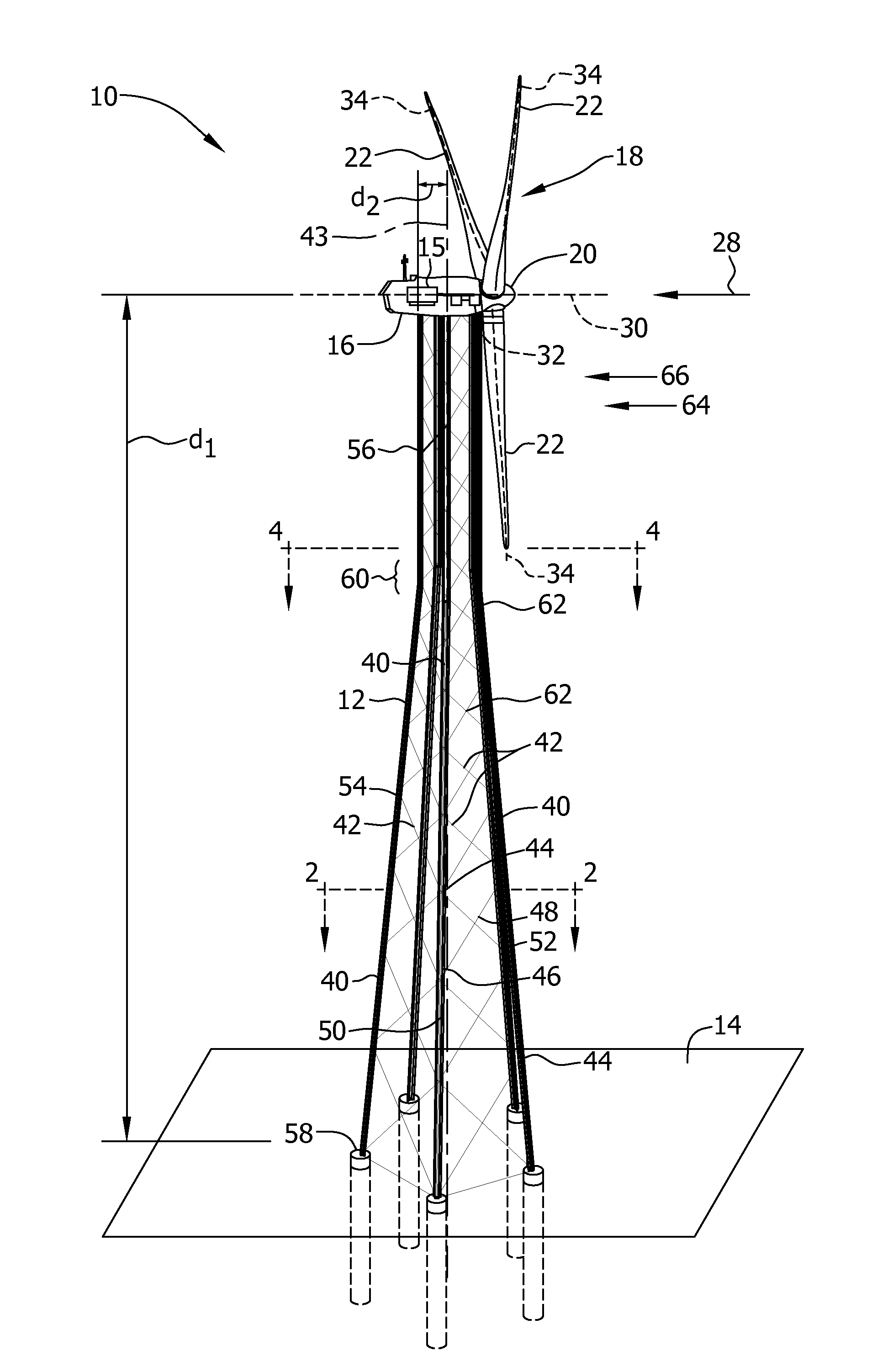

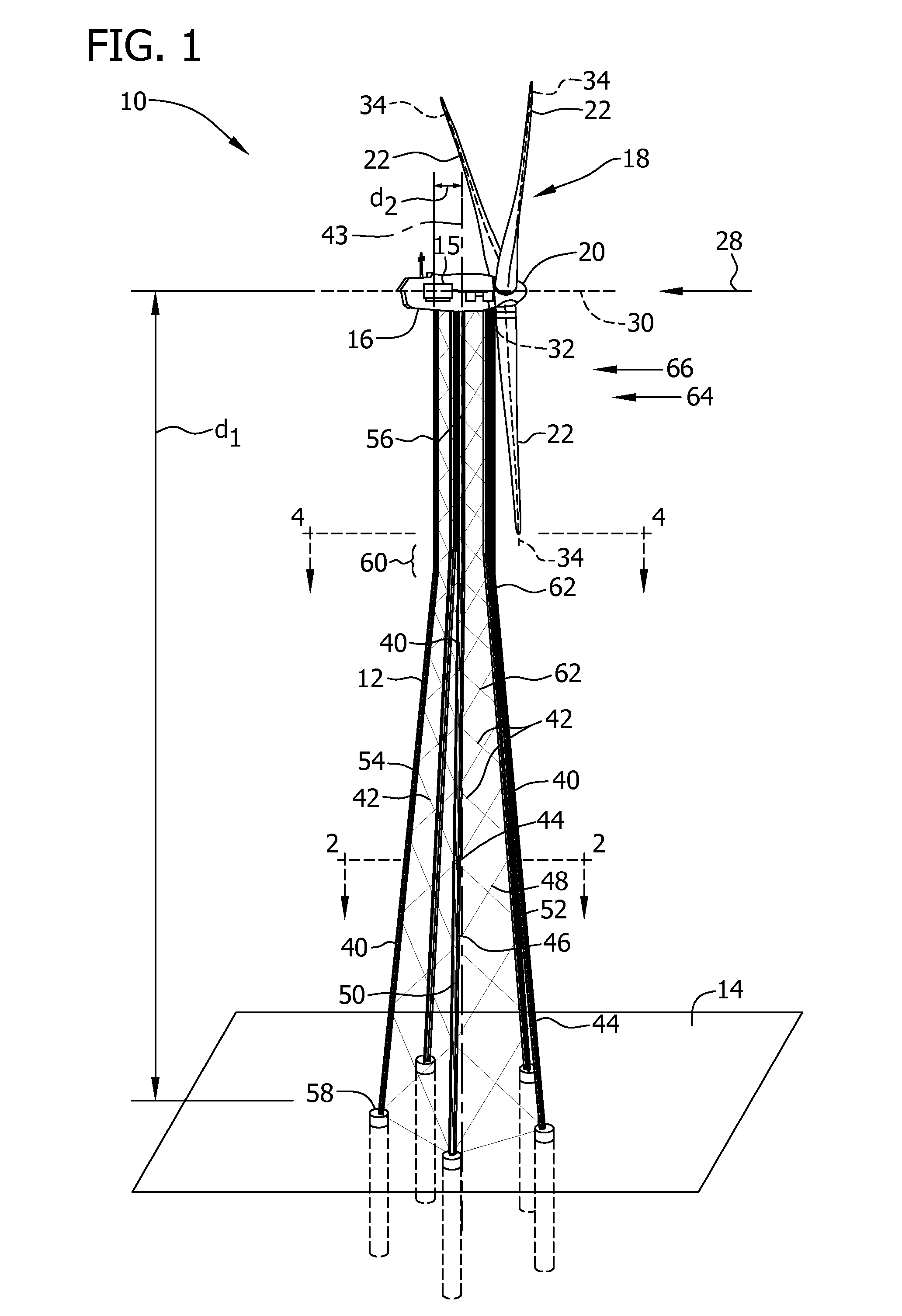

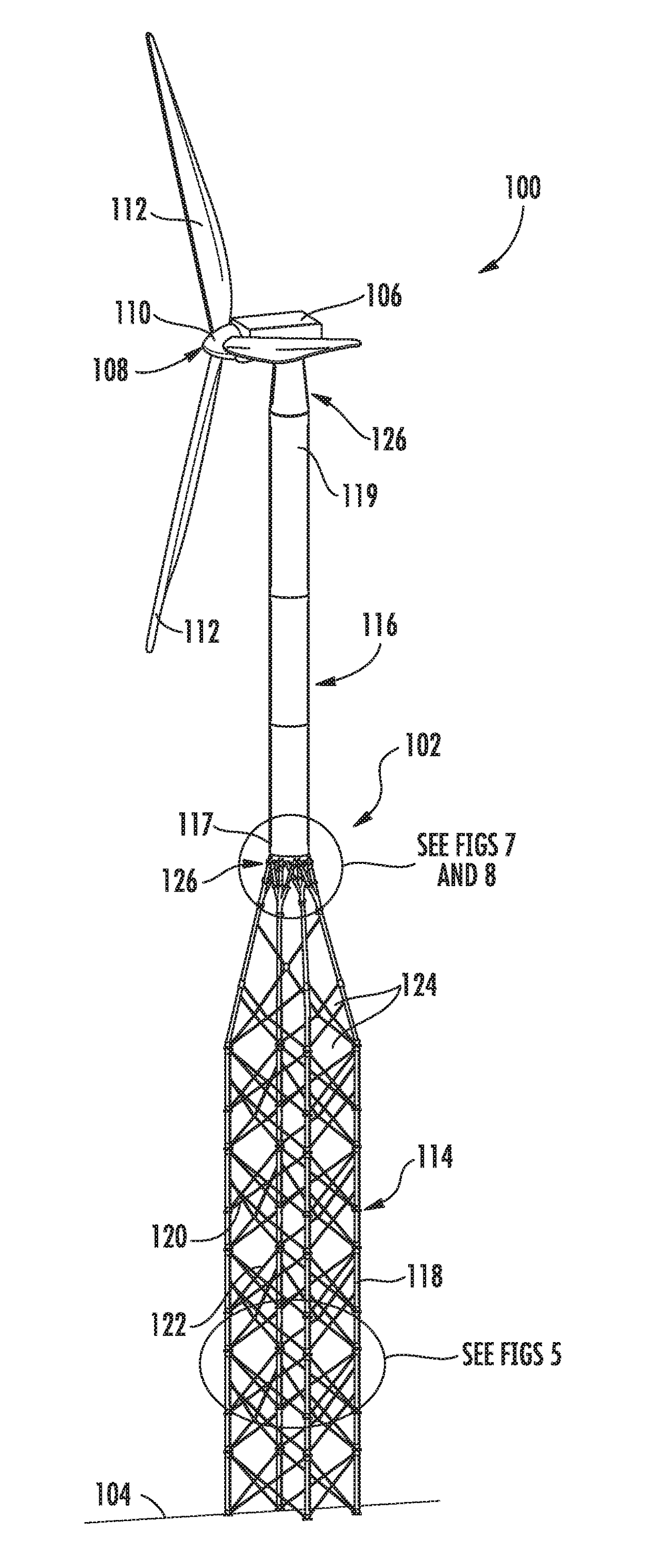

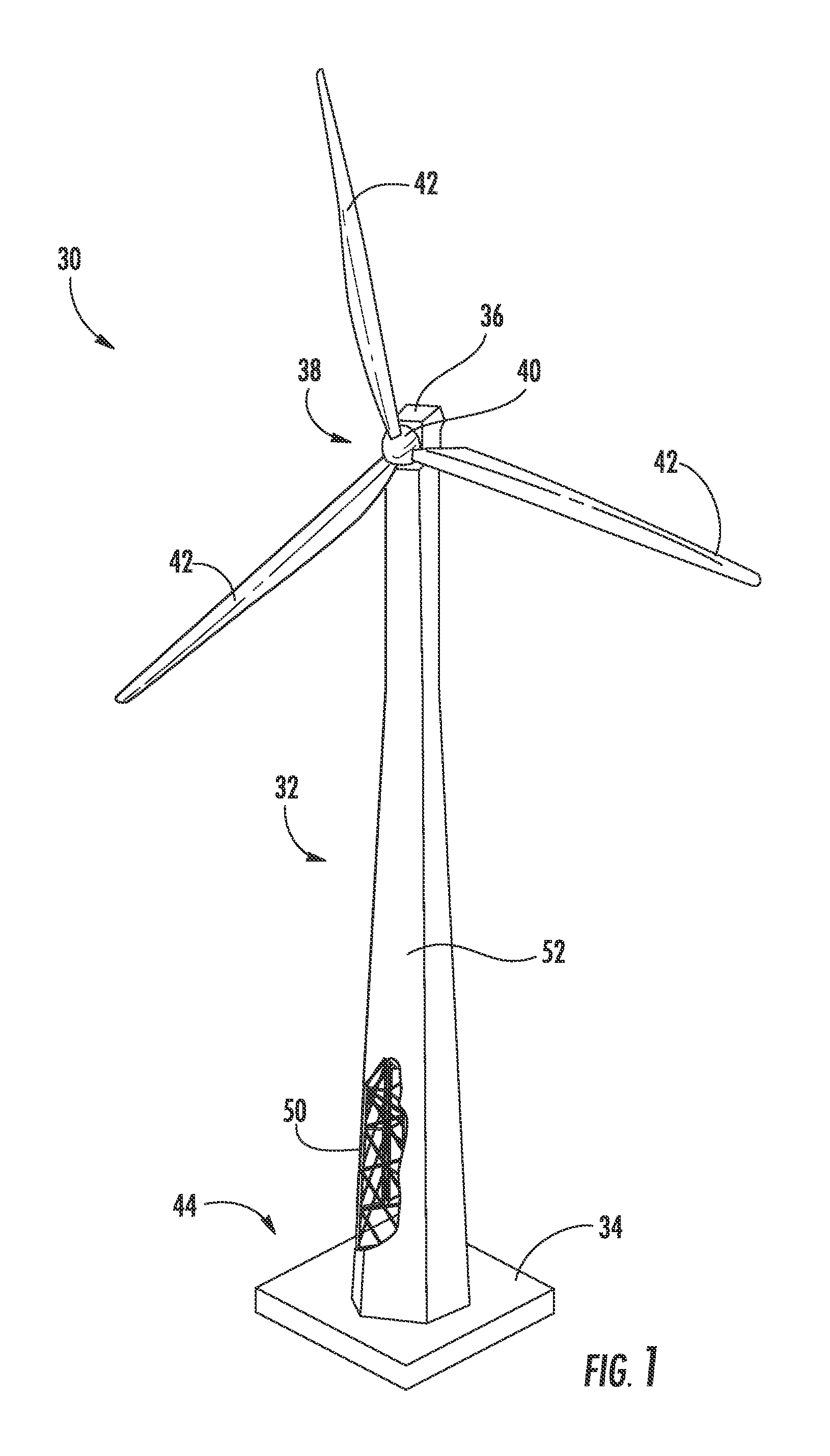

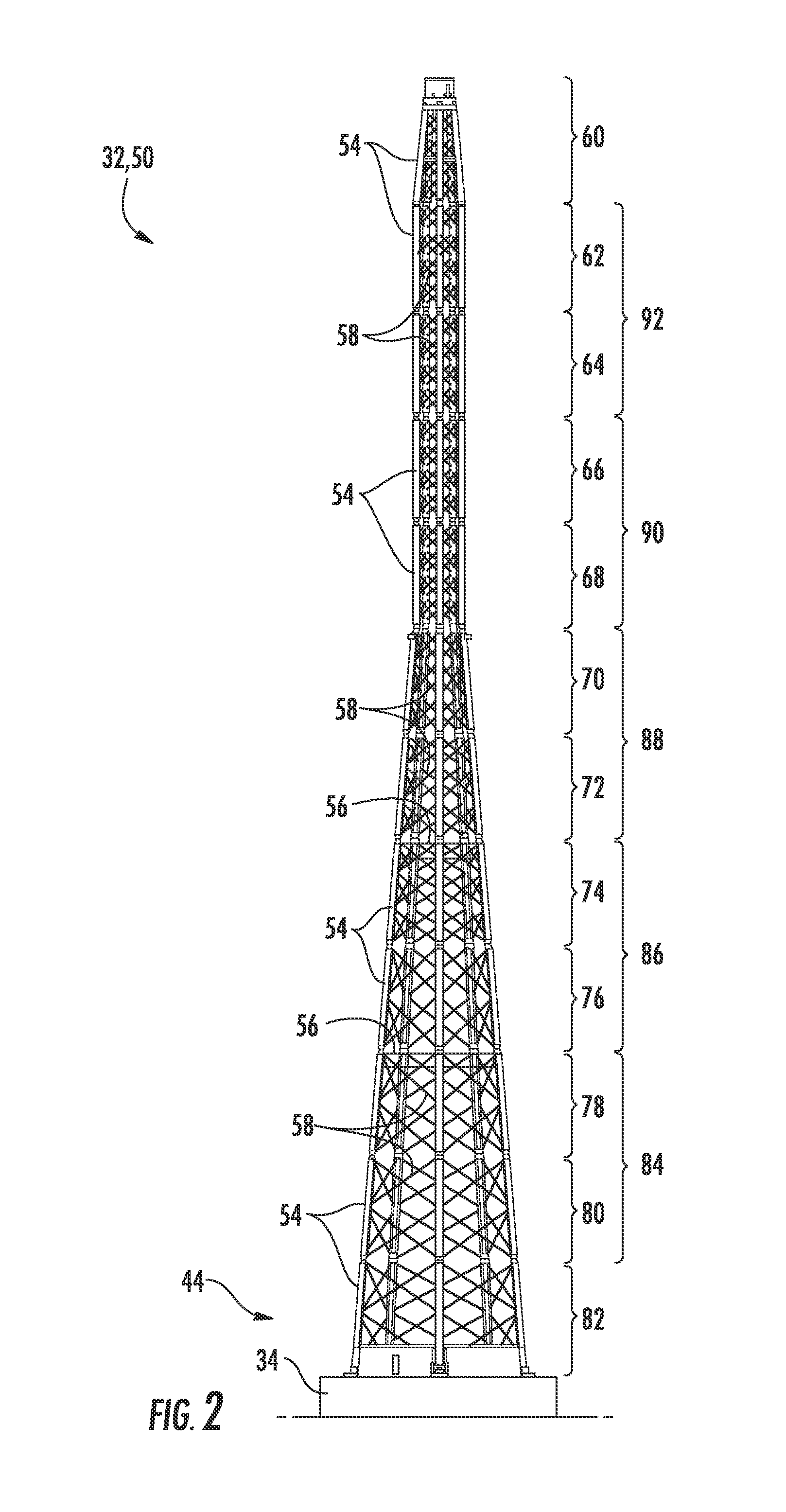

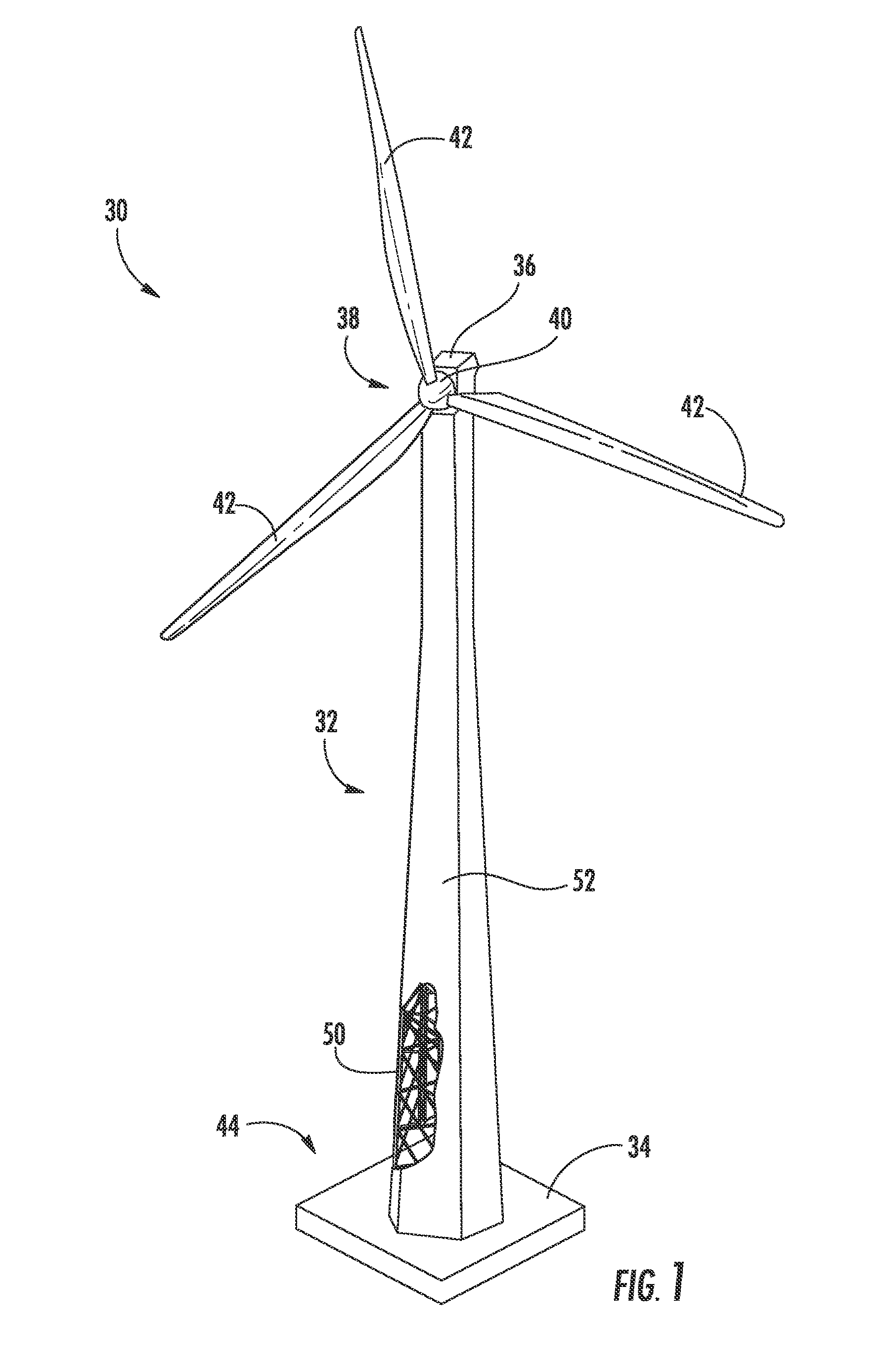

Hybrid tubular lattice tower assembly for a wind turbine

The present disclosure is directed to a tower assembly for a wind turbine. The tower assembly includes a lattice tower portion, a tubular tower portion, and a transition region therebetween. The lattice tower portion includes a plurality of structural members connected together to define an open lattice tower. Further, the structural members include a plurality of supports and a plurality of cross-support members. The cross-support members are connected between the supports so as to define one or more openings. The tubular tower portion includes a lower portion and an upper portion. The first transition region includes a single-piece connection structure, a plurality of arm members, and a plurality of node connectors. The connection structure has a circumferential body configured to receive the lower portion of the tubular tower portion therein. Further, the node connectors join the plurality of supports of the lattice tower portion to the connection structure via the plurality of arm members.

