Patents

Literature

699results about "Flat warp knitting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

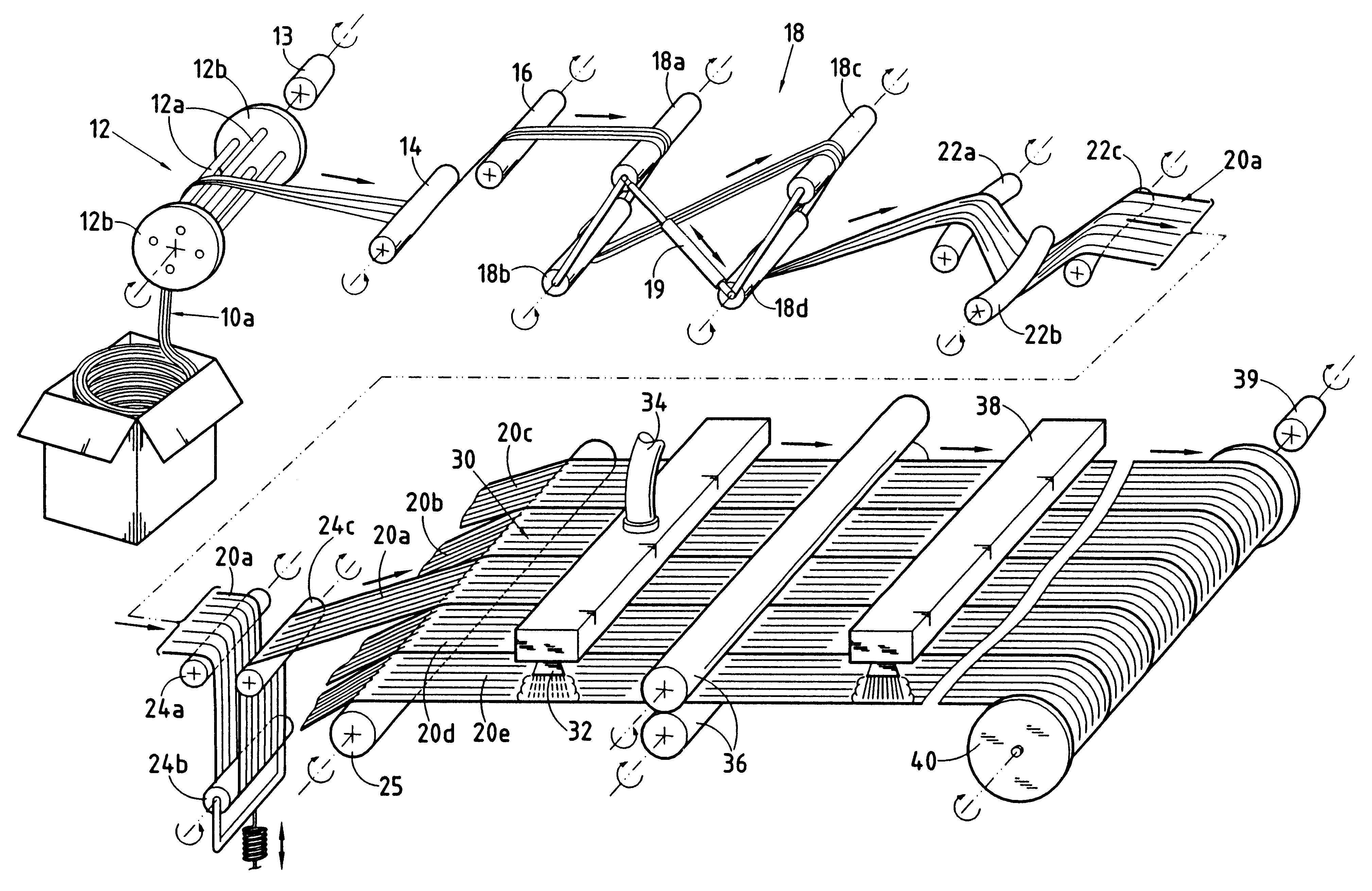

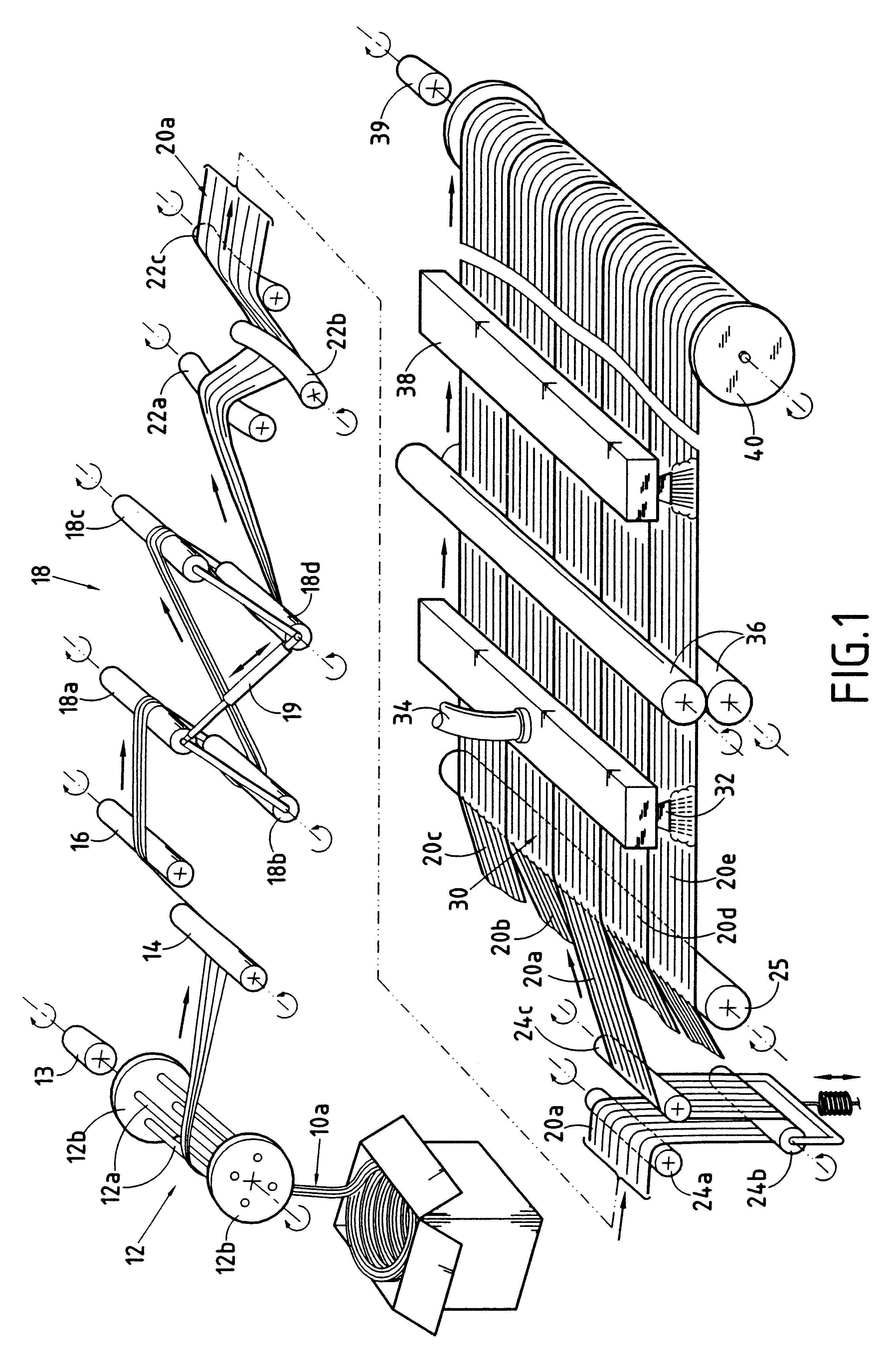

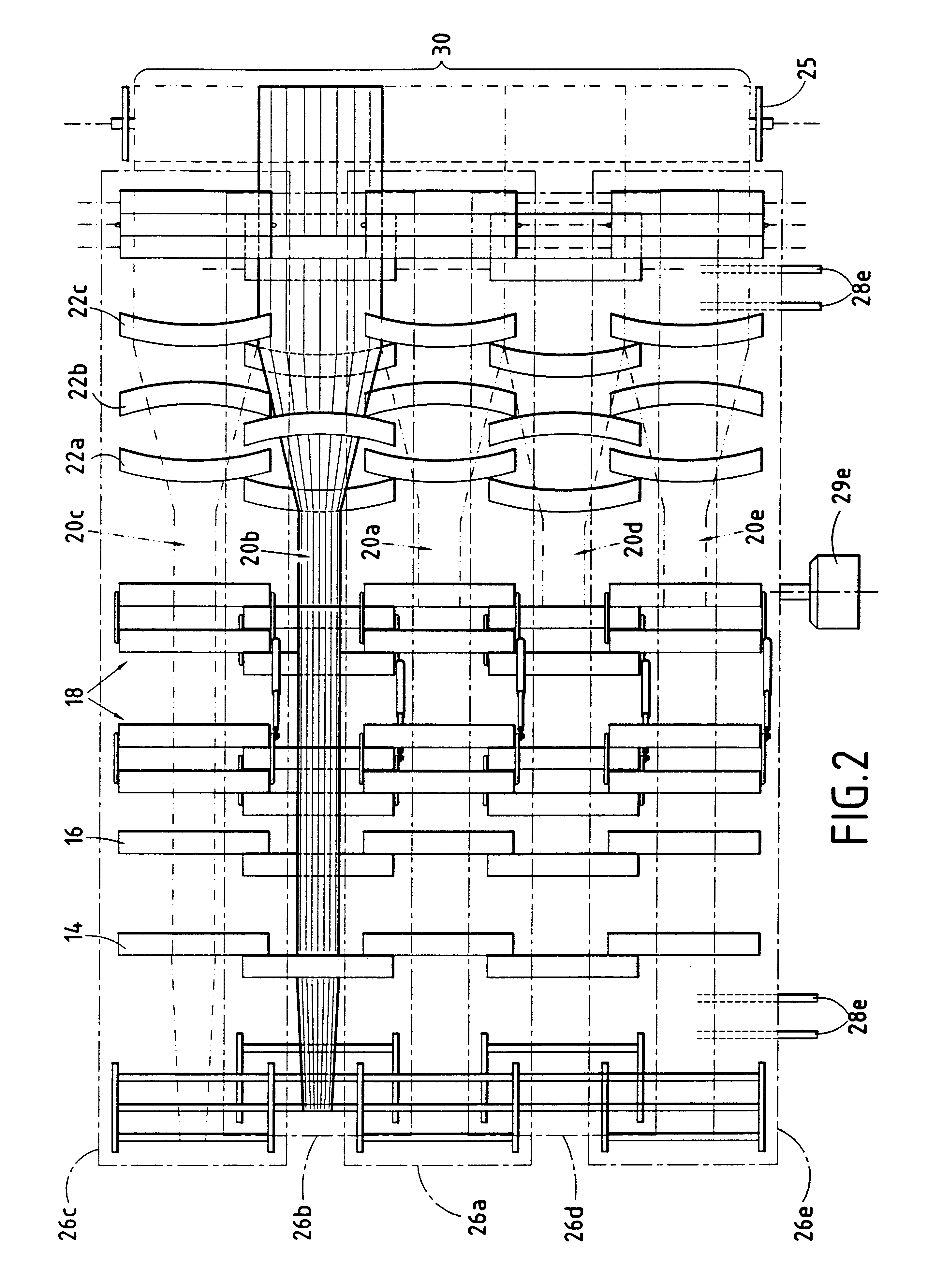

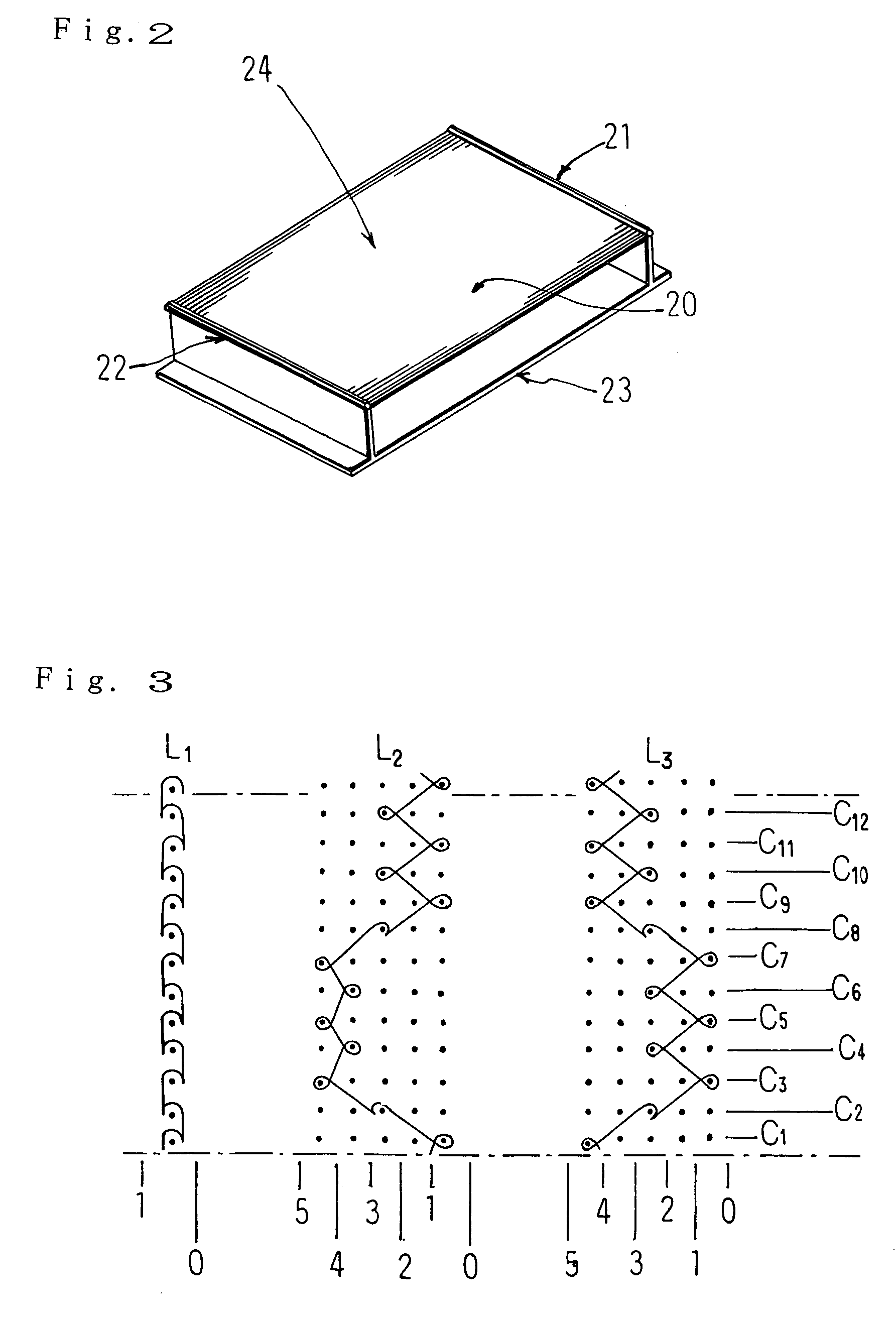

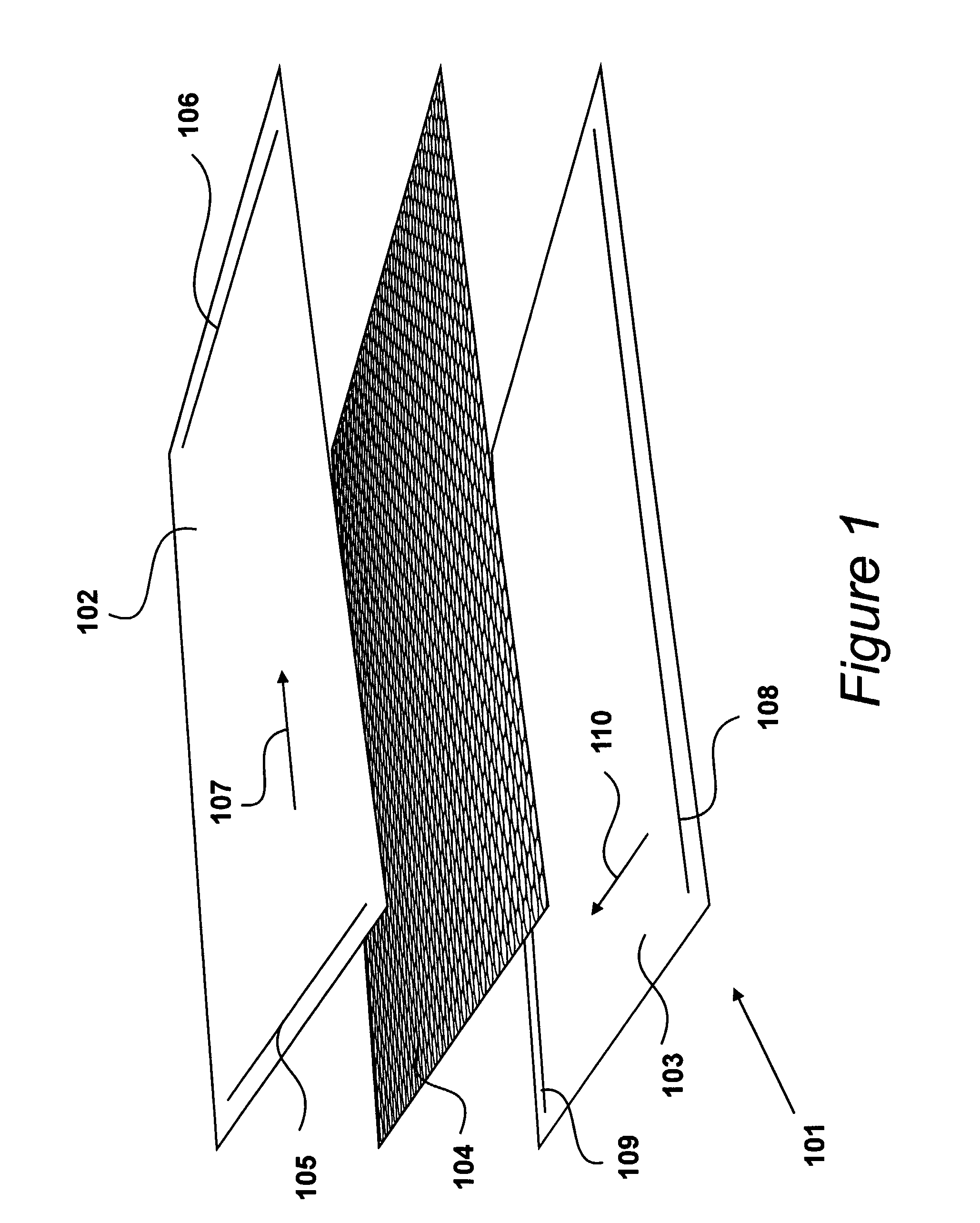

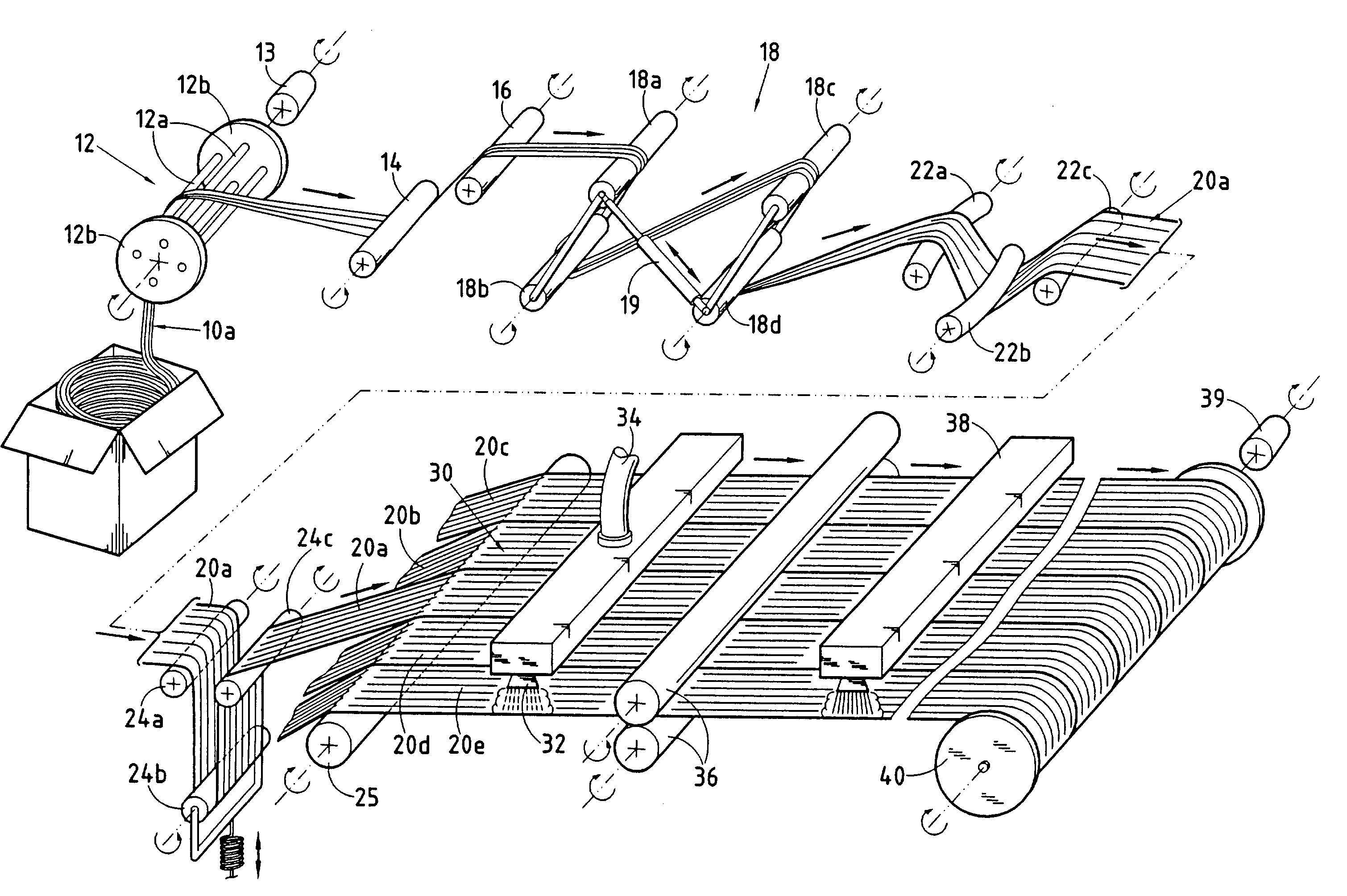

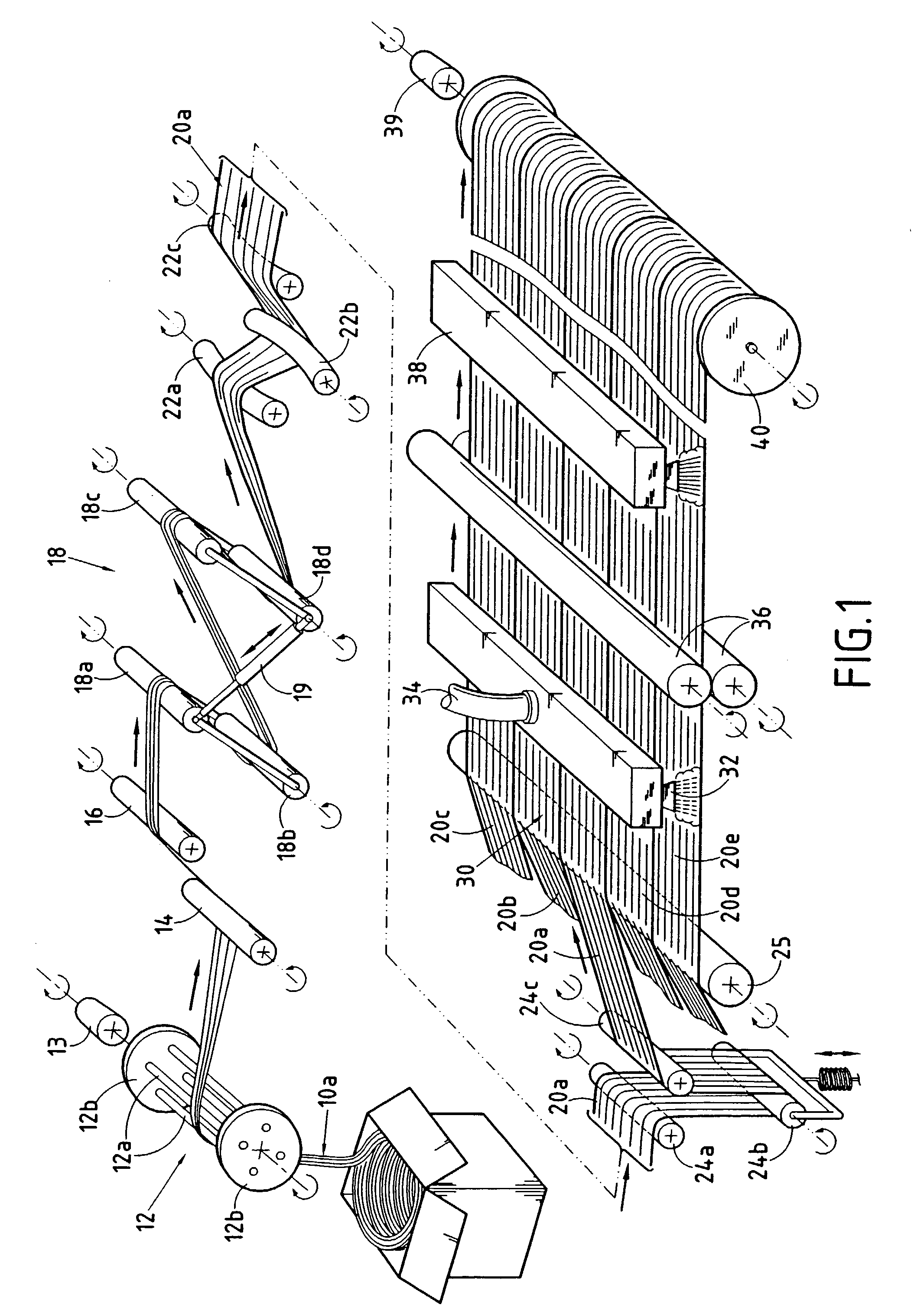

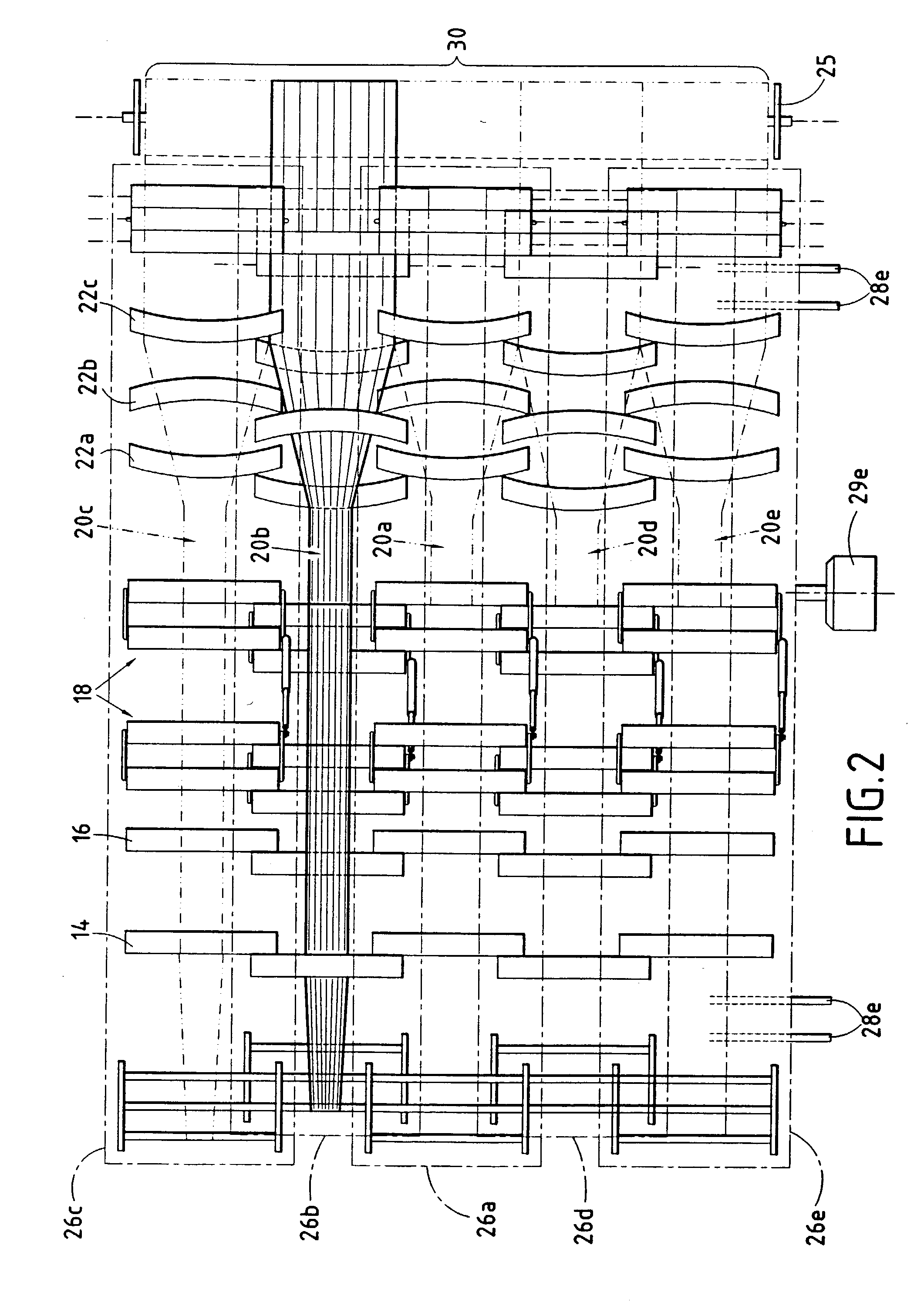

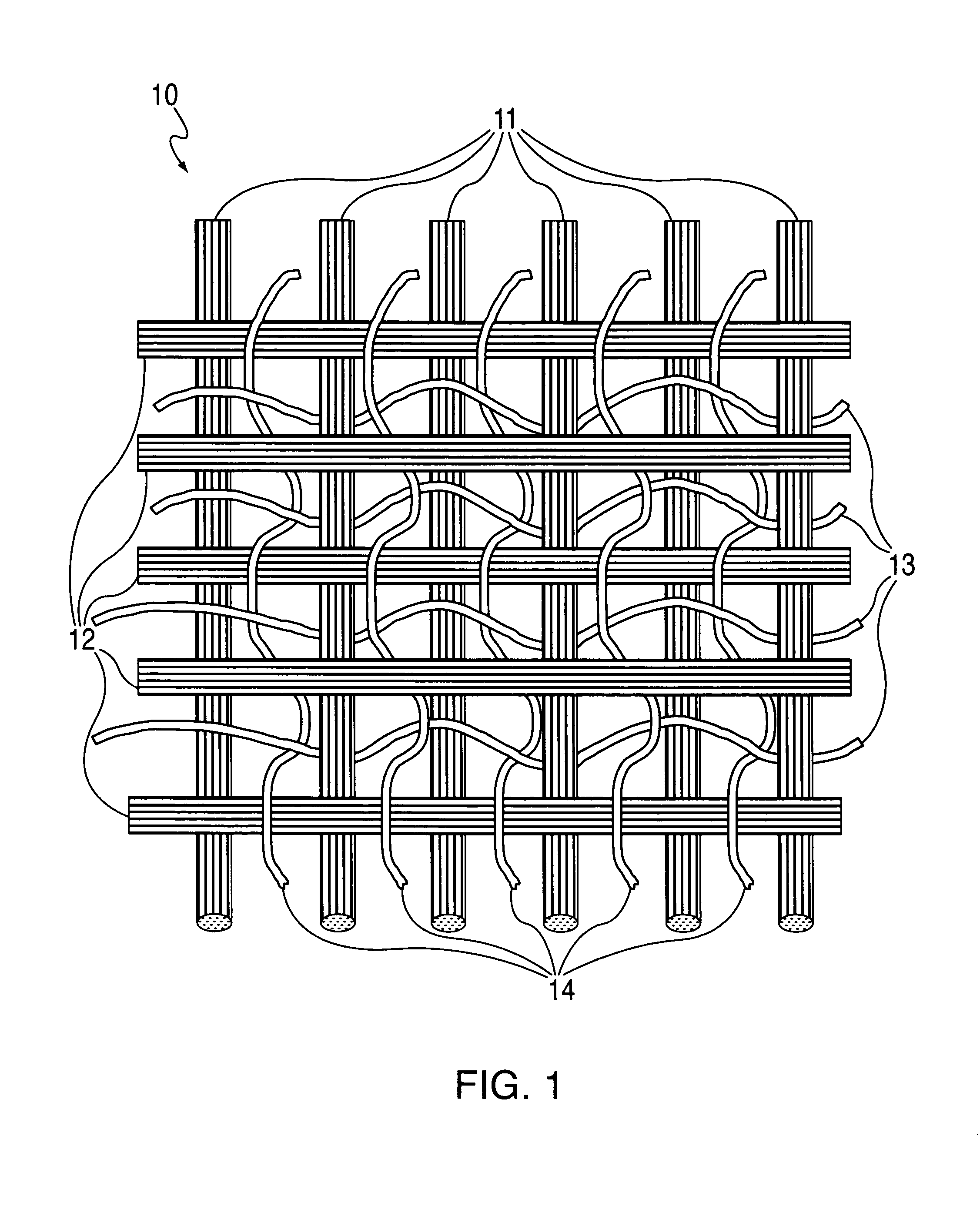

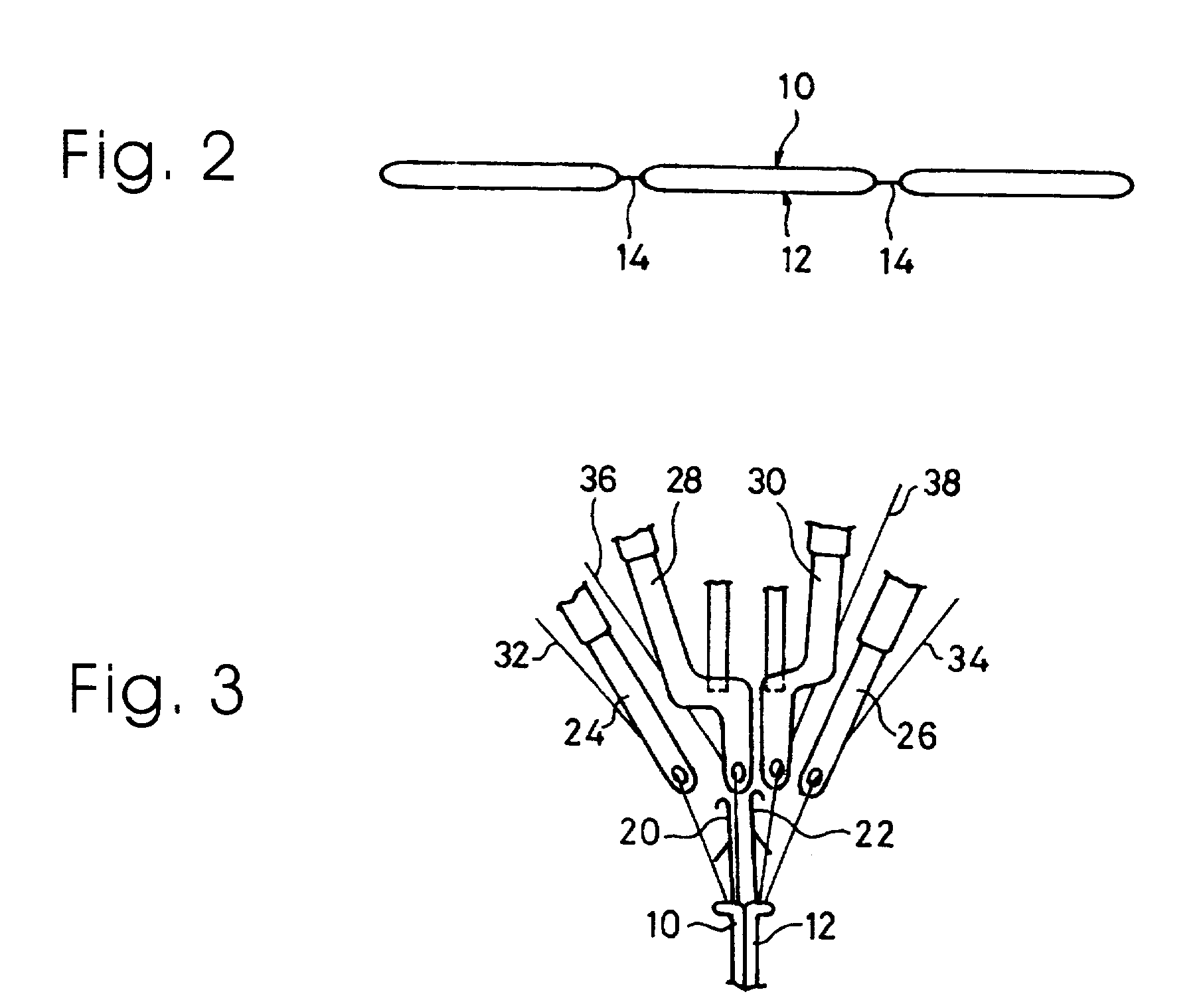

Method and machine for producing multiaxial fibrous webs

InactiveUS6585842B1Reduce manufacturing costLow costLamination ancillary operationsOrnamental textile articlesFiberCarbon fibers

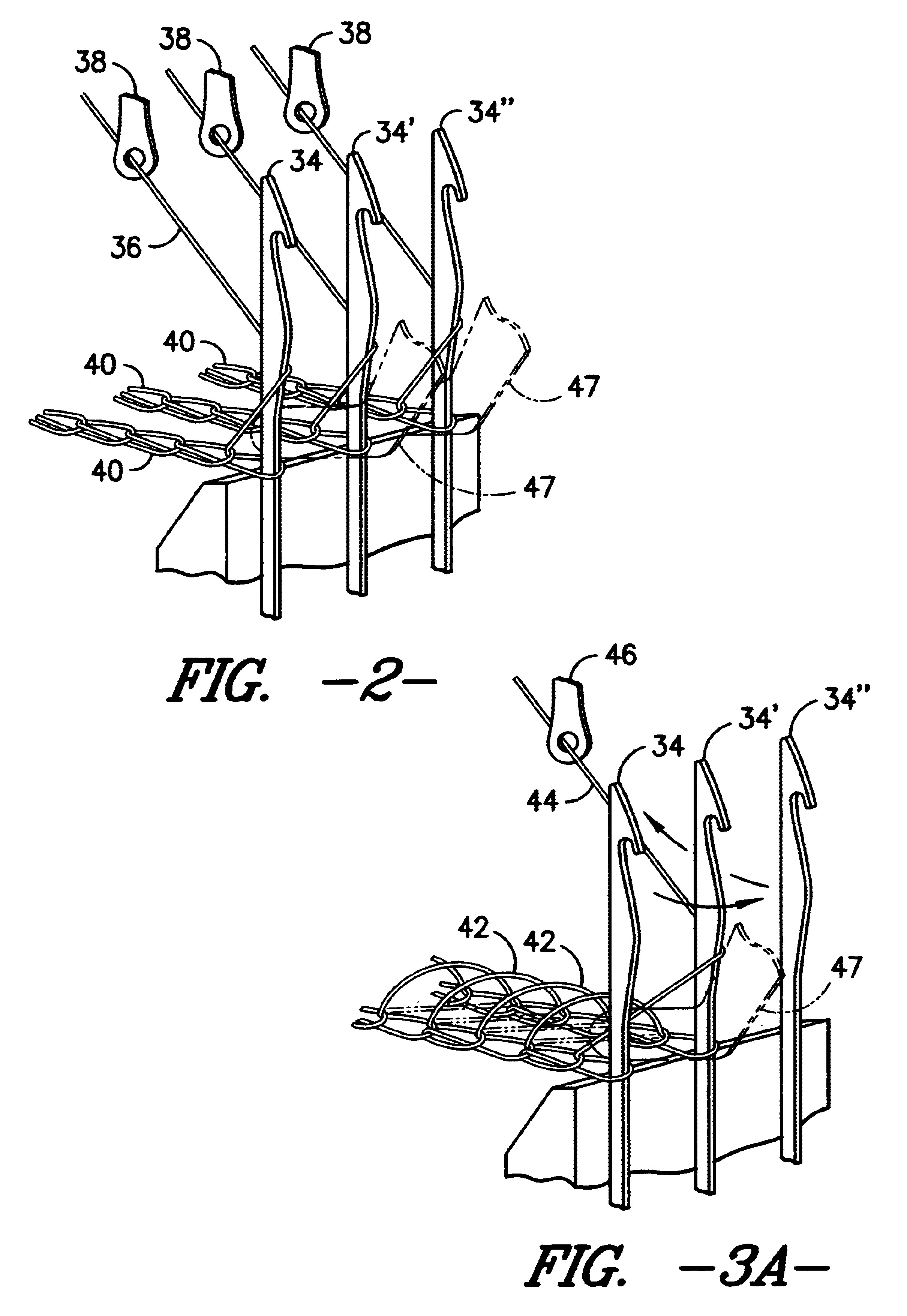

A plurality of unidirectional sheets (30a, 30b, 30c) are superposed in different directions and they are bonded together. At least one of the unidirectional sheets is made by spreading a tow so as to obtain uniform thickness, width not less than 5 cm, and a weight of no more than 300 g / m2, cohesion being imparted to the sheet so as to enable it to be handled prior to being superposed with other sheets. Advantageously, the unidirectional sheets are made of carbon fibers and are obtained by spreading out large tows.

