Patents

Literature

134 results about "Electrically conducting yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electrically conducting yarn is a yarn that conducts electricity. Conducting yarns are used to manufacture carpets and other items that dissipate static electricity, such as work clothes in highly flammable environments, e.g., in the petrochemistry industry.

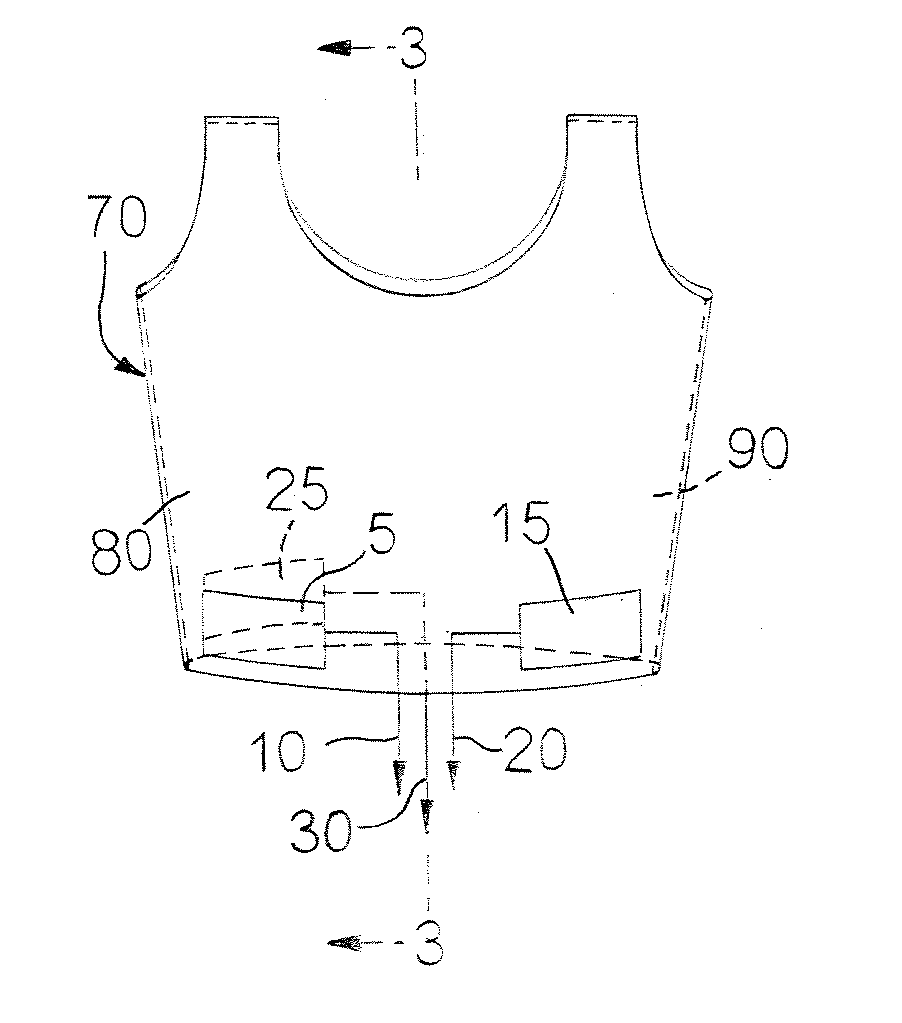

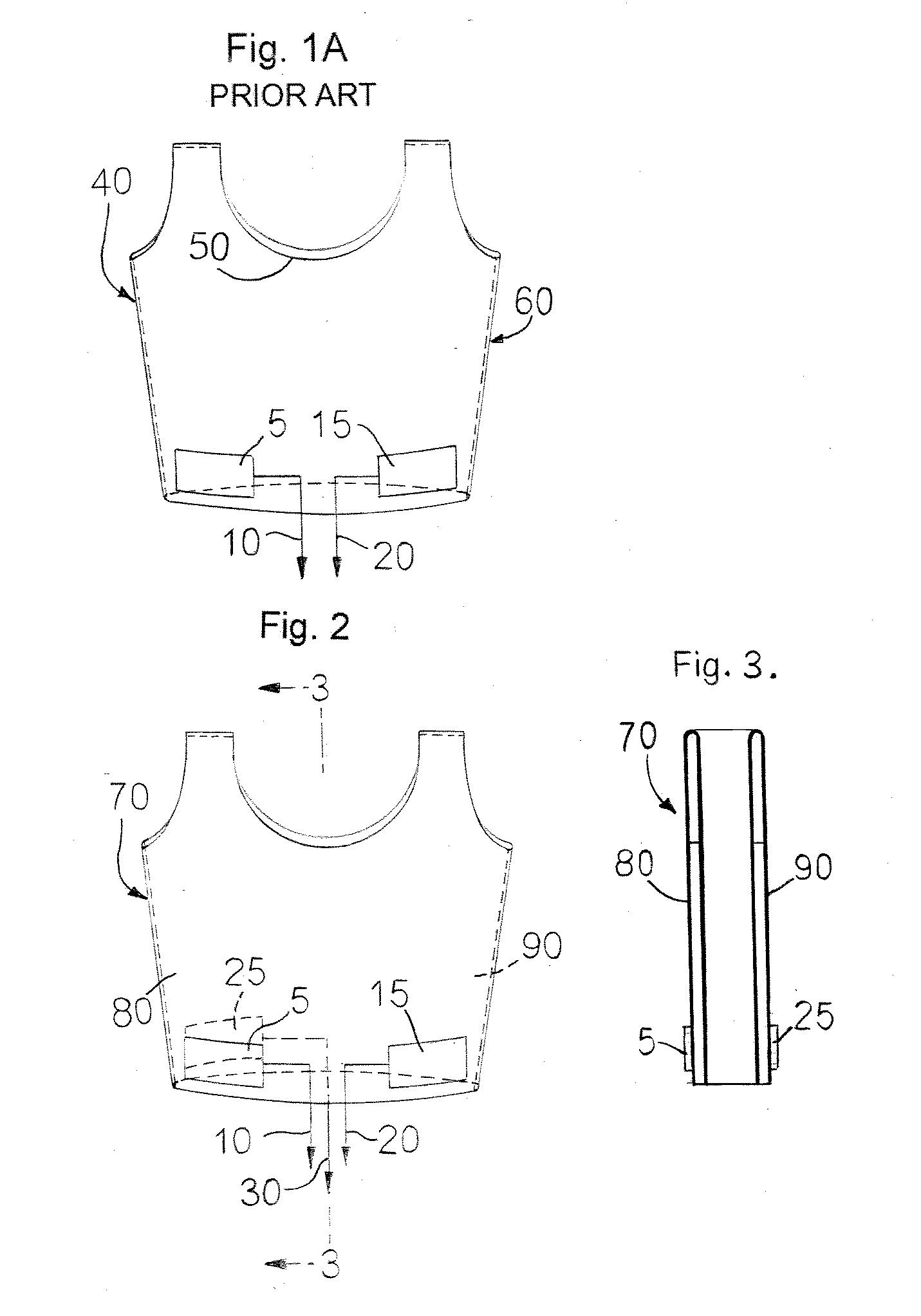

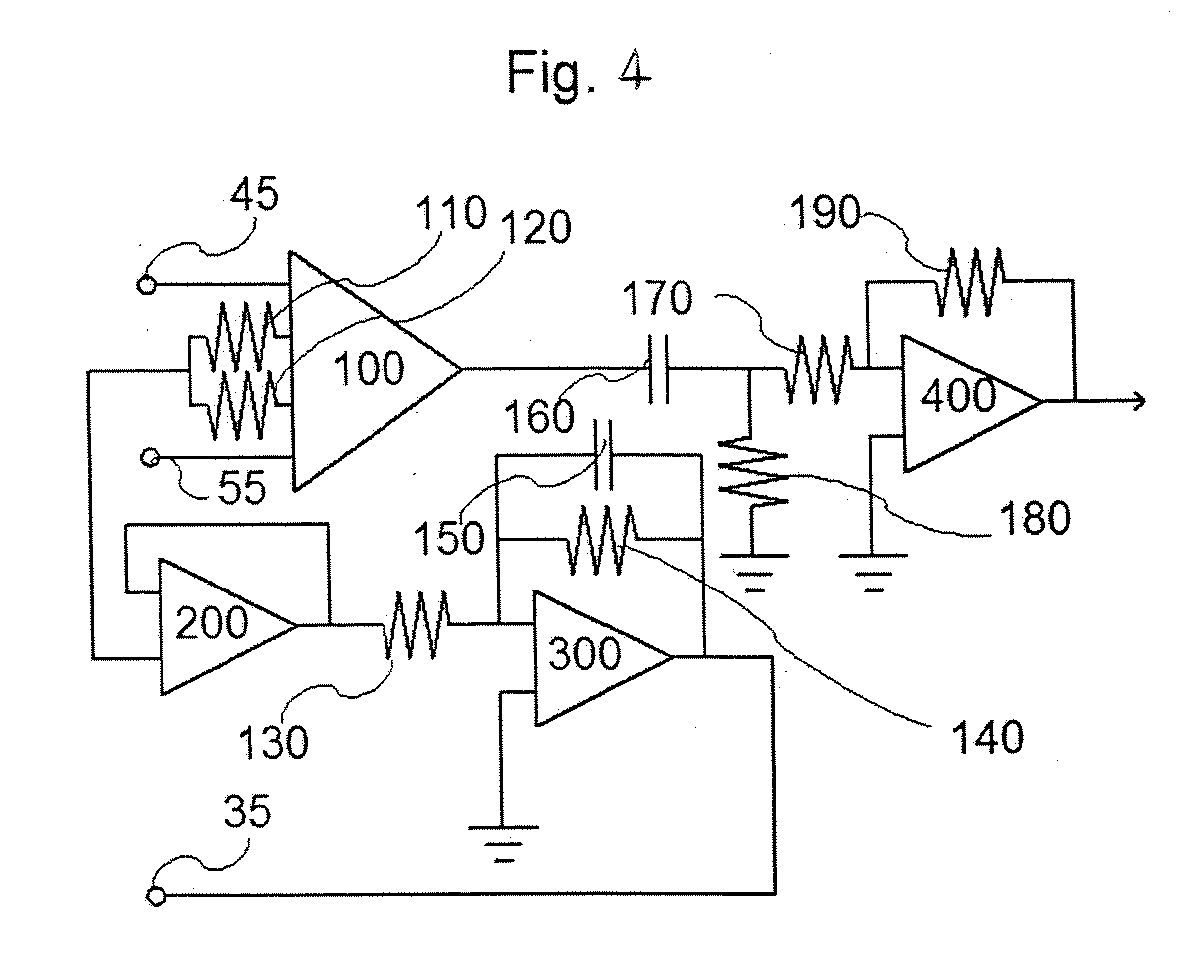

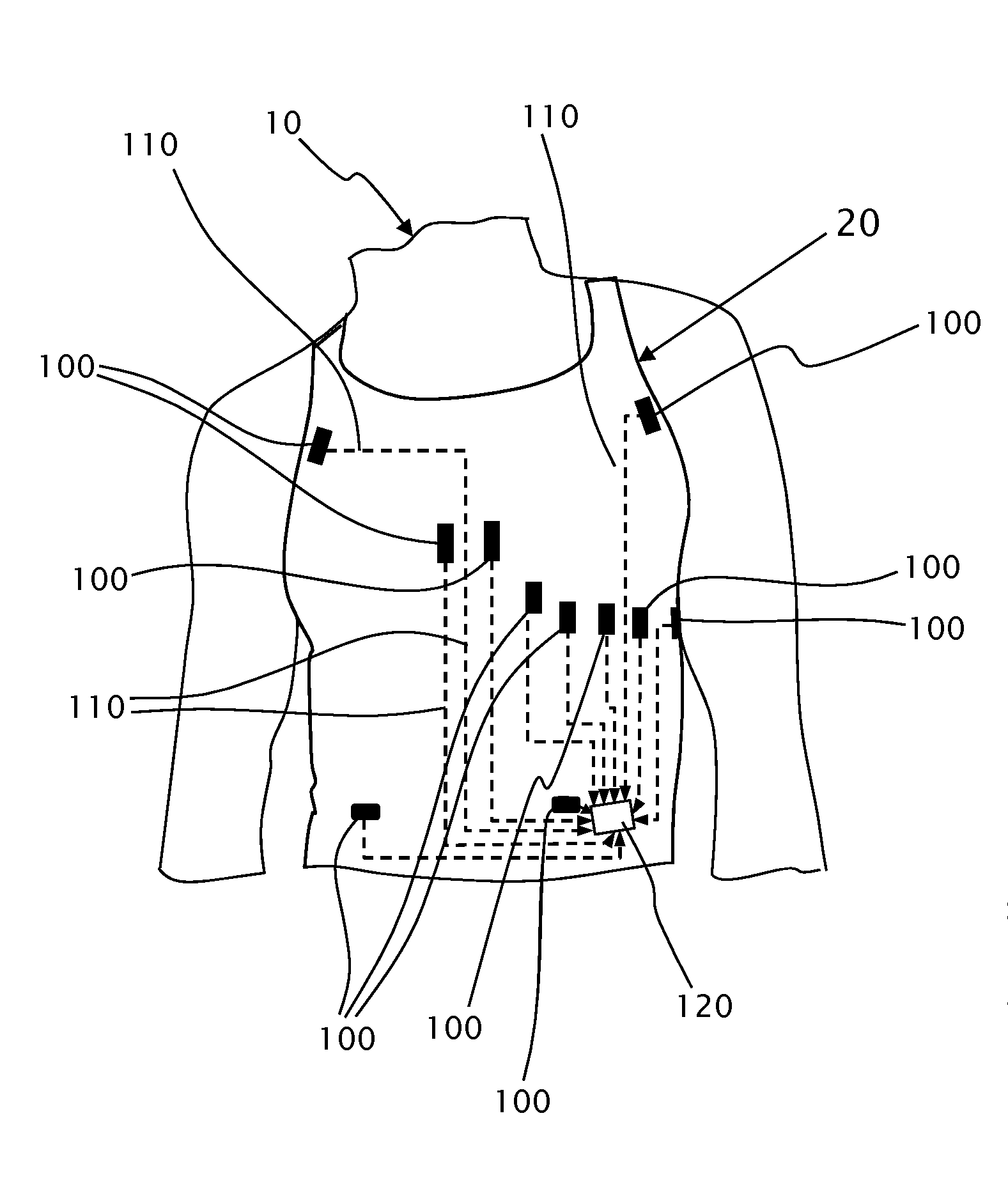

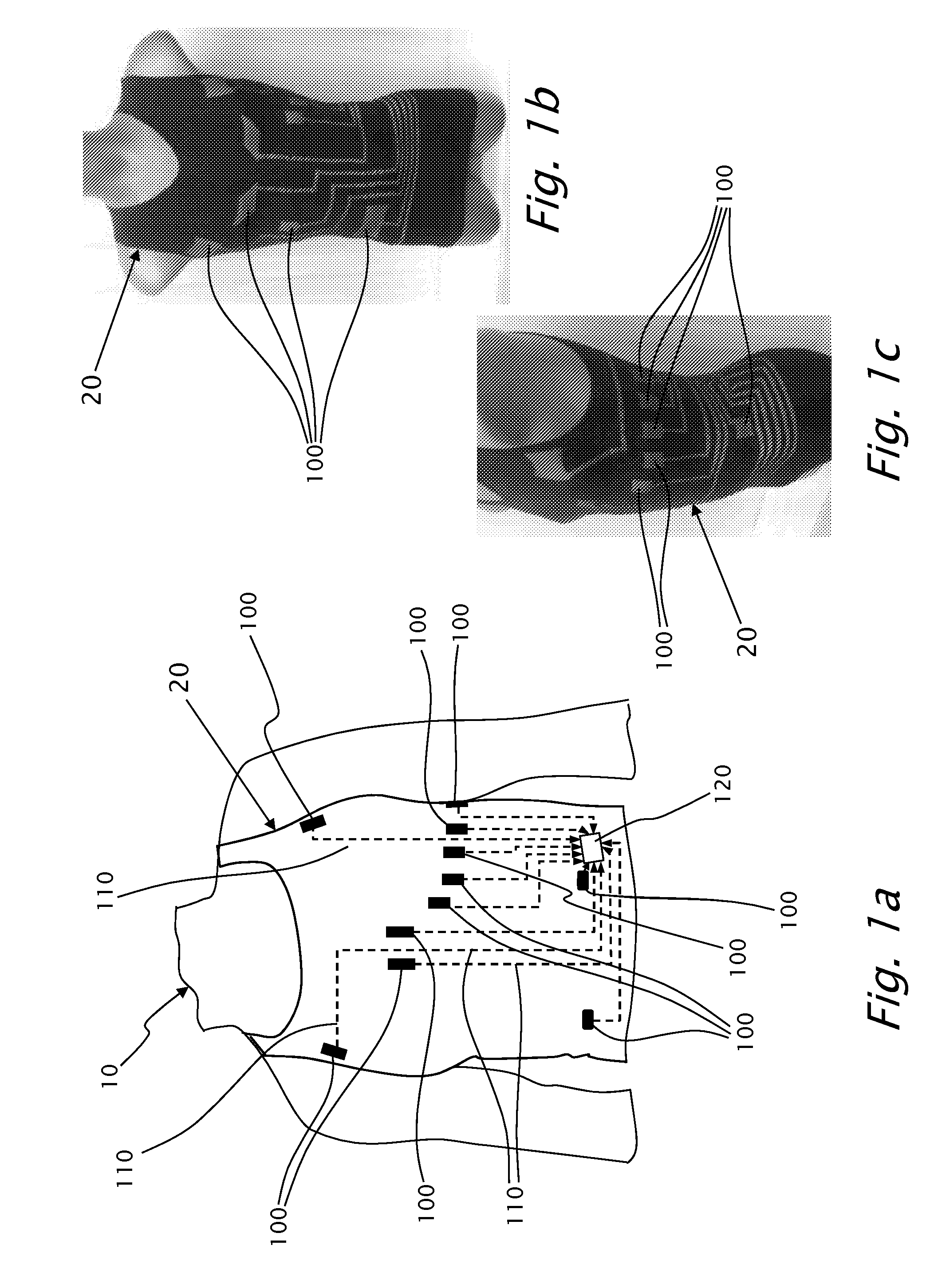

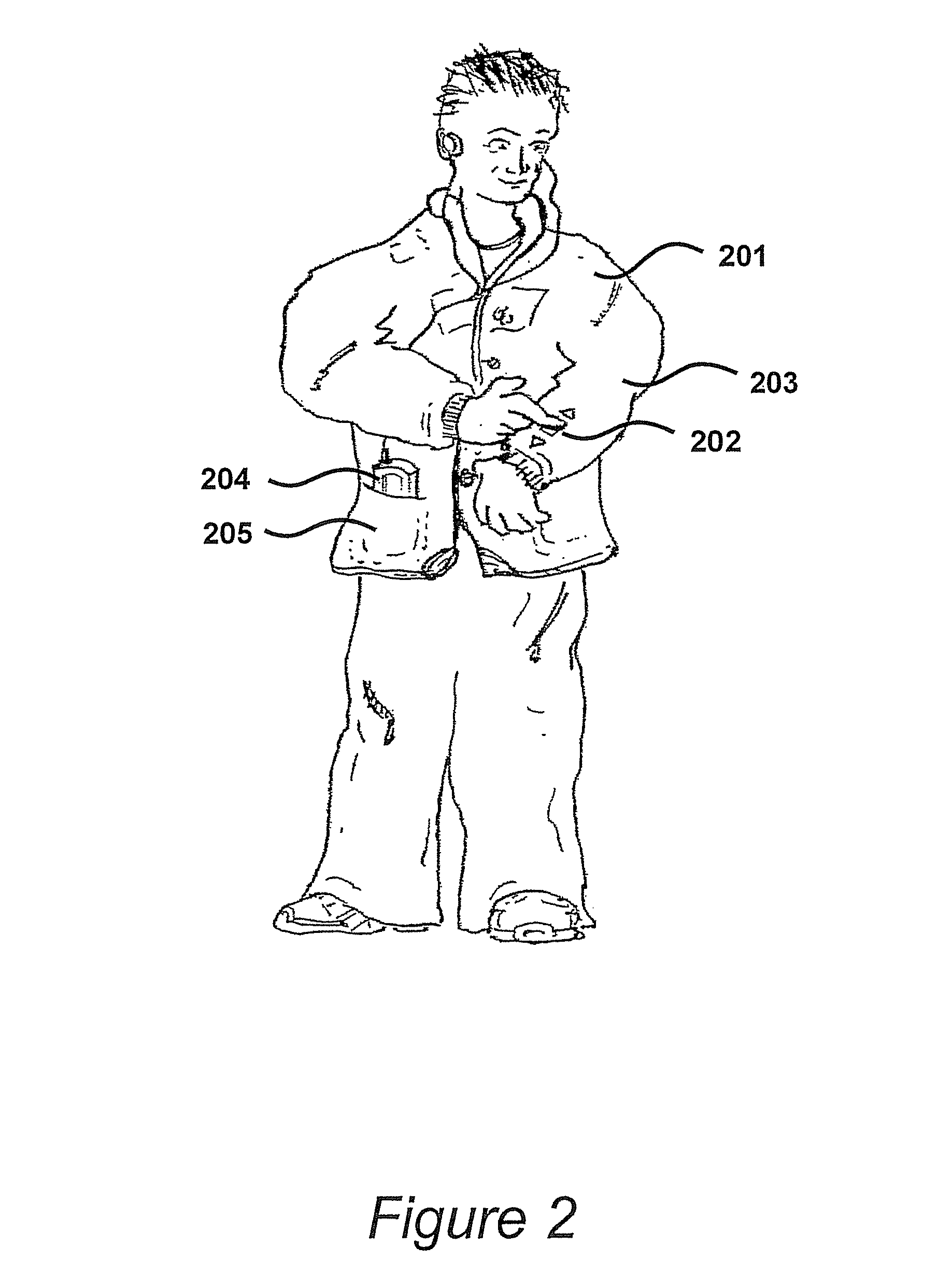

Physiological Monitoring Wearable Having Three Electrodes

A wearable system or garment comprises at least three conductive electrodes that may, for example, be made of stretch-recovery electrically conductive yarns integrated with non-conductive stretch-recovery yarns that make up the remaining portion of the wearable system or garment. The wearable or garment further comprises means for using three electrodes to monitor at least one physiological or biophysical event or characteristic of the wearer. One electrode is specifically used to feed back an inverted noise signal to the wearer to destructively interfere with the wearer generated noise. Specifically, the wearer's heart rate, ECG and associated electrical characteristics may be monitored in high resolution under dry electrode conditions.

