Patents

Literature

90 results about "Conductive textile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A conductive textile is a fabric which can conduct electricity. Conductive textiles can be made with metal strands woven into the construction of the textile or by conductive yarns which are conductive thanks to a metal-coating. There is also an interest in semiconducting textiles, made by impregnating normal textiles with carbon- or metal-based powders.

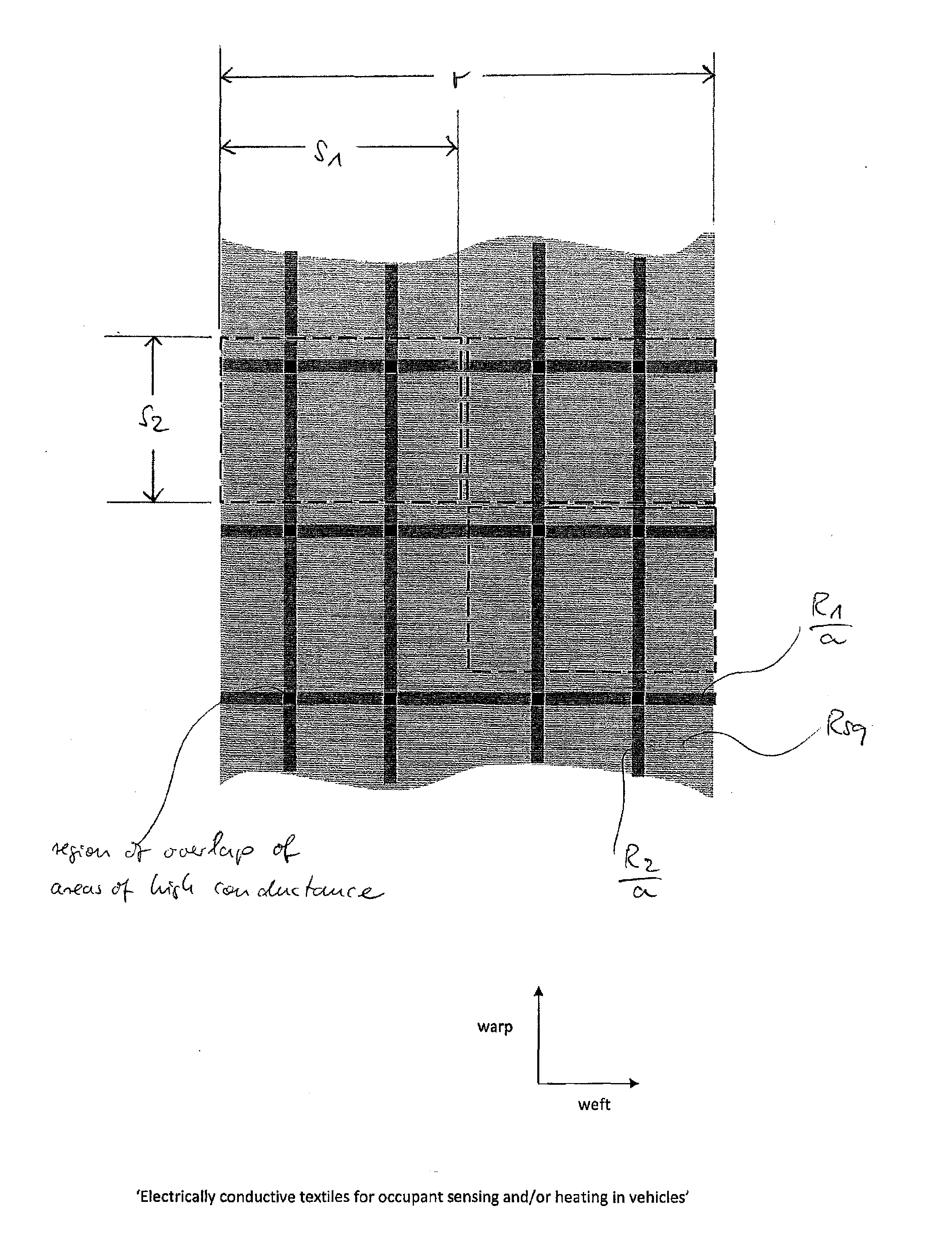

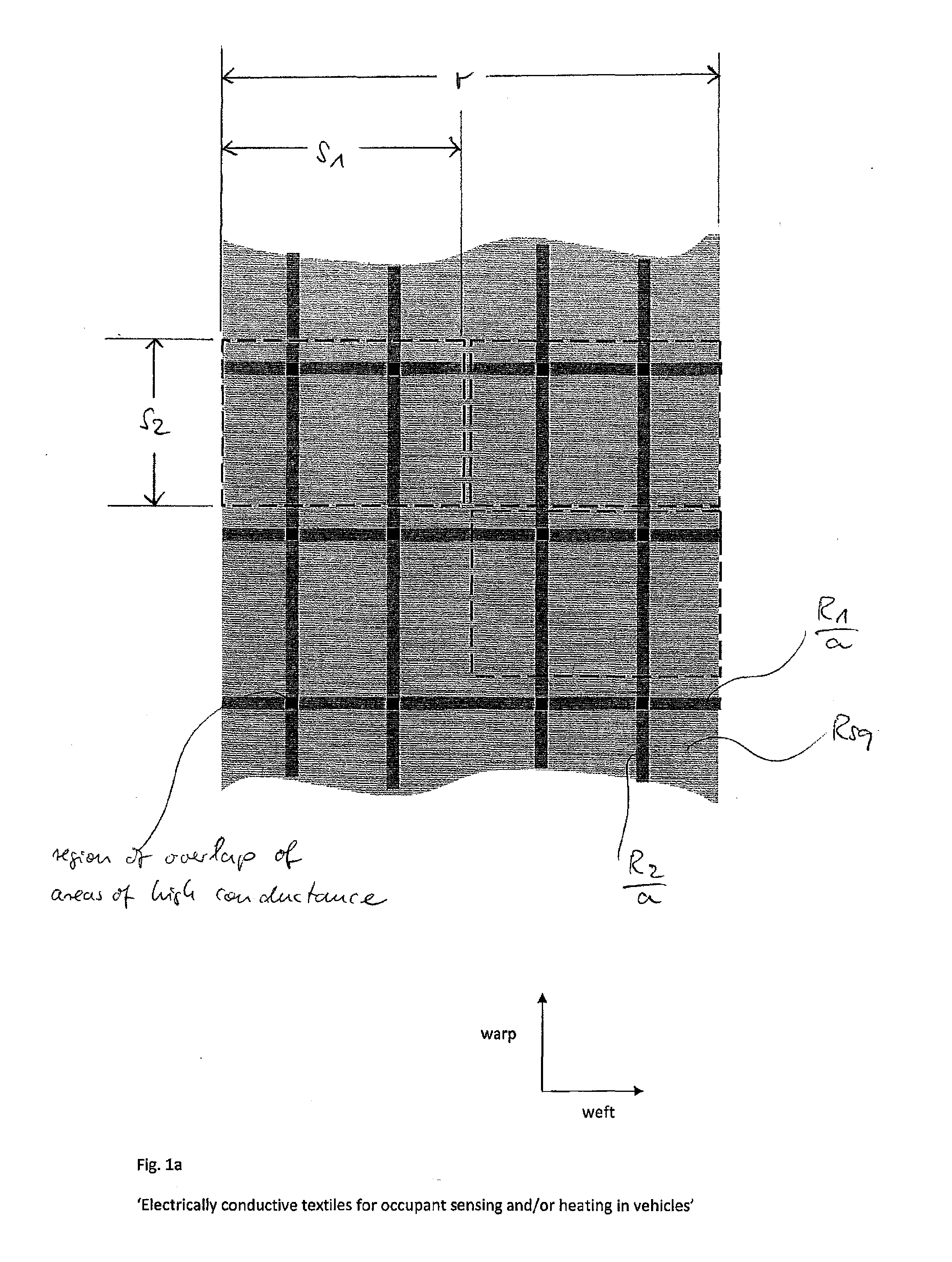

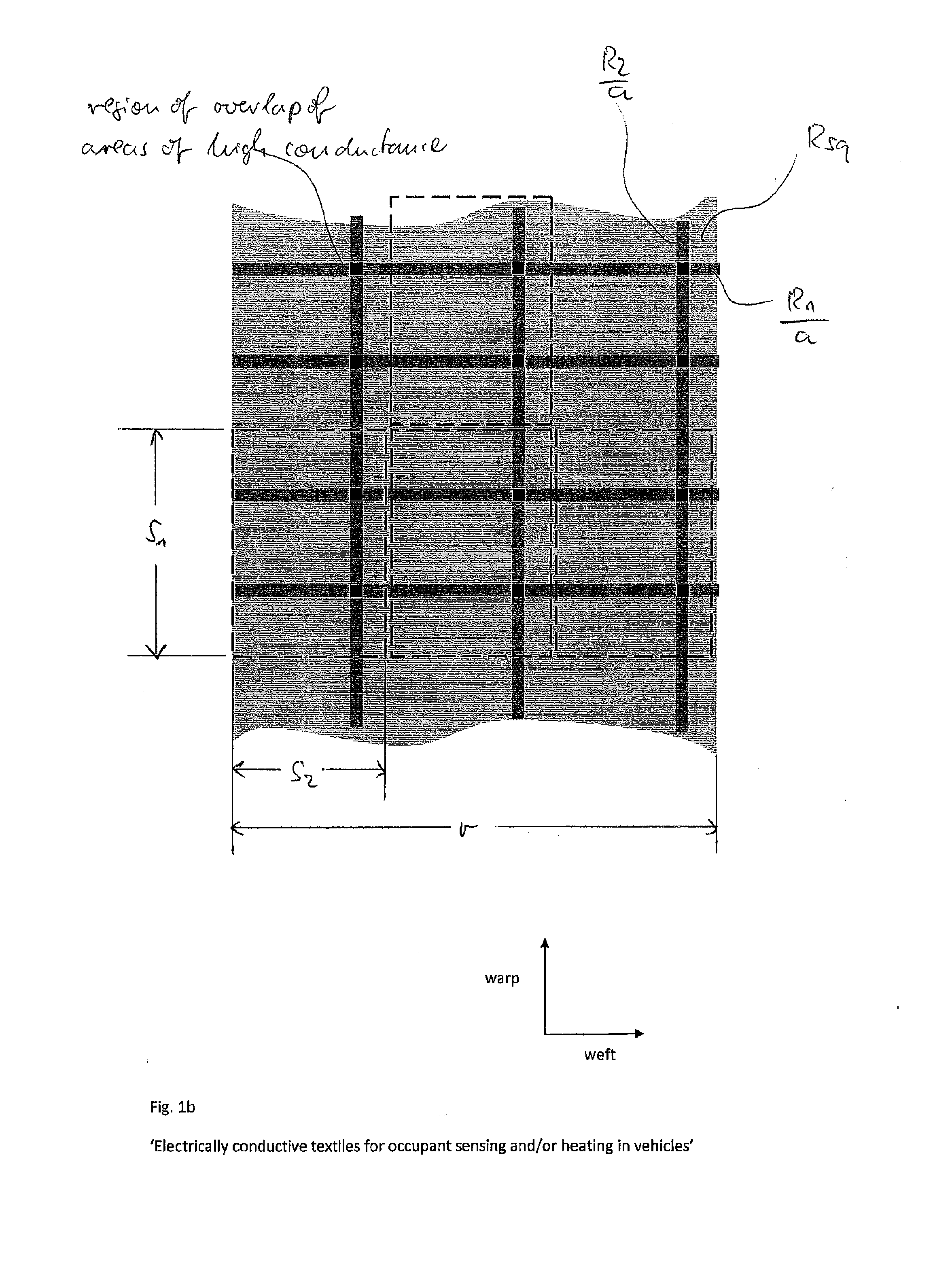

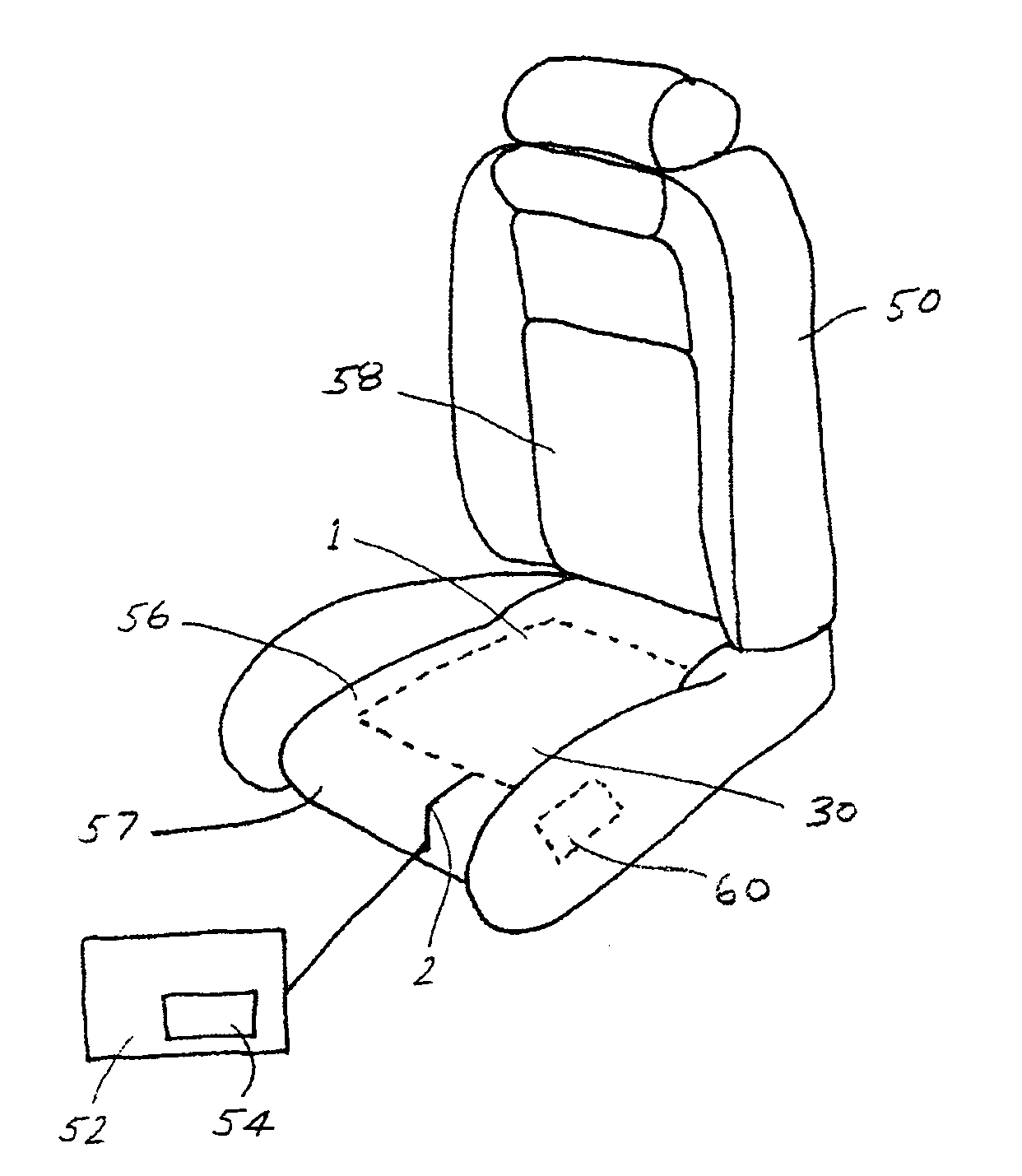

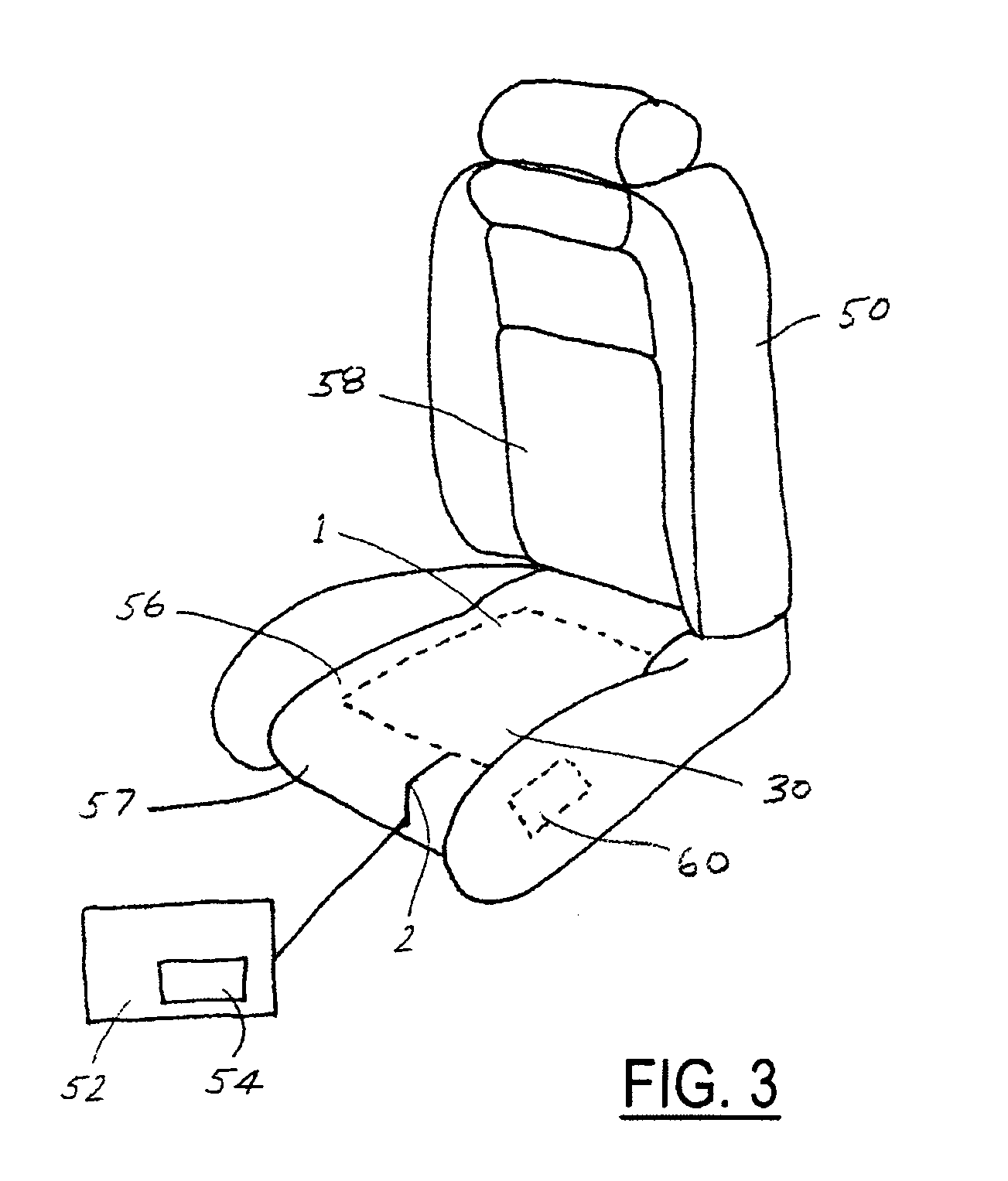

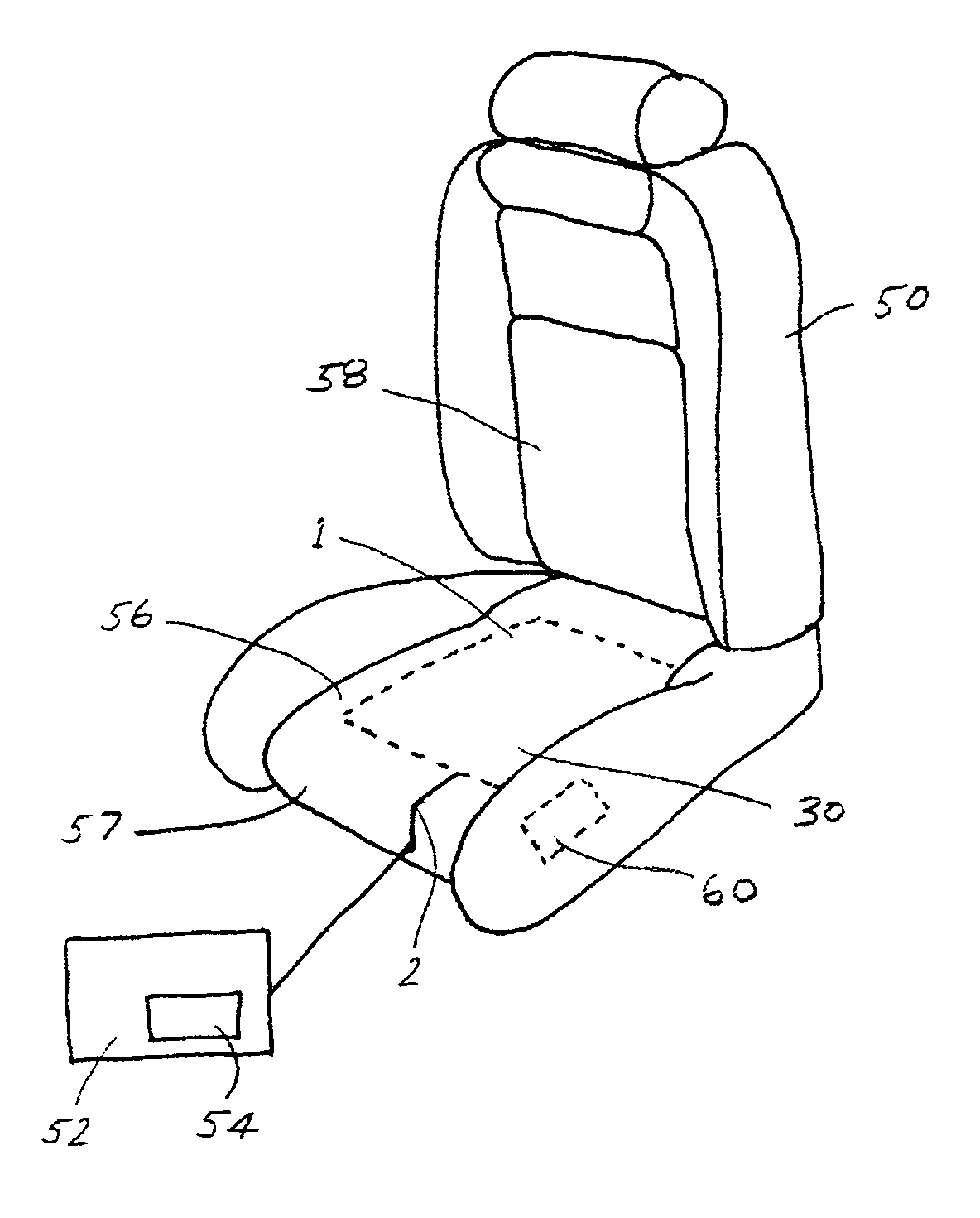

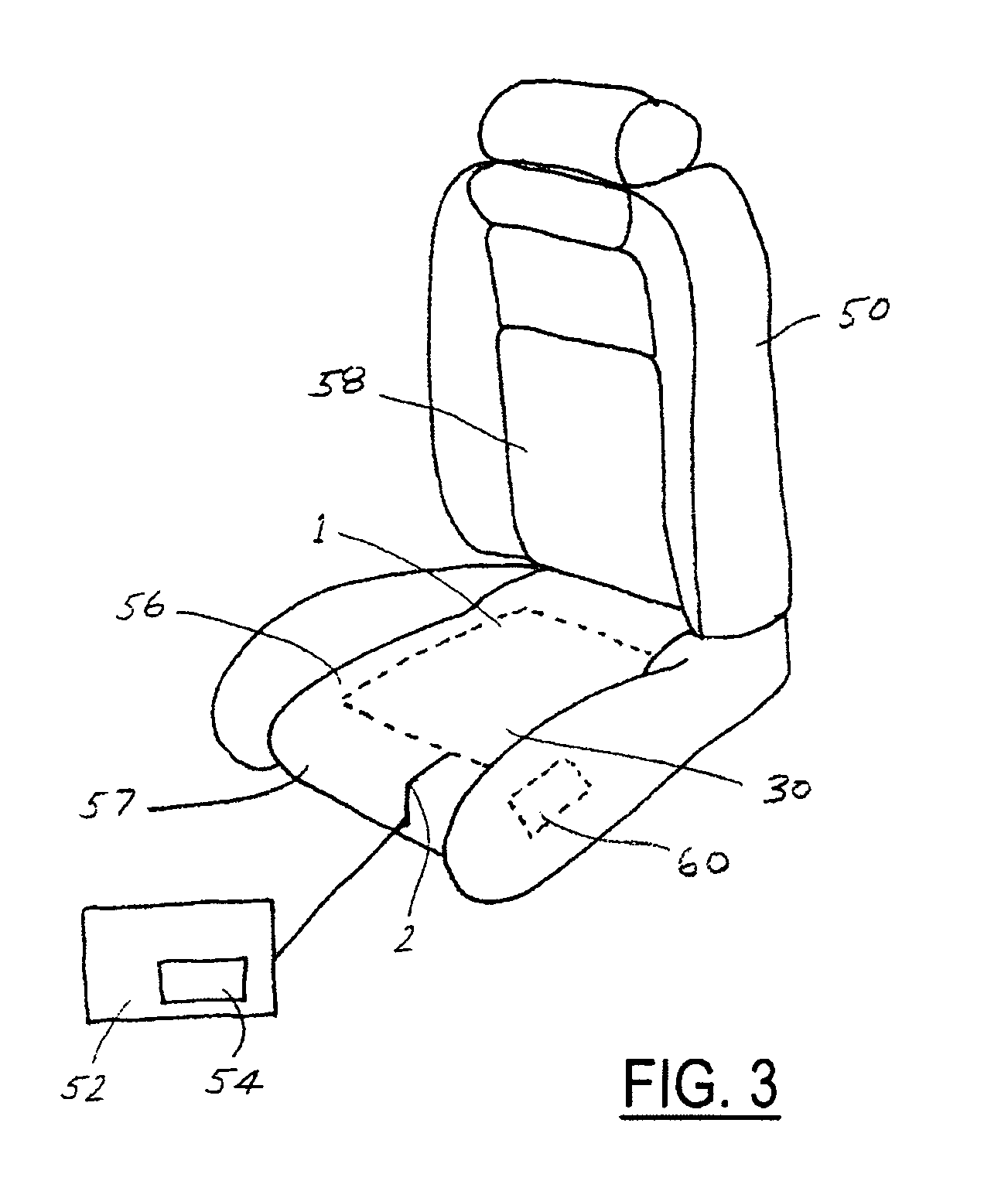

Electrically conductive textiles for occupant sensing and/or heating applications

InactiveUS20140246415A1Maximum of passenger comfortMaximum of operational safetyVehicle seatsOhmic-resistance heating detailsConductive textileElectrical and Electronics engineering

A flexible heater and / or electrode comprises a woven textile material having a warp direction and a weft direction, said textile material comprising at least one region having a low electrical conductance and at least two regions having a high electrical conductance. The at least two regions of high electrical conductance are adjacent to said at least one region of low electrical conductance. At least one of said at least two regions of high electrical conductance is operatively connected to a connection terminal of said heater and / or electrode, said connection terminal for connecting said heater and / or electrode to an electronic control circuit.