Owner:HEXCEL FABRICS +1

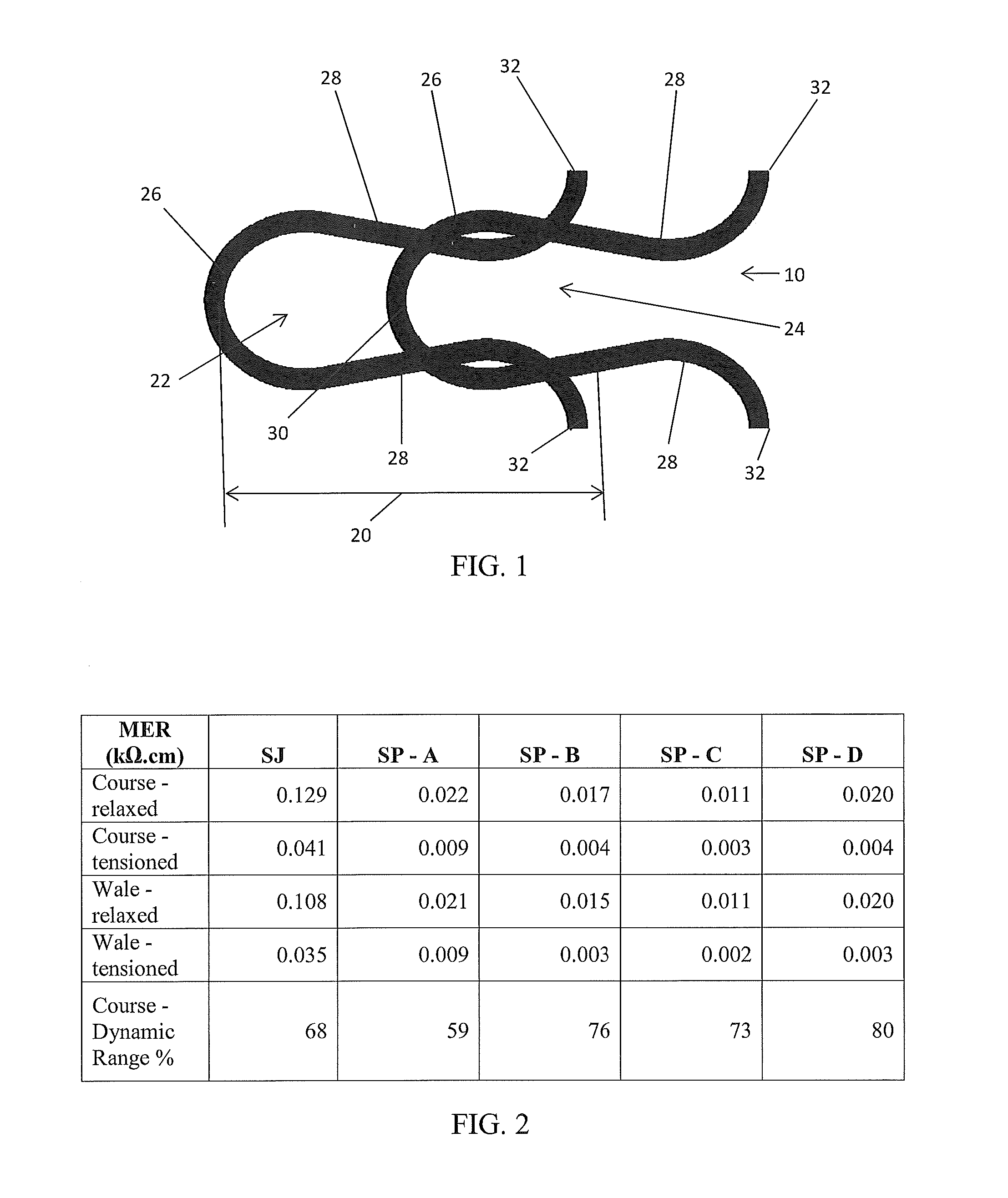

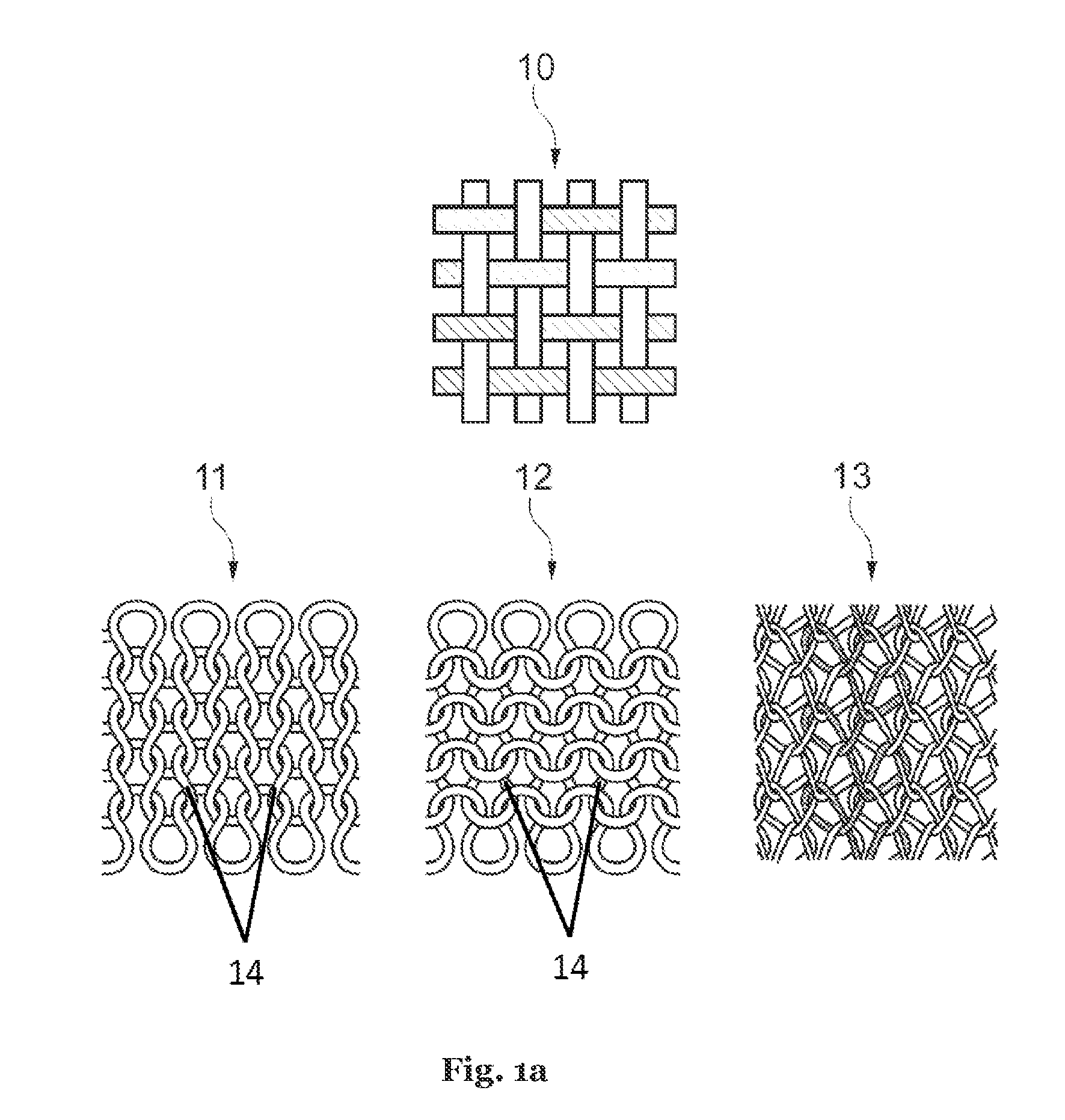

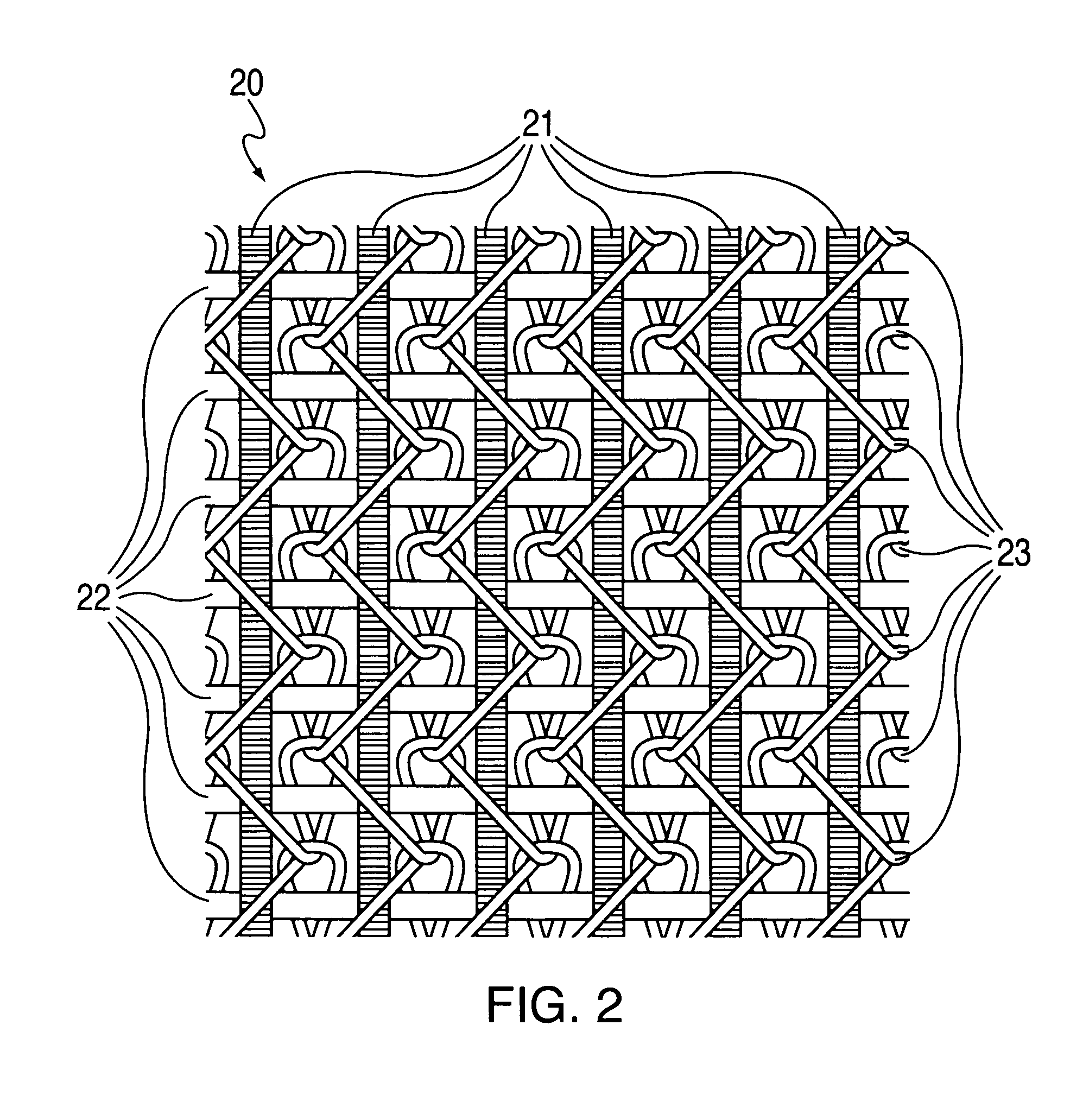

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

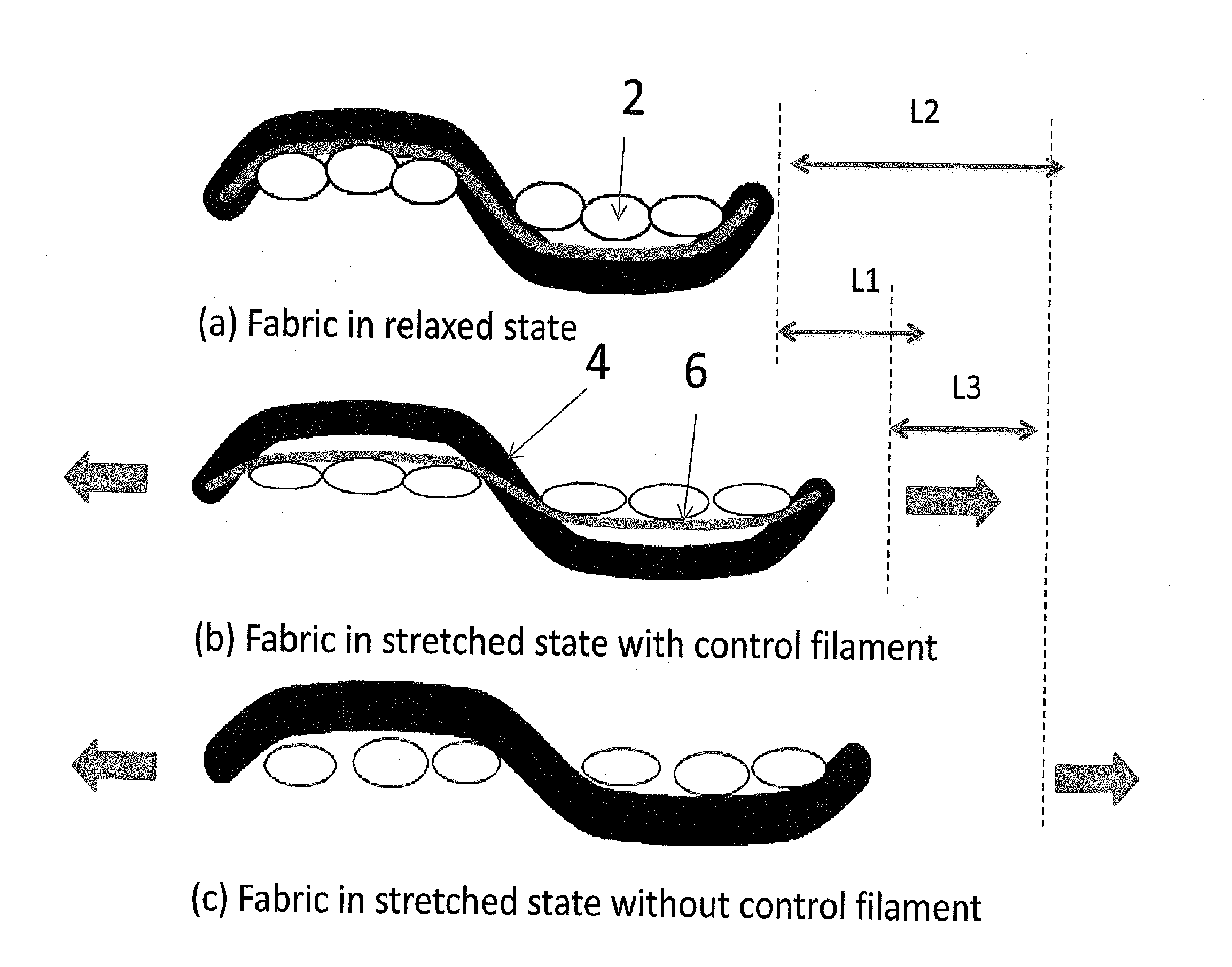

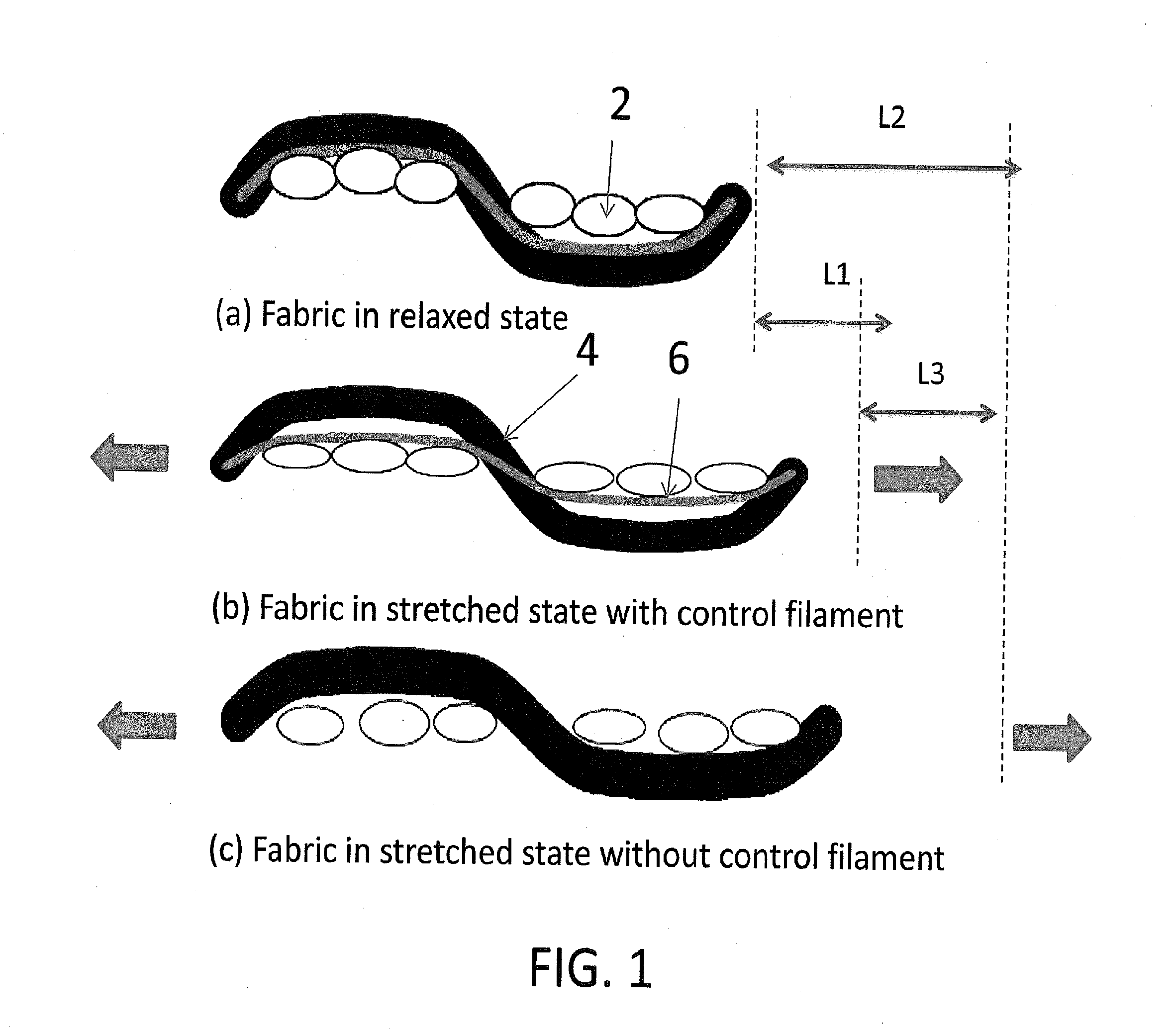

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

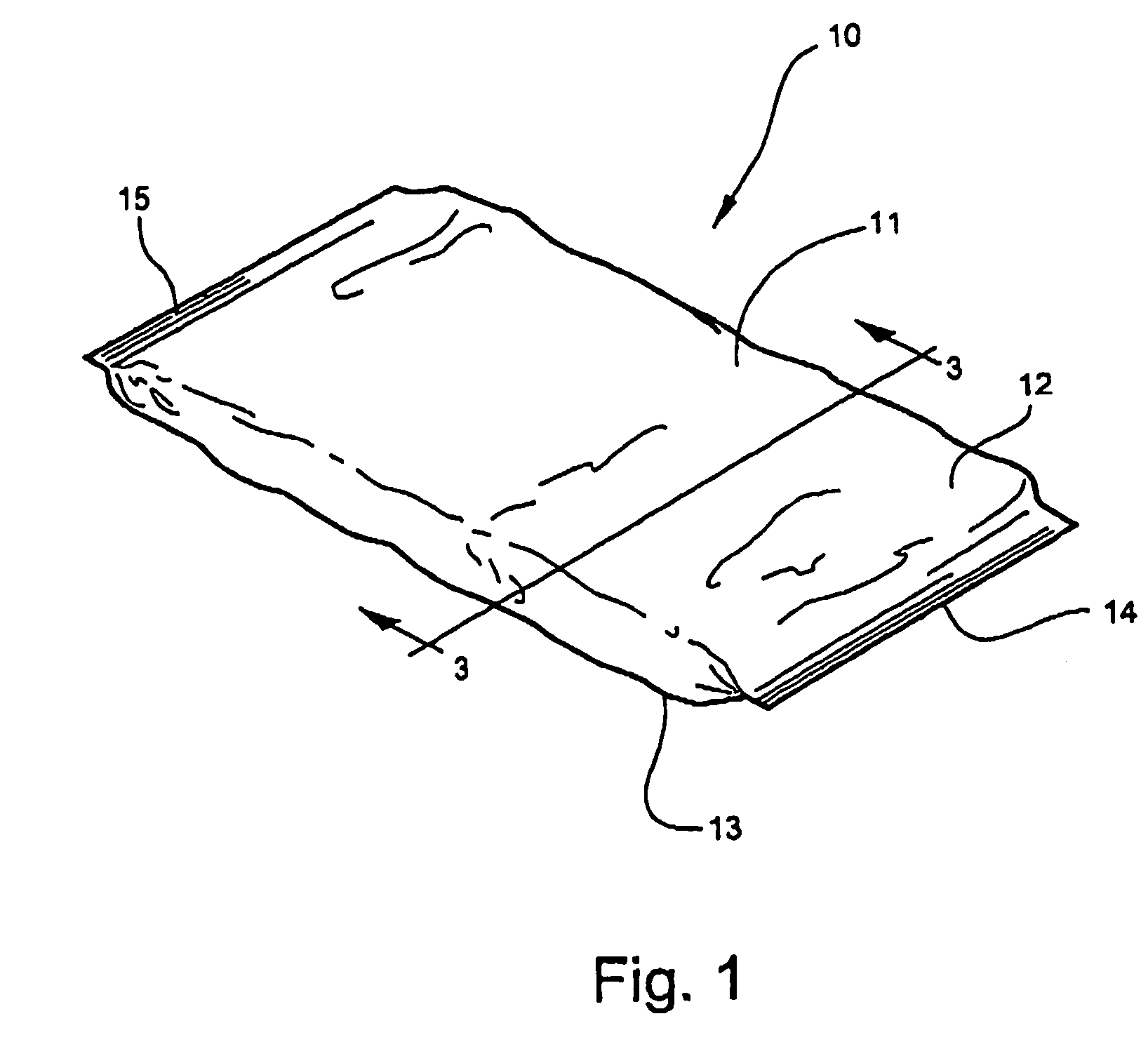

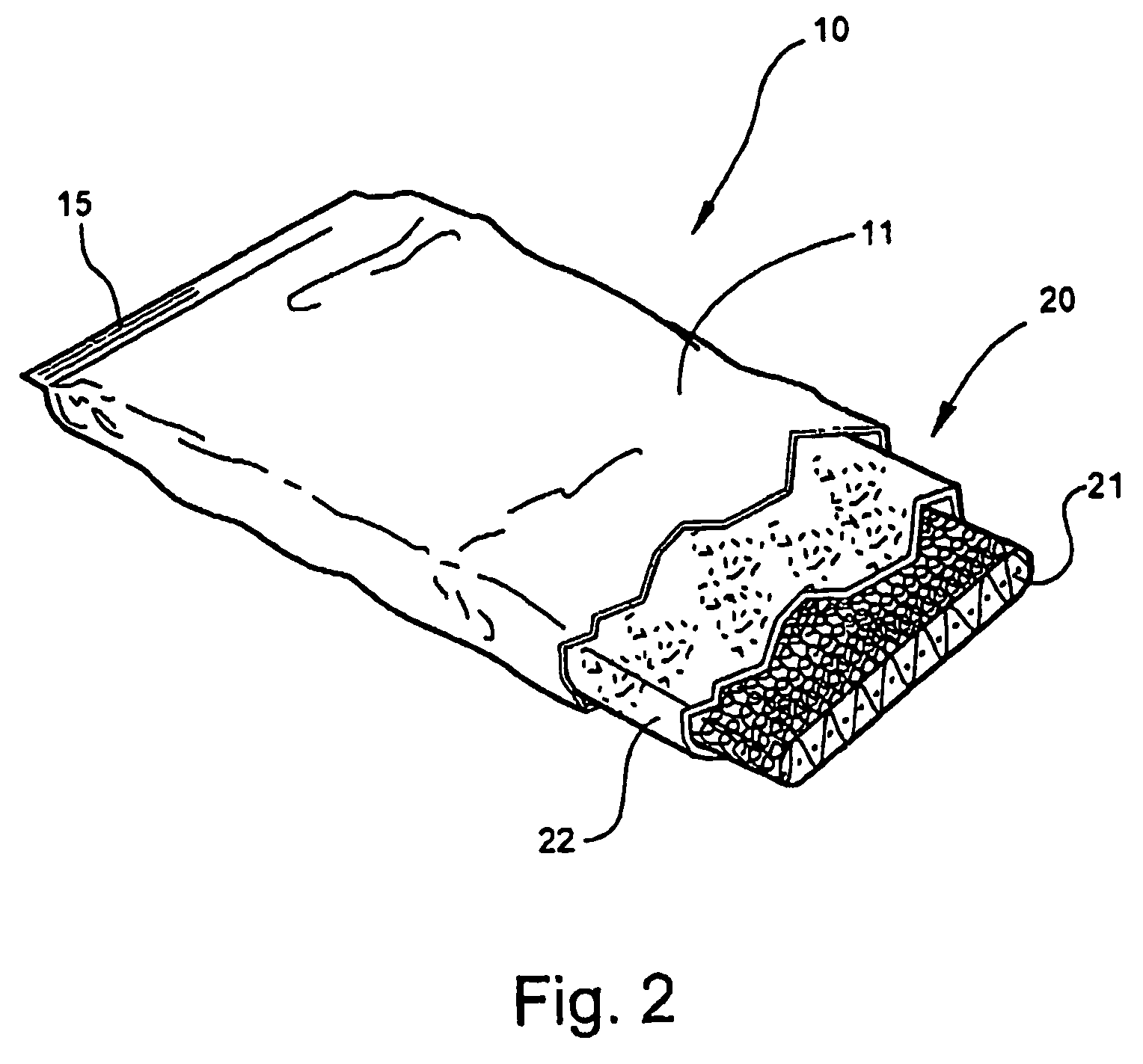

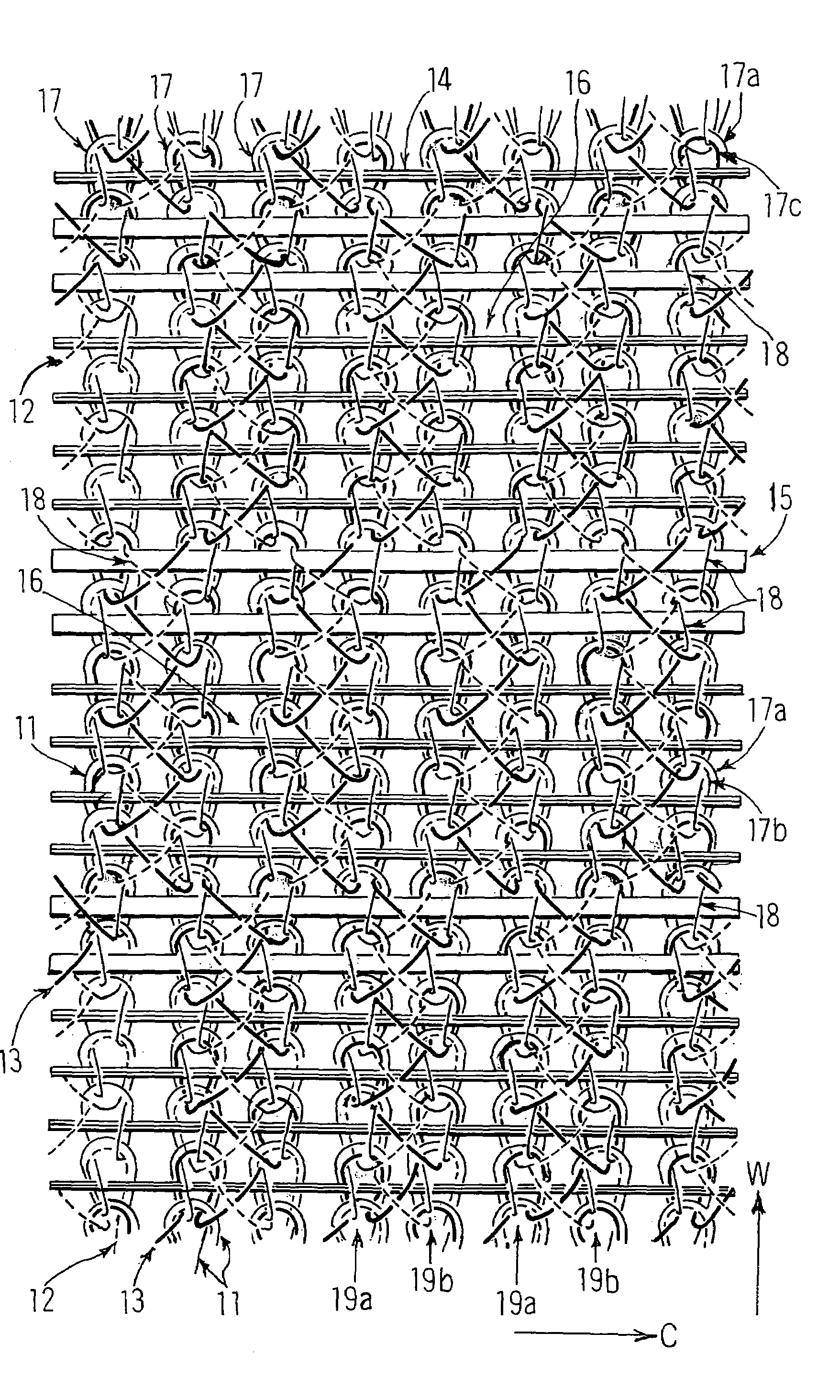

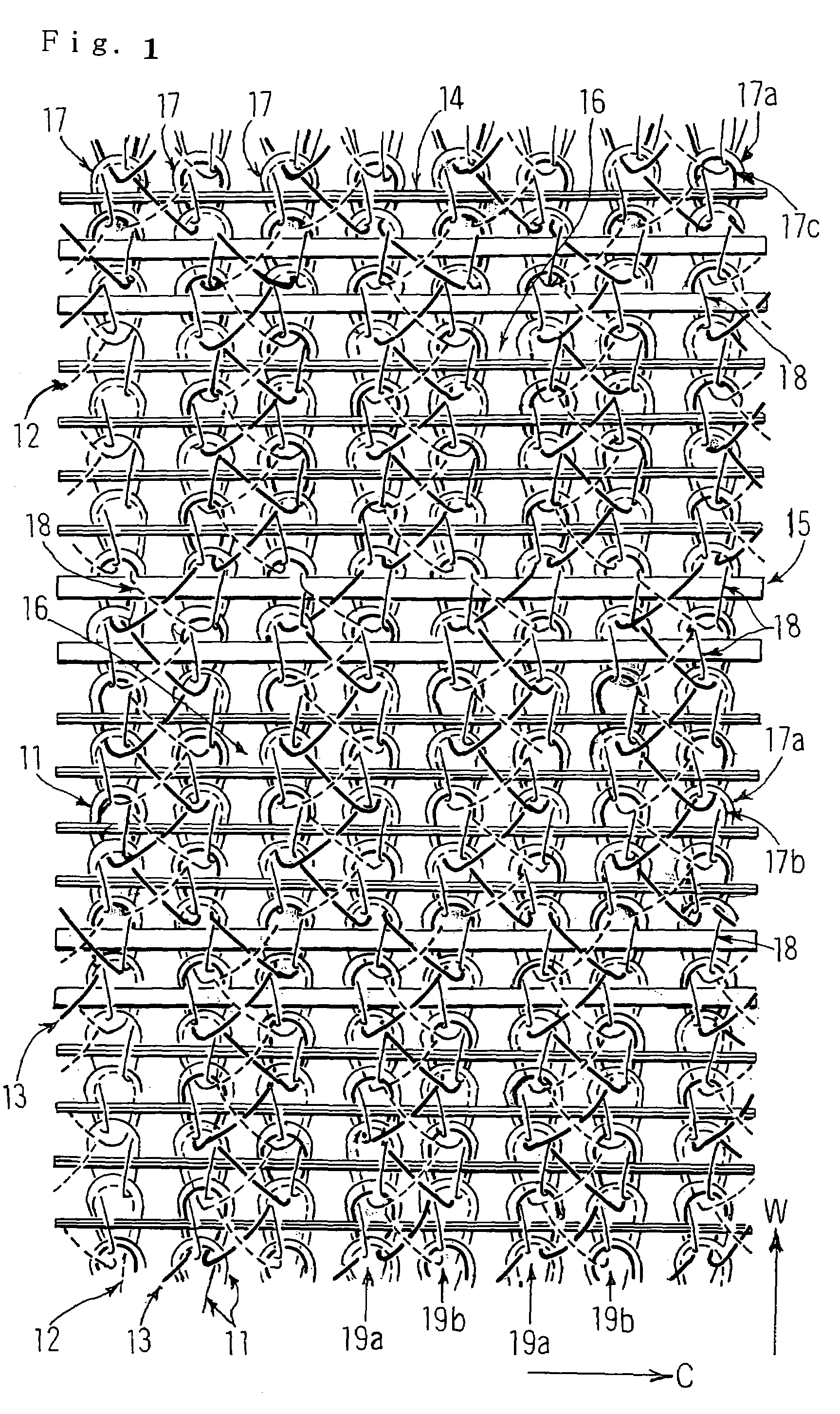

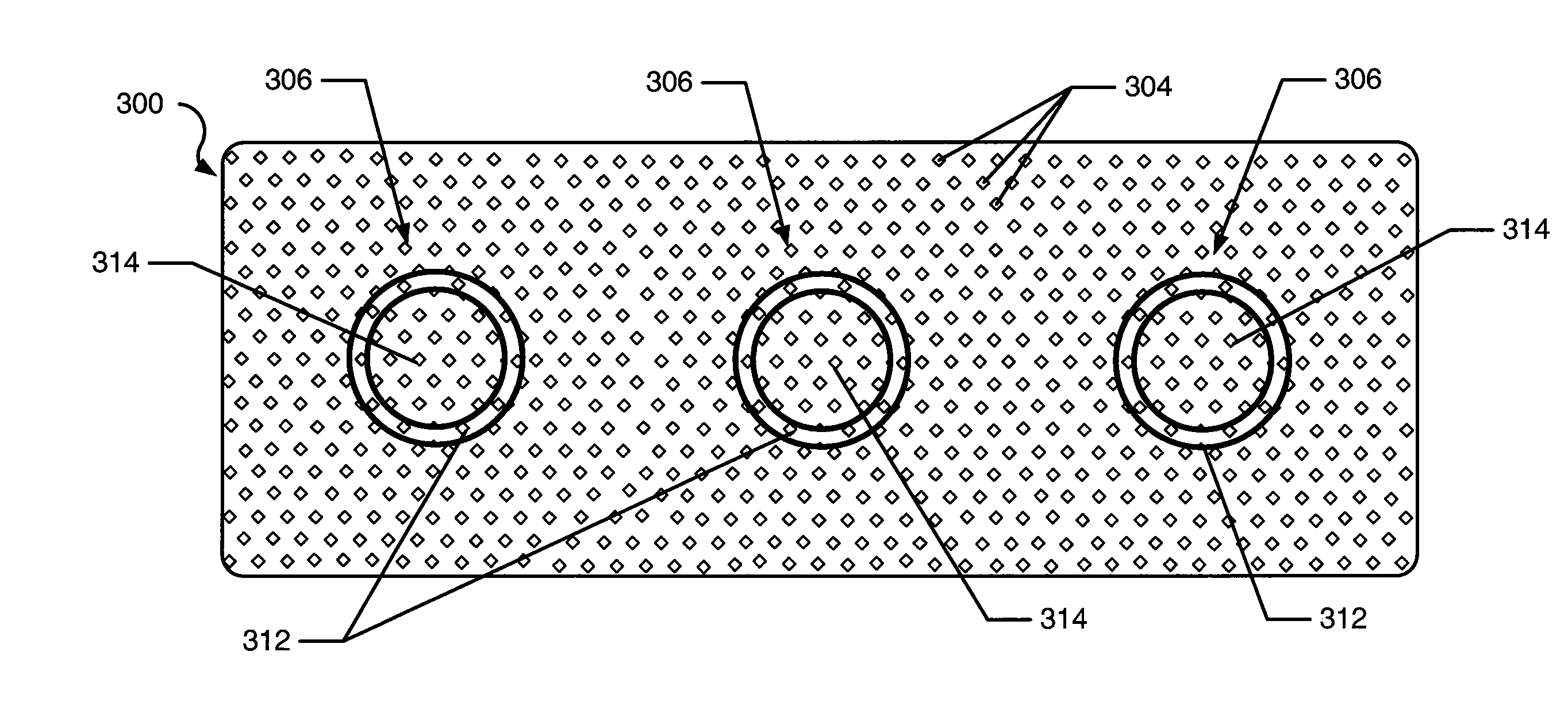

Knitted substrate for use in medical bandaging product, bandaging product and method of forming the same

ActiveUS7854712B2High strengthOrnamental textile articlesPlaster of paris bandagesYarnReactive system

A medical bandaging product having a predetermined length suitable for a given medical use, including an enclosure formed of a moisture-impervious material sealable to prevent entry of moisture and a medical bandage material positioned in the enclosure and sealed therein against entry of moisture until use. The medical bandage material includes a substrate formed from a single integrated knitted fabric layer having a plurality of interconnected knitted fabric yarns forming a three-dimensional structure. A reactive system is impregnated into or coated onto the substrate. The system remains stable when maintained in substantially moisture-free conditions and hardens upon exposure to sufficient moisture to cooperate with the three-dimensional structure to form a rigid, self supporting structure. A soft, flexible protective wrapping encloses the substrate along its length for providing a cushioning barrier interposed between the substrate and a patient when the medical bandage material is in use.