Owner:TEXTRONICS

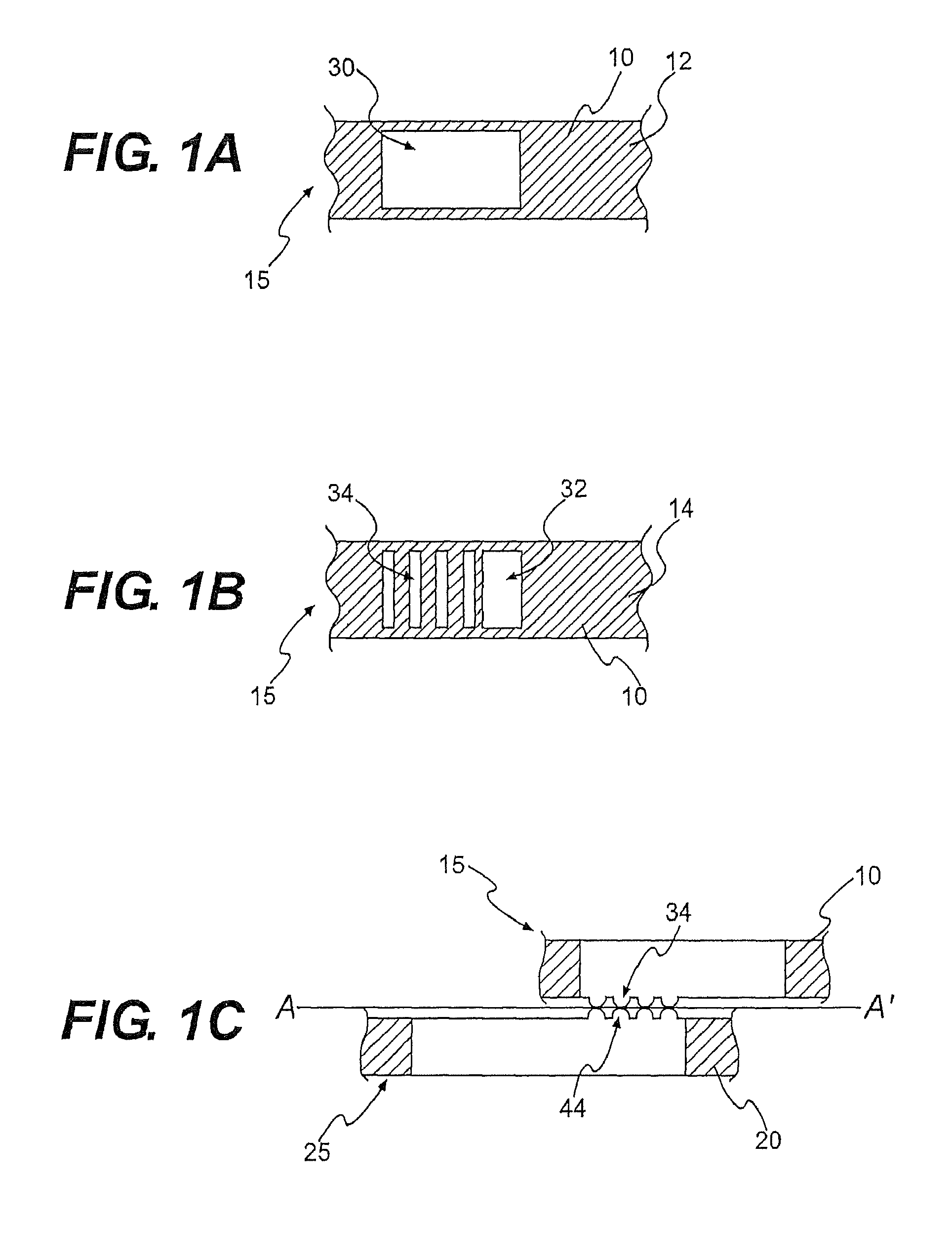

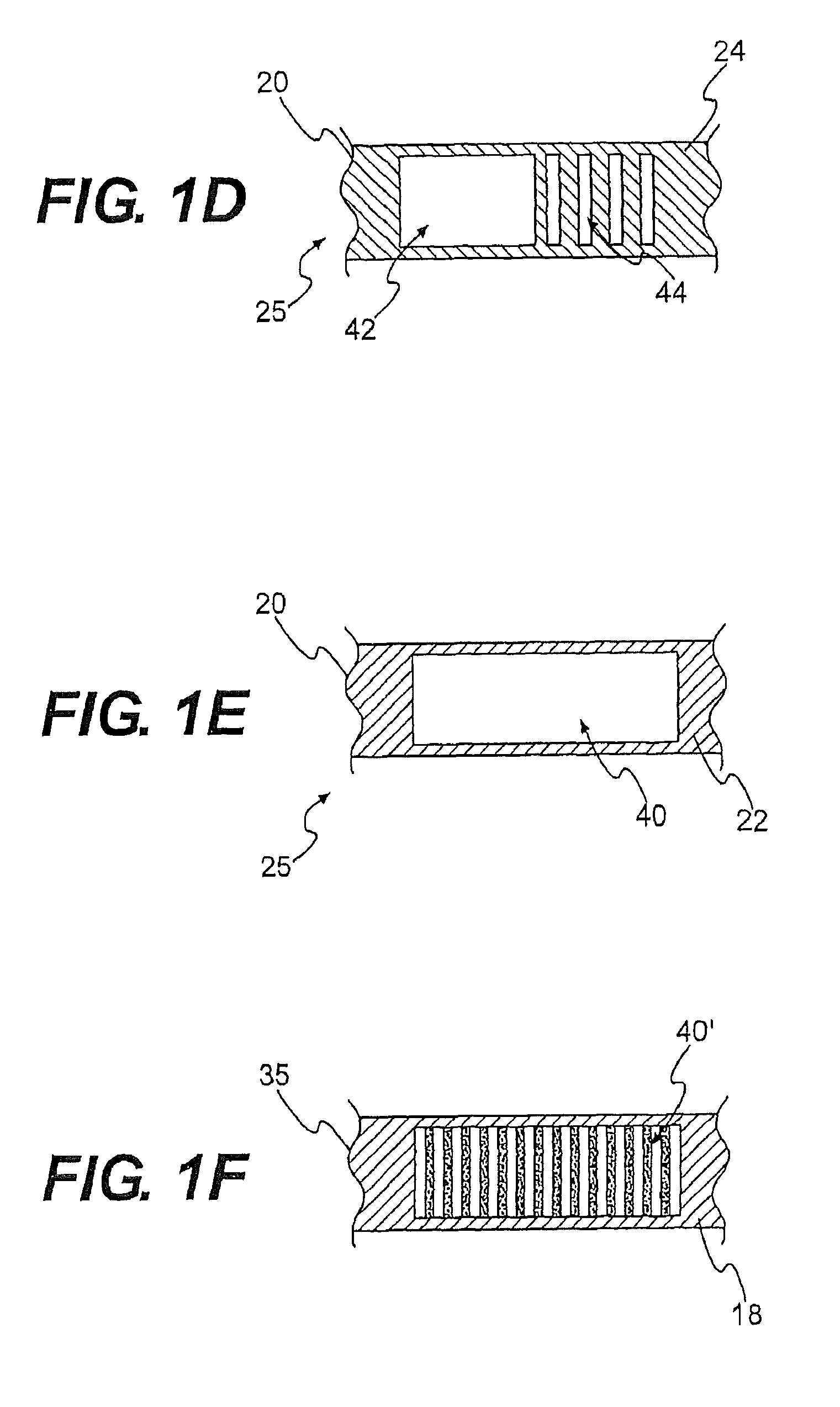

Textile-based electrode

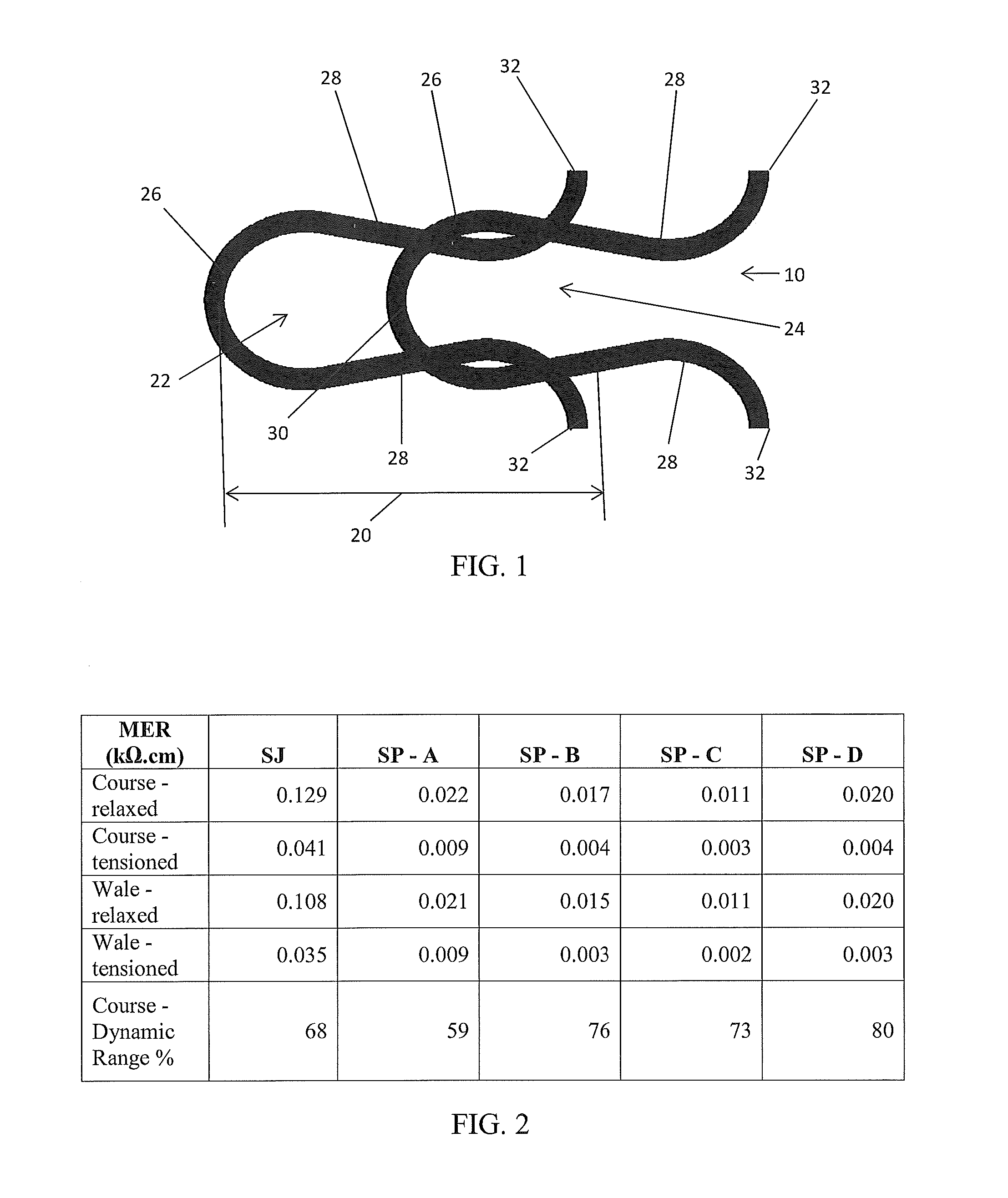

Textile-based electrodes include a fabric portion having stretch-recovery non-conductive yarns and an electrically conductive region having stretch-recovery electrically conductive yarn filaments. The electrodes can further include float yarns and can be configured in a textured or ribbed construction. When incorporated into a garment, the electrodes can be used to monitor biophysical characteristics, such as the garment wearer's heart rate.

