Modular tower for a wind power plant

A facility and truss tower technology, applied in the field of towers of wind power generation facilities, can solve the problems of large number of threaded connections, increased assembly costs and then tightened screws, maintenance costs, operation or assembly problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

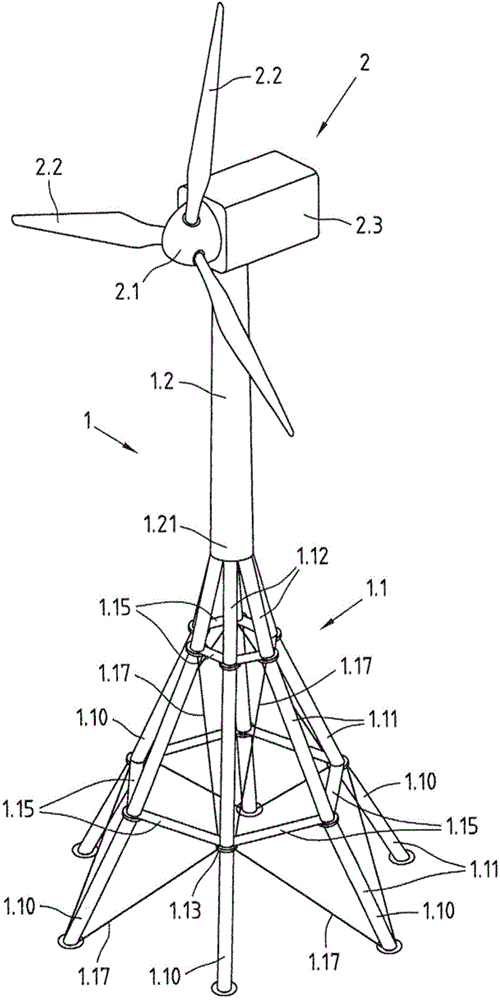

[0025] As shown in the figures, the tower 1 of a wind power plant 2 is constructed from a lower part 1.1 in the form of a lattice or truss tower and an upper part 1.2 in the form of a tubular tower with a circular cross-section.

[0026] Mounted on the upper end of the tubular tower 1.2 is a wind power plant (wind energy plant) 2 mounted so as to be able to rotate about an axis extending substantially vertically. The wind power installation 2 comprises a rotor 2.1 with rotor blades 2.2, which are preferably rotatable about their respective longitudinal axes and thus adjustable in an infinitely variable manner, and a generator arranged in a nacelle casing 2.3 , the shaft of the generator is connected to the rotor 2.1 for common rotation via a transmission mechanism and a clutch.

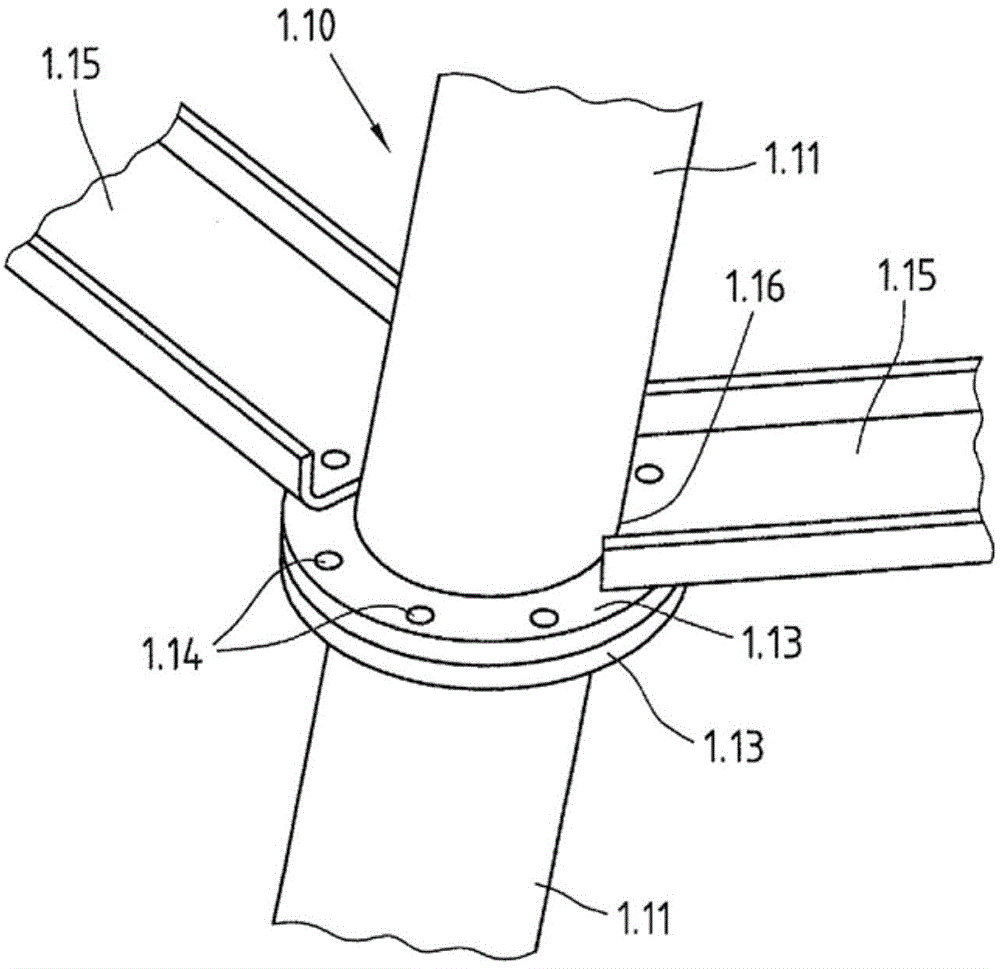

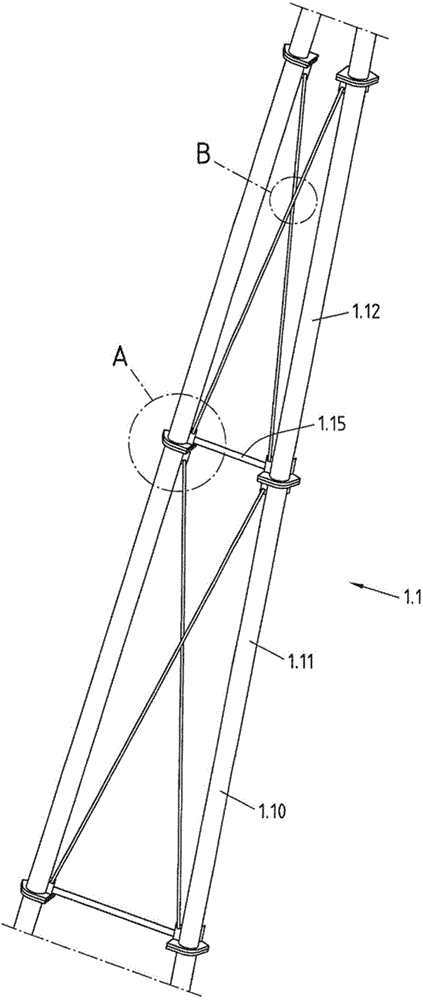

[0027] In the exemplary embodiment shown here, the lattice or truss tower 1.1 has six corner bars 1.10. However, it is also possible to have more or less than 6 corner bars. In either case there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com