Owner:GENERAL ELECTRIC CO

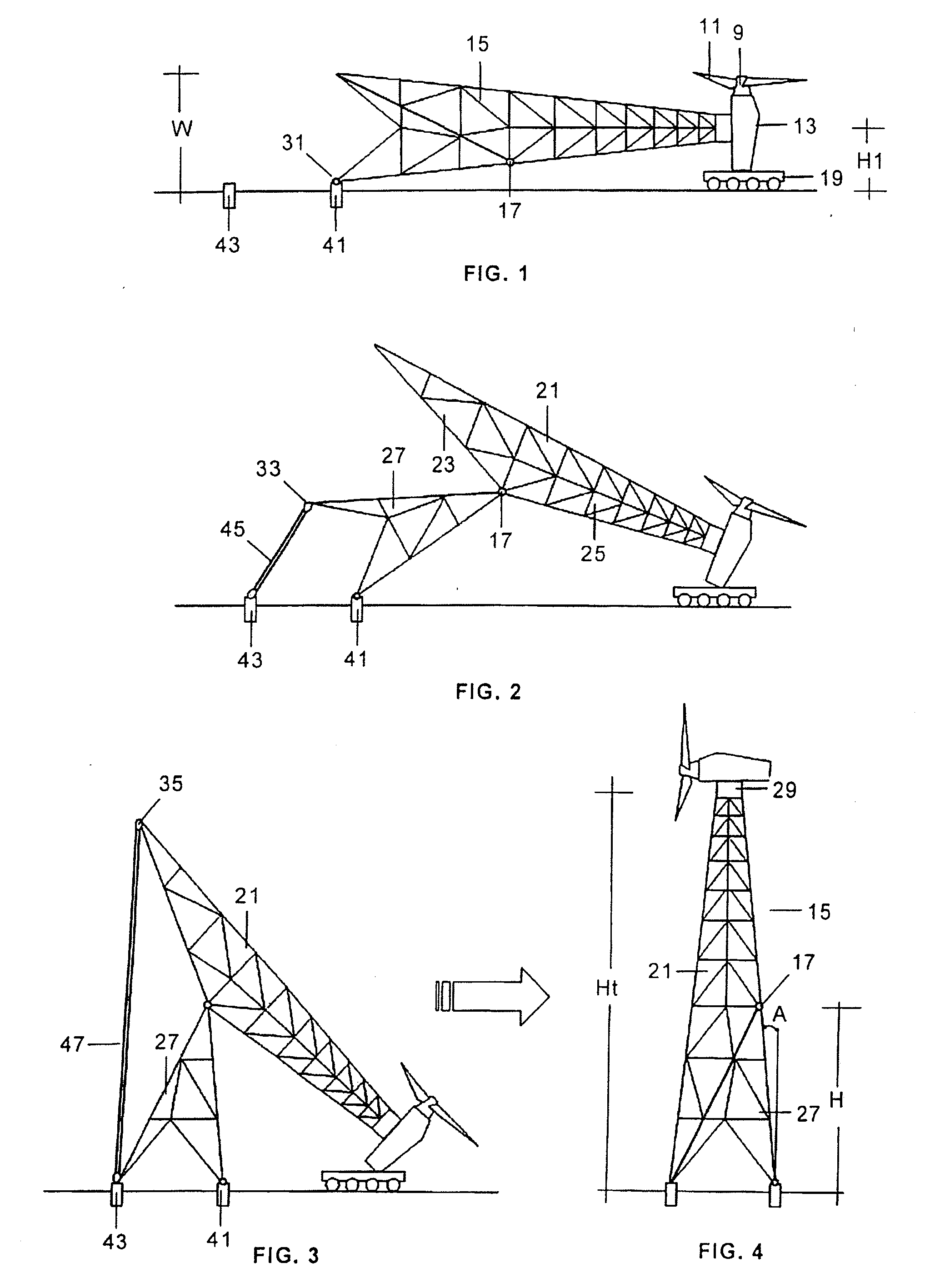

Tower with exterior cable support and a modular base

InactiveUS8919051B1Reduce construction costsReduce the total massWind motor supports/mountsMachines/enginesEngineeringLattice tower

A tower with exterior cable support preferably includes a tower structure, a base plate, a middle support structure, a top plate and at least three cables. The tower structure may be a tapered monopole tower, a step mono tower or a lattice tower. The base plate is attached to a base of the tower. The middle support structure is attached to substantially a midway height of the tower. The top plate is secured to substantially a top of the tower. One end of the at least three cables are secured to the base plate, a perimeter of the at least three cables are supported by the middle support structure and the other end of the at least three cables are secured to the top plate. The modular base preferably includes at least four foundation base members, a tower base member, a perimeter wall base and at least four wall members.