Owner:ADIDAS +1

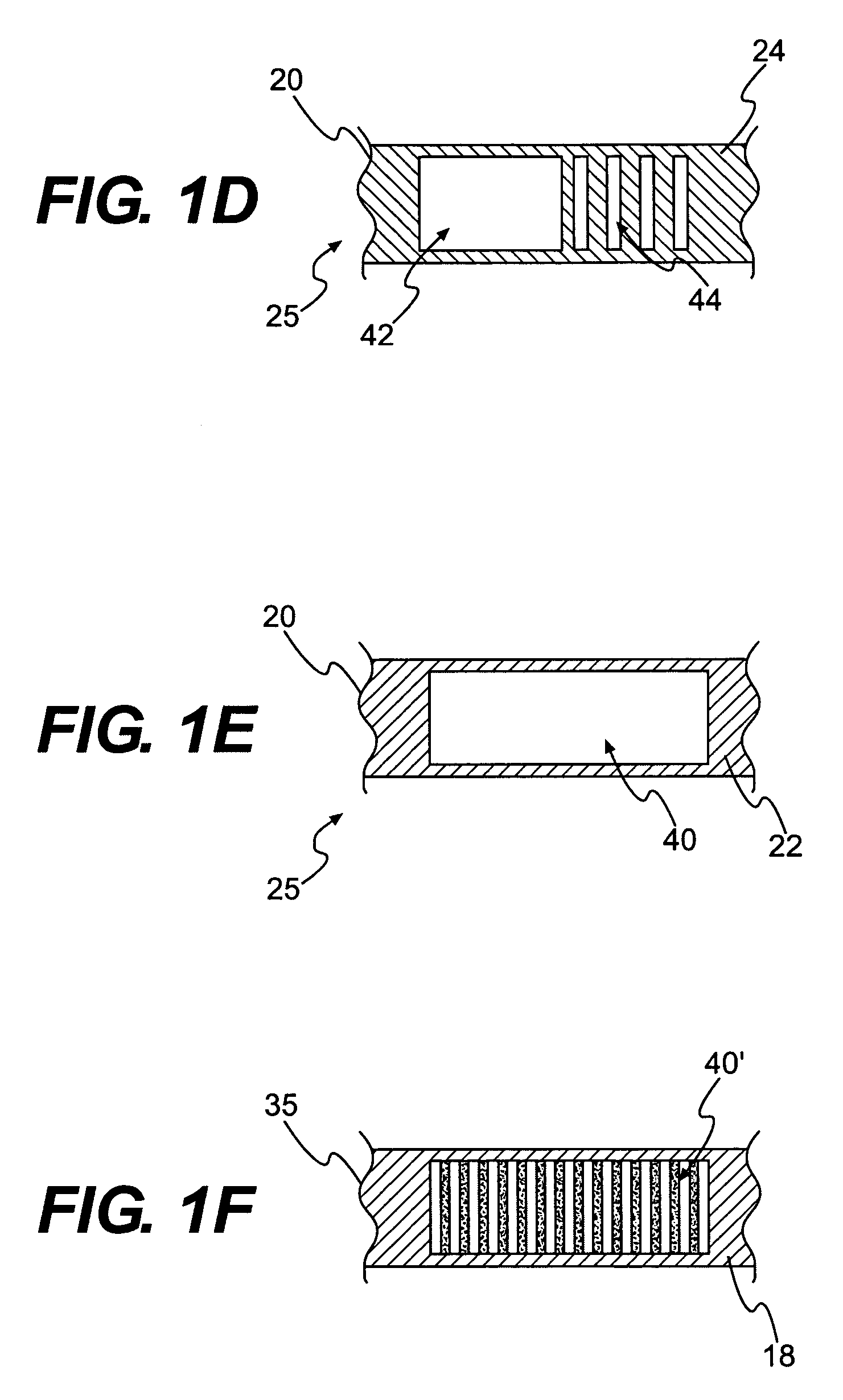

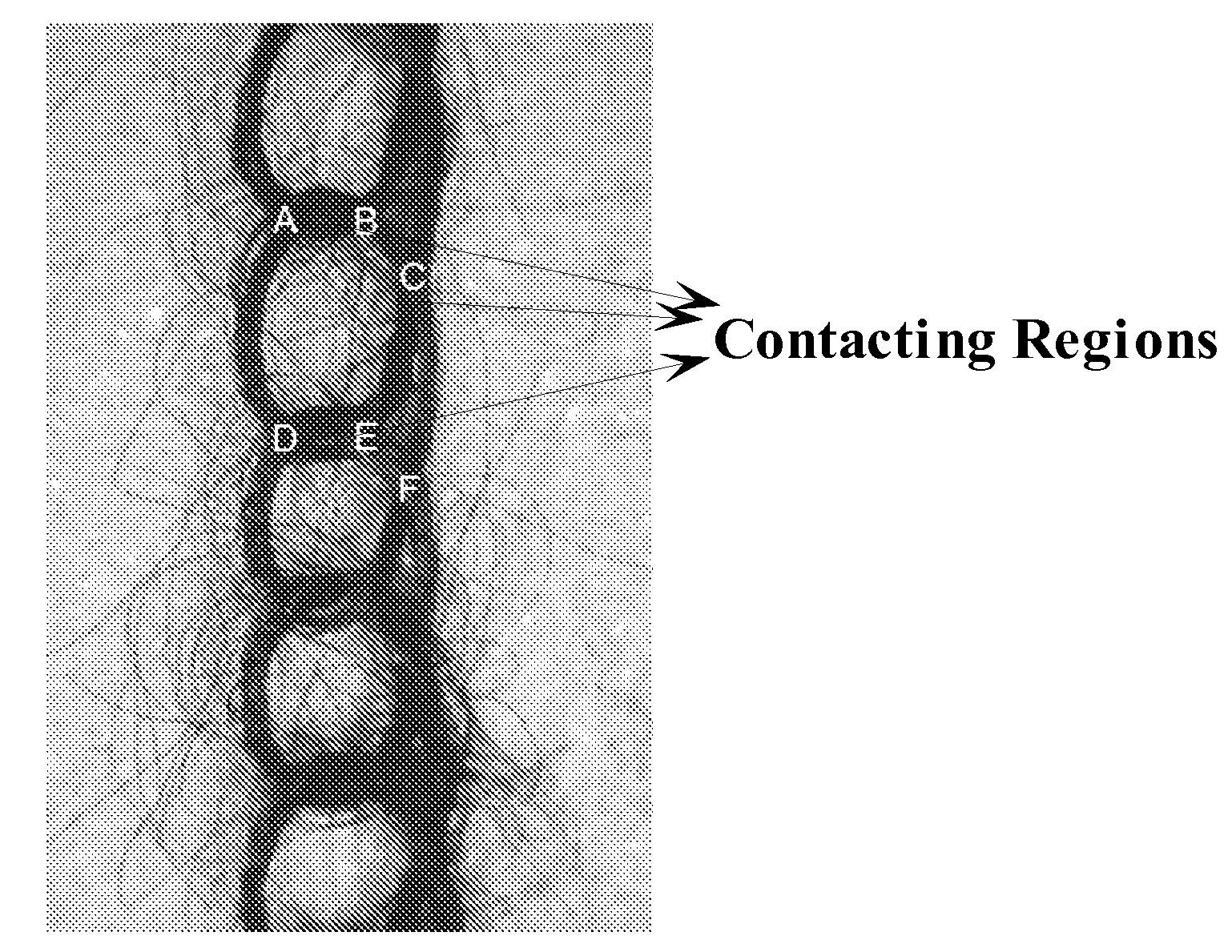

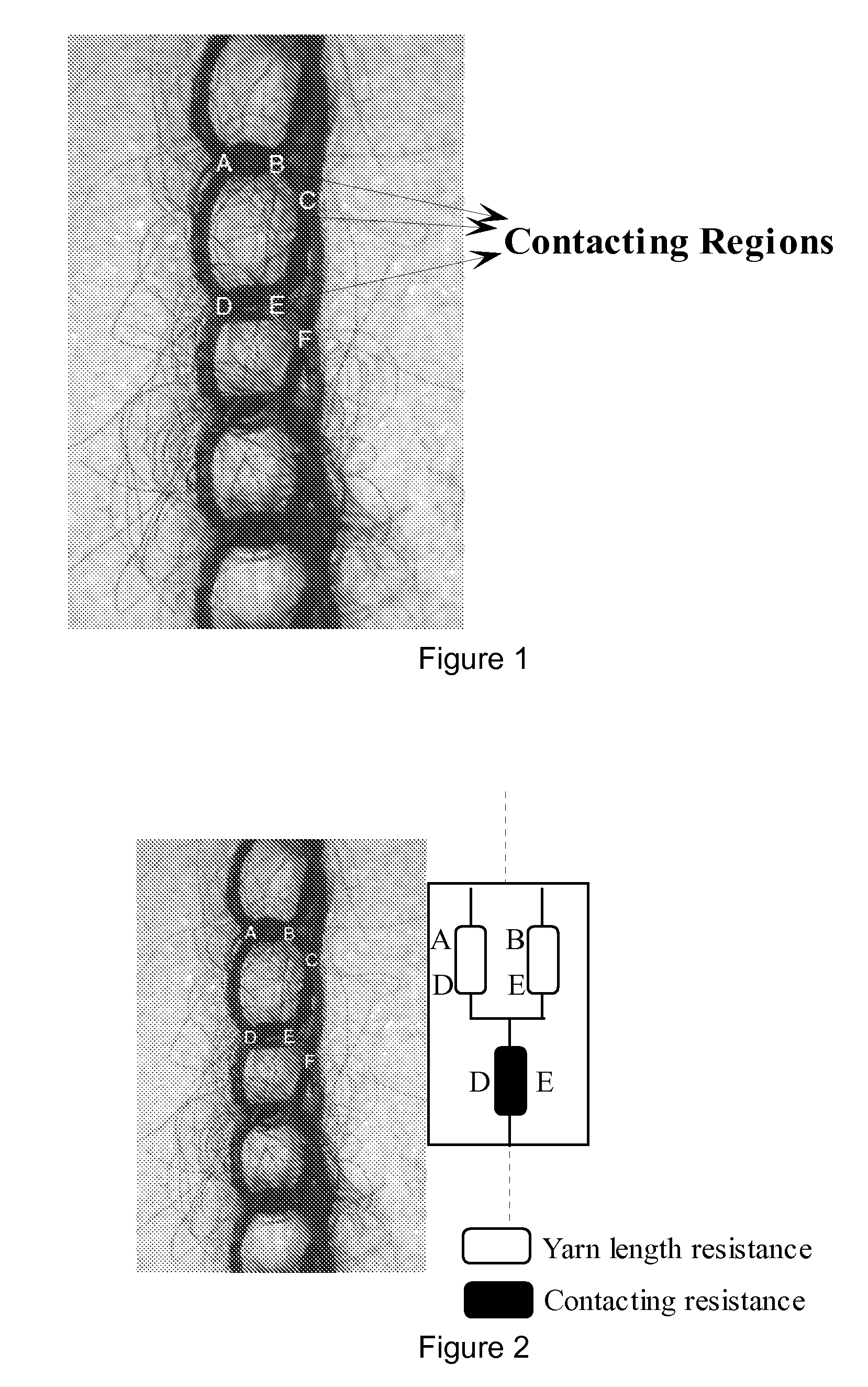

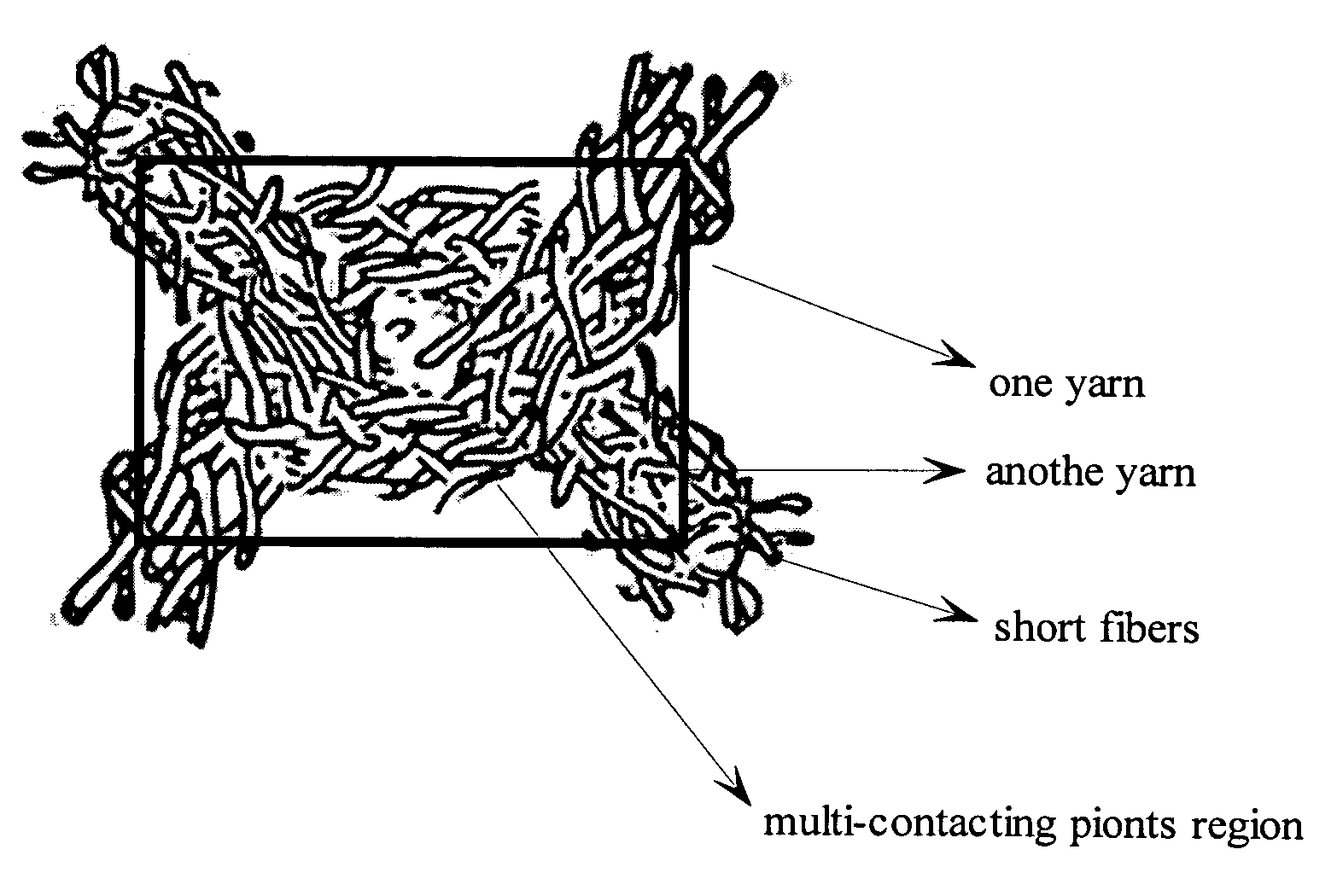

Pressure sensing fabric

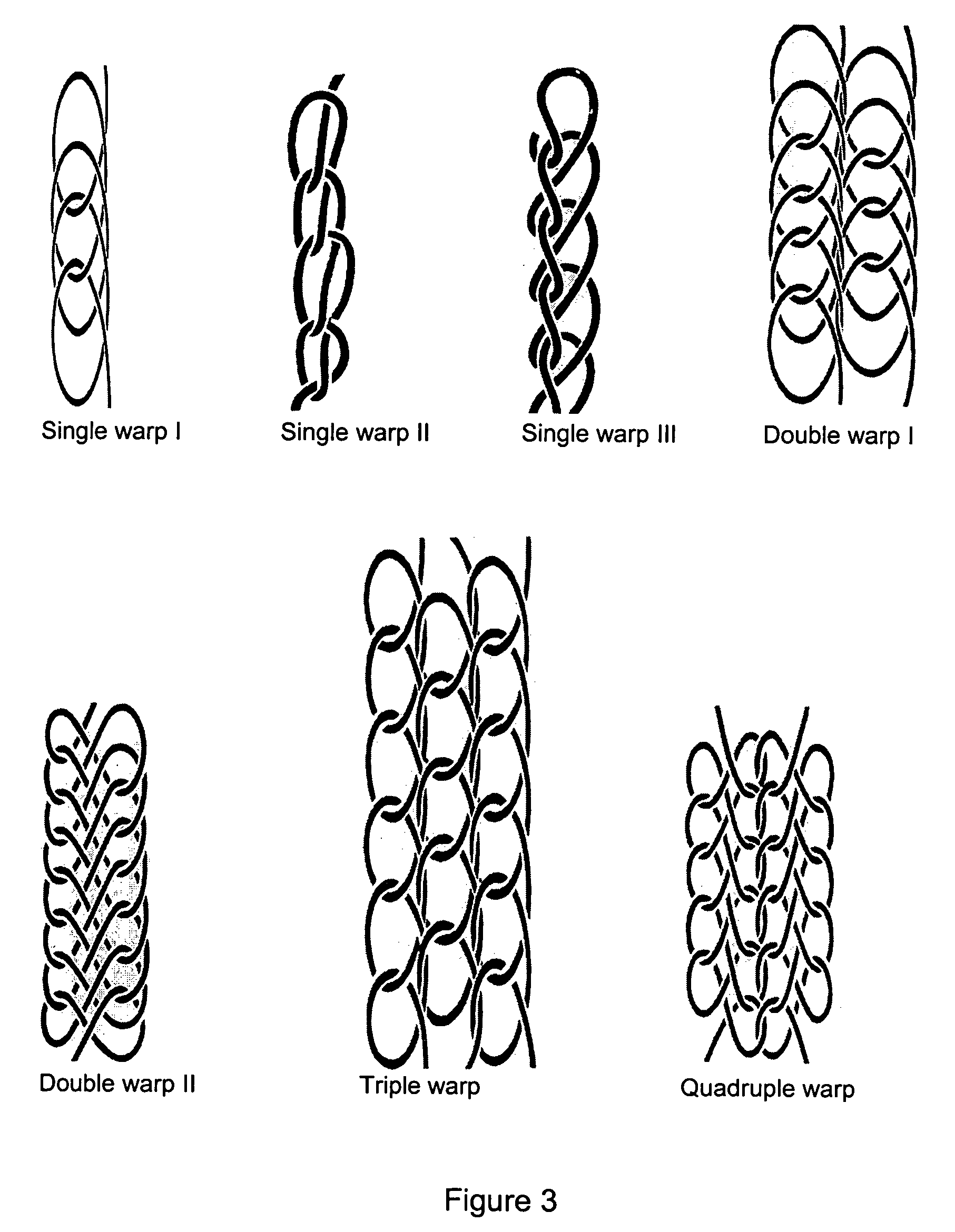

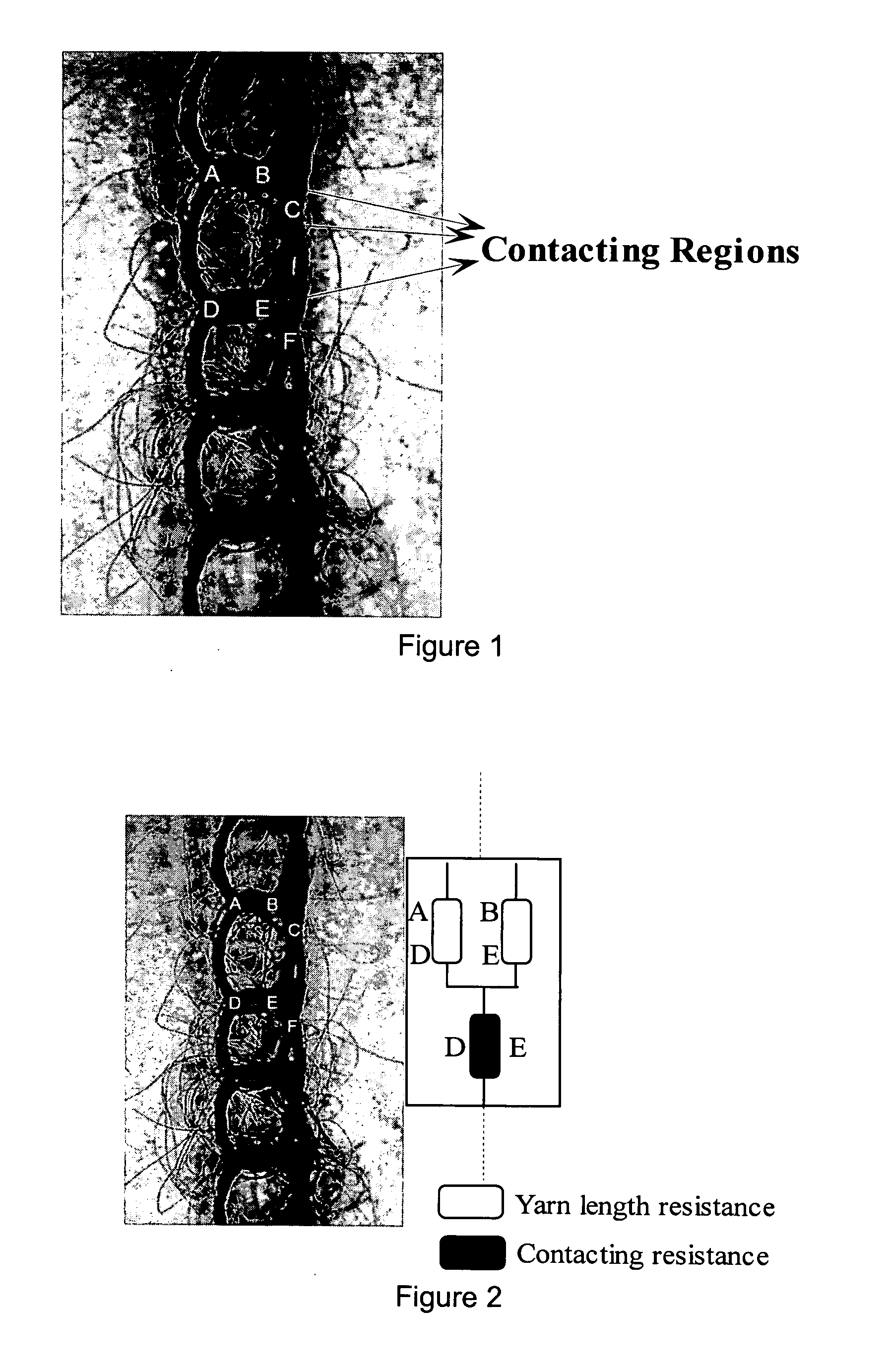

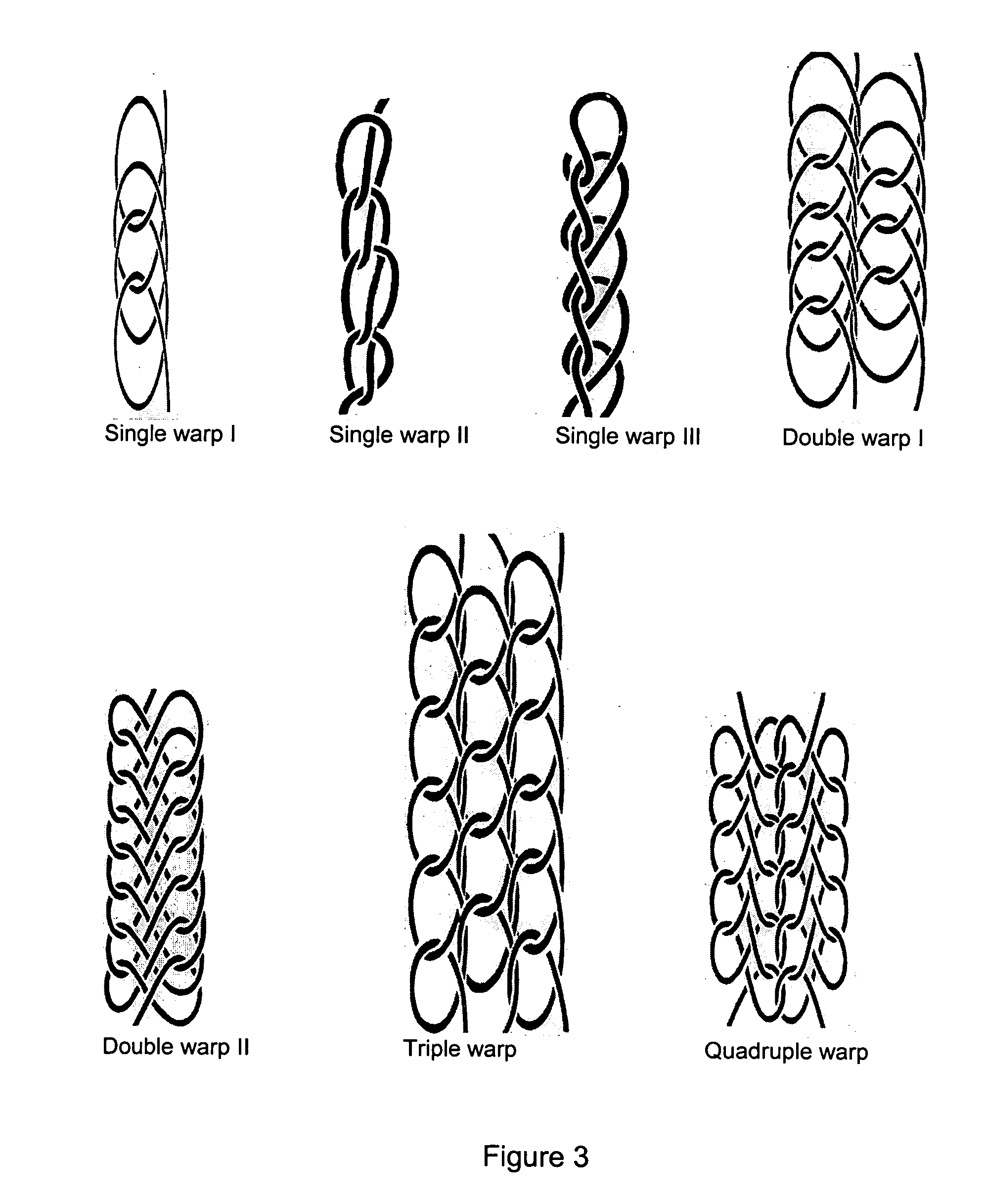

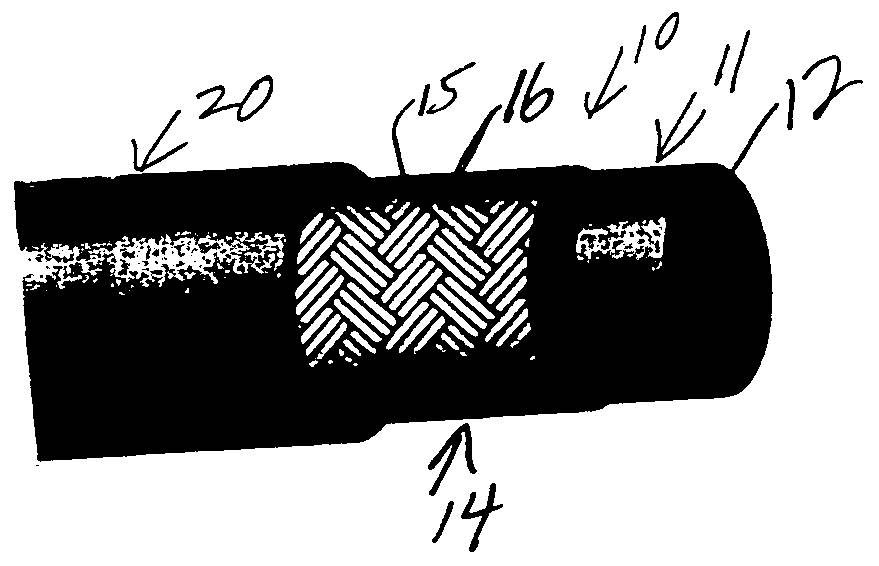

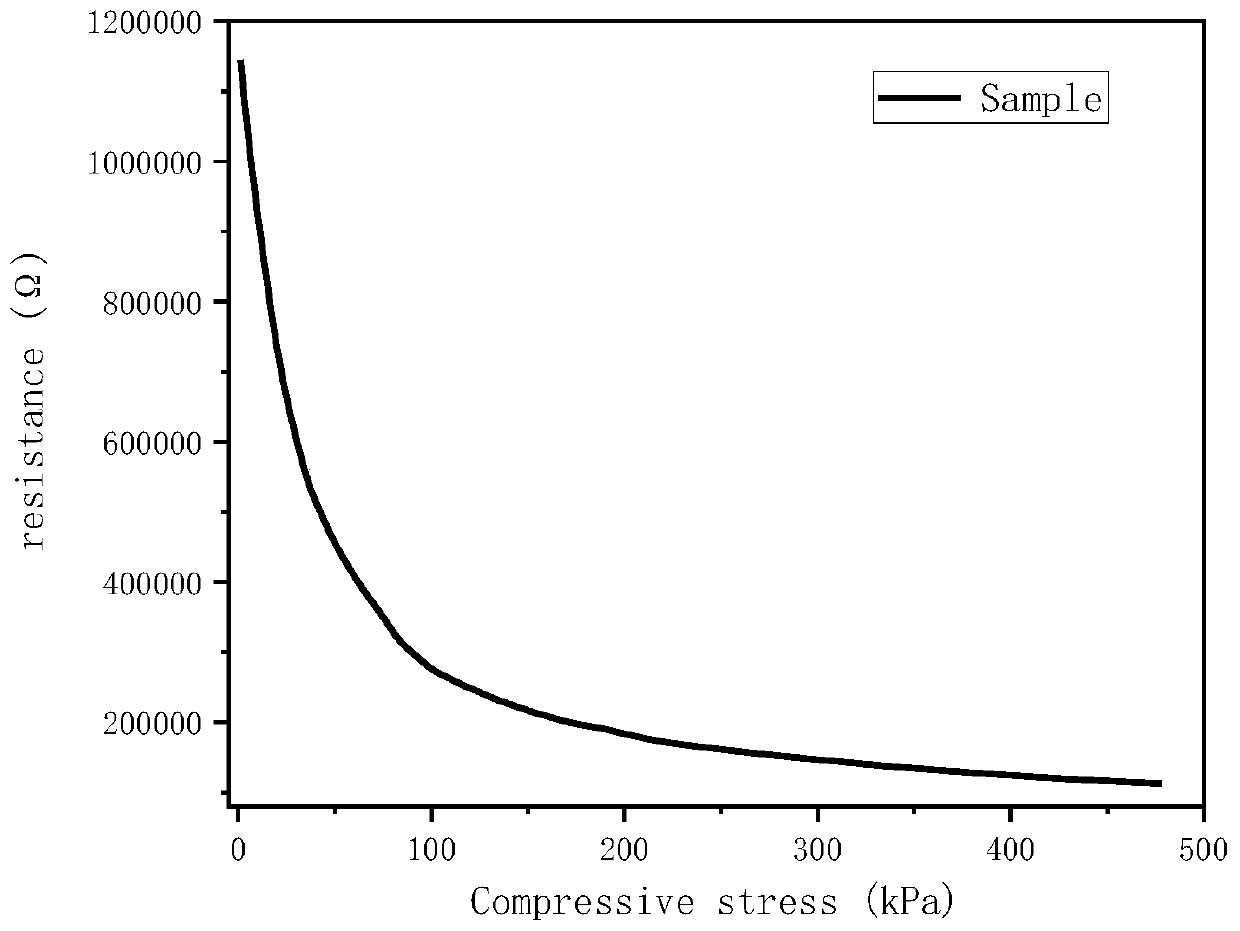

Existing pressure sensing fabrics may involve two portions, i.e., insulating and conductive portions in the fabric, which increases the complexity of the fabric system and more important, and the instablization of the resistance-strain relationship during dynamic deformation which limits the application fields due to intrinsic properties difference between the two portions. These fabrics commonly employ two or more layers to accomplish the detecting functions. Such arrangements increase the thickness, weight, and cost of the sensors with some other disadvantages such as low accuracy, instability, etc. This invention describes a pressure sensing fabric have a general structure as simple as a plurality of electrically conducting yarns forming interlocking loops of yarns. The pressure sensing fabric is found not only be able to sense pressure but also the magnitude of the pressure.