Owner:IEE INT ELECTRONICS & ENG SA

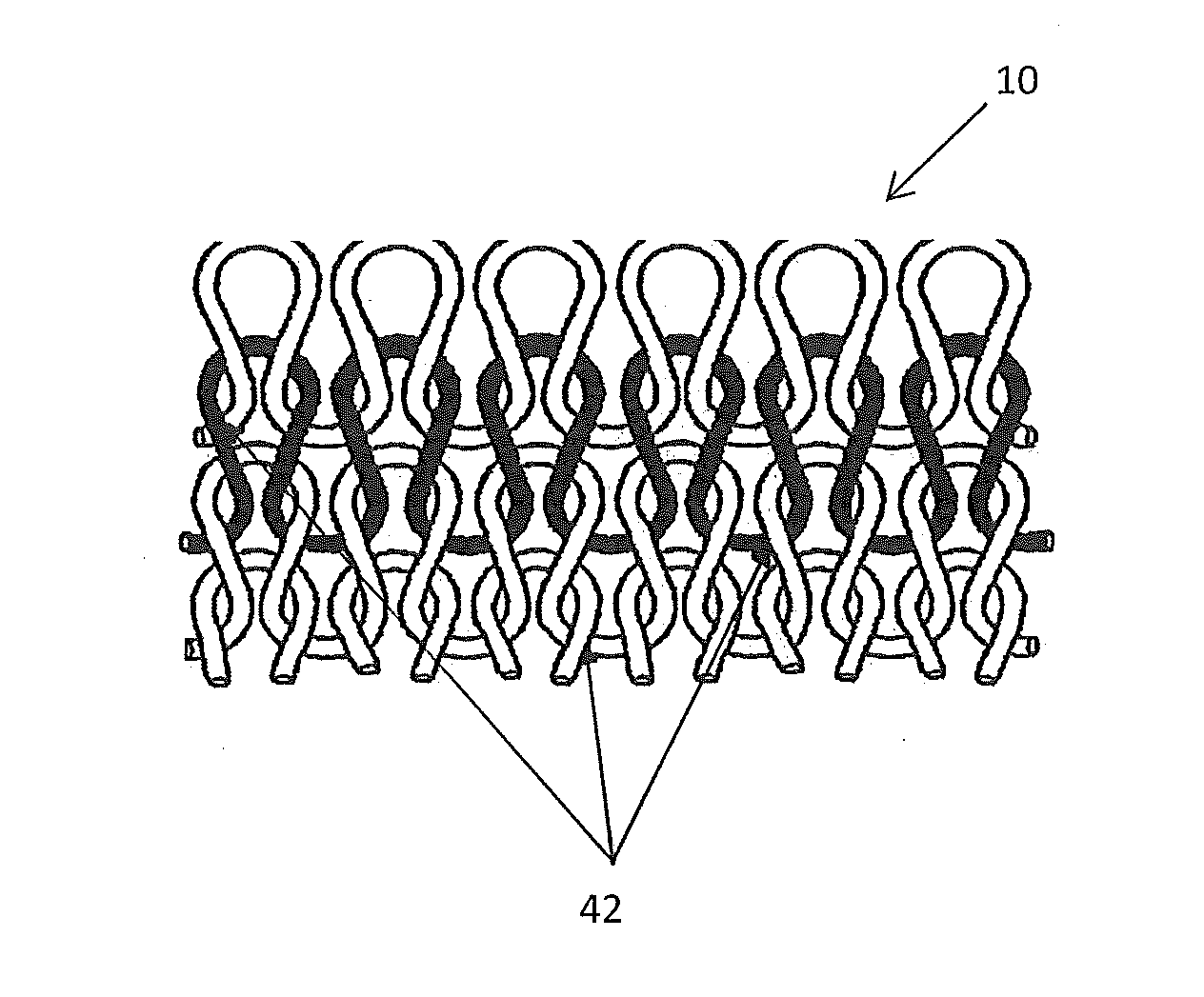

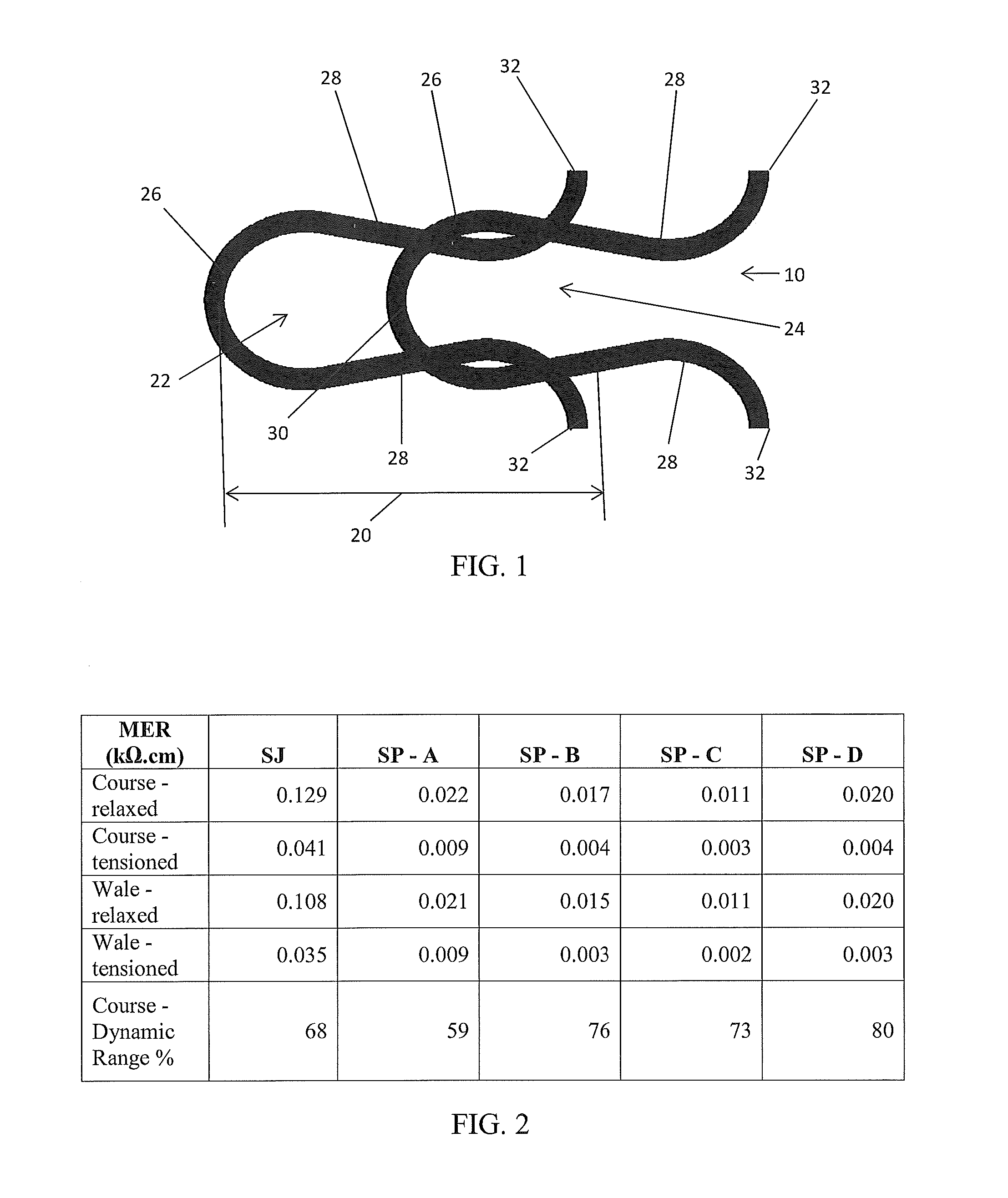

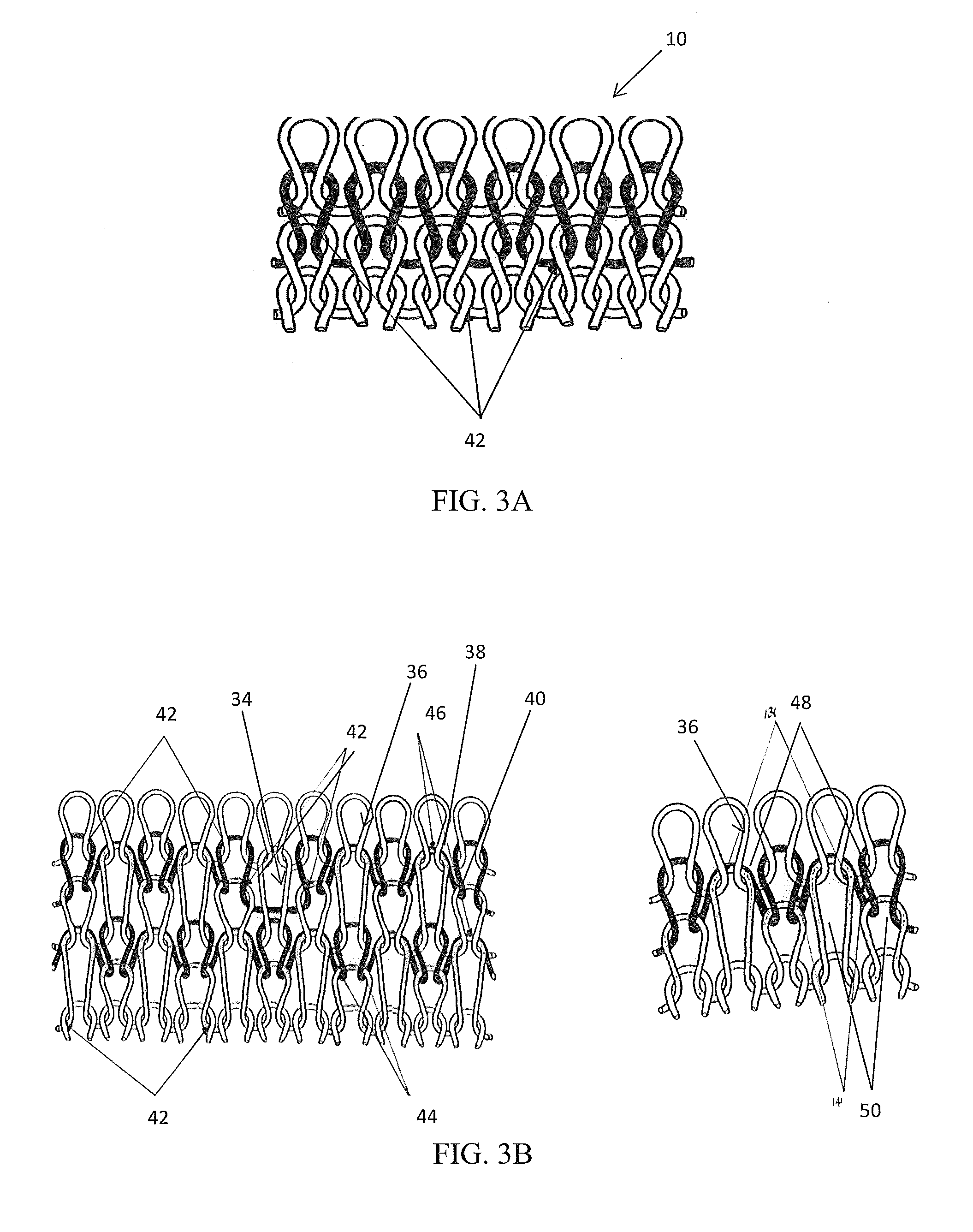

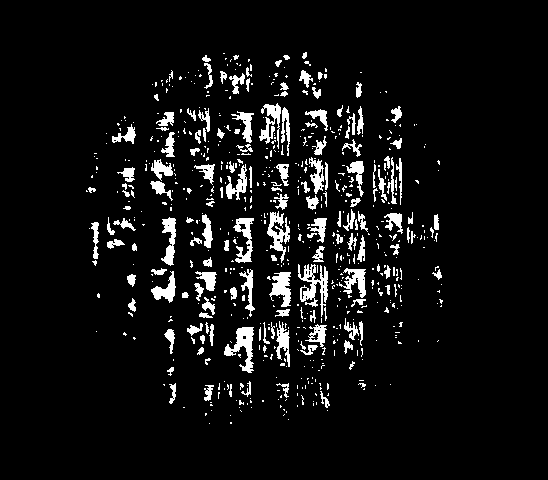

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

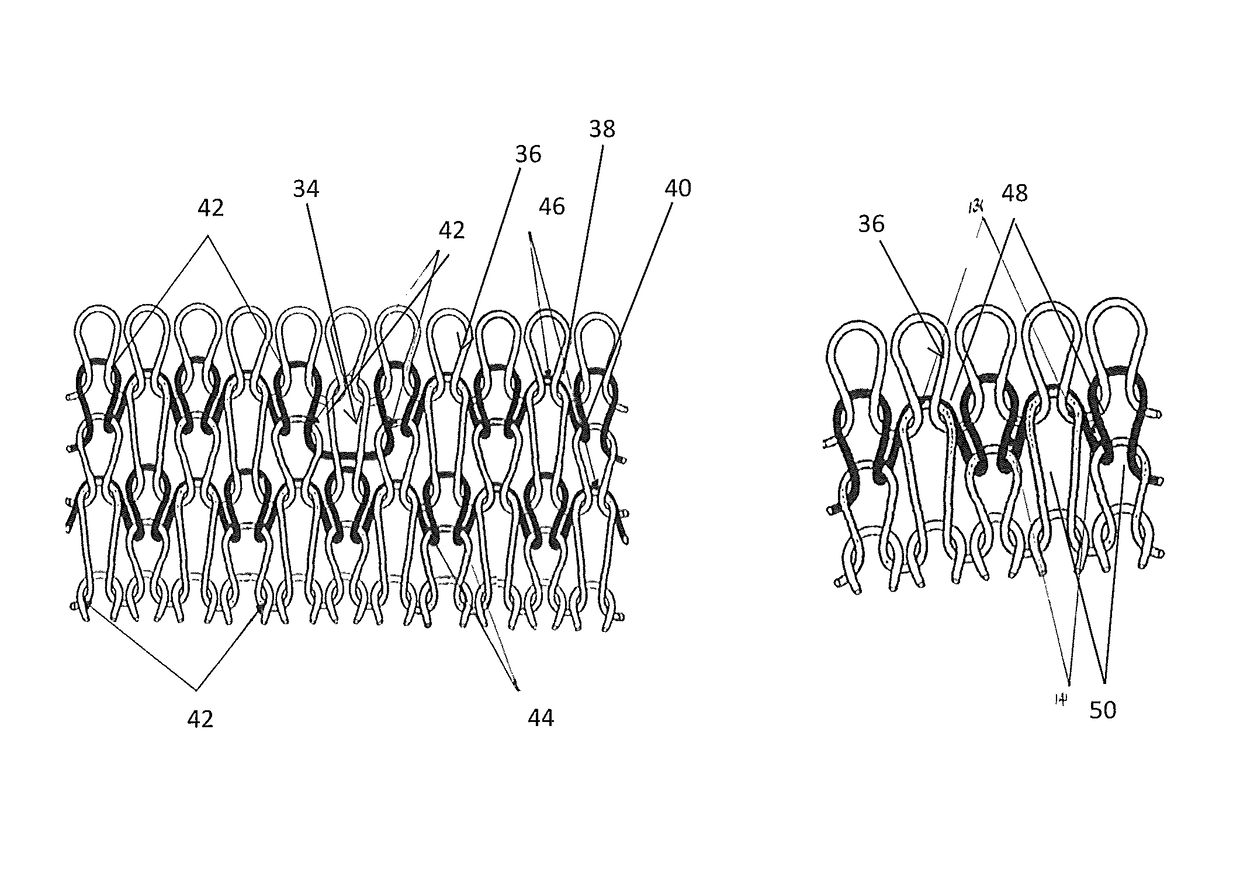

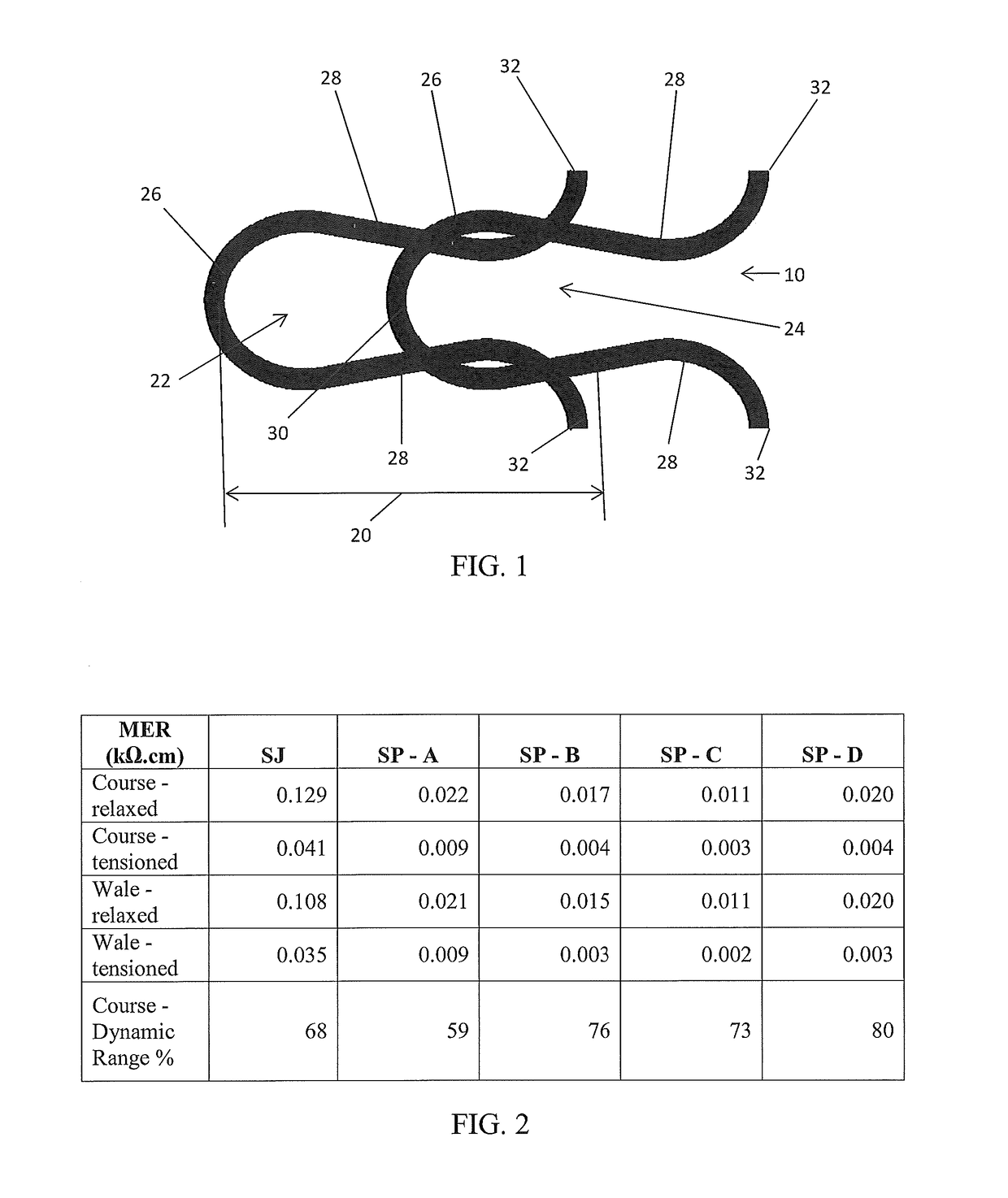

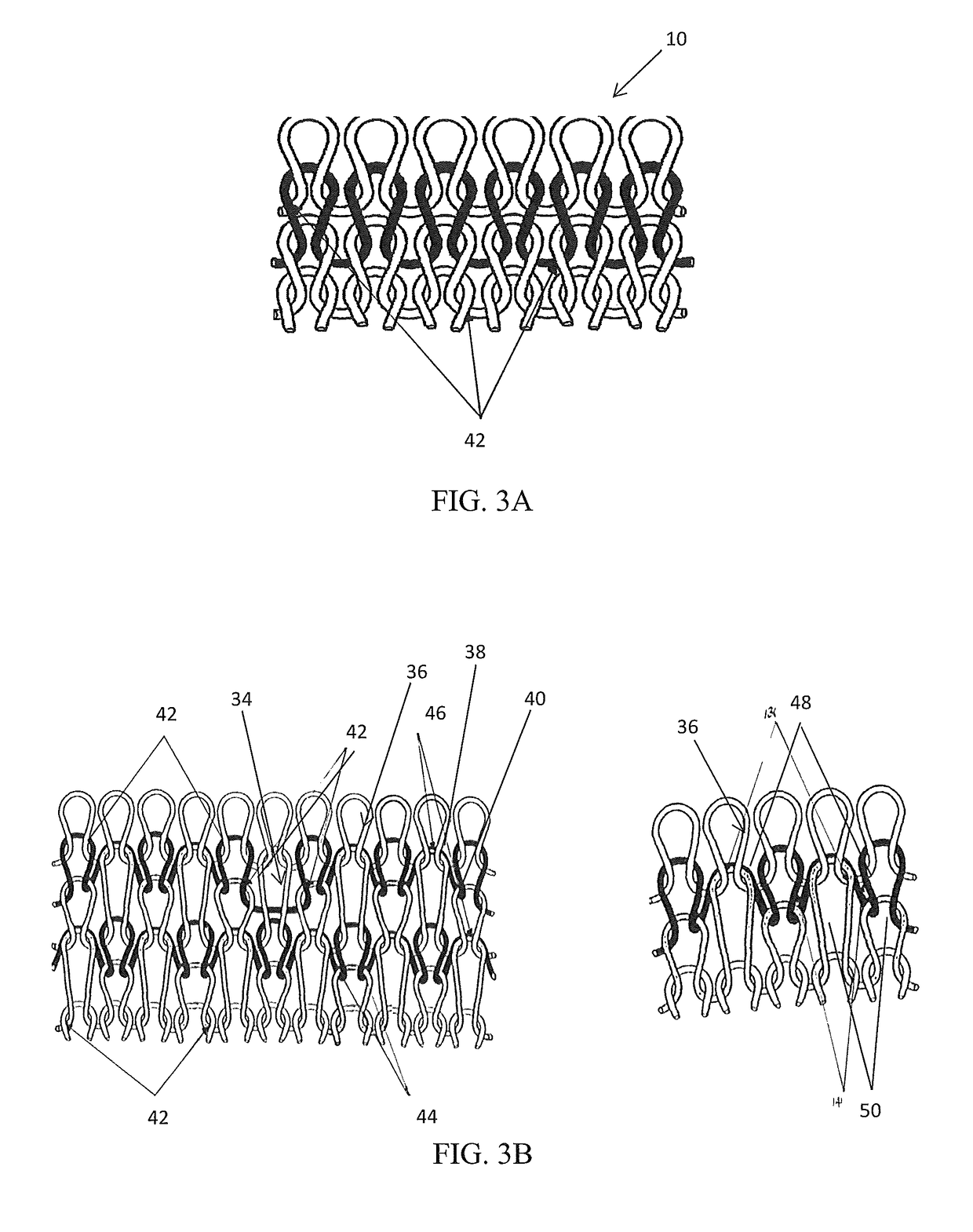

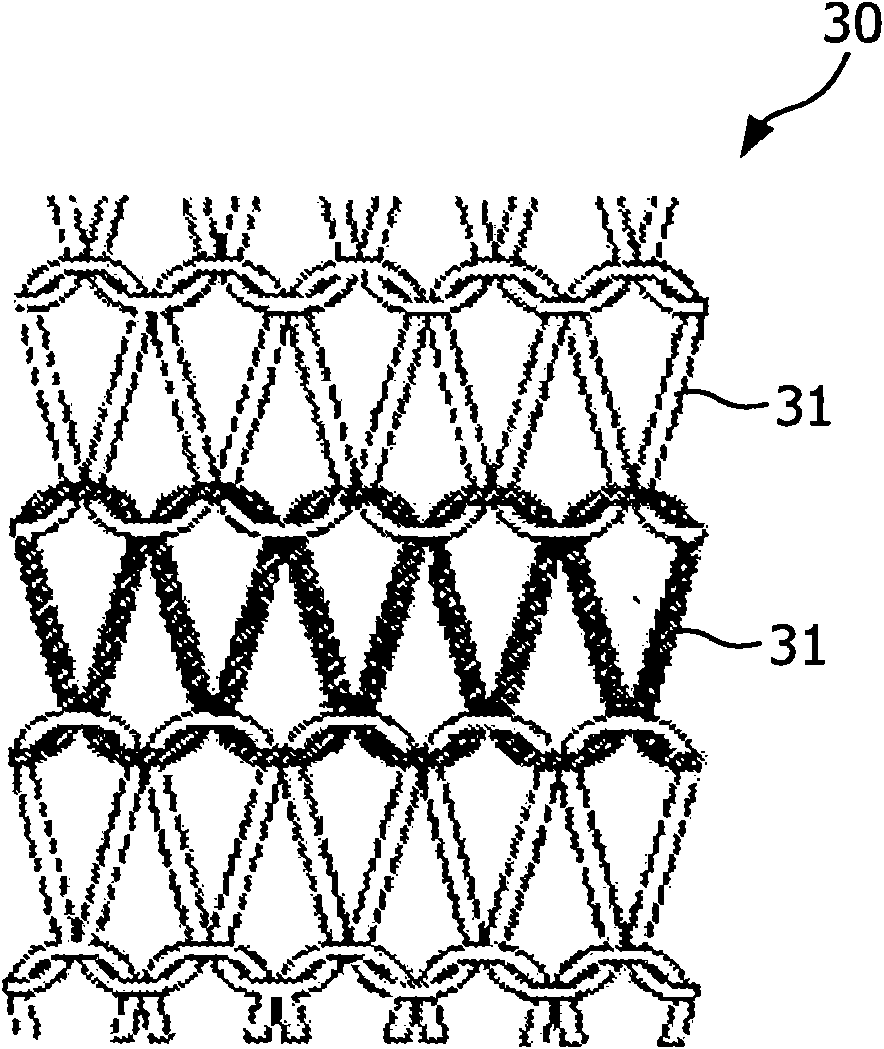

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

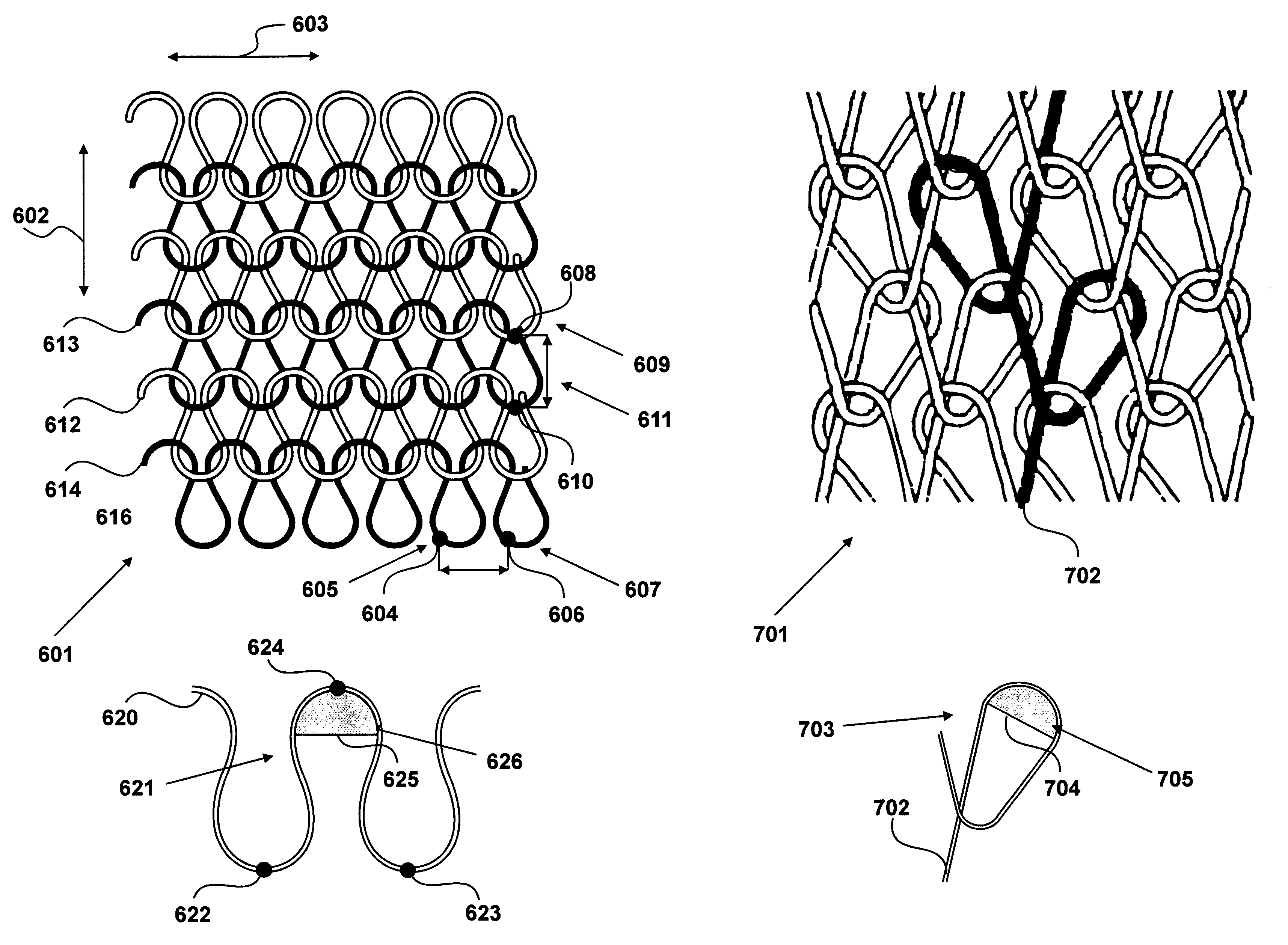

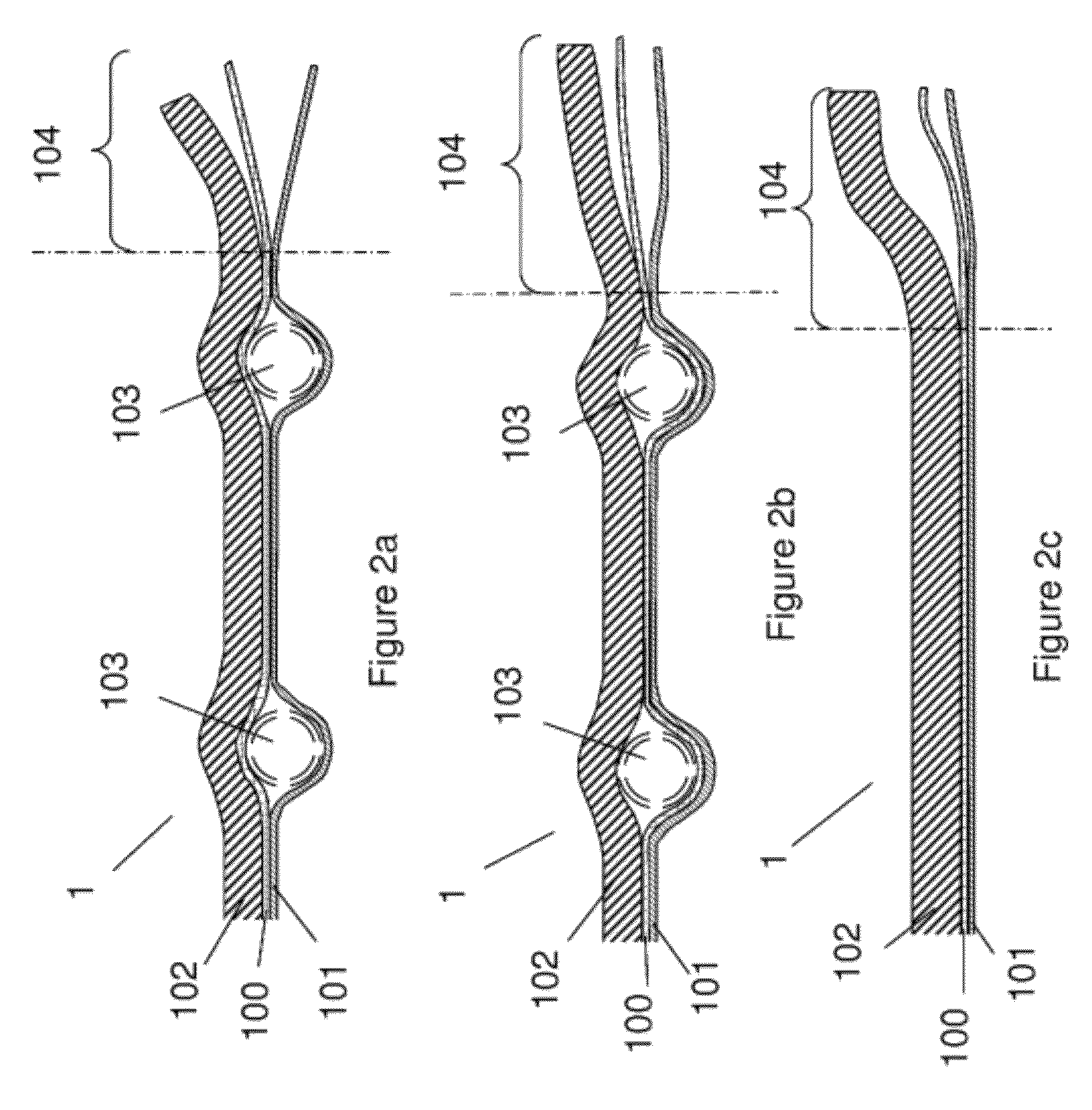

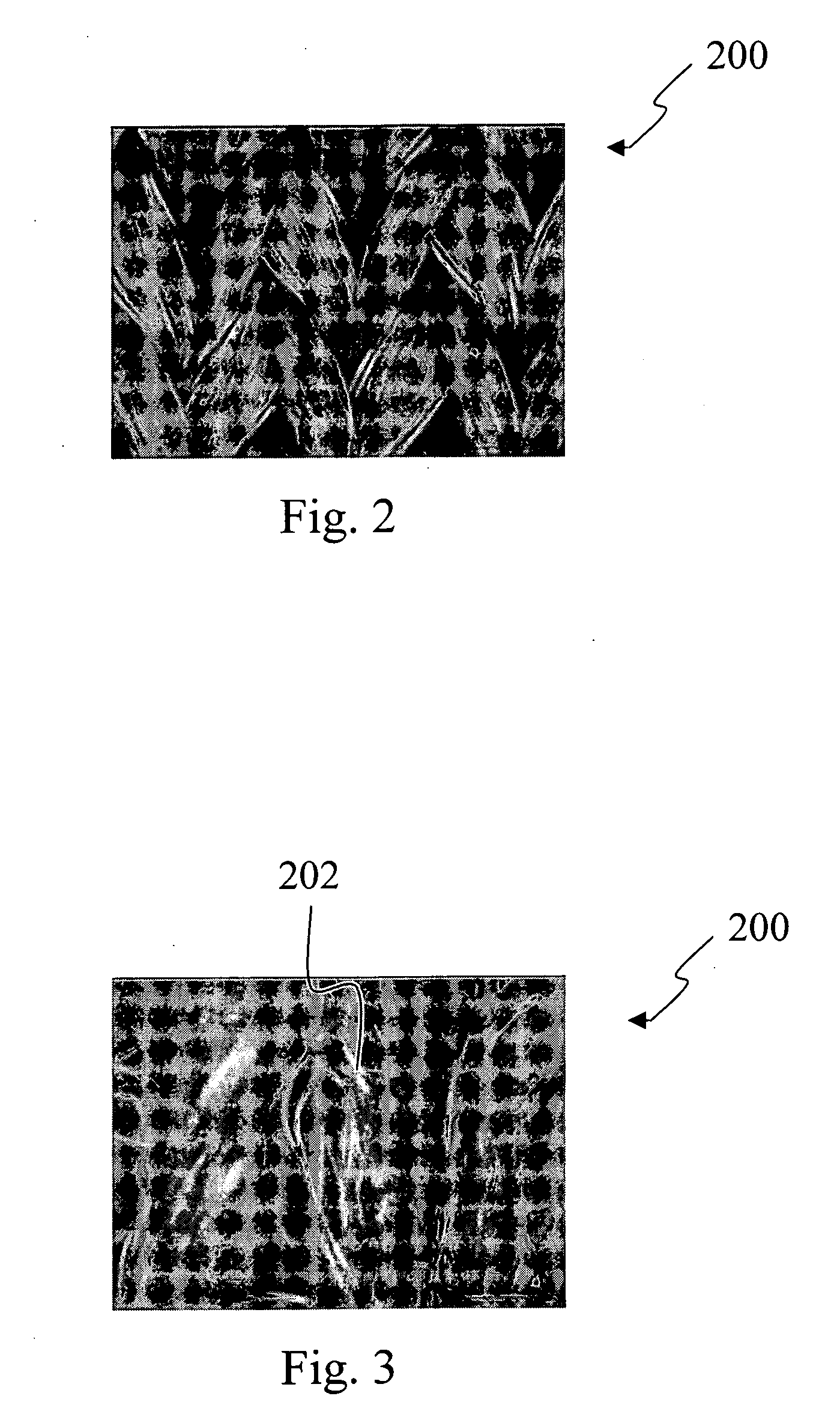

Knitted sensor

A sensor having a three layer construction comprising a first knitted conductive textile plane, a second conductive textile plane and an intermediate separating plane penetrable by the first knitted conductive textile plane to allow the first conductive textile plane and the second conductive textile plane to make electrical contact under a mechanical interaction. The intermediate separating plane defines structural endpoints from which the first knitted conductive textile plane deforms towards the second conductive textile plane under a mechanical interaction. The first knitted conductive textile plane has conductive yarn knitted to form a repeating pattern of stitches each comprising a stitch looping portion SLP having a looping portion footprint LPF. Within the sensor, there is at least one of a plurality of described dimensional relationships between stitches of the first knitted conductive textile plane and structural endpoints of the intermediate separating plane.

Owner:WEARABLE TECH LTD

Textile Electrode

The present invention is related to a textile electrode (1) for measuring an electrical signal from a body part, said electrode comprising, successively from the side to be applied on the body part to the outside: a conductive textile contact (3) to be applied to said body part; a textile support (2) for supporting said textile contact (3); a vapour barrier sheet material (7) able to reduce, in use, evaporation of liquid from said textile electrode (1).

Owner:CECOTEPE ASBL

Electronic stimulation textile for traditional chinese medicine therapy

A textile for providing traditional Chinese medicine therapy to a wearer using electronic stimulation includes at least two conductive paths that are made from conductive textile material, the conductive paths are separated by nonconductive textile material, at least one pair of electrodes attach to the conductive paths corresponding to specific part of body or acupoints according to traditional Chinese medicine theory, and an electronic stimulation signal controller configured to conduct electronic stimulation signals to the electrodes via the conductive paths.