Owner:ECHEMENDIA ABEL +2

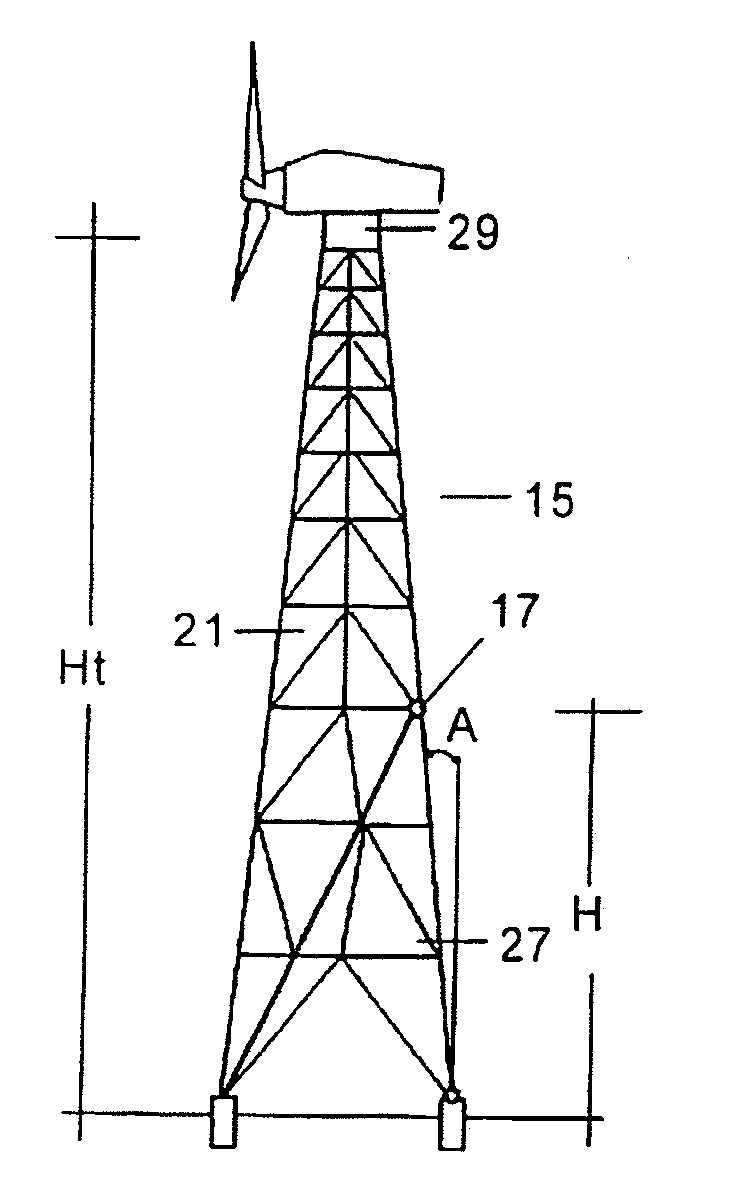

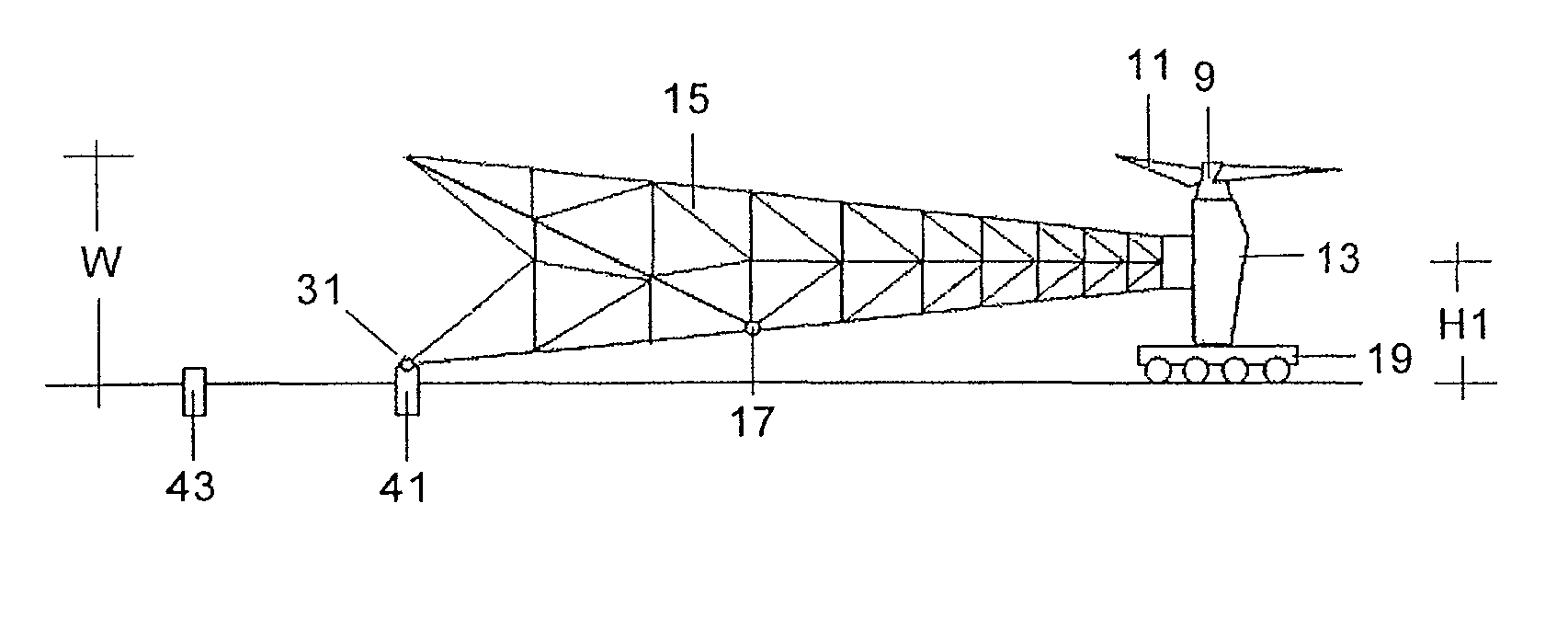

Lattice tower and an erection method for a wind turbine with a lattice tower

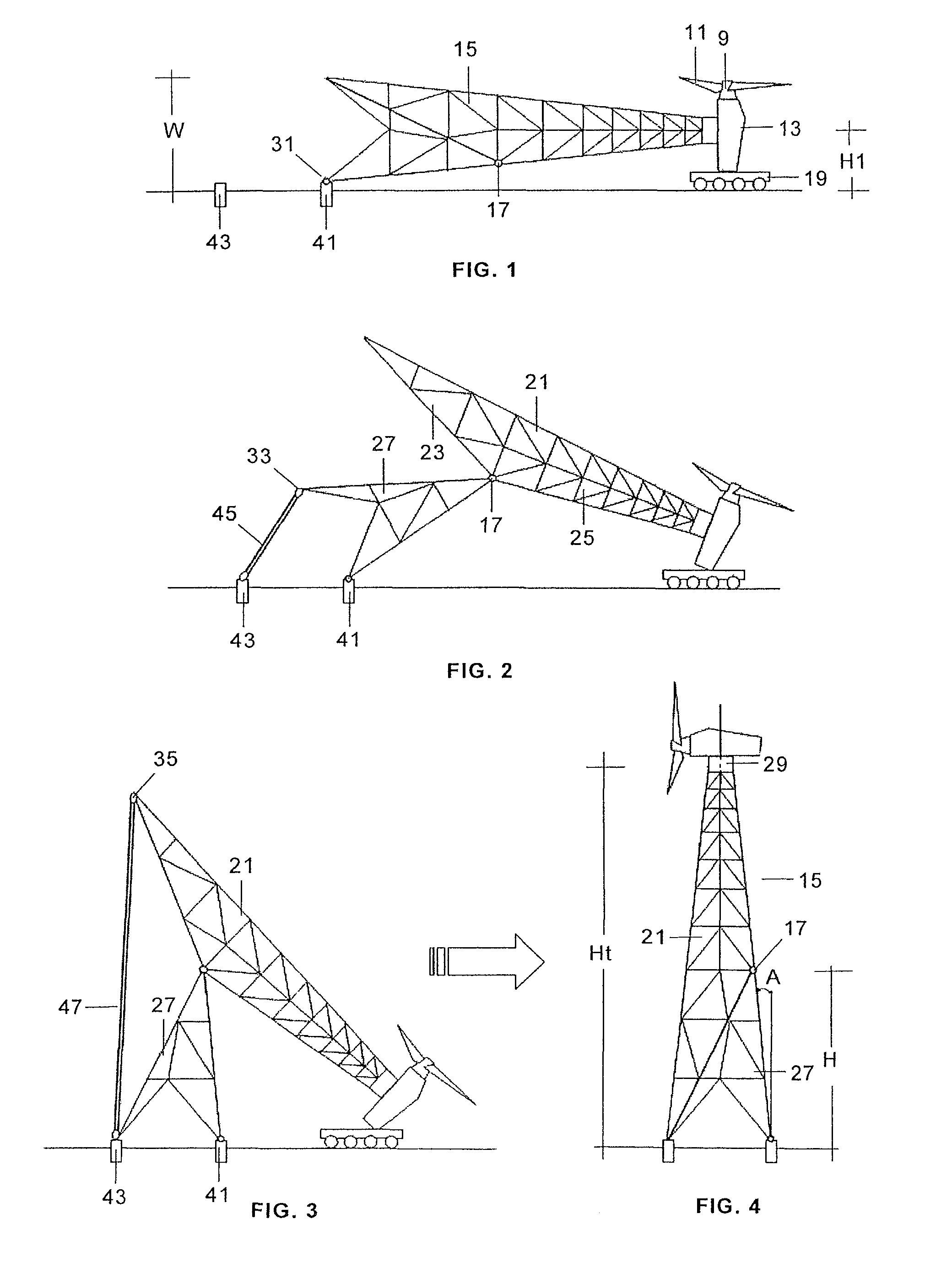

A method of erecting a wind turbine comprising the following steps: Providing the hub (9), the blades (11), the nacelle (13) and a lattice tower (15) comprising first and second sections (21, 27) pivotally connected along an axis (17) at a height H, in which the tower lower part, below height H, is composed by the second section (27), including the tower lower and upper legs (31, 33) and a first part (23) of the first section (21) and in which the tower upper part, above height H, is composed by a second part (25) of the first section (21). Assembling on ground the wind turbine, with the nacelle (13) resting on a carrier (19). Raising the second section (27) and fixing the upper legs (33) to second foundation corners (43). Raising the first section (21) and fixing its first part (23) to the second section (27).

Owner:GAMESA INNOVATION & TECH SA

Friction damping bolt connection for a wind tower lattice structure

InactiveUS8393118B2Increase sliding frictionImprove vibrationTowersProtective buildings/sheltersRelative motionTurbine

A wind turbine lattice tower structure includes a plurality of structural members connected together to define an open lattice tower, with the structural members including vertical leg members and diagonal braces extending between the vertical leg members. Pairs of the diagonal braces form cross braces having an intersection point therebetween. A damping bolt connection assembly is provides at the intersection point of the cross braces and is configured to attach the cross braces together at the intersection point while providing for relative movement of each individual cross brace along a defined longitudinal section of the other respective cross brace.

Owner:GENERAL ELECTRIC CO

Foundation for a wind turbine

An openwork load-bearing structure for a wind turbine, in particular a lattice-tower structure for a wind turbine, in particular a foundation structure for a wind turbine, in particular for anchoring an offshore wind turbine in the ground via driven foundation piles, wherein the openwork load-bearing structure has primary structures, via which loads which occur in the load-bearing structure as a result of the wind turbine are dissipated, and secondary structures, which perform functional, rather than load-dissipating, tasks, wherein the secondary structures are arranged on the primary structures and are connected integrally thereto, and wherein the integral connection between the primary and the secondary structures is in the form of a connecting layer arranged therebetween. Also, a method for producing a lattice-tower structure for a wind turbine, in particular a foundation structure for a wind turbine, in particular for anchoring an offshore wind turbine in the ground via foundation piles.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