Owner:THE HONG KONG POLYTECHNIC UNIV

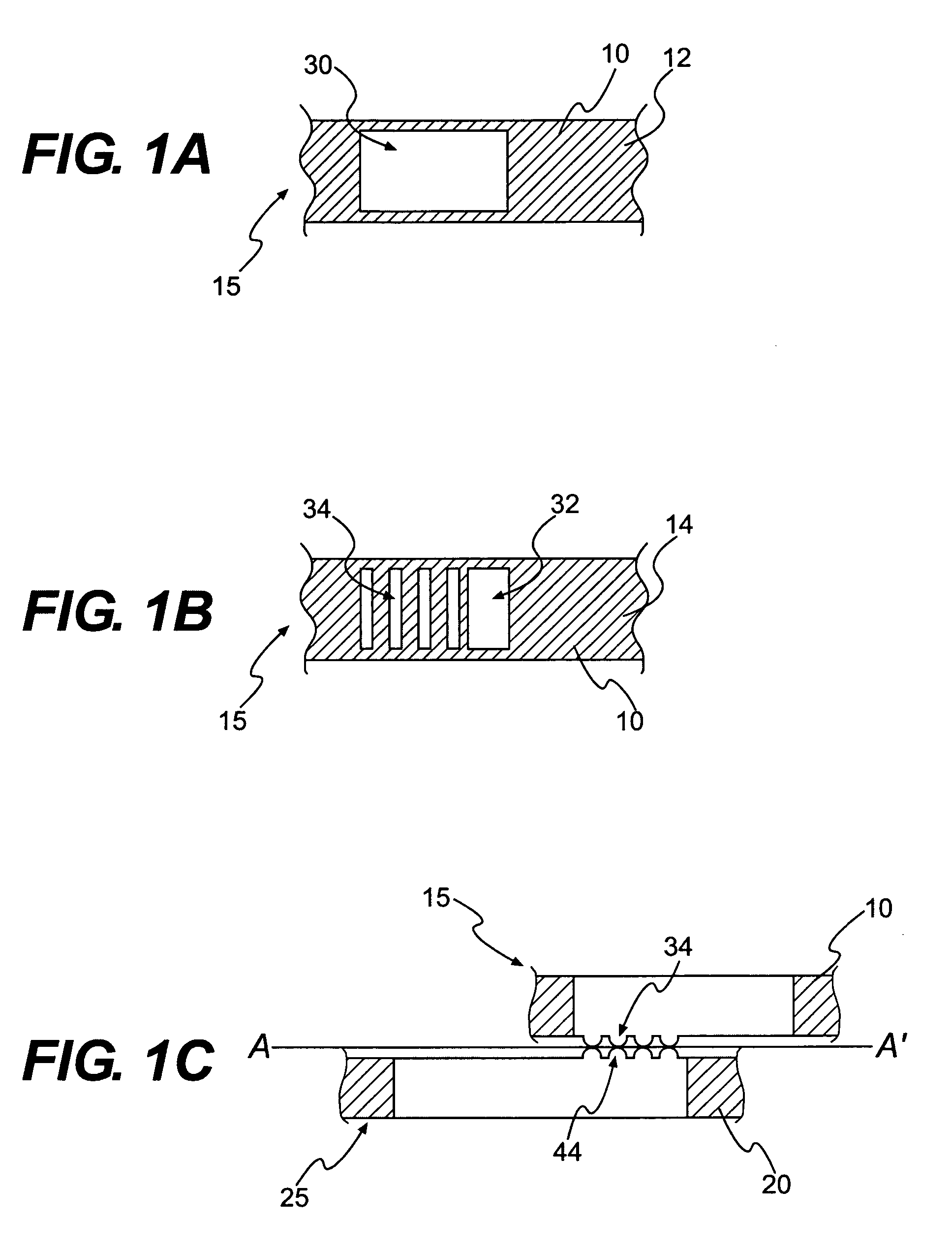

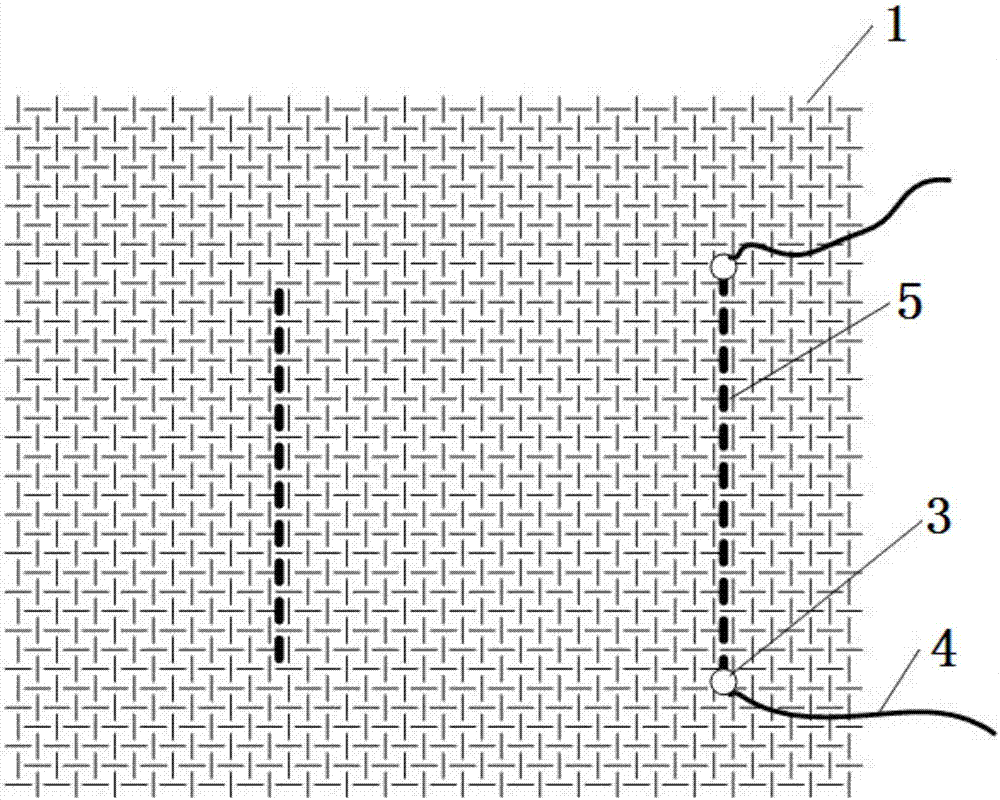

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

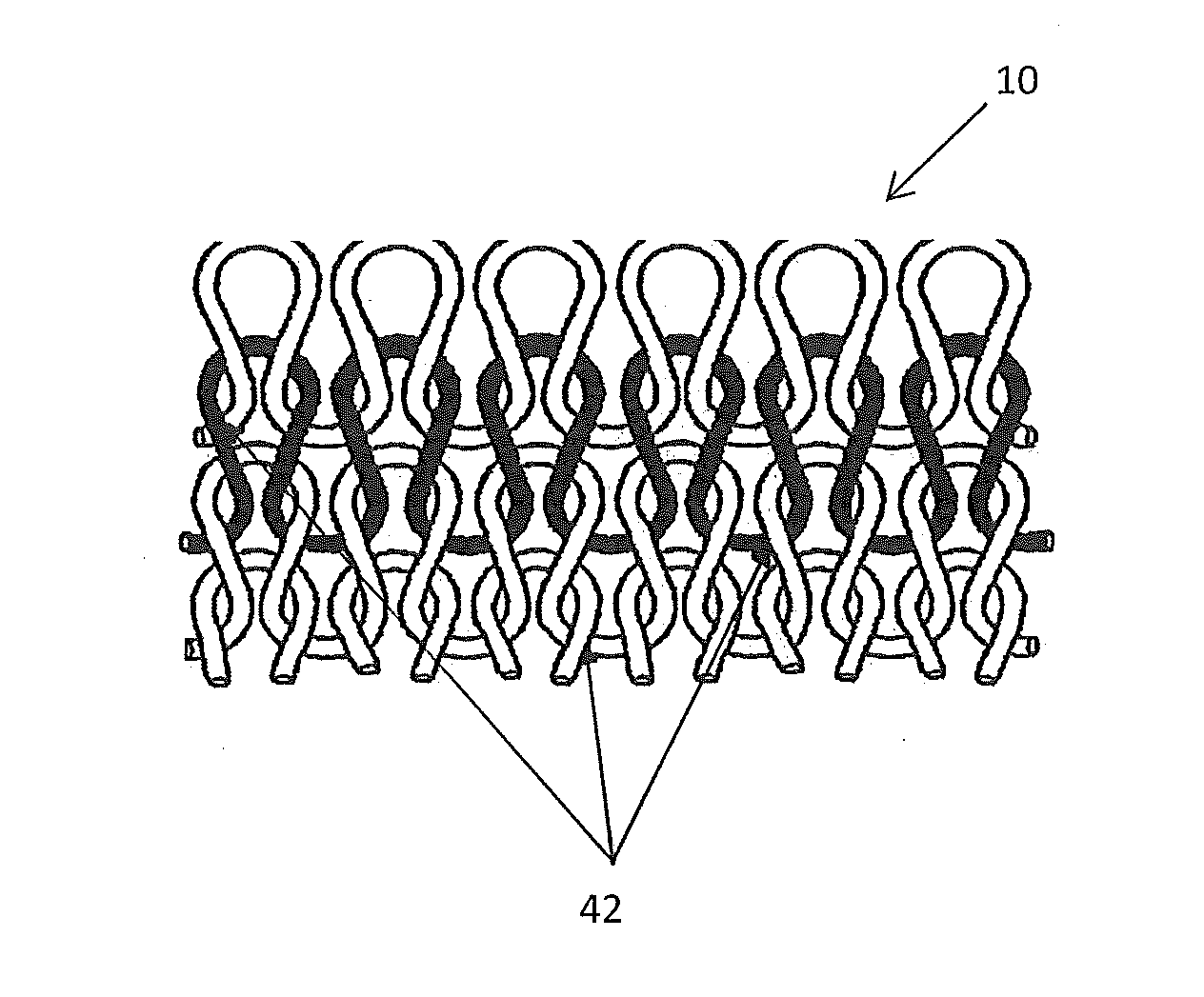

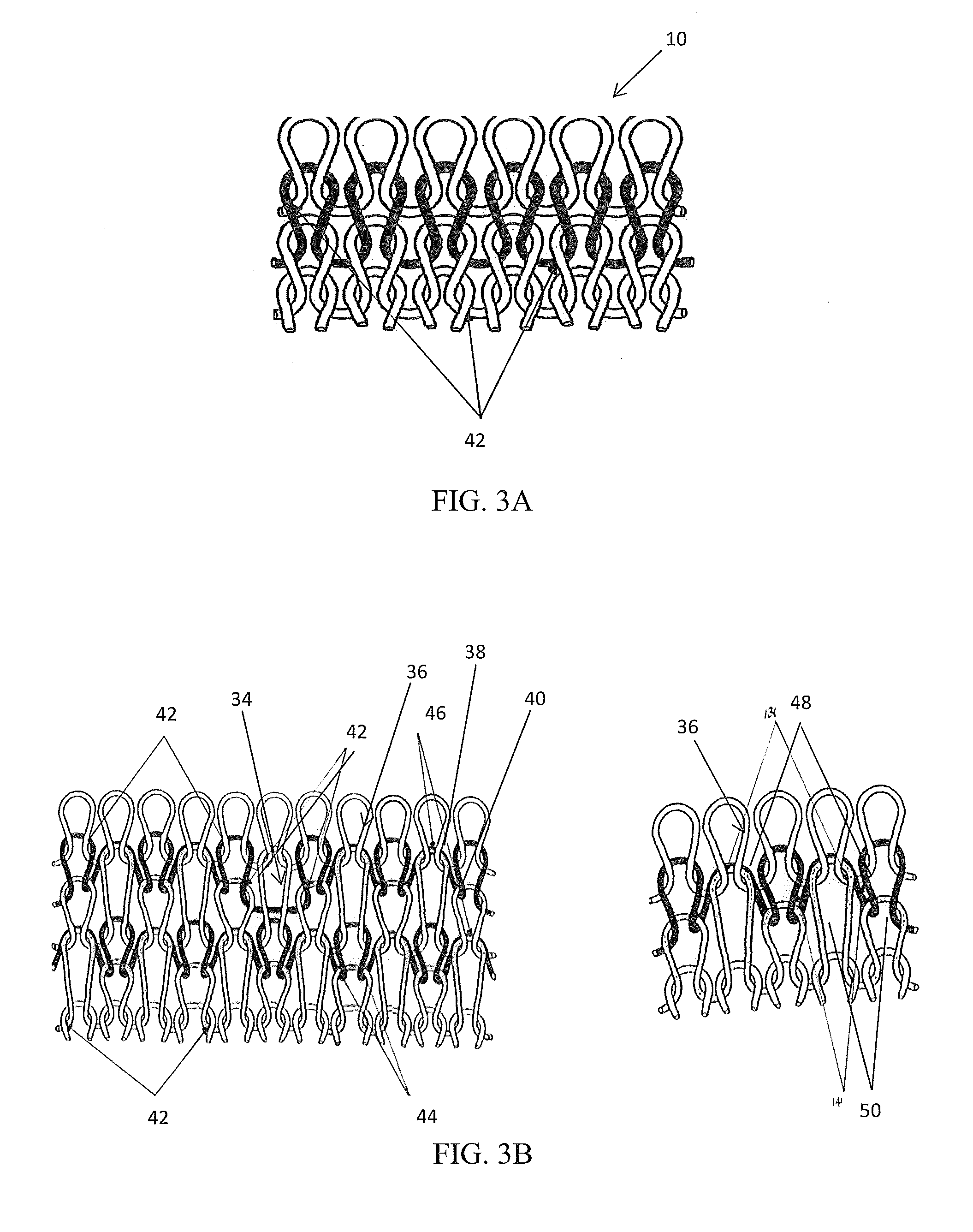

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

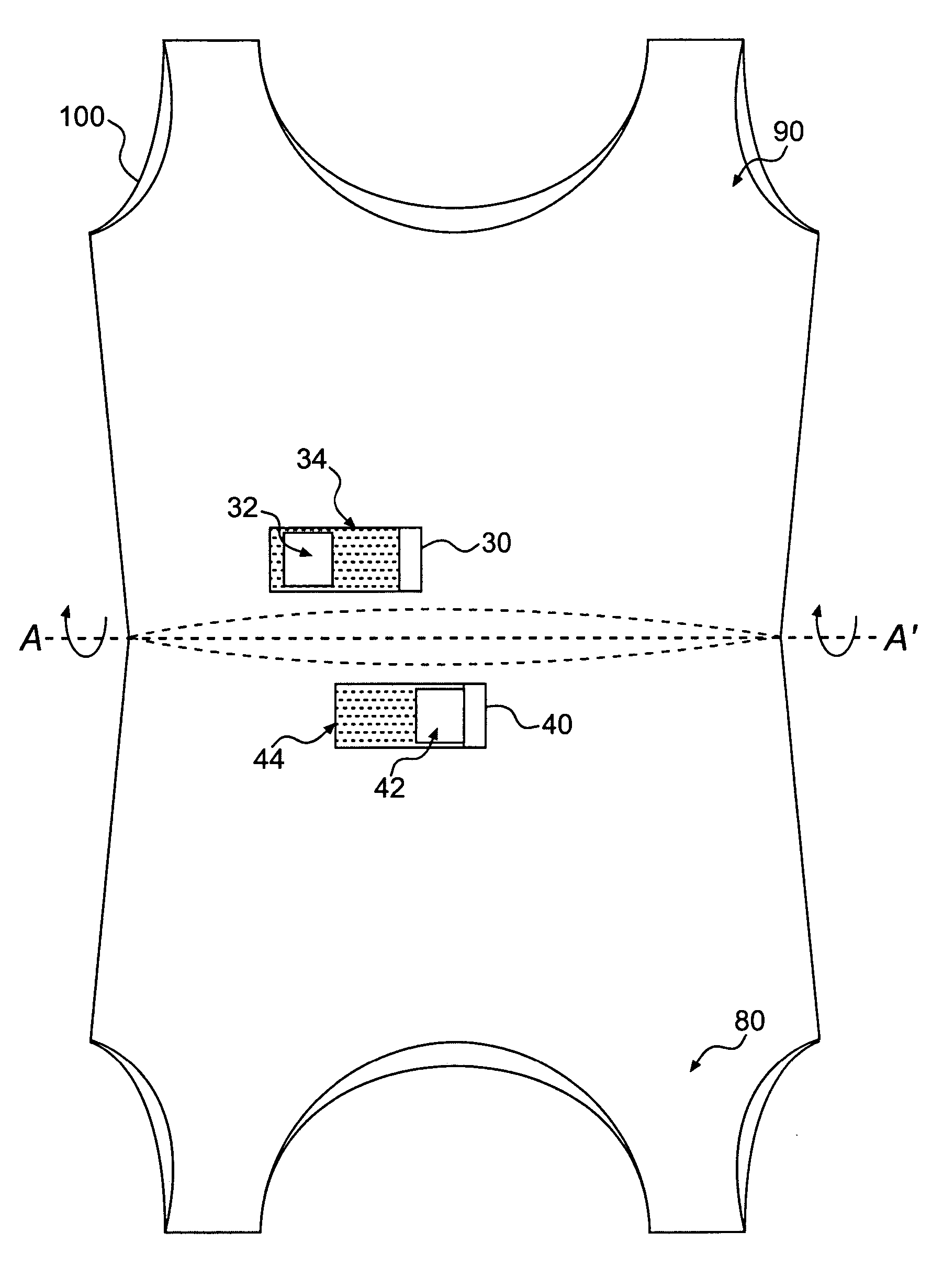

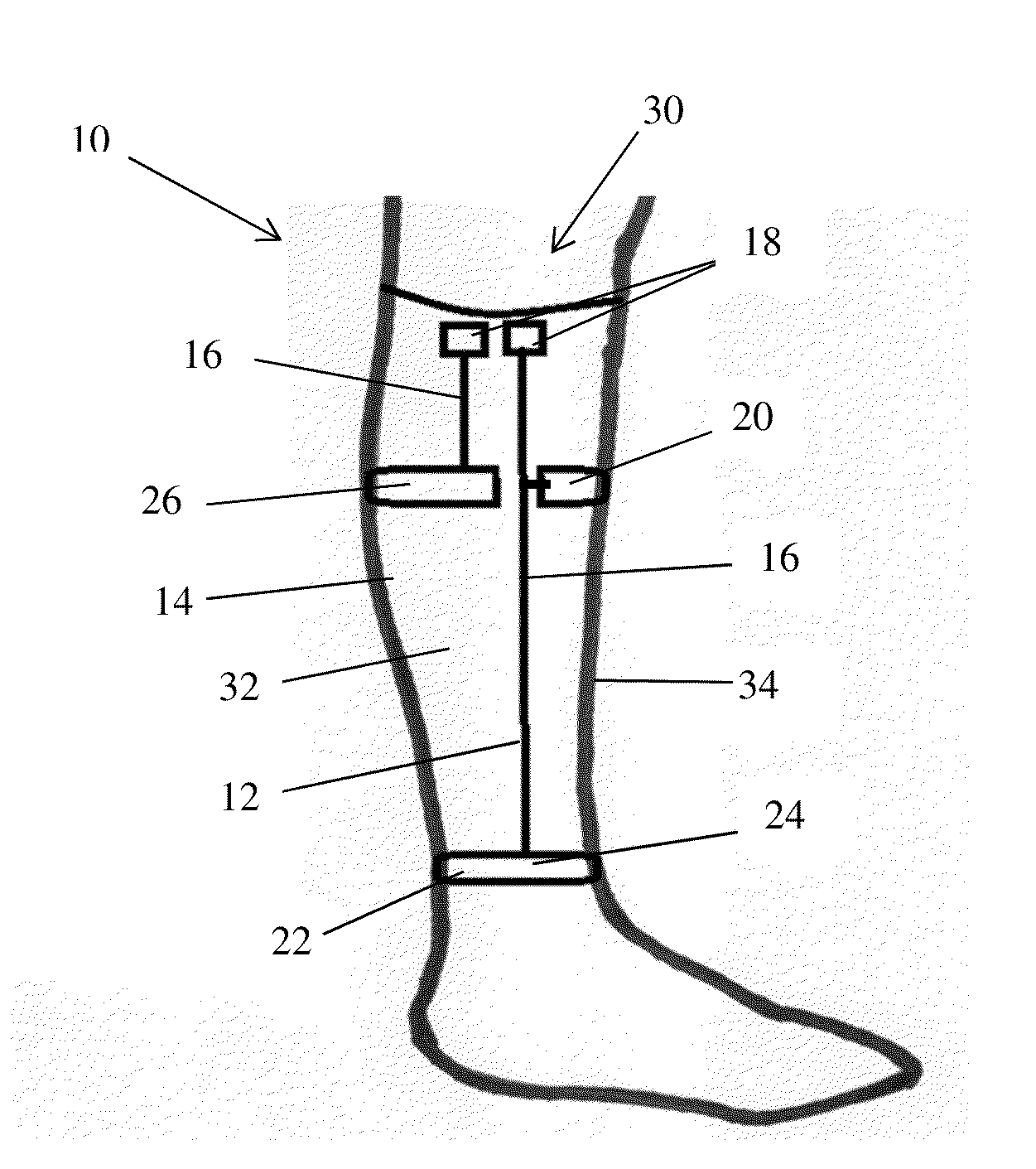

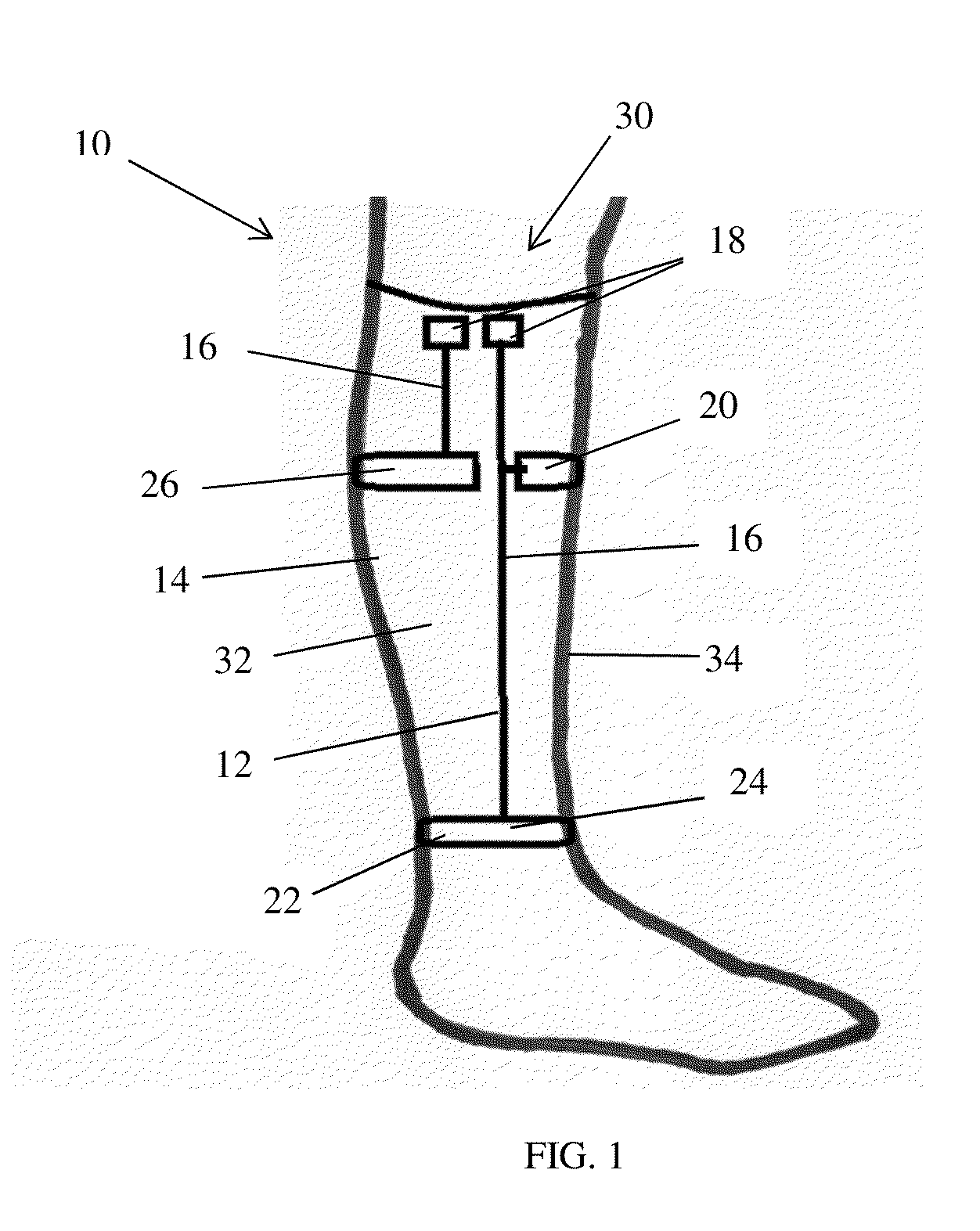

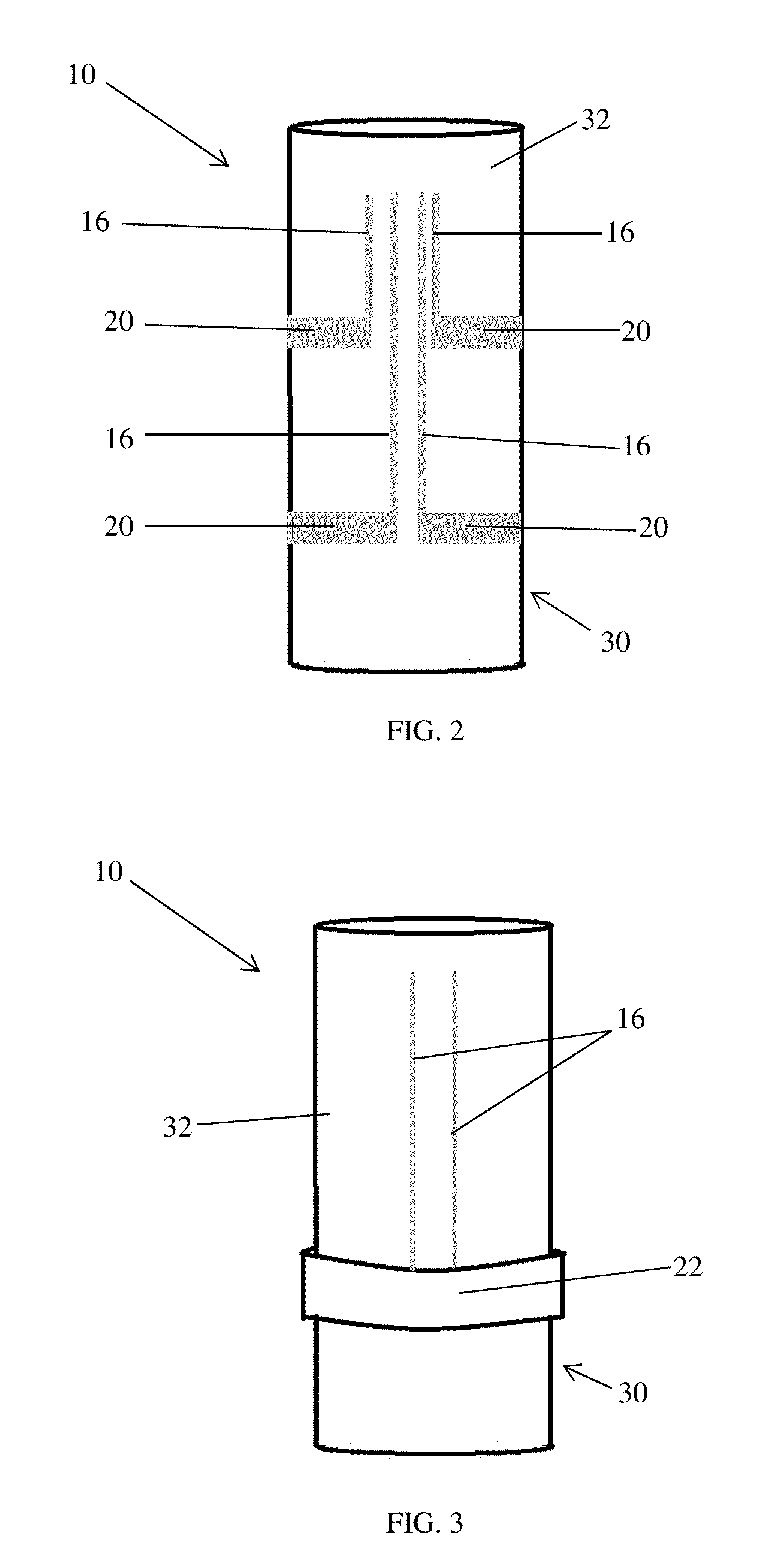

Body Monitoring System and Method

A body monitoring system can include a wearable device, and a circuit for conducting electrical signals having an electrically conductive yarn knitted into the device. The circuit can further include a sensor circuit configured to sense a variable in an area of a body to which the device is applied. The circuit can further include a transmission circuit configured to transmit an electrical signal representing a value of a variable in an area of a body to another location. The other location can be an external device separate from the wearable device, such as an electronic display unit.

Owner:CAROLON

Pressure sensing fabric

ActiveUS20060258247A1Ornamental textile articlesWarp knittingYarnElectrical resistance and conductance

Existing pressure sensing fabrics may involve two portions, i.e., insulating and conductive portions in the fabric, which increases the complexity of the fabric system and more important, and the instablization of the resistance-strain relationship during dynamic deformation which limits the application fields due to intrinsic properties difference between the two portions. These fabrics commonly employ two or more layers to accomplish the detecting functions. Such arrangements increase the thickness, weight, and cost of the sensors with some other disadvantages such as low accuracy, instability, etc. This invention describes a pressure sensing fabric have a general structure as simple as a plurality of electrically conducting yarns forming interlocking loops of yarns. The pressure sensing fabric is found not only be able to sense pressure but also the magnitude of the pressure.

Owner:THE HONG KONG POLYTECHNIC UNIV

Electrically conductive thread

InactiveCN1671901ASmall twistNo obvious mutual interferenceNon-insulated conductorsHeating element shapesEngineeringMechanical engineering

The invention relates to electrically conductive thread. Said thread comprises at least one elastic core thread, at least one electrically conductive thread that is wound around the core thread and at least one binding thread that is wound around the core thread and is non-electrically conductive. The extensibility of the entire electrically conductive thread is restricted by the binding thread.

Owner:W ZIMMERMANN

High pressure flexible hose

InactiveUS20050051226A1Uniform diameterHigh tensile strengthFlexible pipesRigid pipesTextile fiberMetal fiber

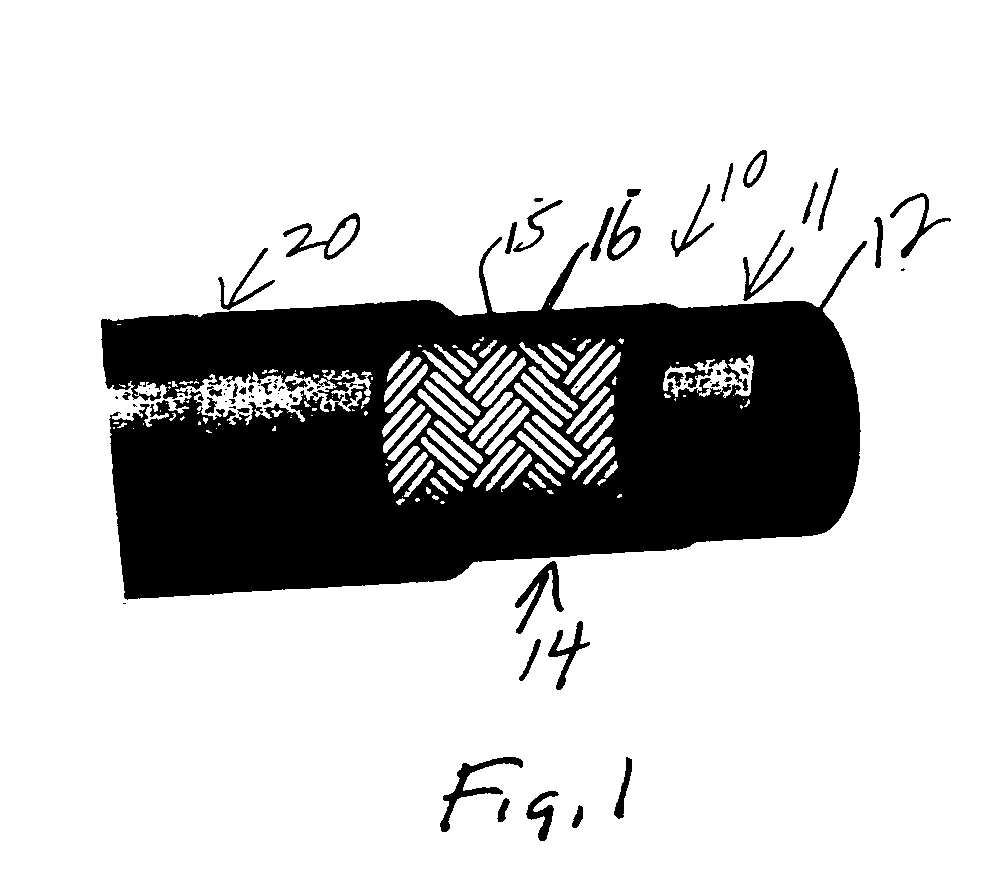

A flexible, thermoplastic hose for high pressure and high velocity flow is provided with a flexible braided reinforcement layer with a static drain therein for conducting static electricity towards a ground. This is achieved by having at least one textile fiber yarn with conductive fibers therein braided with non-conducting textile yarns to form the braided reinforcement layer. The preferred conducting fiber yarn is formed with metal fibers as well as plastic fibers. A method of manufacture of the hose comprises providing electrical conducting yarns and non-conducting yarns in a braiding machine and braiding them about a tube having a hollow bore through which fluid flows. An abrasion resistant outer cover layer of polyurethane is extruded over the braided layer having the drain therein. For higher pressure applications, a second braided reinforcement layer may also be provided over the inner braided layer having the electrically conductive yarns. Several conductive yarns may be used to have spaced electrically conductive yarns, e.g., at 3:00, 6:00, 9:00 and 12:00 in a circular cross-section through the hose.

Owner:DYNAFLEX

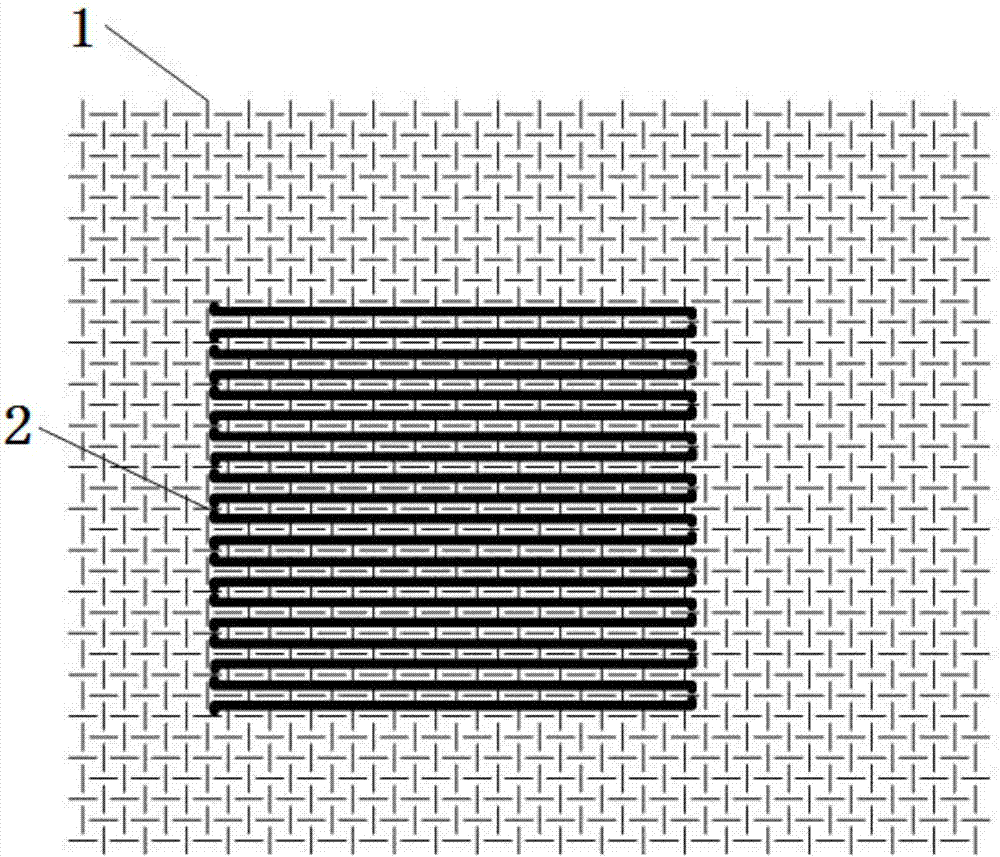

Flexible strain-sensing woven fabric and making process thereof

ActiveCN107385623AThe strain sensing function hasHigh sensitivitySwivel-woven fabricsLappet-woven fabricsYarnSurface pattern

The invention discloses a flexible strain-sensing woven fabric and a making process thereof. The flexible strain-sensing woven fabric comprises non-conducting elastic woven fabric and elastic conducting yarn, wherein the elastic conducting yarn is fixedly connected to the surface of the non-conducting elastic woven fabric as float yarn to form a float pattern, and connectors and leads for electric connection are arranged at the two ends of the elastic conducting yarn. The flexible strain-sensing woven fabric is simple in structure, good in flexibility, high in comfort and washable and has an omnidirectional strain sensing function, continuous production can be achieved, and the woven fabric is high in sensitivity, stability and applicability and has good application prospects in the field of intelligent textiles; besides, the flexible strain-sensing woven fabric has the advantages that the making process is simple, use is convenient, the surface pattern of the strain-sensing fabric can be designed and the fabric has attractiveness; the fabric has high practical value and is worthy of wide application and popularization, and compared with the prior art, the fabric has significant progress.

Owner:上海捻幅智能科技有限公司

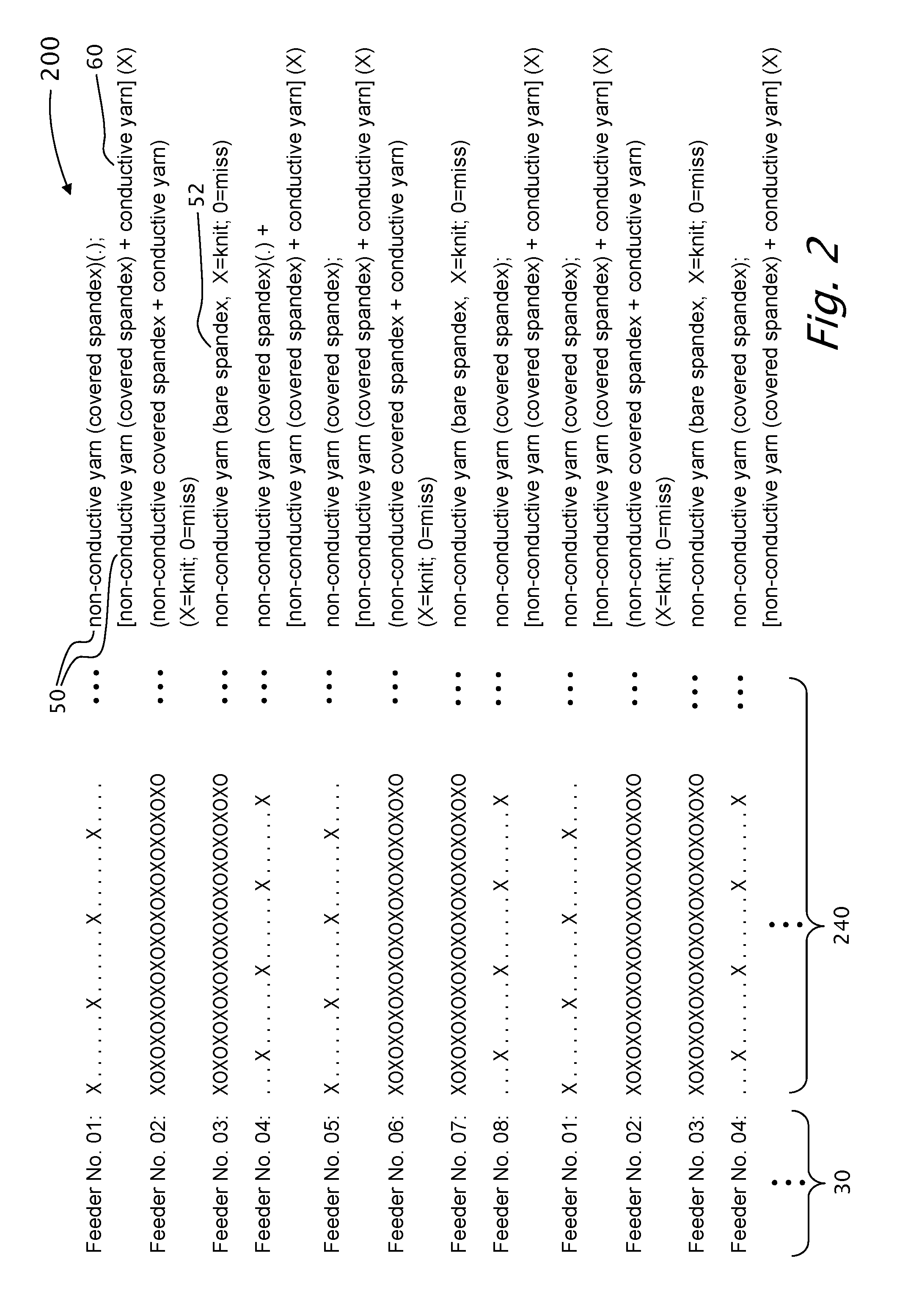

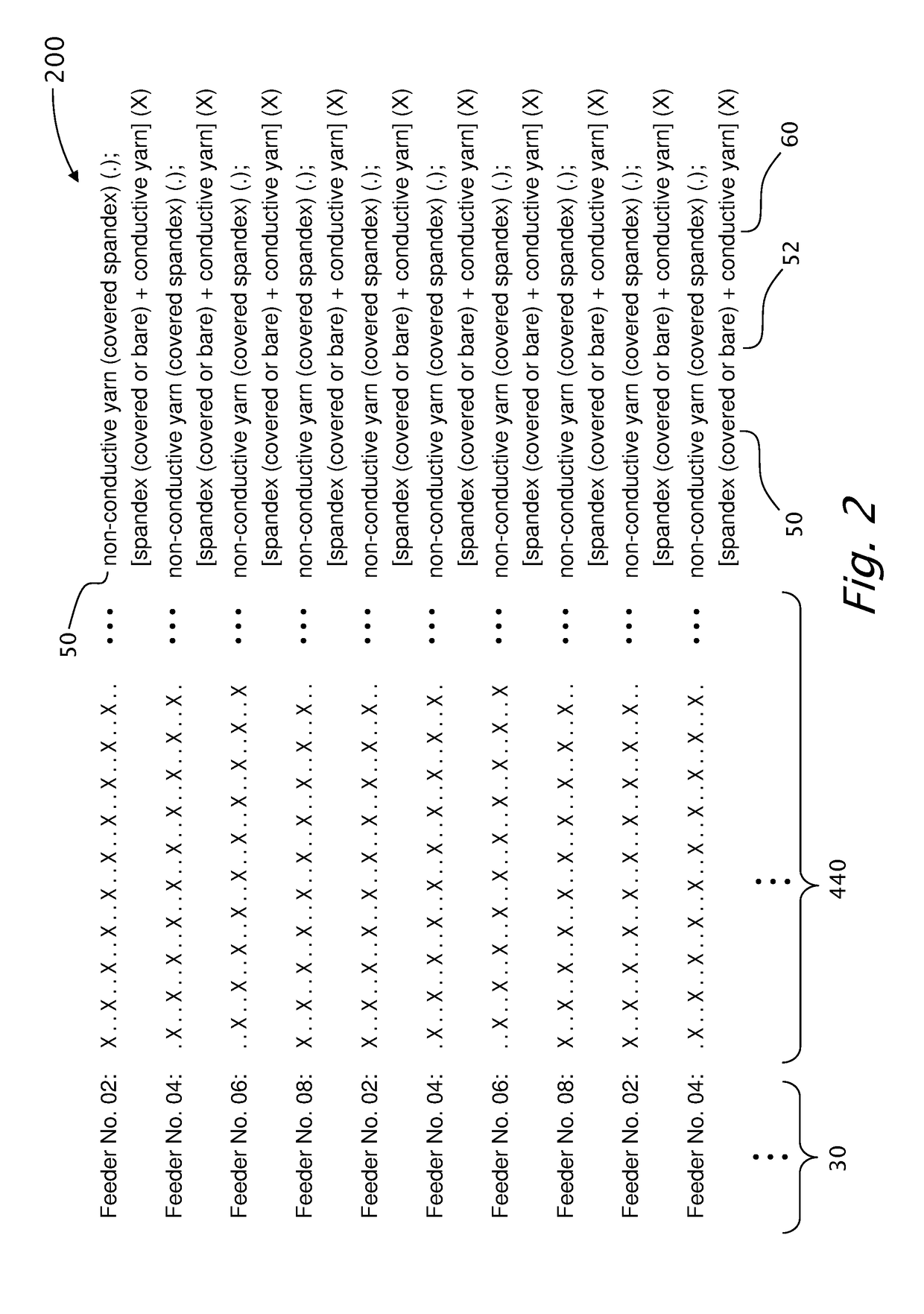

Float loop textile electrodes and methods of knitting thereof

ActiveUS20150297135A1Facilitate acquisitionSmooth connectionCrochetingOrnamental textile articlesConductive yarnLine segment

A method for knitting a garment having a tubular form, including knitting at least one conductive textile electrode on a machine having N participating feeders and M needles. The method includes the steps of continuously knitting the tubular form with one or more flexible non-conductive yarns, and knitting the electrode integrally within the tubular form, using a conductive yarn, in addition to the non-conductive yarns. The conductive yarn is knitted in a float-loop form by knitting a stitch and skipping over y needles, as follows: repeatably knitting a line segment Lk, using feeder Fi and starting at needle D1; and knitting line segment Lk+1, using the next feeder and start stitching the first float-loop at needle D1+s where 0<s<y. The tubular form has a preconfigured 10 knitting density, wherein the electrode has a knitting density that is higher than the preconfigured knitting density of the tubular form.

Owner:AUTONETWORKS TECH LTD

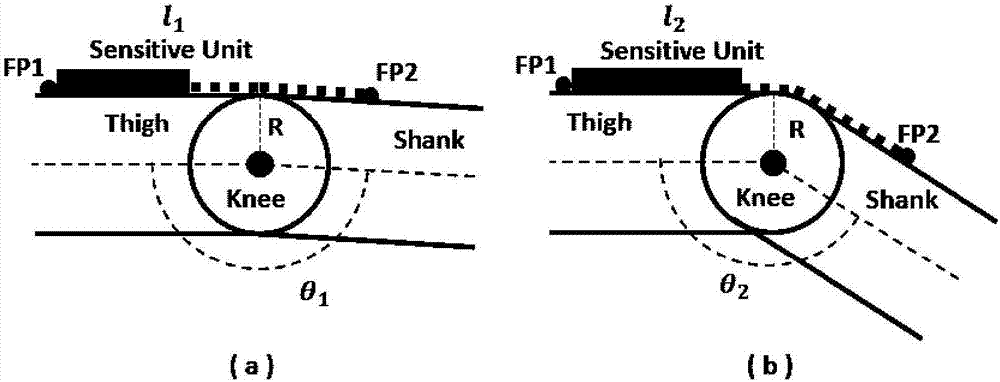

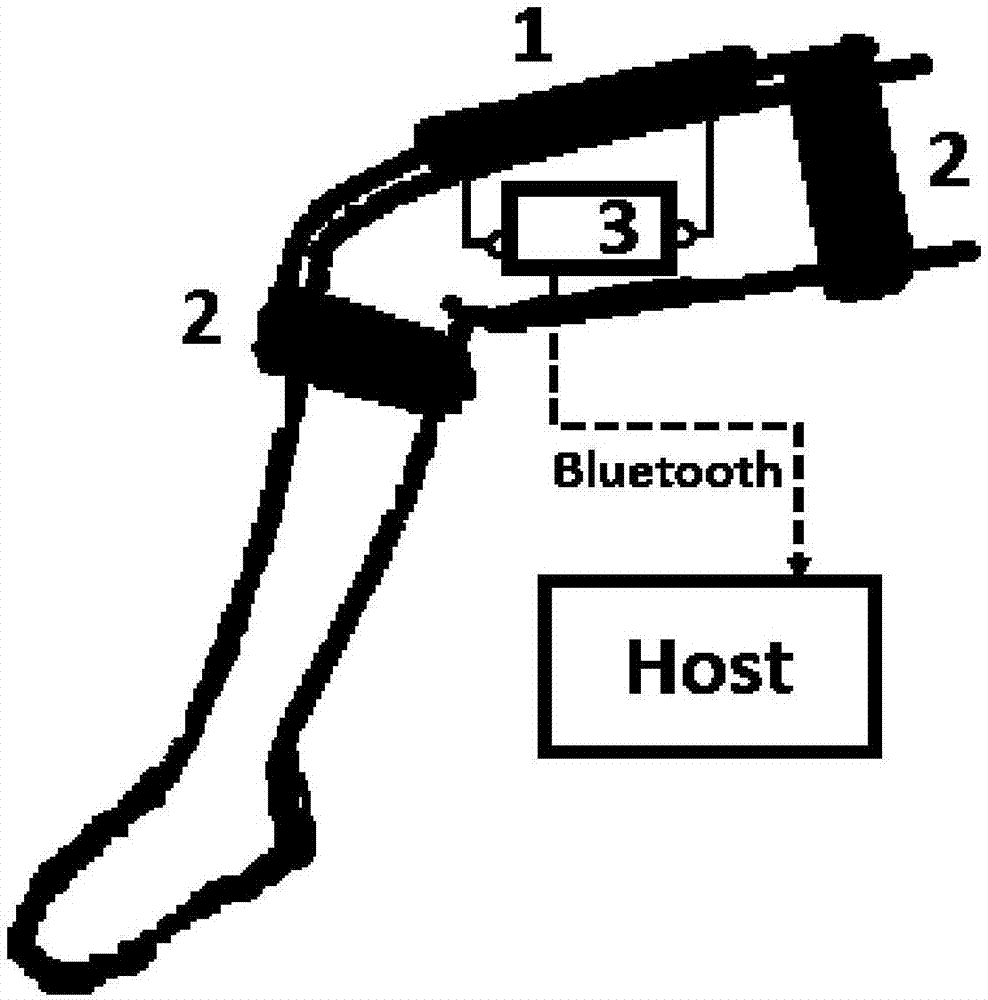

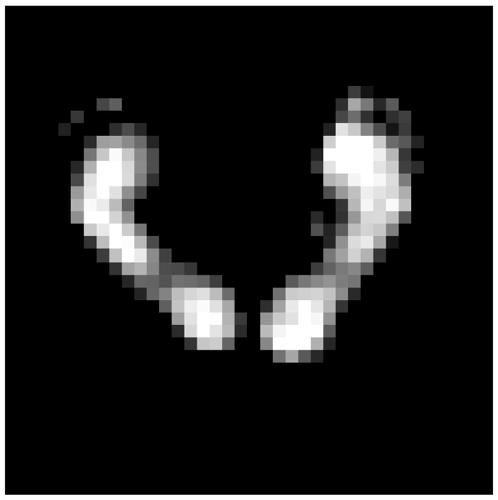

Flexible fabric sensor for measuring human body knee joint movement and method thereof

ActiveCN106889991AComfortable to wearImprove performanceDiagnostic recording/measuringSensorsHuman bodyEngineering

The invention belongs to the field of wearable sensors, and particularly discloses a novel flexible fabric sensor for measuring human body knee joint movement and a method thereof. The current bending angle, formed when a user walks and does movement training, of the knee joint can be measured and output in real time. Common cloth is combined with conductive yarn, a sensitive unit of the flexible fabric sensor is developed, after the sensor is calibrated through a designed method, bending movement of the knee joint is converted into stretching movement of the flexible fabric sensor through a certain wearing mode, the problem that a rotating shaft moves when the knee joint rotates is effectively solved, and the current bending angle of the knee joint of the user is calculated and output. The flexible fabric sensor is convenient to use, low in cost and capable of being not limited by a field and measuring the bending angle of the knee joint of the user in a comfortable mode in real time and has high reliability and a good popularization prospect.