Owner:THE HONG KONG POLYTECHNIC UNIV

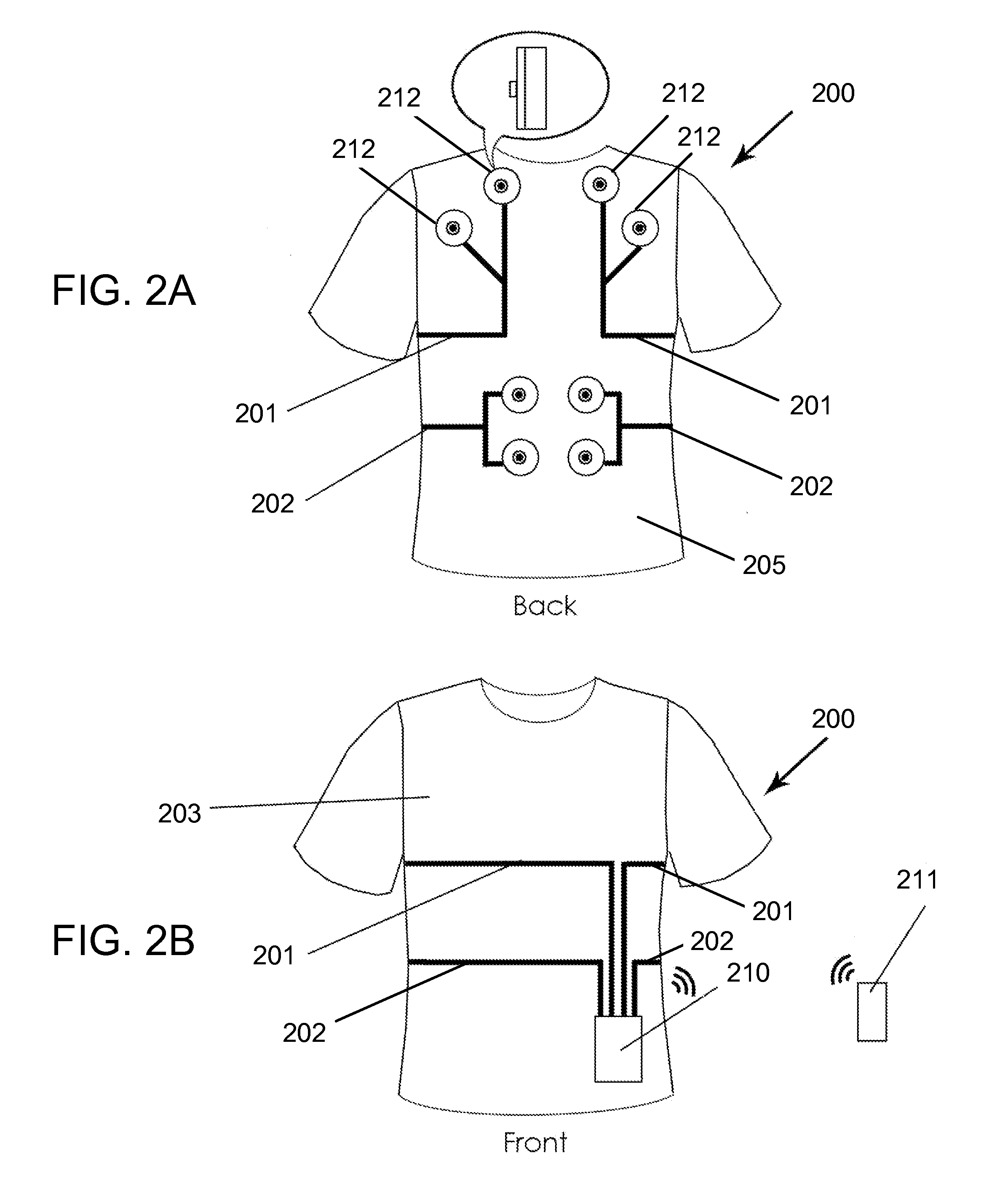

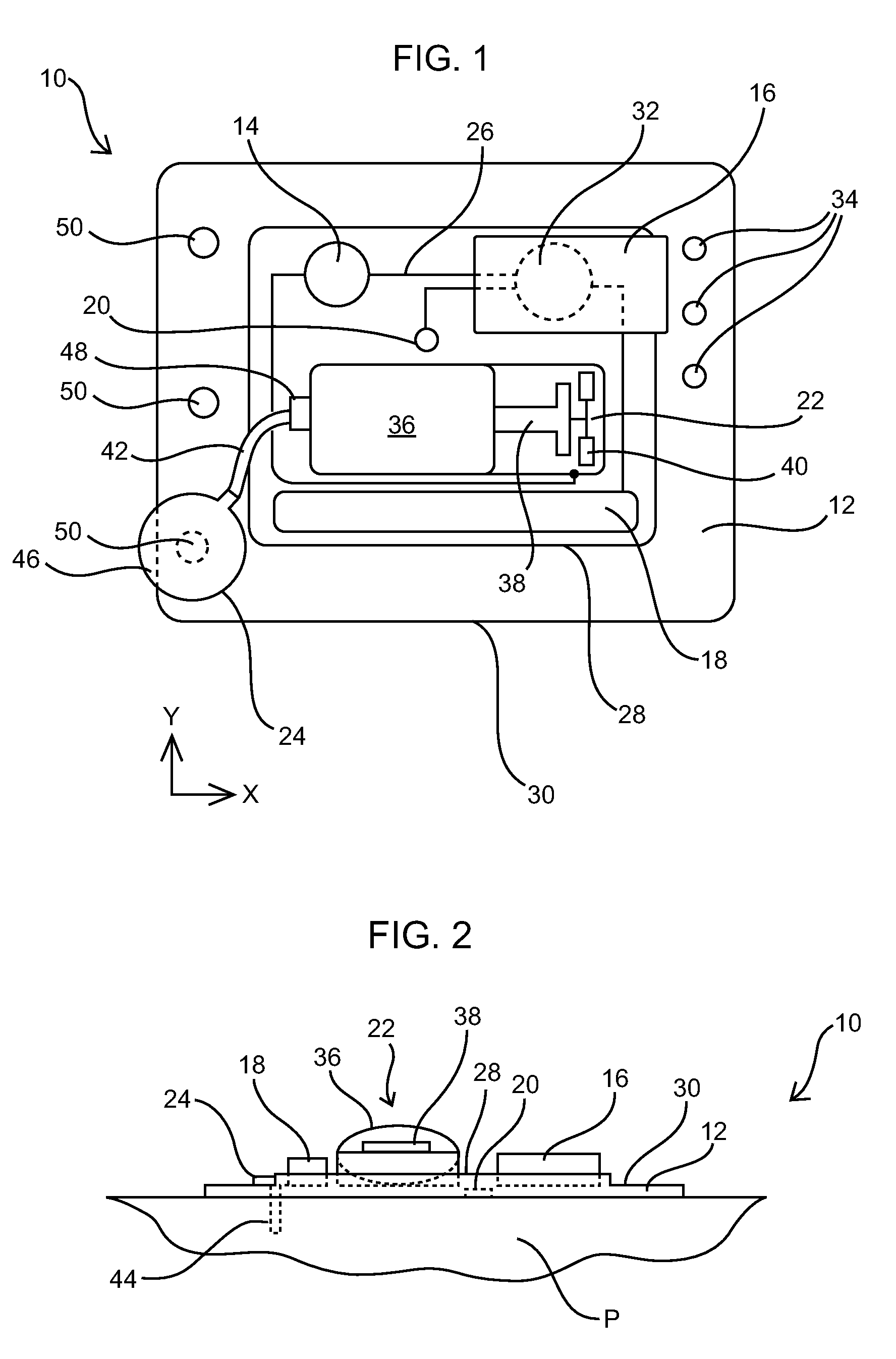

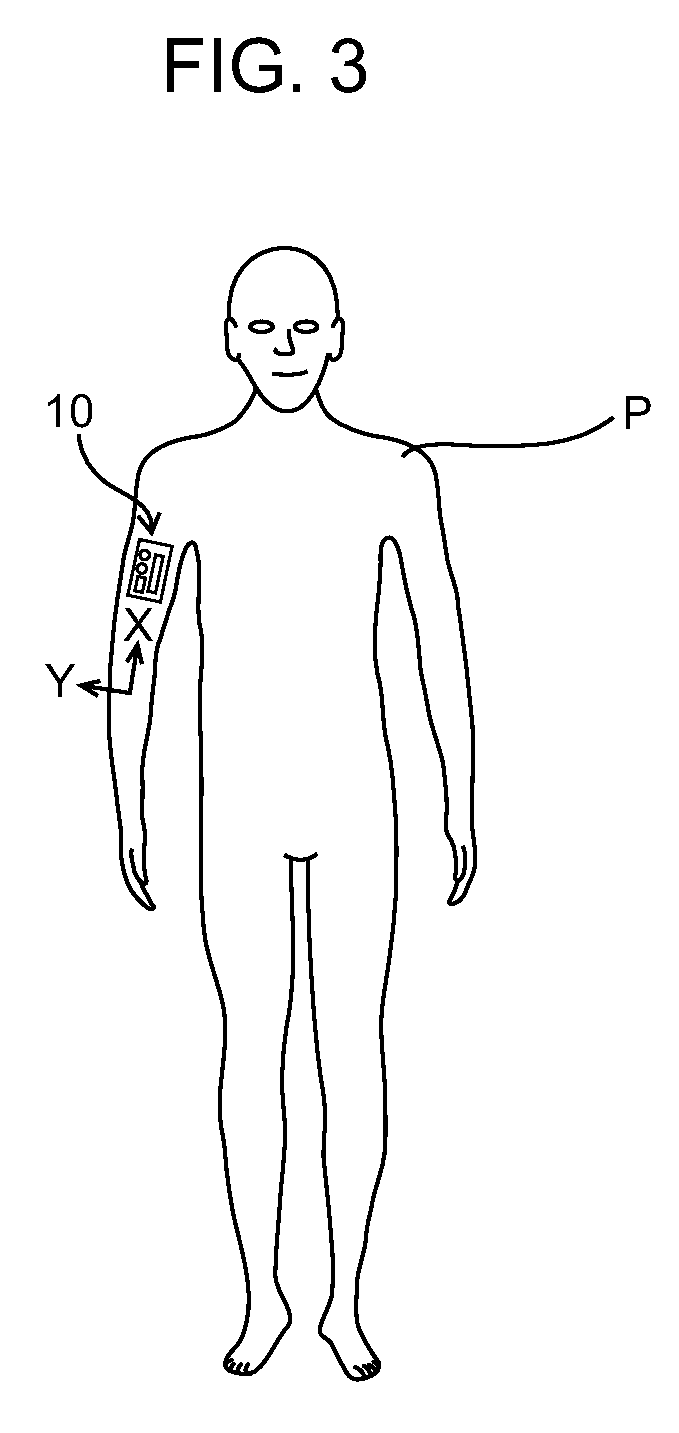

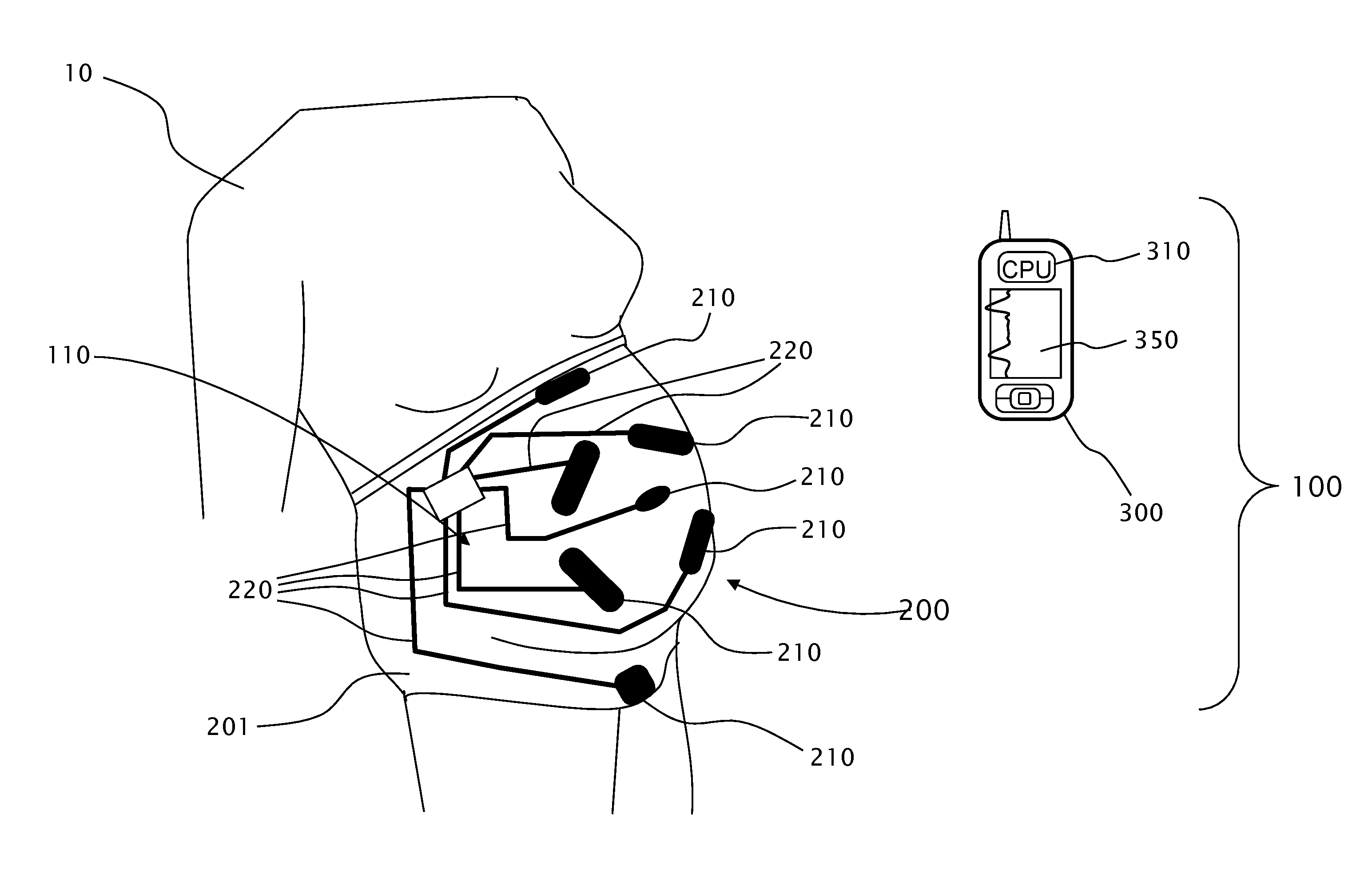

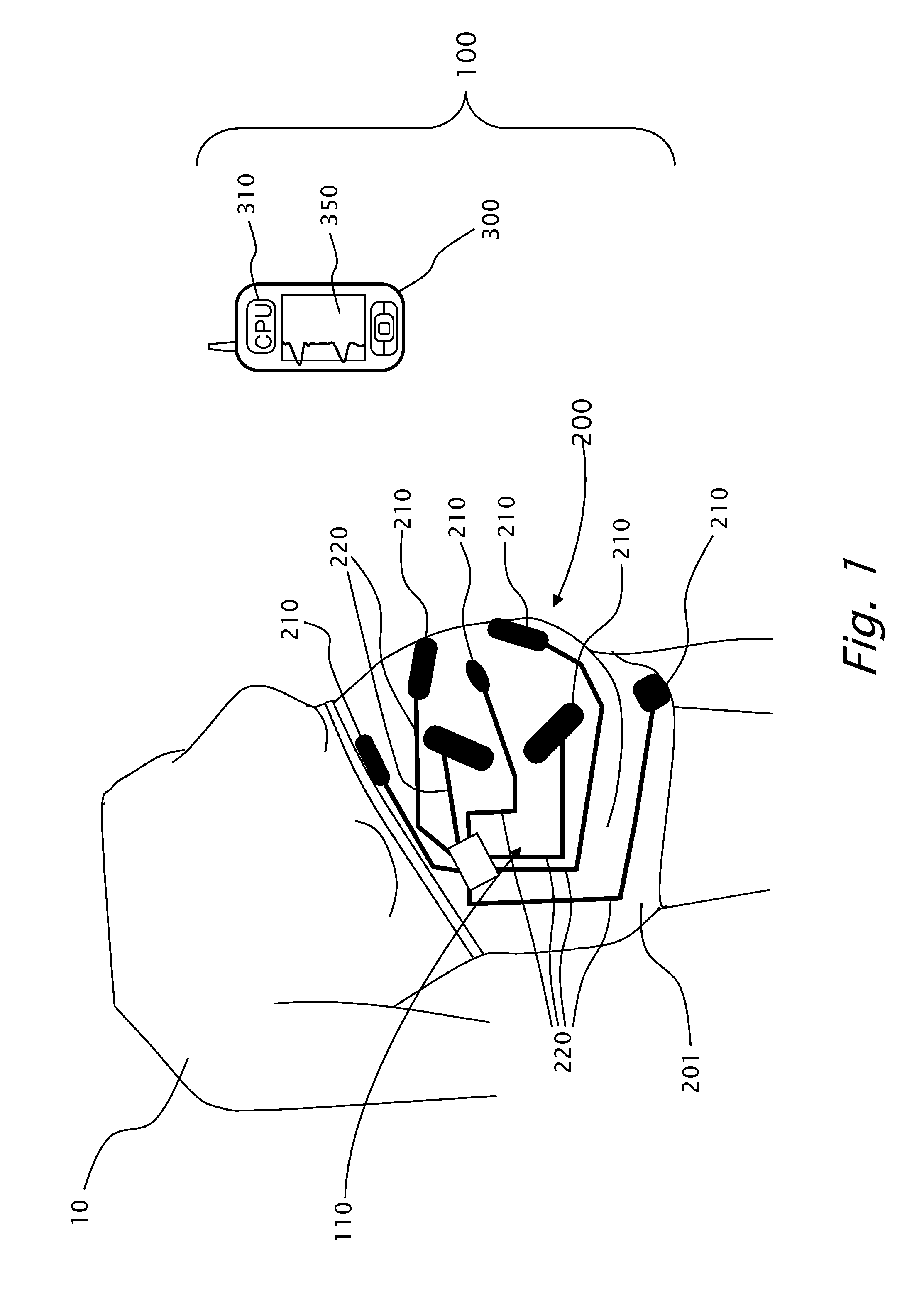

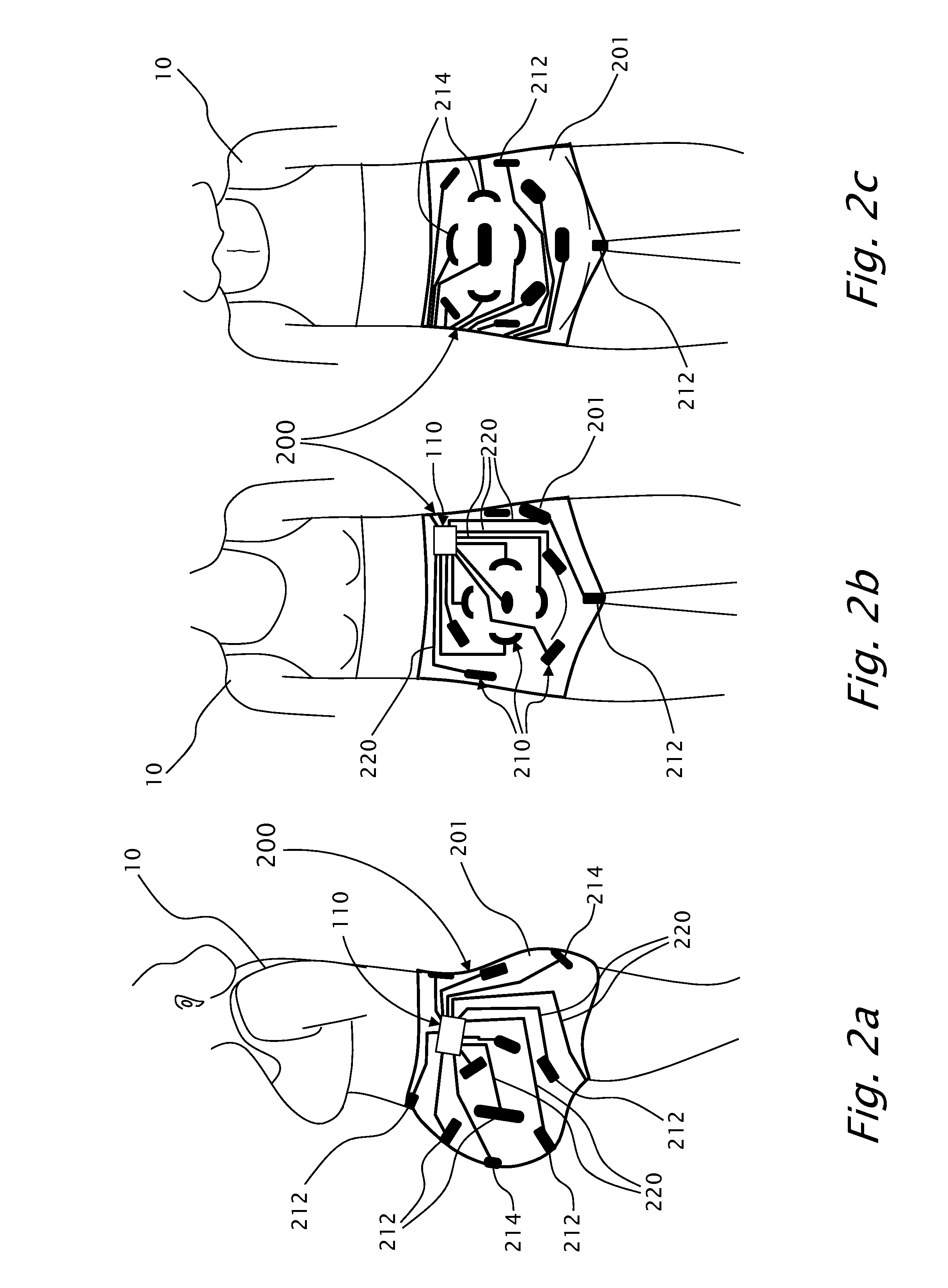

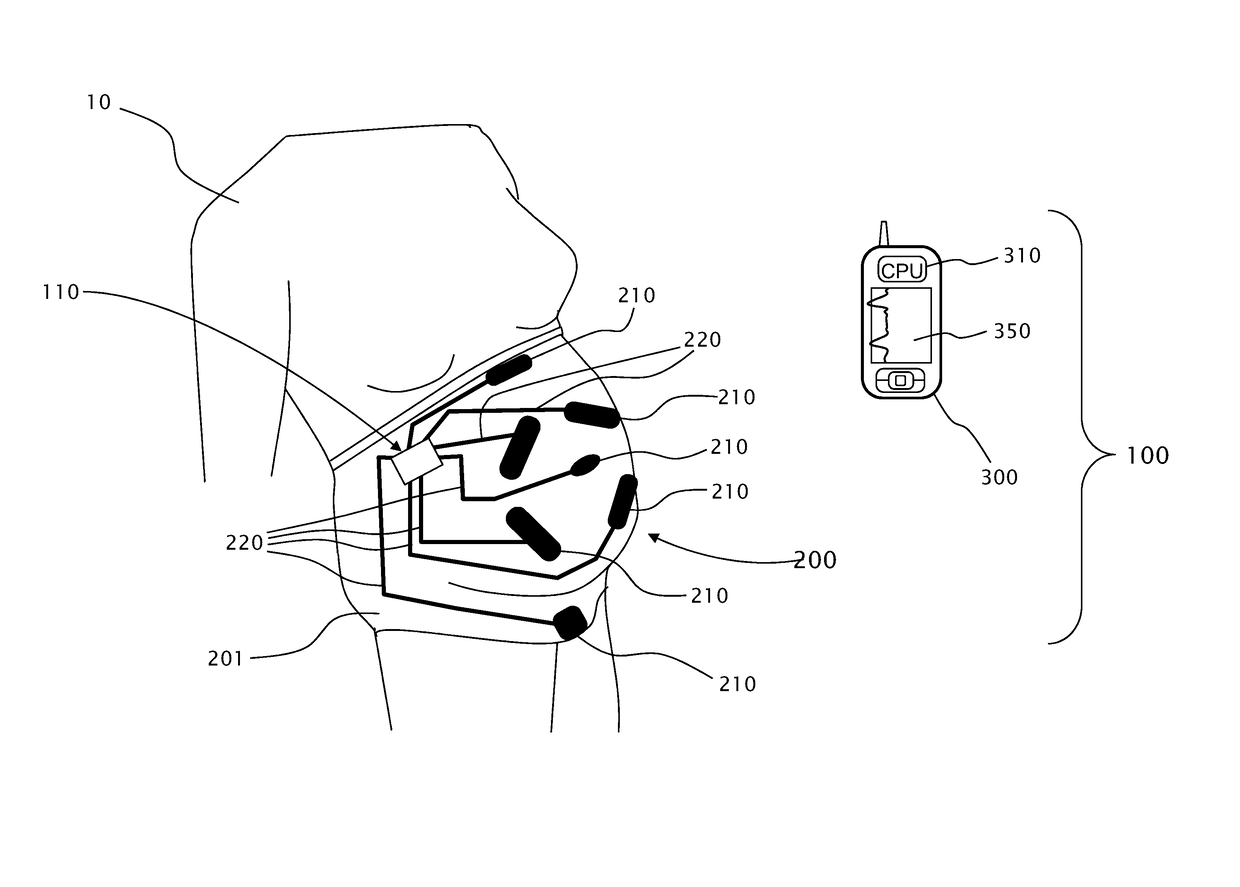

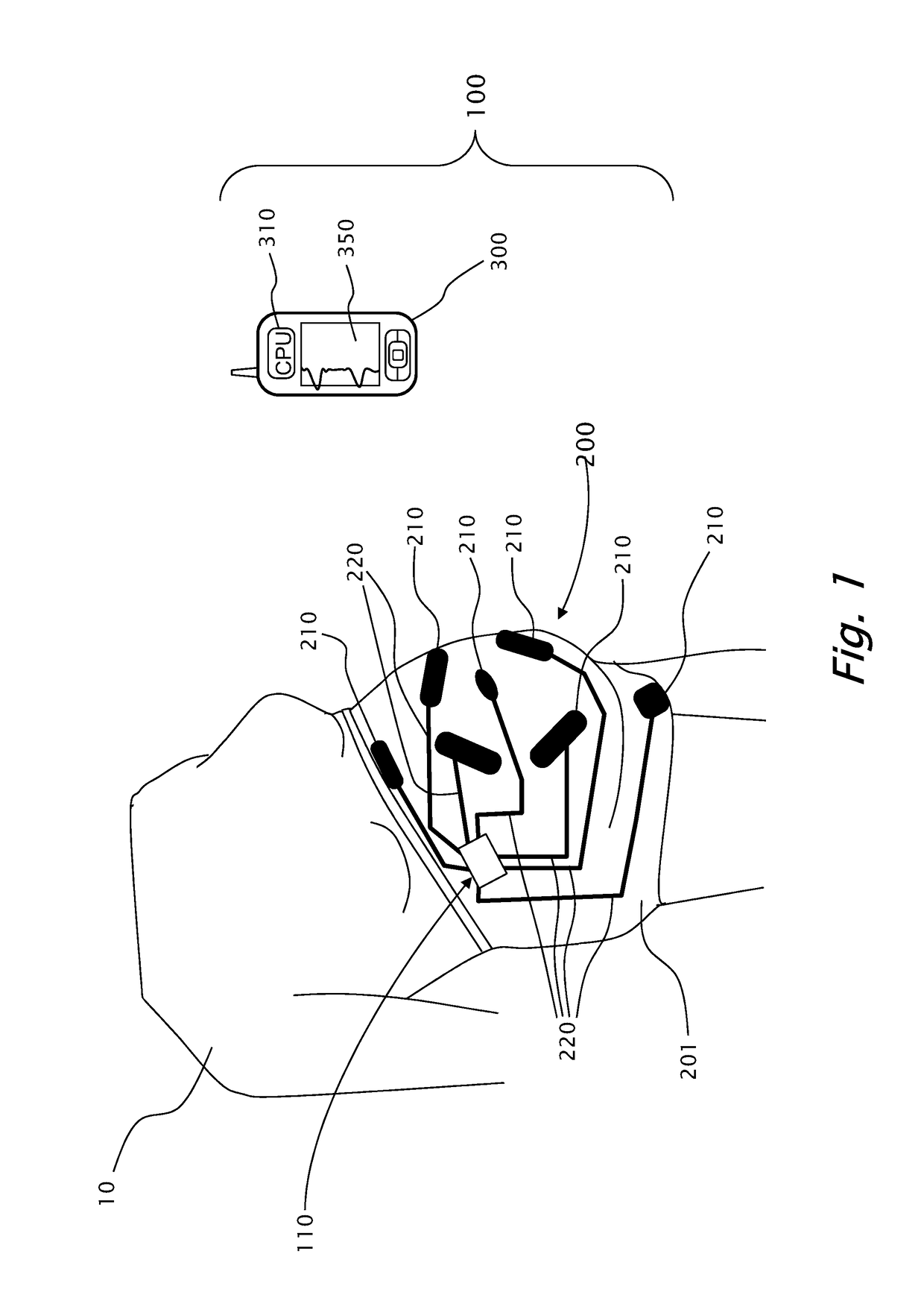

Flexible Patch for Fluid Delivery and Monitoring Body Analytes

InactiveUS20120190952A1Comfortable to useConstructed enoughMedical devicesCatheterConductive textileAnalyte

A wearable, conductive textile patch is provided that may include any of a number of features for monitoring body analytes and / or delivering fluids to a body. In one embodiment of the invention, a single, patch-mounted system monitors glucose levels of a diabetic person and provides appropriate doses of insulin in response to the glucose measurements. A hand-held user interface can be provided for wirelessly controlling the system and / or receiving information from it. Conductive pathways can be formed in the fabric of the patch. Components that can be integrated into the flexible patch include a power source, controller, transmitter, antenna, temperature and other sensors, fluid pump, infusion set, electrical pathways, switches, controls, electrodes, connectors, resistors and other circuit elements. Such components can be embedded, interwoven or coated on to the flexible patch instead of or in addition to surface mounting. Methods associated with use of the flexible patch system are also covered.