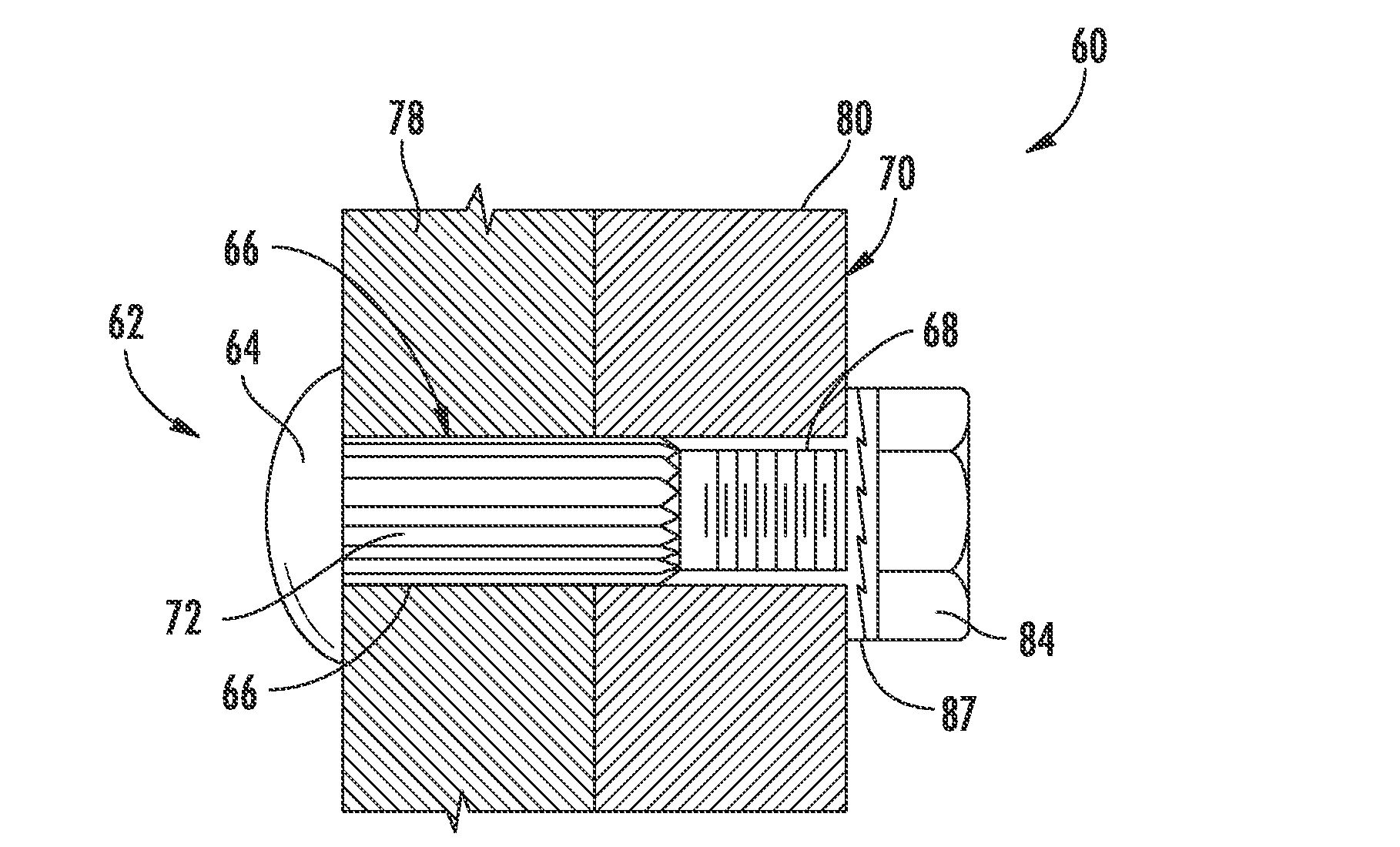

Lattice tower assembly for a wind turbine

The present subject matter is directed to a lattice tower covering and / or assembly for a wind turbine. The lattice tower assembly includes a plurality of structural members connected together to define an open lattice tower. The structural members include a plurality of supports, a plurality of inner cross-support members, and a plurality of outer cross-support members. The inner and outer cross-support members are connected between the supports so as to define one or more openings. The lattice tower covering includes one or more panel elements. Each of the panel elements are retained in position between the supports and cover at least a portion of one or more of the openings. Further, the lattice tower covering has a surface area defined by the plurality of supports and the one or more panel elements.