Owner:NANJING ZHELI INTELLIGENT MFG RES INST CO LTD

Textile-based electrodes incorporating graduated patterns

ActiveUS8443634B2Less stressSolution to short lifeElectrocardiographyWeft knittingBiophysical profileEngineering

Textile-based electrodes incorporating graduated patterns include a fabric portion having non-conductive yarns and an electrically conductive region having electrically conductive yarn filaments. The electrodes can further include float yarns and can be configured in a textured or ribbed construction. When incorporated into a garment, the electrodes can be used to monitor biophysical characteristics, such as the garment wearer's heart rate.

Owner:ADIDAS

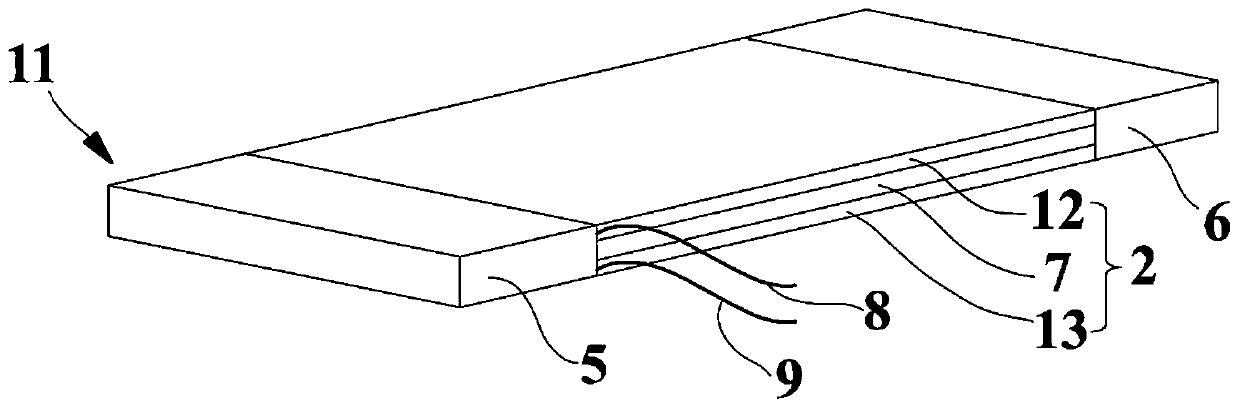

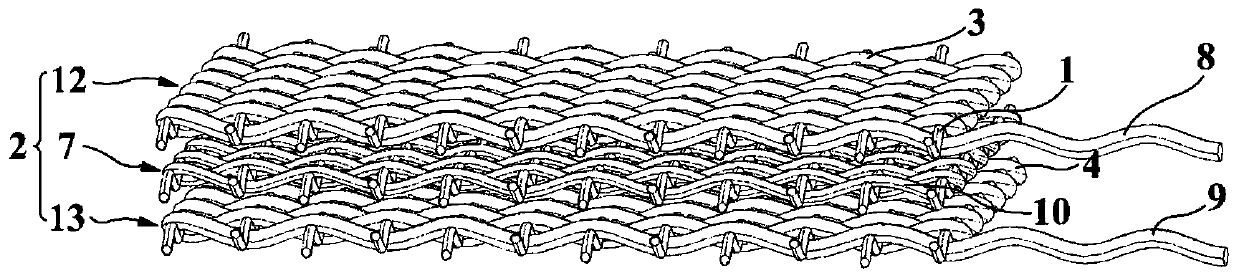

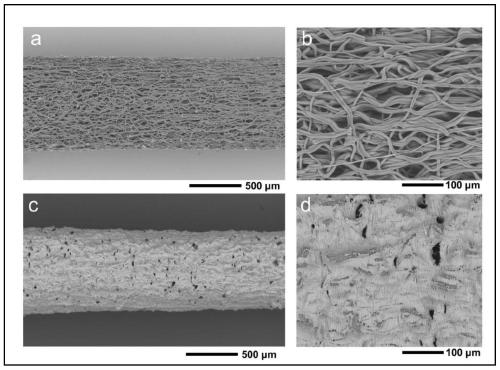

Flexible fabric pressure and strain composite sensor

ActiveCN110926661AImprove structural stabilityImprove mechanical propertiesForce measurementElectrical/magnetic solid deformation measurementPolymer scienceElectrically conducting yarn

The invention relates to a flexible fabric pressure and strain composite sensor. The sensor is characterized by comprising an upper conductive layer fabric, an insulating layer fabric and a lower conductive layer fabric which are stacked in sequence from top to bottom, the upper conductive layer fabric and the lower conductive layer fabric are woven by taking metal-plated conductive yarns as weftyarns and taking elastic yarns as warp yarns; the insulating layer fabric is woven by taking non-conductive yarns as weft yarns and taking non-conductive elastic yarns as warp yarns; the upper conducting layer fabric, the insulating layer fabric and the lower conducting layer fabric are connected into a whole at the two ends of the warp yarn through a surface-inner layer changing three-layer structure, and the tail end of the metal-plated conducting yarn serves as an electrode lead of the flexible fabric pressure and strain composite sensor. The structure stability of an existing capacitive fabric sensor is effectively improved, rapid large-scale preparation is facilitated, pressure detection can be achieved, and meanwhile strain detection can be achieved.

Owner:DONGHUA UNIV

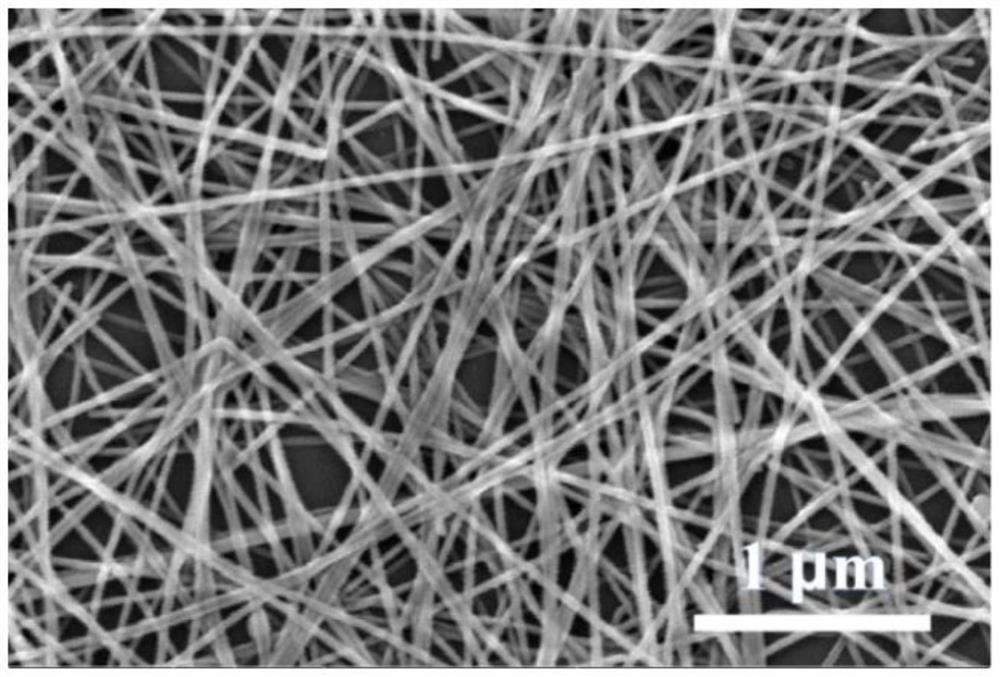

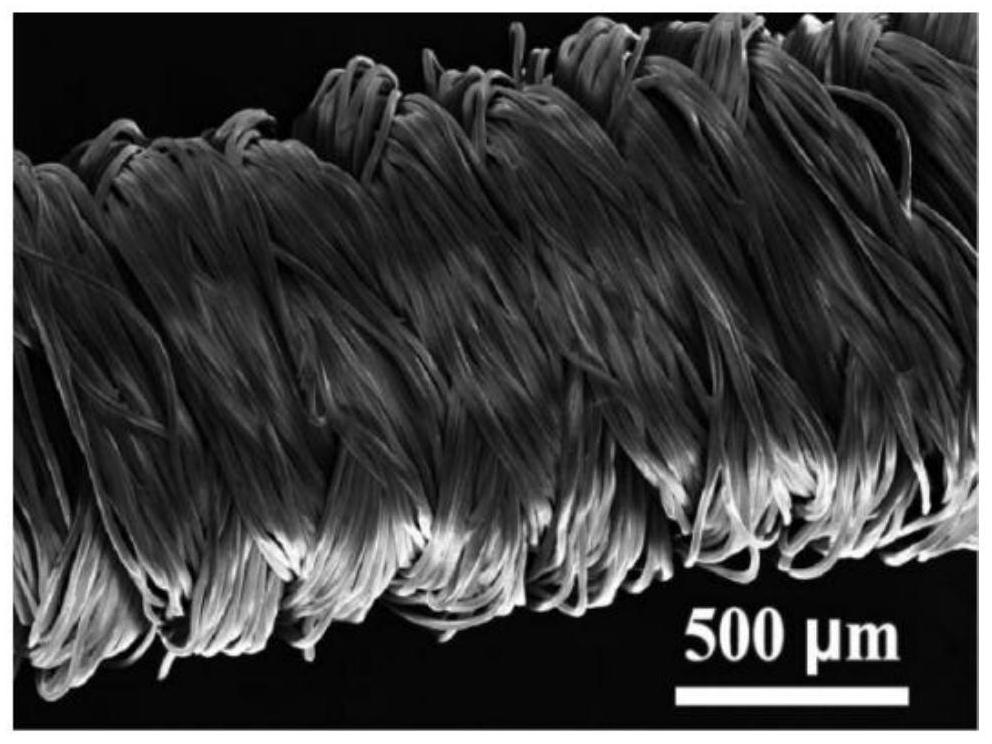

Preparation method of flexible conductive yarn

ActiveCN109797470AIncrease elasticityGood medium and low temperature performanceElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoHysteresis

The invention relates to a preparation method of a flexible conductive yarn and belongs to the technical field of intelligent fabrics. According to the preparation method of the flexible conductive yarn, natural silk is carbonized to serve as the matrix of the flexible conductive yarn, and carbonized silk fiber has the advantages of a honeycomb structure, a large specific surface area, high content of nitrogen, high degree of graphitization and the like; a prepared silver nanowire is compounded with the carbonized silk, so that the prepared f flexible conductive yarn can achieve high electricconductivity; the silk has the advantages of high comfort level, high flexibility and the like, the silver nanowire is excellent in toughness, and the preparation method of the flexible conductive yarn is low in cost and simple in operation process; the prepared flexible conductive yarn is packaged with butadiene rubber, which has the best elasticity among existing rubbers and is good in medium and low-temperature performance, low in hysteresis loss and excellent in warping strength; by means of an electrostatic spinning method, polymer solution or melt can form a jet flow under the action ofan electrostatic field and accordingly can be stretched and cured in the electrostatic field into a fiber in a micro-nano structure for preparing the flexible and stretchable conductive yarn.

Owner:张家港市丰茂纺织有限公司

Knitted flexible sensing fabric based on Mxene coated conductive yarn and preparation method

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

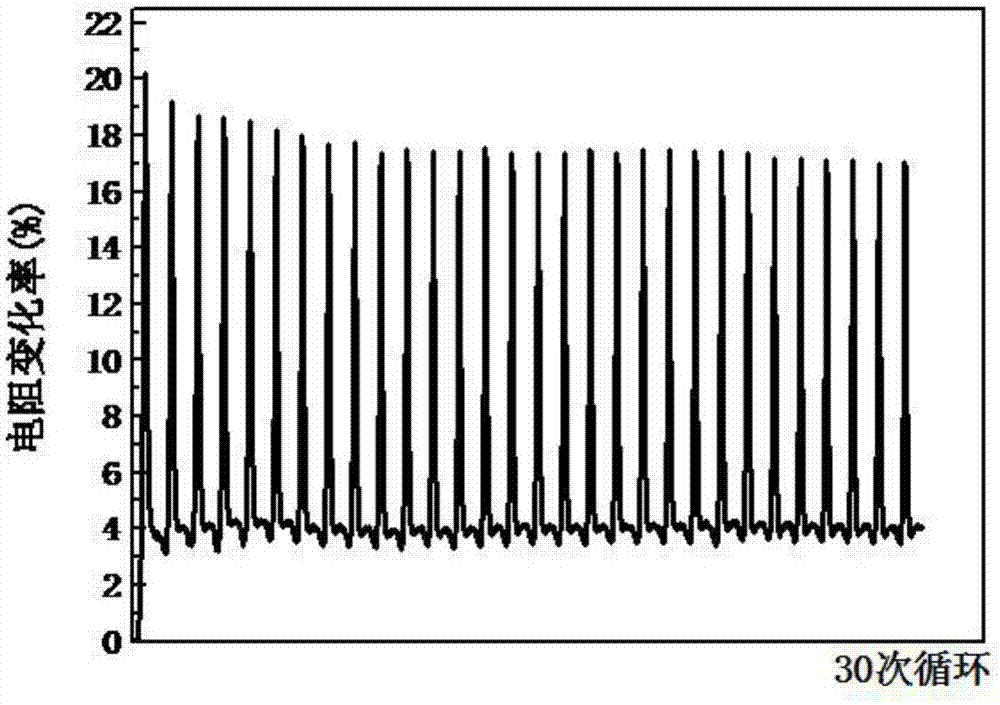

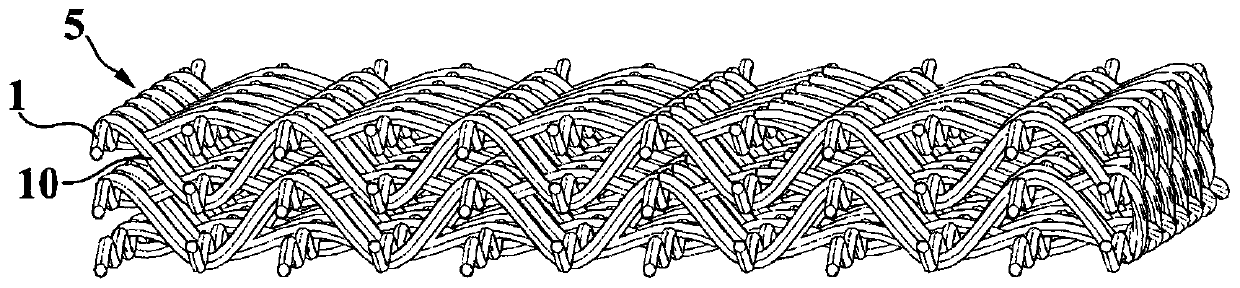

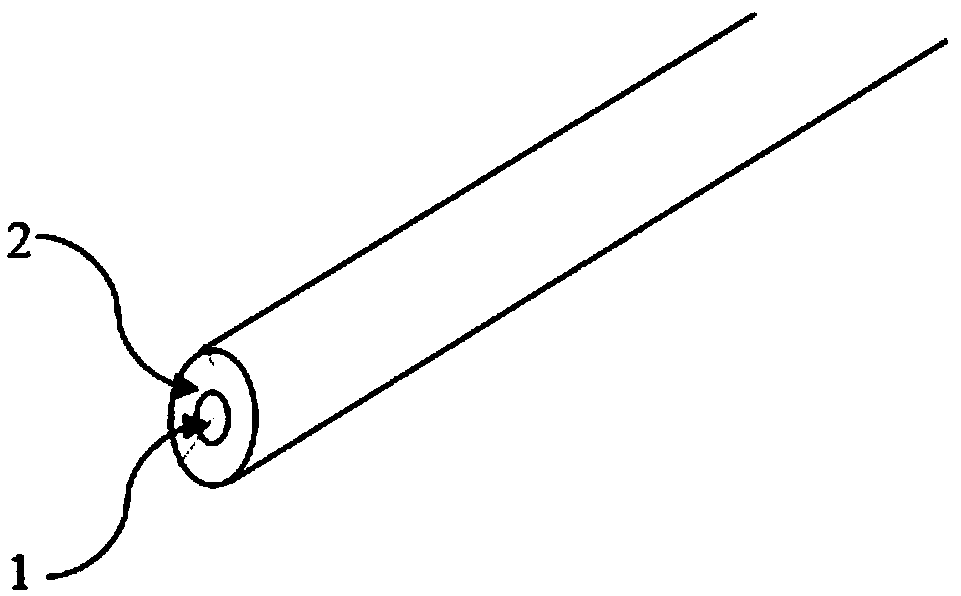

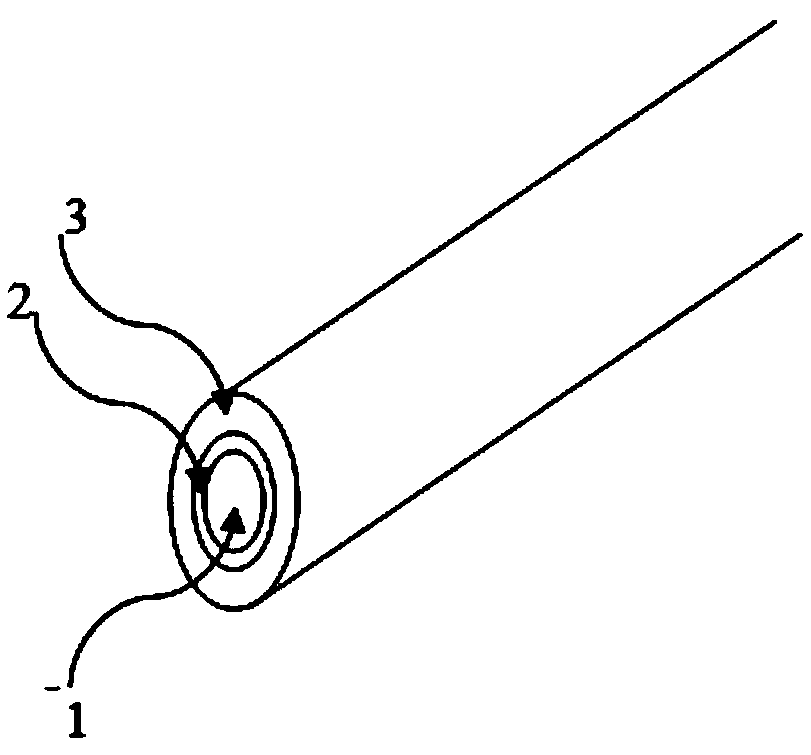

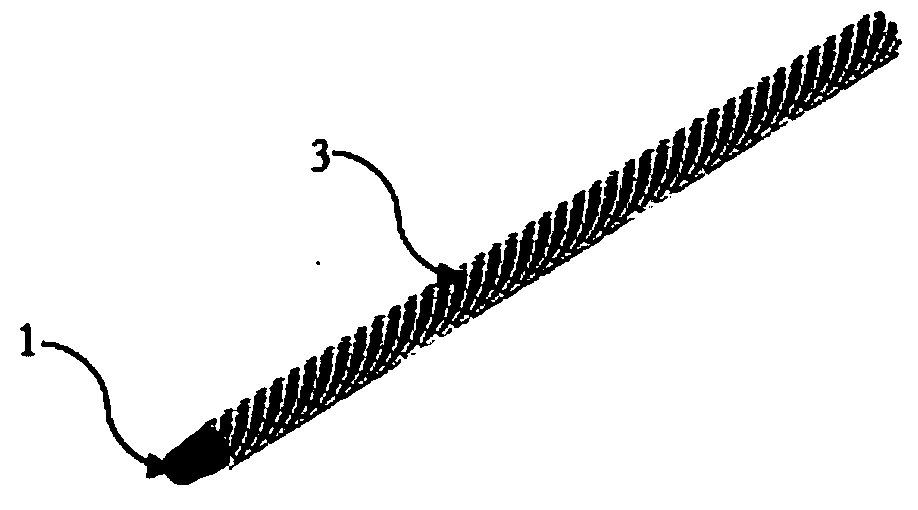

Full-fiber base flexible sensor and preparation method and application thereof

The invention discloses a full-fiber base flexible sensor and a preparation method and application thereof. The full-fiber base flexible sensor comprises an elastic electric conduction rope core and asensing layer which is knitted by electric conduction yarns and is packed on the periphery of the elastic electric conduction rope core, wherein the resistance of the rope core is lower than that ofthe sensing layer. The full-fiber base flexible sensor disclosed by the invention adopts an elastic electric conduction yarn; by a rope knitting method, an electrode layer of a stress sensor is packedin the sensing layer, and a wire-shaped sensing material adopting a wrapper and core structure which compositely integrates the sensor with the electrode, and the wire-shaped sensing material can befurther directly mixed and knitted with ordinary yarns or wire-shaped elastic bodies to obtain pieces to be used as the flexible pressure sensing electronic device; the wire-shaped sensing material isapplied to the fields of detection of human body physical health (pulse ) and total range movement (facial expression, sound producing, and joint movement ) and the like; and the wire-shaped sensingmaterial has the characteristics of being simple in structure, high in stability, simple and convenient in preparation technology, good in reproducibility, high in detection sensitivity and the like.

Owner:WUHAN TEXTILE UNIV +1

Composite yarn and preparation method and application thereof

ActiveCN111334954ASuitable for scaleSuitable for industrial productionFibre typesLiquid/gas/vapor removalPolymer scienceCross linker

The invention discloses composite yarn and a preparation method and application thereof. The composite yarn comprises conductive yarn and a silicone rubber coating covering the surface of the conductive yarn; and the silicone rubber coating is used for triboelectrification, and the conductive yarn is used as an output electrode. The composite yarn can be applied to the preparation of a triboelectric nano-generator or a wearable fabric sensor. The preparation method of the composite yarn comprises the following steps that a cross-linking agent and a silicone rubber prepolymer are mixed uniformly, and then transferred into a vacuum pump for vacuumizing to obtain silicone rubber colloid; the silicone rubber colloid is loaded into a liquid storage pipe connected with a coating nozzle, and thesurface of the conductive yarn is coated in the process of pulling the conductive yarn fed into the liquid storage pipe out of the coating nozzle; and the coated yarn passing through the coating nozzle is solidified to form the composite yarn. The preparation method of the composite yarn can continuously obtain a large amount of composite yarn at a time.

Owner:SUZHOU UNIV

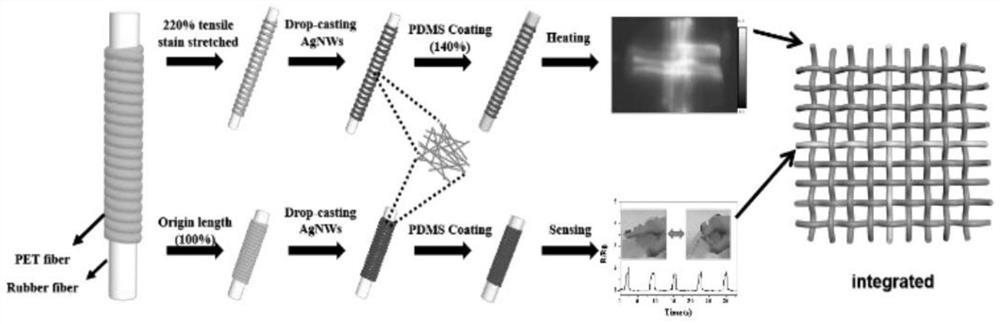

Multifunctional conductive yarn, preparation thereof and application of multifunctional conductive yarn to flexible wearable electronic fabrics

ActiveCN112127147AHighly sensitive heating performanceHigh Sensitive Sensing PerformanceFibre typesYarnElectrically conducting yarnPolymer chemistry

The invention discloses a multifunctional conductive yarn, preparation thereof and an application of the multifunctional conductive yarn to flexible wearable electronic fabrics. A preparation method of the conductive yarn comprises the following steps: (1) obtaining a yarn with a contact angle of 80 degrees or below and strain capacity of 10% or above; (2) pre-stretching the yarn in the step (1),wherein the stretching ratio is 1-2.5, coating the pre-stretched yarn with silver nanowire dispersion liquid, performing drying to obtain a yarn containing a silver nanowire layer, and enabling the resistance value of the yarn containing the silver nanowire layer to be 3-7 ohm / cm, wherein the surface of a silver nanowire contains a PVP layer; and (3) pre-stretching the yarn containing the silver nanowire layer, wherein the stretching ratio is 1-1.4, then coating the surface of the yarn with a precursor of a liquid organic elastic polymer, and then performing curing to form an organic elastic polymer layer completely wrapping the yarn on the surface of the yarn so as to obtain the conductive yarn. The conductive yarn provided by the invention has high mechanical strain stability and high strain sensitivity, and can be used in the flexible wearable electronic fabrics.

Owner:ZHEJIANG UNIV OF TECH

Waterproof conductive yarn

InactiveCN111254536AImprove flexibilityAchieve waterproof effectYarnEngineeringElectrically conducting yarn

The invention discloses a waterproof conductive yarn. The waterproof conductive yarn is of a three-layer structure which is provided with a conductive layer, a waterproof layer and a wrapping layer from inside to outside correspondingly; wherein the conductive layer is located on the innermost layer, the outer layer of the conductive layer is coated with the waterproof layer, and the outer layer of the waterproof layer is wrapped with the wrapping layer. The waterproof conductive yarn has the beneficial effects that the conductive layer can be made into a conductive layer yarn with good flexibility; the waterproof layer can achieve a waterproof effect and provide certain physical strength; the warping layer can improve the overall weavability of the conductive yarn, improve the wear resistance of the yarn, well prevent the waterproof layer from being damaged in the weaving and using processes and improve the performance stability of the waterproof layer; the three-layer conductive yarnis simple in structure, convenient in manufacturing method and high in applicability.