Owner:ABBOTT DIABETES CARE INC

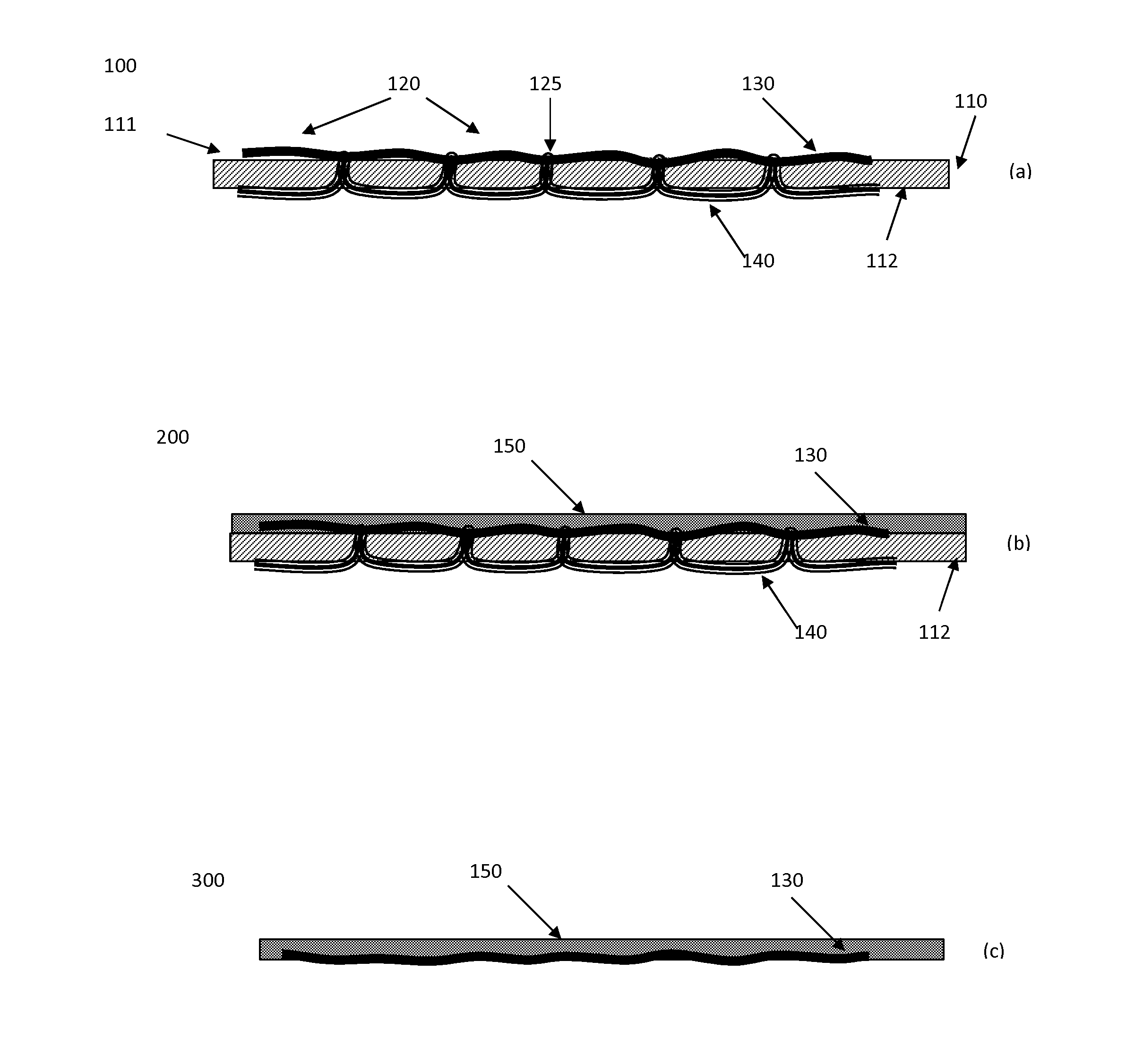

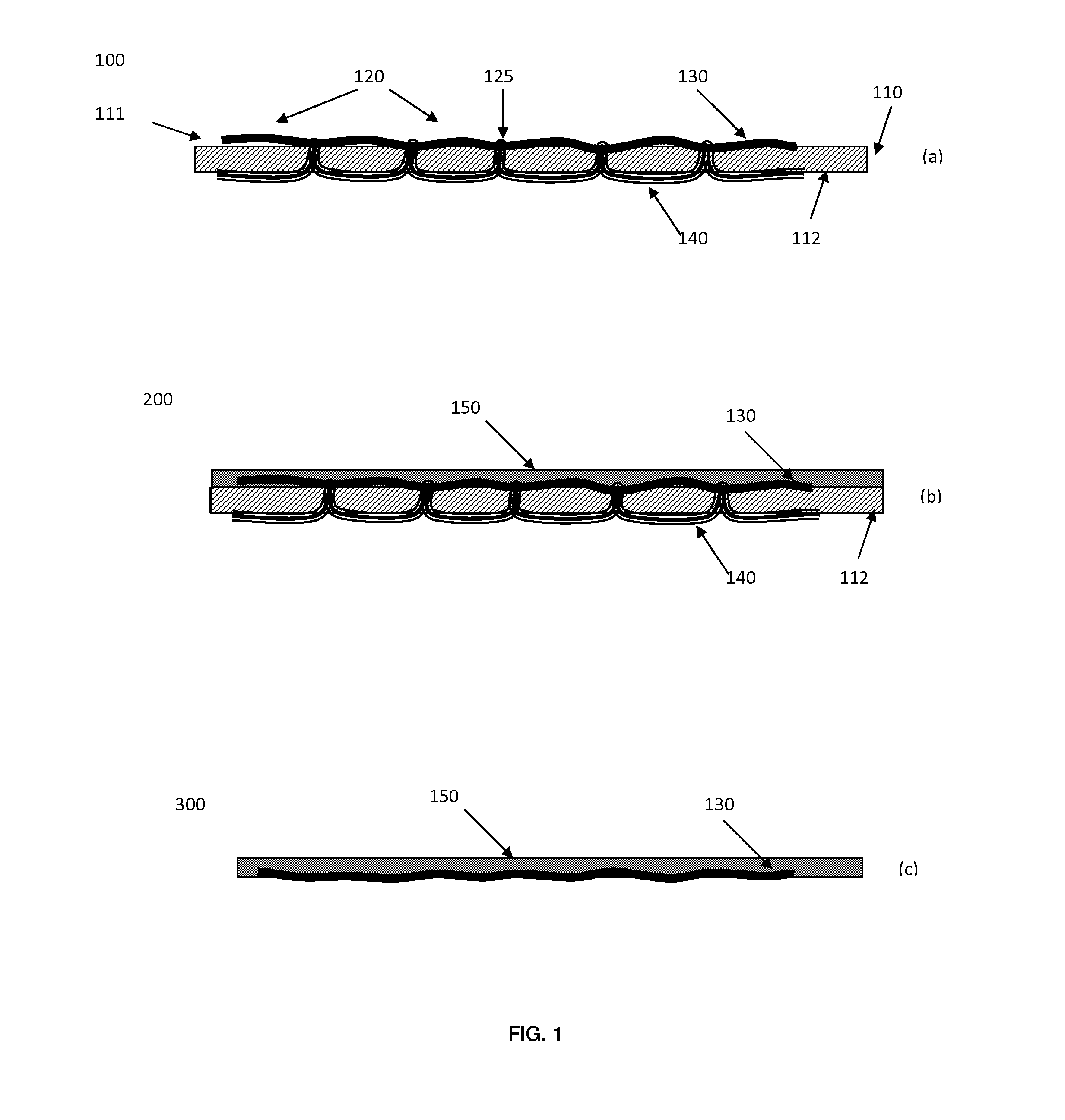

Flexible conducting materials and methods for the manufacture thereof

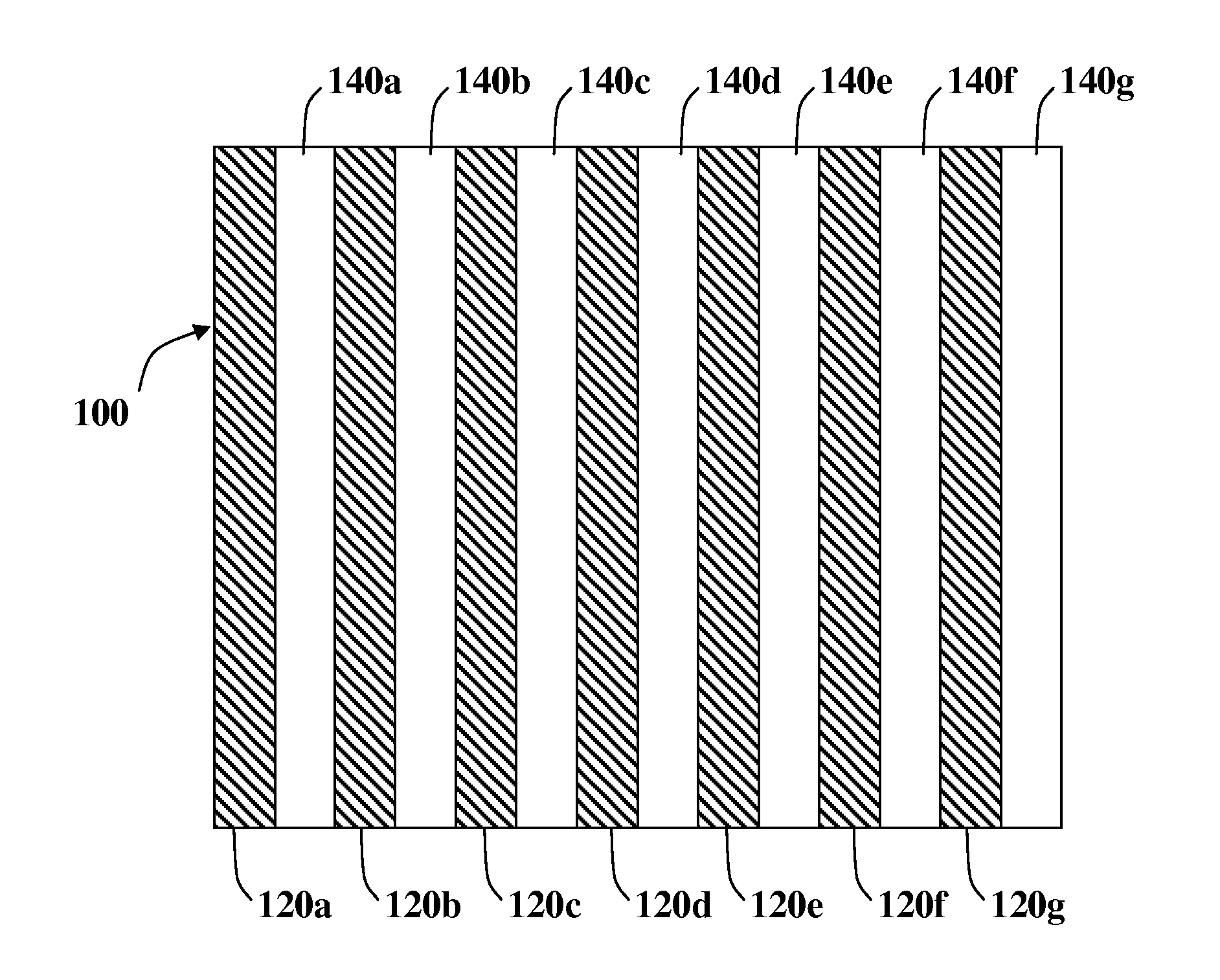

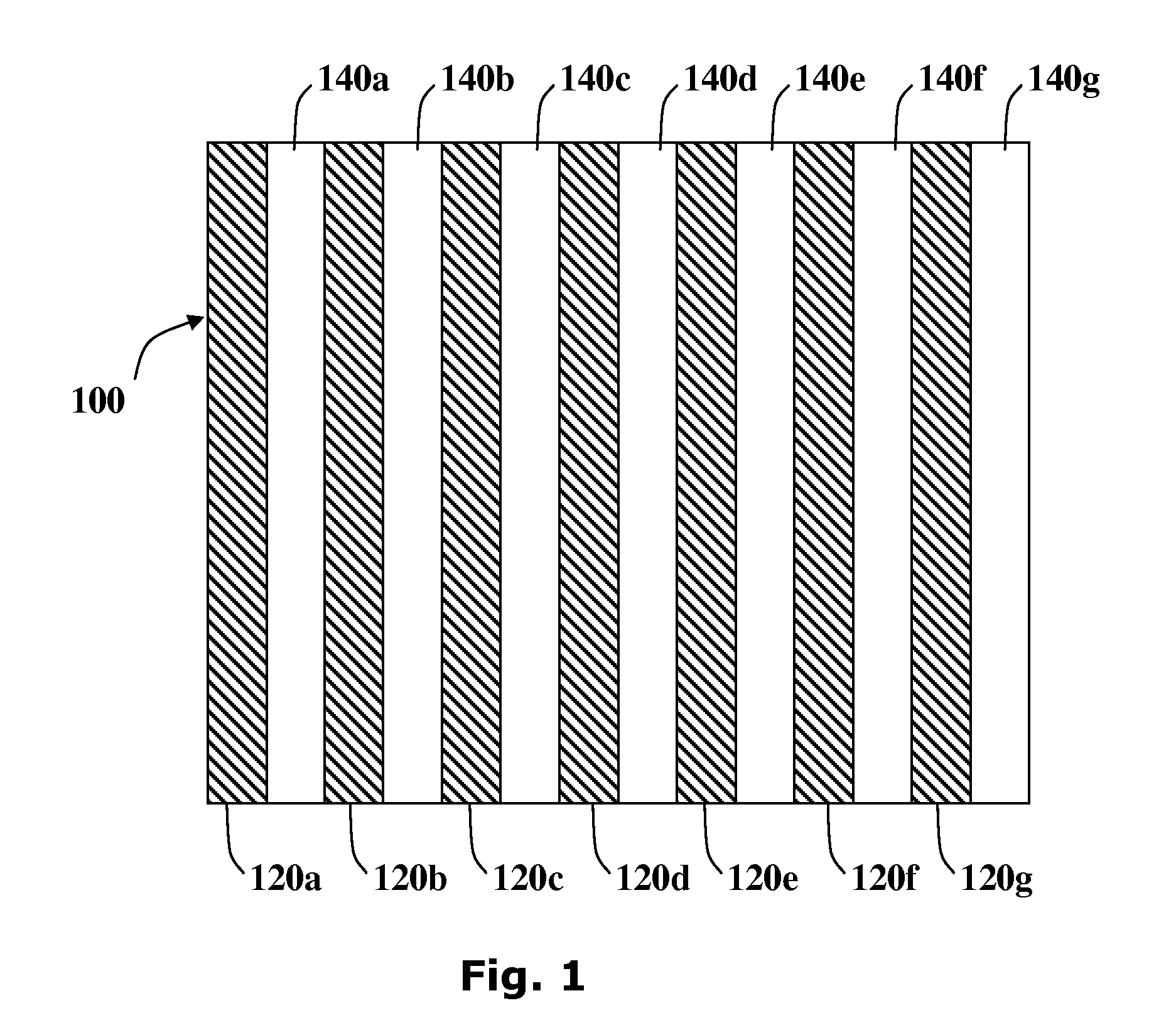

InactiveUS20150294756A1Conductive layers on insulating-supportsLayered productsYarnConductive textile

A flexible conductive material may be a selectively conductive textile fabricated by intertwining yarns having different affinities to conductive impregnation. Another flexible conductive material may be formed from an array of conductive elements connected via sinuous connecting wires embedded in a flexible host material. The regions having a high conductivity may serve as conductive electrodes, for example of a pressure sensing mat.

Owner:ENHANCED SURFACE DYNAMICS

Electrically conductive textile assemblies and manufacture thereof

InactiveUS20160194792A1Less intrusiveLow costCircuit bendability/stretchabilityWeft knittingConductive textileEngineering

There is provided a method of making a conductive assembly for use in textiles, the method comprising providing a composite material comprising: a temporary substrate having a first surface and a second surface opposite the first surface; a stitching pattern comprising a plurality of lockstitches on the temporary substrate, such that a conductive thread is disposed at the first surface of the temporary substrate and a thermo-fusible thread is disposed at the second surface; and an insulating layer comprising an adhesive on top of at least part of the conductive thread on the first surface, the adhesive having an activation temperature which is higher than the Vicat softening point, as measured by method A120 of ASTM D1525, of the thermo-fusible thread; and heating the insulating layer and thermo-fusible thread to the activation temperature and curing the adhesive in the insulating layer of the composite material, thereby securing the conductive thread to the insulating layer. Articles according to the process are also provided.

Owner:MAS INNOVATION

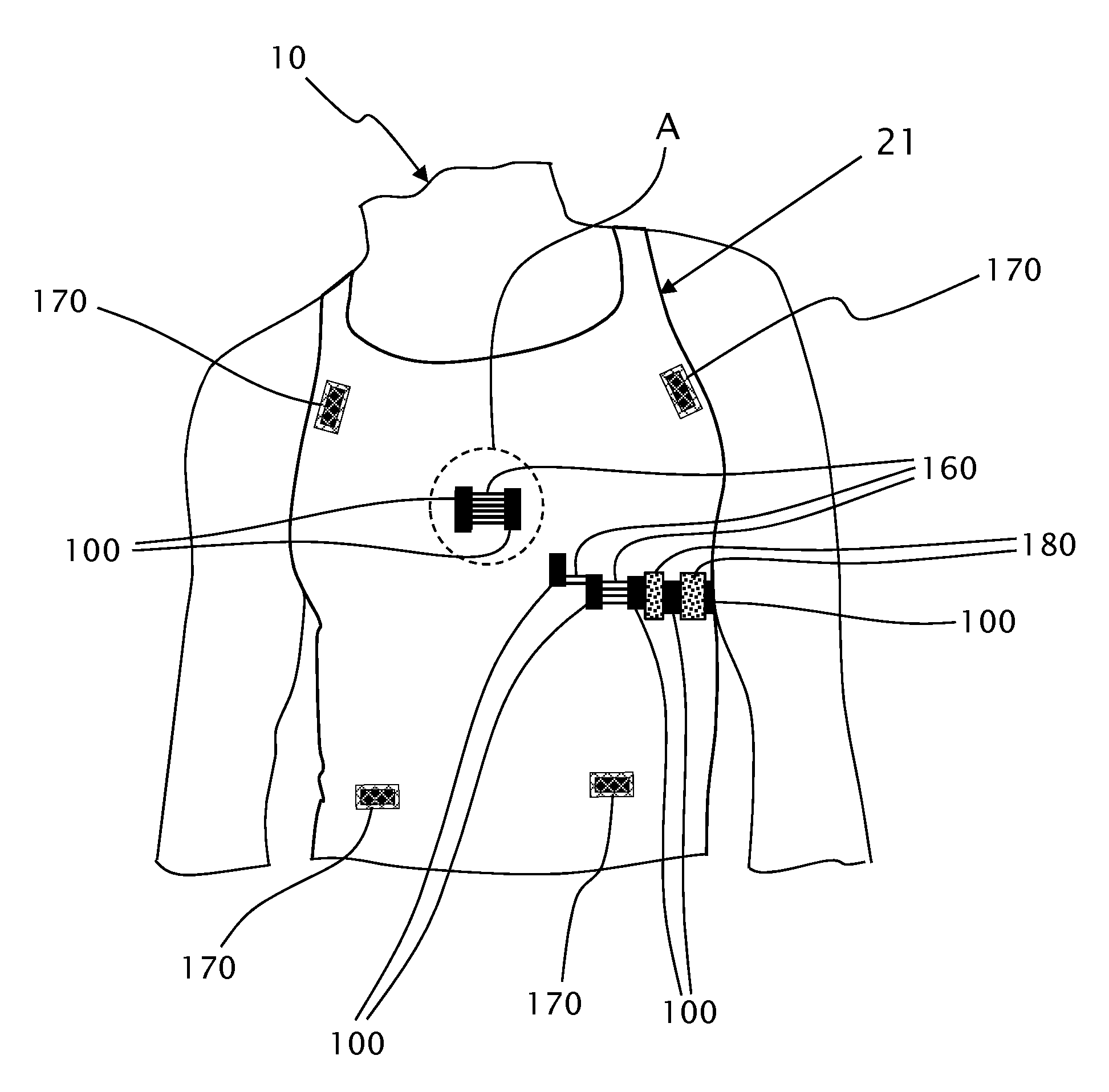

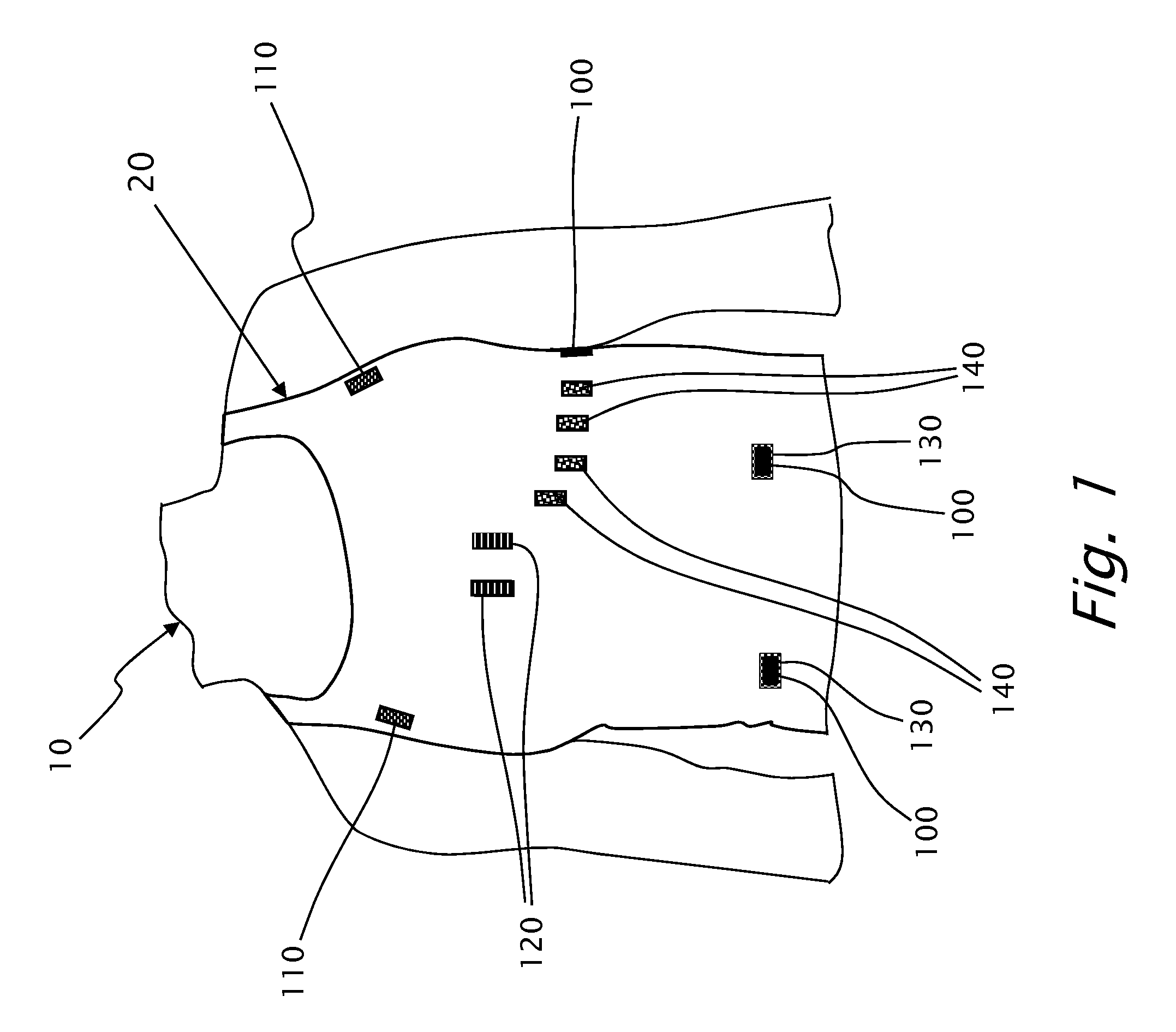

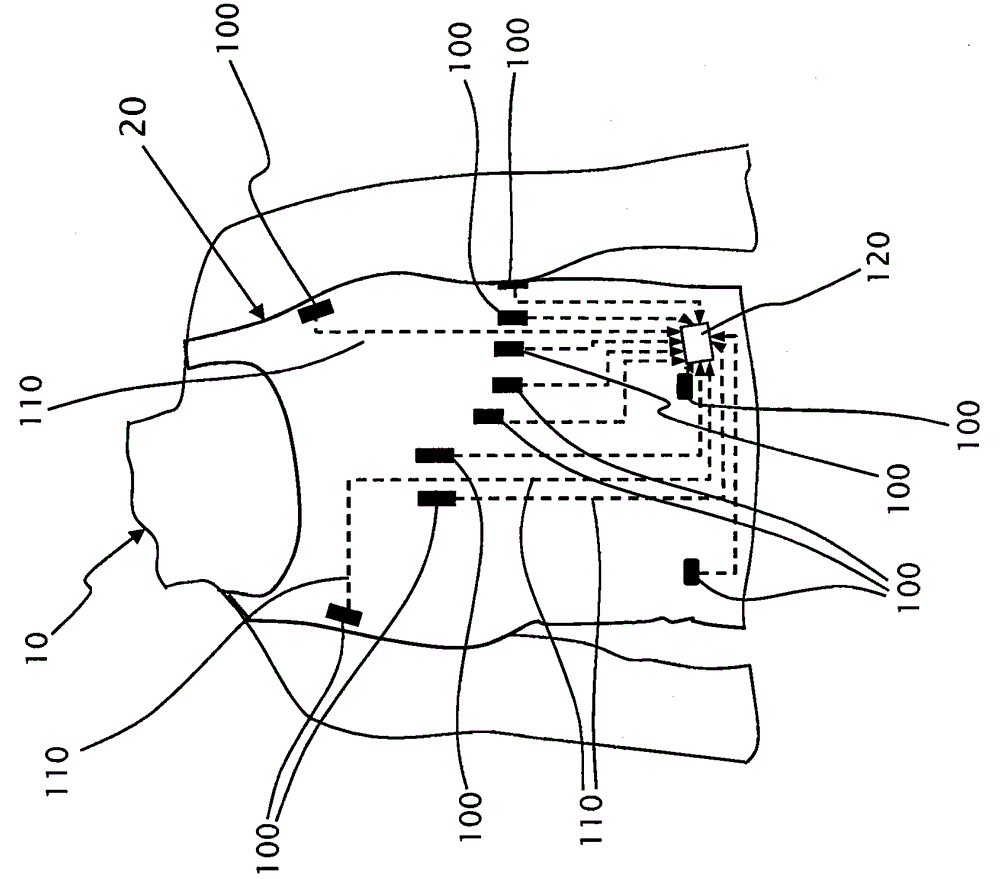

Wearable fetal monitoring system having textile electrodes

ActiveUS20160128594A1Increase the number ofElectrocardiographyElectromyographyElectricityConductive textile

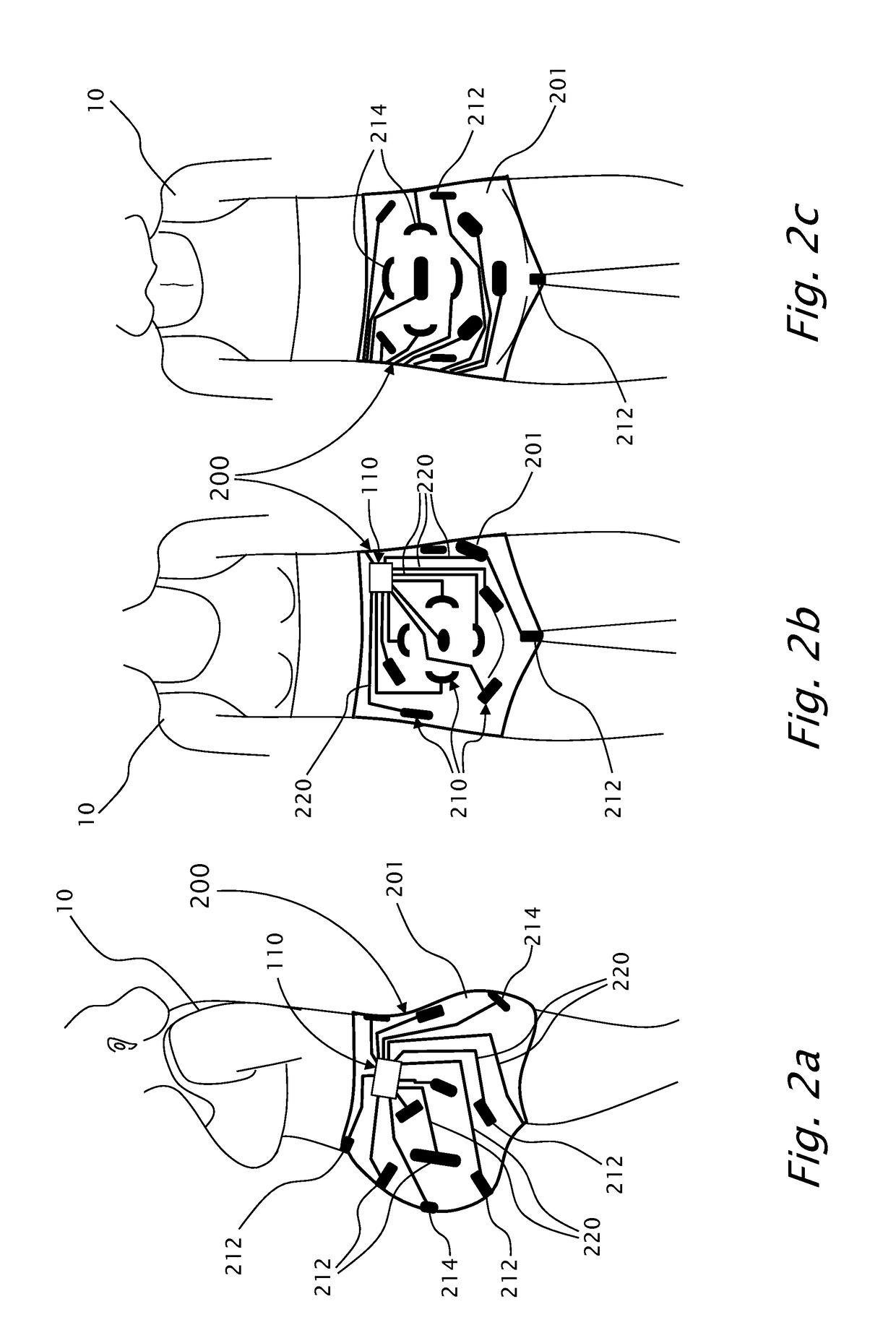

A seamless, smart fetal monitoring garment and methods of using thereof. The system includes a knitted or interwoven garment having a multiplicity of conductive textile electrodes for sensing maternal and fetal electrical vital signals. The maternal and fetal electrical vital signals are selected from a group including maternal heart rate, fetal heart rate and electromyogram (EMG) activities including uterine activities. The method includes wearing the garment, acquiring electrical mixed common, maternal and fetal vital signals from surface region of a pregnant woman, using the plurality of textile electrodes, optimally weighted summing-up the acquired signals, analyzing the summed-up signals to thereby extract the maternal signal and the fetal signal, including determining their heart rates, and including detecting health hazards and in some embodiments, including detecting a uterine contraction sequence suggesting the need to be hospitalized for birth giving.

Owner:AUTONETWORKS TECH LTD

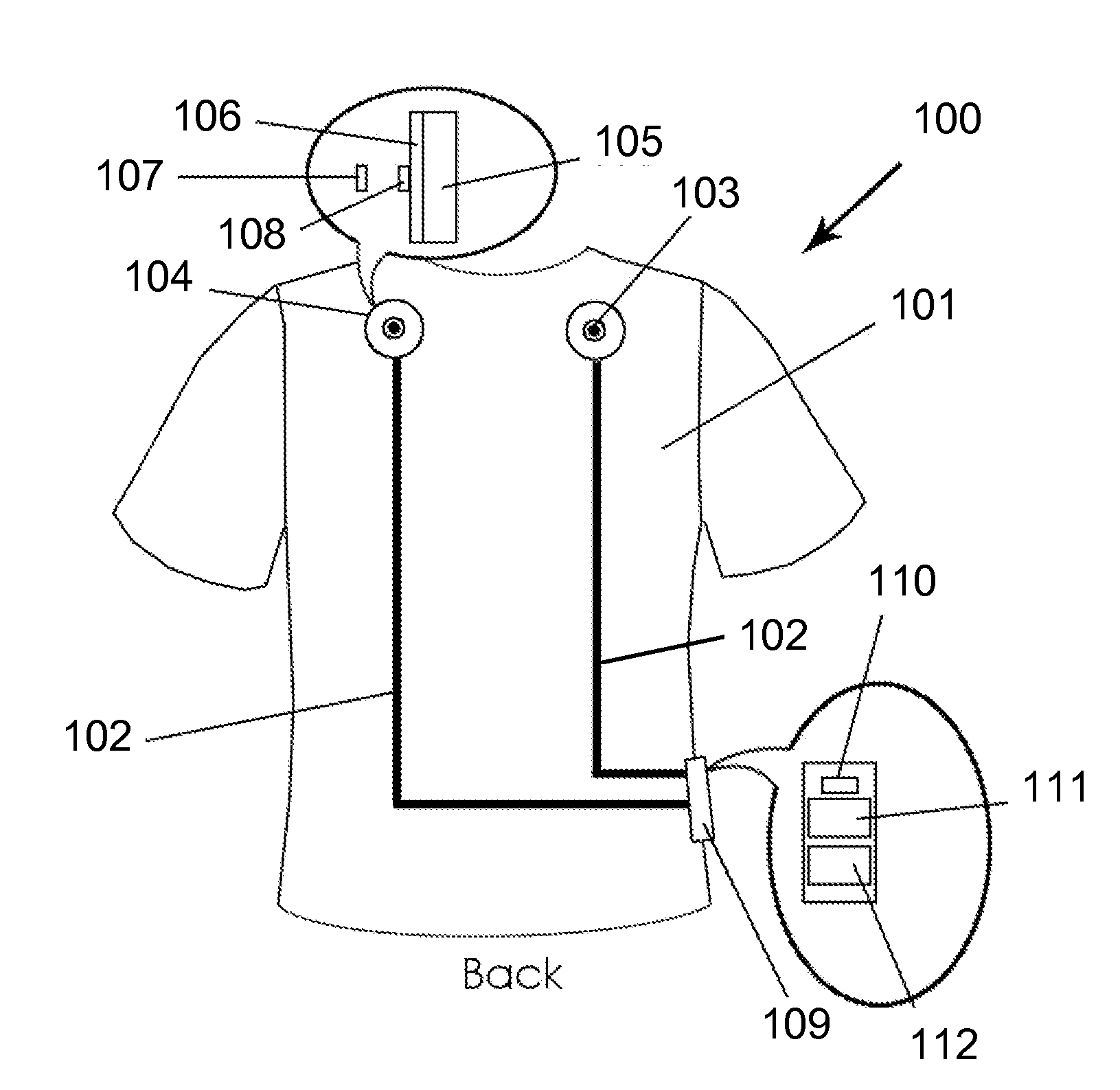

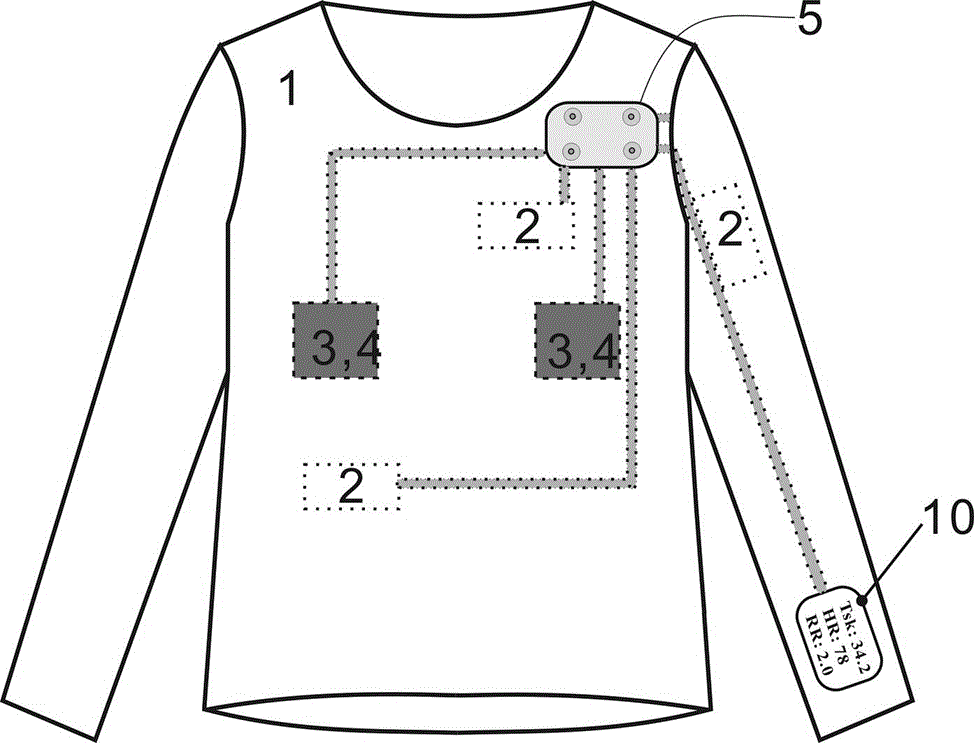

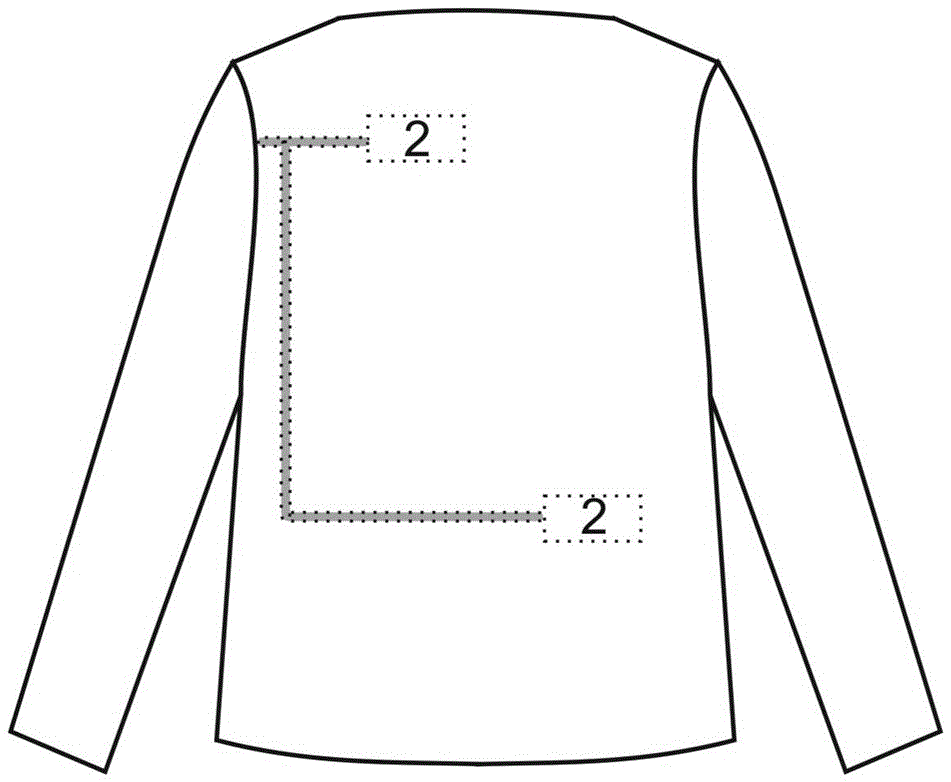

Wearable intelligent garment for monitoring human physiological sign parameters in real time

InactiveCN105640522AReal-time monitoring of heart rateReal-time monitoring of respiratory rateDiagnostic recording/measuringSensorsConductive textileData recording

The invention relates to a wearable intelligent garment for monitoring human physiological sign parameters in real time. The wearable intelligent garment comprises a garment body attached to the human body. A miniature flexible temperature sensor, a heart rate sensor, a respiration sensor, and a detachable miniature data processing and recording system connected with the wearable garment body are arranged in the garment body. The wearable temperature sensor is in a large-area printing type and is implanted into the garment body. The heart rate sensor and the respiration sensor are conductive textile electrodes. The miniature data processing and recording system comprises a signal processing and transmitting module, a central processing unit, a data storage module, an LCD display screen and a power module. The temperature sensor, the heart rate sensor, the respiration sensor and the LCD display screen are connected with the miniature data recording device through flexible wires implanted into the garment body. A wearer can observe individual physiological sign parameters in real time through the LCD display screen implanted into the garment body.