Owner:GENERAL ELECTRIC CO

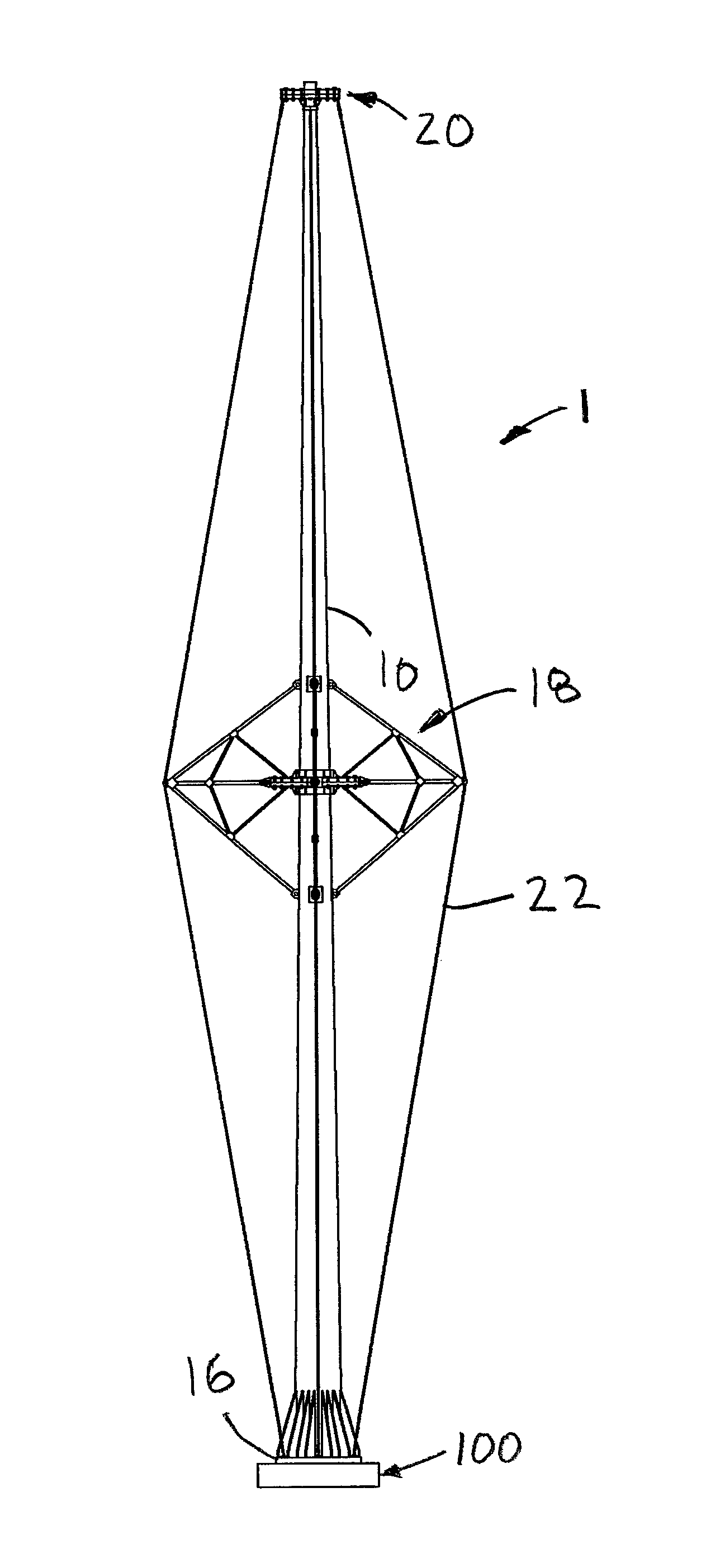

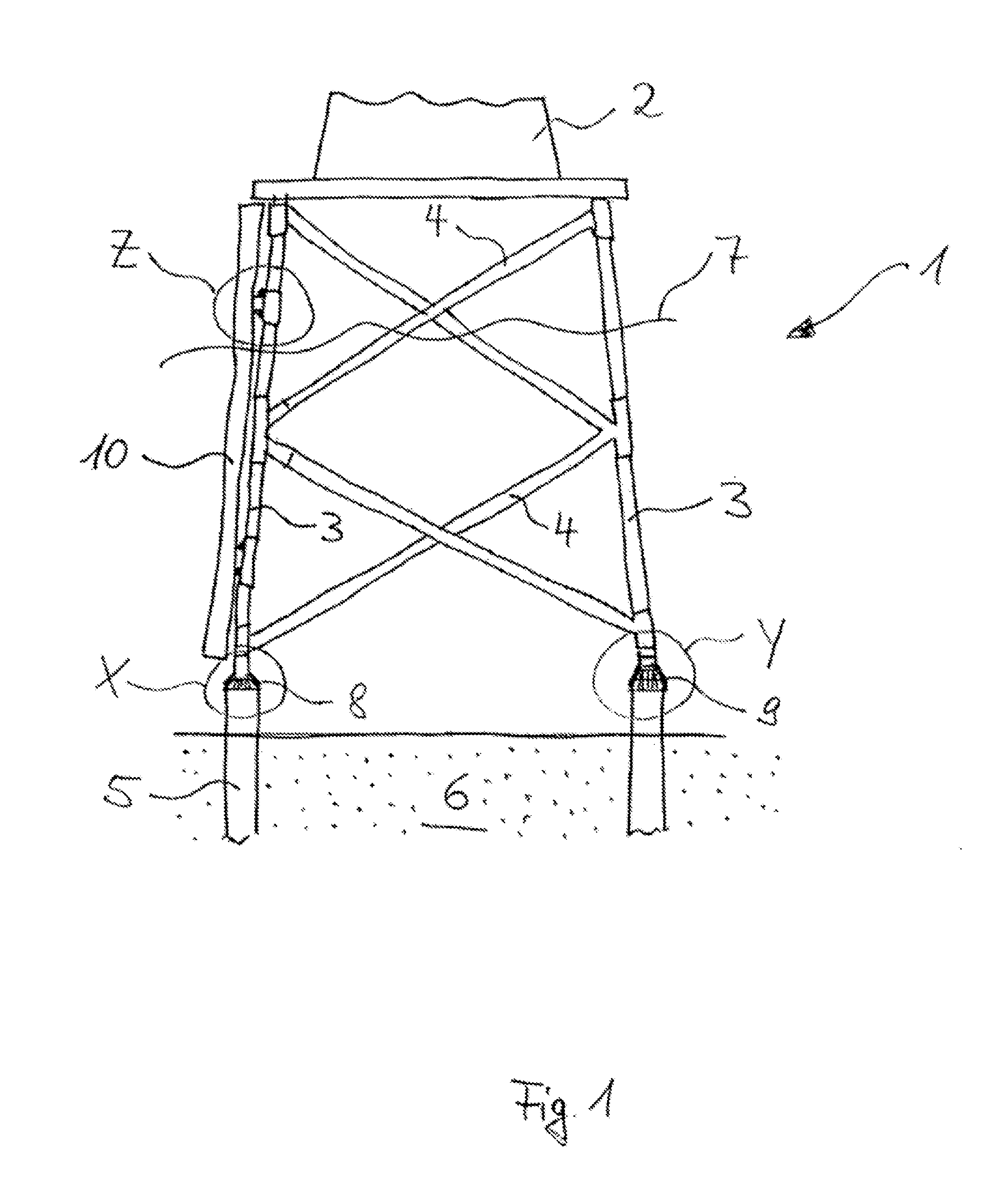

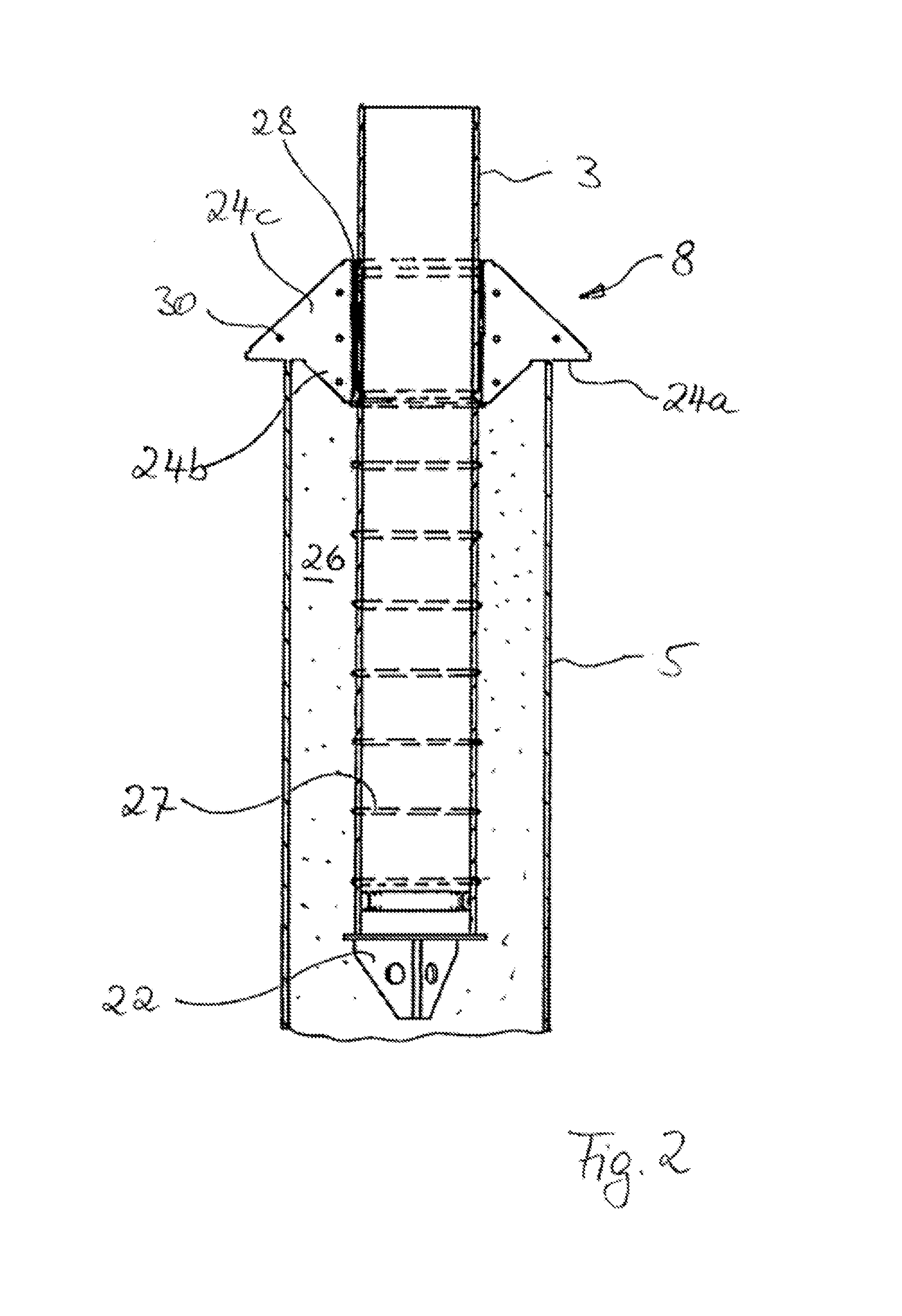

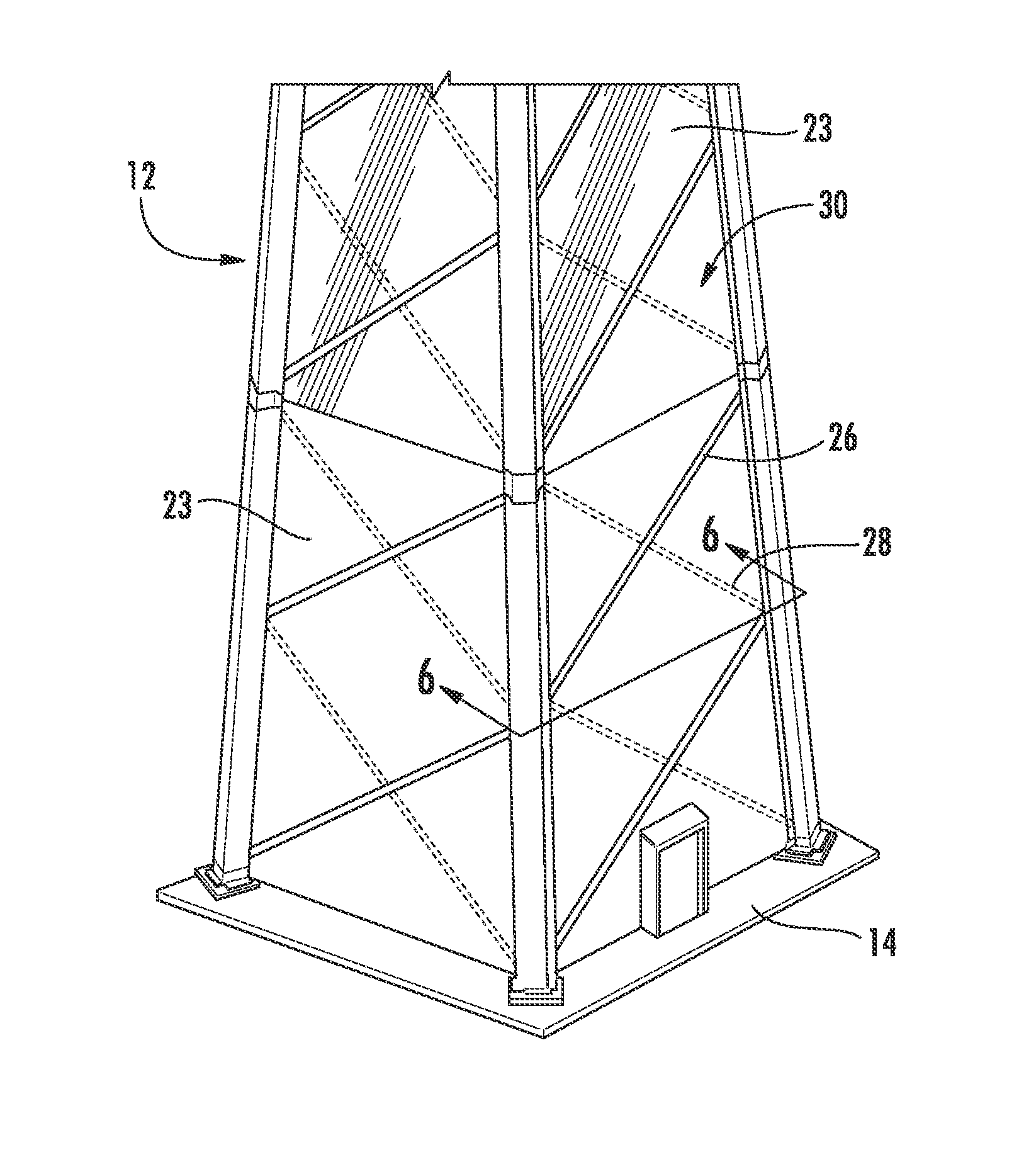

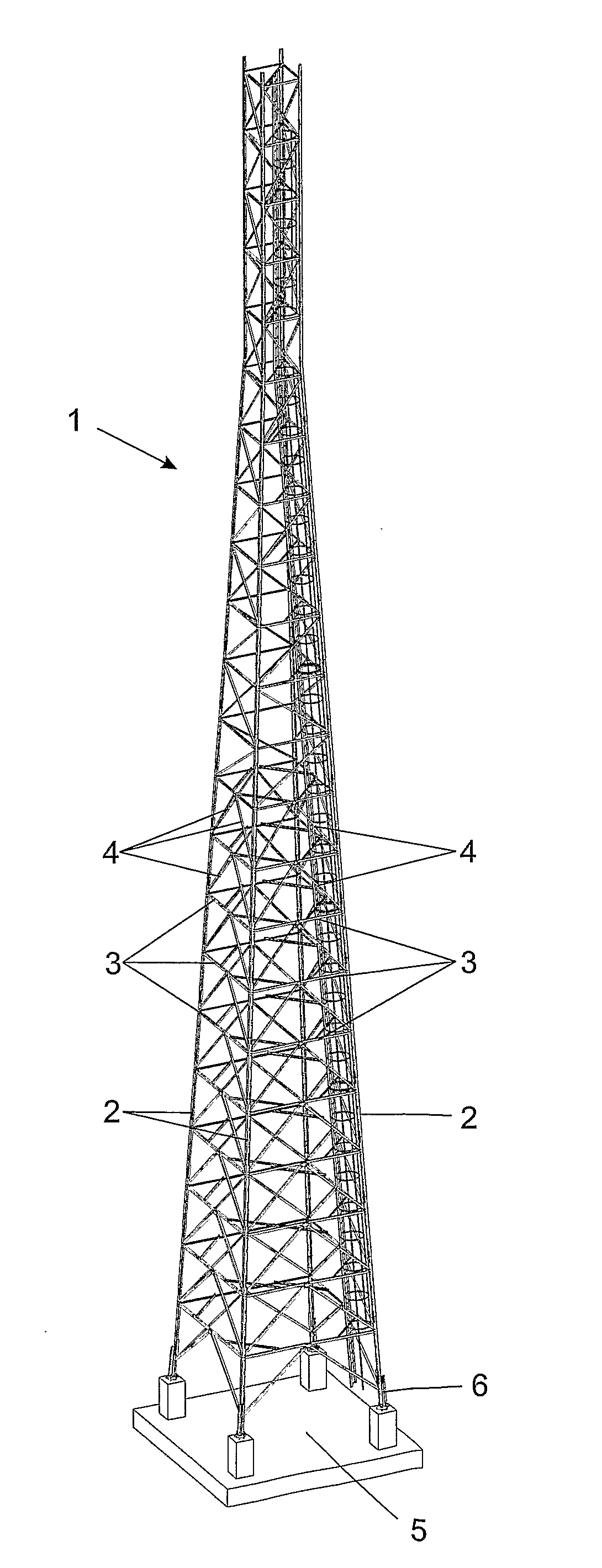

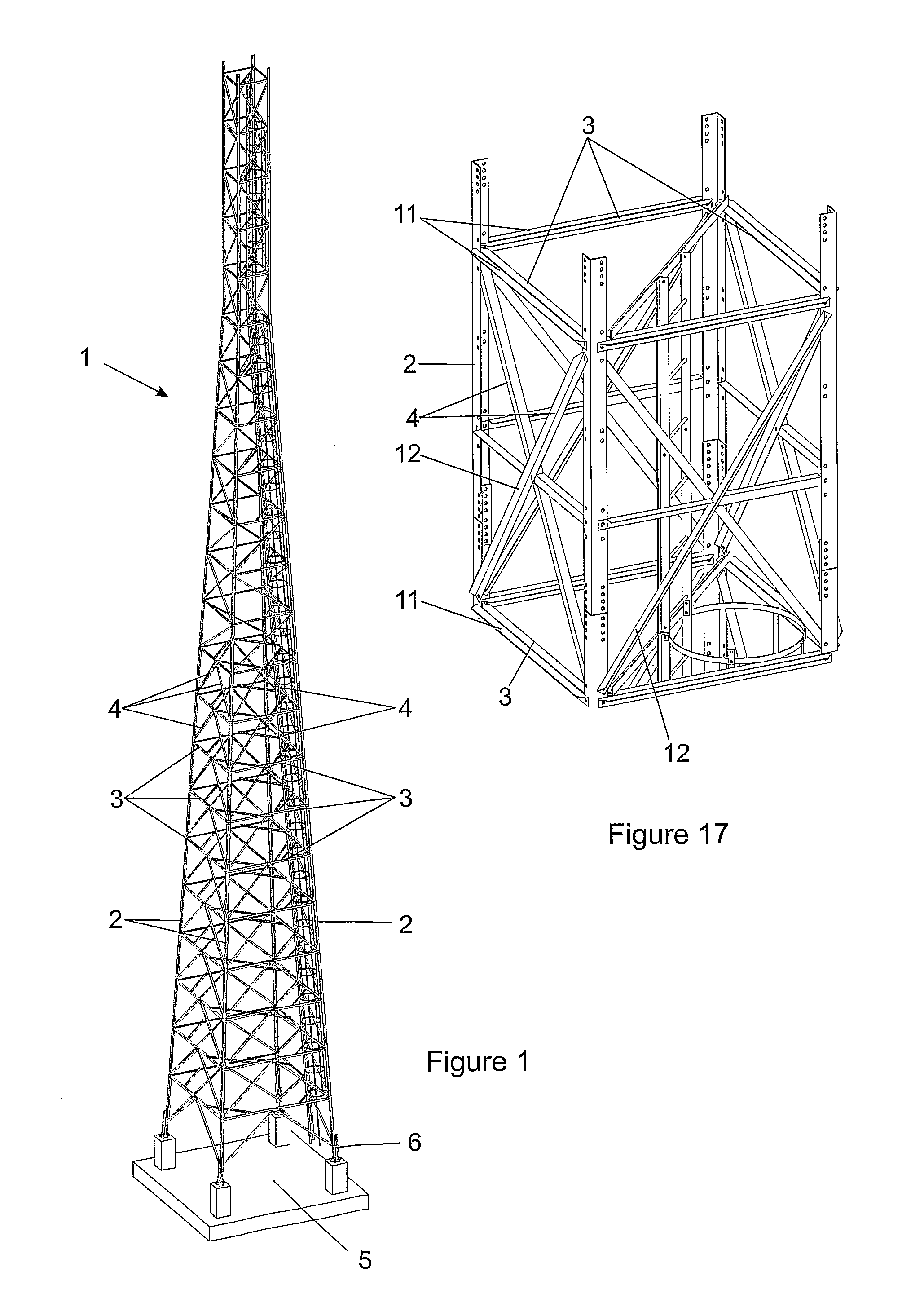

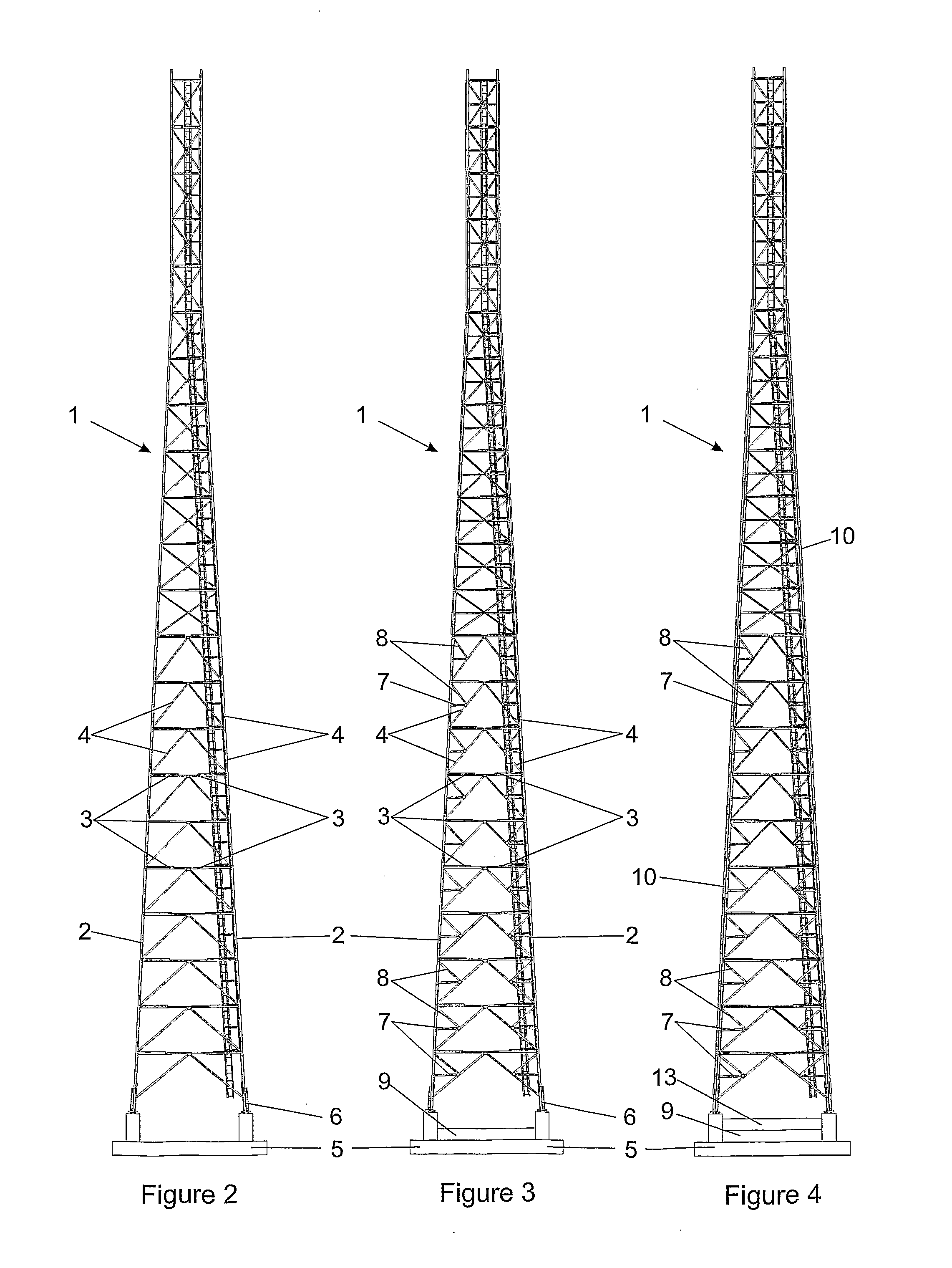

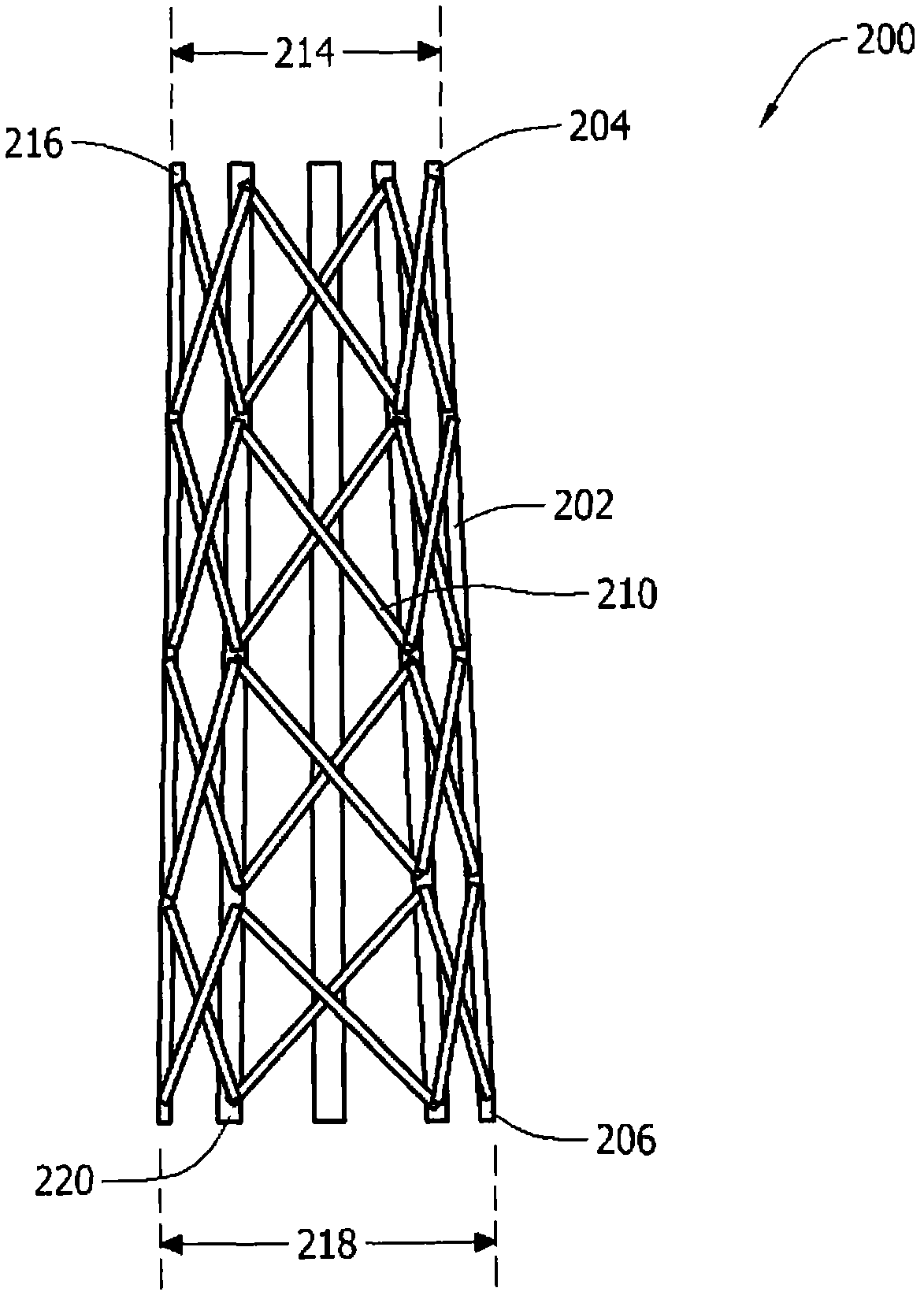

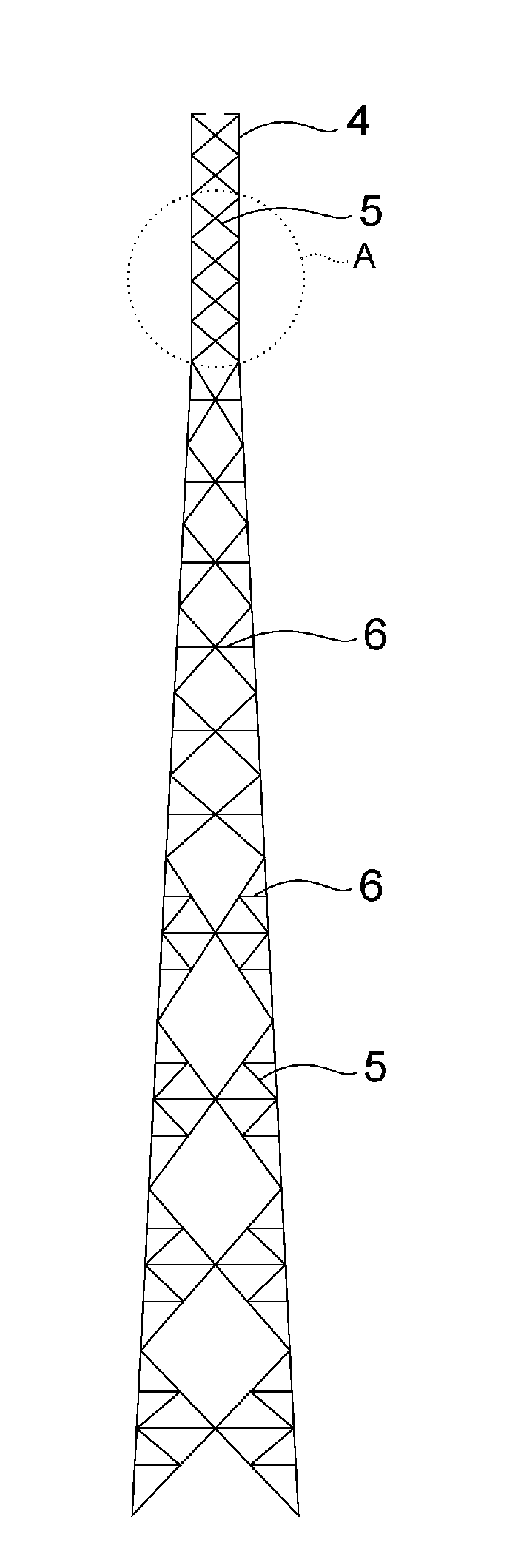

Upgradable lattice tower and components thereof

InactiveUS20110126488A1Halving, the span or buckling length of the basic componentsShorten the lengthTowersAntenna detailsCarrying capacityMarine engineering

A lattice tower (1) is provided comprising generally upright leg elements that are arranged in plan view at the corners of a polygon with horizontal struts and diagonal braces interconnecting the leg elements. The lattice tower has a first arrangement of basic leg elements (2), basic horizontal struts (3) and basic diagonal braces (4) providing a first and basic predetermined load carrying capacity of the tower. Selected basic leg elements and / or basic horizontal struts and / or basic diagonal braces are provided with attachment formations whereby