MXene aerogel fiber as well as preparation method and application thereof

An airgel fiber and airgel technology, applied in the direction of wet spinning, inorganic raw material artificial filament, artificial filament heat treatment, etc., can solve the problem of limiting the feasibility of MXene airgel, affecting the conductivity of MXene airgel, There are no problems reported in the literature, achieving good light-to-heat conversion performance, suitable for large-scale production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

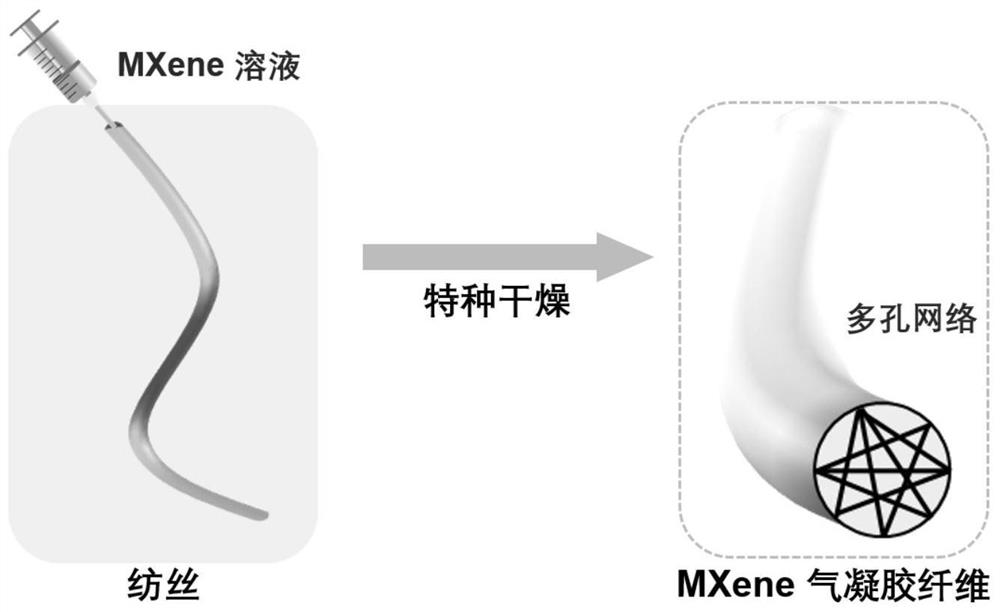

[0039]A kind of preparation method of MXene airgel fiber provided by another aspect of the embodiment of the present invention comprises:

[0040] Perform chemical etching on MAX phase materials to obtain MXene materials and form MXene dispersions;

[0041] Using the MXene dispersion as a spinning solution, using spinning technology to prepare MXene hydrogel fibers;

[0042] The MXene hydrogel fiber is dried to obtain the MXene airgel fiber.

[0043] In some embodiments, the preparation method includes: chemically etching the MAX phase material with a mixture of lithium fluoride and hydrochloric acid or hydrogen fluoride.

[0044] In some embodiments, the MAX phase material includes Ti 3 AlC 2 、Ti 2 AlC and Ti 3 Any one or a combination of two or more of AlCN, etc., but not limited thereto.

[0045] see figure 1 As shown, in some typical implementation cases, the preparation method specifically includes:

[0046] (1) Use LiF and HCl or HF to etch the MAX phase material...

Embodiment 1

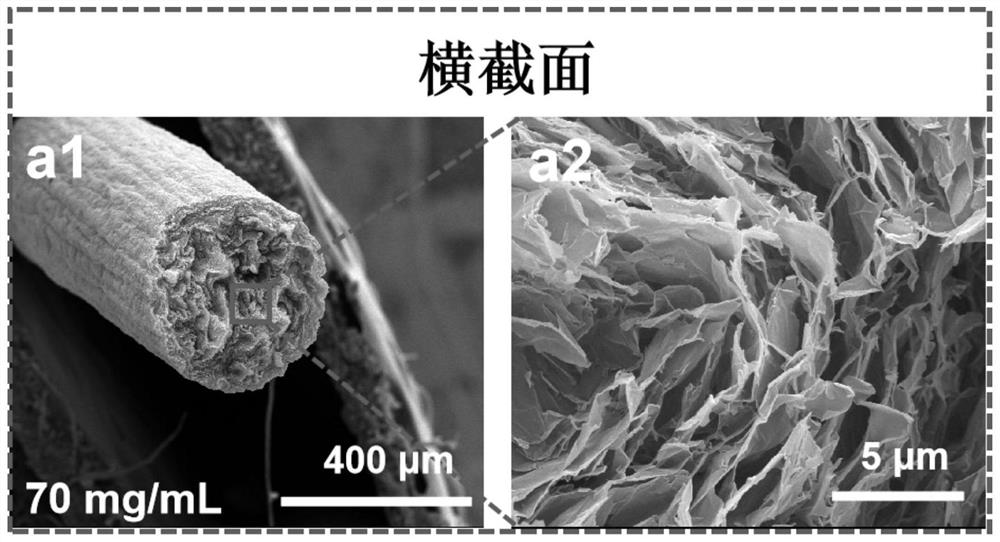

[0064] (1) Etching Ti with LiF and HCl 3 AlC 2 , add water to prepare MXene dispersion liquid, wherein the concentration of MXene dispersion liquid is 70mg / mL;

[0065] (2) The MXene dispersion obtained in step (1) is wet-spun to obtain MXene hydrogel fibers. Specifically, the MXene dispersion is squeezed through a spinning needle with a diameter of 500 μm at an extrusion speed of 100 μL / min. out into 5wt% CaCl 2 In the aqueous coagulation bath, MXene hydrogel fibers are obtained;

[0066] (3) The MXene hydrogel fiber obtained in step (2) is obtained by supercritical drying to obtain the MXene airgel fiber.

[0067] Through the above steps, the digital photos of the MXene airgel fibers prepared in this embodiment are as follows: figure 2 As shown, the cross-section and surface SEM of the obtained MXene airgel fibers are shown in image 3 The specific properties of MXene airgel fibers are shown in Table 1.

Embodiment 2

[0069] (1) Etching Ti with LiF and HCl 2 AlC, add water to prepare MXene dispersion, wherein the concentration of MXene dispersion is 17.5mg / mL;

[0070] (2) The MXene dispersion obtained in step (1) is wet-spun to obtain MXene hydrogel fibers. Specifically, the MXene dispersion is squeezed through a spinning needle with a diameter of 500 μm at an extrusion speed of 10 μL / min. Enter the coagulation bath of 0.2wt% calcium chloride aqueous solution after going out, obtain MXene hydrogel fiber;

[0071] (3) The MXene hydrogel fiber obtained in step (2) is obtained by supercritical drying to obtain the MXene airgel fiber.

[0072] After the above steps, the nitrogen adsorption and desorption curve and pore size distribution diagram of the MXene airgel fiber obtained in this embodiment are as follows: Figure 4a and Figure 4b The specific properties of MXene airgel fibers are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com