Owner:BSN MEDICAL INC

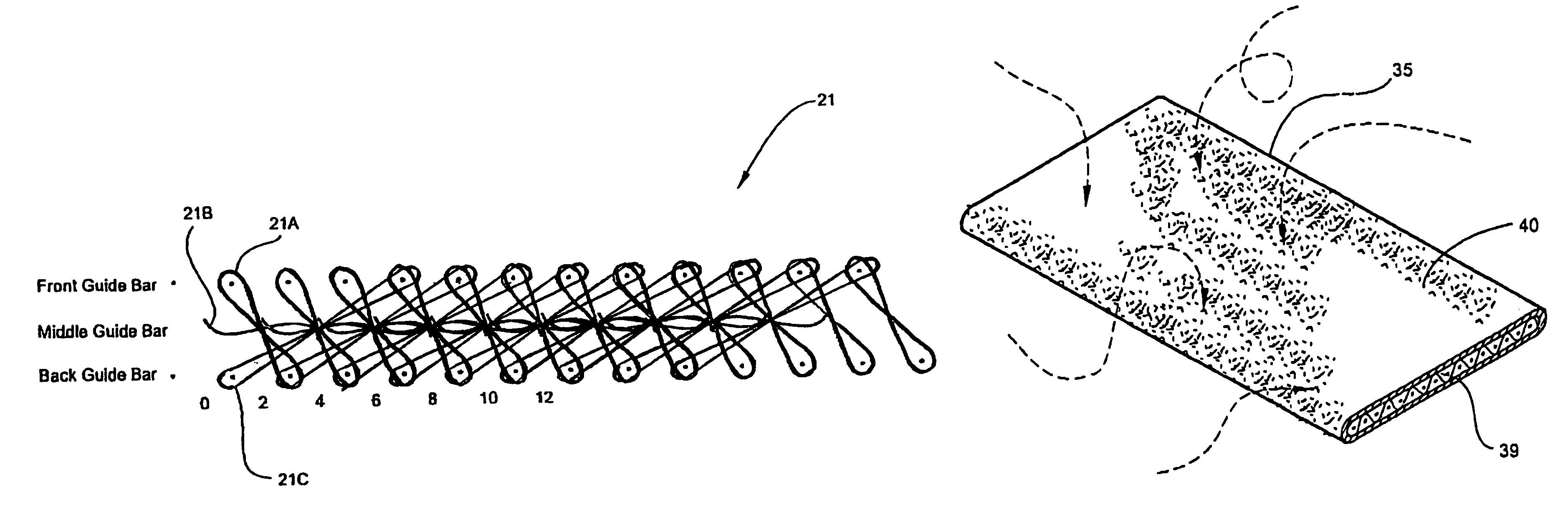

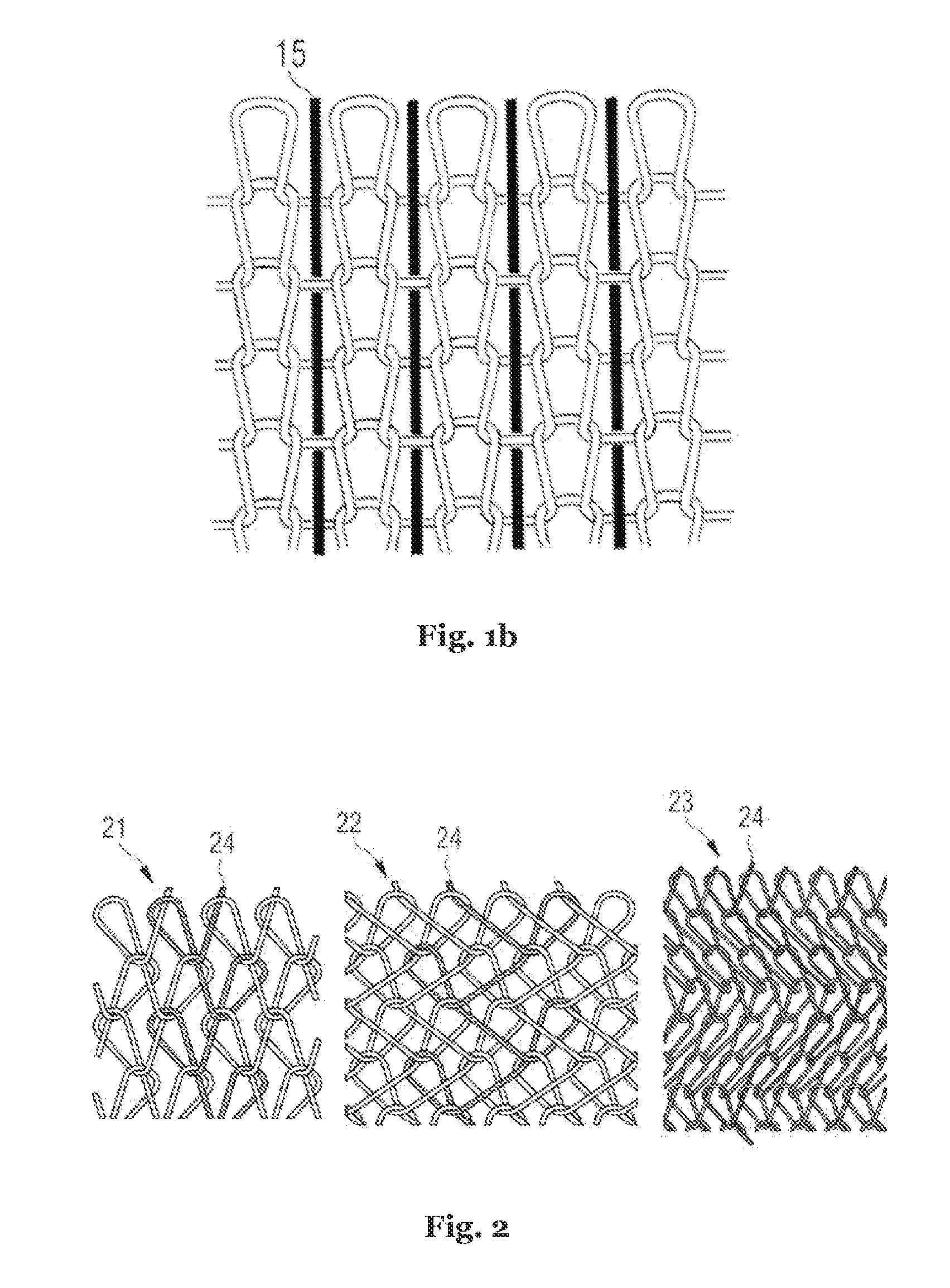

Elastic warp-knit fabric

InactiveUS7201024B2Reduce light reflectionImprove propertiesUpholsteryFlat warp knitting machinesBiomedical engineeringWarp knitting

A fabric article useful for the cushioning surface of a car seat and like items is formed from thick main elastic yarn which is thicker than main stitch yarn, and main inserted yarn which is more bulky and thicker than the main elastic yarn in apparent thickness, are knitted in line in the knitting width direction or in the knitting length direction of a mesh-like base knitted fabric which is knitted up with main stitch yarns by using a warp knitting machine and which have openings which are larger than the needle loops formed from the stitch yarn and extend over plural knitting courses.

Owner:KAWASHIMA SELKON TEXTILES

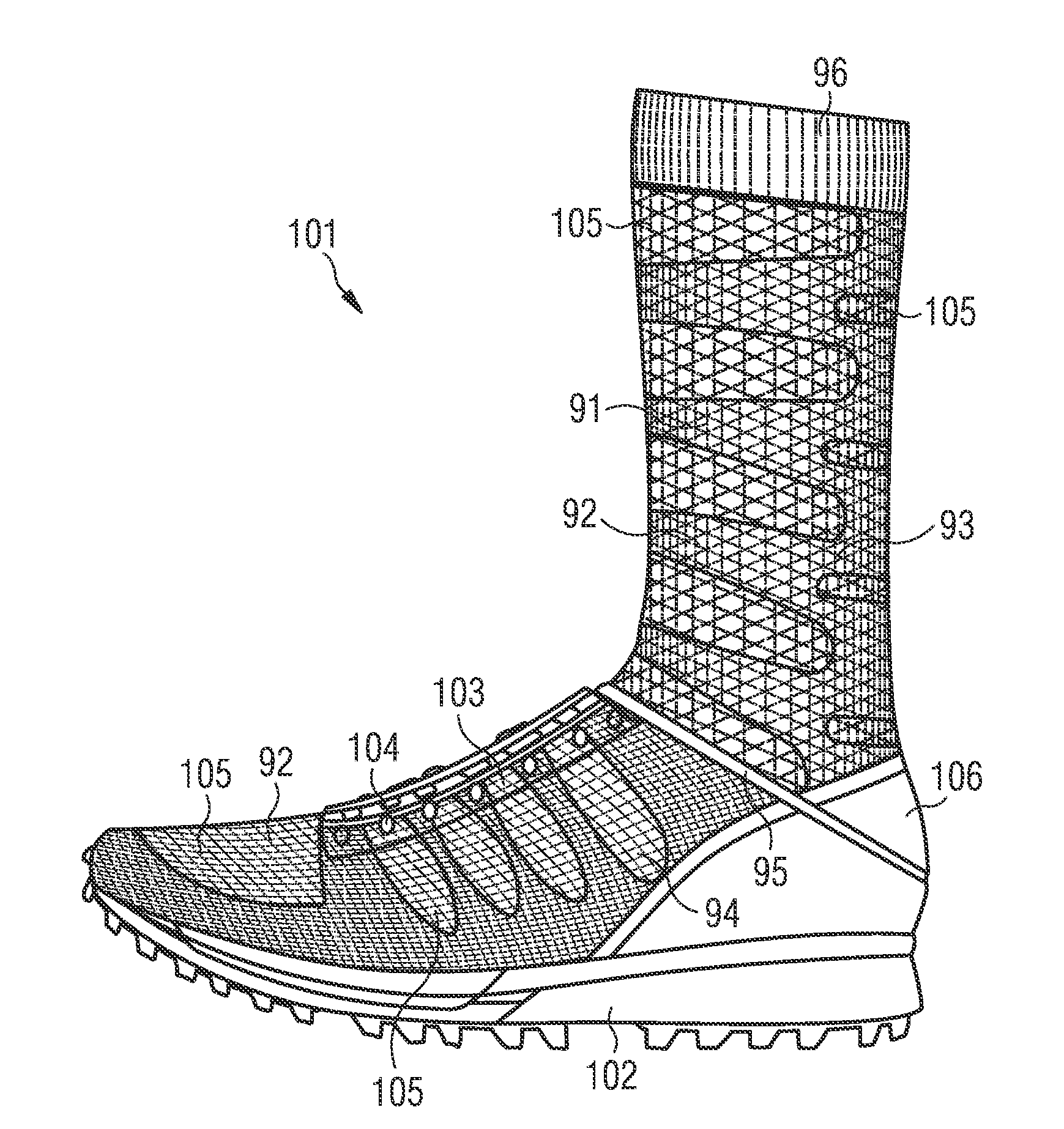

Flat weft-knitted upper for sports shoes

Owner:ADIDAS

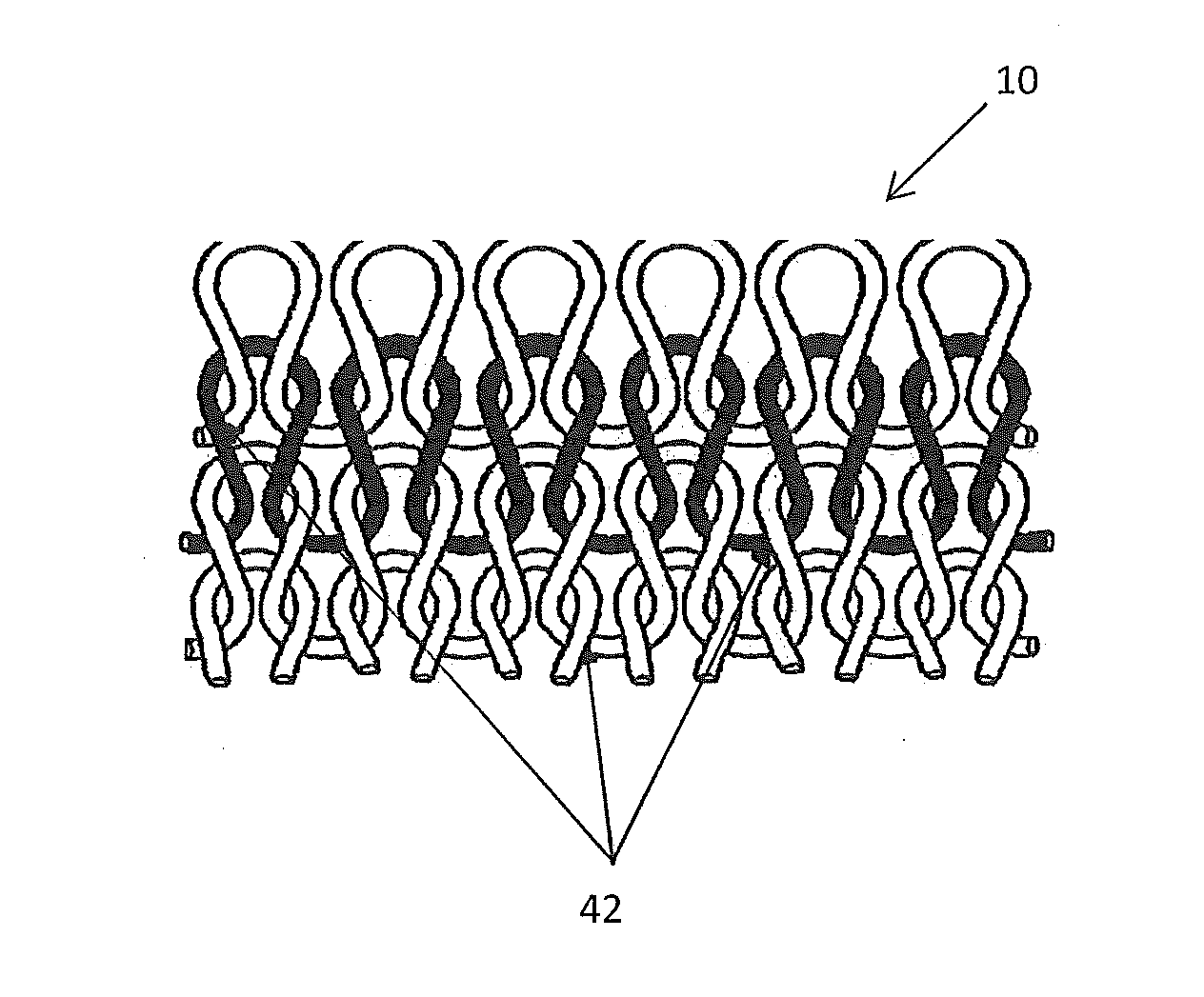

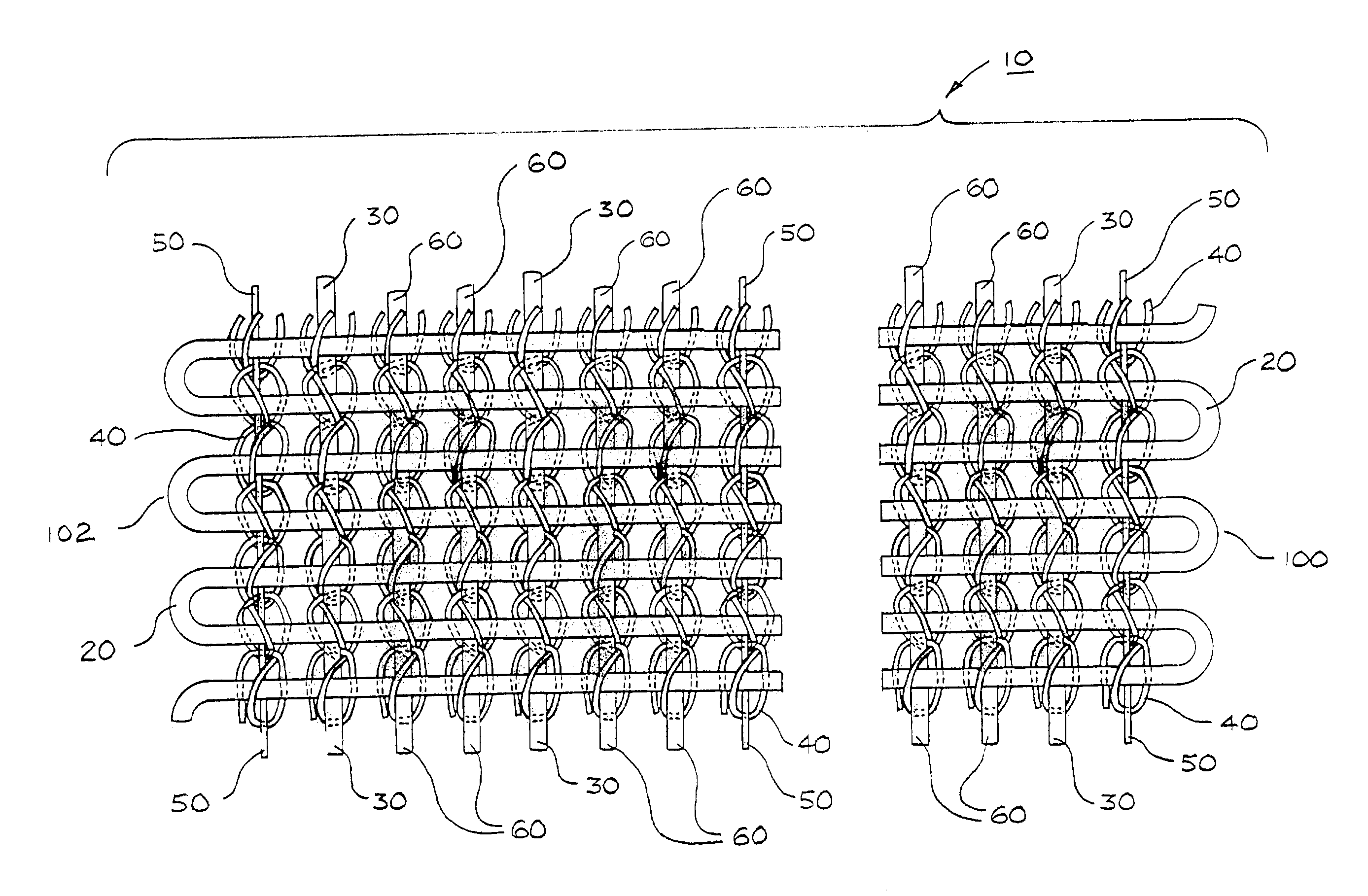

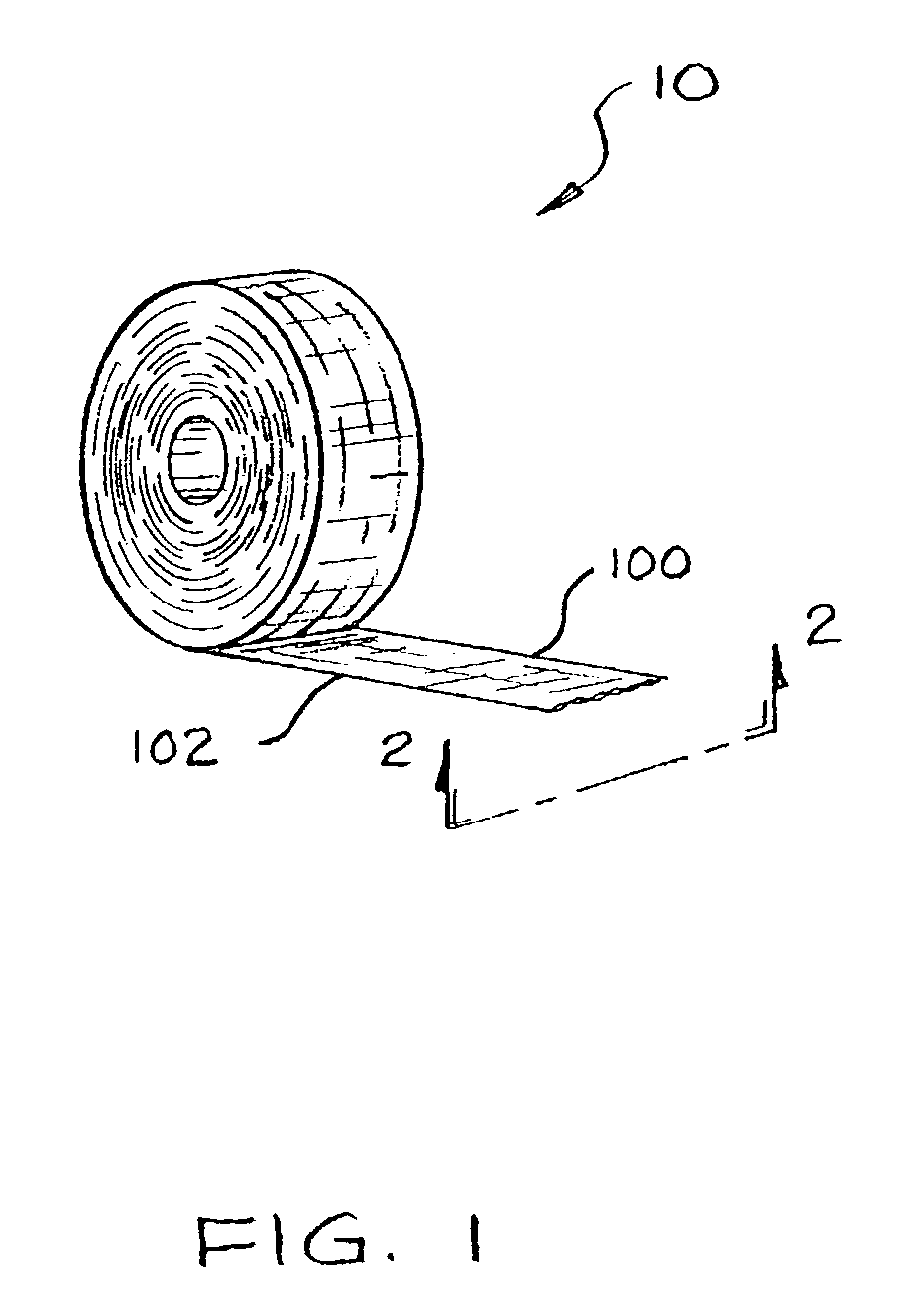

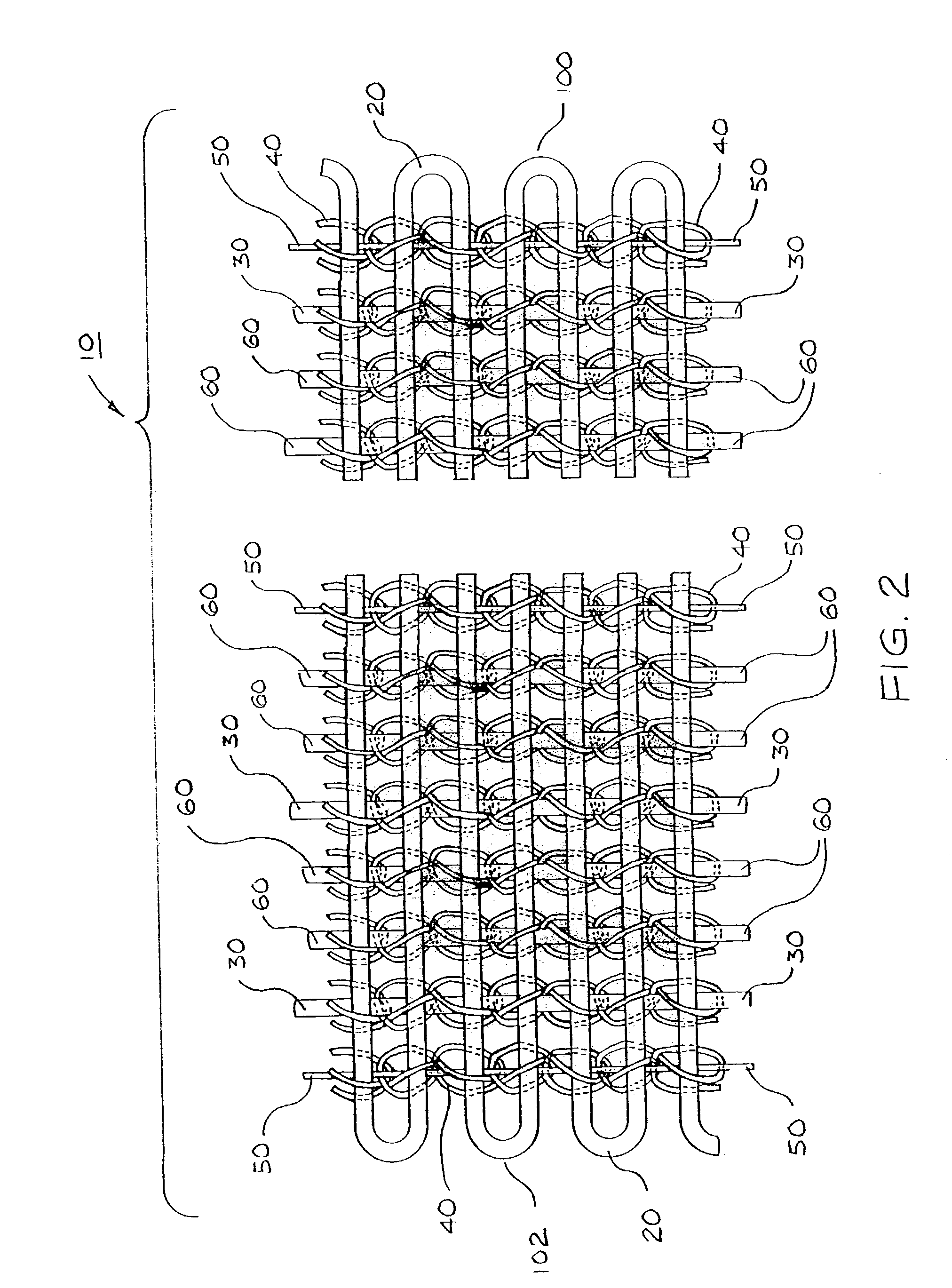

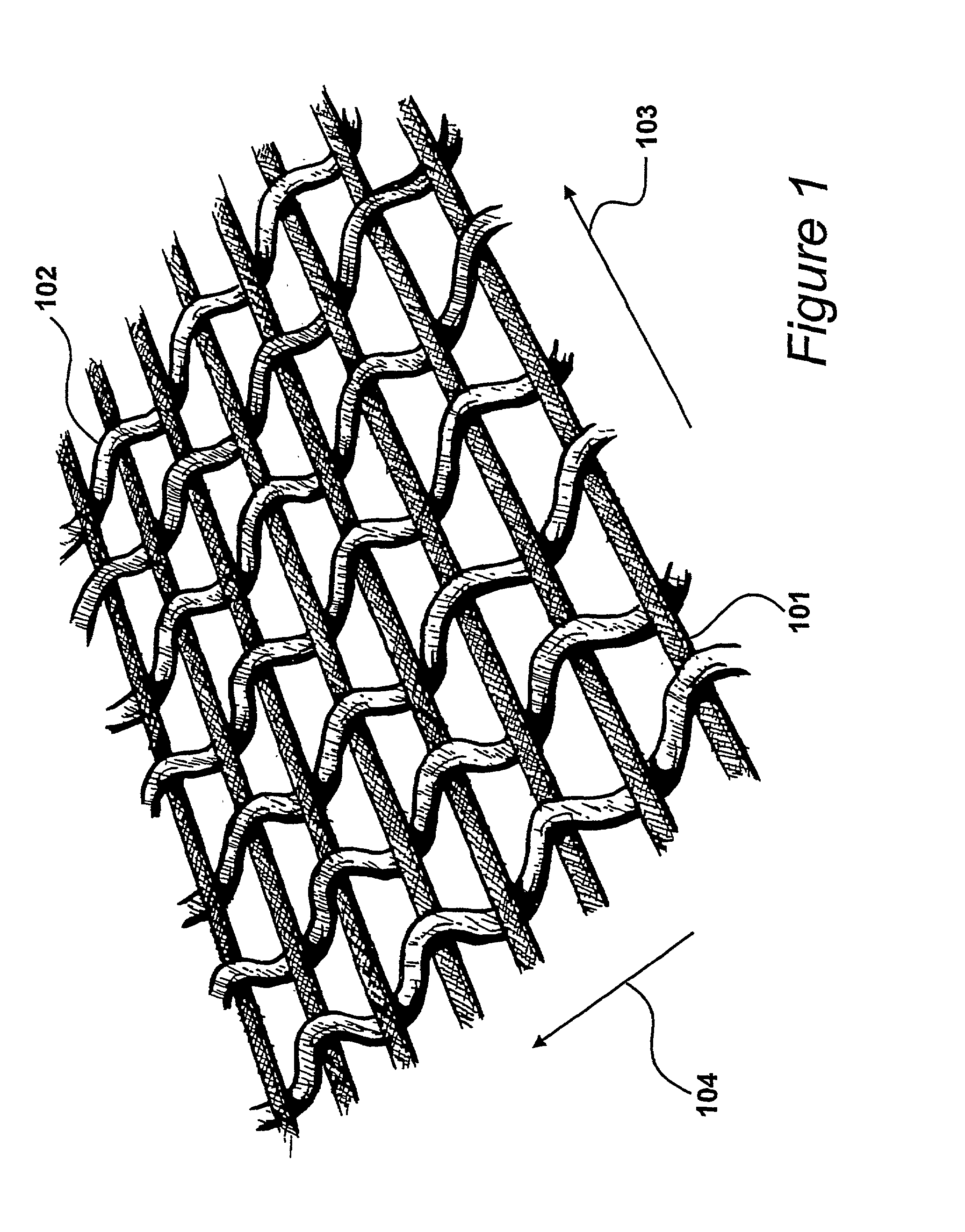

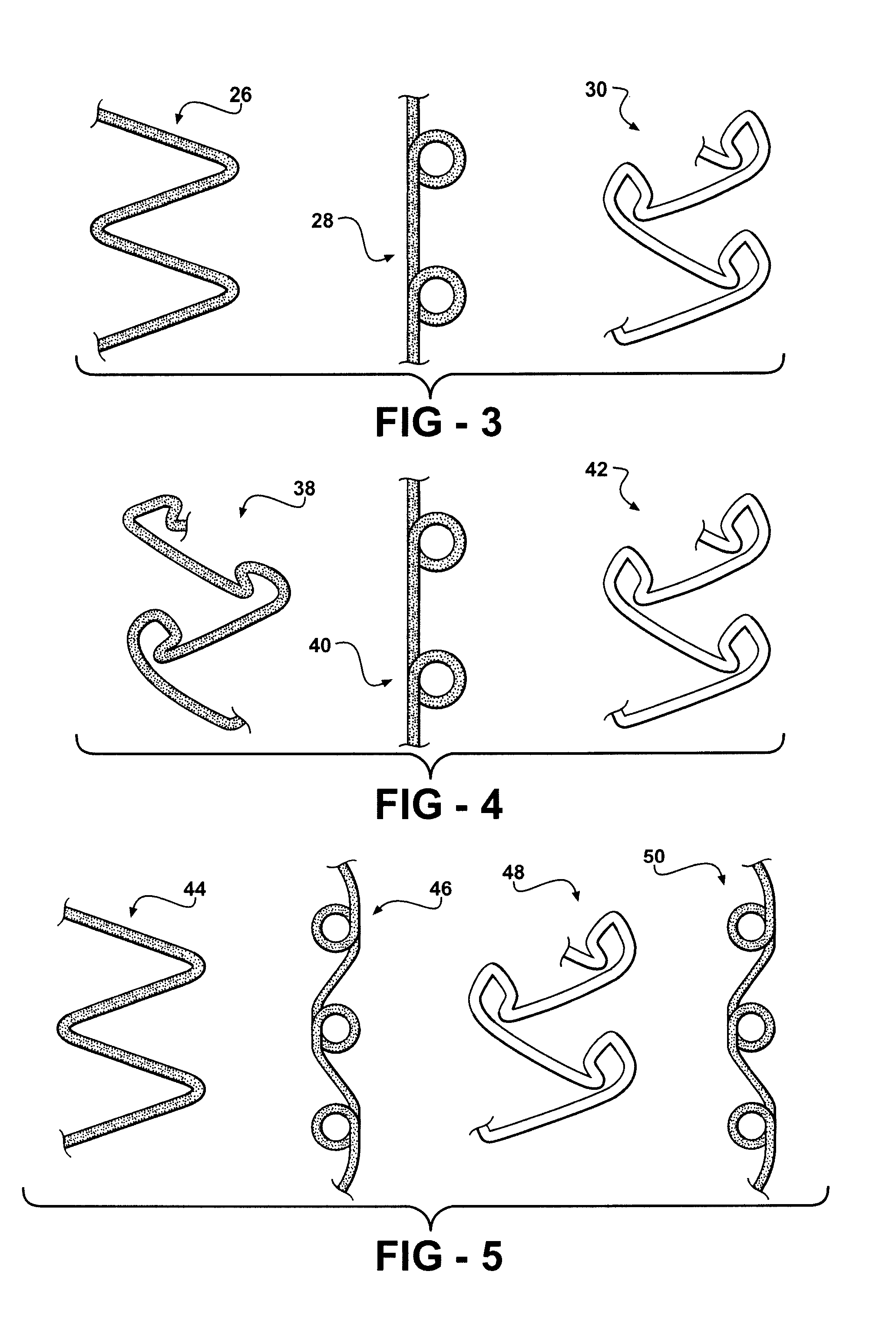

Wire-reinforced elastic webbing

InactiveUS6984596B2Limited elongationEvenly distributedOrnamental textile articlesWire networkYarnPolyester

A wire-reinforced webbing material is disclosed for use in furniture, bedding and the like. The webbing includes a flat knitted fabric comprised of substantially elastic yarns such as polyester. A plurality of reinforcement wires are integrally knitted into the fabric structure in a lengthwise direction. The wires may be thin-gauge titanium or titanium alloy wires. Elastomeric yarns or cards may also be integrally knitted into the fabric structure parallel to the reinforcement wires. The reinforcement wires and elastomeric cords combine with the knitted fabric to yield a webbing material having both a high tensile strength and a resilient responsiveness to applied external loads.