additional leg elements (10) and / or additional horizontal struts (7) and / or additional diagonal braces (8) may be secured to the basic leg elements and / or basic horizontal struts and / or basic diagonal braces to provide an increased predetermined load carrying capacity of the lattice tower.

Owner:HEDINGER JOHAN +1

Systems and method of assembling a tower section

Owner:GENERAL ELECTRIC CO

Metallic tower

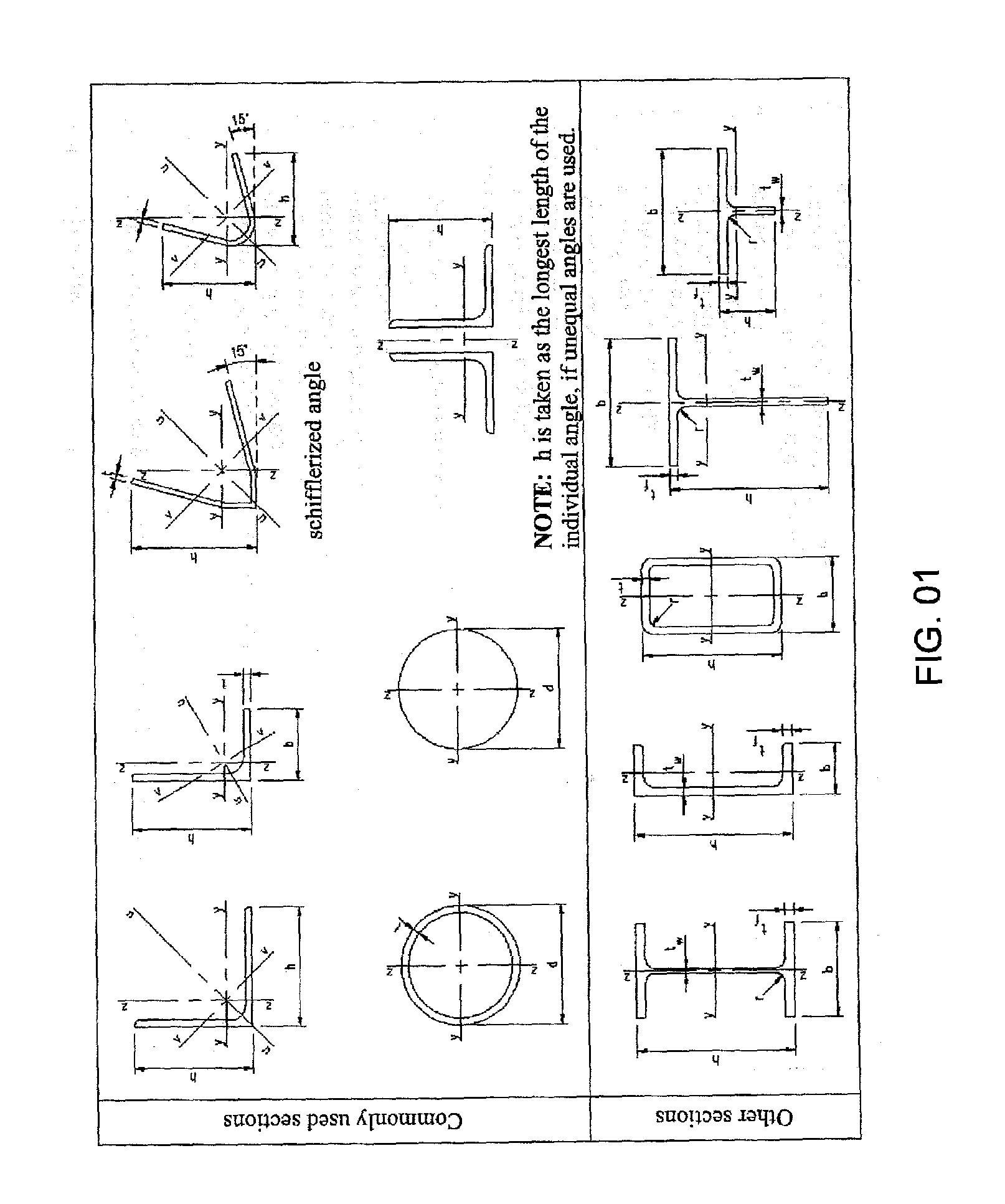

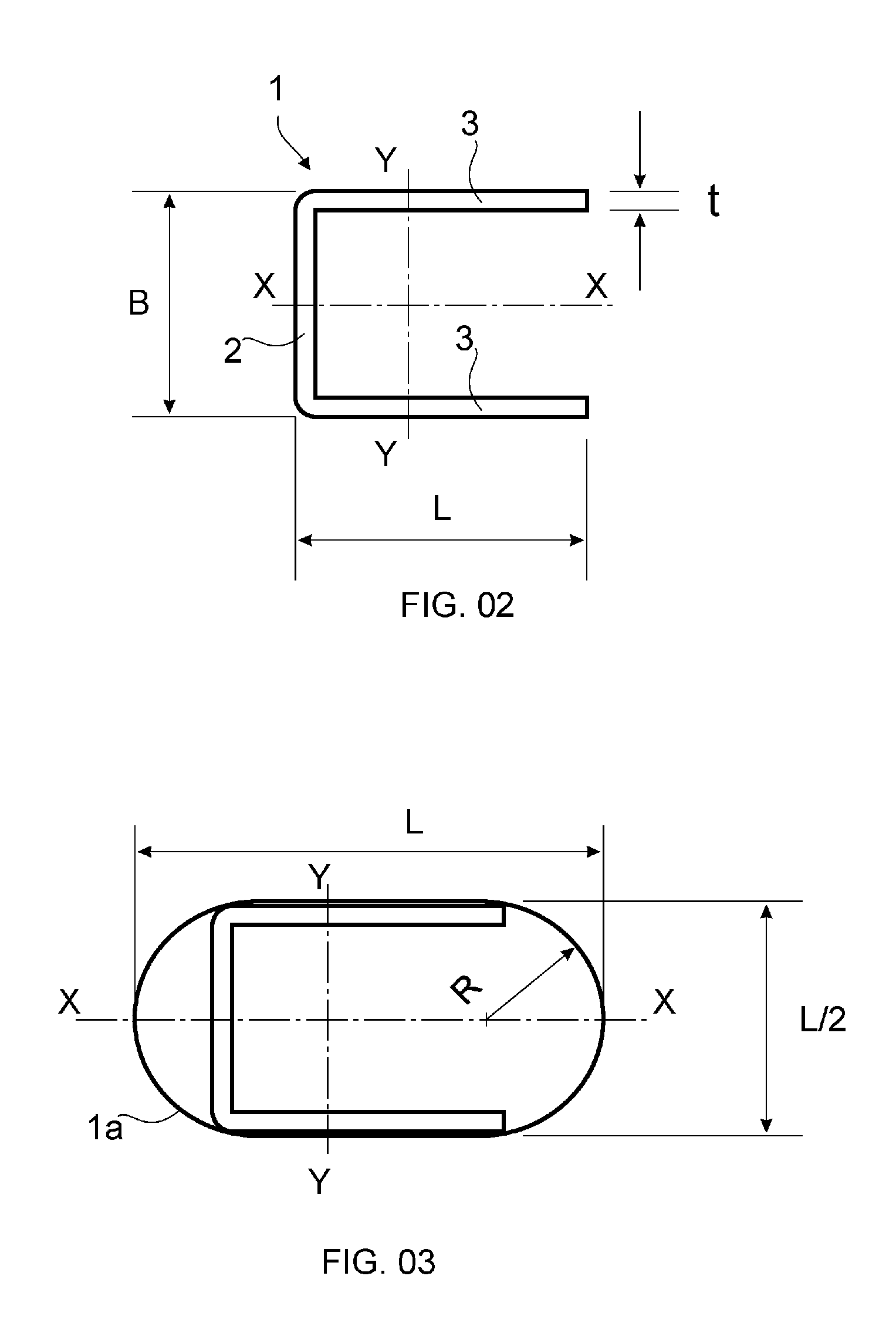

ActiveUS20110265419A1Optimized gyration radiusLow sectionTowersWind energy generationElectric power transmissionLattice tower

This invention relates to metallic towers or the like utilized for electric power transmission lines, telecommunications, wind energy generators and other applications. The standard sections used in lattice towers of the prior art have structural and aerodynamic deficiencies. To overcome the drawbacks and problems the prior art one aspect of the present invention is directed to a metallic tower comprising lattice members with a channel section, wherein the length of the channel web is smaller than the length of the channel legs.

