Method and device for placing a unidirectional thread layer on longitudinal conveyors, method for laying weft threads on warp knitting machines, and device to carry out said methods

A technology of weft yarn and yarn layer is applied in the field of devices for laying unidirectional yarn layers to achieve the effects of increased speed and great mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

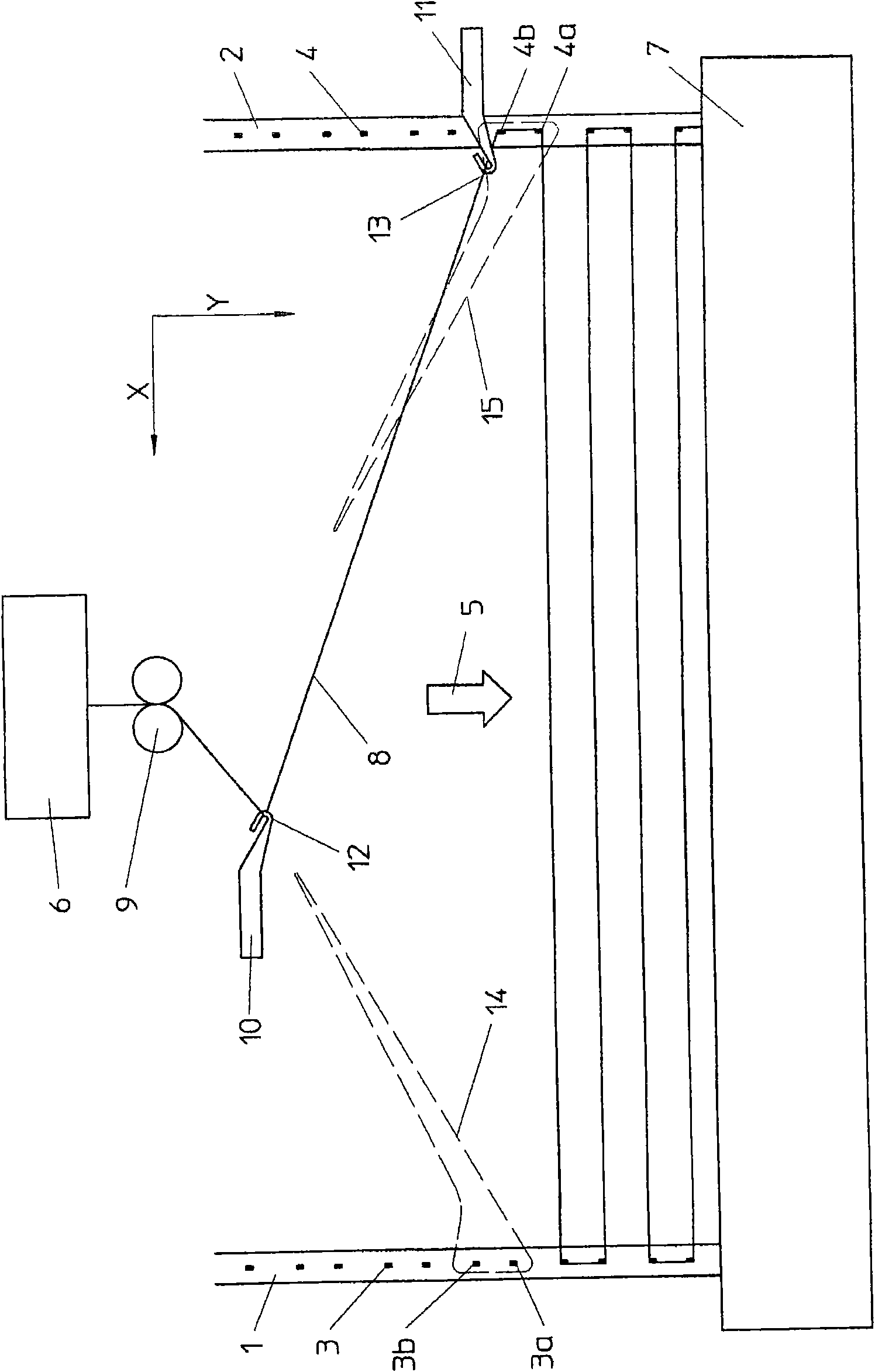

[0047] figure 1 A schematic diagram showing the laying of a unidirectional layer with a not very large width according to the method of the present invention is shown. The process of laying a single thread 8 in a zigzag-shaped parallel store is shown as an example. Two spaced apart driven longitudinal conveyor belts 1 and 2 have fastening hooks 3 and 4 . The longitudinal conveyor belts 1 , 2 move continuously in the conveying direction 5 . In practice, the longitudinal conveyor belts 1, 2 consist of conveyor chains, only the upper branches of which are visible in the figure.

[0048] With the arrangement shown, an infinite number of yarns 8 are delivered from the storage device 6 to the knitting station 7 . The storage device 6 may be a bobbin or, in the case of a wire harness, a creel. The yarn 8 leaving the storage device 6 is conveyed to the first yarn feeding device 10 via the deflection pulley 9 . The yarn 8 runs from here to the second thread delivery device 11 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com