Owner:SUZHOU UNIV

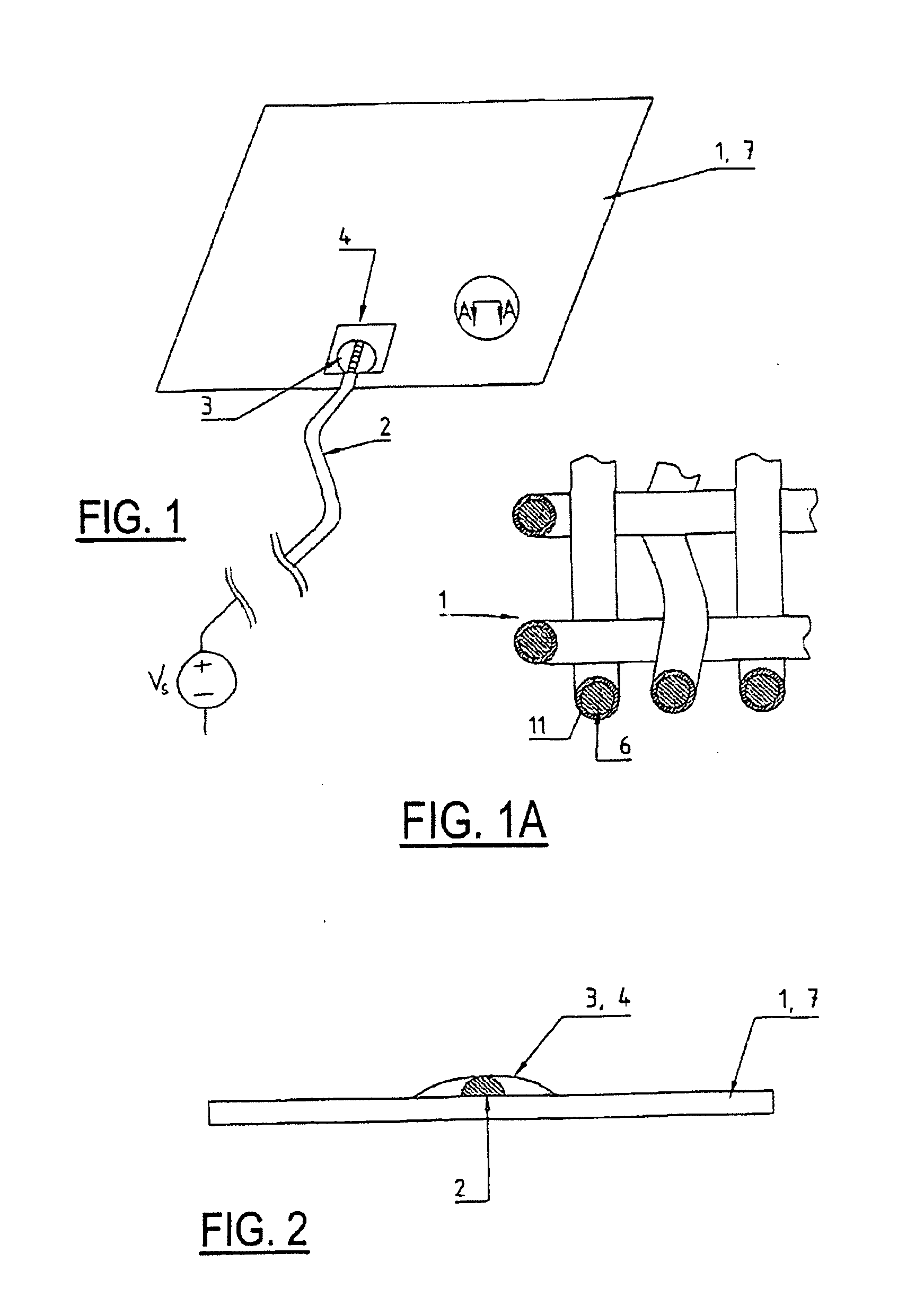

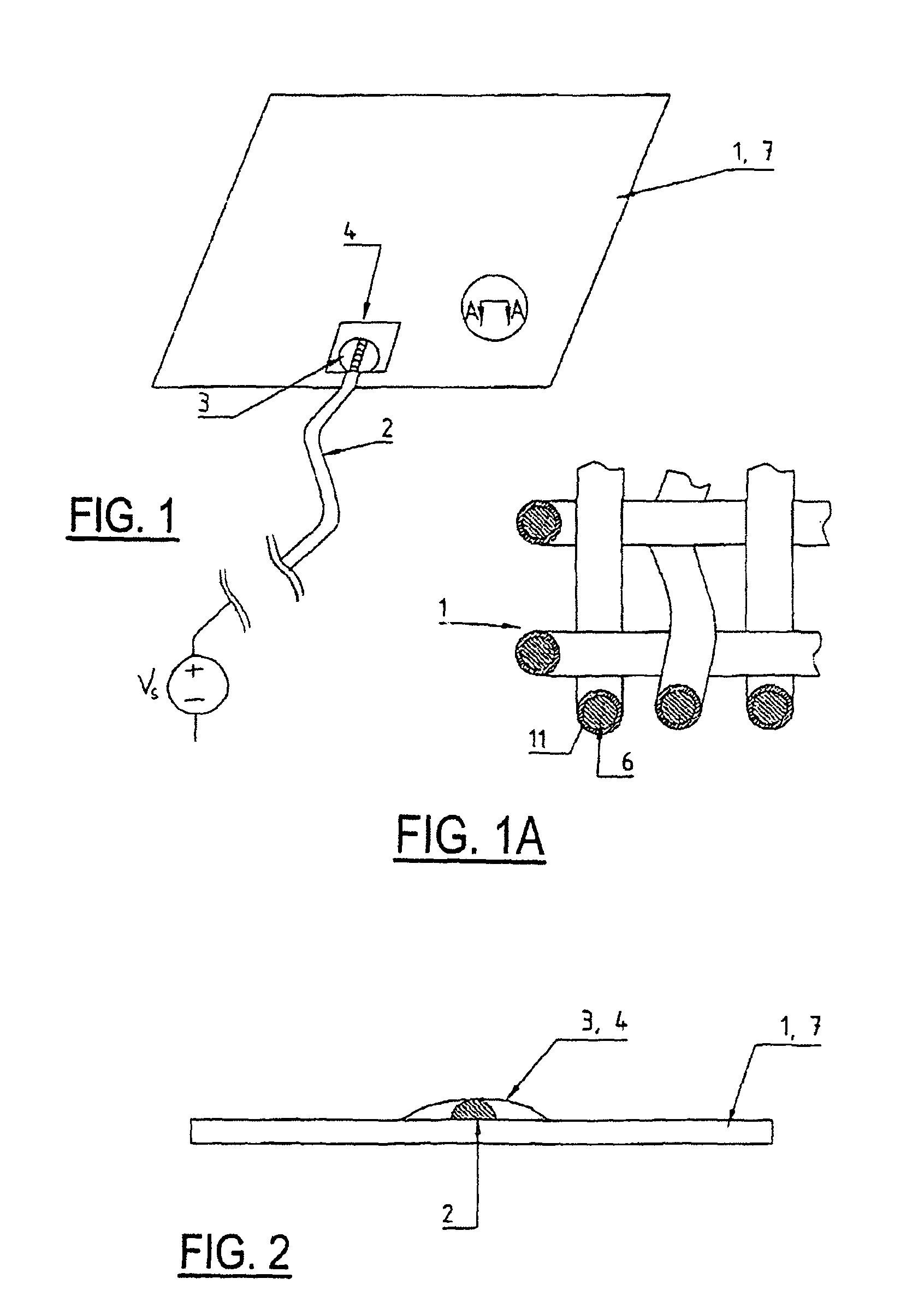

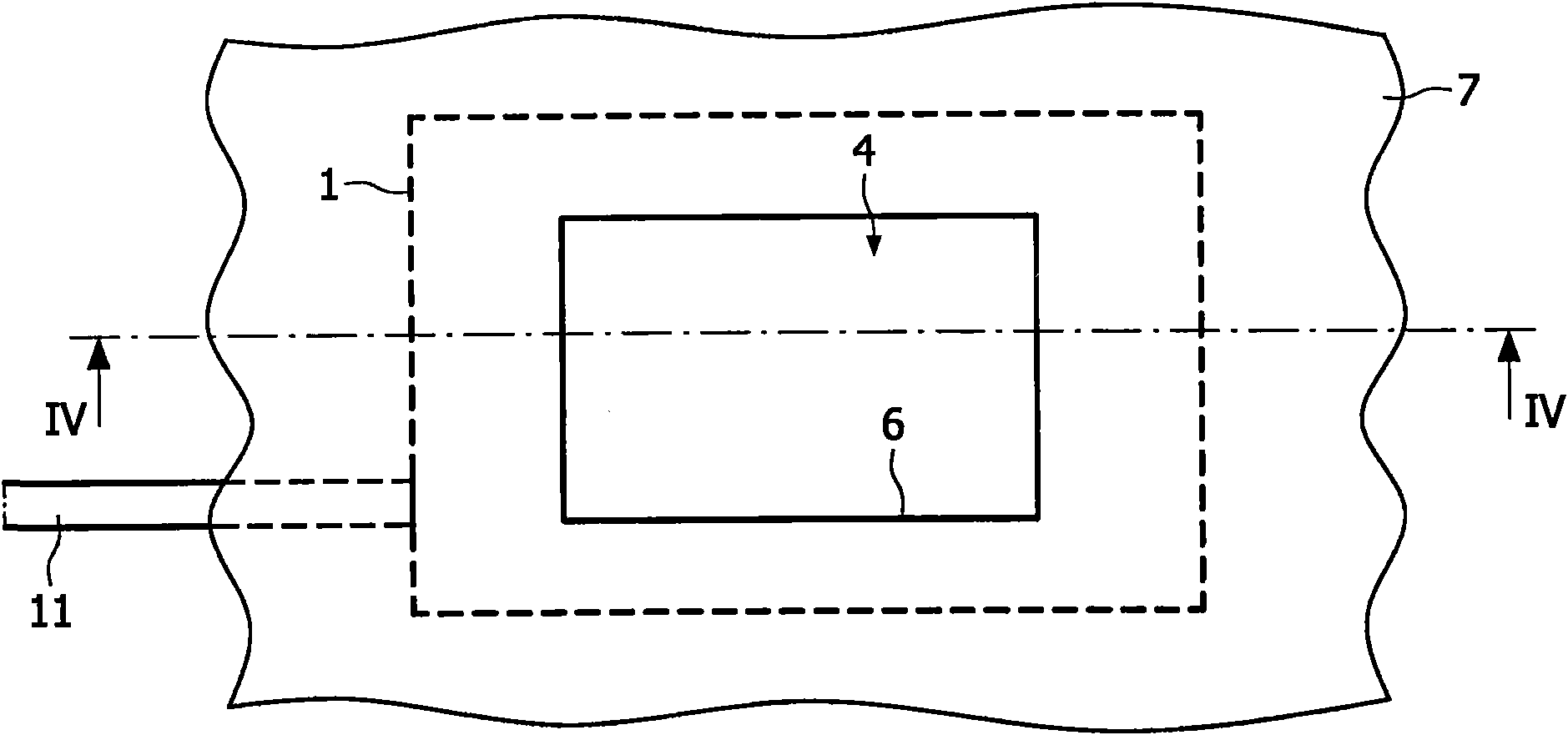

Electrically conductive textile

ActiveUS20060027552A1Improve robustnessProcess stabilityPrinted circuit assemblingVehicle seatsConductive textileConductive coating

A surface structure (1) that is at least partially electrically conductively coated by a conductor coating (11), and which can be connected to an electric power source by at least one electric connecting conductor (2). The connecting conductor (2) electrically contacts the conductor coating (11) at at least one solder point (3), and the conductive coating (11) is thickened at least at one contact zone (4) in the area of the solder point (3) as opposed to other areas (7) of the surface structure (1).

Owner:GENTHERM GMBH

Conductive spinning product

InactiveCN1846026AImprove conductivityControl conductivity levelFibre typesWoven fabricsConductive textilePolymer science

Owner:COMMONWEALTH SCI & IND RES ORG +1

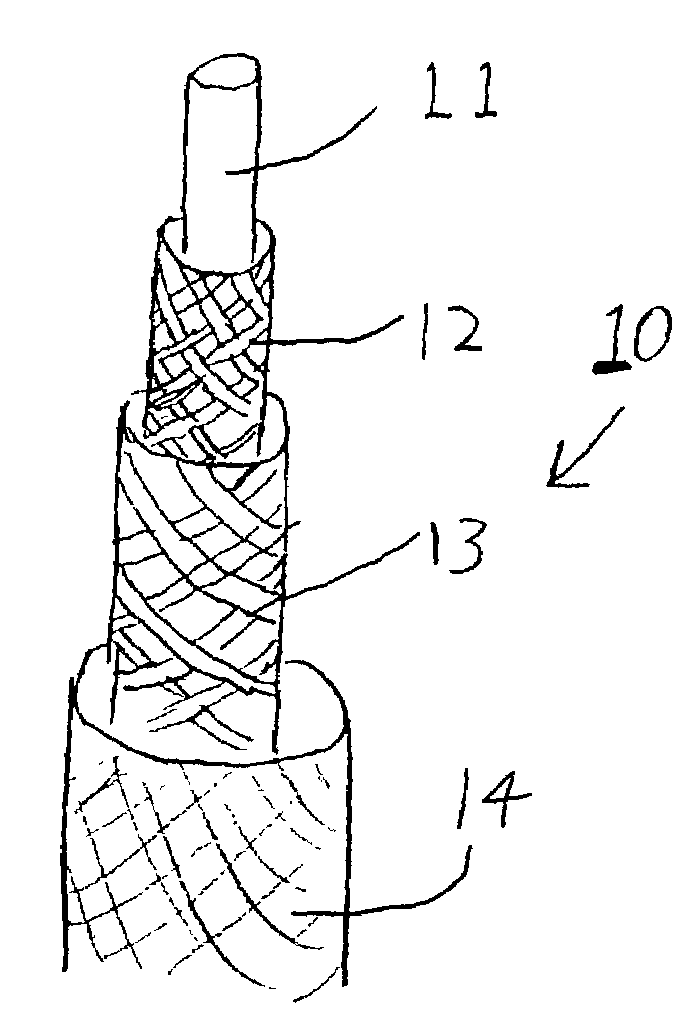

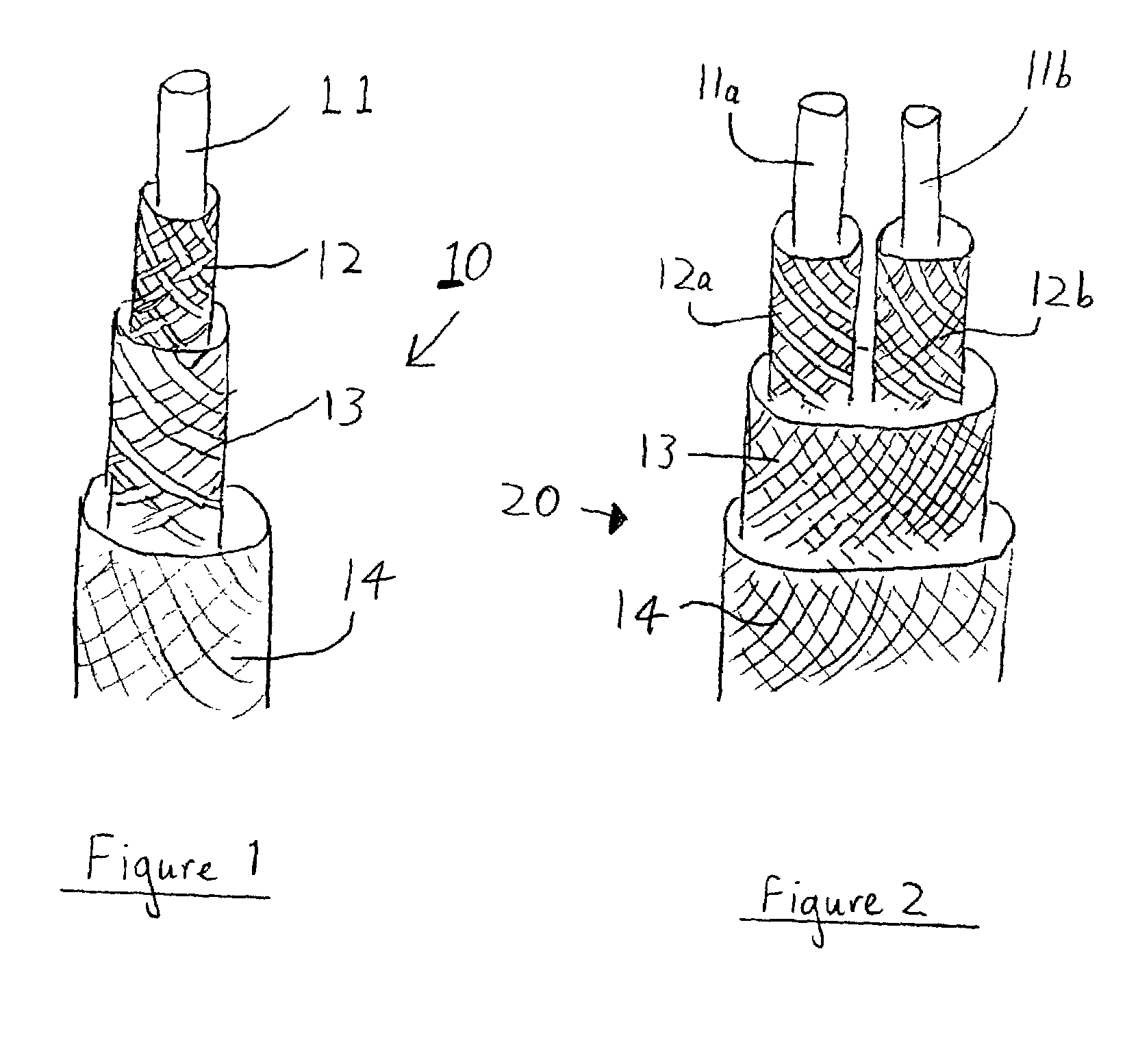

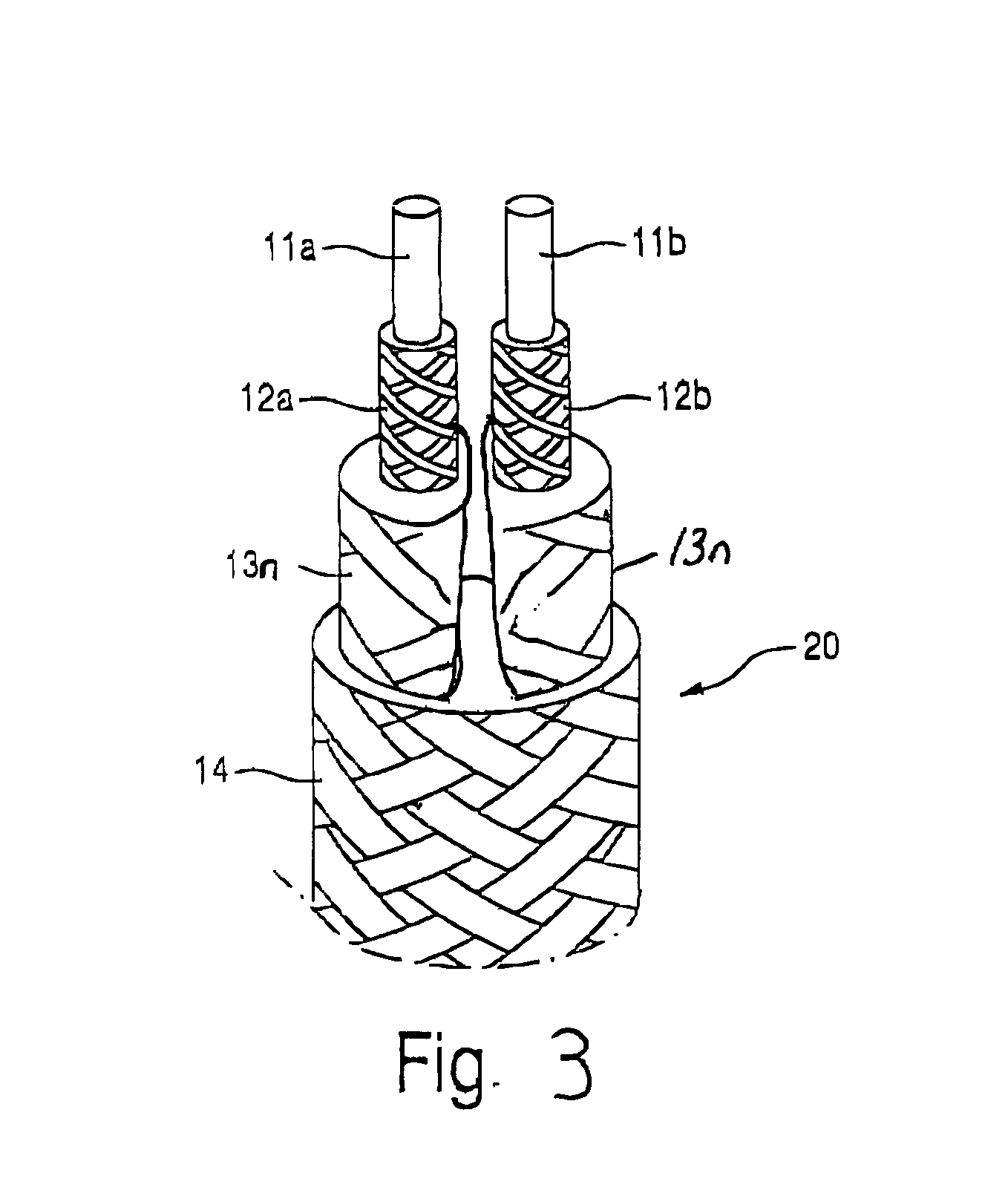

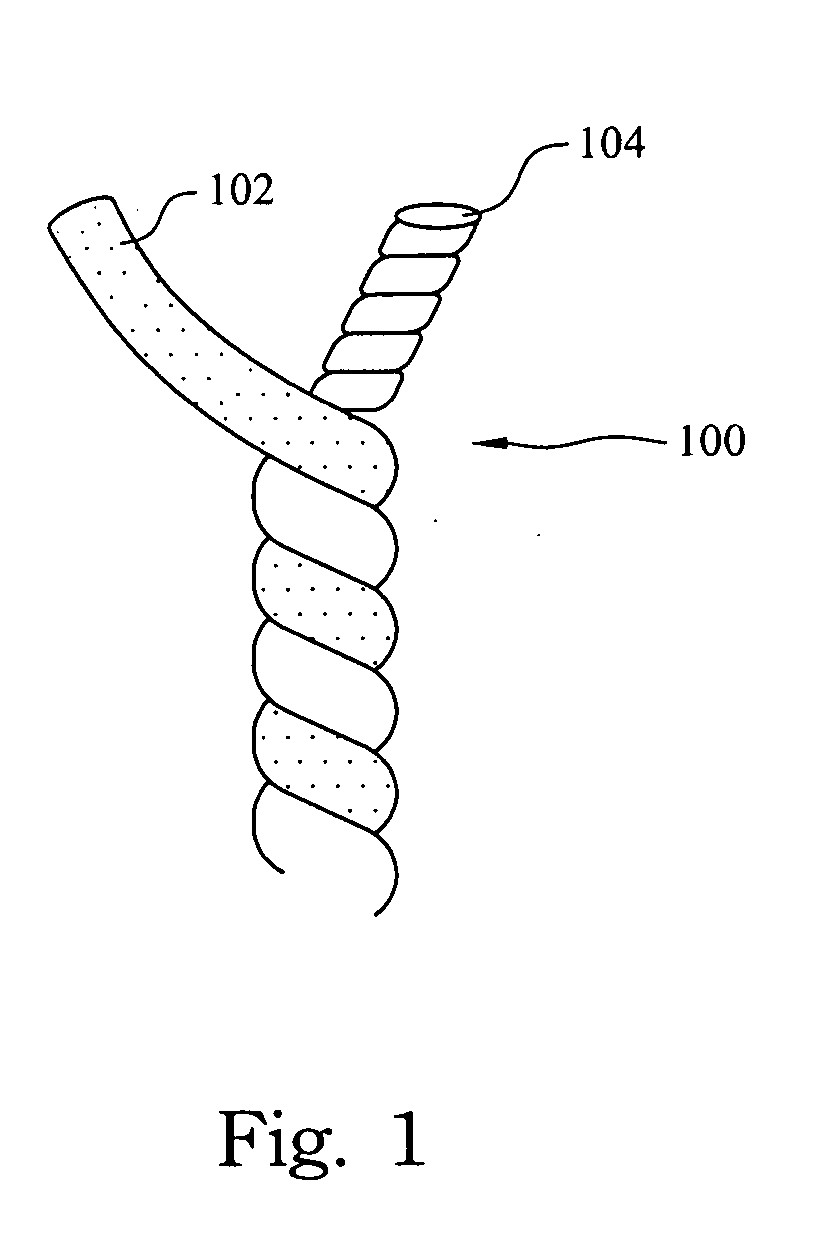

Cable

An electrical cable of all textile construction includes a first conductor of conductive textile material, a first insulator of braided insulating textile material, a second conductor of braided conductive textile material and a second insulator of braided insulating textile material. Such a cable, through being of an all textile construction makes it particularly suitable for incorporation in items such as garments, fashion accessories, upholstered article and other soft furnishings as it can be made very flexible, soft to the touch and of a required color. Furthermore, by making the cables using textile materials that have been developed for use in garments, the cables are capable of being subjected to standard garment care techniques such as machine washing in the home or dry cleaning. This means items, such as garments, that include these cables can be placed in the washing machine for cleaning, with no added risk to the wire, garment or washing machine.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for preparing conductive textile fibre

Owner:江苏正本净化节水科技实业有限公司

Conductive textile product based on layer-by-layer self-assembled silver nanowire/graphene

InactiveCN107558179AImprove conductivityHigh fastnessVegetal fibresAnimal fibresFiberConductive textile

The invention discloses a conductive textile product based on layer-by-layer self-assembled silver nanowire / graphene. Electrostatic attraction is utilized to self-assemble silver nanowires and graphene oxide layer by layer to modify a textile product, finally, graphene oxide is reduced, and ultimately, the conductive textile product with excellent conductive, antibacterial and anti-ultraviolet properties and fastness to washing is obtained. The conductive textile product has the advantages of simple preparation steps, easiness in integration, almost no influence on wearing comfort of fabrics,good durability, low cost, antibacterial and anti-ultraviolet function obtainment and the like, and has important application value in the fields such as wearable devices, thermal textile products, electrothermal textile products, flexible electronic sensors, hyperelastic conductive composite fibers and self-energized textile products.

Owner:赵兵

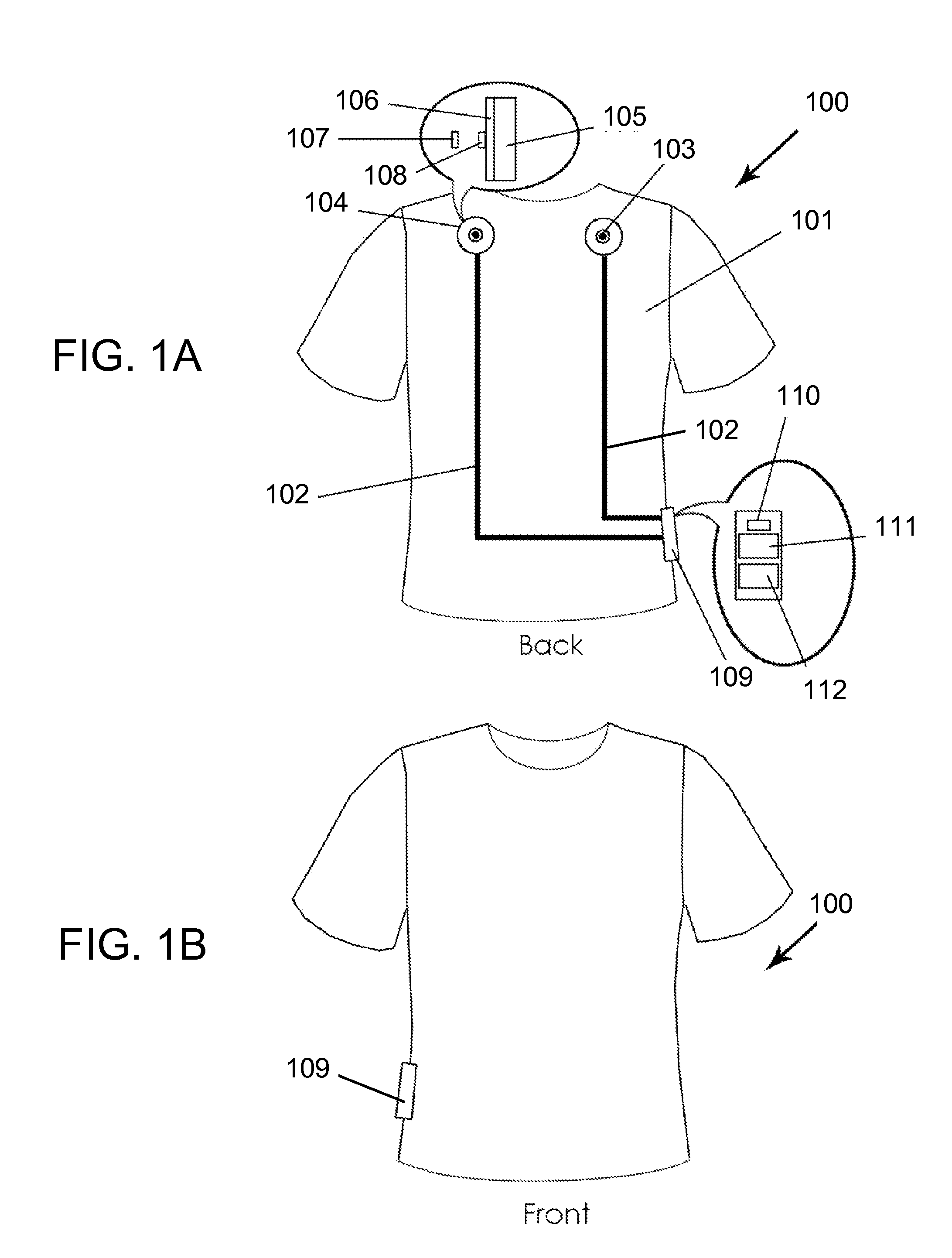

Wearable fetal monitoring system having textile electrodes

A seamless, smart fetal monitoring garment and methods of using thereof. The system includes a knitted or interwoven garment having a multiplicity of conductive textile electrodes for sensing maternal and fetal electrical vital signals. The maternal and fetal electrical vital signals are selected from a group including maternal heart rate, fetal heart rate and electromyogram (EMG) activities including uterine activities. The method includes wearing the garment, acquiring electrical mixed common, maternal and fetal vital signals from surface region of a pregnant woman, using the plurality of textile electrodes, optimally weighted summing-up the acquired signals, analyzing the summed-up signals to thereby extract the maternal signal and the fetal signal, including determining their heart rates, and including detecting health hazards and in some embodiments, including detecting a uterine contraction sequence suggesting the need to be hospitalized for birth giving.