Owner:DONGHUAJINGYUE SUZHOU TEXTILE TECH RES CO LTD

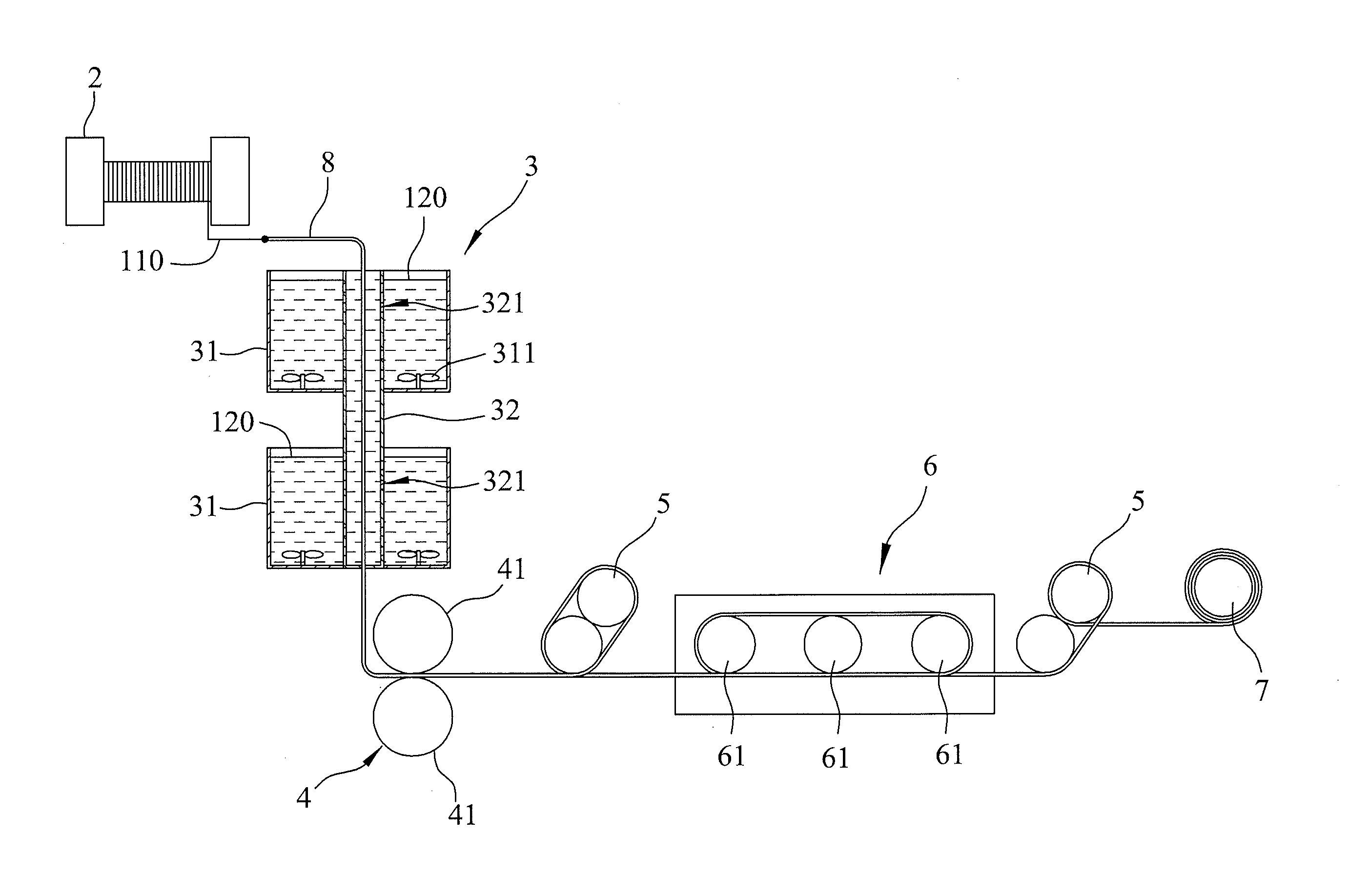

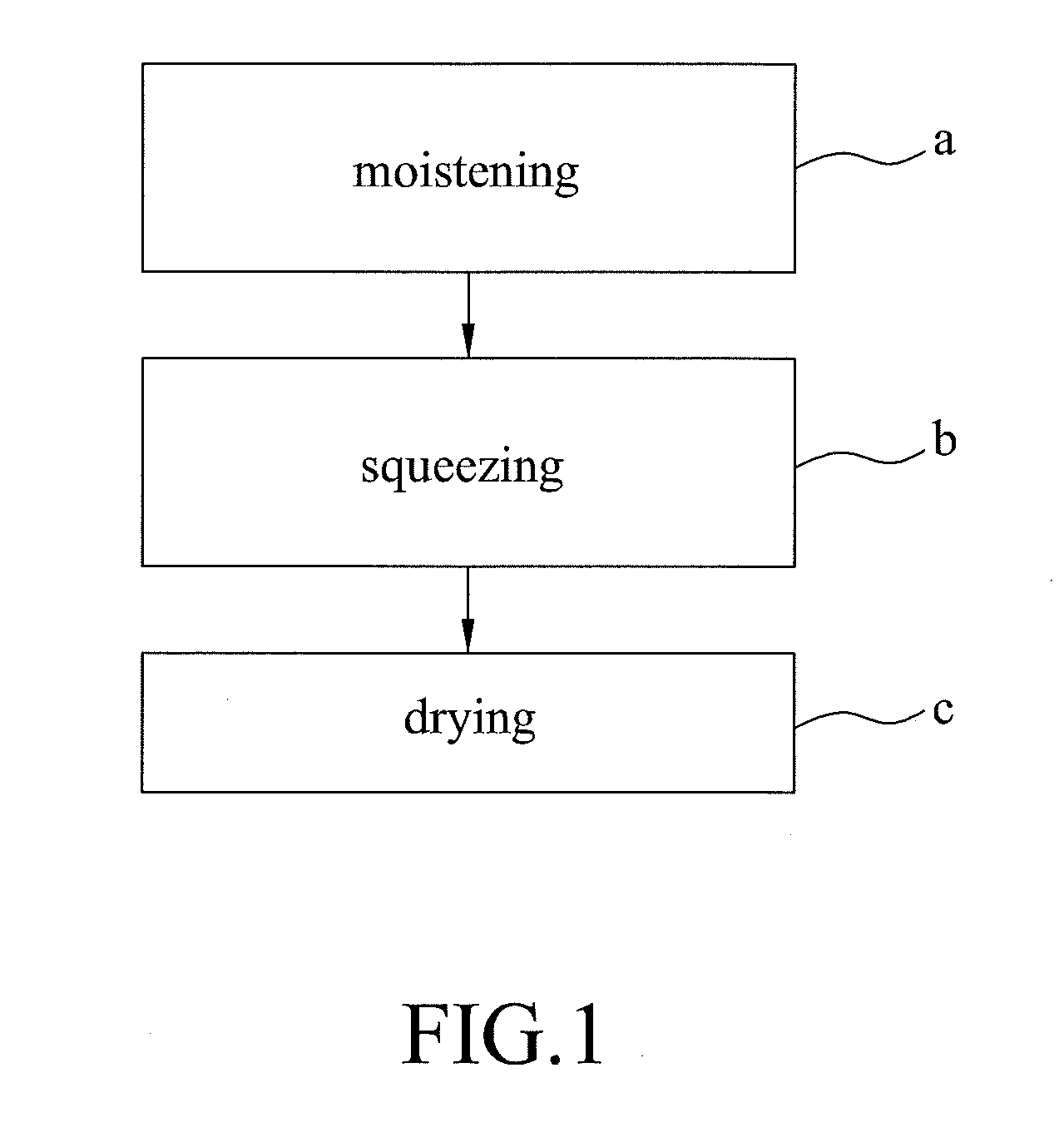

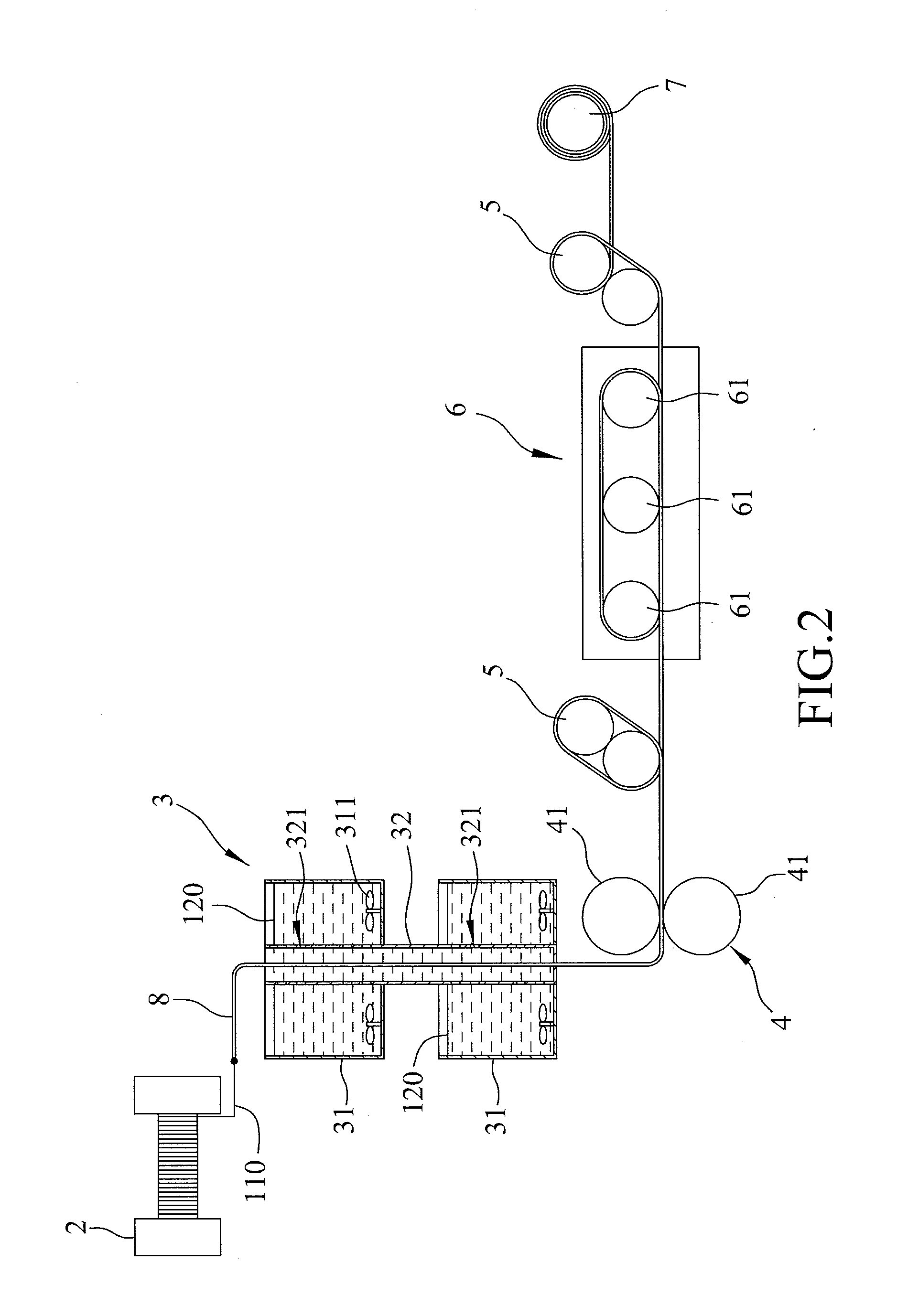

Method for fabricating a conductive yarn and conductive yarn fabricated by the method

InactiveUS20140318857A1Improve conductivityShorten the processing periodMaterial nanotechnologyLubricating devicesPolymer scienceElectrically conducting yarn

A method for fabricating a conductive yarn includes the steps of: moistening a preformed yarn with a conductive slurry to prepare the preformed yarn absorbed with the conductive slurry; and drying the preformed yarn absorbed with the conductive slurry. The conductive slurry includes a conductive nanometer structure, a solvent, and a resin component. The conductive nanometer structure has an aspect ratio sufficient to permit binding of the conductive nanometer structure to the preformed yarn.

Owner:ASIATIC FIBER CORP

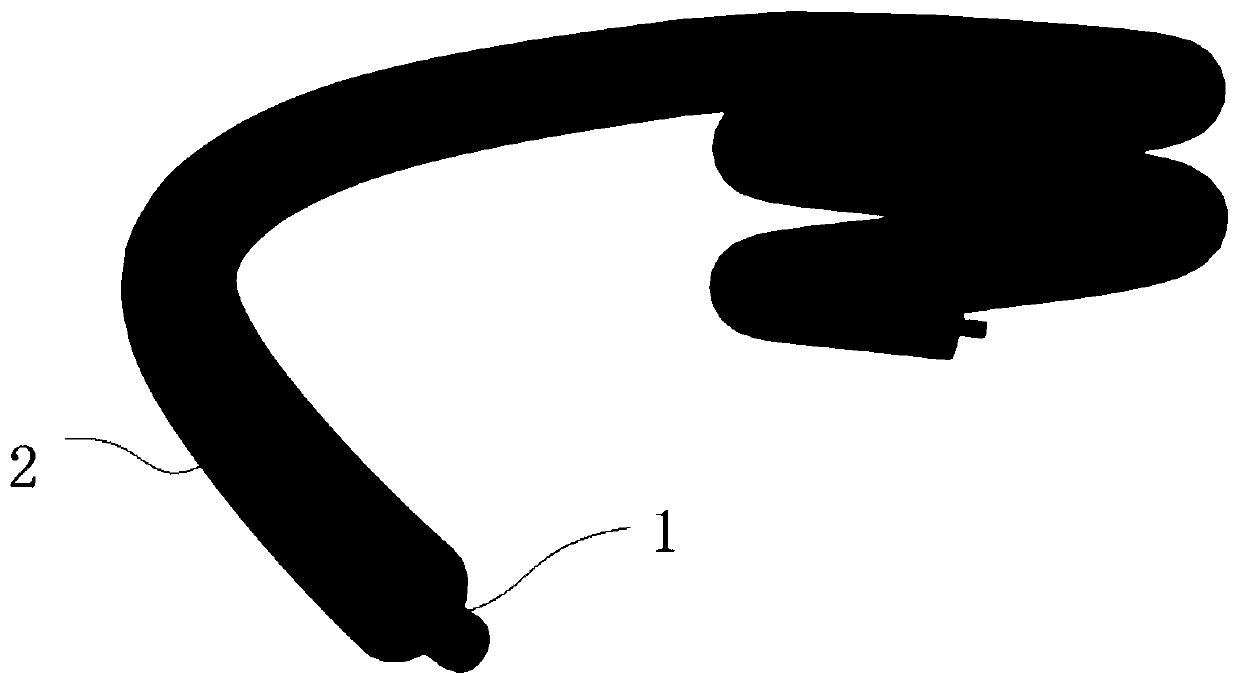

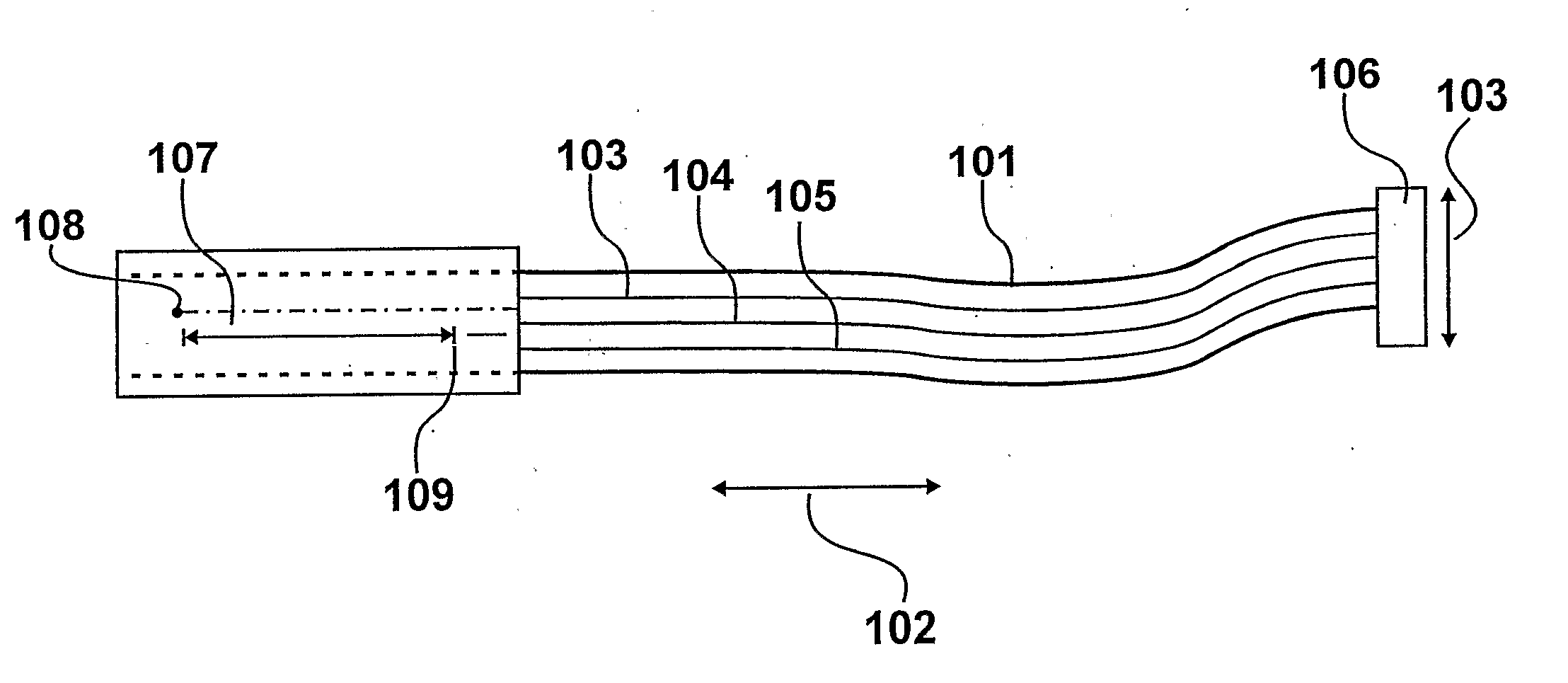

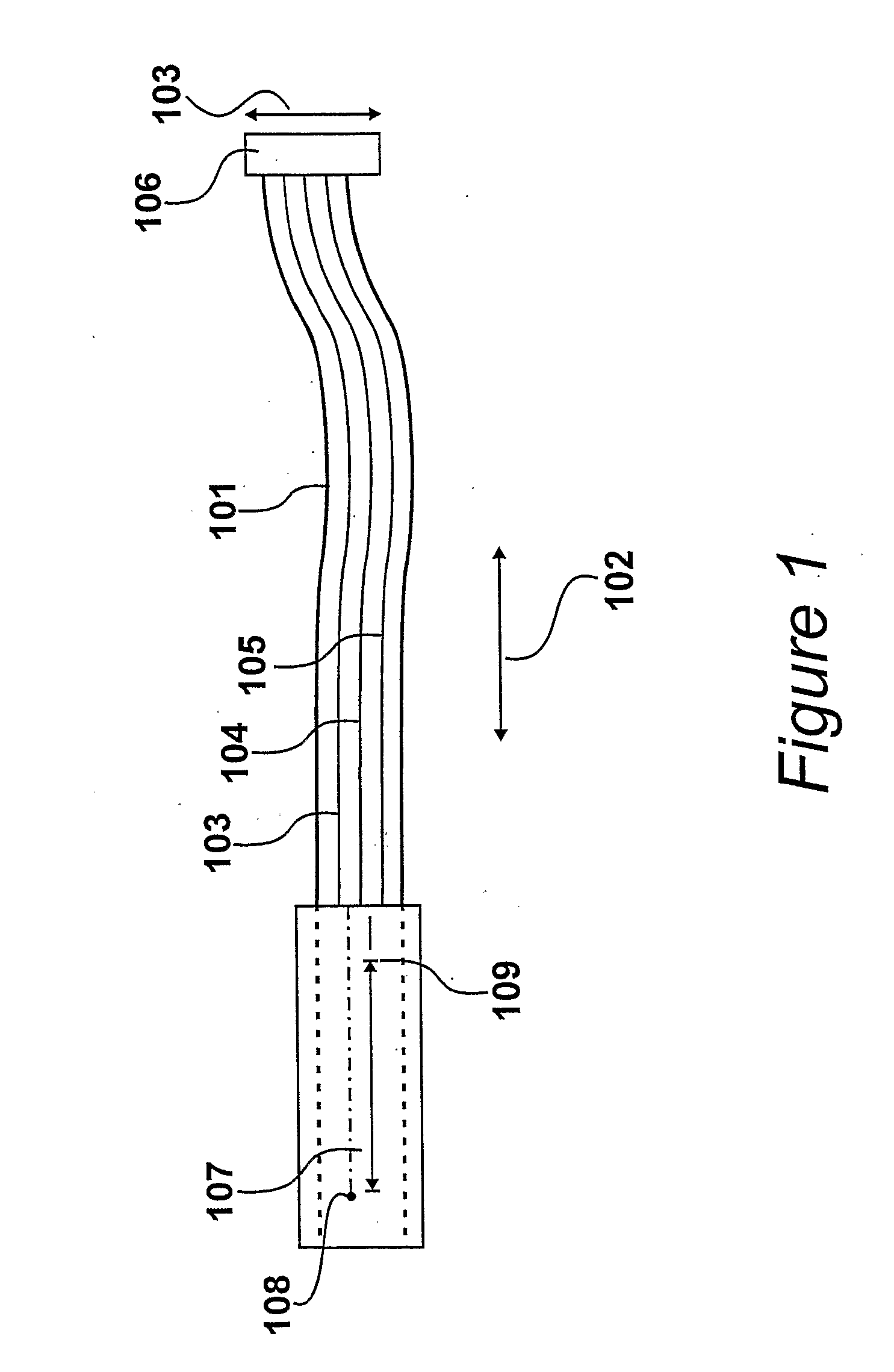

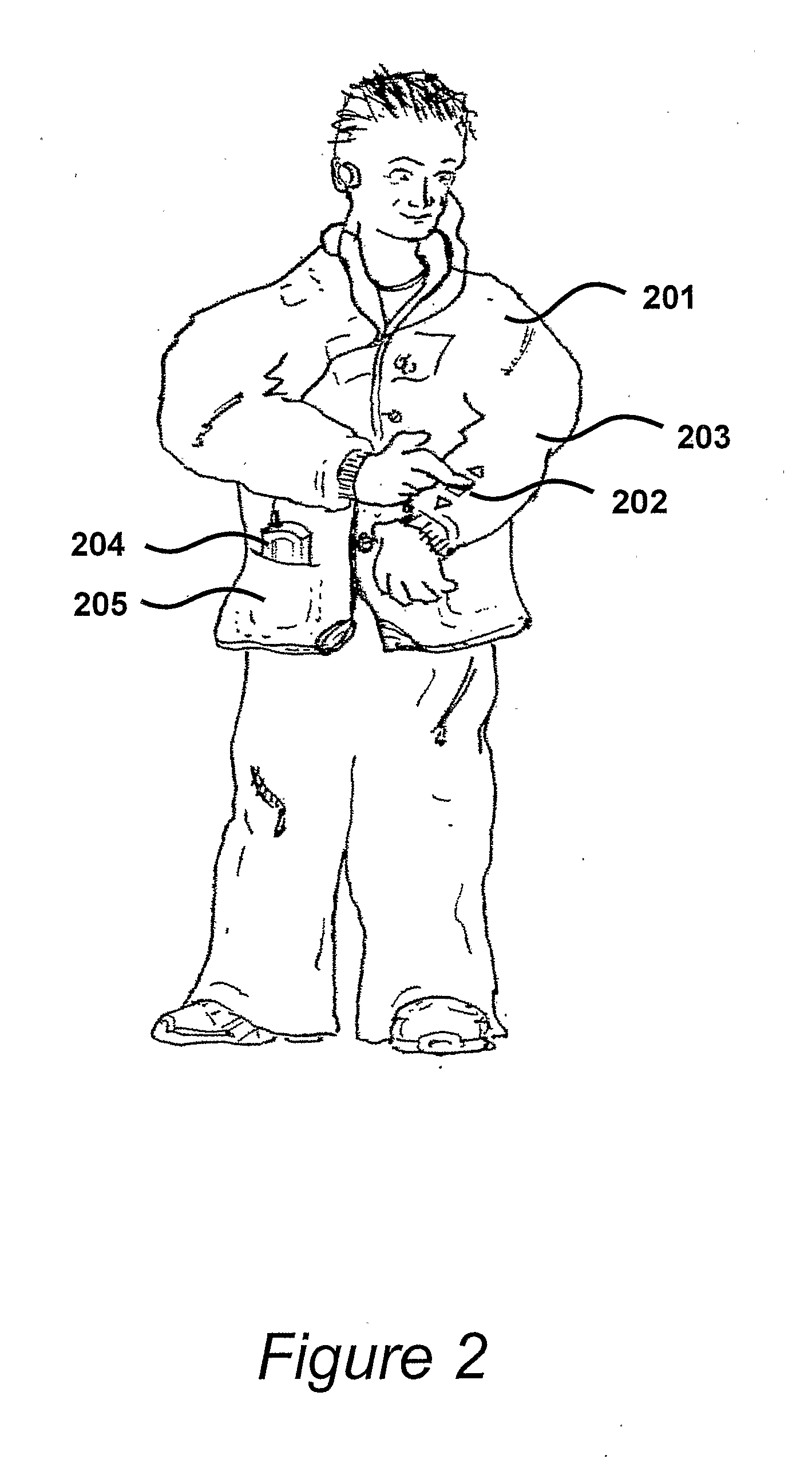

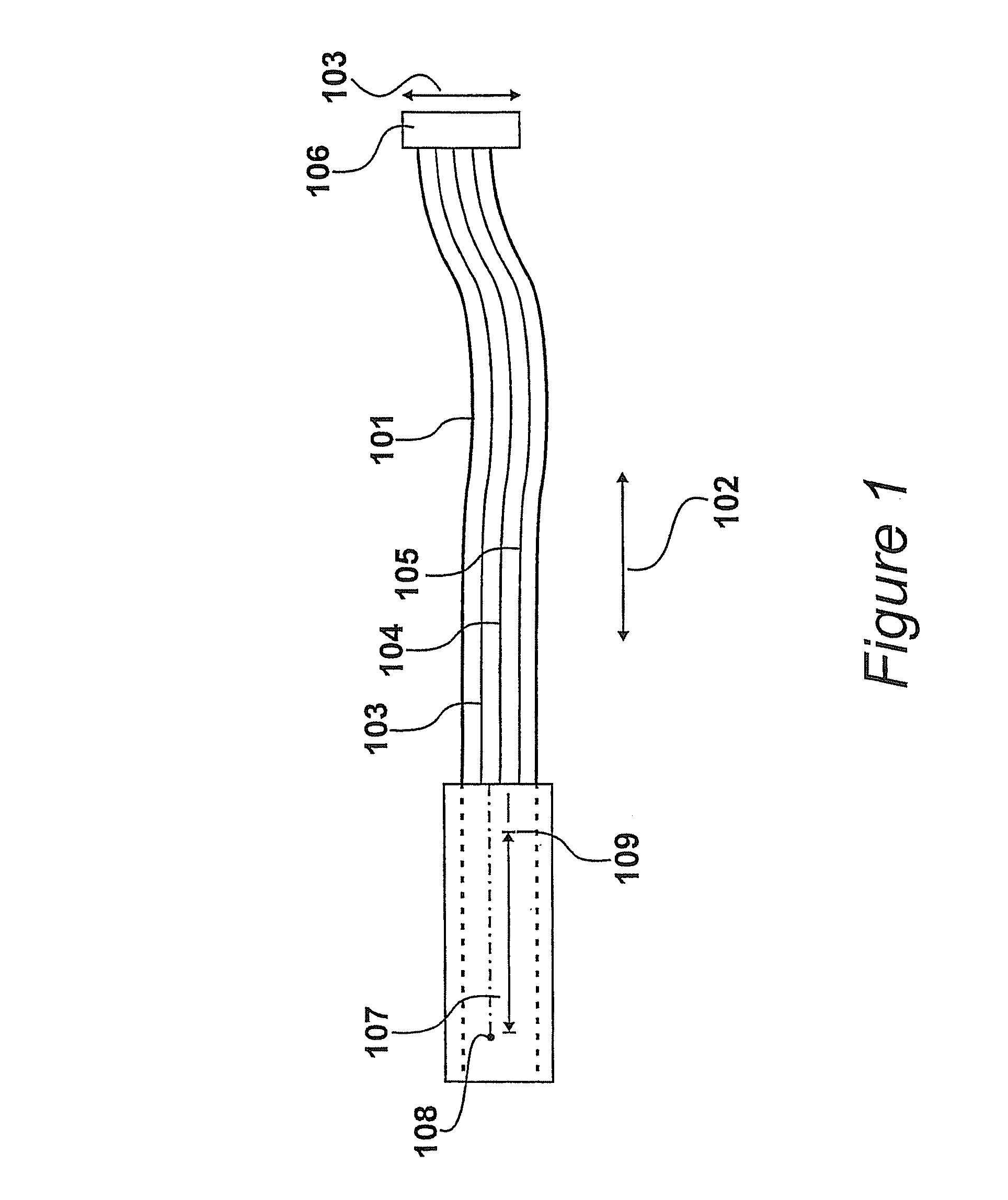

Manually operable position sensor

A manually operable position sensor is shown, for providing control signals to an electronic device, such as an audio player. A fabric ribbon (101) has a length substantially longer than its width with insulating yarns and electrically conducting yarns included therein. The conducting yarns define three conductive tracks (103, 104, 105) running the length of the fabric. The conductive tracks are configured to interface with an electronic device at a first end. At a second end, an active region of the fabric forms part of a sensor assembly that is receptive to a manually applied pressure.