Owner:SECCIONAL BRASIL SA

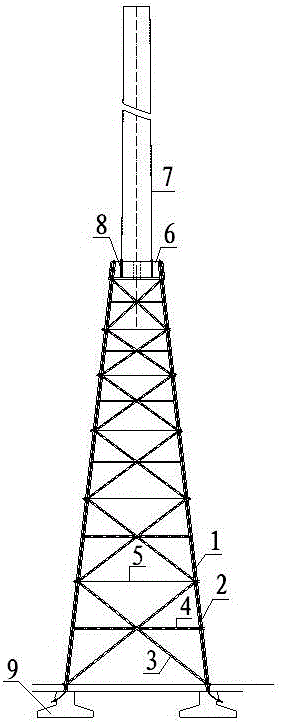

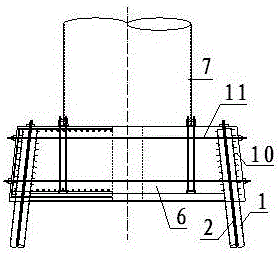

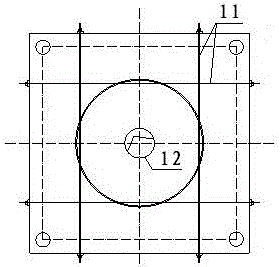

A portable mobile communication tower

ActiveCN101449422AEasy to transportEasy to removeAntenna supports/mountingsTowersEngineeringLattice tower

Owner:ELITE COMM NETWORK SDN BHD

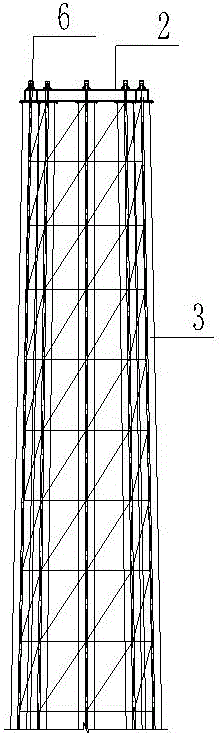

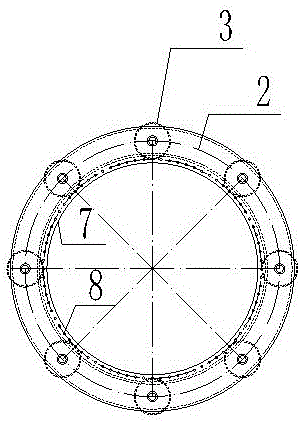

All-direction prestressing force antifatigue composite steel structure wind tower and installing method thereof

PendingCN106545472AEasy to get on and offFirmly connectedWind motor supports/mountsWind energy generationEngineeringLattice tower

The invention discloses an all-direction prestressing force antifatigue composite steel structure wind tower and an installing method thereof. The wind tower comprises a steel structure tower tube, a transition section, a lattice tower frame and basic portions. The steel structure tower tube is fixed in the transition section, the transition section is located at the top of the lattice tower frame, and the lattice tower frame is arranged on the basic portions; the lattice tower frame comprises a tower pillar, prestressing force double steel stranded wires, oblique rods, horizontal rods and diaphragms, and the prestressing force double steel stranded wires penetrate through the tower pillar from the bottom to the top of the tower pillar; bottom ends of the prestressing force double steel stranded wires are fixed in the basic portions in an anchor mode, and the tops of the prestressing force double steel stranded wires are fixed on the top of the tower pillar in a stretch-draw mode; and the oblique rods are fixed on the tower pillar in an intersectional mode, and the horizontal rods and the diaphragms are fixed on the tower pillar in a spaced mode. The structure is reasonable, the force-carrying capability is reliable; and prestressing force is imposed on all sides, the fatigue life is prolonged, material consumption is little, and the construction through the installing method is convenient.

Owner:QINGDAO SINOSTRO TECH CO LTD

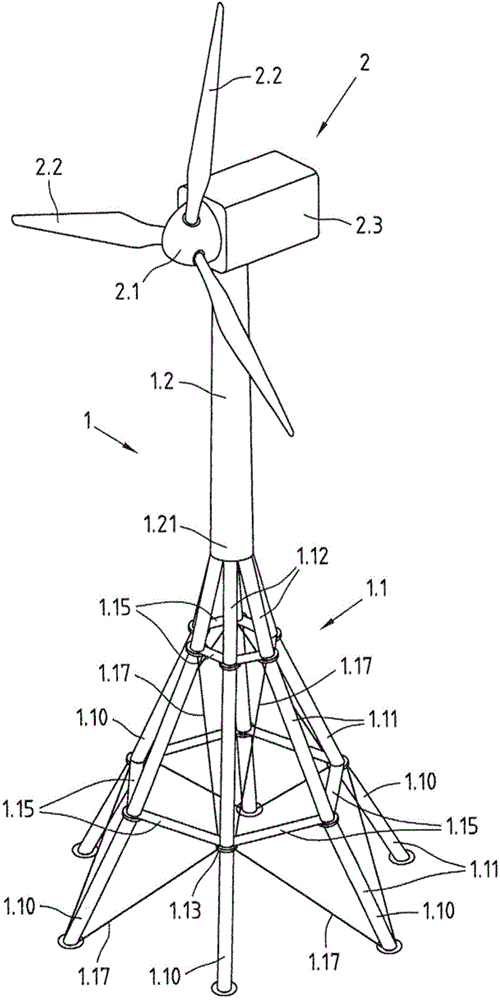

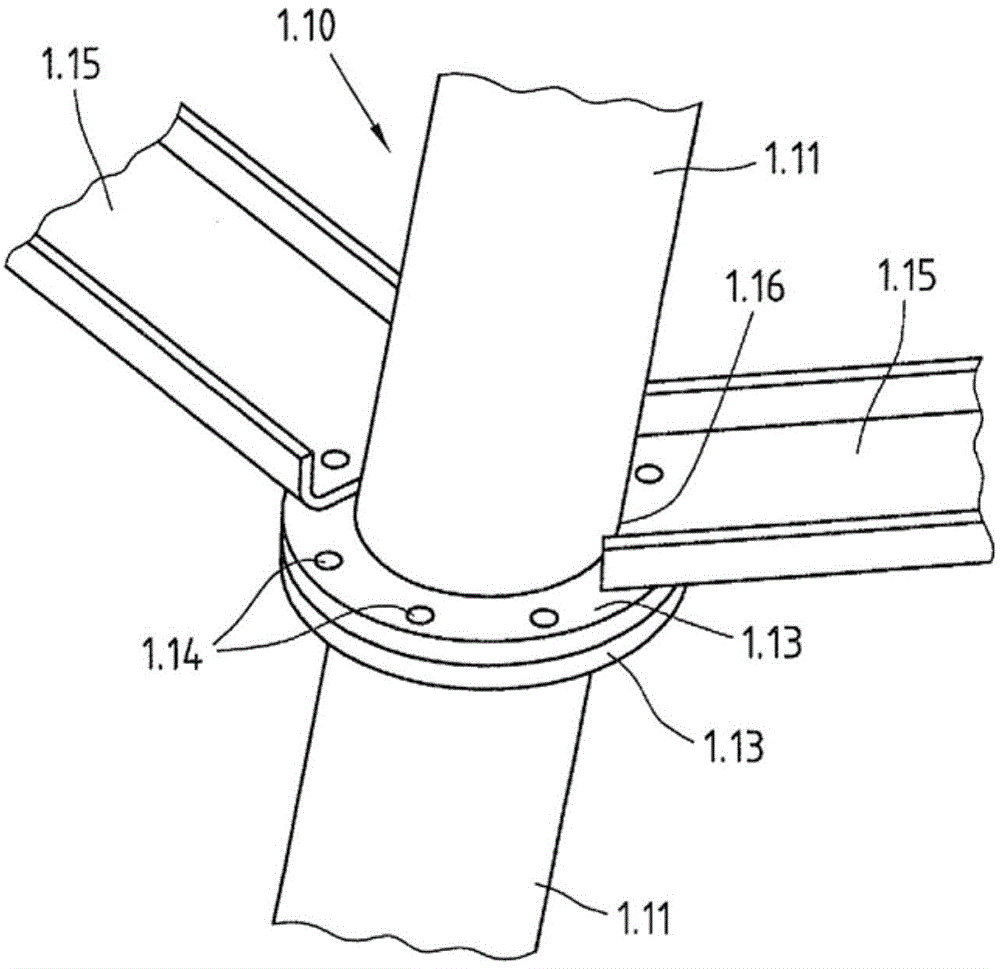

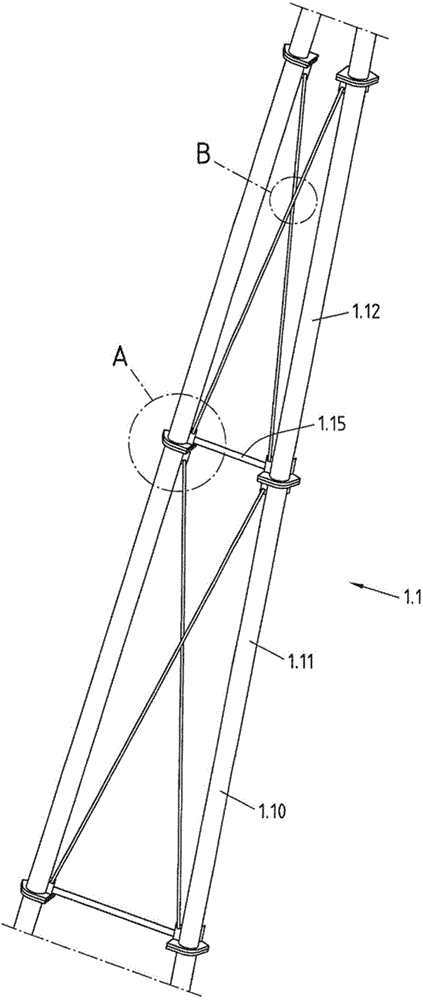

Modular tower for a wind power plant

ActiveCN104641059ASimplify the transfer processSimplify the assembly processArtificial islandsOther chemical processesPeaking power plantEngineering

The invention relates to a tower (1) for a wind power plant, having a lower part (1.1) in the form of a lattice tower or trussed tower having at least two corner legs, and an upper part (1.2) in the form of a tubular tower substantially round in cross-section, wherein each corner leg (1.10) is composed of a plurality of steel tube profiles (1.11, 1.12) connected to one another in the longitudinal direction. In order to achieve good transportability and simplified assembly of the components of such a tower, the invention provides a modular tower concept. According to the invention, each corner leg (1.10) is composed of at least three steel tube profiles (1.11, 1.12) which are furnished with perforated flanges (1.13) for receiving bolts, wherein the corner legs (1.10) are connected to one another by struts (1.15) and / or tie bars (1.17) connected at the flanges (1.13), and wherein the steel tube profiles (1.11, 1.12) of each corner leg (1.10) are spiral seam-welded steel tube profiles.

Owner:THYSSENKRUPP STEEL EURO AG

Prestressed polygon wind tower with direct fan annular box girder at tower top

The invention discloses a prestressed polygon wind tower with a direct fan annular box girder at the tower top. The prestressed polygon wind tower comprises a steel structure lattice tower body, a fan cabin connection flange and an annular box girder, wherein the annular box girder is connected to the top of the steel structure lattice tower body; the steel structure lattice tower body comprises a tower column, a cross rod and an oblique rod; a prestress wire is arranged in the tower column; the annular box girder comprises an annular box girder top flange, an annular box girder web, an annular box girder bottom flange and an annular girder bottom flange; the prestress wire in the tower column is anchored on the annular box girder top flange; and the fan cabin connection flange is connected with the annular box girder. Traditional tower drum segment and transition segment are replaced, force transferring is direct and the material is saved.

Owner:QINGDAO SINOSTRO TECH CO LTD

Lattice tower assembly for a wind turbine

The present subject matter is directed to a lattice tower covering and / or assembly for a wind turbine. The lattice tower assembly includes a plurality of structural members connected together to define an open lattice tower. The structural members include a plurality of supports, a plurality of inner cross-support members, and a plurality of outer cross-support members. The inner and outer cross-support members are connected between the supports so as to define one or more openings. The lattice tower covering includes one or more panel elements. Each of the panel elements are retained in position between the supports and cover at least a portion of one or more of the openings. Further, the lattice tower covering has a surface area defined by the plurality of supports and the one or more panel elements.