Owner:HEALTHWATCH LTD

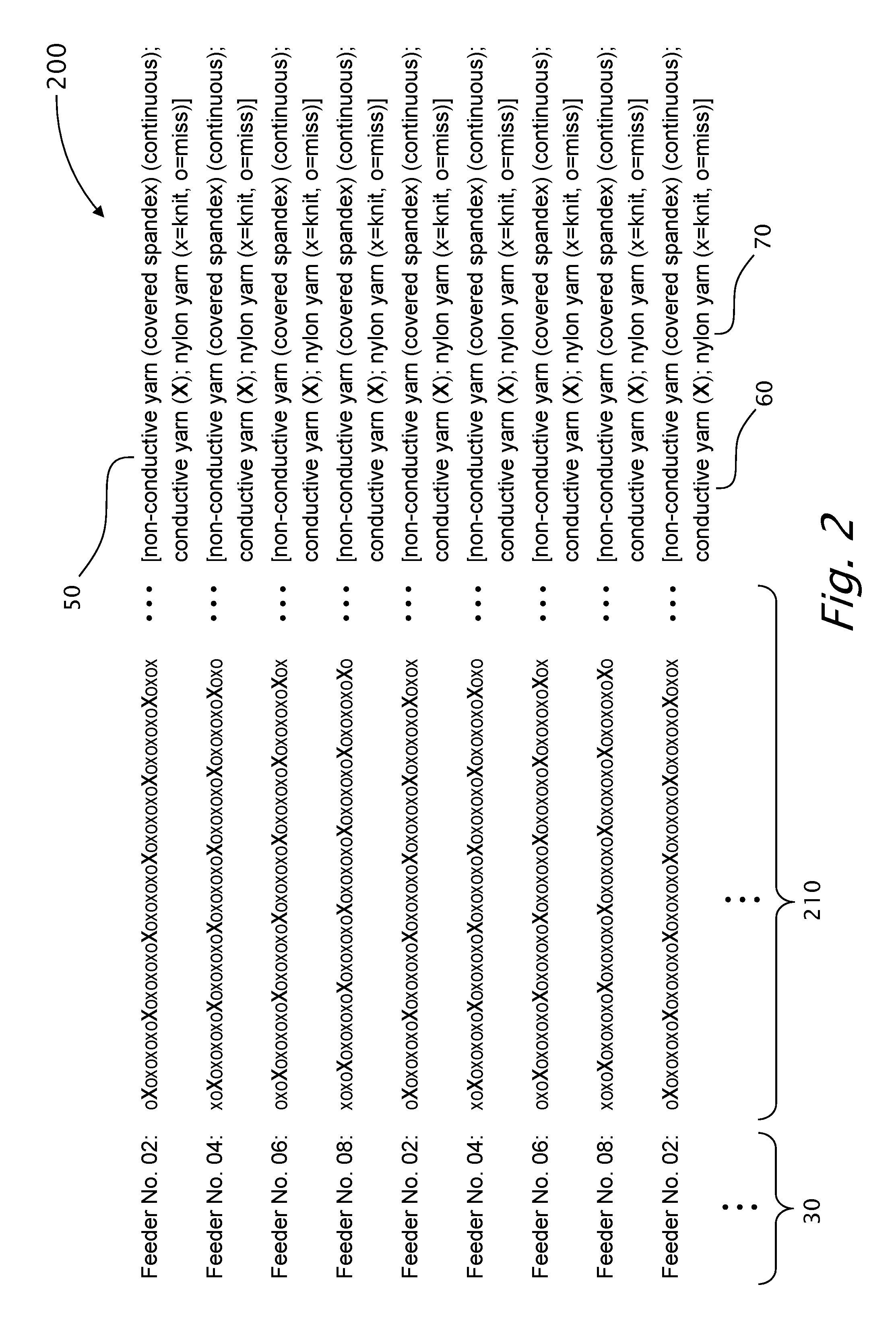

Method for making electrically conductive textiles and textile sensor

ActiveUS10119208B2Increase contact resistanceReduce sensitivityWeft knittingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

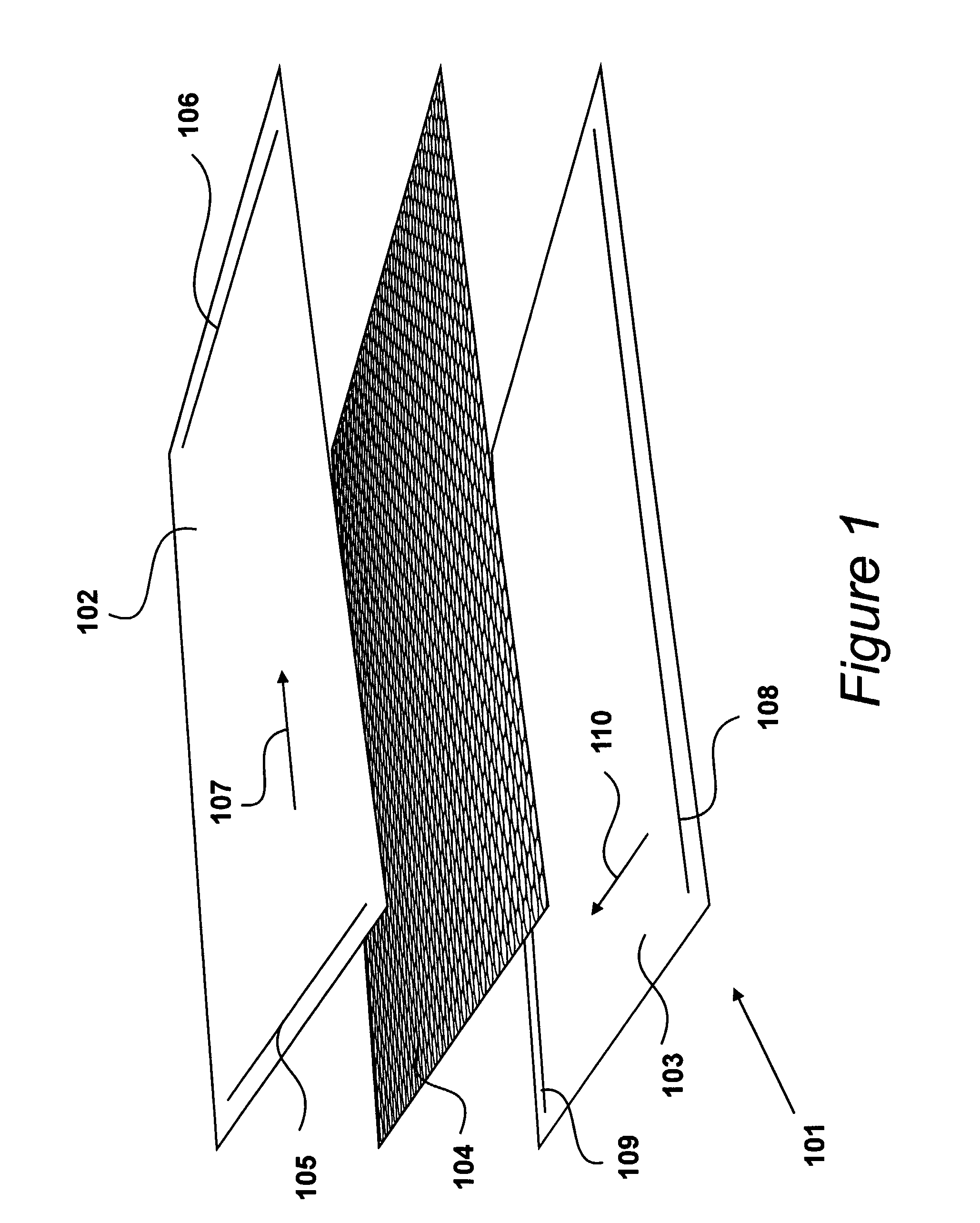

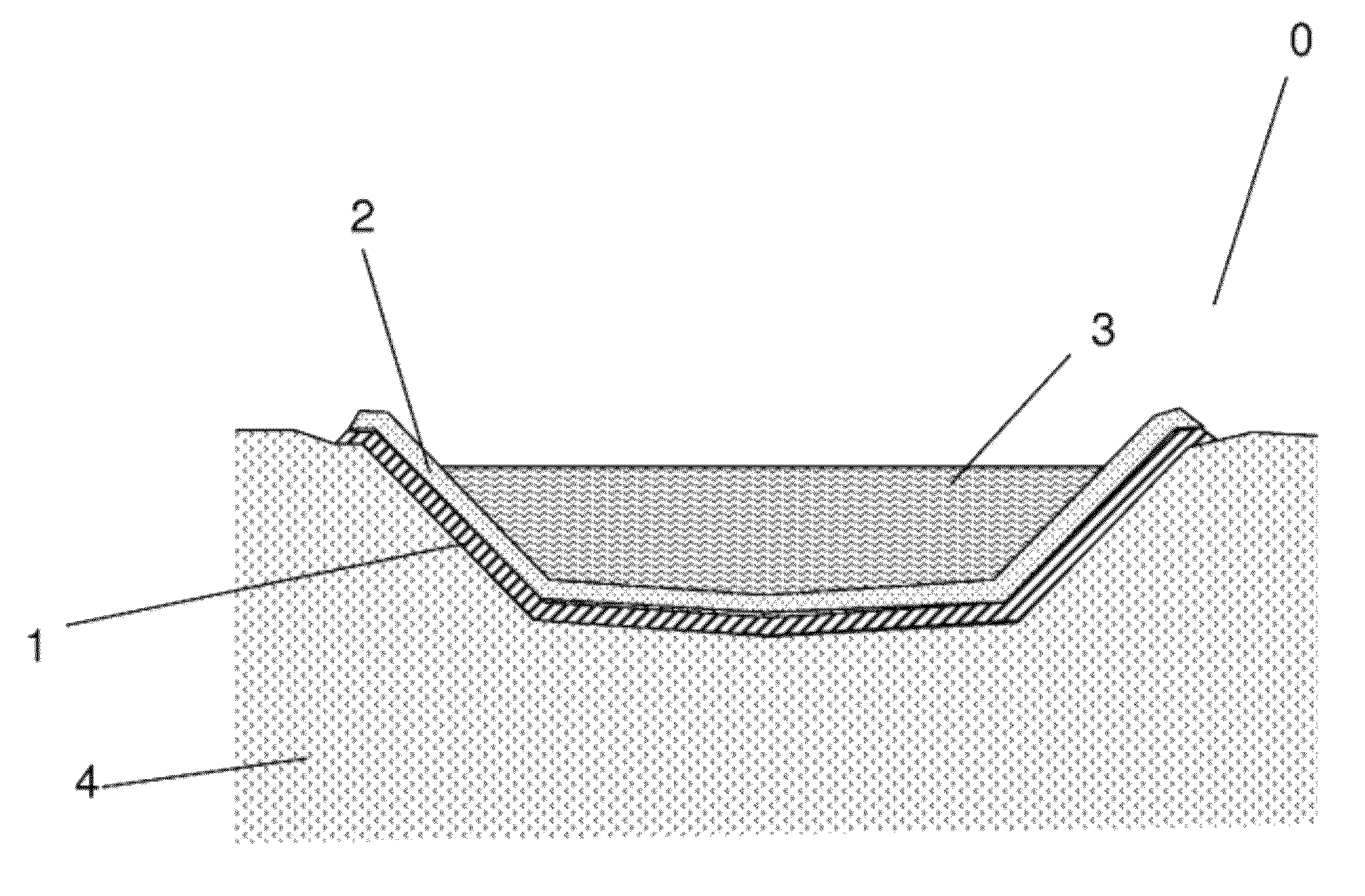

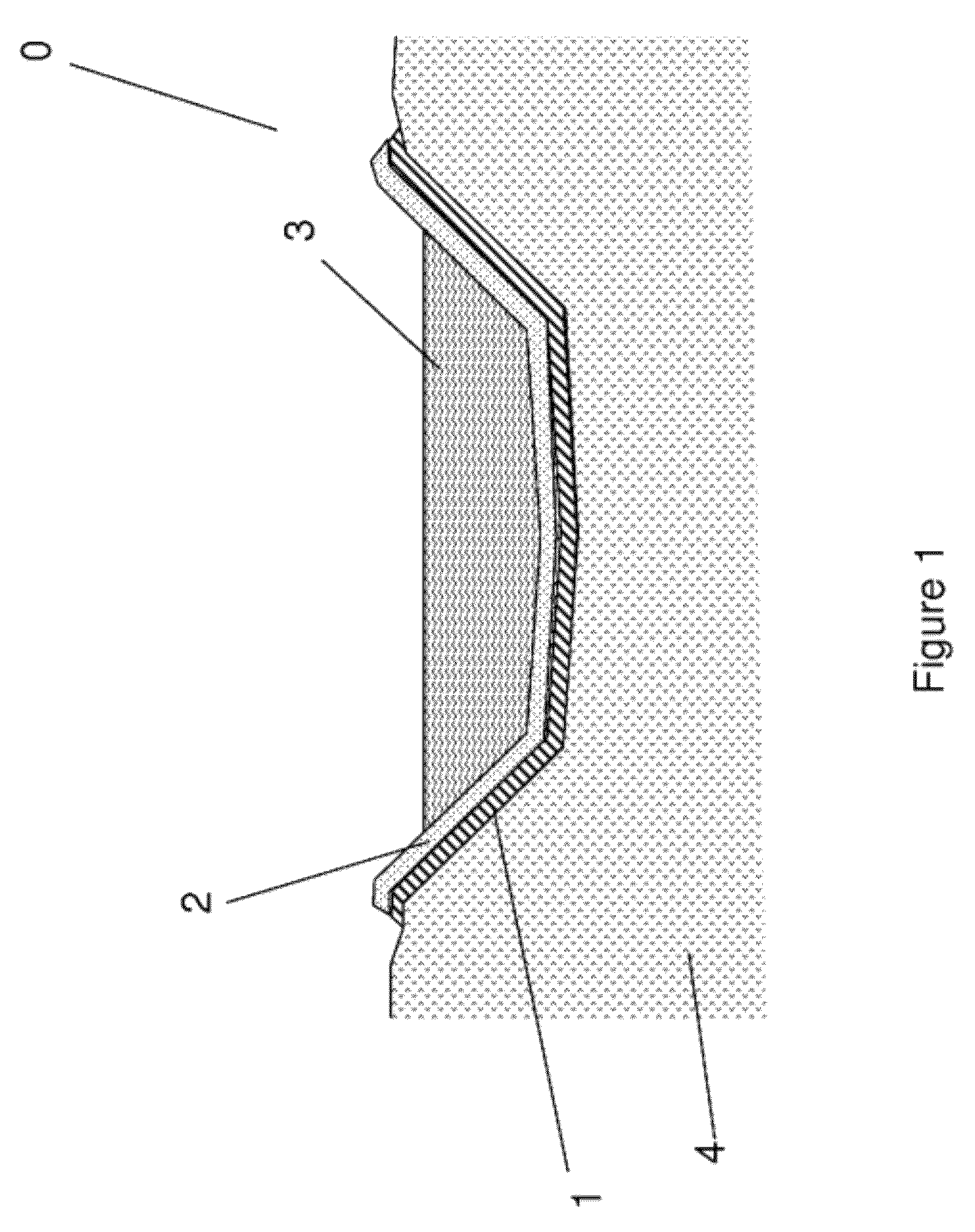

Geocomposite enabling leak detection by electrical scan, and method for use

ActiveUS8970201B2Avoid cloggingMaterial analysis by electric/magnetic meansProtective foundationElectricityConductive textile

A geocomposite for positioning under a geomembrane comprising at least one first geotextile covered by at least one second geotextile at least one electrically conductive textile being positioned between the second geotextile and the first geotextile. The conductive textile having a module for connecting to a phase of an electric generator. The geocomposite being in the form of one or several strips at the edges of which the second geotextile, the first geotextile and the electrically conductive textile are separate from each other, the geocomposite comprising perforated ringed mini-drains positioned parallel with each other on the first geotextile and covered with the second geotextile.

Owner:AFITEX INT

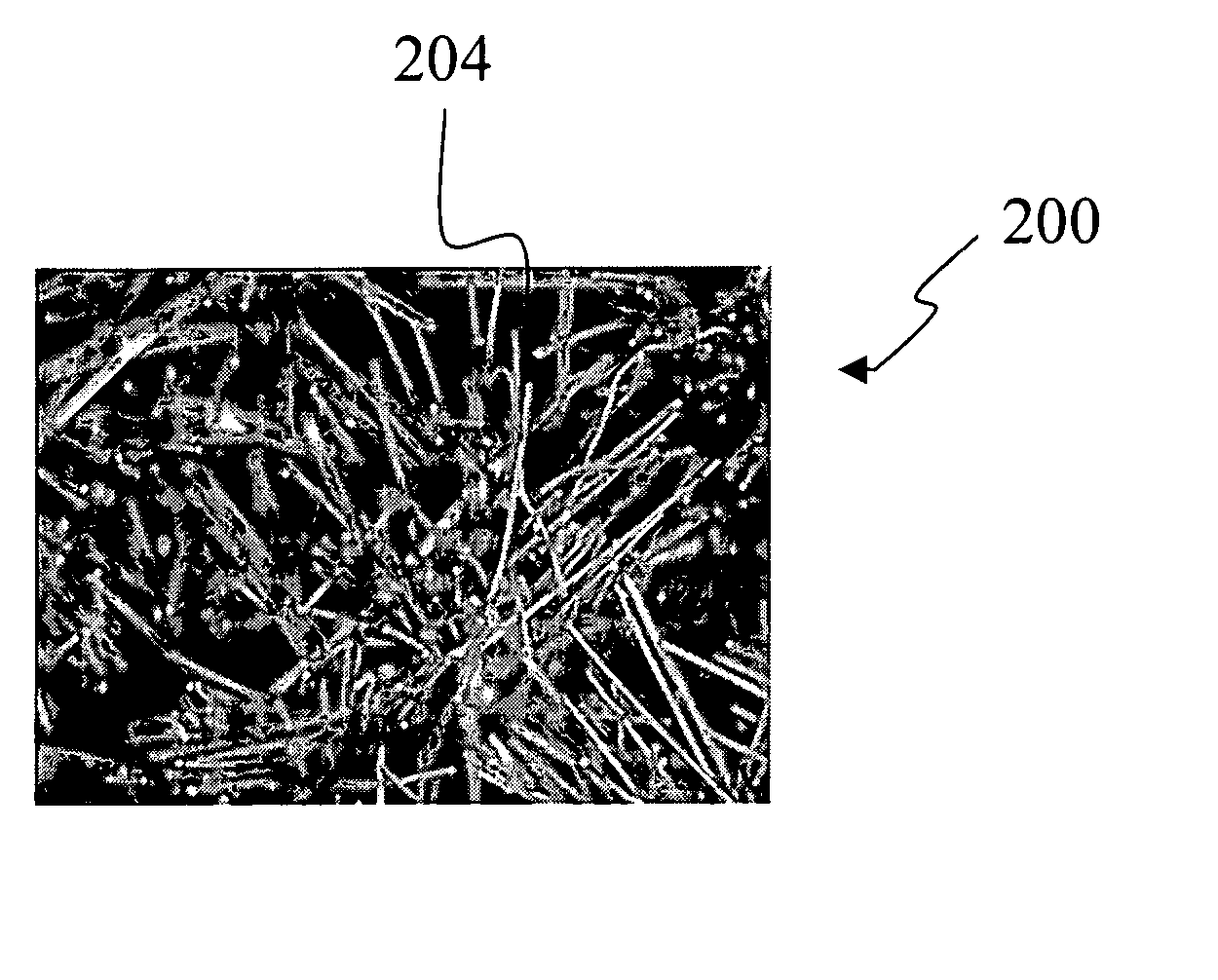

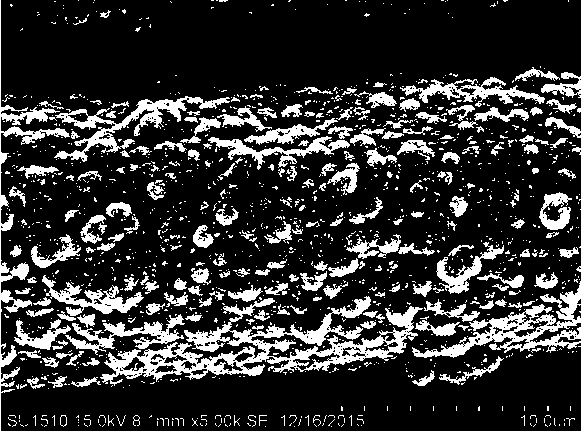

Method of fabricating a conductive textile

InactiveUS20070148399A1Lower on-resistanceImprove conductivityLiquid surface applicatorsLayered productsFiberConductive textile

A method of fabricating a conductive textile is provided. First, erect-interlaced fibers are formed on a textile. Then, a conductive layer is formed on the erect-interlaced fibers and the surface of the textile to form a conductive textile.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Silver nanowire-graphene conductive textile capable of being used for wearable device

The invention discloses a silver nanowire-graphene conductive textile capable of being used for a wearable device. The textile is modified by using layer-by-layer (LBL) self-assembled silver nanowires (AgNWs), and then the outermost layers of the AgNWs are coated with graphene, and the conductive textile with excellent electrical conductivity and washing fastness is finally obtained. The silver nanowire-graphene conductive textile disclosed by the invention has the advantages of simple preparation steps, easiness in integration, good durability, low cost, antibacterial and anti-ultraviolet functions and the like; the wearing comfortableness of the textile is not basically affected; in addition, the silver nanowire-graphene conductive textile has important application value in the fields such as wearable devices, warm-keeping textiles, electric heating textiles, flexible electronic sensors, superelastic conductive composite fibers and self-energized textiles.