Owner:HICKORY SPRINGS MFG

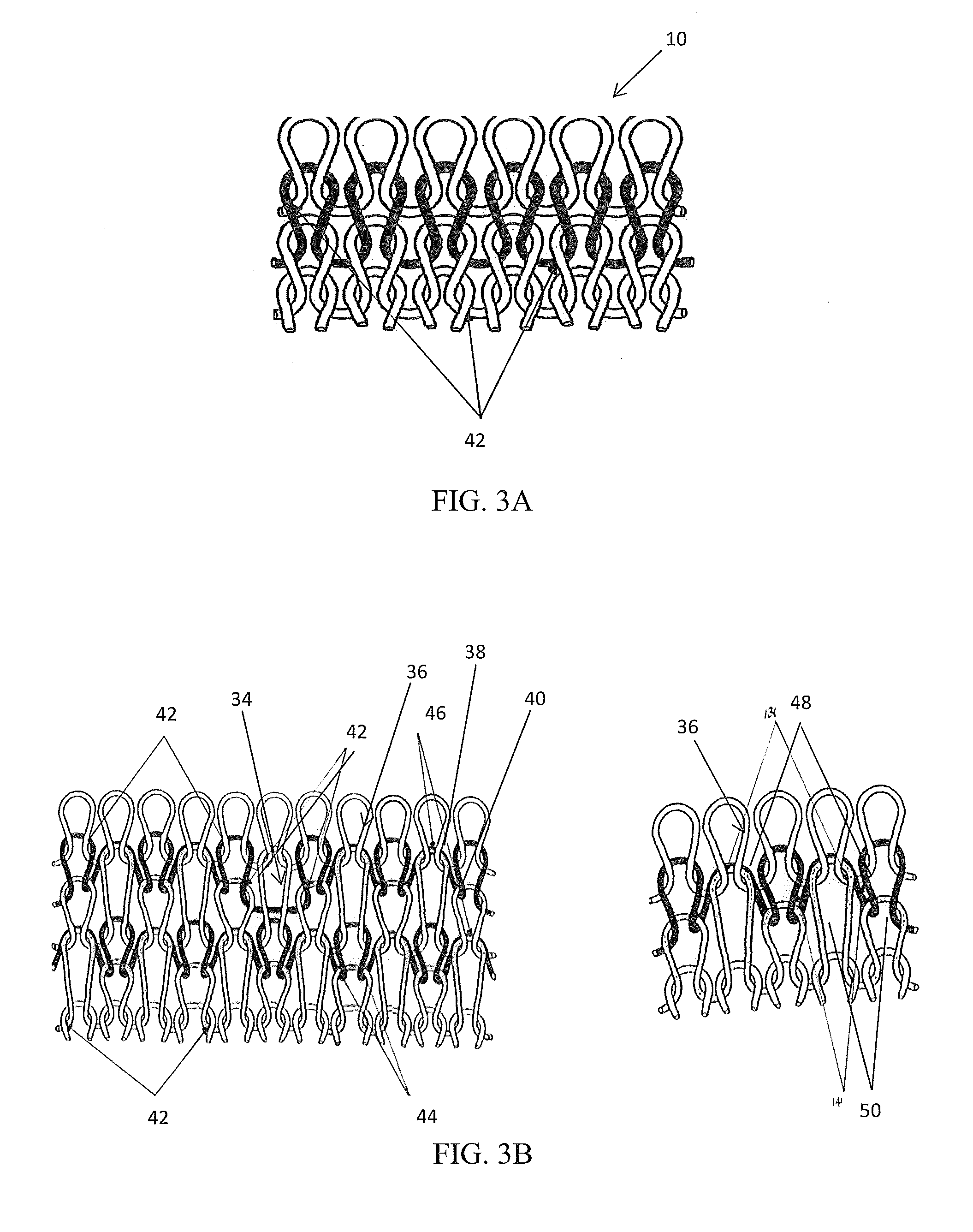

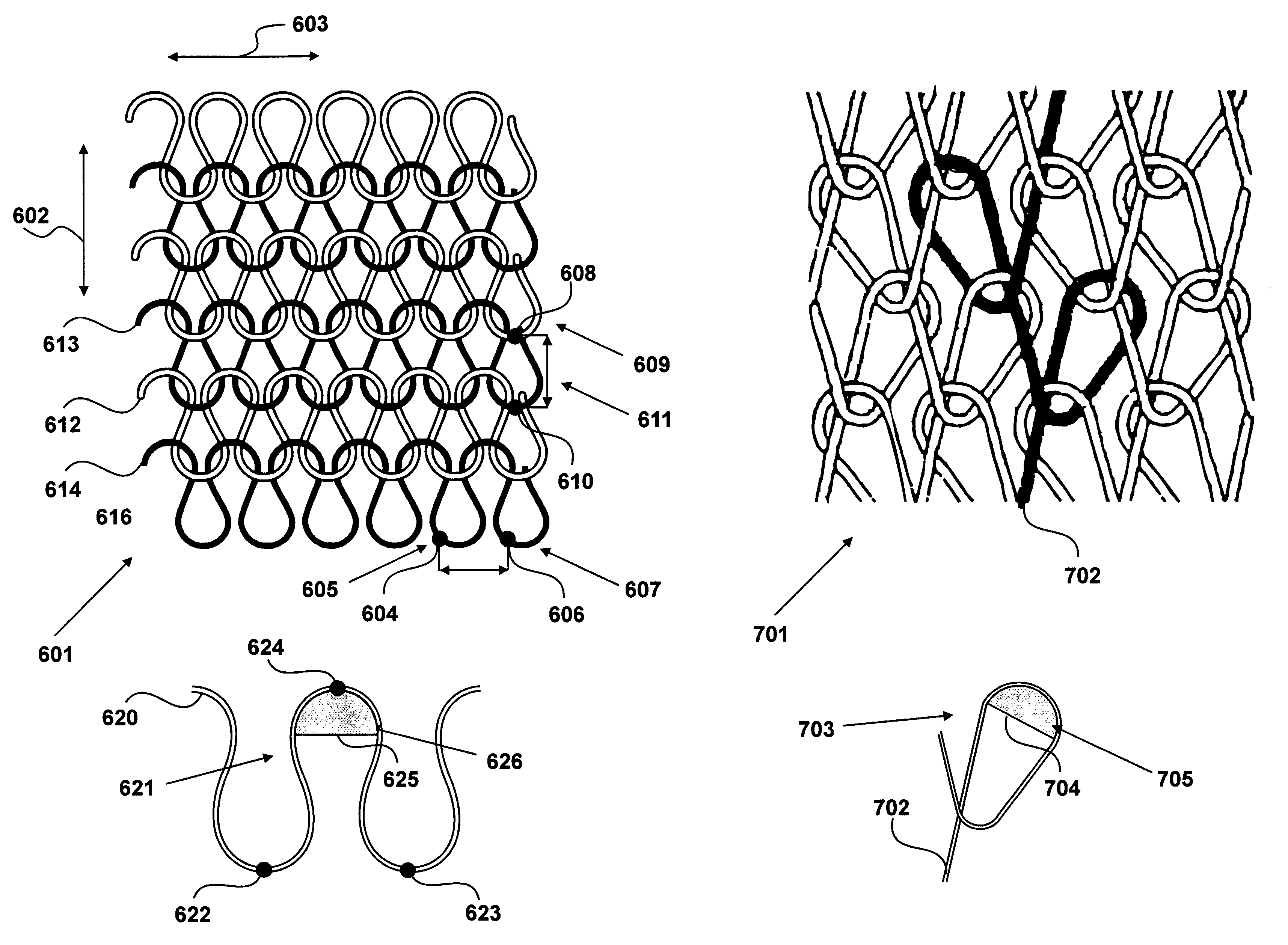

Knitted sensor

A sensor having a three layer construction comprising a first knitted conductive textile plane, a second conductive textile plane and an intermediate separating plane penetrable by the first knitted conductive textile plane to allow the first conductive textile plane and the second conductive textile plane to make electrical contact under a mechanical interaction. The intermediate separating plane defines structural endpoints from which the first knitted conductive textile plane deforms towards the second conductive textile plane under a mechanical interaction. The first knitted conductive textile plane has conductive yarn knitted to form a repeating pattern of stitches each comprising a stitch looping portion SLP having a looping portion footprint LPF. Within the sensor, there is at least one of a plurality of described dimensional relationships between stitches of the first knitted conductive textile plane and structural endpoints of the intermediate separating plane.

Owner:WEARABLE TECH LTD

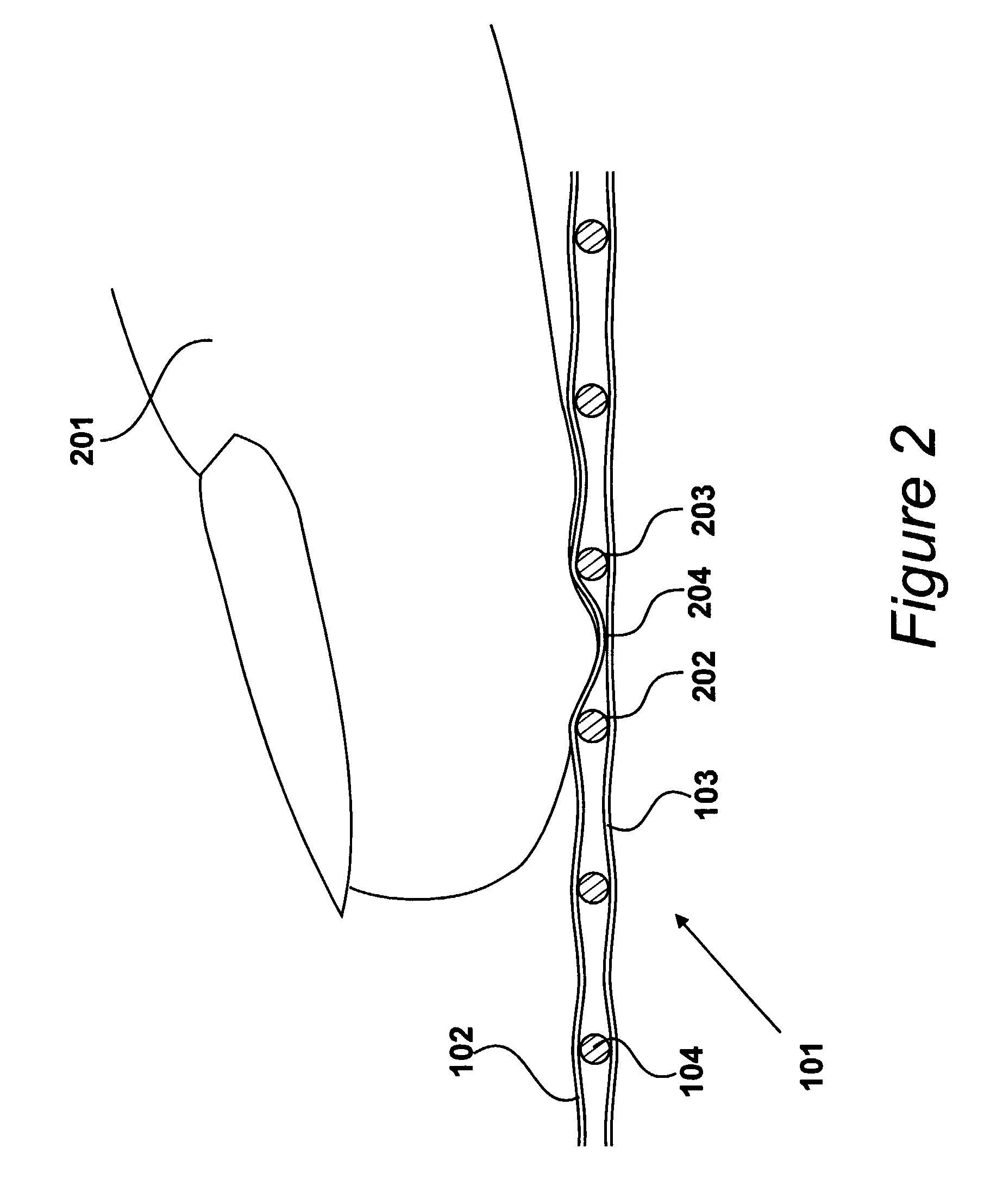

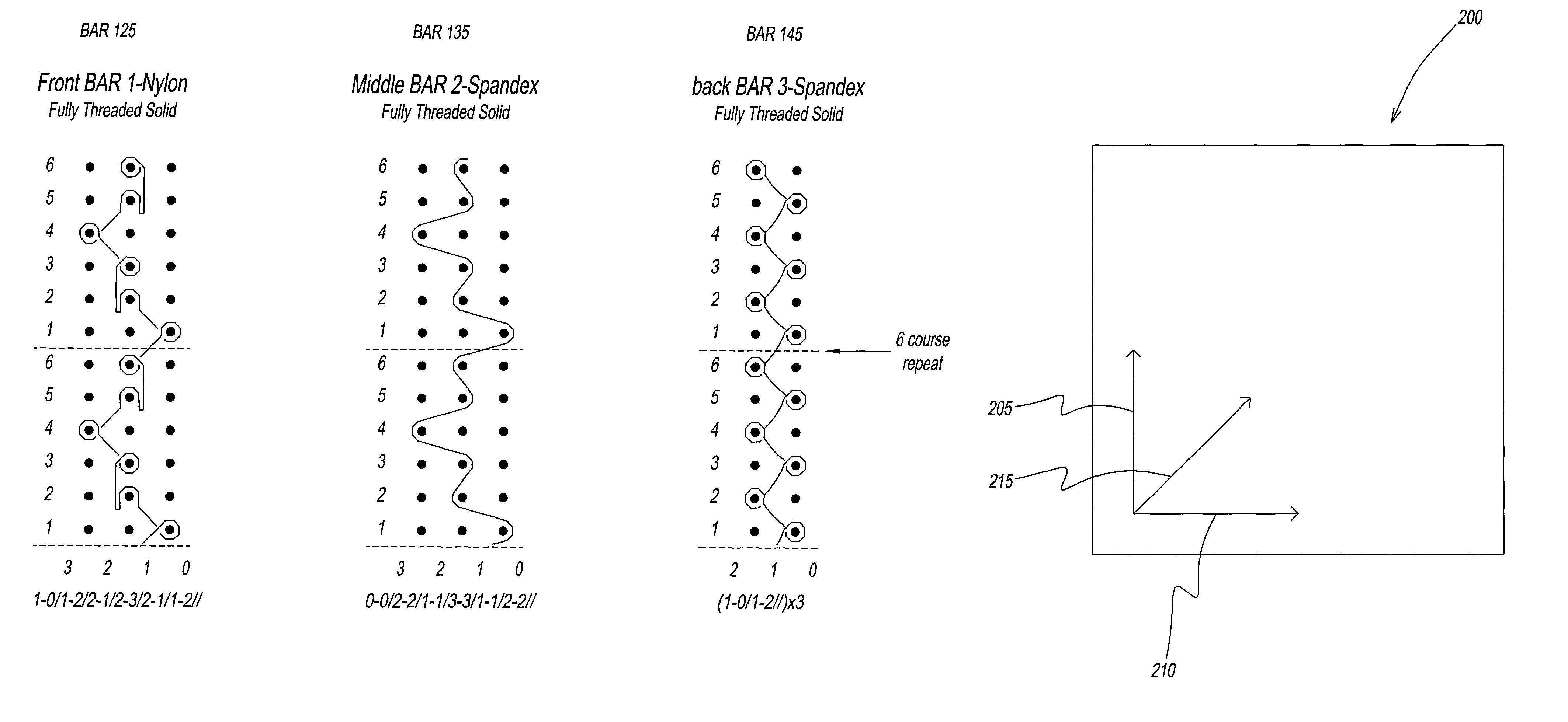

Fabric with equal modulus in multiple directions

ActiveUS8726700B2Balance balanceControl balanceStraight-bar knitting machinesWoven fabricsBi-isotropic materialEngineering

Owner:GLOBAL TRADEMARKS

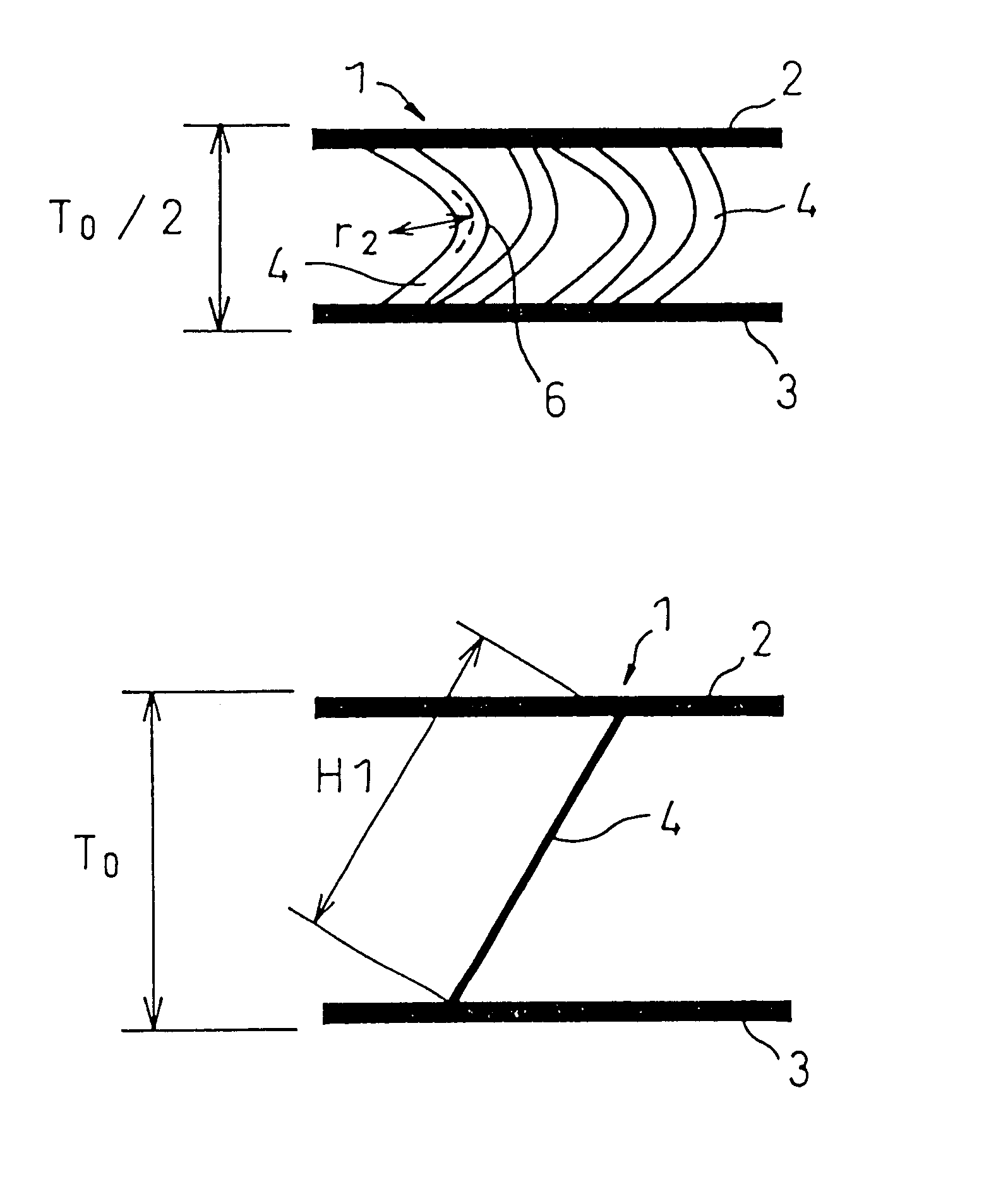

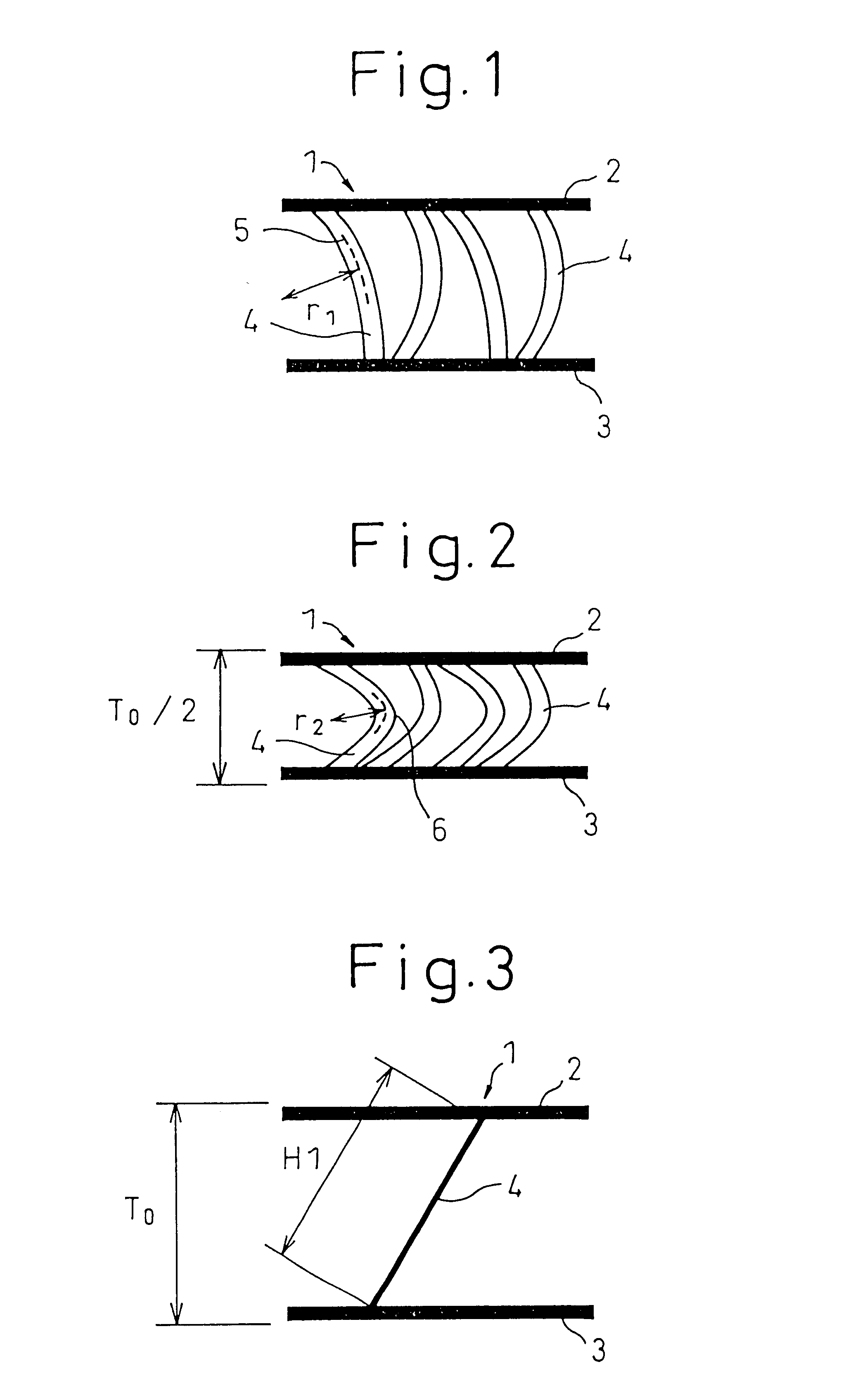

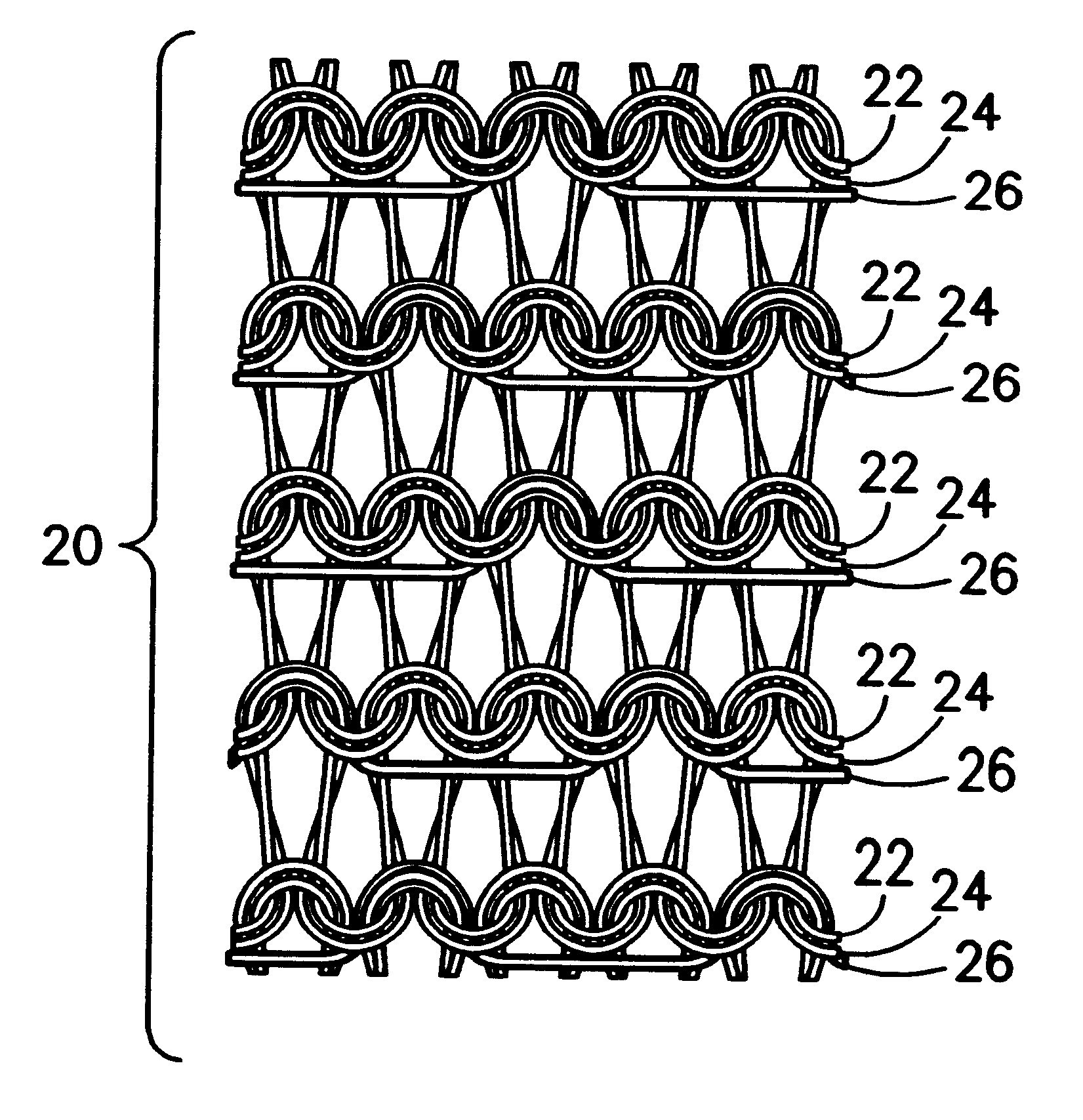

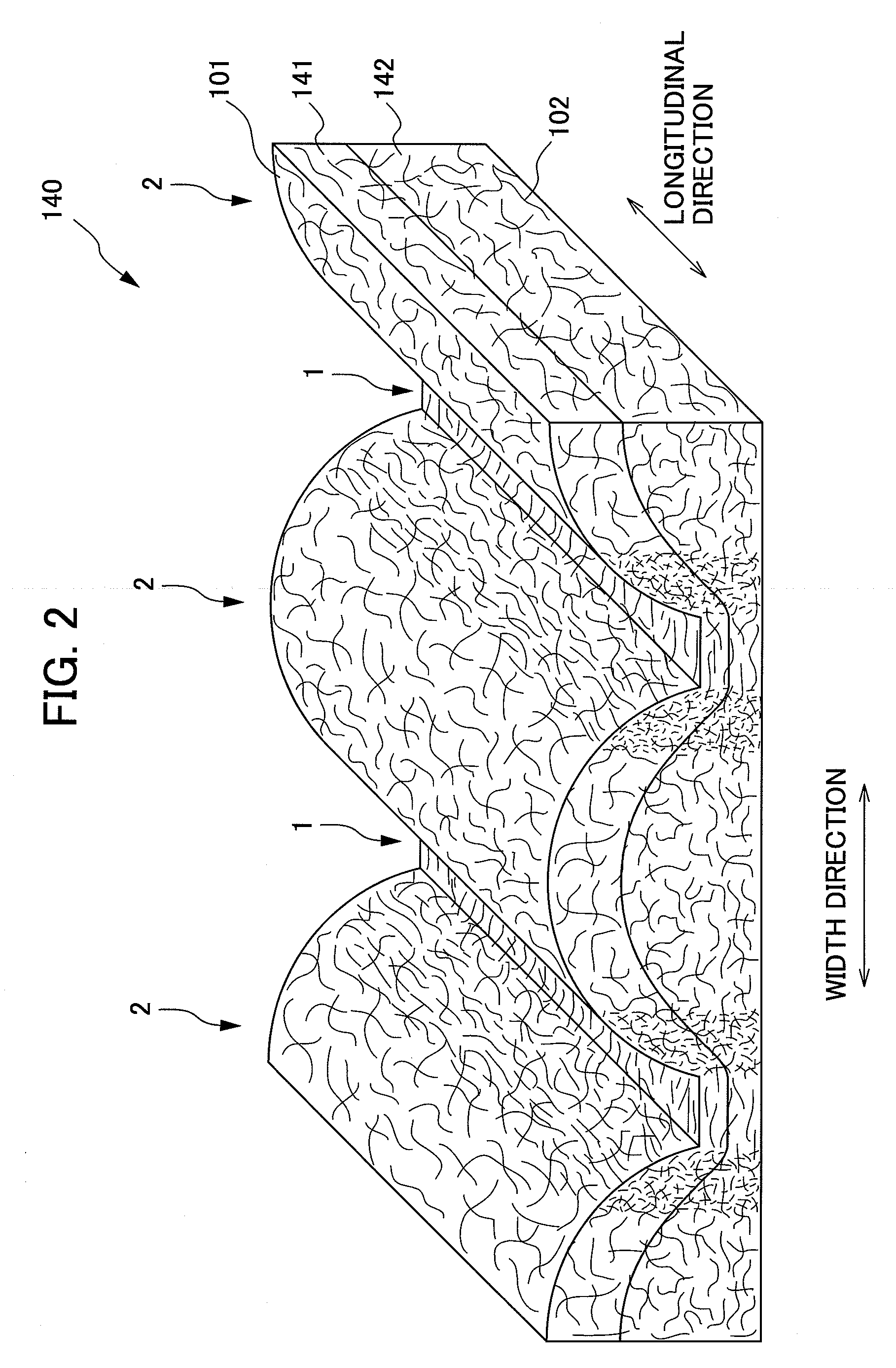

Three-dimensional fabric for seat

InactiveUS6644070B2Shape-retaining property is improvedMinimize hysteresis lossOrnamental textile articlesLayered productsYarnCivil engineering

A three-dimensional knit fabric having front and back knit layers and a monofilament yarn connecting the knit layers to each other, characterized in that the curvature of the monofilament yarn in the three-dimensional knit fabric is in a range from 0.01 to 1.6, and the bending elongation of the monofilament is 20% or less when the three-dimensional knit fabric is compressed to 50%. The three-dimensional knit fabric has a cushioning property in springiness which does not deteriorate even if the fabric is repeatedly used many times or for a long time, and thus this fabric is excellent in terms of durability of the cushioning property. In particular, the fabric is suitable for use as a hammock type seat and exhibits a cushioning property having a favorable springy feeling as well as a good fit feel.