Owner:WEARABLE TECH LTD

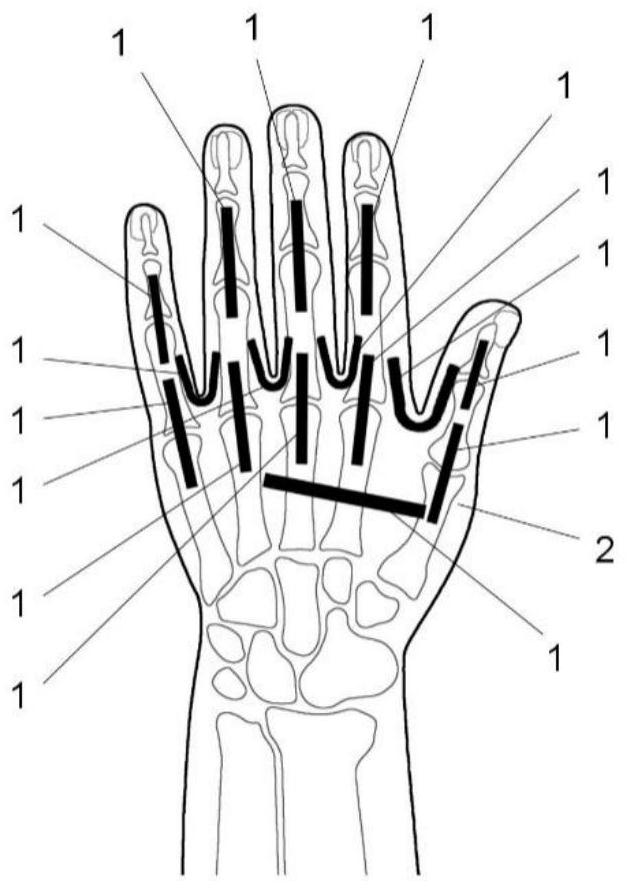

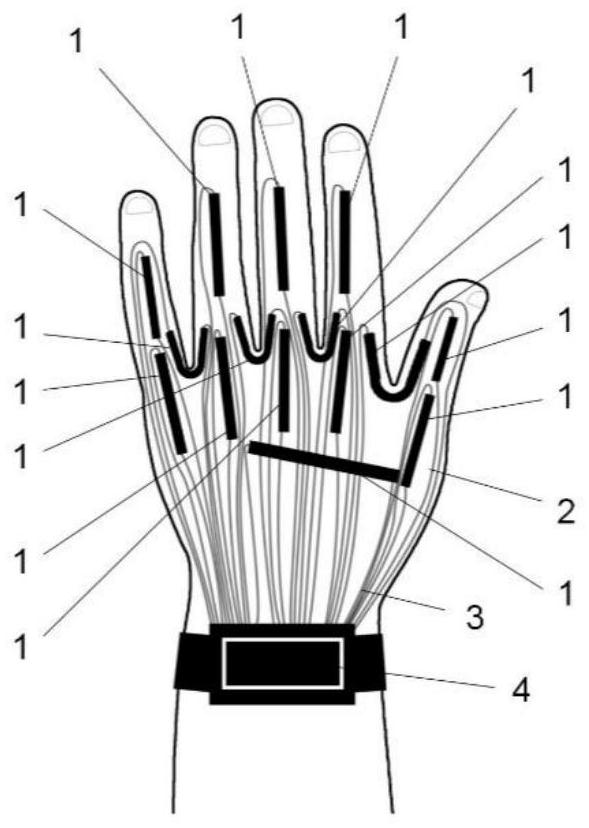

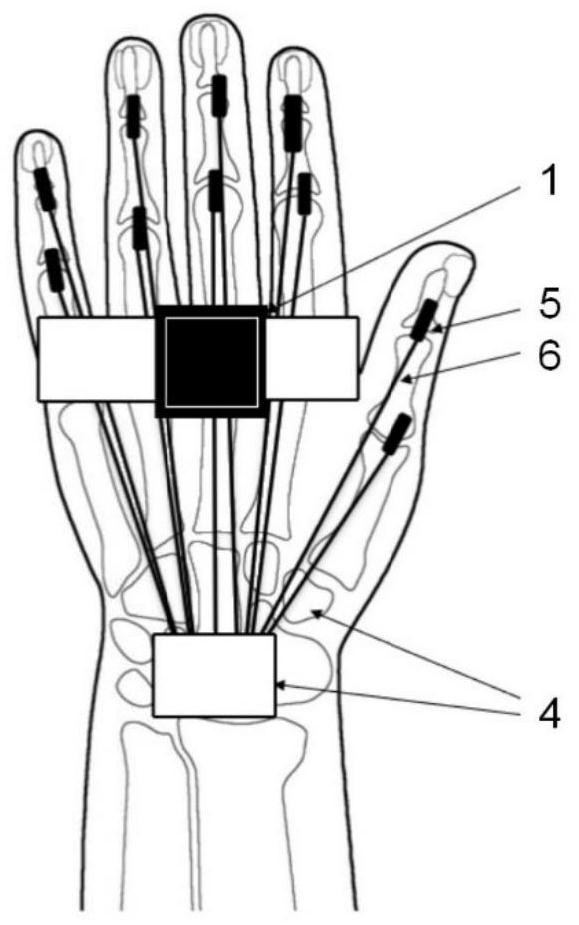

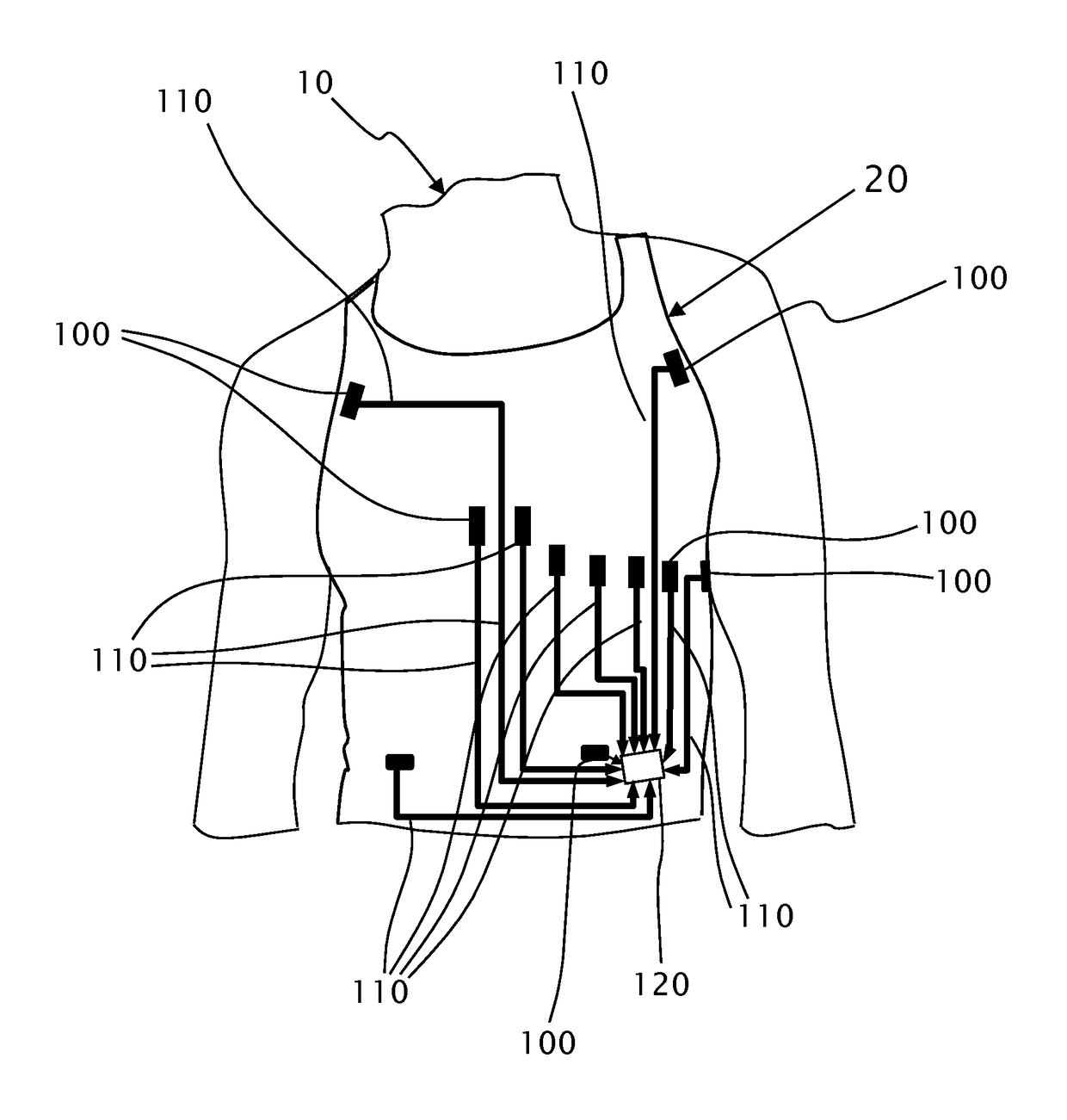

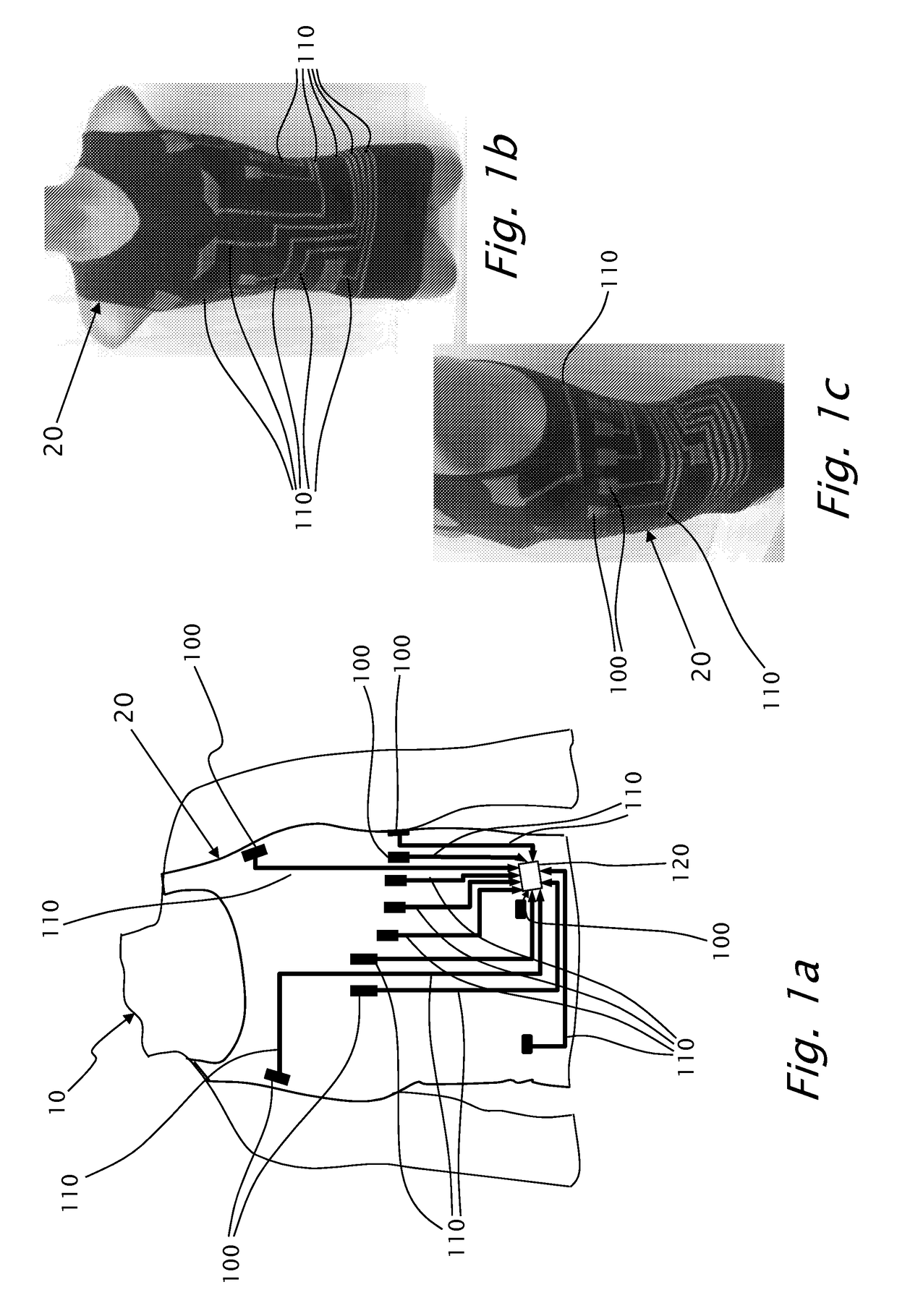

Integrated self-driven full-textile gesture recognition data glove

ActiveCN111665937ARealize structural integrationEase of mass productionInput/output for user-computer interactionGlovesControl circuitElectrically conducting yarn

The invention discloses an integrated self-driven full-textile gesture recognition data glove, which is characterized by comprising a glove base body, self-powered strain sensing parts and flexible weak-sensitive conductive yarns, wherein basic yarns for weaving the glove base body are elastic insulating yarns; the self-powered strain sensing parts are arranged in a plurality of sensing areas of the glove base body; and the self-powered strain sensing parts are connected with a control circuit through the flexible weak-sensitive conductive yarns. The sensor of the data glove is flexibly fiberized under the condition that the electrical property is met, so that the mechanical property for a textile weaving process is met, and the sensing detection and the structure integration of a glove material are realized, and the possibility of batch production is improved. Meanwhile, the self-driven passivity of the detection circuit can effectively reduce the burden of equipment and simplify thecircuit, and avoids the use limitation caused by charging or battery replacement.

Owner:DONGHUA UNIV

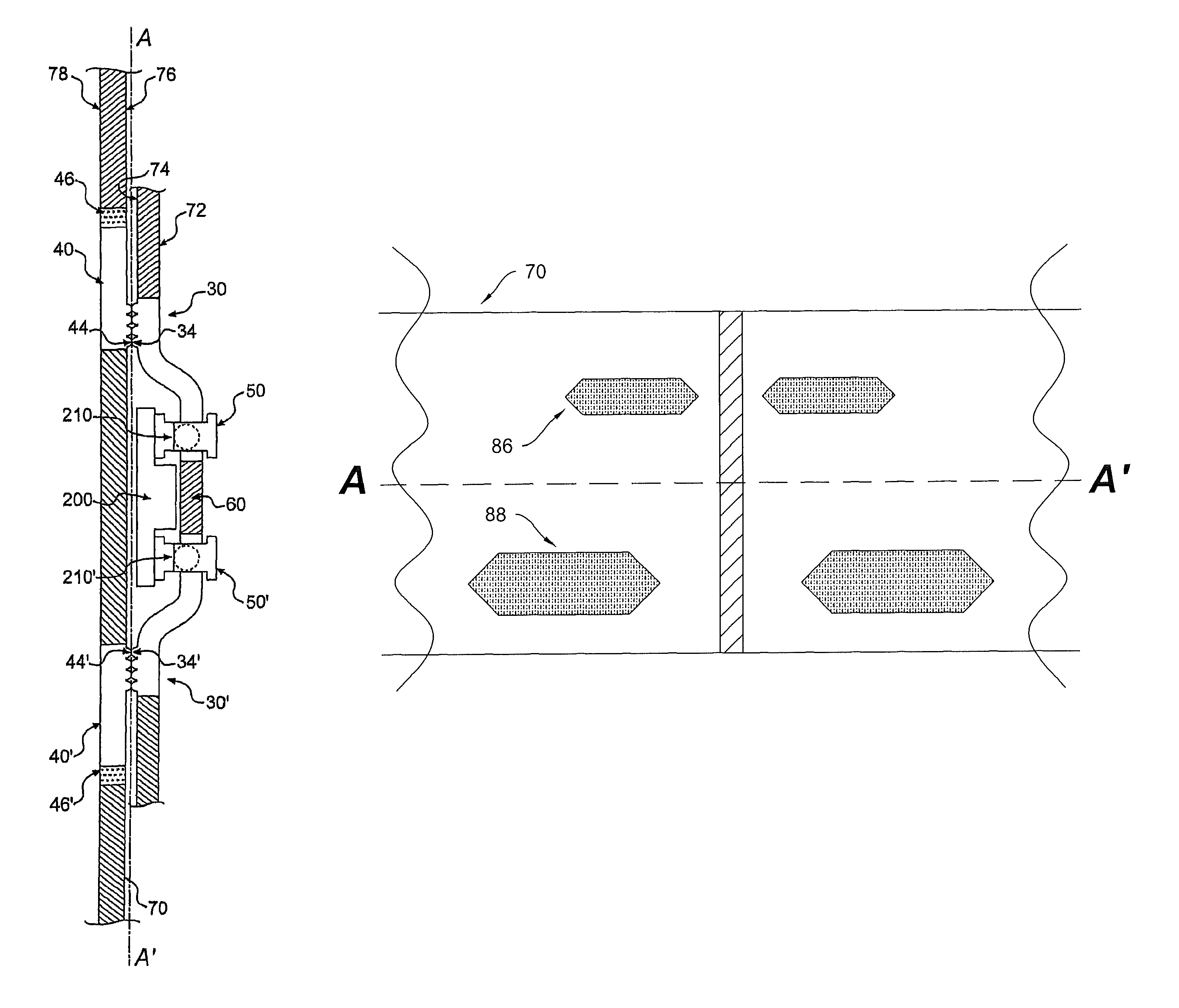

Vertical conductive textile traces and methods of knitting thereof

A method for knitting a garment having a tubular form, including knitting at least one vertical conductive textile trace on a machine having N participating feeders and M needles. The method includes the steps of continuously knitting the tubular form with one or more flexible non-conductive base yarns, and knitting the vertical conductive textile trace integrally within the tubular form, using a conductive yarn, in addition to spandex yarns, but not the base yarns. The conductive yarn is knitted in a float-loop form by knitting a stitch and skipping over y needles, as follows: repeatably knitting a line segment Lk, using feeder Fi and starting at needle D1; and knitting line segment Lk+1, using the next feeder and start stitching the first float-loop at needle D1+s where 0<s<y.

Owner:HEALTHWATCH LTD

Manually operable position sensor

A manually operable position sensor is shown, for providing control signals to an electronic device, such as an audio player. A fabric ribbon (101) has a length substantially longer than its width with insulating yarns and electrically conducting yarns included therein. The conducting yarns define three conductive tracks (103, 104, 105) running the length of the fabric. The conductive tracks are configured to interface with an electronic device at a first end. At a second end, an active region of the fabric forms part of a sensor assembly that is receptive to a manually applied pressure.

Owner:WEARABLE TECH LTD

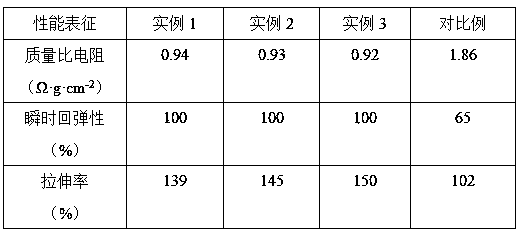

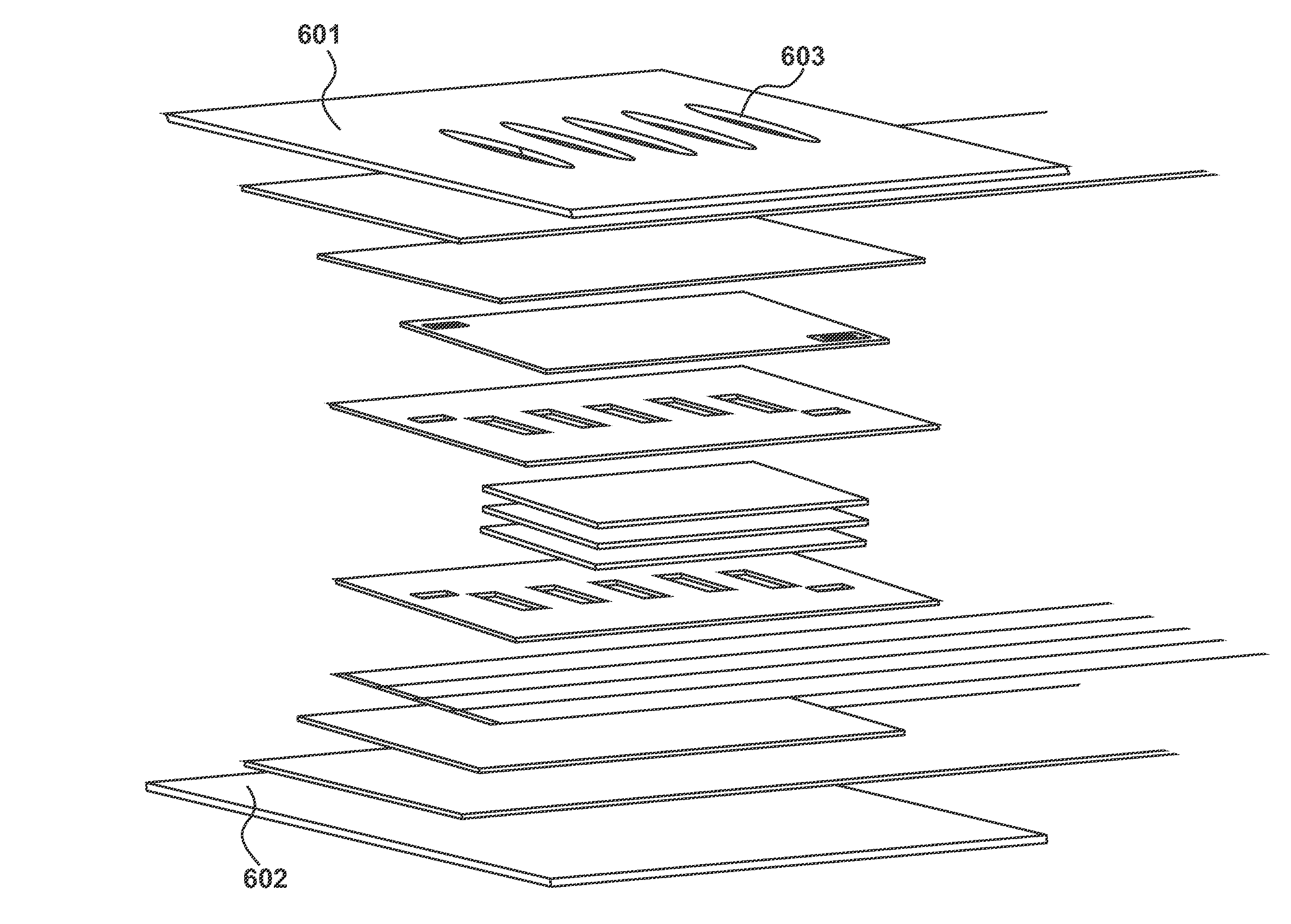

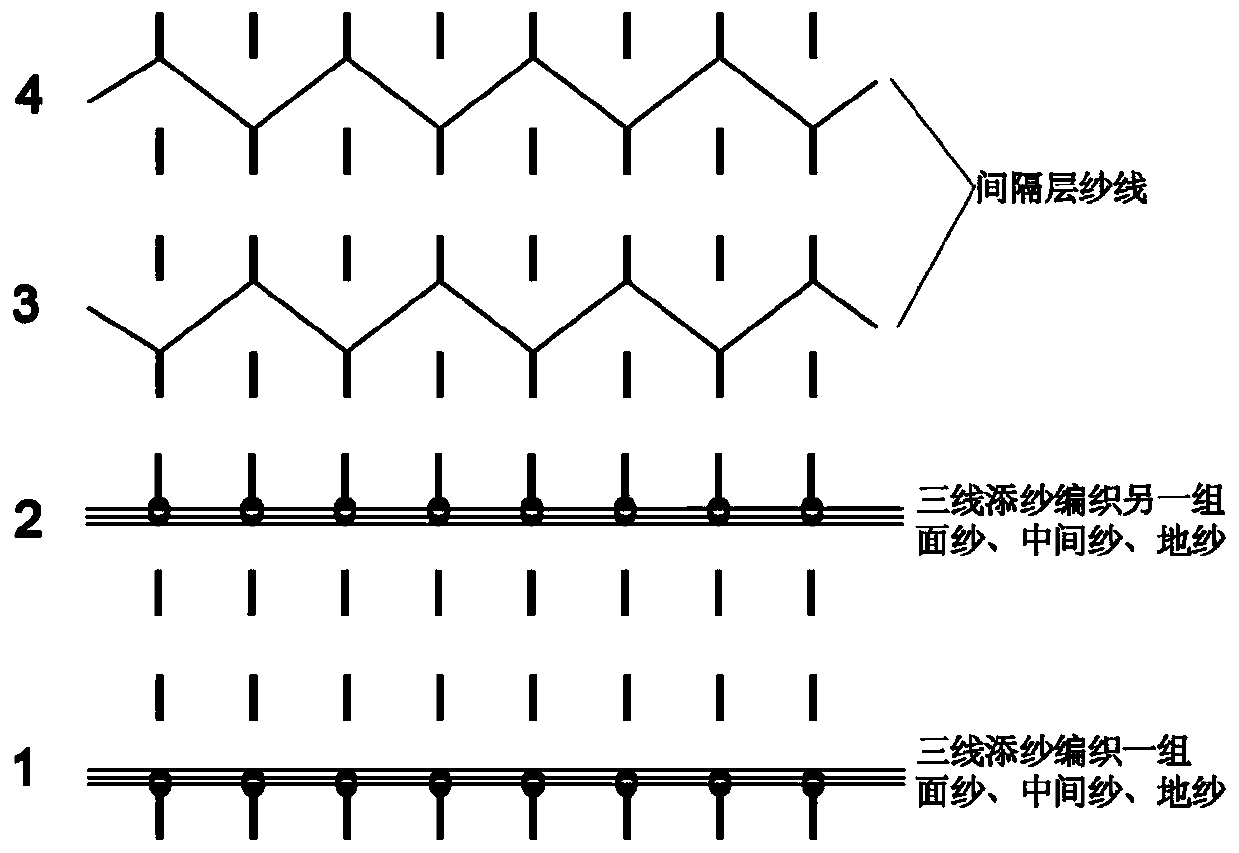

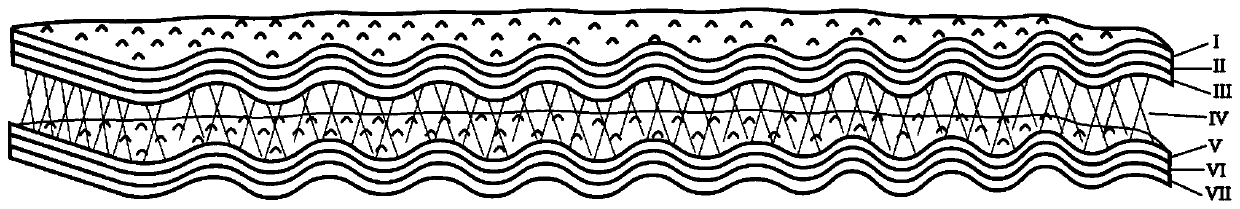

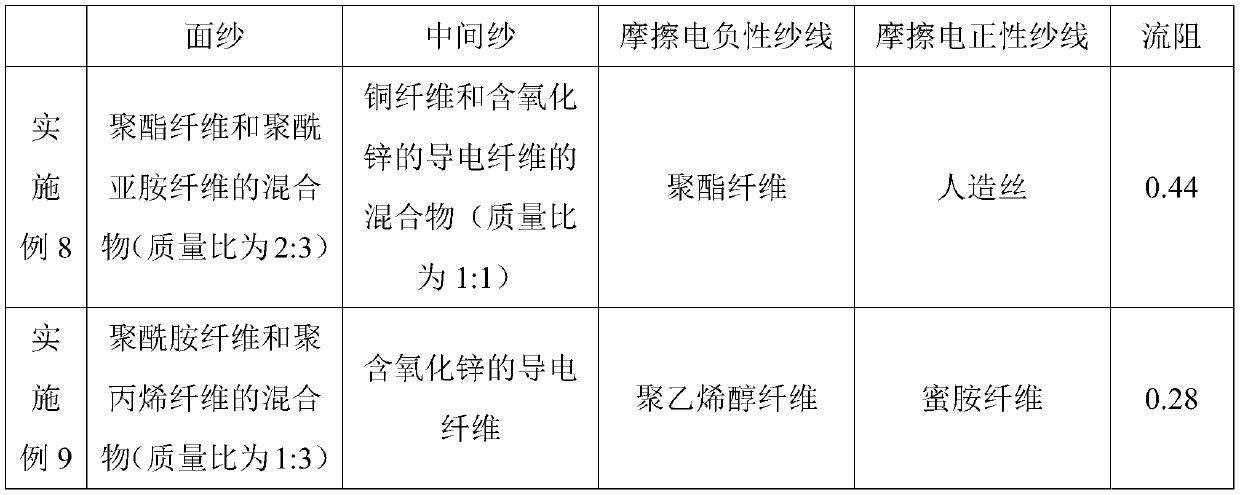

Breathable knitted spacer fabric triboelectric generator and method of making the same

ActiveCN109525140BSimple processImprove weaving efficiencyFriction generatorsEngineeringElectrically conducting yarn

The invention relates to a breathable knitted spacer fabric friction generator and a preparation method thereof. The method comprises the steps of weaving a top layer and a bottom layer by using a three-wire plating process, controlling the yarn angles of surface yarns, intermediate yarns and ground yarns respectively such that the three yarns are sequentially arranged according to a certain positional relationship and then are woven, at the same time, in the weaving process, performing alternate tucking of spacer wires between a top layer ground yarn and a bottom layer ground yarn with a certain number of spacing stitches to form the breathable knitted spacer fabric friction generator, wherein a top layer surface yarn and a bottom layer surface yarn are at the outmost sides of a compositelayer and are insulating yarns, a top layer intermediate yarn and a bottom layer intermediate yarn are conductive yarns, the top layer ground yarn and the bottom layer ground yarn are opposite and are a triboelectric negative yarn and a triboelectric positive yarn correspondingly, and a spacer layer is composed of a set of spacer wires that are simultaneously connected to the top layer ground yarn and bottom layer ground yarn. The preparation method of the invention has the advantages of simple process and high weaving efficiency, and the obtained knitted spacer fabric friction generator hasgood gas permeability and has excellent promotion value.