Owner:赵兵

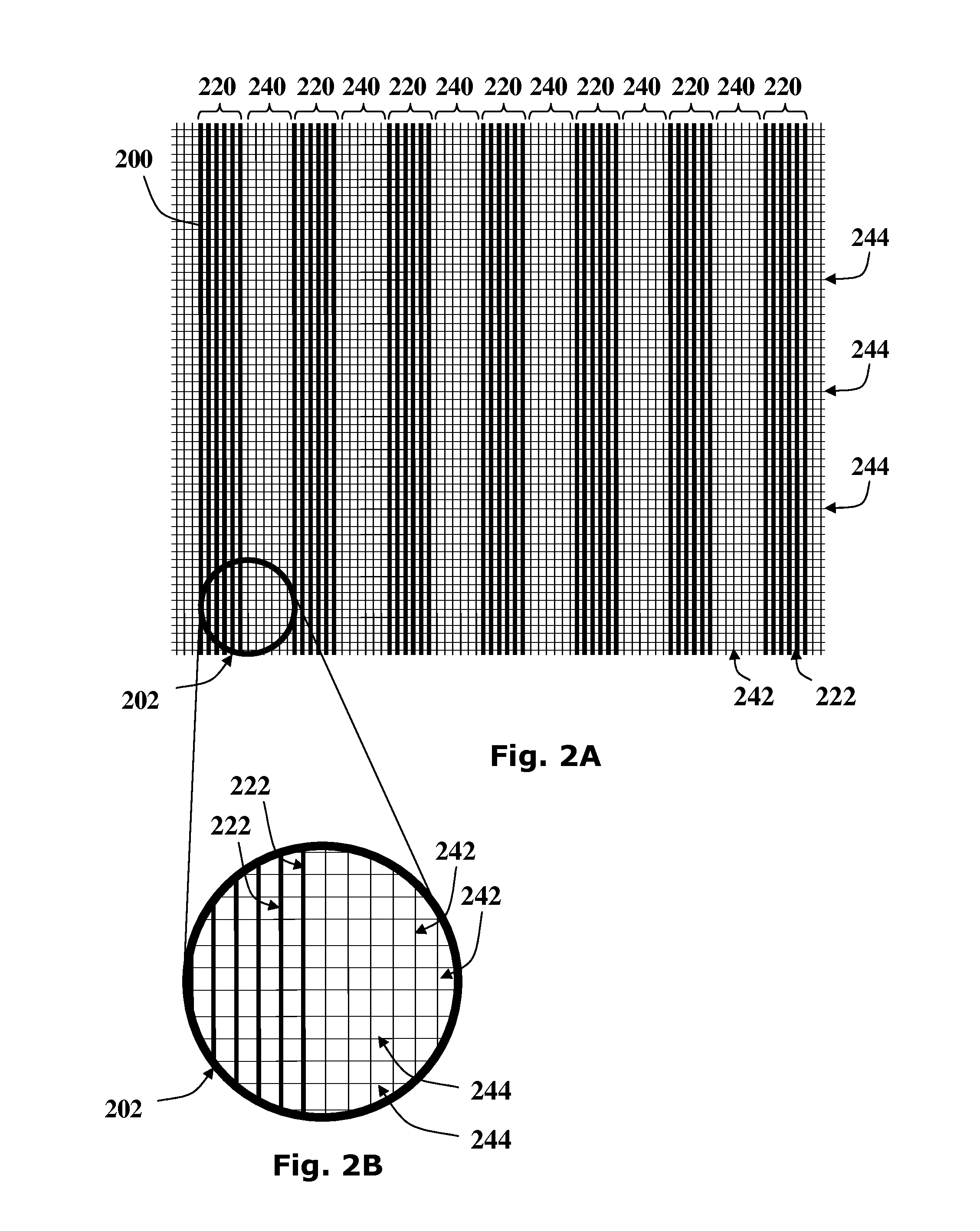

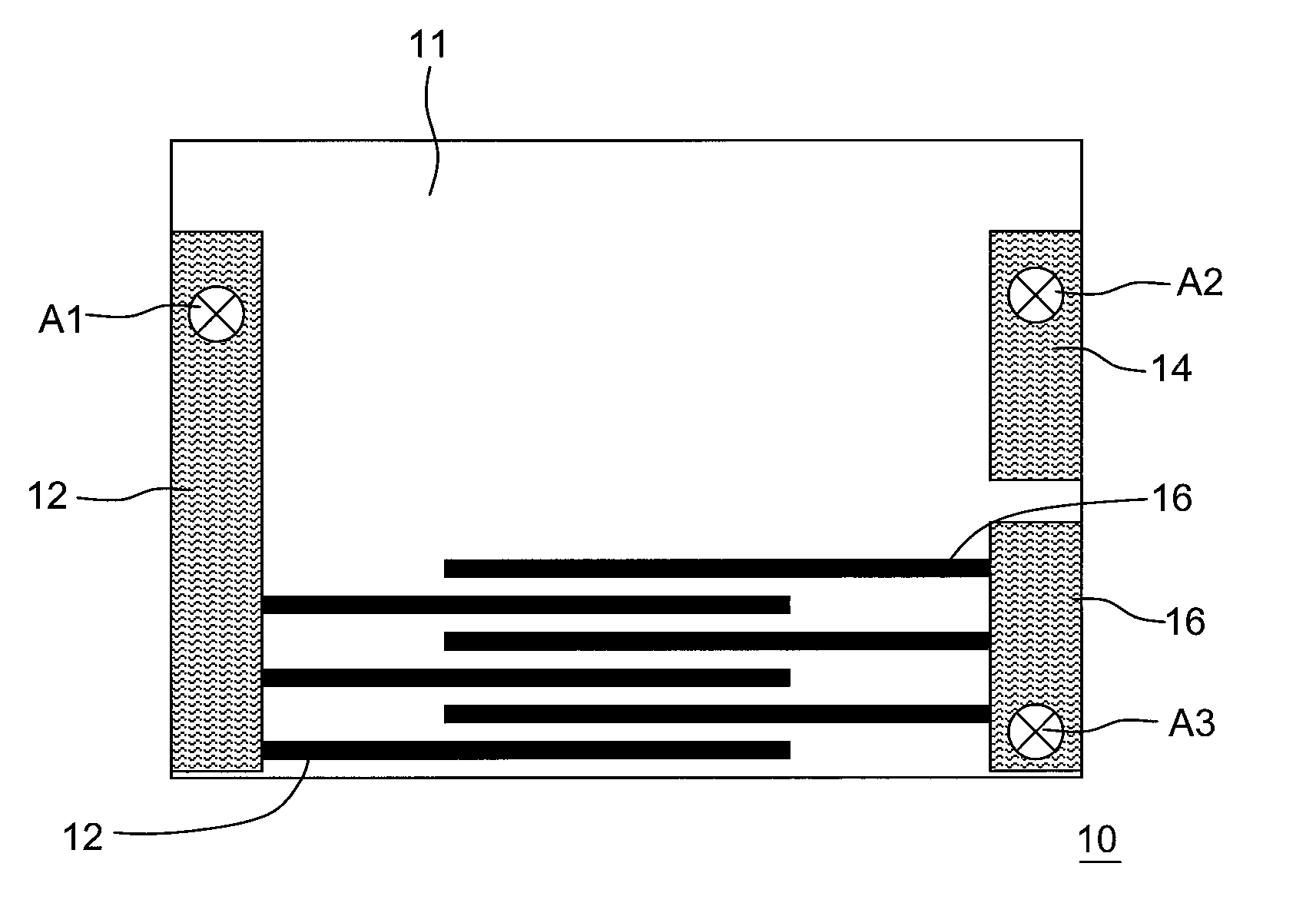

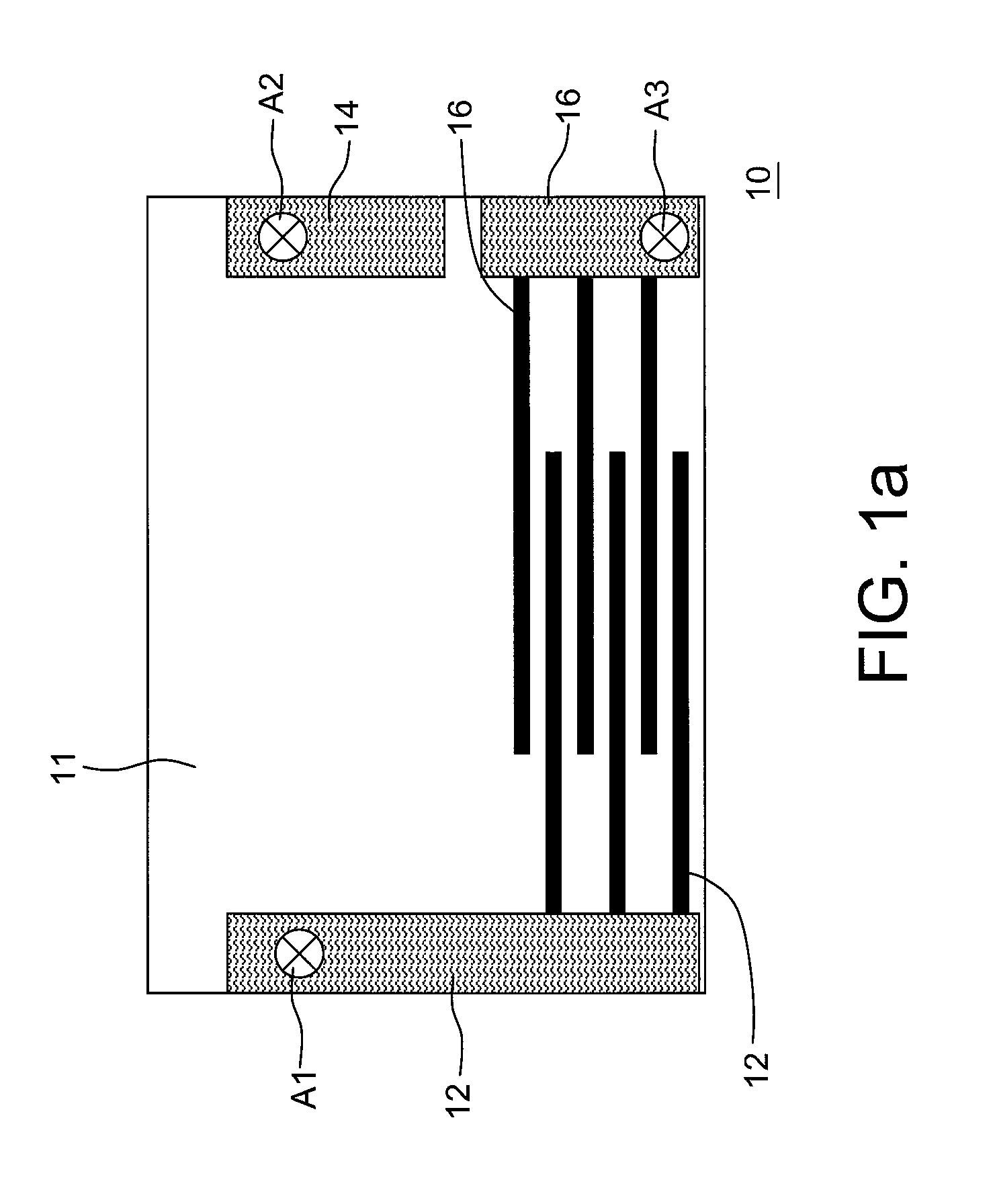

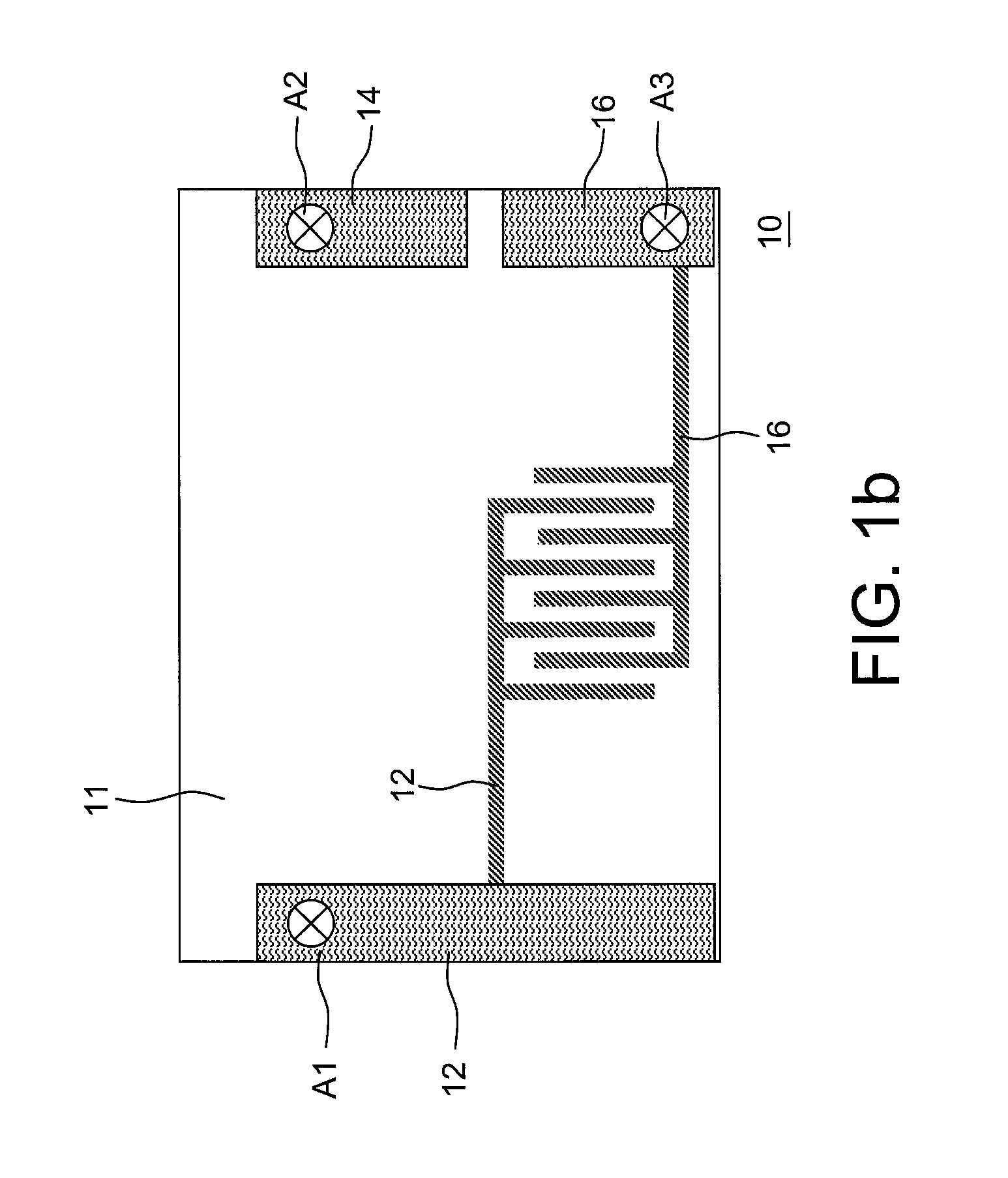

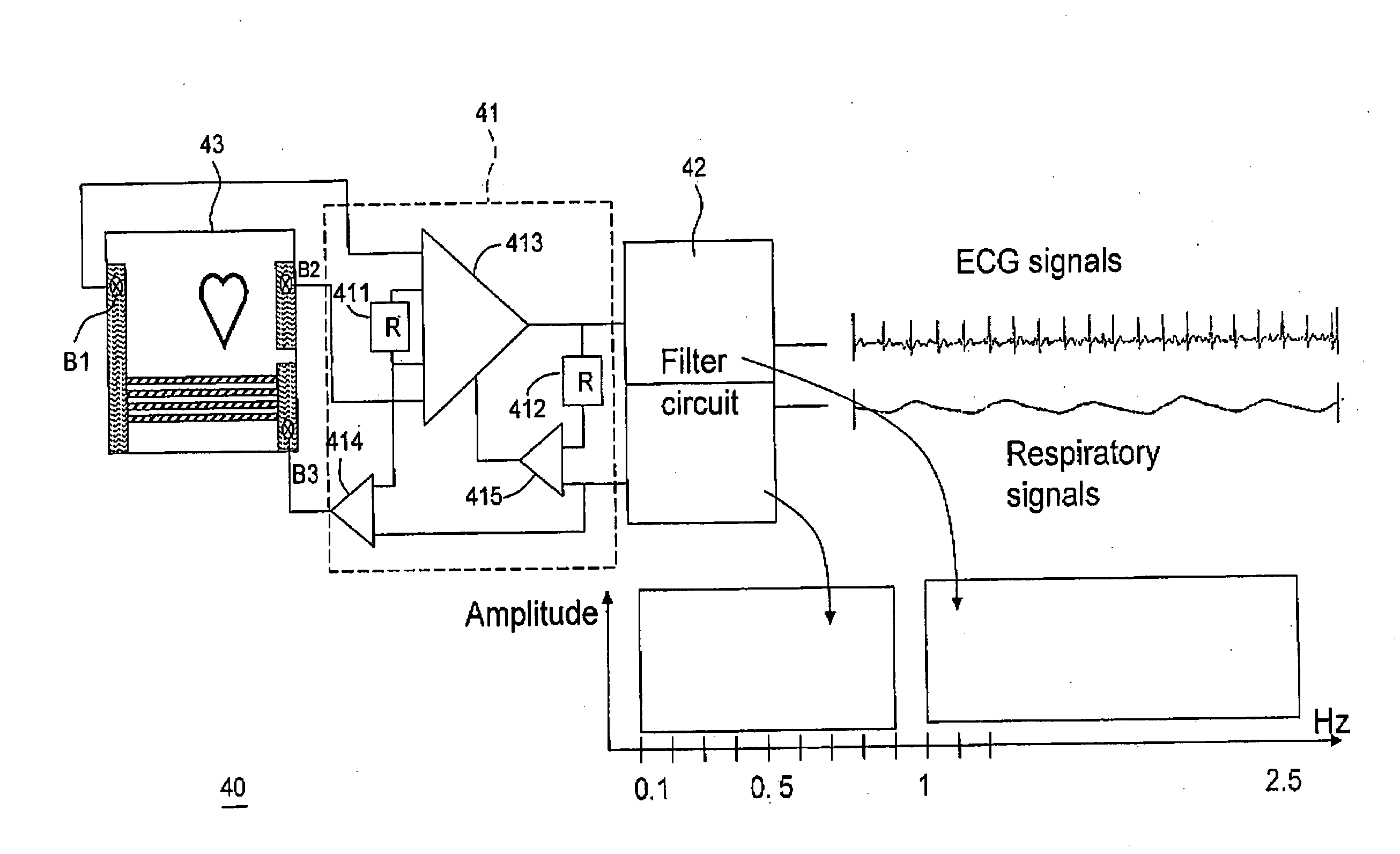

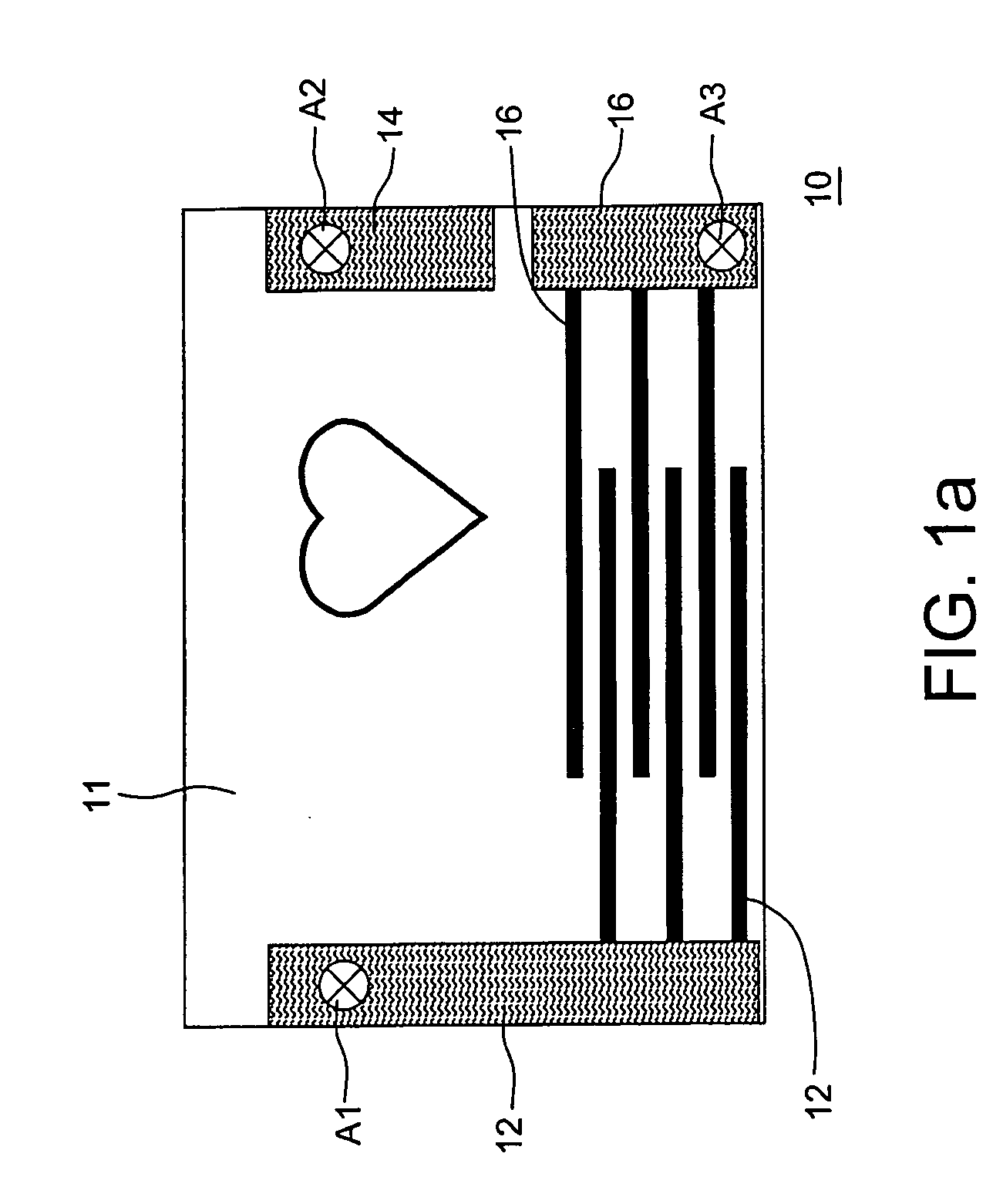

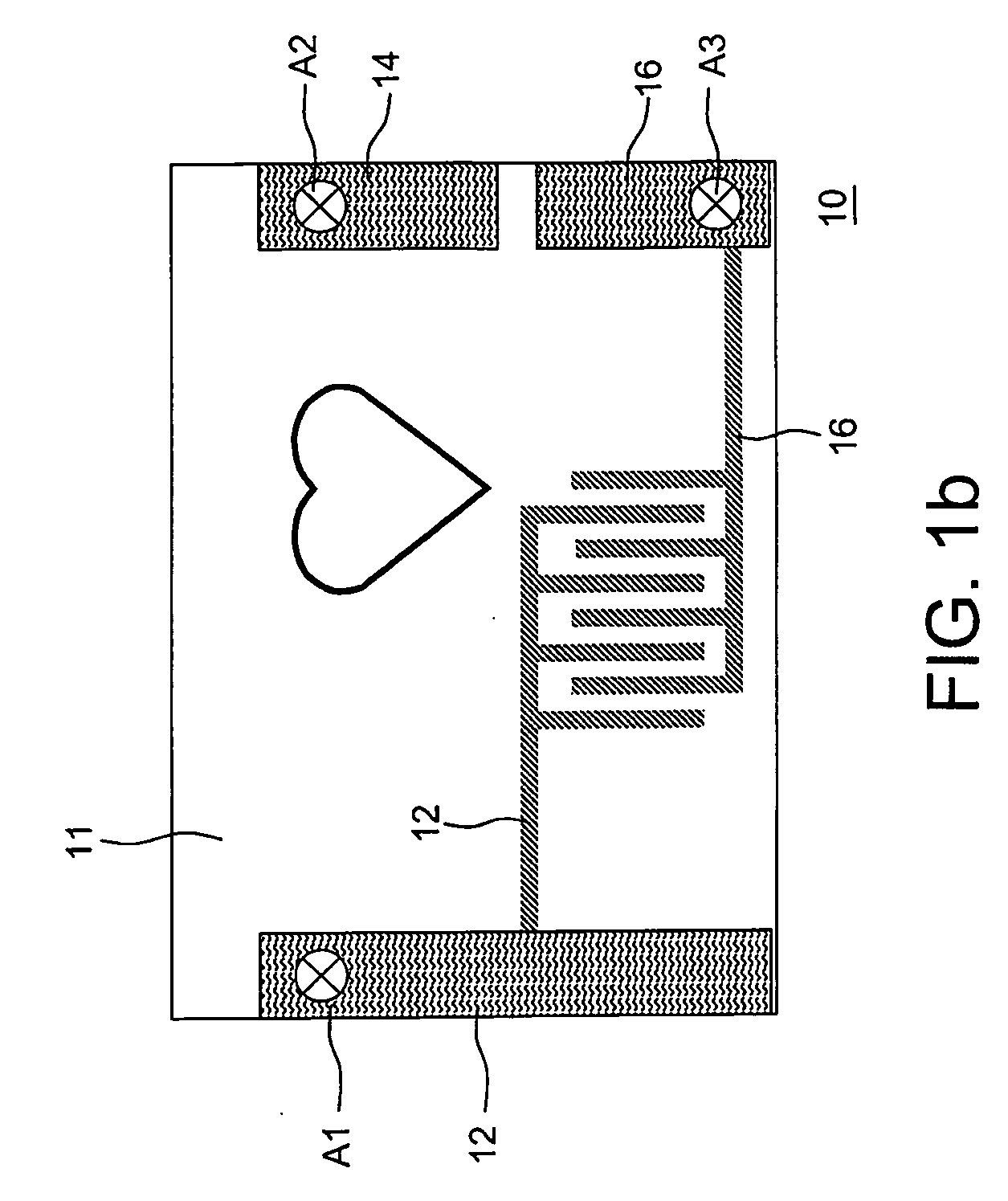

Textile structure for detecting body surface electrical signals of human and signal detector using the same

A textile structure for detecting body surface electrical signals of human is provided. The textile structure includes a non-conductive textile, a conductive textile, and a plurality of test terminals. The non-conductive textile covers the human body. The conductive textile has a first region, a second region, and a third region. The first region is interdigitated into but not electrically coupled to the third region. The first to third test terminals are respectively coupled to the first to third regions of the conductive textile. The first and second test terminals are used for detecting ECG signals. The first and third test terminals are used for detecting respiratory signals.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Electrically conductive textile

ActiveUS8198569B2Improve robustnessSolder connection is firmPrinted circuit assemblingVehicle seatsConductive textileConductive coating

A surface structure (1) that is at least partially electrically conductively coated by a conductor coating (11), and which can be connected to an electric power source by at least one electric connecting conductor (2). The connecting conductor (2) electrically contacts the conductor coating (11) at at least one solder point (3), and the conductive coating (11) is thickened at least at one contact zone (4) in the area of the solder point (3) as opposed to other areas (7) of the surface structure (1).

Owner:GENTHERM GMBH

Textile structure for detecting body surface electrical signals of human and signal detector using the same

A textile structure for detecting body surface electrical signals of human is provided. The textile structure includes a non-conductive textile, a conductive textile, and a plurality of test terminals. The non-conductive textile covers the human body. The conductive textile has a first region, a second region, and a third region. The first region is interdigitated into but not electrically coupled to the third region. The first to third test terminals are respectively coupled to the first to third regions of the conductive textile. The first and second test terminals are used for detecting ECG signals. The first and third test terminals are used for detecting respiratory signals.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Conductive textile product

InactiveCN102936841AImprove conductivityDoes not affect electrical performanceFibre treatmentFiberConductive textile

The invention discloses a conductive textile product. The conductive textile product comprises fiber with polyphenylacetylene combined on the surface. The content of the fiber combined with polyphenylacetylene in the conductive textile product is at least 30wt%. A preparation method of the conductive textile product comprises the steps that: AlCl3 is added into phenylacetylene, and the mixture is heated to 65-75 DEG C; after a reaction is carried out for 3-5min, fiber is delivered through the reaction liquid with a speed of 0.2-0.4m / s; and the fiber is heated for 3-5min under a temperature of 110-120 DEG C; and the fiber is cooled, washed, and spun, such that the e textile product containing at least 30wt% of fiber combined with polyphenylacetylene is obtained. The conductive textile product provided by the invention has good conductivity, washing resistance, and wear resistance.

Owner:WUXI YUTONG FABRIC IND

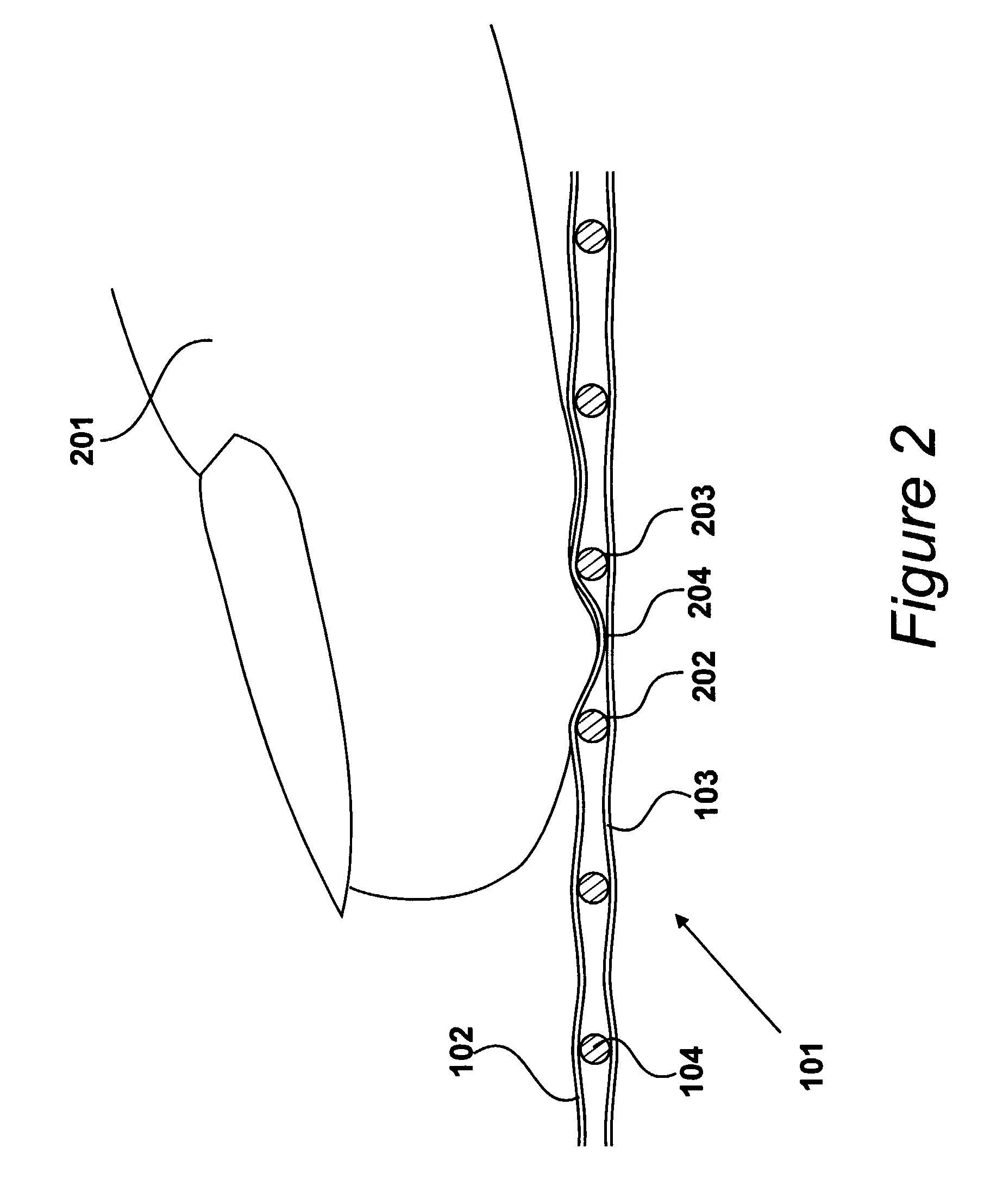

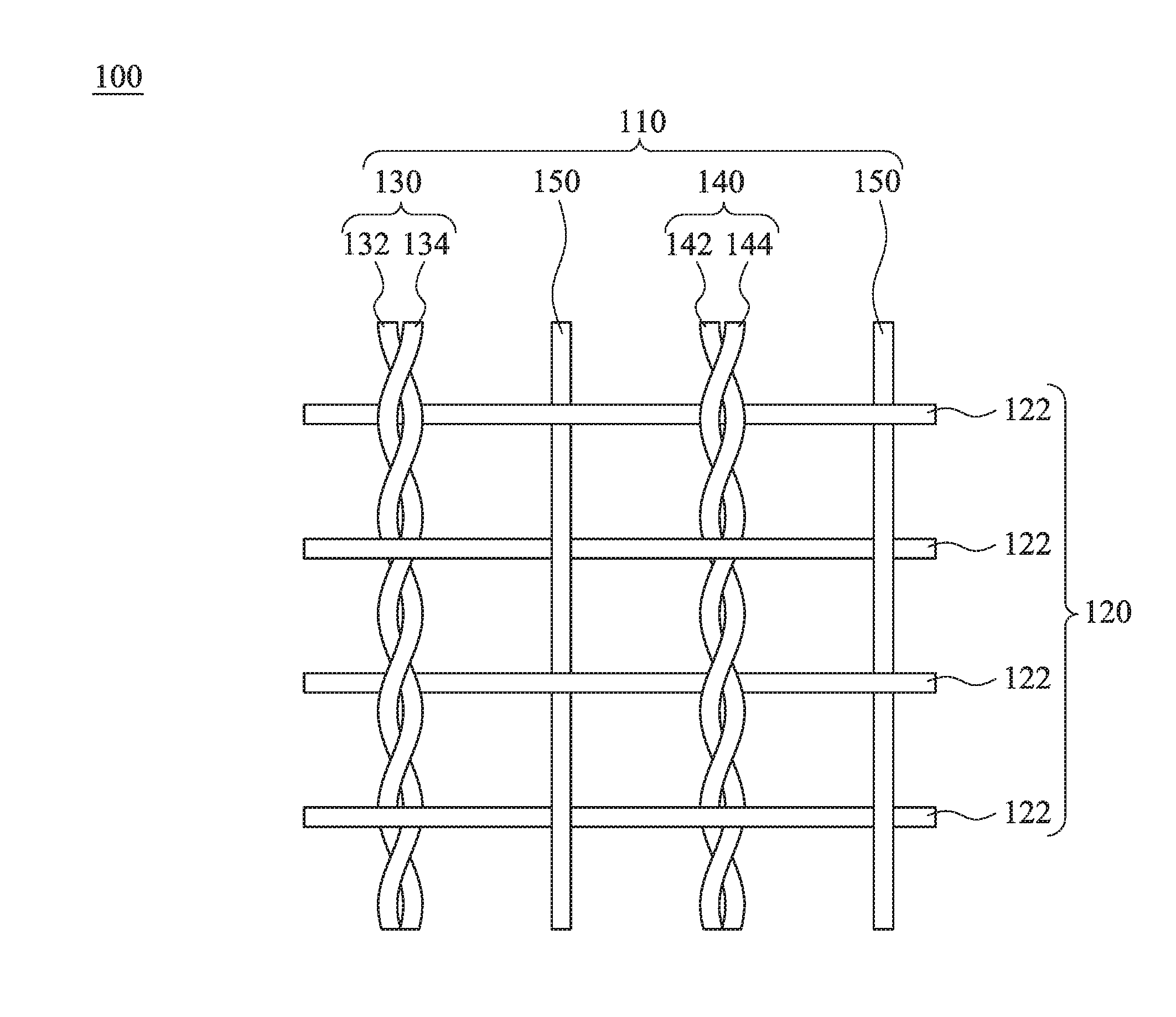

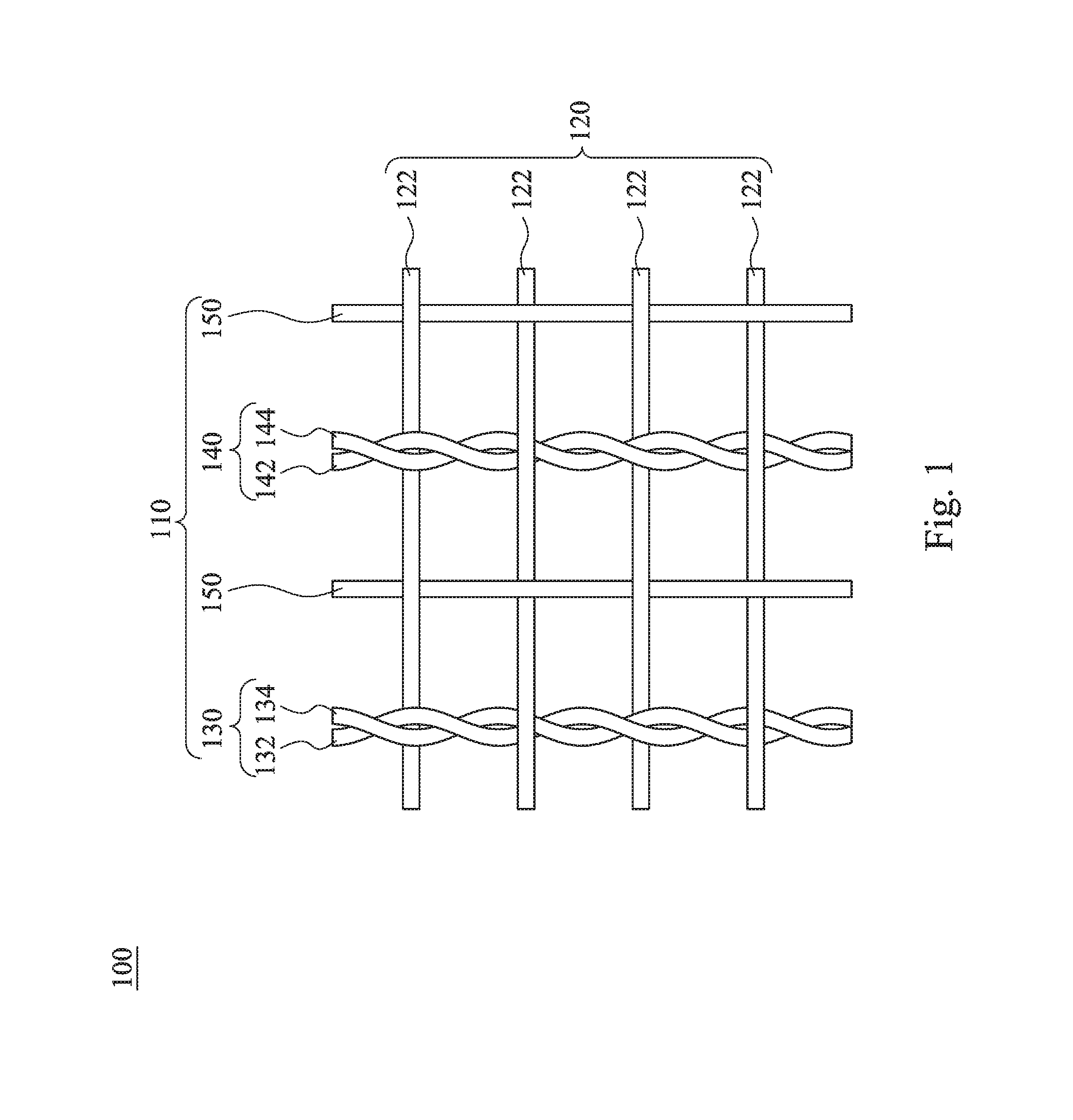

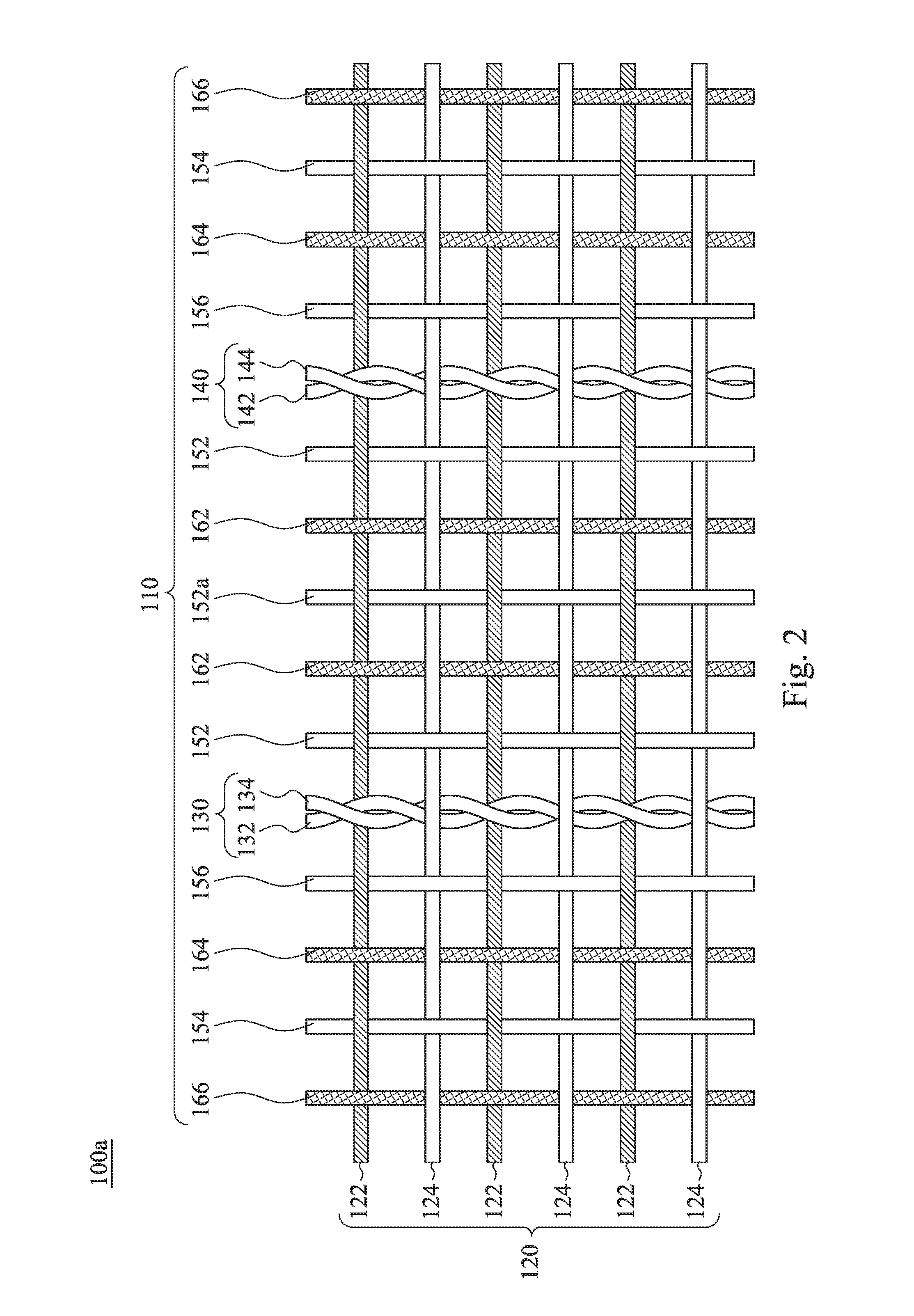

Conductive textile

A conductive textile is provided, including warp and weft, and the warp and the weft are interwoven. The warp includes a signal-transmitting unit, an electrical connecting unit, and at least a first warp conductive fiber. The signal-transmitting unit consists of a first signal-transmitting cable and a second signal-transmitting cable, which are intertwined. Each of the first signal-transmitting cable and the second signal-transmitting cable includes a central conductive fiber and an outer insulating layer. The electrical connecting unit consists of a first power cable and a second power cable. The first warp conductive fiber is disposed between the signal-transmitting unit and the electrical connecting unit. The weft includes a weft conductive fiber.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