Owner:ASAHI KASEI KK

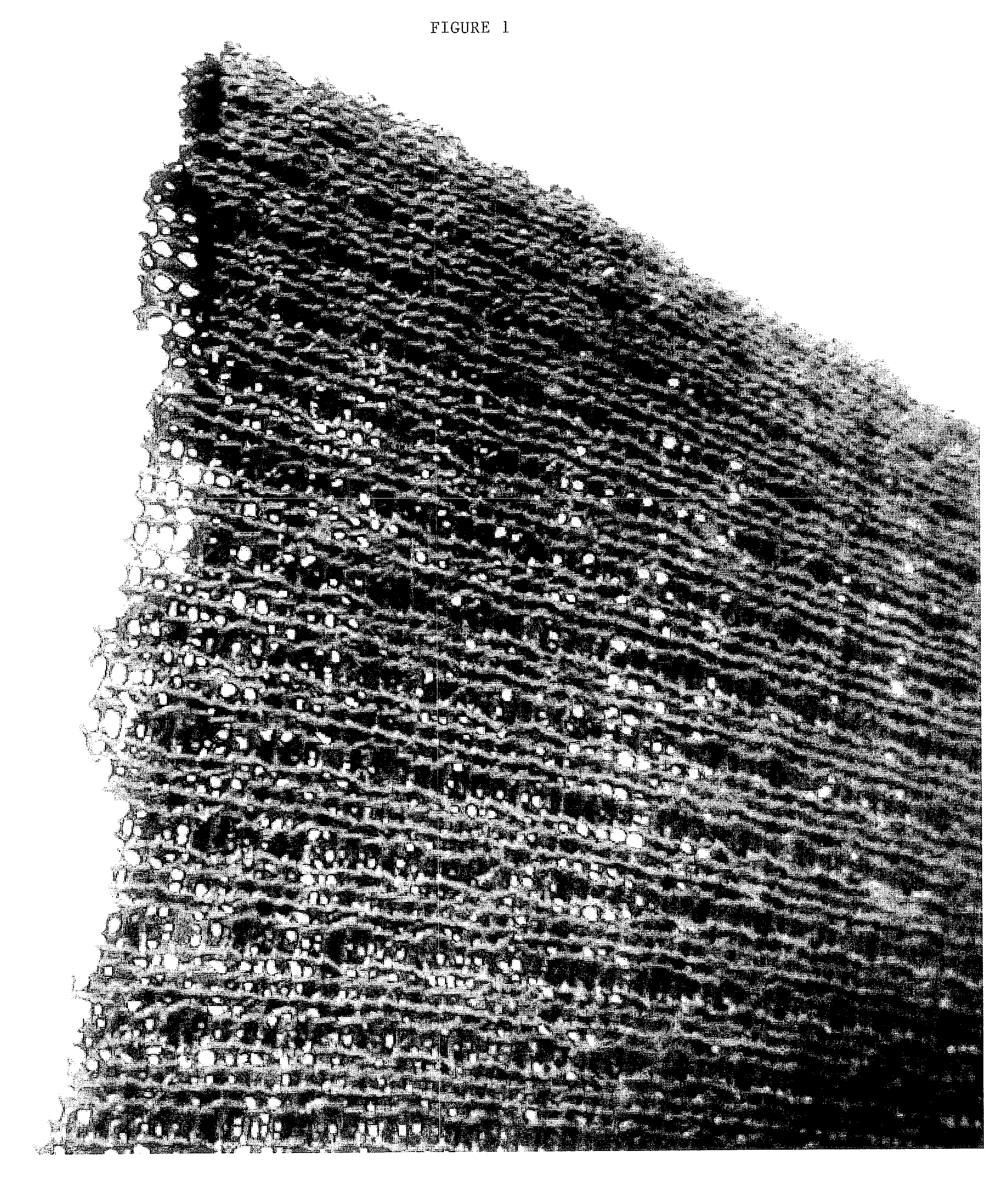

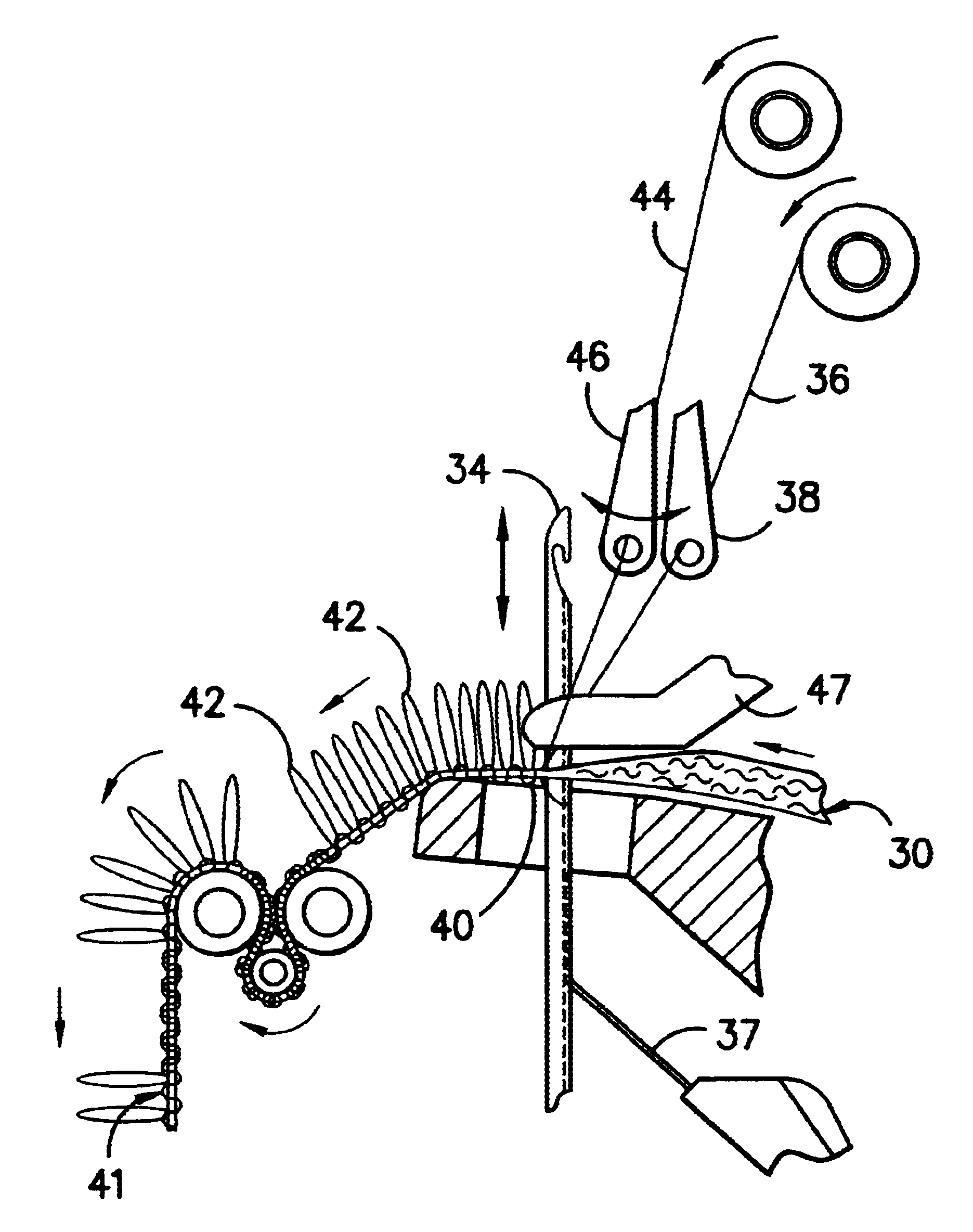

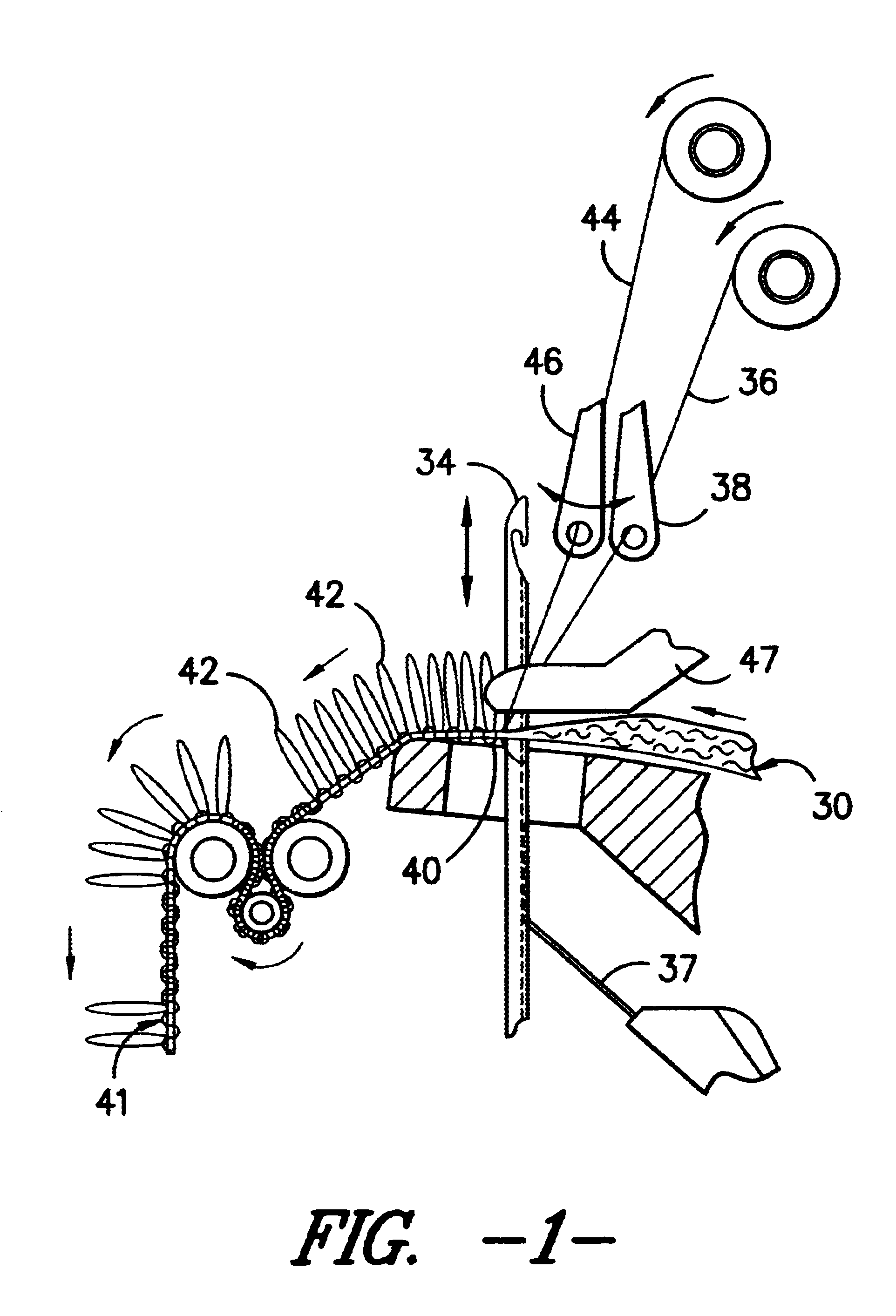

Method and machine for producing multiaxial fibrous webs

InactiveUS20030148082A1Reduce manufacturing costLow costOrnamental textile articlesFilament handlingFiberCarbon fibers

Method and machine for producing multiaxial fibrous webs. A plurality of unidirectional sheets (30a, 30b, 30c) are superposed in different directions and they are bonded together. At least one of the unidirectional sheets is made by spreading a tow so as to obtain uniform thickness, width not less than 5 cm, and a weight of no more than 300 g / m2, cohesion being imparted to the sheet so as to enable it to be handled prior to being superposed with other sheets. Advantageously, the unidirectional sheets are made of carbon fibers and are obtained by spreading out large tows.

Owner:SAFRAN CERAMICS SA

Detector constructed from electrically conducting fabric

InactiveUS7161084B2Ornamental textile articlesStraight-bar knitting machinesConductive yarnElectrically conductive

The present invention relates to a detector constructed from electrically conducting fabric and configured to present a varying electrical characteristic in response to a mechanical interaction. The detector comprises a first conducting layer (401) which is displaced from a second conducting layer (402) such that conduction between the layers results when the layers are mechanically forced together. In addition, the first of the layers has a plurality of lengths of conductive yarn and a plurality of lengths of non-conductive yarn machined therein, such that at least one length of conductive yarn is electrically isolated from another of the lengths of conductive yarn and the conducting yarns in the first of the layers are electrically grouped to define a plurality of identifiable rows. Each identifiable row has a respective electrical conductor; and define specific regions of the detector.

Owner:WEARABLE TECH LTD

Blended woven or knitted fabrics containing polyerethane elastic fibers and process for the production thereof

A blended woven or knitted fabric which contains both highly fusible polyurethane elastic fibers exhibiting a retention of tenacity of 50% or above after the dry heat treatment at 150° C. for 45 s at 100% elongation and a melting point of 180° C. or below and at least one kind of non-elastic yarns and which is produced by fusing the polyurethane elasotomeric fibers to each other or the polyurethane elastic fibers to the non-elastic yarns at the crossover points by dry- or wet-heat setting; and a process for the production thereof.

Owner:NISSHINBO IND INC

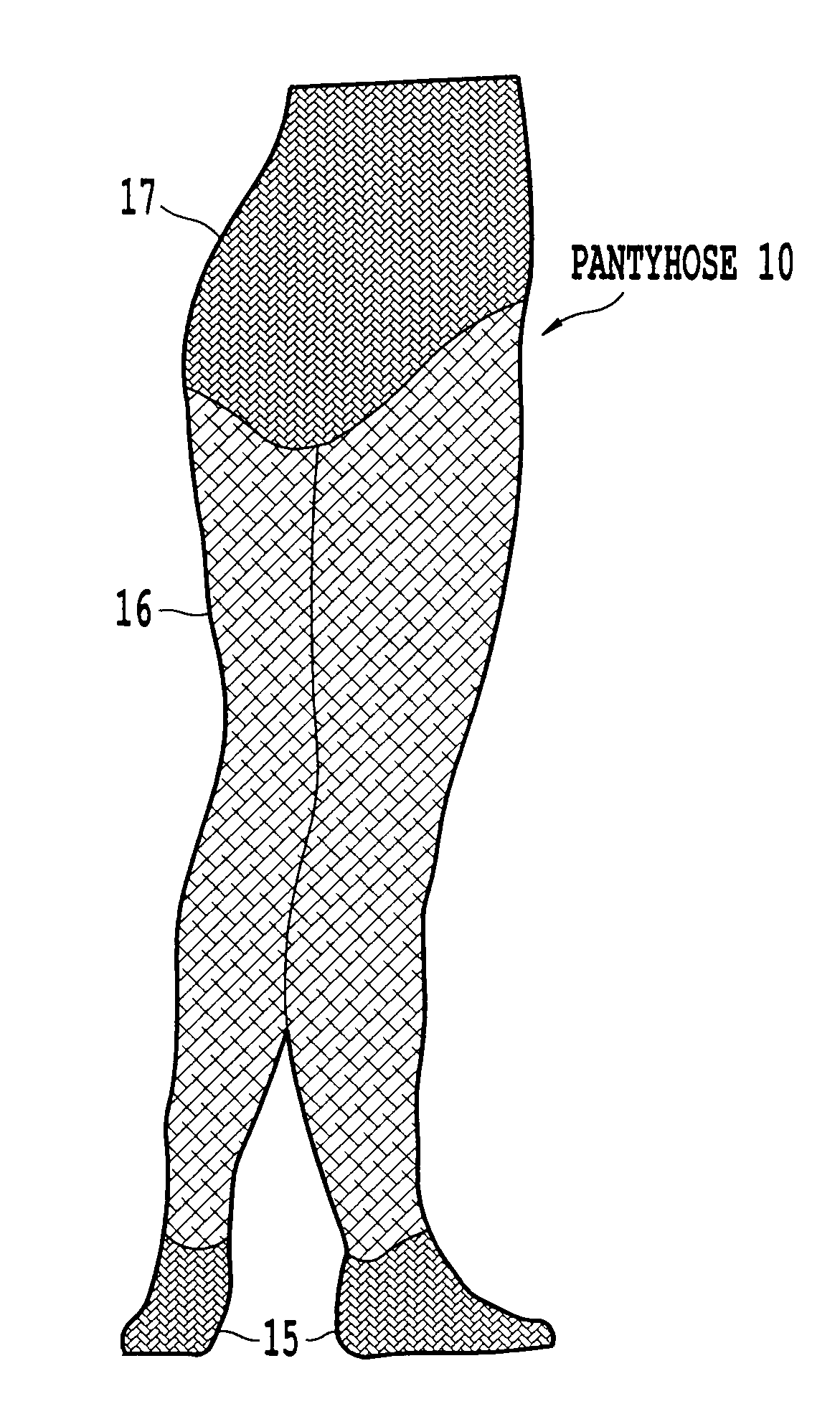

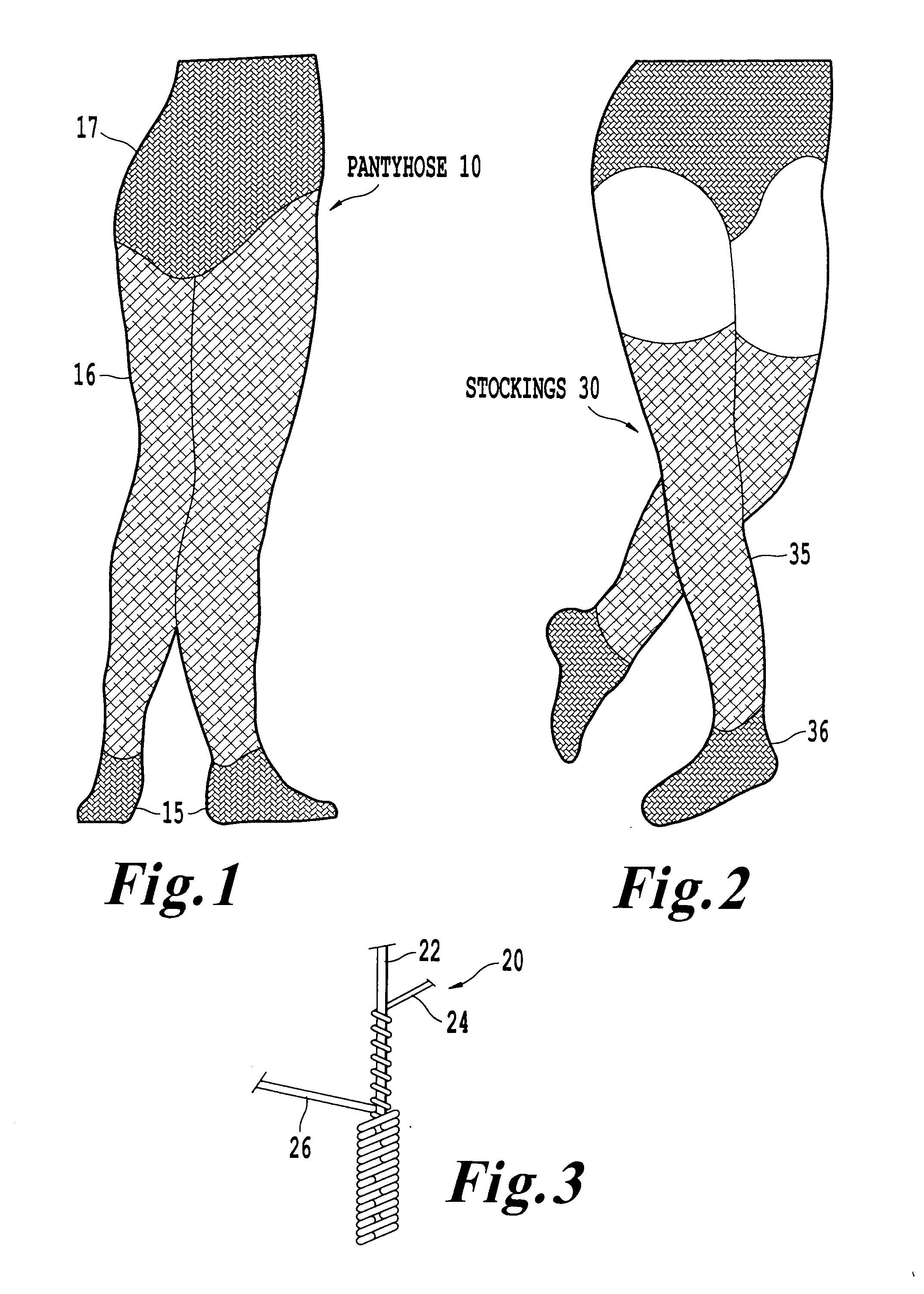

Lightweight, cut and/or abrasion resistant garments, and related protective wear

InactiveUS20100050699A1Improve comfortIncrease flexibilityOrnamental textile articlesGlovesCooling effectBiomedical engineering

The present invention relates to a cut and / or abrasion resistant garment that is lightweight, has improved comfort, flexibility and pliability and provides a cooling effect on the wearer, and is particularly suitable for use as hosiery products such as stockings, pantyhose and tights, or for protective coverings for the arms of the wearer.

Owner:KOLMES NATHANIEL H

Knit fabrics and base layer garments made therefrom with improved thermal protective properties

ActiveUS20090019624A1Effective thermal protective characteristicHigh tensile strengthChemical protectionHeat protectionFiberYarn

Knit fabrics and military apparel such as T-shirts made therefrom are disclosed. The fabrics are constructed from blended yarns made from an intimate combination of nylon and cotton staple fibers. Such fabrics comprise a weight ratio of cotton to nylon which ranges from about 55:45 to about 85:15, and these fabrics also have a weight ranging from about 3 to about 8 oz / yd2. Knit fabrics of this type possess a desirable combination of good thermal protective properties, provided the specified high level of staple fiber blend uniformity is achieved, along with very useful abrasion resistance, bursting strength and drying time characteristics.

Owner:INV PERFORMANCE MATERIALS LLC

Patterned stitch bonded pile fabric

A patterned pile fabric of stitch-bonded construction. The fabric includes a substrate layer with an arrangement of ground yarns extending in stitched relation through the substrate layer so as to define a ground covering across the substrate layer. An arrangement of pile forming yarns extend in stitched relation through the substrate layer such that the pile forming yarns define a patterned arrangement of looped elements projecting away from the ground covering in predefined three dimensional patterned arrays disposed across the fabric.

Owner:TIETEX INT

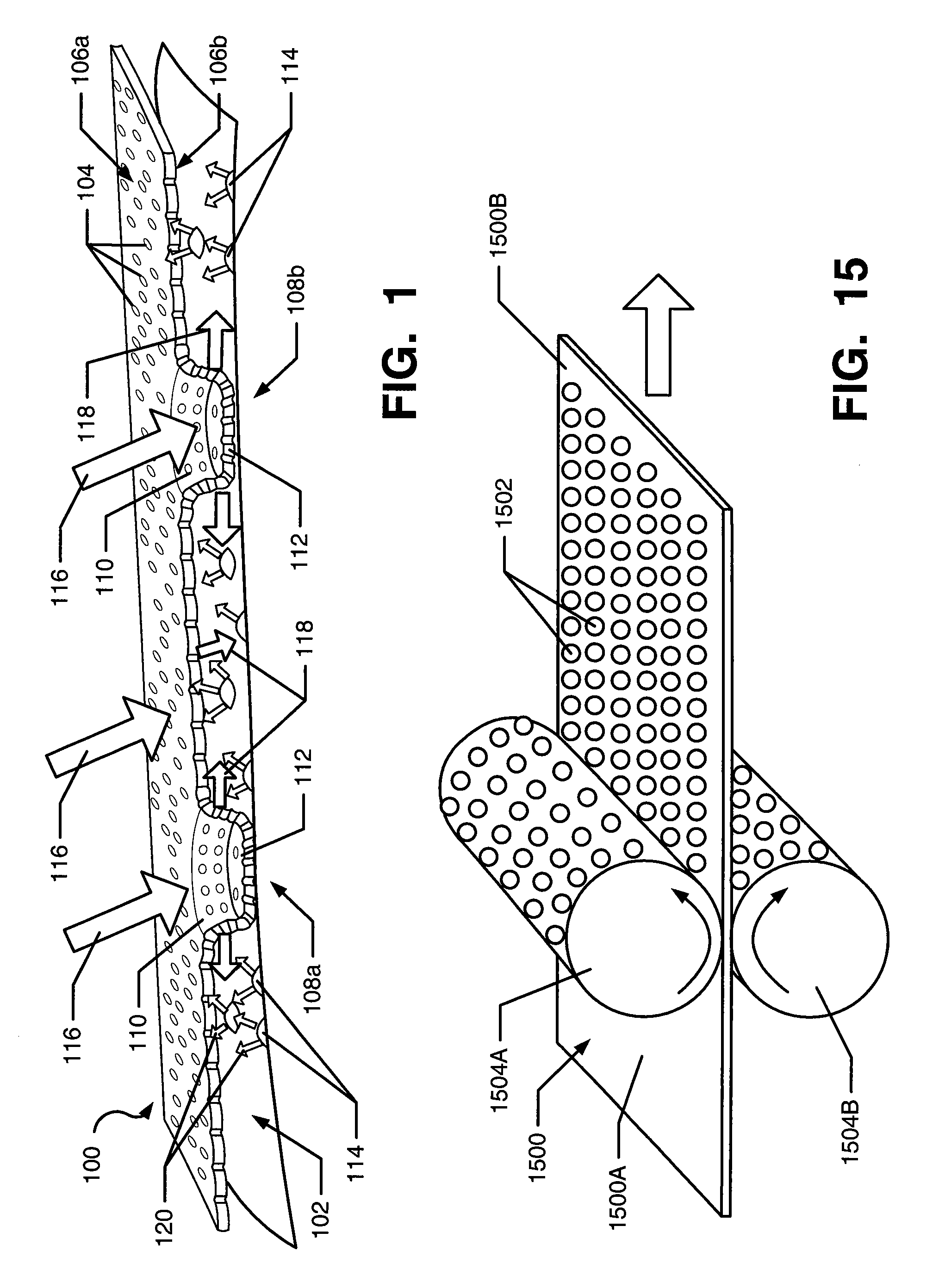

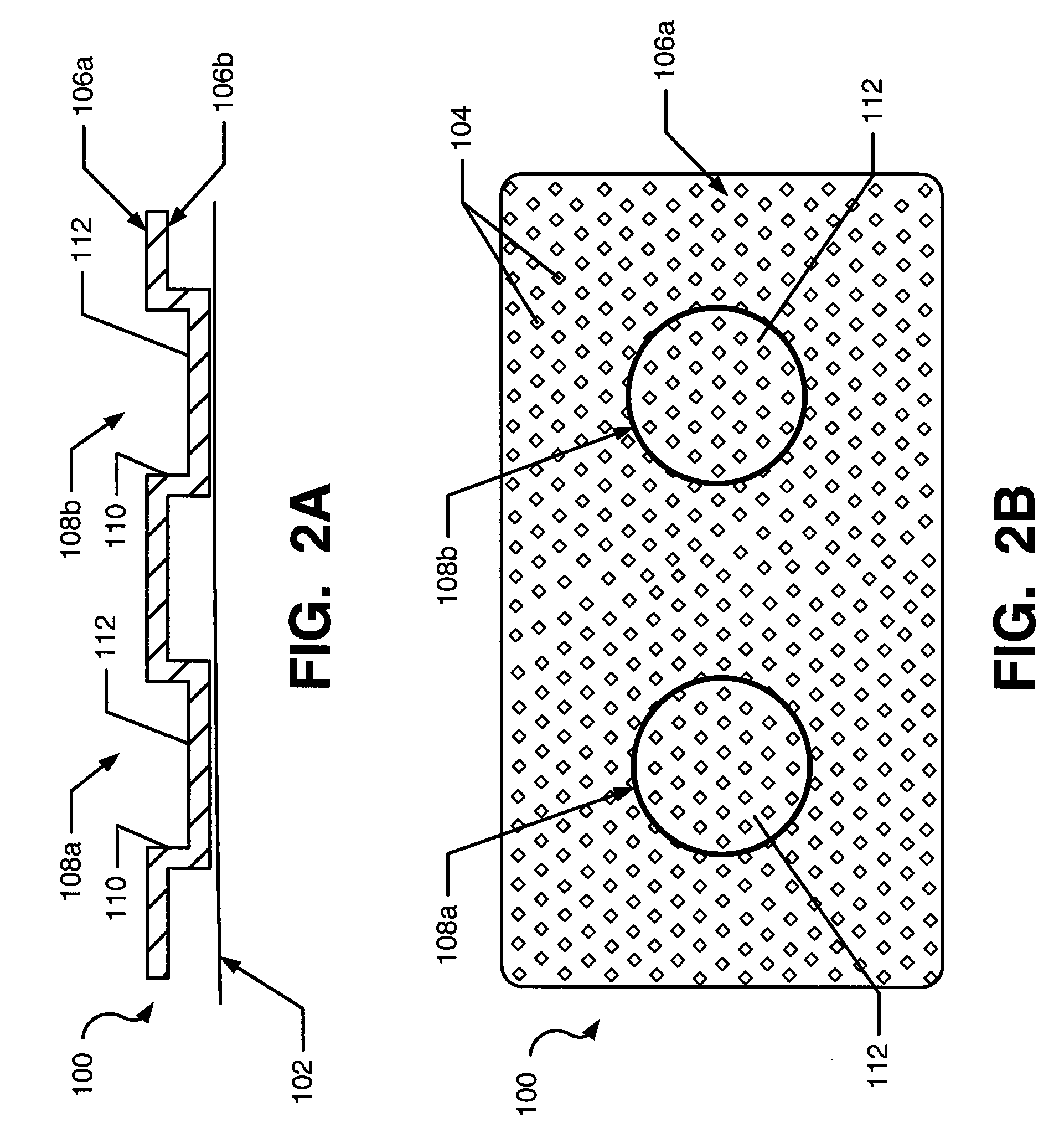

Fabrics and articles of apparel including dimensionalized mesh and other fabrics

Fabrics and garments may include “dimensionalized” structures. The fabric may be “dimensionalized” by integrally forming a plurality of self-standing fabric surface modifying elements in the fabric material to thereby provide a fabric contact level different from (and / or reduced in surface area as compared to) the fabric base level. Garments may include this “dimensionalized” material, e.g., positioned at various locations to promote better evaporative cooling of the body or heat retention, such as along the wearer's spine, sides, and / or other locations that release substantial heat. The “dimensionalizing” structure may be formed in the material, for example, by molding, rolling, embossing, calendering, stretching, crimping, pressing, heating, and / or the like.

Owner:NIKE INC

Elastic fabric and elastic face material

An elastic fabric useable for covering pillows, seats, mattresses and the like is disclosed. The fabric is formed from elastic yarns having a breaking elongation greater than 60%, a rate of elastic recovery after 15% elongation of more than 90% and a stress at 10% elongation greater than 150 N / 5 cm and less than 600 N / 5 cm oriented in a direction parallel to the elastic yarn, and a rate of hysteresis loss between 20% and 45%. The fabric may be woven or knitted and provides a stable, comfortable feeling for sitting or reclining and deforms when supporting weight but returns readily to its undeformed shape.

Owner:TB KAWASHIMA CO LTD

Method for producing speical-finished pure cotton rapid-drying intelligent textile

ActiveCN1580384AGood moisture permeabilityImprove breathabilityGarment special featuresWeft knittingYarnIsomerisms

A method to produce special modified purified cotton high-speed drying intelligent tissue, the keypoint is:first water the surface purified cotton yarn, getting surface hydrophilic yarn, drainage collating internal, getting drainage collating yarn, then getting double layer isomerism tissue using special weaving tech. The invention adopts different collating method to collate double layer isomerism tissue,getting yarn of heterogeneity;the internal layer is discharging purified cotton yarn,which is of good moisture penetrability and permeability; the surface is hydrophilic purified cotton yarn,is of good water absorption. So the difference forms and offers power to transmit water. Internal moisture can impregnate into surface quickly,internal layer keeps dry, so is the sweating function. The tissue is made of 100% purified cotton face fabric,and of good hand feeling and comfortability.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

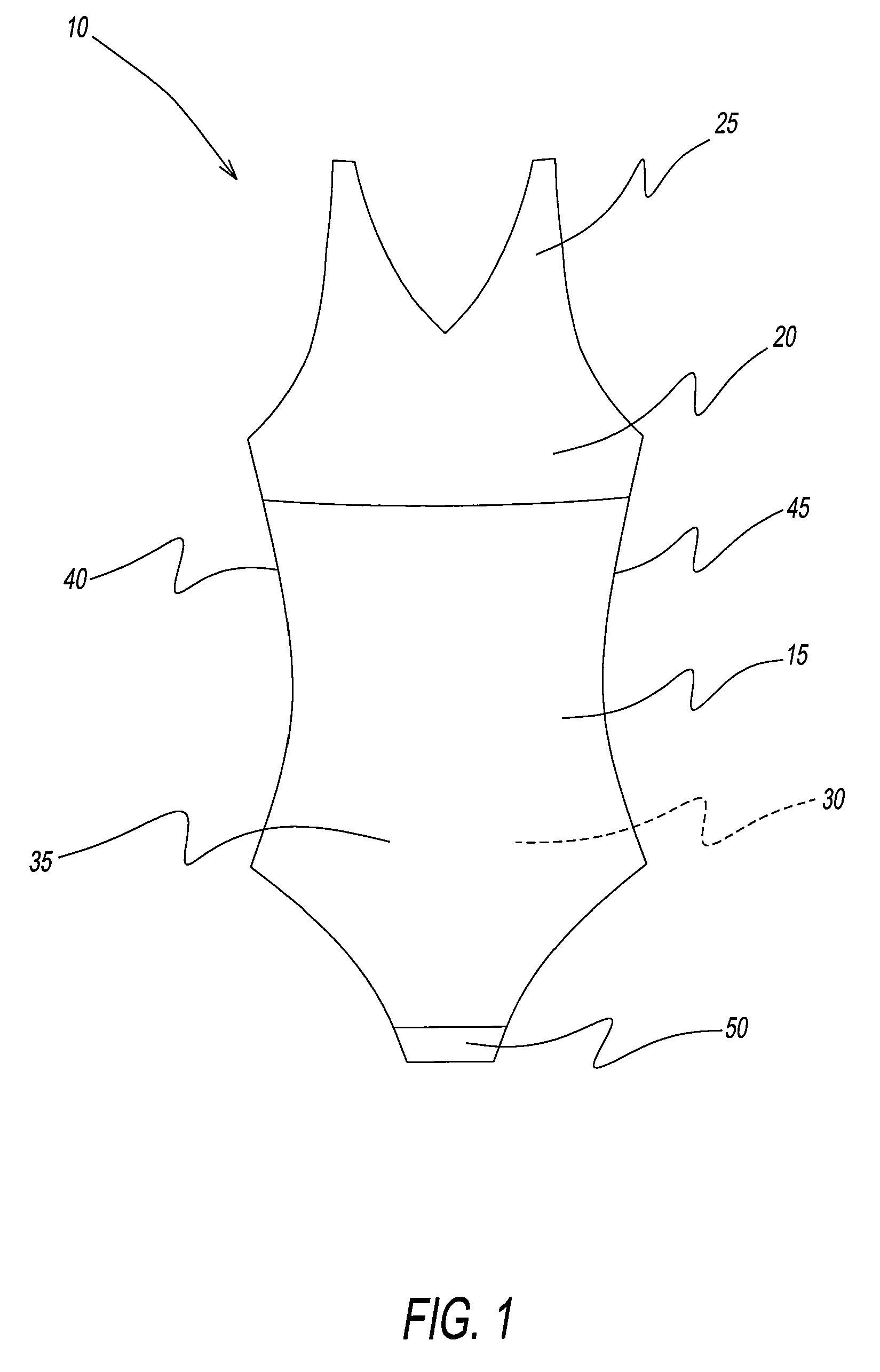

Opaque heat-moldable circular knit support fabrics having very high spandex content

InactiveUS6263707B1Consistent comfortabilityHigh densityCircular knitting machinesStraight-bar knitting machinesFiberShell molding

A fabric and method to support garments comprising opaque heat-moldable circular knit fabrics having relatively high amounts of spandex material as well as sufficient amounts of other fibers to simultaneously provide maximum support and maximum comfort to a wearer and which can be easily molded to the specifications of a wearer's body dimensions. Such high-spandex content, moldable garment fabrics are novel to the industry since the permissible added amount of spandex within such fabrics has been limited due to the power, modulus strength, and elongation of such fibers. Furthermore, the ability to provide moldable, high-spandex circular knit fabrics has been limited, if not impossible, due to the above-noted characteristics of the spandex fibers themselves. The inventive moldable fabrics and garments provide such desirable spandex properties while also increasing the comfortability to the wearer. The method of producing such fabrics is also contemplated within this invention. Both the fabric and the method state that the amount of spandex in the fabric is at least 24% of the total fiber weight in the fabric.

Owner:MILLIKEN & CO

Self-curling knitted sleeve and method of fabrication

InactiveUS20070163305A1Facilitate imparting biasWeft knittingOrnamental textile articlesBuilding constructionCivil engineering

A warp knit self-curling fabric and methods of construction thereof provides an elongate sleeve having overlapping edges for protecting elongate members. The fabric includes warp stitches and a plurality of weft stitches. The fabric comprises at least three yarns warp knit together, wherein one of the weft stitches is knit using a tricot stitch of a monofilament under tension to bias the fabric into a self-curled configuration about a central space. The monofilament forms an inner surface of the sleeve.