Owner:GENERAL ELECTRIC CO

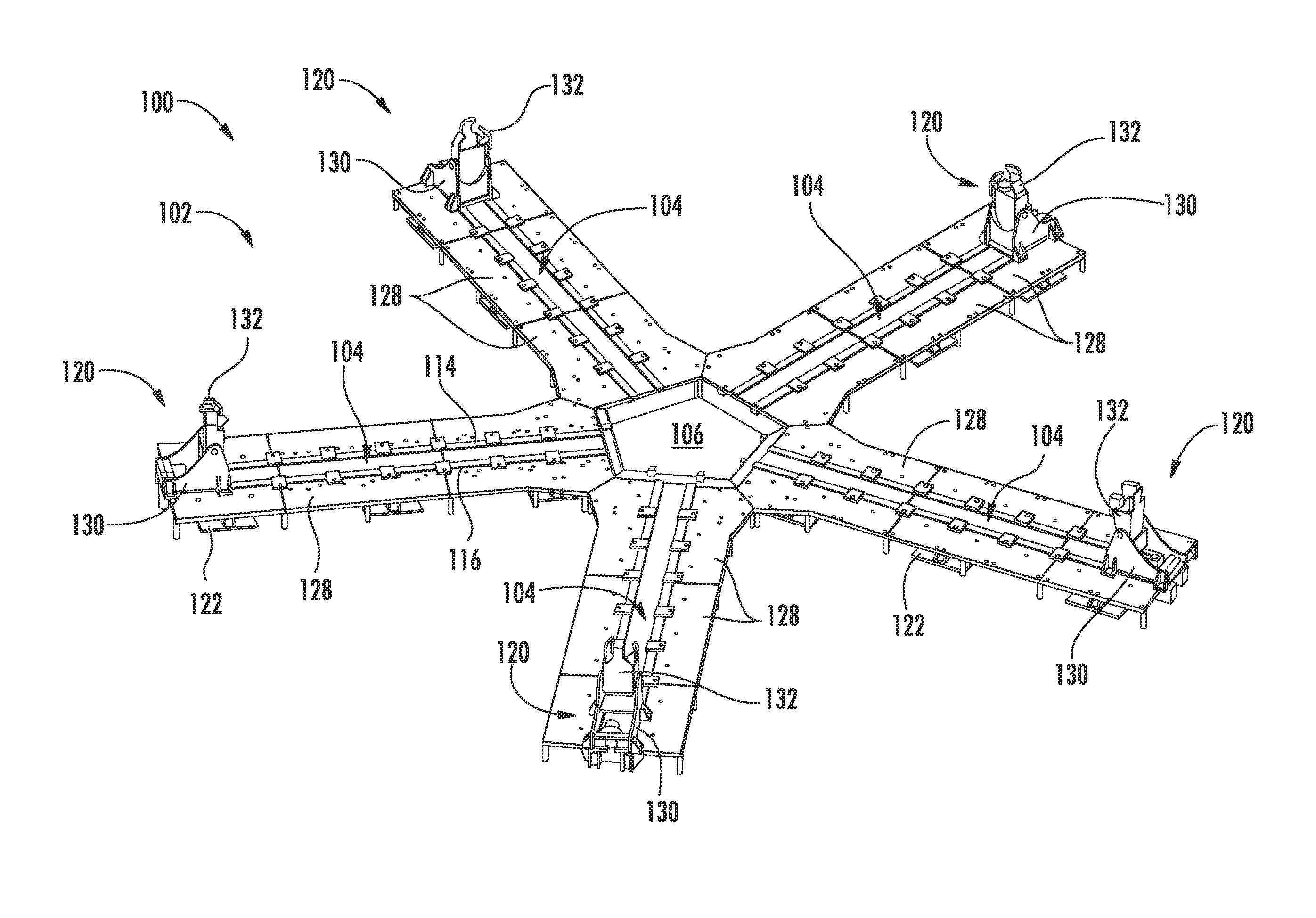

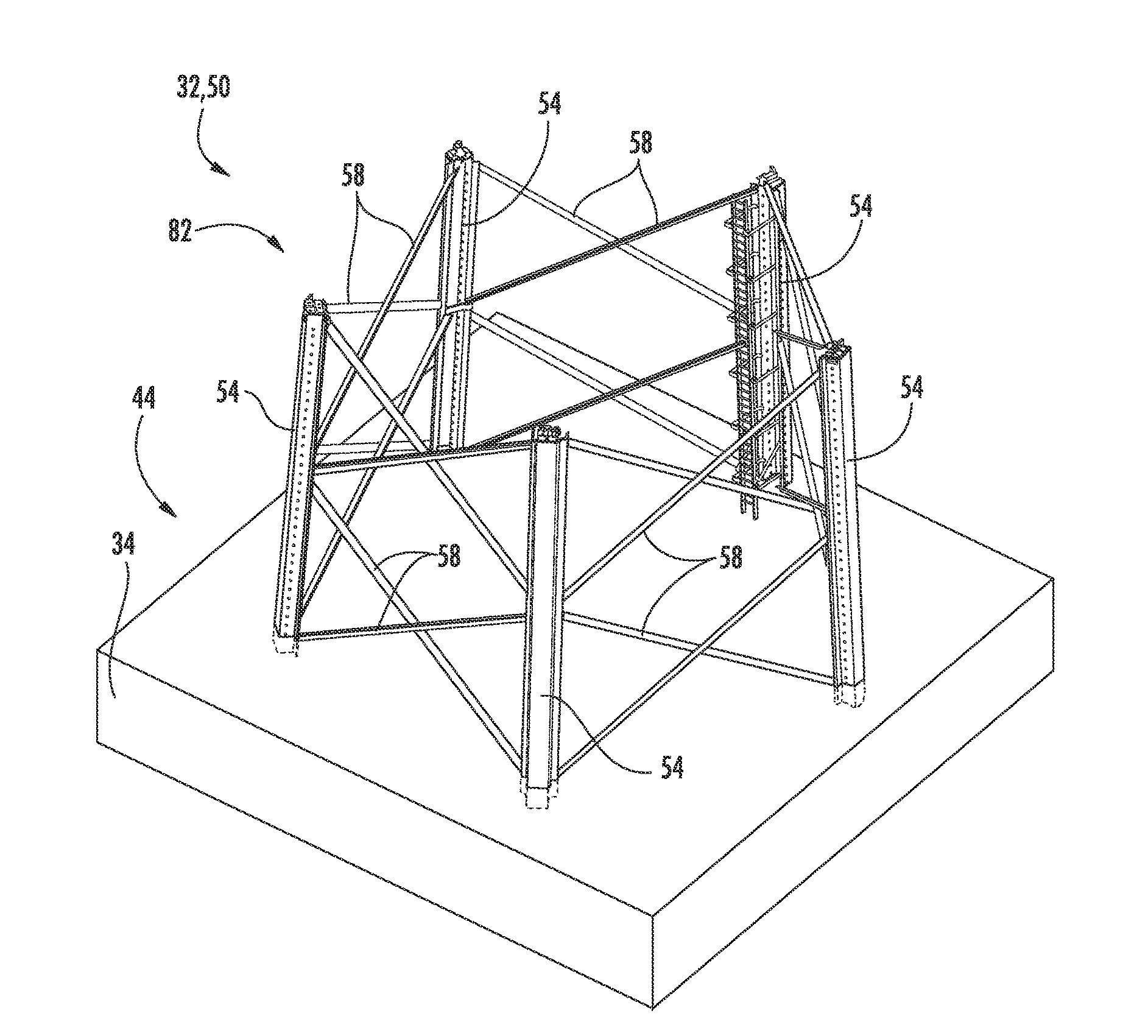

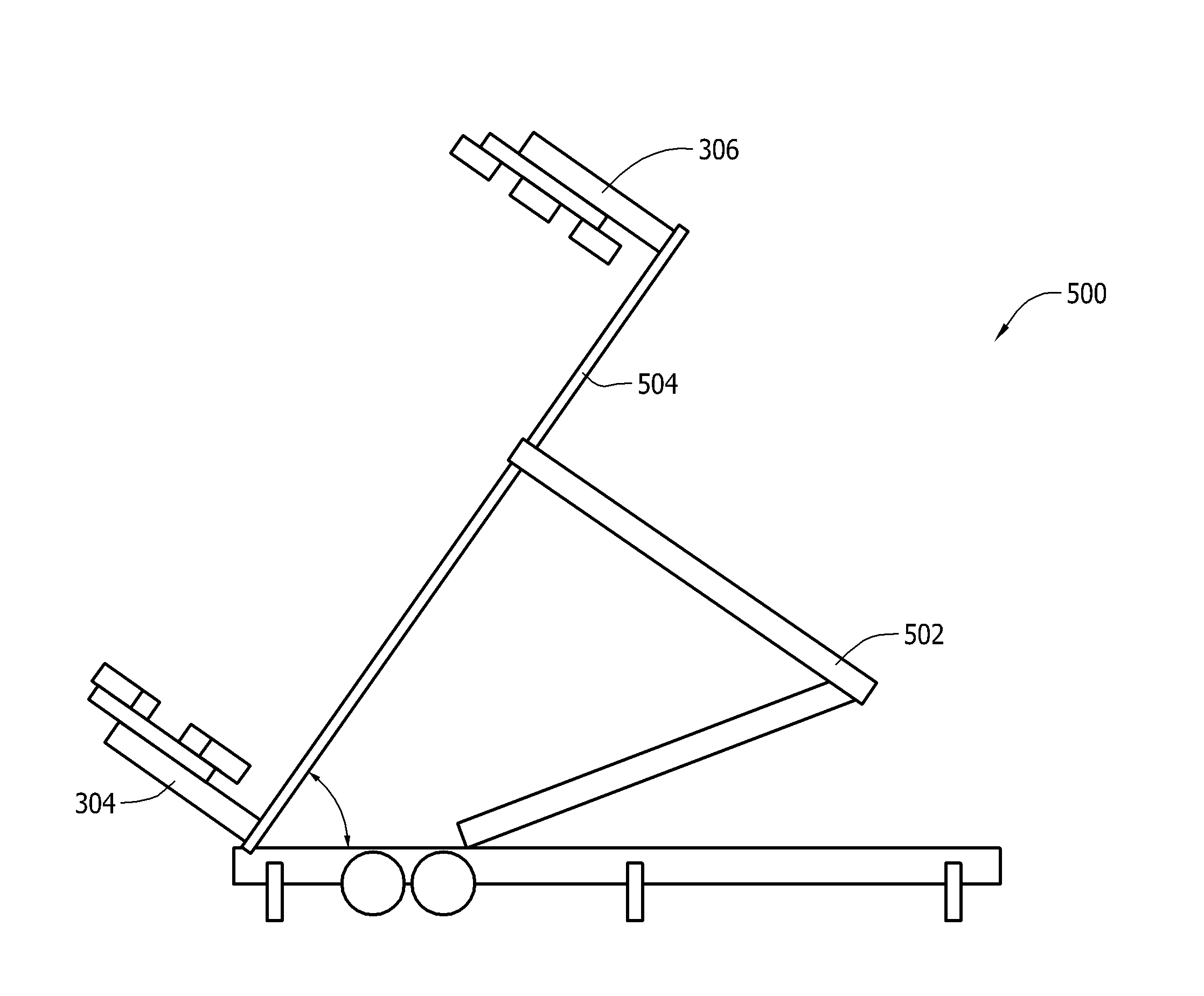

System and method for assembling tower sections of a wind turbine lattice tower structure

A system for assembling a tower section of a lattice tower structure for a wind turbine may generally include a tower assembly fixture having a plurality of radially extending fixture arms, wherein each fixture arm extends between a first end and a second end. In addition, the system may include a plurality of trolleys. Each trolley may include a base frame configured to be coupled to one of the fixture arms between its first and second ends and a leg mount pivotally coupled to the base frame. The leg mount may be configured to be coupled to a bottom end of a support leg of the tower section such that, when each of the support legs is coupled to its respective leg mount, the support legs are supported above the tower assembly fixture at a substantially vertical orientation.

Owner:GENERAL ELECTRIC CO

System and method for assembling tower sections of a wind turbine lattice tower structure

In one aspect, a method for assembling a tower section of a lattice tower structure for a wind turbine on a tower assembly fixture may generally include installing a first trolley onto a first fixture arm of the fixture and installing a second trolley onto a second fixture arm of the fixture. In addition, the method may include securing a first support leg of the tower section to the first trolley, securing a second support leg of the tower section to the second trolley and coupling at least one secondary support member between the first and seconds support legs.

Owner:GENERAL ELECTRIC CO

Lattice tower and an erection method for a wind turbine with a lattice tower

A method of erecting a wind turbine comprising the following steps: Providing the hub (9), the blades (11), the nacelle (13) and a lattice tower (15) comprising first and second sections (21, 27) pivotally connected along an axis (17) at a height H, in which the tower lower part, below height H, is composed by the second section (27), including the tower lower and upper legs (31, 33) and a first part (23) of the first section (21) and in which the tower upper part, above height H, is composed by a second part (25) of the first section (21). Assembling on ground the wind turbine, with the nacelle (13) resting on a carrier (19). Raising the second section (27) and fixing the upper legs (33) to second foundation corners (43). Raising the first section (21) and fixing its first part (23) to the second section (27).

Owner:GAMESA INNOVATION & TECH SA

Systems and method of assembling a tower section

An assembly system for use in assembling a lattice tower section is provided. The system comprises a platform, a first mounting assembly coupled to the platform, and, a second mounting assembly coupled to the platform, the first and second mounting assemblies are configured to secure opposite ends of a plurality of leg members used in assembling the lattice tower section such that each of the plurality of leg members is suspended a distance from the platform, at least one of the first and second mounting assemblies is configured to selectively rotate a leg member of the plurality of leg members suspended therefrom.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com