Owner:HANGZHOU TIANYE JACQUARD

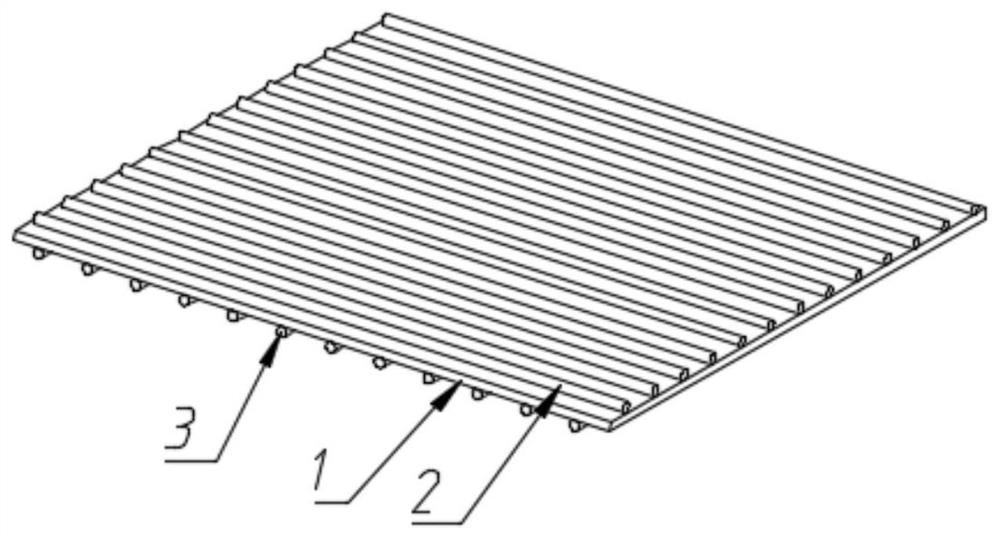

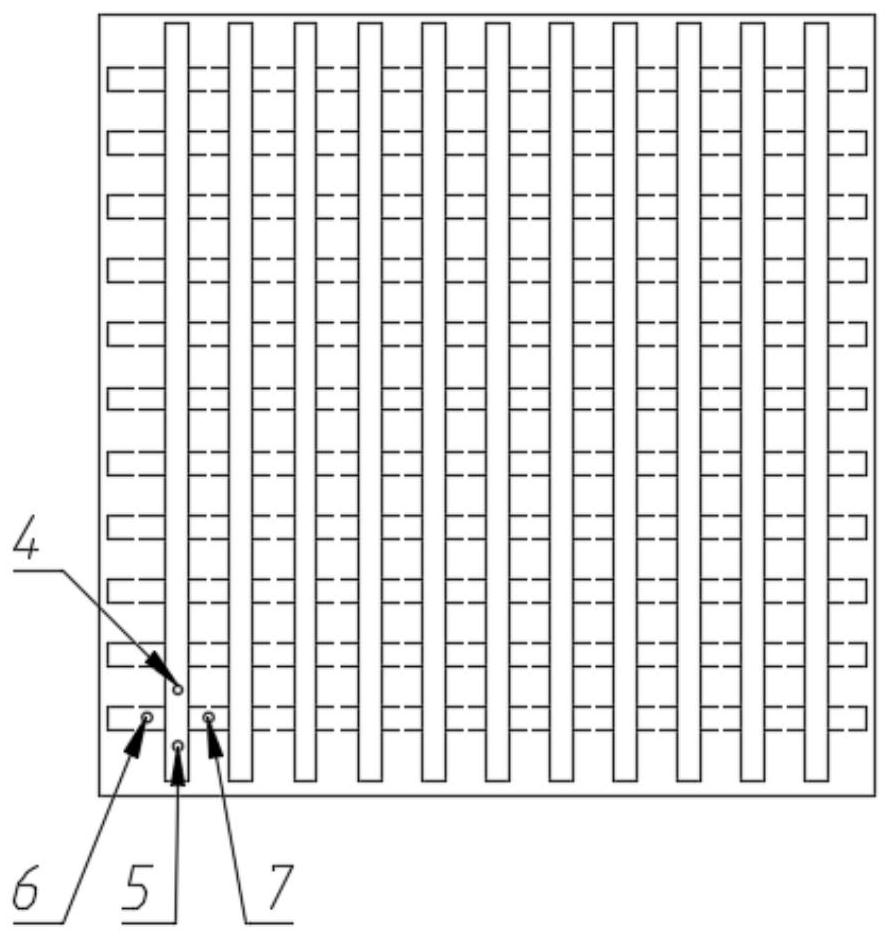

Elastic array pressure sensor

ActiveCN112082675AImprove conductivityAvoiding the Effects of Stress DetectionForce measurement using piezo-resistive materialsYarnFiberSpinning

The invention discloses an elastic array pressure sensor, which applies an elastic conductive fiber technology to an array pressure sensor to realize a technology of detecting pressure under the condition of large deformation. According to the invention, the elastic conductive yarns are arranged on two sides of the sensing layer as electrodes and are sewn on the sensing layer, and the sensing layer is made of conductive cloth, so that the whole sensor is lighter, thinner and softer; according to the preparation method of the elastic conductive yarn, existing spinning equipment and a mature ring spinning process are used, the manufacturing process is simple, the cost is low, and large-scale production is easy to achieve; according to the elastic conductive yarn, when the elastic conductiveyarn is dynamically stretched, the conductive core-spun yarns spirally wound on the outer sides of the elastic fiber filaments are insulated from one another and can extend in the direction of the elastic fiber filaments, the effective conductive length of the elastic conductive yarn is kept unchanged, the resistance value is stable and unchanged, and meanwhile the requirements for flexibility andstretchability are met.

Owner:WUHAN TEXTILE UNIV

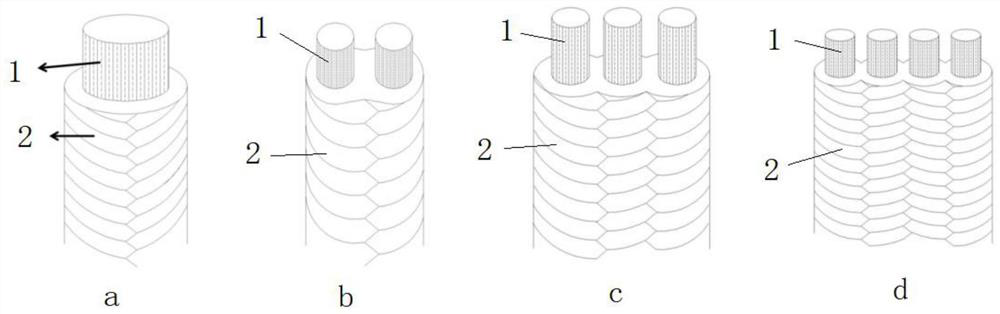

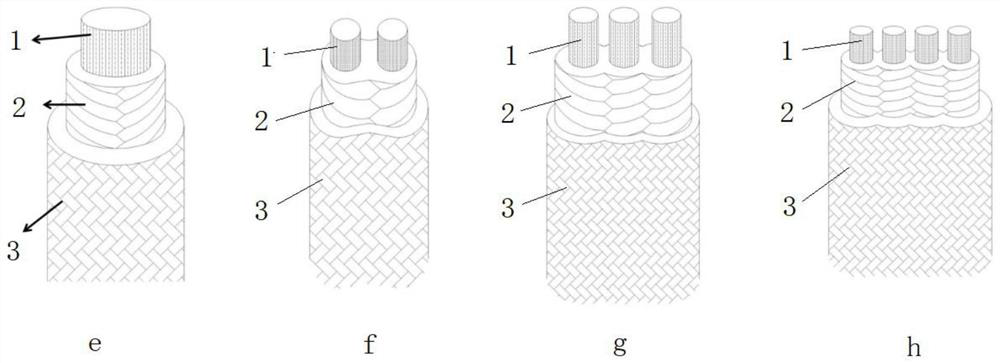

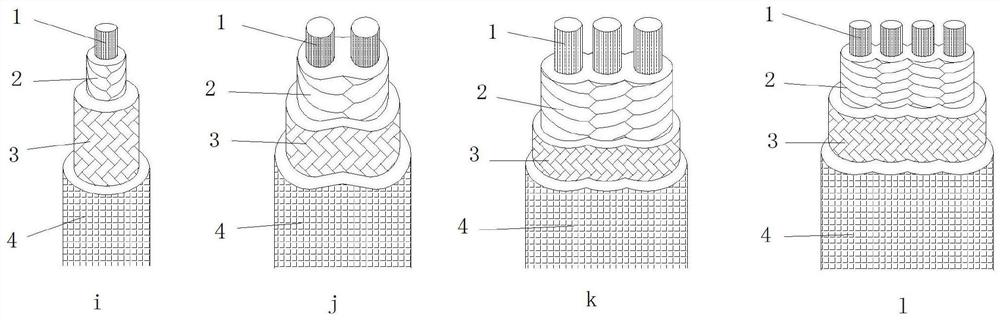

Stretchable multi-core wire with electromagnetic shielding layer and manufacturing method of wire

PendingCN113241215AGuaranteed flexibilityImprove the performance of anti-electromagnetic radiationFlexible cablesCable/conductor manufactureEngineeringElectromagnetic shielding

The invention discloses a stretchable multi-core wire with an electromagnetic shielding layer. The stretchable multi-core wire comprises one or more elastic wire cores, a braid layer wound and wrapped on the outer side of the one or more elastic wire cores, and an elastic shielding layer wrapped on the outer side of the braid layer. The elastic shielding layer is one or more elastic shielding layers wrapping the outer side of the braid layer, and the elastic shielding layer is one or more of a metal woven mesh, a metal knitted shielding mesh, conductive silicone rubber, conductive rubber, conductive plastic, conductive cloth and conductive yarn. According to the scheme, the special structure of the elastic shielding layer and the preparation method are adopted, so that the electromagnetic radiation resistance is enhanced, the elasticity of the elastic wire is ensured, and very good practicability is achieved.

Owner:嘉兴极展科技有限公司

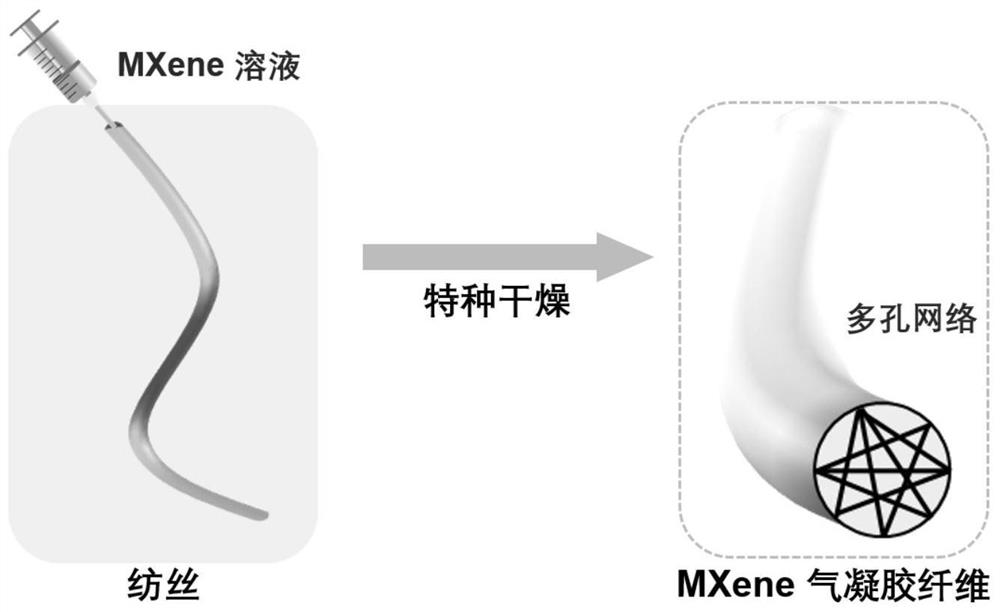

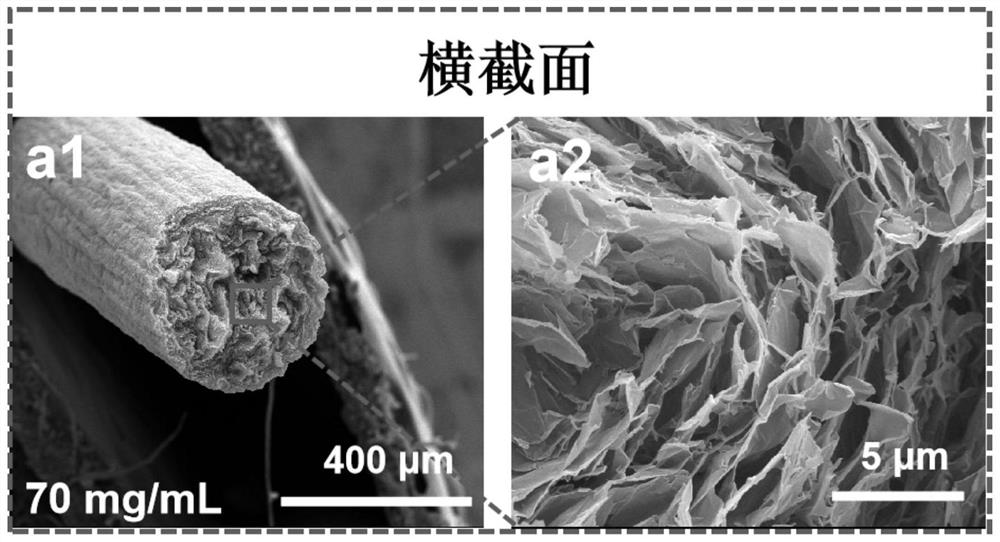

MXene aerogel fiber as well as preparation method and application thereof

ActiveCN113718371ASimple ingredientsLow costInorganic material artificial filamentsArtificial filament heat treatmentFiberSpinning

The invention discloses an MXene aerogel fiber as well as a preparation method and application thereof. The preparation method comprises the following steps of carrying out chemical etching treatment on an MAX phase material to obtain an MXene material, and forming an MXene dispersion liquid; and taking the MXene dispersion liquid as a spinning solution, preparing a MXene hydrogel fiber by adopting a spinning technology, and then drying the MXene hydrogel fibers to obtain the MXene aerogel fiber. The preparation method is simple and rapid, continuous large-scale preparation of the MXene aerogel fiber is facilitated, the prepared MXene aerogel fiber has a continuous MXene three-dimensional hierarchical pore network structure formed by lapping two-dimensional MXene sheet layers, the porosity is high, the specific surface area is large, the diameter is adjustable, the length-diameter ratio is large, the conductivity is high, the conductivity is excellent, the strength and the toughness are good, and the MXene aerogel fiber can be used in the fields of conductive yarns, electric heating, energy devices, composite materials, catalysis, antennas, electromagnetic shielding, wave absorption and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

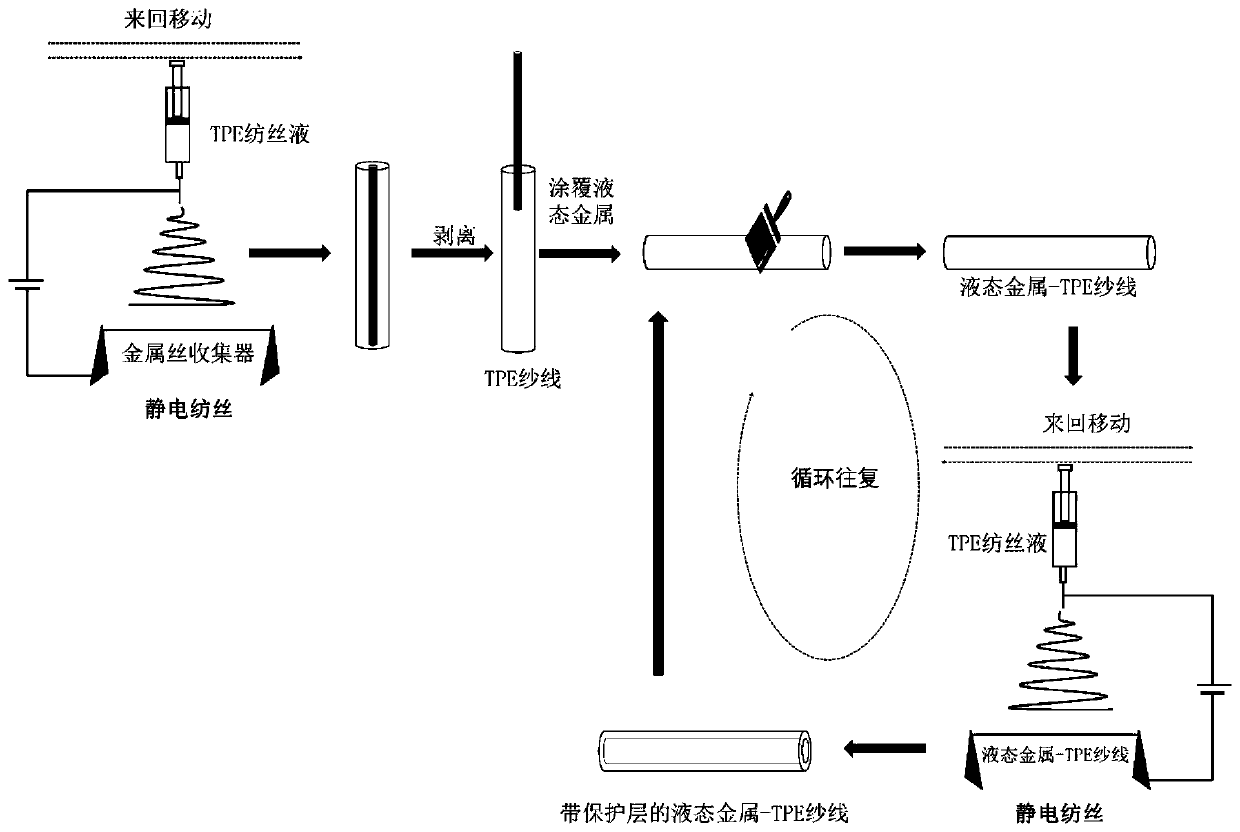

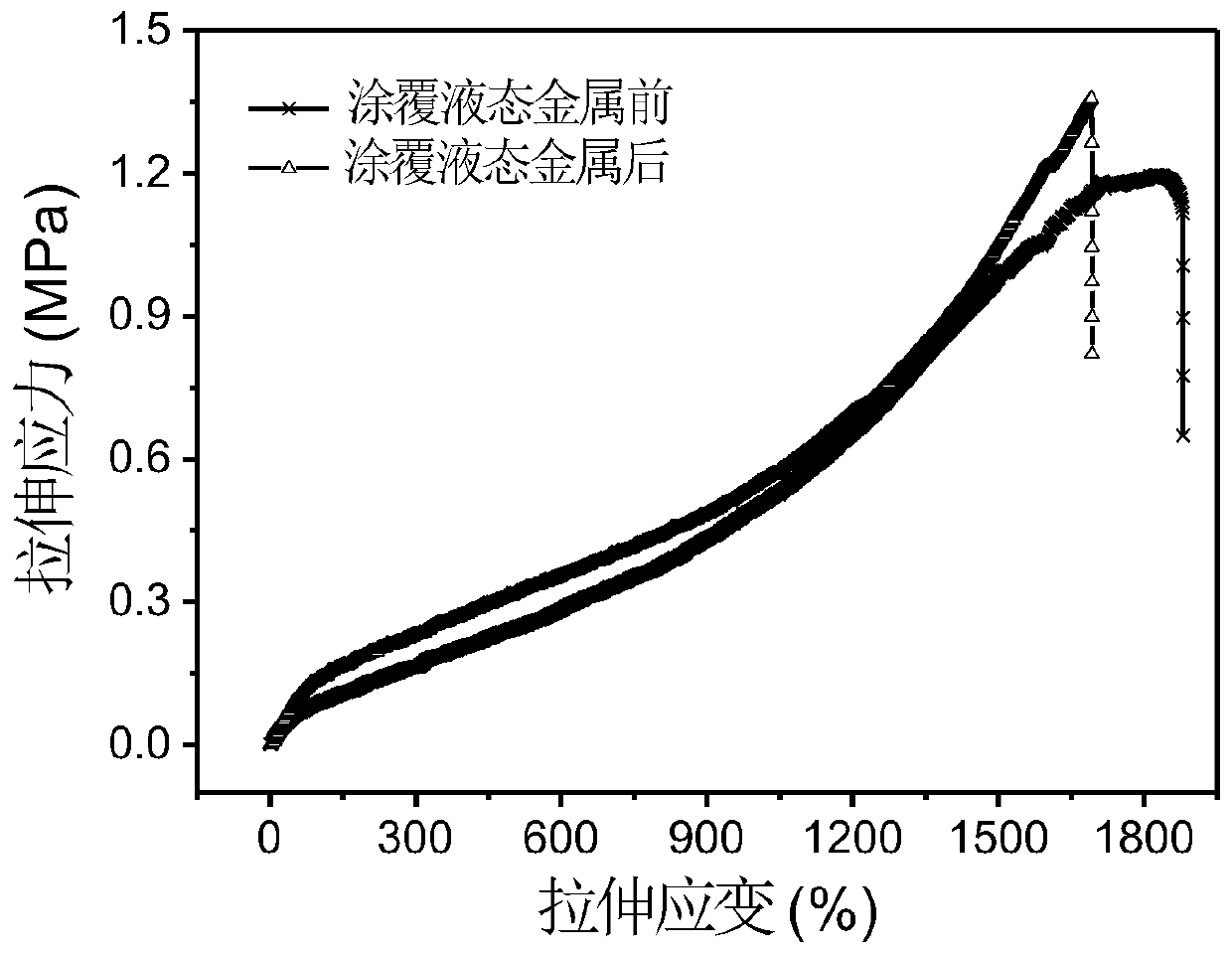

High-conduction-stability superelastic yarn, and preparation method and application thereof

The invention discloses a high-conduction-stability superelastic yarn, and a preparation method and application thereof. The preparation method comprises the following steps of (1) preparing a spinning solution, namely dissolving a thermoplastic elastomer material TPE in an organic solvent to obtain the spinning solution; (2) preparation TPE fiber: preparing TPE micro-nano fiber from the spinningsolution obtained in the step (1) through electrostatic spinning, collecting the TPE fiber by using a metal wire in the spinning process, and coating the TPE fiber onto the surface of the metal wire;(3) peeling the TPE fiber coating the surface of the metal wire from the surface of the metal wire, and performing drying to obtain a TPE yarn; and (4) coating liquid metal onto the surface of the dried TPE yarn to obtain an elastic conductive yarn. The preparation method provided by the invention has the advantages that the method is simple; the efficiency is high; the cost is low; and the methodis applicable to mass production. The high-conductivity and high-conduction-stability superelastic yarn can be used for wearable optoelectronic equipment and all other equipment needing to use stretchable conductor materials.

Owner:SOUTH CHINA UNIV OF TECH

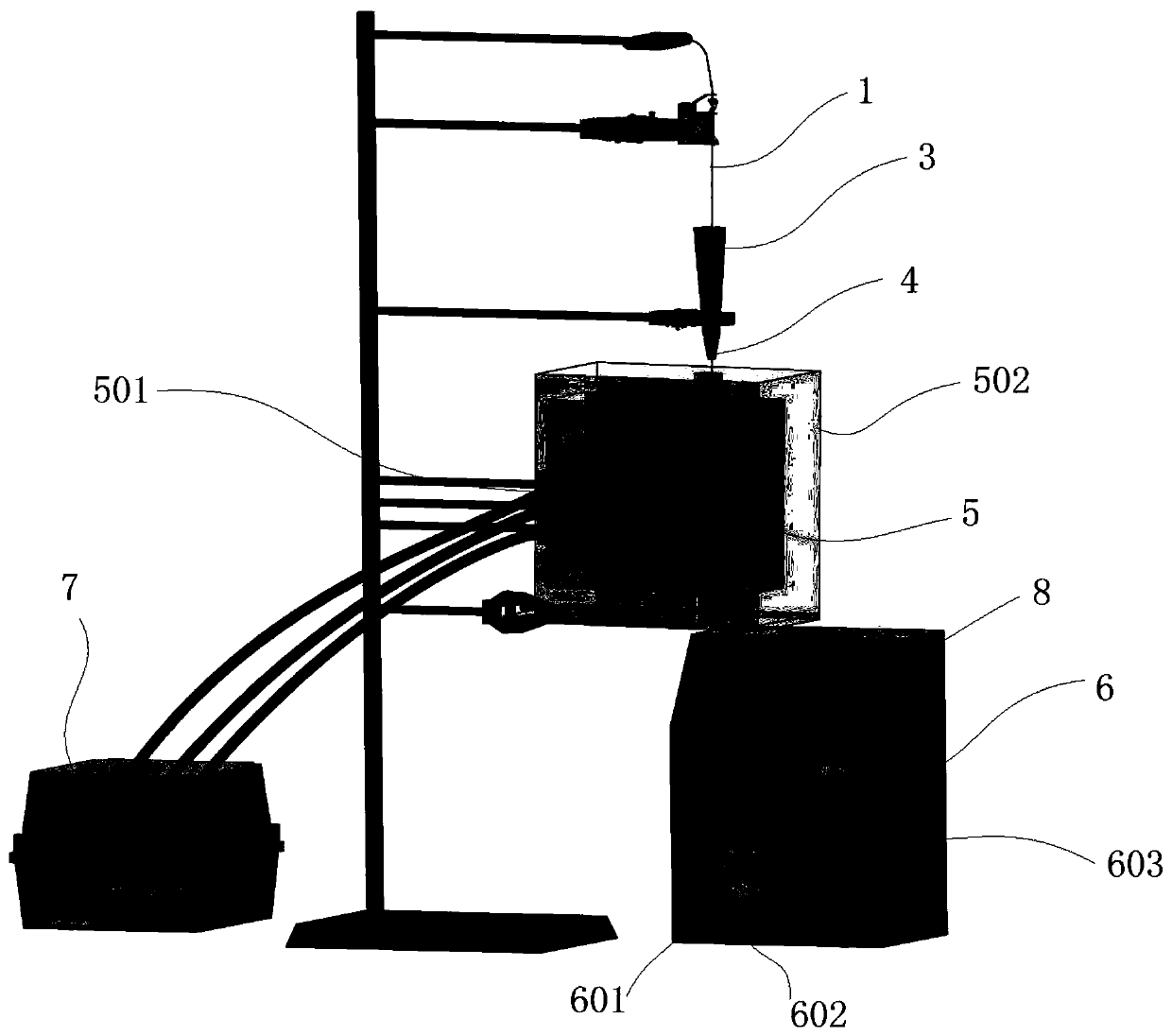

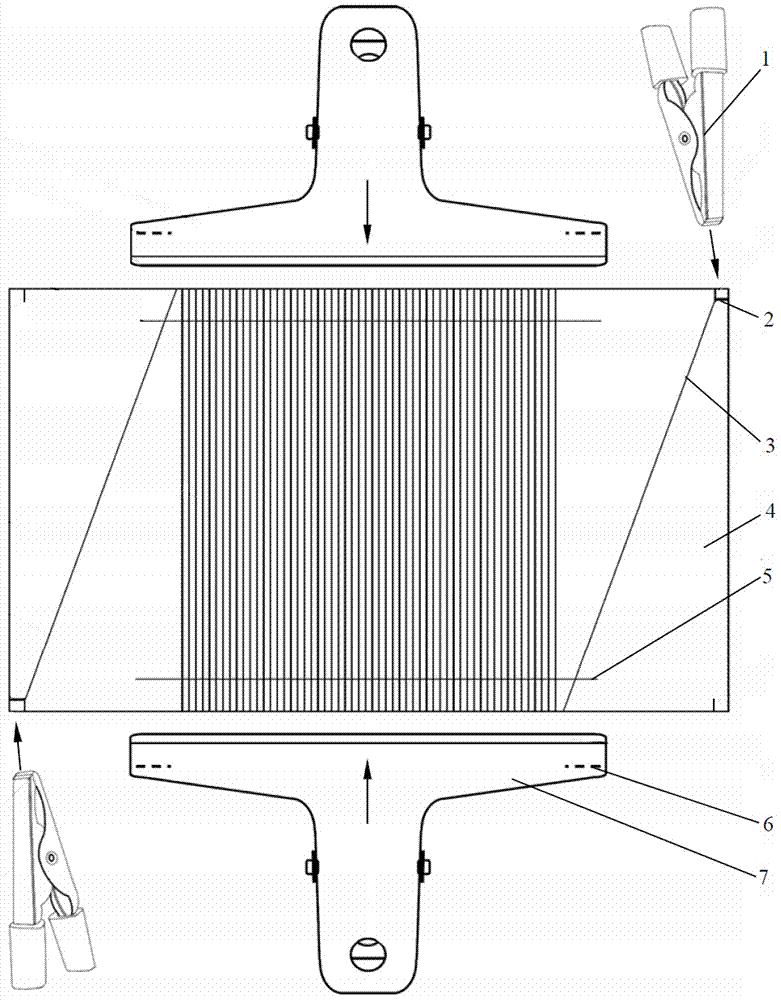

Method and device for resistance detection of conductive yarn

ActiveCN106990293AMeasure the conduction resistanceAvoid layout troublesResistance/reactance/impedenceEngineeringElectrically conducting yarn

The present invention provides a method and device for resistance detection of a conductive yarn. A whole conductive yarn sample is wound on an insulated rectangular plate to allow the winding conductive yarn to form a plurality of yarn sections arranged in parallel at one side of the insulated rectangular plate; the insulated rectangular plate is provided with two yarn end gap ports which are configured to respectively fix head and the tail ends of the conductive yarn sample; conductive clips of the cathode and the anode of a resistance measuring meter are respectively clamped at and connected with the end portions of the conductive yarn sample at the two yarn end gap ports to measure the resistance value of the whole conductive yarn sample; and the conductive clips of the cathode and the anode of a resistance measuring meter are respectively clamped at and connected with two ends of the yarn sections arranged in parallel, the work width of the conductive clips are required to cross the yarn sections to measure the parallel resistance value of the yarns. The method and device for resistance detection of the conductive yarn can conveniently detect the resistance value of the whole conductive yarn and conveniently detect the parallel resistance value of one set of the conductive yarns.

Owner:河南省纺织产品质量监督检验院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com