Owner:FEDERAL MOGUL CORP

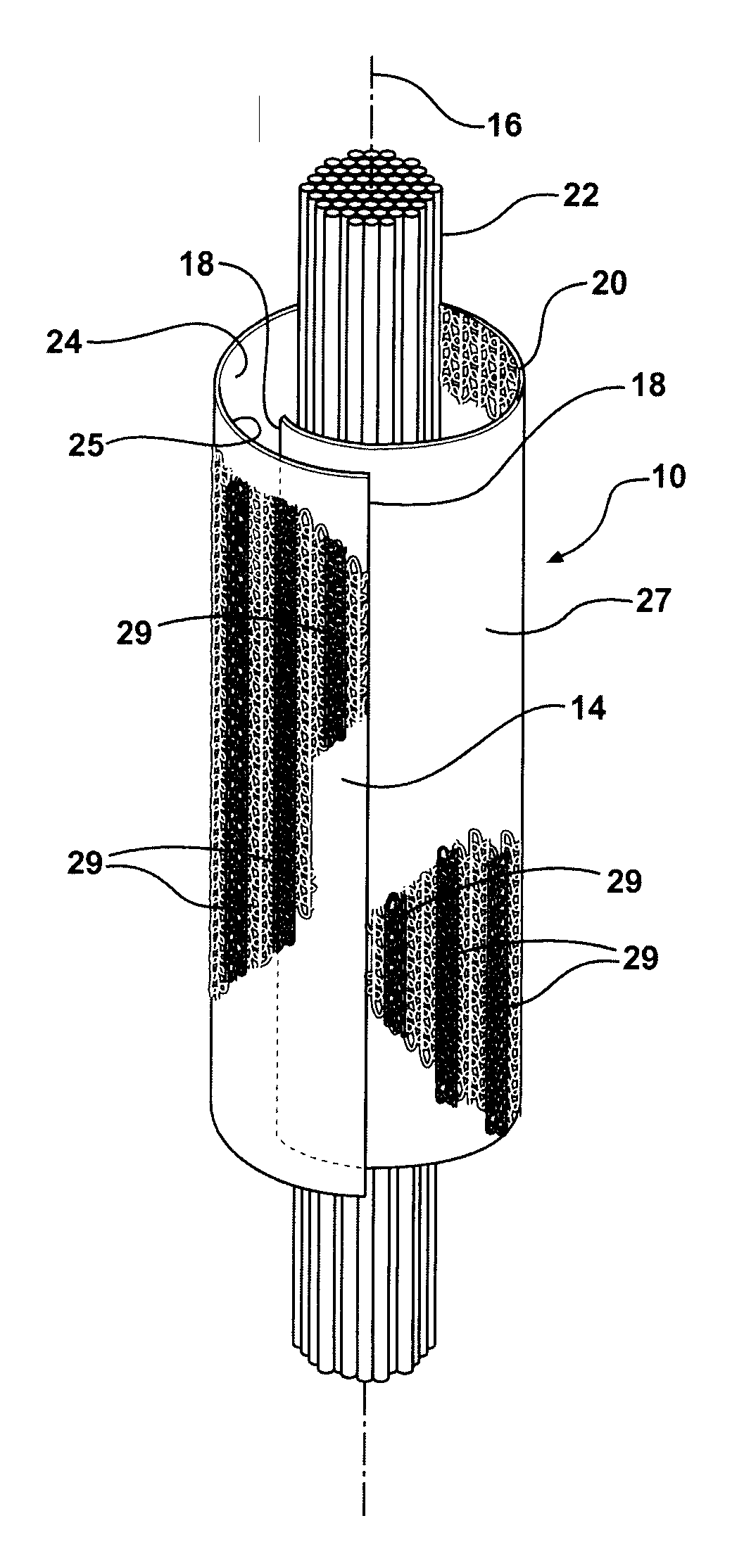

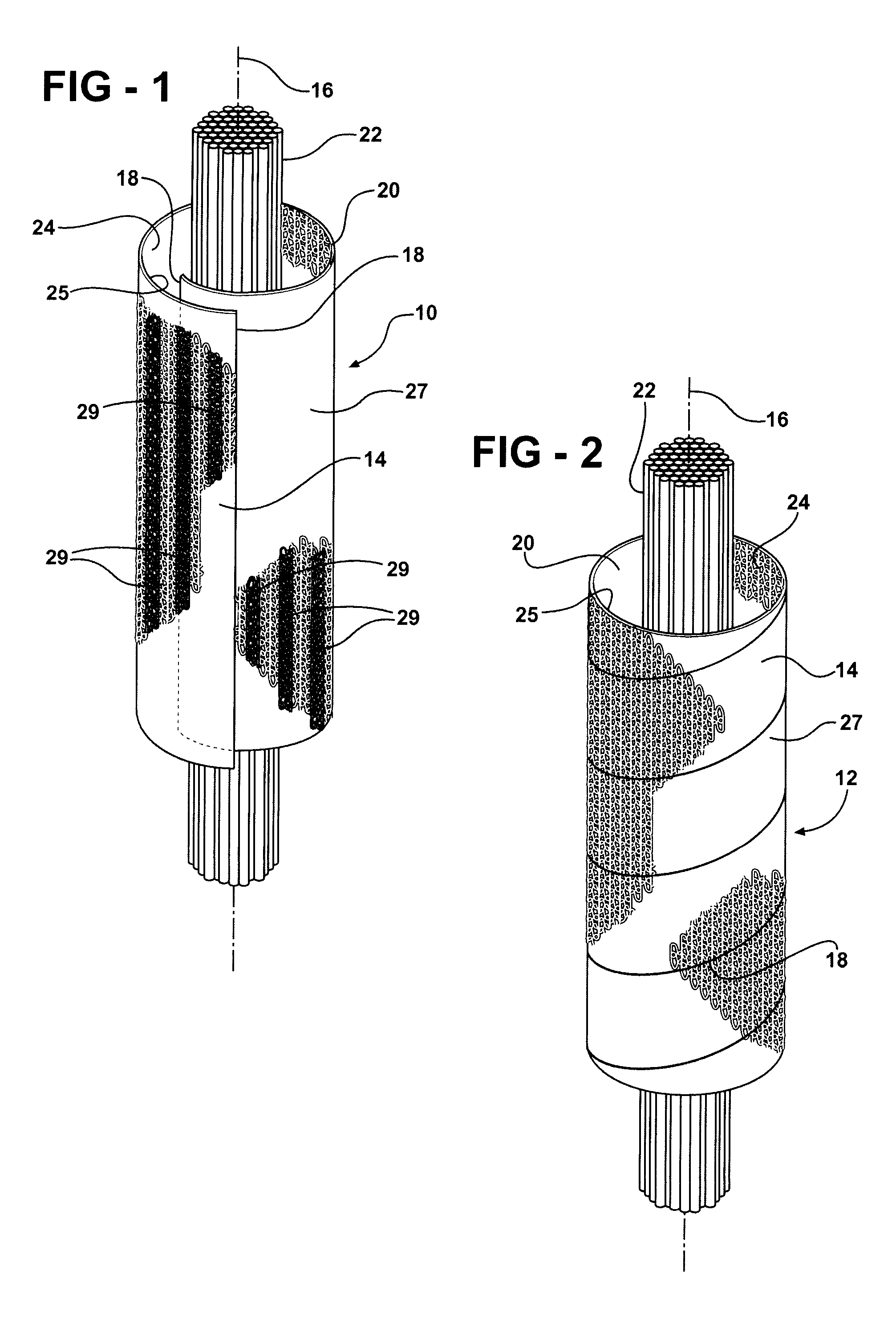

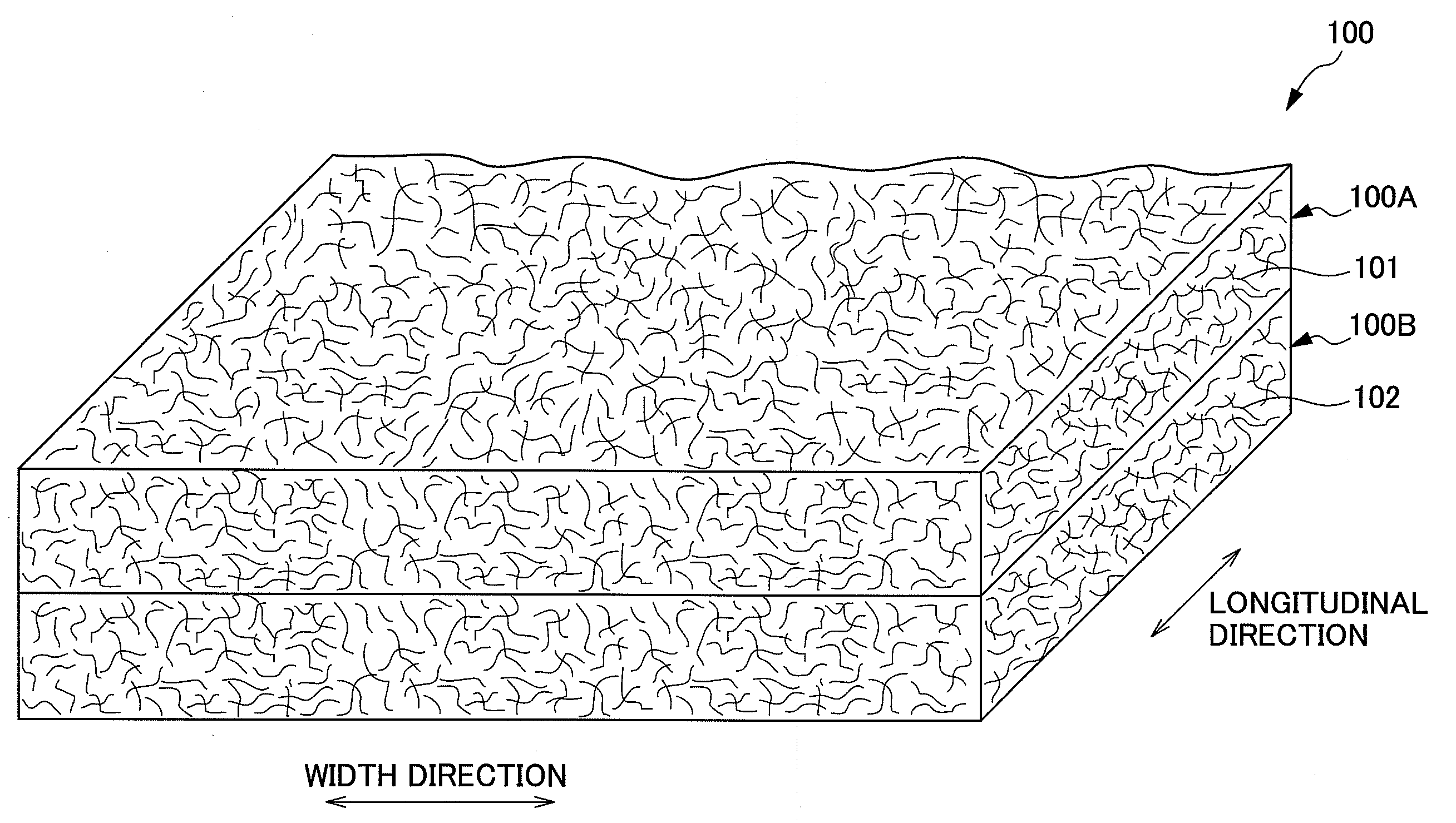

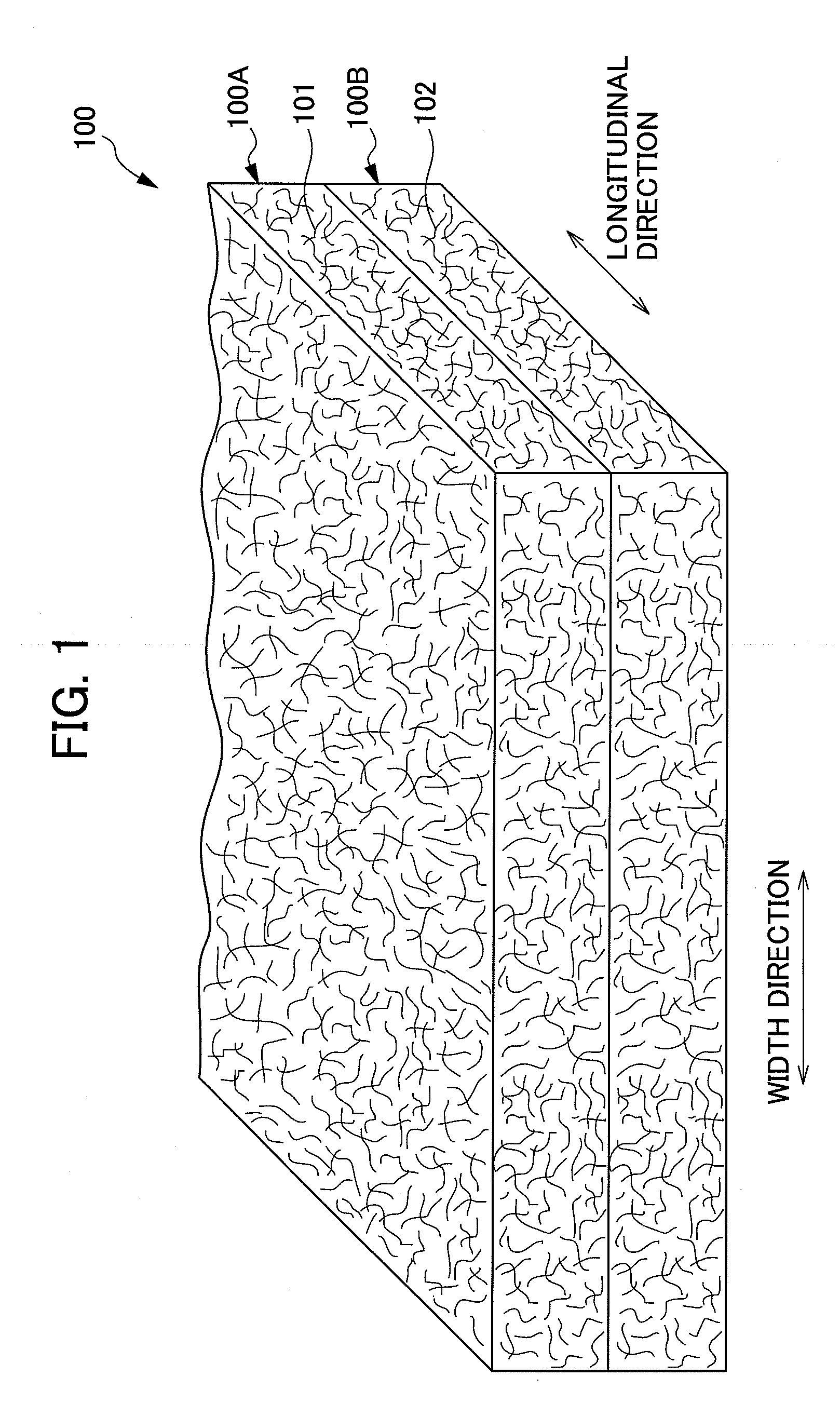

Liquid separation device, flow channel material and process for producing the same

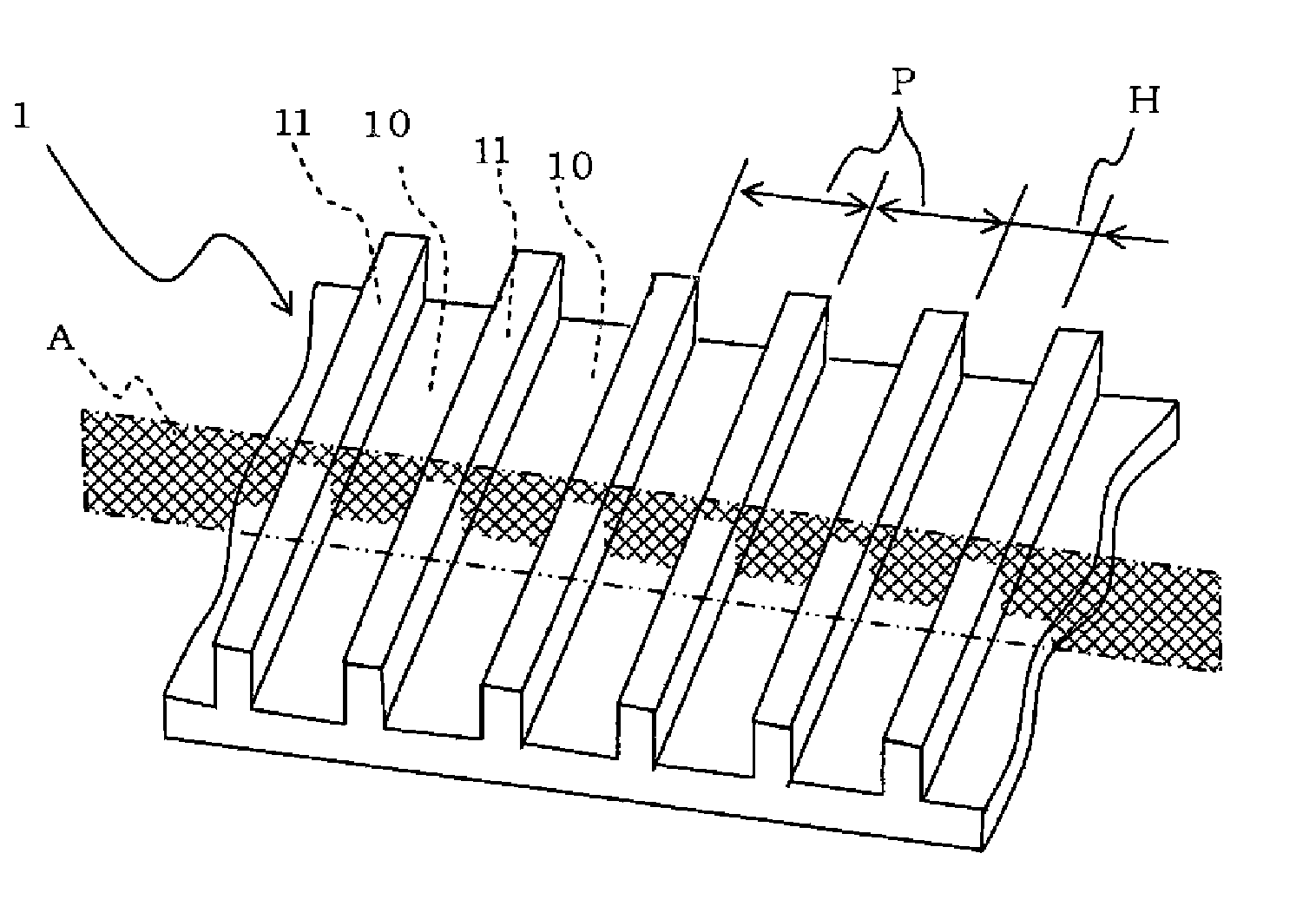

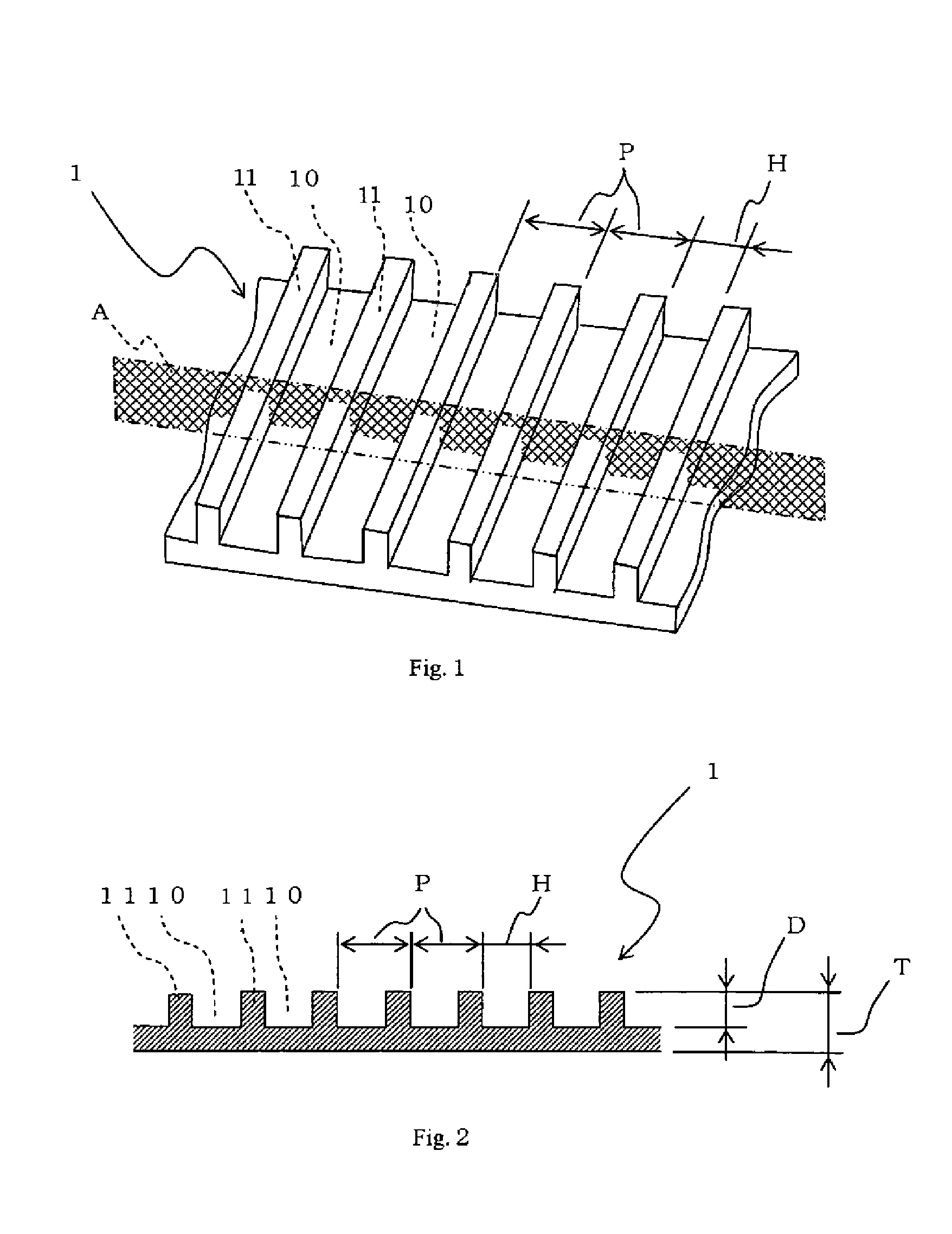

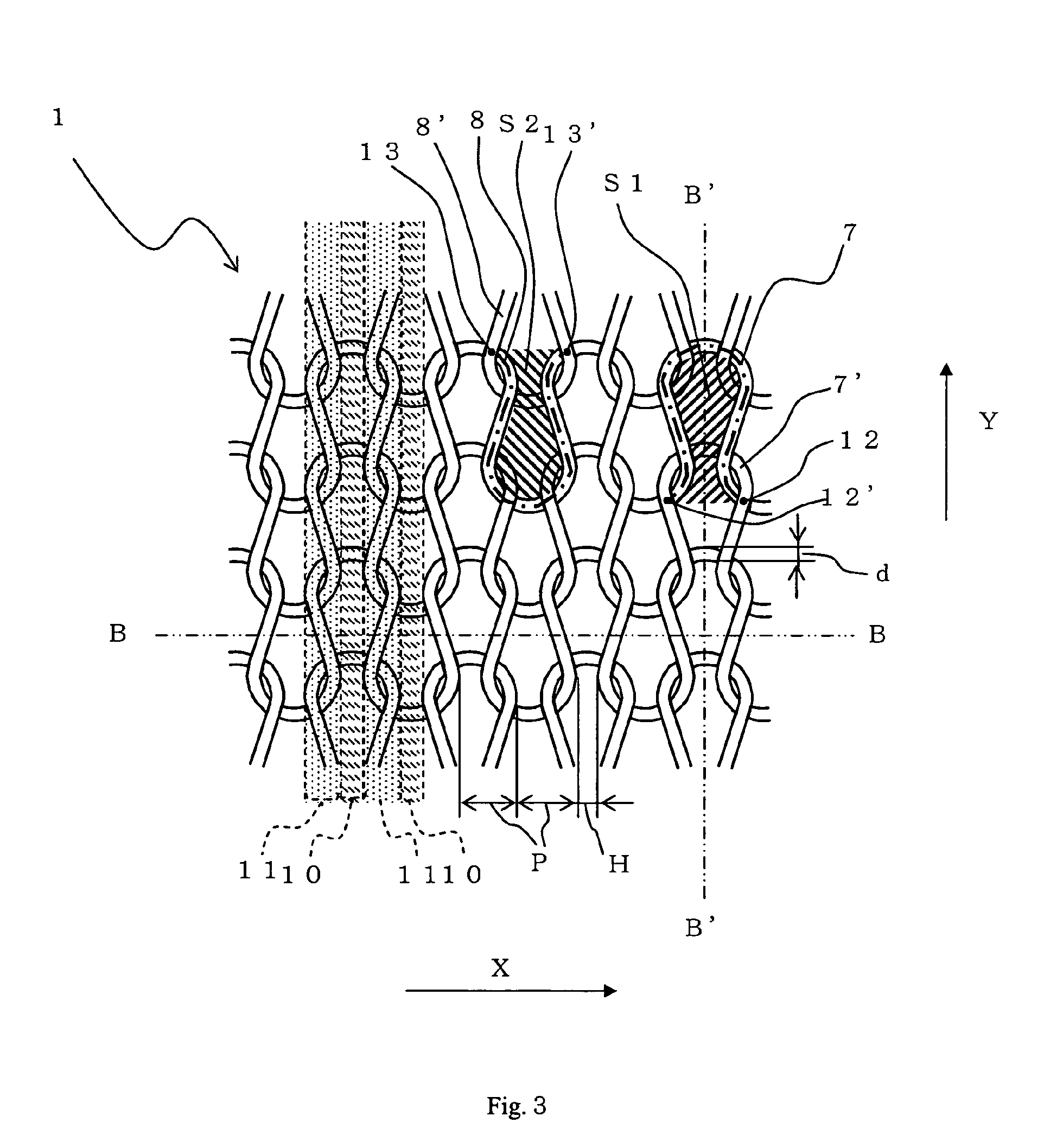

InactiveUS8388848B2Additional drawbackNarrow widthMembranesGeneral water supply conservationGroove widthFiltration

A liquid separation device is provided, and is capable of suppressing the lowering of filtration function due to an increase in flow channel resistance of permeated liquid which results in a separation membrane falling in a groove of a permeated liquid flow channel material along with accompanied breakage of the separation membrane surface. A permeated liquid flow channel material is disposed on the back side of a separation membrane composed of a sheet-like material having a linear groove and a linear crest alternately arrayed on one surface or both surfaces, wherein a groove width of the linear groove in the sheet-like material is 10 to 200 μm, and a ratio of the groove width of the linear groove to the pitch of the linear groove is 0.45 or more.

Owner:TORAY IND INC

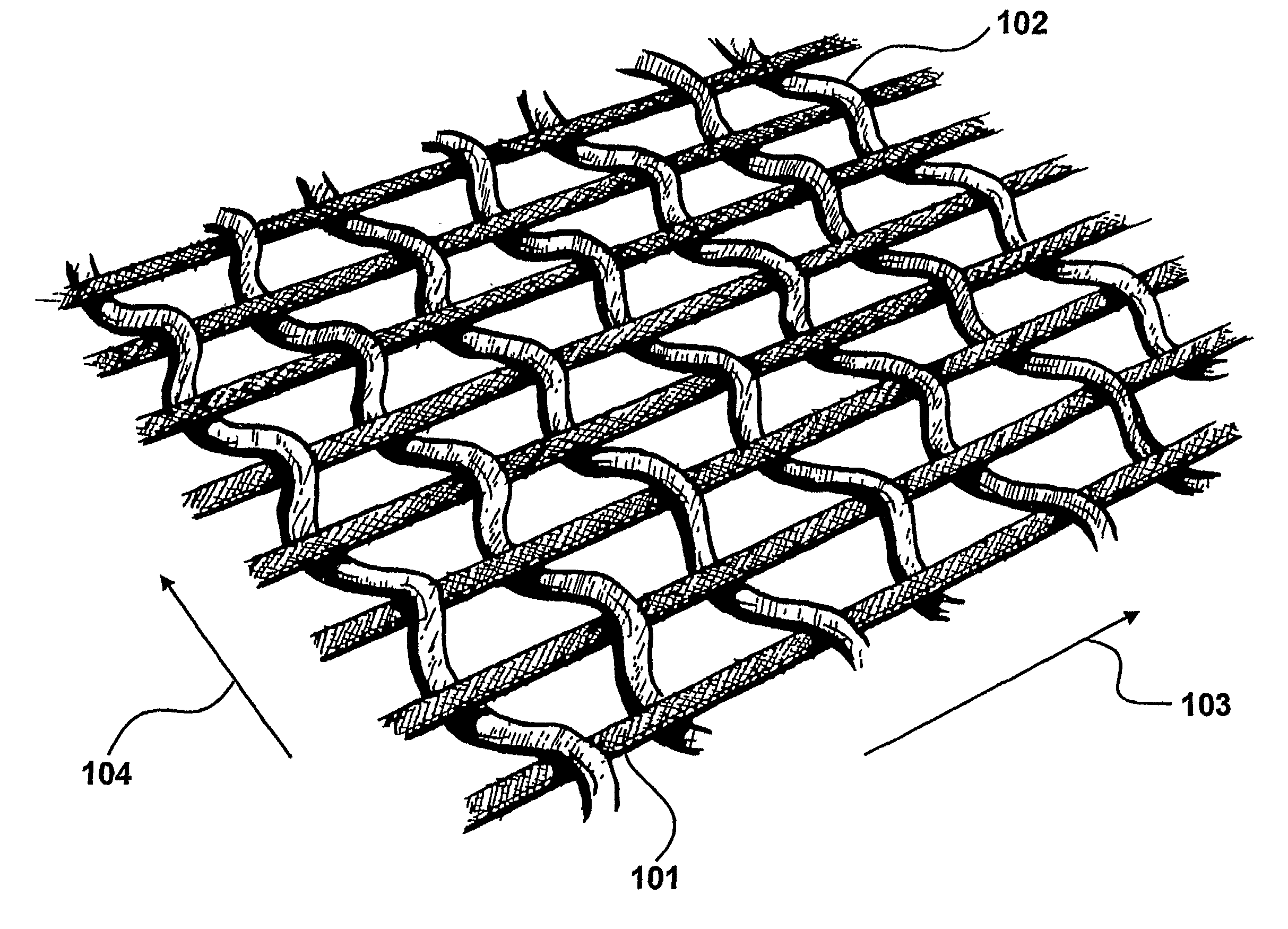

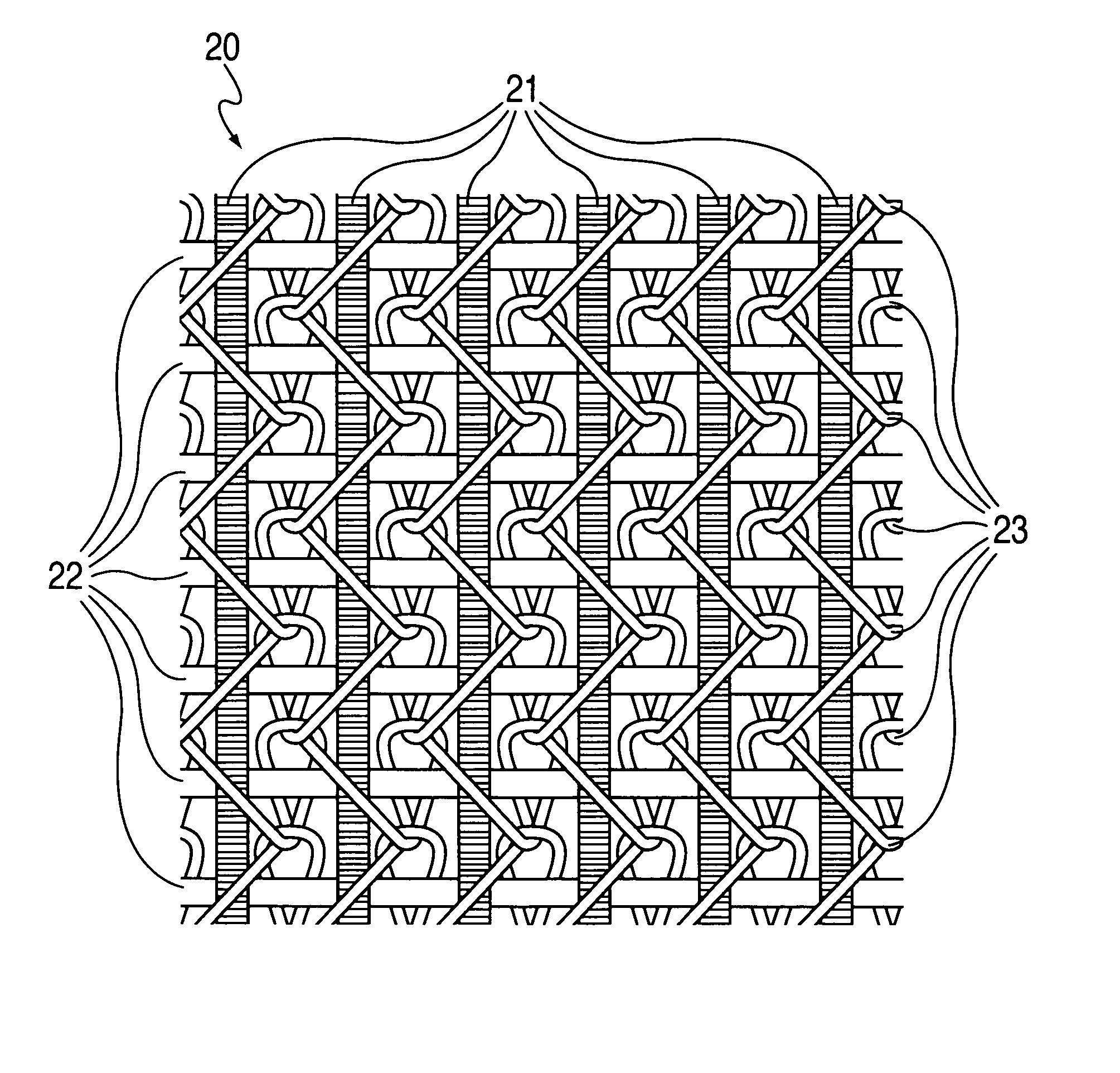

Bi-directional fabric and fabric composites

InactiveUS20050081571A1Increase resistanceSuperior ballistic effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

Bi-directional fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The bi-directional fabrics are comprised of a first set of strong, substantially parallel, unidirectional yarns lying in a first plane; a second set of strong, substantially parallel, unidirectional yarns lying in a second plane above the first plane and arranged transversely to the first set of yarns; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The bi-directional articles of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

Multilayer nonwoven fabric and method of manufacturing the same

A multilayer nonwoven fabric comprises a first fiber layer and a second fiber layer laminated and arranged on a first surface of the first fiber layer, wherein a plurality of groove portions is formed along a prescribed direction in a shape depressed in a thickness direction of the multilayer nonwoven fabric and a plurality of raised ridge portions are formed adjacent to the plurality of groove portions in a shape projected in the thickness direction and in which the basis weight is greater than the basis weight in regions A constituting the bottoms of the groove portions 1 are formed, and the second fiber layer constituting each of the plurality of raised ridge portions is in such a shape that a surface, on the side of the first fiber layer, of the second fiber layer is projected in the same direction as the direction in which the second surface of the first fiber layer is projected.

Owner:UNI CHARM CORP

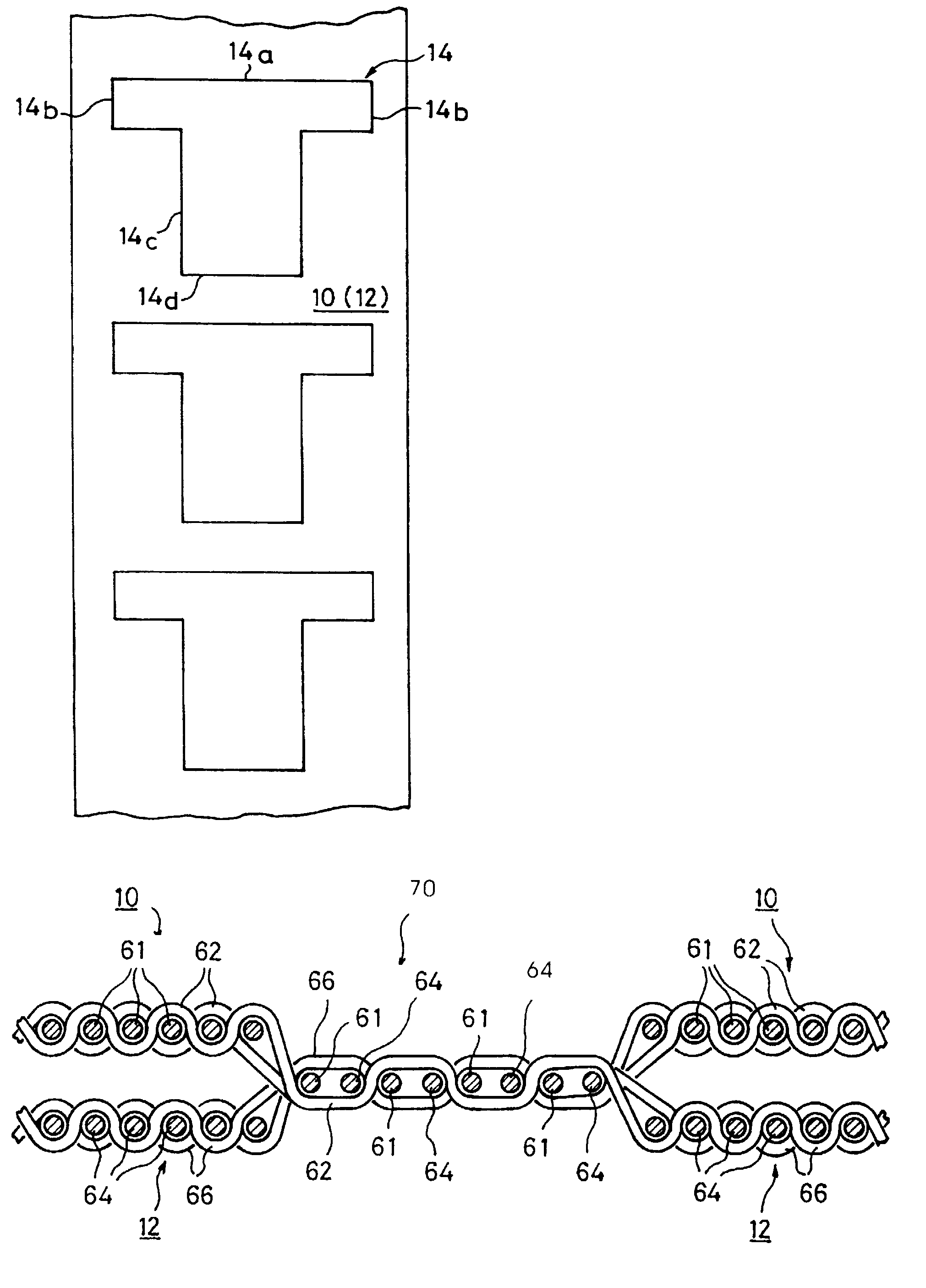

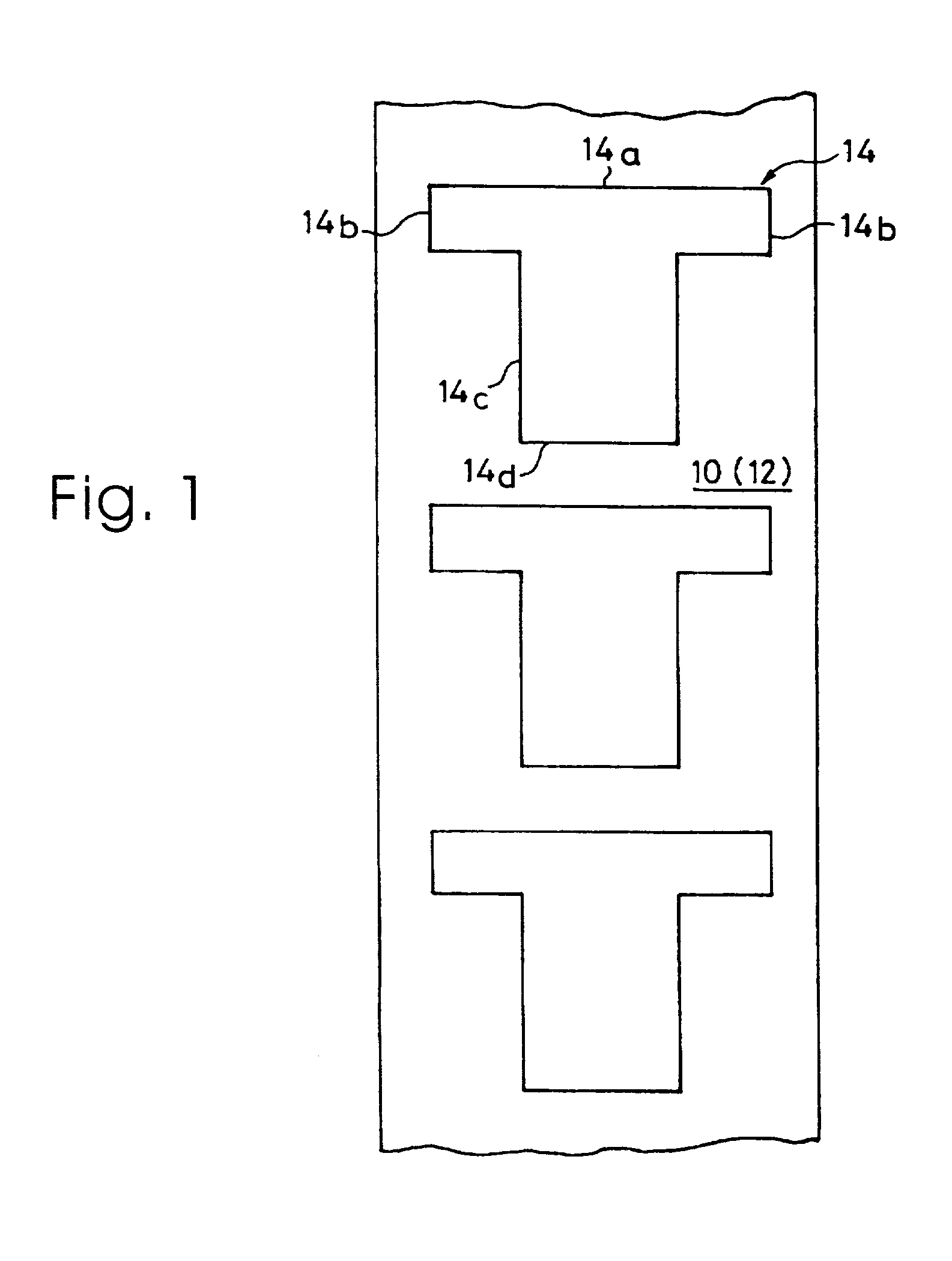

Fabric and method for obtaining garment therefrom and garment

A fabric for cutting therefrom a garment having a first layer for a front body of the garment and a second layer for a back body of the garment, which layers are basically separated from each other. The first and second layers are knitted or woven or stitched along an outer profile 14 of a garment, which is unfinished or semi-finished at locations such as neck hole and sleeve where portions of a wearer are passed. A cutting of the fabric is done along the outline in such a manner that the unfinished or semi-finished garment is separated from the fabric. A cutting of the neck hole is done in such a manner that the size of the neck hole 40A, 40B or 40C is matched to a particular wearer's size and his or her preference.