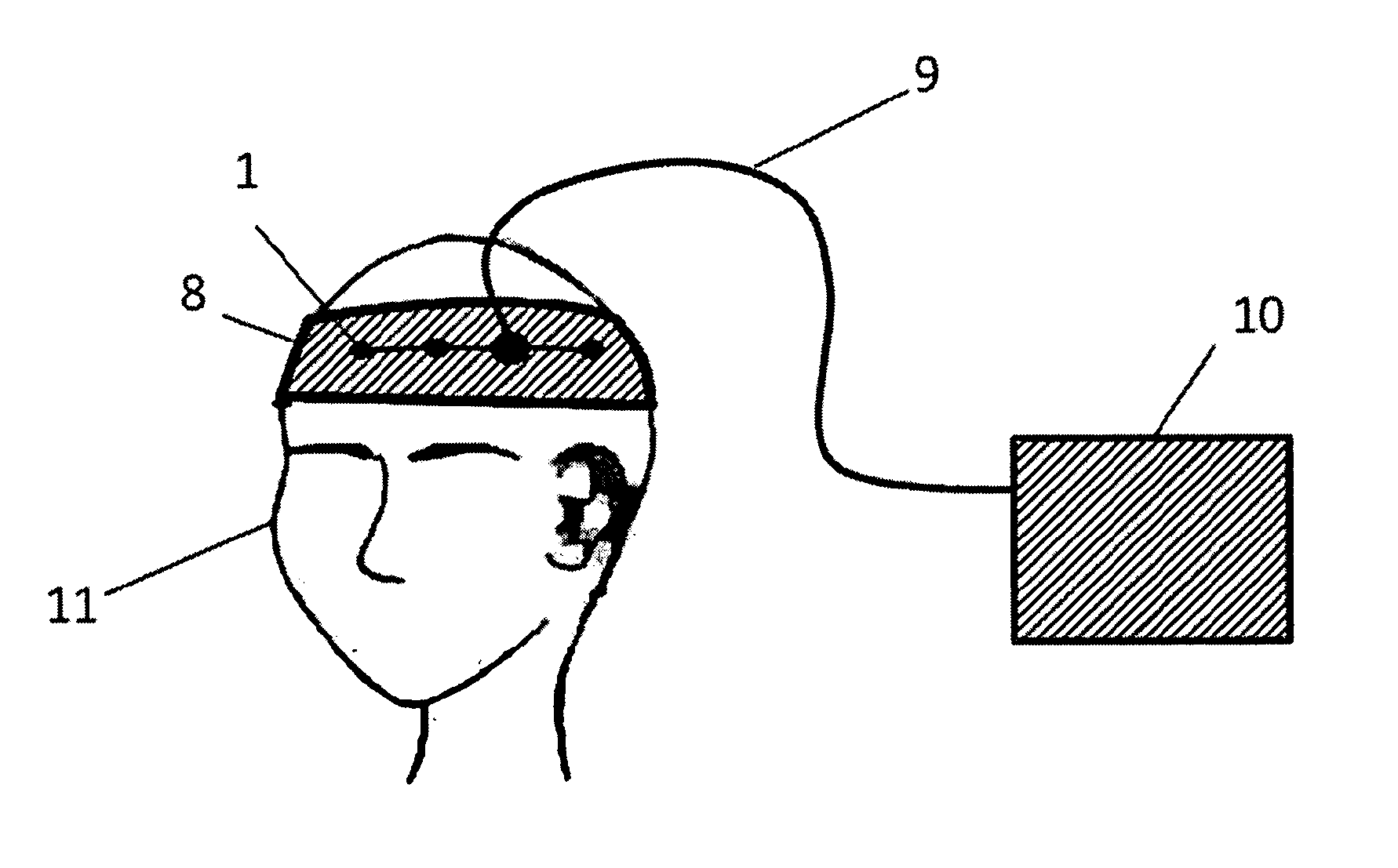

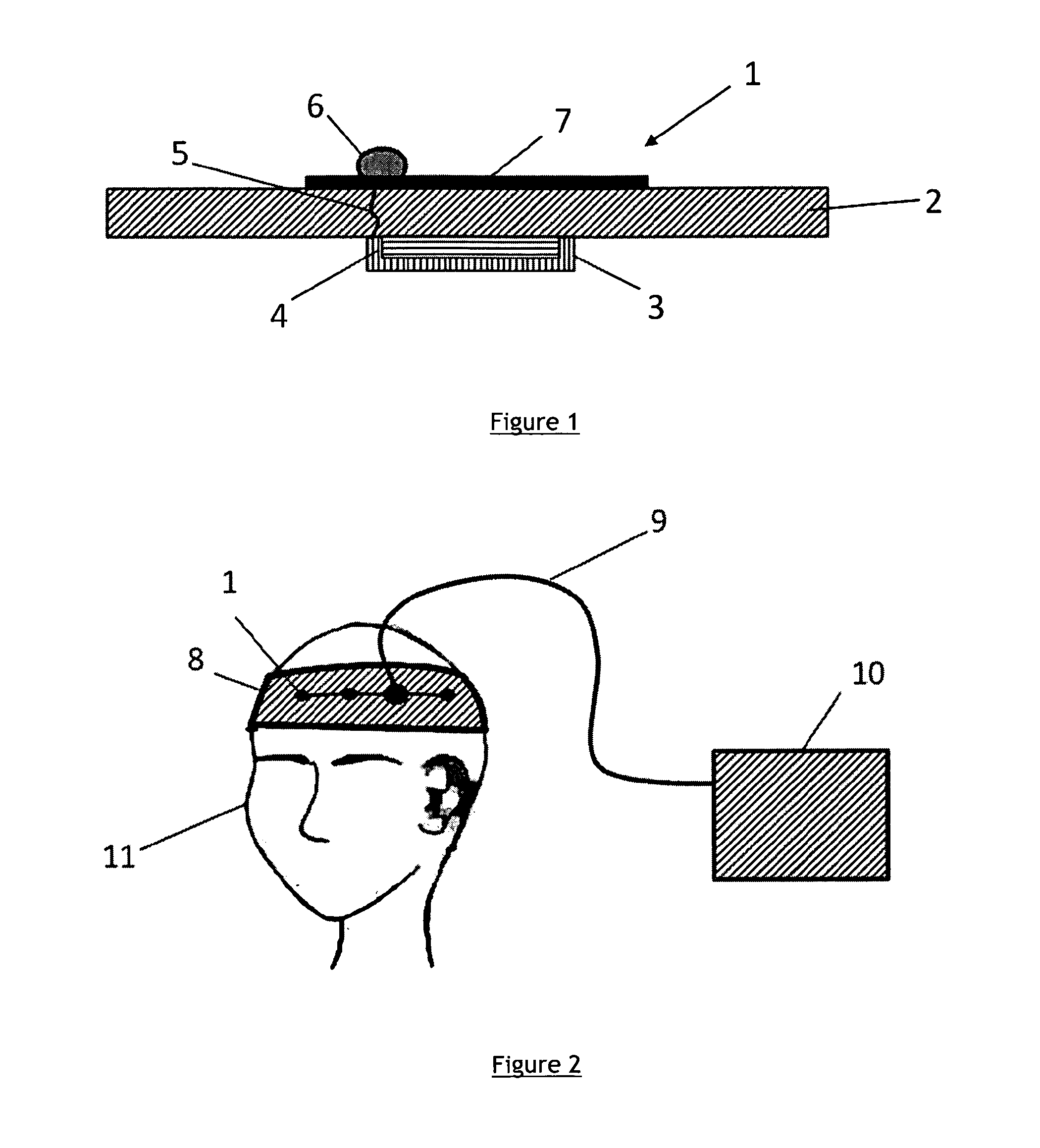

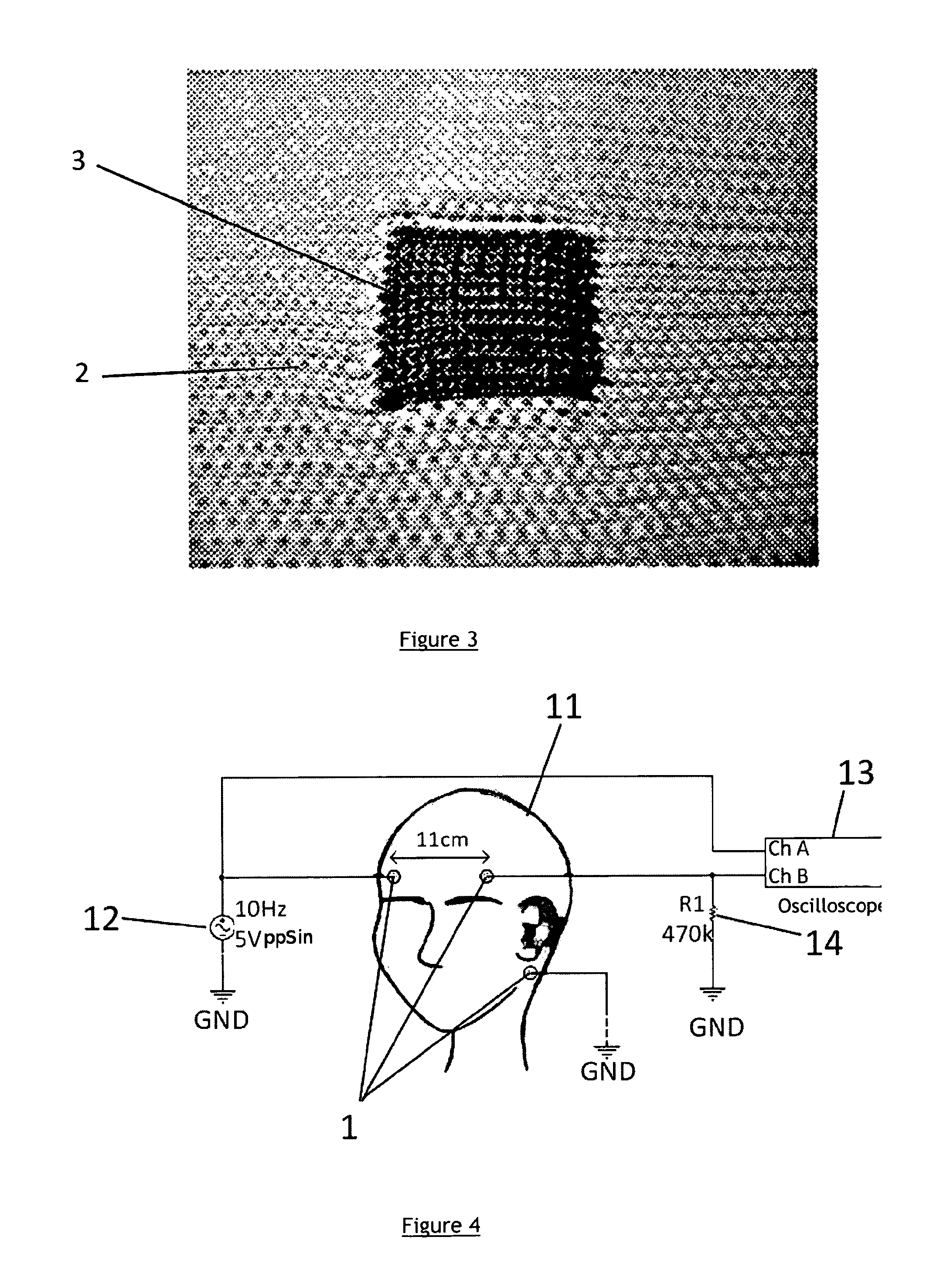

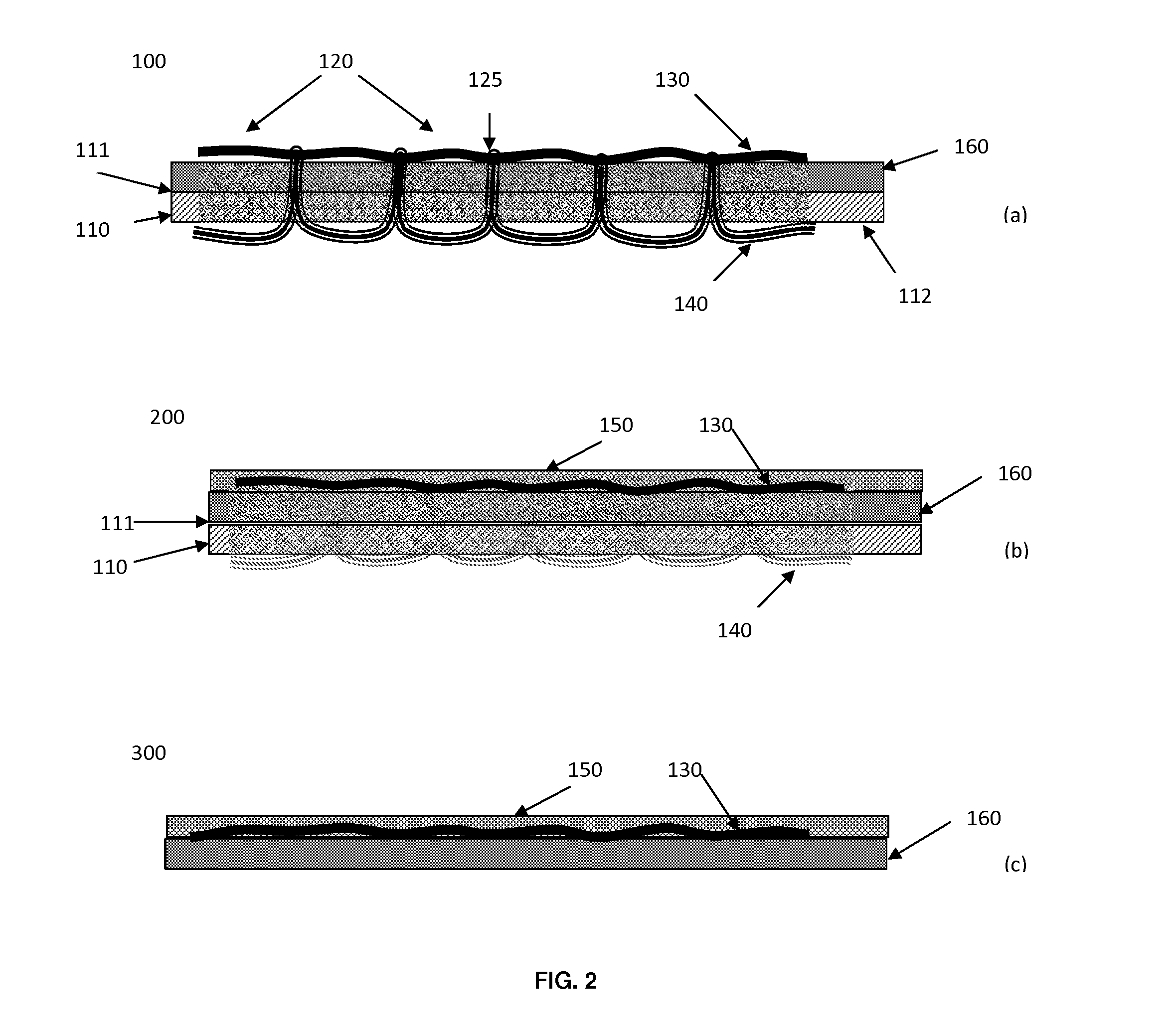

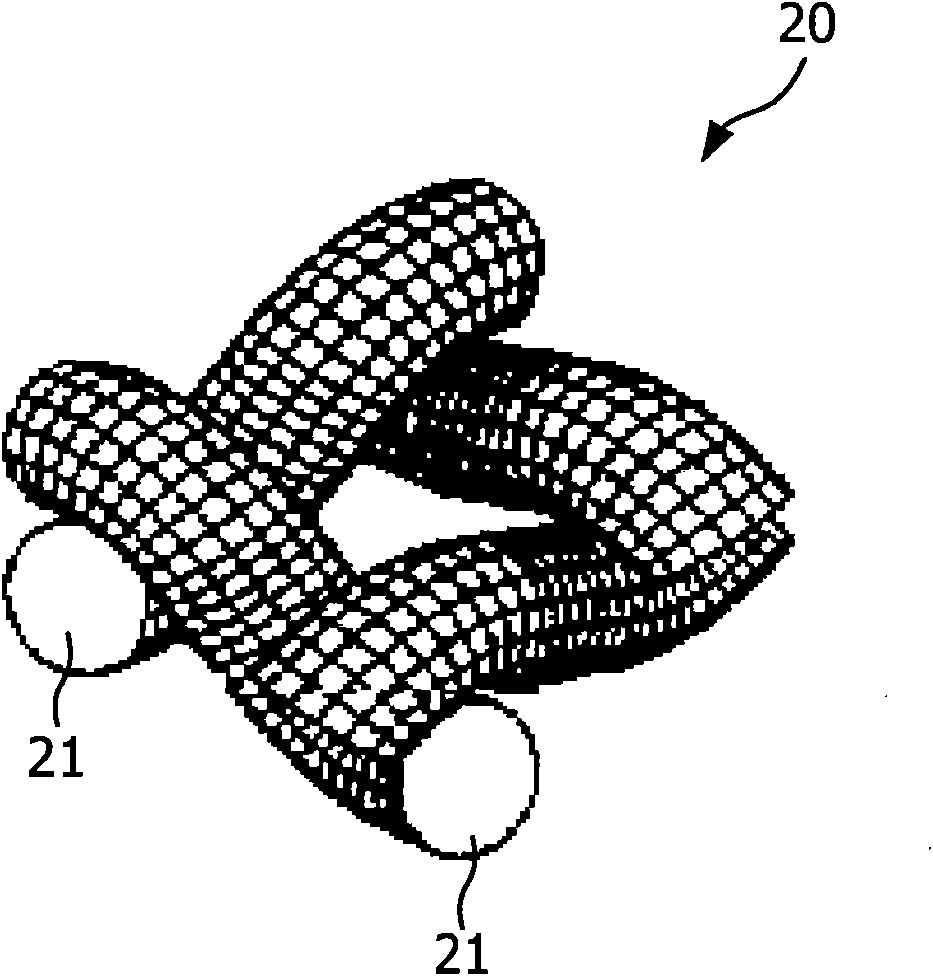

Electrode for acquiring physiological signals of a recipient

InactiveCN101854852AGood electrical conductivityReduce complexityElectrocardiographySensorsConductive textileSignal quality

The present invention relates to an electrode for acquiring physiological signals of a recipient. Furthermore the present invention relates to a textile fabric for use in a garment to be worn by a recipient, and to a monitoring system for monitoring of physiological parameters of a recipient. In order to provide an electrode for acquiring physiological signals of a recipient, which on the one hand provides a soft, and comfortable skin contact, whilst on the other hand assures a high signal quality, an electrode (1) for acquiring physiological signals of a recipient is suggested, which comprises at least two conductive textile layers (2, 3) positioned on top of each other, wherein the first layer (2) is made of a woven material, and the second layer (3) having a working surface (4) to be brought into contact with the recipient's skin is made of a knitted material.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Preparing method for copper ammonia fiber conductive textile

The invention relates to a preparing method for a copper ammonia fiber conductive textile. According to the preparing method, copper ammonia fibers serve as a base material, and polypyrrole layers and copper layers are deposited on the surfaces of the copper ammonia fibers in sequence. The specific technology comprises the steps of cleaning the copper ammonia fibers, carrying out polypyrrole in-situ chemical polymerization, carrying out self-assembly modification through a silane coupling agent, adsorbing cupric ions, reducing potassium borohydride, carrying out electroless copper plating and the like. According to the preparing method, the copper ammonia fibers serve as the base material of the conductive textile, and thus degradation of the materials and recovery and recycle of copper are facilitated. The copper ammonia fibers and conductive substances (polypyrrole and copper) are combined, the ammonia fibers are changed into a conductor from an insulator, and thus the application of the ammonia fibers is developed. The silane coupling agent can serve as a molecule bridge of the polypyrrole layers and the metal layers, and the reliability of products is improved. Conductive macromolecule chemical polymerization and chemical plating are combined, and thus the problems that a conductive textile prepared from macromolecule polymerization or chemical plating alone is poor in conductivity, low in shielding effect and the like are solved. The cost is low, the process is simple, and the degree of dependency on instruments and equipment is low.

Owner:FUDAN UNIV

Method for limiting elasticity of selected regions in knitted fabrics

ActiveUS9416470B2Maintaining dimensionElasticity of moreGarment special featuresElectrocardiographyConductive textileEngineering

A method for substantially reducing the elasticity of at least one selected textile region of a garment. The method includes producing the garment including a conductive textile electrode and rigidifying the at least one selected textile region. The rigidifying process includes applying rigidifying matter onto or into the at least one selected textile region. The at least one selected textile region is selected from the group consisting of a conductive textile electrode and a region of the garment situated between two adjacent textile electrodes. The invention further provides a garment having a tubular form, knitted by a seamless knitting machine with base-yarns. The garment includes at least one conductive textile electrode, composed of multiple knitted line segments, each knitted with a conductive yarn and a spandex yarn, wherein the spandex yarn and at least one base-yarn are knitted continuously.

Owner:HEALTHWATCH LTD

Float loop textile electrodes and methods of knitting thereof

InactiveCN104955346AIncrease pressureImprove tightnessElectrocardiographyWeft knittingConductive textileTextile electrodes

A method for knitting a garment having a tubular form, including knitting at least one conductive textile electrode on a machine having N participating feeders and M needles. The method includes the steps of continuously knitting the tubular form with one or more flexible non-conductive yarns, and knitting the electrode integrally within the tubular form, using a conductive yarn, in addition to the non-conductive yarns. The conductive yarn is knitted in a float-loop form by knitting a stitch and skipping over y needles, as follows: repeatably knitting a line segment Lk, using feeder Fi and starting at needle D1 and knitting line segment Lk+1, using the next feeder and start stitching the first float-loop at needle D1+s where 0<s<y. The tubular form has a preconfigured 10 knitting density, wherein the electrode has a knitting density that is higher than the preconfigured knitting density of the tubular form.

Owner:HEALTHWATCH LTD

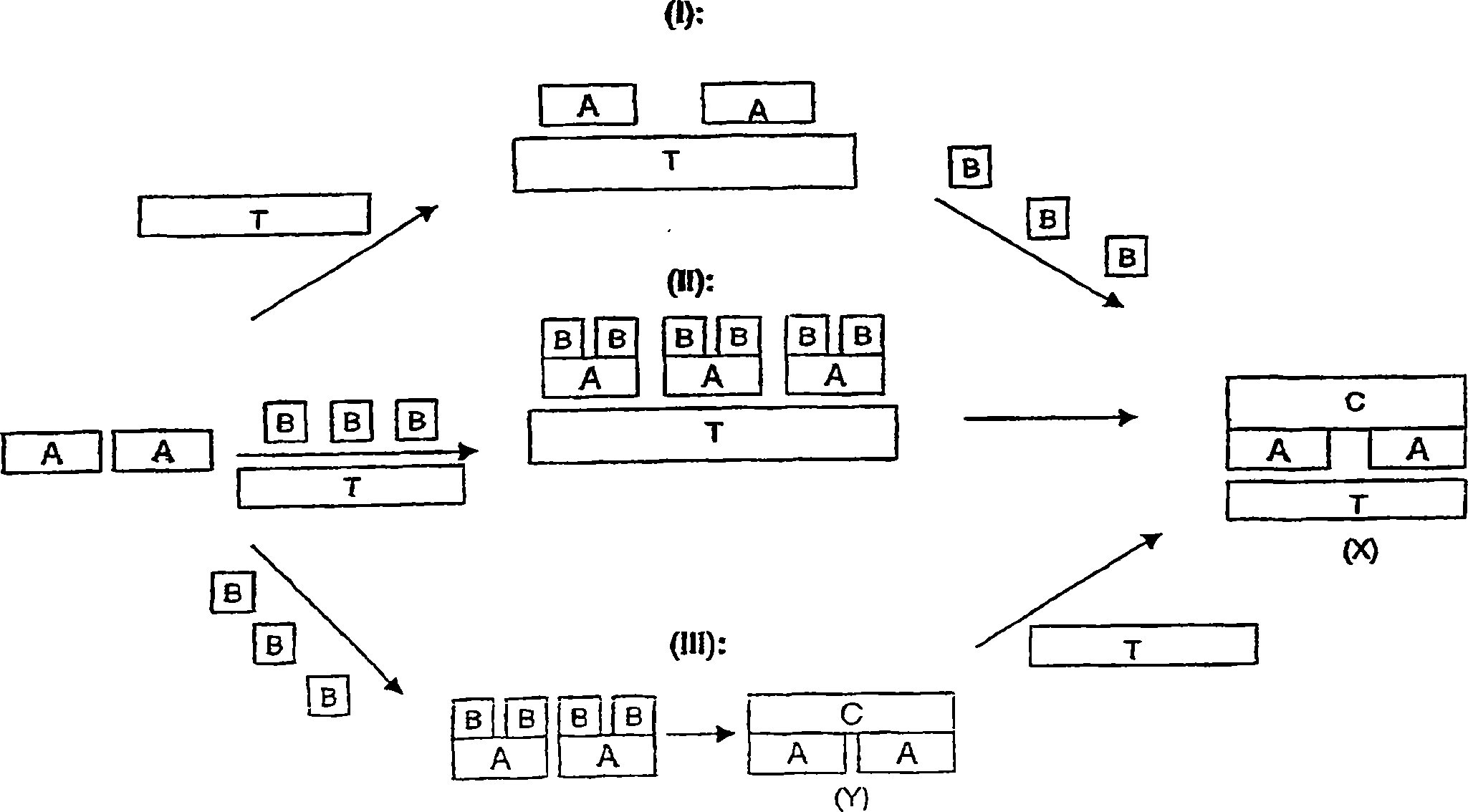

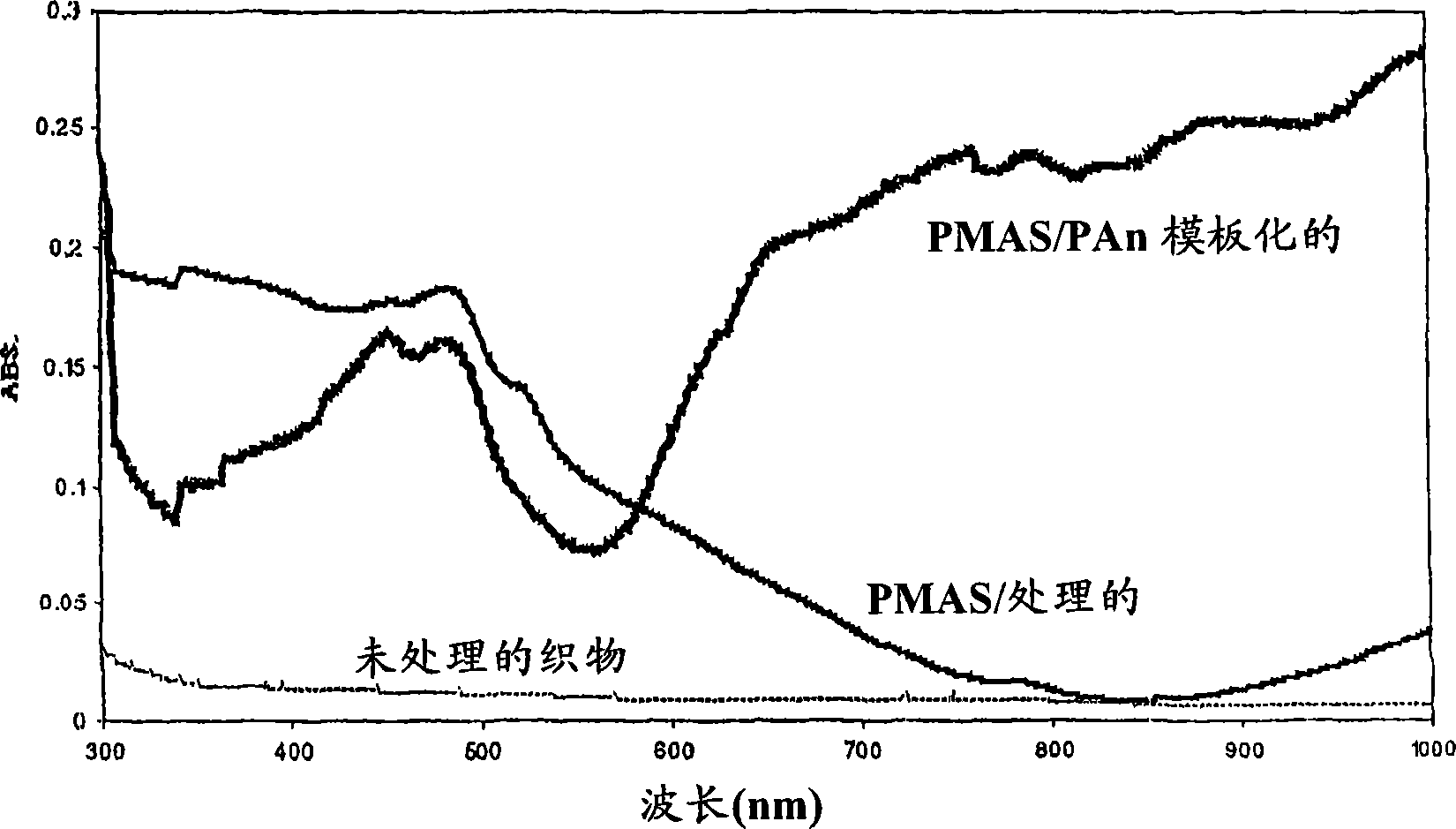

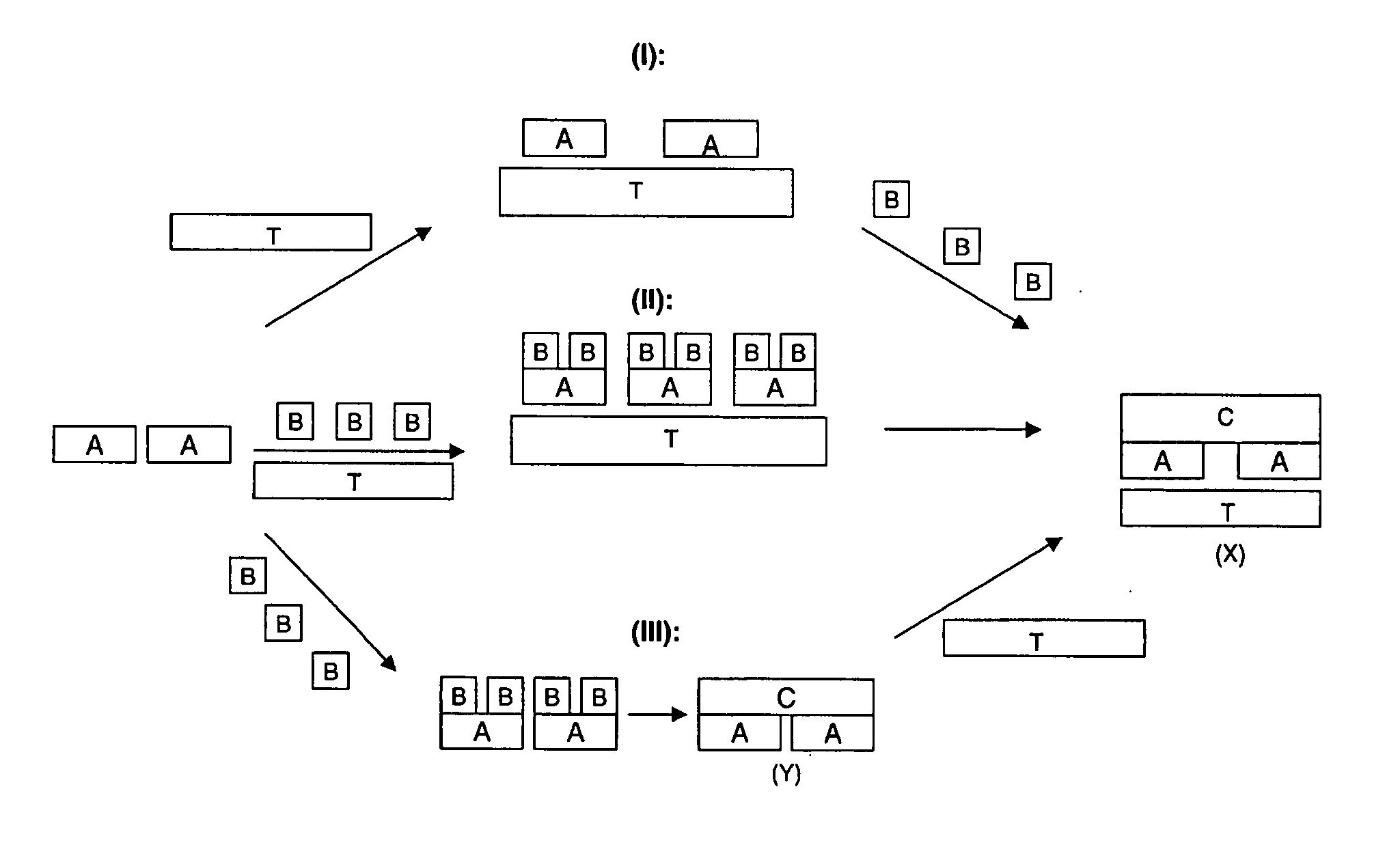

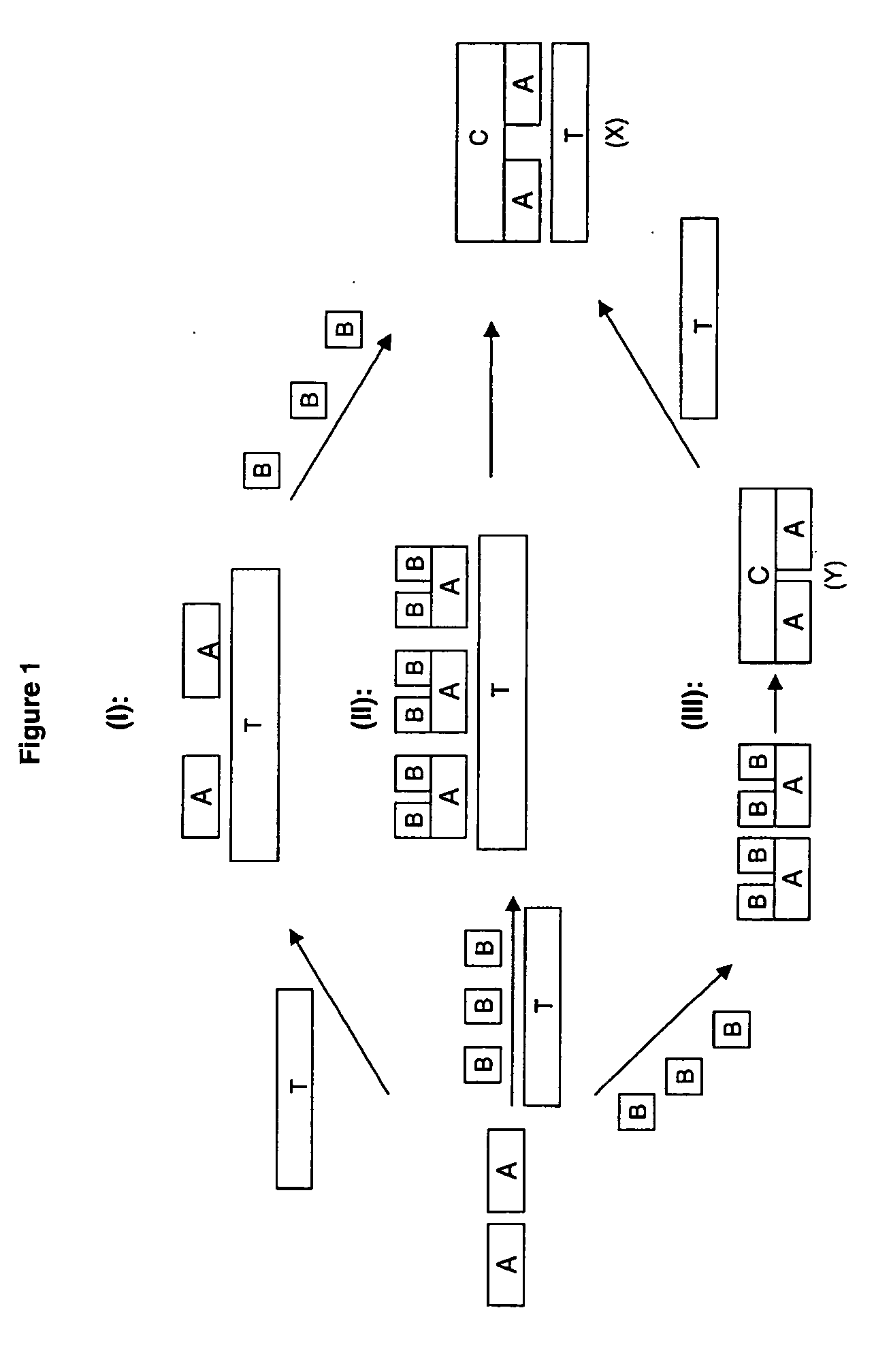

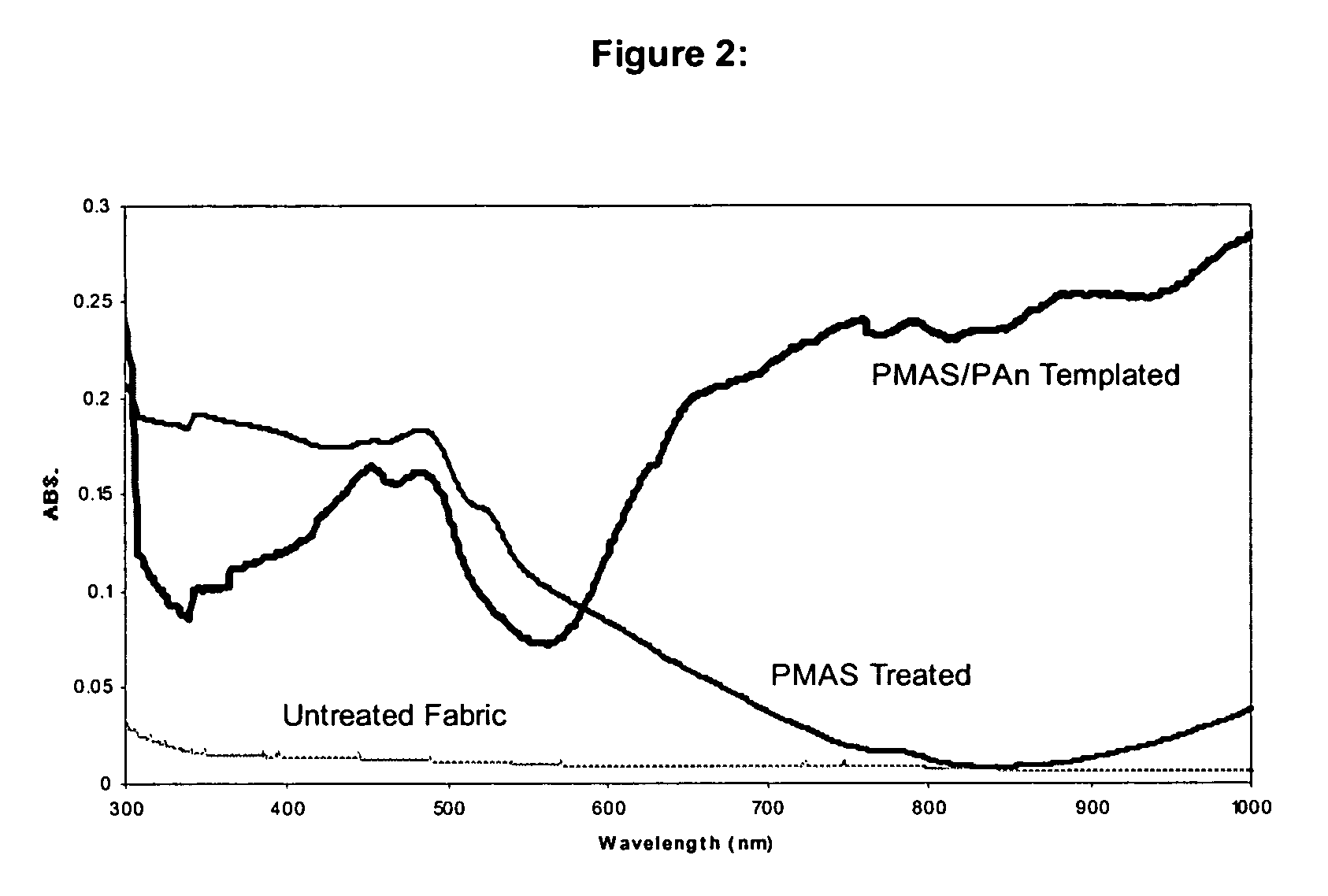

Electroconductive textiles

An electroconductive textile comprising: a non-conductive textile such as a wool-containing fabric, a macromolecular template which is bonded to or entrapped in the non-conductive textile such as poly 2-methoxyaniline-5-sulfonic acid (PMAS), and a conductive polymer which is ordered by and bonded to the macromolecular template such as polyaniline; in which the macromolecular template binds the conductive polymer to the non-conductive textile.

Owner:COMMONWEALTH SCI & IND RES ORG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com