Owner:MIYAKE DESIGN JIMUSHO

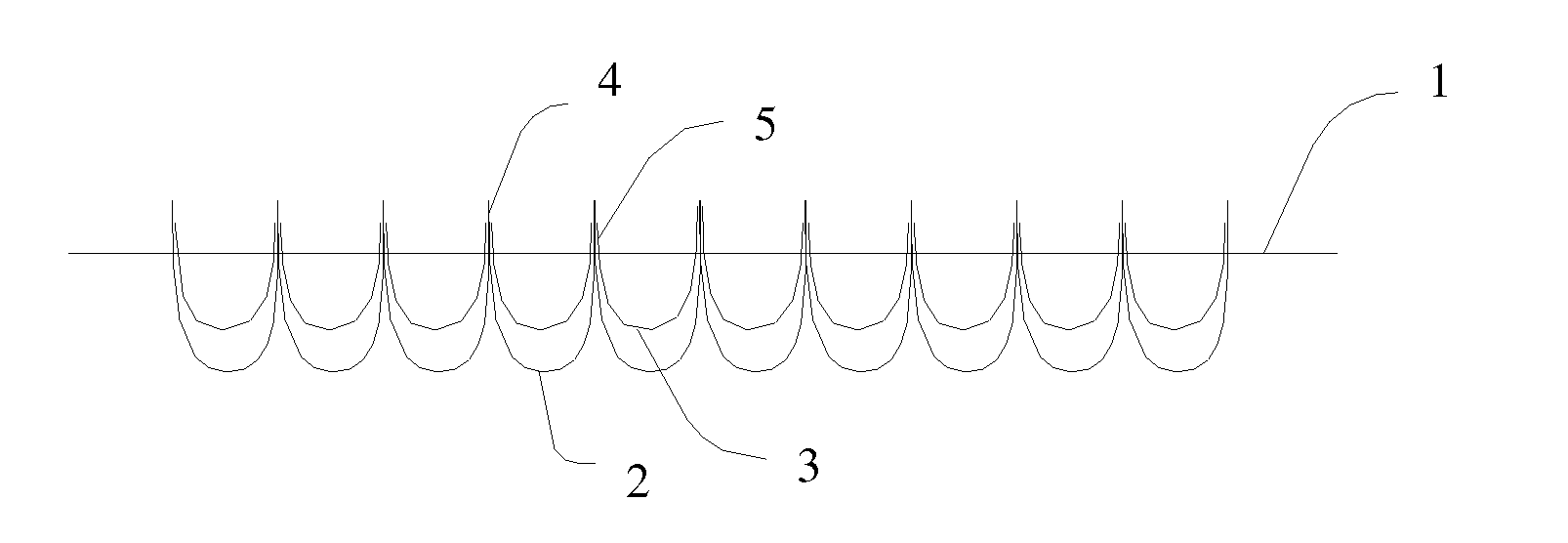

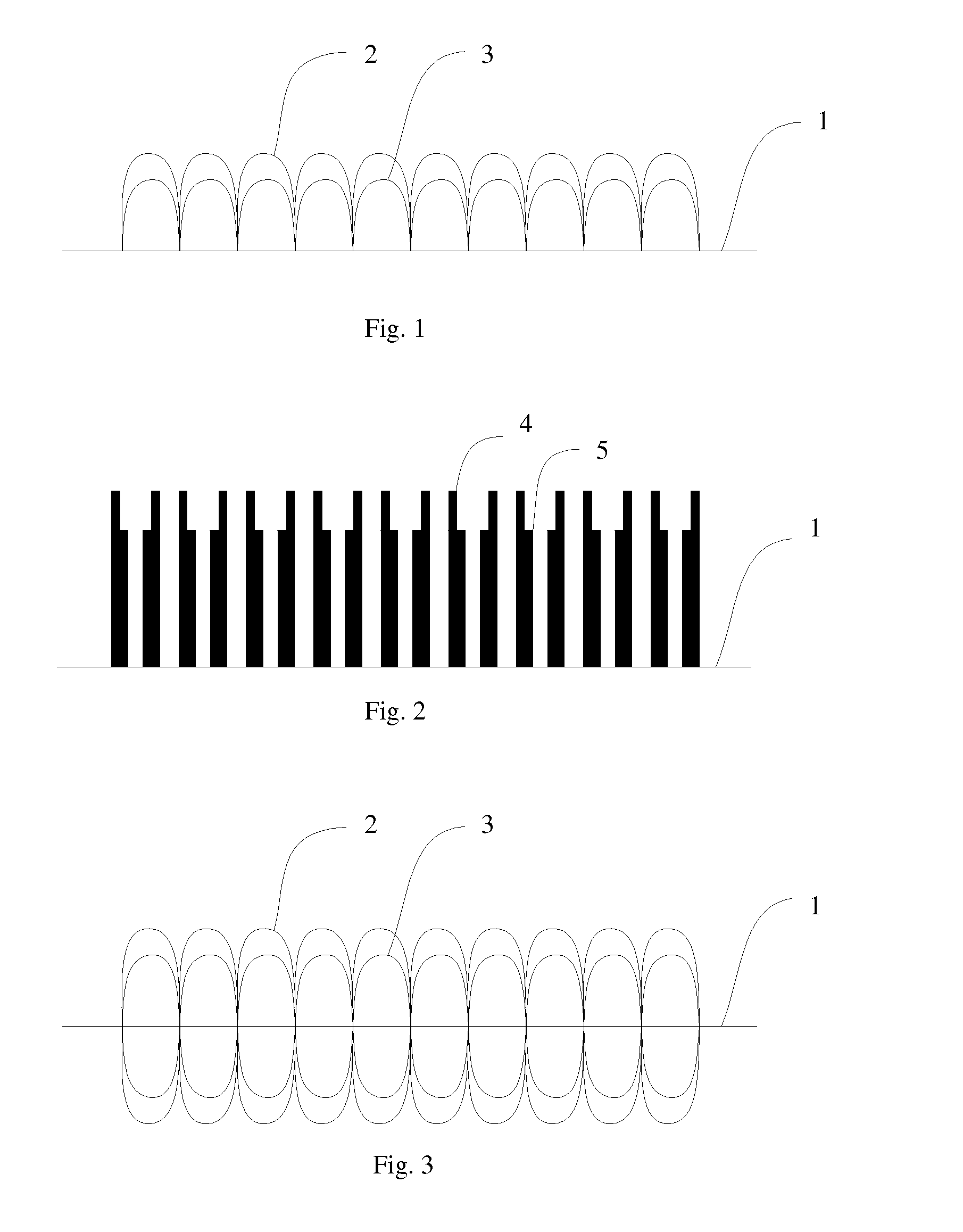

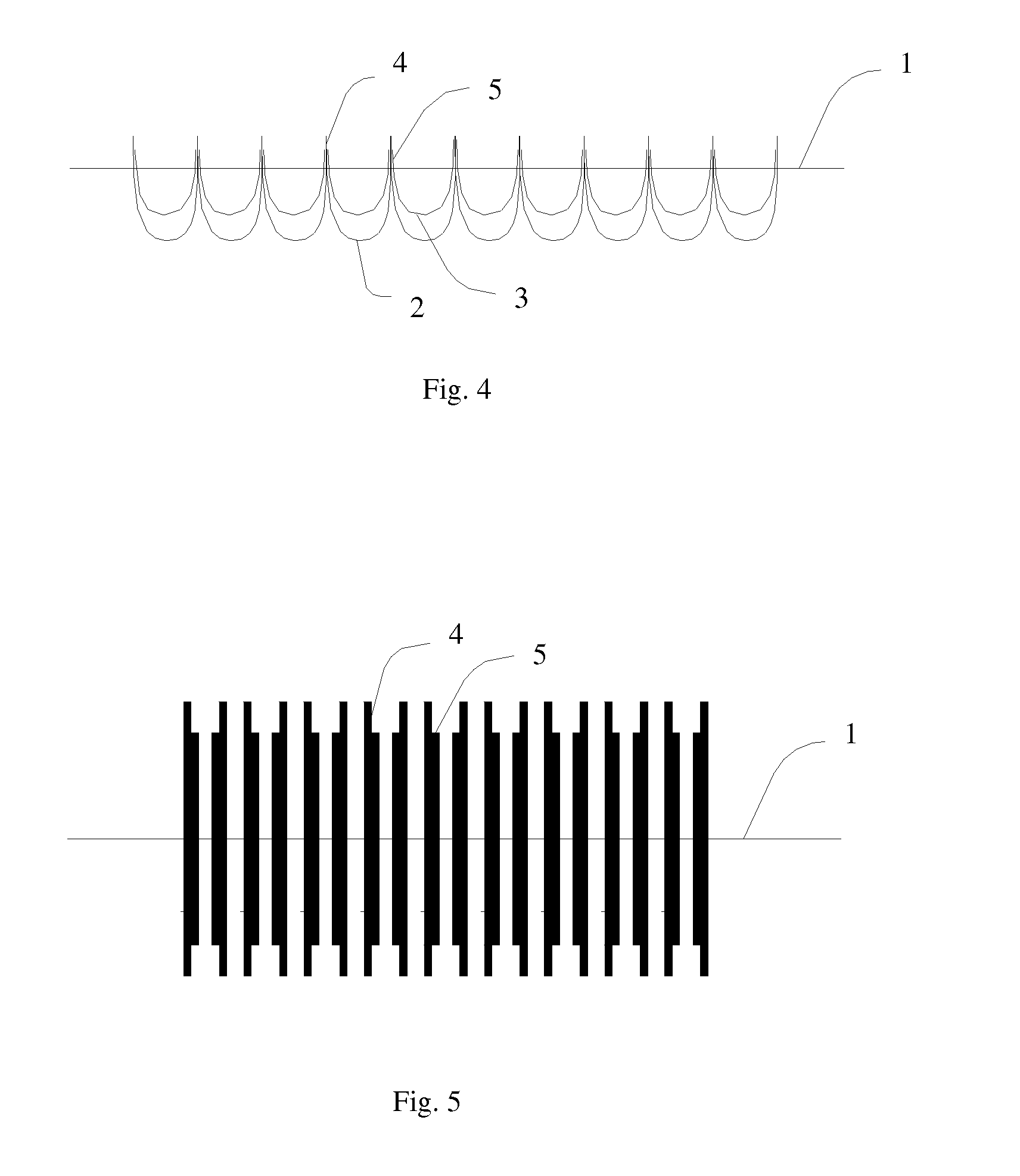

Fabrics having double layers of terry or pile

ActiveUS20120255643A1Good sense of layerImprove performancePile-fabric loomsCircular knitting machinesStructural engineeringNatural fiber

A fabric having a ground fabric, and a double layer terry or a double layer pile on either or both surfaces of the ground fabric, or a double layer terry on one surface and a double layer pile on the other surface. The double layer terry has an outer terry and an inner terry lower than the outer terry; the double layer pile has an outer pile and an inner pile lower than the outer pile. The outer terry or outer pile is a natural fiber, and the lower terry or lower pile is a microfiber. Methods of manufacturing the fabric are also disclosed.

Owner:DUAN HONGWEI

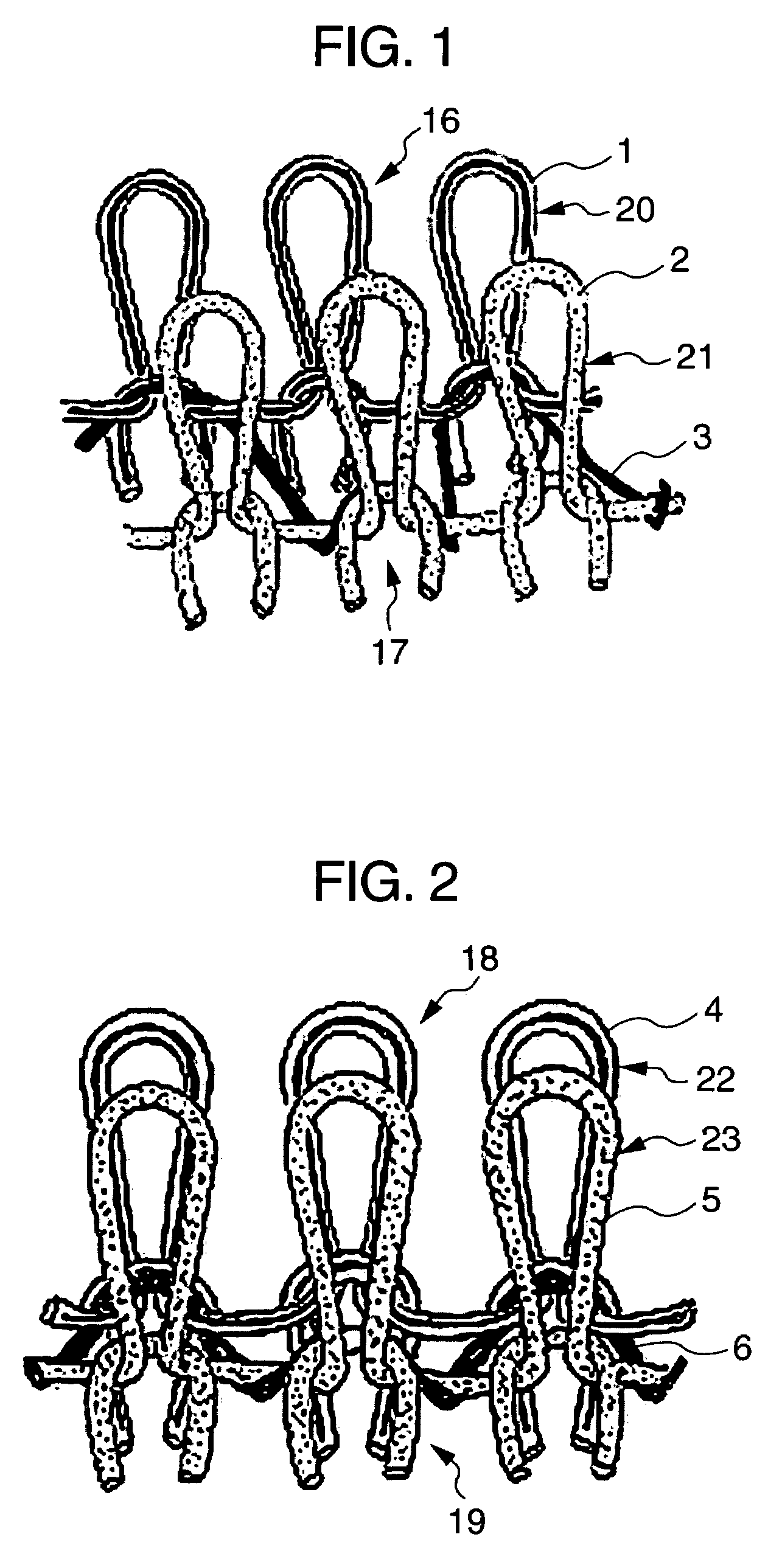

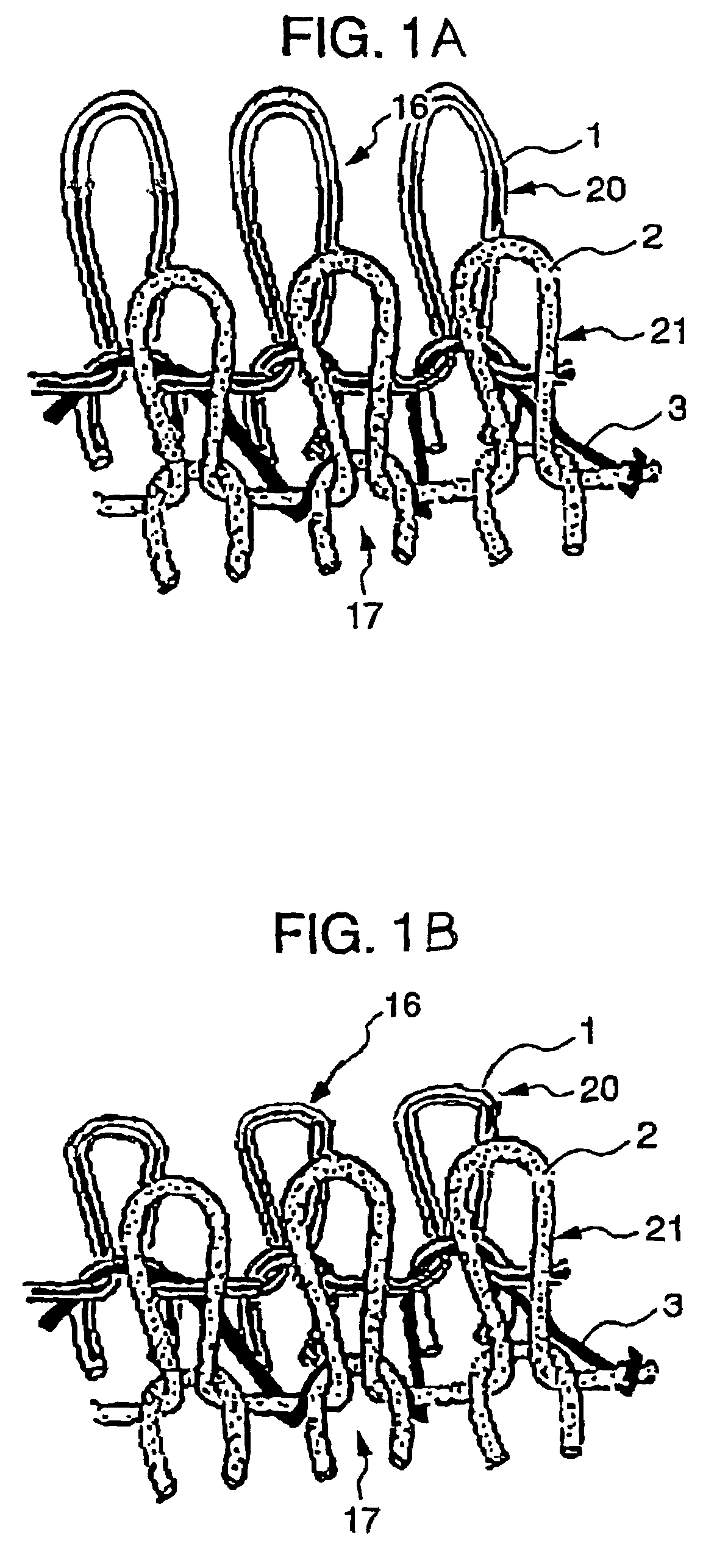

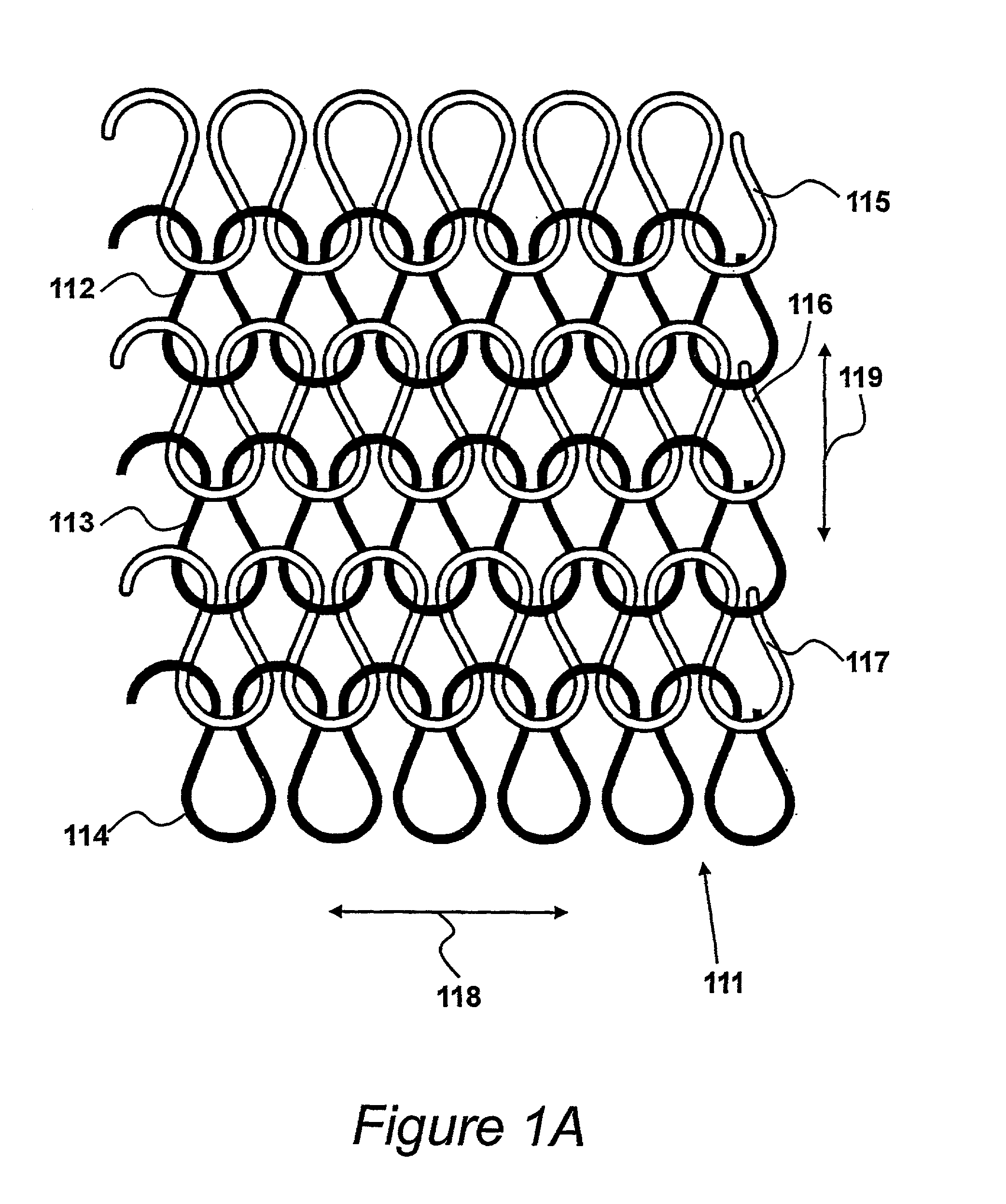

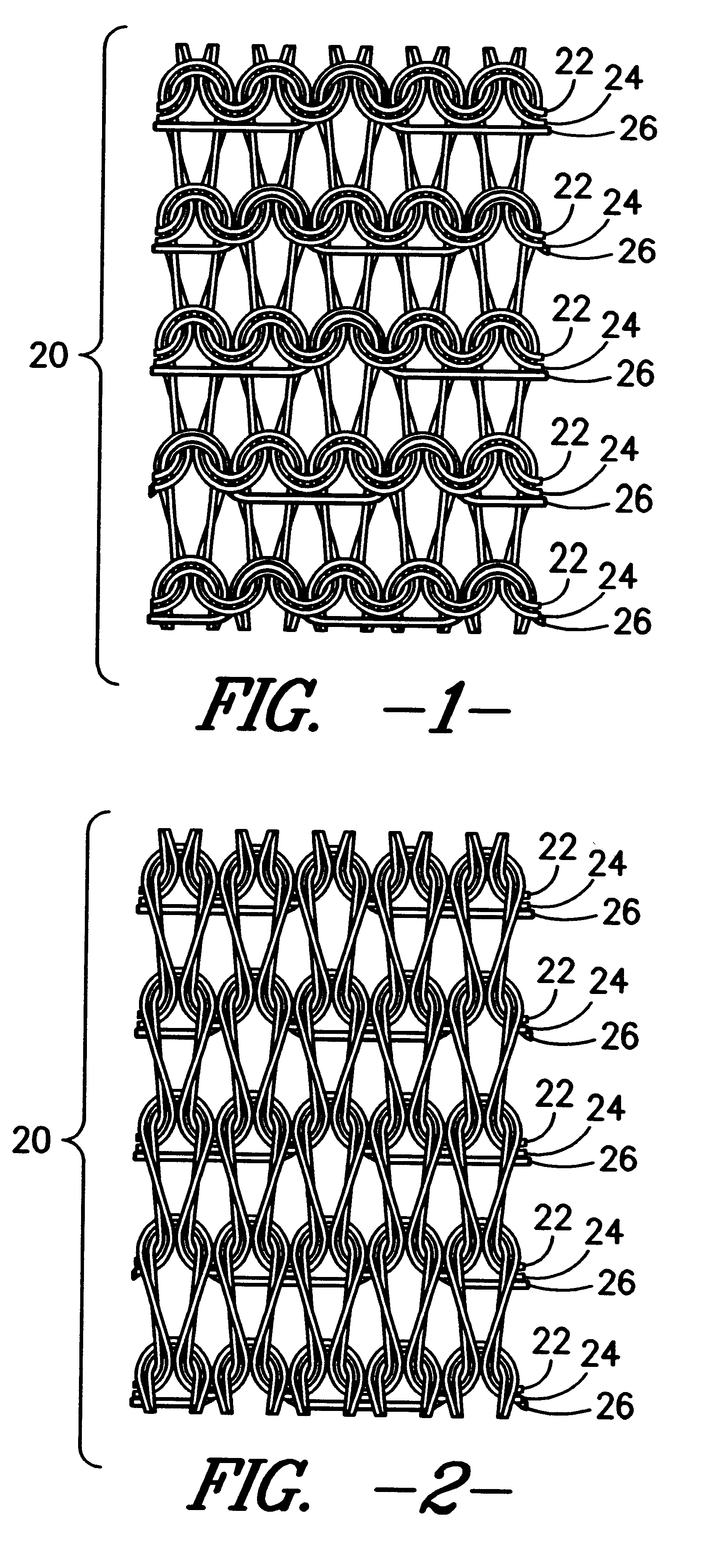

Knit elastic mesh loop pile fabric for orthopedic and other devices

InactiveUS20080072629A1Increase air circulationImprove moisture managementOrnamental textile articlesStraight-bar knitting machinesOrthopedic devicesMuscle tone

An improved fabric for orthopedic devices is provided, being a knitted fabric produced on either a warp or weft knit system and utilizing a filament yarn selected from nylon and polyester as well as spandex. The fabric enhances freedom of movement while stimulating blood flow and muscle tone. The fabric has an elasticity that enables closure of orthopedic and other devices by placing the hook component of a Velcro (®) strip at any convenient point rather than aligning it with the loop component of the Velcro (®). The fabric is more convenient, faster and easier for many incapacitated persons, enhancing wearing comfort. Its mesh structure makes it more porous, which enhances the air circulation and the moisture management in creating a cooling effect on the wearer's skin and ready evaporation of perspiration, while still providing therapeutic warmth without heat buildup.

Owner:GEHRING TEXTILES

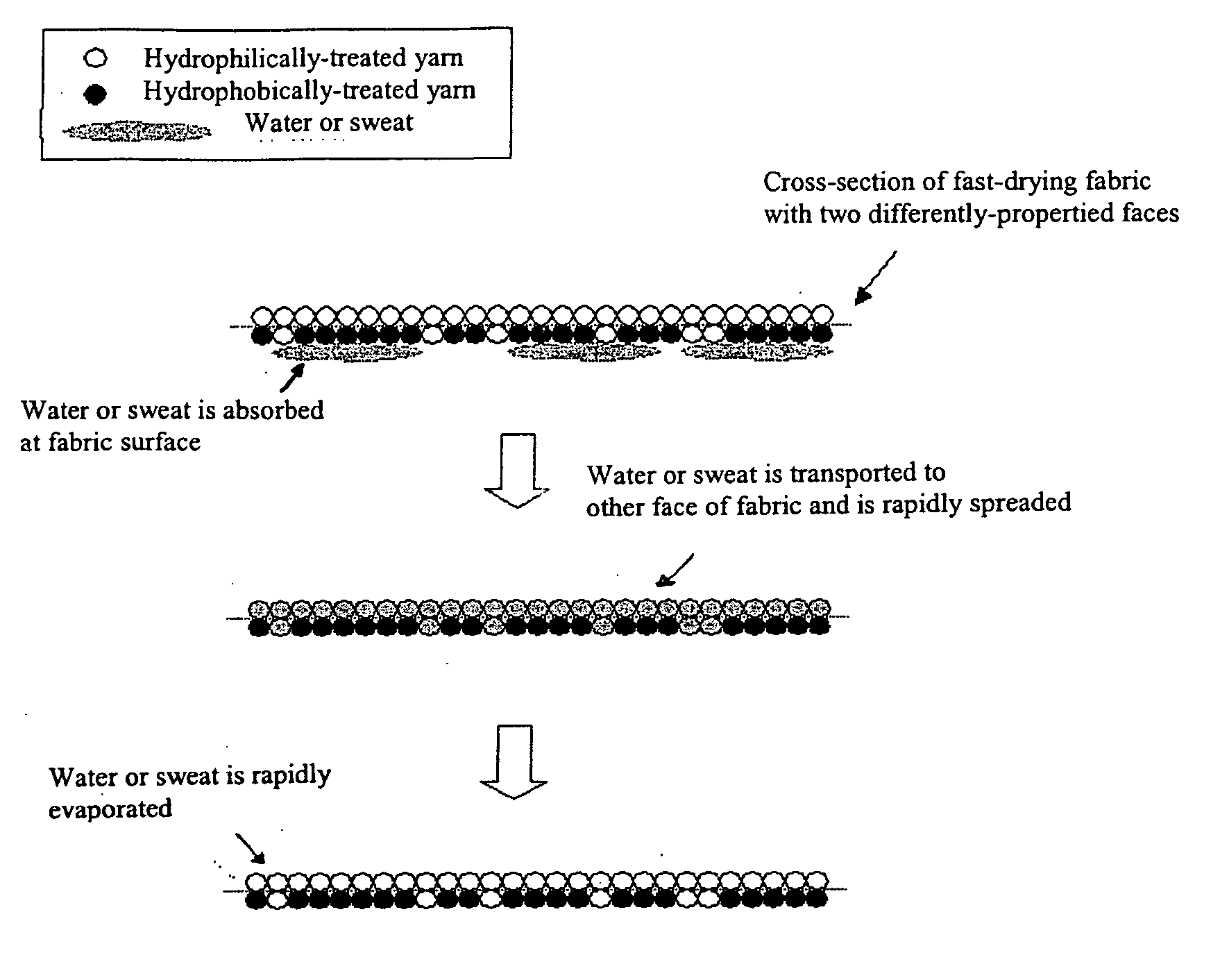

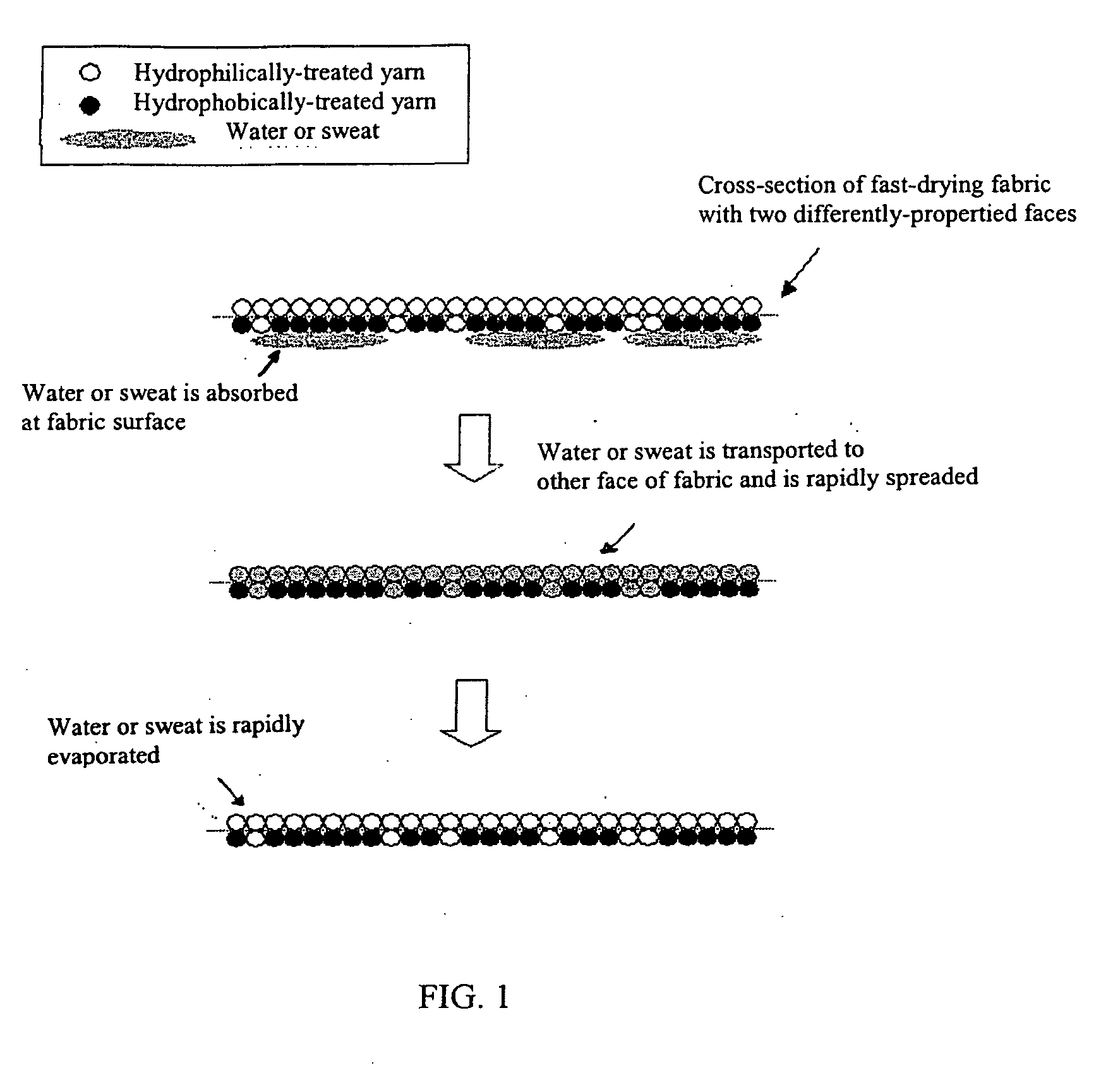

Quick-drying pure cotton fabric with two faces having different properties and a method of producing same

InactiveUS20060148356A1Quick drying-whilePleasing to touchGarment special featuresOrnamental textile articlesYarnCivil engineering

The present invention is a quick-drying pure cotton fabric whose two faces have different properties and a method of producing same. One face of said fabric is a hydrophobic face formed largely or entirely from hydrophobic pure cotton, and the other face is a hydrophilic face formed largely or entirely from hydrophobic pure cotton. Moreover, said fabric is capable of unidirectional transportation of water. The method of producing said fabric consists mainly of separate hydrophobic treatments of pure cotton yarn. The result is hydrophilically-treated yarn and hydrophobically treated yarn. Then the two types of yarn are knit according to a certain knitting process to produce a fabric whose two faces have different properties: hydrophilicity and hydrophobicity. The fabric is also comfortable and has moisture management and fast-drying functions.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

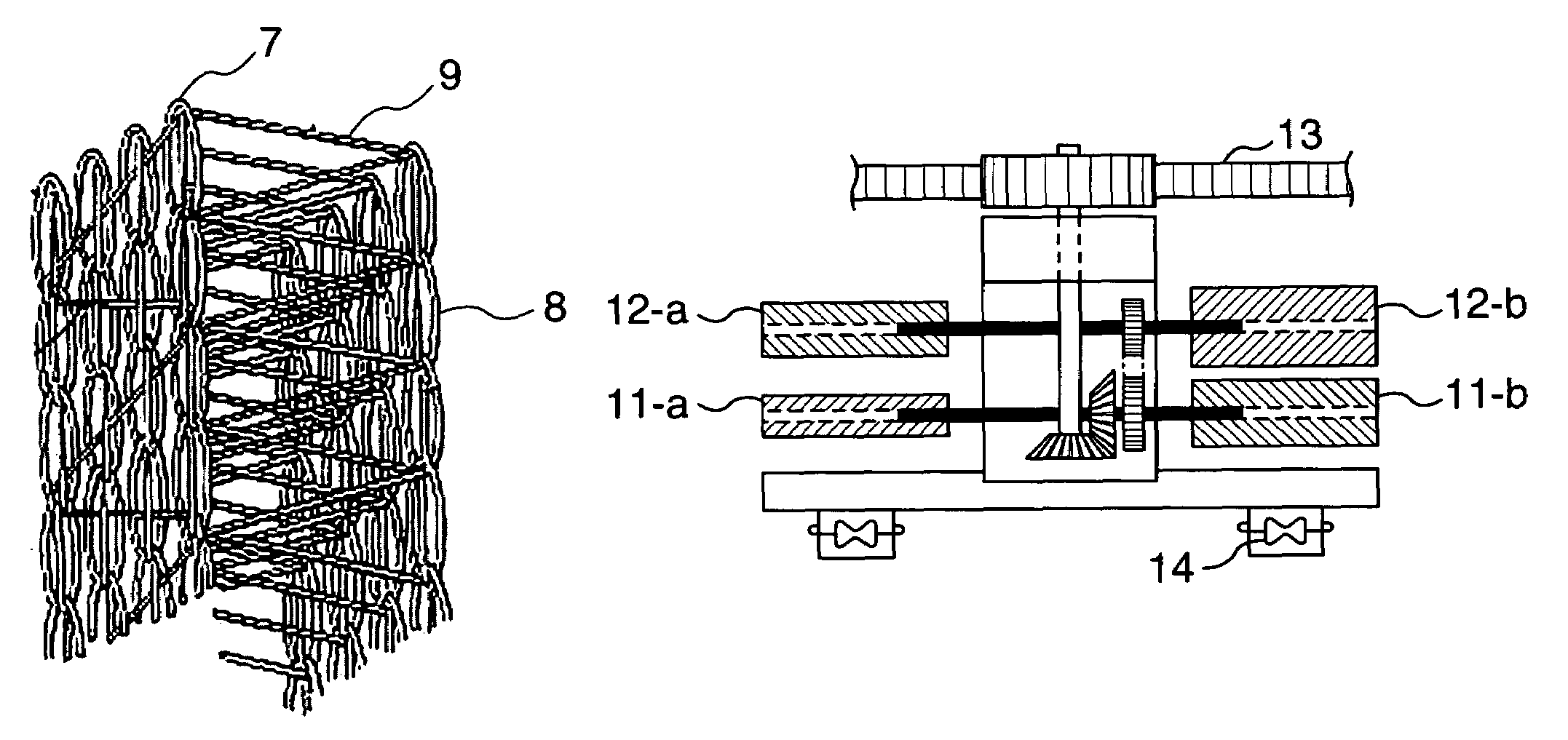

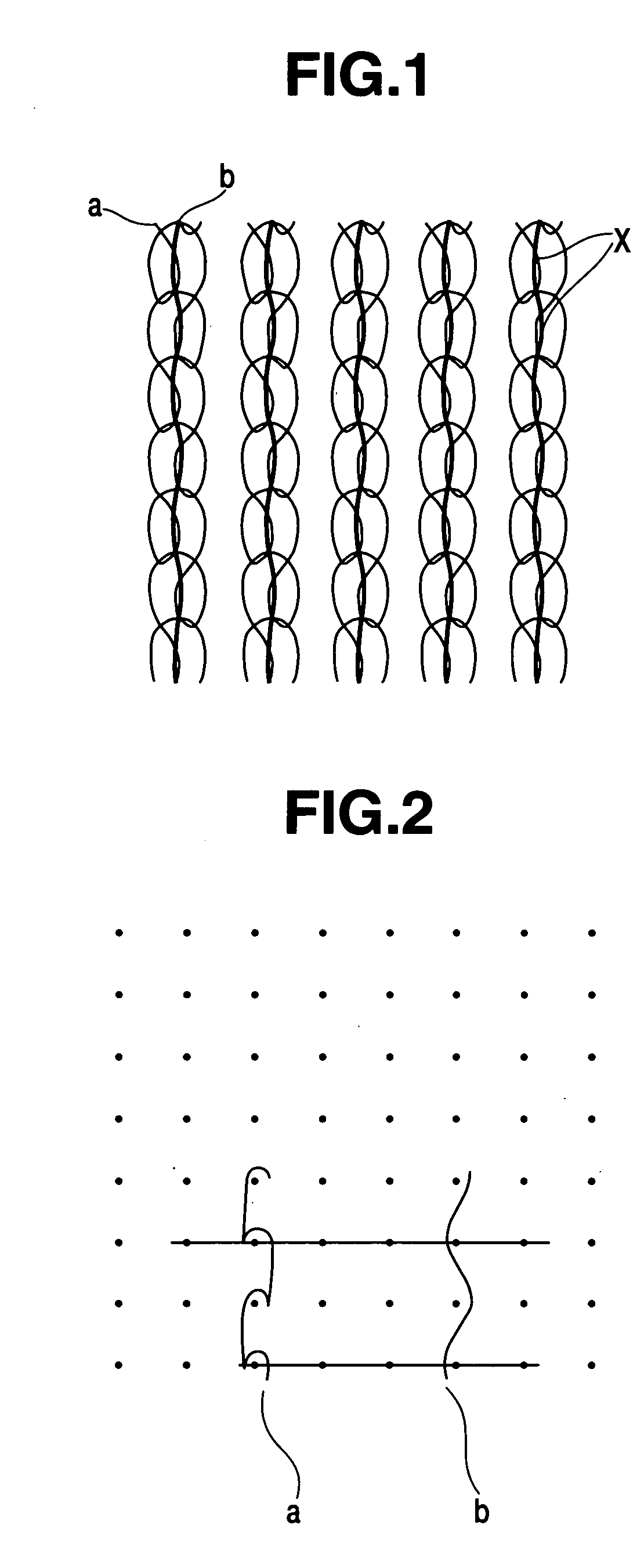

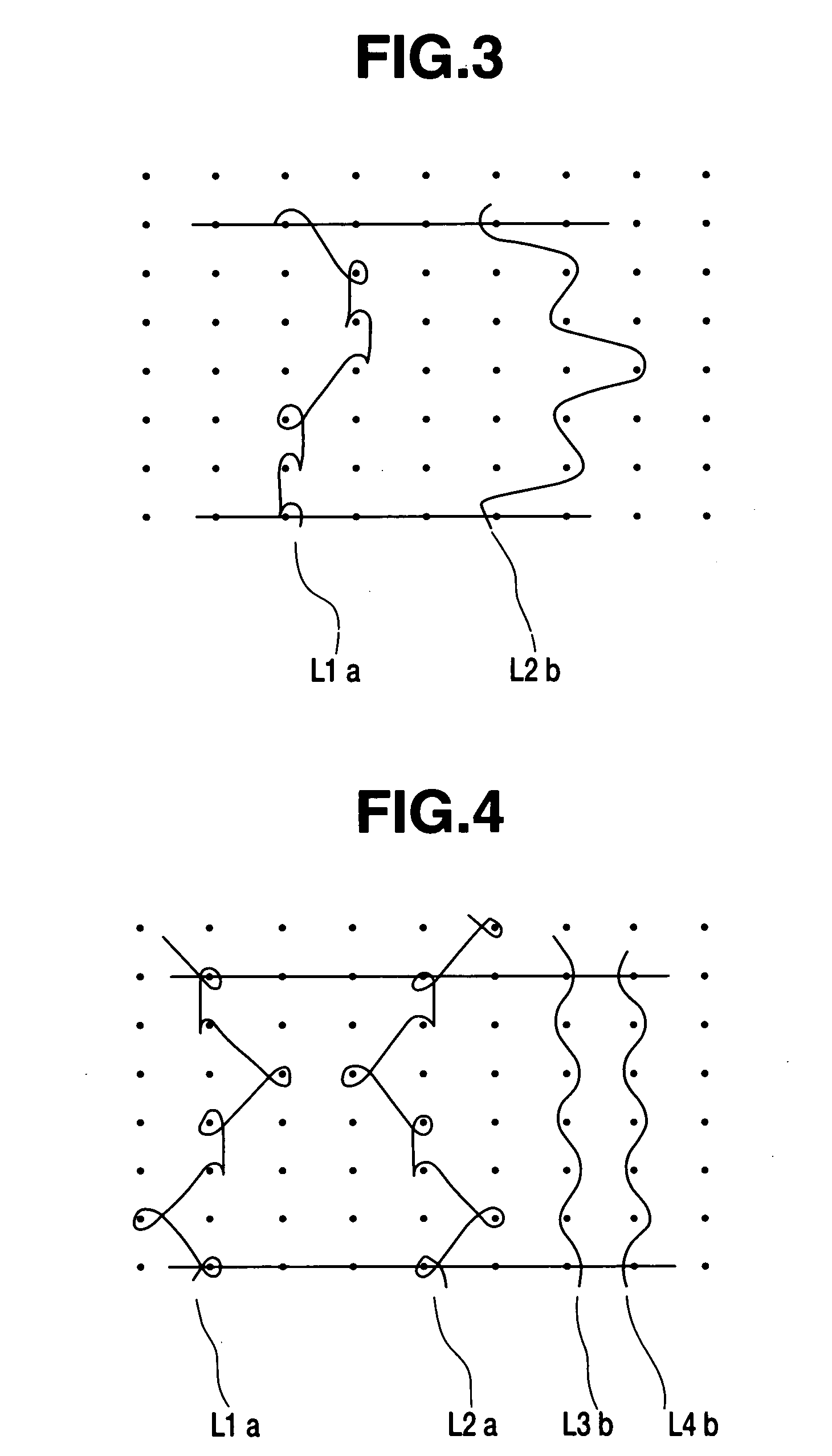

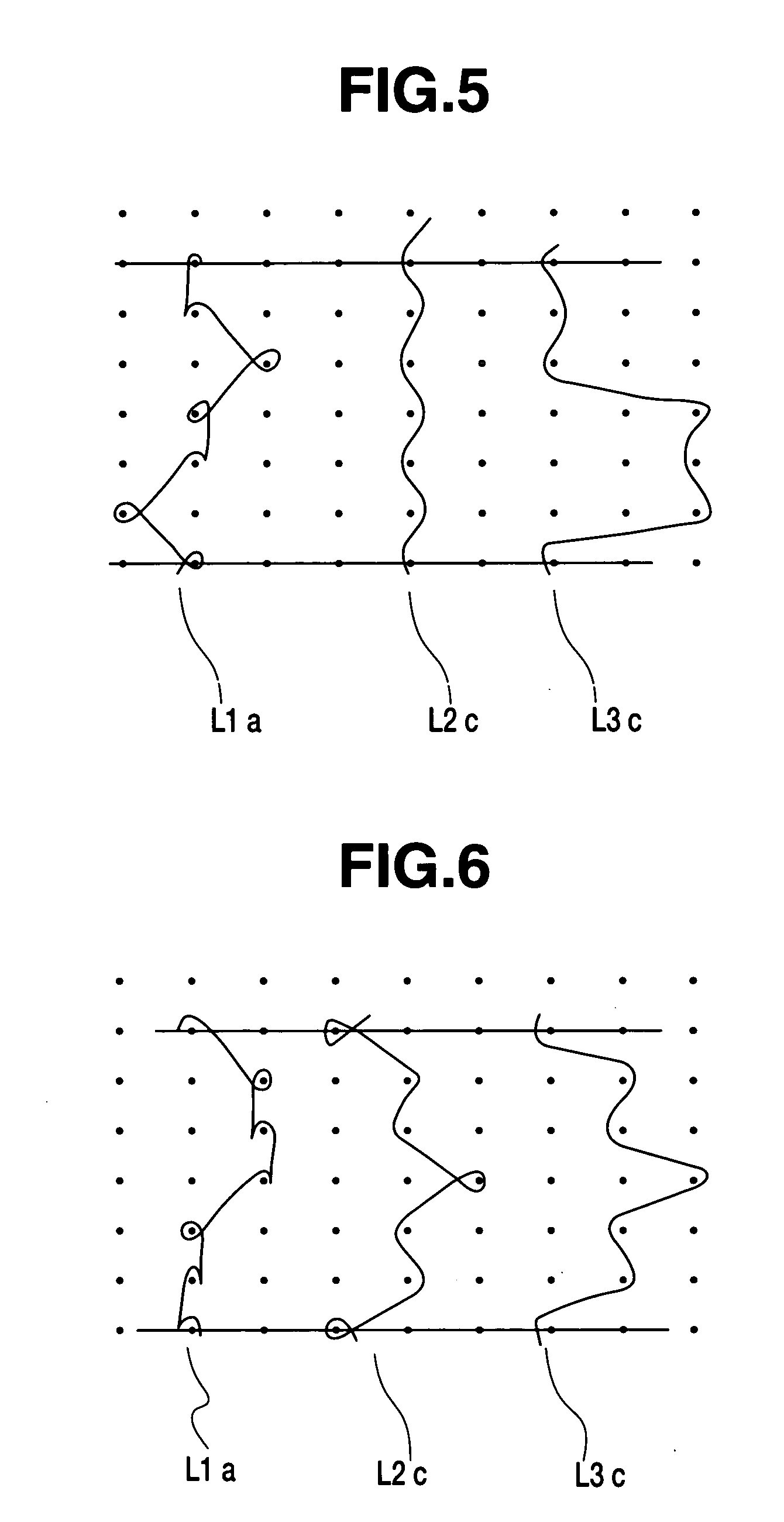

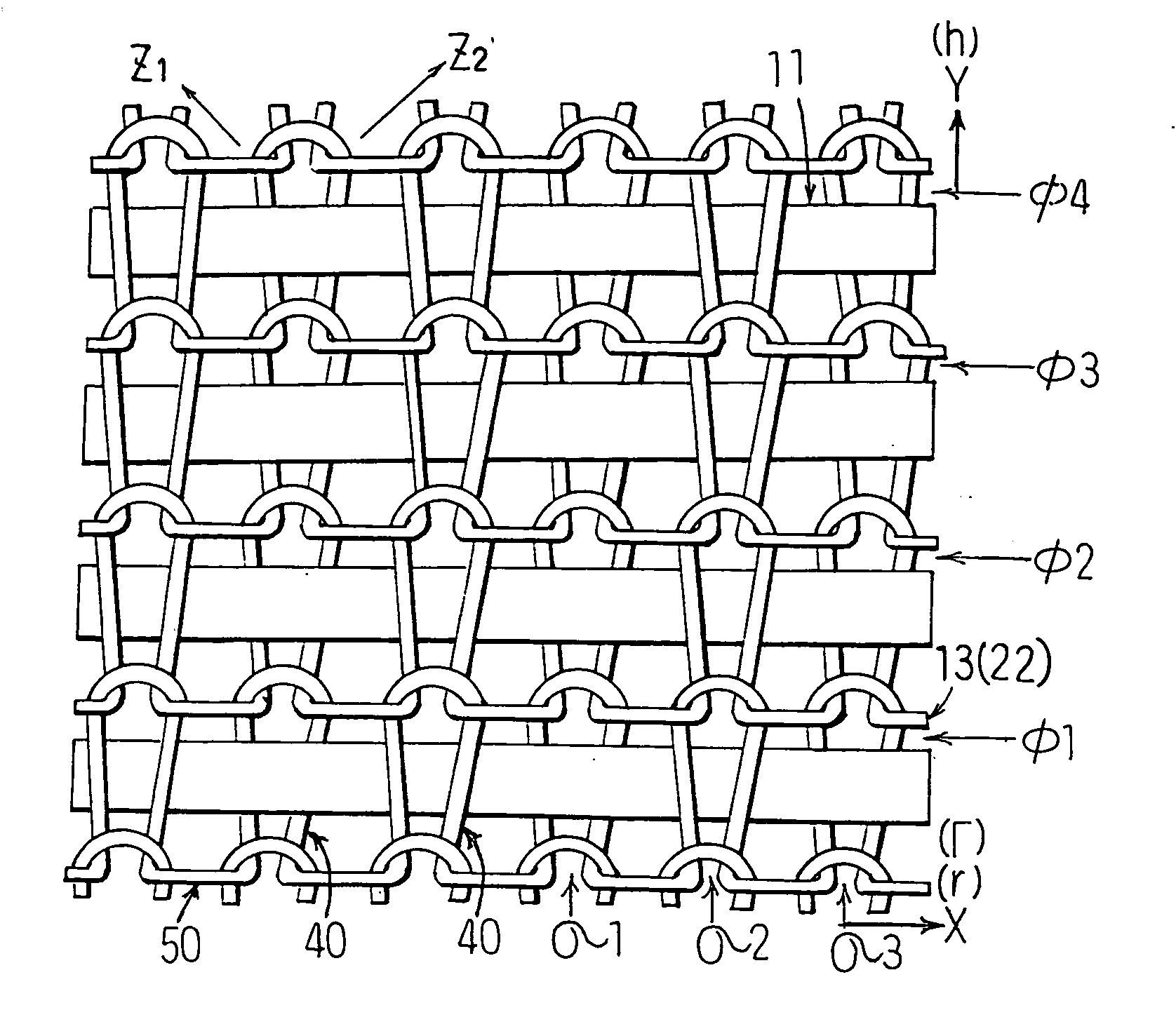

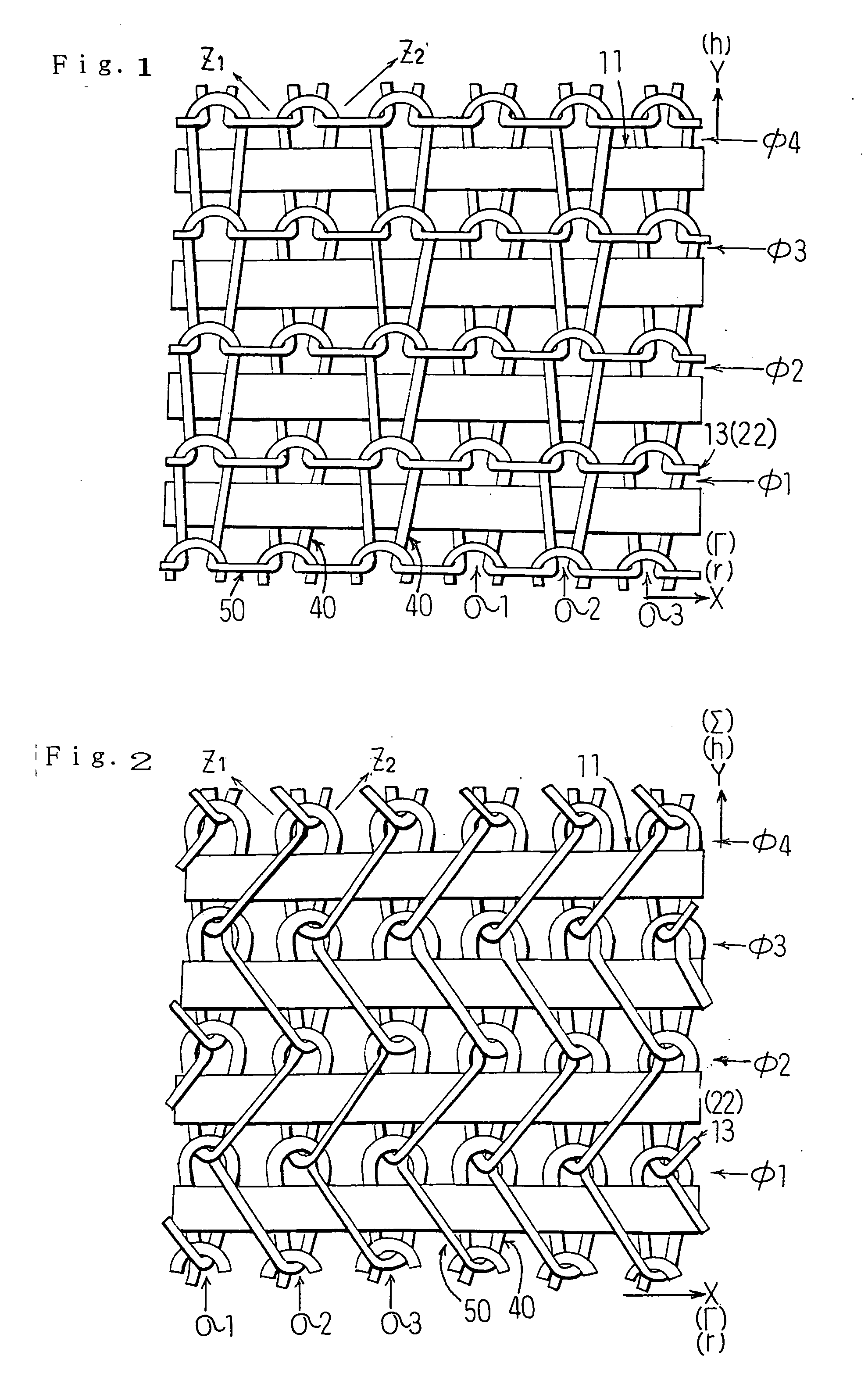

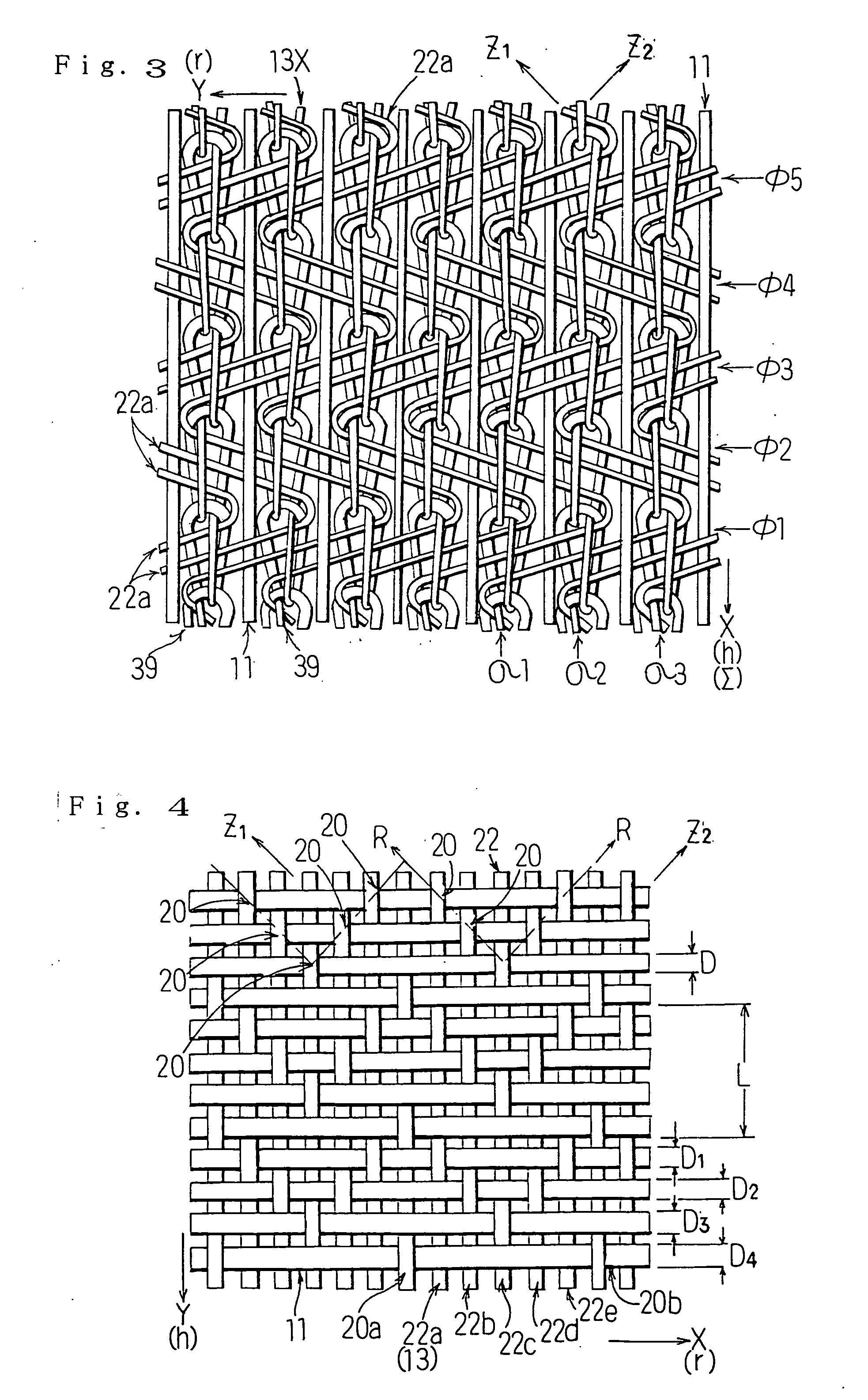

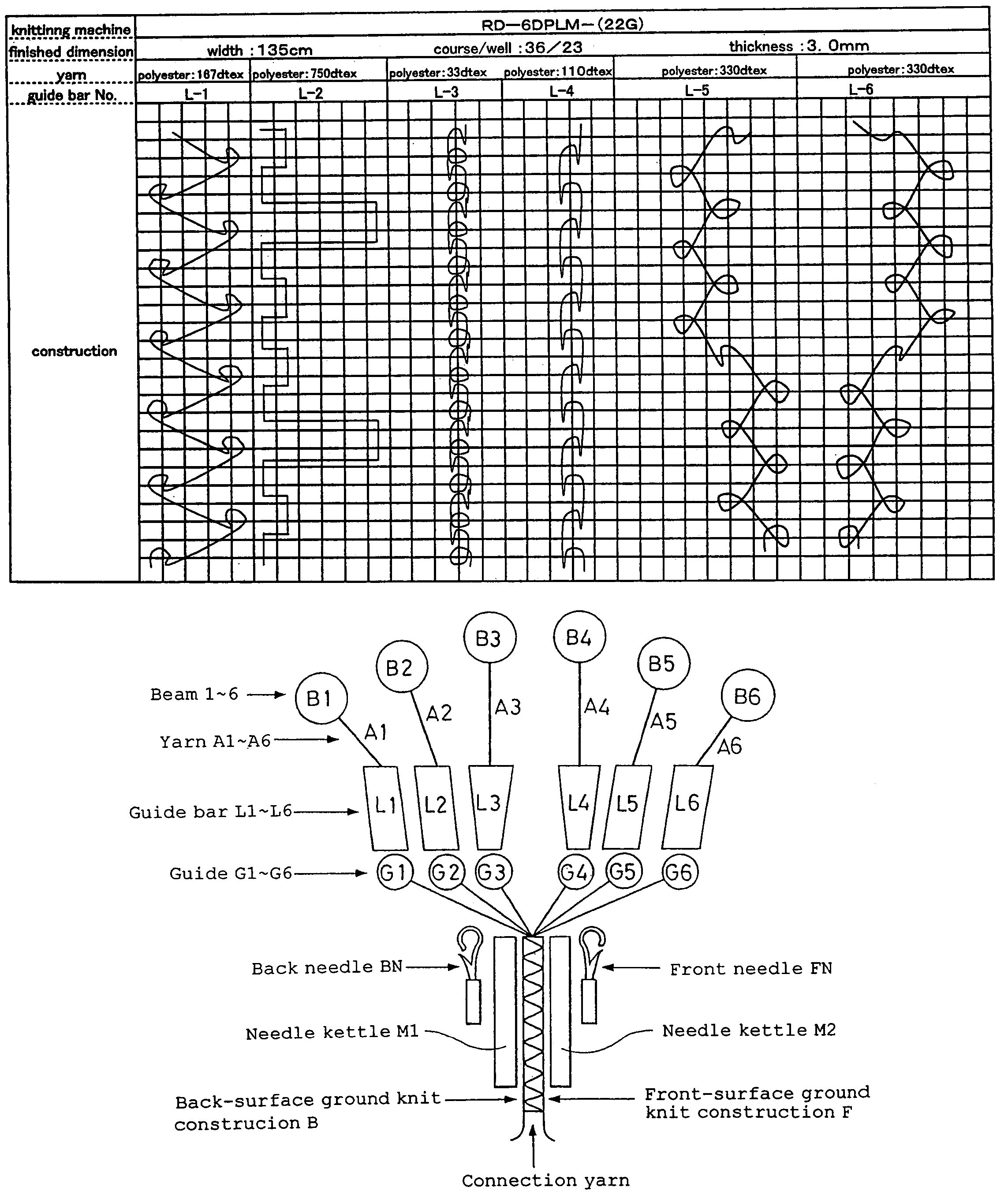

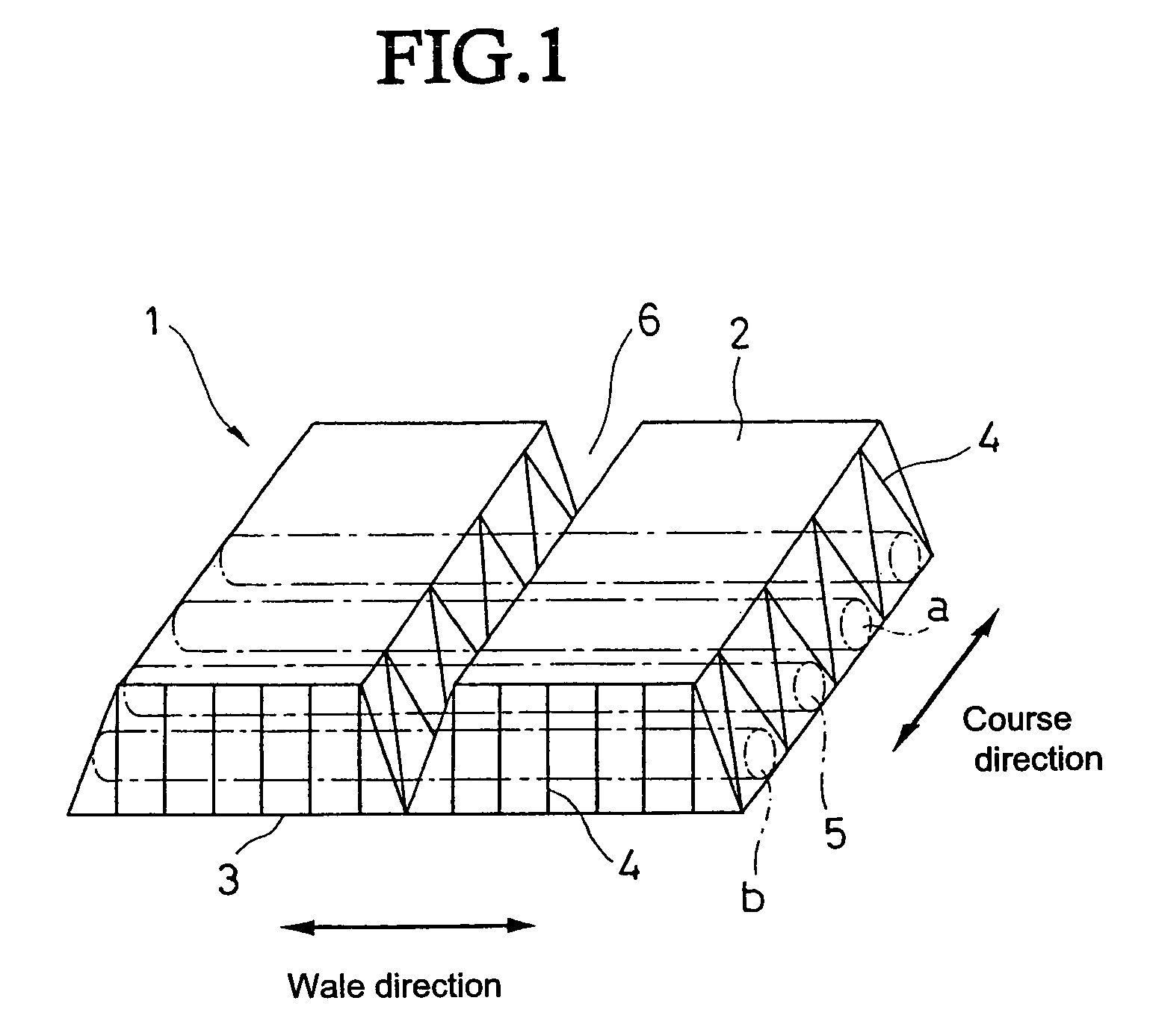

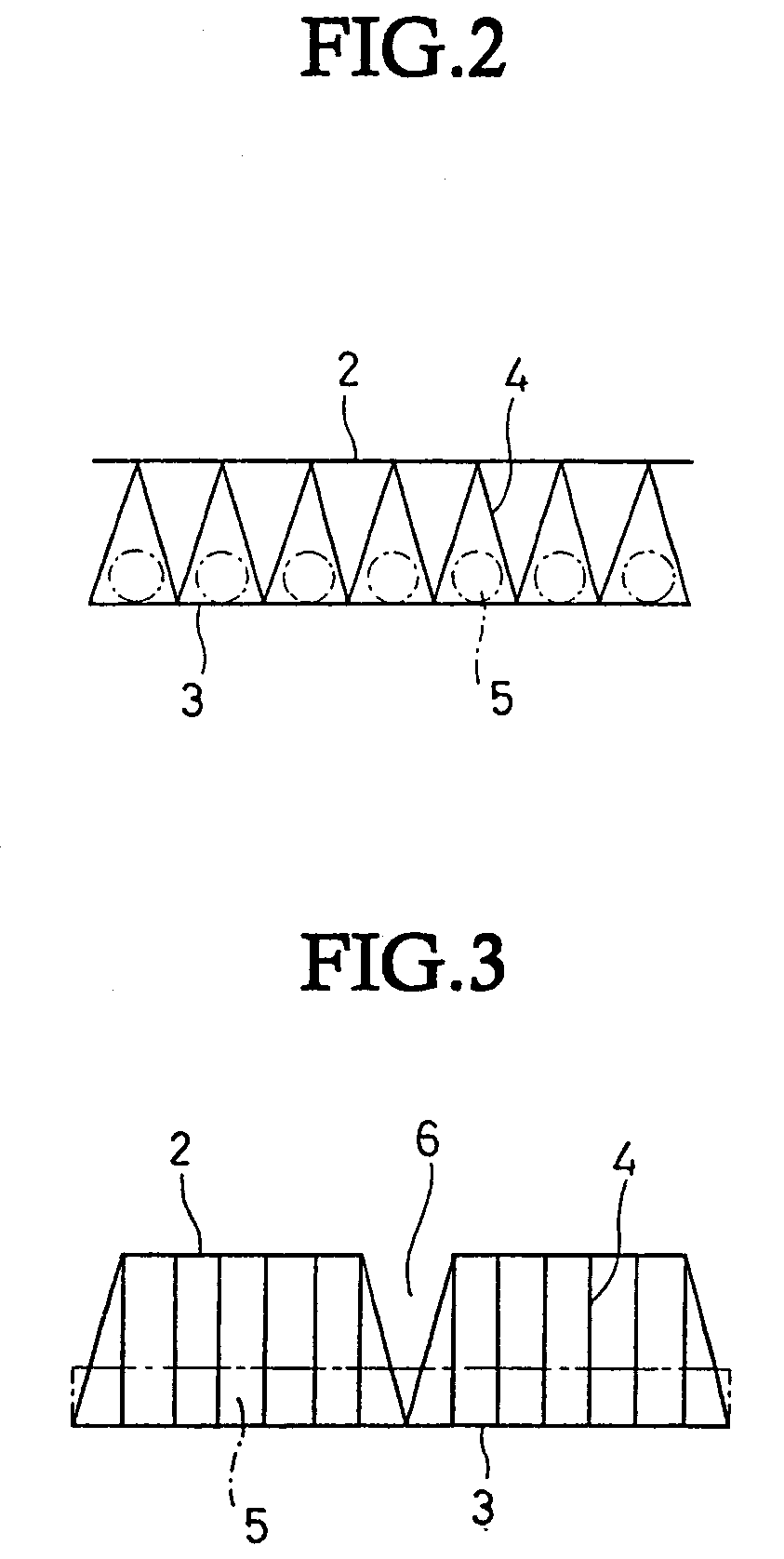

Three-dimensionally constructed warp knit fabric with slippage-preventive yarns

InactiveUS7213421B2Improve stress resistanceWithout impairing cloth flexibilityOrnamental textile articlesCircular knitting machinesEngineeringBuilding construction

A three-dimensionally constructed warp knit fabric formed to include front-surface and back-surface ground knit constructions and connection yarns interconnecting the front-surface and back-surface ground knit constructions has insertion yarns between the connection yarns, in which the insertion yarn is fixed along the inner side of the back-surface ground knit construction. Further, the insertion yarn is fixed by a fixing yarn to the back-surface ground knit construction.

Owner:SEIREN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com